York DJ150 User Manual

INSTALLATION

MANUAL

®

MAGNUM

CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SAFETY CONSIDERATIONS. . . . . . . . . . . . . . . . . .4

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

REFERENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . .5

APPROVALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . .6

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

START-UP (COOLING). . . . . . . . . . . . . . . . . . . . . .39

START-UP (GAS HEAT) . . . . . . . . . . . . . . . . . . . . .39

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . .43

See following pages for a complete Table of Contents.

SINGLE PACKAGE AIR CONDITIONERS AND

SINGLE PACKAGE GAS/ELECTRIC UNITS

DJ150

12-1/2 TON

(10.8 EER)

NOTES, CAUTIONS AND WARNINGS

The installer should pay particular attention to the words:

NOTE, CAUTION, and WARNING. Notes

clarify or make the installation easier. Cautions

to prevent equipment damage. Warnings

installer that personal injury and/or equipment damage

may result if inst allation procedure is no t handled properly.

CAUTION: READ ALL SAFETY GUIDES BEFORE YOU

BEGIN TO INSTALL YOUR UNIT.

SA VE THIS MANUAL

are intended to

are given

are given to alert

T ested in accordance with:

035-19046-002-B-0104

TABLE OF CONTENTS

035-19046-002-B-0104

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . 4

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

RENEWAL PARTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLATION SAFETY INFORMATION . . . . . . . . . . . . . . . 8

PRECEDING INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 8

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

RIGGING AND HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . 11

CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DUCTWORK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DUCT COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CONDENSATE DRAIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

COMPRESSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

THERMOSTAT WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

POWER AND CONTROL WIRING. . . . . . . . . . . . . . . . . . . . 17

POWER WIRING DETAIL. . . . . . . . . . . . . . . . . . . . . . . . . . . 18

OPTIONAL ELECTRIC HEAT. . . . . . . . . . . . . . . . . . . . . . . . 22

OPTIONAL GAS HEAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

GAS PIPING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

GAS CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

LP UNITS, TANKS AND PIPING . . . . . . . . . . . . . . . . . . . . . . .24

VENT AND COMBUSTION AIR . . . . . . . . . . . . . . . . . . . . . . . .25

FACTORY INSTALLED OPTIONS/

FIELD INSTALLED ACCESSORIES . . . . . . . . . . . . . . . . . . 25

ELECTRIC HEAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MOTORIZED OUTDOOR DAMPER . . . . . . . . . . . . . . . . . . . .25

ECONOMIZER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

POWER EXHAUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

RAIN HOOD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

ECONOMIZER AND POWER EXHAUST SET POINT

ADJUSTMENTS AND INFORMATION. . . . . . . . . . . . . . . . . 26

MINIMUM POSITION ADJUSTMENT . . . . . . . . . . . . . . . . . . .26

ENTHALPY SET POINT ADJUSTMENT . . . . . . . . . . . . . . . . .26

POWER EXHAUST DAMPER SET POINT (WITH OR

WITHOUT POWER EXHAUST). . . . . . . . . . . . . . . . . . . . . . . .26

INDOOR AIR QUALITY AQ . . . . . . . . . . . . . . . . . . . . . . . . . . .26

PHASING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

BLOWER ROTATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

AIR BALANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CHECKING AIR QUANTITY. . . . . . . . . . . . . . . . . . . . . . . . . 31

METHOD ONE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 1

METHOD TWO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

SUPPLY AIR DRIVE ADJUSTMENT . . . . . . . . . . . . . . . . . . 32

OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SEQUENCE OF OPERATIONS OVERVIEW. . . . . . . . . . . . 33

