Page 1

____________ _______________________________

OPERATORS MANUAL

Page 2

For use with Software Version 4.05.370

Image Server MAXX 6T

January 2008

Copyright 2008, 360 Systems

All rights reserved

Printed in the United States of America

900-105-0002-07 6T UM

____________________________________________________________________________________

Page 2 MAXX 6T Owner’s Manual

Page 3

TABLE OF CONTENTS

LIST OF FIGURES............................................................................................... 7

PREFACE............................................................................................................ 8

Software and Operations Manual Revisions................................................ 8

Typographical Conventions........................................................................ 8

SAFETY NOTICES ..............................................................................................9

Safety Terms and Symbols .......................................................................... 9

General Safety Caution............................................................................... 9

Personal Injury Precautions ........................................................................ 9

PRODUCT DAMAGE PRECAUTIONS ............................................................. 10

Product Registration ................................................................................. 10

Product Improvements and Upgrades....................................................... 10

Trademarks ..............................................................................................10

Software Copyrights .................................................................................10

Video and Audio Copyright Reminder...................................................... 10

OPERATING ENVIRONMENT .........................................................................11

System Cooling ........................................................................................ 11

Check These Points .................................................................................. 11

Power Conditioning ................................................................................. 11

Recommended UPS Models..................................................................... 12

RFI/EMI interference................................................................................. 12

Static Discharge ....................................................................................... 12

INTRODUCTION ............................................................................................ 13

UNPACKING................................................................................................... 14

Package Contents ..................................................................................... 14

RACK MOUNTING.......................................................................................... 15

Mounting the Audio And Control ( ACX ) Module .................................... 15

Installing the Hard Drives......................................................................... 16

REAR PANEL CONNECTIONS ......................................................................... 17

ACX EXPANSION MODULE CONNECTIONS .................................................19

Audio I/O................................................................................................. 19

Analog Audio Capability .......................................................................... 19

Digital Audio Capability........................................................................... 19

Embedded Audio Capability..................................................................... 20

Audio Word Size and Sample Rate........................................................... 20

Serial Control Ports .................................................................................. 20

GPI Control.............................................................................................. 20

BASIC OPERATION ......................................................................................... 21

POWER ON/OFF ..................................................................................... 21

Connecting the dual power supplies ........................................................ 21

Power On ................................................................................................21

Power Off ................................................................................................21

GRAPHICAL USER INTERFACE ( GUI ) OVERVIEW ......................................... 22

System Menu Bar .....................................................................................23

The Status Bar ..........................................................................................24

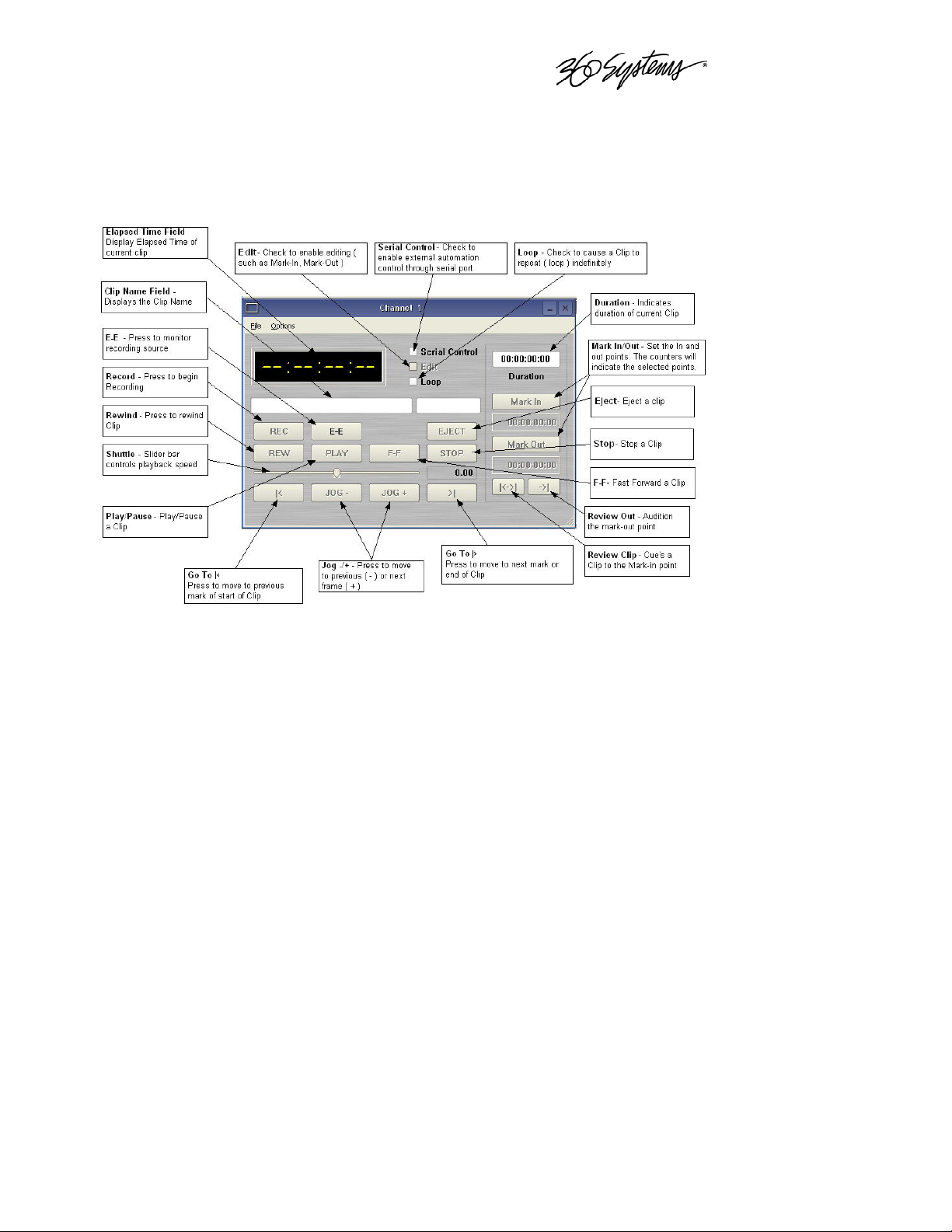

The Transport Channel View .................................................................... 25

Transport Menu Bar.................................................................................. 25

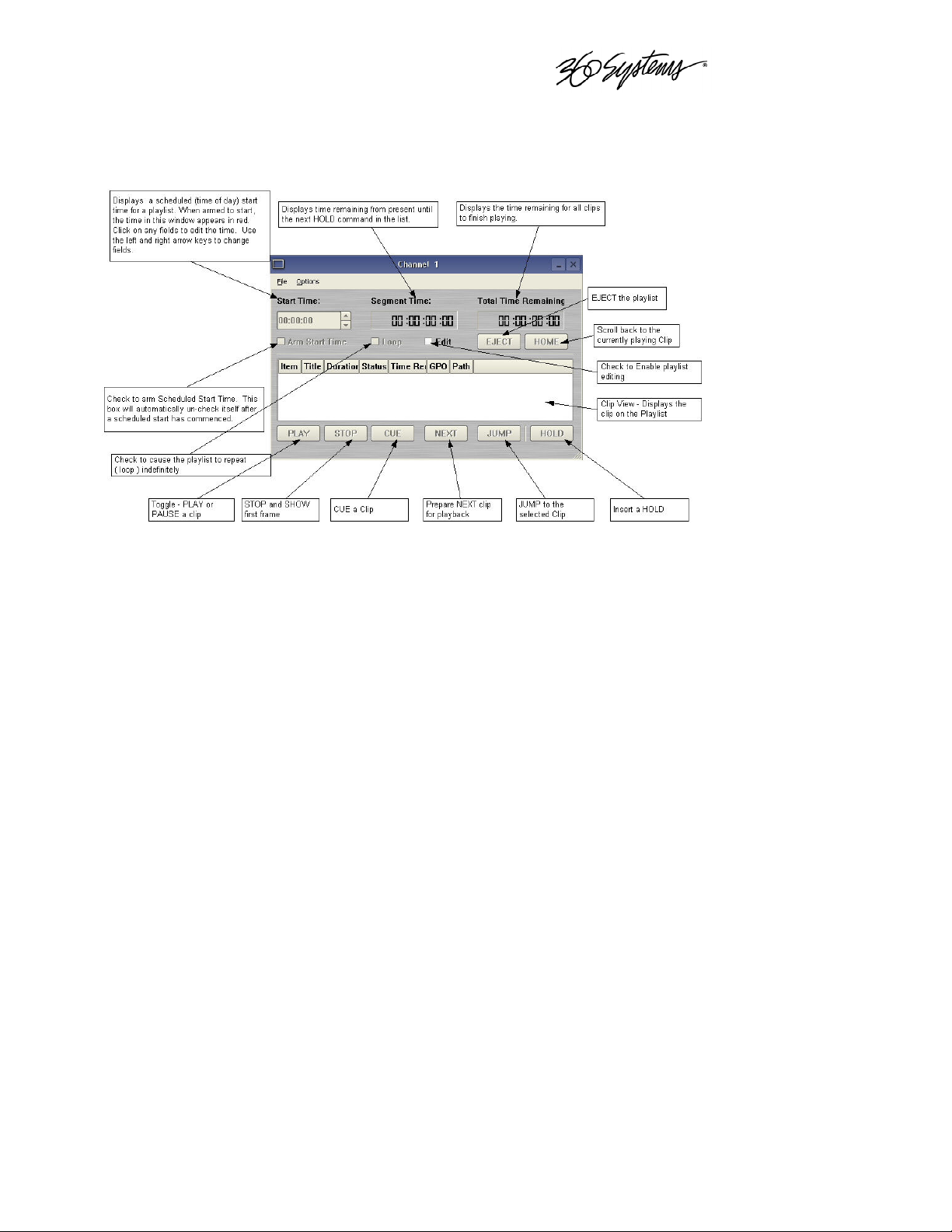

Playlist Menu Bar ..................................................................................... 27

