ANRITSU MW9087 Operation Manual

12th Edition

MW9087 Series

Card OTDR

Operation Manual

For safety and warning information, please read this

manual before attempting to use the equipment.

Keep this manual with the equipment.

ANRITSU CORPORATION

Document No.: M-W3543AE-12.0

Safety Symbols

DANGER

WARNING

CAUTION

To prevent the risk of p ersonal injury or l oss r elated t o equipm ent m alfunct ion, Anrit su Cor poration uses th e following

safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of the

symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu equipment.

In addition, there may be other labels attached to products that are not shown in the diagrams in this manual.

Symbols used in manual

This indicates a very dangerous procedure that could res ult in serious in jur y or

death if not performed properly.

This indicates a hazardous procedure that cou ld r esult i n serio us injury or de ath if

not performed properly.

This indicates a hazardous procedure or danger that could res ult in light -to-severe

injury , or loss rel ated to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precaution s. Ensure that you clearly understand the meanings of the symbols and

take the necessary precautions BEFORE using the equipment.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

This indicates an obligator y sa fety pr eca utio n. The o bli gat or y operation is indicated

symbolically in or near the circle.

This indicates a warning or caution. The contents are indicated symbolically in or

near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

MW9087 Series

Card OTDR

Operation Manual

2 June 2011 (First Edition)

25 September 2020 (12th Edition)

Copyright © 2011-2020, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The operational instructi on s of this manual may be changed without prior notice.

Printed in Japan

ii

For Safety

WARNING

● ALWAYS refer to the operation manual when working near locations

at which the alert mark shown on the left is attached. If the advice in

the operation manual is not followed, there is a risk of personal injury

or reduced equipment performance. The alert mark shown on the left

may also be used with other marks and descriptions to indicate other

dangers.

● Overvoltage Category

This equipment complies with overvoltage category II defined in IEC

61010. DO NOT connect this equipment to the power supply of

overvoltage category III or IV.

● Laser radiation warning

- NEVER look directly into the cable connector on the equipment

nor into the end of a cable connected to the equipment. There is a

risk of injury if laser radiation enters the eye.

- The Laser Safety label is attached to the equipment for safety use

as indicated in "Laser Safety" later in this section.

Electric Shock

Repair

● To ensure that the equipment is grounded, always use the supplied

3-pin power cord, and insert the plug into an outlet with a ground

terminal. If power is supplied without grounding the equipment, there

is a risk of receiving a severe or fatal electric shock or causing

damage to the internal components.

● Only qualified service personnel with a knowledge of electrical fire and

shock hazards should service this equipment. This equipment cannot

be repaired by the operator. DO NOT attempt to remove the equipment

covers or unit covers or to disassemble internal components. There are

high-voltage parts in this equipment presenting a risk of severe injury

or fatal electric shock to untrained personnel. In addition, there is a risk

of damage to precision components.

iii

For Safety

WARNING

Calibration

Falling Over

● The performance-guarantee seal verifies the integrity of the equipment.

To ensure the continued integrity of the equipment, only Anritsu service

personnel, or service personnel of an Anritsu sales representative,

should break this seal to repair or calibrate the equipment. Be careful

not to break the seal by opening the equipment or unit covers. If the

performance-guarantee seal is broken by you or a third party, the

performance of the equipment cannot be guaranteed.

● This equipment should always be positioned in the correct manner. If

the cabinet is turned on its side, etc., it will be unstable and may be

damaged if it falls over as a result of receiving a slight mechanical

shock.

Always set up the equipment in a position where the power switch

can be reached without difficulty.

