yaskawa MX3 Connecting Manual

INSTRUCT!

YASNAC

CNC

CONNECTING

MBNHBHIWW

Before

SYSTEM

operation,

initial

MACHINING

FOR

MANUAL

these

read

instructions

MX3

CENTERS

*

*

.•*3

;TIj

C-

>

7

thoroughly,

f'>»,

and

Fiji

-r

.

r

retain

ii

&

c

>

for

future

%

reference

,

CPS-ION

POWER

OC

I

ITMOÿOVIT

50/60Hz.300VA

SUPPlffsoftCE-

w

-

mw-

+24V

jSSfesss®

!

YASKAWA

JAPAN

jj

EXT

I

YASKAWA

YASNAC

MX3

specifications

external

equipment.

is

a

color

for

connecting

graphic

for

CNC

YASNAC

machining

with

MX3

centers.

machines,

This

manual

machine

describes

interfaces

the

and

Necessary

the

type

connectionsinaccordance

units

programmable

The

MX3

LX3/MX3

1.

CONFIGURATION

1

SYSTEM

1

1

2

STANDARD

INTEGRATED

2.

ENVIRONMENTAL

3.

CABINET

4.

CABINET

CONFIGURATION

CONSTRUCTION

DESIGN

connections

the

of

CNC

cabinet.

System

PC

CABINETS

UNITS

CONDITIONS

FOR

CNC

controller

•

AND

DESIGN

HEAT

be

to

provided

cabinet

supplied

with

system

For

details

(TOE-C843-9

FACTORS

by

the

by

the

combination

{hereafter

of

the

PC,

1)

CONTENTS

1

1

•

1

1

1

3

machine

Yaskawa

for

called

refer

to

12.

CONNECTION

13.

CONNECTION

CONNECTION

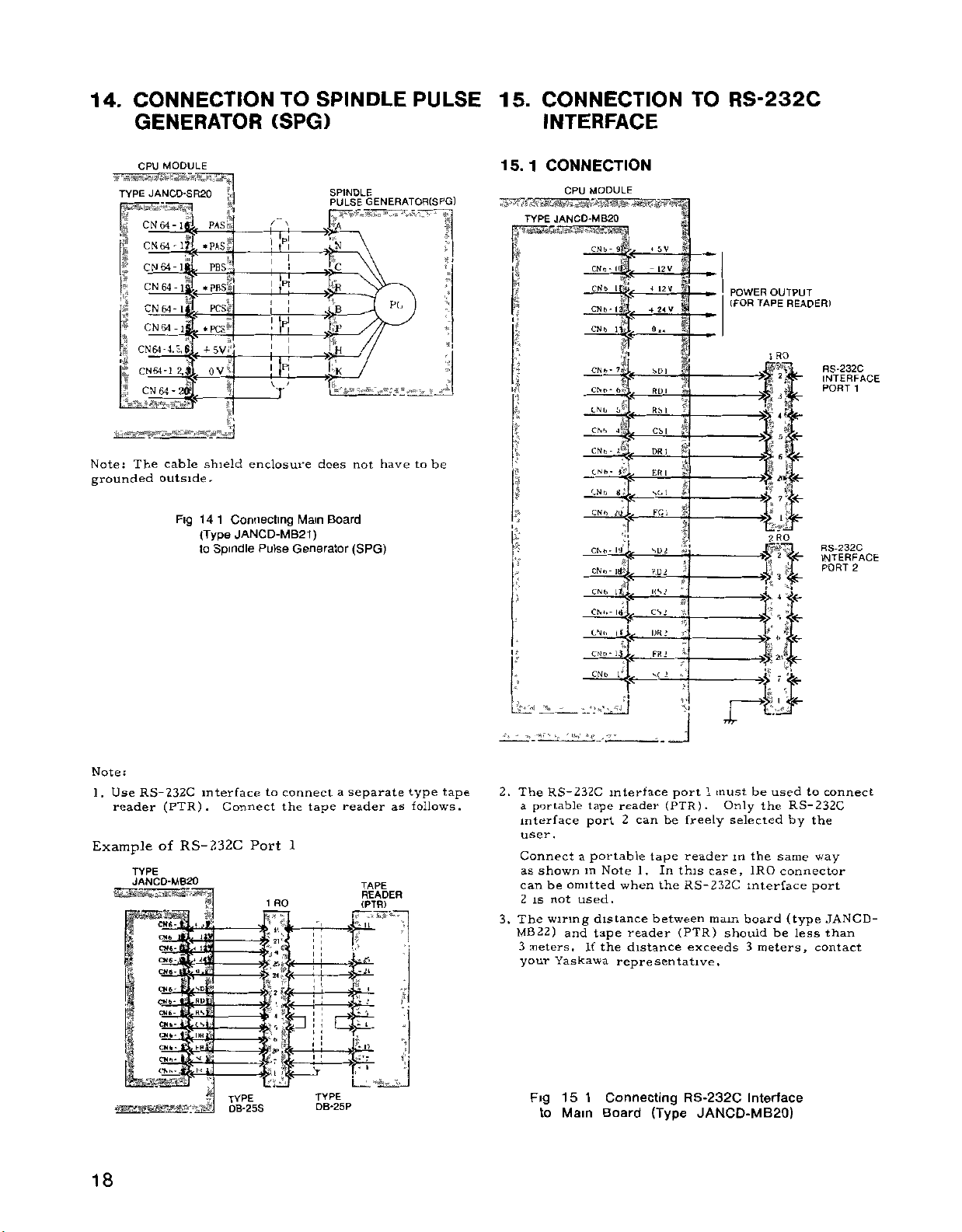

14.

GENERATOR

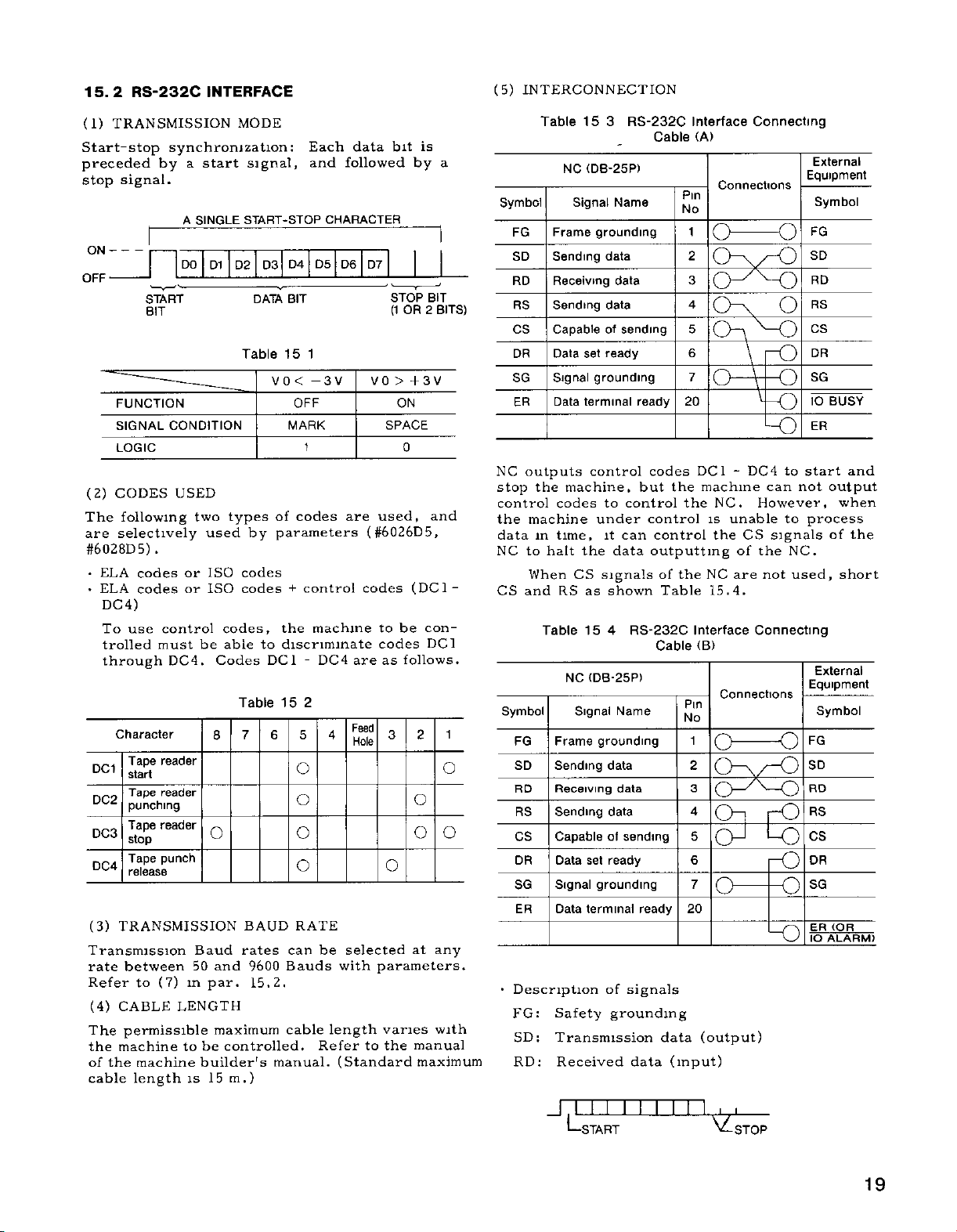

15.

CONNECTION

151

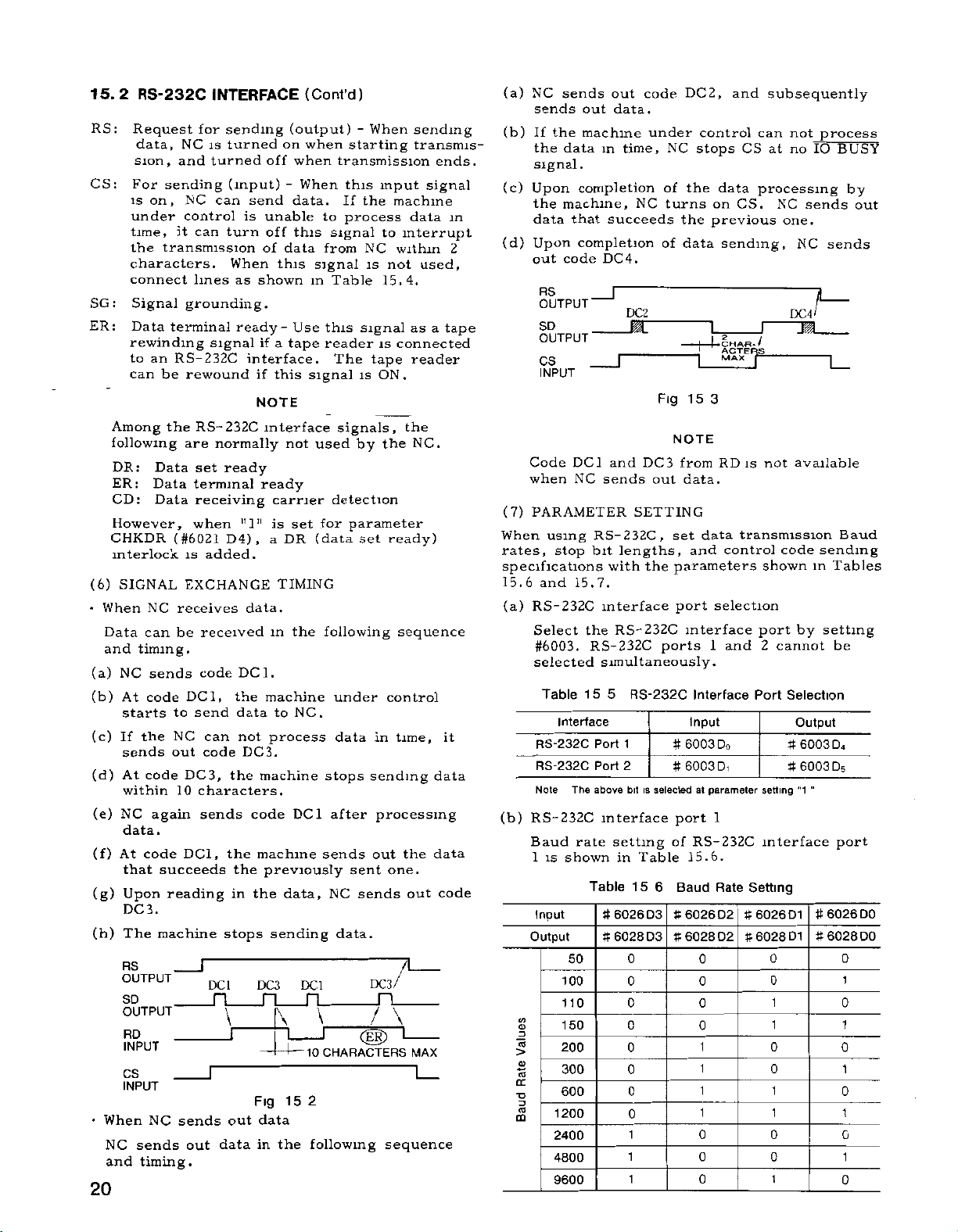

15

2RS-232C

manufacturer

Make

standard

PC)

additions

cabinets

is

installed

Instruction

CONNECTION

INTERFACE

differ

Manual

TO

FEED

SPINDLE

TO

SPINDLE

TO

RS-232C

TO

depending

or

deletions

integrated

and

in

the

for

YASNAC

SERVO

DRIVE

PULSE

INTERFACE

on

of

YASNAC

UNITS

UNIT

12

17

18

18

18

19

4

1

SELECTION

4.2

HEAT

VALUES

5.

CABLE

5.1

5.2

6.

CONNECTION

7.

POWER

7

1

2

7

ENTRANCE

LAYOUT

CLAMPING

CABLE

SUPPLY

POWER

TO

CPU

POWER

STANDARD

8.

CONNECTING

CRT

TO

9.

CONNECTION

10.

CONNECTION

GENERATOR

11.

CONNECTION

1

1

1

11

2

OPERATOR’S

CONNECTION

DETAILS

OF

OF

CABLE

CABLES,

SHIELD

DIAGRAMS

SUPPLY

MODULE

SUPPLY

CABINETS

POWER

OF

OF

SIGNALS

EXCHANGER

HEAT

OF

UNITS

CONNECTORS

AND

GROUNDING

CONNECTION

CONNECTION

CONNECTION

UNIT

PANEL

REMOTE

OF

MANUAL

OF

INPUT

SEQUENCE

AND

I/O

MODULE

PULSE

TO

PC

BOARD

10

10

11

3

3

4

4

4

5

6

6

6

7

8

9

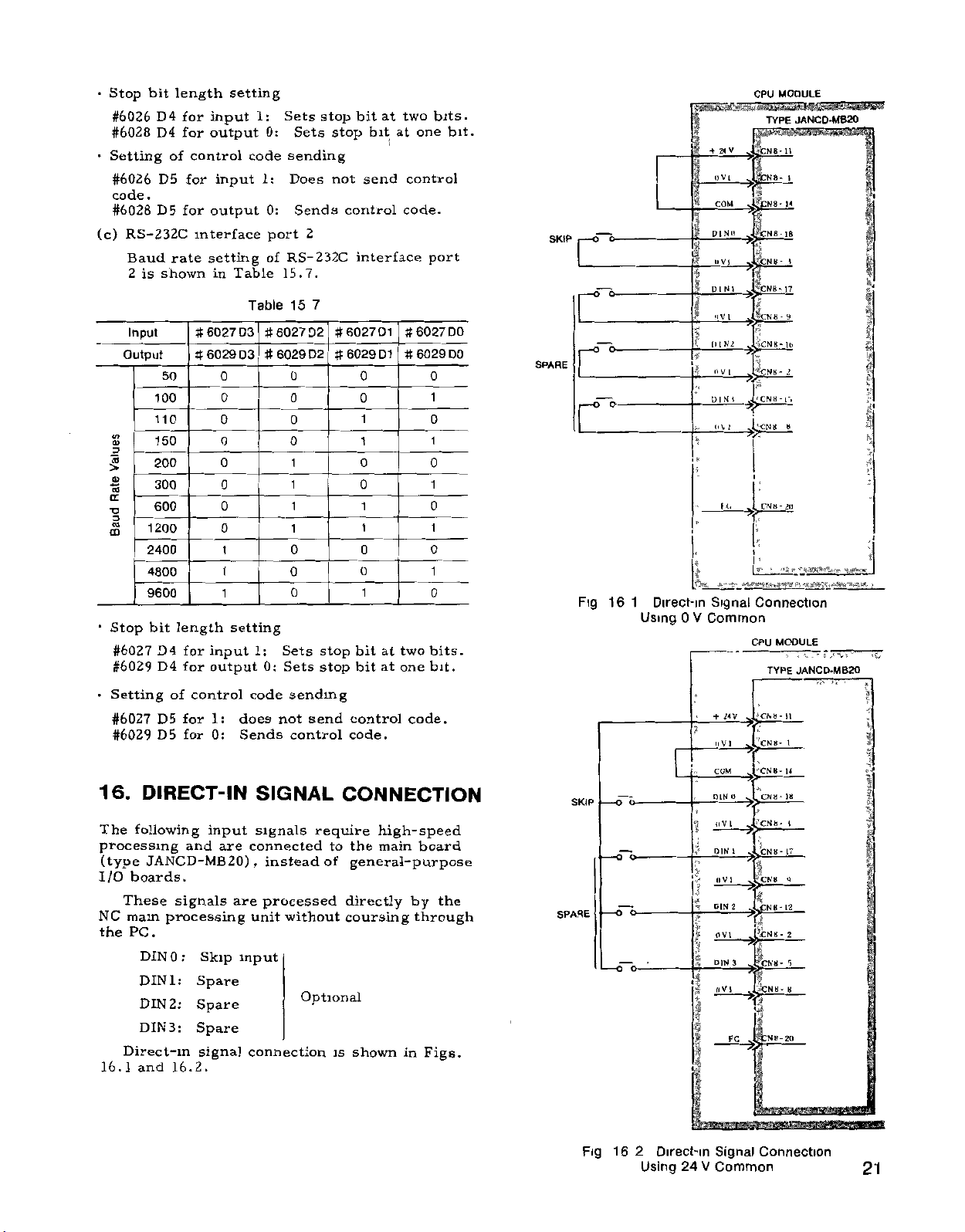

DIRECT-IN

16.

