Page 1

OPERATION

+ CODE MANUAL

SHIFT SELECTOR

OIL LEVEL INFORMATION, DIAGNOSTIC CODES AND PROGNOSTIC FEATURES

FOR 3000/4000 SERIES™ AND TC10™ ALLISON TRANSMISSIONS

Page 2

Table of Contents

General Information ..................................... 1

Basic Operation ......................................... 2

Section 1 - With Prognostics + With Oil Level Sensor

Fluid Levels ............................................ 3

Checking Fluid Levels..................................... 3

Prognostic Features ...................................... 4

Accessing Prognostics .................................... 5

Resetting Prognostics..................................... 6

Exit Prognostics ......................................... 6

Diagnostics Codes ....................................... 7

Section 2 - With Prognostics + Without Oil Level Sensor

Prognostic Features ...................................... 8

Accessing Prognostics .................................... 9

Resetting Prognostics.................................... 10

Exit Prognostics ........................................ 10

Diagnostics Codes ...................................... 11

Section 3 - Without Prognostics + With Oil Level Sensor

Fluid Levels ........................................... 12

Checking Fluid Levels.................................... 12

Diagnostics Codes ...................................... 14

Section 4 - Without Prognostics + Without Oil Level Sensor

Diagnostics Codes ...................................... 15

Diagnostics Transmission Codes

Codes P0122-P077F .................................... 17

Codes P0796-P0994 .................................... 18

Codes P0994-P2637 .................................... 19

Codes P2641-P281B .................................... 20

Codes P281D-U059A.................................... 21

Page 3

General Information

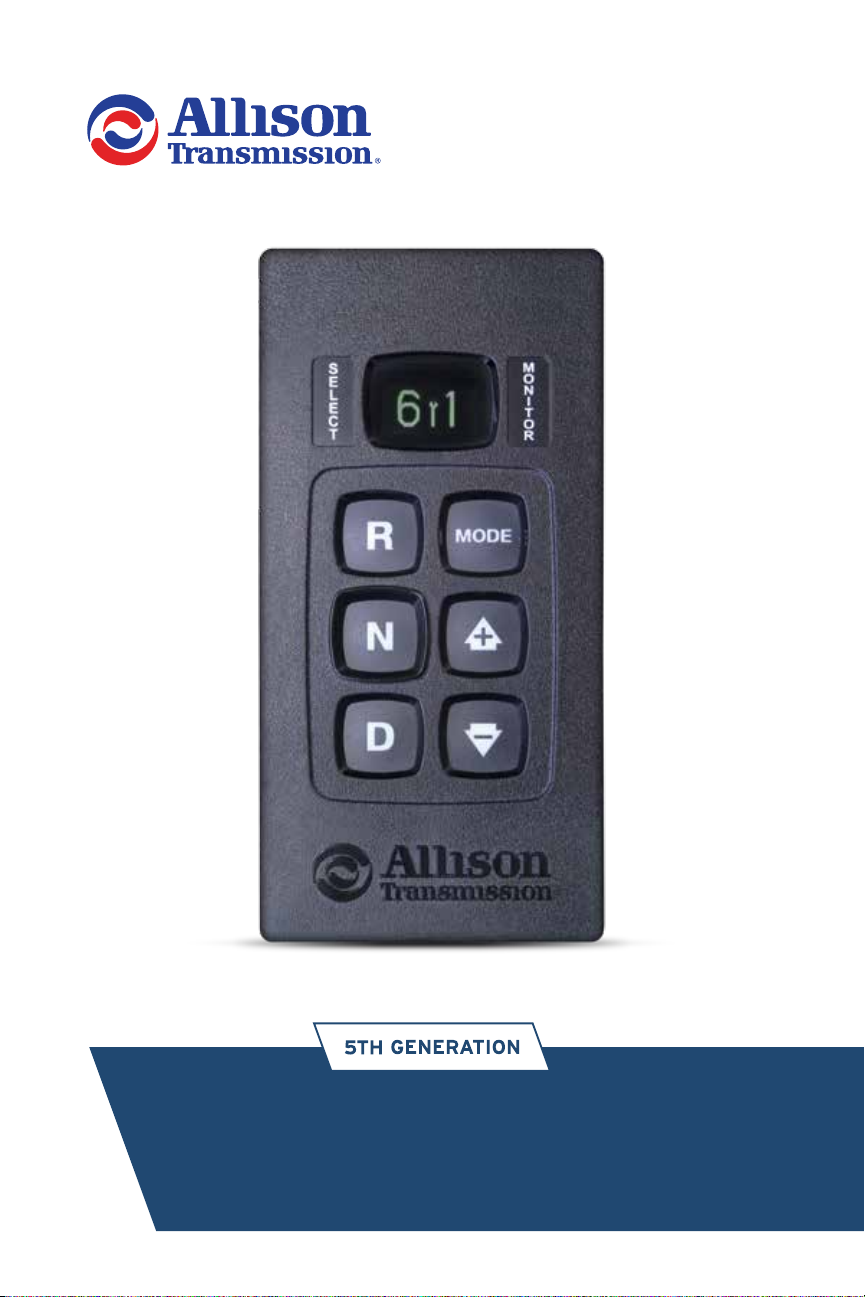

Control. Power. Information. The new 5th Generation Electronic Shift

Selector from Allison puts it all at your fingertips. Literally. Getting started is

easy and the selector’s complete menu of prognostic and diagnostic tools

minimize downtime and keep you on the job. Use this handy reference

booklet for step-by-step instruction on how to get the most from your shift

selector and of course, your Allison fully automatic transmission.

The Allison Advantage

Your Allison Automatic is fully electronically controlled. The Allison

electronic controls package oversees the operation of the transmission,

controlling transmission upshifts and downshifts, and providing important

information on the operation of your drive system.

Through readouts on your shift selector, you will be able to monitor

transmission oil levels, read diagnostic codes and prognostic information.

This manual will help you understand shift selector readouts and enjoy

long, trouble-free operation of your Allison Automatic.

Diagnostics

The Transmission Control Module (TCM) of your Allison Automatic

monitors the transmission’s electronic controls; and when a problem

condition is detected, it:

• May restrict shifting

• Illuminates the CHECK TRANS* light on the instrument panel

• Registers a diagnostic code

Continued illumination of the CHECK TRANS light during vehicle

operation (other than start-up) indicates that the TCM has signaled

a diagnostic code.

NOTE: Displays apply only when using a 5th Gen TCM.

* For some problems, diagnostic codes may be registered without the TCM

activating the CHECK TRANS light. Your Allison Authorized Service Network should

be consulted whenever there is a transmission-related concern. They have the

equipment to check for diagnostic codes and to correct problems.

1

Page 4

Basic Operation

5th Generation Electronic Controls Shift Selectors

As the world leader in medium- and heavy-duty commercial transmissions,

Allison Transmission continues its ongoing improvement initiative with the

introduction of 5th Generation Electronic Controls Shift Selectors.

All 5th Generation Electronic Controls Shift Selectors feature easy-to-read

graphic displays that show both text and symbols.

