Page 1

Agilent E5250A

Low Leakage Switch

Mainframe

User’s Guide

Agilent Technologies

Page 2

Notices

© Agilent Technologies 1995 - 2008

No part of this manual may be reproduced in

any form or by any means (including electronic storage and retrieval or translation

into a foreign language) without prior agreement and written consent from Agilent

Technologies, Inc. as governed by United

States and international copyright laws.

Manual Part Number

E5250-90000

Edition

Edition 1, October 1995

Edition 2, January 1997

Edition 3, August 1997

Edition 4, January 2000

Edition 5, May 2000

Edition 6, January 2001

Edition 7, August 2003

Edition 8, July 2005

Edition 9, May 2008

Agilent Technologies, Inc.

5301 Stevens Creek Blvd

Santa Clara, CA 95051 USA

Warranty

The material contained in this document is provided “as is,” and is subject to being changed, without notice,

in future editions. Further, to the maximum extent permitted by applicable

law, Agilent disclaims all warranties,

either express or implied, with regard

to this manual and any information

contained herein, including but not

limited to the implied warranties of

merchantability and fitness for a particular purpose. Agilent shall not be

liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this document or of any

information contained herein. Should

Agilent and the user have a separate

written agreement with warranty

terms covering the material in this

document that conflict with these

terms, the warranty terms in the separate agreement shall control.

Tec hn ol og y L i c e ns es

The hardware and/or software described in

this document are furnished under a license

and may be used or copied only in accordance with the terms of such license.

defined in FAR 52.227-19(c)(1-2) (June

1987). U.S. Government users will receive

no greater than Limited Rights as defined in

FAR 52.227-14 (June 1987) or DFAR

252.227-7015 (b)(2) (November 1995), as

applicable in any technical data.

Restricted Rights Legend

If software is for use in the performance of a

U.S. Government prime contract or subcontract, Software is delivered and licensed as

“Commercial computer software” as

defined in DFAR 252.227-7014 (June 1995),

or as a “commercial item” as defined in FAR

2.101(a) or as “Restricted computer software” as defined in FAR 52.227-19 (June

1987) or any equivalent agency regulation or

contract clause. Use, duplication or disclosure of Software is subject to Agilent Technologies’ standard commercial license

terms, and non-DOD Departments and

Agencies of the U.S. Government will

receive no greater than Restricted Rights as

Page 3

DECLARATION OF CONFORMITY

According to ISO/IEC Guide 22 and CEN/CENELEC EN 45014

Manufacturer’s Name:

Agilent Technologies International sarl

Manufacturer’s Address:

Supplier’s Address:

Rue de la Gare 29

CH - 1110 Morges

Switzerland

Declares under sole responsibility that the product as originally delivered

Product Name:

Low Leakage Switch Mainframe 10x12 Matrix

Switch24(8x3)CH Multiplexer

24(8x3)CH Multiplexer

Model Number:

Agilent E5250A

Agilent E5252A

Agilent E5255A

Product Options:

This declaration covers all options of the above product(s)

complies with the essential requirements of the following applicable European Directives, and carries

the CE marking accordingly:

Low Voltage Directive (73/23/EEC, amended by 93/68/EEC)

EMC Directive (89/336/EEC, amended by 93/68/EEC)

and conforms with the following product standards

EMC Standard

IEC 61326:2002 / EN 61326:1997 +A1:1998 +A2:2001 +A3:2003

CISPR 11:1997 / EN 55011:1998

IEC61000-4-2:1995 / EN61000-4-2:1995

IEC 61000-4-3:1995 / EN61000-4-3:1995

IEC 61000-4-4:1995 / EN61000-4-4:1995

IEC 61000-4-5:1995 / EN61000-4-5:1995

IEC 61000-4-6:1996 / EN61000-4-6:1996

IEC 61000-4-11:1994 / EN61000-4-11:1994

Canada: ICES-001:1998

Australia/New Zealand: AS/NZS 2064.1

Limit

Group 1 Class A

4 kV CD, 8 kV AD

3 V/m, 80-1000 MHz

0.5 kV signal lines, 1 kV power lines

0.5 kV line-line, 1 kV line-ground

3 V, 0.15-80 MHz

1 cycle, 100%

The product was tested in a typical configuration with Agilent Technologies test systems.

Safety

IEC 61010-1:2001 / EN 61010-1:2001

Canada: CSA C22.2 No. 1010.1:1992, NRTL/C

Supplementary Information:

This DoC applies to above-listed products placed on the EU market after:

September 26, 2006

Date

Toshiyuki Kawaji

QA Manager

Agilent Technologies

For further information, please contact your local Agilent Technologies sales office, agent or distributor,

Page 4

• Herstellerbescheinigung

GEÄUSCHEMISSION

Lpa < 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T. 19

• Manufacturer’s Declaration

ACOUSTIC NOISE EMISSION

Lpa < 70 dB

operator position

normal operation

per ISO 7779

NOTE This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme ?Hla norme NMB-001 du Canada.

This product complies with the WEEE Directive (2002/96/EC) marking

requirements. The affixed label indicates that you must not discard this electrical/

electronic product in domestic household waste.

Product Category: With reference to the equipment types in the WEEE Directive

Annex I, this product is classed as a “Monitoring and Control instrumentation”

product.

Do not dispose in domestic household waste.

To return unwanted products, contact your local Agilent office, or see

www.agilent.com/environment/product/ for more information.

Microsoft, Windows, Win dows NT, Visual C++, and Visual Basic ar e registered trademar ks of Microsoft

Corporation.

LabVIEW are registered trademarks of National Instruments Corporation.

Borland C++ Builder is registered trademark of International, Inc. LabWindows and

Page 5

Safety Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific warnings elsewhere in this manual may impair the

protections provided by the equipment. In addition, it violates safety standards of

design, manufacture, and intended us e of the instrument. Agilent Technologies, Inc.

assumes no liability for customer’s failure to comply with these requirements.

NOTE Agilent E5250A complies with INSTALLATION CATEGORY II for mains input

and INSTALLATION CATEGORY I for measurement input terminals, and

POLLUTION DEGREE 2 defined in IEC 1010-1.

Agilent E5250A is INDOOR USE products.

• GROUND THE INSTRUMENT

This is Safety Class I instrument. To minimize shock hazard, the instrument

chassis and cabinet must be connected to an electrical ground. The power

terminal and the power cable must meet International Electrotechnical

Commission (IEC) safety standards.

• DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

• KEEP AWAY FROM LIVE CIRCUITS

Operation personnel must not remove instrument covers. Component

replacement and internal adjustments must be made by qualified maintenance

personnel. Do not replace components with power cable connected. Under

certain conditions, dangerous voltages may exist even with the power cable

removed. To avoid injuries, always disconnect power and discharge circuits

before touching them.

• DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable of

rendering first aid and resuscitation, is present.

Page 6

• DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not install substitute

parts or perform any unauthorized modification to the instrument. Return the

instrument to a Agilent Technologies Sales and Service Office for services and

repair to ensure that safety features are maintained.

• DANGEROUS PROCEDURE WARNINGS

Warnings, such as example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be

followed.

WARNING Dangerous Voltage, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adju sti n g.

Page 7

Safety Symbols

The general definitions of safety symbols used on equipment or in man uals are

listed below.

Instruction manual symbol: the product will be marked with this symbol when it is

necessary for the user to refer to the instruction manual in order to protect against

damage to the instrument.

Indicates dangerous voltage and potential for electrical shock. Do not touch

terminals that have this symbol when insrument is on.

Affixed to product containing static sensitive devices--use anti-static handling

procedures to prevent electrostatic discharge damage to compone nt.

Protective conductor terminal. For protection against electrical shock in case of a

fault. Used with field wiring terminals to indicate the terminal which must be

connected to ground before operating equipment.

Frame or chassis terminal. A connection to the frame (chassis) of the equipment

which normally includes all exposed metal structures.

Indicates earth (ground) terminal.

Alternating current.

Direct current.

ON (Supply).

OFF (Supply).

STANDBY (Supply).

