Page 1

BACK

GO TO PAGE

BACK

BACK

ALLISON 1000/2000 SERIES

INDEX

CLUTCH AND SOLENOID APPLICATION CHART ........................................................................................... 4

TRANSMISSION IDENTIFICATION TAG INFORMATION .............................................................................. 5

GENERAL DESCRIPTION AND OPERATION .................................................................................................... 6

ELECTRICAL OPERATION ................................................................................................................................... 9

THROTTLE POSITION SENSOR .............................................. ........................................................................... 10

NEUTRAL START BACK UP SWITCH ................................................................................................................. 11

TRANSMISSION CONTROL MODULE CONNECTOR IDENTIFICATION .................................................... 12

DIAGNOSTIC TROUBLE CODE IDENTIFICATION ......................................................................................... 14

SOLENOID IDENTIFICATION AND OPERATION ............................................................................................. 16

INTERNAL WIRING HARNESS SCHEMATIC AND RESISTANCE CHART ................................................... 18

EXTERNAL WIRING HARNESS SCHEMATIC AND TERMINAL IDENTIFICATION ................................... 19

PRESSURE SWITCH ASSEMBLY IDENTIFICATION AND OPERATION ....................................................... 20

RETRIEVING DIAGNOSTIC TROUBLE CODES ................................................................................................ 22

LINE PRESSURE TESTS ................................................... ................................................................................... 23

BELL HOUSING OIL PASSAGE IDENTIFICATION ......................................................................................... 24

MAIN CASE "FRONT" OIL PASSAGE IDENTIFICATION .............................................................................. 26

MAIN CASE "REAR" OIL PASSAGE IDENTIFICATION ................................................................................. 27

OIL PUMP COVER OIL PASSAGE IDENTIFICATION ..................................................................................... 29

SHIFT VALVE BODY OIL PASSAGE IDENTIFICATION ................................................................................. 31

MAIN VALVE BODY "TOP VIEW" OIL PASSAGE IDENTIFICATION .......................................................... 32

MAIN VALVE BODY "BOTTOM VIEW" OIL PASSAGE IDENTIFICATION ................................................ 33

MAIN CASE "BOTTOM VIEW" OIL PASSAGE IDENTIFICATION ............................................................... 35

TRANSMISSION DISASSEMBLY PROCESS ...................................................................................................... 36

COMPONENT REBUILD

TRANSMISSION CASE ASSEMBLY .............................................................................................................. 53

OIL PUMP AND BELLHOUSING ASSEMBLY ............................................................................................ 55

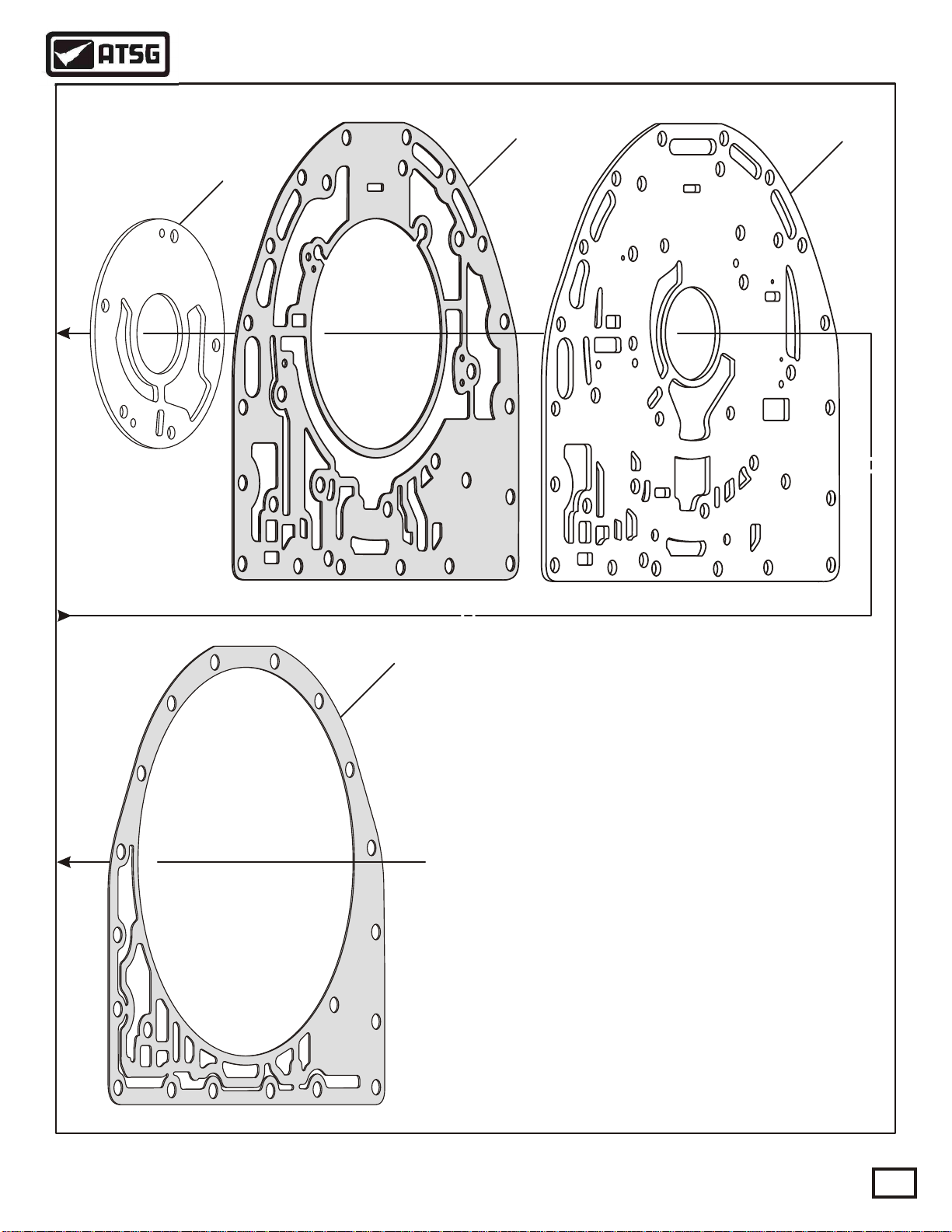

FOUR DIFFERENT BELL HOUSINGS IDENTIFICATION ...................................................................... 66

C1/C2 CLUTCH HOUSING ASSEMBLY ....................................................................................................... 68

C1/C2 CLUTCH HOUSING SNAP RING IDENTIFICATION ..................................................................... 72

VALVE BODY ASSEMBLY ............................................................................................................................. 80

SOLENOID AIR CHECKS ............................................................................................................................... 83

EXTENSION HOUSING ASSEMBLY ............................................................................................................. 91

GEAR TRAIN PARTS ....................................................................................................................................... 96

CASE CLUTCH PARTS .................................................................................................................................... 100

FINAL TRANSMISSION ASSEMBLY PROCESS ................................................................................................ 102

BOLT IDENTIFICATION CHART ........................................................................................................................ 119

TORQUE SPECIFICATION CHART .................................................................................................................... 120

CAUTION: ATSG service manuals are intended for use by professional,

qualified technicians. Attempting repairs or service without the proper

training, tools and equipment could cause injury to you or others and damage

to the vehicle that may cause it not to operate properly.

AUTOMATIC TRANSMISSION SERVICE GROUP

18639 S.W. 107TH AVENUE

MIAMI, FLORIDA 33157

(305) 670-4161

Copyright © ATSG 2000 May, 2000

Page 2

Updated

October, 2003

INTRODUCTION

ALLISON 1000/2000 SERIES

Beginning at the start of production for the 2000 model year, General Motors introduced two new Allison

automatic transmissions referred to as the 1000 Series and the 2000 Series, for light duty (8600-19850 GVW)

and medium duty (19850-3000 GVW) commercial trucks.

The 1000 and 2000 Series transmissions both have helical cut planetary gear systems to minimize noise

concerns and come in two different gear ratio configurations. The 1000 Series uses closer steps to improve the

shift quality that we now expect from an automatic transmission. The 2000 Series uses wider steps to

accommodate the greater vehicle weights associated with the 2000 Series. The gear ratios for both of the new

units are shown in this Manual.

The 1000 and 2000 Series transmissions have a Park position, Reverse, Neutral and five forward speeds with

5th gear being overdrive, and are completely electronic shift controlled. Notice that the standard General

Motors case connector has been utilized, and the Park/Neutral switch is exactly the same switch used currently

on the THM 4L60-E transmission. Two different bottom pan configurations are also provided to make these

units even more versitile. The 1000 and 2000 Series transmissions utilize five clutch packs (No Bands-No

Freewheels) to obtain the five forward gears and reverse. This manual will cover the dis-assembly, rebuild of all

components and re-assembly of both the 1000 and 2000 Series units.

No part of any ATSG publication may be reproduced, stored in any retrieval system or transmitted in any form or

by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise,

without written permission of Automatic Transmission Service Group. This includes all text illustrations,

tables and charts.

"Portions of materials contained herein have been reprinted under

license from General Motors Corp, Service & Parts Operations."

The information and part numbers contained in this booklet have

been carefully compiled from industry sources known for their

reliability, but ATSG does not guarantee its accuracy.

DALE ENGLAND

FIELD SERVICE CONSULTANT

WAYNE COLONNA

TECHNICAL SUPERVISOR

PETER LUBAN

TECHNICAL CONSULTANT

JON GLATSTEIN

TECHNICAL CONSULTANT

JERRY GOTT

TECHNICAL CONSULTANT

GERALD CAMPBELL

TECHNICAL CONSULTANT

Copyright © ATSG 2000

JIM DIAL

TECHNICAL CONSULTANT

ED KRUSE

TECHNICAL CONSULTANT

GREGORY LIPNICK

TECHNICAL CONSULTANT

DAVID CHALKER

TECHNICAL CONSULTANT

MIKE SOUZA

TECHNICAL CONSULTANT

ROLAND ALVAREZ

TECHNICAL CONSULTANT

AUTOMATIC TRANSMISSION SERVICE GROUP

18639 S.W. 107TH AVENUE

MIAMI, FLORIDA 33157

(305) 670-4161

1

Page 3

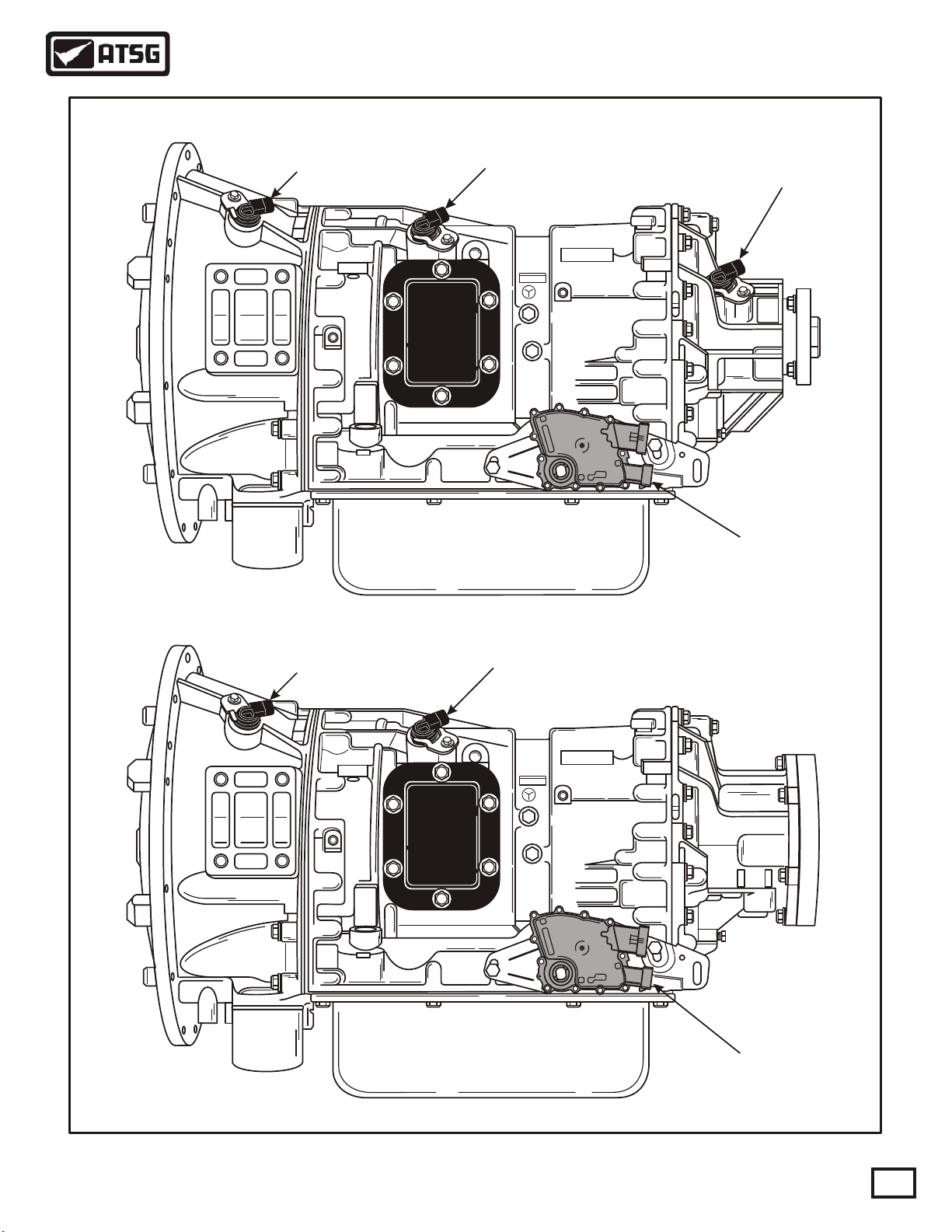

Technical Service Information

ALLISON 1000/2000 SERIES

Engine Speed

Sensor

Turbine Speed

Sensor

AllisonAllison

Output Speed

Sensor

Neutral Start

Switch

Engine Speed

Sensor

TWO WHEEL DRIVE

Turbine Speed

Sensor

AllisonAllison

Neutral Start

Switch

FOUR WHEEL DRIVE

Figure 1

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2000 ATSG

3

Page 4

Technical Service Information

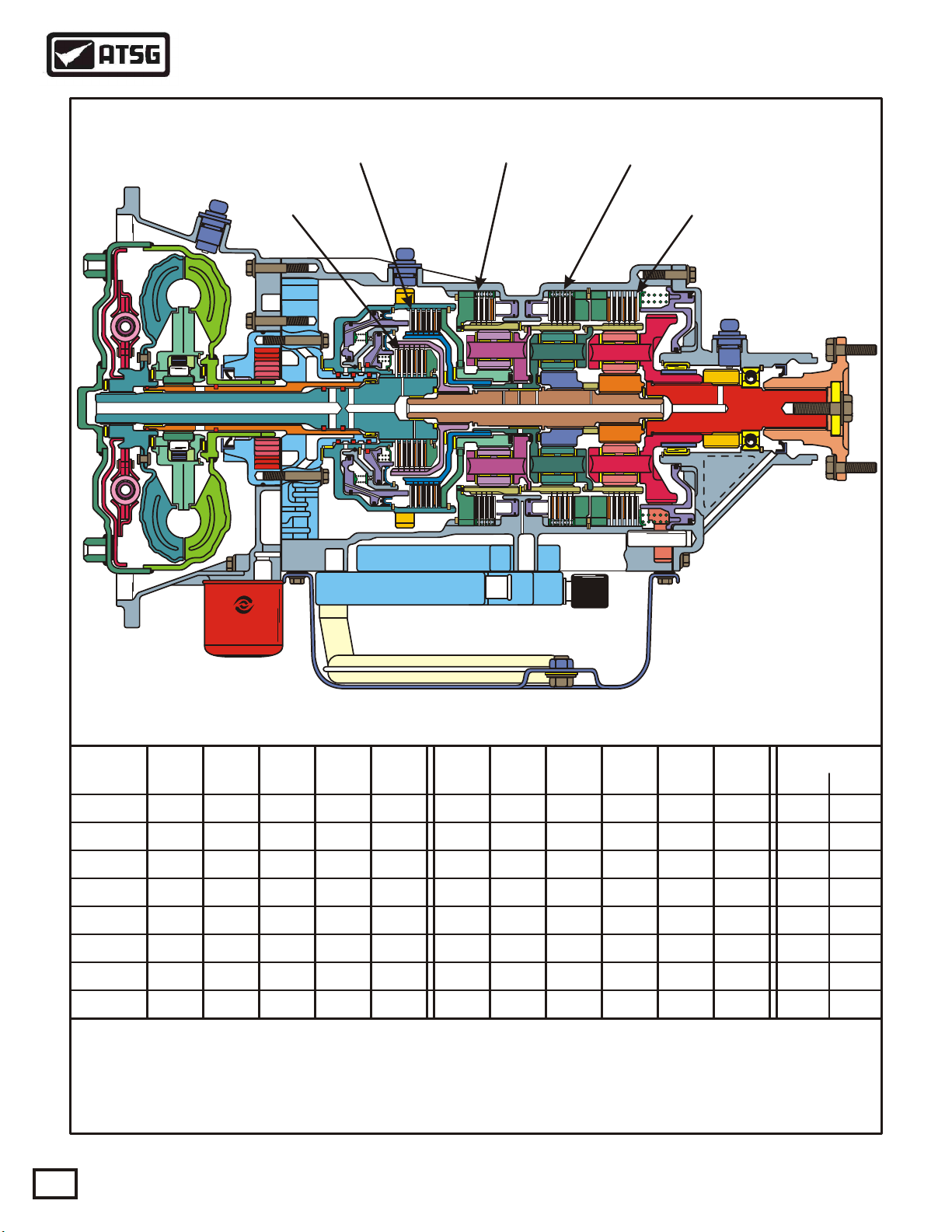

ALLISON 1000/2000 SERIES TRANSMISSION

"C4" CLUTCH "C3" CLUTCH "C2" CLUTCH

"C1" CLUTCH

"C5" CLUTCH

C1

Range

Park

Reverse X

Neutral

OD-1st

OD-2nd

OD-3rd

OD-4th

OD-5th

X = Electrical Power Applied To Solenoid

= Apply Solenoid "F" To Apply Converter Clutch

*

= Solenoids "A" and "B" are "Trim" solenoids used to control oncoming, off-going, and

**

holding pressure to the five clutch packs.

