Page 1

UPS OPERATING INSTRUCTIONS

PROTECT

1.100

PROTECT

1

.

PROTECT 1.150

PROTECT 1.200

Page 2

Thank you for deciding to purchase the PROTECT 1. UPS

from AEG Power Solutions.

The following safety instructions are an important part of

the operating instructions are will protect you against

problems from operating errors and possible dangers.

Please read these instructions carefully prior to

commissioning!

2

Page 3

1 Notes on these Operating

Instructions

Duty to provide information

These operating instructions will help you to install and

operate the Uninterruptible Power Supply (UPS), PROTECT

1.100, PROTECT 1.150 or PROTECT 1.200 as well as the

corresponding external battery units PROTECT 1.100 BP or

PROTECT 1.BP20, all referred to as PROTECT 1 in the

following, safely and correctly. These operating instructions

contain important information for avoiding dangers.

Please read these instructions carefully prior to

commissioning!

These operating instructions are an integral part of

PROTECT 1.

The owner of this unit is obliged to communicate the full

content of these operating instructions to all personnel

transporting or starting the PROTECT 1 or performing

maintenance or any other work on the unit.

Validity

These operating instructions comply with the current technical

specifications of PROTECT 1. at the time of publication. The

contents do not constitute a subject matter of the contract, but

serve for information purposes only.

Warranty and liability

We reserve the right to alter any specifications given in these

operating instructions, especially with regard to technical data

and operation.

Claims in connection with supplied goods must be submitted

within eight days of receiving the goods, along with the

packing slip. Subsequent claims cannot be considered.

The warranty does not apply for damage caused by noncompliance with these instructions (such damage also

includes damage to the warranty seal). AEG will accept no

3

Page 4

liability for consequential damage. AEG will rescind all

obligations such as warranty agreements, service contracts,

etc. entered into by AEG or its representatives without prior

notice in the event of maintenance and repair work being

carried out with anything other than original AEG parts or

spare parts purchased from AEG.

Handling

PROTECT 1. is designed and constructed so that all

necessary steps for start-up and operation can be performed

without any internal manipulation of the unit. Maintenance and

repair work may only be performed by trained and qualified

personnel.

Illustrations are provided to clarify and facilitate certain steps.

If danger to personnel and the unit cannot be ruled out in the

case of certain work, it is highlighted accordingly by

pictographs explained in the safety regulations of chapter 3.

Hotline

If you still have questions after having read these operating

instructions, please contact your dealer or our hotline:

Tel: +49 (0)180 5 234 787

Fax: +49 (0)180 5 234 789

Internet: www.aegpartnernet.com

Copyright

No part of these operating instructions may be transmitted,

reproduced and/or copied by any electronic or mechanical

means without the express prior written permission of AEG.

© Copyright AEG 2009. All rights reserved.

4

Page 5

Table of Contents

1 Notes on these Operating Instructions .............................3

2 General Information ..........................................................7

2.1 Technology................................................................7

2.2 System Description....................................................8

2.3 Technical Data.........................................................11

3 Safety Regulations..........................................................15

3.1 Important Instructions and Explanations .................15

3.2 Accident Prevention Regulations.............................15

3.3 Qualified Personnel .................................................16

3.4 Safety Instructions for PROTECT 1. .......................16

3.5 CE Certificate...........................................................20

4 Set-up..............................................................................20

4.1 Unpacking and Inspection .......................................21

4.2 Transport to Installation Site....................................22

4.3 Set-Up......................................................................23

4.4 Overview: Connections, Operating / Display

Elements..................................................................24

4.4.1 Front view...........................................................24

4.4.2 Display ...............................................................25

4.4.3 Rear view (connections): ...................................26

5 Electrical Connection ......................................................28

5.1 Safety of Personnel .................................................29

5.2 Mains Connection (General)....................................29

5.3 Checklist for Cable Connections .............................29

5.3.1 Connection Cross-Sections and Fuse Protection...30

5.4 Mains Connection..............................................................31

5.4.1 Preparation for the three-phase mains connection.31

5.4.2 Connection of the Three-Phase Input Mains

Voltage...............................................................31

5.4.3 Preparation of the Output Cabling .....................32

5.4.4 Connection of the Loads....................................33

5.5 Connection of External Battery Modules.................33

5.5.1 Connection of the Battery Cubicle

PROTECT 1.100 BP..........................................34

5.5.2 Connection of the Battery Cubicle

PROTECT 1.BP20.............................................35

5.6 Mechanical Blocking of PROTECT 1. .....................36

5

Page 6

6 Start-Up...........................................................................37

6.1 Operating Modes.....................................................38

6.1.1 Normal Operation...............................................38

6.1.2 Battery Operation / Autonomous Operation.......39

6.1.3 Bypass Operation ..............................................40

6.1.4 Manual Bypass ..................................................41

6.1.5 Unit overload......................................................42

7 Interfaces and Communication .......................................43

7.1 Computer Interface RS232......................................43

7.2 Communication Slot ................................................43

7.3 Shutdown and UPS Management Software............43

8 Displays and Troubleshooting.........................................45

8.1.1 Signalling............................................................45

8.1.2 Overview Table of LED Displays / Acoustic

Warning Signals.................................................47

8.2 Faults.......................................................................49

8.2.1 Error Messages..................................................49

9 Parallel Operation ...........................................................51

9.1 Principle of Operation..............................................51

9.2 Set-up / Connection of Parallel Operation Board....52

9.3 Operation of the UPS in a parallel system ..............53

9.3.1 Start-Up..............................................................53

9.3.2 Changes to the parallel system..........................56

10 Maintenance....................................................................57

10.1 Charging the Battery................................................57

10.2 Checks.....................................................................57

10.2.1 Visual Check......................................................57

10.2.2 Checking the Battery..........................................58

10.2.3 Fan Check..........................................................58

11 Storage, Dismantling and Disposal.................................59

11.1 Storage....................................................................59

11.2 Dismantling..............................................................59

11.3 Disposal...................................................................59

12 List of Terms ...................................................................60

12.1 Technical terminology..............................................60

6

Page 7

2 General Information

2.1 Technology

PROTECT 1. is an Uninterruptible Power

upply (UPS) for essential loads such as small

S

i

♦ Mains filter with overvoltage protection (appliance

protection / class D) and mains energy backfeed

protection

♦ Rectifier section with PFC logic

(power factor correction unit)

♦ Separate battery charger with

switch mode power supply technology

♦ IGBT inverter for continuous supply of connected loads

with sinusoidal AC voltage

♦ Automatic electronic bypass (SBS)

as additional, passive redundancy

SBS = S

♦ Manual bypass for maintenance and

service purposes (with automatic

SBS activation upon actuation)

data centres, servers, network components,

telecommunications equipment and similar

units. It consists of:

tatic Bypass Switch

♦ Control unit

on the basis of digital signal processor technology

7

Page 8

2.2 System Description

The UPS is connected between the public utility mains and

the loads to be protected.

The power section of the rectifier converts the mains voltage to

DC voltage for supplying the inverter. The circuit technology

used (PFC) enables sinusoidal current consumption and

therefore operation with little system disturbance. A separate,

second rectifier (charging REC set up using switch mode power

supply technology) is responsible for charging or trickle-charging

the battery connected in the intermediate circuit. The

configuration of this charging REC means the harmonic content

of the charging current for the battery is almost zero, which

increases the service life of the battery even more. The inverter

is responsible for converting the DC voltage into a sinusoidal

output voltage. A microprocessor-driven control based on a

pulse-width modulation (PWM) guarantees, in conjunction with

digital signal processor technology and extremely fast pulsating

8

Page 9

IGBT power semiconductors of the inverter, a voltage system of

the highest quality and availability on the secured busbar.

In the event of mains faults (such as e.g. current failures), the

voltage continues to be supplied from the inverter to the load

without any interruption. From this point onwards, the inverter

draws its power from the battery instead of the rectifier. Since no

switching operations are necessary, there is no interruption in

the supply to the load.

The automatic electronic bypass serves to increase the reliability

of the supply further, especially in the case of individual systems.

It switches the public mains directly through to the load without

any interruption, e.g. when there is an inverter malfunction. As a

result, the automatic bypass represents an extra passive

redundancy for the load.

An integrated, manually operated bypass unit ensures an

uninterrupted supply to the connected loads in the case of

maintenance and/or service work. The internal electronic part

(with the exception of the metal-clad manual bypass) can be

disconnected via the mains input miniature circuit breakers.

