ABB PSR Softstarters Catalog

—

U.S. CATALOG

Softstarter

Type PSR, PSE and PSTX

—

Motors use almost one third of the world’s generated electricity. So it is safe to say that reliable motor operation is crucial to our modern way of life.

SOFTSTARTER CATALOG |

3 |

—

Contents

04– 14 |

ABB softstarter |

15– 24 |

PSR - The compact range |

25– 38 |

PSE - The efficient range |

39– 58 |

PSTX - The advanced range |

59– 61 |

Fieldbus communication |

62–63 |

Marketing materials and tools |

4 |

SOFTSTARTER CATALOG |

—

ABB softstarter

How we are helping the industry

A softstarter from ABB offers you several values and benefits. Whether you are a consultant, OEM, panel builder or end-user, a softstarter will add to your business value by securing motor reliability, improving installation efficiency and increasing application productivity.

SECURE MOTOR

Reliability

IMPROVE INSTALL ATION

Efficiency

INCRE A SE APPLIC ATION

Productivity

ABB softstarters help increase your motor’s lifetime by protecting it from electrical stress. Starting currents are easily optimized to your load, application and motor size. Over ten motor protection features are included to keep your motor safe from different load and network irregularities.

Reduce your installation time and panel size by having all features you need built into your softstarter. Our softstarters are easy to install thanks to their compact design and many built-in features. The built-in bypass saves energy and space while reducing heat generation. A complete motor starting solution in one unit.

Reduce the number of stops in your production by allowing your softstarter to do more than just starting. Our softstarters reduce the mechanical stress on your motor application, which will increase your uptime. Torque control, pump cleaning, motor brake and many other features enable you to operate your process at its full potential.

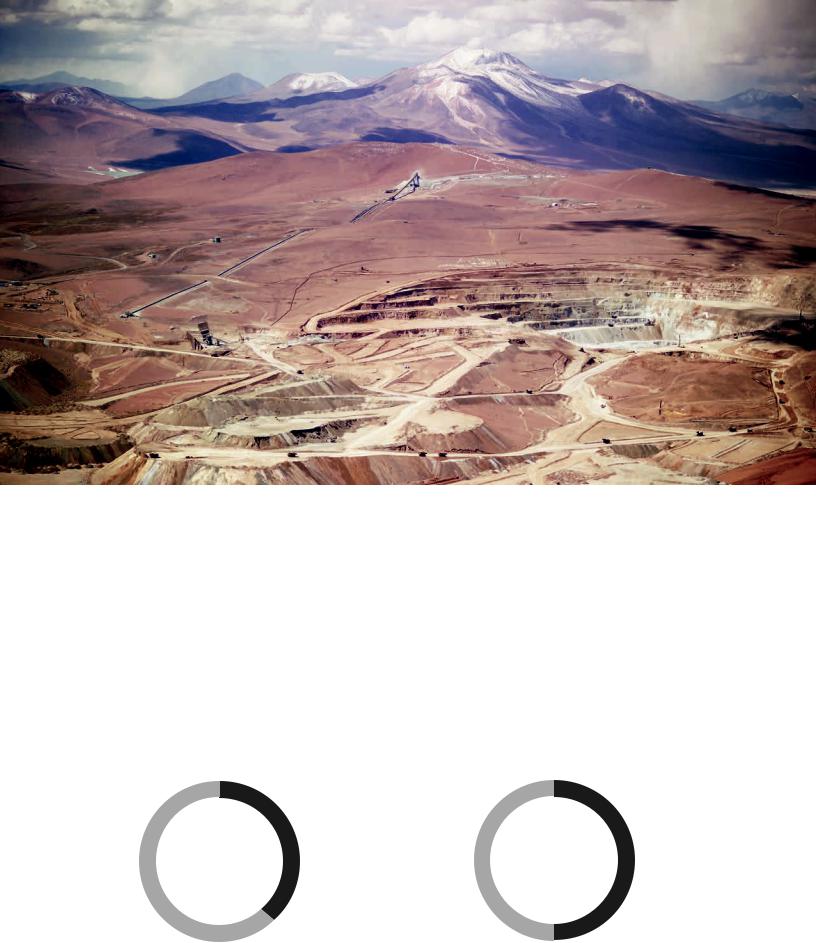

Xylem - South Africa

ABB‘s softstarters providing efficiency to the mining industry

One of Xylem’s water solutions helps to prevent flooding in mines. Previous softstarters needed a lot of extra protection equipment. Xylem was looking for a simpler solution that would ensure reliability even at 3,500 meters depth. Reducing the number of components by 80 percent, shortened installation time by 60 percent. Costs cut to half has helped Xylem sell twice as many panels with softstarters as before.