iv

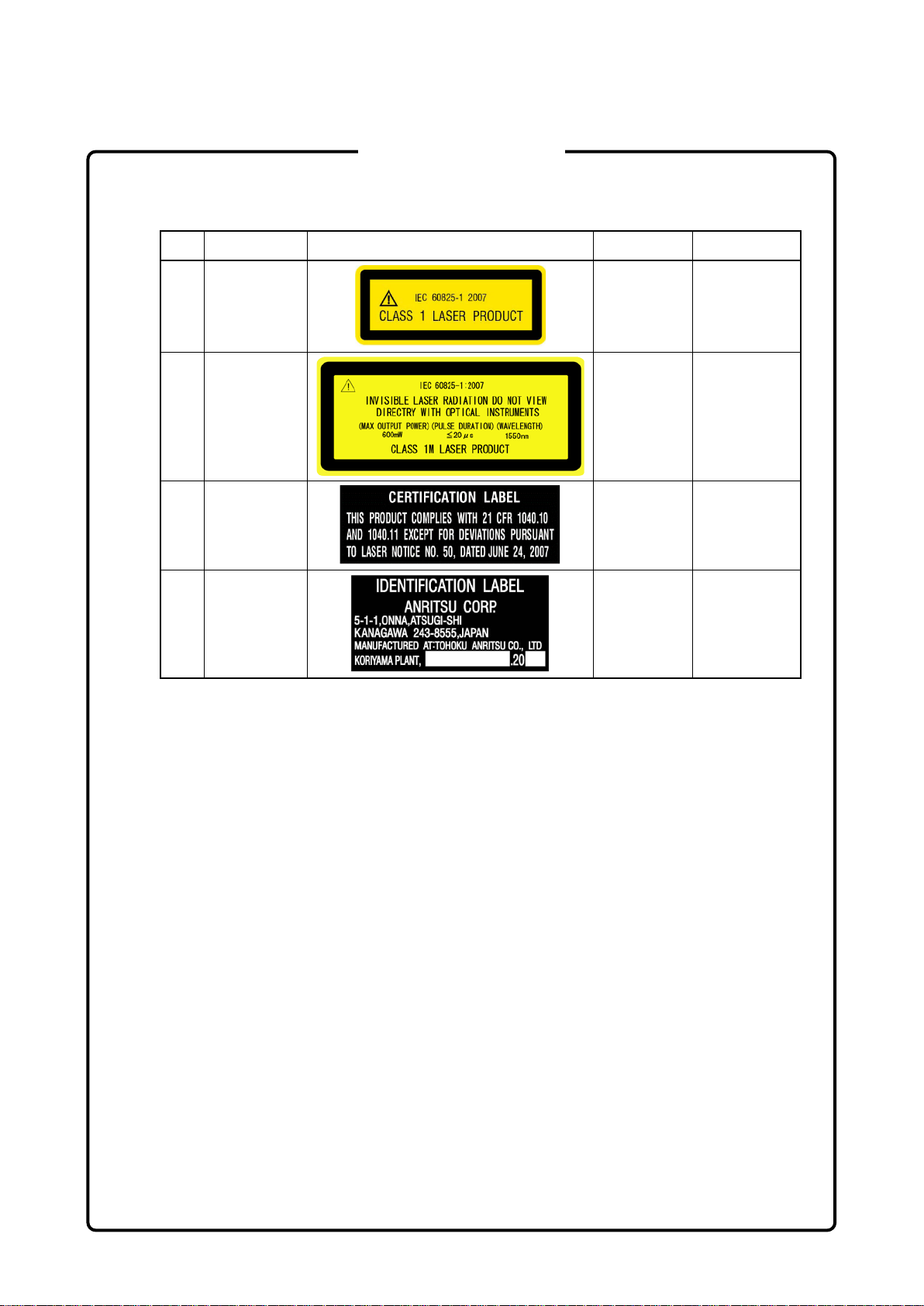

Laser Safety

For Safety

Class 1, and 1M indicate the danger degree of the laser radiatio n

specified below according to IEC 60825-1:2007.

Class 1: Lasers that are safe under reasonably foreseeable conditions

of operation, including the us e of optic al instr um ents for

intrabeam viewing.

Class 1M: Lasers emitting in the wavelength range from 302.5 to 4000

nm that are safe under reasonably foreseeable conditions of

operation, but may be hazardous if the user employs optics

within the beam. Two conditions apply:

a) for diverging beams, if the user views the laser output with

certain optical instruments (for example, eye loupes,

magnifiers and microscopes) within a distance of 100 mm;

or

b) for collimated beams, if the user views the laser output with

certain optical instruments (for example, telescopes and

binoculars).

CAUTION

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

The use of optical instruments with this product will increase eye hazard.

WARNING

The laser in this equip ment is classified as Class 1 or 1M acc ording to

the IEC 60825-1:2007 standard, and is safe under reasonably

foreseeable operating conditions.

Never use optical i nstruments to direct ly view Class 1M l aser products.

Doing so may result in serious damage to the eyes.

v

For Safety

Table 1 Laser Safety Classifications Based on IEC 60825-1:2007

Max.

Model Name Class

MW9087B 1 0.15

MW9087D 1M 0.60

Incorporated

Laser

a) < 0.30 20×10–6/0.019 1650

b) < 1.20 20×10–6/0.019 1550

Optical

Output

Power (W)

Pulse

Width (s)/

Repetition

*

Rate

20×10

0.019

20×10

0.019

*: Indicates the possible optical output power when each and every

reasonably foreseeable single-fault condition is included.

Table 2 Incorporated Laser Specification

Max. Optical

Output Power

*: Maximum output power is the estimated value when something

*

(W)

breaks down.

Emitted

Waveleng

th (nm)

–6

/

1650 11.5 a) Figure 1, [1]

–6

/

1550 11.5 b) Figure 1, [1]

Pulse Width (s)/

Repetition Rate

Beam

Divergence

(deg)

Emitted

Wavelength

(nm)

Incorporated

Laser

Specification

(refer to T able

2)

Beam

Divergence

(deg)

11.5

11.5

Laser

Aperture

vi

For Safety

Table 3 Indication Labels on Product (Ex: Label list)

Type Sample Affixed to: Model Name

1 Explanation Figure 1, A MW9087B

2 Explanation

3 Certification

4 Identification

Figure 2, B MW9087D

Figure 2, C All Models

Figure 2, D All Models

vii

A

[1]

C

D

B

For Safety

Laser Radiatio n Markings

Figure 1 Locations of Laser Beam Apertures and Affixed Labels

Figure 2 Label Locations

viii

Disconnect from

Communication

Use in a

E

Use in

Atmospheres

For Safety

CAUTION

The OTDR Module outputs high-power optical pulses. Disconnect the

communication equipment from the optical fibers before a measurement,

or the optical sensor of the equipment may be broken.

Residential

nvironment

Corrosive

This equipment is designed for an industrial environment.

In a residential enviro nme n t, this equipment may cause radio

interference in which case the user may be required to take adequate

measures.

Exposure to corrosive gases such as hydrogen sulfide, sulfurous acid,

and hydrogen chloride will cause faults and failures.

Note that some organic solvents release corrosive gases.

ix

Equipment Certificate

Anritsu Corporation cer tifies that t his equip ment was tes ted before shi pment

using calibrated measuring instruments with direct traceability to public

testing organizations rec ognized by nationa l research laborator ies, including

the National Institute of Advanced Industrial Science and Technology, and

the National Institute of Information and Communications Technology, and

was found to meet the published specifications.

Anritsu Warranty

Anritsu Corporation will repair this equipment free-of-charge if a malfunction

occurs within one year after shipment due to a manufacturing fault, and

software bug fixes will be performed in accordance with the separate

Software End-User License Agreement, provide, however, that Anritsu

Corporation will deem this warranty void when:

● The fault is outside the scope of the warranty conditions separately

described in the operation manual.

● The fault is due to mishandling, misuse, or unauthorized modification or

repair of the equipment by the customer.

● The fault is due to severe usage clearly exceeding normal usage.

● The fault is due to improper or insufficient maintenance by the customer.

● The fault is due to natural disaster, including fire, wind or flood,

earthquake, lightning strike, or volcanic ash, etc.

● The fault is due to damage caused by acts of destruction, including civil

disturbance, riot, or war, etc.

● The fault is due to explosion, accident, or breakdown of any other

machinery, facility, or plant, etc.

● The fault is due to use of non-specified peripheral or applied equipment or

parts, or consumables, etc.

● The fault is due to use of a non-specified power supply or in a

non-specified installation location.

(Note)

● The fault is due to use in unusual environments

● The fault is due to activities or ingress of living organisms, such as insects,

spiders, fungus, pollen, or seeds.

In addition, this war ran ty is valid o nly f or t he orig inal e quipme nt purchas er. It

is not transferable if the equipment is resold.

Anritsu Corporation shal l assume no liability for damage or financial loss of

the customer due t o the us e of or a fa ilure to us e this equipment , unles s the

damage or l oss is caused due to Anri tsu Corporation’s intentional or gross

negligence.

