Page 1

mtsr

xJMW

SnSsSM?

pr

m

1

a

fU

'v~v

tr

gw

thoroughly,

W

tor

Before

read

future

these

/r?rt/e/

/nsfrucf/ons

and

reference.

opera

retain

ffon

T0E-CQ43-7.30C

INSTRUCTIONS

$8ÿ

g

fÿM

Wm

YASN.

_

tt&

Hi

m

give

and

N

Y

J

s

E

operators

opera¬

optional

features

tool

G

A

Z

U

P

K

T

F

MJ*»

/

•

A

I

7

C

B

V

W

Q

H

0

8

I

I

R

I

9

5

6

4

3

1

2

0

m

to

programming,

basic

optional

specifications

the

the

machine

0

X

I

%

M

L

JB

MX1.

refer

intended

MX1

to

the

The

For

to

f

IJSL

This

instructions

are

of

builder's

tion

This

features

marked

your

manual

and

•f

X

0,2?

\

/

y

V

1

h.

is

for

maintenance.

manual

YASNAC

of

with

YASNAC

manual.

:

•

\»*i

"*

,49.

50.

50.

primarily

YASNAC

applies

a

dagger.

MX1,

704

000

000

YASNAC

MX

1

OPERATOR'S

*81-273

STATION

Page 2

PREFACE

Read

this

mation

possible

The

operations

should

functions

The

determined

NC

control.

the

machine

over

ority

1.

2.

2.1

2.

2.3

2.

2.

2.6

2.

2.

2.

2.

2.1

3.

3.1

3.2

3.3

3.4

4.

CHARACTER

4.1

4.2

4.

4.4

4.5

4.6

4.7

4.8

5.

5.1

5.

manual

contained

contingency

not

not

be

attended

and

combination

a

by

For

builder's

tool

this

manual.

INTRODUCTION

PROGRAMMING

Format

Input

2

Program

Coordinate

4

Traverse

5

Spindle-Speed

Function

Tool

7

Tool

Compensation

8

Miscellaneous

9

Preparatory

10

user

Message

User

PART

Tape

Macro

PROGRAM

Code

1

Programming

NC

Tape

NC

Tape

NC

OPERATOR'S

Pushbuttons,

Power

On

3

Display

Tape

Input/Output

Loading

138

Edit

Input

Data

Verifying

Tape

READER

TAPE

Reader

Tape

T

2

ape

Reels

keeping

herein

to

described

performance

operation

Number

Word

and

Feed

Function

(T-Functton)

Functions

Function

Displayÿ

(C65

110

Punching

113

DISPLAY

Lamps

Operation

/Off

Writing

and

programs

Part

/Output

Compartment

’

149

in

does

be

with

manual

1

and

and

110

145

148

mind

not

met

with

in

the

as

of

machine

of

your

I

1

Sequence

6

Functions

(S-Function)

14

(M-

(C-Function)

C66)

TAPE

113

STATION

114

and

Operation

Operations

Into

Interface

that

cover

the

this

control.

NC

NC

shall

TABLE

13

Function)

83

84

CODINC

Keys

119

of

Memory

148

the

every

manual

machine

machine,

take

Number

9

WITH

114

120

NC

140

infor¬

operation.

the

and

pri¬

OF

13

15

21

110

CRT

DATA

135

Unless

apply

ples

•

Least

•

are

Feed

*

Absolute

•

Reference

(Return

matic

•

Dimensions:

CONTENTS

6.

MACHINE

6.

1

Switching

6.

2

Operation

6

132

OPERATION

7.

7.1

Inspection

7.2

Turning

Manual

7.3

7.4

Preparation

Compensation

7.5

Preparation

7.6

Operation

7.7

Manual

Operation

7.8

Automatic

7.9

MDI

Operation

7.10

Preparation

7.11

Turning

MAINTENANCE

8.

8.

1

Routine

8.2

Battery

8.3

Power

4

8.

Thermal

8.

5

Others

8.6

Trouble

APPENDIX-1

APPENDIX-

APPENDIX-3

COMPENSATION

APPEND!

OUTPUT

otherwise

the

to

shown

Input

Function

return)

Operation

and

Operation

175

Operation

1

76

Off

Inspection

Replacement

Circuit

Overload

Causes

2

4

X-

SIGNALS

description

in

this

Increment:

Zero

Zero

reference

to

CONTROL

Units

Procedure

PROCEDURE

Before

on

Power

for

Stored

for

in

Tape

Operation

Interrupting

for

Power

Breaker

155

LIST

LIST

STORED

LIST

specified,

manual.

Selection:

Point:

Point

:

Qk

MM

in

on

the

Turning

173

173

Stored

Stroke

Automatic

and

Interrupting

in

Turning

176

178

Schedule

Relay

and

Remedies

OF

SETTING

OF

PARAMETER

LEADSCREW

209

OF

STANDARD

213

of

zero

STATION

Control

163

on

Leadscrew

Limit4ÿ

Operation

Memory

Mode

MDI

Automatic

Off

Power

181

Fuses

and

of

Servo

the

following

programming

0.01

mm

(mm

G94

manual

by

155

Station

/

73

Power

Error

173

Mode

Automatic

175

176

178

182

Unit

185

NUMBERS

NUMBERS

ERROR

INPUT/

173

173

175

/min.)

1

55

184

rules

exam¬

and

auto¬

187

192

APPENDIX

APPENDIX-

5

LIST

OF

ALARM

6

LIST

OF

ADDRESS

COOES

CHARACTERS

222

234

Page 3

INDEX

Subject

Absolute

A

Absolute

Address

ADDRESS

ADDRESS

Address

Alarm

Alarm

ALARM

Alarm

Alarm

Argument

Automatic

Automatic

Automatic

AUTOMATIC

Automatic

Automatic

Axis

AXIS

B

Battery

BATTERY

Breakpoint

Buffer

C

Cable

Canned

Cautions

Circle

Circuit

Circuit

Circular

Circular

(M97/M96)

Command

Considerations

Constant

Control

Control

Coordinate

COORDINATE

CRT

Current

CURSOR

CYCLE

D

DATA

Data

Setting

DATA

Decimal

Display

DISPLAY

DISPLAY

DRY

Dwell

Zero

/Incremental

and

Function

CHARACTERS,

Keys

Search

Code

Display

Codes

and

CODES,

Message

Number

Designation

Acceleration

Centering

Coordinate

OPERATION,

Return

Tool

Control,

INTERLOCK

REPLACEMENT

Function

Storaget

Connector

Cycles

in

Programming

Cutting

Breaker

Breaker

Interpolation

Path

t

Data

Display

Commands

Panel

Word

Character

Position,

Keys

START

INPUT

Input

/Output

of

Keys

Point

and

Write

AND

LOCK

RUN

Switch

(G04)

(G92)

Point

Programming

Remedies

OF

LIST

Display

User

of

Function

System

to

Reference

length

4Th

Input

•

Specifications

(G73,

G74,

G13)+

(G12,

for

Servo

of

Composite

Mode

On/Off

Display

and

Remarks

•

* *

WORD

Display

Displaying

Pushbutton

/OUTPUT

Interface

Programming

of

Local

WRITING

/MACHINE

,

Programming

Characters

LIST

by

#8000

Macro

*

*

and

Deceleration

(G36,

Settingf

PREPARATION

Measurement

*

(G02,

INTERFACE,

Point

•

G76,

....

•

Control

Control

G03)

Tool

on

for

and

and

to

Variables

OPERATION

LOCK

(G90,

OF

Command

4

-

•

G3?)+

(G28)

+

G77,

•

Power

Radius

User

Resetting

Lamp

SUPPLEMENT

be

used

and

Switch

of

G91)

•

*

•

G80

Macros

* *

and

Common

•

•

FOR

+

G98,

G89,

to

Supply

Compensation

Rate,

Baud

Variable

TO

Unit

G99)+

*

C

•

Chapter

2

2

2

APPENDIX

4

4

*

*

4

•

8

APPENDIX

2

2

*

2

•

2

2

6

7

2

6

• •

2

6

8

8

•

4

2

4

2

••

3

2

*

8

.

8

•

-

2

2

4

*

•

2

4

2

•

8

2

2

4

4

4

6

4

4

4

2

•

•

2

4

6

6

2

Section

2,9.31

2.9.30

2.1.1

*

6

5

4.1.4

4.3.10

4.3.10

8.6.2

*

•

2.10.1

2.11,10

2.11.2

2.4.6

2.9.19

6.2.2

7.5

2.9.14

6.2.3

2.3.4

6.1.29

8.1.4

2

8.

4.3.11

2.1.5

4.7.4

2.9.29

3.2.3

2.9.9

8.3.5

8.3.1

2.9.4

2.8.6

4.3.2

2.

11.9

4.3.1

2.11.6

8.1.2

2.3.1

2.3

4.1.2

4.3.4

4.1.8

6.1.2

4.7

4.7,2

4.1.5

2.1.3

2.11.8

4.3

1.21

6.

6.1.20

2.9.6

Page

79

79

3

234

116

.....

130

.....

130

185

222

83

----

105

86

----

12

----

37

-

444

•

164

173

.....

.....

.....

.....

......

......

......

.....

......

......

34

164

444

*

•

8

•••ÿ

162

180

181

131

5

114

68

112

28

183

182

24

19

121

102

----

120

99

179

7

6

115

124

117

155

140

140

116

5

102

120

160

160

27

ii

Page 4

Subject

EDIT

£

EDIT

EDIT

Editing

Keys

LOCK

E1A/ISO

EMERGENCY

Stop

Exact

Exercises

EXTERNAL

FI-Digit

F

Feed

Function

FEED

HOLD

Feed

Per

Feedrate

Feedrate

FEEDRATE

FEEDRATE

FUNCTION

Fuse

Blowing

for

Fuse

of

Fuses

of

Fuses

Codes

G

G

G06)

(GOO,

(G01)

Linear

G03)

(G02,

G03)+

(G02,

(G04)

Dwell

(G09,

G61,

(G10)

Tool

Gl3)t

(G12,

(G17,

G18,

G21)ÿ

(G20,

(G22,

G

(G27)

Reference

(G28)ÿAutomatic

(G29)ÿReturn

(G30)ÿReference

(G31)ÿSkip

1

(G33)

Threadcutting

G37)T

(G36,

(G38)ÿZ-Axis

(G40,

G41,

G44,

(G43,

(G45

to

(G5Q,

G51)rScaling

(G52

to

4-

(G60)1

Unidirectional

(G70,

G71,

(G73

G74,

,

(G80,

G81)ÿOutput

(G90/G91)

(C92)

Programming

G95)1

(G94,

(G100

through

Switch

Operation,

Auto-Recognition

STOP

(G09,

G61

User

of

Macro

DECELERATION

Programmingt

Designation

Pushbutton

Revolution+

(F-Function)

.........