The greatest possible supply reliability of connected loads is

attained by the parallel connection of up to max. three

PROTECT1. UPS systems. The n+x technology thus

guarantees maximum reliability through up to double active

redundancy on the one hand as well as on the other hand the

possibility of increased power with simple redundancy or even

only higher UPSpower without any redundancy. The relationship

between the available output power and the degree of active

redundancy can be seen in the following overview:

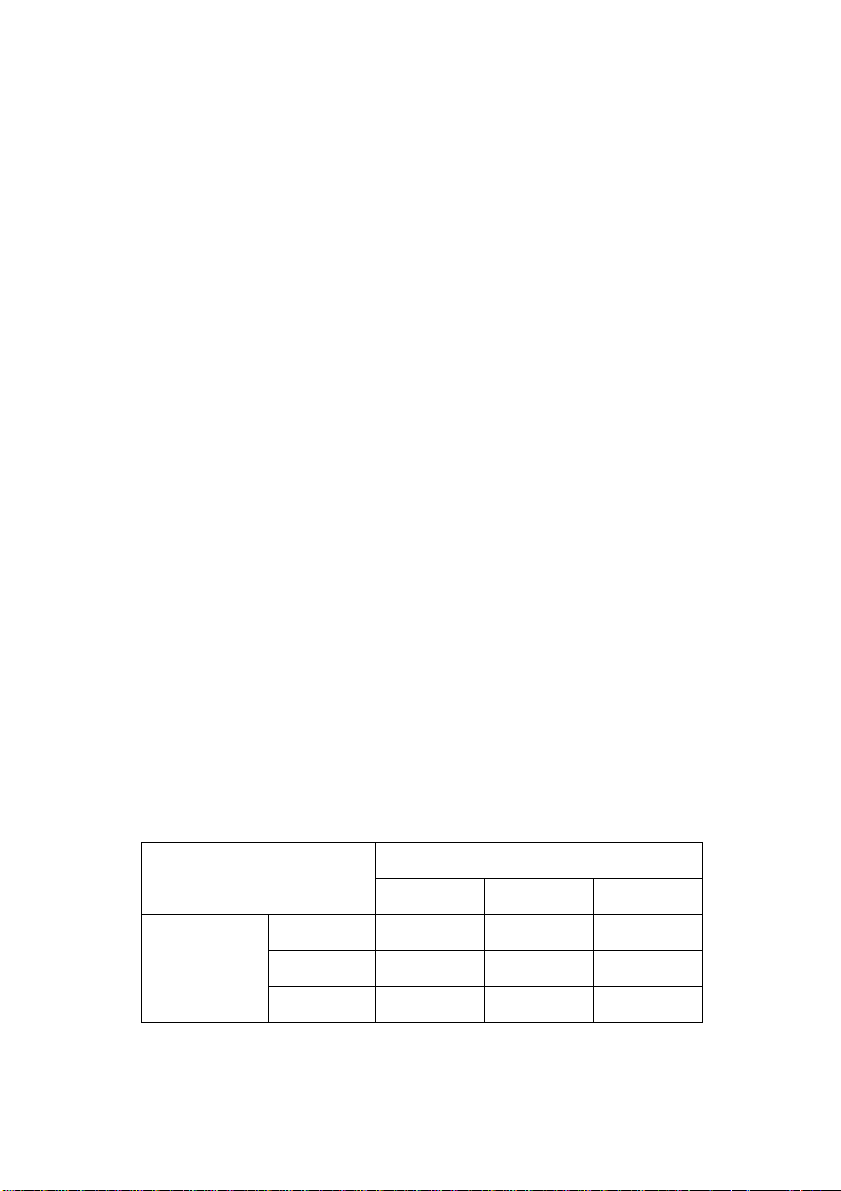

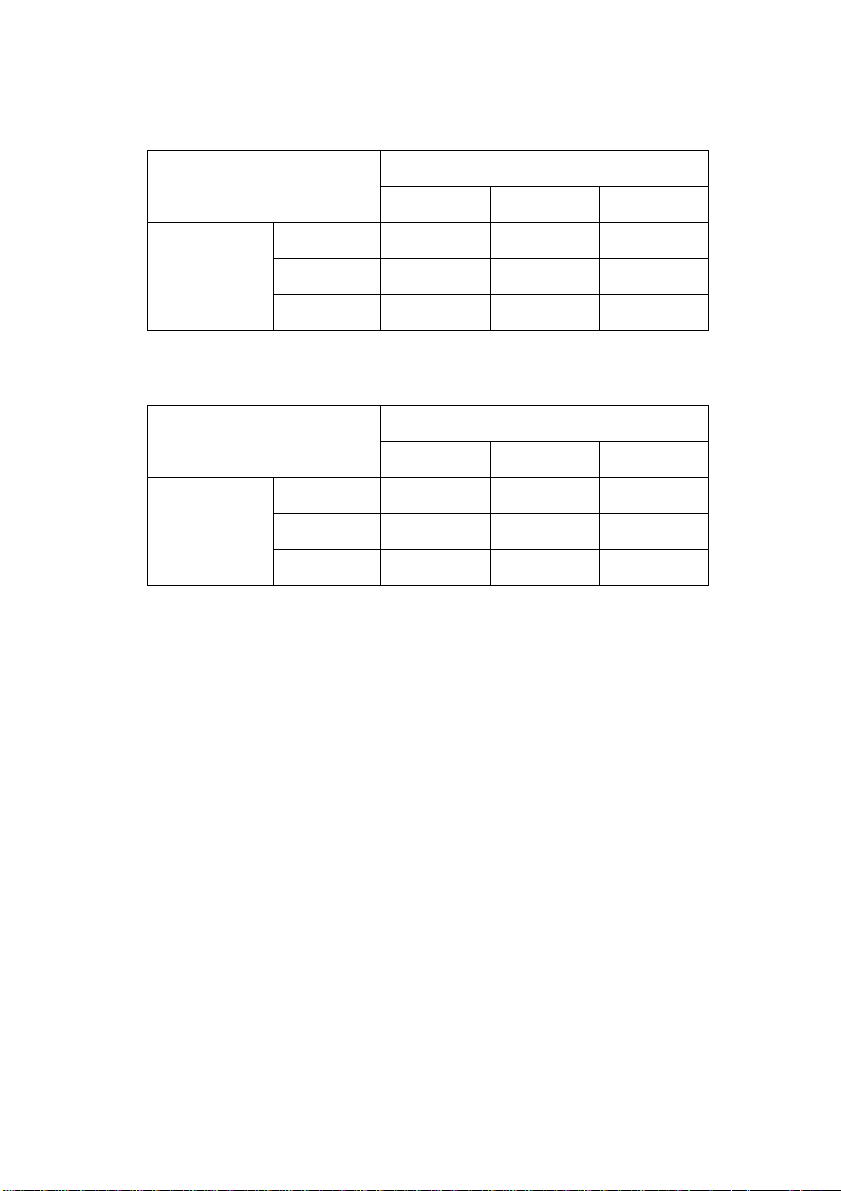

Parallel system with PROTECT 1.100

Available power

Active

redundancy

degree

Number of UPS units

1 2 3

0 10 kVA 20 kVA 30 kVA

1 --- 10 kVA 20 kVA

2 --- --- 10 kVA

9

Page 10

Parallel system with PROTECT 1.150

Available power

Active

redundancy

degree

Parallel system with PROTECT 1.200

Available power

Active

redundancy

degree

0 15 kVA 30 kVA 45 kVA

1 --- 15 kVA 30 kVA

2 --- --- 15 kVA

0 20 kVA 40 kVA 60 kVA

1 --- 20 kVA 40 kVA

2 --- --- 20 kVA

Number of UPS units

1 2 3

Number of UPS units

1 2 3

10

Page 11

2.3 Technical Data

Type rating

PROTECT 1.100 10000 VA (cos ϕ = 0.7 ind.)

PROTECT 1.150 15000 VA (cos ϕ = 0.7 ind.)

PROTECT 1.200 20000 VA (cos ϕ = 0.7 ind.)

UPS input 3ph~ / N / PE

Rated connection voltage 400 V/ 230 VAC

Voltage range without 304 VAC – 478 VAC ± 3 %

battery operation (rectifier)

Frequency 50 Hz / 60 Hz

Frequency tolerance range ± 4 Hz

Current consumption at full load (max.)

PROTECT 1.100 13 A (3ph~) / 46 A (bypass)

PROTECT 1.150 19 A (3ph~) / 68 A (bypass)

PROTECT 1.200 25 A (3ph~) / 91 A (bypass)

System disturbance factor λ 0.95

7000 W

10500 W

14000 W

176 VAC – 261 VAC VAC ± 3 %

(bypass)

(autom. detection)

UPS output

Nominal voltage output 220 / 230 / 240 VAC ± 1%

(configuration via

“CompuWatch” software )

Nominal frequency 50 Hz / 60 Hz ± 0.1%

(dependent on mains frequency)

Type of voltage Sine, distortion

2% THD (linear load)

6% THD (non-linear load)

Crest factor 3:1

11

Page 12

Overload behaviour Up to 105% continuous;

with mains supply > 105% – < 130% for 10 min.

130% for 1s

Following this, automatic,

uninterrupted switchover to

integrated bypass (SBS).

