Page 1

LASERVISION®6.0 and LASERVISION®7.0

MODE D’EMPLOI

A

V

O

I

D

E

X

P

O

S

U

R

E

L

a

s

e

r

r

a

d

i

a

t

i

o

n

i

s

e

m

i

t

t

e

d

f

r

o

m

t

h

i

s

a

p

e

r

t

u

r

e

Z

i

r

c

o

n

C

o

r

p

o

r

a

t

i

o

n

1

5

8

0

D

e

l

l

A

v

e

.

C

a

m

p

b

e

l

l

,

C

A

9

5

0

0

8

T

h

i

s

p

r

o

d

u

c

t

c

o

n

f

o

r

m

s

t

o

A

p

p

l

i

c

a

b

l

e

S

t

a

n

d

a

r

d

s

o

f

2

1

C

F

R

p

a

r

t

s

1

0

4

0

.

1

0

a

n

d

1

0

4

0

.

1

1

Manufactured

at EM:

C

A

U

T

I

O

N

L

A

S

E

R

R

A

D

I

A

T

I

O

N

D

O

N

O

T

S

T

A

R

E

I

N

T

O

B

E

A

M

P

E

A

K

P

O

W

E

R

1

m

W

/

W

A

V

E

L

E

N

G

T

H

6

5

0

n

m

C

L

A

S

S

I

I

L

A

S

E

R

P

R

O

D

U

C

T

INSTRUCTION MANUAL

M

ANUAL DE INSTRUCCIONES

®

Page 2

OPERATING INSTRUCTIONS

LaserVision®6.0 and LaserVision®7.0

The Zircon LaserVision is a high-precision electronic level combined

with a laser module. The LaserVision simplifies the time-consuming

task of laying out a job by allowing the user to mark level reference

points up to 150 ft. (45 m, LaserVision 6.0) or 300 ft. (90 m, LaserVision 7.0)

away. The LaserVision features an electronic LCD display which indicates the

relative deviation from level or plumb and the rotational direction needed to

achieve level or plumb. It also features an audio signal which sounds when level

and plumb are found. The LaserVision 7.0 has three preset angles commonly

used in construction jobs. Both models have the ability to store and recall any

angle over a 360 degree range. The LaserVision requires three AAA batteries

for the level module and three AAA batteries for the laser module.

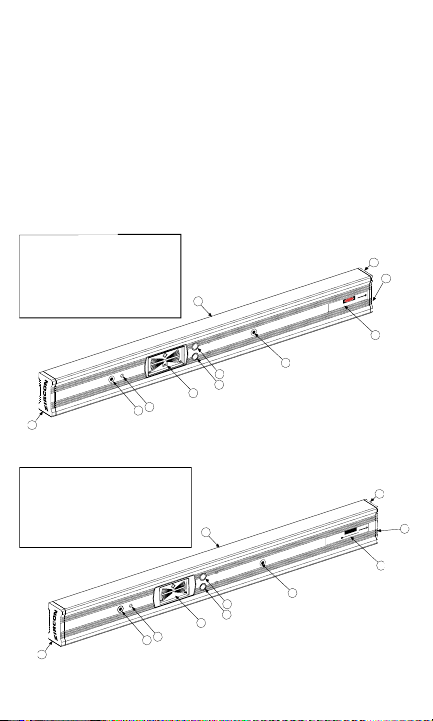

Figure 1a: LaserVision 7.0 Components

Figure 1b: LaserVision 6.0 Components

2

1

2

3

3

4

5

6

7

8

6. On/Off Button

7. Slope Button

8. Extrusion

9. Warning Label

10. Laser Power

Button

1. End Cap

2. End Cap

(Laser End)

3. Level Module

Attach Screw

4. Sound Port

5. Display Module

O

n

/

C

a

l

S

l

o

p

e

C

A

U

T

I

O

N

9

A

v

o

i

d

E

x

p

o

s

u

r

e

L

a

s

e

r

r

a

d

i

a

t

i

o

n

i

s

e

m

i

t

t

e

d

f

r

o

m

t

h

i

s

a

p

e

r

t

u

r

e

Z

i

r

c

o

n

C

o

r

p

o

r

a

t

i

o

n

1

5

8

0

D

e

l

l

A

v

e

.

C

a

m

p

b

e

l

l

,

C

A

9

5

0

0

8

T

h

i

s

p

r

o

d

u

c

t

c

o

n

f

o

r

m

s

t

o

A

p

p

l

i

c

a

b

l

e

S

t

a

n

d

a

r

d

s

o

f

2

1

C

F

R

p

a

r

t

s

1

0

4

0

.

1

0

a

n

d

1

0

4

0

.

1

1

MFG Date:

D

A

N

G

E

R

L

A

S

E

R

R

A

D

I

A

T

I

O

N

-

A

v

o

i

d

D

i

r

e

c

t

E

y

e

E

x

p

o

s

u

r

e

M

a

x

i

m

u

m

O

u

t

p

u

t

P

o

w

e

r

<

5

m

w

@

6

7

0

n

m

C

l

a

s

s

I

I

I

a

L

a

s

e

r

P

r

o

d

u

c

t

10

1

2

3

3

4

5

6

7

8

6. On/Off Button

7. Memory Button

8. Extrusion

9. Warning Label

10. Laser Power

Button

1. End Cap

2. End Cap

(Laser End)

3. Level Module

Attach Screw

4. Sound Port

5. Display Module

O

n

/

C

a

l

S

l

o

p

e

C

A

U

T

I

O

N

A

V

O

I

D

E

X

P

O

S

U

R

E

L

a

s

e

r

r

a

d

i

a

t

i

o

n

i

s

e

m

i

t

t

e

d

f

r

o

m

t

h

i

s

a

p

e

r

t

u

r

e

Z

i

r

c

o

n

C

o

r

p

o

r

a

t

i

o

n

1

5

8

0

D

e

l

l

A

v

e

.

C

a

m

p

b

e

l

l

,

C

A

9

5

0

0

8

T

h

i

s

p

r

o

d

u

c

t

c

o

n

f

o

r

m

s

t

o

A

p

p

l

i

c

a

b

l

e

S

t

a

n

d

a

r

d

s

o

f

2

1

C

F

R

p

a

r

t

s

1

0

4

0

.

1

0

a

n

d

1

0

4

0

.

1

1

Manufactured

at EM:

C

A

U

T

I

O

N

L

A

S

E

R

R

A

D

I

A

T

I

O

N

D

O

N

O

T

S

T

A

R

E

I

N

T

O

B

E

A

M

P

E

A

K

P

O

W

E

R

1

m

W

/

W

A

V

E

L

E

N

G

T

H

6

5

0

n

m

C

L

A

S

S

I

I

L

A

S

E

R

P

R

O

D

U

C

T

9

10

Page 3

3

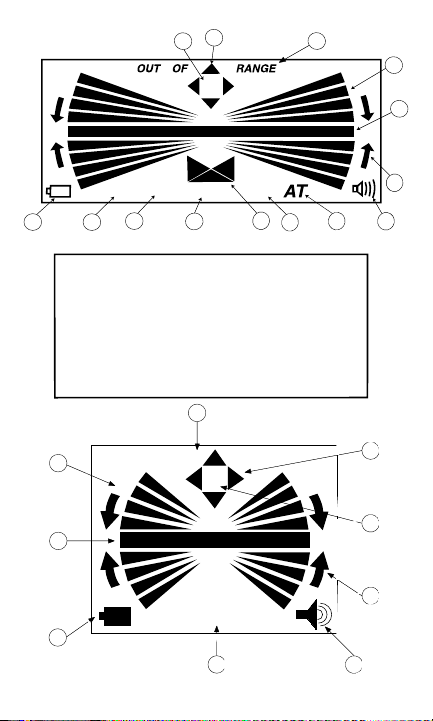

13

OUT OF RANGE

AT

12

1

2

3

5

6

7

8

9

4

Figure 2b: LaserVision 6.0 LCD Components

14

12

11

12

10

1/8" 1/4" 1"

3

2

1

IN/FT

4

Figure 2a: LaserVision 7.0 LCD Components

1. Low Battery Indicator

2. 1/8" per foot slope

Indicator

3. 1/4" per foot slope

Indicator

Units Inch/Foot Indicator

4.

5. Slope Direction Indicator

6. 1" per foot slope

Indicator

7. Angle Transfer Mode

Indicator

5

8. Sound Indicator

9. Directional Rotation

Arrows

10. Level / Plumb Bar

11. Main Display Wedges

12. Out of Range Indicator

13. Not Calibrated

Indicators

14. Calibration Sequence

Indicators

7

6

9

8

Page 4

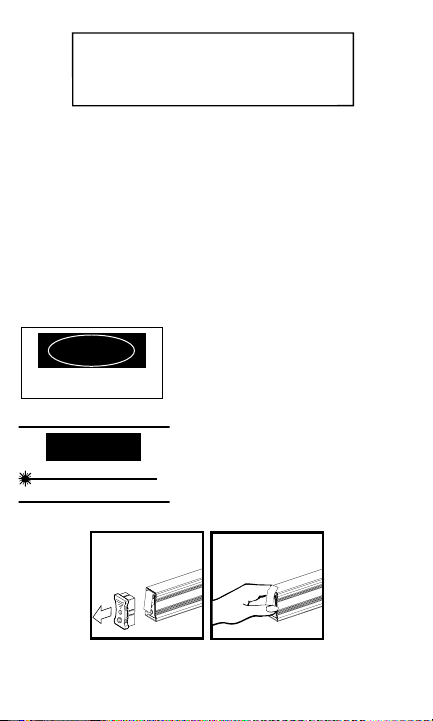

Preparing the LaserVision for Use

For safety reasons, the LaserVision 6.0 and 7.0 laser has been temporarily disarmed. To make the laser operational again:

• Remove the Laser-End Endcap (Figure 3 below).

• Pull up on the battery compartment door to release.

