Delta 45, F-25, 30, 35, 40 User Manual

The

F-25/30/35/40 & 45

Combination Heaters

|

CONFORMS TO |

|

|

ANSI Z 21-10-3/UL 732 |

|

|

CERTIFIED TO |

|

90870 |

CSA B 140.12 |

|

CGA/CAN 1-4.3-M85 |

||

|

||

|

|

- Input from 100,000 to 199,000 Btu/hr -

* I N S T A L L A T I O N A N D M A I N T E N A N C E *

M A N U A L

Warranty Registration Card must be filled out by the customer and mailed within thirty (30) days of installa- NOTICE tion in order to gain warranty coverage.

When receiving Triangle Tube units, any claims for damage or shortage in shipment must be filed immediately against the transportation company by the consignee.

Leave all documentation received with appliance with owner for future reference.

WARNING If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or death.

For Your Safety

•Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

•WHAT TO DO IF YOU SMELL GAS

-Do not try to light any appliance

-Do not touch any electrical switch; do not use any phone in your building.

-Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

-If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier

2004-7 Delta Elite Manual

Table of Contents

PRODUCT AND SAFETY INFORMATION

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Operating Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Code Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION I - PRE-INSTALLATION ITEMS

Code Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Determining Product Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Boiler Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Recommended Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Flooring and Foundation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Residential Garage Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION II - COMBUSTION AIR AND VENTING

Providing Air for Combustion and Ventilation . . . . . . . . . . . . . . . . . . . . . 7-8 Removal of an Existing Boiler from a Common Vent . . . . . . . . . . . . . . . . 8

SECTION III - UNIT PREPARATION

Handling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hydrostatic Pressure Test

Hydrostatic Test Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hydrostatic Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Completion of Hydrostatic Test and Draining . . . . . . . . . . . . . . . . 10

SECTION IV - DOMESTIC PIPING

General Piping Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Domestic Supply Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Thermal Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Water Hammer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Temperature / Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Thermostatic Mixing Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

i

Table of Contents

U-Tube Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Domestic Drain Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Multiple Units Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Storage Tank Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TR/Smart Series Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Domestic Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

SECTION V - PRIMARY PIPING

General Piping Requirements

Low Water Cut-off Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Backflow Preventer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Primary System Piping Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Expansion Tank and Makeup Water

Diaphragm (Bladder) Expansion Tank. . . . . . . . . . . . . . . . . . . . . . 17 Closed-Type (Standard) Expansion Tank . . . . . . . . . . . . . . . . . . . . 17 Circulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Closet (Zero Clearance) Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Sizing Primary Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 System Piping - Zone Circulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 System Piping - Zone Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

System Piping - Radiant Heating with Mixing Valves. . . . . . . . . . . . . . . . 18-19 System Piping - Multiple Units Installation. . . . . . . . . . . . . . . . . . . . . . . . 19 Primary Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-23

SECTION VI - VENTING

General Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Oil Vent Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

Oil Vent -Direct Vent Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Gas Venting - General Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Masonry and Metal Chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Type B Vent Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Vent Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Common Vent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

SECTION VII - FUEL PIPING

Gas Supply Piping Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Pipe sizing -Natural Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Natural Gas Supply Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . . 29

ii

Table of Contents

Pipe Sizing - Propane Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Propane Gas Supply Pressure Requirements . . . . . . . . . . . . . . . . . . . . . . . 30

General Oil Piping Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SECTION VIII - INTERNAL WIRING

General Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Internal Control Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-32

SECTION IX - EXTERNAL WIRING

Installation Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Line Voltage Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Thermostat Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Outdoor Temperature Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

External Control Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-36

SECTION X - START-UP PREPARATION

Check System and Domestic Water Chemistry

Water pH Level 6.0 to 8.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Water Hardness Less Than 7 Grains . . . . . . . . . . . . . . . . . . . . . . . 37 Chloride Concentration Less Than 80mg/L . . . . . . . . . . . . . . . . . . 37 Chlorinated Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Flush Primary and Domestic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Check and Test Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Use of Antifreeze in the Primary System . . . . . . . . . . . . . . . . . . . . . . . . . 38 Filling the Inner (Domestic) Tank and System . . . . . . . . . . . . . . . . . . . . . 38 Filling the Outer (Primary) Tank and System . . . . . . . . . . . . . . . . . . . . . . 38-39 Check Low Water Cut-off Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 Check for Gas Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 Check Thermostat Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

