Page 1

Encoder Feedback Option Card

r

PG-X2

1. Part Number: PG-X2.

2. Applicability: F7, G7, GPD515/G5, G5HHP.

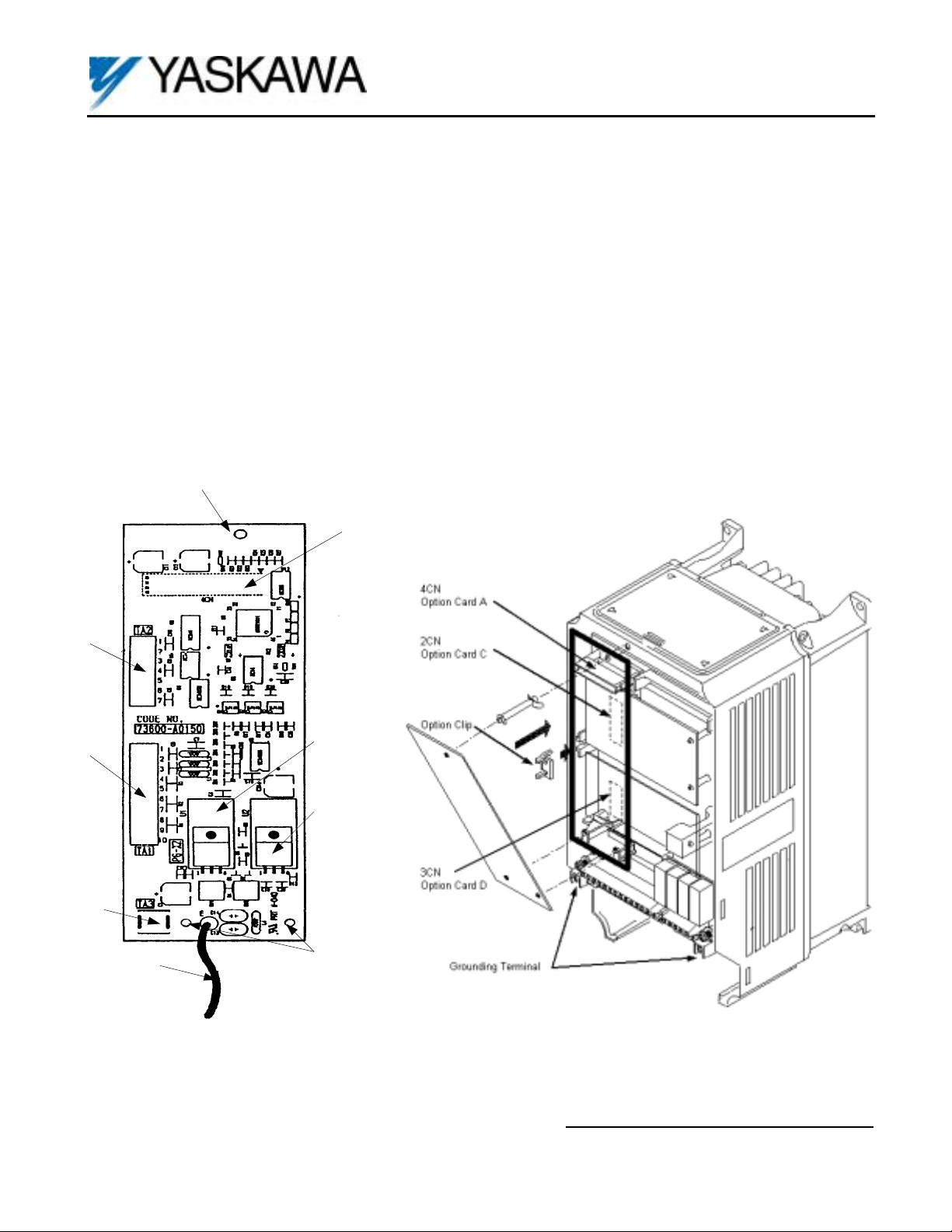

3. Introduction: The PG-X2 encoder feedback option card (Figure 1) is mounted on the drive’s Control Board and performs

speed feedback using the pulse generator (PG) on the motor to correct speed fluctuation caused by motor slip. Motor rotation

direction is detected by phase A and phase B PG pulse inputs. The terms encoder, PG (pulse generator), and pulse train are

used interchangeably in this guide. The card can be used for flux vector control or V/Hz with PG feedback control.

