Page 1

LSM 510 and LSM 510 META

Laser Scanning Microscopes

Operating Manual

Release 3.2

Page 2

INTRODUCTION LSM 510

Carl Zeiss LSM 510 META

Knowledge of this manual is required for the operation of the instrument. Would you therefore please

make yourself familiar with the contents of this manual and pay special attention to hints concerning the

safe operation of the instrument.

The specifications are subject to change; the manual is not covered by an update service.

© Unless expressly authorized, forwarding and duplication of this document, and the utilization and

communication of its contents are not permitted. Violations will entail an obligation to pay

compensation.

All rights reserved in the event of granting of patents or registration of a utility model.

Developed in

Collaboration with the European Molecular Biology Laboratory (EMBL)

PF 102209

Meyerhofstr. 1

69012 Heidelberg

GERMANY

Phone: ++49-6221-387-0

Telefax: ++49-6221-387-306

Issued by Carl Zeiss

Advanced Imaging Microscopy

07740 Jena

GERMANY

Phone: ++49-3641 64-34 00

Telefax: ++49-3641 64-31 44

E-mail: micro@zeiss.de

Internet: www.zeiss.de/lsm

Number of this manual: B 45-0008 e

Date of issue: 10/2002

II B 45-0008 e 10/02

Page 3

LSM 510 INTRODUCTION

LSM 510 META Carl Zeiss

How to make best use of the LSM 510 operating instructions

A few symbols in these operating instructions will help you to recognize the nature and purpose of

information immediately:

The WARNING symbol warns against hazards for the user that might arise when operating the

laser.

This WARNING symbol warns against hazards from dangerously high voltages.

The CAUTION symbol warns against faults and hazards that might arise during operation and

which might cause damage to the unit.

☞

Depending on the problem, these operating instructions will supply you with various possibilities:

• If you want to know where to find certain general areas of information, refer to the following outline

of sections to get a general overview.

• You will find a detailed table of contents at the start of every chapter. There you will see at a glance

what topics are dealt with in detail.

Always remember: The time you invest in getting acquainted with the product will pay

The NOTE symbol will help you to optimally solve your work problem. It represents a practical

tip which will help you to find out which settings and methods are capable of improving or

accelerating a procedure.

The HOT SURFACE symbol warns against hazards for the user that might arise when touching

the lamp housing during operation.

The MAINS PLUG symbol remembers service personal to pull the mains plug before opening

the device housing.

for itself many times over in your application task.

B 45-0008 e 10/02 III

Page 4

INTRODUCTION LSM 510

Carl Zeiss LSM 510 META

Scope of Equipment Supplied

Country: ..............................................

Order number: ..............................................

Serial number: ..............................................

Delivery date: ..............................................

Custom configuration: ..............................................

Axioskop 2 FS mot 000000-1056-2308

Axioplan 2 imaging

Axiovert 200 M SP 000000-1115-092

Axiovert 200 M BP 000000-1115-094

Axiovert 200 M BP/SP 000000-1115-289

Objectives: ..............................................

..............................................

..............................................

Confocal Laser Scanning Module LSM 510

Configuration 1 000000-1219-975

Configuration 2 000000-1219-977

Configuration 3 000000-1219-978

Configuration 4 000000-1219-979

Configuration 5 000000-1219-980

Configuration 9 000000-1219-981

Configuration 11 000000-1219-982

Configuration 12 000000-1219-983

Configuration 13 000000-1219-984

Configuration 15 000000-1219-985

Configuration 16 000000-1219-986

Configuration 18 000000-1219-987

Configuration 3 META 000000-1219-995

Configuration 13 META 000000-1219-997

Configuration 15 META 000000-1220-000

Configuration 18 META 000000-1220-004

Control computer 000000-0438-360

21“ monitors 000000-1060-089

TFT monitors 000000-0435-035

MOT (ie) 000000-1166-265

The license to the LSM control software is included in each configuration 1...18 (META).

IV B 45-0008 e 10/02

Page 5

LSM 510 INTRODUCTION

LSM 510 META Carl Zeiss

Optional software:

Image VisArt option 000000-1207-934

3D for LSM option 000000-1207-919

3D Deconvolution option 000000-1207-920

Physiology option 000000-1207-930

Topography option 000000-1207-933

Multiple Time Series option 000000-1207-926

Macro Reader and Editor option 000000-1207-925

StitchArt option 000000-1207-932

Canon S 830 D Photo printer 000000-0445-508

Kodak XLS 8650 PS printer 000000-1113-131

Transparency exposure device (D) 412410-9011-000

Large system table 453031-0000-000

Small system table 453032-0000-000

System baseplate 000000-1171-342

Active anti-vibration table 30" x 30" 000000-1177-841

Active anti-vibration table 1200 mm x 1400 mm 000000-1198-394

Active anti-vibration table 1800 mm x 1400 mm 000000-1150-353

UV laser 412410-9015-000

XY scanning stage for Axiovert 200 M BP 000000-1113-509

XY scanning stage for Axioplan 2 imaging

MOT 000000-1027-823

Piezo objective drive W = 0.8" 000000-1210-045

High resolution Z stage HRZ 200 for Axiovert 200 M 000000-1115-248

High resolution Z stage HRZ 200 for Axioplan 2 imaging

MOT (ie) 000000-1115-245

Set of INDO filters 447960-0000-000

Set of SNARF filters 447961-0000-000

AxioCam HRm 000000-0445-553

AxioCam HRc 000000-0412-312

B 45-0008 e 10/02 V

Page 6

INTRODUCTION LSM 510

Carl Zeiss LSM 510 META

The LSM 510 in the configuration as checked above

was installed and handed to the customer in functional condition

on ................................................

by ................................................

Phone: ................................................

Fax: ................................................

The customer has been instructed on how to operate and

maintain the equipment.

(Place)......................................................, (date) .....................................

...............................................................

Carl Zeiss Jena GmbH

Microscopy Division

...............................................................

Customer

One copy to be kept by customer

One copy to be kept by Carl Zeiss

VI B 45-0008 e 10/02

Page 7

LSM 510 INTRODUCTION

LSM 510 META Carl Zeiss

1

2

3

4

5

Notes on Device Safety

This section contains general notes on device safety, safe operation, and possible hazards

caused by failure to observe the instructions.

LSM 510 - Setup Requirements

The Setup Requirements section outlines the installation and supply requirements of the

LSM 510 Microscope System, together with the relevant specifications.

Introduction to Laser Scanning Microscopy

Here you will find an introduction to Laser Scanning Microscopy, with an explanation of the

principles of confocal imaging. The section also outlines the ways to present LSM image series

in three dimensions, and introduces you to the performance features of your LSM 510.

Quickstart

Operation in Expert Mode

In the Operation section you will find the most important steps and procedures of the

LSM menu structure. The step-by-step description how to get an image will be shown by

typical application examples including the WINDOWS NT 4.0 graphic user environment.

6

7

8

9

10

11

VBA Programming for LSM

Routine Mode and Tools

This section contains a description of the Routine Mode for scanning images using the

LSM scanning module and the use of the tools for setting the microscope.

3D for LSM 510

This section contains a description of the LSM 3D software package (basic program and addons). At the same time, all functions and settings are presented in a systematic form and in

the order in which they can be reached from the basic menu via sub-menus and dialog boxes.

Annex

The annex contains the Application-specific Configurations and special notes and information

for using the LSM microscope.

Multiphoton Laser Scanning Microscopy - Using the Zeiss LSM 510 NLO

Certification

B 45-0008 e 10/02 VII

Page 8

INTRODUCTION LSM 510

Carl Zeiss LSM 510 META

VIII B 45-0008 e 10/02

Page 9

LSM 510 NOTES ON DEVICE SAFETY

LSM 510 META Contents Carl Zeiss

CHAPTER 1 NOTES ON DEVICE SAFETY

CONTENTS

Page

1 NOTES ON DEVICE SAFETY...................................................................................................1-3

1.1 General...................................................................................................................................1-3

1.2 Regulations .............................................................................................................................1-3

1.3 Notes on Setting up the Microscope System.............................................................................1-4

1.4 Notes on Handling the Computer and Data Media................................................................... 1-5

1.5 Notes on Care, Maintenance and Service .................................................................................1-6

1.6 Notes on Handling the Laser Components ............................................................................... 1-7

1.7 Warning and Information Labels..............................................................................................1-8

B 45-0008 e 10/02 1-1

Page 10

NOTES ON DEVICE SAFETY LSM 510

Carl Zeiss Contents LSM 510 META

1-2 B 45-0008 e 10/02

Page 11

LSM 510 NOTES ON DEVICE SAFETY

LSM 510 META General / Regulations Carl Zeiss

1 NOTES ON DEVICE SAFETY

1.1 General

The LSM 510 laser scanning microscope, including its original accessories and compatible accessories

from other manufacturers, may only be used for the purposes and microscopy techniques described in

this manual (intended use).

The manufacturer will not assume liability for any malfunction or damage caused by any thing

other than the intended use of the LSM 510 or individual modules or parts of it, nor by any

repair or other service operation performed or attempted by persons other than duly

authorized service staff. Any such action will invalidate any claim under warranty, including

parts not directly affected by such action. This also includes the modification of the system

computer with new cards, etc. by the user.

1.2 Regulations

Extensive knowledge of the hardware/the system is indispensable for safe operation of the LSM 510.

☞

⇒

The LSM 510 has been designed, built and tested in conformity with the standards DIN EN 61010-1

⇒

As the system is largely operated via menus on a computer, you should be acquainted with the

⇒

In accordance with WHO regulations, the LSM 510 is a device that belongs to laser hazard class 3 B.

Read these operating instructions and all device publications belonging to the system

conscientiously before operating the LSM 510! You can obtain additional information on the

hardware configuration delivered and on optional system extensions from the manufacturer or

via the service hotline.

(IEC 1010-1) "Safety requirements for electrical instrumentation and control and laboratory

apparatus", and DIN EN 60825-1 (IEC publication 825-1) "Safety of laser equipment", and taking

relevant CSA and UL specifications into account.

principles of the operating system and its WINDOWS NT 4.0 and WINDOWS 2000 graphical user

interface. The respective manuals are supplied together with the programs.

WHO recommendations concerning health and industrial protection when handling laser devices

must be observed. The operator of the unit must also observe all and any relevant statutory

accident prevention regulations.

B 45-0008 e 10/02 1-3

Page 12

NOTES ON DEVICE SAFETY LSM 510

Carl Zeiss Notes on Setting up the Microscope System LSM 510 META

1.3 Notes on Setting up the Microscope System

☞

The LSM 510 laser scanning microscope is delivered in several crates:

• Crate 1: microscope stand, laser scanning module, control unit

• Crate 2: computer

• Crate 3: monitor

• Crate 4: large system table

• Crate 5: second microscope stand

• Crate 6: small system table

• Crate 7: scan module META

• Crate 8: upgrade kit META

Do not set up the unit in the proximity of heat sources such as radiators or direct sunlight. To avoid heat

build-ups, the ventilation louvers on the microscope system must not be covered up.

The unit must be connected to a properly installed socket outlet with earthing contact by means of the

mains cables supplied. Continuity of PE connection must not be affected by the use of extension leads.

Setting up, assembly on the system base plate and commissioning of the LSM 510 must be

performed by authorized Carl Zeiss service staff, who are also advised to give the customer's

operators a basic introduction to operation and maintenance.

The LSM 510 must be set up so as to ensure that the minimum clearance between the wall

and the rear of the system is no less than 0.5 m. This clearance is needed for adjustment and

maintenance operations.

Before connecting the mains cables, please check whether your mains voltage corresponds to

the voltage specified on the rating plate of the laser module.

For reasons of laser safety, the TV port on the microscope must either be equipped with a

camera or covered by a cap.

Maintenance, repairs, modifications, removal or exchange of components, or other

interference with the equipment beyond the operations described in this manual may only be

carried out by the manufacturer Carl Zeiss or by persons expressly authorized by us to do so.

