Page 1

Troubleshooting Manual

5000, 6000, 8000, 9000 Series

Off-Highway Transmissions

Commercial Electronic Controls 2 (CEC2)

TS3353EN

Page 2

Troubleshooting

Manual

Allison Off-Highway

5000, 6000, 8000, 9000 Series Transmissions

TS3353EN

Commercial Electronic Controls 2 (CEC 2)

M 5610A, M 5610AR

S 5610H, S 5610NR, S 5610M

M 6610A, M 6610AR

S 6610H, S 6610HR, S 6610M

M 8610A, M 8610AR

S 8610H, S 8610HR, S 8610M, S 8610MR

M 9610A, M 9610AR

S 9610A, S 9610AR, S 9610M, S 9610MR

S 9810A, S 9810AR, S 9810H, S 9810HR, S 9810M, S 9810MR

2000 SEPTEMBER

Division of General Motors Corporation

P.O. Box 894 Indianapolis, Indiana 46206-0894

www.allisontransmission.com

Printed in the U.S.A. Copyright © 2000 General Motors Corp.

Page 3

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

FOREWORD — How to Use This Manual

This manual provides troubleshooting information for Allison Transmission Division, 5000, 6000, 8000, and

9000 Series Off-Highway Transmissions which have CEC 2. Service Manuals SM1866EN (5000, 6000),

SM1228EN (8000) and SM1833EN (9000), plus Parts Catalogs PC1860EN (5000, 6000), PC1249EN (8000) and

PC1830EN (9000) may be used in conjunction with this manual.

This manual includes:

•

Description of the CEC 2 system.

•

Description of the electronic control system components.

Description of diagnostic codes, system responses to faults, and troubleshooting.

•

•

Wire, terminal, and connector repair information.

Specific instructions for using many of the available or required service tools and equipment are not included in

this manual. The service tool manufacturer will furnish instructions for using the tools or equipment.

Additional information may be published from time to time in Service Information Letters (SIL) and will be

included in future revisions of this and other manuals. Please use these SILs to obtain up-to-date information

concerning Allison Transmission products.

This publication is revised periodically to include improvements, new models, special tools, and procedures. A

revision is indicated by a letter suffix added to the publication number. Check with your Allison Transmission

service outlet for the currently applicable publication. Additional copies of this publication may be purchased from

authorized Allison Transmission service outlets or from:

SGI, Inc.

Attn: Allison Literature Fulfillment Desk

8350 Allison A venue

Indianapolis, IN 46268

TOLL FREE: 888-666-5799

INTERNATIONAL: 317-471-4995

Take time to revie w the Table of Contents and the manual. Reviewing the Table of Contents will aid you in quickly

locating information.

NOTE: Allison Transmission is providing for service of wiring harnesses and wiring harness components as

follows:

•

Repair parts for the internal wiring harness and for wiring harness components attached to the

shift selector will be available through the Allison Transmission Parts Distribution Center (PDC).

Use the P/N from your appropriate parts catalog or from Appendix E in this manual. Allison

Transmission is responsible for warranty on these parts.

•

Repair parts for the external harnesses and external harness components must be obtained from

St. Clair Technologies Inc. (SCTI). SCTI provides parts to any Allison customer or OEM and is

responsible for warranty on these parts. SCTI recognizes ATD, manufacturers, and SCTI part

numbers. SCTI provides a technical HELPLINE at 519-627-1673 (Wallaceburg). SCTI will have

parts catalogs available. The SCTI addresses and phone numbers for parts outlets are:

St. Clair Technologies, Inc.

1050 Old Glass Road

Wallaceburg, Ontario, N8A 3T2

Phone: (519) 627-1673

Fax: (519) 627-4227

St. Clair Technologies, Inc.

1111 Mikesell Street

Charlotte, MI 48813

Phone: (517) 541-8166

Fax: (517) 541-8167

St. Clair Technologies, Inc.

c/o Mequilas Tetakawi

Carr. Internationale KM 1969

Guadalajara – Nogales, KM2

Empalme, Sonora, Mexico

Phone: 011-52-622-34661

Fax: 011-52-622-34662

•

St. Clair Technologies, Inc. stocks a CEC 2 external harness repair kit, P/N 29532362, as a source

for some external harness repair parts. SCTI is the source for external harness repair parts.

ii Copyright © 2000 General Motors Corp.

Page 4

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

IMPORTANT SAFETY NOTICE

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings and cautions

used in this manual. These warnings and cautions advise against using specific service

procedures that can result in personal injury, equipment damage, or cause the equipment to

become unsafe. These warnings and cautions are not exhaustive. Allison Transmission could

not possibly know, evaluate, or advise the service trade of all conceivable procedures by which

service might be performed or of the possible hazardous consequences of each procedure.

Consequently, Allison Transmission has not undertaken any such broad evaluation.

Accordingly, ANYONE WHO USES A SERVICE PROCEDURE OR TOOL WHICH IS NOT

RECOMMENDED BY ALLISON TRANSMISSION MUST first be thoroughly satisfied

that neither personal safety nor equipment safety will be jeopardized by the service

procedures used.

Also, be sure to review and observe WARNINGS, CAUTIONS, and NOTES provided by the

vehicle manufacturer and/or body builder before servicing the Allison transmission in that

vehicle.

Proper service and repair is important to the safe and reliable operation of the equipment.

The service procedures recommended by Allison Transmission and described in this manual

are effective methods for performing troubleshooting operations. Some procedures require

using specially designed tools. Use special tools when and in the manner recommended.

The WARNINGS, CAUTIONS, and NOTES in this manual apply only to the Allison transmission

and not to other vehicle systems which may interact with the transmission. Be sure to review and

observe any vehicle system information provided by the vehicle manufacturer and/or body b uilder

at all times the Allison transmission is being serviced.

WARNINGS, CAUTIONS, AND NOTES

Three types of headings are used in this manual to attract your attention:

WARNING!

Is used when an operating procedure, practice, etc., which, if not correctly followed,

could result in injury or loss of life.

CAUTION:

NOTE: Is used when an operating procedure, practice, etc., is essential to highlight.

Is used when an operating procedure, practice, etc., which, if not strictly observed, could

result in damage to or destruction of equipment.

Copyright © 2000 General Motors Corp. iii

Page 5

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

INTRODUCTION

TRADEMARKS USED IN THIS MANUAL

The following trademarks are the property of the companies indicated:

®

•

LPS

Cleaner is a registered trademark of LPS Laboratories.

•

Loctite

•

Teflon

•

Pro-Link

®

is a registered trademark of the Loctite Corporation.

®

is a registered trademark of the DuPont Corporation.

®

is a registered trademark of MicroProcessor Systems, Inc.

iv Copyright © 2000 General Motors Corp.

Page 6

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

TABLE OF CONTENTS

Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

SAFETY INFORMATION

Important Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warnings, Cautions, and Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Trademarks Used in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

SECTION 1. GENERAL DESCRIPTION

1–1. TRANSMISSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1–2. ELECTRONIC CONTROL UNIT (ECU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1–3. SHIFT SELECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

A. Pushbutton Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

B. Lever Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1–4. THROTTLE POSITION SENSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1–5. SPEED SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1–6. ELECTRO-HYDRAULIC VALVE COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1–7. WIRING HARNESSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

A. External Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

B. Internal Wiring Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

1–8. VEHICLE INTERFACE MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

1–9. AUTODETECT FEATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

Page

SECTION 2. DEFINITIONS AND ABBREVIATIONS

2–1. CHECK TRANS LIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2–2. DIAGNOSTIC DATA READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2–3. ABBREVIATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

SECTION 3. BASIC KNOWLEDGE

3–1. BASIC KNOWLEDGE REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3–2. USING THE TROUBLESHOOTING MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–3. SYSTEM OVERVIEW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–4. IMPORTANT INFORMATION IN THE TROUBLESHOOTING PROCESS . . . . . . . . . . . . . . . . 3–2

3–5. BEGINNING THE TROUBLESHOOTING PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

SECTION 4. WIRE CHECK PROCEDURES

4–1. CHECKING OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND . . . . . . . . . 4–1

4–2. CHECKING AT TRANSMISSION CONNECTOR AND THE INTERNAL HARNESS

FOR OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND. . . . . . . . . . . . . . . . 4–2

Copyright © 2000 General Motors Corp. v

Page 7

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

TABLE OF CONTENTS

SECTION 5. DIAGNOSTIC CODES

5–1. DIAGNOSTIC CODE MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5–2. CODE READING AND CODE CLEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5–3. DIAGNOSTIC CODE RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

5–4. SHIFT SELECTOR DISPLAYS RELATED TO ACTIVE CODES . . . . . . . . . . . . . . . . . . . . . . . . 5–3

5–5. DIAGNOSTIC CODE LIST AND DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

5–6. DIAGNOSTIC CODE TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–11

A. Beginning the Troubleshooting Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–11

B. Wire/Terminal Numbering Scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–11

SECTION 6. VEHICLE INTERFACE WIRING

6–1. ECU POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6–2. SYSTEM GROUNDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

6–3. POWER AND GROUND USING A BUS BAR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

6–4. INSTALLING A MASTER DISCONNECT SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

6–5. IGNITION POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

6–6. CHECK TRANS LIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

6–7. NEUTRAL START. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

6–8. SPEEDOMETER SIGNAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–8

6–9. REVERSE WARNING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–9

6–10. SHIFT SELECTOR/DISPLAY DIMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–10

6–11. SERIAL COMMUNICATION INTERFACE (SCI) — J1587/J1708. . . . . . . . . . . . . . . . . . . . . . . 6–11

6–12. COMMUNICATION INTERFACE — SAE J1939 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–12

(cont’d)

Page

SECTION 7. INPUT AND OUTPUT FUNCTIONS

7–1. INPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

7–2. OUTPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

vi Copyright © 2000 General Motors Corp.

Page 8

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

TABLE OF CONTENTS

SECTION 8. GENERAL TROUBLESHOOTING OF PERFORMANCE COMPLAINTS . . . . . . . .8–1

APPENDICES

A. IDENTIFICATION OF POTENTIAL CIRCUIT PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . .A–1

B. WIRE/CONNECTOR CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B–1

C. CONNECTOR PART NUMBERS, TERMINAL PART NUMBERS,

TOOL PART NUMBERS, AND REPAIR INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C–1

D. THROTTLE POSITION SENSOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D–1

E. WELDING ON VEHICLE/VEHICLE INTERFACE MODULE . . . . . . . . . . . . . . . . . . . . . . . . . .E–1

F. HYDRAULIC SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–1

G. CEC 2 WIRING SYSTEM/ECU WIRING SCHEMATICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G–1

H. EXTERNALLY-GENERATED ELECTRONIC INTERFERENCE . . . . . . . . . . . . . . . . . . . . . . . .H–1

J. PRO-LINK

K. WIRING SCHEMATICS — SPECIFIC INPUT/OUTPUT FUNCTION . . . . . . . . . . . . . . . . . . . .K–1

L. SUMP THERMISTOR TROUBLESHOOTING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . L–1

®

9000 DIAGNOSTIC DATA READER INFORMATION. . . . . . . . . . . . . . . . . . . . . . J–1

(cont’d)

Page

Copyright © 2000 General Motors Corp. vii

Page 9

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

TABLE OF CONTENTS

NOTES

(cont’d)

viii Copyright © 2000 General Motors Corp.

Page 10

SHIFT SELECTOR

RANGE AND

MODE SWITCH

DISPLAY

VIM

INPUTS OUTPUTS

ECU

SPEED SENSORS

THROTTLE POSITION SENSOR

V03469.01

TEMPERATURE SENSOR

(SUMP)

VEHICLE/ENGINE

COMMUNICATION LINKS

SOLENOIDS

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

S

ECTION

1 — GENERAL DESCRIPTION

1–1. TRANSMISSION

The Commercial Electronic Controls 2 (CEC 2) system features clutch control to provide superior shift quality

over a wide range of operating conditions.

The ranges available in CEC 2-equipped Off-Highway transmissions are as follows.