COOLING SEQUENCE OF OPERATION . . . . . . . . . . . . . . 33

CONTINUOUS BLOWER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

INTERMITTENT BLOWER. . . . . . . . . . . . . . . . . . . . . . . . . . . .33

NO OUTDOOR AIR OPTIONS. . . . . . . . . . . . . . . . . . . . . . . . .34

ECONOMIZER WITH SINGLE ENTHALPY SENSOR -. . . . . .34

ECONOMIZER WITH DUAL ENTHAL PY SENSORS - . . . . . .34

ECONOMIZER (SINGLE OR DUAL) WITH POWER

EXHAUST -. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

MOTORIZED OUTDOOR AIR DAMPERS - . . . . . . . . . . . . . . .34

COOLING OPERATION ERRORS. . . . . . . . . . . . . . . . . . . . . .34

HIGH-PRESSURE LIMIT SWITCH. . . . . . . . . . . . . . . . . . . . . .34

LOW-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . . . . . . . . .35

FREEZESTAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

LOW AMBIENT COOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

SAFETY CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

COMPRESSOR PROTECTION. . . . . . . . . . . . . . . . . . . . . . 35

FLASH CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

ELECTRIC HEATING SEQUENCE OF OPERATIONS. . . . 36

ELECTRIC HEATING OPERATION ERRORS . . . . . . . . . . 36

TEMPERATURE LIMIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

LIMIT SWITCH (LS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

FLASH CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

ELECTRIC HEAT ANTICIPATOR SETPOINTS. . . . . . . . . . 36

GAS HEATING SEQUENCE OF OPERATIONS . . . . . . . . . 37

IGNITION CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . 37

FIRST STAGE OF HEATING . . . . . . . . . . . . . . . . . . . . . . . . . .37

SECOND STAGE OF HEATING. . . . . . . . . . . . . . . . . . . . . . . .37

RETRY OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

RECYCLE OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

GAS HEATING OPERATION ERRORS. . . . . . . . . . . . . . . . 37

LOCK-OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

TEMPERATURE LIMIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

FLAME SENSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

GAS VALVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

SAFETY CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

LIMIT SWITCH (LS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

AUXILIARY LIMIT SWITCH (ALS) . . . . . . . . . . . . . . . . . . . . . .38

PRESSURE SWITCH (PS). . . . . . . . . . . . . . . . . . . . . . . . . . . .38

ROLLOUT SWITCH (ROS). . . . . . . . . . . . . . . . . . . . . . . . . . . .38

INTERNAL MICROPROCESSOR FAILURE . . . . . . . . . . . . . .38

FLASH CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

RESETS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

GAS HEAT ANTICIPATOR SETPOINTS. . . . . . . . . . . . . . . 39

START-UP (COOLING). . . . . . . . . . . . . . . . . . . . . . . . . . . 39

PRESTART CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . 39

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . 39

POST START CHECK LIST. . . . . . . . . . . . . . . . . . . . . . . . . 39

START-UP (GAS HEAT) . . . . . . . . . . . . . . . . . . . . . . . . . . 39

PRE-START CHECK LIST. . . . . . . . . . . . . . . . . . . . . . . . . . 39

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . 39

LIGHTING THE MAIN BURNERS. . . . . . . . . . . . . . . . . . . . . . .39

POST START CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . 40

SHUT DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

MANIFOLD GAS PRESSURE ADJUSTMENT. . . . . . . . . . . 4 0

CHECKING GAS INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

NATURAL GAS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

ADJUSTMENT OF TEMPERATURE RISE . . . . . . . . . . . . . 42

BURNERS/ORIFICES INSPECTION/SERVICING . . . . . . . 42

CHARGING THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

PREDATOR“ MAGNUM FLASH CODES. . . . . . . . . . . . . . . 43

COOLING TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . 46

GAS HEAT TROUBLESHOOTING GUIDE . . . . . . . . . . . . . 49

2 Unitary Products Group

035-19046-002-B-0104

LIST OF FIGURES

Fig. # Pg. #

1 UNIT SHIPPING BRACKET . . . . . . . . . . . . . . . . . . . . . 8

2 COMPRESSOR SECTION . . . . . . . . . . . . . . . . . . . . . . 9

3 PREDATOR“ MAGNUM COMPONENT LOCATION . 10

4 UNIT 4 POINT LOAD . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 UNIT 6 POINT LOAD . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 UNIT CENTER OF GRAVITY . . . . . . . . . . . . . . . . . . . 12

7 UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8 BOTTOM DUCT OPENINGS (FROM ABOVE). . . . . . 14

9 REAR DUCT DIMENSIONS . . . . . . . . . . . . . . . . . . . . 15

10 PREDATOR“ MAGNUM ROOF CURB

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

11 SUNLINE™ TO PREDATOR“ MAGNUM

TRANSITION ROOF CURBS . . . . . . . . . . . . . . . . . . . 16

12 SIDE PANELS WITH HOLE PLUGS. . . . . . . . . . . . . . 16

13 RETURN DOWNFLOW PLENUM WITH PANEL . . . . 17

14 DISCHARGE PANEL IN PLACE. . . . . . . . . . . . . . . . . 17

15 CONDENSATE DRAIN. . . . . . . . . . . . . . . . . . . . . . . . 17

Fig. #

16 ELECTRONIC THERMOSTAT FIELD WIRING . . . . . 18

17 FIELD WIRING 24 VOLT THERMOSTAT . . . . . . . . . 19

18 FIELD WIRING DISCONNECT - COOLING UNIT

WITH/WITHOUT EL ECTRIC HEAT . . . . . . . . . . . . . . 19

19 FIELD WIRING DISCONNECT - COOLING UNIT

WITH GAS HEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

20 SIDE ENTRY GAS PIPING. . . . . . . . . . . . . . . . . . . . . 23

21 BOTTOM ENTRY GAS PIPING . . . . . . . . . . . . . . . . . 23

22 ENTHALPY SET POINT CHART . . . . . . . . . . . . . . . . 27

23 HONEYWELL ECONOMIZER CONTROL W7212. . . 27

24 BELT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . 28

25 DRY COIL DELTA P. . . . . . . . . . . . . . . . . . . . . . . . . . 32

26 TYPICAL FLAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

27 TYPICAL GAS VALVE . . . . . . . . . . . . . . . . . . . . . . . . 42

28 BASIC TROUBLESHOOTING FLOWCHART . . . . . . 44

29 POWER ON FLOW CHART . . . . . . . . . . . . . . . . . . . . 44

30 TRIP FAILURE FLOW CHART. . . . . . . . . . . . . . . . . . 45

Pg. #

LIST OF TABLES

Tbl. # Pg. #

1 UNIT VOLTAGE LIMITATIONS. . . . . . . . . . . . . . . . . . 11

2 UNIT TEMPERATURE LIMITATIONS 11

3 UNIT WEIGHTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2

4 4 POINT LOAD WEIGHT. . . . . . . . . . . . . . . . . . . . . . . 12

5 6 POINT LOAD WEIGHT. . . . . . . . . . . . . . . . . . . . . . . 12

6 UNIT CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 CONTROL WIRE SIZES . . . . . . . . . . . . . . . . . . . . . . . 17

8 ELECTRICAL DATA DJ150 (12-1/2 TON) WITHOUT

POWERED CONVENIENCE OUTLET . . . . . . . . . . . . 21

9 ELECTRICAL DATA DJ150 (12-1/2 TON) WITH

POWERED CONVENIENCE OUTLET . . . . . . . . . . . . 21

10 PHYSICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

11 MINIMUM SUPPLY AIR CFM . . . . . . . . . . . . . . . . . . . 22

12 GAS HEAT APPLICATION DATA . . . . . . . . . . . . . . . . 2 3

13 GAS PIPE SIZING - CAPACITY OF PIPE. . . . . . . . . . 23

14 SUPPLY AIR LIMITATIONS . . . . . . . . . . . . . . . . . . . . 28

15 DJ150, 12-1/2 TON STANDARD MOTOR DOWN

SHOT BLOWER PERFORMANCE . . . . . . . . . . . . . . . 29

Tbl. #

16 DJ150, 12-1/2 TON OPT IONAL MOT OR DOWN

SHOT BLOWER PERFORMANCE. . . . . . . . . . . . . . . 29

17 DJ150, 12-1/2 TON STANDARD MOTOR SIDE

SHOT BLOWER PERFORMANCE. . . . . . . . . . . . . . . 30

18 DJ150, 12-1/2 TON OPT IONAL MOT OR SIDE

SHOT BLOWER PERFORMANCE. . . . . . . . . . . . . . . 30

19 INDOOR BLOWER SPECIFICATIONS. . . . . . . . . . . . 31

20 ADDITIONAL STATIC RESISTANCE. . . . . . . . . . . . . 33

21 MOTOR SHEAVE DATUM DIAMETERS . . . . . . . . . . 33

22 ELECTRIC HEAT LIMIT SETTING . . . . . . . . . . . . . . . 36

23 ELECTRIC HEAT ANTICIPATOR SETPOINTS . . . . . 36

24 GAS HEAT LIMIT CONTROL SETTINGS. . . . . . . . . . 38

25 GAS HEAT ANTICIPATOR SETPOINTS . . . . . . . . . . 39

26 GAS HEAT STAGES. . . . . . . . . . . . . . . . . . . . . . . . . . 40

27 GAS RATE CUBIC FEET PER HOUR . . . . . . . . . . . . 41

28 UNIT CONTROL BOARD FLASH CODES . . . . . . . . . 43

29 IGNITION CONTROL FLASH CODES . . . . . . . . . . . . 43

Pg. #

Unitary Products Group 3

GENERAL

YORK Predator Magnum units are single package air conditioners with optional gas heating designed for outdoor

installation on a rooftop or slab and for non-residential use.

These units can be equipped with factory or field installed

electric heaters for heating applications.

035-19046-002-B-0104

If the information in this manual is not followed

exactly, a fire or explosion may result causing property damage, personal inj ury or loss of life.

These units are completely assembled on rigid, permanently

attached base rails. All piping, refrigerant charge, and electrical wiring is factory installed and tested. The units require

electric power, gas supply (where applicable), and duct connections. The electric heaters have nickel-chrome elements

and utilize single-point power connection.