This applies especially to the microscope system, the laser scanning module, lasers, the PC

system, the power supply units, cable connections and other system components.

Please note that the LSM 510 is a high-precision opto-electronic instrument. Inexpert handling

may easily impair it’s function or even damage it.

After installation or after conversion of the LSM system, authorized specialized staff must carefully check

that it is in a proper condition and, particularly, that covers protecting against laser radiation are

provided.

Tube openings or other unused mounts should always be protected against dust and moisture with the

corresponding device components or with termination covers/blind plugs.

By establishing a corresponding workplace environment, please ensure that the formation of electrostatic

charges by electronic components is avoided.

To avoid vibrations during operation, the LSM 510 should only be operated in conjunction with the

system table (vibration damping).

1-4 B 45-0008 e 10/02

Page 13

LSM 510 NOTES ON DEVICE SAFETY

LSM 510 META Notes on Handling the Computer and Data Media Carl Zeiss

1.4 Notes on Handling the Computer and Data Media

The computer used as standard in your LSM system is an IBM-compatible high-end pentium computer

with WINDOWS NT 4.0 or WINDOWS 2000 operating system.

As standard, your computer has one hard disk drive, one drive for 1.44 MB diskettes and one CD-ROM

drive. An CD reader/writer is installed.

☞

☞

Do make sure, though, that you receive your LSM system with the operating system installed,

with initialization and start files set up and with the LSM program also installed.

When working with the hard disk, it is important to know that the more data it contains, the

slower its operation will become. Therefore, data that you do not need permanently should be

stored on a diskette or CD-ROM.

When handling diskettes, avoid data losses by protecting them against extreme temperatures,

moisture and magnetic fields. The data on a diskette is stored in the form of magnetic signals.

To some extent, monitors, telephones or even lamps generate magnetic fields that might

destroy this data. Also, never open the metal cover on diskette cases. A diskette´s surface can

also be destroyed by touching it.

Never turn your computer off before you have exited the LSM program and run down the

WINDOWS NT operating system. Otherwise, the program and/or data files may get lost.

When handling discs of the CD reader/writer, do not touch the data side of the disc (the side

of the disc with no label or printing).

Do not apply paper labels or write on any part of the disc, data side or label side. If dust or

fingerprints get on the disc, wipe it with a soft cloth from the center to the edge, but do not

use benzine, paint thinner, record cleaner, or static repellent. This can damage the disc.

Do not place the disc in any place where it is exposed to direct sunlight or high temperatures.

B 45-0008 e 10/02 1-5

Page 14

NOTES ON DEVICE SAFETY LSM 510

Carl Zeiss Notes on Care, Maintenance and Service LSM 510 META

1.5 Notes on Care, Maintenance and Service

The manufacturer of the unit cannot be held liable for damage resulting from operating errors,

negligence or unauthorized tampering with the device system, particularly as the result of removal or

replacement of parts of the unit or as the result of the use of unsuitable accessories from other

manufacturers.

Any such action will also render all warranty claims null and void.

You are well advised to arrange a service agreement with your nearest Zeiss representative to guarantee

perfect functioning of the microscope system in the long term.

Modifications and conversion work on the components of the system must only be carried out by the

manufacturer, by the service agency or by persons authorized and trained for this purpose by the

manufacturer.

Damaged units or parts may only be repaired or maintained by the responsible service agency.

Care operations that may be carried out by operating staff are limited to cleaning painted and glass

surfaces.

• Cleaning painted surfaces

To do this, use a clean cloth that has been moistened in a mixture of water and some detergent; do

not use any solvent, however. Dry with a lint-free cloth.

• Cleaning glass surfaces

Glass surfaces that have become soiled or which are marked with fingerprints may be rubbed with a

clean optical cleaning cloth.

If soiling is persistent, dip the optical cleaning cloth into a mixture of distilled water and a small

quantity of detergent.

To complete cleaning, lightly breathe on the glass surface and rub it dry with a clean cloth. Lint or

dust is best removed with a clean hairbrush.

The air filter mat at the bottom of the LSM 510 Control Unit must be cleaned every six months.

Filter mats can be ordered from our Service Department.

1-6 B 45-0008 e 10/02

Page 15

LSM 510 NOTES ON DEVICE SAFETY

LSM 510 META Notes on Handling the Laser Components Carl Zeiss

1.6 Notes on Handling the Laser Components

The LSM 510 is a laser hazard class 3 B instrument and is marked as such.

This moderate-risk class embraces medium-power lasers. You must take care not to expose

yourself to the radiation of such lasers. In particular, never look into the laser beam!

The following laser types are currently recommended for use in the LSM 510.

1 Ar 351/364 (UV)

2 Ar/ML 458/477/488/514

3 HeNe 543

4 ArKr 488/568

5 HeNe 633

☞

If used properly, the LSM 510 will not pose any laser radiation risks for operating staff. The dangerous

laser radiation area is limited to the beam path and to a distance of up to around 10 cm from the

specimen. Nevertheless, you should observe the following warnings:

Please contact Carl Zeiss if you intend to use a laser type with a wavelength other than the

ones above.

• If necessary - insofar as specified by law - inform the laser protection officer before

commissioning the laser.

• Always store laser key switches and, if applicable, keys for further laser power supply units,

where they are inaccessible to persons not authorized to operate the laser.

• Do not place any reflecting objects into the beam path.

• Never open any covers or panelings.

• Never look into the laser beam, not even to simply view the specimen, whether with the aid

of optical instruments or without. Otherwise you risk going blind!

• Do not leave any screw positions of the nosepiece uncovered.

☞

B 45-0008 e 10/02 1-7

Suitable protective measures must be taken if gases, dust or vapors hazardous to health,

secondary radiation or explosive objects should arise on the specimen as a result of laser

radiation.

Page 16

NOTES ON DEVICE SAFETY LSM 510

Carl Zeiss Warning and Information Labels LSM 510 META

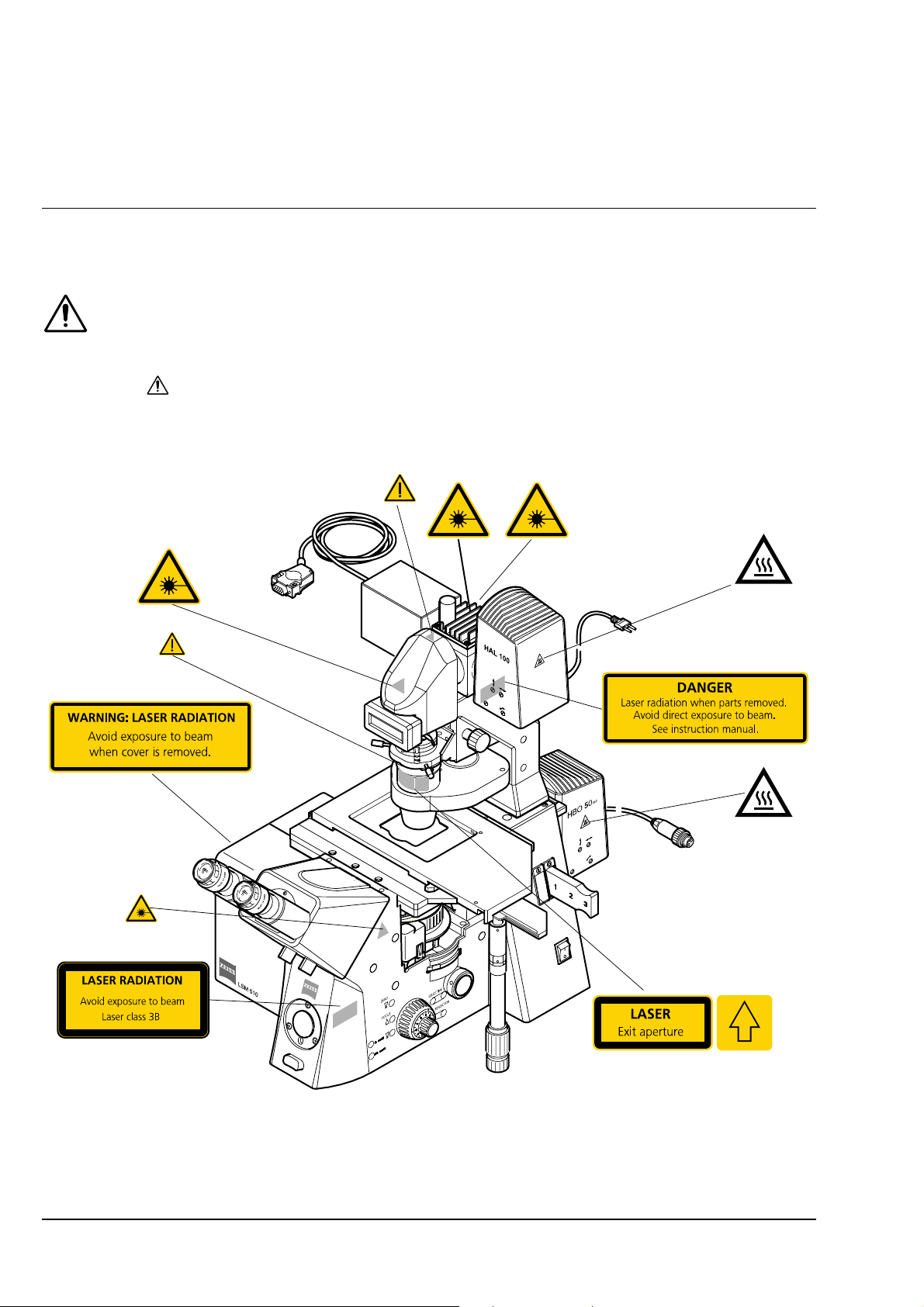

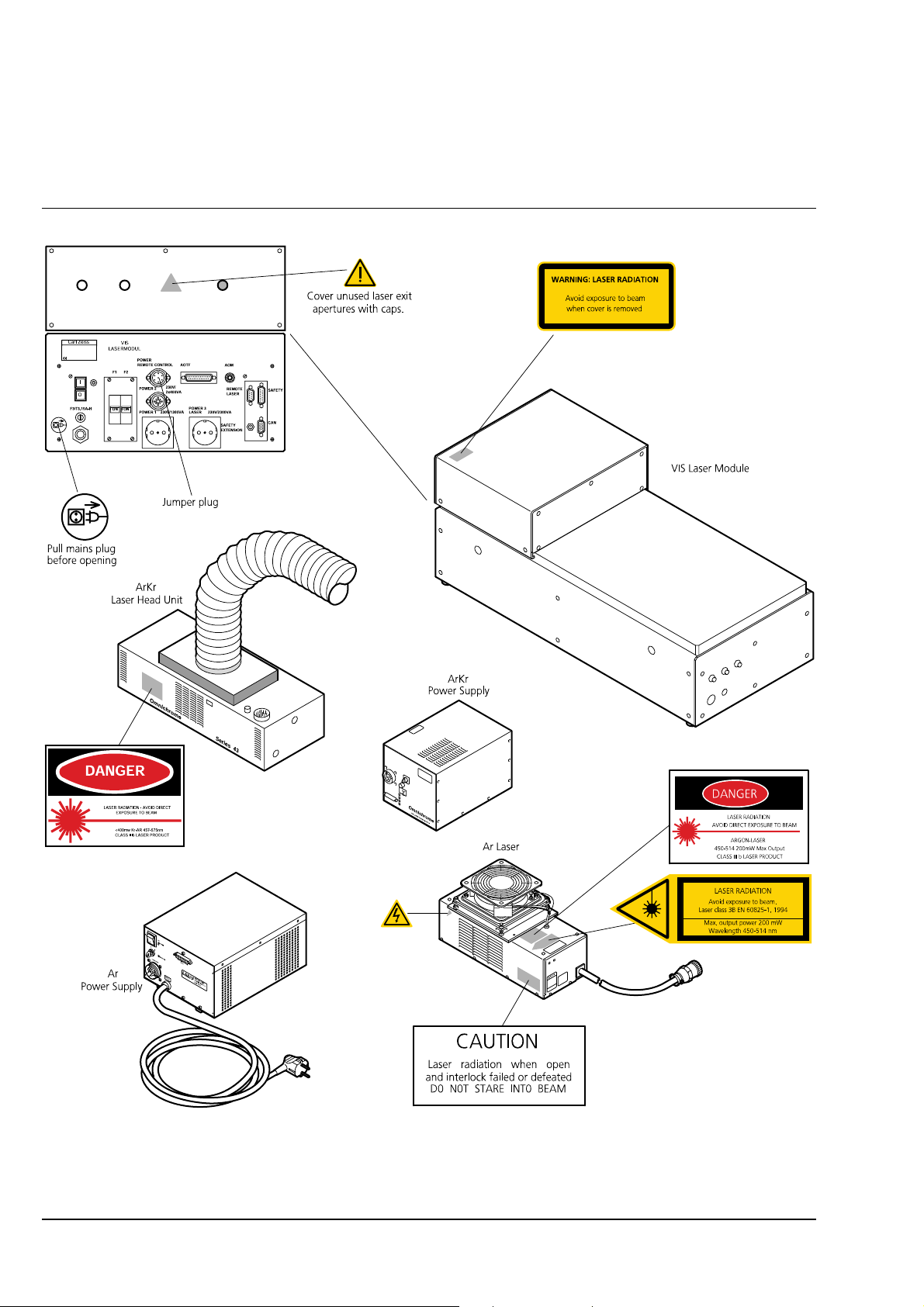

1.7 Warning and Information Labels

The warning and information labels attached on the LSM 510 must be observed. Check

whether all of the labels shown below are provided on your instrument, and contact Carl Zeiss

Germany or one of the service agencies if you should discover that any of the labels should be

missing. You will receive a free replacement.