• Carefully remove the protective sticker from the laser module battery making

sure not to leave any pieces behind that might prevent the batteries from making contact (Figure 4 below).

• Close and latch the battery compartment door.

• Put the Laser-End Endcap back in place.

The LaserVision is now ready for use.

LaserVision 7.0:

Warning: Be sure not to shine the

laser beam directly into anyone's eyes.

This can cause serious eye injury

or even blindness.

LaserVision 6.0:

Warning: Be sure not to shine the

laser beam directly into anyone's eyes.

This can cause serious eye injury

or even blindness.

Figure 3: Removing Figure 4: Removing

the Laser End Cap Protective Sticker

4

X

m

1. Main Display Wedges

2. Level and Plumb Bar

3. Low Battery Indicator

4. Angle Transfer Mode

Indicator

5. Sound Indicator

6. Directional Rotation

Arrows

7. Calibration Sequence

Indicators

8. Not Calibrated Indicators

9. Out of Range Indicator

DANGER

LASER RADIATION - Avoid Direct Eye Exposure

Maximum Output Power < 5 mW @ 670 nm

Class IIIa Laser Product

CAUTION

LASER RADIATION

DO NOT STARE INTO BEAM

PEAK POWER 1 mW / WAVELENGTH 650 nm

CLASS II LASER PRODUCT

E

La

e

F

O

R

E

R

M

U

O

S

V

E

E

1

F

O

R

E

R

M

U

O

S

V

E

E

Page 5

TTuurrnniinngg tthhee LLaasseerrVViissiioonn OOnn aanndd OOffff

FFoorr tthhee LLeevveell

• Press the yellow ON/OFF button located next to the LCD (Figure 1, page 2).

To conserve batteries, the level portion of the LaserVision turns itself off after

one minute of inactivity. Once leveled, you can continue using the laser beam

even though the level itself has turned off.

FFoorr tthhee LLaasseerr

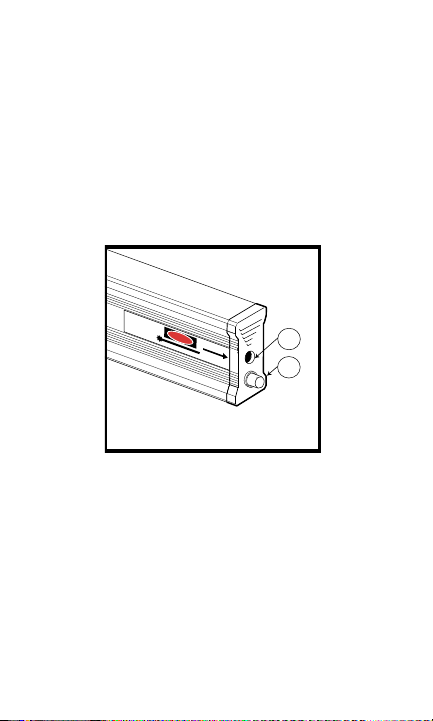

• Press the push button on the laser end cap (Figure 5 below). When the laser is

activated, the push button glows red.

Warning: The LaserVision 7.0 has been outfitted with a Class IIIa laser (the

Laservision 6.0, with a Class II laser). Avoid direct eye exposure at all times.

For instance, do not look into the hole in the laser end cap to see if it is on.

Figure 5: Laser End Components

CChheecckkiinngg yyoouurr LLaasseerrVViissiioonn ffoorr pprrooppeerr ccaalliibbrraattiioonn

Prior to using any level, you should check its calibration. This is easy to

do if a flat, relatively level surface is available.

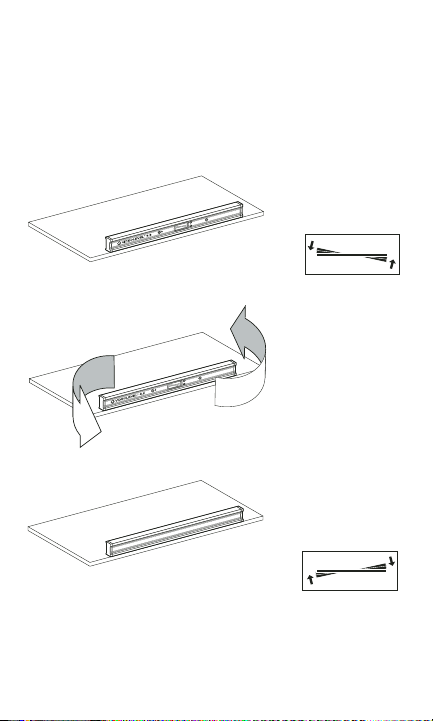

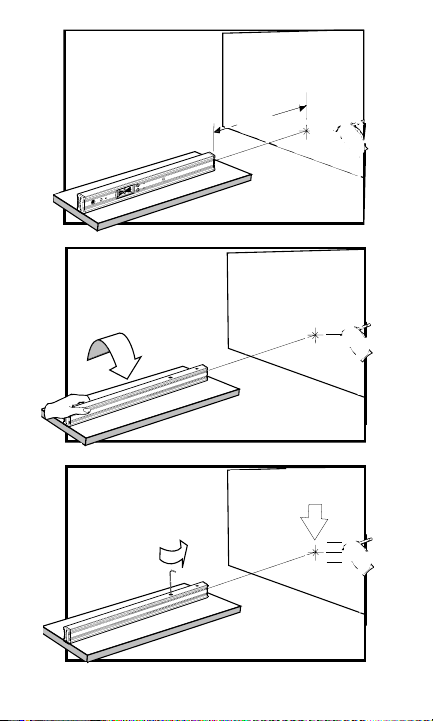

• In the case of the Zircon LaserVision, place the level on the surface and try to

align it with an edge or line on the surface.

• Turn the unit on.

• Note which end of the surface is indicated on the display to be higher and by

how many bars. For example, you may see the center bar with two bars on top

on the left side of the display and two bars on the bottom on the right side of

the display (Figure 6, page 6).

• Now turn the level around end for end with the same surface of the level

touching the relatively level surface and aligning the level to the same edge or

line on the surface (Figure 7, page 6). The display should now show the same

5

Z

i

r

:

c

o

n

e

1

C

t

5

o

8

r

p

0

a

o

D

r

C

a

e

t

a

l

D

i

l

o

m

A

n

p

v

e

b

.

e

l

G

l

,

C

A

F

T

9

h

5

i

s

0

M

0

p

8

r

t

o

o

d

A

u

c

p

t

p

c

l

o

i

o

c

f

n

a

2

f

b

o

1

l

e

r

C

m

S

1

F

s

0

t

R

a

4

n

0

p

d

.

a

1

a

r

0

r

t

d

s

D

a

s

n

d

A

1

0

L

N

4

A

0

S

.

E

G

1

R

1

R

E

A

D

I

A

R

M

T

I

a

O

x

N

i

m

-

u

A

m

v

o

O

i

d

A

u

t

D

p

i

v

u

C

r

e

t

l

c

o

a

P

t

s

o

s

E

i

w

E

y

I

d

e

I

e

I

r

a

x

E

<

L

x

p

a

5

p

s

o

m

e

o

s

r

W

u

P

s

r

@

e

r

o

u

d

6

u

7

r

c

0

t

e

n

m

L

a

s

e

r

e

r

m

a

d

i

t

i

t

a

e

t

d

i

o

f

n

r

a

o

i

p

m

s

e

r

t

t

h

u

i

r

s

e

1

2

1. Laser Exit Point

2. Laser Power Button

Page 6

end of the surface as higher by the same amount of bars, plus or minus one

bar. Taking the same example, the display should now show the center bar

with two bars on top on the right side of the display and two bars on the bottom on the left side of the display (Figure 8 below).

If this is not the case, the level is out of calibration and should be recalibrate

before being used.

Note: This process of turning the level end for end and comparing the

two indications relative to the surface is applicable to all levels, including bubble levels.

Figure 6: Checking the LaserVision in One Direction

Figure 7: Turning the LaserVision End-for-End

Figure 8: Checking the LaserVision in the Other Direction

CCaalliibbrraattiinngg tthhee LLaasseerrVViissiioonn

The LaserVision's level module can be re-calibrated at any time to the original factory specifications to ensure precision.

6

Page 7

NOTES: 1. The calibration process must be done on a solid, flat surface that is reasonably level (when calibrating the level axes) or reasonably plumb (when calibrating the plumb axes). If the surface is too far from true level or plumb, “Out of

Range“ will appear on the LCD. If this indication appears, move the LaserVision to

a surface that is closer to level or plumb.

2. There is a cluster of four arrows at the top of the LCD display. These arrows

indicate which axes are not calibrated. They will appear after the unit has lost its

calibration which is normally after the batteries have been dead or removed for

sometime. During the calibration process, as noted below, the arrow corresponding

to the axis being calibrated will at various times blink, and finally, after calibration

is complete, will disappear. After all four axis have been calibrated, none of the calibration arrows will be showing. If one or more of the arrows are showing, the

corresponding axis is not calibrated, and the LaserVision cannot be used

in this axis until it is calibrated.

3. For better accuracy, align the level with an edge of the surface or a line on the

surface when calibrating so you can maintain the same location easily.

4. The LaserVision must be in the standard mode (with no slope indicators or "AT"

across the bottom of the LCD) in order to calibrate properly. It will not calibrate in

a preset slope mode and will only memorize the current slope in "AT" mode.

