Advantech ADAM-4572 User Manual

User Manual

ADAM-4572

1 port Modbus Gateway

Copyright

The documentation and the software included with this product are copyrighted 2013 by Advantech Co., Ltd. All rights are reserved. Advantech Co., Ltd. reserves the right to make improvements in the products described in this manual at any time without notice. No part of this manual may be reproduced, copied, translated or transmitted in any form or by any means without the prior written permission of Advantech Co., Ltd. Information provided in this manual is intended to be accurate and reliable. However, Advantech Co., Ltd. assumes no responsibility for its use, nor for any infringements of the rights of third parties, which may result from its use.

Acknowledgements

Intel and Pentium are trademarks of Intel Corporation.

Microsoft Windows and MS-DOS are registered trademarks of Microsoft Corp. All other product names or trademarks are properties of their respective owners.

Product Warranty (5 years)

Advantech warrants to you, the original purchaser, that each of its products will be free from defects in materials and workmanship for two years from the date of purchase.

This warranty does not apply to any products which have been repaired or altered by persons other than repair personnel authorized by Advantech, or which have been subject to misuse, abuse, accident or improper installation. Advantech assumes no liability under the terms of this warranty as a consequence of such events.

Because of Advantech’s high quality-control standards and rigorous testing, most of our customers never need to use our repair service. If an Advantech product is defective, it will be repaired or replaced at no charge during the warranty period. For out- of-warranty repairs, you will be billed according to the cost of replacement materials, service time and freight. Please consult your dealer for more details.

If you think you have a defective product, follow these steps:

1.Collect all the information about the problem encountered. (For example, CPU speed, Advantech products used, other hardware and software used, etc.) Note anything abnormal and list any onscreen messages you get when the problem occurs.

2.Call your dealer and describe the problem. Please have your manual, product, and any helpful information readily available.

3.If your product is diagnosed as defective, obtain an RMA (return merchandize authorization) number from your dealer. This allows us to process your return more quickly.

4.Carefully pack the defective product, a fully-completed Repair and Replacement Order Card and a photocopy proof of purchase date (such as your sales receipt) in a shippable container. A product returned without proof of the purchase date is not eligible for warranty service.

5.Write the RMA number visibly on the outside of the package and ship it prepaid to your dealer.

Part No. 2009457200 |

Edition 1 |

Printed in Taiwan |

April 2014 |

ADAM-4572 Series User Manual |

ii |

Declaration of Conformity

CE

This product has passed the CE test for environmental specifications when shielded cables are used for external wiring. We recommend the use of shielded cables. This kind of cable is available from Advantech. Please contact your local supplier for ordering information.

CE

This product has passed the CE test for environmental specifications. Test conditions for passing included the equipment being operated within an industrial enclosure. In order to protect the product from being damaged by ESD (Electrostatic Discharge) and EMI leakage, we strongly recommend the use of CE-compliant industrial enclosure products.

FCC Class A

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Technical Support and Assistance

1.Visit the Advantech web site at www.advantech.com/support where you can find the latest information about the product.

2.Contact your distributor, sales representative, or Advantech's customer service center for technical support if you need additional assistance. Please have the following information ready before you call:

–Product name and serial number

–Description of your peripheral attachments

–Description of your software (operating system, version, application software, etc.)

–A complete description of the problem

–The exact wording of any error messages

iii |

ADAM-4572 Series User Manual |

Safety Instructions

1.Read these safety instructions carefully.

2.Keep this User Manual for later reference.

3.Disconnect this equipment from any AC outlet before cleaning. Use a damp cloth. Do not use liquid or spray detergents for cleaning.

4.For plug-in equipment, the power outlet socket must be located near the equipment and must be easily accessible.

5.Keep this equipment away from humidity.

6.Put this equipment on a reliable surface during installation. Dropping it or letting it fall may cause damage.

