Page 1

Network Master Series

µ

Operation Manual

23rd Edition

●

This document explains the operation of the

,

●

●

MU909014A/A1/B/B1/C/C6

MU909015A6/B/B1/C/C6

OTDR Module

MT9090A main frame, MU909014A/A1/B/B1/C/C6

MU909015A6/B/B1/C/C6 µOTDR modules

For safety and warning information, please read this

manual before attempting to use the equipment.

Keep this manual with the equipment.

.

ANRITSU CORPORATION

Document No.: M-W3586AE-23.0

Page 2

Safety Symbols

DANGER

WARNING

CAUTION

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the following

safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of the

symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu equipment.

In addition, there may be other labels attached to products that are not shown in the diagrams in this manual.

Symbols used in manual

This indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

This indicates a hazardous procedure that could result in serious injury or death if

not performed properly.

This indicates a hazardous procedure or danger that could result in light-to-severe

injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precautions. Ensure that you clearly understand the meanings of the symbols and

take the necessary precautions BEFORE using the equipment.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

This indicates an obligatory safety precaution. The obligatory operation is indicated

symbolically in or near the circle.

This indicates a warning or caution. The contents are indicated symbolically in or

near the triangle.

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

Network Master Series

MU909014A/A1/B/B1/C/C6, MU909015A6/B/B1/C/C6

OTDR Module

µ

Operation Manual

15 January 2012 (First Edition)

8 January 2021 (23rd Edition)

Copyright © 2012-2021, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The operational instructions of this manual may be changed without prior notice.

Printed in Japan

ii

Page 3

Replacing Battery

Battery Disposal

For Safety

DANGER

● When replacing the battery, use the specified battery and insert it with

the correct polarity. If the wrong battery is used, or if the battery is

inserted with reversed polarity, there is a risk of explosion causing

severe injury or death.

● DO NOT expose batteries to heat or fire. This is dangerous and can

result in explosions or fire. Heating batteries may cause them to leak

or explode.

WARNING

Repair

● ALWAYS refer to the operation manual when working near locations

at which the alert mark shown on the left is attached. If the advice in

the operation manual is not followed, there is a risk of personal injury

or reduced equipment performance. The alert mark shown on the left

may also be used with other marks and descriptions to indicate other

dangers.

● Overvoltage Category

This equipment complies with overvoltage category II defined in IEC

61010. DO NOT connect this equipment to the power supply of

overvoltage category III or IV.

● Laser radiation warning

- NEVER look directly into the cable connector on the equipment

nor into the end of a cable connected to the equipment. There is a

risk of injury if laser radiation enters the eye.

- The Laser Safety label is attached to the equipment for safety use

as indicated in "Laser Safety" later in this section.

● Only qualified service personnel with a knowledge of electrical fire and

shock hazards should service this equipment. This equipment cannot

be repaired by the operator. DO NOT attempt to remove the equipment

covers or unit covers or to disassemble internal components. There are

high-voltage parts in this equipment presenting a risk of severe injury

or fatal electric shock to untrained personnel. In addition, there is a risk

of damage to precision components.

iii

Page 4

Battery Fluid

LCD

High

For Safety

WARNING

Calibration

temperature

● The performance-guarantee seal verifies the integrity of the equipment.

To ensure the continued integrity of the equipment, only Anritsu service

personnel, or service personnel of an Anritsu sales representative,

should break this seal to repair or calibrate the equipment. Be careful

not to break the seal by opening the equipment or unit covers. If the

performance-guarantee seal is broken by you or a third party, the

performance of the equipment cannot be guaranteed.

● DO NOT short the battery terminals and never attempt to disassemble

the battery or dispose of it in a fire. If the battery is damaged by any of

these actions, the battery fluid may leak.

This fluid is poisonous.

DO NOT touch the battery fluid, ingest it, or get in your eyes. If it is

accidentally ingested, spit it out immediately, rinse your mouth with

water and seek medical help. If it enters your eyes accidentally, do

not rub your eyes, rinse them with clean running water and seek

medical help. If the liquid gets on your skin or clothes, wash it off

carefully and thoroughly with clean water.

● This equipment uses a Liquid Crystal Display (LCD). DO NOT subject

the equipment to excessive force or drop it. If the LCD is subjected to

strong mechanical shock, it may break and liquid may leak.

This liquid is very caustic and poisonous.

DO NOT touch it, ingest it, or get in your eyes. If it is ingested

accidentally, spit it out immediately, rinse your mouth with water and

seek medical help. If it enters your eyes accidentally, do not rub your

eyes, rinse them with clean running water and seek medical help. If

the liquid gets on your skin or clothes, wash it off carefully and

thoroughly with soap and water.

● Turn off the unit and allow alkaline batteries to cool before touching or

removing. The temperature of batteries may rise by approximately

+20°C if used continuously for an extended period of time.

iv

Page 5

For Safety

Class 1, 1M and 3R indicate the danger degree of the laser radiation

Laser Safety

specified below according to IEC 60825-1:2007.

Class 1: Lasers that are safe under reasonably foreseeable conditions

of operation, including the use of optical instruments for

intrabeam viewing.

Class 1M: Lasers emitting in the wavelength range from 302.5 to 4000

nm that are safe under reasonably foreseeable conditions of

operation, but may be hazardous if the user employs optics

within the beam. Two conditions apply:

a) for diverging beams, if the user views the laser output with

certain optical instruments (for example, eye loupes,

magnifiers and microscopes) within a distance of 100 mm;

or

b) for collimated beams, if the user views the laser output with

certain optical instruments (for example, telescopes and

binoculars).

Class 3R: Lasers that emit in the wavelength range from 302.5 to 10

where direct intrabeam viewing is potentially hazardous but

the risk is lower than for Class 3B lasers.

6

nm

CAUTION

Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

The use of optical instruments with this product will increase eye hazard.

v

Page 6

For Safety

WARNING

Laser Safety

Model Name Class

Before using this instrument, always ensure that the warning light is lit

when the optical output switch is turned on. If this warning light does not

turn on, the equipment may be faulty and for safety reasons should be

returned to an Anritsu service center or representative for repair.

The laser in this equipment is classified as Class 1, 1M, or 3R according

to the IEC 60825-1: 2007 standard.

Never use optical instruments to directly view Class 1M laser products.

Doing so may result in serious damage to the eyes.

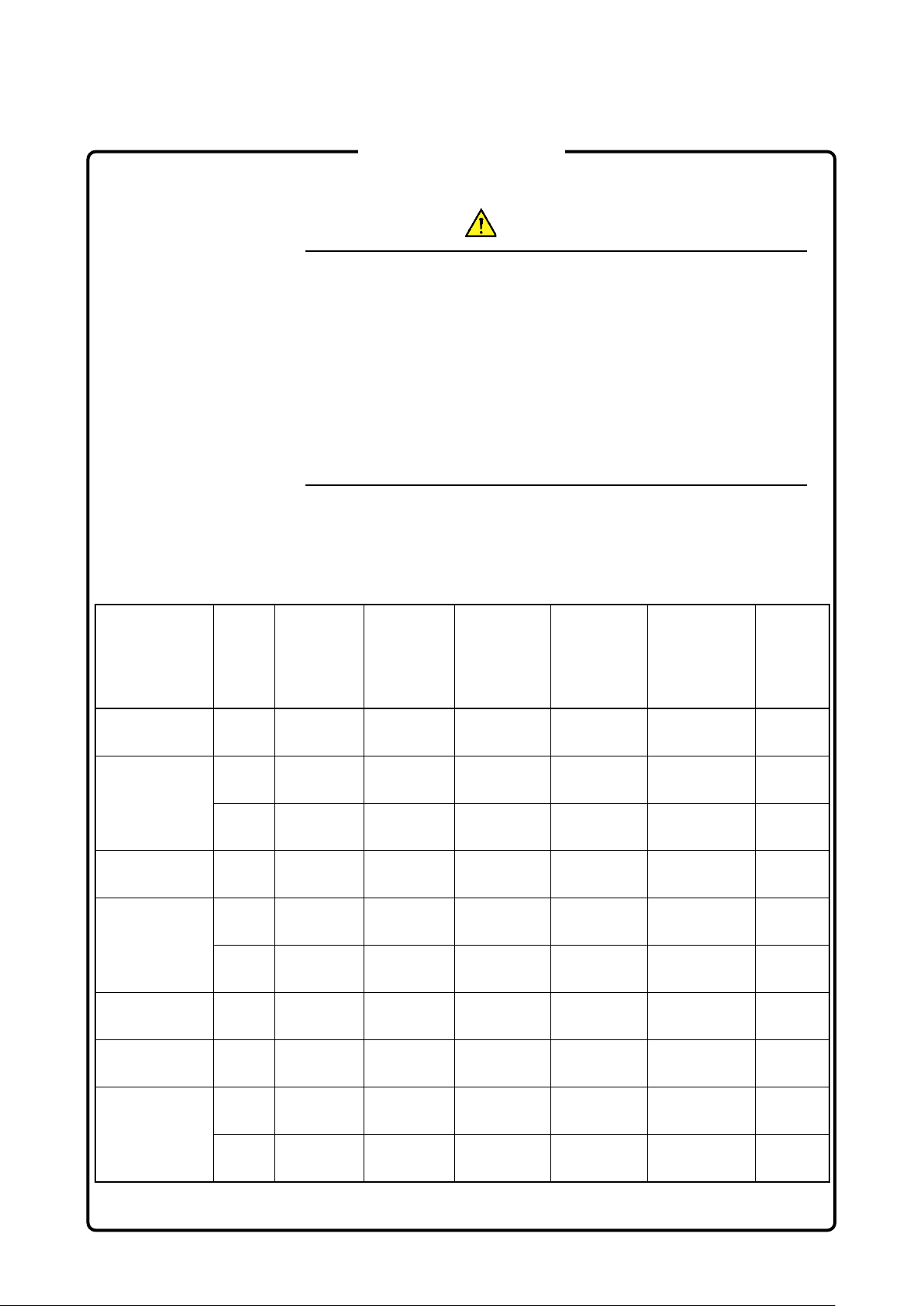

Table 1 Laser Safety Classifications Based on IEC 60825-1:2007

Max.

