Page 1

YASKAWA

Machine Controller MP930

USER'S MANUAL

DESIGN AND MAINTENANCE

YA S K A WA

MANUAL NO. SIEZ-C887-1.1

Page 2

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precau-

tions provided in this manual can result in serious or possibly even fatal injury or damage to the prod-

ucts or to related equipment and systems.

Safety Information

WARNING

!

Caution Indicates precautions that, if not heeded, could result in relatively serious or minor

!

The warning symbols for ISO and JIS standards are different, as shown below.

The ISO symbol is used in this manual.

Both of these symbols appear on warning labels on Yaskawa products. Please abide by

these warning labels regardless of which symbol is used.

Indicates precautions that, if not heeded, could possibly result in loss of life or

serious injury.

injury, damage to the product, or faulty operation.

ISO JIS

Yaskawa, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form,

or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of

Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is subject to

change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the

information contained in this publication.

iii

Page 3

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

A

EXAMPLE

INFO

IMPORTANT

TERMS

Indicates application examples.

"

Indicates supplemental information.

Indicates important information that should be memorized.

Describes technical terms that are difficult to understand, or appear in the text without an

explanation being given.

iv

Page 4

TABLE OF CONTENTS

TABLE OF CONTENTS

Safety Information iii...............................................

Visual Aids iv.....................................................

Overview ix.......................................................

Using This Manual x...............................................

Safety Precautions xi..............................................

1 MP930

1.1 Overview of the MP930 1 - 2.....................................

1.1.1 Appearance of MP930 Units 1 - 2...........................................

1.1.2 Features of the MP930 1 - 3................................................

1.2 Control Using the MP930 1 - 5....................................

1.2.1 Types of Program 1 - 5.....................................................

1.2.2 Ladder Logic Programs 1 - 6................................................

1.2.3 MC Programs 1 - 8........................................................

1.2.4 Control Signals 1 - 9.......................................................

1.3 Operation from Programming Devices 1 - 10.......................

1.3.1 File Manager 1 - 10.........................................................

1.3.2 System Information Definitions 1 - 11.........................................

1.3.3 Programming 1 - 12........................................................

1.3.4 Debugging and Monitoring 1 - 13.............................................

1.3.5 Printing 1-13.............................................................

2 MP930 Specifications and System Configuration

2.1 Specifications 2 - 2..............................................

2.1.1 General Specifications 2 - 2................................................

2.1.2 Hardware Specifications 2 - 3...............................................

2.1.3 Function List 2 - 4.........................................................

2.2 Basic System Configuration 2 - 31.................................

2.2.1 List of Basic Units 2 - 31....................................................

2.2.2 Basic System Configuration 2 - 32............................................

2.2.3 Precautions on System Configuration 2 - 33...................................

2.2.4 Programming Device 2 - 34..................................................

3 Basic System Operation

3.1 Operating Modes 3 - 2...........................................

3.1.1 Online Operating Mode 3 - 2................................................

3.1.2 Offline Stop Mode 3 - 2....................................................

3.2 Start and Stop Sequences 3 - 3..................................

3.2.1 DIP Switch Settings 3 - 3...................................................

3.2.2 Start Sequence 3 - 5......................................................

v

Page 5

3.3 Power Failures 3 - 8.............................................

3.3.1 Power Failure Detection 3 - 8...............................................

3.4 User Programs 3 - 9.............................................

3.4.1 Drawings (DWGs) 3 - 9....................................................

3.4.2 Execution Control of Parent Drawings 3 - 10...................................

3.4.3 Motion Programming 3 - 14..................................................

3.5 Functions 3 - 22..................................................

3.5.1 Standard System Functions 3 - 22............................................

3.5.2 Creating User Functions 3 - 23...............................................

3.6 Registers 3 - 28..................................................

3.6.1 Register Designation Methods 3 - 28..........................................

3.6.2 Data Types 3 - 29..........................................................

3.6.3 Types of Register 3 - 33.....................................................

3.6.4 Using Subscripts I and J 3 - 36...............................................

3.6.5 I/O and Registers in Functions 3 - 38.........................................

3.6.6 Register Ranges in Programs 3 - 39..........................................

3.7 Managing Symbols 3 - 40.........................................

3.7.1 Symbols in Drawings 3 - 40..................................................

3.7.2 Symbols in Functions 3 - 41.................................................

3.7.3 Upward Linking of Symbols 3 - 42............................................

3.7.4 Automatic Register Number Allocation 3 - 43...................................

4 System Startup

4.1 Part Names 4 - 2................................................

4.1.1 MC Unit 4-2.............................................................

4.1.2 I/O Unit 4-6.............................................................

4.2 Connection Methods 4 - 8.......................................

4.2.1 Names and Locations of Connectors 4 - 8....................................

4.2.2 System Connection Example 4 - 9...........................................

4.2.3 Standard Cables 4 - 10.....................................................

4.2.4 Connector Pin Layout and I/O Circuits 4 - 12...................................

4.2.5 Connections to the Servopack and Motor 4 - 21................................

4.3 System Startup Methods 4 - 24....................................

4.3.1 Overview of the Startup Procedure 4 - 24......................................

4.3.2 Test Unit Configuration 4 - 25................................................

4.3.3 Equipment Preparations 4 - 26...............................................

4.3.4 Mounting the Units 4 - 27....................................................

4.3.5 Connecting the Devices 4 - 30...............................................

4.3.6 Starting the CP-717 4 - 39...................................................

4.3.7 Motion Parameter Settings 4 - 53.............................................

4.3.8 Creating and Saving Motion Programs 4 - 56..................................

4.3.9 Ladder Logic Programs 4 - 60................................................

4.3.10 Transferring Definitions, Parameters, and Programs 4 - 75......................

4.3.11 Checking Operations 4 - 81.................................................

vi

Page 6

TABLE OF CONTENTS

5 Parameters

5.1 Description of Parameters 5 - 2..................................

5.1.1 Parameter Classifications 5 - 2..............................................

5.1.2 Parameter Lists 5 - 3......................................................

5.2 Parameter Settings 5 - 17.........................................

5.2.1 Fixed Parameters 5 - 17....................................................

5.2.2 Setting Parameters 5 - 21...................................................

5.2.3 Monitor Parameters 5 - 30...................................................

6 Controlled Axis Support Functions

6.1 Support Functions for Controlled Axes 6 - 2......................

6.1.1 Reference Unit 6 - 2.......................................................

6.1.2 Electronic Gear 6 - 3......................................................

6.1.3 Override Function 6 - 5....................................................

6.1.4 Infinite Length Positioning 6 - 6.............................................

6.1.5 Stroke Limit Function 6 - 8.................................................

7 Absolute Position Detection

7.1 Structure of the Absolute Position Detection Function 7 - 2........

7.1.1 Description of the Function 7 - 2............................................

7.1.2 Structure of Absolute Position Detection 7 - 2.................................

7.2 Starting the Absolute Position Detection Function 7 - 5............

7.2.1 System Startup Procedure 7 - 5.............................................

7.2.2 Setting Related Parameters 7 - 6............................................

7.2.3 Initializing the Absolute Encoder 7 - 8........................................

7.3 Using an Absolute Encoder 7 - 10.................................

7.3.1 Finite Length Mode Axis 7 - 10...............................................

7.3.2 Infinite Length Mode Axis 7 - 14..............................................

8 Maintenance and Inspection

8.1 Inspection Items 8 - 2...........................................

8.1.1 Daily Inspections 8 - 2.....................................................

8.1.2 Regular Inspections 8 - 3...................................................

8.2 Battery 8 - 5....................................................

8.2.1 Battery Life 8 - 5..........................................................

8.2.2 Battery Replacement 8 - 5..................................................

vii

Page 7

9 Troubleshooting

Reading this Chapter (Troubleshooting Procedures) 9 - 2..............

9.1 Overview of Troubleshooting 9 - 3................................

9.1.1 Basic Troubleshooting Flow 9 - 3............................................

9.1.2 Indicator Errors 9 - 4.......................................................

9.2 System Errors 9 - 7..............................................

9.2.1 Overview of System Errors 9 - 7............................................

9.2.2 Processing Flow When a System Error Occurs 9 - 8...........................

9.2.3 Processing Flow When a User Program Error Occurs 9 - 9.....................

9.2.4 System Register Configuration 9 - 10.........................................

9.3 Motion Errors 9 - 23..............................................

9.3.1 Description of Motion Errors 9 - 23...........................................

9.3.2 Processing Flow When a Motion Error Occurs 9 - 24............................

A External Dimensions

A.1 External Dimensions of the MP930 Unit A - 2......................

A.2 Ladder Instructions and Standard System Functions A - 8..........

B Command List

B.1 Motion Command List B - 2......................................

B.2 Ladder Instructions and Standard System Functions B - 8.........

C Parameter Lists

C.1 Fixed Parameter List C - 2.......................................

C.2 Setting Parameter List C - 3......................................

C.3 Monitor Parameter List C - 5.....................................

D Monitor Parameter Alarm List

D.1 Motion Program Error D - 2......................................

D.2 Setting Errors in Fixed and Setting Parameters D - 4...............

D.3 Monitor Parameter Number 23 Alarms D - 5.......................

E List of System Registers

E.1 System (S) Register Allocation E - 2..............................

E.2 System Service Registers E - 3...................................

viii

Page 8

Overview

Overview

About this Manual

J

This manual describes the design and maintenance for the MP930 Machine Controller, including the

following information.

D Overview and component specifications

D Installation and wiring

D Examples of internal panel layout and drilling plan

Read this manual carefully to ensure the proper use of the MP930 Machine Controller. Also, keep

this manual in a safe place so that it can be referred to whenever necessary.