17.

CONNECTION

I/O

SIGNALS

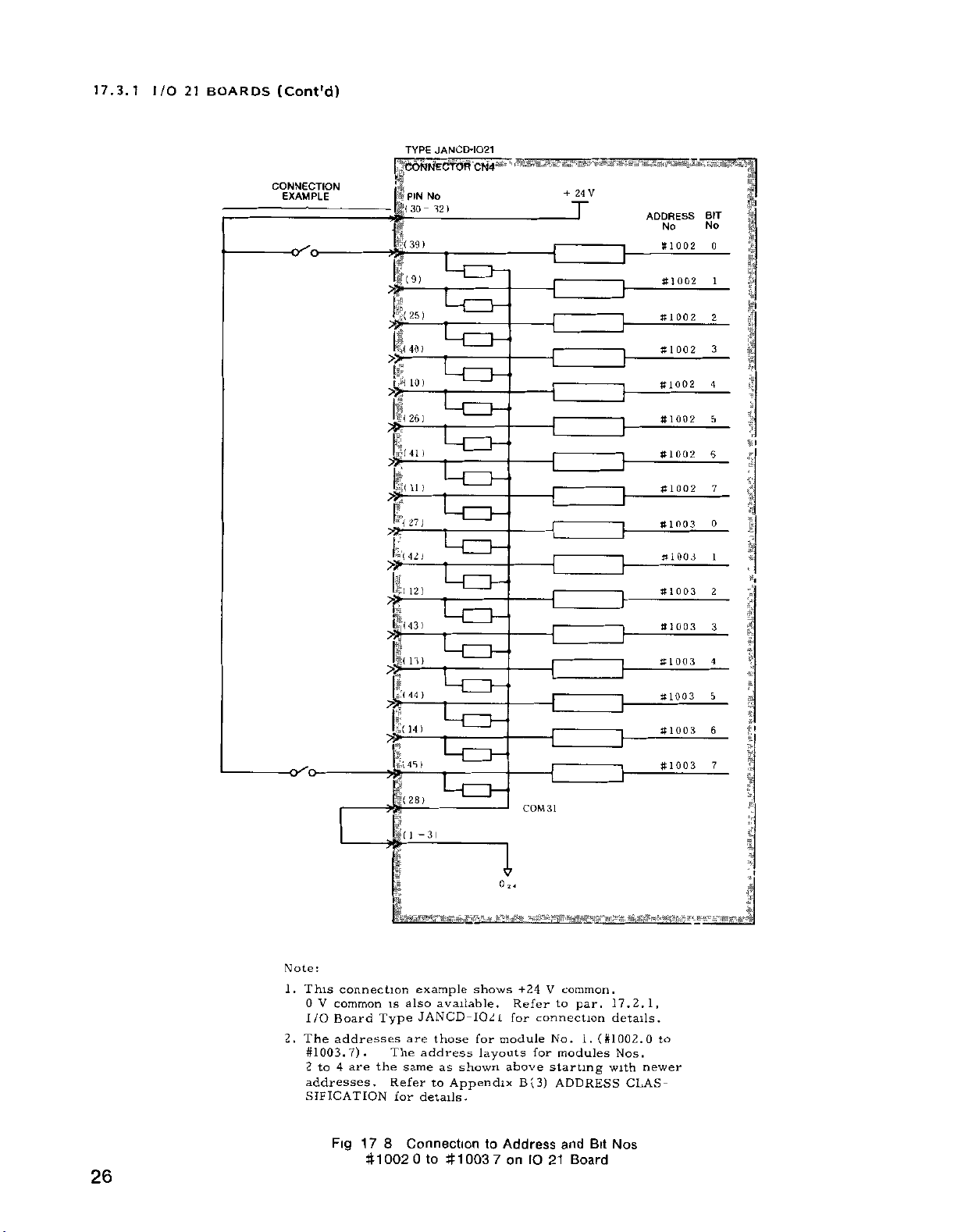

1711/0

17

17

18.

18.1

18

18

19.

19.1

PORTS

2

1/0

CIRCUITS

3

1/0

SIGNAL

CABLES

OF

LIST

2

LIST

OF

3

SPECIFICATIONS

STANDARD

LISTOFNC

SIGNALS

2

19

DETAILS

APPENDIX

APPENDIX

APPENDIX

OF

YASNAC

A

B

C

SIGNAL

CABLES

CONNECTION

TO

GENERAL-PURPOSE

OF

I/O

PORTS

INTERFACE

CONNECTORS

OF

CABLE

I/O

SIGNALS

STANDARD

OF

SIGNALS

DIMENSIONS

I/O

PORT

ADDRESS

STANDARD

WIRING

I/O

in

mm

SETTING

COLORS

21

22

22

22

25

46

46

47

47

50

50

58

83

93

94

INDEX

Subject

Alarm

A

Auxiliary

Axis

Interlock

CABINET

C

CABINET

CABLE

CABLES

Canned

CLAMPING

CONFIGURATION

CONNECTING

OPERATOR’S

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CONNECTION

CPU

Module

CRT

Operator’s

Output

and

Function

CONSTRUCTION

DESIGN

ENTRANCE

Cycle

External

Inputs

Spindle

CABLES,

POWER

PANEL

DIAGRAMS

OF

OF

OF

TO

TO

TO

TO

TO

Panel

Error

Input

Lock

FOR

HEAT

Control

AND

UNIT

INPUT

MANUAL

REMOTE

SERVO

FEED

GENERAL-PURPOSE

RS-232C

SPINDLE

SPINDLE

Detect

DESIGN

FACTORS

GROUNDING

PC

AND

SEQUENCE

PULSE

I/O

MODULE

UNITS

INTERFACE

DRIVE

UNIT

PULSE

GENERATOR

GENERATOR

Inputs

CABLE

BOARD

I/O

•

•

SHIELD

CRT

TO

SIGNALS

Chapter

19

......

......

••

••

......

••

19-

••

•

•••

19

3

.

..

4.

5

18

19

.....

-5

.....

1

8

11

15

.....

6

••••

11

10

.

••

9

12

17

15

13

14

••ÿ18

18

18

-•••18

Section

2

23

19

2

19

17

19

2

39

19229

5

2

111

15

1

2

1

2 2

Page

-66

••

65

75

1

••

3

4

46

70

4

1

7

10

18

•

5

10

•

9

8

12

22

18

17

•

18

-

47

47

DETAILSOFSIGNALS

D

DETAILSOFSIGNALS

DIMENSION

DIRECT-IN

Display

Dry

Edit

E

Emergency

End-ot-Program

ENVIRONMENTAL

External

External

External

External

External

F

F1

Feed

Feedrate

Gear

G

Non-Contact

Gear

H

HEAT

I/O

I/O

I/O

I/O

I/O

Reset

Input

Run

Lock

Data

Deceleration

Input,

Power

Reset

-Digit

Command

Drive

Override

Selection

Shift

VALUES

21

Boards

Board

Board

CIRCUITS

PORT

in

mm

SIGNAL

Inputs

Stop

Input

Input,

Input

Verify

ON-OFF

Input

Unit

Input

Command

Output

Input

On

OF

Type

JANCD-1021

JANCD-SP20

Type

OF

ADDRESS

I/O

CONNECTION

Rewind

CONDITIONS

Inputs/Outputs

and

and

S5-Digit

or

and

UNITS

PORTS

SETTING

Input,

Output

Input

ON

Reset

and

Feed

Input/Output

Spindle

•

and

Signals

Output

Override

S4-Digit

Analog

Output

Orientation

Rewind

Cancel

Input'

ON

Input

•

Outputs

•

•

......

11

19

APPENDIX

16

1

9-

1

9-

19

11

19

2-

.....

