Page 1

LaserWriter Pro 810

Service Technical Documentation

Table of Contents

Section 1. Introduction

Section 2. Setup Menu

Section 3. Preventive Maintenance

Section 4. Take Apart

Section 5. Troubleshooting

Section 6. Interface Configurations

Appendix A. Memory Expansion Upgrade

Appendix B. Illustrated Parts List

Page 2

All rights reserved. No part of this document may be reproduced without the

express permission of Apple Computer, Inc.

The material in this document is for informational purposes and is subject to

change without notice Apple Computer, Inc. assumes no responsibility for errors

or omissions in this document. Nor is any liability assumed for any damages

resulting from the use of the information it contains.

TRADEMARK ACKNOWLEDGEMENTS

HP Laserjet Series IIP is a trademark of Hewlett Packard, Inc.

PostScript is a registered trademark of Adobe System Incorporated.

Apple and LaserWriter are a registered trademarks of Apple Computer, Inc.

Macintosh is a trademark licensed to Apple Computer, Inc.

First Edition June 1993

WARNING

FCC Regulations state that any unauthorized changes or modifications to the

equipment not expressly approved by the manufacturer could void the user's

authority to operate this equipment.

NOTE

This equipment has been tested and found to comply with the limits for a Class A

digital device pursuant to Part 15 of FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may

cause interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

NOTE

In order to maintain compliance with FCC regulations, shielded data cables must

be used with this equipment.

BESCHEINIGUNG DES HERSTELLERS/IMPORTEURS

Hiermit wird bescheinigt, daß der Laser Drucker Typ LaserWriter Pro 810 in

Übereinstimmung mit den Bestimmungen der Vfg. 1046/1984 funk-entstört ist.

Der Deutchen Bundespost wurde das Inverkehrbringen dieses Gerätes angezeigt

und die Berechtigung zur Überprüfung der Serie auf Einhaltung der Bestimmungen

eingeräumt

Apple Computer, Inc.

.

Page 3

CERTIFICATE OF MANUFACTURER/IMPORTER

This is to certify that the Laser Printer Model LaserWriter Pro 810 is shielded

against radio interference with the provisions of Vfg. 1046/1984.

The German Postal services have been advised that this device is being put on the

market and are entitled to inspect the series for compliance with the regulations.

Apple Computer, Inc.

USER SAFETY

The Printer is certified as a Class 1 laser product under the U. S. Department of

Health and Human Services (DHHS) Radiation Performance Standard according to

the Radiation Control for Health and Safety Act of 1968. The product is safe to

use during normal operation and maintenance.

Protective housing and external covers completely confine the laser light emitted

inside the printer. The laser beam cannot escape from the machine during any

phase of normal user operation.

CAUTION

Performance of procedures other than those specified in this manual could result

in hazardous radiation exposure.

Regulations implemented on August 2, 1976, by the Center for Devices and

Radiological Health (CDRH) of the U. S. Food and Drug Administration (FDA) apply

to laser products manufactured from August 1, 1976. Laser products sold in the

United States must comply with these regulations.

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of

the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits redioelectriques depassant les

limites applicables aux appareils numeriques de la class A prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le ministetre des

Communications du Canada.

LITHIUM BATTERY INFORMATION

CAUTION

Danger of explosion if battery is incorrectly replaced. Replace only with the same

or equivalent type recommended by the manufacturer. Dispose of used batteries

according to the manufacturer's instructions.

A "dead" lithium battery is considered hazardous waste and has some potential

for explosion if improperly handled. Mark the battery "Dead". Place it in a ziplock wrapper and the packaging used to ship the replacement battery, and return

the dead battery to Apple, where it will be disposed of following EPA guidelines.

Exception: If the battery is physically damaged, do not return it to Apple. Dispose

of the battery locally according to local ordinances.

(Instructions for replacing the battery are given in this manual.)

CAUTION

Invisible laser radiation when open and interlocks defeated. Avoid exposure to

laser beam.

Page 4

LaserWriter Pro 810

Section 1: Introduction

Page 5

LaserWriter Pro 810 Nov 93 Introduction/1-2

GENERAL

The printer consists of two major blocks—the controller and the print

engine. The controller functions as the interpreter of the source print data

and creates dot pattern information. The print engine prints the data based

upon the dot pattern information it receives from the controller.

The print engine includes the Laser Scanner Unit (laser/optical unit), EP

cartridge (developer, drum, toner, main charger), and paper feed

mechanisms. The print engine mechanisms are controlled by the DC

Controller.

This section of the manual describes the overall print process, Laser

Scanner Unit functions, and DC Controller functions. Locations of other

major parts and assemblies are provided as well as a brief description of

their functions.

NOTE: Many of the drawings in this manual show a two-tray model of the

LaserWriter Pro laser printer. All pictures of the two-tray model used in

this manual accurately represent the three-tray LaserWriter 810.

Apple Computer does not include a two-tray printer in the LaserWriter

810 product offering. If this manual is revised in the future the graphics

will be changed to reflect the three-tray configuration.

Page 6

LaserWriter Pro 810 Nov 93 Introduction/1-3

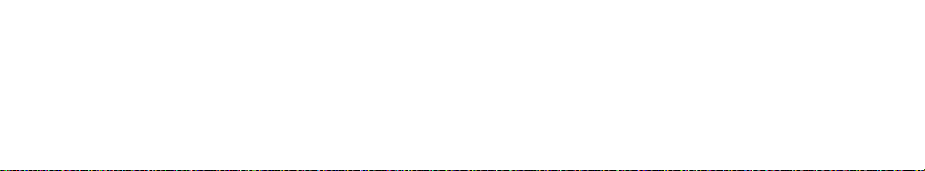

PRINTING PROCESS

MAIN

CHARGER

EP CARTRIDGE

MAGNETIC

ROLLER

TRANSPORT

CHUTE

PAPER PATH

ERASE LAMP

HEAT ROLLER

LASER SCANNER

UNIT

DRUM

PRESSURE

ROLLER

DRUM CLEANING

BLADE

DETACK

SAW

TRANSFER

CHARGER

FIRST TRAY

SECOND TRAY

THIRD TRAY

CONTROLLER

WAFER BOX

FEED

ROLLERS

Charging The main charger places a negative charge on the drum.

Exposure When an image signal is received, the laser emits light to the drum and

erases the negative charges to form an electrostatic latent image.

Developing The magnetic roller is covered by a thin film of magnetic toner. The toner

(negatively charged) is attracted to the latent image on the drum and forms

a visible image on the drum.

Transfer The transfer charger applies a positive charge to the bottom surface of

paper that transfers the toner image from the drum to the paper.

Separation The paper is separated from the drum by a combination of the detack saw

bias voltage and the paper's characteristics.

Fusing The toner image is fused to the paper by the heat and pressure applied by

the fuser rollers.

Cleaning The cleaning blade scrapes off any residual toner on the drum. At the same

time, the erase lamp transmits light to the drum and erases any residual

electrical charge. Following the cleaning process the print process starts

again from the charging cycle.

Page 7

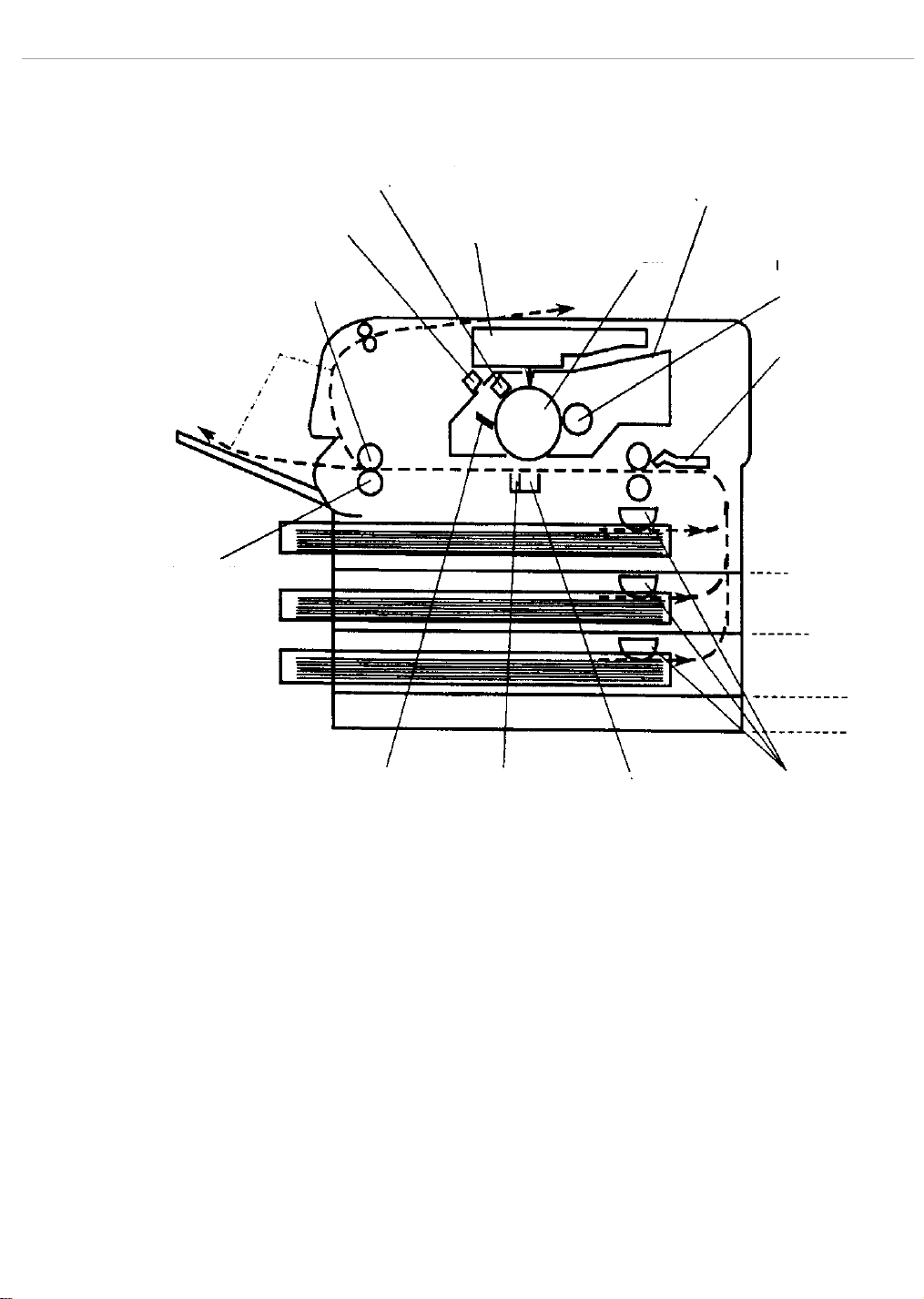

LaserWriter Pro 810 Nov 93 Introduction/1-4

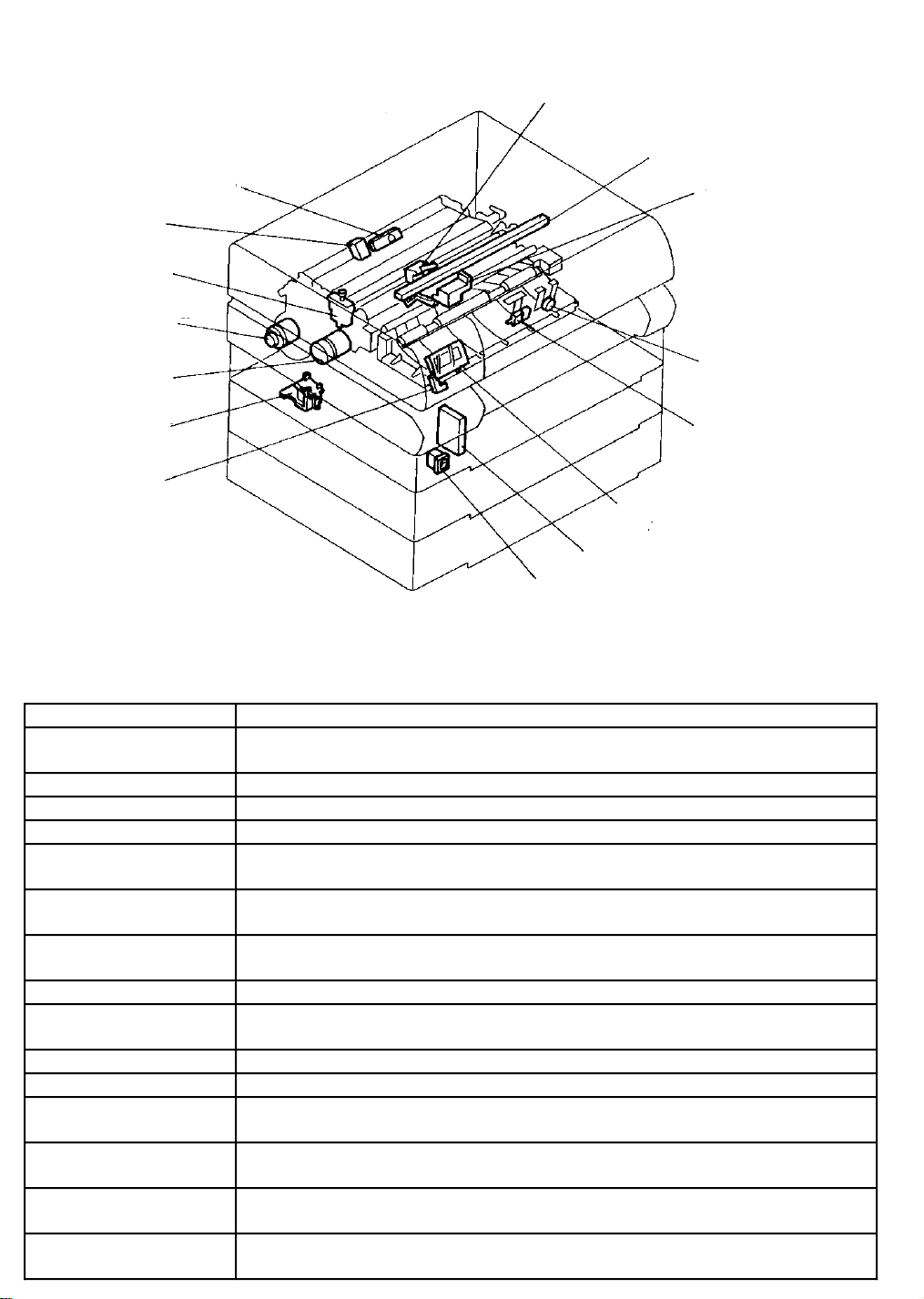

PART NAMES AND PART FUNCTIONS

LASER SCANNER

UNIT

HIGH VOLTAGE

DC CONTROLLER

MAIN MOTOR

POWER SUPPLY

LOW VOLTAGE

POWER SUPPLY

FUSER

FAN

ASSEMBLY

TABLE 1-1. PART NAMES AND FUNCTIONS

Name Main function

Main Motor Supplies the main mechanical drive for the printer. A fan on the

motor shaft cools the drive unit.