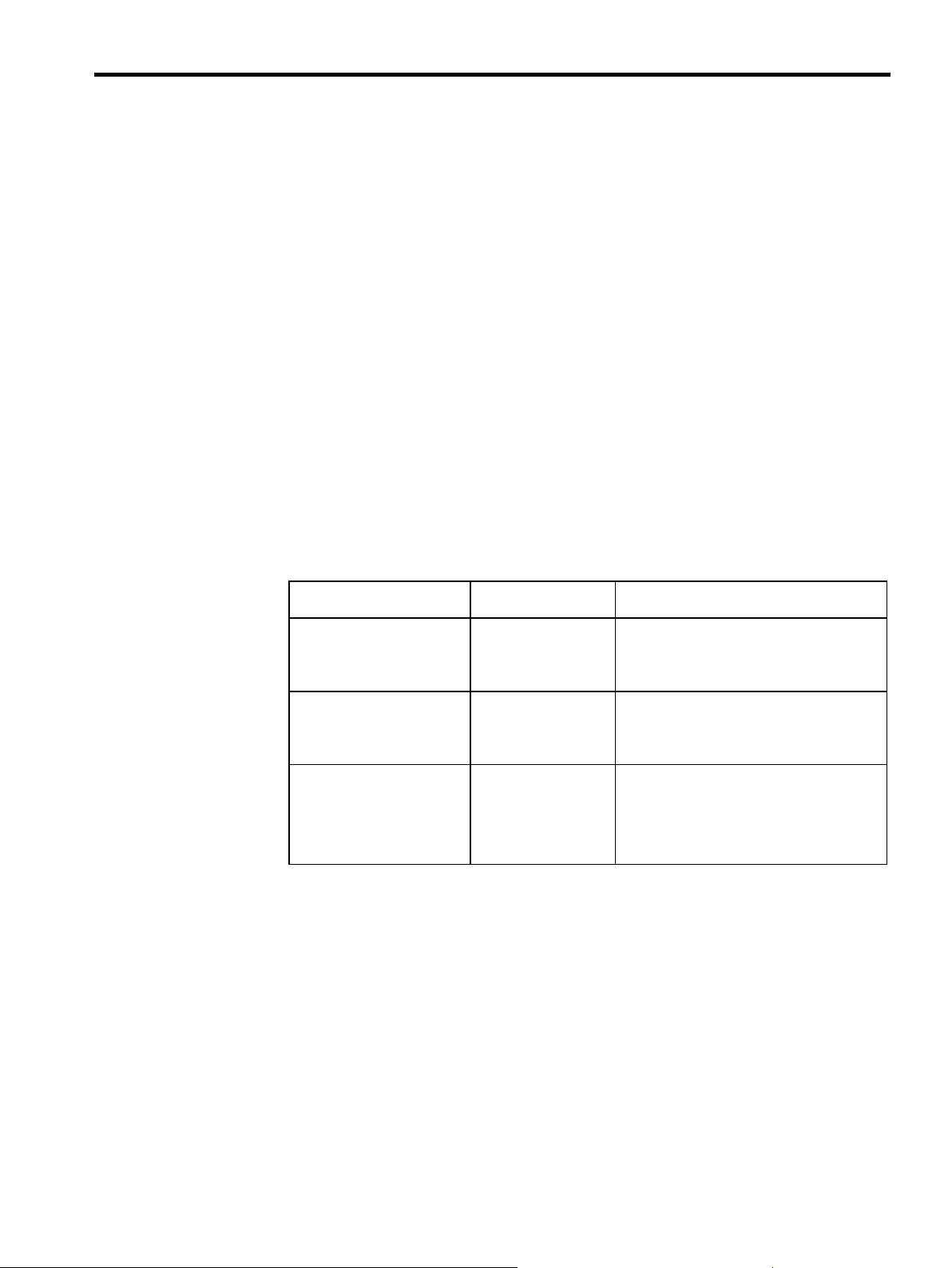

Related Manuals

J

Refer to the following related manuals as required.

Thoroughly check the specifications, restrictions, and other conditions of the product before at-

tempting to use it.

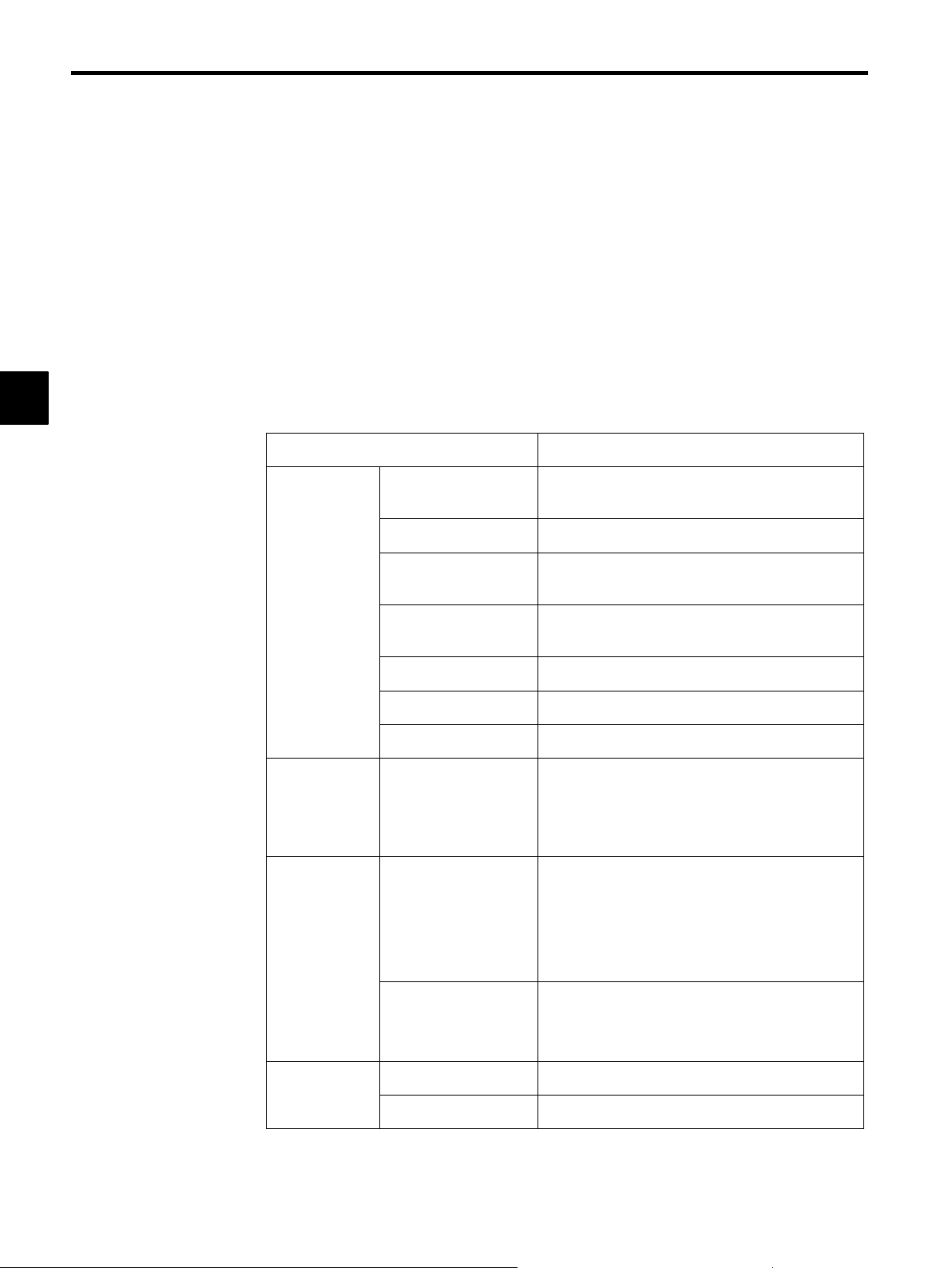

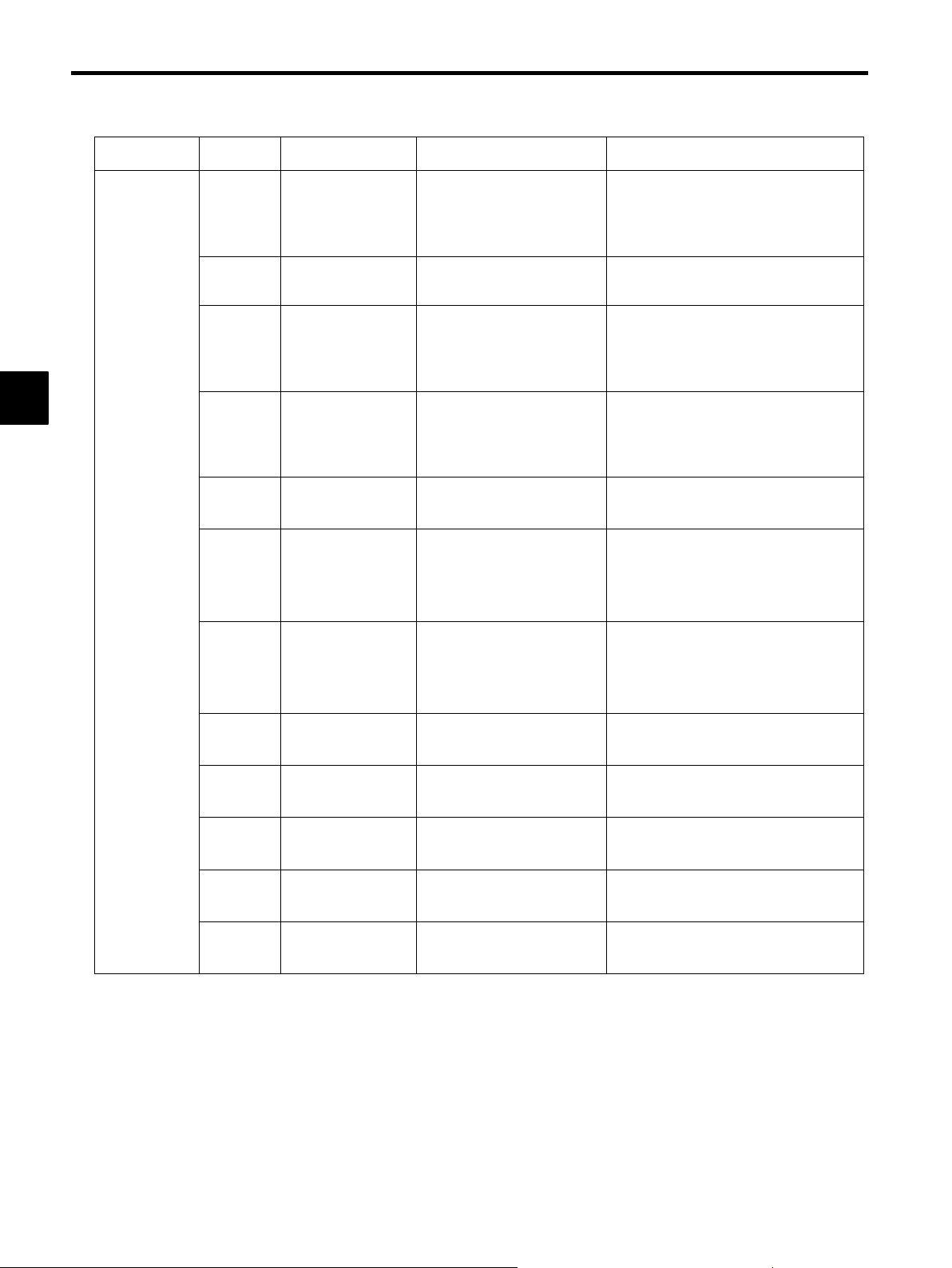

Manual Name Manual Number Contents

MP9jjMachine Controller

Ladder Programming

User’s Manual

MP9jjMachine Controller

Motion Programming

User’s Manual

MP9jjMachine Controller

Programming Software

User’s Manual

SIEZ-C887-1.2 Describes the instructions used in MP9

ladder logic programming.

SIEZ-C887-1.3 Describes the motion instructions used by

MP9jjMachine Controllers.

Part 1:

SIEZ-C887-2.2−1

Part2:

SIEZ-C887-2.2−2

Describes the installation and operating procedures for the CP-717 Engineering Tool

Programming Software for MP9

Machine Controllers.

jj

jj

ix

Page 9

Using This Manual

Intended Audience

J

This manual is intended for the following users.

D Those responsible for estimating the MP930 system

D Those responsible for deciding whether to apply the MP930 system

D Those responsible for designing the MP930 system so that it can be mounted in the control and

operating panels

D Those responsible for making, inspecting, testing, adjusting, and maintaining the control and op-

erating panels in which the MP930 is mounted

Description of Technical Terms

J

In this manual, the following terms are defined as follows:

D PP = Programming Panel

D PC = Programmable Logic Controller

D “−− ” in “MOV [axis1]−−...” represents numeric data for axis 1.

x

Page 10

Safety Precautions

This section describes precautions that apply to ladder programming. Before programming, always

read this manual and all other documents provided to ensure correct programming. Before using the

equipment, familiarize yourself with equipment details, safety information, and all other precau-

tions.

Installation

J

D Firmly tighten the Module mounting screws and terminal block mounting screws to

prevent them from loosening during operation.