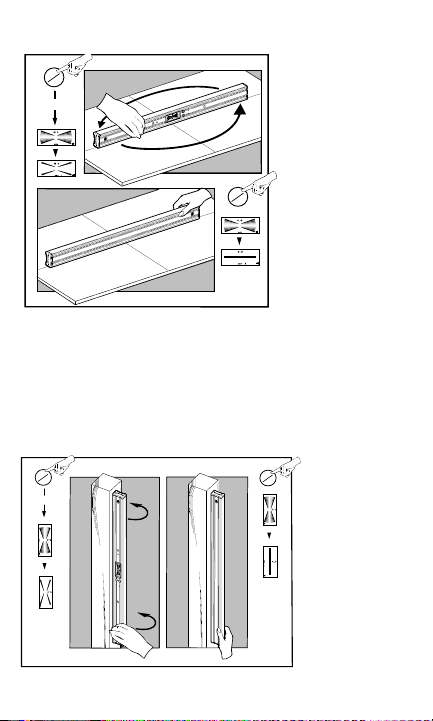

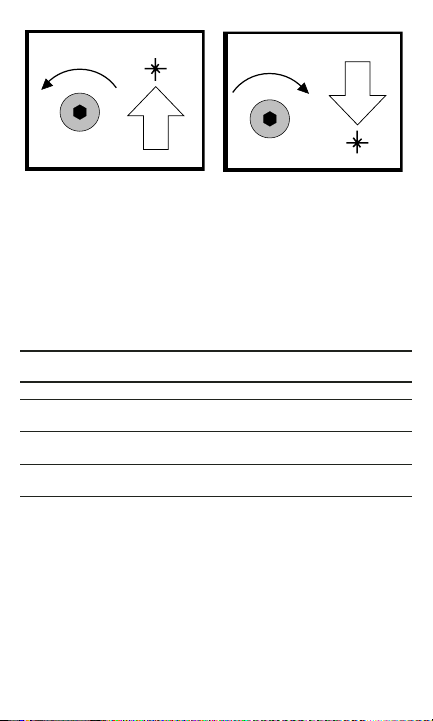

Calibrating to Level

• Place the LaserVision on a flat, solid, relatively level surface (see note (1) above).

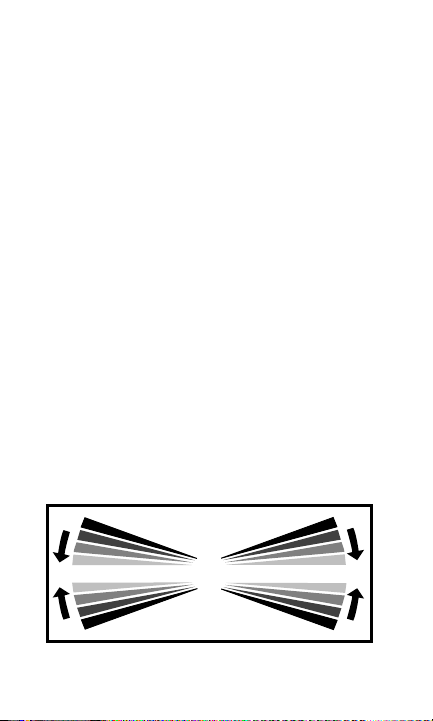

• Press and hold the ON/OFF button for about three seconds, until the bars start

moving up and down (Figure 9 below) and an audio tone sounds. The axis

arrow and the number 1 will blink while the unit is calibrating the first position.

• When the indicators stop moving and the second audio tone sounds, the

number 2 will appear. Rotate the unit end for end (Figure 10, page 8).

• Place the level in the same location.

• Press and release the ON/OFF button once again and wait for the calibration

indicators to stop moving, the axis arrow to disappear, and the final audio tone

to sound. This axis is now calibrated.

• Flip the level over and calibrate the opposite surface of the level by following

the same procedure. Both level axis arrows should now have disappeared.

Figure 9: Calibration Display

7

Page 8

Figure 10: Calibrating to Level

Calibrating to Plumb

• Place the LaserVision against a stable, nearly vertical surface (See note (1) above).

• Press and hold the ON/OFF button for about three seconds until the bars start

moving up and down (Figure 9, page 7) and an audio tone sounds. The axis

arrow and the number 1 will blink while the LaserVision is calibrating the first

position.

• When the indicators stop moving and the second audio tone sounds, the number 2

will appear. Rotate the LaserVision 180 degrees while keeping the same end up

(Figure 11 below).

8

Figure 11: Calibration to Plumb

on

off

1a

3 sec

A

B

1b

on

off

A

B

on

3 sec

off

2a

A

B

2b

A

B

on

off

Page 9

• Place the level in the same location.

• Press and release the ON/OFF button once again and wait for the calibration

indicators to stop moving, the axis arrow to disappear, and the final audio tone to

sound. This axis is now calibrated.

• Rotate the level end for end and calibrate the other plumb direction by following the

same procedure. Both plumb axis arrows should now have disappeared.

Allen Wrenches

The LaserVision comes with two allen wrenches packed in the end cap opposite

the laser. They can be stored there. When replacing the batteries, use the larger

3/32" allen wrench to remove the two front screws that hold the level module in

place. When aligning the laser, use the smaller 5/64" allen wrench to turn the

calibration screw.

Calibrating the LaserVision’s Laser

Although calibrated when leaving the factory, the LaserVision's laser can be easily recalibrated to the original factory specifications to ensure precision.

• In order to check or calibrate the laser module, place the LaserVision level on

a flat, stable surface with a target area located approximately 50 ft. (15 m)

away (Figure 12, page 10).

NOTE: The surface need not be level.

• Turn on the laser and mark the position of the center of the laser spot on the

remote target, see point 1 (P1).

• Turn the LaserVision over.

• Return to the target area and mark the new position of the center of the spot,

see P2. If the second mark is above the first, then the calibration screw (which

is the screw closest to the center, on the bottom of the LaserVision) should be

turned clockwise using the smaller 5/64" Allen wrench provided in the end

cap opposite the laser. If the second mark is below the first, then turn the

calibration screw counter-clockwise (Figure 13, page 11). Adjust the calibration screw until the laser spot is halfway between the two marks, see P3.

NOTE: Do not turn the screw closest to the end as it will disassemble the laser

unit and invali date your warranty.

• Return the LaserVision to the upright position and check the spot location.

The laser spot should match the midpoint. If it does not, redo the above steps

until there is no change when the level is turned over.

NOTE: Do not turn the screw closest to the laser end. This screw keeps the laser

module in place. If this screw is turned, your warranty will no longer be valid.

9

Page 10

Figure 12: Calibrating the Laser

10

P3

P2

P1

P2

P1

~50ft.

P1

Page 11

Figure 13: Aligning the Laser Spot

Finding Level and Plumb

The LaserVision features four segmented bars which indicate the angular

proximity of the LaserVision to level or plumb. (See Table I for Working Precision

Display.) The arrows displayed on both sides of the segment bars further indicate

which way to rotate the LaserVision to reach level or plumb. When level or plumb

is found, the LCD indicates a single bar and sounds an audio tone (unless the

sound has been turned off).

Working Precision Display:

Deviation from Level or Plumb: Maximum (Typical)

LCD

Segment Inches/100 Feet mm/m Degrees

Center Bar 0.50 in.(0.25 in.) 0.42(0.21) 0.02(0.01)

1st Bar

from Center 1.00 in.(0.50 in.) 0.83(0.42) 0.05(0.02)

2nd Bar

from Center 2.00 in.(1.00 in.) 1.66(0.83) 0.10(0.05)

3rd Bar

from Center 4.00 in.(2.00 in.) 3.04(1.66) 0.17(0.09)

Table I

Using the Laser

• Turn on the LaserVision and adjust to level or plumb.

• Push the laser power button located on the laser end cap (Figure 5, page 5).

When the laser is on, the button glows red.

• Point the LaserVision in the desired direction.

• Then mark the position of the laser spot.

NOTE: 1. Since the laser spot gets larger as it gets further from the LaserVision,

to ensure maximum accuracy, be sure to always mark the center of the spot.

2. The laser spot is projected from the center of the laser end cap and

is one inch from either top or bottom surface of the level. Be sure to

compensate for this one-inch difference.

11

CW

CCW

Page 12

Using the Slope Mode (LaserVision 7.0 only)

The LaserVision 7.0 features three common angle presets: 1/8, 1/4 and 1 inch

per foot. These presets can be used in either direction. Once activated, the

LaserVision 7.0 uses the selected angle as its reference point until changed

(Table II). After pressing the SLOPE button, the angle and direction appear at

the bottom of the display.

• To get to the desired angle and direction, press the SLOPE button repeatedly

until the desired angle and direction are found (Figure 14 below).

NOTE: Unless intentionally changed, the LaserVision 7.0 stays in the same

preset slope the next time the unit is turned on.

Pre-set Slopes (Laservision 7.0 only)

Slope 1 Slope 2 Slope 3

1/8 in./ft. 1/4 in./ft. 1 in./ft.

Table II

Figure 14: Selecting a Slope

Memorizing an Angle

The LaserVision also has the ability to store and recall any desired angle.

• Press the SLOPE button(7.0) or the MEMORY button(6.0) repeatedly until AT

appears at the bottom of the LCD.

• Place and hold the LaserVision at the desired angle to be memorized. Ensure

that the unit is steady.

• Press and hold the ON/OFF button until the bars start moving up and down

(Figure 9, page 7) and a short audio tone sounds. Once the bars stop moving,

the new angle has been memorized. This angle remains in the LaserVision's

memory until another angle is saved and will be recalled when AT is again

selected.

NOTE: Unless the mode is purposely changed, the LaserVision automatically

returns to the AT mode the next time the LaserVision is turned on. Pressing the

mode switch once returns the LaserVision to the standard mode.

12

STD

1/8"

1/8"

1/4"

slope

slope

slope

slope

1/4"

1"

1"

AT

(Angle

Transfer)

slope

slope

slope

slope

Page 13

Replacing the Batteries in the Level Module

The LaserVision requires three AAA batteries, which should exceed one year of

normal use. Extensive use of the backlight greatly diminishes the battery's life.

When the batteries run low, a battery icon appears in the lower left corner of the

LCD. After the icon appears, the unit operates another five to ten hours normally

before becoming inoperable.

To Remove Batteries

• Remove the plastic end cap from the left side of the unit and locate the larger

3/32" allen wrench in the end cap.