4. Receiving: All equipment is tested against defect at the factory. Report any damages or shortages evident when the

equipment is received to the commercial carrier who transported the equipment.

5. Cautions:

a. Hazardous voltage can cause severe injury or death. Lock all power sources feeding the drive in the “OFF” position.

b. This option card uses CMOS IC chips. Use proper electrostatic discharge (ESD) protective procedures when

handling the card to prevent I.C. damage or erratic drive operation.

c. If other option cards are to be installed at the Option C (2CN) or Option D (3CN) positions (See Figure 2), their

installation and wiring should be completed before installation of this option.

d. Before installing this option, a technically qualified individual, who is familiar with this type of equipment and the

hazards involved, should read this entire installation guide.

Mounting Hole

Connector, Rear

Side of Board to

Control Bd., 4CN

Terminal

Block TA2

Terminal

Block TA1

Terminal TA3

Connect Shield

Here

Ground Lead WireConnects to Grounding

Terminal on Control Board

Figure 1. PG-X2 Encoder Feedback Card

Variable Resistor,

Adjusts

+12V PG Power

Variable Resistor,

Adjusts

+5V PG Powe

2 Mounting Holes

Figure 2. PG-X2 Option Card installation

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60, Page 1 of 8

Date: 07/01/04, Rev:04-07

Page 2

Encoder Feedback Option Card

6. Precautions and Preliminary Installation:

a. Remove contents from package. Verify that a mounting spacer

(P/N 5RNT41028-9) is included with the card. See Figure 3.

b. Disconnect all electrical power to the drive.

c. Remove the drive’s front cover.

d. Check that the “CHARGE” indicator lamp inside the drive is off.

e. Use a voltmeter to verify voltage at incoming power terminals

(L1, L2, L3) has been disconnected.

f. Insert the spacer into the mounting hole in the base of the drive,

just above the top edge of the control board. See Figure 2.

g. Note: When re-installing the cover, please take care not to pinch

any of the encoder wires.

h. Important: GPD 515/G5 models 20P2 to 22P2 and 40P2 to 41P5 have two closely spaced mounting holes. Insert

the spacer into the hole closest to the control board’s connector 4CN. If inserted in the wrong hole, the spacer WILL

NOT properly align with the PG-W2’s mounting hole.

7. PG-X2 Installation: See Figure 2.

a. Position the bottom edge of the option card into the mounting bracket on the control board’s terminal block. Align two

mounting holes in the card with pins on the bracket.

b. Then angle the top edge of the card into place, carefully aligning connector 4CN on the back of the card with

connector 4CN on the control board. Gently press the card into place until 4CN and the spacer click into place.

8. Wiring: Refer to Figure 4 and Tables 1 & 2. Make wire connections between the PG-X2 card and encoder as well as any

external monitoring circuits. Observe the following:

a. The need for the marker Z (C) channel depends on the installed custom (CASE) software. Standard software does

not use the marker pulse.

b. Keep the PG-X2 (i.e. control circuit) wiring separate from main circuit input/output wiring. A separate metallic

grounded conduit with ONLY the PG wiring running through it is preferred.

c. To prevent erroneous operation caused by noise interference, use shielded cable for control signal wiring, and limit

the distance to 50m (165 feet) or less.

d. Recommended cable is twisted pair, 22AWG, with overall shield, such as Belden 9504. Refer to “Electrical

Installation” in the drive technical manual for further information on use of shielded cable. The shielded sheath

connection points on the PG-X2 card are terminal TA3.

e. Strip back insulation for a distance of 0.22 in. on wire leads connected to the PG-X2 terminals.

f. Connect the option card ground wire (E) to the drive’s ground terminal TB3 (12 for G5).

9. Adjustment: The+12VDC and +5VDC outputs of the PG-X2 card are factory calibrated. No adjustment should be

necessary.

10. Cover: Reinstall and secure drive’s front cover.

11. Programming: Table 3 lists all drive parameters related to encoder feedback. Ensure that all of these parameters are

programmed to meet the requirements of the application.