CAT 1

WARNING The warning sign denotes a hazard. It calls attention to a procedure, practice,

CAUTION The caution sign denotes a hazard. It calls attention to an operating procedure,

Means INSTALLATION CATEGORY I. Measurement terminals on the rear panel

comply with INSTALLATION CATEGORY I.

condition or the like, which, if not correctly performed or adhered to, could result in

injury or death to personal.

practice, condition or the like, which, i f not correctly perfor med or adhered to , could

result in damage to or destruction of part or all of the product.

Page 8

In This Manual

This manual is a user’s guide for Agilent E5250A, and consists of the following

chapters:

• Introduction

Provides an overview of the E5250A Low Leakage Switch Mainframe, E5252A

10×12 Matrix Switch, and E5255A 24 (8×3) Channel Multiplexer.

• Installation

Describes requirements to install the E5250A and tasks for installation.

• Executing Self-Test and Leak Test

Describes how to execute the three Self-Test items (Controller Test, Front Panel

Interface Test, and Relay Test) and the Leak Test.

• Setting up Measurement Environment

Explains how to connect your instruments to the E5250A input, and how to

connect the E5250A output to your wafer prober or test fixture.

• Controlling the E5250A

Introduces several methods for controlling the E5250A, gives basic information

for controlling the relay switc hes on the plug-in cards, and describes how to use

Virtual Front Panel (VFP) utility furnished with the E5250A.

• Programming the E5250A

Describes how to create programs that contain SCPI commands to control the

E5250A.

• Command Reference

Describes the SCPI commands available to operate the E5250A via GPIB

interface and the status reporting structure.

• VXIplug&play Driver

Introduces the VXIplug&play driver available for the E5250A.

• Executing Sample Programs

Explains how to execute a nd modify the sample programs stored in t h e pr ogram

disk that is furnished with the E5250A.

Page 9

• Specifications

Lists specifications, typical data, supplemental data, and reference data for the

E5250A, E5252A, and E5255A.

• Error Messages

Lists and describes the error messages for the E5250A.

• SCPI Command Summary

This is a quick reference for the SCPI subsystem commands available for the

E5250A.

Text Co nventions

The following text conventions are used in this manual:

Screen Text Represents text that appears on screen of the controller.

Italic Refers to a related document, or is used for emphasis.

Page 10

Page 11

Contents

1. Introduction

Agilent E5250A Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Front Panel Tour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Rear Panel Tour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Agilent E5252A Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Agilent E5255A Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2. Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

To Inspect the E5250A and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Storage and Shipping Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Installing the E5250A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

To Install Plug-in Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

To Install Blank Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

To Configure E5255A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

E5255A Configuration Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

To Set GPIB Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

To Connect GPIB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Agilent E5250A User’s Guide, Edition 9 Contents - 1

Page 12

Contents

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

3. Executing Self-Test and Leak Test

Executing Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

To Execute Self-Test (Standalone) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

To Execute Self-Test using External Controller . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Using the Self-Test Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

To Start the Self-Test Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

To Execute Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

To Execute Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

4. Setting up Measurement Environment

Connector Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Connector Plates for the E5252A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Connector Plates for E5255A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Blank Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Connecting 8-Channel Shielded Coaxial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Mounting Connectors Directly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

To Make Interlock Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

To Connect Connectors to DUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Connecting the E5250A Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

To Connect Instruments to Input Connectors . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

To Connect Bias Source to the E5255A Bias Input . . . . . . . . . . . . . . . . . . . . 4-18

To Connect GNDU to the E5250A Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 18

Connecting the E5250A Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Contents - 2 Agilent E5250A User’s Guide, Edition 9

Page 13

Contents

To Connect the E5252A Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

To Connect the E5255A Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Measurement Cable Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

5. Controlling the E5250A

Methods for Controlling the E5250A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Creating Your Own Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Modifying a Sample Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Using the Virtual Front Panel (VFP) Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Switch Control Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Channel List and Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Connection Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Connection Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Bias Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Couple Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

E5252A Channel List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

E5255A Channel List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Using Virtual Front Panel Utilit y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Functions of Virtual Front Panel Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Starting the Virtual Front Panel Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-27

Confirming the E5250A Card Configurations . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Changing the VFP Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Defining Labels for the E5250A Input Ports . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

Making Connections and Changing the Setup Data . . . . . . . . . . . . . . . . . . . . 5-33

Saving/Loading the Setup Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

6. Programming the E5250A

SCPI Programming Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

SCPI Command Hierarchy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Agilent E5250A User’s Guide, Edition 9 Contents - 3

Page 14

Contents

Controlling E5250A by Using HP BASIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Creating a Control Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Defining Channel Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Defining Connection Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Defining Connection Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Using Bias Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Using Couple Port (for E5252A only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Controlling Relay Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Channel Creation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Bias Mode Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Couple Port Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Using the VFP Data Upload Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

VFP Data Upload Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-25

Before Executing Your Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Using the Capacitance Compensation Routine . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Capacitance Compensation Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Required Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-30

Programming Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Before Executing Your Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

7. Command Reference

Common Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

:DIAGnostic Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

:ROUTe Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

:SYSTem Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-42

Contents - 4 Agilent E5250A User’s Guide, Edition 9

Page 15

Contents

Status Reporting Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Status Reporting Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-48

Status Byte Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-50

Service Request Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-52

Standard Event Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-53

Standard Event Status Enable Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Output Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

8. VXIplug&play Driver

System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Installing VXIplug&play Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Driver Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

9. Executing Sample Programs

Vth and Capacitance Measurement Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Setting up the Measurement Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Executing the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Modifying the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

HCI Measurement Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Adding the Bias Source Control Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Setting up the Measurement Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

Executing the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

Modifying the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

10. Specifications

11. Error Messages

Agilent E5250A User’s Guide, Edition 9 Contents - 5

Page 16

Contents

12. SCPI Command Summary

Contents - 6 Agilent E5250A User’s Guide, Edition 9

Page 17

1 Introduction

Page 18

Introduction

This chapter gives an overview of Agilent E5250A, E5252A, and E5255A.

• “Agilent E5250A Product Description”

• “Agilent E5252A Product Description”

• “Agilent E5255A Product Description”

• “Options and Accessories”

1-2 Agilent E5250A User’s Guide, Edition 9

Page 19

Agilent E5250A Product Description

Agilent E5250A Low Leakage Switch Mainframe is a computer-controlled

switching matrix mainframe designed for semiconductor dc characteristics

measurement applications. The E5250A has four slots for installing the modules

(plug-in cards) listed in Table 1-1.

These cards can be used in various switching matrix configurations in the E5250A.

For example, using four E5252As, you can configure a maximum 10-input

48-output switching matrix, or using four E5255As, you can configure a maximum

2-input × 96-output multiplexer.

Table 1-1 Available Plug-in Cards for E5250A

Model No. Description

E5252A 10×12 Matrix Switch

E5255A 24 (8×3) Channel Multiplexer

Introduction

Agilent E5250A Product Description

Figure 1-1 E5250A Front Panel

Agilent E5250A User’s Guide, Edition 9 1-3

Page 20

Introduction

Agilent E5250A Product Description

Front Panel Tour

The E5250A has 2 hard keys and 4 LED indicators on the front panel as shown in

Figure 1-1.

LINE key Used to turn the E5250A on or off.

Line LED Turns on when the E5250A is turned on.

Local/Self Test key If "Remote" LED is on, pressing this key releases the

E5250A from remote GPIB control by an external controller.

If "Remote" LED is off, pressing this key executes the Relay

Test. Before pressing this key, make sure the Relay Test

Adapter is connected. For details of Relay Test, refer to

Chapter 3. During Relay Test execution, the LED in this key

is ON.

Remote LED Turns on when the E5250A is in the GPIB remote status.

System Fail LED Turns on if system error occurs in the E5250A. Contact you r

nearest Agilent Technologies Service Center.

Fail LED Tu rns on if the E525 0A fails Self-test (in cluding Relay Test).

If this LED turns on after executing Relay Test, a plug-in

card may be defective. And if this LED turns on after turning

the E5250A on again, the E5250A is defective. If so, contact

your nearest Agilent Technologies Service Center.

Rear Panel Tour

Rear panel of the E5250A is shown in Figure 1-2. The E5250A has 4 slots for

installing plug-in cards, and 10 input connectors for connecting measur ement cables

from instruments.