The

label means: "Do not remove securing screw as otherwise laser beam will escape. For

use by service only!"

Fig. 1-1 Warning and information labels on the Axiovert 200 M microscope with the LSM 510

scanning module

1-8 B 45-0008 e 10/02

Page 17

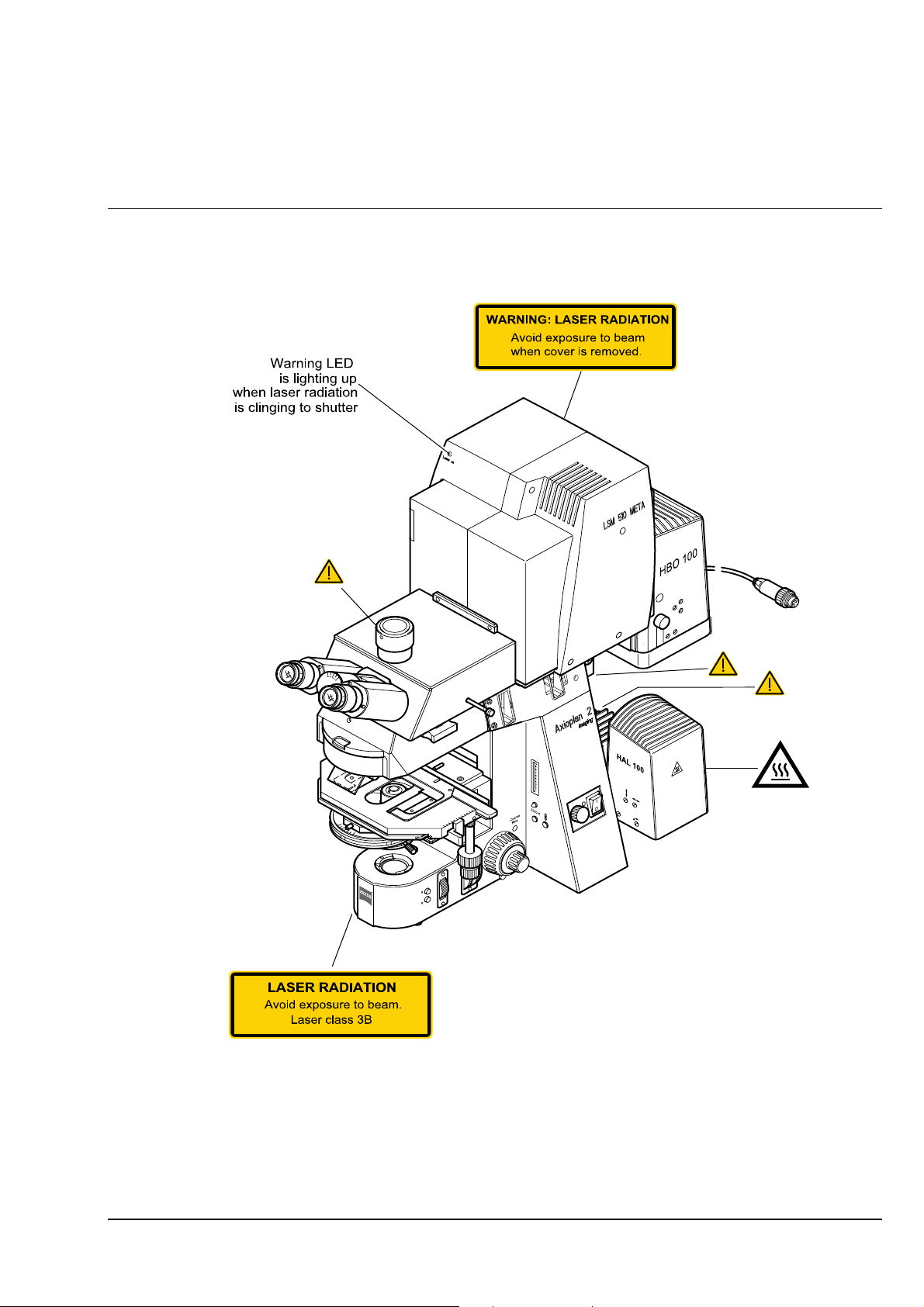

LSM 510 META NOTES ON DEVICE SAFETY

LSM 510 Warning and Information Labels Carl Zeiss

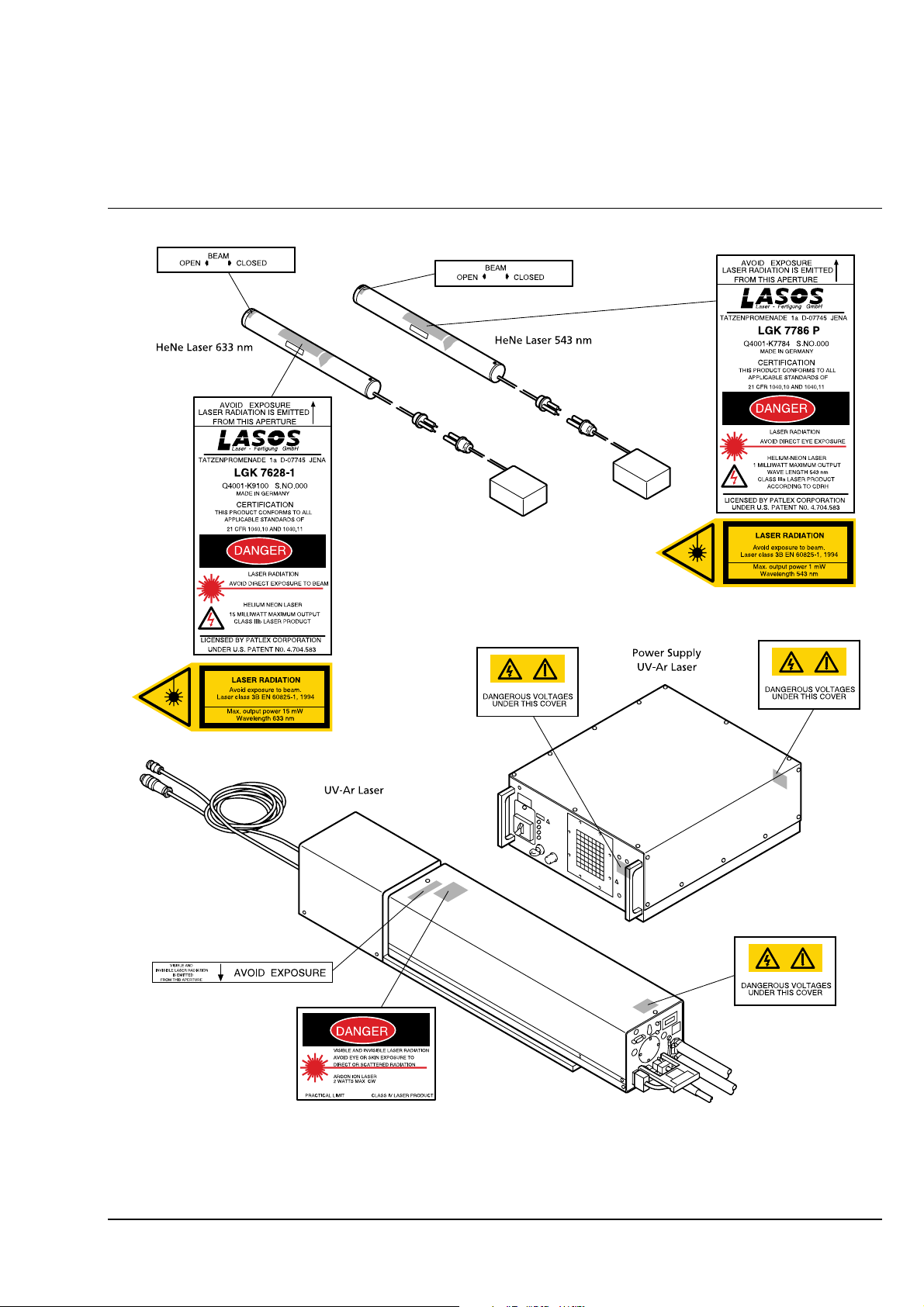

Fig. 1-2 Warning and information labels on the Axioplan 2 imaging MOT microscope with LSM 510

