Page 1

YASNAC PC NC

Operating Manual

Version: Beta 1.0

Page 2

YASNAC PCNC Operating Manual Introduction

SAFETY INFORMATION

PRECAUTIONS

1. Read this instruction manual in its en ti rety before using the op era ti ng functions availabl e in the

YASNAC PCNC.

2. The following warning symbols are used to indicate precautions that the user must be aware of

to safely use this equipment. Failure to follow these preca ut ions can result in serious or possi bly

even fatal injury and damage to pro duc ts or related equipment or systems.

WARNING

WARNING

WARNING

This sym b ol indica tes the pre s en ce of a potentially hazardous condition which, if not avoided,

could result in serious personal injury or death.

This precautionary symbol appears in labels attached to YASNAC products to alert the user to

conditions requiri ng concern for safety.

SPECIAL SAFETY NOTE: This symbol indicates that ELECTRICAL SHOCK HAZARD

condition exists. DO NOT TOUCH any electrical connection terminals when the power is on, and

for at least 5 minutes after switching off the power supply. Warning label is located on the PCNC

PCNC Unit

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

xxxxxxxxx

WARNING LABEL

NOTICE

Printed _______. 1999. The informatio n contained within thi s doc ument is the proprietary property of

Yasakawa Electric America, I nc. , and ma y not be c opied, reproduced or tra nsm it te d t o other parties without

the expressed wr itte n authorization of Yasakawa Electric America, Inc.

No pattent liability is assumed with respect to the uses of the information contained herein. Moreover,

becaus e Yaskawa is constantly improving i ts high quality product, the informati o n contained in this manual

is subject to chan ge without notice. Every precaution h as be en taken in the prepa ra ti on of this document .

i

Page 3

YASNAC PCNC Operating Manual Introduction

INFORMATION INDICATORS

The following symbols are used in this operating manual to empha siz e particular inform at ion to the user:

Indicates important information to be remembered, i.e., precautionary alarm

POINT

displays to prevent damaging devices.

SUPPLEMENT

TERMS

Indicates supplementary material.

Indicates definitions of terminology that has not been explained before.

NOTES REGARDING SAFE OPERATION

It is important that the user should read this manual before inst al li ng, operating, perfor mi ng any

mainten ance or ins p ecting th e

<$61$&3&1&

Also, the functions and performance of a NC machine tool

are not determine d by t he CNC unit itself, therefore thoroughly read and familiarize yourself with the

machine builder’s documentation conc erning the safe an d mo st effic ie nt wa ys to u se the machine too l.

Nevertheless, Yasa kawa assumes no responsibility for da ma ge s resulting from the use of the informat io n

contained within this publication.

ii

Page 4

YASNAC PCNC Operating Manual Introduction

TABLE OF CONTENTS

1. OUTLINE OF THE PRODUCT

1.1 OUTLINE of the YASNAC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 -2

1.1.1 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.3 Machine Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.1.4 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2 PROTECTIVE FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.2.1 Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.2.2 Overtravel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.2.3 Stored St roke Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1.2.4 Interlock Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

2. BASIC OPERATION OF YASN AC PCNC

2.1 GENERAL OPERATION FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 INSECTION BEFORE TURNING THE POWER ON . . . . . . . . . . . . . . . . . . 2-4

2.2.1 Inspection of the PCNC unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.2 Prepartion before Turning the Power ON. . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3 TURNING THE POWER ON/OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

AND INSPECTION AFTER POWER ON/OFF . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.3.1 Procedure for Turning the Power ON . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.2 Checking the Motors for Abnormalities. . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.3 Procedure for Turning the Power OFF. . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.4 Inspection of the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

iii

Page 5

YASNAC PCNC Operating Manual Introduction

2.4 MANUAL OPERATION (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.4.1 Manual Rapid Traverse (RAPID). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.4.2 Jog Feed (JOG). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.4.3 Step Feed (STEP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.4.4 Handle Feed (HANDLE)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.5 MANUAL OPERATION(2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.5.1 Simultaneous 2- o r 3-axis Handle Feed* . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.5.2 Manual Reference Point Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.5.3 Manual Reference Point Ret urn t o the Second Reference Point l . . . . . 2-18

2.5.4 1-line MDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.6 AUTOMATIC OPERATION (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.6.1 Preparation of Automatic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.6.2 Memory Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.6.3 MDI Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.6.4 Feed Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.6.5 Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.7 AUTOMATIC OPERATION (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.1 Optional Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.2 Optional Block Skip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.7.3 Dry Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.7.4 Display Lock and Machine Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.7.5 Auxiliary Function Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.7.6 Z-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.7.7 4th-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.7.8 5th-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

iv

Page 6

YASNAC PCNC Operating Manual Introduction

2.8 OPERATION INTERVENTION (during automatic operation) . . . . . . . . . . . . 2-29

2.8.1 Manual Operation Intervention (during automati c ope ra ti on) . . . . . . . . 2-3 0

2.8.2 MDI Operation Intervention ( duri ng automatic operation) . . . . . . . . . . 2-30

2.8.3 Automatic Handle Mode Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2.8.4 Manual Absolute. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

3. BASICS OF DISPLAY AND WRITING OPERATION

3.1 USER INTERFACE OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.0 User InterfaceOverview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.1 Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.2 Battery Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.3 NC Execution Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.1.4 Motion Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.1.5 Alarm Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.1.6 Warning Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.1.7 Time/Dat e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.1.8 Mode / MDI / Tool Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.1.9 Mode Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.1.10 Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.2 RECURRING COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.2.1 Positioning the Cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.2.2 Nest Level Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.2.3 Shortcuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.2.4 Number Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

3.2.5 File Browser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

v

Page 7

YASNAC PCNC Operating Manual Introduction

3.3 RUN MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

3.3.1 Production Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.3.2 Proveout Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.3.3 NC Switch Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

3.3.4 Timers Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3.4 PROGRAM MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3.4.1 File Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

3.4.2 Editor Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

3.4.3 List Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

3.4.4 Macro Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

3.5 TOOL MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3.5.1 Offset Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3.5.2 Magazine Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

3.6 SETUP MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3.6.1 Workshift Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

3.6.2 Four (4) Position Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

3.6.3 One (1) Position Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

3.7 UTILITIES MENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3.7.1 Log in Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

3.7.2 System Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

3.7.3 Maintenance Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

3.7.4 Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

3.7.5 Backup and Restore Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

3.7.6 CPU Monitor Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

3.7.7 Setting Parameters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-67

vi

Page 8

YASNAC PCNC Operating Manual Introduction

3.7.8 NC Parameters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

3.7.9 Machine Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-71

3.7.10 Pitch Error Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-72

3.7.11 Torque Ripple Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-74

3.7.12 Parameter Search Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-75

3.7.13 High Speed Cutting Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-77

3.7.14 User Install Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-78

3.7.15 MTB Install Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-81

3.7.16 PLC Parameters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-82

3.7.17 PLC Diagnosis Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-83

3.7.18 Ladder Monitor Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-88

3.7.19 Switch Label Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-88

3.8 ALARM MENU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

3.8.1 NC Alarm Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-91

3.8.2 PLC Alarm Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-93

3.8.3 Alarm History Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-95

3.9 Help Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-96

3.10 MMI Map Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-96

3.11 Manual Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-97

3.12 Offline Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

3.13 Offline Mode Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-98

4. MAINTENANCE

4.1 MAINTENANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.1 Checking the Status of Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.1.2 Checking the NC Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.3 Display of Alarm Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.1.4 Cause of Alarm and Corrective Action. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

vii

Page 9

YASNAC PCNC Operating Manual Introduction

4.1.5 Troubleshooting (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.1.6 Troubleshooting (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

4.1.7 Alarms Not Indicated by Alarm Numbers . . . . . . . . . . . . . . . . . . . . . . . . .4-16

4.1.8 PCNC Alarms Not Indicated by Alarm Numbers . . . . . . . . . . . . . . . . . . .4-28

4.1.9 Touch Screen Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-28

4.1.10 Mode of PCNC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

4.1.11 Self-D i a gnosi s Func ti on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-30

4.1.12 Hard Drive Mounting Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

APPENDIX 1. LIST OF PCNC INPUT/OUTPUT SIGNALS

1.1 INPUT SIGNALS ( PLC > NC ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-2

1.2 OUTPUT SIGNALS ( NC > PLC ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A1-9

APPENDIX 2. ALARM TABLE

2.1 CLASSSIFICATION OF ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2-2

2.2 ALARM TABLE ( PCNC ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2-3

2.3 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A2-21

APPENDIX 3. PARAMETER TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A3-1

viii

Page 10

YASNAC PCNC Operating Manual Introduction

USING THIS MANUAL

This manual decribes the procedures for operating the

<$61$&3&1&

RELAT ED INFORMATION SOURCES

For additonal information, refer to the follow in g ma nuals:

TITLE OF DOCUMENT CONTENTS

YASNAC PCNC Programming Manual

(YEA-SIE-C844-2.2)

YASNAC PCNC/PLC Programming Manual

(YEA-SIE-C844-0.1)

YASNAC PCNC I/O Signal Manual

(YEA-SIE-C844-2.3)

YASNAC PCNC Connection Manual

(YEA-SIE-C844-0.2)

YASNAC PCNC Maintenance Manual

(YEA-SIE-C844-2.9)

.