SMU INPUT SMU INPUT connectors are for semiconductor dc

characteristics measurements.

The E5250A has six SMU INPUT ports , which are tri axial type

connectors. The connectors can also be used for a maximum

three Kelvin connection inputs by coupling two ports as

follows:

• SMU INPUT 1 and 2

• SMU INPUT 3 and 4

• SMU INPUT 5 and 6

1-4 Agilent E5250A User’s Guide, Edition 9

Page 21

Introduction

Agilent E5250A Product Description

AUX INPUT AUX INPUT connector s are for C-V measurements, pulse

input, and so on.

The E5250A has 4 AUX INPUT ports: HF1, HF2, CV1, CV2.

These are BNC type connectors.

The AUX INPUT connectors are used only with the E5252A

and are not used with the E5255A.

CAUTION The maximum measurement voltage that can be applied to any input terminal is

±200 Vdc. The maximum measurement current is 1 Adc at ±200 Vdc. The

maximum voltage that can be applied between input terminals is 300 Vdc. Do not

apply an input signal over these limits to the E5250A inputs. If you do, the E5250A

will be damaged.

If you use a bias source that has current limit capability, set the bias source current

limit to less than 1 Adc.

Figure 1-2 E5250A Rear Panel

Agilent E5250A User’s Guide, Edition 9 1-5

Page 22

Introduction

Agilent E5252A Product Description

Agilent E5252A Product Description

The E5252A 10×12 Matrix Switch is a 10-input to 12-output switching matrix card

for the E5250A. The E5252A is designed for semiconductor dc parametric

measurement applications that need to switch some instruments connected to

Device Under Test (DUT), or need to scan instrument input/output for many DUTs,

automatically.

The E5250A can be installed w ith maximum f our E525 2As. And the in put termin als

of the E5252As are connected together inside the E5250A. So, the E5250A can

configure a 10×24 matrix (two E5252As), 10×36 matrix (three E5252As), and

10×48 matrix (four E5252As). The E5252A block diagram and output connectors

are shown in Figure 1-3 and Figure 1-4.

Figure 1-3 E5252A Block Diagram

1-6 Agilent E5250A User’s Guide, Edition 9

Page 23

Introduction

Agilent E5252A Product Description

Input Ports The E5252A has 10 input ports via the E5250A.

Input paths for SMU1 and SMU2 are designed for low current

measurement.

There are actually only six input paths, so two of the input paths

are shared by three ports each as follows:

• SMU5, HF1, and CV1 ports share same input path

• SMU6, HF2, and CV2 ports share same input path

So, for these two input paths, you can only use one input po rt at

a time. For example, you cannot use HF1 and CV1 input ports

at the same time.

Output Ports The E5252A has 12 output ports. Two ports can be coupled for

Kelvin connection out put fo r a maxi mum o f six Kelv in out puts:

• OUTPUT1 and OUTPUT2

• OUTPUT3 and OUTPUT4

• OUTPUT5 and OUTPUT6

• OUTPUT7 and OUTPUT8

• OUTPUT9 and OUTPUT10

• OUTPUT11 and OUTPU T12

The output ports are triaxial connectors.

Figure 1-4 E5252A Output Ports

WARNING Do not touch the force and guard terminals of the output connectors while the

E5250A is turned on. Dangerous voltages up to the maximum input voltage

may be present at the output connectors.

Agilent E5250A User’s Guide, Edition 9 1-7

Page 24

Introduction

Agilent E5255A Product Description

Agilent E5255A Product Description

The E5255A 24 (8×3) Channel Multiplexer is a 2-input to 24-output multiplexer

card for the E5250A. The E5 255A cons ists of 3 blocks ( three 2×8 m ultiplexers). So,

one E5255A can be configured as a 2×8 multiplexer, 2×16 multiplexer, or 2×24

multiplexer. "2-input" means one BIAS input and one IV input.

The E5255A is designed for semiconductor device reliability testing which needs to

automatically scan instrument input/output for many DUTs.

A maximum of four E5255As can be installed in the E5250A, which can use the

multiplexers in several configurations. For example, the E5250A can configure

twelve 8-output multiplexers, six 16-output multiplexers, four 24-output

multiplexers, three 32-output multiplexers, two 48-output multiplexers, or one

96-output multiplexer.

The E5255A block diagram is shown in Figure 1-5.

BIAS Input The BIAS INPUT ports are used to apply ac or dc bias to DUT.

BIAS INPUT ports are BNC connectors. Each BIAS INPUT

port is assigned to a 2×8 multiplexer block as shown in Table

1-2. And you can make internal connections to connect a BIAS

INPUT port to multiple blocks. Refer to Chapter 2.

IV Input IV input is used for measuring/forcing dc current/voltage. You

can connect the IV input to desired SMU INPUT connector

(SMU1 to SMU6) of the E5250A by making an internal

connection. Refer to Chapter 2. The E5250A AUX INPUT

connectors are not used with the E5255A.

OUTPUT

Connectors The E5255A has three 8-channel coaxial output connectors as

shown in Figure 1-6. Each output con nector is assigned to a 2×8

multiplexer as shown in Table 1-2.

1-8 Agilent E5250A User’s Guide, Edition 9

Page 25

Agilent E5255A Product Description

Resistors Resistors connected between BIAS path and IV path are for

protecting DUT from electrical damage. When shipped from

factory, 0 Ω resistance is used in the E5255A. You can easily

replace with desired resistors. Refer to Chapter 2. The

following resistors are furnished with the E5255A:

•0 Ω resistors (3 sets with 10 resistors in each set)

• 1.2 kΩ resistors (3 sets with 10 resistors in each set)

•22 kΩ resistors (3 sets with 10 resistors in each set)

If you replace initial 0 Ω resistors with other res istor s, you must

cut the initial resistors. Then, if you need 0 Ω resistors again,

use the ones listed above.

WARNING Be careful about the following when selecting protective resistors:

• If only one E5255A is installed in the mainframe, total power consumption

by resistors must be less than 16W.

• If multiple E5255As are installed in the mainframe, total power

consumption by resistors must b e less than 32W.

Introduction

• Consider the current flows to re sistor when DUT shorts, and make sure the

power consumption by resistor will be within specif ication of resistor.

Do not use resisto rs th at hav e specifications inadequate for your

applications, which will result in resistors heating up, burning, or s moking.

Be careful about the heating of the rear panel of mainframe or plug-in card,

which may be heated by resistors, even if you follow this warning.