Loose screws may result in a malfunction of the MP930.

Safety Precautions

Caution

Module mounting screw (M4, Phillips head)

D Be sure to turn OFF the MP930 before installing it.

D Insert the connectors of the cables that are to be connected to the MP930 and secure them well.

Incorrect insertion of the connectors may result in a malfunction of the MP930.

Wiring

J

Caution

D Always connect a power supply that meets the given specifications.

Connecting an inappropriate power supply may cause fires.

D Wiring must be performed by qualified personnel.

Incorrect wiring may cause fires, product failure, or malfunctions.

D Do not accidentally leave foreign matter such as wire chips on the Mounting Base or in

the Module when wiring.

This may cause fires, failures, and malfunctions.

xi

Page 11

Mandatory

D Always use the ground the FG terminal to a ground resistance 100 Ω or less.

Failure to ground the MP930 may result in electrical shocks or malfunctioning.

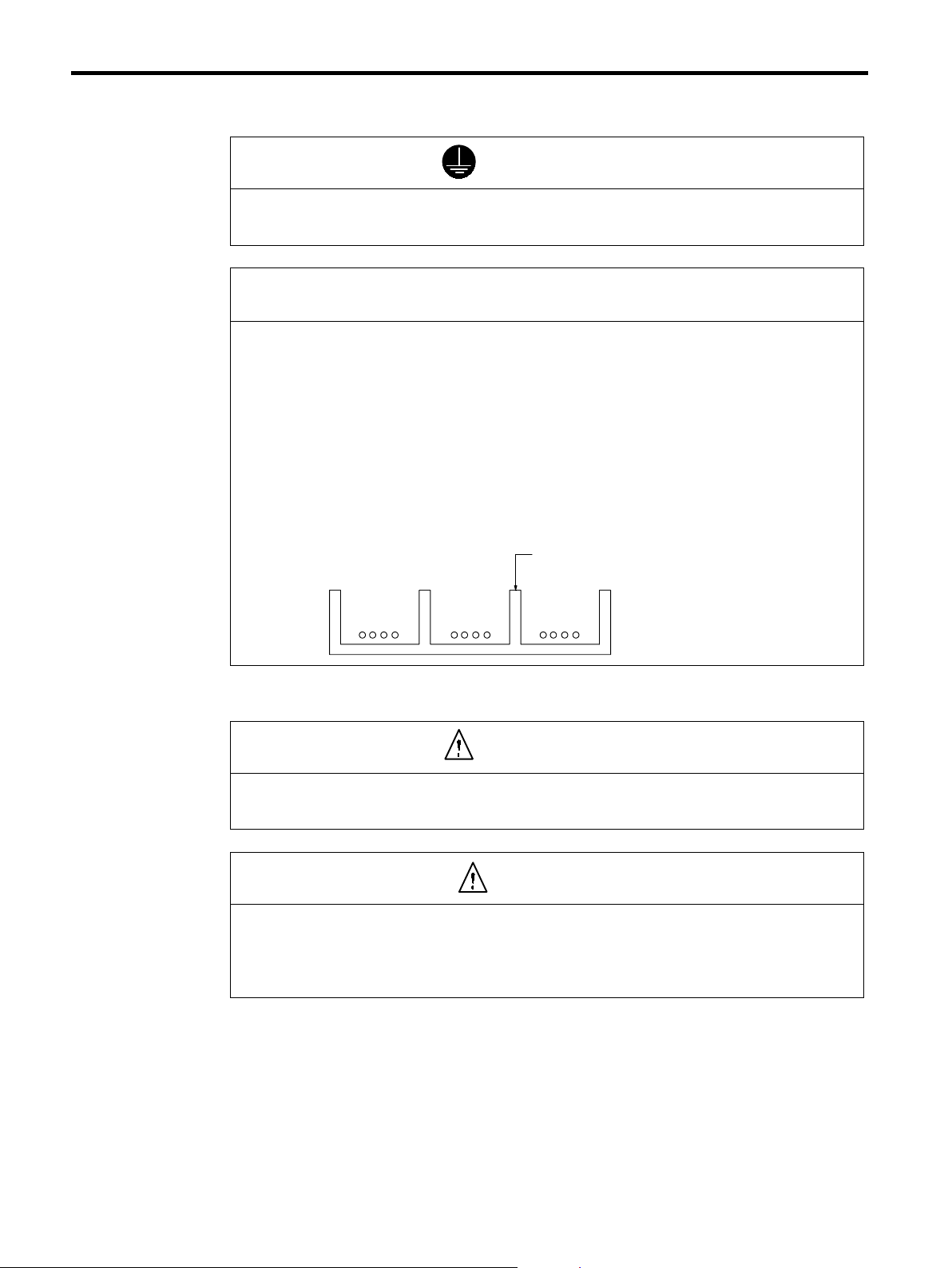

Select, separate, and lay external cables correctly.

D Consider the following items when selecting the I/O signal lines (external cables) to connect the

MP930 Module to external devices.

S Mechanical strength

S Noise interference

S Wiring distance

S Signal voltage, etc.

D Separate the I/O signal lines from the power lines both inside and outside the control panel to re-

duce the influence of noise from the power lines.

If the I/O signal lines and power lines are not separated properly, malfunctioning may result.

Example of Separated External Cables

Power

circuit

cables

General

control circuit cables

Steel separator

Digital I/O

signal

cables

J Application Precautions

WARNING

D Do not touch any Module terminals when the system power is ON.

There is a risk of electrical shock.

Caution

D Do not attempt to modify the MP930 programs, force outputs, switch between RUN and STOP, or

performed other similar operations while the MP930 is operating without knowing the direct and

indirect consequences of the operation.

Incorrect programming or operation may damage the equipment or cause an accident.

xii

Page 12

Safety Precautions

J Maintenance Precautions

WARNING

D Make sure that the polarity of the Module’s built-in battery is correct. The battery must be installed

correctly and must not be charged, disassembled, heated, thrown into fire, or short-circuited.

Improper handling may cause the battery to explode or ignite.

Caution

D Do not attempt to disassemble or modify the MP930 Module in any way.

Doing so can cause fires, product failure, or malfunctions.

D The customer must not replace the built-in fuse.

If the customer replaces the built-in fuse, the MP930 Module may malfunction or break down.

The built-in fuse must always be replaced by Yaskawa service staff.

J General Precautions

Always note the following to ensure safe use.

D MP930 was not designed or manufactured for use in devices or systems directly related to human

life. Users who intend to use the product described in this manual for special purposes such as

devices or systems relating to transportation, medical, space aviation, atomic power control, or

underwater use must contact Yaskawa Electric Corporation beforehand.

D MP930 has been manufactured under strict quality control guidelines. However, if this product is to

be installed in any location in which a failure of MP930 involves a life and death situation or in a

facility where failure may cause a serious accident, safety devices MUST be installed to minimize

the likelihood of any accident.

D Drawings in this manual show typical product examples that may differ somewhat from the product

delivered.

D This manual may change without prior notice due to product improvements and specification

changes or for easier use. We will update the manual number of the manual and issue revisions

when changes are made. The revision number of the revised manual appears on the back of the

manual.

D Contact your nearest Yaskawa sales representative or the dealer from whom you purchased the

product and quote the manual number on the front page of the manual if you need to replace a

manual that was lost or destroyed.

D Contact your nearest Yaskawa sales representative or the dealer from whom you purchased the

product to order new nameplates whenever a nameplate becomes worn or damaged.

D Products modified by the customer are not covered by the Yaskawa warranty, nor does Yaskawa

assume any liability for injury or damage that may result from such modifications.

xiii

Page 13

1

MP930

This chapter describes the type of work that can be done by the MP930 sys-

tem, and gives an easy-to-understand overview of the MP930.

1.1 Overview of the MP930 1 - 2................

1.1.1 Appearance of MP930 Units 1 - 2...................

1.1.2 Features of the MP930 1 - 3.......................

1.2 Control Using the MP930 1 - 5...............

1.2.1 Types of Program 1 - 5............................

1.2.2 Ladder Logic Programs 1 - 6.......................

1.2.3 MC Programs 1 - 8...............................

1.2.4 Control Signals 1 - 9..............................

1

1.3 Operation from Programming Devices 1 - 10....

1.3.1 File Manager 1 - 10................................

1.3.2 System Information Definitions 1 - 11................

1.3.3 Programming 1 - 12...............................

1.3.4 Debugging and Monitoring 1 - 13....................

1.3.5 Printing 1 - 13.....................................

1-1

Page 14

1

MP930

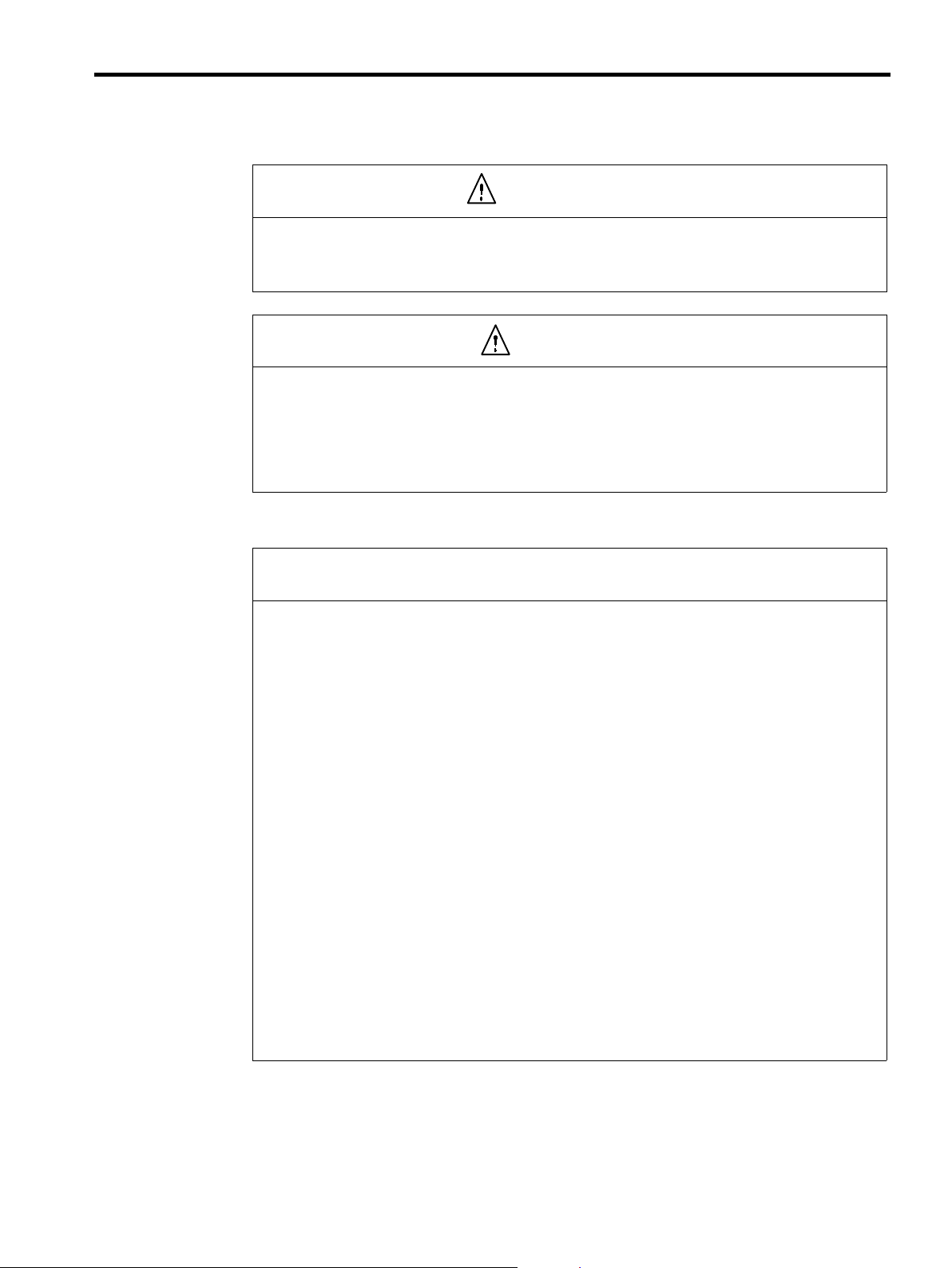

1.1.1 Appearance of MP930 Units

1.1 Overview of the MP930

This section gives an overview of the MP930.

