Page 1

YASKAWA

Varispeed G5/F7/G7 OPTION CARD

PG SPEED CONTROLLER CARD PG-B2

INSTRUCTIONS

Upon receipt of the product and prior to initial operation, read these instructions

thoroughly and retain them for future reference.

YA S K A W A

MANUAL NO. TOBP C730600 09A

Page 2

Copyright © 2004 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

NOTES FOR SAFE OPERATION

Before installation, operation, maintenance or inspection of this option, a technically quali-

fied individual who is familiar with this type of equipment and the hazards involved should

read this entire manual thoroughly. In this manual, the NOTES FOR SAFE OPERATION

are classified as “CAUTION”.

CAUTION

NOTE

NOTE

Indicates a potentially hazardous situation that, if not avoided, may result in minor

or moderate injury to personnel and damage equipment.

Failure to heed notices labeled with may result in dangerous situations or

equipment damage.

Steps to be taken to insure proper operation and to avoid malfunctions.

CAUTION

CAUTION

• The option card uses a CMOS IC chip. It may break if touched by bare fingers because of static

electricity. Be careful when handling.

• When removing the option card from the drive for transportation or storage, the card should be

placed in the anti-static package it was received in.

• DO NOT alter wiring or connect or disconnect connectors while equipment power is ON.

Failure to observe these cautions may re sult in injury or equipment damage!

Before use,

1. Before installing the Encoder (PG) Feedback Card (the PG-B2 card), read this manual and the man-

ual for the installation of the drive.

2. Before connecting the PG-B2 card or external terminals, turn OFF the main power to the drive and

verify that the CHARGE indicator lamp of the Drive is OFF.

3. When ordering the PG-B2 card, specify the product type and code number.

3

Page 4

Contents

NOTES FOR SAFE OPERATION - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

1 Inspection after Delivery - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

2 Introduction and Component Names - - - - - - - - - - - - - - - - - - 6

3 Installation Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

3.1 Before Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

3.2 Drive Installation Procedure - - - - - - - - - - - - - - - - - - - - - - - - - 7

4 Interconnection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

5 Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

5.1 Terminal Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

5.2 Wiring Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

6 Application of Encoder (PG) - - - - - - - - - - - - - - - - - - - - - - - 13

7 PG-B2 Card Parameter List - - - - - - - - - - - - - - - - - - - - - - - 14

Revision History

4

Page 5

1 Inspection after Delivery

• Verify that the products received are the products ordered.

Installation of incorrect product may lead to injury or damage.

Prior to shipment, all Yaskawa products undergo rigorous inspection procedures to ensure accu-

racy and reliability. We recommend checking the following items upon receipt.

• Check that the code number (73600-A013X) and product type (PG-B2) labeled on the

actual card correspond to product ordered.

• Check for damage or shortage caused during transportation.

Report any material or manufacturing defects on the card to your Yaskawa representative.

1 Inspection after Delivery

CAUTION

5

Page 6

2 Introduction and Component Names

The Encoder (PG) Feedback Card (hereafter referred to the PG-B2 card) is mounted on the

drive’s control board to provide speed and direction feedback. The drive’s control logic can use

this information for purposes such as correcting for speed fluctuation caused by motor slip and

maintaining the velocity.

Using standard software, the PG-B2 card can be used for closed loop control (Flux Vector or

V/F with PG). The marker (C or Z) pulse cannot be used from the encoder.

The PG-B2 card is compatible with the G5, F7 and G7 Yaskawa drives.