SAFETY CONSIDERAT IONS

Should overheating occur, or the gas supply fail to

shut off, shut off the manual gas valve to the furnace

before shutting off the electrica l supply.

Do not use this furnace if any part has been under

water. Immediately c all a qualified service technician

to inspect the furnace and to replace any part of the

control system and any gas control which has been

under water.

Due to system pressure, moving parts, and electrical components, installation and servicing of air conditioning equipment

can be hazardous. Only qualified, trained service personnel

should install, repair, or service this equipment. Untrained

personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

WHAT TO DO IF YOU SMELL GAS:

a. Do not try to light any appliance.

b. Do not touch any electrical switch; do not use

any phone in your building.

c. Immediately call your gas supplier from a neigh-

bor’s phone. Follow the gas supplier’s instructions.

d. If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a

qualified installer, service agency or the gas supplier.

INSPECTION

As soon as a unit is received, it should be i nspected for possible damage during transit. If damage is evident, the extent of

the damage should be noted on the carrier’s freight bill. A

separate request for inspection by the carrier’s agent should

be made in writing.

Observe all precautions in the literature, labels, and tags

accompanying the equipment whenever working on air conditioning equipment. Be sure to follow all other applicable

safety precautions and codes including ANSI Z223 .1 or CSAB149.1- latest edit ion.

Wear safety glasses and work gloves. Use quenching cloth

and have a fire extinguisher available during brazing operations.

4 Unitary Products Group

This furnace is not to be used for temporary heating

of buildings or stru ctures under construction.

Before performing service or maintenance operations on unit, turn off main power swit ch to unit. Electrical shock could cause personal injury. Improper

installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer

to this manual. For assistance or additional information consult a qualified installer, service agency or

the gas supplier.

035-19046-002-B-0104

REFERENCE

Additional information is available in the following reference

forms:

• Technical Guide - DJ150, 036- 21484-002

• General Installation - DJ150, 035-19046-002

• Pre-s tart & Post-start Check List - 035-18466-000

• Economizer Accessory Downflow Factory Installed, 035-18286-000

Downflow Field Inst alled, 035-18285-000

Horizontal Field Installed, 035-18287-000

• Motorized Outdoor Air Damper 035-18283-000

• Manual Outdoor Air Damper (0-100%) 035-1 8282-000

• Manual Outdoor Air Damper (0-35%) 035-18 281-000

• Gas Heat Propane Conversion Kit 035-17374-000

• Gas Heat High Alt it ude Kit (Natural Gas) 035-17282-000

• Gas Heat High Alt it ude Kit (Propane) 035-17281- 000

•–60°F Gas Heat Kit 035-18216-000

• Electric Heater Accessory 035-17291-001

APPROVALS

Design certified by CSA as follows:

1. For use as a cooling only unit, cooling unit with supplemental electric heat or a forced air furnace.

2. For outdoor installation only.

3. For installation on combustible material and may be

installed directly on combustible flooring or, in the U.S.,

on wood flooring or Class A, Class B or Class C roof covering materials.

4. For use with n a tu ral gas (converti b le to LP with k it).

This product must be installed in strict compliance

with the enclosed installation instructions and any

applicable local, state, and national codes including,

but not limited to, building, electrical, and mechanical

codes.

• Unit Renewal Parts List 035-19085-000

All forms referenced in this instruction may be ordered from:

Standard Register

T o ll Free Fax: (877) 379-7920

T oll Free Phone: (877) 318-9675

RENEWAL PARTS

Refer to York’s USER’S MAINTENANCE and SERVICE

INFORMATION MANUAL Part Number 035-19047-001.

Incorrect installation may create a condition where the

operation of the product could cause personal injury

or property damage.

The installer should pay particular attention to the words:

NOTE, CAUTION, and WARNING. NOTES are intended to

clarify or make the installation easier. CAUTIONS are given

to prevent equipment dam age. WARNINGS are given to alert

installer that personal injury and/or equipment damage may

result if installation procedure is not handled properly.

Unitary Products Group 5

NOMENCLATURE

035-19046-002-B-0104

12½ Ton Predator Model Number Nomenclature

D J N15

Product Category

D = Air Cond., Single Package

Product Identifier

J = R-22 Ultra High Efficiency

Nominal Cooling Capacity - MBH

150 = 12-½ Ton

Heat Type & Nominal Heat Capacity

C00 = Cooling Only. Suitable for field installed electric heat

Gas Heat Options

N 15 = 150 MBH Output Aluminized Steel

N 20 = 200 MBH Output Aluminized Steel

S 15 = 150 MBH Output Stainless Steel

S 20 = 200 MBH Output Stainless Steel

Electric Heat Options

E18 = 18 kW Electric Heat

E24 = 24 kW Electric Heat

E36 = 36 kW Electric Heat

E54 = 54 kW Electric Heat

A2A

Voltage

2 = 208/230-3-60

4 = 460-3-60

5 = 575-3-60

AA 3150

Product Generation

3 = Third Generation

Installation Options

A = No Options Installed

B = Option 1

C = Option 2

D = Options 1 & 2

E = Option 3

F = Option 4

G = Options 1 & 3

H = Options 1 & 4

J = Options 1, 2 & 3

K = Options 1, 2 & 4

L = Options 1, 3 & 4

M = Options 1, 2, 3 & 4

N = Options 2 & 3

P = Options 2 & 4

Q = Options 2, 3 & 4

R = Options 3 & 4

S = Option 5

T = Options 1 & 5

U = Options 1, 3 & 5

V = Options 1, 4 & 5

W = Options 1, 3, 4 & 5

X = Options 3 & 5

Y = Options 4 & 5

Z = Options 3, 4 & 5

Options

1 = Disconnect

2 = Non-Pwr’d Conv Outlet

3 = Smoke Detector S. A.

4 = Smoke Detector R. A.

5 = Pwr’d Conv Outlet

Additional Options

(See Next Page)

Airflow

A = Standard Motor

B = Standard Motor/Economizer/Barometric Relief (Downflow only)

C = Standard Motor/Economizer/Power Exhaust (Downflow only)

D = Standard Motor/Motorized Damper (Downflow only)

E = Standard Motor/Horizontal Economizer (No Barometric Relief)

F = Standard Motor/Slab Economizer/Power Exhaust (Downflow only)

G = Standard Motor/Slab Economizer/Barometric Relief (Downflow only)

L = Standard Motor/BAS Ready Econ (NoBASController)/Barometric Relief w/2" Pleated Filters (Downflow only)

M = Standard Motor/BAS Ready Econ (NoBASController)/Power Exhaust w/2" Pleated Filters (Downflow only)

N = High Static Motor

P = High Static Motor/Economizer/Barometric Relief (Downflow only)

Q = High Static Motor/Economizer/Power Exhaust (Downflow only)

R = High Static Motor/Motorized Damper (Downflow only)

S = High Static Motor/Horizontal Economizer (No Barometric Relief)

T = High Static Motor/Slab Economizer/Power Exhaust (Downflow only)

