Page 1

K

Service Source

LaserWriter 16/600 PS

LaserWriter 16/600 PS

Page 2

K

Service Source

Basics

LaserWriter 16/600 PS

Page 3

Basics Read Me First - 1

Read Me First

The LaserWriter 16/600 PS has the same form factor as

the LaserWriter Pro 600/630, though some functions and

parts are entirely different. If you want a detailed

description of the new servicing issues presented by this

printer, go to the document “New Servicing Issues” that is

included on this CD. Below is a brief outline of this

document.

New rear housing layout

– I/O controller easier to access

– D/C controller harder to access

– New I/O connectivity procedures

– Fax card option

– Internal hard drive option

Page 4

Basics Read Me First - 2

Faster engine

– Modules not backward-compatible

– Feeders not backward-compatible

– Two new fans for ventilation

– Slightly louder (52 dB vs. 49 dB printing)

New printer utilities

Advanced multi-platform performance

New printer diagnostic

Page 5

Basics Printer Utilities - 3

Printer Utilities

The printer utility that you use depends on the type of

computer you use. This topic briefly describes the various

utilities. Refer to chapters 3 and 4 of the user’s guide for

complete information

Note:

Settings made with any of these printer utilities

become default parameters and affect all printed documents,

regardless of the computer that originated the print request.

Page 6

Basics Printer Utilities - 4

Apple Printer Utility for Macintosh Computers

The Apple Printer Utility for Macintosh computers works

only with the LaserWriter 16/600 PS. You use this utility

to set parameters that reside on the printer’s I/O controller

board. You can use this utility to perform many functions,

some of which are listed below.

– Naming the printer

– Initializing SCSI hard drives

– Downloading fonts

– Setting default printer resolution

– Setting default paper-handling options

– Setting default print density

– Printing configuration page

– Turning off the startup test page

– Setting communication protocols

Note:

The LaserWriter Utility for Macintosh computers

Page 7

Basics Printer Utilities - 5

does not work with the LaserWriter 16/600 PS.

The Apple Printer Utility has a hierarchical interface that

is completely different than the LaserWriter Utility for the

Macintosh that serves other laser printers.

After you launch the Apple Printer Utility and select a

printer, a window opens that shows four headings. These

headings are like folders in the Finder. If you click an

arrow, the folder expands to show more items. The command

“Print Configuration Page” is located in the File menu in

the menu bar.

Page 8

Basics Printer Utilities - 6

LaserWriter Utility for Windows

The LaserWriter Utility for Windows has the same functions

as the Apple Printer Utility for Macintosh computers,

except for certain hard drive and font functions which are

absent from the Windows printer drive interface.

NetWare Utilities

There are two DOS utilities, LWPMAN and LWFORM, that

perform a subset of Apple Printer Utility functions in a

NetWare environment.

TCP/IP Printer Configuration Utility for UNIX

To configure the printer from a UNIX environment, run the

TCP/IP Printer Configuration Utility by using the Telnet

program.

Page 9

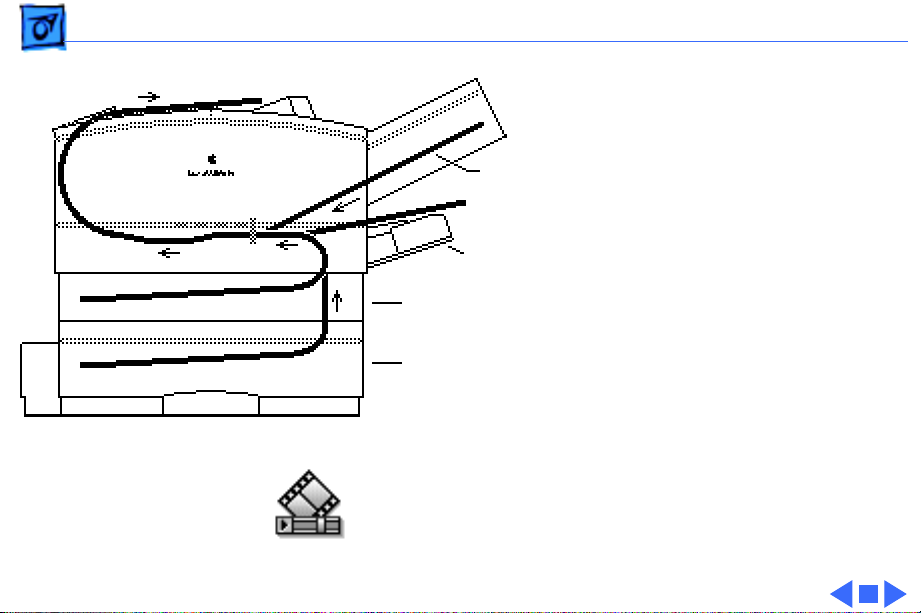

Basics Paper Path - 7

Paper Path

There are four paper

Optional

*

Standard

Cassette (250)

Optional Sheet

Feeder (500)

Envelope

Feeder (75)

Multipurpose

Tray (100)

sources and one output tray

in a complete system. The

number in parenthesis is

the capacity of the paper

source.

Note:

The asterisk at the

point where the paper paths

meet denotes a synchronization pause. See PS602

in “Sensing System Theory”

in this chapter.

Page 10

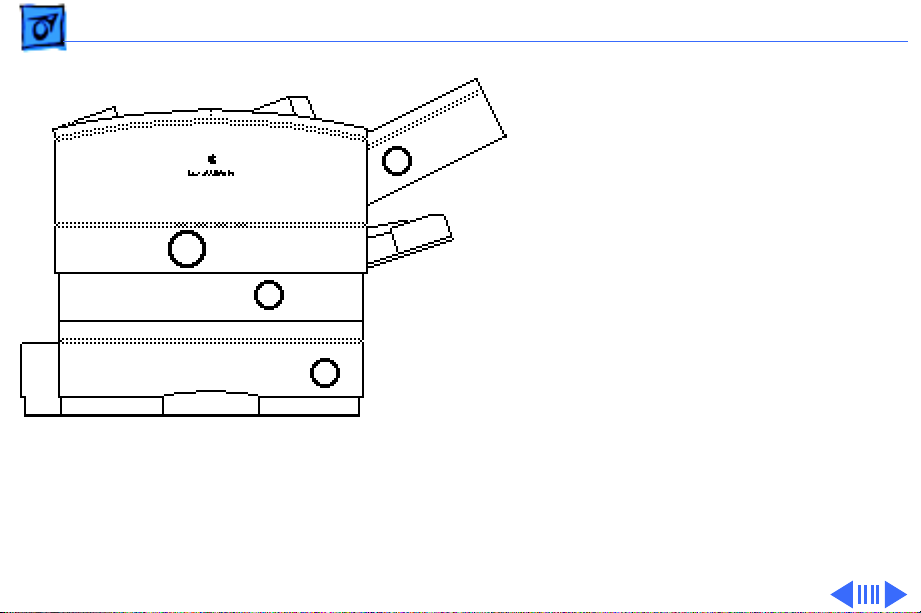

Basics Mechanical Drive Theory - 8

Mechanical Drive

M1

M3

M2

M4

Theory

There are four motors and

four separate drive trains in

a complete system. Two are

in the printer engine and one

is in each of the optional

feeders.

