Page 1

Catalog CA.P7.01

P7 Drives for Industrial Automation

Date: 4/1/08

Page 2

Page 3

Table of Contents

P7 Drive (P7)

Description ................................................................... 3

Standard Drives ................................................................... 4

Ring Kit Options ................................................................... 6

Enclosure Options ................................................................... 7

Reactor Options ................................................................... 8

Control Options ................................................................... 10

Communications Options ................................................................... 11

Dimensions and Data ................................................................... 12

P7/Configured Package (P7C)

Description ................................................................... 13

Configured Drives and Options ................................................................... 16

Dimensions and Data ................................................................... 24

Page

P7/Configured NEMA 3R (P7CR)

Description ................................................................... 27

Configured Drives and Options ................................................................... 30

Dimensions and Data ................................................................... 34

P7/Bypass Package (P7B)

Description ................................................................... 37

Bypass Drives and Options ................................................................... 40

Dimensions and Data ................................................................... 48

P7/Bypass NEMA 3R (P7BR)

Description ................................................................... 53

Bypass Drives and Options ................................................................... 56

Dimensions and Data ................................................................... 60

Software, Drawings, Manuals ................................................................... 62

Technical Training ................................................................... 63

Terms and Conditions ................................................................... 64

Options Matrix ................................................................... 66

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 1

Data subject to change without notice

Page 4

This price book may describe trademarked equipment, which is the property of other companies. These

trademarks are the property of the registered owner companies and may include the following:

TM

DeviceNet

Profibus

Modbus

, trademark of ODVA.

®

, trademark of PROFIBUS International

®

, trademark of Schneider Automation, Inc.

Other Documents and Manuals are available to support special use or installation of this product. These

documents may be provided with the product or upon request. Contact Yaskawa Electric America, Inc. or visit

www.yaskawa.com, as required. Documents may include the following:

TM.P7.01... Drive Technical Manual included on CD ROM with product

TM.P7.02... Programming... Drive Programming Manual included on CD ROM with product

TM.AFD.12... Profibus-DP... Manual included on CD ROM with product

TM.AFD.13... DeviceNet... Manual included on CD ROM with product

TM.AFD.26... EtherNet/IP... Included on CD ROM with product

DriveWizard... Software and Manual... Included on CD ROM with product

Options Instructions... Included on CD ROM with product

REVISIONS

Change Page

Changed revision date all pages

Updated Remote Operator Kit information 10

Added BACnet information 11

Minor text changes

4-6, 8-9, 12-14, 16-17, 20-21, 27, 29, 34-35,

37, 48-49, 53, 60-61

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 2

Page 5

For industrial applications such as centrifugal fans and pumps, the P7 drive is an ideal choice. The drive is

provided in Normal Duty ratings with 110% overload capability. V/f control mode, network communication

options, and an array of input/output options are available.

This drive is designed for tough industrial environments. It is rugged and reliable, with an MTBF of 28 years.

A variety of enclosure options provide the right environmental protection. Providing the right power

requirements is also easy with 208/240 and 480 volt ratings, built-in bus choke above 30 HP, common bus

capability, and other energy savings options.

The P7 supports communications choices such as DeviceNet, Profibus-DP and others. Drive coordination

with other equipment is simplified with inputs and outputs for 4 to 20 mA, 0-10V and an assortment of

programmable contacts.

With an optional phase-shifting input transformer, the P7 dual-diode bridge can be operated in 12-pulse

rectification mode, reducing input current harmonic distortion factor by over 90%. With lower EMI/RFI

emission and lower total harmonic distortion contribution, the P7 meets or exceeds the generally accepted

power quality standards.

The P7 has been designed to provide the features and options commonly needed for fan and pump

applications.

Performance Features

• Ratings: 5-150 HP, 208 VAC

5-150 HP, 230 / 240 VAC

5-500 HP, 480 VAC

• Overload capacity: nominal 110% for 60

sec. (150% peak)

• Starting torque: 100% at 3 Hz

• DC injection braking: at start or stop,

adjustable, current-limited (anti-windmilling)

• Motor preheat function

• Adjustable accel/decel: 0.1 to 6000 sec.

• Controlled speed range: 40:1

• Critical frequency rejection: 3 selectable,

adjustable bands

• Torque-limiting: 30-180%

• Energy $aving control

• Torque boost: full range, auto

• Power loss ride-thru: 2 sec.

• Inertia ride-thru

• Auto restart after power loss or resettable

fault, selectable, programmable

• Feedback signal loss detection

• Serial communications loss detection

• “Up/Down” floating point control capability

• Stationary motor auto-tuning

• Sleep function

• Run-permissive input

Protective Features

• Current-limited stall prevention

• Heat sink over-temperature, speed foldback

• Bi-directional start into rotating motor

• Current-limiting DC bus fuse

• Optically-isolated controls

• Short circuit protection: Phase-phase and

phase-neutral

• Ground fault protection

• Short circuit withstand rating: 100K RMS

• Electronic motor overload: UL

• Current limit

• Fault display: last 10 faults

• Fault circuit: OC, OV, OT

• Over torque and under torque protection

• Reverse prohibit selectability

Service Conditions

• Ambient Temperature: -10°C to 40°C

NEMA 1, 45°C protected chassis

(14° F to 104° F, 113° F)

• Humidity: 95% RH, non-condensing

• Altitude: 3300 ft; higher by derate

• Input voltage: +10%/-15%

• Input frequency: 50/60 Hz ± 5%

• 3-phase, 3-wire, phase sequence

insensitive

Design Features

• LCD keypad display, 5 lines x 16 characters, backlit, 6 languages, copy function

• Multi-step speed settings: 5 available

• Setpoint (PI) control

• 32-bit microprocessor logic

• Non-volatile memory, program retention

• Displacement power factor: 0.98

• Output frequency: 0.1 to 120 Hz

• Frequency resolution: 0.06 Hz

• Frequency regulation: 0.1%

• Control Terminal Board: Quick disconnect

• Carrier frequency: selectable to 15 kHz

• 3% DC bus reactor: 30-150 HP, 208 VAC;

30-150 HP, 240 VAC; 40-500 HP, 480 VAC;

optional on lower ratings

• 24 VDC control logic, PNP / NPN selectable

• Transmitter/Option power supply

• Input/output terminal status

• Timer function: Elapsed time, Delay on

start, Delay on stop

• RS-422/485 port: Modbus protocol

• Volts/hertz ratio: Preset and programmable

V/Hz patterns

• Meter Functions: Volt, amp, kilowatt,

elapsed run time, speed command

• NEMA 1 or protected chassis

• UL, cUL listed and CE marked; IEC 146;

• MTBF: exceeds 28 years

• DriveWizard™ upload/download and

monitoring/graphing software

Description

5 - 500HP

Inputs and Outputs

• Output contacts: One form C and two

programmable form A

• Input terminals: 5 programmable multifunction input terminals

• Fault input: Programmable

• Remote speed command: 0-10 VDC or 420mA, direct or reverse-acting

• Analog outputs: Programmable, two, 0-10

VDC

Options

• Remote digital operator kit

• Input and/or output reactor

• Twelve-pulse rectification with input

transformer: 30 -150 HP at 240 VAC,

40-500 HP at 480 VAC

• Communication Interface: DeviceNet,

Profibus, LonWorks, Ethernet, and

Modbus Plus

• RFI/EMI filter / EMC

• Pressure transducer, 3-15 PSI

• Analog outputs: programmable, two,

4-20 mA

P7

Page 3

Data subject to change without notice

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 6

P7

23P71 16.8 5

25P51 23

5

(3)

31 7.5

31 10

20111 46.2 15 NEMA 1

20151 59.4 20

20181 74.8 25

20221 88 30

20301 115 40

20370 162 50

20450 192 60

20550 215 75

20750 312 100

20900 360 125

21100 415 150

23P71 16.8 5

25P51 23 7.5

27P51 31 10

20111 46.2 15

20151 59.4 20

20181 74.8 25

20221 88 30

20301 115 40

162 50

162 60

20450 192 75

20550 215

75

(3)

312 100

312 125

20900 360 150

21100 415

150

(3)

(Amps)

Nominal HP

(2)

Rated Input

Voltage

CIMR-P7U

Protected Chassis

NEMA 1

Protected Chassis

Drive List Price $

NEMA 1

Protected Chassis

Protected Chassis

Protected Chassis

Standard Enclosure

208V

240V

230V

NEMA 1

Protected Chassis

NEMA 1

NEMA 1

27P51

20370

20750

NEMA 1

NEMA 1

NEMA 1

Protected Chassis

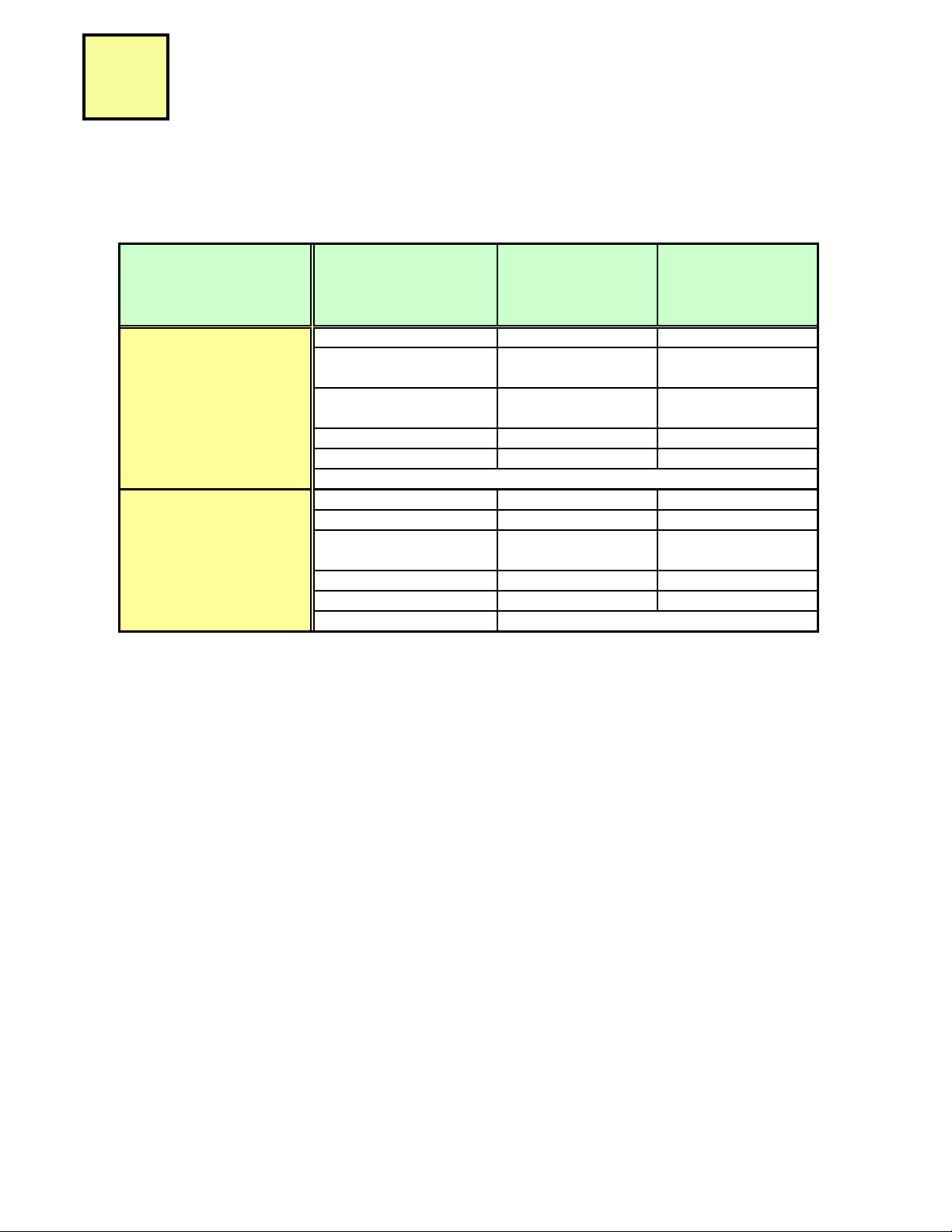

Standard Drives

P7 Drives - 5-500HP, 208-230/240 and 480V, 3-phase

Rated Output Current

Drive Model Number

(1)

input, NEMA 1 or protected chassis enclosure

(1) For single-phase input applications, consult Yaskawa Drives Applications Engineering for proper sizing