MAKING A RECORDING FROM THE GUI ...................................................... 29

Record Configuration Options.................................................................. 29

Set Channel 1 to the Transport View ........................................................ 29

Setting the Sync Source ............................................................................ 29

Setting the Video Input Source .................................................................30

Arming the Audio tracks........................................................................... 31

Setting the Recording Format ................................................................... 31

Setting the Time Code Source .................................................................. 31

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 3

Page 4

Beginning Recording................................................................................ 32

USING E-E Mode to Monitor the Recording Source.................................. 34

PLAYING A CLIP FROM THE GUI.................................................................... 35

Beginning Playback.................................................................................. 35

Looping a Clip.......................................................................................... 35

Pausing a Clip .......................................................................................... 36

Ejecting a Clip .......................................................................................... 36

Using Jog .................................................................................................36

Using GO-TO .......................................................................................... 36

Using Fast Forward / Rewind.................................................................... 36

Using Shuttle to Control Playback Speed.................................................. 36

EDITING A CLIP............................................................................................... 37

Using Edit-while-Recording ...................................................................... 37

SYSTEM CONFIGURATION ............................................................................39

Assigning Names to the Server and Transport Channels ........................... 39

Programming GPIO Outputs ....................................................................40

Programming GPIO Inputs .......................................................................41

Configuring Linear Time Code ( LTC ) ......................................................42

Configuring the Network.......................................................................... 42

Setting the Date and Time ........................................................................ 44

Calibrating Channels ................................................................................ 45

CLIP NAVIGATOR ........................................................................................... 46

Creating Folders ....................................................................................... 46

Renaming and Deleting Folders ............................................................... 47

Navigating Folders ...................................................................................47

Moving and Copying Clips....................................................................... 47

Renaming and Deleting Clips ................................................................... 48

Sorting Clips............................................................................................. 48

Finding Clips............................................................................................ 48

Finding Clips Using Wildcards ................................................................. 49

Finding Clips Using Regular Expressions ..................................................50

USING PLAYLISTS ........................................................................................... 51

The Playlist View ..................................................................................... 52

Creating and Running a Playlist................................................................ 53

Status Indications ..................................................................................... 54

Loading a Playlist ( FILE->LOAD ) ........................................................... 55

Saving a new Playlist ( FILE->SAVE AS ) ................................................. 55

Saving an existing Playlist ( FILE->SAVE ) ................................................ 55

Setting a Start Time for a Playlist............................................................... 55

Stopping a Playlist ( STOP ) ...................................................................... 55

Pausing a Playlist ( PLAY/PAUSE ) ............................................................ 55

Cueing a Clip ( CUE ) ............................................................................... 55

Looping a Playlist ( LOOP [X] ) ................................................................ 55

Showing the First Frame of a CUED clip ( SHOW ) .................................. 55

Preparing the Next Clip for Playback ( NEXT ).......................................... 55

Jumping to a selected Clip ( JUMP ).......................................................... 56

Automatically scrolling to the currently playing Clip ( HOME ) ................ 56

Setting the Maximum Number of Played Items to Keep............................ 56

Enabling As-Run Logging.......................................................................... 56

Viewing, Editing and Archiving Playlists................................................... 56

____________________________________________________________________________________

Page 4 MAXX 6T Owner’s Manual

Page 5

EDITING PLAYLISTS ........................................................................................ 57

Removing a Clip from a Playlist................................................................ 57

Removing All Clips Above or Below the Selected Clip ............................. 57

Inserting a HOLD into a Playlist ............................................................... 57

Appending a Playlist ( FILE->APPEND )................................................... 57

Changing the duration of Clips in a Playlist ..............................................57

Mapping GPO to Playlist events ............................................................... 58

Mapping GPI to Control a Playlist ............................................................ 59

USING AUTOMATION CONTROL ................................................................. 60

Remote Serial Control ..............................................................................60

Configuring the automation interface ....................................................... 61

Other Automation Options....................................................................... 62

Tested Automation Controllers ................................................................. 65

Tested Remote Control Panels and Switchers ........................................... 65

ADVANCED TOPICS ....................................................................................... 66

System Timing.......................................................................................... 66

Using Embedded Audio ........................................................................... 66

Using Audio Sample Rate Conversion ...................................................... 68

Using Channel Ganging ........................................................................... 69

Using DV Video and Graphics ................................................................. 70

Importing TARGA Graphics Files ............................................................. 71

Animation Import..................................................................................... 71

Still Frames .............................................................................................. 71

FTP F

ILE TRANSFERS

Gigabit Ethernet Cable Quality................................................................. 72

Configuring the FTP interface ................................................................... 72

Logging in to Maxx 6T ............................................................................. 73

Supported file types.................................................................................. 74

USING NETWORK TIME PROTOCOL ............................................................. 76

Automatic Date/Time Updates ................................................................. 76

Connecting to the Network ......................................................................76

Configuring NTP ...................................................................................... 77

Selecting the Time Zone........................................................................... 77

Entering Network Parameters ................................................................... 78

USING THE REMOTE WORKSTATION INTERFACE ........................................ 80

System Requirements ............................................................................... 81

About the Remote Workstation Interface .................................................. 81

Operations ............................................................................................... 81

Installation ...............................................................................................82

After Installation ....................................................................................... 82

USING IMAGE SERVER WITH FINAL CUT PRO............................................... 84

Recording IMX Content............................................................................ 85

Transferring IMX Content from Image Server to Final Cut PRO................. 85

Editing Content in Final Cut PRO .............................................................87

Exporting and Playing Content on the Image Server .................................87

MAINTENANCE............................................................................................... 89

FAULT DIAGNOSTICS..................................................................................... 89

Front Panel Indicators............................................................................... 89

Troubleshooting Other Conditions ........................................................... 90

Gigabit Ethernet Indicators ....................................................................... 91

Gigabit Ethernet Indicators ....................................................................... 91

ACCESS TO COMPONENTS ............................................................................ 91

Deploying the Front Panel........................................................................ 91

Removing the Top Cover.......................................................................... 91

General Handling Precautions.................................................................. 92

Mechanical Concerns............................................................................... 92

Installing/Removing I/O Cards .................................................................. 93

........................................................................................... 72

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 5

Page 6

Accessing the Motherboard ...................................................................... 93

HARD DISK MANAGEMENT ........................................................................... 94

About RAID 6 .......................................................................................... 95

Improved Write Performance ...................................................................95

MANAGING DISK ARRAYS ............................................................................. 96

Error Notification and Repair.................................................................... 96

Log-In to the RAID Utilities ...................................................................... 97

Determining the Condition of the RAID Array .......................................... 98

Displaying the Alarm Log of the Raid Array.............................................. 99

Checking Status of the Drives ................................................................. 100

Removing the Degraded Drive from the RAID Unit................................ 101

Rebuilding the RAID Array..................................................................... 102

Replacing Hard Drives ........................................................................... 103

FACTORY REPAIR POLICY ............................................................................104

REGULATORY CERTIFICATIONS ..................................................................104

Safety ..................................................................................................... 104

Laser Compliance................................................................................... 104

Laser Safety ............................................................................................ 104

Radio Interference Compliance ..............................................................105

PRODUCT WARRANTY ................................................................................ 106

END USER LICENSE AGREEMENT ................................................................. 107

APPENDIX A – SETTING THE AUDIO JUMPERS FOR ANALOG/DIGITAL ..... 109

APPENDIX B – PROFILES AND GOP STRUCTURES....................................... 111

APPENDIX C – INPUT CHANNEL FACTORY SETTINGS ................................ 112

APPENDIX D – USING THE CVBS INPUT FRAME SYNCHRONIZER ............. 113

APPENDIX E – AS-RUN LOGGING DETAIL ................................................... 114

As-Run Naming Convention................................................................... 114

Sample As-Run Log ................................................................................114

As-Run Log Page Header ........................................................................ 114

As-Run Log Body.................................................................................... 115

APPENDIX F – GPIO INTERFACING .............................................................. 116

GPI Connector Pinout ............................................................................116

APPENDIX G – PLAYLIST MANAGEMENT DETAIL........................................ 118

APPENDIX H - AUDIO LEVEL CALIBRATION ................................................ 121

APPENDIX I - PROGRAM UPDATES VIA CD-ROM ........................................ 124

APPENDIX J - CONNECTOR SPECIFICATIONS .............................................. 125

Audio XLR-3 Connector Pinout .............................................................. 125

Serial Control Connector Pinout ............................................................. 125

BNC Connectors ....................................................................................125

GPIO Connector ....................................................................................126

GPI Connector Pinout ............................................................................126

APPENDIX K - SERIAL COMMAND PROTOCOLS ......................................... 127

VDCP Command Table .......................................................................... 127

P2 Serial Command Table ...................................................................... 129

Odetics® Protocol................................................................................... 130

APPENDIX L - TECHNICAL SPECIFICATIONS ................................................ 133

APPENDIX M – IMPORTING MPEG PROGRAM STREAM FILES .................... 135

APPENDIX N - KEYBOARD SHORTCUTS ...................................................... 137

APPENDIX O - MECHANICAL DIMENSIONS ................................................ 138

INDEX ...........................................................................................................139

____________________________________________________________________________________

Page 6 MAXX 6T Owner’s Manual

Page 7

LIST OF FIGURES

Figure 1 - Drive Bay Organization................................................................................................................ 16

Figure 2 - Rear Panel View ........................................................................................................................... 17

Figure 3 - ACX Expansion Module ................................................................................................................19

Figure 4 - User Interface ............................................................................................................................... 22

Figure 5 - Transport Channel View ............................................................................................................... 25

Figure 6 - Playlist Channel View................................................................................................................... 27

