Page 1

K

Service Source

Apple Multiple Scan 20

Display

Apple Multiple Scan 20 Display

Apple Multiple Scan 20 Display, Rev. B

Page 2

K

Service Source

Basics

Apple Multiple Scan 20 Display

Page 3

Basics Version Differences - 2

Version Differences

Overview

The Apple Multiple Scan 20 Display and Apple Multiple Scan

20 Display Rev. B have the same overall appearance.

However, the Rev. B version offers improved performance

and better screen resolution.

To distinguish the two versions, check the last three digits of

the serial number. The serial number for the Rev. B version

ends in one of the following:

• 5B4

• 5J2

• 5JE

• 5JF

Page 4

Basics Version Differences - 3

Multiple Scan 20 Display

Dot pitch 0.31 mm.

Multiple Scan 20 Display, Rev. B

Dot pitch 0.26 mm.

Requires Rev. B parts for Main Deflection Board,

Microprocessor Controller Board, and Power Supply.

As you go through this manual, consider the information

applicable to both versions unless specified otherwise.

Page 5

Basics Monitor Distortion - 4

Monitor Distortion

Overview

All large-screen monitors are susceptible to distortions

caused by environmental conditions. These distortions are

usually not visible on monitors with smaller screens.

Important:

appear distorted when set up in a new environment.

Common environmentally caused distortions are shown on

this and the following cards. Always check first for

environmental causes before attempting to exchange or

adjust a monitor with a distorted raster.

Ê

Even monitors set to factory specifications may

Page 6

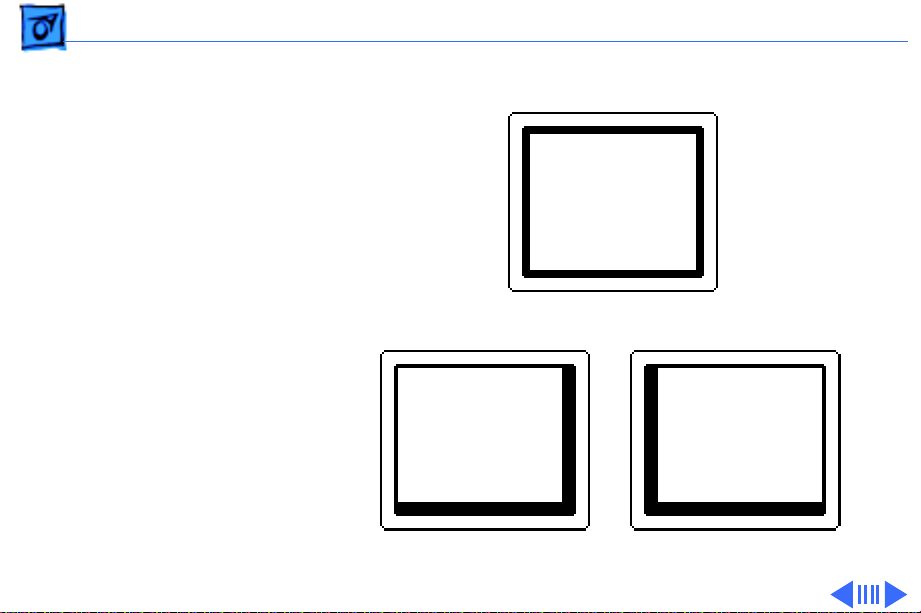

Basics Monitor Distortion - 5

Ideal Raster

Raster Shifted Up

and Left

Raster Shifted Up

and Right

Page 7

Basics Monitor Distortion - 6

Environmental Influences

The following environmental conditions may distort the

raster:

• Proximity to metal objects, such as metal desks, file

cabinets, and bookshelves. Metal objects affect the

earth’s magnetic field. Earth magnetism usually distorts

only the edges of the screen.

• Fluorescent lights, other monitors, or electronic

appliances such as coffee makers and copy machines.

These objects cause dynamic raster distortion, that is,

movement or jitter of the image.

Page 8

Basics - 7

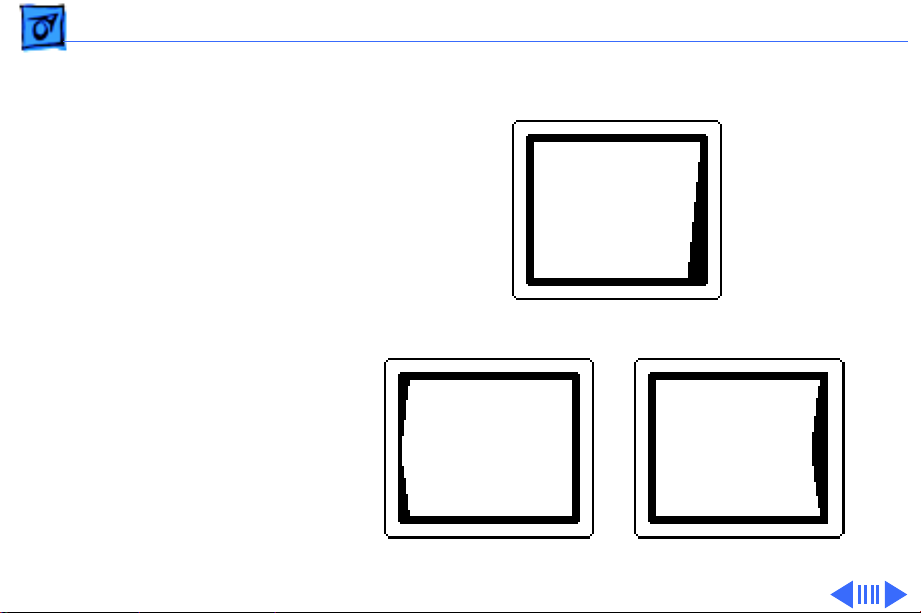

Right Edge Not Straight

Left Side Bowed Out Right Side Bowed In

Page 9

Basics - 8

Troubleshooting

Important:

environmental distortion problems.

Note:

go ahead and adjust it using the user controls. However, keep

in mind that if you then move the monitor you may need to

readjust the centering controls.

Before adjusting a monitor with a distorted raster, try the

following:

• Swivel or move the monitor, or

• Remove the monitor from the building and recheck it in

another location.

Exchanging the monitor cannot correct

If the monitor has shifted up/down or right/left only,

Page 10

Basics - 9

If the display changes (for better or worse) when you move

it to another location, the environment is the source of the

problem. Relocate your monitor or remove the distortioncausing object.

If the display does not change when you move it to another

location, continue troubleshooting the problem (refer to

Troubleshooting).