PCNC Program creation instructions

PLC Program creation instructions

Describes functions between PCNC and PLC

Instructions for connecting PCNC with machines,

machine interface and peripheral equipment

Describes service and maintenance procedures.

ix

Page 11

YASNAC PCNC Operating Manual Introduction

CAUTIONS

This manual describes all the option functions (identified by the “*” sym bol ) but some of these may not

be available with your YASNAC PCNC. T o determine the option functions installed in your PCNC,

refer to the specification docume nt or manuals publishe d by t he machine tool buil der.

Unless otherwise specified, the follow i ng conditions apply in prog ramming explan ations and

programm i ng examples.

l

Metric system for input and metric system for output / movement

l

Zero point in the base coo rdi nate system

l

Reference point

Yaskawa has made every effort to de scribe individual func ti ons a nd their relationships to oth er fun ct ions

as accurate ly a s possible. However, there are many things that cannot or must not be performed and it is

not possible to describe al l of th ese . Accordingly, readers are requested to understand that un le ss it is

specifically stat ed that something can be pe rformed, it should be assumed that it cannot be perfor med.

Also, bear in mind that the performanc e a nd functions of an PCNC m a chine tool are not de te rm ined

solely by the PCNC unit. The entire contr ol system consists of the mechanical system, then machine

operatio n pa nel and other machine related equ ip ment in addition to the PCNC. Therefore, read the

manuals publ ished by the machine tool builder for detailed information rela ti ng t o the ma chine.

x

Page 12

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

1

Outline of the YASNAC System

Chapter 1 describes the outline of the YASNAC system and the operating features and functions that should be thoroughly understood for the safe and efficient operation of the system.

1.1 Outline of the YASNAC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.1 System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.1.2 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.1.3 Machine Operation Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.1.4 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.2 Protective Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.2.1 Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.2.2 Overtravel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

1.2.3 Stored St roke Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.2.4 Interlock Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1 - 1

Page 13

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

1.1 Outline of the YASNAC System

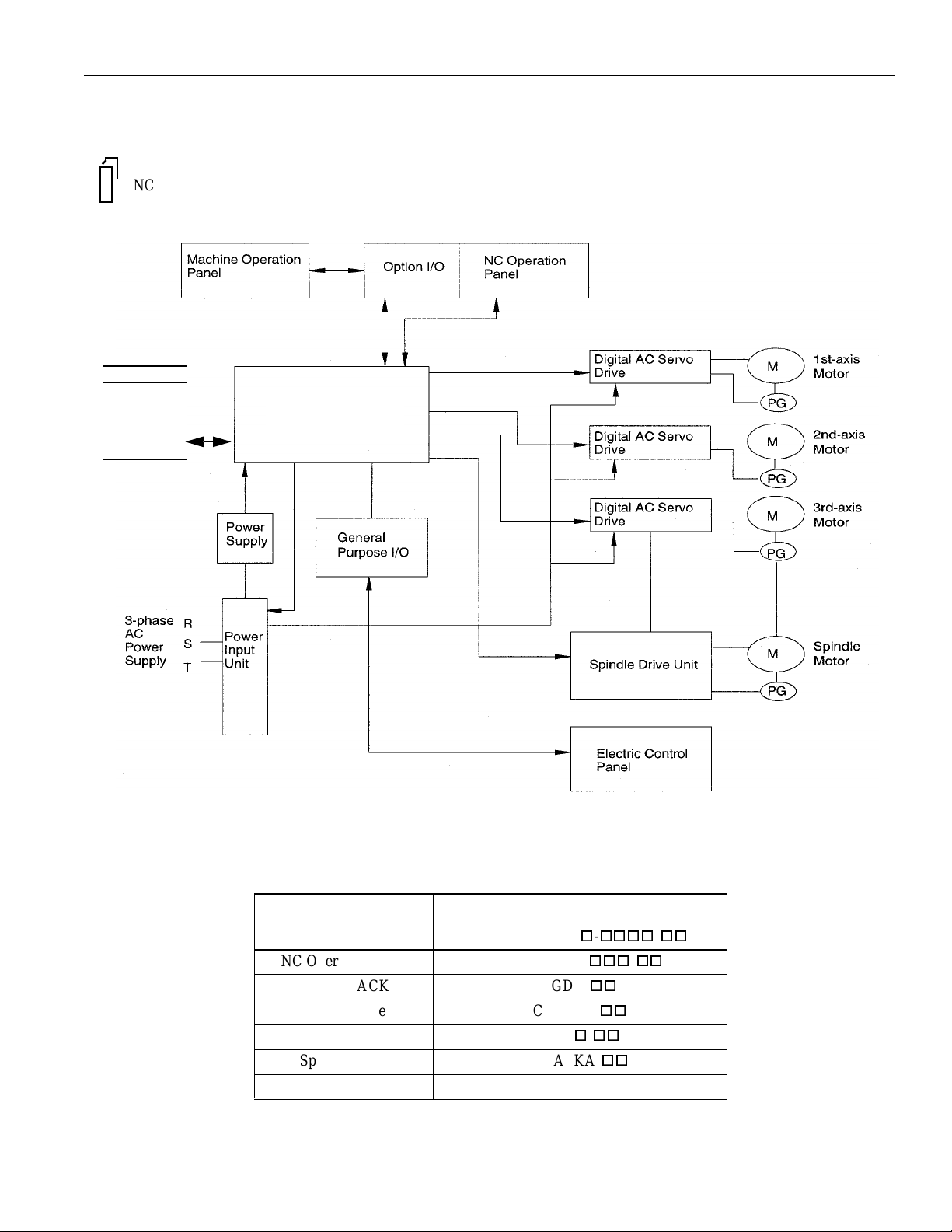

1.1.1 System Configuration

PCNC

Remote

Machine

Pendant

The configuration of the Y ASNAC PCNC system and the list of components are described below.

Unit

YASNAC PCNC

Unit

FIGURE 1.1.1.1: Standard Configuration of PCNC System

Table 1.1.1.1: List of YASNAC PCNC System Components

COMPONENT NAME MODEL NAME

CPU rack JZNC-JPCRKM-

NC Operation Panel JZNC-JPCOP-

SERVOPACK SGDC-

Spindle drive CIMR-M5

Servomotor SGMo-

Spindle motor UAASKA-

Remote Pendant TBA

o-oooo-oo

ooo-oo

oo

oo

oo

oo

1 - 2

Page 14

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

1.1.2 Environmental Requirements

Requirements for the installation of an PCNC unit are indicated below. Install the PCNC unit in a

location where only these requirements are satisfied to avoid possible malfunctioning.

CAUTION!

Avoid using it in an environment where it may be subject to high temperatures, high humidity, dust,

corrosive gases, vibration or physical impacts that may cause fire, electric shock or malfunction.

• Use the product in an environment meeti n g the following conditions:

• Free from gases or vapors that create a potentially explosive atmosphere.

• Free from oil, organic solvents, et c.

• Relative humidity in the range 10 to 90% RH, with no condensation.

• Ambient temperature in the 0°C to 55°C with no freezing.

(Installation site must not be exposed to direct sunlight, must be distanced from heat generating devices,

and must be indoors.)