(2) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

(3) Check motor FLA for proper drive sizing

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Three-Phase Alternating Current Motors

Page 4

Page 7

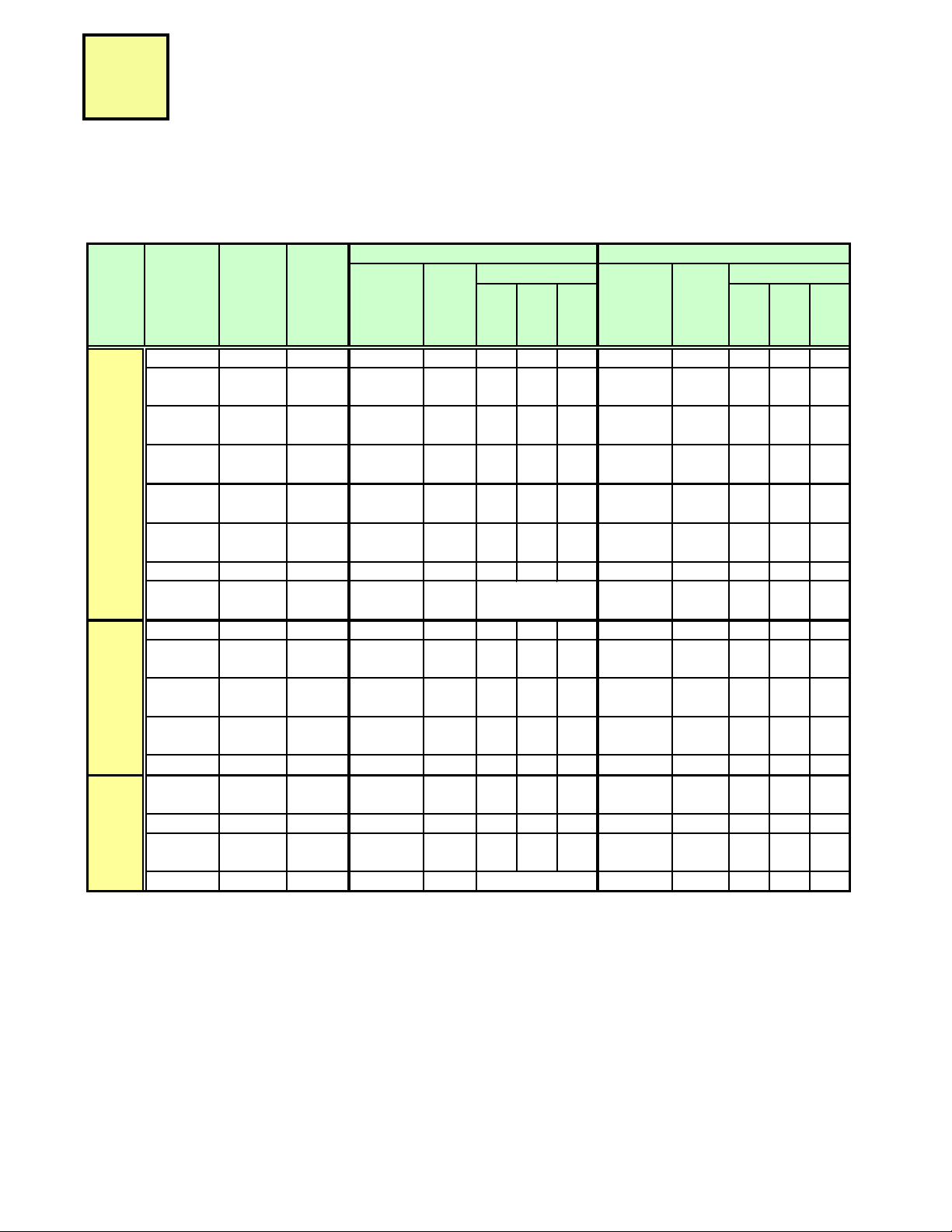

P7 Drives (Continued)

43P71 7.6 5

44P01 8.7

5

(3)

45P51 12.5 7.5

47P51 17 10

49P01 21 15

40111 27 20

40151 34 25

40181 40 30

40221 50.4

30

(3)

NEMA 1

40241 52 40

40301 67.2 50

40371 77 60

40451 96 75

40551 125 100 NEMA 1

40750 156 125

40900 180 150

41100 240 200

41320 260

200

(3)

300

350

400

450

675

NEMA 1

304

414

515

250

500

Protected Chassis

Protected Chassis

Protected Chassis

NEMA 1

Drive List Price $

NEMA 1

NEMA 1

Standard Enclosure

NEMA 1

NEMA 1

(Amps)

Nominal HP

(2)

Rated Input

Voltage

CIMR-P7U

480V

41600

41850

42200

43000

Protected Chassis

Protected Chassis

Protected Chassis

Standard Drives

P7

Drive Model Number

Rated Output Current

(1) For single-phase input applications, consult Yaskawa Drives Applications Engineering for proper sizing

(2) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(3) Check motor FLA for proper drive sizing

Page 5

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 8

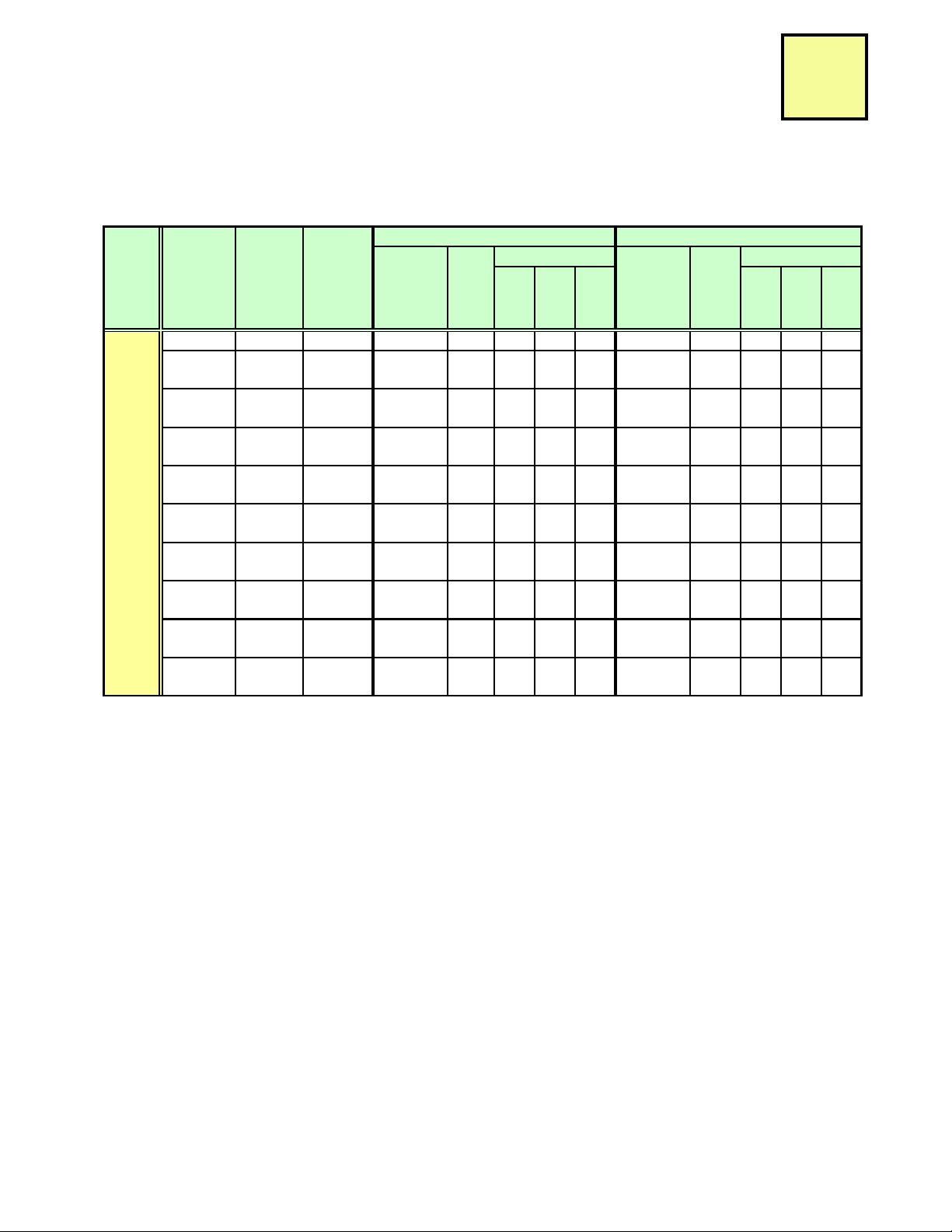

Ring Kit Options

20P41 thru 25P51 D

27P51

20111

20151

20181

20221 F

20301 E

20370 thru 21100

40P41 thru 45P51 D

47P51 thru 40111 C

40151

40181

40221 thru 40301 E

40371 thru 40551 A

40750 thru 43000

Not Available

208-230/240V

C

B

Not Available

Rated Input Voltage

Drive Model Number

CIMR-P7U

Kit Model No.

UDA00417-

Kit List Price $

480V

B

P7

Ring Kit - These kits allow installation of the drive into a customer's enclosure with the heatsink mounted out the back to

reduce overall enclosure size. Each kit includes all of the necessary components, including hardware and instructions.

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 6

Page 9

Enclosure Options

Height (in.) Width (in.) Depth (in.)

20P41 thru 20301

20370

20450

20550

20750

20900 F 49.33 20.43 No Change

21100

40P41 thru 40551

40750

40900

41100

41320

41600 P 52.52 23.39 No Change

41850

42200

43000

480V

Not Available

C

E

F

No Change

Rated Input

Voltage

Drive Model

Number

CIMR-P7U

Kit Model No.