7.The openings on the enclosure are for air convection. Protect the equipment from overheating. DO NOT COVER THE OPENINGS.

8.Make sure the voltage of the power source is correct before connecting the equipment to the power outlet.

9.Position the power cord so that people cannot step on it. Do not place anything over the power cord.

10.All cautions and warnings on the equipment should be noted.

11.If the equipment is not used for a long time, disconnect it from the power source to avoid damage by transient overvoltage.

12.Never pour any liquid into an opening. This may cause fire or electrical shock.

13.Never open the equipment. For safety reasons, the equipment should be opened only by qualified service personnel.

14.If one of the following situations arises, get the equipment checked by service personnel:

–The power cord or plug is damaged.

–Liquid has penetrated into the equipment.

–The equipment has been exposed to moisture.

–The equipment does not work well, or you cannot get it to work according to the user's manual.

–The equipment has been dropped and damaged.

–The equipment has obvious signs of breakage.

15.DO NOT LEAVE THIS EQUIPMENT IN AN ENVIRONMENT WHERE THE STORAGE TEMPERATURE MAY GO BELOW -20° C (-4° F) OR ABOVE 60° C (140° F). THIS COULD DAMAGE THE EQUIPMENT. THE EQUIPMENT SHOULD BE IN A CONTROLLED ENVIRONMENT.

16.CAUTION: DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED. REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE RECOMMENDED BY THE MANUFACTURER, DISCARD USED BATTERIES ACCORDING TO THE MANUFACTURER'S INSTRUCTIONS.

17.The sound pressure level at the operator's position according to IEC 704-1:1982 is no more than 70 dB (A).

DISCLAIMER: This set of instructions is given according to IEC 704-1. Advantech disclaims all responsibility for the accuracy of any statements contained herein.

ADAM-4572 Series User Manual |

iv |

Chapter 1 |

Introduction.......................................... |

1 |

1.1 |

Overview ................................................................................................... |

2 |

1.2 |

Features .................................................................................................... |

2 |

1.3 |

Package Check List .................................................................................. |

3 |

Chapter |

2 |

Getting Started..................................... |

5 |

||

|

2.1 |

Understanding Modbus Gateways ............................................................ |

6 |

||

|

|

2.1.1 |

Protocol Overview......................................................................... |

6 |

|

|

|

|

Figure 2.1 |

Modbus System Architecture 1................................... |

7 |

|

|

|

Figure 2.2 |

Modbus System Architecture 2................................... |

7 |

|

|

2.1.2 |

Modbus RTU................................................................................. |

8 |

|

|

|

2.1.3 |

Modbus ASCII............................................................................... |

8 |

|

|

|

|

Table 2.1: Comparison of Modbus RTU and ASCII Modes......... |

8 |

|

|

|

2.1.4 |

Modbus TCP ................................................................................. |

8 |

|

|

2.2 |

Specifications ............................................................................................ |

|

9 |

|

|

2.3 |

Hardware................................................................................................. |

|

10 |

|

|

|

2.3.1 |

LED Indicators ............................................................................ |

10 |

|

|

|

|

Table 2.2: The Advantech Modbus Gateway LED Indicators.... |

10 |

|

|

|

2.3.2 |

Dimensions (Units: mm).............................................................. |

11 |

|

|

|

|

Figure 2.3 |

Front View of the Advantech Modbus Gateway ....... |

11 |

|

|

|

Figure 2.4 |

Back View of the Advantech Modbus Gateway........ |

11 |

|

|

|

Figure 2.5 |

Bottom View of the Advantech Modbus Gateway .... |

12 |

|

|

|

Figure 2.6 |

Side View of the Advantech Modbus Gateway......... |

12 |

|

2.4 |

Connecting Hardware ............................................................................. |

13 |

||

|

|

2.4.1 |

Choosing the Location ................................................................ |