Clut

ON ON

ON

ON ON

4

C2

ClutC3ClutC4ClutC5Clut

ONON

ON

ONON

ON

ON

ON

AUTOMATIC TRANSMISSION SERVICE GROUP

Sol

"A"

**

**

**

**

**

**

**

Figure 2

Sol

"B"

**

**

**

**

**

**

**

**

Sol

"C"

X

X

X

Sol

"D"

XXON

X

X

Sol

"E"

X

X

X

Sol

"F"

*

*

X

X

*

***

Copyright © 2000 ATSG

Ratios

1000 2000

4.49

3.10

1.81

1.41

1.00

0.71

5.09

3.51

1.90

1.44

1.00

0.74

Page 5

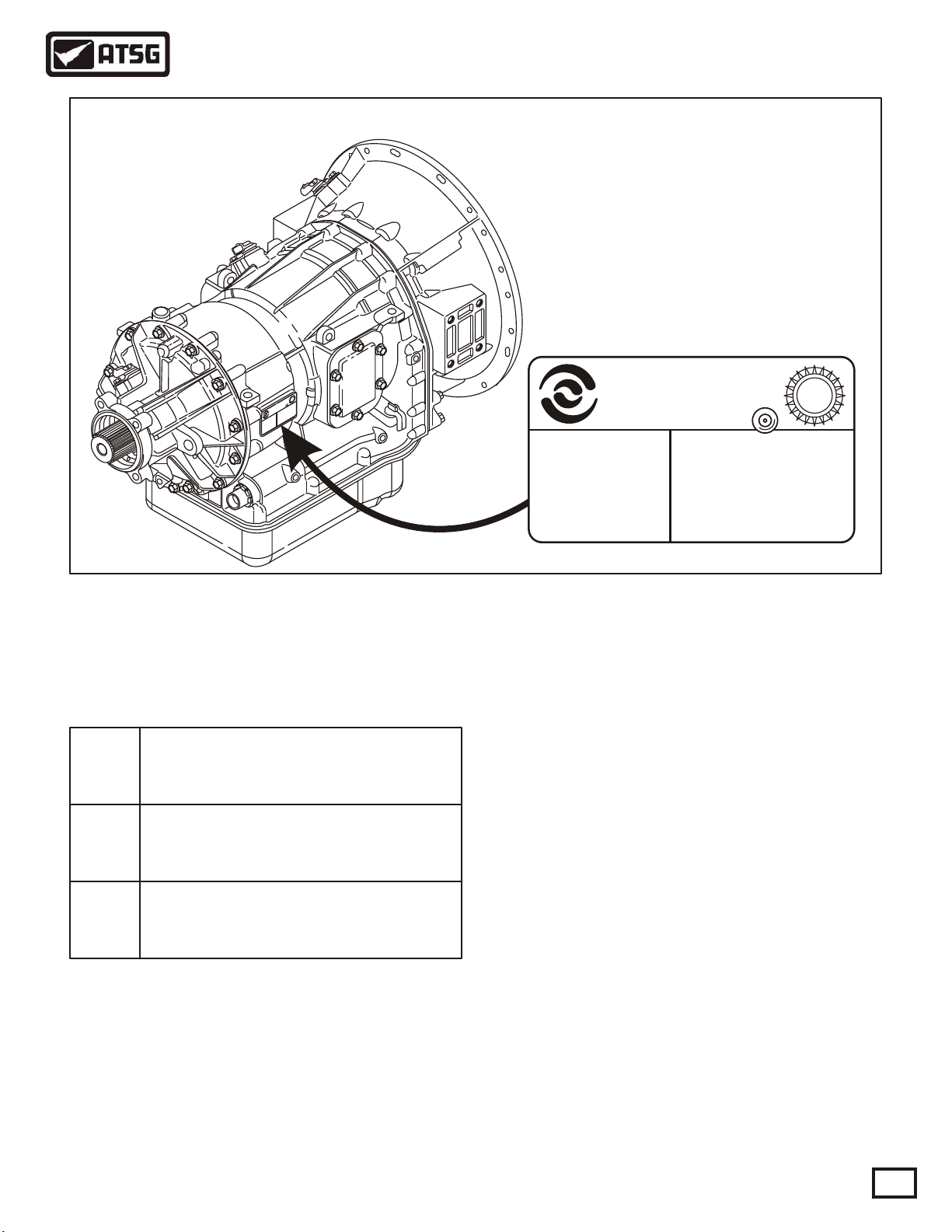

Technical Service Information

ALLISON IDENTIFICATION TAG LOCATION

9

.8

9

.8

9

.8

9

.8

9

.8

9

.8

9

.8

9

.8

9

9

.8

.8

W

A

U

3

3

9

X

X

n

X

n

.

X

P

o

R

X

-

i

O

X

C

X

s

S

X

R

iso

X

s

O

l

A

i

X

T

l

O

X

AN

-

M

X

L

X

m

X

A

NDI

X

I

A

R

s

X

X

,

X

S

NE

I

X

E

n

L

X

X

G

-

O

X

P

a

X

A

OF

X

X

N

N

r

X

X

X

A

O

I

I

X

X

X

S

T

I

ND

X

V

X

I

-

I

X

D

X

X

X

X

X

X

X

X

X

X

-

X

X

L

X

X

E

X

X

X

D

I

X

OD

T

X

S

M

-

IE

X

X

X

R

X

X

E

X

E

S

T

X

0

-

DA

0

0

.

X

1

X

X

O

X

N

X

L

1

A

2

I

F

X

R

9

X

E

9

S

X

X

N

X

X

X

FC

X

E

X

X

X

X

X

X

X

X

9

.

8

9

.

8

9

.

8

9

.

8

9

.

8

9

.

8

MODEL

1000 SERIES

99F21 X X

SERIAL NO.

X X X X X X X X X X

X X X X X X X X X

Allison

TransmissionTransmission

DIVISION OF GENERAL MOTORS CORP.

INDIANAPOLIS, INDIANA

X X - X X X X X X - X X X X

DATE

EFCN

X X - X X X X X X - X X X X

TID

X X - X X X X X X - X X X X

X X - X X X X X X - X X X X

X X - X X X X X X - X X X X

UAW

933

Figure 3

TRANSMISSION IDENTIFICATION TAG

Several different transmission configurations are

available within the 1000/2000/2400 Series. The

different models are identified as follows:

1000

Series

2000

Series

2400

Series

Each transmission is identified by a model

designation, group numbers, and serial number. This

information is included on the transmission

identification tag located on the right rear side of the

transmission case, as shown in Figure 3.

Heavy-duty automatic transmission

with parking pawl.

Maximum GVW = 19850 lb.

Heavy-duty automatic transmission

without parking pawl.

Maximum GVW = 30000 lb.

Heavy-duty automatic transmission

with parking pawl.

Maximum GVW = 26000 lb.

Copyright © 2000 ATSG

This information must be used when discussing

specific service issues, or when parts replacement is

necessary. The transmission identification tag also

includes the date of manufacture, and also the

transmission identification number used with the

diagnostic systems.

Special Note:

Allison Series 1000/2000/2400 transmissions are

designed and manufactured to metric standards, and

metric tools are required for service.

The cooler ports and the main line pressure tap are

the only non-metric fittings on the transmission

case. The output flange/yoke retaining bolt is also

non-metric.

AUTOMATIC TRANSMISSION SERVICE GROUP

5

Page 6

Technical Service Information

GENERAL DESCRIPTION AND OPERATION

Allison 1000/2000/2400 Series transmissions are

torque converter driven fully automatic units. All

models have neutral, reverse, and up to 5 forward

speeds, with 5th gear being overdrive. Refer to

Figure 2 for the different gears ratios available in the

different models.

The torque converter housings of these units mate

directly to SAE No. 2, SAE No. 3, or direct to the

engine block in some cases. Flexplate drive is used

for all engine to transmission torque transfer.

Several different torque converters are available to

match the transmissions to a wide variety of diesel

and gasoline engines. The torque converter is a single

stage, three element unit, consisting of a pump, stator,

and turbine, with the addition of a converter clutch to

provide direct drive from the engine to the

transmission. The converter clutch is applied and

released electronically, and changes the direction of

fluid flow in the converter as in most typical

converters today.

Internally these units contain 2 rotating clutches (C1

and C2), and 3 brake clutches (C3, C4 and C5), to

direct the flow of torque through the unit. All clutch

packs are hydraulically applied and spring released,

with automatic wear compensation, and their

locations in the transmission are shown in the cutaway in Figure 2.

The Transmission Control Module (TCM) signals

six different solenoids, located on the valve body, to

apply and release clutches based on vehicle speed and

power combinations, and the range selected by the

operator.

The planetary gear train consists of three constant

mesh, helical gear planetary sets, refered to as P1, P2,

and P3. By the engagement of the 5 clutch packs in

various combinations, the planetary gear sets react

singly or together to provide 5 forward speeds,

neutral, and reverse.

A common hydraulic system provides fluid for all

hydraulic operations, lubrication, and cooling. The

front oil pump, driven by the converter, provides the

pressure needed for the hydraulic system, and comes

from the common sump in the bottom pan.

A suction filter, located in the bottom pan provides

general protection to the entire hydraulic system, and

a spin-on filter provides full time protection for the

control solenoids and multipass protection for the

entire system.

The spin-on filter is located externally on the

converter housing at the lower left front of the

transmission.

Some 1000/2000/2400 Series transmissions are

available with an optional extension housing that

accommodates an OEM installed two shoe,

expanding type, drum parking brake.

The 1000/2000/2400 Series transmissions use lever

type shift selectors, as shown in Figure 4. The vehicle

may be equipped with one or two shift selectors,

depending on the number of operator stations for

driving the vehicle and/or operating a variety of

chassis mounted equipment. The shift positions on

the shift selector can vary according to the shift

selector installed in the vehicle.

NOTE: Refer to Figure 5 for the various Shift

Selector positions, and corresponding ranges that

can be attained for all 1000/2000/2400 Series

models.

TYPICAL MANUAL SHIFT TOWER

DO NOT

SHIFT

P

R

N

D

4

2

1

DO NOT

SHIFT

Copyright © 2000 ATSG

Figure 4

6

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 7

Technical Service Information

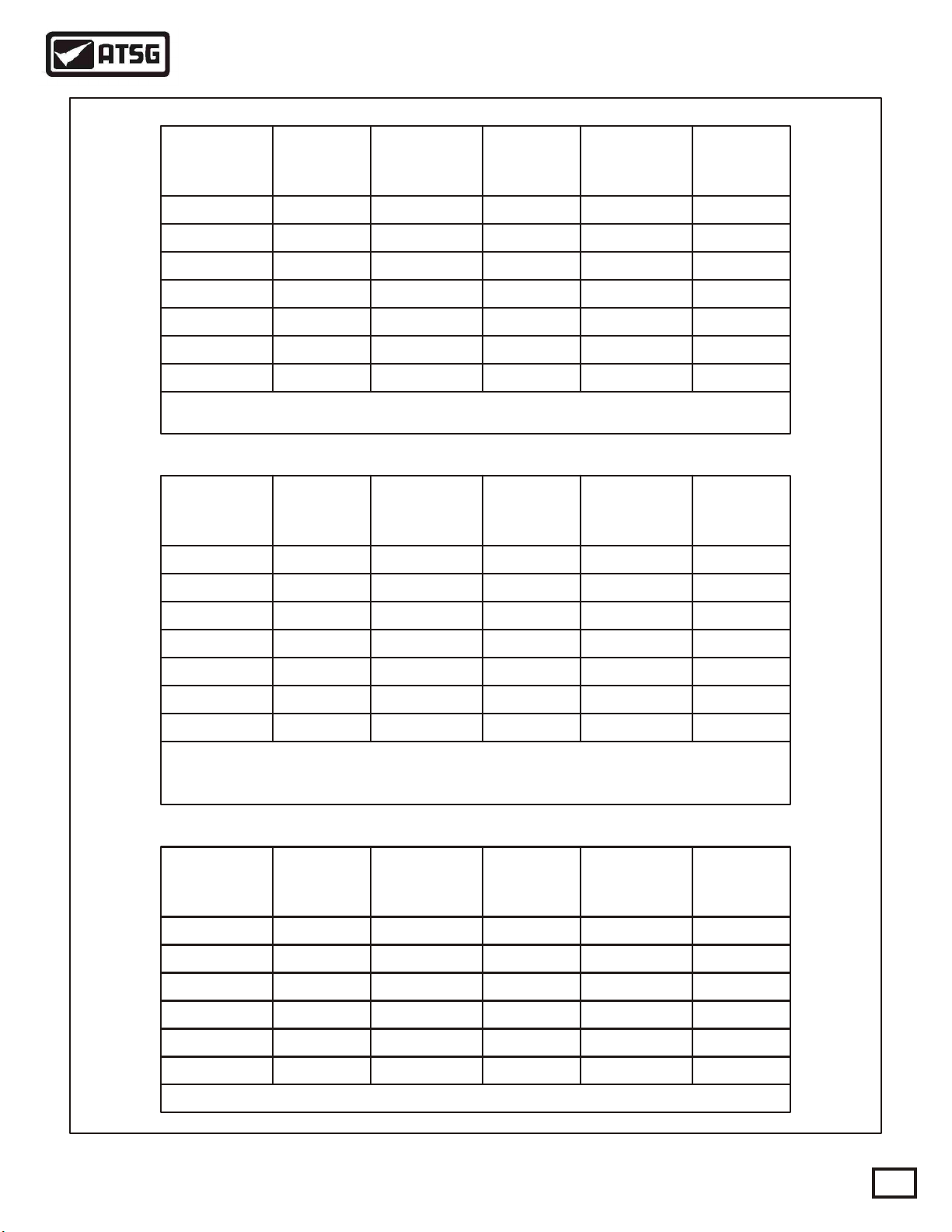

ALL 1000 AND 2400 SERIES

Shift

Selector

Position

P (Park)

R (Reverse)

N (Neutral)

D (Drive)

4 (Fourth)

3 (Third)

1 (First)

* With Park Pawl Engaged

** 4 Speed Calibration or Trailering Mode

Gears

Available

Neutral*

Reverse

Neutral

1-5

1-4

1-3

1st

Selector

Position

P (Park)

R (Reverse)

N (Neutral)

D (Drive)

4 (Fourth)

2 (Second)

1 (First)

ALL 2000 SERIES "WITH" AUTO-APPLY PARKING BRAKE

Shift

Selector

Position

PB = (Park)

R (Reverse)

Gears

Available

Neutral*

Reverse

Selector

Position

PB = (Park)

R (Reverse)

Shift

Shift

Gears

Available

Neutral*

Reverse

Neutral

1-5

1-4

1-2

1st

Gears

Available

Neutral*

Reverse

Shift

Selector

Position

P (Park)

R (Reverse)

N (Neutral)

D (Drive)

3 (Third)

2 (Second)

1 (First)

Shift

Selector

Position

PB = (Park)

R (Reverse)

Gears

Available

Neutral*

Reverse

Neutral

1-5 (1-4)**

1-3

1-2

1st

Gears

Available

Neutral*

Reverse

N (Neutral)

D (Drive)

4 (Fourth)

3 (Third)

1 (First)

* With Auto-Apply Parking Brake Engaged

** 4 Speed Calibration or Trailering Mode

PB = Auto-Apply Parking Brake

Neutral

1-5

1-4

1-3

1st

N (Neutral)

D (Drive)

4 (Fourth)

2 (Second)

1 (First)

ALL 2000 SERIES "WITHOUT" AUTO-APPLY PARKING BRAKE

Shift

Selector

Position

R (Reverse)

N (Neutral)

D (Drive)

4 (Fourth)

3 (Third)

Gears

Available

Reverse

Neutral

1-5

1-4

1-3

Selector

Position

R (Reverse)

N (Neutral)

D (Drive)

4 (Fourth)

2 (Second)

Shift

Neutral

1-5

1-4

1-2

1st

Gears

Available

Reverse

Neutral

1-5

1-4

1-2

N (Neutral)

D (Drive)

3 (Third)

2 (Second)

1 (First)

Shift

Selector

Position

R (Reverse)

N (Neutral)

D (Drive)

3 (Third)

2 (Second)

Neutral

1-5 (1-4)**

1-3

1-2

1st

Gears

Available

Reverse

Neutral

1-5 (1-4)**

1-3

1-2

1 (First)

** 4 Speed Calibration or Trailering Mode

1st

1 (First)

AUTOMATIC TRANSMISSION SERVICE GROUP

Figure 5

1st

1 (First)

1st

Copyright © 2000 ATSG

7

Page 8

Technical Service Information

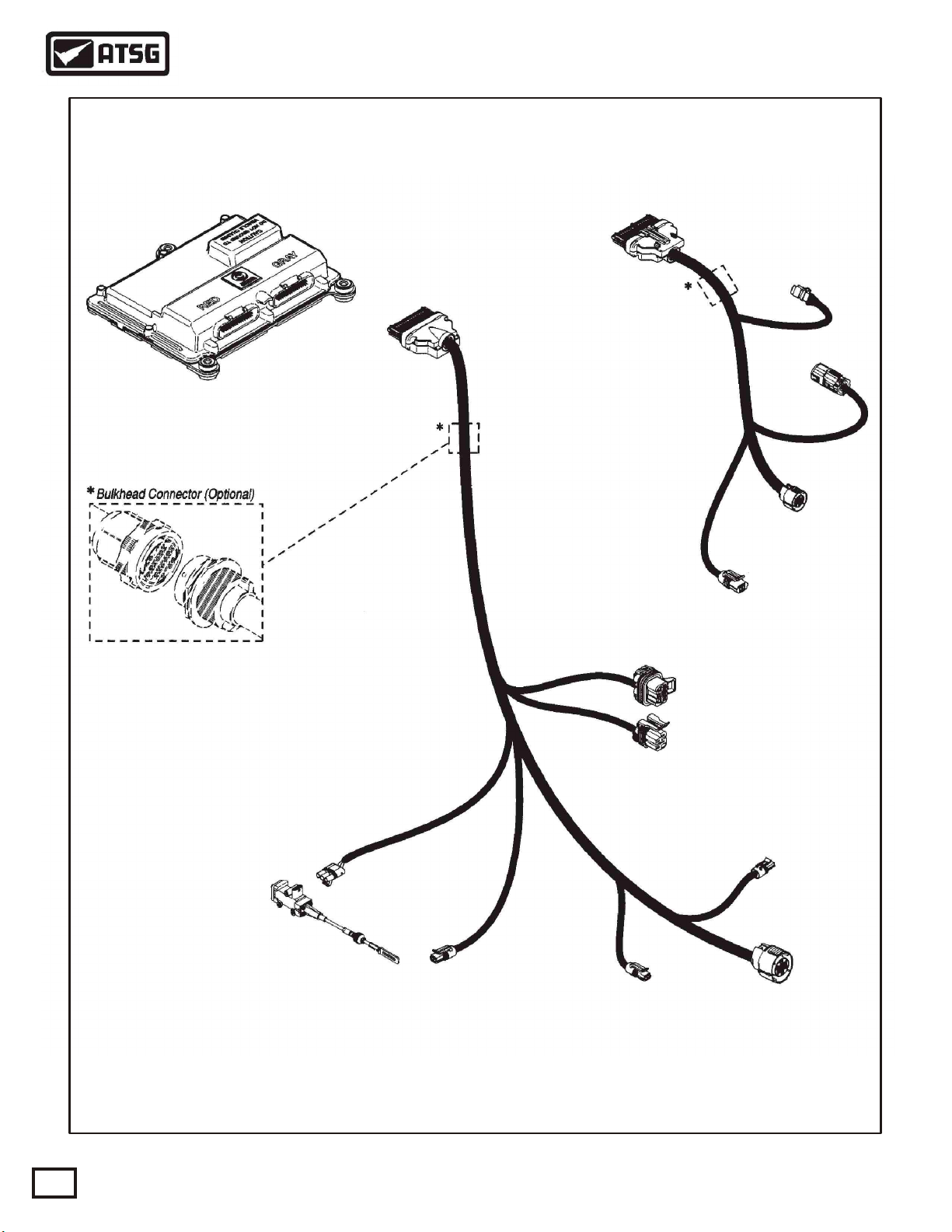

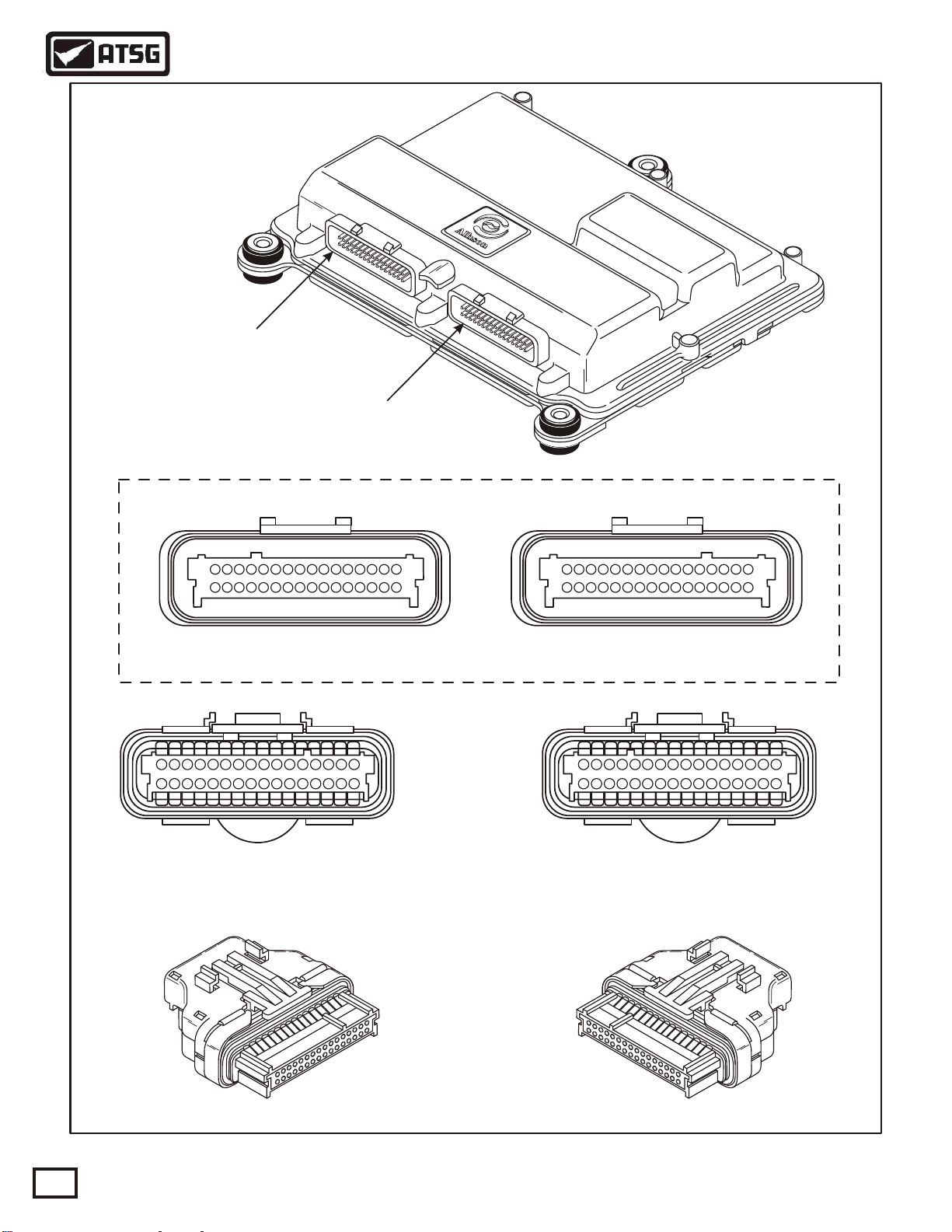

TYPICAL TRANSMISSION CONTROL MODULE

AND VEHICLE HARNESS

TRANSMISSION CONTROL

MODULE (TCM)

TRANSMISSION (J2)

HARNESS

"J2"

CONNECTOR

(RED)

"J1"

CONNECTOR

(GRAY)

VEHICLE (J1)

HARNESS

J 1939

CONNECTOR

(OPTIONAL)

VIW "X"

CONNECTOR

VIW "Y"

CONNECTOR

GP 19

CONNECTOR

THROTTLE

POSITION

SENSOR (TPS)

Actual harness configuration may differ from this illustration.