Laser Scanner Unit Receives a signal from the user system through the DC Controller

board, and converts the signal into a laser beam that is transmitted to

the drum to form an electrostatic latent image.

Low Voltage Power

Supply (LVPS)

Generates the +5, +15, and +24 voltages for the various printer

assemblies from the AC voltage input. Includes the main power

switch.

High Voltage Power

Supply (HVPS)

Generates the high DC/AC voltage for the transfer charger, main

charger, and magnetic roller.

DC Controller Controls the whole operation of the printer based on data from each

sensor and commands from the user system.

Fuser Fan Assembly Serves as the exhaust fan to prevent temperature in the printer from

rising.

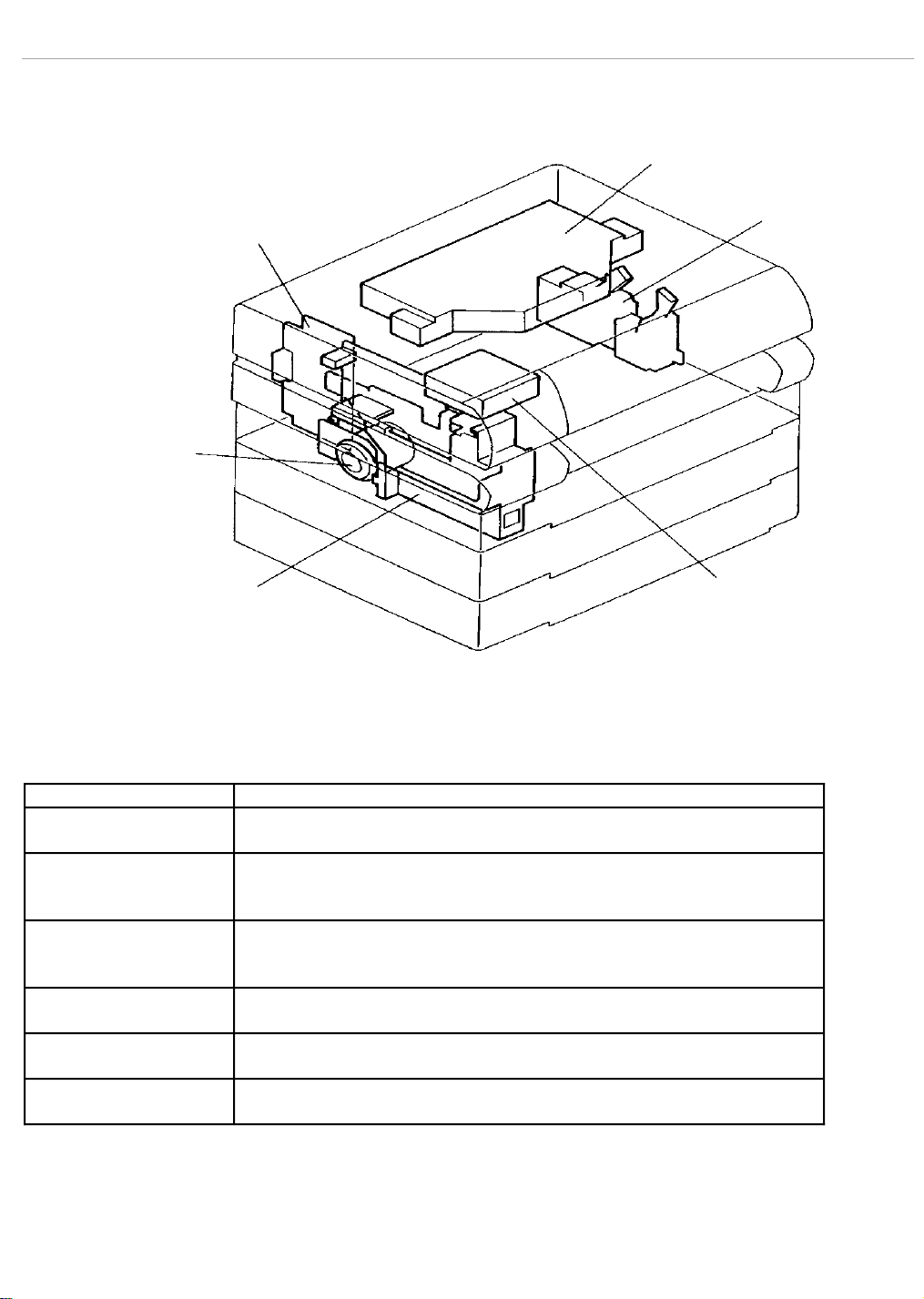

Page 8

LaserWriter Pro 810 Nov 93 Introduction/1-5

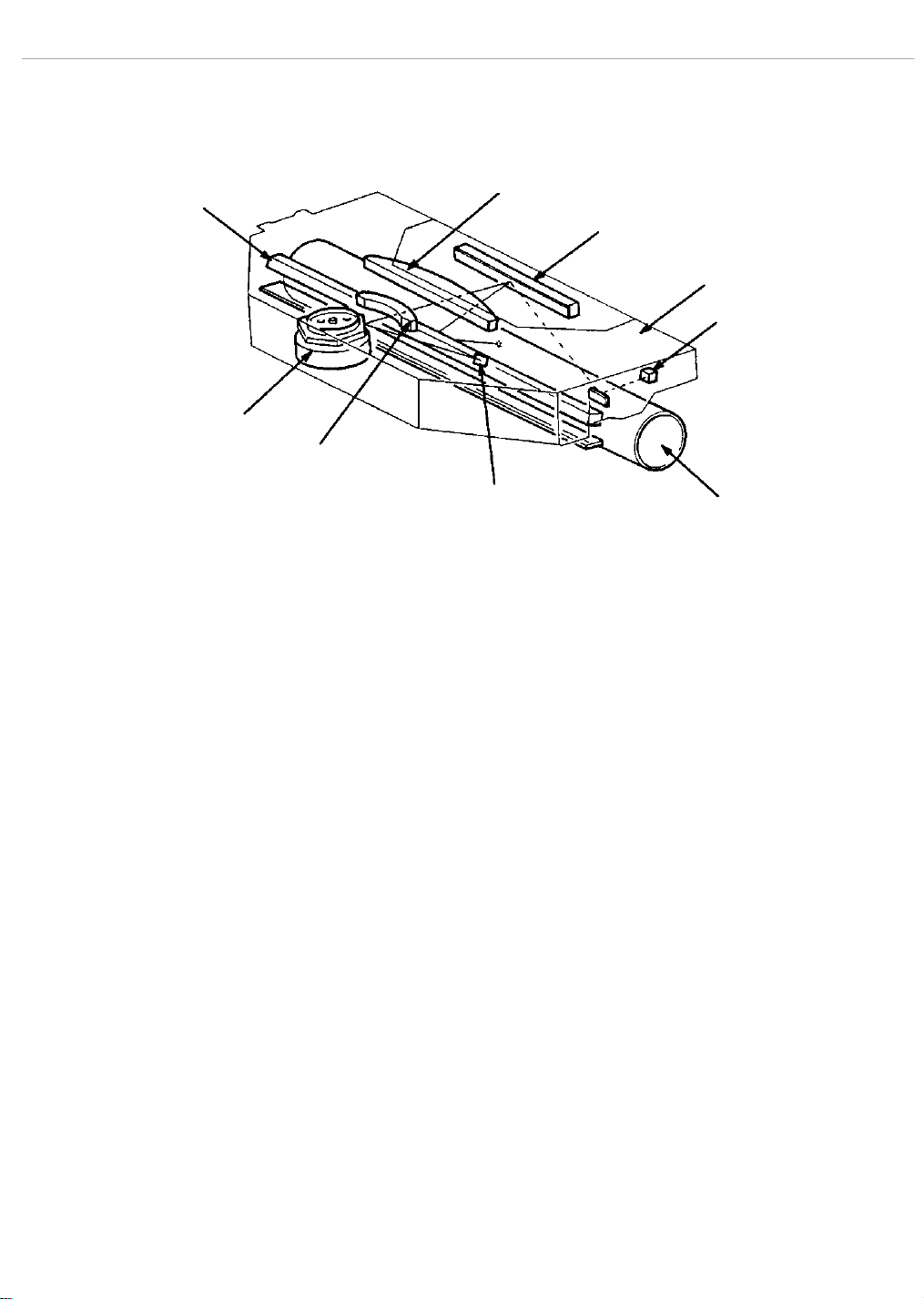

PRE-REGISTRATION

SENSOR

TONER OUT

SENSOR

EP CARTRIDGE

SENSOR

INTERLOCK

SWITCH

RANSPORT ROLLER

CLUTCH

REGISTRATION

CLUTCH

PAPER FEED

SOLENOID

EXIT

SENSOR

TABLE 1-1. PART NAMES AND FUNCTIONS (CONTINUED)

ERASE LAMP

PAPER

OUT

SENSOR

FUSER THERMOSTAT

TEMPERATURE

SENSOR

CONTROL PANEL

ASSEMBLY

PAPER SIZE

SENSOR

POWER

SWITCH

Name Main function

Control Panel Assembly Displays the printer's operating status, error messages, and corrective

actions. The keypad is used for setting printer operating parameters.

Erase Lamp Light Emitting Diodes (LED) used to erase any residual charge on the drum.

Power Switch Turns AC power supply ON and OFF. The switch is part of the LVPS.

Cartridge Sensor Determines that the EP cartridge is seated correctly.

Temperature Sensor Detects the surface temperature of the heat roller and transmits a signal to

the DC Controller board to keep the heat roller temperature constant.

Fuser Thermostat Shuts off AC voltage to the fuser bulb when heater roller temperature gets

too high because of trouble with the temperature sensor, DC Controller, etc.

Paper Size Sensor Detects the size of a cassette installed in the printer by a combination of

“ON" and “OFF" signals transmitted by four independent sensors.

Paper Out Sensor Detects the absence of paper in the paper cassette.

Interlock Switch When the top cover is opened, the AC power for the fuser bulb, 24 VDC, and

15 VDC is interrupted and the printer stops immediately.

Exit Sensor Detects a paper jam at the paper exit.

Toner Empty Sensor Detects a no toner condition in the EP cartridge.

Pre-Registration Sensor Detects paper movement as well as no paper conditions when using the

manual feed guide.

Registration Clutch Rotates and stops the registration roller to position paper for a toner image

transfer from the drum.

Paper Feed Solenoid Electrically controls the rotation/stop operation of the feed roller that

moves the paper from a cassette.

Transport Roller Clutch Controls rotation/stop operation of the transport roller that moves the

paper from the cassette to the upper transport roller or registration roller.

Page 9

LaserWriter Pro 810 Nov 93 Introduction/1-6

EXPOSURE PROCESS

MIRROR 2

POLYGON

MIRROR

LENS 2

MIRROR 1

WINDOW

SOS

SENSOR

LENS 1

LASER DIODE

AND CYLINDER

LENS

DRUM

Except for the semiconductor, diode-type laser, the printer uses the same

Xerographic process as conventional copiers. When the printer receives a

print start signal from the I/O Controller, the laser diode starts emitting

light.

The laser beam from the laser diode is collimated by a cylinder lens before

being transmitted to the polygon mirror. The six-sided polygon mirror is

driven by the scanner motor that rotates at a constant speed (RPM). Each

rotation of the polygon mirror causes one scan line.

The laser beam, reflected by the polygon mirror, is transmitted to the

drum through lenses 1 and 2, mirrors 1 and 2, and the window. On the

right side of mirror 2 is a mirror for the Start of Scan (SOS) sensor. This

configuration keeps a constant scanning position for each scan line.

Page 10

LaserWriter Pro 810 Nov 93 Introduction/1-7

DC CONTROLLER FUNCTIONS

The DC Controller has the following main functions.

User System/Printer Communications

Receives video data synchronized with the video clock signal from the I/O

Controller and sends the video data synchronization signal and status signal

to the I/O Controller.

Sensor And Switch Signal Detection

Inputs signals from the sensors and switches that detect the status of the

printer before and during the print sequence.

Laser Scanner Unit Control

Monitors the scanner motor RPM and receives the SOS (Start of Scan)

signal to synchronize the start of laser beam scanning. Sends the video

print data to the Laser Scanner Unit in synchronization with the SOS signal.

Control Panel Display and Input

Displays error and status messages. Receives the input signals from the

keypad.

Print Sequence Control

Using sensor data and timers, it controls the print sequence of paper feed,

movement, and discharge.

Engine Self-Test and Diagnostics

The self-test print and diagnostic functions aid in the detection of print

engine errors and malfunctions.

LASER SCANNER UNIT BOARD FUNCTIONS

The board in the Laser Scanner Unit has the following functions:

Receives video data from the DC Controller board and uses it to control the

laser beam to form a latent image on the drum.

Controls the scanner motor so that it keeps rotating at a constant speed.

