Page 1

NX100 OPTIONS

1/210

INSTRUCTIONS

FOR INDEPENDENT/COORDINATED CONTROL FUNCTION

Upon receipt of the product and prior to initial operation, read these instructions thoroughly, and retain

for future reference.

MOTOMAN INSTRUCTIONS

MOTOMAN- INSTRUCTIONS

NX100 INSTRUCTIONS

NX100 OPERATOR’S MANUAL

NX100 MAINTENANCE MANUAL

The NX100 operator’s manuals above correspond to specific usage.

Be sure to use the appropriate manual.

Part Number: 149648-1CD

Revision: 4

MANUAL NO. RE-CKI-A443

4

Page 2

MANDATORY

CAUTION

2/210

• This manual explains the independent/coordinated control function of

the NX100 system and general operations. Read this manual carefully

and be sure to understand its contents before handling the NX100.

• General items related to safety are listed in Chapter 1: Safety of the

NX100 Instructions. To ensure correct and safe operation, carefully

read the NX100 Instructions before reading this manual.

• Some drawings in this manual are shown with the protective covers or

shields removed for clarity. Be sure all covers and shields are replaced

before operating this product.

• The drawings and photos in this manual are representative examples

and differences may exist between them and the delivered product.

• Y ASKAWA may modify this model without notice when necessary due to

product improvements, modifications, or changes in specifications. If

such modification is made, the manual number will also be revised.

• If your copy of the manual is damaged or lost, contact a YASKAWA representative to order a new copy. The representatives are listed on the

back cover. Be sure to tell the representative the manual number listed

on the front cover.

• YASK A WA is not responsible for incidents arising from unauthorized

modification of its products. Unauthorized modification voids your product’s warranty.

ii

Page 3

Notes for Safe Operation

WARNING

CAUTION

MANDATORY

PROHIBITED

NOTE

3/210

Read this manual carefully before installation, operation, maintenance, or inspection of the

NX100.

In this manual, the Notes for Safe Operation are classified as “WARNING,” “CAUTION,”

“MANDATORY,” or ”PROHIBITED.”

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury to personnel.

Indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury to personnel and damage to equipment. It may also be used to alert against unsafe

practices.

Always be sure to follow explicitly the items listed under this

heading.

Must never be performed.

Even items described as “CAUTION” may result in a serious accident in some situations. At

any rate, be sure to follow these important items.

To ensure safe and efficient operation at all times, be sure to follow all instructions, even if

not designated as “CAUTION” and “WARNING.”

iii

Page 4

WARNING

TURN

4/210

• Before operating the manipulator, check tha t servo power is turned OFF

when the emergency stop buttons on the front door of the NX100 and

programming pendant are pressed.

When the servo power is turned OFF, the SERVO ON LED on the programming pendant is turned OFF.

Injury or damage to machinery may result if the emergency stop circuit cannot stop the

manipulator during an emergency. The manipulator should not be used if the emergency

stop buttons do not function.

Emergency Stop Button

• Once the emergency stop button is released, clear the cell of all items

which could interfere with the operation of the manipulator. Then turn

the servo power ON.

Injury may result from unintentional or unexpected manipulator motion.

Release of Emergency Stop

• Observe the following precautions when performing teaching operations

within the P-point maximum envelope of the manipulator :

- View the manipulator from the front whenever possible.

- Always follow the predetermined oper ating procedure.

- Ensure that you have a safe place to retreat in case of emergency.

Improper or unintended manipulator operation may result in injury.

• Confirm that no persons are present in the P-point maximum envelope of

the manipulator and that you are in a safe location before:

- Turning ON the NX100 power

- Moving the manipulator with the programming pendant

- Running the system in the check mode

- Performing automatic operations

Injury may result if anyone enters the P-point maximum envelope of the manipulator during operation. Always press an emergency stop button immediately if there are problems.The emergency stop buttons are located on the right of the front door of the NX100

and the programming pendant.

iv

Page 5

• Perform the following inspection procedures prior to conducting manip-

CAUTION

5/210

ulator teaching. If problems are found, repair them immediately, and be

sure that all other necessary processing has been performed.

-Check for problems in manipulator movement.

-Check for damage to insulation and sheathing of external wires.

• Always return the programming pendant to the hook on the NX100 cabinet after use.

The programming pendant can be damaged if it is left in the P-point maximum envelope

of the manipulator, on the floor, or near fixtures.

• Read and understand the Explanation of Warning Labels in the NX100

Instructions before operating the manipulator.

Definition of Terms Used Often in Th is Manual

The MOTOMAN manipulator is the YASKAWA industrial robot product.

The manipulator usually consists of the controller, the programming pendant, and supply

cables.

In this manual, the equipment is designated as follows:

Equipment Manual Designation

NX100 Controller NX100

NX100 Programming Pendant Programming Pendant

v

Page 6

PAGE

GO BACK

6/210

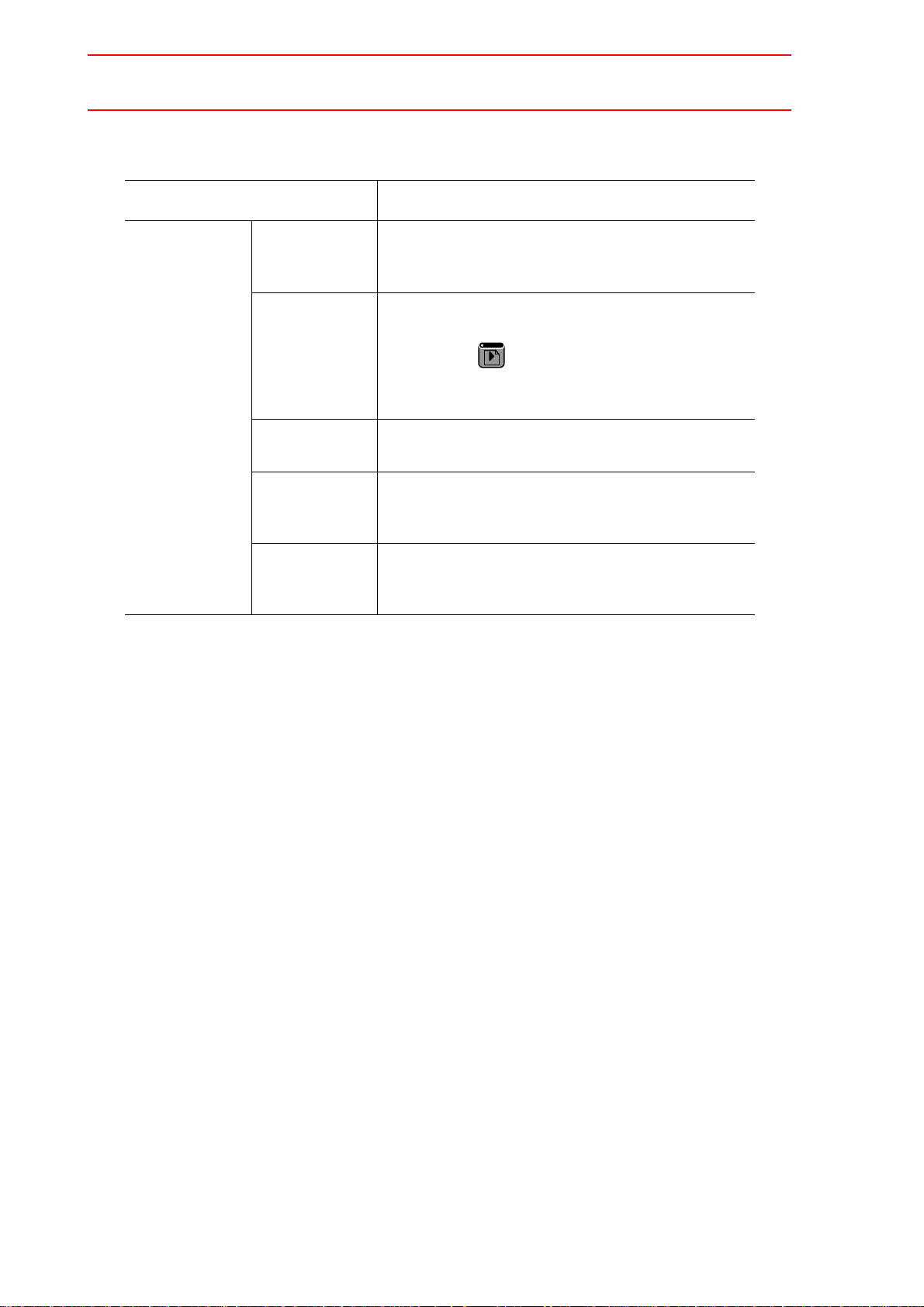

Descriptions of the programming pendant keys, buttons, and displays are shown as follows:

Equipment Manual Designation

Programming

Pendant

Character Keys The keys which have characters printed on them are

denoted with [ ].

ex. [ENTER]

Symbol Keys The keys which have a symbol printed on them are

not denoted with [ ] but depicted with a small picture.

ex. page key

The cursor key is an exception, and a picture is not

shown.

Axis Keys

Numeric Keys

Keys pressed

simultaneously

Displays The menu displayed in the programming pendant is

“Axis Keys” and “Numeric Keys” are generic names

for the keys for axis operation and number input.

When two keys are to be pressed simultaneously,

the keys are shown with a “+” sign between them,

ex. [SHIFT]+[COORD]

denoted with { }.

ex. {JOB}

Description of the Operation Procedure

In the explanation of the operation procedure, the expression "Select • • • " means that the

cursor is moved to the object item and the SELECT key is pressed, or that the item is directly

selected by touching the screen.