Name Code No. Functions

PG speed controller card

PG-B2

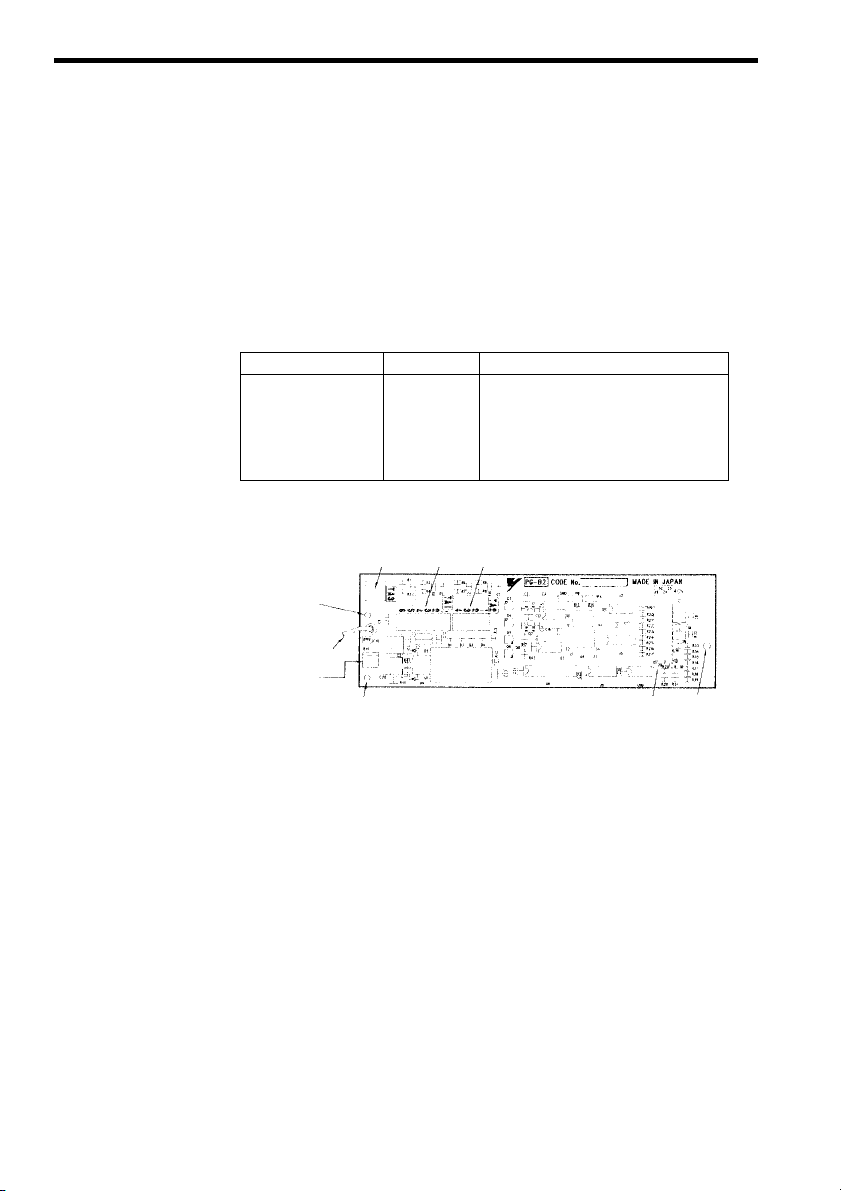

The external appearance and component names are shown in Fig. 1

73600-A013X • Applicable to complementary output PG

• Phase A and phase B pulse (2-phase pulse)

inputs for vector control

• Maximum input PG frequency: 32,767 Hz

• Pulse monitor output: +24 V, 30 mA (max.)

(Open collector output)

Spacer mounting

hole (3.2 mm dia.)

Grounding lead wire

(connected to the grounding terminal

(G5: 12 (G), G7 or F7: E (G)) of Inverter

control board)

Variable resistor for

adjusting +12V power

Terminal TA3

(for connecting

shielded sheath)

Spacer mounting

hole (3.2 mm dia.)

Terminal block

TA1

Terminal block TA2

Fig. 1 Encoder (PG) Feedback Card (PG-B2)

Connector to Inverter

control board (4CN)

Spacer mounting

hole (4.0 mm dia.)

6

Page 7

3 Installation Procedure

3.1 Before Installation

Remove contents from package and verify that a mounting spacer (code number

SRNT41028-9) is included with the PG-B2 card (see Fig. 2).

Drive End Option Card End

3 Installation Procedure

0.567 in. (14.4 mm)

0.197 in. (5 mm)

3.2 Drive Installation Procedure

1. Turn OFF the main power and wait for the time specified on the cover of the Drive for

voltage to bleed off the DC bus capacitors. Remove the cover and verify that the

CHARGE indicator lamp is OFF.

2. Insert the spacer (SRNT41028-9) into the spacer mounting hole in the mounting base of

the Drive (see Fig. 3). Drive models of 3.7 kW or smaller capacities have two closely

spaced mounting holes. Insert the spacer into the hole closest to the 7CN connector on

the control board. Insertion of the spacer into the incorrect hole will stack the spacer. Be

careful to insert in the proper hole in the proper inserting direction.