• Remove the two screws located on either side of the LCD using the Allen

wrench and carefully slide the module out of the unit. The ON/OFF button

and the SLOPE/MEMORY button should fall back into the extrusion and

come out with the level module.

• Undo the battery compartment on the back of the module and replace the batteries (Figure 15 below).

Figure 15: Replacing the Batteries in the Level Module

To Replace the Module

• Slide the module back in place so that the screw holes are lined up.

• Replace the screws, and tighten each screw a little at a time to be sure that the

ON/OFF button and the SLOPE/MEMORY button do not get stuck. Be careful not to put one of the screws in the buzzer hole, which is right next to a

screw hole, because this could damage the buzzer.

• Replace the end cap.

NOTE: The level module remains calibrated for at least two minutes without

batteries. The LaserVision needs to be re-calibrated if the batteries become

completely inoperable or it takes more than two minutes to change them.

Replacing the Batteries in the Laser Module

The LaserVision laser module uses three AAA batteries, which should last

approximately 15 hours with continuous use of the laser.

• Remove the laser end cap from the LaserVision and locate the battery compartment at the top of the laser module.

13

+

+

+

Page 14

14

• Open the battery module by lifting up on the door so it hinges outward.

• Remove the dead batteries and insert the new batteries, negative (-) end side

first, and close the battery compartment cover (Figure 16 below).

• Replace the end cap.

Figure 16: Replacing the Batteries in the Laser Module

The Audio Feature

The LaserVision's audio tone sounds near level or plumb, which is useful in "blind"

situations. It is activated when level or plumb is within the center three bars.

• The audio feature can be turned off by quickly pressing the ON/OFF button

twice when turning on the LaserVision. When the audio mode is off, the

sound icon found on the bottom right of the LCD disappears.

• To turn the sound back on, turn the LaserVision off and on again.

The Backlight (LaserVision 7.0 only)

The LaserVision 7.0 has been equipped with a backlight for use in

low-light situations.

• To turn on the backlight (after turning on the LaserVision level), press and

hold the SLOPE button for two seconds (Figure 17, page 15).

• To turn off the backlight, press and hold the SLOPE button for two seconds

(Figure 17, page 15).

NOTES: 1. Unless purposefully turned off, the backlight automatically lights the

next time the LaserVision is turned on.

2. To obtain maximum battery life, it is recommended that the backlight only be

used when needed for operation in low-light.

2

1

Page 15

15

Figure 17: Turning the Backlight On

General information

The Zircon LaserVision is shock resistant, but it should be treated like a precision instrument. If the LaserVision is dropped it may need to be re-calibrated.

Refer to the section "Checking Your LaserVision for Proper Calibration" for

further instructions.

While the LaserVision is water resistant, it is not waterproof and should be

handled accordingly.

Technical Information

Size: 18.5 in. L x 1.2 in. W x 2.0 in. H (47.0 cm L x 2.8 cmW x 5.0 cm H)

Weight: 21.8 oz (618 g)

Battery: Level: 3 AAA

Laser: 3 AAA

Battery Life: Level: 100 hours or 1 year with normal use

Laser: 15 hours of continuous operation

Accuracy: LaserVision 7.0: ±1/4 in. at 100 ft. (±6.25 mm at 30 m)

LaserVision 6.0: ±3/8 in. at 100 ft. (±9.52 mm at 30 m)

Laser: Type: Visiable Laser Diode

Wavelength: 650 nm - Red (6.0) 650 nm - Red (7.0)

Power: LaserVision 7.0: Class IIIa

(<5mW peak power)

LaserVision 6.0: Class II (<1mW peak power)

Typical Spot Size: 5/32 in. vertical height at 50 feet

(4 mm vertical height at 15 meters)

Audio: Loudness: 70 dB at 18 in. (46 cm)

Frequency: 880 Hz

Temper ature: Operating : +20˚F to +120˚F (-7˚C to +49˚C)

Storage: -20°F to +150˚F (-29˚C to +66˚C)

Humidity: 80% RH (non-condensing)

slope

On

Hold

2 Sec

Page 16

LIMITED 1 YEAR WARRANTY

Zircon Corporation ("Zircon") warrants this product to be free from defects in

materials and workmanship for one year from the date of purchase. Any in-warranty defective product returned to Zircon*, freight prepaid with proof of purchase date and $5.00 to cover postage and handling, will be repaired or replaced

at Zircon's option. This warranty is limited to the electronic circuitry and original case of the product and specifically excludes damage caused by abuse,

unreasonable use or neglect. This warranty is in lieu of all other warranties,

express or implied, and no other representations or claims of any nature shall

bind or obligate Zircon. Any implied warranties applicable to this product are

limited to the one year period following its purchase. IN NO EVENT WILL

ZIRCON BE LIABLE FOR ANY SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING FROM POSSESSION, USE OR

MALFUNCTION OF THIS PRODUCT.

In accordance with government regulations, you are advised that:

(i) some states do not allow limitations on how long an implied warranty lasts

and/or the exclusion or limitations of incidental or consequential damages, so

the above limitations and/or exclusions may not apply to you, and further (ii)

this warranty gives you specific legal rights and you may also have other rights

which vary from state to state.

Zircon Corporation

Attn: Returns Department

9731 Siempre Viva Road, Suite B & C

San Diego, CA 92173, U.S.A.

Tel: (800) 245-9265 or (408) 866-8600

Customer Service

When customer service is required within one year of original purchase, send

the LaserVision product to Zircon Corporation, freight prepaid.

All LaserVision products returned for service must include your return address

and a check or money order for $5.00 to cover postage and handling. Requests

for in-warranty service must include proof of purchase (dated sales receipt, etc.).

Out-of-warranty service and repair, where proof of purchase is not provided,

shall be returned with repairs charged C.O.D.

FCC Part 15 Class B Registration Warning

This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment

is operated in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of the

following measures:

(1) Reorient or relocate the receiving antenna.

16

Page 17

(2) Increase the separation between the equipment and receiver.

(3) Connect the equipment into an outlet on a circuit, different from that which

the receiver is connected.

(4) Consult the dealer or an experienced radio/TV technician for help.

El LaserVision™ 6.0 y 7.0

El LaserVision de Zircon es un nivel electrónico de alta precisión combinado

con un módulo láser. Simplifica la tarea de planificación de una obra que lleva

tanto tiempo, al permitir al usuario marcar los puntos de nivelación de referencia

a una distancia de hasta 45 m (150 pies, LaserVision 6.0) o de 90 m (300 pies,

LaserVision 7.0). Tiene la pantalla electrónica de cristal líquido (LCD) que indica la desviación relativa del nivel o la plomada y la dirección de rotación necesaria para alcanzarlos. También viene con una señal de audio que suena al

encontrar el nivel o la plomada. El LaserVision 7.0 tiene precalibradas tres pendientes que se usan habitualmente en construcción y ambos modelos tienen la

capacidad de almacenar en la memoria y repetir cualquier ángulo en un rango

de 360 grados. El LaserVision requiere tres pilas AAA para el módulo de

nivelación y tres pilas AAA para el módulo láser.

Figura 1a página 2: Componentes del LaserVision 7.0:

1. Tapa del extremo

2. Agujero para colgar

3. Tornillo

4. Orificio del sonido

5. Pantalla

6. Botón de Encendido/Calibración

8. Extrusión

9. Advertencia

10. Botón interruptor de láser

Figura 1b página 2: Componentes del LaserVision 6.0

1. Tapa del extremo

2. Agujero para colgar

3. Tornillo

4. Orificio del sonido

5. Pantalla

6. Botón de Encendido/Calibración

8. Extrusión

9. Advertencia

10. Botón interruptor de láser

Figura 2a página 3: Componentes de la pantalla LCD del LaserVision 7.0

1. Indicator de las pilas

2. Inclinación de .3 cm (1/8 de pulgada/pie)

3. Inclinación de .6 cm (1/4 de pulgada/pie)

4. Unidades por pulgada/pie

17

ESPAÑOL

Page 18

5. Dirección de la inclinación

6. Inclinación de 2.54 cm (una pulgada por pie)

7. Activación de transferencia de ángulo

8. Señal sonora activa

9. Flecha de rotación direccional

10. Barra de nivel/plomada

11. Cuñas de la pantalla principal

12. Indicador de fuera de alcance

13. Indicadores de falta de calibración

14. Indicador de proceso de calibración

Figura 2b página 3: Componentes de la pantalla LCD del LaserVision 6.0

1. Cuñas de la pantalla principal

2. Barra de nivel y plomada

3. Indicador de las pilas

4. Activación de la transferencia de ángulo

5. Activación de la señal sonora

6. Flecha de rotación direccional

7. Indicadores de la secuencia de calibración

8. Indicadores de flata de calibración

9. Indicador de fuera de alcance

Preparación del LaserVision para Usarlo

Por razones de seguridad, se ha desarmado temporalmente el láser tanto del

LaserVision 6.0 como del LaserVision 7.0; a fin de que vuelvan a estar listos

para funcionar es necesario:

• Sacar la tapa al final del extremo del láser (Figura 3, pagina 4).

• Jalar hacia arriba la puerta del compartimiento de pilas para abrirlo.

• Sacar con cuidado la etiqueta adhesiva de protección de las pilas del módulo

de láser fijándose de que no quede ningún pedazo que pueda interferir con

que las pilas establezcan contacto (Figura 4, pagina 4).

• Cerrar y asegurar la puerta del compartimiento de pilas.

• Volver a colocar en su sitio la tapa al final del extremo del láser.

El LaserVision ya está listo para usarse

LaserVision 7.0:

Advertencia: Cerciórese de no dirigir el haz de láser directamente a los ojos de

ninguna persona ya que puede causar una lesión grave de los ojos e incluso

ceguera.

LaserVision 6.0:

Advertencia: Cerciórese de no dirigir el haz de láser directamente a los ojos de

ninguna persona ya que puede causar una lesión grave de los ojos e incluso

ceguera.