.

x

Note:

For the purpose of this Warranty, "unusu al envir o nme n t s" means use:

● In places of direct sunlight

● In dusty places

● Outdoors

● In liquids, such as water, oil, or organic solvents, and medical fluids, or

places where these liquids may adhere

● In salty air or in place chemically active gases (sulfur dioxide, hydrogen

sulfide, chlorine, ammonia, nitrogen dioxide, or hydrogen chloride etc.)

are present

● In places where high-intensity static electric charges or electromagnetic

fields are present

● In places where abnormal power voltages (high or low) or instantaneous

power failures occur

● In places where condensation occurs

● In the presence of lubricating oil mists

● In places at an altitude of more than 2,000 m

● In the presence of frequent vibration or mechanical shock, such as in cars,

ships, or airplanes

Anritsu Corporation Contact

In the event of this equipment malfunctions, please contact an Anritsu

Service and Sales off ice. Contac t informat ion can be f ound on the last page

of the printed version of this manual, and is available in a separate file on the

PDF version.

xi

This product and its manuals may require an Export License/Approval by

the Government of the product's country of origin for re

country.

Before

whether they are export

When you dispose of export-controlled items, the products/manuals need

to be broken/shredded so as not to be unlawfully used for military

purpose.

Anritsu group promotes recycling activities in order to reuse available

resources and save energy. This product may use recycled parts

(mechanical components) that conform to Anritsu’s quality standards.

The life span of certain part s used in th is instrument is determin ed by the

operating time or the power-on time. Due consideration should be given to

the life spans of th ese parts when perf orming continuous oper ation over

an extended period. These parts must be replaced at the customer's

expense even if within the guaranteed period described in Warranty at the

beginning of this manual.

Notes On Export Management

-export from your

re-exporting the product or manuals, please contact us to confirm

-controlled items or not.

Reuse parts

Lifetime of Parts

xii

Crossed-out Wheeled Bin Symbol

Equipment marked w ith the Cr ossed-out Wheeled Bin Symbo l complies with

council directive 2012/19/EU (the “WEEE Directive”) in European Union.

For Products placed on the EU market after August 13 , 2005, pleas e contact

your local Anritsu representative at the end of the product's useful life to

arrange disposal in accor dance with your initial contract and the local law.

xiii

Software End-User License Agreement (EULA)

Please carefully read and accept this Software End-User License Agreement (hereafter this EULA)

before using (includes executing, copying, installing, registering, etc.) this Software (includes programs,

databases, scenarios, etc., used to operate, set, etc., Anritsu electronic equipment, etc.). By using this

Software, you shall be deemed to have agreed to be bound by the terms of this EULA, and Anritsu

Corporation (hereafter Anritsu) hereby grants you the right to use this Software with the Anritsu

specified equipment (hereafter Equipment) for the purposes set out in this EULA.

Article 1. Grant of License and Limitations

1. You may not to sell, transfer, rent, lease, lend,

disclose, sublicense, or otherwise distribute

this Software to third parties, whether or not

paid therefor.

2. You may make one copy of this Software for

backup purposes only.

3. You are not permitted to reverse engineer,

disassemble, decompile, modify or create

derivative works of this Software.

4. This EULA allows you to install one copy of

this Software on one piece of Equipment.

Article 2. Disclaimers

To the extent not prohibited by law, in no

event shall Anritsu be liable for direct, or any

incidental, special, indirect or consequential

damages whatsoever, including, without

limitation, damages for loss of profits, loss of

data, business interruption or any other

commercial damages or losses, and damages

claimed by third parties, arising out of or

related to your use or inability to use this

Software, unless the damages are caused due

to Anritsu’s intentional or gross negligence.

Article 3. Limitation of Liability

1. If a fault (bug) is discovered in this Software,

failing this Software to operate as described

in the operation manual or specifications

even though you have used this Software as

described in the manual, Anritsu shall at its

own discretion, fix the bug, or replace the

software, or suggest a workaround,

free-of-charge, provided, however, that the

faults caused by the following items and any

of your lost or damaged data whatsoever

shall be excluded from repair and the

warranty.

i) If this Software is deemed to be used for

purposes not described in the operation

manual or specifications.

ii) If this Software has been used in

conjunction with other

non-Anritsu-approved software.

iii) If this Software or the Equipment has

been modified, repaired, or otherwise

altered without Anritsu's prior

approval.

iv) For any other reasons out of Anritsu's

direct control and responsibility, such

as but not limited to, natural disasters,

software virus infections, or any devices

other than this Equipment, etc.

2. Expenses incurred for transport, hotel, daily

allowance, etc., for on-site repairs or

replacement by Anritsu engineers

necessitated by the above faults shall be

borne by you.

3. The warranty period for faults listed in

Section 1 of this Article shall be either 6

months from the date of purchase of this

Software or 30 days after the date of repair

or replacement, whichever is longer.

xiv

Article 4. Export Restrictions

You shall not use or otherwise export or

re-export directly or indirectly this Software

except as authorized by the laws and

regulations of Japan and the United States,

etc. In particular, this Software shall not be

exported or re-exported (a) into any Japan or

US embargoed countries or (b) to anyone

restricted by the Japanese export control

regulations, or the US Treasury

Department's list of Specially Designated

Nationals or the US Department of

Commerce Denied Persons List or Entity

List. In using this Software, you warrant

that you are not located in any such

embargoed countries or on any such lists.

You also agree that you will not use or

otherwise export or re-export this Software

for any purposes prohibited by the Japanese

and US laws and regulations, including,

without limitation, the development, design

and manufacture or production of missiles or

nuclear, chemical or biological weapons of

mass destruction, and conventional weapons.

Article 5. Change of Terms

Anritsu may change without your approval

the terms of this EULA if the changes are for

the benefit of general customers, or are

reasonable in light of the purpose of this

EULA and circumstances of the changes. At

the time of change, Anritsu will inform you of

those changes and its effective date, as a

general rule 45

website, or in writing or by e-mail.

days, in advance on its

Article 6. Termination

1. Anritsu may terminate this EULA

immediately if you violate any conditions

described herein. This EULA shall also be

terminated immediately by Anritsu if there

is any good reason that it is deemed difficult

to continue this EULA, such as your

violation of Anritsu copyrights, patents, etc.

or any laws and ordinances, or if it turns out

that you belong to an antisocial organization

or has a socially inappropriate relationship

with members of such organization.