Page 11

Basics - 10

Upper-Right Corner Rounded

Left Edge S-Shaped Raster Tilted Right

Page 12

Basics EEPROM Settings - 11

EEPROM Settings

Caution:

EEPROM settings before you replace the microprocessor

board.

See Troubleshooting for instructions on saving the EEPROM

settings from the old microprocessor board and restoring

the settings on the new microprocessor board.

If the settings are lost before they can be written to the new

EEPROM, the display will be impossible to repair, and the

whole display will need to be replaced.

To prevent data loss or corruption, always save

Page 13

Basics EEPROM Settings - 12

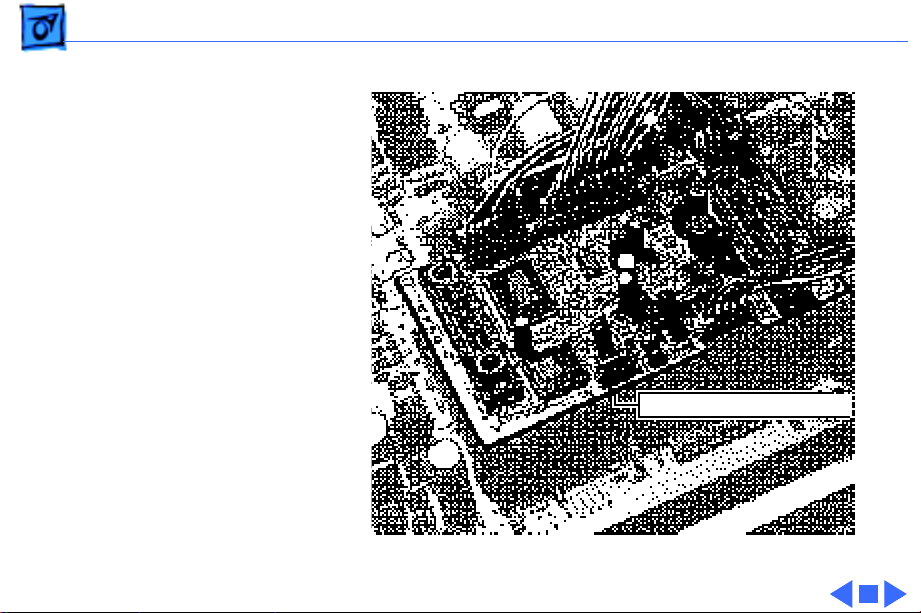

Microprocessor Board

Page 14

K

Service Source

Specifications

Apple Multiple Scan 20 Display

Page 15

Specifications Characteristics - 1

Characteristics

Picture Tube

Screen Resolution

Scan Rates

Cable Connector

20-in. diagonal Trinitron CRT (19.1-in. viewable image)

Multiple scan

Bonded glass panel with antiglare/antistatic multilayer coating

640x480 to 1280x1024

0.31-mm stripe pitch

0.26-mm stripe pitch for Multiple Scan 20 Display, Rev. B

Vertical refresh range: 50 to 150 Hz

Horizontal scan range: 29 to 82 kHz

Macintosh, VGA, SVGA, and VESA compatible

15-pin miniature D-type

Page 16

Specifications Characteristics - 2

Video Input Signals

System Requirements

Video: red, green, and blue analog signals; RS-343A

standard;.714 V peak to peak; positive going

Sync on green: RS-343A compatible level;.286 V ± 10%

negative-going during blanking intervals

Separate Sync: 1 to 5 V peak to peak; negative or positive going

Composite Sync: 1 to 5 V peak to peak; negative or positive going

Power Macintosh, Macintosh Centris, Macintosh Quadra, or any

NuBus compatible Macintosh with a Macintosh Display Card

24AC.

Macintosh II family, PowerBooks, Duo and Mini Dock, Macintosh

Performa, Macintosh LC, LC II, LC III, and Macintosh

computers with Display Cards 4•8, 8•24, 8•24GC work in

640x480 mode. Other modes possible with additional adapters.

System software version 7.1 or later

Page 17

Specifications Controls and Ports - 3

Controls and Ports

User Controls

I/O Ports

Front panel: power, reset, and control buttons; brightness and

contrast controls

Additional controls available using the command button: horizontal

and vertical shift, horizontal and vertical size, rotation,

horizontal and vertical convergence, and color temperature

Automatic degauss at power on; manual degauss by turning power

switch off, then on (capable of full degauss after monitor is

turned off for 20 minutes or more)

Two Apple Desktop Bus (ADB) ports and one ADB pass-through

port

Page 18

Specifications Physical and Electrical - 4

Physical and Electrical

Power Supply

Size and Weight

Universal power supply

Voltage: 90–132 and 198–264 VAC, self-configuring

Frequency: 47–63 Hz

Power: 165 W maximum (less than 15 W in energy-saver mode)

Height: 18.5 in. (474 mm)

Width: 18.5 in. (474 mm)

Depth: 19.6 in. (501.5 mm)

Monitor weight: 66 lb. (30 kg)

Fully boxed weight: 80 lb. (36 kg)

Page 19

Specifications Physical and Electrical - 5

Monitor Stand

Built-in, tilt-and-swivel stand; tilt: -5 to +15°; swivel range:

±45° minimum

Three ADB ports (two ADB ports are in the front of the stand and

one ADB port is at the rear of the stand)

Page 20

Specifications Environmental - 6

Environmental

Temperature

Altitude

Humidity

Power Savings Feature

Operating: 50°F to 104°F (10°C to 40°C)

Storage: 32°F to 140°F (0°C to 60°C)

Shipping: -4°F to 140°F (-40°C to 60°C)

Operating: to 10,000 ft. (1,067 m)

Shipping: to 35,000 ft. (3,048 m)

Operating: 10-80% maximum, noncondensing

Storage: 5-90% maximum, noncondensing

Shipping: 5-95% maximum, noncondensing

Conforms to the Energy Star Program of the United States

Environmental Protection Agency

Page 21

K

Service Source

Troubleshooting

Apple Multiple Scan 20 Display

Page 22

Troubleshooting General - 1

General

The Symptom Charts included in this chapter will help you

diagnose specific symptoms related to your product. Because cures

are listed on the charts in the order of most likely solution, try

the first cure first. Verify whether or not the product continues to

exhibit the symptom. If the symptom persists, try the next cure.

(Note: If you have replaced a module, reinstall the original module

before you proceed to the next cure.)

If you are not sure what the problem is, or if the Symptom Charts

do not resolve the problem, refer to the Flowchart for the product

family.

