Yaskawa P1000 Catalog

P1000

240V Class: ¾ to 175 HP

480V Class: 1 to 1000 HP

600V Class: 2 to 250 HP

The Flexible and Intuitive Solution for Fan and Pump Applications.

The P1000 drive provides simple, reliable, cost-effective control for variable-torque loads through 1000 HP.

Specic application features, energy savings, and network connectivity make the P1000 a great choice for

industrial fans and pumps.

2

Contents

Features, Benets, and Specications 4

Drives and Accessories Selection 16

Mechanical Installation Planning 34

Electrical Installation Planning 39

Yaskawa Industrial Drives Family 42

Global Service Network

44

3

Features and Benets

Exceptional Quality

Enjoy peace of mind by knowing that you are considering a product from Yaskawa, the factory automation

controls company with the highest reputation for quality and reliability. Historically, Yaskawa drives have

demonstrated extremely high reliability with an average MTBF (mean time between failure) of 28 years or

more. The new 1000 series products take reliability to the next level with a calculated design life that is twice

as long as previous generations.

Highly Integrated Design results in fewer parts and interconnections,

reducing the number of failure points.

Component Derating extends the life of any single part by selecting higher

specications (e.g., voltage, current) than what a circuit requires for normal

operation.

Latest Generation IGBT Power Modules, capable of four times more thermal

cycles than previous designs.

Enhanced Short Circuit Detection and Self Diagnostics provide additional

protection against severe catastrophic conditions.

In addition, the P1000 is designed for use around the world, and carries agency certications for all

major geographical regions

4

Easy to Apply and Maintain

The P1000 is supported by user-friendly conguration tools. For local eld access,

the keypad interface features a multi-language LCD display, parameter storage, and

application presets to make programming a simple task. It also has built-in memory for

backup purposes. In addition, a USB Copy Unit can be loaded with a drive’s program for

convenient portable transfer of conguration between an ofce environment and the

factory oor.

USB Copy Unit

HVAC

Fan

Pump

Fan and Pump Application

Presets

Start-up time has been reduced with

preprogrammed application presets

that allow for simple and easy start-up

by answering simple motor and

application information.

Application Presets: General Purpose;

Pump & Pump with PI Feedback Control;

Fan & Fan with PI Feedback Control

DriveWizard® computer software delivers conguration, monitoring, and trending functions enhanced

by direct connectivity through the P1000’s standard USB port.

Features, Benets, and Specications

• Online and Ofine Editing

• Application Wizard

• Monitoring and Diagnostic Panels

• Trend Recorder and Playback

• Network Congurator

• Multidrive Support

• Drive Flash Support

• Project Converter

• Report and Export Generation

• Search Engine

55

Features and Benets

Easy to Apply and Maintain

Real Time Clock (RTC)

Take advantage of the battery-backed clock that’s built into

the P1000’s keypad display. With this feature, the P1000 can

be controlled based on time of day, and can also provide timestamped event information.

PI Process Control

Two separate process control loops are embedded in the

P1000. One modies drive speed based on setpoint and sensor

feedback. A second control loop (with its own setpoint and

feedback inputs) can be output to control something completely

independent of the drive. Additionally, the P1000 provides a

24VDC, 150mA supply for applying power to sensors.

U3-21 = Year

U3-22 = Month/Date

U3-24 = Time of Fault

U5-01 = Transducer

Feedback

Selectable and User-Customizable Engineering Units

Allow for easy conguration of keypad display to match process

and feedback devices such as PSI, GPM, Feet.

Preventative Maintenance Monitors

Maximize production and intelligently schedule your

maintenance by making use of the P1000’s special monitors that

provide alarm information when a drive requires attention. Use

this information to trigger discrete outputs or send the status

across a network for upper level decision making.

