Page 1

Color LaserWriter 12/600 PS and 12/660 PS

Service Technical Documentation

Steve Rancourt 5/95

This document was created with FrameMaker 4.0.4

Page 2

About Graphics

Using the magnifier tool enables you to zoom

Thumbnails

Bookmarks

Could not open the specified file...

If you get this message when trying to launch a QuickTime movie, you may not have

enough memory to run MoviePlayer. Try quitting out of other applications.

This error also may occur if you copied files from the CD to a hard drive and have not

foldered the files identically to the arrangement of folders on the CD.

into graphics and see greater detail.

About Printing

pages out of Acrobat. Page numbers that appear on the

paper do not reflect their true order within the document.

:

:

Always use these numbers when printing

Page 3

K

Service Source

Color LaserWriter

Color LaserWriter 12/600 PS

Color LaserWriter 12/660 PS

Page 4

Color LaserWriter 12/660 PS

96.11.13.15.58

Page 5

Color LaserWriter 12/660 PS 3–2

Overview

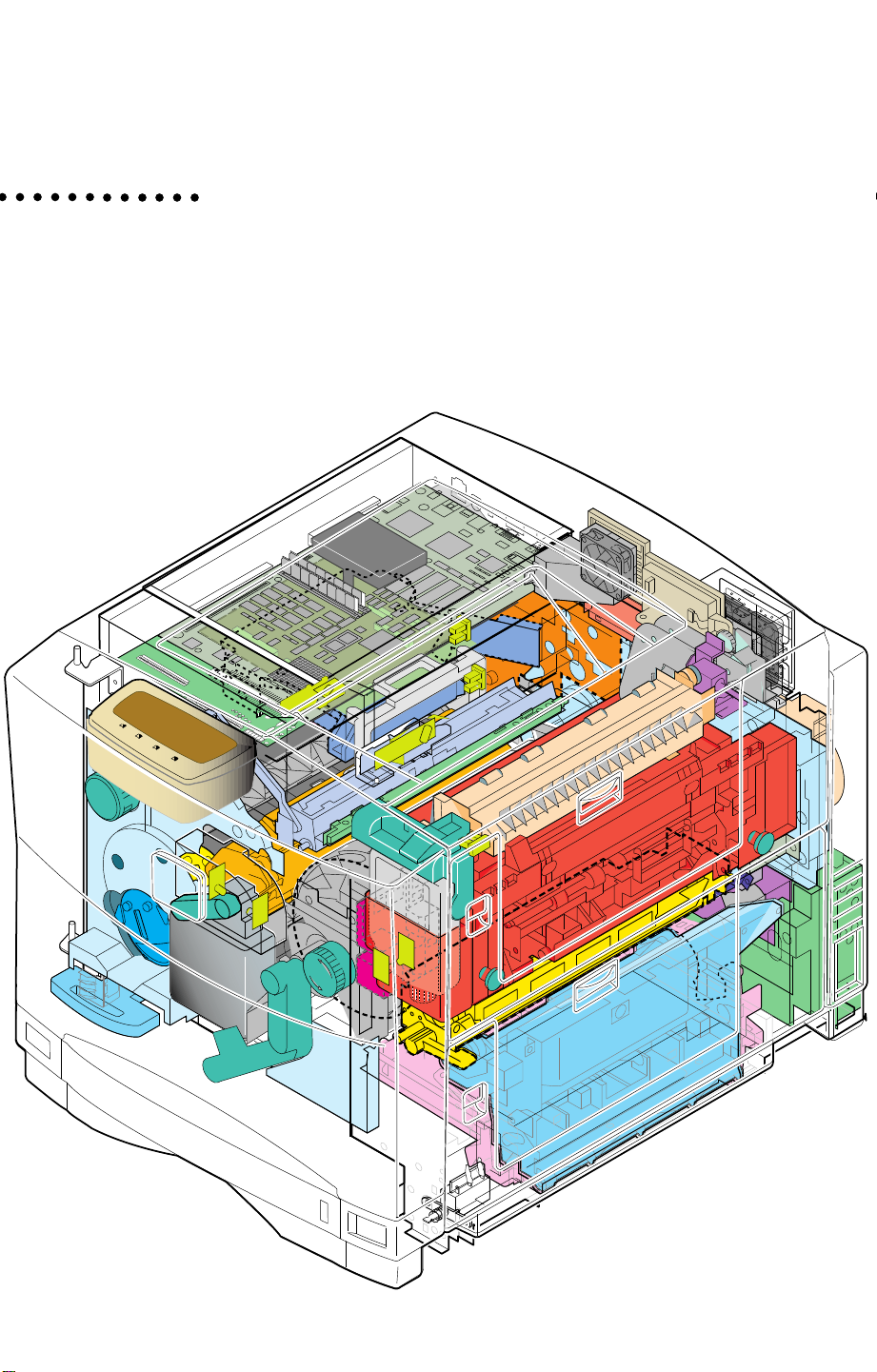

The Color LaserWriter 12/660 PS is an enhanced version of the

original Color LaserWriter 12/600 PS. The 12/660 engine and

plastics are identical to the original in every respect, and all

finished goods and service part numbers apply equally to both

printers. The sole differences between the two versions are in

the packaging and setup, the ROM and RAM on the I/O

controller board, and the driver software.

Packaging and Setup Changes

The Color LaserWriter 12/660 PS requires two extra steps

during setup, the leveling of the printer and the removal of oil

absorption sheets from the fuser assembly.

Note

: The orange flag that identifies the shipping screw has

also been enlarged in the new version of the printer.

The leveling procedure helps to alle viate oil o v erflow problems

within the fuser assembly. The level and shim kit that comes

with the 12/660 PS is also available separately as P/N 076-0622

for those who would to perform the procedure on the original

version of the printer. After removing the packing tape from

the outside of the printer, performing the leveling procedure

below before proceeding any further.

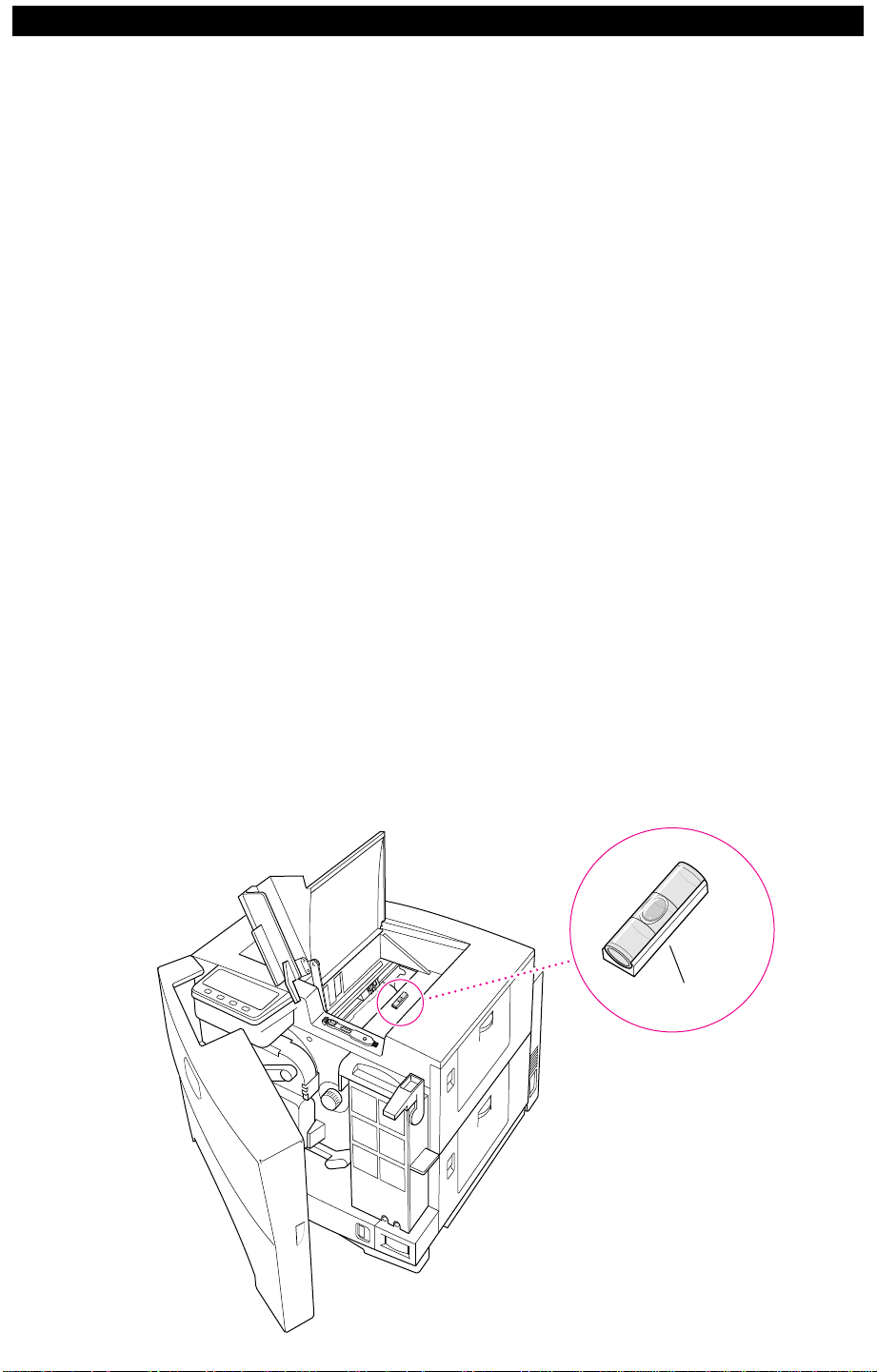

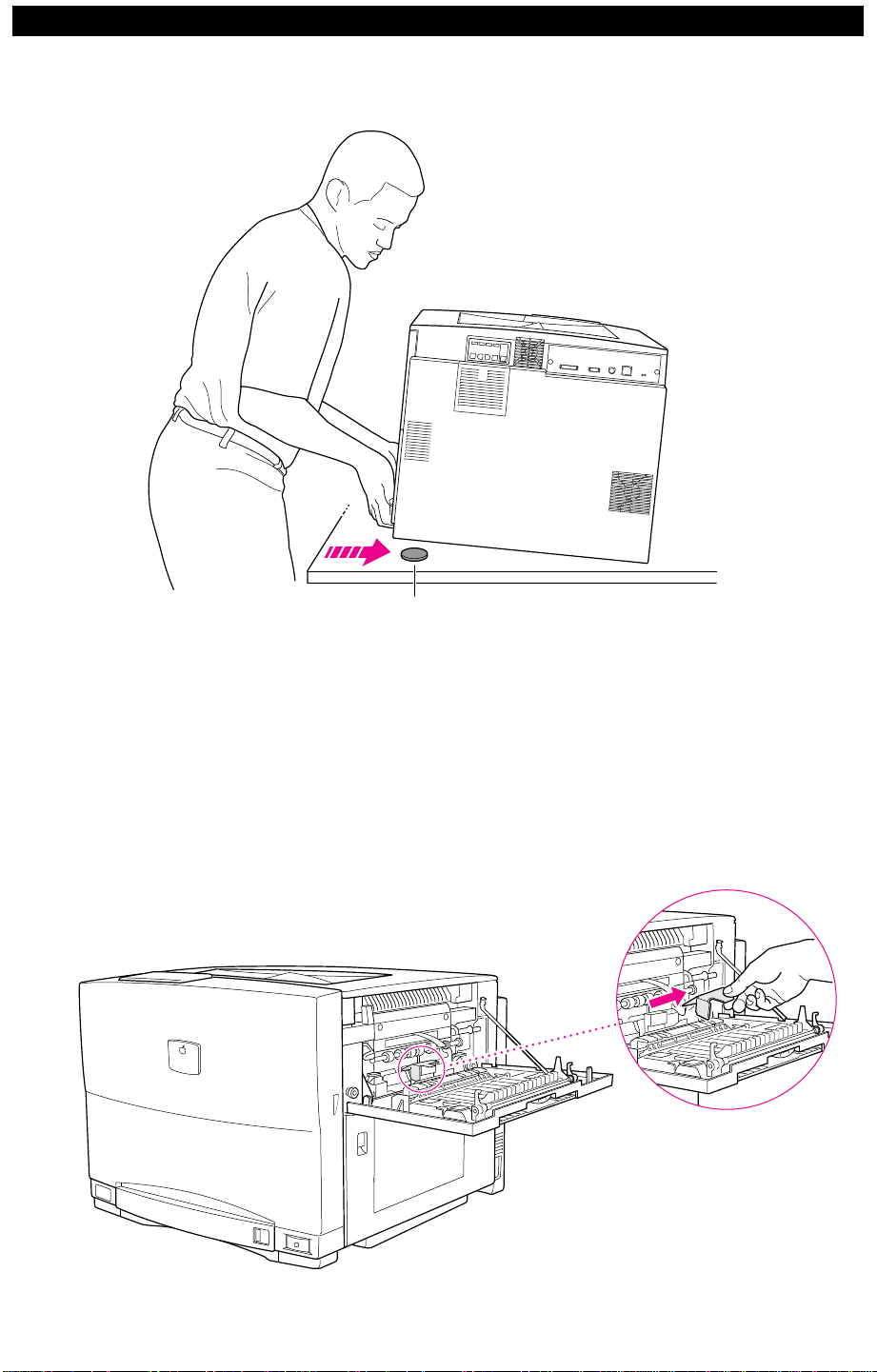

1 Remove the spirit level and the round black rubber shims from

their package. Snap the spirit level into its base.