1/10

OVERRIDE

OVERRIDE

Keys

(Alarm

Control

Servo

Composite

Input

Power

Groups

and

Positioning

Interpolation

Circular

Helical

G64)

Exact

Value

Offset

Circle

G19)

Plane

Inch/Metric

23)

+

Stored

Point

Return

from

Point

Function

Automatic

Reference

G42)+Tool

G49)"*’Tool

G48)

Tool

Position

G59)tWork

G72)

Hole

G76,

G80

Absolute

Feed

Function

102)

Summary

Pushbutton

G64)

,

and

CANCEL

Switch

331,

No.

Power

Control

Unit

,

of

List

Interpolation

Interpolation

Stop

Designation

Cutting

Designation

Designation

Stroke

Limit

Check

to

Reference

Return

Centering

Surface

Radius

Length

Offset

Function

Coordinate

Approach

Pattern

G89,

to

External

for

/Incremental

of

Absolute

Designation

High-Speed

of

•

Input

G95)t

(G94,

Lamp

Switch

332)

Unit

Power

Supply

Reference

Zero

Function

Offset

Compensation

Compensation

System

Cycles

G98,

Motion

Programming

Zero

Cutting

INDEX

*

*

+

s

Signal

•

*

*

•

...

.

•

*

-

-

Unit

....

G

by

Code

.

Point

•

Setting

.

G99rCanned

Point

•

Feature

* *

*

*

ion

•

*

•

Sect

4.

6

4.1.

6.1.28

4.8.4

3.1.2

6.1.4

2.9.7

2.

ii.

6.

1.30

2.4.4

2.9.32

6.1.3

2.4.5

2.4.2

2.4.3

6.1.13

6.1.12

4.1.3

8.4.1

8.3.4

8.3.2

8.3.3

2.9.1

2.9.2

2.9.3

2.9.4

2.9.5

2.9.6

2.9.7

2.9.8

2.9.9

2.9.

2.9.

2.9.12

2.

9.13

2.9.14

2.9.

2.9.16

2.9.

2.

9.

2.9.19

2.

9.

2.9.21

2.9-

2.9.23

2.9.24

2.9.

2.9.26

2.9.27

2.9.29

2.9.

2.9-30

2.9.31

2.9.32

2.9.33

Page

10

138

117

162

146

-

•

110

.

155

.

n

27

105

162

.

.

.

.

.

11

80

155

12

10

11

159

157

.

115

.

184

183

182

183

21

23

23

24

26

27

27

28

-

10

11

15

28

31

31

32

33

34

35

36

17

18

20

22

36

37

37

39

39

53

55

60

25

62

64

65

68

28

67

79

79

80

80

Chapter

4

4

6

4

3

6

2

2

6

2

2

6

2

2

2

6

6

4

8

8

8

8

2

2

2

2

2

2

2

2

2

2

2

2

*

2

2

2

2

2

2

*

C

2

2

2

2

2

2

2

2

2

Cycles

•

•

-

2

2

2

2

2

2

iii

Page 5

INDEX

Subject

H

andD-function

H-

HANDLE

HANDLE

HANDLE

Helical

AXIS

Dial”!'

Dials

Interpolation

High-Speed

Pattern

Hole

l

Inch/Metric

Input

Format

INPUT

Input

FORMAT

/Output

Input/Output

INSPECTION

Interface,

Internal

Toggle

INTRODUCTION

JOG

J

L

M

FEEDRATE

JOG

Pushbuttons

Skip

Label

Input

Least

Linear

Interpolation

(MOO,

M01

(M90

(M91/M90)t

(M93/M92)+

(M95/M94)

(M97/M96)+

Compensation

(M98,M99)

M

M

M

Codes

Codes

Codes,

to

M199)

for

for

M-FUNCTION

MACHINE

Maintenance

MAINTENANCE

MANUAL

MANUAL

MANUAL

TION

MANUAL

MANUAL

Manual

Maximum

Message

MDI

MDl

MEM

MIRROR

Mirror

Miscellaneous

MISCELLANEOUS

MODE

Return

Display

MODE,

OPERATION

DATA

IMAGE

Image

SKI,

(H,

Select

(Manual

for

Simultaneous

Cutting

Cycles

Designation

Signals

Signals,

3EFORE

and

Type

Switches

Switch

Function

Increment

,

M02,

M30)

M

Codes

Program

Active

Multi-

Mirror

Image

Circular

C

Subroutine

Internal

(MOO,

Stop

Call,

*

LOCK

Before

Other

CONTROL

ABSOLUTE

OPERATION

OPERATION

MULTIPLY

PULSE

REFERENCE

to

Reference

Programmable

by

AUTOMATIC

INTERRUPTING

(Memory

AXIS

On

/Off

Function

EOT

FUNCTION

Switches

Codes)

D

Switchÿ*

(G02,

Feature

(G70,

Generator)

Pulse

G03)

(G100

G71,

G

by

Displaying

TURNING

Functions

........

•

and

Least

(G01)

Codes

M

Internal

for

Interruption

Registers

On

/Off

Mode

Path

Program

Processing

,

M01

Switch

(Auxiliary

STATION

Switch

INTERRUPTING

Select

POINT

Point

Dimensions

Control-Out

OPERATION

Data)

Keys

SELECTOR

(M95/M94)

(B-Function)

• • •

*

*

Control

*

of

•

+

through

G72)+

(G20,

Code

On/Off

POWER

ON

* *

of

Output

Stop

for

Processing

On

/Off

On/Off

On

M02,

RETURN

(M-FUNCTION)

on

/Off

(M90

to

M30)

Function

AUTOMATIC

Switch+

Switcht

Control-In

and

IN

AUTOMATIC

Switch

,

2Nd

+

up

G102)

....

G21)t

of

*

•

Increment

Tool

99)

Ml

...

to

Three

*

* *

Radius

. . .

*

*

Lock)

OPERA¬

OPERATION

Axes*

*

.

Chapter

**

.

.

•

Section

2

6

6

6

2

2

2

2

2

2

8

4

7

4

4

1

6

r

6

2

2

2

2

2

2

2

2

2

2

2

2

2

6

2.7.3

6.

1.6

6.

1.5

6.

1.8

2.9.5

2.9.33

2.9.27

2.9.11

2.1.1

2.1

8.6.3

4.3.13

7.1

4.7.1

4.3.8

6.1.10

6.

1.9

2.

1.4

2.3.5

2.9.

2.8.1

2.8.2

2.8.3

2.8.

2.8.5

2.8.6

2.8.7

2.

8.

2.8.

2.8.8

6.

1.23

6

8

8

6

7

7

6

6

6

2

2

7

7

4

6

2

2

2

6

•

8.6.4

6.

7.2

7.7

6.1.7

6.1.

6.2.

2.3.6

2.

7.

7.9

4.

6.

2.8.5

2.8.9

2.8

6.1.1

1.24

10.

8

1.11

1.25

3

4

2

L

•••

15

1

••

2

Page

14

156

156

157

26

80

65

31

-

1

1

185

132

173

140

•

130

1

157

157

5

8

23

15

16

16

6

1

16

19

19

16

15

20

160

155

186

178

160

173

175

156

159

163

9

83

175

176

117

160

16

•

•

20

15

•

155

;

iv

Page 6

Subject

.Multi-

M

N

O

P

Active

Multi’

Active

OPERATOR'S

NC

NC

TAPE

NC

Tape

NC

Tape,

NC

Tape

NC

TAPE

NEXT

Key

On-Line

Operation

OPERATION

OPERATION

Operations

Operation

Optional

OPTIONAL

OPTIONAL

(Origin)

ORG

OTHERS

Output

Overload

Overview

Keys

PAGE

Paper

Tape

PARAMETER

Parameters,

Part

Program,

Part

Program

Part

Program

Part

Program

Part

Program

Part

Program

PART

PROGRAM

Program

Part

Part

Program

Part

Program

Part

Program,

PROGRAMS

PART

Plane

Designation

Playback

Positioning

POWER

POWER

Power

On/Off

PREPARATION

PREPARATORY

Process

Program

Program

PROGRAM

PROGRAMMING

PROGRAMMING

Registers'

Registers

*

Check.

Keeping

Punch

PUNCHING

...

Diagnostics

Commands

PROCEDURE

PROCEDURE

using

Time

Block

BLOCK

STOP

for

External

(Alarm

of

User

Select

NUMBERS,

Displaying

Display

Form,

Tape

Tape

to

Function

(GOO,

CIRCUIT

/OFF

ON

Sheet

Interruption

Number

NUMBER

STATION

*

*

Data

Display

(/l-/9)

Skip

SKIP

Switch

Key

Motion

No.

Macro

Adding

Block,

Block,

MDI

by

General

TAPE

into

Verifying

Paper

Making

INTO

(GI7,

G06)

BREAKER

OPERATION

Pushbuttons

TURNING

FOR

FUNCTION

AND

On

/On

Input

Switch

352)

,

351

Body

LIST

and

......

Deleting

Modifying

,

Loading

.