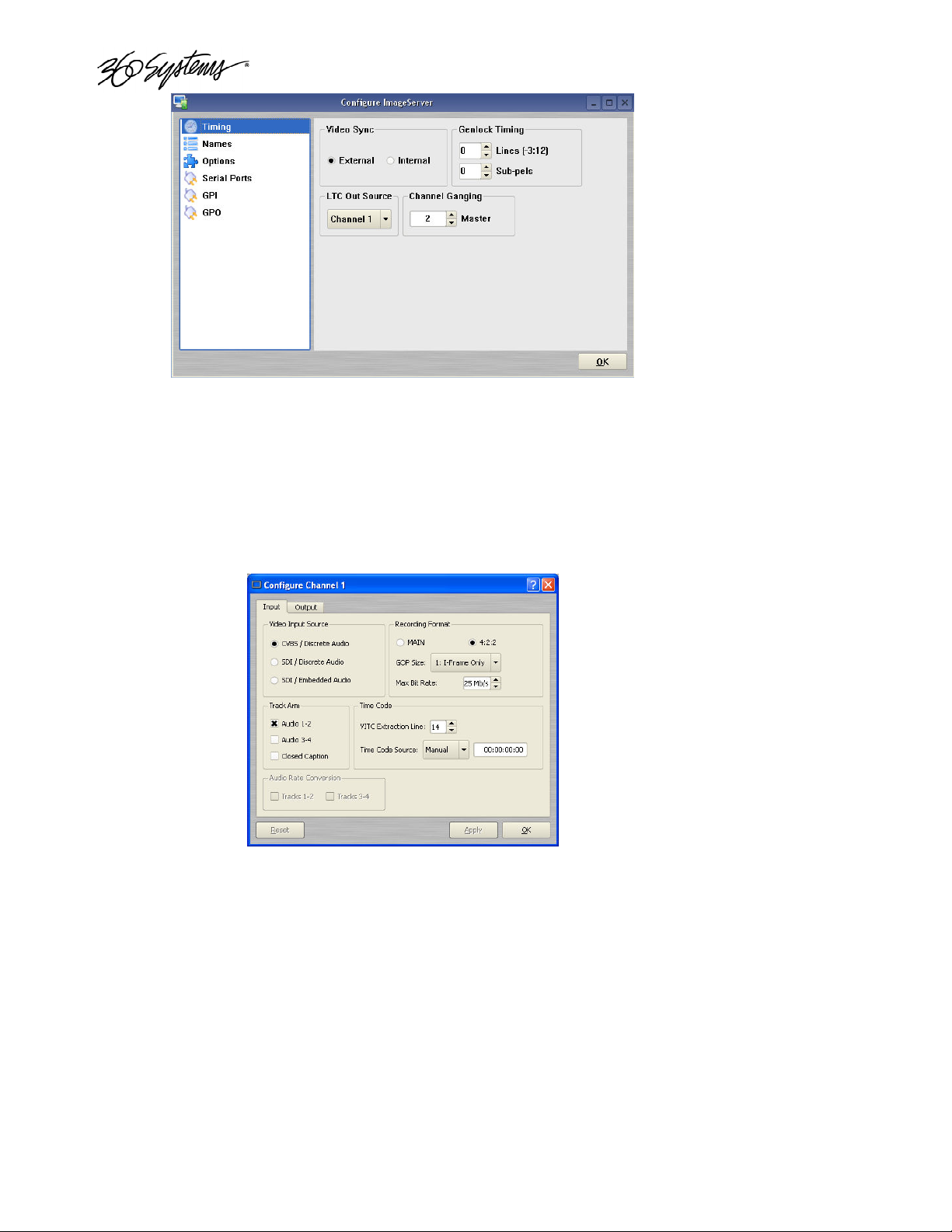

Figure 7 - Timing Configuration Screen ........................................................................................................30

Figure 8 - Channel Configure Dialog ............................................................................................................ 30

Figure 9 - Channel 1 Clip Navigator "New" mode ........................................................................................ 32

Figure 10 - Channel 1 Ready To Record .......................................................................................................33

Figure 11 - Channel 1 Clip Navigator in “Open” Mode ................................................................................35

Figure 12 - Configure Names Screen ............................................................................................................ 39

Figure 13 - GPO Configuration Screen ........................................................................................................40

Figure 14 - GPI Configuration Screen ...........................................................................................................41

Figure 15 - Network Configuration Screen.................................................................................................... 42

Figure 16 - Time/Date Configuration Screen................................................................................................. 44

Figure 17 - Playback Channel Configuration ................................................................................................. 45

Figure 18 - Clip Navigator ............................................................................................................................ 46

Figure 19 - Clip Navigator with folders .........................................................................................................47

Figure 20 - Clip Locator ................................................................................................................................ 49

Figure 21 - Channel 1 Playlist View .............................................................................................................. 52

Figure 22 – Active Playlist ............................................................................................................................53

Figure 23 - Channel 1 Playlist with Clip Navigator ....................................................................................... 54

Figure 24 - Channel Playlist Configure Screen ..............................................................................................56

Figure 25 - GPO Config Screen ....................................................................................................................58

Figure 26 - GPO Editor ................................................................................................................................. 59

Figure 27 - ACX Module...............................................................................................................................60

Figure 28 - Serial Port Configuration Screen ................................................................................................. 62

Figure 29 - Channel Configuration Screen ....................................................................................................67

Figure 30 - Timing Configuration Screen ......................................................................................................69

Figure 31 – Result of a network file transfer.................................................................................................. 74

Figure 32 - NTP Network Block Diagram ..................................................................................................... 76

Figure 33 - Date/Time Configuration Screen................................................................................................. 77

Figure 34 - Network Configuration Screen.................................................................................................... 78

Figure 35 - Remote Workstation Deployments .............................................................................................81

Figure 36 – Remote Workstation Properties Page ......................................................................................... 83

Figure 37 - RAID 6 Array Schematic ............................................................................................................. 95

Figure 38 - GUI Drive Fault Indication ......................................................................................................... 96

Figure 39 - RAID Utilities Login Screen ........................................................................................................97

Figure 40 - RAID Array Condition Screen .....................................................................................................98

Figure 41 - RAID Array Status Screen............................................................................................................99

Figure 42 - RAID Array Maintenance Screen ..............................................................................................100

Figure 43 - Removing Failed Drive From Array........................................................................................... 101

Figure 44 - Selecting A drive to rebuild ......................................................................................................102

Figure 45 - Front Panel Deployed – Disk Unlatched................................................................................... 103

Figure 46 - Audio PCB Removal Detail....................................................................................................... 109

Figure 47: Jumper location on audio card for selection of analog or digital audio. ...................................... 110

Figure 48 - GPIO Connection Schematic .................................................................................................... 117

Figure 49 - Audio Board Trimpot Location..................................................................................................121

Figure 50 - Mechanical Dimensions ...........................................................................................................138

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 7

Page 8

PREFACE

This manual provides installation, setup and operating instructions for 360 Systems MAXX 6T Image

Server™. It is organized to provide quick access to topics of primary interest. An extensive Table of

Contents is provided at the beginning and a subject Index at the end, to assist in locating

information.

If you have already used hard disk video servers (or VTRs), you may find discussion of the basic

server to be covering familiar topics. However, it is strongly recommended that engineering

managers and staff members operating the MAXX 6T read through this manual. Being familiar with

its operation can prevent operational mistakes, and will make all users aware of important set-up

and maintenance issues.

Software and Operations Manual Revisions

Software revisions are released from time-to-time that introduce new product features, or improve

the performance of the product. When such revisions are shipped in the form of a CD-ROM,

printed operational notes will be included. When revisions are introduced in the course of product

production, an updated Operations Manual will be shipped with new servers.

The title page of an Operations Manual indicates its revision number, which should always match

the software revision of the server with which it is used. Operations Manuals for the latest revision

may be obtained from 360 Systems Customer Service, or from 360 Systems’ web site.

Your comments are welcome. If anything in this manual seems unclear, please let us know by

sending an email to support@360systems.com.

Typographical Conventions

The following typographical conventions are used to clarify meaning:

• Connector or indicator labeling that appears on the unit is shown in Arial Narrow Bold.

• GUI menu items are shown in Arial Bold.

• Test typed into the GUI and Key Commands are shown in Courier Bold.

• GUI sub-menu paths are shown by the > symbol.