•

5610, 6610, 9610 — six forward, neutral, two reverses

•

8610 — six forward, neutral, reverse

9810 — eight forward, neutral

•

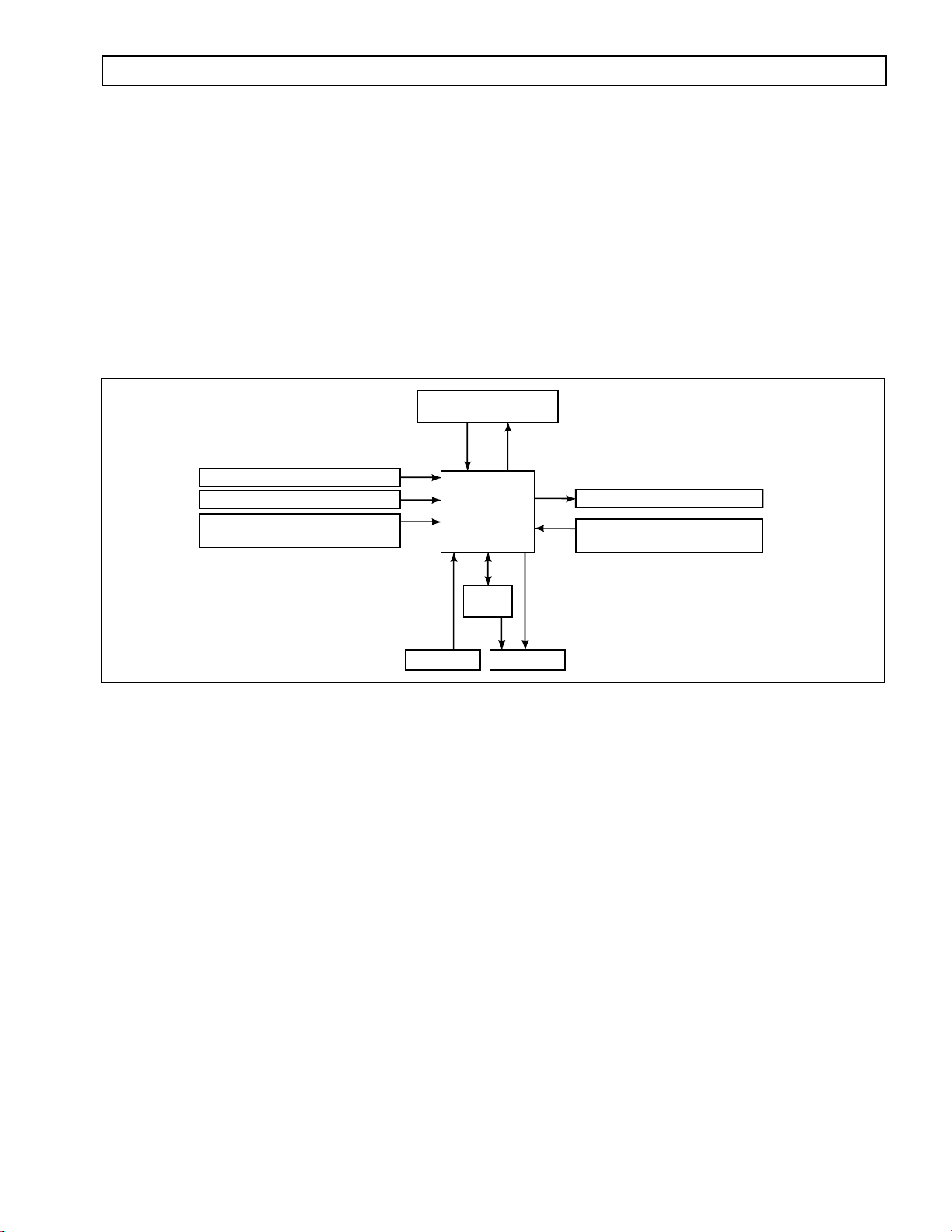

Figure 1–1 is a block diagram of the basic system inputs and outputs.

Figure 1–1. Electronic Control Unit Block Diagram

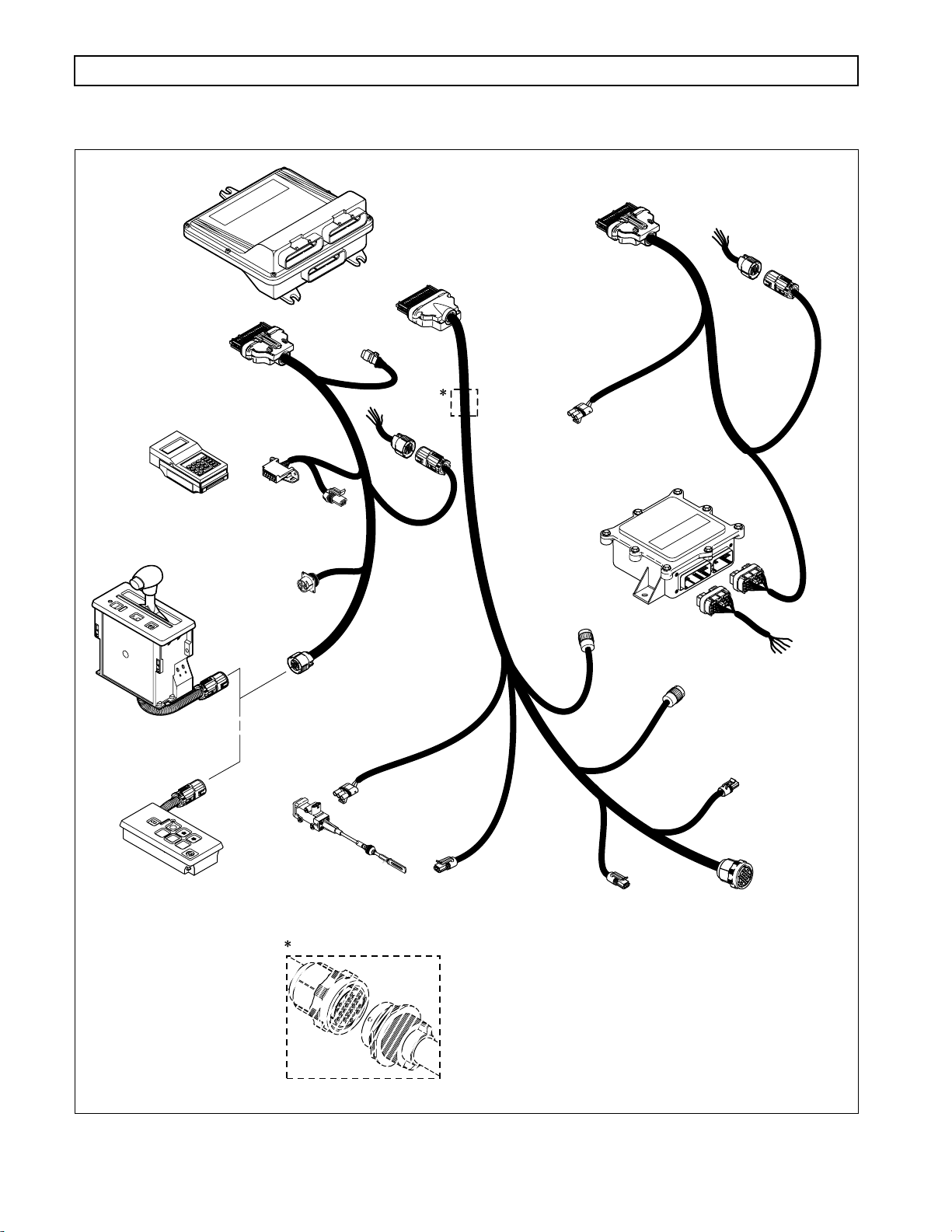

Figure 1–2 shows the CEC 2 electronic control components.

CEC 2 consists of the following elements:

Remote 12/24V Max Feature Sealed Electronic Control Unit (ECU)

•

•

Remote Pushbutton or Lever Shift Selector

•

Optional Secondary Shift Selector

Throttle Position Sensor (TPS) (or electronic engine throttle data)

•

•

Input, Turbine, and Output Speed Sensors

Electro-Hydraulic Valve Bodies

•

Wiring Harnesses

•

•

Vehicle Interface Module (VIM)

NOTE:

•

All external harnesses are OEM supplied

The VIM is an OEM option

•

Copyright © 2000 General Motors Corp. 1–1

Page 11

BLUE

BLUE

BLACK

GRA

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

ELECTRONIC

CONTROL

UNIT

(ECU)

SELECTOR (S)

HARNESS

®

PRO-LINK

DIAGNOSTIC

REMOTE

SELECTOR

TOOL

LEVER

BLACK

B

“S”

CONNECTOR

(BLACK)

DIAGNOSTIC

DATA READER (DDR)

CONNECTOR

DEUTSCH DDR

CONNECTOR

SCI (J 1587)

CONNECTOR

(OPTIONAL)

(OPTIONAL)

LUE

Y

A

GR

E

BLU

J 1939

CONNECTOR

(OPTIONAL)

TRANSMISSION (T)

HARNESS

“T”

CONNECTOR

(BLUE)

VIW–S

CONNECTOR

“V”

CONNECTOR

(GRAY)

TPS

CONNECTOR

(OPTIONAL)

VEHICLE

INTERFACE

MODULE

(VIM)

TRIM

BOOST

CONNECTOR

VEHICLE (V)

HARNESS

CONNECTOR

VIM

CONNECTORS

VIW–V

PUSHBUTTON

.

REMOTE

SELECTOR

T

C

E

L

E

S

SHIFT

SELECTOR

CONNECTOR

THROTTLE POSITION

E

D

O

M

R

N

D

THROTTLE

POSITION

SENSOR (TPS)

SENSOR (TPS)

CONNECTOR

SPEED SENSOR

CONNECTOR

TURBINE

INPUT (ENGINE)

SPEED SENSOR

CONNECTOR

Bulkhead Connector (Optional)

NOTE: Illustration is not to scale. Actual harness

configuration may differ from this illustration.

TEMP SENSOR/

LOCKUP

CONNECTOR

SPEED SENSOR

CONNECTOR

TRANSMISSION

MAIN VALVE

BODY

CONNECTOR

OUTPUT

V06587

Figure 1–2. CEC 2 Components

1–2 Copyright © 2000 General Motors Corp.

Page 12

BLUE

BLUE

BLACK

GRA

⇑

⇓

⇑

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

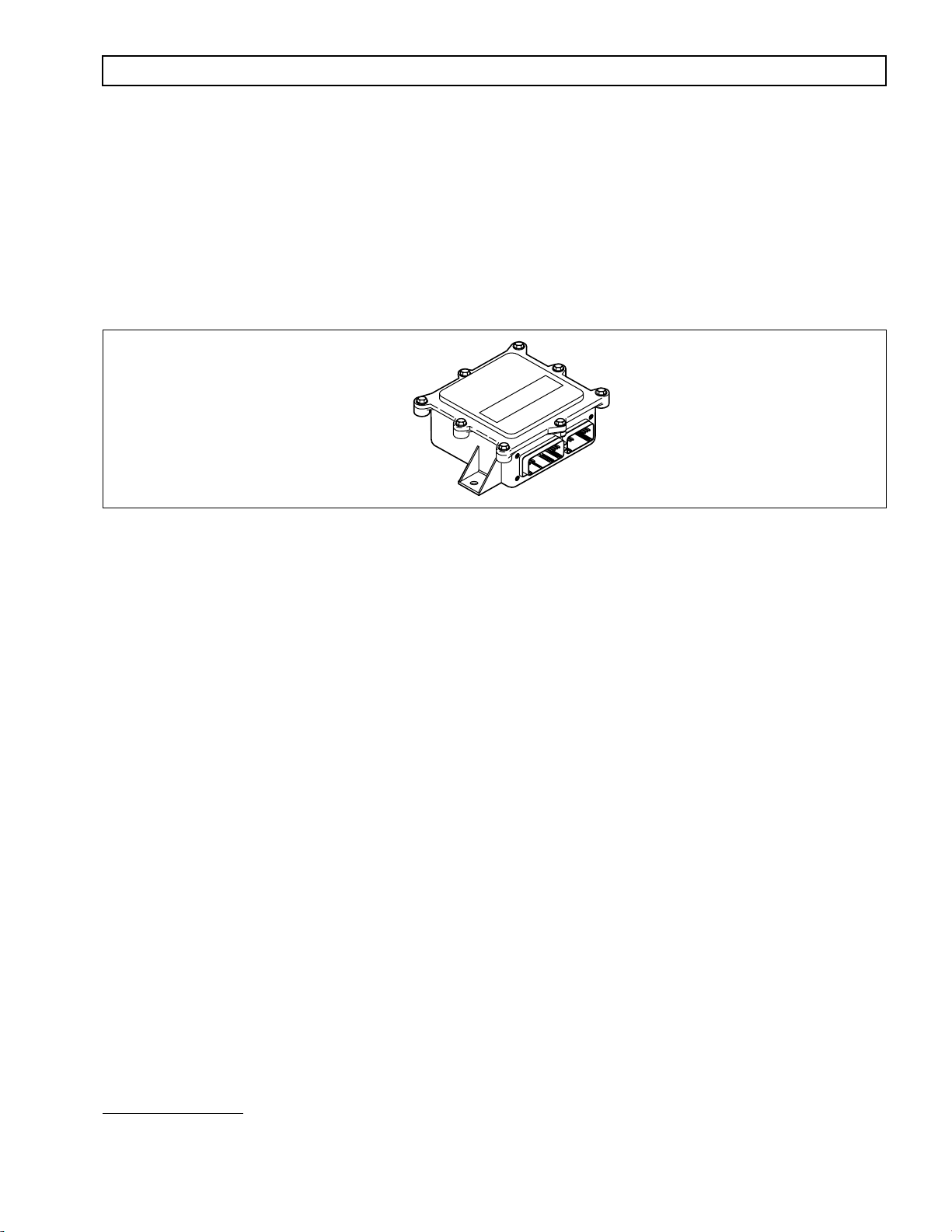

1–2. ELECTRONIC CONTROL UNIT (ECU)