-

CODING

Memory,

Tape,

Addition

MEMORY,

G18,

On/Off

SEQUENCE

CRT

WITH

/Output

•

•

+

(G80,

G81)T

*'*

OF

Writing

-

*

Loading

Outputting

*

to

LOADING

9)

1

G

FUSES

AND

POWER

OFF

(G-FUNCTION)

(M91/M90)t

INDEX

•

CHARACTER

Interface

*

*

*

•

* *

*

*

*

•

•

-

NUMBER

DISPLAY

V

huptc'f

••

4

3

3

3

3

3

4

8

2

6

7

4

4

2

6

6

4

8

2

8

2

4

3

APPENDIX

4

4

4

4

4

4

3

3

4

4

4

4

4

2

6

2

8

4

4

7

2

3

2

2

2

3

2

\

St'-.

lv'<

1

.

t

2.

S.

4

3.

3.3.3

3.4.2

3.3.2

3.3

4.1.6

8.6.

2.11.5

6.2

4.7.5

4.

3.9

2.2.3

6.1.19

6.

1.

4.

1.9

8.5

2.

9.

8.4.

2.11.3

1,7

4.

3.3.1

•

2

4.3.7

4.6.

4.6.2

4.6.3

5.

4.

4.6.

3.2.2

*

5,

4.

•

4.8.3

*

4.4,

*

4.

5.

4.5

•

2.

9.

*

6.2.5

•

2.9.2

•

8.3

•

4.2

*

4.

1.

7.

10

*

2.9

•

2.

3.

2,8.3

-

-

2.2.1

•

2.2

*

3.2

P.-'sjV

t-

1

114

l

13

----

113

113

113

113

116

1

18

28

2

4

3

1

1

5

2

10

1

I

185

99

163

----

173

144

----

130

6

159

...

159

----

117

185

67

184

----

87

----

117

113

.....

192

128

139

138

139

137

138

112

110

135

145

133

.....

136

135

31

.....

170

23

182

119

115

176

21

1

10

16

6

6

10

1

1

v

Page 7

INDEX

Subject

Program

P

PUSHBUTTONS,

Rapid

R

RAPID

Reference

REFERENCE

Reference

Registration

Registered

Remote

RESET

Return

ROUTINE

S

S2-Digit

5-Digit

S

Scaling

Sequence

Servomotor

Setting

Setting

Setting

Setting

SETTING

Setting

Simultaneously

Simultaneously

SINGLE

Function

Skip

SPINDLE

SPINDLE-SPEED

Splicing

STANDARD

START

STORED

STORED

STORED

Stored

Subroutine

SWITCHING

T

T2-Digit

T4-Digit

Feed

Tape

TAPE

Code

Tape

TAPE

TAPE

TAPE

Reader

Tape

Tape

Reader

TAPE

TAPE

Tape

Reels,

Reels,

Tape

TAPE

Restart

Traverse

TRAVERSE

Point

POINT

Point

of

Program

On

Power

Key

from

Reference

INSPECTION

Programming

Programming

Function

Number

and

Parameter

and

and

Data

and

Data

Data,

Displaying

NUMBERS,

of

Baud

BLOCK

(G3I)+

SPEED

Tape

NC

INPUT

Input

LOCK

LEADSCREW

LEADSCREW

STROKE

Stroke

AND

CODE

FEED

INPUT

READER

READER

Limit

Program

UNITS

Programming

Programming*

Switch

MEMORY

and

/OUTPUT

•

Handling

Handling

REELS’*"

RATE

(G27)+

Lamps+

Macros

Number,

Pushbuttons

Zero

SCHEDULE

t

(G50,

G51)t

.......

•

Motor

Tape

Parameter

Parameter

LIST

and

/OUTPUT

(or

ERROR

ERROR

LIMIT*,

(G22,

(M98,

THE

ON

AND

OVERRIDE

(G30)t

.

*

for

Verifying

Data,

Data

and

OF

Others

Axes

Axes

Switch*

Switch)

PREPARATION

G23)*

M99)

LAMPS

Rate

Check

Return

User

/Off

DC

Rate

Controllable

Controllable

Switch

OVERRIDE

FUNCTION

...

and

System

MODE,

SYSTEM

-

-

COMPARTMENT

OPERATION

No.

OPERATIONS

i

8-inch

6-inch

KEYS

Switch

.....

•

.

*

No.

•

.

.

Inputting

to

Paper

of

Serial

of

Four-axis

of

Three-

Switch

of

•

«

*

LIST

STATION

IN

OF

NC

Display

(G29)ÿ

Spindle

Writing

(S-FUNCTION)

SIGNALS,

COMPENSATION

COMPENSATION

CONTROL

Switches

*

*

•

*

-

Tape,

Ingerface

axis

•

OF

FOR

....

DATA

Outputting

Controlt

Control

•

AND

•

•

*

•

.

•

:

•

Chapter

6

4

2

6

2

6

2

2

.

.

4

.

.

4

.

.

4

2

8

2

2

2

2

8

4

4

•

4

•

4

APPENDIX

4

2

2

6

2

6

2

3

APPENDIX

6

APPENDIX

7

2

2

6

2

2

5

7

3

3

4

4

5

8

5

5

5

5

5

Section

6,2.4

...

4.1

2.4.1

6.1.11

2.9.13

6.1.16

16

2.9.

2.11.7

4.5.4

4.2.3

4.1.12

2.9.15

8.1

2.5.1

2.5.2

2.9.24

2.2.2

8.1.3

4.8.1

4.4.2

4.4.4

1

«

•

-

-

4.3.6

4.7.3

2.3.3

2.3.2

6.1.17

2.9.17

1.

14

6.

2.5

1

3.4.

4

6.1.27

3

7.4

2.9.12

2.8.7

6.

1

2.6.1

2.6.2

5.

1.

I

7.6

3.

1.

1

•••

3.1

4.1.13

4

4.

5.

1.2

8.1.1

5.1

5.2.2

5.2.1

5.2

Page

•

167

114

----

••

•*

.....

.....

••

•••

.....

......

......

9

157

33

159

36

101

137

120

118

35

178

----

13

13

60

6

179

145

133

133

127

187

141

•

7

7

159

36

159

13

113

213

162

209

----

173

32

----

19

155

14

14

148

175

U0

*

*

•

10

1

118

132

148

----

1.

179

148

148

149

149

149

vi

Page 8

Subject

T

Tape

TAPE

TG

THERMAL

Threadcutting

TOOL

Tool

TOOL

Tool

TOOL

Tool

Tool

Tool

Tool

Tool

Tool

Tool

Tool

TRAVERSE

TROUBLE

TURNING

Turning

TURNING

Turning

TV

Unidirectional

U

USER

User

USER

V

Variables

W

Work

Writing

Z

Z-AXIS

Z-Axis

Tumble

Box

VERIFYING

Error

'Alarm

OVERLOAD

COMPENSATION

Compensation,

FUNCTION

Length

Offset

Offset

Offset

Offset

Offsets

Offsets

Position

Radius

Compensation

LENGTH

Data,

Memory

Value

Value

from

to

Offset

Compensation

AND

CAUSES

OFF

off

Power

ON

POWER

Power

on

(Tape

Check

Approach

Call

in

Blocks

FEED

Reference

(G65,

NEGLECT

MACRO

Macro

MESSAGE

Coordinate

392)

391,

No.

RELAY

~

{

33)

G

Outline

(T-FUNCTION)

MEASUREMENT

Displaying

Designation

Tape

Tape,

Paper

FEED

POWER

Vertical

Commands

DISPLAY

System

and

Surface

*

*

Verifying

Inputting

Tape,

(G45

FUNCTIONS

REMEDIES

AND

(060)+

G66)

Setting

Displaying

Switch

(G43,

to

C

Parity

Offset

SERVO

OF

of

G44,

Pushbutton

and

Writing

(G10)

Outputting

'

G48)

(G40,

Check)

•

(G52

Contents

(G38)i‘

*

*

G41

«

*

*

*

/

to

INDEX

UNIT

G49)

*

and

•

*

•

G42)t

,

G59)ÿ

by

*

Lampt

MDI

tion

•

•

•

•

•

*

• •

*

*

*

•

*

•

•

•

.

•

*

•

•

•

-

•

•

•

-

*

-

-

.

-

•

*

•

*

i>i*v

5.1.3

4.8

8.4.3

8.4

2.9.

2.7

2.

7.1

2.6

2.9.22

6.

1.

4.3.5

2.7.2

2.9.8

4.8.2

4.4.]

4.4.3

2.9.23

2.9.21

2.4

8.6

7.

11

4.2.2

7.2

2.

4.

3.2.4

2.9.

2.11

2.11.1

10

2.

2.

11.4

2.9.25

4.3.3

6.

1.22

2.9.20

l\UJC>

...

-

18

26

1

26

148

145

184

----

184

37

14

14

13

53

162

126

14

28

145

132

133

55

39

9

185

176

119

173

119

113

64

84

84

83

84

62

•••

123

160

39

Chapter

5

.

4

S

2

2

2

2

•

•'

-

2

6

4

.

.

2

•

2

4

4

.

4

•

2

•

•

2

2

8

7

4

7

•

-

-

•

4

•

•

3

2

2

.

•

2

-

2

2

*

*

*

*

•

2

•

4

•

-

6

2

vii

Page 9

INTRODUCTION

1.

YASNAC

The

simultaneously

center,

ing

machining,

feedback

With

cessors

the

gauging

NC

and

corporates

capabilities.

semi-permanent

used

mum

The

ed

2.1

2.1.1

A

6313

in

advantage.

data

in

concept,

INPUT

variable

is

combination

input-output

FORMAT

INPUT

used

MX1

controlling

with

emphasis

unattended

logic

various

compact

a

The

and

and,

FORMAT

block

format

YASNAC

for

is

a

high-performance

automatic

control.

incorporating

LSIs,

design

memory

comprises

programmable

utilize

to

interface

addition

in

conforming

MX1.

or

3

4

placed

axes

operation,

16-bit

YASNAC

the

withawide

each

has

to

CNC

a

of

on

high-speed

micropro¬

MX!

range

permanent,

software

to

been

maxi¬

expand¬

one

conventional

2.

JISÿB

to

for

machin¬

or

in¬

of

interfaces

now

is

modes

new

long-distance

YASNAC

The

machine

edited

storage

PROGRMMING

Table

following

indicate

2.

such

available

of

interface,

easily

shows

1

the

the

FACIT

as

accommodate

to

operations

transmission.

data

can

incorporate

and

the

from

input

the

address

programmable

and

such

the

NC

operator's

characters

number

RS

as

a

logic

format.