U =High Static Motor/Slab Economizer/Barometric Relief (Downflow only)

Y = High Static Motor/BAS Ready Econ (NoBASController)/Barometric Relief w/2" Pleated Filters (Downflow only)

Z = High Static Motor/BAS Ready Econ (NoBASController)/Power Exhaust w/2" Pleated Filters (Downflow only)

6 Unitary Products Group

035-19046-002-B-0104

NOMENCLA TURE, ADDITIONAL OPTIONS:

AA None

AC Coil Guard

AD Dirty Filter Switch

AG Coil Guard & Dirty Filter Switch

CA CPC Controller with Dirty Filter Switch & Air Proving Switch

CC CPC Controller, DFS, APS & Coil Guard

CE CPC Controller, DFS, APS & Tech nico at Cond. Coil

CG CPC Controller, DFS, APS, Technicoat Cond. Coil, & Coil Guard

CJ CPC Controller, DFS, APS & Technicoat Evap. Coil

CL CPC Controller, DFS, APS, Technico at Evap. Coil, & Coil Guard

CN CPC Controller, DFS, APS & Technicoat Evap. & Cond Coils

CQ CPC Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Coil Guard

CV CPC Controller, DFS, APS, & 2” Pleated Filters

HA Hon eyw e ll E xcel 10 Con troller with Dirty Fil ter Sw it ch & Air P rov in g Switch

HC Honeywell Excel 10 Controller, DFS, APS & Coil Guard

HE Honeywell Excel 10 Controller, DFS, APS & Technicoat Cond. Coil

HG Honeywell Excel 10 Controlle r, DFS, APS, Technicoat Cond. Coil, & Coil Guard

HJ Honeywe ll Excel 10 Contro ller, DFS, APS & Technicoat Evap. Coil

HL Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. Coil, & Coil Guard

HN Honeyw ell Exce l 10 Controller, DFS, APS & Technicoat Evap. & Cond Coils

HQ Honeywell Ex cel 10 Controller, DFS, APS, Technicoat Evap. & Co nd Coils, & Coil Guard

JA Johnson UNT Controller with Dirty Filter Switch & Air Proving Switch

JC Johnson UNT Controller , DFS, APS & Coil Guard

JE Johnson UNT Controller, DFS, APS & Techni coat Cond. Coil

JG Johnson UNT Controller, DFS, APS, Technicoat Con d. Coil, & Coil Guard

JJ Johnson UNT Controller, DFS, APS & Technicoat Evap. Coil

JL Johnson UNT Controller, DFS, APS, Technicoat Evap. Coil, & Coil Guard

JN Johnson UNT Controlle r, DFS, APS & Technicoat Evap. & Cond Coils

JQ Johnson UNT Controller, DFS, APS, Te chnicoat Evap. & Cond Coi ls, & Coil Guard

NA Novar ETC-3 Controller with Dirty Filter Switch & Air Proving Switch

NC Novar ETC-3 Controller , DFS, APS & Coil Guard

NE Novar ETC-3 Controller, DFS, APS & Technicoat Cond. Coil

NG Novar ETC-3 Controller, DFS, APS, Technicoat Cond. Coi l, & Coil Guard

NJ No var ETC-3 Controller, DFS, APS & Technicoat Evap. Coil

NL Novar ETC-3 Controlle r, DFS, APS, Technicoat Evap. Coi l, & Coil Guard

NN Novar ETC-3 Controller, DFS, APS & Te chnicoat Evap. & Cond Coils

NQ Novar ETC-3 Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Coil Guard

TA Technicoat Condenser Coil

Unitary Products Group 7

TC Technicoat Condenser Coil & Coi l G uard

TD Technicoat Condenser Coil & Dirty Filter Switch

TG Technic oat Condenser Coil , C oil Guard , & Dirty Filter Swit ch

TJ Technicoat Evaporator Coil

TL Technicoat Evaporator Coil & Coil Guard

TM Technicoat Evaporator Coil & Dirty Filter Switch

TQ Technicoat Evaporator Coil, Coil Guard, & Dirty Filter Switch

TS Technicoat Evaporator & Condenser Coils

TU Technicoat Evaporator & Condenser Coils & Coil Guard

TV Technicoat Evaporator & Condenser Coils & Dirty Filter Switch

TY Technicoat Evaporator & Co ndenser Coils, Coil Guard, & Dirty Filter Switch

INSTALLATION

INSTALLATION SA FETY INFOR MATION

035-19046-002-B-0104

Read these instructions before continuing this appliance

installation. This is an outdoor combination heating and cooling unit. The installer must assure that these instructions are

made available to the consumer and with instructions to

retain the m fo r fu tu re reference.

1. Refer to the furnace rating plate for the approved type of

gas for this furnace.

2. Install this furnace only in a location and position as

specified on Page 11 of these instructions.

3. Never test for gas leaks with an open flame. Use commercially available soap solution made specifically for

the detection of leaks when checking all connections, as

specified on Pages 8, 24, 25 and 40 of these instructions.

4. Always install furnace to operate within the furnace's

intended temperature-rise range with the duct system

and within the allowable external static pressure range,

as specified on the unit name/rating plate, specified on

Page 42 of these instructi ons.

5. This equipment is not to be used for temporary heating

of buildings or structures under construction.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warning exactly could

result in serious inj ury, death or property damage.

Never test for gas leaks with an open flame. use a

commercially available soap solution made specifically for the detection of leaks to check all connections. A fire or explosion m ay result caus ing property

damage, personal injury or loss of life.

