Page 1

ALESIS

QUADRAVERB II SERVICE MANUAL

V2.00 12/12/95

Alesis QuadraVerb II 2.00 I 07/19/06

Page 2

PREFACE

This document is intended to assist the service technician in the operation, maintenance and repair of the

QuadraVerb II Digital Stereo Effects Processor. Together with the QVII Reference Manual, this document

provides a complete description of the functionality and serviceability of the QVII. Any comments or

suggestions you may have pertaining to the document are welcome and encouraged.

WARNINGS

TO REDUCE THE RISK OF ELECTRIC SHOCK OR FIRE, DO NOT EXPOSE THIS PRODUCT

TO WATER OR MOISTURE.

CAUTION

RISK OF ELECTRIC SHOCK

The arrowhead symbol on a lightning flash inside a triangle is intended to alert the user to the

presence of un-insulated "dangerous voltage" within the enclosed product which may be of

sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point inside a triangle is intended to alert the user to the presence of

important operating, maintenance and servicing instructions in the literature which

accompanies the product.

DO NOT OPEN

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same type or equivalent type

recommended by the equipment manufacturer.

Battery Manufacturer: Panasonic/Matsushita

Type: BR2325

Rating 3V, 5mA

REPAIR BY ANY PERSON OR ENTITY OTHER THAN AN AUTHORIZED ALESIS SERVICE

CENTER WILL VOID THE ALESIS WARRANTY.

PROVISION OF THIS MANUAL DOES NOT AUTHORIZE THE RECIPIENT TO COMPETE

WITH ANY ALESIS DISTRIBUTOR OR AUTHORIZED REPAIR SERVICE CENTER IN THE

PROVISION OF REPAIR SERVICES OR TO BE OR MAKE REPAIRS AS AN AUTHORIZED

SERVICE CENTER.

ALL REPAIRS DONE BY ANY ENTITY OTHER THAN AN AUTHORIZED ALESIS SERVICE

CENTER SHALL BE SOLELY THE RESPONSIBILITY OF THAT ENTITY, AND ALESIS

SHALL HAVE NO LIABILITY TO THAT ENTITY OR TO ANY OTHER PARTY FOR ANY

REPAIRS BY THAT ENTITY.

Alesis QuadraVerb II 2.00 II 07/19/06

Page 3

SAFETY SUGGESTIONS

Carefully read the applicable items of the operating instructions and these safety suggestions before using

this product. Use extra care to follow the warnings written on the product itself and in the operating

instructions. Keep the operating instructions and safety suggestions for reference in the future.

1. Power Source. The product should only be connected to a power supply which is described either in the operating

instructions or in markings on the product.

2. Grounding the Plug

This plug can only be used in a grounding power outlet. If the plug does not insert into the outlet you are using, the outlet

probably is not a grounding type of power outlet. Contact your electrician to replace the obsolete outlet with a grounding

type of outlet instead of defeating the safety feature of the grounding type of plug.

3. Periods of Non-use

should be unplugged from the AC outlet.

4. Foreign Objects and Liquids

5. Water or Moisture

6. Heat

7. Ventilation

8. Mounting

9. Cleaning

10. Service

11. Damage to the Product

. Do not place the product near heat sources such as stoves, heat registers, radiators or other heat producing

equipment.

. When installing the product, make sure that the product has adequate ventilation. Improperly ventilating the

product may cause overheating, which may damage the product.

. The product should only be used with a rack which the manufacturer recommends. The combination of the

product and rack should be moved carefully. Quick movements, excessive force or uneven surfaces may overturn the

combination which may damage the product and rack combination.

. The product should only be cleaned as the manufacturer recommends.

. The user should only attempt the limited service or upkeep specifically described in the operating instructions for

the user. For any other service required, the product should be taken to an authorized service center as described in the

operating instructions.

limitation when:

a. Liquid has spilled or objects have fallen into the product,

b. The product is exposed to water or excessive moisture,

c. The AC power supply plug or cord is damaged,

d. The product shows an inappropriate change in performance or does not operate normally, or

e. The enclosure of the product has been damaged.

. This product has a 3-wire grounding type of plug (a plug with a grounding pin) for safety purposes.

. If the product is not used for any significant period of time, the product's AC power supply cord

. Take care not to allow liquids to spill or objects to fall into any openings of the product.

. The product should not be used near any water or in moisture.

. Qualified service personnel should service the unit in certain situations including without

Alesis QuadraVerb II 2.00 III 07/19/06

Page 4

General Troubleshooting

While this manual assumes that the reader has a fundamental understanding of electronics and basic

troubleshooting techniques, a review of some of the techniques used by our staff may help.

1. Visual Inspection - A short visual inspection of the unit under test will often yield results without the

need of complex signal analysis (burnt, or loose components are a dead giveaway).

2. Self Test - Alesis products that utilize microprocessor control contain built in test software which

exercises many of the units' primary circuit functions. Self test should always be done following any

repair to ensure basic functionality.

3. Environmental Testing - Applying heat and cold (heat gun/freeze spray) will often reveal thermally

intermittent components (Clock crystals, I.C.s, and capacitors are particularly prone to this type of

failure).

4. Burn in Testing - Leaving a unit running overnight often reveals intermittent failures such as capacitors

that begin to leak excess current after a significant amount of time.

5. Cable Checks - Wiggling cables can reveal intermittent failures such as loose cables or poorly soldered

headers. Remember to check power supply cables as well.

6. Flexing the PC Board - Poor solder joints and broken traces can often be found by pressing the PC

Board in various places.

7. Tapping Components - Sometimes tapping on a component (particularly crystals) will cause it to fail.

8. Power Down/up - Turning the unit off and back on rapidly several times may reveal odd reset and/or

power supply failures.

9. Reset Threshold - A Variac (variable transformer) can be used to check reset threshold levels. This can

be particularly useful in helping customers with low line problems.

10. Compressors - Using a compressor/limiter is often helpful when attempting to solve low level noise

problems, as well as assisting with DAC adjustments.

11. Sweep Tests - Sweep generators are very useful in checking the frequency response envelopes of antialiasing filters.

12. Piggybacking - Piggybacking I.C.s is particularly useful when troubleshooting large sections of logic.

This is especially true when working with older units.

Alesis QuadraVerb II 2.00 IV 07/19/06

Page 5

Table Of Contents

PREFACE.......................................................................................................ii

WARNINGS....................................................................................................ii

SAFETY SUGGESTIONS .............................................................................. iii

General Troubleshooting................................................................................iv

1.00 General Description................................................................................ 1

2.00 Power Supply .........................................................................................1

2.10 PUP Circuit.................................................................................... 1

3.00 Analog Signal Paths ............................................................................... 2

3.10 Audio Input Section.......................................................................2

3.20 Audio Output Section .................................................................... 2

4.00 A-D/D-A Converters................................................................................ 3

4.10 Analog to Digital............................................................................3

4.20 Digital to Analog............................................................................3

5.00 Digital Signal Paths.................................................................................4

5.10 The 8031.......................................................................................4

5.11 Reset................................................................................. 4

5.12 SRAM................................................................................ 5

5.20 DSP ............................................................................................... 5

5.21 Clock Sources and VCOs..................................................6

5.30 MIDI Hardware..............................................................................6

5.40 Encoder Interface.......................................................................... 7

5.50 Footswitch interface ......................................................................7

6.00 Appendix 1 Updates and Corrections..................................................... A-1

6.10 Important Production Changes...................................................... A-1

6.11 VCO Mod .......................................................................... A-1

6.12 SRAM Current Increase.................................................... A-2

6.13 Main PCB change.............................................................A-2

6.14 Reset Circuit Change........................................................ A-2

6.15 Revision A & C Input Changes..........................................A-6

6.16 Revision A. Sampling Modification.................................... A-7

6.17 Revision A & C VCO Changes..........................................A-8

7.00 Appendix 2 Test Procedures .................................................................. B-1

7.10 Self Test........................................................................................B-1

7.20 Further Testing..............................................................................B-1

7.21 Audio................................................................................. B-1

7.22 Digital I/O .......................................................................... B-1

7.23 MIDI ..................................................................................B-1

8.00 Appendix 3 Helpful Hints & Common Solutions..................................... C-1

9.00 Appendix 4 Schematics.......................................................................... D-1

9.10 Revision A.....................................................................................D-3

Alesis QuadraVerb II 2.00 V 07/19/06

Page 6

9.20 Front Panel Control I/O. ............................................................... D-5

9.20 Revision A Component I.D............................................................D-6

9.30 Revision C Component I.D............................................................D-7

10.00 Appendix 5 Software History ................................................................ E-1

11.00 Appendix 6 MIDI Implementation.......................................................... F-1

11.10 V1.0X .......................................................................................... F-1

11.20 V2.0X .......................................................................................... F-21

12.00 Appendix 7 Service Manual History...................................................... G-1

13.00 Appendix 8 Service Parts List............................................................... H-1

Alesis QuadraVerb II 2.00 VI 07/19/06

Page 7

1.00 General Description

The QuadraVerb II, and other digital reverbs, achieve their results by slicing analog signals

into segments, and then converting them to a numeric value, corresponding to the amplitude of

the signal at that particular instant. These values are then mathematically manipulated, and stored

at various locations in a memory "loop" for eventual playback. By varying the placement and

amplitude of incoming samples, discrete time delays are achieved. When mixed together, and

converted back into analog, these delays simulate the reflections associated with natural reverbs,

and delays, as well as non natural effects such as reverse reverbs, and gated reverbs. The added

capabilities of an 80C31 micro controller allow for user manipulation and storage of algorithm

parameters. Some of the PCBs in the unit have undergone revision. The reference designators

used in the text apply to the REV. C Main PCB schematic and Comp. I.D. unless otherwise noted.

2.00 Power Supply

J13 is the AC power input. Its voltage is derived from the a 20 volt/ampere external

transformer. The Q2 draws about three quarters of an amp while in operation.

SW1 connects the AC power jack to the input of the power supply which generates +12V,

+5V, and -12V. The +12V rail is generated by a voltage doubler (C4, D8, D6, and C20) supplying

roughly +20V DC (and about a volt of ripple) to the input of regulator U15. The +12V output of U15

is filtered by C23. The -12V rail is generated in a similar method through a negative voltage

doubler (C13, D9, D10, and C21), a -12V regulator (U17), and filtered by C31. The +5V rail

requires a rectifier diode (D4), five input filter capacitors (C9, C19, C22, C24, C51), a +5V

regulator (U16), and an output filter capacitor (C29).

2.10 PUP Circuit

Since the Q2 is used as outboard gear in audio recording studios, it is important not to

generate audible thumps at the outputs during power up. These are caused by applying power to

the output amplifiers in a non symmetrical manner, and in extreme cases this could actually

damage studio monitors. To prevent this situation the Q2 employs a Power UP mute circuit that

effectively eliminates any power up transients at the output jacks.

The RESET signal (see section 5.11) is routed through R116 to the base of Q9, which in

turn controls other transistors that apply power to the output amplifier U18.

C49 adds a reasonable delay after the RESET signal goes high, so that the power supply is

fully stabilized before it is engaged to the output amplifier.

D21 acts as a switch to quickly discharge C49 in case of intermittent power loss.

When Q9 is turned on it starts a chain of events that turns on Q6, Q8 and finally Q7. The

biasing resistors for these transistors are: R118, R115, R177, R112, R113, R110, and R111. C27

is a bypass capacitor for the positive supply while C25 serves to bypass the negative supply.

Alesis QuadraVerb II 2.00 1 07/19/06

Page 8

3.00 Analog Signal Paths

3.10 Audio Input Section

The Q2 can be used in several stereo or mono audio applications. Additionally it can

support both balanced and single ended configurations. A balanced circuit requires three analog

connections per channel (i.e. signal +, signal -, and ground). A single ended application requires

only two connections (signal and ground). Regardless of the application, the audio signals are

routed to and from the unit via balanced stereo 1/4" phono plugs which utilize tip, ring, and sleeve

connections.