2

• Vibration not exceeding 4.9 m/s

.

• Do not store the product in locations subje ct to rain, w ater droplets, harmful gases or liquid s.

Failure to observe this caution may result in product failure.

• Select a storage area indoors that is clean and meets the following temperature and humidity

requirements.

Ambient temperature: –15° C to 65° C (–5° F to 149° F)

Relative humidity: 10% to 90%

Failure to observe this caution may result in product failure.

(1) Ambient Temperature

For operation:0°C to 55°C

For storage and transportation:–15° C to 65° C

Install the PC NC unit in a location not subject to direct sunlight, distant from heat sources,

and indoors.

(2) Humidity

Relative humidi ty m ust be in the range of 10 to 90%RH (non -condensing).

(3) Vibration

During operation: Max. 4.9 m/s

2

1 - 3

Page 15

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

(4) Atmosphere

Avoid the following locations:

• Dusty places

• Places where concentration of coolant and/or organic solvent mist is ext remely high.

(5) Power Sou rce

Input voltage:AC (single-phase) 180V ~ 264V

Frequency:50/60 Hz –2 to +2 Hz

1.1.3 Machine Operation Panel

An example of t h e machine operation panel is indicate d below. Arra ngement and names of

switch es and indicator la mps vary according to the mach ine model. For deta ils, refer to the

machine tool man ua l.

FIGURE 1.1.3. 1: Example of Mac h i ne Operation Panel

1 - 4

Page 16

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

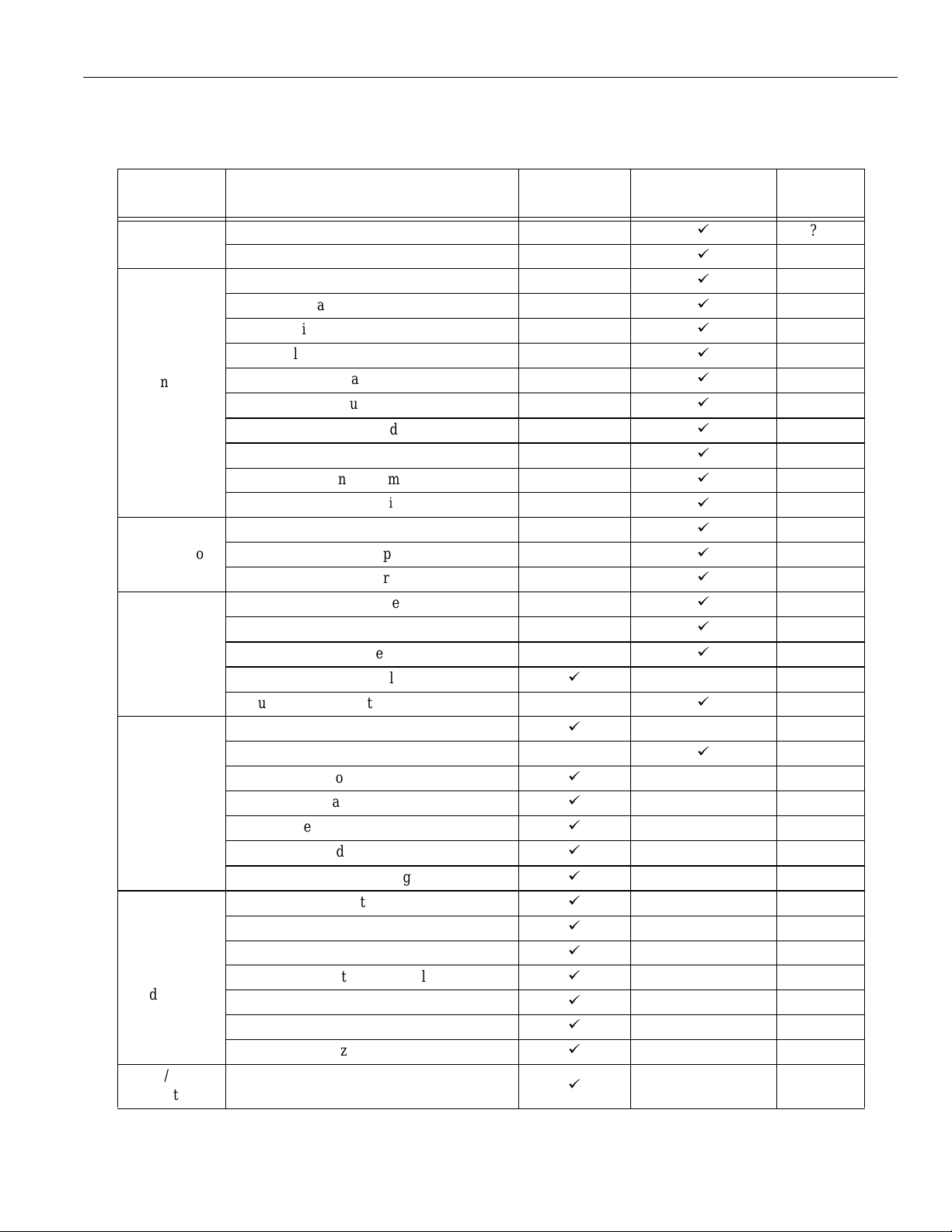

1.1.4 Gene ra l Speci fic ations

(1) Standard Specifications

CATEGORY ITEM AND FUNCTION

Controlled

axes

Input

command

Interpolation

Feed

Storage and

editing of

program

Operation

and

display

Input/Output

function

Number of simultaneously controlled axes

Maximum programmable value

Absolute/incremental programming

Automatic acceleration and deceleration

Controlled axes

Least i nput increment

Least output incre ment

Decimal point input

Input unit 10 times

Tape code

NC tape

Input format

Buffer register

Positioning

Linear interpol ation

Circular interpolation

Rapid traverse

Cutting feed

Dwell

Incremental feed

Program storage capacity

Number of programs

Program editing

Program number search

Sequence number search

Address search

MDI editing

Operation panel

MDI function

l-line MDI

Operation and display

Calendar display

Pop-up menu

Buzzer function

Input/Output interface

OPERATION

MANUAL

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

PROGRAMMING

MANUAL

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

SECTION

NO.

???

1 - 5

Page 17

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

CATEGORY ITEM AND FUNCTION

Tool function

Miscellaneous function

Tool offset

Coordinate

system

Operation

support

function

Programming

support

function

Safety

and

maintenance

Environment

requirements

Automatic return to reference point

Automa tic return to second reference point

Circular interpolation by R command

Self-diagnostics (always displayed)

Tool length offset

Tool position offset

Number of tool offset data sets

Manual return to reference point

Reference point return check

Return from reference point

Base coordinate system setting

Label sk ip

Single block

Optional stop

Optional block skip

Dry run

Machine lock

Miscellaneous function lock

Display lock

Manual absolute

Numerical value set-up

Break-point function

Operat ion mode

Feed hold

Repetitive circle interpolation

Subprogram

Exact stop check

Exact stop chec k mode

Emergency stop input

Overtravel

Axis interlock

Stored stroke limit

Power supply

Ambient temperature

Humidity

OPERATION

MANUAL

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

PROGRAMMING

MANUAL

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

SECTION

NO.

1 - 6

Page 18

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

(2) Option Spe cific a tions

CATEGORY ITEM AND FUNCTION

Controlled

axes

Least input/output increment of rotary axis

Input

command

Interpolation Helical interpolation

Feed

Storage

and editing

of program

Operation

and

display

Input/output

function and

device

Spindle, tool

and

miscellaneous

functions

T ool offset

Automatic third/fourth reference point return

Coordinate

system

Expanded number of workpiece coordinate

Number of controlled axes

Rotary axis cont rol

Inch/metric switching

Multi-active reg isters

Synchronized feed (solid tap)

High-speed mode operation

F1-digit

Simultaneous1-axis handle feed

Simultaneous 2-axis handle feed

Simultaneous 3-axis handle feed

Addition of program storage capaci ty

Addition of number of programs

Playback

Internal toggle switch

NC program drawing

Comment display func ti on

Tape reader without take-up reels

Tape reader with take-up reels

RS-232C interface

T4-digit command

Second miscellaneous function

Tool radius offset

Additi on of tool offset data sets

Manual second reference point return

Workpiece coordinate system setting

systems

Local coordinate system

Rotation of workpiece coordinate system

OPERATION

MANUAL

á

á

á

á

á

á

á

á

á

á

á

PROGRAMMING

MANUAL

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

SECTION

NO.