19-

19

19

11

19

19

18

19

•••

19

19

4

17

17-

17

17

APPENDIX

11

2

19

•

•19

•19

19

112

19

-19

19

19

11

19

19

18

19

19

19

4

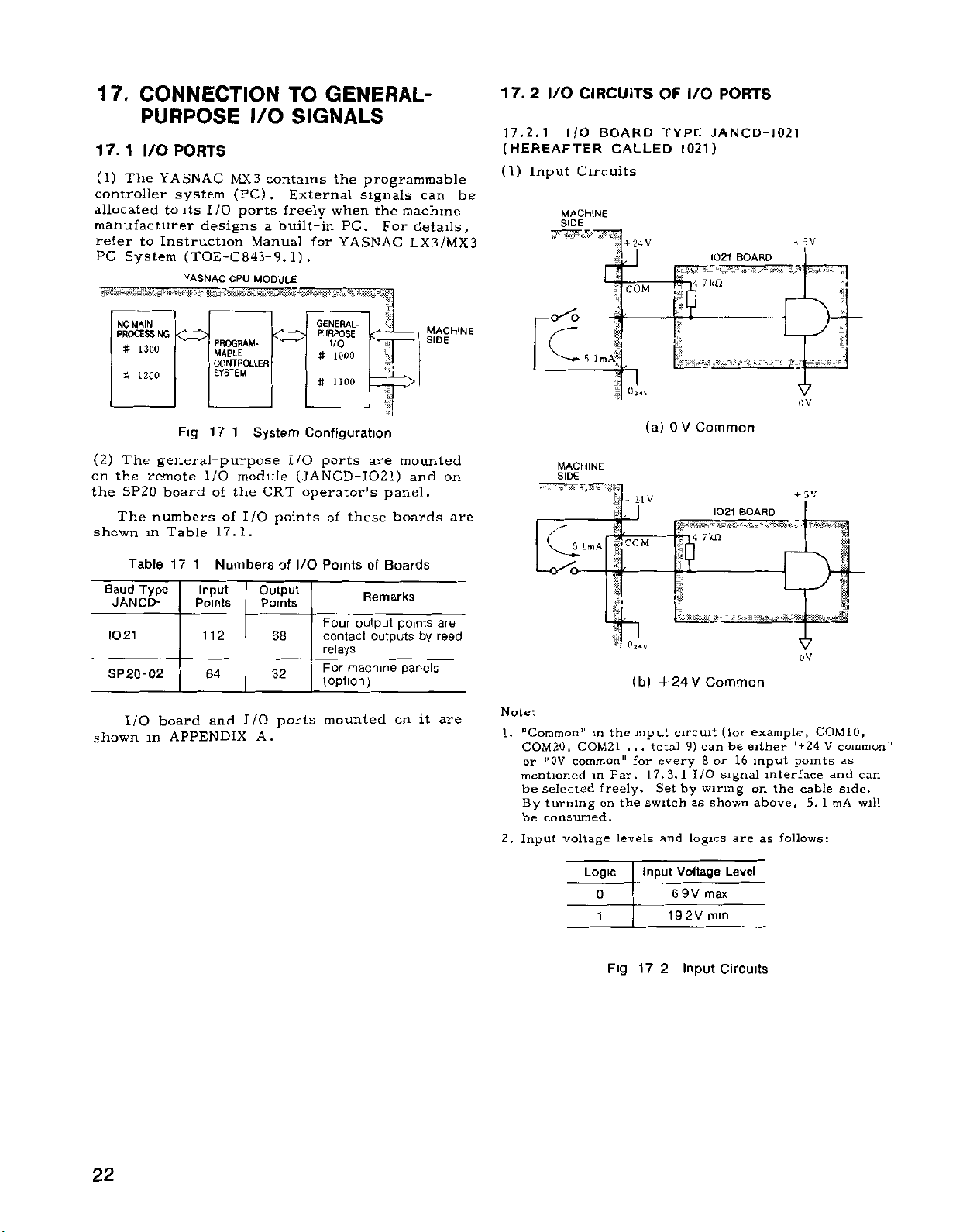

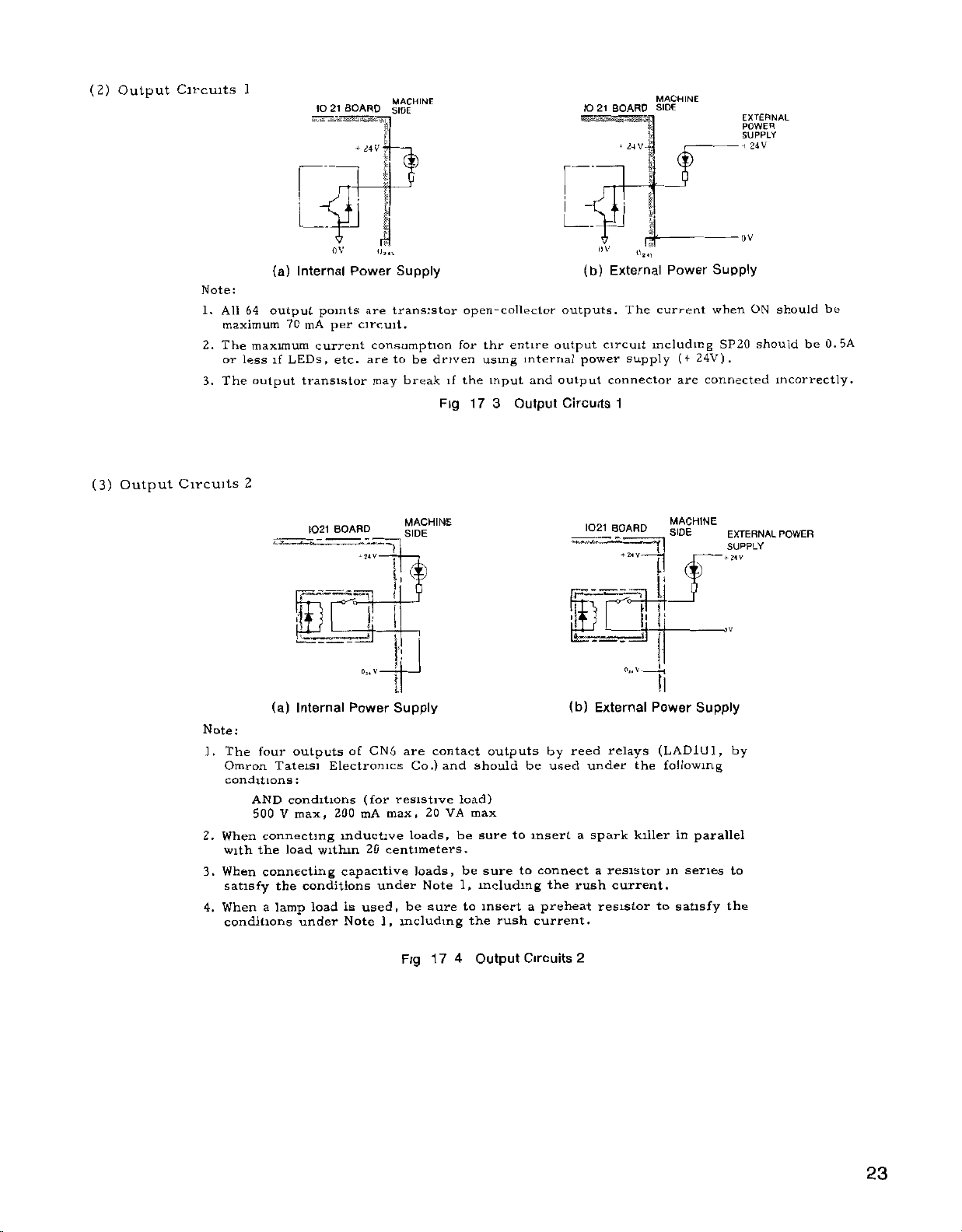

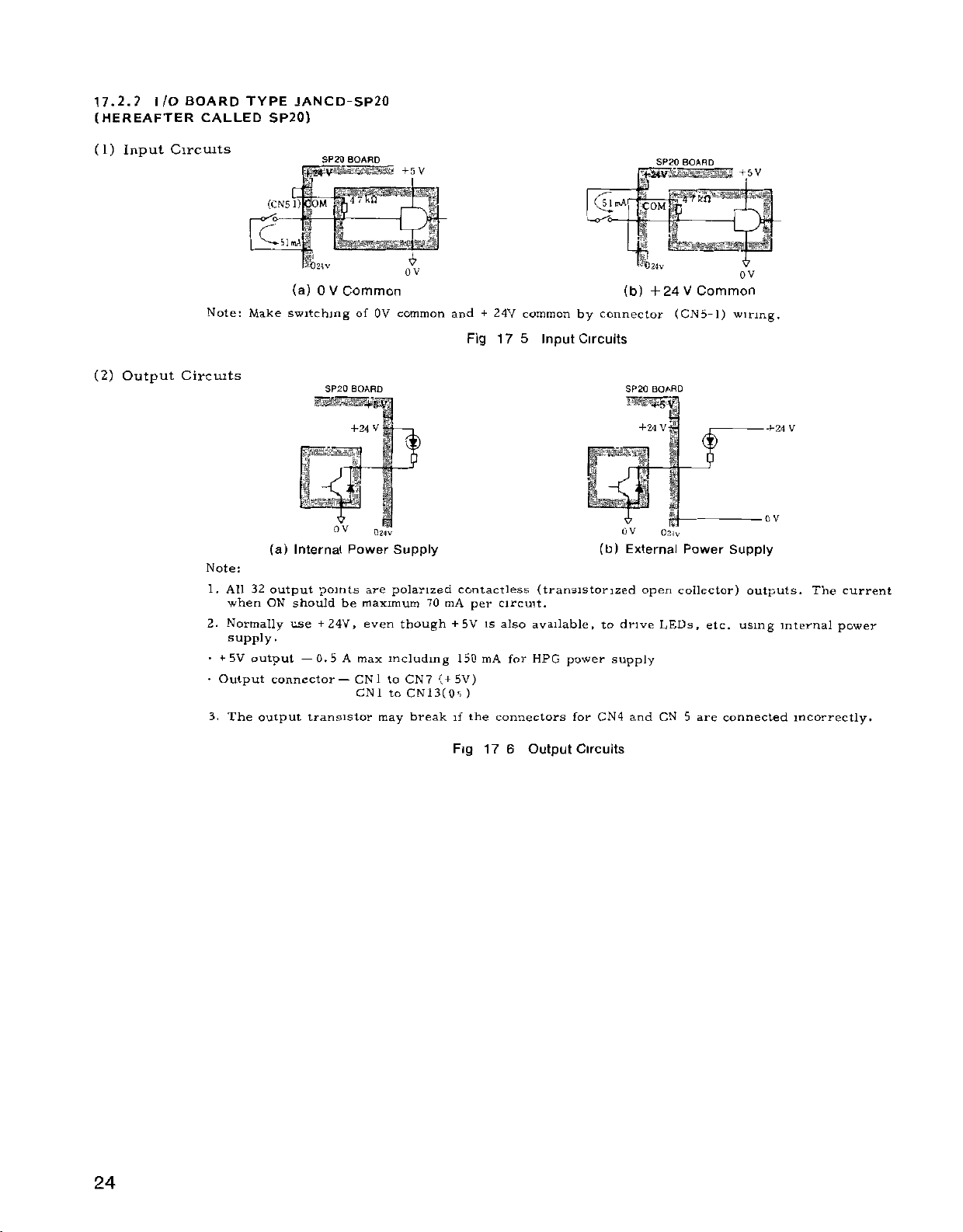

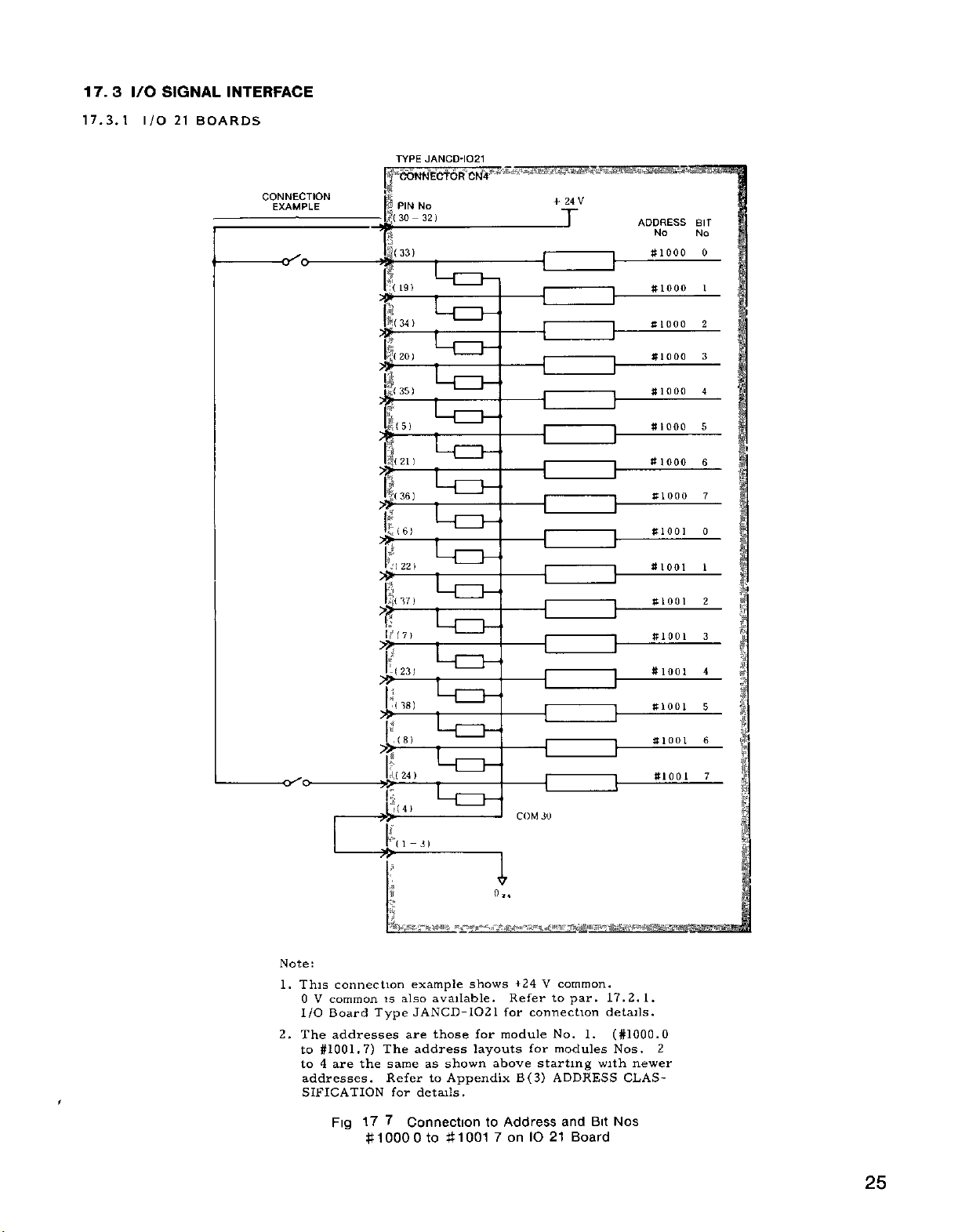

1731

1721

1722

2

A-

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2-

2

B

......

•

••

.....

.....

•••

11

58

83

21

.....

•

37

14-

1

2

27-

28-

31

47

3

20

32

4

5

42

43

6

75

-

•

64

•

65

•••

11

•

68

1

68

72

79

11

66

73

47

61

77

78

.....

3

25

22

24

•

-22

93

I/O

I/O

Input

PORTS

SIGNAL

and

INTERFACE

Output

for

Control

Operation

Modes

•17

•

17

-

1

17

-19

•

3

2

2

•

17

......

22

25

58

ii

INDEX

(Cont’d)

Subject

Input

for

Interface

Interface

Interlock

LAYOUT

L

LIST

LIST

LISTOFNC

M

M,

Machine

Machine-Ready

Manual

Manual

Manual

Manual

Manual

Mirror

NC

N

NC

Optional

O

Overload

Overtravel

Playback

P

Positioning

POWER

POWER

POWER

Signals

Cycle

Start

Input

Output

Input

OF

OF

CABLES

OF

CONNECTORS

T

S,

and

Lock

absolute

Feed

Handle/Step

JOG

Rapid

Image

Power

Unit

Block

Input

Input

SUPPLY

SUPPLY

SUPPLY

Cycle

for

and

Signal

Signals

CABLE

STANDARD

Codes

*B

and

Input

ON/OFF

Axis

Direction

Feedrate

Feeding

and

ON

Delete

Inputs

Completion

CONNECTION

CONNECTION

CONNECTION

and

Start

Feedhold

UI0-UI1

CONNECTORS

SIGNALS

I/O

Inputs/Outputs

Display

Servo

-

Lock

Input

Selection

Multiplication

Selection

Selection(RT)

Power

Input

••

Outputs

Stop,

UO0-UO1

5,

Input

Input

ON

TO

TO

Output

5

Input

Factor

Input

Input

MODULE

CPU

STANDARD

Signals

•

••

CABINETS

Chapter

19---•19

19

•

19--

1

9-

5

18

18

....19-

19

19

19

19

19

-.19

•

•

--19

...

.19...

•

•

19

11-

4

19 19

.....

11

19

..

19-

•

-19

.

7

.

..

7-

7

Section

19

•

19

•

19

•5

1...

•

18

•

18

•19

•

192

•19

19

•19

•

19

19

......

-19

-

-19

•

19

• •

11

-421.

•11

•19

•

•

19240

--•

-19225

••

-7

1

7

2

2

2

2

2

1

2

1

2

2

2

2

2

2

2

2

21

2

2

2

1

33

34

21

24

13

19

10

4

5

7

3

23

12

4

18

..

Page

58

-

•

•

73

••

•

74

•

66

4

46

47

50

••

••66

64

•

-

65

63

•ÿ

60

61

60

•66

11

3

•

64

11

65

•

75

•

67

6

•

6

6

Program

Program

R

Rapid

Reference

Remote

RS-232C

S

S4-Digit

Command

S5-Digit

SELECTION

Servo

Servo

Single

SKIP

SP20

SPECIFICATIONS

Spindle

Spindle

STANDARD

STANDARD

STANDARD

SYSTEM

Tool

T

Tool

Travel

Interrupt

Restart

Feedrate

I/O

Override

Point

Module

INTERFACE

Command

External

Command

OF

OFF

Signal

Unit

Input

Block

Input

Boards

Speed

Override

Reached

Speed

CABINETS

I/O

WIRING

CONFIGURATION

Length

Life

Control

ON,

Offset

Tapping

Input

Input

Return

HEAT

SIGNALS

•

Input

Control

External

Outputs

Inputs/Outputs

EXCHANGER

CABLE

OF

Inputs

Input

AND

COLORS

Inputs/Outputs

Signals

Canned

and

•

I/O

Outputs

INTEGRATED

OF

Cycle

Signals

S5-Digit

and

.

-

YASNAC

ON

•••

UNITS

--

Outputs

• •

1

9-

19-

19-

.....

1918-

15-

•

19

19

-

4-

-19

•

-

......

•

...

•

-19

-

-

••

4

19 19

19

.17

18

19

19

APPENDIX

1

19-

19

19

19

2

36

19

2

15

•

19

2

8

19

2

9

3

18

2

2

15

•

-19246-

19

2

-

•

.....

-19

•

1.

4

19

•422"

19

•

17

•

18

19

19

1

2

C

1

1

19

9

1

41

2

30

2

11"

2

35-

3

2

3

2

45--

44

2

•

2

38

2

48-

2

26

75

•

65

62

• •

62

47

.....

19

79

-

-

76

3

-

•

72

•

3

64

74

•

•••

40

47

78

78

1

-

50

94

•

1

-75

•

-81

68

-

-

iii

CONFIGURATION

1.

3.

CABINET

CONSTRUCTION

DESIGN

1.1

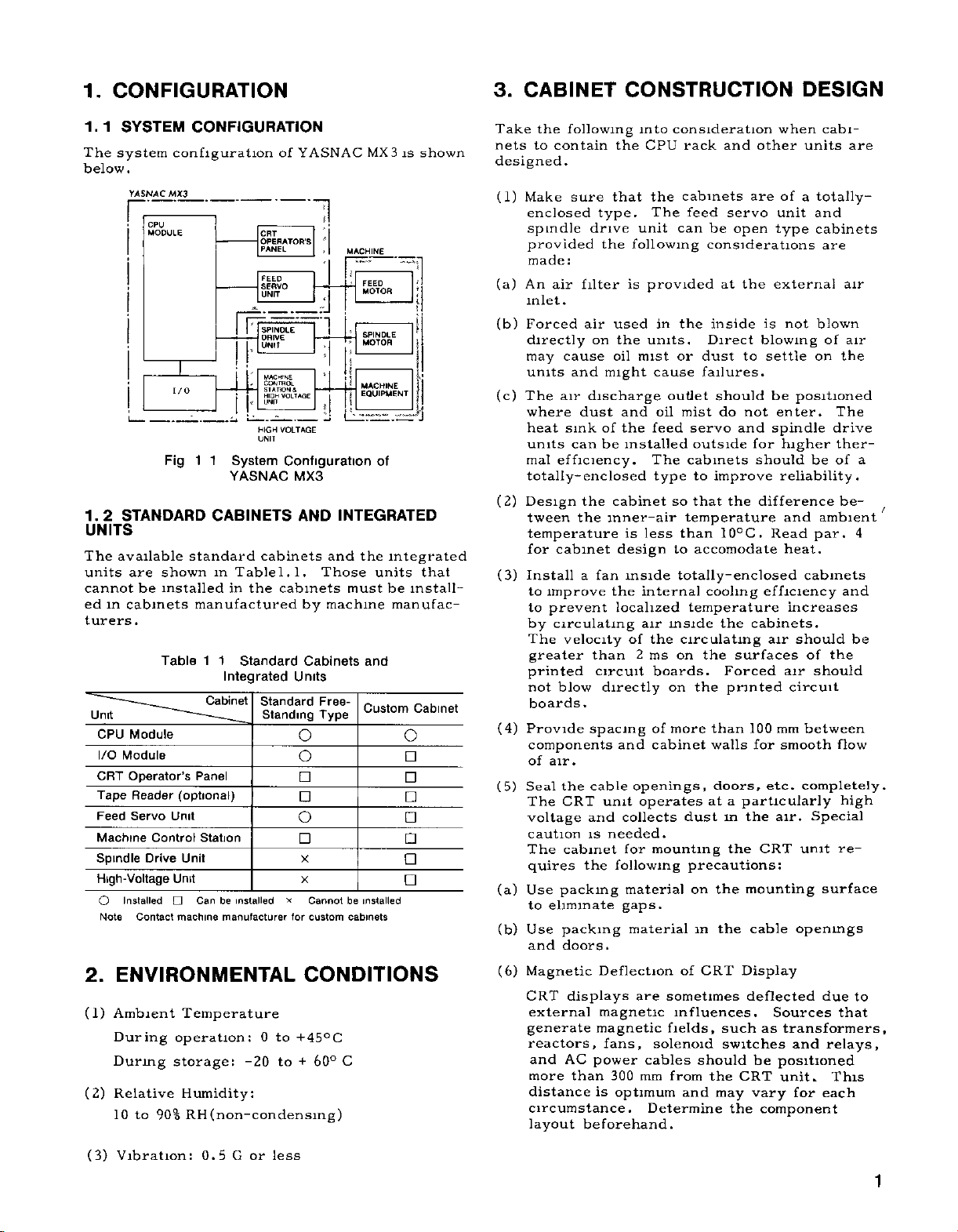

The

SYSTEM

system

CONFIGURATION

configuration

below.

VASNAC

MX3

Fr=

CPU

MODULE

T

I/O

Fig

1

1

STANDARD

1.2

UNITS

The

available

units

cannot

ed

in

turers

Unit

CPU

I/O

CRT

Tape

Feed

Machine

Spindle

High-Voltage

O

Note

2.

(1)

During

During

(2)

Relative

10

shown

are

be

installed

cabinets

.

Table

Module

Module

Operator’s

Reader

Servo

Control

Drive

Installed

Contact

ENVIRONMENTAL

Ambient

to

90%

CABINETS

standard

in

manufactured

1

1

Cabinet

Panel

(optional)

Unit

Station

Unit

Unit

Can

machine

Temperature

operation:

storage:

Humidity:

RH(non-condensing)

CRT

OPERA

PANEL

FEED

SERVO

UNIT

[T

SPINDLE

DRIVE

—

UNIT

MACHINE

CONTROL

t

STATION

-

HIQH

—

UNIT

HIGH

UNIT

System

YASNAC

cabinets

Table

the

in

Standard

Integrated

Standard

Standing

installed

be

manufacturer

0

-20

of

YASNAC

MX

~

1

TOR'S

&

VOLTAGE

VOLTAGE

Configuration

MX3

AND

1.1.

cabinets

Units

o

o

o

x

for

to

+45°C

to

+

MACHINE

l

FEED

i.