2. You and Anritsu may terminate this EULA

by a written notice to the other party 30 days

in advance.

Article 7. Damages

If Anritsu suffers any damages or loss,

financial or otherwise, due to your violation

of the terms of this EULA, Anritsu shall have

the right to seek proportional damages from

you.

Article 8. Responsibility after Termination

Upon termination of this EULA in

accordance with Article 6, you shall cease all

uses of this Software immediately and shall

as directed by Anritsu either destroy or

return this Software and any backup copies,

full or partial, to Anritsu.

Article 9. Negotiation for Dispute

Resolution

If matters of interpretational dispute or

items not covered under this EULA arise,

they shall be resolved by negotiations in good

faith between you and Anritsu.

Article 10. Governing Law and Court of

Jurisdiction

This EULA shall be governed by and

interpreted in accordance with the laws of

Japan without regard to the principles of the

conflict of laws thereof, and any disputes

arising from or in relation to this EULA that

cannot be resolved by negotiation described

in Article 9 shall be subject to and be settled

by the exclusive agreed jurisdiction of the

Tokyo District Court of Japan.

Revision History:

February 29th, 2020

xv

virus security protection in

place.

Cautions Against Computer Virus Infection

● Copying files and dat a

Only files that have been provided directly from Anritsu or generated

using Anritsu equipment should be copied to the instrument.

All other required files should be transferred by means of USB flash

drive or CompactFlash media after undergoing a thorough virus

check.

● Adding software

Do not download or install software that has not been specifically

recommended or licensed by Anritsu.

● Network connections

Ensure that the network has sufficient anti-

xvi

CE Conformity Marking

Anritsu affixes the CE conformity marking on the following product(s) in

accordance with the Decision 768/2008/EC to indicate that they conform

to the EMC, LVD, and RoHS directive of the European Union (EU).

CE marking

1. Product Model

Model: MW9087 Series Card OTDR

2. Applied Directive

EMC: Directive 2014/30/EU

LVD: Directive 2014/35/EU

RoHS: Directive 2011/65/EU

3. Applied Standards

EMC: Emission: EN 61326-1: 2013 (Class A)

•

Immunity: EN 61326-1: 2013 (Table 2)

Performance Criteria*

IEC 61000-4-2 (ESD) B

IEC 61000-4-3 (EMF) A

IEC 61000-4-4 (Burst) B

IEC 61000-4-5 (Surge) B

IEC 61000-4-6 (CRF) A

IEC 61000-4-11 (V dip/short) B, C

*: Performance Criteria

A: The equipment shall continue to operate as intended during and

after the test. No degradation of performance or loss of function

is allowed below a performance level specified by the

manufacturer, when the equipment is used as intended.

The performance level may be replaced by a permissible loss of

performance. If the minimum performance level or the

permissible performance loss is not specified by the

manufacturer, either of these may be derived from the product

description and documentation and what the user may

reasonably expect from the equipment if used as intended.

xvii

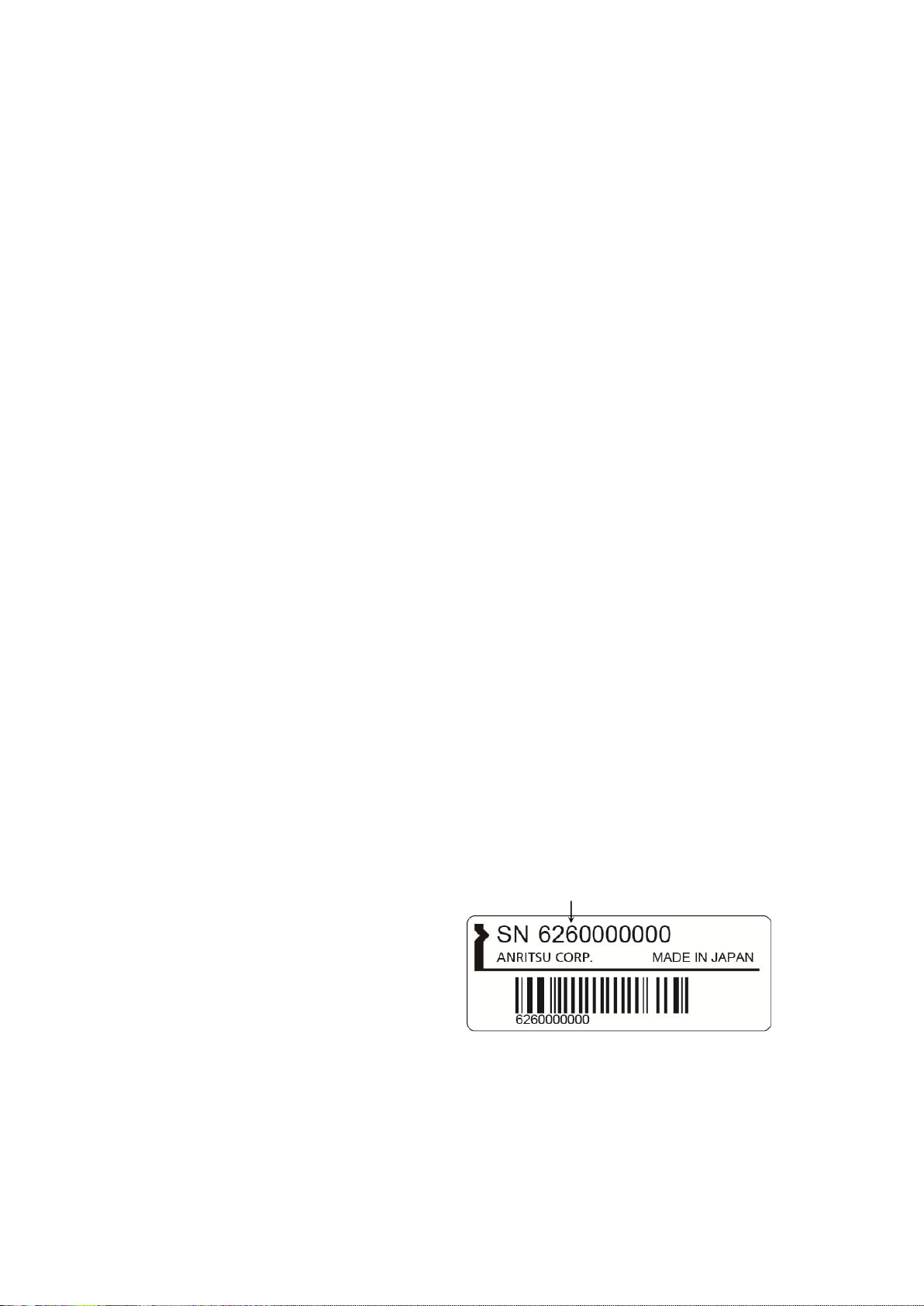

Serial number example

If the third digit of the serial number is "7", the product

complies with Directive 2011/65/EU as amended by (EU)

2015/863.