3. Align the two holes of the PG-B2 card and projections as shown in the detailed side

view, first at location (a) and then at (b), and precisely place the card on the option A

connector. Insert the spacer mounted at 2 above into the PG-B2 spacer mounting hole.

(See part A of the side view on the next page.)

4. Rotate the top edge of the card down into place, carefully aligning connector 4CN on

the back of the card with connector 4CN on the control board.

5. Gently press the card into place until 4CN and the spacer click into place.

6. Connect the grounding lead wire of the PG-B2 card to the grounding terminal (G5: 12

(G), G7 or F7: E (G)) on the control board.

1.32 in. (33.6 mm) 0.224 in. (5.7 mm)

Fig. 2 Spacer

7

Page 8

PG-B2

4CN Option

A connector

2CN Option

C connector

3CN Option

D connector

Connector

terminal

Grounding terminal

(G5: 12 (G), G7 or F7: E (G))

Spacer mounting hole for option A

4CN

Option A connector

2CN

Option C connector

Option A installation spacer

(Comes with option A.)

Option clip

(To secure option C or D)

3CN

Option D connector

Spacer mounting hole

Option A

Top

Option A installation spacer

(SRNT41028-9, comes with PG-B2)

Option C

PG-B2

Control board

Option D

(b)

(a)

Bottom

Details

Front View Side view

Mounting base of Inverter

Mounting base of Inverter

Spacer mounting hole

Control board

Mounting

base side

Option A side

Spacer

Installation of spacer

Option C installaiton spacer

Option C

Option D

Option D installation spacer

Option A

Option A installation spacer

Note: Be sure to remove the option clip before installing the PG-B2 card. If

the card is installed with the clip attached, the card cannot be correctly installed, and the card will perform poorly.

Fig. 3 Installation of the PG-B2 Card

8

Page 9

4 Interconnection

Fig. 4 shows interconnection between the Drive, the PG-B2 card, and peripheral equipment.

Inverter

R

S

T

U

V

W

Varispeed G7

E (G)

Grounding lead wire

Note: The PG terminal symbols are the examples when using a Yaskawa’s motor.

PG type: LMA-B-S185Y (complementary output)

The pulse monitor emitter is connected to common inside the PG-B2.

The emitter common must be used for external circuits.

Fig. 4 Basic Interconnection Diagram (Example when Used with a G7-series Inverter)

Motor

Pulse A

Pulse B

Divider

4 Interconnection

Pulse monitor outputs

Pulse A

Pulse B

Pulse A

Pulse B

(Forward rotation)

9

Page 10

5 Wiring

5.1 Terminal Functions

Terminal Block

Symbol

PG Signal Output

The PG signal output (phases A and B) may vary according to installation location on the

motor. Refer to Fig. 4 for correct wiring.

In general, motor forward direction is counterclockwise (CCW) as viewed from the load

shaft. For YASKAWA’s motor, phase A of PG output leads phase B by a phase angle of 90°

in clockwise (CW) rotation. According to PG, phase A lags phase B by a phase angle of 90°

in clockwise (CW) rotation. In this case, when PG is installed at the opposite drive end, con-

nect phases A and B output from PG to the option card as it is.

For YASKAWA’s Inverter motor with PG, PG is installed at the opposite drive end. Then,

phase A lags phase B by a phase angle of 90° at motor forward run. (Motor runs CCW as

viewed from PG.) Therefore, when using this motor or similar motors, connect phases A

and B to the option card after replacing phase output. The pulse monitor on this option

shows phase A leading phase B by a phase angle of 90°.

Table 1 Terminal Functions of PG-B2

Pin

No.

TA1 1 +12 V +12 V power supply

20 V

3+A Pulse

4 −

5+B Pulse

6 −

TA2 1 + A P u ls e

2 −

3+B Pulse

4 −

TA3 Shielded sheath connection terminal

* Up to +14 V ±5 % can be supplied by adjusting variable resistor RV1.

RV1 is set to 13.0 V at the factory prior to shipment.

Functions Remarks

(+12 V ±5 %, maximum current 200 mA)

Encoder (Pulse generator, PG)

signal input.

Pulse monitor output. Open collector

Power supplies

*

for PG

Signal input level

H: +8 V to +12 V

L: +1 V or lower

24 V max.

30 mA max.

10

Page 11

5.2 Wiring Precautions

Make sure of the followings when wiring.

5 Wiring

NOTE

• Separate the control signal wires (terminal blocks TA1 and TA2) of the PG-B2 card from the main

circuit wires and other power cables.