2 Open the printer’s top access cover and place the spirit level on

top of the fuser to level the printer , first from front-to-back, then

from side-to-side.

Spirit Level

96.11.13.15.58

Page 6

Color LaserWriter 12/660 PS 3–3

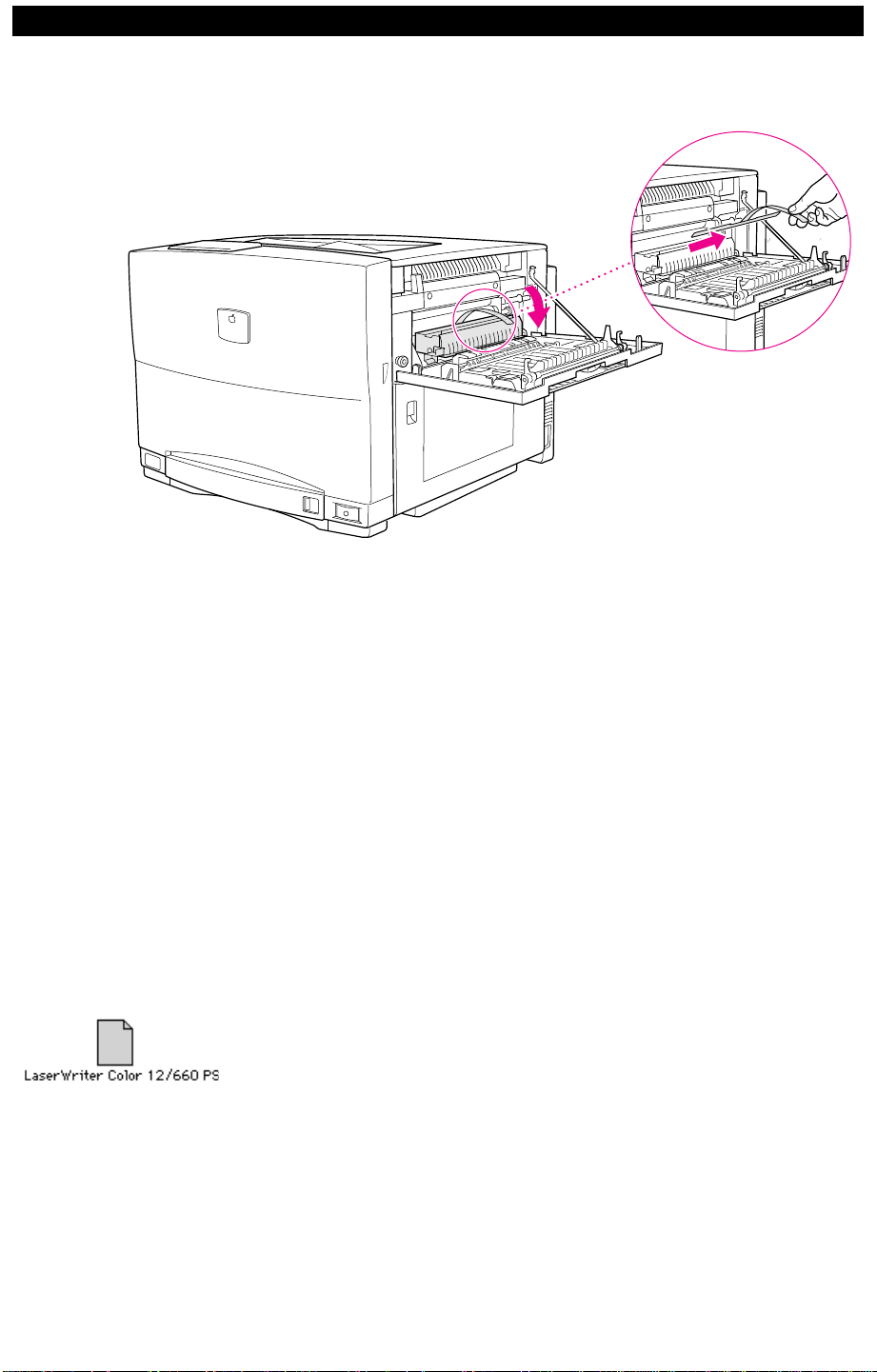

3 Place the shims under the printer’s feet (as needed) to level the

printer.

Shim

The oil absorption sheets have been installed to eliminate

migration of silicon oil during shipping. After leveling the

printer, remove the shipping spacers and absorption sheets as

described below.

1 Open the fuser access door and remove the two orange spacers

and the oil absorption sheet from inside.

96.11.13.15.58

Page 7

Color LaserWriter 12/660 PS 3–4

2 Open the fuser assembly and remove the oil absorption sheet

from the inside of the fuser assembly.

I/O Controller Board Changes

Driver Software

The Color LaserWriter 12/660 PS comes standard with 16 MB

of DRAM and version 2.0 of ROM. All other characteristics of

the board remain the same.

Note

: Version 2.0 of ROM contains fixes for variety of system

and networking bugs that have been reported since the release

of the original printer. (I/O controllers with 2.0 ROM will also

output new startup and demo pages). If you want to upgrade an

existing printer, see “Upgrade Path” later in this chapter.

The new version of the Color LaserWriter printer does not

require a driver upgrade. However, the printer name has

changed in ROM. Consequently, with older drivers you must

manually select the “LaserWriter Color 12/600 PS” PPD when

setting up the new printer in the Chooser.

Alternately, if copy the new “LaserWriter Color 12/660 PS”

PPD into the Printer Descriptions folder (path: System

Folder:Extensions folder), Chooser setup will be automatic.

This PPD can be found on the Service Source CD (path:

Service Manuals:Clips:CLW 12/660 PPD).

96.11.13.15.58

Page 8

Color LaserWriter 12/660 PS 3–5

Upgrade Path

You can upgrade a Color LaserWriter 12/600 PS to a Color

LaserWriter 12/660 PS by installing version 2.0 ROMs onto the

customer’s I/O controller board. The version 2.0 R OM upgrade

kit is available as P/N 076-0621. The contains eight ROM ICs,

a user manual addendum, a software installation CD, and

upgrade labels.

Note

: Install new ROM only if the customer’s printer is exhibiting one of the problems described below. Install a replacement I/O controller board (P/N 661-0133) only if your

troubleshooting has found the board to be defective. All service

stock for the I/O controller board will include version 2.0 of

ROM.

After installing the new R OM, affix the labels that are provided

in the kit as described in the instructions that accompany the

ROM upgrade kit.

Feature added in ROM v2.0

System bugs fixes

in ROM v1.2

Caution:

of the ROM also appeared in version 1.2.

All but one of the bug fixes contained in version 2.0

If your I/O

controller board has version 1.2 of ROM, do not upgrade

unless it is specifically for the Windows 95 feature described

immediately below. You can identify the ROM version by

inspecting the margin text on the startup page.

• Plug and play support for Windows 95

Plug and play support means that the user can connect the

printer to the system, boot Windows 95, and automatically see

the printer name in the “New Hardware Found” dialog box

during the installation process. After installation is complete,

the Device ID string and related information will be returned

whenever the printer is queried for its device id.

• System error at address 0x132460

When printing a complex document to the Color LaserWriter

12/600 PS, a page is printed stating “printer restarted due to

system error at address 0x132460.”

• System error at address @0x33F844

A bug in version 1.0 ROM caused certain complex Adobe Illus-

trator files to reset the printer and to print a page stating “printer

restarted due to system error at address @0x33F844.

• Image stitching problem

When an image has a very fine line running across its body and

the line does not seem to belong to the image, that may be a

stitching problem. If the same problem occurs when printing to

another printer, for example a LaserWriter 16/600 PS, the

96.11.13.15.58

Page 9

Color LaserWriter 12/660 PS 3–6

problem is likely in the application and the ROM upgrade will

not help.

If possible, try printing the problem file to a printer with version

2.0 ROMs. If there is no improvement, then the problem is

elsewhere.

• NetWare port number not set properly

When setting the NetWare port number through the Apple

Printer Utility, the number did not stick.

• Changing AppleTalk type fails

Changing the AppleTalk “type” on version 1.0 ROMs fails

when PAPTest is run through a LocalTalk port. (Unlikely to

affect normal user).

• EtherTalkZone and LocalTalkType strings

EtherTalkZone strings and LocalTalkType strings did not take

input longer than 31 characters. (Unlikely to affect normal

user).

• LocalTalk ports turns off; EtherTalk remains active

In some cases, the LocalTalk port turned off after printing a

very large number of PostScript test files to a printer using both

EtherTalk & LocalTalk ports, even though the EtherTalk port

remained active and could be seen from any host. (Unlikely to

affect normal user).

• Specific PostScript Code resets printer

Sending the following PostScript code caused the printer to

reset itself (unlikely to affect normal user):

[(%disk1%) <</InitializeAction 1>> setdevparams]

• PowerPoint v3.0 gradients

Some PowerPoint slides containing complex gradients or

patterns would freeze the printer.

• TraySwitch not saved

Enabling the TraySwitch feature on a Color LaserWriter

12/600-J (Kanji version) did not survive power cycles.

• One-byte PostScript filename on printer hard drive

Creating a one-byte long PostScript filename on a printer’s hard

disk caused an I/O error. (Unlikely to affect normal user).

• Configuration switch and image data

This issue only affects printing from PC computers using the

parallel port. Once the printer’s configuration switch w as used,

96.11.13.15.58

Page 10

Color LaserWriter 12/660 PS 3–7

the default protocol for the parallel port (TBCP) was changed

to Normal and not returned back to TBCP, regardless of configuration switch position. In this scenario text documents would

print, but documents with images (binary data) would not. The

printer’s ready light would flash for a while, stop, and then

nothing would print.

Networking bugs

fixes in ROM v1.2

• NetWare polling

If the printer was in NetWare PServer mode configuration, it

would likely stop polling its NetWare print queue after being

powered on for more than 24 hours.

• Name lengths increased

The pserver and rprinter name length has been increased to 47

characters maximum.

96.11.13.15.58

Page 11

Color LaserWriter 12/660 PS 3–8

Installation Reimbursement Program

Beginning October 21, 1996, Authorized Apple Resellers and

institutions are entitled to receive a $150 reimb ursement on the

installation(s) of the Color Laserwriter 12/660 PS.

Customers who purchase the printer beginning October 21,

1996 are entitled to have the printer set up and installed in the

location of their choice at their site.

How customers will be informed

A letter will be included with the printer informing customers

to contact their Authorized Apple reseller, or Apple directly to

perform the installation.

This letter also stipulates special tasks for the customer to

perform before a service technician arrives at their location.

These tasks include:

• Preparing a suitable location for the printer.

• Having someone available to help the service technician lift

the printer from the floor to the table or counter.

• Providing appropriate power, networking connections, and

cabling.

• Ensuring that a network administrator (or other knowledge-

able person) is available for consultation with the service

technician.

• Providing a computer that is configured with the appropriate

system software and is functioning on the network.

• Arranging for the storage and disposal of packing materials.

Installation procedures

If everything is prepared, the service technician should be able

to complete the setup and installation in about 45 minutes.

The file “CLW 12/660 Setup.pdf” is the first chapter of the

Color LaserWriter 12/660 PS. Read this chapter for the special

considerations required when setting up and installing this

printer. Click on the icon below to open the file.