232C,

requirements

high-speed,

RS

programmable

diagram

in

of

can

station.

Numerals

Table

digits.

422

for

be

2.

1

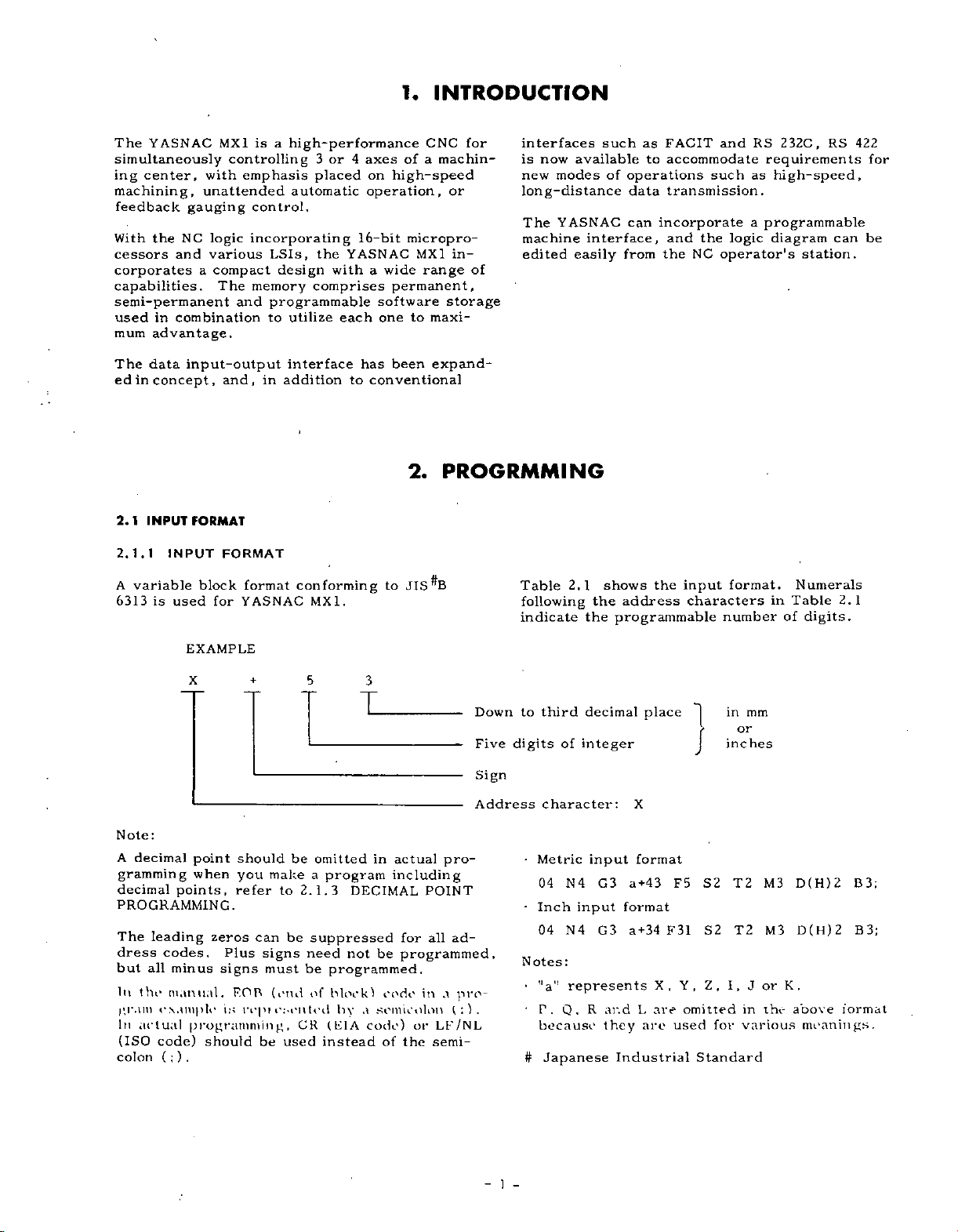

EXAMPLE

X

Note:

A

decimal

gramming

decimal

point

when

points,

PROGRAMMING.

The

dress

but

In

gram

In

(ISO

colon

leading

codes.

all

the

example

actual

code)

(

zeros

minus

manual

programming,

should

)

;

.

should

you

refer

Plus

signs

FOP

.

is

rcpie.-.eiited

can

signs

must

be

make

to

be

(end

used

5

be

omitted

a

program

2.1.3

suppressed

need

be

of

OR

instead

3

I

in

DECIMAL

be

not

programmed.

block!

(E1A

by

code

.semicolon

a

code)

of

actual

pro¬

including

POINT

for

all

ad¬

programmed,

in

a

(:).

or

Ll'/NL

the

semi¬

pro¬

Down

Five

Sign

Address

to

digits

-

Notes:

#

third

of

character:

Metric

04

N

Inch

input

N

04

represents

"a'1

Q,

F.

because

Japanese

decimal

integer

input

G3

4

4

G3

R

and

they

place

X

format

a+43

format

a+34

X,

are

L

are

Industrial

F5

F31

used

|

/

S2

S2

Y,

omitted

Standard

Z,

for

in

mm

or

inches

T2

T2

I,

in

various

D(H)2

M3

D(H)2

M3

J

K.

or

the

above

meanings.

B3;

B3;

format

1

-

Page 10

No.

Address

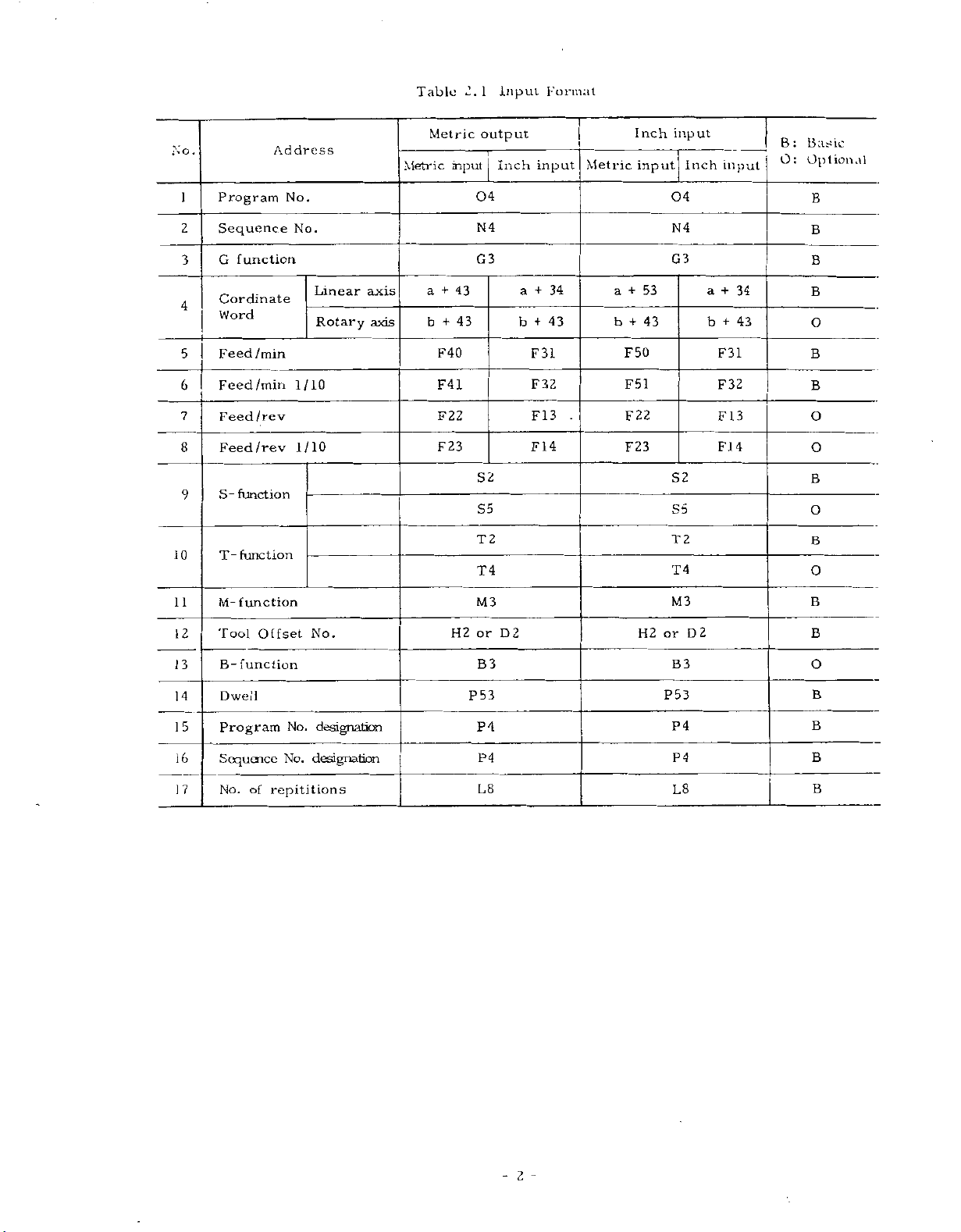

Table

Metric

Metric

input

2.

InpuL

1

output

Inch

Format

input

Metric

Inch

input

input

Inch

input

B:

O:

Bathe

Optional

10

11

12

2

3

4

5

6

7

8

9

Program

Sequence

G

function

Cordinate

Word

Feed

/min

Feed

/min

Feed/rev

Feed

/rev

S-

function

function

T-

M-

function

Tool

Offset

No.

No.

1/10

1

Linear

Rotary

0

1

/

No.

axis

axis

+

+

F50

F51

F22

F23

53

H2

43

04

B

B

G3

+

34

a

+

43

b

F31

F32

FI3

F14

S2

S5

T2

T4

M3

2

or

D

B

B

O

B

B

O

O

B

0

B

O

B

B

04

N4 N4

G3

+

a

43

43

+

b

F40

F41

F22

F23

+

34

a

b

43

+

a

b

F31

F32

.