The ECU (Figure 1–3) contains the microcomputer which is the brain of the control system. The ECU receives and

processes information defining: shift selector position, throttle position, sump temperature, input speed, turbine

speed, and transmission output speed. The ECU uses the information to control transmission solenoids and valves,

supply system status, and provide diagnostic information.

Each ECU has a date code stamped on the label which is attached to the outer case of the ECU. This is the date

when the ECU passed final test. This date is commonly used to denote the change configuration level of the ECU.

It is normal for the ECU date displayed electronically to be a few days prior to the date shown on the label.

Y

A

R

G

NOTE: ECU wiring harness connector retainers

are individually keyed and color-coded to

ensure that the proper connector is attached

K

C

A

L

B

BLUE

to the correct ECU socket. The color of the

connector retainer should match the color of

the connector strain relief (see Appendix C,

BLUE

ECU

Paragraph 1–1).

Figure 1–3. Electronic Control Unit (ECU)

V03352.01

1–3. SHIFT SELECTOR

Pushbutton and lever shift selectors for CEC 2 are remote mounted from the ECU and connected to the ECU by a

wiring harness. Both of these shift selectors have a single digit LED display and a mode indicator LED. During

normal transmission operation, illumination of the LED indicator shows that a secondary or special operating

condition has been selected by pressing the MODE button. During diagnostic display mode, illumination of the

LED indicator shows that the displayed diagnostic code is active. Display brightness is regulated by the same

vehicle potentiometer that controls dash light display brightness. More information on both types of shift selectors

is continued below.

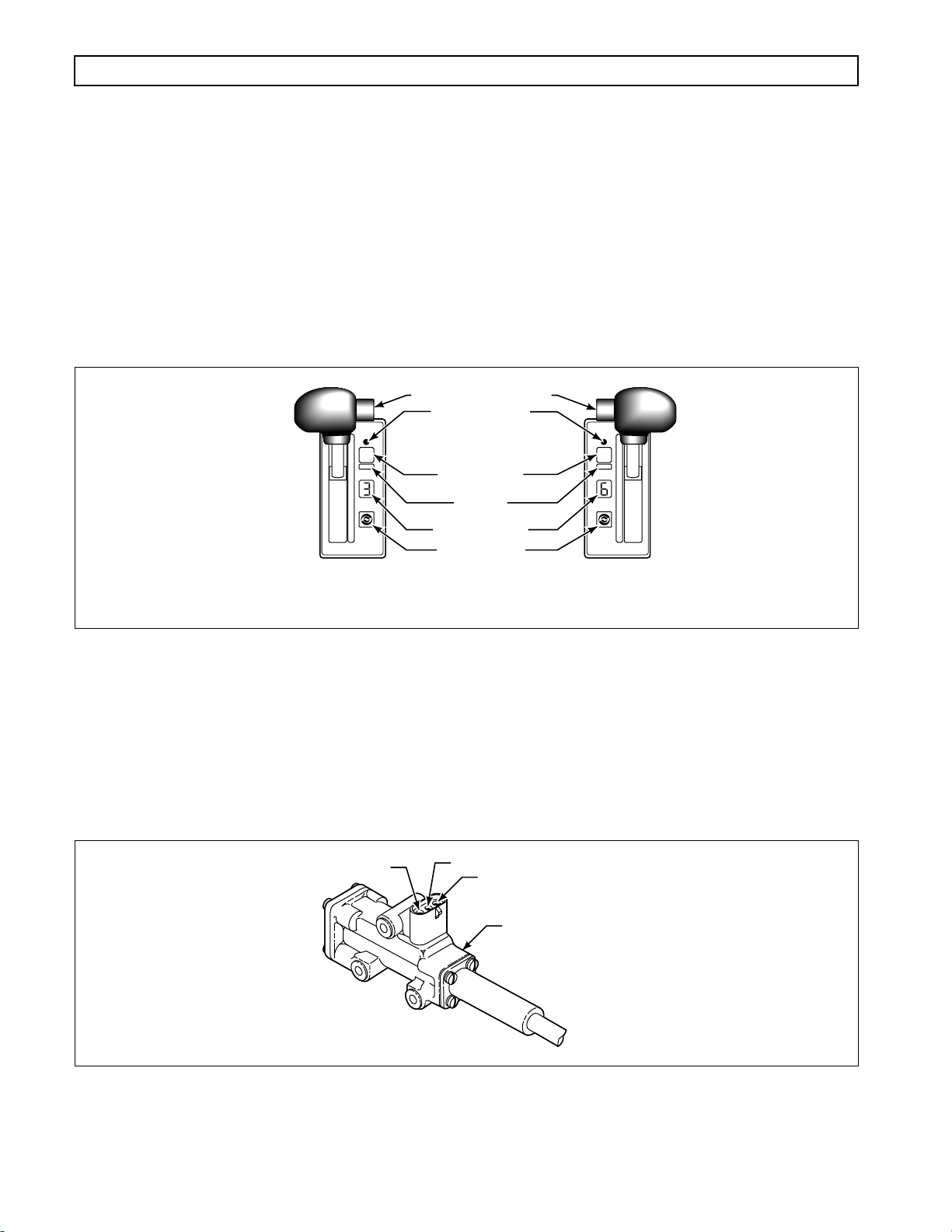

A. Pushbutton Shift Selector (Figure 1–4)

There is a full-function pushbutton shift selector. A full-function shift selector has a MODE button

and diagnostic display capability through the single digit LED display. The full-function pushbutton

shift selector has six (6) pushbuttons which are R (Reverse), N (Neutral), D (Drive), ⇓ (Down),

(Up), and MODE . Manual forward range downshifts and upshifts are made by pressing the

(Down) or ⇑ (Up) arrow buttons after selecting D (Drive). The N (Neutral) button has a raised lip to

aid in finding it by touch. The MODE button is pressed to select a secondary or special operating

condition, such as ECONOMY shift schedule. Diagnostic information is obtained by pressing the

(Up) and ⇓ (Down) arrow buttons at the same time.

MODE ID

MODE

R

N

D

MODE INDICATOR (LED)

PUSHBUTTON

SELECTOR

Figure 1–4. Pushbutton Shift Selector

Copyright © 2000 General Motors Corp. 1–3

V06588

Page 13

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

B. Lever Shift Selector (Figure 1–5)

The lever shift selector can have as many as six forward range positions, as well as two R (Reverse)

positions ( R1 and R2 ) and N (Neutral). There is a hold override button which must be pressed and

held in order to move between certain selector positions. The hold override button must be pressed

when shifting between R , N, and D . The hold override button is released when the desired selector

position is reached. The selector lever can be moved freely between D and the numbered forward

ranges without pressing the hold override button. The lever selector can be chosen with the lever on

the left side or on the right side and with the R (Reverse) position toward the front or toward the rear

of the selector. Diagnostic information is obtained from the single digit LED display by pressing the

“display mode” button.

HOLD OVERRIDE BUTTON

MODE INDICATOR

(LED)

1

MODE

2

3

4

5

D

N

R

SIX-SPEED, LEFT-HAND

LEVER SELECTOR

WITH REVERSE TO REAR

MODE BUTTON

MODE ID

DIGITAL DISPLAY

DISPLAY MODE/

DIAGNOSTIC BUTTON

SIX-SPEED, RIGHT-HAND

LEVER SELECTOR

WITH REVERSE TO FRONT

R

MODE

N

D

5

4

3

2

1

V03355.02

Figure 1–5. Typical Lever Shift Selector

1–4. THROTTLE POSITION SENSOR (Figure 1–6)

The Throttle Position Sensor (TPS) can be mounted to the engine, chassis, or transmission. The TPS contains a pull

actuation cable and a potentiometer. One end of the cable is attached to the engine fuel lever and the other , inside a

protective housing, to the TPS potentiometer. Output voltage from the TPS is directed to the ECU through the

external harness. The voltage signal indicates the throttle position and, in combination with other input data,

determines shift timing.

A

Figure 1–6. Throttle Position Sensor

B

C

THROTTLE SENSOR

V00628

1–4 Copyright © 2000 General Motors Corp.

Page 14

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

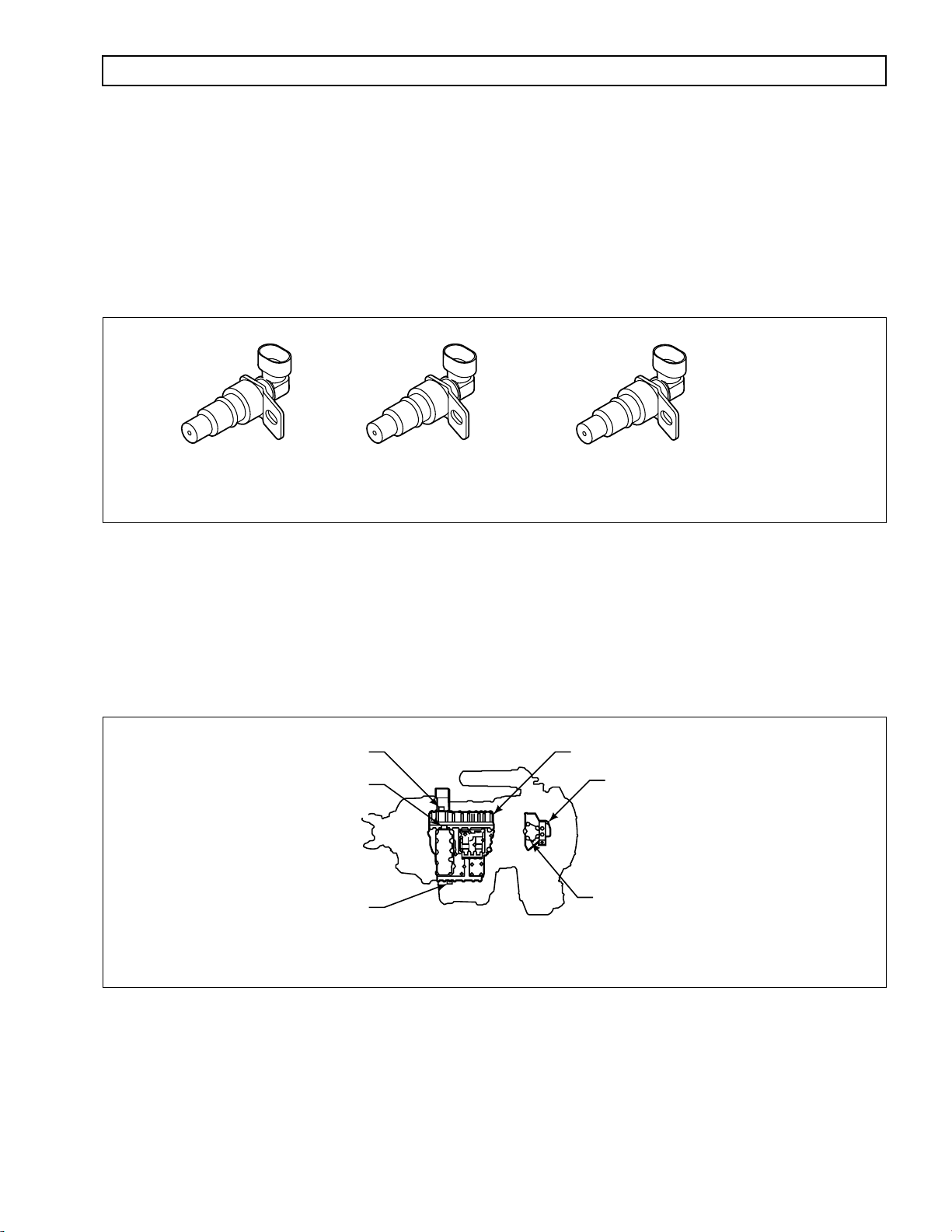

1–5. SPEED SENSORS

(Figure 1–7)