MOTOR

SPINDLE

1

MOTOR

*

MACHINE

EQUIPMENT

EEE3#j

INTEGRATED

and

the

Those

must

machine

by

Cabinets

x

x

Cannot

custom

Free-

Type

and

Custom

be

installed

cabinets

CONDITIONS

C

60°

3

is

of

integrated

units

be

install¬

manufac¬

o

shown

*

*

1

I

i

i

I

{

that

Cabinet

Take

the

to

nets

designed

(1)

Make

enclosed

spindle

provided

made

(a)

An

air

inlet.

(b)

Forced

directly

may

units

(c)

The

where

heat

units

mal

totally-enclosed

(2)

Design

tween

temperature

for

(3)

Install

to

improve

to

prevent

by

The

greater

printed

not

boards

(4)

Provide

components

of

air.

(5)

Seal

The

voltage

caution

The

quires

(a)

Use

eliminate

to

(b)

Use

and

(6)

Magnetic

CRT

external

generate

reactors,

and

more

distance

circumstance.

layout

following

contain

.

sure

type.

drive

the

:

filter

air

on

cause

and

might

air

discharge

dust

sink

of

can

be

efficiency.

the

the

cabinet

fan

a

circulating

velocity

than

circuit

blow

directly

.

spacing

cable

the

CRT

unit

and

is

cabinet

the

packing

packing

.

doors

Deflection

displays

magnetic

magnetic

fans,

AC

power

than

is

beforehand.

into

CPU

the

that

unit

following

is

provided

used

the

units.

oil

mist

and

the

installed

cabinet

inner-air

is

less

design

inside

internal

the

localized

air

of

2

and

openings,

operates

collects

needed.

for

following

material

gaps.

material

are

cables

300

mm

optimum

Determine

consideration

rack

cabinets

the

The

feed

can

be

considerations

the

or

outlet

mist

inside

Direct

dust

failures.

servo

in

cause

oil

feed

outside

The

cabinets

to

type

that

so

temperature

than

accomodate

to

totally-enclosed

cooling

temperature

inside

the

circulating

on

the

ms

boards.

the

on

more

than

walls

doors,

at

of

cabinet

dust

mounting

precautions:

on

m

of

CRT

sometimes

influences.

fields,

solenoid

should

the

from

and

and

are

servo

open

the

at

to

should

do

not

and

for

improve

the

10°C.

the

cabinets.

surfaces

Forced

printed

100

for

a

particularly

the

in

the

mounting

the

cable

the

Display

deflected

such

switches

be

CRT

may

vary

the

when

other

of

a

unit

type

external

is

not

blowing

settle

be

positioned

enter.

spindle

higher

should

reliability.

difference

and

Read

heat.

efficiency

increases

should

air

air

circuit

mm

smooth

etc.

completely.

air.

CRT

unit

openings

Sources

transformers,

as

and

positioned

unit.

for

component

cabi¬

units

totally-

and

cabinets

are

air

blown

of

the

on

The

drive

ther¬

of

be

be¬

ambient

par.

cabinets

and

the

of

should

between

flow

high

Special

re¬

surface

due

that

relays,

This

each

are

air

a

4

be

to

(3)

Vibration:

0.5

less

G

or

1

3.

CABINET

(Cont’d)

(7)

To

the

ing

other

should

(a)

Separate

(b)

Separate

of

(8)

The

to

tape

proof

in

splash

around

(9)

Mount

removal

work

(10)

Read

and

Heat

cabinet

This

from

and

•

Example

prevent

transformers,

the

locations

more

units

VDC

90

components.

be

AC

the

front

panels

cabinet

reader,

type.

them.

on

the

the

units

and

complied

.

the

instruction

spindle

sink

should

to

reduce

increases

an

open

reduces

CONSTRUCTION

malfunction

than

or

greater,

and

DC

primary

line

of

surfaces,

and

PO

However,

where

Be

mounting

so

reinstalling

drive

units

be

the

type

the

capacity

due

mm

100

The

with

cables.

filters,

the

unit

cutting

sure

sections.

as

AC

following

during

and

units

such

should

do

to

allow

from

power

secondary

not

fluid

to

during

manualsofthe

when

installed

internal

thermal

possibilities

to

a

totally-

the

of

to

noise,

wiring:

etc.

that

as

the

install

may

seal

easy

maintenance

mounting

outside

for

enclosed

heat

DESIGN

mount

cables

precautions

are

be

completely

feed¬

lines,

sides

exposed

CRT

dust-

of

a

them

directly

checking,

feed

servo

them.

the

losses.

a

change

type

exchanger.

and

unit,

(b)

Allow

inside

directly

boards.

forced

the

on

6

air

unit.

the

&

at

more

Be

surfaces

VENTILATING

DUCT

3

(a)

Good

FORCED

BLOWN

than

careful

of

AIR

DIRECTLY

2

not

the

printed

i

lc><51

ms

B

to

to

circulate

blow

circuit

air

(11)

(a)

RADIATOR

FIN

AIR

J

Precautions

Observe

during

Mount

Fig.

3.1.

the

mounting

the

unit

0

n

for

Mounting

following

in

UP

DOWN

0

SERVO

FEED

SPINDLE

Rack

CPU

CPU

direction

particularly

rack:

shown

points

the

of

the

Q

5

g.

3

cr

•5

o

n

DRIVE

in

AND

UNITS

(c)

Provide

upper

of

maintenance.

the

Fig

spacing

section

unit

for

3

2

and

better

(b)

Poor

Mounting

of

more

100

of

than

in

mm

ventilation

Fan

the

50

lower

mm

and

in

the

section

easier

Fig

3

1

Mounting

of

Units

2

4.

CABINET

FACTORS

1

4.

SELECTION

The

cabinets

should

units

inner-air

should

nets

needed

be

may

the

heat

equipment.

ity

1.

2.

follows:

as

AT:

Pv:

:

Cabinet

k

A:

qh:Heat

Calculate

equipment

Pv

Calculate

=

A

The

air

are

to

be

temperature

be

less

inside

generated

Determine

Air

temperature

heat

Total

(w)

ment

Calculate

circulating

Effective

exchange

exchanger.

the

.

(Heat

2

=

the

x

(W(width)

2

x

D(depth)

surfaces

ineffective

DESIGN

OF

HEAT

contain

of

heat

based

radiation

total

effective

that

the

a

totally-enclosed

differential

than

the

the

by

the

rise

generated

transmission

on

fan

is

ratio

heat

value

x

2

+

are

areas.

FOR

HEAT

EXCHANGER

module

CPU

inside

10°C.

cabinets

installed.

value

of

heat

H(height)}

ID(depth)

not

Heat

installed

heat

exchanger

inside

electric

by

[W/(m2’°C)l

6W/(m2-°C)

cabinet(m2)

of

area

of

necessary

Pv

unit)

each

radiation

exposed

depending

cabinet(°C)

of

and

type.

the

exchangers

electric

equip¬

a

if

heat

the

electric

area

(W(width)

2

+

x

H(height)t

external

to

other

The

cabi¬

on

capac¬

A.

2

4.

4.2.1

4.2.2

Unit

Note

1

2

3

HEAT

NC

SERVO

Type

CACR*

SR05SB

SR10SB

SR15SB

SR20SB

SR30SB

SR44SB

The

servo

80%

The

internal

fin

Is

installed

Heat

value

on

the

VALUES

UNIT

Table

Module

CPU

NC

Operator's

Tape

I/O

Module

Table

unit

heat

created

frequency

4

Unit

Reader

UNIT

4

2

Total

Value

100

110

130

140

220

270

uses

valueisthe

outside

by

of

OF

1

Heat

Heat

(W)

three

regenerative

rapid

Heat

Panel

shafts,

feed

UNITS

Values

Value

Internal

Value

and

heat

value

resistance

starts

its

and

Heat

of

57

61

68

71

95

110

load

remaining

of

Servo

Heat

<W)

stops

NC

Value

70

20

factor

will

Unit

25

5

(W)

Unit

Regenerative

Resistance

10-20

20-40

30-50

60-100

80-120

100-140

should

be

inside

the

if

depending

differ

70

heat

(W)

to

/

/ ////

(FLOOR)

3.

4.

5.

3

/r’/

Note:

bottom

Calculate

ensures

cabinet

Pv'

heat

A

value

heat

A

following

capacity)

heat

value

qh

/ /

50

If

mm

areas

the

the

(AT)

k-A-

=

exchanger

S

Pv

exchanger

heat

qh

Pv1

(Pv-Pv')

=

gg-gq

.

less

or

ineffective.

are

allowable

temperature

be

less

to

(W)

AT

L

10°C

6W(m2.

-

is

allowable

has

exchange

if

total

heat

.

/AT

L

INEFFECTIVE

from

heat

increase

than

°C)

needed

not

heat

to

be

ratio

value

(W/°C)

10°C

AREAS

floor,

the

value

10°C.

value

installed

(heat

Pv

Pv'

within

total

if

Pv'.

with

exchanger

allowable

>

that

heat

the

3

5.

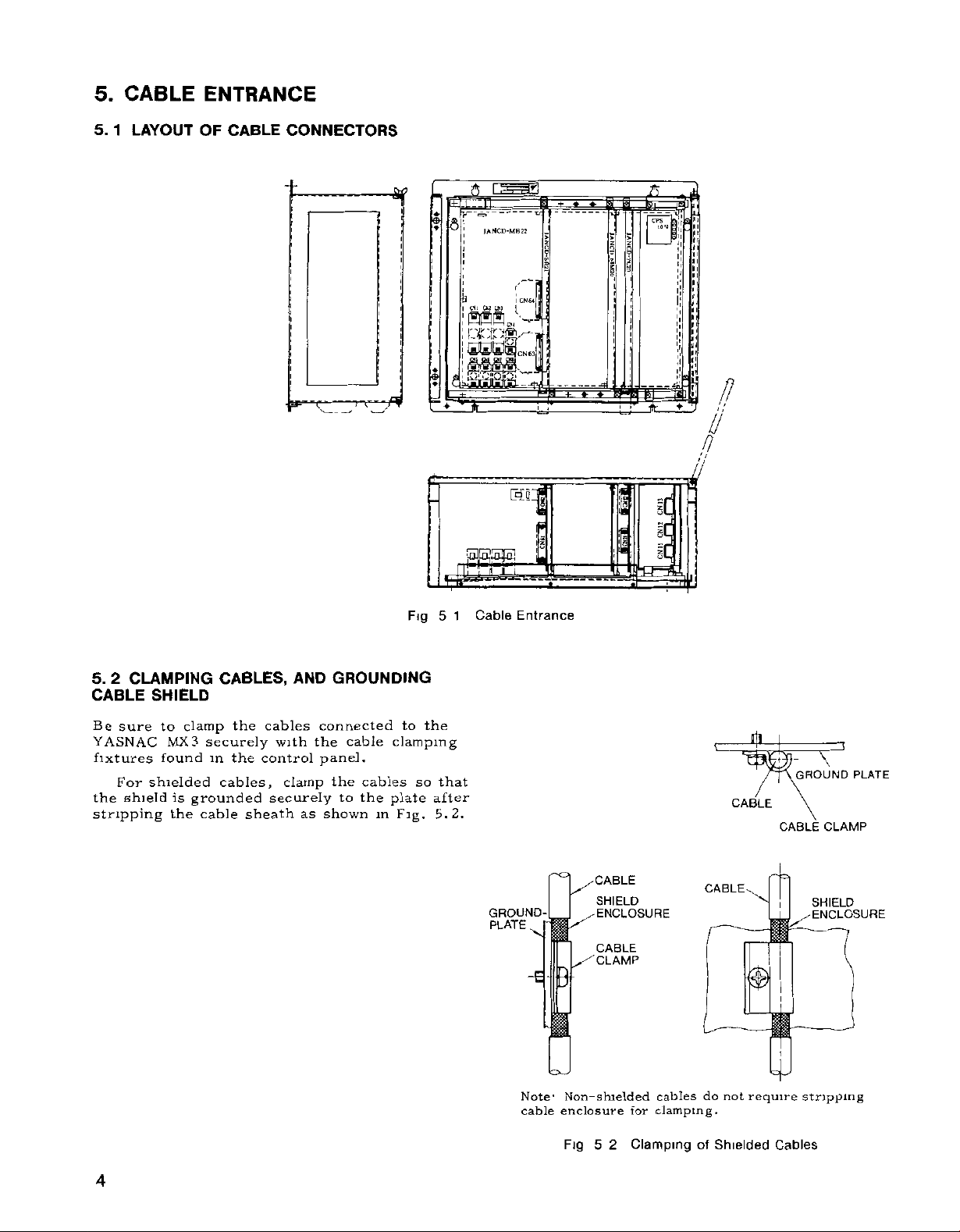

5.

1

CABLE

LAYOUT

ENTRANCE

CABLE

OF

CONNECTORS

y-rwm,R

Fig

V~

s

I

&

£

5

1

ar-

JANCD-MB22

sm

CN«4

l,

c'-

63

CN

gg

ga

CilCMCM

000

sr

su

HO:

CTjajSja]

Cable

I

Entrance

'

1

'f

>

E

CPS

i-

S

ION

I

i

i

-q

!ii

,/7

//

/?

//

I

I

II

i

II

2

CLAMPING

5.

CABLE

Be

sure

YASNAC

fixtures

For

the

shield

stripping

SHIELD

to

clamp

MX3

found

shielded

is

grounded

the

CABLES,

the

securely

the

in

cables,

cable

cables

with

control

securely

sheath

AND

clamp

as

GROUNDING

connected

the

cable

panel.

the

cables

to

the

shown

in

the

to

clamping

so

plate

Fig.

that

after

5.2.

GROUND-

PLATE

-E

Note1

cable

CABLE

SHIELD

ENCLOSURE

CABLE

Non-shielded

enclosure

for

cables

clamping.

CABLE

do

not

4

CABLE

require

t-

GROUND

CABLE

4-

V

PLATE

CLAMP

SHIELD

ENCLOSURE

stripping

Fig

5

2

Clamping

of

Shielded

Cables

4

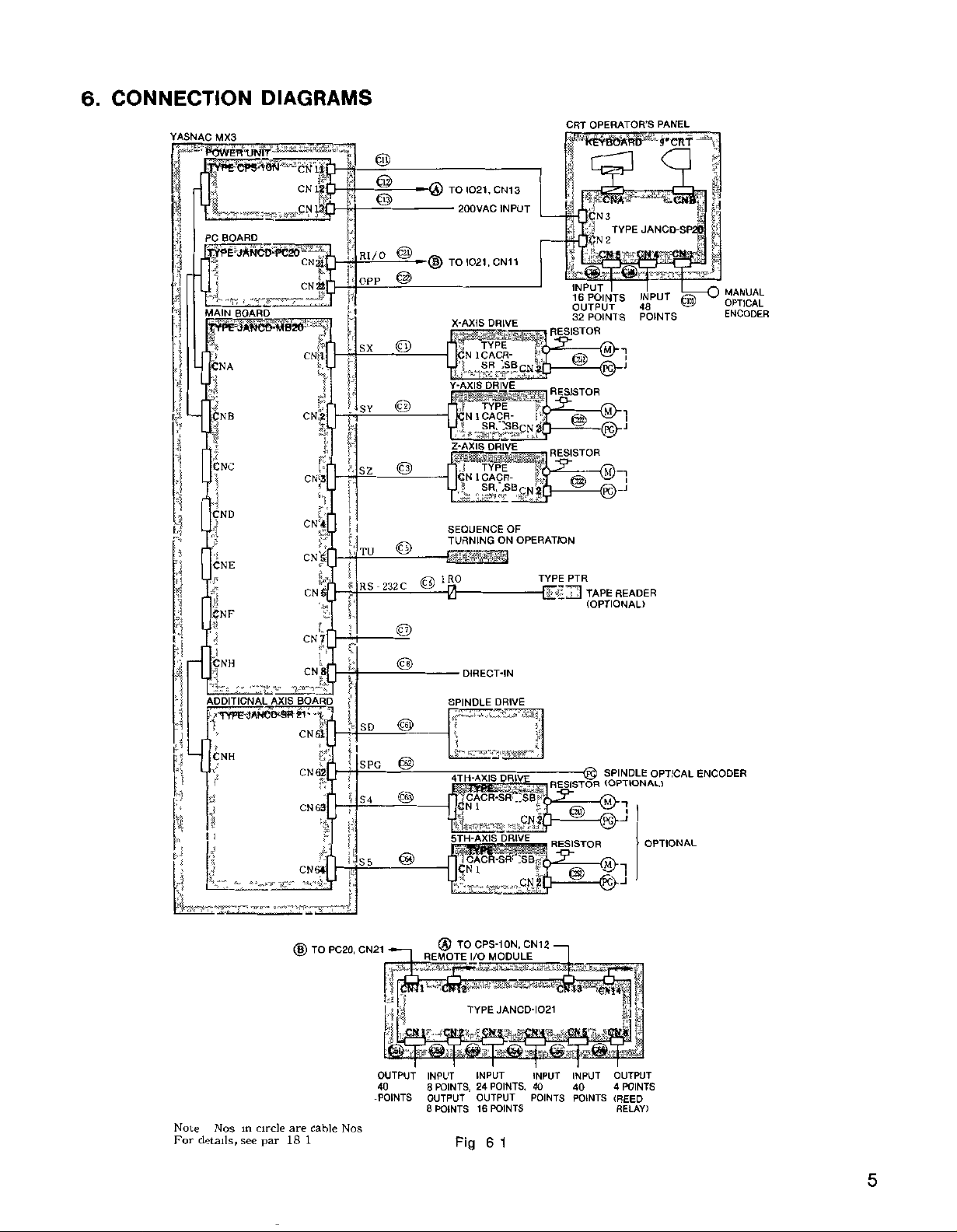

CONNECTION

6.