1 - 7

Page 19

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

Operation

support

function

Programming

support

function

Accuracy

correction for

mechanical

system

Automation

support

function

Safety and

maintenance

Optional block skip B

Automatic mode handle offset

Program restart

Automa tic tool length measuremen t (TLM)

Manual interruption point return

Canned cycle

Canned cycle B

Circle cutting

Macroprogram

Programmable mirror image

Scaling

Coordinate syst em rotation

Automa tic comer override

Programmable data input

Hole ma chining pattern cycle

Program copy

Stored pitch error compe nsa ti on

Unidirectional approach

Skip function

Tool life control function

Program interruption

Stored stroke limit B

Stored stroke limit C

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

á

1 - 8

Page 20

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

1.2 Protective Functions

1.2.1 Emergency Stop

Press the emergency stop button immediately if a problem occurs with the system or line. The

execution of all c om m ands stops instantaneously when the emergency stop button is pressed.

Servo power supply of the PCNC is shut OFF and dynamic br ake is applied to stop all

mechanical movement. In the emergency stop state, the PCNC is in the alarm stat e “3002”. If the

emergency stop signal is “opened”, the PCNC stops the en tire operation, and the SVMX and

BKX signals are “opened”.

PCNC

This operation is executed by setting the pins on the board. The pins differ between J300M

and J100M.

1.2.2 Overtravel

The overtravel function stops axis feed operation when an axis reaches the travel limit; for the

detection of travel limit, a limit switch and a dog are used and if an axis reaches the travel limit,

the limit switch outputs a signal a nd th e function stops axis feed operati on i n response to this

input. The axis rea ched and stopped at the tr avel limit can be moved manually into the axis movable range.

When the overtravel input is “opened”, axis movement is stopped in the manner as indicated in

Table 1.3. In response to thi s inpu t, the alarm output (ALM) i s “closed” and the corresponding

alarm message is di sp la ye d on the screen.

Table 1.2.1. 1: E mergency Related Signals

Signal Name Pin Setting

Emergency Stop Input CN12-19 pin on JZNC-JFC 10 board

SVMX CN12-17 pin on JZNC-JFC 10 board

BKX CN12-16 pin on JZNC-JFC 10 board

Table 1.2.2.1: Axis Stop Direction with Overtravel Input “Opened”

Manual Operation Mode Automatic Operation Mode

*+X to *+5

input is “opened”

*-X to *-5

input is “opened”

* Normally closed contact

Movement in the *+X to *+5

direction is stopped.

Movement in the *-X to *-5

direction is stopped.

Movement of all axes is

stopped in all directions.

If the overtravel inpu t is “opened”, select the manual mode (jog, pulse handle) and move the axis

in the direction opposite to the direction for which the overtravel input is “opened” to “close” the

input. After that press the [RESET] key on the NC operation panel, the alarm output and display

are canceled.

1 - 9

Page 21

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

1. After the oc currence of an ala r m d ue to the “open” of the overtravel input, the M, S, and

T code read output signa ls (MF, SF and TF) are not turned OFF.

2. If it is necessary to in te rrupt the operatio n ca ll ed by M, S and/or T code, set th e i nte rl ock

by an external seque nce.

3. The alarm numbers at the occur rence of overtravel are 2001 to 2005. If the overtra v e l

alarm occurs, axis move is stopped. Note that the servo is not turned OFF.

1.2.3 Stored Stroke Limit

To ensure improved safety in operation, this function prevents axis from entering the preset entry

prohibited are as bo th in manual and autom atic operation.

(

1) Stored Stroke Limit

To use the stored stroke limi t fu nction, the axis movable area is set by parame te rs wit h the

coordinate values in the machine coordinate system. Th e a rea outside the set bou nda ry is

established as the entry prohibited area. If an axis enters the entry prohibited area, the

function stops axis movement and displays an alarm message. The functi o n is made va lid

upon completio n of th e manua l re f er en ce point return after the power is turned ON. In

automatic operation, if even o ne axis caus es the alarm, all axis are stopped.

In manual operati on, only the axis tha t caused an alarm is stopped.

FIGURE 1.2.3. 1: Stored Stroke Limit

1 - 10

Page 22

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

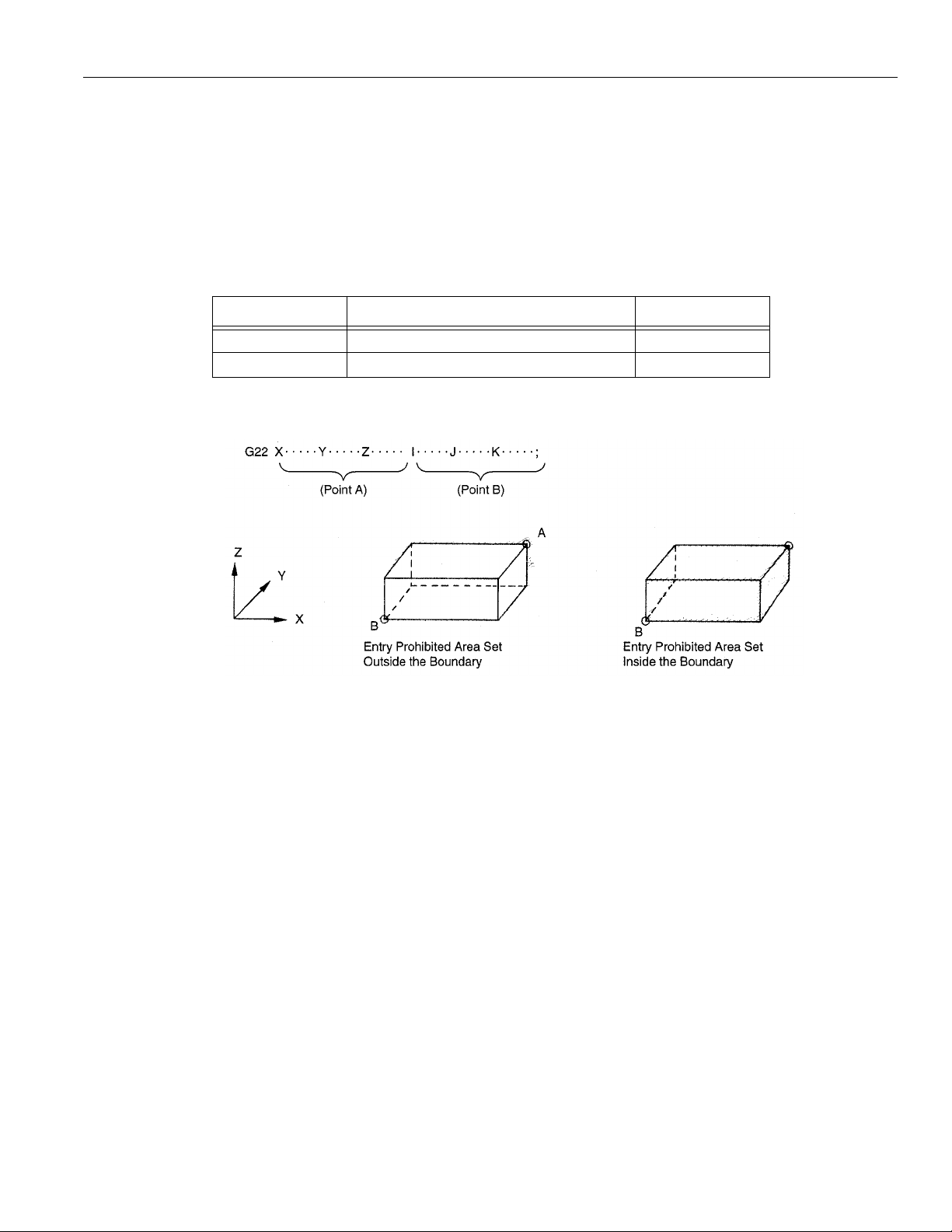

(2) Stored Stroke Limit B, C (G22, G23) *

The area either outside or in s id e the boundary set by par ameters or by the commands in a

program is established as the entry prohibited area. The boundary is set with the coordinate va lues in the m achine coordinate system. W h ether the entry prohibited area is esta blished outside or inside the boundary can be determined by the setting for a par ameter.