1.1.1 Appearance of MP930 Units

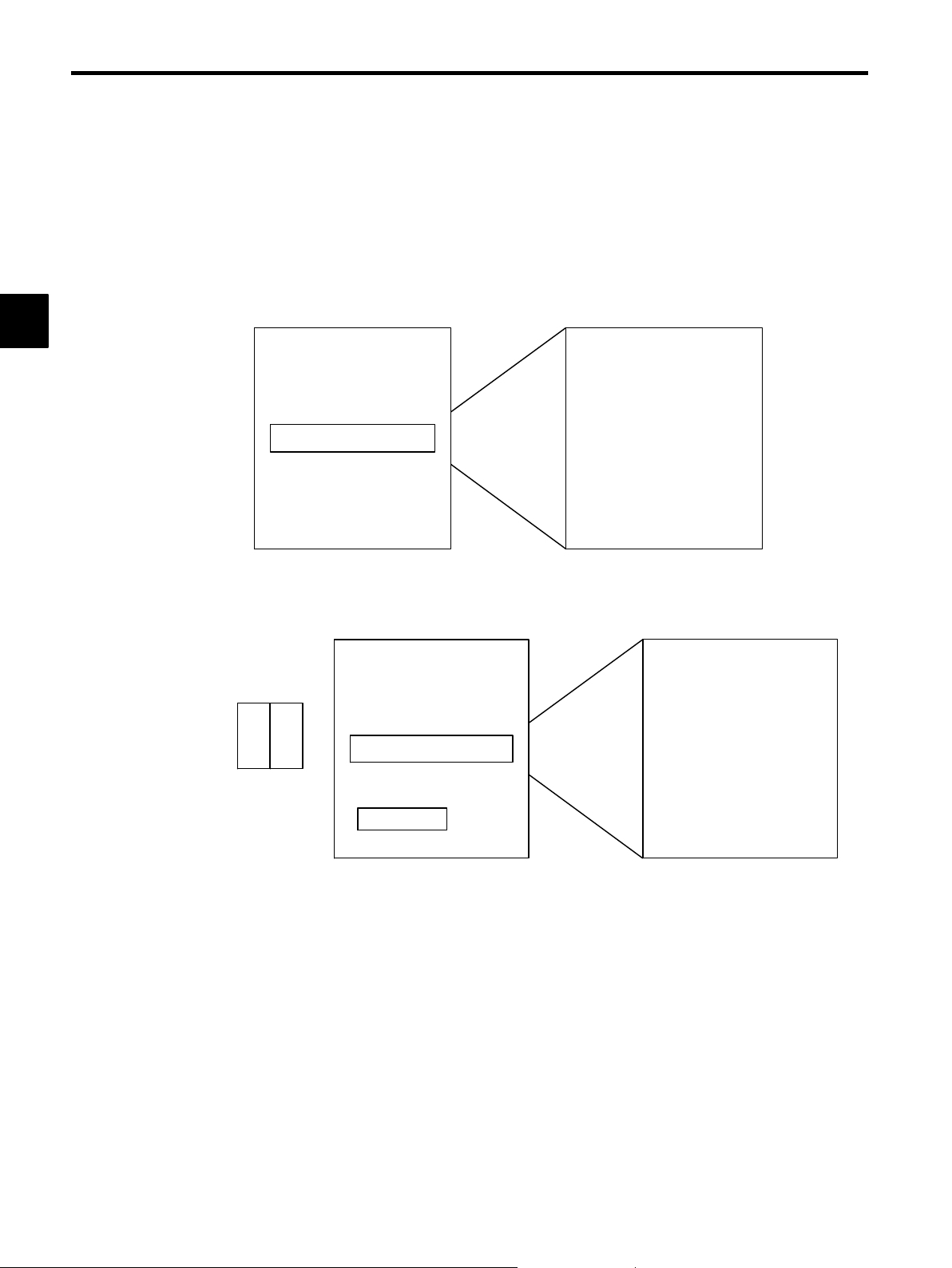

J Appearance of the MC Units

MC Unit Model No.: The follo win g illustr ation s ho ws the app ear anc e of the JEPMC-

MC350 Machine Controller Unit.

J Appearance of the I/O Units

I/O Unit Model No.: The follo win g illustr ation s ho ws the app ear anc e of the JEPMC-

IO350 I/O Unit.

1-2

Page 15

1.1.2 Features of the MP930

The MP930 has the following features:

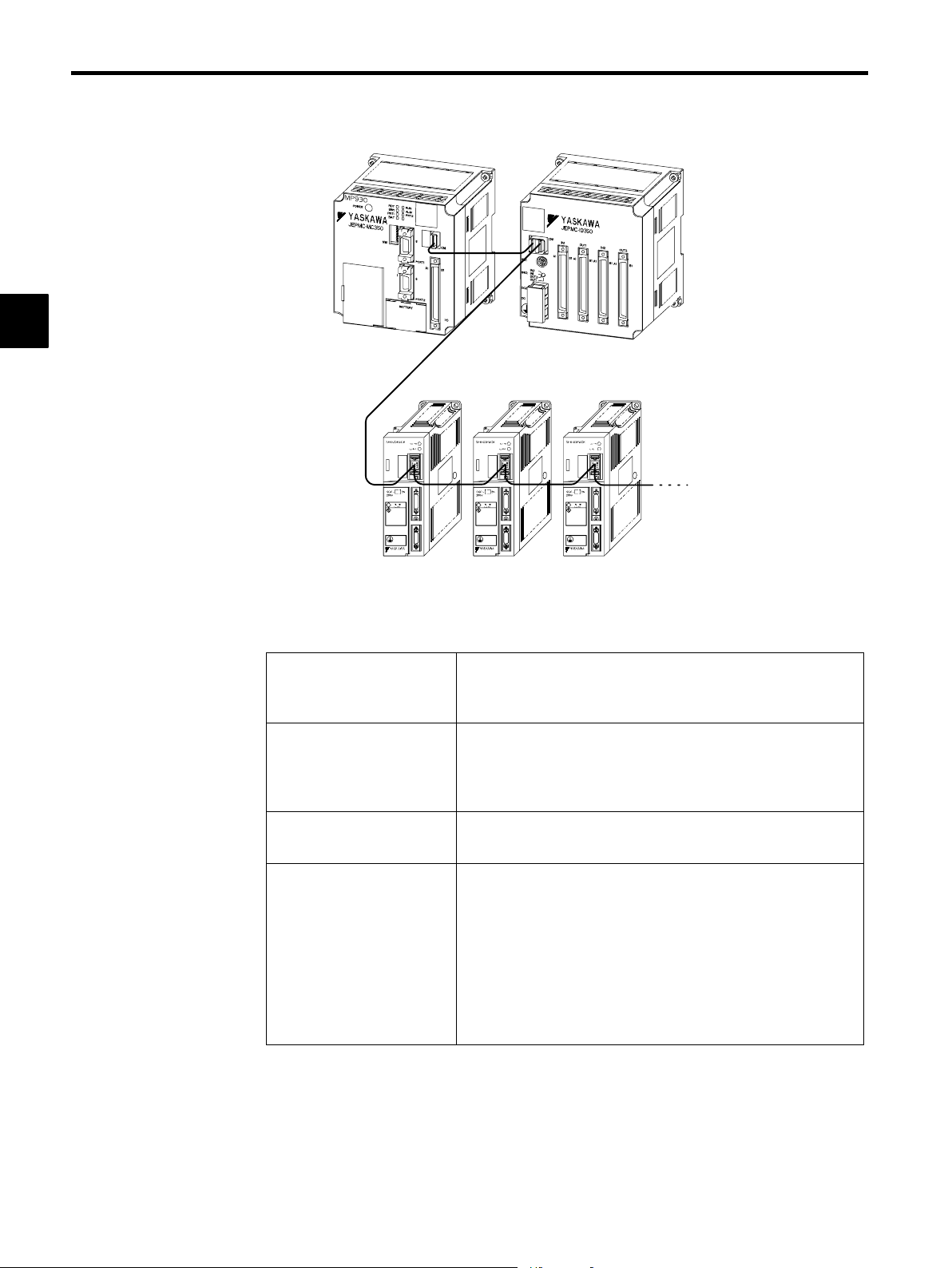

J The MP930 Machine Controller Unit is a micro machine controller

with a one−piece construction that integrates the power supply,

CPU, communications, and I/O.

The MP930 consists of an MC Unit, which provides both motion control functions and se-

quence control functions, and an I/O Unit. The servo amplifier and the I/O Unit are connected

to the MC Unit by a high-speed field network called MECHATROLINK. One MC Unit can

control a total of 14 servos and I/O Units.

J Motion programs can be executed in parallel.

D Multiple motion programs can be executed in parallel.

D Four program blocks can be executed in parallel in one motion program.

1.1 Overview of the MP930

1

Ladder Logic Program

MSEE MPM001 DA0000

MSEE MPM002 DA0002

MSEE MPM003 DA0004

MSEE MPM004 DA0006

J Reduced Startup Time and High Reliability

The use of the MECHATROLINK high-speed field network reduces startup time.

D The control panel startup time is reduced.

D High reliability is achieved.

a) Shielded twisted-pair cable

b)Only three lines to wire

c) Half the number of connectors

Motion Program MPM001

Motion Program MPM002

Motion Program MPM003

Motion Program MPM004

Motion Program MPM001

PFORK S1, S2, S3, S4;

S1

S2

S3

S4

S5: PJOINT

1-3

Page 16

1

MP930

1.1.2 Features of the MP930

MC Unit I/O Unit

MECHATROLINK-compatible

Servopacks

J Wide Range of Motion Commands

Commands such as those shown in the following table can be used.