SECTION XI - START-UP PROCEDURES

Final Checks Before Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ELITE Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-41

iii

Table of Contents

SECTION XII - TEMPERATURE LIMITS

Setting Primary Thermostat Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Adjustment of Secondary Thermostat Limit . . . . . . . . . . . . . . . . . . . . . . . 42

Setting the Thermostatic Mixing Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SECTION XIII - CHECK-OUT PROCEDURES

Check-out Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SECTION XIV - INSTALLATION RECORD

Installation Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SECTION XVII - REPLACEMENT PARTS

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-49

PRODUCT SPECIFICATIONS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-51

iv

Product & Safety Information

The following terms are used throughout this manual to bring attention to the presence of potential hazards or to important information concerning the product.

DANGER

NOTICE

Indicates the presence of a hazardous situation which, if ignored, will result in death, serious injury or substantial property damage.

Indicates special instructions on installation, operation or maintenance, which are important to equipment but not related to personal injury hazards.

WARNING

Indicates a potentially hazardous situation which, if ignored, can result in death, serious injury or substantial property damage.

CAUTION

Indicates a potentially hazardous situation which, if ignored, may result in minor injury or property damage.

BEST PRACTICES

Indicates recommendations made by Triangle Tube for the installers which will help to ensure optimum operation and longevity of the equipment

NOTICE

Triangle Tube reserves the right to modify the technical specifications and components of its products without prior notice.

1

Product & Safety Information

WARNING

Bacteria can develop in the domestic water system if certain minimum water temperatures are not maintained.

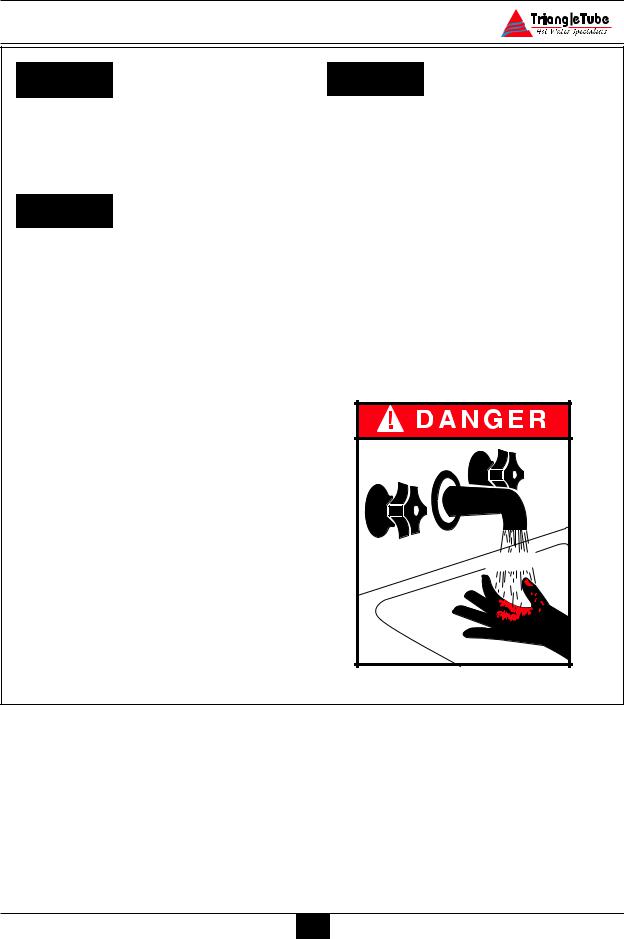

DANGER

Water temperature over 125ºF can cause severe burns instantly or death from scalds.

•Children, disabled and elderly are at highest risk of being scalded.

-Never leave them unattended in or near shower, bathtub or sink.