Optical

Output

Power

(W)*

Pulse

Width(s)/

Repetition

Rate

Emitted

Wavelength

(nm)

Beam

Divergence

(deg)

Incorporated

Laser

Specification

(refer to

Table 2)

Laser

Aperture

MU909014A

-053/063

MU909014A1

-053/063

MU909014A

-054/064

MU909014A1

-054/064

MU909015A6-

053/063

MU909015A6-

054/064

MU909014B

MU909015B

-056/066

1 0.15

1 0.15

3R 0.003 CW 650 11.5 f)

1 0.15

1 0.15

3R 0.003 CW 650 11.5 f)

1 0.15

1 0.15

1M 0.15

1 0.15

20×10–6/

0.009

–6

20×10

0.009

20×10–6/

0.009

–6

20×10

0.009

20×10–6/

0.009

20×10–6/

0.009

–6

20×10

0.015

–6

20×10

0.009

1625 11.5 d)

/

/

/

/

1625 11.5 d)

1650 11.5 e)

1650 11.5 e)

1625 11.5 d)

1650 11.5 e)

1310 11.5 a)

1550 11.5 c)

Figure

1, [1]

Figure

2, [1]

Figure

2, [2]

Figure

1, [1]

Figure

2, [1]

Figure

2, [2]

Figure

1, [1]

Figure

1, [1]

Figure

1, [1]

Figure

1, [1]

vi

Page 7

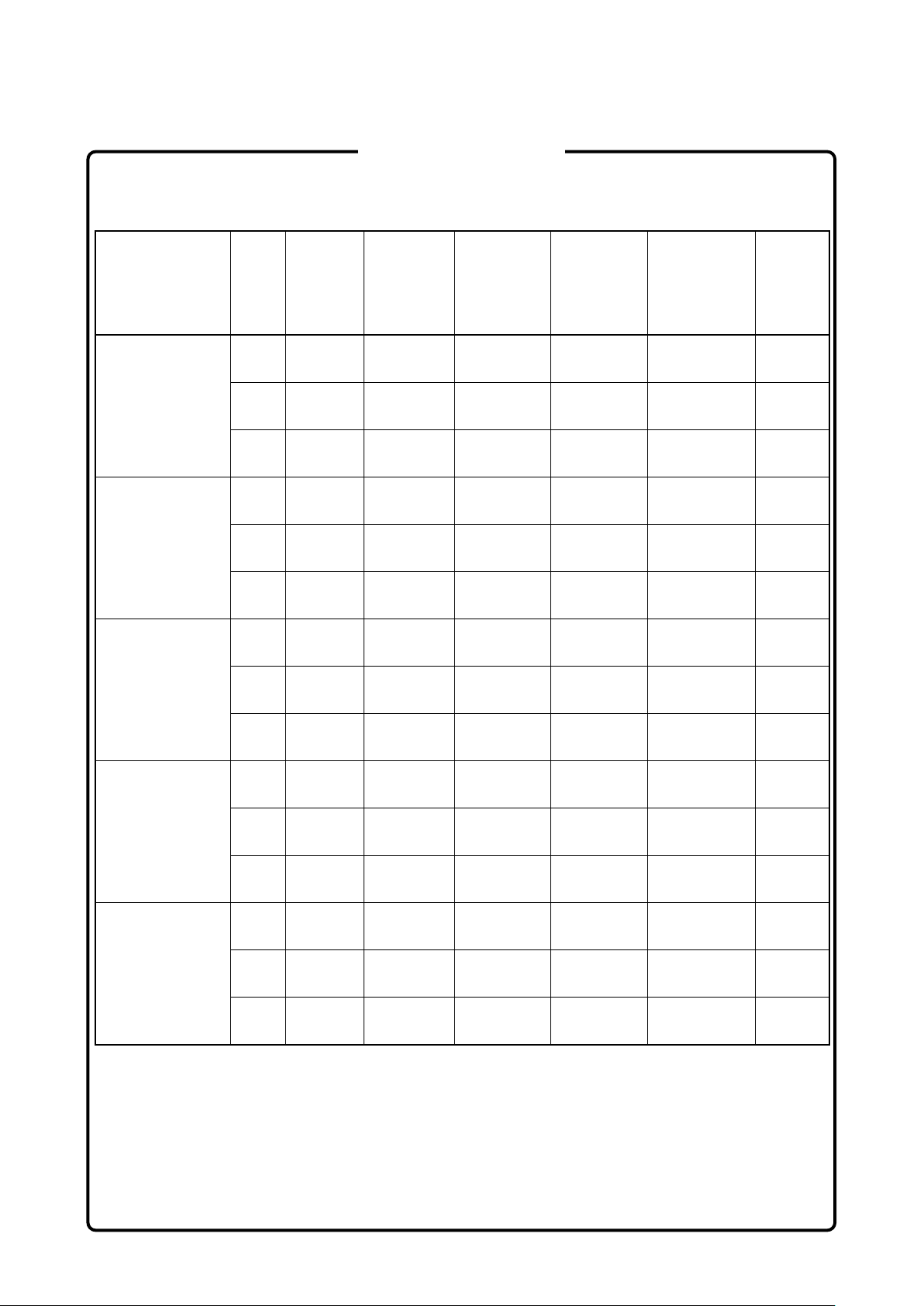

For Safety

Table 1 Laser Safety Classifications Based on IEC 60825-1:2007 (Continued)

Model Name

MU909014B1

MU909015B1

-056/066

MU909014C/C6

MU909015C/C6

-057/067

MU909014C/C6

MU909015C/C6

-058/068

MU909015C

-059/069

MU909015C6

-059/069

Max.

Optical

Class

Output

Power

(W)*

1M 0.15

1 0.15

Pulse

Width(s)/

Repetition

Rate

–6

20×10

/

0.015

–6

20×10

/

0.009

Emitted

Wavelength

(nm)

Beam

Divergence

(deg)

1310 11.5 a)

1550 11.5 c)

Incorporated

Laser

Specification

(refer to

Table 2)

3R 0.003 CW 650 11.5 f)

–6

1M 0.15

1 0.15

1 0.15

1M 0.15

1 0.15

1 0.15

1M 0.15

1 0.15

1 0.15

1M 0.15

1 0.15

1 0.15

20×10

20×10

20×10

20×10

20×10

20×10

20×10

20×10

20×10

20×10

20×10

20×10

0.015

0.009

0.009

0.015

0.009

0.009

0.015

0.009

0.009

0.015

0.009

0.009

/

–6

/

–6

/

–6

/

–6

/

–6

/

–6

/

–6

/

–6

/

–6

/

–6

/

–6

/

1310 11.5 a)

1550 11.5 c)

1625 11.5 d)

1310 11.5 a)

1550 11.5 c)

1650 11.5 e)

1310 11.5 a)

1490 11.5 b)

1550 11.5 c)

1310 11.5 a)

1490 11.5 b)

1550 11.5 c)

Laser

Aperture

Figure

2, [1]

Figure

2, [1]

Figure

2, [2]

Figure

3, [1]

Figure

3, [1]

Figure

3, [2]

Figure

3, [1]

Figure

3, [1]

Figure

3, [2]

Figure

1, [1]

Figure

1, [1]

Figure

1, [1]

Figure

3, [1]

Figure

3, [1]

Figure

3, [1]

*: Indicates the possible optical output power when each and every

reasonably foreseeable single-fault condition is included.

vii

Page 8

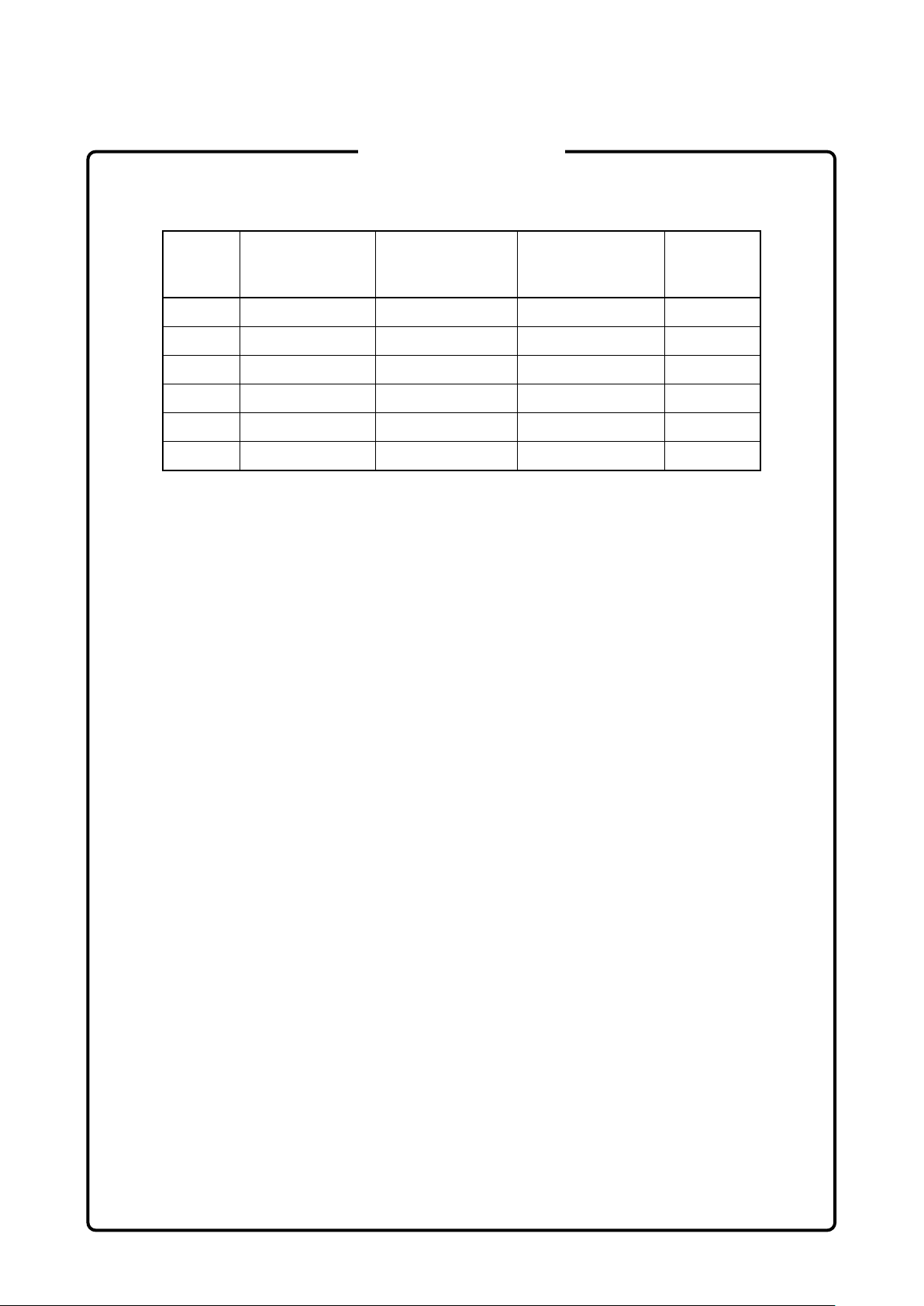

For Safety

Table 2 Incorporated Laser Specifications

Incorpor

ated

Laser

a) 0.3 20×10–6/0.015 1310 11.5

b) 0.3 20×10–6/0.009 1490 11.5

c) 0.3 20×10–6/0.009 1550 11.5

d) 0.3 20×10–6/0.009 1625 11.5

e) 0.3 20×10–6/0.009 1650 11.5

f) 0.003 CW 650 11.5

Max. Optical

Output Power

1

(W)*

*1: Maximum output power is the estimated value when something

breaks down.

*2: This product incorporates a laser diode module with optical fiber

output.