META scanning module

B 45-0008 e 10/02 1-9

Page 18

NOTES ON DEVICE SAFETY LSM 510

Carl Zeiss Warning and Information Labels LSM 510 META

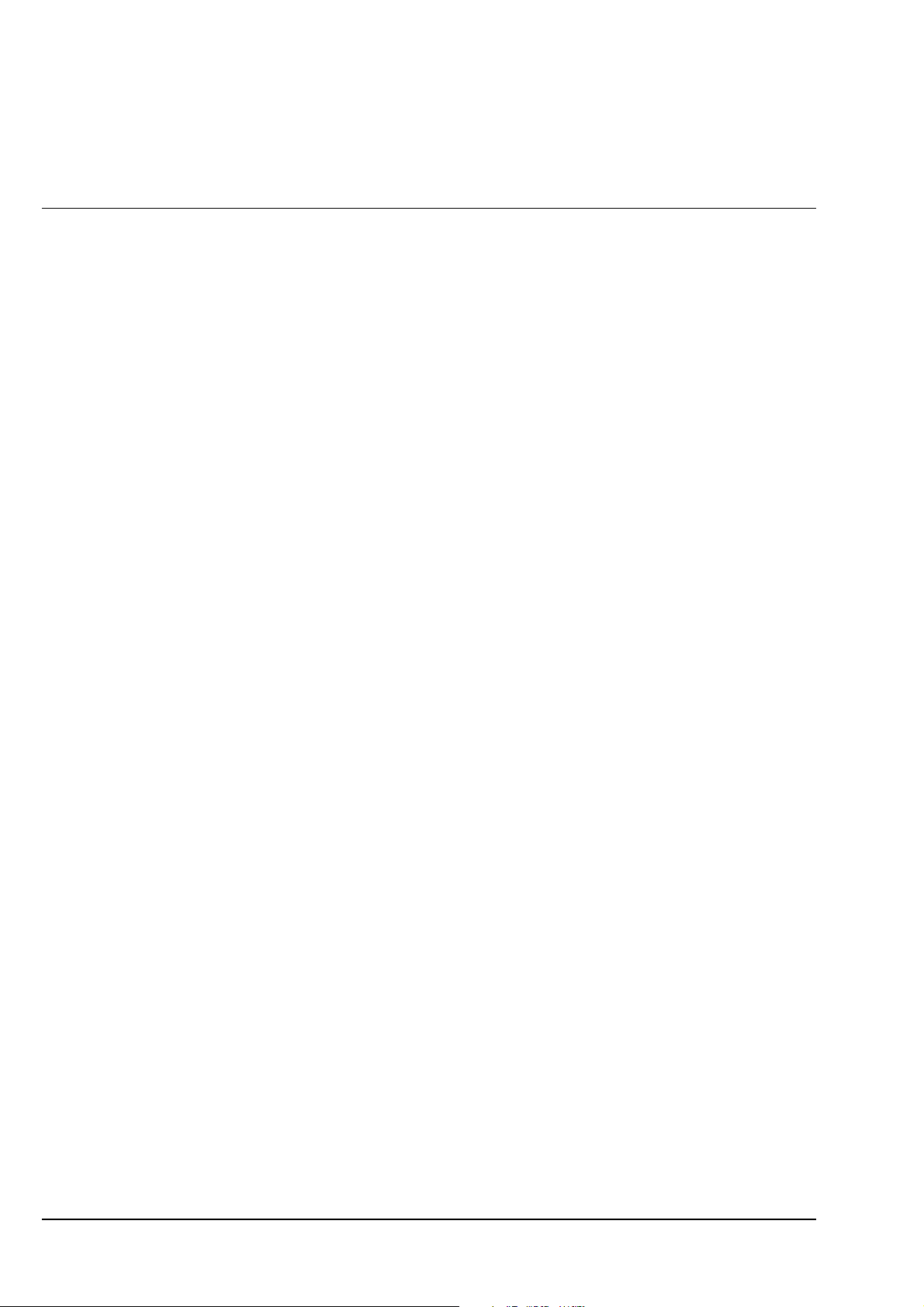

Fig. 1-3 Warning and information labels on laser components (page 1)

1-10 B 45-0008 e 10/02

Page 19

LSM 510 META NOTES ON DEVICE SAFETY

LSM 510 Warning and Information Labels Carl Zeiss

C

O

H

E

R

E

n

T

E

n

T

E

R

P

R

IS

E

PEAK

maximum

water

pressure

SEARCH

60 p.s.I.

E4

OUT

E

n

T

E

R

P

R

IS

E

C

O

H

E

R

E

n

T

water

J37

E5

E4

J6

Fig. 1-3 Warning and information labels on laser components (page 2)

B 45-0008 e 10/02 1-11

Page 20

NOTES ON DEVICE SAFETY LSM 510

Carl Zeiss LSM 510 META

1-12 B 45-0008 e 10/02

Page 21

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META Contents Carl Zeiss

CHAPTER 2 LSM 510 - SETUP REQUIREMENTS

CONTENTS

Page

2 LSM 510 - SETUP REQUIREMENTS................................................................................ 2-3

2.1 Space Requirements ........................................................................................................2-3

2.1.1 LSM (one microscope, large system table): 300 × 250 cm ................................................. 2-3

2.1.2 LSM with Ar UV Laser......................................................................................................2-4

2.1.3 LSM prepared for Two Photon Lasers (NLO)......................................................................2-6

2.2 Power Requirements........................................................................................................2-8

2.2.1 Phase 1 (LSM).................................................................................................................. 2-9

2.2.2 Phase 2 (LSM, Power 3) ...................................................................................................2-9

2.2.3 Separate Connection .......................................................................................................2-9

2.3 Physical Dimensions....................................................................................................... 2-10

2.4 Dimension of Shipment Crates....................................................................................... 2-11

2.5 Environmental Requirements..........................................................................................2-11

2.6 Vibrations...................................................................................................................... 2-12

2.7 Laser Specifications........................................................................................................ 2-12

2.7.1 Coherent Enterprise 653 II: 352, 364 nm, 80 mW, Laser Class 3 B ..................................2-12

2.7.2 Point Source i-flex 2000: 405 nm, 25 mW, Laser Class 3 B..............................................2-12

2.7.3 LASOS LGK 7786 P / Power supply 7460 A: 543 nm, 1 mW, Laser Class 3 B ...................2-13

2.7.4 LASOS LGK 7628-1: 633 nm, 5 mW, Laser Class 3 B ...................................................... 2-13

2.7.5 LASOS LGK 7812 ML-4 / LGN 7812: 458, 477, 488, 514 nm, 30 mW, Laser Class 3 B.....2-13

2.7.6 Melles Griot 643-YB-A02 / Power supply 171B: 488, 568 nm, 30 mW, Laser Class 3 B.... 2-13

2.7.7 AOTF.............................................................................................................................2-13

2.8 Microscopes ..................................................................................................................2-14

2.9 Scanning Module........................................................................................................... 2-15

2.10 Laser Module VIS (405, 458, 477, 488, 514, 543, 633 nm).............................................2-16

2.11 Laser Module UV (351, 364 nm) ....................................................................................2-16

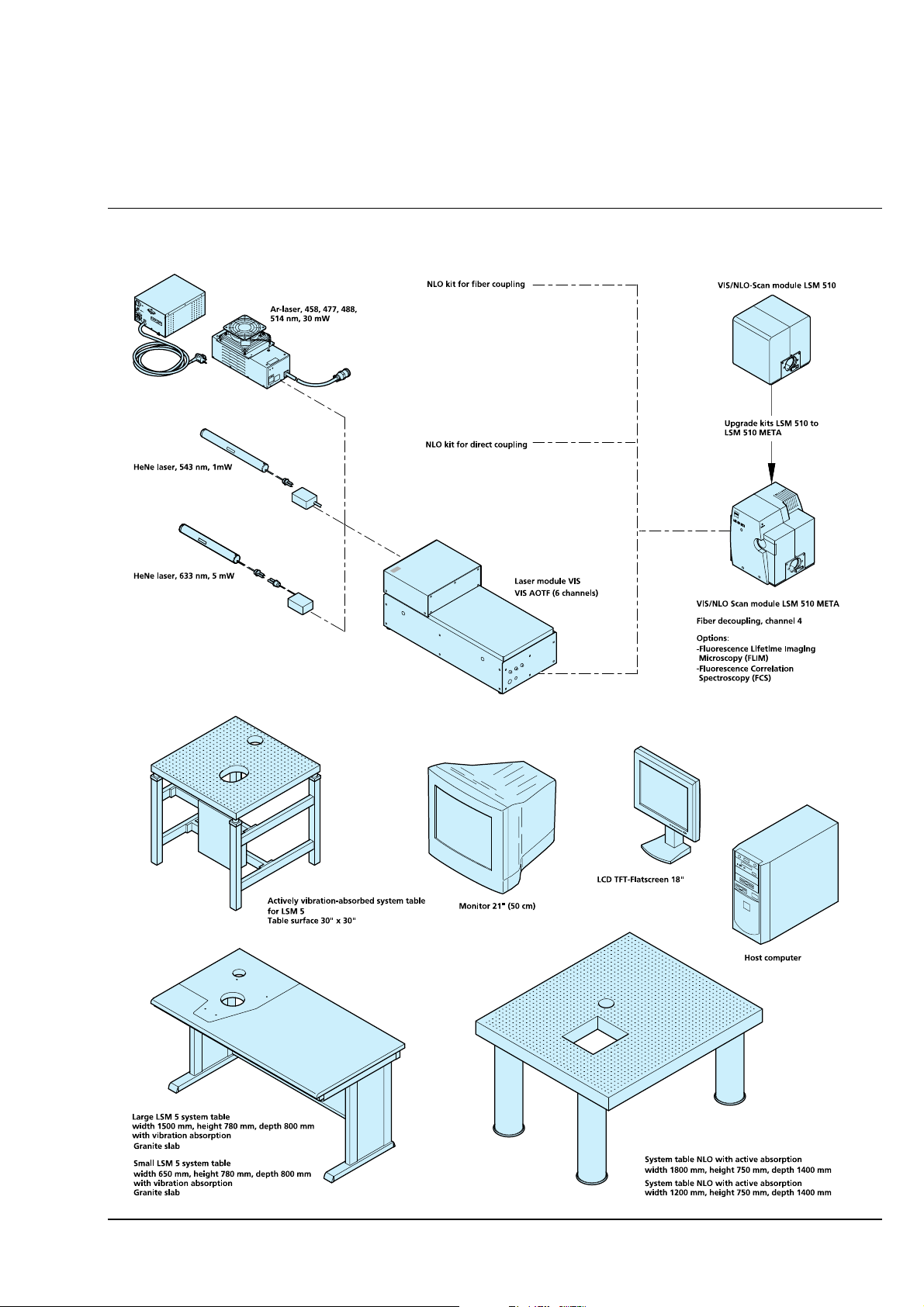

2.12 System Overview LSM 510 META...................................................................................2-17

2.13 System Overview LSM 510 META - NLO .........................................................................2-19

B 45-0008 e 10/02 2-1

Page 22

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss Contents LSM 510 META

2-2 B 45-0008 e 10/02

Page 23

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META Space Requirements Carl Zeiss

2 LSM 510 - SETUP REQUIREMENTS

2.1 Space Requirements

2.1.1 LSM (one microscope, large system table): 300 × 250 cm

Power Plug

System rack

1000

Large system table

1500

3000

Fig. 2-1

500

2500

800

The system rack contains the laser module (Helium-Neon laser 543 nm, 633 nm and Argon ion laser), the

power supply for the Argon ion laser, for HBO lamp and halogen lamp, the electronic control unit (ECU)

and the MCU28 unit (if a motorized XY stage is applied).

B 45-0008 e 10/02 2-3

Page 24

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss Space Requirements LSM 510 META

2.1.2 LSM with Ar UV Laser

☞

We recommend placing the cooling unit of the Ar laser (UV) in a separate room to prevent

heat accumulation and vibration. Length of the water hose: 400 cm

One microscope:

To Cooling Unit

System

Rack I

500

Large system table

Power Plugs

LSM UV

System

Rack II

1000

500

3000

800

1500

3000

Fig. 2-2

2-4 B 45-0008 e 10/02

Page 25

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META Space Requirements Carl Zeiss

Two microscopes:

To Cooling Unit

Small

system table

650

System

Rack I

500

Large system table

800

3500

Power Plugs

LSM UV

System

Rack II

1000

500

3000

800

1500

Fig. 2-3

The system rack I contains the VIS laser module (Helium-Neon laser 543 nm, 633 nm and Argon ion

laser) and the Argon UV laser module. The system rack II contains the power supplies for lasers, for HBO

and halogen lamps, the electronic control unit (ECU) and the MCU28 unit (if a motorized XY stage is

applied).

B 45-0008 e 10/02 2-5

Page 26

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss Space Requirements LSM 510 META

2.1.3 LSM prepared for Two Photon Lasers (NLO)

2.1.3.1 Coherent "Mira 900" Direct-coupling with Inverted Stand

(Upright Stand also possible)

Power Plug LM VIS

Large NLO system table

Cooling UnitPower Supplies

1400

System

Rack

1000

500

2000

800

1800

PC table

1200

4000

Fig. 2-4

2.1.3.2 Spectra Physics "MaiTai" Direct-coupling with Upright Stand

(Upright Stand also possible)

Power Plug LM VIS

1000

Cooling Unit

Power Supply

1400

System

Rack

500

2500

Small NLO

system table

1200

3000

PC table

1200

800

Fig. 2-5

2-6 B 45-0008 e 10/02

Page 27

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META Space Requirements Carl Zeiss

2.1.3.3 Coherent "Mira" Fiber-coupling with Inverted Stand (Upright Stand also possible)

1400

Power Plug LM VIS

LSM

1800

Large NLO

system table

System

Rack

1000

Large system table

1500

3500

500

500

Fig. 2-6

2.1.3.4 Coherent "Chameleon" Direct-coupling with Upright Stand

(Inverted Stand also possible)

Power Plug LM VIS

1000

Cooling Unit

Power Supply

System

Rack

500

2500

1400

2500

Small NLO

system table

1200

3000

PC table

1200

800

Fig. 2-7

B 45-0008 e 10/02 2-7

Page 28

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss Power Requirements LSM 510 META

2.2 Power Requirements

☞

Line voltage 230 V AC: 220...240 V AC (±10 %) 115 V AC: 100...125 V AC (±10 %)

Line frequency 50...60 Hz 50...60 Hz

LSM incl. VIS laser

− Max. current

− Power consumption

− Power plug

Argon UV laser

- Line Voltage 208...240 V AC

− Max. current

The LSM 510 comes with a mains power supply cord and plug, either CEE red (230 V, 16 A,

3 phases), or CEE yellow (115 V, 32 A, 3 phases), and with the matching mains socket outlet.