F13

F14

S2

S5

2

T

T4

M3

H2

or

D2

13

14

15

16

17

B-

function

Dwell

Program

Sequence

of

No.

No.

No.

designation

repititions

designation

B3

P53

P4

P4

L8

B3

P53

P4

P4

L8

O

B

B

B

B

-

2

Page 11

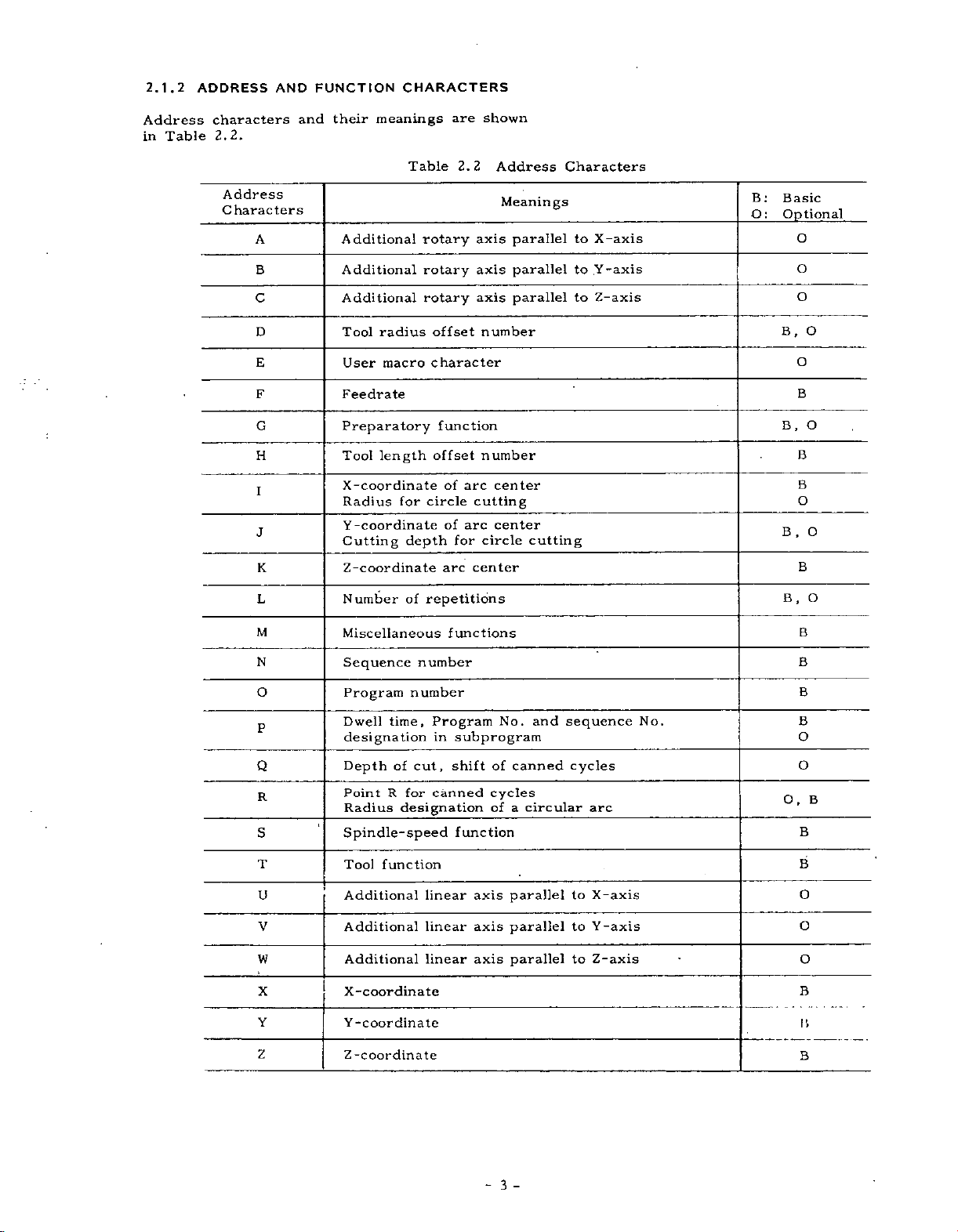

2.1.2

Address

Table

in

ADDRESS

characters

2.2.

AND

FUNCTION

their

and

CHARACTERS

meanings

are

shown

Address

Characters

A

B

C

D

E

F

G

H

I

J

K

L

Additional

Additional

Additional

Tool

radius

User

macro

Feedrate

Preparatory

Tool

length

X

-coordinate

Radius

Y

for

-coordinate

Cutting

Z-coordinate

Number

Table

rotary

rotary

rotary

offset

character

offset

circle

depth

of

repetitions

2.2

function

of

arc

of

arc

for

center

arc

Address

axis

axis

axis

number

number

center

cutting

center

circle

Meanings

parallel

parallel

parallel

cutting

Characters

to

X-axis

Y-axis

to

to

Z-axis

B:

Basic

Q:

Optional

O

O

O

B,

0

O

B

O

B.

B

B

O

,

O

B

B

,

O

B

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

Miscellaneous

Sequence

Program

Dwell

number

time,

designation

cut,

Depth

Point

Radius

of

R

for

designation

Spindle-speed

function

Tool

Additional

Additional

Additional

X-coordinate

Y-coordinate

Z

-coordinate

functions

number

Program

in

canned

linear

linear

linear

subprogram

No.

of

shift

cycles

of

function

axis

axis

axis

and

canned

circular

a

parallel

parallel

parallel

sequence

cycles

arc

to

X-axis

to

Y-axis

to

Z-axis

No.

B

B

B

B

O

0

O,

B

B

B

0

O

O

B

I’.

B

-

3

-

Page 12

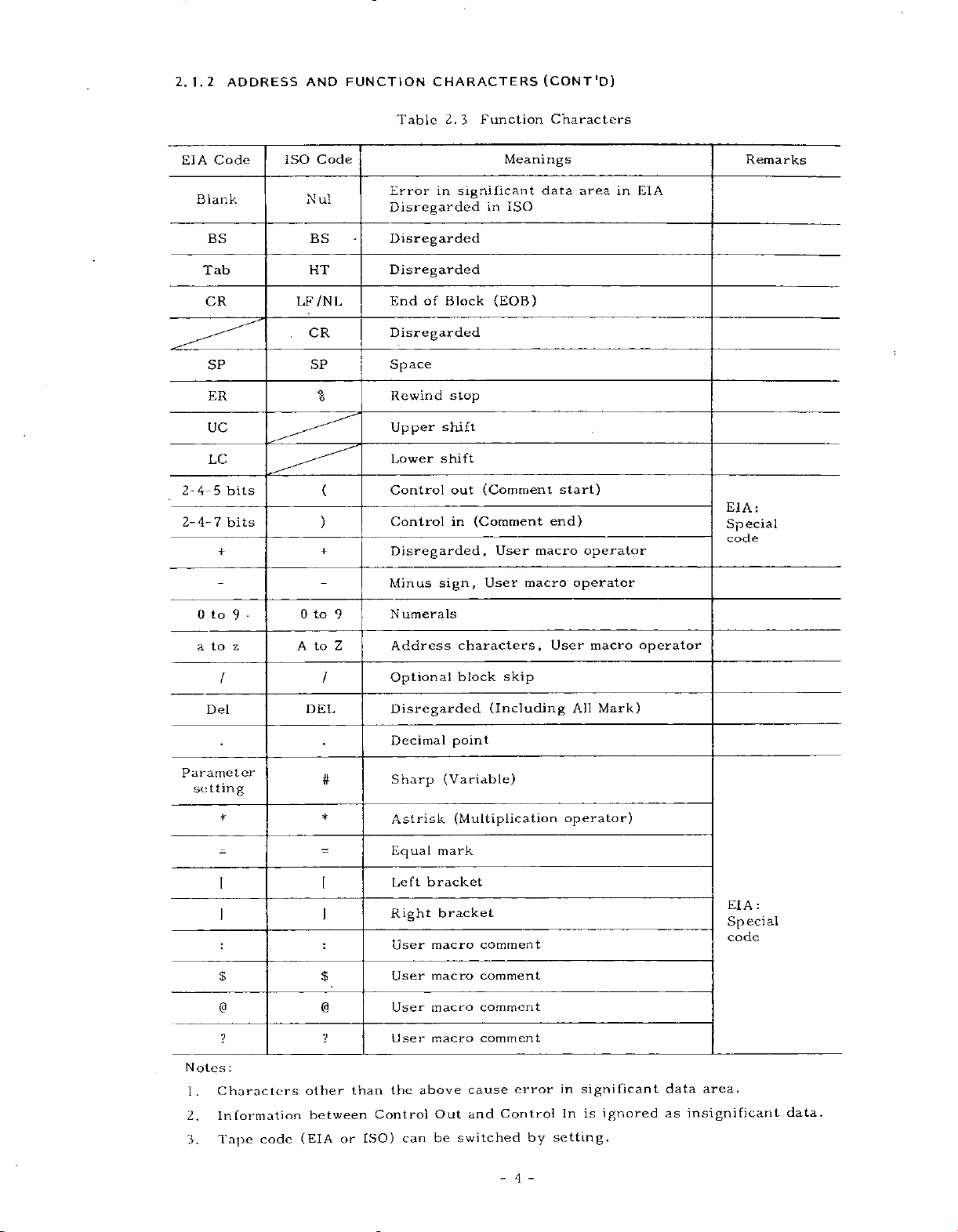

2.1.2

ADDRESS

AND

FUNCTION

CHARACTE

RS

(CONT

'D)

EIA

Blank

2-4-5

2-4-7

BS

Tab

CR

SP

ER

UC

LC

Code

bits

bits

+

ISO

LF/NL

.