Figura 3 página 4. Retiro de la tapa del extremo del láser

Figura 4 página 4. Retiro de la etiqueta adhesiva de protección

18

Page 19

Encendido y Apagado del LaserVisión

Del nivel

• Oprima el botón amarillo ON/OFF que está junto a la pantalla LCD

(Figura1, pagina 2)

Para ahorrar pilas, la porción de nivel del LaserVision se apaga espon táneamente después de un minuto de estar inactiva. Una vez nivelado, puede

continuar usando el haz de láser no obstante que el nivel en sí esté apagado.

Del láser

• Oprima el botón que está en la tapa del extremo del láser (Figura 5, pagina 5).

Cuando el láser está activado, el botón tiene un resplandor rojo.

Advertencia: El LaserVision 7.0 está equipado con un láser clase IIIa (el

LaserVision 6.0 lo está con un láser clase II). Evite todo el tiempo la exposición

directa de los ojos. Por ejemplo, no mire por el orificio para ver si el láser está

encendido.

Figura 5 página 5: Componentes del Láser

1. Punto de partida del láser

2. Botón interruptor de láser

Verificación de la Calibración Adecuada de su LaserVision

Antes de usar cualquier nivel, se debe verificar su calibración. Esto es fácil de

hacer si dispone de una superficie plana y relativamente nivelada.

• En el caso del LaserVision de Zircon, coloque el nivel sobre la superficie y

trate de alinearlo con el borde o una línea de la superficie.

• Encienda la unidad

• Tome nota de cuál extremo de la superficie aparece en la pantalla como el

más alto y por cuántas barras. Por ejemplo, puede ser que vea la barra central

con dos barras por encima en el lado izquierdo de la pantalla y dos barras

abajo en el lado derecho de la pantalla (Figura 6, pagina 6).

• Ahora gire el nivel de un extremo al otro pero mantenga la misma cara del

nivel en contacto con la superficie relativamente nivelada y alinee el nivel

sobre el mismo borde o línea de la superficie (Figura 7, pagina 6). La pantalla

debe mostrar ahora el mismo extremo de la superficie como el más alto y con

el mismo número de barras, más o menos una barra. Si seguimos el mismo

ejemplo, la pantalla debe mostrar ahora la barra central con dos barras por

encima en el lado derecho de la pantalla y dos barras por debajo en el lado

izquierdo de la pantalla (Figura 8, pagina 6).

Si éste no es el caso, el nivel está descalibrado y se debe volver a calibrar antes

de usarlo.

Nota: Este proceso de girar el nivel de un extremo al otro y comparar las dos

indicaciones en relación a la superficie se puede usar en todos los niveles,

incluyendo los de burbujas.

Figura 6 página 6: Verificación del LaserVision en una Dirección

Figura 7 página 6: Giro del LaserVision de un Extremo al Otro

Figura 8 página 6: Verificación del LaserVision en la Otra Dirección

19

Page 20

Calibración del LaserVision

A fin de asegurar su precisión, el módulo de nivel del LaserVision se puede volver a

calibrar en cualquier momento a las especificaciones originales de fábrica.

NOTA: 1. El proceso de calibración se debe hacer en una superficie plana y sólida

que esté razonablemente nivelada (cuando se estén calibrando los ejes del nivel) o

a plomada (cuando se estén calibrando los ejes de la plomada). Si el plano de la

superficie está demasiado alejado del nivel o la plomada vedaderos, se leerá en la

pantalla LCD "Out of Range" (fuera de rango). Si aparece esa indicación mueva el

VideoLevel a una superficie que esté más cerca del nivel o la plomada.

2. Hay un conglomerado de cuatro flechas en la parte superior de la pantalla

LCD las cuales indican qué ejes no están calibrados y aparecen después que la

unidad haya perdido su calibración lo cual es habitual cuando las pilas están

descargadas o se han retirado por algún tiempo. Durante el proceso de calibración, como se indica posteriormente, la flecha que corresponde al eje que se

está calibrando se encenderá intermitentemente y finalmente desaparecerá

cuando se haya completado la calibración. Después que se hayan calibrado los

cuatro ejes, no se verá ninguna de las flechas de calibración. Si se ven una o

más flechas, los ejes correspondientes no están calibrados y se deben calibrar

antes de usar el nivel en esos ejes.

3. Para obtener una mayor precisión cuando esté calibrando, alinee el nivel con

el borde o una línea de la superficie para que pueda mantener con facilidad la

misma ubicación.

4. Para llevar a cabo una calibración adecuada, el LaserVision debe estar en el

modo estándar (sin indicadores de pendiente ni "AT" a través de la parte inferior

de la pantalla LCD). Si está en el modo de una pendiente preestablecida, no

quedará calibrado y en el modo "AT" solamente memorizará el ángulo en que está.

Calibración del Nivel

• Coloque el LaserVision sobre una superficie plana y sólida que esté

relativamente nivelada (ver la nota (1) de la sección anterior).

• Mantenga oprimido el botón de ON/OFF alrededor de tres segundos hasta que

las barras comiencen a moverse hacia arriba y hacia abajo (Figura 9, pagina 7) y

se escuche el sonido de audio. La flecha del eje y el numeral 1 se encenderán

intermitentemente mientras la unidad se esté calibrando en la primera posición.

• Cuando los indicadores dejen de moverse y se escuche un segundo sonido de

audio, aparecerá el numeral 2. Gire el instrumento de un extremo al otro

(Figura 10, pagina 8).

• Coloque el nivel en el mismo lugar.

• Oprima y suelte nuevamente el botón ON/OFF y espere a que los indicadores

dejen de moverse, desaparezca la flecha del eje, y se escuche el sonido final

de audio. Ahora ya está calibrado este eje.

• Dele la vuelta al nivel y calibre el nivel de la superficie opuesta con el mismo

procedimiento. Al concluir deben haber desaparecido las fle chas de

nivelación de ambos ejes.

Figura 9 página 7: Pantalla de Calibración

Figura 10 página 8: Calibración del Nivel

20

Page 21

Calibración de la Plomada

• Coloque el LaserVision sobre una superficie plana casi vertical (ver la nota

(1) de la sección anterior).

• Mantenga oprimido el botón de ON/OFF alrededor de tres segundos hasta que

las barras comiencen a moverse hacia arriba y hacia abajo (Figura 9, pagina 7) y se

escuche el sonido de audio. La flecha del eje y el numeral 1 se encenderán

intermitentemente mientras la unidad se esté calibrando en la primera posición.

• Cuando los indicadores dejen de moverse y se escuche un segundo sonido de

audio, aparecerá el numeral 2. Gire el instrumento 180 grados pero mantenga

hacia arriba el mismo extremo (Figura 11, pagina 8).

• Coloque el nivel en el mismo lugar.

• Oprima y suelte nuevamente el botón ON/OFF y espere a que los indicadores

dejen de moverse, desaparezca la flecha del eje, y se escuche el sonido final

de audio. Ahora ya está calibrado este eje.

• Gire el nivel de un extremo al otro y calibre la plomada en la superficie

opuesta con el mismo procedimiento. Ahora deben haber desaparecido las fle

chas de plomada de ambos ejes.

Figura 11 página 8: Calibración de la plomada

Llaves Allen

El LaserVision viene con dos llaves Allen que están en la tapa del extremo

opuesto al láser y se pueden guardar allí. Cuando cambie las pilas, use la llave

Allen más grande de 3/32 plg. para sacar los tornillos delanteros que mantienen

el módulo de nivel en su sitio. Cuando esté alineando el láser, use la llave Allen

más pequeña de 5/64 plg para girar el tornillo de calibración.

Calibración del Láser del LaserVision

No obstante que el láser del LaserVision viene calibrado de fábrica, se puede

recalibrar fácilmente a las especificaciones originales de fábrica para asegurar su

precisión.

• Para recalibrar o comprobar la calibración del módulo láser, coloque el nivel

LaserVision sobre una superficie plana y estable frente a un objetivo localizado

a aproximadamente 15 metros (50 pies) (vea la Figura 12, pagina 10).

NOTA: No es necesario que la superficie esté nivelada.

• Encienda el láser y marque la posición del centro del haz de láser en el

objetivo remoto, vea el punto 1 (P1).

• Voltee el LaserVision.

• Regrese al área del objetivo y marque la nueva posición en el centro del haz,

vea P2. Si la segunda marca está por encima de la primera, entonces el tornil

lo de calibración (el más cercano al centro en la parte inferior del LaserVision)

se debe girar en el sentido de las agujas del reloj con la llave Allen más

pequeña de 5/64 plg que viene en la tapa del extremo opuesto al láser. Si la

segunda marca está por debajo de la primera, gire entonces el tornillo en el sen

tido contrario a las agujas del reloj (Figura 13, pagina 11). Ajuste el tornillo de

calibración hasta que el haz de láser esté en el medio de las dos marcas, vea P3.

NOTA: No gire el tornillo que está más cerca del extremo ya que desarmaría la

unidad del láser e invalidaría su garantía.

21

Page 22

• Regrese el LaserVision a su posición original y examine la ubicación del

foco. El foco del láser debe coincidir con el punto medio. Si no es así, repita

los pasos anteriores hasta que no haya cambios cuando se voltee el nivel.

NOTA: No gire el tornillo que está mas cerca del extremo del láser. Este tornillo mantiene

el módulo láser en su sitio. Si este tornillo se gira, su garantía deja de ser válida.

Figura 12 página 10: Calibración del Láser

Figura 13 página 11: Alineación del Foco del Láser

Para Encontrar el Nivel y la Plomada

El LaserVision tiene cuatro segmentos de barra que indican su proximidad angular al

nivel o la plomada (la precisión de trabajo se presenta en la Tabla 1 a bajo). Las flechas que se ven en ambos lados de los segmentos de barra indican además en qué

dirección se debe girar el LaserVision para alcanzar el nivel o la plomada. Al encontrar el nivel o la plomada, la pantalla LCD mostrará una sola barra y el audio emitirá

un sonido (a menos que se haya apagado el sonido).

