Page 1

LIMITED 1 YEAR WARRANTY

®

Zircon Corporation, ("Zircon") warrants this product to be free from

defects in materials and workmanship for one year from the date of

purchase. Any in-warranty defective product returned to Zircon*,

freight prepaid with proof of purchase date and $5.00 to cover

postage and handling, will be repaired or replaced at Zircon’s option.

This warranty is limited to the electronic circuitry and original case of

the product and specifically excludes damage caused by abuse,

unreasonable use or neglect. This warranty is in lieu of all other

warranties, express or implied, and no other representations or claims

of any nature shall bind or obligate Zircon. Any implied warranties

applicable to this product are limited to the one year period

following its purchase. IN NO EVENT WILL ZIRCON BE LIABLE FOR

ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES

RESULTING FROM POSSESSION, USE OR MALFUNCTION OF THIS

PRODUCT.

In accordance with government regulations, you are advised that:

(i) some states do not allow limitations on how long an implied

warranty lasts and/or the exclusion or limitation of incidental or

consequential damages, so the above limitations and/or exclusions

may not apply to you, and further (ii) this warranty gives you specific

legal rights and you may also have other rights which vary from state

to state.

Return product freight prepaid with proof of purchase date (dated

sales receipt) and $5.00 to cover postage and handling, to:

Zircon Corporation

*Attn: Returns Department

2390 Boswell Road, Suite 300

Chula Vista, CA 91914-3510 USA

Be sure to include your name and return address. Out of warranty

service and repair, where proof of purchase is not provided, shall be

returned with repairs charged C.O.D. Allow 4 to 6 weeks for delivery.