Page 9

SAFETY NOTICES

Safety Terms and Symbols

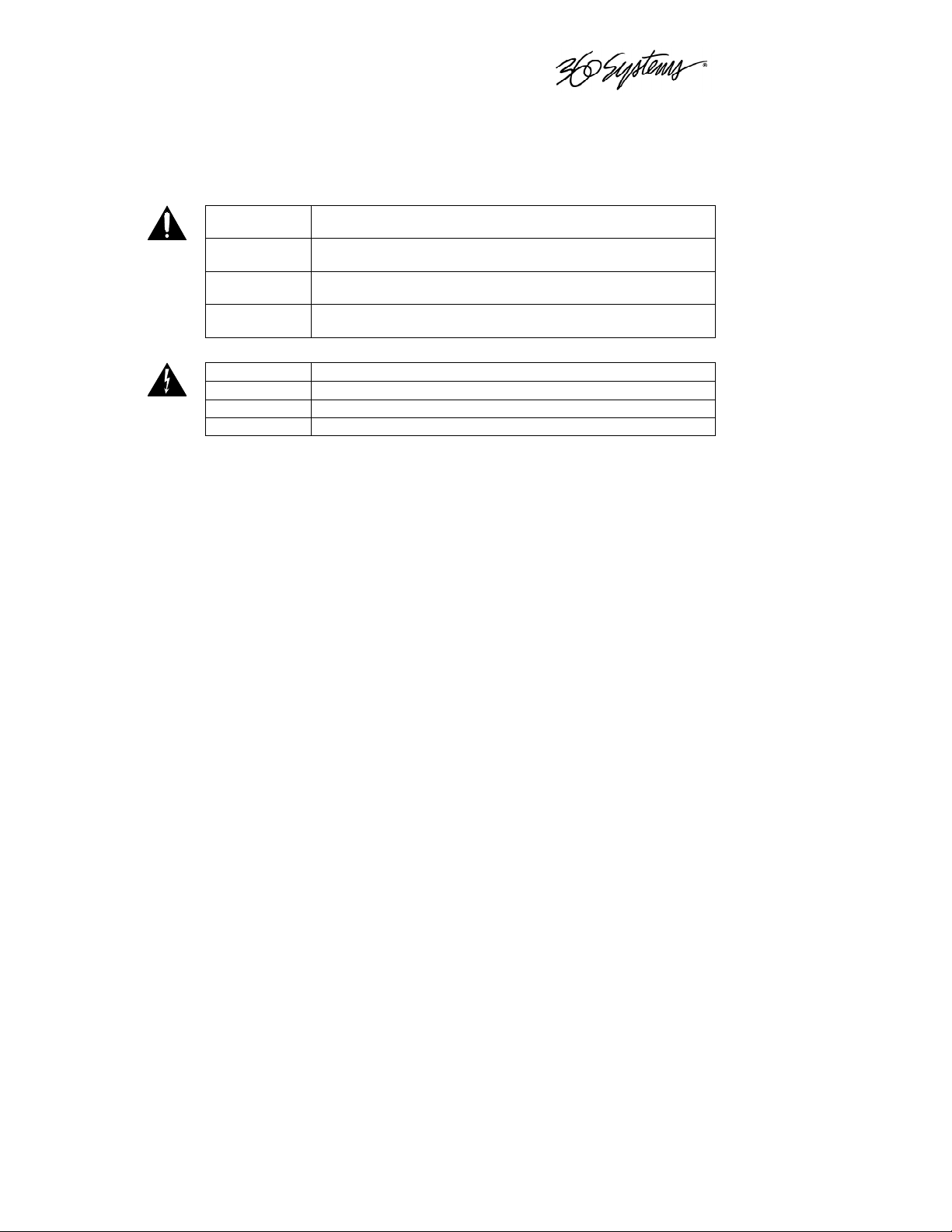

THE FOLLOWING WARNING SYMBOLS ARE USED IN THIS MANUAL:

ENGLISH ATTENTION: REFER TO OWNER’S MANUAL FOR IMPORTANT

FRANÇAIS ATTENTION: VEUILLEZ VOUS RÉFÉRER AU MODE D’EMPLOI

ITALIANO ATTENZIONE: FATE RIFERIMENTO AL MANUALE PER

ESPAÑOL ATENTCION: FAVOR DE REFERIR AL MANUAL DE OPERACION

INFORMATION.

POUR UNE INFORMATION IMPORTANTE.

INFORMAZIONI IMPORTANTI.

POR INFORMACION IMPORTANTE.

ENGLISH

FRANÇAIS AVERTISSEMENT: DANGER DE CHOC ÉLECTRIQUE.

ITALIANO AVVERTIMENTO: PERICOLO DI SHOCK ELETTRICO.

ESPAÑOL ADVERTENSIA: PELIGRO DE CHOQUE ELECTRICO.

WARNING

:

ELECTRICAL SHOCK HAZARD.

General Safety Caution

• Heed the following important cautions regarding the MAXX 6T in order to avoid personal injury

or equipment damage.

• Only qualified personnel should perform installation and service. Refer to appropriate sections

of this product manual for instruction. Contact 360 Systems Customer Support for further

explanation, or to clarify any uncertainty.

• Disconnect the power cord before removing the cover.

Personal Injury Precautions

• To avoid electric shock, do not operate this product with covers removed.

• To avoid risk of fire, replace the power cord only with same type and rating as specified.

Replace damaged power cords immediately.

• This product is grounded through the grounding conductor of the power cord. To avoid electric

shock, do not remove or modify the contacts on the plug.

• Prevent the power cord from being walked on, pinched, or abraded.

• To reduce the risk of fire or electric shock, do not expose this unit to rain or moisture.

• Remove jewelry, such as rings, watches, or necklaces before servicing this equipment.

• Lifting or moving the unit should be done using appropriate carts and/or dollies. Use two people

to lift the unit.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 9

Page 10

PRODUCT DAMAGE PRECAUTIONS

• MAXX 6T recorders contain hard disk drives and other fragile electronic and mechanical

devices. While this product is very reliable, it is still vulnerable to shock. Handle it with care,

and exercise caution not to drop or bump the recorder as damage to internal components may

result. Turn off power before moving the server.

• Do not obstruct air vents. Maintain an ambient temperature below 30°C (86°F).

• Clean only with a soft cloth dampened with water. Do not spray cleaners or solvents directly on

the product.

CAUTION

Replace battery only with the same, or equivalent, battery type. Follow all local laws

regarding the disposal of BR and CR Lithium batteries. Batteries should be fully discharged

prior to disposal.

CAUTION

Never use the rear-panel power supply switch to shutdown the MAXX 6T. Doing so may

cause errors in the hard disk array. Should this happen, the array can be reinitialized without

any data loss; however, the process may take several hours. Shutdown the system only by

momentarily pressing the front panel power button, or through the On-Screen user interface.

Product Registration

Important: As the owner of new capital equipment, you will want to take advantage of the product

information, enhancements, upgrades, or notifications issued by 360 Systems. Send in your

Warranty Card so 360 Systems can remain in contact with you. Mail or fax it to 360 Systems offices

in the USA at the address given below.

:

:

Product Improvements and Upgrades

360 Systems reserves the right to make changes and/or improvements to its products without

incurring any obligation to incorporate such changes or improvements in units previously sold.

Certain features mentioned in this document may not be present in all models. MAXX 6Ts are not

offered for sale in all countries.

Trademarks

MAXX 6T Image Server, Multi-Format Image Server, 360 Systems, 360 Systems Broadcast, Bit-for-Bit, and

Direct Digital Import are trademarks or registered trademarks of 360 Systems in the U.S. and/or foreign

countries. Other trademarks referred to in this document are the property of their respective owners.

Software Copyrights

Software in this product is based on the work of, or is copyright by, 360 Systems, SuSE® GmbH, Trolltech, and

FreeType Team. Copyright 2003-2008 by 360 Systems.

Video and Audio Copyright Reminder

It is illegal to use this product to make copies of copyrighted material without the express permission of the

copyright holder.

____________________________________________________________________________________

Page 10 MAXX 6T Owner’s Manual

Page 11

OPERATING ENVIRONMENT

System Cooling

When many pieces of equipment are mounted in an equipment rack, a considerable amount of heat

may be produced, which must be removed efficiently. Further, a lower operating temperature will

make equipment operate more reliably, and last longer. In the extreme case, excessive

temperatures cause rapid equipment failure, and damage which can be difficult to repair.

Heat in an equipment rack should be removed by forced air. This is often accomplished by blowers

installed in the top of the rack, venting into the room. An alternative is to draw hot air from the top

of the rack into an air-conditioning return duct, and not vent it into the equipment room. Cold air

should be ducted into the bottom of the rack. The optimum air temperature for cooling electronic

equipment is 25° C (72° F). When many pieces of equipment are contributing to the heat load, a

substantial air-flow will be needed, and the inlet temperature may need to be lower.

Check These Points

• Are all ventilation holes in the MAXX 6T free of obstruction?

• Can blowers or HVAC system adequately remove heat from the equipment rack?

• Have you measured the actual temperature inside the rack? Do this near the top.

• Verify that the HVAC system is not on a timer that can shut off on weekends or holidays.

• What procedures are in place to protect the equipment when the HVAC system fails?

Power Conditioning

It is good practice to operate an on-air video server from an Uninterruptible Power Source, or UPS.

All utility power systems experience occasional transient events, including brownouts and dropouts,

which are capable of taking a server off the air. It is the station operator’s job to plan for and

overcome such contingencies. UPS units come in two varieties:

Change-over UPS Design

This design senses drop-outs and low-line voltage, and switches its output to an internal inverter

operating from a battery. This UPS is low in cost, and is most often used in non-critical applications

such as desk-top computers. A disadvantage is that it may create its own power transients when

switching between utility power and its inverter supply. For this reason 360 Systems does not

recommend this type for use with the MAXX 6T.

Continuous Conversion UPS Design

This improved design continuously converts utility power to DC, stores it in a battery, then

produces isolated AC power from an inverter. It never switches, and is immune to input transients,

brownouts, and blackouts. Models are available with batteries of almost any size, making the

continuous-conversion UPS suitable for transient suppression or long-term operating power in the

absence of utility power.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 11

Page 12

Recommended UPS Models

The following makes of continuous conversion UPS systems are suitable for use with 360 Systems’

MAXX 6T products:

• APC Smart-UPS 2200-XL

• Eaton/Powerware Corporation, Model 9125, www.powerware.com

This unit is available in several different configurations to accommodate various current load

and power failure support times.

The minimum requirement for a single MAXX 6T is 500 Watts.

RFI/EMI interference

Many people are not aware that cell phones can attain a very substantial power output, even when

no conversation is taking place. You may have experienced the effect of a cell phone interfering

with a common desk phone or radio placed nearby. Carrying a cell phone into a machine room

where it is in close proximity to broadcast equipment and its associated wiring is unwise. They are

able to interfere with serial control commands, video synchronization, and in some cases can crash

the CPU in equipment.

Some major broadcasters prohibit the carrying of cell phones into certain machine areas. 360

Systems believes that the risk of undesired equipment behavior from their RF fields is very real.

Static Discharge

Static electricity discharge is accepted by most people as an inevitable consequence of living in a

dry area. It is, rather, a result of floor coverings that may enhance appearances, but are

inappropriate for use around critical pieces of broadcast equipment. Static discharge can do two

adverse things:

• Discharge into a connector can—and will—destroy internal circuitry of equipment. The result

will always be difficult to diagnose and repair. This includes the unconnected ends of cables

connected to the equipment.

• Discharge to equipment frames or wiring can cause unpredictable behavior including data loss

and crashes that can take the station off the air. Several steps can be taken to protect equipment

from static discharge:

• Do not install critical broadcast equipment (video servers) in a room with carpeting.

• Connect equipment racks directly to an earth ground with a heavy copper conductor.

• Do not operate equipment with a lifted safety ground (green frame ground).

• Install a humidifier to reduce the level of static discharge.