UDA00365-

208-230/240V

15.55

20.43

40.83

Not Available

No Change49.33

18.43

Kit List

Price $

Not Required

Not Required

No Change

No Change

Overall Drive Dimensions

E

18.43

32.24

40.83

End Cap Kit

Leg Kit

End Cap Kit, NEMA 1 - This option consists of a top and bottom cover to convert a protected chassis drive to a NEMA

1 enclosed unit. This option DOES NOT provide additional space for mounting auxilliary components (i.e. circuit breaker, input

fuses, reactor, etc.).

P7

Freestanding Leg Kit, NEMA 3R - This option allows the NEMA 3R wall-mount enclosures to be mounted on legs so

that the control can be freestanding and off the ground. Either kit can be used on any of the wall-mount enclosures. (All

floor-mount enclosures come standard with freestanding legs.)

12" Leg Kit

Model No. UDA00548-1 .................................... List $

30" Leg Kit

Model No. UDA00548-2 .................................... List $

Page 7

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

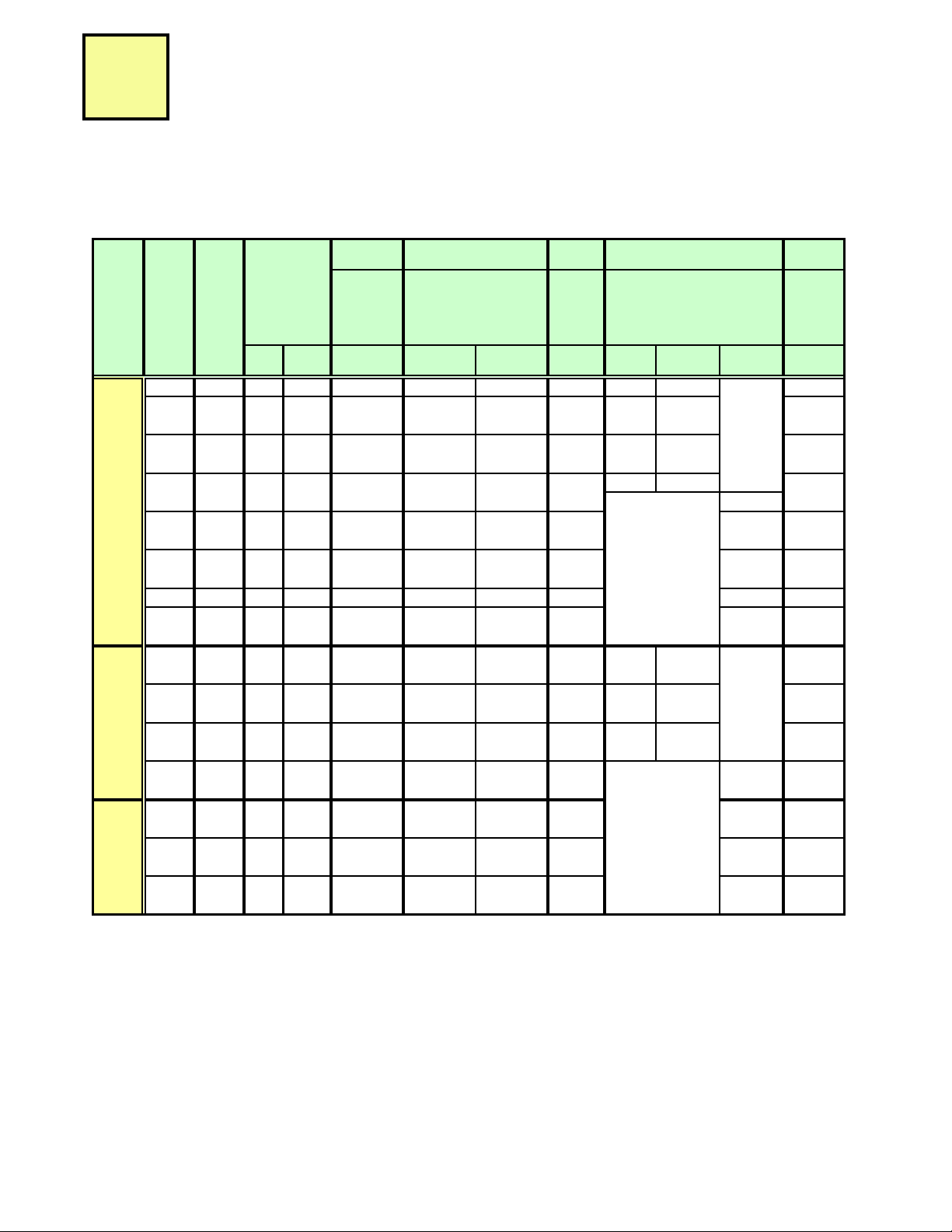

Page 10

Reactor Options

HLW HLW

23P71 16.8 5 0041 13.0 13.0 13.0 0036 8.0 8.0 6.0

7.5 0041 0047

10 0046 0051

20111 46.2 15 0054 0055

20151 59.4 20 0058 0059

20181 74.8 25 0058

20221 88 30 0067

20301 115 40 0066 0067

20370 162 50 0072 0073

20450 192 60 0077 0078 13.0 13.0 13.0

20550 215 75 0082 0083 24.0 17.0 17.0

20750 312 100 0087 24.0 17.0 17.0 0088 24.0 17.0 17.0

20900 360 125 0092

21100 415 150 0096

23P71 16.8 5 0036 8.0 8.0 6.0 0037 8.0 8.0 6.0

25P51 23 7.5 0041 0042

27P51 31 10 0046 0047

20111 46.2 15 0050

20151 59.4 20 0054

20181 74.8 25 0058 0059

20221 88 30 TBD 0058

20301 115 40 0066 13.0 13.0 13.0 0067 13.0 13.0 13.0

50 0066 0067

60 0072 0073

20450 192 75 0077 13.0 13.0 13.0 0078 13.0 13.0 13.0

100 0082 13.0 13.0 13.0 0083

125 0087 24.0 17.0 17.0 0088

20900 360 150 TBD 0092 24.0 17.0 17.0

17.0 17.024.0

List

Price

$

Dimensions (in.) Dimensions (in.)

Part

Number

05P00620-

List

Price

$

13.0

13.0

13.0

13.0

13.0

13.0

13.0 13.0 13.0

13.0

13.013.0

13.013.

0

17.0

13.0 13.0 13.0

13.0

24.0 17.0

13.0

13.0

13.0

TBD

13.0 13.0

13.0 13.0

13.0

230V

20370

20750

162

312

Nominal

HP

(1)

31

13.0

13.0

TBD

TBD

TBD

13.0 13.0

240V

27P51

0055

13.0

13.013.0 13.0

13.0 13.0

13.0

13.0 13.0 13.0

13.0 13.0 13.0

5% Enclosed Reactor

Rated

Input

Voltage

Drive

Model

Number

CIMR-P7U

13.0 13.0

3% Enclosed Reactor

13.013.0

208V

Rated

Output

Current

(Amps)

13.0

Part

Number

05P00620-

13.0

13.0 13.0

P7

Reactor, 3% and 5% Impedance - May be used on either the input or output of a drive to reduce the effect of load or

line side transients on the drive. The three-phase reactors are provided in a separate NEMA 1 enclosure.

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Three-Phase Alternating Current Motors

Page 8

Page 11

Reactor, 3% and 5% Impedance (continued for 480V)

HLW HLW

43P71 7.6 5 0033 8.0 8.0 6.0 0029 8.0 8.0 6.0

45P51 12.5 7.5 0037 0034 8.0 8.0 6.0

47P51 17 10 0037 0038 13.0 13.0 13.0

49P01 21 15 0042 0043

40111 27 20 0047 0048

40151 34 25 0047 0048

40181 40 30 0051 0052

40241 52 40 0055 0056

40301 67.2 50 0059 0060

40371 77 60

40451 96 75

40551 125 100 0067 0068

40750 156 125 0073 0074

40900 180 150 0078 13.0 13.0 13.0 0079 13.0 13.0 13.0

41100 240 200 0083 24.0 17.0 17.0 0084 24.0 17.0 17.0

41600 304 250 0088 0089

41850 414 300 & 350 0092 0093

42200 515 400 & 450 0100 24.0 17.0 17.0 0101 24.0 17.0 17.0

43000 675 500 0104 30.0 24.0 24.0 0105 30.0 24.0 24.0

480V

13.0

5% Enclosed Reactor

Rated

Input

Voltage

Drive

Model

Number

CIMR-P7U

8.0 8.0

3% Enclosed Reactor

Rated

Output

Current

(Amps)

Nominal

HP

(1)

13.0 13.0

13.0 13.0

Part

Number

05P00620-

List

Price

$

Dimensions (in.) Dimensions (in.)

Part

Number

05P00620-

13.0

13.0 13.0 13.0

13.0 13.0

24.0 17.0 17.0

6.0

13.0 13.0 13.0

13.0 13.0

13.0

0062

13.0

13.0

13.0 13.0 13.0

13.0 13.0

0063

List

Price

$

17.0

13.0 13.0 13.0

13.0 13.0 13.0

24.0 17.0

Reactor Options

P7

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

Page 9

Data subject to change without notice

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 12

Control Options

P7

Control Options - These cards, cables and devices add control functionality to the standard drive. Items are shipped

loose, unmounted. See Configured Section for factory mounted and wired control.

Analog Input Options

Trim Potentiometer. This option provides a 5kOhm potentiometer

for use as a dropping resistor for maximum or minimum analog

input trim.

Mounts to control terminal strip

Model No. AI-001 .....................................List $

3-15PSI Transducer. This option provides for the interface of a 3 to

15PSI pneumatic signal, and provides a 4 to 20mA output signal

proportional to the input signal to the drive.

Mounts to control terminal strip

Model No. AI-010 .....................................List $

Analog Output Options

Analog Output Monitor, 4-20mA. The standard drive provides two

programmable 0-10VDC outputs. This option will convert either, or

both, of these outputs to 4-20mA output signals. It can be used for

remote metering of any of the “U1” parameters, including: output

frequency, output current, DC bus voltage, etc.

This option replaces and mounts in the same location as the drive’s

standard terminal PCB.

Model No. ETC618121..................... List $

Digital Input Options

120VAC Logic Interface (7-Input). This option provides for the

interface of 120VAC control logic circuits to the drive. This option is

used for digital inputs S1 to S7.

Mounts to control strip

Model No. DI-002.....................................List $

Digital Operator Options

Digital Operator (LCD). This option is the standard digital operator

found on the drive. This option is only needed if the original keypad

is lost or damaged.

Features include:

LCD keypad display, 5 lines x 16 characters, backlit

7 languages

Copy function

Mounts to keypad port

Model No. 300-016-999 ...........................List $

UL Rated Remote Operator Kits. This option is used to extend

the existing Digital Operator to the wall of a separately priced,

oversized UL Type 1, 3R,4, 4X, or 12 enclosure (IPX6 environment).