Page 11

LaserWriter Pro 810 Nov 93 Introduction/1-8

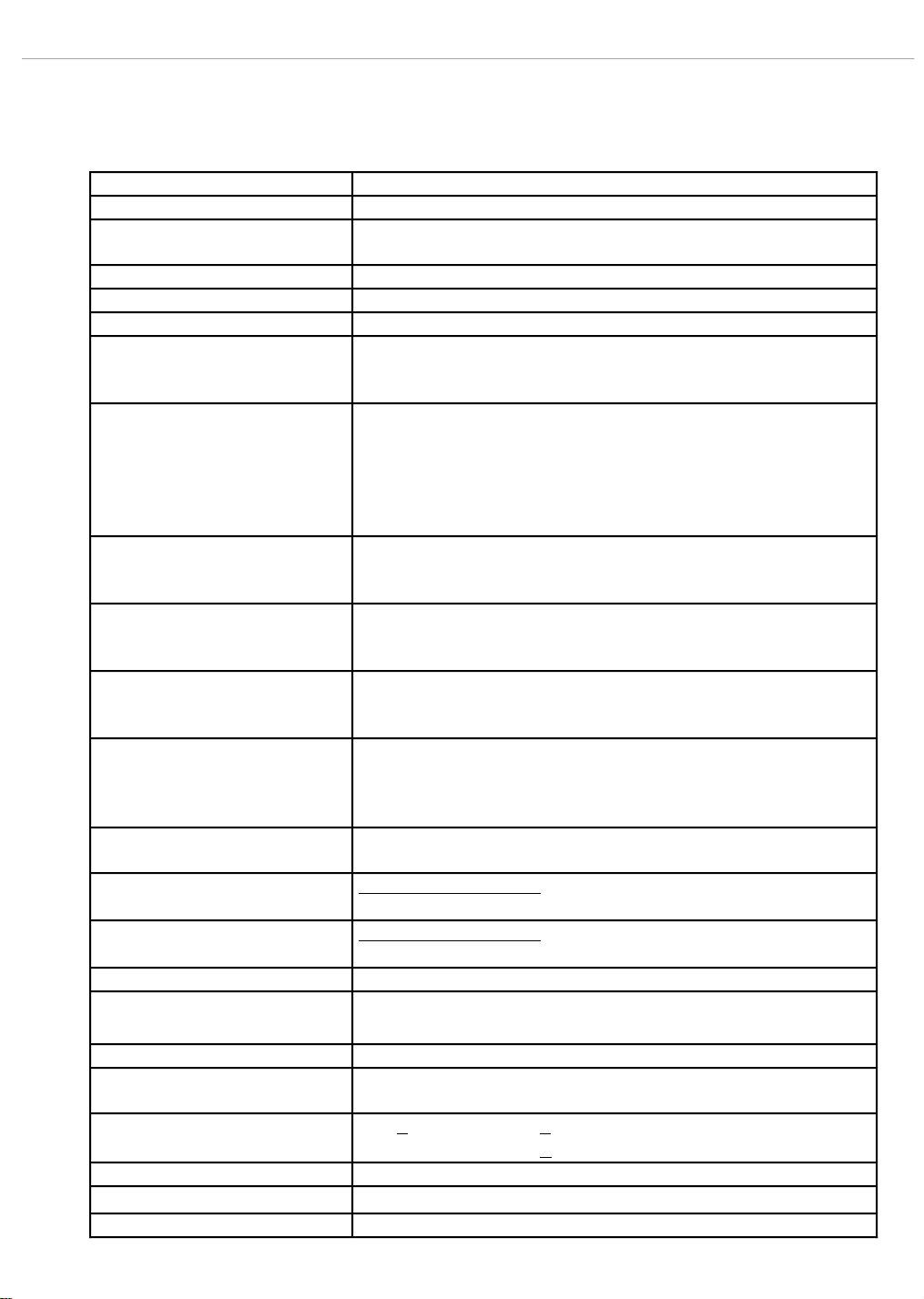

PRINTER SPECIFICATIONS

TABLE 1-2. PRINTER SPECIFICATIONS

ITEM DESCRIPTION

Type Desk top type

Page description

language/Emulation

Printing system Laser xerography system; Write black.

Print speed, maximum 20 sheets per minute

Resolution 300,400,600, and 800 dots/inch.

Paper feed Cassette paper feed

Paper cassettes,

standard

Optional cassette sizes Letter (8.4" x 11")

Paper sizes, manual feed Paper size: A4LEF, A4SEF, Executive, Legal, Letter LEF,

Paper weight Cassette feed: 52-82 g/m

Paper capacity Cassette: 250 sheets (64 g/m

Exit tray capacity Face up: 250 sheets (64 g/m

Printer size in millimeters Width Depth Height

Printer size in inches Width Depth Height

Printer weight 24.6 Kg, 54.23 lbs.

Warm-up time

Time to first print approximately 20 seconds

Noise level During operation: 53 dBA or less

Power supply 115 +10 VAC, 50/60 +2 Hz or

Power consumption Maximum 0.8 kW or less

Working Temperature

Humidity 15% to 85% RH non-condensing

Postscript Level 2 and HP LaserJet IIP

Manual paper feed

Multi media power feeder (Option)

Standard in 115 volt printers:

Letter (8.5" x 11")

Ledger (11" x 17")

Standard in 220/240 volt printers:

A3 (297 mm x 420 mm)

A4 (210 mm x 297 mm)

US Ledger (11" x 17")

Universal - all standard sizes

Letter SEF, Folio, B4, B5 and Invoice.

Envelope Size: Com-10, Monarch, C5, and DL

2

paper

Manual feed: 52-139 g/m2 paper or postcard stock 190

2

g/m

2

paper)

Multi media power feeder:

100 sheets (64 g/m

2

paper)

15 envelopes

2

letter -size paper

Face down: 250 sheets (64 g/m2 letter-size paper)

519 410 487

20.4 16.14 19.17

approximately 1 minute, at room temperature (22oC to 35oC

or 72oF to 95oF).

During standby: 40 dBA or less

220/240 VAC, 50/60

+2 Hz (International market)

10o to 35oC (50o to 95o F)

Page 12

LaserWriter Pro 810 Nov 93 Introduction/1-9

STORING CONSUMABLES

Paper should be stored in a cool, dry place. Keep it out of direct sunlight.

Avoid storing paper in an area with high humidity. When the printer isn't

going to be used for a long time, remove all the paper from the cassettes and

wrap it in the original wrapper.

EP Cartridges should be stored in a cool, dry place. Do not store them in

direct light. Avoid storing the EP cartridges in areas with high

temperature and humidity (0-35o C, 32-95o F and 10-80% relative

humidity). Do not store the cartridges on their sides or on end.

Be especially careful of conditions that could cause condensation to form on

the drum.

Page 13

LaserWriter Pro 810

Section 2: Setup Menu

Page 14

LaserWriter Pro 810 Nov 93 Setup Menu/2-2

GENERAL

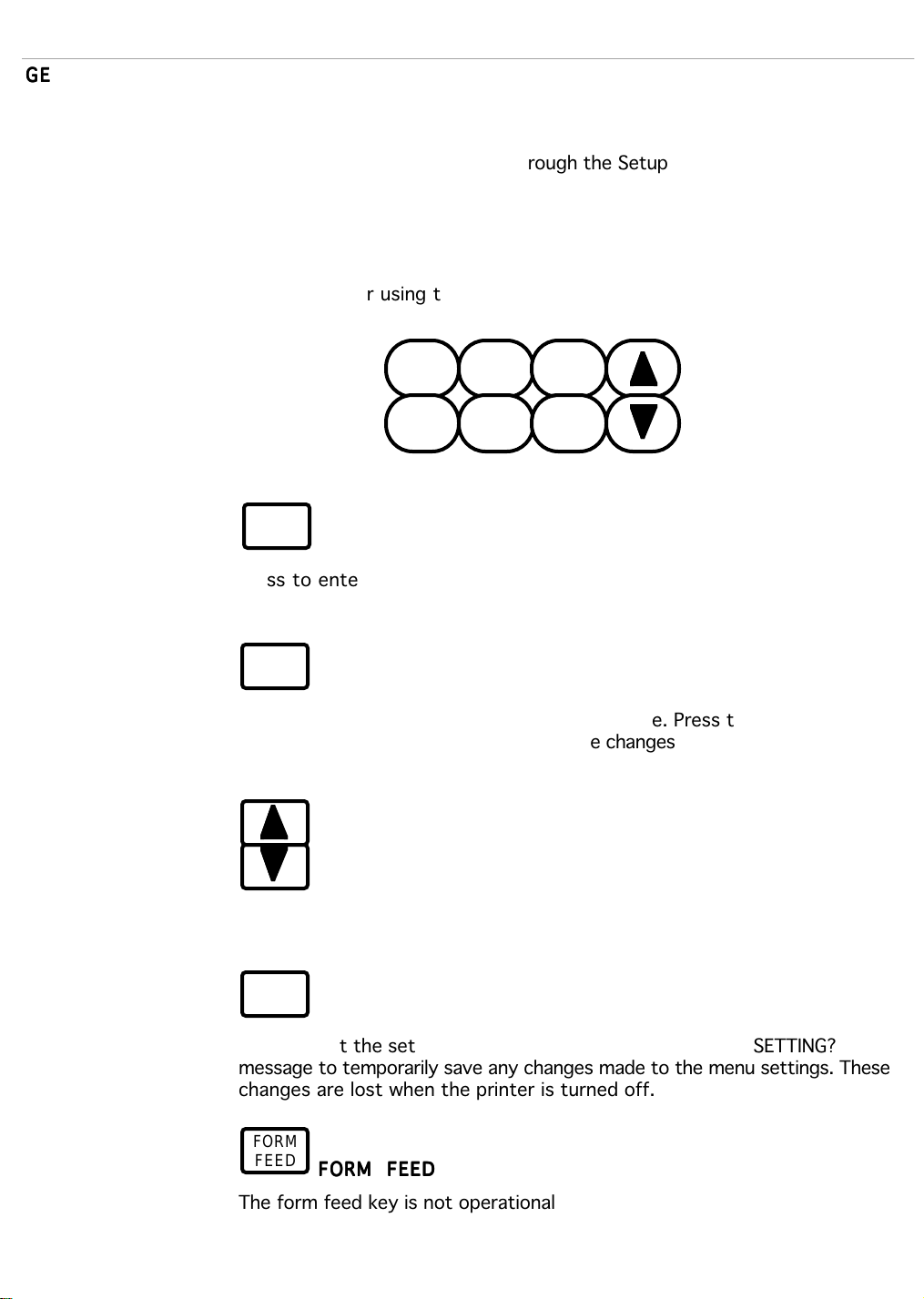

Setup Menu Keys

MENU KEY

ENTER KEY

ARROW KEYS

ONLINE KEY

FORM FEED

This section tells you how to use the Setup Menu to change the printer's

operating parameters. Operating parameters, such as input port, printer

type, and paper source are set through the Setup Menu.

The control panel keys that are used to get around in the setup menu are

illustrated and described below. See the User's Manual for more detailed

instructions for using the Setup Menu.

MENU

ONLINE

RESET

FORM

FEED

PRINT

STATUS

MENU

ENTER

Press to enter the Setup Menu after the printer is off-line. Press ENTER to

select a value.

ENTER

Press to select a menu item or a displayed value. Press to permanently save

any changes made to the setup menu. The changes are retained even if the

printer is turned off.

Press to scroll through a menu or sub-menu level.

ONLINE

Press to exit the setup menu. Press in response to a SAVE SETTING?

message to temporarily save any changes made to the menu settings. These

changes are lost when the printer is turned off.

FORM

FEED

The form feed key is not operational

Page 15

LaserWriter Pro 810 Nov 93 Setup Menu/2-3

Setup Menu Messages

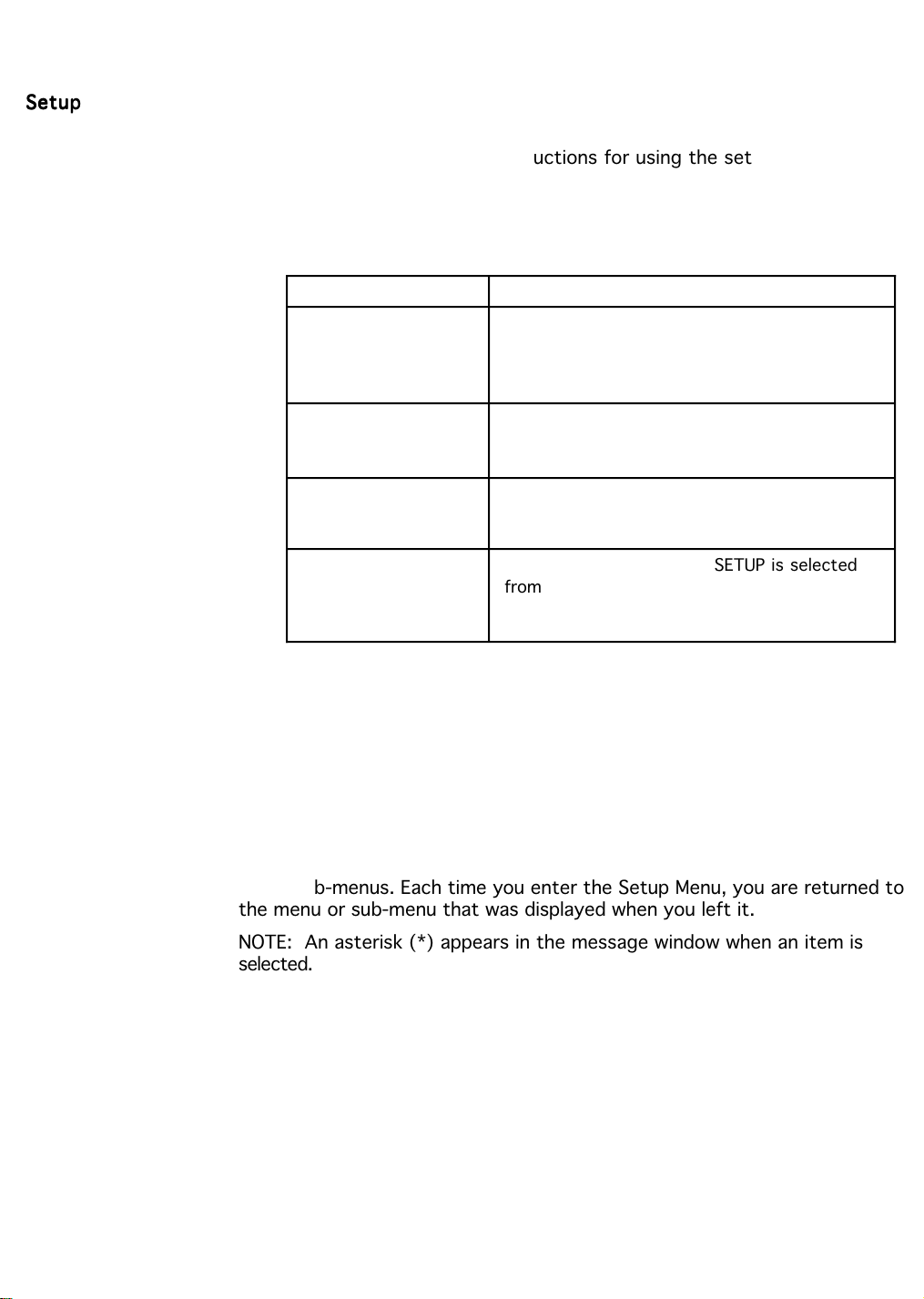

TABLE 2-1. MENU MESSAGES

Setup Menu Description

The messages that you may encounter while using the setup menu are listed

and described in Table 2-1. Instructions for using the setup menu are in

the User's Manual.

Menu Message Description

SAVE SETTINGS?

ENTER=PERMANENT

ONLINE=TEMPORARY

TEMPORARY After setup menu changes have been

PERMANENT After setup menu changes have been

FACTORY SETUP?

ENTER=RESTORE

ONLINE=CANCEL

After changes have been made to the setup

menu, the ENTER and ONLINE prompts are

displayed alternately until the ONLINE or

ENTER key is pressed.

temporarily saved by pressing the ONLINE key,

this message is displayed.

permanently saved by pressing the ENTER key,

this message is displayed.

When RESTORE FACTORY SETUP is selected

from the Misc. menu, the ENTER and ONLINE

prompts are displayed alternately until the

ONLINE or ENTER key is pressed.

