Page 1

0

Engine

Vacuum

5

10

15

20

25

30

10

9

8

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

Fuel

Pump

psi

0

Engine

Vacuum

5

10

15

20

25

30

10

9

8

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

Fuel

Pump

psi

0

Engine

Vacuum

5

10

15

20

25

30

10

9

8

7

6

5

4

3

2

1

0

1

2

3

4

5

6

7

Fuel

Pump

psi

®

CP7803

VACUUM GAUGE/

PRESSURE TESTER KIT

INSTRUCTIONS

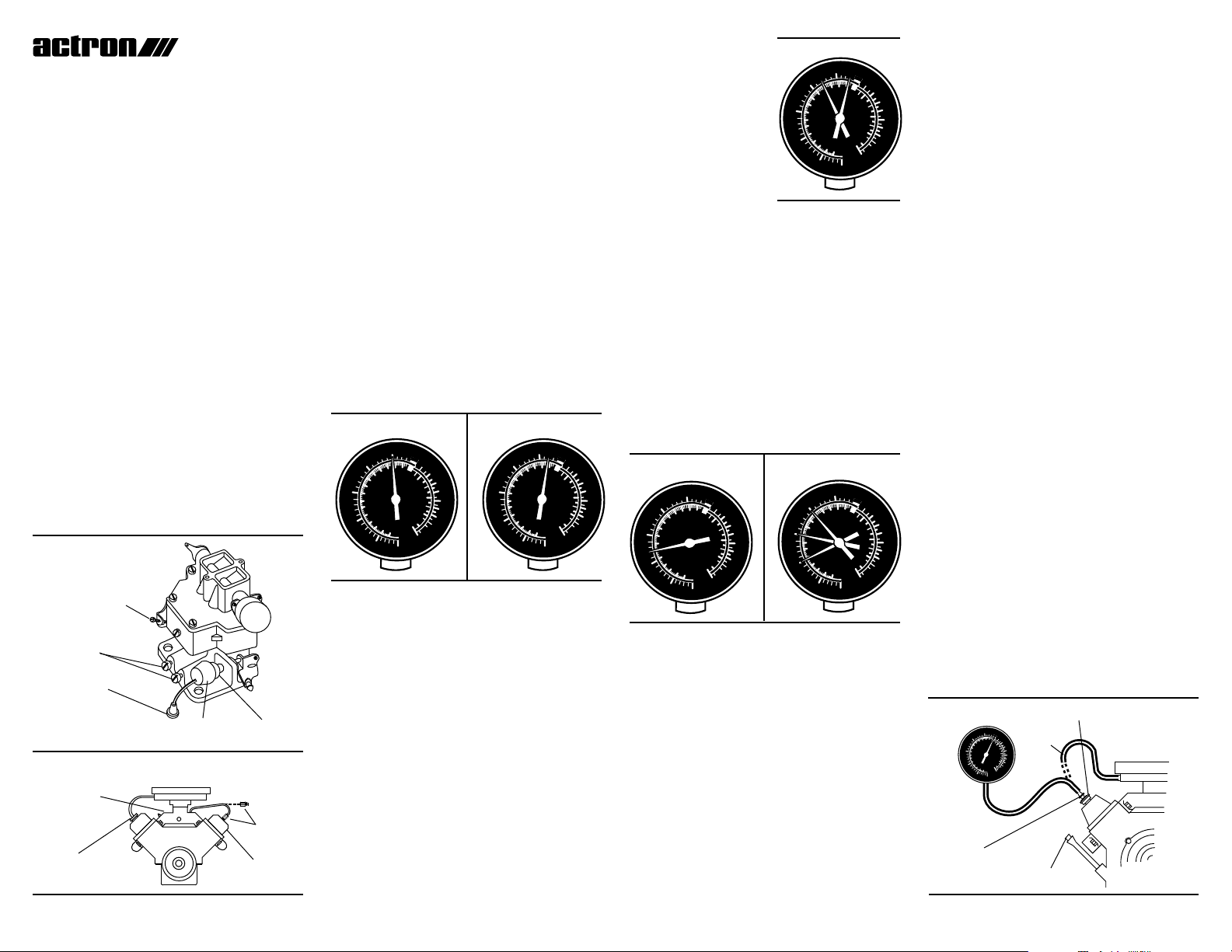

CRANKING VACUUM TESTS

Engine Condition Test

1. Start engine and allow it to warm to normal

operating temperature. Stop engine. To prevent the engine from starting, disable the ignition system.