Registered Trademark

In this manual, names of companies, corporations, or products are trademarks, registered

trademarks, or brand names for each company or corporation. The indications of (R) and TM

are omitted.

vi

Page 7

1 Independent/Coordinated Control Function

7/210

1.1 Coordinated Control

1.2 Independent Control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

2 Coordinated Positioner System

2.1 Outline

2.2 Function Keys

2.2.1 Arc Welding Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.2 General Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.3 Example of Job Teaching

2.4 System Setup

2.4.1 Registering Group Combination . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.4.2 Calibration between Manipulator and Station . . . . . . . . . . . . .2-10

2.5 JOB CONTENT Window

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Calibration Tool Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Teaching Positions for Calibration. . . . . . . . . . . . . . . . . . . .2-11

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

. . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

. . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.6 Synchronized/Single

2.6.1 Synchronized. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

2.6.2 Single. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2.7 Selecting Axis to be Handled

2.7.1 When There is an Edit Job . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2.7.2 When There is No Edit Job . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2.8 Registering Job

2.9 Registering Move Instruction (S)MOV+MOVJ

2.9.1 Operating Master Side (Station) . . . . . . . . . . . . . . . . . . . . . . .2-22

2.9.2 Operating Slave Side (Manipulator) . . . . . . . . . . . . . . . . . . . .2-23

2.10 Registering Reference Point Instruction

(SREFP)

3 Jigless System

3.1 Outline

3.2 Specific Keys

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

. . . . . . . . . . . . . . . . . . . . . .2-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

. . . .2-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.3 Opening and Closing Handling Tool

3.4 Example of Teaching Job

3.5 System Setup

3.5.1 Registering Group Combination . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.5.2 Calibration between Manipulators . . . . . . . . . . . . . . . . . . . . . . .3-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

vii

. . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

. . . . . . . . . . . . . . . .3-4

Page 8

8/210

Calibration Tool Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Teaching Position for Calibration . . . . . . . . . . . . . . . . . . . . . 3-9

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.6 Job Content Display

3.7 Synchronized/Single

3.7.1 Synchronized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.7.2 Single . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.8 Selecting Axis to be Handled

3.8.1 When There is an Edit Job . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.8.2 When There is No Edit Job . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

3.9 Registering Job

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

. . . . . . . . . . . . . . . . . . . . . 3-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.10 Registering Move Instruction (S)MOV+MOV

3.10.1 Operating Master Side (Workpiece) . . . . . . . . . . . . . . . . . . . 3-18

3.10.2 Operating Slave Side (Torch) . . . . . . . . . . . . . . . . . . . . . . . . 3-19

3.11 Registering Reference Point Instruction

(SREFP)

3.12 Registering Handling Instructions

3.13 Other Convenient Features

3.13.1 Example of Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.13.2 Operation Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3.13.3 Manipulator Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Basic axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Wrist axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Synchronized/Single . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

. . . . . . . . . . . . . . . . 3-21

. . . . . . . . . . . . . . . . . . . . . . 3-22

.3-18

4 Twin Synchronous System

4.1 Outline

4.2 Function Keys

4.2.1 Arc Welding Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.2 General Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3 Job Configuration

4.4 Leader and Follower

4.5 Synchronizing with TSYNC

4.6 Job Example

4.7 JOB CONTENT Window

4.8 Synchronized/Single

4.8.1 Synchronized/Single Movement Between Station

4.8.2 Job Synchronized Mode for Subtask 1 and 2 . . . . . . . . . . . . . 4-15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

and Manipulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Synchronized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Single . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

. . . . . . . . . . . . . . . . . . . . . . . . . 4-8

. . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

viii

Page 9

9/210

4.9 Selecting Axis to be Handled

4.9.1 When There is an Edit Job . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.9.2 When There is No Edit Job . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

4.10 Registering Job

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

. . . . . . . . . . . . . . . . . . . . . .4-17

4.11 Registering Move Instruction (S)MOV+MOVJ

4.11.1 Operating Master Side (Station) . . . . . . . . . . . . . . . . . . . . . .4-19

4.11.2 Operating Slave Side (Manipulator) . . . . . . . . . . . . . . . . . . .4-20

4.12 Registering Reference Point Instruction

(SREFP)

4.13 Switching Tasks

4.14 Creating a Job in a Subtask - Method 1 and 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

. . . .4-23

4.15 Method 1: Copy One Subtask Job and

Create Another Job

4.15.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

4.15.2 Teaching and Mirror Shift . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Converting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Jobs Not to be Converted . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Group Axes for Conversion . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Position Type Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-27

4.15.3 Correcting Positional Dislocation . . . . . . . . . . . . . . . . . . . . .4-28

Setting the Items for Conversion . . . . . . . . . . . . . . . . . . . . .4-28

Setting the Shift Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

Executing Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

. .4-19

4.16 Method 2: Perform Teaching for

Each Manipulator

4.16.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

4.16.2 Teaching using Master Task . . . . . . . . . . . . . . . . . . . . . . . . .4-34

4.16.3 Teaching using SUPERVISORY Window. . . . . . . . . . . . . . .4-36

4.17 Job in Master Task

4.18 Confirming Operation

4.18.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

4.18.2 Precautions for Confirming Operation. . . . . . . . . . . . . . . . . .4-42

Stops during Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-42

When “Multi-job operation mode” is Set

in the TEACHING CONDITION Window . . . . . . . . . . . . . . .4-43

4.19 Playback

4.19.1 Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

4.19.2 Automatic Correction of Shift Value . . . . . . . . . . . . . . . . . . .4-45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

. . . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

ix

Page 10

10/210

5 Triple Synchronous System

5.1 Outline

5.2 Function Keys

5.2.1 Arc Welding Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.2.2 General Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 Job Configuration

5.4 Leader and Follower

5.5 Synchronizing with TSYNC

5.6 Job Example

5.7 JOB CONTENT Window

5.8 Synchronized/Single

5.8.1 Synchronized/Single Movement Between Station and

5.8.2 Job Synchronized Mode for Subtask 1, 2, and 3 . . . . . . . . . . 5-16

5.9 Selecting Axis to be Handled

5.9.1 When There is an Edit Job . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.9.2 When There is No Edit Job . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

. . . . . . . . . . . . . . . . . . . . . . . . . 5-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

. . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Manipulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Synchronized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Single . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

. . . . . . . . . . . . . . . . . . . . . 5-18

5.10 Registering Job

5.11 Registering Move Instruction (S)MOV+MOVJ

5.11.1 Operating Master Side (Station). . . . . . . . . . . . . . . . . . . . . . 5-20

5.11.2 Operating Slave Side (Manipulator) . . . . . . . . . . . . . . . . . . . 5-21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

. . 5-20

5.12 Registering Reference Point Instruction

(SREFP)

5.13 Changing Tasks

5.14 Creating a Job in a Subtask - Method 1 and 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

. . . . 5-23

5.15 Method 1: Copy One Subtask Job and

Create Other Two Jobs

5.15.1 Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.15.2 Teaching and Mirror Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Converting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Jobs Not to be Converted . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Group Axes for Conversion . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Position Type Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

5.15.3 Correcting Positional Dislocation . . . . . . . . . . . . . . . . . . . . . 5-29

Setting the Items for Conversion . . . . . . . . . . . . . . . . . . . . 5-29

Setting the Shift Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Executing Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-33

. . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

5.16 Method 2: Perform Teaching for

Each Manipulator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-34

x

Page 11

5.16.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-34

11/210

5.16.2 Teaching using Master Task . . . . . . . . . . . . . . . . . . . . . . . . .5-34

5.16.3 Teaching using SUPERVISORY Window. . . . . . . . . . . . . . .5-37

5.17 Job in Master Task

5.18 Confirming Operation

5.18.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-42

5.18.2 Precautions for Confirming Operation. . . . . . . . . . . . . . . . . .5-43

Stops during Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-43

When “Multi-job operation mode” is Set in the

TEACHING CONDITION Window. . . . . . . . . . . . . . . . . . . .5-44

5.19 Playback

5.19.1 Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

5.19.2 Automatic Correction of Shift Value . . . . . . . . . . . . . . . . . . .5-46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-45

6 Coordinated Control

6.1 Outline

6.2 Group Combination

6.3 Coordinated and Individual Interpolations

6.3.1 Coordinated Interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.3.2 Individual Interpolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.3 Changing Interpolation Mode . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-40

. . . . . . . . . . . . . . . . . . . . . . . . . . . .5-42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

. . . . . . . . . . .6-2

6.4 Restriction

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

7 Independent Control

7.1 Independent Control

7.2 Startup Method

7.2.1 Starting a Job always Fixed (Master Job) . . . . . . . . . . . . . . . . .7-3

7.2.2 Starting Various Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.3 Switching Task Window

7.4 Registering Instructions

7.4.1 PSTART Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

7.4.2 PWAIT Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

7.4.3 TSYNC Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

7.5 Registering Job

7.5.1 Robot Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

7.5.2 Concurrent Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

7.6 Job Examples

7.6.1 Non-Synchronous Operation . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

7.6.2 Synchronous Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

7.7 Confirming Operation

xi

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-18

Page 12

12/210

7.7.1 FWD/BWD Operation and Test Run . . . . . . . . . . . . . . . . . . . . 7-18

Confirming the Operation of the Task being Displayed . . . 7-18

Confirming the Operation of All Tasks . . . . . . . . . . . . . . . . 7-18

7.7.2 Switching Operating Method. . . . . . . . . . . . . . . . . . . . . . . . . . 7-18

Switching by [SHIFT]+[SMOV] . . . . . . . . . . . . . . . . . . . . . . 7-18

Switching on TEACHING CONDITION Window . . . . . . . . . 7-19

7.7.3 BWD Operation of Concurrent Job . . . . . . . . . . . . . . . . . . . . . 7-19

7.8 Playback

7.8.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

7.8.2 Registering Master Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Registering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Cancelling Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.8.3 Calling Master Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

When the Master Job in the Master Task is Called . . . . . . 7-24

When the Master Job in a Subtask 1/2/3 is Called . . . . . . . 7-25

7.8.4 Registration of Root (startup) Job. . . . . . . . . . . . . . . . . . . . . . 7-26

Registrering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-27

Cancelling Registration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

7.8.5 Confirming Operating Status (SUPERVISORY

Window) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

7.8.6 Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

Stopping and Restarting a Subtask Alone . . . . . . . . . . . . . 7-31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

8 Servo Power Supply Individual Control Function

8.1 Outline

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.2 Connection of Signals for Servo Power Supply

Individual Control

8.3 Confirming Connection

8.4 Application Examples

8.4.1 Turning ON Only the Servo Power Supply for

the Selected Control Group at Teaching . . . . . . . . . . . . . . . . . 8-4

8.4.2 Turning OFF Only the Servo Power Supply for

the Selected Control Group at Playback . . . . . . . . . . . . . . . . . 8-4

8.5 System Output Signals

8.5.1 Servo Power ON Status Signal for Each Control Group. . . . . . 8-6

8.5.2 “During Servo ON” Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.6 Operation of Job Without Control Group

