Page 1

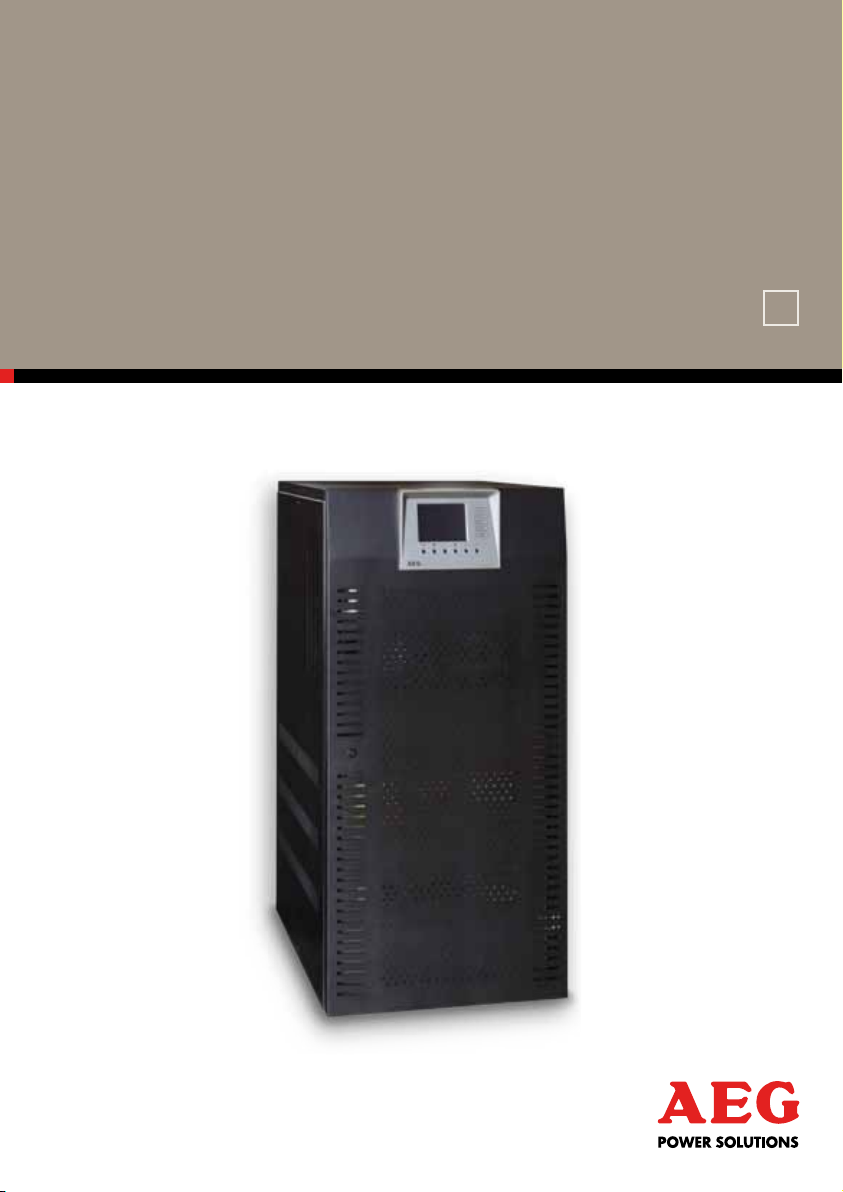

Protect

2.33 2.0

USER MANUAL

Uninterruptible

Power Supply UPS

EN

Page 2

2

CONTENTS

1. Introduction ....................................................................................... 5

1.1. Using this manual .............................................................................................5

1.1.1. Symbols and conventions used ....................................................................6

1.1.2. For more information and help ..............................................................7

1.1.3. Safety and instructions ............................................................................7

2. Quality and standard guarantee ....................................................... 8

2.1. Management declaration ................................................................................8

2.2. Standards ..........................................................................................................9

2.3. Environmental protection ................................................................................9

3. Presentation ..................................................................................... 10

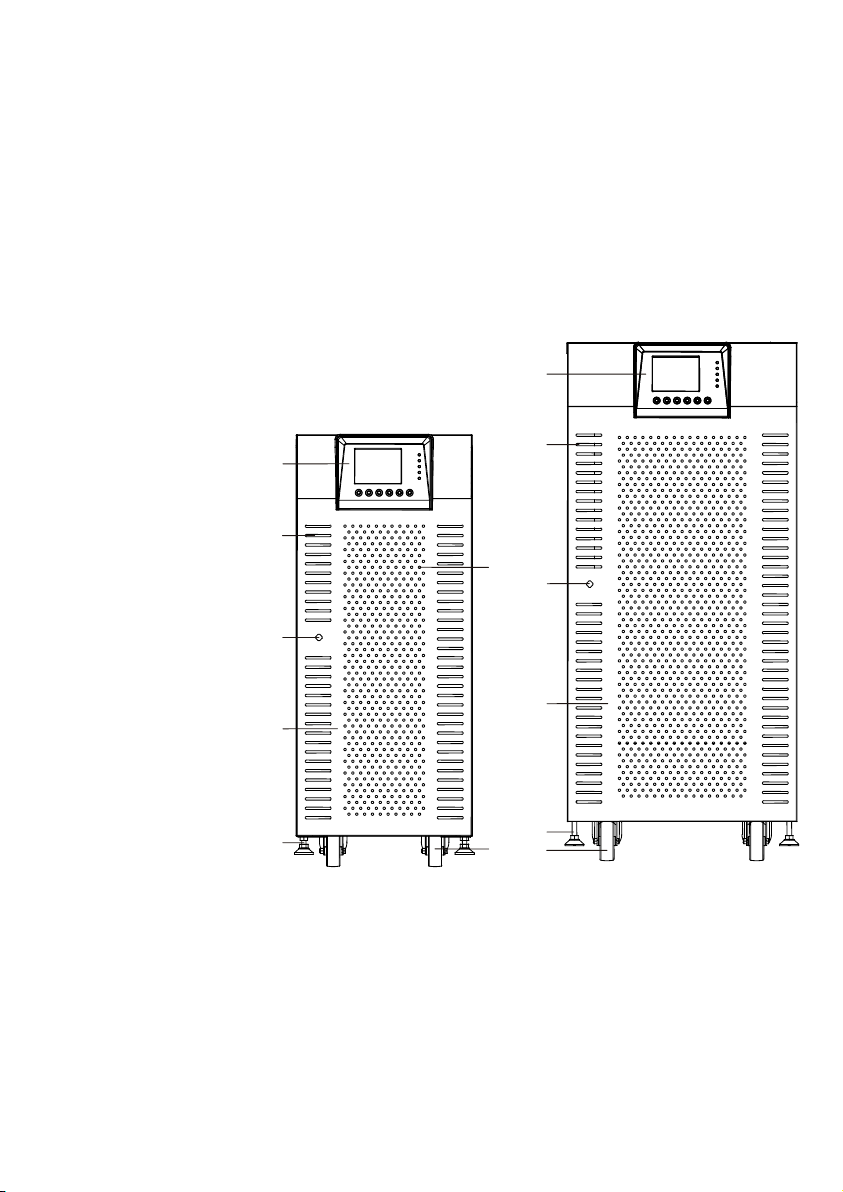

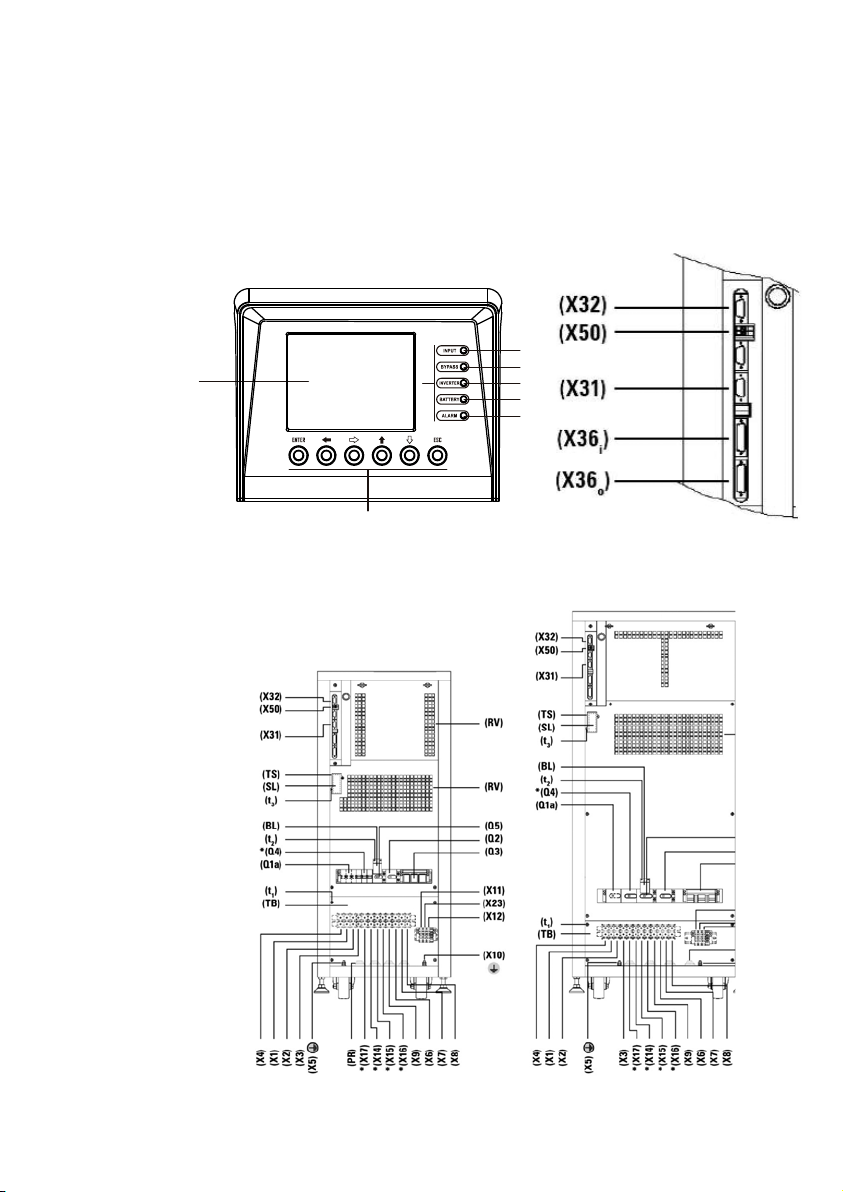

3.1. Views ...............................................................................................................10

3.1.1. Views of the equipment ........................................................................10

3.1.2

3.2. Structure .........................................................................................................15