96.11.13.15.58

Page 12

1

Basics and Theory

Page 13

Color LaserWriter 12/600 PS Basics & Theory 1–2

Chapter Contents

I General Information

Features ......................................................................................................... 1–5

Specifications..................................................................................................1– 6

Safety Information ..........................................................................................1–10

Laser Safety ..............................................................................................1–10

Toner Safety .............................................................................................. 1–10

Ozone Safety ............................................................................................ 1–10

Status Panel ................................................................................................... 1–11

Outline .......................................................................................................1–11

Configurations ...........................................................................................1–12

Density Control Panel ....................................................................................1–13

Panel Layout .............................................................................................1–13

Density Adjustments .................................................................................1–14

Test Page Pattern Selection.......................................................................1–15

Separation Voltage Designation ................................................................1–16

Registration Adjustments........................................................................... 1–17

II Basic Operation

Paper Path Animation..................................................................................... 1–19

Functions ........................................................................................................1–20

Outline of Electrical System ........................................................................... 1–21

Outline of Major Circuit Boards ...................................................................... 1–22

DC Controller Input/Output Signals ...........................................................1–23

Mechanical Controller Board Input/Output Signals ...................................1–26

Outline of Drive System .................................................................................1–28

III Laser/Scanner System

Laser System ................................................................................................. 1–32

Scanner System ............................................................................................. 1–38

IV Image Formation System

Outline ............................................................................................................1–41

Photoconductor Cartridge .............................................................................. 1–43

Toner Cartridge ..............................................................................................1–44

Stages of Imaging .......................................................................................... 1–47

Stage 1: Electrostatic Latent Image Formation ........................................1–48

Stage 2: Developing .................................................................................1–50

Stage 3: Photosensitive Drum Cleaning .................................................. 1–51

Stage 4: Transfer ..................................................................................... 1–53

Stage 5: Transfer Drum Cleaning and Discharge ....................................1–57

Stage 6: Fusing ........................................................................................1–59

High-Voltage Control ...................................................................................... 1–60

Photosensitive Drum Life Detection ...............................................................1–68

Toner Carousel Control ..................................................................................1–71

Toner Cartridge Installation .......................................................................1–73

Carousel Rotation...................................................................................... 1–75

Toner Cartridge Stop.................................................................................. 1–79

Toner Cartridge Press ...............................................................................1–80

Developing Cylinder Drive ........................................................................1–81

Toner Cartridge Separation ....................................................................... 1–82

Image Quality Stability Control ....................................................................... 1–84

Temperature/Humidity Sensing System .................................................... 1–85

Density Calibration System .......................................................................1–86

95.08.23.11.28

Page 14

Color LaserWriter 12/600 PS Basics & Theory 1–3

V Pickup/Feed System

Outline ............................................................................................................1–89

Paper Pickup .................................................................................................. 1–90

Overhead Transparency Detection ................................................................1–96

Cassette Pickup Board ...................................................................................1–97

Transfer Drum and Peripherals ......................................................................1–100

Gripper Control .........................................................................................1–102

Attraction Roller ........................................................................................1–103

Separation .................................................................................................1–105

Transfer Drum Cleaning Assembly ...........................................................1–106

Discharge Roller .......................................................................................1–107

Cleaning Brush Motor Drive Circuit ...........................................................1–109

Fuser Assembly .............................................................................................. 1–110

Transparency Mode ..................................................................................1–112

Fuser Assembly Errors ..............................................................................1–115

Oil Circulation System ...............................................................................1–122

Fuser Cleaner Assembly ...........................................................................1–124

Main Motor Drive Circuit .................................................................................1–125

Paper Jam Detection ......................................................................................1–126

Pickup Delay Jam ..................................................................................... 1–127

Paper Top Position Delay Jam .................................................................. 1–128

Grip Jam ...................................................................................................1–129

Separation Delay Jam ...............................................................................1–130

Separation Stationary Jam ........................................................................1–131

Delivery Delay Jam ...................................................................................1–132

Delivery Stationary Jam ............................................................................1–133

Multi-Fed Paper Stationary Jam ...............................................................1–134

Non-Dedicated Transparency Jam ...........................................................1–135

Wrong Paper Length Feed Jam ................................................................1–136

Initial Residual Jam ...................................................................................1–137

VI System Interface

Outline ............................................................................................................1–139

Video Interface ...............................................................................................1–140

VII Power Supply

Outline ............................................................................................................1–143

Remote Switch ...............................................................................................1–145

VIIISheet Feeder

Outline of Electrical Circuit .............................................................................1–147

Sheet Feeder Controller Board Input/Output .................................................1–148

Pickup/Feed System ...................................................................................... 1–149

Power Supply .................................................................................................1–150

95.08.23.11.28

Page 15

Color LaserWriter 12/600 PS Basics & Theory 1–4

I. General Information

Page 16

Color LaserWriter 12/600 PS Basics & Theory 1–5

Features

Some of the main features of the Color LaserWriter 12/600 PS are as

follows:

Print Quality

Speed

Multiplatform

Support

Connectivity

Automatic

Traffic Control

Fonts

Energy

Savings

Hard Disk

Option

The printer has a resolution of 600x600 dots per inch, with color PhotoGrade.

The printer prints up to 12 pages per minute in black, cyan, magenta, or

yellow; 3 pages per minute in two or more colors; and 1 transparency

per minute.

You can connect the printer to Macintosh, Windows, DOS, and UNIX

computers.

The printer offers LocalTalk, Ethernet, and parallel connections.

Without any user intervention, the printer can accept jobs simulta-

neously from AppleTalk, TCP/IP, and NetWare networks and from the

parallel port.

The printer supports both TrueType and PostScript fonts. The printer

has 39 built-in PostScript fonts.

The printer can automatically lower its power consumption when it’s

not being used.

You can install an internal hard disk or attach up to six external hard

disks to store downloadable fonts.

Paper Handling

You can print up to 350 sheets (250 in the standard paper cassette plus

100 in the multipurpose tray) without changing paper. You can also add

a 250-sheet feeder.

95.08.23.11.28

Page 17

Color LaserWriter 12/600 PS Basics & Theory 1–6

Specifications

Marking

Engine

Laser

Controller

Canon HX LBP print engine

• 3 ppm in color; 12 ppm in black, cyan, magenta, or yellow; 1 ppm

for transparencies

• 600x600 dpi with Color PhotoGrade

• Enhanced 600 dpi grayscale imaging (effective 200-line screen half-

tone, 122 gray levels)

Semiconductor laser GaAlAs

• Wavelength: 780 nm

• Output power: 1 mW

The specifications for the I/O controller board are as follows:

• AMD Am29030 30-MHz microprocessor

• 8 MB of ROM (including 39 Type 1 fonts)

• 12 MB of RAM (16 MB on CLW 12/660); 8 MB soldered + 4 MB

(or 8 MB) SIMM

(expandable to 40 MB total)

• 128 K parameter SRAM

True 600 dpi

• SCSI interface for internal/external hard disk(s)

• LocalTalk interface

• High-speed parallel interface (IEEE P1284 ECP, bidirectional)

• Ethernet interface with three protocols: EtherTalk, Novell NetWare

IPX (PSERVER or RPRINTER), and TCP/IP (BSD lpd)

• External Ethernet transceivers a vailable for thin coaxial, twisted pair

(10Base-T), and thick coaxial (IEEE 802.3 AUI)

• Two-position communication configuration switch

• All ports/protocols simultaneously active

• Color-rendering acceleration

• Data compression/decompression system

• Adobe PostScript Level 2 (version 2014)

The Color LaserWriter 12/600 PS is a true 600 dpi printer because

every aspect of its architecture is designed to a 600 dpi specification. In

addition, its 8-bit per pixel capability can assign levels of color or gray

to each pixel, thereby further enhancing print quality.

96.09.11.09.27

Page 18

Color LaserWriter 12/600 PS Basics & Theory 1–7

Printer Fonts

The following fonts are resident in the printer ROM:

• AvantGarde Book, AvantGarde BookOblique, AvantGarde Demi,

AvantGarde DemiOblique

• Bookman Demi, Bookman DemiItalic, Bookman Light, Bookman

LightItalic

• Courier, Courier Bold, Courier BoldOblique, Courier Oblique

• Helvetica, Helvetica Bold, Helvetica BoldOblique, Helvetica

Narrow, Helvetica Narrow Bold, Helvetica Narrow BoldOblique,

Helvetica Narrow Oblique, Helvetica Oblique

• Helvetica Condensed, Helvetica Condensed Bold, Helvetica

Condensed BoldOblique, Helvetica Condensed Oblique

• NewCentury Schoolbook Bold, NewCentury Schoolbook Bold-

Italic, NewCentury Schoolbook Italic, NewCentury Schoolbook

Roman

• Palatino Bold, Palatino BoldItalic, Palatino Italic, Palatino Roman

• Symbol

• Times Bold, Times BoldItalic, Times Italic, Times Roman

Life

Expectancies

• Zapf Chancery MediumItalic

• Zapf Dingbats

Minimum life expectancy for the printer is 5 years or 300,000 pages in

black and white or 150,000 color pages, with no monthly page limit.

Recommended maintenance interval is 60,000 pages due to wear on

fuser and rollers.

Toner Cartridge: 4,000 pages per color when printing documents with

average page coverage of 5%.

Photoconductor cartridge: 40,000 pages black and white or 10,000

pages color (for continuous printing); 13,000 pages black and white or

6,500 pages color (printing only single-page documents).

Fuser oil life: 10,000 pages

Fuser assembly life: 60,000 pages

Transfer drum cleaner life: 60,000 pages

Ozone filter life: 60,000 pages

Air filter life: 60,000 pages

Separation Discharge Assembly life: 60,000 pages

95.08.23.11.28

Page 19

Color LaserWriter 12/600 PS Basics & Theory 1–8

Speed

Printing

Materials

Transparencies

Paper Sizes

and Capacity

Suggested

Paper Brands

Prints 12 pages per minute in monochrome; 3 pages per minute

maximum in color; and 1 page per minute for transparencies. Actual

speed depends on the images printed and paper size.

Uses 16- to 28-pound laser-quality bond (60 to 90 g/m2). Most textured

and colored stock is accepted but discouraged, as it will adversely

affect color print quality.

The paper used should not scorch, melt, transfer material, or release

°

hazardous emissions when heated to 200

C (392° F) for 0.1 seconds.

Use only Apple Color LaserWriter 12/600 PS Transparencies A4 or

Letter.

Supports U.S. letter and A4 in the standard paper cassette. The paper

2

cassette holds 250 sheets of 20-pound (75 g/m

) paper. The multipurpose tray can hold up to 100 sheets of standard U.S. letter paper, and

other paper sizes up to U.S. legal. Optional 250-sheet universal

cassettes are available that support letter, A4, B5, and U.S. legal paper

sizes. Cassettes are compatible with both the printer and the optional

sheet feeder.

Apple has tested the following papers and found them to be acceptable.

• Aussydat-lay (A4, France) 100 g/m

2

• Boise Cascade Laser, 20 and 24 pound

• Classic Crest, 24 pound

• Hammermill Laser Print, 24 pound

• Legacy Laser Paper, 24 pound

• Nekoosa Laser 1000, 24 pound

• Neusiedler (A4, Austria) 100 g/m

2

• Xerox 4024 (LTR and A4), 20, 24, and 28 pound

• Nekoosa Laser 1000, 24 pound

Note

: Recycled paper is not recommended. It tends to produce more

paper dust, degrading image quality and necessitating more frequent

replacement of the fuser assembly.

95.08.23.11.28

Page 20

Color LaserWriter 12/600 PS Basics & Theory 1–9

Dimensions

Weight

Environmental

Conditions

Acoustic

Output

Wait Times

Voltage

Requirements

Power

Consumption

Height: 18 in. (46 cm)

Width: 21 in. (54 cm)

Depth: 23 in. (58 cm)

Approximately 110 lb. (50 kg) for the printer body only

During printer operation: Temperature 50° to 86° F (10° to 30° C) and

humidity 20 to 80 percent RH noncondensing (for optimum print

quality, operate at 35 to 70 percent RH)

°

In storage (both toner cartridges and printer): Temperature –4

°

F (–20

to 40° C) and humidity 10 to 95 percent RH noncondensing

to 104°

Standby, less than 45 dB

Printing, less than 55 dB

• Either 120 or 240 V, 3.5 minutes maximum

• Either 100 or 220 V, 4.5 minutes maximum

100 to 120 V (50/60 Hz) or 220 to 240 V (50 Hz), voltage tolerance

plus or minus 10%

Energy-saving mode

• Approximately 42 W (meets EPA Energy Star)

Standby average

• 100/120 V, approximately 215 W

• 220/240 V, approximately 238 W

Operating average

• 100/120 V, approximately 535 W

• 220/240 V, approximately 524 W

Maximum power consumption

• 100/120 V, approximately 1.1 KW

• 220/240 V, approximately 1.0 KW

95.08.23.11.28

Page 21

Color LaserWriter 12/600 PS Basics & Theory 1–10

Safety Information

Laser Safety

The invisible laser beam irradiated within the laser/scanner assembly

can be harmful if it comes into contact with your eyes. Consequently,

never disassemble the laser/scanner assembly. A cautionary label has

been affixed to the top of the laser/scanner assembly.