PRECEDING INSTALLATION

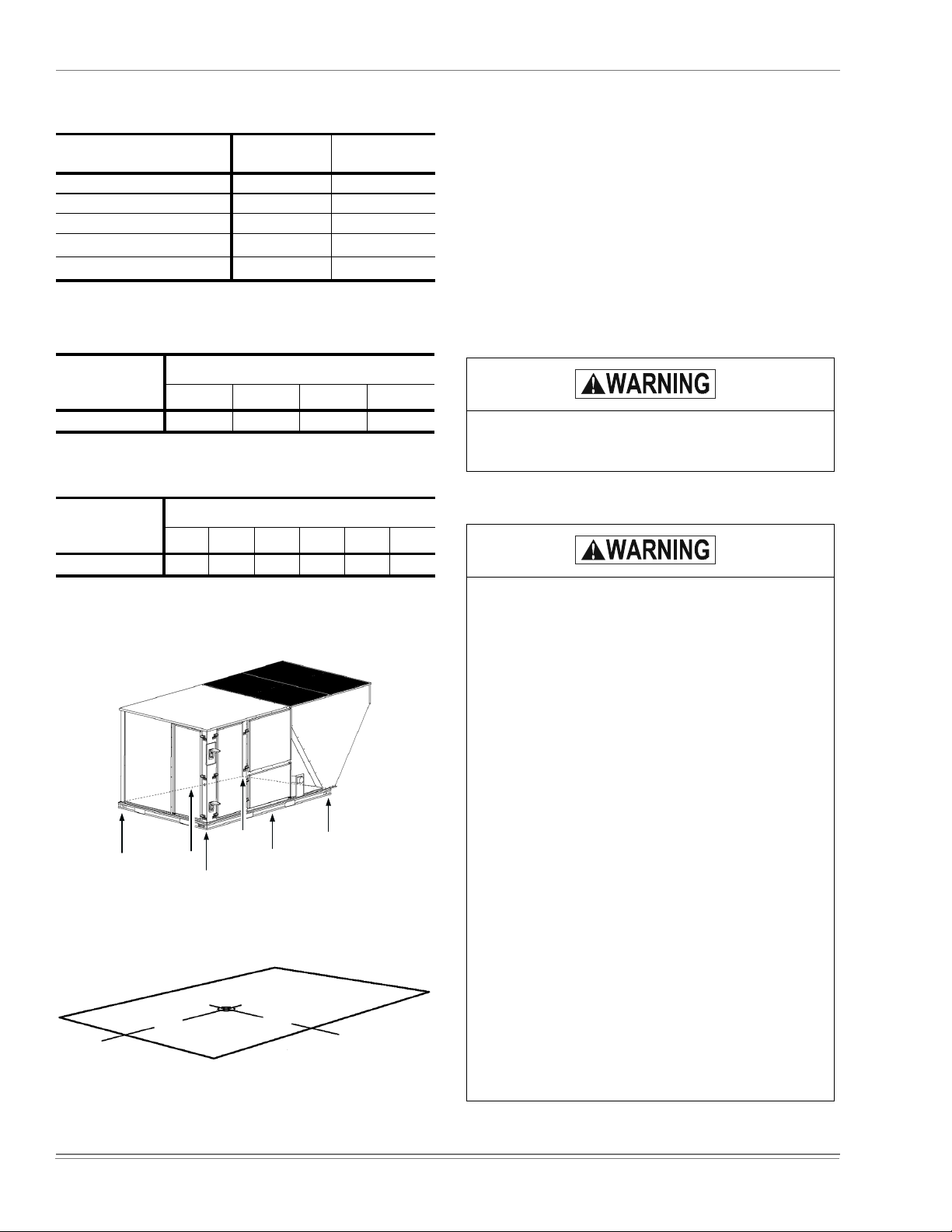

1. Remove the two screws holding the brac ket s in t he front,

rear and compressor side fork-lif t sl ots.

Bracket

Screws

Turn down

FIGURE 1 - UNIT SHIPPING BRACKET

8 Unitary Products Group

035-19046-002-B-0104

2. Turn each bracket toward the ground and the protective

plywood cov e rin g w ill d ro p to the gr ound.

3. Remove the condenser coil external protective covering

prior to operati on.

4. Remove the toolless doorknobs and instruction packet

prior to installation.

Toolless

Doorknobs

Installation

Instruction

Packet

LIMITATIONS

These units must be installed in accordance with the following:

In U.S.A.

1. National Electrical Code, ANSI/NFPA No. 70 - Latest

2. National Fuel Gas Code, ANSI Z223.1 - Latest Edition

3. Gas-Fired Central Furnace Standard, ANSI Z21.47a. -

4. Local building codes, and

5. Local gas utility requirem ents

In Canada

1. Canadian Electrical Code, CSA C22.1

2. Installation Codes, CSA - B149.1.

3. Local plumbing and waste water codes, and

4. Other applicable local codes.

:

Edition

Latest Edition

:

FIGURE 2 - COMPRESSOR SECTION

This product must be installed in strict compliance

with the enclosed installation instructions and any

applicable local, state and national codes including,

but not limited to, building, electrical, and mechanical codes.

The furnace and its individual shut-off valve must be

disconnected from the gas supply piping system

during any pressure testing at pressures in excess

of 1/2 PSIG.

Pressures greater than 1/2 PSIG will cause gas

valve damage resulting in a hazardous condi tion. If it

is subjected to a pressure greater than 1/2 PSIG, the

gas valve must be replac ed.

The furnace must be isolated from the gas supply

piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than 1/2 PSIG.

Refer to Tables 1 & 2 for unit appli cation data.

After installation, gas fired units must be adjusted to obtain a

temperature rise within the range specified on the unit rating

plate.

If components are to be added to a unit to meet local codes,

they are to be installed at the dealer’s and/or customer’s

expense.

Size of unit for propos ed installation should be based on heat

loss/heat gain calculation made according to the methods of

Air Conditioning Contractors of America (ACCA).

This furnace is not to be used for temporary heating of buildings or structures under construction.