Three speed sensors — input speed, turbine speed, and output speed — provide information to the ECU. The input

speed signal is generated by the gear teeth on the top PTO gear . The turbine speed signal is generated by serrations

on the pitot can attached to the splitter low drum. The output speed signal is generated by a toothed member

attached to the output shaft. The speed ratios between the various speed sensors allow the ECU to determine if the

transmission is in the selected range. Hydraulic problems are detected by comparing the speed sensor information

for the current range to that range’s speed sensor information stored in the ECU memory.

INPUT

(EXTERNAL)

TURBINE

(EXTERNAL)

Figure 1–7. Speed Sensors

OUTPUT

(EXTERNAL)

V06589

1–6. ELECTRO-HYDRAULIC VALVE COMPONENTS (Figure 1–8)

The CEC 2 electro-hydraulic valve bodies contain v arious solenoids to control the absence or presence of solenoid

pressure. Solenoid pressure, or lack of pressure, positions shift valves which apply or release transmission clutches

to produce the range commanded by the ECU inputs. The ECU is connected to the solenoids by a wiring harness

with sealed multi-pin twist-lock connectors at the control valve bodies.

(Solenoids A – G)

PLATE & COVER CONNECTOR

(Solenoids H, I, & J)

8610, 9610, 9810

TRIM BOOST CONNECTOR

(Solenoid J)

5610, 6610

5/6/8/9000 SERIES OFF-HIGHWAY TRANSMISSION

Figure 1–8. CEC 2 Control Module

MAIN VALVE BODYMAIN CONNECTOR – ALL MODELS

LOCKUP VALVE BODY

LOCKUP CONNECTOR – ALL MODELS

(K Solenoid and sump

temperature sensor)

V06590

Copyright © 2000 General Motors Corp. 1–5

Page 15

a

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

The sump temperature sensor in the lockup body sends information to the ECU. When oil temperature is below

–25ºF (–32ºC), all shifts are blocked. When oil temperature is between –25ºF

transmission shifting is limited to neutral, to limited forward ranges

a

, and reverse. Above 250ºF

a

(–32ºC) and 20ºF

a

(–7ºC),

a

(121ºC), the Hot

light comes on (if equipped), and a trouble code is stored in memory. See chart in Section 5, Code 24 for sump

temperature sensor (thermistor) characteristics. Some applications (emergency vehicles, for example) are often

exempt from shift inhibit during temperature extremes, b ut the

CHECK TRANS

light may still come on and codes

may be logged in the ECU memory.

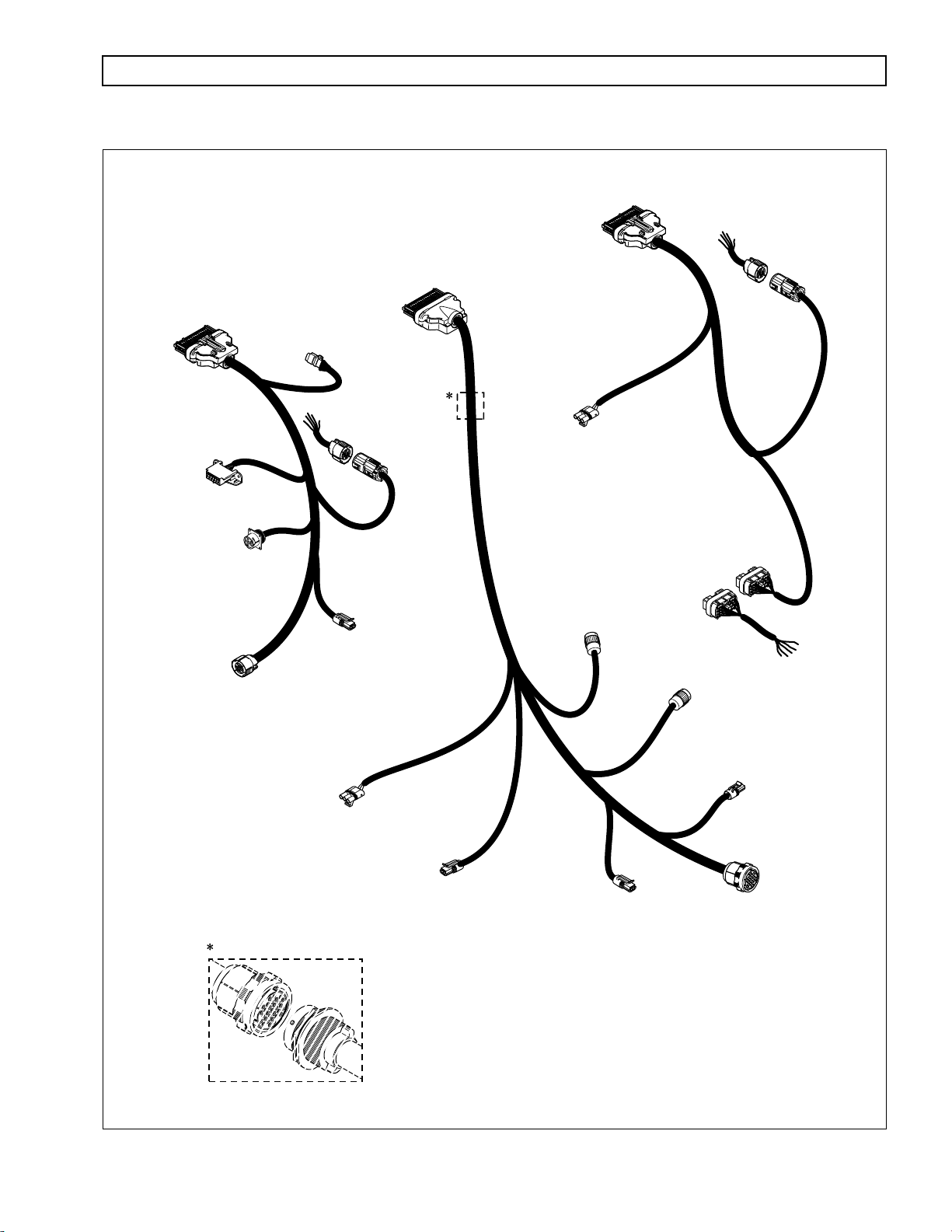

1–7. WIRING HARNESSES

A. External Wiring Harness (Figure 1–9)

CEC 2 uses three external wiring harnesses to provide a connection between the ECU, the

transmission (including input, turbine, and output speed sensors), the throttle position sensor, the

vehicle interface module (VIM), shift selectors, diagnostic tool connector, and vehicle interface. The

transmission harness may include a bulkhead fitting to separate cab and chassis components.

NOTE: Allison Transmission is providing for service of wiring harnesses and wiring harness components as

follows:

•

Repair parts for the internal wiring harness and for wiring harness components attached to the

shift selector will be available through the Allison Transmission Parts Distribution Center

(PDC). Use the P/N from your appropriate parts catalog or from Appendix C in this manual.

Allison Transmission is responsible for warranty on these parts.

Repair parts for the external harnesses and external harness components must be obtained from

•

St. Clair Technologies Inc. (SCTI). SCTI provides parts to any Allison customer or OEM and is

responsible for warranty on these parts. SCTI recognizes ATD, manufacturers, and SCTI part

numbers. SCTI provides a technical HELPLINE at 519-627-1673 (Wallaceburg). SCTI will have

parts catalogs available. The SCTI addresses and phone numbers for parts outlets are:

St. Clair Technologies, Inc.

1050 Old Glass Road

Wallaceburg, Ontario N8A 3T2

Phone: (519) 627-1673

Fax: (519) 627-4227

St. Clair Technologies, Inc.

1111 Mikesell Street

Charlotte, MI 48813

Phone: (517) 541-8166

Fax: (517) 541-8167

St. Clair Technologies, Inc.

c/o Mequilas Tetakawi

Carr. Internationale KM 1969

Guadalajara – Nogales, KM2

Empalme, Sonora, Mexico

Phone: 011-52-622-34661

Fax: 011-52-622-34662

•

St. Clair Technologies, Inc. stocks a CEC 2 external harness repair kit, P/N 29532362, as a source

for some external harness repair parts. SCTI is the source for external harness repair parts.

This is a programmed value subject to change.

1–6 Copyright © 2000 General Motors Corp.

Page 16

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

VEHICLE (V)

HARNESS

SELECTOR (S)

HARNESS

“S”

CONNECTOR

(BLACK)

PRO-LINK®

DIAGNOSTIC

DIAGNOSTIC

TOOL

DATA READER (DDR)

CONNECTOR

DEUTSCH DDR

CONNECTOR

(OPTIONAL)

SHIFT

SELECTOR

CONNECTOR

J 1939

CONNECTOR

(OPTIONAL)

TRANSMISSION (T)

VIW–S

CONNECTOR

SCI (J 1587)

CONNECTOR

(OPTIONAL)

HARNESS

CONNECTOR

(BLUE)

“T”

“V”

CONNECTOR

(GRAY)

TPS

CONNECTOR

(OPTIONAL)

TRIM

BOOST

CONNECTOR

VIM

CONNECTORS

TEMP SENSOR/

LOCKUP

CONNECTOR

VIW–V

CONNECTOR

THROTTLE POSITION

SENSOR (TPS)

CONNECTOR

Bulkhead Connector (Optional)

OUTPUT

SPEED SENSOR

CONNECTOR

TURBINE

SPEED SENSOR

CONNECTOR

NOTE: Illustration is not to scale. Actual harness

configuration may differ from this illustration.

INPUT (ENGINE)

SPEED SENSOR

CONNECTOR

TRANSMISSION

MAIN VALVE

BODY

CONNECTOR

V06591

Figure 1–9. CEC 2 External Wiring Harnesses

Copyright © 2000 General Motors Corp. 1–7

Page 17

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

B. Internal Wiring Harnesses (Figure 1–10)

The internal wiring harnesses provide connection between the external harness, solenoids, and the

temperature sensor.

INTERNAL

HARNESS

A

B

C

D

E

F

INTERNAL

HARNESS

G

LOCKUP BODY

ALL MODELS

MAIN BODY SOLENOIDS & COVER

ALL MODELS

TRIM BOOST PLATE & COVER

9610 MODEL

J SOLENOID CONNECTOR

INTERNAL

HARNESS

INTERNAL

HARNESS

FIRST or LOW-LOW PLATE & COVER

8610, 9810 MODEL

INTERNAL

HARNESS

TRIM BOOST TRIMMER COVER

5610, 6610 MODEL

Figure 1–10. CEC 2 Internal Wiring Harnesses

1–8 Copyright © 2000 General Motors Corp.