Price includes a faceplate bezel with digital operator carrier and

membrane to cover the operator cutout in the enclosure door, a 3foot cable, a 10-foot cable, and a 1:1 template for cutting the

necessary cutouts in the enclosure. Keypad can be removed after

kit installation.

Mounts to keypad port and enclosure wall.

Model No. UUX000458 (Blank Membrane) .....................List $

Model No. UUX000459 (Yaskawa Logo Membrane) ...... List $

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Remote Operator Kit. This option is used to extend the existing

Digital Operator to the wall of a separately priced, oversized NEMA

1 enclosure (No UL rating). Price includes a faceplate membrane to

cover the operator cutout in the enclosure door, a 3-foot cable, a 10foot cable, a remote digital operator carrier, and a 1:1 template for

cutting the necessary cutouts in the enclosure.

Note: Keypad cannot be removed after initial installation.

Mounts to keypad port and enclosure wall.

Model No. UUX000444 (Yaskawa Logo Membrane) ...... List $

Page 10

Page 13

Communications Options

Communications Options - These communications options are provided loose, unmounted. Network

communications are available for most popular protocols.

P7

DeviceNet. This option complies with the ODVA (Open DeviceNet

Vendor Association) specifiation and AC drive profile. All parameter,

diagnostics and operational commands are accessible via

DeviceNet. The option board provides a DeviceNet standard open

tap connector. Each DeviceNet network supports up to 63 drives.

Controllers are available from many PLC and/or PC suppliers.

Electronic Data Sheets may be downloaded from

www.yaskawa.com to assist with network configuration and drive

setup.

Mounts at option connector 2CN. Covers 3CN.

Model No. CM058 ..................................List $

Profibus DP. This option complies with the Profibus DP protocol

specification. All parameters, diagnostics and operational

commands are accessible via Profibus. The option board provides

convenient Phoenix-type teminations for landing the shielded,

twisted-pair wiring. Each Profibus network supports up to 99 drives.

This option supports all of the Profibus data rates from 9.6 Kbps to

12 Mbps. Up to 32 bytes of input data and 32 bytes of output data

are provided per message transaction. GSD files may be

downloaded from www.yaskawa.com to assist with network

configuration and drive setup.

Mounts at option connector 2CN.

Model No. CM061 ..................................List $

LonWorks. This option is compatible with the Lon Mark

Interoperability Association and complies with the Functional Profile

for a Variable Frequency Motor Drive. The option board features the

FFT-10A Free Topology Twisted-Pair Transceiver. Network

connectivity is facilitated by either a Phoenix-style screw termination

or RJ-45 connector. The kit includes a 12-inch pigtail (UWR00567-

1) for interface wiring of the phoenix terminal block. Optional longer

pigtail assemblies are available for use when drive is mounted

within another enclosure. The 20-inch cable is for wall mount

enclosures. The 78-inch cable may be used with any enclosure and

may be cut to any length required.

Mounts at option connector 2CN. Covers 3CN. Blocks 4CN.

Model No. CM048 .............................................................List $

Model No. UWR00567-2 (20-inch cable) .........................List $

Model No. UWR00567-3 (78-inch cable) .........................List $

Modbus TCP/IP. This option complies with the Modbus TCP/IP

protocol specification. This allows for communication over 10/100

Mbps Ethernet networks. This option has the ability to configure the

IP Address from a user specified IP address, from a DHCP host or

from a BootP host. All parameters, diagnostics and operational

commands are accessible via Modbus TCP/IP. Auto-tuning the

motor is also possible through this option using the DriveWizard PC

program. This option supports up to 10 simultaneous PLC/PC

connections.

Mounts at option connector 2CN.

Model No. CM090.................................. List $

EtherNet/IP. This option complies with the EtherNet/IP protocol

specification. This allows for communication over 10/100 Mbps

Ethernet networks. This option has the ability to configure the IP

Address from a user specified IP address, from a DHCP host or

from a BootP host. All parameters, diagnostics and operational

commands are accessible via EtherNet/IP. Auto-tuning the motor is

also possible through this option using the DriveWizard PC

program.

Mounts at option connector 2CN.

Model No. CM092.................................. List $

BACnet. This option complies with the BACnet protocol

specification. This allows for communication over MS-TP (RS-485)

BACnet networks. All parameters, diagnostics and operational

commands are accessible via BACnet. BACnet is supported and

maintained by ASHRAE Standing Standard Project Committee. The

kit includes a 12-inch pigtail (UWR00567-1) for interface wiring of

the drive Modbus terminals. Optional longer pigtail assemblies are

available for use when drive is mounted within another enclosure.

The 20-inch cable is for wall mount enclosures. The 78-inch cable

may be used with any enclosure and may be cut to any length

required.

Mounts at option connector 2CN.

Model No. CM049.............................................................List $

Model No. UWR00567-2 (20-inch cable).........................List $

Model No. UWR00567-3 (78-inch cable).........................List $

Modbus Plus. This option complies with Modicon's ModConnect

Partners program and provides a seamless interface to Quantum,

984 and Compact PLCs. All parameters, diagnostics and

operational commands are accessible via Modbus Plus. The option

board provides a 9-pin D-shell connector for easy wiring and

communicates via a 1 Mbps, twisted-pair, Local Area Network.

Each Modbus Plus network supports up to 63 drives.

Mounts at option connector 2CN. Covers 3CN.

Model No. CM071 ..................................List $

Page 11

Data subject to change without notice

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 14

P7

H W D Heatsink Internal Total

23P71 16.8 5 11.02 5.51 7.09 8.8 DD.P7.FR2.N1.01 110 74 184

27P51 31.0 7.5 & 10 11.81 13.2 DD.P7.FR3A.N1.01 219 113 332

20111 46.2 15 12.20 15.4 DD.P7.FR3B.N1.01 357 168 525

20151 59.4 20 13.78 DD.P7.FR4A.N1.01 416 182 598

20181 74.8 25 14.96 DD.P7.FR4C.N1.01 472 208 680

20221 88 30 21.06 10.00 53 DD.P7.FR5.N1.01 583 252 835

20301 115 40 24.21 10.98 59 DD.P7.FR6A.N1.01 883 333 1216

20370 162 50 11.81 125 DD.P7.FR7.IP00.01 1010 421 1431

20450 192 60 12.99 139 DD.P7.FR8.IP00.01 1228 499 1727

20550 215 75 189 1588 619 2207

20750 312 100 191 1956 844 2800

20900 360 125 33.46 19.69 14.17 238 DD.P7.FR11.IP00.01 2194 964 3158

21100 415 150 34.84 22.64 14.96 330 DD.P7.FR12.IP00.01 2733 1234 3967

23P71 16.8 5 110 74 184

25P51 23.0 7.5 164 84 248

27P51 31.0 10 11.81 13.2 DD.P7.FR3A.N1.01 219 113 332

20111 46.2 15 12.20 15.4 DD.P7.FR3B.N1.01 357 168 525

20151 59.4 20 13.78 DD.P7.FR4A.N1.01 416 182 598

20181 74.8 25 14.96 DD.P7.FR4C.N1.01 472 208 680

20221 88 30 21.06 10.00 53 DD.P7.FR5.N1.01 583 252 835

20301 115 40 24.21 10.98 59 DD.P7.FR6A.N1.01 883 333 1216

20370 162 50 & 60 11.81 125 DD.P7.FR7.IP00.01 1010 421 1431

20450 192 75 12.99 139 DD.P7.FR8.IP00.01 1228 499 1727

20750 312 100 & 125 28.54 17.72 13.78 191 DD.P7.FR10.IP00.01 1956 844 2800

20900 360 150 33.46 19.69 14.17 238 DD.P7.FR11.IP00.01 2194 964 3158

43P71 7.6 5 80 68 148

45P51 12.5 7.5 127 81 208

47P51 17.0 10 193 114 307

49P01 21.0 15 210 140 350

40111 27.0 20 232 158 390

40151 34.0 25 DD.P7.FR4B.N1.01 296 169 465

40181 40.0 30 DD.P7.FR4A.N1.01 389 201 590

40221 50.4 30 420 233 653

40241 52 40 510 260 770

40301 67.2 50 691 298 989

40371 77 60 25.00 DD.P7.FR9A.N1.01 801 332 1133

40451 96 75 28.15 901 386 1287

40551 125 100 28.15 1204 478 1682

40750 156 125 194 1285 562 1847

40900 180 150 196 1614 673 2287

41100 240 200 224 1889 847 2736

41320 260 200 264 2388 1005 3393

41600 304 250 36.06 22.64 14.96 352 DD.P7.FR13.IP00.01 2791 1144 3935

41850 414 300 & 350 572 2636 1328 3964

42200 515 400 & 450 616 3797 1712 5509

43000 675 500 58.07 36.06 16.34 891 DD.P7.FR15.IP00.01 5838 2482 8320

240V

Heat Loss (watts)

(4)

208V

Weight

(lbs.)

(2)

Rated

Input

Voltage

Drive

Model

Number

CIMR-P7U

Rated

Output

Current

(Amps)

Nominal

HP

(1)

Physical

Dimensions (in.)

7.87

Standard

Enclosure

Dimension

Drawing

Number

(3)

Protected

Chassis

Protected

Chassis

DD.P7.FR10.IP00.01

DD.P7.FR2.N1.01

DD.P7.FR2.N1.01

DD.P7.FR3A.N1.01

DD.P7.FR6B.N1.01

DD.P7.FR9B.N1.01

DD.P7.FR10.IP00.01

DD.P7.FR11.IP00.01

DD.P7.FR14.IP00.01

13.2

22

53

88

24.2

8.8

24.2

8.8

8.27

10.24

7.09

11.22

7.87

8.27

10.24

17.72

19.69

27.95

13.78

14.17

16.34

7.87

9.45

14.76

5.51

7.87

9.45

10.98

12.95

21.06

28.54

33.46

51.38

23.62

11.02

11.81

13.78

10.24

23.62

28.54

11.02

14.76

17.72

5.51

13.78

7.09

7.87 7.87

9.45 8.27

230V

480V

NEMA 1

NEMA 1

Protected

Chassis

NEMA 1

NEMA 1

Protected

Chassis

NEMA 1

NEMA 1

Dimensions and Data

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

(2) This data represents the drive weight only, not shipping weight.

(3) Please refer to Yaskawa’s website at www.yaskawa.com for dimension drawings.

(4) Total Heat Loss is the amount of heat dissipated by the drive at full load. This data is separated into "Heatsink" and "Internal" values.

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Three-Phase Alternating Current Motors

The value in the "Heatsink" column is the amount of heat dissipated by the heatsink, and would not need to be considered when

calculating the enclosure size for applications that may require mounting the heatsink out the back of the enclosure using the Ring Kit

option.

Page 12

Page 15

Description

5-500HP

P7/Configured

NEMA 1/12 FVFF

The P7/Configured package provides a P7 in a NEMA 1 or NEMA 12 FVFF enclosure, with space for several

commonly used options, such as reactors, RFI filters, circuit breakers, etc. The P7 and P7/Configured have

been designed for flexibility in providing the features and options commonly demanded by facility designers.