Complete Range of Move

Commands

Immediately Effective

Acceleration/Deceleration

Commands

Many Control Commands

POSITIONING, LINEAR INTERPOLATION, CIRCULAR INTERPOLATION, HELICAL INTERPOLATION, HOME RETURN,

SKIP, SET TIME POSITIONING, and EXTERNAL POSITIONING

ACCELERATION/DECELERATION TIME, S-CURVE TIME

CONSTANT, FEED SPEED SETTING, INTERPOLATION FEED

ACCELERATION/DECELERATION TIME SETTING, MAXIMUM INTERPOLATION FEED SPEED SETTING, and so on

I/O WAIT, IF statement, WHILE statement, Parallel Execution commands, Select Execution commands, and so on

Up to 14 stations

Wide Range of Math and

Logic Commands

Integer arithmetic commands: ADD, SUBTRACT, MULTIPLICATION, DIVISION

Floating-point commands: Addition, Subtraction, Multiply, Divide

Logic operations, SET BIT, RESET BIT

BCD-TO-BINARY, BINARY-TO-BCD

Trigonometric functions, inverse trigonometric functions, SQUARE

ROOT, and so on

1-4

Page 17

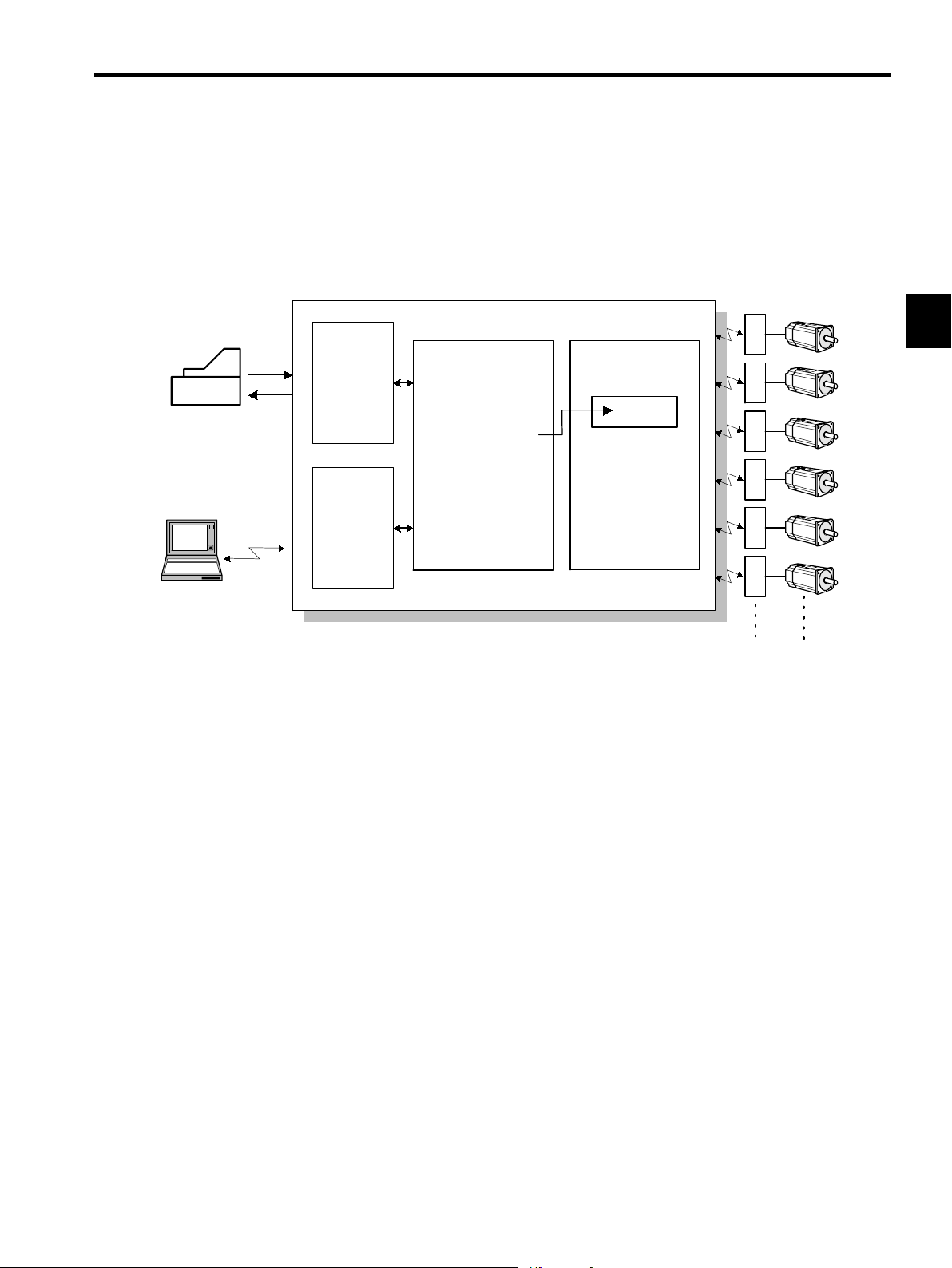

1.2 Control Using the MP930

The MP930 is a machine controller with fully integrated sequence control and motion control. One

Controller simultaneously performs motion control and sequence control.

1.2 Control Using the MP930

I/O

processing

Operation panel

Programming Device

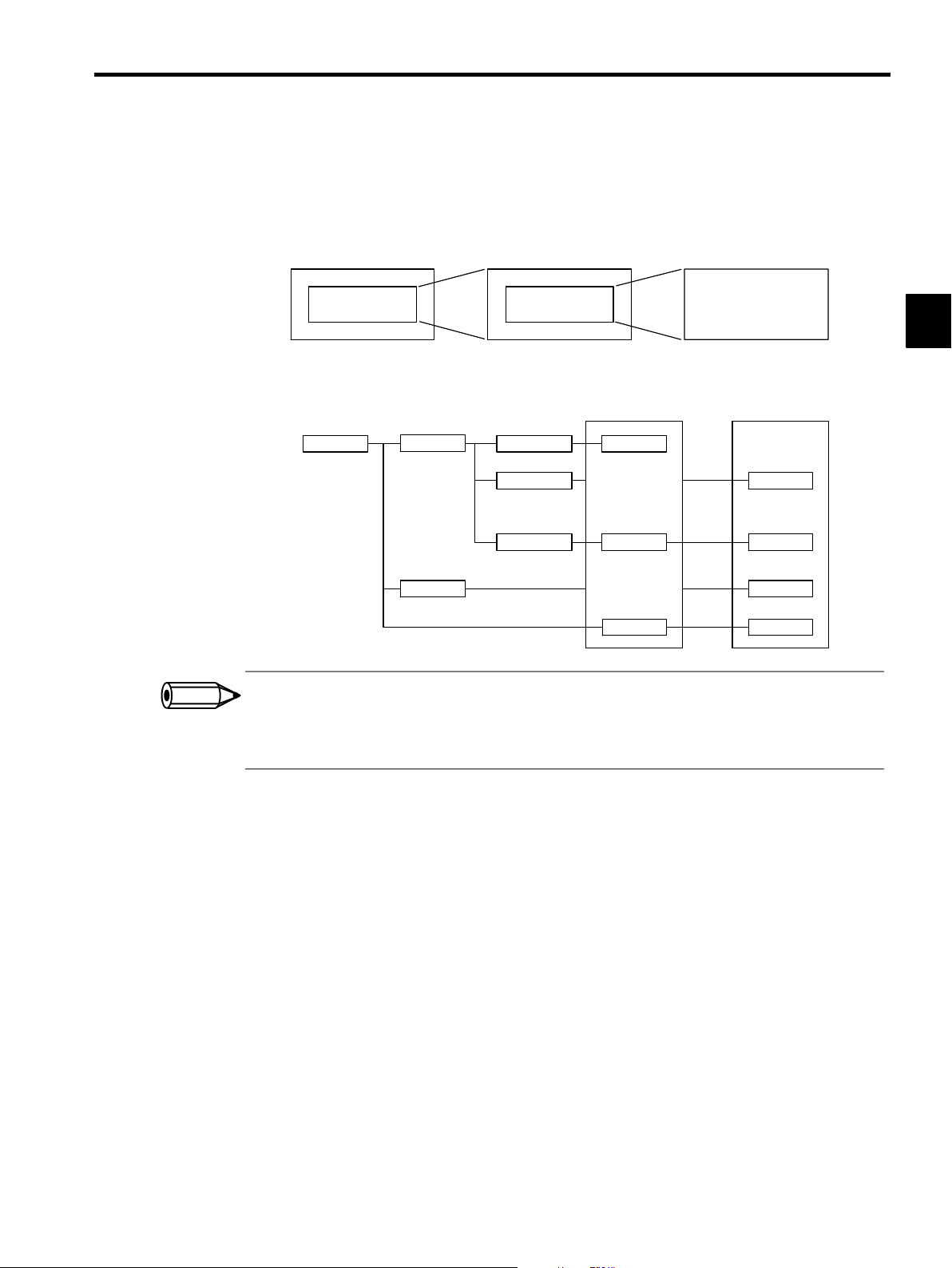

Figure 1.1 MP930 System Concept

1.2.1 Types of Program

Communications

control

Ladder logic program

Sequence control

MC program start

MSEE MPM001 DAXXX

MC program

Motion control

MPMxxx

.

.

.

.

.

.

.

Servo

amplifier

14 axes max.

Servomotor

1

Programs consist of ladder logic programs, which are designed mainly for sequence control,

and motion programs (called MC programs), which are designed mainly for servo control.

1-5

Page 18

MP930

Equival

20

K

f

ladderl

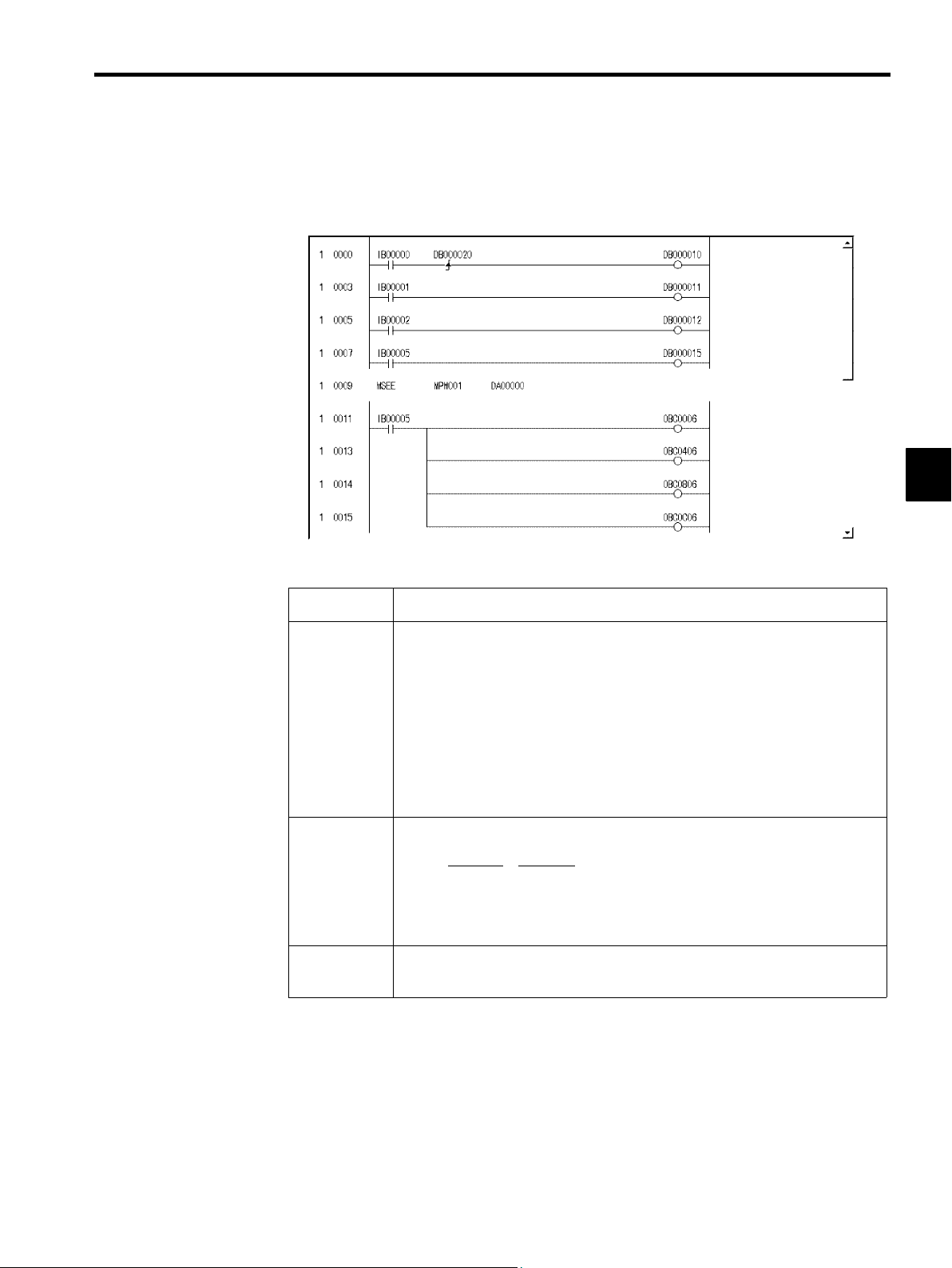

1.2.2 Ladder Logic Programs

1.2.2 Ladder Logic Programs

J Types of Drawing

A ladder logic program is a program used for coding the sequence logic for conditional control

and sequence control, and for coding the sequence logic that starts an MC program. The ladder

logic program is created as the basic unit called drawings (DWGs).