2. Remove the air filter. Back out the idle speed

screw (see Figure 1) until the throttle valve is

tighly closed. If the carburetor is also equipped

with an idle air bleed screw, turn the screw

clockwise until it bottoms lightly. In both cases,

count the number of turns so the screws can be

returned to their original positions after the tests.

3. If the vehicle is equipped with an idle stop

solenoid (See Figure 1), disconnect the electrical wire at the base of the solenoid under the

rubber boot or at the connector as shown.

4. If the engine is equipped with a PCV (Positive

Crankcase Ventilation) system, remove the PCV

valve at the engine rocker arm cover (see Fig-

Fig. 1

IDLE

SPEED

SCREW

IDLE MIXTURE

SCREWS

DISCONNECT

ELECTRICAL

CONNECTOR OR

TERMINAL UNDER

RUBBER COVER

Fig. 2

SOURCE OF

MANIFOLD

VACUUM

CLOSED

BREATHER

CAP

RUBBER

COVER

AIR CLEANER

ROCKER ARM

VALVE COVER

IDLE STOP

SOLENOID

PCV

VALVE

ure 2) and plug the valve on the bottom with

tape or other suitable means.

5. Using the hose supplied, connect the Vacuum

Gauge to a source of manifold vacuum. This

may be a fitting on the carburetor below the

throttle plate, or a fitting in the intake manifold.

See Figures 2 and 9.

6. Crank the engine and note Vacuum Gauge

reading.

(After testing, return adjustment screws to their

original positions.)

Test Results

The general condition of an engine is indicated by

one of three possible gauge readings:

A.(Figure 3) A reasonably steady vacuum read-

ing of 4 inches or more on emission controlled

engines, and 10 inches or more on non-emission controlled engines (pre-1968) indicates

correct engine vacuum. Readings may vary

considerably on different engines, but should

not fall below these minimums. (See

manufacturer’s specifications).

Fig. 3

10

15

20

Engine

Vacuum

25

5

0

1

0

1

2

3

Fuel

Pump

4

5

6

7

9

10

30

Fig. 4

5

0

2

3

4

5

psi

6

7

8

10

Engine

Vacuum

15

20

25

1

2

0

3

1

2

4

3

Fuel

5

Pump

4

6

5

6

7

7

8

9

10

30

B.(Figure 4) An excessively low, steady vacuum

is caused by a condition which affects all cylinders equally.

Check for:

1. Leaking carburetor flange gasket.

2. Worn carburetor throttle shaft.

3. Leaking vacuum lines.

4. Improper valve timing.

5. Slow engine cranking due to:

A. Battery

B. Battery cable connections

C. Defective starter motor

D. Excessive mechanical drag in engine caused by:

1. Tight fitting pistons in rebuilt engine.

2. Thickened oil due to excessive oxidation.

C.(Figure 5) A reading which pulses unevenly

indicates a leaky condition which affects one or

more, but not all cylinders.

NOTE: A certain amount

of even pulsing is nor-

Fig. 5

mal, notably on 6 and 4

cylinder engines, and

does not necessarily indicate a leaky condition.

Check for:

1. Burned or stuck valve.

2. Intake manifold leak

at one cylinder.

3.Worn intake valve

guide.

4. Broken piston or piston rings.

RUNNING VACUUM TEST

Engine Condition Test

While performing a running vacuum test, it is

possible to obtain a different gauge indication than

that obtained under the cranking vacuum test.

1. Connect the vacuum gauge to a source of

manifold vacuum. See Figures 2 and 9.

2. Run the engine at normal operating temperature and idle speed.

Fig. 6

5

Engine

Vacuum

25

0

1

2

0

1

2

3

Fuel

Pump

4

5

6

7

8

9

10

30

psi

10

15

20

Test Results

A.(Figure 6) A steady reading between 15 and 22

inches indicates a mechanically sound engine.