Specification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

xii

Page 13

9 Robot Language (INFORM II) Instructions

13/210

9.1 Coordinated Motion Instructions

9.2 Independent Control Instructions

. . . . . . . . . . . . . . . . . . . .9-1

. . . . . . . . . . . . . . . . . . .9-5

10 CONVSFT Instruction ( Coordinate System

Conversion Instruction of the Shift Value)

10.1 Outline

10.2 CONVSFT Instruction

10.2.1 Explanation of CONVSFT . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Instructed Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Converted Shift Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Base Point Shift Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

Master Robot (Station) Position . . . . . . . . . . . . . . . . . . . . .10-3

Coordinate System to be Converted . . . . . . . . . . . . . . . . . .10-3

10.3 Example of Conversion

10.4 Alarm

4499 UNDEFINED POSITION VARIABLE . . . . . . . . . . . . .10-6

4495 UNDEFINED ROBOT CARIBRATION . . . . . . . . . . . .10-6

4500 UNDEFINED USER FRAME . . . . . . . . . . . . . . . . . . .10-6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

. . . . . . . . . . . . . . . . . . . . . . . . . .10-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

10.5 Supplementary Note

About the need to make parallel shift on the master tool

coordinate system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

xiii

Page 14

1.1 Coordinated Control

NOP

SMOVL

+MOVL

Job

14/210

1 Independent/Coordinated Control

Function

With the NX100, a system can be configured to control multiple manipulators or stations

simultaneously with a single controller.

With the independent / coordinated control function, manipulators and/or stations can be operated together or individually. Operation can be optimized for the jobs.

1.1 Coordinated Control

With this function, manipulators or stations execute jobs in a coordinated motion.

<Example>

Using two coordinated manipulators to execute a job.

1-1

Page 15

1.2 Independent Control

NOP

Job

(Work job)

NOP

SMOVL

+MOVJ

MOVJ

Job

(Home position return job)

15/210

1.2 Independent Control

With this function, manipulators and/or stations execute jobs independently without synchronization.

<Example>

While executing a work job at one station, the other station executes a job to return to the

home position for the next job.

1-2

Page 16

2.1 Outline

Manipulator

Station

Slave

MOVL

+MOVJ

SMOVL

+MOVJ

Master

16/210

2 Coordinated Positioner System

2.1 Outline

The coordinated positioner system is a system which coordinates a job where a positioner

(hereinafter called “station”) holds a workpiece while a manipulator holds a tool.

In order to operate a station and a manipulator simultaneously, a coordinated job is needed.

In the coordinated job, there are two operations: a coordinated interpolation where a station

and a manipulator perform a reciprocal movement as master and slave, and an individual

interpolation where a station and a manipulator move individually.

The move instruction in a coordinated job displays two lines: The first line is for the slave side

(manipulator), and the second line is for the master side (station).

2-1

Page 17

2.2 Function Keys

89

56

13

0-

REFP

CUR/VOL

RETRACT

FEED

CUR/VOL

ARCON

ARCOFF

TIMER

GAS

7

SYNCRO

SINGLE

4

SMOV

HOLDSTART

PLAY

TEACH

REMOTE

!?

2

.

1

TIMER

0

REFP

17/210

2.2 Function Keys

The function keys for the coordinated positioner system are assigned to the Numeric keys as

shown in the figures below.

2.2.1 Arc Welding Application

Registers a timer instruction “TIMER” in a job.

Registers a reference point “REFP” in a job, or modifies the registered reference point.

[REFP] + [FWD]

Moves the manipulator to the registered reference point.

2-2

Page 18

2.2 Function Keys

8

ARCON

5

ARCOFF

GAS

INTER

LOCK

+

5

ARCOFF

GAS

9

FEED

6

RETRACT

3

CUR/VOL

-

CUR/VOL

7

SYNCRO

SINGLE

4

SMOV

SUPPLE-

MENT

NO TE

18/210

Registers a welding start instruction “ARCON.”

Registers a welding end instruction “ARCOF.”

(These keys are for future use and disabled in the current version.)

Used for the gas flow control.

Pressing [INTERLOCK] + [GAS ARCOFF] once opens the gas valve for 20

seconds, and then the valve automatically closes.

Pressing [INTERLOCK] + [GAS ARCOFF] again within the 20 seconds,

the gas valve can be manually closed.

Used for wire inching. Press [FEED] to feed the wire, and press

[RETRACT] to retract the wire.

While these keys are pressed, the wire feed motor operates.

When the following are pressed simultaneously, wire inching is performed

in the high speed mode.

[HIGH SPEED] + [FEED]

[HIGH SPEED] + [RETRACT]

Modifies the welding current/voltage while welding during the play mode.

Press [3/CUR/VOL] to increase the current/voltage value, and press

[/CUR/VOL] to decrease the current/voltage value.

(Refer to “11.6 Changing Welding Conditions During Playback” in the

Operator’s Manual.)

Changes the type of movement for the manipulator when teaching a coordinated job. Each time this key is pressed, the movement type changes.

SYNCRO: The mark for “synchronized” appears in the status display area.

When the master side is moved, the slave side will follow the

movement of the master.

SINGLE: Only the selected group axis moves.

Selects either a coordinated or an individual interpolation when teaching a

coordinated job. Each time this key is pressed, the operation type

changes.

Coordinated: All the move instructions that are registered in this mode

become coordinated instructions.

Individual: The master-slave relationship is cancelled. Each manipulator

and station moves independently.

Wire retraction, high-speed inching, or high-speed retraction cannot be performed depending on the Power Source.

[7:SYNCRO/SINGLE] and [4: SMOV] keys are available only when "FUNCTION" setting

for each key is specified to "MAKER" in both KEY ALLOCATION(EACH) screen and KEY

ALLOCATION(SIM) screen.

2-3

Page 19

2.2.2 General Application

789

456

123

0.-

TOOLON

TOOLON

JOB

SYNCRO

SINGLE

SMOV

TOOLOF

TOOLOF

JOB

HOLDSTART

PLAY

TEACH

REMOTE

!?

2

TOOLON

.

TOOLOF

3

TOOLON

JOB

-

TOOLOF

JOB

19/210

2.2 Function Keys

Registers the TOOLON instruction.

If [INTERLOCK] is pressed simultaneously, the TOOLON operation is executed.

Registers the TOOLOF instruction.

If [INTERLOCK] is pressed simultaneously, the TOOLOFF operation is executed.

Registers the CALL instruction for the reserved job TOOLONxx.

Registers the CALL instruction for the reserved job TOOLOFxx.

2-4

Page 20

2.2 Function Keys

7

SYNCRO

SINGLE

4

SMOV

NO TE

20/210

[7:SYNCRO/SINGLE] and [4: SMOV] keys are available only when "FUNCTION" setting

for each key is specified to "MAKER" in both KEY ALLOCATION(EACH) screen and KEY

ALLOCATION(SIM) screen.

Changes the type of movement for the manipulator when teaching a coordinated job. Each time this key is pressed, the movement type changes.

SYNCRO: The mark for “synchronized” appears in the status display area.

When the master side is moved, the slave side will follow the

movement of the master.

SINGLE: Only the selected group axis moves.

Selects either a coordinated or an individual interpolation when teaching a

coordinated job. Each time this key is pressed, the operation type changes.

Coordinated: All the move instructions that are registered in this mode

become coordinated instructions.

Individual: The master-slave relationship is cancelled. Each manipulator and

station moves independently.

2-5

Page 21

2.3 Example of Job Teaching

Stand-by

Starting

Ending

Separate from the workpiece

Step Instruction

001 MOVJ VJ=50.00

+MOVJ

002 SMOVL V=200

+MOVJ

SWVON WEV#(1)

ARCON ASF#(1)

003 SMOVL V=200

+MOVJ

004 SMOVL V=200

+MOVJ

005 SMOVL V=200

+MOVJ

ARCOF AEF#(1)

SWVOF

006 MOVJ VJ=50.00

+MOVJ

007 MOVJ VJ=50.00

+MOVJ

The torch moves to the cleaner. The workpiece is unloaded.

Coordinated operation

21/210

2.3 Example of Job Teaching

2-6

Page 22

2.4 System Setup

EDIT

DISPLAY UTILITY

DATA

Short Cut

Main Menu

GROUP COMBINATION

GROUP AXIS MASTER

R1

S1

ADD GROUP

MODIFY GROUP

DELETE GROUP

EDIT

DISPLAY UTILITYDATA

Short Cut

Main Menu

GROUP COMBINATION

GROUP AXIS MASTER

22/210

2.4 System Setup

2.4.1 Registering Group Combination

Register a combination of a station and a manipulator.

Operation Explanation

1 Select {SETUP} under the

main menu.

2 Select {GRP COMBINATION}. The GROUP COMBINATION window appears.

3 Press [SELECT]. The selection dialog box appears.

2-7

Page 23

Operation Explanation

GROUP COMBI SET

NO.1 CONTROL GROUP

NO.2 CONTROL GROUP

MASTER

CANCEL

EXECUTE

EDIT

DISPLAY UTILITY

DATA

Short Cut

Main Menu

GROUP COMBI SET

NO.1 CONTROL GROUP

NO.2 CONTROL GROUP

MASTER

R1: ROBOT1

S1: STATION1

CANCELEXECUTE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

R1

S1

S1

GROUP COMBI SET

NO.1 CONTROL GROUP

NO.2 CONTROL GROUP

MASTER

CANCELEXECUTE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

23/210

4 Select “ADD GROUP.” The GROUP COMBI SET window appears.

5 Press [SELECT]. The selection dialog box appears.

2.4 System Setup

6 Select a group axis to be set. Set a station as “MASTER.”

2-8

Page 24

2.4 System Setup

GROUP COMBINATION

GROUP AXIS MASTER

R1

S1

R1+R2 R2

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

24/210

Operation Explanation

7 Select “EXECUTE.” The GROUP COMBINATION window reappears.

2-9

Page 25

2.4 System Setup

TOOL

TOOL NO. : 0 / 1

NAME

X

Y

Z

W

Xg

Yg

Zg

0.000

0.000

0.000

STANDARD TOOL

mm

mm

mm

0.000 kg

0.000

0.000

0.000

mm

mm

mm

Rx

Ry

Rz

Ix

Iy

Iz

0.000

0.000

deg.

deg.

deg.