Agilent E5250A User’s Guide, Edition 9 1-9

Page 26

BIAS Input 1

Output

Resistor

IV Input 1

BLOCK 1

1 2 34 56 7 8

BIAS Input 3

Output

Resistor

IV Input 3

BLOCK 3

17 18 19 20 21 22 23 24

BIAS Input 2

Output

Resistor

IV Input 2

BLOCK 2

9 10111213141516

Introduction

Agilent E5255A Product Description

Figure 1-5 E5255A Block Diagram

1-10 Agilent E5250A User’s Guide, Edition 9

Page 27

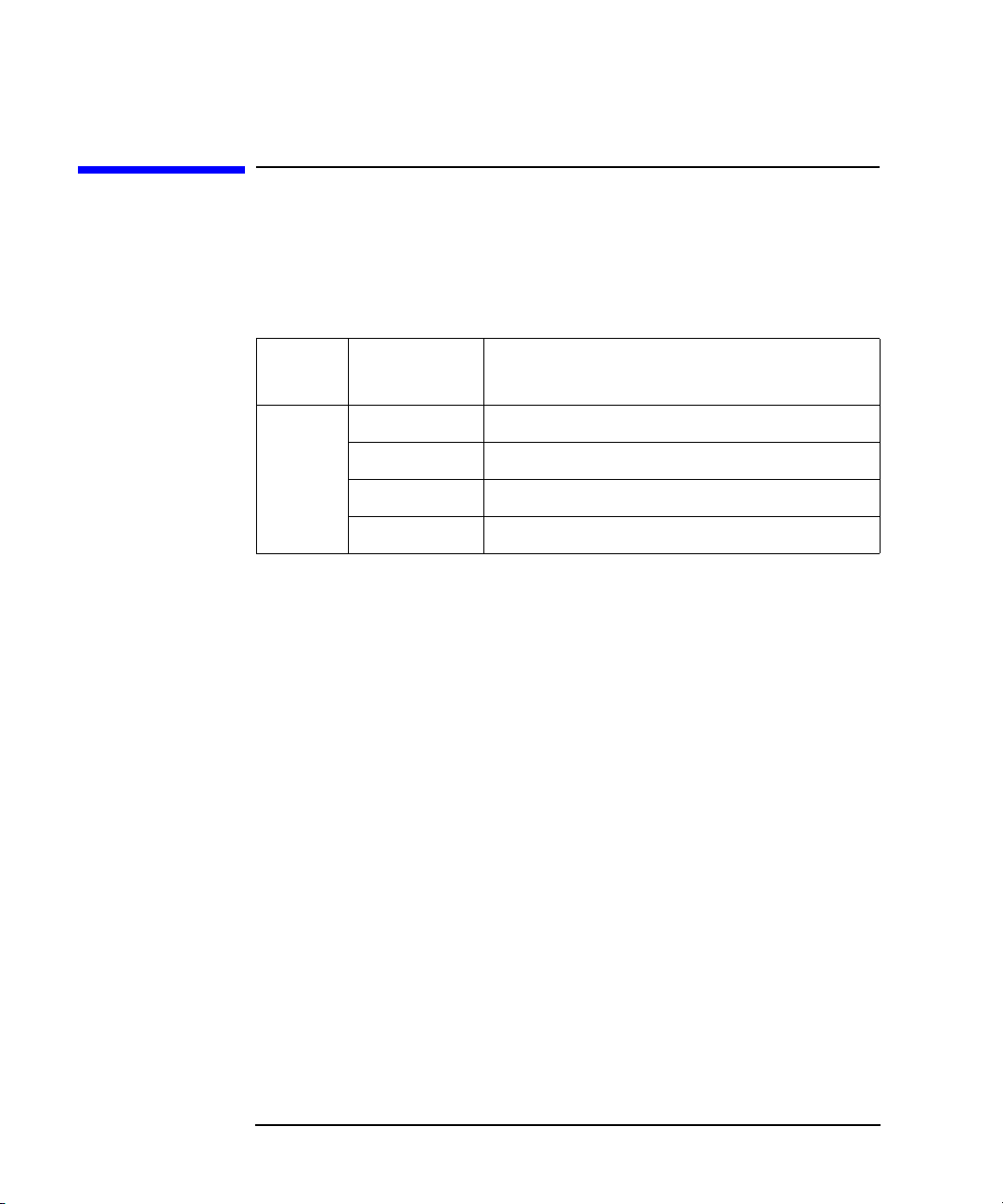

Table 1-2 E5255A Input/Output Connectors

Introduction

Agilent E5255A Product Description

2×8 multiplexer

Block No.

Block1 BIAS1 (51) Output 1 to 8 Left

Block2 BIAS2 (52) Output 9 to 16 Center

Block3 BIAS3 (53) Output 17 to 24 Right

Figure 1-6 E5255A BIAS INPUT Connectors and OUTPUT Connectors

WARNING Do not touch the force and guard terminals of the OUTPUT connectors while

the E5250A is turned on. Danger ous vol tages up t o the maximum input vol tage

may be present at the OUTPUT connectors.

CAUTION The maximum voltage that can be applied to any input terminal is ±200 Vdc. The

maximum current is 1 Adc at ±200 Vdc. The maximum voltage that can be applied

between input terminals is 300 Vdc. Do not apply an input signal over these limits to

the E5255A inputs. If you do, the E5255A will be damaged.

BIAS INPUT

(Port No.)

Output Port No.

OUTPUT

Connector

(Location)

If you use a bias source that has current limit capability, set the bias source current

limit to less than 1 Adc.

Agilent E5250A User’s Guide, Edition 9 1-11

Page 28

Introduction

Options and Accessories

Options and Accessories

This section lists the options and accessories available for the E5250A.

Table 1-3 lists the options available for the E5250A.

Table 1-3 Options

Model

Number

E5250A Low Leakage Switch Mainframe

Option Ite m Description

E5250A-301 Relay Test Adapter

E5250A-A6J ANSI Z540 compliant calibration

E5250A-UK6 Commercial cal. certificate w/ test data

1-12 Agilent E5250A User’s Guide, Edition 9

Page 29

Table 1-4 lists accessories furnished with the E5250A, E5252A, and E5255A.

Table 1-4 Furnished Accessories

Introduction

Options and Ac cessories

Model

Number

Part Number Description Qty.

E5250A E5250-90000 Agilent E5250A User's Guide 1

E5250-17001

E5250A VXI Plug&Play Driver Disk

a

E5250-17003 Agilent E525 0A Progr am Disk. See next

page. (LIF formatted, 3.5in diskette)

04155-60007 Module Extractor 1

8710-2151 Wrench (for removing plug-in card) 1

− Power Cable 1

E5252A E5252-90000 Agilent E5252A Installat i on Gui de 1

8710-2151 Wrench (for removing plug-in card) 1

E5255A E5255-90000 Agilent E5255A Installat i on Gui de 1

1250-0929 BNC Short Cap 3

E5255-65000 BIAS Input Modification Kit

(BNC Open Cap × 2, wire × 2)

E5255-65001 0 Ω Resistor Set (10 resistors) 3

1

1

1

E5255-65 002 1.2 kΩ Resistor Set (10 re si stors) 3

E5255-65 003 22 kΩ Resistor Set (10 resistors) 3

8710-2151 Wrench (for removing plug-in card) 1

a. The Agilent E5250A VXIplug&play driver supports Windows XP Pro-

fessional, Wi ndows 2000, Windows NT 4.0, Windows 98, and W i ndows

95.

Agilent E5250A User’s Guide, Edition 9 1-13

Page 30

Introduction

Options and Accessories

Contents of the E5250A Program Disk:

Virtual Front

Panel Utility Interactive control program for the E5250A. Runs on Agilent

4155/4156's built-in IBASIC controller. Refer to Chapter 5.

VFP Data Upload

Library Subprogram library used for upl oading the E5250A con trol data

(made by Vi rtual Front Panel Utility) to your program. Runs on

HP BASIC. Refer to Chapter 6.

Capacitance

Compensation

Routine Subprogram to compensate for capacitance error caused by the

E5250A and E5252A. Ru ns on H P BAS IC . This subprogram is

used to compensate the capacitance data measured by Agilent

4284A Precision LCR Meter. Refer to Chapter 6.

Sample Programs Three sample programs: one for Vth and C measurement using

the E5252A, and two for HCI test and analysis using the

E5255A. Runs on HP BASIC. Refer to Chapter 9.

Self-test Utility Self-test and relay test program for the E5250A. Runs on the

4155/4156's built-in IBASIC controller. Refer to Chapter 3.

1-14 Agilent E5250A User’s Guide, Edition 9

Page 31

Table 1-5 lists accessories available for the E5250A.

Table 1-5 Available Accessories

Introduction

Options and Ac cessories

Model

Number

E5252A 10×12 Matrix Sw itch

E5255A 24 (8×3) Channel Multiplexer

16494A Triaxial Cable

16494B Kelvin Triaxial Cable (4156 kelvin to E5250 kelvin)

16494C Kelvin Triaxial Cable (4142 kelvin to E5250 kelvin)

16494D 8 Channel Shielded Coaxial Cable

16494E Wide Temperature 8 Channel Shielded Coaxial Cable

16495C Connector plate with 6 connectors for 16494D

16495D Connector plate with 12 connectors for 16494D

16495E Blank plat e

16495F Connector plate with 12×triaxial, intlk, GNDU

16495G Connector plate with 24×triaxial, intlk, GNDU

Option

Item

16494A-001 1.5 m length

16494A-002 3 m length

16494A-003 80 cm length

16494B-001 1.5 m length

16494B-002 3 m length

16494B-003 80 cm length

16494C-001 1.5 m length

16494C-002 3 m length

16494D-001 1.5 m length

16494D-002 3 m length

16494E-001 3m length

16495F-001 Bulkhead feedthrough connectors (female to female)

16495F-002 Connectors to contacts for soldering

16495G-001 Bulkhead feedthrough connectors (female to female)

16495G-002 Connectors to contacts for soldering

Description

Agilent E5250A User’s Guide, Edition 9 1-15

Page 32

Introduction

Options and Accessories

1-16 Agilent E5250A User’s Guide, Edition 9

Page 33

2 Installation

Page 34

Installation

This chapter describes requirements to install Agilent E5250A and the tasks for

installation, and is organized into the following three sections:

• “To Inspect the E5250A and Accessories” describes how to inspect the E5250A

when you receive it.