• Cooling Fan Remaining Life

• IGBT (Power Module) Remaining Life

• Bus Capacitor Remaining Life

• Precharge Relay

• Drive (Heatsink) Temperature

6

6

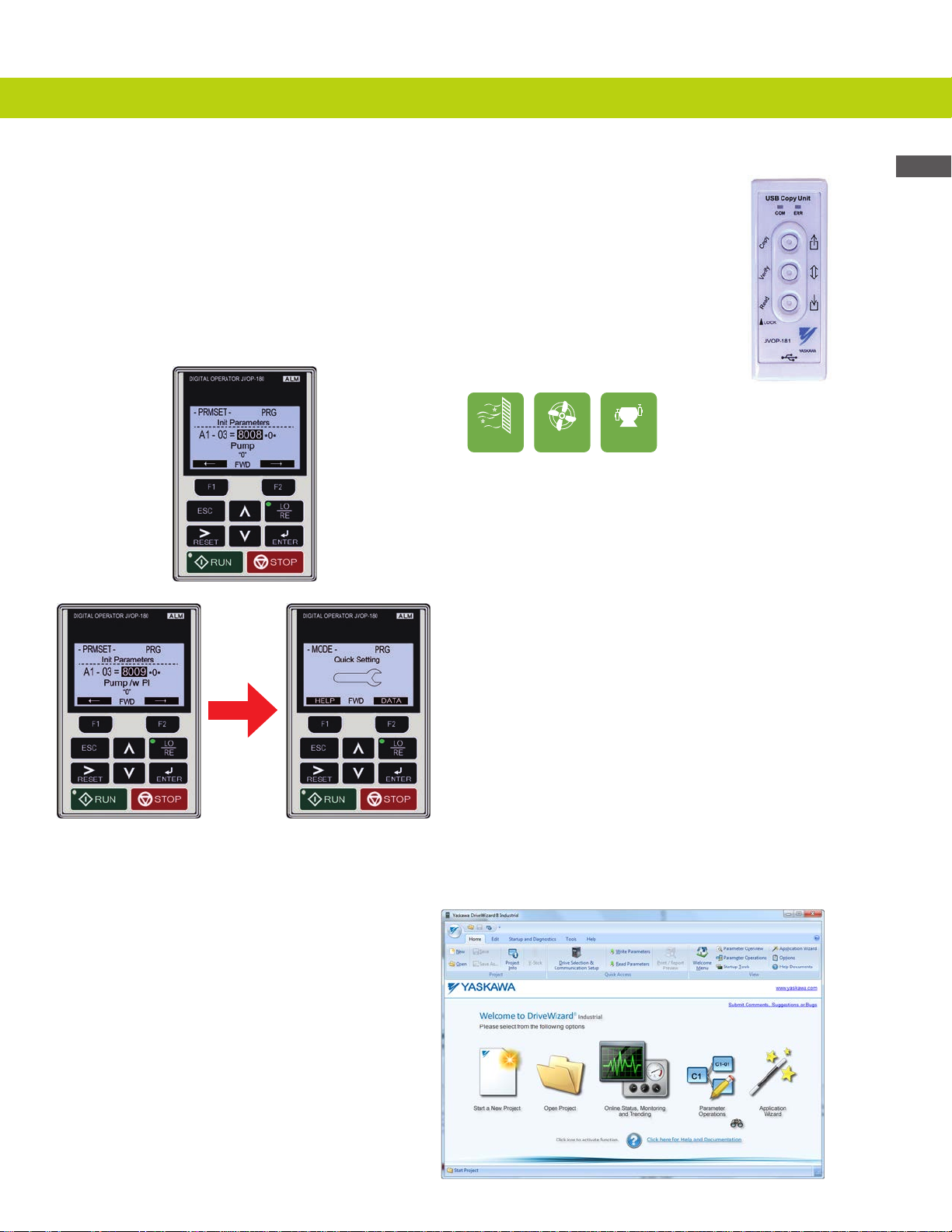

Easy to Apply and Maintain

Highly Reliable and Easily Replaceable

Cooling Fans

• Improved location for convenient access, even when

mounted with heatsink external

• No tools required

• All ratings are 24Vdc powered

Removeable I/O Terminal Board with Drive

Backup Memory

• All parameter changes automatically saved to both main

control board and I/O board

• Leave I/O connected when replacing a drive

• Conguration is downloaded to replacement drive

• Reduces MTTR (Mean Time To Repair)

Features, Benets, and Specications

Underload Detection

Monitors the load and will stop the system in the event of a fan

belt or pump shaft failure.

Dynamic Noise Control

Monitors the load at all times and reduces the output voltage

automatically, reducing motor audible noise.

7

7

Features and Benets

Maximum Flexibility

Enjoy a signicant amount of standard control points. The P1000 can also expand to support popular

communication networks.

Standard I/O and Communications

• Digital Inputs (8)

• Analog Inputs (3)

• Pulse Inputs (1)

• Digital Outputs (4)

• 2 Form C Relays

• 2 Form A Relays

• Analog Outputs (2)

• RS485 Modbus RTU Communication

Expansion Capability

• Analog Output Module

(3 additional outputs)

• DeviceNet

• EtherNet/IP

• Modbus TCP/IP

• PROFIBUS-DP

• PROFINET

• BACnet

• Lonworks

• Metasys (N2)

• Apogee (P1)

Auxiliary Control Power Input

Keep your drives communicating over the network, even

while main power is removed. The Auxiliary Control Power

Input uses facility supplied 24Vdc to keep the drive’s control

and communication intact. Service your drive cabinets with

the benet of live control and communications without the

need for main power and associated Arc Flash protection.

8

Maximum Flexibility

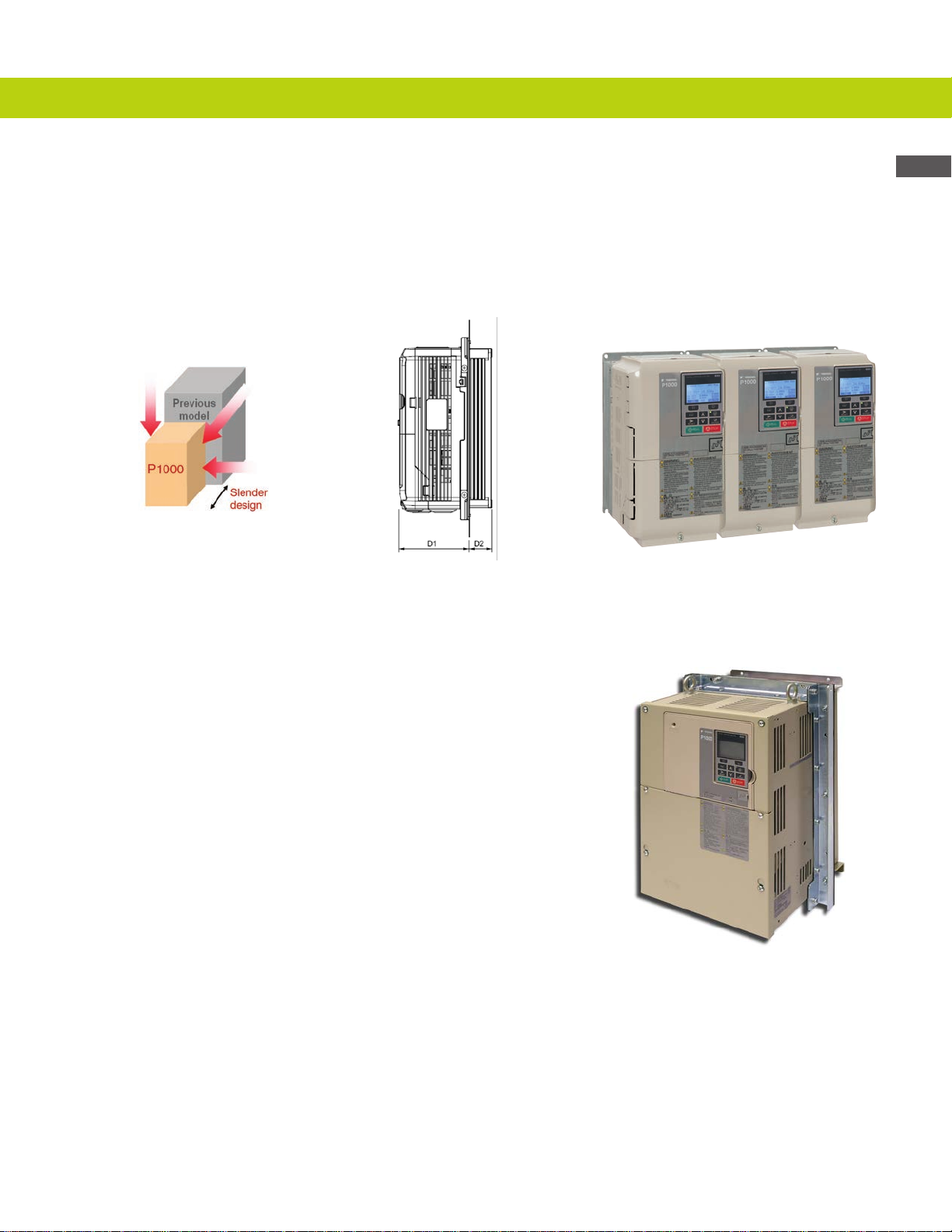

Space Saving Features

The P1000 offers world class power density resulting in an average size reduction of 30% as compared to

previous generations (see individual rating dimensions). In addition, even more cabinet space can be saved

by taking advantage of External Heatsink Mounting and Zero Side Clearance capability.