Pulse Width

(s)/Repetition

Rate

Emitted

Wavelength (nm)

Divergence

Beam

(deg)

*2

viii

Page 9

For Safety

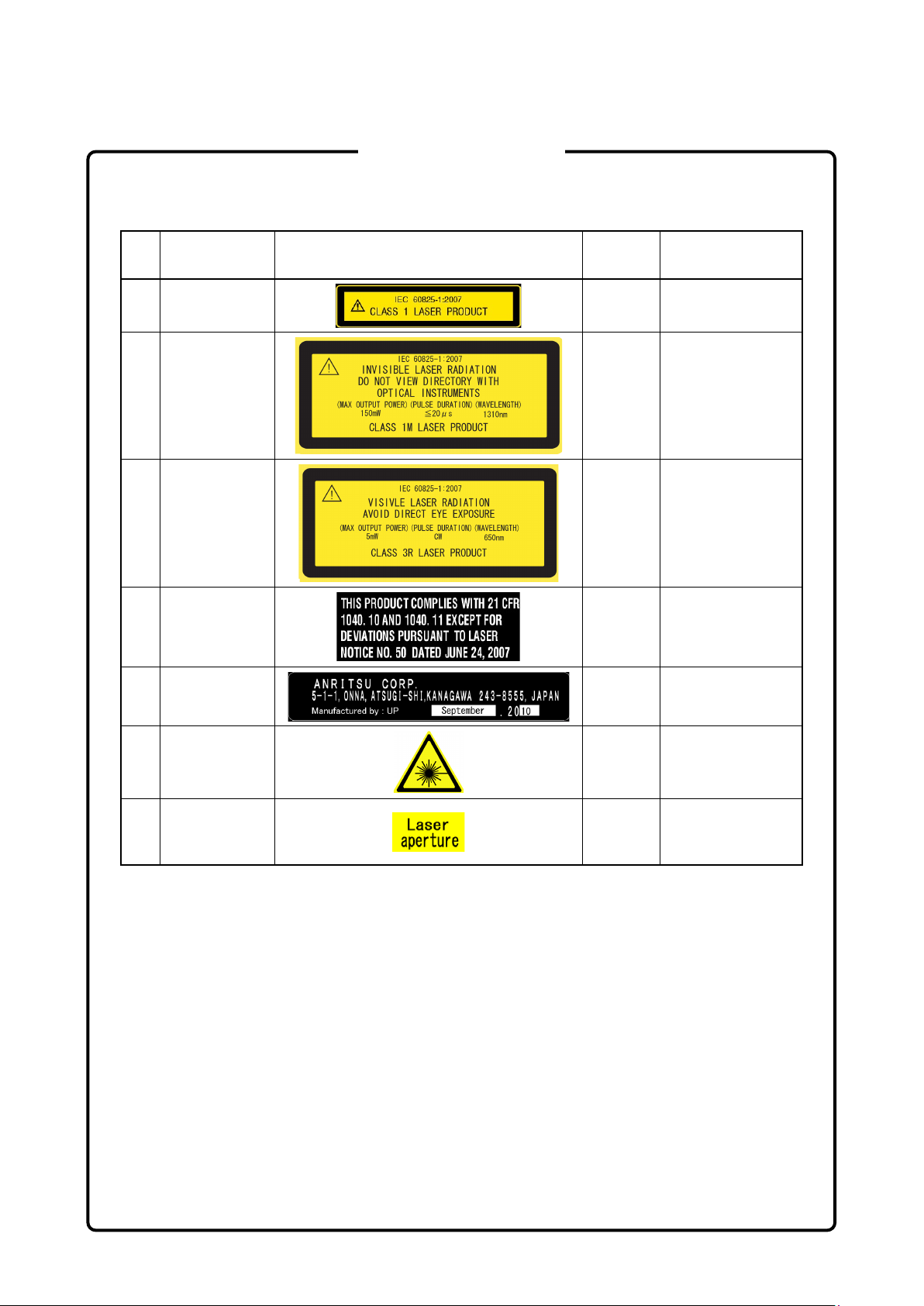

Table 3 Labels on Product

Type Label

1 Explanation

2 Explanation

3 Explanation

4 Certification

5 Identification

Affixed

to:

Figure 4,

A

Figure 4,

B

Figure 4,

C

Figure 4,

D

Figure 4,

E

Model Name

MU909014A

MU909015A6

MU909014B/C/C6

MU909015B/C/C6

MU909014A1/

MU909014B1/

MU909015B1

All models

All models

6 Warning

7 Aperture

Figure 4,

F

Figure 4,

G

MU909014A1/

MU909014B1/

MU909015B1

MU909014A1/

MU909014B1/

MU909015B1

ix

Page 10

[1]

[2]

[1]

[2]

[1]

For Safety

Laser Radiation Markings

Figure 1 Locations of Laser Beam Apertures (MU909014A/B MU909015A6/B and

MU909015C-059/069)

Figure 2 Locations of Laser Beam Apertures (MU909014A1/B1 and MU909015B1)

Figure 3 Locations of Laser Beam Apertures (MU909014C/C6 and MU909015C/C6)

x

Page 11

A

E

C

G

B

F

Laser

aperture

D

For Safety

Figure 4 Locations of Affixed Labels

xi

Page 12

Ni-MH

For Safety

FOR U.S. CUSTOMERS

Please Recycle.

The product that you have purchased contains a rechargeable battery.

The battery is recyclable. At the end of its useful life, under various state

and local laws, it may be illegal to dispose of this battery into the

municipal waste stream. Check with your local solid waste officials for

details in your area for recycling options or proper disposal.

Before disposing of this product, discharge the battery and mail it to your

Anritsu Service or Sales office.

1. Attach the battery pack to the product.

2. Disconnect the AC adapter, if used.

3. Turn the power switch to on.

4. Set Auto Backlight to

5. Leave the product on until the power indicator goes off; the battery is

now discharged.

6. Remove the battery.

7. Insulate the battery terminals with adhesive tape.

8. Mail it to your Anritsu Service or Sales office, or to the following

address.

ANRITSU COMPANY

490 Jarvis Drive, Morgan Hill, CA 95037-2809, USA

and Auto Power Off to

Off

Off

.

xii

Page 13

Ni-MH

For Safety

FOR EU & EFTA CUSTOMERS

Please Recycle.

Read the following when using products to which the mark shown on the

above is attached.

The product that you have purchased contains a rechargeable battery.

The battery is recyclable. At the end of its useful life, under various state

and local laws, it may be illegal to dispose of this battery into the

municipal waste. Check with your local solid-waste disposal officials for

details of recycling options or proper disposal in your area.

Before disposing of this product, discharge the battery and mail it to your

Anritsu Service or Sales office.

1. Disconnect the AC adapter, if used.

2. Turn the power switch to on.

3. Leave the product on until the power indicator goes off; the battery is

now discharged.

4. Remove the battery.

5. Insulate the battery terminals with adhesive tape.

6. Please recycle in accordance with your national or regional

legislation.

Nach Gebrauch der Ver Kaufsstelle Zurückgeben.

Après usage à rapporter au point de vente.

xiii

Page 14

External

Storage Media

Hard disk

Use in a

E

Use in

Atmospheres

For Safety

CAUTION

This equipment uses a USB flash drive as external storage media for

storing data and programs. If this media is mishandled or becomes faulty,

important data may be lost.

It is recommended to periodically back up all important data and

programs to protect them from being lost accidentally.

Anritsu will not be held responsible for lost data.

Pay careful attention to the following points.

● Never remove the USB flash drive from the equipment while it is

being accessed.

● The USB flash drive may be damaged by static electric charges.

● Anritsu has thoroughly tested all external storage media shipped with

this equipment. Users should note that external storage media not

shipped with this equipment may not have been tested by Anritsu,

thus Anritsu cannot guarantee the performance or suitability of such

media.

The equipment is uses internal flash memory for storing data and

programs. If this media is mishandled or becomes faulty, important data

may be lost. It is recommended to periodically back up all important data

and programs to protect them from being lost accidentally.

Anritsu will not be held responsible for lost data.

xiv

Residential

nvironment

Corrosive

To reduce the possibility of data loss, particular attention should be given

to the following points.

● The equipment should only be used within the recommend

temperature range, and should not be used in locations where the

temperature may fluctuate suddenly.

● Exercise care not to bang or shake the equipment whilst the power is

on.

This equipment is designed for an industrial environment.

In a residential environment, this equipment may cause radio

interference in which case the user may be required to take adequate

measures.

Exposure to corrosive gases such as hydrogen sulfide, sulfurous acid,

and hydrogen chloride will cause faults and failures.

Note that some organic solvents release corrosive gases.

Page 15

Equipment Certificate

Anritsu Corporation certifies that this equipment was tested before shipment

using calibrated measuring instruments with direct traceability to public

testing organizations recognized by national research laboratories, including

the National Institute of Advanced Industrial Science and Technology, and

the National Institute of Information and Communications Technology, and

was found to meet the published specifications.

Anritsu Warranty

Anritsu Corporation will repair this equipment free-of-charge if a malfunction

occurs within one year after shipment due to a manufacturing fault, and

software bug fixes will be performed in accordance with the separate

Software End-User License Agreement, provide, however, that Anritsu

Corporation will deem this warranty void when:

● The fault is outside the scope of the warranty conditions separately

described in the operation manual.

● The fault is due to mishandling, misuse, or unauthorized modification or

repair of the equipment by the customer.

● The fault is due to severe usage clearly exceeding normal usage.

● The fault is due to improper or insufficient maintenance by the customer.

● The fault is due to natural disaster, including fire, wind or flood,

earthquake, lightning strike, or volcanic ash, etc.

● The fault is due to damage caused by acts of destruction, including civil

disturbance, riot, or war, etc.

● The fault is due to explosion, accident, or breakdown of any other

machinery, facility, or plant, etc.

● The fault is due to use of non-specified peripheral or applied equipment or

parts, or consumables, etc.

● The fault is due to use of a non-specified power supply or in a

non-specified installation location.

● The fault is due to use in unusual environments

● The fault is due to activities or ingress of living organisms, such as insects,

spiders, fungus, pollen, or seeds.

In addition, this warranty is valid only for the original equipment purchaser. It

is not transferable if the equipment is resold.

Anritsu Corporation shall assume no liability for damage or financial loss of

the customer due to the use of or a failure to use this equipment, unless the

damage or loss is caused due to Anritsu Corporation’s intentional or gross

negligence.

(Note)

.

xv

Page 16

Note:

For the purpose of this Warranty, "unusual environments" means use:

● In places of direct sunlight

● In dusty places

● In liquids, such as water, oil, or organic solvents, and medical fluids, or

places where these liquids may adhere

● In salty air or in place chemically active gases (sulfur dioxide, hydrogen

sulfide, chlorine, ammonia, nitrogen dioxide, or hydrogen chloride etc.)

are present

● In places where high-intensity static electric charges or electromagnetic

fields are present

● In places where abnormal power voltages (high or low) or instantaneous

power failures occur

● In places where condensation occurs

● In the presence of lubricating oil mists

● In places at an altitude of more than 2,000 m

● In the presence of frequent vibration or mechanical shock, such as in cars,

ships, or airplanes

Anritsu Corporation Contact

In the event of this equipment malfunctions, please contact an Anritsu

Service and Sales office. Contact information can be found on the last page

of the printed version of this manual, and is available in a separate file on the

PDF version.

xvi

Page 17

This product and its

the Government of the product's country of origin for re

country.

Before re

whethe

W

controlled items, the products/manuals need

to be broken/shredded so as not to be unlawfully used for military

purpose.

Notes On Export Management

manuals may require an Export License/Approval by

-export from your

-exporting the product or manuals, please contact us to confirm

r they are export-controlled items or not.

hen you dispose of export-

xvii

Page 18

Crossed-out Wheeled Bin Symbol

Equipment marked with the Crossed-out Wheeled Bin Symbol complies with

council directive 2012/19/EU (the “WEEE Directive”) in European Union.