Switch-off after 1 min if overload

continues to be present. (Switch

back if overload decreases = load

< 90%)

Overload behaviour with Up to 105% continuous;

battery operation > 105% for 10 s

Short-circuit behaviour 2.5 x I

for 100 ms

N

Battery

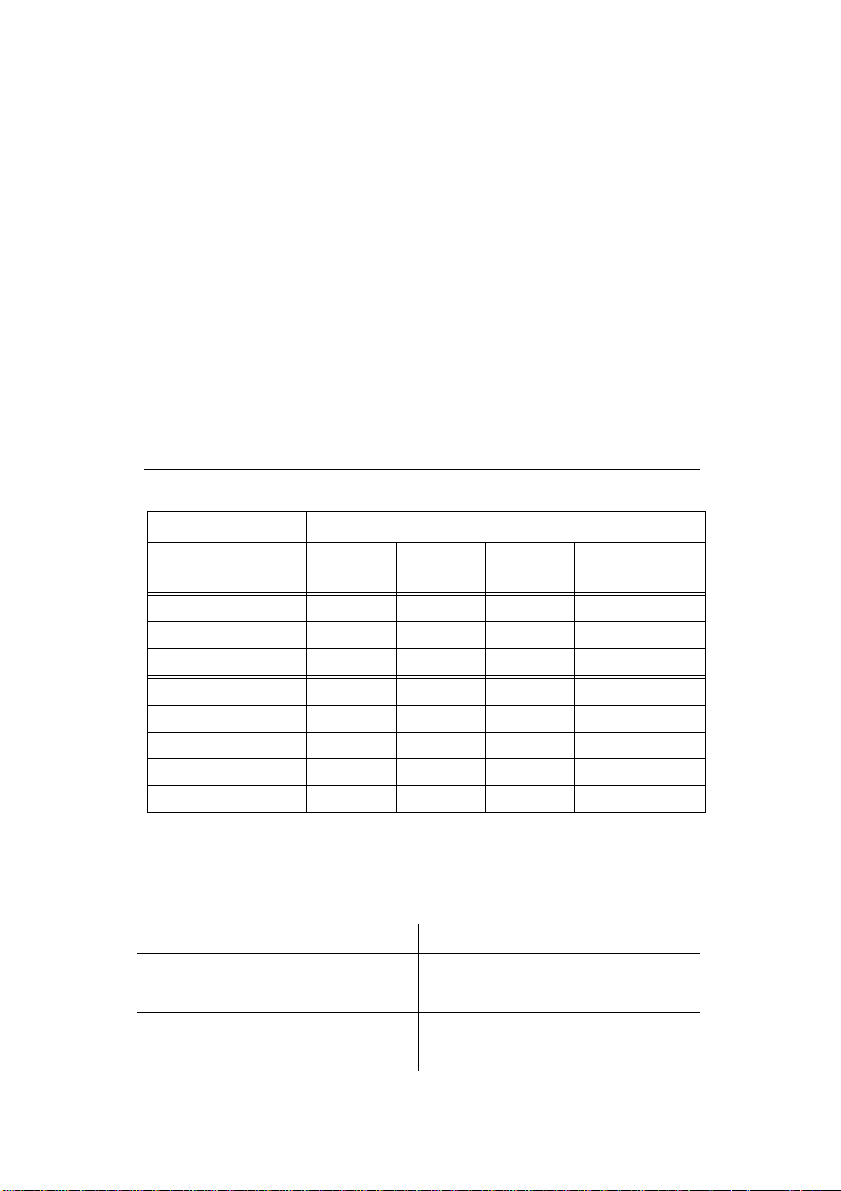

Standby times with external standard battery units

Standby times (full load / half load) [min.]

Coupled

battery cubicles

1 x PROTECT 1.100 BP 16 / 42 --- --- 5h

2 x PROTECT 1.100 BP 42 / 97 --- --- 7h

3 x PROTECT 1.100 BP 60 /134 --- --- 10h

1 x PROTECT 1. BP 20 19 / 47 10 / 29 6 / 19 5h

2 x PROTECT 1. BP 20 47 / 103 29 / 68 19 / 47 9h

3 x PROTECT 1. BP 20 78 / 77 47 /103 34 / 62 13h

4 x PROTECT 1. BP 20 103 /243 68 / 153 47 /103 18h

5 x PROTECT 1. BP 20 138 /312 85 / 202 63 /138 24h

PROTECT

1.100

PROTECT

1.150

PROTECT

1.200

Recharging time

to 90% capacity

Nominal DC voltage (intermediate circuit): 240 VDC

Trickle charge voltage: 274 VDC ± 1%

Battery charging current (max.): 4.2 ADC

Type Sealed, maintenance-free

PROTECT 1.100 BP 2x20 blocks 12V 9Ah,

e.g. CSB HR 1234WF2

PROTECT 1.BP20 1x20 blocks 12V 20Ah,

e.g. Panasonic LC-X1220P

12

Page 13

Communication

Interfaces RS232

Sub-D (9-pin)

Additionally: Communication slot

for expansions (e.g. AS/400 /

USB / remote signal indicator /

SNMP, …)

Shutdown software on CD “CompuWatch” for all common

operating systems, e.g.

Windows, Linux, Mac, Unix,

FreeBSD, Novell, Sun

General data

Classification VFI SS 111 acc. to IEC 62040–3

Sustained transformer

technology

Full load efficiency > 90% / > 88%

(AC-AC / DC-AC)

Inherent noise (1m distance)

PROTECT 1.100 < 55 dB(A)

PROTECT 1.150 < 60 dB(A)

PROTECT 1.200 < 60 dB(A)

Cooling type Forced air cooling through

variable-speed fans

Operating temperature range 0°C to +40°C

Recommended: +15°C to +25°C

(due to battery system)

Storage temperature range 0°C to +40°C

Relative humidity < 95% (without condensation)

Site altitude Up to 1000 m at nominal output

Use more than 1000 m above

sea level results in the following

reduction in output power:

Height(m) 1000 1500 2000 2500 3000

Output power 100% 95% 90% 85% 80%

13

Page 14

Housing colour: Blackline

Weight:

PROTECT 1. 100 39 kg

PROTECT 1. 150 55 kg

PROTECT 1. 200 55 kg

PROTECT 1. 100 BP 135 kg

PROTECT 1. BP20 170 kg

Dimensions W x H x D:

PROTECT 1.100/1.150/1.200 260 mm x 717 mm x 670 mm

PROTECT 1.100 BP 260 mm x 717 mm x 670 mm

PROTECT 1.BP 20 260 mm x 717 mm x 810 mm

Directives

The PROTECT 1. meets the product standard EN 50091.

The CE mark on the unit confirms compliance with the EC

outline directives for 73/23 EEC – Low voltage and for 89/336

EEC – Electromagnetic compatibility if the installation

instructions described in the operating instructions are

observed.

For 73/23 EEC low-voltage

directive reference number EN 62040-1-1 : 2003

For 89/336 EMC directive

reference number EN 50091-2 : 1995

EN 61000-3-2 : 1995

EN 61000-3-3 : 1995

Warning:

This is a product for industrial and commercial

i

use in the second environment – to prevent

malfunctions, restrictions on the installation or

additional measures may be required.

14

Page 15

3 Safety Regulations

3.1 Important Instructions and Explanations

The instructions for operation and maintenance, as well as

the following safety regulations must be complied with to

ensure the safety of personnel as well as the continued

availability of the unit. All personnel installing/dismantling,

starting up, operating or servicing the units must be familiar

with and observe these safety regulations. Only trained and

qualified personnel may perform the work described, using

tools, equipment, test equipment and materials intended for

the purpose and in perfect working condition.

Important instructions are emphasized by the words

“Caution”, “Attention”, “Note” and indented text.

Caution

This symbol identifies all working and operational

procedures requiring absolute compliance to

avoid any danger to persons.

Attention

This symbol identifies all working and operational

procedures requiring absolute compliance to

prevent any damage, irreparable or otherwise, to

the unit and its components.

Note

This symbol identifies technical requirements and

i

additional information requiring the operator's

attention.

3.2 Accident Prevention Regulations

Compliance with the accident prevention regulations valid in

the respective country of use and the general safety

regulations in accordance with IEC 364 is mandatory. The

following safety rules must be observed prior to performing

any work on the PROTECT 1.:

♦ Disconnect the unit from the power supply

♦ Secure the unit against being switched back on

15

Page 16

♦ Verify that the unit is disconnected from the power

supply

♦ Earth and short-circuit the unit

♦ Provide protection by covers or barriers for any

neighbouring live parts

3.3 Qualified Personnel

The PROTECT 1. may only be transported, installed,

connected and serviced by qualified personnel who are

familiar with the pertinent safety and installation regulations.

All work performed must be inspected by responsible expert

personnel.

The qualified personnel must be authorised by the

responsible safety officer of the installation to perform the

work required.

Qualified personnel is defined as personnel

♦ having completed training and gained experience in the

respective field,

♦ familiar with the pertinent standards, rules and

regulations and accident prevention regulations,

♦ having received instruction on the mode of operation

and operating conditions of the PROTECT 1.,

♦ capable of recognising and preventing dangers.

Regulations and definitions for qualified personnel can be

found in DIN 57105/VDE 0105 Part 1.

3.4 Safety Instructions for PROTECT 1.

The UPS is live, and the voltage can be

dangerous. The unit may only be installed and

if necessary opened by trained and qualified

personnel. Repairs may only be carried out by

qualified customer service staff!

The output can be live, even when the UPS is not

connected to the mains supply!

16

Page 17

For health and safety reasons, the unit must be

earthed correctly!

The PROTECT 1. may only be operated with or connected to

a three-phase power system with protective grounding using

a mains connection cable with PE conductor that has been

tested according to German standards (VDE).

Risk of burning!

The battery has powerful short-circuit currents.

Incorrect connection or isolation faults can lead to

melting of the plug connections, sparking potential

and severe burns!

The unit has a warning signal that sounds when

the battery voltage of PROTECT 1. is exhausted

or when the UPS is not working in its normal

mode (see also chapter 8 "Signalling”, page 47

and the following).

Observe the following safety instructions to

ensure permanent operational safety of and safe

work with the UPS and the battery modules

(special accessories):

♦ Do not dismantle the UPS!

(The UPS does not contain any parts that require

regular maintenance. Bear in mind that the warranty

will be invalidated if the unit is opened!)

♦ Do not install the unit in direct sunshine or in close

proximity of heaters!