Why softstarting matters to Xylem

Installation time reduced by |

Total panel cost reduced by |

6 |

SOFTSTARTER CATALOG |

—

ABB softstarter

How we are helping the industry

A softstarter can do wonders with your operations. Packed with useful features, it reduces the wear of your equipment, improve the reliability of your processes and increase overall productivity.

Controlling pumps

ELIMINATING WATER HAMMERING WITH TORQUE CONTROL

Water hammering is a common problem with pumps. It typically results in a lot on wear of pipes and valves when stopping the pump. The ABB softstarter feature torque control stop eliminates water hammering and prolongs the lifetime of the system, while reducing pump downtime.

KEEP PIPES AND PUMPS CLE AN

Many pumps risk getting clogged over time. This will cause reduced flow and increased risk of pump damage. Thanks to the feature to reverse the direction of the flow and start again with kick-start, ABB softstarters can help prevent and solve pump clogging and associated downtime.

AVOID RUNNING DRY WITH UNDERLOAD PROTEC TION

Damages due to pumps running dry can be avoided with the softstarter feature underload protection. It stops the motor which saves the pump from additional wear and contributes to prolonging its lifetime.

Controlling fans

SOF T STARTING ADJUSTED TO APPLIC ATION

Fans normally have a high moment of inertia, which makes starting tough and current high. Using an ABB softstarter, the voltage is increased gradually during start, which reduces the current and removes the inrush peak. It is possible to adjust the settings to fit almost any starting condition, from unloaded to fully loaded.

FA ST STOPS WITH MOTOR BR AKING

It can also take a long time to stop the fan. Active braking using the dynamic brake feature reduces stopping times. This improves process safety when the load has a high moment of intertia and makes fan operation easier for the operator.

AVOID UNWANTED MOVEMENTS WITH STAND STILL BR AKE

An idle fan that is rotating backwards, due to wind or airflow from another fan, can be kept still using the stand still brake. It prevents unwanted airflow and improves the control of the system without the need for an external mechanical brake.

SOFTSTARTER CATALOG |

7 |

Controlling conveyor belts

AVOID OVERHE ATING WITH OVERLOAD PROTEC TION

Too much material on a conveyor belt may cause overload and overheating, reducing the reliability and longevity of the motor. ABB’s overload protection feature shuts down the motor in case of overload, avoiding overheating.

INCRE A SED FLE XIBILIT Y WITH JOG WITH SLOW SPEED

After stopping the belt, it may be necessary to run the motor at low speed to correctly position the belt before resuming operation. The jog with slow speed feature makes it possible to position the belt manually, in both forward and reverse direction, before re-starting the belt. This improves process efficiency and eliminates the need for a variable speed drive, a considerably more expensive solution for solving the problem.

CONTINUOUS OPER ATION WITH LIMP MODE

Shorted thyristor is a possible problem for a softstarter, putting it out of operation until the component has been replaced. Using limp mode, the softstarter will continue to work with one thyristor shorted, avoiding costly unplanned stoppages.

Controlling compressors

FULL CONTROL OF CURRENT WITH CURRENT LIMIT

Many applications are sensitive to high or variable starting currents. The feature current limit makes it possible to start the motor securely even in a weaker network, improving the availability of the equipment and system. Reducing the current means reducing the stress on cables, network and motor.

FULL VOLTAGE START FOR SCROLL COMPRESSORS

For scroll compressors it is often necessary to start the motor in a very short time while still maintaining a low starting current. Full voltage start is a start mode that gives you almost a direct start but without the current peak.

PHA SE RE VERSAL PROTEC TION FOR PROBLEM - FREE COMMISSIONING

A motor rotating in the wrong direction, which may occur due to connecting the phases wrongly, may cause severe damage to a compressor. Using phase reversal protection, the motor won‘t start in the wrong direction, avoiding costly compressor downtime and repairs.