The input jacks J6 and J7 are interconnected such that any signal plugged into J7 will be

automatically routed to J6 as long as a phone plug is not already inserted into J6.

The input signal from J7's tip is routed to op amp U22A by means of a simple RC network.

C17 filters any high frequency while R57 sets the op amps ground reference while also acting as a

fairly high input impedance (510K). Finally, R48 protects the op amps input from transients.

Op amp U22B is used for balanced signals. If a mono plug is used, the non inverting input

is automatically grounded through the RC network of C79, R97, and R96. If however a stereo plug

is used, that RC network is used to match the input impedance as well as to provide a high

frequency filter. Since tip and ring input impedances must be matched, these resistors are all 1%

tolerance.

The output from op amp U22B is now sent to U26A. It's input resistor (R56) is used with the

right input potentiometer to allow for a gain of 10. Finally this signal is routed to the A to D

converter (U14) through a DC blocking capacitor (C10) and current limiting resistor R81. Also

clamping diodes (D16 and D17) limit the A to D input from roughly ground to 5 volts.

J6 has an identical input section built around op amp U26C, U22D, and U22A.

3.20 Audio Output Section

The left output channel is routed from the D-A (see sec. 4.20) through R58 and R65 to the

inputs of op amp U26D, which is configured as a differential amp with R55 and R59 setting the

gain to two. C28 and C46 act as high frequency attenuators. Note that single ended mode occurs

when a mono plug is inserted into the output jack.

The output of op amp U26D is routed through a DC blocking capacitor (C26) and is then

scaled by the output potentiometer for proper output level.

Op amp U18C and U18D are the left channel's output amplifiers and have 6dB when single

ended mode is selected on the output jack. This is accomplished through a series of input and

feedback resistors (R68, R67, R99, R104, R105, R98, R15, R77, R69, and R74).

The output jack is terminated with R106 and R107, along with C80 and C15 to ensure

amplifier stability.

The right output channel is identical and is built around op amps U26D, U18A, and U18B.

Alesis QuadraVerb II 2.00 2 07/19/06

Page 9

4.00 A-D/D-A Converters

4.10 Analog to Digital

The A to D is a 128 times over sampling Philips 7360 high performance device. It is a

stereo part utilizing high Sigma-Delta conversion techniques that eliminates the need for sample

and holds, and extensive anti aliasing filters.

The right channel is input through R81, while R45 and C74 are the feedback network to the

A to D's internal input buffer amplifier. R47 and R46 provide negative and positive inputs to the A

to D's internal sigma delta modulator. C25 is a small filter cap placed between these inputs.

The left input is identical and uses R43, C69, C33, R37, and R38.

C68, C71, C72, and C73 are the bypass filters for the internal voltage reference. C44 along

with R49 and R52 act as filters for the negative and positive internal DAC reference inputs. Analog

power is supplied through current limiters (R53, and R91) which help suppress current spikes.

C76, C42, and C43 act as bypass filters for the analog supply. The digital supply is filtered by

C45, C77, and R2.

R54 is a current reference and has a tolerance of 1% for precision.

The A to D's stereo output is transmitted from the A/D-IN line to the DSP chip (U6).

4.20 Digital to Analog

The digital to analog converter is U12 which is an AKM 4318 DAC. Like the A to D, this D to

A is a high performance over sampling stereo device. It can achieve an outstanding signal to

noise ratio of 98 dB which is unprecedented in it's price range. Also, the over sampling nature

significantly reduces output filter requirements.

The analog power supply filter consists of C59, and C81, while the digital is supplied via

resistor R78, and is filtered by C53, and C55. It's bit clock, which is 3.072MHz, is buffered by

nand gate U23B.

The D to A outputs are balanced and routed through differential amplifiers to the unit's

output jacks, via the analog output section (see sec. 3.20).

Alesis QuadraVerb II 2.00 3 07/19/06

Page 10

5.00 Digital Signal Paths

5.10 The 8031

The Q2's operation is directed by U8 which is the 8031 micro controller. It has an internal

clock generator that drives the crystal (M2) to provide a 12MHz master clock. C7 and C8 are small

capacitors from each side of the crystal to ground that provide oscillator stability.

The software is stored in the EPROM (U2) which as of this time is a 1 Megabyte part.

To access external memory devices the 8031 utilizes a multiplexed lower address buss. U7

is a 74HC573 octal latch that is used to decode these lower address bits from the data buss. It is

controlled by the ALE output from the 8031.

U5 is a 74HC138 3 to 8 decode device. Controlled by the 8031, it enables data transfers to

various circuit locations. It clocks octal registers U10, U11, U25, provides the LCD enable, and

also allows for extended EPROM addressing by clocking the D flip flop U20A.

U10 lights front panel LEDs by pulling the select lines low. Each output is followed by a 270

Ω resistor to provide current limiting.

U25 lights the front panel LED bar graph display and also utilizes 270Ω current limiting

resistors on it's outputs.

In the same manner U11 lights four of the front panel LEDs, and with it's four additional

outputs it pulses the front panel switch matrix columns. Rows are then read back by four

dedicated port pins on the 8031 to identify any switch closures that might have occurred.

5.11 Reset

This is an especially important circuit that safely halts processing when power is removed

or briefly disturbed. The two transistors, Q4 and Q5 turn on when external power is connected. Q5

is biased by resistive divider R13 and R10. C1 works with D1 to prevent engaging reset mode too

easily. R11 is a bias resistor for Q4 which triggers a reset that is delayed by the RC network of

R12 and C3.

U4B generates the RESET signal while U4C generates the compliment RESET signal. C6

is a feedback capacitor that provides hysteresis to the reset generator.

Note that reset is active on power down as well as power up. This is necessary to prevent

noise on the microprocessor data and address busses from corrupting SRAM data.

Alesis QuadraVerb II 2.00 4 07/19/06

Page 11

5.12 SRAM

The 8031 utilizes two 32K X 8 SRAMs (U1 and U13) to store program data. These memory

chips are necessary for proper command execution and must be powered even when the unit is

turned off.

A 3 volt battery (B1) supplies power to the SRAMs when the unit is turned off.

WARNING: Danger of explosion if battery is incorrectly replaced. Replace only with the same type

or equivalent type recommended by the equipment manufacturer.

Battery Manufacturer: Panasonic/Matsushita

Type: BR2325

Rating 3V, 5mA

D2 acts as a switch to apply battery current to the SRAMs through R50, when the power supply is

off.

When the power supply is on, Q1 switches memory power over to the power supply which

causes D2 to be reversed biased thereby cutting off battery current.

R51 supplies base current to Q1. D7 pulls the base voltage up by one diode drop (≈ 0.7V)

thus allowing the emitter voltage, which supplies the SRAMs, to be at 5V. Without D7 the SRAM

supply would be below the address and data voltages which would cause the SRAMs to

malfunction.

U3 is also powered from the SRAM supply voltage (+5MEM) and it serves to decode and

chip enable the SRAMs.

5.20 DSP

The heart of the Q2 is U6, it's custom VLSI audio DSP ASIC which handles all data

processing requirements, timing for the A/D and D/A converters, DRAM interface control, and

optical input/output communication protocol. The chip was designed specifically by Alesis

engineers with the intent of providing the new standard in state of the art multi effects processors.

The DSP chip is programmed by the host 8031 microprocessor and the interface consists

of the 8 bit data buss, 4 low order address bits, RD, WR, and FX-CS which is the ASIC's chip

select.

Convincing signal processing requires large amounts of memory to implement long delays

in order to achieve excellent sonic results. For example, in this case, we wanted to achieve a

maximum delay of about 5 seconds. With a sample period 20 microseconds (48KHz sample rate)

this would equate to nearly one quarter of a million samples. This is accomplished by utilizing U21,

which is a 16M DRAM arraigned as 256K words of 16 bits each. It's interface consists of a 16 bit

data buss, a 9 bit multiplexed address buss, and control signals RAS, CAS, and WRN.

The digital I/O package (J9) is a fully integrated transmitter and receiver device. It takes the

input from a fiber optic cable, from which it derives logic level outputs to present to the ASIC. In

turn, the ASIC presents logic levels to J9, that get converted and transmitted via second output

fiber optic cable. This digital I/O is broadcast and received in an NRZ format that ranges from

about 1 MHz to 6MHz, and it is nearly a DC free code.

5.21 Clock Sources and VCOs

Alesis QuadraVerb II 2.00 5 07/19/06

Page 12

The DSP ASIC has four clock sources that are required to cover the full range of Q2 applications.

The simplest is the 48KHz external sync clock which is provided by J12. R89 in conjunction with

clamping diodes D19 and D20 protect the ASIC's input from unruly transients that could otherwise

inflict damage thereby reducing the chips longevity.

This ASIC also has an internal clock generator that is driven by M3, a 6.144MHz crystal

which is stabilized by C63, C64 and a high impedance parallel resistor R119.

The sample VCO which operates at 24.576MHz, is constructed around U24, a CMOS unbuffered inverting amplifier.

L1 and D12 comprise a tank circuit that has a voltage controlled resonant frequency. The

capacitance value of D12 varies as function of the control voltage. This voltage is set by the DSP

ASIC's phase control output pin contributing to a storage capacitor (C2).

R28, R29, C2, and C67 make up a stabilizing filter that allows the VCO to track over it's

entire frequency range. C65 and C66 act as coupling capacitors to effectively connect the tank

circuit to the amplifier. R27 acts as a self biasing resistor to keep the inverter (U24A) biased to it's

midpoint, which allows it to behave essentially as a linear amplifier.

The remaining clock source is the digital VCO which is constructed around U19. It's

operation is very similar to the sample VCO with the addition of coupling capacitor C39, an

additional bias resistor (R42), and a tank coupling resistor (R40).

The digital VCO operates at half the speed of the sample VCO, or 12.288MHz.

The digital VCO's control voltage is derived through a charge pumping scheme that is

controlled by the DSP ASIC. When DVCO+ is pulsed high, C40 delivers small quantized packets

of charge to gradually increase the control voltage which effectively speeds up the VCO (and thus

increasing DSP speed for maintaining sample rate accuracy). This charge is delivered through

D14, while Q2 supplies current to replenish C40 when the brief charge transfer is completed.

Conversely, when DVCO- is pulsed high, small charge packets are effectively removed for

the storage capacitor C2. This gradually reduces the control voltage and causes the VCO to slow

down (and thus decreasing DSP speed, again maintaining sample rate accuracy). Again this

charge is transferred through D13 while Q3 allows C41 to retain it's nominal voltage without

bleeding the storage capacitor.

R1 and R30 act as current limiters to suppress current spikes that could degrade the VCO's

performance.

Note that the Revision E Main PC Board incorporates a new custom digital VCO IC (UX)

5.30 MIDI Hardware

MIDI protocol is a standard that all manufacturers follow when designing MIDI systems so

that electronic music products can communicate via a common protocol.

MIDI IN is provided by J8. The opto isolator (U9) prevents unwanted electrical interference,

and is required by the MIDI specifications, as is R18 and D3.

U9's output is sent to the 8031's RXD port pin so that serial MIDI information can be deciphered.

R22 provides a current source for the opto, while R21 acts as a pullup.

J2 is the MIDI output jack and is driven through R17, by inverters U4D and U4E, which are

buffering the 8031's TXD port. R14 is a pullup resistor.

Alesis QuadraVerb II 2.00 6 07/19/06

Page 13

5.40 Encoder Interface

U27 is a quad XOR gate package which conditions the outputs from the front panel

encoder such that they can be easily interfaced to the 8031.

U27A is a transition detector pulse generator. One input is routed directly to the encoder

while the other is delayed by an RC time consent of R123 and C52. R122 is a pullup resistor.

U27C is an identical transition detector pulse generator. It's output is used to clock D flip

flop U20B which produces an output that allows the 8031 to determine if the encoder is moving in

a clockwise or counter clockwise direction.

U27D is used as an inverter since one of it's inputs is connected to +5V. It's output is used

to reset the direction D flip flop (U20B).