The P7 Drive is a variable torque AC drive, designed specifically for industrial applications. A new

benchmark for size, cost, performance, benefits and quality, the P7 includes numerous built-in features such

as Network Communications, PI control and energy-savings functions.

The P7 has embedded communications for Modbus. An optional interface card is also available for

DeviceNet, Profibus, EtherNet, and LonWorks.

P7C

Performance Features

• VT Ratings: 5-150 HP, 208 VAC

5-150 HP, 230/240 VAC

5- 500 HP, 480 VAC

• Overload capacity: 110% for 60 sec.

(150% peak)

• Starting torque: 100% at 3 Hz

• DC injection braking: at start or stop,

adjustable, current limited (anti-windmilling)

• Motor preheat function

• Adjustable accel/decel: 0.1 to 6000 sec.

• Controlled speed range: 40:1

• Critical frequency rejection: 3 selectable,

adjustable bands

• Torque limiting: 30-180%

• Energy $aving control

• Torque boost: full range, auto

• Power loss ride-thru: 2 sec.

• Inertia ride-thru

• Auto restart after power loss or resettable

fault, selectable, programmable

• Feedback signal loss detection

• Serial communications loss detection

• "Up/Down" floating point control capability

• Stationary motor auto-tuning

• Customizable monitor display

• Sleep function

• Run permissive input

• Ramp-to-stop or coast-to-stop selection

• Runtime changes in control and display

• Project-specific parameter reinitialization

Service Conditions

• Ambient Temperature:

-10°C to 40°C(14°F to 104°F)

• Humidity: 95% RH, non-condensing

• Altitude: 3300 ft; higher by derate

• Input voltage: +10%/-15%

• Input frequency: 50/60 Hz ± 5%

• 3-phase, 3-wire, phase sequence

insensitive

Protective Features

• Current limited stall prevention

• Heat sink over-temperature, speed

fold-back

• Cooling fan operating hours recorded

• Bi-directional start into rotating motor at

synchronized speed

• DC bus charge indicator

• Current limiting DC bus fuse

• Optically-Isolated controls

• Short circuit protection: Phase-phase and

phase-neutral

• Ground fault protection

• Electronic motor overload: UL

• Current and torque limit

• Fault display: last 10 faults

• Fault circuit: OC, OV, OT

• Over torque and under torque protection

• Program security code

• "Hunting" prevention logic

• Reverse prohibit selectability

Configured Options

• Circuit breaker / Motor circuit protector

• RFI/EMI filter

• Input fuses

• Input reactor

• Output reactor

• Engraved nameplates

• Speed potentiometer

• Pressure/electrical transducer

• Analog outputs: 2 programmable,

4-20 mA

• HOA Selector Switch

• 200VA Control Transformer (fused)

• Communication Interface: DeviceNet,

Profibus, EtherNet, LonWorks, Johnson

Controls METASYS N2, and Siemens

APOGEE FLN

• DriveWizardTM upload/download and

monitoring/graphing software

Design Features

• 32-bit microprocessor logic

• Flash upgradeable firmware

• Non-volatile memory, program retention

• Surface-mount devices

• Displacement power factor: 0.98

• Output frequency: 0.1 to 120 Hz

• Frequency resolution: 0.06 Hz

• Frequency regulation: 0.1%

• Control Terminal Board: Quick disconnect,

removable

• Carrier frequency: selectable to 15 kHz

• 3% DC bus reactor: 30-150 HP, 208 VAC;

• 30-150 HP, 240 VAC; 40-500 HP, 480 VAC;

optional on lower ratings

• Keypad Operator: built-in copy feature,

6 languages

• LCD display: 5 lines, 16 characters each

• 24 VDC control logic

• Transmitter/Option power supply

• Output contacts: One form C and two programmable form A

• Input/output terminal status

• Input terminals: 5 programmable multifunction input terminals

• Fault input: Programmable

• Diagnostic fault indication in selected language

• Timer function: Elapsed time, Delay on

start, Delay on stop

• RS-422/485 port: Modbus

• Volts/hertz ratio: Preset and programmable

V/Hz patterns

• Multi-speed settings: 5 available

• Remote speed command: 0-10 VDC or

4-20 mA, direct or reverse-acting

• Setpoint (PI) control with inverse or square

root input, differential control via two feedback capability

• Feedback signal: low pass filter

• Speed command: bias and gain

• Analog outputs: Programmable, two,

0-10 VDC

• Meter Functions: Volt, amp, kilowatt,

elapsed run time, speed command

• Output Current Transformers, qty 3

• NEMA 1 or NEMA 12 FVFF enclosure

• UL, cUL listed; CE marked; IEC 146

• MTBF: exceeds 28 years

Page 13

Data subject to change without notice

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 16

Description

V

G

B

D

BASE NUMBER OPTIONS

Enclosure

Current

Voltage

208V

230/240V

480V

Rated Amps Code

(Ex.: “040” = 40A)

A

B

C

None (leave blank)

Circuit Breaker/MCCB

Circuit Breaker

F

None (leave blank)

Fuses

Input Fuses

Input Filter

None (leave blank)

N Cap Filter

E RFI Filter

P 7 C

Communications

None (leave blank)

DeviceNet

H Profibus

V Modbus (Internal)

L LonWorks

Q Modbus TCP/IP

J METASYS N2

2 EtherNet/IP

U Siemens APOGEE FLN

M

Added Control

None (leave blank)

4-20 mA Output

T 200VA Transformer

B Both

S

Speed Control

None (leave blank)

Speed Pot

Y Hand/Off/Auto Switch

A Both

P

3-15 PSI Transducer

None (leave blank)

3-15 PSI Trans

W

Custom Nameplates

None (leave blank)

Custom Nameplates

K

Load Reactor

None (leave blank)

5% Load Reactor

P7CVB040CXSH

(3)

(3)

X

Line Impedance

None (leave blank)

3% Bus Reactor

Z 5% Bus Reactor

R 3% Input Reactor

(1)

(1)

(2)

(1) 3% and 5% Bus Reactors are only available as an option

on base numbers up to and including P7C_D074, A068,

and B040; larger drives have a Bus Reactor as standard.

(2) 3% Input Reactor, when combined with the standard Bus

Reactor (available on base numbers P7C_D088, A080,

and B052 and above), yields a total of 5% input impedance.

(3) Option (A) must be ordered instead of option (S) when:

A) Option (S) and (P) are ordered together, or,

B) Option (S) and (D, G, H, J, V , L, Q or U) are ordered

together.

NEMA 1

NEMA 12 FVFF

P7C

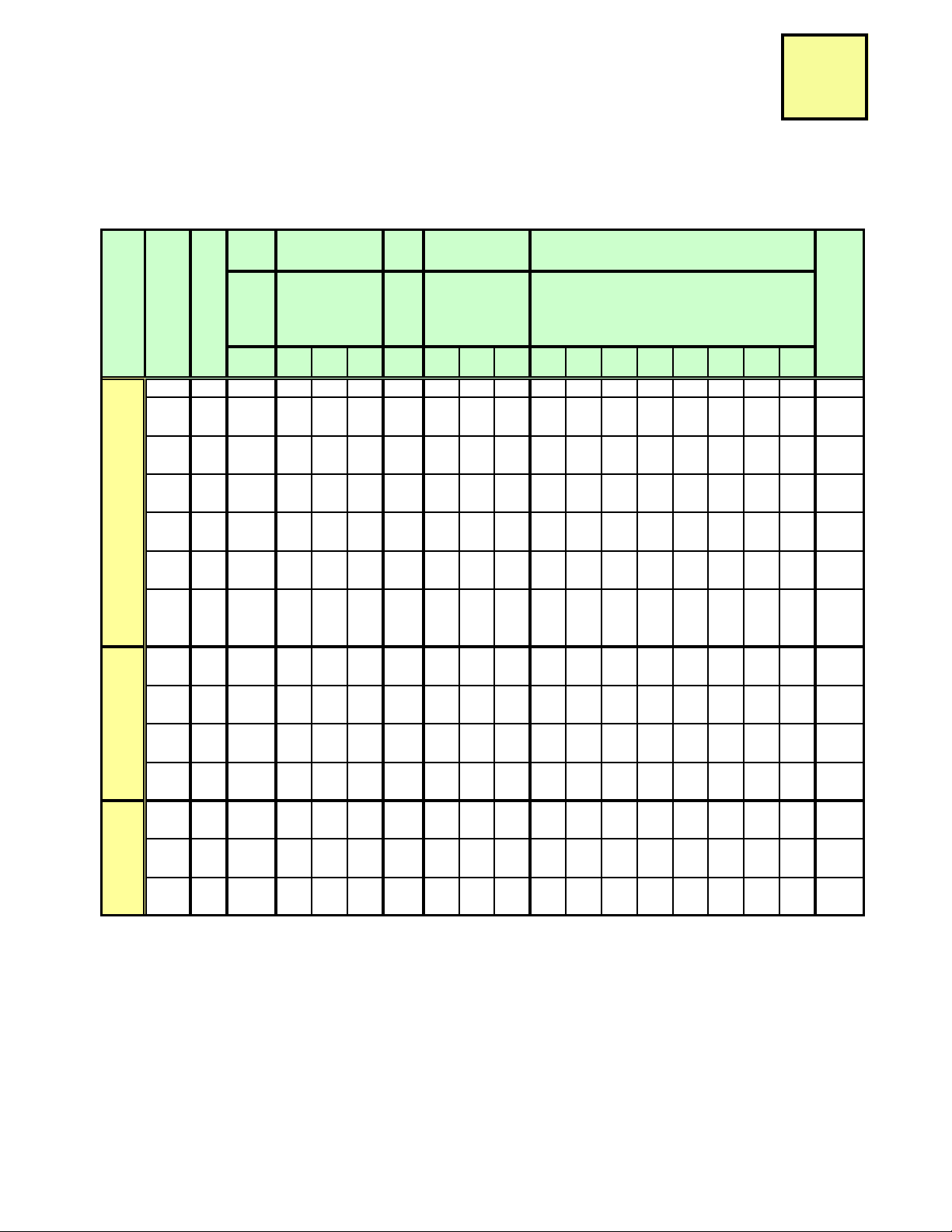

Model Number Configuration & Pricing:

Step 1. First complete the Base Number for the required enclosure type, voltage and current rating.

Step 2. Add the Option code letter for each required option. If an option is not wanted, no character is inserted.

Step 3. Find the list price for the Base Number selected from the following pages. Add the list price of each selected option

Example: P7 Configured package (P7CV) with a 40 Amp, 480V drive (B040), with Circuit Breaker (C), 3% Bus reactor

5-500HP

P7/Configured

NEMA 1/12 FVFF

to this base price.

X), door-mounted speed pot (S) and Profibus communication capability (H). Model number is:

(

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 14

Page 17

Description

5-500HP

P7/Configured

NEMA 1/12 FVFF

Configured Option Descriptions:

(V, B) Enclosure: The drive and options are provided in either a NEMA Type 1 (V) ventilated or NEMA Type 12 FVFF (force ventilated

fan filter) (B) enclosure, large enough to accommodate any or all of the package options. Enclosures for Base Numbers up to,

and including, D114 (40HP, 208V), A104 (40HP, 240V),and B124 (100HP, 480V) are wall-mounted; larger drives are in floormount enclosures.