0.000

0.000

0.000

kg m2

0.000

kg m2

kg m2

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

25/210

2.4.2 Calibration between Manipulator and Station

For a coordinated motion between a manipulator and a station, prior registration of the settings for mutual positioning is required. This relationship is set by calibration between the

manipulator and the station.

Calibration Tool Setting

Operation Explanation

1 Mount a tool for calibration on

Use a tool whose exact dimensions are known.

the manipulator.

2 Select {ROBOT} under the

main menu.

3 Select {TOOL}. The TOOL window appears.

4 Enter the tool dimensions.

5 Press [ENTER].

2-10

Page 26

2.4 System Setup

C1

Point P

C2

Turn

C3

Turn

NOTE

26/210

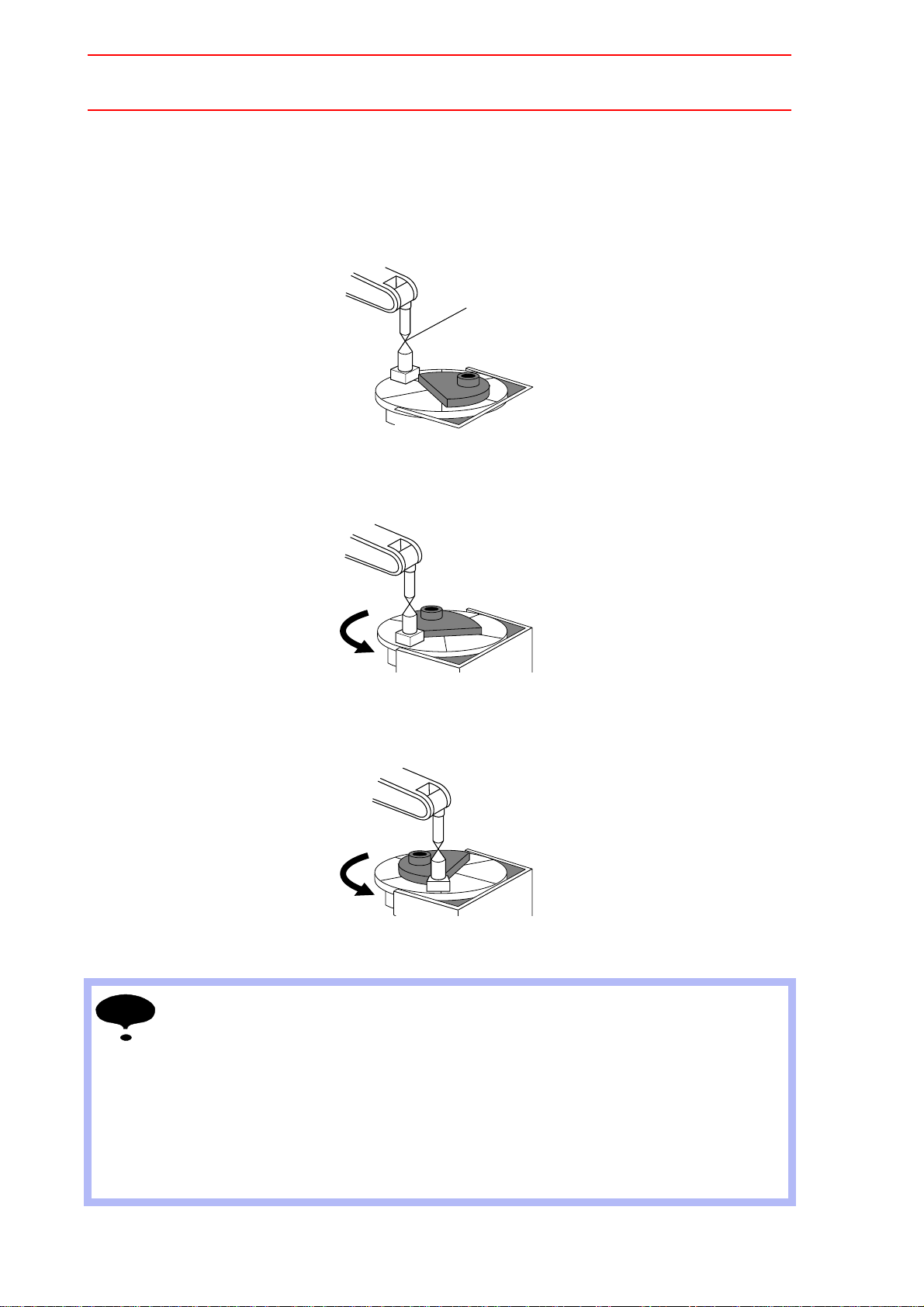

Teaching Positions for Calibration

For a station with one rotating axis

1. Determine an arbitrary point (point P) on the turntable of the station axis. Point P

should be as far as possible from the turntable rotation center. Align the TCP of the

manipulator with point P, and register it as C1.

2. Turn the station axis. The amount of turning is not limited but should be 30or more. It

does not matter if the rotational direction is positive or negative. Then, align the TCP of

the manipulator to point P, and register it as C2.

3. Turn the station axis further in the same direction as in step 2. Then, align the TCP of

the manipulator to point P, and register it as C3.

• To minimize teaching error, attach a tool with a pointed end tool on the station axis as

shown in the figure above, and use this pointed end as an arbitrary point (point P) when

teaching.

• When registering C2 and C3, the manipulator tool should keep as much as possible the

same orientation as when C1 was registered.

• The manipulator at teaching should have its L-axis at a 90 angle to the ground and its Uaxis parallel to the ground.

• Do not teach with the L-axis and U-axis fully extended or tightly contracted. Otherwise,

inaccurate calibration will result.

2-11

Page 27

2.4 System Setup

C1

Point P

C2

Turn

C3

Turn

C4

Turn

27/210

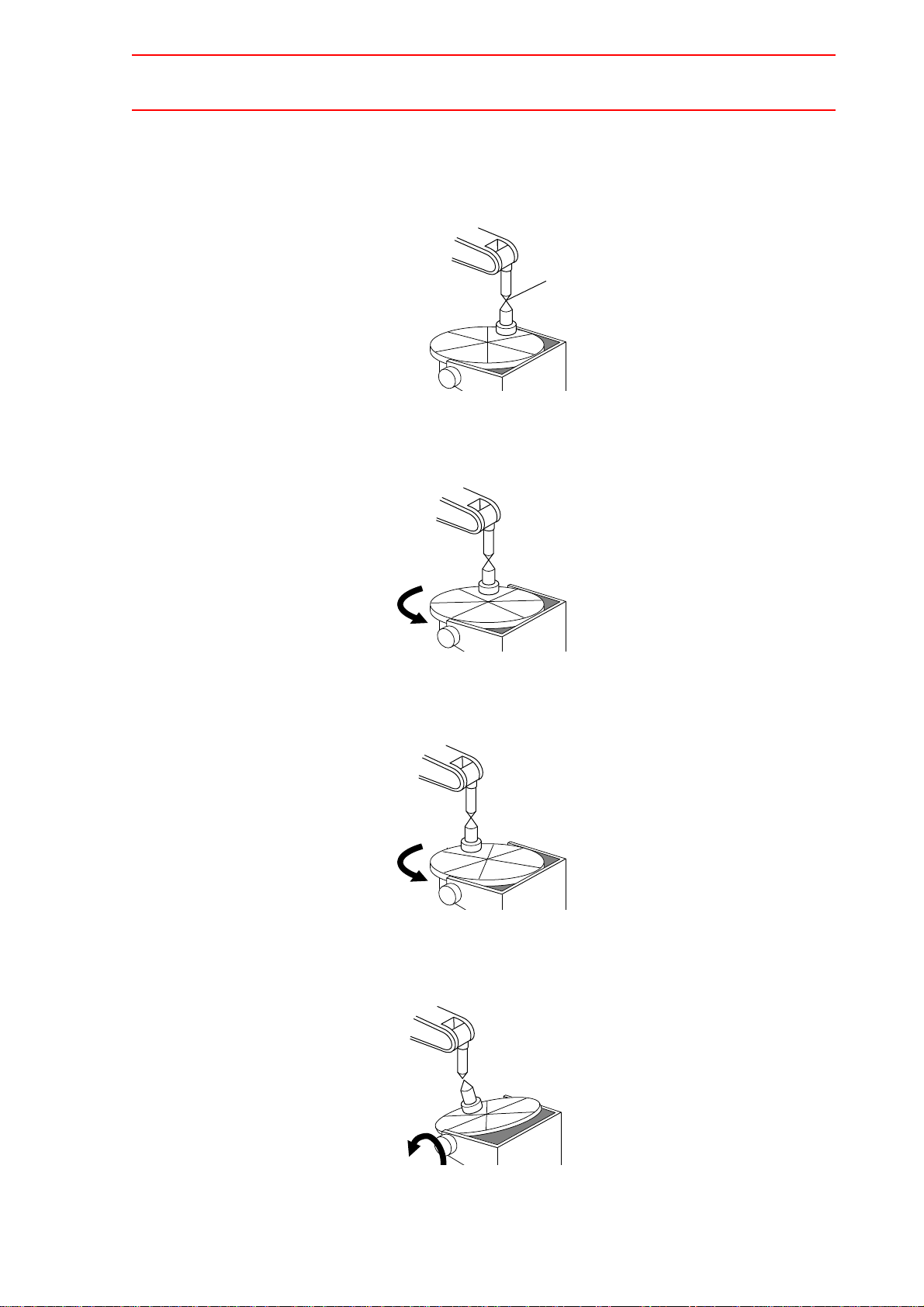

For a station with two rotating axes

1. Determine an arbitrary point (point P) on the turntable. Point P should be as far as

possible from the rotation center of the turntable. With the 1st station axis parallel to

the ground, align the TCP of the manipulator to point P, and register it as C1.

2. Turn the 2nd station axis about 30. Align the TCP of the manipulator to point P, and

register it as C2.

3. Turn the 2nd station axis again for about 30. Align the TCP of the manipulator to point

P, and register it as C3.