-Never allow small children to use a hot water faucet or draw their own bath.

•If any one using hot water in the building fits this description or codes require specific water temperatures at hot water faucet, we recommend:

a)ensure the factory installed thermostatic mixing valve is working properly.

b)to set the thermostatic mixing valve for the lowest temperature which satisfies your hot water need.

CAUTION

.

Protection must be taken against excessive temperature and pressure!

TO PROTECT AGAINST EXCESSIVE TEMPERATURE AND PRESSURE

•Check if the Temperature and Pressure (T&P) relief valve is in the location provided. (Domestic Water)

•Check if the 30 psi relief valve supplied is in the location provided. (Primary water)

•To avoid injury, install the relief devices to comply with local code requirements.

HOT |

BURN |

2

Product & Safety Information

DANGER |

WARNING |

|

Do not use this appliance if any part has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system which has been under water.

DANGER

WHAT TO DO IF YOU SMELL GAS - Do not try to light any appliance

Should overheating occur or the gas supply fails to shut off, turn OFF the manual gas control valve external to the appliance.

CAUTION

To prevent damage to inner tank, installer must:

-Do not touch any electrical switch; do not use any phone in your building.

-Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

-If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

•Fill inner tank prior to outer tank during start-up.

•Relieve primary system pressure below 15 psig prior to draining inner tank.

WARNING |

|

|

|

NOTICE |

|

|

|

|

|

|

|

|

|

Qualified Installer: |

|

|

Please reference the unit’s model num- |

|||

Prior to installing this product |

read all |

ber and the serial number from the rat- |

||||

ing label when inquiring about service or |

||||||

instructions included |

in this |

manual. |

||||

|

Perform all installation steps required in this |

|

|

troubleshooting. |

|

||

|

|

|

|

|

|

||

|

manual in the proper order given. Failure to |

|

|

|

|

|

|

|

adhere to the guidelines within this manual |

|

|

NOTICE |

|

|

|

|

can result in severe personal injury, death or |

|

|

|

|

||

|

|

|

|

|

|

||

|

substantial property damage. |

|

|

Triangle Tube accepts no liability for any |

|

||

|

|

|

|

|

|

||

|

|

|

|

|

damage resulting from incorrect instal- |

|

|

|

Homeowner: |

|

|

lation or from the use of components or |

|

||

|

|

|

fittings not specified by Triangle Tube. |

|

|||

|

-This product should be maintained / ser- |

|

|

|

|||

|

|

|

|

|

|

||

|

viced and inspected annually by a qual- |

|

|

|

|

|

|

|

ified service technician. |

|

|

|

|

|

|

|

- This manual is intended for use by a |

|

|

|

|

|

|

|

qualified Installer/Service Technician. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

|

|

|

|

|

Product & Safety Information

OPERATING RESTRICTIONS

•Maximum working pressure for inner (domestic water) tank is 150 psig.

•Maximum working pressure for outer (primary water) tank is 45 psig.

•Inner tank has factory installed Temperature & Pressure Relief Valve with an AGA rating of 100,000 Btu/hr for PG-25 and 200,000 Btu/hr for PG30/35/40/45.

•Outer tank has a factory installed 30 psig relief valve rated at 535,000 Btu/hr

•Electrical rating:120 V, 60 Hz, less than 12 amperes

•pH & chloride limits for the ELITE are:

-Chloride, less than 80 mg/l.

-pH, 6.0 - 8.0.

NOTICE

Any water conditioning system must be installed and maintained in accordance with manufacturer’s specifications.

•180º Maximum operating temperature - primary side.

•120º Maximum outlet/mixed temperature - domestic side.

CODE RESTRICTIONS

Single wall heat exchanger in the ELITE complies with National Standard Plumbing Code, provided that:

-Outer tank water (including additives) is practically non-toxic, having toxicity rating or Class of 1, as listed in Clinical Toxicology of Commercial Products,

-Outer tank pressure is limited to maximum 30 psig by approved relief valve.

Single wall heat exchangers are permitted under the Uniform Plumbing code - Paragraph L3.2. if they satisfy all of the following requirements.