13 |

|

|

|

|

Figure 2.7 |

The Advantech Modbus Gateway Panel Mounting |

|

|

|

|

|

Bracket Dimensions.................................................. |

14 |

|

|

|

Figure 2.8 |

The Advantech Modbus Gateway Panel Mounting .. |

14 |

|

|

|

Figure 2.9 |

DIN-rail Adapter........................................................ |

15 |

|

|

|

Figure 2.10DIN-rail Mounting...................................................... |

15 |

|

|

|

2.4.2 The Advantech Modbus Gateway Serial Port Wiring.................. |

16 |

||

|

|

|

Figure 2.11Pin assignment of 3P to DB 9 cable ......................... |

16 |

|

|

|

|

Figure 2.12Wiring RS-232 Connection ....................................... |

16 |

|

|

|

|

Figure 2.13Wiring RS-485 Connection ....................................... |

17 |

|

|

|

|

Figure 2.14Wiring RS-422 Connection ....................................... |

17 |

|

Chapter |

3 |

Configuration ..................................... |

19 |

|

|

3.1 |

Installing the Configuration Utility............................................................ |

20 |

|

|

3.2 |

Starting the Configuration Utility.............................................................. |

23 |

|

|

3.3 |

Discovering Modbus Gateways............................................................... |

24 |

|

|

|

3.3.1 |

Auto Searching ........................................................................... |

24 |

|

|

3.3.2 Clear Device List and Search Again ........................................... |

27 |

|

|

|

3.3.3 |

Manual Appending ...................................................................... |

27 |

|

3.4 |

Setting Ethernet Parameters................................................................... |

28 |

|

|

3.5 |

Setting Serial Communication Parameters ............................................. |

30 |

|

|

|

3.5.1 |

Basic Configuration..................................................................... |

30 |

|

|

3.5.2 |

Operation Configuration.............................................................. |

32 |

|

3.6 |

System |

.................................................................................................... |

36 |

|

3.7 |

Function Accessible Setting .................................................................... |

37 |

|

|

3.8 |

Monitoring Modbus Status ...................................................................... |

38 |

|

|

3.9 |

Administrator Settings ............................................................................. |

39 |

|

|

|

3.9.1 Import Export Device Settings .................................................... |

39 |

|

|

|

3.9.2 Import/Export Serial Port Setting ................................................ |

39 |

|

|

|

3.9.3 Locate the Modbus Data Gateway.............................................. |

40 |

|

|

|

3.9.4 |

Lock Device ................................................................................ |

40 |

1 |

ADAM-4572 User Manual |

|

3.9.5 Restore to Factory Default Settings............................................ |

41 |

|

|

3.9.6 Update Firmware ........................................................................ |

42 |

|

Appendix A Slave ID Mapping Mechanism.......... |

45 |

||

A.1 |

Slave Mode ............................................................................................. |

|

46 |

|

Figure A.1 |

: Master Mode Slave ID Mapping Example .............. |

46 |

A.2 |

Master Mode ........................................................................................... |

|

47 |

|

Figure A.2 |

: Master Mode Slave ID Mapping Example .............. |

47 |

Appendix B Modbus Exception Codes ................ |

49 |

||

B.1 |

Modbus Exception Codes ....................................................................... |