4. Turn the 1st station axis about 30. Align the TCP of the manipulator to point P, and

register it as C4.

2-12

Page 28

2.4 System Setup

C5

Turn

NOTE

28/210

5. Turn the 1st station axis again for about 30. Align the TCP of the manipulator to point

P, and register it as C5.

• To minimize teaching error, attach a tool with a pointed end tool on the station axis as

shown in the figure above, and use this pointed end as an arbitrary point (point P) when

teaching.

• When registering C2 to C5, the manipulator tool should keep as much as possible the

same orientation as when C1 was registered.

• The manipulator at teaching should have its L-axis at a 90 angle to the ground and its Uaxis parallel to the ground.

• Do not teach with the L-axis and U-axis fully extended or tightly contracted. Otherwise,

inaccurate calibration will result.

• For C1, C2, and C3, the position of the 1st station axis must be the same.

• The position of the 2nd station axis for C4 and C5 must be the same as that for C3.

2-13

Page 29

Calibration

ROBOT CALIBRATION

NO. SET ROBOT

01

02

03

04

05

06

07

08

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

ROBOT CALIBRATION

NO. :01 ROBOT

C1:

C2:

C3:

POSITION

C1

<STATUS>

CANCELCOMPLETE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

ROBOT CALIBRAION

NO. :01 ROBOT

C1:

C2:

C3:

POSITION

C1

<STATUS>

R1+S1

CANCELCOMPLETE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

29/210

Operation Explanation

1 Select {ROBOT} under the

main menu.

2 Select {ROBOT CALIB}. The ROBOT CALIBRATION list window appears.

2.4 System Setup

3 Select a robot calibration No. The ROBOT CALIBRATION window for teaching appears.

4 Select “ROBOT.” The selection dialog box appears.

2-14

Page 30

2.4 System Setup

ROBOT CALIBRATION

NO. :01 ROBOT

C1:

C2:

C3:

POSITION

C1

<STATUS>

R1:S

L

U

R

B

T

R1+S1

TOOL:00

CANCELCOMPLETE PAGE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

C1:

C2:

C3:

C1

R1:S

L

U

R

B

T

R1+S1

C1

C2

C3

ROBOT CALIBRATION

NO. :01 ROBOT

POSITION

<STATUS>

TOOL:00

CANCELCOMPLETE PAGE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

PAGE

GO BACK

C1:

C2:

C3:

C1

R1:S

L

U

R

B

T

R1+S1

12345

1025

10230

1010

521

2340

ROBOT CALIBRATION

NO. :01 ROBOT

POSITION

<STATUS>

TOOL:00

CANCELCOMPLETE PAGE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

30/210

Operation Explanation

5 Select a group axis combina-

The teaching positions are displayed.

tion for calibration.

6 Select “POSITION.” The selection dialog box appears.

7 Press the axis key to move the

manipulator to the desired

position.

8 Press [MODIFY] and

[ENTER].

The positions for calibration are registered.

Repeat Operations 7 and 8 to teach set positions C1 to C3.

On the window, “” indicates that the teaching is completed while

“” indicates that the teaching is not completed.

The calibration positions appear according to the selected group

axis. Press the page key to change the window.

2-15

Page 31

2.4 System Setup

01

02

03

04

05

06

07

08

ROBOT CALIBRATION

NO. SET ROBOT

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

31/210

Operation Explanation

9 Select “COMPLETE.” The robots are calibrated. When the calibration is completed, the

ROBOT CALIBRATION list window reappears.

2-16

Page 32

2.5 JOB CONTENT Window

JOB CONTENT

JOB NAME: TEST

CONTROL GROUP: R1+S1:S1

STEP NO.: 002

TOOL: 00

0001

0002

0003

SMOVL V=138

+MOVJ

MOVL V=138

+MOVJ VJ=3.12

END

SMOVL V=138

+MOVJ

Instructions

Synchronized/Single

Group axis being handled

Coordinated interpolation/

Independent interpolation

EDIT

DISPLAY

UTILITY

JOB

Short Cut

Main Menu

32/210

2.5 JOB CONTENT Window

An example of the contents of a coordinated job is shown below.

Instructions

For a coordinated job, the move instruction is displayed in two lines: The first line is the

instruction to the slave side; the second line is the instruction to the master side.

SMOVL V=138 Slave, a manipulator

+MOVJ Master, a station

Synchronized/Single

Synchronized/single are the types of movement available for the manipulator during axis

operation. This mark appears when synchronized movement is selected.

Switch between movements by pressing [SYNCRO/SINGLE].

Group axis being handled

Displays the group axis being handled.

Pressing [ROBOT] selects the manipulator.

Pressing [EX. AXIS] selects the station.

Coordinated interpolation/Individual interpolation

Switch between coordinated interpolation and individual interpolation by pressing [SMOV].

2-17

Page 33

2.6 Synchronized/Single

UTILITY

UTILITY

When "Single" is selected, nothing appears here.

33/210

2.6 Synchronized/Single

There are two ways to handle axes when teaching: “Synchronized” and “Single.”

Switch between movements by pressing [SYNCRO/SINGLE].

2.6.1 Synchronized

If the axes are handled in the “Synchronized” mode, the slave (manipulator) follows the master (station) when the master moves. This feature is used to keep the position of the manipulator relative to the station.

However, the master does not move when the slave is moved.

• A master axis is moved:

2-18

Page 34

2.6 Synchronized/Single

NOTE

34/210

2.6.2 Single

If an axis is handled in “Single” mode, the manipulator or the station whose axis has been

handled, moves.

This feature is used where a manipulator and a station each execute an individual job.

• A slave axis is moved:

• A master axis is moved:

• The selected mode, Synchronized or Single, is maintained until the next selection is

made.

• When an edit job is changed, “Single” is automatically selected.

2-19

Page 35

2.7 Selecting Axis to be Handled

35/210

2.7 Se le ct ing Ax is to be Ha nd led

In a coordinated system with multiple numbers of group axes, select a group axis to be handled in the following manner.

2.7.1 When There is an Edit Job

When the edit job is displayed, the group axes registered in the displayed job is the one to be

handled.

Pressing [ROBOT] selects a manipulator for axis handling.

Pressing [EX. AXIS] selects a station for axis handling.

2.7.2 When There is No Edit Job

When there is no edit job, move a manipulator in the following manner.

1. Press [SHIFT]+[ROBOT] to change the manipulator for axis handling. The LED of

[ROBOT] flashes.

Press [SHIFT]+[EX. AXIS] to change the station for axis handling. The LED of [EX.

AXIS] flashes.

2. Select the group axes to be moved, and then move it by pressing the axis key.

3. Press [ROBOT] or [EX. AXIS] to return to the original window.

2-20

Page 36

2.8 Registering Job

NEW JOB CREATE

JOB NAME

COMM.

GROUP SET R1

CANCELEXECUTE

EDIT

DISPLAY

UTILITY

JOB

Short Cut

Main Menu

36/210

2.8 Registering Job

Operation Explanation

1 Select {JOB} under the main

menu.

2 Select {CREATE NEW JOB}. The NEW JOB CREATE window appears.

3 Enter a job name. Select “JOB NAME,” and then enter a job name by entering the

characters. Refer to “1.2.7 Character Input” of the Operator’s

Manual.

4 Press [ENTER].

5 Select “GROUP SET.”

6 Select a group combination.

7 Select “EXECUTE.” The job name is registered in the memory of NX100, and the JOB

CONTENT window appears.

2-21

Page 37

2.9 Registering Move Instruction (S)MOV+MOVJ

UTILITY

UTILITY

UTILITY

When "Single" is selected, nothing appears here.

37/210

2.9 Registering Move Instruction (S)MOV+MOVJ

Register a move instruction in the following manner.

2.9.1 Operating Master Side (Station)

Operation Explanation

1 Call the JOB CONTENT win-

dow in teach mode.

2 Press [EX. AXIS]. The master side (station) is selected for axis handling.

3 Select either “synchronized” or

“single.”

4 Press the axis key to move to

the desired position.

Press [SYNCRO/SINGLE] to select either “synchronized” or “single.”

When “synchronized” is selected, the mark in the window below

appears.

When the slave side is supposed to follow the master side

motion, select “synchronized.”

2-22

Page 38

2.9 Registering Move Instruction (S)MOV+MOVJ

Short CutMain Menu

SMOVL V=138

+MOVJ

SMOVC V=138

+MOVJ

Short CutMain Menu

0003 SMOVC V=138

+MOVJ

NOTE

38/210

2.9.2 Operating Slave Side (Manipulator)

Operation Explanation

1 Press [EX. AXIS]. The slave side (manipulator) is selected for axis handling.

2 Press the axis key to move to

the desired position.

3 Select either a coordinated

Press [SMOV] to select either interpolation.

interpolation or an independent interpolation.

4 Select an interpolation type. Press [MOTION TYPE] to select an interpolation type.

5 Confirm the speed.

6 Press [ENTER]. The registration is completed as follows.

• When joint interpolation is set for the slave side (manipulator), teaching cannot be done

during a coordinated operation.

• When “JOINT” is selected, the interpolation type will not change to a coordinated interpolation, even if [SMOV] is pressed.

• When “JOINT” is selected during coordinated interpolation, a coordinated move instruction such as “SMOVL” in the input buffer line changes to “MOVJ,” and the interpolation

type becomes individual interpolation.

Parameter Contents and Set Value

S2C164 Specifies whether the speed inputting for move instructions of the

master side robot in a coordinated job is permitted or not.

<Example> 0: Not Provided 1: Provided

SMOVL

+MOVJ Master

V=100 SMOVL V=100

+MOVJ VJ=10.00

side

Speed specification not

provided

Master

side

Speed specification

provided

Initial

Value

0

2-23

Page 39

2.10 Registering Reference Point Instruction (SREFP)

0003

0004

0005

0006

0007

SMOVL V=558

+MOVJ

CALL JOB: TEST

SMOVL V=138

+MOVJ

Immediately before

the line where the

reference point

instruction is to

be registered

SREFP 1

SREFP 2

Ref-point_no.=

SREFP

0003

0004

0005

0006

0007

0008

SMOVL V=558

+MOVJ

CALL JOB:TEST

SREFP 1

SMOVL V=138

+MOVJ

The reference point

instruction is registered.