TPS

CONNECTOR

TURBINE

SPEED SENSOR

CONNECTOR

7 PIN

4 PIN

NSBU SWITCH

CONNECTORS

OUTPUT

SPEED SENSOR

CONNECTOR

ENGINE

SPEED SENSOR

CONNECTOR

Copyright © 2000 ATSG

Figure 6

8

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 9

Technical Service Information

ELECTRICAL OPERATION

The electronic control of the transmission is

performed by the Transmission Control Module

(TCM). Transmissin Control Modules are available

in both 12V and 24V configurations, to match the

configuration of the vehicle electrical system.

The TCM, shown in Figure 6, recieves and processes

signals from various switches and sensors. The TCM

determines shift sequences, shift timing, and clutch

apply and release pressures. The TCM uses this

information to control solenoids and valves, supply

system status, and provide diagnostic information for

service technicians.

EXTERNAL COMPONENTS

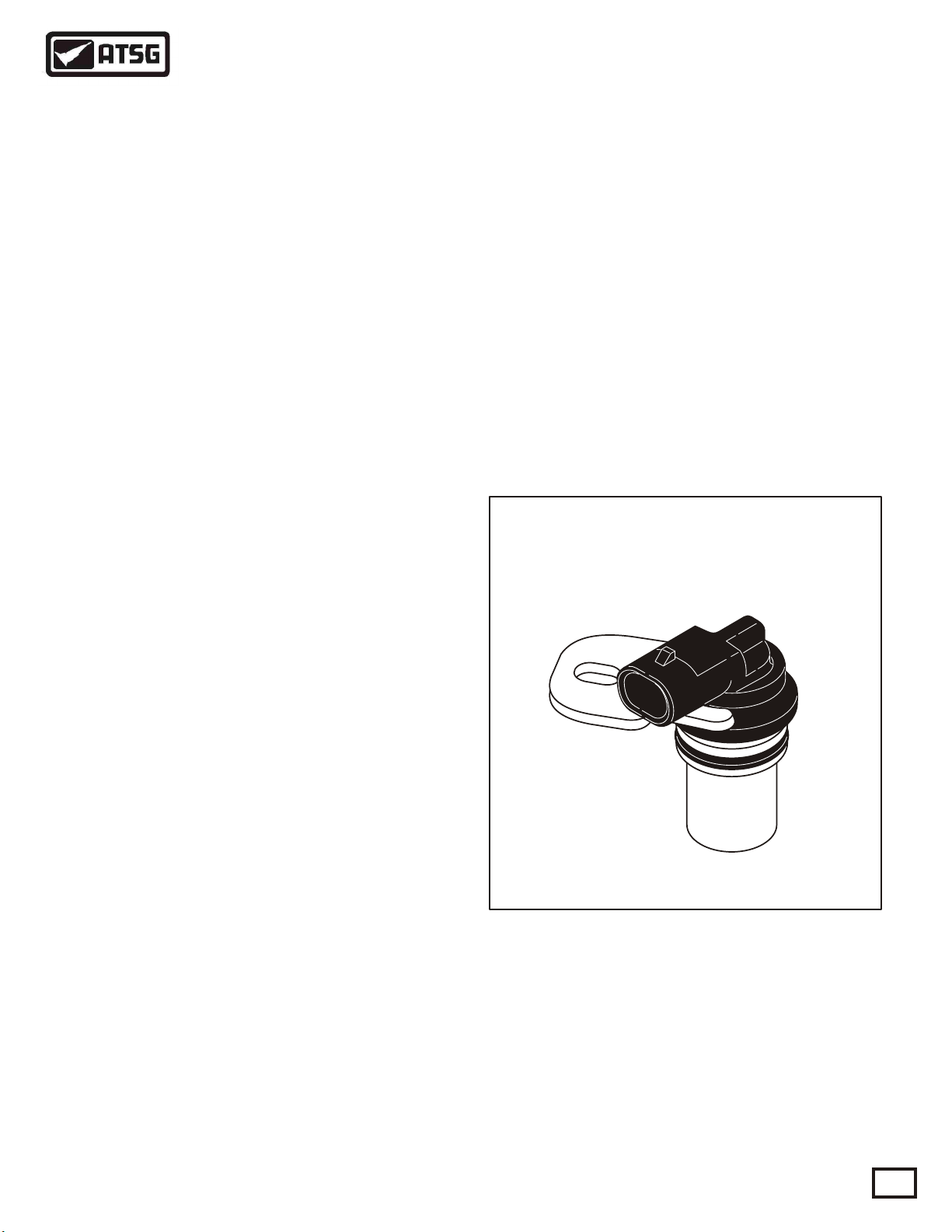

SPEED SENSORS

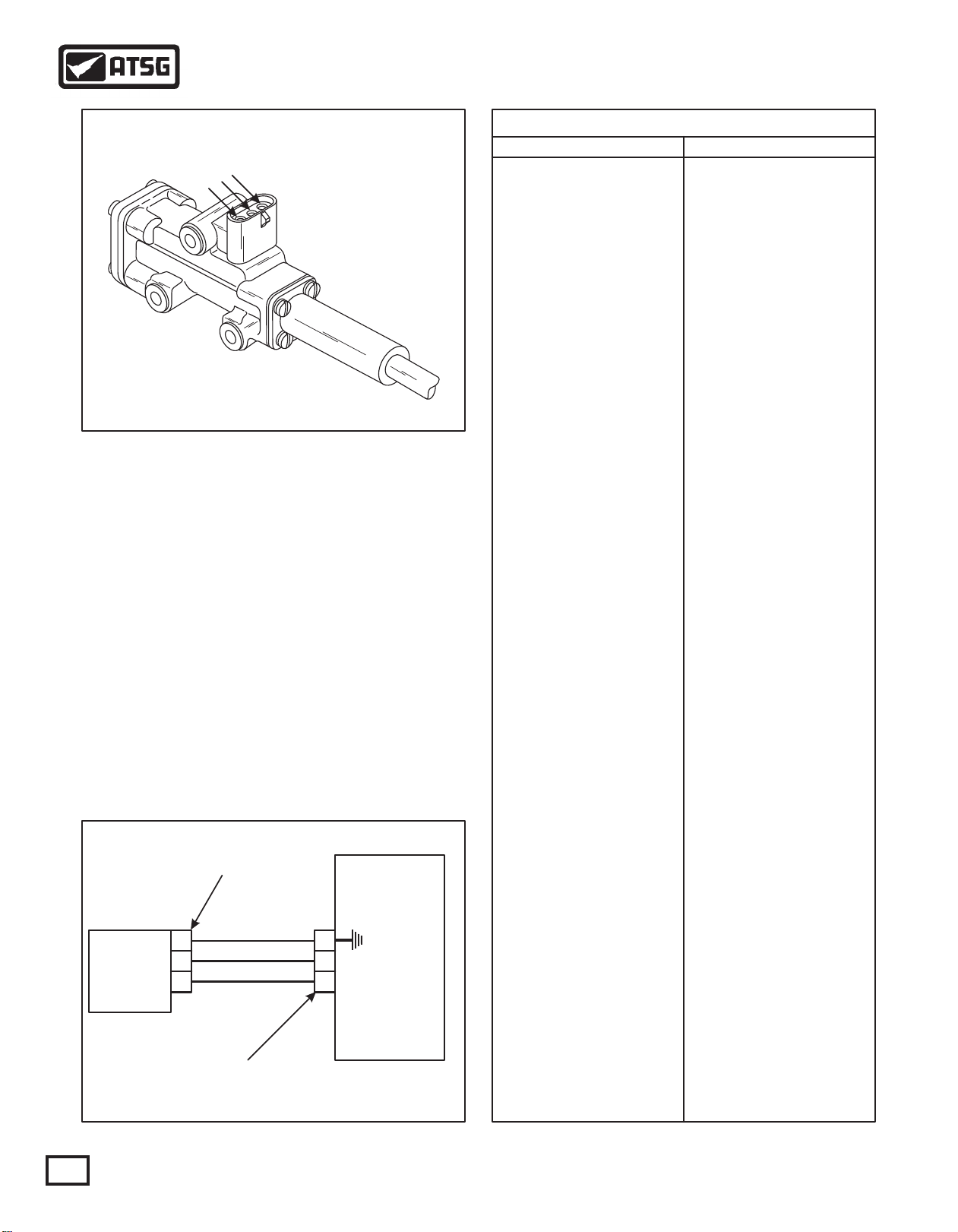

The speed sensors are variable reluctance devices

which convert mechanical motion to an AC voltage.

Each sensor consists of a wire coil wrapped around a

pole piece that is adjacent to a permanent magnet.

These elements are contained in a housing which is

mounted adjacent to a rotating ferrous member, such

as a gear tooth. Two signal wires extend from one end

of the housing and an exposed end of the pole piece is

at the opposite end of the housing. As a ferrous object,

such as a gear tooth approaches and passes through

the gap at the end of the pole piece, an AC voltage

pulse is induced in the wire coil. The TCM calculates

the frequency of these AC pulses and converts it to a

speed value. The AC voltage generated varies from

150mV at low speed to 15V at high speed. The signal

wires from the sensor are formed as twisted pairs to

cancel magnetically induced fields. The cable is also

shielded to protect from voltage-related fields. The

typical speed sensor is shown in Figure 7. Noise from

other sources is eliminated by using two-wire

differential inputs at the TCM.

ENGINE SPEED SENSOR

The Engine Speed Sensor is externally mounted in

the torque converter housing, and directed at the ribs

protruding from the torque converter as shown in

Figure 1.

TURBINE SPEED SENSOR

The Turbine Speed Sensor is externally mounted in

the main transmission case, and directed at the tone

wheel or PTO drive gear attached to the C1/C2 clutch

housing as shown in Figure 1.

OUTPUT SPEED SENSOR

The Output Speed Sensor is externally mounted in

the extension housing and directed at the teeth of a

tone wheel splined to and rotating with the output

shaft as shown in Figure 1.

TYPICAL SPEED SENSOR

Copyright © 2000 ATSG

Figure 7

AUTOMATIC TRANSMISSION SERVICE GROUP

9

Page 10

Technical Service Information

THROTTLE POSITION SENSOR

C

B

A

Copyright © 2000 ATSG

Figure 8

THROTTLE POSITION SENSOR

The Throttle Position Sensor (TPS) can be mounted to

the engine, chassis, or transmission. The TPS

contains a pull actuation cable and a potentiometer.

One end of the cable is attached to the throttle lever

and the other end, inside a protective housing, to the

potentiometer. Output voltage from the TPS is

directed to the Transmission Control Module (TCM)

through the external harness. The voltage signal will

vary and indicates the throttle position and in

combination with other input data will determine shift

timing. Refer to the chart provided in Figure 10 for

approximate voltages at various throttle openings. It

is basically the same as most current GM models with

0.5 volts at idle, to 5.0 volts at wide open throttle.

TPS

Throttle

Position

Sensor

(TPS)

Connector

Green, Ground

A

Blue, Signal Ret.

B

Pink, 5V Supply

C

TCM "J2" (RED)

Connector

Transmission

Control Module

(TCM)

20

9

19

(TPS) Distance of Travel Versus Volts

mm/inch

0/0

1/.039"

2/.079"

3/.118"

4/.157"

5/.197"

6/.236"

7/.275"

8/.314"

9/.354"

10/.394"

11/.433"

12/.472"

13/.511"

14/.551"

15/.590"

16/.629"

17/.669"

18/.708"

19/.748"

20/.787"

21/.826"

22/.866"

23/.905"

24/.945"

25/.984"

26/1.023"

27/1.063"

28/1.102"

29/1.142"

30/1.181"

31/1.220"

32/1.260"

33/1.299"

34/1.339"

35/1.378"

36/1.417"

37/1.457"

38/1.496"

39/1.535"

40/1.575"

41/1.614"

42/1.654"

43/1.693"

44/1.732"

45/1.772"

46/1.811"

Volts

0

0.11

0.22

0.33

0.44

0.55

0.66

0.77

0.88

0.99

1.10

1.20

1.30

1.43

1.54

1.65

1.76

1.87

1.98

2.08

2.19

2.30

2.41

2.52

2.63

2.74

2.85

2.96

3.07

3.18

3.29

3.40

3.51

3.62

3.73

3.84

3.95

4.06

4.17

4.28

4.39

4.50

4.61

4.72

4.83

4.94

5.05

10

Figure 10Figure 9

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 11

Technical Service Information

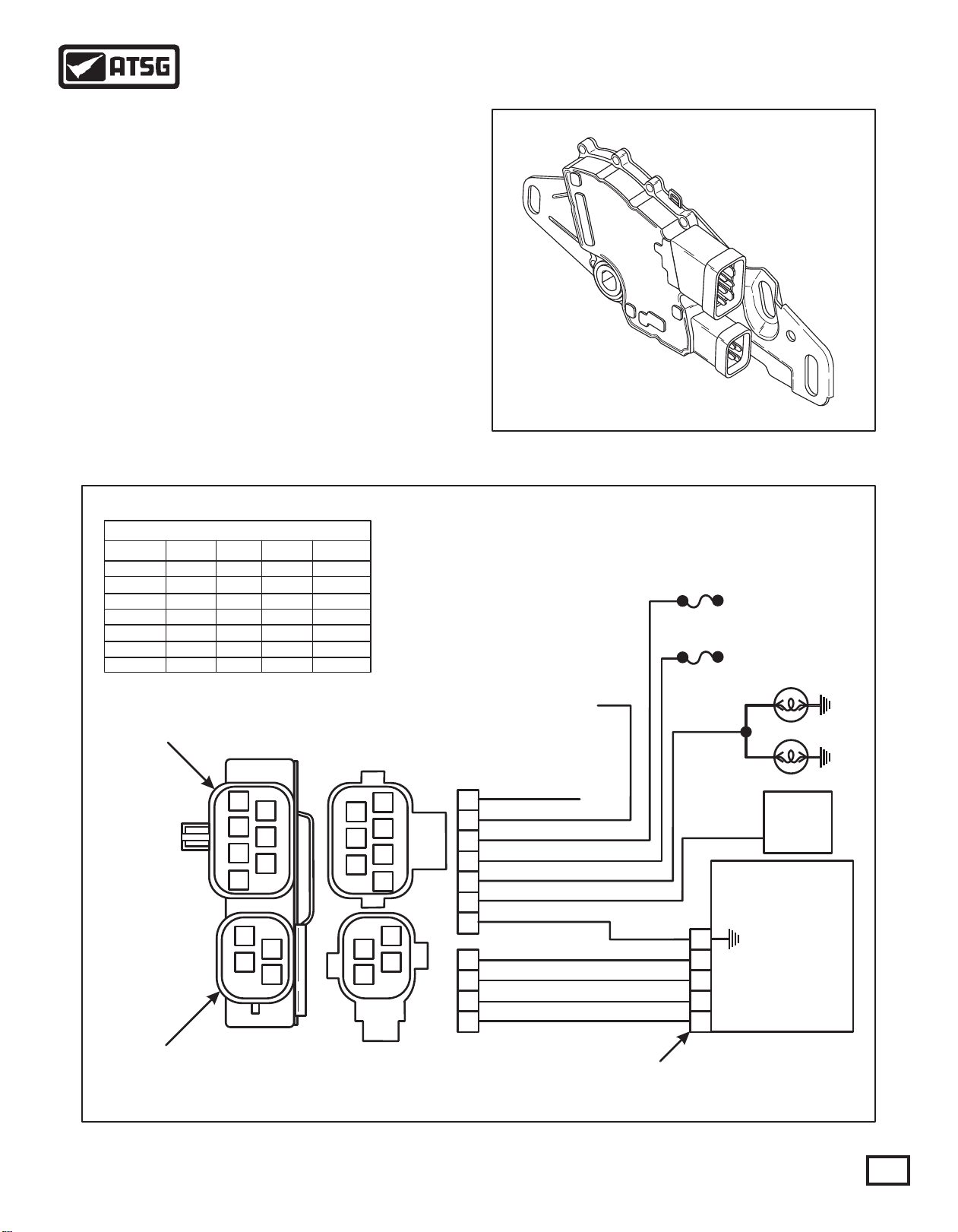

NEUTRAL START BACK-UP SWITCH

The installation of a transmission mounted Neutral

Start/ Reverse Signal switch is required. This switch

commonly refered to as an "NSBU Switch", mounts

directly onto the transmission case from the outside

and detects the angular position of the manual shift

selector shaft. This position is relayed to the TCM so

that certain vehicle control functions can be

coordinated with the position of the shift controls.

The NSBU Switch has redundant circuitry to alert the

TCM in the event of a single wire or switch failure.

The switch is interfaced to the starter circuit, and the

reverse signal provision may be used to activate

vehicle back-up lights and/or reverse warning

devices.

Refer to Figures 11 and 12.