For additional assistance, contact Apple Technical Support.

Page 23

Troubleshooting First Checklist - 2

First Checklist

Important:

modules returned for repair are found to be fully operational.

Read this checklist before you return a module. Prevent needless

module replacement and unnecessary time delays.

Over 60% of the Apple Multiple Scan 20 Display

The Apple Multiple Scan 20 Display is not fully

compatible with all Macintosh computers and

PowerBooks.

If you suspect a loss of functionality, especially with the number

of screen resolutions available (in Control Panels), check the

Tech Info Library or contact Apple Technical Support.

Page 24

Troubleshooting First Checklist - 3

The CRT raster will not always resemble a perfect

rectangle.

CRT tolerances allow for some distortion. Additional distortion can

be caused by magnetized metal objects (desks, file cabinets, etc.).

Move the unit to a different location if you notice raster bowing or

bent raster edges.

Jitter, faint lines, or screen movement can be caused

by external interference such as electronic devices

and fluorescent lights.

Move the unit to another room or building to help determine if

external interference is the source of the problem.

Page 25

Troubleshooting First Checklist - 4

A misadjusted screen can mimic the symptoms of

deflection board or CRT failures.

By performing the adjustment procedures, you might determine if

one or more of the adjustments is the cause of the problem.

CRTs rarely fail.

Needless CRT replacements can be prevented by checking display

adjustments, checking the possibility of other defective modules,

and accepting small imperfections in screen display.

If you have any doubts about whether a CRT is defective, contact

Apple Technical Support.

Page 26

Troubleshooting Display Setting Restoration/Connect the Hardware - 5

Display Setting Restoration

Each Multiple Scan 20 Display has an EEPROM (located on the

microprocessor controller board) that contains adjustment

information specific to that monitor. Before you replace the

microprocessor board, save this EEPROM information.

Use MacTest Pro Display Setting Restore Utility to preserve the

monitor adjustment settings.

Connect the Hardware

There are two ways to connect the hardware to use the MacTest Pro

Display Setting Restore Utility:

1 Connect a serial cable (MINI DIN-8) between the

malfunctioning display and a separate computer running

MacTest Pro. Use either the modem port or the printer port

on the computer. (If you use the printer port, AppleTalk

Page 27

Troubleshooting Display Setting Restoration - 6

must be turned off). Also connect a power cable to the display.

Advantage:

or quit MacTest Pro to complete the repair.

You do not have to shut down the host computer

Disadvantage:

computer (with display).

2 Connect the display as usual, using a video cable and power

cable. Also, connect a serial cable (MINI DIN-8) between the

display and either the modem or printer port on the

computer.

Advantage:

display under repair is the only display required.

Disadvantage:

needs to be replaced, the display may not be working well

enough to view this utility in MacTest Pro.

Another disadvantage is that after creating the data file from

This method requires a separate host

This method lends itself to on-site repair; the

Since the microprocessor board on the display

Page 28

Troubleshooting Display Setting Restoration/Save the EEPROM Information - 7

the old EEPROM, you must quit MacTest Pro and shut down

the computer to install the new EEPROM.

Save the EEPROM Information

To save information from the old EEPROM, create a data file:

1 Start MacTest Pro.

2 Choose “Apple Multiple Scan 20 Display.”

3 Select “Test.”

4 Click “Create File.”

Install the Microprocessor Board

See Take Apart for instructions on installing the new

microprocessor board.

Page 29

Troubleshooting Display Setting Restoration/Restore the EEPROM Information -

After the new microprocessor board is installed, the new EEPROM

will have default settings that allow you to read the display, but

with difficulty. When the settings from the old EEPROM are

transferred to the new EEPROM, the display should be clear and

the last color temperature mode chosen restored.

Restore the EEPROM Information

To download the saved adjustment information to the new EEPROM,

1 Start MacTest Pro.

2 Choose “Apple Multiple Scan 20 Display.”

3 Select “Test.”

4 Click “Write File.”

Page 30

Troubleshooting Display Setting Restoration - 9

Caution:

important information about the EEPROM data file. If data is lost

or corrupted, you will have to return the display to Apple for

repair.

• Make sure that the data in the saved file is written back to the

• Make sure that the data file is deleted after writing the data

• Do not delete the new data file before it’s written to the new

Make certain that you are aware of the following

display used to create the file. Each display is unique, so

writing the wrong data to a display may cause severe

adjustment problems.

back to the display. This erasure ensures that data from one

display is not accidentally written to another.

EEPROM. If the file is lost before the data can be written to the

new EEPROM, the repair will be impossible to complete and the

whole display will need to be returned.

Page 31

Troubleshooting Symptom Charts/Raster - 10

Symptom Charts

Raster

No raster; power

indicator light on

1 Ensure monitor’s video cable is properly connected to

computer or video card in the computer.

2 Replace main deflection board.

3 Replace microprocessor board after downloading settings as

described in “Display Setting Restoration” in this chapter.

Caution:

EEPROM settings before you replace the microprocessor

board.

To prevent data loss or corruption, always save

Page 32

Troubleshooting Symptom Charts/Raster

(Continued)

- 11

Raster

Raster jumps Replace microprocessor board after downloading settings as

described in “Display Setting Restoration” in this chapter.

Caution:

EEPROM settings before you replace the microprocessor board.

Raster edges have

color blotches when

displaying an allwhite screen

1 Degauss monitor with an external degaussing coil.

2 Move monitor to different location and repeat degaussing

(Continued)

To prevent data loss or corruption, always save

procedure.

Note:

This symptom is caused by strong magnetic fields in

the environment. Exchanging boards will not cure the

symptom. Refer to “First Checklist” in this chapter.

Page 33

Troubleshooting Symptom Charts/Raster

(Continued)

- 12

Raster distorted; no

picture

Raster

1 Replace microprocessor board after downloading settings as

2 Replace main deflection board.

(Continued)

described in “Display Setting Restoration” in this chapter.

Caution:

EEPROM settings before you replace the microprocessor

board.

To prevent data loss or corruption, always save

Page 34

Troubleshooting Symptom Charts/Power - 13

Power

Monitor does not

power up

Monitor shuts down 1 Ensure monitor’s video cable is properly connected to

1 Ensure monitor’s video cable is properly connected to

computer or video card in the computer, and check other

cable connections.

2 Replace power supply.

computer or video card in the computer.