50 |

|

ADAM-4572 User Manual |

2 |

Chapter 1

1 Introduction

1.1 Overview

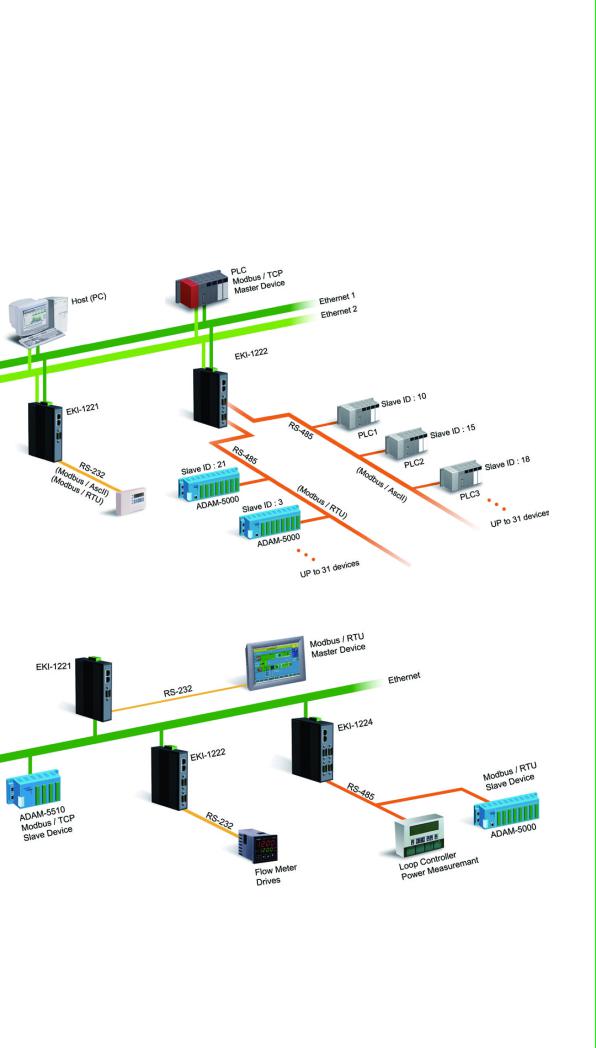

Advantech’s Modbus GatewayModbus Gateway is a robust, feature-rich, and cost effective way to integrate of Ethernet and Serial Modbus devices. The Advantech’s Modbus Gateway provides one, two or four serial ports, one or two Ethernet ports, a wide range of power inputs, and a compact slim design, making them an ideal solution for connecting multiple Modbus/ RTU and Modbus/ASCII serial devices to Modbus TCP (Ethernet).

Originally developed for PLCs in industrial automation and manufacturing control applications, Modbus is one of the most popular open standard protocols in use today. The communication mode can be Modbus RTU/ASCII (Serial) or Modbus TCP (Ethernet). Many industrial devices use Modbus as their communication standard. However, the Ethernet-based Modbus protocol is different from the original serialbased protocols that a Modbus Gateway is needed to be a bridge for integration.

The Modbus/RTU and Modbus/ASCII protocols define how a “master” device polls one or more “slave” devices and write real-time data over RS-232, RS-422, or RS485 serial data communication. The Advantech’s Modbus Gateway provides a feature that can allow users to select master or slave operation for each serial port. The Advantech’s Modbus Gateway not only allows Ethernet master can control serial slaves, but also allow serial masters to control Ethernet or serial slaves.

The Advantech’s Modbus Gateway supports various operating modes: RTU Master, RTU Slave, ASCII Master, and ASCII Slave.

1.2Features

Provides a 10/100 Mbps auto-sensing Ethernet port

Compact design without any hardware configuration

Integration of Modbus TCP and Modbus RTU/ASCII networks

Supports COM port's baud rate up to 921.6 kbps

Supports up to 16 TCP connections and 32 requests simultaneously

Supports 31 slaves (RS-485) per serial port

Provides easy to use configuration utility

Software selectable RS-232/422/485 communication

Auto searching slave ID over configuration utility

Mounts on DIN-rail, wall, or panel

ADAM-4572 User Manual |

2 |

1.3Package Check List

1 x Advantech’s Modbus Gateway

1 x Document and software CD

1 x DIN-rail kit

1 x 30 cm 3P to DB9 cable for RS-232 connection

Note! Please check above items, if any one of them is missing or damaged, contact your sales representative.