Note

: The laser/scanner assembly cannot be adjusted in the field, nor

are any of its components available from Apple.

Toner Safety

Ozone Safety

Laser Safety Label

If you get toner on your skin or clothes, remove as much as possible

with dry tissue and then wash with cold water. Do not let toner come

into contact with vinyl material.

The charging roller and separation discharge assembly generate very

small amounts of ozone gas when the printer is operating. The printer

meets the Underwriters Laboratory (UL) ozone emission standard.

95.08.23.11.28

Page 22

Color LaserWriter 12/600 PS Basics & Theory 1–11

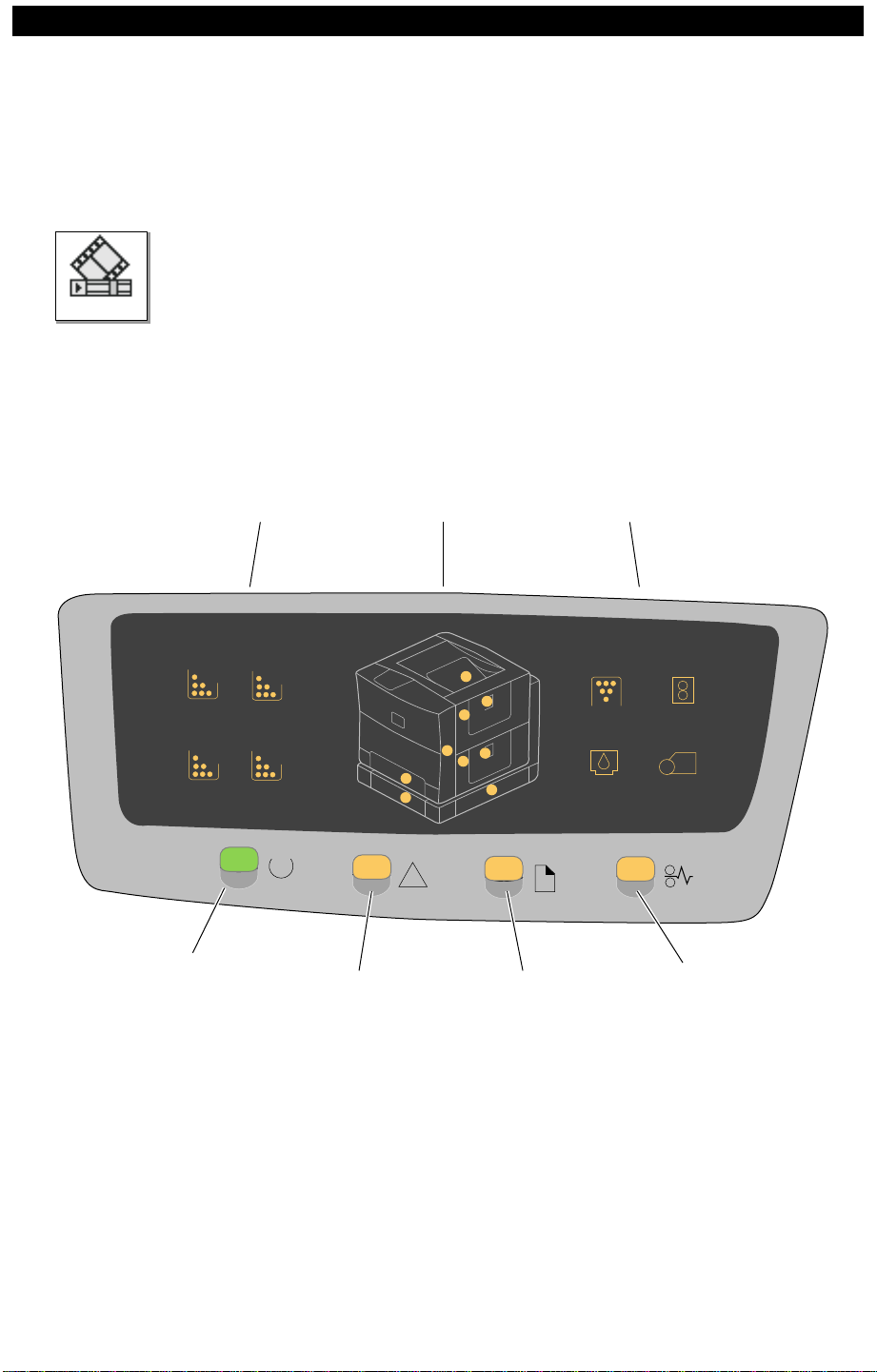

Status Panel

Outline

Movie

The Color LaserWriter 12/600 PS status panel consists of 4 primary and

17 secondary lights. The primary lights, arranged horizontally along

the bottom of the panel, are similar to those on the LED panels on many

of Apple’s previous printers.

During normal operation, primary lights report general readiness states

for consumables, paper supply , and paper feed. Secondary lights report

on specific consumables and highlight locations of a consumable, paper

jam, or paper problems. The QuickTime movie to the left shows the

normal operational behavior of the status panel when the printer starts

up. See Chapter 2 for information on the Power-On Self Test (POST).

Access Lights Maintenance LightsToner Lights

MC

Waste

Toner

Fuser

Assembly

Bk

Ready/In-Use

Light

Y

Oil Photo-

conductor

!

Alert

Light

Paper-Out

Light

Paper Jam

Light

95.08.23.11.28

Page 23

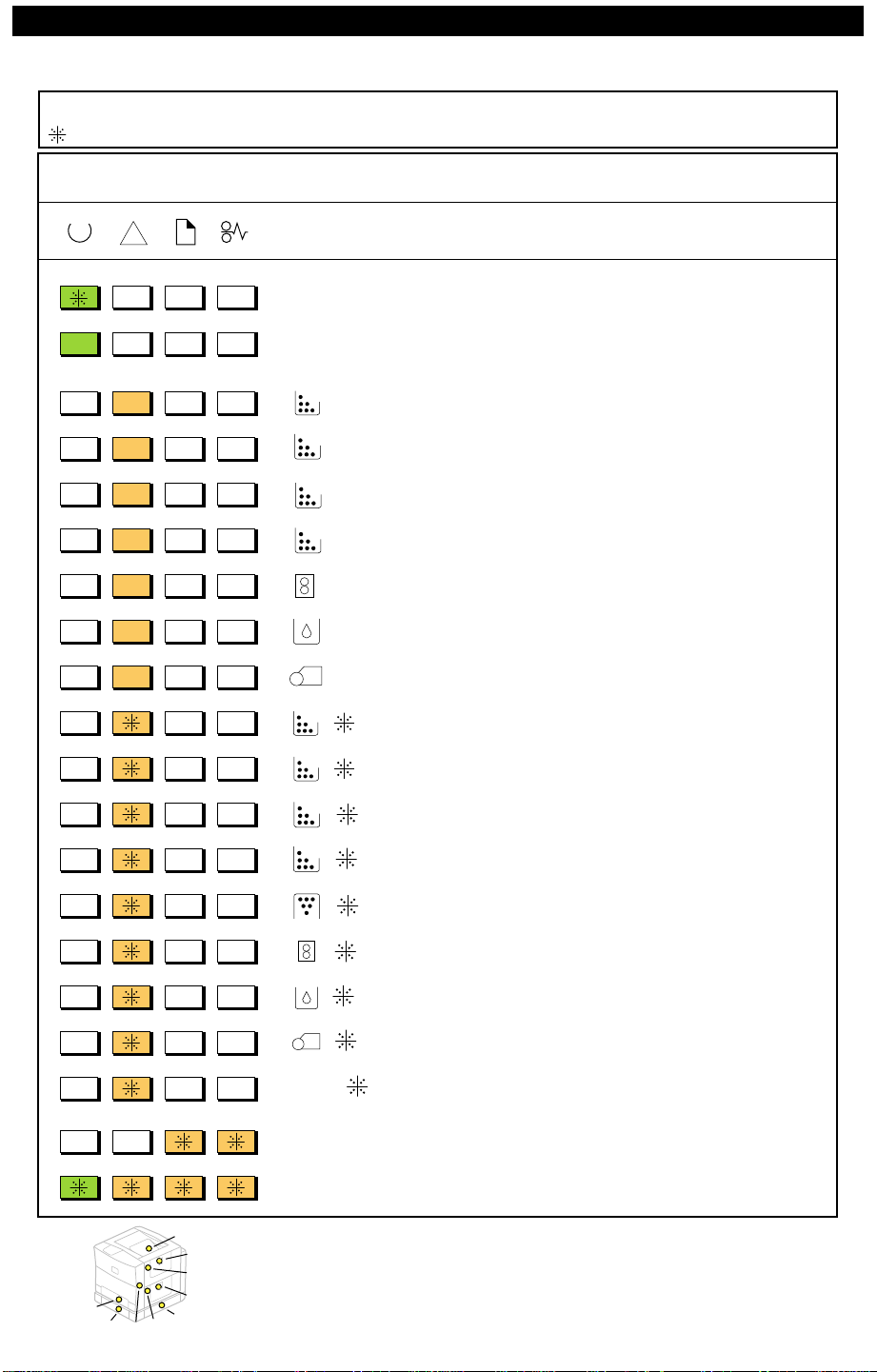

Color LaserWriter 12/600 PS Basics & Theory 1–12

= Flashing

Status Panel Lights

These are the possible arrays that customers can see during normal printer operation.

!

M

C

Y

Bk

Description

Warming Up /Processing

Printer Ready

Low Magenta

Low Cyan

Low Yellow

Low Black

Low Fuser Assembly

Low Fuser Oil

Printer

Stops

No

No

No

No

500 pages later

50 pages later

M

C

Y

Bk

Access

Lights

Photoconductor Warning

No Magenta Cartridge

No Cyan Cartridge

No Yellow Cartridge

No Black Cartridge

Toner Disposal Box Full

No Fuser Assembly

No Fuser Oil

No Photoconductor Cartridge

Door Open

(See "POST Code Matrix" in Chapter 2)