5.50 Footswitch interface

J3 is the footswitch jack. The footswitch can be used for program advance or tap tempo

delay. It is coupled to an 8031 port pin through a transient protection resistor (R6). It is also

connected to pullup resistor R3.

J4 is the bypass foot switch jack and is coupled to the 8031 through R5, and utilizes R4 as

a pullup resistor.

Both foot switches default to the normally open momentary type unless a normally closed

type is installed before power up, in which case the processor will

Alesis QuadraVerb II 2.00 7 07/19/06

Page 14

6.00 Appendix 1 Updates and Corrections

6.10 Important Production Changes

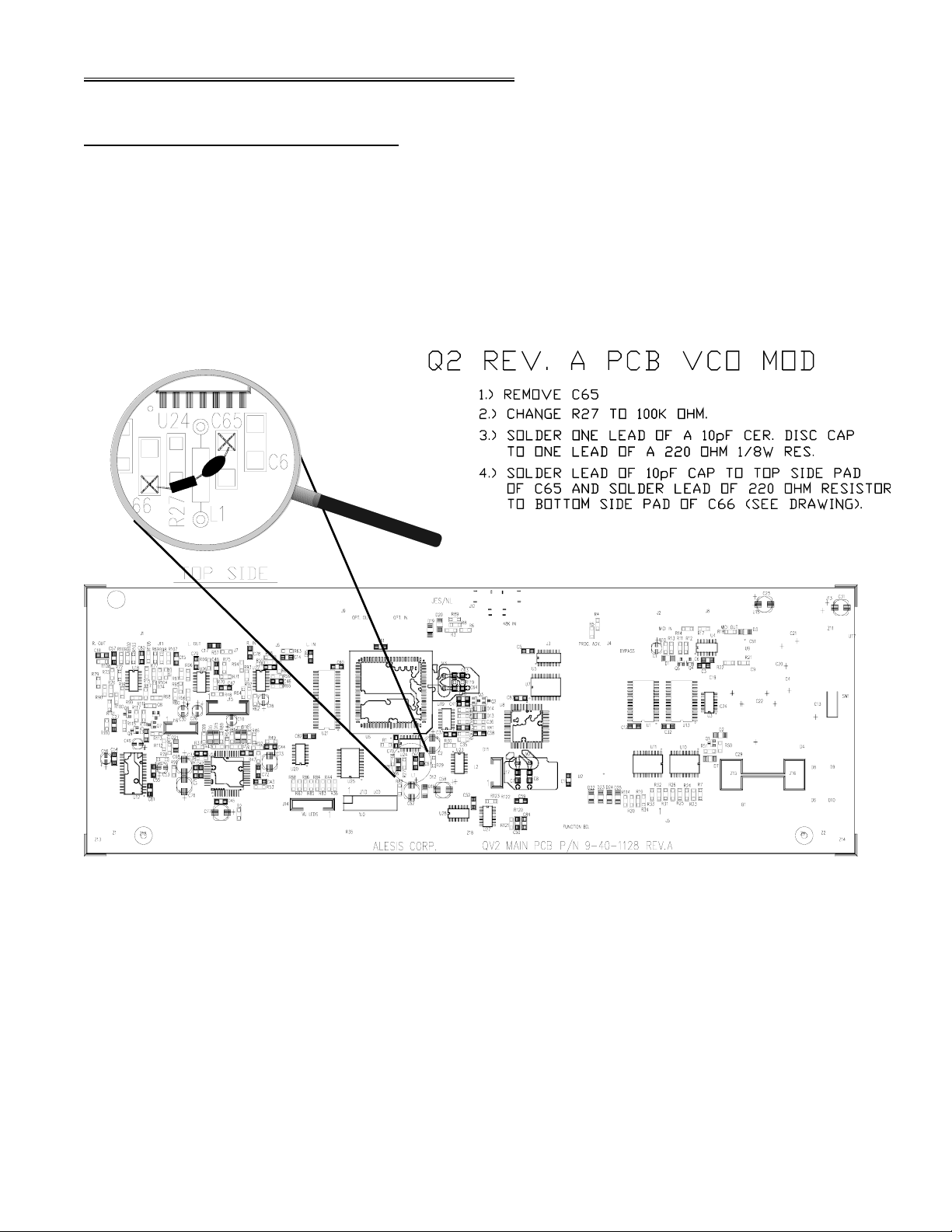

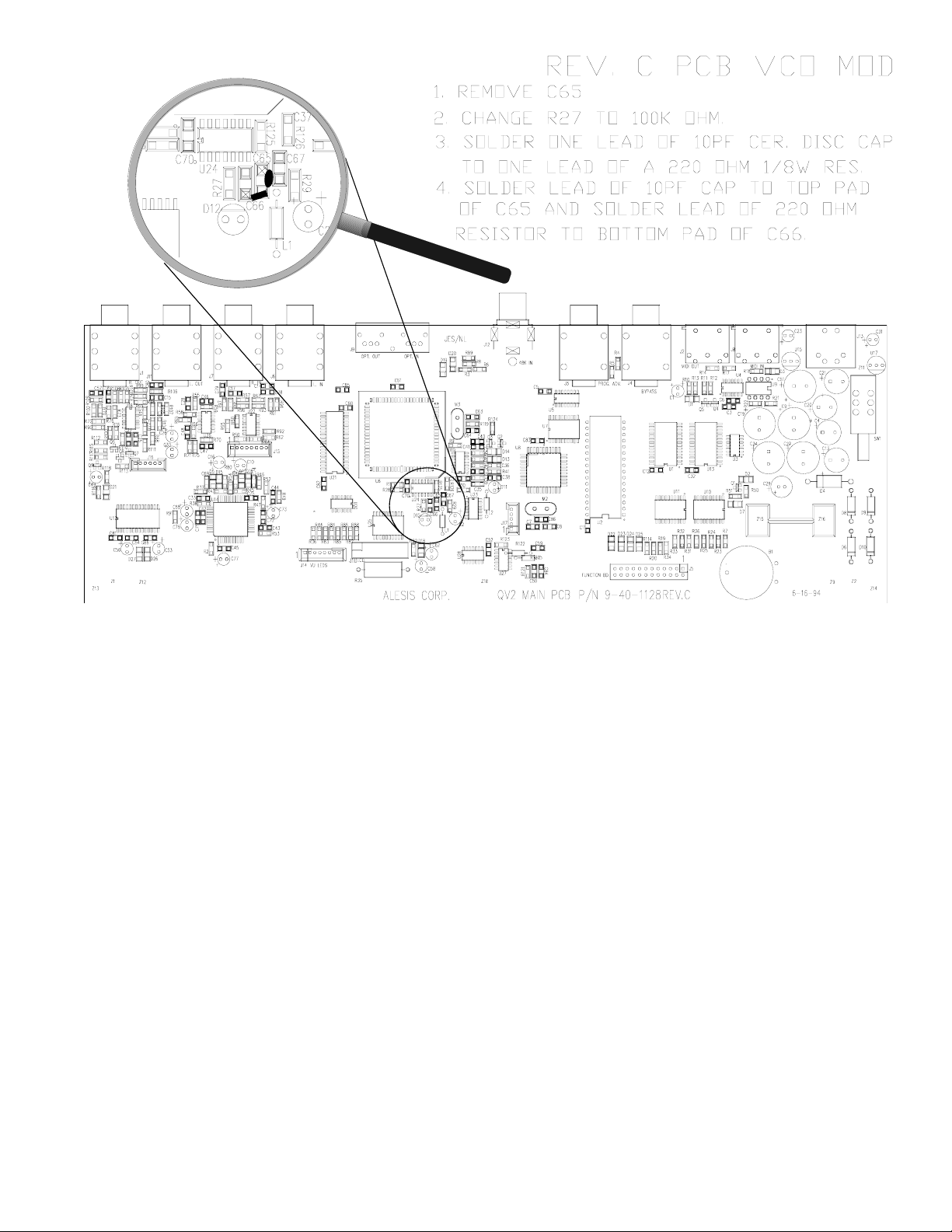

6.11 VCO Mod

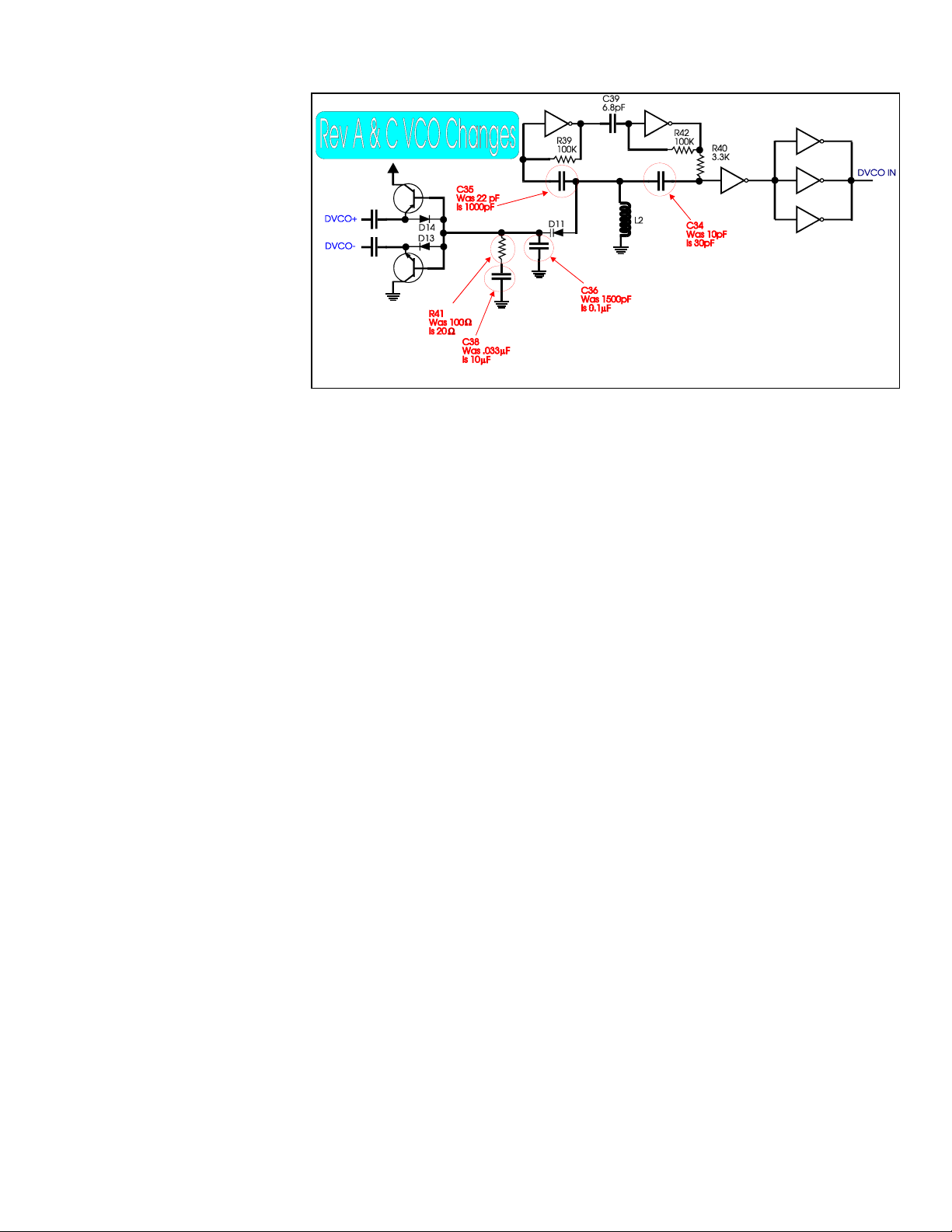

The following changes (Diagrams 1 and 2) improve VCO (Voltage Controlled Oscillator)

performance, and prevents the unit from possibly detuning by itself.

Diagram 1

Alesis QuadraVerb II 2.00 A-1 07/19/06

Page 15

Diagram 2

6.12 SRAM Current Increase

R50 was changed from 100K to 10K. R51 was changed from 100K to 4.7K. These changes

ensure that the SRAM gets enough current to holds it's memory by making Q1 switch faster.