• Use a shielded wire to connect the encoder (PG). Connect the wires as shown in Fig. 5 to prevent

noise interference. The wire distance must be 328 ft. (100 m) or less. Provide an exclusive cable.

(Refer to the table below.)

2

Also, use type of KPEV-S, 0.5 mm

.

Wire specification: Polyethylene insulated wire for instrumentation manufactured by NIHON

ELECTRIC WIRE & CABLE.

KPEV-S 0.5 mm

2

(1.25 mm2) 3-pair wire

Terminal TA1 specification: MKDS1 series manufactured by Phoenix Contact GmbH & Co.

Cable length YASKAWA Code No.

32.8 ft. (10 m) 72616-W5010

98.4 ft. (30 m) 72616-W5030

164 ft. (50 m) 72616-W5050

328 ft. (100 m) 72616-W5100

• Cable length for pulse monitor output must be 98.4 ft. (30 m) or less.

Wire specification: Polyethylene insulated wire for instrumentation manufactured by NIHON

ELECTRIC WIRE & CABLE.

2

KPEV-S 0.5 mm

2-pair wire

Terminal TA2 specification: MKDS1 series manufactured by Phoenix Contact GmbH & Co.

• To prevent noise, use shielded wire and separate from heavy current circuits (200 VAC or greater)

or relay drive circuits. (Wire length to the PG connector must be 328 ft. (100 m) or less.)

• If the PG signal is affected by noise, disconnect the grounding lead wire (E) from the grounding

terminal (G5: 12 (G), G7 or F7: E (G)) of the control board of the Inverter.

• The recommended tightening torque is 0.22 to 0.25 Nxm.

Shielded Sheath

Outer Jacket

PG-B2 Connection

Connect to terminal block

TA3 on PG-B2 card

Do not connect

or ground sheild at

Insulate these parts

with insulting tape

this end

Fig. 5 Shielded Wire Termination

11

Encoder (PG) End

Page 12

Applicable wire specifications for terminal blocks TA1 and TA2 are shown in Table 2.

Terminal: MKDS1 series manufactured by Phoenix Contact GmbH & Co.

Strip back insulation for a distance of 0.22 inches (5.5 mm) on wire leads connected to the

PG-B2 card.

Notes on selecting cables

NOTE

Table 2 Wire Specifications

2

AWG I (amps) VAC

)

(mm

Thin Twisted Wire

Solid Wire

UL

CSA

CSA

0.22 in. (5.5mm)

Fig. 6 Connecting Wire End for Terminal Blocks TA1 and TA2 Side

• The thicker a cable is, the greater the pressure on the option card and the greater the possibility of

a failure occurring will be.

• The thinner a cable is, the poorer the electrical contact and the greater the possibility of the con-

ductor breaking will be.

• The longer the cable is, the more likely a voltage drop in the PG power supply or PG signal will

occur.

1 16 12 125

1.5 16 12 125

− 22-16 10 300

− 28-16 10 300

− 28-16 10 150

12

Page 13

6 Application of Encoder (PG)

The maximum frequency of the encoder (PG) output pulses that can be detected is

32,767 Hz.

Therefore, select a PG that outputs about 20 kHz at the motor rotation speed at maximum

frequency output.

-1

Motor rotation speed (min

Motor Rotation Speed

at Maximum Frequency

Output (min

1800 600 18,000

1500 800 20,000

1200 1000 20,000

900 1200 18,000

Note: 1. The motor rotation speeds at maximum frequency output are

represented

PG power supply is +12 V.

2.

3. If the PG power current is 200 mA or greater, provide a sep-

arate power supply. (If momentary power loss ride-through

function is necessary, provide backup capacitor or take other

necessary measures.)

) at max. frequency output

60

Examples of PG Selection

-1

)

as synchronous rotation speeds.

PG Parameter

(p/rev)

6 Application of Encoder (PG)

× *PG constant (p/rev) = 20,000 Hz

PG Output Frequency at

Maximum Frequency

Output (Hz)

PG power supply

Backup capacitor momentary power loss recovery

Signal

Fig. 7 Connection Example with Encoder (PG) when Using Separate Power Supply

13

Page 14

7 PG-B2 Card Parameter List

If using the PG-B2 card with any Yaskawa drives other than the G5, F7, or G7, refer to the

instruction manual of the drive being used.