For Products placed on the EU market after August 13, 2005, please contact

your local Anritsu representative at the end of the product's useful life to

arrange disposal in accordance with your initial contract and the local law.

xviii

Page 19

Software End-User License Agreement (EULA)

Please carefully read and accept this Software End-User License Agreement (hereafter this EULA)

before using (includes executing, copying, installing, registering, etc.) this Software (includes programs,

databases, scenarios, etc., used to operate, set, etc., Anritsu electronic equipment, etc.). By using this

Software, you shall be deemed to have agreed to be bound by the terms of this EULA, and Anritsu

Corporation (hereafter Anritsu) hereby grants you the right to use this Software with the Anritsu

specified equipment (hereafter Equipment) for the purposes set out in this EULA.

Article 1. Grant of License and Limitations

1. You may not to sell, transfer, rent, lease, lend,

disclose, sublicense, or otherwise distribute

this Software to third parties, whether or not

paid therefor.

2. You may make one copy of this Software for

backup purposes only.

3. You are not permitted to reverse engineer,

disassemble, decompile, modify or create

derivative works of this Software.

4. This EULA allows you to install one copy of

this Software on one piece of Equipment.

Article 2. Disclaimers

To the extent not prohibited by law, in no

event shall Anritsu be liable for direct, or any

incidental, special, indirect or consequential

damages whatsoever, including, without

limitation, damages for loss of profits, loss of

data, business interruption or any other

commercial damages or losses, and damages

claimed by third parties, arising out of or

related to your use or inability to use this

Software, unless the damages are caused due

to Anritsu’s intentional or gross negligence.

Article 3. Limitation of Liability

1. If a fault (bug) is discovered in this Software,

failing this Software to operate as described

in the operation manual or specifications

even though you have used this Software as

described in the manual, Anritsu shall at its

own discretion, fix the bug, or replace the

software, or suggest a workaround,

free-of-charge, provided, however, that the

faults caused by the following items and any

of your lost or damaged data whatsoever

shall be excluded from repair and the

warranty.

i) If this Software is deemed to be used for

purposes not described in the operation

manual or specifications.

ii) If this Software has been used in

conjunction with other

non-Anritsu-approved software.

iii) If this Software or the Equipment has

been modified, repaired, or otherwise

altered without Anritsu's prior

approval.

iv) For any other reasons out of Anritsu's

direct control and responsibility, such

as but not limited to, natural disasters,

software virus infections, or any devices

other than this Equipment, etc.

2. Expenses incurred for transport, hotel, daily

allowance, etc., for on-site repairs or

replacement by Anritsu engineers

necessitated by the above faults shall be

borne by you.

3. The warranty period for faults listed in

Section 1 of this Article shall be either 6

months from the date of purchase of this

Software or 30 days after the date of repair

or replacement, whichever is longer.

xix

Page 20

Article 4. Export Restrictions

You shall not use or otherwise export or

re-export directly or indirectly this Software

except as authorized by the laws and

regulations of Japan and the United States,

etc. In particular, this Software shall not be

exported or re-exported (a) into any Japan or

US embargoed countries or (b) to anyone

restricted by the Japanese export control

regulations, or the US Treasury

Department's list of Specially Designated

Nationals or the US Department of

Commerce Denied Persons List or Entity

List. In using this Software, you warrant

that you are not located in any such

embargoed countries or on any such lists.

You also agree that you will not use or

otherwise export or re-export this Software

for any purposes prohibited by the Japanese

and US laws and regulations, including,

without limitation, the development, design

and manufacture or production of missiles or

nuclear, chemical or biological weapons of

mass destruction, and conventional weapons.

Article 5. Change of Terms

Anritsu may change without your approval

the terms of this EULA if the changes are for

the benefit of general customers, or are

reasonable in light of the purpose of this

EULA and circumstances of the changes. At

the time of change, Anritsu will inform you of

those changes and its effective date, as a

general rule 45

website, or in writing or by e-mail.

days, in advance on its

Article 6. Termination

1. Anritsu may terminate this EULA

immediately if you violate any conditions

described herein. This EULA shall also be

terminated immediately by Anritsu if there

is any good reason that it is deemed difficult

to continue this EULA, such as your

violation of Anritsu copyrights, patents, etc.

or any laws and ordinances, or if it turns out

that you belong to an antisocial organization

or has a socially inappropriate relationship

with members of such organization.

2. You and Anritsu may terminate this EULA

by a written notice to the other party 30 days

in advance.

Article 7. Damages

If Anritsu suffers any damages or loss,

financial or otherwise, due to your violation

of the terms of this EULA, Anritsu shall have

the right to seek proportional damages from

you.

Article 8. Responsibility after Termination

Upon termination of this EULA in

accordance with Article 6, you shall cease all

uses of this Software immediately and shall

as directed by Anritsu either destroy or

return this Software and any backup copies,

full or partial, to Anritsu.

Article 9. Negotiation for Dispute

Resolution

If matters of interpretational dispute or

items not covered under this EULA arise,

they shall be resolved by negotiations in good

faith between you and Anritsu.

Article 10. Governing Law and Court of

Jurisdiction

This EULA shall be governed by and

interpreted in accordance with the laws of

Japan without regard to the principles of the

conflict of laws thereof, and any disputes

arising from or in relation to this EULA that

cannot be resolved by negotiation described

in Article 9 shall be subject to and be settled

by the exclusive agreed jurisdiction of the

Tokyo District Court of Japan.

Revision History:

February 29th, 2020

xx

Page 21

virus security protection in

place.

Cautions Against Computer Virus Infection

● Copying files and data

Only files that have been provided directly from Anritsu or generated

using Anritsu equipment should be copied to the instrument.

All other required files should be transferred by means of USB flash

drive or CompactFlash media after undergoing a thorough virus

check.

● Adding software

Do not download or install software that has not been specifically

recommended or licensed by Anritsu.

● Network connections

Ensure that the network has sufficient anti-

xxi

Page 22

Prior to the software installation

When using this software and connecting with the measuring instrument

protection against computer viruses.

This software may not operate normally if any of the following operations

are performed

For how to turn off

with your computer.

Protection Against Computer Virus Infections

Before installing this software or any other software recommended or

approved by Anritsu, run a virus scan on your computer, including

removable media (e.g. USB flash drive and CF memory card) you

want to connect to your computer.

● Copying files and data

On your computer, do not save any copies other than the following:

- Files and data provided by Anritsu

- Files created by this software

- Files specified in this document

Before copying these files and/or data, run a virus scan, including

removable media (e.g. USB flash drive and CF memory card).

● Connecting to network

Connect your computer to the network that provides adequate

Cautions on Proper Operation of Software

on your computer:

● Simultaneously running any software other than that recommended

or approved by Anritsu

● Closing the lid (Laptop computer)

● Turning on the screen saver function

● Turning on the battery-power saving function (Laptop computer)

the functions, refer to the operation manual that came

xxii

Page 23

CE Conformity Marking

Anritsu affixes the CE conformity marking on the following product(s) in

accordance with the Decision 768/2008/EC to indicate that they conform

to the EMC, LVD, and RoHS directive of the European Union (EU).

CE marking

1. Product Model

Model: MT9090A Main frame

MU909014A1

MU909014B

MU909014B1

MU909014C

MU909014C6

MU909015A6

MU909015B

MU909015B1

MU909015C

MU909015C6

2. Applied Directive

EMC: Directive 2014/30/EU

LVD: Directive 2014/35/EU

RoHS: Directive 2011/65/EU, (EU) 2015/863

3. Applied Standards

EMC: Emission: EN 61326-1: 2013 (Class A)

•

Immunity: EN 61326-1: 2013 (Table 2)

Performance Criteria*

IEC 61000-4-2 (ESD) B

IEC 61000-4-3 (EMF) A

IEC 61000-4-4 (Burst) B

IEC 61000-4-5 (Surge) B

IEC 61000-4-6 (CRF) A

IEC 61000-4-8 (RPFMF) A

IEC 61000-4-11 (V dip/short) B, C

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

xxiii

Page 24

*: Performance Criteria

A: The equipment shall continue to operate as intended during and

after the test. No degradation of performance or loss of function

is allowed below a performance level specified by the

manufacturer, when the equipment is used as intended.

The performance level may be replaced by a permissible loss of

performance. If the minimum performance level or the

permissible performance loss is not specified by the

manufacturer, either of these may be derived from the product

description and documentation and what the user may

reasonably expect from the equipment if used as intended.

B: The equipment shall continue to operate as intended after the

test. No degradation of performance or loss of function is

allowed below a performance level specified by the

manufacturer, when the equipment is used as intended.

The performance level may be replaced by a permissible loss of

performance. During the test, degradation of performance is

however allowed. No change of actual operating state or stored

data is allowed. If the minimum performance level or the

permissible performance loss is not specified by the

manufacturer, either of these may be derived from the product

description and documentation and what the user may

reasonably expect from the equipment if used as intended.

C: Temporary loss of function is allowed, provided the function is

self-recoverable or can be restored by the operation of the

controls.

Harmonic current emissions:

EN 61000-3-2: 2014 (Class A equipment)

No limits apply to this equipment with an active input

power under 75 W.

LVD: EN 61010-1: 2010 (Pollution Degree 2)