The function is made valid upon completion of the reference point return after turning ON

the power.

Table 1.2.3.1: G Code Used to Turn ON/OFF the Stored Stroke Limit B Function

G CODE FUNCTION GROUP

G22 Turning ON the stored stroke limit B 04

G23

Turning OFF the stored stroke limit B

04

FIGURE 1.2.3.2: Stored Stroke Limit B Function

• In addition to the stored stroke limit s A and B, stor ed stroke limit C can be added.

• With the stored stroke limit C, set the boundary of the area and inside or outside the

boundary by parameters.

• Accord in g to the setting for the parameter or the input signal , one of the stor e d str o ke

limit C (third to fifth prohibited area ) ca n be ma de valid.

• For details of the stored stroke limit B, C, refer to 4.2. 3 “Stored Stroke Limit B and C

(G22, G23)” in the PROGRAMMING MANUAL.

1 - 11

Page 23

YASNAC PCNC Operating Manual Chapter 1: Outline of YA SNAC System

1.2.4 Interlock Inputs

The interlock input is the signal used to disable axis mov em ent, and is provided for each axis.

• When an axis is interlocked during movement, it is stopped after deceleration.

• When the interlock is re leased, the axis con tinues mo ving to co mplete th e remainin g com-

mands. Upon com ple tion of the commands, the program advances to the next block.

• For simu ltaneous two or three axis interpolation commands, interpolation operation is disabled if one of the s e two or three axis is int erlocked.

Fig. 1.6 Interlock Inputs

1 - 12

Page 24

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2

PCNC System Outline

Chapter 2 describes various operations including power ON procedure,

manual operation and automat ic oper ation.

2.1 Gen eral Operation Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2 Insection before Turning the Power ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.1 Inspection of the PCNC unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.2 Prepartion before Turning the Power ON. . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3 Turning the Power ON/OFF and Inspection after Power ON/OFF . . . . . . . . . . . 2-8

2.3.1 Procedure for Turning the Power ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.2 Checking the Motors for Abnormalities . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.3 Procedure for Turning the Power OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.3.4 Inspection of the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2 - 1

Page 25

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.4 Manual Operation (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.4.1 Manual Rapid Traverse (RAPID). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2.4.2 Jog Feed (JOG). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.4.3 Step Feed (STEP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.4.4 Handle Feed (HANDLE)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.5 Manual Operation (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2.5.1 Simultaneous 2- o r 3-axis Handle Feed* . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2.5.2 Manual Reference Point Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2.5.3 Manual Reference Point Return to the Second Reference Point . . . . . . . .2-18

2.5.4 1-line MDI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2.6 Automatic Operation (1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2.6.1 Preparation of Automatic Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2.6.2 Memory Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2.6.3 MDI Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2.6.4 Feed Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2.6.5 Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2.7 Automatic Operation (2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2.7.1 Optional Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2.7.2 Optional Block Skip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2.7.3 Dry Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2.7.4 Display Lock and Machine Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2.7.5 Auxiliary Function Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2.7.6 Z-axis Command Neglect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2.7.7 4th-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2.7.8 5th-axis Command Neglect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

2 - 2

Page 26

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.8 OPERATION INTERVENTION (during automatic operation). . . . . . . . . . . . . . .2-29

2.8.1 Manual Operation Intervention during automatic ope ra ti on . . . . . . . . . . .2-29

2.8.2 MDI Operation Intervention during automatic operation. . . . . . . . . . . . . .2-30

2.8.3 Automatic Handle Mode Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

2.8.4 Manual Absolute. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2.9 AUTOMATIC OPERATIONS AT ENHANCED LEVEL. . . . . . . . . . . . . . . . . . .2-34

2.9.1 Tool Length Measurement* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

2.9.2 Return to the Operation Interrupted Point* . . . . . . . . . . . . . . . . . . . . . . . .2-37

2.9.3 Manual Centering Operation* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

2.9.4 Program Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

2.9.5 Playback Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

2 - 3

Page 27

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.1 General Operation Flow

The operatio n proc edure usually followed for daily operation is i ndi cated in Figure 2.1. This

chapter explains these operation items.

Setting Part Program

Loading NC program from PC

by Ethernet or from touch

screen and executing the

Program numbers

FIGURE 2.1.1: Operation Proc edure

2 - 4

Page 28

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.2 Inspection Before Turning the Power ON

Before turning the power ON for YASN AC PCN C, it is necessary to carry out inspe c ti on t o

Ensure safety. If the power is turned ON while the system has trouble, it could cause malfunctioning of the system itself and create a hazards conditions for the operations. Make sure to carryout daily inspection bef ore turni n g the power ON.

WARNING!

• Always turn all power OFF (including the primary power supply) before carrying out daily

inspection.

Performing the inspection with the power ON may lead to electric shock.

• Wait 5 minutes after turni ng the power (including the primary power supply ) OFF befo re

removing or replacing any unit or part.

Failure to observe this warning could lead to electric shock and equipment failure.

• Do no t touch any unit, terminals, e tc., while the powe r is ON.

Failure to observe this warning could lead to electric shock or device malfunction.

• Immediately after switching the power OFF, the product retains some electric charge. Do not

touch any parts (which are live when the power is ON) for 5 mi nutes after switching the po w er

OFF.

Failure to observe this warning could lead to electric shock or device malfunction.

• Do not damage cables, subject them to exc essive stress, or pinch them.

Excessive load on cables may cause electric shock.

• When the equi pment is po w ered ON, never tou ch its rota ting parts.

Failure to observe this warning could result in personal injury.

• Ne ver modify the produ ct.

Failure to observe this warning could result in electric shock, fire, or product failure.

2 - 5

Page 29

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

CAUTION!

• To prevent personnel other than those invo lv ed in maintenance and in spe ct io n w ork from

turning the power ON whi l e mai nt ena nc e and i nspe ct io n is in progress, place signs stating

“DO NOT TURN THE POWER ON” or words to that effect at the primary power

supplies of related cont rol pan el s and othe r re le va nt l oca t ion s.

Failure to observe this caution could lead to electric shock.

• Electronic devices such as CMO S ICs are used on the control boards. If you touch the IC’s

with your bare fingers, static electrical charge in your body could destroy these IC’s, care must

be taken when handling these devices. Before handling these devices for maintenance purposes,

first discharge the static electricity in your body by touching a gro unded metal device.

Failure to observe this caution could lead to personal injury and product failure.

• Do not install or remove boards, wiring, connectors, etc., while the power is ON.

Failure to observe this caution could lead to electric shock, product failure, and malfunction.

• Do not let foreign matter such as ele ct ric a l wire scrap enter the unit .

Failure to observe this caution could result in fire, product failure or malfunction.

• Be sure to check the follow in g points after comple t ing maintenance and inspection work:

• Check that al l fastening bolts are tightened.

• Check that no tools or other objects have been left inside the control panel.

• Check that the control panel door is closed properly.

Failure to carry out these checks could lead to electric shock, injuries, fire, and malfunction.

• Never attem pt to disa ssemble the NC unit modify units/dev ices inside the PC N C unit.

Failure to observe this caution could lead to fire, product failure and malfunction.

• Do not change the se t values of the devices, variab le resistors, et c., in the control panel.

Failure to observe this caution could lead to fire, product failure, and malfunction.

2.2.1 Inspection of the NC Unit

In this subsection, the items to be inspected before turning ON the power are indicated for the

standard PCNC box supplied by Yaskawa. For the machine tool’s control box, refer to the

machine tool man ua ls.

(1) Inspecting the Machine Cabinet Doors

Make sure that the doors are secu rely closed before turning th e power ON.

The PCNC CPU ra ck is not protected against oil mists or ot he r ai rborne foreign matt er.

The door of the machine cabinet doors must always be kept closed before powering ON.