39/210

2.10 Registering Reference Point Instruction (SREFP)

Register a reference point instruction (SPEFP) for a coordinated interpolation in the following

manner.

Operation Explanation

1 Select {JOB} under the main

menu.

2 Select {JOB}.

3 Move the cursor. Move the cursor to the line immediately before the line where the

reference point instruction is to be registered.

4 Grasp the Enable switch.

5 Press the axis key. Turn ON the servo power with the Enable switch. Move the

manipulator to the position which will be a reference point.

6 Select the coordinated interpo-

Press [SMOV] to select a coordinated operation.

lation.

7 Press [REF PNT]. The reference point instruction appears in the input buffer line.

8 Change the reference point

number.

Move the cursor to the reference point number,

[SHIFT] +

the cursor key

to change the reference point number.

and press

If you use the Numeric keys to change the reference point number, press [SELECT] when the cursor is on the reference point

number. Input the number and press [ENTER].

9 Press [INSERT]. The [INSERT] key lamp lights up.

When registering immediately before the END instruction, pressing [INSERT] is not needed.

10 Press [ENTER]. The REFP instruction is registered.

2-24

Page 40

3.1 Outline

To NX100

Coordinated operation

Individual operation

Slave

MOVL

+MOVL

SMOVL

+MOVL

Master

40/210

3 Jigless System

3.1 Outline

A jigless system is a system that welds by coordinating two manipulators; one holding the

workpiece while the other holds the torch.

To coordinate the movements of the two manipulators, a coordinated job is needed.

In a coordinated job, there is a coordinated operation where two manipulators, master and

slave, perform a reciprocal movement, and an individual operation where each of the two

manipulators performs an independent movement.

A move instruction in coordinated jobs displays two lines. The first line is for the slave side

(torch); the second line is for the master side (workpiece).

3-1

Page 41

3.2 Specific Keys

1

TIMER

0

REFP

8

ARCON

41/210

3.2 Specific Keys

The specific keys for the jigless system are allocated to the number keys as shown in the figure below.

Registers a timer instruction “TIMER” in a job.

Registers a reference point “REFP” in a job, or modifies the registered reference point.

[REFP] + [FWD]

Moves the manipulator to the registered reference point.

Registers a welding start instruction “ARCON” in a job.

3-2

Page 42

3.2 Specific Keys

5

ARCOFF

GAS

INTER

LOCK

+

5

ARCOFF

GAS

9

FEED

6

RETRACT

7

SYNCRO

SINGLE

4

SMOV

SUPPLE-

MENT

NO TE

42/210

Registers a welding end instruction “ARCOF” in a job.

(These keys are for future use and disabled in the current version.)

Used for the gas flow control.

Pressing [INTERLOCK] + [GAS ARCOFF] once opens the gas valve for 20

seconds, and then the valve automatically closes.

Pressing [INTERLOCK] + [GAS ARCOFF] again within the 20 seconds,

the gas valve can be manually closed.

Used for wire inching. Press [FEED] to feed the wire, and press

[RETRACT] to retract the wire.

While these keys are pressed, the wire feed motor operates.

When the following are pressed simultaneously, wire inching is performed

in the high speed mode.

[HIGH SPEED] + [FEED]

[HIGH SPEED] + [RETRACT]

Changes the type of movement for the manipulator when teaching a coordinated job. Each time this key is pressed, the movement type changes.

SYNCRO: The mark for “synchronized” appears in the status display area.

When the master side is moved, the slave side will follow the

movement of the master.

SINGLE: Only the selected group axis moves.

Selects either a coordinated or an individual interpolation when teaching a

coordinated job. Each time this key is pressed, the operation type

changes.

Coordinated: All the move instructions that are registered in this mode

become coordinated instructions.

Individual: The master-slave relationship is cancelled. Each manipulator

and station moves independently.

Wire retraction, high-speed inching, or high-speed retraction cannot be performed depending on the Power Source.

[7:SYNCRO/SINGLE] and [4: SMOV] keys are available only when "FUNCTION" setting

for each key is specified to "MAKER" in both KEY ALLOCATION(EACH) screen and KEY

ALLOCATION(SIM) screen.

3-3

Page 43

3.3 Opening and Closing Handling Tool

NOTE

INTER

LOCK

+

2

TOOLON

INTER

LOCK

+

.

TOOLOF

INTER

LOCK

+

3

TOOLON

JOB

INTER

LOCK

+

-

TOOLOF

JOB

43/210

3.3 Opening and Closing Handling Tool

This section explains how to open and close a handling tool by teaching. It is unrelated to the

content of the job being taught. To close and open a handling tool by pressing the specific

keys, the general output signals #17 to 20 are used.

The general output signal No. can be changed by the parameter A1P.

A1P026 Tool1 ON general output No. (Initial value: 17)

A1P027 Tool1 OFF general output No. (Initial value: 18)

A1P028 Tool 2 ON general output No. (Initial value: 19)

A1P029 Tool 2 OFF general output No. (Initial value: 20)

Sends an open instruction to Tool 1.

Only while the keys are pressed, general output signal #17 is ON.

Sends a close instruction to Tool 1.

Only while the keys are pressed, general output signal #18 is ON.

Sends an open instruction to Tool 2.

Only while the keys are pressed, general output signal #19 is ON.

Sends a close instruction to Tool 2.

Only while the keys are pressed, general output signal #20 is ON.

3-4

Page 44

3.4 Example of Teaching Job

Stand-by

Starting

During an operation

The torch moves to the cleaner. The workpiece is uncloaded.

Ending

Separate from the workpiece

Step Instruction

001 MOVJ VJ=50.00

+MOVJ

002 SMOVL V=200

+MOVL

SWVON WEV#(1)

ARCON ASF#(1)

003 SMOVL V=200

+MOVL

004 SMOVL V=200

+MOVL

ARCOF AEF#(1)

SWVOF

005 MOVJ VJ=50.00

+MOVJ

006 MOVJ VJ=50.00

+MOVJ

Coordinated operation

44/210

3.4 Example of Teaching Job

3-5

Page 45

3.5 System Setup

EDIT

DISPLAY UTILITY

DATA

Short Cut

Main Menu

GROUP COMBINATION

GROUP AXIS MASTER

R1

R2

ADD GROUP

MODIFY GROUP

DELETE GROUP

EDIT

DISPLAY UTILITYDATA

GROUP COMBINATION

GROUP AXIS MASTER

GROUP COMBI SET

NO.1 CONTROL GROUP

NO.2 CONTROL GROUP

MASTER

CANCEL

EXECUTE

EDIT

DISPLAY UTILITY

DATA

Short Cut

Main Menu

45/210

3.5.1 Registering Group Combination

Register a combination of two manipulators.

Operation Explanation

1 Select {SETUP} under the

main menu.

2 Select {GRP COMBINATION}. The GROUP COMBINATION window appears.

3.5 System Setup

3 Press [SELECT]. The selection dialog box appears.

4 Select “ADD GROUP.” The GROUP COMBI SET window appears.

3-6

Page 46

3.5 System Setup

GROUP COMBI SET

NO.1 CONTROL GROUP

NO.2 CONTROL GROUP

MASTER

R1: ROBOT1

R2: ROBOT2

CANCELEXECUTE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

R1

R2

R1

GROUP COMBI SET

NO.1 CONTROL GROUP

NO.2 CONTROL GROUP

MASTER

CANCELEXECUTE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

GROUP COMBINATION

GROUP AXIS MASTER

R1

S1

R1+R2 R2

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

46/210

Operation Explanation

5 Press [SELECT]. The selection dialog box appears.

6 Select a group axis to be set. Set R2: ROBOT2 as “MASTER.”

7 Select “EXECUTE.” The GROUP COMBINATION window reappears.

3-7

Page 47

3.5 System Setup

Tool for calibration

TOOL

TOOL NO. : 0 / 1

NAME

X

Y

Z

W

Xg

Yg

Zg

0.000

0.000

0.000

STANDARD TOOL

mm

mm

mm

0.000 kg

0.000

0.000

0.000

mm

mm

mm

Rx

Ry

Rz

Ix

Iy

Iz

0.000

0.000

deg.

deg.

deg.

0.000

0.000

0.000

kg m2

0.000

kg m2

kg m2

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

47/210

3.5.2 Calibration between Manipulators

For a coordinated operation between manipulators, prior registration of the settings for mutual

positioning is required. This relationship is set by calibration between manipulators.

Calibration Tool Setting

Operation Explanation

1 Mount a tool for calibration on

Use a tool whose exact dimensions are known.

the manipulator.

2 Select {ROBOT} under the

main menu.