DIGITAL

DISPLAY

MODE

BUTTON

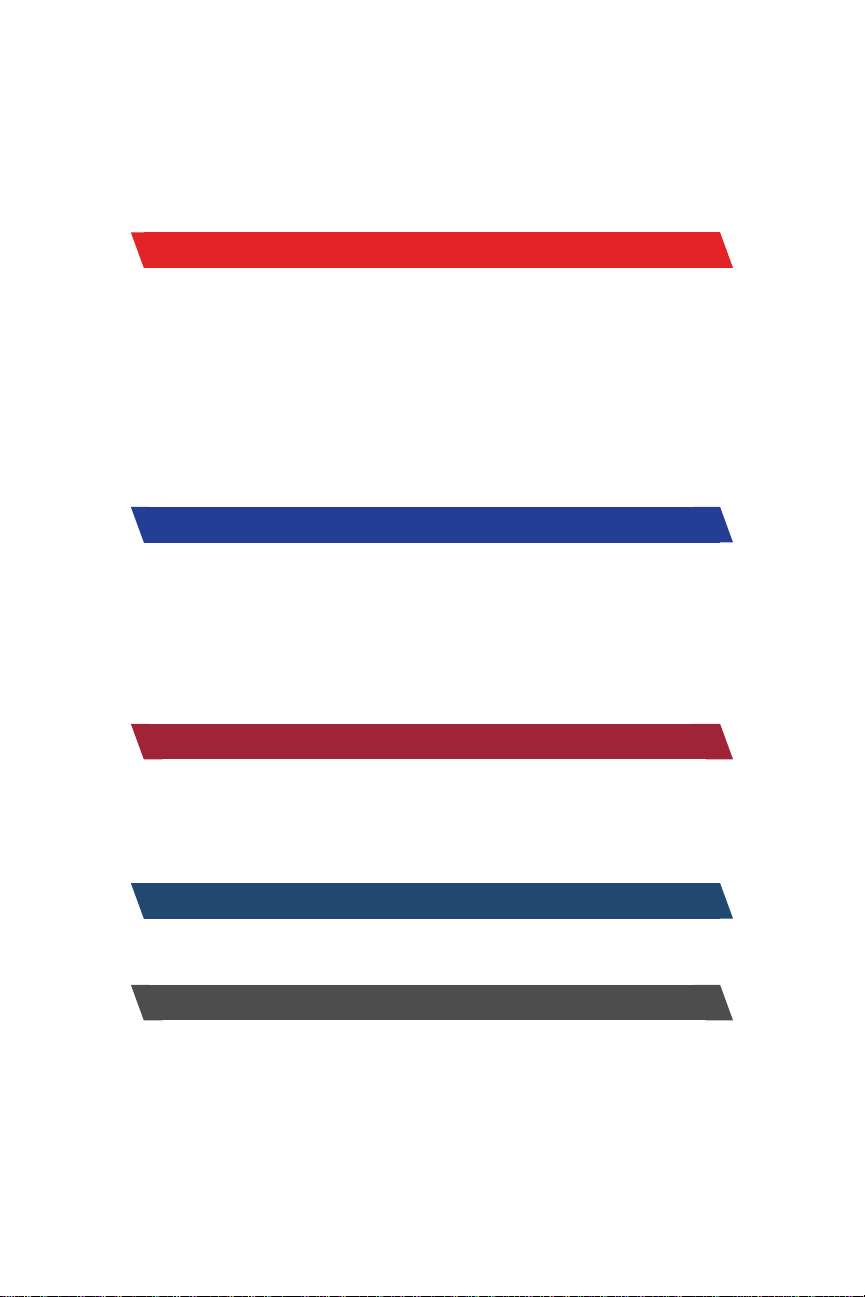

UP/DOWN

ARROWS

DIGITAL

DISPLAY

DIAGNOSTICS

BUTTON

BUMP LEVER

PUSHBUTTON

R - REVERSE N - NEUTRAL D - DRIVE

OEMs may supply shift selectors for some vehicles equipped with 5th

Generation Electronic Controls. If your vehicle is not equipped with an

Allison-supplied shift selector, contact your OEM.

Mode Button

Allison Automatics offer primary and secondary shift

schedule modes to enhance performance or fuel

economy. The vehicle always defaults to the primary

mode [MODE is not shown on graphic display].

If equipped as such you can switch to the secondary

mode by pushing the MODE button [MODE is shown on

graphic display].

Your vehicle may be equipped with FuelSense –

Allison’s next generation in fuel-savings technology.

FuelSense is a set of unique packages of software and

electronic controls that can potentially increase fuel

economy by 20%. FuelSense icons will appear at start

up if your vehicle utilizes a FuelSense package.

2

Page 5

SECTION 1

WITH PROGNOSTICS +

WITH OIL LEVEL SENSOR

Fluid Levels

The transmission fluid cools, lubricates and transmits hydraulic power,

so it is important that the proper fluid level be maintained at all times.

If the fluid level is too low, the converter and clutches do not receive an

adequate supply of fluids. If the fluid level is too high, the fluid can aerate

causing the transmission to shift erratically or overheat.

Checking Fluid Levels

Use the following procedure to display oil level information.

To enter the oil level function:

1. Park the vehicle on a level surface, shift to N (NEUTRAL)

and apply the parking brake.

2. Using a pushbutton shift selector, simultaneously

press the UP and DOWN arrows one time.

For a bump lever shift selector, press

the DIAGNOSTICS button one time.

3. The fluid level reading will be delayed until the following

conditions are met.

• Engine must be at idle.

• Transmission is in N (NEUTRAL).

• Output speed must be zero.

• Fluid temperature must be between 104F (40C)

and 220F (104C).

• Vehicle has been stationary for two minutes to allow

the fluid to settle.

3

Page 6

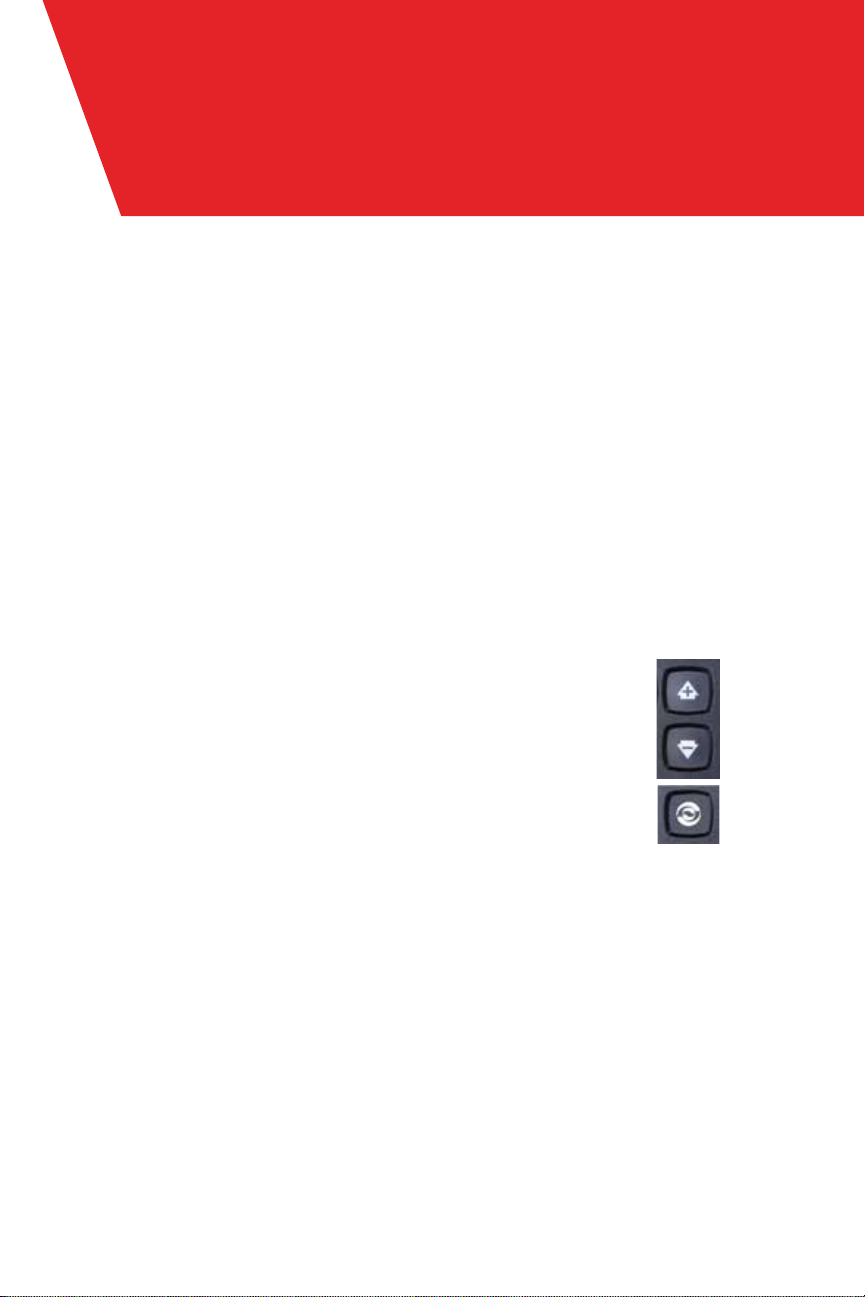

4. The shift selector displays the oil level data as follows:

• CORRECT FLUID LEVEL – The fluid is within the

correct fluid level zone when OK is shown.