Table 3 PG-B2 Card Parameter List

PG-B2 Card Parameter List

Digital

Operator

Function

Group

Digital

Operator

Display

Param-

eter

No.

Parameter

Name

Setting

Range

Factory

Setting

Change

During

Opera-

*1

tion

Data Selection

Control Method

G5, G7, F7 G7

*9

*2

PG

Option

Setup

PG Pulses/

Rev

PG Fdbk

Loss Sel

PG Overspeed Sel

PG Devia-

tion Sel

PG Rotation

Sel

PG Output

Ratio

PG Ramp PI/

I Sel

PG Overspd

Level

PG Overspd

Time

PG Deviate

Level

PG Deviate

Time

F1-01 PG constant 0 to 60000 600

F1-02 Operation

selection at PG

open circuit

(PGO)

F1-03 Operation

selection at

overspeed (OS)

F1-04 Operation

selection at

deviation

F1-05 PG rotation 0,1 0

F1-06 PG division rate 1 to 132 1

F1-07 Integral value

during accel/

decel enable/

disable

F1-08 Overspeed

detection level

F1-09 Overspeed

detection delay-

time

F1-10 Excessive speed

deviation detec-

tion level

F1-11 Excessive speed

deviation detec-

tion delay time

0 to 3 1

0 to 3 1

0 to 3 3

0,1 0

0 to 120 % 115 %

0 to 2.0 s

0 to 50 % 10 %

0 to 10 s 0.5 s

0.0 s

(1.0 s)

14

V/f Control

××{ × { ×

×

0: Ramp to Stop

1: Coast to Stop

2 : F a s t - S t o p

3: Alarm Only

× { × { ×

××{ × {{

××{ × {{

×

×

×

0 : F w d = C C W

1: Fwd=CW

Set the pulse

output division

rate of the PGB2 card:

Division rate =

(1+n)/m

(n = 0 or 1,

m = 1 to 32)

F1-6 =

0: Disabled

1: Enable

× { × { ×

× { × { ×

m

n

× { ×××

××{ × {{

*3

××{ × {{

*4

××{ × {{

××{ × {{

Open loop Vector

Flux Vector

Open loop Vector 2

V/f w/PG Fdbk

Page 15

Digital

Operator

Function

Group

Digital

Operator

Display

Param-

eter

No.

Table 3 PG-B2 Card Parameter List (cont’d)

PG-B2 Card Parameter List

Parameter

Name

Setting

Range

Factory

Setting

Change

During

Opera-

*1

tion

Data Selection

7 PG-B2 Card Parameter List

Control Method

*2

G5, G7, F7 G7

*9

PG# Gear

PG

Option

Setup

Teeth 1

PG# Gear

Teeth 2

PGO Detect

Time

ASR P Gain 1C5-01 ASR propor-

ASR

Tuning

*6

ASR I Time 1C5-02 ASR integral (I)

ASR P Gain 2C5-03 ASR propor-

F1-12 Number of PG

F1-13 Number of PG

F1-14 PG open-cir-

*5

gear teeth 1

gear teeth 2

cuit detection

tional (P) gain 1

tional (P) gain 2

ASR I Time 2C5-04 ASR integral (I)

ASR Limit C5-05 ASR limit 0.0 to 20

ASR Delay

Time 1

ASR Gain

SW Freq

C5-06 ASR primary

*8

C5-07 ASR switching

*8

delay time 1

frequency

ASR Limit *8C5-08 ASR integral (I)

ASR Delay

Time 2

C5-10 ASR primary

*7

delay time 2

* 1. { = Enable, × = Disable

{ = Setting enable, × = Setting disable

* 2.

* 3. For flux-vector control

* 4. For V/f with PG feedback control

* 5. For the F7, setting and refe rence are enabled for the software No. (U1-14) of 1030 or after.

* 6. ASR - Automatic Speed Regulator

* 7. For the G7 only

* 8. If using the flux-vector control with the F7, be sure to use an Inverter with a design revision

number of E or later. Versions C or earlier do not support the flux-vector control.

time

time 1

time 2

limit

0 to 1000 0

0 to 1000 0

0 to 10 s 2 s

0 to

0 to

0 to

0 to

%

00 to

20.00

(0.20)

0.500 s

(0.200 s)

20.00

(0.02)

0.500 s

(0.050 s)