8 |

SOFTSTARTER CATALOG |

—

ABB softstarters

Why motor starting and stopping matters

There are some common issues associated with starting and stopping electrical motors. Depending on requirement, different starting and stopping methods can be used.

D IR EC T- O N - LINE

Direct-on-line starting (DOL) is the easiest and most commonly used starting method. It is suitable for stable networks and mechanically stiff and well-dimensioned shaft systems due to the high current and torque generated during start.

DOL starting is uncontrolled, which means that the motor will start with maximum current and torque regardless of load type.

S TA R - DELTA

A star-delta starter reduces current and torque during start. The starting current is about one third compared to direct-on-line starting, although it also reduces the starting torque to about 25 percent.

Star-delta is not adjustable, so if the torque is reduced too much, the motor will not start. Current peaks will happen when switching from star to delta connection.

Torque |

Motor current |

DOL

DOL

Star-delta

Star-delta

Softstarter

Typical torque and current curves from starting a motor using DOL, star-delta and softstarter.

SOF TS TA RTER

Like direct-on-line and star delta starters, softstarters are used to start and stop motors in full-speed applications. It eliminates common problems associated with motor starting and stopping, including electrical surges, spikes and high inrush currents.

Because it offers soft starting and stopping, a softstarter is the optimal compromise between a direct-on-line or star-delta starter and a variable speed drive in many full-speed motor applications.

VARIABLE SPEED DRIVE

Like a softstarter, a variable speed drive (VSD) can perform soft motor starting and stopping. However, the VSD was designed primarily to control motor speed, resulting in energy efficient motor operation in variable speed applications. Using a VSD with the sole purpose of

ensuring soft starting and stopping of fullspeed motors can therefore be considered an unnecessarily advanced solution.

SOFTSTARTER CATALOG |

9 |

—

ABB softstarters

A solution for every need

ABB’s softstarter offering consists of three ranges, covering every need. The products help you secure motor reliability, improve installation efficiency and increase application productivity.

|

PSR – The compact range |

|

|

|

|

|

|

|

|

|

|

|

|

PSE – The efficient range |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PSTX – The advanced range |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Technical data: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Rated motor current |

|

|

|

3...105 A |

|

|

|

|

|

|

Rated motor current |

|

|

|

|

30...370 A |

|

|

|

|

|

|

|

|

|

|

|

Rated motor current |

|

30...1250 A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(inside delta: 2160 A) |

|

|

|

|

|

|

|

|||||||||||||||

|

Main motor voltage |

|

|

|

|

208...600 V |

|

|

|

|

|

|

Main motor voltage |

|

|

|

|

208...600 V |

|

|

|

|

|

|

|

|

|

|

Main motor voltage |

|

208...690 V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Control supply voltage |

|

100...240 V AC or |

|

|

|

|

|

Control supply voltage |

|

|

100...250 V AC |

|

|

|

|

|

|

|

|

Control supply voltage |

|

100...250 V AC |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

24 V AC/DC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

SOF TSTARTER FE ATURE SELEC TION GUIDE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