____________________________________________________________________________________

Page 12 MAXX 6T Owner’s Manual

Page 13

INTRODUCTION

The Image Server MAXX 6T is the logical evolution of the successful Image Server line of Broadcast

Digital Video Server products. The MAXX 6T is designed from the ground up to deliver outstanding

performance and value in a multi-channel MPEG-2 and DV-format server. MAXX 6T adds a 6

Terabyte hot-swappable RAID-6 array and a new intuitive hierarchical file system for organizing

large amounts of content. Three video outputs with analog, digital, and Gigabit Ethernet interfaces

make it an excellent choice for the next-generation plant.

• 6 Terabytes of Double Fault tolerant RAID-6 storage space ( 4.6Terabytes useable )

• Hot swappable drives with front access

• Redundant Power Supplies

• Playout for MPEG-2, DV-25, key-and-fill TARGA graphics and optionally IMX ( D10 )

• 1 Input with Frame Synch for capturing content from asynchronous sources such as VTRs.

• 3 simultaneous outputs.

• SDI and composite video

• Fast file import via FTP over Gigabit Ethernet

• Content exchange with NLEs

• Optional round-trip support for Final Cut Pro® with the IMX Option.

• MXF Compliant

• Intuitive graphical user interface

• Remote Control from a PC using the Remote Workstation software

• Intuitive hierarchical file system

• Advanced Playlisting capability

• +4dBu balanced analog or AES/EBU digital, with SDI embedded audio, four audio channels

per video channel.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 13

Page 14

UNPACKING

CAUTION!!

Image Server MAXX 6T weighs more than 75 pounds with all disks installed. Please use appropriate

carts and lifting techniques when following these instructions.

Package Contents

Confirm that all items on the packing list have been received. Contact 360 Systems if any item is

missing.

Image Server MAXX 6T

Keyboard

2-Button Scroll Mouse.

Software CD-ROM, backup copy

Remote Workstation Software CD

ACX Expansion Module

ACX Expansion Interface Cable

Twelve 500Gb Hard Drives

Rack Mount Hardware Kit

Operations Manual

Power cords ( 2 )

Warranty Card

NOTE

Before unpacking hard drives, refer to the following sections on RACK MOUNTING (Page 15) and

INSTALLING THE HARD DRIVES (Page 16) before removing the drives.

____________________________________________________________________________________

Page 14 MAXX 6T Owner’s Manual

Page 15

RACK MOUNTING

CAUTION!!

It is recommended that you first rack mount the MAXX 6T before installing the drives. This will

reduce the weight significantly and simplify the mounting process.

Refer to instructions packaged with the Rack Mount Hardware Kit for specific installation

information.

Note: If you plan to use digital audio, be sure to change the configuration of the Analog/ Digital

Audio Jumpers inside the unit before mounting the MAXX 6T in a rack. The jumpers are factory set

to the Analog audio position. For more information about changing the jumpers, see APPENDIX A

– SETTING THE AUDIO JUMPERS FOR ANALOG/DIGITAL.

In North America, the MAXX 6T will usually be mounted in a 19” rack enclosure having 10-24 or

10-32 tapped holes. In countries with metric standards, the user will need to supply appropriate

fasteners.

Cables attached to the rear of the MAXX 6T should be supported by the rack mounting rails. Do not

support substantial cable weight from the MAXX 6T.

Install the included rack mount slide rails in the rack. They must be securely mounted at both the

front and back of the rack. Extend the slides in the slide rails. Carefully mate them with the rails on

the sides of the MAXX 6T – this process requires at least two people unless an adjustable lift is

available. Slide the MAXX 6T into the rack.

Deploy the front panel to expose the rack screw slots. Unscrew the knurled fasteners and pull

forward and down to deploy the front panel. Fasten the MAXX 6T into the rack using #10 flat-head

Phillips screws (provided in North America). Retract the front panel. Tighten the front panel access

screws.

Mounting the Audio and Control ( ACX ) Module

The supplied ACX module may also be rack mounted in a Standard 1-RU space above or below the

MAXX 6T. Four elongated screw holes are provided to facilitate rack mounting of the ACX Module.

The ACX module is connected to the MAXX 6T using the supplied 68 Pin cable. Connect one end of

the cable to the mating connector on the rear of the ACX Module. Connect the other end to the ACX

connector on the rear panel of the MAXX 6T. Refer to Figure 2 on Page 17.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 15

Page 16

Connecting the Monitor, Mouse and Keyboard

The MAXX 6T is not shipped with a video monitor. Select a VESA-compliant CRT or LCD monitor

with a minimum refresh rate of 75Hz. Note that the MAXX 6T may not start correctly if an

unsuitable monitor is connected. Connect the monitor to the VGA port on the rear of the unit. Refer

to Figure 2 on Page 17

Connect the keyboard to the PS-2 keyboard port on the rear of the unit; connect the mouse to the

mouse port. Refer to Figure 2 on page 17. NOTE: If the mouse and keyboard connections are

interchanged, the MAXX 6T may not boot up properly. Be especially careful about this when using

extender cables.

If you own more than one MAXX 6T, it may be appropriate to use a single keyboard, monitor, and

mouse with a KVM switch to select between servers. Not all KVM switching systems are

compatible. The KVM switch must supply an active signal to the Image Server at all times, even

when switched away from it. When first powering up the MAXX 6T, use only the supplied

keyboard and mouse directly connected. Then test the KVM switch system that will be used

thoroughly before installation is completed.

Installing the Hard Drives

MAXX 6T uses twelve, 500 GB drives in its 6 Terabyte RAID 6 array. These are packaged in a

separate carton inside the main carton. The drives are fully configured and ready to run the MAXX

6T application. It is important that the drives be installed in the correct positions in the RAID

array. Each drive has a number affixed to its packaging material. Install each drive in the

corresponding numbered bay according to Figure 1.

Deploy the drive bay door by loosening the knurled screws and pulling lightly forward and down.

Install each hard drive in the corresponding numbered slot as follows.

1. Open the blue locking lever by pulling forward slightly

2. Insert the drive in the bay by sliding it in till you feel it “seat”

3. Close the locking lever.

Figure 1 - Drive Bay Organization

____________________________________________________________________________________

Page 16 MAXX 6T Owner’s Manual

Page 17

REAR PANEL CONNECTIONS

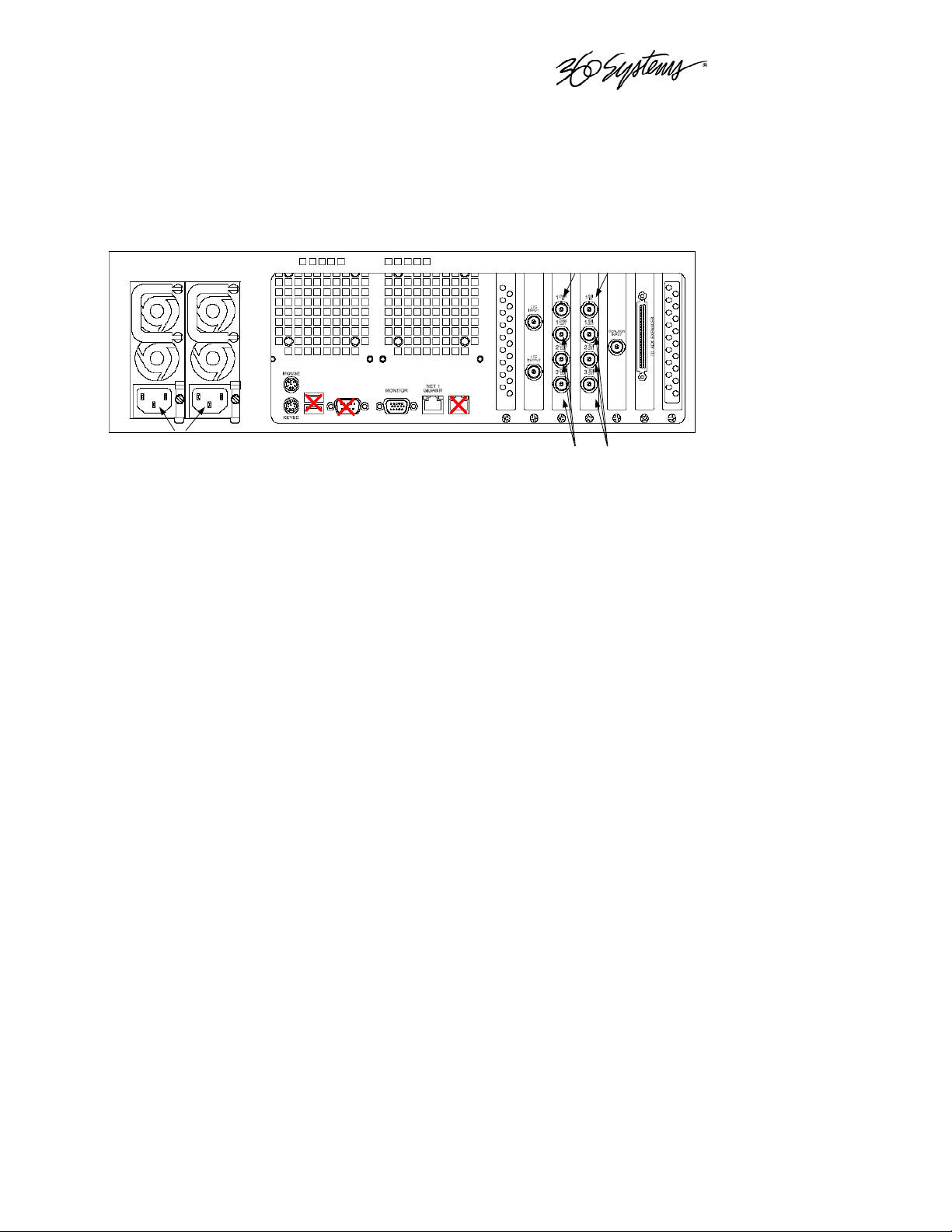

Figure 2 indicates the Rear Panel connections on MAXX 6T. Each connection is described briefly in

the following text. Make all connections appropriate to your workflow before applying power to the

MAXX 6T.