• LOW FLUID LEVEL – The display shows the number

of quarts the transmission oil is low.

• HIGH FLUID LEVEL – The display shows the number

of quarts the transmission oil is overfilled.

Delayed Fluid Level Check

If the fluid level check cannot be completed, one of the following

Oil Level Display faults will be shown:

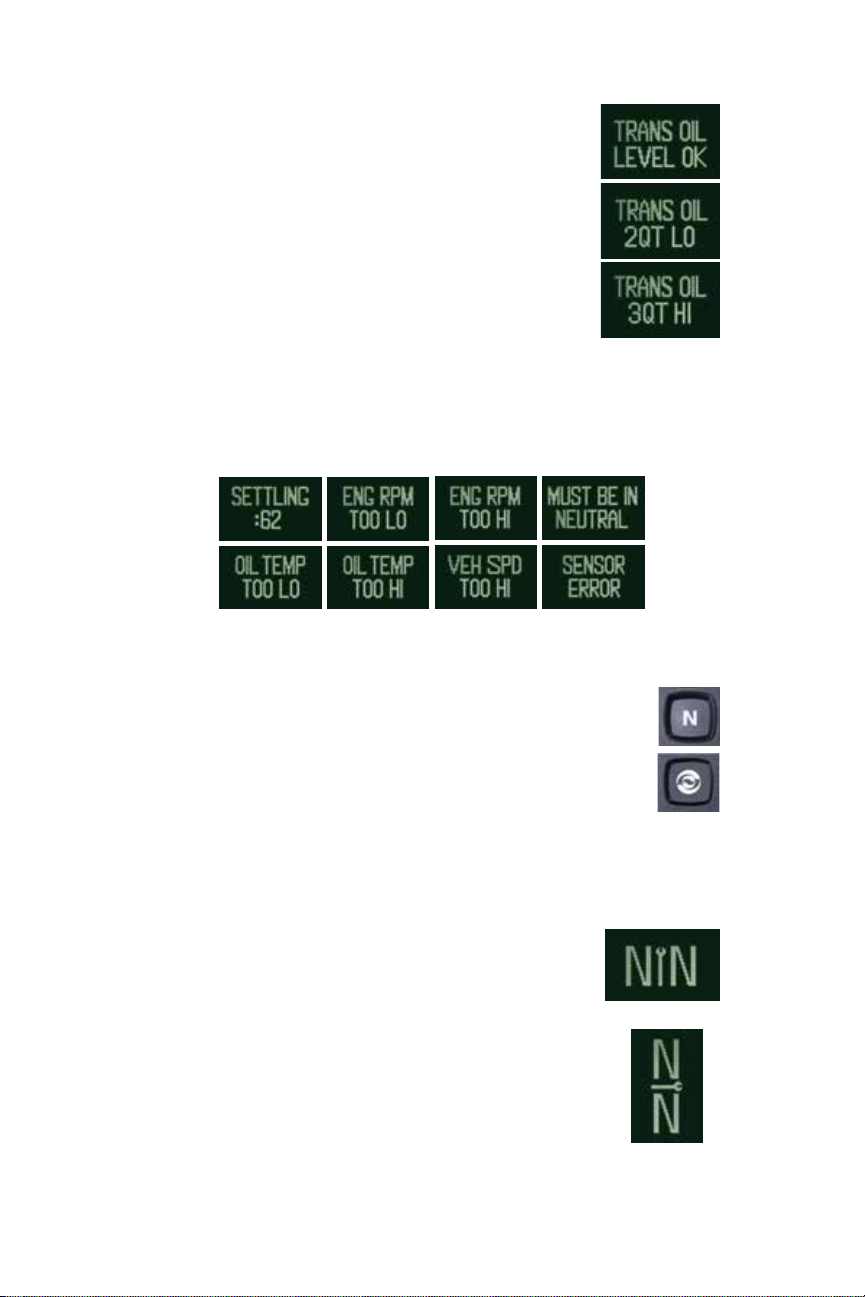

To exit the oil level function:

• For pushbutton shift selector,

press N (NEUTRAL) button.

• For bump lever shift selector, press the

DIAGNOSTICS button until you return to range display.

Prognostic Features

5th Generation Electronic Controls Shift

Selectors display prognostics in text form to

provide at-a-glance status of Oil Life, Filter Life

and Transmission Health.

The WRENCH ICON will illuminate briefly after you turn

the key to the run position on your Allison-equipped

vehicle to indicate that prognostics are enabled. If the

WRENCH ICON remains on or flashes, this indicates there

is a service issue relating to clutch, filter or fluid life.

PUSHBUTTON

BUMP LEVER

4

Page 7

Oil Life Monitor

The status of the oil life is displayed as a percentage

(OIL LIFE 100%) until fluid is due for a change.

Filter Life Monitor

The status of filter life is displayed as OIL FILTERS OK

and alerts when filters are due for a change with REPLACE FILTERS.

Transmission Health Monitor (not available for TC10)

The status of transmission health is displayed as OK or LO.

Accessing Prognostics

When you are alerted via the WRENCH ICON on the shift selector that service

is due, you can check the status by toggling through the shift selector

display as follows. Be sure to park the vehicle on a level surface, shift to

N (NEUTRAL) and apply the parking brake before accessing prognostics

through the shift selector.