• M1 Main Motor

• M2 Pickup Block Motor

• M3 Sheet Feeder Motor

• M4 Envelope Feeder

Motor

Page 11

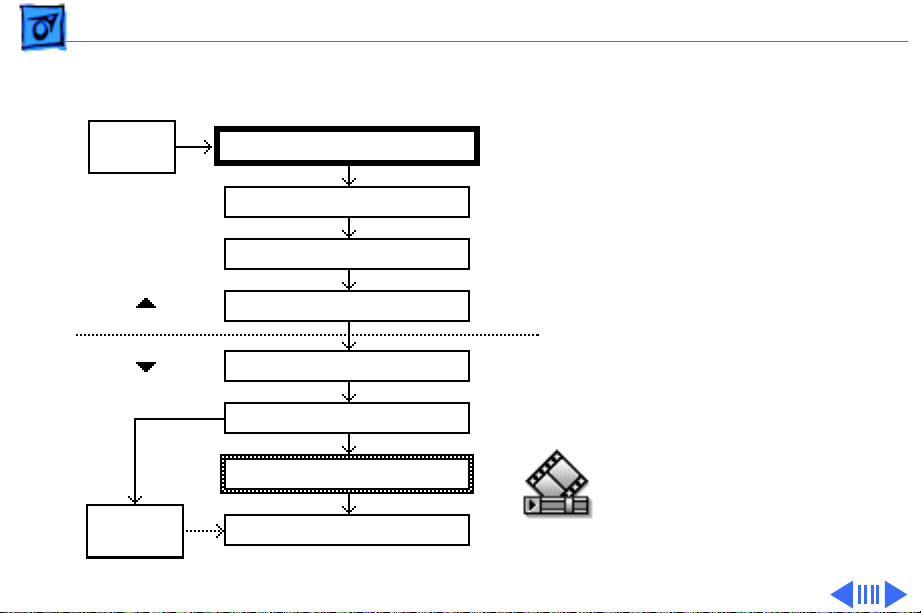

Basics Mechanical Drive Theory - 9

M1 Main Motor Drive

Power

Supply

Toner Cartridge

Transfer Roller

DC Controller Board

Connecting Cable

Main Motor

Drive Assembly

D

Fuser Assembly

Gears/Rollers

E

Delivery Roller Assy

Gears/Belt/Rollers

A

The main motor powers the

system that transports

paper from the toner

cartridge to the delivery

tray on top of the printer.

B

Note:

The letters next to the

boxes correspond to the

C

labels in the mechanical

drive animations that are

available on the CD.

F

G

Page 12

Basics Mechanical Drive Theory - 10

M2 Pickup Block Motor Drive

Power

Supply

DC Controller Board

Connecting Cable

Pickup Controller Board

A

The pickup block motor

powers the system that

transports paper into the

engine, through the pickup

H

block, and up to the toner

cartridge.

Pickup

Solenoids

Pickup Sensor Board

Pickup Block Motor

Gear/Roller System

J

Note:

The DC controller

board does not connect

K

directly to the pickup block

motor. Make sure to

troubleshoot the three

intermediate blocks if there

is a failure in pickup block

drive. Ê

Page 13

Basics Mechanical Drive Theory - 11

M3 Sheet Feeder Motor Drive

Power

Supply

ENGINE

SHEET FEEDER

DC Controller Board

Connecting Cable

Pickup Controller Board

Connecting Cable

Controller Block

Feeder Controller Board

Sheet Feeder Motor

A

The sheet feeder motor

powers the system that

transports paper from the

H

500-sheet cassette upward

into the printer engine.

Note:

Once the paper

L

reaches the lower feed

roller in the pickup block,

M

engine components supply

mechanical drive.

N

Pickup

Solenoid

Gear/Roller System

Page 14

Basics Mechanical Drive Theory - 12

Power

Supply

ENGINE

ENV FEEDER

Pickup

Rollers

DC Controller Board

Connecting Cable

Pickup Controller Board

Connecting Cable

Connecting Cable

Feeder Controller Board

Feeder Controller Board

Envelope Feeder Motor

Drive Assembly

Primary Feed Roller

Separation Drive Assy

A

M4 Envelope Feeder Motor Drive

The envelope feeder motor

H

O

P

Q

powers the system that

separates envelopes and

feeds them into the printer

engine.

Note:

Once an envelope

reaches the upper feed

rollers in the pickup block,

engine components supply

mechanical drive.

Page 15

Basics Sensing System Theory - 13

Sensing System Theory

There are six paper sensors, one dual-purpose sensor, and

seven sensing switches in a LaserWriter 16/600 PS

system:

Paper Sensors

– PS601: Cassette Paper Sensor

– PS602: Registration Paper Sensor

– PS701: Multipurpose Paper-End Sensor

– PS702: Multipurpose Paper-Present Sensor

– PS851: Sheet Feeder Paper-Present Sensor

– PS931: Envelope Paper-Present Sensor

– PS201: Delivery/Interlock Sensor

Sensing Switches

– SW601: Top Cover Interlock Switch

– SW603: Upper Cassette Size Sensing Switch

Page 16

Basics Sensing System Theory - 14

– •SW604: Upper Cassette Size Sensing Switch

– •SW605: Upper Cassette Size Sensing Switch

– •SW851: Lower Cassette Size Sensing Switch

– •SW852: Lower Cassette Size Sensing Switch

– •SW853: Lower Cassette Size Sensing Switch

Page 17

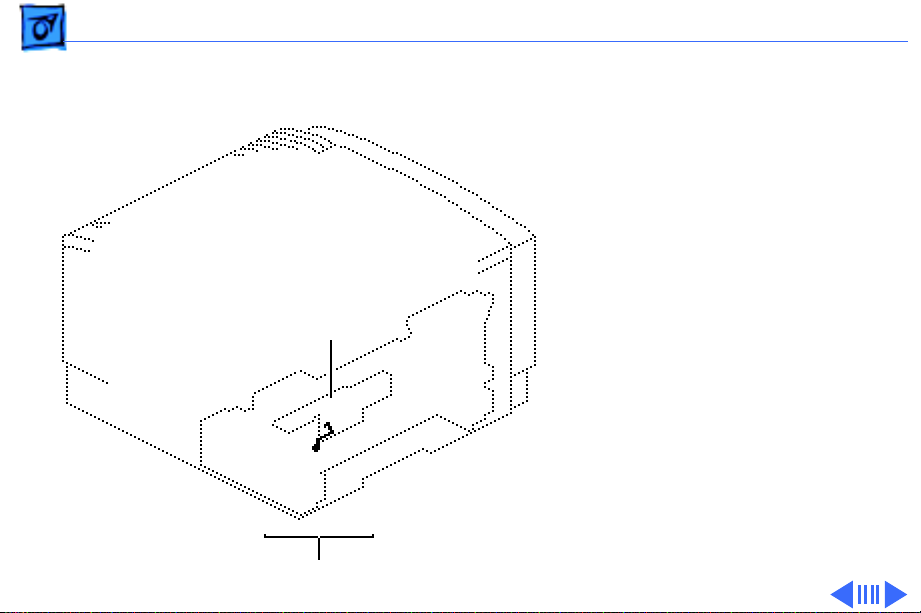

Basics Sensing System Theory - 15

Actuator

OPEN

CLOSED

Photointerrupter

Paper Sensors

Paper sensors consist of an

actuator, a U-shaped photo

interrupter, and circuitry.

Sensors are tripped as the

actuator swings against

movement of paper and

blocks the gap of the U. An

actuator can be passive

(governed by gravity) or

spring-loaded.

Note:

Sensor failure can be

either mechanical or

electrical. When

troubleshooting sensors,

first confirm that the arm

Page 18

Basics Sensing System Theory - 16

or lever moves freely without snagging, that any springs are

applying correct resistance, and that the actuator is not

broken. Then check that all cable connections are secure. If

you have eliminated mechanical issues, proceed with

electrical troubleshooting.

Page 19

Basics Sensing System Theory - 17

PS601

Cassette Paper Sensor

Actuator: A passive lever in

the sensor holder assembly

is tripped by insertion of a

loaded cassette tray.

Sensor

Holder

Assembly

PS601

Paper

Pickup Block

Page 20

Basics Sensing System Theory - 18

PS602

Registration Paper Sensor

Actuator: A spring-loaded

lever in the sensor holder

assembly is tripped by

arriving paper.

Sensor

Holder

Assembly

PS602

Paper

Pickup Block

All paper stops at PS602

and waits for proper

synchronization with drum

rotation and mechanical

drive.

Note:

If paper does not

reach sensor PS602 within

the prescribed time after

the pickup signal is issued, a

Page 21

Basics Sensing System Theory - 19

pickup unit delay jam exists and the controller stops

printing.

If paper reaches the sensor but does not clear it within the

correct time, a pickup unit stationary jam exists. The time

allowed for paper to clear is a function of paper size, which

is detected by PS701 (for manually fed paper) and by

sensing switches (for cassette-fed paper).

Page 22

Basics Sensing System Theory - 20

PS702

Multipurpose PaperPresent Sensor

Actuator: A spring-loaded

lever in the paper pickup

block is tripped by the

Pickup

Sensor

Board

PS702

Paper

Pickup Block

leading edge of paper as it is

loaded in the multipurpose

tray.

Page 23

Basics Sensing System Theory - 21

PS701

Multipurpose Paper-End

Sensor

Actuator: A passive lever in

the paper pickup block is

tripped by the trailing edge

Pickup

Sensor

Board

PS701

Paper

Pickup Block

of paper leaving the

multipurpose tray.

Sensor PS701 detects the

size of paper fed from the

multipurpose tray.

Page 24

Basics Sensing System Theory - 22

PS201

Delivery/Interlock Sensor

Actuator: A plastic tab on

the fuser door and a sensing

lever in the fuser assembly

Delivery/Interlock Sensor

act independently to trip a

photo interrupter.

PS201 detects two things:

paper exiting the fuser and

closure of the fuser door.

Note:

If paper does not

reach sensor PS201 within

5.2 seconds after it reached

registration sensor J602, a

delivery unit delay jam

Page 25

Basics Sensing System Theory - 23

exists and the controller stops printing.

If paper reaches the sensor but does not clear it within the

correct time, a delivery unit stationary jam exists. The

time allowed for paper to clear is a function of paper size,

which is detected by PS701 (for manually fed paper) and by

sensing switches (for cassette-fed paper).

Page 26

Basics Sensing System Theory - 24

PS851

Sheet Feeder PaperPresent Sensor

Actuator: A passive lever in

the controller block is

tripped by insertion of a

loaded cassette tray.

PS851

Controller

Block

Page 27

Basics Sensing System Theory - 25

PS931

Envelope Feeder PaperPresent Sensor

Actuator: A spring-loaded

lever is tripped by

placement of envelopes into

the feeder.

Page 28

Basics Sensing System Theory - 26

Circuit Board

Leaf Spring

Microswitch

Actuator

Microswitch ON

Microswitch OFF

Sensing Switches

Sensing switches attach to a

circuit board and do not use

photo interrupters.

Switches are actuated by leaf

springs that press inward as

you insert a cassette tray or

close the top cover.

Failure in sensing switches

can be either mechanical or

electrical. When

troubleshooting switches,

first confirm that the

actuator has not broken off

and then confirm that the

leaf springs are not bent or

Page 29

Basics Sensing System Theory - 27

misshapen. You should be able to press the leaf spring with

your finger and hear the clicking of the microswitch.

If you have eliminated mechanical issues, proceed with

electrical troubleshooting.

Page 30

Basics Sensing System Theory - 28

SW601

Top Cover Interlock Switch

Actuator: A tab on the top

cover actuates a leaf spring

Cover Interlock Arm

Cover Interlock Spring

Cover Interlock Actuator

SW601

Pickup

Controller

Board

Paper

Pickup Block

and pin, which press the

microswitch on the pickup

controller board. See

“Troubleshooting Tips” in

Troubleshooting for

information on defeating the

top cover interlock switch.