2 phases at 16 A

Phase 1 = 1.8 kVA max.

Phase 2 = 2 kVA max.

2000 VA per phase 2000 VA per phase

CEE red (230 V, 16 A):

3 phases+N+PE, phases 1 and 2

connected

(±10 %) 50 / 60 Hz

1 phase at 63 A

Note: For Line Voltage 220 V the

connector and power plug are rated

for 63 Amps, However wiring and

fuse should be rated for 32 Amps.

2 phases at 25 A

Phase 1 = 1.8 kVA max.

Phase 2 = 2 kVA max.

CEE yellow (115 V, 32 A):

3 phases+N+PE, phases 1 and 2

connected

208...240 VAC

(±10 %) 50 / 60 Hz

1 phase at:

208 V: 34 Amps

230 V: 31 Amps

240 V: 29 Amps

− Power consumption

Class of protection I I

Type of protection IP 20 IP 20

Overvoltage category II II

Pollution degree 2 2

☞

2-8 B 45-0008 e 10/02

If the line voltage in your country is 115 V AC, you need to order an additional 2.5 kW stepup-transformer, part no. 234.366, to be able to run the ArKr laser. Reason: The ArKr laser

requires a 220 V input.

7000 VA 7000 VA

Page 29

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META Power Requirements Carl Zeiss

Power distribution inside the Laser Module VIS:

Fig. 2-8

2.2.1 Phase 1 (LSM)

feeds the following units: Laser Module

HeNe 2×

via Power 1 (5-socket adapter)

Computer + monitor

Microscope

MCU28

Scanning Module

via Power 2:

HAL lamp

HBO lamp

2.2.2 Phase 2 (LSM, Power 3)

feeds the following units: Ar laser 2000 VA

or ArKr laser 2000 VA

2.2.3 Separate Connection

Ar laser (UV) 7000 VA

B 45-0008 e 10/02 2-9

Page 30

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss Physical Dimensions LSM 510 META

2.3 Physical Dimensions

Length (cm) Width (cm) Height (cm) Weight (kg)

Large system table 150 80 78 100

Small system table 65 80 78 60

Active anti-vibration table 75 75 75 125

Active anti-vibration table (NLO)

For Mai Tai Laser or Chameleon

Active anti-vibration table (NLO)

For Mira or Tsunami Laser

Scanning Module LSM 510 25 20 25 15

Scanning Module LSM 510 META 28 27 30.5 13

Microscope 50 35 50 20

Laser Module, VIS(ible light) 90 40 50 60

Laser Module, UV 140 20 20 60

Electronics box 50 30 30 10

Power supply for Ar, ArKr 30 30 20 10

Power supply for Ar (UV) 50 50 30 30

Cooling unit for Ar (UV) 80 45 50 30

Water hose for Ar (UV) 700

Fiber optic cable, VIS(ible) 200

Fiber optic cable, UV 200

Cables 250

SCSI cable 200

120 140 75 200

180 140 75 400

2-10 B 45-0008 e 10/02

Page 31

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META Dimensions ... / Environmental Requirements Carl Zeiss

2.4 Dimension of Shipment Crates

Crate containing Length (cm) Width (cm) Height (cm) Weight (kg)

Large system table 160 85 95 120

Small system table 90 75 80 80

Active anti-vibration table 145 115 115 150

Active anti-vibration table

(NLO)

For Mai Tai Laser or Chameleon

Active anti-vibration table

(NLO)

For Mira or Tsunami Laser

LSM 190 85 120 350

145 160 110 330

200 160 110 460

Monitor, computer 120 80 90 80

UV laser unit 125 55 50 100

UV cooling unit 120 60 90 50

META scan head 52 47 47 13

META upgrade kit 64.5 60.5 42.5 20

2.5 Environmental Requirements

1. Operation, specified performance T = 22 °C ± 3 °C without interruption (24 h a day

independently whether system is operated or

switched-off)

2. Operation, reduced performance T = 10 °C to 35 °C, any conditions different from 1.

and 5.

3. Storage, less than 16 h T = -40 °C to 55 °C

4. Storage, less than 6 h T = -55 °C to 70 °C

5. Temperature gradient ± 0.5 °C/h

6. Warm up time 1 h, for high-precision and/or long-term measure-

ments ≥ 2 h

7. Relative humidity < 65 % at 30 °C

8. Operation altitude max. 2000 m

B 45-0008 e 10/02 2-11

Page 32

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss Vibrations / Laser Specifications LSM 510 META

2.6 Vibrations

Vibrations under operation conditions

Shipping shock (LSM 510 box)

(with system table)

5 µm pp at 5 Hz 3 g

10 µm pp at 10 Hz

10 µm pp at 20 Hz

2.7 Laser Specifications

2.7.1 Coherent Enterprise 653 II: 352, 364 nm, 80 mW, Laser Class 3 B

Line voltage 208...240 V

Line frequency 50...60 Hz

Max. current

1 phase at:

208 V: 34 Amps

230 V: 31 Amps

240 V: 29 Amps

Power consumption 7000 VA

With heat exchanger LP5:

Water flow 8.0 l/min (max. 16 l/min)

Water pressure 1.4...4.2 kg/cm²

Water temperature 10...60 °C at 8.0 l/min

2.7.2 Point Source i-flex 2000: 405 nm, 25 mW, Laser Class 3 B

Line voltage 100...240 V

Line frequency 50...60 Hz

Power consumption 30 VA

2-12 B 45-0008 e 10/02

Page 33

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META Laser Specifications Carl Zeiss

2.7.3 LASOS LGK 7786 P / Power supply 7460 A: 543 nm, 1 mW, Laser Class 3 B

Line voltage 115/230 V with factory setting

Line frequency 50...60 Hz

Power consumption 20 VA

2.7.4 LASOS LGK 7628-1: 633 nm, 5 mW, Laser Class 3 B

Line voltage 100...240 V with factory setting

Line frequency 50...60 Hz

Power consumption 20 VA

LASOS LGK 7812 ML-4 / LGN 7812: 458, 477, 488, 514 nm, 30 mW, Laser Class 3 B

Line voltage 100...240 V with factory setting

Line frequency 50...60 Hz

Max. current 1 phases at 25 A

Power consumption 2000 VA

Cooling fan on top of laser head

2.7.6 Melles Griot 643-YB-A02 / Power supply 171B: 488, 568 nm, 30 mW, Laser Class 3 B

Line voltage 100...240 V with factory setting

Line frequency 50...60 Hz

Max. current 1 phase at 16 A

Power consumption 2000 VA

2.7.7 AOTF

☞

B 45-0008 e 10/02 2-13

In the unlikely case of complete utilization of the acousto-optical tunable filter (100 % intensity

of all AOTF-supported lines) the tolerable limits of the EMV regulations could be slightly

exceeded in the MHz range.

Page 34

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss Microscopes LSM 510 META

2.8 Microscopes

Upright Axioplan 2 imaging

MOT

Upright Axiotron 2 mot

Inverted Axiovert 200 M BP or SP

Upright Axioskop 2 FS

MOT

Upright Axioskop 2 MAT mot

All Zeiss ICS objectives and accessories can be accommodated.

Z motor DC servomotor, opto-electronically coded

Least Z interval: 50 nm (Axioplan 2 imaging

MOT,

Axiovert 200 M BP or SP)

100 nm (Axioskop 2 FS

MOT)

HRZ 200 Galvanometer-driven precision focusing stage

Max. travel 200 µm; resolution 6 nm; accuracy 40 nm

Allows continuous Z-scan at up to 10 Hz

Piezo Objective focus Piezo-driven single objective drive

Max. travel 100 µm; resolution 5 nm

Allows continuous Z-scan at up to 20 Hz

2-14 B 45-0008 e 10/02

Page 35

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META Scanning Module Carl Zeiss

2.9 Scanning Module

2 individually driven galvanometric scanners

Scanning speed

Field resolution

Field of view

Zoom

Channels a) Up to 4 channels simultaneously or

4 confocal reflection/fluorescence channels (PMT) or 3 PMT and 1 META

1 transmitted light channel (PMT) and 3 NDD or 4 NDD

1 reference monitor diode

Cooled PMTs (option, forthcoming)

Fiber-optic adaptation of external detectors (option, forthcoming)

Dynamic range 12-bit DAC for each detection channel

Pinholes 4 individual variable pinholes (one per confocal channel)

Computer controlled automatic alignment

Up to ~5 frames/sec (512 × 512 pixels)

Max. 2048 × 2048 pixels (individually adjustable for each axis)

10 × 10 mm² with a 1.25× objective

1× ... 40×, continuous control

b) 3 traditional confocal channels and 1 META channel

B 45-0008 e 10/02 2-15

Page 36

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss Laser Module VIS / Laser Module UV LSM 510 META

2.10 Laser Module VIS (405, 458, 477, 488, 514, 543, 633 nm)

Single-mode polarization preserving fiber

Laser beam attenuation for all lasers by VIS-AOTF

HeNe laser (543 nm, 1 mW)

HeNe laser (633 nm, 5 mW)

Diode laser (405 nm, 25 mW)

Ar laser (458, 477, 488, 514 nm, 30 mW)

ArKr laser (488, 568 nm, 30 mW)

Fuses and automatic circuit breakers

for 230 V: G-type fuse 5 × 20 mm; slow-blow 3.15 A / H / 250 V, acc. to IEC 127

2 circuit breakers; C 10 A

for 110 V: G-type fuse 5 × 20 mm; slow-blow 3.15 A / H / 250 V, acc. to IEC 127

Circuit breaker; B 25 A

Circuit breaker; C 25 A

Circuit breaker; B 16 A

Circuit breaker; B 10 A

2.11 Laser Module UV (351, 364 nm)

Single-mode polarization preserving fiber

Laser beam attenuation for all lasers by UV-AOTF

Ar laser (351, 364 nm, 80 mW)

2-16 B 45-0008 e 10/02

Page 37

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META System Overview LSM 510 META Carl Zeiss