1

The following types of drawing are provided: Start drawing, high-speed scan drawings, low-

speed scan drawings, and user functions.

D Startup Drawings

Startup drawings are executed once when the power is turned ON. The logic used to set

constants and initialize operation is normally coded in these drawings.

D High-speed Scan Drawings

High-speed scan drawings are executed at regular intervals. The scan time is within the

range of 2 to 32 ms, and scan times can be set at 2-ms intervals. The circuits used to

the MC program are coded in the high

speed scan drawings.

-

start

D Low-speed Scan Drawings

Low-speed scan drawings are executed at regular intervals. The scan time is within the

range of 2 to 300 ms, and scan times can be set at 2-ms intervals. Sequence logic that does

not require high-speed processing, such as lamp output and display circuits, should be

coded in low-speed scan drawings.

D User Functions

User functions are defined as user commands in the coded drawings, using the commands

provided for the MP930. User functions can be used in startup drawings, high-speed scan

drawings, and low-speed scan drawings.

Types of Drawing Maximum Number

of Drawings

Startup Drawings

High-speed Scan Drawings

Low-speed Scan Drawings

User Functions

64 DWG.A

100 DWG.H

100 DWG.L

200 FUNC-xxx

Drawing and

Function Notation

1-6

Remarks

S 500 steps max. per drawing

S

S Security function can be set separately for

S Separate revision history or each drawing.

ent to

ic program memory

each drawing.

steps max. o

og-

Page 19

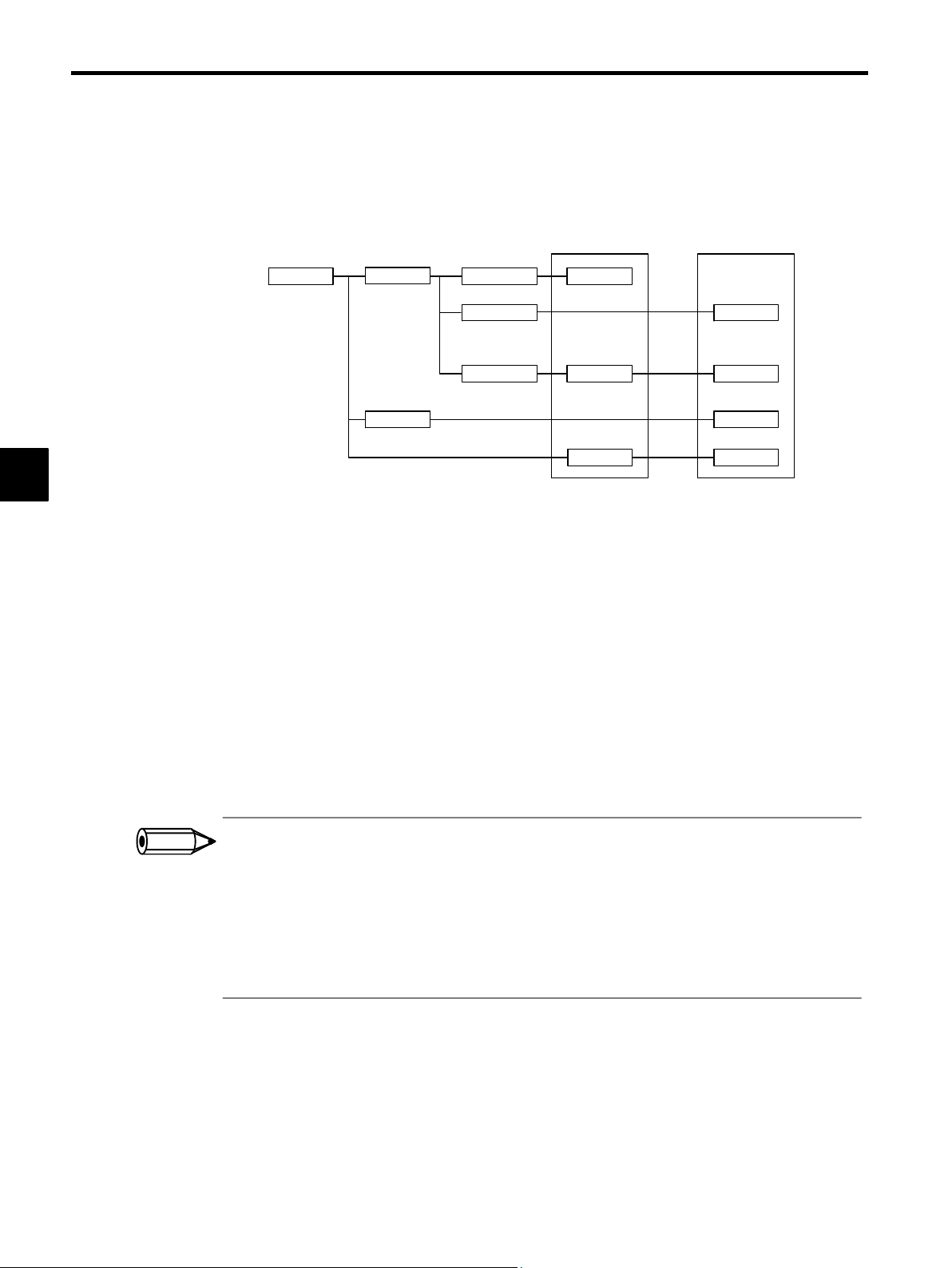

1.2 Control Using the MP930

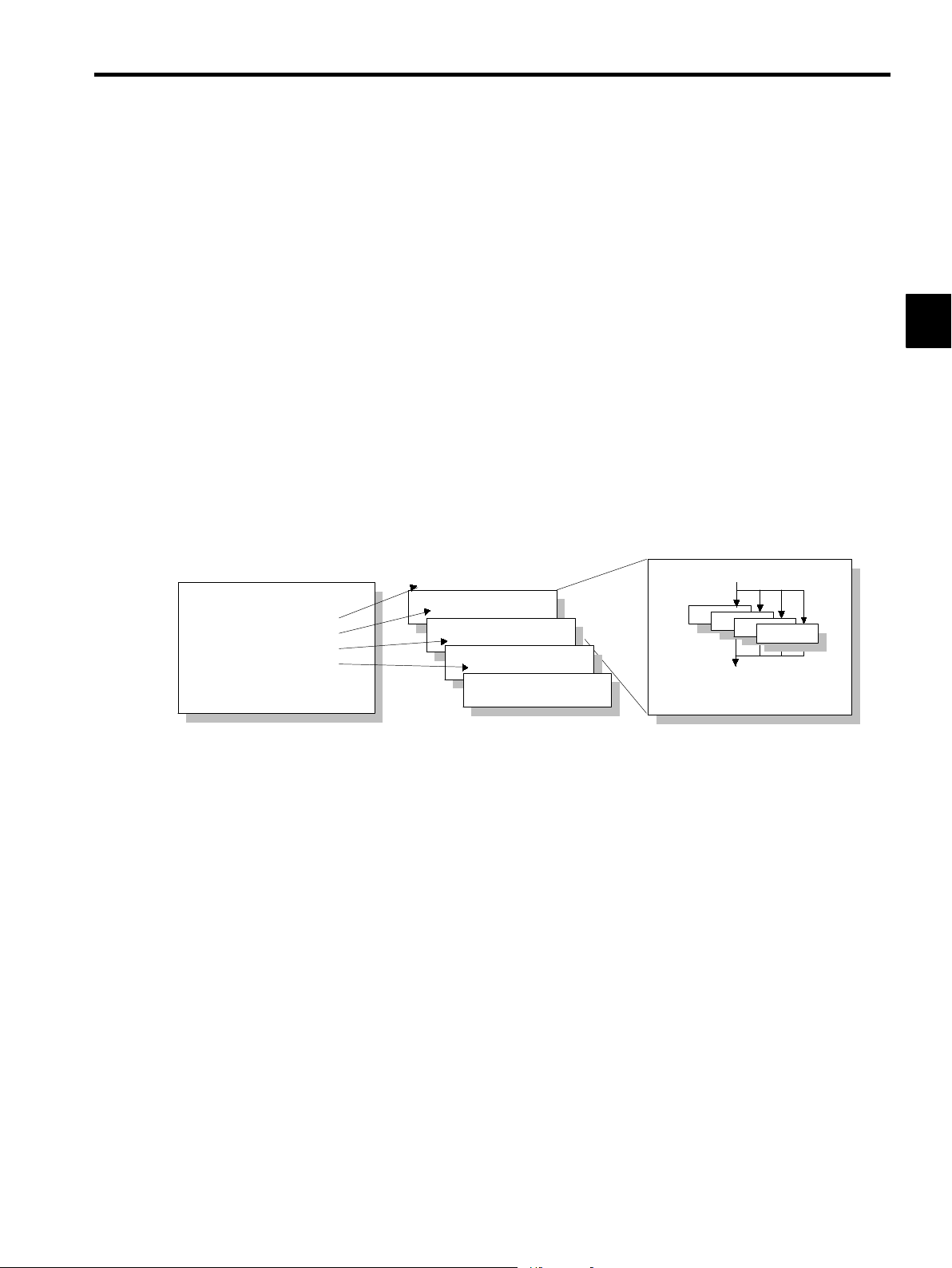

J Configuration of Drawings

Drawings can be arranged in up to three hierarchical levels: parent, child, and grandchild draw-

ings. These drawings are developed downward using the SEE instruction.

Functions can be started from any drawing.

INFO

SEE Child

drawing number

Parent drawing Child drawing Grandchild drawing

Parent drawing Child drawing Grandchild

DWG.X DWG.X01.01

DWG.X01

SEE Grandchild

drawing number

Motion programs

drawing

DWG.X01.01

.

.

DWG.X01.01

DWG.Xnn

1.

X is replaced by A, H, or L.

2. A motion program can be started only from an H drawing.

3.

Motion programs are started with the MSEE instruction.

MPM001

.

.

.

MPM002

.

.

.

MPM015

User constants

FUNC-001

.

.

FUNC-006

.

.

FUNC-032

.

.