6.13 Main PCB change.

The Q2 Main PCB has changed from Revision A to Revision C. The new board offers

improved performance and incorporates several earlier changes.

6.14 Reset Circuit Change

The following three pages reflect changes made to the Q2 reset circuit. These changes

must be made to all Revision A and C Main PC Boards in order to maintain data integrity. The

first page applies to both Revision A and C PCBs, while sheet 2 applies to Revision A only, and

sheet 3 applies to Revision C only.

Alesis QuadraVerb II 2.00 A-2 07/19/06

Page 16

Alesis QuadraVerb II 2.00 A-3 07/19/06

Page 17

Alesis QuadraVerb II 2.00 A-4 07/19/06

Page 18

Alesis QuadraVerb II 2.00 A-5 07/19/06

Page 19

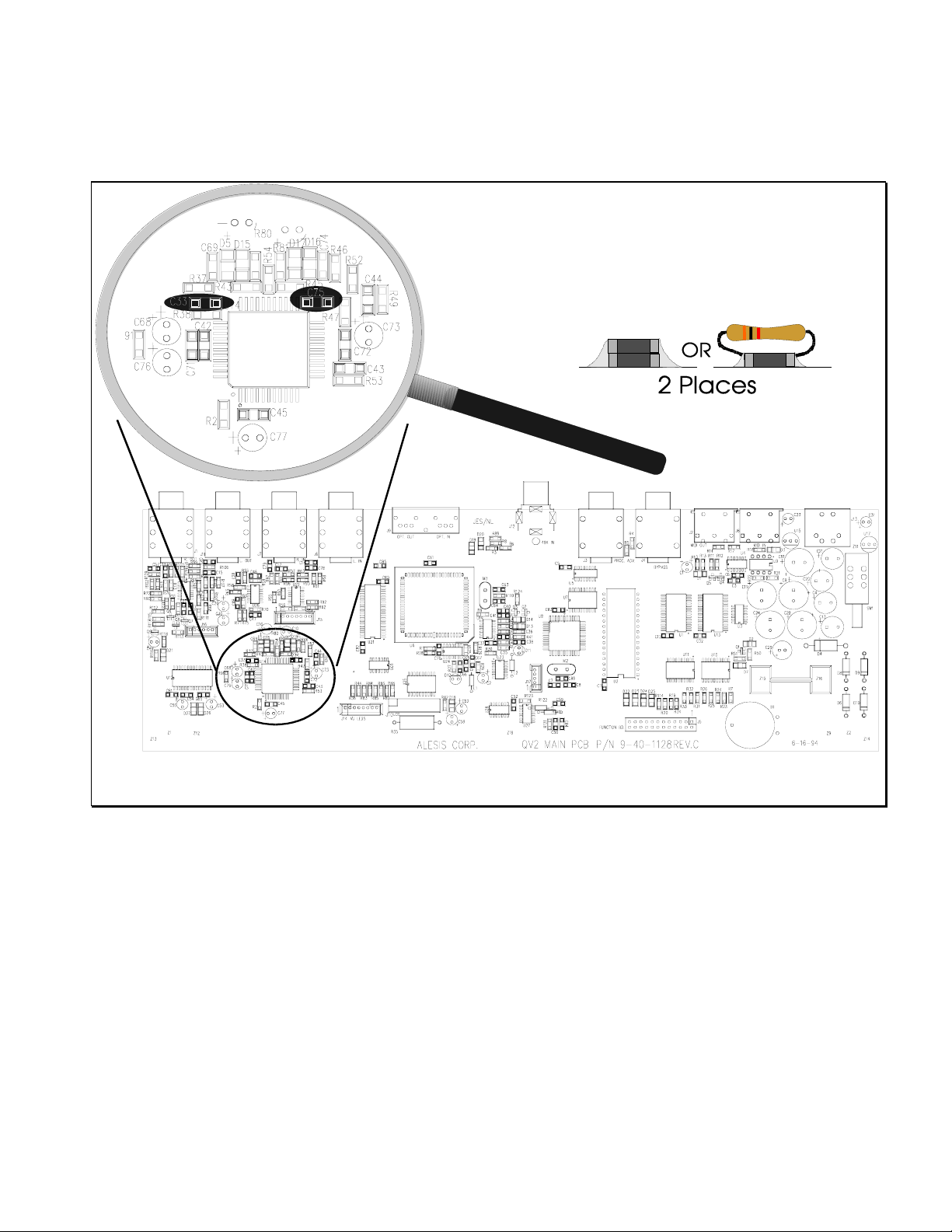

6.15 Revision A & C Input Changes

Add 2 3K resistors (AlPartNo.s 0-10-0302 {Surface Mount} or 0-00-0302 {Through Hole})

across capacitors C33 and C75 (See diagram 6 for locations). This change prevents the audio

outputs from inverting when the unit is clipping, reducing noise under these conditions.

Diagram 6

Alesis QuadraVerb II 2.00 A-6 07/19/06

Page 20

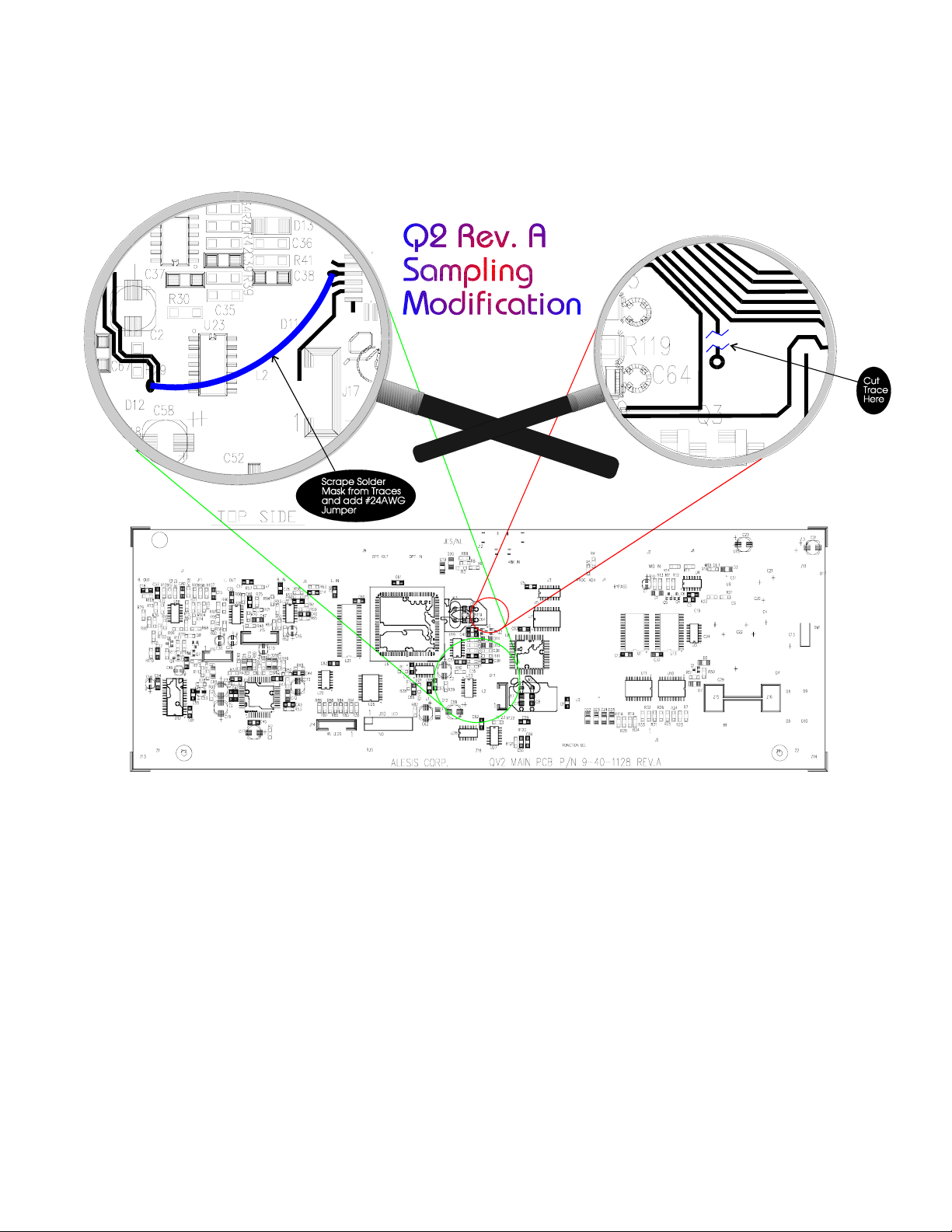

6.16 Revision A. Sampling Modification

To take advantage of the sampling feature included in software version 2.00 or higher it will

be necessary modify Revision A PCBs. The details of the modification are shown in Diagram 7. If

this modification is not performed when upgrading the software will display "UNIT NEEDS

SAMPLING UPGRADE" any time the sampling configuration is called up.

Diagram 7

Alesis QuadraVerb II 2.00 A-7 07/19/06

Page 21

6.17 Revision A & C VCO Changes

This update

eliminates clock jitter that

can cause some

"crackling" sounds when

using digital I/O. Note

that this modification can

only work on units that

have software version

2.01 or higher, and thus

should only performed on

older units if there is a

specific complaint of Dig

I/O noise.

Diagram 8

Alesis QuadraVerb II 2.00 A-8 07/19/06

Page 22

7.00 Appendix 2 Test Procedures

If possible, user data should be saved (a DataDisk is recommended) prior to any servicing.

This, of course, may not always be possible (i.e. dead power supply, bad reset signal, corrupt

data, etc.). Saving user data may also be accomplished after unit functionality is restored (i.e.

power supply, or reset line, is repaired), and prior to further servicing, and testing. The unit should

always be reinitialized (power unit up while holding "PROGRAM", "COMPARE", and "←BLOCK "

buttons down) after changing the EPROM, SRAM, or any part of the battery backup.

7.10 Self Test

The following Steps outline the use of the Q2's self test routines. To initiate the self test

hold "PROGRAM" and "BLOCK →" while powering the unit up. The unit will then proceed to test

the following:

$ LEDs-All front panel LEDs are lit sequentially and immediately proceeds to the next test.

$ SWITCHES -Pressing Individual front panel buttons toggles the LEDs for each button

("BLOCK ←", "BLOCK →", "PAGE ←", and "PAGE →" toggle the LED of the adjacent button.)

All LEDs are toggled if "VALUE/ENTER" is pressed. Holding the buttons down causes the

LEDs to flash. Press "PROGRAM" and "BLOCK →" simultaneously to exit to the next test.

$ CUSTOM CHARACTERS (All)-Displays all custom LCD segments simultaneously. Press

"PROGRAM" and "BLOCK →" simultaneously to exit to the next test.

$ CUSTOM CHARACTERS (Single)-Use the "VALUE/ENTER" wheel to select individual custom

LCD characters. Press "PROGRAM" and "BLOCK →" simultaneously to exit to the next test.

$ ROM CKSUM-Checks the ROM's checksum for accuracy. Press "PROGRAM" and

"BLOCK →" simultaneously to exit the test routines.

7.20 Further Testing

7.21 Audio

Using a clean audio source (CD or DAT preferred) set up the Q2 according to the user

manual. Listen to the output of the Q2 for any distortion or unusual clicks and pops.

7.22 Digital I/O

The digital fiber optic input can be tested by connecting an optical cable from the optical

input of the Q2 to the output of any compatible unit (such as ADAT or QuadraSynth), and turning

on the Q2's "DIGITAL INPUT" (in the "GLOBAL" functions). Audio output should sound clean and

undistorted.

Similarly, the digital output can tested with either a digital or audio input using a unit that is

compatible (such as ADAT).

7.23 MIDI

MIDI is easily tested with a system exclusive storage unit (such as DataDisk or MIDI

equipped computer) by sending all programs to, and receiving them back from the storage unit.

Keyboard controllers, and patch changers also be used to test MIDI in.