Unitary Products Group 9

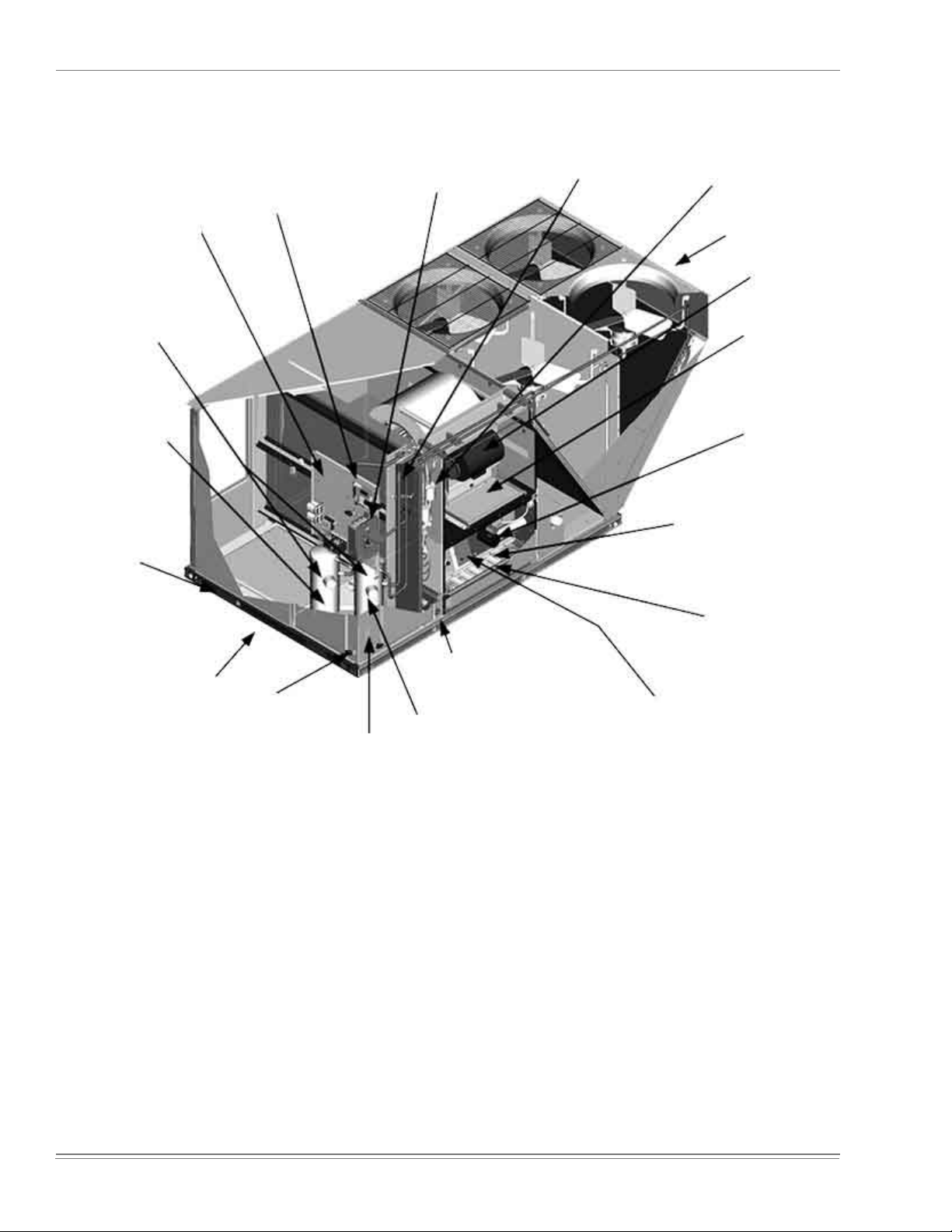

035-19046-002-B-0104

Second model

nameplate inside

hinged access panel

Dual stage cooling

for maximum comfort

Compressor #2

access (high-

efficiency compressor

w/crankcase heater)

Base rails w/forklift

slots (three sides)

and lifting holes

"Simplicity™" Control

board w/screw

connectors for T-stat

wiring and Network

connection

Disconnect

location

(optional disconnect switch)

Filter access

(2" throw-away)

Filter drier

(solid core)

Condenser

Section

Belt-drive blower

motor

Slide out motor

and blower

assembly for easy

adjustment and

service

Power ventor

motor

20-gauge

aluminized steel tubular

heat exchanger for long

life (stainless steel option)

Roof curbs in eight and

fourteen-inch heights.

Roof curbs for

transitioning from York

Sunline™ footprint to

the DM/DH/DJ/DR Series

footprint are available

(field-installed accessory)

Tool-less door

latch

Side entry power

and control wiring

knockouts

Slide-out drain pan

with brass 3/4" FPT

connection

Compressor #1 access

(high-efficiency

compressor w/

crankcase heater)

FIGURE 3 - PREDATO R MAGNUM COMPONENT LOCATION

Two-stage gas heating to

maintain warm,

comfortable temperature

Intelligent control

board for safe and

efficient operation

10 Unitary Products Group

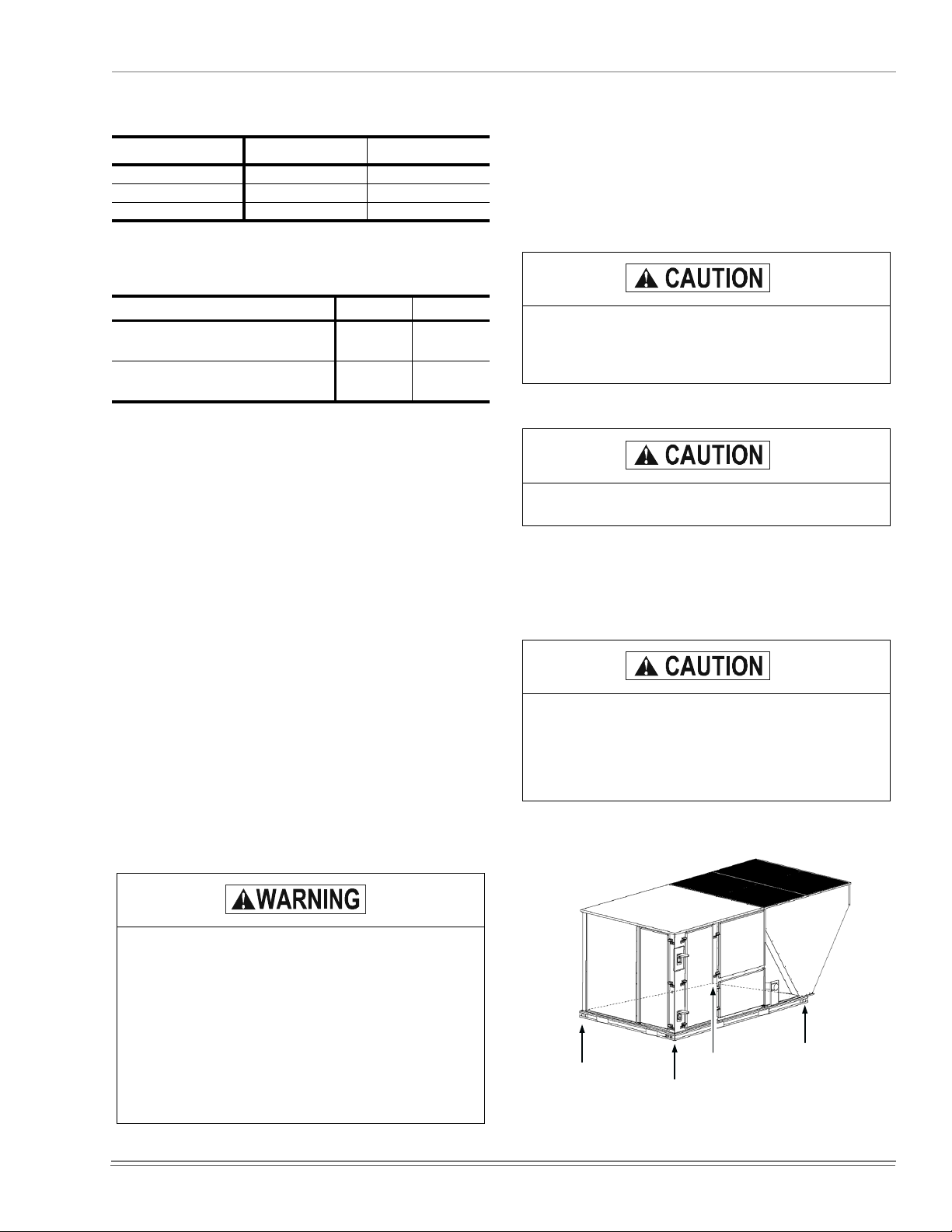

035-19046-002-B-0104

A

D

B

C

LEFT

FRONT

TABLE 1: UNIT VOLTAGE LIMITATIONS

Power Rating

208/230-3-60 187 252

460-3-60 432 504

575-3-60 540 630

*.

Utilization range “A” in accordance with ARI Standard 110.

*

Minimum Maximum

TABLE 2: UNIT TEMPERATURE LIMITATIONS

Temperature Min. Max.

Wet B ulb Temperature (°F) of Air on

Evapora tor C oil

Dry Bulb Temperature (°F) of Air on

Condens er Coil

*.