1.The heat transfer medium is potable water or contains only substances which are recognized as safe by the U.S. Food and Drug Administration.

2.The pressure of the heat transfer medium is maintained less than the normal minimum operating pressure of the potable water system

3.The equipment is permanently labeled to indicate that only additives recognized as safe by the FDAshall be used in the heat transfer medium.

Or, per Uniform Plumbing Code paragraph L3.3 as follows:

Other heat exchanger designs may be permitted where approved by the Administrative Authority.

4

Pre-Installation Items

SECTION I - Pre-Installation Items

Code Compliance

This product must be installed in accordance to the following:

•All applicable local, state, national and provincial codes, ordinances, regulations and laws.

•The National Fuel Gas Code NFPA54/ ANSI Z332.1 - Latest edition.

•Installation of Oil Burning Equipment NFPA 31 - Latest Edition

•National Electric Code ANSI/NFPA 70.

•For installations in Canada -“Installation Code for Gas Burning Equipment” CGA/B149.

•For installations in Canada - Installation code for Oil Burning Equipment - CSA/B139.

Determining Product Location

Before locating the ELITE check for convenient locations to:

-Domestic water supply piping

-Heating system piping

-Venting

-Gas or oil supply piping

-Electrical service

Ensure the area chosen for the installation of the ELITE is free of any combustible materials, gasoline and other flammable liquids.

WARNING

Failure to remove or maintain the area free of combustible materials, gasoline and other flammable liquids or vapors can result in severe personal injury, death or substantial property damage.

Ensure the ELITE and its controls are protected from dripping or spraying water during normal operation or service.

The ELITE should be installed in a location so that any water leaking from the tank or piping connections or relief valves will not cause damage to the area surrounding the unit or any lower floors in the structure.

-When such a location is unavoidable a suitable drain pan with adequate drainage should be placed under the unit. The drain pan must not restrict the flow of combustion air to the unit.

Boiler Replacement

If the ELITE is replacing an existing boiler / hot water heater system, the following items should be checked and corrected prior to installation:

•Primary and domestic piping leaks and corrosion.

•Improper location and sizing of the expansion tank on the primary heating loop.

•Improper sizing of the thermal expansion tank (if used) on the domestic supply line.

•Vent condition and sizing.

Recommended Clearances

The ELITE is approved for zero clearance to combustibles, excluding the vent hood and vent piping.

Vent hood and vent piping - 6 inches from combustible materials when using type “L” double wall vent.

Vent Piping - 18 inches from combustible materials when using single wall vent.

Primary and domestic hot water piping - 1 inch from combustible material.

5

Pre-Installation Items

BEST PRACTICES

To provide serviceability to the unit it is recommended that the following clearances be maintained:

Top and vent hood area - 36 inches.

Front and burner area - 24 inches.

Rear and primary piping areas - 12 inches.

WARNING

When installing the ELITE in a confined space, sufficient air must be provided for proper combustion and venting and to allow under normal operating condition, proper air flow around the product to maintain ambient temperatures within safe limits to comply with the National Fuel Gas Code NFPA 54 - latest edition.

Flooring and Foundation

The ELITE is approved for installation on combustible floors, but never on carpeting.

WARNING

Do not install the ELITE on carpeting even with a metal or wood foundation base. Fire can result causing severe personal injury, death or substantial property damage.

Installer should provide a solid brick or concrete foundation pad, at least 2 inches above the floor level if:

-There is a potential for the floor to become flooded. The height of the foundation should be such to sufficiently elevate the unit.

-The floor is dirt, sand, gravel or other loose material.

-The flooring is severely uneven or sloped.

The minimum foundation size required is 24 inches x 23 inches.

Residential Garage Installations

When installing the ELITE in a residential garage the following special precautions per NFPA 54/ANSI Z223.1 must be taken:

-Mount the unit with a minimum 18 inches above the floor level of the garage. Ensure the burner and ignition devices / controls are no less than 18 inches above the floor level.