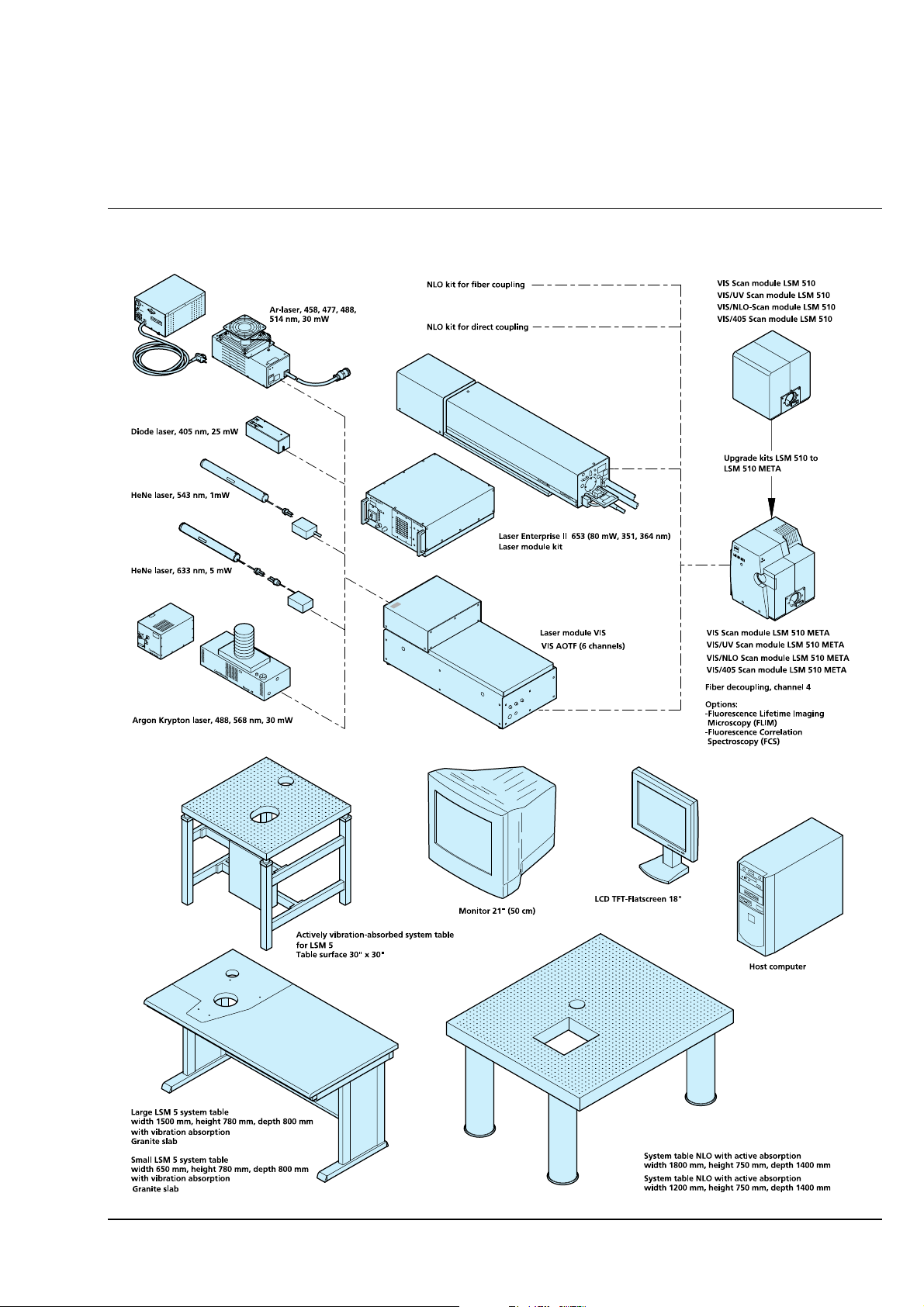

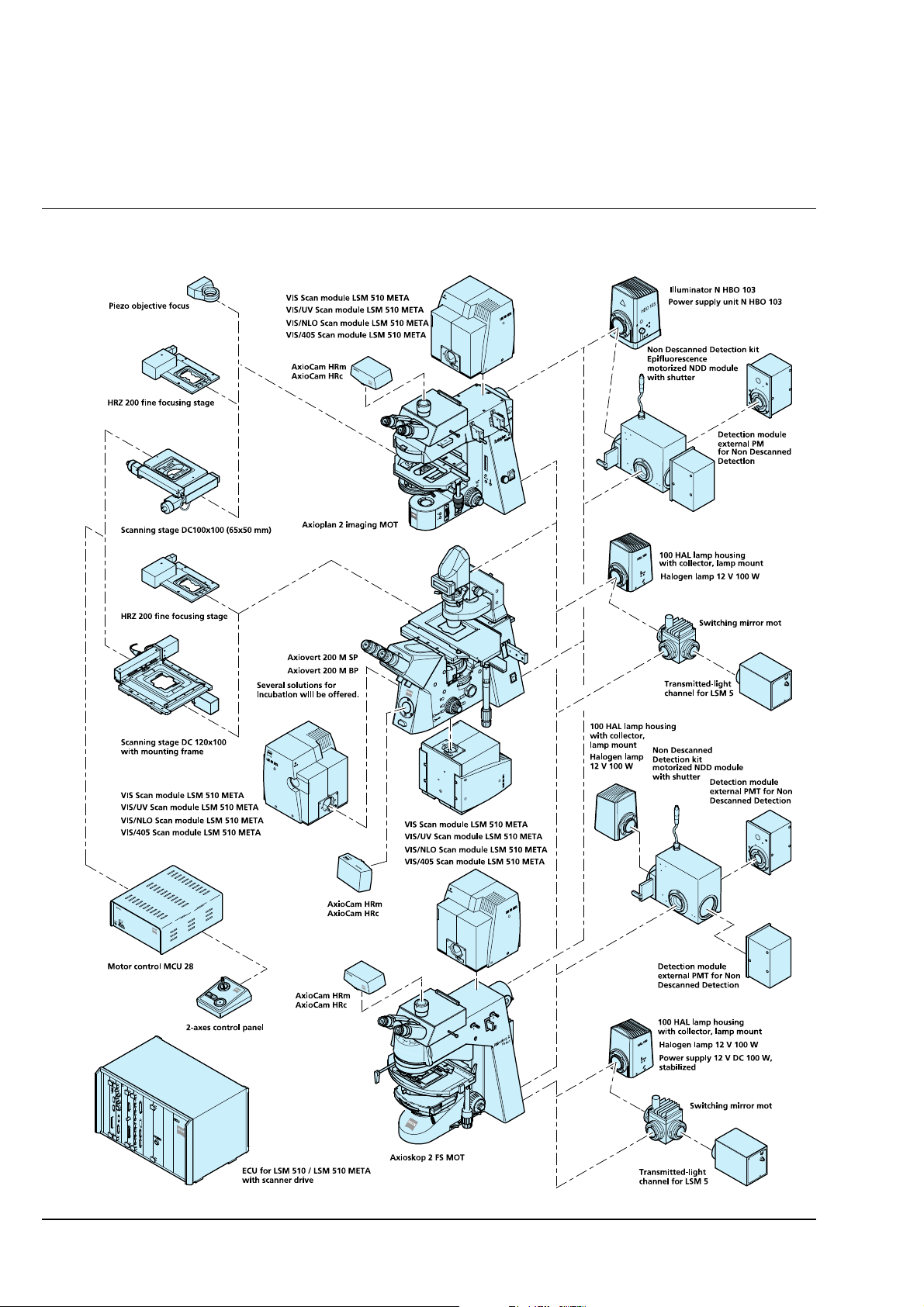

2.12 System Overview LSM 510 META

B 45-0008 e 10/02 2-17

Page 38

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss System Overview LSM 510 META LSM 510 META

2-18 B 45-0008 e 10/02

Page 39

LSM 510 LSM 510 - SETUP REQUIREMENTS

LSM 510 META System Overview LSM 510 META - NLO Carl Zeiss

2.13 System Overview LSM 510 META - NLO

B 45-0008 e 10/02 2-19

Page 40

LSM 510 - SETUP REQUIREMENTS LSM 510

Carl Zeiss System Overview LSM 510 META - NLO LSM 510 META

2-20 B 45-0008 e 10/02

Page 41

LSM 510 INTRODUCTION TO LASER SCANNING MICROSCOPY

LSM 510 META Contents Carl Zeiss

CHAPTER 3 INTRODUCTION TO

LASER SCANNING MICROSCOPY

CONTENTS

Page

3 INTRODUCTION TO Laser Scanning Microscopy..........................................................3-3

3.1 Principle of Laser Scanning Microscopy.............................................................................3-3

3.2 Three-Dimensional Presentations of LSM Image Stacks .....................................................3-4

3.3 Optical Diagram of the LSM 510 (Schematic)....................................................................3-6

3.4 Performance Features of the LSM 510..............................................................................3-7

3.4.1 Optical and Mechanical Aspects.......................................................................................3-7

3.4.2 Microscope Equipment of the LSM 510 System ................................................................3-8

3.4.3 Computer Hardware and Software ................................................................................3-10

B 45-0008 e 10/02 3-1

Page 42

INTRODUCTION TO LASER SCANNING MICROSCOPY LSM 510

Carl Zeiss Contents LSM 510 META

3-2 B 45-0008 e 10/02

Page 43

LSM 510 INTRODUCTION TO LASER SCANNING MICROSCOPY

LSM 510 META Principle of Laser Scanning Microscopy Carl Zeiss

3 INTRODUCTION TO LASER SCANNING MICROSCOPY

3.1 Principle of Laser Scanning Microscopy

To yield information on their inner structure by conventional transmitted-light microscopy, specimens

have to be very thin and translucent; otherwise image definition will be poor. In many cases it is a

problem to satisfy these requirements.

The essential considerations have led to trailblazing changes in conventional microscopy and supplied a

successful solution to the above problem.

• Unlike the practice of even illumination in conventional microscopy, the LSM technique projects the

light of a point light source (a laser) through a high-NA objective onto a certain object plane of

interest as a nearly diffraction-limited focus. However, if not for another "trick", the stray light

produced outside the object plane, or the fluorescence of fluorescent specimens, would disturb the

in-focus image of object point of interest, resulting in a blurred image of poor contrast. The problem

therefore is how to capture only the light coming immediately from the object point in focus, while

obstructing the light coming from out-of-focus areas of the specimen.

• The light reflected, or the fluorescence light

produced, at the focus of the high-NA objective

is projected onto a variable pinhole diaphragm

by the same objective and a tube lens. The

focus inside the specimen and the pinhole are

situated at optically conjugate points (confocal

imaging). The decisive advantage of this

arrangement is the fact that essentially no other

light than that coming from the object plane of

interest can pass the narrow pinhole and be

registered by a detector. Unwanted light

coming from other specimen areas is focused

outside the pinhole, which passes only a small

fraction of it. The smaller the pinhole, the less

stray light or fluorescence from out-of-focus

areas will get on the detector. The image point

thus generated is largely free from blur caused

by unwanted light.

Fig 3-1 Principle of confocal imaging

B 45-0008 e 10/02 3-3

Page 44

INTRODUCTION TO LASER SCANNING MICROSCOPY LSM 510

Carl Zeiss Three-Dimensional Presentation of LSM Image Stacks LSM 510 META

• In order to obtain an image of the selected object plane as a whole, it is necessary to scan the object

plane in a point-by-point, line-by-line raster by means of an XY light deflection system. The detectors as a rule, photomultipliers - convert the optical information into electric signals. This allows the image

of any object plane to be generated and stored within less than a second. By a defined focusing

(Z axis) movement it is possible to look at any object plane of interest. By scanning a succession of

object planes in a specimen, a stack of slice images can be produced.

This way, the LSM technique in conjunction with ICS optics (Infinity Color-Corrected System) has brought

decisive improvements over conventional microscopy in terms of resolving power and confocal depth

contrast:

Object features in the order of 0.2 µm can be resolved, and height differences of less than

0.1 µm made visible, without the use of interference methods.

3.2 Three-Dimensional Presentations of LSM Image Stacks

One of the advantages of the LSM technique is that it can present structures in three dimensions. This

opens up many ways to process images. Outlined below are some of the possible methods to extract

spatial information from stacks of slice images.

• Gallery

The simplest presentation of 3D information is a gallery showing the individual slice images (sections)

of a stack arranged side by side, with each slice apart from the next by a defined, selectable interval

on the Z axis.

• Virtually infinite depth of focus

The entire set of data can be imaged as a single projection. The computer establishes an image

composed of all in-focus optical sections. The image produced by this so-called composite method

has a virtually infinite depth of focus, since the result is made up of information from in-focus planes

only.

• Rotary animation

A sequence of projections is computed, with the specimen being apparently rotated by a certain

angle from image to image, for example by a full turn about an axis. If such a sequence is displayed

on the monitor screen in rapid succession, the visual effect is that of a rotating three-dimensional

object.

• Stereo image pairs

The computer establishes a pair of images corresponding to those we see with the right and the left

eye, respectively. The two images forming the stereo pair can be shown on the monitor side by side.

