Zenith 4 SERVICING Diagram

SERVICING

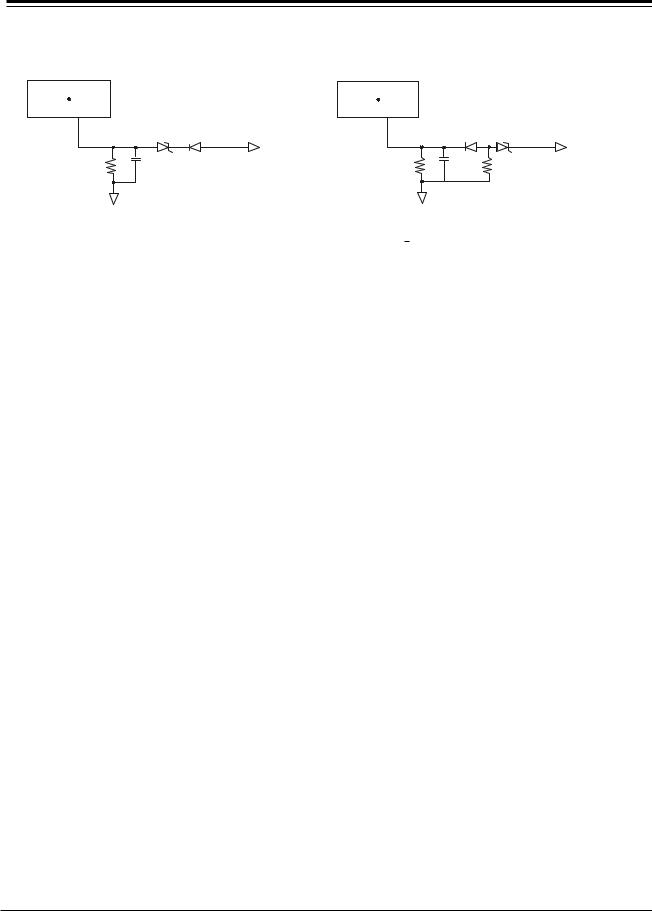

GA Shutdown Circuits

|

GA1 |

|

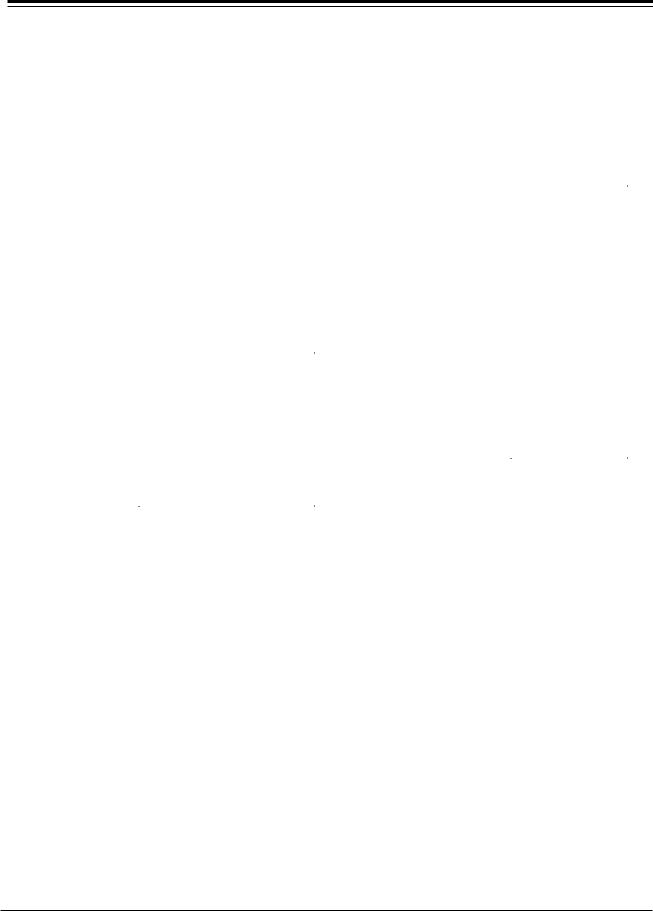

GA2 & GA3 |

|

ICX2200 |

|

|

ICX2200 |

|

P29 |

|

|

P29 |

|

|

DX3003 |

FROM_RESISTOR_DIVIDER |

DX3005 |

ZDX3004 |

RL |

C |

DX3002 |

C |

FROM_RESISTOR_DIVIDER |

|

RL2 |

RL1 |

||

|

GND |

|

GND |

|

GENERAL INFORMATION

NOTE: 19" and 20" GA1 chassis is a line connected chassis. When servicing chassis, use an isolation transformer to prevent possible shock hazard!! The 25" and 27" GA2 and GA3 chassis has an isolated supply.