•

xxiv

Page 25

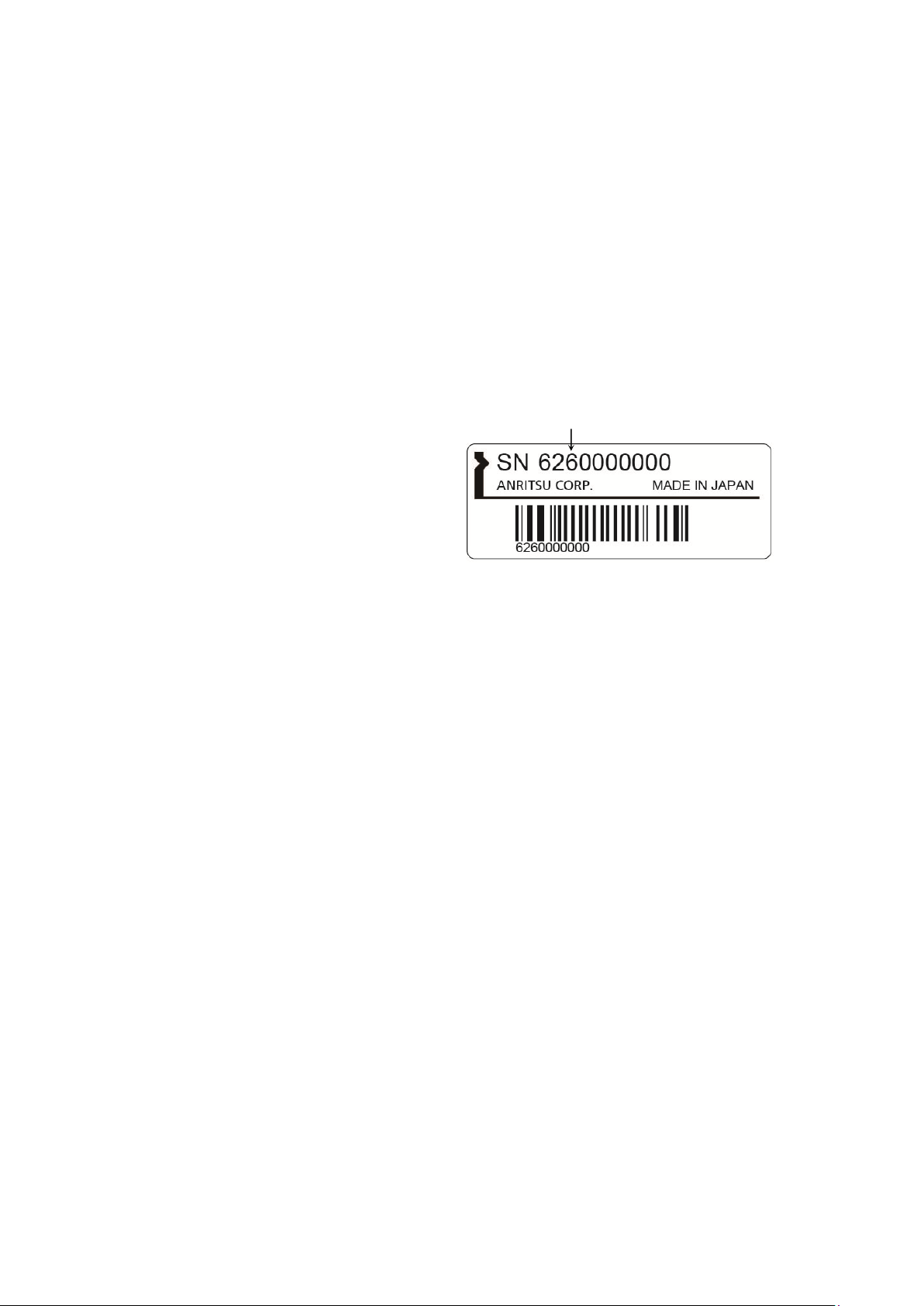

Serial number example

If the third digit of the serial number is "7", the product

complies with Directive 2011/65/EU as amended by (EU)

2015/863.

(Pb,Cd,Cr6+,Hg,PBB,PBDE,DEHP,BBP,DBP,DIBP)

If the third digit of the serial number is "6", the product

complies with Directive 2011

(Pb,Cd,Cr6+,Hg,PBB,PBDE)

Third digit

RoHS: EN IEC 63000: 2018 (Category 9)

•

/65/EU.

4. Contact

Name: Anritsu GmbH

Address, city: Nemetschek Haus, Konrad-Zuse-Platz 1

81829 München,

Country: Germany

Name: ANRITSU EMEA Ltd.

Address, city: 200 Capability Green, Luton

Bedfordshire, LU1 3LU

Country: United Kingdom

xxv

Page 26

RCM Conformity Marking

Anritsu affixes the RCM mark on the following product(s) in accordance

with the regulation to indicate that they conform to the EMC framework of

Australia/New Zealand.

RCM marking

1. Product Model

Model: MT9090A Main frame

MU909014A

MU909014A1

MU909014B

MU909014B1

MU909014C

MU909014C6

MU909015A6

MU909015B

MU909015B1

MU909015C

MU909015C6

2. Applied Standards

EMC: Emission: EN 61326-1: 2013 (Class A equipment)

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

OTDR Module

µ

xxvi

Page 27

About This Manual

This document explains the methods for operating, calibrating, and

maintaining the MT9090A Network Master main frame and following

µOTDR modules.

MU909014A/A1

MU909014B/B1

MU909014C/C6

MU909015A6

MU909015B/B1

MU909015C/C6

In particular, make sure you read Chapter 1 “Overview” so you have a

clear understanding of the basic functions and operations. The other

chapters provide more details; use them in conjunction with the glossary

at the back of the manual to quickly find what you need.

Refer to the figure in Section 4.1 “Measurement Procedure” for a quick

summary of the operation flow.

I

Page 28

Table of Contents

For Safety .................................................... iii

About This Manual........................................ I

Chapter 1 Outline ............................................... 1-1

1.1 Overview of µOTDR ...................................................... 1-2

1.2 Application .................................................................. 1-11

1.3 Terminology ................................................................ 1-12

Chapter 2 Preparation ....................................... 2-1

2.1 Product Configuration ................................................... 2-2

2.2 Name of Each Part ....................................................... 2-6

2.3 Basic Notes on Use .................................................... 2-12

2.4 Supplying Power ......................................................... 2-13

2.5 Using Ni-MH Battery Pack .......................................... 2-14

2.6 Connecting Fiber to Measurement Port ...................... 2-18

2.7 Cleaning optical connector and adapter ..................... 2-19

2.8 Cautions on Handling Optical Fiber Cables ................ 2-23

2.9 Changing Optical Connector ....................................... 2-25

2.10 Connecting Peripheral Devices .................................. 2-27

2.11 Changing Test Module ................................................ 2-30

II

Chapter 3 General Operation and System Setups

......................................................... 3-1

3.1 Powering Up and Down ................................................ 3-2

3.2 Titles of Screen Parts ................................................... 3-4

3.3 Changing General Settings ........................................... 3-6

3.4 Managing Files – Mass Storage ................................. 3-18

3.5 Capturing Screen Images ........................................... 3-27

3.6 Using Softkey Board ................................................... 3-28

3.7 Using Help Function ................................................... 3-30

3.8 Confirming Version Information .................................. 3-31

3.9 Setting Screen Displayed after Power-Up .................. 3-33

Page 29

Chapter 4 Locating Fiber Faults ....................... 4-1

4.1 Measurement Procedure .............................................. 4-2

4.2 Setting Parameters and Preferences ........................... 4-3

4.3 Starting Measurement ................................................ 4-19

4.4 Viewing Trace ............................................................. 4-22

4.5 Analyzing Trace .......................................................... 4-33

4.6 Setting header to trace ............................................... 4-42

4.7 Saving trace manually ................................................ 4-44

4.8 Loading Trace Data (Mass Storage-Load) ................. 4-47

4.9 Restoring Defaults (All Defaults) ................................. 4-49

4.10 Calculation Method ..................................................... 4-50

4.11 Using VFL (Visual Fault Locator) ................................ 4-58

4.12 Measuring with Fiber Visualizer .................................. 4-59

4.13 Creating a Summary ................................................... 4-72

Chapter 5 Locating Drop Cable Faults ............ 5-1

5.1 Models That Support the DCFL Function ..................... 5-2

5.2 Measurement Procedure .............................................. 5-3

5.3 Measuring a Drop Cable ............................................... 5-4

5.4 Viewing Trace ............................................................. 5-11

5.5 Saving Trace Data ...................................................... 5-11

5.6 Loading Trace Data .................................................... 5-11

1/11

2/12

3

4

5

6

7

Chapter 6

6.1 Using PON Power Meter .............................................. 6-2

Measuring Optical Power of PON System

......................................................... 6-1

Chapter 7 Checking Fiber Connection End ..... 7-1

7.1 Confirming Fiber Connection End

(Optical Fiber Identification) .......................................... 7-2

7.2 Using Light Source ....................................................... 7-3

7.3 Measuring Optical Power .............................................. 7-5

Chapter 8 Measuring Loss of Optical Parts .... 8-1

8.1 Measuring Optical Loss ................................................ 8-2

8.2 Measuring Procedures of Optical Loss ......................... 8-7

III

8

9

10

Index Appendix

Page 30

Chapter 9 Inspecting Fiber Surface ................. 9-1

9.1 Component Parts of Fiberscope ................................... 9-2

9.2 Connecting VIP ............................................................. 9-5

9.3 Using VIP ...................................................................... 9-7

9.4 Analyzing VIP Images ................................................. 9-13

9.5 Creating a Report ....................................................... 9-15

9.6 Working with VIP Image Files ..................................... 9-20

Chapter 10 Remote GUI and Folder Sharing . 10-1

10.1 Configuring the Network Settings for µOTDR ............. 10-2

10.2 Setting the Remote GUI Password ........................... 10-18

10.3 File Sharing Setting .................................................. 10-19

10.4 Using the Remote GUI .............................................. 10-23

Chapter 11 Performance Test and Calibration

....................................................... 11-1

11.1 Performance Test ....................................................... 11-2

11.2 Calibration ................................................................. 11-32

11.3 Performance Test Result Sheet ................................ 11-33

Chapter 12 Maintenance ................................. 12-1

12.1 Daily Maintenance ...................................................... 12-2

12.2 Updating Firmware ..................................................... 12-3

12.3 Notes On Storage ....................................................... 12-8

12.4 Transporting and Disposal .......................................... 12-9

IV.

Appendix A Specifications ......................... A-1

Appendix B Default Value ........................... B-1

Appendix C Software License .................... C-1

Index .......................................................... Index-1

Page 31

1-1

Outline

Chapter 1 Outline

This chapter describes the functional overview, application, and

terminology of the MT9090A Network Master.

Overview of µOTDR ...................................................... 1-2

1.1

1.1.1 OTDR Function ................................................. 1-4

1.1.2 Connection Verification Function ...................... 1-6

1.1.3 Live Communications Detection Function ........ 1-6

1.1.4 Visual Fault Locator (VFL) Option .................... 1-6

1.1.5 PON Power Meter Function ............................. 1-7

1.1.6 Light Source Function....................................... 1-7

1.1.7 Optical Power Meter Function .......................... 1-8

1.1.8 Optical Loss Measurement Function ................ 1-8

1.1.9 DCFL Function ................................................. 1-9

1.1.10 Fiber Surface Inspection Function .................. 1-10

1.2 Application .................................................................. 1-11

1.3 Terminology ................................................................ 1-12

1.3.1 Explanation of Terms ...................................... 1-12

1.3.2 Abbreviations .................................................. 1-14

1

Page 32

Chapter 1 Outline

1-2

1.1 Overview of µOTDR

The main frame of the MT9090A Network Master series is a

multi-platform instrument that supports various measurement functions

according to installed modules.

This manual describes how to operate the MT9090A main frame (the

main frame hereafter) and fiber maintenance tester (the modules

hereafter).

Figure 1.1-1 Front Panel Layout

The MT9090A Network Master series fits easily in one hand and has an

OTDR function for measuring loss and detecting fault points in optical

fiber systems. Some models have the functions of the PON power meter,

light source, visual fault locator (VFL) optical source, power meter and

optical loss test addition to OTDR function.

By connecting the accessory fiberscope, the end surface of the fiber can be

displayed on the module. This function allows the inspection of the end

surface of the fiber for scratches, damage, and dirt.

Measured traces and screenshots can be captured on a PC via USB

connection.

The MT9090A Network Master series include the following models which

consist of different specifications and functions.

Page 33

1.1 Overview of µOTDR

1-3

Outline

PON Power

Meter

Fiber

Inspection

MU909014A

30

MU909014A1

30

MU909014B

30

MU909014B1

30

MU909014C

*1 *1

30

MU909014C6

*1 *1

30

MU909015A6

35

MU909015B

35

MU909015B1

35

MU909015C

*1 *1 *1

35

MU909015C6

*1 *1 *1

35

Table 1.1-1 Model Name and Difference in Specifications

Spec.

Model

*1: Select either one of wavelengths according to the module option.

This document describes all functions above. Refer to the corresponding

section of the function in your model.