They can be seen as a 3D image with suitable optical aids. Another possibility is to present both

images in registration, with one image in the red channel and the other in the green one (anaglyph).

Viewed through red and green color filters in a spectacle frame, which only pass the image intended

for the respective eye, the two images form a 3D image in the brain

3-4 B 45-0008 e 10/02

Page 45

LSM 510 INTRODUCTION TO LASER SCANNING MICROSCOPY

LSM 510 META Three-Dimensional Presentation of LSM Image Stacks Carl Zeiss

• Color-coded height slices

Each level, i.e. each slice is assigned a different color. For direct evaluation, a color scale is shown,

indicating the actual height above the bottom slice.

• Orthogonal sections

This computation produces a triplet of mutually perpendicular sectional images.

• Oblique sections

A section through the stack is made along an oblique plane defined by the selection of five

coordinates, i.e. X, Y, Z, angle of rotation, and angle of tilt.

• Topography (option)

A computing program for surface topography presentations (as required in materials research) is

available.

• Physiology (option)

With a special software, kinetic processes can be tracked, which is especially of interest to physiology.

• Image VisArt (option)

Three-dimensional display of floating transparent structures (cells) or opaque structures (material

• 3D Deconvolution (option)

)

B 45-0008 e 10/02 3-5

Page 46

INTRODUCTION TO LASER SCANNING MICROSCOPY LSM 510

Carl Zeiss Optical Diagram of the LSM 510 LSM 510 META

3.3 Optical Diagram of the LSM 510 (Schematic)

λ-

Fig. 3-2 Optical path, schematic (4-channel configuration)

AOTF Acousto Optical Tunable Filter

DBC Dichroic Beam Combiner

DBS Dichroic Beam Splitter

EF Emission Filter

HAL Halogen Lamp

HBO Mercury Vapor Short-Arc Lamp

LSF Line Selection Filter

MDBS Main Dichroic Beam Splitter

NDF Neutral Density Filter

VP Variable Pinhole

PMT Photomultiplier

T-PMT Transmission-Photomultiplier

The diagram above is a schematic representation of the LSM system.

Laser light is focused onto the specimen through an objective in a diffraction-limited mode. Light emitted

at the focal plane and at planes below and above it is directed via an XY scanner onto a main dichroic

beam splitter (MDBS), which separates the emissions from the excitation light. The fluorescences are

separated from each other by a series of dichroic beam splitters (DBS1 ... maximally DBS4) and directed

to individual photomultipliers (PMT1 ... maximally PMT4).

3-6 B 45-0008 e 10/02

Page 47

LSM 510 INTRODUCTION TO LASER SCANNING MICROSCOPY

LSM 510 META Performance Features of the LSM 510 Carl Zeiss

3.4 Performance Features of the LSM 510

3.4.1 Optical and Mechanical Aspects

The highly integrated system design makes for the shortest possible optical paths, top-grade optical

precision and high stability. The compact scanning module can be fitted to an inverted (Axiovert 200 M

BP or SP) or upright (Axioplan 2 imaging

MOT) microscope in less than three minutes. On the Axiovert,

the scanning module may be mounted either to the base port directly below the microscope or to the

side port.

The spectral range available extends from the UV to the IR region.

For the VIS (visible-light) Laser Module, the user can select from up to five lasers with wavelengths of

633, 568, 543, 514, 488, 477, 458 and 405 nm. The UV Laser Module provides wavelengths of 351 and

364 nm. Coupling of the laser light is through polarization-preserving single-mode optical fibers. One

variable beam collimator each for the UV and visible ranges provides optimum adaptation of the

respective laser wavelength to the objective used and, thus, optimum correction for Z aberrations.

Acousto-optical tunable filters (AOTF) adjust the necessary brightness for up to 6 desired laser lines

within microseconds.

A monitor diode permanently registers the laser output; it can be used for the on-line checking of the

intensity of the exciting light. This check is also possible selectively for the different wavelengths if a line

selection filter is inserted.

The four simultaneous image acquisition channels, usable for reflection or fluorescence, and an

additional transmitted-light channel are ideal for the investigation of multiple fluorescence specimens.

Separately in each of the four channels, the diameters of the pinholes and their XY positions can be

optimized, and the desired emission filter placed into the beam path, by servo-motor control. In the case

of pinhole VP1, this adjustment also includes positioning along Z. In the simultaneous registration of

multiple fluorescences, identical optical sections can be obtained in each confocal channel. This is of

importance, e.g., with the FISH method (fluorescence in-situ hybridization) used for genome analysis in

cytogenetic studies.

The microscope's transmitted-light channel is equipped with a photomultiplier, too. It is therefore

possible to superimpose a multiple fluorescence image on a brightfield, differential interference or phase

image.

A fiber-optic cable connection to external special detectors, such as cooled PMTs or spectrometers, is

under development.

In addition to the emission filters for all standard and special applications, available in motor-controlled

filter wheels, the user can easily install his own emission filters in two of the channels.

The high-NA C-APOCHROMAT objectives specially developed for the LSM technique reach the physical

limit in resolving power, and can be used throughout the 350...700 nm spectral range with the same

high quality, producing brilliant images.

A two-mirror scanner system, controlled by a digital signal processor (DSP), offers several advantages.

The large deflection angle of the scanning mirrors allows a wide area to be scanned. With a 1.25×

objective, the object area scanned is 10 × 10 mm².

The scanning field size can be freely selected between 4 × 1 and 2048 × 2048 pixels.

B 45-0008 e 10/02 3-7

Page 48

INTRODUCTION TO LASER SCANNING MICROSCOPY LSM 510

Carl Zeiss Performance Features of the LSM 510 LSM 510 META

It is possible to rotate the XY scanning field through 360° and carry out XY scans without having to

rotate the specimen itself under laser radiation load.

Selection of the specimen detail of interest for zooming is fast and convenient, and the zoomed image is

automatically centered. This saves the job of specimen centration with the microscope stage.

Using a bi-directional scanning facility will double the scanning rate to approx. 5 frames/sec (at 512 ×

512 pixels); if two different laser wavelengths are used for the two scanning directions (wavelength 1 for

left-to-right, and wavelength 2 for right-to-left scanning), two fluorochrome dyes can be viewed and

documented in a quasi-simultaneous mode. This will absolutely prevent "bleeding".

3.4.2 Microscope Equipment of the LSM 510 System

The LSM 510 system is equipped either with the inverted Axiovert 200 M BP or SP microscope or with

the upright Axioplan 2 imaging

MOT, Axiotron 2 or Axioskop 2 FS mot microscopes.

Only the differences from the delivered operating manual "Axiovert 200 M" will be explained here.

(1) Stand

a) The motorized objective nosepiece 5× H DIC is firmly fixed to the stand, where no operating elements

can be found for the nosepiece. Operation will be performed via LSM 5 software control. The

"Restriction of the nosepiece height to protect the objectives during motorized objective change" is

inactivated. The nosepiece will be moved down automatically before each motorized objective change.

b) The reflector mount is motorized and provided with the Axiovert 200 reflector turret. The reflector

turret has 5 positions: One transmitting light position, which is identical to the LSM position, and four

further positions for fluorescence filter sets (reflector modules). If you want to use more than five

conventional fluorescence filter sets, it is advisable to use a further reflector turret. When changing the

reflector turret position you must make sure that the turret will click into position, since otherwise the

image area will be cut.

c) The stand has a motorized focusing drive (fine coarse). Sensitivity of the focusing drive is adjusted to

the delivered objectives by the manufacturer. If you want to use other objectives, sensitivity and

parfocality can be adjusted via the Axioset program.

d) The stand features an integrated power supply for the internal motors and stand electronics. The

power supply can be switched on at the right side of the stand. External power supply units will be used

for the mercury vapor short arc lamp.

3-8 B 45-0008 e 10/02

Page 49

LSM 510 INTRODUCTION TO LASER SCANNING MICROSCOPY

LSM 510 META Performance Features of the LSM 510 Carl Zeiss

e) The analyzer slider for conventional DIC methods will be operated from the right side and is located

just below the nosepiece.

When the rod is pushed in, the analyzer is located in the beam path. In the LSM-mode, the analyzer

must not be located in the beam path, and the analyzer rod must be pulled out.

f) The stands dispose of five additional ports: two side ports, front ports and base ports.

The side port or the front is equipped with the LSM 5 special interface, one of the others with the TV

interface. The LSM 510 scanning module can be mounted to the special interface port. Different camera

systems can be adapted to the TV interface using the TV adapters 452982/83/92/94/95/97/98-0000-000.

(2) Specimen stages and fine focus drives

a) Mechanical stage

The stage with coaxial drive must be mounted on the right side of the stand.

b) Scanning stage

c) HRZ 200 fine focusing stage

d) Piezo objective focus drive

(3) Transmitted-light illumination

a) The illuminator support contains a security circuit which activates a shutter preventing laser light from

reaching the stand when the support is moved to the back. A complementary shutter built in the stand

prevents laser light from reaching the eyepieces during the scanning mode.

b) The illuminator support is equipped with a rotary polarizer. The Axiovert description contains the

adjustment for the DIC mode during conventional observation.

For scanning in the transmitted-light DIC mode, the polarizer in the transmitted light support works like

an analyzer and must be adjusted in such a manner that direct laser light will be blocked.

The conventional analyzer slider in the stand must not be located in the beam path because the laser

light is already polarized.

c) A fully motorized, LSM 5 software-controlled switching mirror is mounted as an option on the

illuminator support. Alternatively, the light is directed to the LSM 5 T-light detector or enables

conventional transmitted-light observation.

d) The focusing screen for conventional transmitted-light is located in a support in front of the halogen

lamp housing.

e) Further information on the halogen lamp and the condensers is provided in the Axiovert operating

manual.

(4) Reflected light fluorescence

With the exception of the reflector slider, all the Axiovert fluorescence accessories can be used.

Further information is provided in the Axiovert operation manual.

B 45-0008 e 10/02 3-9

Page 50

INTRODUCTION TO LASER SCANNING MICROSCOPY LSM 510

Carl Zeiss Performance Features of the LSM 510 LSM 510 META

(5) Imaging optics

Optovar sliders cannot be used.

The analyzer for the conventional DIC mode will be operated from the right side and is located just

below the nosepiece.

Use of sliders with auxiliary objects (473704/14-0000-000) is not possible.

(6) Photo equipment

The stand does not feature an integrated SLR-port, but microscope cameras as described in the Axiovert

operation manual can be used.

(7) TV adaptation

The TV port at the side and the tubes can be used as described in the Axiovert operation manual.

The TV interface side port or base port can be used with TV adapters 44 or LSM adapters.

3.4.3 Computer Hardware and Software

The LSM 510 is controlled via a standard high-end Pentium PC. Linking to the electronic control system is

made via an ultrafast SCSi interface. The PC comes with the 32-bit WINDOWS NT 4.0 or WINDOWS

2000 operating system.

The instrument is fully motorized, permitting fast change-over between methods as well as automatic

operation. Parameters once set or complex examination sequences once established can be saved and

reproduced; therefore, complete application programs can be loaded and performed by pushbutton

control.

The software of the LSM 510 has two levels. On the simple operator interface level, a result will be

achieved after a few prompts; graphical prompting of the user in conjunction with automatic setting of

many parameters is an ideal tool for daily routine jobs. The expert level offers perfect facilities for

individual settings of functions and parameters.

Conversion of the light signals into a digital image is effected by means of four 12-bit A/D converters,

each of which can generate 4096 brightness levels.

The software provides an enormously wide range of image processing functions, including all standard

2D/3D (stereo, projection) functions identical to sophisticated 3D reconstruction capabilities (surface and

alpha rendering), digital processing of voxels and 3D measurement functions (surface areas, volumes).

As all files and images are recorded in MS Access databases, elegant image database editing is just as

easy as transferring the records to other programs.