B.(Figure 7) A pointer which sweeps or wanders

erratically through several inches indicates a

malfunction affecting all cylinders unequally

and inconsistently. To help isolate the troubled

area, run the engine at about 2000 RPM. If the

pointer steadies, check for:

1. Ignition and/or timing.

2. Carburetor mixture adjustment at idle.

If the sweep gets larger, check for weak or

broken valve springs. If the sweep becomes

shorter and more rapid, check for:

1. Carburetor or intake manifold leaks.

2. Sticky valves.

Fig. 7

3

4

5

psi

6

7

EXHAUST RESTRICTION TEST

With vacuum gauge connected to a source of

manifold vacuum, increase engine speed to 2000

RPM, maintain this speed, and note the vacuum

gauge reading. A gradually decreasing vacuum

reading may indicate a restricted exhaust system.

(Partially blocked muffler or tailpipe.)

POSITIVE CRANKCASE

VENTILATION (PCV) VALVE TEST

1. Unplug the PCV valve, plugged previously with

a piece of tape (Step 4, Cranking Vacuum

Tests) and crank engine.

A. If the PCV valve is operating properly, the

vacuum will drop to about one-half the value

noted in Step 6, Cranking Vacuum Tests.

B. A reading much lower than one-halfindicates

excessive flow which could upset the proper

carburetor air/fuel ratio causing rough idling

and burned valves.

C. No change in the vacuum indicates a clogged

PCV valve.

2. Return the idle screw (and idle air bleed screw)

to its original position. (See Step 2, Cranking

Vacuum Tests).

3. Re-enable the ignition system.

4. Re-connect the wire to the idle stop solenoid.

5. Re-connect all hoses and vacuum lines.

6. Re-install the PCV valve in its proper location.

PCV SYSTEM TEST

1. Operate the engine at normal temperature and

idle speed.

2. Remove the hose connected between the air

cleaner and valve cover or oil filler/breather cap

as shown in Figure 8. Plug the oil dipstick tube

to prevent an air leak.

Fig. 8

UNIVERSAL

RUBBER

ADAPTER

PLUG OIL

DIPSTICK HOLE

FILLER/BREATHER CAP

VENT

HOSE

AIR

CLEANER

Page 2

3. Hold the vacuum gauge with rubber universal

adaptor firmly over the valve cover hole or filler/

breather cap opening.

A. A properly working PCV system will draw a

vacuum of about 3 to 5 inches within 10 seconds.

B. If there is very little or no change in the

gauge reading in the first 10 to 15 seconds of

the test the PCV valve is clogged or frozen, or

there is excessive air leakage in the vacuum

hose between the intake manifold and PCV

valve (or other leakage into the crankcase).

4. Repair or replace the defective parts as needed

and reconnect hoses.

DISTRIBUTOR VACUUM

ADVANCE MECHANISMS

The amount of spark ignition advance needed is

determined by the intake manifold vacuum and

engine speed.

The vacuum advance mechanism in the distributor

is connected to the intake manifold or carburetor by

a rubber hose. To measure the amount of vacuum

at any RPM, disconnect the hose from the distributor and insert a “Tee” connector (Item 4, Figure 12)

in line with this hose and another back to the

distributor as shown in Figure 9. Also, connect the

gauge to the “Tee” as shown.

Fig. 9

5

ALTERNATE VACUUM

CONNECTION ON CARBURETOR

MANIFOLD VACUUM

CONNECTION

Test Results

On many systems, little or no vacuum is applied to

the distributor at idle; as the throttle is opened wider

(engine RPM increases), the vacuum gradually increases. The manifold vacuum drops when the engine is accelerated in proportion to the amount of

throttle advance. The gauge should read between

18 and 21 for normal engines. Check vehicle manual

for your car for proper value.

If the vacuum gauge does not change or changes very

little with a change in RPM as described above, the

vacuum hose may be open or cracked, or the diaphram

in the advance mechanism may be punctured.

0

1

10

2

0

3

1

Engine

2

4

Vacuum

15

3

Fuel

5

psi

Pump

4

6

5

6

7

7

20

8

9

10

25

30

NOTE: The vacuum reading can appear to be

normal during the above tests while the advance

mechanism is defective; that is, frozen due to rust,

dirt or corrosion.