NSBU SWITCH WIRE SCHEMATIC

NSBU SWITCH RANGE CHART ON SCAN TOOL

Range A B C P

P

R

N

D

3

2

1

OFF

OFF

ON

ON

OFF

OFF

ON

ON ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

NEUTRAL START BACK-UP SWITCH

Copyright © 2000 ATSG

Figure 11

Rev/Park Accessory

Battery Feed

PK/NEUT Start

Battery Feed

7-Way NSBU

Switch Receptacle

(Face View)

4-Way NSBU

Switch Receptacle

(Face View)

Park Accessory

Back-up Lamps

Not Used

A

G

B

F

C

E

D

C

A

D

B

Harness Connectors

A

G

B

F

C

E

D

C

A

D

B

NSBU Switch

(Face View)

A

B

C

E

F

G

D

A

B

C

D

Tan

Blue

Yellow

Pink

Orange

Green

Blue

Gray

White

Yellow

TCM "J2" (RED)

Connector

20

5

7

8

6

Copyright © 2000 ATSG

Starter

Relay

Transmission

Control Module

(TCM)

Figure 12

AUTOMATIC TRANSMISSION SERVICE GROUP

11

Page 12

TCM "J2" (Red)

Receptacle

Technical Service Information

RED

RED

R

R

ED

ED

G

G

GR

GR

R

R

A

A

A

A

Y

Y

Y

Y

TCM "J1" (Gray)

Receptacle

TRANSMISSION CONTROL MODULE (TCM)

S

S

IS

IS

TO

TO

SSI

SSI

D TO

D TO

N

N

ND

ND

U

U

CHASS

CHASS

U

U

CHA

CHA

E

E

O

O

E

E

N

N

N

N

L

L

R

R

RO

RO

C

C

ICL

ICL

I

I

IO

IO

H

H

T G

T G

T

T

TIO

TIO

EH

EH

O

O

U

U

OT G

OT G

VE

VE

V

V

N

N

A

A

AU

AU

N

N

O

O

O

O

C

C

C

C

D

D

D

D

1322313304295286278251023122114

TCM "J2" (Red)

Receptacle

14

13

151816

19

20

17

9

11

25

23

21

24

22

10

12

TCM "J2" (Red)

Harness Connector

(Face View)

72692411221320151816

7

26

1322313304295286278

1322313304295286278251023122114

19

17

72692411221320151816

19

17

TCM "J1" (Gray)

Receptacle

14

11

13

151816

21

19

22

20

17

7269

25

23

24

10

12

1322313304295286278

TCM "J1" (Gray)

Harness Connector

(Face View)

12

Copyright © 2000 ATSG

Figure 13

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 13

Technical Service Information

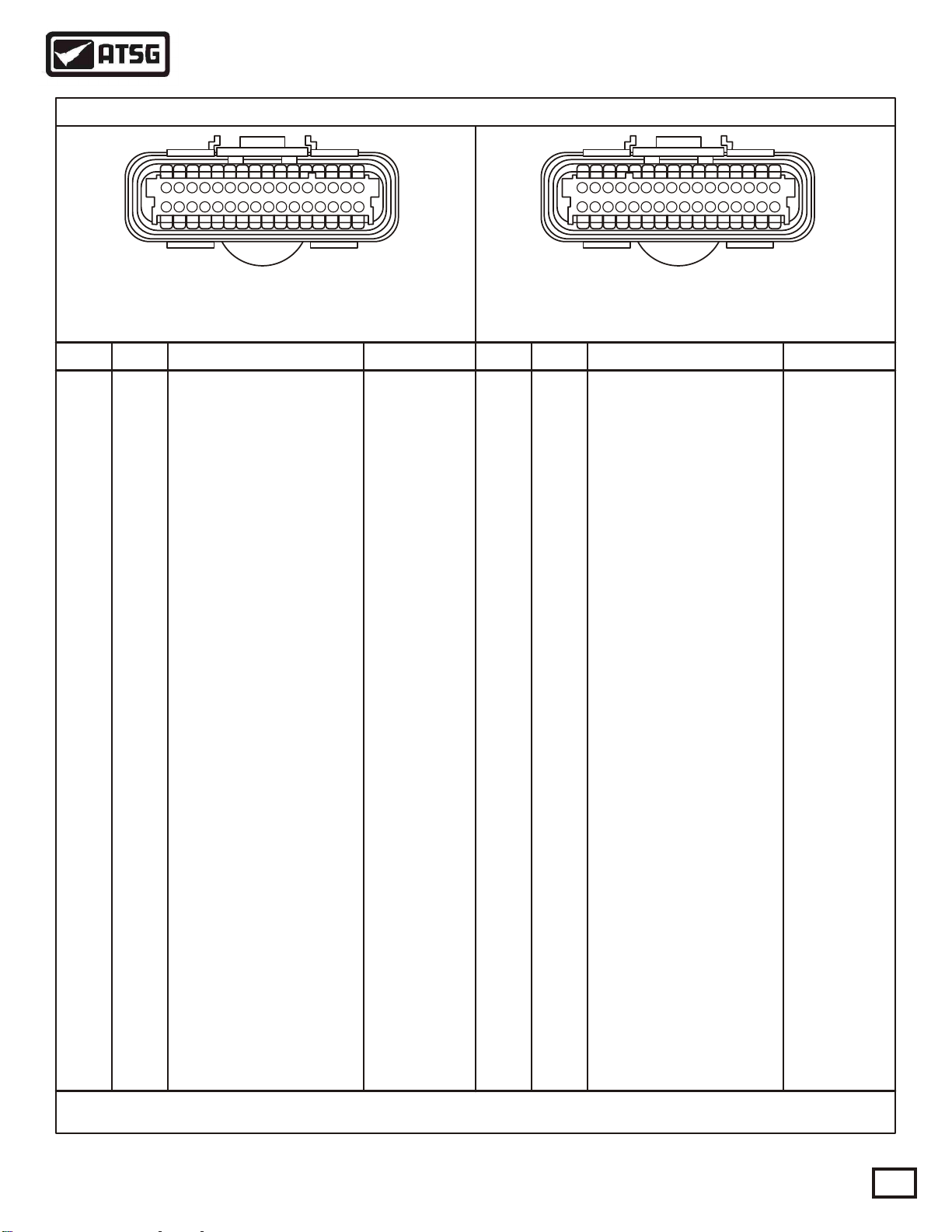

TCM CONNECTOR PIN IDENTIFICATION CHART

14

11

13

151816

21

19

22

20

17

7269

25

23

24

10

12

TCM "J2" (Red)

Harness Connector

(Face View)

Term. Term.Color ColorCircuit Ends Circuit Ends

Blue Trans-D Vehicle System

1 1

2 2

Pink

3 3

White

4 4

Green

Blue

5 5

Yellow

6 6

Gray

7 7

White

8 8

Blue

9 9

10 10

Orange

11 11

12 12

13 13

14 14

15 15

16 16

17 17

18 18

19 19

20 20

21

22

23

24

25

26

27

28

29

30

31

32

Blue

Orange

Blue

Yellow

Green

Orange

Pink

Green

Yellow

Yellow

White

Pink

Orange

Green

Blue

Gray

White

Orange

Green

Circuit Function Circuit Function

PSA Input Battery Ground

PSA Input

PSA Input

PSA Input

NSBU Input

NSBU Input

NSBU Input

NSBU Input

Throttle Position Sensor

Tan

Tan

Tan

Trans Sump Temp Input

Retarder Temp Input (Opt)

Engine Coolant Temp

Turbine Speed Sensor (High)

Turbine Speed Sensor (Low)

Output Speed Sensor (High)

Output Speed Sensor (Low)

Engine Speed Sensor (High)

Engine Speed Sensor (Low)

TPS Voltage Supply

Analog Ground

TRANS ID

Trim Solenoid A (High)

Trim Solenoid A (Low)

Trim Solenoid B (High)

Trim Solenoid B (Low)

C Solenoid Ground (On/Off)

D Solenoid Ground (On/Off)

E Solenoid Ground (On/Off)

F Solenoid Low (PWM)

G Solenoid Low (PWM)(Opt)

C, D, E Solenoid V Supply

F Solenoid High (PWM)

1322313304295286278

Trans-F

Trans-E

Trans-K

NSBU-4A

NSBU-4D

NSBU-4B

NSBU-4C

TPS-B

Trans-G

R Temp-A

ECTS-A

TSS-A

TSS-B

OSS-A

OSS-B

ESS-A

ESS-B

TPS-C

Trans-H, ECTS-A,

Temp-B, NSBU-7D

R-Temp-B, TPS-A

Trans-T

Trans-L

Trans-M

Trans-N

Trans-P

Trans-A

Trans-B

Trans-W

Trans-J

Trans-J

Trans-C

Trans-S

21

22

23

24

25

26

27

28

29

30

31

32

Gray

Yellow

Pink

Yellow

Gray

Blue

Orange

Green

White

Yellow

Green

Blue

Pink

Orange

Yellow

White

Pink

Green

Tan

Orange

White

Blue

Pink

White

Green

Tan

Pink

Yellow

Red

Blue

Green

Black

14

11

13

151816

21

19

22

20

17

7269

25

23

24

10

12

TCM "J1" (Gray)

Harness Connector

(Face View)

Ignition Power

Battery Power

Ignition Power

Battery Ground

GPI 1

GPI 2

GPI 3

GPI 4

GPI 5

GPI 6

GPI 7

GPI 8

GPI 9

Retarder Mod. Reg. (Opt)

PWM Throttle

Sensor Power

Analog Ground

GPO 1

GPO 2

GPO 3

GPO 4

Range Inhibit Indicator

GPO 6

CHECK TRANS

Vehicle Speed

Vehicle Speed

Digital Ground

CAN High

ISO 9141

CAN Shield

CAN Low

1322313304295286278

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

RMR-B

Vehicle System

RMR-C

RMR-A

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

Vehicle System

J 1939 A or H

Vehicle System

J 1939 C or S

J 1939 B or L

Figure 14

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2000 ATSG

13

Page 14

DTC Description

Technical Service Information

DIAGNOSTIC TROUBLE CODE (DTC) CHART

"Check Trans"

Light

P0117

P0118

P0121

P0122

P0123

P0218

P0561

P0562

P0563

P0602

P0606

P0700

P0703

P0705

P0706

P0708

P0711

P0712

P0713

P0716

P0717

P0721

P0722

P0726

P0727

P0731

P0732

P0733

P0734

P0735

P0736

P0741

P0742

P0746

P0747 YES

P0763

P0768

P0776 YES

P0777 YES

Engine Coolant Temperature Circuit Low Voltage (High Temperature)

Engine Coolant Temperature Circuit High Voltage (Low Temperature)

Throttle Position Sensor Performance Problem

Throttle Position Sensor Circuit Low Voltage

Throttle Position Sensor Circuit High Voltage

Transmission Fluid Over Temperature

Urealistic variations in vehicle system voltage

System Voltage Low

System Voltage High

TCM Not Programmed

Transmission Control Module Internal Performance

MIL Illumination requested

Brake Switch Circuit

Transmission Range Sensor Circuit (PRNDL Input)

Transmission Range Sensor Circuit Performance

Transmission Range Sensor Circuit High Input

Transmission Fluid Temperature Circuit Performance

Transmission Fluid Temperature Circuit Low Voltage (High Temperature)

Transmission Fluid Temperature Circuit High Voltage (Low Temperature)

Turbine Speed Sensor Circuit Performance

Turbine Speed Sensor Circuit No Signal

Output Speed Sensor Circuit Performance

Output Speed Sensor Circuit No Signal

Engine Speed Sensor Circuit Performance

Engine Speed Sensor Circuit No Signal

Incorrect 1st Gear Ratio

Incorrect 2nd Gear Ratio

Incorrect 3rd Gear Ratio

Incorrect 4th Gear Ratio

Incorrect 5th Gear Ratio

Incorrect Reverse Gear Ratio

Torque Converter Clutch System Stuck Off

Torque Converter Clutch System Stuck On

Torque Converter Clutch Solenoid ElectricalP0742 YES

Solenoid A controlled Clutch Stuck Off

Solenoid A controlled Clutch Stuck On

Pressure Control Trim Solenoid "A" ElectricalP0748 YES

Shift Solenoid "C" Electrical

Shift Solenoid "D" Electrical

Shift Solenoid "E" ElectricalP0773 YES

Solenoid B controlled Clutch Stuck Off

Solenoid B controlled Clutch Stuck On

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

14

Figure 15

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2000 ATSG

Page 15

DTC Description

Technical Service Information

DIAGNOSTIC TROUBLE CODE (DTC) CHART

"Check Trans"

Light

P0778

P0836

P0840

P0841

P0842

P0843

P0845

P0846

P0847

P0848

P1688

P1709

P1710

P1711

P1712

P1713

P1714

P1715

P1716

P1720

P1721

P1723

P1724

P1726

P1727

P1760

P1835

P1860

P1891

Pressure Control Trim Solenoid "B" Electrical

4 Wheel Drive Low Switch Circuit Malfunction (may also be listed as P1875)

Transmission Pressure Switch, Solenoid C Circuit

Transmission Pressure Switch, Solenoid C Circuit Stuck Open

Transmission Pressure Switch, Solenoid C Circuit Stuck Closed

Transmission Pressure Switch, Solenoid C Circuit High

Transmission Pressure Switch, Solenoid D Circuit

Transmission Pressure Switch, Solenoid D Circuit Stuck Open

Transmission Pressure Switch, Solenoid D Circuit Stuck Closed

Transmission Pressure Switch, Solenoid D Circuit High

Transmission Pressure Switch, Solenoid E Circuit HighP0870 YES

Transmission Pressure Switch, Solenoid E Circuit Stuck OpenP0871 YES

Transmission Pressure Switch, Solenoid E Circuit Stuck ClosedP0872 YES

Transmission Pressure Switch, Solenoid E Circuit HighP0873 YES

Reverse Pressure Switch MalfunctionP0875 YES

Reverse Pressure Switch Circuit Stuck OpenP0876 YES

TCM Power Input SignalP0880 YES

Unmanaged Engine Torque Delivered To TCM

Transmission Pressure Switch, Solenoid E Circuit

Transmission Pressure Switch, Solenoid E Circuit Stuck Open

Transmission Pressure Switch, Solenoid E Circuit Stuck Closed

Transmission Pressure Switch, Solenoid E Circuit High

Transmission Pressure Switch, Reverse Circuit

Transmission Pressure Switch, Reverse Circuit Stuck Open

Transmission Pressure Switch, Reverse Circuit Stuck Closed

Transmission Pressure Switch, Reverse Circuit High

Trim Solenoid "A" Controlled Clutch Not Engaged

Trim Solenoid "B" Controlled Clutch Not Engaged

Trim Solenoid "A" Controlled Clutch Not Engaged

Trim Solenoid "B" Controlled Clutch Not Engaged

Shift Solenoid "D" Controlled Clutch Not Engaged

Shift Solenoid "E" Controlled Clutch Not Engaged

TCM Supply Voltage

Engine Torque Delivered to TCMP1779 NO

Kickdown Circuit

TCC (PWM) Solenoid Circuit-Electrical

Throttle Position Sensor Clutch PWM Signal Low Input

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

YES

YES

NO

P1892

U1016

U1300

U1301

U2105

Throttle Position Sensor Clutch PWM Signal High Input

Class 2 Powertrain Controller State Of Health

Serial Data Communication Link Low (Class 2)

Serial Data Communication Link High (Class 2)

CAN Bus Error ECM

Figure 16

AUTOMATIC TRANSMISSION SERVICE GROUP

NO

NO

NO

NO

NO

Copyright © 2000 ATSG

15

Page 16

Technical Service Information

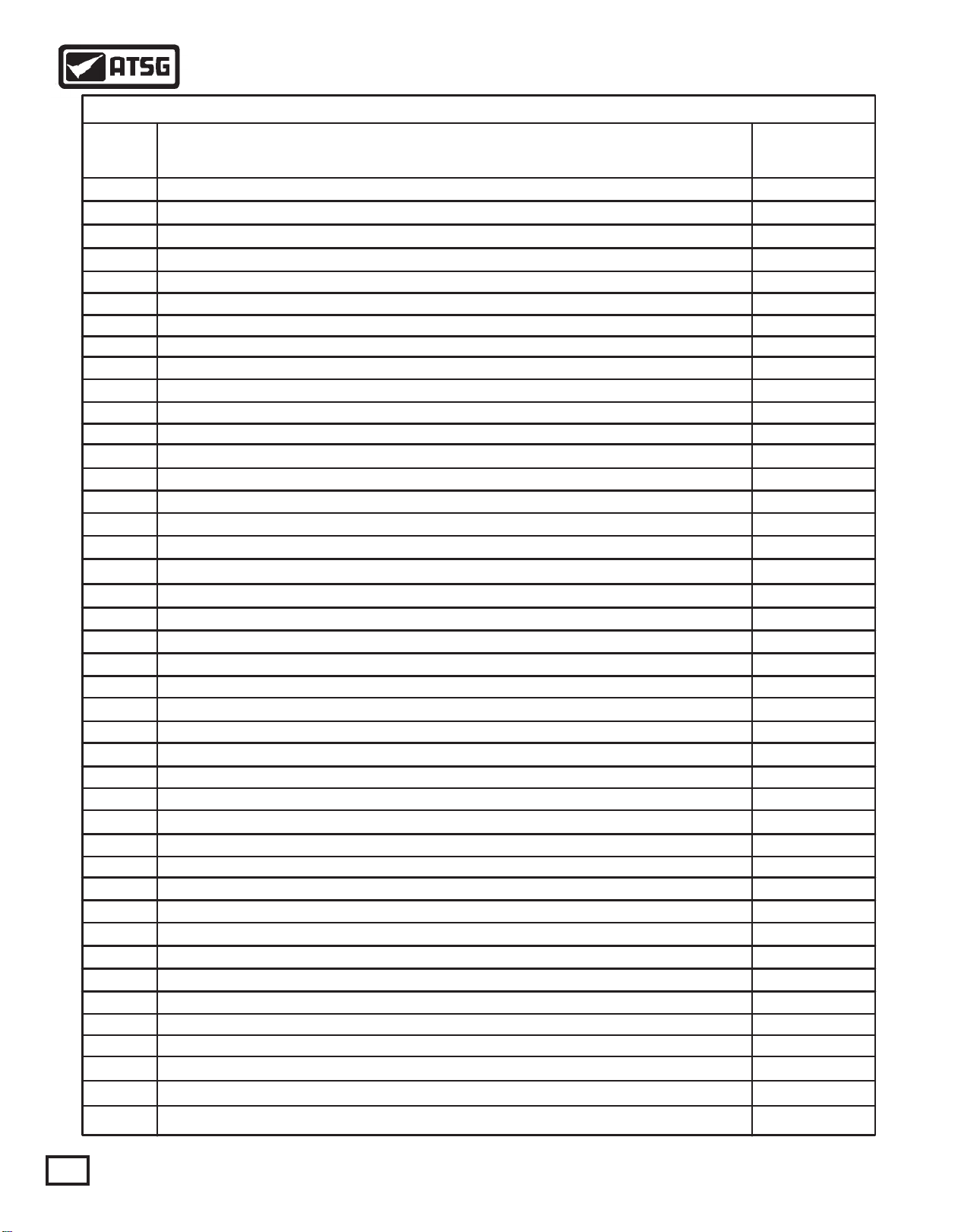

SOLENOID LOCATIONS

Shift Solenoid "E"

(Normally Closed)

Shift Solenoid "C"

(Normally Closed)

Trim Solenoid "A"

(Normally Closed)

Trim Solenoid "B"

(Normally Open)

PRESSURE SWITCH

ASSEMBLY

TCC (PWM) Solenoid "F"

(Normally Closed)

Figure 17

Shift Solenoid "D"

(Normally Closed)