8910

13

6

7

2

3

1

Figure 2 - Rear Panel View

1. Dual Power Supply 2. Mouse

3. Keyboard 4. Monitor

5. Gigabit Ethernet Port (NET1) 6. LTC Input

7. LTC Output 8. Channel 1 CVBS ( Analog ) Input

9. Channel 1,2 and 3 CVBS ( Analog ) Output 10. Channel 1 SDI (Digital ) Input

11. Channel 1,2 and 3 SDI ( Digital ) Output 12. Genlock Input

13. ACX Expansion Module Connector

4 5

12

11

Video Inputs (8, 10)

The MAXX 6T records video on channel #1. It has separate BNC inputs for SDI (serial digital per

SMPTE 259M) and analog video (CVBS) signals. Both video inputs have a fixed 75-ohm

termination. The graphic user interface selects between the two.

Video Outputs (9, 11)

Video outputs are provided in SDI and Composite (CVBS) formats simultaneously. Digital video

appears in SDI format at 270 Mb/s and conforms to SMPTE 259M. Analog video is composite

(CVBS).

Gigabit Ethernet Port (5)

A Gigabit Ethernet port is provided on the MAXX 6T. The NET 1 port is intended for external

transfer of program content between video servers. The server supports MXF file transfer (MPEG-2,

Op 1a ), which allows content interchange between products from different manufacturers, as well

as file import in various formats from desktop editors. The NET 1 port is also used for remote

control using the optional Remote Workstation software. The NET 2 port is reserved for future use

and is not active. Use only the NET 1 port.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 17

Page 18

Genlock Sync Reference (12)

The MAXX 6T can be referenced to an external genlock reference in the form of CVBS black. The

GENLOCK input provides a fixed 75-ohm termination. An internal crystal reference is also provided

so that the server can be used as a stand-alone player.

LTC Time Code Input (6)

A LTC time code input is provided on the LTC IN BNC connector. The LTC input provides a >10k

ohm termination. This input may be selected by means of the On-Screen user interface and used as

a start time reference. Note that time code is not actually recorded, the time code read at the start

of recording is captured. When the clip is played back, the time code (in display, VITC and LTC

outputs) starts from the captured time and proceeds continuously.

LTC Time Code Output (7)

An LTC time code output is provided on the LTC OUT BNC connector. It may be selected by means

of the On-Screen user interface to output time code from any of the three video channels during

playback. The LTC output has a source impedance of <5 ohms.

Keyboard (3)

Attach the alphanumeric keyboard to the purple 5-pin KEYBD connector to control the server and

manage clips with the On-Screen graphic user interface. Note that the server will only recognize

the keyboard if it is attached before power up.

Mouse (2)

A two-button scroll mouse is provided with the MAXX 6T. Plug the mouse into the green 5-pin

MOUSE port. Do not use the USB ports, even if the supplied mouse is USB capable. Note that the

server will only recognize the mouse if it is attached before power up.

Monitor (4)

A VESA-compliant computer monitor may be connected to the 15-pin VGA video port. The MAXX

6T resolution is fixed at 1024 x 768 pixels, with a refresh rate of 72 Hz. This is best-viewed on 17inch or larger monitors. 360 Systems does not provide monitors for the server. Note: Do not use

older monitors that are not VESA compliant. The server may not start properly if an unsuitable

monitor is connected.

Serial Port

The system board serial port is not used. Make no connection.

USB Ports

The system board USB ports are not used. Make no connection.

Power (1)

An IEC mains socket is provided on the rear panel for power input. The MAXX 6T will accept

world-wide power sources in the range of 100-240 volts AC, 50-60 Hz. The server is shipped with

a power cord appropriate for the region in which it is sold. Replace the power cord only with one

of the same type and rating.

____________________________________________________________________________________

Page 18 MAXX 6T Owner’s Manual

Page 19

ACX EXPANSION MODULE CONNECTIONS

The ACX Module is a 1RU Rack-mountable module that provides for connection of the audio, serial

and GPI equipment. Connect The ACX Module to the Expansion connector on the rear panel of

MAXX 6T using the supplied 68 Pin SCSI connector. Figure 3 indicates the ACX module’s

connectors and their functions.

Figure 3 - ACX Expansion Module

Audio I/O

The MAXX 6T provides audio inputs and outputs in three formats:

• Balanced analog audio at a reference level of +4 dBu, corresponding to a digital level

of -20dBFS.

• Digital audio in AES/EBU format per AES-3-2000. 48 KHz sample rate, 24 bit.

• SDI embedded audio, 4-channels on SDI audio group 1, channels 1, 2, 3 and 4. 20 bit.

Note that both analog and AES/EBU audio signals are not available at the same time on a given

input or output channel. Internal jumpers select between analog or digital; however, each

channel’s pair of inputs and outputs can be set up differently, if desired. A set of XLR-3 connectors

allows high-quality connections to be made in either format. Refer to Appendix A for instruction on

how to set the unit up for analog or digital audio. Embedded audio appears in the SDI output stream

at all times.

Analog Audio Capability

When the analog audio format is selected, each video channel has two audio channels, recorded

together as a stereo pair. Internal trimmers allow adjustment to unity gain. Refer to APPENDIX H AUDIO LEVEL CALIBRATION. The outputs carry channels 1 and 2 when four channel material is

played back.

Digital Audio Capability

When AES/EBU digital audio is selected, each video channel has four audio channels, which are

recorded as two stereo pairs. Because a single XLR connector carries a stereo pair in AES/EBU

format, and only one (monaural) channel in analog, the server provides an extra pair of audio

channels when used with AES/EBU audio signals.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 19

Page 20

Embedded Audio Capability

When SDI embedded audio is selected, four audio channels are available for recording. Embedded

audio is always inserted in the video outputs. Note that discrete audio (analog or AES/EBU) is also

available on XLR connectors, at the same time embedded audio appears in the video stream.

Embedded audio has a 20-bit resolution. Refer to Using Embedded Audio on Page 66 for details on

using embedded audio.

Audio Word Size and Sample Rate

The MAXX 6T employs 24-bit audio A/D and D/A converters, and records audio into a 24-bit frame,

regardless of the word size received. The sample rate is fixed at 48K. When using the AES/EBU

digital input, the 48K sample rate of the incoming digital audio must be derived from the video

genlock reference. If not, or if a different sample rate is used, the MAXX 6T’s input sample rate

converters must be selected. Refer to Using Sample Rate Conversion on page 68.

Note:

Encoded audio streams, such as Dolby E® must be referenced to video genlock, and the input

sample rate converters must be disabled when recording such streams.

Serial Control Ports

Each of the MAXX 6T’s three 9-pin “D” connectors permits independent control of any of the three

video channels. They can accept serial commands in VDCP, Sony BVW or Odetics protocol. The

multiple serial ports allow simultaneous connection of an automation controller and a desktop

controller. See the chapter on Automation Control for further details.

Most broadcast automation systems, and some remote control panels, employ the VDCP protocol.

A list of supported VDCP commands will be found in APPENDIX K - SERIAL COMMAND

PROTOCOLS. Many controllers used for transport, instant replay, and edit control employ Sony

BVW or Odetics protocol.

GPI Control

The MAXX 6T provides six GPI inputs for control of machine functions, which appear on the 25-pin

GPI connector. This “General Purpose Interface” can be connected to switch contacts or an opencollector transistor output. GPI inputs are programmable, and can provide machine control such as

PLAY, STOP, or RECORD through simple external switches.

The MAXX 6T also provides six GPI status outputs which may be used to confirm that a command

has been received, or for other purposes. The functions of these open-collector outputs are

programmable, and may be used to operate an LED, or they can be connected to a suitable logic

input. The pin-out for the GPI connector will be found in APPENDIX I on Page126.

____________________________________________________________________________________

Page 20 MAXX 6T Owner’s Manual

Page 21

BASIC OPERATION

POWER ON/OFF

Connecting the dual power supplies

Maxx 6T is equipped with fully redundant power supplies. Connect each power supply to a

separate source of AC power. Looking at the rear of the unit, the two IEC main power receptacles

are located on the left. The unit will operate indefinitely on a single supply. If AC power is lost on

one of the two supplies, a high-pitched alarm will sound to indicate the power loss. The MAXX 6T

will accept world-wide power sources in the range of 100-240 volts AC, 50-60 Hz. The server is

shipped with a power cord appropriate for the region in which it is sold. Replace the power cord

only with one of the same type and rating.

Power On

The blue front panel button initiates start-up and shut-down of the MAXX 6T. Press it momentarily

to start the server. A sequence of start-up screens will appear, ending with the display of the 3channel Graphic User Interface (GUI) (Figure 4 on Page 22 ).

During the first power on the system must be connected to a keyboard, monitor and mouse. The

Image Server will ask you to accept the Software Licensing Agreement before it will operate. This

screen will only appear during the initial startup.

Power Off

When the MAXX 6T is running, pressing the blue button momentarily will cause the system to begin

an orderly shutdown. This can also be initiated from the GUI by selecting

START > SHUTDOWN > SHUTDOWN. In most cases the power will shut off automatically,

however if the front panel lights begin to blink the file system has been properly closed and it is safe

to force the power off by holding the front panel button in for 4 seconds.

In the event that the system has stopped responding to commands and will not shutdown, hold the

button in for 4 seconds to force a power down.

CAUTION:

LOSS OF DATA CAN OCCUR IF THE POWER IS TURNED OFF WITHOUT A SHUTDOWN.

USE THE FOUR SECOND SHUTDOWN ONLY IF THE SYSTEM IS NOT RESPONDING OR DOES

NOT TURN THE POWER OFF AUTOMATICALLY.

CAUTION:

A

LWAYS DISCONNECT BOTH POWER CABLES ANY TIME THE TOP PANEL IS TO BE REMOVED

Serious damage to the server can occur if service is attempted with AC power attached.

The front panel power switch does not disconnect AC power!

____________________________________________________________________________________

MAXX 6T Owner’s Manual

.