Nul

BS

HT

CR

SP

Code

%

(

)

Table

Error

2.3

in

Disregarded

Disregarded

Disregarded

End

of

Block

Disregarded

Space

Rewind

Upper

Lower

shift

shift

Control

Control

Disregarded,

Function

significant

in

(EOB)

stop

(Comment

out

(Comment

in

Meanings

ISO

User

Characters

data

start)

end)

macro

area

operator

Remarks

in

EIA

;

EIA:

Special

code

to

0

9

z

to

a

l

Del

Parameter

setting

*

I

$ $

macro

Minus

•

0

A

to

to

DEL

9

Z

/

Optional

Disregarded

umerals

N

Address

sign,

Decimal

#

*

—

Sharp

Astrisk

Equal

Left

Right

User

User

User

mark

bracket

bracket

macro

macro

macro

User

characters,

skip

block

(Including

point

(Variable)

(Multiplication

comment

comment

comment

operator

User

All

operator)

macro

Mark)

operator

EIA:

Special

code

Notes

1.

Z.

3.

?

:

Characters

Information

code

Tape

other

between

(EIA

User

the

macro

above

can

?

than

Control

ISO)

or

Out

be

comment

cause

and

switched

error

Control

by

4

-

in

In

setting.

significant

is

ignored

data

as

insignificant

area.

data.

Page 13

2.1.3

Numerals

as

the

DECIMAL

dimensional

coordinates

Decimal

dress

words.

Coordinate

U,

Time

Feed

EXAMPLE

V,

W,

word:

rate

X15.

5

Y20.

(G94)F25.6

containing

(distance),

points

words:

Q,

R

P

word:

—

POINT

can

[

X15.

Y20.

F25.0

(for

data

be

X,

F

mm]

000

500

F4.0)

PROGRAMMING

decimal

a

of

addresses

and

time

in

used

Y,

mm

mm

mm/min

the

Z,I,J,

or

or

or

may

point

speed.

following

K,

[

inch

X15.0000

Y

20.

F25.6

(for

be

related

B,

A,

]

inches

inches

5000

inches/min

F3.1)

used

to

ad¬

C,

2.1.5

,

During

read

made

blocks

in

for

contain

2,1.6

For

between

read

BUFFER

normal

advance

in

for

the

the

In

data

of

advance

next

the

up

MULTI-ACTIVE

the

portion

M93

in

advance.

M

code

M92

operation,

follow-on

tool

radius

or

and

compensation

operation

128

to

and

REGISTER

and

compensation

compensation

up

to

is

characters

part

of

M92,

Multi-active

block

one

operation.

4

blocks

computing

executed.

including

REGISTERS

programs

blocks

5

up

to

Meaning

register

of

data

computing

C+mode,

of

data!

One

EOB

t

sandwiched

of

off

is

read

are

required

block

.

data

is

two

can

in

are

G95F.2+

G04P1.

Normally,

inputted,

(or

0.0001

parameter

regard

to

2.1.4

In

becomes

CRT.

•

•

While

on

neglected.

the

dicates

end

"l"

parameter

LABEL

the

cases

When

When

the

the

punched

MEM

of

the

-

when

the

inches,

setting,

as

named

effective,

power

the

the

RESET

label

When

(memory)

the

presence

part

F0.20

(

for

Dwell

data

control

mm

1

#601

SKIP

skip

tape

program.

mm/rev

F2.

,

1

000

without

regards

0.001

or

the

(or

9q6)

•

FUNCTION

below,

and

supply

key

function

up

LSK

EDIT

or

of

2)

control

inch

1

LSK

is

is

to

is

displayed

a

pointer

or

sec

a

decimal

"1"

deg.),

may

or

label

the

is

displayed

turned

pushed.

effective,

is

the

first

(editing)

F0.200

(for

as

but

be

1

deg.).

on

at

inches/rev

3)

FI.

point

0.001

with

made

skip

on.

EOB

the

mode,

the

mm

to

Refer

function

on

the

all

code

CRT

it

leading

is

a

data

are

in¬

power

control

stoppage

made

so

time

ready

Multi-active

is

is

in

can

that

reading

of

advance

not

is

to

be

M93

Note;

reset,

marked

When

the

with

Inter-block

of

is

advance

program

time

processing

blocks

NOTE:

Advance

but

M93

in

of

is

always

mode.

data.

reading

applied

the

be

the

5

of

reading

made

made

register

or

state

eliminated

automatic

blocks

for

up

the

every

to

of

is

of

on

control

M

code

when

operation

longer

next

blocks

5

5

blocks

is

the

than

5

in

-

5

-

Page 14

7.1

2.2.1

PROGRAM

PROGRAM

NUMBER

NUMBER

AND

SEQUENCE

NUMBER

When

search

to

hand

searching

.

or

for

specify

sequence

program

numbers,

numbers

be

sure

before¬

Program

the

for

Up

to

character

program

trol,

and

employing

One

program

with

ends

placed

placed

%

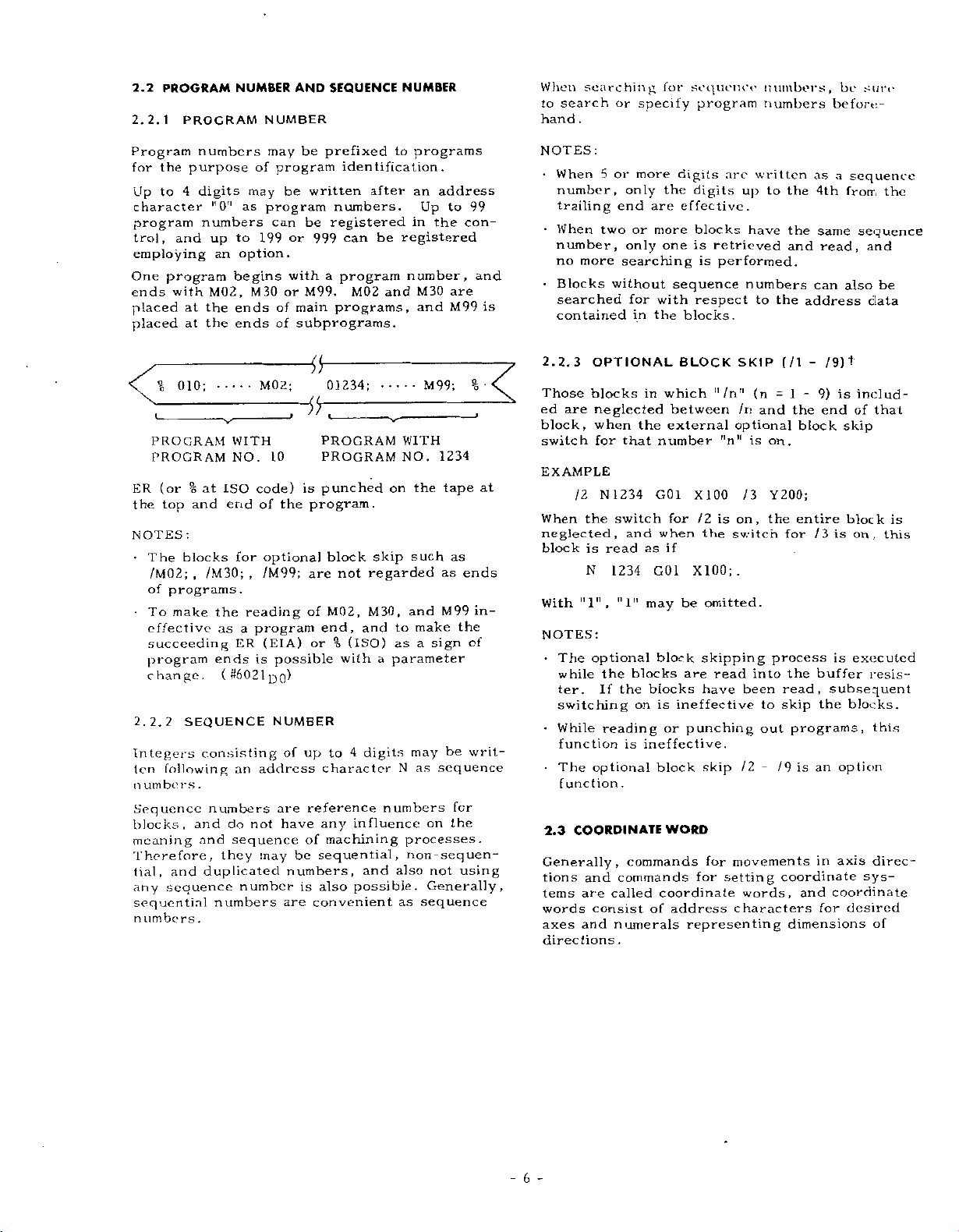

PROGRAM

PROGRAM

(or

ER

the

top

NOTES:

•

The

/M02;

programs.

of

•

To

make

effective

succeeding

program

change.

2.2.2

Integers

following

ten

n

umbers

Sequence

blocks,

meaning

Therefore,

and

tial.

sequence

any

sequential

numbers

numbers

purpose

4

at

at

010;

%

and

blocks

,

digits

may

"0"

as

numbers

to

up

an

option.

begins

M02,

M30

the

ends

ends

the

.....

WITH

NO.

ISO

at

end

for

/M30;

,

the

reading

as

a

ER

ends

(#6021pQ)

SEQUENCE

consisting

an

.

numbers

do

sequence

they

duplicated

number

numbers

not

and

and

.

may

of

program

be

program

can

or

199

with

or

of

of

M02;

r-#r

10

code)

the

of

optional

/M99;

program

(EIA)

possible

is

NUMBER

of

address

are

have

may

numbers,

are

be

prefixed

identification.

written

numbers.

be

registered

can

999

a

program

M99.

main

subprograms.

is

M02

programs,

01234;

PROGRAM

PROGRAM

punched

program.

block

not

are

M02,

of

end,

(ISO)

or

%

with

4

to

up

character

reference

influence

any

machining

of

be

sequential,

is

possible.

also

convenient

to

programs

an

after

be

and

.....

on

skip

regarded

M30,

and

a

digits

numbers

address

Up

in

the

registered

number,

M30

and

M99;

WITH

1234

NO.

the

such

and

make

to

a

as

sign

parameter

may

sequence

N

as

on

to

are

M99

tape

as

as

M99

be

for

the

processes.

non-sequen-

not

also

and

as

Generally,

sequence

99

con¬

and

%

ends

in¬

the

of

writ¬

using

is

<

at

NOTES:

When

number,

trailing

•

When

number,

more

no

•

Blocks

searched

contained

2.2.3

Those

ed

block,

switch

EXAMPLE

blocks

are

OPTIONAL

neglected

when

for

12

When

the

neglected,

is

block

N

"1",

With

NOTES:

•

The

optional

while

ter.

switching

•

While

function

The

optional

function

2.3

COORDINATE

Generally,

and

tions

are

tems

words

axes

directions

consist

and

5

or

only

end

two

only

searching

without

that

N

1234

switch

and

read

1234

"1"

the

If

the

reading

is

.

commands

commands

called

numerals

.

more

the

are

more

or

one

with

for

the

in

which

in

the

number

G01

when

as

if

G01

may

block

blocks

blocks

on

is

or

ineffective.

block

WORD

coordinate

of

digits

digits

effective.

blocks

is

is

sequence

respect

blocks.