♦ The unit is designed to be installed inside in heated

rooms. Never install the housing in the vicinity of water

or in an excessively damp environment!

♦ Condensation may occur if the UPS is brought from a

cold environment into the room where it is to be

installed. The UPS must be absolutely dry prior to startup. As a result, leave it to acclimate for at least two

hours.

♦ Never connect the mains input and the UPS output!

17

Page 18

♦ Ensure that no fluids or foreign bodies can penetrate

the housing!

♦ Do not block the air vents of the unit! Make sure, for

example, that children do not insert any objects in the

ventilation openings!

♦ Do not connect household appliances such as

hairdryers to the UPS! Also take care when working

with motor loads. It is essential to avoid back-feeding

the inverter, e.g. if the load is intermittently operated in

regenerative mode.

Danger! Electric shocks!

Even after the mains voltage has been

disconnected, the components within the UPS

remain connected to the battery and can thus

cause electric shocks. It is therefore imperative

to disconnect the battery circuit before carrying

out any maintenance or repair work!

If it is necessary to replace the battery or carry

out maintenance work, this must be done by or

under the supervision of a specialist familiar

with batteries and the necessary safety

precautions!

Only authorized persons are allowed in the

vicinity of the batteries!

When replacing the batteries, the following must be observed:

Only ever use identical, maintenance-free sealed lead

batteries with the same data as the original batteries.

Danger! Explosive!

Never throw batteries into open fire.

Never open or damage batteries. (Electrolyte

may leak out and damage skin and eyes. It may

be toxic!)

Batteries can cause electric shocks and high

short-circuit currents.

18

Page 19

Therefore, take the following safety precautions when working

with batteries:

♦ Take off watches, rings and other metallic objects!

♦ Only use tools with insulated handles!

Avoid using multiple outlet adapters with a

central on/off switch as protection against

i

Switch OFF the UPS using its main switch if you do not intend

to use it for some time. PROTECT 1. must be switched off

every evening if the electricity supply in your company is

switched off every night. Otherwise, the battery will be

discharged. Frequent and exhaustive discharging of the

battery leads to a shorter service life of the battery and should

therefore be avoided!

uncontrolled load switch-off as well as for

avoiding peak inrush currents.

For personal safety reasons, never switch on

the main switch when the mains connector of

PROTECT 1. is disconnected!

19

Page 20

3.5 CE Certificate

20

Page 21

4 Set-up

4.1 Unpacking and Inspection

The unit has been completely checked and inspected.

Although the unit has been packed and shipped with the

usual care, transport damage cannot be completely excluded.

Any claims due to transport damage must

always be asserted against the transport

i

Check the shipping container for damage on arrival. If

necessary, ask the transport company to check the goods

and make a record of the damage in the presence of the

transport company employee and report the damage to the

AEG representative or dealer within eight days of delivery.

Check that the delivery is complete:

♦ PROTECT 1. with 10000, 15000 or 20000 VA

♦ Cable clamping unit

♦ Special battery connection cable (PROTECT 1.100)

♦ 25-pin parallel operation cable

♦ RS232 communication cable

♦ Management software “CompuWatch” on CD

♦ Operating instructions

company!

Delivery of external battery modules includes:

♦ External battery unit

♦ Battery connection cable

♦ Battery fuses and terminal connectors (PROTECT 1.

BP20)

Please contact our hotline (see page 4) in case of any

discrepancy.

The original packaging provides effective protection against

mechanical shocks and should be retained so the unit can be

transported safely later on.

21

Page 22

Please keep plastic packaging bags away from babies and

children in order to safeguard against suffocation accidents.

Handle the components with care. Please take into account

the weight. It may be necessary to engage the help of a

second person.

4.2 Transport to Installation Site

The PROTECT 1. is equipped with transport rolls for easy

transport to the intended installation site. It is recommended

to install the UPS where:

♦ The connection work can be conveniently carried out;

♦ There is enough space for proper operation and, if

necessary, for periodic and extraordinary maintenance

work; in this regard, the connection cables should be

long enough to move the UPS (to open the UPS if

necessary) without having to switch it off.

♦ The use of an external manual bypass is recommended

♦ The UPS is protected against external atmospheric

influences;

♦ The humidity and the ambient temperature are within

the limits;

♦ The fire protection standards are observed.

The battery service life strongly depends on the ambient

temperature. Ambient temperatures between+15° and +25°C

are optimum.

Attention!

Only transport the PROTECT 1. in an upright

position! Never tilt or cant it; avoid displacing

the centre of gravity!

Make sure that no magnetic storage media are stored and/or

operated close to PROTECT1.

22

Page 23

4.3 Set-Up

Note the following points when setting up the UPS system

and its external battery units (special accessories):

♦ The contact surface must be smooth and level. It must

also be sufficiently strong and sturdy to avoid vibration

and shocks.

♦ Make sure that the mounting is able to support the

weight, especially in conjunction with external battery

units (special accessories).

♦ Set up the units so that adequate air circulation is

assured. There must be at least 200 mm clearance

behind the rear fans for ventilation purposes. Do not

block the intake openings on the front and, if present,

on the side of the unit. There must be a gap of at least

50 mm here.

♦ External battery units must be placed on the side of the

UPS system. To ensure the greatest possible

mechanical stability, do not place the external battery

unit(s) above or below the UPS system.

♦ Avoid extreme temperatures! We recommend an

ambient temperature from 15°C to 25°C in order to

maximize the service life of the batteries. Do not

expose the units to direct sunlight or operate them

close to other heat sources such as radiators.

♦ Protect the units against external effects (in particular

moisture and dust). In this regard, please also refer to

the instructions in chapter 3, page 15 in these operating

instructions.

If you transport the unit from a cold room into a warm one, or

if the room temperature suddenly drops, then condensation

may form inside the unit. To avoid any damage due to

condensation, let the unit acclimate for 2 hours before you

switch it on.

23

Page 24

4.4 Overview: Connections, Operating / Display

Elements

4.4.1 Front view

PROTECT 1.100 PROTECT 1.150 PROTECT 1.200

PROTECT 1.100BP PROTECT 1.BP20

24

Page 25

4.4.2 Display

12

11

10

9

8

7

3

6

4

5

2

1

1. OFF pushbutton

2. ON pushbutton / alarm off

3. Orange-coloured Bypass LED

4. Green Inverter LED

5. Orange-coloured Battery LED

6. Green Line LED

7 – 11. Bar graph LED (7-10 green, 11 orange-coloured)

for UPS capacity utilisation or remaining battery

capacity

7. LED load (0-35%) battery capacity (96-100%)

8. LED load (36-55%) battery capacity (76-95%)

9. LED load (56-75%) battery capacity (51-75%)

10. LED load (76-95%) battery capacity (26-50%)

11. LED load (96-105%) battery capacity (0-25%)

12. Red Fault LED

A detailed explanation of the displays is found on page 45.

25

Page 26

4.4.3 Rear view (connections):

N L1 L2 L3 JP1 JP2 L N

JP1 JP2

PROTECT 1.100

8

7

6

2

1

PROTECT 1.150 / 1.200

6

7

8

2

5

4

3

6

5

3

13

11

10

9

1.1 1.2 1.3

13

11

10

9

1.1 1.3 1.2

4

11

12

11

1

N L1 L2 L3 + - L N

26

Page 27

Explanations:

1. Connection terminal cover for mains/UPS input

(1.1) and output (1.3), additional pair of terminals

for setting individual or parallel operation (1.2);

Battery connection terminals

(PROTECT 1.150 / 1.200)

2. Mains input miniature circuit breaker

3. Manual bypass switch

4. Socket for external battery module

(PROTECT 1.100) or connection terminals for

external battery (PROTECT 1.150/1.200)

5. Connectors for parallel operation

6. Fan (attention: Leave at least 10 cm clearance

behind fan for unobstructed airflow out!)

7. Communication slot for optional expansion boards:

SNMP, AS/400, USB

8. Communication interface RS232 (Sub-D9)

9. Cable clamping unit (is mounted instead of the

cover from no. 1)

10. Strain relief clamps

11. PE/earthing terminals

12. Macrolon plate as additional insulation to prevent

short circuits when using uninsulated cable lugs

(PROTECT 1.150/1.200)

13. Cover of the cable clamping unit

27

Page 28

5 Electrical Connection

Caution

Prior to commencing work, ensure that the

connection cables are de-energised and that it

is not possible to activate the power supply.

In order to avoid deformation of the supporting

rail and to protect the base of the connection

i

The protective measure of earth connection serves to prevent

excessive touch voltage on freely accessible metal parts. The

PROTECT 1. is earthed by the provided earthing bolts ( /

PE). Prior to start-up, it must be ensured that the PROTECT 1. is

earthed in accordance with valid regulations, e.g. VDE 0100.

Before the connection work is carried out, check that:

♦ The values of the nominal voltage (input voltage) and

♦ The earth connection matches the prescribed IEC

♦ The UPS is connected to the electrical mains via a

♦ The power fuse in the MI distribution has the same or

terminal against torsional forces, it is advisable

to hold the cable in position when tightening the

clamping screw.

frequency match those on the nameplate of the UPS.

standards or the local regulations,

separate supply line equipped with fuses on the supplyside MI distribution.

higher value as the one indicated on the nameplate of

the UPS system.