L06592

Page 18

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

a

1–8. VEHICLE INTERFACE MODULE

(Figure 1–11)

The vehicle interface module (VIM) provides relays, fuses, and connection points to interface with the vehicle

electrical system. VIMs are available for both 12V and 24V electrical systems. The VIM for 12V systems uses all

12V relays. The VIM for 24V systems has all 24V relays. Refer to the P arts Catalog for the transmission assembly

number that you are servicing for detailed parts information. Refer to Pages B–19 and B–20 for VIM wire number

and terminal information. Further information is available in Appendix E.

Some OEMs may provide their own equi valent for the VIM which performs the same functions as the VIM shown

in Figure 1–11.

V00631.02

Figure 1–11. Vehicle Interface Module (VIM)

1–9. AUTODETECT FEATURE

Autodetect is active on the first 10

a

engine starts. Autodetect takes place within the first 5–25

engine start monitored. For CEC 2, autodetect searches for the presence of a throttle information source.

Autodetect searches for a TPS (analog) source or a data link source via J1939 or J1587.

a

seconds of each

This is a programmed value subject to change.

Copyright © 2000 General Motors Corp. 1–9

Page 19

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

GENERAL DESCRIPTION

NOTES

1–10 Copyright © 2000 General Motors Corp.

Page 20

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

S

ECTION

2 — DEFINITIONS AND ABBREVIATIONS

2–1. CHECK TRANS LIGHT

When the ECU detects an abnormal condition, the

instrument panel) illuminates and action is automatically taken to protect operator, v ehicle, and the transmission. A

diagnostic code will nearly always be registered when the

codes will turn on the

CHECK TRANS

light. Codes related to the

chart (refer to Section 5).

Illumination of the

CHECK TRANS

light indicates that a condition was detected that requires service attention.

Operation of the transmission may or may not be restricted. Depending upon the cause for the

light illumination, the ECU may or may not respond to shift selector requests. The transmission may be locked in a

range. The range selected will flash on the shift selector display. Both upshifts and downshifts may be restricted

when the

Each time the engine is started, the

CHECK TRANS

light is illuminated. Seek service assistance as soon as possible.

CHECK TRANS

lighting shows the light circuit is working properly. If the light does not come on during engine start, request

service immediately.

2–2. DIAGNOSTIC DATA READER

The current Diagnostic Data Reader (DDR) is the Pro-Link® 9000 diagnostic tool which is available through

Micro Processor Systems, Inc. (MPSI). A portable microcomputer-based receiver/transmitter/display unit, the

Pro-Link® transmits and receives data to and from the ECU, processes the data, and displays appropriate

information. Use the Pro-Link® during installation checkout and troubleshooting. There is a new Pro-Link®

cartridge needed for use with CEC 2. The new Multi-Protocol Cartridge (MPC) contains a programmed PCMCIA

card which allows for reprogramming of GPI/GPO packages. Reprogramming includes selection of a GPI/GPO

package, enabling/disabling of wires and modification of certain data parameters. Operating instructions are

supplied with each Pro-Link

Pro-Link

®

9000 to the diagnostic connector provided in the selector wiring harness.

Manufacturer’s description and part numbers for the Pro-Link

®

and further information is also included in Appendix J of this manual. Connect the

CHECK TRANS

CHECK TRANS

light illuminates briefly and then goes off. This momentary

Figure 2–1)

(

light (usually located on the vehicle

CHECK TRANS

®

are as follows:

light is on; howev er , not all diagnostic

light are detailed in the code

CHECK TRANS

Product Part Number

Allison CEC 1 and 2 transmission systems reprogramming card*

800007

Includes: Allison CEC 1 and 2 systems card and manual

* Allison training certificate required

Pro-Link

Multi-Protocol Cartridge (MPC)

®

Plus main unit

Includes: VT Pro-Link

®

software, power and data cable, and storage case

108004

208040

Supports: J1708, J1939, 160 baud, and ISO 9141 communications,

OEM specific application memory cards

Printer

178001

Includes: One roll of thermal paper, an AC power converter,

Instruction manual, built-in Ni-Cad battery and a cable to connect

the printer to the Pro-Link

®

Plus

6-Pin Deutsch Adapter 404024

PC/Terminal Cable Set

501005

Required to update PC card application

Pro-Link

®

9000 Operator’s Manual 950007

Copyright © 2000 General Motors Corp. 2–1

Page 21

A

C

C

C

D

D O N

D

C

D

E

G

G

L

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DEFINITIONS AND ABBREVIATIONS

NOTE: The new MPC must be used to reprogram CEC 2 systems.

Figure 2–1. Pro-Link

®

9000 Diagnostic Tool

V04842

2–3. ABBREVIATIONS

A/N

Amp Unit of electrical current.

CAN

CEC 1/CEC 2

COP

CT

DDR

DDU

DNS

DVOM

ssembly N umber

ontroller A rea N etwork — A network for all SAE J1939 communications in a vehicle

(engine, transmission, etc.)

ommercial E lectronic C ontrols 1 or 2 — Designation for electronic controls used in

off-highway and some older on-highway transmissions.

omputer O perating P roperly — Hardware protection which causes the ECU to reset if

software gets lost.

losed T hrottle

iagnostic D ata R eader — Diagnostic tool; most current version is the Pro-Link

made by MicroProcessor Systems, Inc. Used to interrogate the ECU for diagnostic

information and for reprogramming I/O packages in a calibration.

igital D isplay U nit — Optional means of obtaining diagnostic information.

OT S HIFT — Refers to the DO NOT SHIFT diagnostic response during which the

CHECK TRANS light is illuminated and the transmission will not shift and will not

respond to the Shift Selector.

igital v olt/ o hm m eter

®

9000

ECU

GPI

lectronic C ontrol U nit (also commonly referred to as the “computer”)

eneral P urpose I nput — Input signal to the ECU to request a special operating mode or

condition.

GPO

eneral P urpose O utput — Output signal from the ECU to control vehicle components

(such as PTOs, backup lights, etc.) or allow a special operating mode or condition.

J1587 Engine/transmission serial data communications link.

J1939 High-speed vehicle serial data communications link.

LED

2–2 Copyright © 2000 General Motors Corp.

ight- E mitting D iode — Electronic device used for illumination.

Page 22

N

O

P

P

P

P

P

S

S

S

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DEFINITIONS AND ABBREVIATIONS

T

V

V

V

V

V

2–3. ABBREVIATIONS

NVL

OEM

Ohm Unit of electrical resistance.

PCCS

PCMCIA

PROM

PSS

PTO

SCI

SOL OFF All SOL enoids OFF

SPI

SSS

eutral V ery L ow — The ECU has sensed turbine speed below 150 rpm when output

speed is below 100 rpm and engine speed is above 400 rpm when N (Neutral) was selected.

riginal E quipment M anufacturer — Maker of vehicle or equipment.

ROM C alibration C onfiguration S ystem

ersonal C omputer M emory C ard I nternational A ssociation — Memory device for use

with Pro-Link

rogrammable R ead O nly M emory

rimary S hift S elector — Main shift selector in a two-selector control system.

ower T ake o ff

erial C ommunication I nterface — Used to transmit data and messages between the

diagnostic tool and the ECU and other systems such as electronically-controlled engines.

erial P eripheral I nterface — The means of communication between the microprocessor

and the interface circuits.

econdary S hift S elector — Alternate shift selector in a two-selector control system.

(cont’d)

®

containing Allison Transmission programming and diagnostics.

TPS

V

V

VDC

VIM

VIW

Volt Unit of electrical force.

VOM

WOT

∞

hrottle P osition S ensor — Potentiometer for signaling the position of the engine fuel

control lever.

ersion — Abbreviation used in describing ECU software levels.

olt — i.e., 24V

olts D irect C urrent (DC)

ehicle I nterface M odule — A w atertight box containing relays and fuses — interfaces the

transmission electronic control system with components on the vehicle.

ehicle I

the vehicle wiring.

V

olt/ohmmeter

W

Infinity — Condition of a circuit with higher resistance than can be measured, effectively

an open circuit.

nterface Wiring — Interfaces ECU programmed input and output functions with

ide Open Throttle

Copyright © 2000 General Motors Corp. 2–3

Page 23

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DEFINITIONS AND ABBREVIATIONS

NOTES

2–4 Copyright © 2000 General Motors Corp.

Page 24

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

S

ECTION

3 — BASIC KNOWLEDGE

3–1. BASIC KNOWLEDGE REQUIRED

T o service CEC 2, the technician must understand basic electrical concepts. Technicians need to know how to use a

volt/ohmmeter (VOM) to mak e resistance and continuity checks. Most troubleshooting checks consist of checking

resistance, continuity, and checking for shorts between wires and to ground. The technician should be able to use

jumper wires and breakout harnesses and connectors. Technicians unsure of making the required checks should ask

questions of experienced personnel or find instruction.

The technician should also have the mechanical aptitude required to connect pressure gauges or transducers to

identified pressure ports used in the troubleshooting process. Pressure tap locations and pressure values are shown

in the Service Manual for the transmission being checked.

Input power , ground, neutral start circuitry, etc., can cause problems with electronic controls or vehicle functioning

and may not generate a diagnostic code. A working knowledge of CEC 2 vehicle installation is necessary in

troubleshooting installation-related problems.

Refer to Section 8 for information concerning performance complaints (non-code) troubleshooting. A complete

wiring schematic is shown in Appendix G. Refer to the CEC 2 Controls and Off-Highway Sales Tech Data Book

(SA3227EN) for information concerning electronic controls installation and the Installation Checklist. Reliable

transmission operation and performance depend upon a correctly installed transmission. Also review the

Installation Checklist in the Off-Highway Sales Tech Data Book (SA1861EN) to ensure proper installation.

NOTE: Allison Transmission is providing for service of wiring harnesses and wiring harness components as

follows:

Repair parts for the internal wiring harness and for wiring harness components attached to the

•

shift selector will be available through the Allison Transmission Parts Distribution Center (PDC).

Use the P/N from your appropriate parts catalog or from Appendix C in this manual. Allison

Transmission is responsible for warranty on these parts.

•

Repair parts for the external harnesses and external harness components must be obtained from

St. Clair Technologies Inc. (SCTI). SCTI provides parts to any Allison customer or OEM and is

responsible for warranty on these parts. SCTI recognizes ATD, manufacturers, and SCTI part

numbers. SCTI provides a technical HELPLINE at 519-627-1673 (Wallaceburg). SCTI will have

parts catalogs available. The SCTI addresses and phone numbers for parts outlets are:

St. Clair Technologies, Inc.

1050 Old Glass Road

Wallaceburg, Ontario N8A 3T2

Phone: (519) 627-1673

Fax: (519) 627-4227

•

St. Clair Technologies, Inc. stocks a CEC 2 external harness repair kit, P/N 29532362, as a source

for some external harness repair parts. SCTI is the source for external harness repair parts.

St. Clair Technologies, Inc.

1111 Mikesell Street

Charlotte, MI 48813

Phone: (517) 541-8166

Fax: (517) 541-8167

St. Clair Technologies, Inc.

c/o Mequilas Tetakawi

Carr. Internationale KM 1969

Guadalajara – Nogales, KM2

Empalme, Sonora, Mexico

Phone: 011-52-622-34661

Fax: 011-52-622-34662

Copyright © 2000 General Motors Corp. 3–1

Page 25

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

BASIC KNOWLEDGE

3–2. USING THE TROUBLESHOO TING MANU AL

Use this manual as an aid to troubleshooting CEC 2. Every possible problem and its solution cannot be

encompassed by any manual. Howe ver , this manual does pro vide a starting point from which most problems can be

resolved.

3–3. SYSTEM OVERVIEW

CEC 2 functions are controlled by the ECU. The ECU reads shift selector range selection, output speed, and

throttle position to determine when to command a shift. When a shift occurs, the ECU monitors turbine speed,

output speed, and throttle position during the shift.

When the ECU detects an electrical fault, it logs a diagnostic code indicating the faulty circuit and may alter the

transmission operation to prevent or reduce damage.

When the ECU detects a non-electrical problem while trying to make a shift, the ECU may try that shift a second or

third time before setting a diagnostic code. Once that shift has been retried, and a fault is still detected, the ECU

sets a diagnostic code and holds the transmission in a lock-to-range mode of operation.