Precisión de Trabajo:

Desvío del Nivel o la Plomada: Máximo (Típico)

LCD

SEGMENTO PLG/100 PIES M/MM GRADOS

Barra

Central 0.50 plg (0.25 plg) 0.42 (0.21) 0.02 (0.01)

1era Barra

desde el Centro 1.00 plg (0.50 plg) 0.83 (0.42) 0.05 (0.02)

2nda Barra

desde el Centro 2.00 plg (1.00 plg) 1.66 (0.83) 0.10 (0.05)

3era Barra

desde el Centro 4.00 plg (2.00 plg) 3.33 (1.66) 0.17 (0.09)

Table I

Uso del Láser

• Encienda el LaserVision y haga los ajustes para el nivel o la plomada.

• Presione el botón de encendido del láser que se encuentra en la tapa del

extremo del láser (Figura 5, pagina 5). Cuando el láser está encendido, el

botón tiene un resplandor rojo.

• Apunte el LaserVision en la dirección que desee.

• Luego marque la posición del foco de láser.

NOTAS: 1. Para obtener la máxima precisión, asegúrese de marcar siempre el

centro del foco, ya que el foco del láser se agranda conforme aumenta la distancia desde el LaserVision.

2. El foco del láser se proyecta desde el centro de la tapa del extremo del láser y

está a una pulgada por encima o por debajo de la superficie del nivel.

Asegúrese de compensar por esta pulgada de diferencia.

Uso del Modo de Pendiente (Solamente LaserVision 7.0)

22

Page 23

El LaserVision 7.0 tiene precalibrados tres ángulos de uso común: 1/8, 1/4 y 1

pulgada por pie. Estos ángulos precalibrados se pueden usar en cualquier dirección. Una vez activado, el LaserVision 7.0 usa el ángulo seleccionado como su

punto de referencia hasta que se cambie (Tabla II a bajo). Después de presionar

el botón SLOPE (pendiente), aparecerán el ángulo y la dirección en la parte

inferior de la pantalla.

• Para obtener el ángulo y la dirección que desee, oprima varias veces el

botón SLOPE hasta encontrarlos (Figura 14, pagina 12).

NOTA: A menos que se cambie intencionalmente, el LaserVision 7.0 permanecerá en la

misma pendiente precalibrada la próxima vez que se encienda.

Pendientes Precalibradas (Solamente LaserVision 7.0)

Pendiente 1 Pendiente 2 Pendiente 3

1/8 plg/pie 1/4 plg/pie 1 plg/pie

Table II

Figura 14 página 12: Selección de una Pendiente

Memorización de un Ángulo

El LaserVision también tiene la capacidad de guardar en la memoria y reproducir cualquier ángulo que se desee.

• Oprima el botón de SLOPE (7.0) o el botón AT (6.0) repetidas veces hasta

que aparezca AT en la parte inferior de la pantalla LCD.

• Coloque y sostenga el LaserVision en el ángulo que desee guardar en la

memoria. Asegúrese de que la unidad esté firme.

• Mantenga presionado el botón ON/OFF hasta que las barras empiecen a

moverse hacia arriba y abajo (Figura 9, pagina 7) y suene un tono corto.

Cuando las barras dejen de moverse, el nuevo ángulo ha sido memorizado.

Este ángulo per manecerá en la memoria del LaserVision hasta que se guarde

otro ángulo y se podrá reproducir cuando seleccione nuevamente AT.

NOTA: A menos que se cambie en forma intencional, el LaserVision regresa

automáticamente al modo AT la siguiente vez que se activa. Para regresar el

LaserVision al modo estándar, oprima una vez el botón de modo.

Cambio de las Pilas del Módulo de Nivel

El LaserVision requiere tres pilas AAA, las cuales deben durar por más de un

año de uso normal. El uso extenso de la iluminación de fondo disminuye considerablemente la duración de las pilas. Cuando las pilas están bajas, aparece el

icono de la pila en la esquina izquierda inferior de la pantalla LCD. Después que

aparece el símbolo, la unidad todavía funcionará normalmente de cinco a diez

horas más antes de dejar de hacerlo.

Para Sacar las Pilas

• Retire la tapa de plástico del extremo izquierdo de la unidad y ubique la llave

Allen grande de 3/32 plg que está en la tapa del extremo.

• Saque los dos tornillos que están en cualquiera de los lados de la pantalla

LCD con la llave Allen y saque con cuidado el módulo de la unidad deslizán

23

Page 24

dolo. Los botones ON/OFF y SLOPE/MEMORY deben hundirse y salir junto

con el módulo de nivel.

• Desarme el compartimiento que está en la parte posterior del módulo y

reemplace las pilas (Figura 15, pagina 13).

Figura 15 página 13: Reemplazo de las Pilas en el Módulo de Nivel

Reemplazo del Módulo

• Vuelva a deslizar el módulo a su sitio de modo que los orificios para los

tornillos queden alineados.

• Vuelva a colocar los tornillos, y ajuste cada tornillo un poco cada vez para

cerciorase de que los botones ON/OFF y SLOPE/MEMORY no se a traquen;

tenga cuidado de no colocar un tornillo en el orificio de la señal sonora que

está a la derecha del orificio para el tornillo, ya que podría dañarla.

• Vuelva a colocar la tapa del extremo.

NOTA: El módulo de nivel permanece calibrado por lo menos dos minutos sin

pilas. La unidad necesitará ser recalibrada si las pilas dejaron de funcionar

completamente o si se demora más de dos minutos en cambiarlas.

Cambio de las Pilas en el Módulo Láser

El módulo láser requiere tres pilas AAA, que deben durar aproximadamente 15

horas de uso continuo del láser.

• Retire la tapa del extremo del LaserVision y localice el compartimiento de las

pilas en la parte superior del módulo láser.

• Levante la tapa del compartimiento de pilas de modo que quede abierta hacia

afuera.

• Saque las pilas gastadas y coloque las nuevas, poniendo primero el polo

negativo (-), y cierre la cubierta del compartimiento de pilas (Figura 16,

pagina 14).

• Vuelva a colocar la tapa del extremo.

Figura 16 página 14: Cambio de las Pilas del Módulo Láser

La Señal de Audio

La señal de audio del LaserVision emite un tono cuando se acerca al nivel o la

plomada, lo que es útil en situaciones ciegas. Se activa cuando el nivel o la

plomada esté dentro de las tres barras centrales.

• La característica de audio se puede desconectar presionando rápida mente el

botón ON/OFF dos veces cuando se enciende el LaserVision. Cuando el

modo de audio está desconectado, el icono de audio que estaba en la parte

inferior derecha de la pantalla LCD desaparece.

• Para volver a activar el sonido, apague y encienda nuevamente el LaserVision.

Iluminación de Fondo (Solamente LaserVision 7.0)

El LaserVision 7.0 está equipado con una luz de fondo para usar en situaciones

de poca luz.

• Para encender la luz posterior (después de encender el nivel LaserVision)

mantenga oprimido el botón de SLOPE (pendiente) durante dos segundos

(Figura 17, pagina 15).

24

Page 25

25

• Para apagar la iluminación de fondo, mantenga oprimido el botón de SLOPE

(pendiente) durante dos segundos (Figura 17, pagina 15)

NOTAS: 1. A menos que se desconecte intencionalmente, la iluminación de fondo

se encenderá automáticamente la siguiente vez que se active el LaserVision.

2. Para obtener la máxima duración de las pilas, se recomienda usar la

iluminación de fondo solamente cuando se necesite trabajar con poca luz.

Figura 17 página 15: Encendido de la Iluminación de Fondo

Información general

El LaserVision de Zircon es resistente a los golpes, pero deber ser tratado como

un instrumento de precisión. Si la unidad se cae puede ser necesario recalibrarla.

Para mayor información, vea la sección sobre "Verificación de la calibración adecuada de su LaserVisión".

No obstante que el LaserVision es resistente al agua, no es a prueba de agua lo

que se debe tener en cuenta al manejarlo.

Información Técnica

Dimensiones: 47,0 cm de longitud x 2,8 cm de anchura x 5,0 cm

de anchura (18,5 plg. 1,2 plg. y 2.0 plg. respectivamente

Peso: 618 g (21.8 oz)

Pilas: Nivel: 3 pilas AAA

Láser: 3 pilas AAA

Duración de Nivel: 100 horas o un año de uso normal

las pilas: Láser: 15 horas de funcionamiento continuo

Exactitud: LaserVision 7.0: ± 6.25 mm a 30 m (± 1/4 plg a 100 pies)

LaserVision 6.0: ± 9.52 mm a 30 m (± 3/8 plg a 100 pies)

Láser: Tipo: Diodo de láser visible

Longitud de onda: 650 nm - rojo (6.0) 650 nm - rojo (7.0)

Energía: LaserVision 7.0: clase IIIa

(< 5 mW de energía pico)

LaserVision 6.0: clase II

(< 1 mW de energía pico)

Tamaño típico del foco: 4 mm de altura vertical a 15 metros

(5/32 plg dealtura vertical a 50 pies)

(< 5/32 de pulgada de altura vertical)

Audio: Intensidad: 70 dB a 46 cm (18 plg)

Frecuencia: 880 Hz

Temperatura: Operación: -7°C a +49°C (+20°F a +120°F)

Almacenamiento: -29°C a +66°C (-20°F a +150°F)

Humedad: Humedad relativa de 80% (sin condensación)

GARANTÍA LIMITADA DE UN AÑO

Zircon Corporation ("Zircon") garantiza por un año, a partir de la fecha de

compra, que este producto estará sin defectos debidos a los materiales o la fabricación. Cualquier producto defectuoso, cubierto por la garantía, que se devuelva

a Zircon* con flete prepagado, prueba de la fecha de compra y 5.00 dólares

estadounidenses para cubrir los gastos de correo y manejo, será reparado o reem-

Page 26

plazado, a la opción de Zircon. Esta garantía está limitada a los circuitos electrónicos y a la caja original del producto y excluye específicamente los daños

causados por abuso, uso que no sea razonable y negligencia. Esta garantía reemplaza a todas las otras garantías, explícitas o implícitas, y ninguna otra

representación, ni pretensiones de cualquier naturaleza comprometen ni obligan

a Zircon. Cualquier garantía implícita que sea pertinente a este producto está

limitada al periodo de un año a partir de su compra. EN NINGÚN CASO,

SERÁ ZIRCON RESPONSABLE POR LOS DAÑOS ESPECIALES,

INCIDENTALES O INDIRECTOS QUE RESULTEN DE LA POSESIÓN,

EL USO O EL MAL FUNCIONAMIENTO DE ESTE PRODUCTO.