28

Page 29

5.1 Safety of Personnel

Note the following points when setting up the UPS system

and its external battery units (special accessories):

♦ Disconnect the unit from the power supply

♦ Secure the unit against being switched back on

♦ Verify that the unit is disconnected from the power

supply

♦ Earth and short-circuit the unit

♦ Provide protection by covers or barriers for any

neighbouring live parts

5.2 Mains Connection (General)

In order to ensure the correct functioning of the UPS and its

additional equipment, it is necessary to equip the mains cable

with the corresponding fuses.

5.3 Checklist for Cable Connections

The connection and earthing terminals of all PROTECT 1.

units are structured in a similar way. The cables are

connected as follows:

♦ Remove terminal cover (retain the four screws).

♦ Insert the cables to be connected into the terminal

space of the PROTECT 1. from the rear.

♦ Connect the wires of the supply lines to the

corresponding terminal block. Connect the PE to the

terminal block of the PROTECT 1.100 or to the strain

relief unit of the PROTECT 1.150 or 1.200.

♦ Fasten the supplied cable clamping unit (no. 9, p. 26/27)

with the previously removed screws.

In the case of the PROTECT 1.150 and 1.200, also

remove the lateral earthing bolts beforehand and use them

to fasten the cable clamping unit as well.

♦ Check to ensure that the cables are secured correctly

and tighten the fixing bolts if necessary.

♦ Remove any cable debris, tools, bolts, etc. from the

connection panel.

29

Page 30

♦ Mechanically secure the cables with the strain relief

clamps of the cable clamping unit.

♦ Mount the connection cover of the cable clamping unit.

5.3.1 Connection Cross-Sections and Fuse Protection

The required dimensions can be found in the following table:

PROTECT

1.100

Max. current consumption

(bypass)

Incoming mains

cable (UPS input)

Load connection

(UPS output)

Battery connection Via enclosed

Mains fuse (UPS input) 50A gl 80A gl 100A gl

max.)

min.

max.

min.

max.

46A 68A 91A

10 mm²

16 mm²

10 mm²

16 mm²

battery

connection

cable protectted against

polarity

reversal

When using line safety switches, observe

trigger characteristic: “D”

Line safety switch “B” characteristicLoad fuse (recommended

16A 20A 25A

PROTECT

1.150*

16 mm²

35 mm²

16 mm²

35 mm²

Min. 16 mm², Max. 35

mm² per terminal

Battery connection cable

is included with the

battery unit

Observe earth-fault- and

short-circuit-proof routing!

PROTECT

1.200*

25 mm²

35 mm²

25 mm²

35 mm²

* To ensure a reliable strain relief, individual wires must be

laid especially for connecting the 15 and 20 kVA UPS

systems.

Recommended connection cable acc. to VDE 0298-4:

Specially for 15 and 20 kVA: Special rubber-insulated wire

NSGAÖU or NSGAFÖU

or NYY or

Radox 4GKW-AX

e.g. Huber & Suhner

30

Page 31

Alternatively, the 10 kVA UPS system can also be connected

via a multi-wire rubber-sheathed cable.

5.4 Mains Connection

5.4.1 Preparation for the three-phase mains connection

Before connection work is performed on the UPS, make sure

that:

♦ The values of the nominal voltage (supply) and

frequency match those on the nameplate of the UPS.

♦ The earth connection matches the prescribed IEC

standards or the local regulations,

♦ The UPS can be connected to the electrical mains via a

separate supply line equipped with fuses in the supplyside MI distribution.

♦ Back-up fuses or line safety switches are used that

correspond to the values listed in chapter 5.2.2.

♦ The connection cable from the back-up fuse to the UPS

is configured with a minimum cross-section acc. to

chapter 5.2.2 “Connection Cross-Sections and Fuse

Protection”.

The UPS can be live, and the voltage can be

dangerous. The unit may only be installed and

if necessary opened by trained and qualified

personnel. Repairs may only be carried out by

qualified customer service staff!

5.4.2 Connection of the Three-Phase Input Mains Voltage

In order to ensure the safety of personnel during installation

work, make sure that the connections are made under the

following conditions:

♦ No mains voltage present.

♦ The loads are switched off.

♦ The PROTECT 1. is switched off (display completely

blank).

To disconnect the PROTECT 1, carry out the following steps

as well:

31

Page 32

♦ Place the “maintenance switch” manual bypass on the

voltage), label

back of the UPS in the “bypass” position. To do this, first

remove the 4 screws of the cover (no.3, p. 26/27).

♦ Put the mains input miniature circuit breaker (no.2,

p. 26/27) in the “OFF” position.

Connect the UPS terminal “ /PE “ (earth) with the

corresponding earth terminal in the distribution cabinet.

Connect the supply cable from the MI distribution to the

terminals 1.1 of the UPS that are marked with “INPUT”:

/ PE = Ground

N = Neutral conductor

L1/L2/L3 = Phases

Check the jumper between “JP1” and “JP2”

(terminal designation “JUMPER”).

Only remove the cable if you want to use the UPS

in parallel operation with further PROTECT 1. units

of the same type (see also chapter 9).

5.4.3 Preparation of the Output Cabling

Before you connect the loads to the UPS, the nominal output

listed on the nameplate must be greater than or equal to the

sum of the load power outputs.

The output of the PROTECT 1. should supply further separate

circuits in a subdistribution. Make sure that the fuse protection is

selectively designed (see also chapter 5.2.2).

For the connection between the PROTECT 1. and the

subdistribution, cable cross-sections acc. to the table

“Connection Cross-Sections and Fuse Protection” on p. 30

must be used. In the subdistribution, note at least the

following information:

♦ Maximum permissible total load

♦ Maximum permissible load of the individual load circuits

i

In the case of a common distribution cabinet

(circuits with mains as well as UPS

each circuit with the respective supply (mains or

UPS).

32

Page 33

5.4.4 Connection of the Loads

In order to ensure the safety of personnel during installation

work, make sure that the connections are made under the

following conditions:

♦ No mains voltage present.

♦ The loads are switched off.

♦ UPS is switched off (display completely blank).

To disconnect the PROTECT 1., carry out the following steps:

♦ Place the “maintenance switch” manual bypass on

the back of the UPS in the “bypass” position. For

this purpose, first remove the 4 screws of the

cover (no. 3, p. 26/27).

♦ Put the mains input miniature circuit breaker (no.2, p.

26/27) to the “OFF” position.

Connect the loads as follows (terminals 1.3, p. 26/27):

Connect the UPS terminals /PE = ground, N = neutral

conductor, L = phase that are marked with “OUTPUT” with the

corresponding terminals of your UPS subdistribution.

5.5 Connection of External Battery Modules

The PROTECT 1. requires the use of at least one external

battery module. Two preconfigured battery cubicle types are

available. Both versions guarantee an increase in the

attainable standby time due to their parallel connection

capability (see also chapter 2.3).

PROTECT 1.100 PROTECT 1.150 PROTECT 1.200

PROTECT

1.100 BP

PROTECT

1.BP20

The two cubicle types are distinguished in the following.

Follow 5.4.1 if you use the PROTECT 1.100 BP or 5.4.2 when

using the PROTECT 1.BP20.

No

mix !

- -

33

Page 34

5.5.1 Connection of the Battery Cubicle PROTECT 1.100 BP

This battery cubicle is completely preconfigured. The

connection to the UPS unit is ready to be plugged in as a

result of the supplied battery connection cable.

PROTECT 1.100 with 1 battery unit PROTECT 1.100 BP

PROTECT 1.100 BP is only intended

for connection to the UPS type PROTECT 1.100.

i

Connect further battery cubicles of identical design (!) to the

second battery connection socket of the neighbouring battery

cubicle. Insert the battery connection plugs quickly and firmly

into the battery connectors.

34

Page 35

5.5.2 Connection of the Battery Cubicle PROTECT 1. BP20

Fig.: Rear view of the PROTECT 1.BP20 with cover removed.

The battery cubicle is supplied with a separate battery string

and separately enclosed battery fuses for safety and transport

protection reasons. Please also note the separate

documentation enclosed with the battery cubicle.

After the battery cubicle has been removed from the pallet,

first remove the rear cover. Now create the electrical

connections with the enclosed connectors (see also circuit

diagram X1/X2/X3) and

The PROTECT 1.100 is connected to the UPS at the socket

using the special battery connection cable enclosed with

the UPS, and in the case of the PROTECT 1.150 or

PROTECT 1.200 with the battery connection cables enclosed

with the battery cubicle at the terminals. Make sure to observe

the terminal block assignment concerning the correct polarity

"+" and "-" as well as an earth-fault- and short-circuit-proof

routing, in addition to the proper earthing of the battery

cubicle.

35

Page 36

If the battery cubicle is used in connection with the

PROTECT 1.1.50 or PROTECT 1.200, the strain relief is

implemented with clamps.

The battery system can now be activated. To do this, insert

the two fuses .

As the last step, fasten each cover that was initially removed.

Fig.: PROTECT 1.BP20 in connection with the PROTECT 1.100

PROTECT 1.100 & 1.BP20: When connecting

the battery connection cable, make sure that the

i

Prepare further PROTECT 1.BP20 battery cubicles as

described above and then connect them to the terminals

(X2 and X3) of the previously installed battery cubicle with the

enclosed battery connection cables. Observe the correct

polarity "+" and "-" as well as an earth-fault- and short-circuitproof routing during connection.

plugs are inserted quickly and firmly in the

battery connectors.

5.6 Mechanical Blocking of PROTECT 1.

After completing the connection work, fasten the connection

terminal cover again. At the final installation site, block the

cubicles against slipping.