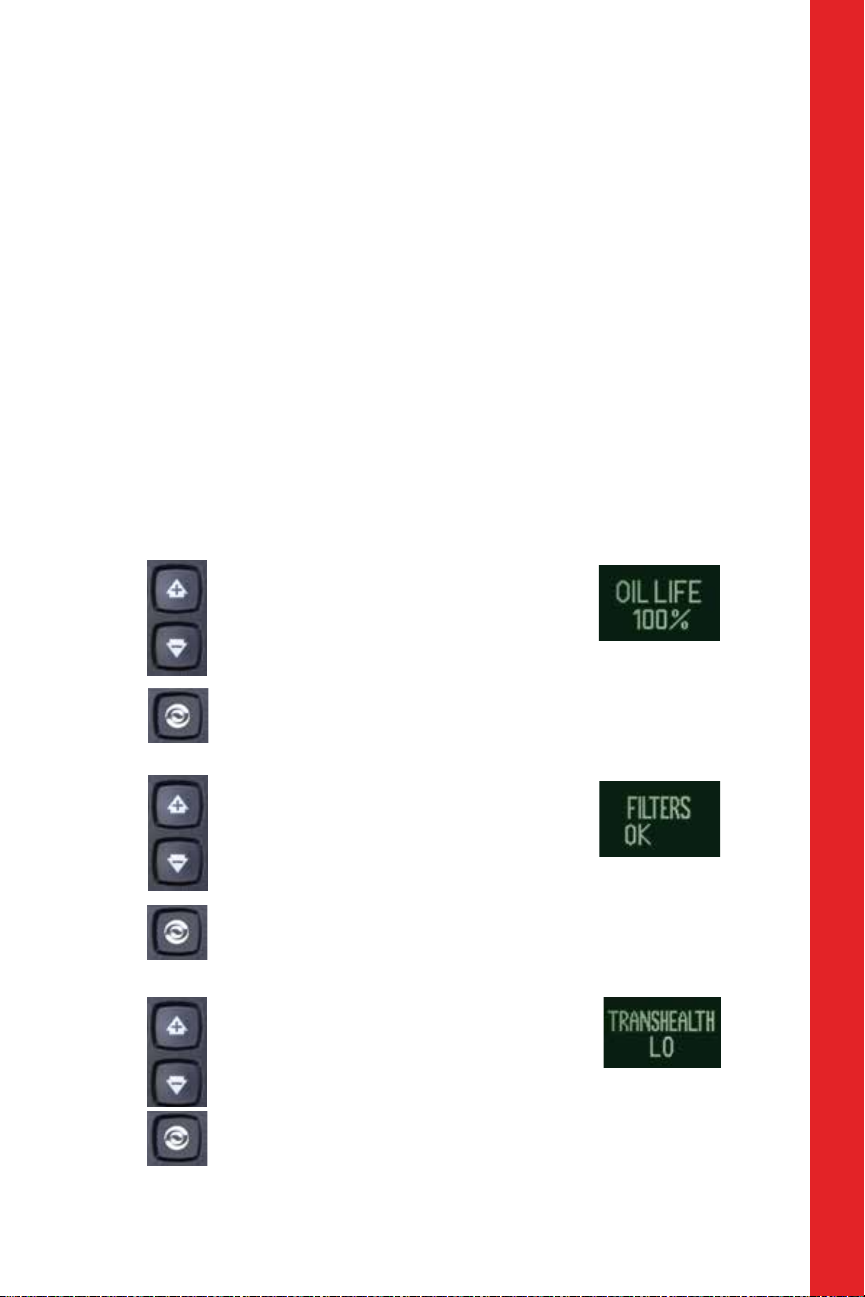

Oil Life Monitor

For a pushbutton shift selector,

simultaneously press the UP and DOWN

arrows two times.

For a bump lever shift selector,

press the DIAGNOSTICS button two times.

The percentage of the

fluid life remaining is

displayed. New fluid is

shown as OIL LIFE 100%.

WITH PROGNOSTICS + WITH OIL LEVEL SENSOR

Filter Life Monitor

For a pushbutton shift selector,

simultaneously press the UP and DOWN

arrows three times.

For a bump lever shift selector, press

the DIAGNOSTICS button three times.

Transmission Health Monitor

For a pushbutton shift selector,

simultaneously press the UP and DOWN

arrows four times.

For a bump lever shift selector, press

the DIAGNOSTICS button four times.

5

Acceptable filter life status

is shown as FILTERS OK,

unacceptable filter life status

is shown as REPLACE FILTERS.

When TRANS HEALTH OK is

shown, clutch maintenance

is not required. When TRANS

HEALTH LO is displayed, clutch

maintenance is required.

Page 8

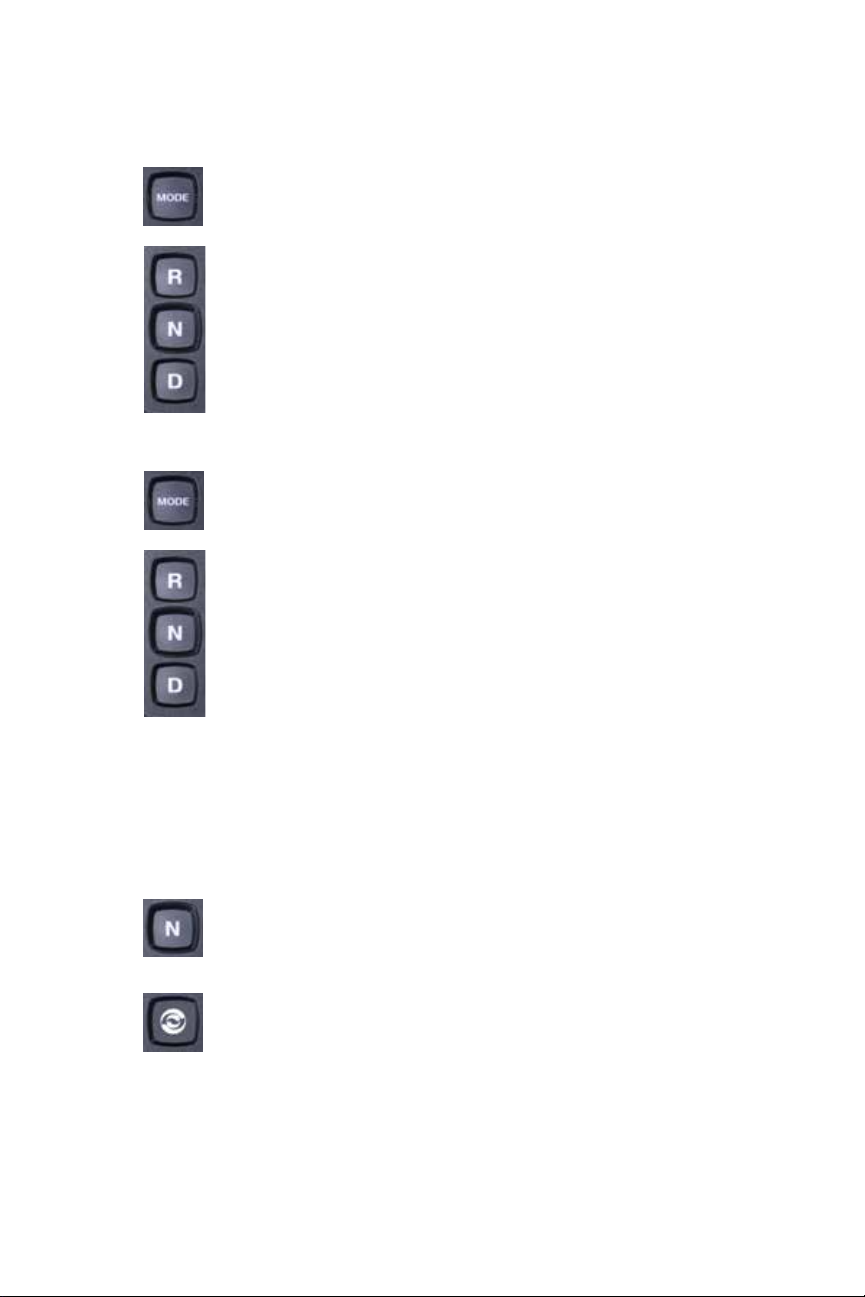

Resetting Prognostics

Oil Life Monitor

For either a pushbutton or bump lever shift selector, press

and hold the MODE button for approximately 10 seconds

while in Oil Life Monitor mode.

Or

For either a pushbutton or bump lever shift selector,

perform the following shift sequence with the ignition

on, but the engine off. Do not stop the sequence

for more than three seconds once you have started.

N-D-N-D-N-R-N

Filter Life Monitor

For either a pushbutton or bump lever shift selector, press

and hold the MODE button for approximately 10 seconds

while in Filter Life Monitor mode.

Or

For either a pushbutton or bump lever shift selector, perform the

following shift sequence with the ignition on, but the engine off.

Do not stop the sequence for more than three seconds once you

have started.

N-R-N-R-N-D-N

Transmission Health Monitor

This must be reset manually using Allison DOC

program after correcting a clutch system issue.

Exit Prognostics

For a pushbutton shift selector, press the N (NEUTRAL)

range button.

For a bump lever shift selector, press the DIAGNOSTICS

range button until back to range display.

6

®

for PC diagnostic

Page 9

Diagnostic Codes

To enter the diagnostic code function:

1. Bring the vehicle to a complete stop.

Apply the parking brake.

2. For a pushbutton shift selector, simultaneously press

the UP and DOWN arrows five times (four times for TC10).

For a bump lever shift selector,

press the DIAGNOSTICS button five times.