dual |

current |

|

limit |

|

|

|

protection |

|

|

protection |

|

|

|

|

|

|

|

|

protectionprotection |

|

|

|

|

|

possible keypad |

|

|

|

|

count |

|

functions |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

reverse |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

protection |

|

|

|

|

|

protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

forward/ |

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||

|

|

Current |

Current |

|

|

|

and |

|

overload |

|

|

Locked |

Current/VoltagePhase |

imbalance |

|

|

|

for |

motor |

|

Inside |

|

Graphical |

|

|

|

and |

|

|

|

|

|

|

start |

|

|

|

|

|

|

|

|

- trip |

|

|

|

- cool |

Event |

|

Multiple |

Electricity Torque |

Torque |

|

Coated |

Limp |

|

|

Jog with |

Dynamic |

Sequence Full |

voltageKick |

|

Automatic |

|

cleaning |

||||||||||||||||||||||||||||||||||||

|

|

Electronic Dual |

|

Underload Power |

Customer Motor |

|

PTC/PT100Overvoltage/undeEarth rvoltageBuilt |

|

DetachableMotor |

|

|

ProgrammableDiagnosticsOverload |

Overload |

Analog |

to |

Fieldbus |

|

|

|

|

Stand |

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

limit |

limit |

ramp |

motor |

|

|

protection |

|

underload protection |

|

protection |

|

|

|

input |

|

|

|

|

protection |

|

|

connection |

|

|

keypad |

|

and |

|

warning |

|

|

time |

- to |

time |

- |

|

communication |

languages |

metering |

|

|

|

|

|

|

|

|

slow |

speed |

brake |

|

|

brake |

start |

|

|

start |

|

|

|

|

pump |

|

||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

protection |

|

rotor |

reversal |

|

defined |

heating |

|

|

|

- fault |

- delta |

|

|

|

display |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

output |

|

limit |

PCBA |

|

mode |

|

|

still |

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

overload |

|

|

|

factor |

|

|

|

|

|

|

|

|

|

- in |

bypass |

|

|

|

|

|

|

|

|

runtime |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

log |

|

|

|

|

|

|

control |

|

|

|

|

|

|

|

|

|

|

|

|

start |

|

|

|

|

|

|

||||||||||||||||||||||||

|

PSR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

PSE |

• |

|

|

• |

|

|

|

|

• |

|

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

|

|

|

o |

o |

|

|

|

|

|

• |

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PSTX |

• |

• |

• |

|

|

• |

|

• |

|

• |

• |

|

• • |

• |

|

• |

|

• • |

• |

|

|

|

• |

• |

|

• |

|

|

|

• |

|

• |

|

|

• |

|

|

• |

|

|

• |

|

|

• |

|

|

• |

|

|

|

• |

• |

|

17 |

|

• |

• |

• |

|

• |

• |

|

|

• |

• |

|

|

• |

|

|

• |

• |

|

|

• |

|

|

• |

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

Secure motor reliability |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Improve installation efficiency |

|

|

|

|

|

|

|

|

Increase application productivity |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Standard o Optional |

|

Not available |

|

10 |

SOFTSTARTER CATALOG |

—

ABB softstarters

A part of your motor starting solution

Motor starting requires several components to work perfectly together. ABB is a one-stop shop for motor starting, offering all the necessary components and complete motor starting solutions, proven together in numerous installations worldwide.

—

Can I use a Softstarter for an ATEX motor?

ATEX

ABB’s softstarters PSR, PSE and PSTX can be used to start ATEX classified motors in Ex environments if the following considerations are taken into account:

-The softstarter has to be placed outside the Ex area. Either in another location or inside an ATEX approved panel.

-A separate ATEX approved overload relay from ABB has to be used together with a line contactor. This overload relay will replace the built-in EOL in the softstarter and has an ATEX approved tripping curve.

-Select softstarter according to normal or heavy-duty start depending on application and line contactor and overload relay with type 2 coordination.

—

Can I use a softstarter on a ship?

ABB’s softstarters PSE and PSTX have marine approvals and are certified for marine environment.

Ships uses IT-networks which means that there is a floating electrical ground. It is possible to use an ABB softstarter in such a network but it is recommended to not connect the functional ground on the softstarter to the ship to avoid disturbances from the network to effect the electronics inside the softstarter.