-Locate or protect the unit in a matter so it cannot be damaged by a moving vehicle.

6

Combustion Air and Venting

SECTION II - Providing Air for Combustion and Ventilation

WARNING

The installer must provide adequate combustion and ventilation to the area in which the ELITE is installed. Providing adequate air ensures proper combustion and reduces the potential risk of severe personal injury or death from carbon monoxide emissions if a flue gas leakage occurred.

WARNING

The installer should not install an exhaust fan in the room with the ELITE. The exhaust fan could affect the combustion of the burner or cause potential flue gas leakage resulting in severe personal injury or death.

NOTICE

The installer should take the condition and age of the building when determining air for ventilation. Older building (buildings with single pane windows and minimal weather-stripping around doors and windows) tend to have adequate natural infiltration and ventilation without providing dedicated air openings. Newer buildings (buildings with double pane windows and weather-stripped doors and windows) are unlikely to have natural infiltration and ventilation, thus must be provided with dedicated air openings.

The installer must follow the requirements of state, provincial or local codes when sizing and locating adequate air openings for combustion and ventilation.

In absence of the codes the installer may opt to use the following guidelines when the ELITE is installed in a confined room as defined by NFPA 31 as a room with less than 7200 cubic feet per 1 GPH of input of all appliances located in the area (7200 cubic feet is define as a room with 8 foot ceiling and 33.5 ft x 33.5 ft in dimension):

Two Permanent Openings - One opening must commence within 12 inches of the ceiling and the other opening within 12 inches of the floor. The opening must have a minimum height or length dimension of 3 inches, the actual dimensions are based on:

Using Inside Air - Each opening must be connected freely to the areas having adequate infiltration from the outside. Each opening should be at least 140 sq. inches per 1 GPH of input (1 sq. inch per 1000 BTU input). This input should include all appliances (gas and/or oil) plus any appliances that may draw air from the room such as clothes dryers.

Using Outside Air - Each opening should be connected directly or by ducts to the outdoors or to a crawl space or attic area that is freely connected with the outdoors. The openings should be sized as follows:

Through outside wall or vertical ducts -

The openings should be a minimum 35 sq inches per 1 GPH input (1 sq. inch per 4000 BTU input) of all appliances (gas and/or oil) plus any appliances that may draw air from the room such as clothes dryers.

Through horizontal ducts - The openings should be a minimum 70 sq. inches per 1 GPH input (1 sq. inch per 2000 BTU input) of all appliances (gas and/or oil) plus any appliances that may draw air from the room such as clothes dryers.

Where ducts are used, the size of the duct should equal the free area of the opening in which the duct is connected to.

7

Combustion Air and Venting

The installer should compensate for any louvers, grilles or screens when determining the free air of the opening. The installer should refer the louver or grille manufacturer’s instruction for determining free area. In absence of the manufacturer’s instructions the installer should use the following as a guideline:

-Wood louvers will provide 20 to 25% free area

-Metal louvers or grilles will provide 60 to 75% free air

Installers should lock louvers in the open position or provide an interlock system to prove the louvers are in the open position prior to operation of the ELITE.

Removal of an Existing Boiler from a Common Vent System

BEST PRACTICES

For installations in which the ELITE is replacing an existing boiler / hot water heater system, which was connected to a common vent system with other appliances, the following steps shall be conducted with each remaining appliance connected to the common venting system:

1.Any unused openings in the common venting system must be sealed.

2.A visual inspection of the venting system must be conducted for proper sizing and horizontal pitch. The inspection should ensure no blockage or restriction is within the vent system, and there is no leakage, corrosion or other items, which could cause an unsafe condition.

3.To adequately test the venting system, close all exterior doors and windows and all doors between the area containing the remaining appliances connected to the common vent system and other areas of the building. Turn on any clothes dryers and any other gas appli-

ance not connected to the common vent system. Turn on all exhaust fans, i.e. range hoods and bathroom exhaust fans, preferably at maximum speed. Close any fireplace dampers.