Servicing the GA is the same as with other single board chassis. If the set is dead, check the power supply first. First the standby voltages, then the switched voltages. If the switched voltages do not appear check the power “On” circuit.

If the power supply is OK and the set will turn on, then the horizontal sweep needs to be verified next. Is the horizontal drive available from the video processor? If the sweep system does not start-up, sweep derived voltages will not be generated.

If sweep and high voltage is OK and video or audio are missing, then those circuits and the tuner need to be analyzed.

If the receiver is working but some feature or accessory is not working, check the Service Menu.

WARNING: If the power supply is operational and the set still goes into Shutdown or shuts off, this means that the vertical sweep or X-ray protection is being activated by the micro. Check for vertical pulse at the micro (IC6000) pin 2, or the HV Shutdown Circuit. The set will not turn on again unless the micro is reset by unplugging the AC line cord.

The Vertical CRT Deflection Circuit must work in order to generate the Vertical (Pulse) Signal, if not, the Vertical Protection Circuit will be activated by the micro and the set will shutdown. In case of X-RAY protection activation, check the +130V source first and then the shutdown network. To turn it on again, reset the microcontroller or unplug the set.

If the sweep and high voltage is OK and video or audio are missing, then those circuits and the tuner need to be checked.

HIGH-VOLTAGE AND X-RADIATION PROTECTION

A potential source of X-rays is the picture tube, if the high-voltage (HV) is out of specification. When the HV is operating properly, there is no X-radiation. For the GA chassis family, the HV has no adjustments. A HV shutdown circuit is used to prevent excessive HV and X-ray emissions.

THEORY OF OPERATION (SHUTDOWN CIRCUIT)

The HV shutdown circuit appears on sheet 4 and sheet 5 of the schematics for 9-1869/71, 9-1789/91 and 9- 1996/97 respectively. The basic HV shutdown circuit is illustrated below.

This circuit basically monitors the sweep, pulse voltage derived from the sweep transformer (TX3202 pins 7 & 9 in GA 19/20”; GA1 or TX3204 pins 5 & 6 in GA 25/27”; GA2 and GA3. This voltage is rectified and applied to a 9.1 V zener diode (DX3003 in GA 19/20”; GA1 or ZDX3004 in GA 25/27”; GA2 & GA3). When the HV reaches its maximum allowed value (see table below) the zener diode conducts, the voltage on pin 29 of the video processor (ICX2200) increases until it reaches the threshold voltage of 3.5 VDC, and shuts down the TV.

If the shutdown circuit has operated, the microcontroller will prevent the TV from being turned on again, without first having to unplug and plug the AC cord to reset the microcontroller.

TIP: Make a momentary short circuit between the OUTPUT and GND of the IC6002 (RESET CIRCUIT), this will reset the microcontroller IC6000.

NOTE: In GA 19/20” or GA1 only, the R3212 is used for the CRT heater and the shutdown circuit. So if the video output board is unplugged from the CRT, the voltage on pin 29 of ICX 2200 will be increased, and the shut down circuit will activate. If it is required to test the module without the CRT or without the video output connected, then add a load of 9 OHMS 5% 10W WIREWOUND RESISTOR between pins 9 & 10 of the wireless socket at the video output board.

CM150 |

3-1 |

GA - SERVICING |

SERVICING (continued)

HV MEASUREMENT PROCEDURE

Apply signal through the video generator, or tune the TV color receiver to crosshatch pattern. Connect an accurate HV meter between the picture tube anode and chassis ground. Access Video Menu and adjust Brightness and Contrast controls for minimum screen luminance. Wait until the Video Menu or display disappear. Read HV meter.