Trace (nm)

1310

Function other than OTDR

(dB)

1490

1550

1625

*1 *1

*1 *1

*1 *1

Dynamic range

1650

VFL

Light source

Power meter

1

Loss test

surface

You can see demonstration movies on the following homepages.

https://www.anritsu.com/en-US/test-measurement/video-gallery/mt9090a

connectorcare

(MT9090A Connector Care)

https://www.anritsu.com/en-US/test-measurement/video-gallery/mt9090a

frompowerontotracesaving

(MT9090A From Power on to Trace Saving)

https://www.anritsu.com/en-US/test-measurement/video-gallery/mt9090a

manualanalysisofcapturedtrace

(MT9090A Manual Analysis of Captured Trace)

https://www.anritsu.com/en-US/test-measurement/video-gallery/mt9090a

otdrmeasurementapplicationedition

(MT9090A OTDR Measurement Application Edition)

https://www.anritsu.com/en-US/test-measurement/video-gallery/mt9090a

nonotdrmeasurementfunctions

(MT9090A Non OTDR Measurement Functions)

https://www.anritsu.com/en-us/test-measurement/video-gallery/fibervisua

lizer

(OTDR - Fiber Visualizer)

Page 34

Chapter 1 Outline

1-4

Range

Range

Pulse width

1.1.1 OTDR Function

An OTDR (Optical Time Domain Reflectometer) measures the loss and

reflection of an optical fiber.

The OTDR launches optical pulses into the optical fiber and also receives

optical pulses that are returned by internal reflection in the optical fiber.

The loss of the optical fiber is calculated by the OTDR from the measured

received optical pulses. The elapsed time from when optical pulses are

launched into the fiber until they return is used to calculate the distance

to and loss of displayed faults in the fiber.

The loss and distance data is stored in memory and displayed as traces

on the screen. For accurate measurement, an optical pulse launched into

the fiber must reach the far end of the optical fiber and the backscattered

light returned by the end surface must be returned to the OTDR before

the next optical pulse is launched into the fiber. Consequently, a distance

range corresponding to the length of the optical fiber being measured is

specified by

are set to Auto, the OTDR determines the optimum values for these

settings.

on the Test Setup screen. If

and

Figure 1.1.1-1 Example of OTDR Measurement Results

Page 35

1.1 Overview of µOTDR

1-5

Outline

The OTDR has functions of detecting and analyzing points in the fiber

where loss and reflected light occur using the measured results. These

detected points are called ‘events’, which are displayed on the Trace

Analysis screen.

1

Figure 1.1.1-2 Example of Event Display

The MT9090A Network Master series has the Fiber Visualizer function

to see the fiber status visually when measured by the OTDR. With the

error points and connection conditions displayed graphically, the fiber

statuses can be easily checked.

Figure 1.1.1-3 Example of Fiber Visualizer

Page 36

Chapter 1 Outline

1-6

GOOD, FAI R

POOR

1.1.2 Connection Verification Function

The connection verification function is used to verify that the optical fiber

is connected correctly to the module before starting OTDR

measurements.

The verification result is displayed as

Refer to Section 4.3 “Starting Measurement” for more details.

1.1.3 Live Communications Detection Function

The live communications detection function detects the presence of

optical signals used for live communications in the fiber before starting

OTDR measurements.

A warning message is displayed if light with a wavelength of 1550 nm is

detected.

Refer to Section 4.2.2 “Setting Measurement Method

(Setup-Preferences)” for more details.

1.1.4 Visual Fault Locator (VFL) Option

It is a visible (red) light source. Since the light is visible, it is useful for

locating faults in the dead zone by visually checking for diffuse escaping

light.

Refer to Section 4.10 “Using VFL (Visual Fault Locator)” for more details.

, or

.

Figure 1.1.4-1 Visual Fault Locator (VFL)

Page 37

1.1 Overview of µOTDR

1-7

Outline

1.1.5 PON Power Meter Function

The PON power meter function enables the simultaneous measurement

of the optical power of two wavelengths used for the downstream signal

of the Passive Optical Network (PON).

The optical power with wavelength of 1490 nm used for video

communications and the optical power with wavelength of 1550 nm used

for data communications are displayed.

Refer to Chapter 6 “Measuring Optical Power of PON System” for more

details.

1

Figure 1.1.5-1 PON Power Meter Screen

1.1.6 Light Source Function

The light source function outputs continuous optical signals or modulated

optical signals.

The fiber core contrast and loss can be measured with the combination of

the light source function and optical power meter.

Refer to Section 7.2 “Using Light Source” for more details.

Page 38

Chapter 1 Outline

1-8

1.1.7 Optical Power Meter Function

The optical power meter function is used to detect the presence of an

optical signal in the fiber cable and to confirm that the level of live

communication signals meets the specified value.

Refer to Section 7.3 “Measuring Optical Power” for more details.

Figure 1.1.7-1 Optical Power Meter Screen

1.1.8 Optical Loss Measurement Function

The optical loss measurement function measures the optical loss of fibers

and optical parts using the light source function and power meter

function.

Refer to Chapter 8 “Measuring Loss of Optical Parts” for more details.

Figure 1.1.8-1 Loss Test Screen

Page 39

1.1 Overview of µOTDR

1-9

Outline

1.1.9 DCFL Function

The DCFL function is a useful function to investigate faults occurring in

a drop cable. It consists of the Power Meter function and OTDR function,

so you are not required to switch measuring instruments or applications.

Refer to Chapter 5 “Investigating Fiber Abnormalities (Faults)” for more

details.

1

Figure 1.1.9-1 DCFL Function Screens

Page 40

Chapter 1 Outline

1-10

1.1.10 Fiber Surface Inspection Function

By connecting the accessory fiberscope to MT9090A, you can view

magnified images of the surfaces of the optical I/O connector and the end

surface of the connected optical fiber on the LCD of the MT9090A.

Check for scratches or dirt on the end surfaces of the optical I/O

connector and the optical fiber, using the fiberscope.

Refer to Chapter 9 “Inspecting Fiber Surface” for more details.

Figure 1.1.10-1 Fiber End Surface Display

Page 41

1.2 Application

1-11

Outline

1.2 Application

Optical Backbone

Optical Drop Cables

Carrier’s office

Optical communications

1550 nm

1490 nm

Closure

Cabinet

Subscriber’s home

1330 nm

Finding Faults in Optical Fibers

The OTDR, PON power meter, power meter, and fiberscope functions of

the MT9090A Network Master are used in a subscriber’s home to

troubleshoot faults in optical cables between the subscriber’s home and

carrier’s office.

With the communication method called PON (Passive Optical Network),

the optical signals at wavelength of 1310/1490/1550 nm are used for

communications between the subscriber ’s home and carrier’s office.

The µOTDR modules find faults using optical signals at wavelengths of

1310 nm and 1550 nm. When optical signals at wavelengths of 1490 nm

and 1550 nm are used for one optical fiber like the PON, it is difficult to

measure the power at each wavelength using the optical power meter.

The PON power meter function can identify which wavelength has the

failure by measuring the optical power at each wavelength.

1

Since wavelengths of 1625 nm and 1650 nm are different from the

wavelengths used for live optical communications, they have no impact

on the live network. (Optical filter is required for ONU or OLT to block

1625/1650 nm light.)

Figure 1.2-1 Finding Faults in Fiber from Each Subscriber’s Home (Passive Optical Network

Measurement)

Page 42

Chapter 1 Outline

1-12

Pref(W)

Pin(W)

Optical fiber

}{

)log(10

IOR

PWBSC

refP

refPBSL

•

∝

=

Distance

Level

l1: Dead Zone (Fresnel) Reflection)

1.5 dB

0.5 dB

l2: Dead Zone (Backscatter)

l1

l2

1.3 Terminology

1.3.1 Explanation of Terms

This section describes the terms used in this manual.

BSC (Backscatter Coefficient)

The BSC is the proportion of reflected light to light propagating in the

fiber during optical transmissions.

The BSC varies according to the fiber structure and materials.

BSL (Backscatter Level)

BSL is the level of the light reflected back to the module.

The BSL is proportional to the BSC and pulse width and inversely

proportional to the Index of Refraction.

Figure 1.3.1-1 Definition of BSL

Dead Zone

The dead zone is a region of the optical fiber where BSL cannot be

observed correctly due to traces caused by reflections.

The following diagram shows the dead zone as defined in Appendix A:

Specifications.

Figure 1.3.1-2 Dead Zone

Page 43

1.3 Terminology

1-13

Outline

Dynamic Range

The dynamic range is the ratio of the maximum and minimum

measurable levels.

For an OTDR, it is the ratio of the level at the connection point of the

measuring instrument and the noise level.

Refer to Section 11.1.4 “Dynamic range” for the dynamic range

measurement method.

IOR (Index of Refraction)

This is the IOR of the optical fiber. The OTDR calculates distance using

the time taken for the optical pulse launched into the fiber to return and

the IOR.

Pulse Width

This is the width of the optical pulse launched into the fiber. A large

pulse width increases the power of the optical signal returned by the

fiber and faults in the fiber, so the dynamic range becomes wider.

Conversely, the dead zone and resolution also become larger. Using a

shorter pulse width reduces the dead zone and resolution.

Refer to Section 11.1.3 “Pulse Width” for more details about setting the

pulse width measurement method.

1

Page 44

Chapter 1 Outline

1-14.

AC

Alternating Current

AVG

Averaging

BSC

Back Scattering Coefficient

CW

Continuous Wave

DC

Direct Current

DCFL

Drop Cable Fault Locator

IOR

Index of Refraction

LS

Light Source

LSA

Least Squares Approximation

min

Minute

MM

Multi Mode fiber

MOD

Modulation

N/A

Not Applicable

ORL

Optical Return Loss

OTDR

Optical Time Domain Reflectometer

PM

Power Meter

PON

Passive Optical Network

Pt

Point

PW

Pulse Width

RES

Resolution

sec

second

SM

Single Mode fiber

S/N

Signal to Noise Ratio

TRT

Total Run Time

UPC

Ultra Physical Contact

USB

Universal Serial Bus

VIP

Video Inspection Probe

WL

Wavelength

1.3.2 Abbreviations

The following table lists the abbreviations used in this manual.

Table 1.3.2-1 List of Abbreviations

Abbreviations Full Term

Page 45

2-1

Preparation

Chapter 2 Preparation

This chapter describes the parts of the MU909014x/15x and the

preparations before use.