BLOCK

between

external

X100/3

/

for

the

X100;

omitted.

be

skipping

are

have

ineffective

punching

skip

for

address

representing

arc

retrieved

performed.

SKIP

11

In"

In

optional

"n"

2

on,

is

switch

.

read

/

movements

for

setting

characters

written

up

to

have

numbers

to

(n

and

is

on.

Y200;

the

process

into

been

to

out

2

words,

as

the

4th

the

same

and

can

the

address

(/1

-

9)

-

1

=

the

block

entire

/

for

the

buffer

read,

skip

programs,

is

an

/9

in

coordinate

and

dimensions

sequence

a

from,

sequence

read,

also

+

/9)

is

includ¬

end

of

skip

block

on,

is

3

executed

is

subsequent

the

blocks.

option

axis

coordinate

for

desired

the

and

be

data

that

is

this

resis¬

this

direc¬

sys¬

of

-

6

-

Page 15

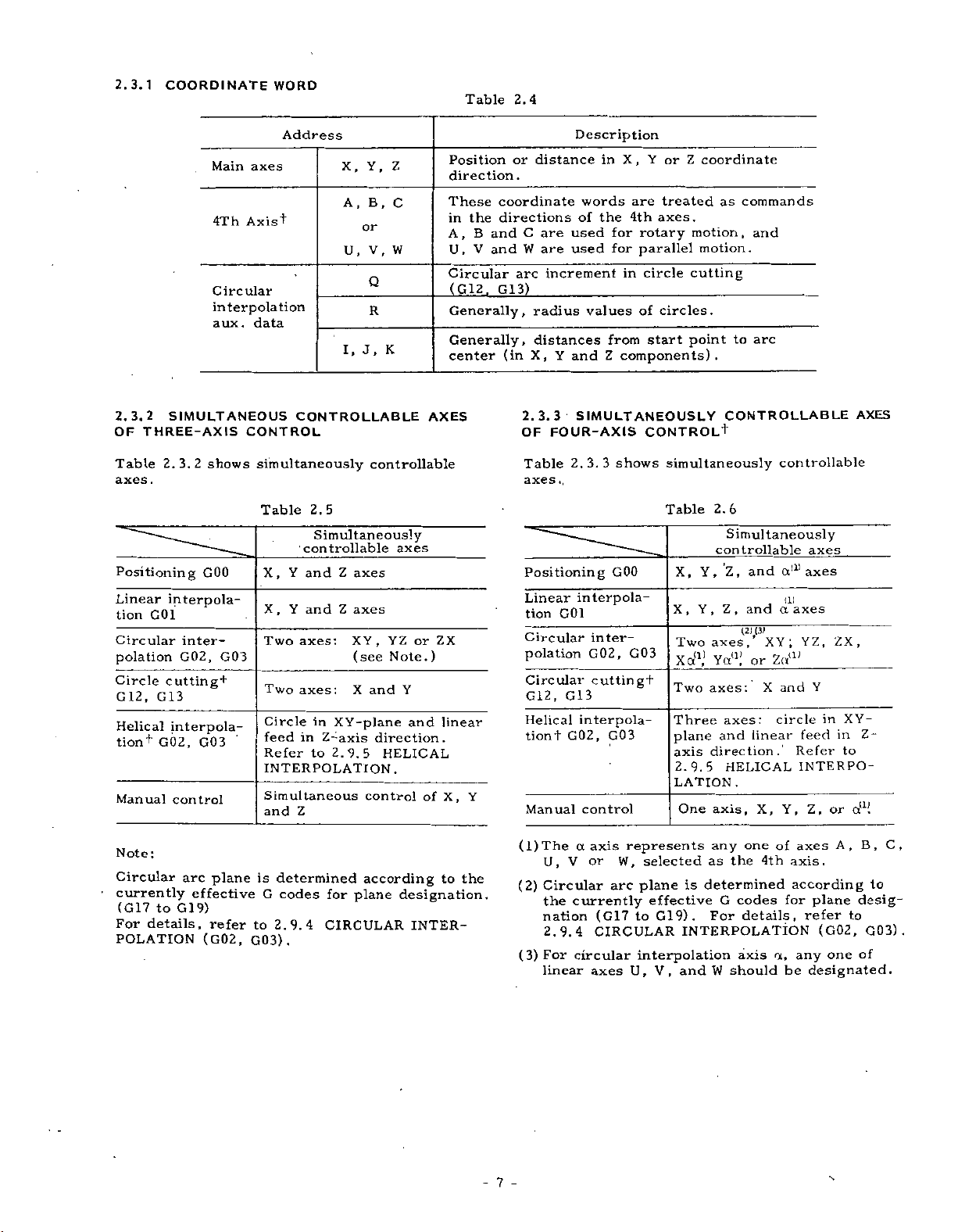

2.3.1

COORDINATE

WORD

Table

2.4

2.3.2

OF

Table

axes

SIMULTANEOUS

THREE-AXIS

2.3.2

.

Positioning

Linear

G01

tion

Circular

polation

Circle

G

Helical

tion'’'

Manual

12,

cutting

G13

G02,

Main

4Th

Circular

interpolation

aux.

shows

GOO

interpola¬

intei

—

G02,

interpola¬

G03

control

Address

axes

Axis’’’

data

CONTROL

simultaneously

Table

X,

,

X

Two

G03

+

Two

Circle

feed

Refer

INTERPOLATION.

Simultaneous

and

Y,

X,

B,

A,

or

V,

U,

Q

R

I,

J.

CONTROLLABLE

controllable

2.5

Simultaneously

controllable

Y

Y

and

and

axes:

axes:

in

to

Z

in

XY-plane

Z-axis

2.9.5

Z

Z

axes

axes

XY

(see

X

control

and

,

direction.

Z

C

W

K

AXES

axes

YZorZX

)

Note.

Y

and

HELICAL

of

Position

direction.

These

the

in

B

A,

U,

V

Circular

(

G12

Generally,

Generally,

center

linear

X,Y

or

coordinate

directions

C

and

and

arc

G13)

,

(in

2.3.3

OF

Description

distance

are

used

W

are

used

increment

radius

distances

X,

Y

and

SIMULTANEOUSLY

FOUR-AXIS

tion

2.

interpola¬

G01

Table

axes

Positioning

Linear

Circular

polation

Circular

G12,

G13

Helical

G02,

tiont

Manual

in

words

of

the

for

for

_

values

from

Z

components).

3.

shows

3

GOO

inter¬

G02,

cuttingf

interpola-

G03

control

X,

Y

or

are

treated

axes.

4th

rotary

parallel

circle

in

circles.

of

start

CONTROL+

simultaneously

Table

X,

X

Two

G03

Xcx1,1

Two

Three

plane

axis

2.9.5

LATION.

One

Z

coordinate

commands

as

motion,

motion.

cutting

to

point

CONTROLLABLE

2.6

Simultaneously

controllable

Z,

Y,

,

Y,Z

axes,

,

and

(21,(3)

Yet11,’

axes:

axes

and

direction.’

HELICAL

,X,Y,

axis

and

arc

and

XY;

or

X

:

linear

controllable

axes

axes

a111

(l)

axes

a

YZ,

Z«a'

Y

and

in

circle

feed

Refer

INTERPO¬

,

Z

or

ZX,

in

to

AXES

XY-

Z-

a11!

:

Note

Circular

currently

(G17

to

details,

For

POLATION

arc

effective

9)

G1

plane

refer

(G02,

is

determined

G

codes

to

2.9.4

G03)

.

according

for

plane

CIRCULAR

to

designation.

INTER¬

the

-7-

(l)The

(2)

(3)

a

V

U,

Circular

currently

the

nation

2.9.4

For

circular

linear

represents

axis

or

W,

selected

plane

arc

(G17

to

CIRCULAR

interpolation

U,

axes

any

as

determined

is

effective

G19).

G

For

INTERPOLATION

V,

and

W

one

the

codes

details,

axis

should

4th

a,

axes

of

axis.

according

for

any

be

A,

plane

to

refer

(G02,

one

designated.

B,

to

desig¬

G03)

of

C,

.