FUNC-064

1

1-7

Page 20

1

MP930

1.2.3 MC Programs

1.2.3 MC Programs

An MC program codes the logic used for servo control in a motion control language. An MC

program is started using the MOTION PROGRAM CALL instruction (MSEE) in the ladder

logic program. There are two methods of designating an MC program: Direct designation of

the program number, and indirect designation of the number of the register in which the MPM

number is to be stored.

ABS;

MOTION PROGRAM

CALL instruction

MSEE MPM001 DA0000

↑

MPM number

MOV [X] _ [Y] _

MVS [X] _ [Y] _ F

IOW MB0001

MOV [X] _ [Y] _

.

.

.

Ladder logic program

0 3

Setting device

MC program

Figure 1.2 Starting an MC Program by Direct Designation

ABS;

MOTION PROGRAM

CALL instruction

MSEE MW00200 DA0000

MPM number

Ladder logic program

MW00200

MOV [X] _ [Y] _

MVS [X] _ [Y] _ F

IOW MB0001

MOV [X] _ [Y] _

Figure 1.3 Starting an MC Program by Indirect Designation

.

.

.

MC program

1-8

Page 21

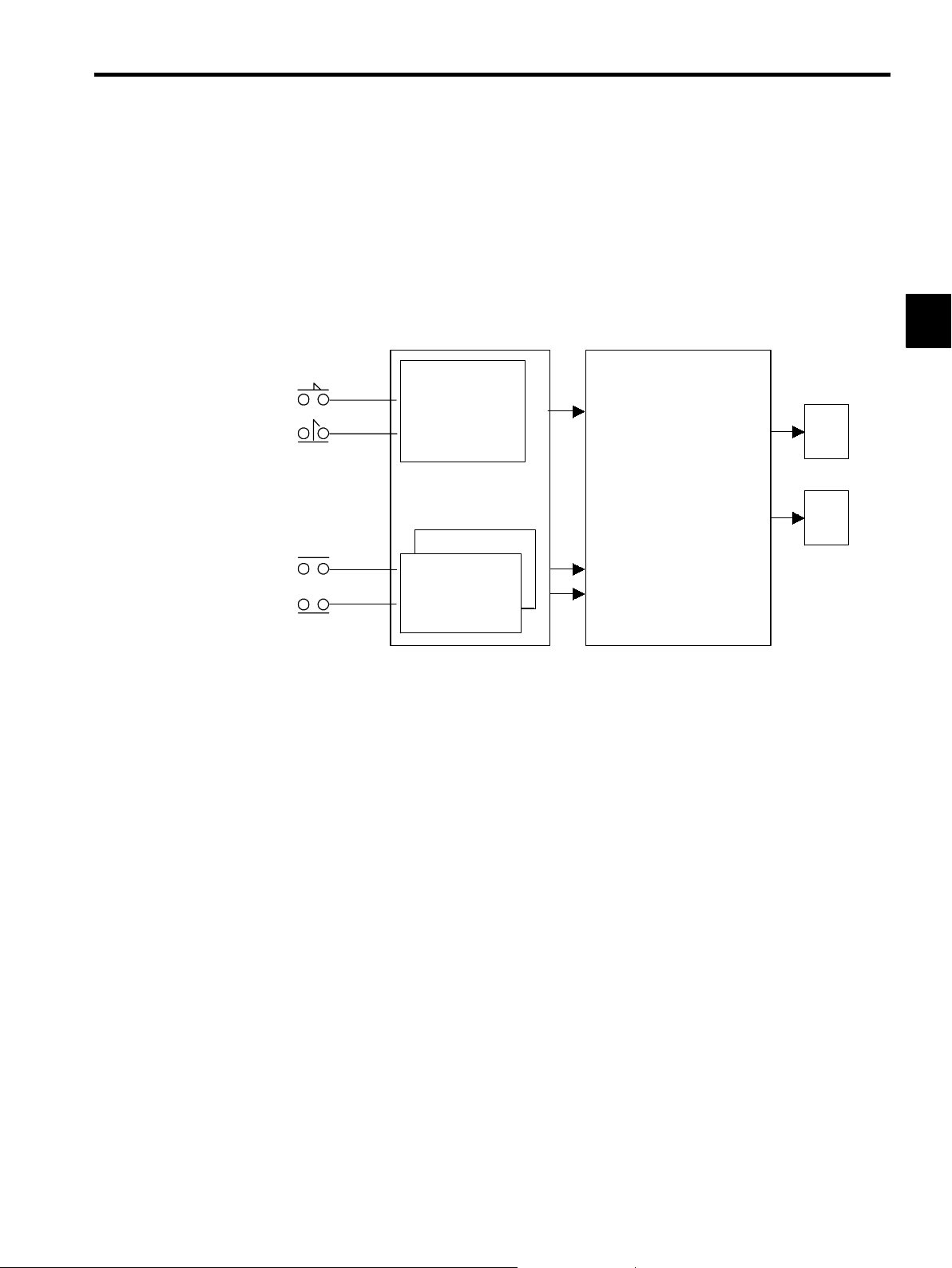

1.2.4 Control Signals

There are two types of control signal: 1) Group input control signals, which are shared by

groups, such as automatic operation start signals and emergency stop signals, and 2) Axis input

signals, which are used by designated axes only, such as servo ON signals and JOG signals.

The signals (variables) to be used as control signals are allocated on the Group Definition

Screen.

1.2 Control Using the MP930

Control signals

:

:

Group input signals

Automatic operation start,

emergency stop, override,

operation mode, etc.

X axis input signals

X axis input signals

Servo ON

JOG

Other

MC program

ABS;

MOV [X] _ [Y] _

X axis

MOV [X] _ [Y] _ F _

IOW MB0001

MOV [X] _ [Y] _

Y axis

.

.

.

.

.

1

1-9

Page 22

1

MP930

1.3.1 File Manager

1.3 Operation from Programming Devices

This section gives an overview of the types of operation that can be performed using peripheral

devices.

A computer running the CP-717 programming software for the ladder logic programs and motion

programs for the MP930 is called a “Programming Device.”

Communications with the Unit are enabled by connecting a Programming Device to the MEMO-

BUS port of the MP930 MC Unit using a special cable.

The following operations can be performed from the Programming Device.

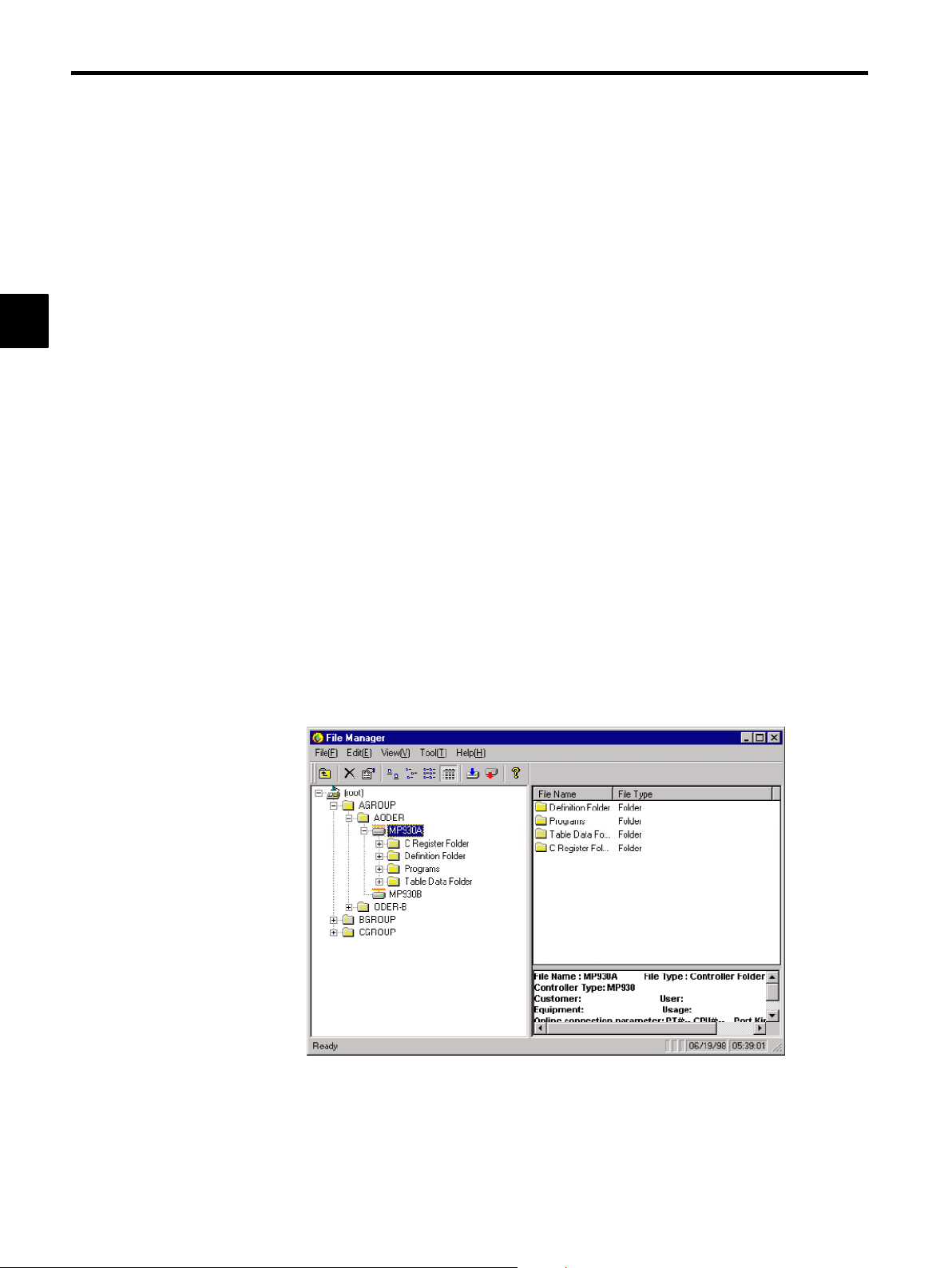

1.3.1 File Manager

The following folder and file management functions and file transfer functions are performed.

D File management

D User management

D File transfer

D Online/offline

D Logging off

D CPU control

1 -10

Page 23

1.3.2 System Information Definitions

The following information definitions are set.

D System definitions

D Scan time settings

D Application settings

1.3 Operation from Programming Devices

D Module configurations

D Failure monitoring

D Data traces

D Group definitions

D Motion parameters

1

1-11

Page 24

MP930

1.3.3 Programming

1.3.3 Programming

The following ladder logic programs and motion programs are edited.

D Main program creation

D Table format program creation

D Adjustment panel creation

1

D C registers

D Table data definitions

D Motion editor

1 -12

Page 25

1.3.4 Debugging and Monitoring

The following functions are provided for debugging.

D Register list

D Adjustment panel

D Program monitor

1.3 Operation from Programming Devices

D Position monitor

D Task monitor

D Failure monitor

D Data trace monitor

1.3.5 Printing

1

The following data created for definitions and programming can be printed.

D Definitions

D Drawings and functions

D Motions

D Table data

D Registers

1 -13

Page 26

2

MP930 Specifications and System

Configuration

This chapter explains the MP930 Unit specifications, together with the

products used in the system configuration of the MP930.