Options (Power)

(C) Circuit Breaker: The standard configuration provides no branch short circuit protection or input disconnecting means. This

option provides a thermal-magnetic circuit breaker that meets NEC branch circuit protection requirements, with a flangemounted operating handle.

(N, E) Input Filter: The standard configuration does not include a filter. The cap filter, option (N), is a delta-wye capacitive network,

while the RFI filter (E) provides noise attenuation to help meet CE requirements. This option requires the addition of the add-on

box - see Dimensions and Data.

(F) Input Fuses: The standard configuration does not include Drive Input Fuses. This option provides high-speed semi-conductor

drive input fuses, rated for 200,000 amp RMS symmetrical interrupting capacity, that provides both drive input I2T protection

and NEC approved branch circuit and short circuit protection.

P7C

(X, Z, R) Line Impedance: Drives above Base Numbers D074 (25HP, 208V), A068 (25HP, 240V) and B040 (30HP, 480V) include a 3%

DC bus reactor in the standard package and do not provide any additional impedance. Option (X), 3% impedance, and option

(Z), 5% impedance, are not available for ratings larger than these. To achieve a 5% total input impedance, select option (R) this 3% input reactor is available only for the HP ratings greater than the HP's listed above, and combines with the drive's

standard DC bus reactor. If this option is combined with a drive that includes a bus reactor, the add-on box is required - see

Dimensions and Data.

(K) Load Reactor: No form of output impedance is normally required. A 5% load reactor, option (K), is available if additional output

impedance is desired (usually for long lead-lengths or noise reduction). This option may require the add-on box for wall-mount

enclosures - see Dimensions and Data.

Options (Control and Communications)

(W) Custom Nameplates: Custom engraved nameplates with white lettering on black lamicoid are available with option (W), for

special tagging purposes (Example: "AHU #1"). Note that this option requires the text to be specified by the customer. Leave

this field blank if no special nameplates are required.

(S, Y, A) Speed Control:

control - this is the standard configuration. A door-mounted 2.5K ohm speed potentiometer is available for manual speed control

with option (S). This also includes a 2.5K ohm trim pot and is suitable for NEMA 1 and NEMA 12 installations. A door-mounted

Hand/Off/Auto Switch is available when option (Y) is specified, and both a speed pot and HOA switch are provided with option

(A).

(P) 3-15 PSI Transducer: No transducer is provided with the standard configuration. To add an optional transducer that accepts a

3-15 PSI pneumatic signal and converts it to a 4-20mA signal that is sent to the drive, specify option (P).

(M, T, B) Added Control: The standard Configured package provides two programmable 0-10VDC outputs. To convert these outputs to

4-20mA output signals, specify option (M). Option (T) adds a 200VA control transformer, to provide more control circuit

capacity. Option (B) can be selected if both options are desired.

The drive's digital operator is always brought out to the front of the Configured panel, so it is available for speed

(G, H, L, Q,

2, V, J, U)

Communications: All configurations provide the hardware and software required for network communications, but these are

not enabled in the standard configuration. Option (V) provides the programming and jumpers necessary to enable Modbus

communications at no additional cost. DeviceNet option (G), Profibus option (H), Lonworks option (L), Modbus TCP/IP option

(Q), and EtherNet/IP option (2) all require the addition of an optional board. Option (J) Johnson Controls METASYS N2 and

option (U) Siemens APOGEE FLN require a software change, but no hardware change.

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 15

Data subject to change without notice

Page 18

P7C

Circuit

Breaker

Input

Fuses

Load

Reactor

C=MCP F=Fuses K=5%

P7CV

Base

List $

C

List $

N

List $

E

List $

(2)

F

List $X List $Z List $

R

List $

K

List $

(2)

16.7 5 D016

24.2 7.5 D024

30.8 10 D030

46.2 15 D046

59.4 20 D059

74.8 25 D074

88 30 D088

114 40 D114

143 50 D143

169 60 D169

211 75 D211

273 100 D273

343 125 D343

396 150 D396

15.2 5 A015

22 7.5 A022

28 10 A028

42 15 A042

54 20 A054

68 25 A068

80 30 A080

104 40 A104

130 50 A130

154 60 A154

192 75 A192

248 100 A248

312 125 A312

360 150 A360

Rated

Input

Voltage

Rated

Output

Current

(Amps)

HP

(1)

NEMA 1

Configured

Input Filter

N=Cap

E=RFI

X=3% Bus Reactor

Z=5% Bus Reactor

R=3% Input Reactor

Line Impedance

240V

230V

208V

N/A

N/A

3% DC Bus Reactor is

included as standard

3% DC Bus Reactor is

included as standard

Configured Drives and Options

NEMA 1

P7 Configured Drives

- 5-500HP, 208-230/240 and 480V, 3-phase input, NEMA 1 enclosure, with factory-installed

and wired options

Nominal

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This price includes the add-on box, when required. If more than one of the following: RFI Filter, 3% Input Reactor, and 5% Load Reactor

is selected, DEDUCT $100 list from all but one of these options

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 16

Page 19

P7 Configured Drives (Continued)

Name-

p

Transducer

W=NP

P=3-15

PSI

W

List $S List $Y List $A List $P List $M List $T List $B List $G List $H List $

V

(3)

List $

L

List $Q List $2 List $J List $U List $

16.7 5 23P71A

24.2 7.5 27P51A

30.8 10 27P51A

46.2 15 20111A

59.4 20 20151A

74.8 25 20181A

88 30 20221A

114 40 20301A

143 50 20370A

169 60 20450A

211 75 20550A

273 100 20750A

343 125 20900A

396 150 21100A

15.2 5 23P71A

22 7.5 25P51A

28 10 27P51A

42 15 20111A

54 20 20151A

68 25 20181A

80 30 20221A

104 40 20301A

130 50 20370A

154 60 20370A

192 75 20450A

248 100 20750A

312 125 20750A

360 150 20900A

240V

230V

208V

Added Control

M=4-20mA

T=200VA

B=Both

Rated

Input

Voltage

Rated

Output

(Amps)

Nom.

HP

(1)

Speed Control

S=Speed Pot

Y=HOA Switch

A=Both

Uses

Drive

Model

CIMR-

P7U

Communications

G=DeviceNet, H=Profibus

V=Modbus, L=LonWorks

Q=Modbus TCP/IP, 2=EtherNet/IP, J=METASYS N2

U=APOGEE FLN

Custom

lates

Configured Drives and Options

NEMA 1

P7C

Current

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This price includes the add-on box, when required. If more than one of the following: RFI Filter, 3% Input Reactor, and 5% Load Reactor

is selected, DEDUCT $100 list from all but one of these options

(3) Included in the Base Price

Page 17

Data subject to change without notice

Number

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 20

Configured Drives and Options

Circuit

Breaker

Input

Fuses

Load

Reactor

C=MCP F=Fuses K=5%

P7CV

Base

List $

C

List $

N

List $

E

List $

(2)

F

List $X List $Z List $

R

List $

K

List $

(2)

7.6 5 B007

11 7.5 B011

14 10 B014

21 15 B021

27 20 B027

34 25 B034

40 30 B040

52 40 B052

65 50 B065

77 60 B077

96 75 B096

124 100 B124

156 125 B156

180 150 B180

240 200 B240

302 250 B302

361 300 B361

414 350 B414

477 400 B477

515 450 B515

590 500 B590

NEMA 1

Configured

Input Filter

N=Cap

E=RFI

X=3% Bus Reactor

Z=5% Bus Reactor

R=3% Input Reactor

Line Impedance

Rated

Input

Voltage

Rated

Output

Current

(Amps)

HP

(1)

480V

3% DC Bus Reactor is

included as standard

N/A

P7C

P7 Configured Drives (Continued)

NEMA 1

Nominal

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This price includes the add-on box, when required. If more than one of the following: RFI Filter, 3% Input Reactor, and 5% Load Reactor

is selected, DEDUCT $100 list from all but one of these options

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 18

Page 21

P7 Configured Drives (Continued)

Name-

p

Transducer

W=NP

P=3-15

PSI

W

List $S List $Y List $A List $P List $M List $T List $B List $G List $H List $

V

(3)

List $

L

List $Q List $2 List $J List $U List $

7.6 5 43P71

11 7.5 45P51

14 10 47P51

21 15

27 20

34 25 40151

40 30 40181

52 40

65 50

77 60 40371

96 75 40451

124 100 40551

156 125 40750

180 150 40900

240 200 41100

302 250 41600

361 300 41850

414 350 41850

477 400 42200

515 450 42200

590 500 43000

40111

40301

Uses

Drive

Model

CIMR-

P7U

Communications

G=DeviceNet, H=Profibus

V=Modbus, L=LonWorks

Q=Modbus TCP/IP, 2=EtherNet/IP, J=METASYS N2

U=APOGEE FLN

Rated

Input

Voltage

Rated

Output

(Amps)

Nom.

HP

(1)

Speed Control

S=Speed Pot

Y=HOA Switch

A=Both

Added Control

M=4-20mA

T=200VA

B=Both

480V

Custom

lates

Configured Drives and Options

NEMA 1

P7C

Current

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This price includes the add-on box, when required. If more than one of the following: RFI Filter, 3% Input Reactor, and 5% Load Reactor

is selected, DEDUCT $100 list from all but one of these options

(3) Included in the Base Price

Page 19

Data subject to change without notice

Number

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 22

P7C

Circuit

Breaker

Input

Fuses

Load

Reactor

C=MCP F=Fuses K=5%

P7CB

Base

List $

C

List $

N

List $

E

List $

(2)

F

List $X List $Z List $

R

List $

K

List $

(2)

16.7 5 D016

24.2 7.5 D024

30.8 10 D030

46.2 15 D046

59.4 20 D059

74.8 25 D074

88 30 D088

114 40 D114

143 50 D143

169 60 D169

211 75 D211

273 100 D273

343 125 D343

396 150 D396

15.2 5 A015

22 7.5 A022

28 10 A028

42 15 A042

54 20 A054

68 25 A068

80 30 A080

104 40 A104

130 50 A130

154 60 A154

192 75 A192

248 100 A248

312 125 A312

360 150 A360

N/A

N/A

3% DC Bus

Reactor is

included as

standard

3% DC Bus

Reactor is

included as

standard

240V

230V

208V

Input Filter

N=Cap

E=RFI

X=3% Bus Reactor

Z=5% Bus Reactor

R=3% Input Reactor

Line Impedance

Rated

Input

Voltage

Rated

Output

Current

(Amps)

HP

(1)

NEMA 12 FVFF

Configured

Configured Drives and Options

NEMA 12 FVFF

P7 Configured Drives

- 5-500HP, 208-230/240 or 480V, 3-phase input, NEMA 12 enclosure, with factory-installed

and wired options

Nominal

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This price includes the add-on box, when required. If more than one of the following: RFI Filter, 3% Input Reactor, and 5% Load Reactor

is selected, DEDUCT $100 list from all but one of these options

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 20

Page 23

P7 Configured Drives (Continued)

Name-

p

Transducer

W=NP

P=3-15

PSI

W

List $S List $Y List $A List $P List $M List $T List $B List $G List $H List $

V

(3)

List $

L

List $Q List $2 List $J List $U List $

16.7 5 23P71

24.2 7.5

30.8 10

46.2 15 20111

59.4 20 20151

74.8 25 20181

88 30 20221

114 40 20301

143 50 20370

169 60 20450

211 75 20550

273 100 20750

343 125 20900

396 150 21100

15.2 5 23P71

22 7.5 25P51

28 10 27P51

42 15 20111

54 20 20151

68 25 20181

80 30 20221

104 40 20301

130 50

154 60

192 75 20450

248 100 20750

312 125 20750

360 150 20900

27P51

20370

Uses

Drive

Model

CIMR-

P7U

Communications

G=DeviceNet, H=Profibus

V=Modbus, L=LonWorks

Q=Modbus TCP/IP, 2=EtherNet/IP, J=METASYS N2

U=APOGEE FLN

Added Control

M=4-20mA

T=200VA

B=Both

Rated

Input

Voltage

Rated

Output

(Amps)

Nom.