3–4. IMPORTANT INFORMATION IN THE TROUBLESHOOTING PROCESS

Before beginning the troubleshooting process, read and understand the following:

•

CEC 2 wire identification presents the wire number followed by the ECU terminal source

(i.e., 157-S30). If there is a letter suffix following the wire number, there is a splice between the ECU

source and wire destination (i.e., 116A-T19).

•

Shut off the engine and ignition before any harness connectors are disconnected or connected.

•

Remember to do the following when checking for shorts and opens:

Shorts: Minimize movement of wiring harnesses when looking for shorts. Shorts involve wire-to-

—

wire or wire-to-ground contacts and moving the harnesses may eliminate the problem.

—

Opens: Wiggle connectors, harnesses, and splices when looking for opens. This simulates vehicle

movements which occur during actual operation.

•

When disconnecting a harness connector, be sure that pulling force is applied to the connector itself and

not the wires extending from the connector.

•

Resistance checks involving the wiring between the ECU connectors and other components adds about

one ohm of resistance to the component resistance shown.

•

Inspect all connector terminals for damage. Terminals may have bent or lost the necessary tension to

maintain firm contact.

•

Clean dirty terminals or connectors with isopropyl alcohol and a cotton swab, or a good quality, nonresidue, non-lubricating, cleaning solvent such as LPS Electro Contact Cleaner

Electro Contact Cleaner

3–2 Copyright © 2000 General Motors Corp.

®

.

®

or LPS NoFlash

Page 26

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

BASIC KNOWLEDGE

The cleaning solvent must not be chlorine based, contain petroleum distillates, or conduct

electricity. The cleaning solvent should evaporate quickly to prevent the possibility of

CAUTION:

condensation within the connectors. Always blow or shake any excess cleaner from the

connector before assembling it to its mating connector or hardware. Cleaner trapped in the

connector can affect the connector seal. (Refer to SIL 17-TR-94 for detailed information

on the recommended cleaners.)

CAUTION:

Diagnostic codes displayed after system power is turned on with a harness connector disconnected, can

•

Care should be taken when welding on a vehicle equipped with electronic controls. Refer

to Appendix E, Paragraph 1–1.

be ignored and cleared from memory. Refer to Section 5, Diagnostic Codes, for the code clearing

procedure.

3–5. BEGINNING THE TROUBLESHOO TING PROCESS

1. Begin troubleshooting by checking the transmission fluid level and ECU input voltage. Remember

that some problems may be temperature related. Do troubleshooting at the temperature level where

the problem occurs. Check diagnostic codes by:

•

Using the shift selector display. (See Paragraph 5–2 for code reading.)

Using the Pro-Link

•

2. When a problem exists but a diagnostic code is not indicated, refer to the Performance Complaint

Section (Section 8) for a listing of various electrical and hydraulic problems, their causes, and remedies.

3. If a diagnostic code is found in the ECU memory, record all available code information and clear the

active indicator (refer to Section 5).

®

9000 diagnostic tool.

4. Test drive the vehicle to confirm a diagnostic code or performance complaint.

•

If the code reappears, refer to the Diagnostic Code section (Section 5) and the appropriate code

chart. The Diagnostic Code section lists diagnostic codes and their description. Locate the

appropriate troubleshooting chart and follow the instructions.

If the code does not reappear, it may be an intermittent problem. Use the Pro-Link

•

®

and the code

display procedure described in Section 5. The code display procedure will indicate the number of

times the diagnostic code has occurred. Refer to the troubleshooting chart for possible cause(s) of

the problem.

Appendix A deals with the identification of potential circuit problems. Refer to Appendix A if a

•

circuit problem is suspected.

NOTE: Information concerning specific items is contained in the appendices located in the back of this

manual. The appendices are referred to throughout the manual.

Copyright © 2000 General Motors Corp. 3–3

Page 27

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

BASIC KNOWLEDGE

NOTES

3–4 Copyright © 2000 General Motors Corp.

Page 28

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

S

ECTION

4 — WIRE CHECK PROCEDURES

4–1. CHECKING OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND

(Use Digital Volt/Ohmmeter J 34520-A and Jumper Wire Set J 39197)

NOTE: Please refer to Paragraph 3–5 to begin the troubleshooting process.

1. Make sure all connectors are tightly connected and re-check the circuit.

2. Disconnect and inspect all connectors.

3. Thoroughly clean corroded or dirty terminals. If dirty or corroded terminals are the probable cause of

the problems, reconnect the clean connectors and operate the vehicle normally. If the problem recurs,

proceed with Step (4).

The cleaning solvent must not be chlorine based, contain petroleum distillates, or

conduct electricity. The cleaning solvent should evaporate quickly to prevent the

CAUTION:

4. Review the CEC 2 wire numbering system described in Paragraph 3–4.

possibility of condensation within the connectors. Always blow or shake any excess

cleaner from the connector before assembling it to its mating connector or hardware.

Cleaner trapped in the connector can affect the connector seal. (Refer to SIL 17-TR-94

for detailed information on the recommended cleaners.)

5. If all connectors are clean and connected correctly, determine which wires in the chassis harness are

indicated by the diagnostic code. For example, Code 45 12, indicates a failure in the F solenoid

circuit — wires 102-T1 and 120-T4.

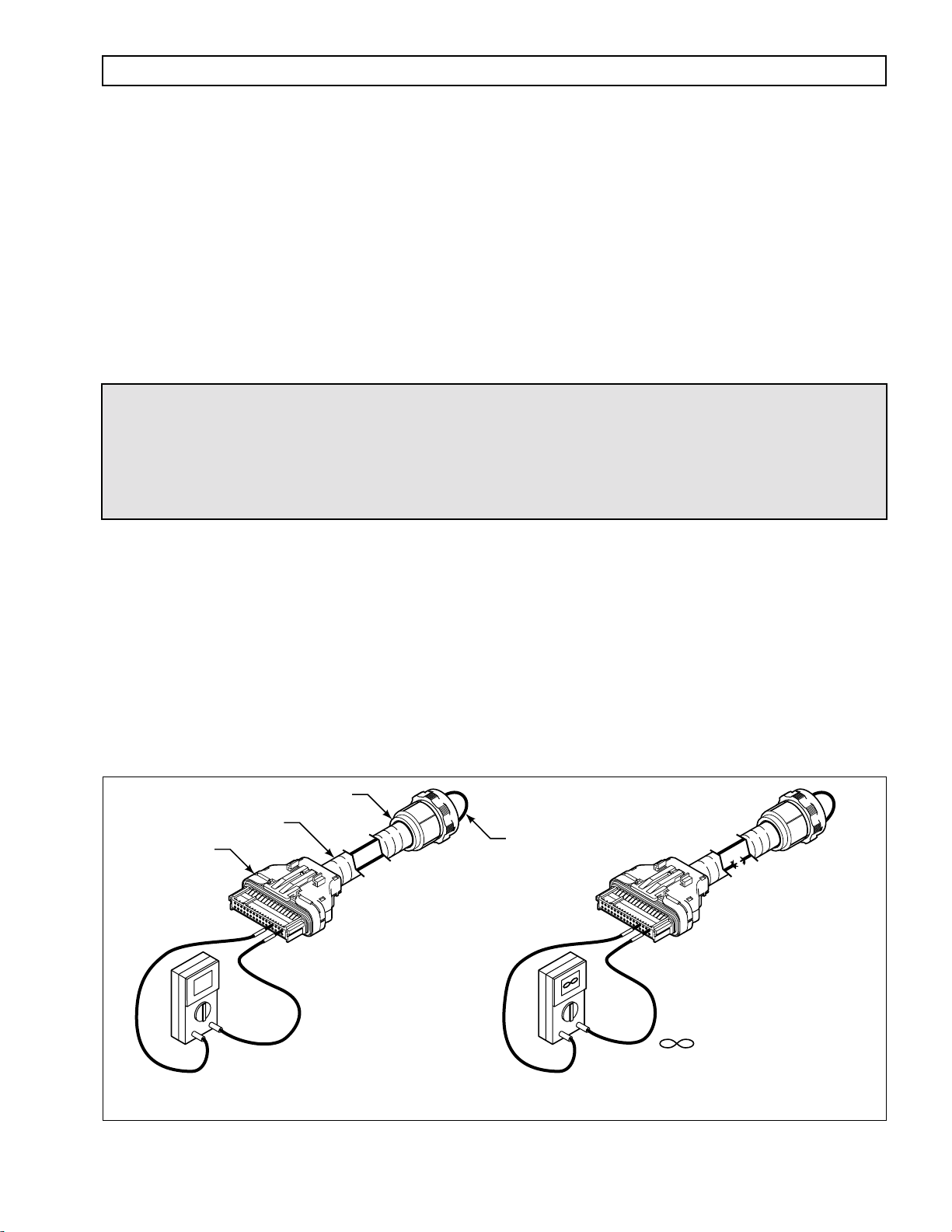

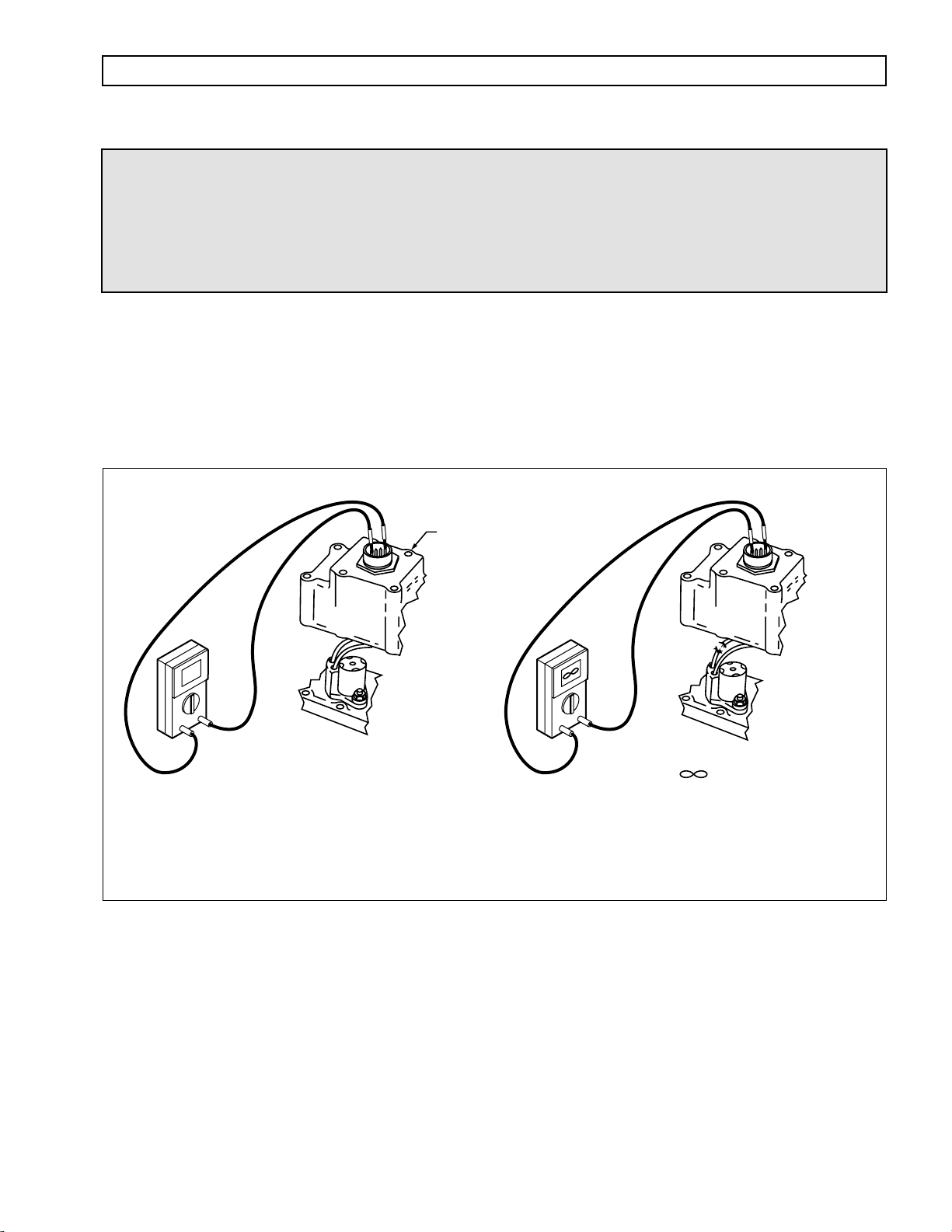

a. Check continuity of wires 102-T1 and 120-T4 by performing the following (refer to Figure 4–1):

(1) Disconnect the blue “T” connector from the ECU and disconnect the harness from the

transmission main connector. At one end of the harness, using jumper wire kit J 39197 and

connector probes in J 39775-CP, connect wire 102-T1 and 120-T4 to each other, being careful

not to distort the terminals. Jumping the wires together creates a circuit between wires 102-T1

and 120-T4.