The Setup Menu for the printer works like many menu-driven software

packages. When you select an item in one menu, another menu may be

called up. You can continue to choose from each new menu until you get to

the selection you need.

The Setup Menu is illustrated in the diagram on the following pages. In the

diagram, the first item listed in a sub-menu is the factory default. After

changes have been made, the newly selected items or values are listed first

in the sub-menus. Each time you enter the Setup Menu, you are returned to

the menu or sub-menu that was displayed when you left it.

NOTE: An asterisk (*) appears in the message window when an item is

selected.

Page 16

LaserWriter Pro 810 Nov 93 Setup Menu/2-4

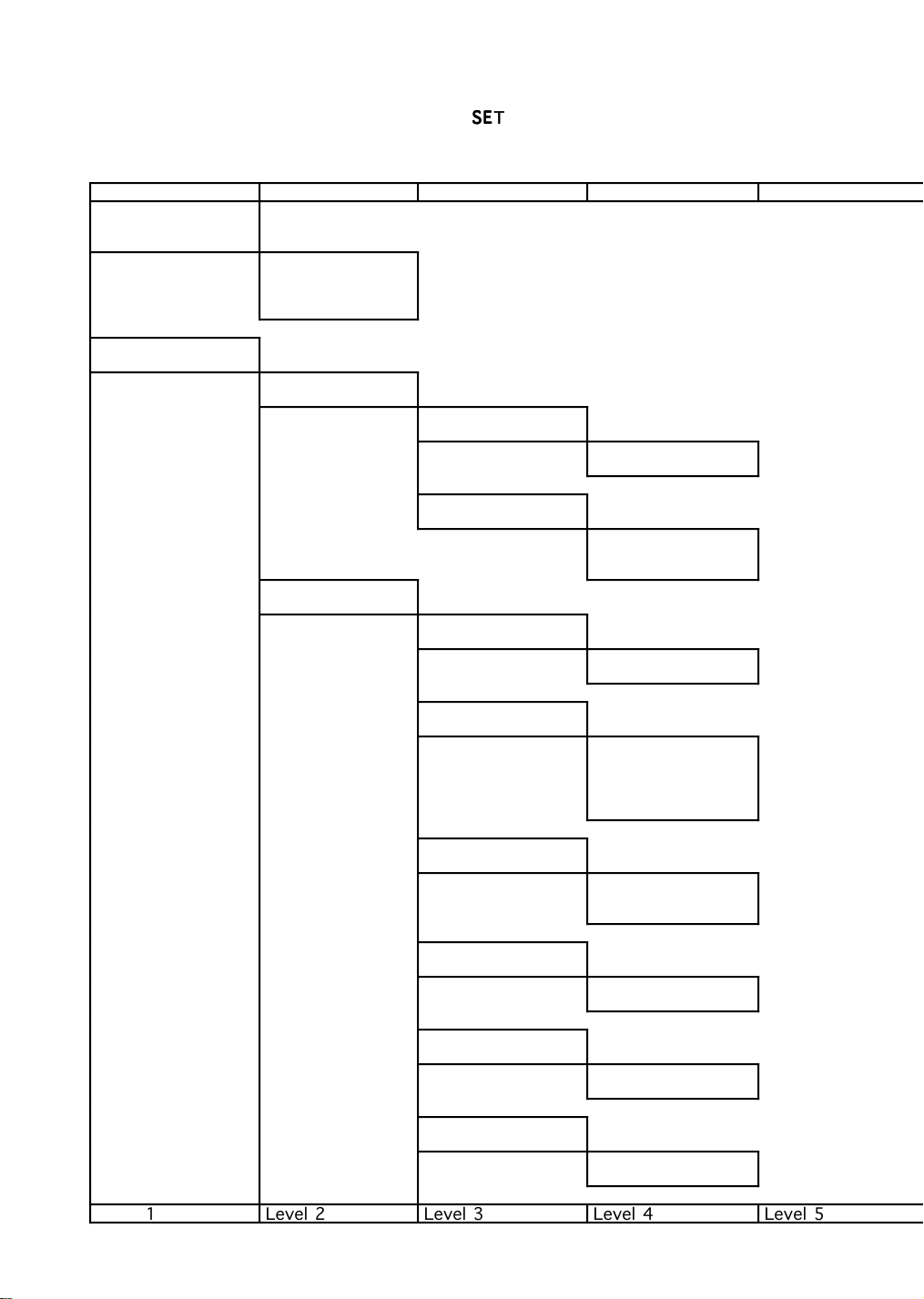

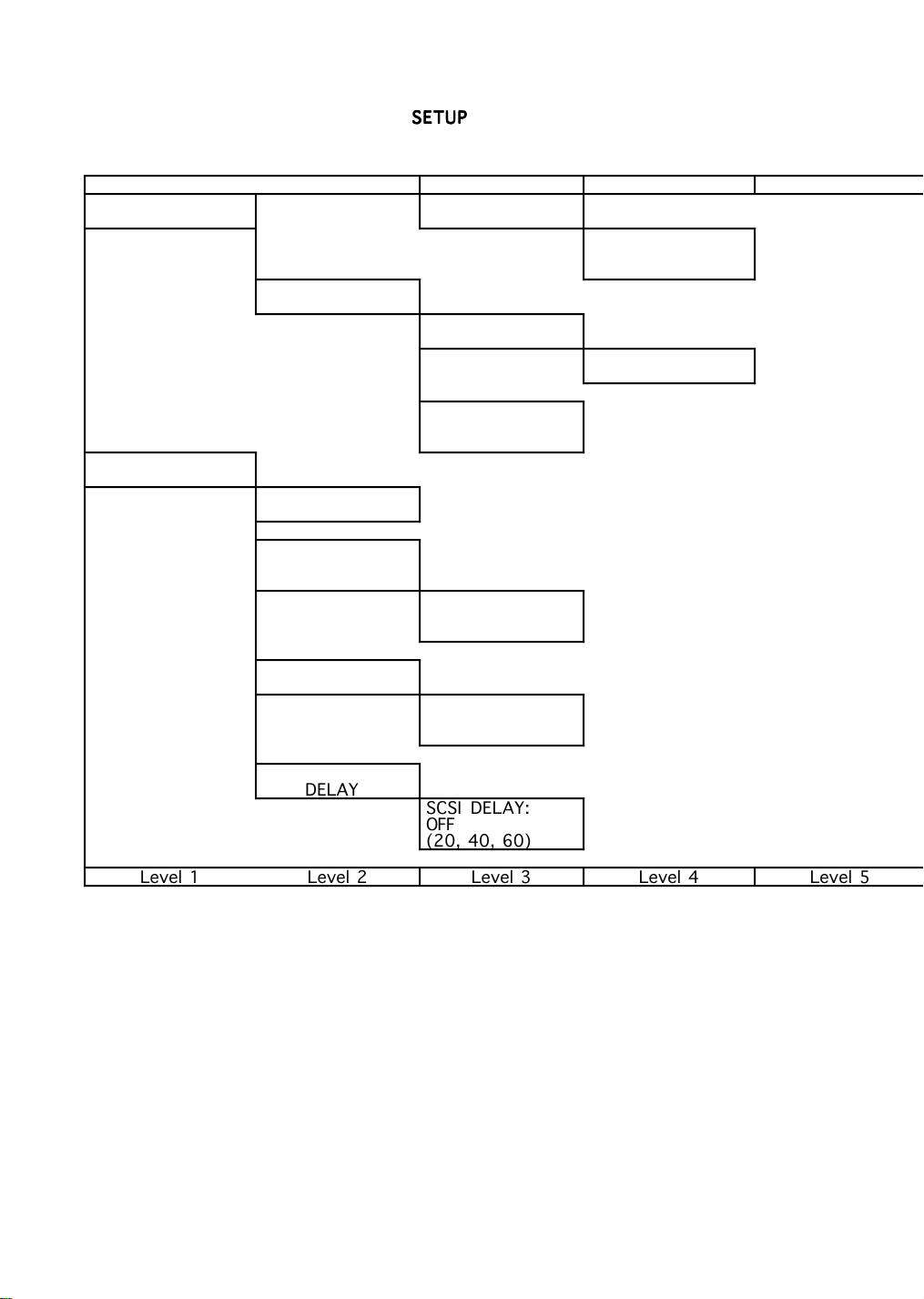

SETUP MENU

Level 1 Level 2 Level 3 Level 4 Level 5

MENU:

POSTSCRIPT

RESOLUTION

POSTSCRIPT

RESOLUTION

300, 400, 600,

800

MENU:

INPUT PORT

INPUT PORT

PARALLEL

PARALLEL

ENABLE

ENABLE

YES (N0)

PARALLEL

PRINTER TYPE

PRINTER TYPE

POSTSCRIPT

(LJETIIP)

INPUT PORT

RS232

RS232

ENABLE

ENABLE

YES (NO)

RS232

BAUD

BAUD

9600 (19200,

38400, 300, 600,

1200, 2400,

4800)

RS232

PARITY

PARITY

NONE (EVEN, ODD,

MARK, SPACE)

RS232

FLOW CONTROL

FLOW CONTROL

XON-XOFF (DTR)

RS232

STOP BITS

STOP BITS

1 (2)

RS232

DATA BITS

DATA BITS

8 (7)

Level 1 Level 2 Level 3 Level 4 Level 5

Page 17

LaserWriter Pro 810 Nov 93 Setup Menu/2-5

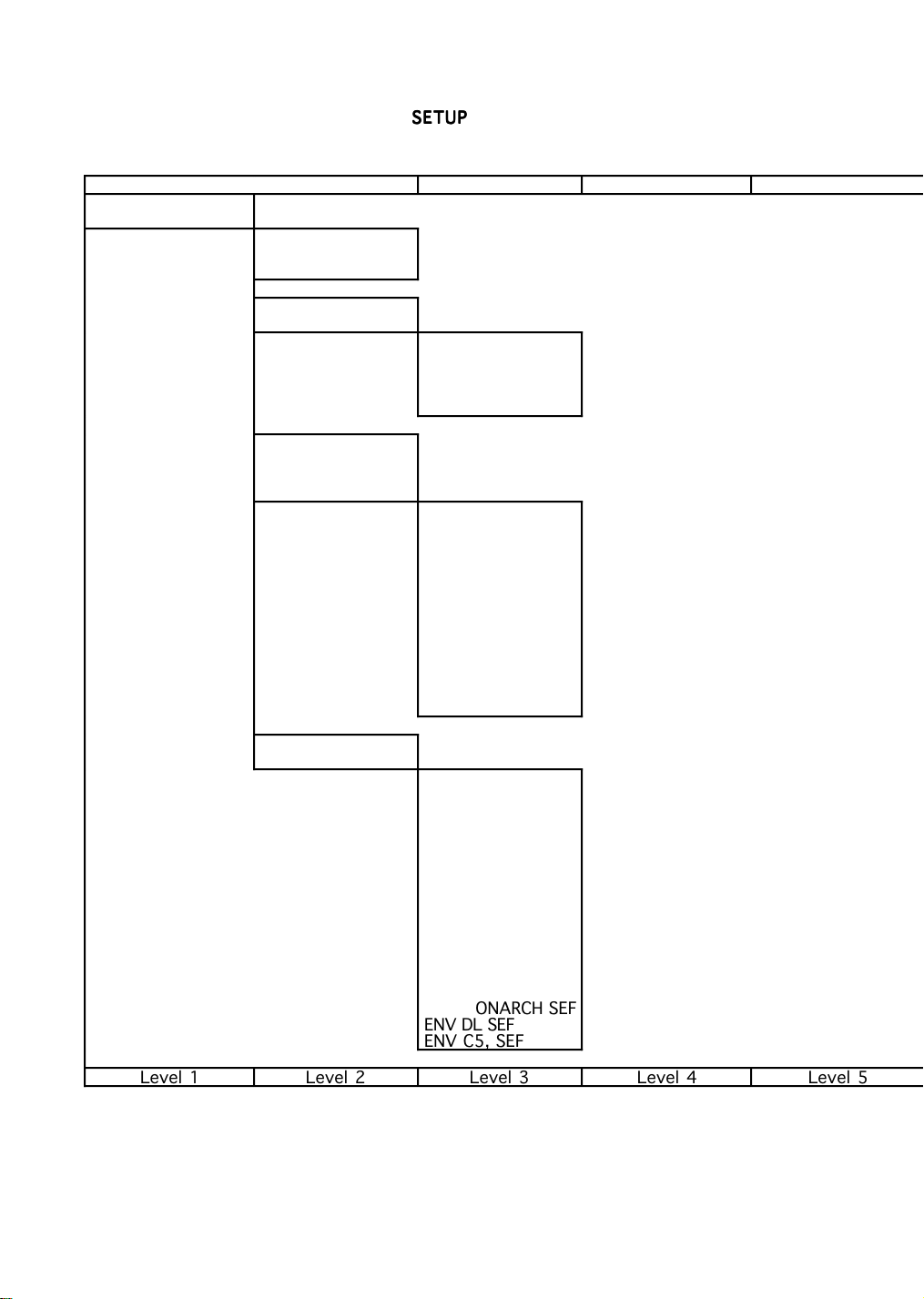

SETUP MENU (Continued)

Level 1 Level 2 Level 3 Level 4 Level 5

MENU:

INPUT PORT

INPUT PORT

LOCALTALK

MENU:

MISC

MISC RESTORE

FACTORY SETUP

MISC

EXIT JAM

REPRINT

RS232

PRINTER TYPE

PRINTER TYPE

POSTSCRIPT

(LJET IIP)

LOCALTALK

ENABLE

ENABLE

YES (NO)

PRINTER TYPE

POSTSCRIPT

(LJET IIP)

EXIT JAM

REPRINT DISABLE

(ENABLE)

MISC

START-UP PAGE

START-UP PAGE

ENABLE

(DISABLE)

MISC

SCSI DELAY

SCSI DELAY:

OFF

(20, 40, 60)

Level 1 Level 2 Level 3 Level 4 Level 5

Page 18

LaserWriter Pro 810 Nov 93 Setup Menu/2-6

SETUP MENU (Continued)

Level 1 Level 2 Level 3 Level 4 Level 5

MENU:

PAPER SOURCE

PAPER SOURCE

TRAY 1 (TRAY 2,

TRAY 3)

PAPER SOURCE

AUTO CASCADE

AUTO CASCADE

TRAY 1 & 2 & 3

(TRAY 1 & 2,

TRAY 1 & 3,

TRAY 2 & 3)

PAPER SOURCE

M-M PWR FEEDER

M-M PWR FEEDER

LETTER(8.5X11)

[LEGAL(8.5X14),

STAT(5.5X8.5),

EXEC(7.25X10.5),

FOLIO(210X330),

A4(210X297),

A5(210X148.5),

B5(182X257),

COM-10 ENV,

MONARCH ENV,

INT'L DL ENV,

INT'L C5 ENV]

PAPER SOURCE

MANUAL FEED

MANUAL FEED

LETTER, LEF

(LEDGER, SEF

LEGAL, SEF

STATEMENT, SEF

EXECUTIVE, SEF

LETTER, SEF

A4, SEF

A4, LEF

A5, SEF

A5, LEF

B5, LEF

B4, SEF

ENV COM-10, SEF

ENV MONARCH SEF

ENV DL SEF

ENV C5, SEF

Level 1 Level 2 Level 3 Level 4 Level 5

Page 19

LaserWriter Pro 810 Nov 93 Setup Menu/2-7

MENU POSTSCRIPT:/RESOLUTION

MENU:/INPUT PORT

The POSTSCRIPT RESOLUTION menu selects either 300, 400, 600 or 800

Dots-Per-Inch (DPI) resolution whenever POSTSCRIPT is the selected

printer type. Changing the resolution to 400, 600 or 800 (DPI) has no

effect when the printer type is LJET IIP (HP LaserJet IIP).