Alesis QuadraVerb II 2.00 B-1 07/19/06

Page 23

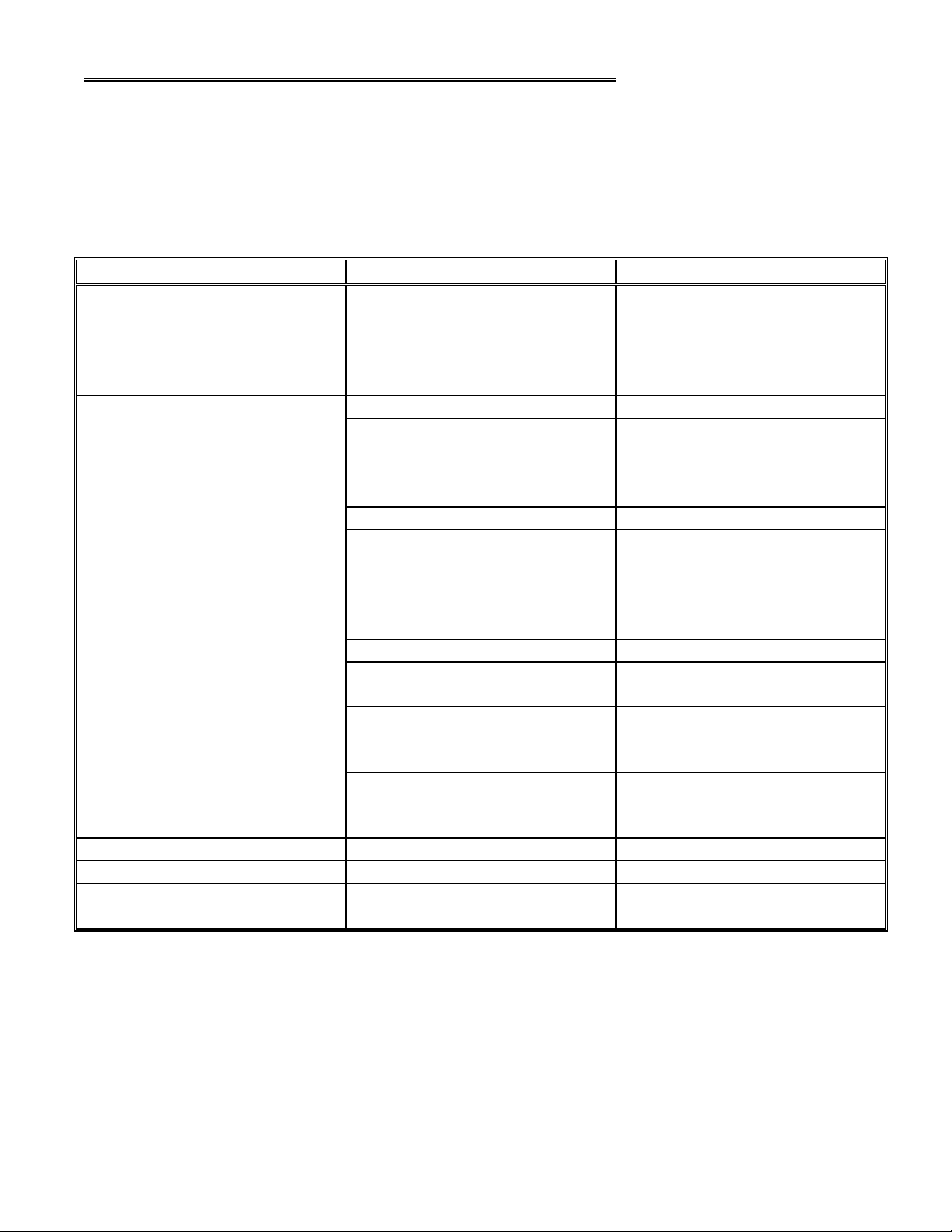

8.00 Appendix 3 Helpful Hints & Common Solutions

Troubleshooting a complex device, such as the QuadraVerb II, can range from the

simplicity of looking, seeing, and reseating a loose cable, to examining complex timing

relationships of data and control, and replacing the "slightly" bad latch. The following table is

presented in an effort to relieve the beleaguered technician from having to "discover" some of the

common fixes we have seen. Please note that we only cover the most likely causes, not all of

them.

SYMPTOM POSSIBLE CAUSE SOLUTION

Unit is Dead (No lights, no

function).

Faulty digital (+5V) power

No LCD. Loose LCD cable. Check LCD cable and retest.

Faulty LCD cable. Replace and retest.

Faulty RESET signal. Troubleshoot and repair as

Faulty LCD. Replace and retest.

Software parameters out of

Distortion. Faulty Power analog (+12V, -

Faulty DAC (U12). Replace and retest.

Software parameters out of

Faulty PUP circuit. Troubleshoot and repair as

Faulty RESET signal. Troubleshoot and repair as

No MIDI in. Faulty opto-isolator (U9). Replace and retest.

No MIDI out. Hex inverter (U4) is faulty. Replace and retest.

No digital I/O. Faulty F/X ASIC (U6) Replace and retest.

No 48K in. Faulty F/X ASIC (U6) Replace and retest.

Faulty A.C. adapter. Replace and retest.

Troubleshoot and repair as

supply.

range.

12V) supply.

range.

necessary (see section 2.00

for details)

necessary (see section 5.11

for details)

Reinitialize unit and retest.

Troubleshoot and repair as

necessary (see section 2.00

for details)

Reinitialize unit and retest.

necessary (see section 2.10

for details)

necessary (see section 5.11

for details)

Alesis QuadraVerb II 2.00 C-1 07/19/06

Page 24

9.00 Appendix 4 Software History

DATE VERSION COMMENTS

07/26/94 1.00 Checksum: F3AAH. Initial software release.

07/26/94 1.01 Checksum: F6D5H.

1. Changed the names of a couple presets.

08/04/94 1.02 Checksum: 8896H.

1. Block move has been extended to include modulations.

2. The default footswitch range is now 0 Preset to 99 User.

3. The FX are updated when in ROUTE & COMPARE.

4. VUs reflect digital input selections and are turned off when the channel

is 3 through 8.

5. A stack overflow was fixed which happened when using processor

effects and editing a reverb decay parameter.

6. MIDI sysex receive ON/OFF works.

7. Changing modulation parameters no longer affect parameters on the

same page.

8. MIDI controller 0 can be used for program bank select when the table

is off (0 = Preset, 1 to 127 = User).

9. MIDI mods will no longer affect the program table and the program

table will no longer affect MIDI mods.

10. Defaults are added to the envelope and peak followers in blank

programs upon user memory clear.

11. PROGRAM switch goes to program page 1 if in page 2.

12. Program title now displays “User” or ”Preset”.

13. Data from the ADC is in 18 bit mode.

08/24/94 1.03 Checksum: 3ED2H.

1. The preset programs were changed

10/28/94 1.05 Checksum: 6ADDH.

1. Hold time was added to the ENVELOPE local generator.

2. The RAMP local generator was added.

3. Tap tempo delays are set by to MIDI clock.

4. Programs load 2x faster.

5. A program write protect was added under the Store pages.

6. VU meters no longer freeze when using external 48kHz clock.

7. MIDI sysex bugs were fixed.

8. Test routines for MIDI, optical I/O, and sram were added.

9. Reverb gate not affected by changing other parameters.

10. Modulation of parameters is more time consistent.

11. Modulation of Leslie speed is smoother.

12. Error message displayed when “MEMORY FULL” is caused by a

delay note value change.

13. Program change to a program containing a Leslie will not cause

occasional audio glitches.

07/06/95 2.00 Checksum: 9BFDH.

Alesis QuadraVerb II 2.00 D-1 07/19/06

Page 25

1. Added features are:

- Sampling

- Phase Inversion

- Triggered Panning

- Triggered Mono/Stereo Flanging

- Soft/Hard Overdrive

- Block Copy/Paste

- Advance and Bypass pedals as local modulation generators

- 100 more user programs

- Negative flanger feedback

- Block Bypass

- Improved Stereo Leslie with Linear/Circular mode

- Quick routing when a block is added

- LFO local modulation generator

- “DIG” indicator flashes when digital input not valid

2. The MIDI sysex additions are:

- In MIDI EDIT, Block Type can be edited

- The MIDI Global Dump accommodates the

larger footswitch range

- An “ENTER” command

- User Bank 1 dump and dump request

- Block Bypass dump and dump request

- MIDI program table dump and dump request

10/23/95 2.01 Checksum: D9ABH.

1. The test constraints to determine if the sampling hardware mod is

working have been loosened. This corrects the hardware problem

that is causing “SAMPLE HARDWARE UPDATE NEEDED”

error messages, allowing units allowing units with the VCO chip

mod to sample; pre-VCO chip units still work.

2. The test for the sampling hardware mod has been added to the self

test routines.

3. The footswitch local generator won’t retain modulation after

power-down.

4. If adding “quick” routes causes a “DSP FULL” message the

display is updated immediately to not show the routes.

5. On power-up the FX RAM (DRAM) is completely cleared so

quick power cycles won’t cause stuttering audio remnants to play.

6. The program bank selection by controller 0 is fixed.

7. The spelling of “ATTACK TIME” in the footswitch mod. pages is

corrected.

8. Transmitting MIDI to the Q2 during power-up will no longer

cause problems.

Alesis QuadraVerb II 2.00 D-2 07/19/06

Page 26

10.00 Appendix 5 MIDI Implementation

10.10 V1.0X

V1.0X September 9, 1994

SYSTEM EXCLUSIVE FORMAT

The QuadraVerb II MIDI System Exclusive message format is as follows:

F0 System exclusive status

00 00 0E Alesis manufacturer id#

0F QuadraVerb id#

cc Opcode

dd Data

: :

: :

F7 End-Of-Exclusive

OPCODES:

01 - MIDI Edit F0 00 00 0E 0F 01<function#> <block#> <page#> <parameter#> <data

16> F7

<function#> = 0= PARAMETER, 1= MIX, 2= GLOBAL

<block#> = (1-8) # of block to be edited. Doesn’t matter for GLOBAL edits.

<page#> = (1-#of last page under function) page # for value to be edited.

<parameter#> = (1-#of last parameter on page) parameter # of value

<data 16> is in format described below. It is a 16-bit value, which is transmitted in three

MIDI bytes, LSB first.

TWO QUADRAVERB II BYTES:

0: A7 A6 A5 A4 A3 A2 A1 A0 (LSB)

1: B7 B6 B5 B4 B3 B2 B1 B0 (MSB)

TRANSMITTED AS:

0: 0 A7 A6 A5 A4 A3 A2 A1

1: 0 A0 B7 B6 B5 B4 B3 B2

2: 0 B1 B0 0 0 0 0 0

02 - MIDI User Program Dump F0 00 00 0E 0E 02 <prog.#> <data> F7

<program#>= 0..99 selects individual user programs, 100 selects edit

<data> is in a packed format in order to optimize data transfer. Eight MIDI bytes are used to

transmit each block of 7 QuadraVerb II data bytes. If the 7 data bytes are looked at as one

56-bit word, the format for transmission is eight 7-bit words beginning with the most

significant bit of the first byte, as follows:

Alesis QuadraVerb II 2.00 E-1 07/19/06

Page 27

SEVEN QUADRAVERB II BYTES:

0: A7 A6 A5 A4 A3 A2 A1 A0

1: B7 B6 B5 B4 B3 B2 B1 B0

2: C7 C6 C5 C4 C3 C2 C1 C0

3: D7 D6 D5 D4 D3 D2 D1 D0

4: E7 E6 E5 E4 E3 E2 E1 E0

5: F7 F6 F5 F4 F3 F2 F1 F0

6: G7 G6 G5 G4 G3 G2 G1 G0

TRANSMITTED AS:

0: 0 A6 A5 A4 A3 A2 A1 A0

1: 0 B5 B4 B3 B2 B1 B0 A7

2: 0 C4 C3 C2 C1 C0 B7 B6

3: 0 D3 D2 D1 D0 C7 C6 C5

4: 0 E2 E1 E0 D7 D6 D5 D4

5: 0 F1 F0 E7 E6 E5 E4 E3

6: 0 G0 F7 F6 F5 F4 F3 F2

7: 0 G7 G6 G5 G4 G3 G2 G1

There are 306 data bytes sent for a single program dump, which corresponds to 256 bytes

of program data. With the header, the total number of bytes transmitted with a program

dump is 314. The location of each parameter within a program dump is shown in the next

section: QuadraVerb II Program Data Format.