36

Page 37

6 Start-Up

Compare the setting of the nominal output voltage of the UPS

with the rated voltage valid in your country. The factory

presetting is 230 V. Changes to 220 VAC or 240 VAC can be

made with the software “CompuWatch”.

Switching on the PROTECT 1. on the mains

1. Make sure that all connections have been made

according to the installation instructions.

2. Make sure that all loads are switched off.

3. Put the “maintenance switch” manual bypass

switch (no. 3, p. 26/27) on the back of the UPS

back to the “USV“ position. Next fasten the cover

again with the 4 previously removed screws.

4. Now insert the back-up fuse in your low-voltage main

distribution (where the UPS system is connected to

the mains on the input side) or switch on the

corresponding line protection switch there.

5. Next actuate the mains input miniature circuit

breakers on the UPS (no. 2, p. 26/27). Move this

to the "ON" position.

i

6. Now switch on the inverter of the UPS. To do this,

press the ON pushbutton for approx. 2 seconds.

7. After switching on, the UPS carries out a self-test,

during which the LED’s for load and battery state

go on and off consecutively in increasing order.

After the successful synchronization of the

inverter, the Inverter LED lights up a few seconds

later, whereby the UPS is now in normal

operating mode. When the mains supply is intact

(mains within tolerance), the "Line" LED also

lights up.

Factory presetting: The loads are supplied via

the integrated bypass, which connects the

phase L1 with the UPS output. Do not switch on

your loads yet, however.

37

Page 38

Please shut down the entire system again if you

cannot solve a problem that occurs. To do this,

i

press the OFF pushbutton for approx. 2 seconds.

Disconnect the UPS from the mains by actuating

the mains input miniature circuit breaker (no.2,

p. 26/27). Please contact our hotline (see p. 4).

8. When the displays are correctly lit as described,

switch on your loads one after the other. When

doing this, take care not to exceed the maximum

permitted load capacity of the UPS.

6.1 Operating Modes

The following operating modes are distinguished:

Operation with mains supply (6.1.1)

Operation with faulty mains supply (6.1.2)

Operation with faulty inverter (6.1.3)

Manual bypass (6.1.4)

6.1.1 Normal Operation

Power circuit with

mains supply

Secured

busbar

Load

Main

s

Schematic

diagram

Manual bypass path

Mains input

miniature circuit

breaker

REC

Load

REC

Battery

SBS

INV

Manual

bypass

Once you have connected the UPS to a suitable mains

connection, you can start operation using the UPS main

switch. Normally, the UPS operates continuously. The UPS

now supplies the output with voltage, which is signalled by the

mains symbol (Line LED) and the inverter symbol (Inverter

LED) being lit.

This operating mode, generally referred to as “online” mode,

ensures the greatest protection, in particular when there are

mains fluctuations and mains failures, because the loads are

38

Page 39

continuously supplied with reliable and “clean” voltage with no

interruptions in this operating mode.

The bar graph LED (LED chain above the pictograph)

indicates the current capacity utilisation of the UPS in this

operating mode (see chapter 8, p. 45).

6.1.2 Battery Operation / Autonomous Operation

Power circuit with

faulty mains supply

Secured

busbar

Load

Mains

Schematic

diagram

Manual bypass path

Mains input

miniature circuit

breaker

REC INV

SBS

Load

REC

Battery

Manual

bypass

The mains is not within the required tolerance range or has

failed. In this case, power is supplied to the inverter from the

charged battery without interruption. The power supply to the

loads is therefore also ensured in the event of a mains failure.

This drains the capacity of the battery and it is discharged.

This status is signalled by the battery symbol lighting up

(Battery LED), as well as an intermittent acoustic signal, at

first every 4 seconds and then every second shortly before

switching off. The initial alarm can be suppressed by pressing

the “Alarm off” button. The alarm is automatically reactivated

when the battery capacity decreases. Depending on the

expansion level, age and condition of the battery and in

particular on the load to be supplied, the standby time can

vary from a few minutes to several hours.

39

Page 40

The inverter is switched off if the battery voltage drops below

a factory-set minimum voltage value.

Never store the unit in this condition! The discharged battery

system should be recharged within a week at the latest.

When the voltage and frequency are within the tolerance

range again after the mains is restored, the rectifiers switch

back on automatically. The supply of the inverter through the

mains is resumed and the battery charger charges the

battery.

The bar graph LED (LED chain above the pictograph)

indicates the remaining battery capacity during this operating

mode (see chapter 8, p. 45).

6.1.3 Bypass Operation

Power circuit with

faulty INV

Secured

busbar

Load

Mains

Schematic

diagram

Manual bypass path

Mains input

miniature circuit

breaker

REC INV

SBS

Load

REC

Battery

Manual

bypass

If the inverter is overloaded or if overtemperature is detected,

e.g. also if an inverter defect is detected, voltage is supplied

to the load without interruption via the static bypass switch

(SBS) that switches on automatically. This is signalled by the

Bypass LED.

40

Page 41

This so-called passive redundancy protects against the total

failure of the voltage supply on the secured busbar; however,

in this operating mode, mains faults would directly affect the

load. As a result, the electronics continuously attempt to

switch back to "online" / normal operating mode (e.g. when

the overload or overtemperature goes away).

The bypass consists of an inverse-parallel thyristor stack and

functions as an extremely rapidly switching link between a

load and the mains. The synchronization unit ensures that the

frequency and phase of the inverter voltage is synchronized

with the mains and can therefore be switched over without

interruption (within the tolerance limits).

The bar graph LED functions as the display of

the UPS capacity utilisation. The acoustic signal

i

6.1.4 Manual Bypass

sounds every 2 seconds during this operating

mode.

41

Page 42

The manual bypass enables maintenance and service

If the current supply fails while the manual

bypass is active, a total failure of the load supply

reason, it should be switched

back to normal operating mode as soon as

personnel to perform work on the PROTECT 1. without

having to switch off the load circuit.

6.1.5 Unit overload

The load on the UPS should never exceed the specified rated

load of the unit. If a unit overload occurs nevertheless (from

105% of the specified unit rated load) then the Fault LED lights

up and an acoustic signal sounds (twice per second). The

connected loads continue to be supplied for a certain length of

time depending on the level of the overload. However, the

connected load must be reduced without delay.

Non-observance of the "unit overload" condition may cause

the total loss of all UPS functions!

Also avoid short-term unit overloads, which may, for example,

occur when connecting a laser printer or laser fax machine.

Do not connect any household appliances or machine tools to

the UPS.

results. For this

possible.

Never connect or switch on any additional loads

to the UPS if there is a mains failure, i.e. if the

UPS is working in emergency power mode!

As a rule, if there has never been an overload during normal

mode, there will not be one in battery mode either.

When the Fault LED lights up in connection with

a continuous acoustic signal, this is an indication

of a deactivating fault. Follow the instructions on

page 49.

42

Page 43

7 Interfaces and Communication

activates the

7.1 Computer Interface RS232

For the control of the UPS and convenient reading of status

messages and measured values, various interfaces are

available. The interface protocol is designed for operation with

the "CompuWatch" shutdown and UPS management software

from AEG. Use the supplied RS232 communication cable to

connect your PC. Plug the cable into a corresponding serial

port on your PC.

RS232 interface: The RS232 is connected via the 9-pin Sub-D

socket strip on the back of the unit (no. 8, p. 26/27). Pin

assignment: 2 = TxD; 3 = RxD; 5 = GND.

7.2 Communication Slot

On the back of the UPS, there is a cover (see p. 26/2727, no.

7). When this is removed, additional, optionally available

communication components can be installed there, e.g.:

AS/400 board: Slot board with status messages, realised via

potential-free relay contacts

USB board: Slot board for communication via USB

SNMP board: Slot board for direct connection of the UPS to

the Ethernet network with RJ 45 (TCP/IP)

Details can be found in the description enclosed with the

particular optional component. Other boards in preparation.

Using the communication slot de

RS232 interface from chapter 7.1.

i

7.3 Shutdown and UPS Management Software

The "CompuWatch" software specially developed for these

purposes by AEG continuously checks the mains supply and

the UPS status.

In conjunction with the “intelligent” UPS, this guarantees the

availability of the EDP components as well as the data

security.

43

Page 44

The "CompuWatch" shutdown software supports different

operating systems, e.g. Windows 98SE/ME, Windows

NT/2000/XP, Windows Vista, Linux, Novell Netware, IBM AIX,

HP-UX, SUN Solaris, Mac OS X, and others.

Example of a “CompuWatch” screen

Refer to the manual on the CD for details about installing the

software on the various operating systems. Download of

updates at www.aegpartnernet.com >> PRODUCTS >>

Software >> CompuWatch

44

Page 45

8 Displays and Troubleshooting

8.1.1 Signalling

1. OFF pushbutton Press the button for approx.

2 seconds to switch off the UPS.

2. ON button: Press the button for approx. 2

seconds to switch the UPS on.

Deactivate acoustic alarm: Press the button

during the alarm for approx. 2 seconds to switch

off the alarm.

UPS test: Press this button during normal mode

for approx. 2 seconds to carry out a UPS self-test.

3. Bypass LED: The orange-coloured LED lights up

when voltage is supplied via the integrated bypass

of the UPS.

4. Inverter LED: The green LED lights up when

voltage is supplied via the inverter of the UPS

system.