(Pb,Cd,Cr6+,Hg,PBB,PBDE,DEHP,BBP,DBP,DIBP)

If the third digit of the serial number is "6", the product

complies with Directive 2011/65/EU.

(Pb,Cd,Cr6+,Hg,PBB,PBDE)

Third digit

B: The equipment shall continue to operate as intended after the

test. No degradation of performance or loss of function is

allowed below a performance level specified by the

manufacturer, when the equipment is used as intended.

The performance level may be replaced by a permissible loss of

performance. During the test, degradation of performance is

however allowed. No change of actual operating state or stored

data is allowed. If the minimum performance level or the

permissible performance loss is not specified by the

manufacturer, either of these may be derived from the product

description and documentation and what the user may

reasonably expect from the equipment if used as intended.

C: Temporary loss of function is allowed, provided the function is

self-recoverable or can be restored by the operation of the

controls.

Harmonic current emiss ion s :

EN 61000-3-2: 2014 (Class A equipment)

No limits apply to this equipment with an active input

power under 75 W.

LVD: EN 61010-1: 2010 (Pollution Degree 2)

•

RoHS: EN 50581: 2012 (Catego r y 9)

•

xviii

4. Contact

Name: Anritsu GmbH

Address, city: Nemetschek Haus, Konrad-Zuse-Platz 1

81829 München,

Country: Germany

Name: ANRI T SU EM EA Lt d.

Address, city: 200 Capability Green, Luton

Bedfordshire, LU1 3LU

Country: United Kingdom

xix

RCM Conformity Marking

Anritsu affixes the RCM mark on the following product(s) in accordance

with the regulation to indicate that they conform to the EMC framework of

Australia/New Zealand.

RCM marking

1. Product Model

Model: MW9087 Series Card OTDR

2. Applied Standards

EMC: Emission: EN 61326-1: 2013 (Class A equipment)

xx

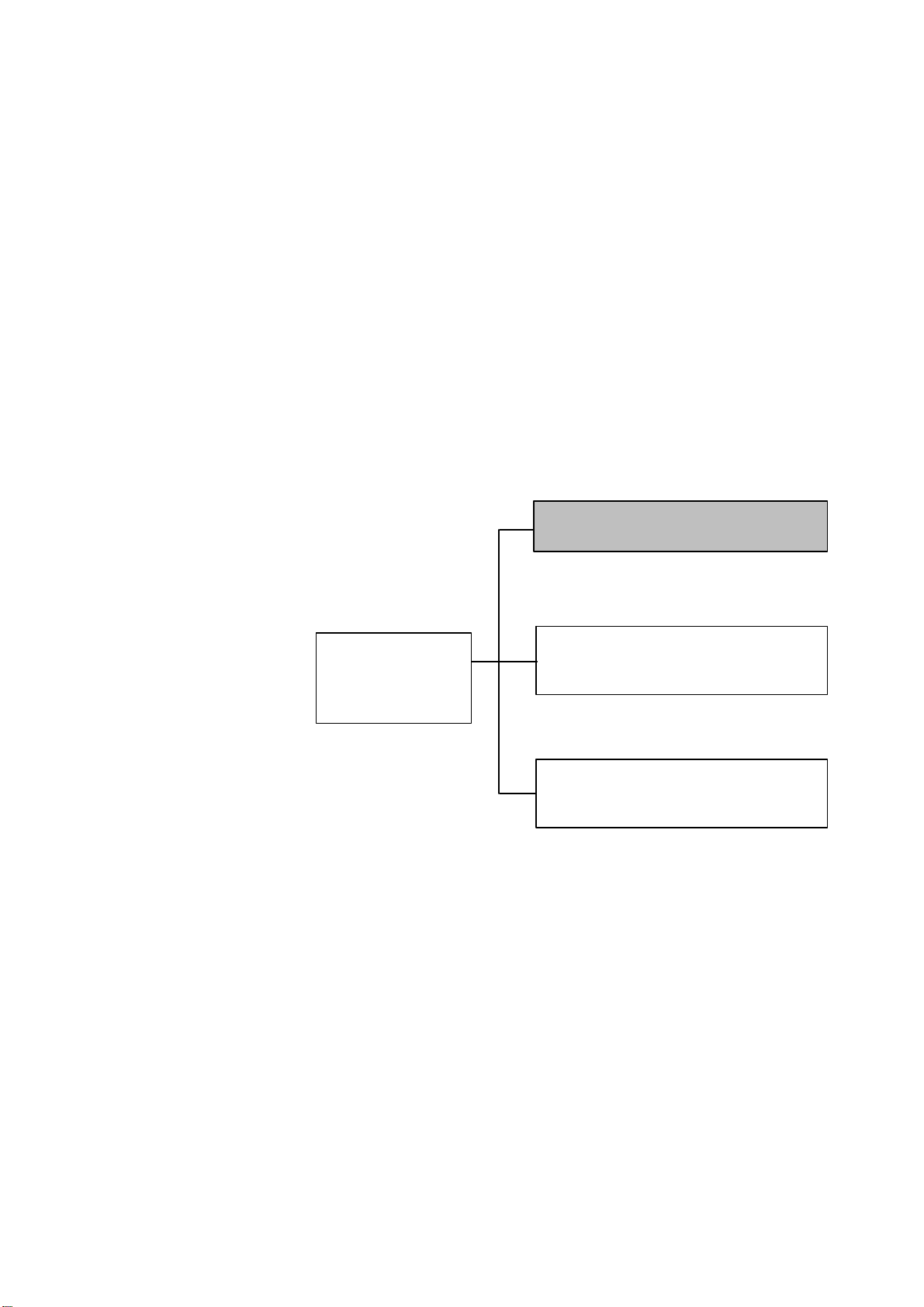

About This Manual

The configuration of the MW9087 Series Card OTDR operation manual is

divided into the following three parts: Card OTDR Mainframe, LED

Interface, and Password function.