2 Replace main deflection board.

3 Replace CRT/video board.

Page 35

Troubleshooting Symptom Charts/Indicator Lights - 14

Indicator Lights

Convergence

indicator light blinks

or stays on; power

indicator light might

also blink

Replace microprocessor board after downloading settings as

described in “Display Setting Restoration” in this chapter.

Caution:

EEPROM settings before you replace the microprocessor board.

To prevent data loss or corruption, always save

Page 36

Troubleshooting Symptom Charts/Indicator Lights

(Continued)

- 15

Rotation indicator

light blinks or stays

on; power indicator

light might also blink

Indicator Lights

Replace main deflection board.

(Continued)

Page 37

Troubleshooting Symptom Charts/Indicator Lights

(Continued)

- 16

Size indicator light

blinks or stays on;

power indicator light

might also blink

Indicator Lights

1 Replace main deflection board.

2 Replace CRT/video board.

3 Replace microprocessor board after downloading settings as

described in “Display Setting Restoration” in this chapter.

Caution:

EEPROM settings before you replace the microprocessor

board.

To prevent data loss or corruption, always save

(Continued)

Page 38

Troubleshooting Symptom Charts/Indicator Lights

(Continued)

- 17

Centering indicator

light blinks or stays

on; power indicator

light might also blink

Indicator Lights

1 Replace main deflection board.

2 Replace microprocessor board after downloading settings as

described in “Display Setting Restoration” in this chapter.

Caution:

EEPROM settings before you replace the microprocessor

board.

To prevent data loss or corruption, always save

(Continued)

Page 39

Troubleshooting Symptom Charts/Miscellaneous - 18

Miscellaneous

Picture dim;

adjusting front panel

controls does not

increase brightness

Picture has vertical

jitter

1 Ensure that screen does not face a window or other source of

ambient light. This type of environment gives screen a dim

appearance.

2 Replace CRT/video board.

1 Move monitor to different location and see if symptom

persists.

Note:

This symptom is often caused by electromagnetic

interference (electronic devices, fluorescent lights, power

lines, etc.) Refer to “First Checklist” in this chapter.

2 Replace main deflection board.

Page 40

Troubleshooting Symptom Charts/Miscellaneous

(Continued)

- 19

Miscellaneous

Monitor emits

snapping sound;

raster blinks for an

instant

Picture color uneven Adjust rotation and color uniformity. Refer to “Geometry’’ in the

Focus blurry on one

side of screen

Note:

This symptom, caused by foreign particles inside the CRT,

normally occurs only in new monitors. If the symptom persists

after 40 hours of operation, there is a hardware problem.

1 Replace power supply.

2 Check to see if arcing on main deflection board is cause. If so,

replace main deflection board. If not, CRT is defective.

Adjustments chapter.

1 Adjust focus. Refer to “Convergence” in the Adjustments

chapter.

2 Replace main deflection board.

(Continued)

Page 41

Troubleshooting Symptom Charts/Miscellaneous

(Continued)

- 20

Upon first use,

monitor screen

shows cloth-like

pattern of black, dark

gray, or white fine

vertical lines

Miscellaneous

1 Select the all white display pattern, and adjust size and

rotation controls on the monitor’s front panel. Aim for

reducing the visibility of the lines while minimizing

discoloration.

2 At power-on, lightly tap the side of the monitor so you see

the display image move. After the display has warmed up for

30 minutes, tap the monitor again.

3 Call Service Provider Support at 1-800-919-2775

(Option 6) to replace the display.

(Continued)

Page 42

K

Service Source

T ak e Apart

Apple Multiple Scan 20 Display

Page 43

Take Apart Rear Cover - 1

Rear Cover

No preliminary steps are

required before you begin

this procedure.

±

Rear Cover

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 44

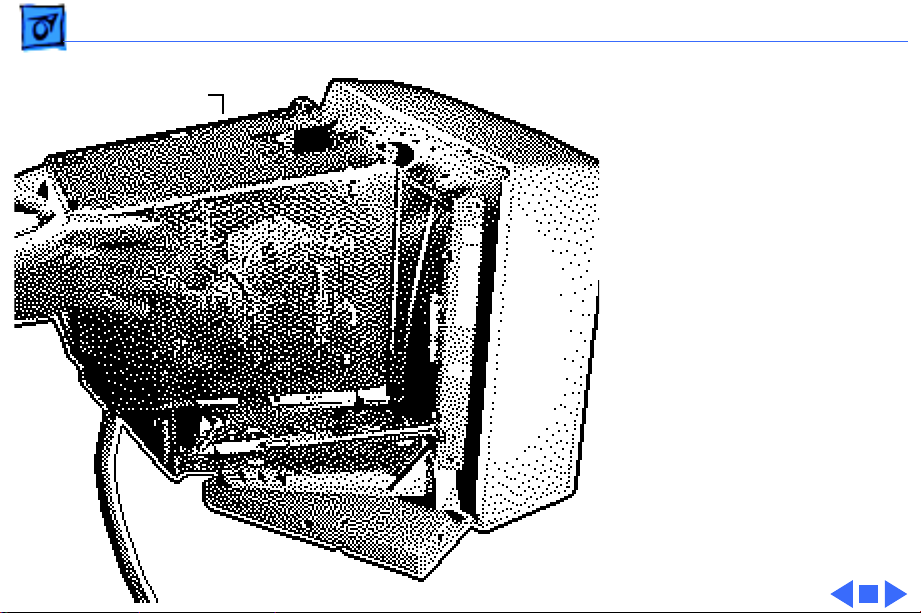

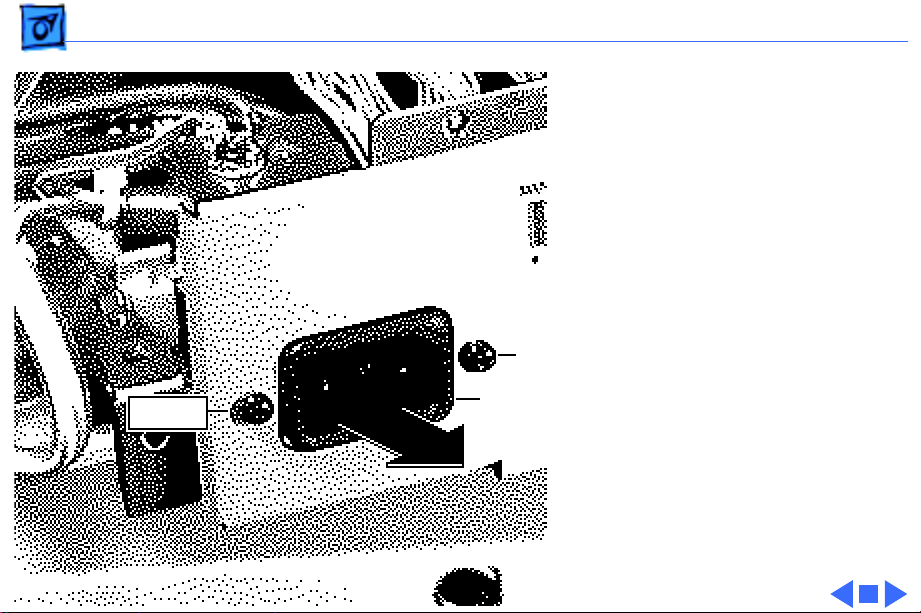

Take Apart Rear Cover - 2

1 With the monitor face-

down on a protective pad,

remove the four case

Video

Cable

screws and pull the rear

cover off the chassis.