• “Requirements” explains the information required for operating, storing, and

shipping the E5250A.

• “Installing the E5250A” describes how to install the E5250A.

• “Maintenance” describes about performance verification and cleaning.

WARNING The maximum input voltage of the E5250A is ±200 V. And dangerous voltages

may be present at the E5250A output terminals. To prevent electric shock, you

must observe the following safety precautions when using the E5250A.

• Use a three-conductor ac power cable to connect cabinet (if used) and the

E5250A to an electric ground (safety ground).

• If you need to touch the force and guard terminals of the output connector,

turn off the E5250A and discharge any capacitors whenever possible.

• Warn workers around the E5250A about dangerous conditions.

2-2 Agilent E5250A User’s Guide, Edition 9

Page 35

Installation

To Inspect the E5250A and Accessories

To Inspect the E5250A and Accessories

When you receive and open the box that contains the E5250A, check the following:

• Before unpacking any components, inspect all boxes for any signs of damage

that might have occurred during shipment such as:

•Dents

• Scratches

•Cuts

• Water marks

• When you open the boxes that contain the E5250A, check the components

against the contents lists that are attached to the boxes.

• After installing the E5250A, check the E5250A operation by executing self-test

shown in Chapter 3.

If anything is wrong, notify your local Agilent Technologies sales office.

When shipping the E5250A

When you unpack the E5250A, retain all packing materials for future use. If it

becomes necessary to reship the E5250A, repack it in the original packing materials

and shipping carton.

Agilent E5250A User’s Guide, Edition 9 2-3

Page 36

Installation

Requirements

Requirements

This section describes the following requirements for the E5250A.

• “Power Requirements”

•“Power Cable”

• “Operating Environment”

• “Storage and Shipping Environment”

Power Requirements

CAUTION Before applying ac line power to the E5250A, ensure that the correct power cable is

used.

The E5250A can operate from any single-phase ac power source supplying 100 to

240 V ±10 % in the frequency range from 47 to 63 Hz. The maximum power

consumption is 100 VA. For details, refer to Chapter 10, “Specifications.”

Power Cable

In accordance with international safety standards, this instrument is equipped with a

three-wire power cable. When connected to an appropriate ac power outlet, this

cable grounds the instrument frame. The type of power cable shipped with each

instrument depends on the country of destination. Refer to the following table for

the part numbers of the power cables available.

If the plug on the cable does not fit the power outlet, or the cable is to be attached to

a terminal block, cut the cable at the plug end and re-wire it. This work should be

performed by a qualified electrician all local electrical codes being strictly observ ed.

The color coding used in the cable will depend on the cable supplied. If a new plug

is to be connected, it must meet local safety requirements and include the following

features:

• Adequate load-carrying capacity. (refer to Chapter 10, “Specifications.”)

• Ground connection.

• Cable clamp.

2-4 Agilent E5250A User’s Guide, Edition 9

Page 37

Installation

Requirements

• Plug: BS 1363/A,

250 V, 10 A

• Cabl e : 8120-4420,

8120-1351

• Plug: NEMA 6-15P,

250 V, 10 A

• Cabl e : 8120-3996,

8120-0698

• Plug: JIS C 8303,

125 V, 12 A

• Cabl e : 8121-0743,

8120-4753

• Plug: AS 3112, 250 V ,

10 A

• Cable: 8120-4419,

8120-1369

• Plug: SEV 1011, 250

V, 1 0 A

• Cable: 8120-2104

• Plug: Israel SI 32, 250

V, 1 0 A

• Cable: 8120-5182

• Plug: CEE 7 sheet

VII, 250 V, 10 A

• Cable: 8120-4519,

8120-1689

• Plug: SR 107-2-D1,

250 V, 10 A

• Cable: 8120-2956

• Plug: IRAM 207310A, 250 V, 10 A

• Cable: 8120-6870

• Plug: NEMA 5-15P,

125 V, 10 A

• Cable: 8120-6825,

8120-1378,

8120-1395

• Plug: IS 1293 and IS

6538, 250 V, 10 A

• Cable: 8121-1582,

8120-4211

• Plug : CEI 23-16, 250

V, 10 A

• Cable: 8120-6978

• Plug: GB 1002 figure

3 , 250 V, 10 A

• Cabl e : 8120-8376

• Plug : CS 0017:2003,

250 V, 10 A

• Cable: 8120-8871,

8120-0674,

8121-1638

• Plug: SANS 164-1,

250 V, 10 A

• Cable: 8121-0564,

8120-4211

• Plug: CNS 10917-2,

125 V, 10 A

• Cable: 8121-1635,

8120-6825

Agilent E5250A User’s Guide, Edition 9 2-5

Page 38

Installation

Requirements

WARNING For protection from electrical shock, the power cable ground must not be

defeated.

Operating Environment

The E5250A must be operated within the following environmental conditions:

• T emp e rature: 5 °C to 40 °C (41 °F to 104 °F)

• Humidity: 5 % to 80 % RH at 40 °C (104 °F), non-condensing

• Altitude: 0 m to 2000 m

Storage and Shipping Environment

The E5250A should be stored or shipped in environments within the following

limits:

• Temperature: −40 °C to 70 °C (−40 °F to 158 °F).

• Humidity: 5 % to 90 % RH at 65 °C (149 °F).

• Altitude: 0 m to 15,240 m

Protect the E5250A from temperature extremes to prevent condensation from

forming inside the E5250A.

2-6 Agilent E5250A User’s Guide, Edition 9

Page 39

Installation

Installing the E5250A

Installing the E5250A

This section describes how to install the E5250A.

• “To Install Plug-in Card”

• “To Install Blank Panel”

• “To Configure E5255A”

• “E5255A Configuration Examples”

• “To Set GPIB Ad dress”

• “To Connect GPIB Cable”

WARNING To prevent electrical shock, turn off the mainframe and remove the power

cable before starting the instruction.

CAUTION Be careful about the module pins used for internal connection to th e mainframe. The

pins can be damaged easily.

Use clean handling and anti-static procedures when removing, configuring, and

installing the modules. The modules contain components that can be damaged by

static electricity.

NOTE Plug-in module is shipped from the factory after the specifications are confirmed.

Agilent can guarantee that the modules will function and that the module

performance is designed to meet its speci ficat ion s. However, if you have any

trouble, contact your nearest Agilent Technologies service center.

If you require that the modules be guaranteed to their specifications (for ISO

compliance, etc.), then you must perform a calibration on the instrument (modules

and mainframe together). For calibration, contact your nearest Agilent Technologies

service center.

Agilent E5250A User’s Guide, Edition 9 2-7

Page 40

Installation

Installing the E5250A

To Install Plug-in Card

The E5252As and E5255As are plug-in cards (modules). You install these cards in

card slots 1 to 4 of the E5250A. The following procedure explains the card

installation and removal:

1. Turn off the E5250A, then wait at least 10 seconds before you remove or install

a card.

2. Remove a blank panel or a card attached to the slot you want to install a new

card, as follows.

To remove blank panel, do as follows:

a. Loosen the screws on both the left and right edges of the blank panel by

using the wrench furnished with the E5250A.

b. Remove the blank panel.

To remove a card, do as follows:

a. Screw the Module Extractor into the screw hole for the extractor. See Figure

2-1. Module Extractor is furnished with the E5250A.

b. Loosen the screws on left and right edges of the card by using the wrench

furnished with the E5250A.

c. Gently pull the Module Extractor to extract the card from the card slot.