Features, Benets, and Specications

Physical Size Reduction External Heatsink Solution

(Side View)

Type 12 Flange Configuration

P1000 is available in all ratings as a Type 12 Flange conguration

that allows for mounting the drive with its heatsink out the back

of any Type 12 enclosure. This allows for the majority of the

drive’s heat to dissipate on the external side, while keeping the

enclosure small and sealed with Type 12 integrity.

Zero Side Clearance

(40°C max ambient)

9

Features and Benets

Power

supply

voltage

Motor

speed

Trip-free Operation

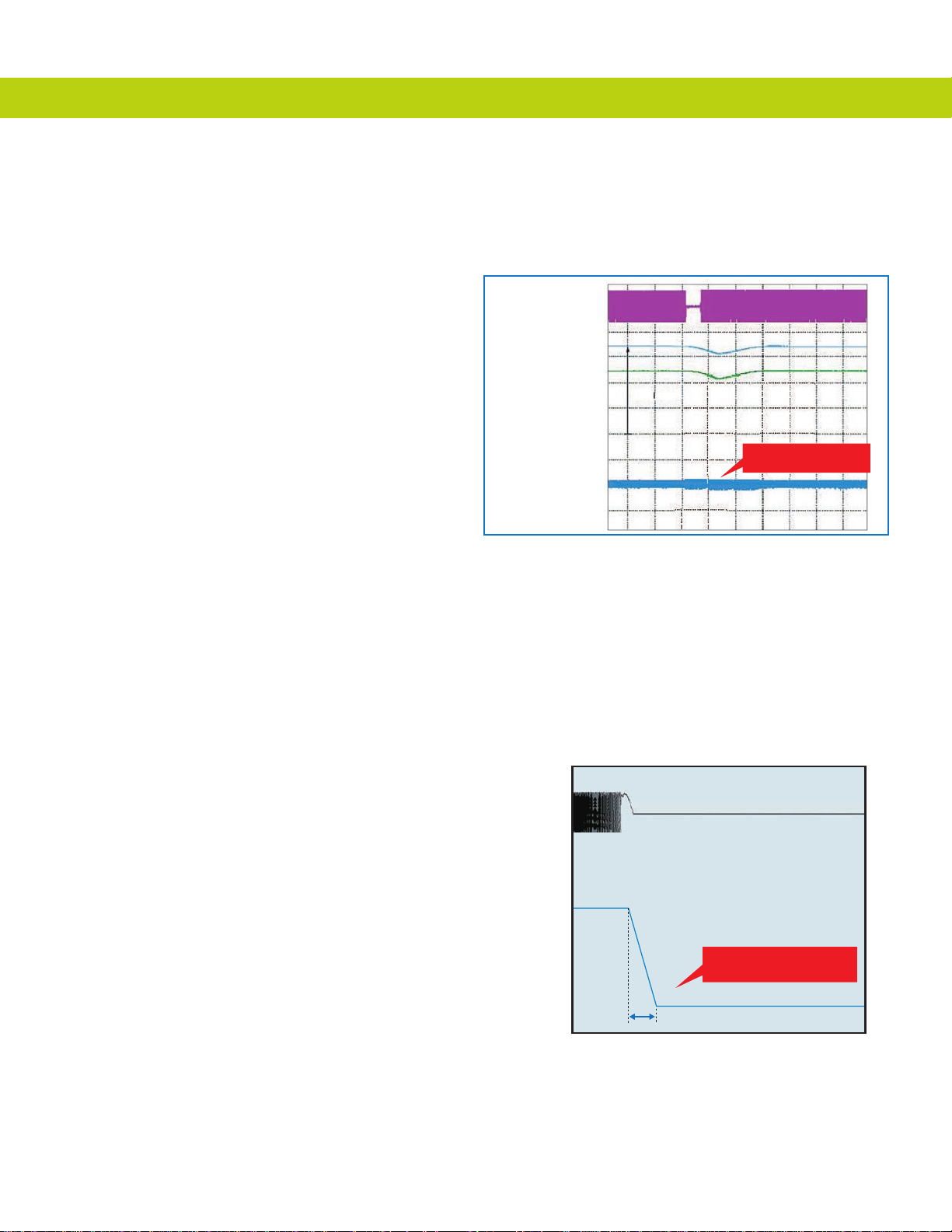

Keep your applications running with features designed to avoid interruptions that are typical with

demanding load conditions.

• Optimal Decel automatically extends the

programmed deceleration time based on

the load condition and drive capability.

• Overvoltage Suppression limits the

DC bus voltage by modulating output

frequency to keep the drive out of the

regenerative region.

• Overload Fault Prevention responds

to heavy load conditions by adjusting

output frequency and voltage to keep the

drive’s current within operating limits.

• Momentary Power Loss Ride-Thru

puts the drive in standby mode

during transient power losses and

then automatically restarts, avoiding

potentially costly power related shut

down conditions.

• Bi-directional speed search allows the

drive to start into a rotating load by

quickly sensing the speed and direction

of the motor and then seamlessly

matching the drive’s output.

• For applications that can dissipate losses

in the motor, Over-Excitation Braking

and High Slip Braking are goodperforming, money-saving alternatives

to dynamic braking.

• In the event of a power loss, Kinetic

Energy Braking uses energy stored in the

rotating load to keep the drive powered

and bring the process to a controlled stop.