Introduction 1 Chapter

3 |

ADAM-4572 User Manual |

ADAM-4572 User Manual |

4 |

Chapter 2

2 Getting Started

2.1 Understanding Modbus Gateways

Networks have become increasingly vital for industrial automation applications. Many control devices today do not have a network port and can only communicate with a dedicated local PC or control panel. Advantech’s revolutionary network-enabling technology is now allowing control devices with serial ports to connect to the Ethernet and share networks quickly and cost-effectively. The Advantech Modbus Gateway is network-based, Modbus gateways for integrating new and existing Modbus/RTU and Modbus/ASCII serial devices to newer TCP/IP networked-based devices. Manufacturers, system integrators, and end users can now take advantage of Modbus gateways to create networked applications for remote managing and accessing data for their control devices that wasn’t possible before.

2.1.1 Protocol Overview

Originally developed for PLCs in industrial automation and manufacturing control application, Modbus has become one of the most popular open standard protocols in use today. When it comes to planning data communication for open, multi-vendor industrial control systems, Modbus is the first choice of end-users and integrators. Although it’s not the most powerful protocol available, its rare simplicity allows not only rapid implementation, but also remains flexible enough to be applied in virtually all industrial situations. The communication mode of Modbus can be ASCII, RTU, or TCP/IP. Modbus gateways are used to support applications such as protocol conversion between serial (Modbus/ASCII or Modbus/RTU) and networked (Modbus/TCP) Modbus devices or it can be used to bridge Modbus serial devices over TCP/IP network.

The Modbus/RTU and Modbus/ASCII protocols define how a “master” device polls one or more “slave” devices to read and write real-time data over RS-232, RS-422, or RS-485 serial data communication. The simplicity of Modbus/RTU not only allows rapid implementation, but can also remain flexible enough to be applied in virtually all industrial situations.

During Modbus network communication, the protocol determines how each controller will know its device address, recognize a message addressed to it, determine the kind of action to be taken, and extract any data or other information contained in the message. If a reply is required, the controller will construct the reply message and send it back using Modbus protocol.

The way controllers communicate with each other is by using a master-slave technique, in which only one device (the master) can initiate queries. The other devices (the slaves) respond by supplying the requested data to the master, or by taking the action requested in the query. Typical master devices include host processors and programming panels. Typical slaves include programmable controllers.

It is the master that can address individual slaves and initiate a broadcast message to all slaves. On the other hand, slaves return a response to queries that are addressed to them individually. Responses are not returned to broadcast queries from the master.

ADAM-4572 User Manual |

6 |

The Modbus protocol has a definite format for the master’s query, which incorporates the device (or broadcast) address, a function code defining the requested action, any data to be sent, and an error-checking field. The slave’s response message, which is also constructed using Modbus protocol, contains fields confirming the action taken, any data to be returned, and an error-checking field. If an error occurred in receipt of the message, or if the slave is unable to perform the requested action, the slave will construct an error message and send it as its response.

The basic system architecture is as below:

Figure 2.1 Modbus System Architecture 1

Figure 2.2 Modbus System Architecture 2

Started Getting 2 Chapter

7 |

ADAM-4572 User Manual |

2.1.2 Modbus RTU

The Modbus/RTU protocol defines how a “master” device polls one or more “slave” devices to read and write data in real-time over RS-232, RS-422, or RS-485 serial data communication.

When using RTU mode, each 8-bit byte in a message contains two 4-bit hexadecimal characters. The main advantage of this mode is that its greater character density allows better data throughput than ASCII mode for the same baud rate. Nevertheless, each message must be transmitted in continuous stream.

2.1.3 Modbus ASCII

When using ASCII mode, each 8-bit byte in a message is sent as two ACSII characters. The primary advantage of this ASCII mode is that it allows time intervals of up to one second to occur between characters without causing an error.