03 - MIDI User Program Dump Request F0 00 00 0E 0F 03 <program#> F7

<program#>= 0..99 selects individual user programs, 100 selects current edit,

101 is a dump all request in which all user programs are dumped

as individual program dumps (02) followed by a global dump (07)

When received, the QuadraVerb II will respond to this message with a MIDI user program

dump (02) of the program number selected.

07 - MIDI Global Data Dump F0 00 00 0E 0F 07 <data> F7

<data> is in the same format as described in 00, but with a different number of bytes due to

the difference in the global parameter size. The total number of data bytes sent for a global

data dump is 16, which corresponds to 14 bytes of global data.

08 - MIDI Global Data Dump Request F0 00 00 0E 0F 08 F7

When received, the QuadraVerb II will respond to this message with a MIDI global data

dump (07).

09 - MIDI Bypass or Compare F0 00 00 0E 0F 09 <function> <off/on> F7

<function> = 0= BYPASS, 1= COMPARE

<off/on> = 0= function off, 1= function on

When received, the QuadraVerb II will respond to this message by turning

BYPASS/COMPARE OFF/ON.

Alesis QuadraVerb II 2.00 E-2 07/19/06

Page 28

0A - MIDI DSP Error Message F0 00 00 0E 0F 0A <data> F7

<data> = 1= “EFFECT MEMORY IS FULL”

2= “OUT OF LFOs”

4= “DSP IS FULL”

8= “BLOCK COMBINATION NOT ALLOWED”

PARAMETER FORMAT

The following specific parameter information shows the locations in which each parameter

resides after unpacking the data from its 7 bit MIDI format into the 8 bit format as described in opcode

00, program data dump.

GLOBAL DATA FORMAT

The Global parameters are comprised of 14 bytes of data. Unlike the Program, the Global parameters are

not packed so that each parameter occupies its own byte. This results in unused bits for most global bytes.

These bits must remain at 0. For direct parameter editing (sysex command 01H), the Page# and Parameter# are

given in the table below. The Function# should be set to 2 (=Global), and the Block# should be 1-8.

# Parameter name Page Parm lo lim hi lim bits bit address

0. LCD contrast 1 1 1 10 8 0:7-0:0

1. Footswitch range head 2 1 0 199 8 1:7-1:0

2. Footswitch range tail 2 2 0 199 8 2:7-2:0

3. VU meter peak hold 3 1 0 1 8 3:7-3:0

4. Input audio source 4 1 0 1 8 4:7-4:0

5. Sample clock source 5 1 0 1 8 5:7-5:0

6. Digital left input channel 6 2 1 8 8 6:7-6:0

7. Digital right input channel 6 3 1 8 8 7:7-7:0

8. Digital left output channel 6 4 1 8 8 8:7-8:0

9. Digital right output channel 6 1 1 8 8 9:7-9:0

10. Digital output mode 7 1 0 1 8 10:7-10:0

11. Tap tempo footswitch 8 1 0 2 8 11:7-11:0

12. Global direct signal 9 1 0 1 8 12:7-12:0

13. Reserved for future use (set to 0) 9 1 0 1 8 13:7-13:0

QUADRAVERB II PROGRAM DATA FORMAT

Programs contain 256 bytes of packed parameter data. The first 92 bytes are common

parameters for all programs. The next 164 bytes depend on the number of bytes required for

parameters of the effect blocks and the number of routes enabled. Usually, not all of these bytes are

used, and in this case the end of the routing is designated by 0FFH, 0FFH. Only numbers with

negative offsets are in 2’s complement form.

# Parameter name lo lim hi lim bits byte:msb-byte:lsb

PROGRAM NAME:

0. Program name ASCII digit 0 32 127 8 0:7-0:0

1. Program name ASCII digit 1 32 127 8 1:7-1:0

...

Alesis QuadraVerb II 2.00 E-3 07/19/06

Page 29

13. Program name ASCII digit 13 32 127 8 13:7-13:0

BLOCK TYPES:

14a. Block 1 type definition 0 4 * 3 14:7-14:5

14b. Block 1 subtype definition 0 ** 5 14:4-14:0

15a. Block 2 type definition 0 4 * 3 15:7-15:5

...

20b. Block 7 subtype definition 0 ** 5 20:4-20:0

21a. Block 8 type definition 0 4 * 3 21:7-21:5

21b. Block 8 subtype definition 0 ** 5 21:4-21:0

* Block type definitions are given in the next section: Block type definitions

** The upper limit and definition for the block subtype depend on the block type. The upper limit and

definition for the subtype are given in the section: Block subtype defintions

MODULATION:

22. Mod. 1 source 0 129 * 8 22:7-22:0

23. Mod. 1 target block # 1 11 ** 8 23:7-23:0

24a. Mod. 1 target type: parameter, route, or mix 0 2 *** 2 24:7-24:6

24b. Mod. 1 target # 0 *** 6 24:5-24:0

25. Mod. 1 amplitude -99 +99 8 25:7-25:0

26. Mod. 2 source 0 129 * 8 26:7-26:0

...

49. Mod. 7 amplitude -99 +99 8 49:7-49:0

50. Mod. 8 source 0 129 * 8 50:7-50:0

51. Mod. 8 target block # 1 11 ** 8 51:7-51:0

52a. Mod. 8 target type: parameter, route, or mix 0 2 *** 2 52:7-52:6

52b. Mod. 8 target # 0 *** 6 52:5-52:0

53. Mod. 8 amplitude -99 +99 8 53:7-53:0

* Definitions of the modulation sources are in the section: Modulation source definitions

** Target block # definition: 1 = block 1, ..., 8 = block 8, 9 = left out, 10 = right out, 11 = mix

parameters.

*** Definitions of the modulation targets are in the section: Modulation target definitions

Alesis QuadraVerb II 2.00 E-4 07/19/06

Page 30

BLOCK MIXES:

54. Direct level 0 100 8 54:7-54:0

55. Block 1 level 0 100 8 55:7-55:0

56. Block 1 inmix level 0 100 8 56:7-56:0

57. Block 2 level 0 100 8 57:7-57:0

...

68. Block 7 inmix level 0 100 8 68:7-68:0

69. Block 8 level 0 100 8 69:7-69:0

70. Block 8 inmix level 0 100 8 70:7-70:0

71. Master effects level 0 100 8 71:7-71:0

LOCAL GENERATORS:

72. Generator 1 type 0 1 * 8 72:7-72:0

73. Generator 1 trigger source channel 0 2 ** 8 73:7-73:0

74. Generator 1 attack threshold -32 0 8 74:7-74:0

75. Generator 1 release threshold -48 0 8 75:7-75:0

76. Generator 1 attack time 0 250 *** 8 76:7-76:0

77. Generator 1 release or decay time 0 250 *** 8 77:7-77:0

78. Generator 1 input gain 0 99 8 78:7-78:0

79. Reserved for future use (set to 0) 8 79:7-79:0

80. Reserved for future use (set to 0) 8 80:7-80:0

81. Reserved for future use (set to 0) 8 81:7-81:0

82. Generator 2 type 0 1 * 8 82:7-82:0

83. Generator 2 trigger source channel 0 2 ** 8 83:7-83:0

84. Generator 2 attack threshold -32 0 8 84:7-84:0

85. Generator 2 release threshold -48 0 8 85:7-85:0

86. Generator 2 attack time 0 250 *** 8 86:7-86:0

87. Generator 2 release or decay time 0 250 *** 8 87:7-87:0

88. Generator 2 input gain 0 99 8 88:7-88:0

89. Reserved for future use (set to 0) 8 89:7-89:0

90. Reserved for future use (set to 0) 8 90:7-90:0

91. Reserved for future use (set to 0) 8 91:7-91:0

* Generator type: 0 = Envelope generator, 1 = Peak follower

** Trigger source channel: 0 = Left channel, 1 = Right channel, 2 = Left & Right channels

*** This number is multiplied by 0.04 to get the decay in seconds.

BLOCK PARAMETERS

92. Parameter #1 for 1st defined block* (MSB) ** ** ** **

93. Parameter #1 for 1st defined block* (LSB) *** ** ** ** **

94. Parameter #2 for 1st defined block* (MSB) ** ** ** **

...

* Block parameters are not stored for blocks that are off. Parameters are stored in order of appearance on the

Quadraverb II display - by block #, parameter page #, and from left to right within the page; the 1st stored

parameter appears on the display at the left most block that is not off, on it’s 1st parameter page, at the left.

** The parameter definitions are given for each block type and subtype in the section: Block parameter

definitions

*** Exists only if the block parameter requires two bytes.

BLOCK ROUTING

92* Route #1 position byte (LSB) 0 255 ** 8 92*:7-92*:0

Alesis QuadraVerb II 2.00 E-5 07/19/06

Page 31

93* Route #1 position byte (MSB) 0 1 ** 1 93*:7-93*:7

93* Route #1 level 0 58 *** 7 93*:6-93*:0

94* Route #2 position byte (LSB) 0 255 ** 8 94*:7-94*:0

...

* This number is offset by the number of block parameter bytes that are stored.

** An equation for calculating the route position byte is given in the section: Route position definitions

*** This number has a corresponding dB level given by the table in the section: Route level definitions

BLOCK TYPE DEFINITIONS

This table defines the block types for a given parameter:

Parameter: Block type:

0 OFF

1 EQ

2 PCH

3 DLY

4 RVB

BLOCK SUBTYPE DEFINITIONS

These tables define the block subtypes for a given parameter. Different block subtype tables are

defined for each block type.

Type = EQ

Parameter: Block subtype

0 Lowpass filter

1 Bandpass filter

2 Highpass filter

3 Lowpass shelf eq

4 1 Band low parametric

5 1 Band high parametric

6 Highpass shelf eq

7 2 Band sweep shelf eq

8 3 Band parametric eq

9 4 Band parametric eq

10 5 Band graphic eq

11 Resonator

12 Mono tremolo

13 Stereo tremolo

14 Stereo simulator

Alesis QuadraVerb II 2.00 E-6 07/19/06

Page 32

Type = PCH

Type = DLY

Type = RVB

Parameter: Block subtype

0 Mono chorus

1 Stereo chorus

2 Quad chorus

3 Mono flanging

4 Stereo flanging

5 Phasor

6 Mono lezlie

7 Stereo lezlie

8 Pitch shifter

9 Pitch detune

10 Ring modulator

Parameter: Block subtype

0 Mono delay

1 Stereo delay

2 Ping pong delay

3 Multi tap delay

4 Tap tempo mono delay

5 Tap tempo ping pong dela

Parameter: Block subtype

0 Mono room

1 Room 1

2 Hall 1

3 Plate 1

4 Chamber 1

5 Room 2

6 Hall 2

7 Plate 2

8 Chamber 2

9 Large plate

10 Large room

11 Spring

12 Nonlinear

13 Reverse

Alesis QuadraVerb II 2.00 E-7 07/19/06

Page 33

MODULATION SOURCE DEFINITIONS

t

Parameter: Block subtype

0 Pitch bend

1 After touch

2 Note number

3 Note velocity

4 Controller 000

... ...

127 Controller 123

128 Local generator 1

129 Local generator 2

MODULATION TARGET DEFINITIONS

The modulation target type and target # make up an 8 bit word: TTNNNNNN (where TT denotes the

target type and NNNNNN denotes the target #). The targets are for the effect block or mix specified

by the target block #.

TT Modulation target type

00 Block parameter

01 Route level

10 Mix level

If TT = 00

NNNNNN Modulation target parame

0 Parameter #1

1 Parameter #2

... ...