Page 31

Basics Sensing System Theory - 29

Cassette

(None)

Legal

Letter

A4

Executive

B5

SW603 SW604 SW605

OFF OFF OFF

ON ON

ON ON

OFF

OFF

OFF OFF

OFF

OFF

ON ON

ON

OFF

ON

Paper

Pickup Block

Pickup

Controller

Board

SW603

SW604

SW605

SW603/4/5

Cassette Size Sensing

Switches (Upper)

Actuator: Plastic tabs on the

side of the cassette trays

actuate leaf springs, which

press microswitches on the

pickup controller board.

The tab/switch configurations are as shown.

Note:

See the next page for a

note regarding the 250sheet universal cassette.

Page 32

Basics Sensing System Theory - 30

SW851/2/3

Cassette Size Sensing

Switches (Lower)

Actuator: Plastic tabs on the

side of a cassette tray

actuate leaf springs, which

Sheet Feeder

Controller Board

SW851

SW852

SW853

press microswitches on the

sheet feeder controller

board.

Note:

The sheet feeder uses

a 500-sheet universal

cassette. As with the upper

250-sheet universal

cassette, the tabs are set

manually by adjusting a

selection dial on the cassette.

Page 33

Basics Sensing System Theory - 31

When you are troubleshooting, be aware that human error

can be a factor in paper-size sensing for these universal

cassettes.

Page 34

Basics Test/Configuration Pages - 32

Test/Configuration Pages

There are three special pages that an operational

LaserWriter 16/600 PS can print. Each indicates

information that can isolate problems and/or identify the

configuration of the printer.

Startup Test Page

The printer generates a startup test page 2-3 minutes after

you switch on the printer. Successful printing of this page

indicates that the I/O board is operational.

Note:

The startup test page may not print due to

software disabling (see “Printer Utilities” in Basics).

Page 35

Basics Test/Configuration Pages - 33

Service Test Page

The printer generates a service test page when you press the

service test page button. Successful printing of this page

indicates that the printer engine is operational.

Configuration Page

The printer generates a configuration page when you issue

the “Print Configuration Page” command with the printer

utility.

Note:

The “Print Configuration Page” command in the

Apple Printer Utility is located in the File menu.

Page 36

Basics Test/Configuration Pages - 34

Ê

Startup Test Page

Printer Names

Communication parameters and

printer control language selected

for an individual printer port

ROM

version

Installed RAM

Printer Resolution

Number of pages

the I/O board has

produced

Other startup icons

FinePrint enabled

PhotoGrade enabled

Hard drive on-line

Optional feeders

installed

Page 37

Basics Test/Configuration Pages - 35

Service Test Page

To access the service test

page button, open the

multipurpose tray. The

button is located in the

upper right corner of the

opening. The button is small

and difficult to see against

the black plastic. Use a

paper clip or similar tool to

press the button.

Page 38

Basics Test/Configuration Pages - 36

The service test page pattern

is a series of vertical lines

that cover the imageable

area of the page.

Page 39

Basics Test/Configuration Pages - 37

Configuration Page

This page provides the

following information to the

service technician.

• Network address settings

(1)

• Amount and allocation of

RAM memory and readout

of EEPROM integrity (2)

• Switch configurations

(3)

• HP LaserJet® emulator

version (4)

• Startup page setting (on

or off) (5)

• LaserWriter serial

number (6)

Page 40

Basics Test/Configuration Pages - 38

• Halftone screen settings (7)

• System administrator password (8)

• Timeout settings (9)

• SCSI ID of printer and attached drives (10)

• Default paper tray and margin offsets (11)

If possible, always print a configuration page before calling

Apple Technical Assistance Center.

Page 41

Basics Configuration Switch - 39

Configuration Switch

Configuration

Switch

Communication

Ports

The configuration switch is

located at the top of the I/O

controller board end

bracket. Configuration

refers to the communication

protocols that you assign to

each of the three ports.

When you set communication

protocols on older

LaserWriter printers, you

typically set a configuration

switch that has numerical

settings similar to a SCSI ID

switch. The number you

Page 42

Basics Configuration Switch - 40

choose corresponds to one of ten codes in a predefined

configuration matrix.

With the LaserWriter 16/600 PS, the configuration switch

is a toggle between standard (down) and custom (up) values.

You define custom settings through software (see “Printer

Utilities” in Basics). This scheme allows users greater

flexibility in establishing configuration.

Page 43

Basics LaserWriter Safety - 41

LaserWriter Safety

Unplug Printer

LaserWriter printers operate at high voltages. To prevent

serious injury, always switch off the printer and unplug the

AC power cord before servicing the printer.

Laser Beam Safety

Never disconnect the beam-detect cabling or laser shutter

when the printer is switched on. Also be careful not to place

screwdrivers or other shiny objects in the path of the laser

beam. The reflected laser beam, though invisible, can

permanently damage your eyes.

Never remove the cover of a laser/scanner assembly,

whether the printer is powered on or not.

Page 44

Basics LaserWriter Safety - 42

Fuser Heat

The fuser assembly rollers become very hot during printer

operation. Before servicing the fuser assembly, switch off

the printer for at least 5 minutes to allow the fuser

assembly roller to cool.

Toner Safety

Toner is a nontoxic substance composed of plastic, iron, and

a small amount of pigment. Clean skin and clothing by

removing as much toner as possible with a dry tissue, then

washing with cold water. Hot water causes toner to jell and

permanently fuse into clothing. Toner attacks vinyl

materials, so avoid contact with vinyl.

Weight

LaserWriter printers are heavy. When lifting or moving

the printer, be careful not to strain your back.

Page 45

K

Service Source

Specifications

LaserWriter 16/600 PS

Page 46

Specifications Engine - 1

Engine

Engine

Printing Method

Optical System

Resolution

Canon LBP-P430 engine

Electrophotography using single-component microfine toner

Semiconductor laser and a rotating six-faced prism scanning

mirror

600 dpi

Page 47

Specifications Engine - 2

Dimensions

Clearance Required

Weight

Operating

Environment

Height: 12.08 in. (307 mm)

Width: 16.73 in. (425 mm)

Depth: 16.89 in. (429 mm)

50.4” x 24.25” x 19.75” high (1282 x 616 x 501 mm)

Printer with cassette: 42.02 lb. (19.1 kg):

Toner cartridge: 3.3 lb. (1.5 kg)

Temperature: 50-90.5° F (10-32.5° C)

Humidity: 20-80% relative humidity

Atmospheric Pressure: 570-760 mmHg

Page 48

Specifications Engine - 3

Power Consumption

Noise Level

Printing Speed

Duty Cycle

Approximately 0.79 kW at 71° F (20° C)

Sound Power Level:

66 dB or less (printing)

47 dB or less (standby)

Sound Pressure Level (Bystander Position)

52 dB or less (printing)

34 dB or less (standby)

17.1 pages per minute (letter)

16.2 pages per minute (A4)

No limit in pages per month

Page 49

Specifications Engine - 4

Consumables

Service Life

Macintosh

Requirement

Pickup Rollers: 200,000 pages

Separation Pad: 200,000 pages

Fuser Assembly: 200,000 pages

Transfer Roller: 200,000 pages

Power Supply Fan: 25,000 hours

Controller Board Fan 25,000 hours

Front Fan 10,000 hours

Replace the multipurpose pickup roller and separation pad

together. The separation pad is contained in the multipurpose

tray guide assembly.