SOFTSTARTER CATALOG |

11 |

—

ABB softstarters

Wall mounting instructions

|

Minimum distance to wall mm (in) |

|

|

|

|

Softstarter, type |

A1) |

B1) |

|

C |

D |

PSR |

|

|

|

|

|

PSR3 ... PSR16 |

0 |

0 |

25 (0.98) |

N/A |

|

PSR25 ... PSR30 |

0 |

0 |

25 (0.98) |

N/A |

|

PSR37 ... PSR45 |

0 |

0 |

25 (0.98) |

N/A |

|

PSR60 ... PSR105 |

0 |

0 |

25 (0.98) |

N/A |

|

PSE |

|

|

|

|

|

PSE18 ... PSE105 |

100 (3.94) |

10 (0.39) |

20 (0.79) |

N/A |

|

PSE142 ... PSE170 |

100 (3.94) |

10 (0.39) |

20 (0.79) |

N/A |

|

PSE210 ... PSE370 |

100 (3.94) |

10 (0.39) |

20 (0.79) |

N/A |

|

PSTX |

|

|

|

|

|

PSTX30 ... PSTX105 |

100 (3.94) |

10 (0.39) |

20 (0.79) |

35 (1.38) |

|

PSTX142 ... PSTX170 |

100 (3.94) |

10 (0.39) |

20 (0.79) |

35 (1.38) |

|

PSTX210 ... PSTX370 |

100 (3.94) |

10 (0.39) |

20 (0.79) |

35 (1.38) |

|

PSTX470 ...PSTX570 |

150 (5.91) |

15 (0.59) |

20 (0.79) |

35 (1.38) |

|

PSTX720 ... PSTX840 |

150 (5.91) |

15 (0.59) |

20 (0.79) |

35 (1.38) |

|

PSTX1050 ... PSTX1250 |

150 (5.91) |

15 (0.59) |

20 (0.79) |

35 (1.38) |

|

1) PSR, Only for wall mounted Softstarters |

|

|

|

|

|

Minimum distance to front

C |

D |

|

Minimum distance to wall |

Maximum mounting angle |

|

|

|

30 |

30 |

|

|

|

O |

|

O |

|

|

|

|

|

|

A |

|

|

|

B |

A |

B |

|

|

30O

30

O

Items included in the box with the softstarter

|

|

Multi-language manual |

Terminal kit |

Cable and mounting kit for detachable keypad |

||||

|

|

|

|

|

|

|

|

|

|

PSR3 … PSR105 |

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PSE18 … PSE370 |

• |

|

• |

|

|

|

||

|

|

|

|

|

|

|

|

|

PSTX30 … PSTX1250 |

• |

|

• |

|

• |

|||

12 |

SOFTSTARTER CATALOG |

—

ABB softstarters

Certifications and approvals

The table below shows the certifications and approvals for ABB‘s softstarters. For other certifications and/or approvals, please contact ABB.

Certifications and approvals

|

|

|

Certifications |

|

|

|

|

|

Approvals: ship classification societies |

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Abbreviation |

CE |

cULus |

CCC |

EAC |

ANCE |

C-tick |

ABS |

DNV GL |

Lloyd’s |

CCS |

PRS |

Class |

||||||||||

approved in |

EU |

Canada |

China |

Russia |

Mexico |

Australia |

|

|

|

|

|

|

Register |

|

|

|

|

NK |

||||

|

|

USA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PSR3 ... PSR105 |

• |

• |

• |

• |

• |

• |

|

|

|

|

|

|

|

|

|

|

|

|

• |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PSE18 ... PSE370 |

• |

• |

• |

• |

• |

• |

|

• |

|

• |

|

• |

|

• |

• |

|

• |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PSTX30 ... PSTX1250 |

• |

• |

• |

• |

• |

• |

|

• |

|

• |

|

• |

|

• |

• |

|

• |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: • Standard design approved, the products bear the certification mark when it is required.

Directives and standards

No. 2006/95/EC |

Low voltage equipment |

No. 2004/108/EC |

Electromagnetic compability |

EN 60947-1 |

Low-voltageswitchgear and controlgear - Part 1: General rules |

EN 60947-4-2 |

AC semiconductor motor controllers and starters |

UL 508 |

Industrial Control Equipment |

CSA C22.2 No 14 |

Industrial Control Equipment |

SOFTSTARTER CATALOG |

13 |

The PSR softstarter is the most compact of all the softstarter ranges which allows for design of a compact starting equipment. The PSR combined with a manual motor starter makes up a far more compact starting solution than the complex star-delta starter, and with the built-in bypass, the energy losses inside the softstarter are highly reduced.

14 |

SOFTSTARTER CATALOG |

SOFTSTARTER CATALOG |

15 |

—

PSR - The compact range

16– 17 |

PSR - The compact range |

18 |

Overview |

19 |

Ordering details |

20 |

Accessories |

21 |

Technical data |

22 |

Dimensions |

23 |

Circuit diagrams |

16 |

SOFTSTARTER CATALOG |

—

PSR - The compact range

Introduction

•Two-phase controlled

•Operational voltage: 208...600 V AC

•Wide rated control supply voltage:

100...240 V AC, 50/60 Hz or 24 V AC/DC

•Rated operational current: 3...105 A

•Soft start with voltage ramp

•Soft stop with voltage ramp

•Built-in bypass for energy saving and easy installation

•Easy set-up by three potentiometers

•Fieldbus communication with FieldBusPlugadapter and the FieldBusPlug

•Run and Top of Ramp relays available for monitoring

•Connection kits available for connection to ABB´s manual motor starters (MMS)

SECURE MOTOR

Reliability

IMPROVE INSTALL ATION

Efficiency

INCRE A SE APPLIC ATION

Productivity

REDUCE THE ELEC TRIC AL STRESSES AND KEEP THE MOTOR PROTEC TED WITH THE MMS

The PSR reduces the starting current for the motor. The possibility to connect it to the manual motor starter makes it possible to build a compact and complete starting solution with overload and short-circuit protection.