De conformidad con regulaciones gubernamentales se le avisa que:

(i) algunos estados no permiten limitaciones en el tiempo de duración de una

garantía implícita y/o en la exclusión o limitación de los daños incidentales o

indirectos; por consiguiente, puede ser que las limitaciones y/o exclusiones que

se indican anteriormente no sean aplicables en su caso, y además (ii) esta

garantía le otorga derechos legales específicos y puede tener otros derechos que

varían según el estado.

Zircon Corporation

Attn: Returns Department

9731 Siempre Viva Road, Suite B & C

San Diego, CA 92173, U.S.A.

Tel: (800) 245-9265 or (408) 866-8600

Servicio al Consumidor

Cuando necesite el servicio al consumidor dentro del año de la compra original,

devuelva el producto LaserVision, con flete prepagado a Zircon Corporation. Se

debe adjuntar la dirección del remitente a todos los productos LaserVision que nos

envíen para servicio. También se debe adjuntar un cheque o giro postal por 5.00

dólares estadounidense para cubrir los gastos de correo y manejo. Los pedidos de

servicio dentro de la garantía, deben incluir prueba de la compra (recibo con

fecha, etc.). Los pedidos de servicio y las reparaciones fuera de la garantía, que no

se acompañen con prueba de la compra, se devolverán con un cargo C.O.D por las

reparaciones.

Advertencia de Registro, Clase B, Acápite 15 de las Regulaciones de

la FCC (siglas en inglés de la Comisión Federal de Comunicaciones

de EE.UU.)

Este equipo ha sido probado y se ha encontrado que cumple con los límites para

dispositivos digitales de clase B de acuerdo con las especificaciones del acápite

15 de las regulaciones de la FCC. Estos límites han sido establecidos para proporcionar una protección razonable contra interferencias dañinas en el uso residencial. Este equipo genera, utiliza y puede irradiar energía de radiofrecuencia y,

si no se instala de acuerdo con las instrucciones, puede causar interferencias

dañinas en las radiocomunicaciones. Sin embargo, no hay garantía de que no se

vaya a producir interferencia en una instancia particular. Si este equipo causa

interferencia dañina en la recepción de radio o televisión, lo cual se puede

determinar encendiéndolo y apagándolo, se recomienda al usuario que trate de

corregir la interferencia con una de las siguientes medidas:

(1) Cambiar la orientación o ubicación de la antena de recepción.

26

27

Page 27

(2) Aumentar la distancia entre el equipo y el receptor.

(3) Conectar el equipo y el receptor en enchufes o circuitos diferentes.

(4) Consultar con el distribuidor o un técnico con experiencia en radio y

televisión y obtener su ayuda.

LaserVisionMC6.0 et 7.0

Le Zircon LaserVision est un niveau électronique de haute précision muni d'un

module laser. Cet appareil simplifie les préparatifs, car il permet à l'utilisateur de

marquer des repères à une distance atteignant 45 m (150 pieds, LaserVision 6.0),

ou 90 m (300 pieds, LaserVision 7.0). Le LaserVision est doté d’un écran à

affichage à cristaux liquides qui indique la déviation relative par rapport au

niveau ou à l’aplomb, ainsi que le sens de la rotation nécessaire pour obtenir le

niveau ou l'aplomb. Un signal sonore permet de savoir lorsque le niveau ou

l'aplomb est atteint. Le LaserVision 7.0 comporte trois angles préréglés des plus

utiles dans le bâtiment. Les deux modèles peuvent également mémoriser et

restituer n'importe quel angle allant jusqu'à 360 degrés. Le LaserVision est alimenté par trois piles AAA pour le module de niveau et par trois piles AAA pour

le module au laser.

Figure 1a page 2: Éléments du LaserVision 7.0

1. Capuchon

2. Trou d’accrochage

3. Vis

4. Entrée audio

5. Écran d’affichage

6. Bouton d’allumage

7. Bouton de pente/d’angle

8. Élément extensible

9. Avertissement

10. Commutateur du laser

Figure 1b page 2: Éléments du LaserVision 6.0

1. Capuchon

2. Trou d’accrochage

3. Vis

4. Entrée audio

5. Écran d’affichage

6. Bouton d’allumage

7. Bouton de pente/d’angle

8. Élément extensible

9. Avertissement

10. Commutateur du laser

Figure 2a page 3: Éléments de l’écran du LaserVision 7.0

1. Indicateur d’épuisement des piles

2. Pente de .3 cm (1/8 po/pi)

FRANÇAIS

Page 28

28

3. Pente de .6 cm (1/4 po/pi)

4. Unités po/pi

5. Direction de la pente

6. Pente d’ 2.54 cm (1 po/pi)

7. Transfert d’angle activé

8. Fonction audio activée

9. Sens de la rotation

10. Barre de niveau/d’aplomb

11. Barres d’affichage

12. Indicateur d’erreur

13. Indicateurs de non calibration

14. Indicateur de calibration séquence

Figure 2b page 3: Éléments de l’écran du LaserVision 6.0

1. Barres d’affichage

2. Barre de niveau et d’aplomb

3. Indicateur d’épuisement des piles

4. Transfert d’angle activé

5. Fonction audio activée

6. Sens de la rotation

7. Indicateurs de séquence de calibration

8. Indicateurs de non calibration

9. Indicateur d’erreur

Préparation pour Utiliser le LaserVision

Le laser des unités LaserVision 6.0 et 7.0 a été temporairement désarmé pour

des raisons de sécurité. Pour réactiver le laser :

• Enlevez le capuchon du laser (Figure 3, page 4).

• Tirez sur le couvercle du compartiment à piles pour le dégager.

• Détachez doucement l’étiquette de protection du module laser, en prenant

garde de ne laisser aucun morceau pouvant entraver le contact des piles

(Figure 4, page 4).

• Fermez et verrouillez le couvercle du compartiment à piles.

• Remettez en place le capuchon du laser.

Le LaserVision est prêt à l’emploi.

LaserVision 7.0 :

Avertissement: Il faut absolument éviter de diriger le rayon laser dans les yeux

de quiconque, car cela risquerait de causer des lésions graves aux yeux ou même

la cécité.

LaserVision 6.0 :

Avertissement: Il faut absolument éviter de diriger le rayon laser dans les yeux

de quiconque, car cela risquerait de causer des lésions graves aux yeux ou même

la cécité.

Figure 3 page 4: Enlèvement du Capuchon du LaserVision

Figure 4 page 4: Enlèvement de L’étiquette de Protection

Page 29

Allumer et Éteindre le LaserVision

Pour le Niveau

• Appuyez sur le bouton ON/OFF jaune se trouvant à côté de l'écran (Figure 1,

page 2).

Pour économiser les piles, le niveau du LaserVision s'éteint automatiquement

après une minute d'inactivité. Vous pouvez continuer à utiliser le laser après

avoir défini le niveau, même si ce dernier est éteint.

Pour le Laser

• Appuyez sur le bouton-poussoir se trouvant sur le capuchon (Figure 5, page 5).

Lorsque le laser est allumé, le bouton-poussoir devient rouge.

Mise en garde: Le LaserVision 7.0 est muni d'un laser de classe IIIa (un laser de

classe II pour le LaserVision 6.0). Évitez toute exposition directe des yeux. Évitez

par exemple de regarder dans le trou du capuchon du laser pour voir s’il est allumé.

Figure 5 page 5: Éléments de L’extrémité du Laser

1. Point de sortie du laser

2. Commutateur du laser

Vérification de la Calibration Correcte de Votre LaserVision

Avant d’utiliser un niveau quel qu’il soit, il faut s’assurer qu’il est bien calibré,

ce qui ne pose aucune difficulté si l’on dispose d’une surface plate et relativement de niveau.

• Placez le niveau LaserVision de Zircon sur la surface, en essayant de

l’aligner par rapport à la bordure ou à une ligne quelconque sur la surface.

• Allumez l’unité.

• Notez quel côté de la surface apparaît le plus haut sur l’écran, et de

combien de barres. Par exemple, il y aura peut-être deux barres audessus de la

barre centrale du côté gauche de l’écran, et deux barres en dessous à droite

(Figure 6, page 6).

• Ensuite, inversez le niveau, posez la même partie de celui-ci sur la surface

relativement plane et alignez le niveau par rapport à la même bordure ou à la

même ligne (Figure 7, page 6). L’écran doit maintenant montrer que le même

coté de la surface est plus haut du même nombre de barres, à une près. Pour

reprendre le même exemple, il y aura deux barres au-dessus de la barre cen

trale du côté droit de l’écran, et deux barres en dessous à gauche (Figure 8,

page 6). Dans le cas contraire, le niveau n’est pas bien calibré et il faudra

refaire la calibration avant de l’utiliser.

Remarque: Tous les niveaux, même ceux à bulle, se prêtent à cette façon de les

inverser et de comparer deux indications relatives à une sur face.

Figure 6 page 6: Vérification du LaserVision dans une Direction

Figure 7 page 6: Renversement du LaserVision

Figure 8 page 6: Vérification du LaserVision dans L’autre Direction

Calibration du LaserVision

On peut recalibrer le module de niveau du le LaserVision selon la calibration initiale

de fabrication afin d'en assurer la précision.