System Software 7.0 or later

Page 50

Specifications Engine - 5

Printable Area (in

inches)

US Letter: 8.11 by 10.79

US Legal: 8.11 by 13.79

A4: 7.89 by 11.44

B5: 6.72 by 9.81

Page 51

Specifications I/O Board - 6

I/O Board

CPU

RAM

ROM

AMD 29030 (RISC) running at 25 MHz

8 MB, expandable to 32 MB.

Refer to “Upgrading RAM” in Upgrades for more information.

4 MB standard

ROM may be either soldered or in the form of SIMMs. If you are

returning an I/O controller board to Apple that uses ROM

SIMMs, those SIMMs must accompany the board. Replacement

I/O controller boards that do not have soldered ROM will have

separately-bagged ROM SIMMs that you will need to install

onto the board.

Page 52

Specifications I/O Board - 7

Pinouts

Settings

Imaging Languages

Supported

LocalTalk, Ethernet, and parallel connections

The LaserWriter 16/600 PS features automatic traffic control.

The printer can accept jobs simultaneously from AppleTalk,

TCP/IP, and NetWare networks and from the parallel port,

automatically switching between PostScript and PCL5

languages. No manual intervention is required if the standard

communication settings are adequate. See “Configuration

Switch” in Basics for information about customizing these

settings.

QuickDraw, PostScript Level 2 (2014), and HP PCL 5

Page 53

Specifications Fax Card - 8

Fax Card

Features

When equipped with the fax card, the LaserWriter 16/600 PS

• Sends documents to any Group III-compatible fax machine or

printer from an Apple Macintosh or IBM PC compatible

computer.

• Receives and prints faxes at 200dpi from Group III-compatible

fax machines.

• Receives and prints faxes at 600dpi from other printers

equipped with PostScript fax capability.

• Send PostScript-language files to other printers that have

PostScript fax capability so that documents print at the

resolution of the receiving printer.

• Sends and receives documents at speeds up to 9600 bps.

Note:

There are two fax cards available from Apple, one for use

in the United States and one for international use. The USA fax

Page 54

Specifications Fax Card - 9

card has built-in modem capability and can be connected

directly to an analog phone line. The international fax card is

designed to connect into an external modem.

Page 55

Specifications Sheet Feeder - 10

Sheet Feeder

Dimensions

Weight

Power Consumption

Height: 5.28 in. (134 mm)

Width: 16.38 in. (416 mm)

Depth: 18.15 in. (461 mm)

13.2 lb. (6.0 kg) with cassette

24 VDC supplied by printer

Page 56

Specifications Envelope Feeder - 11

Envelope Feeder

Dimensions

Weight

Power Consumption

Height: 5.03 in. (127.8 mm)

Width: 12.04 in. (306.5 mm)

Depth: 11.53 in. (293 mm)

5.72 lb. (2.6 kg)

24 VDC supplied by printer

Page 57

Specifications Paper - 12

Paper

Input Sources and

Capacities

Output Source

Paper Sizes

Standard cassette (250)

Multipurpose tray (100)

Lower cassette (500)

Envelope feeder (75)

Face-down delivery tray

Standard Cassette:

A4, B5, legal, letter, or executive plain paper (16-24 lb.)

Cassettes available: letter, A4, or universal

Multipurpose Tray

Plain paper from 7.16 in. by 10.1 in. to 8.5 in. by 14 in. (16-

32 lb.), envelopes, and fuser-compatible labels and film

Page 58

Specifications Paper - 13

Lower Cassette

A4, B5, legal, letter, or executive plain paper (16-24 lb.)

Cassette available: universal

Envelope Feeder

COM-10, DC, Monarch, C5, B5 (recommended envelope); from

3.54 in. by 7.44 in. to 7.0 in. by 10.0 in.

Note:

Do not use envelopes with clasps, snaps, windows, or

synthetic materials. Envelopes with peel-off adhesive strips

or double sealable flaps must use fuser-compatible adhesive.

Page 59

K

Service Source

Troubleshooting

LaserWriter 16/600 PS

Page 60

Troubleshooting General - 1

General

Troubleshooting contains quick-reference troubleshooting

information for the LaserWriter 16/600 PS. We encourage you

to review and print out this chapter before troubleshooting a

printer.

At the end of this chapter are troubleshooting flowcharts and

tables. If a table name clearly addresses your problem, you can go

directly to that table. If not, you should go to the flowchart

associated with the version of the printer you are working on.

Page 61

Troubleshooting Power–On Self Test (POST) - 2

Power–On Self Test (POST)

When you switch on power, the LEDs are designed to illuminate in

a specific sequence as the printer comes ready. In a functioning

printer, all LEDs briefly illuminate about a second after you turn

on the printer to confirm power distribution . They then

extinguish and pulse as the fans power up and main motor rotation

takes place. About 5-6 seconds into printer startup, all LEDs will

again illuminate for one second. This marks the beginning of the

Power-On Self Test (POST).

POST is a diagnostic procedure built into the I/O controller board

that tests four areas: the SIMM/CPU, the I/O controller, the

engine, and a fax or hard drive, if present. As each checks passes,

the leftmost LED extinguishes. When all four checks have passed,

all LEDs remain extinguished for one second. The ready LED will

then flash once. The Power-On Self Test then ends, and control

passes over to the PostScript interpreter.

Page 62

Troubleshooting Power–On Self Test (POST) - 3

Note:

The LED array that POST uses has no correlation to jam,

low-toner, or paper-out conditions. POST simply uses those LEDs

to relay coded feedback. Once control passes over to the PostScript

interpreter, the engine sensing system engages and LEDs do

correlate to their labels.

When POST does detect an error, it exits the LED-extinguishing

sequence and alternately flashes the toner and jam LEDs until you

turn off the printer. Observing which LEDs had extinguished

prior to the error array can help isolate the fault to one of the

four areas indicated.

POST Pass POST Fail LED Arrays

This movie shows where

POST occurs during startup.