2 Route the video cable

through the cover.

Page 45

Take Apart Bezel - 3

Bezel

Before you begin, remove

Bezel

the following:

• Rear cover

• EMI shield

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 46

Take Apart Bezel - 4

1 Remove the grounding

screw.

Grounding Screw

Page 47

Take Apart Bezel - 5

2 Remove the four large

Bezel

hex head screws and

remove the bezel.

Hex Head Screw

Page 48

Take Apart EMI Shield - 6

EMI Shield

EMI Shield

Before you begin,

• Remove the rear cover

• Discharge the CRT

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

±

Warning:

grounding wriststrap until

after discharging the CRT.

Note:

The EMI shield is not

replaceable.

This product

Never use a

Page 49

Take Apart EMI Shield - 7

1 Remove the 12 screws

from the shield. (Three

EMI Shield

screws are located on the

left side of the EMI

shield.)

Page 50

Take Apart EMI Shield - 8

EMI Shield

2 Slide the shield toward

the back of the monitor

and lift off the shield.

Page 51

Take Apart CRT/Video Board - 9

CRT/Video Board

Before you begin,

CRT/Video

Board

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

This product

Page 52

Take Apart CRT/Video Board - 10

±

NTC Connector

Ground Strap

Warning:

grounding wriststrap until

after discharging the CRT.

1

Caution:

removing the ground

strap from the CRT/

video board, be careful

not to apply excessive

pressure to the neck of

the CRT.

Disconnect the ground

strap from the terminal

on the front of the CRT/

video board shield.

2 Disconnect the NTC

connector.

Never use a

When

Page 53

Take Apart CRT/Video Board - 11

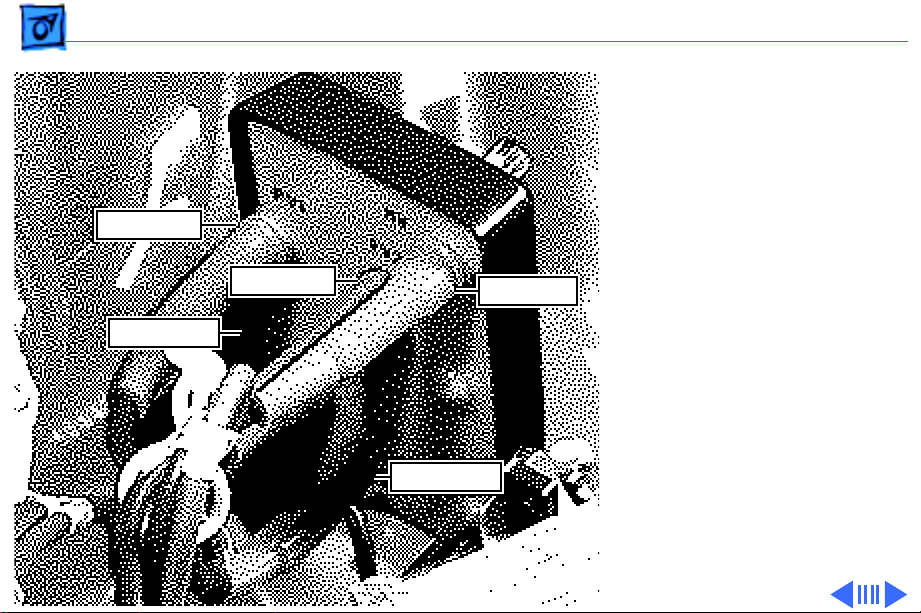

R,G,B Cables

CN302

CN301

CN303

Caution:

When

disconnecting the following

cables from the CRT/video

board, be careful not to

apply excessive pressure to

the neck of the CRT.

3 Disconnect these cables

from the CRT/video

board:

• 11-wire cable

(CN302)

• 7-wire cable

(CN303)

• 3-wire cable

(CN301)

• R, G, and B video

cables

Page 54

Take Apart CRT/Video Board - 12

CN304

CN701

CN702

Caution:

When

disconnecting the following

cables from the CRT/video

board, be careful not to

apply excessive pressure to

the neck of the CRT.

4 Disconnect these cables

from the CRT/video

board:

• 1-wire cable

(CN702)

• 6-wire cable

(CN304)

• 3-wire cable

(CN701)

Ê

Page 55

Take Apart CRT/Video Board - 13

Video Cable Clip

Caution:

When removing

the video cable from the

CRT/video board, be careful

not to apply excessive

pressure to the neck of the

CRT.

5 Remove the screw

securing the video cable

clip to the CRT/video

board shield.

Page 56

Take Apart CRT/Video Board - 14

CRT/Video Board

Mounting Screw

Caution:

Twisting, bending,

or applying force to the

CRT/video board could

damage the neck of the CRT.

Be sure to pull the CRT/

video board straight off the

CRT.

6 Loosen the mounting

screw and pull the CRT/

video board straight off

the neck of the CRT.

Page 57

Take Apart CRT/Video Board - 15

7 Remove the two plastic

cable clips on the focus

VR control cables.

8 Disconnect the FV1 and

FV2 cables from the

FV1 Cable

FV2 Cable

Plastic Cable Clip

focus control board.

Page 58

Take Apart Power Supply - 16

Power Supply

Before you begin,

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

±

Power Supply

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

±

Warning:

grounding wriststrap until

after discharging the CRT.