The printer has three Input/Output (I/O) connectors available. Since a

different system can be connected to each of the I/O connectors, the printer

can be shared by three user systems.

NOTE: PostScript documentation refers to the printer interfaces (I/O) as

channels. Port is another word sometimes used to refer to the interface

connectors and circuitry.

When the printer is shared by two or more systems, the interfacing

circuitry checks or polls each interface for incoming data. When data is

received on a port, that job is processed without interruption. Once the job

is completed, polling for incoming data resumes.

The Input Port Menu lets you disable an interface and/or set up the

required operating parameters that control communication between the

computer system(s) and the printer. The two serial channels can each be

set up with different protocols and baud rates.

The Input Port Menu also lets you select the PRINTER TYPE for each

channel. All three ports can be setup with PostScript as the Printer Type.

However, a combination of PostScript and HP LaserJet Series IIP can be

implemented. The printer type factory default for all three ports is

Postscript.

Page 20

LaserWriter Pro 810 Nov 93 Setup Menu/2-8

MENU:/MISC

MENU:/PAPER SOURCE

The Miscellaneous Menu is a selection of several miscellaneous features and

functions of the printer. It includes:

• resetting the printer to the factory defaults (RESTORE FACTORY

SETUP)

• enabling the EXIT JAM REPRINT function

• disabling the START-UP PAGE function

• setting a delay time for a hard disk drive

• selecting the language for the control panel messages

RESTORE FACTORY SETUP can be used whenever the printer needs to be

reset to the factory defaults. This is useful if changes have been made that

do not seem to be functioning as planned.

Three factory defaults, one of which is selectable from the Setup Menu,

cannot be changed by the RESTORE FACTORY SETUP. The three are Display

Language, printer name, and page count.

The EXIT JAM REPRINT function enables the printer to reprint a page that

may be in the exit area when a jam occurs. This means that two pages,

instead of one, are reprinted. Because reprinting two pages uses more of

the printer memory, the function can be turned off to free more memory.

The START-UP PAGE function can be turned off after the printer is set up.

However, printing the start-up page is a good way to be sure that the

printer is operating correctly.

The SCSI DELAY function sets the length of time the printer will wait for a

hard disk drive to come ready during the power on cycle. Some disk drives

may take longer than the printer to power up. The delay avoids the

possible problem of the printer not seeing the disk drive.

A DISPLAY LANGUAGE menu is displayed when this feature is supported. It

lets you select the language that is used for the messages that are displayed

on the control panel. English is the default.

The PAPER SOURCE Menu is used to select a paper source. If the printer

model has only one cassette and the multi media power feeder is not

installed, only manual feed and tray one are displayed on the Setup Menu.

Manual feed and the multi-media power feeder both have sub-menus for

selecting the paper and envelope sizes.

The Auto Cascade function can be enabled in this menu. For this feature to

work, each cassette (tray) must contain the same paper size.

Page 21

LaserWriter Pro 810

Section 3: Preventive Maintenance

Page 22

LaserWriter Pro 810 Nov 93 Preventive Maintenance/3-2

GENERAL

This section describes a preventive maintenance procedure that should be

carried out whenever other service is required by the user. By checking the

printer on a service call, you can instruct the user about printer care and

possibly prevent future problems. The procedure can be completed in 10

minutes or less.

PREVENTIVE MAINTENANCE PROCEDURE

1 . Record the total number of pages fed through the printer to date.

• Turn the printer on while pressing the DOWN arrow key to enter

the diagnostic mode.

• Press the DOWN arrow key once again to enter the total counter

display. The LED displays a cumulative count in six digits.

• Estimate the life of the consumables from the counter reading.

2 . Check overall printer operation by doing the following:

• Turn off the printer.

• Turn the printer on while pressing the ENTER key to enter the

print test mode.

NOTE: If the multi media power feeder is installed, make several

prints using it as the paper source. See Section 5 for more

information about using the print test mode.

• Make several prints in the test print mode.

• Listen for abnormal noises as the test printout is printing.

• Check the test printout for print quality problems.

3 . Check the transfer charger assembly.

CAUTION: Be careful not to break the charger and guide wires

while cleaning the transfer charger.

• Take out the transfer charger and clean it with a brush or a dry

cloth.

• Be sure to clean the transport rollers.

CAUTION: Do not expose the drum to light for more than five

minutes. Print quality can deteriorate.

• If the transfer charger is badly soiled, clean it with a cloth

slightly moistened with water and then with a dry cloth.

4 . Check the fuser heat roller cleaner for paper dust and dirt build-up.

• Remove the fuser heat roller cleaner from the fuser.

• Remove deposits of paper dust and toner from the cleaning felt. A

firm bristled brush may help.

Page 23

LaserWriter Pro 810 Nov 93 Preventive Maintenance/3-3

5. Check the registration roller and transport chute.

• Clean them with a brush and dry cloth.

• If they are badly soiled, clean them with a cloth slightly moistened

with water and then with a dry one.

NOTE: Do not leave any rollers dirty. Dirty rollers can cause

print quality and paper handling problems.

6 . Check the fan exhaust inlet.

• If the top cover is removed during maintenance, use a brush to

remove the dirt, toner, and paper dust from the fan exhaust.

7. Recheck printer operation.

• Make several more test prints.

• Check again for print quality, paper feed, and abnormal noises.

8 . Turn the printer off and on to enter the normal mode.

9 . Make a final print test by sending data from the users system.

1 0 . Report to the user any potential or real problems that you found.

Page 24

LaserWriter Pro 810

Section 4: Take Apart Procedures

Page 25

LaserWriter Pro 810 Nov 93 Take Apart/4-2

GENERAL

Section 4 does not cover all printer parts. Some parts are omitted because

they require neither adjustment nor special consideration in removing or

installing them. If no Take Apart procedure is provided in this section,

carefully check an installed part before removing it. For plug and

connector locations, see the figures and table at the end of this section.

CAUTION: Turn the printer off and unplug the power cord before starting

any Take Apart procedure.

Recommended Tools

The only tools needed to remove or install any assembly are:

1 . Screwdrivers, Philips head, several sizes and lengths (magnetized

would be useful).

2. Chip puller.

3. Blade screwdriver (various sizes).

4. Wire cutters.

Page 26

LaserWriter Pro 810 Nov 93 Take Apart/4-3

LIST OF TAKE APART PROCEDURES

POWER CORD COVER 4 - 5

TOP COVER 4 - 7

FRONT COVER 4 - 8

LEFT COVER 4 - 9

RIGHT COVER 4-10

REAR COVER 4-11

ELECTRICAL BOX COVER 4-12

TRANSFER CHARGER/DETACK SAW ASSEMBLY 4-13

PAPER TRANSFER UNIT 4-14

REGISTRATION CLUTCH 4-15

PRE-REGISTRATION SENSOR 4-16

TRANSPORT CLUTCH (TRAY 1) 4-17

PAPER FEED ROLLER ASSEMBLY 4-18

PAPER FEED SOLENOID (TRAY 1) 4-19

PAPER OUT SENSOR (TRAY 1) 4-20

PAPER SIZE SENSOR (TRAY 1) 4-21

OUTER TURN-CHUTE ASSEMBLY 4-22

INNER TURN-CHUTE ASSEMBLY 4-23

TRANSPORT CHUTE ASSEMBLY 4-24

FUSER UNIT 4-25

FUSER BULB 4-27

FUSER THERMOSTAT 4-28

FUSER TEMPERATURE SENSOR 4-29

PAPER EXIT SENSOR 4-30

OUTER EXIT-CHUTE ASSEMBLY 4-31

DIRECTION CHUTE 4-32

INNER EXIT-CHUTE 4-33

EXIT ROLLER ASSEMBLY 4-34

BELT (FUSER AREA) 4-35

LASER SCANNER UNIT 4-36

ERASE ASSEMBLY 4-37

TONER SENSOR 4-38

TONER SENSOR BRACKET 4-39

Page 27

LaserWriter Pro 810 Nov 93 Take Apart/4-4

EP CARTRIDGE SENSOR BRACKET 4-40

EP CARTRIDGE SENSOR 4-41

FUSER FAN 4-42

DRIVE UNIT 4-43

LOW VOLTAGE POWER SUPPLY (LVPS) 4-45

CONTROL PANEL ASSEMBLY 4-46

HIGH VOLTAGE POWER SUPPLY (HVPS) 4-48

DC CONTROLLER 4-49

I/O CONTROLLER 4-50

FEEDER UNIT 4-52

LOWER CHUTE ASSEMBLY 4-53

PAPER OUT SENSOR (TRAY 2 & 3) 4-54

PAPER FEED ROLLER ASSEMBLY 4-55

PAPER FEED SOLENOID (TRAY 2 & 3) 4-56

PAPER SIZE SENSOR (TRAY 2 & 3) 4-57

OUTER TURN-CHUTE ASSEMBLY 4-58

INNER TURN-CHUTE ASSEMBLY 4-59

MULTI MEDIA POWER FEEDER 4-60

TOP COVER (MULTI MEDIA POWER FEEDER) 4-61

TRAY ASSEMBLY (MULTI MEDIA POWER FEEDER) 4-62

MULTI MEDIA FEEDER PCB 4-63

PAPER FEED SENSOR (MULTI MEDIA POWER FEEDER) 4-64

PAPER OUT SENSOR (MULTI MEDIA POWER FEEDER) 4-65

MOTOR ASSEMBLY (MULTI MEDIA POWER FEEDER) 4-66

FEED ROLLER ASSEMBLY (MULTI MEDIA POWER FEEDER) 4-67

TAKE-AWAY ROLLER ASSEMBLY(MULTI MEDIA POWER FEEDER) 4-68

RETARD ASSEMBLY (MULTI MEDIA POWER FEEDER) 4-69

FAX CARTRIDGE INSTALLATION 4-70

PLUG/CONNECTOR LOCATIONS 4-73

Page 28

LaserWriter Pro 810 Nov 93 Take Apart/4-5

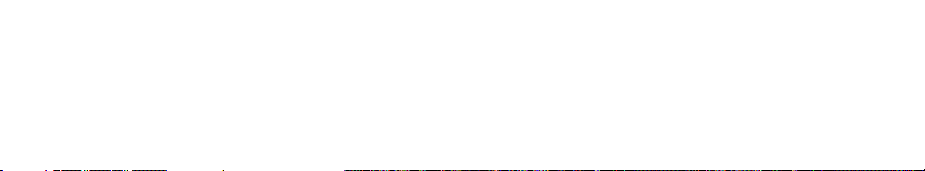

POWER CORD COVER

Removal To remove the power cord cover:

1 . Carefully pull the rear end of the power cord cover away from the side

of the printer. Use a coin, or similar object, if needed, to pry the

cover loose.

2 . Slide the whole cover toward the front of the printer until it can be

removed.

POWER

CORD

COVER

FIGURE 4-1. POWER CORD COVER REMOVAL

Installation To install the power cord cover:

1 . Lay the power cord along the base of the printer. Be sure the power

cord is secured by the hooks provided

POWER

CORD

HOOKS

FIGURE 4-2. POWER CORD COVER INSTALLATION

COVER

Page 29

LaserWriter Pro 810 Nov 93 Take Apart/4-6

2 . Attach the front of the power cord cover to the printer.

3 . Carefully press on the rear end of the cover to lock it in place.

Page 30

LaserWriter Pro 810 Nov 93 Take Apart/4-7

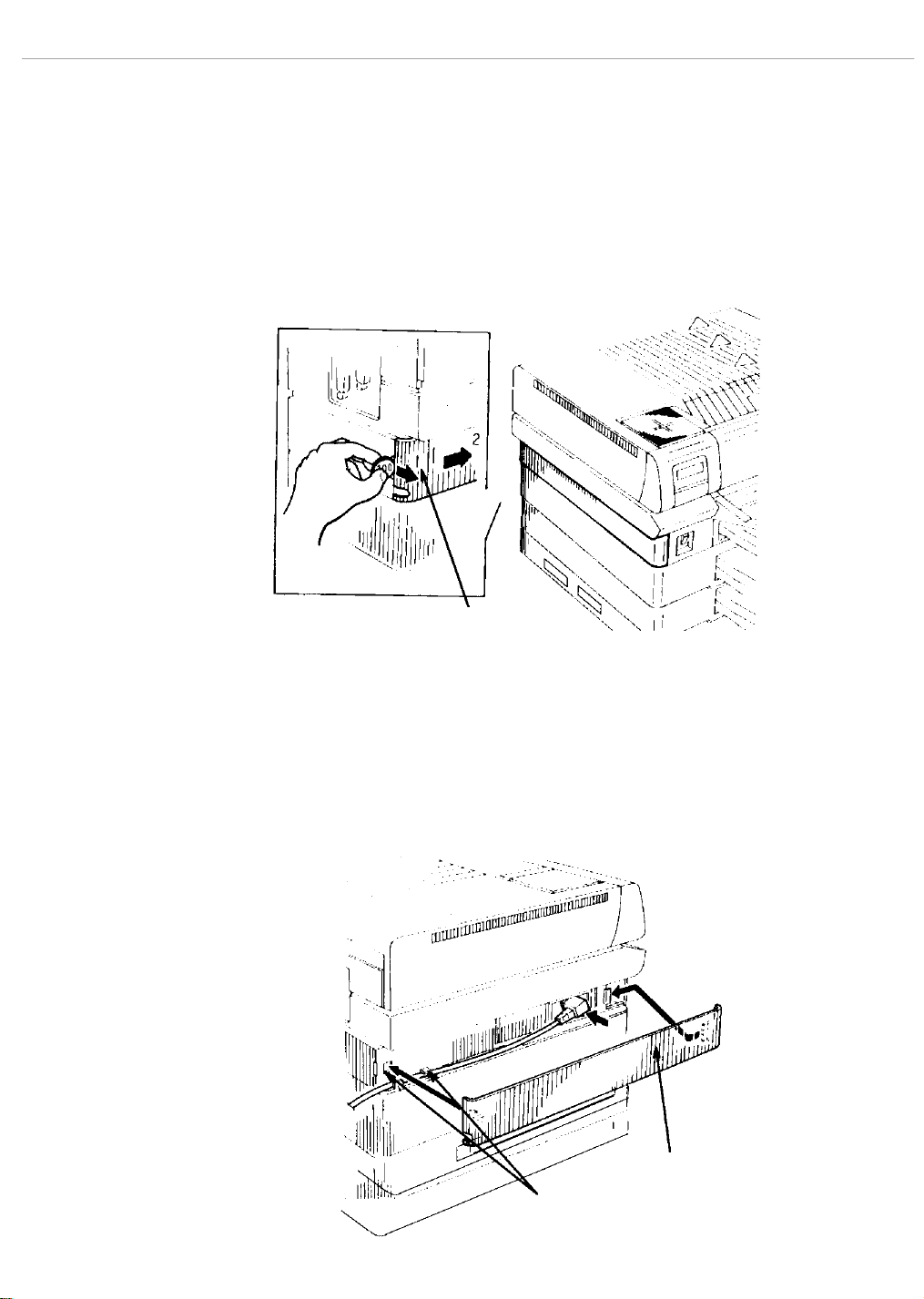

TOP COVER

Removal To remove the top cover:

1 . Turn off the printer and unplug the power cord from the electrical

outlet.