12. Start-up: Refer to Section 2 in the drive’s technical manual for testing and start-up information.

13. IG Storage: Place this instruction guide with the drive’s technical manual.

Figure 3. Mounting Spacer

PG-X2

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60, Page 2 of 8

Date: 07/01/04, Rev:04-07

Page 3

Encoder Feedback Option Card

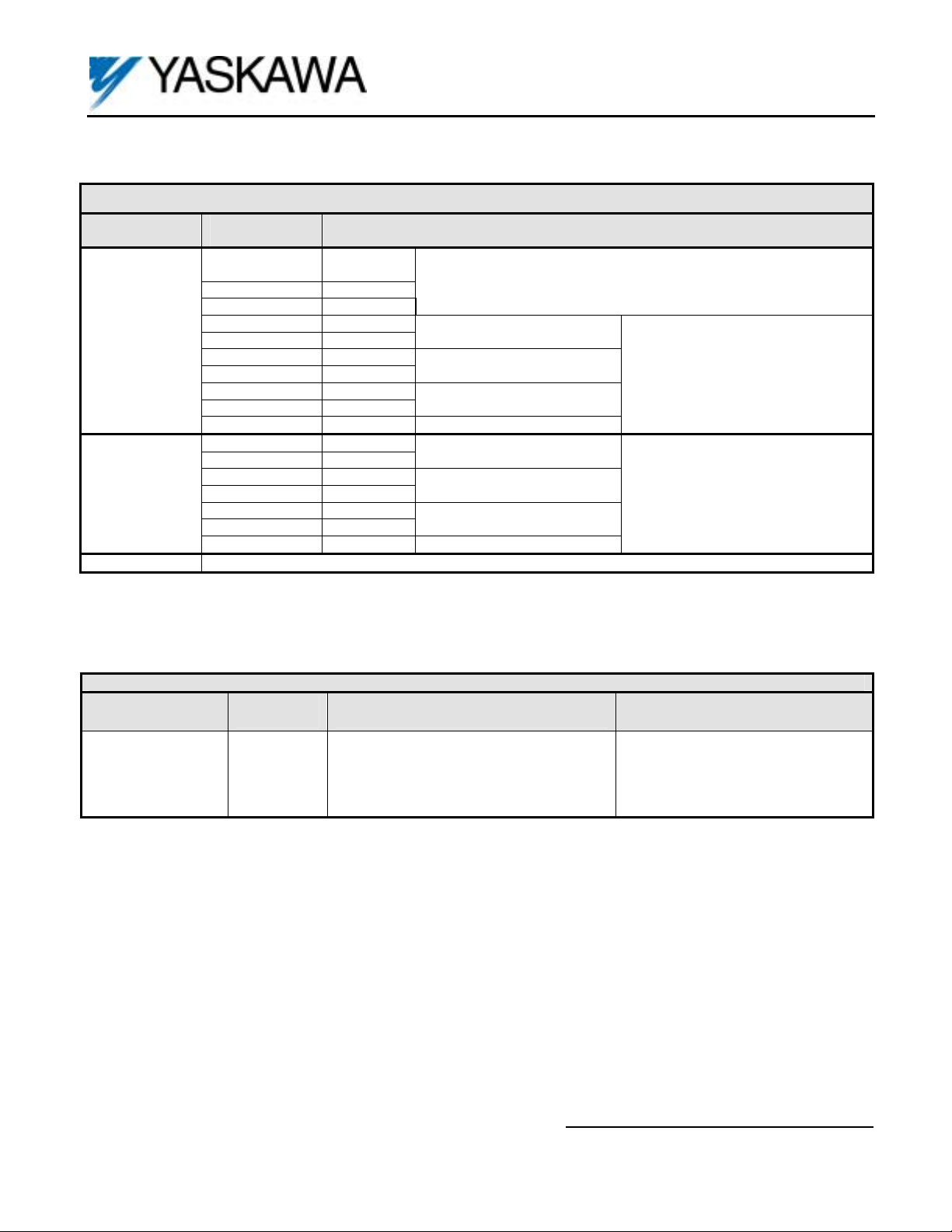

Table 1. Terminal Functions

Terminal

Block

TA1

TA2

TA3

* Not required for standard software. May be required for custom software.