3. Install the card as follows:

a. Align the card with the left and right slot guide rails. The component side

should be fac i ng up.

b. Push the card into the slot until you feel it seat firmly into the connector at

the back of the card slot.

c. Screw in the screws on the left and right edges of the card by using the

wrench furnished with the E5250A.

4. Execute the Relay Test and Leak Test:

After installing the cards, perform the Relay Test and Leak Test described in

Chapter 3 to check the operation and leak current of the E5250A with installed

cards.

CAUTION If you want to confirm that the E5250A with installed cards meets its specifications,

return the E5250A with installed cards to your nearest Agilent Technologies Service

Center to do the Performance Verification.

2-8 Agilent E5250A User’s Guide, Edition 9

Page 41

Figure 2-1 Module Extractor and Location of the Screw Hole

Module Extractor

Screw Hole

for Module Extractor

Agilent E5255A

Agilent E5252A

Installation

Installing the E5250A

To Install Blank Panel

CAUTION To prevent thermal damage to the E5250A cards, be sure that blank panels (Agilent

part number E5250-60003) are installed in all unused slots.

If the blank panel is not installed to cover an unused slot, install the blank panel as

follows:

1. Align the blank panel over the unused slot.

2. Screw in the screws on the left and right edges of the blank panel by using the

wrench furnished with the E5250A.

Agilent E5250A User’s Guide, Edition 9 2-9

Page 42

Installation

Installing the E5250A

To Configure E5255A

The Agilent E5255A has three 2-input 8-output multiplexers. You can configure

several multiplexers by modifying some internal connections. Component locations

on the E5255A are shown in Figure 2-2, and the relationship of the multiplexer

blocks and the component s is sho wn in Table 2-1. Table 2-2 shows the initial s ettin g

of the E5255A internal connections. The setting does not depend on the slot in

which the module is installed.

Table 2-1 Mu ltiplexer Blocks and Components

Multiplexer

block

Block 1 holder 1 - BIASout1 IVin1 IVout1 DIP SW1

Block 2 holder 2 BIASin2 BIASout2 IVin2 IVout2 DIP SW2

Block 3 holder 3 BIASin3 - IVin3 IVout3 DIP SW3

Table 2-2 Agilent E5255A Initial Setup

Block number IVin cable connection BIASin/BIASout Protective resistor

Resistor

holder

1 SMU1 BIAS INPUT 51 0 Ω

2 SMU2 BIAS INPUT 52 0 Ω

3 SMU3 BIAS INPUT 53 0 Ω

BIASin BIASout

IVin

cable

IVout

connector

To Modify IV Input

IV input connection is defined by the connection of IVin cable and the setting of

DIP switch shown in Figure 2-2. For actual examples of modifications, see

“E5255A Configuration Examples”.

DIP SW

Each DIP switch has four bit switches. Bits 1 to 3 are used to specify which SMU

input connector is connected to the IV input. Bit 4 of DIP switch is used to specify

whether the protective resistors are 0 Ω or not. The DIP switche s m ust be set

properly after you complete the internal connection. Make sure you set the DIP

switches correctly. If not, dangerous voltages may be applied to unexpected output

connectors.

2-10 Agilent E5250A User’s Guide, Edition 9

Page 43

Figure 2-2 Agilent E5255A Component Locations

SMU6

SMU5

SMU4

SMU3

SMU2

SMU1

IVout3

connector

IVout2

connector

IVout1

connector

IVin1

cable

IVin3

cable

IVin2

cable

DIP SW2

DIP SW3

DIP SW1

Resistors

(Total 24)

Resistor holder 1

Screws

(Total 48)

Block 1

Block 3

Block 2

Resistor holder 3

Resistor holder 2

BIASin2

terminal

BIASin3

terminal

BIASout1

terminal

BIASout2

terminal

SMU input connectors

BIT1 (1)

BIT3 (4)

BIT4 (R)

BIT2 (2)

Resistors BIT4

0ohm 0

other 1

To BIAS INPUT 51 To BIAS INPUT 5 2

To BI AS I N P UT 5 3

IVin cable DIP SW setting

connection BIT1 BIT2 BIT3

SMU1 10 0

SMU2 01 0

SMU3 11 0

SMU4 00 1

SMU5 10 1

SMU6 01 1

1: ON

0: OFF

Module pins

Installation

Installing the E5250A

To Modify BIAS Input

Each multiplexer block has an independent BIAS input. You can change the BIAS

input internally using the BIASin/BIASout terminals shown in Figure 2-2, or

externally using the BIAS INPUT connectors. For actual examples of modifications,

see “E5255A Configuration Examples”.

To Use Multiplexer Blocks on another E5255A

When a module is installed in a mainframe slot, six module pins are connected to

the mainframe internal bus. So, if multiplexers on different E5255As use the same

module pin, the IV inputs are connected together via the internal bus.

Agilent E5250A User’s Guide, Edition 9 2-11

Page 44

Installation

Installing the E5250A

For example, if a mainframe installs four E5255As which the IVin1 cable is

connected to the SMU1 input connector and the IVin2 and IVin3 cables are not

connected, the E5250A configures a 32-output multiplexer that uses the SMU

INPUT 1 connector as the IV input.

To Mount Protective Resistors

To protect the device (DUT) from electrical damage, you can mount resistors

between the IV input and BIAS input of multiplexer. The following procedure

shows how to mount the resistors. See Figure 2-2 for the component locations.

When shipped from the factory, 0 Ω resistors are mounted, and bit 4 of all DIP

switches is set to OFF (0).

1. Cut the original resistors (0 Ω) off.

2. Loosen the screws from both sides of the resistor holder.

3. Put resistors in holder, and tig hten screws. And confirm that the resistors are

held properly. Resistors should be mounted on each multiplexer block that you

will use (8 resistors/block).

4. Set bit 4 to ON (1) for the DIP switch of the related block. For example, if you

mount resistors for Block 1 and 2 m ultip lexers, s et bi t 4 to ON for DIP SW1 and

SW2.

To Select Protective Resistors

Be careful about the following when selecting protective resistors. Also, be careful

about the heating of the rear panel of mainframe or plug-in module, which may be

heated by resistors, even if you follow this warning.

• If only one E5255A is installed in the mainframe:

Total power consumption by resistors must be less than 16W.

• If multiple E5255As are installed in the mainframe:

Total power consumption by resistors must be less than 32W.

• Consider the current flows to resistor when DUT shorts, and make sure the

power consumption by resistor will be within specification of resistor. Do not

use resistors that have specifications inadequ ate for your applications , which

will result in resistors heating up, burning, or smoking.

2-12 Agilent E5250A User’s Guide, Edition 9

Page 45

Installing the E5250A

E5255A Configuration Examples

The following example configurations are described:

• “24-output multiplexer (3-BIAS inputs, 1-IV input, 1 module)”

• “24-output multiplexer (1-BIAS input, 1-IV input, 1 module)”

• “96-output multiplexer (1-BIAS input, 1-IV input, 4 modules)”

24-output multiplexer (3-BIAS inputs, 1-IV input, 1 module)

To make this multiplexer, you need a E5255A. See Figure 2-3 for example setup.

The example uses the SMU INPUT 1 connector as the IV input, and uses 0 Ω

resistors.

Figure 2-3 24- output multiplexer (3-BIAS inputs, 1-IV input, 1 module)

Installation

1. Connect the IVin1 cable to the SMU1 input connector on the E5255A.

2. Connect the IVin2 cable to the IVout1 connector.

3. Connect the IVin3 cable to the IVout2 connector.

Agilent E5250A User’s Guide, Edition 9 2-13

Page 46

Installation

Installing the E5250A

4. Set bit 1 to ON (1) and bit 2 thru 4 to OFF (0) for DIP SW1 to SW3.

5. Install the module into the slot 1 of the mainframe. For installing module, see

“To Install Plug-in Card” on page 2-8.

24-output multiplexer (1-BIAS input, 1-IV input, 1 module)

T o make this multiplexer, you need a E5255A, two wires (furnished), and two BNC

open caps (furnished). See Figure 2-4 for example setup. The example uses the

SMU INPUT 1 connector as the IV input, and uses 0 Ω resistors.