2 - 6

Page 30

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

(2) Inspecting the Shielding Parts in the Machine Cabinet

Inspect the shielding parts in the Machine Cabin et eve ry m onth for gaps and/or damag e.

Open the doors and check the packings installed around the door for dama ge.

ó

Inspect the inside of the Machine Cabinet for abnormal contamination. If the inside is

abnormally dirty, clean it immediately after loc a ti ng the cause of contamination.

ì

Lock the doors secure ly a nd in spect the doors to make sure that th ere are no gaps.

By carrying out th e inspection procedures indicated above at regular int erv als, the

YASNAC PCNC can pe rform efficiently for a long time .

2.2.2 Preparation before Turning the Power ON

Before turning the power ON, confirm the following con dit io ns:

• Make sure that the front side of the PCNC unit is closed. If the door is open or if there is a

gap between the door and the box panels, securely close and loc k t he door.

• Carry out the inspection for the machine an d machine related controllers according to the

instructions in t h e machine to ol manuals.

2 - 7

Page 31

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.3 Turning the Power ON and Inspecting After Power ON

In this section, the procedure to be used for turning the power ON is explained. Inspect io n tha t

must be conducted after turning the power ON is als o descr ib ed.

WARNING!

• Be sure to turn the power OFF before replacing the battery.

Failure to observe this warning could lead to electric shock and product failure.

CAUTION!

• Replace fuses and bat teries with the recommend ed products.

Failure to observe this caution could result in fire or product failure.

• Use the product wi th the “System Number Switch” of the CPU set to “0”.

Using while set to another number could lead to malfunction.

• Wait at least 2 seconds afte r tu rning th e p ower OFF before turning it ON again.

Failure to observe this caution could lead to malfunction.

2.3.1 Proc ed u re for Tur n in g the Power O N

Turn the power ON in the following sequence.

Make sure that the power supplied to the PCNC unit is from an external power source.

ó

Press the POWER ON butt on on the N C ope ra ti on pa ne l. Con trol power is turned

ON and the co ol ing fan starts rotating .

ì

Make sure that air is flo wing out at the upper part on the side of the N C uni t.

• In approximately 20 seconds, the con tro l is re ady for turning ON the servo power

(alarm code 3000).

ö

Press the POWER ON button again - one time.

• The ser vo power is turned ON. When the machine is ready fo r op eration, th e NC

enters th e re ady state.

• When the power is correctly turned ON to th e N C unit, the NRD (NC ready) signal

is output.

• When the power is turned ON at the machine side in response to the NRD signal, the

MRD (machine ready) signal will be returned to the NC. The READY lamp goes on

when the MRD signal is r eturned. Note that a READY lamp is not used with some

types of machines.

2 - 8

Page 32

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

• When th e NC unit enters the ready state, the alarm message (displayed on the screen)

will go off.

ú

If the NC unit fails to enter the ready state, locate the cause by referring to Section 7.2,

“ALARM DISPLAY JOB”, and take appropriate steps. For turning the power O N,

there ar e items that must be inspected at th e machine side in addition to t he NC unit

related items. For the former items, refer to the machine t o ol manuals .

5

PCNC Boots MMI screens

FIGURE 2.3.1.1: Power O N Seque nce

2.3.2 Checki n g the Mot ors for Abnormalities

Check the operation of the motors runni ng. If abnormal vibrat ion or noise occurs, turn the pow er

OFF and contact th e m ai ntenance personnel.

2.3.3 Proc edu re for Tur n in g Power OFF

Turn the power OFF in the following sequenc e:

Make sure that the CYCLE START lamp on the mach ine operation panel is OFF

with the machine stopped.

ó

Make sure that there is no al arm message displayed on t he CRT screen. If an alarm

message is displayed, locat e the c ause by referring to Chapter 4, “MAI NTENAN-

ACE” and take appropriate measures to clear it.

ì

Carry out necessary STEPS for turn in g the power OFF at the machine side. For

details , refer to t he machine to ol manuals.

ö

Press the EMERGENCY STOP button on the machine operation pa ne l t o tur n the

servo power OFF.Press SHUTDOWN button to clo se all opened window s of PCNC.

ú

When the safe SHUTDOWN mess age is displayed on CRT ,Press the POWER OFF

button on the NC operation panel to shut off the power to PCNC.

2 - 9

Page 33

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

÷

Turn the power supply to the NC OFF by turn in g O FF a circuit breaker, etc.

PCNC

PCNC Display

Shut Down button

Shut Down of PC Side

Closing Windows NT

Safe to Turn Off Windows NT

FIGURE 2.3.3.1: Power OFF Sequen ce

2.3.4 Inspection of the Battery

After turning the power ON, if th er e is a battery alarm , a broken battery icon will be displa ye d,

or a solid battery is displayed to indicate everyt hi ng is normal. After two minute s this norm al

battery indicator will disappear. When battery alarm is disp la ye d by red battery icon, the bat tery

must be replaced imm e diately. Standard bat teries cannot be used. Fo r a re pla c em ent of battery,

contact your Yaskawa represent at iv e for Battery type: ER6VC3, Parts code: BA510

(1) Checking the Battery Which Needs Replacing

Follow the procedure indicated below to determine whether or not battery must be replaced.

Press the POWER OFF button.

ó

If a door interlock switch is installed, place the door interlock key in the OFF position.

This makes a power O N con dit io n possi ble with the door opened.

ì

Open the door so that the front part of the PCNC unit i s visi ble .

ö

Press the POWER ON button again - once.

2 - 10

Page 34

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

ú

Check th e r ed color LE D on the JANC D-JFC10 bo ar d. If it is lit , the batter y must be

replaced.

I/O module power out put

verification LED

I/O module power output

verification LED

Battery power supply

connector (C N0 6)

Battery

Fuse (HM03, 0.3A)(F1)

Fuse (5A) (F2)

(Behind Battery)

FIGURE 2.3.4.1: Location of the Battery on the PCNC board

2 - 11

Page 35

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2) Replacing the Ba tt ery

Replace the battery easily with the following procedure.

Turn the PCNC power OFF.

ó

Remove connec t o r of Ba tt ery.Then, remov e th e battery from the holder by desoldering.

ì

Fit the new battery in the holder and carefully solder RED(+) and BLACK (-) wires to

the Battery. Put the battery in its holder.Then pu t back batt er y connector, the connector may be inserted in either direction, it must be securely inserted, otherw ise , t he

power will not be suppli ed by the ba tt ery. (See Fig. 2.7.)

Connect Red wir e

( + )

B

A

T

T

E

R

Y

Connect Black wire ( - )

FIGURE 2.3.4.2: Connecting the Battery Connector

ö

Turn the power ON.

ú

Make sure that “BAT” is not blinking on the CRT screen, and that the red color LED

in the board is OFF.

1. If the red color LED remains lit after rep lacin g the batter y , th e connecto r might be inserted

incorrectly or the battery might be faulty.

2. Power OFF operati on i s all owed a few seconds after turni ng t he power ON.

3. After turning the power OFF, replace the battery quickly. If the PCNC unit is left with the

battery removed, the data stored in the memory could be lost.

2 - 12

Page 36

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.4 Manual Operation (1)

This section desc ri be s ge ne rally the manual ope ration. To move an axis manually, select the

operation mode of RAPID, JOG, STEP, or HANDLE with the MODE SELECT switch on

the machine operatio n panel.

2.4.1 Manual Rapid Traverse (RAPID)

An axis can be move d at a rapid traverse rate. Follow the procedure in dic ated below.

Select the rapid mode by placing the MOD E SE LE CT switch on the machine

operation pane l i n the RAPID po s ition.

ó

Select the feedrat e to be use d for a xis feed operation by the RAPID TRAVERSE and

RATE OVERRIDE sw itch on the mac h i n e operation p anel.

• Override setting is possible in four steps of 100%, 50%, 25%, and F

. The feedrate

0

corresponding to the settin g at 100%, 50%, and 25% is set for parameters pm2801

to pm2805. For the setting at F

• Optionally, F

the switch setting at F

ì

On the machine operation panel, pres s th e JOG button that corresp onds to the axis

and F2 positions are select able. Feedrate to be selected according to

1

and F2 is set for parameters pm 2448 and pm2449.