This manual describes the operation/maintenance method for MW9087

Series Card OTDR.

Refer to Chapter 2 "Before Use" to understand the setting of this device

and precautions.

Also, refer to Chapter 3 "Measurement Method" to understand the

overview of operation flow.

MW9087 Series

Operation Manual

Configuration

MW9087 Series Card OTDR

Operation Manual (This manual)

Describes basic operations of

MW9087 Series Card OTDR

MW9087 Series Card OTDR

Option 001 LED Interface

Operation Manual

Described the operation method of

the LED interface.

MW9087 Series Card OTDR

Password Function Option

Operation Manual

Describes the operation method of

the password functio n.

I

Table of Contents

For Safety .................................................... iii

About This Manual........................................ I

Chapter 1 Outline ....................................... 1-1

1.1 Introduction to MW9087 Series Card OTDR ............. 1-2

1.2 Features ..................................................................... 1-3

1.3 Outline of OTDR ........................................................ 1-5

Chapter 2 Before Use ................................. 2-1

2.1 Product Configuration ................................................ 2-2

2.2 Names of Parts .......................................................... 2-3

2.3 Installing the Card OTDR ........................................... 2-5

2.4 Power Connection ..................................................... 2-8

2.5 Communication Settings ............................................ 2-9

2.6 Installation/Uninstallation for USB Serial Driver ........ 2-11

2.7 Confirmation of COM Ports ........................................ 2-25

2.8 Connecting the Optical Fiber Cable ........................... 2-29

2.9 Cautions on Handling Optical Fiber Cables ............... 2-31

2.10 Replacing the Optical Connector ............................... 2-33

2.11 Precautions ................................................................ 2-34

II

Chapter 3 Measurement Method ............... 3-1

3.1 Setting before Measurement ..................................... 3-2

3.2 Measurement Procedures ......................................... 3-3

3.3 Setting Measurement Conditions............................... 3-4

3.4 Measurement ............................................................. 3-5

3.5 Waveform Analysis .................................................... 3-6

3.6 Calculation Method .................................................... 3-7

3.7 Obtaining State .......................................................... 3-14

1

Chapter 4 Command Reference ................ 4-1

4.1 Command Format ...................................................... 4-2

4.2 Transmission Procedures .......................................... 4-3

4.3 Command List ............................................................ 4-5

4.4 Command Details ...................................................... 4-15

4.5 Error Code ................................................................. 4-53

Chapter 5 Performance Test and

Maintenance .............................. 5-1

5.1 Performance Test ...................................................... 5-2

5.2 Updating Software ..................................................... 5-16

5.3 Cautions on Storage .................................................. 5-17

5.4 Transporting and Disposal ......................................... 5-18

2

3

4

5

Appendix

Appendix A Specifications ......................... A-1

Appendix B Relationship between Pulse

Width Distance Range ............ B-1

Appendix C Factory Shipment Defaults .... C-1

Appendix D Command Compatibility ........ D-1

Appendix E Performance Test Result

Form ........................................ E-1

III

IV.

Chapter 1 Outline

1-1

Outline

This chapter explains the features of the MW9087 Series Card OTDR

Introduction to MW9087 Series Card OTDR ............. 1-2

1.1

1.2 Features ..................................................................... 1-3

1.3 Outline of OTDR ........................................................ 1-5

1

Chapter 1 Outline

1-2

MW9087B

1650 nm

41 dB

MW9087D

1550 nm

50 dB

1.1 Introduction to MW9087 Series Card OTDR

MW9087 Series Card OTDR is a module form for the optical fiber

measurement device.

Figure 1.1-1 Card OTDR Appearance (MW9087B)

This device has multiple models depending on wavelengths and dynamic

ranges.

1550 nm wavelength is used for communications.

To monitor the fiber loss/deterioration or breaks without effects on

communications, the model with wavelength of 1650 nm is used.

To measure the fiber loss of the wavelength used for communications, the

model with wavelength of 1550 nm is used.

If the fiber loss is large or the communication path has the fiber loss due

to optical coupler, the model with a large dynamic range is used.

Table 1.1-1 Model Name of Card OTDR

Model Wavelength Dynamic range

(Typ.)