FUEL PUMP TESTING

CAUTION: Use extreme care in disconnecting

fuel lines. Catch all gasoline in a container and

discard. Leaking gasoline is a serious fire

hazard.

Initial Inspection

Before testing, check tightness of all fittings and

connections.

Check the rubber fuel lines at the fuel pump for

deterioration, such as splitting, cracking and

spongyness.

If leaks are evident in lines or fittings, repair or

replace as necessary. If leakage is detected in the

pump at the diaphragm flange, in the sheet metal

cover, or in casting breather holes, replace the

fuel pump. Check fuel level and remove any kinks

in the fuel line. It is not necessary to remove the

fuel pump for any of these inspections.

Procedure

1. Disconnect the fuel line between the fuel pump

and the carburetor and attach the vacuum gauge

hose to the fuel line, using adaptors as necessary. (See Figure 10).

NOTE: The fuel in the carburetor fuel bowl will be

sufficient to run the engine for these tests.

2. Operate the engine at idle. Hold gauge at

carburetor height and note the reading. Stop

engine and re-connect fuel line.

Test Results

Compare the observed reading with the

manufacturer’s specifications. If specifications are

not immediately available, fuel pump pressure

can be considered satisfactory if it is between 4

and 6 PSI, with lower readings for smaller displacement engines. If pressure reading falls outside this range, consult the manufacturer’s specifications before replacing the fuel pump.

Fig. 10

5

0

1

10

2

0

3

1

Engine

2

4

Vacuum

15

3

Fuel

5

psi

Pump

4

6

5

6

7

7

20

8

9

10

25

30

TO

FUEL

TANK

CARBURETOR

CONNECTION

Fig. 11

GASOLINE

CARBURETOR

CONNECTION

TO

FUEL

TANK

VOLUME TEST

1. Operate engine with fuel line connected to fill

carburetor fuel bowl. Stop Engine.

2. Disconnect the fuel line at the carburetor and

connect a flexible hose to the fuel line using the

adapter as shown in Figure 11. Insert the other

end of the hose in a proper gasoline container.

3. Have an assistant start the engine. While holding the gasoline can, carefully collect the discharge from the fuel pump for exactly 30

seconds. The assistant must count off the time

precisely and turn off the engine after the 30

seconds to get an accurate measurement. Reconnect the fuel line to the carburetor.

4. Remove the gasoline from the engine area.

Pour the contents of the gasoline can into

another container marked off in fluid ounces

such as a kitchen measuring cup. Record the

fuel quantity.

5. After taking all measurements, return the fuel to

the vehicle’s gas tank.

Test Results

Consult the manufacturer’s specifications for required fuel delivery rate. If specifications are not

readily available, use the following table as a guide.

Engine Displacement Ozs. Collected

(CID) (30 seconds)

Up to 225 8

225 to 350 11

Over 350 16

If the above conditions are not met, replace or

repair the defective components.