32 Parameter #33

If TT = 01

NNNNNN Modulation target route

0 In left

1 In right

2 Block 1 inmix

3 Block 1 mix

4 Block 1 left

5 Block 1 right

6 Block 2 inmix

... ...

33 Block 8 right

Alesis QuadraVerb II 2.00 E-8 07/19/06

Page 34

If TT = 10

NNNNNN Modulation target mix

0 Direct level

1 Block 1 out level

2 Block 1 inmix level

3 Block 2 out level

4 Block 2 inmix level

... ...

16 Block 8 inmix level

17 Master fx level

BLOCK PARAMETER DEFINITIONS

These parameters are packed as 8 or 16 bit words MSB first in programs, but are always

considered 16 bit words LSB first in parameter edits.

EQ:

Parameter Page ParamBytes Low limit Hi limit Step

LOWPASS FILTER: type = 1, subtype = 0

lowpass fc 1 1 2 20 10,000 10

BANDPASS FILTER: type = 1, subtype = 1

bandpass fc 1 1 2 20 4,000 10

bw 1 2 1 20 200 1

HIGHPASS FILTER: type = 1, subtype = 2

highpass fc 1 1 2 200 20,000 10

LOWPASS SHELF EQ: type = 001, subtype = 3

lowpass 1 1 2 20 10,000 10

gain 1 2 2 -140 +140 1

1 BAND LOW PARAMETRIC: type = 1, subtype = 4

bandpass 1 1 2 20 2,000 10

gain 1 2 2 -140 +140 1

oct 1 3 1 20 200 1

1 BAND HIGH PARAMETRIC: type = 1, subtype = 5

bp 1 1 2 1500 10,000 10

gain 1 2 2 -140 +140 1

oct 1 3 1 20 250 1

HIGHPASS SHELF EQ: type = 1, subtype = 6

highpass 1 1 2 100 20,000 10

gain 1 2 2 -140 +140 1

2 BAND SWEEP SHELF EQ: type = 1, subtype = 7

lowpass 1 1 2 20 10,000 10

gain 1 2 2 -140 +140 1

highpass 2 1 2 100 20,000 10

gain 2 2 2 -140 +140 1

3 BAND PARAMETRIC EQ: type = 1, subtype = 8

lowpass 1 1 2 20 10,000 10

gain 1 2 2 -140 +140 1

mid band 2 1 2 20 2,000 1

Alesis QuadraVerb II 2.00 E-9 07/19/06

Page 35

dB 2 2 2 -140 +140 1

oct 2 3 1 20 200 1

highpass 3 1 2 100 20,000 10

gain 3 2 2 -140 +140 1

4 BAND PARAMETRIC EQ: type = 1, subtype = 9

lowpass 1 1 2 20 10,000 10

gain 1 2 2 -140 +140 1

low mid 2 1 2 20 2,000 1

dB 2 2 2 -140 +140 1

oct 2 3 1 20 200 1

high mid 3 1 2 1500 10,000 10

dB 3 2 2 -140 +140 1

oct 3 3 1 20 250 1

highpass 4 1 2 100 20,000 10

gain 4 2 2 -140 +140 1

5 BAND GRAPHIC EQ: type = 1, subtype = 10

63Hz 1 1 1 -14 +14 1

250Hz 1 2 1 -14 +14 1

1KHz 1 3 1 -14 +14 1

4KHz 1 4 1 -14 +14 1

16kHz 1 5 1 -14 +14 1

RESONATOR: type = 1, subtype = 11

tuning 1 1 1 0 60 1

decay 1 2 1 0 99 1

MONO TREMOLO: type = 1, subtype = 12

speed 1 1 1 0 99 1

depth 1 2 1 0 99 1

shape 1 3 1 0 1 1

STEREO TREMOLO: type = 1, subtype = 13

speed 1 1 1 0 99 1

depth 1 2 1 0 99 1

shape 1 3 1 0 1 1

STEREO SIMULATOR: type = 1, subtype = 14

degrees 1 1 1 0 99 1

Alesis QuadraVerb II 2.00 E-10 07/19/06

Page 36

PCH:

Parameter Page ParamBytes Low limit Hi limit Step

MONO CHORUS: type = 2, subtype = 0

speed 1 1 1 0 99 1

depth 1 2 1 0 99 1

feedback 1 3 1 0 99 1

chorus predelay 2 1 1 0 100 1

STEREO CHORUS: type = 2, subtype = 1

speed 1 1 1 0 99 1

depth 1 2 1 0 99 1

feedback 1 3 1 0 99 1

predelay chr1 2 1 1 0 100 1

chr2 2 2 1 0 100 1

STEREO CHORUS: type = 2, subtype = 2

speed 1 1 1 0 99 1

depth 1 2 1 0 99 1

feedback 1 3 1 0 99 1

predelay chr1 2 1 1 0 100 1

chr2 2 2 1 0 100 1

predelay chr3 3 1 1 0 100 1

chr4 3 2 1 0 100 1

MONO FLANGING: type = 2, subtype = 3

speed 1 1 1 0 99 1

depth 1 2 1 0 99 1

feedback 1 3 1 0 99 1

flanging shape 2 1 1 0 1 1

STEREO FLANGING: type = 2, subtype = 4

speed 1 1 1 0 99 1

depth 1 2 1 0 99 1

feedback 1 3 1 0 99 1

flanging shape 2 1 1 0 1 1

PHASOR: type = 2, subtype = 5

phasor speed 1 1 1 0 99 1

depth 1 2 1 0 99 1

MONO LEZLIE: type = 2, subtype = 6

lezlie motor 1 1 1 0 1 1

speed 1 2 1 0 1 1

high rotor level 2 1 1 -12 +6 1

STEREO LEZLIE: type = 2, subtype = 7

lezlie motor 1 1 1 0 1 1

speed 1 2 1 0 1 1

high rotor level 2 1 1 -12 +6 1

stereo separation 3 1 1 0 99 1

PITCH SHIFTER: type = 2, subtype = 8

pitch shift fine 1 1 1 -99 +99 1

coarse 1 2 1 -12 +12 1

PITCH DETUNE: type = 2, subtype = 9

detune amount 1 1 1 -99 +99 1

Alesis QuadraVerb II 2.00 E-11 07/19/06

Page 37

DLY:

Parameter Page ParamBytes Low limit Hi limit Step

MONO DELAY: type = 3, subtype = 0

delay 1 1 2 1 50,000 1

note value 1 2 1 0 12 1

feedback 2 1 1 0 99 1

STEREO DELAY: type = 3, subtype = 1

L dly 1 1 2 1 50,000 1

note value 1 2 1 0 12 1

L feedback 2 1 1 0 99 1

R dly 3 1 2 1 50,000 1

note value 3 2 1 0 12 1

R feedback 4 1 1 0 99 1

PING PONG DELAY: type = 3, subtype = 2

delay 1 1 2 1 25,000 1

note value 1 2 1 0 12 1

feedback 2 1 1 0 99 1

MULTI TAP DELAY: type = 3, subtype = 3

delay 1 1 2 1 50,000 1

tap level 1 2 1 0 38 1

L<- ->R 1 3 1 1 99 1

fb 1 4 1 0 99 1

delay 2 1 2 1 50,000 1

tap level 2 2 1 0 38 1

L<- ->R 2 3 1 1 99 1

fb 2 4 1 0 99 1

delay 3 1 2 1 50,000 1

tap level 3 2 1 0 38 1

L<- ->R 3 3 1 1 99 1

fb 3 4 1 0 99 1

delay 4 1 2 1 50,000 1

tap level 4 2 1 0 38 1

L<- ->R 4 3 1 1 99 1

fb 4 4 1 0 99 1

delay 5 1 2 1 50,000 1

tap level 5 2 1 0 38 1

L<- ->R 5 3 1 1 99 1

fb 5 4 1 0 99 1

master feedback 6 1 1 0 99 1

TAP TEMPO MONO DELAY: type = 3, subtype = 4

delay 1 1 2 1 50,000 1

note value 1 2 1 0 38 1

feedback 2 1 1 0 99 1

TAP TEMPO PING PONG DELAY: type = 3, subtype = 5

delay 1 1 2 1 25,000 1

note value 1 2 1 0 38 1

feedback 2 1 1 0 99 1

Alesis QuadraVerb II 2.00 E-12 07/19/06

Page 38

RVB:

Parameter Page ParamBytes Low limit Hi limit Step

MONO ROOM: type = 4, subtype = 0

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

gate trig 5 1 1 0 2 1

gated level 5 2 1 0 99 1

gate hold 6 1 2 0 500 10

release 6 2 2 10 500 10

ROOM 1: type = 4, subtype = 1

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

gate trig 5 1 1 0 2 1

gated level 7 2 1 0 99 1

gate hold 5 2 2 0 500 10

release 6 1 2 10 500 10

HALL 1: type = 4, subtype = 2

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

gate trig 5 1 1 0 2 1

gated level 5 2 1 0 99 1

gate hold 6 1 2 0 500 10

release 6 2 2 10 500 10

ROOM 1: type = 4, subtype = 3

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

Alesis QuadraVerb II 2.00 E-13 07/19/06

Page 39

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

gate trig 5 1 1 0 2 1

gated level 5 2 1 0 99 1

gate hold 6 1 2 0 500 10

release 6 2 2 10 500 10

PLATE 1: type = 4, subtype = 4

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

gate trig 5 1 1 0 2 1

gated level 5 2 1 0 99 1

gate hold 6 1 2 0 500 10

release 6 2 2 10 500 10

CHAMBER 1: type = 4, subtype = 5

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

gate trig 5 1 1 0 2 1

gated level 5 2 1 0 99 1

gate hold 6 1 2 0 500 10

release 6 2 2 10 500 10

ROOM 2: type = 4, subtype = 6

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

reflection level 5 1 1 0 99 1

spread 5 2 1 0 99 1

reverberation swirl 6 1 1 0 99 1

gate trig 7 1 1 0 2 1

gated level 7 2 1 0 99 1

gate hold 8 1 2 0 500 10

release 8 2 2 10 500 10

Alesis QuadraVerb II 2.00 E-14 07/19/06

Page 40

HALL 2: type = 4, subtype = 7

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

reflection level 5 1 1 0 99 1

spread 5 2 1 0 99 1

reverberation swirl 6 1 1 0 99 1

gate trig 7 1 1 0 2 1

gated level 7 2 1 0 99 1

gate hold 8 1 2 0 500 10

release 8 2 2 10 500 10

PLATE 2: type = 4, subtype = 8

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

reflection level 5 1 1 0 99 1

spread 5 2 1 0 99 1

reverberation attack 6 1 1 0 99 1

gate trig 7 1 1 0 2 1

gated level 7 2 1 0 99 1

gated hold 8 1 2 0 500 10

release 8 2 2 10 500 10

CHAMBER 2: type = 4, subtype = 9

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

reflection level 5 1 1 0 99 1

spread 5 2 1 0 99 1

reverberation attack 6 1 1 0 99 1

gate trig 7 1 1 0 2 1

gated level 7 2 1 0 99 1

gate hold 8 1 2 0 500 10

release 8 2 2 10 500 10

Alesis QuadraVerb II 2.00 E-15 07/19/06

Page 41

LARGE PLATE: type = 4, subtype = 10

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

reflection level 5 1 1 0 99 1

spread 5 2 1 0 99 1

reverberation swirl 6 1 1 0 99 1

gate trig 7 1 1 0 2 1

gated level 7 2 1 0 99 1

gate hold 8 1 2 0 500 10

release 8 2 2 10 500 10

LARGE ROOM: type = 4, subtype = 11

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

reflection level 5 1 1 0 99 1

spread 5 2 1 0 99 1

reverberation swirl 6 1 1 0 99 1

gate trig 7 1 1 0 2 1

gate level 7 2 1 0 99 1

gate hold 8 1 2 0 500 10

release 8 2 2 10 500 10

SPRING: type = 4, subtype = 12

decay 1 1 1 0 99 1

damping hi 1 2 1 0 99 1

lo 1 3 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

gate trig 5 1 1 0 2 1

gate level 5 2 1 0 99 1

gate hold 6 1 2 0 500 10

release 6 2 2 10 500 10

Alesis QuadraVerb II 2.00 E-16 07/19/06

Page 42

NONLINEAR: type = 4, subtype = 13

gate hold time 1 1 1 0 99 1

reverb density 2 1 1 0 99 1

diffusion 2 2 1 0 99 1

input high freq roll off 3 1 2 200 20,000 50

predelay 4 1 1 1 250 1

mix direct<- ->dly 4 2 1 1 99 1

ROUTE POSITION DEFINITIONS

Route position byte (9bits) = Sroute + [4*(Sblock-1)] + [34*(Dblock-1)]

where,

Sroute= route source #: 0= Input L, 1= Input R, 2= Block inmix, 3= Block mix, 4= Block L, 5= Block R