5. Battery LED: The orange-coloured LED lights up

when power is supplied from the battery system.

45

Page 46

6. Line LED (mains status): The green LED lights

up when the mains voltage present is within the

specified tolerance range. If this LED flashes,

either the UPS connection has an incorrect pin

assignment (observe phase sequence / neutral

conductor connection position) or the mains is

outside of the specified tolerance range.

7. to 11. Bar graph LED as the measure of the UPS

capacity utilisation or the remaining battery

capacity.

These LED’s show the current UPS capacity

utilisation when mains voltage is present (normal

mode):

11. Orange LED 96% – 105%

10. Green LED 76% – 95%

9. Green LED 56% – 75%

8. Green LED 36% – 55%

7. Green LED 0% – 35%

In battery mode, the LED’s indicate the capacity of

the batteries:

11. Orange LED 0% – 25%

10. Green LED 26% – 50%

9. Green LED 51% – 75%

8. Green LED 76% – 95%

7. Green LED 96% – 100%

12. Fault LED: The red LED lights up with an acoustic

warning signal when a fault is present in the UPS

system.

46

Page 47

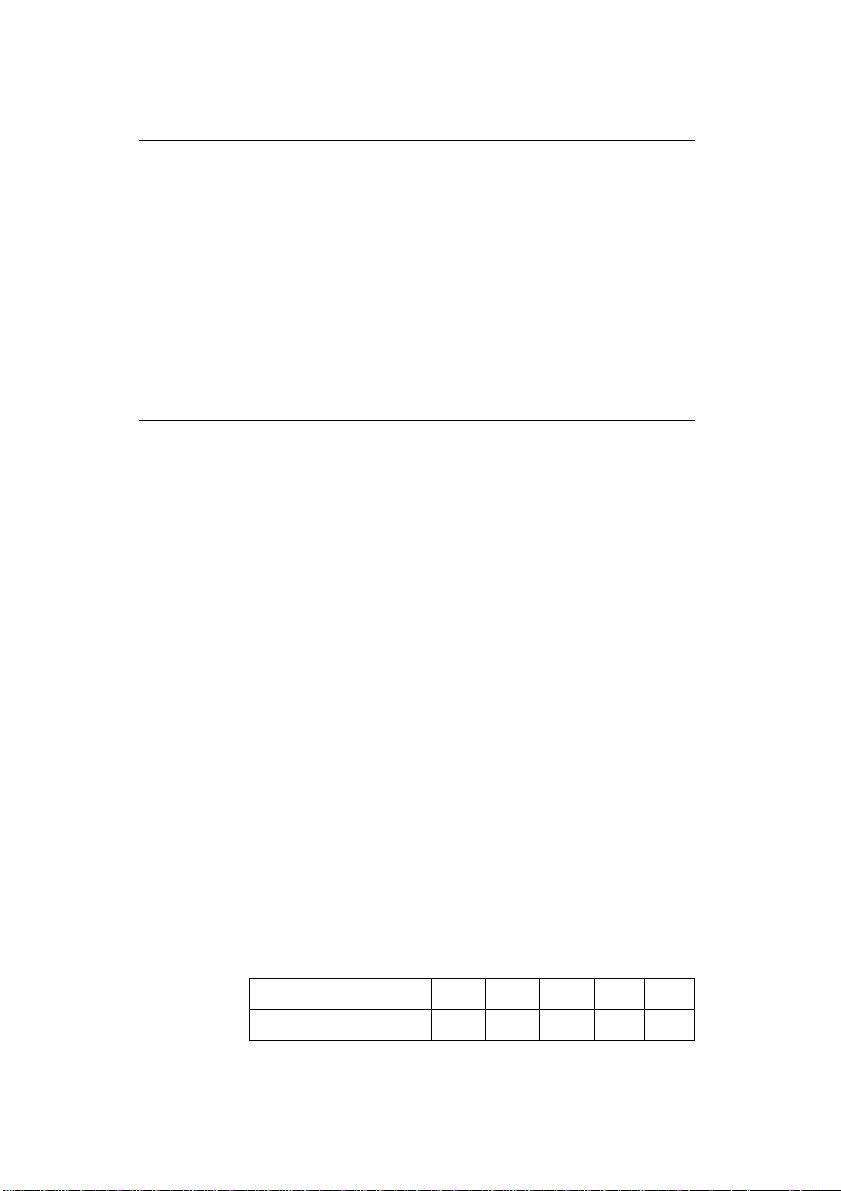

8.1.2 Overview Table of LED Displays / Acoustic Warning Signals

warning signal

warning signal

warning signal

No. Operating mode

LED display (see chapter 8 on page 47)

Warning

signal

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

0% – 35%

utilisation

36% – 55%

utilisation

56% – 75%

utilisation

76% – 95%

utilisation

96% – 105%

Normal mode

(mains present)

utilisation

0% – 20%

capacity

21% – 40%

capacity

41% – 60%

capacity

61% – 80%

Bat t e r y mo d e

capacity

81% – 100%

capacity

Load supply via

bypass of the UPS

Unit overload UPS in

INV mode

Unit overload UPS

in bypass mode

Mains abnormal

Overload in battery

mode, early warning

Overload in battery

mode, switch-off

Overtemperature fault Continuous

signal per sec.

1acoustic signal

every 4 seconds

1acoustic signal

every 4 seconds

1acoustic signal

every 4 seconds

1acoustic signal

every 4 seconds

1acoustic signal

every 2 minutes

signals per sec.

signals per sec.

signals per sec.

none

none

none

none

none

1 acoustic

2 acoustic

2 acoustic

2 acoustic

Continuous

Inverter fault Continuous

18

Note: = LED lights up

= LED flashes

= Display / acoustic signal state undetermined;

unimportant for displayed operating mode

47

Page 48

Overview table of LED displays / warning signals, cont.

warning signal

warning signal

warning signal

warning signal

warning signal

wa

rning signal

No. Operating mode

Short-circuit output

19

side

BUSvoltage

20

abnormal

DC circuit faulty;

21

poss. battery fault

Battery charger

22

faulty

Fan fault

23

Fault ininverter

24

output relay

Communication

25

faulty

Parallel operation

26

fault

LED display (see chapter 8 on page 47)

Note: = LED lights up

= LED flashes

= Display / acoustic signal state undetermined;

unimportant for displayed operating mode

Warning

signal

Continuous

Continuous

1 acoustic

signal per sec.

Continuous

1 acoustic

signal per sec.

Continuous

Continuous

Continuous

48

Page 49

8.2 Faults

PROTECT 1. outputs detailed error messages by means of

which you or the service personnel can quickly and accurately

localise and interpret any malfunctions that occur. You can

find suggestions for action / solutions in the following to

correct problems using error descriptions according to chapter

8.1.2:

8.2.1 Error Messages

Message / display Cause Solution

No display, no acoustic

signal although system

is connected to the

mains current supply.

Mains and/or

battery voltage not

in tolerance range,

poss. totally

discharged battery.

Check mains connection

again. Check the backup fuse and the mains

input miniature circuit

breaker as well.

Mains OK, but UPS

does not switch to

bypass

“Line” LED flashes and

“Battery” LED lights up

“Inverter" LED and

"Battery" LED light up.

The acoustic signal

sounds every 4 seconds

(operating states 7-10).

“Inverter" LED and

"Battery" LED light up.

The acoustic signal

sounds every second

(operating state no.6).

“Fault” LED lights up,

warning signal sounds

twice per second (error

descriptions no. 12/13).

PositionMains input

use is in “OFF”

position

Mains voltage

and/or mains

frequency are

outside of tolerance

Mains voltage

supply interrupted.

Automatic

switchover to

battery mode.

Overload of the

UPS System.

Switch mains input

miniature circuit breaker

to “ON”

Check the mains

(voltage, frequency)

Try to re-establish the

mains voltage (poss.

fuse triggered in the

subdistribution?).When

the acoustic signal

sounds every second,

the battery is almost

completely discharged.

Carry out a system

shutdown of your IT

equipment at this point

in time at the latest.

Immediately reduce the

capacity utilisation of the

UPS by disconnecting

part of your loads.

49

Page 50

Message / display Cause Solution

Duration of the

emergency power

supply shorter than

setpoint.

“Line” LED and “Fault”

LED light up, continuous

warning signal (error

description no. 17).

Error description no. 19 Switch-off due to

Batteries not

completely charged

/ batteries aged or

faulty.

Switch-off due to

UPS internal

overtemperature

detection

short-circuit in UPS

output

Charge the batteries for

at least the recharging

time acc. to chapter 2.3,

and check their capacity.

If the problem remains,

contact your dealer.

Make sure that no

overload is present, the

UPS fans are not

blocked and the ambient

temperature is in the

tolerance range. Wait for

10 min. cooling down

phase, then switch on

again.

Correct short-circuit.

Switch UPS on again,

connect loads one after

the other again.

“Fault” LED lights up,

“Battery” LED flashes,

warning signal sounds

once per second (error

description 21).

“Fault” LED lights up,

continuous warning

signal.

Fault in DC circuit

or battery system

faulty.

Fault in the UPS. Notify dealer!

Notify dealer!

Further diagnoses can also be found in the table list in

chapter 8.1.2.

If you cannot solve the problem that has occurred, stop the entire

procedure, switch off the UPS and disconnect the UPS from the

mains. Please contact our hotline in this case (see p.4).

Please have the serial number of the unit as well as the

purchase date at hand. The hotline will provide you with

technical support and can inform you about further

procedures once you have described the problem.