3.2.1. Structural schema ..................................................................................15

3.3. Operating principle ........................................................................................15

3.3.1. Normal operation ..............................................................................16

3.3.2. Operation with mains failure ............................................................16

3.3.3. Operation with inverter not active ...................................................16

3.3.4. Operation in manual bypass ...........................................................17

3.4. Parallel operation ...........................................................................................17

Corresponding legends for the equipment views ....................................13

4. Installation ........................................................................................ 19

4.1. Important safety instructions .........................................................................19

4.1.1. Battery safety instructions .....................................................................20

4.1.2. Cabinet access .......................................................................................21

4.2. Set up and installation ....................................................................................23

4.2.1. Unpacking and content checking .........................................................23

4.2.2. Storage ...................................................................................................24

4.2.3. Transportation to site ............................................................................24

4.2.4. Location ..................................................................................................25

Page 3

4.3. Connection .....................................................................................................26

4.3.1. To the mains connection, terminals (X1 to X4) ....................................26

4.3.2. Connection of the output, terminals (X6 to X9) ..................................28

4.3.3. UPS connection to each battery pack in cabinet,

terminals (X11, X12, X23 and X47, X48, X49) ......................................29

4.3.4. Connection main protective earthing terminal (

and protective earth bonding terminal ( ) ........................................30

4.3.5. Interface relay contacts, connector (X32) .............................................30

4.3.6. COM-interface RS232 and RS485, connector (X31) ...........................31

4.3.7. EPO terminals (X50) ..............................................................................33

4.3.8 Parallel BUS connection (X36)................................................................33

)

5. Operation ......................................................................................... 35

5.1. Start up ...........................................................................................................35

5.1.1. Control before start up .........................................................................35

5.1.2. Start up procedure ................................................................................35

5.2. Complete UPS shutdown ..............................................................................37

5.3. Emergency power off (EPO) operation ........................................................38

5.4. Bypass manual switch (Maintenance) ............................................................38

5.4.1. Principle of operation ............................................................................38

5.4.2. Transfer to maintenance bypass ...........................................................38

5.4.3. Transfer to normal operation ................................................................39

6. Control panel and display description ............................................ 41

6.1. Control panel parts ........................................................................................41

6.1.1. Touch Screen ..........................................................................................41

6.2. Basic functions of keyboard from synoptic ...................................................41

6.2.1.

6.2.2. Menu structure ......................................................................................44

6.3. Screen description ..........................................................................................45

6.3.1. Main level (screen menu 0.0) ................................................................45

6.3.2. UPS status control (screen menu 1.0) ...................................................46

Messages menus and classification in submenus ..................................43

3

Page 4

4

6.3.3.

6.3.4.

6.3.5. ‘‘ALARMS” level (screen menu 4.0) ......................................................56

6.3.6. ‘‘DATA LOGGER” level (screen menu 5.0) ..........................................69

‘‘MEASURES” level (screen menu 2.0) ....................................................48

‘‘SETTINGS” level (screen menu 3.0) ....................................................51

7. Maintenance, warranty and service ................................................ 71

7.1. Basic maintenance guide ...............................................................................71

7.1.1. Battery fuses ..........................................................................................71

7.1.2. Batteries .................................................................................................71

7.1.3. Cooling Fan ............................................................................................72

7.1.4. Capacitors ..............................................................................................72

7.2. Warranty conditions .......................................................................................72

8. Annexes ...........................................................................................73

8.1. General technical Specification .....................................................................73

8.2 Safety Instructions ...........................................................................................76

Page 5

1. INTRODUCTION

We would like to thank you in advance for the trust you have placed in us by purchasing this product. Read this instruction manual carefully before starting up the

equipment and keep it for any possible future consultation that may be required.

We remain completely at your disposal for any further information or any query

you should wish to make.

• The equipment here described can cause significant physical damage due to

• According to our policy of constant evolution, we reserve the right to modify

• All reproduction or third party concession of this manual is prohibited without

5

Yours sincerely,

AEG Power Solutions

improper handling. This is why the installation, maintenance and/or fixing of the

equipment described here must be done by our staff or specifically authorised

personnel.

the specifications in part or in whole without advance warning.

the previous written authorization of our firm.

1.1. USING THIS MANUAL

The goal of this manual is to give explanations and procedures for the installation

and operation of the equipment. This manual has to be read carefully before

instaling and operating the equipment. Keep this manual for future consultation.

This equipment has to be installed by qualified staff. With the simple help of this

manual, it can be operated by personnel without specific training.

Page 6

6

1.1.1. SYMBOLS AND CONVENTIONS USED

Warning

Carefully read the indicated paragraph and take the stated prevention measures.

Danger of electrical discharge

Pay special attention to it, both in the indication on the equipment and in the

paragraph referred in this user manual.

Main protective earthing terminal

Connect the earth cable coming from the installation to this terminal.

Earth bonding terminal

Connect the earth cable coming from the installation to this terminal.

Notes of information

Additional topics that complement the basic procedures.

Preservation of the environment

The presence of this symbol in the product or in its associated documentation

states that, when its useful life is expired, it will not be disposed with the domestic

refuse. In order to avoid possible harm to the environment, separate this product

from other refuse and recycle it appropriately. Users may contact their provider or

with the relevant local authorities to be informed on how and where they can take

the product to be recycled and/or disposed of correctly.

Page 7

1.1.2. FOR MORE INFORMATION AND HELP

For more information and/or help with the version of your specific unit, contact

our Service and Technical Support (S.T.S.).

1.1.3. SAFETY AND INSTRUCTIONS

Together with the equipment and this “user and installation“ manual, information

pertaining to “safety instructions” is provided. These can be found in chapter 8.2

of this manual. Before proceeding to installation or commissioning, check that

both sets of information are available. Please refer to chapter 8.2 carefully. Compliance with “safety instructions” are available for you to understand and observe.

Once read, keep the safety instructions available for future reference.

7

Page 8

8

2. QUALITY AND STANDARD GUARANTEE

2.1. MANAGEMENT DECLARATION

Our goal is the client’s satisfaction, therefore this management has decided to

estab lish a quality and environmental policy, by means of installation a quality and

environmental management system that becomes us capable to comply the

requirements demanded by the standard ISO 9001 and ISO 14001 and by our

clients and concerned parts too.

Likewise, the enterprise management is committed to the development and

improvement of the quality and environmental management system, through:

• The communication to all the company about the importance of satisfaction

both in the client’s requirements and in the legal regulations.

• Publicizing the quality and environmental policy diffusion and meeting the

quality and environment targets.

• To carry out revisions by the management.

• To provide the needed resources.

Quality and environmental officer

The management designated person in charge of the quality and environment

department, who, independent of other responsibilities, has the responsibility and

authority to assure that the processes of the quality and environmental management

systems are established and maintained; to inform the management about the

operation of the quality and environmental management system, including areas for

improvement; and to promote the knowledge of the requirements and environmental

requirements at all levels of the organization.

The following process map represents the interaction among all the processes of

the quality and environmental system:

CONTINUOUS IMPROVEMENT PROCEDURE / MANAGEMENT REVISION

QUALITY MANAGEMENT PROCESS ENVIRONMENT MANAGEMENT PROCESS

CLIENTS

Fig.1:

Process map of quality and environmental system.

R & D PROCESS

COMMERCIAL PROCESS PRODUCTION PROCESS

INTERNAL LOGISTICS PROCESS

MAINTENANCE PROCESS

TECHNICAL OFFICE PROCESS

TRAINING PROCESS

CLIENT:

- PRODUCT

- SERVICE

Page 9

2.2. STANDARDS

The UPS series product is designed, manufactured and certified in

accordance with the standard ISO 9001 of quality management systems.

The marking shows the conformity to the EEC directive (quoted between

brackets) by means of the application of the following standards:

• 2006/95/EC: Low voltage directive.

• 2004/108/EC: Electromagnetic Compatibility directive (EMC)

In accordance with the specifications of the harmonized standards:

• EN-IEC 62040-1: Uninterruptible power supply (UPS). Part 1-1: General and

safety requirements for UPSs used in accessible areas by end users.

• EN-IEC 60950-1: IT equipment. Safety. Part 1: General requirements.

• EN-IEC 62040-2: Uninterruptible power supply (UPS). Part 2: Prescriptions

for Electromagnetic compatibility (EMC).

• EN-IEC 62040-3: Uninterruptible power supply (UPS). Part 3: Methods of

operation specification and test requirements.

The manufacturer’s responsibility is excluded in the event of any modification or

tampering with the product on the customer’s side.

9

2.3. ENVIRONMENTAL PROTECTION

This product has been designed to respect the environment and has been

manufactured in accordance with the standard ISO 14001.

Equipment recycling at the end of its useful life:

Our company is committed to use the services of authorised institutions and

according to the regulations to safely dispose of the recovered product at the end

of its useful life (contact your distributor).

• Packing:

• Batteries:

To recycle the packaging, follow the legal regulations in force.

The batteries pose a serious danger for health and the environment.

The disposal of them must be carried out in accordance with the standards

in force.

Page 10

10

3. PRESENTATION

3.1. VIEWS

3.1.1. VIEWS OF THE EQUIPMENT

(fig. 4)

(fig. 4)

(RV)

(CL)

(PF)

(PB)

Fig.2: Cabinet front view for UPS up to

20 kVA with front door closed

(RV)

(RV)

(CL)

(PF)

(PB)

(RD) (RD)