Terminal

Number

1 +12VDC

2 0V +12VDC, 200mA max

3 +5VDC +5VDC, 200mA max

4 +

5 6 +

7 8 +

9 -

10 0V Common Terminal

1 +

2 3 +

4 5 +

6 7 IG5 Isolated Common Terminal

Power supply for Pulse Generator (PG).

Important: Use either +12V or +5V, but never both at the same time.

A Pulse

B Pulse

Z Pulse*

A Pulse

B Pulse

Z Pulse*

Shield Drain for Encoder Wiring

PG-X2

Function

PG Signal Inputs

RS-422 Level Input

Pulse Monitor Output

RS-422 Level Output

Terminal Symbol

TA1, TA2 M2

Terminal

Screw

Table 2. Terminal and Wire Specifications

Clamping Torque

Lb-in (N-m)

1.8 to 2.2

(0.22 to 0.25)

Wire Range

AWG (mm 2)

26 to 16

(Stranded: 0.14 to 1)

(Solid: 0.14 to 1.5)

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60, Page 3 of 8

Date: 07/01/04, Rev:04-07

Page 4

Encoder Feedback Option Card

PG-X2

Notes:

(1) Power Supply for PG (from PG-X2)

TA1 1-2: +12VDC, 200mA max.

Ta1 3-2: +5VDC, 200mA max

Do Not Use Both Supplies at the

Same Time.

(2) H20 Dynapar Encoder Connections Shown

Figure 4. PG-X2 Interconnection Diagram

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60, Page 4 of 8

Date: 07/01/04, Rev:04-07

Page 5

Encoder Feedback Option Card

y

PG-X2

14. Application: If the encoder’s power requirement is greater than 200mA, provide a separate power supply source as

shown in Figure 5. If the momentary power loss ride thru function of the drive is to be used, include a backup capacitor in the

PG power wiring or take other necessary precautions.

PG Power Suppl

PG-X2 Card

AC

TA1

IP12

IG

IP5

A (+)

A (–)

B (+)

B (–)

Z (+)

Z (–)

IG

TA3

0V 12V

1

2

3

4

5

6

7

8

9

10

*

P

*

+

P

P

Backup capacitor, for momentary

power loss recovery function

PG

(2)

ENCODER

12V

0V

Figure 5. Using Separate PG Power Supply

15. Maximum Input Frequency: The maximum input frequency of the PG-W2 card is 300kHz. To find the output frequency

of the encoder (PG) in Hertz, use the following formula. Please make sure a 20% safety margin is built-in.

fPG (Hz)

Maximum Motor Speed (RPM)

=

x Encoder PPR (Pulses/Rev)

60

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60, Page 5 of 8

Date: 07/01/04, Rev:04-07

Page 6

Encoder Feedback Option Card

16. Signal type / level requirements: The PG-X2 card requires a “quadrature line driver with compliments” signal type from

the encoder (pulse generator). As shown in Figure 6, line driver signals include both a primary signal (Signal A+) and it’s

compliment (Signal A-). The compliment is the inverse of the primary signal. This scheme is used to improve the noise

immunity of the system. The encoder output signal voltage should be between +5VDC and +12VDC. An “open collector”

signal type WILL NOT work with the PG-X2 card.

A quadrature signal is one that lags the primary signal by 90 electrical degrees (1/2 of a pulse). The purpose of this is so that

the drive can detect the direction of the encoder rotation. As shown in Figure 6, for “forward” rotation of the encoder, signal A+

will lead signal B+ by 90

If any one of the four signals is missing, the drive cannot accurately measure the encoder rotation speed or direction.

17. Viewing Signals With An Oscilloscope: The PG-X2 option card has test points that can be used to connect an

oscilloscope. Test points PA, PB, and PZ are after the compliment is subtracted out and the signals are buffered through the

opto-isolators. See Figure 4. The voltage level on all test points varies between 0 and +5VDC (TTL).

Caution:

Always use an un-grounded oscilloscope so no noise is introduced into the common.

Test Point Description

GND

PA Channel A (Terminals 4 & 5)

PB Channel B (Terminals 6 & 7)

PZ Channel Z (Terminals 8 & 8)

o

.

Table 3. PG-X2 Test Points

Although labeled GND, it is NOT earth ground. This test point should only be used in conjunction

with test points PA, PB, and PZ.