Page 21

Page 22

GRAPHICAL USER INTERFACE (GUI) OVERVIEW

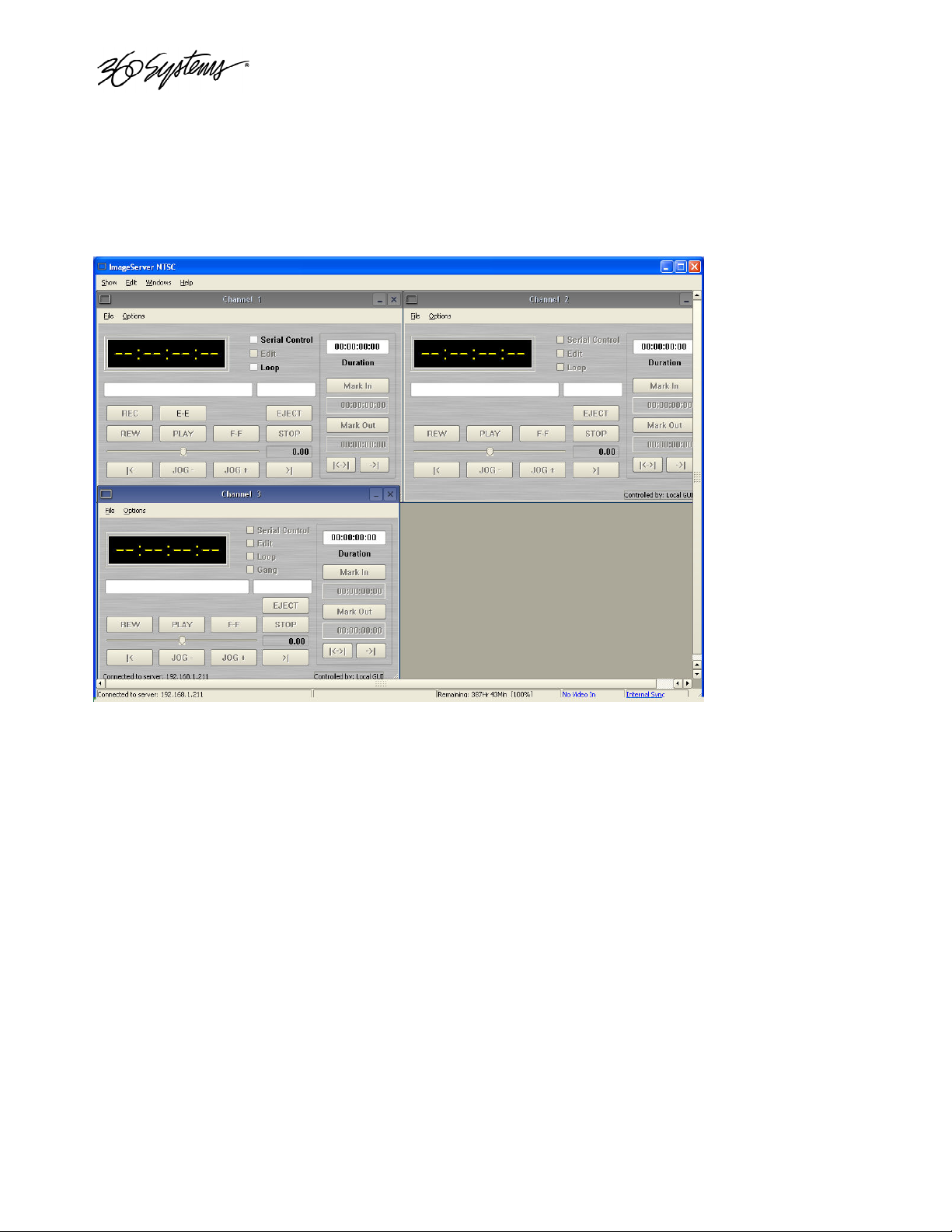

Once MAXX 6T has successfully powered up, the VGA monitor will display the GUI of Figure 4.

This view provides:

• A main System Menu bar for configuration operations

• A Status Bar that displays various system messages

• Three VTR-like transport controls, one for each of the three video channels.

Figure 4 - User Interface

When using the mouse, all buttons of all channels will operate immediately, without first selecting a

window to activate it. (Channel 3 is active in the illustration above, indicated by its blue title bar.)

When using key commands, the active window is the only transport that will respond. Use the

CTRL+TAB key combination to change the active window in rotation, or use the mouse to activate

the desired window by clicking anywhere in it.

Windows can be moved, resized and overlapped by dragging the title bar, the edges or the resize

tab at the lower right corner of each window. The CTRL+TAB key combination will also bring the

activated window to the top, in front of all other windows.

____________________________________________________________________________________

Page 22 MAXX 6T Owner’s Manual

Page 23

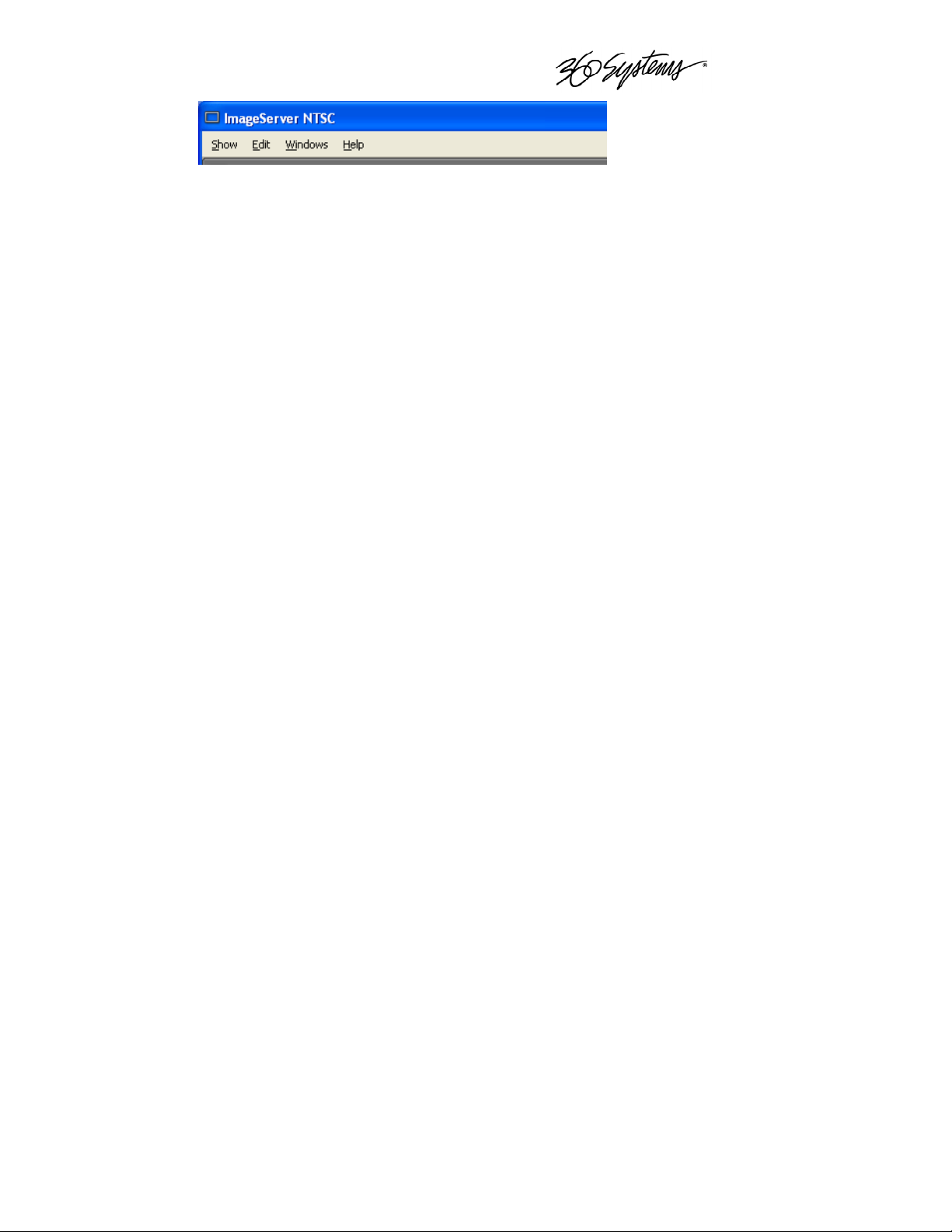

System Menu Bar

The System Menu bar contains four menus: Show, Edit, Windows and Help.

Show Menu

Contains selections for the three Channels and the clip management windows.

Channel 1

Channel 2

Channel 3

Opens the specified window if it is closed, brings it to the top and activates it.

Key Commands – F1, F2, F3

Clip List

Opens the Clip Navigator window if it is closed, brings it to the top and activates it. See page

46.

Key Command – Ctrl+L.

Find Clips

Opens the Clip Locator dialog. See page 48.

Key Command – Ctrl+F.

Edit Menu

Contains a single selection, Configuration. This opens the main System Configuration dialog. See

page 39.

Windows Menu

Choices in this menu change the way the windows are displayed. Use the CTRL+TAB key

combination to change the active window in rotation, or use the mouse to activate the desired

window.

Cascade

Arranges all open windows so that they are overlapping, but offset. It is useful as a starting

point to rearrange the windows. This choice is especially useful with small monitors.

Tile

Arranges all open windows so that each is fully visible at the same time. This choice is

especially useful with larger monitors. In case the Windows don’t tile as expected, select

Cascade to restore their original size and order, then select Tile.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 23

Page 24

In addition, there are selections for each open transport window. Selecting one of these brings that

transport to the top of the display and makes it the active window.

Help Menu

Contains a single item, About, which displays the Image Server software versions, serial number

and Unit ID.

The Status Bar

A status bar appears at the bottom of the window that provides system information to the user

including

CONNECTED TO HOST

GENLOCK, INPUT VIDEO DETECTED

or

CONNECTION TO HOST REFUSED

, and

TIME REMAINING—PERCENT FULL

are also displayed as diagnostics. Error and

. Messages such as

status messages from the RAID system can also be displayed here.

Channel 1 is the only channel that can either Record or Play video content. Channels 2 and 3 can

play back content. All channels may be used at the same time.