Customer Service, 800/245-9265 or 408/866-8600

Monday – Friday, 8 a.m. to 5 p.m., PST

E-mail: customerservice@zircon.com

www.zircon.com

©2001 Zircon Corporation • P/N00000 • REV A 03/01

Zircon Corporation

1580 Dell

800-245-9265 408-866-8600

Campbell, CA 95008

www.zircon.com

Remote Controlled Rotator

RCR

Instructions

Contents

Components . . . . . . . . . . .2

Setting Up . . . . . . . . . . . .3

Operation . . . . . . . . . . . . .5

Laser Receiver . . . . . . . . .7

Changing Batteries . . . . . .9

Calibration . . . . . . . . . . . .10

Technical Data . . . . . . . . .11

Warranty . . . . . . . . . . . . .12

Page 2

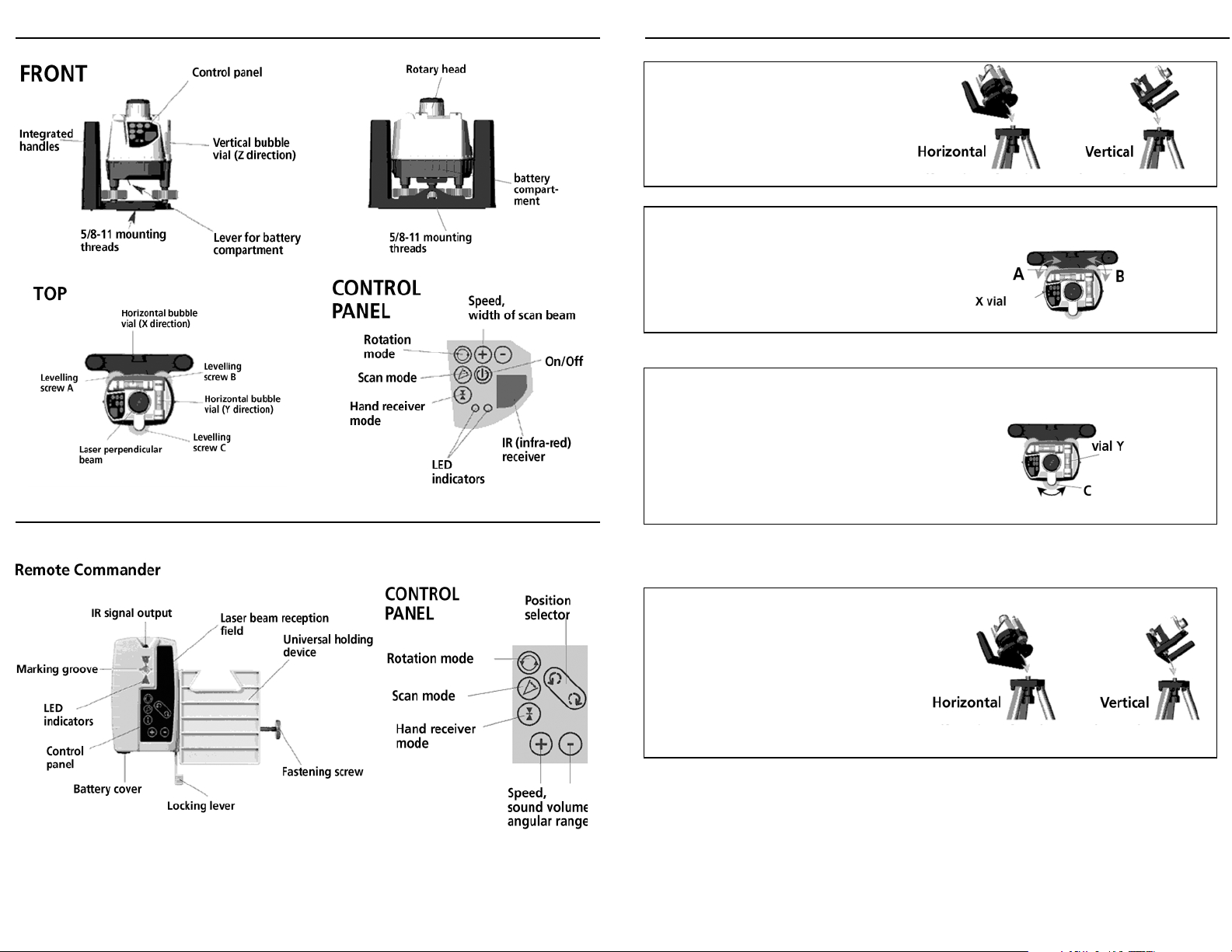

RCR Components

Remote Commander Components

Setting Up

Set the RCR up on a firm base or mount it

onto a tripod with a 5/8-11 thread.

Adjusting horizontal settings

Start adjusting the level bubble vial X by

turning the levelling screws (A) and (B).

X-vial

Always look vertically at the vial in order to

avoid reading errors. Now turn the levelling

screw (C) to adjust the bubble vial Y.

Y-vial

Repeat the whole action as necessary.

Adjusting vertical settings

Set the RCR up vertically on its integrated

handles or mount the RCR onto a tripod.

Now adjust only the vertical bubble level

vial (Z) with the levelling screw (C).

Page 3

Operation

Operation

Switch on RCR:

Press and hold the "On/Off" button for

1 second until the head of RCR starts

rotating. The rotation mode is

activated.

Spot mode:

The rotating laser sends out a spot

laser beam that can be focused on one

point. In order to get into the spot

mode, reduce the speed by pressing

the minus button to zero.

To rotate laser

Change its position by manually

turning the rotary head

Scan mode

Scan Mode is a light-intensive segment

of line at user-selected width, with an

adjustable position.

To activate Scan Mode, press the

ACTIVATE button on the control panel or

on the Remote Commander control

panel.

To change scan angle, press the + and buttons on either control panel.

To change position of the scan area,

manually turn the rotary head, or use

the Change Position buttons on the

Remote Commander.

Rotation mode

A laser beam rotating 360° with a speed

of up to 120 rpm, or 550 rpm if using

receiver.

Using either control panel, activate

Rotation Mode by pressing the spin

button.

Rotate laser with Remote

Commander

Change position by pressing the

Position Selector buttons.

Change rotation speed by pressing the +

or - buttons.

Page 4

Operation

Using the Remote Commander as a Laser Receiver

Hand receiver mode

Hand receiver mode gives you

optimum reception quality with a

constantly high speed of rotation

(maximum speed = 550 rpm).

Activate this mode by pressing the Hand

Receiver button on the RCR control

panel.

Pressing the same button on the Remote

Commander control panel activates the

Remote Commander as a laser receiver.

Note referring to all modes

The red LED lights up when you've

reached the limit of range (e.g.

maximum speed, biggest scan angle).

Sound volume control

Use the + and - buttons to adjust volume

after pressing the receiver activation

button. The LEDs light up to indicate

low, medium, and maximum sound,

or sound off.

Working with the laser receiver

The receiver can detect the laser beam at distances of up to 400 feet.

Hold the laser receiver with the IR receiver at the height

of the rotating laser beam and facing the laser beam.

By means of LEDs and sound signals you can find the

exact height of the laser level beam.

If the top LED lights, a descending series of tones sounds.

Move the Remote Commander downwards.

If the bottom LED lights, and an ascending series

of tones sounds, move the Remote Commander

upwards.

Using the Remote Commander as a Laser Receiver

Activating the laser receiver

mode

Switch on the laser receiver mode.

In order to ensure that the mode is also

activated on the RCR, point the IR

transmitting diode of the

RemoteCommander at the RCR unit.

Activation is indicated by lighting of

red/green LEDs and a signal sound on

the Remote Commander.

When the middle LED is yellow, you are very close,

and the two-note tone tells you to move the

Remote Commander slowly upwards or downwards,

until the middle LED turns green.

When the middle LED is green, a series of equal tones sounds.

The Remote Commander is exactly at laser level.

Note:

When the middle LED gives off yellow light, you are already

within a 3/16" range round the laser level (free-hand

measuring). You will achieve a more accurate result (fine measuring), when

the RemoteCommander is fixed (e.g. attached to a levelling staff). Then the

green LED shows the exact center.