Copyright © 2000 ATSG

16

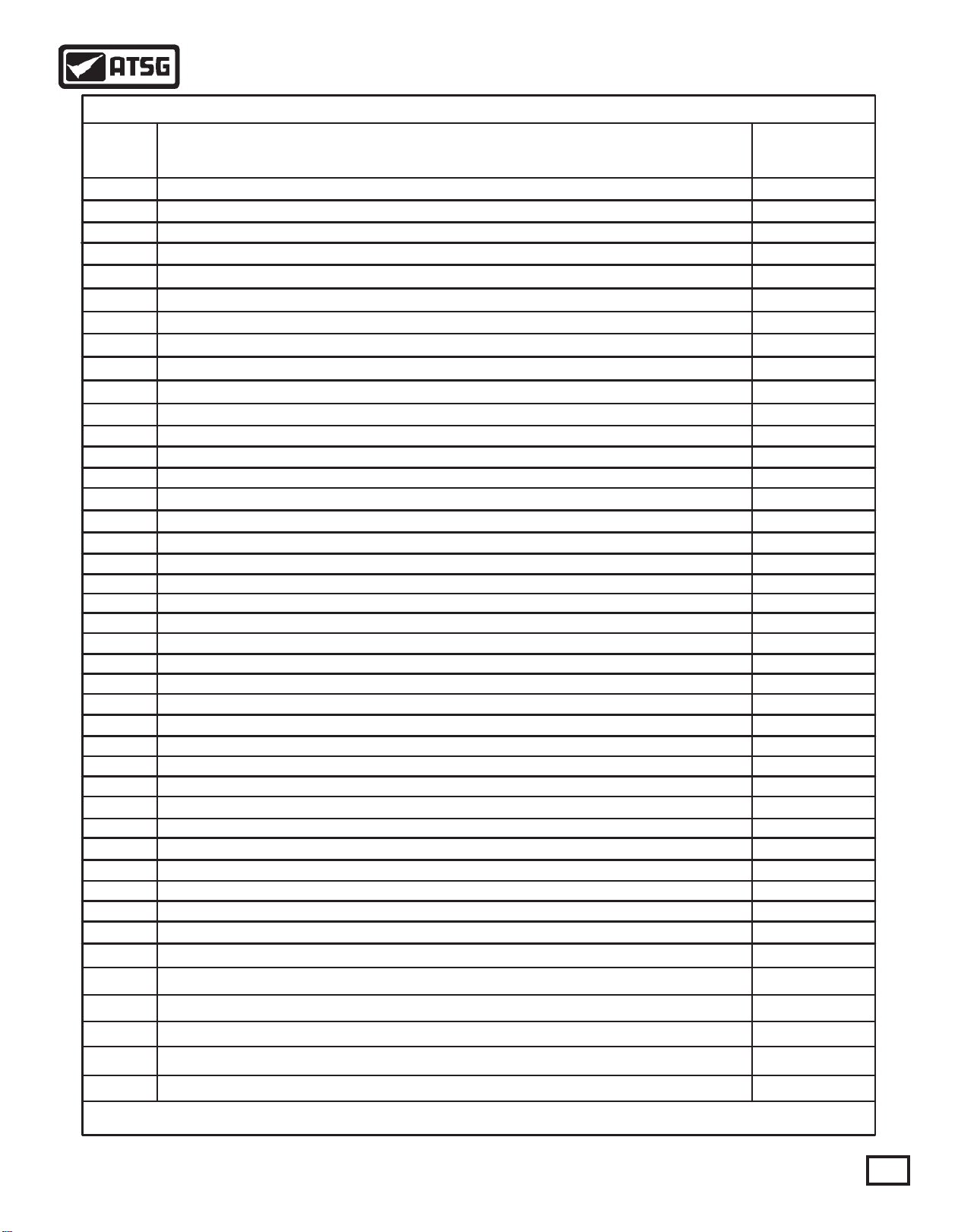

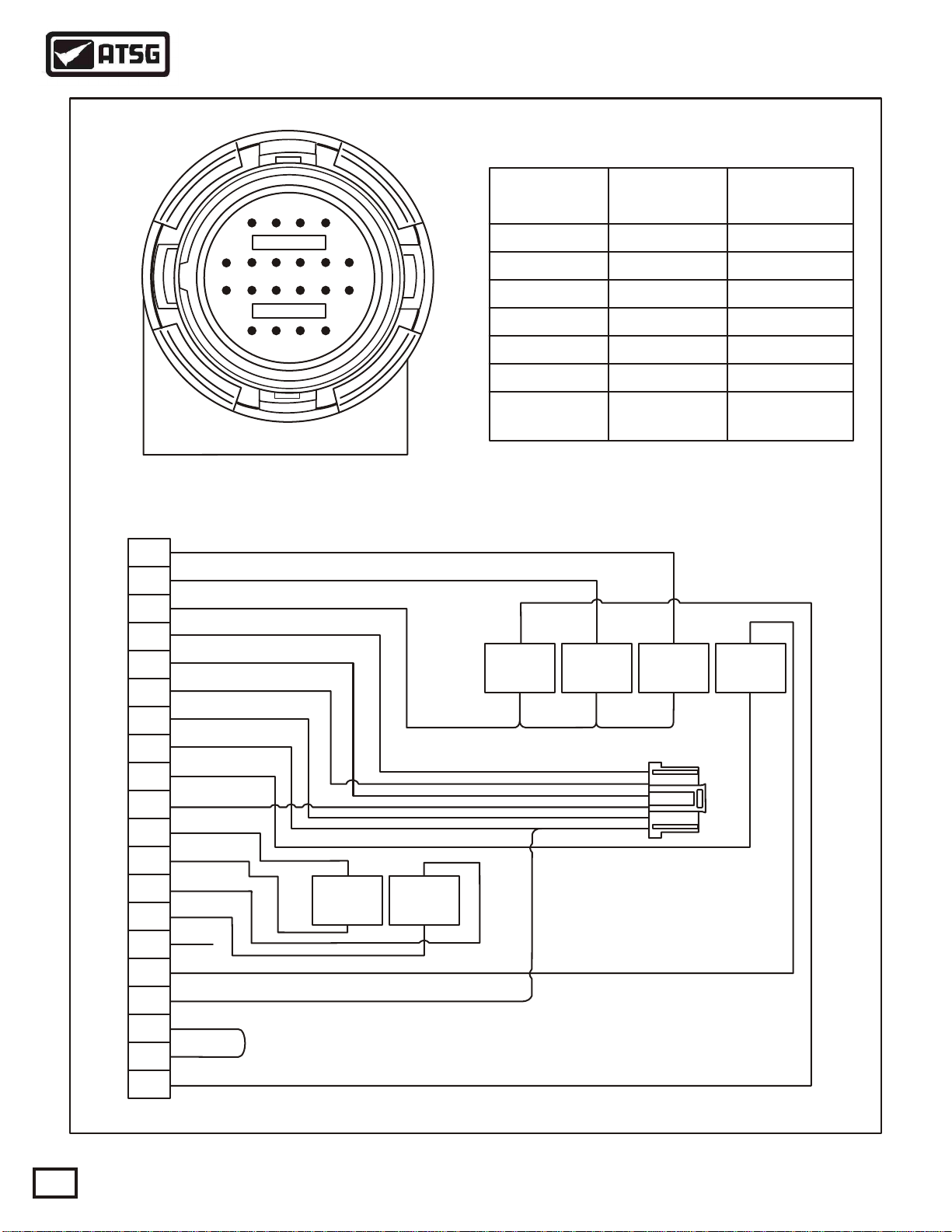

Internal Wiring Harness And

Case Connector Assembly

Copyright © 2000 ATSG

Figure 18

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 17

Technical Service Information

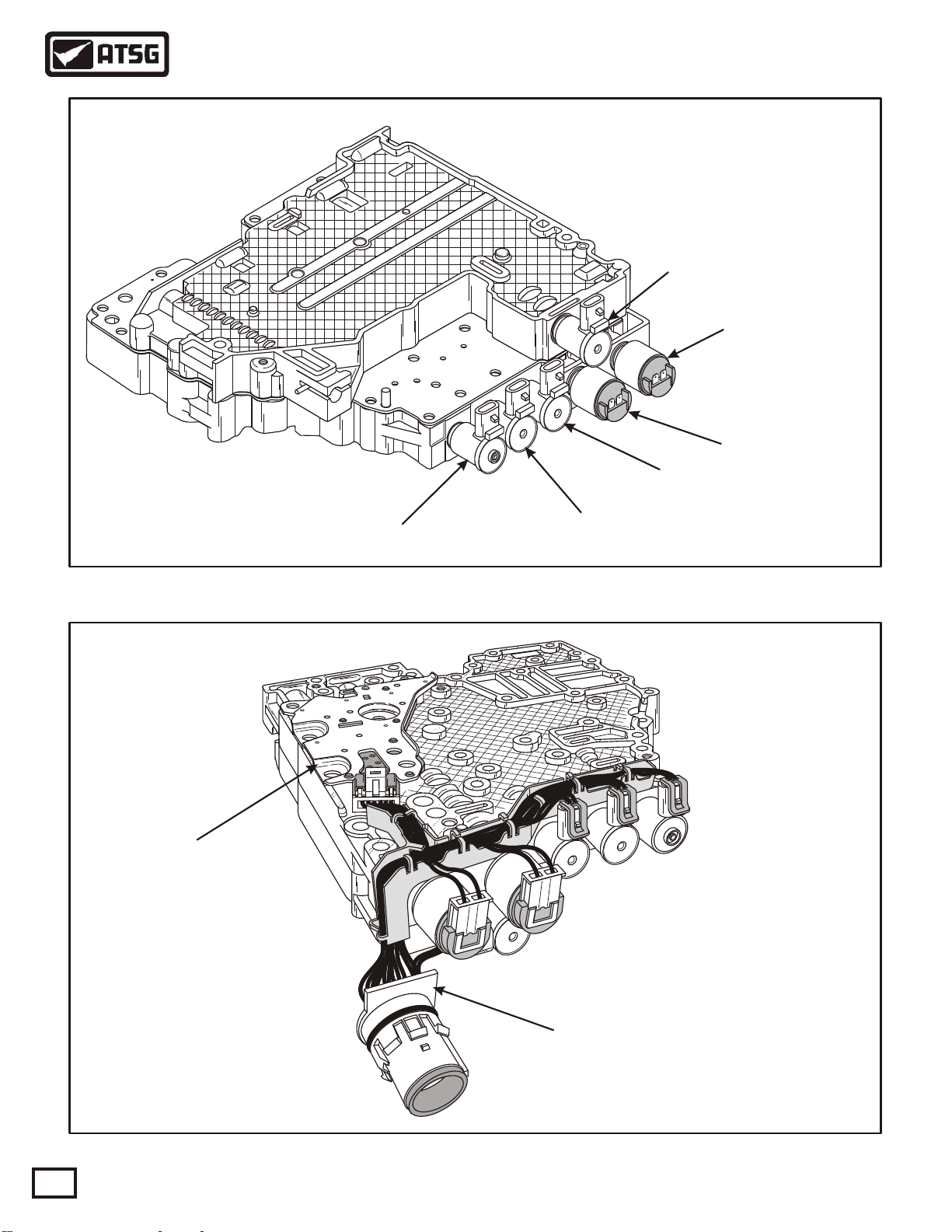

INTERNAL COMPONENTS

Several components of the 1000/2000/2400 Series

electrical control system are located inside of the

transmission as part of the main control valve body.

These components include three different types of

solenoids for controlling the hydraulic action of the

valves in the valve body, and the pressure switch

assembly. An internal wiring harness and case

connector assembly links the internal components

with the Transmission Control Module.

SOLENOIDS

The 1000/2000/2400 Series solenoid locations are

shown in Figure 17. The solenoids may be normally

closed or normally open. A normally closed solenoid

remains closed until a signal from the TCM energizes

the solenoid. A normally open solenoid remains open

until the TCM energizes the solenoid.

TCC (PWM) Solenoid F - This solenoid a normally

closed, pulse width modulated, and operates at a

frequency of 100 Hz (cycles per second) during a

shift. The percentage of time the voltage is ON

during each 100th of a second is called the solenoid

duty cycle.

INTERNAL WIRING HARNESS ASSEMBLY

A 100 percent duty cycle indicates a maximum signal

to the solenoid. A zero percent duty signal indicates a

minimum or no signal to the solenoid. The TCM,

using pulse width modulation programming, varies

the percentage of voltage ON time during a cycle. As

the pulse width, or duty cycle is increased, the

solenoid is ON longer.

Shift Solenoids C, D, E - Shift Solenoids C, D, & E

are normally closed solenoids that provide the

necessary logic to distribute fluid to the correct clutch

packs in the transmission. The shift solenoids provide

either full control line pressure, or exhaust, to the

lands of each of the corresponding Shift V alves C, D,

and E. Shift Solenoids C, D, and E may operate in the

open or closed state with no modulation capability at

all.

Trim Solenoids A and B - Trim Solenoid A and B are

used to control oncoming, off-going, and holding

pressure to the five clutch packs. These solenoids are

reffered to as Pressure Proportional to Current (PPC)

solenoids, since the output hydraulic pressure

supplied by these solenoids is proportional to the

current commanded. Trim Solenoids A and B operate

using a frequency of 1000 Hz. The current causes a

force on the armature and shaft assembly, which is

balanced by fluid pressure acting on the end of the

shaft. The trim solenoids operate using battery

voltage. Trim Solenoid A is a Normally Closed

solenoid, providing 86 psi (590 kpa) at zero current,

and no trim pressure at full current. Trim Solenoid A

allows for limp-home capability in the event of a

power or TCM failure. Trim Solenoid B is a

Normally Open solenoid, and prrovides zero pressure

at zero current.

Serviced as an assembly under

Allison Part Number 15321154.

Copyright © 2000 ATSG

Figure 19

AUTOMATIC TRANSMISSION SERVICE GROUP

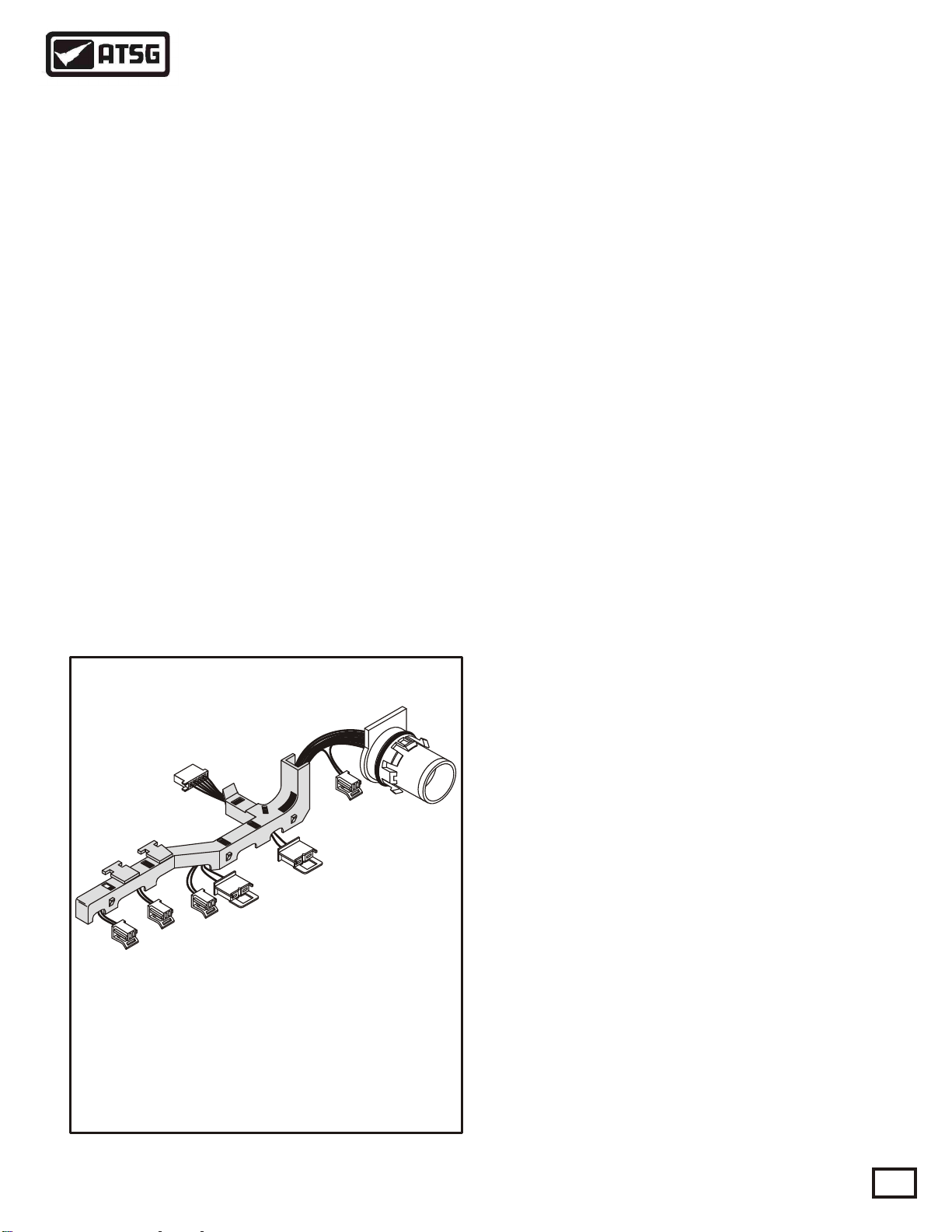

INTERNAL WIRING HARNESS

The Internal Wiring Harness Assembly connects the

shift solenoids, clutch trim solenoids, torque

converter clutch solenoid, pressure switch assembly

and temperature sensor to the external harness that

leads to the Transmission Control Module. Refer to

Figure 18 and 19. Figure 20 on Page 18 gives you an

internal wire schematic for all of the internal

components, and pin identification for the external

transmission case connector

Continued on Page 18.

17

Page 18

Technical Service Information

INTERNAL WIRING SCHEMATIC

A

B

M

G

F

N

T

UCV

E

L

D

HPJRK

S

W

PED 4

TRANSMISSION EXTERNAL

CONNECTOR FACE VIEW

Dark Green

A

Orange/Black

B

Pink

C

Light Green

D

Red

E

Blue

F

Orange

G

Black

H

Brown

J

Tan

K

Red/Black

L

Light Blue

M

N

P

R

S

T

U

V

W

Gray

Purple

N/A

Black

Tan

Green

Green

Black/Tan

TRIM (N/C)

SOLENOID

"A"

TRIM (N/0)

SOLENOID

"B"

Solenoid Terminals

Resistance In

Ohms @ 72°F

TRIM "A" 5.5 - 8.0 W

TRIM "B"

SHIFT "C"

SHIFT "D"

SHIFT "E"

TCC "F"

TEMP

SENSOR

SHIFT

SOLENOID

"E"

SHIFT

SOLENOID

"D"

L and M

N and P

C and A

C and B

C and W

J and S

H and G

SHIFT

SOLENOID

"C"

To Pressure

Switch Assembly

5.5 - 8.0 W

TCC

SOLENOID

"F"

A

B

C

D

E

F

20 -30 W

20 -30 W

20 -30 W

8 - 15 W

2.8K W

@ 72° F

18

Copyright © 2000 ATSG

Figure 20

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 19

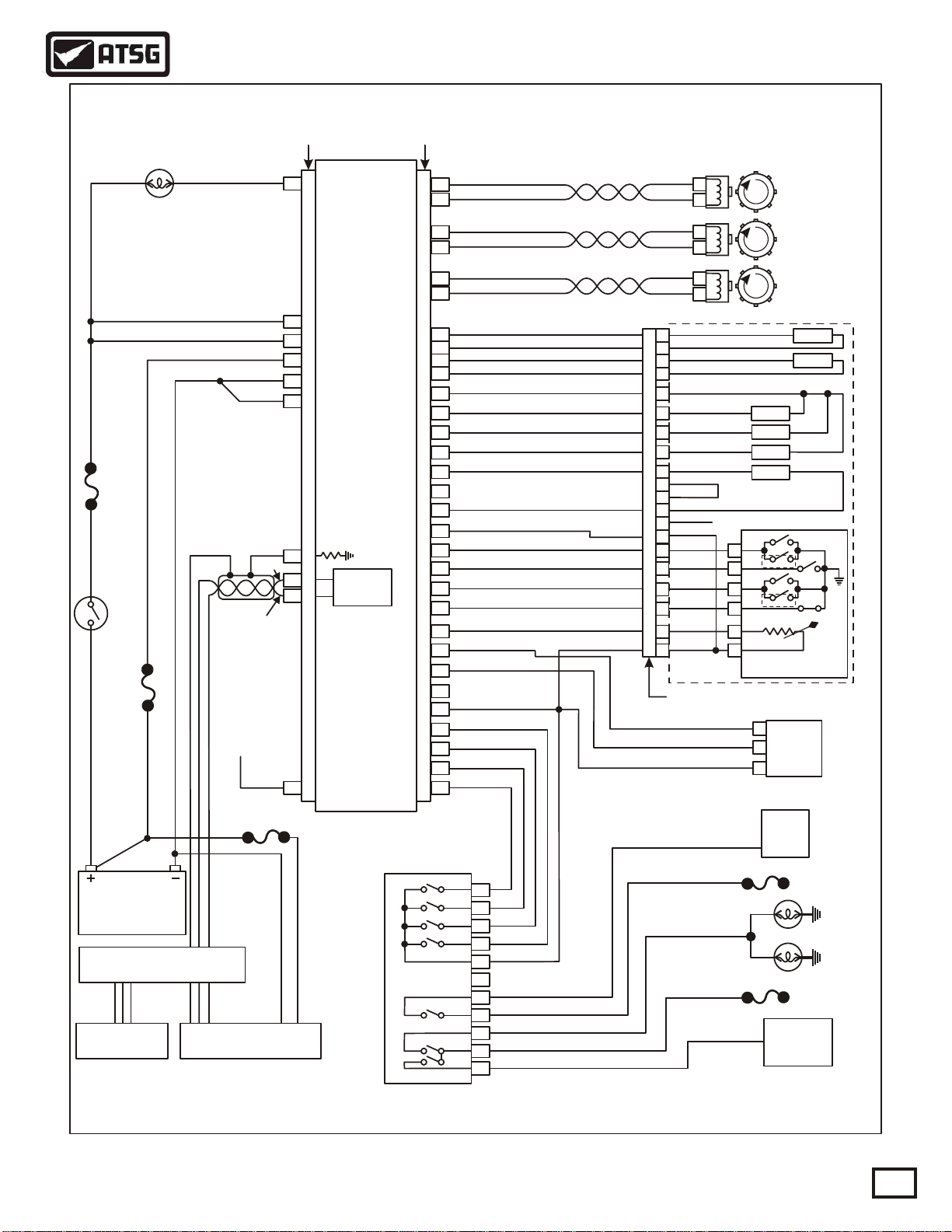

Technical Service Information

See Pages 12 and 13 For

TCM Connector Pin I.D.