Product Configuration ................................................... 2-2

2.1

2.1.1 Standard configuration ..................................... 2-2

2.1.2 Options ............................................................. 2-4

2.2 Name of Each Part ....................................................... 2-6

2.2.1 Front Panel ....................................................... 2-6

2.2.2 Top Connector Panel ........................................ 2-8

2.2.3 Back Panel ..................................................... 2-10

2.2.4 Bottom Panel .................................................. 2-11

2.3 Basic Notes on Use .................................................... 2-12

2.4 Supplying Power ......................................................... 2-13

2.5 Using Ni-MH Battery Pack .......................................... 2-14

2.5.1 Installing Ni-MH Battery Pack ......................... 2-14

2.5.2 Battery Replacement – Battery pack to

AA batteries .................................................... 2-16

2.6 Connecting Fiber to Measurement Port ...................... 2-18

2.7 Cleaning optical connector and adapter ..................... 2-19

2.8 Cautions on Handling Optical Fiber Cables ................ 2-23

2.9 Changing Optical Connector ....................................... 2-25

2.10 Connecting Peripheral Devices .................................. 2-27

2.10.1 Type A USB Port ............................................ 2-28

2.10.2 Type B USB Port ............................................ 2-29

2.11 Changing Test Module ................................................ 2-30

2

Page 46

Chapter 2 Preparation

2-2

Main frame

MT9090A

Main frame

1

MU909014A

µOTDR Module

1

Wavelength: 1625 nm or 1650 nm*2

VFL (Visual Fault Locator)

Wavelength: 1625 nm or 1650 nm*2

Wavelength: 1310 /1550 nm

Dynamic range: 30 dB

VFL (Visual Fault Locator)

Dynamic range: 30 dB

3 wavelengths*2,

Power meter

3 wavelengths*2,

power meter, Loss Test

1 wavelength*2,

Power meter

Wavelength: 1310/1550 nm

Dynamic range: 35 dB

VFL (Visual Fault Locator)

Dynamic range: 35 dB

3 wavelengths*2,

Power meter

3 wavelengths*2,

power meter, Loss Test

2.1 Product Configuration

2.1.1 Standard configuration

The parts included in the standard configuration are listed below.

Contact your Anritsu Service and Sales Office or agent if any parts are

missing or damaged.

Table 2.1.1-1 Standard Configuration

Item

Module*

Model/Ordering

Number

MU909014A1 µOTDR Module 1

MU909014B µOTDR Module 1

MU909014B1 µOTDR Module 1

MU909014C µOTDR Module 1

MU909014C6 µOTDR Module 1

1

MU909015A6 µOTDR Module

Name Q’ty Remarks

Wavelength: 1310 /1550 nm

Dynamic range: 30 dB,

Dynamic range: 30 dB,

Light source, Power meter, PON

Dynamic range: 35 dB,

1

Light source, PON power meter,

MU909015B µOTDR Module 1

MU909015B1 µOTDR Module 1

MU909015C µOTDR Module

MU909015C6 µOTDR Module 1

Wavelength: 1310/1550 nm

1

*1: Select either one

*2: Specify the number of required wavelengths when purchasing

modules.

Dynamic range: 35 dB,

Dynamic range: 35 dB,

Light source, Power meter, PON

Page 47

2.1 Product Configuration

2-3

Preparation

MU909014A/A1/B/B1/C/C6,

MU909014A/A1/B/B1/C/C6,

Operation Manual (CD-R)

Table 2.1.1-1 Standard Configuration (Cont’d)

Item

Accessory

Model/Ordering

Number

– Optical Connector 1 Select one option.

W3585AE

Z1579A

MU909015A6/B/B1/C/C6

µOTDR Module

Quick Guide

MU909015A6/B/B1/C/C6

µOTDR Module

Name Q’ty Remarks

1 English (Printed version)

1 English, Quick Guide

2

Page 48

Chapter 2 Preparation

2-4

MT9090A-001

Dedicated for uOTDR Module

MU909014A-053

SMF 1625nm µOTDR Module (UPC)

MU909014A1-053

SMF 1625nm µOTDR Module (UPC/VLD)

MU909014A-054

SMF 1650nm µOTDR Module (UPC)

MU909014A1-054

SMF 1650nm µOTDR Module (UPC/VLD)

MU909014A-063

SMF 1625nm µOTDR Module (APC)

MU909014A1-063

SMF 1625nm µOTDR Module (APC/VLD)

MU909014A-064

SMF 1650nm µOTDR Module (APC)

MU909014A1-064

SMF 1650nm µOTDR Module (APC/VLD)

MU909014B-056

SMF 1310/1550nm µOTDR Module (UPC)

MU909014B1-056

SMF 1310/1550nm µOTDR Module (UPC/VLD)

MU909014B-066

SMF 1310/1550nm µOTDR Module (APC)

MU909014B1-066

SMF 1310/1550nm µOTDR Module (APC/VLD)

MU909014C-057

SMF 1310/1550/1625nm µOTDR Module (UPC)

MU909014C6-057

SMF 1310/1550/1625nm µOTDR Module (UPC/OPM/LS)

MU909014C-067

SMF 1310/1550/1625nm µOTDR Module (APC)

MU909014C6-067

SMF 1310/1550/1625nm µOTDR Module (APC/OPM/LS)

MU909014C-058

SMF 1310/1550/1650nm µOTDR Module (UPC)

MU909014C6-058

SMF 1310/1550/1650nm µOTDR Module (UPC/OPM/LS)

MU909014C-068

SMF 1310/1550/1650nm µOTDR Module (APC)

MU909014C6-068

SMF 1310/1550/1650nm µOTDR Module (APC/OPM/LS)

MU909015A6-053

SMF 1625nm µOTDR Module (UPC/OPM/LS)

MU909015A6-063

SMF 1625nm µOTDR Module (APC/OPM/LS)

MU909015A6-054

SMF 1650nm µOTDR Module (UPC/OPM/LS)

MU909015A6-064

SMF 1650nm µOTDR Module (APC/OPM/LS)

MU909015B-056

SMF 1310/1550nm µOTDR Module (UPC)

MU909015B1-056

SMF 1310/1550nm µOTDR Module (UPC/VLD)

MU909015B-066

SMF 1310/1550nm µOTDR Module (APC)

MU909015B1-066

SMF 1310/1550nm µOTDR Module (APC/VLD)

MU909015C-057

SMF 1310/1550/1625nm µOTDR Module (UPC)

MU909015C6-057

SMF 1310/1550/1625nm µOTDR Module (UPC/OPM/LS)

2.1.2 Options

The following options are available for use with the main frame. Select

the required options as necessary. Refer to Appendix A “Specifications”

for details on the specifications.

Table 2.1.2-1 Main frame Option

Model Name

Table 2.1.2-2 Module Options

Model Name

Page 49

2.1 Product Configuration

2-5

Preparation

MU909015C-067

SMF 1310/1550/1625nm µOTDR Module (APC)

MU909015C6-067

SMF 1310/1550/1625nm µOTDR Module (APC/OPM/LS)

MU909015C-058

SMF 1310/1550/1650nm µOTDR Module (UPC)

MU909015C6-058

SMF 1310/1550/1650nm µOTDR Module (UPC/OPM/LS)

MU909015C-068

SMF 1310/1550/1650nm µOTDR Module (APC)

MU909015C6-068

SMF 1310/1550/1650nm µOTDR Module (APC/OPM/LS)

MU909015C-059

SMF 1310/1490/1550nm µOTDR Module (UPC)

MU909015C6-059

SMF 1310/1490/1550nm µOTDR Module (UPC/OPM/LS)

MU909015C-069

SMF 1310/1490/1550nm µOTDR Module (APC)

MU909015C6-069

SMF 1310/1490/1550nm µOTDR Module (APC/OPM/LS)

-037

FC Connector

-039

DIN 47256 Connector

-040

SC Connector

-025

FC-APC Connector key width 2.0mm

-026

SC-APC Connector

Table 2.1.2-2 Module Options (Cont’d)

Model Name

Table 2.1.2-3 Connector Option

Model Model

2

Page 50

Chapter 2 Preparation

2-6

Start

Down, Left

Right

2.2 Name of Each Part

2.2.1 Front Panel

The front panel contains the controls, which operate unit, and the LCD

display.

Figure 2.2.1-1 Front Panel

[1]

LCD display

[2]

to (Function key):

Each function key is designated depending on the current operating

mode of the unit. You can find the function of each key to its

immediately left in the display.

[3]

[4]

(

Press

Press

key:

Waveform display screen—

•

Decrease the width of the trace or move the marker left.

General Setups—

•

Move the highlight left.

key):

to start measurement.

during measurement to stops measurement.

(Up,

, and

keys):

Page 51

2.2 Name of Each Part

2-7

Preparation

Event

Event

Menu/Power

Menu/Power

Menu/Power

key:

Waveform display screen—

•

Increase the width of the trace or move the marker right.

General Setups—

•

Move highlight right.

key:

Waveform display screen—

•

Increase the height of the trace or move the marker to the left

event (Limited when Loss Mode is

General Setups—

•

Move up the highlight.

key:

Waveform display screen—

•

Decrease the height of the trace or move the marker to the right

event (Limited when Loss Mode is

General Setups—

•

Move down the highlight.

).

).

2

[5]

(Set key):

Confirm the values entered and each selection.

[6]

(

Press

•

Press

•

current screen if the unit is powered on.

key):

key to power up the unit.

key to display the pop-up menu for the

Page 52

Chapter 2 Preparation

2-8

2.2.2 Top Connector Panel

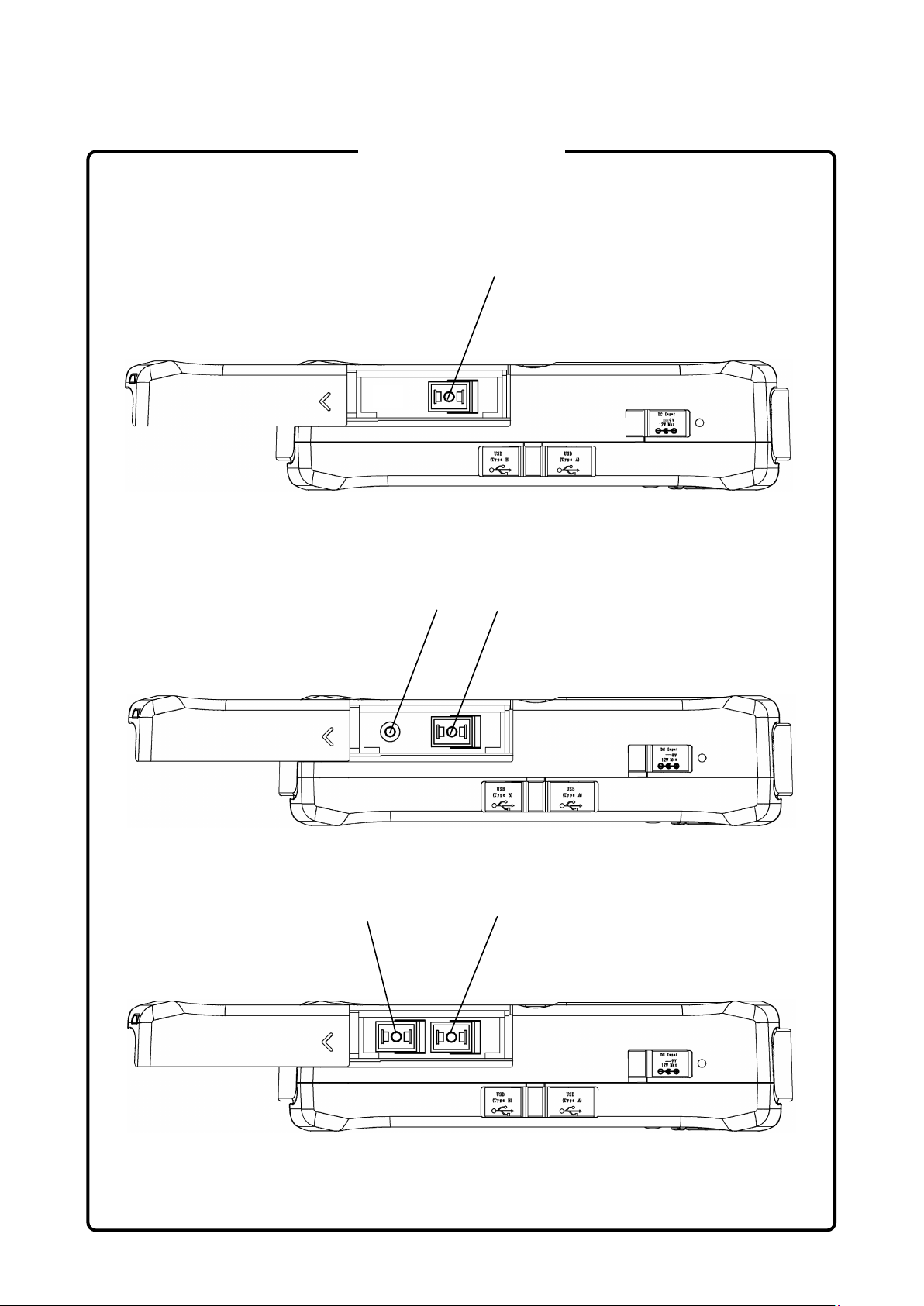

The top connector panel of the unit contains the measurement port, USB

ports, DC Input port, and battery status LED.