Figure 2-4 24- output multiplexer (1-BIAS input, 1-IV input, 1 module)

1. Connect the IVin1 cable to the SMU1 input connector on the E5255A.

2. Connect the IVin2 cable to the IVout1 connector.

3. Connect the IVin3 cable to the IVout2 connector.

4. Set bit 1 to ON (1) and bit 2 thru 4 to OFF (0) for DIP SW1 to SW3.

2-14 Agilent E5250A User’s Guide, Edition 9

Page 47

Installation

To Bias Source

BNC T-adapter

BNC cable

Agilent E5255A

Installing the E5250A

5. Connect wires between BIASout1 and BIASin2, also between BIASout 2 and

BIASin3.

6. Install the module into the slot 1 of the mainframe. For installing module, see

“To Install Plug-in Card” on page 2-8.

7. Connect BNC open caps to BIAS INPUT 52 and 53 connectors. So, the BIAS

INPUT 51 connector will be the BIAS input.

This example internally connects all BIAS INPUT connectors together. So, when

bias is applied to a BIAS INPUT connector, the bias will also be applied to all the

other BIAS INPUT connectors.

Do not forget to connect the BNC open caps to the unused BIAS INPUT conn ectors.

Otherwise, you will be shocked if you touch the connectors while bias is applied.

DO NOT connect the BNC short cap to the connectors. If you do, the E5255A and

the Bias Source will be destroyed when the bias is applied.

To connect BIAS inputs externally.

You can use the BIAS INPUT connectors instead of the BIASin/out internal

connections shown above. See Figure 2-5. This example uses three BNC cables and

two BNC-T type (f-m-f) adapters. Recommended p arts fo r the BNC-T type adap ters

are listed below.

• Agilent part number 1250-0781: female(side)-male(center)-female(side)

• Agilent part number 1250-2405: male(side)-female(center)-female(side)

Figure 2-5 Interconnection of BIAS INPUT Connectors

Agilent E5250A User’s Guide, Edition 9 2-15

Page 48

Installation

Installing the E5250A

96-output multiplexer (1-BIAS input, 1-IV input, 4 modules)

To make this multiplexer, you need four E5255As, eight wires (furnished), five

BNC open caps (furnished), and three BNC cables. The example uses the SMU

INPUT 1 connector as the IV input, and uses 0 Ω resisto rs.

1. See “24-output multiplexer (1-BIAS input, 1-IV input, 1 module)” and make

four 24-output multiplexers. Then the IVin1 cable on all modules must be

connected to the SMU1 input connector.

2. Install the modules into the mainframe. For installing module, see “To Install

Plug-in Card” on page 2-8.

3. Connect BNC open caps to the BIAS INPUT 51 connector of the module in the

slot 1 and all BIAS INPUT 52 connectors.

4. Connect BNC cables between the following connectors:

• BIAS INPUT 51 (slot 4) and BIAS INPUT 53 (slot 3)

• BIAS INPUT 51 (slot 3) and BIAS INPUT 53 (slot 2)

• BIAS INPUT 51 (slot 2) and BIAS INPUT 53 (slot 1)

So, the BIAS INPUT 53 connector of the module in the slot 4 will be the BIAS

input.

Figure 2-6 96- output multiplexer (1-BIAS input, 1-IV input, 4 modules)

Do not forget to connect the BNC open caps to the unused BIAS INPUT conn ectors.

Otherwise, you will be shocked if you touch the connectors while bias is applied.

DO NOT connect the BNC short cap to the connectors. If you do, the E5255A and

the Bias Source will be destroyed when the bias is applied.

2-16 Agilent E5250A User’s Guide, Edition 9

Page 49

Installation

Installing the E5250A

To Set GPIB Address

Every device on the GPIB bus must have a unique address.

If you need to change the GPIB address of the E5250A, make sure the E5250A is

turned off. With a small flatblade screwdriver, set the GPIB ADDRESS switch on

the rear panel to the new address (0 to 30).

The new GPIB address is recognized only at power on. The E5250A leaves the

factory with the GPIB address set to 22.

To Connect GPIB Cable

To connect the E5250A with a computer or peripheral device via GPIB (IEEE Std.

488), connect an GPIB cable between the GPIB connector on the E5250A rear panel

and the GPIB connector on the peripheral device.

Including the controller , a total of 15 GPIB interfaces can be connected on the same

GPIB bus. The following are rules for connecting GPIB interfaces:

• If total number of interfaces ≤ 10:

Max. total cable length = number of interfaces × 2 m.

• If total number of interfaces > 10:

Max. total cable length = 20 m.

• Maximum cable length between interfaces is 4 m.

• Star connection and cascade connection are allowed. Loop connection is not

allowed.

Agilent E5250A User’s Guide, Edition 9 2-17

Page 50

Installation

Maintenance

Maintenance

Maintenance should be performed periodically to keep the E5250A in good

condition.

Performance Verification

Performance verification must be performed periodically so that the instruments

satisfy the specifications, and keep a good condition. It is recommended to perform

the performance verification once a year at least. For the performance verification,

contact your nearest Agilent Technologies Service Center . T rained service personnel

will perform the performance verification.

Cleaning

Before performing cleaning, turn off the instrument, and disconnect power cable

from the rear panel. Use a dry cloth to clean the external case parts.

To prevent electrical shock, do not perform cleaning when the instrument is turned

on, and do not use a wet cloth.

2-18 Agilent E5250A User’s Guide, Edition 9

Page 51

3 Executing Self-Test and Leak Test

Page 52

Executing Self-Test and Leak Test

This chapter describes how to execute the Self-Test and the Leak Test.

The Self-Test consists of three tests that check the operation of Agilent E5250A

firmware, LEDs, and key that are on the E5250A front panel, and the relays on the

cards installed in the E5250A.

Self-Test should be executed every day as an operation check before using the

E5250A.

The Leak Test checks leakage current of cards installed in the E5250A.

Leak Test can be executed by using Agilent 4155/4156 Semiconductor Parameter

Analyzer with the Self-Test Utility progr am that is o n the E5250A Program Disk

furnished with the E5250A.

NOTE Performance Verification

The Self-Test and the Leak Test cannot be used to verify the specifications of the

E5250A, E5252A, and E5255A.

To verify the specifications, return the E5250A with the cards installed to your

nearest Agilent Technologies Service Center. The performance verification should

be done by service personnel who are trained to service the E5250A, and should be

performed once a year.

• “Executing Self-Test” introduces the test items of the Self-Test and describes

how to execute the Self-Test.

• “Using the Self-Test Utility” describes how to execute the Self-Test and the

Leak Test interactively from Agilent 4155/4156 semiconductor parameter

analyzer.

3-2 Agilent E5250A User’s Guide, Edition 9

Page 53

Executing Self-Test

The Self-Test of the E5250A consists of the following three tests:

Table 3-1 E5250A Self-Test Items

Test Item Description Executed by Refer to

Executing Self-Test and Leak Test

Executing Self-Test

Controller

Test

Front

Panel

Interface

Test

Relay Test Checks the operation of

Checks the operation of

the E5250 A firmware.

Checks the operation of

the LEDs and key that

are on the E5250A front

panel.

the relays on the cards

installed in the E5250A.

Turning on the E5250A. page 3-4

Entering SCPI Command. pa ge 3-6

Using Self-Test Utility. page 3-10

Entering SCPI Command page 3-6

Using Self-Test Utility. page 3-10

Pressing the Local/

Self Test key.

Entering SCPI Command. pa ge 3-6

Using Self-Test Utility. page 3-10

page 3-4

Agilent E5250A User’s Guide, Edition 9 3-3

Page 54

Executing Self-Test and Leak Test

Executing Self-Test

To Execute Self-Test (Standalone)

Controller Test is executed automatically when you turn on the E5250A. You

execute the Relay Test by pressing the

panel.

Executing the Controller Test

1. Turn on the E5250A.

Local/Self Test key on the E5250A front

2. Wait until the LED in the

Local/Self Test key t urns off.