The HV maximum value for each chassis is specified in the following table:

SCREEN |

B+ VDC |

HV NOM |

HV MAX |

|

SIZE |

(0 BEAM) |

KV |

KV |

|

|

COMPONENT LEVEL REPAIR |

|

||

19 |

130 +/- 0.8 |

26.5 |

27 |

|

20 |

130 +/- 0.8 |

26.5 |

27 |

|

25 |

124 +/- 0.5 |

28.5 |

29 |

|

27 |

124 +/- 0.5 |

28.5 |

29 |

|

SERVICING THE MODULE

After a module is serviced, access the Service Menu and check that all items are set properly. When the factory mode is off only the first seven items in the Service Menu are available. Place factory mode to 1 to see all Service Menu adjustments. Be sure the factory mode is set to 0, which is Off, when the Service Menu is exited. Also make sure that item 04 LEVEL is set to match the Level as indicated on the model number sticker on the back of the set. The Level is changed by placing a short across pins 3 and 4 of connector 4G9 on the main module. Then using the remote control, bring up the Service Menu and select item 04. Press the adjust button to make a change. Be sure to remove the shorting jumper when the adjustment is completed. Confirm that item #25 is set correctly to match the set being serviced! If not, and No Audio condition will arise.When in the Private label mode, the set will only respond to IR code 121. .

SERVICING THE POWER SUPPLY GA1 19”/20”

NOTE: Use an isolation transformer when servicing 9- 1869, 1870, 1871, 1871-01 and 1950 chassis !!

STANDBY VOLTAGES

Check the Standby Voltage at the following points: +13 volts DC at CX3411

+12 volts DC at pin 1 of ICX3402

+5 volts DC at pin 3 of ICX3402

POWER ON (9-1869/70/71 AND 9-1950)

Keyboard input at IC6000 pin 7 and 8 IR input at IC6000 pin 15

Power “On” output at IC6000 pin 32

Base of QX3402 power supply switching transistor (about 0.7 volts).

+5 volts IC6000 pin 27

SWITCHED VOLTAGES

Turn the set On and check the Switched voltages at the following points.

+130 volts DC at FX3402

+150 volts DC at CX3406

+180 volts DC at + of C3207

SWEEP DERIVED VOLTAGES

+5 volts DC at cathode of ZD3206

+9 volts DC at pin 3 of IC3201

+12 volts DC at + OF CX3213

+14 volts DC at + side of C3222

+25 volts DC at D3202 cathode

+180 volts DC at C3207

SERVICING THE POWER SUPPLY

GA2 & GA3 25”/27” 9-1789/90/91 & 9-1831

Standby Voltages

+150 volts DC at RX3404

+123 volts DC at CX3420

+15 volts DC at emitter Q3403

+5 volts DC at cathode of ZD3401

SWITCHED VOLTAGES

Turn set On and check the Switched voltages at the following points:

+5 volts DC at cathode of ZD3402

+9 volts DC at pin 3 of IC3431

+15 volts DC at collector of Q3404

+15 volts DC at collector of Q3403

SWEEP DERIVED VOLTAGES

+25 volts DC at RX3242

CM150 |

3-2 |

GA - SERVICING |

SERVICING (continued)

+35 volts DC at CX3272

+215 volts DC at junction CX3296 and RX3277 CRT filament at pins 1 and 2 of connector 2F5

VIDEO PROCESSOR ICX2200

Key Operating Signals:

Composite Video out at pin 47

Video in at pin 37

Luminance in pin 43

Chroma in pin 45

Composite Audio out at pin 2

Horizontal Drive at pin 32

Vertical Drive at pin 24

Video Output Blue at 2C5 pin 3

Video Output Green at 2C5 pin 2

Video Output Red at 2C5 pin 1

B+ 9 volts pins 9, 46 and 48

Serial Data, Serial Clock pins 27 and 28

VERTICAL CIRCUIT

Vertical drive pulse pin 4

+25 volts pin 6

Vertical out pin 2

HORIZONTAL CIRCUIT

Horizontal drive to base of Q3201 predriver

Driver transformer output base of Q3202

Shutdown voltage anode ZFX3004

SERVICE ADJUSTMENTS (Mechanical)

1. Video Gain (19"/20" Models) Adjusts R9738 for 1

CM150 |

3-3 |

GA - SERVICING |

SERVICING (continued)

volt P-P at emitter of Q9706.