4.Place in operation the first appliance being inspected that is connected to the common vent system. The remaining appliances should not be in operation. Follow the appliance’s lighting instructions and adjust the thermostat to allow the appliance to operate continuously.

5.Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Spillage can be detected using the flame of a match or candle or with smoke from a cigarette.

6.Once it has been determined that each remaining appliance connected to the common vent system is properly vented, return doors, windows, exhaust fans, fireplace dampers and any operating gas appliance to their previous condition.

Should any improper operation of the common venting system be detected in the outlined test, the condition should be corrected so the vent system conforms with the National Fuel Gas Code, NFPA 54/ ANSI Z223.1 - latest edition. Canadian installations must conform with B149.1 or 149.2 Installation Code.

8

Unit Preparation

SECTION III - Unit Preparation

Handling Instructions

The ELITE is generally easier to handle and maneuver once removed from the shipping carton and pallet.

To remove the shipping carton and pallet:

a.Remove the shipping straps and open the top of the shipping carton to remove the wood shipment insert.

b.Lift the shipping carton over the unit to remove. If ceiling height is limited the carton maybe cut open using care not to damage the exterior jacket of the unit.

c.Discard all packing materials.

Hydrostatic Pressure Test

BEST PRACTICES

Prior to permanently connecting water, oil/gas supply or electrical supply, perform a pressure hydrostatic test of the outer tank to ensure all piping connections were not damaged during shipment.

Hydrostatic Test Preparation

1.Mount the circulator on the supply pipe as shown in Fig. 7 page 20.

2.Temporarily plug the primary return connections as shown in Fig. 7 page 20 using a 1” NPT pipe plug. Use pipe dope sparingly to allow removal of the plugs upon completion of the test.

3.On the outlet flange of the circulator pipe install a 1” NPT nipple and shut-off valve. Use pipe dope sparingly to allow removal of the fittings upon completion of the test.

NOTICE

To avoid getting water onto the unit and/or surrounding area additional piping from the shut-off to a catch bucket or drain may be required.

4.Connect a hose to the primary circuit drain valve located per Fig. 28 page 50, Item 2 and connect the other end to a fresh water supply. Ensure the hose can be used as a drain hose upon completion of the test.

Hydrostatic Test Procedures

1.Open the shut-off valve installed on the outlet flange of the circulator.

2.Open the fresh water supply valve and then open slowly the primary circuit drain valve to fill the outer tank with water.

3.When the water within the outer tank reaches the shut-off on the primary supply, close the primary circuit drain valve.

4.Close the shut-off valve, on the top of the circulator.

5.Slowly reopen the primary circuit drain valve until the test pressure on the temperature / pressure gauge reaches 10 psig maximum. Close the primary circuit drain valve.

CAUTION

To prevent damage to the inner tank the test pressure must not exceed 10 psig.

6.Allow the test pressure to remain for 10 minutes.

WARNING

Do not leave the unit unattended while pressurized. A cold water fill could expand and cause excessive pressure, resulting in severe personal injury, death or substantial property damage.

9

Unit Preparation

7.Ensure constant gauge pressure has been Completion of Hydrostatic Test and Draining maintained throughout the 10 minute test. 1. Disconnect the fill hose from the freshCheck for leaks at all fitting joints. Repair

if found.

WARNING

Leaks must be repaired immediately when detected. Failure to repair leaks can damage the unit, resulting in substantial property damage.

8.Check continuity using a voltmeter across the terminals of the LWCO device. The contacts on the LWCO should be closed. See item 6 in Fig. 24 page 47 for location of the LWCO.

water source and direct the hose to a suitable place of drainage.

2.Open the primary drain valve and completely drain the unit. To aid in draining, open the shut-off valve on the primary supply.

3.Remove the hose from the primary drain valve when draining is complete.

4.Remove the plugs, nipple, shut-off valve and any other piping unless they will remain for use in the system piping.

10

Domestic Piping

SECTION IV - Domestic Piping

General Piping Requirements

•All plumbing must meet or exceed all local, state and national plumbing codes.

•Use pipe dope or tape suitable for potable water.