HP

(1)

Speed Control

S=Speed Pot

Y=HOA Switch

A=Both

208V

240V

230V

Custom

lates

Configured Drives and Options

NEMA 12 FVFF

P7C

Current

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This price includes the add-on box, when required. If more than one of the following: RFI Filter, 3% Input Reactor, and 5% Load Reactor

is selected, DEDUCT $100 list from all but one of these options

(3) Included in the Base Price

Page 21

Data subject to change without notice

Number

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 24

Configured Drives and Options

Circuit

Breaker

Input

Fuses

Load

Reactor

C=MCP F=Fuses K=5%

P7CB

Base

List $

C

List $

N

List $

E

List $

(2)

F

List $X List $Z List $

R

List $

K

List $

(2)

7.6 5 B007

11 7.5 B011

14 10 B014

21 15 B021

27 20 B027

34 25 B034

40 30 B040

52 40 B052

65 50 B065

77 60 B077

96 75 B096

124 100 B124

156 125 B156

180 150 B180

240 200 B240

302 250 B302

361 300 B361

414 350 B414

477 400 B477

515 450 B515

590 500 B590

480V

Rated

Input

Voltage

Rated

Output

Current

(Amps)

HP

(1)

NEMA 12 FVFF

Configured

Input Filter

N=Cap

E=RFI

X=3% Bus Reactor

Z=5% Bus Reactor

R=3% Input Reactor

Line Impedance

N/A

3% DC Bus

Reactor is

included as

standard

P7C

P7 Configured Drives (Continued)

NEMA 12 FVFF

Nominal

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This price includes the add-on box, when required. If more than one of the following: RFI Filter, 3% Input Reactor, and 5% Load Reactor

is selected, DEDUCT $100 list from all but one of these options

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 22

Page 25

P7 Configured Drives (Continued)

Name-

p

Transducer

W=NP

P=3-15

PSI

W

List $S List $Y List $A List $P List $M List $T List $B List $G List $H List $

V

(3)

List $

L

List $Q List $2 List $J List $U List $

7.6 5 43P71

11 7.5 45P51

14 10 47P51

21 15

27 20

34 25 40151

40 30 40181

52 40

65 50

77 60 40371

96 75 40451

124 100 40551

156 125 40750

180 150 40900

240 200 41100

302 250 41600

361 300 41850

414 350 41850

477 400 42200

515 450 42200

590 500 43000

480V

Added Control

M=4-20mA

T=200VA

B=Both

Rated

Input

Voltage

Rated

Output

(Amps)

Nom.

HP

(1)

Speed Control

S=Speed Pot

Y=HOA Switch

A=Both

Uses

Drive

Model

CIMR-

P7U

Communications

G=DeviceNet, H=Profibus

V=Modbus, L=LonWorks

Q=Modbus TCP/IP, 2=EtherNet/IP, J=METASYS N2

U=APOGEE FLN

40111

40301

Custom

lates

Configured Drives and Options

NEMA 12 FVFF

P7C

Current

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) This price includes the add-on box, when required. If more than one of the following: RFI Filter, 3% Input Reactor, and 5% Load Reactor

is selected, DEDUCT $100 list from all but one of these options

(3) Included in the Base Price

Page 23

Data subject to change without notice

Number

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 26

P7C

HWD

D016 16.7 5

D024 24.2 7.5

D030 30.8 10

D046 46.2 15

D059 59.4 20

D074 74.8 25

D088 88 30

D114 114 40

D143 143 50 847

D169 169 60

D211 211 75

D273 273 100 1214

D343 343 125 1330

D396 396 150 1423

A015 15.2 5

A022 22 7.5

A028 28 10

A042 42 15

A054 54 20

A068 68 25

A080 80 30

A104 104 40

A130 130 50 847

A154 154 60

A192 192 75

A248 248 100 1214

A312 312 125 1330

A360 360 150 1376

230V

115

127

Rated

Input

Voltage

Rated

Output

Current

(Amps)

Nominal

HP

(1)

Dimensions (in.)

Configured

P7CR

943

26.00

Weight

(lbs.)

(2)

208V

240V

Dimension

Drawing

Number

(4)

DD.AFD.087.01

DD.AFD.087.01

DD.AFD.088.01

DD.AFD.091.01

14.6625.63

DD.AFD.091.01

208

221

943

115

127

208

221

DD.AFD.088.01

Dimension

Drawing Number

(w/ Add-on Box)

(3, 4)

DD.AFD.087.01.A0

DD.AFD.088.01.A0

N/A

DD.AFD.087.01.A0

DD.AFD.088.01.A0

N/A

29.00 19.00 13.66

40.00

84.00

29.00

40.00

26.0084.00 37.75

37.75

19.00

25.63

13.66

14.66

Dimensions and Data

NEMA 1/12 FVFF

Physical

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) Data represents the total approx. weight of the drive with all possible standard options, not shipping weight.

(3) Add-on box (required with specified options - see options description) adds up to 15” to ‘H’ dimension and 91 lbs. Max. to total drive

weight.

(4) Please refer to Yaskawa’s website at www.yaskawa.com for dimension drawings.

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 24

Page 27

Dimensions and Data

HWD

B007 7.6 5

B011 11 7.5

B014 14 10

B021 21 15

B027 27 20

B034 34 25

B040 40 30

B052 52 40 203

B065 65 50

B077 77 60

B096 96 75

B124 124 100

B156 156 125

B180 180 150

B240 240 200 37.75 1240 DD.AFD.091.01

B302 302 250 37.75 1352 DD.AFD.091.01

B361 361 300 1740 DD.AFD.096.01

B414 414 350 1800 DD.AFD.096.01

B477 477 400 1800

B515 515 450 2125

B590 590 500 2125

73.25 27.00

115

127

13.66

14.66

27.00

25.63

37.75

27.00

73.25

Dimension

Drawing

Number (w/ Add-

on Box)

(3, 4)

Dimension

Drawing

Number

(4)

DD.AFD.087.01.A0

Weight

(lbs.)

(2)

19.00

142

232

241

943

Rated

Input

Voltage

Rated

Output

Current

(Amps)

Nominal

HP

(1)

Dimensions (in.)

Configured

P7CV

or

P7CB

480V

29.00

40.00

84.00

84.00

84.00

DD.AFD.087.01

DD.AFD.088.01

DD.AFD.091.01

DD.AFD.096.01

DD.AFD.088.01.A0

N/A

N/A

N/A

NEMA 1/12 FVFF

Physical

P7C

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) Data represents the total approx. weight of the drive with all possible standard options, not shipping weight.

(3) Add-on box (required with specified options - see options description) adds up to 15” to ‘H’ dimension and 91 lbs. Max. to total drive

weight.

(4) Please refer to Yaskawa’s website at www.yaskawa.com for dimension drawings.

Page 25

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 28

This page intentionally left blank

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 26

Page 29

Description

5-500HP

P7/Configured

NEMA 3R

The P7/Configured package provides a P7 in a NEMA 3R enclosure, with space for several commonly used

options, such as reactors, circuit breakers, etc. The P7 and P7/Configured have been designed for flexibility

in providing the features and options commonly demanded by facility designers.

The P7 Drive is a variable torque AC drive, designed specifically for industrial applications. A new

benchmark for size, cost, performance, benefits and quality, the P7 includes numerous built-in features such

as Network Communications, PI control and energy-savings functions.

The P7 has embedded communications for Modbus. An optional interface card is also available for

DeviceNet, Profibus, EtherNet, and LonWorks.

This P7 package has a UL Type 3R rating.

P7CR

Performance Features

• VT Ratings: 5-150 HP, 208 VAC

5-150 HP, 230/240 VAC

5- 500 HP, 480 VAC

• Overload capacity: 110% for 60 sec.

(150% peak)

• Starting torque: 100% at 3 Hz

• DC injection braking: at start or stop,

adjustable, current limited (anti-windmilling)

• Motor preheat function

• Adjustable accel/decel: 0.1 to 6000 sec.

• Controlled speed range: 40:1

• Critical frequency rejection: 3 selectable,

adjustable bands

• Torque limiting: 30-180%

• Energy $aving control

• Torque boost: full range, auto

• Power loss ride-thru: 2 sec.

• Inertia ride-thru

• Auto restart after power loss or resettable

fault, selectable, programmable

• Feedback signal loss detection

• Serial communications loss detection

• "Up/Down" floating point control capability

• Stationary motor auto-tuning

• Customizable monitor display

• Sleep function

• Run permissive input

• Ramp-to-stop or coast-to-stop selection

• Runtime changes in control and display

• Project-specific parameter reinitialization

Service Conditions

• Ambient Temperature:

-10°C to 40°C(14°F to 104°F)

• Humidity: 95% RH, non-condensing

• Altitude: 3300 ft; higher by derate

• Input voltage: +10%/-15%

• Input frequency: 50/60 Hz ± 5%

• 3-phase, 3-wire, phase sequence

insensitive

Protective Features

• Current limited stall prevention

• Heat sink over-temperature, speed

fold-back

• Cooling fan operating hours recorded

• Bi-directional start into rotating motor at

synchronized speed

• DC bus charge indicator

• Current limiting DC bus fuse

• Optically-Isolated controls

• Short circuit protection: Phase-phase and

phase-neutral

• Ground fault protection

• Electronic motor overload: UL

• Current and torque limit

• Fault display: last 10 faults

• Fault circuit: OC, OV, OT

• Over torque and under torque protection

• Program security code

• "Hunting" prevention logic

• Reverse prohibit selectability

Configured Options

• Circuit breaker

• Input fuses

• Input reactor

• Output reactor

• Engraved nameplates

• Pressure/electrical transducer

• Analog outputs: 2 programmable,

4-20 mA

• HOA Selector Switch

• Communication Interface: DeviceNet,

Profibus, EtherNet, LonWorks, Johnson

Controls METASYS N2, and Siemens

APOGEE FLN

• DriveWizardTM upload/download and

monitoring/graphing software

• Surge suppressor

• Space heater

• Keypad viewing window

• 50°C ambient

• Leg kits (shipped loose)