3. Up to five codes may be recorded in memory.

4. Each code remains in the display until the MODE button is pushed, then

the next code is shown. Active codes are shown first, newest to oldest,

followed by any inactive codes still in the memory.

ACTIVE CODES: INACTIVE CODES:

For a detailed list of Diagnostic Transmission Codes for 5th Generation

Electronic Controls Shift Selectors, see pages 17 through 21.

WITH PROGNOSTICS + WITH OIL LEVEL SENSOR

To exit the diagnostic code function:

Any of the following methods may be used.

1. For a pushbutton shift selector, press the N (NEUTRAL)

range button.

2. For a bump lever shift selector, press the DIAGNOSTICS

range button until back to range display.

3. Wait approximately 10 minutes and the system will

automatically return to normal operating mode.

4. Turn off the vehicle engine ignition switch.

Drive the vehicle and check for code recurrence. If codes continue to

recur, bring the vehicle to an Allison Authorized Service Network to

diagnose and repair the problem causing the codes.

7

Page 10

SECTION 2

WITH PROGNOSTICS +

WITHOUT OIL LEVEL SENSOR

Prognostic Features

5th Generation Electronic Controls Shift

Selectors display prognostics in text form to

provide at-a-glance status of Oil Life, Filter Life

and Transmission Health.

The WRENCH ICON will illuminate briefly after you turn

the key to the run position on your Allison-equipped

vehicle to indicate that prognostics are enabled. If the

WRENCH ICON remains on or flashes, this indicates there

is a service issue relating to clutch, filter or fluid life.

Oil Life Monitor

The status of the oil life is displayed as a percentage

(OIL LIFE 100%) until fluid is due for a change.

PUSHBUTTON

BUMP LEVER

Filter Life Monitor

The status of filter life is displayed as OIL FILTERS OK

and alerts when filters are due for a change with REPLACE FILTERS.

Transmission Health Monitor (not available for TC10)

The status of transmission health is displayed as HIGH to LO.

8

Page 11

Accessing Prognostics

When you are alerted via the WRENCH ICON on the shift selector that service

is due, you can check the status by toggling through the shift selector

display as follows. Be sure to park the vehicle on a level surface, shift to

N (NEUTRAL)

through the shift selector.

and apply the parking brake before accessing prognostics

Oil Life Monitor

For a pushbutton shift selector,

simultaneously press the UP and DOWN

arrows one time.

For a bump lever shift selector,

press the DIAGNOSTICS button one time.

The percentage of the

fluid life remaining is

displayed. New fluid is

shown as OIL LIFE 100%.

Filter Life Monitor

For a pushbutton shift selector,

simultaneously press the UP and DOWN

arrows two times.

For a bump lever shift selector, press

the DIAGNOSTICS button two times.

Acceptable filter life status

is shown as FILTERS OK,

unacceptable filter life status

is shown as REPLACE FILTERS.

WITH PROGNOSTICS + WITHOUT OIL LEVEL SENSOR

Transmission Health Monitor

For a pushbutton shift selector,

simultaneously press the UP and DOWN

arrows three times.

For a bump lever shift selector, press

the DIAGNOSTICS button three times.

9

When TRANS HEALTH OK is

shown, clutch maintenance

is not required. When TRANS

HEALTH LO is displayed, clutch

maintenance is required.

Page 12

Resetting Prognostics

Oil Life Monitor

For either a pushbutton or bump lever shift selector, press

and hold the MODE button for approximately 10 seconds

while in Oil Life Monitor mode.

Or

For either a pushbutton or bump lever shift selector,

perform the following shift sequence with the ignition

on, but the engine off. Do not stop the sequence

for more than three seconds once you have started.

N-D-N-D-N-R-N

Filter Life Monitor

For either a pushbutton or bump lever shift selector, press

and hold the MODE button for approximately 10 seconds

while in Filter Life Monitor mode.

Or

For either a pushbutton or bump lever shift selector, perform the

following shift sequence with the ignition on, but the engine off.

Do not stop the sequence for more than three seconds once you

have started.

N-R-N-R-N-D-N

Transmission Health Monitor

This must be reset manually using Allison DOC

program after correcting a clutch system issue.

Exit Prognostics

For a pushbutton shift selector, press the N (NEUTRAL)

range button.

For a bump lever shift selector, press the DIAGNOSTICS

range button until back to range display.

10

®

for PC diagnostic

Page 13

Diagnostic Codes

To enter the diagnostic code function:

1. Bring the vehicle to a complete stop.

Apply the parking brake.

2. For a pushbutton shift selector, simultaneously

press the UP and DOWN arrows four times.

For a bump lever shift selector,

press the DIAGNOSTICS button four times.

3. Up to five codes may be recorded in memory.

4. Each code remains in the display until the MODE button is

pushed, then the next code is shown. Active codes are shown first,

newest to oldest, followed by any inactive codes still in the memory.

ACTIVE CODES: INACTIVE CODES:

For a detailed list of Diagnostic Transmission Codes for 5th Generation

Electronic Controls Shift Selectors, see pages 17 through 21.

WITH PROGNOSTICS + WITHOUT OIL LEVEL SENSOR

To exit the diagnostic code function:

Any of the following methods may be used.

1. For a pushbutton shift selector, press the N (NEUTRAL)

range button.

2. For a bump lever shift selector, press the DIAGNOSTICS

range button until back to range display.

3. Wait approximately 10 minutes and the system will

automatically return to normal operating mode.

4. Turn off the vehicle engine ignition switch.

Drive the vehicle and check for code recurrence. If codes continue to

recur, bring the vehicle to an Allison Authorized Service Network to

diagnose and repair the problem causing the codes.

11

Page 14

SECTION 3

WITHOUT PROGNOSTICS +

WITH OIL LEVEL SENSOR

Fluid Levels

The transmission fluid cools, lubricates and transmits hydraulic power,

so it is important that the proper fluid level be maintained at all times.

If the fluid level is too low, the converter and clutches do not receive an

adequate supply of fluids. If the fluid level is too high, the fluid can aerate

causing the transmission to shift erratically or overheat.

Checking Fluid Levels

Use the following procedure to display oil level information.

To enter the oil level function:

1. Park the vehicle on a level surface, shift to N (NEUTRAL)

and apply the parking brake.

2. Using a pushbutton shift selector, simultaneously

press the UP and DOWN arrows one time.

For a bump lever shift selector, press

the DIAGNOSTICS button one time.

3. The fluid level reading will be delayed until

the following conditions are met.

• Engine must be at idle.

• Transmission is in N (NEUTRAL).

• Output speed must be zero.

• Fluid temperature must be between 104F (40C)

and 220F (104C).

• Vehicle has been stationary for two minutes to allow

the fluid to settle.

12

Page 15

4. The shift selector displays the oil level data as follows:

• CORRECT FLUID LEVEL – The fluid is within the

correct fluid level zone when OK is shown.

• LOW FLUID LEVEL – The display shows the number

of quarts the transmission oil is low.

• HIGH FLUID LEVEL – The display shows the number

of quarts the transmission oil is overfilled.

Delayed Fluid Level Check

If the fluid level check cannot be completed, one of the following

Oil Level Display faults will be shown:

WITHOUT PROGNOSTICS + WITH OIL LEVEL SENSOR

To exit the oil level function:

• For pushbutton shift selector, press N (NEUTRAL)

button one time.

• For bump lever shift selector, press the

DIAGNOSTICS button until back to range display.

13

Page 16

Diagnostic Codes

To enter the diagnostic code function:

1. Bring the vehicle to a complete stop.

Apply the parking brake.

2. For a pushbutton shift selector, simultaneously

press the UP and DOWN arrows two times.

For a bump lever shift selector,

press the DIAGNOSTICS button two times.

3. Up to five codes may be recorded in memory.

4. Each code remains in the display until the MODE button is pushed, then

the next code is shown. Active codes are shown first, newest to oldest,

followed by any inactive codes still in the memory.