•Use isolation valves to isolate system components.

•Install unions for easy removal of the ELITE from the system piping.

Domestic Supply Pressure

For applications in which the domestic supply pressure exceeds 70 psig it is recommended to install a pressure reducing valve on the cold water supply.

Maintaining the cold water supply at or below 70 psig will prevent normal thermal expansion from repeatedly forcing the T&P relief valve open.

Thermal Expansion

If the cold water supply contains a backflow preventer, check valve and / or a pressure reducing valve, the installer must install a domestic thermal expansion tank on the cold water supply. (See Fig. 2 page 14)

Installing a thermal expansion tank will prevent normal thermal expansion from repeatedly forcing the T&P relief valve open.

When installing a thermal expansion tank ensure the charge pressure of the tank is equal to the cold water supply pressure at the point of installation. Consult the thermal expansion tank manufacturer’s instructions for further information on installation and sizing.

CAUTION

The Temperature / Pressure relief valve is not intended for constant duty, such as relief of pressure due to normal thermal expansion.

Water Hammer

Water hammer is the effect of sudden pressure changes occurring in the domestic piping. These pressure changes are typically the result of “fast acting” positive shut-off valves closing. These types of valves can be typically found on dishwashers and clothes washers.

The effects of water hammering can cause damage to system components and tank welds on the unit.

Installation of hammer arresters is recommended at these types of appliances, which incorporate “fast-acting” positive shut-off valves. Consult the manufacturer of water hammer arresters for recommendation on sizing and installation requirements.

Temperature / Pressure Relief Valve

The ELITE has a factory installed Temperature / Pressure Relief valve. Ensure the rating of the T&P relief valve is correctly sized as follows per AGA:

Model |

AGA Rating |

F-25 |

100,000 Btu/hr |

F-30 |

200,000 Btu/hr |

F-35 |

200,000 Btu/hr |

F-40 |

200,000 Btu/hr |

F-45 |

200,000 Btu/hr |

|

|

11

Domestic Piping

The installer must install discharge piping onto the T&P relief valve. The discharge piping must be:

•Made of material serviceable for temperatures of 250ºF or greater.

•Directed so that any hot water discharge flows away from all persons.

•Directed to a suitable place of drainage.

•Installed as to allow complete draining of the T&P relief valve and the discharge piping.

•Terminated with a plain end, not with threads.

WARNING

DO NOT install any valves between the T&P relief valve and the discharge piping. DO NOT plug the T&P relief valve or the discharge piping. Improper placement and piping of the T&P relief valve can cause severe personal injury, death or substantial property damage.

Thermostatic Mixing Valve

The ELITE contains a factory installed thermostatic mixing valve with built-in check valve.

The operating range of the thermostatic mixing is 90ºF to 120ºF.

CAUTION

Failure to properly direct the discharge piping of the T&P relief valve may result in flooding of the area adjacent to the unit and or lower floors in the structure causing substantial property damage.

The installer must not install the T&P relief valve discharge piping in a manner that is:

•Excessively long: Using more than 2 elbows and/or 15 feet of discharge piping can reduce the discharge capacity.

•Terminated directly into a drain: The discharge piping must terminate within 6 inches of the drain. Check with local plumbing codes for termination guidelines.

•The discharge piping is plugged, reduced in size or restricted in any manner.

•The discharge piping is subject to freezing.

For applications with a domestic recirculation loop, the recirculation pump should be controlled by an aquastat. The maximum recommended setting of the aquastat is 10ºF lower than the thermostatic mixing valve setting.

DANGER

For proper operation of the thermostatic mixing valve and to prevent potential scalding hazards, the recirculation loop should be controlled by an aquastat. DO NOT use continuous recirculation.