Fig.3: Cabinet front view for UPS from

30 to 80 kVA with front door closed

Page 11

2

Fig.4: Control panel view

11

a

b

1

3

c

d

e

Fig.5: Communication connectors details

*Not available for Protect 2.33 2.0

Fig.6: Cabinet front view for UPS up

to 20 kVA with front door opened

Fig.7: Cabinet front view for UPS up to

30 to 80 kVA with front door opened

Page 12

12

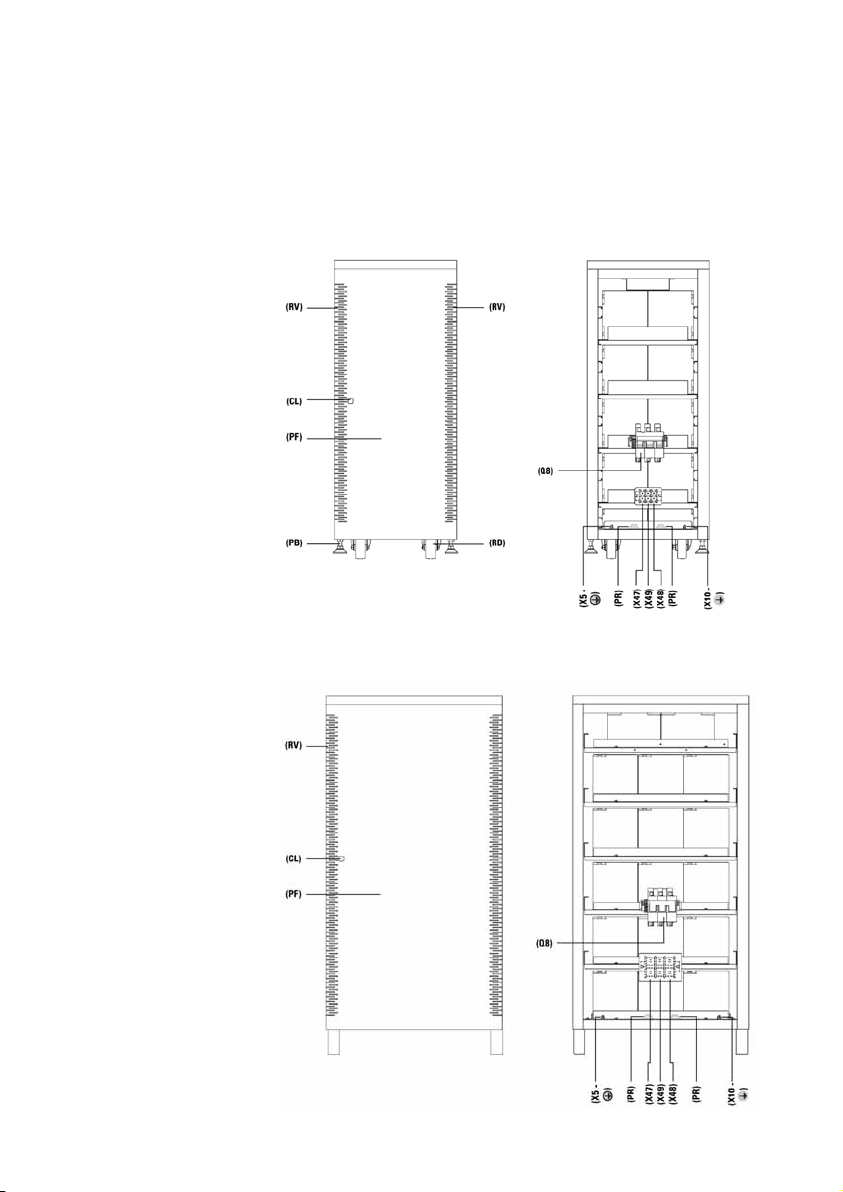

Fig.8: No. 1–3 battery cabinet front view

with front door closed

Fig.10: No. 4 battery cabinet front view with

front door closed

Fig.9: No. 1–3 battery cabinet front view with

front door opened

Fig.11: No. 4 battery cabinet front view with

front door opened

Page 13

3.1.2

CORRESPONDING LEGENDS FOR THE EQUIPMENT VIEWS

Protection and handling elements (Q):

(Q1a) Input circuit breaker or switch according to power of the equipment

(Q2) Output switch

(Q3) Battery fuse holder switch with 3 fuses (models up to 40 kVA) or switch

(for higher models)

(Q4) Not available for Protect 2.33 2.0

(Q5) Maintenance bypass switch

(Q8) Battery fuse holder switch 3 fuses, located in the battery cabinet

Connecting elements (X):

(X1) Phase input terminal R

(X2) Phase input terminal S

(X3) Phase input terminal T

(X4) Neutral input terminal N

(X5) Main protection earthing terminal (

(X6) Phase output terminal U

(X7) Phase output terminal V

(X8) Phase output terminal W

(X9) Neutral output terminal N

(X10) Earth bonding terminal for load or loads and/or battery cabinet ( )

(X11) Battery terminal +

(X12) Battery terminal –

(X23) Battery terminal N

(X31) DB9 connector COM RS232- and RS485 ports

(X32) DB9 connector relay interface

(X36) Connector for connecting cable for parallel use

(X47) Battery terminal + of external batteries cabinet

(X48) Battery terminal – of external batteries cabinet

(X49) Battery terminal N (middle tap) of external batteries cabinet

(X50) Terminals for external EPO

)

13

Page 14

14

Keyboard and optical indications control panel (PC):

(LCD) Graphic LCD

(ENT) Key “ENTER”

(ESC) Key “ESC”

() Key up

() Key down

() Key move to right

() Key move to left

(a) Rectifier input voltage OK LED (green)

(b) Output voltage unit from the bypass LED (orange)

(c) Inverter is working LED (green)

(d) Unit working from batteries - mains failure - LED (red)

(e) General alarm. In case of any alarm of the unit LED (red)

Other abbreviations:

(BL) Mechanical block for manual bypass switch (Q5)

(CL) Lock for cabinet front door

(PB) Levelers and immobilizing elements

(PC) Control panel

(PF) Cabinet front door

(PR) Cable routing or wire cones

(RD) Scroll wheel

(RV) Ventilation grille

(SL) Slot for optional intelligent card

(TB) Terminal cover

(TS) Slot cover (SL)

(t1) Screws fixing for terminals cover (TB)

(t2) Screws fixing for mechanical block (BL) for switch (Q5)

(t3) Screws fixing for slot cover (TS)

Page 15

3.2. STRUCTURE

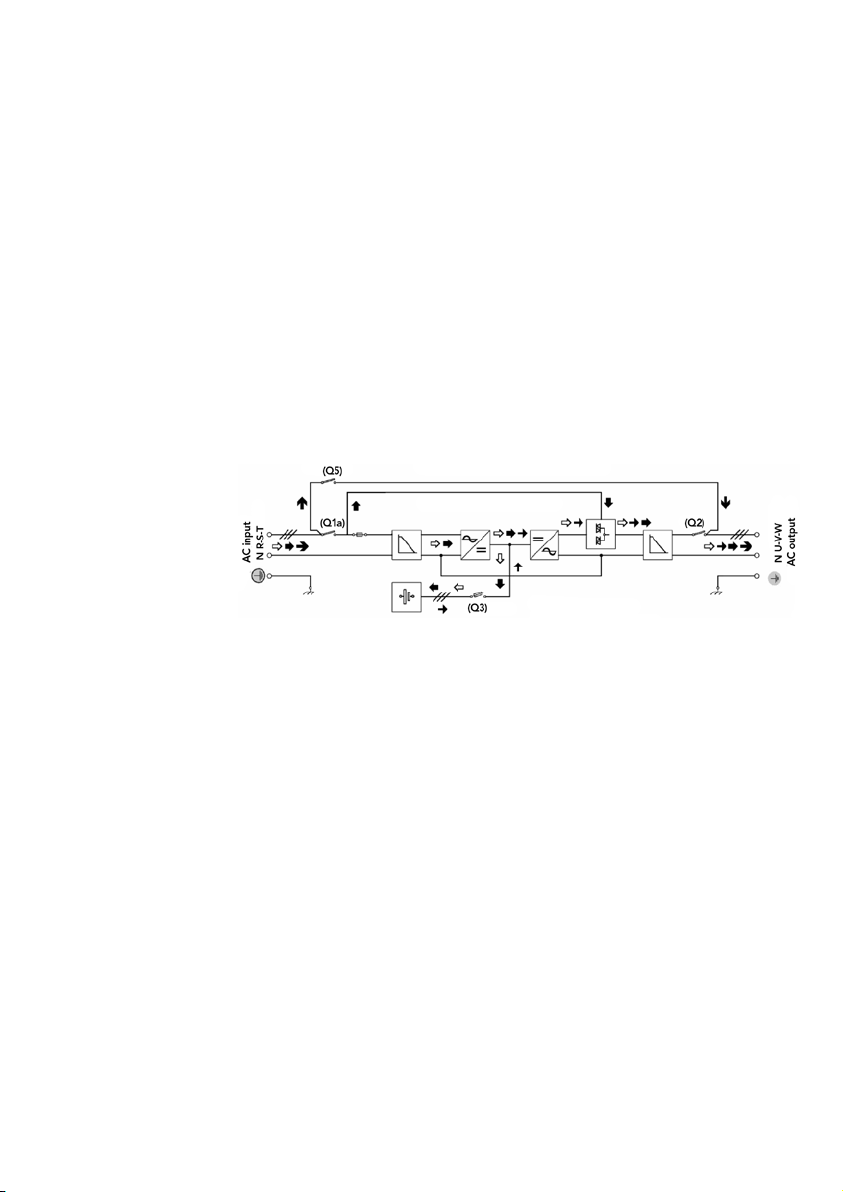

3.2.1. STRUCTURAL SCHEMA

In a single line diagram, figure 12 shows the basic structure of standard

equipment and another one with separate bypass line, for a three phase input

and output configuration. For any other configuration, only the quantity of cables

and terminals at the input, output and bypass will vary. The internal structure of

the equipment will never vary.

Maintenance line (manual bypass).

Emergency line (static bypass)

Normal operation

Mains failure

Inverter operation not active

(provided that the EPO inactive)

Operation on bypass manual

15

Fig.12:

UPS block diagram with operating flows

3.3. OPERATING PRINCIPLE

Protect 2.33 2.0 is a double conversion system AC/DC, DC/AC with a sine wave

output that gives safe protection in extreme conditions of power supply

(variations in voltage, frequency, electrical noises, blackout and other power

disturbances, etc…). Whatever the kind of load that has to be protected, these

devices are prepared to assure quality and continuity in the electrical supply.

The operation is basically as follows:

• Rectifier, an IGBT three phase rectifier, converts the AC voltage into DC by

absorbing a pure sine wave current (THD < 2,5 %*), and charging batteries at

constant current / voltage.

• The batteries supply the power needed by the inverter in the event of mains

failure.

• The inverter deals with transforming the voltage of the DC bus into AC by

providing a sine wave, alternating output stabilized in voltage and frequency

suitable for supplying the loads connected on the output.

*

from 50 % load

Page 16

16

• The basic double conversion structure is complemented by two new functional

blocks, the static bypass commuter switch and the manual bypass commuter

switch.

• The static bypass commuter switch connects the output load directly to the

bypass network in special circumstances such as overloading or overheating and

reconnects it to the inverter when normal conditions are restored.

• The manual bypass commuter switch isolates the UPS from the mains and from

the loads connected on the output, so that maintenance operations may be

performed in the UPS without any need to interrupt the supply to the loads.

3.3.1. NORMAL OPERATION

With the mains present, the rectifier transforms the AC input voltage into DC,

raising the DC voltage to a suitable level for supplying the inverter and to charge

the batteries.

The inverter deals with transforming the voltage of the DC bus into AC, providing

a sine wave alternating output, stabilized in voltage and frequency to supply the

loads connected to the output (Fig.12).