1.2 Features

1-3

Outline

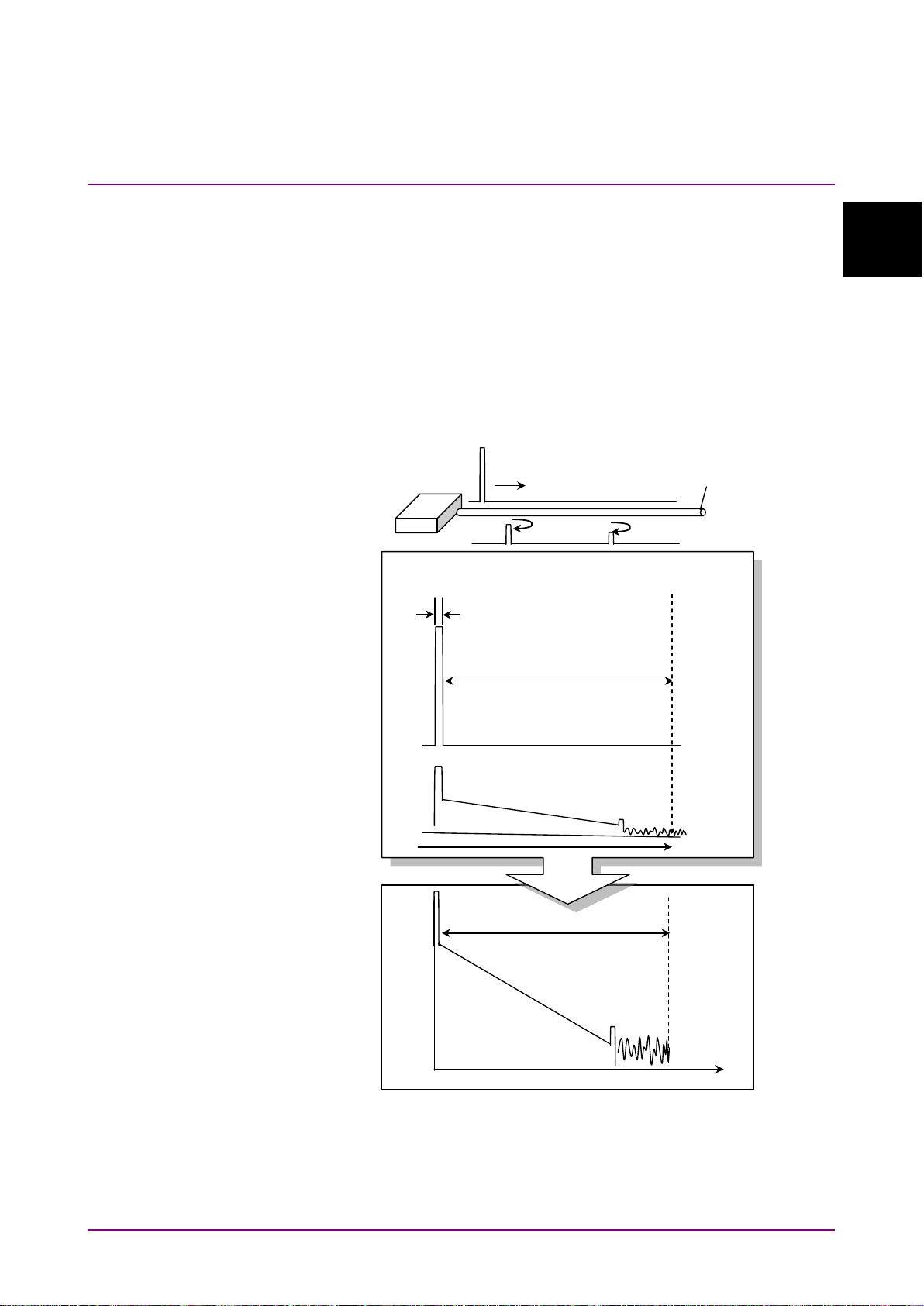

1.2 Features

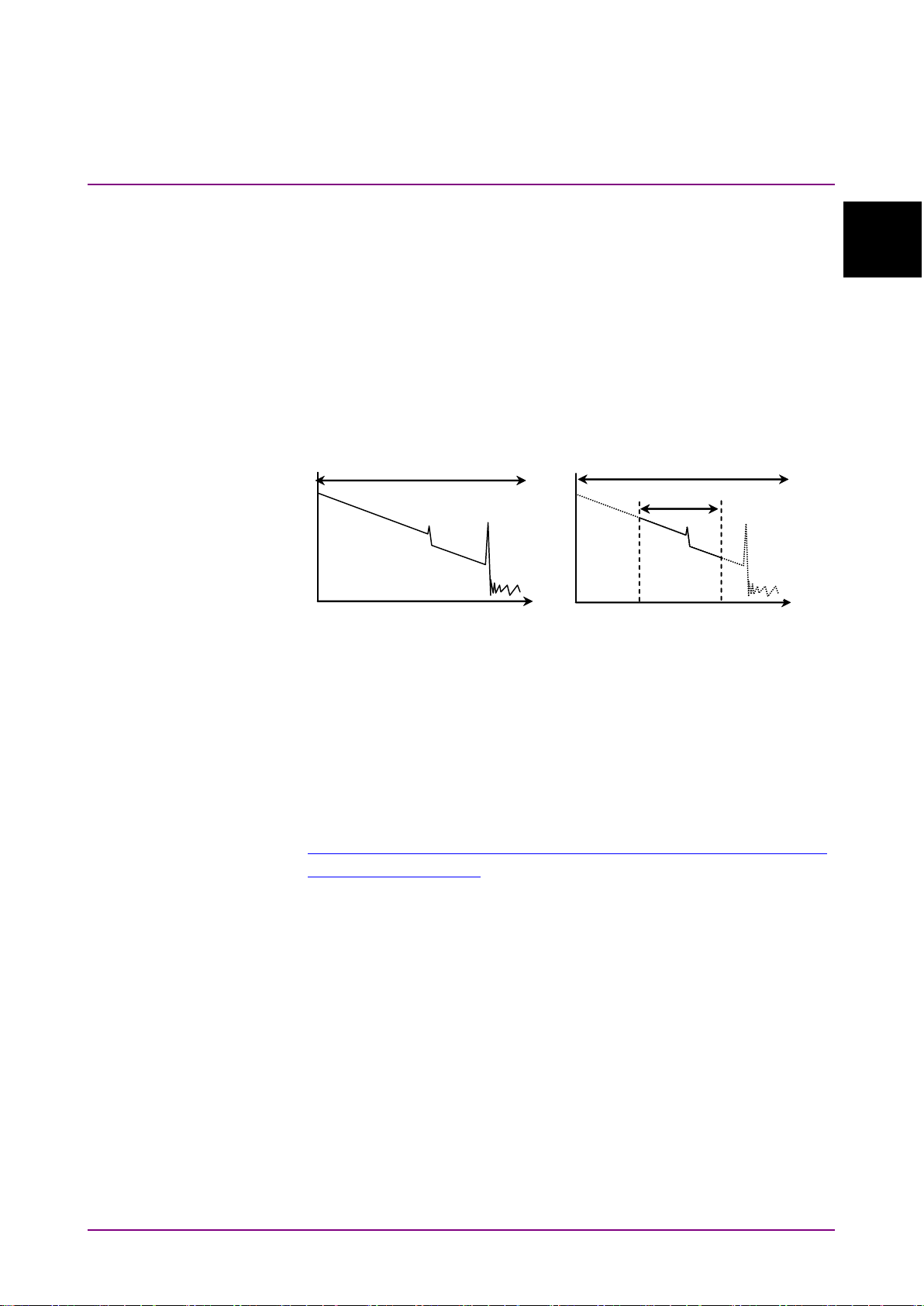

Normal measurement

Partial sampling

Distance range

Distance range

Measurement range

Distance

Distance

The MW9087 Series Card OTDR has been developed in order to monitor

faults in the optical fiber system.

You can control it via Ethernet; therefore, it can be used for

automatic/remote measurement.