Table 2.1: Comparison of Modbus RTU and ASCII Modes

Mode |

RTU |

ASCII |

|

|

|

Coding System |

8-bit binary. |

Hexadecimal. |

|

Two hexadecimal |

One hexadecimal |

|

character contained in |

character contained in |

|

each ASCII character of |

each ASCII character of |

|

the message |

the message |

Bits per Byte |

1 start bit, |

1 start bit , |

|

8 data bits, |

7 data bits, |

|

1 bit for even/odd parity; |

1 bit for even/odd parity; |

|

no bit for parity |

no bit for parity |

|

1 stop bit if parity is used; |

1 stop bit if parity is used; |

|

2 bits if no parity |

2 bits if no parity |

Error Check |

CRC |

LRC |

2.1.4 Modbus TCP

As a new extension of Modbus/RTU, the Modbus/TCP protocol defines how Modbus/ RTU messages are encoded within and transported over TCP/IP-based networks. Modbus/TCP is just as simple to implement and flexible to apply as the original Modbus/RTU. The Modbus/TCP protocol is defined by its form of encapsulation for a Modbus request or response. That means the Modbus request or response data is encapsulated in TCP frame that has a six-byte header in Modbus/TCP protocol.

Modbus/TCP enables the use of Modbus messaging in an Intranet running the TCP/ IP protocols. Modbus/TCP is most commonly used for Ethernet attachment of PLC’s or I/O modules to other simple field buses or I/O networks.

ADAM-4572 User Manual |

8 |

2.2 Specifications

LAN |

|

|

Ethernet |

10/100 Mbps, RJ45 |

|

Protection |

Built-in 1.5 KV magnetic isolation |

|

Serial Interface |

|

|

Interface |

|

RS-232/422/485 |

No. of Ports |

|

1 |

Connector Type |

Terminal block |

|

Parity |

|

None, Even, Odd, Space, Mark |

Data bits |

|

7, 8 |

Stop bits |

|

1, 2 |

Flow Control |

|

RTS/CTS, XON/XOFF |

Speed |

|

50 bps to 921.6 kbps |

Signals |

|

|

RS-232 |

TxD, RxD, GND |

|

RS-422 |

Tx+, Tx-, Rx+, Rx-, GND |

|

RS-485 |

Data+, Data-, GND |

|

Protection |

15 KV ESD for all signals |

|

Software Features |

|

|

Operation Mode |

Modbus RTU master/slave, Modbus ASCII master/slave |

|

Utility |

|

Serial Device Server Configuration Utility |

Power Requirements |

||

Power Input |

|

10 to 30 VDC |

Power Connector |

Terminal block |

|

Power Consumption 2.5W

Environment |

|

Operating Temperature |

0 to 60 °C (32 to 140 °F) |

Storage Temperature |

-20 to 80 °C (-4 to 176 °F) |

Started Getting 2 Chapter

9 |

ADAM-4572 User Manual |

2.3 Hardware

The following instructions will give the overview of the Advantech Modbus Gateway hardware and its installation.

2.3.1 LED Indicators

There are LEDs display the two sets of power status, system status, dual networks status, and serial communication status on the front panel of the Advantech Modbus Gateway. Each of them has its own specific meaning as below table.