This product

Never use a

Page 59

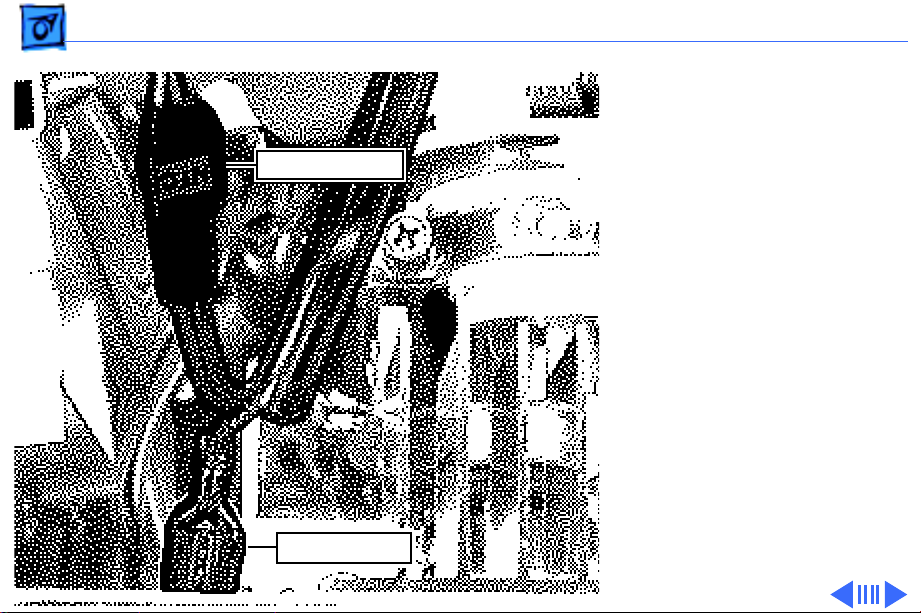

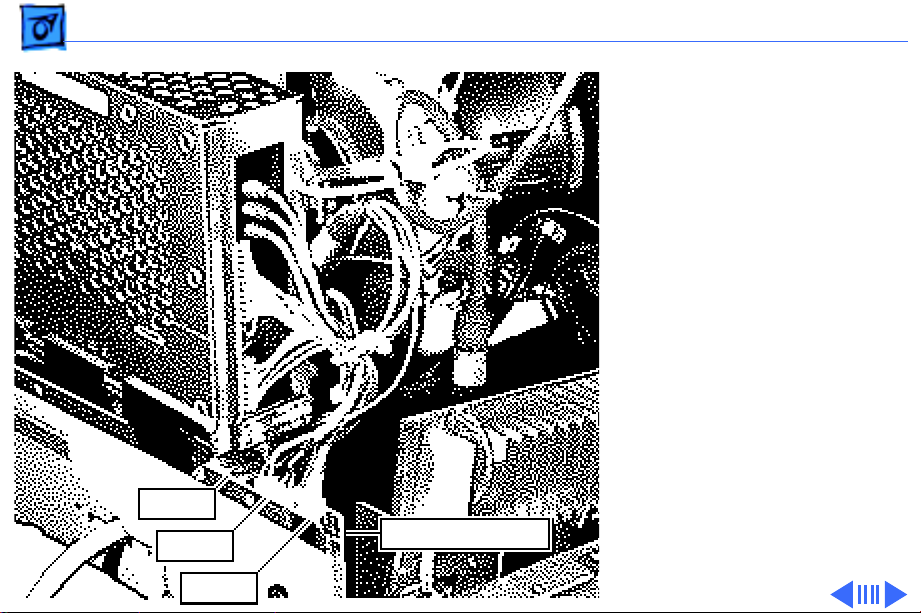

Take Apart Power Supply - 17

1 Disconnect these cables

from the power supply:

• 8-wire cable

(CN602)

CN602

Ground

Strap

CN603

CN604

•5-wire cable

(CN603)

• 2-wire cable

(CN604)

• Ground strap

2 Remove the wiring

harness from the plastic

cable clip.

Page 60

Take Apart Power Supply - 18

3 Disconnect these cables

from the AC interconnect

board:

• CN1600

• CN1601

4 Remove plastic cable

clips.

CN1601

CN1600

Plastic Cable Clips

Page 61

Take Apart Power Supply - 19

5 Remove the screw

securing the ground

strap to the chassis.

6 Remove the screw

securing the power

Screw

supply to the chassis.

7 Slide the power supply

toward the rear of the

monitor and lift out the

power supply.

Ground Strap Screw

Page 62

Take Apart Power Supply - 20

8 D isconnect connector

CN601.

CN601

Page 63

Take Apart Fuse - 21

Fuse

Before you begin,

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

• Remove the power supply

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

Fuse

This product

Page 64

Take Apart Fuse - 22

±

Warning:

grounding wriststrap until

after discharging the CRT.

1 Remove the plastic cover

from the fuse holder.

2 Pry the fuse from the

fuse holder using a

jeweler’s screwdriver.

Never use a

Fuse Holder

Replacement Note:

sure to replace the fuse

with another fuse of the

same amperage and

voltage rating.

Be

Page 65

Take Apart Focus VR Control - 23

Focus VR Control

Before you begin,

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

Focus VR Control

This product

Page 66

Take Apart Focus VR Control - 24

±

FV1 Cable

VIDF Cable

FV2 Cable

HIDF Cable

MV Cable

Warning:

grounding wriststrap until

after discharging the CRT.

1 Disconnect these cables

from the focus control:

•MV

• FV1

• FV2

• VIDF

• HIDF

Never use a

Page 67

Take Apart Focus VR Control - 25

2 Remove the screw

securing the ground

strap to the chassis.

Focus Control

Focus Control

Screw

3 Remove the screw

securing the focus

control to the chassis.

4 Lift out the focus

control.

Ground

Strap

Screw

Page 68

Take Apart AC Inlet Assembly - 26

AC Inlet Assembly

Before you begin,

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

• Remove the power supply

±

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

AC Inlet Assembly

This product

Page 69

Take Apart AC Inlet Assembly - 27

±

CN1601

CN1600

Warning:

grounding wriststrap until

after discharging the CRT.

1 Disconnect these cables

from the AC interconnect

board:

• CN1600

• CN1601

2 Remove the screw

securing the AC inlet

ground strap to the

chassis.

Screw

Never use a

Page 70

Take Apart AC Inlet Assembly - 28

3 Remove the two screws

securing the AC inlet

assembly to the chassis.

4 Lift out the AC inlet

assembly.

Screw

Screw

AC Inlet

Assembly

Page 71

Take Apart Serial I/O Board - 29

Serial I/O Board

Before you begin,

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

±

Serial I/O Board

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

±

Warning:

grounding wriststrap until

after discharging the CRT.