Page 16

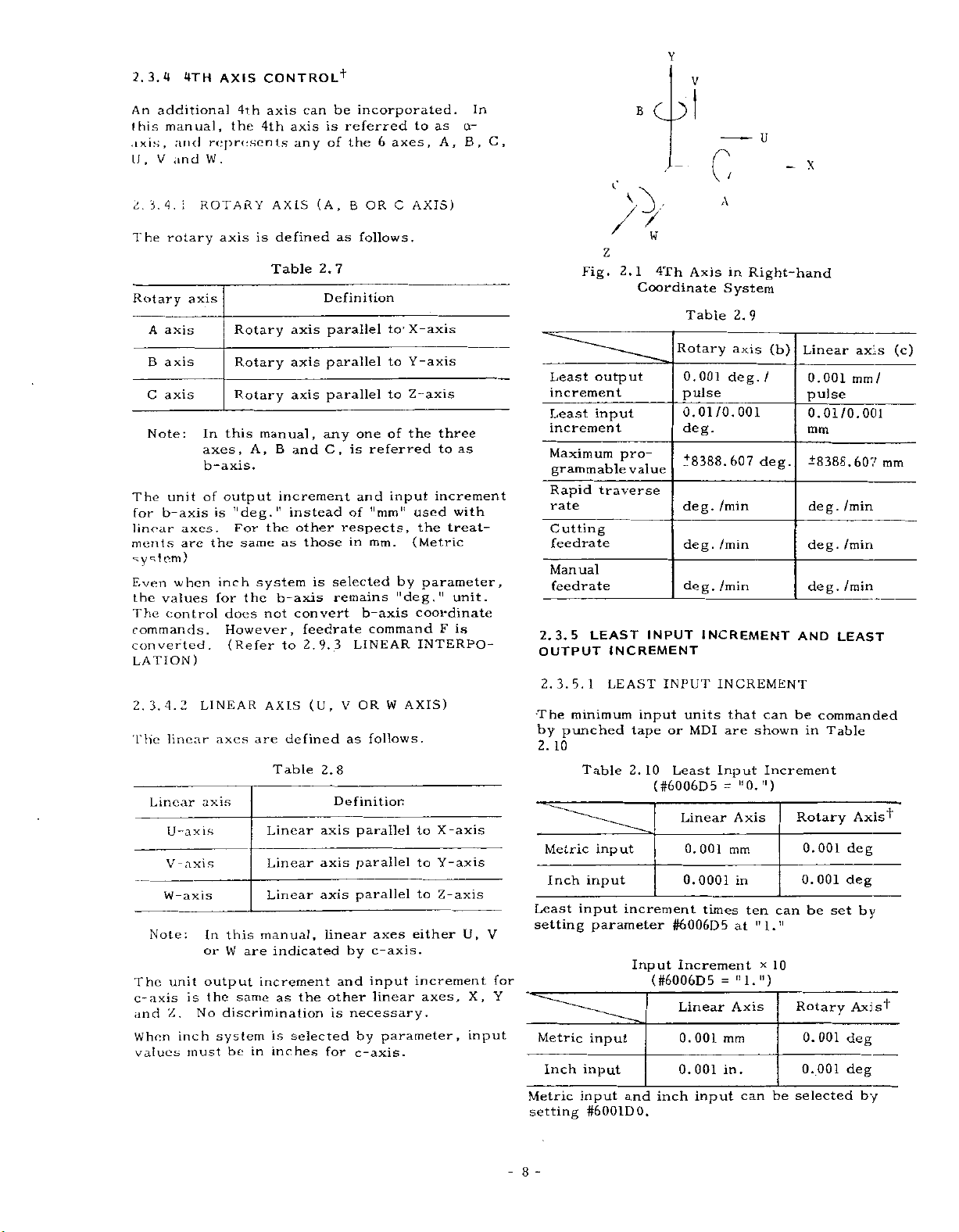

2.3.4

An

this

axis,

U

2.

The

Rotary

The

for

linear

ments

additional

manual,

and

V

and

r

3.

4.

rotary

axis

A

axis

B

C

axis

Note

unit

b-axis

4TH

i

:

axes.

are

system)

when

Even

values

the

control

The

commands.

verted

con

LATION

4.

3.

linear

Linear

2

2.

The

U-axis

-

V

axis

W-axis

Note

:

unit

The

c-axis

and

When

values

is

Z.

inch

AXIS

represents

.

W

ROTARY

axis

axis

In

axes,

b-axis.

of

is

the

inch

for

.

)

LINEAR

axes

axis

In

or

output

the

No

discrimination

system

must

4th

the

is

Rotary

Rotary

Rotary

this

A,

output

Tldeg.,T

For

same

system

the

does

However,

(Refer

are

this

W

are

increment

same

be

in

CONTROL

can

axis

axis

4th

any

AXIS

defined

Table

axis

axis

axis

manual,

and

B

increment

instead

the

other

as

those

b-axis

convert

not

feedrate

2,9.3

to

AXIS

defined

Table

Linear

Linear

Linear

manual,

indicated

the

as

selected

is

inches

+

be

is

of

(A,

as

2.7

Definition

parallel

parallel

parallel

any

C,

selected

is

remains

(U,

2.8

Definition

axis

axis

axis

linear

and

other

is

for

incorporated.

referred

6

the

OR

B

follows.

to1

to

to

one

of

referred

is

and

of

’'mm"

respects,

in

mm.

b-axis

command

LINEAR

W

OR

V

as

follows.

parallel

parallel

parallel

axes

c-axis.

by

input

linear

necessary.

parameter,

by

c-axis.

axes,

C

X-axis

Y-axis

Z-axis

the

input

by

"deg."

AXIS)

to

as

A,

AXIS)

three

to

increment

with

used

treat¬

the

(Metric

parameter,

unit.

coordinate

F

is

INTERPO-

to

X-axis

to

Y-axis

to

Z-axis

either

increment

axes,

as

In

a-

B,

U,

X,

input

B

O

C,

U

X

0

\

0

7

w

Z

2.1

Fig.

Least

output

increment

Least

input

increment

Maximum

grammable

Rapid

rate

Cutting

feedrate

traverse

Manual

feedrate

3.5.

punched

10

Metric

Inch

LEAST

1

LEAST

minimum

Table

input

input

input

parameter

input

input

input

#6001D0.

INCREMENT

2.3.5

OUTPUT

2.

•The

by

2.

Least

setting

V

for

Y

Metric

Inch

Metric

setting

4Th

Coordinate

pro¬

value

INPUT

input

tape

2.

10

(#6006D5

increment

Input

(#6006D5

and

inch

INPUT

or

Least

#6006D5

A

Axis

System

Table

Rotary

0.001

pulse

0.01/0.001

deg.

/min

deg.

/min

deg.

/min

deg.

INCREMENT

INCREMENT

units

are

MDI

Input

-

Linear

0.

001

0.0001

times

Increment

=

Linear

0.

mm

001

0.001

in.

input

in

Right-hand

2.

9

axis

deg.

607

that

shown

"O.”)

Axis

mm

in

ten

11

at

"l.")

Axis

can

(b)

/

deg.

AND

can

be

Increment

Rotary

can

l.!l

x

10

Rotary

be

selected

Linear

0

.

001

mm

pulse

0.01/0.001

mm

±8388.607

deg.

min

/

/min

deg.

/min

deg.

LEAST

commanded

in

Table

0.001

deg

0.

001

deg

set

be

Axis*!*

0.

001

deg

0.001

deg

axis

/

Axisÿ

by

by

(c)

mm

-

8

Page 17

:

Notes

Selection

made

Selection

eter

setting

offset

Tool

(or

mm

is

possible

0.01

In

eration

•

Programming

Write

•

Programming

•

Program

NOTES:

•

NC

If

or

to

increment,

the

intended

•

the

If

contents

machine

the

commanded

•

When

taped,

stored"

ment

of

by

setting

of

value

0.0001

in

mm

increment

must

operation

editing

tape

stored

increment

of

will

the

stored

the

regardless

system.

(#6001D0).

or

1

system

x

metric

x

(#6006D5).

must

inch,

or

units,

these

be

made

for

operation

MDI

in

for

operation

operation

programmed

in

an

equipment

the

machine

dimensions.

system

NC

tape

by

move

dimensions.

program

stored

figures

10

always

0.001

system,

in

the

mode.

are

ten

of

switching

is

by

will

is

stored

times

is

or

inch

made

be

deg+.),

the

unit

TAPE

in

MEMORY

in

EDT

in

0.001

set

move

switched

punched

are

system

param¬

by

written

and

following

0.01

of

modet.

mm

by

ten

in

memory,

or

one

punched

of

the

in

mm.

mode.

is

0.01

times

when

tenth

out

incre¬

is

0.001

offset

op¬

modet.

fed

mm

the

on

out

in¬

the

"as

of

the

incremental

In

exceed

not

In

absolute

axis

value

Note:

a

move

value

mable

dresses

mand

accumulative

The

mum

Table

Metric

Inch

Listed

inch

2.4

TRAVERSE

2.4.1

2.4.1.1

the

programming,

not

must

.

machine

The

command

is

given.

J,

I,

2.13

input

input

RAPID

also

values

addresses

accumulative

input

output

RAPID

programming,

maximum

exceed

the

may

the

over

above

The

apply

Q

R,

K,

Y,

X,

value

values

Maximum

Linear

99999.

±

9999.9999

±

values

do

system.

FEED

AND

TRAVERSE

TRAVERSE

input

programmable

move

maximum

function

not

maximum

maximum

distance

to

addition

in

Z,

a.

not

must

shown

Accumlative

axis

mm

999

in.

depend

not

FUNCTIONS

RATE

RATE

values

amount

programmable

properly

programmable

program¬

command

to

move

exceed

below.

Values

Rotary

99999.999

±

99999.999

±

on

must

value.

of

each

com¬

the

axist

metric/

if

ad¬

maxi¬

deg

deg

3.

5.

2.

Least

output

motion.

parameter

by

Metric

Inch

2.3.6

Maximum

mand

are

Table

Metric

output

Inch

output

2

LEAST

increment

Selection

Table

output

output

MAXIMUM

programmable

shown

2,12

Metric

Inch

Metric

Inch

OUTPUT

is

of

(S6007D3)

2.11

metric

setting.

Least

Linear

0.001

0.0001

PROGRAMMABLE

dimensions

below.

Maximum

input

input

input

input

Programmable

Linear

±8388.

±330.2601

±21307.062

±838.8607

INCREMENT

the

minimum

or

inch

output

Increment

axis

mm

in.

axis

607

mm

in.

mm

in.

unit

output

Rotary

DIMENSIONS

of

001

0.

0.

001

move

Dimensions

is

axis'!"

deg

deg

com¬

Rotary

±8388.607

±8388.607

±8388.607

±8388.607

of

axis

tool

made

deg

deg

deg

deg

for

the

since

by

for

rapid

are

rate

the

the

reached

Fo,

/min

traverse

the

motion

motion

.

The

they

and

The

machine

individual

traverse

independent

Therefore,

25%,

rates,

set

by

TRAVERSE

be

can

(or

machine

traverse

machine

for

trav¬

are

are

at

50%

are

a

set

deg/

rate

rates.