Figure 2.2.2-1 Top Connector Panel (MU909014A/B, MU909015A6/B

and MU909015C-059/069)

Figure 2.2.2-2 Top Connector Panel (MU909014A1/B1, MU909015B1)

Figure 2.2.2-3 Top Connector Panel (MU909014C/C6, MU909015C/C6

and MU909015C6-059/069)

[1]

Slide Cover

[2]

Measurement Port

1625 nm or 1650 nm OTDR (MU909014A, MU909015A6)

1310/1550 nm OTDR (MU909014B, MU909015B)

1310/1490/1550 nm OTDR (MU909015C-059/069)

Page 53

2.2 Name of Each Part

2-9

Preparation

[3]

Measurement Port

1625 nm or 1650 nm OTDR (MU909014A1)

1310/1550 nm OTDR (MU909014B1, MU909015B1)

[4]

Visual Fault Locator Port

[5]

Measurement Port

1310/1550 nm OTDR (MU909014C/C6, MU909015C/C6)

1310/1490/1550 nm OTDR (MU909015C6-059/069)

[6]

Measurement Port

1625 nm or 1650 nm OTDR (MU909014C/C6, MU909015C/C6)

Optical power meter (MU909015C6-059/069)

[7]

USB (Type B) Port

[8]

USB (Type A) Port

[9]

DC Input port

[10]

Battery Status LED

2

Page 54

Chapter 2 Preparation

2-10

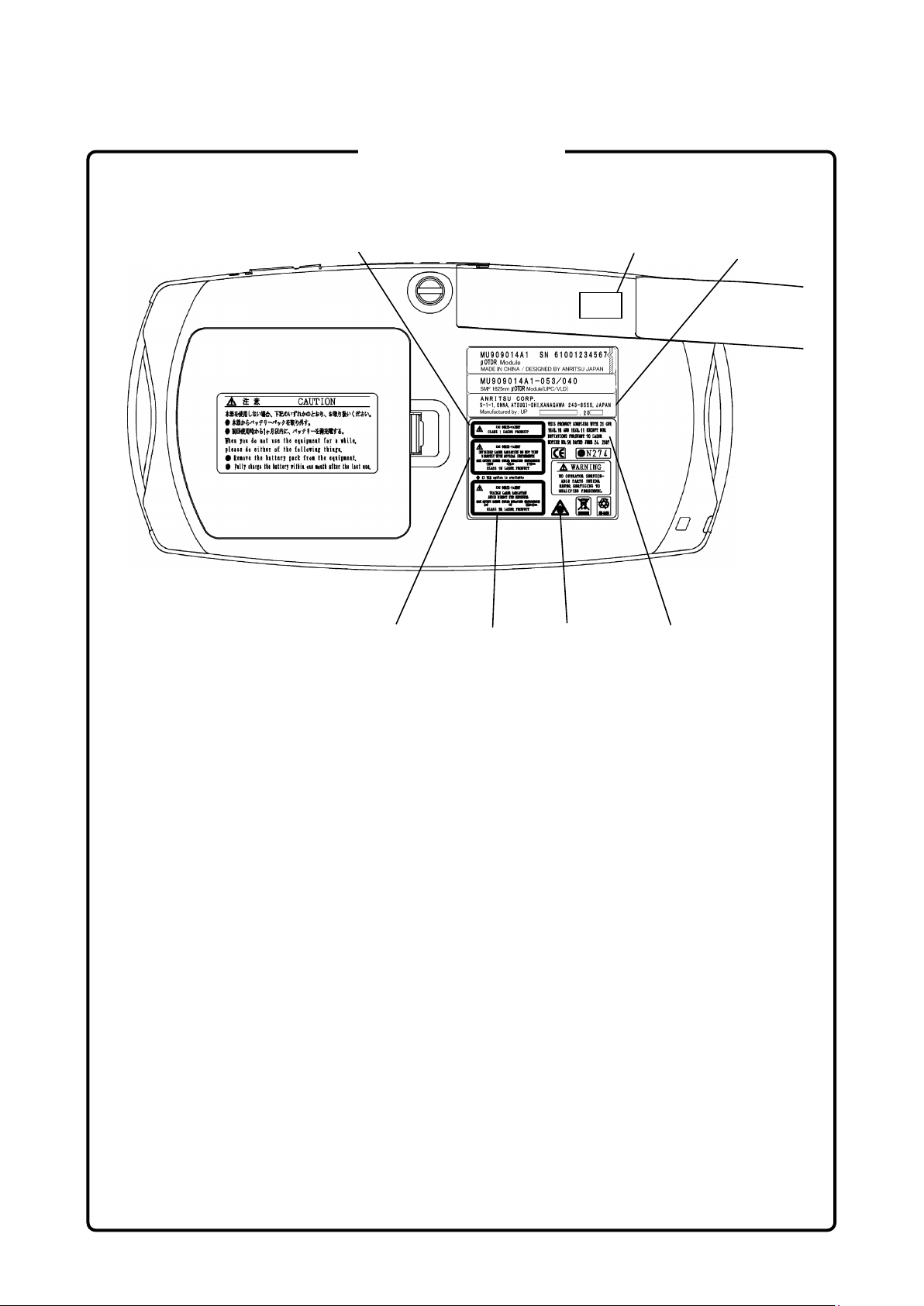

2.2.3 Back Panel

The back panel contains the battery compartment and a fastener that

secures the test module to the Network Master main unit.

There are also various compliance and warning labels as well as the

model and serial number label (item 3 in Figure 2.2.3-1).

Figure 2.2.3-1 Back Panel

[1]

Battery Compartment

[2]

Fastener

[3]

Model and serial number label

[4]

Compliance and warning labels

Page 55

2.2 Name of Each Part

2-11

Preparation

2.2.4 Bottom Panel

The bottom panel of the main frame is provided with the model and

serial number label.

Figure 2.2.4-1 Bottom Panel

[1]

Model and serial number label

①

2

Page 56

Chapter 2 Preparation

2-12

2.3 Basic Notes on Use

Keep the measurement port cover closed except when a

cable is connected. This cover prevents dust and other

contaminants from collecting on the measurement port.

Condensation may occur on the inside surface of the unit

when it is carried into a room (high temperature) from an

outdoor location (low temperature), etc. If this occurs,

allow the unit to dry out thoroughly before turning on the

power. Water droplets and dust in the MT9090A, etc., can

cause a short circuit, resulting in a fire, electric shock, or

accident.

CAUTION

Use the unit within the operating temperature range

(–10°C to +50°C) and storage temperature range (–30°C to

+70°C). If the unit is placed in a car or other enclosed

space for a long time, the ambient temperature may

exceed the specified range, resulting in a unit malfunction.

Do not use any AC charger/adapter or Ni-MH battery pack

other than the one supplied. Otherwise, the unit may be

damaged due to nonconformity with specifications.

Never look directly into the cable connector on the

equipment nor into the end of a cable connected to the

equipment. If laser radiation enters the eye, there is a

risk of injury.

In addition, the unit outputs high-power optical pulses.

Remove the communication device from the optical fiber

before measurement to prevent damage to the photo

receiving circuit of the communication device connected

to the optical fiber to be measured, Anritsu will take no

responsibility for damage to the communication or any

other device.

Anritsu recommends that the unit be inspected once a

year at Anritsu Customer Services (a fee will be charged).

Page 57

2.4 Supplying Power

2-13

Preparation

For other notes on use, read the safety-related information

in this manual thoroughly before use.

2.4 Supplying Power

Connecting AC charger/adapter

Use the AC charger/adapter provided as a standard accessory of the main

frame.

Using other AC adapters may result in damage to the unit and/or battery

pack.

CAUTION (Continued)

2

Figure 2.4-1 AC Adapter

1. Open the DC Input connector cover (Figure 2.2.2-1) and plug the AC

charger/adapter jack to the DC Input connector.

2. Plug the AC charger/adapter’s transformer into an AC outlet.

Page 58

Chapter 2 Preparation

2-14

2.5 Using Ni-MH Battery Pack

2.5.1 Installing Ni-MH Battery Pack

Follow the procedure below to install a Ni-MH battery pack.

Always power down the Network Master before removing

the Ni-MH battery pack. The battery pack and/or the unit

may be damaged when you remove the battery pack with

the Network Master powered on.

Remove the Ni-MH battery pack to avoid damage to the

battery pack and/or the unit when storing the Network

Master for a long period of time (several months).

Otherwise, be sure to recharge the unit periodically (every

one or two months).

CAUTION

1. Power down the unit if operating. Disconnect the AC

charger/adapter if connected.

2. Hold down the latch and lift the battery compartment cover (Figure

2.2.3-1) to open.

3. Remove batteries if installed.

4. Plug the battery pack connector into the battery pack plug of the

module. The battery pack connector has an alignment tab to prevent

reverse polarity connection. Align the connector tab with the plug

slot to make the correct connection.

CAUTION

Correctly plug the three-pin battery pack connector into

the battery plug. Wrong connection may damage the

battery pack and main frame.

5. Slide the Ni-MH battery pack into the battery compartment, making

sure the followings:

The battery release ribbon (red) is tucked underneath, leaving a

•

certain amount exposed to use when removing the battery pack.

The THIS SIDE UP label is facing up.

•

6. Reattach the battery compartment cover.

Page 59

2.5 Using Ni-MH Battery Pack

2-15

Preparation

2

Figure 2.5.1-1 Battery Compartment

[1]

Ni-MH battery pack plug

[2]

Module release latch

[3]

Ni-MH battery pack

[4]

Battery release ribbon (Red)

Page 60

Chapter 2 Preparation

2-16

2.5.2 Battery Replacement – Battery pack to AA batteries

MT9090A can also be powered by AA Ni-MH or alkaline batteries.

Follow the procedure below to replace the battery pack with AA batteries:

CAUTION

Always power down the unit before removing old AA

batteries. Settings and data files may be lost if the

batteries are removed with powered on.

If storing the unit for a long period of time (1 to 2 months),

remove replaceable batteries from the unit. When periods

without use in the Network Master, they may corrode or

leak and damage the main frame.