ACTIVE CODES: INACTIVE CODES:

For a detailed list of Diagnostic Transmission Codes for 5th Generation

Electronic Controls Shift Selectors, see pages 17 through 21.

To exit the diagnostic code function:

Any of the following methods may be used.

1. For a pushbutton shift selector, press the N (NEUTRAL)

range button.

2. For a bump lever shift selector, press the DIAGNOSTICS

range button until back to range display.

3. Wait approximately 10 minutes and the system will

automatically return to normal operating mode.

4. Turn off the vehicle engine ignition switch.

Drive the vehicle and check for code recurrence. If codes continue to

recur, bring the vehicle to an Allison Authorized Service Network to

diagnose and repair the problem causing the codes.

14

Page 17

SECTION 4

WITHOUT PROGNOSTICS +

WITHOUT OIL LEVEL SENSOR

Diagnostic Codes

To enter the diagnostic code function:

1. Bring the vehicle to a complete stop.

Apply the parking brake.

2. For a pushbutton shift selector, simultaneously

press the UP and DOWN arrows one time.

For a bump lever shift selector,

press the DIAGNOSTICS button one time.

3. Up to five codes may be recorded in memory.

4. Each code remains in the display until the MODE button is pushed, then

the next code is shown. Active codes are shown first, newest to oldest,

followed by any inactive codes still in the memory.

ACTIVE CODES: INACTIVE CODES:

For a detailed list of Diagnostic Transmission Codes for 5th Generation

Electronic Controls Shift Selectors, see pages 17 through 21.

15

Page 18

To exit the diagnostic code function:

Any of the following methods may be used.

1. For a pushbutton shift selector, press the N (NEUTRAL)

range button.

2. For a bump lever shift selector, press the DIAGNOSTICS

range button until back to range display.

3. Wait approximately 10 minutes and the system will

automatically return to normal operating mode.

4. Turn off the vehicle engine ignition switch.

Drive the vehicle and check for code recurrence. If codes continue to

recur, bring the vehicle to an Allison Authorized Service Network to

diagnose and repair the problem causing the codes.

16

Page 19

Diagnostic Transmission Codes

DIAGNOSTIC TRANSMISSION MAIN CODES P0122-P077F

DIAGNOSTIC

CODE

P0122 PEDAL POSITION SENSOR CIRCUIT LOW VOLTAGE

P0123 PEDAL POSITION SENSOR CIRCUIT HIGH VOLTAGE

P0218 TRANSMISSION FLUID OVER TEMPERATURE CONDITION

P0562 SYSTEM VOLTAGE LOW

P057C BRAKE PEDAL POSITION SENSOR LOW

P057D BRAKE PEDAL POSITION SENSOR HIGH

P0602 TCM NOT PROGRAMMED

P0603 INTERNAL CONTROL MODULE KEEP ALIVE MEMORY ERROR

P0604 CONTROL MODULE RANDOM ACCESS MEMORY (RAM)

P0607 CONTROL MODULE PERFORMANCE

P060C MAIN PROCESSOR MONITOR FAULT

P0614 TORQUE CONTROL DATA MISMATCH - ECM/TCM

P0634 TCM INTERNAL TEMPERATURE TOO HIGH

P0642 SENSOR REFERENCE VOLTAGE “A” CIRCUIT FAULT

P0652 SENSOR REFERENCE VOLTAGE “B” CIRCUIT FAULT

P0657 ACTUATOR SUPPLY CIRCUIT VOLTAGE 1 OPEN (HSD 1)

P0658 ACTUATOR SUPPLY CIRCUIT VOLTAGE 1 LOW (HSD 1)

P0659 ACTUATOR SUPPLY CIRCUIT VOLTAGE 1 HIGH (HSD 1)