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

1

2

3

4

9

6

8

7

Access Lights

5

95.08.23.11.29

Page 24

Color LaserWriter 12/600 PS Basics & Theory 1–13

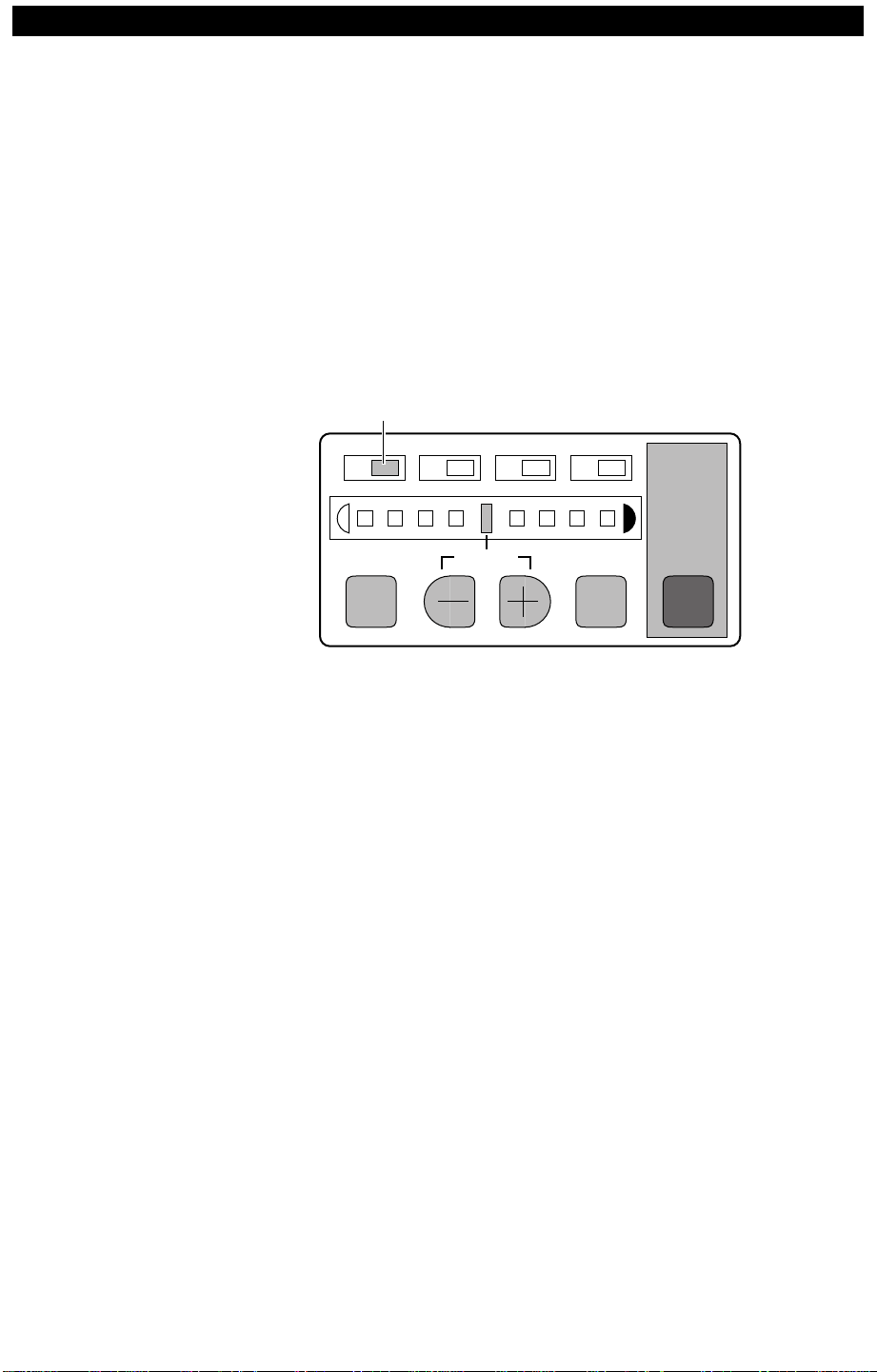

Density Control Panel

The density control panel on the rear of the printer can be used to

generate a service test page and to set three distinct types of adjustments. Some adjustment settings are persistent (i.e., they will remain in

effect after a printer restart), and some are nonpersistent (i.e., they will

default to factory setting after a printer restart).

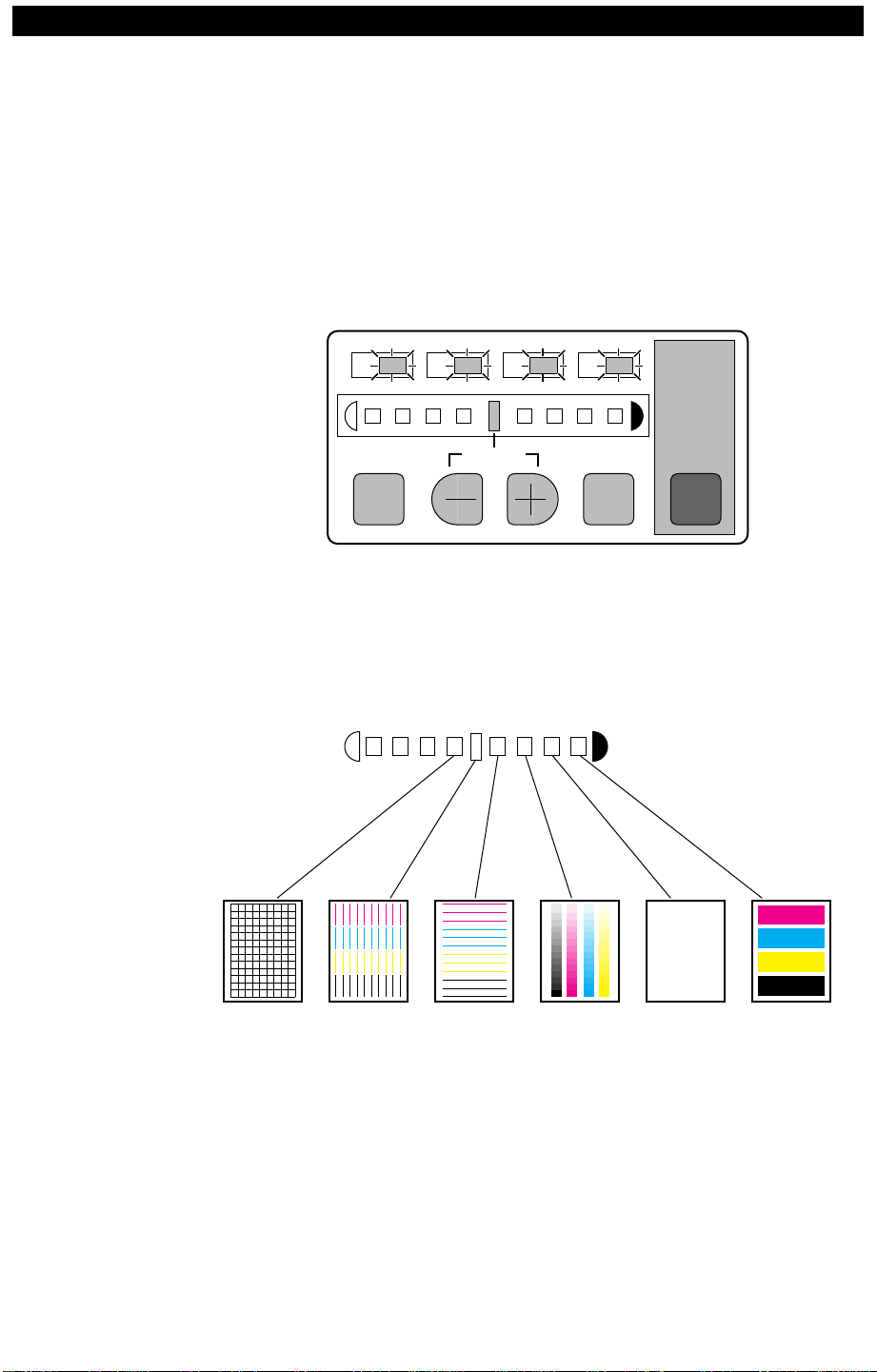

Panel Layout

In addition to the test print button, the density control panel has four

toner-indicator lights along the top, an LED density gauge in the

middle, and four input buttons along the bottom of the panel.

Toner

Lights

Density

Gauge

TEST PRINT

•

Important

M C Y Bk

COLOR

SELECT

DEFAULT ENTER

TEST

PRINT

button: Press this button to generate a service test page.

: If the printer is in energy-saving mode, you must print to

the printer or restart the printer before you can run a service test page.

•

ENTER

Note

button: Engages the currently selected value.

: The next four items are labelled on the panel according to their

density adjustment functions. During other adjustments, ignore the

labels and the functions described below.

COLOR SELECT

•

button: Selects the color whose density you want to

adjust.

• Density gauge: Indicates the currently selected density value for the

selected color, light density to the left, dark to the right.

Note

: During printer-ready state, you can tell if the density settings are

not at the factory default by looking at the center density gauge LED

above the word

DEFAULT

. If this LED is off, then the density settings

have been changed from the default.

5 Plus/minus (+/-) buttons: Advance the density gauge setting.

6 Toner Lights: An illuminated toner light indicates the color that is

being adjusted.

95.08.23.16.19

Page 25

Color LaserWriter 12/600 PS Basics & Theory 1–14

Density

Adjustments

This feature is offered for customers who have multiple Color LaserWriter 12/600 PS printers in a single location and need to adjust one

printer to match the output of another.

Important

: The range of settings is limited. Use this feature only if

you have prior experience in four-color density adjustments.

The printer needs to be switched on and in a ready state to make density

adjustments. Density adjustments are persistent. To adjust the density,

1 Press the

COLOR SELECT

button as many times as necessary until the

desired toner light illuminates.

Selected Color

M C Y Bk

COLOR

SELECT

DEFAULT ENTER

TEST

PRINT

2 Press the plus or minus button to change the setting for that color. The

density gauge LED will light whenever the selected setting differs from

the previously entered setting.

3 Repeat steps 1 and 2 if you want to adjust other colors.

4 Press the

Note

: If you want to quickly return the printer to its factory defaults,

ENTER

button to engage the settings.

press and hold both the plus and minus buttons for at least five seconds.

95.08.23.11.29

Page 26

Color LaserWriter 12/600 PS Basics & Theory 1–15

Test Page

Pattern

Selection

This feature allows you to select one of six test page patterns based

upon which one would best confirm a print quality issue.

Test pattern selection is nonpersistent. After restart, the test page

reverts to the vertical line pattern. To select a pattern,

1 Hold down the

COLOR SELECT

button and press the

ENTER

button

eight times. The four toner lights will flash to indicate that you are in

the test pattern selection mode.

M C Y Bk

COLOR

SELECT

DEFAULT ENTER

TEST

PRINT

2 Using the plus or minus buttons, advance the density gauge to illumi-

nate the LED corresponding to the desired pattern. The density gauge

will flash when the selected setting differs from the previously entered

setting. Only LEDs 4 through 9 on the density gauge correspond to

available patterns.

Usage Tips

Grid

3 Press the

Vertical

ENTER

Lines

Lines

GradationHorizontal

Solid

White

button to engage the setting. If you make no further

Solid

Colors

adjustments, the panel will exit from the test pattern selection mode in

30 seconds.

Each pattern will inherently reveal a different type of defect. For

example, color registration problems are revealed best by the grid

pattern, while dirty rollers are revealed by printing a solid white page.

Note

: By measuring the distance between repeating print defects, you

can isolate the problem to a specific roller within the printer. See

“Roller Diameters” in Chapter 2.

95.08.23.11.29

Page 27

Color LaserWriter 12/600 PS Basics & Theory 1–16

Separation

Voltage

Designation

This feature allows you to override the printer sensing system and force

the separation discharge assembly on or off. Forcing-on is intended as

a fail-safe in low temperature/low humidity conditions where paper is

not properly separating from the transfer drum, and as a countermeasure in some image-offset problems. Forcing-off is a countermeasure

against toner displacement.

The separation voltage designation is nonpersistent. After restart, the

designation will revert to automatic. To designate the separation

voltage,

1 Hold down the

COLOR SELECT button and press the ENTER button

three times. The yellow and black toner lights will flash to indicate that

you are in the separation voltage designation mode.

2 Using the plus or minus buttons, advance the density gauge to illumi-

nate the LED corresponding to the desired designation. The density

gauge will flash whenever the selected setting differs from the previously entered setting. Only LEDs 4, 5, and 6 on the density gauge

correspond to available designations.

3 Press the

Separation Voltage Forced OFF

Automatic (Separation Voltage

Determined by Sensing System)

Separation Voltage Forced ON

ENTER button to engage the setting.