TRANSMISSION CONNECTOR

WIRING HARNESS

“T” CONNECTOR

ECU

+

0

VOLT/OHM-

METER

–

(VOM)

JUMPER

–

+

0 OHMS OHMS

Circuit has continuity. Jumper

from 102 or 120 to another wire

produces a complete circuit. VOM

reading is near zero Ohms.

Circuit does not have continuity due

to a broken wire (open circuit).

VOM reading is very high

(infinite Ohms or OL – overlimit).

V03374.01

Figure 4–1. Open Circuit

Copyright © 2000 General Motors Corp. 4–1

Page 29

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

WIRE CHECK PROCEDURES

(2) On the opposite end of the harness, check the continuity of the jumpered pair. No continuity in a

jumpered pair circuit (infinite resistance reading) indicates an open in the wire being tested.

Locate and repair the damaged portion of the wire.

b. If the continuity check is good (0–2 Ohms resistance), remove the jumpers. Check the harness for

shorts between wires and shorts-to-ground by performing the following (refer to Figure 4–2):

(1) At the ECU end of the harness, touch one VOM probe to one wire of the circuit being tested

and touch the other probe to each terminal in the same connector, then touch the probe to chassis ground and to the transmission main housing. Do this for both wires in the circuit being

tested.

(2) If at any time the VOM shows zero to low resistance, or the meter’s continuity beeper sounds,

there is a short between the two points being probed — wire-to-wire or wire-to-ground. Isolate

and repair the short.

TRANSMISSION CONNECTOR

WIRING HARNESS

“T” CONNECTOR

ECU

0

+

VOLT/OHM-

METER

–

(VOM)

Wires shorted

together

Shorted to

ground on

metal frame

rail

Ground

to metal

0

–

+

frame rail

0 OHMS0 OHMS

Two wires have frayed and are shorted

together. Continuity beeper of VOM will

sound, or reading will go to zero Ohms

when these two wires are probed with

the VOM.

Figure 4–2. Short Between Wires or to Ground

Harness has been chafed and one or more

wires are shorted-to-ground. VOM continuity

beeper will sound, or reading will go to zero

Ohms when meter is probing between this wire

and chassis ground.

V03375

4–2. CHECKING AT TRANSMISSION CONNECTOR AND THE INTERNAL HARNESS

FOR OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND

1. Disconnect the external wiring harness from the transmission.

2. Inspect the connectors. Any terminals which are corroded or dirty must be thoroughly cleaned.

3. If the connectors are clean and connected correctly, determine which wires in the harness to test.

Use the diagnostic code system schematic to locate the wire terminals. For this example, Code 45 12

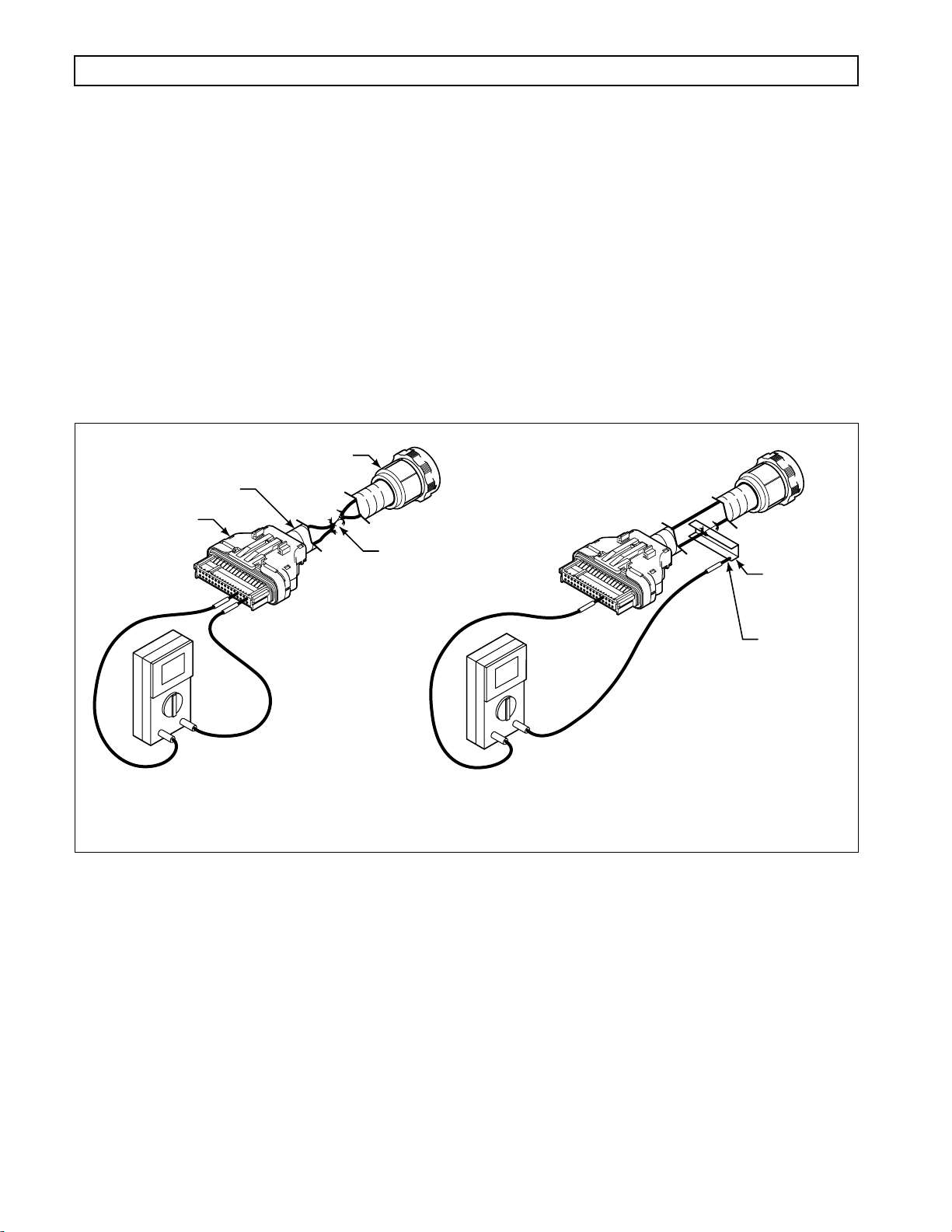

indicates a failure in the F solenoid circuit — wires 102-T1 and 120-T4 (refer to Figure 4–3 and 4–4).

4–2 Copyright © 2000 General Motors Corp.

Page 30

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

WIRE CHECK PROCEDURES

The cleaning solvent must not be chlorine based, contain petroleum distillates, or

conduct electricity. The cleaning solvent should evaporate quickly to prevent the

CAUTION:

NOTE: Resistance of all solenoids (except J on 5610, 6610 models only) should be 12–24 Ohms. Solenoid J

resistance on the 5610, 6610 should be 10–13 Ohms.

a. At the transmission main valve body connector, check the resistance of the F solenoid circuit.

possibility of condensation within the connectors. Always blow or shake any excess

cleaner from the connector before assembling it to its mating connector or hardware.

Cleaner trapped in the connector can affect the connector seal. (Refer to SIL 17-TR-94

for detailed information on the recommended cleaners.)

Resistance of the solenoid circuit should be 12–24 Ohms. No continuity in the circuit (infinite

resistance) indicates an open in the internal harness, the feedthrough connector, or the solenoid

coil. Locate and repair the open in the internal harness or replace the internal harness, replace the

feedthrough connector, or replace the solenoid.

MAIN VALVE BODY

CONNECTOR

18

–

+

VOLT/OHM-

METER

(VOM)

12–24 OHMS

AT NORMAL OPERATING

TEMPERATURE*

Circuit has continuity.

* Refer to Appendix J

Figure 4–3. Checking Continuity

–

+

INFINITE ( ) OHMS

Circuit does not have continuity due to a

broken wire (open circuit). VOM reading is

very high (infinite ohms or OL–overlimit).

This could also be due to an open solenoid

coil or bad connection.

b. If the resistance check is good, check the harness for shorts between wires and to ground by per-

forming the following (refer to Figure 4–4):

V06593

(1) At the transmission connector, touch one probe of the VOM to one wire of the circuit being

tested and touch the other probe to each terminal in the connector and to chassis ground and

the transmission main housing. Do this for both wires in the circuit being tested.

(2) If the VOM shows zero to low resistance, or the continuity beeper sounds, there is a short

between the two points being probed, wire-to-wire or wire-to-ground. An indication of a short

may be caused by a splice to the wire being checked. Check the wiring diagram in Appendix G

for splice locations. If the short is not a splice, then isolate and repair the short.

Copyright © 2000 General Motors Corp. 4–3

Page 31

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

WIRE CHECK PROCEDURES

MAIN VALVE BODY

CONNECTOR

Shorted

to metal

0

–

+

0

–

+

Bare wires

touching

each other

VOLT/OHM-

METER

(VOM)

0 OHMS0 OHMS

Two wires have frayed and are shorted

together. Continuity beeper of VOM will

sound, or reading will go to zero Ohms

when these two wires are probed with

the VOM.

Figure 4–4. Short Between Wires or to Ground

NOTE: When conducting circuit checks that include the external harness, add one (1) Ohm to the

values shown.

Harness has been chafed and one or more

wires are shorted to ground. VOM continuity

beeper will sound or meter reading will go

to zero Ohms when meter is probing between

this wire and chassis ground.

V06594

4–4 Copyright © 2000 General Motors Corp.

Page 32

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

S

ECTION

5 — DIAGNOSTIC CODES

5–1. DIAGNOSTIC CODE MEMORY

Diagnostic codes are logged in a list in memory (sometimes referred to as the queue), listing the most recently

occurring code first and logging up to five codes. The codes contained in the list have information recorded as

shown in the table below (codes are examples). Access to the code list position, main code, subcode and active

indicator is through either the shift selector display or the Pro-Link® diagnostic tool. Access to ignition cycle

counter and event counter information is through the diagnostic tool only. Further detail on the use of

Pro-Link

Code List

Displayed on shift selector and diagnostic tool

d = “diagnostic”

®

9000 DDR is presented in Appendix J of this manual.

Table 5–1. Code List

Ignition Cycle

Position

d1

d2 45 12 YES 00 04

d3 23 12 YES 08 02

d4 34 12 YES 13 01

d5 56 11 YES 22 02

Main Code Subcode Active Indicator

21 12 YES 00 10

YES = LED indicator

illuminated

Counter

Not available on shift selector display

Event Counter

The following paragraphs define the different parts of the code list.

A. Code List Position.

“d1” through “d5” (Code List Position #1 through Code List Position #5).

B. Main Code.

C. Subcode.

D. Active Indicator.

selector is illuminated or the diagnostic tool displays

E. Ignition Cycle Counter.

the code list. The counter is increased by one each time a normal ECU power down occurs (ignition

turned off). Inactive codes are cleared from the code list after the counter exceeds 25.

F. Event Counter.

code list and the code is again detected, that code is moved to position d1, the active indicator is

turned on, the Ignition Cycle Counter is cleared, and 1 is added to the Event Counter.

The general condition or area of fault detected by the ECU.

The specific area or condition related to the main code in which a fault is detected.

The position which a code occupies in the code list. Positions are displayed as

Indicates when a diagnostic code is active. The MODE indicator LED on the shift

YES

.