YASNAC

9

1

:

:

I

f

>

&

.

:

.

j

I

5

*1

:

8

1

N

5

:

i

i

p

51

4

I

M

5*L

MX3

TJr

PC

BOARD

1

pi-

Tt

BOARD

MAIN

*k

-j

L-

CNA

•t

B

J

CNB

y

a

J-

CNC

't

CND

M

1

ONE

K

ii

CNF

’•

u

;

CNH

1

Br.

f

ADDITIONAL

TYPF

'

1

:

CNH

:

4

rf

i

1

1

1

>

;;

CIIL'ISZXI

DIAGRAMS

CN1

CN

I;-

CN

-T

f

CNrl

K

ih

CNifl

ET

rt*

P

CN&

;

IT

t'r,

CN!4

?ÿ?

r,

CNÿ

S'

i

fcf,

CN

$

:

CN

7]

fWc

:

CN

nr

*

AXIS

BOARD

*-w**

wr*

?1-

Ifi

CN6i

a

62

CN

f.

CN

69

*$»

CN

Jr8*

-ic"

TO

(g)

JANCOSR

t

*

&

e

j

PC20,

h-"

«ÿ

?r

r

..

f

f*

1

t

'

:

•"

*

L

!

-t

K

!

<*

L

t

I

t

e-:

RI/O

OPP

sx

SY

SZ

TU

RS

SD

SPC

S

4

CN21

®

©

©

_

-

@

©

©

©

©

C

232

©

@>

_

_

TO

®

200

-

1021,

TO

(§)

X-AXIS

fp3HiE

KN

Ji

n.rÿTKv:

Y-AXIS

ru

feNlCACR-

Z-AXIS

J

CN1CACR-

yg®

SEQUENCE

TURNING

iR0

©

0

DIRECT-IN

SPINDLE

7H3TZTi!I73c

I

1

4TH-AXIS

5TH-AXIS

"N

%

TO

®

REMOTE

I

1021,

CN13

INPUT

VAC

CN11

DRIVE

1CACR-

SR

;SBCM

DRIVE

™

DRIVE

TYPE

OF

ON

DRIVE

wwwag

DRIVE

DRIVE

CACR-SR'

1

CPS-10N,

I/O

MODULE

%*&

RESISTOR

STVS

RESISTOR

IT

RESISTOR

?

OPERATION

TYPE

-fFpTH

W,

©

-

RESISTOR

RESISTOR

:SB«o

m

CN12

—

SSCTSH

CRT

OPERATOR’S

PANEL

|»MMokTO*-«-CRf

}

?

a

i

.ÿ

N

M

ON

JJU

t

m

INPUT

POINTS

16

OUTPUT

32

POINTS

@

@

®

PTR

TAPE

(OPTIONAL)

@

®

®

SE3

3

TYPE

2

I

®”\

<S)

i

READER

SPINDLE

(OPTIONAL)

<§H

®~~\

0-J

JANCD-SP5*®

INPUT

48

POINTS

OPTICAL

OPTIONAL

H

f-

O

ENCODER

MANUAL

OPTICAL

ENCODER

Note

For

Nos

details,

in

see

circle

par

18

are

cable

1

Nos

•ij

*;

.

OUTPUT

40

-POINTS

INPUT

POINTS,

8

OUTPUT

POINTS

8

Fig

TYPE

INPUT

24

OUTPUT

16

6

JANCD-1021

POINTS.

POINTS POINTS

POINTS

1

i9M

INPUT

40

g.j|

INPUT

40

J11

OUTPUT

4

POINTS

(REED

RELAY)

5

7.

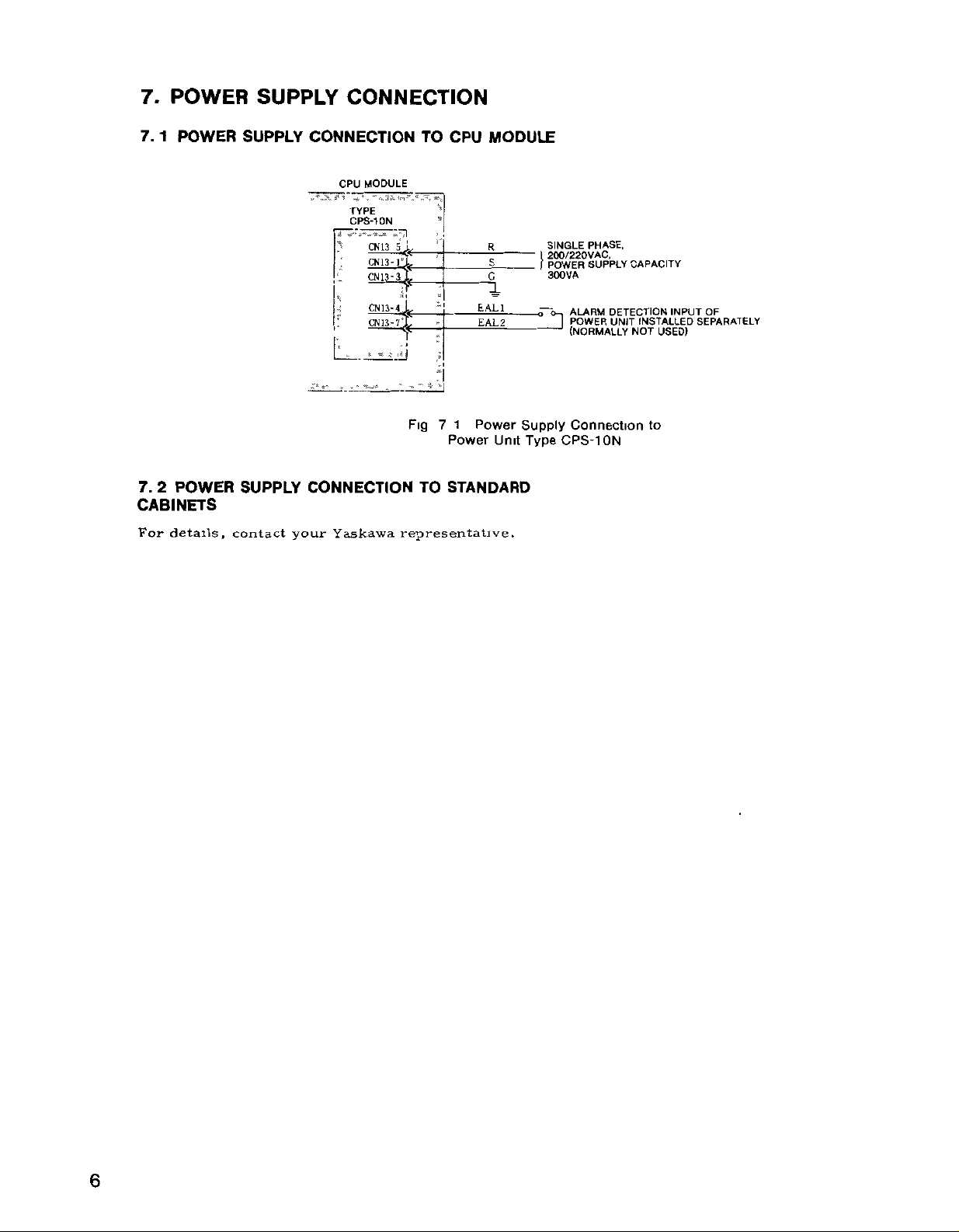

POWER

1

7.

POWER

SUPPLY

SUPPLY

CONNECTION

CONNECTION

MODULE

CPU

TYPE

CPS-10N

w-tjw*

a

s**

n;

CN13

CN13-1X

CN13-3L

i

,*<

CN13*

i

CN13

___

IL:

UISJI

<t~

•Z*

=P!

5

L

>M

4

7'

-

¥=j

1

.

J

TO

CPU

*ÿ»

*

*

«

H

MODULE

R

S

G

EAL1

EAL2

SINGLE

200/220VAC,

POWER

300VA

ALARM

-o

o-j

POWER

(NORMALLY

PHASE,

SUPPLY

DETECTION

UNIT

CAPACITY

INPUT

INSTALLED

USED)

NOT

OF

SEPARATELY

POWER

2

7.

CABINETS

For

details,

SUPPLY

contact

CONNECTION

Yaskawa

your

Fig

1

7

Power

STANDARD

TO

representative.

Power

Unit

Supply

Type

Connection

CPS-10N

to

6

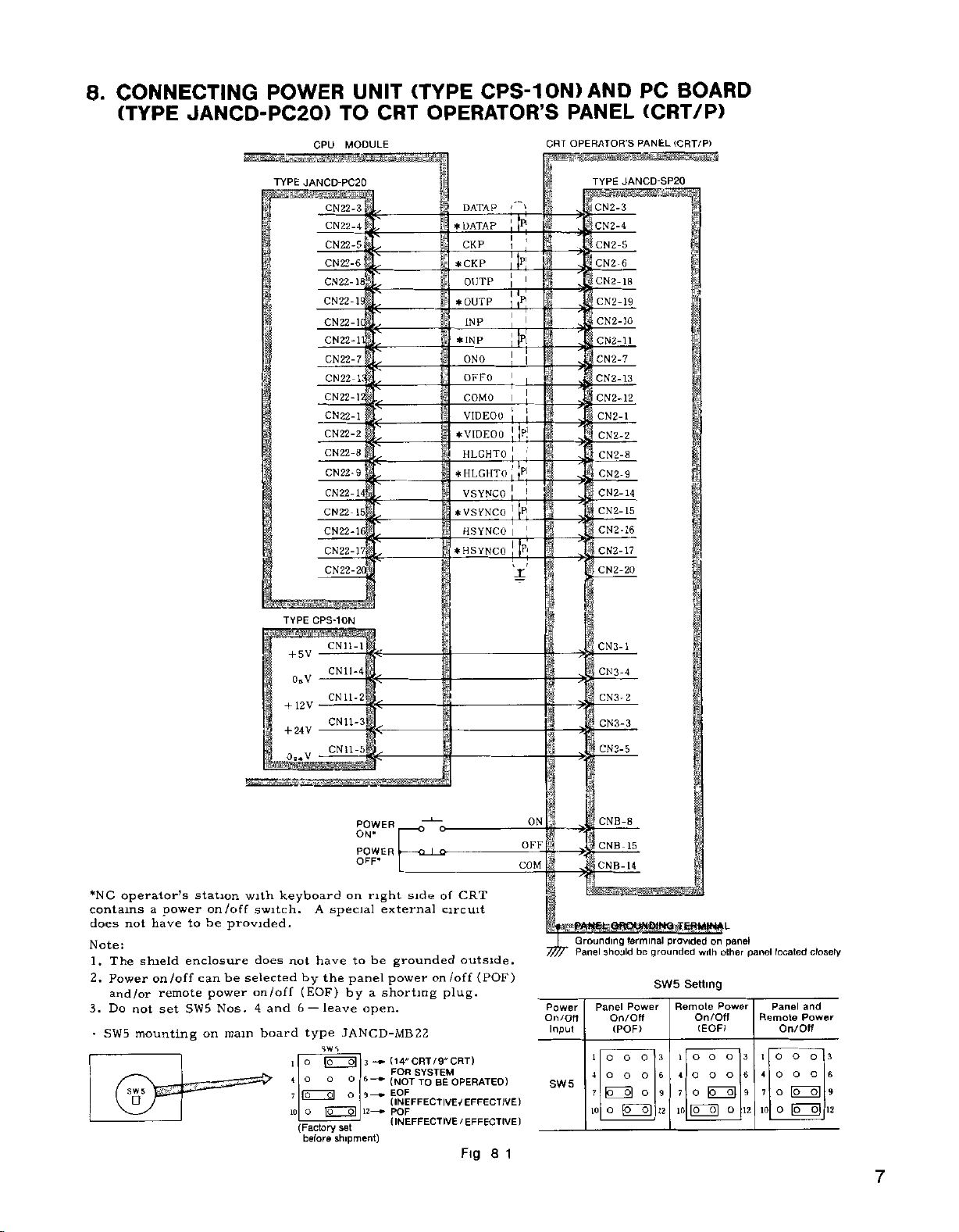

8.

CONNECTING

(TYPE

JANCD-PC20)

POWER

TYPE

JANCD-PC20

ss

1

S

r

‘

s

I

I

1

•i

;n

i

2

i

-

i

TO

CPU

CNZ2-3

CN22-4

CN22-5

CN22-6

CN22-18,

CN22-11

CN22-11

CN22-1

CN22-7

CN22-13

CN22-1

CN22-1

CN22-2

CN22-8

CN22-9

CN22-1-

CN22-15

CN22-li

CN22-1

CN22-:

UNIT

CRT

MODULE

it

S-

fcr

I

C<r

£

£

(TYPE

CPS-10N)AND

OPERATOR’S

DATAP

,

[

-

i

*

DATAP

CKP

*

*

HLGHTO

HSYNCO

CKP

OIJTP

OUTP

INP

INP

0N0

OFFO

COMO

VIDEOO

VIDEOO

HLGHTO

VSYNCO

1

*

P

i

P

1

P

1P

1

,

fP1

1

P

p

_L

\

PANEL

OPERATOR'S

CRT

*

9-

*

*

-

4

-

3

i

T

m

*1

/

1

n

m

1

I

1

..

TYPE

CN2-3

CN2-4

CN2-5

CN2-6

CN2-18

CN2-19

CN2-10

CN2-11

CN2-7

CN2-13

JANCD-SP20

CN2-12

CN2-L

CN2-2

CN2-8

CN2-9

CN2-14

CN2-L5

CN2-16

CN2-17

CN2-20

BOARD

PC

(CRT/P)

(CRT/P)

PANEL

*NC

contains

does

Note:

The

1.

Power

2.

and/or

Do

3.

•

SW5

operator’s

a

power

not

have

shield

on

remote

not

set

mounting

SW5

I£

u

station

to

enclosure

/off

SW5

on

be

can

power

on

with

/off

provided.

be

selected

Nos.

main

switch.

does

on

/off

and

4

board

CPS-10N

TYPE

wax*

ms|

5V

+

08V

12V

+

V

24

+

0,4V

2*2

keyboard

A

not

have

by

(EOF)

6

—

type

o

1

o

4

10

7

O

10

Factory

before

CNll-l

CN1I-4

CNIi-2

CN11-3

CN11-5

v'

•'

-

: :

*

POWER

ON*

POWER

OFF*

on

right

special

to

the

panel

a

by

leave

open.

JANCD-MB22

sws

01

lo

3

o

o

6

O

9

Ol

1Z-

IQ

Ol

set

shipment)

9

:

£

*1

<-

'

'ft

:

-

-

o

Q

o

1

-

on

CRT/

SYSTEM

TO

BE

CRT

of

circuit

outside.

/off

plug.

CRT)

9"

OPERATED)

/

Fig

side

external

be

grounded

power

shorting

(14"

FOR

(NOT

EOF

(INEFFECTIVE/EFFECTIVE)

POF

(

INEFFECTIVE

(POF)

EFFECTIVE

8

1

ON

OFF

COM

)

3

3

2

I

-

Power

On/Oft

Input

SW5

-

CN3-1

CN3-4

CN3-

CN3-3

I

CN3-5

1

s

I

CNB-8

1

S

CNB-15

CNB-14

Grounding

Panel

should

Panel

1

O

4

o

7

to

o

10

2

terminal

Power

On/Off

(POF)

O

o

ol

to

be

grounded

O

o

o

ol

provided

SW5

3

6

9

12

;

I

W.