95.08.23.11.29

Page 28

Color LaserWriter 12/600 PS Basics & Theory 1–17

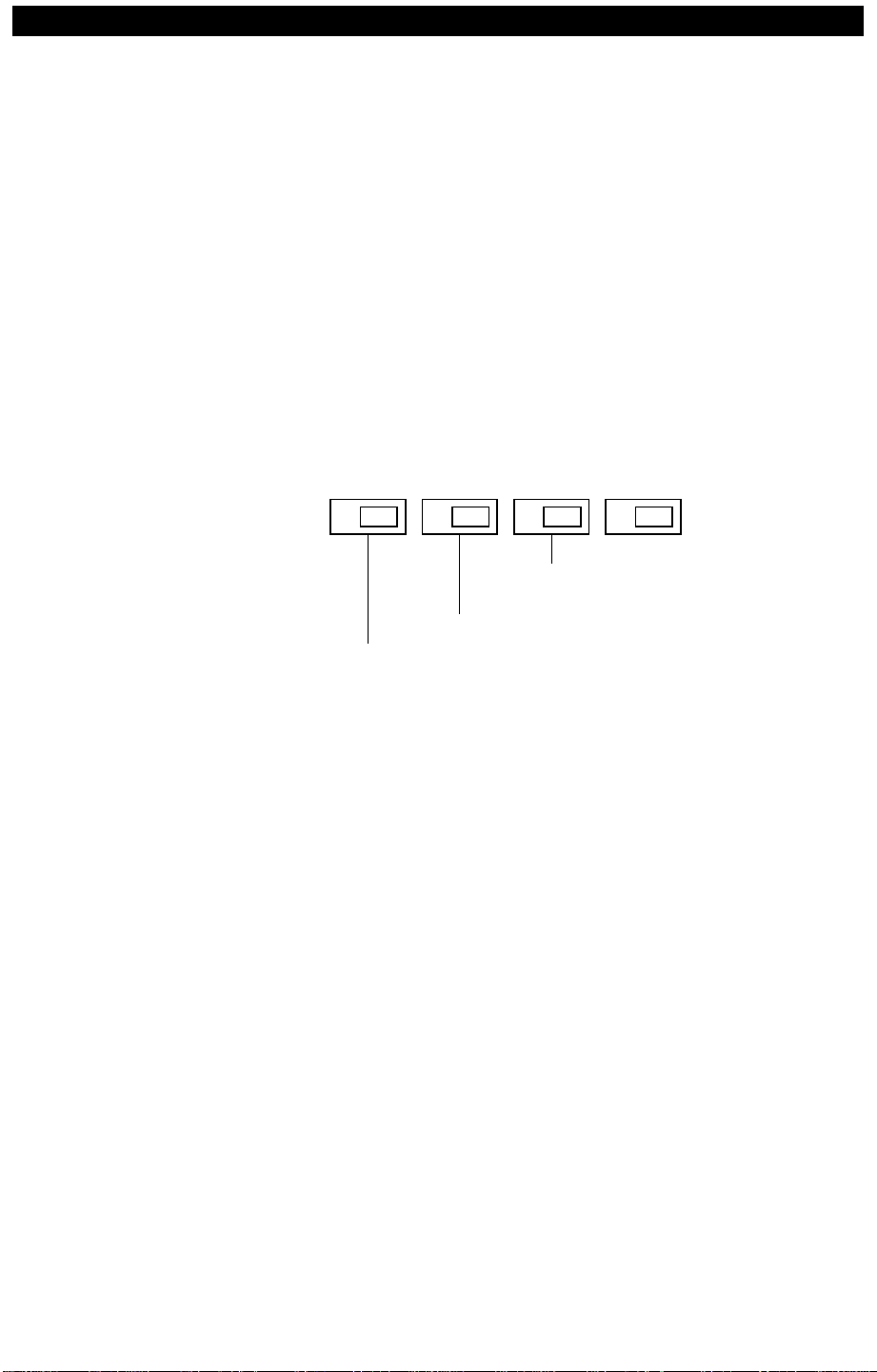

Registration

Adjustments

This feature allows you to adjust the placement of the image area on the

page. Registration adjustments require that the printer be placed into a

service adjustment mode. Consequently, these adjustments are not

designed to be available to end users. Registration adjustments are

persistent. To adjust the registration,

1 Turn off the printer. Press and hold the

TEST PRINT button and switch

the printer back on. The normal startup sounds will not occur.

Continue to hold the

TEST PRINT button down for 25 seconds, at which

time you will notice a slight slowing of the controller fan.

2 Press the

COLOR SELECT button once. The black toner light will flash

to indicate that you are in the service adjustment mode. In addition,

one of the other toner lights will illuminate steadily. Keep pressing the

COLOR SELECT button until you come to the setting that you want.

M C Y Bk

Leading Edge

Registration Adjustment

Cassette Edge Registration Adjustment

Manual Feeding Tray Edge Registration Adjustment

3 Using the plus or minus buttons, advance the density gauge to illumi-

nate the LED corresponding to the desired adjustment value. For

leading edge registration adjustment, each step in the gauge is equal to

.012 inch (.3 mm). For the other two adjustments, each step in the

gauge is equal to .017 inch (.425 mm).

4 Press the

ENTER button to engage the setting.

Note: If you want to quickly return the printer to its factory defaults,

press and hold both the plus and minus buttons for at least five seconds.

95.08.23.11.29

Page 29

Color LaserWriter 12/600 PS Basics & Theory 1–18

II. Basic Operation

Page 30

Color LaserWriter 12/600 PS Basics & Theory 1–19

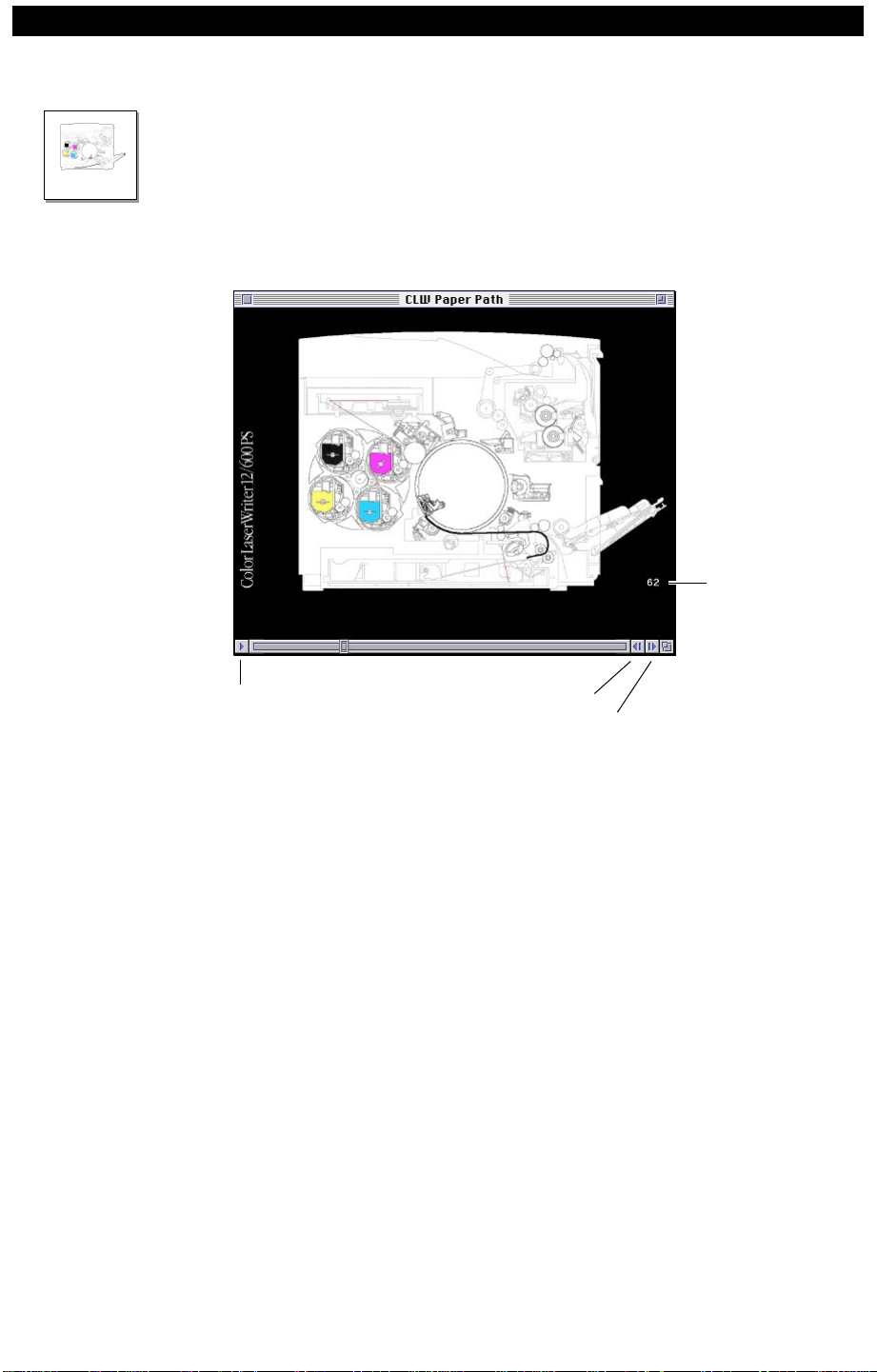

Paper Path Animation

The icon to the left appears at key points throughout this manual.

Clicking it launches a QuickTime animation called “CLW Paper Path.”

Animation

This animation shows one complete print cycle through the Color

LaserWriter 12/600 PS, starting at the point where the final sheet of

paper is picked up from the cassette, and ending with the delivery of the

paper at the top of the printer.

Frame Number

Step BackPlay

Step Forward

The animation is very detailed and moves very quickly. By using the

“Step Back” and “Step Forward” buttons at the bottom right of the

frame, you can step frame-by-frame through the animation. Whenever

applicable, specific frame numbers that best illustrate a given topic are

called out.

95.08.23.11.29

Page 31

Color LaserWriter 12/600 PS Basics & Theory 1–20

Functions

Printer functions can be divided into four systems: the overall control

system, the image formation system, the laser/scanner system, and the

paper pickup/feed system.

I/O Controller Board

I/O Interconnect Board

DC Controller Board

Laser/Scanner Assembly

Scanner

Motor

Laser

Diode

Scanning Mirror

Beam

Position

Detector

Carousel

Primary

Charging

Roller

Toner

Overall Control System

Mechanical Controller Board

Face-Down Tray

Cleaning

Unit

Separation

Discharge

Assembly

Photo-

sensitive

Drum

Transfer Drum

External

Device

Paper Pickup/Feed System

Fuser

Assembly

Transfer

Drum

Cleaning

Assembly

To

Face-

Up

Delivery

Image Formation System

Attraction Roller

Cassette

Sheet Feeder (Optional)

Discharge Roller

Pickup

Block

Manual

Feed Tray

95.08.23.11.29

Page 32

Color LaserWriter 12/600 PS Basics & Theory 1–21

Outline of Electrical System

The operation sequence for the printer is controlled by the microcomputers on the DC controller and the mechanical controller boards.

When the printer is turned on and enters the standby state, the microcomputer on the DC controller sends signals for driving the laser diode,

fuser heaters, and other loads in response to the print signal entered

from the I/O controller board. Simultaneously, the microcomputer on

the DC controller sends the print sequence command to the microcomputer on the mechanical controller. Subsequently, the latter microcomputer outputs the signals for driving various loads, including the highvoltage power supply, motors, and solenoids.

External Device

I/O Controller Board

I/O Interconnect Board

Density Sensing Board

Cassette

Size-Sensing

Board

Laser/Scanner Assembly

Scanner Motor

Beam-Detect Board

Laser Driver Board

Various Sensors

Status Panel

Ejection

Sensing

Board

DC Controller

Board

High-Voltage

Power Supply

Mechanical

Controller

Board

Power Supply

Low-Voltage

Power Supply

Primary Charging Roller

Developing Bias

Transfer Charging Roller

Attraction Roller

Discharge Roller

Separation Discharge

Upper Fuser Roller

Pickup Motor

Cassette Pickup Board

Sensors/Solenoids/Clutches

Main Motor

Drum Motor

Toner Carousel Motor

Cleaning Brush Motor

Various Fan Motors

Various Sensor/

Solenoids/Clutches

Temperature/Humidity

Sensor Board

Toner Sensor

Main Switch

AC Drive Circuit

Fuser Heaters (Upper/Lower)

95.08.23.11.29

Page 33

Color LaserWriter 12/600 PS Basics & Theory 1–22

Outline of Major Circuit Boards

This section describes the functions of the DC controller board and the

mechanical controller board. See “Circuit Boards” in the Parts chapter

for additional information.

DC Controller

Board

Mechanical

Controller

Board

This board controls the printer. When the

/PRNT signal is received from

the I/O controller, the DC controller sends the print sequence command

to the mechanical controller, which then starts controlling various

loads. The DC controller also provides

• Laser/scanner control

• Image stabilization control

• Fuser temperature control

• Power-off time measurement

• Various detection functions

• I/O interface control

This board controls various loads in response to signals from the DC

controller board. The mechanical controller returns the status signals to

the DC controller. The mechanical controller controls the cassette

pickup board, the high-voltage power supply, and the sheet feeder

controller board via its serial communications. The mechanical

controller also provides

• Drive of various motors and fan motors

• Control of the toner carousel

• Control of the fuser assembly

• Control of the transfer drum and its peripheral assemblies

• Control of the cassette pickup board, the high-voltage power supply ,

and the sheet feeder controller board

• Toner stirring function, toner-low detection, and toner cartridge

detection

• Photosensitive drum life detection

• Waste toner collection system control

• Energy-saving mode control

95.08.23.11.29

Page 34

Color LaserWriter 12/600 PS Basics & Theory 1–23

DC Controller Input/Output Signals

Laser/Scanner Assembly DC Controller Board

J111-23

Laser

Control

Board

-22

-17

-1,-3,-4,-5,

-6,-7,-13,15

-9

/VDOENB

/LSON

NHD

SCK1

M1 to M8

"L" when video data can be written.

"L" to switch ON the laser diode forcibly.

Reset signal

Clock signal

PWM mode-setting signal

-11

Analog signals are output to control

the laser power.

Voltage is input in proportion to the

laser power.

Video data signals

Laser Diode

J110-7

-5

-11,-13,-15,-17,

-19,-21,-23,-25

-9

LLCNT

PDIN

Dv2 to Dv9

+5V

J102-4

-3

-2

/BDI

"L" when the BD signal is input.