CHECK TRANS

CHECK TRANS

LIGHT

LIGHT

IGNITION POWER

IGNITION POWER

BATTERY POWER

TCM GROUND

10A

IGNITION

IGNITION

SWITCH

SWITCH

10A

OPTIONAL SPEEDO

SIGNAL RETURN

TCM "J1" (Gray)

TCM "J1" (Gray)

Yellow

Yellow

Pink

Gray

Gray

Green

Red

Black

Green

CONNECTOR

CONNECTOR

25

CONTROL MODULE

CONTROL MODULE

2

4

3

1

5

GRAYGRAY

31

+

29

_

32

DO NOT GROUND TO

DO NOT GROUND TO

EXTERNAL WIRE SCHEMATIC

TCM "J2" (Red)

TRANSMISSION

TRANSMISSION

(TCM)

(TCM)

CAN 2.08

J=1939

DATA LINK

CAUTIONCAUTION

VEHICLE CHASSIS

VEHICLE CHASSIS

TCM "J2" (Red)

CONNECTOR

CONNECTOR

15

16

13

14

17

18

23

22

24

25

31

26

27

28

29

REDRED

30

32

21

1

2

3

4

10

5V

19

9

12

20

5

6

7

88

RECOMMENDED

WIRE COLORS

Yellow

Green

Orange

Blue

Tan

Orange

White

Yellow

Pink

Orange

Tan

Green

Blue

Gray

White

Green

Yellow

Blue

Pink

White

Green

Tan

Pink

Blue

Green

Blue

Yellow

Gray

White

ALLISON

TRANS ID

A

B

A

B

A

B

Lt Blue

M

Red/Black

L

Gray

N

Purple

P

Pink

C

Dk Green

A

Orange/Black

B

Black/Tan

W

Brown

J

Green

U

V

Black

S

Orange

R

T

D

NOT USED

Tan

Lt Green

Blue

Red

Tan

Orange

Black

TRANSMISSION CASE CONNECTORTRANSMISSION CASE CONNECTOR

A

BF

CE

DK

EG

FH

OUTPUT SPEED

OUTPUT SPEED

SENSOR

SENSOR

TURBINE SPEED

TURBINE SPEED

SENSOR

SENSOR

ENGINE SPEED

ENGINE SPEED

SENSOR

SENSOR

SOL "A"

SOL "B"

SOL "C"

SOL "D"

SOL "E"

SOL "F"

C

NOT USED

D

E

NOT USED

R

PRESSURE SWITCH

PRESSURE SWITCH

ASSEMBLY

ASSEMBLY

C

THROTTLE

THROTTLE

B

POSITION

POSITION

SENSOR

SENSOR

A

TEMP

SENSOR

12V OR 24V12V OR 24V

SAE J-1939 BACKBONESAE J-1939 BACKBONE

ENGINE

ENGINE

INTERFACE

INTERFACE

SAE STANDARD 9-PIN

SAE STANDARD 9-PIN

DIAGNOSTIC CONNECTOR

DIAGNOSTIC CONNECTOR

AUTOMATIC TRANSMISSION SERVICE GROUP

TRANSMISSION

TRANSMISSION

NSBU SWITCH

NSBU SWITCH

P

C

B

A

Figure 21

4C

4B

4D

4A

7D

7A

7G

7E

7F

7C

7B

STARTER

STARTER

RELAY

Orange

Yellow

Pink

Blue

Tan

RELAY

REVERSE LAMPSREVERSE LAMPS

ACCESSORY

ACCESSORY

Copyright © 2000 ATSG

PK/NEUT

PK/NEUT

VOLT FEED

VOLT FEED

REV & PARK

REV & PARK

VOLT FEED

VOLT FEED

PARK

PARK

19

Page 20

NOT USED (N/O)

Terminal Identification

Cast In Connector Here

Technical Service Information

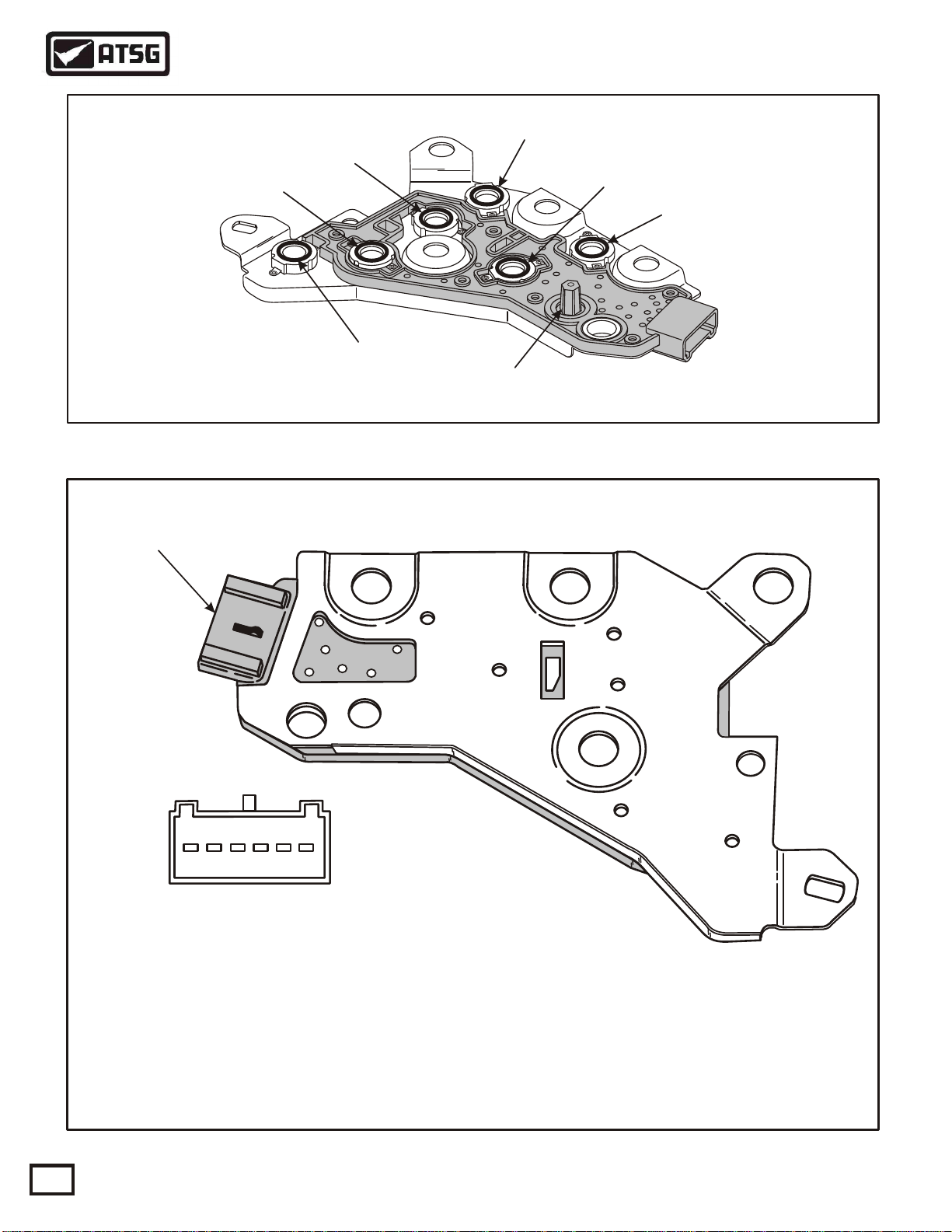

PRESSURE SWITCH ASSEMBLY

NOT USED (N/O)

"E" SHIFT (N/O)

"D" SHIFT (N/O)

"C" SHIFT (N/O)

REVERSE (N/C)

TEMP SENSOR

(THERMISTER)

Copyright © 2000 ATSG

Figure 22

PRESSURE SWITCH CONNECTOR

PIN FUNCTION AND IDENTIFICATION

A

B

C

D

E

F

A B C D E F

Pressure Switch Assembly

Receptacle (Face View)

(A) SHIFT "C" SIGNAL TO PCM (CASE CONNECTOR TERMINAL "D")

(B) SHIFT "D" SIGNAL TO PCM (CASE CONNECTOR TERMINAL "F")

(C) SHIFT "E" SIGNAL TO PCM (CASE CONNECTOR TERMINAL "E")

(D) REVERSE SWITCH TO PCM (CASE CONNECTOR TERMINAL "K")

(E) TEMP SENSOR HIGH (CASE CONNECTOR TERMINAL "G")

(F) TEMP SENSOR LOW (CASE CONNECTOR TERMINAL "H")

20

Copyright © 2000 ATSG

Figure 23

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 21

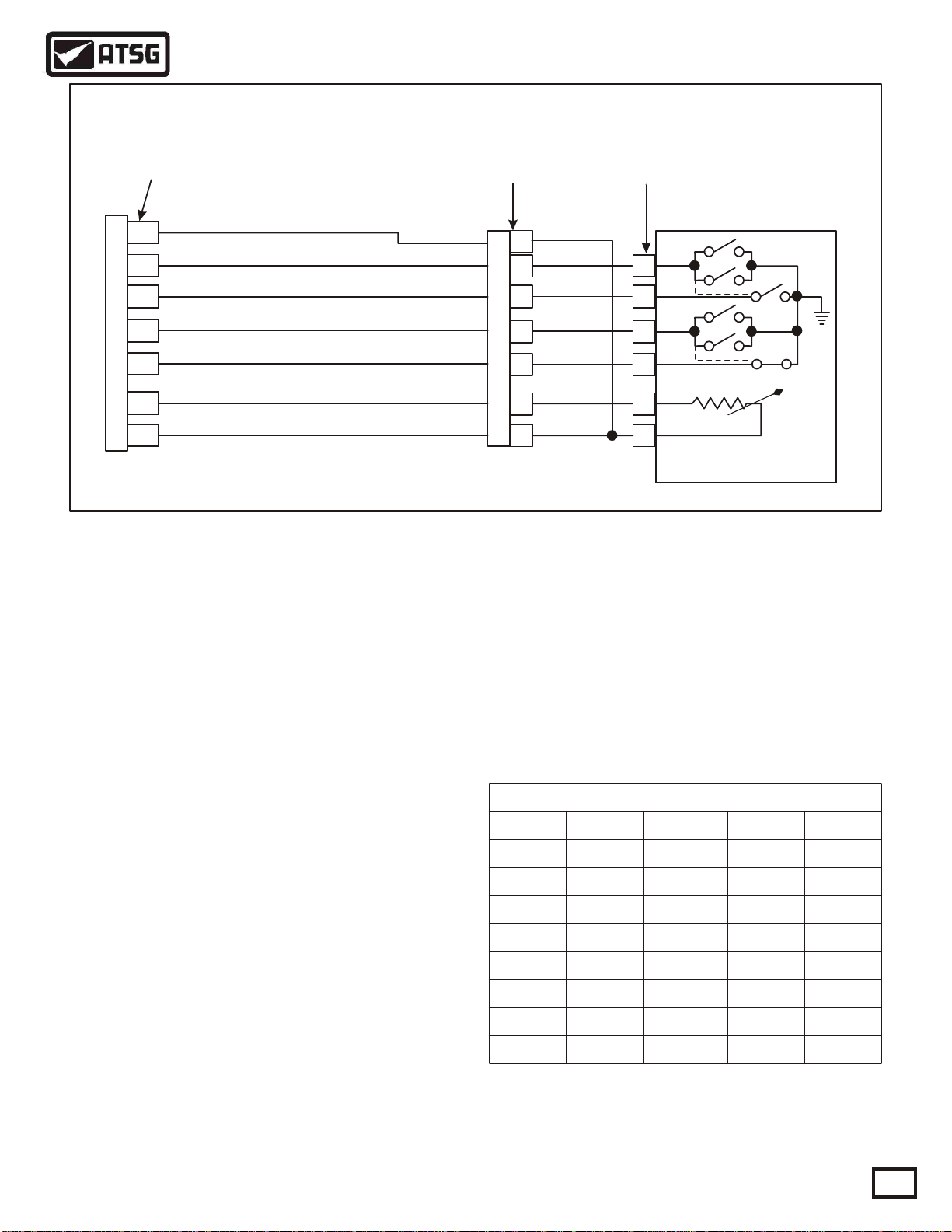

Technical Service Information

PRESSURE SWITCH CONNECTOR

PIN FUNCTION AND IDENTIFICATION

TCM "J2" (Red)

Connector

21

1

2

3

4

10

20

Yellow TRANS ID

Blue

Pink

White

Green

Tan

Green

Transmission

Case Connector

Figure 24

PRESSURE SWITCH ASSEMBLY

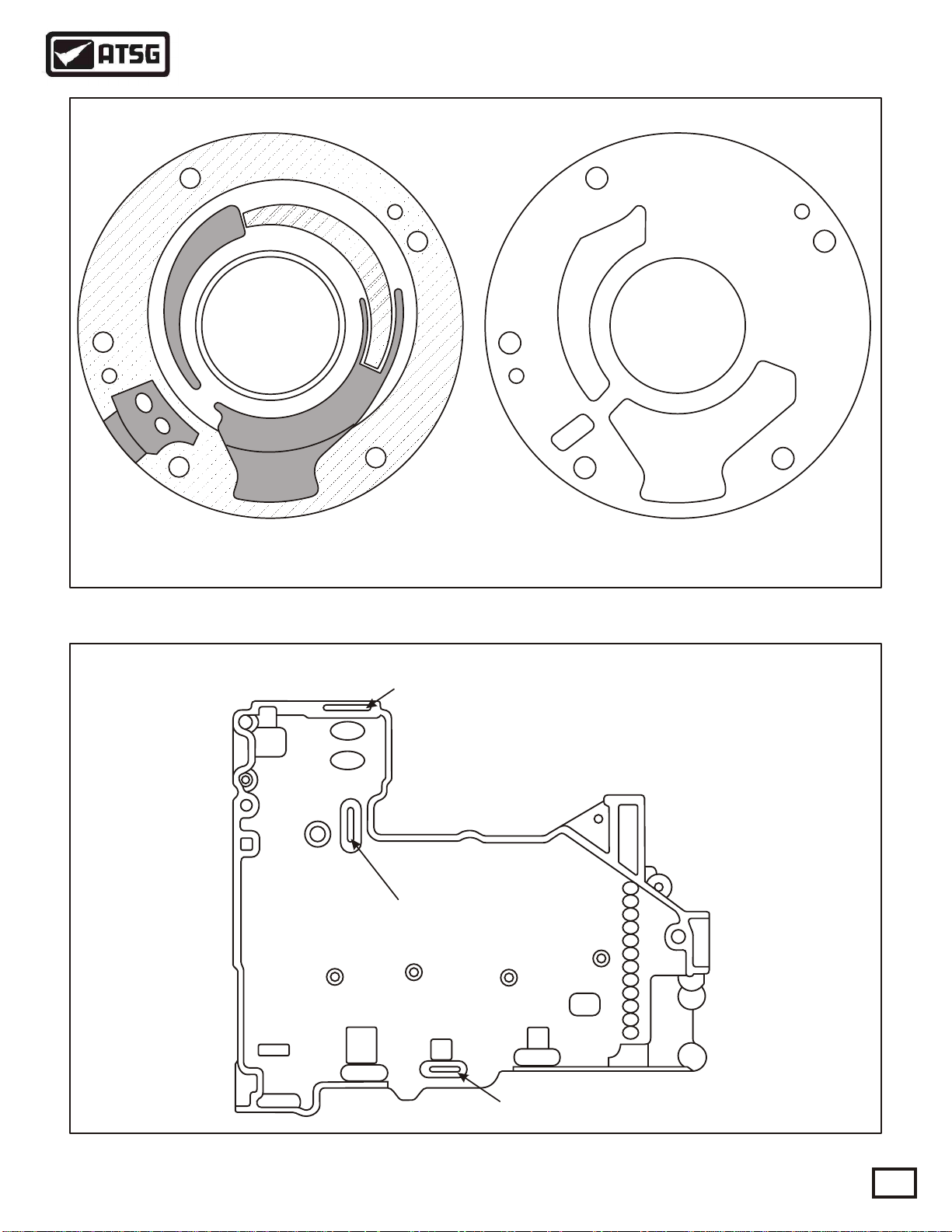

The Pressure Switch Assembly (PSA) is made up of

three normally open switches and one normally

closed switch. There are also 2 additional switches in

the PSA that are not used. All switches and their

locations are identified in Figure 22. Fluid pressure is

fed from shift valves C, D, and E to C, D, and E

switches, and from the manual valve to the reverse

switch. This logic indicates the current transmission

operating range to the TCM.

The three pressure switches corresponding to the

shift valves are normally open (N/O) when there is no

pressure to the switch, so that electrical current is

stopped at the switch. When pressure is routed to the

switch from the shift valves, the switch closes and

allows current to flow from the positive contact and

through the switch. Refer to Figure 24.

The pressure switch corresponding to reverse is a

normally closed (N/C) switch, and pressure is fed to

the switch when the transmission is placed into the

reverse position.

The Pressure Switch Assembly also contains the

temperature sensor (thermister) to notify the TCM of

the current sump temperature. Changes in fluid

temperature are indicated by changes in sensor

resistance. Increasing temperature will create

decreased sensor resistance.

Pressure Switch

Connector

Tan

T

Lt Green

D

Blue

Red

Ta n

Orange

Black

C

A

NOT USED

D

BF

E

CE

NOT USED

R

DK

EG

FH

PRESSURE SWITCH

PRESSURE SWITCH

ASSEMBLY

ASSEMBLY

Copyright © 2000 ATSG

TEMP

SENSOR

The PSA terminal identification and functions are

illustrated in Figure 23 to assist in switch diagnosis.

There is also a complete wiring schematic from the

Pressure Switch Assembly through the transmission

case connector and to the TCM shown in Figure 24.

We have also provided a pressure switch logic state

chart in Figure 25.

Pressure Switch Logic State Chart

Range

Park

Rev

Neut

OD

4

3

2

1

"C"

On

On

On

Off

On

On

Off

Off

"D"

On

On

On

Off

Off

Off

Off

On

"E"

On

On

On

On

On

Off

Off

Off

Reverse

Off

On

Off

Off

Off

Off

Off

Off

Figure 25

AUTOMATIC TRANSMISSION SERVICE GROUP

21

Page 22

Technical Service Information

RETRIEVING DIAGNOSTIC CODES

A or H

Pause

Break

Scroll

Lock

Print

Home

Scrn

Backspace

F12

F11

_

-

F10

F9

0

F8

9

F7

F6

7

F5

6

F4

5

F3

F2

3

F1

2

ESC

1

W

~

`

Q

b

Ta

A

ps Lock

Ca

Shift

rl

Ct

Fn

Y

4

T

R

G

E

F

D

V

S

C

X

Z

Alt

n

Wi

P

8

O

I

L

U

K

<

J

,

H

M

N

B

PgUp

+

|

=

\

}

PgDn

]

r

{

Ente

[

:

;

>

.

Alt

End

"

ift

'

Sh

?

/

Del

Ins

C or SB or L

J-1939 Connector

Copyright © 2000 ATSG

Figure 26

CHECK TRANS LIGHT

The electronic control system is programmed to

inform the operator of any type problem with the

transmission system and automatically take action to

protect the operator, vehicle and transmission. To do

this, the TCM turns on the Check Trans light on the

instrument panel, which will notify the operator that a

Diagnostic Trouble Code (DTC) has been stored in

the TCMs memory.

Each time the engine is started, the Check Trans

light will illuminate momentarily and then go off after

a few seconds. This momentary lighting is to ensure

that the Check Trans light circuit is working properly.

Illumination of the Check Trans light at any time after

start-up, indicates that the TCM has stored a DTC, or

the TCM is not working properly. Anytime the Check

Trans light is on, upshifts and downshifts will be

restricted and direction changes may not occur. The

converter clutch is also shut off when transmission

shifting is restricted.

If power is interrupted while the transmission is

operating in a forward range, the default positions of

the shift valves and solenoids will enable application

of two clutches to maintain forward range operation

(Either 3 or 5th). If power is interrupted while the

transmission is operating in R(Reverse) or

N(Neutral), the transmission defaults to or continues

Neutral operation untill a key cycle.

The operator may turn off and restart the engine,

and the manual selector lever will provide reverse

when in R, Neutral when in P/N, and 3rd Gear when

in any forward range, regardless of the range where

the failure occured.