1

, feedrate set for parameter pm2447 is used.

0

and the direction in w hi ch the axis should move. The axis moves at a rapid traverse

rate while the button is held pressed.

2 - 13

Page 37

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.4.2 Jog Feed (JOG)

It is possible to move an axis in the jog feed mode. Follow the procedure indicated below.

Select the jog mode by placing the M ODE SELECT switch on the machine operati on

panel in the JOG position.

ó

Select the feedrate with the J OG FEEDRATE sw itch on the machine operation panel.

• Feedrate can be selected from 32 steps, with actua l fe edrates of individual settin g

positions set for paramete rs pm2 400 to pm2431. The actual number of steps and

feedrates sele ctable by the JOG FEE D RATE switch var y depend ing on the m achine

model. For details, refer to the ma nua l s pu bl ishe d by the machine tool buil de r.

ì

Press the JOG swit ch corresponding to the axis to be moved and the required axis

move direction.

ö

The axis moves at the selected feedrate while the JOG switch is held pressed.

2.4.3 Step Feed (STEP)

Manual step feed operation is possible. Follow the procedure indicated below.

Select the step mode by plac in g the MODE SELECT swit ch on the machin e oper atio n

panel in the STEP position.

ó

Select the feed distance per step with the MANUAL PULSE MULTIPLY switch on

the machine operatio n panel.

Metric system : 0.001, 0.01, 0.1, 1.0, 10.0 , 100 .0 mm (pe r step)

Inch system : 0.0001, 0.001, 0.01, 0.1, 1. 0, 10.0 inch (per step)

ì

Press the JOG swit ch corresponding to the axis to be moved and the required axis

move direction.

ö

Each time th e JOG switch is pressed, th e selected axis moves in the selected direction

by the set feed distance per step.

2.4.4 Handl e F ee d (HANDLE)*

When the NC is equipped with a manual pulse generator, pulse handle feed operation is possible.

Follow the procedure ind ic at e d bel ow.

Select the handle mode by placing th e MO D E SELECT switch on the ma chine operation panel in the HANDLE position.

ó

Select the axis to be moved by the HANDLE AXIS selection switch on the machine

operation panel .

ì

With the MANUAL PULSE MULTIPLY switch on the machine operation panel,

select the axis feed di stance per pulse (one division of the pulse handle).

2 - 14

Page 38

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

Clockwise rota ti on: I n the positive direction

Counterclockwise directi on: In the negative direction

Metric system: 0.001, 0.01, 0. 1 mm (p er division)

Inch system: 0.0001 , 0.001 , 0.01 inch (per division)

ö

Turn th e pulse handle. The axis moves in the positive or nega tive directio n acco r d ing

to the direction in which the pulse handle is turned.

2 - 15

Page 39

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.5 Manual Operation (2)

This section descri bes manual operation s car rie d out in da i ly production using the manual

operation func tions explained in 2.4 “MANUAL OPERATION (1)“.

2.5.1 Simultaneous 2 or 3-axis Handle Feed *

By installing the pulse handle for the individual axis, it is possible to move up to three axis among

the X-, Y-, Z-, α-, and β-axis simulta neously. Follow the proce dure indicated belo w.

FIGURE 2.5.1.1: Simultaneous 2 or 3-axis Pulse Handle Feed

Select the handle mode by pl acing the M O D E SELECT switch on th e machin e

operation panel in the HANDLE positi on .

ó

Select the axis feed distance per graduation of the pulse handle with the MANUAL

PULSE MULTIPLY switch on the machine operation panel. This switch is used in

common for the three pulse handles.

ì

Turn the pulse handle. The selected axis is moved in the positive or negative direction

according to the handle tu r ning direction.

2 - 16

Page 40

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.5.2 Manual Refe rence P oint Return

Axes can be returne d to the refe re nce point in manual op eration. Follow the proc edure indicated

below.

Select the rapid or jog m ode by placing the MODE SELECT switch on the m ac hine

operation pane l i n the RAPID or JOG posit ion.

ó

Move an axis manually (manual rapid traverse or jog feed) to a posi tion away from

the reference point (within the reference point return enabled area).When an axis is

located in range A in Fig. 2.9, reference point return can be executed correctly.

ì

Turn ON the REFERENCE POINT RETU RN sw itch.

ö

Keep the JOG switch pressed corresponding to the axis returning to the reference point

and in the return direction. When the JOG switch is held pressed, the corresponding

axis starts moving in t h e s ame manner as ordinary m anual axis feed o peration.When

the axis reaches the deceleration point, feedrate is decelerated to a low feedrate and

the axis s tops autom atically at the reference point.

ú

Upon comple ti on of the reference po int ret urn, the REFERENCE POINT lamp of

that axis lights.

FIGURE 2.5. 2.1: Manual Reference Point Return

t

Refere nc e Point is a specific p osition in th e machine coordinate system . I t is also ca lled the

machine ze ro poi nt or the machine refe rence point.

1. Once the refere nce point return is compl eted, point C indicated in Fig. 2. 9 is stor ed to the

NC. Therefore, if reference point ret urn i s att empted while an axis is in are a B, an error

occurs. In this case, the axis should first be returned to area A and then the reference point

return should be executed.

2. The axis for whi ch t he refe rence point return has been c om pleted can be moved in

2 - 17

Page 41

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

the reference point re tu rn direction manuall y onl y if t he re ference point return swit ch

is turne d OFF.

3. If command s h av e be en read to the buffer area du ring automatic op eration, manual

reference point return must not be executed. If manual return operation is executed,

the data in the buffer area is cleared.

1. Immediately after the power is turn e d ON, the axi s star t man ual or automatic reference

point return operation independent of the present axis position. However, reference point

return cannot be executed correctly if the axis is located in area B. In this case, the axis

must be returned to a rea A before executing reference point return.

2. If the MODE SELECT switch setting is changed while an axis is moving automatically to

the reference point, an alarm (alarm 2141 to 2145 reference point return interruption error)

occurs.

3. Reference poi nt return cannot be exec ut ed when the MACHI N E LOCK switch is ON.

4. With a rota r y axis, it is possible to execute autom atic reference point return as with a

linear axis.With a rotary axis, if it has been mov ed by more than ± 360.000° from the

reference point established first, reference point return is executed to the closest reference

point in the preset di rection of referenc e point return.

The illustration below shows how the reference point return is executed from points A and

B. (The reference poi nt ret urn direction is determ in ed by the setting for pm4002 D3 and

D4.)

5. Once the reference point return is completed, second and later reference point return is

executed at a high-speed mod e. This is call ed “high-speed reference point return”. However, if the setting is so made to execute the reference point return at a low speed (pm4003

D6 = 1), second and later refer ence point return is executed at a low sp eed.

2 - 18

Page 42

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.5.3 Manual Reference Point Return to the Second Reference P oint *

The axis are automatically positioned at the second reference point. This operation allows positioning at the second reference point independent of the present axis position, whether it is in

the negative side or positive side from the second reference position. Follow the procedure indicated be low.

Select the jog or rap id mode by placing the MODE SE LE CT switch in the JOG or

RAPID position.

ó

Turn ON the ZRN2 (second zero poin t return request) switch on the m ac hi ne operation pa nel.

ì

Keep the JOG swit ch co rre sp ondin g to the ax i s and d ire ct ion o f r efer enc e poi nt r et urn.

The corresponding axis is positioned at the second zero point at the jog feedrate or

rapid traverse rate ac cording to the selecte d m ode.

• If the ZRN2 switch is turned OFF while an axis is moving to the second reference

point, the axis stops moving . To restart the second reference poi nt re tu rn ope ration,

turn ON the ZRN2 swi tch and turn OFF the JOG switch having been pressed once,

then press it once again.

• If the JOG switch is pressed again to be turned OFF while the X-axis is moving to the

second zero point, the axis stops moving. In this case, press the JOG switch again to

turn it ON, and the X-axi s rest art s mo vi ng to the sec ond z ero point.With the Y- and

Z-axis, this is also app lied.