I

is

i

si

Setting

Remote

On/Off

(EOF)

O O

1

4

O

O

7

|o

10

with

on

O

lo

o)

panel

other

Power

O

O

Q|

O

panel

3

6

9

12

located

Panel

Remote

On/Off

O

t

4

o

7

O

o

10

O

o

|Q

|o

closely

and

Power

O

o

Ol

o|

3

6

9

12

7

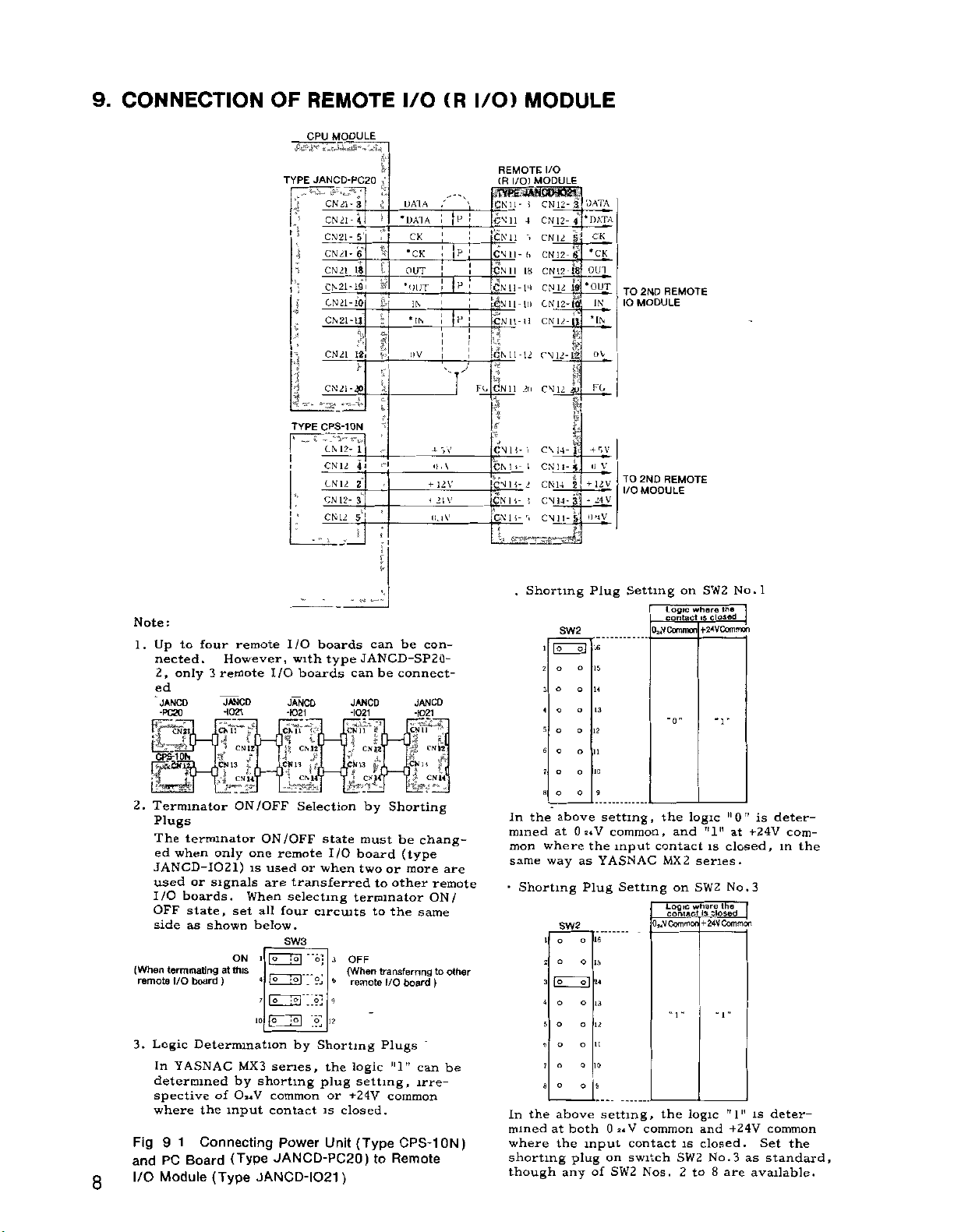

9.

CONNECTION

Note

:

to

1.

Up

nected.

2,

only

ed

JANCD

-PC20

RpÿN*

tirsL

OPTION

fr

I

2.

Terminator

Plugs

The

terminator

ed

when

JANCD-I021)

or

used

boards.

I/O

OFF

state,

side

as

(When

terminating

I/O

8

remote

3.

Fig

andPCBoard

I/O

board

Logic

Determination

In

YASNAC

determined

spective

where

1

9

Module

remote

four

However,

3

remote

JANCD

H021

i

CN

lz

-1

CN13

;

y|

*•"

ON

one

only

is

signals

When

set

shown

below.

ON

at

this

)

10

MX

by

of

0MV

the

input

Connecting

(Type

(Type

OF

REMOTE

CPU

TYPE

JANCD-PC20

i1

CN21

4

CN

CN21-

CN21-

4

CN

*1

CN21

:

l

CN21-I0

i

CN21-U

v

J

CN

1

CN21-J0

U.

TYPE

CPS-10N

i

v*'V-

-

—

CM2-

CN

CN

CN

I

4

CN

»

i.

-

boards

1/0

with

type

boards

I/O

JANCD

*1021

fi

CM2

-irryÿH

1

/OFF

Selection

ON

/OFF

state

remote

used

are

all

rÿ~~T5i

jo

4

7

i°

3

series,

shorting

common

contact

Power

JANCD-PC20)

JANCD-1021

or

transferred

selecting

four

circuits

SW3

-o]

;Q|“o!

I°J

is

by

Shorting

I/O

when

12

the

plug

or

is

Unit

MODULE

i

-

21

-

4

5

e

lj

21

1

15

-

$

12

21

*•*>,

j

1

i

4

12

12

2

12-

3

12

5.

nn

can

JANCD-SP20-

can

JANCD

J021_

1

J.

CN|2

»/

%4

by

must

board

two

terminator

3

OFF

(When

b

remote

9

logic

setting,

+24V

closed.

(Type

)

I/O

t

*c

UA1A

•DATA

ft

t

2?

•OUT

-!

&

£

tr

it

?

*“

'

l-

be

be

connect-

Shorting

be

(type

or

to

other

to

the

transferring

board

I/O

Plugs

11

1"

common

CPS-1

to

Remote

CK

•CK

OUT

IN

•IN

ciV

JANCD

-1021

1

ff"

!*

change

more

same

can

irre¬

12

+

4

21V

IUV

con¬

cJ

?r

CNM

remote

ON/

to

)

(R

V

are

other

be

ON

P

p

p

P

1

)

I/O)

REMOTE

(R

I/O)

CN'll-

11

CN

CN11

11-

CN

11

CN

CSNU-H

tgNIMO

n-ii

BN

li

u

[CN

11*12

H

F(JCN11

6

re

k?NH-

ICNU-

H-

[CN

am

CN

1

In

mined

mon

same

•

In

minedatboth

where

shorting

though

MODULE

I/O

MODULE

i

CN

12-

3j

CN

4

12-

4l*HATA

gj

CN

'»

12

(»

12-6

CN

18

CN

12-

Is

CN

12

ft

CNl2-fe

CNl2-m

fe

CN

12-13

2d

CN

12

iuj

!

g

£

1

c\

14-

L

1

CN

1-

1

4.

&

CN

2

2

14

a

r

14

CN

5

-

V

r»

CN

Shorting

1

lo

2

3

4

5

6

7

8

the

where

way

Shorting

l

2

3

4

5

6

7

6

the

1-

1

SW2

O

O

o

o

O

o

o

above

at

SW2

o

o

|o

O

o

O

O

above

the

plug

any

%

0

of

O

O

o

o

o

o

o

24

as

Plug

o

o

ol

O13O

O

o

O

o

input

1-

.

DATA

CK

*CK

OUT

*QUT

IN

*IN

<>V

FC

y

4-

»>

i)

V

12V

+

24_V

-

OMV

Plug

16

15

14

13

12

n

10

9

setting,

V

common,

the

YASNAC

16

16

14

12

11

10

9

setting,

0

on

SW2

of

TO

10

MODULE

TO

I/O

Setting

input

Setting

2*V

contact

switch

2ND

REMOTE

REMOTE

2ND

MODULE

Logic

contact

Common

02<V

”0"

the

contact

MX2

Logic

coniact

0„V

Common

“1

the

common

Nos.

on

and

on

-

is

SW2

2

SW2

whore

is

+24V

logic

"l"

series.

SW2

where

Is

+

logic

and

closed.

to

closed

“

is

closed

24V

“

No.

8

No.l

the

Common

"

1

0

"

at

closed,

No.

the

Common

1

"

,T1"

+24V

3

are

is

deter¬

"

+24V

in

3

is

deter¬

common

Set

as

standard,

available.

com¬

the

the

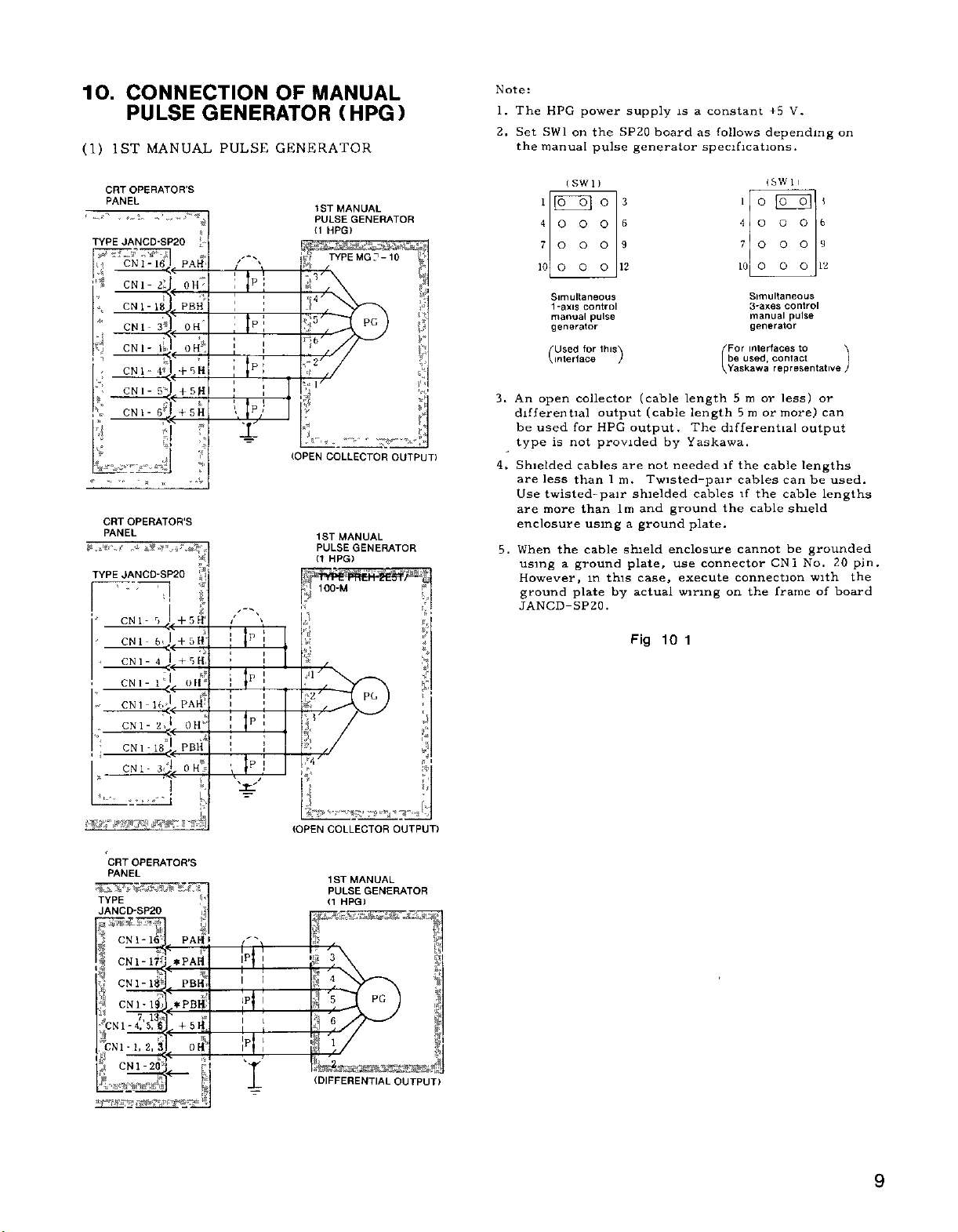

10.

CONNECTION

PULSE

(1)

1ST

MANUAL

OPERATOR’S

CRT

PANEL

JANCD-SP20

TYPE

CNl-

A

*1

4ÿ

4<

V

»

>J

S:

V

;

<*•

P

TYPE

,

•i

CRT

PANEL

I

16.

CN

1

III

-

Tv

CNl-

18

CNl-

3*J.

T

iy,

CNl-

—

-

CNl

4M.

CNl

-

5**J

6ÿ1

1-

CN

si

OPERATOR

a.*

t

A

JANC0-SP20

i

cni-

r’<'<+5ÿ

-

CNl

6*

«

4

CN

1

-

-

CNI

CNl

CN

CNl

CN1-

1

-

-

lbÿ

-

-

r

2*

18

3ÿ

?

L

I

L

1

8I

OF

GENERATOR

GENERATOR

P

p

p

p

PAH-

OH

PBH

OH

OH*:

—

+

+

+

5

6H

5H

r

a

rV

H

m

PULSE

x

v:

«<<

-V

-

S

$

<

\

5

+

r>

+

—

o

H

PAH'

OH

PBH

OH},

3

-rJi

HI

T

H>

S

b

L

p

p

4

p

P

MANUAL

(HPG)

1ST

MANUAL

PULSE

HPG)

<1

TYPE

r

_

/

*

147

3

V

i

(OPEN

COLLECTOR

MANUAL

1ST

PULSE

(1

HPG)

100-M

f

)

2

i

/

*

7r

3:.:

\r

4

:*

?=

(OPEN

COLLECTOR

GENERATOR

10

MG?-

pc

OUTPUT)

GENERATOR

PREH-2E5T/

PG

13.21

OUTPUT)

-

!

£>

A

i

V

ft

C

V.

'

t:

K

j;

::

I

,

V

h

*

**

F

3

b

Note:

The

1.

2,

Set

the

3.

An

differential

be

type

4.

Shielded

are

Use

are

enclosure

5.

When

using

However,

ground

JANCD-SP20

HPG

power

SW1

on

manual

SW

!

i

0|

[O

4

O

O

7

O

O

10

o o o

Simultaneous

1

control

-axis

manual

generator

for

Used

(

interface

collector

open

for

used

is

not

cables

less

than

twisted-pair

than

more

the

cable

a

ground

plate

the

pulse

)

1

O

O

O

pulse

this

output

HPG

provided

1

using

this

in

by

.

supply

SP20

generator

3

6

9

12

)

output.

are

m*

shielded

lm

a

ground

shield

plate,

case,

actual

Fig

(cable

and

a

is

board

as

specifications

length

(cable

length

The

Yaskawa.

by

needed

not

Twisted-pair

cablesifthe

ground

plate.

enclosure

use

connector

execute

wiring

10

1

constant

follows

For

be

Yaskawa

5

differential

if

the

connection

on

+5

depending

(SW

1

0

4

O O

7

O O

o

10

Simultaneous

3-axes

manual

generator

interlaces

used,

m

or

or

5

m

the

cable

cables

cable

cannot

CNl

the

V*

.

)

1

1°

°1

O

O

o

o

control

pulse

to

contact

representative

less)

more)

output

lengths

be

can

cable

shield

be

grounded

No.

with

of

frame

on

b

9

12

or

can

used.

lengths

20

board

pin.

the

CRT

OPERATOR

PANEL

TYPE

JANCD-SP20

CNl

i

CNl

CNl-llH

I

CNl-

I

11

7

—

7,

4

TNI

-4.

3

1,

~CN1-

d

S

E

-

16

PAH

*5*

-

*PAH

17ÿ

PBH

lÿJ>PBl|:

-

13ÿ1

$L

5.

+5H..

-

2,

3

oH

MANUAL

1ST

GENERATOR

3-

$

u

U

frr)

r

‘

P

p

*"

»

&

3

PULSE

HPG)

(1

i.

7

?—

?

*

I4

6

I

ii

(DIFFERENTIAL

PC

;*P

t

I

1

OUTPUT)

9

11.

CONNECTION

OF

INPUT

SEQUENCE

11.1

CONNECTION

CPU

MODULE

$

%

!|

TYPE

JANCD

70

mA

MAX

MB

S

QV

22

CNr>-

CN5-

CNr>-l|

l

1

T24

NCM

1

SVMX

NCMX

SVMX

POWER

NC

SERVO

ON

POWER

ON

ov

INPUT,

EMERGENCY

’

V:

CN5-1#

'

£

iv

r

P

I

i|l

I

p

-p

P

i

#

P

%

§

x*

2

p

P

P

-Nl:

P

£

--y

ife

CN

r>

CN

CN5-

CNT-1I

CN

CN

CN

>;%-

?x~

TFS

*

Si

TOL;

-

%

*

Q-

Q

%

I

-

-

r>

EON

fcCM

12

P

1

-

0

2

-

r)

2§

I

a

p

1

:P

4

1

P

EOF

4.