This movie shows an example

of a detected engine problem.

This image shows the

normal meanings of LEDs.

Page 63

Troubleshooting Printer Diagnostic (EPOST) - 4

Printer Diagnostic (EPOST)

Whereas the Power-On Self Test (POST) occurs during every

printer startup, the Extended Power-On Self Test (EPOST) occurs

only with intervention of the service technician. EPOST is a

diagnostic built into the I/O controller board that is designed to

run when the printer is in a modified state of operation.

To enable EPOST, turn off the printer, install a serial loopback

connector into the I/O controller serial port, and set the

configuration switch to the “up” position. Turn the printer on.

EPOST startup behavior is identical to POST up to the point where

an error is detected. In POST, startup is terminated and a general

error display is reported to the LED panel. In EPOST, error

reportingis extended. Consequently, about a dozen, more specific,

error codes are able to be displayed. See next page for a chart of

failure error codes.

Page 64

Troubleshooting Printer Diagnostic (EPOST) - 5

If EPOST detects an error, the LEDs will cycle through the

following sequence until you turn off the printer. The QuickTime

movie below animates this cycle.

• All LEDs on for one second

• All LEDs off for one second

• Failure error code for two seconds

• All LEDs off for one second

Caution:

diagnostic, be sure to remove the serial loopback cable and set the

configuration switch in its original position. Any readout other

than those shown above is an unknown error that cannot be

detailed any more specifically.

When you have finished running the Extended POST

Page 65

Troubleshooting Printer Diagnostic (EPOST) - 6

Ê

I/O Controller Board

ROM SIMM A

RAM Size

RAM SIMM (Low)

RAM SIMM (High)

Engine Controller (Interface or NVRAM)

Fuser Assembly

Laser/Scanner Assembly

Misc. Engine (Operator or Unknown Error)

Engine Fan (1 or More)

Main Motor

SCSI Hard Drive (Present but Failing)

Page 66

Troubleshooting Printer Diagnostic (EPOST) - 7

The LaserWriter 16/600 PS requires the mini DIN-8 serial

loopback connector that is listed as part of one of the diagnostics

kits available from Apple. This connector can also be ordered

separately as part number 922-1489.

Serial Loopback Connector

Page 67

Troubleshooting Printer Diagnostic (EPOST) - 8

For those service providers who would like to build their own

loopback connector, the plug consists of a male mini DIN-8

connector with pins 1 and 2 tied together using a piece of smallgauge wire-wrap wire. The pins on the male end of the mini DIN8 connector are numbered as shown:

678

34 5

12

Page 68

Troubleshooting Maintaining I/O Connectivity - 9

Maintaining I/O Connectivity

If you want to troubleshoot the printer while maintaining

connectivity to a host computer, you must temporarily reposition

the printer’s I/O controller board. In this reconfigured state, you

will be able to print from a paper source other than the standard

cassette, observe the behavior of LEDs during startup, or run the

printer diagnostic, while still having the engine open for

troubleshooting.

To reconfigure the I/O controller in this way, remove the rear

panel, I/O controller board, and I/O shield. Remove the printer

interface cable from the I/O controller board and temporarily

substitute a Quadra 900/950 floppy drive 20-pin cable.

Connect the free end of this long interface cable to connector J207

on the DC controller board. Reconnect the power cable to

connector J15.

Page 69

Troubleshooting Maintaining I/O Connectivity - 10

Ê

Maintaining

I/O Connectivity

I/O Board

Quadra 900/950 Floppy Drive Cable

J207

Page 70

Troubleshooting Troubleshooting Tips - 11

Troubleshooting Tips

Multimeter Probes

The connectors within the LaserWriter 16/600 PS are very

small and require sharp needle-point probes to make good contact.

Do not use probes that do not make proper contact. To see whether

a set of probes works properly, test resistance at connector J210

on the DC controller board in the manner described below (the

cable must connected to the board).

Set your multimeter to resistance and insert the probes at pins 1

and 10. If the reading indicates continuity then the probes are

making good contact. If the reading indicates infinite resistance,

then the probes do not make contact and should not be used with

this printer.

Page 71

Troubleshooting Troubleshooting Tips - 12

Forcing a Feed Cycle

If you want to print from anything other than the standard 250sheet cassette tray, you must be connected to a CPU and select the

feed option that you want. It is not possible to print a service test

page from any source other than the standard cassette.

Page 72

Troubleshooting Troubleshooting Tips - 13

Interrupting a Print Cycle

Interrupting a print cycle and inspecting the photosensitive drum

can help isolate the cause of print quality problems. If the image

on the surface of the drum exhibits the same problem as the

printed page, the fault is before the drum, probably in the

imaging system.

If the image on the drum is OK, the fault is after the drum,

probably in the fuser assembly, transfer block, or high-voltage

power supply. To inspect the drum in this way, run a print and

wait until the paper clears the synchronization pause at the

registration paper sensor. Open the toner access door, remove the

toner cartridge, and pull back the shield to inspect the drum.

Page 73

Troubleshooting Troubleshooting Tips - 14

Maintaining Pickup Connectivity

To troubleshoot the paper pickup block, you must temporarily

reconfigure the printer’s paper path so that the pickup block is

exposed. In this reconfigured state, you will be able to take

voltage readings from the pickup controller board and observe

paper feeding from the cassette.

Note:

Since paper will jam due to the disruption of the paper

path, you must disable the startup test page (see “Printer

Utilities” in Basics) before turning the printer back on. Make

sure to enable the startup test page before returning the printer

to the customer.

To reconfigure the paper path, remove the pickup block, set it at

an angle to the printer, and reconnect cables J601 and J603 at the

leading edge of the pickup controller board. Insert the cassette

tray into the pickup block. Press down the top cover interlock

actuator and force the interlock switch closed by wedging in the

Page 74

Troubleshooting Troubleshooting Tips - 15

hooked end of the green cleaning brush. Reinstall the top cover and

cover liner and close the lid.

If you want to test pickup from the multipurpose tray or the

envelope feeder, you must maintain I/O connectivity (see

previous topic). You cannot run a service test page from any

source other than the standard 250-sheet cassette.

Caution:

the metal chassis when performing this procedure.

Do not let the pickup controller board brush up against

Page 75

Troubleshooting Troubleshooting Tips - 16

Defeating the Top Cover Interlock

You may occasionally need to defeat the top cover interlock to

simulate a “top cover shut” condition. To defeat this sensor, open

the toner access cover and wedge a stiff, non-metallic insert into

the interlock switch opening. Push the insert down to depress the

interlock leaf spring.