50

Page 51

9 Parallel Operation

9.1 Principle of Operation

PROTECT 1. has been designed for parallel operation with n+x

technology (“n” here stands for the number of units required for

load supply, “x” for the degree of redundancy). Up to 3 units of the

same type can be connected in parallel here to increase the

output power and/or achieve higher availability.

NS Hauptverteilung MI main distribution

USV Einspeisung UPS feed

Parallelfeld / Handumgehung plus USV

Unterverteilung

This results in the following constellations with n+x technology:

1 + 0 Use of 1 unit max. 10, 15 or

20 kVA

1 + 1 Use of 2 units max. 10, 15 or

20 kVA

1 + 2 Use of 3 units max. 10, 15 or

20 kVA

2 + 0 Use of 2 units max. 20, 30 or

40 kVA

2 + 1 Use of 3 units max. 20, 30 or

40 kVA

3 + 0 Use of 3 units max. 20, 30 or

40 kVA

Parallel field / manual bypass plus UPS

subdistribution

No redundancy

Single redundancy

Double redundancy

(max. expansion level)

No redundancy

Single redundancy

(max. expansion level)

No redundancy (max.

expansion level)

51

Page 52

The actively redundant parallel operation automatically

switches to power-increasing operation if the output power

requirement exceeds the UPS single block power, i.e. the

degree of redundancy is decreased or is completely eliminated.

Conversely, the active UPS redundancy degree automatically

increases again when the power consumption decreases.

The connection normally takes place in the low-voltage main

distribution, which also contains the external manual bypass

and the following subdistribution of connected load circuits.

Such a parallel board can be purchased in a wall housing incl.

external HU as well as feeder and load distribution board from

AEG Power Solutions via your specialist dealer.

9.2 Set-up / Connection of Parallel Operation Board

The mains connection of each individual UPS takes place in

the same way as described in chapter 5.

The three-phase mains connection secured for

each UPS must always have the same phase

sequence, i.e. all UPS units are supplied at the

input terminals L1, L2 and L3 by the same

phase each time (no mix!).

In UPS bypass mode, the phase L1 is used to

connect the single-phase load with the mains.

The central external manual bypass, which must

have an all-pole design, must also be supplied

by this phase L1.

The UPS outputs are each connected with the parallel

operation busbar via an isolator. The instructions from

chapter 5 apply here too.

The following always holds true for the UPS input and output

conductors: The difference in length in conductors up to 20 m

per UPS can be max. 20% and max. 10% for lengths > 20 m

per UPS.

The jumper installed between “JP1” and “JP2” on the

connection panel of every UPS at the factory must be

removed. The UPS output distribution also has to take place

according to the instructions in chapter 5. In particular, make

sure that the individual switching elements are correctly

labelled, in order to prevent operating errors later as well. The

52

Page 53

communication of the units switched in parallel takes place

via the 25-pin parallel operation cable(s) included in the scope

of delivery.

For this purpose, first remove the parallel port covers

(no. 5, p. 26/27) and connect the UPS units with each other

with one parallel operation cable each. Use one

operation cable for 2 units and two

3 units (do not create a ring structure!).

(Communicative) parallel operating connection

... for 2 units: ... for 3 units:

After connecting the parallel operation cables, fasten the

previously removed parallel port covers. Turn these by 180°

so that the slot of the cover is facing downwards.

The hardware-related installation is now complete.

parallel operation cables for

parallel

9.3 Operation of the UPS in a parallel system

The start-up process is uncomplicated, does not require any

prior knowledge and is basically oriented to the procedure

described in chapter 6. If you have obtained the parallel

operation board from AEG Power Solutions, you can find

further special instructions there. The displays in the parallel

system function the same way as described for the individual

UPS units in chapter 8.

9.3.1 Start-Up

1. Make sure that all connections have been made

according to the installation instructions.

2. Make sure that all loads are switched off.

3. Make sure that all “maintenance switch” manual

bypass switches (no. 3, p. 26/27) on the back of

53

Page 54

each UPS are in the “Bypass” position and all

mains input miniature circuit breakers (no. 2, p.

26/27) on the back of each UPS are in the “OFF”

position.

4. Check the position of the central external manual

bypass. This must be in the “Bypass” position, i.e.

supply of the load busbar by the supplying mains.

5. Now close all isolators in the output of each UPS,

i.e. connect the output of each UPS with the

parallel operation busbar.

6. Now insert the back-up fuses in your low-voltage

main distribution (where the central external manual

bypass as well as the individual UPS systems are

connected to the mains on the input side) or switch

on the corresponding line protection switches there.

The load supply now takes place via the central

external manual bypass, and the parallel

i

operation busbar is supplied with power via the

integrated manual bypasses of each UPS.

However, the parallel operation busbar and load

busbar are not yet connected to each other at

this time!

54

Page 55

7. Now actuate the mains input miniature circuit breakers

(no.2, p.26/27) on each UPS one after the other.

Move them to the "ON" position.

8. Move the “maintenance switch” manual bypass

switches (no. 3, p. 26/27) on the back of each

UPS to the “UPS” position. Finally, fasten the

covers on each UPS again using the 4 respective

screws that were previously removed.

The voltage supply of the parallel operation

busbar now takes place via the integrated

i

9. Now actuate your central external manual bypass:

i

10. Now switch on the inverters of the UPS systems.

i

electronic bypass switches of the UPS systems

used. Check this operating state on the display

panel of each UPS = Bypass (chapter 6.1.3).

Switch from the “Bypass” position to “UPS operation”,

i.e. connect your load busbar to the UPS parallel

operation busbar.

This is done using a manual bypass switch with

overlapping switching contacts without any

interruption in the load voltage, i.e. completely

interruption-free.

To do this, press the ON pushbutton of each UPS

for approx. 2 seconds one after the other.

After switching on, each UPS carries out a selftest and synchronizes itself with the parallel

operation busbar, while the LED’s for load and

battery state switch on and off consecutively in

increasing order. After the successful

synchronization of all inverters, the Inverter LED

on each UPS lights up a few seconds later,

whereby the UPS systems now work in parallel

normal operating mode and supply the parallel

operation / load busbar with UPS voltage.

The central external manual bypass switch must

be protected against accidental actuation. Never

actuate it when the UPS systems are in inverter

mode.

55

Page 56

11. When the displays are lit as described, switch on

your loads one after the other. When doing this,

take care not to exceed the maximum permitted

load capacity of the UPS systems. Also take into

account the reserve capacities if active

redundancy should be required.

9.3.2 Changes to the parallel system

If you would like to add a UPS to the parallel system or

remove a UPS from the parallel system, this step is always

done by returning the UPS systems to BYPASS operating

mode.

Load supply through mains operation!

(No UPS protection during this measure).

i

First, switch off the inverters of the UPS systems one after the

other (actuate the “OFF” pushbuttons). All UPS systems

function in SBS/bypass operation. Check the operating state

on the operating panels. Next, active the integrated manual

bypasses (no. 3, p. 26/27) on the back of each UPS. To do

this, first remove the 4 screws of the covers on the back.

Put the mains input miniature circuit breakers of each UPS

(no.2, p. 26/27) to “OFF” position. Use your central external

manual bypass to bypass the loads, i.e. activate the bypass

operation and remove the load supply from the UPS busbar.

The voltage of each UPS is disconnected in its low-voltage

main distribution. You can now expand or reduce your parallel

system. Pay attention to the jumpers “JP1” / “JP2” and the

parallel operation cables. The subsequent start-up is carried

out as described in chapter 9.3.1.

If you only want to switch off a UPS in the

parallel system, press the “OFF” pushbutton

i

twice in succession to do this. In this way,

individual UPS systems can be disconnected

from the parallel operation busbar.

56

Page 57

10 Maintenance

The PROTECT 1. consists of state-of-the-art, non-wearing

components. We do, however, recommend visual checks

(above all battery and fan checks) at regular intervals (at least

every 6 months) to maintain continuous availability and

operational reliability.

CAUTION!

Ensure that the work area is cordoned off and

always observe the safety instructions!

10.1 Charging the Battery

The battery is automatically charged when the mains is

connected, irrespective of the operating mode. This is

signalled by the Load LED’s lighting up (see also chapter

4.4.2).

The complete charging time of the battery after a long

discharge time depends especially on the number of

additional external battery units (see chapter 2.3).

10.2 Checks

The following maintenance work should be performed:

Task Interval Described in

Visual check 6 months Chapter 10.2.1

Battery/fan check 6 months Chapter 0 / 0

10.2.1 Visual Check

When visually inspecting the unit, check whether …

♦ there is any mechanical damage or foreign bodies can

be found in the system,

♦ any conductive dirt or dust has accumulated in the unit,

♦ accumulation of dust affects heat supply and

dissipation.

57

Page 58

CAUTION!

power supply prior to carrying out the following

PROTECT 1. must be disconnected from the

work.

If large quantities of dust have accumulated, the unit should,

as a precaution, be cleaned with dry compressed air, in order

to ensure adequate heat dissipation.

The intervals at which visual checks should be performed are

largely determined by the site conditions.

10.2.2 Checking the Battery

Progressive ageing of the battery system can be detected by

regular capacity checks. Every 6 months, perform

measurements to compare the achievable standby times, e.g.

by simulating a mains failure. In this case, the load should

always have approximately the same capacity demand.

Please contact our hotline if the time drops drastically