2

P

m

H

I

FC

.'.O

I:

vi

::

nates*-**

a

h

:

P

<

>

—

o

O

I

NCMX

SVMX

o

o-

o-

o

MACHINE

<ro-

MACHINE

OVERLOAD

(NORMALLY

EXTERNAL

EXTERNAL

NCM

SVM

TSJ

MAGNETIC

CONTACTOR

STOP

END

END

INPUT

NOT

POWER

POWER

LS

RELEASE

USED)

ON

OFF

10

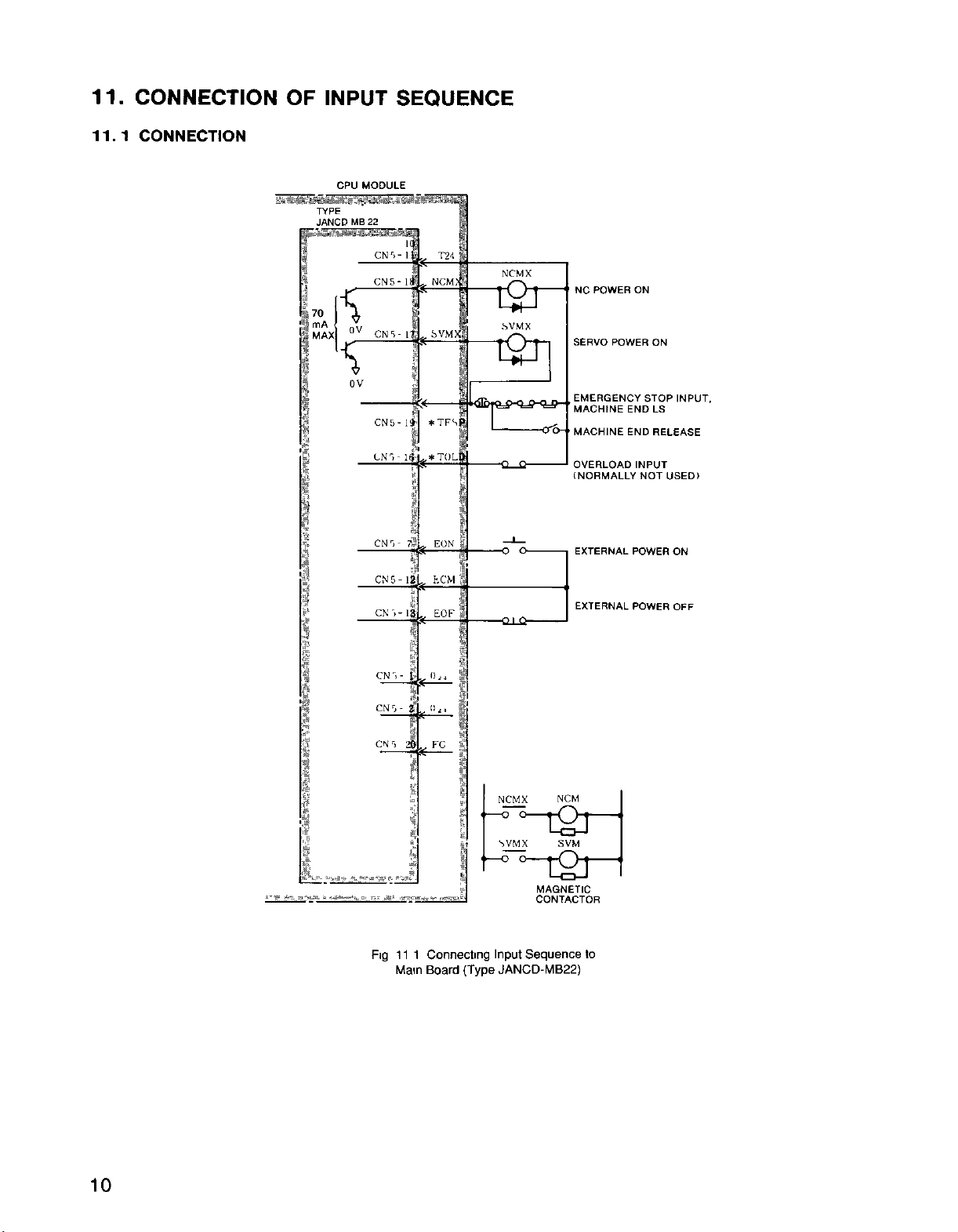

Fig

111

Main

Connecting

(Type

Board

Input

Sequence

JANCD-MB22)

to

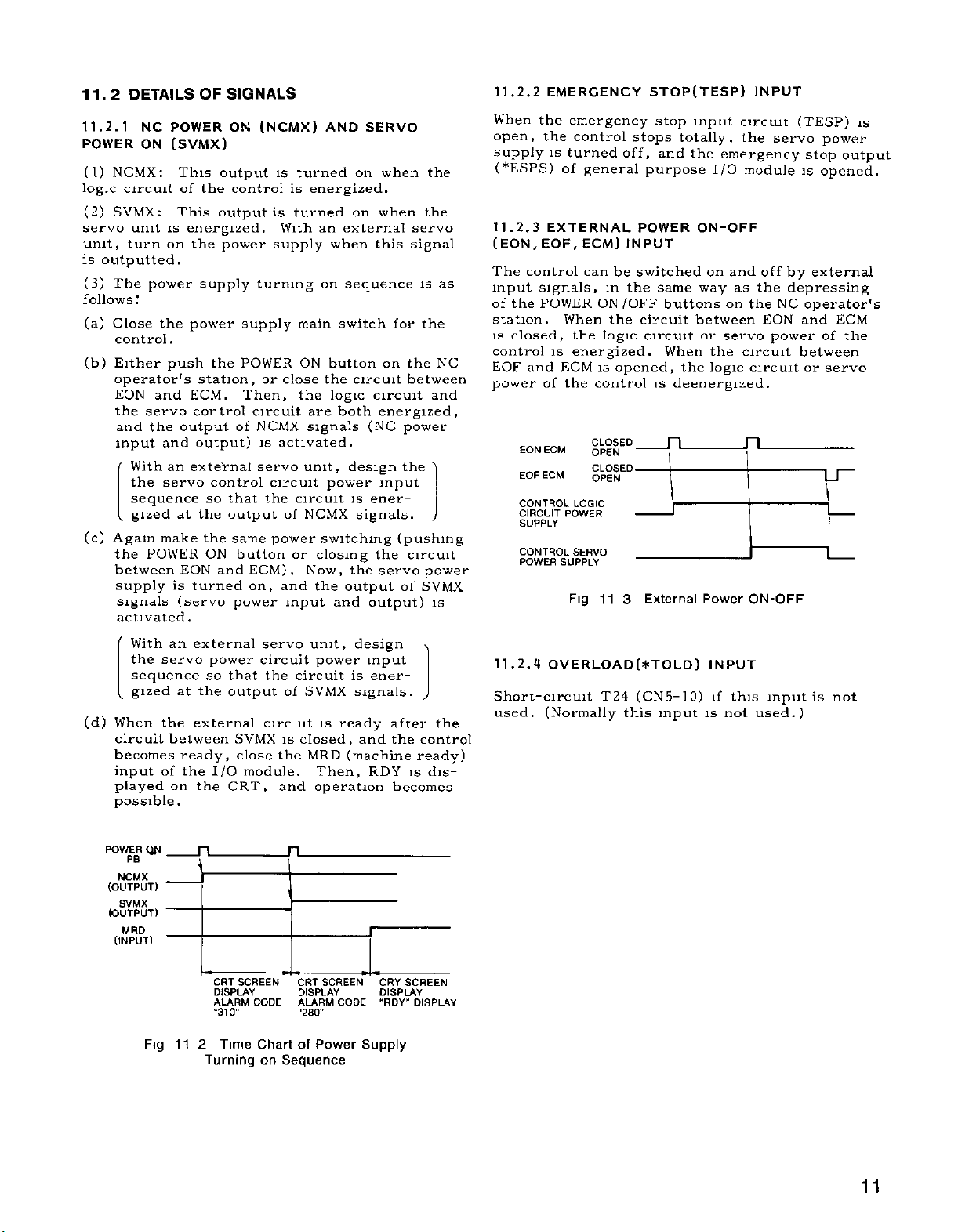

11.2

11.2.1

POWER

(1)

NCMX:

logic

(2)

SVMX:

servo

unit,

is

outputted

(3)

The

follows

(a)

Close

control

(b)

Either

operator's

EON

the

and

input

(c)

Again

the

between

supply

signals

activated

(d)

When

circuit

becomes

input

played

possible

DETAILS

NC

ON

circuit

unit

turn

power

;

the

and

servo

the

and

'

With

the

sequence

gized

4

make

POWER

With

the

servo

sequence

gized

s

the

of

OF

POWER

(SVMX)

This

of

This

is

energized.

the

on

.

power

.

push

station,

ECM.

control

output

output)

an

external

servo

the

at

EON

is

turned

(servo

.

external

an

the

at

external

between

ready,

the

on

the

.

SIGNALS

ON

output

control

the

output

power

supply

the

control

that

so

output

the

same

ON

and

power

power

that

so

output

SVMX

I/O

CRT,

(NCMX)

turning

supply

POWER

or

Then,

circuit

of

NCMX

is

servo

the

button

ECM)

on,

servo

circuit

the

circ

close

module.

turned

is

is

is

turned

With

supply

main

ON

close

the

signals

activated.

unit,

circuit

circuit

of

NCMX

power

or

Now,

.

and

input

circuit

of

SVMX

ut

closed,

is

the

MRD

and

AND

on

energized.

on

an

external

when

on

sequence

switch

button

the

circuit

logic

both

are

design

power

is

signals.

switching

closing

the

the

output

and

unit,

design

power

is

signals.

is

ready

and

(machine

Then,

operation

SERVO

when

when

this

for

the

on

between

circuit

energized,

(NC

power

the

input

ener-

(pushing

the

circuit

servo

of

output)

input

ener-

after

the

RDY

is

becomes

the

the

servo

signal

is

the

and

power

SVMX

is

control

ready)

dis¬

as

NC

the

11.2.2

When

open,

EMERGENCY

the

the

supply

(+ESPS)

11.2.3

(EON,

The

input

of

station.

is

control

signals,

the

POWER

closed,

EXTERNAL

EOF,

control

EOF

and

power

11.

of

ECM

EON

ECM

EOF

CONTROL

CIRCUIT

SUPPLY

CONTROL

POWER

U

2.

Short-circuit

used.

(Normally

STOP(TESP)

emergency

control

is

turned

of

general

ECM)

can

in

ON

When

the

is

OVERLOAD(*TOLD)

logic

energized.

ECM

is

the

control

CLOSED

OPEN

CLOSED

OPEN

LOGIC

POWER

SERVO

SUPPLY

Fig

113

T24

stops

off,

purpose

POWER

INPUT

be

switched

the

/OFF

the

circuit

circuit

opened,

External

(CN5-10)

this

stop

and

same

is

input

input

totally,

the

I/O

ON-OFF

on

way

buttons

between

or

When

the

the

logic

deenergized.

J

Power

INPUT

if

is

INPUT

circuit

the

servo

emergency

module

and

off

the

as

on

the

NC

EON

servo

power

circuit

circuit

ON-OFF

this

input

used.)

not

(TESP)

power

stop

output

is

opened,

external

by

depressing

operator's

ECM

and

the

of

between

or

servo

U~

is

not

is

POWER

PB

NCMX

(OUTPUT)

SVMX

(OUTPUT)

MRD

(INPUT)

Fig

11

CRT

DISPLAY

ALARM

“310"

2

Time

Turning

SCREEN

CODE

Chart

on

CRT

SCREEN

DISPLAY

ALARM

"280'’

of

Power

Sequence

CODE

CRY

DISPLAY

“RDY"

Supply

SCREEN

DISPLAY

11

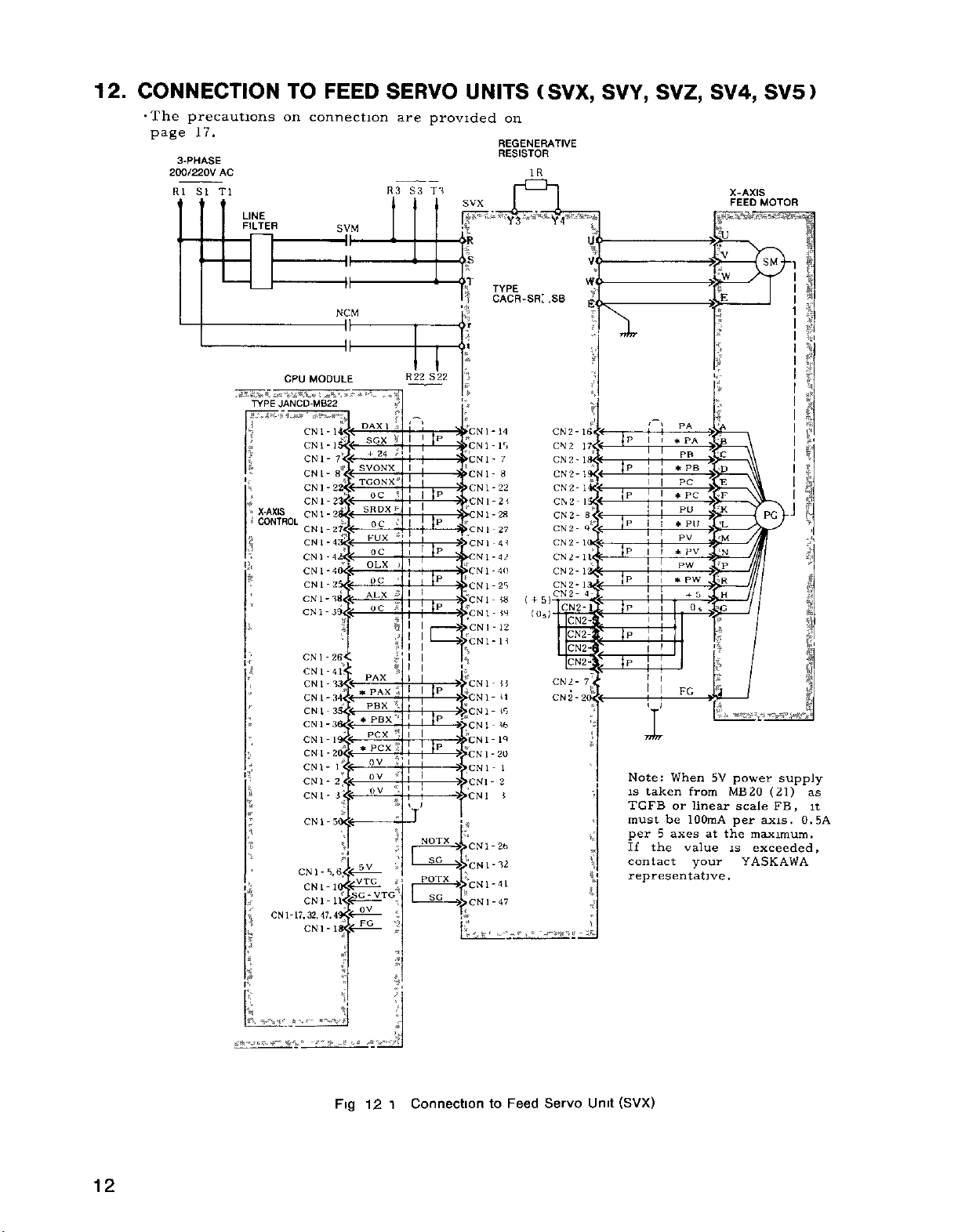

12.

CONNECTION

•The

page

3-PHASE

200

R

1

precautions

17.

/220V

AC

T

SI

1

-;at--vr8y.

LINE

FILTER

TYPE

«

4

1

1

•Si

5

r,

X-AXIS

-

CONTROL

*

5

h

t

l

"

4

r

:

r

8

I’

a

*

tr

f

t*

1

%

‘i

4

s£

%

J

S

<v

a

:::

TO

FEED

on

connection

SVM

NCM

MODULE

CPU

,*v.

«

«

‘

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

CN

r*0

-

1

14«

-

1

13<4

-

1

1

-

22<|&

-

1

-

1

23&

2$&

1

-

-43<£

42<£

-4<X»

-

1

18.

1

-

1-39.