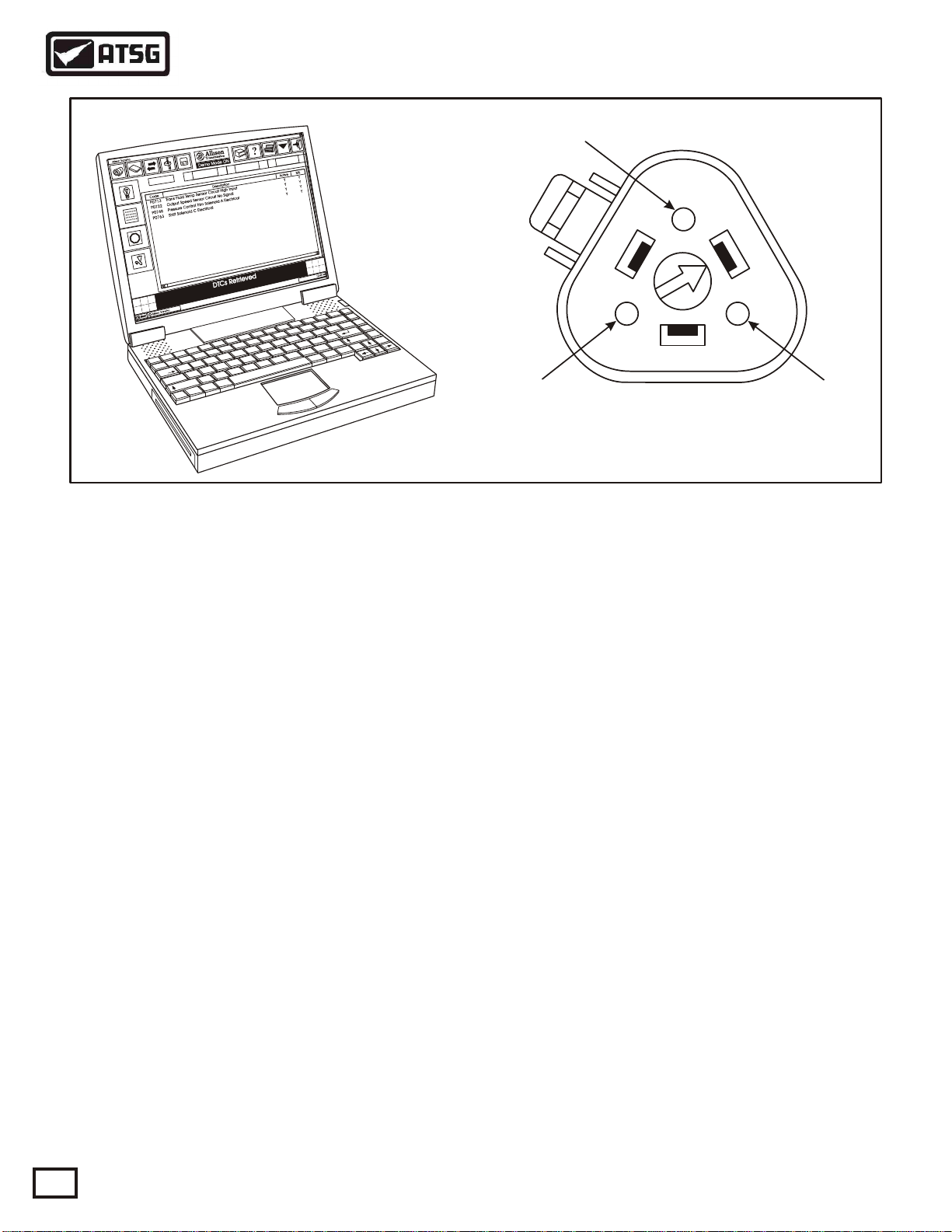

RETRIEVING DIAGNOSTIC CODES

Currently you must use PC Tool Software called

TransPro® which is available through Kent-Moore

Heavy-Duty Division, and must be loaded onto a

Windows 95/98 Lap-T op PC as shown in Figure 26.

The TransPro® software transmits and recieves data

to and from the TCM via the J-1939 connector, as

shown in Figure 26, processes the data, and displays

the appropriate information on the screen.

The use of TransPro® is describeded in detail in the

instruction manual that is furnished with each set of

software. We have provided you with a typical

screen, that is utilized in the TransPro® software, for

retrieving DTCs in Figure 27.

Hopefully aftermarket scanner manufacturers will

be able to provide us with a cartridge for the more

popular scanners in the future.

22

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 23

Technical Service Information

Allison TransPro

3 4 6 9 1 2 6 0

5 8 1 3 6 5 2 2

6 4 5 4 8 9 1 0

4 3 3 6 7 3 3 8

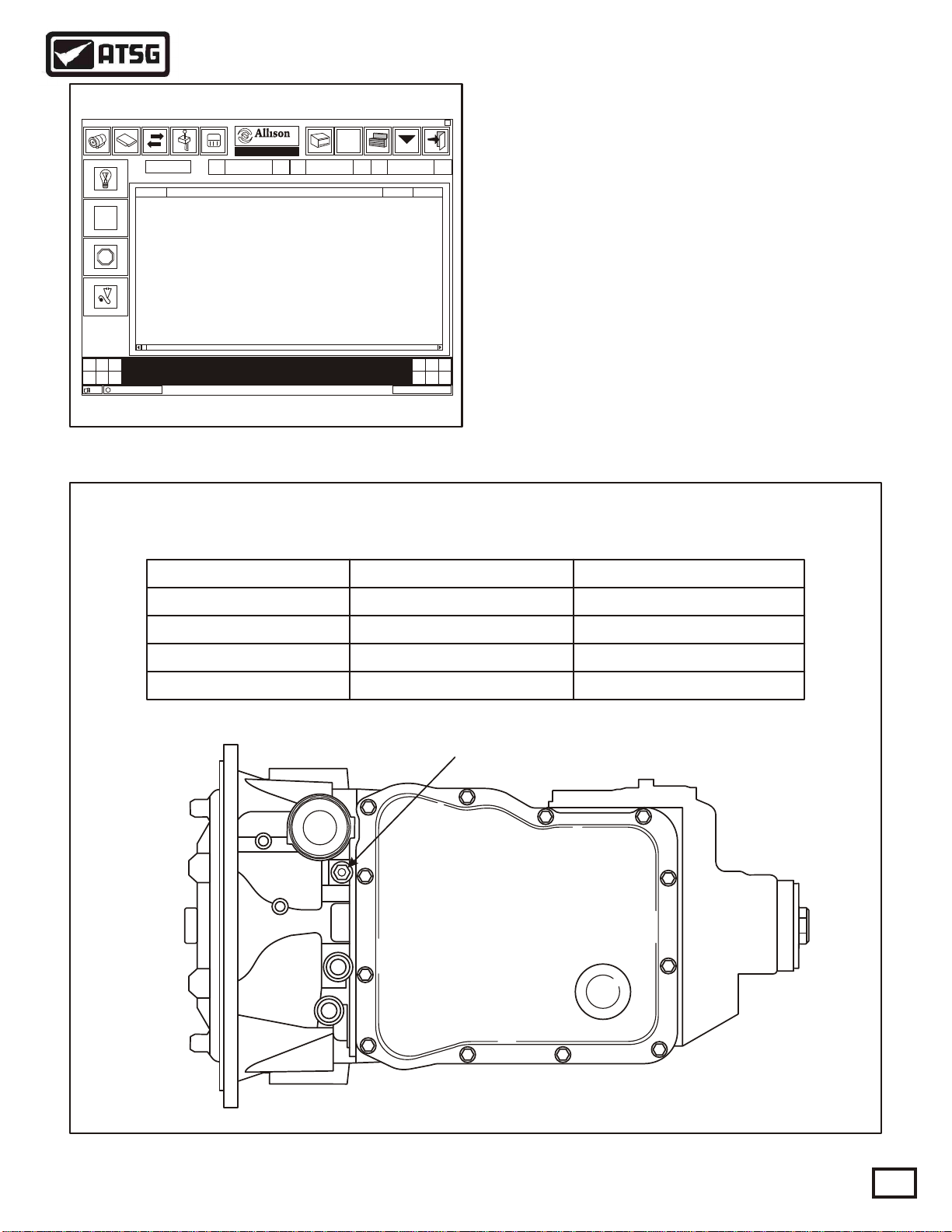

TYPICAL TransPro® DISPLAY

Transmission

Demo Mode ON

P0713 Trans Fluid Temp Sensor Circuit High Input Y Y

P0722 Output Speed Sensor Circuit No Signal

P0748 Pressure Control Trim Solenoid A Electrical

P0763 Shift Solenoid C Electrical

DTCs RetrievedDTCs Retrieved

Allison TransProStartStart

Copyright © 2000 ATSG

Figure 27

?

MAIN PRESSURE TAP LOCATION AND SPECIFICATIONS

ActiveDescriptionCode

Y Y

Y Y

Y Y

MIL

10:45 AM

LINE PRESSURE TEST

Check transmission fluid level. All transmission

XX

fluid level and pressure checks must be made at

normal operating temperatures (160-200°F).

Connect a 0-300 psi oil pressure guage to the main

pressure tap as illustrated in Figure 28, and compare

readings with the pressure chart in Figure 28.

Take precautions against vehicle movement during

the pressure tests, and use a guage with an extended

line so that it can be read from inside the vehicle.

Range

PARK/NEUTRAL

REVERSE

FORWARD (TCC Off)

FORWARD (TCC On)

MAIN PRESSURE TEST SPECIFICATIONS

Pressure @ 600 RPM

900-1655 kpa (130-240 psi)

800-1380 kpa (115-200 psi)

800-1380 kpa (115-200 psi)

Main Pressure Tap

TO COOLERTO COOLER

FROM COOLERFROM COOLER

Pressure @ 1200 RPM

1515-1795 kpa (220-260 psi)

1515-1795 kpa (220-260 psi)

1515-1795 kpa (220-260 psi)

1000-1170 kpa (145-170 psi)

Figure 28

AUTOMATIC TRANSMISSION SERVICE GROUP

23

Page 24

Technical Service Information

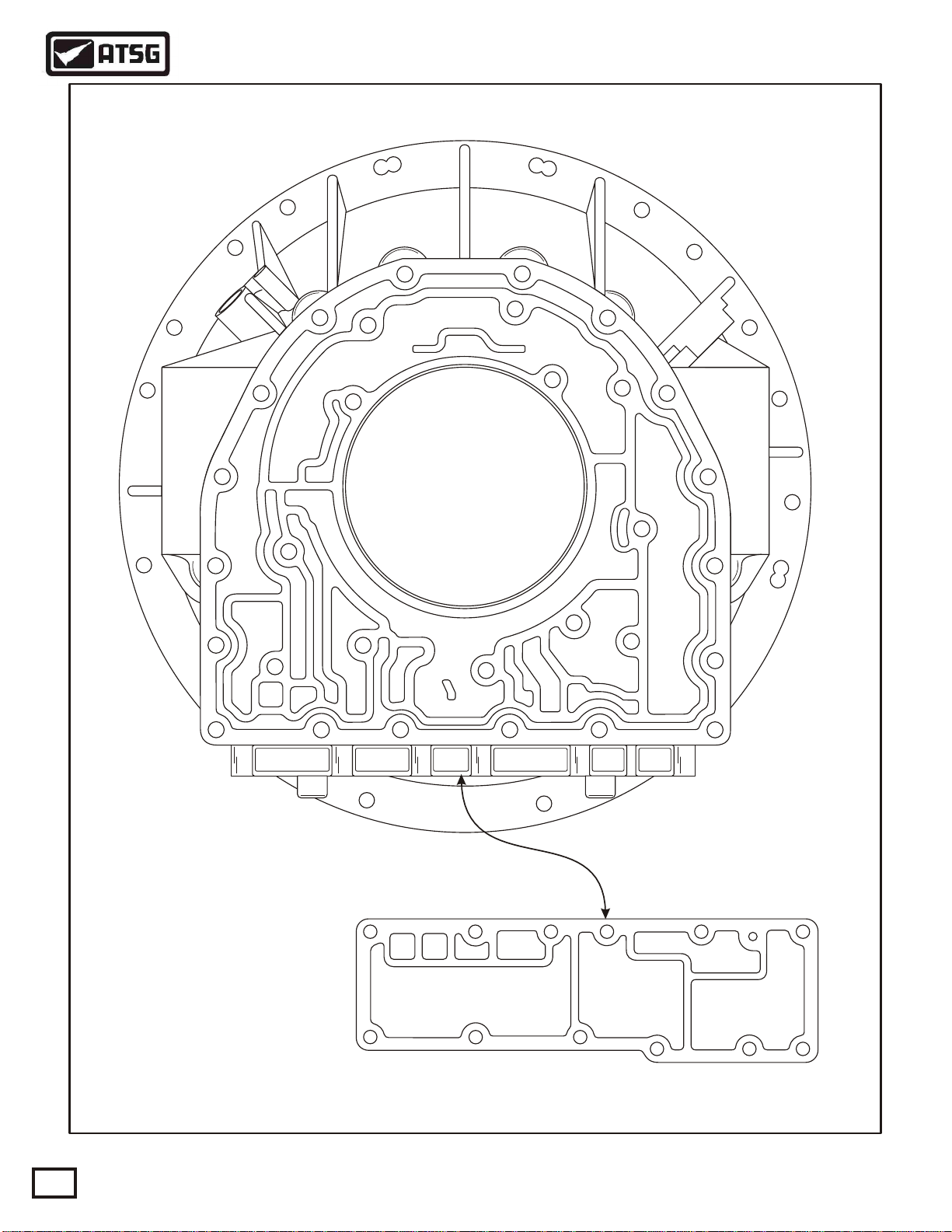

BELL HOUSING OIL PASSAGE IDENTIFICATION

16

16

9

15

16

16

29536810

3

2

1

13

2

9

14

2

10

3

3

16

3

1

8

1

16

7

1

6

11

1. PUMP SUCTION

2. LINE PRESSURE

3. OVERAGE (CONV RELEASE)

4. CONVERTER IN

5. CONVERTER OUT

6. TO COOLER

7. FROM COOLER

8. LUBE OIL

9. LOCK-UP APPLY

10. C1 CLUTCH

11. C2 CLUTCH

12. LOCK-UP SIGNAL

13. CUT-BACK (5TH GEAR)

14. LINE - TO FILTER

15. LINE - FROM FILTER

16. EXHAUST

24

15 14

16

2

16

6

BOTTOM BELL HOUSING COOLER MANIFOLD SURFACE

Figure 29

AUTOMATIC TRANSMISSION SERVICE GROUP

7

16

Copyright © 2000 ATSG

Page 25

Technical Service Information

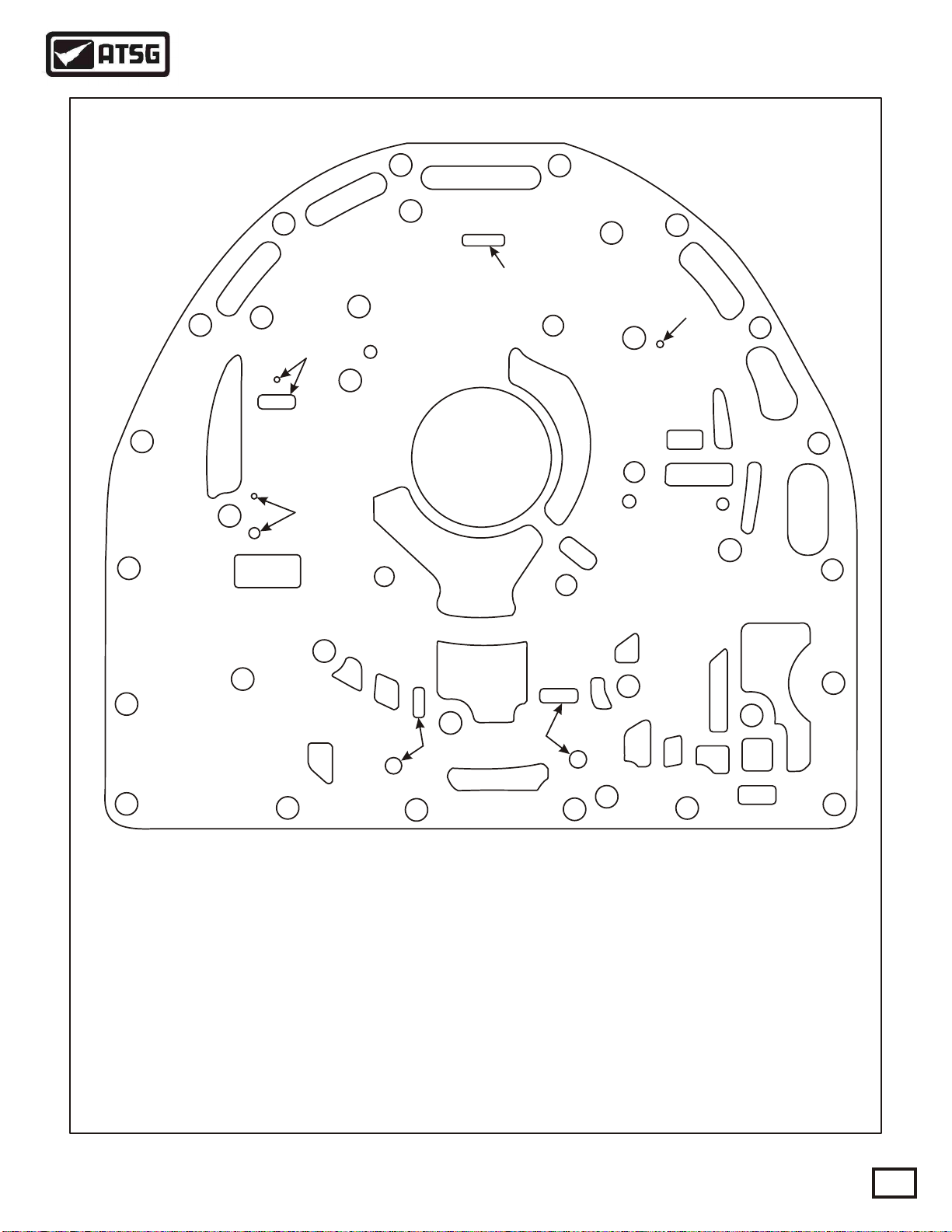

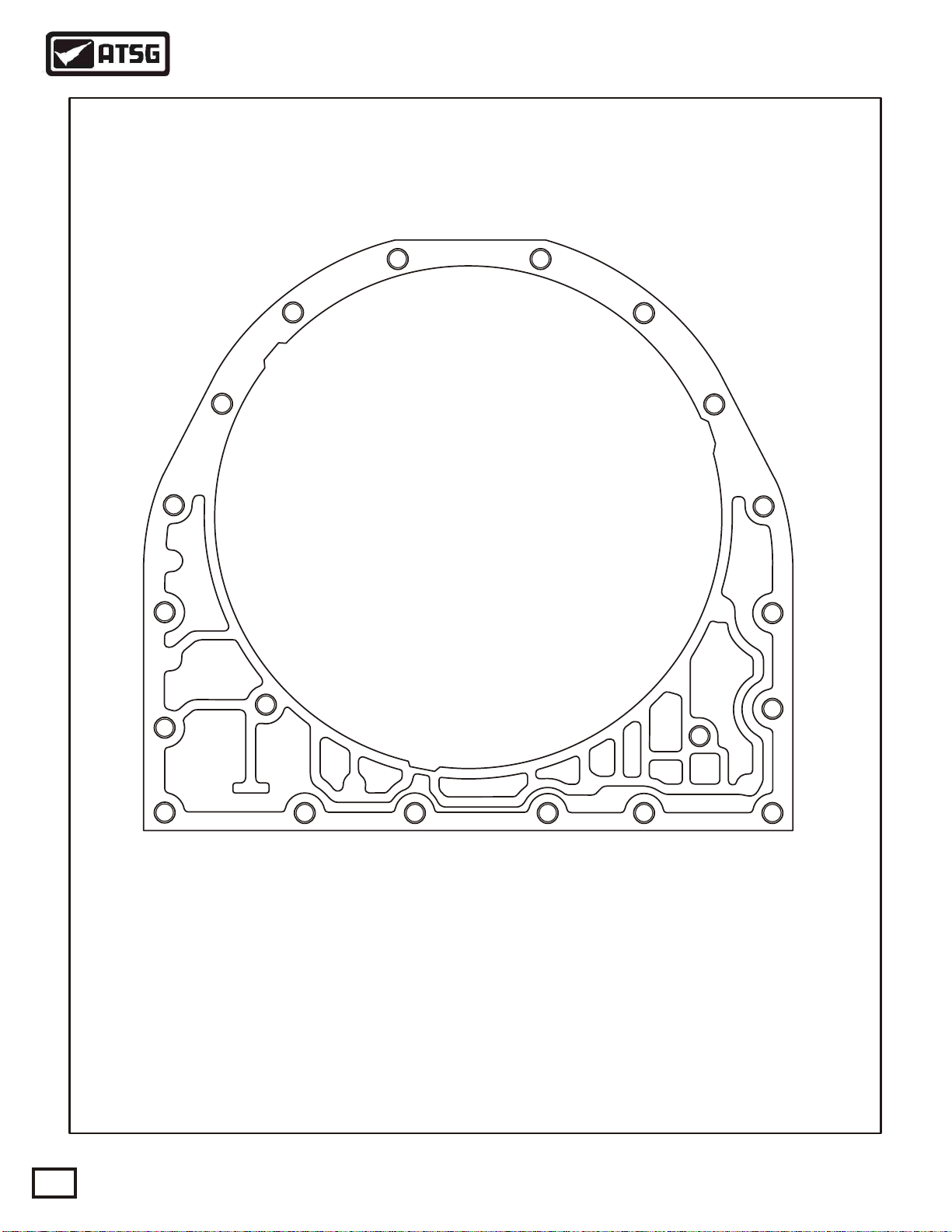

PUMP COVER SPACER PLATE OIL PASSAGE I.D.