A low ambient acc essory is available for operation

down to -20 °F.

57 72

*

0

125

LOCATION

Use the following guidelines to select a suitable location for

these units:

1. Unit is designed for outdoor installation only.

2. Condenser coils must have an unlimited supply of air.

Where a choice of locat ion is possible, position the unit

on either north or east side of building.

3. Suitable for mounting on roof curb.

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. Rig

the unit by attaching chain or cable slings to the lifting holes

provided in the base rails. Spreader bars, whose length

exceeds the largest dimension across the unit, MUST be

used across the top of the unit.

If a unit is to be installed on a roof curb other than a

YORK roof curb, gasketing must be applied to all

surfaces that come in contact with the unit underside.

Before lifting, make sure the unit weight is distributed equall y on the riggi ng cables so it wil l lift evenl y.

Units may be moved or lifted with a forklift. Slotted openings

in the base rails are prov ided for this purpose.

LENGTH OF FORKS MUST BE A MINIMUM OF 60

INCHES.

4. For ground level install ation, use a level concret e slab

with a minimum thickness of 4 inches. The length and

width should be at lea st 6 in ches greater than the unit

base rails. Do not tie slab to the building foundation.

5. Roof structures must be ab le to sup port t he weight of t he

unit and its options/accessories. Unit must be installed

on a solid, level roof curb or appropriate ang le i ron

frame.

6. Maintain level tolerance to 1/2” across the entire width

and length of unit.

Excessive exposure of this furnace to contaminated

combustion air may result in equipment damage or

personal injury. Typical contaminates include: permanent wave soluti on, chlorinated waxes and cleaners, chlorine based swimming pool chemicals, water

softening chemicals, carbon tetrachloride, Halogen

type refrigerants, cleaning solvents (e.g. perchloroethylene), printing inks, paint removers, varnishes,

hydrochloric acid, cements and glues, antistatic fabric softeners for clothes dryers, masonry acid washing materials.

All panels must be secured in place when the unit is

lifted.

The condenser coils should be protected from rigging cable damage with plywood or other suitable

material.

FIGURE 4 - UNIT 4 POINT LOAD

Unitary Products Group 11

035-19046-002-B-0104

TABLE 3: UNIT WEIGHTS

Model DJ150

Cooling Unit Only

w/Economizer

w/Power Exhaust

w/Gas Heat

*

w/Electric Heat

*.

8 Tube Heat Exchanger

†.

54 kW heat er

†

Shipping

Weight (lb.)

1415 1400

85 84

150 148

110 110

49 49

TABLE 4: 4 POINT LOAD WEIGHT

Model

ABCD

DJ150

*.

Weights include largest gas heat option.

282 323 424 371

Locati on (lbs .)

TABLE 5: 6 POINT LOAD WEIGHT

Model

ABCDEF

DJ150

*.

Weights include largest gas heat option.

184 201 220 289 264 242

Location (lbs .)

Operating

Weight

*

*

(lb.)

CLEARANCES

All units require particular clearances for proper operation

and service. Installer must make provisions for adequate

combustion and ventilation air in accordance with section 5.3

of Air f or Combustion and Ventil ation of th e National Fuel G as

Code, ANSI Z223.1 – Latest Edition (in U.S.A.), or Sections

7.2, 7.3, or 7.4 of Gas Installation Codes, CSA-B149.1 (in

Canada) - Latest Edition, and/or applicable provisions of the

local building codes. Refer to Table 6 for clearances required

for combustible construction, servicing, and proper unit operation.

Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet, combustion

air inlet or vent outlet s.

Excessive exposure to contaminated combustion air

will result in safety and performance related problems. To maintain combustion air quality, the recommended source of combustion air is the outdoor air

supply. The outdoor air supplied for combustion

should be free from contaminants due to chemical

exposure that may be present from the following

sources.

• Commercial buildings

• Indoor pools

• Laundry rooms

• Hobby or craft rooms

• Chemical st orage areas

LEFT

A

B

C

F

FIGURE 5 - UNIT 6 POINT LOAD

FRONT

D

E

The following substances should be avoided to

maintain outdoor combustion air quality.

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool cleaners

• W ater softening chemicals

• De-ici ng salts or chemicals

• Carbon tetrachloride

• Halogen ty pe refrigerants

• Cleaning solvents (such as perchloroethylene)

47-½"

25-½"

• Print ing inks, paint removers, varnishes, etc.