Sblock= route source block #: 1= Input, 1= Block 1, ..., 8= Block 8

Dblock= route destination block #: 1= Block 1, ..., 8= Block 8, 9= Out L, 10= Out R

ROUTE LEVEL DEFINITIONS

Below is a table that gives the corresponding dB level for a given route level #:

Rout level # Parameter dB

0 OFF

1 -48.0 dB

2 -42.0 dB

3 -38.0 dB

4 -36.0 dB

5 -34.0 dB

6 -32.0 dB

7 -31.0 dB

8 -30.0 dB

9 -29.0 dB

10 -28.0 dB

11 -27.0 dB

12 -26.0 dB

13 -25.0 dB

14 -24.0 dB

15 -23.0 dB

16 -22.0 dB

17 -21.0 dB

18 -20.0 dB

19 -19.5 dB

20 -19.0 dB

Alesis QuadraVerb II 2.00 E-17 07/19/06

Page 43

21 -18.5 dB

22 -18.0 dB

23 -17.5 dB

24 -17.0 dB

25 -16.5 dB

26 -16.0 dB

27 -15.5 dB

28 -15.0 dB

29 -14.5 dB

30 -14.0 dB

31 -13.5 dB

32 -13.0 dB

33 -12.5 dB

34 -12.0 dB

35 -11.5 dB

36 -11.0 dB

37 -10.5 dB

38 -10.0 dB

39 -9.5 dB

40 -9.0 dB

41 -8.5 dB

42 -8.0 dB

43 -7.5 dB

44 -7.0 dB

45 -6.5 dB

46 -6.0 dB

47 -5.5 dB

48 -5.0 dB

49 -4.5 dB

50 -4.0 dB

51 -3.5 dB

52 -3.0 dB

53 -2.5 dB

54 -2.0 dB

55 -1.5 dB

56 -1.0 dB

57 -0.5 dB

58 -0.0 dB

Alesis QuadraVerb II 2.00 E-18 07/19/06

Page 44

10.20 V2.0X

Version 2.0X 6/26/95

SYSTEM EXCLUSIVE FORMAT

The QuadraVerb 2 MIDI System Exclusive message format is as follows:

F0 System exclusive status

00 00 0E Alesis manufacturer id#

0F QuadraVerb id#

cc Opcode

dd Data

: :

: :

F7 End-Of-Exclusive

OPCODES:

01 - MIDI Edit F0 00 00 0E 0F 01 <function#> <block#> <page#>

<parameter#> <data> F7

<function#> = 0= PARAMETER, 1= MIX, 2= GLOBAL, 3= TYPE*

<block#> = (1-8) # of block to be edited. Doesn’t matter for GLOBAL edits.

<page#> = (1-#of last page under function) page # for value to be edited.

<parameter#> = (1-#of last parameter on page) parameter # of value

<data> is in format described below. It is a 16-bit value, which is transmitted in three MIDI

bytes, LSB first.

TWO QUADRAVERB 2 BYTES:

0: A7 A6 A5 A4 A3 A2 A1 A0 (LSB)

1: B7 B6 B5 B4 B3 B2 B1 B0 (MSB)

TRANSMITTED AS:

0: 0 A7 A6 A5 A4 A3 A2 A1

1: 0 A0 B7 B6 B5 B4 B3 B2

2: 0 B1 B0 0 0 0 0 0

* Editing of a flashing TYPE parameter should be followed by an ‘ENTER’ MIDI sysex message

(0B).

02 - MIDI User Program Dump

<program#>= 0..99 selects individual user bank 0 programs, 100 selects edit

<data> is in a packed format in order to optimize data transfer. Eight MIDI bytes are used to

transmit each block of 7 QuadraVerb 2 data bytes. If the 7 data bytes are looked at as one

56-bit word, the format for transmission is eight 7-bit words beginning with the most

significant bit of the first byte, as follows:

F0 00 00 0E 0E 02 <prog.#> <data> F7

Alesis QuadraVerb II 2.00 E-19 07/19/06

Page 45

SEVEN QUADRAVERB 2 BYTES:

0: A7 A6 A5 A4 A3 A2 A1 A0

1: B7 B6 B5 B4 B3 B2 B1 B0

2: C7 C6 C5 C4 C3 C2 C1 C0

3: D7 D6 D5 D4 D3 D2 D1 D0

4: E7 E6 E5 E4 E3 E2 E1 E0

5: F7 F6 F5 F4 F3 F2 F1 F0

6: G7 G6 G5 G4 G3 G2 G1 G0

TRANSMITTED AS:

0: 0 A6 A6 A5 A4 A3 A2 A1

1: 0 A0 B7 B6 B5 B4 B3 B2

2: 0 B1 B0 C7 C6 C5 C4 C3

3: 0 C2 C1 C0 D7 D6 D5 D4

4: 0 D3 D2 D1 D0 E7 E6 E5

5: 0 E4 E3 E2 E1 E0 F7 F6

6: 0 F5 F4 F3 F2 F1 F0 G7

7: 0 G6 G5 G4 G3 G2 G1 G0

There are 306 data bytes sent for a single program dump, which corresponds to 256 bytes

of program data. With the header, the total number of bytes transmitted with a program

dump is 314. The location of each parameter within a program dump is shown in the next

section: QuadraVerb 2 Program Data Format.

03 - MIDI User Bank 0 Program Dump Request F0 00 00 0E 0F 03 <program#> F7

<program#>= 0..99 selects individual user programs in User Bank 0, 100 selects

current edit, 101 is a dump all request

When received, the QuadraVerb 2 will respond to this message with a MIDI user program

dump (02) of the User Bank 0 program or edit selected.

For the dump all request User Bank 0 programs are dumped as individual program dumps

(02) followed by all User Bank 1 programs dumped as individual program dumps (0C), a

global parameter dump (07), and finally a MIDI program table dump (11).

07 - MIDI Global Data Dump F0 00 00 0E 0F 07 <data> F7

<data> is in the same MIDI data format as described in 02, but with a different number of

bytes due to the difference in the global parameter size.The global parameters for the MIDI

dump are packed into 14 Quadraverb 2 bytes (see below) and transferred as 16 MIDI bytes.

The last byte packs the most significant bit of the footswitch head parameter into bit address

13:0 and the msb of the footswitch tail into bit address 13:1. The following table outlines

this:

Alesis QuadraVerb II 2.00 E-20 07/19/06

Page 46

GLOBAL PARAMETER PACKING:

Parameter name lo lim hi lim bits bit address

LCD contrast 1 10 8 0:7-0:0

Footswitch range head LSB* 0 299 8 1:7-1:0

Footswitch range tail LSB* 0 299 8 2:7-3:0

VU meter peak hold 0 1 8 3:7-3:0

Input audio source 0 1 8 4:7-4:0

Sample clock source 0 1 8 5:7-5:0

Digital left input channel 1 8 8 6:7-6:0

Digital right input channel 1 8 8 7:7-7:0

Digital left output channel 1 8 8 8:7-8:0

Digital right output channel 1 8 8 9:7-9:0

Digital output mode 0 1 8 10:7-10:0

Tap tempo footswitch 0 2 8 11:7-11:0

Global direct signal 0 1 8 12:7-12:0

Footswitch range head MSB, tail MSB* 0 299 2 13:1-13:0

*The MSBs for the footswitch parameters are stored in bit address 13:1 and13:0.

Bits 13:7 through 13:2 should be set to 0.

08 - MIDI Global Data Dump Request F0 00 00 0E 0F 08 F7

When received, the QuadraVerb 2 will respond to this message with a MIDI global data

dump (07).

09 - MIDI Bypass or Compare F0 00 00 0E 0F 09 <function> <off/on> F7

<function> = 0= BYPASS, 1= COMPARE

<off/on> = 0= function off, 1= function on

When received, the QuadraVerb 2 will respond to this message by turning

BYPASS/COMPARE OFF/ON.

0A - MIDI DSP Error Message

<data> = 1= “EFFECT MEMORY IS FULL”

2= “OUT OF LFOs”

4= “DSP IS FULL”

8= “BLOCK COMBINATION NOT ALLOWED”

0B - MIDI Enter Message

This performs the ENTER function on the current parameter. It is useful for

acting on flashing parameters.

0C - MIDI User Bank 1 Program Dump F0 00 00 0E 0E 0C<prog.#> <data> F7

<program#>= 0..99 selects individual User Bank 1 programs, 100 selects edit

<data> is the same format as the <data> of the User Bank 0 Dump opcode (02)

F0 00 00 0E 0F 0A <data> F7

F0 00 00 0E 0F 0B F7

Alesis QuadraVerb II 2.00 E-21 07/19/06

Page 47

0D - MIDI User Bank 1 Program Dump Request F0 00 00 0E 0F 0D<program#>F7

<program#>= 0..99 selects individual user programs in User Bank 1, 100 selects

current edit, 101 is a dump all request

When received, the QuadraVerb 2 will respond to this message with a MIDI user program

dump (0C) of the User Bank 1 program or edit selected.

For the dump all request User Bank 0 programs are dumped as individual program dumps

(02) followed by all User Bank 1 programs dumped as individual program dumps (0C), a

global parameter dump (07), and finally a MIDI program table dump (11).

0F - MIDI Block Bypass Dump F0 00 00 0E 0F 0F <data> F7

<data> is in format described below. It is an 8-bit value, which is transmitted in two MIDI

bytes. Bit A7 corresponds to the block bypass of block #8, likewise,

A6 corresponds to block #7 ... and A0 corresponds to block#1. If thebit value= 1,

the block is bypassed; if thebit value= 0, the block is not bypassed.

ONE QUADRAVERB 2 BYTE:

0: A7 A6 A5 A4 A3 A2 A1 A0

TRANSMITTED AS:

0: 0 A7 A6 A5 A4 A3 A2 A1

1: 0 A0 0 0 0 0 0 0

10 - MIDI Block Bypass Dump Request F0 00 00 0E 0F 10 F7

When received, the QuadraVerb 2 will respond to this message with a MIDI Block Bypass

Dump (0F).

11 - MIDI Program Table Dump F0 00 00 0E 0F 11 <data> F7

<data> is in format described below. The 128 MIDI program table entries are

9-bits each, and are transmitted in two MIDI bytes. Values in the range 0-99 correspond to

Presets 0-99, values 100-199 correspond to User bank 0 programs 0-99, and values 200-

299 correspond to User bank 1 programs 0-99.

TWO QUADRAVERB 2 MIDI TABLE ENTRIES:

0: A7 A6 A5 A4 A3 A2 A1 A0

1: 0 0 0 0 0 0 0 A8

2: B7 B6 B5 B4 B3 B2 B1 B0

3: 0 0 0 0 0 0 0 B8

TRANSMITTED AS:

0: 0 A6 A5 A4 A3 A2 A1 A0

1: 0 0 0 0 0 0 A8 A7

2: 0 B6 B5 B4 B3 B2 B1 B0

3: 0 0 0 0 0 0 B8 B7

12 - MIDI Program Table DumpRequest F0 00 00 0E 0F 12 F7

Alesis QuadraVerb II 2.00 E-22 07/19/06

Page 48

When received, the QuadraVerb 2 will respond to this message with a MIDI Program Table

Dump (11).

PARAMETER FORMAT