®

Actron Manufacturing Company

9999 Walford Avenue

Cleveland, Ohio 44102-4696

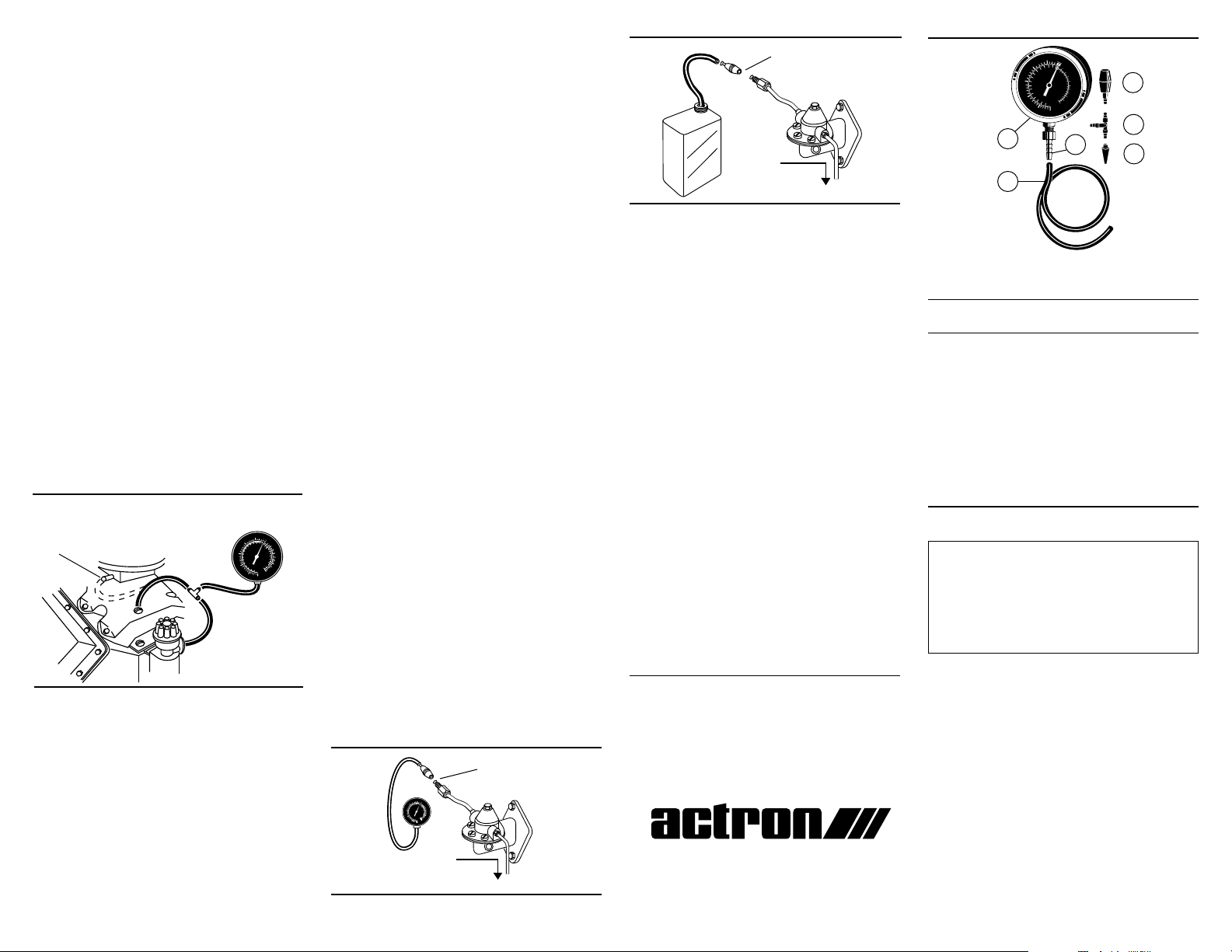

Fig. 12

5

0

10

1

0

2

1

3

Engine

2

Vacuum

15

20

4

3

Fuel

5

psi

Pump

4

6

5

7

6

7

8

9

10

25

30

3

4

1

6

5

2

Vacuum & Pressure Tester Kit

Repair Parts

Key

No. Part No. Description

1 31-269 Vacuum and Pressure Gauge

2 400-384 Black Rubber Hose for air

and fuel (24")

3 1000-1113 Universal Adapter –

Fuel line, air and PVC

4 400-810 "Tee" Fitting

5 400-819 Tapered Hose Adapter

6 180-784 1/8 NPT X 0.187 Barb

2-202002 Instruction Manual

One Year Warranty

If within one year from the date of purchase this

equipment fails due to defect in materials or workmanship, return it to Actron and Actron will repair it

free of charge.

This warranty gives you specific legal rights, and you

may also have other rights which may vary from state

to state.

Customer Service

For product information or customer service

please call 1-800-ACTRON-7 (1-800-228-7667)

Monday through Friday, between 8:30 a.m. and

4:30 p.m. Eastern time or fax anytime at

(216) 651-2388.

Actron can also be reached by Email or on the

Internet.

Email address: sunpro@actron.com

Internet home page: http://www.actron.com

©1997 Actron Manufacturing Company. Sunpro is a

registered trademark of Snap-On Tools Company and is

used under exclusive license.

2-202002

Loading...

Loading...