3.3.2. OPERATION WITH MAINS FAILURE

In the event of mains failure or power disturbance occur, the group of batteries

supplies the power needed to supply the inverter.

The inverter continues working normally, independent of the lack of mains, and

the back-up time of the device depends only on the capacity of the group of

batteries (Fig.12).

When the battery voltage reaches the end of back-up time, the control blocks the

output as protection against a deep battery discharge.

When the mains returns and following the first seconds of analysis, the UPS

operates once more as in section “Normal operation”.

3.3.3. OPERATION WITH INVERTER NOT ACTIVE

The inverter is inactive due to the existence of alarm conditions such as overloads,

overheating, end of back-up time, etc. In this case the rectifier continues charging

the batteries to maintain their optimal charge state.

The inverter is also inactive if the unit has not been started up with the keyboard.

In this case, the rectifier will be inactive.

Page 17

17

In all these cases the output voltage of the UPS is supplied by the emergency

bypass line through the static bypass commuter switch (Fig. 12), provided that the

EPO is inactive.

3.3.4. OPERATION IN MANUAL BYPASS

When we wish to perform some maintenance check on the device, it may be

disconnected from the mains without any need to cut the power supply to the

system and affect the critical load. The UPS may be altered, only by technical or

maintenance personnel. For maintenance bypass follow the special instructions

for that purpose (refer chapter 5.4).

3.4. PARALLEL OPERATION

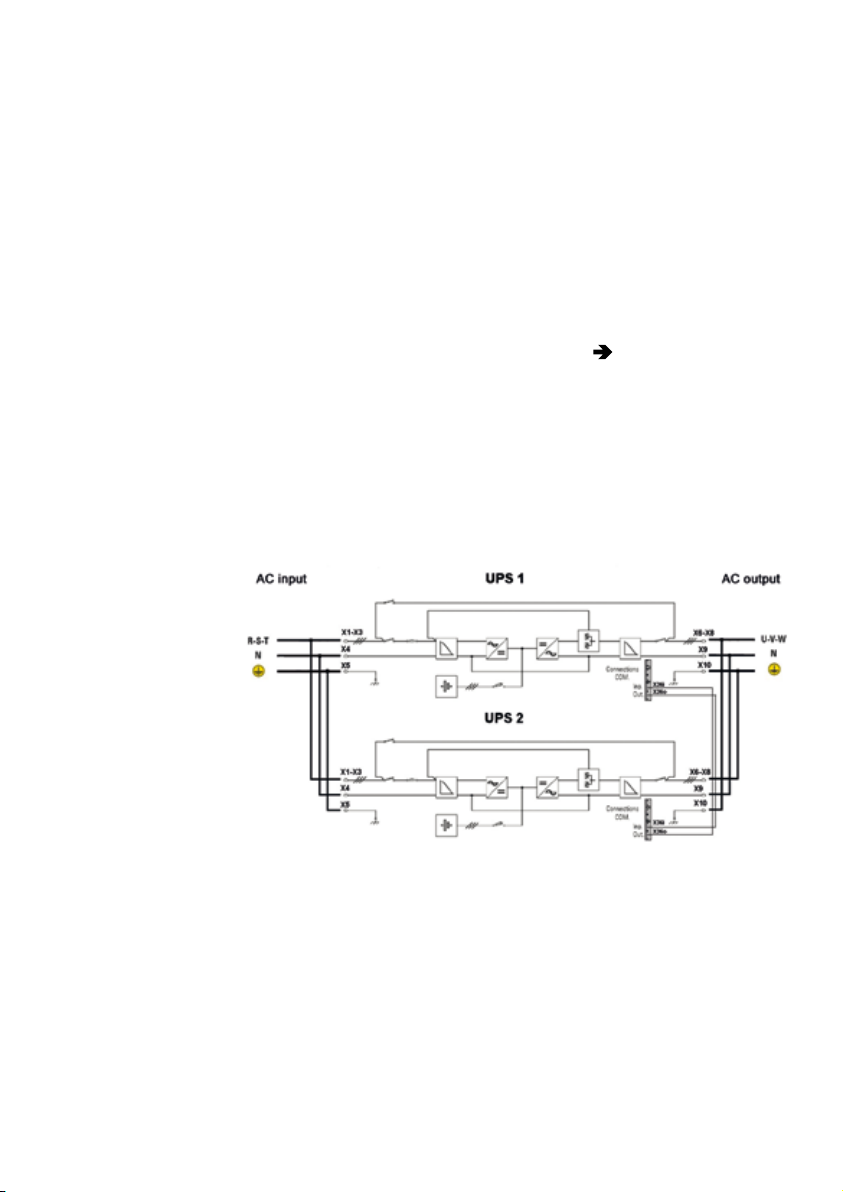

Fig.13: Single line diagram for UPS parallel system

2 UPS’s can be paralleled to one UPS system for redundancy purposes or to

double the maximal load level. Only identical UPS with the same ratings can

be paralleled. Fig.13 shows the single line diagram of a parallel system of

Protect 2.33 2.0 showing the power connections and the control bus cables.

Two UPS running in parallel always do load-sharing. Parallel operation offers

several advantages like higher availability or “modular” adaption of the UPS

system to cover increasing power demands.

The parallel system management is based on a dynamic MASTER-SLAVE principle,

where the first UPS in normal operating mode will become MASTER. It has the

control of the second UPS (SLAVE).

Page 18

18

There are two operation modes possible:

• Redundant system: As long as both UPS do not exceed the level of 50 % load

one UPS is able to take over the full load if one of the UPS in the system fails.

After the failed UPS was repaired it can be restarted and will recover the redundancy condition. In case of more than 50 % load per UPS the system will generate an alarm. In case one UPS fails at more than 50 % load per UPS the second

UPS will take over and will run into overload. It will supply the load according to

the UPS overload capability. After that condition both UPS will switch to bypass.

• Parallel system for power enhancement: Paralleling two UPS will double the

maximum power. There will be no alarm “Redundancy lost”.

Page 19

4. INSTALLATION

19

• Refer to the safety instructions.

• Ensure that the data on the rating plate of the UPS match those required for

installation.

• Any incorrect connection or handling may cause damage to the UPS and/or

the loads connected to it. Read these instructions carefully and follow the steps

indicated in the correct order.

• This UPS must be installed by qualified staff and is usable by personal with no

specific training. All staff using this equipment should become familiar with the

contents of this of this “Manual”.

• Should a power increase be required in the future through parallel switching,

consider that larger cable diameters may be required. Likewise, the additional

installation of an external manual bypass switch for each device is

recommended.

4.1. IMPORTANT SAFETY INSTRUCTIONS

As this is a device with class I protection against electric shocks, it is essential to

install a protective earth conductor (connect earth (()). Connect the conductor to

the terminal (X5), before connecting the power supply to the UPS input.

All connections in the device, including those for control (interface, remote

control, ...), will be performed with the switches at rest and without any mains

feed present (UPS power line cut off “Off”).

It must never be forgotten that the UPS is a generator of electrical power, users

must take all necessary precautions against direct or indirect contact.

Warning labels should be placed on all primary power switches installed in places

away from the device to alert the electrical maintenance personnel of the presence

of a UPS in the circuit. The label should contain the following or an equivalent text:

Before working on this circuit:

• Isolate Uninterruptible Power System (UPS).

• Then check for hazardous voltage between all terminals including the

protective earth.

Risk of voltage feedback

Page 20

20

Once the power supply is connected to the input of the UPS (with static bypass

included or with an independent static bypass line), although the inverter is “Off”

(shut-down), it does not mean that no output voltage is available at the output

terminals.

To do this, it is required to switch (Q1a), (Q4) and (Q2) to position “Off”. It is

possible that the UPS might be supplying output voltage from the manual bypass,

so this must be considered for the purpose of safety. If the output power supply of

the UPS has to be interrupted in this situation, deactivate the switch (Q5).

In devices with battery terminals, precautions must be taken as they are not

electrically insulated from the alternating input line, and there might be dangerous

voltage between the battery terminals and the ground.

4.1.1. BATTERY SAFETY INSTRUCTIONS

The manipulation and connection of the batteries shall be only be carried out and

supervised by personnel with battery knowledge.

For units requested without batteries, the acquisition, installation and connection

of the batteries will always be done by the customer and it is under his

responsibility. The relevant information on the batteries (number, capacity and

voltage) are indicated in the battery label pasted beside the nameplate of the

equipment. Strictly respect this data, the battery polarity connection and the

circuit diagram provided with this documentation.

The battery supply can involve the risk of electric shock and can produce high short

circuit current. Observe the following preventive measures before manipulating any

terminal block identified in the labeling as “Battery”:

• Disconnect the corresponding protection elements.

• When connecting a battery cabinet to the equipment, respect the cable’s

polarity and color (red-positive; black-negative) indicated in the manual and

in the corresponding labeling.

• Wear rubber gloves and shoes.

• Use tools with insulated handles.

• Removes watches, rings or other metal objects.

• Do not place metal tools or objects on the batteries.

• Never manipulate directly with your hands or through conducting objects, do

not short the battery terminal block or the battery enclosure.

• Never short the battery terminals as it involves a high risk. It may result in

damage to the equipment and batteries.

Page 21

21

• Avoid mechanical exertions and any impacts.

• Do not open or damage the battery. Released electrolyte can be harmful to the

skin and eyes.

• Do not dispose of batteries in a fire. The batteries may explode.

• In case of contact with the battery acid, wash immediately with plenty water and

immediately call the nearest medical facility.

• Batteries involve a serious risk for health and for the environment.

• Their disposal should be carried out according to any existing laws.

4.1.2. CABINET ACCESS

All the UPS units and battery packs have terminals as power connection parts

and a DB9 connector for the communication channel located in the inside of the

equipment. Follow the steps described next to gain access to them:

• Unlock the lock (CL) with the special supplied key.

• Rotate it 45º clockwise and open the front door (PF) completely.

DB9 connectors from communication ports and terminals for remote EPO

button will be revealed.

• Remove the screws (t1), which fix the terminal cover (TB) inside of the cabinet

and remove it; the power terminals will be revealed.

• The connecting cables can be connected to the terminals located below the

clamps and can be fixed to the aluminum rail.

• Once the connection of the UPS is complete, replace the cover (TB) and close

the door (PF) with the lock (CL).

The cable cross section of the bypass, input and output lines shall be determined

from the maximum currents for the two first and from nominal ones for the output,

by respecting the local and/or country low voltage electro-technical standards.

To calculate the cross cable sections, take the Figures of the current as stated in

table 1 depending on the model and nominal voltage value of the UPS. In the

nameplate of the equipment are printed the nominal currents as stated in the

safety standard EN-IEC 62040-1.