16

16

16

16

16

3

3

2

8

1

2

7

6

1

16

16

2

16

3

2

16

9

16

9

1. PUMP SUCTION

2. LINE PRESSURE

3. OVERAGE (CONV RELEASE)

4. CONVERTER IN

5. CONVERTER OUT

6. TO COOLER

7. FROM COOLER

8. LUBE OIL

9. LOCK-UP APPLY

10. C1 CLUTCH

11. C2 CLUTCH

12. LOCK-UP SIGNAL

13. CUT-BACK (5TH GEAR)

14. LINE - TO FILTER

15. LINE - FROM FILTER

16. EXHAUST

11

10

1

2

13

Figure 30

AUTOMATIC TRANSMISSION SERVICE GROUP

15

14

Copyright © 2000 ATSG

25

Page 26

Technical Service Information

MAIN CASE "FRONT" PASSAGE I.D.

16

16

16

1. PUMP SUCTION

2. LINE PRESSURE

3. OVERAGE (CONV RELEASE)

4. CONVERTER IN

5. CONVERTER OUT

6. TO COOLER

7. FROM COOLER

8. LUBE OIL

9. LOCK-UP APPLY

10. C1 CLUTCH

11. C2 CLUTCH

12. LOCK-UP SIGNAL

13. CUT-BACK (5TH GEAR)

14. LINE - TO FILTER

15. LINE - FROM FILTER

16. EXHAUST

16

16

11

16

N/A

9

13

2

1

10

14

15

Copyright © 2000 ATSG

26

Figure 31

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 27

Technical Service Information

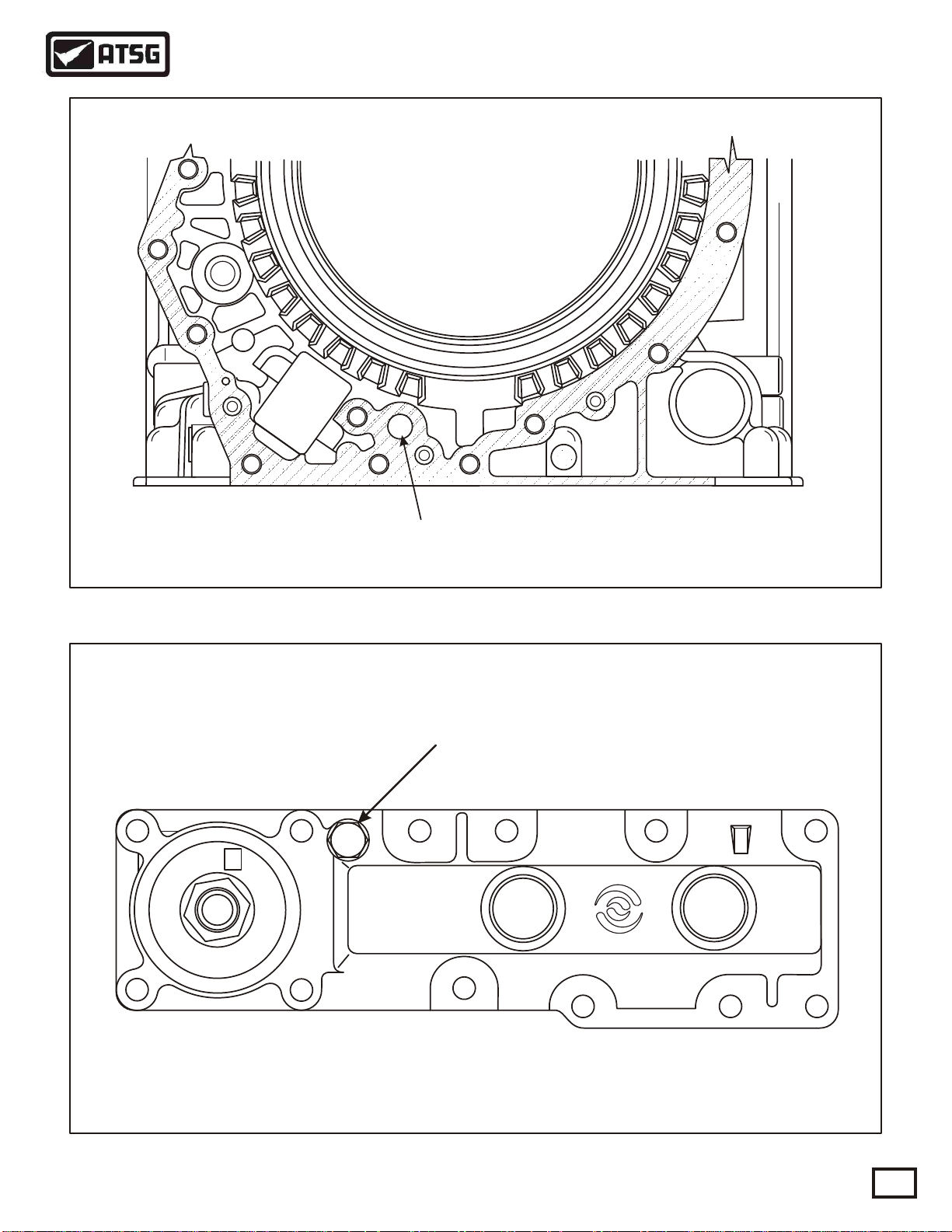

MAIN CASE "REAR" PASSAGE I.D.

15

14

C5 CLUTCH

Figure 32

COOLER MANIFOLD PASSAGE I.D.

MAIN LINE

PRESSURE TAP

TO

TO

CLR

CLR

Copyright © 2000 ATSG

FROM

76

FROM

CLR

CLR

6. TO COOLER

7. FROM COOLER

14. LINE - TO FILTER

Figure 33

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2000 ATSG

27

Page 28

Technical Service Information

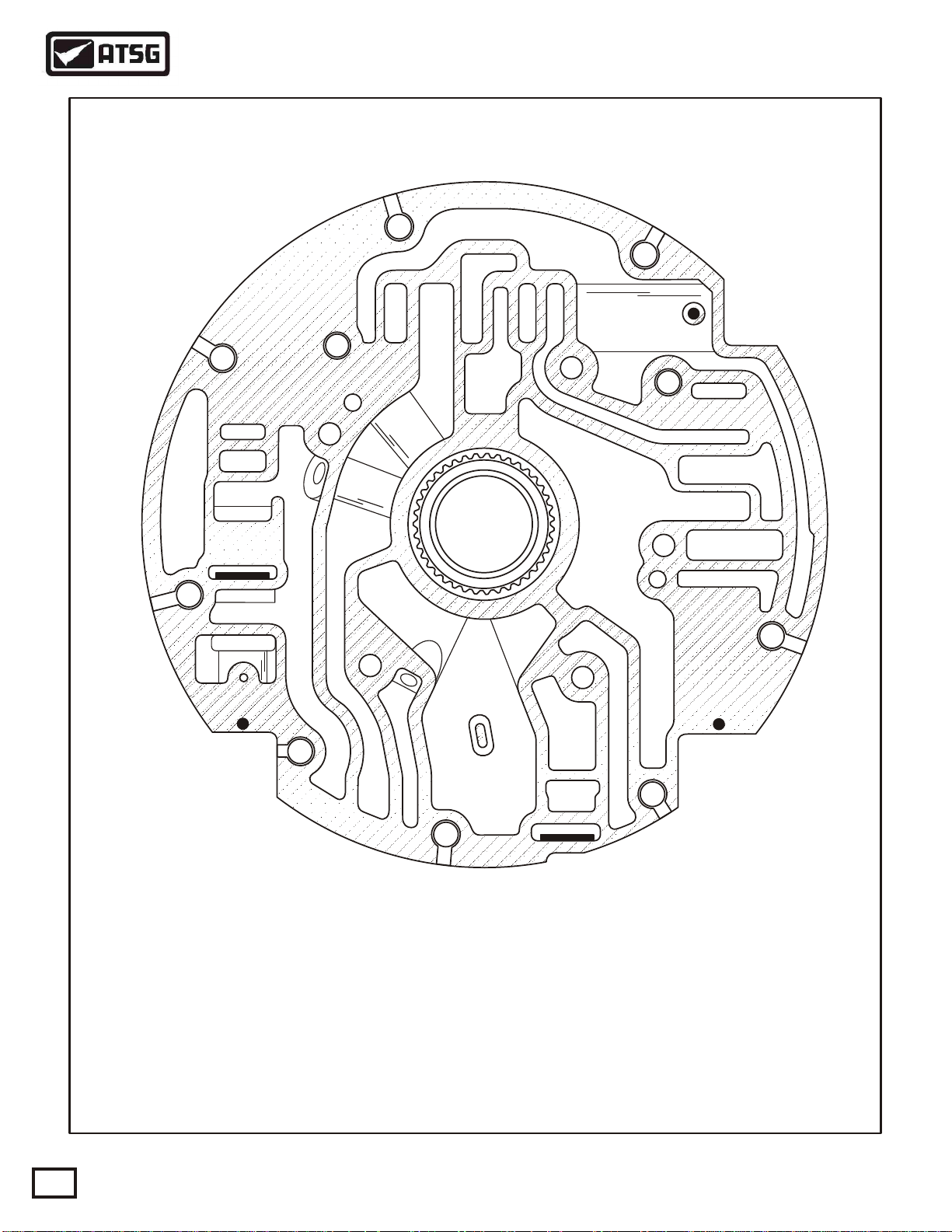

PUMP COVER OIL PASSAGE I.D.

9

3

16

9

5

6

3

3

8

6

8

1

11

4

4

16

12

9

2

2

1

16

2

10

12

2

13

3

16

9

28

7

1. PUMP SUCTION

2. LINE PRESSURE

3. OVERAGE (CONV RELEASE)

4. CONVERTER IN

5. CONVERTER OUT

6. TO COOLER

7. FROM COOLER

8. LUBE OIL

9. LOCK-UP APPLY

10. C1 CLUTCH

11. C2 CLUTCH

12. LOCK-UP SIGNAL

13. CUT-BACK (5TH GEAR)

16. EXHAUST

AUTOMATIC TRANSMISSION SERVICE GROUP

6

1

10

16

Copyright © 2000 ATSG

Figure 34

Page 29

Technical Service Information

OIL PUMP PASSAGE I.D.

2

2

14

1. PUMP SUCTION

2. LINE PRESSURE

14. EXHAUST

14

1

1

Copyright © 2000 ATSG

Figure 35

SHIFT VALVE BODY "TOP VIEW" PASSAGE I.D.

Exhaust

Exhaust

Exhaust

Figure 36

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2000 ATSG

29

Page 30

Technical Service Information

LEGEND FOR FIGURES 38, 39, AND 41.

Passage No.

1

2

9

10

11

12

13

14

16

15

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

Reverse Park/Neut 1st 2nd

Pump Suction

Main Line Pressure

TCC Apply

Exhaust Backfill/ C-1 Clutch

C-2 Clutch/Exhaust Backfill C-2 Clutch

Lock-Up Signal

Cut-Back (5th Gear)

Control Main Line Pressure To Filter

Exhaust To Sump

Control Main Line Pressure From Filter

Reverse Pressure Switch

"D" Shift Valve Pressure Switch

"E" Shift Valve Pressure Switch

"C" Shift Valve Pressure Switch

C-3 Clutch C-3 Clutch C-3 Clutch

Exhaust Backfill

Main Line Pressure

Exhaust Backfill

C-3/B Trim

Exhaust Backfill

C-3/B Trim OD/B TrimC-4/B Trim

C-1/B Trim

"D" Signal TCC Interlock

Exhaust Backfill/ C-3 Clutch EBF/C-3 Clutch

C-4 Clutch

C-5 Clutch

Exhaust Backfill

"A" Trim Solenoid Signal

"B" Trim Solenoid Signal

"A" Clutch Trim

"B" Clutch Trim

"A" Clutch Trim Feedback

"B" Clutch Trim Feedback

"D" Solenoid Signal

"E" Solenoid Signal

"C" Solenoid Signal

C-1/Main

Control Main After "B" Solenoid Screen

B Trim

"E" Shift Valve Interlock

C-2/EBF

Exhaust Backfill/C-5 Clutch (Power Off State)

C-3/EBF

C-2/EBF

Thermister

Exhaust Backfill

C-1/Main

3rd 4th 5th

EBF/ C-1 ClutchC-1 Clutch

C-1/B Trim

C-2/B Trim

C-1/B TrimC-1/B Trim

C-2/B Trim

C-4/EBF OD/EBF

C-2/Main

Exhaust

C-2/Main

C-1/EBF

Cut-BackC-3/EBF

C-1/EBFC-1/EBF

30

Copyright © 2000 ATSG

Figure 37

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 31

56

56

37

30

30

37

47

10

37

10

30

55

11

11

16

16

Technical Service Information

SHIFT VALVE BODY "BOTTOM VIEW" PASSAGE I.D.

56

37

47

13

13

37

37

11

16

37

31

56

31

13

34

40

36

56

37

16

31

37

37

53

49

2

44

31

53

16

32

2

49

54

47

37

35

57

2

51

37

52

45

44

37

2

37

37

57

16

37

2

31

44

53

54

41

57

33

15

52

46

44

44

41

2

2

14

37

2

2

37

14

32

32

15

40

16

LEGEND FOUND ON PAGE 30.

15

46

16

16

41

37

2

15

15

40

15

48

Figure 38

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2000 ATSG

Copyright © 2000 ATSG

31

Page 32

Technical Service Information

MAIN VALVE BODY "TOP VIEW" PASSAGE I.D.

16

16

16

16

33

15

32

42

38

14

14

30

16

37

32

16

40

2

40

32

16

16

16

30

39

38

2

37

2

2

16

37

41

2

43

16

33

2

44

44

37

16

39

15

32

31

15

44

45

35

45

37

40

57

2

57

44

37

51

37

2

53

32

11

30

2

14

16

44

34

34

36

34

35

51

40

5454

47

36

56

37

53

16

16

16

2

9

9

31

56

36

51

15

34

40

40

56

55

47

15

37

11

9

5

11

13

2

10

10

30

6

9

15

37

30

15

9

37

11

30

31

32

16

16

11

14

16

LEGEND FOUND ON PAGE 30.

Figure 39

AUTOMATIC TRANSMISSION SERVICE GROUP

14

10

9

13

15

14

Copyright © 2000 ATSG

Page 33

Technical Service Information

MAIN VALVE BODY "BOTTOM VIEW" PASSAGE I.D.

16

30

39

16

16

16

31

30

DuPage

29536840

30

16

16

32

38

50

33

16

16. EXHAUST.

30. REVERSE PRESSURE SWITCH.

31. "D" SHIFT VALVE PRESSURE SWITCH.

32. "E" SHIFT VALVE PRESSURE SWITCH.

33. "C" SHIFT VALVE PRESSURE SWITCH.

38. "A" TRIM SOLENOID SIGNAL.

39. "B" TRIM SOLENOID SIGNAL.

50. FLUID TEMPERATURE SENSOR (THERMISTER).

AUTOMATIC TRANSMISSION SERVICE GROUP

Copyright © 2000 ATSG

Figure 40

33

Page 34

Technical Service Information

TYPICAL VALVE BODY SPACER PLATE

56

36

16

3534

15

16

43

37

41

39

38

37

40

2

42

16

56

30

15

37

37

9

14

11

55

30

10

30

13

47

13

37

11

47

14

55

2

10

31

2

53

56

36

40

34

51

53

31

35

47

54

51

32

45

37

44

37

40

15

57

37

2

2

33

2

44

57

54

53

44

31

2

2

2

37

16

11

32

32

14

14

6837

34

LEGEND FOUND ON PAGE 30.

Copyright © 2000 ATSG

Figure 41

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 35

Technical Service Information

MAIN CASE "BOTTOM VIEW" PASSAGE I.D.

16

11

16

35

1

29536808

34 16

36

56

10

14

13

2

15

9

1. SUCTION.

2. MAIN LINE PRESSURE.

9. TCC APPLY.

10. C-1 CLUTCH.

11. C-2 CLUTCH.

13. CUT-BACK (OverDrive).

14. CONTROL MAIN TO FILTER.

15. CONTROL MAIN FROM FILTER.

16. EXHAUST TO SUMP .

34. C-3 CLUTCH.

35. C-4 CLUTCH.

36. C-5 CLUTCH.

56. C-5 CLUTCH (Power -Off State).

AUTOMATIC TRANSMISSION SERVICE GROUP

Figure 42

Copyright © 2000 ATSG

Copyright © 2000 ATSG

35

Page 36

Technical Service Information

TRANSMISSION DISASSEMBLY

EXTERNAL COMPONENTS

1. Remove the six PTO cover retaining bolts or

the Power Take Off whichever it is equipped

with, on the right hand side of the transmission

as shown in Figure 43.

2. Install holding fixture similar to the one shown

in Figure 43, onto the PTO surface, to be used

with the bench fixture base.

Caution: Because of the mass and the weight

of this unit, we feel it necessary to use holding

fixture shown in Figure 43, with the fixture

base or in a suitable turn-over stand.

3. Using a suitable hoist, lift the transmission and

install into bench fixture base, or the suitable

turn-over stand.

4. With transmission assembly locked, in the pan

facing down position, remove the converter by

pulling it straight out (See Figure 44).

Caution: This torque converter weighs about

60 pounds, so exercise extreme caution.

5. Remove the engine speed sensor, turbine speed

sensor and output speed sensor, as shown in

Figure 45.

Note: The engine speed sensor, if equipped,

the turbine speed sensor, and the output speed

sensor on 2WD models are all the same part

number (See Figure 45).

6. Remove and discard the "O" rings from the 3

speed sensors (See Figure 45).

7. Remove the Neutral Start Back-Up switch from

the side of case, as shown in Figure 45.

Note: The NSBU Switch is exactly the same

as the 4L60-E switch (See Figure 45).

8. Rotate the transmission in the fixture so that

the oil pan is facing up (See Figure 46).

Continued on Page 38

36

9

.8

9

.8

9

.8

9

.8

9

.8

9

.8

9

.8

9

.8

9

9

.8

.8

W

A

U

3

3

9

X

X

n

X

n

.

X

P

o

R

X

-

i

O

X

C

s

X

so

S

R

X

i

s

X

O

l

i

A

T

X

l

O

X

AN

-

I

M

X

L

X

D

m

X

A

N

X

I

A

R

X

s

X

,

E

X

S

N

X

I

n

E

L

X

X

G

-

O

F

X

a

P

X

X

A

O

X

r

N

N

X

X

X

A

O

I

X

I

X

X

D

S

T

I

N

X

X

V

I

-

I

X

D

X

X

X

X

X

X

X

X

X

X

-

X

-

X

L

X

X

E

X

X

D

X

D

I

X

T

S

X

MO

-

E

X

I

X

X

R

X

X

E

X

S

TE

X

A

0

-

D

0

0

X

.

1

X

X

O

X

N

X

L

1

2

A

X

I

F

R

X

9

E

9

S

X

X

N

X

C

X

X

F

X

E

X

X

X

X

X

X

X

X

9

.

8

9

.

8

9

.

8

9

.

8

9

.

8

9

.

8

BENCH FIXTURE BASE

HOLDING FIXTURE

Copyright © 2000 ATSG

Figure 43

AUTOMATIC TRANSMISSION SERVICE GROUP

Page 37

Technical Service Information

1

3

0

1

3

5

9

2

n

n

onAlli

on

o

o

s

s

s

s

Alli

Alli

Alli

ENGINE SPEED SENSOR

(SOME MODELS)

TURBINE SPEED SENSOR

(ALL MODELS)

1

3

0

1

3

5

9

2

Figure 44

lli

lli

llis

llis

A

A

A

Copyright © 2000 ATSG

OUTPUT SPEED SENSOR

(2WD MODELS)

nA

n

n

n

o

o

so

so

NSBU SWITCH

29536408