Power supply

voltage

Motor speed

Output frequency

Output current

1750 r/min

Speed Search

Uses regenerative energy to

keep the application running

Motor decelerates quickly to

protect the application

Controlled ramp to stop

Kinetic Energy Braking

10

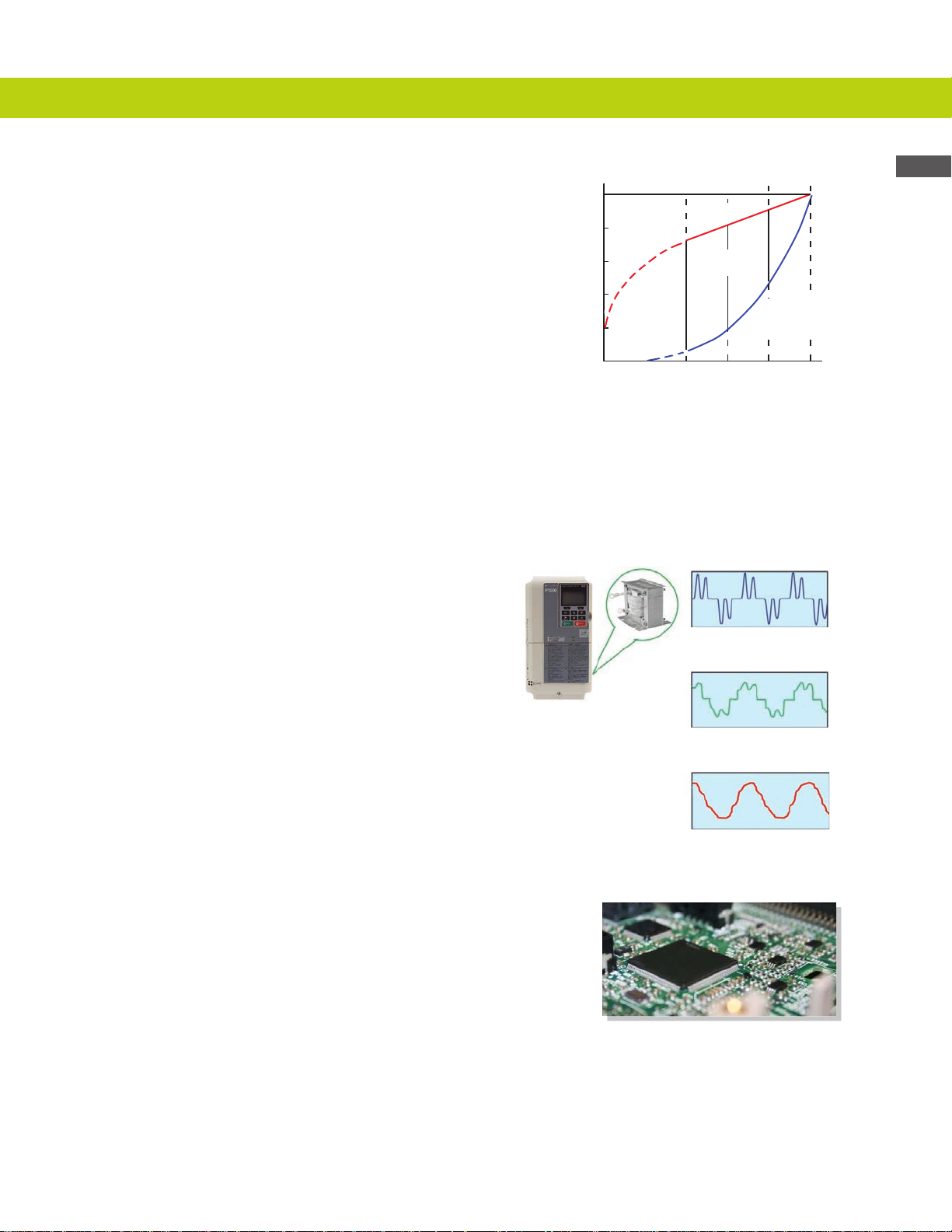

Environmental

Reduce your energy bill and contribute towards a cleaner

environment with sustainable features designed into the

P1000.

Energy Savings Benefits of Variable Speed

Using variable speed on pumps and fans results is very

large energy savings as compared to other uid or air

control methods (valves, guide vanes, dampers, etc.).

Additionally, the P1000 provides even greater savings

with its Energy Saving Control that reduces unnecessary

magnetizing current at reduced speeds.

Power Quality Conscious

Built-in DC reactors (30 HP and larger) provide

input harmonics benet, and protection from input

disturbances.

100%

80&

60%

40%

POWER (%)

20%

0

Comparison of Power Requirements for

Variable Speed and Throttling method

BYPASS METHOD

THROTTLING

METHOD

POWER

SAVINGS

40 60 80 100

FLOW (%)

6-Pulse Drive without Reactor

(Approximately 88% THD)

6 Pulse Drive with Reactor

(Approximately 40% THD)

ADJUSTABLE

SPEED

METHOD

Features, Benets, and Specications

To further reduce harmonics reected back to the

utility power line, the P1000 is available with an

integrated 12-pulse diode bridge from 40 to 1000

HP @ 480VAC (also requires the use of an external

phase-shifting transformer).

Product Life Cycle Responsibility

The future of our environment and the earth’s natural

resources is very important to Yaskawa. The P1000

has been designed to minimize the use of harmful

materials (e.g. lead, mercury, cadmium, etc.) and

meets the requirements of RoHS (Restriction of

Hazardous Substances)

12 Pulse Drive

(Less than 15% THD)