Safety characteristics:

• For the input power failure circuit breaker Type B.

• For the output (supply loads) , circuit breaker with tripping characteristics C.

Minimum currents are stated in table 1 depending on the model and nominal

voltage value of the UPS.

Page 22

22

The cross sections of all of the connecting cables must in each case be sized

according the fuse selected.

In cases were added input, output or bypass peripherals to the UPS (e.g.

transformers or autotransformers) currents are stated in the nameplates of the

peripherals and must to be taken into account in order to use suitable cross

sections. Always respect the local and/or national low voltage electro-technical

regulations.

PROTECT 2.33 2.0

Equipment

3 x 380 V 3 x 400 V 3 x 415 V

power

(kVA)

Input

Output

Input

Bypass

Output

Input

Bypass

Bypass

Output

10 15 15 - 14 15 - 14 14 -

15 22 23 - 21 22 - 20 21 -

20 30 30 - 28 29 - 28 28 -

30 44 45 - 43 43 - 40 41 -

40 59 61 - 57 58 - 53 55 -

60 89 91 - 85 87 - 80 82 -

80 118 122 - 113 116 - 107 110 -

Table 1: Input, output and bypass currents for standard single phase Protect 2.33

standard systems

If isolation transformers are present in the installation at the input and/or output

of the UPS, they have to be fitted in with protection against indirect contacts

(earth leakage breaker) at the output of each transformer. Electrically insulated

of the transformer will impede the tripping of protection installed at the primary

winding of the transformer in cases were an short circuit in the secondary winding

(output of isolation transformer) may occur.

Note that all neutral terminals for input, output and battery are connected inside

the UPS.

The cable routing or housing passages supplied fitted to the metal structure are

those recommended to correctly fix the input, output and bypass wires with the

sections determined by the national low voltage electro-technical regulations in

accordance with the currents of the device.

Page 23

23

If these sections should have to be changed for any reason, this should be

implemented with a separate distribution box and the sections indicated should

be maintained from the device to the distribution box.

In standard equipment up to 40 kVA, batteries are supplied inside the UPS

enclosure and for higher power rates they are supplied in a separate cabinet. By

default, the UPS has a battery fuse-holder switch (Q3) with 3 fuses for models up

to 40 kVA or battery switch (Q3) for models with higher power rate.

From 60 kVA upwards, no UPS internal batteries are installed, instead you will find

a circuit breaker (Q8) in the battery cabinet. Fuses are includes in the delivery of

the UPS. Open the fuse box (Q3) and (Q8) and install the three fuses. Connect the

battery with the UPS and then follow the startup procedure prompted via the UPS

display.

IMPORTANT FOR YOUR SAFETY: Do not turn the battery fuse holder switch or

switch (Q3) located in the equipment or its equivalent (Q8) in the battery cabinet

to “On” (Close) until the equipment is switched on completely, because it can

cause irreversible damage to the equipment or accidents.

4.2. SET UP AND INSTALLATION

4.2.1. UNPACKING AND CONTENT CHECKING

On receiving the device, make sure that it has not suffered any damage during

transport. Make all damage claims to your supplier or to our company. Check

the data in the nameplate, which is fixed inside the front door (PF) and that it

corresponds to that specified in the purchase order. To check this, it will be

necessary to unpack the UPS. If this is not possible, any non-conformity must

be sent at the earliest possible date, quoting the device manufacturing number

and any references on the delivery remittance.

When the device has been accepted, it is best to pack the UPS away once more

until it is to be commissioned in order to protect it from any possible mechanical

knocks, dust, dirt, etc.

The packaging of the device consists of a wooden pallet, a cardboard or wooden

surround (depending on the case), expanded polystyrene corner pieces,

polyethylene sleeve and band. All are recyclable materials and should therefore

be disposed of according to current regulations. However, we recommend that

the packaging should be kept in case its use is necessary in the future.

To unpack, cut the bands on the cardboard surround and remove it from above.

Page 24

24

If the surround is made of wood; remove the corner pieces and the plastic sleeve

first. The UPS will be unpacked on the pallet, to lower it, suitable means (fork

truck, crane, hoist) must be used that can operate within the safety tolerance

limits for the approximate weights displayed in tables 5 and 6 (Page 73 – 75).

4.2.2. STORAGE

Equipment should be stored in a dry, ventilated place protected from rain,

splashing water and chemicals. It is recommended to store the UPS and batteries

in their original packing. This offers the best protection during transport and storage.

If ordered with the UPS, closed lead accumulators are built into the UPS or

the battery cabinet. To ensure problem free operation of the 10 – 20 kVA

equipment you should not store for longer than 3 months and absolutely no

longer than 6 months.

If longer storage is required, the batteries must be recharged after the

aforementioned periods

Store batteries or equipment with built-in batteries at 20 – 25 °C.

Deviation from this may result in a reduction of maximum storage availability.

4.2.3. TRANSPORTATION TO SITE

All UPSs are fitted with rollers to facilitate transport to site. Be sure to observe

tables 5 and 6 (page 73 – 75) for indicated weights in the selection of an

appropriate site and the selection of transport route (floor, elevators, stairs etc.)

Page 25

25

Fig.14: Front view UPS location for single unit

Fig.15: Top view UPS location for single unit

4.2.4. LOCATION

The security instructions indicate that it is necessary to leave a minimum of 25cm

around the equipment for ventilation (2 UPS devices in parallel operation should

be set 50 cm apart from each other. See Fig.14 and 15.) Nevertheless, we recommend to leave another 75cm additional space to facilitate maintenance of the

equipment or technical service intervention in event of a breakdown.

The UPS may be put in any place as long as the safety instruction requirements are

fulfiled and the weights are considered as indicated in table 5 and 6.

The UPS includes 2 leveling elements (PB) located near the front castors, which

serve to immobilise the unit once it is in place.

Open the front door (PF) of the cabinet and proceed as follows:

• By hand, loosen the leveling elements (PB) by turning them anti-clockwise until

they touch the floor. Then, using a spanner, continue loosening until the castors

are raised off the floor by a maximum 0.5cm, ensuring that it is level.

• Close the door (PF).

Page 26

26

Fig.16: Front view for parallel system

Fig.17: Floor view for parallel system

4.3. CONNECTION

4.3.1. TO THE MAINS CONNECTION, TERMINALS (X1 TO X4)

As this is a device with class I protection against electric shocks, it is essential to

install a protective earth conductor (connect earth

the terminal (X5), before connecting the power supply to the UPS input.

In accordance with safety standard EN-IEC 62040-1, installation has to be

provided with a “feedback protection” system(e.g. a contactor) which will prevent

the appearance of voltage or dangerous energy in the input mains during a mains

fault (see Fig.18 and respect the wiring diagram of “feedback protection”.

There can be no deviation in the line that goes from the “feedback protection”

to the UPS, as the standard safety would be infringed.

Warning labels should be placed on all primary power switches installed in places

( )

). Connect the conductor to

Page 27

away from the device to alert electrical maintenance personnel to the presence

of a UPS in the circuit.

27

Fig.18: Block diagram for the «feedback protection» application, for the different configurations

Fig.19: Single line diagram of parallel system connection(UPS) with protection panel and

feedback protection

Page 28

28

The label should contain the following or an equivalent text:

Before working on this circuit:

• Isolate Uninterruptible Power System (UPS).

• Then check for Hazardous Voltage between all terminals including the

protective earth.

Risk of voltage feedback

To connect the mains cables to the respective terminals according to configuration

of the available equipment.

Connection to the mains:

Connect the power supply cables N-R-S-T to the input terminals (X4), (X1), (X2)

and (X3), respecting the order of neutral and phases indicated on the label of the

device and in this manual. If the order of the phases is not respected, the UPS

cannot be started and displays an error message.

When there are discrepancies between the labeling and the instructions in this

manual, the label will always prevail.

4.3.2. CONNECTION OF THE OUTPUT, TERMINALS (X6 TO X9)

As this is a device with class I protection against electric shocks, it is essential to

install a protective earth conductor (connect earth

to the terminal (X5), before connecting the power supply to the UPS input.

To connect the output cables to the respective terminals according to

configuration of the available equipment.

Connection to the output:

Connect the load cables N-U-V-W to the output terminals (X9), (X6), (X7) and

(X8), respecting the order of neutral and phases indicated on the label of the

device and in this manual. If the order of the phases is not respected, the UPS

cannot be started and displays an error message.

When there are discrepancies between the labeling and the instructions in

this manual, the label will always prevail.

It is recommended that a connected load over an external distribution over

multiple (min. 3) automatic circuit breakers share 1/3 of the maximum UPS

nominal output current. If one of these outlets short circuits, then the

( )

). Connect the conductor

Page 29

29

corresponding circuit breaker should trigger without affecting the supply of the

remaining outlets (selective).

4.3.3. UPS CONNECTION TO EACH BATTERY PACK IN CABINET, TERMINALS (X11, X12, X23 AND X47, X48, X49)

As this is a device with class I protection against electric shocks, it is essential

to install a protective earth conductor (connect earth ( )). Connect the

conductor to the terminal (X5), before connecting the power supply to the

UPS input.

IMPORTANT FOR YOUR SAFETY: Do not turn the battery fuse holder switch or

switch (Q3) located in the equipment or its equivalent (Q8) in the battery cabinet

to “On” (Close), until the equipment prompts you during the startup procedure

via the display, because it can cause irreversible damage to the equipment or

accidents because the engineer is exposed to ELECTRICAL DISCHARGE

DANGERS. The UPS prompts before connection with the battery cabinet.

UPS connection with battery pack will be implemented with the supplied trunk

cable by connecting one side to terminals (X11), (X23) and (X12) of the UPS and

the other one to terminals (X47), (X49) and (X48) on the battery pack. Always

respect the stated polarity in the labeling of each part and in this manual. The

color of the cables (red for positive, black for negative, blue for middle tap (N)

and green-yellow for earth bonding), see Fig. 20.

Turn off multiple battery packs in parallel. Firstly connect the black wire from the

negative terminal of the UPS to the negative terminal of the first battery pack and

then from there to the others. Proceed with the cables (positive: red, center tap:

blue, protective earth, green-yellow) accordingly.

Electrical discharge danger. If after starting up the UPS, it is required to

disconnect the battery cabinet, the equipment has to be completely shutdown

(see section 5.2). Turn off the battery fuse holder switch (Q8) located in the battery

cabinet and/or fuse holder switch or switch (Q3) located in the UPS. Wait at least

5 min. until the filter capacitors have been discharged.