2.Audio Balance (19"/20" Models) Adjusts R9745 for equal output at collectors of Q9701 and Q9703.

3.HORIZONTAL WIDTH (25"/27" Models) Adjusts R3249 for 1/2" overscan on both sides of the picture.

FOCUS ADJUSTMENT

Connect a color bar pattern to the receiver and adjust the user controls for a good picture. Adjust the Focus control, then push the menu button to video menu then proceed until there is no distortion in the letters of the menu.

GA1/GA2 RGB CUTOFF (1164 Micro)

The G2 control must be adjusted before RGB drive.

1.If the main module or CRT has been replaced, set items #23 G GAIN and #24 B GAIN, in the Service

|

GA1 |

|

GA2 |

|

Tube Size |

19” |

20” |

25” |

27” |

Customer Contrast |

0 |

0 |

0 |

0 |

RF Bright/Aux Bright |

36 |

36 |

26 |

28 |

Customer Brightness |

31 |

31 |

31 |

31 |

Red Cutoff |

0 |

0 |

10 |

5 |

Green Cutoff |

0 |

0 |

10 |

5 |

Blue Cutoff |

0 |

0 |

10 |

5 |

Green Gain |

90 |

90 |

90 |

90 |

Blue Gain |

90 |

90 |

90 |

90 |

Menu, to the default setting for the correct screen size as listed in the Service Menu (see above table).

2.Set color level to minimum and Tint to midrange.

3.Connect the output of an NTSC generator to the antenna input of the receiver. Set the generator to a pure white signal, chroma off.

4.Access the Service menu to gain access to the cutoff adjustments, (Factory mode item 00 must be set to 1 to gain access to these adjustments).

5.Set items 22 R Cut, 23 G Cut and 24 B. Cut to the values shown in the above table.

6.Carefully observe which color is predominant on the CRT - DO NOT adjust the cutoff control for this color. Adjust the other two cutoff controls for the best white screen display.

7.Set the generator to a color bar patter and turn the chroma off. Check that the set displays a good gray

scale from black to white. If black level is too high readjust the item #9 RF Brightness.

8. Return the color level control to normal.

GA3 OF RGB CUTOFF (1305 Micro)

The G2 control must be adjusted before RGB drive.

1. If the main module or CRT has been replaced, select

|

GA3 |

|

Tube Size |

25” |

27” |

Customer Contrast |

0 |

0 |

RF Bright/Aux Bright |

40 |

40 |

Customer Brightness |

32 |

32 |

Color Temp |

Cool |

Cool |

Red Cut 1 |

15 |

15 |

Green Cut 1 |

8 |

5 |

Blue Cut 1 |

12 |

12 |

Green Gain 1 |

95 |

100 |

Blue Gain 1 |

70 |

80 |

Color Temp |

Warm |

Warm |

Red Cut 2 |

15 |

16 |

Green Cut 2 |

10 |

8 |

Blue Cut 2 |

17 |

16 |

Green Gain 2 |

70 |

75 |

Blue Gain 2 |

25 |

32 |

“Cool” in the user video menu under Color Temp. Then set items #25 Gain 1 (Green gain cool) and #26 B Gain 1 (Blue gain cool), in the Service Menu to the default setting for the correct screen size as listed in the Service Menu (see table above). Set Color level to minimum and Tint to mid range.

2.Connect the output of an NTSC generator to the antenna input of the receiver. Set the generator to the Pure white signal, chroma off.

3.Access the Service Menu to gain access to the cutoff adjustments, (Factory mode item 00 must be set to 1 to gain access to these adjustments).

4.Set items 22 R Cut, 23 G Cut, 24 B cut to the values shown in the table.

5.Carefully observe which color is predominant on the CRT. DO NOT adjust the cutoff control of this color. Adjust the other two cutoff controls for the best white screen display.

6.Set the generator to a color bar pattern and turn

CM150 |

3-4 |

GA - SERVICING |

Loading...

Loading...