-

1

26<

-41&

-

1

I3<t

1

3w

-

-

3S&-

l

7<SF

jpT

f

~

-

-

JANCD-MB22

4

«»ir

*4-

’

*

CN1-2

CNl

CN1

CN1

CN

CN

CN

CN1

CN1-36A-

19«-

CN1*

&ÿ

-20

CN

1

1

*

-

CN

1

«

CN

1

-

2"<Sfc

-

3

CN

1

if

CN

1

50<fe-

-

i

i

CN1-S,6ÿ-5V

lOQf

CN1-

-

CN

n

1

47.49<fe-ÿ

32,

CNl-17,

CN1-

at

«

::

%

a-wvrj

r~

ft--.

-a1"

jF~*

»

SERVO

R

vn*i

DAX

1

SGX

24

+

SVONX

TGONX

PC

SRDX

PC

FUX

—

OLX

££

ALX

C

0

PAX

PAX

*

PBX

PBX4*

*

PCX

PCX

*

ov

0V

PV

VTG

VTG

-

3

r

!

a

r

1

Is-

5

J5J

-

<>

s

*

1

*1

4

*<i

8

c

%

)

:>

*

i

x.

V

a

tt

&

1

„

•v

•>

are

R22

(

v

>

«

t

provided

T3

S3

S

(

JZ

IE

IT

IT

IT

>

T

NOTX

—

POTX

SC

22

9S>CNl-2l

P

P

»CN

»CN

»CN

>>CN

»CN1-

4>CN

>>CN

“©ÿCN

»CNl-20

»CN

SpCNl

vCN

f

—

»CN1-41

»CN

UNITS

on

REGENERATIVE

RESISTOR

SVX

ja

t

R

s

•T

TYPE

CACR-SR:

-

<!

a

**«

>«

a

*

.*

o

1-14

CN

13

1

-

7

1

-

i

1-8

CN

•CN

22

1

-

-

28

CN

1

--

CN

1-27

-

CN

4

1

CN

1-42

-40

CN

1

!•

2r>

-

CN

1

-

*8

1

-

IS

1

1

12

-

-

i

n

i

K

-

H

1

U

lr;

1

-

-

lb

1

1

-

11

1

1

-

-

2

i

1

1

.

-

2b

1

32

l

-

1-47

it

w11"1,

fc-

-r.

%>

*

(SVX,

1R

,SB

(

5)

+

(Os)

11

i

IT

16«

CN2-

CN

2

I7<fe

13&

CN2-

CN2-

1

CN

2

l&fr

-

-

CN

2

1S«-

CN2-

8<<

-

CN

2

<*«

CN

2

-

lOcfe

CN

2-1

12ÿ

CN2-

-

CN

2

13<&

4-Y

CN2-

CN2-

]CN2ÿj

"

CN2-!

CN2

CN2-j

CN2-

7V

*

CN

2GN»

2

-

%

~

f

SVY,

K

(

V

f

*'<

t*

*t

SNC*

US-

l

1.1

5

1

r<

•*

a

i1

4

4

1

SVZ,

P

IT

IT

IT

IT

IT

IT

IT

TP

Note:

When

taken

is

TGFB

or

be

must

5

axes

per

If

the

contact

representative

PA

PA

*

PH_dC

PB

*

PC

PC

»

PU

PW

»

PV

PV

*

PW

PW

*

+

FG

from

100mA

value

SV4,

3

»>£

3

yLF

>>L

JJN

3

3

D

$

linear

at

your

dJ

:w

-

2

•r

|S

a

V

a

ft

IA

jD

:K

/M

•IP

•:•

-ÿ

&

X.

fsj,

5V

V

E

H

the

.

X-AXIS

FEED

MOTOR

C,»»V>tyg*

*

power

20

MB

scale

axis.

per

maximum.

exceeded,

is

YASKAWA

SV5)

SM

1

f

2*

S

**ÿ

#

4

I

a-

tr

f

*

c

f

r

-

I

I

r

h

PCYJ

>*

5

*•£

-

$

&

I!

I

>a.Ar

supply

(21)

FB,

0.5A

a

,

-

as

it

12

Fig

12

Connection

1

to

Feed

Servo

Unit

(SVX)

U-C

TYPE

I

At

i

i

*4

Y-AXIS

’

CONTROL

I

4

ft

;

4

1

I

$

::

>:

11

4

I

1

%

:W

M

)

%

"I

3

:3

•

-

3-PHASE

200/220VAC

MODULE

CPU

'

JANCD

MB22

i,~l

Si*

<

CN2-1W

CN

2

CN2-

2

CN

CN2-28*»

CN

2

CN2-

CN2-42A

CN

2

CN2-25«

2

CN

CN2

CN

2

CN2CN

2

CN

2

CN2-

2-3

CN

2-1

CN

CN

2

CN

2

CN

2

CN

2

CN2-

2-5,

CN

CN2-

CN2-

CN2-17

32.47.4

CN2-

•

-----

m,

*

-

15<3£

7&

23«

-

-

27ÿ£

43<fc

-

4Q«*r

3

-

-

39&

I

r

26<

-

4X*<

-

-

34«-

35<C-

-

20<£

-

1

-

2<«

3«t

'

50«

f

,4

"gVTC

1

>t<sG-

It

•

j

1

st]

S!

•

-

,

:

i

R

R22

S

22'

<

•*.

!??•«

DAY

SGY

4-

24

SVONY:

SRDY

C

0

FUY

oc

OLY

OC

ALY

OC

PAY

PAY

PBY

PBY

PCY

PCY

V

0

ov

ov

V

5

VTG

V

0

FG

**

<*

*

*;

r

s

r

;

V

«•

f1

I

L

H

l

L

J-

i:

I

-

<<

£ÿ

t,

*:

*

r

s?

?

S*"

V

£

T

.

EP*ÿ

u

E

£>CN1

-

®CN

-

r—

1

»CN

-

»CN

I

-

IP

X»

-

*

-35JCN1

»CN1

E

*NCN1

,

«wCNl

-ScN

—

T

»CN1

-

*£ÿ

icN

—

»CN1

-

1

»CN

-

E

*CN

P

Tÿ“

fCNl-lH

»CN

-

*

»CN

-

»-CNl

-

»CN

-

NOTZ

»CN

Sÿ-»CNl

POTZ

»CNl-4l

SG

»CNl-47

SVY

*

S

T

*

>

3

r

'ÿ

>

CN

1

.V.

Tu

i

!

i

1-

N1

1

1

1-

1

1

1

1

1

1

l

1

1

1

1

;

REGENERATIVE

2R

RESISTOR

xa

J

uYr

TYPE

CACR-SR['.]SB

12

-

lr>

-

7

8

-

i

2

-

28

-27

1

4

-42

40

2*»

-

4H

I

»

51

io

U>,)

14

-

H

-

H

-

<4

-

ir'

-

-

20

-

1

-

2

-

i

-

20

«

Y4

CN

CN2-

CN

CN2CN

CN2

CN

CN

CN

CN2-

CN

CN

CN

CN

CN2-

*

2

2-

2

2

2

2

2

2-

2

CN2-

CN2-I

CN2-:

CN2

CN2-;

2

r

&

wo

6*

!

l

it

I

s

\

4!

1S<*

17«t

l&fe

19ÿ&

!4dE

15&

a

-

-

-

llkK

IKK

-

12&

1

*

4

:•

7

V

20«£

is

>t

L

i

&

'4

3

>ÿ

li

s

_

1

IE

E

IE

]

E

[P

E

E

z

p

I

Y-AXIS

MOTOR

FEED

*

SMri

P

t?.

#

i

«

.c

J

i

n>

PA

PA

*

C

PB

jL’u

PB

*

PC

E

[»F

PC

*

*

PU

>

PU

*

PV

XM

PV

«©*

*

PW

*

4ÿ

pw

XH

*

4

5

>y-

c

P9

)

-

FC

&

«<*

g

9

4

...

f

£

-

?

?

I

l

£

PcV-l

5

«•

C-

»»

>a

1;

tj

Uj

?

%

S.

'H

S,

~

:

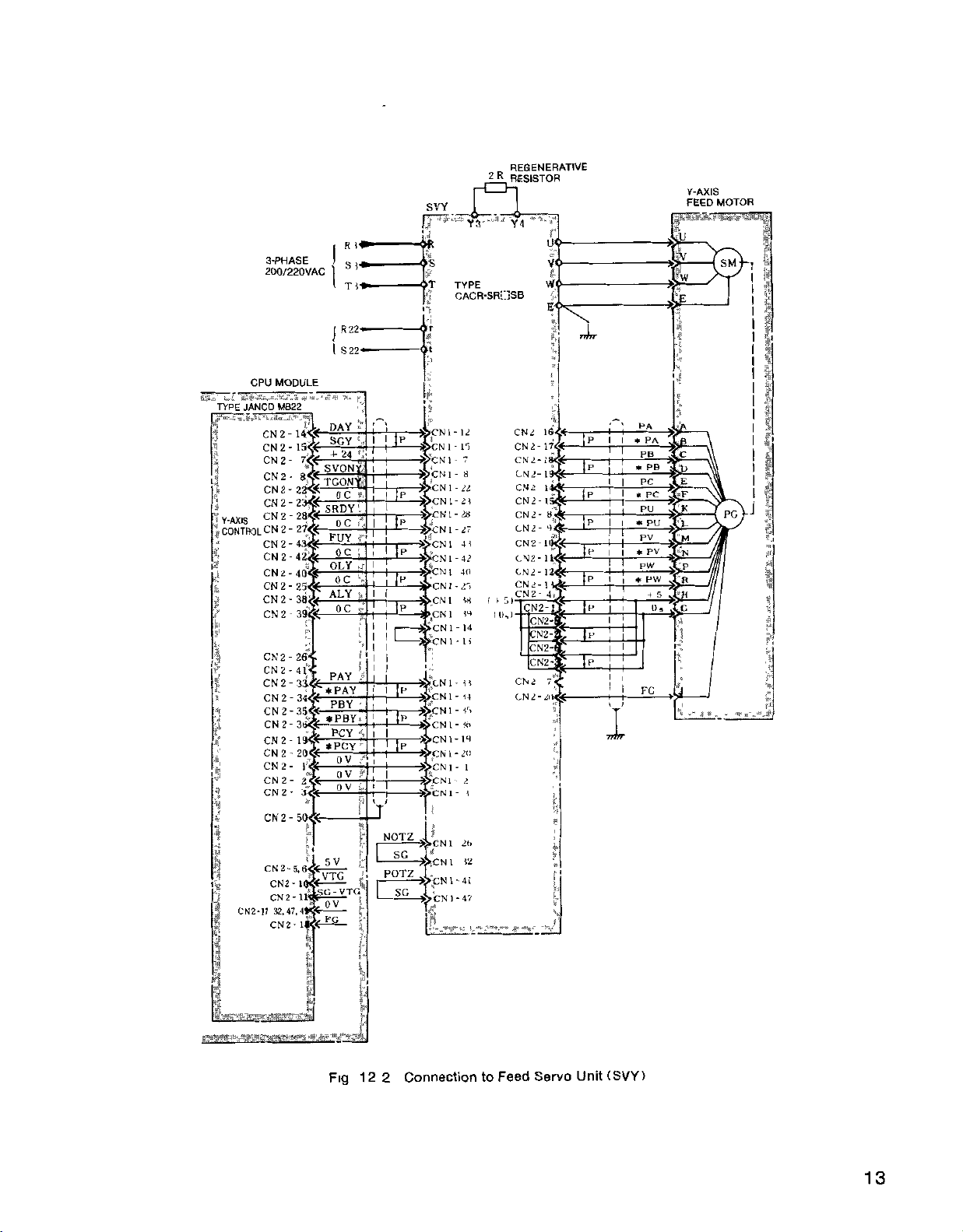

Fig

12

Connection

2

to

Feed

Servo

Unit

(SVY)

13

12.

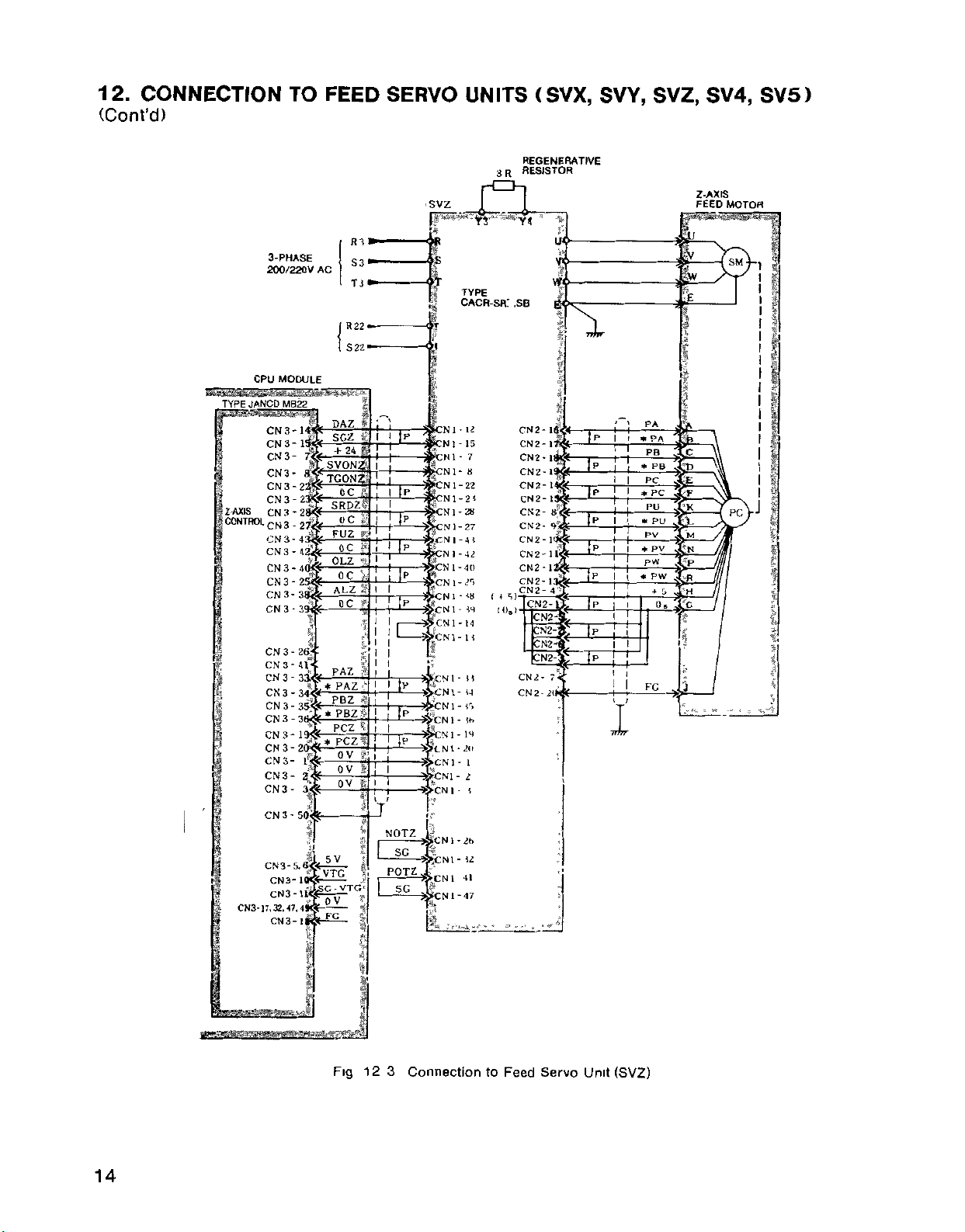

CONNECTION

(Cont’d)

CPU

JANCD

TYPE

Z-AXIS

CONTROL

*:

£

CN3-17,32.47,4#»

TO

FEED

3

R

3-PHASE

200/220V

CN3CN3CN3-

CN

CN

CN

CN

CN

CN3-4i&

CN

CN3-

CN3-2»&

CN

CN3-

CN

CN

CN

CN

CN

CN3-36&

CNJ-Z»*,PCZ'

CN

CN

CN

CN

CN

CN3-l(Wf

CN3-'#fv

CN3-

MODULE

MB22

1

1!

:

3

-

-

3

2»|-

2ÿ

-

3

3

2

-

3

27&

-

3

-

4Z<&

4{HS

3

-

3$fe

3S&

c

-

3

26*

3

-

4X<

-

3

3

£&

3

-

3

-

3

-

3

2j«

-

3

S&

-

3

50

-

2

?

li

5,

3~

6p

AC

L

riiij

Z

»

$

VTC

-

SVON

TGON

5V

R22

S

22

I

I

£

DAZ

scz

|

I

JP

OC

-

SRDZ;

OC

fe

rUZ_ÿ

OC

£

OLZ

3

y

oc

ALZ

£

;

oc

'I

2

h

c

PAZ

i?

.

PAZ

2

PBZ

|

PBZ

_

ov

I

V

I

0

OV

f

-

/i-

s

;

e

VTO1

-

?

%

|

->

t

,

v-

2

:

A-

2

I

SERVO

SVZ

p’

2

'*

i

UNITS

'

-ft

TYPE

CACR-SR:

i

N1

12

IE

I

r.

—

TF-I™1-28

1

-

F

p

-

;

-

IP