Page 30

30

4.3.4. CONNECTION MAIN PROTECTIVE EARTHING

TERMINAL ( ) AND PROTECTIVE EARTH BONDING

TERMINAL ( )

As this is a device with class I protection against electric shocks, it is essential to

install a protective earth conductor (connect earth ( )). Connect the conductor to

the terminal (X5), before connecting the power supply to the UPS input.

Make sure that all the loads connected to the UPS are only connected to the

protective earth bonding terminal

or loads and/or the batteries case/s or cabinet/s to this single point,

ground loops which can affect operational safety.

All of the terminals identified as protective earth bonding

to the main protective earthing terminal ( ) and to the frame of the device.

( )

. By not restricting the earthing of the load

can lead to

( )

, are joined together,

Fig.20: Connection example between a UPS and two battery cabinets

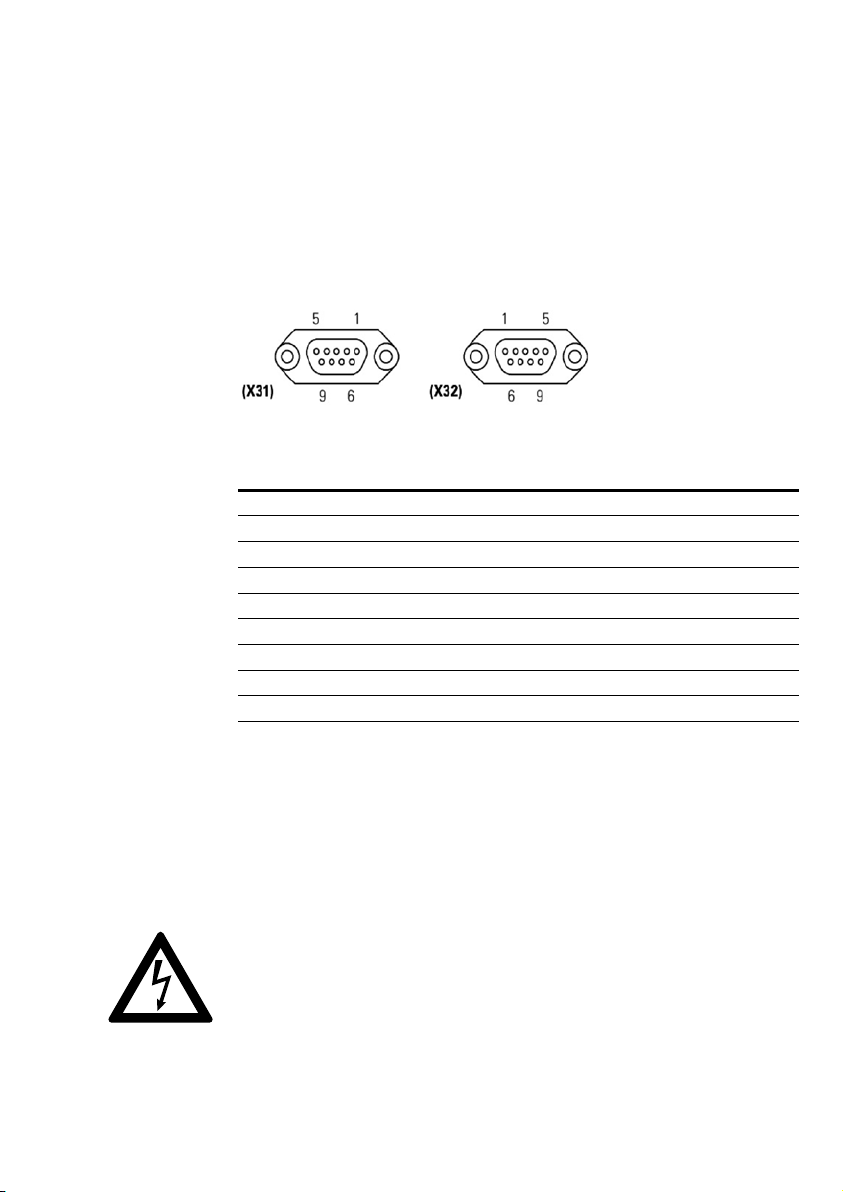

4.3.5. INTERFACE RELAY CONTACTS, CONNECTOR (X32)

The remote signal lines operate over low voltage. To ensure safe and problem free

communication, install at a safe distance from the power supply lines to the UPS.

The built in relays provide a digital signal over a potential free contact.

The permissible contact load is 6 A 30 VDC or 6 A 100 VAC. Supplemental to the

DB9 connector you will find parallel screw terminals on the communication board.

Remote signaling operates over fiver output relays (one is adjustable), the

Page 31

common ground is connected to pin 5. Furthermore, an input signal can be used

to shut down the UPS (5 VDC – 12 VDC.)

Fig.21: Connector DB9 (X31) & (X32)

PIN-OUT NO. DESCRIPTION N.C.-N.O. POSITION

1 Shutdown signal + -

2 Shutdown signal – -

3 Configurable Not connect

4 Discharge - Mains failure N.C.

1

5 Common -

6 Equipment in Bypass N.O.

2

7 Low battery N.O.

8 General alarm N.O.

9 Discharge - Mains failure N.O.

31

1

N.C.: Normally closed contact. On the alarm having activated the contact

is opened.

2

N.O.: Normally open contact. On the alarm having activated the contact

is closed.

Table 2: Alarms interface to relays connector DB9 (X32)

4.3.6. COM-INTERFACE RS232 AND RS485, CONNECTOR (X31)

The serial communications interface operates over low voltage. To ensure safe and

trouble-free communication, install at a safe distance from the power supply lines

to the UPS.

The X31 DB9-connector is used for communication to RS232 or RS485 standard

connectors. Both standards cannot be used simultaneously.

Both channels are in use for connecting the UPS with any machine or devices that

has this standard bus. The RS232 consists of the transmission of serial data, so it is

possible to send a large amount of information through a communication cable of

just 3 wires.

Page 32

32

Physical structure of the RS232.

• Pin-out

- Pin 2. RXD. Serial data reception.

- Pin 3. TXD. Serial data transmission.

- Pin 5. GND. Signal mass.

• Communication protocol of the RS232.

The communication protocol used is of “MASTER/SLAVE” type.

The computer or computer system (“MASTER”) asks about a certain data,

and the UPS (“SLAVE”) answers immediately with the required data. Firstly it

will be programmed the communication channel of the computer with the

same parameters as the communication channel of the UPS. Then we will be

prepared to start the communication and therefore send the UPS the first

question. If we have any problem in the middle of the communication, it will

be advisable to repeat the channel initialization sequence.

Physical structure of the RS485.

Unlike other serial communication links, this uses only 2 wires (pins 4 and 9 of the

female DB9 connector) to perform the dialogue between the systems connected

to the network. The communication will be established by sending and receiving

signals in differential mode, which gives the system great immunity to noise and

a long reach (approx. 800 m).

• Pin-out

- Pin 4. Output signal A (+)

- Pin 9. Output signal B (–)

• Communication protocol

The communication protocol of the RS485 channel is developed to enable

the UPS to communicate with other computer systems that use the same bus.

The communication parameters RS232 and RS485 are the following:

• Communication speed: 1200, 2400, 4800, 9600 or 19200 Baud.

• No. information bits: 8 Bits.

• No. stop bits: 1 or 2 stop bits.

• Parity bit: - Even, Odd

Page 33

4.3.7. EPO TERMINALS (X50)

The equipment has two terminals ready for external remote (Emergency Power

Off (EPO)).

In case where there is a requirement to install a switch or button (EPO), the cable

bridge that closes the circuit has to be removed from terminal strip (X50).

The switch or button (EPO) has to open the circuit between the terminal strip

(X50) to activate the emergency shutdown. To restore the UPS to normal mode,

reverse the position of the switch or button (EPO), -close the circuit in terminal

strip (X50).

To understand the operation of (EPO), see section 5.3 of this manual.

33

Fig.22: Terminals for connection of external push-button (EPO), property of the user

Note: In a parallel system there is an emergency stop switch to one of the two

UPS devices. Detailed information on emergency shutdown can be found in

chapter 5.6.

4.3.8 PARALLEL BUS CONNECTION (X36)

This section is only relevant for parallel systems.

• For the correct parallel operation both UPS communicate to each other via the

parallel BUS. For redundancy purposes the BUS connection consists of 2 cables

which are connected in a loop.

• Connect the parallel BUS connection after all power connections have been

done. In the accessory of each UPS you can find one 5 meters, 15-pole parallel

BUS cable (HDB 15 connector male/female). If you connect 2 UPS to one

parallel system each UPS comes with one cable.

• Connect X36o of UPS 1 to X36i of UPS 2 and X36i of UPS 1 to X36o of UPS 2.

An additional termination of the connection is not needed.

Page 34

34

• Fix the BUS cables to the bottom of the UPS using the plastic clips below the

communication interfaces.

Note: Always use the original lines to ensure trouble free parallel operation.

Fig.23: Parallel BUS Connection

Page 35

5. OPERATION

35

Note: The following descriptions relate to operation of the UPS using the keys

below the display screen. Operation can also be carried out using the touchscreen

capability, juts type in the appropriate files or text.

5.1. START UP

5.1.1. CONTROL BEFORE START UP

Ensure that all the connections have been made correctly and are sufficiently tight,

respecting the labeling of the device and the instructions in chapter 4. “Installation

and wiring of the unit”.

Check that the UPS switches and the battery cabinet or cabinets are turned off

(position “Off”).

Be sure that all the loads are turned “Off”.

5.1.2. START UP PROCEDURE

It is very important to operate “start-up” in the established order and to

considering the following instructions.

If you start up a UPS in a parallel system, the written procedures apply to both

UPS devices. You can use the procedure described below step by step for the first

UPS and then for the 2nd UPS until you see the message “Close battery switch!”

Now you can close both battery switches. It is irrelevant which UPS starts first.

If the UPS connects to an external battery cabinet, set the fuse holder switch of

the battery cabinet (Q8) to “On”.

If the power supply to the UPS has a general switch, set the general switch of the

header board to “On”.

Turn the input switch (Q1a) to “On” position. The display of the Control Panel (PC)

will be turned on automatically.

If the following alarm message appears on the Control Panel Display ...

PHASE REVERSE INPUT POWER

… and an audible alarm sounds, the UPS cannot be started because of incorrect

input phase sequence. Disconnect the input switch (Q1a) and the general cut-off

of the header board, swap the phases of the input terminals of the UPS according

to the labeling and repeat the start-up process described previously.

Page 36

36

At this point, with no alarm active, green LED indications of input voltage OK,

and orange LED indication of Unit on Bypass should light ((a), (b) from Fig.25).