2. Open the top cover. Remove the EP cartridge and put it in a safe place.

3. Raise the top cover as far as possible.

4 . Loosen the two front screws with the silver flanges.

5 . Push back on the top cover and then lift it upward to remove it.

TOP

COVER

COVER

SCREWS

FIGURE 4-3. TOP COVER REMOVAL

Installation To install the top cover:

Reverse the removal procedure.

CAUTION: Be sure that the hooks on the rear of the cover are engaged with

the frame.

Page 31

LaserWriter Pro 810 Nov 93 Take Apart/4-8

FRONT COVER

Removal To remove the front cover:

1 . Remove the two screws with silver flanges from the front cover.

2 . Push down on the front cover as you move it toward you. The lower

edge must be unhooked from the frame. Use a thin tool such as a T-pin

or a jewler's screwdriver to unhook the tabs.

FRONT

COVER

SCREWS

FIGURE 4-4. FRONT COVER REMOVAL

Installation To install the front cover:

Reverse the removal procedure.

FRONT

COVER

Page 32

LaserWriter Pro 810 Nov 93 Take Apart/4-9

LEFT COVER

Removal To remove the left cover:

1. Remove the power cord cover. Disconnect the power cord.

2. Remove the top cover.

3 . Remove the front cover.

4 . Remove the four screws with silver flanges from the left cover.

5. While pulling the left cover assembly toward you, carefully pull out

on the front edge of the cover to unhook it from the power switch.

6 . Carefully move the left cover assembly toward the left to remove it.

LEFT

COVER

SCREWS

LEFT COVER

FIGURE 4-5. LEFT COVER REMOVAL

Installation To install the left cover:

Reverse the removal procedure.

LEFT COVER

SCREW (FRONT)

Page 33

LaserWriter Pro 810 Nov 93 Take Apart/4-10

RIGHT COVER

Removal To remove the right cover:

1. Remove the top cover.

2 . Remove the front cover.

3 . Remove the outer exit-chute assembly.

4 . Remove the three screws with silver flanges from the right cover.

5 . Lift the right cover and carefully pull it straight out and away from

the frame.

RIGHT

COVER

SCREWS

RIGHT COVER

SCREW

FIGURE 4-6. RIGHT COVER REMOVAL

Installation To install the right cover:

Reverse the removal procedure.

RIGHT

COVER

Page 34

LaserWriter Pro 810 Nov 93 Take Apart/4-11

REAR COVER

Removal To remove the rear cover:

1. Remove the power cord cover.

2 . Remove the manual feed tray or the multi media power feeder.

3. Remove the top cover.

4 . Remove the front cover.

5 . Remove the left cover.

6 . Remove the right cover.

7 . Remove the remaining two screws with silver flanges that attaches the

rear cover to the frame.

8 . Pull the rear cover straight out and away from the frame.

REAR

COVER

REAR COVER

SCREWS

FIGURE 4-7. REAR COVER REMOVAL

Installation To install the rear cover:

Reverse the removal procedure.

Page 35

LaserWriter Pro 810 Nov 93 Take Apart/4-12

ELECTRICAL BOX COVER

Removal To remove the electrical box cover:

1. Remove the power cord cover.

2. Remove the top cover.

3 . Remove the front cover.

4 . Remove the left cover.

5. Remove the fuser fan.

6 . Remove the seven screws with silver flanges from the electrical box

cover.

7 . Move the electrical box cover straight out and away from the printer.

BEFORE REMOVING THE ELECTRICAL

BOX COVER SCREWS, NOTE THE

LOCATION OF THE TWO

HOLES FOR THE LEFT

COVER SCREWS.

COVER

SCREWS

GROUND

WIRE

TERMINAL

COVER

SCREWS

FIGURE 4-8. ELECTRICAL BOX COVER REMOVAL

Installation To install the electrical box cover:

1 . Reverse the removal procedure. Be sure that the electrical box cover

screws are not installed in the left cover screw holes.

CAUTION: Be sure the ground wire is attached when installing the electrical

box cover mounting screws.

ELECTRICAL BOX COVER

Page 36

LaserWriter Pro 810 Nov 93 Take Apart/4-13

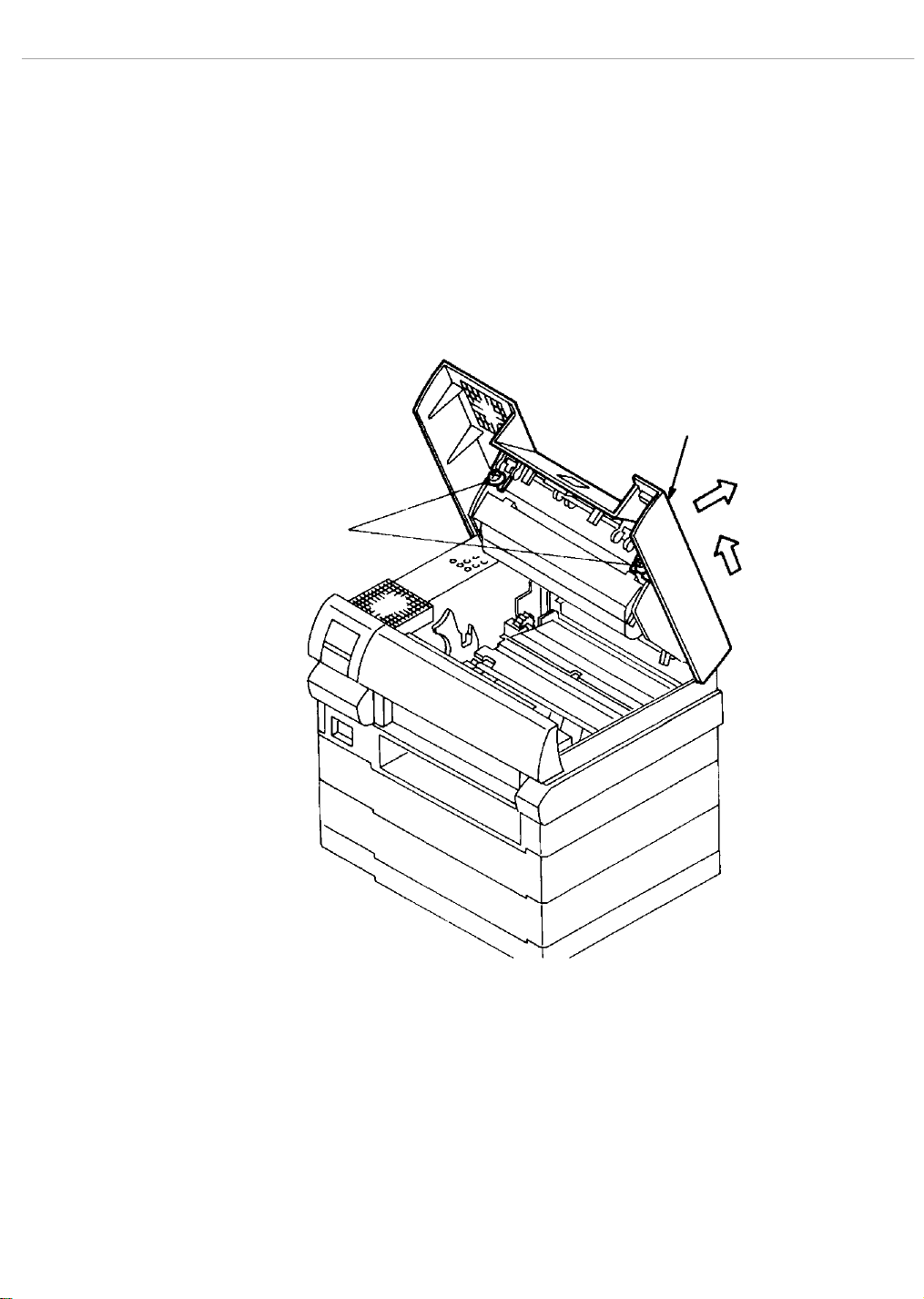

TRANSFER CHARGER/DETACK SAW ASSEMBLY

Removal To remove the transfer charger/detack saw assembly:

1. Open the top cover.

2 . Raise the right side of the transfer charger/detack saw assembly

slightly. See Figure 4- 9

3 . Slide the transfer charger/detack saw assembly to the right until it

can be lifted from the printer.

TRANSFER

CHARGER/DETACK

SAW ASSEMBLY

FIGURE 4-9. TRANSFER CHARGER/DETACK SAW ASSEMBLY REMOVAL

Installation To install the transfer charger/detack saw assembly:

Reverse the removal procedure.

Page 37

LaserWriter Pro 810 Nov 93 Take Apart/4-14

PAPER TRANSFER UNIT

Removal To remove the Paper Transfer Unit:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the registration clutch connector P/J9 from the DC

Controller.

4 . Remove the two black screws from the inlet chute to remove it.

5 . Remove the two screws with silver flanges from the Paper Transfer

Unit.

6 . Raise the Paper Transfer Unit.

7 . Move the Paper Transfer Unit forward in the direction of arrow.

CAUTION: To prevent the ground plate on the left side from dropping, hold it

securely when removing the Paper Transfer Unit.

INLET

CHUTE

SCREW

PAPER

TRANSFER

UNIT

SCREWS

FIGURE 4-10. PAPER TRANSFER UNIT REMOVAL

Installation To install the Paper Transfer Unit:

Reverse the removal procedure.

INLET

CHUTE

INLET

CHUTE

SCREW

PAPER

TRANSFER

UNIT

NOTE: Before securing the Paper Transfer Unit, position the ground plate

to the left and route the ground wire to the right. Be sure that the unit

rests on the frame.

Page 38

LaserWriter Pro 810 Nov 93 Take Apart/4-15

REGISTRATION CLUTCH

Removal To remove the registration clutch:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the Paper Transfer Unit.

4 . Remove the C-ring from the gear and slide the gear from the frame.

5. Disconnect the transport clutch connector P/J51 and the preregistration sensor connector P/J52.

6 . Remove the E-ring from the registration clutch and slide the clutch

out of the frame.

C-RING

GEAR

PAPER TRANSFER

UNIT

E-RING

REGISTRATION

CLUTCH

FIGURE 4-11. REGISTRATION CLUTCH REMOVAL

Installation To install the registration clutch:

Reverse the removal procedure.

Page 39

LaserWriter Pro 810 Nov 93 Take Apart/4-16

PRE-REGISTRATION SENSOR

Removal To remove the pre-registration sensor:

1. Open the top cover. Remove the EP cartridge, and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the Paper Transfer Unit.

4. To remove the pre-registration sensor, release the four clips that

secure the pre-registration sensor to the Paper Transfer Unit.

PRE-REGISTRATION

SENSOR

FIGURE 4-12. PRE-REGISTRATION SENSOR REMOVAL

Installation To install the pre-registration sensor:

Reverse the removal procedure.

PAPER TRANSFER

UNIT

Page 40

LaserWriter Pro 810 Nov 93 Take Apart/4-17

TRANSPORT CLUTCH (TRAY 1)

Removal To remove the transport clutch:

1. Open the top cover. Remove the EP cartridge, and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the Paper Transfer Unit.

4 . Remove the C-ring from the gear and slide it from its shaft.

5. Disconnect the transport clutch connector P/J51.

6. Remove the E-ring from the transport clutch.

7. Lift the transport roller shaft out of the Paper Transfer Unit frame.

8. Slide the transport clutch from the roller shaft.

C-RING

E-RING

FIGURE 4-13. TRANSPORT CLUTCH REMOVAL

Installation To install the transport clutch:

Reverse the removal procedure.

TRANSPORT

ROLLER

PAPER TRANSFER

UNIT

Page 41

LaserWriter Pro 810 Nov 93 Take Apart/4-18

PAPER FEED ROLLER ASSEMBLY

Removal To remove the feed roller assembly:

1. Open the top cover. Remove the EP cartridge, and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the Paper Transfer Unit.

4 . Remove the KL clip on the right side of the feed roller shaft.

5 . Move the feed roller assembly to the right then raise it until it can be

removed from the printer.

FIGURE 4-14. FEED ROLLER ASSEMBLY REMOVAL

Installation To install the feed roller assembly:

Reverse the removal procedure.

CAUTION: Be sure the flange side of KL clip faces inward when it is

installed.

KL CLIP

PAPER FEED

ROLLER

ASSEMBLY

Page 42

LaserWriter Pro 810 Nov 93 Take Apart/4-19

PAPER FEED SOLENOID (TRAY 1)

Removal To remove the paper feed solenoid:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the Paper Transfer Unit.

4 . Remove the feed roller assembly.

5 . Remove the electrical box cover.

6 . Remove connector P/J8 from the DC Controller.

7 . Remove the screw with the black flange from the paper feed solenoid.

8 . Lift the paper feed solenoid up and out of the printer base.

MOUNTING

SCREW

FIGURE 4-15. PAPER FEED SOLENOID REMOVAL

Installation To install the paper feed solenoid:

Reverse the removal procedure.

PAPER

FEED

SOLENOID

Page 43

LaserWriter Pro 810 Nov 93 Take Apart/4-20

PAPER OUT SENSOR (TRAY 1)

Removal To remove the paper out sensor:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the Paper Transfer Unit.

4. Disconnect P/J42.

5 . Release the four clips securing the paper out sensor, and remove it.

PAPER

OUT

SENSOR

FIGURE 4-16. PAPER OUT SENSOR REMOVAL

Installation To install the paper out sensor:

Reverse the removal procedure.