3 Select {TOOL}. The TOOL window appears.

4 Enter the tool dimensions.

5 Press [ENTER].

3-8

Page 48

3.5 System Setup

C1

C2

C3

NOTE

48/210

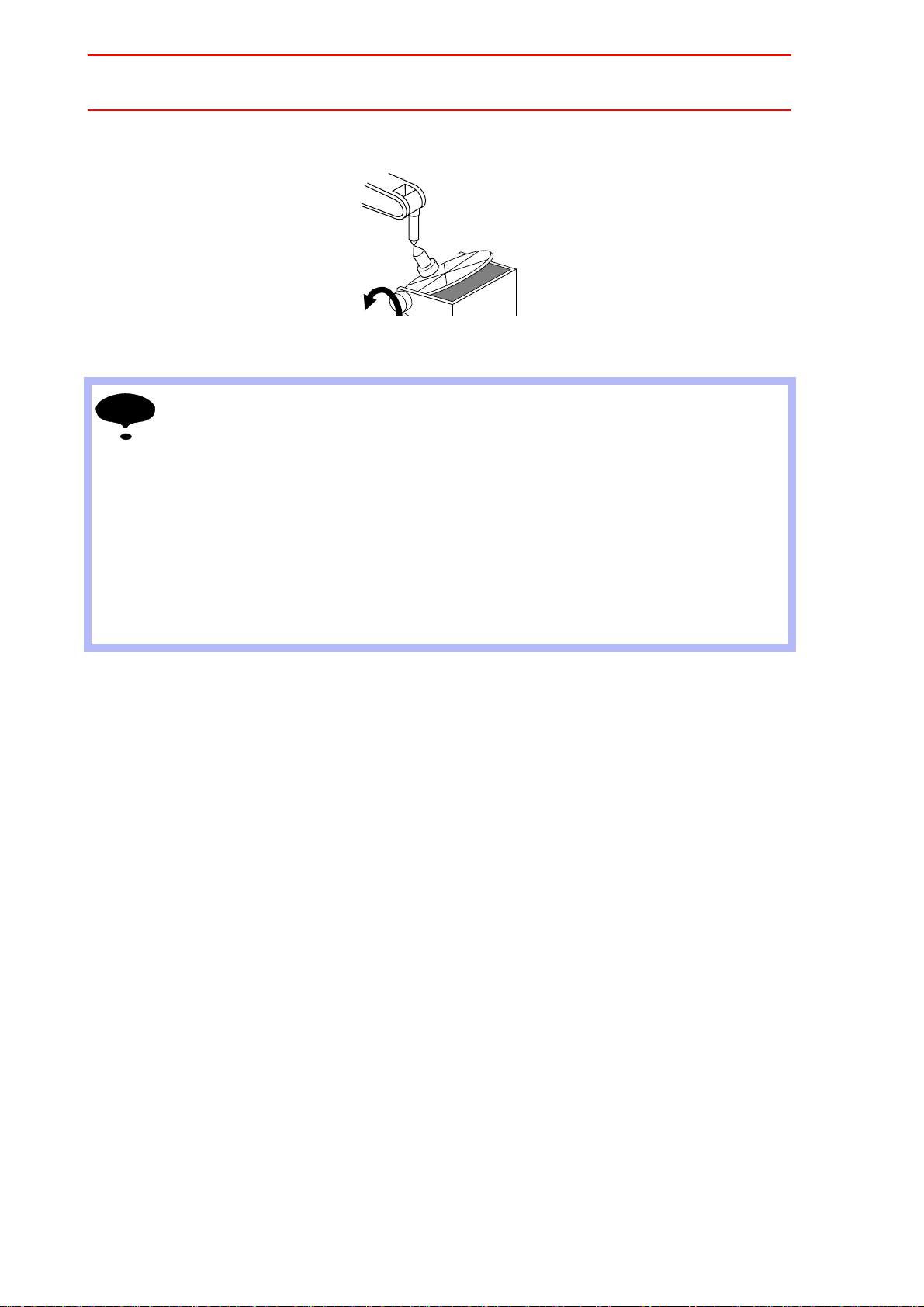

Teaching Position for Calibration

Calibrate the control point for two manipulators at three arbitrary points (C1 to C3) in the

space between the manipulators.

1. Move a manipulator to an arbitrary position. Align the tool center point of the other

manipulator or to the tool center point of the first manipulator by handling the axis.

Register it as C1.

2. Register C2 and C3 in the same manner as C1.

• When registering C2 and C3, the manipulator tool should keep as much as possible the

same orientation as when C1 was registered.

• The standard distance between C-1and C-2, C2 and C3, and C3 and C1 should be 1 m or

more.

• Teach C1, C2, and C3 so that a triangle, not a straight line, is formed.

• Do not teach with the LU axis fully extended or tightly contracted. Otherwise, inaccurate

calibration will result.

3-9

Page 49

Calibration

ROBOT CALIBRATION

NO. SET ROBOT

01

02

03

04

05

06

07

08

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

ROBOT CALIBRATION

NO. :01 ROBOT

C1:

C2:

C3:

POSITION

C1

<STATUS>

CANCELCOMPLETE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

ROBOT CALIBRAION

NO. :01 ROBOT

C1:

C2:

C3:

POSITION

C1

<STATUS>

R1+R2

CANCELCOMPLETE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

49/210

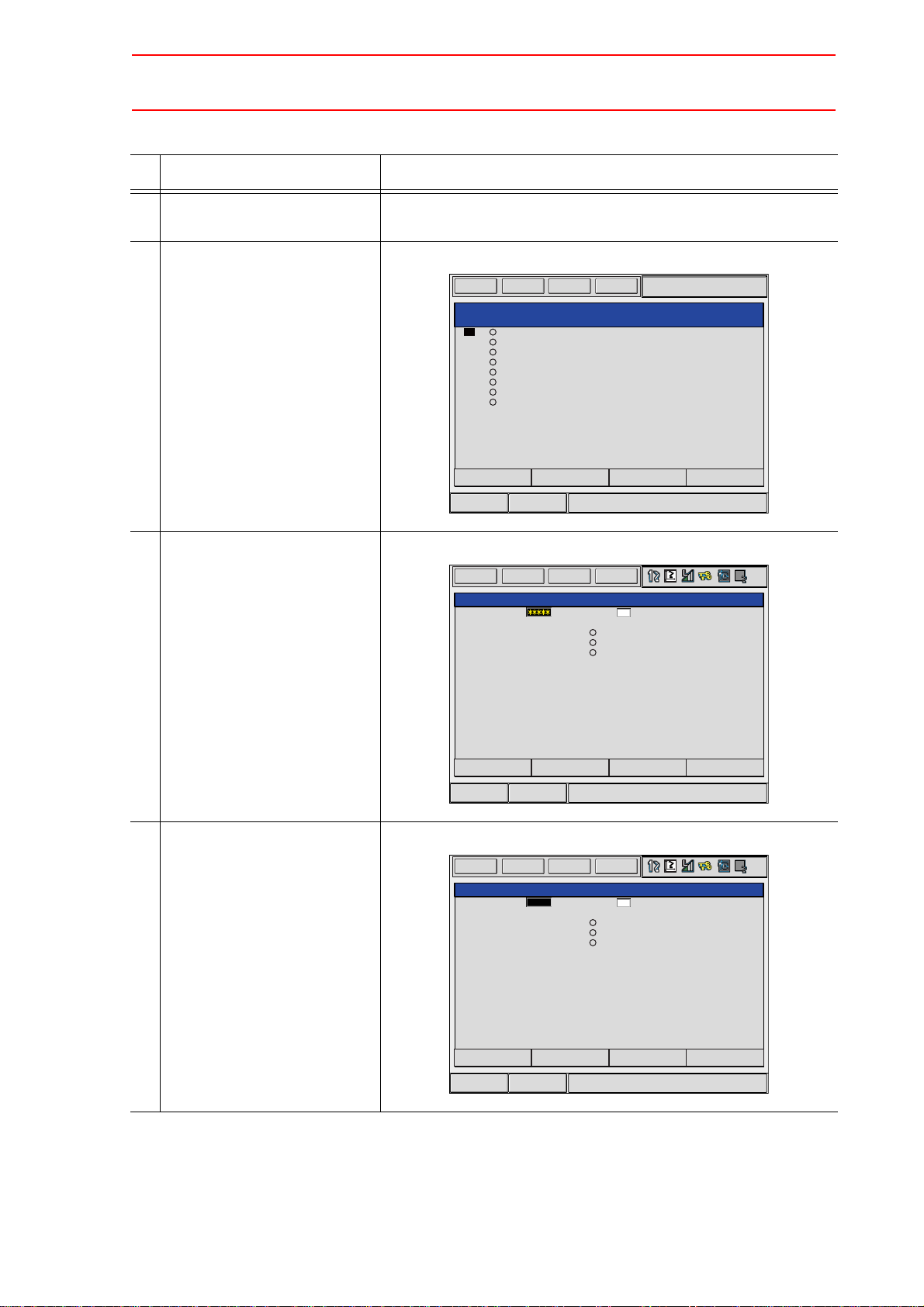

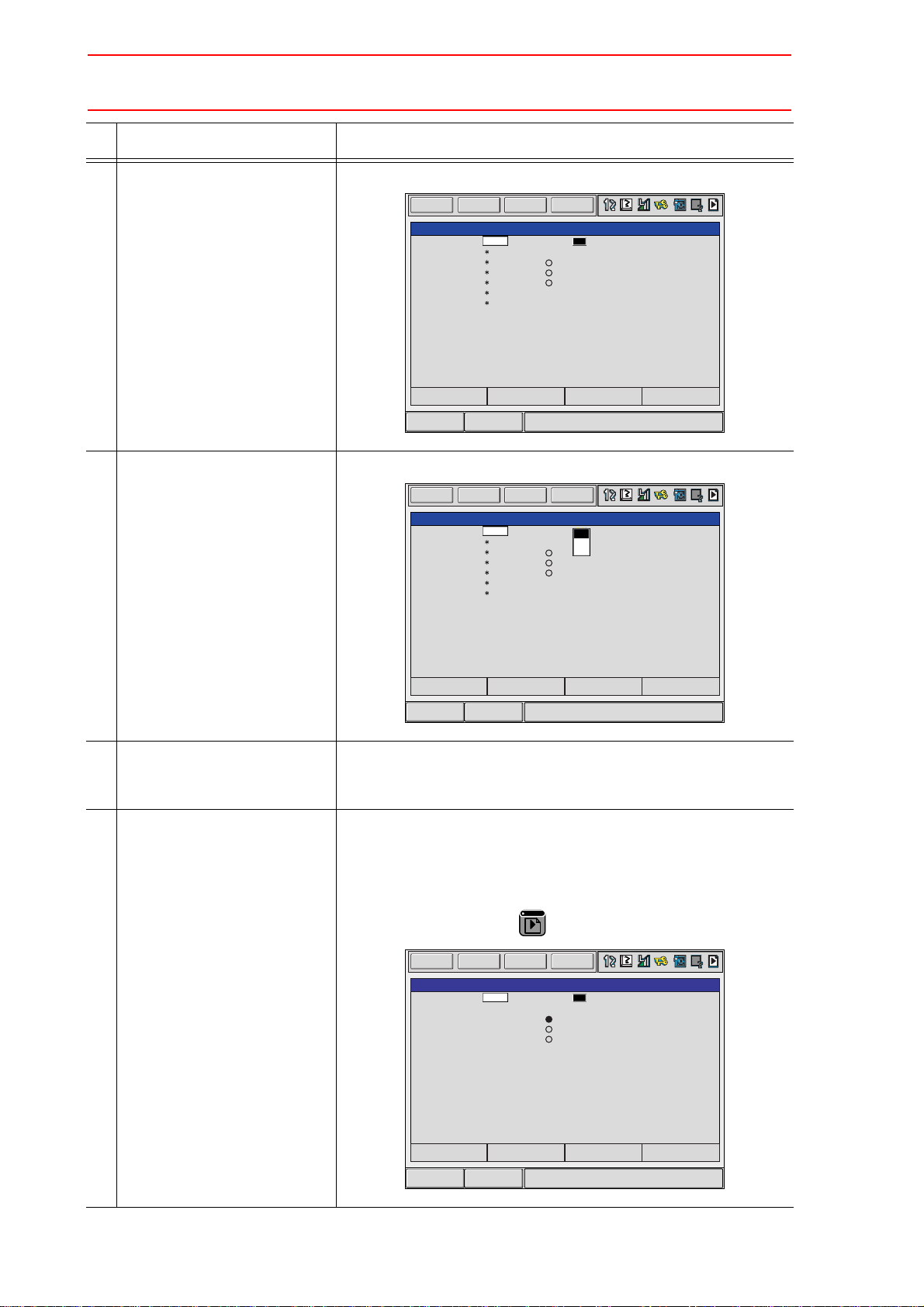

Operation Explanation

1 Select {ROBOT} under the

main menu.