Turn the output switch (Q2) to “On”. It is now powered by the built in Thyristor

supply voltage

Start up the inverter. The start-up operation will be done through the keypad of

the control panel ((3) from Fig.25). Select “CNTL” and press (ENT) into control

submenu (screen 1.0), and then select “ON” and press (ENT) once. You will get to

screen 1.1, asking you to start the unit up “yes” or “no”, you can select “Yes” by

pressing (ENT). See following screen diagram (Fig.24).

After a few seconds, the UPS will be running (rectifier working, inverter working),

and the output will be supplied from the inverter.

Confirm YES

screen 1.1

screen 1.2

screen 1.3

screen 1.0

Turn ON UPS

Confirm YES

Turn OFF UPS

Confirm YES

DO Battery Test

Main

screen 0.0

()()

(

) ()

(Ent)

Control

screen 1.0

()()

(

) ()

ON

OFF

Battery Test

Back

(Ent)

(Ent)

(Ent)

(Ent)

Fig.24:

Procedure start-up / shutdown

Before continuing, be sure that the LED indication (c) Inverter is working and is it

(green), and (b) Unit on Bypass is turned OFF (see Fig.25).

Once the rectifier is completely working, it initiates a process of equalization

(DC bus voltage starts to equalize with battery voltage). After a few seconds

(depending on the battery level), an alarm message like this will be displayed:

CLOSE BATTERY SWITCH

…it indicates that the equalizing process has been finished,

the battery fuse holder switch or switch of the UPS (Q3) can be turned on.

DO NOT TRY to close any battery fuse holder switch at any other moment,

because this operation could damage the equipment and/or possibly cause accidents. They can only be turned on by following the previous steps.

and at this moment

Page 37

37

Start up the loads to be supplied in a progressive way. The system is started up

completely, and the loads are protected through the UPS.

a

2

Fig.25:

LED indications control panel (PC)

1

3

b

c

d

e

5.2. COMPLETE UPS SHUTDOWN

• Shutdown the loads.

• If the system has outgoing distribution protection, switch them “Off”.

• Shutdown the inverter. Through the keypad of the control panel ((3) from

Fig.25), go down to “CNTL” submenu (screen 1.0), and select “OFF”.

You will get to screen 1.2, asking you to shut down the unit by pressing (ENT),

see Fig.24.

• Turn the output switch (Q2) to “Off” position.

• Set the input switch (Q1a) to “Off” position.

• Turn fuse holder switch from battery cabinet (Q8) and/or battery fuse holder

switch or switch from UPS (Q3), to “Off”.

• Cut the power supply of the UPS and the bypass with the cut-off or general

switch on the header board. The system will be completely deactivated.

Electrical discharge hazard. If, after shutdown of the equipment, it is necessary to

disconnect the separate battery pack/s, wait several minutes (5 min. approx), until

the electrolytic capacitors have been discharged.

The equipment is completely shut down.

Page 38

38

5.3. EMERGENCY POWER OFF (EPO) OPERATION

Emergency Power Off (EPO) is equivalent to a complete unit system halt:

• All UPS converters are turned off (rectifier and inverter off).

• No output voltage is supplied to the loads.

See table below for operation:

E.P.O. FUNCTION Terminals (X50).

Normally closed circuit by means of the provided cable

bridge (it allows an external switch (EPO)).

ACTIVATION

(PERFORM SYSTEM

HALT)

RETURN TO

NORMAL-MODE.

Remote button or switch has to be opened permanently

in terminal strip (X50).

The equipment has to be shut down and de-energized

completely (turn off all switches), wait until DC bus is

discharged (all LEDs and LCD have to be turned off).

The equipment has to be started up according to

section 5.1.2. “Start-up procedure”.

Table 3: Emergency Power Off (EPO) operation

Note: In parallel mode it is sufficient , when the emergency shutdown is activated

for one UPS.

5.4. BYPASS MANUAL SWITCH (MAINTENANCE)

5.4.1. PRINCIPLE OF OPERATION

The integrated manual bypass of the UPS is a very useful element, but

unwarranted use can have irreversible consequences both for the UPS and

for the loads connected to its output. It is therefore important to handle it

as described in the following paragraphs.

5.4.2. TRANSFER TO MAINTENANCE BYPASS

Note: The bypass switch connects the load at the electrical output before the

input switch (Q1a) and after the output switch (Q2). In practice, the input switch

is combined directly with the output terminals. If you switch off all of the other

switches after switching on the bypass switch, the UPS is internally without power

(neutral conductors are not connected.) For equipment fitted with internal

Page 39

39

batteries you will find a 2nd battery switch used for measuring the battery voltage

inside the top of the unit (3-pole circuit breaker.) To switch equipment power off

completely you will also need to open this switch. Beware of possible residual

charge in the capacitors inside the equipment and wait for 5 minutes so that they

can discharge.

Procedure for passing from normal operation to maintenance bypass:

• Shut down the inverter. Through the keypad of the control panel ((3) from

Fig.25), go down to “CNTL” submenu (screen 1.0), and select “OFF”.

You will get to

see Fig.24.

• Remove the screws that attach the mechanical block (BL).

• Remove the mechanical block (BL) of the manual bypass switch (Q5) and set it

to “On” position.

• Set the output switch (Q2) to “Off” position.

• Set the Battery Fuse Holder or battery switch (Q3) to “Off”. In models with

inde pendent battery pack/s also turn Battery Fuse Holder (Q8) of each pack

to “Off”.

• Set the input switch (Q1a) to “Off” position.

The UPS is supplying output voltage directly from the mains through the manual

bypass. The UPS is completely shut down and inactive.

screen 1.2, asking you to shut down the unit by pressing (ENT),

5.4.3. TRANSFER TO NORMAL OPERATION

Procedure for switching from maintenance bypass to normal operation:

• In model with an external battery cabinet, set fuse holder switch from battery

cabinet (Q8) to “On” position.

• Set the input switch (Q1a) to “On” position.

• Set the output switch (Q2) to “On” position.

• Make sure that the UPS is in bypass mode (green and yellow LEDs signal “

bypass”)

• Set the manual bypass switch (Q5) to “Off” position and refit the mechanical

block (BL) and the screws (t2).

It is an essential requirement for safety to refit the mechanical block (BL), as this

avoids dangerous usage of the UPS and the loads connected to it.

Start up the inverter. The startup operation will be initiated through the keypad

of the control panel ((3) from Fig.25). Select “CNTL” and Press (ENT) into control

Page 40

40

submenu (screen 1.0), and then select “ON” and Press (ENT) once. You will get to

screen 1.1, asking you to start the unit up “yes” or “no”. You can select “Yes” by

pressing (ENT).

The UPS supplies output voltage entirely protected against voltage variations,

electric noise, etc.

Wait for alarm message to appear:

CLOSE BATTERY SWITCH

Battery fuse holder switch or switch from UPS (Q3) can only be turned “On”

when the previous alarm message has been canceled.

DO NOT TRY to close any battery fuse holder switch at any other moment

because this operation could damage the equipment and/or possibly cause

accidents. They can only be turned on by following the quoted previous steps.

The UPS delivers output voltage that is protected against all power disturbances.

Page 41

6. CONTROL PANEL AND DISPLAY DESCRIPTION

6.1. CONTROL PANEL PARTS

(1) (LEDs) LED indications:

(a) Rectifier Input Voltage OK (green)

(b) Unit on Bypass (orange)

(c) Inverter is working (green)

(d) Unit working from batteries -mains failure (red).

(e) In case of any alarm of the unit (red)

(2) Graphic Display

(3) Keyboard

ENT “Enter” key. Confirmation of orders, program values

(or other specified functions)

“Left” key for submenu navigation, or cursor displacement

“Right” key for submenu navigation, or cursor displacement

“Up” key for menu page navigation, or digit modification

“Down” key menu page navigation, or digit modification.

ESC “Escape” key. Return to previous screen, cancel/finish programming

(or other specified functions)

By pressing the “right“ and “left“ keys you will see the titles on the sub menus

and can navigate between the different displays.

41

6.1.1. TOUCH SCREEN

The touch functionality of the screen can be used by touching the screen. Simply

type with your finger on the appropriate fields or text.

6.2. BASIC FUNCTIONS OF KEYBOARD FROM SYNOPTIC

Through keys advance and return , there is access to all the menus of the LCD

panel, and being able to move from one to another.

Through keys right or left , there is access to the screens of all the

submenus of the LCD panel, being able to move from one to another with

themselves.

Page 42

42

Key (ENT), has different purposes depending on the menu we are:

• Setting values. Press key (ENT) to activate the function setting, the Figures in

the screen will blink. With keys

- the character to set is selected and with

keys - the value is selected. To confirm press (ENT). Next field will blink, to

continue doing settings proceed in the same way or press (ESC) to return to

no-setting situation.

• Validation of orders or commands.

When pressing key (ESC) you will go back to the previous screen of any screen of

any submenu, , unless you are in the “Parameters” menu and in the process of

setting any of them. If so, by pressing the (ESC) key the value will stop blinking,

and by pressing it a second time you will go back to the previous screen.

With the UPS in bypass mode, use the ESC button to cancel alarms. In this way the

audible alarm is turned off.

Notes related with the screen map (see Fig. 27):

• Some screens have a certain number of “–” characters. Each screen represents

one function so the maximum length of the field will be determined by the

number of characters.

• Each screen is labeled with a number located in its right bottom corner. It is only

included as a mere reference for its next description and explanation.

a

b

2

Fig.26:

Control panel parts

1

c

d

e

Page 43

6.2.1.

MESSAGES MENUS AND CLASSIFICATION IN SUBMENUS

Use ( ) ( ) and ( ) ( ) keys to choose between different menus (1.0, …, 5.0)

and Press ENT to enter into the subscreen.

43

CNTL (Control &

Status of the unit)

MEAS (Measures)

()()

MAIN

screen 0.0

The input/output/battery

voltage and the power flow

Fig.27:

Display messages menus and classification in submenus.

(

) ()

DATA (Datalogger)

SET (Settings)

ALARM (Alarms)

(Ent)

screen 1.0

screen 2.0

(Ent)

screen 3.0

(Ent)

screen 4.0

(Ent)

screen 5.0

(Ent)

Page 44

44

6.2.2. MENU STRUCTURE

Page 45

6.3. SCREEN DESCRIPTION

6.3.1. MAIN LEVEL (SCREEN MENU 0.0)

Screen 0.0:

Main presentation screen, with time and date indication.

Initialization: After power on

45

Use (ESC) key or Enter the Icon home on any screen of any submenu, to go

back to main screen (Screen 0.0).

Fig.28: Screen 0.0 Main Screen

Page 46

46

6.3.2. UPS STATUS CONTROL (SCREEN MENU 1.0)

Screens 1.1 and screen 1.2:

Starting and switching off the equipment.