1. If the JOG switches of [+] an d [ –] are pressed at the same time, the corresponding axis

stops moving sin ce this ope r ation is ass umed to have turned O FF the JOG switch.

2. It is not allowed to use the first zero point return mode and the second reference point

return mode at the same tim e. If both input signals are ON at the sa me ti me, both of the

modes are invalid and nei ther jog nor rapid feed is exe cu te d. Thi s fea tu re is provided to

ensure safety.

3. If the NC is in either the machine lo ck s tate (includ ing the machine lock for individual

axis) or the Z-a x is command disregard stat e, the secon d zero point return operation cannot be executed. When a JOG switch is pressed under such a state, normal jog operation

is preformed.

4. With the axis for which seco nd zero point return ha s bee n completed, manu al axi s mov e

operation is allowed on ly a fte r th e Z RN2 (second reference point retu rn) swi tc h is tu rne d

OFF.

2 - 19

Page 43

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

1. If the second zero point return input signal is turned ON in the state that the first zero point

return h as not bee n co mpleted , th e input is in v alid and the second r eference p oint return

mode cannot be set .

2. In the second reference point return mode, inpu t fro m t he JOG switch [-X] ([-Y], [-Z]) is

valid. If the mode is cha nged, the ZRN2 switch is assumed to have been turned OFF.

2.5.4 1-line M D I

During the execution of manual operation, it is possible to execute one block of a part program by

directly entering it to the CRT screen. For this type of operation, a maximum of 40 characters can

be written and the function codes that are allowed are M, S, T, F, and E codes.

However, M00, M01, M02, M30, M90 to M99, an d M190 to M199 cannot be specified. A n

offset command with a T co mman d is also disregarded . With the system that car ries out set-up by

using a T command, a T command must not be specified for this 1-line MDI operation.

Follow the procedure ind ic at e d bel ow.

Select the manual mode with the MODE SELECT switch on the machine operation

panel. 1-line MDI op era ti on is not possible in the automa t ic or edit m ode.

ó

Enter the program from the operation panel.

ì

Press the CYCLE START switch on the machine operation panel, and the entered

program is executed. When the execution of the program is completed, the pr ogram

displayed in the key ent ry di spl ay are a is c leare d.

• If the mode is chan ge d w h i le the program is executed (waiting for FIN), the FIN is

not returned forcibly and the NC rem ains in the st ate waiting for the in p ut of FIN.

2 - 20

Page 44

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

2.6 Automatic Operation (1)

This section descri be s basic in formation necessary for pe rforming automatic operation.

CAUTION!

• Before carrying out a cutting operation with a new program, confirm safety by performing the

single block operat ion and dry run operation.

If this pr e ope ratio nal chec k is not perfor med, unexp ected o perati on may result due to mis-setting of the amo unt of

offset, leading to tool damage due to interference. The resulting interference may cause injury to personnel.

• Strictly observe the caut i o ns in the user’s manual when using programming func tions.

Ignoring these cautions could lead to accidents involving injuries to personnel and malfunctions.

2.6.1 Prep aration of Automatic Operation

After turning the power ON, the ax is mu st be positioned at the start point defined in a program

before starting automatic operation. Set the coordinate system to be used for machining either

manually or by specifyi ng appropriate comma nds in a program. Several examp le s are giv en

below to explain how the coordinate system should be set. For details, refer t o the machine tool

manuals.

(1) Setting the Coordinate System

The origin of the c oordinate system to be use d for e xecuting the comma nds should be set.

(a) When G92 is not specified in the program

The coordinate syst em for which the origin is set at othe r th an the reference point f or th e

program not containing the coordinat e system setting comman d (G 92) is called a coordinate system for machining. The procedure for setting a coordinate system for machining is

indicated below.

Return t h e axis to the r eference point by fo llowing th e manual re f erence point return

procedure (see 2.4. 2).

ó

Select the MDI mode by pl ac ing the MODE SELECT swit ch on the machine opera tion panel in the MDI position .

2 - 21

Page 45

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

ì

Write the program for setting the coordinate system.

For example,

G92X • • • Y • • • Z • • • ;

FIGURE 2.6.1. 1: Coordinate Sy stem for Machining

ö

Execute the progr am by pressing the CYCLE START switch on the mach ine ope ration pa nel.

(b) When G92 is specified in the program, return the axis to the reference point by manual ref-

erence point return operation.

Example of Pr ogramming

EOR;

N1 G92X • • • Y • • • Z • • • ;

(c) When G28 (automat i c re ference program poi nt return) and G92 are sp ec if ie d in the

program, move the axis manually to a position (in the area where reference point return

operation is allowed) aw ay from the refe rence point.

Example of Pr ogramming

EOR;

N1 G28 • • • Y • • • Z • • • ;

N2 G92X • • • YO • • • Z • • • ;

2 - 22

Page 46

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

(2) Start Lock

Keep the machine in the start lock state until it is confirmed that machine operation is

permitted. Follow the procedure indicated below.

Before starting machine operation, turn the START LOCK switch on the machine

operation panel O N .

ó

After safety is conf ir med , tu r n the S TART LOCK switch OFF.

2.6.2 Memory Operati on

Memory mode operation is used to carry out automatic operation by using programs stored in the

PCNC memory. Follow the procedure indi cated below.

Make sure t h at the alarm icon on the PCNC MMI is green . If the alarm icon is red,

touch the alarm icon button and locate the cause by referring to 9.1.4, “Cause of Al arm

and Corrective Action” and take appropriate measures to clear it.

ó

Check the tool offset amounts and correct the m if necessary, then position the axis at

the start point. For details of tool offset, refer to 5.3, “TOOL DATA CONTROL

JOB”.

ì

Carry out necessary settings with the switches on the machine operation panel.

• Selec t the memory mode by placing the MODE SELECT switch in the MEM pos ition.

• Set the SINGLE-BLOCK switc h O N or OF F. To execute the program blo ck -by-

block, set it ON.

• Set the rapid tra v e r s e rate with th e RA P ID TRAVERS E RATE OV ERRIDE swi tc h .

• Set the MANUAL ABSOLUTE switch ON or OFF. Set the switch ON to return the

tool by manual operation interven t ion to the previously located position .

• Set the OPTIONAL BLOCK SKIP switch ON or OFF . Set the switch ON to disregard

the blocks that include the “/” (slash) code.

• Set the OPTIONAL STOP switch ON or OFF. To execute the optional stop function

(M01), set the switch ON.

• Set the DRY RUN switch. ON or OFF. Set the switch ON when checking the

program.

• With the FEEDRATE OVERRIDE and JOG FEEDRATE switches, set the feedrate.

ö

Press the RESET button on the PCNC MMI operation panel. The program is rewound

to the beginning.

ú

Press the CYCLE START switch on the machine operation panel to start automatic

operation.

÷

To suspend operation temporarily, press the FEED HOLD switch on the machine

operation panel .

2 - 23

Page 47

YASNAC PCNC Operating Manual Chapter 2: Basic Operation of YASNAC PCNC

1. In case of emergency, press the EMERGENCY STOP butt on on the machine opera tion

panel to stop th e machine immediately.

2. It is possible to start a program half way in the memory mode operation. Locate the cursor

at the required start bl oc k by using the Run This bu tton, and press the CYCLE START

button. For this operation, however, the modal G codes must be set before starting the program.

3. In the memory mode , add ress search must always be execu ted by spe ci fyi ng “address +

nemeral”.

2.6.3 MDI Operation

Automatic operation is possible by inputting a program in the MDI mode. Follow the procedure

indicated below.

Select the MDI mode with the MODE SELECT switch on the machin e operation

panel.

ó

ì

2.6.4 Feed Hold

The feed hold function suspends automatic operation temporarily. Follow the procedure indicated

below.

ó

1. If the execution of a drilling canned cyc le is sto ppe d halfway due to the sing le blo ck

function, the FEED HOLD lamp auto matically goes ON to indicate that the operation

is suspended during the execution of a dr illi ng canned cycle.

Enter the block of co mmands from the keyboard. For details of program entry

operation in the MDI mode, refer to 6.2, “MDI OPERATION JOB”.

Press the CYC LE S TART switch on the machine ope ration panel and the executio n

of the entered pr ogr am is star ted.