REMARQUES:1. La calibration doit se faire sur une surface plane et stable

qui est raisonnablement conforme au niveau (si l'on calibre les axes de

29

Page 30

niveau) ou à l'aplomb (si l'on calibre les axes de l'aplomb). Si la surface n’est pas

assez de niveau ou d’aplomb, un message d'erreur apparaît à l'écran (Out of

Range). Dans ce cas, mettez l'unité sur une surface plus conforme au niveau ou à

l'aplomb.

2. Un groupe de quatre flèches se trouve en haut de l'écran. Ces flèches

indiquent quel axe n'est pas calibré, et elles apparaissent si l’unité n’est plus

calibrée (en général lorsque les piles sont à plat ou ont été sorties du compartiment depuis quelque temps). Durant le processus de calibration décrit cidessous, la flèche correspondant à l'axe concerné clignote plusieurs fois, pour

ensuite disparaître lorsque l'axe est calibré. Une fois les quatre axes calibrés,

toutes les flèches disparaissent. Si une ou plusieurs flèches apparaissent, l'axe

correspondant n'est pas calibré, et on doit calibrer le LaserVision avant son utilisation dans cet axe.

3. Pour améliorer la précision pendant la calibration, alignez le niveau par rap-

port à la bordure ou à une ligne de la surface, afin de garder plus aisément cette

même position.

4. Le LaserVision doit être en mode normal (on ne voit alors ni les indicateurs

de pente, ni les lettres « AT » au bas de l’écran), afin que la calibration réussisse. La calibration est impossible en mode de pente préréglé, et seule la pente

actuellement utilisée sera mémorisée en mode « AT ».

Calibration Selon le Niveau

• Placez le LaserVision sur une surface plane et relativement de niveau

(voir Remarque 1 cidessus).

• Gardez le bouton ON/OFF enfoncé pendant environ trois secondes, jusqu'à ce

que les barres commencent à monter et descendre (Figure 9, page 7) et qu'un

signal sonore se fasse entendre. La flèche d'axe et le chiffre 1 clignotent pen

dant que l'unité calibre la première position.

• Lorsque les indicateurs s'immobilisent et qu'un second signal se fait entendre,

le chiffre 2 apparaît. Inversez l'unité (Figure 10, page 8).

• Remettez le niveau à la même place.

• Pressez et relâchez le bouton ON/OFF, puis attendez que les indicateurs de cal

ibration cessent de bouger, que les flèches d'axe disparaissent et que le dernier

signal sonore se fasse entendre. Cet axe est maintenant calibré.

• Inversez le niveau et calibrez la surface opposée de la même façon. Les deux

flèches de niveau ne doivent plus être affichées à l’écran.

Figure 9 page 7: Écran de Calibration

Figure 10 page 8: Calibration Selon le Niveau

Calibration Selon L'aplomb

• Placez le LaserVision sur une surface stable et presque verticale (voir

Remarque 1 ci-dessus).

• Gardez le bouton ON/OFF enfoncé pendant environ trois secondes, jusqu'à ce

que les barres commencent à monter et à descendre (Figure 9, page 7) et

qu'un signal sonore se fasse entendre. La flèche d'axe et le chiffre 1 clignotent

pendant que le LaserVision calibre la première position.

• Lorsque les indicateurs s'immobilisent et qu'un second signal se fait entendre,

le chiffre 2 apparaît. Tournez l'unité sur 180 degrés sans l'inverser (Figure

11, page 8).

30

Page 31

• Remettez le niveau à la même place.

• Pressez et relâchez le bouton ON/OFF, puis attendez que les indicateurs de cal

ibration cessent de bouger, que les flèches d'axe disparaissent et que le dernier

signal sonore se fasse entendre. Cet axe est maintenant calibré.

• Inversez le niveau et calibrez selon l’aplomb dans l’autre sens de la même

façon. Les deux flèches d’aplomb ne doivent plus être affichées à l’écran.

Figure 11 page 8: Calibration Selon L’aplomb

Clés Allen

Le LaserVision est fourni avec deux clés hexagonales se trouvant à l’intérieur du

capuchon, au bout opposé au laser. Cet espace sert également à les ranger. Lors

du remplacement des piles, la grosse clé (3/32) sert à enlever les deux vis à l’

avant qui maintiennent le module de niveau en place. La petite clé (5/64) sert à

tourner la vis de calibration lorsqu’on veut aligner le laser.

Calibration du Laser du LaserVision

Le laser du LaserVision est calibré à l’usine, et il est facile de rétablir cette calibration initiale afin d’assurer la précision de l’appareil.

• Pour vérifier ou calibrer le module laser, placez le LaserVision sur une surface

plane et stable; la cible ne doit pas se trouver à plus de 15 m (50 pieds) de

distance (Figure 12, page 10).

Remarque: La surface n'a pas besoin d'être de niveau.

• Allumez le laser et marquez la position du centre du faisceau sur la cible (voir

point 1, P1).

• Renversez l’appareil.

• Visez à nouveau la cible et marquez la nouvelle position du centre du

faisceau (voir P2). Si le deuxième repère est au-dessus du premier, il faut

tourner la vis de calibration (la vis la plus proche du milieu, sur la partie

inférieure du LaserVision) dans le sens des aiguilles d'une montre, au moyen de

la petite clé hexagonale (5/64 po) se trouvant dans le capuchon du côté

opposé à celui du laser. Si le deuxième repère est en dessous du premier, il

faut tourner cette vis dans le sens inverse (Figure 13). Tournez la vis de calibra

tion jusqu'à ce que le faisceau laser se trouve à mi-chemin entre les deux

repères (P3).

Remarque:Ne tournez pas la vis qui se trouve le plus près de l’extrémité, car

elle sert à démonter l’unité laser, ce qui entraînerait l’annulation de votre

garantie.

• Remettez l'unité d'aplomb et vérifiez l'emplacement du faisceau. Le faisceau

laser devrait correspondre au nouveau point central. Si ce n'est pas le cas,

reprenez les étapes précédentes jusqu'à ce qu'il n'y ait plus de changement

quand on retourne le niveau.

Remarque: Ne tournez pas la vis qui se trouve le plus près de l’extrémité, car elle sert

à démonter l’unité laser, ce qui entraînerait l’annulation de votre garantie.

Figure 12 page 10: Calibration du Laser

Figure 13 page 11: Alignement du Faisceau Laser

31

Page 32

Obtenir le Niveau et L'aplomb

Le LaserVision affiche quatre barres indiquant le rapprochement angulaire de l'unité par rapport au niveau ou à l'aplomb (voir le Tableau I au dessous) pour obtenir

les valeurs relatives à la précision de travail). Les flèches de part et d'autre des barres montrent dans quel sens tourner l'appareil pour obtenir le niveau ou l'aplomb.

Lorsque le niveau ou l'aplomb est atteint, une seule barre apparaît à l'écran et un

signal sonore se fait entendre (si cette fonction est activée).

Diagramme des Valeurs Précises de Travail:

Déviation Maximale Type par Rapport au Niveau ou à L'aplomb

Segment

affiché Pouces/100 pieds mm/m Degrés

Barre centrale 0,50 po (0,25 po) 0,42 (0,21) 0,02(0,01)

1re barre

depuis le centre 100 po (0,50 po) 0,83 (0,42) 0,05 (00,2)

2e barre

depuis le centre 2,00 po (1,00 po) 1,66 (0,83) 0,10 (0,05)

3e barre

depuis le centre 4,00 po (2,00 po) 3,33 (1,66) 0,17 (0,09)

Tableau I

Utilisation du Laser

• Allumez le LaserVision et calibrez-le selon le niveau ou l’aplomb.

• Poussez le bouton de mise en marche du laser se trouvant sur le capuchon du

laser (Figure 5, page 5). Lorsque le laser est allumé, le bouton devient rouge.

• Pointez le laser vers le repère voulu.

• Marquez cette position.

Remarque: 1. Puisque la taille et la forme du faisceau laser varient en fonction

de la distance, marquez toujours le centre du faisceau afin d'assurer une précision maximale.

2. Le faisceau laser est projeté du centre du capuchon du laser et se trouve à un

pouce du haut ou du bas de la surface du niveau. N’oubliez pas la compensation

nécessaire pour combler cet écart d’un pouce.

Utilisation du Mode de Pente (LaserVision 7.0 uniquement)

Le LaserVision comporte trois angles préréglés des plus utiles : 1/8 po/pi, 1/4

po/pi et 1 po/pi (1 %, 2 % et 8 %.) Ces valeurs peuvent servir dans n'importe

quel sens. Une fois mise en marche, le LaserVision 7.0 utilise l'angle choisi

comme repère tant qu'il n'a pas été modifié (Tableau II, page 33). Lorsqu'on

appuie sur le bouton SLOPE, l’angle et le sens sont affiché au bas de l’écran.

• Pour obtenir l'angle et le sens voulus, appuyer à plusieurs reprises sur le bou

ton SLOPE (Figure 14, page 12).

N.B.: A moins d’avoir été modifié, le LaserVision 7.0 retourne automatiquement

à la pente préréglée chaque fois qu'on l'allume.

32

Page 33

Pentes Préréglées (LaserVision 7.0 uniquement)

Modèle d'écran Pente 1 Pente 2 Pente 3

Amérique du Nord 1/8 po/pi 1/4 po/pi 1 po/pi

Table II

Figure 14 page 12: Choix d’une pente

Mise en Mémoire d’un Angle

Le LaserVision peut également mémoriser et restituer n'importe quel angle.

• Appuyez sur le bouton SLOPE (7.0) ou sur le bouton AT (6.0) à plusieurs

reprises jusqu'à ce que les lettres AT apparaissent au bas de l'écran.

• Placez et gardez le LaserVision à l'angle devant être mémorisé. Assurez-vous

que l’unité est stable.