SAVING TIME AND MONE Y WITH BUILTIN BYPA SS AND E A SY SETUP

On the PSR, the bypass is built in and verified by ABB, saving you time during

installation and space in your panel. Set-up is done through three potentiometers making it very fast and easy.

REDUCE THE MECHANIC AL STRESSES ON YOUR MOTOR

Soft start and stop with PSR will reduce mechanical wear and tear on the application and increase the availability and uptime.

SOFTSTARTER CATALOG |

17 |

MOTOR PROTEC TION WITH MANUAL MOTOR STARTER

Use the PSR together with the MMS to get a complete motor starter with soft start and stop together

with overload and short circuit protection.

CONNEC TION KIT (OPTIONAL)

The connection kits simplifies installation of the PSR by making the connection to the MMS screwless.

SCRE W OR DIN - R AIL MOUNTED

PSR is fast and easy to install by using screw mounting or DIN-rail mounting (PSR3 ... PSR45).

OUTPUT SIGNAL REL AYS

PSR has output relays for Run and Top of ramp (PSR25 ... PSR105).

LED INDIC ATORS

PSR has LED indicators for On/

Ready and Run/Top of ramp.

THREE POTENTIOMETERS FOR SET TINGS

Set-up is made very easy with only three potentiometers, for start ramp time, stop ramp time and initial/end voltage level.

SET TINGS |

|

|

|

|

|

|

|

|

|

1 |

Start = 1...20 sec |

|

|

|

|

|

|

|

|

2 |

Stop = 0...20 sec - including the step down voltage |

|

|

|

|

|

|

Step down |

|

|

Step down = 2% reduction for each second increased stop ramp |

|

|

|

|

2 |

|||

3 |

|

|

|

|

|

|

|

||

|

Uini= 40...70% results in end voltage = 30...60% |

1 |

3 |

Uini |

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

Uend |

|

|

2 |

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

1 |

Start |

2 |

Stop |

|

|

18 |

SOFTSTARTER CATALOG |

—

PSR - The compact range

Overview

|

|

|

|

<![if ! IE]> <![endif]>1SFC132020V0001 |

|

|

|

|

<![if ! IE]> <![endif]>1SFC132072V0001 |

|

|

<![if ! IE]> <![endif]>1SFC132024V0001 |

|

|

<![if ! IE]> <![endif]>1SFC132028V0001 |

|

|

|

|

|

PSR3 ... PSR16 |

|

PSR25 ... PSR30 |

PSR37 ... PSR45 |

|

PSR60 ... PSR105 |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Normal start |

PSR3 |

PSR6 |

|

PSR9 |

|

PSR12 |

PSR16 |

PSR25 |

|

PSR30 |

PSR37 |

|

PSR45 |

PSR60 |

PSR72 |

PSR85 |

PSR105 |

In-line connected |

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(400 V) kW |

1.5 |

3 |

|

4 |

|

5.5 |

7.5 |

11 |

|

15 |

18.5 |

|

22 |

30 |

37 |

45 |

55 |

IEC, max. A |

3.9 |

6.8 |

|

9 |

|

12 |

16 |

25 |

|

30 |

37 |

|

45 |

60 |

72 |

85 |

105 |

(440-480 V) hp |

2 |

3 |

|

5 |

|

7.5 |

10 |

15 |

|

20 |

25 |

|

30 |

40 |

50 |

60 |

75 |

UL, max. FLA |

3.4 |

6.1 |

|

9 |

|

11 |

15.2 |

24.2 |

|

28 |

34 |

|

46.2 |

59.4 |

68 |

80 |

104 |

|

400 V, 40 ºC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Using manual motor |

Manual motor starter (50 kA) |

|

|

|

|

|

|

|

|

|

|

|

|||||

starters type 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

coordination will |

|

MS116 |

|

|

MS132 |

|

|

MS450 |

|

MS495 |

|

— |

|||||

be achieved 1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Using gG fuses type 1 |