11

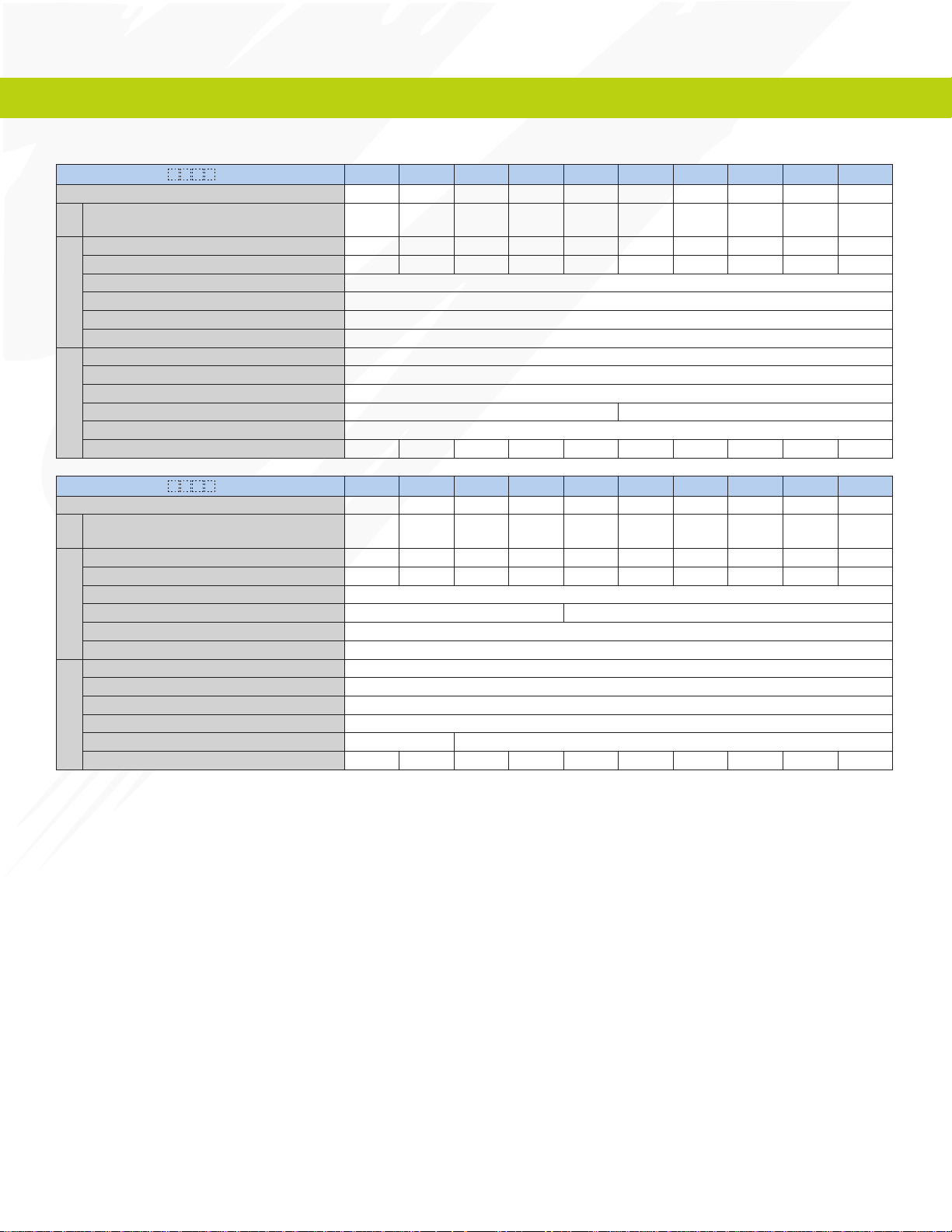

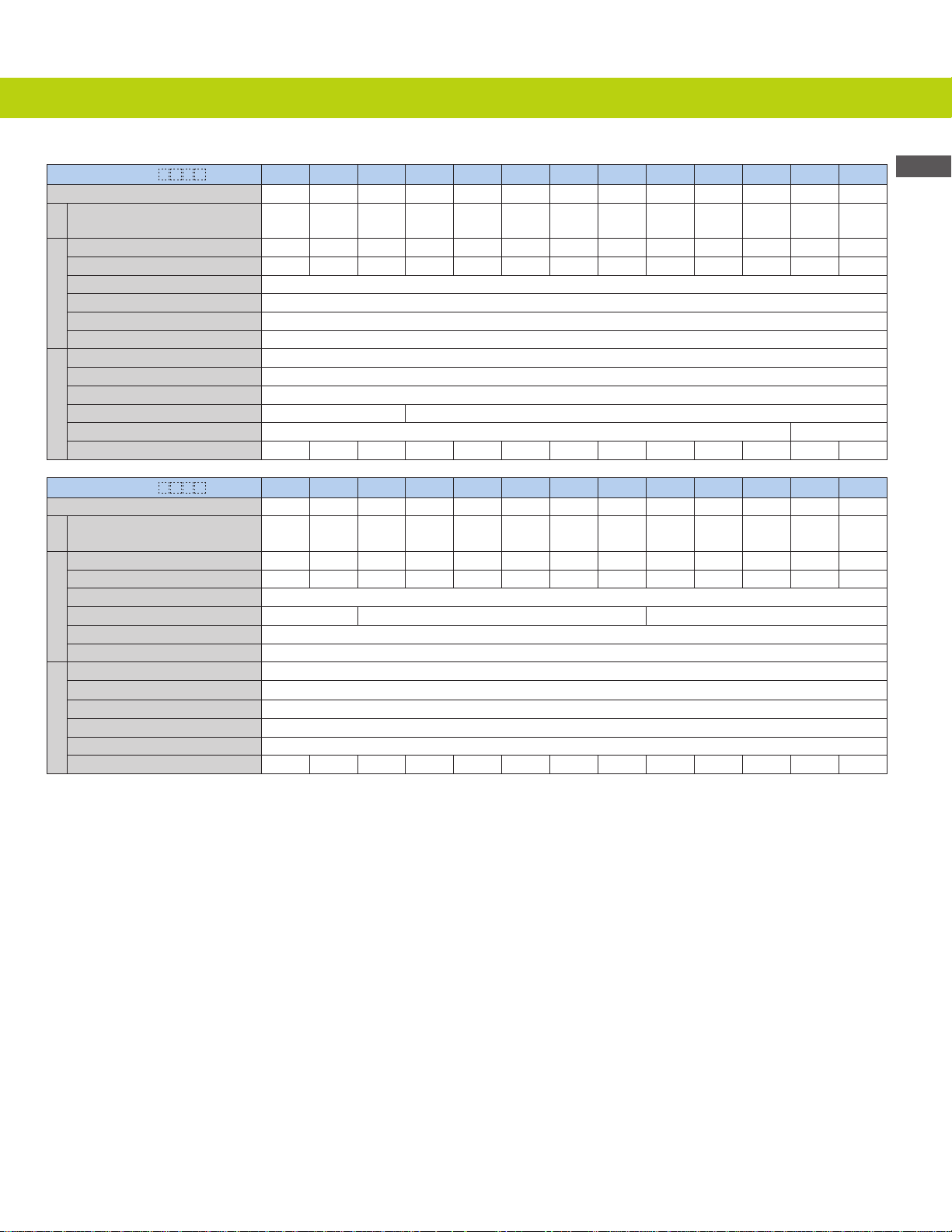

Specications

240V Class

Model CIMR-PU2A

*1

Max. Applicable Motor Capacity

Rated Input Current*2 A

Input

Rated Output Capacity

Rated Output Current

HP

*4,*5

kVA

*5

A

Overload Tolerance 120% of rated output current for 60 sec.

Carrier Frequency (User Adjustable) 2 to 15 kHz

Output

Max. Output Voltage Three-phase 200 to 240 V (relative to input voltage)

Max. Output Frequency 400 Hz

Rated Voltage/Rated Frequency Three-phase 200 to 240 Vac 50/60 Hz 270 to 340 Vdc

Allowable Voltage Fluctuation

Allowable Frequency Fluctuation ±5%

Fan No fan With fan

Power

DC Link Choke External Option

Power Supply kVA

0004 0006 0008 0010 0012 0018 0021 0030 0040 0056

0.75 1.5 2 3 3 5 7.5 10 15 20

3.9 7.3 8.8 10.8 13.9 18.5 24 37 52 68

1.3 2.3 3 3.7 4.6 6.7 8 11.4 15.2 21

3.5 6 8 9.6 12 17.5 21 30 40 56

-

15% to +10%

2.2 3.1 4.1 5.8 7.8 9.5 14 18 27 36

*3

Model CIMR-PU2A

*1

Max. Applicable Motor Capacity

Rated Input Current*2 A

Input

Rated Output Capacity

Rated Output Current

HP

*4,*5

kVA

*5

A

0069 0081 0110 0138 0169 0211 0250 0312 0360 0415

25 30 40 50 60 75 100 125 150 175

80 96 111 136 164 200 271 324 394 471

26 31 42 53 64 80 95 119 137 158

69 81 110 138 169 211 250 312 360 415

Overload Tolerance 120% of rated output current for 60 sec.