This product

Never use a

Page 72

Take Apart Serial I/O Board - 30

1 Disconnect these cables

from the serial I/O

board:

• CN250

• CN253 (from video

cable)

• CN254 (from CRT/

video board)

CN253

Screw

CN254

Screw

CN250

Serial I/O Board

2 Remove the two screws

securing the serial I/O

board to the rear panel.

3 Lift out the serial I/O

board.

Page 73

Take Apart Serial I/O Board - 31

Replacement Note:

3-pin connector from

the video cable connects

to connector CN253 and

the 3-pin connector

from the CRT/video

board connects to

connector CN254.

The

Page 74

Take Apart Video Cable - 32

Video Cable

Before you begin,

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

±

Video Cable

Warning:

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

±

Warning:

grounding wriststrap until

after discharging the CRT.

This product

Never use a

Page 75

Take Apart Video Cable - 33

1 Disconnect connector

CN253 from the serial

I/O board.

2 Disconnect the R, G, and

B cables from the CRT/

R,G,B Cables

CN253

Serial I/O Board

video board.

Page 76

Take Apart Video Cable - 34

3 Caution: When

removing the video

cable from the CRT/

video board, be careful

not to apply excessive

pressure to the neck of

the CRT.

Remove the screw

securing the video cable

Video Cable Clip

clip to the CRT/video

board shield.

4 Remove the plastic cable

clip.

Page 77

Take Apart Video Cable - 35

5 Remove the two screws

securing the rear panel

to the chassis.

6 Rotate the rear panel

away from the chassis.

7 Remove the rear panel

from the chassis.

Rear Panel

Page 78

Take Apart Video Cable - 36

8 Remove the two screws

securing the cable

clamp to the rear panel.

9 Remove the video cable.

Screw Screw

Page 79

Take Apart Main Deflection Board - 37

Main Deflection Board

Before you begin,

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

• Remove the power supply

±Warning: This product

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

Main Deflection Board

Page 80

Take Apart Main Deflection Board - 38

1 Disconnect the MV cable

from the focus VR

control.

2 Remove the two plastic

cable clips on the focus

VR control cables.

Plastic Clip

Plastic Clip

MV Cable

3 Remove the screw

securing the ground

strap to the chassis.

4 Remove the screw

securing the focus

control to the chassis.

5 Lift out the focus

control and let it hang

outside the chassis.

Page 81

Take Apart Main Deflection Board - 39

6 Disconnect these cables

from the serial I/O

board:

• CN250

• CN253 (from video

cable)

• CN254 (from CRT/

video board)

Replacement Note: The

3-pin connector from

the video cable connects

to connector CN253 and

the 3-pin connector

from the CRT/video

board connects to

CN253

CN254

CN250

Serial I/O Board

connector CN254.

Ê

Page 82

Take Apart Main Deflection Board - 40

7 Caution: When

disconnecting the

following cables from

the CRT/video board, be

careful not to apply

R,G,B Cables

excessive pressure to

the neck of the CRT.

Disconnect these cables

from the CRT/video

CN302

board:

• 11-wire cable

(CN302)

• 7-wire cable

(CN303)

• R, G, and B video

CN303

cables

Ê

Page 83

Take Apart Main Deflection Board - 41

8 Caution: When

removing the video

cable from the CRT/

video board, be careful

not to apply excessive

pressure to the neck of

the CRT.

Remove the screw

securing the video cable

Video Cable Clip

clip to the CRT/video

board shield.

Page 84

Take Apart Main Deflection Board - 42

9 Disconnect these cables

from the main deflection

board:

• 2-wire cable

(CN401)

• 2-wire cable

(CN502)

• 2-wire cable

(CN1604)

• 6-wire cable

(CN505)

• 5-wire cable

(CN504)

• 5-wire cable

(CN400)

Page 85

Take Apart Main Deflection Board - 43

• 6-wire cable

(CN501)

• gold-colored connector

• 6-pin connector

(control panel)

Page 86

Take Apart Main Deflection Board - 44

10 Remove the cables from

the plastic cable clip.

Page 87

Take Apart Main Deflection Board - 45

11 Remove the two screws

securing the main

deflection board carrier

to the chassis. (Only one

screw is shown in the

illustration. The other

screw is on the opposite

side of the carrier.)

12 Slide back the carrier.

13 Remove the main

deflection board.

Screw

Page 88

Take Apart Microprocessor Board - 46

Microprocessor Board

Before you begin,

• Save EEPROM settings

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

• Remove the power supply

• Remove the main

deflection board

Important: Before you

Microprocessor Board

replace the microprocessor

board, save the EEPROM

settings. See

Troubleshooting for

instructions.

Page 89

Take Apart Microprocessor Board - 47

±Warning: This product

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

±Warning: Never use a

grounding wriststrap until

after discharging the CRT.

Page 90

Take Apart Microprocessor Board - 48

Important: Make sure you

save the EEPROM settings

CN908

before replacing the

microprocessor board.

1 Disconnect these cables

CN902

from the

microprocessor board:

CN901

• 11-wire cable

(CN901)

• 7-wire cable

(CN902)

• 6-wire cable

CN907

(CN907)

• 5-wire cable

(CN908)

2 Remove the

microprocessor board.

Page 91

Take Apart Tilt/Swivel Assembly - 49

Tilt/Swivel Assembly

Before you begin,

• Remove the rear cover

• Discharge the CRT

• Remove the EMI shield

• Remove the power supply

• Remove the main

deflection board

±Warning: This product

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

Tilt/Swivel

Assembly

Page 92

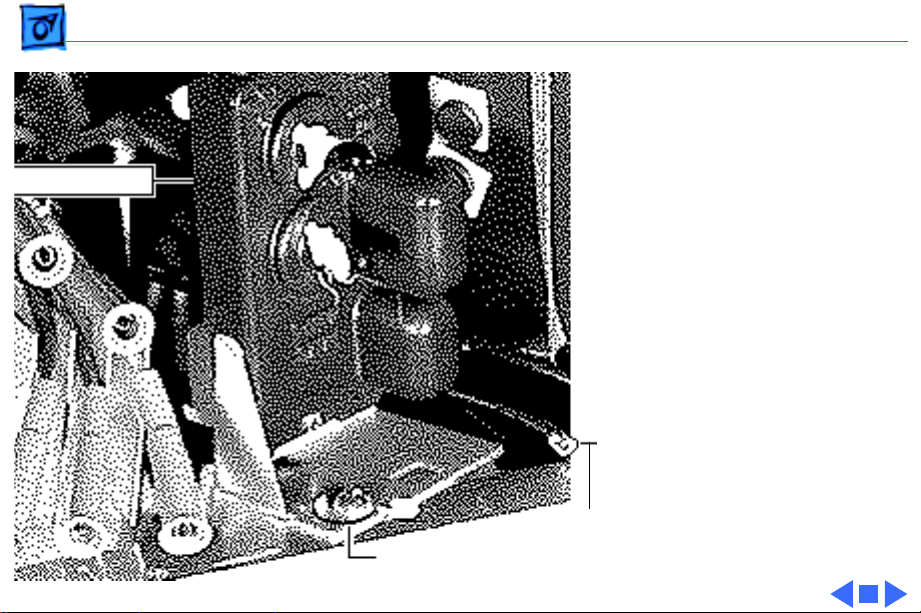

Take Apart Tilt/Swivel Assembly - 50

±Warning: Never use a

grounding wriststrap until

after discharging the CRT.