Fuse protection (50 kA) gG Fuse |

|

|

|

|

|

|

|

|

|

|

||||||

coordination will |

10 A |

16 A |

|

25 A |

|

32 A |

50 A |

|

63 A |

100 A |

|

125 A |

200 A |

250 A |

|||

be achieved 1) |

|

|

|

|

|||||||||||||

Suitable switch fuse for |

Switch fuse |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the above gG fuses 1) |

|

|

|

|

|

OS32G |

|

|

|

|

|

OS125G |

|

|

OS250 |

|

|

J-type fuses for UL |

Max. fuse, J-type |

|

|

|

|

|

|

|

|

|

|

|

|

||||

coordination 1) |

|

|

|

35 A |

|

|

|

60 A |

|

90 A |

110 A |

125 A |

150 A |

200 A |

|||

Overload protection is |

Thermal overload relay |

|

|

|

|

|

|

|

|

|

|

|

|

||||

used to protect the motor |

|

|

|

|

|

|

TF42DU |

|

|

|

|

|

|

TA75DU |

|

TA110DU |

|

from over heating 1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

The line contactor is not required for the softstarter itself but often used

to open if OL trips 1)

Line contactor

AF9 |

AF12 |

AF16 |

AF26 |

AF30 |

AF38 |

AF52 |

AF65 |

AF80 |

AF96 |

AF116 |

|

|

|

|

|

|

|

|

|

|

|

1) This is an example of coordination.

SOFTSTARTER CATALOG |

19 |

—

PSR - The compact range

Ordering details

Typical applications

-Bow thruster

-Centrifugal pump

-Compressor

-Conveyor belt (short)