Page 5

Using the Remote Commander as a Laser Receiver

Calibration

Special features of Remote

Commander

By using the universal holding device the

RemoteCommander can be attached to a

levelling staff. LEDs on the back show the

same readings as the front so you can work

from behind the receiver.

Through the integrated magnet the Remote Commander can also be

used as an electronic target plate, e.g. in acoustic ceiling construction

and when setting up and adapting metal and storage shelves.

Changing Batteries

RCR:

When the red LED is constantly flashing,

the batteries must be changed. To do

this, pull the lever under the unit slightly

downward and forward. Remove the

door and insert new batteries with

polarities shown on case indicating

which end of battery faces out. Replace

door. Requires four AA batteries.

RemoteCommander:

The RCR is a high-precision rotating laser and has

been factory calibrated within the tolerance

specified. Regularly check the calibration before

use, after transporting and after long storage

periods.

Be aware that a re-calibration performed by the

user is only as an approximation and the accuracy

of calibration depends on your care.

X/Y-axis Preparation

Note: For the purpose of calibration or

verifying level, the unit should be placed at a

distance of approx. 40-60 ft. from a vertical

target (e.g. wall).

1.Turn the levelling screws all the way down until

they stop.

2.Make a reference mark on each with a pencil.

Using the mark as an aid, turn the levelling screws

each up again by 3 turns.

3.Set the unit on a flat, somewhat level surface or

screw it onto a tripod.

4.Align the surface or the tripod in such a way that

the bubbles of the RCR are coarsely adjusted and

move freely.

Turn the knob on the bottom side and

remove it. Change batteries inserting

with plus sign facing in and replace

knob. Requires two AA batteries.

Connection of an external AC adaptor to the rotation laser

When connecting an external AC adaptor, the batteries will be bypassed. It is not

possible to charge rechargeable batteries with the power supply attached to the

rotation unit. Please use only the AC adaptor supplied.

Note:

Batteries should not be exposed to excessive heat, such as sunshine or fire. å

Checking the calibration of the Y axis

1. Mark either levelling screw A or B as a reference

screw. Align the unit only with the other levelling

screws.

2. Level the unit with the other two levelling

screws. Turn on and shine beam on a vertical

target surface 50 to 65 feet away.

Note:

Any mode can be used but spot mode will be

brighter and more visible at longer distances.

3. When levelled, mark the point A on the target.

Page 6

Calibration

Calibration

4. Turn the unit 180° without changing the

tripod

or surface height.

5. Using the same two levelling screws,

relevel unit.

6. Mark point B on the target.

If point B is at the same height as

point A, then the Y level is accurately

calibrated. If this is not the case, the

unit must be recalibrated.

Re-calibration of the Y axis:

1. Adjust the levelling screws (do not

use the reference screw) until the laser

is exactly centered between points A

and B. Take time to be as precise as

possible.

2. Remove the caps on the ends of the

bubble vial and reset the vial with the

calibrating screws using the hex

wrench supplied.

3. Gently raise or lower either end of

the vial as needed to center the

bubble. Replace caps.

Checking and re-calibration - X

axis

Proceed in the same way as for

checking and calibration of the Y axis

but turn the unit 90°, to align the laser

beam over the X vial.

Z axis: Calibrate vertical vial

Note: Prior to any Z axis calibration, make sure that the

horizontal vials (X and Y vials) have been correctly calibrated.

1. Set the unit up horizontally between two targets. (Remove

the protective cap at the side of the

bubble vial before calibrating)

2. Mark points A1 and B1 on the

targets.

3. Set the unit up vertically in the

vicinity of target A.

4. The laser strikes the first target and marks point A2 at the

same time.

5. Measure the distance between A1 and A2 (a).

6. Transfer the distance measured (a) to target B.

7. Adjust the laser beam with the levelling screw to the height

of B2.

8. If the bubble does not indicate

levelled, gently raise or lower either

end of the vial as needed to center

the bubble. Replace caps.

Technical Data

Laser Class II

Output power <= 1 mW horizontal; <0.33 mW vertical

Wavelength 635 nm

Accuracy ± 1/8” at 50 ft. (± 3.1mm at 15 m)

Vials ground glass, 1.75 arc minutes

Beam splitter ±20 arc seconds

Functions

Operating modes rotating, scan, spot and receiver

Settings change of position, speed, sound, volume, angular range, position

Speed of rotation 0 ... 120 rpm variable; 550 rpm for receiver

Remote control Infra-red, up to 50 ft. range

Power supply

Battery service life 40 hrs (4AA, alkaline

Continuous operation Jack for AC power adaptor

Other technical data

Working temperature 32°F to 122°F (0°C to 50°C)

Storage temperature 14°F to 158°F (-10°C to 70°C)

Loading...

Loading...