Carrier Frequency (User Adjustable) 2 to 15 kHz 2 to 10 kHz

Output

Max. Output Voltage Three-phase 200 to 240 V (relative to input voltage)

Max. Output Frequency 400 Hz (user-set)

Rated Voltage/Rated Frequency Three-phase 200 to 240 Vac 50/60 Hz 270 to 340 Vdc

Allowable Voltage Fluctuation

-

15% to +10%

*3

Allowable Frequency Fluctuation ±5%

Fan With fan

Power

DC Link Choke External Option Included

Power Supply kVA

44 52 51 62 75 91 124 148 180 215

*1. The motor capacity (HP) refers to a NEC rated 4-pole motor. The rated output current of the drive output amps should be equal to or greater than the

motor current. Select the appropriate capacity drive if operating the motor continuously above motor nameplate current.

*2. Assumes operation at the rated output current. Input current rating varies depending on the power supply transformer, input reactor, wiring

connections, and power supply impedance.

*3. Direct application of DC power is not presently supported by the P1000’s UL listing.

*4. Rated motor capacity is calculated with a rated output voltage of 230V.

*5. Carrier frequency is set to 2 kHz. Current derating is required in order to raise the carrier frequency.

12

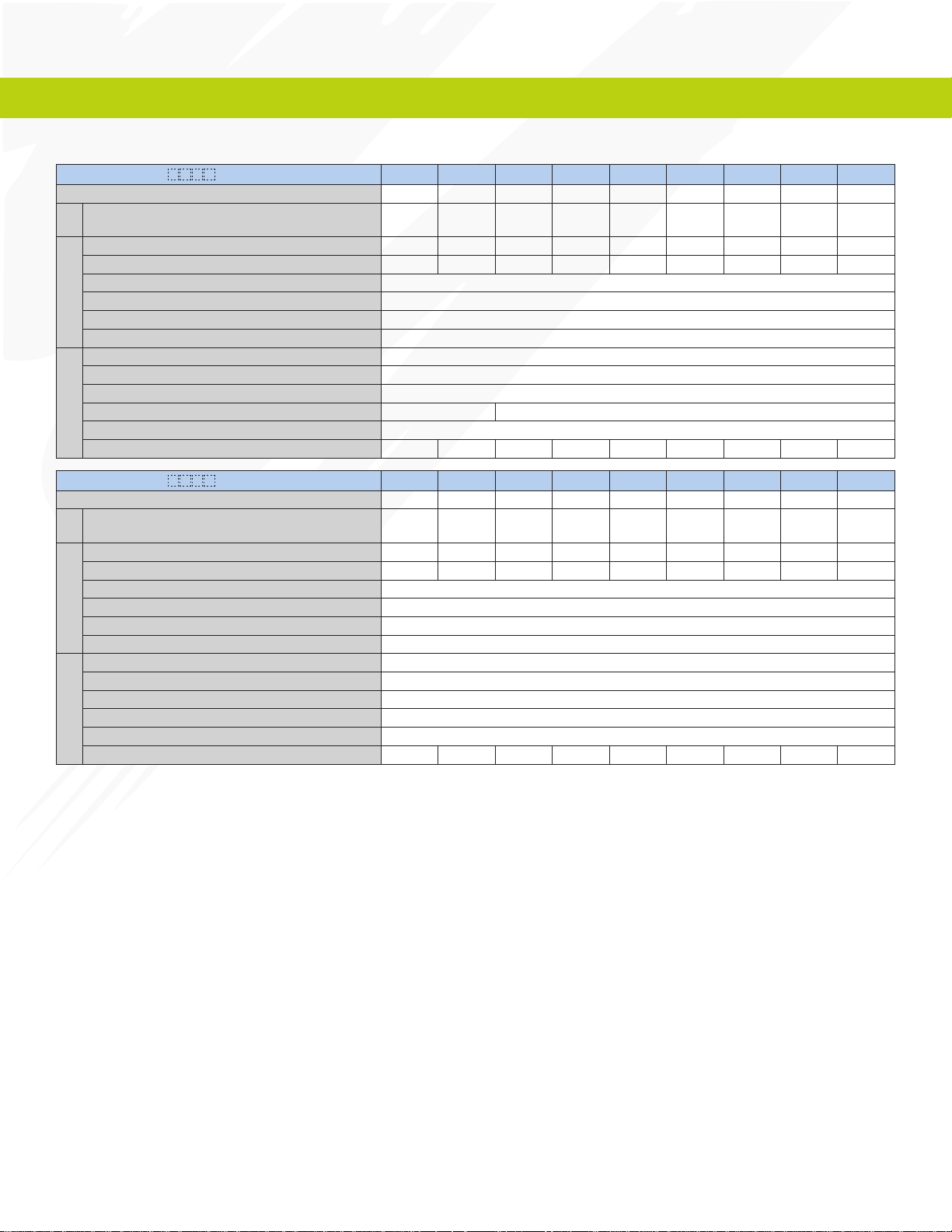

480V Class

Model CIMR-PU4A

Max. Applicable Motor Capacity

*1

HP

0002 0004 0005 0007 0009 0011 0018 0023 0031 0038 0044 0058 0072

1 2 3 3 5 7.5 10 15 20 25 30 40 50

Rated Input Current*2 A

Input

Rated Output Capacity

Rated Output Current

*4,*5

kVA

*5

A

2.1 4.3 5.9 8.1 9.4 14 20 24 38 51 60 58 71

1.6 3.1 4.1 5.3 6.7 8.5 13.3 17.5 24 29 34 44 55

2.1 4.1 5.4 6.9 8.8 11.1 17.5 23 31 38 44 58 72

Overload Tolerance 120% of rated output current for 60 sec.