-Elevator

|

|

|

<![if ! IE]> <![endif]>1SFC132020V0001 |

|

|

<![if ! IE]> <![endif]>1SFC132072V0001 |

|

|

<![if ! IE]> <![endif]>1SFC132024V0001 |

|

<![if ! IE]> <![endif]>1SFC132028V0001 |

|

|

|

PSR3 ... PSR16 |

|

PSR25 ... PSR30 |

|

PSR37 ... PSR45 |

PSR60 ... PSR105 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||

Rated operational voltage Ue, 208...600 V AC |

|

|

|

|

|

|

|

||||||

Rated control supply voltage, Us, 100...240 V AC, 50/60 Hz |

|

|

|

|

|

|

|||||||

IEC |

|

|

|

UL/CSA |

|

|

|

|

Type |

Order code |

Weight |

|

|

Rated operational |

|

Rated operational |

|

|

|

|

|

pkg |

|

||||

power |

|

|

current |

power |

|

|

|

current |

|

|

(1 pce) |

|

|

|

230 V 400 V 500 V |

|

200/208 V 220/240 V 440/480 V 550/600 V |

|

|

|

|

|

|||||

|

Pe |

Pe |

Pe |

Ie |

Pe |

Pe |

Pe |

Pe |

FLA |

|

|

|

|

|

kW |

kW |

kW |

A |

hp |

hp |

hp |

hp |

A |

|

|

kg |

(lb) |

|

0.75 |

1.5 |

2.2 |

3.9 |

0.5 |

0.75 |

2 |

2 |

3.4 |

PSR3-600-70 |

1SFA896103R7000 |

0.45 |

(0.99) |

|

1.5 |

3 |

4 |

6.8 |

1 |

1.5 |

3 |

5 |

6.1 |

PSR6-600-70 |

1SFA896104R7000 |

0.45 |

(0.99) |

|

2.2 |

4 |

4 |

9 |

2 |

2 |

5 |

7.5 |

9 |

PSR9-600-70 |

1SFA896105R7000 |

0.45 |

(0.99) |

|

3 |

5.5 |

5.5 |

12 |

3 |

3 |

7.5 |

10 |

11 |

PSR12-600-70 |

1SFA896106R7000 |

0.45 |

(0.99) |

|

4 |

7.5 |

7.5 |

16 |

3 |

5 |

10 |

10 |

15.2 |

PSR16-600-70 |

1SFA896107R7000 |

0.45 |

(0.99) |

|

5.5 |

11 |

15 |

25 |

7.5 |

7.5 |

15 |

20 |

24.2 |

PSR25-600-70 |

1SFA896108R7000 |

0.65 |

(1.43) |

|

7.5 |

15 |

18.5 |

30 |

7.5 |

10 |

20 |

25 |

28 |

PSR30-600-70 |

1SFA896109R7000 |

0.65 |

(1.43) |

|

7.5 |

18.5 |

22 |

37 |

10 |

10 |

25 |

30 |

34 |

PSR37-600-70 |

1SFA896110R7000 |

1.00 |

(2.20) |

|

11 |

22 |

30 |

45 |

15 |

15 |

30 |

40 |

46.2 |

PSR45-600-70 |

1SFA896111R7000 |

1.00 |

(2.20) |

|

15 |

30 |

37 |

60 |

20 |

20 |

40 |

50 |

59.4 |

PSR60-600-70 1SFA896112R7000 |

2.20 |

(4.85) |

|

|

22 |

37 |

45 |

72 |

20 |

25 |

50 |

60 |

68 |

PSR72-600-70 1SFA896113R7000 |

2.27 |

(5.00) |

|

|

22 |

45 |

55 |

85 |

25 |

30 |

60 |

75 |

80 |

PSR85-600-70 1SFA896114R7000 |

2.27 |

(5.00) |

|

|

30 |

55 |

55 |

105 |

30 |

40 |

75 |

100 |

104 |

PSR105-600-70 1SFA896115R7000 |

2.27 |

(5.00) |

|

|

|

|

|

|

|

|

|

|

|||||

Rated operational voltage Ue, 208...600 V AC |

|

|

|

|

|

|

|

||||||

Rated control supply voltage, Us, 24 V AC/DC, 50/60 Hz |

|

|

|

|

|

|

|

||||||

|

0.75 |

1.5 |

2.2 |

3.9 |

0.5 |

0.75 |

2 |

2 |

3.4 |

PSR3-600-11 |

1SFA896103R1100 |

0.45 |

(0.99) |

|

1.5 |

3 |

4 |

6.8 |

1 |

1.5 |

3 |

5 |

6.1 |

PSR6-600-11 |

1SFA896104R1100 |

0.45 |

(0.99) |

|

2.2 |

4 |

4 |

9 |

2 |

2 |

5 |

7.5 |

9 |

PSR9-600-11 |

1SFA896105R1100 |

0.45 |

(0.99) |

|

3 |

5.5 |

5.5 |

12 |

3 |

3 |

7.5 |

10 |

11 |

PSR12-600-11 |

1SFA896106R1100 |

0.45 |

(0.99) |

|

4 |

7.5 |

7.5 |

16 |

3 |

5 |

10 |

10 |

15.2 |

PSR16-600-11 |

1SFA896107R1100 |

0.45 |

(0.99) |

|

5.5 |

11 |

15 |

25 |

7.5 |

7.5 |

15 |

20 |

24.2 |

PSR25-600-11 |

1SFA896108R1100 |

0.65 |

(1.43) |

|

7.5 |

15 |

18.5 |

30 |

7.5 |

10 |

20 |

25 |

28 |

PSR30-600-11 |

1SFA896109R1100 |

0.65 |

(1.43) |

|

7.5 |

18.5 |

22 |

37 |

10 |

10 |

25 |

30 |

34 |

PSR37-600-11 |

1SFA896110R1100 |

1.00 |

(2.20) |

|

11 |

22 |

30 |

45 |

15 |

15 |

30 |

40 |

46.2 |

PSR45-600-11 |

1SFA896111R1100 |

1.00 |

(2.20) |

|

15 |

30 |

37 |

60 |

20 |

20 |

40 |

50 |

59.4 |

PSR60-600-11 |

1SFA896112R1100 |

2.20 |

(4.85) |

|

22 |

37 |

45 |

72 |

20 |

25 |

50 |

60 |

68 |

PSR72-600-11 |

1SFA896113R1100 |

2.27 |

(5.00) |

|

22 |

45 |

55 |

85 |

25 |

30 |

60 |

75 |

80 |

PSR85-600-11 |

1SFA896114R1100 |

2.27 |

(5.00) |

|

30 |

55 |

55 |

105 |

30 |

40 |

75 |

100 |

104 |

PSR105-600-11 |

1SFA896115R1100 |

2.27 |

(5.00) |

Loading...

Loading...