Page 44

LaserWriter Pro 810 Nov 93 Take Apart/4-21

PAPER SIZE SENSOR (TRAY 1)

Removal To remove the paper size sensor:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the power cord cover.

3. Remove the top cover.

4 . Remove the front cover.

5 . Remove the left cover.

6 . Remove the fuser assembly.

7 . Remove the electrical box cover.

8 . Remove the low voltage power supply. See page 4-43 for

instructions.

9 . Use a small blade screwdriver to release the three clips securing the

paper size sensor. See Figure 4-17.

10 . Disconnect P/J10 from the DC Controller.

1 1. Carefully pull the sensor harness from the printer to remove the

paper size sensor.

PAPER SIZE

SENSOR

FIGURE 4-17. PAPER SIZE SENSOR REMOVAL

Installation To install the paper size sensor:

Reverse the removal procedure.

Page 45

LaserWriter Pro 810 Nov 93 Take Apart/4-22

OUTER TURN-CHUTE ASSEMBLY

Removal To remove the outer turn-chute assembly:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the Paper Transfer Unit.

4. Remove the power cord cover.

5. Remove the top cover.

6 . Remove the front cover.

7 . Remove the left cover.

8 . Remove the right cover.

9 . Remove the rear cover.

10 . Remove the right and left springs from the outer turn-chute

assembly. Be sure to save the washers.

1 1. Carefully pull the outer turn-chute assembly out of the back of the

printer.

SPRING

OUTER

TURN-CHUTE

ASSEMBLY

FIGURE 4-18. OUTER TURN-CHUTE ASSEMBLY

SPRING

Installation To install the outer turn-chute assembly:

Reverse the removal procedure.

CAUTION: Be sure to install the washers for the turn-chute assembly.

Page 46

LaserWriter Pro 810 Nov 93 Take Apart/4-23

INNER TURN-CHUTE ASSEMBLY

Removal To remove the inner turn-chute assembly:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the Paper Transfer Unit.

4. Remove the power cord cover.

5. Remove the top cover.

6 . Remove the front cover.

7 . Remove the left cover.

8 . Remove the right cover.

9 . Remove the rear cover.

1 0. Remove the outer turn-chute assembly.

1 1 . Remove the right and left springs from each side of the inner turn-

chute assembly.

1 2. Slide the inner turn-chute to the left or right to free the shaft and

remove the turn-chute.

SPRING

INNER

TURN-CHUTE

ASSEMBLY

SPRING

FIGURE 4-19. INNER TURN-CHUTE ASSEMBLY REMOVAL

Installation To install the inner turn-chute assembly:

Reverse the removal procedure.

Page 47

LaserWriter Pro 810 Nov 93 Take Apart/4-24

TRANSPORT CHUTE ASSEMBLY

Removal To remove the transport chute assembly:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Loosen the two captive screws on each side of the transport chute

assembly.

3. Lift the transport chute assembly out of the printer.

CAPTIVE

SCREWS

FIGURE 4-20. TRANSPORT CHUTE ASSEMBLY REMOVAL

Installation To install the transport chute assembly:

Reverse the removal procedure.

Page 48

LaserWriter Pro 810 Nov 93 Take Apart/4-25

FUSER UNIT

Removal To remove the fuser unit:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

CAUTION: The fuser unit is very hot when the printer is first turned off.

Wait for the fuser unit to cool before continuing.

2 . Remove the transfer charger/detack saw assembly.

3 . Remove the transport chute assembly.

4 . Disconnect the three plugs located under the fan.

FAN

P62 FUSER BULB

P31 TEMPERATURE SENSOR

P32 EXIT SENSOR

FIGURE 4-21. FUSER UNIT HARNESS REMOVAL

5 . Loosen the two captive screws on the fuser unit.

FIGURE 4-22. FUSER UNIT REMOVAL

NOTE: When lifting the fuser unit out of the printer, do not press on the

roller cleaner cover.

6 . Hold the fuser unit by the two metal flanges sticking out of the top, and

lift it diagonally out of the printer.

Page 49

LaserWriter Pro 810 Nov 93 Take Apart/4-26

FIGURE 4-23. FUSER UNIT REMOVAL

Installation To install the fuser unit:

1 . Set the fuser unit down on the guides and align the inner sides.

2 . Make sure the fuser is seated correctly. There should be no space

between the fuser unit screws and the printer frame.

0mm

FIGURE 4-24. FUSER UNIT INSTALLATION

CAUTION: If the fuser unit is not perfectly seated inside of the guides, paper

jam problems can occur.

3 . Tighten the two captive screws on the fuser unit. Check to be sure the

unit is secure.

4 . Plug the three connectors from the fuser unit wires into the

connectors under the fan. See Figure 4-21.

5. Install the transfer charger.

6 . Install the transport chute/detack saw assembly.

7. Close the top cover.

8. Plug in the printer.

Page 50

LaserWriter Pro 810 Nov 93 Take Apart/4-27

FUSER BULB

Removal To remove the fuser bulb:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

plate.

2 . Remove the fuser unit.

3 . Remove the screw with a gold flange from the right end of the roller

cleaner cover, and remove it.

4 . Remove the roller cleaner.

5 . Remove the two screws with black flanges from the outer cover, and

remove it.

6 . Carefully pull outward on the metal clamp securing the fuser bulb.

7 . Slide the fuser bulb out of the heat roller.

FUSER

UNIT

FIGURE 4-25. FUSER BULB REMOVAL

Installation To install the fuser bulb:

Reverse the removal procedure.

FUSER

BULB

CLAMP

FUSER

BULB

Page 51

LaserWriter Pro 810 Nov 93 Take Apart/4-28

FUSER THERMOSTAT

Removal To remove the fuser thermostat:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the fuser unit.

3 . Remove a screw with a gold flange from the right side of roller

cleaner cover assembly and remove it.

4 . Remove the roller cleaner.

5 . Remove the right and left screws with black flanges from the outer

cover, and remove it.

6 . Remove the fuser bulb.

7 . Remove the four screws with black flanges from the inner cover

assembly, and remove it.

8 . Remove the two gold screws from the fuser thermostat to remove it.

INNER

COVER

SCREWS

INNER COVER

ASSEMBLY

THERMOSTAT

FIGURE 4-26. FUSER THERMOSTAT REMOVAL

Installation To install the fuser thermostat:

Reverse the removal procedure.

THERMOSTAT

SCREWS

INNER

COVER

SCREWS

FUSER

BASE

Page 52

LaserWriter Pro 810 Nov 93 Take Apart/4-29

FUSER TEMPERATURE SENSOR

Removal To remove the fuser temperature sensor:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the fuser unit.

3 . Remove the screw with a gold flange from the right end of the roller

cleaner cover assembly, and remove it.

4 . Remove the roller cleaner.

5 . Remove the right and left screws with black flanges from the outer

cover, and remove it.

6 . Remove the fuser bulb.

7 . Remove four screws with black flanges from the inner cover, and

remove it.

8 . Remove the gold screw from the temperature sensor, and remove it.

TEMPERATURE

SENSOR

SENSOR

SCREW

FIGURE 4-27. FUSER TEMPERATURE SENSOR REMOVAL

Installation To install the fuser temperature sensor:

Reverse the removal procedure.

INNER COVER

ASSEMBLY

Page 53

LaserWriter Pro 810 Nov 93 Take Apart/4-30

PAPER EXIT SENSOR

Removal To remove the paper exit sensor:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2 . Remove the fuser unit.

3 . Remove the screw with a gold flange from the right end of the roller

cleaner cover assembly, and remove it.

4 . Remove the roller cleaner.

5 . Remove right and left screws with black flanges from the outer cover,

and remove it.

6 . Remove the fuser bulb.

7 . Remove the four screws with black flanges from the inner cover

assembly and remove it.

8 . Remove the gold screw from the paper exit sensor to remove it.

EXIT

SENSOR

SENSOR

SCREW

FIGURE 4-28. PAPER EXIT SENSOR REMOVAL

Installation To install the paper exit sensor:

Reverse the removal procedure.

INNER COVER

ASSEMBLY

Page 54

LaserWriter Pro 810 Nov 93 Take Apart/4-31

OUTER EXIT-CHUTE ASSEMBLY

Removal To remove the outer exit-chute:

1 . Open the outer exit-chute assembly.

2 . Carefully pull outward on the right and left bearings until the outer

exit-chute assembly can be removed.

BEARING

BEARING

OUTER EXIT-CHUTE ASSEMBLY

FIGURE 4-29. OUTER EXIT-CHUTE REMOVAL

Installation To install the outer exit-chute assembly:

Reverse the removal procedure.

Page 55

LaserWriter Pro 810 Nov 93 Take Apart/4-32

DIRECTION CHUTE

Removal To remove the direction chute:

1 . Remove the outer exit-chute assembly.

2 . Remove the E-ring and spring from the direction chute to remove it.

DIRECTION

CHUTE

E-RING

SPRING

FIGURE 4-30. DIRECTION CHUTE REMOVAL

Installation To install the direction chute:

Reverse the removal procedure.

Page 56

LaserWriter Pro 810 Nov 93 Take Apart/4-33

INNER EXIT-CHUTE

Removal To remove the inner exit-chute:

1 . Remove the outer-exit chute assembly.

2 . Remove the direction chute.

3 . Remove screws with silver flanges from each side of the inner exit-

chute inner to remove it.

SCREWS

FIGURE 4-31. INNER EXIT-CHUTE REMOVAL

Installation To install the inner exit-chute:

Reverse the removal procedure.

INNER

EXIT-CHUTE

Page 57

LaserWriter Pro 810 Nov 93 Take Apart/4-34

EXIT ROLLER ASSEMBLY

Removal To remove the exit roller assembly:

1 . Remove the outer exit-chute assembly.

2 . Remove the direction chute.

3. Remove the inner exit-chute.

4 . Remove the fuser fan. See page 4-40 for instructions.

5 . Remove the belt on the right end of the exit roller assembly. See the

next procedure for instructions.

6 . Remove the E-rings from each end of the roller shaft.

7 . Slide the pulley and bearing off of the right end of the exit roller

shaft.

8 . Slide the exit roller shaft to the left and remove the exit roller

assembly from the printer.

BEARING

E-RING

BEARING

FIGURE 4-32. EXIT ROLLER ASSEMBLY

Installation To install the exit roller assembly:

Reverse the removal procedure.

PULLEY

E-RING

BELT

LOCATION

Page 58

LaserWriter Pro 810 Nov 93 Take Apart/4-35

BELT (FUSER AREA)

Removal To remove the belt:

1. Remove the top cover.

2 . Remove the front cover.

3 . Remove the right cover.

4 . Remove the outer exit chute assembly.

5 . Remove the E-ring.

6 . Slide the idler shaft inward.

7. Remove the belt.

BELT

IDLER

SHAFT

FIGURE 4-33. FUSER AREA BELT REMOVAL

Installation To install the belt:

Reverse the removal procedure.

E-RING

Page 59

LaserWriter Pro 810 Nov 93 Take Apart/4-36

LASER SCANNER UNIT

Removal To remove the Laser Scanner Unit:

1. Remove the top cover.

2 . Remove right and left screws with silver flanges from the laser

scanner unit.

3. Disconnect P21 from J21.

4 . Open the laser scanner unit shield and lift the laser scanner unit out

of the printer.

CAUTION: Keep the Laser Scanner Unit in a safe place.

MOUNTING

SCREW

LASER

SCANNER

UNIT

FIGURE 4-34. LASER SCANNER UNIT REMOVAL

MOUNTING

SCREW

Installation To install the Laser Scanner Unit:

Reverse the removal procedure.

Page 60

LaserWriter Pro 810 Nov 93 Take Apart/4-37

ERASE ASSEMBLY

Removal To remove the erase assembly:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the top cover.

3 . Remove the two black screws from the erase assembly.

4 . Disconnect P22 from J22. Remove the erase assembly.

MOUNTING

SCREW

ERASE ASSEMBLY

FIGURE 4-35. ERASE ASSEMBLY REMOVAL

Installation To install the erase assembly:

Reverse the removal procedure.

MOUNTING

SCREW

Page 61

LaserWriter Pro 810 Nov 93 Take Apart/4-38

TONER SENSOR

Removal To remove the toner sensor:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the top cover.

3. Disconnect P23 from J23.

4 . Release the four clamps that secure the toner sensor to the bracket to

remove the toner sensor.

TONER

SENSOR

CLAMPS

FIGURE 4-36. TONER SENSOR REMOVAL

Installation To install the toner sensor:

Reverse the removal procedure.

Page 62

LaserWriter Pro 810 Nov 93 Take Apart/4-39

TONER SENSOR BRACKET

Removal To remove the toner sensor bracket:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the top cover.

3. Remove the toner sensor.

4 . Remove the E-ring from the left end of the shaft.

5 . Move the shaft to the left.

6 . Remove the toner sensor bracket.

CAUTION: Keep the spring in a safe place for the installation procedure.

TONER SENSOR BRACKET

SPRING

E-RING

FIGURE 4-37. TONER SENSOR BRACKET REMOVAL

Installation To install the toner sensor bracket:

Reverse the removal procedure.

Page 63

LaserWriter Pro 810 Nov 93 Take Apart/4-40

EP CARTRIDGE SENSOR BRACKET

Removal To remove the EP cartridge sensor bracket:

1. Open the top cover. Remove EP cartridge and keep it in a safe place.

2. Remove the top cover.

3 . Remove the E-ring from the end of the shaft.

4 . Slide the shaft to the right.

5 . Slide the EP cartridge sensor bracket out of the printer.

6. Remove the EP Cartridge sensor if needed.

CAUTION: Do not lose or discard the spring. It must be installed again.

E-RING

SPRING

EP

CARTRIDGE

SENSOR

BRACKET

FIGURE 4-38. EP CARTRIDGE SENSOR BRACKET REMOVAL

Installation To install the EP cartridge sensor bracket:

Reverse the removal procedure.

Page 64

LaserWriter Pro 810 Nov 93 Take Apart/4-41

EP CARTRIDGE SENSOR

Removal To remove the EP cartridge sensor:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the top cover.

3 . Remove the EP cartridge sensor bracket.

4. Disconnect P24 from J24.

5 . Release the upper and lower clips that secure the sensor to the EP

cartridge sensor bracket.

6. Remove the EP cartridge sensor.

EP

CARTRIDGE

SENSOR

FIGURE 4-39. EP CARTRIDGE SENSOR REMOVAL

Installation To install the EP cartridge sensor:

Reverse the removal procedure.

Page 65

LaserWriter Pro 810 Nov 93 Take Apart/4-42

FUSER FAN

Removal To remove the fuser fan:

1 . Remove the three long, gold screws from the fuser fan.

2. Disconnect P33 from J33.

3 . Remove the fan wire harness from the wire clamp.