Beam-Detect

Board

J451-1

-2

-3

+24V

J102-10,-11

-6

-8

-9

-5,-7

SCNCLK

/SCNON

/SCNRDY

Reference clock signal

"L" to drive the scanner motor.

"L" when the scanner motor

is rotating normally.

Scanner

Motor

J701-1,-2

-6

-4

-3

-5,-7

Oil-Low Sensor

PS13

Cleaning Belt

Sensor

PS5

Transfer Drum

Top Sensor

PS8

Waste Toner

Sensor

PS12

Cassette

Size-Sensing Switch

CSW3

CSW2

CSW1

J312-1

-2

-3

-4

J61-3

Sensing Switch

J1602-4

-3

-2

-1

J631-3

-1

-2

J41F-1

-3

-2

J631-3

-1

-2

Ejection

SW1601

-1

-2

J106-6

J106-1

J105-13

J1601-1

-5

-4

-3

-2

-11

-12

J107-1

J107-7

-2

-3

-4

-3

-2

-6

-5

-4

OILSNS

LEDON

WEBSNS

+5V

TOPREG

LEDON

TNFUL

/CSIZE3

/CSIZE2

/CSIZE1

"H" when oil runs out.

"L" when the power-saving mode is set.

"H" when the cleaning belt has run out.

"H" switched to "L" when the TOP

position of the transfer drum is detected.

"L" switched to "H" when the

registration position is detected.

"L" when the power-saving mode is set.

"H" when the waste toner is full.

The cassette size and the pulling

operation for the ejector are detected.

95.08.23.11.29

Page 35

Color LaserWriter 12/600 PS Basics & Theory 1–24

DC Controller Board

Power Supply

Power

Switch

SW1

Door

Switch

SW2

Power Supply Control IC

Fuser Abnormality

Detection Circuit

Safety

Circuit

+24V

+5V

Relay

+5V

Mechanical

Controller

Board

J101-6

J112-31

-30

-29

-28

-26

-27

-5

-7

POFF

PCONT

DOPN

FXSTS

SFSNS

/FXROF

/FXENB

/FXUON

/FXLON

"L" when the power

switch is ON.

"L" to turn ON the printer.

"H" when the front door,

pickup door, or fuser access

door is open.

"L" when the fuser assembly

is properly installed;

"H" when improperly

installed; pulse signal when

fuser heater is ON.

"H" when the safety circuit

turns OFF the relay.

"L" to turn OFF the relay.

The fuser heater can be

turned ON when pulses

are output.

"L" to turn ON the upper

fuser heater.

"L" to turn ON the lower

fuser heater.

Thermoswitch

TP1

Thermoswitch

TP2

Fuser Roller

Temperature

Detection

Fuser Assembly

Upper

Fuser Heater

H1

Lower

Fuser Heater

H2

Thermistor

TH

J112-24

J112-22

The voltage decreases

as the fuser roller

THI

temperature increases.

/FXSNS

"L" when the fixing unit

is installed.

95.08.23.11.29

Page 36

Color LaserWriter 12/600 PS Basics & Theory 1–25

DC Controller Board

Temperature/

Humidity Sensor

J73-1

-3,-5

-2

-4

J2005-5

-4

-2

-1,-3

Mechanical

Controller Board

J2007-6

-7

-9

-8,-10

J112-6

-8,-10

-7

HUMSNS

-9

TMPSNS

+5V

Humidity sensor signal

Temperature sensor signal

Density Sensing

Board

Density Control

Panel

J103-14

-3

-5,-6,-7,-8,-9,-10,-11,-12

-13

J114-1 to 8

+24V

+5V

-1

-2

DSNS

/DSEL

Density sensor signal

"H" to enter the color toner

density sensing mode.

"L" to enter the black toner

density sensing mode.

/D0 to /D7

/DENB

-4

LED power control signal

"L" to turn ON the LED.

Serial Communications

95.08.23.11.29

Page 37

Color LaserWriter 12/600 PS Basics & Theory 1–26

Mechanical Controller Board Input/Output Signals

Mechanical Controller Board

High-Voltage Power Supply

Cassette Pickup Board

Toner Carousel Sensors

Toner

PS4

Carousel

Position

Sensor

Toner

PS3

Cartridge

Position

Sensor

CL2

Toner Carousel

Drive Clutch

CL1

Toner Carousel

Brake Clutch

Fuser Assembly

PS10

Oil Overflow

Sensor

J2008

J2002

J2006-4

-6

-5

J2006-1

-3

-2

J2017-4

-3

J2017-2

-1

J2009-12

-14

-13

Serial Communications

Serial Communications

5VSAVE

DEVHP

"H" when a flag is detected.

See "Carousel Rotational Detection" in

this chapter.

5VSAVE

"L" when the toner cartridge is pressed

DEVCAM

against the photosensitive drum.

"H" when the toner cartridge is separated

from the photosensitive drum.

+24V

/DEVON

"L" to turn ON CL2, rotating the toner carousel

"H" to turn OFF CL2, rotating the cartridge sleeve.

+24V

/DEVBRK

"L" to turn ON CL1, braking the toner carousel.

5VSAVE

OILFUL

"H" when oil overflows from oil pan.

Paper Delivery

Sensor

Fuser Assembly

Drive Clutch

Cleaning Belt

Drive Solenoid

Attraction Roller

Press Solenoid

Drum Press

Solenoid

Transfer Drum

Cleaner Press

Solenoid

Discharge Roller

Press Solenoid

PS9

CL4

SL3

SL6

SL7

SL8

SL9

J2009-9

-11

-10

J2011-2

J2009-8

J2014-2

J2014-4

J2014-5

J2014-10

POUT

+24V

-1

/FIXON

+24V

-7

/WEBSL

+24V

-1

/ATTSLON

+24V

-3

/DDSLON

+24V

-6

/TDCSLON

+24V

-9

/DCSLON

5VSAVE

"H" when paper is detected.

"L" to turn ON SL3, rotating the rollers in the fuser

assembly.

"L" to turn ON SL12. This solenoid is used to drive

the cleaning belt.

"L" to turn ON SL6, operating the attraction roller press

cam. SL6 is used to control the pressing/separation

between the attraction roller and the transfer drum.

"L" to turn ON SL7, operating the transfer drum press

cam. SL7 is used to control the pressing/separation

between the photosensitive drum and the transfer drum.

"L" to turn ON SL8, operating the cleaning brush press

cam. SL8 is used to control the pressing/separation

between the cleaning brush and the transfer drum.

"L" to turn ON SL9, operating the discharge roller press

cam. SL9 is used to control the pressing/separation

between the discharge roller and the transfer drum.

95.08.23.11.29

Page 38

Color LaserWriter 12/600 PS Basics & Theory 1–27

Transfer Drum

PS6

Attraction

Sensor

PS8

Transfer Drum

Top Sensor

PS7

Separation

Sensor

Gripper Drive

Solenoid

Separation

Solenoid

SL4

SL5

Receiver Emitter

Toner Sensor PS11

Main Motor

Toner Carousel Motor

Drum Motor

Cleaning Brush Motor

Fuser Fan Motor

DC Controller Board

J105

-3

-11

-8

-4

-10

-5

-2

J112

-20

-19

-18

-4

-17

-16

M2

M3

M4

M5

FM1

J2007

-12

-13

-14

-15

-28

-16

J2007-21

J2017-5

J2013-6

J2016-1

J2015-1

J2014-8

-7

J2012-3

-2

-1

ATTSNS

TOPREG

SEPSNS

TNSNS

+5V

-6

-7

-1

MLOW

-2

/MRDY

-3

/MON

-4

-5

COMA

-2

COMB

-4

/AO

-5

BO

-6

/BO

-8

AO

COMA

-2

COMB

-4

/AO

-5

BO

-6

/BO

-8

AO

/TDCON

FAND1

FANLK1

GRIPON

+24V

SEPON

Mechanical Controller Board

"H" when print paper is rolled

over the transfer drum.

"L" switched to "H" when the transfer

drum reaches the registration position.

"H" switched to "L" when the transfer

drum reaches the TOP position.

"H" when print paper separates

from the transfer drum.

"H" to turn ON SL4, operating the

gripper drive solenoid.

"H" to turn ON SL4, operating the

separation claw.

"L" when there is no toner or cartridge.

/TONLED

"H" to turn ON the LED.

"L" to rotate the main motor at the

normal speed, "H" to operate it at

half speed.

"L" when main motor rotates normally.

"L" to turn ON the main motor.

Toner Carousel Drive Signal

Drum Motor Drive Signal

+24V

"L" to turn ON the cleaning brush motor.

+24VC (0V in the energy-saving mode)

"L" when the fan motor rotates normally.

Main Fan Motor

Controller Fan Motor

FM2

FM3

J2019-3

J2010-3

-2

-1

-2

-1

FAND2

FANLK2

FAND3

FANLK3

+24VC (0V in the power-saving mode)

"L" when the fan motor rotates normally.

Normally 24V. 16V in the

energy-saving mode with the fan

motor rotating at half speed.

"L" when the fan motor rotates

normally.

95.08.23.11.29

Page 39

Color LaserWriter 12/600 PS Basics & Theory 1–28

Outline of Drive System

The printer has six motors: the pickup motor, main motor, drum motor,

toner carousel motor, cleaning brush motor, and scanner motor. See

“Motors/Fans/Heaters” in the Parts chapter for additional information.

Pickup Motor

(M1)

About the

Printer Drive

Assembly

The pickup motor is a two-phase stepping motor in the paper pickup

block and is controlled by the cassette pickup board. The pickup motor

provides mechanical drive to the following parts:

• Cassette pickup roller

• Separation roller

• Registration roller

• Manual feed pickup roller

• Manual feed paper lifting cam

• Feed rollers 1 and 2

The printer drive assembly houses three separate drive trains for main

motor M2, toner carousel motor M3, and drum motor M4. Their

delivery points and destinations are as shown:

23

8

1

7

6

9

5

Main motor (M2) drive train

Fuser assembly

1

Paper delivery assembly (via the delivery drive assembly)

2

Waste toner screw

3

Transfer drum peripherals

4

Toner carousel motor (M3) drive train

Toner carousel rotation

5

Toner cartridge press (via cartridge press drive gear)

6

Developing cylinder rotation (outer gear)

7

Drum motor (M4) drive train

Photosensitive drum (coupling at the center of the gear)

8

Transfer drum

9

4

95.08.23.11.29

Page 40

Color LaserWriter 12/600 PS Basics & Theory 1–29

Main Motor

(M2)

Toner

Carousel Motor

(M3)

The main motor is a DC brushless motor. It is controlled by the CPU

on the mechanical controller board and provides mechanical drive to

the following parts:

• Fuser assembly

–Upper and lower fuser rollers

–Fuser delivery roller

–Oil-applying roller

–Oil pump

• Paper delivery assembly

• Transfer drum peripherals

–Attraction roller press cam

–Transfer drum press cam

–Cleaning brush press cam

–Discharge roller press cam

• Waste toner screw inside the photoconductor cartridge

The main motor itself is not a part of the printer drive assembly but is

available separately as P/N 922-1370.

The toner carousel motor is a two-phase stepping motor controlled by

the toner carousel motor driver (Q2003) on the mechanical controller

board. This motor is part of the printer drive assembly and provides

mechanical drive to the toner carousel.

Drum Motor

(M4)

The drum motor is a two-phase stepping motor controlled by the drum

motor driver (Q2002) on the mechanical controller board. The drum

motor is part of the printer drive assembly. It provides mechanical

drive to the photosensitive drum and to the transfer drum.

Drum Motor M4

Toner Carousel

Motor M3

Cleaning

Brush Motor

(M5)

Position of

Main Motor M2

The cleaning brush motor is a DC motor. It is controlled by the CPU on

the mechanical controller board and provides the mechanical drive that

rotates the transfer drum cleaning brush.

Scanner Motor The scanner motor is a three-phase, eight-pole DC brushless motor with

a built-in hall element. The scanner motor rotates a six-sided mirror that

in turn scans the laser beam, which has been emitted from the laser

diode, in the horizontal scanning direction.

95.08.23.11.29

Page 41

Color LaserWriter 12/600 PS Basics & Theory 1–30

Basic Sequence of Operation

Outline The following table describes the five periods of printer operation. .

Period & Duration Purpose Remarks

WAIT (Wait)

From power-on until the

fuser roller temperature reaches the target

value. This period finishes in about three

minutes at normal room

temperature.

STBY (Standby)

From the end of the

WAIT period until the

/PRINT signal is input

from the I/O controller.