P0701 TRANSMISSION CONTROL SYSTEM PERFORMANCE

P0703 BRAKE SWITCH CIRCUIT

P0708 TRANSMISSION RANGE SENSOR CIRCUIT HIGH

P070C TRANSMISSION FLUID LEVEL SENSOR CIRCUIT LOW

P070D TRANSMISSION FLUID LEVEL SENSOR CIRCUIT HIGH

P0712 TRANSMISSION FLUID TEMPERATURE SENSOR CIRCUIT LOW

P0713 TRANSMISSION FLUID TEMPERATURE SENSOR CIRCUIT HIGH

P0715 TURBINE SHAFT SPEED SENSOR CIRCUIT

P0716 TURBINE SHAFT SPEED SENSOR CIRCUIT PERFORMANCE

P0717 TURBINE SHAFT SPEED SENSOR CIRCUIT NO SIGNAL

P071A NEUTRAL AT STOP INPUT FAILED ON

P071D GENERAL PURPOSE INPUT FAULT

P0720 OUTPUT SHAFT SPEED SENSOR CIRCUIT

P0721 OUTPUT SHAFT SPEED SENSOR CIRCUIT PERFORMANCE

P0722 OUTPUT SHAFT SPEED SENSOR CIRCUIT NO SIGNAL

P0725 ENGINE SPEED SENSOR CIRCUIT

P0726 ENGINE SPEED SENSOR CIRCUIT PERFORMANCE

P0727 ENGINE SPEED SENSOR CIRCUIT NO SIGNAL

P0729 INCORRECT 6TH GEAR RATIO

P0731 INCORRECT 1ST GEAR RATIO

P0732 INCORRECT 2ND GEAR RATIO

P0733 INCORRECT 3RD GEAR RATIO

P0734 INCORRECT 4TH GEAR RATIO

P0735 INCORRECT 5TH GEAR RATIO

P0736 INCORRECT REVERSE RATIO

P0 741 TORQUE CONVERTER CLUTCH (TCC) SYSTEM STUCK OFF

P0752 SHIFT SOLENOID 1 VALVE PERFORMANCE - STUCK ON

P076F INCORRECT 7TH GEAR RATIO

P0776 PRESSURE CONTROL SOLENOID (PCS) 2 STUCK OFF

P0777 PRESSURE CONTROL SOLENOID (PCS) 2 STUCK ON

P077F INCORRECT REVERSE 2 RATIO

CODE

DESCRIPTION

17

Page 20

DIAGNOSTIC

CODE

P0796 PRESSURE CONTROL SOLENOID (PCS) 3 STUCK OFF

P0797 PRESSURE CONTROL SOLENOID (PCS) 3 STUCK ON

P07D9 INCORRECT 8TH GEAR RATIO

P07F6 INCORRECT 9TH GEAR RATIO

P07F7 INCORRECT 10TH GEAR RATIO

P081B CRANK ENABLE CIRCUIT HIGH

P0837 FOUR WHEEL DRIVE (4WD) SWITCH CIRCUIT RANGE/PERFORMANCE

P083C TRANSMISSION FLUID PRESSURE SWITCH 6 CIRCUIT LOW

P083C TRANSMISSION FLUID PRESSURE SWITCH 6 CIRCUIT LOW

P083D TRANSMISSION FLUID PRESSURE SWITCH 6 CIRCUIT HIGH

P083D TRANSMISSION FLUID PRESSURE SWITCH 6 CIRCUIT HIGH

P0842 TRANSMISSION FLUID PRESSURE SWITCH 1 CIRCUIT LOW

P0843 TRANSMISSION FLUID PRESSURE SWITCH 1 CIRCUIT HIGH

P0847 TRANSMISSION FLUID PRESSURE SWITCH 2 CIRCUIT LOW

P0848 TRANSMISSION FLUID PRESSURE SWITCH 2 CIRCUIT HIGH

P084C TRANSMISSION FLUID PRESSURE SWITCH TCC CIRCUIT LOW

P084D TRANSMISSION FLUID PRESSURE SWITCH TCC CIRCUIT HIGH

P0872 TRANSMISSION FLUID PRESSURE SWITCH 3 CIRCUIT LOW

P0873 TRANSMISSION FLUID PRESSURE SWITCH 3 CIRCUIT HIGH

P0877 TRANSMISSION FLUID PRESSURE SWITCH 4 CIRCUIT LOW

DIAGNOSTIC TRANSMISSION MAIN CODES P0796-P0994

P0878 TRANSMISSION FLUID PRESSURE SWITCH 4 CIRCUIT HIGH

P0880 TCM POWER INPUT SIGNAL

P0881 TCM POWER INPUT SIGNAL PERFORMANCE

P0882 TCM POWER INPUT SIGNAL LOW

P0883 TCM POWER INPUT SIGNAL HIGH

P088A TRANSMISSION FILTER MAINTENANCE ALERT

P088B TRANSMISSION FILTER MAINTENANCE REQUIRED

P0894 UNEXPECTED MECHANICAL GEAR DISENGAGEMENT

P0897 TRANSMISSION FLUID DETERIORATED

P0960 MAIN PRESSURE MODULATION SOLENOID CONTROL CIRCUIT OPEN

P0961 MAIN PRESSURE MODULATION SOLENOID SYSTEM PERFORMANCE

P0962 MAIN PRESSURE MODULATION SOLENOID CONTROL CIRCUIT LOW

P0963 MAIN PRESSURE MODULATION SOLENOID CONTROL CIRCUIT HIGH

P0964 PRESSURE CONTROL SOLENOID (PCS) 2 CONTROL CIRCUIT OPEN

P0966 PRESSURE CONTROL SOLENOID (PCS) 2 CONTROL CIRCUIT LOW

P0967 PRESSURE CONTROL SOLENOID (PCS) 2 CONTROL CIRCUIT HIGH

P0968 PRESSURE CONTROL SOLENOID (PCS) 3 CONTROL CIRCUIT OPEN

P0970 PRESSURE CONTROL SOLENOID (PCS) 3 CONTROL CIRCUIT LOW

P0971 PRESSURE CONTROL SOLENOID (PCS) 3 CONTROL CIRCUIT HIGH

P0973 SHIFT SOLENOID 1 CONTROL CIRCUIT LOW

P0974 SHIFT SOLENOID 1 CONTROL CIRCUIT HIGH

P0976 SHIFT SOLENOID 2 CONTROL CIRCUIT LOW

P0977 SHIFT SOLENOID 2 CONTROL CIRCUIT HIGH

P0979 SHIFT SOLENOID 3 CONTROL CIRCUIT LOW

P097A SHIFT SOLENOID 1 CONTROL CIRCUIT OPEN

P097B SHIFT SOLENOID 2 CONTROL CIRCUIT OPEN

P097C SHIFT SOLENOID 3 CONTROL CIRCUIT OPEN

P0980 SHIFT SOLENOID 3 CONTROL CIRCUIT HIGH

P0989 RETARDER PRESSURE SENSOR CIRCUIT LOW

P0990 RETARDER PRESSURE SENSOR CIRCUIT HIGH

P0994 TRANSMISSION FLUID PRESSURE SWITCH 5 CIRCUIT LOW

CODE

DESCRIPTION

18

Page 21

DIAGNOSTIC

CODE

P0994 TRANSMISSION FLUID PRESSURE SWITCH 5 CIRCUIT LOW

P0995 TRANSMISSION FLUID PRESSURE SWITCH 5 CIRCUIT HIGH

P0995 TRANSMISSION FLUID PRESSURE SWITCH 5 CIRCUIT HIGH

P0A0B HIGH VOLTAGE INTERLOCK LOOP 1 INVALID

P0A2F DRIVE MOTOR OVER TEMPERATURE

P0A44 DRIVE MOTOR OVERSPEED

P0A7D ENERGY STORAGE SYSTEM OVER DISCHARGE

P0A90 DRIVE MOTOR INVALID DIRECTION

P0AA6 ISOLATION STATUS INVALID

P0B37 SERVICE DISCONNECT INVALID

P0C19 DRIVE MOTOR TORQUE DELIVERED PERFORMANCE

P0C26 ELECTRIC PUMP POWER DRAW TOO HIGH

P0C2C ELECTRIC PUMP SPEED INCORRECT

P0C30 ENERGY STORAGE SYSTEM OVER CHARGE

P0C76 HIGH VOLTAGE BUS DISCHARGE TIME TOO LONG

P0DA8 HYBRID BATTERY VOLTAGE/DRIVE MOTOR INVERTER VOLTAGE

P1739 INCORRECT LOW GEAR RATIO

P1790 GEAR SHIFT MODULE 1 CALIBRATION INVALID

P1791 GEAR SHIFT MODULE 2 CALIBRATION INVALID

P1891 THROTTLE POSITION SENSOR PWM SIGNAL LOW

P1892 THROTTLE POSITION SENSOR PWM SIGNAL HIGH

P1901 COUNTERSHAFT SPEED SENSOR CIRCUIT

P1902 COUNTERSHAFT SPEED SENSOR PERFORMANCE

P1903 COUNTERSHAFT SPEED SENSOR NO ACTIVITY

P1907 SHIFT FORK STUCK MOVING TO REVERSE POSITION

P1922 TRANSMISSION FLUID PRESSURE SWITCH A CIRCUIT LOW

P1923 TRANSMISSION FLUID PRESSURE SWITCH A CIRCUIT HIGH

P1927 TRANSMISSION FLUID PRESSURE SWITCH B CIRCUIT LOW

P1928 TRANSMISSION FLUID PRESSURE SWITCH B CIRCUIT HIGH

P192C TRANSMISSION FLUID PRESSURE SWITCH C CIRCUIT LOW

P192D TRANSMISSION FLUID PRESSURE SWITCH C CIRCUIT HIGH

P1A01 TRANSMISSION CONTROL SYSTEM 2 PERFORMANCE

P1A0C TRANSMISSION FLUID LEVEL SENSOR 2 CIRCUIT LOW

P1A0D TRANSMISSION FLUID LEVEL SENSOR 2 CIRCUIT HIGH

P1A11 DC/DC CONVERTER “A” FAULT ACTIVE

P1A12 DC/DC CONVERTER “B” FAULT ACTIVE

P1A13 ELECTRIC PUMP FAULT ACTIVE

P1A14 ENERGY STORAGE SYSTEM FAULT ACTIVE

P1A15 INVERTER FAULT ACTIVE

P1A20 HIGH VOLTAGE INTERLOCK LOOP 2 INVALID

P1A30 INVERTER OPERATING MODE NOT CORRELATED

P1A31 ENERGY STORAGE SYSTEM OPERATING MODE NOT CORRELATED

P1A32 DC/DC CONVERTER “A” OPERATING MODE NOT CORRELATED

P1A33 DC/DC CONVERTER “B” OPERATING MODE NOT CORRELATED

P1A34 ELECTRIC PUMP OPERATING MODE NOT CORRELATED

P1A3F INVERTER ISOLATION FAULT

P1A40 HIGH VOLTAGE BUS POWER BALANCE

P2184 ENGINE COOLANT TEMPERATURE SENSOR 2 CIRCUIT LOW

P2185 ENGINE COOLANT TEMPERATURE SENSOR 2 CIRCUIT HIGH

P2637 TORQUE MANAGEMENT FEEDBACK SIGNAL A

CODE

DESCRIPTION

CORRELATION

DIAGNOSTIC TRANSMISSION MAIN CODES P0994-P2637

19

Page 22

DIAGNOSTIC TRANSMISSION MAIN CODES P2641-P281B

DIAGNOSTIC

CODE

P2641 TORQUE MANAGEMENT FEEDBACK SIGNAL B

P2669 ACTUATOR SUPPLY CIRCUIT VOLTAGE 2 OPEN (HSD 2)

P2670 ACTUATOR SUPPLY CIRCUIT VOLTAGE 2 LOW (HSD 2)

P2671 ACTUATOR SUPPLY CIRCUIT VOLTAGE 2 HIGH (HSD 2)