Carrier Frequency (User Adjustable) 2 to 15 kHz

Output

Max. Output Voltage Three-phase 380 to 480 V (relative to input voltage)

Max. Output Frequency 400 Hz

Rated Voltage/Rated Frequency Three-phase 380 to 480 Vac 50/60 Hz 510 to 680 Vdc

Allowable Voltage Fluctuation

-

15% to +10%

*3

Allowable Frequency Fluctuation ±5%

Fan No fan With fan

Power

DC Link Choke External Option Included

Power Supply kVA

Model CIMR-PU4A

*1

Max. Applicable Motor Capacity

Rated Input Current*2 A

Input

Rated Output Capacity

Rated Output Current

HP

*4,*5

kVA

*5

A

2.3 4.3 6.1 8.1 10 14.5 19.4 28.4 37.5 46.6 54.9 53 64.9

0088 0103 0139 0165 0208 0250 0296 0362 0414 0515 0675 0930 1200

60 75 100 125 150 200 250 300 350 450 600 800 1000

86 105 142 170 207 248 300 346 410 465 657 922 1158

67 78 106 126 159 191 226 276 316 392 514 709 915

88 103 139 165 208 250 296 362 414 515 675 930 1200

Overload Tolerance 120% of rated output current for 60 sec.

Carrier Frequency (User Adjustable) 2 to 15 kHz 2 to 10 kHz 2 to 5 kHz

Output

Max. Output Voltage Three-phase 380 to 480 V (relative to input voltage)

Max. Output Frequency 400 Hz (user-set)

Rated Voltage/Rated Frequency Three-phase 380 to 480 Vac 50/60 Hz 510 to 680 Vdc

Allowable Voltage Fluctuation

-

15% to +10%

*3

Allowable Frequency Fluctuation ±5%

Fan With fan

Power

DC Link Choke Included

Power Supply kVA

78.6 96 130 156 189 227 274 316 375 425 601 843 601

*1. The motor capacity (HP) refers to a NEC rated 4-pole motor. The rated output current of the drive output amps should be equal to or greater than the

motor current. Select the appropriate capacity drive if operating the motor continuously above motor nameplate current.

*2. Assumes operation at the rated output current. Input current rating varies depending on the power supply transformer, input reactor, wiring

connections, and power supply impedance.

*3. Direct application of DC power is not presently supported by the P1000’s UL listing.

*4. Rated motor capacity is calculated with a rated output voltage of 460V.

*5. Carrier frequency is set to 2 kHz. Current derating is required in order to raise the carrier frequency.

Features, Benets, and Specications

13

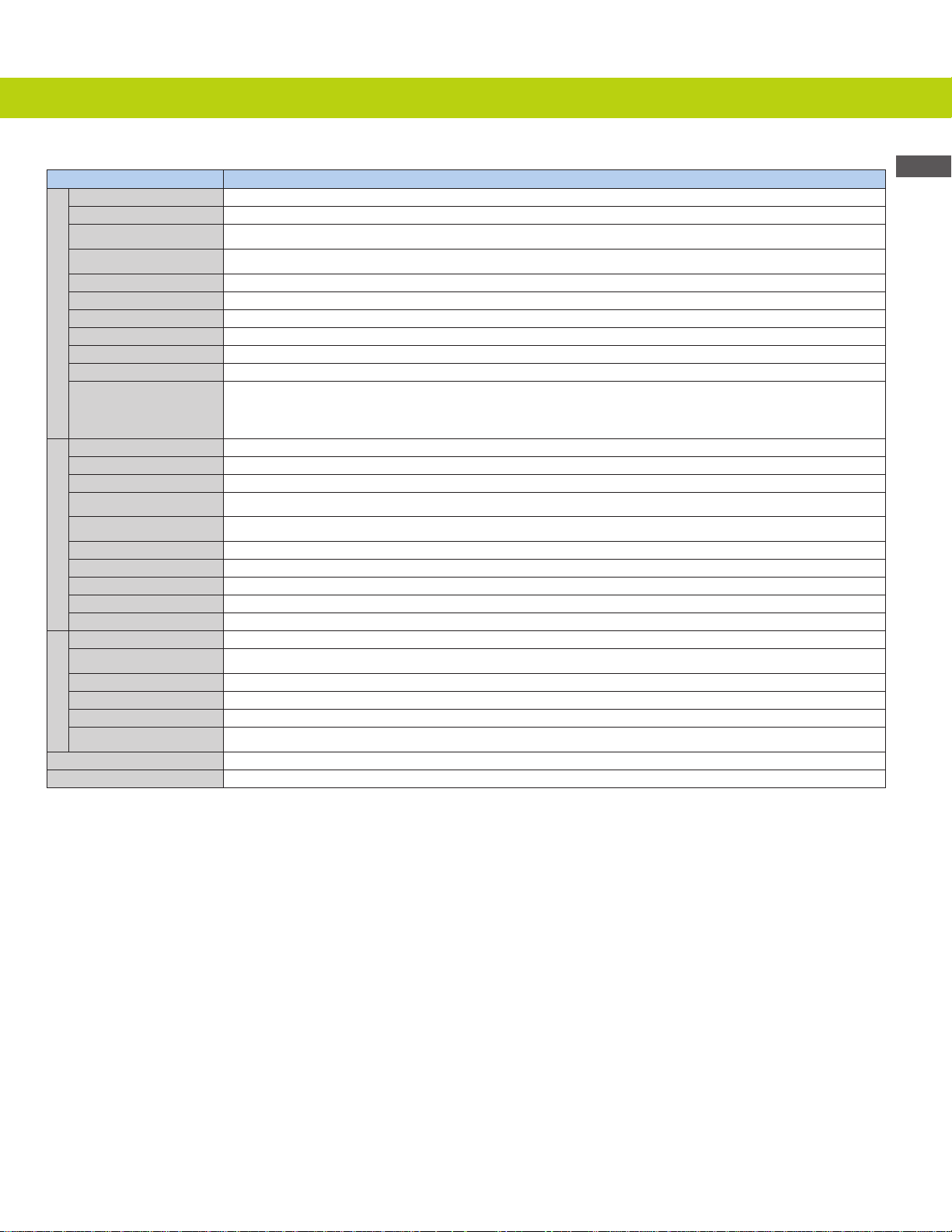

Specications

600V Class

Model CIMR-PU5A

Max. Applicable Motor Capacity

Rated Input Current*2 A

Input

Rated Output Capacity

Rated Output Current

Overload Tolerance 120% of rated output current for 60 sec.

Carrier Frequency 2 to 15 kHz

Output

Max. Output Voltage Three-phase: 500 to 600 V (proportional to input voltage)

Max. Output Frequency 400 Hz

Rated Voltage/Rated Frequency Three-phase 500 to 600 Vac 50/60 Hz

Allowable Voltage Fluctuation

Allowable Frequency Fluctuation ±5%

Fan No fan With fan

Power

DC Link Choke External option

Power Supply kVA

*1

HP

*3,*4

kVA

*4

A

0003 0004 0006 0009 0011 0017 0022 0027 0032

2 3 5 7.5 10 15 20 25 30

3.6 5.1 8.3 12 16 23 31 38 45

2.7 3.9 6.1 9 11 17 22 27 32

2.7 3.9 6.1 9 11 17 22 27 32

-10 (-15) to +10%

4.1 5.8 9.5 14 18 26 35 43 51

Model CIMR-PU5A

Max. Applicable Motor Capacity

Rated Input Current*2 A

Input

Rated Output Capacity

Rated Output Current

Overload Tolerance 120% of rated output current for 60 sec.