3-10 B 45-0008 e 10/02

Page 51

LSM 510 QUICKSTART

LSM 510 META Contents Carl Zeiss

CHAPTER 4 QUICKSTART

CONTENTS

Page

4 QUICKSTART......................................................................................................................4-3

4.1 Purpose of this Section and other Operating Manuals...........................................................4-3

4.1.1 Software .............................................................................................................................4-3

4.1.2 Windows and Window Elements..........................................................................................4-4

4.1.3 Convention for the Text in this Manual.................................................................................4-5

4.1.4 Backup................................................................................................................................4-6

4.1.5 Software Operation .............................................................................................................4-6

4.2 Switching on the System......................................................................................................4-7

4.2.1 Log on to WINDOWS NT......................................................................................................4-8

4.2.2 Switching on the Enterprise UV Laser .................................................................................4-10

4.2.3 Starting the LSM 5 Program............................................................................................... 4-10

4.3 Quick Start in the Expert Mode .......................................................................................... 4-13

4.3.1 Start the Expert Mode........................................................................................................ 4-13

4.3.2 Set the Microscope............................................................................................................4-14

4.3.2.1 Axioplan 2 imaging

4.3.2.2 Axiovert 200 M .............................................................................................................4-15

4.3.2.3 Axioskop 2 FS

4.3.3 Turn on the Lasers .............................................................................................................4-16

4.3.4 Set the Beam Path .............................................................................................................4-17

4.3.5 Scan an Image...................................................................................................................4-18

4.3.6 Store the Image................................................................................................................. 4-22

MOT.................................................................................................4-14

MOT.........................................................................................................4-15

4.4 Shut-Down Procedure........................................................................................................4-24

4.4.1 Exiting the LSM Program....................................................................................................4-24

4.4.2 Shut Down the WINDOWS Operating System..................................................................... 4-25

4.4.3 Turning Power Off............................................................................................................. 4-26

B 45-0008 e 10/02 4-1

Page 52

QUICKSTART LSM 510

Carl Zeiss Contents LSM 510 META

4-2 B 45-0008 e 10/02

Page 53

LSM 510 QUICKSTART

LSM 510 META Purpose of this Section and other Operating Manuals Carl Zeiss

4 QUICKSTART

4.1 Purpose of this Section and other Operating Manuals

This section describes the operation of the LSM 510 and LSM 510 META Laser Scanning Microscopes

exemplified by typical applications in conjunction with the LSM 5 software and its graphic user

environment.

When starting up and operating the microscope system, mind the operating instruction manuals for the

Axioplan 2 imaging

− B 40-042 e Axioplan 2 imaging MOT, Operating Manual

− B 40-080 e Axiovert 200 M, Operating Manual

MOT, Axiovert 200 M and Axioskop 2 FS microscopes:

− B 40-076 e Axioskop 2 FS MOT, Operating Manual

4.1.1 Software

The LSM 5 software, Version 3.2, controls the microscope, the scanning and laser modules, tools (filters,

stand, Axioset) and the image acquisition process, and displays and analyzes the images. It is based on

the network-capable graphic 32-bit Microsoft ® WINDOWS NT 4.0 operating system and WINDOWS

2000, respectively.

Portions © Copyright 1996, Microsoft Corporation. All rights reserved.

The installation of the software for the LSM 510 and the basic settings of the equipment

components are carried out by Carl Zeiss service staff. This job includes the creation of a

customized software configuration in line with the specific hardware components of the

customer's microscope system.

The LSM 5 software is menu-controlled and normally uses its own windows for the activation of the

various functions; within these windows, further submenus (panels) can be displayed and removed.

Images of the specimens to be examined, created by scanning, are displayed in separate Image Display

windows.

Theoretically, the number of simultaneously opened windows for software operation or image display is

unlimited, but should not be too excessive so that an overview is still possible.

Identical functions, e.g. Laser Control, can be performed in several software windows. Changes made

by the software are recorded immediately and are automatically transferred to all the other windows

concerned.

B 45-0008 e 10/02 4-3

Page 54

QUICKSTART LSM 510

Carl Zeiss Purpose of this Section and other Operating Manuals LSM 510 META

4.1.2 Windows and Window Elements

Window element Description / Explanation

Window (e.g.: Laser Control window)

− Window displayed after activation of a function

button (e.g.: Laser button in the toolbar of the

Expert Mode).

Panel (e.g.: Argon panel)

− Limited function range within a window

List box or selection box

− Selection of one of the displayed options at a click of

the mouse.

− Open the box by clicking on the arrow button.

Input box

− Input of text or numeric values via the keyboard.

Scrollbar with slider

− Setting of numbers in the relevant input box by

moving the slider or clicking on the arrow buttons or

clicking on the slider and moving via the arrow keys

of the keyboard. Press the Shift or Ctrl key while

clicking on the arrow button to change the numeric

values in coarse or fine steps.

4-4 B 45-0008 e 10/02

Page 55

LSM 510 QUICKSTART

LSM 510 META Purpose of this Section and other Operating Manuals Carl Zeiss

Window element Description / Explanation

Check box

− Activates / deactivates setting options.

Button

− Selection / performance of a function via mouse

click.

4.1.3 Convention for the Text in this Manual

All the originally used terms of the software interface, e.g.

− names of windows,

− panels,

− input boxes,

− list / selection boxes,

− check boxes,

− menu items,

− names of buttons and

− keyboard keys,

are displayed in bold letters to allow easier identification.

B 45-0008 e 10/02 4-5

Page 56

QUICKSTART LSM 510

Carl Zeiss Purpose of this Section and other Operating Manuals LSM 510 META

4.1.4 Backup

System backup

− A complete backup is contained on the enclosed backup CD-ROM.

User files backup

The following user-generated files need to be included in a backup procedure (keep directory structure):

− Image database files: *.mdb (but not system_configuration_*.mdb

− LSM Image files: *.lsm

− Exported images: *.* (*.Tiff, *.LSM-Tiff, *.BMP, ...)

− Palette files: AIM \ Palette \ *.lut

− Filter files: AIM \ Filter \ *.krn

− Pinhole setting files: AIM \ PH*.pos

− Log files: AIM \ *.log

The following files generated during the system integration should also be included in a backup

procedure:

− Parameter file for pinhole setting: AIM \ *.set

− Parameter file after pinhole adjustment: AIM \ *.adj

− Scanner files: AIM \ bin \ *.bin

− Microscope stand database: AIM \ database \ system_configuration_*.mdb

4.1.5 Software Operation

The LSM 5 software can be operated using the mouse, the PC keyboard, or both.

The operation of the mouse and the keyboard is identical to that of the Microsoft ® WINDOWS

operating system and is therefore not dealt with in detail in this manual.

If required, see the Microsoft manual or online help for relevant information.

4-6 B 45-0008 e 10/02

Page 57

LSM 510 QUICKSTART

LSM 510 META Switching on the System Carl Zeiss

4.2 Switching on the System

The LSM system is turned on with the REMOTE CONTROL switch. This switches all the system

components on except for the "Enterprise" UV laser.

If the UV laser shall be used, it can be switched on after the start of the WINDOWS ® NT operating

system - but must always be switched on before the LSM 5 software is started.

If REMOTE CONTROL switch is not used, turn the system on with the "I" button on the laser module;

in addition, the jumper plug supplied must be connected to the POWER REMOTE CONTROL terminal.

• Turn the REMOTE CONTROL switch to "ON"

position (see Fig. 4-1).

− This switches the entire system on.

− Microscope and laser will be ready for

operation after a short time.

− Computer boots up.

− Computer hardware system test runs.

Drive "A" of the computer must not

contain a floppy disk.

The monitor shows a dialog box for selection of

the operating system version.

Fig. 4-1 REMOTE CONTROL switch

Fig. 4-2 Selecting the operating system version

B 45-0008 e 10/02 4-7

Page 58

QUICKSTART LSM 510

Carl Zeiss Switching on the System LSM 510 META

• Confirm the default setting of the "Windows

NT Workstation Version 4.00" by pressing the

Enter key.

− WINDOWS NT operating system is being

loaded.

Fig. 4-3 Begin Logon window

− The Begin Logon window appears on the

screen.

4.2.1 Log on to WINDOWS NT

Fig. 4-4 Logon Information window

• Press the three keys Ctrl, Alt and Del at the

same time.

− The Logon Information window appears

on the screen, permitting you to log on to

the WINDOWS NT 4.0 operating system.

• Enter the valid user name into the User name

text box.

• Enter your password into the Password text

box.

4-8 B 45-0008 e 10/02

Page 59

LSM 510 QUICKSTART

LSM 510 META Switching on the System Carl Zeiss

• After entries, confirm by clicking the OK button or Enter.

− The WINDOWS NT operating system desktop appears on the screen, showing a number of icons.

Change Filters icon

Stand Select icon

LSM 510 icon

LSM 510 Image Examiner icon

LSM 510 Image Browser icon

Fig. 4-5 WINDOWS NT operating system desktop

B 45-0008 e 10/02 4-9

Page 60

QUICKSTART LSM 510

Carl Zeiss Switching on the System LSM 510 META

4.2.2 Switching on the Enterprise UV

Laser

• If the UV laser is required, switch it on via the

toggle switch (4-6/1) of the power supply.

− It will be ready for operation after a few

seconds.

Fig. 4-6 Power supply of UV-Ar laser

Fig. 4-7 Starting the LSM 5 software

4.2.3 Starting the LSM 5 Program

The LSM 5 software program can be operated in

two different modes (with or without connected

instrument system). In the on-line mode, the entire

program package (image recording and analysis) is

available, while only a part of the software

functions (image analysis only of already stored

images) and no hardware functions are available in

the off-line mode. Of course, the off-line mode

can also be started when the instrument system is

connected. In that case, it is not necessary that the

lasers and the microscope are switched on.

• Double-click on the LSM 510 icon on the desktop of WINDOWS to start the LSM 5 software program

(see Fig. 4-5).

− The LSM 510 Switchboard menu appears on the screen (see Fig. 4-8).

4-10 B 45-0008 e 10/02

Page 61

LSM 510 QUICKSTART

LSM 510 META Switching on the System Carl Zeiss

Fig. 4-8 LSM 510 Switchboard menu

The LSM 510 Switchboard menu presents the following items for selection:

− Scan New Images

Clicking on this button activates the complete LSM hardware (on-line mode).

− Use Existing Images

This item allows you to process and analyze previously acquired images with the LSM 5 software. In

this mode, control of the hardware (laser module ...) is not possible (off-line mode).

Please note that the Scan New Images button must be activated before setting up the Routine

Mode or the Expert Mode. Otherwise, the hardware can not be controlled by the LSM 5

software.

− Start Routine Mode

Click on this button if you want to work with pre-configured system settings (typical applications).

B 45-0008 e 10/02 4-11

Page 62

QUICKSTART LSM 510

Carl Zeiss Switching on the System LSM 510 META

− Start Expert Mode

Use of this mode requires to be thoroughly familiar with the exact microscope procedures and

interrelations.

You need to set all parameters and functions upon your own decision; this mode therefore provides

you with the greatest flexibility of operation.

It is also possible, however, to call up stored configurations and to modify the parameters / settings if

necessary.

After the start of the Expert Mode or the

Routine Mode, instrument initialization is

performed and can be monitored in the

Initialization window and interrupted with a click

on the Cancel button, if required.

Depending on the selected option (Scan New

Fig. 4-9 OFF LINE Initialization window

Images or Use existing Images), initialization is

performed in the offline or online mode.

Existing images can only be loaded and processed in the Expert Mode.

If you want to change from the Expert Mode to the Routine Mode and vice versa, close all

the windows first.

Some printers (for example KODAK Thermo Printer) will produce an error message "hard key

not found" in case the printer is not switched on.

Remedy: turn on the printer before starting the LSM 5 software.

Don’t switch off the KODAK printer during the scanning process.

4-12 B 45-0008 e 10/02

Page 63

LSM 510 QUICKSTART

LSM 510 META Quick start in the Expert Mode Carl Zeiss

4.3 Quick Start in the Expert Mode