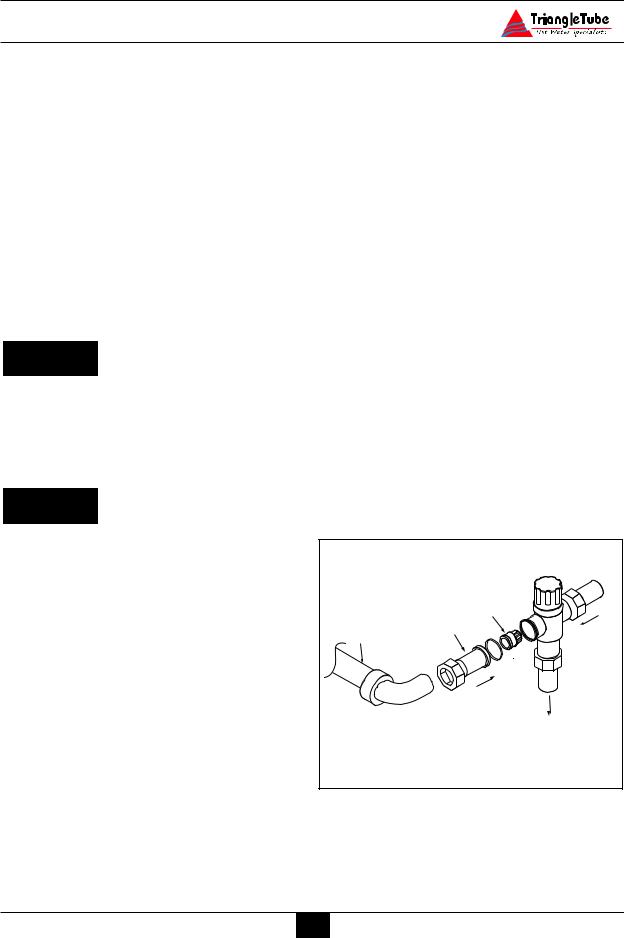

U-Tube Assembly

The ELITE is supplied with a U-Tube Assembly that directs cold water to the thermostatic mixing valve.

To install the U-Tube Assembly the installer must:

1.Disconnect the cold inlet adapter/union from the thermostatic mixing valve.

2.Using needle-nose pliers remove the plastic check valve assembly from the adapter.

12

Domestic Piping

3.Solder the U-Tube Assembly onto the adapter. (See Fig. 1)

4.Once the adapter has sufficiently cooled, re-insert the check valve assembly making sure of orientation and reconnect onto the mixing valve.

If the installation of the ELITE requires domestic hot water for a commercial dishwasher, the installer may insert a tee connection between the unit and the mixing valve to provide 140ºF domestic hot water. The installer must reference local plumbing codes to ensure if this type of application is permissible.

DANGER

The thermostatic mixing valve MUST be installed and utilized on the ELITE. Removal of the thermostatic mixing valve will result in severe personal injury or death.

CAUTION

The installer should remove the thermostatic mixing valve from the units and install a single thermostatic mixing valve at the outlet of the hot water manifold. The thermostatic mixing valve should be sized according to the required flow rate and pressure drop. Refer to the thermostat mixing valve manufacturer specification and installation instructions for more details.

Reference Fig. 4, page 15 for piping diagram.

Storage Tank Application

For applications requiring large volumes of domestic hot water in a relative short period, the installer may include a storage type tank (see Fig. 5 page 16) in the domestic piping. The installer must:

1.Relocate the thermostatic mixing valve from the ELITE to the outlet of the storage tank.

2.Provide recirculation from the storage tank back to the ELITE using a bronze type circulator. Maximum recommended flow rate is 5 to 10 gpm.

The manual valve on the U-Tube assembly must remain in the full open position for proper operation of the thermostatic mixing valve.

Domestic Drain Valve

-The installer must install a drain valve and drain leg as shown in Fig. 2 page 14 or Fig. 3 page 15.

-The drain valve should be positioned close to the floor to aid in the siphon action required to drain the inner tank.

Multiple Units Installation

For applications using multiple units the domestic piping should be piped using a balanced manifold arrangement.

Check Valve |

|

Adapter |

ot |

H |

|

U-Tube Assembly |

|

Cold |

|

|

Mixed |

Fig. 1: Mixing Valve Assembly |

|

13

Loading...

Loading...