1 With the monitor face-

down on a protective pad,

remove the two screws

securing the tilt/swivel

assembly to the chassis.

(Only one screw is

shown in the

illustration. The other

screw is on the opposite

Screw

side of the tilt/swivel

assembly.)

2 Lift and remove the tilt/

swivel assembly.

Page 93

Take Apart Control Panel - 51

Control Panel

Before you begin,

• Remove the cover

• Discharge the CRT

• Remove the anode cap

• Remove the EMI shield

• Remove the power supply

• Remove the main

deflection board

• Remove the tilt/swivel

assembly

Control Panel

Page 94

Take Apart Control Panel - 52

±Warning: This product

contains high voltage and a

high-vacuum picture tube.

To prevent serious injury,

review CRT safety in

Bulletins/Safety.

±Warning: Never use a

grounding wriststrap until

after discharging the CRT.

Page 95

Take Apart Control Panel - 53

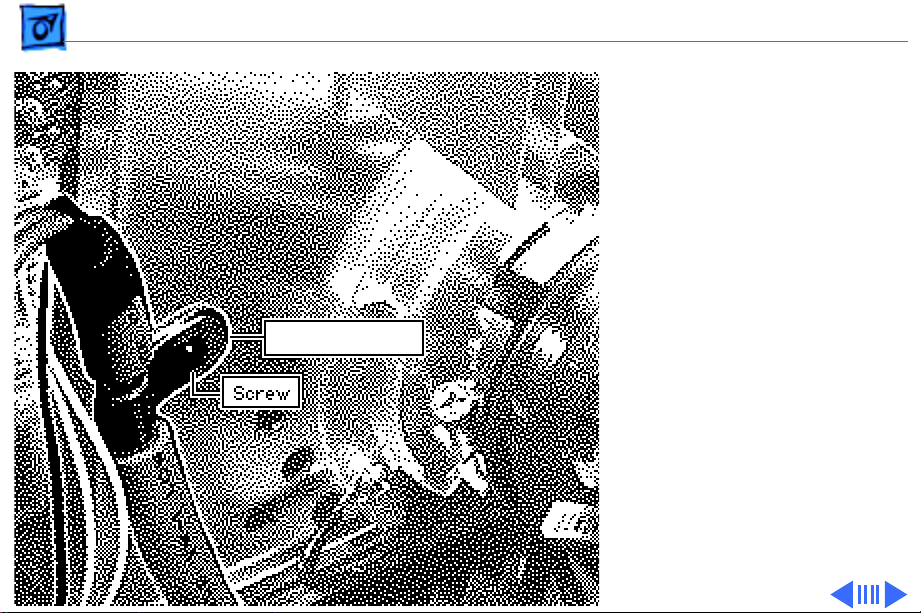

1 Remove the screw

securing the control

panel ground strap to the

chassis.

2 Remove the ground wire

from the plastic cable

Grounding Strap

clip.

3 Remove the two screws

securing the control

panel board support to

the front bezel.

4 Lift out the control panel

board and support.

Plastic

Cable

Clip

Control

Panel

Page 96

Take Apart ADB Board - 54

ADB Board

No preliminary steps are

required before you begin

this procedure.

ADB Board

Page 97

Take Apart ADB Board - 55

1 With the monitor face-

down on a protective pad,

remove the two screws

securing the ADB board

cover and remove the

cover.

2 Lift out the ADB board.

Page 98

K

Service Source

Adjustments

Apple Multiple Scan 20 Display

Page 99

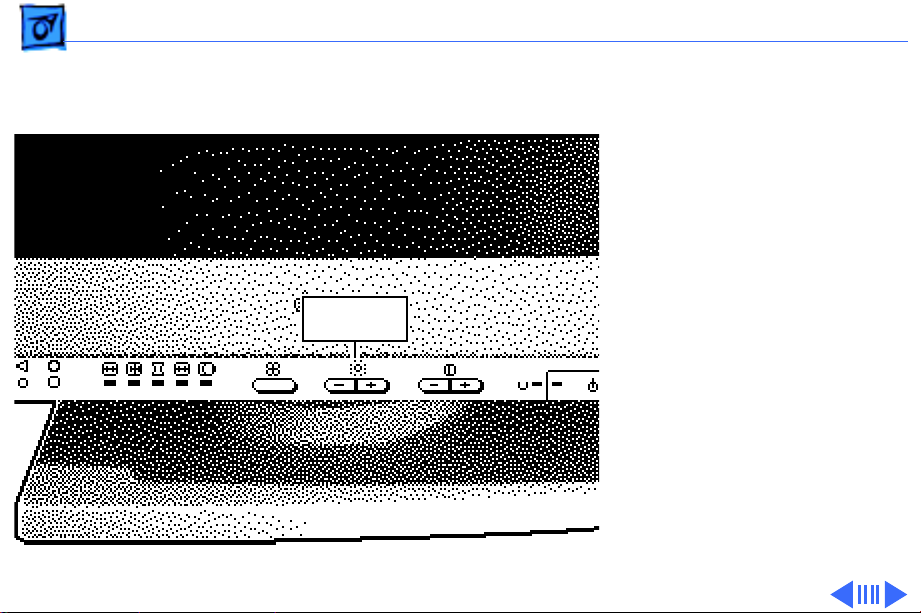

Adjustments Brightness and Contrast - 1

Brightness and Contrast

No preliminary steps are

required before you begin

this procedure.

Adjustment controls are

located on the front panel.

Front Panel

Page 100

Adjustments Brightness and Contrast - 2

Brightness

1 Press the + button to

increase the brightness.

2 Press the – button to

decrease the brightness.

Brightness

Controls

Loading...

Loading...