4. Remove the fan cover and fuser fan.

MOUNTING

SCREWS

FUSER FAN

FIGURE 4-40. FUSER FAN REMOVAL

Installation To install the fuser fan:

Reverse the removal procedure.

Page 66

LaserWriter Pro 810 Nov 93 Take Apart/4-43

DRIVE UNIT

Removal To remove the drive unit:

1. Remove the power cord cover.

2. Remove the top cover.

3 . Remove the front cover.

4 . Remove the left cover.

5. Remove the fuser fan.

6 . Remove the electrical box cover.

7 . Remove the control panel assembly.

8 . Remove the following connectors (see “Plug/Connector Locations" at

the end of this section):

•P/J61 (on the Low Voltage Power Supply PCB)

•P/J73 (on the Drive Unit PCB)

•P/J62 (Fuser Bulb)

•P/J31 (Temperature Sensor)

•P/J32(Exit Sensor)

•P/J1, P/J4, P/J7, P/J8, P/J9, and P/J10 (DC Controller)

9. Remove the screw that secures the cables to the DC Controller

connectors P/J81, P/J82, P/J83, P/J84, P/J91, P/J92, P/J93,

and P/J94, and the green ground wire.

1 0 . Remove the four screws with silver flanges from the side frame

assembly and remove it from the printer.

SIDE

FRAME

ASSEMBLY

PRINTER

FRAME

SIDE

FRAME

SCREWS

SIDE FRAME

SCREW

FIGURE 4-41. SIDE FRAME ASSEMBLY REMOVAL

Page 67

LaserWriter Pro 810 Nov 93 Take Apart/4-44

CAUTION: While doing the following step, be careful NOT to tilt the unit and

let the drive gears fall from their shafts.

11. Remove the five gold screws and the black hex head screw from the

drive unit to remove it from the side frame assembly.

PRINTER

FRAME

DRIVE

UNIT

DRIVE UNIT

SCREWS

FIGURE 4-42. DRIVE UNIT REMOVAL

Installation To install the drive unit:

1 . Reverse the installation procedure. See “Plug/Connector Locations" at

the end of this section for wire and cable routing.

Page 68

LaserWriter Pro 810 Nov 93 Take Apart/4-45

LOW VOLTAGE POWER SUPPLY (LVPS)

Removal To remove the low voltage power supply:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the power cord cover.

3. Remove the top cover.

4 . Remove the front cover.

5 . Remove the left cover.

6 . Remove the electrical box cover.

7. Remove the fuser fan.

8 . Remove the control panel assembly.

CAUTION: To avoid damage, hold the Low Voltage Power Supply PCB while

disconnecting P61 from J61.

9 . Disconnect P/J61 and P/J62 from the Low Voltage Power Supply

PCB.

1 0 . Remove the four screws from the low voltage power supply to remove

it.

LOW VOLTAGE

POWER SUPPLY

MOUNTING

SCREWS

FIGURE 4-43. LOW VOLTAGE POWER SUPPLY REMOVAL

Installation To install the low voltage power supply:

1 . Reverse the removal procedure.

See “Plug/Connector Locations" at

the end of this section for help in routing and connecting cables.

CAUTION: When installing the fuser fan, be sure the its harness is secured

by the wire clamp.

CAUTION: The connectors P2 and P3 on the DC Controller must be connected

and routed prior to replacement of the Low Voltage Power Supply.

MOUNTING

SCREW

Page 69

LaserWriter Pro 810 Nov 93 Take Apart/4-46

CONTROL PANEL ASSEMBLY

Removal To install the control panel assembly:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the power cord cover.

3. Remove the top cover.

4 . Remove the front cover.

5 . Remove the left cover.

6 . Remove the electrical box cover.

7. Remove the fuser fan.

NOTE: The keypad should remain open while doing the following steps.

8. Open the control panel keypad.

9 . Remove the three screws with silver flanges from the control panel

assembly.

CONTROL

PANEL

ASSEMBLY

MOUNTING

SCREWS

FIGURE 4-44. CONTROL PANEL ASSEMBLY REMOVAL

1 0. Remove the low voltage power supply.

CAUTION: Note the location and routing of the wire harness before

disconnecting and removing it.

1 1 . Disconnect the plugs from the DC Controller connectors P/J2 and

P/J3.

12. Carefully free the wire harness from the printer frame before

removing the control panel assembly.

Installation To install the control panel assembly:

1 . Reverse the removal procedure.

See “Plug/Connector Locations" at

the end of this section for help in routing and connecting cables.

Page 70

LaserWriter Pro 810 Nov 93 Take Apart/4-47

NOTE: Wire leads for the back-light break easily from the LCD panel.

During installation, be careful to position the Control Panel PCB correctly.

If the Control Panel PCB is not aligned properly the wires may be damaged.

CAUTION: When installing the fuser fan, be sure the its harness is secured

by the wire clamp.

Page 71

LaserWriter Pro 810 Nov 93 Take Apart/4-48

HIGH VOLTAGE POWER SUPPLY (HVPS)

Removal To remove the high voltage power supply:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the top cover.

3 . Remove the front cover.

4 . Remove the outer exit chute assembly.

5 . Remove the right cover assembly.

6 . Remove the transfer charger/ detack saw assembly.

7 . Remove the Paper Transfer Unit.

8 . Remove the feed roller assembly.

9. Disconnect P41 from J41.

1 0 . Remove the screw with a silver flange from the high voltage power

supply.

1 1 . Move the high voltage power supply to the left then lift it out of the

printer base as shown by the arrows in Figure 4-46.

FIGURE 4-45. HIGH VOLTAGE POWER SUPPLY REMOVAL

Installation To install the high voltage power supply:

Reverse the removal procedure.

HIGH VOLTAGE

POWER SUPPLY

(HVPS)

MOUNTING

SCREW

Page 72

LaserWriter Pro 810 Nov 93 Take Apart/4-49

DC CONTROLLER

Removal To remove the DC Controller:

1. Open the top cover. Remove the EP cartridge and keep it in a safe

place.

2. Remove the power cord cover.

3. Remove the top cover.

4 . Remove the front cover.

5 . Remove the left cover.

6 . Remove the electrical box cover.

7 . Remove the following connectors:

•P/J61 (on the Low Voltage Power Supply PCB)

•P/J73 (on the Drive Unit PCB)

•P/J1, P/J2, P/J3, P/J4, P/J7, P/J8, P/J9, P/J10 P12 (DC

Controller)

•Remove connectors P/J81, P/J82, P/J83, and P/J84, P/J91,

P/J92, P/J93, and P/J94.

8 . Remove the two screws with silver flanges from the back panel and

remove it.

9 . To remove the DC Controller, remove the two screws with silver

flanges that attach it to the back panel.

BACK PANEL

BACK PANEL

SCREWS

DC

CONTROLLER

SCREWS

DC

CONTROLLER

PCB

4-46. DC CONTROLLER REMOVAL

Installation To install the DC Controller:

FIGURE

Reverse the removal procedure.

See “Plug/Connector Locations" at the end

of this section for help in routing and connecting cables.

CAUTION: When reinstalling the DC Controller, make sure that cables are

installed in the connectors P81-P84, P91-94 and P12.

Page 73

LaserWriter Pro 810 Nov 93 Take Apart/4-50

I/O CONTROLLER

Removal To remove the I/O Controller:

1 . Remove the screw from the front corner of the wafer box cover.

2 . Remove the screw from the back corner of the wafer box cover.

3 . Remove the four screws that attach the I/O Controller to the interface

bracket.

INTERFACE

BRACKET

SCREWS

FIGURE 4-47. WAFER BOX COVER REMOVAL

WAFER BOX

COVER SCREWS

4 . Holding onto to the wafer box cover, slide the I/O Controller out of the

printer until the power and ribbon cables can be reached.

5. Note the cable connector directions and disconnect the power and

ribbon cables.

6 . Slide the I/O Controller completely out of the wafer box.

7 . If replacing the I/O Controller, remove the two screws that attach the

PCB to the wafer box brackets.

8 . Remove the I/O Controller from the wafer box bracket.

CAUTION: When the I/O Controller board is removed, the printer can

collapse preventing the I/O board from seating correctly. This collapse can

result from moving or applying pressure to the top of the printer while the

I/O board is removed.

Page 74

LaserWriter Pro 810 Nov 93 Take Apart/4-51

POWER CABLE

PLUG (J7)

I/O CONTROLLER

WAFER BOX

RIBBON

CABLE PLUG

(J6)

FIGURE 4-48. I/O CONTROLLER REMOVAL

Installation To install the I/O Controller:

1 . Position the I/O Controller on the wafer box cover brackets with the

edge of the I/O Controller Board in the slots.

2 . Install the two mounting screws.

3 . Slide the I/O Controller into the right guide in the wafer box.

4 . Continue to insert the I/O Controller into the wafer box until it slides

into the left guide that begins about halfway.

5 . Plug in the power and ribbon cables when the I/O Controller Board is

almost fully inserted.

6. Fully insert the I/O Controller Board.

7 . Install two screws on each side of the wafer box cover.

8 . Install the four screws removed from the interface bracket.

Page 75

LaserWriter Pro 810 Nov 93 Take Apart/4-52

FEEDER UNIT

Removal To remove the feeder unit:

1. Remove the power cord cover.

2. Remove the top cover.

3 . Remove the front cover.

4 . Remove the left cover.

5 . Remove the right cover.

6 . Remove the electrical box cover.

7 . Remove the four screws with silver flanges that attach the feeder unit

to the print engine body.

8 . Remove the following connectors:

•P/J81, P/J82, P/J83, P/J84.

•P/J91, J/J92, P/J93, P/J94.

9 . Remove the screw that attaches the two feeder unit ground wires to the

print engine. It is located in front of the DC Controller.

10 . Lift the print engine from the feeder unit.

1 1 . To separate the two feeder units, remove the four screws that attach

the upper feeder unit to the lower feeder unit.

1 2 . Lift the upper feeder unit off of the lower feeder unit, if needed.

MOUNTING

SCREWS

UPPER

FEEDER

UNIT

LOWER

FEEDER

UNIT

MOUNTING

SCREWS

FIGURE 4-49. FEEDER UNIT REMOVAL

Installation To install the feeder unit:

Reverse the removal procedure.

Page 76

LaserWriter Pro 810 Nov 93 Take Apart/4-53

LOWER CHUTE ASSEMBLY

Removal To remove the lower chute assembly from a feeder unit:

1 . Remove the feeder unit.

2 . Remove the five screws from the lower chute assembly.

3 . Lift and remove it.

LOWER CHUTE

ASSEMBLY

MOUNTING

SCREWS

MOUNTING

SCREWS

FIGURE 4-50. LOWER CHUTE ASSEMBLY REMOVAL

Installation To install the lower chute assembly in a feeder unit:

Reverse the removal procedure.

Page 77

LaserWriter Pro 810 Nov 93 Take Apart/4-54

PAPER OUT SENSOR

Removal To remove the paper out sensor from a feeder unit:

1 . Remove the feeder unit.

2 . Release the four spring clips that attach the paper out sensor to the

lower chute assembly.

PAPER OUT SENSOR

FIGURE 4-51. PAPER OUT SENSOR (FEEDER UNITS)

Installation To install the paper out sensor in a feeder unit:

Reverse the removal procedure.

Page 78

LaserWriter Pro 810 Nov 93 Take Apart/4-55

PAPER FEED ROLLER ASSEMBLY

Removal To remove the paper feed roller assembly from a feeder unit:

1 . Remove the feeder unit.

2 . Remove the lower chute assembly.

3 . Lift the paper feed roller assembly out of the feeder unit.

PAPER FEED

ROLLER

ASSEMBLY

FIGURE 4-52. PAPER FEED ROLLER ASSEMBLY (FEEDER UNITS)

Installation To install the paper feed roller assembly in a feeder unit:

Reverse the removal procedure.

Page 79

LaserWriter Pro 810 Nov 93 Take Apart/4-56

PAPER FEED SOLENOID (TRAYS 2 & 3)

Removal To remove a paper feed solenoid from a feeder unit:

1 . Remove the feeder unit.

2 . Remove the lower chute assembly.

3 . Remove the paper feed roller assembly.

4. Remove the screw with a black flange that attaches the paper feed

solenoid to the feeder unit.

5. Slide the paper feed solenoid to one side and lift it out of the feeder

unit.

PAPER FEED

MOUNTING

SCREW

SOLENOID

4-53. PAPER FEED SOLENOID REMOVAL (FEEDER UNITS)

Installation To install a paper feed solenoid in a feeder unit:

Reverse the removal procedure.

Page 80

LaserWriter Pro 810 Nov 93 Take Apart/4-57

PAPER SIZE SENSOR (TRAYS 2 & 3)

Removal To remove the paper size sensor from a feeder unit:

1 . Remove the feeder unit.

2 . Using a screwdriver release the three clamps that attach the paper

size sensor to the side frame of the feeder unit.

PAPER SIZE

SENSOR

FIGURE 4-54. PAPER SENSOR REMOVAL (FEEDER UNITS)

Installation To install the paper size sensor in a feeder unit:

Reverse the removal procedure.

Page 81

LaserWriter Pro 810 Nov 93 Take Apart/4-58

OUTER TURN-CHUTE ASSEMBLY

Removal To remove the outer turn-chute assembly from a feeder unit:

1 . Remove the feeder unit.

2 . Remove the lower chute assembly.

3 . Remove the spring on each side of the outer turn-chute assembly.

4 . Move the turn chute assembly downward and out of the feeder unit.

NOTE: To remove the outer turn chute assembly from the top tray of a 2-

tray feeder unit, separate the two units first.

SPRING

OUTER TURN-CHUTE ASSEMBLY

FIGURE 4-55. OUTER TURN-CHUTE ASSEMBLY REMOVAL (FEEDER UNITS)

SPRING

Installation To install the outer turn-chute assembly in a feeder unit:

Reverse the removal procedure.

Page 82

LaserWriter Pro 810 Nov 93 Take Apart/4-59

INNER TURN-CHUTE ASSEMBLY

Removal To remove the inner turn-chute assembly from a feeder unit:

1 . Remove the feeder unit.

2 . Remove the lower chute assembly.

3 . Remove the spring from each side of the inner turn-chute assembly.

4 . Push the shaft of the inner turn chute assembly inward to remove it

from the feeder unit.

INNER TURN-CHUTE ASSEMBLY

FIGURE 4-56. INNER TURN-CHUTE ASSEMBLY REMOVAL (FEEDER UNITS)

Installation To install an inner turn chute assembly in a feeder unit:

Reverse the removal procedure.

Page 83

LaserWriter Pro 810 Nov 93 Take Apart/4-60

MULTI MEDIA POWER FEEDER

Removal To remove the multi media power feeder:

1 . Turn off the printer and disconnect the multi media power feeder