Page 76

Troubleshooting Troubleshooting Tips - 17

Defeating the Fuser Door Interlock

You may occasionally need to defeat the fuser door interlock to

simulate a “fuser door shut” condition (for example if you wanted

to observe paper as it exits the fuser rollers). To defeat this

sensor, open the fuser access door and wedge the brush end of the

green cleaning brush into the delivery/interlock sensor.

Green Cleaning Brush

Page 77

Troubleshooting Troubleshooting Tips - 18

Caution:

removing the brush, make sure that the delivery sensing arm

moves freely and is not snagged.

Do not insert the brush too far into the sensor. After

Page 78

Troubleshooting Troubleshooting Tips - 19

Sheet Feeder Bypass

You can visually troubleshoot a functioning stand-alone sheet

feeder by bypassing connector J603 on the printer’s pickup

controller board.

Disable the startup test page, and remove the top cover, rear

panel, and right corner panel from the printer. Disconnect J603

from the exposed edge of the pickup controller board and connect a

spare sheet feeder interface cable (P/N 922-0219). Plug the

opposite end of the interface cable into the sheet feeder receptacle.

Page 79

Troubleshooting Troubleshooting Tips - 20

Observing Envelope Feed

You can visually inspect and/or take multimeter readings from a

fully functioning envelope feeder. Remove the covers of the feeder

and install it into the printer. The feeder will operate in normal

fashion.

Envelope Feeder

(without covers)

Page 80

Troubleshooting Troubleshooting Tips - 21

Drum Exposure

Cover the toner cartridge when you remove it from the printer.

Prolonged exposure to light can result in print quality problems.

If this has occurred, store the toner cartridge in a dark place. The

drum will return to its normal condition after about 24 hours.

Page 81

Troubleshooting Capacitor Discharge - 22

Capacitor Discharge

When there is a failure of the fusing system, the DC controller

board shuts off current to the fuser roller heater and charges

capacitor C208 to prevent overheating. If there is a failure of the

fusing system, you must turn the power off for about 10 minutes

or manually discharge the capacitor before switching power back

on.

C208

DC Controller Board

Page 82

Troubleshooting Capacitor Discharge - 23

Caution:

before performing this procedure.

To discharge capacitor C208, switch off the printer and remove

the rear panel, I/O controller board, and I/O shield. Carefully

jumper the two wires at the base of the capacitor using some kind

of conductor.

Note:

the capacitor: a flat blade screwdriver, paper clip, or aluminum

foil doubled over. The tool illustrated is a length of lead solder. It

has the advantage of being ductile and is less apt to damage the

controller board.

Be sure to switch off power and unplug the printer

There are many different tools that can be used to discharge

Page 83

Troubleshooting Capacitor Discharge - 24

Discharging

Capacitor C208

C208

Page 84

Troubleshooting Expansion Post Connectors - 25

Expansion Post Connectors

The LaserWriter 16/600 PS has several cable receptacles that

are secured to the printer by finned post connectors. The fins

expand when you insert the connector, but once the connector is

installed it can be difficult to remove.

If you cannot remove these connectors with your fingers, try

small bent-nose pliers, a 5 mm nut driver, or grip-rings forced

around the post.

Caution:

upside-down, they will not couple properly.

The cable receptacles are keyed. If you install them

Page 85

Troubleshooting Expansion Post Connectors - 26

Fin

Cross Section

Fin

Expansion Post Connector

Page 86

Troubleshooting Toner Cartridge Modification - 27

Toner Cartridge Modification

LaserWriter toner cartridge part number M2473G/A is the only

cartridge from Apple specifically designed for the LaserWriter

16/600 PS.

However, you may also use Revision B LaserWriter Pro 600/630

toner cartridges in the LaserWriter 16/600 PS. The Revision B

cartridges were introduced in late 1993 and were designed to be

forward-compatible.

Warning:

LaserWriter Pro 600/630 toner cartridge in the LaserWriter

16/600 PS. You can distinguish the new revision B toner

cartridge by the 1” x 3.5” molded ridge on the top surface. If this

ridge is not present, do not use the toner cartridge with the

LaserWriter 16/600 PS.

You must not use the original version of the

Page 87

Troubleshooting Toner Cartridge Modification - 28

Toner Cartridge

Modification

Page 88

Troubleshooting Circuit Board Diagrams - 29

Circuit Board Diagrams

On the following pages are diagrams of the circuit boards and

high-voltage contacts listed below:

• I/O Controller Board

• Fax Card (Domestic)

• Fax Card (International)

• DC Controller Board

• Pickup Controller Board

• Pickup Sensor Board

• High-Voltage Power Supply

• Envelope Feeder Controller Board

• Sheet Feeder Controller Board

Page 89

Troubleshooting Circuit Board Diagrams - 30

ROM SIMM Slots (empty if soldered ROM)

RAM SIMMs

(To Engine)

J1

IOP ROM

BA DC

Soldered ROM (not

present on all boards)

J23

(To Power)

J21 Connector for Internal Hard Drive

(see “Addiing Hard Drives” in Upgradess)

I/O Controller Board

Configuration Switch

Centronics Parallel

J15 Fax

Opening for Fax Port

Ethernet

LocalTalk

SCSI

Page 90

Troubleshooting Circuit Board Diagrams - 31

Solder Side Component Side

Fax Card

(Domestic)

J2

(Fax Card)

mates into

J15

(I/O Board)

Ghosted image is outline of I/O controller board.

Fax Card (Domestic)

Speaker

Battery

Fuse

Modem

IC

J2

Page 91

Troubleshooting Circuit Board Diagrams - 32

Solder Side Component Side

Fax Card

(International)

J3

(Fax Card)

mates into

J15

(I/O Board)

Ghosted image is outline of I/O controller board.

Fax Card (International)

Battery

J3

Page 92

Troubleshooting Circuit Board Diagrams - 33

C208

J201

J203 J206

J204 J205

J211

J212J214

VR201 (see “Registration

Adjustment” in Adjustments.)