For how to start and switch off see chapter 5.1 and 5.2.

Screen 1.3:

Ordering a battery test. In the second row, information about the battery test is given.

Possible messages:

• “NOT AVAILABLE“: The battery test is not available.

• “PRESS <ENTER>“: Press <ENTER> to run the battery test.

• “EXECUTING“: The battery test is running.

• “SUCCESSFUL“: The battery test has been successful.

• “NOT SUCCESSFUL”: The battery test has not been successful.

Fig.29: Screen 1.0 Control & status screen

Confirm YES

screen 1.1

screen 1.2

screen 1.3

screen 1.0

Turn ON UPS

Confirm YES

Turn OFF UPS

Confirm YES

DO Battery Test

ON

(Ent)

()()

(

) ()

(Ent)

Control

screen 1.0

Main

screen 0.0

Fig.30:

”Control & status” level

()()

(

) ()

OFF

Battery Test

Back

(Ent)

(Ent)

(Ent)

Page 47

Screen 1.1 Turn on UPS

47

Screen 1.2

Screen 1.3

Turn off UPS

Battery Test

Page 48

48

6.3.3.

‘‘MEASURES” LEVEL (SCREEN MENU 2.0)

Screen 2.1:

• Input voltages phase to phase (display units 0.1 V)

• Three phase input voltages phases to neutral (display units 0.1 V)

• Input current per each phase (display units 0.1 A)

• Three phase output voltages phases to neutral (display units 0.1 V)

• Output current per each phase (display units 0.1 A)

• DC bus voltages positive and negative (display units 0.1 V)

• Battery voltages positive and negative (display units 0.1 V)

Screen 2.2:

• Three phase inverter output voltages phases to neutral (display units 0.1 V)

• Inverter output current per each phase (display units 0.1 A)

• Three phase bypass voltages phases to neutral (display units 0.1 V)

• Bypass current per each phase (display units 0.1 A)

Page 49

• Charge battery currents positive and negative (display units 0.1 A)

• Discharge battery currents positive and negative (display units 0.1 A)

Screen 2.3:

• Input, bypass and output frequencies (display units 0.1 Hz)

• Rectifier, inverter and battery temperatures (display units1 ºC)

• Input apparent power of L1 (display units 0.1 kVA)

• Input apparent power of L2 (display units 0.1 kVA)

• Input apparent power of L3 (display units 0.1 kVA)

• Input active power of L1 (display units 0.1 kW)

• Input active power of L2 (display units 0.1 kW)

• Input active power of L3 (display units 0.1 kW)

• Total input apparent power and active power (display units 0.1 kVA & 0.1 kW)

• Input power factor per each phase (display units 0.01)

49

Page 50

50

Screen 2.4:

• Apparent output power L1 (display units 0.1 kVA)

• Apparent output power L2 (display units 0.1 kVA)

• Apparent output power L3 (display units0.1 kVA)

• Active output power L1 (display units 0.1 kW)

• Active output power L2 (display units 0.1 kW)

• Active output power L3 (display units 0.1 kW)

• Total apparent and active powers (display units 0.1 kVA and 0.1 kW)

• Output power factor of each phase (display units 0.01)

• Output load of three phases (display units 0.1 %)

• Total input load and total output load (display units 0.1 %)

• Calculated bridging time under the current load conditions

(display unit intervals 1 minute)

Page 51

6.3.4.

‘‘SETTINGS” LEVEL (SCREEN MENU 3.0)

Fig.31: Screen 3.0 “Settings” and its submenus.

51

Screen 3.1: “Default settings“

The color scheme cannot be modified in the current software version.

Setting the time and date format

The following display languages are available :

• “German”

• “English”

• “French”

• “Spanish”

• “Czech”

• “Chinese”

The modbus address for communication over RS232/ 485 is fixed. In the current

Page 52

52

software version this cannot be changed.

If not already entered by your AEG PS service team: Enter your service contact

Screen 3.2:

In this screen you can program the baud rate of communication (port 0 and port

2). The options are the following

• “1200“

• “2400“

• “4800“

• “9600“

• “19200“

You can program the parity communication (port 0 and port 2). The options are

the following:

• “NONE“

• “ODD“

• “EVEN“

You can program the number of stop bits communication (port 0 and port 2).

The options are the following:

• “1“

• “2“

You can program the protocol communication (port 0 and port 2). The options are

the following:

• “SEC“

• “MODBUS“

Page 53

Note: For problem free communication with the SNMP adapter and

CompuWatch, you should not change the settings.

Screen 3.3:

The screen for programming the frequency of the automatic battery test.

The options for the Type to be programmed are the following:

• “DISABLED”: The automatic battery test is disabled.

• “WEEKLY”: The automatic battery test runs once per week.

• “MONTHL”: The automatic battery test runs once per month.

• “YEARLY”: The automatic battery test runs once per year.

For weekly testing choose a weekday. Choose from the following options:

• “MON”: The selected day to run the weekly battery test is Monday.

• “TUE”: The selected day to run the weekly the battery test is Tuesday.

• “WED”: The selected day to run the weekly the battery test is Wednesday.

• “THU”: The selected day to run the weekly the battery test is Thursday.

• “FRI”: The selected day to run the weekly the battery test is Friday.

• “SAT”: The selected day to run the weekly the battery test is Saturday.

• “SUN”: The selected day to the run weekly the battery test is Sunday.

Set the time here (24 h format).

For monthly testing choose a month and day for the battery test:

• “JAN“: The annual battery test will run in January.

• “FEB“: The annual battery test will run in February.

• “MAR“: The annual battery test will run in March.

• “APR“: The annual battery test will run in April.

• “MAY“: The annual battery test will run in May.

• “JUN“: The annual battery test will run in June.

53

Page 54

54

• “JUL“: The annual battery test will run in July.

• “AUG“: The annual battery test will run in August.

• “SEP“: The annual battery test will run in September.

• “OCT“: The annual battery test will run in October.

• “NOV“: The annual battery test will run in November.

• “DEC“: The annual battery test will run in December.

Screen 3.4. “Advanced Setting”

In this section basic setting can be changed on the UPS. There is the risk that

changes made can affect the function or cause damage to the UPS. Changes

contained within this section should only be made by authorized personnel.

Page 55

55

Screen 3.5 “Information“

In the screen “Information” you can check the UPS configuration of the unit.

Configuration and status of the unit:

• “Single” Single connection.

• “Parallel-Single” parallel connection. Unit is in “single” state.

• “Parallel-Master” parallel connection. Unit is in “master” state.

• “Parallel-Slave” parallel connection. Unit is in “slave” state.

Internal firmware versions of both Digital Signal Processor (“DSP Ver:”) and

micro controller (“uC Ver:”).

UPS Serial Number, expressed with 10 characters.

Service information in the basic settings should be used.

Page 56

56

Screen 3.6

Information about the set-point values:

IP.V and OP.V shows the desired values for the input voltage at the rectifier and the

output voltage.

In addition, you will see the maximum permissible voltage imbalance at the

rectifier and the bypass input, the current at the output and the battery charging

current. Furthermore, the current of the battery and the input will be displayed.

6.3.5. ‘‘ALARMS” LEVEL (SCREEN MENU 4.0)

When “Alarm” appears, in the main menu, you can only see one alarm, but you

can enter “Alarm” into the menu’ to check which alarms are in the current unit as

in the following:

Screen 4.0 “Alarms

Page 57

57

The illustration shows some examples of messages that may be displayed. Table 4

contains a list of all of the warning messages that can be displayed.

REPRESENTATION IN DISPLAY LCD ALARMS FOR NO.

Rectifier overload Rectifier 1

Inverter overload

Mains failure, low battery level 3

Inverter voltage out of margins 4

DC voltage detected at the output. 5

Maintenance bypass. inverter not available 6

Battery discharging

High temperature. Reduce output load. 8

Battery switch open. Switch it ON. 9

Bypass failure. Not synchronized inverter. 10

Unit on bypass. Initialise UPS. 11

Some unit(s) blocked due to maintenance

bypass.

CAN BUS 1 Communication failure. 13

CAN BUS 2 Communication failure. 14

End of battery life. 15

Battery temperature too high. 16

Battery test not succeeded. 17

Battery disconnection. Shutdown &

restart.

Mains phase rotation. UPS start disabled. 19

Bypass phase rotation. UPS start disabled. 20

EEPROM failure. 77

Input voltage wrong. Rectifier stop.

Rectifier desaturation. Rectifier stop. 22

DSP internal error. Rectifier stop. 23

Input phase rotation. Rectifier stop. 24

DC BUS voltage wrong. Rectifier stop. 68

Parallel system rectifier stop 69

Cont. Test fail rectifier stop. 75

Inverter desaturation. Inverter stop.

Inverter overload. Inverter stop. 26

Inverter

UPS

Rectifier stops

Inverter stops

2

7

12

18

21

25

Page 58

58

Inverter stopped due to shutdown

Maintenance bypass. Inverter stop 28

Parallel system disconnection. Inverter stop 29

High overload. Inverter stop 30

Over temperature. Inverter stop 31

Rectifier overload. Inverter stop 32

DSP internal error. Inverter stop 33

Output short-circuit. Inverter stop 34

Bypass phase rotation. Inverter stop 35

Inverter failure/overload. Inverter stop 65

Voltage ramp error. Inverter stop 67

Parallel system inverter stop 70

Low battery. UPS stop

DSP internal error. UPS stop 37

PFC., Inv. stop UPS stop 71

Parallel system UPS stop 72

Emergency power off. No output voltage

Output short-circuit. No output voltage 39

DSP internal error. UPS block all 40

DC BUS voltage wrong. Rectifier block

Rectifier blocked. BLK. UPS -> BLK rec. 42

Rectifier desaturations. Rectifier block 43

Voltage ramp error. Rectifier block 44

DSP execution error. Rectifier block 45

DSP internal error. Rectifier block 46

Contactor test failure. Rectifier block 47

Voltage ramp error. Inverter block

Output DC voltage. Inverter block 49

Inverter blocked. BLK. UPS -> BLK inverter 50

Inverter desaturations. Inverter block 51

DSP execution error. Inverter block 52

DSP internal error. Inverter block 53

Inverter failure. Inverter block 66

UPS blocked. BLK. Rectifier -> BLK. UPS UPS blocks 54

Inverter stops

UPS stops

Byp stops

Rectifier blocks

Inverter blocks

27

36

38

41

48

Page 59

59

Internal initialization error. UPS block (DSP)

Internal execution error. UPS block (DSP) 56

UPS blocked. BLK. Inverter -> BLK. UPS 57

Internal communication. UPS block (DSP) 58