Table 2.2: The Advantech Modbus Gateway LED Indicators

LED Name |

LED Color |

Status |

LED Description |

Status/Power |

GREEN |

ON |

Heartbeat (1 time/sec), system is ready |

|

|

OFF |

System is not working |

|

RED |

ON |

Power is on |

|

|

OFF |

Power is off |

Speed/Link |

GREEN |

ON |

100 Mbps speed |

|

|

OFF |

10 Mbps speed |

|

RED |

ON |

Valid network link |

|

|

OFF |

Invalid network link |

Serial |

GREEN |

ON |

Data being transmitted |

|

|

OFF |

No data being transmitted |

|

RED |

ON |

Data being received |

|

|

OFF |

No data being received |

ADAM-4572 User Manual |

10 |

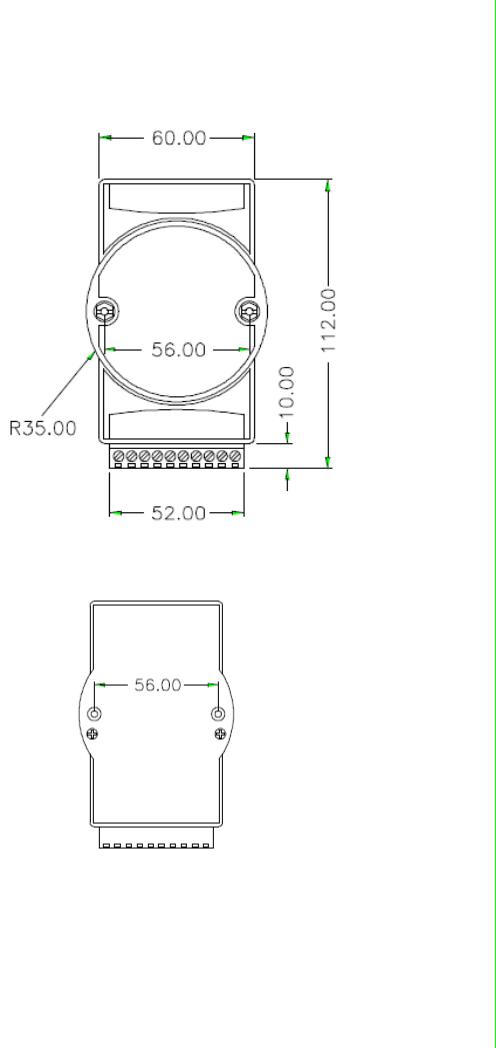

2.3.2 Dimensions (Units: mm)

Advantech’s Modbus Gateway

Figure 2.3 Front View of the Advantech Modbus Gateway

Figure 2.4 Back View of the Advantech Modbus Gateway

Started Getting 2 Chapter

11 |

ADAM-4572 User Manual |

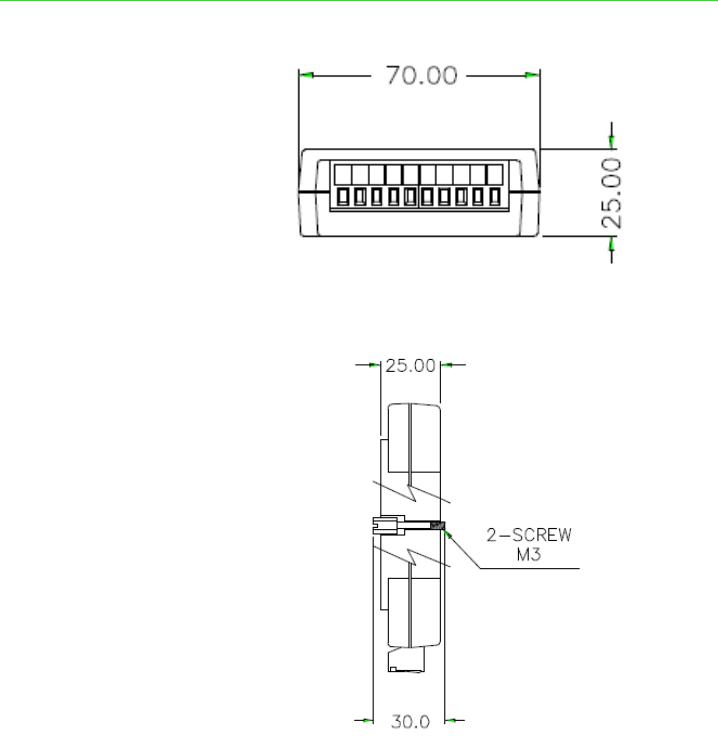

Figure 2.5 Bottom View of the Advantech Modbus Gateway

Figure 2.6 Side View of the Advantech Modbus Gateway

ADAM-4572 User Manual |

12 |

Loading...

Loading...