From the end of the

LSTR period until the

/PRNT signal is input

from the I/O controller

or the power switch is

turned off.

INTR (Initial Rotations)

After the /PRNT signal

has been input from the

I/O controller until the

transfer drum rotates

up to the top position

for the first color.

T o warm up the fuser

roller to put the

printer in the standby

state.

To hold the fuser

roller at the target

value to keep the

printer ready to print.

To stabilize the

sensitivity of the

photosensitive drum

in preparation for

printing.

During this period, the

printer checks for

jammed paper and for

availability of all the

toner cartridges. It

also performs image

stabilization and other

tasks.

If the printer stays in

the standby state for

30 minutes or more, it

drives the main motor

for 0.5 second to

rotate the fuser roller,

so that the fuser roller

will not be deformed.

When the scanner

motor reaches the

target speed, the DC

controller sends the

print sequence

command to the

mechanical controller.

PRINT (Print)

From the end of the

INTR period and the

subsequent completion

of transfer until the

transfer drum rotates

up to the registration

position.

LSTR (Last Rotations)

From the end of the

PRINT period until the

main motor stops.

To form an image on

the photosensitive

drum according to

the /VDO signal input

from the I/O

controller and to

transfer the image to

the paper.

To deliver the last

print and to

discharge the

transfer drum.

Cleaning of the

transfer drum occurs

after every 100 prints.

95.08.23.11.29

Page 42

Color LaserWriter 12/600 PS Basics & Theory 1–31

III. Laser/Scanner System

Page 43

Color LaserWriter 12/600 PS Basics & Theory 1–32

Laser System

Outline When the /PRNT signal is sent from the I/O controller, the DC

controller performs Automatic Photoemission Control (APC) to stabilize the intensity of the laser beam. Upon completion of APC, the DC

controller generates 8-bit video data signals (

with the video signals (

VDO0-VDO7) sent by the I/O controller and then

sends them to the PWM-IC in the laser/scanner assembly . According to

the laser drive signal (internal signal in the laser/scanner assembly)

output from the PWM-IC, the laser driver circuit turns the laser diode

on or off to produce the modulated laser beam.

External Device

I/O Controller Board

/TOP/LSYNC

VDO 0-7

DV2-DV9) in accordance

IMCHR

/PRNT

LLCNT

PDIN

M1-M8 Dv2-Dv9 /VDOENB

PWM-IC

Laser Driver

Board

BD Mirror

Collimator

Lens

Reflecting

Mirror

DC Controller Board

/LSON

Cylindrical

Lens

/BDI

/SCNON

Scanner Motor

Scanning Mirror

Focusing Lens

Photosensitive

Drum

BD Board

The modulated laser beam is converted to a parallel beam with the

collimator lens and cylindrical lens, and the beam then strikes the scanning mirror, which is rotating at a constant speed.

The laser beam reflected by the scanning mirror focuses on the photosensitive drum after passing through the focusing lens and being

reflected by the reflecting mirror. Since the scanning mirror rotates at a

constant speed, the laser beam scans at a constant speed across the

photosensitive drum which also rotates at a constant speed. As a result,

a latent image is formed on the photosensitive drum.

Example: The laser beam comes on in frame 62 for the magenta layer .

The scanner mirror projects it right to left off the reflecting mirror,

which projects it downward and to the right onto the surface of the

Animation

photosensitive drum.

95.08.23.11.29

Page 44

Color LaserWriter 12/600 PS Basics & Theory 1–33

Video Data

Processing

The video data supplied by the I/O controller is composed of 8-bit

video signals (

VDO0-VDO7) for each of four colors, M (Magenta), C

(Cyan), Y (Yellow), and K (Black), and the Image Mode Select signal

IMCHR) which is used to set either the text mode (binary mode) or the

(

image mode (halftone mode).

Laser Driver BoardDC Controller Board

IC403

PWM-IC

Laser

Drive

Signal

Laser

Driver Circuit

VDO 0-7

IMCHR

IC111

Line

Memory

IC109

Image

Masking

Halftone

Correction

Dv2 to 9

M 1 to 8

Note: In order to ensure that text and halftone images are each properly

printed out, the printer switches its image mode via the

IMCHR signal

sent by the I/O controller.

In the image data of the printer there is both full-color mode and mono-

chrome mode. In the full-color mode, the I/O controller sends the

video signals in the order of M, C, Y, and K to the DC controller. In the

monochrome mode, it sends the video signals for only a single color.

The video signals (

VDO0-VDO7) and the IMCHR signal sent to the DC

controller by the I/O controller are sent to the gate array (IC109) via

IC111 (line memory). IC109 processes

VDO0-VDO7 to perform the

image masking, halftone correction, etc.

Note: The printer incorporates the halftone correction table in the DC

controller so that the ideal halftone image can be obtained. This allows

the video signals (

corrected and converted to the video data signals (

VDO0-VDO7) sent by the I/O controller to be

DV2-DV9). They are

subsequently output to the laser driver.

The signals are then converted to 8-bit video data signals (

and mode setting signals (

board in the laser/scanner assembly. The

data signals containing halftone information. The

M1-M8) in IC109 and then sent to the PWM

DV2-DV9 signals are video

M1-M8 signals

DV2-DV9)

control the image mode selection, etc. The PWM circuit modulates the

DV2-DV9 signals into PWM signals and sends them as laser drive

signals to the laser driver board.

The printer includes an anti-counterfeiting function whereby a pattern

unique to the printer is invisibly marked on every printout.

95.08.23.11.29

Page 45

Color LaserWriter 12/600 PS Basics & Theory 1–34

Laser Control Circuit

Laser Emission The DC controller generates 8-bit video data signals (

mode setting signals (

with the video signals (

IMCHR) sent by the I/O controller. It sends those signals to the PWM-

(

M1-M8) in the gate array (IC109) in accordance

VDO0-VDO7) and image mode select signal

IC in the laser driver board. Based on the above signals, the PWM-IC

produces laser drive signals with the pulse width corresponding to the

halftone, and then sends them to the laser driver circuit. At this time,

when the forcible laser-on signal (

is “H” and the video-enable signal (

/LSON) sent to the laser driver circuit

/VDOENB) is “L,” the laser driver

board turns the laser diode on in accordance with the laser drive signal.

DC Controller Board

/TOP

/LSYNC

VDO7 to 0

IMCHR

G.A.

(IC109)

Dv2 to 9

M1 to 8

/BDI

Laser Driver

Board

Laser Drive Dignal

BD Board

PWM IC

(IC403)

DV2-DV9) and

LD

PD

CPU

(IC101)

Laser Driver

Circuit

+5V

APCENB

APCLW

APCUP

PD

12VON

APC-IC

(IC103)

/VDOENB

/LSON

LLCNT

PDIN

+12V

Current/Voltage

Conversion Circuit

Switching Circuit

Constant

Current Circuit

Note: The APC-IC monitors the voltage levels of the 5 V and 24 V

power supplies. If both voltage levels exceed the specified value, the

laser driver board uses 12 V power supply produced from the 24 V

power supply.

95.08.23.11.29

Page 46

Color LaserWriter 12/600 PS Basics & Theory 1–35

Laser Intensity

Control

The CPU in the DC controller controls the intensity of the laser beam

by using the

fine control. The APC-IC (IC103) adds the

to produce the laser beam intensity control signal (

APCUP signal for rough control and the APCLW signal for

APCUP and APCLW signals

LLCNT), which is

then output to the laser driver circuit in the laser/scanner assembly. The

CPU performs automatic power control (APC) of the laser diode and

adjusts the

LLCNT signal so that the laser diode will emit the laser beam

at the constant intensity. The APC is composed of initial APC and

between-pages APC.

Initial APC The printer performs the initial APC in the following steps while it is

executing the initial rotations.

1 When the APC enable signal

(/APCENB) goes “L,” the CPU

decreases the output values of the laser power control signals

APCLW and APCUP) to zero. After resetting the laser current, the

(

CPU rotates the scanner motor.

Note: The

/APCENB signal goes “L” when the 5 V and 24 V power

supplies are at the specified voltage.

2 The CPU sets the forcible laser-on signal (

video-enable signal (

the D/A output value of the

/VDOENB) to “L” via the gate array . It changes

APCUP signal and gradually increases

/LSON) to “L” and the

the laser diode current. When the laser current increases, the laser

diode starts emitting the laser beam. The intensity of the laser beam

emitted by the laser diode is detected by the photodiode (PD) and its

output voltage is fed back as the laser power detect signal (

PDIN) to

the APC-IC.

3 The CPU monitors the

PDIN signal. Until its value reaches the spec-

ified value stored in the CPU, step 2 is continued.

4 The between-pages APC described below is subsequently

performed during the remaining period of the initial rotations to

correct the offset from the target value.

5 The CPU sets the

/LSON signal to “H” to complete the initial APC

and then proceeds to the between-pages APC.

95.08.23.11.29

Page 47

Color LaserWriter 12/600 PS Basics & Theory 1–36

BetweenPages APC

Horizontal

Sync Control

Immediately after the initial APC, the printer performs the betweenpages APC for pages and colors. The CPU sets the

/VDOENB signal to

“H” during the unblanking period.

Note: In order to detect the

/BDI signal, the laser diode is turned on

even during the period that it does not scan the laser beam across the

drum. This is referred to as the “unblanking period.”

This causes the laser diode to emit the laser beam at the intensity set

during the initial APC. To ensure that the

value, the

APCLW signal (8-bit) is changed to correct the LLCNT signal

PDIN signal is at the specified

so as to compensate for the offset from the target value.

A small beam-detect (BD) mirror is fixed in the optical path of the laser

beam. Upon reaching the scanning start position, the laser beam is

reflected by the BD mirror to the BD board in the laser/scanner

assembly during the unblanking period. On receiving the laser beam,

the BD board generates the beam detect input signal (

/BDI) and then

sends it to the gate array in the DC controller board. The gate array

produces the horizontal sync signal (

LSYNC) based on the /BDI signal

and then sends it to the I/O controller.

95.08.23.11.29

Page 48

Color LaserWriter 12/600 PS Basics & Theory 1–37

Laser Diode

Emission

Control

The laser driver circuit turns the laser diode on or off in accordance

with the laser drive signal received from the PWM-IC when the videoenable signal (

/VDOENB) is “L” and the forcible laser-on signal (/LSON)

supplied by the DC controller is “H.” The gate array (IC109) applies

left/right and top/bottom margin masking to the video signals (

VDO0) in accordance with the paper size data sent by the I/O controller,

and then sends them as

DV2-DV9 signals to the PWM-IC in the

VDO7-

laser/scanner assembly. The paper size data is supplied to the CPU by

the cassette-size sensing switch for cassette paper feed or by the paper

size specification command issued by the I/O controller for manual

paper feed.

Notes:

1 The shaded area permits writing with the laser beam.

2 Times T1 and T2 vary depending on the paper size.

3 If no paper size is specified by the paper size specification command

from the I/O controller for manual feed, the printer does not recognize the paper width. So the T1 and T2 values are assumed to be

legal size, the maximum paper width for the printer. The CPU determines the actual paper size from the paper length detected by the

paper leading-edge sensor (PS303) when the leading edge of the

paper has passed through PS303. Subsequently, the image is

masked based on the detected paper size.

/LSYNC

Left/Right Margin

Masking Signal

T2

T1

2 mm

2 mm 2 mm

/TOP

Top/Bottom Margin

Masking Signal

8 mm

95.08.23.11.29

T3

Page 49

Color LaserWriter 12/600 PS Basics & Theory 1–38

Scanner System

Outline The scanning mirror is a critical part in the scanner unit. It is mounted

on the scanner motor shaft and rotates with the scanner motor. The

rotation of the scanner motor is controlled by the scanner driver, so that

the laser beam reflected by the scanning mirror scans across the photosensitive drum at a constant speed. When the scanner motor drive signal

/SCNON) and the scanner clock signal (SCNCLK) are sent to the

(

scanner driver by the DC controller, the scanner driver rotates the

scanner motor.

Laser/Scanner Assembly

Scanner

Mirror

Motor

Scanner

Unit

/SCNRDY

/SCNON

/SCNCLK

DC

Controller

Board

95.08.23.11.29

Page 50

Color LaserWriter 12/600 PS Basics & Theory 1–39

Scanner Motor

Circuit

The scanner motor is a three-phase, 8-pole DC brushless motor with a

hall element. It is incorporated in a single unit with the scanner driver

which controls it so that the motor rotates at a constant speed. When

the printer is turned on, the oscillation frequency of the crystal oscillator (X103) is divided by the gate array (IC109) and the resulting