PG-X2

Note: All signals shown are in relation to power supply common, Terminal 2 of the PG-X2.

Figure 6. Encoder (PG) Signals – Forward Direction

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60, Page 6 of 8

Date: 07/01/04, Rev:04-07

Page 7

Encoder Feedback Option Card

Function Group

Digital Operator

PG Pulse/Rev F1-01 PG Constant

PG Fdbk Loss

PG Overspeed

PG Deviation

PG Rotation

Table 3. GPD 515/G5, F7, and G7 Encoder Feedback Parameter List

Display

Digital Operator

Sel

Sel

Sel

Sel

F1-02

F1-03

F1-04

F1-05 PG Rotation 0,1 0 X

Parameter Number

Parameter Name

Operation at

Open PG

Circuit

Operation

Selection at

Overspeed

Operation

Selection at

Deviation

PG-X2

Control

Method (2)

Setting Range

0 to

60000

0 to 3 1 X O O

0 to 3 1 X O O

0 to 3 3 X

Factory Setting

1024 X O O

Operation (1)

Change During

Data Selection

0: Ramp to Stop

1: Coast to Stop

2: Fast-Stop

3: Alarm Only

0: Fwd = CCW

1: Fwd = CW

V/f w/ PG

Feedback

O O

O O

Flux Vector

PG

Option

Setup

PG Ramp PI/I

Sel

PG Overspeed

Level

PG Overspeed

Time

PG Deviation

Level

PG Deviation

Time

PG# Gear

Teeth 1

PG# Gear

Teeth 2

PGO Detect

Time

Speed

Detection

Filter Selection

F1-07

F1-08

F1-09

F1-10

F1-11

F1-12

F1-13

F1-14

F1-15

Integral

Control during

Accel/Decel

Overspeed

Detection

Level

Overspeed

Detection

Delay Time

Speed

Deviation

Detection

Level

Speed

Deviation

Detection

Delay Time

Number of

Gear Teeth 1

Number of

Gear Teeth 2

PGO Detection

Time

Speed

Detection Filter

Selection

0,1 0 X

0 to

120%

0 to 2.0s 1.0s X O O

0 to 50% 10% X O O

0 to 10s 0.5s X O O

0 to 1000 0 X O X

0 to 1000 0 X O X

0 to 10s 2s X O O

0, 1 1 X

115% X O O

0: Disabled

1: Enable

0: No Average

1: 2 Scan Moving

Average

O X

O O

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60, Page 7 of 8

Date: 07/01/04, Rev:04-07

Page 8

Encoder Feedback Option Card

Function Group

Digital Operator

ASR P Gain 1 C5-01

ASR I Time 1 C5-02

ASR P Time 2 C5-03

ASR

Tuning

ASR I Time 2 C5-04

Table 3. GPD 515/G5, F7, and G7 Encoder Feedback Parameter List

Display

Digital Operator

ASR Limit C5-05 ASR Limit

Parameter Number

Parameter Name

ASR

Proportional

Gain 1

ASR Integral

Time 1

ASR

Proportional

Gain 2

ASR Integral

Time 2

Setting Range

0 to

300.00

0 to

10.000s

0 to

300.00

0 to

10.000s

0.0 to

20%

PG-X2

Control

Method (2)

Operation (1)

Factory Setting

0.00 O O O

0.00s O O O

0.00 O O O

0.00s O O O

0.0% X O X

Change During

Data Selection

V/f w/ PG

Feedback

Flux Vector

ASR Delay

Time

ASR Gain SW

Freq

ASR Integral

Limit

(1) O = Yes, X = No.

(2) O = Available, X = Hidden. The PG-X2 is not applicable for A1-02 = 0 (V/f Control) or 2 (Open Loop Vector).

C5-06

C5-07

C5-08

ASR Primary

Delay Time

ASR Switching

Frequency

ASR Integral

Limit

0.000 to

0.500s

0.0 to

400.00Hz

0 to

400%

0.000s X X O

0.0Hz X X O

400% X X O

Yaskawa Electric America, Inc. – www.drives.com

IG.AFD.60, Page 8 of 8

Date: 07/01/04, Rev:04-07

Loading...

Loading...