If System Fail LED or Fail LED stays on after executing the Controller Test, contact

your nearest Agilent Technologies Service Center.

Executing the Relay Test

Requirements:

• Relay Test Adapter (E5250A-301)

• BNC Short Caps (3 caps are furnished with each E5255A)

Procedure:

1. Disconnect all cables from the E5250A input connectors.

2. Open all outputs of the plug-in cards as follows: If cable is connected to output

connector of plug-in card, open output at DUT end of cable. If end of cable is

Kelvin connection, disconnect the cable or make non-Kelvin connection at end

of cable.

3. Attach the Relay Test Adapter to the E5250A input connectors as shown in

Figure 3-1.

4. Set switch on the Relay Test Adapter to Relay Test position.

5. For each E5255A card installed in the E5250A:

a. Disconnect any cables from the BIAS INPUT connectors of the E5255A.

b. Connect a BNC Short Cap to each E5255A BIAS INPUT connector.

6. (If Remote LED is on, press the

Local/Self Test key to return to Local control.

The Remote LED should turn off.)

7. Press the

8. Wait until the LED in

Local/Self Test key. The Relay Test executes.

Local/Self Test key turns off.

3-4 Agilent E5250A User’s Guide, Edition 9

Page 55

NOTE If Fail LED is ON after Relay Test

Relay Test Adapter

After executing the relay test, if the Fail LED turns on, the cause is one of the

following:

• The Relay Test Adapter is not connected or a cable is still connected to input

connector.

• Output is not open. See step 2 of previous procedure.

• You did not properly install the E5255A. See “To Configure E5255A” on page

2-10.

• A plug-in card may be defective. Contact your nearest Agilent Technologies

Service Center.

Figure 3-1 Relay Test Adapter Connection

Executing Self-Test and Leak Test

Executing Self-Test

NOTE Settings after Relay Test

After Relay Test, the E5250A settings are change d to same as after :SYST:CPON

command execution.

Agilent E5250A User’s Guide, Edition 9 3-5

Page 56

Executing Self-Test and Leak Test

Executing Self-Test

To Execute Self-Test using External Controller

You can execute Self-T est fr om an external controller by using SCPI commands in a

program.

This section describes the requirements, SCPI commands, and a s ample program for

Self-Test execution from an external controller. For details about the SCPI

commands, refer to Chapter 7.

Requirements

• Controller

• GPIB Cable

• Relay Test Adapter

• BNC Short Caps (3 caps are furnished with each E5255A)

SCPI Commands for Self-Test

Table 3-2 shows the SCPI commands used to execute Self-Test. Keyword of the

SCPI command first level is :DIAG.

The :DIAG commands ignore the E5250A channel configuration mode (NORMAL

or AUTO).

For :DIAG commands that require a card number, you specify 1, 2, 3, 4, or ALL.

If the Fail LED turns on after executing the Self-Test, the E5250A or modules may

be defective. Contact your nearest Agilent Technologies Service Center.

NOTE Before executing Relay Test, be careful about following:

• Attach the Relay Test Adapter to the E5250A input connectors. Refer to Figure

3-1. Then set the switch on the adapter to the Relay Test position.

• Open all outputs of the plug-in cards as follows: If cable is connected to output

connector of plug-in card, open output at DUT end of cable. If end of cable is

Kelvin connection, disconnect the cable or make non-Kelvin connection at end

of cable.

• For each E5255A installed in the E5250A, connect a BNC short cap to each

E5255A BIAS INPUT connector.

3-6 Agilent E5250A User’s Guide, Edition 9

Page 57

Table 3-2 SCPI Commands for Self-Test

Test Item Description SCPI Command

Executing Self-Test and Leak Test

Executing Self-Test

Controller

Test

Executes Controller Test,

then returns test result.

Returns test result. :DIAG:TEST:FRAM:STAT? CONT

Clears test result. :DIAG:TEST:FRAM:CLE CONT

Front Panel

Interface

Executes I/F Test, then

returns test result.

(I/F) Test

Returns test result. :DIAG:TEST:FRAM:STAT? FPAN

Clears test result. :DIAG:TEST:FRAM:CLE FPAN

Relay Test Executes Relay T est, then

returns test result.

Returns test result. :DIAG:TEST:CARD:STAT? ALL

Clears test result. :DIAG:TEST:CARD:CLE ALL or

NOTE Front Panel Interface Test

After the :DIAG:TEST:FRAM:EXEC? FPAN command is executed, the Remote,

System Fail, Fail, and Local/Self Test LEDs on the E5250A front panel blink for

about 10 seconds. If an LED does not blink, the LED is defective.

:DIAG:TEST:FRAM:EXEC? CONT

:DIAG:TEST:FRAM:EXEC? FPAN

:DIAG:TEST:CARD:EXEC? ALL

or Card No. (1, 2, 3, or 4)

or Card No. (1, 2, 3, or 4)

Card No. (1, 2, 3, or 4)

Confirm that the four LEDs are blinking, then press the

Local/Self Test key on the

E5250A front panel within 10 seconds. The LEDs should stop blinking.

If you do not press the

Local/Self Test key within 10 seconds, the E5250A returns a

fail result for the Front Panel Interface Test, which turns on the Fail LED.

If you pressed

it means the

Local/Self Test key within 10 seconds, and the Fail LED still turns on,

Local/Self Test key is defective.

If you find any problem, contact your nearest Agilent Technologies Service Center.

Agilent E5250A User’s Guide, Edition 9 3-7

Page 58

Executing Self-Test and Leak Test

Executing Self-Test

Self-Test Programming Example

This sample program is effective for an E5250A that has four card s installed. If your

E5250A does not have four cards installed, delete the Relay Test program lines for

the empty card slots. The program runs on HP BASIC.

10 ! Self-Test by Ext er na l Co nt ro ll er

20 !

30 REAL A

40 ASSIGN @Hp5250 TO 722

50 OUTPUT @Hp5250;":DIAG:TEST:FRAM:CLE CONT"

60 OUTPUT @Hp5250;":DIAG:TEST:FRAM:CLE FPAN"

70 OUTPUT @Hp5250;":DIAG:TEST:CARD:CLE ALL"

80 DISP "Press Continue to go to Controller Test."

90 PAUSE

100 ! Controller Tes t

110 OUTPUT @Hp5250;":DIAG:TEST:FRAM:EXEC? CONT"

120 ENTER @Hp525 0; A

130 IF A=0 THEN GOTO 160

140 DISP "Failed . Pr es s Co nt in ue to go to I/ F Te st ."

150 GOTO 170

160 DI SP "Pass ed . Pr es s Co nt in ue to go to I/ F Te st ."

170 PAUSE

180 ! Front Panel I/ F Te st

190 OUTPUT @Hp5250;":DIAG:TEST:FRAM:EXEC? FPAN"

200 DISP "Press Lo ca l/ Se lf Tes t Ke y wi th in 10 se c. "

210 ENTER @Hp5250;A

220 IF A=0 THEN GOTO 250

230 DISP "Failed . Pr es s Co nt in ue to go to Re la y Te st ."

240 GOTO 260

250 DISP "Passed . Pr es s Co nt in ue to go to Re la y Te st ."

260 PAUSE

270 ! Relay Test

280 OUTPUT @Hp5250;":DIAG:TEST:CARD:EXEC? 1"

290 ENTER @Hp5250;A

300 IF A=0 THEN GOTO 330

310 DISP "Card 1 failed. Press Continue to test Card 2"

320 GOTO 340

330 DISP "Card 1 passed. Press Continue to test Card 2"

340 PAUSE

350 OUTPUT @Hp5250;":DIAG:TEST:CARD:EXEC? 2"

360 ENTER @Hp5250;A

370 IF A=0 THEN GOTO 400

380 DISP "Card 2 failed. Press Continue to test Card 3"

390 GOTO 410

400 DISP "Card 2 passed. Press Continue to test Card 3"

410 PAUSE

420 OUTPUT @Hp5250;":DIAG:TEST:CARD:EXEC? 3"

3-8 Agilent E5250A User’s Guide, Edition 9

Page 59