2 Select {ROBOT CALIB}. The ROBOT CALIBRATION list window appears.

3.5 System Setup

3 Select a robot calibration No. The ROBOT CALIBRATION window for teaching appears.

4 Select “ROBOT.” The selection dialog box appears. Select a control group for cali-

bration.

3-10

Page 50

3.5 System Setup

ROBOT CALIBRATION

NO. :01 ROBOT

C1:

C2:

C3:

POSITION

C1

<STATUS>

R1:S

L

U

R

B

T

R1+R2

TOOL:00

CANCELCOMPLETE PAGE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

C1:

C2:

C3:

C1

R1:S

L

U

R

B

T

R1+R2

C1

C2

C3

ROBOT CALIBRATION

NO. :01 ROBOT

POSITION

<STATUS>

TOOL:00

CANCELCOMPLETE PAGE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

PAGE

GO BACK

C1:

C2:

C3:

C1

R1:S

L

U

R

B

T

R1+R2

12345

1025

10230

1010

521

2340

ROBOT CALIBRATION

NO. :01 ROBOT

POSITION

<STATUS>

TOOL:00

CANCELCOMPLETE PAGE

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

50/210

Operation Explanation

5 Select a group axis combina-

The teaching positions are displayed.

tion for calibration.

6 Select “POSITION.” The selection dialog box appears. Select a position to be taught.

7 Press the axis key to move the

manipulator to the desired

position.

8 Press [MODIFY] and

[ENTER].

The positions for calibration are registered.

Repeat Operations 7 and 8 to teach set positions C1 to C3.

On the window, “” indicates that the teaching is completed while

“” indicates that the teaching is not completed.

The calibration positions appear according to the selected group

axis. Press the page key to change the window.

3-11

Page 51

3.5 System Setup

01

02

03

04

05

06

07

08

ROBOT CALIBRATION

NO. SET ROBOT

EDIT

DISPLAY

UTILITY

DATA

Short Cut

Main Menu

R1+R2

51/210

Operation Explanation

9 Select “COMPLETE.” The robots are calibrated. When the calibration is completed, the

ROBOT CALIBRATION list window reappears.

3-12

Page 52

3.6 Job Content Display

JOB CONTENT

JOB NAME: TEST

CONTROL GROUP: R1+R2:R1

STEP NO.: 001

TOOL: 00+01

0000

0001

0002

0003

NOP

SMOVL V=138

+MOVL

MOVL V=138

+MOVL V=138

END

MOVL V=138

+MOVL V=138

Instructions

Synchronized/Single

Group axis being handled

Coordinated interpolation/

Independent interpolation

EDIT

DISPLAY

UTILITY

JOB

Short Cut

Main Menu

52/210

3.6 Job Content Display

The contents of a coordinated job are displayed as shown below.

Instructions

For coordinated jobs, the move instruction, the weaving instruction, the shift instruction, and

others are displayed in two lines. The first line is the instruction to the slave side; the second line is the instruction to the master side.

SMOVL V=138 Slave, the manipulator holding a torch

+MOVL Master, the manipulator holding a workpiece

Synchronized/Single

Synchronized/single are the types of movement available for the manipulator during axis

operation. This mark appears when synchronized movement is selected.

Switch between movements by pressing [SYNCRO/SINGLE].

Group axis being handled

Displays the group axis being handled.

Press [ROBOT] to change the group axis to be handled.

Coordinated operation/Individual operation

Switch between coordinated operation and individual operation by pressing [SMOV].

3-13

Page 53

3.7 Synchronized/Single

UTILITY

UTILITY

When "Single" is selected, nothing appears here.

53/210

3.7 Synchronized/Single

There are two ways to handle axes when teaching: “Synchronized” and “Single”.

Switch between movements by pressing [SYNCRO/SINGLE].

3.7.1 Synchronized

If the axes are handled in the “Synchronized” mode, the slave (torch) follows the master

(workpiece) when the master moves. This feature is used to keep the position of the manipulator relative to the other manipulator.

However, the master does not move when the slave is moved.

3-14

Page 54

3.7 Synchronized/Single

Only the manipulator whose

axis is handled moves.

NOTE

54/210

3.7.2 Single

If an axis is handled in “Single” mode, only the manipulator whose axis is being handled

moves.

This feature is used where each of the two manipulators executes an individual job.

• The selected mode, Synchronized or Single, is maintained until the next selection is

made.

• When an edit job is changed, “Single” is automatically selected.

3-15

Page 55

3.8 Selecting Axis to be Handled

UTILITY

UTILITY

2

55/210

3.8 Se le ct ing Ax is to be Ha nd led

This section explains the methods to select a manipulator to be handled in teach mode.

3.8.1 When There is an Edit Job

Each time [ROBOT] is pressed, a manipulator to be handled changes.

3.8.2 When There is No Edit Job

When there is no edit job, move the manipulator in the following manner.

1. Press [SHIFT]+[ROBOT] to change the manipulator to be handled. The LED of

[ROBOT] flashes.

2. Select the group axes to be moved, and then move it by pressing the axis key.

3. Press [ROBOT] to return to the original display.

3-16

Page 56

3.9 Registering Job

NEW JOB CREATE

JOB NAME

COMM.

GROUP SET R1

CANCELEXECUTE

EDIT

DISPLAY

UTILITY

JOB

Short Cut

Main Menu

56/210

3.9 Registering Job

Operation Explanation

1 Select {JOB} under the main

menu.

2 Select {CREATE NEW JOB}. The NEW JOB CREATE window appears.

3 Enter a job name. Select “JOB NAME,” and then enter a job name by entering the

characters. Refer to “1.2.7 Character Input” of the Operator’s

Manual.

4 Press [ENTER].

5 Select “GROUP SET.”

6 Select a group combination.

7 Select “EXECUTE.” The job name is registered in the memory of NX100, and the JOB

CONTENT window appears.

3-17

Page 57

3.10 Registering Move Instruction (S)MOV+MOV

UTILITY

UTILITY

UTILITY

When "Single" is selected, nothing appears here.

SMOVL V=138

+MOVJ

Short CutMain Menu

57/210

3.10 Registering Move Instruction (S)MOV+MOV

Register a move instruction in the following manner.

3.10.1 Operating Master Side (Workpiece)

Operation Explanation

1 Call the JOB CONTENT win-

dow in teach mode.

2 Press [EX. AXIS]. The master side (station) is selected for axis handling.

3 Select either “synchronized” or

“single.”

4 Press the axis key to move to

the desired position.

5 Select an interpolation type. Press [MOTION TYPE] to select an interpolation type.

Press [SYNCRO/SINGLE] to select either “synchronized” or “single.”

When “synchronized” is selected, the mark in the window below

appears.

When the slave side is supposed to follow the master side

motion, select “synchronized.”

3-18

Page 58

3.10 Registering Move Instruction (S)MOV+MOV

2

Short CutMain Menu

SMOVL V=138

+MOVL

SMOVC V=138

+MOVL

Short CutMain Menu

0003 SMOVC V=138

+MOVL

NOTE

58/210

3.10.2 Operating Slave Side (Torch)

Operation Explanation

1 Press [EX. AXIS]. The slave side (manipulator) is selected for axis handling.

2 Press the axis key to move to

the desired position.

3 Select either a coordinated

Press [SMOV] to select either interpolation.

interpolation or an independent interpolation.

4 Select an interpolation type. Press [MOTION TYPE] to select an interpolation type.

5 Confirm the speed.

6 Press [ENTER]. The registration is completed as follows.

• When joint motion is set for the slave side (torch), teaching cannot be done during a coordinated operation.

• When “JOINT” is selected, the interpolation type will not change to a coordinated operation, even if [SMOV] is pressed.

• When “JOINT” is selected during coordinated interpolation, a coordinated move instruction such as “SMOVL” in the input buffer line changes to “MOVJ”, and the interpolation

type becomes individual interpolation.

3-19

Page 59

3.11 Registering Reference Point Instruction (SREFP)

0003

0004

0005

0006

0007

SMOVL V=558

+MOVL

CALL JOB: TEST

SMOVL V=138

+MOVL

Immediately before

the line where the

reference point

instruction is to

be registered

SREFP 1

SREFP 2

Ref-point_no.=

SREFP

0003

0004

0005

0006

0007

0008

SMOVL V=558

+MOVL

CALL JOB:TEST

SREFP 1

SMOVL V=138

+MOVL

The reference

point instruction

is registered.

59/210

3.11 Registering Reference Point Instruction (SREFP)

Register a reference point instruction (SPEFP) for a coordinated operation in the following

manner.

Operation Explanation

1 Select {JOB} under the main

menu.

2 Select {JOB}.

3 Move the cursor. Move the cursor to the line immediately before the line where the

reference point instruction is to be registered.

4 Grasp the Enable switch.

5 Press the axis key. Turn ON the servo power with the Enable switch. Move the

manipulator to the position which will be a reference point.

6 Select the coordinated interpo-

Press [SMOV] to select either interpolation.

lation.

7 Press [REF PNT]. The reference point instruction appears in the input buffer line.

8 Change the reference point

number.

Move the cursor to the reference point number,