• Hydrochloric acid

LEFT

FRONT

FIGURE 6 - UNIT CENTE R OF GRAVITY

• Cements and glues

• Anti-static fabric softeners for clothes dryers

• Masonry acid washing materials

12 Unitary Products Group

035-19046-002-B-0104

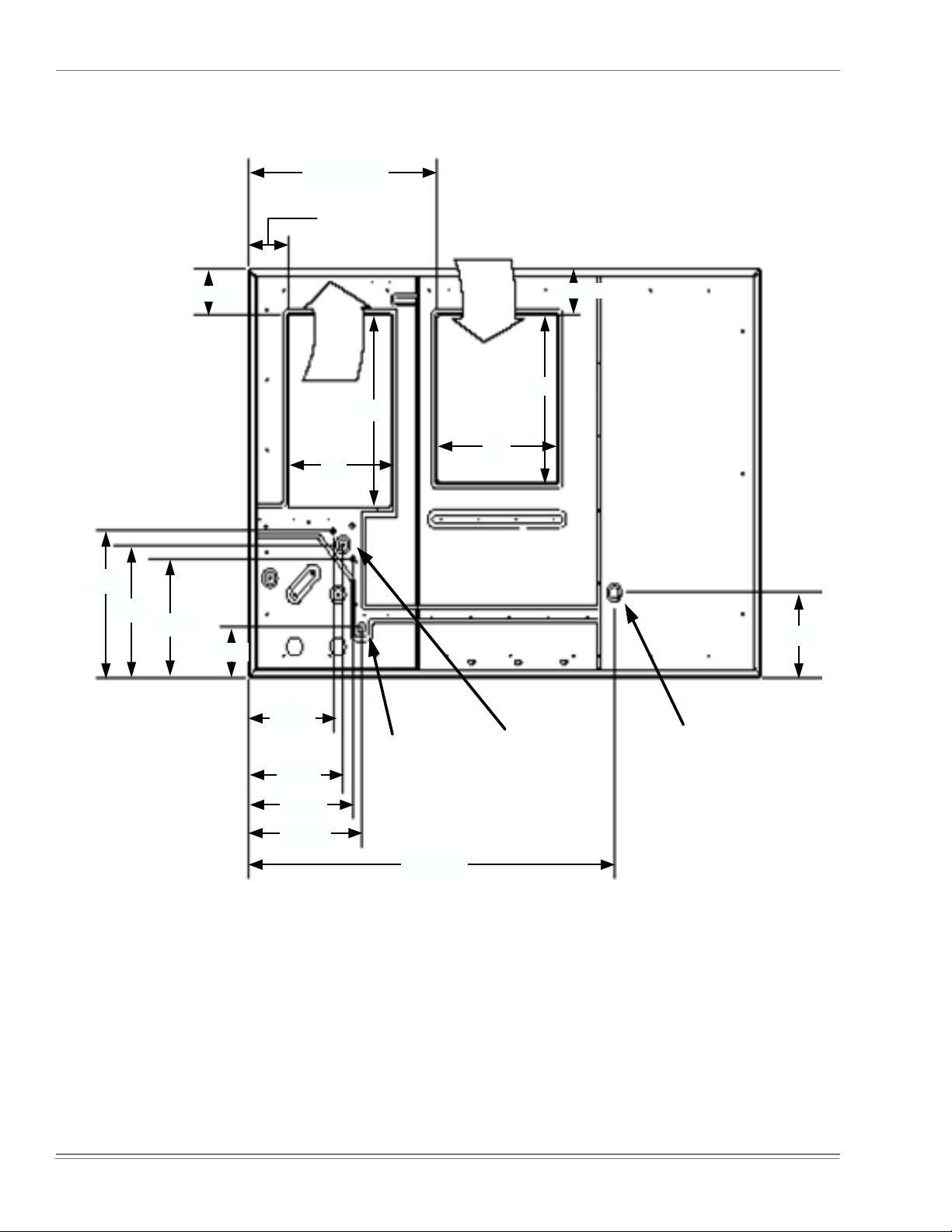

119-7/16

30-11/32

50-3/4

4-1/4

59

LEFT

FIGURE 7 - UNIT DIMENSIONS

DETAIL A

5 - 1 / 4

G a s P i p e I n l e t

1 7 - 1 3 / 1 6

30-3/16

24-3/16

B a s e

P a n

Power

Entry

2-1/2

Control

Entry 7/8

17-3/16

6-3/16

Con-

venience

Outlet

Con-

venience

Outlet

Power

Entry

7/8

27

DETAIL B

For Drain Dimensions

See Detail C

89

FRONT

3 - 3 / 4

See Detail A

2 - 3 / 8

11-1/2

For

Baserail

Dimensions

See

Detail B

V i e w o f W a l l A c r o s s f r o m C o i l

TABLE 6: UNIT CLEARANCES

*

Top

†

Front

‡

Rear

*.

Units must be installe d outdoors. Overha nging struc-

72”

36”

36”

Bottom

Right

Left

DETAIL C

12”

36”

**

0”

5 - 3 / 8

3 - 9 / 1 6

ture or shrubs should not obstruct condenser air discharge outlet.

†.

The products of combusti on must not be allowed to

accumu late within a confined space and re-circulate.

‡.

To remove the slid e-out drain pan, a rear clearance of

sixty inches is required. If spac e is unavailable, the

drain pan can be removed through the front by separat-

NOTE: If the unit includes gas heating, locate the unit so

the flue exhaust is at least:

• Three (3) feet ab ove a ny f orced a ir i nlet locat ed with in 10

horizontal feet (excluding those integral to the unit).

ing the corner wall.

**.

Units may be installed on combustible floors made from

wood or class A, B or C roof covering materials.

• Four (4) feet below, four (4) horizontal feet from, or one

(1) foot above any door or grav ity air inlet into the building.

NOTE: A one-inch clearance must be provided between

any combustible material and the supply ductwork

for a distance of 3 feet from the unit.

• Four (4) feet from elect ri c m eters, gas meters, regulators, and relief equ ipment.

Unitary Products Group 13

035-19046-002-B-0104

6

.

32-11/16

6-13/16

21-3/16

19-3/16

17-3/16

6-13/16

LEFT

7-1/8

14-

23/32

16-3/8

18-1/16

19-5/8

Return

Air

18

27-1/2

Bottom

Condensate

Entry

FRONT

Supply

Air

21

Bottom

Power, Control

and

Convenience

Outlet Wiring

Entries

6-13/16

24

12-15/1

Bottom Gas

Supply Entry

63-1/2

FIGURE 8 - BOTTOM DUCT OPENINGS (FROM ABOVE)

14 Unitary Products Group

035-19046-002-B-0104

18-1/4

5-5/32

Supply

Air

28-1/4

Dot Plugs

Return

Air

18-1/4

28-1/4

18-1/16

2-31/32

31-11/16

FIGURE 9 - REAR DUCT DIMENSIONS

DUCTWORK

Ductwork should be designed and sized according to the

methods in Manual D of the Air Conditioning Contractors of

America (ACCA) or as recommended by any other recognized authority such as ASHRAE or SMACNA.

A closed return duct system should be u sed. Th is will not

preclude use of economizers or outdoor fresh air intake. The

supply and return air duct connections at the unit should be

made wit h fl exib le joints to minimiz e noi s e.

The supply and return air duct systems should be designed

for the CFM and static press ure requi rement s of the job. They

should NOT be sized to match the dimensions of the duct

connections on t he unit.

Refer to Figure 8 for bottom air duct openings. Refer to Figure 9 for rear air duct openings.

DUCT COVERS

Units are shipped with the side duct openings covered and a

covering over the bottom of the unit. For bottom duct application, no duct cover changes are necessary. For side duct

application, remove the side duct covers and install over the

bottom duct openings. The panels removed from the side

duct connecti ons are designed to be reused by securing each

panel to its respective downflow opening. But keep in mind

that the supply panel is installed with the painted surface UP,

facing the heat exchanger, while the return panel is installed

with the painted surface DOWN, facing the downflow duct

opening. The supply panel is secured with the bracket

(already in place from the facto ry) and two screws. I t’s a snug

fit for the panel when sliding it between the heat exchanger

and unit bottom, but there is room. The return panel is

secured with four screws .

Unitary Products Group 15

035-19046-002-B-0104

R I G H T

8 0 - 5 / 8

2 0

2 0

6

S U P P L Y

I N S U L A T E D D E C K U N D E R

C O N D E N S E R S E C T I O N

2 T Y P .

3 0

5 0 - 1 / 2

R E T U R N

8 o r 1 4

I N S U L A T E D D E C K U N D E R

C O M P R E S S O R S E C T I O N

FIGURE 10 - PREDATOR MAGNUM ROOF CURB DIMENSIONS

2 T Y P

2 3

5 0 - 1 / 2

7 6 - 5 / 8

F R O N T

3 0 - 1 / 2

R E T U R N

9 4

4

S U P P L Y

F R O N T

2 6

8 0 - 5 / 8

1 0

5 9 - 1 / 4

6 4 - 1 / 4

R I G H T

FIGURE 11 - SUNLINE™ TO PREDATOR

MAGNUM TRANSITION ROOF CURBS

When fastening ductwork to side duct flanges on

unit, insert screws through duct flanges only. DO

NOT insert screws through casing. Outdoor ductwork must be insulated and water-proofed.

FIGURE 12 - SIDE PANELS WITH HO LE PL U GS

Note orientation. Panel is “insulation” side up.

16 Unitary Products Group

Loading...

Loading...