1

Partial sampling

Distance range to be measured can be set, and only the range set can be

measured. This feature will shorten the measurement time.

Figure 1.2-1 Normal Measurement and Partial Sampling

SR-4731 file format

The measurement results can be saved with Telcordia standard SR-4731

OTDR Data Format-compliant files. These files have the extension of

SOR, and waveforms can be displayed with TraceView software.

This software is available from the following URL.

http://www.anritsu.com/en-US/Downloads/Software/Drivers/Software-Do

wnloads/DWL2761.aspx

Chapter 1 Outline

1-4

Figure 1.2-2 Waveform Display with TraceView software

Note:

The obtained waveform using the partial sampling cannot be

displayed with the Trace View software properly.

1.3 Outline of OTDR

1-5

Outline

1.3 Outline of OTDR

Level

Time

Transmitted light

level

Received light

level

Measurement time

Pulse width

Distance range

Distance

OTDR

Fiber

Time change between the light pulse transmitted

and the light level received by OTDR

Waveform data of OTDR

OTDR operating principle

OTDR (Optical Time Domain Reflectometer) transmits brief optical

pulses to the fiber to measure the intensity and time difference of lights

reflected from within the fiber.

The distance of the reflection point is calculated from the time difference,

light speed, and index of refraction (IOR) of the fiber.

The light attenuation (fiber loss) is calculated from the light intensity

reflected from within the fiber.

1

Figure 1.3-1 OTDR Transmitted/Received Waveform and

Waveform Data

Chapter 1 Outline

1-6

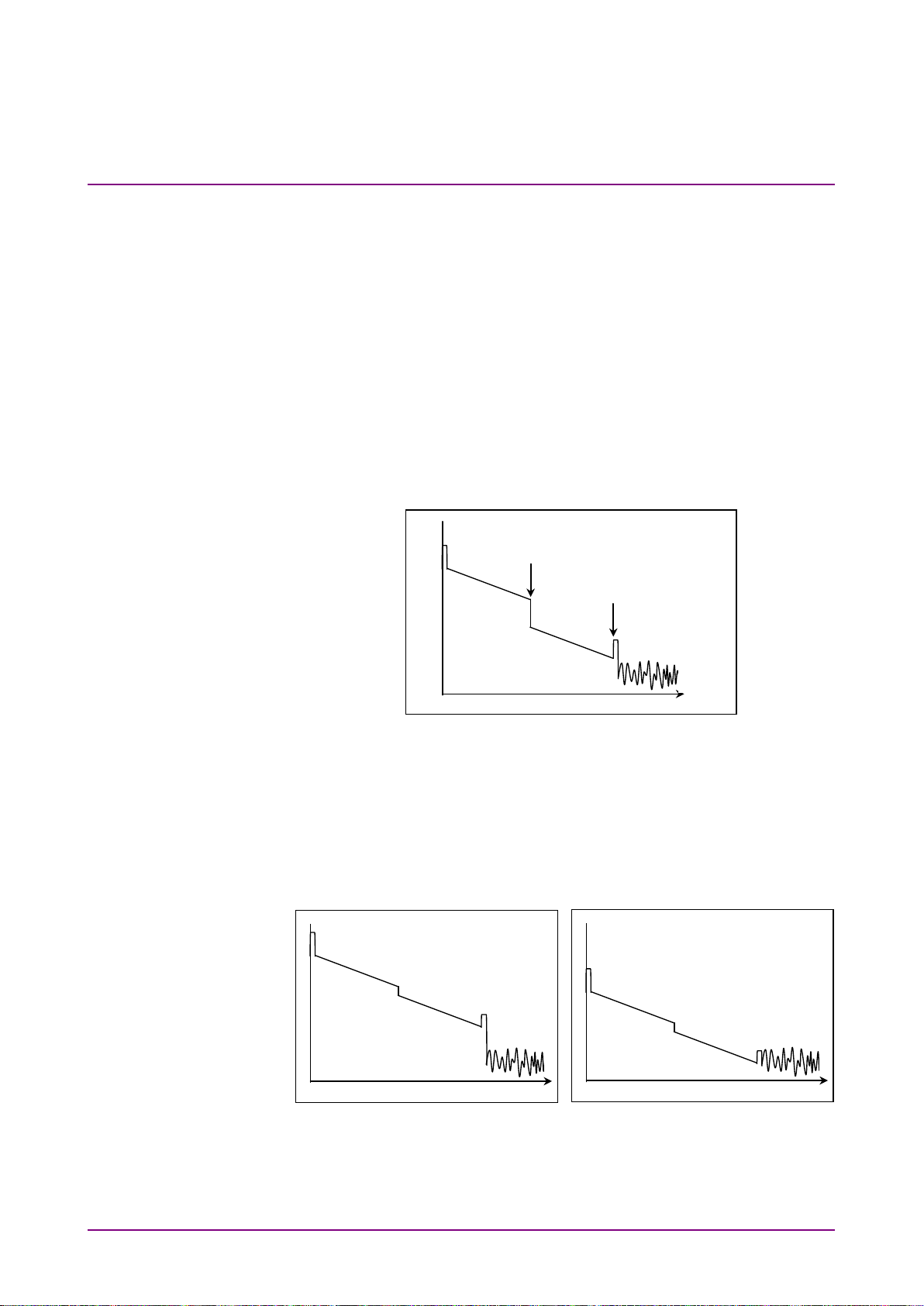

Level

Loss occurred

Distance

Reflection occurred

When pulse width is large

Distance

Level

When pulse width is narrow

Distance

The maximum measurable distance (distance range) is determined by the

time when OTDR measures the received light level after the optical pulse

is transmitted.

Transmitted optical pulse is reflected little by little within the fiber. The

more distant the reflected light is, the lower is the light level received by

OTDR. Therefore, the waveform of measurement result becomes a

downward-sloping rectilinear graph.

OTDR fiber measurement

In places where the fiber is connected or damaged, the fiber loss or the

light reflection may become larger. These changes make the waveform of

measurement result discontinuous.

Figure 1.3-2 Detection of Fiber Loss and Reflection

Waveform change with pulse width

The larger is the transmitted optical pulse width, the higher is the

received light level. Therefore, make the pulse width larger for the

measurement system with large fiber loss such as the case of a long

distance range.

Figure 1.3-3 Level Change with Pulse Width

Loading...

Loading...