P2684 ACTUATOR SUPPLY CIRCUIT VOLTAGE 3 OPEN (HSD 3)

P2685 ACTUATOR SUPPLY CIRCUIT VOLTAGE 3 LOW (HSD 3)

P2686 ACTUATOR SUPPLY CIRCUIT VOLTAGE 3 HIGH (HSD 3)

P26E7 ACTUATOR SUPPLY CIRCUIT VOLTAGE 4 OPEN (HSD 4)

P26E8 ACTUATOR SUPPLY CIRCUIT VOLTAGE 4 LOW (HSD 4)

P26E9 ACTUATOR SUPPLY CIRCUIT VOLTAGE 4 HIGH (HSD 4)

P2714 PRESSURE CONTROL SOLENOID (PCS) 4 STUCK OFF

P2715 PRESSURE CONTROL SOLENOID (PCS) 4 STUCK ON

P2718 PRESSURE CONTROL SOLENOID (PCS) 4 CONTROL CIRCUIT OPEN

P2720 PRESSURE CONTROL SOLENOID (PCS) 4 CONTROL CIRCUIT LOW

P2721 PRESSURE CONTROL SOLENOID (PCS) 4 CONTROL CIRCUIT HIGH

P2723 PRESSURE CONTROL SOLENOID (PCS) 1 STUCK OFF

P27 24 PRESSURE CONTROL SOLENOID (PCS) 1 STUCK ON

P2727 PRESSURE CONTROL SOLENOID (PCS) 1 CONTROL CIRCUIT OPEN

P2729 PRESSURE CONTROL SOLENOID (PCS) 1 CONTROL CIRCUIT LOW

P2730 PRESSURE CONTROL SOLENOID (PCS) 1 CONTROL CIRCUIT HIGH

P2732 PRESSURE CONTROL SOLENOID (PCS) 5 STUCK OFF

P2733 PRESSURE CONTROL SOLENOID (PCS) 5 STUCK ON

P2736 PRESSURE CONTROL SOLENOID (PCS) 5 CONTROL CIRCUIT OPEN

P2738 PRESSURE CONTROL SOLENOID (PCS) 5 CONTROL CIRCUIT LOW

P2739 PRESSURE CONTROL SOLENOID (PCS) 5 CONTROL CIRCUIT HIGH

P273F RETARDER OIL TEMPERATURE SENSOR OVER TEMPERATURE CONDITION

P2742 RETARDER OIL TEMPERATURE SENSOR CIRCUIT LOW

P2743 RETARDER OIL TEMPERATURE SENSOR CIRCUIT HIGH

P274B TRANSMISSION FLUID TEMPERATURE SENSOR “C” CIRCUIT

P274C TRANSMISSION FLUID TEMPERATURE SENSOR “C” CIRCUIT LOW

P274D TRANSMISSION FLUID TEMPERATURE SENSOR “C” CIRCUIT HIGH

P274F TRANSMISSION FLUID SENSOR “C” OVER TEMPERATURE

P2761 TORQUE CONVERTER CLUTCH (TCC) PRESSURE CONTROL

P2763 TORQUE CONVERTER CLUTCH (TCC) PRESSURE CONTROL

P2764 TORQUE CONVERTER CLUTCH (TCC) PRESSURE CONTROL

P2789 TRANSMISSION CLUTCH LIFE EXPIRED (CLUTCH ADAPTIVE

P2793 GEAR SHIFT DIRECTION CIRCUIT

P2808 PRESSURE CONTROL SOLENOID (PCS) 6 STUCK OFF

P2809 PRESSURE CONTROL SOLENOID (PCS) 6 STUCK ON

P2812 PRESSURE CONTROL SOLENOID (PCS) 6 CONTROL CIRCUIT OPEN

P2814 PRESSURE CONTROL SOLENOID (PCS) 6 CONTROL CIRCUIT LOW

P2815 PRESSURE CONTROL SOLENOID (PCS) 6 CONTROL CIRCUIT HIGH

P2817 PRESSURE CONTROL SOLENOID (PCS) 7 STUCK OFF

P2818 PRESSURE CONTROL SOLENOID (PCS) 7 STUCK ON

P281B PRESSURE CONTROL SOLENOID (PCS) 7 CONTROL CIRCUIT OPEN

CODE

DESCRIPTION

RANGE/PERFORMANCE

CONDITION

SOLENOID (PCS) CONTROL CIRCUIT/OPEN

SOLENOID (PCS) CONTROL CIRCUIT HIGH

SOLENOID (PCS) CONTROL CIRCUIT LOW

LEARNING AT LIMIT)

20

Page 23

DIAGNOSTIC

CODE

P281D PRESSURE CONTROL SOLENOID (PCS) 7 CONTROL CIRCUIT LOW

P281E PRESSURE CONTROL SOLENOID (PCS) 7 CONTROL CIRCUIT HIGH

P2824 PRESSURE CONTROL SOLENOID (PCS) 8 CONTROL CIRCUIT OPEN

P2826 PRESSURE CONTROL SOLENOID (PCS) 8 CONTROL CIRCUIT LOW

P2827 PRESSURE CONTROL SOLENOID (PCS) 8 CONTROL CIRCUIT HIGH

P2832 SHIFT FORK POSITION CIRCUIT PERFORMANCE

P2833 SHIFT FORK POSITION CIRCUIT LOW

P2834 SHIFT FORK POSITION CIRCUIT HIGH

P2849 SHIFT FORK STUCK MOVING TO FORWARD POSITION

P284D SHIFT FORK UNREQUESTED MOVEMENT

P2879 ENGINE/HYBRID CLUTCH SYSTEM SLIPPING

P287A ENGINE CLUTCH STUCK ON

C1312 RETARDER REQUEST SENSOR CIRCUIT LOW

C1313 RETARDER REQUEST SENSOR CIRCUIT HIGH

U0073 CAN COMMUNICATION BUS 1 OFF

U0074 CAN COMMUNICATION BUS 2 OFF

U0100 LOST COMMUNICATIONS WITH ECM A

U0103 LOST COMMUNICATION WITH GEAR SHIFT MODULE 1

U0110 LOST COMMUNICATION WITH DRIVE MOTOR CONTROL MODULE

U0111 LOST COMMUNICATION WITH ENERGY STORAGE SYSTEM

U0287 LOST COMMUNICATION WITH ELECTRIC PUMP

U0291 LOST COMMUNICATION WITH GEAR SHIFT MODULE 2

U0298 LOST COMMUNICATION WITH DC/DC CONVERTER “A”

U0299 LOST COMMUNICATION WITH DC/DC CONVERTER “B”

U0304 GEAR SHIFT MODULE 1 INCOMPATIBLE

U0333 GEAR SHIFT MODULE 2 INCOMPATIBLE

U0404 GEAR SHIFT MODULE 1 INVALID DATA

U0411 INVERTER INVALID DATA

U0412 ENERGY STORAGE SYSTEM INVALID DATA

U0588 ELECTRIC PUMP INVALID DATA

U0592 GEAR SHIFT MODULE 2 INVALID DATA

U0599 DC/DC CONVERTER “A” INVALID DATA

U059A DC/DC CONVERTER “B” INVALID DATA

CODE

DESCRIPTION

CONTROL MODULE

DIAGNOSTIC TRANSMISSION MAIN CODES P281D-U059A

21

Page 24

Information contained in this brochure is designed to give you

an overview of the Oil Level Sensor, Diagnostics and Prognostic

Features on your Allison Automatic and is not intended to replace

your Operator’s Manual.

To order an Operator’s Manual, go to allisontransmission.com or

call toll free 888-666-5799.

One Allison Way

Indianapolis, Indiana, USA 46222-3271

Information or specifications subject to

change without notice or obligation.

allisontransmission.com

SA7497EN (2014/10)

ISO/QS 9000 and ISO 14001 Certified

© 2014 Allison Transmission Inc.

All rights reserved.

Loading...

Loading...