Determines when inactive diagnostic codes are automatically cleared from

Counts the number of occurrences of a diagnostic code. If a code is already in the

5–2. CODE READING AND CODE CLEARING

Diagnostic codes can be read and cleared by two methods: by using the Pro-Link® 9000 diagnostic tool or by

entering the diagnostic display mode and using the shift selector display . The use of the Pro-Link

tool is described in the instruction manual furnished with each tool and briefly in Appendix J of this manual. The

method of reading and clearing codes described in this section refers to entering the diagnostic display mode by the

proper button movements on the shift selector.

®

9000 diagnostic

Copyright © 2000 General Motors Corp. 5–1

Page 33

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

The diagnostic display mode may be entered for viewing of codes at any speed. Active codes can only be cleared

when the output speed = 0 and no output speed sensor failure is active.

A. Reading Codes. Enter the diagnostic display mode by pressing the ⇑ ( Up ) and ⇓ ( Down ) arrow

buttons at the same time on a pushbutton selector, or by momentarily pressing the “display mode”

button on a lever shift selector.

NOTE: If a DO NOT SHIFT condition is present (CHECK TRANS light illuminated) at this time, the shift

selector may or may not respond to requested range changes.

The code list or queue position is the first item displayed, followed by the main code and the subcode. Each item is

displayed for about one second. The display cycles continuously until the next code list position is accessed by

pressing the

MODE

button. The following list represents the display cycle using code 25 11 as an example:

1. Code list position — d,

2. Main code — 2,

3. Subcode —1,

4. Cycle repeats — d, 1, 2, 5, 1,

To view the second, third, fourth, and fifth positions (d2, d3, d4, and d5), momentarily press the

explained above.

Momentarily press the

positions.

An active code is indicated by the illumination of the LED indicator when a code position is displayed while in the

diagnostic display mode.

Any code position which does not have a diagnostic code logged will display “–” for both the main and subcodes.

No diagnostic codes are logged after an empty code position.

B. Clearing Active Indicators.

code inhibit to be cleared but remains in the queue as inactive.

The active indicator clearing methods are:

1. Power down — All active indicators, except code 69 34 (refer to the code chart), are cleared at

ECU power down.

MODE

5

1

button after the fifth position is displayed to restart the sequence of code list

1

1

MODE

A diagnostic code’s active indicator can be cleared, which allows the

button as

2. Self-clearing — Some codes will clear their active indicator when the condition causing the code

is no longer detected by the ECU.

3. Manual — Some active indicators can be cleared manually, while in the diagnostic display mode,

after the condition causing the code is corrected.

If an active indicator is cleared while the transmission is locked in a forward range

CAUTION:

5–2 Copyright © 2000 General Motors Corp.

(lock-to-range), the transmission will remain in the forward range after the clearing

procedure is completed. Neutral must be manually selected.

Page 34

D o N

•

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

C. Manually Clearing Codes and Active Indicators fr om the Code List. To clear active indicators or

all codes:

1. Enter the diagnostic display mode.

2. Press and hold the MODE button for approximately three seconds until the LED indicator flashes.

All active indicators are cleared. To remove all inactive codes, press and hold the MODE button

for about ten seconds until the LED indicator flashes again. All active indicators will be cleared at

ECU power down.

3. Codes that cannot be manually cleared will remain.

D. Exiting the diagnostic display mode. Exit the diagnostic display mode using one of the following

procedures:

1. On a pushbutton shift selector, press the ⇑ ( Up ) and ⇓ ( Down ) arrow buttons at the same time or

press any range button, D, N, or R. The shift (D, N, or R) is commanded if not inhibited by an

active code.

2. On a le ver shift selector , momentarily press the “display mode” b utton or mov e the shift lev er to any

shift position other than the one it was in when the diagnostic display mode was activated. If the

shift is inhibited, the ECU will continue to command the current transmission range attained and the

lever should be returned to its original position.

3. Wait until timeout (approximately 10 minutes) and the system will automatically return to the

normal operating mode.

4. Turn off power to the ECU (turn off the vehicle engine at the ignition switch).

5–3. DIAGNOSTIC CODE RESPONSE

The following ECU responses to a fault provide for safe transmission operation:

•

•

ot S hift (DNS) Response

—

Release lockup clutch and inhibit lockup operation.

Inhibit all shifts.

—

—

Turn on the CHECK TRANS light.

—

Shift selector display flashes the range selected.

Ignore any range selection inputs from the pushbutton or lever shift selector.

—

SOL enoid OFF (SOL OFF) Response

—

All solenoids are commanded off.

5–4. SHIFT SELECTOR DISPLAYS RELATED TO ACTIVE CODES

“Cateye” — The forward slash segments and the middle horizontal segments (-\-) may be on under the

following conditions:

—

RSI link fault is active (code 23 12 or 23 14)

When two COP timeouts occur within two seconds of each other (reference code 69 33)

—

—

Shift selector display line fault is active (23 16)

Copyright © 2000 General Motors Corp. 5–3

Page 35

•

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

All Segments Displayed — All display segments will be illuminated if a severity 1 diagnostic code is

present during initialization, or if an electrical code for any solenoid is logged before initialization

completes.

5–5. DIAGNOSTIC CODE LIST AND DESCRIPTION

Table 5–2. CEC 2 Diagnostic Codes

CHECK

Main

Code

Subcode Description

TRANS

Light

Inhibited Operation

Description

13

(pg 5–12)

21 12 Throttle position sensor, failed low Yes Use throttle default values

(pg 5–16) 23 Throttle position sensor, failed high Yes Use throttle default values

22

(pg 5–20)

23

(pg 5–24)

13 Primary shift selector mode function

12 ECU input voltage, low Yes DNS

23 ECU input voltage, high Yes DNS

14 Engine speed sensor reasonableness

test

15 Turbine speed sensor reasonableness

test

16 Output speed sensor reasonableness

test

12 Primary shift selector or RSI link fault Yes Hold in last valid direction. May cause

fault

14 Secondary shift selector or RSI link

fault

15 Secondary shift selector mode

function fault

Yes Use default engine speed

Yes DNS, lock in current range

Yes DNS, lock in current range

“cateye” display.

No Mode change not permitted

Yes Hold in last valid direction. May cause

“cateye” display.

No Mode change not permitted

16 Shift Selector display line fault Yes None. May cause “cateye” display.

24 12 Sump fluid temperature, cold Yes DNS, lock-to-range

(pg 5–26) 23 Sump fluid temperature, hot Yes No upshifts above a calibration range

25

(pg 5–30)

5–4 Copyright © 2000 General Motors Corp.

11 Output speed sensor, detected at

0 output rpm, 1st

22 Output speed sensor, detected at

0 output rpm, 2nd

33 Output speed sensor, detected at

0 output rpm, 3rd

Yes DNS, lock in current range (1st)

Yes DNS, lock in current range (2nd)

Yes DNS, lock in current range (3rd)

Page 36

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

Table 5–2. CEC 2 Diagnostic Codes (cont’d)

CHECK

Main

Code

Subcode Description

TRANS

Light

Inhibited Operation

Description

25 (cont’d) 44 Output speed sensor, detected at

0 output rpm, 4th

55 Output speed sensor, detected at

0 output rpm, 5th

66 Output speed sensor, detected at

0 output rpm, 6th

77 Output speed sensor, detected at

0 output rpm, 7th

88 Output speed sensor, detected at

0 output rpm, 8th

26

(pg 5–33)

33

(pg 5–34)

34

(pg 5–37)

00 Throttle source not detected No Use throttle default values

12 Sump fluid temperature sensor failed

low

23 Sump fluid temperature sensor failed

high

12 Factory calibration compatibility

number wrong

13 Factory calibration fault Yes DNS, SOL OFF

Yes DNS, lock in current range (4th)

Yes DNS, lock in current range (5th)

Yes DNS, lock in current range (6th)

Yes DNS, lock in current range (7th)

Yes DNS, lock in current range (8th)

Yes Use default value of 93˚C (200˚F)

Yes Use default value of 93˚C (200˚F)

Yes DNS, SOL OFF

14 Power off fault Yes Use previous location, or factory

calibration

15 Diagnostic queue fault Yes Use previous location, or clear diagnostic

queue

16 Real time fault Yes DNS, SOL OFF

17 Customer modifiable constants fault Yes DNS, SOL OFF

35

(pg 5–38)

36

(pg 5–41)

45 12 General solenoid failure — F Yes DNS

(pg 5–42) 13 General solenoid failure — K Yes DNS, Inhibit lockup

00 Power interruption (code set after

power restored)

16 Real time write interruption Yes DNS, SOL OFF

00 Hardware/software not compatible Yes DNS, SOL OFF

14 General solenoid failure — B Yes DNS, Inhibit Reverse

No None (hydraulic default during

interruption)

Copyright © 2000 General Motors Corp. 5–5

Page 37

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

Table 5–2. CEC 2 Diagnostic Codes (cont’d)

CHECK

Main

Code

45 (cont’d) 15 General solenoid failure — G Yes DNS

Subcode Description

16 General solenoid failure — E Yes DNS

21 General solenoid failure — H/J Yes Turn off trim boost J, DNS H

22 General solenoid failure — A Yes No action taken

23 General solenoid failure — D Yes DNS

24 General solenoid failure — I Yes No action taken

26 General solenoid failure — C Yes DNS

TRANS

Light

Inhibited Operation

Description

46 21 Hi side overcurrent, H/J solenoid Yes Turn off H/J solenoid, DNS 8610, 9810

(pg 5–46) 26 Hi side overcurrent, C, D, E solenoid

circuit

27 Hi side overcurrent, A, B, F, G, I, K

solenoid circuit

56 11 Range verification ratio test, 1st Yes DNS

(pg 5–48) 22 Range verification ratio test, 2nd Yes DNS

33 Range verification ratio test, 3rd Yes DNS

44 Range verification ratio test, 4th Yes DNS

55 Range verification ratio test, 5th Yes DNS

66 Range verification ratio test, 6th Yes DNS

77 Range verification ratio test, 7th or R1 Yes DNS

88 Range verification ratio test, 8th or R2 Yes DNS

65

(pg 5–50)

66

(pg 5–52)

00 Engine rating too high Yes DNS, Lock-in-neutral

00 Serial communications interface fault No Use default throttle values

Yes Turn off C, D, E solenoids

Yes DNS. Turn off A, B, F, G, I, K solenoids.

69

(pg 5–54)

5–6 Copyright © 2000 General Motors Corp.

27 ECU, inoperative A, B, F, G, I, K

solenoid

28 ECU, inoperative H/J solenoid Yes DNS, SOL OFF

29 ECU, inoperative C, D, E solenoid Yes DNS, SOL OFF

33 ECU, Computer Operating Properly

(COP) fault

Yes DNS, SOL OFF

Yes Reset ECU, shutdown ECU on 2nd

occurrence (power loss; hydraulic

defaults). May cause “cateye” display or

all segments blank display

Page 38

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

Table 5–2. CEC 2 Diagnostic Codes (cont’d)

CHECK

Main

Code

69 (cont’d) 34 ECU, EEPROM, fault Yes DNS, SOL OFF

Subcode Description

35 ECU, EEPROM, fault Yes Reset ECU

39 Communication chip addressing error Yes Use defaults for J1939 data

42 SPI output failure No GPO 1–8 and reverse warning inoperable

43 SPI input failure Yes DNS, lock-in-range

TRANS

Light

Inhibited Operation

Description

Copyright © 2000 General Motors Corp. 5–7

Page 39

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

NOTES

5–8 Copyright © 2000 General Motors Corp.

Page 40

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

TRANSMISSION

COMPONENT

WIRING DIAGRAMS

AND

DIAGNOSTICS

Copyright © 2000 General Motors Corp. 5–9

Page 41

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

NOTES

5–10 Copyright © 2000 General Motors Corp.

Page 42

COMMERCIAL ELECTRONIC CONTROLS 2 (CEC 2) TROUBLESHOOTING MANUAL

DIAGNOSTIC CODES

5–6. DIAGNOSTIC CODE TROUBLESHOOTING

A. Beginning The Tr oubleshooting Process

1. Begin troubleshooting by checking the transmission fluid level and ECU input voltage. Check

diagnostic codes by:

•

Using the shift selector display.

Using the Pro-Link

•