5.0 %

0.004 s

0.0 Hz

300.00

10.000 s

300.00

10.000 s

0.000 to

0.500 s

400.00 Hz

0 to 400 % 400 %

0.000 to

0.500 s

0.010 s

V/f Control

××{ ×××

××{ ×××

××{ × { ×

*3

{ × { × {{

*4

*3

{ × { × {{

*4

*3

{ × { × {{

*4

*3

{ × { × {{

*4

*4

××{ ×××

*3

× ×××{{

× ×××{{

× ×××{{

× ××××{

V/f w/PG Fdbk

Open loop Vector

Flux Vector

Open loop Vector 2

*3

15

Page 16

Revision History

MANUAL NO.ޓTOBP C730600 09A

Published in Japan September 200704-12 3

Date of

publication

Date of original

publication

Revision number

12345

6

The revision dates and numbers of the revised manuals are given on the bottom of the back cover.

Date of

Publication

December 2004

August 2005

January 2007

September 2007

January 2008

July 2008

April 2010

Rev.

No.

−

Section Revised Content

New edition that was created by binding together the Japanese version (TO-C736-40.2) and the

−

Back cover

Back cover

Back cover

Back cover

Back cover

Back cover

English version (TOE-C736-40.2) of the VARISPEED-616G5 OPTION CARD PG SPEED CONTROLLER CARD PG-B2 INSTRUCTIONS and by adding information on the Varispeed F7 and

the Varispeed G7 Inverters.

Revision: Address

Revision: Address

Revision: Address

Revision: Address

Revision: Address

Revision: Address

Page 17

Varispeed G5/F7/G7 OPTION CARD

PG SPEED CONTROLLER CARD PG-B2

INSTRUCTIONS

IRUMA BUSINESS CENTER (SOLUTION CENTER)

480, Kamifujisawa, Iruma, Saitama, 358-8555, Japan

Phone: 81-4-2962-5696 Fax: 81-4-2962-6138

YASKAWA ELECTRIC CORPORATION

New Pier Takeshiba South Tower, 1-16-1, Kaigan, Minatoku, Tokyo, 105-6891, Japan

Phone: 81-3-5402-4511 Fax: 81-3-5402-4580

http://www.yaskawa.co.jp

YASKAWA ELECTRIC AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone: (800) YASKAWA (800-927-5292) or 1-847-887-7000 Fax: 1-847-887-7310

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL COMÉRCIO LTDA.

Avenda Fagundes Filho, 620 Bairro Saude, São Paulo, SP04304-000, Brasil

Phone: 55-11-3585-1100

http://www.yaskawa.com.br

YASKAWA ELECTRIC EUROPE GmbH

Hauptstraβe 185, 65760 Eschborn, Germany

Phone: 49-6196-569-300 Fax: 49-6196-569-398

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods, Cumbernauld, G68 9LF, United Kingdom

Phone: 44-1236-735000

YASKAWA ELECTRIC KOREA CORPORATION

7F, Doore Bldg. 24, Yeoido-dong, Youngdungpo-Ku, Seoul, 150-877, Korea

Phone: 82-2-784-7844

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-02A, New Tech Park, 556741, Singapore

Phone: 65-6282-3003

YASKAWA ELECTRIC (SHANGHAI) CO., LTD.

No. 18 Xizang Zhong Road, Room 1702-1707, Harbour Ring Plaza, Shanghai, 200001, China

Phone: 86-21-5385-2200

YASKAWA ELECTRIC (SHANGHAI) CO., LTD. BEIJING OFFICE

Room 1011A, Tower W3 Oriental Plaza, No. 1 East Chang An Ave.,

Dong Cheng District, Beijing, 100738, China

Phone: 86-10-8518-4086

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, Taiwan

Phone: 886-2-2502-5003

Fax: 55-11-5581-8795

Fax: 44-1236-458182

Fax: 82-2-784-8495

Fax: 65-6289-3003

Fax: 86-21-5385-3299

Fax: 86-10-8518-4082

Fax: 886-2-2505-1280

YASKAWA ELECTRIC CORPORATION

YASKAWA

In the event that the end user of this product is to be the military and said product is to be

employed in any weapons systems or the manufacture thereof, the export will fall under

the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade

Regulations. Therefore, be sure to follow all procedures and submit all relevant

documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice

for ongoing product modifications and improvements.

© 200 4-2010 YASKAWA ELECTRI C CORPO RATION. All rights reser ved.

MANUAL NO. TOBP C730600 09A

Published in Japan April 2010 04-12

10-3-3

6 -0

Loading...

Loading...