Design Features

• 32-bit microprocessor logic

• Flash upgradeable firmware

• Non-volatile memory, program retention

• Surface-mount devices

• Displacement power factor: 0.98

• Output frequency: 0.1 to 120 Hz

• Frequency resolution: 0.06 Hz

• Frequency regulation: 0.1%

• Control Terminal Board: Quick disconnect,

removable

• Carrier frequency: selectable to 15 kHz

• 3% DC bus reactor: 30-150 HP, 208 VAC;

30-150 HP, 240 VAC; 40-500 HP, 480 VAC;

optional on lower ratings

• Keypad Operator: built-in copy feature,

6 languages

• LCD display: 5 lines, 16 characters each

• 24 VDC control logic

• Transmitter/Option power supply

• Output contacts: One form C and two programmable form A

• Input/output terminal status

• Input terminals: 5 programmable multifunction input terminals

• Fault input: Programmable

• Diagnostic fault indication in selected language

• Timer function: Elapsed time, Delay on

start, Delay on stop

• RS-422/485 port: Modbus

• Volts/hertz ratio: Preset and programmable

V/Hz patterns

• Multi-speed settings: 5 available

• Remote speed command: 0-10 VDC or

4-20 mA, direct or reverse-acting

• Setpoint (PI) control with inverse or square

root input, differential control via two feedback capability

• Feedback signal: low pass filter

• Speed command: bias and gain

• Analog outputs: Programmable, two,

0-10 VDC

• Meter Functions: Volt, amp, kilowatt,

elapsed run time, speed command

• Output Current Transformers, qty 3

• UL Type 3R rating

• MTBF: exceeds 28 years

• Thermostatically controlled cabinet fans

• Lifting eyes

• Padlock hasp

Page 27

Data subject to change without notice

CA.P7.01, 04/01/08

Yaskawa Electric America

Page 30

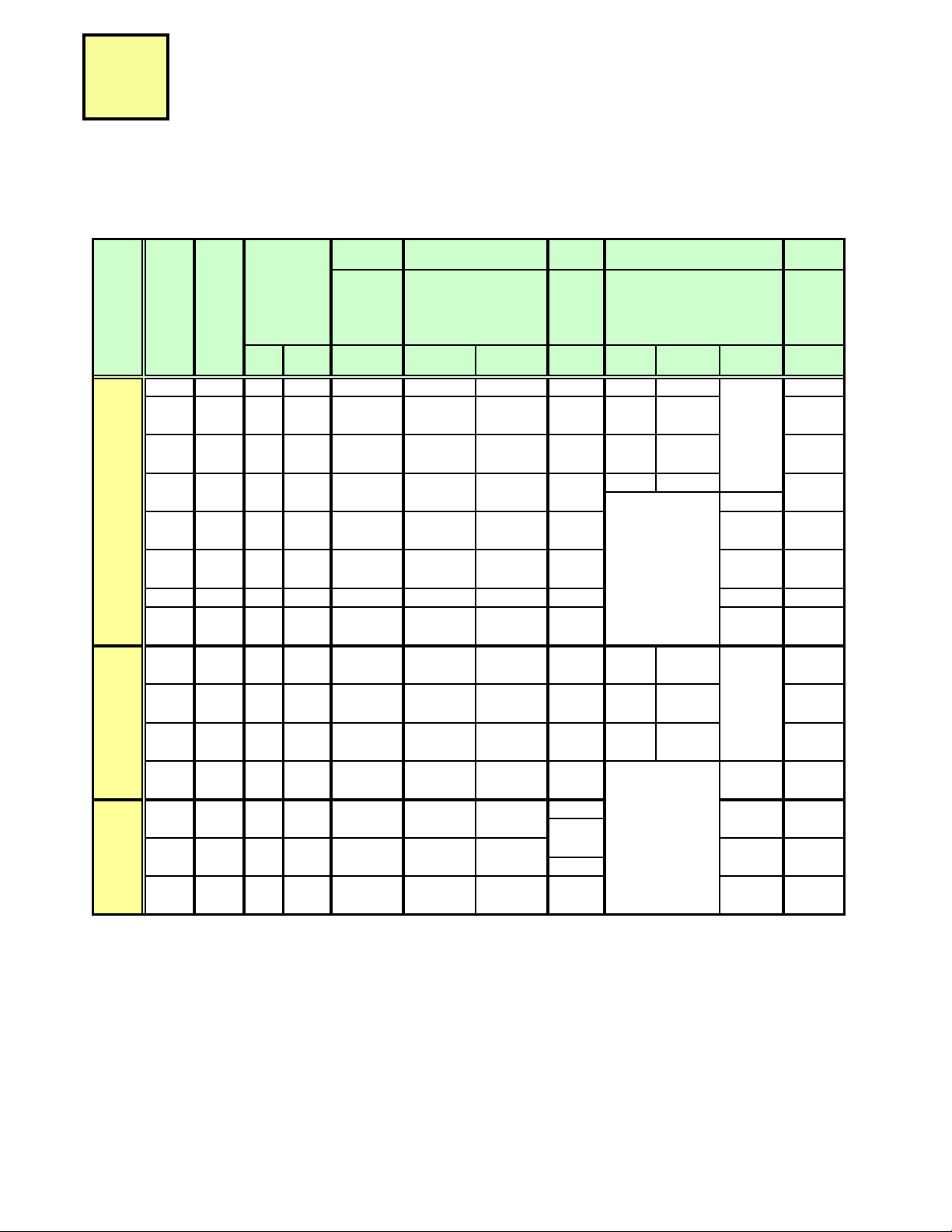

Description

P 040 T

R

D

A

2

G

H

J

L

Q

M

P

Y

W

3

C

D

F

R

K

X

Z

N

2

3

( E x . : "040" = 40A)

P Options (Power)

NEMA 3R

BA S E NUM BE R

Encl osur e

Rat ed Amps Code

T Options (Control and Communications)

EtherNet/IP

DeviceNet

OP TI ONS

P O W E R

C ONTROL

C u rre n t

Vol t ag e

208V

230/240V

B 480V

P 7 C R B

Choose None or One

Choose None or One

Choose None or One

Choose None or One

Choose None or One

Ci r c ui t Br eak er

Di s c onnec t Switch

I nput Fus es

Profibus

Metasys N2

LonWorks

Choose None

or One

Choose None or One

Choose None or One

Choos e None or One

Modbus TCP/IP

U

Siemens APOGEE FLN

V

Modbus (Internal)

4-20 mA Output

3-15 PSI Transducer

Hand-Off-Auto Switch

5% Load Reactor

3% Bus Reactor

(1)

(1)

5% Bus Reactor

3% Input Reactor

Choose None

or One

Choose None

or One

Choose None

or One

Surge Suppressor

Custom Nameplate

Keypad Internal

4

Keypad Viewing Window

Choose None or One

Choose None or One

Cap Filter

4 50°C Ambient

Space Heater

P7CRB040PCXT2

P7CR

Model Number Configuration & Pricing:

Step 1. To construct the complete Configured model number, first find the Base Number for the required enclosure type,

Step 2. Add the Option code letter for each required option. Any Power option must be preceded by (P); any Control &

Step 3. Find the corresponding list price for the Base Number selected from the following pages. Add the list price of each

Example: P7 NEMA 3R Configured package (P7CR) with a 480V, 40 Amp P7 drive (B040), with Circuit Breaker and a 3%

5-500HP

P7/Configured

NEMA 3R

voltage and current rating.

Communications option by (T). No more than eight options may be selected. The letters

no options of that type are selected.

selected option to this base price.

Bus reactor (

P followed by CX), Ethernet/IP communications capability (T followed by 2). Model number is:

P and T must be deleted if

(1) 3% and 5% Bus Reactors are only available as an option on base numbers up to and including P7CR_D074, A068 and B040; larger

drives have a Bus Reactor as standard.

CA.P7.01, 04/01/08

Data subject to change without notice

Yaskawa Electric America

Page 28

Page 31

Configured Option Descriptions:

(R) Enclosure: The drive and options are provided in a NEMA Type 3R ventilated enclosure, large enough to accommodate any or

all of the package options. Enclosures for Base Numbers up to, and including, D114 (40HP, 208V), A104 (40HP, 240V),and

B124 (100HP, 480V) are wall-mounted; larger drives are in floor-mount enclosures.

(C) Circuit Breaker: The standard configuration provides no branch short circuit protection or input disconnecting means. This

option provides a thermal-magnetic circuit breaker that meets NEC branch circuit protection requirements, with a flangemounted operating handle.

(D) Disconnect: The standard configuration provides no input disconnecting means. This option provides a non-fused disconnect

with a flange-mounted operating handle.

(N) Input Filter: The standard configuration does not include a filter. The cap filter, option (N), is a delta-wye capacitive

network.

(F) Input Fuses: The standard configuration does not include Drive Input Fuses. This option provides high-speed semi-conductor

drive input fuses, rated for 200,000 amp RMS symmetrical interrupting capacity, that provides both drive input I2T protection

and NEC approved branch circuit and short circuit protection.

P Options (Power)

Description

5-500HP

P7/Configured

NEMA 3R

P7CR

(X, Z, R) Line Impedance: Drives above Base Numbers D074 (25HP, 208V), A068 (25HP, 240V) and B040 (30HP, 480V) include a 3%

DC bus reactor in the standard package and do not provide any additional impedance. Option (X), 3% impedance, and option

(Z), 5% impedance, are not available for ratings larger than these. To achieve a 5% total input impedance, select option (R) this 3% input reactor is available only for the HP ratings greater than the HP's listed above, and combines with the drive's

standard DC bus reactor.

(K) Load Reactor: No form of output impedance is normally required. A 5% load reactor, option (K), is available if additional output

impedance is desired (usually for long lead-lengths or noise reduction).

(2) Surge Suppressor: This option will offer some degree of protection from transient surges coming through the power line

cables. Lightning strikes are the most common source of surges.

(3) Space Heater: This option maintains the internal cabinet temperature to reduce condensation.

(4) 50°C Ambient: This option will allow the enclosure to be operated in an ambient temperature of 50°C (122°F). The standard

basic design is rated for 40°C ambient.

T Options (Control and Communications)

(W) Custom Nameplates: Custom engraved nameplates with white lettering on black lamicoid are available with option (W), for

special tagging purposes (Example: "AHU #1"). Note that this option requires the text to be specified by the customer. Leave

this field blank if no special nameplates are required.

(Y) Hand/Off/Auto:

control - this is the standard configuration. A door-mounted Hand/Off/Auto Switch is available when option (Y) is

specified.

(P) 3-15 PSI Transducer: No transducer is provided with the standard configuration. To add an optional transducer that accepts a

3-15 PSI pneumatic signal and converts it to a 4-20mA signal that is sent to the drive, specify option (P).

(M) 4-20mA Output: The standard Configured package provides two programmable 0-10VDC outputs. To convert these outputs to

4-20mA output signals, specify option (M).

(G, H, L, Q,