Carrier Frequency 2 to 15 kHz

Output

Max. Output Voltage Three-phase: 500 to 600 V (proportional to input voltage)

Max. Output Frequency 400 Hz (user-set)

Rated Voltage/Rated Frequency Three-phase 500 to 600 Vac 50/60 Hz

Allowable Voltage Fluctuation

Allowable Frequency Fluctuation ±5%

Fan With fan

Power

DC Link Choke Included

Power Supply kVA

*1. The motor capacity (HP) refers to a NEC rated 4-pole motor. The rated output current of the drive output amps should be equal to or greater than the

motor current. Select the appropriate capacity drive if operating the motor continuously above motor nameplate current.

*2. Assumes operation at the rated output current. Input current rating varies depending on the power supply transformer, input reactor, wiring

connections, and power supply impedance.

*3. Rated motor capacity is calculated with a rated output voltage of 575V.

*4. Carrier frequency is set to 2 kHz. Current derating is required to raise the carrier frequency.

*1

HP

*3,*4

kVA

*4

A

0041 0052 0062 0077 0099 0125 0145 0192 0242

40 50 60 75 100 125 150 200 250

41 52 62 77 99 129 158 228 263

41 52 62 77 99 124 144 191 241

41 52 62 77 99 125 145 192 242

-10 (-15) to +10%

50 62 75 91 123

14

Common Specifications

Item Specications

Control Methods V/f Control (V/f)

Frequency Control Range

Frequency Accuracy

(Temperature Fluctuation)

Frequency Setting Resolution

Output Frequency Resolution

Frequency Setting Methods

Starting Torque

Speed Control Range

Accel/Decel Time 0.0 to 6000.0 s (4 selectable combinations of independent acceleration and deceleration settings)

Control Characteristics

<1>

<1>

V/f Characteristics User-selected programs and V/f preset patterns possible

Main Control Functions

Motor Protection Electronic thermal overload relay

Momentary Overcurrent Protection

Overload Protection Drive stops after 60 seconds at 120% of rated output current

Overvoltage Protection

Undervoltage Protection

Momentary Power Loss Ride-Thru

Heatsink Overheat Protection

Protection Function

Stall Prevention Stall Prevention is available during acceleration, deceleration, and during run.

Ground Fault Protection

Charge LED Remains lit until DC bus voltage falls below 50 V

Area of Use Indoors

Ambient Temperature

Humidity 95% RH or less (no condensation)

Storage Temperature

Altitude Up to 1000 meters without derating, up to 3000 m with output current and voltage derating

Operating Environment

Shock

Standards and Certications UL 508C, CSA C22.2, EN 61800-5-1

Protection Design IP00 enclosure, IP20/NEMA Type 1 enclosure

<1> The accuracy of these values depends on motor characteristics, ambient conditions, and drive settings. Specications may vary with different motorsand with changing motor

temperature. Contact Yaskawa for consultation.

<2> Overload protection may be triggered when operating with 150% of the rated output current if the output frequency is less than 6 Hz.

<3> May be shorter due to load conditions and motor speed.

<4> A separate Momentary Power Loss Ride-Thru Unit is required for models 2A0004 to 2A0056, 4A0002 to 4A0031, and 5A0003 to 5A0032 if the application needs to continue

running for up to 2 seconds during a momentary power loss.

<5> Ground protection cannot be provided when the impedance of the ground fault path is too low, or when the drive is powered up while a ground fault is present at the output.

<6> Removing the top protective cover or bottom conduit bracket from an IP20/NEMA Type 1 enclosure drive voids NEMA Type 1 protection while maintaining IP20 conformity.

This is applicable to models 2A0004 to 2A0211, 4A0002 to 4A0165, and 5A0003 to 5A0032.

0.01 to 400 Hz

Digital input: within ±0.01% of the max output frequency (-10 to +40 °C)

Analog input: within ±0.1% of the max output frequency (25 °C ±10 °C)

Digital inputs: 0.01 Hz

Analog inputs: 1/2048 of the maximum output frequency setting (11 bit plus sign)

0.001 Hz

0 to +10 V, 4 to 20 mA, Pulse Train Input, Network Communications, Keypad

V/f: 150% at 3 Hz

V/f: 1:40

Momentary Power Loss Ride-Thru, Speed Search, Overtorque/Undertorque Detection, 17 Step Speed (max), Accel/decel Switch, S-curve Accel/decel, 3-wire

Sequence, Auto-tuning (rotational, stationary tuning), Dwell, Cooling Fan on/off Switch, Slip Compensation, Torque Compensation, Frequency Jump, Upper/

lower Limits for Frequency Reference, DC Injection Braking at Start and Stop, Overexcitation Braking, High Slip Braking, PID Control (with sleep function),

Energy Saving Control, Modbus Comm. (RS-422/485 max, 115.2 kbps), Fault Restart, Application Presets, Removable Terminal Block with Parameter Backup

Function, Dynamic Noise Control.

Drive stops when output exceeds 170%

<2>

240V class: Faults when DC bus voltage exceeds approx. 410 V; 480V class: Faults when DC bus voltage exceeds approx. 820 V;

600V class: Faults when DC bus voltage exceeds approx. 1040 V.

240V class: Faults when DC bus voltage falls below approx. 190 V; 480V class: Faults when DC bus voltage falls below approx. 380 V;

600V class: Faults when DC bus voltage falls below approx. 475 V.

Stops modulating after 15 ms or longer power loss

<3> .

Resumes operation if power loss is less than 2 s (standard)

<4>

Thermistor

Electronic circuit protection

-10 to +50°C (Chassis Installation)

-10 to +40°C (Chassis with zero side clearance, or Type 1)

-

20 to +60˚C (short-term temperature during transportation)

10 to 20 Hz: 9.8 m/s

2.0 m/s

<5>

2

20 to 55 Hz: 5.9 m/s2 (2A0004 to 2A0211, 4A0002 to 4A0165, and 5A0003 to 5A0032)

2

(2A0250 to 2A0415 and 4A0208 to 4A0675)

<6>

Features, Benets, and Specications

15

Loading...

Loading...