Each channel can be controlled in two different views.

1. The Transport View

2. The Playlist View

____________________________________________________________________________________

Page 24 MAXX 6T Owner’s Manual

Page 25

The Transport Channel View

The Transport Channel View is shown in Figure 5 - Transport Channel View. This is the default

view of each channel. Basic transport operations such as play, stop, record, and head/tail trimming

appear in the Clip Transport window for each channel. These operate in familiar VTR fashion.

Figure 5 - Transport Channel View

Transport Menu Bar

There are two menus, File and Options.

File Menu

Contains six selections in Channel 1, five in Channels 2 and 3.

New

Channel 1 only. Opens the Clip Navigator to allow naming of a new clip, then prepares the

channel for recording. See page 32.

Key Command – Ctrl+N.

Open

Opens the Clip Navigator to allow choosing a clip to load into the transport.

Key Command – Ctrl+D.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 25

Page 26

Save

Saves an edited clip using its existing file name.

Key Command – Ctrl+S.

Save As

Opens the Clip Navigator to allow saving an edited version of the clip with a new name.

This allows making alternate versions of a clip or making multiple segments of a master clip.

Key Command – Ctrl+A.

Playlist

Switches from Transport View to Playlist View.

Close

Closes the Transport window. This has the same effect as the Close box in the upper right

corner of the window. Note that this will not stop playback or eject a loaded clip.

Options Menu

This menu contains two selections.

Take Control

Takes control of the video channel from another user (the Serial Control, a Remote

Workstation, or if you are using a Remote Workstation possibly the local GUI.) This item is

grayed out when the window has control.

Key Command – Ctrl+T.

Configure

Opens the video channel’s Configuration dialog. See pages 29 and 45.

Key Command – Ctrl+C.

____________________________________________________________________________________

Page 26 MAXX 6T Owner’s Manual

Page 27

The Playlist Channel View

The Playlist Channel View is shown in Figure 6 - Playlist Channel View. This view allows multiple

clips to be loaded in a “playlist” and played in sequence.

Figure 6 - Playlist Channel View

Playlist Menu Bar

There are two menus, File and Options.

File Menu

Open

Opens the Clip Navigator to allow choosing a clip to load into the transport.

Key Command – Ctrl+D.

Append

Opens the Playlist Selection dialog to allow choosing a Playlist to Append to the currently

loaded list. This can be done while playing to allow continuous playback of new Playlists.

See page 57.

Save

Saves an edited Playlist using its existing file name.

Key Command – Ctrl+S.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 27

Page 28

Save As

Opens the Clip Navigator to allow saving an edited version of the clip with a new name.

This allows making alternate versions of a clip or making multiple segments of a master clip.

Key Command – Ctrl+A.

Rename

Opens the Playlist Selection dialog to allow renaming the currently loaded Playlist.

Transport

Switches from Playlist View to Transport View.

Eject

Ejects the currently loaded Playlist in preparation for creating a new one. (It is not necessary

to Eject a list to load another saved list.)

Key Command – Ctrl+N.

Close

Closes the Playlist window. This has the same effect as the Close box in the upper right

corner of the window. Note that this will not stop playback or eject a loaded list.

Options Menu

This menu contains two selections.

Take Control

Takes control of the video channel from another user (the Serial Control, a Remote

Workstation, or if you are using a Remote Workstation possibly the local GUI.) This item is

grayed out when the window has control.

Key Command – Ctrl+T.

Configure

Opens the Playlist’s Configuration dialog. See page 56. Note that this is different than the

dialog for the video channel setup, which must be accessed from the Transport View

window.

Key Command – Ctrl+C.

____________________________________________________________________________________

Page 28 MAXX 6T Owner’s Manual

Page 29

MAKING A RECORDING FROM THE GUI

Video recordings are made using the Transport View of Channel 1. Channel 1 can record or play

back clips but cannot do both at the same time. Channels 2 and 3 are playback only. Follow these

steps to record a clip on MAXX 6T. Note that most of these configuration setting steps can be

skipped once an established workflow is in place.

Record Configuration Options

Set Channel 1 to the Transport View

If necessary, set channel 1 to the Transport View (Figure 5 ). Click FILE >TRANSPORT in the

Channel 1 Playlist View to switch to the Transport View.

Setting the Sync Source

To use a genlocked source, select External Sync using the GUI as follows:

A. From the main menu bar select EDIT->CONFIGURE. The screen of Figure 7

appears. Select the TIMING option.

B. Select EXTERNAL as the sync source.

C. Check that the front panel GENLOCK LED is now illuminated and the word

GENLOCKED now appears in the bottom right of the main GUI window.

D. If necessary set the LINES and SUB-PELS settings. See System Timing on page 66.

About Genlock Signal Quality

A genlock signal connected to the MAXX 6T must conform to the SMPTE318M standard or EBU

Technical Standard N14-1998. An unstable genlock source may result in unwanted artifacts in the

video output or recorded data.

To use a non-genlocked CVBS source, follow the instructions above but select either INTERNAL or

EXTERNAL Sync.

NOTE: The CVBS input of the MAXX 6T is equipped with an Input Frame Buffer that allows

recording from non-genlocked sources. No configuration is required to use the frame buffer. Refer

to Appendix D for more information.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 29

Comment [b1]: Delete if the SDI

input gets frame buffering.

Comment [b2]: Remove this if the SDI

frame sync is ever fixed.

Page 30

Figure 7 - Timing Configuration Screen

Setting the Video Input Source

The MAXX 6T can accept a video signal at either its composite video input (CVBS), or its serial

digital (SDI) input. Verify that the input to be used is currently active. For a discussion of the SDI –

Embedded Audio option, refer to Configuring Embedded Audio on Page 67.

Select OPTIONS->CONFIGURE from the Channel 1 Transport Window.

The Dialog of Figure 8 appears. Select the appropriate Video Input source by clicking the related

radio button in the Video Input Source section of the dialog. Click APPLY or OK.

Figure 8 - Channel Configure Dialog

____________________________________________________________________________________

Page 30 MAXX 6T Owner’s Manual

Page 31

Arming the Audio tracks

The MAXX 6T can record either two or four audio tracks according to a selection made in the

Channel 1 Configuration window. When a selection is made it will be saved for future recordings.

Select OPTIONS->CONFIGURE from the Channel 1 Transport Window. Refer again to Figure 8 for

a view of the Channel 1 Configuration Dialog.

• Check Audio 1-2 if you wish to record on tracks 1 and 2 only

• Check Audio 3-4 if you wish to record on tracks 3 and 4 (only when using AES-EBU or SDI

Embedded audio input.)

• Check BOTH Audio 1-2 AND Audio 3-4 if you wish to record on tracks 1, 2, 3 and 4

• Uncheck all boxes if you don’t want to record audio.

• Check Closed Caption for all above cases if you want to record closed caption data into a

separate, dedicated track (See Setting the Recording Format below).

Bit-for-Bit® Recording & Playback

The recording, storage and playback of audio program material such as Dolby®-E, Dolby Digital

(AC-3) or DTS® requires that upon playout the data stream be identical to the original. Do not use

the audio sample rate converters when working with these encoded audio formats.

The Image Server and a Dolby® encoder must be supplied with the same genlock signal.

Audio Sync Reference

The audio sample rate is derived from the selected video sync reference. Audio is recorded at a

nominal 48K sample rate, so the 0.1% pull-down for 29.97 NTSC is taken into account when

generating the audio sample rate for color NTSC. There is no drop frame in PAL video.

Setting the Recording Format

Refer again to Figure 8.

Select either Main (Main Profile @ Main Level (4:2:0), or 4:2:2 (4:2:2 Profile@ Main Level) by

selecting the corresponding radio button. Refer to Appendix B for a discussion of Profiles.

Select either 1:I-Frame Only, 6:IBBPBB or 15:IBBPBB…

Refer to Appendix B for a discussion of the GOP structure.

Select the Bit Rate. The range is 4 – 50 Mb/s unless Main profile is selected. In Main profile, the

maximum rate is 15 Mb/s. Generally, very good quality video can be achieved at rates as low as

8 Mb/s with IBBPBB settings.

The MAXX 6T always records Closed Caption data directly into the video. However, when using bit

rates below 10 Mb/s it is advisable to enable the dedicated Closed Caption track in the Arm Tracks

section described above. This will guarantee that the encoding process will not affect the Closed

Caption data.

Setting the Time Code Source

This function selects the time code source for newly recorded clips. A time code value is obtained

from the selected input source at the start of a new recording. Refer to Figure 8. Choose VITC, LTC

or Manual input source. For MANUAL, enter the desired time value for the first frame of the

recording in the Starting Time Code entry field.

____________________________________________________________________________________

MAXX 6T Owner’s Manual

Page 31

Page 32

Beginning Recording

When the steps outlined above in “Setting up for Recording” are done, you are ready to record.

Place Channel 1 in the Record Ready mode as follows.

A. From the Channel 1 Transport Window, Select FILE->NEW. The dialog of Figure 9 appears.

Figure 9 - Channel 1 Clip Navigator "New" mode

B. Note the Folder Structure in the FOLDERS window to the left. If you have not added any

folders (Refer to Organizing Clips on Page 44) no folders will be shown. If you have already

created a folder structure you can select the destination folder for your clip at this time by

clicking on the folder you want it to be placed in. You can always move or copy it later as

well.

C. Enter a clip name using the keyboard. You may use up to 31 characters. Spaces may be used;

however, some characters other than upper or lower case letters and numbers may not be

used. These characters will not enter into the name field when typed. They include * ( ) + =

; : ‘ “ < > , . / and ? A list of existing clips will appear in the large window, and can be used

as a name reference when creating new clip names.

Note: File naming is case sensitive. Upper case letters sort before lower case. The name FILE sorts

in the order shown, based on differing capitalization: FILE, File, fiLe, and file. When using the

Image Server with automation systems or other remote controls, it is not a good practice to

distinguish files only by differences in case.

____________________________________________________________________________________

Page 32 MAXX 6T Owner’s Manual

Page 33