J207

J208

J213

J209

J210

TB201

DC Controller Board

Page 93

Troubleshooting Circuit Board Diagrams - 34

Service Test

Page Button

Cover Interlock

J604

J605

Cassette Size

Microswitches

SW601

Switch

SW602

SW603

SW604

SW605

J601

J603

J602

Pickup Controller Board

J604

J605

Page 94

Troubleshooting Circuit Board Diagrams - 35

J704

J703

J702

PS702

Multipurpose Tray

Paper-Present

Sensor

PS701

Multipurpose Tray

Paper-End

Sensor

Pickup Sensor Board

Pickup Controller

Board Receptacle

J701

Page 95

Troubleshooting Circuit Board Diagrams - 36

J402

VR401

TB406

TB405

TB403TB404

High-Voltage Power Supply

PS Interface Board

Receptacle

J401

TB402 TB401

Page 96

Troubleshooting Circuit Board Diagrams - 37

Envelope Feeder

Controller Board

J931

PS931

J932

Page 97

Troubleshooting Circuit Board Diagrams - 38

Sheet Feeder

Controller Board

J853 J851

PS851 J852

SW851

SW852

SW853

Tab Cutout

Cassette Size

Microswitches

Page 98

Troubleshooting Wiring Diagram - 39

Wiring Diagram

The LaserWriter 16/600 PS wiring diagram can be found on the

next page. The detail in this document is too small to read easily at

100% view. You should either zoom into the diagram using the

zoom tool above, or print the diagram on a laser printer with a

resolution of 300 dpi (600 dpi preferred).

Page 99

TP1

H1

PRI

DEV

ANTIN

TONER

CARTRIDGE

67

3

FUSER ASSEMBLY

TH1

J744

LOW

UP

F

GND

2

TB406

TB402

TR

TB401

TB405

TB403

GND

TB404

TRANSFER

BLOCK

34

12

J136

8

1

J743

123

PICKUP CONTROLLER BOARD

J402

ANT

D742

D741

J401

GND

8

7

6

5

4

3

2

1

B5

A5

B4

A4

B3

A3

B2

A2

B1

A1

HV

REF

POWER

SUPPLY

13

J601

1

4

J603

1

J602

B

A

5

(Solder Side)

HIGH-VOLTAGE

CONNECTOR BOARD

8

7

6

5

4

3

2

1

J743

J742

B5

A5

B4

A4

B3

A3

B2

A2

B1

A1

LED

STATUS

PANEL

1

J604

4

1

1

J605

6

Main Power

J741

10

9

8

7

6

5

4

3

2

1

GND

GND

6

DISP4

5

DISP3

4

DISP2

3

DISP1

2

1

+5V

HVRST

/TVOUT

SLI2

SL02

1

2

3

4

5

6

M1

GNDTH

FSRTH

+24VB

+5V

TVIN

J204

J211

GND

+24VD

1234

J131

J210

1234

/MON

/MRDY

5

/TXD

+24VD

J203

12345678910

+5V

/RXD

SW101

12

J102

POWER SUPPLY

J104

123

RLD

/FSRD

THOUT

123

J212

12345678910111213

1234

GND

GND

SLO1

MAIN MOTOR

Switch

123456

+5V

123456

PAP

PBP

SLI1

LINE

INPUT

1

J101

2

3

J105

4

J103

+5V

GND

GND

GND

+24VA

TB201

DC CONTROLLER BOARD

J201

+5V

GND

GND

+24VA

+24VA

+24VB

+24VB

DOPEN

PDS

1

2

J15

3

4

1234567891011121314151617181920

/BD

GND

1234567891011121314151617181920

1234567 123456 1234

LASERWRITER

16/600 PS I/O BOARD

/STS

/RDY

/PCLK

/SBSY

/VSREQ

APCIN

/VDATA

/LON

/ENBL

/CBSY

/PPRDY

GND

APCOUT

LASER DRIVER

J2

/PRNT

J207

+5V

GND

/CMD

/VSYNC

/CPRDY

/SCNRDY

/SCNON

+24VA

SCANNER

MOTOR UNIT

GND

/CCLK

J205J206

GND

SCNCLK

M5

/VDO

GND

J13

GND

1

40

GND

123

J209

'H' When

Tripped

123456781234567

+5V

/BDI

GND

J731J151J721

BEAM DETECT

IC UNIT

FM1

FAND

J214

J213

J208

GND

FLOCK

EXHAUST

FAN

1

2

3

1

2

3

4

1

2

3

DELIVERY/

INTERLOCK

EXHAUST

FANS

FAND

FLOCK

GND

FAND

FLOCK

GND

123

PS201

SENSOR

PSNS

GND

FM2

FM3

PSL

LASER/SCANNER ASSEMBLY

SL851

Pickup Roller

Clutch Solenoid

M3

A

/A

B

/B

SW852

SW853

SW851

Cassette Size

Sensing Switches

J853

1

2

PS851

3

1

2

Sheet Feeder

3

Paper-Present

4

Sensor

J852

J851

+24VA

2NDO

2NDI

GND

1

2

3

4

F

F

SHEET

FEEDER

(Optional)

J135

ENVELOPE

FEEDER

(Optional)

1

2

J603

3

J604

4

1234

EBVI

EBVO

+24VA

J136

J931

1234

PS931

Envelope Feeder

Paper-Present Sensor

GND

F

F

J932

4

1

2

3

1 2 3 4 5 6 7 8 9 10 1112 13

J601

A

/A

M4

B

/B

PAPER SENSOR

'H' When Door

Is Open

J605

123456

GND

1STL

1STS

'L' When

Tripped

123 123

PS601 PS602

CASSETTE

PICKUP CONTROLLER BOARD

SW601

'L' When Tripped

SENSOR HOLDER

ASSEMBLY

GND

RESL

RESS

REGISTRATION

PAPER SENSOR

'H' When Tripped

'L' When Tripped

J602

A1 B1A2 B2 A3 B3 A4 B4 A5 B5

A1 B1A2 B2 A3 B3 A4 B4 A5 B5

PA

/PAMP/PB

PS701

Multipurpose

Paper-End

Sensor

PB

1ST

MPS

PS702

Multipurpose

Paper-Present

Sensor

MPE

GND

PICKUP SENSOR BOARD

SW602

Service Test

Page Switch

J701

J702

+24VA

J703

J704

Sensing Switches

+24VA

1

MPD

2

GND

3

PA

1

/PA

2

PB

3

/PB

4

+24VA

1

1STD

2

Cassette Pickup Roller

SW603/4/5

Cassette Size

Multipurpose

Pickup Roller

Clutch Solenoid

SL702

SL701

Clutch Solenoid

M2

Page 100

Troubleshooting Connector J136 Locator - 41

Connector J136 Locator

J136 is the connector that the envelope feeder mates into. To see

it, open the multipurpose tray and remove the closure panel. The

illustration below shows the connector as it appears from the

outside of the printer.

A voltage reading of 24V between pins 1 (+24VA) and 4 (GND)

during printer startup indicates that motor power is reaching the

envelope feeder.

34

12

Loading...

Loading...