2.1 Specifications 2 - 2.........................

2.1.1 General Specifications 2 - 2.......................

2.1.2 Hardware Specifications 2 - 3......................

2.1.3 Function List 2 - 4................................

2.2 Basic System Configuration 2 - 31.............

2.2.1 List of Basic Units 2 - 31............................

2.2.2 Basic System Configuration 2 - 32...................

2.2.3 Precautions on System Configuration 2 - 33..........

2.2.4 Programming Device 2 - 34.........................

2

2-1

Page 27

R

2

MP930 Specifications and System Configuration

2.1.1 General Specifications

2.1 Specifications

This section gives an overview of the specifications and functions of the MP930 Units.

2.1.1 General Specifications

J General Specifications of the MP930 Units

Table 2.1 lists the general specifications of the MP930 Units.

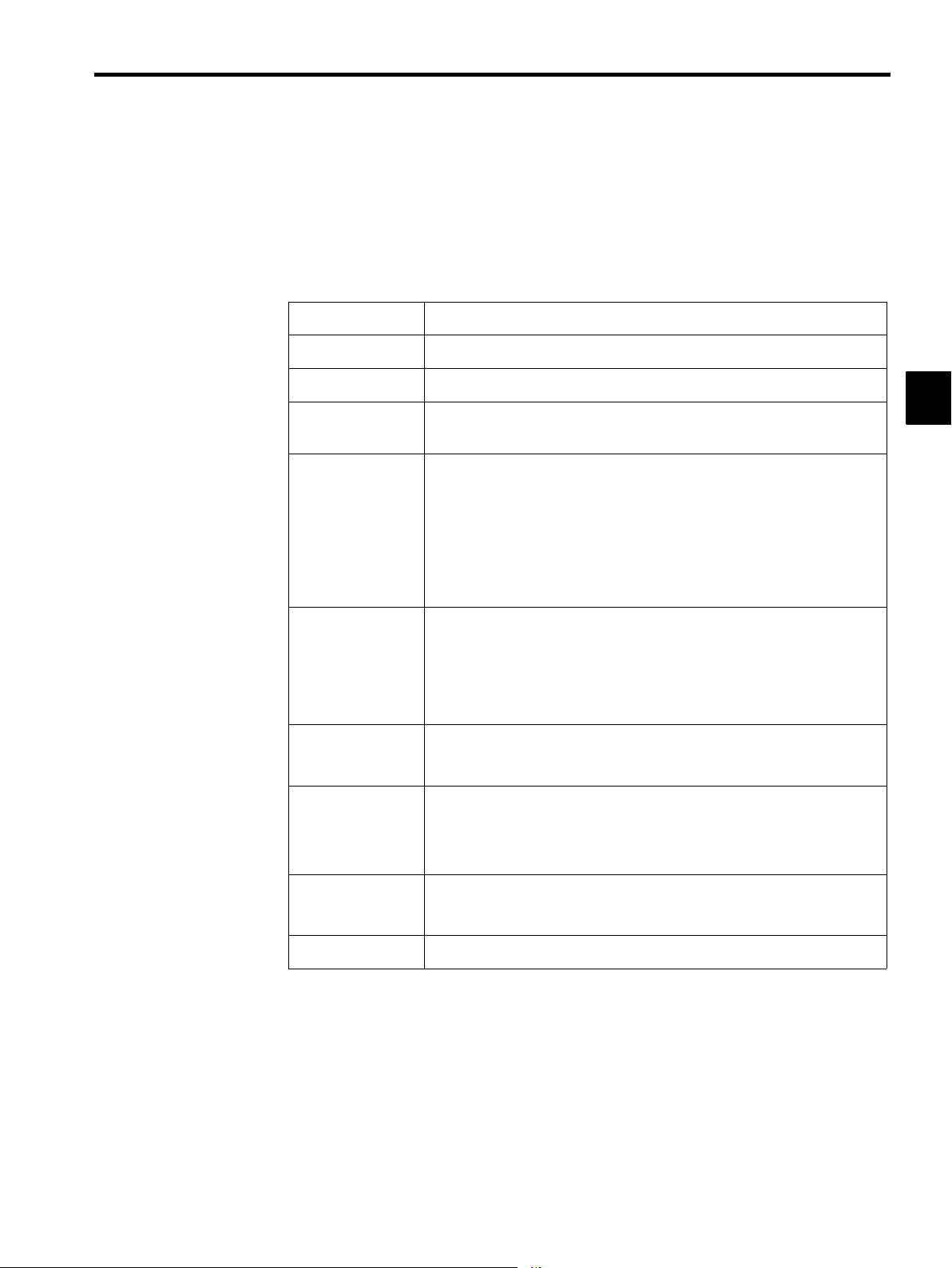

Table 2.1 General Specifications of the MP930 Units

Item Specifications

Environmental

Conditions

Electrical

Operating

Conditions

Mechanical

Operating

Conditions

Ambient Operating

Temperature

Storage Temperature

Ambient Operating

Humidity

Ambient Storage

Humidity

Pollution Level

Corrosive Gas

Operating Altitude

Noise Resistance

Vibration Resistance

0to55°C

−25 to 85 °C

30% to 95% RH (with no condensation)

5% to 95% RH (with no condensation)

Pollution level 1 (conforming to JIS B 3501)

There must be no combustible or corrosive gas.

2,000 m above sea level or lower

Conforming to JIS B 3502:

1,500 V (p-p) in either normal or common modes with

a pulse width of 100 ns/1µs and a rise time of 1 ns

(tested with impulse noise simulator)

Conforming to JIS B 3502:

10 to 57 Hz with single-amplitude of 0.075 mm

57 to 150 Hz with fixed acceleration of 9.8 m/s2(1G)

10 sweeps each in X, Y, and Z directions

(sweep time: 1 octave/min)

Shock Resistance

Installation

equirements

Ground

Cooling Method

2-2

Conforming to JIS B 3502:

2

Peak acceleration of 147 m/s

each in the ±X, ±Y, and ±Z directions

Ground to 100 Ω max.

Natural cooling

(15G) twice for 11 ms

Page 28

2.1.2 Hardware Specifications

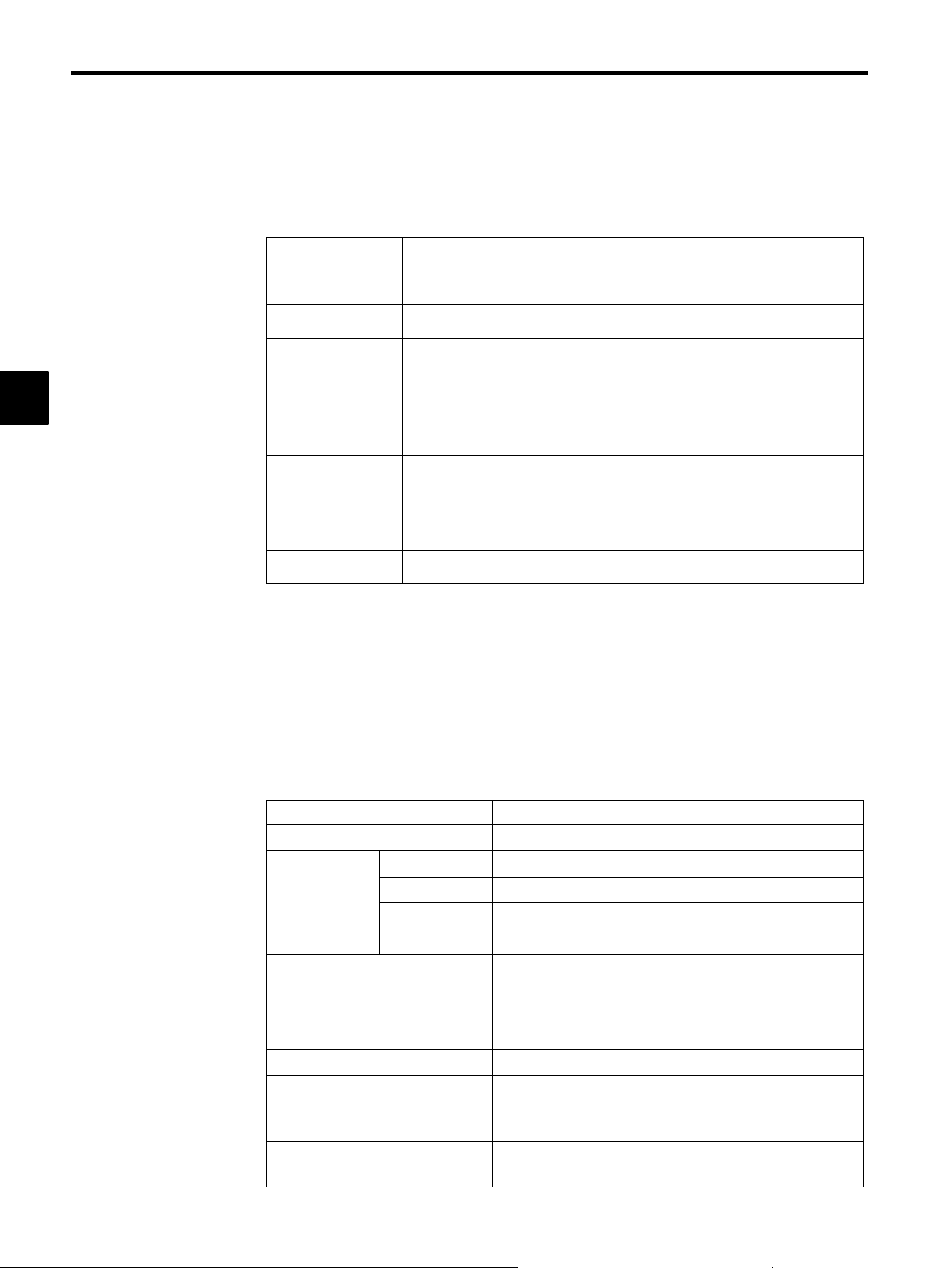

J MP930 MC Unit Hardware Specifications

Table 2.2 lists the hardware specifications of the MP930 MC Unit.

Table 2.2 MC Unit Hardware Specifications

Item Specifications

2.1 Specifications

Name

Model Number

Memory

Communications

Ports

I/O Signals

Field Bus

Display Switch

*1, *2

MC Unit

JEPMC-MC350

2

Flash: 1 MB

RAM: 2 MB (battery backup)

RS-232C × 2 ports

Baud rate: 19.2 kbps

Female 9-pin D-sub connector (special pin assignments)

S MEMOBUS

S No protocol (custom)

S MELSEC

Inputs: 16 points

24 VDC (20.4 to 28.8 V)

5 mA, combined sinking/sourcing

Outputs: 16 points

24 VDC, 50 mA, sinking outputs

MECHATROLINK (high-speed field network)

Up to 14 servos and I/O stations can be connected.

Unit status indicators

I/O signal indicators

DIP switch for mode setting

Power Supply

Dimensions

*1. The I/O signal functions can be allocated.

*2. The Expansion I/O Unit can be used with MECHATROLINK communications.

24 VDC (20.4 to 28.8 V)

Rated current: 1 A; In-rush current: 50 A

120 (W) × 130 (H) × 105 (D) mm

2-3

Page 29

MP930 Specifications and System Configuration

2.1.3 Function Lists

J I/O Unit Hardware Specifications

Table 2.3 lists the hardware specifications of the I/O Unit.

Table 2.3 I/O Unit Hardware Specifications

2

Item

Name

Model Number

I/O Signals

MC Unit Interface

Unit Power

Supply

Dimensions

* The maximum rating per point is 100 mA (depending on derating conditions).

2.1.3 Function Lists

J MP930 Motion Control Function Specifications

Specifications

I/O Unit

JEPMC-IO350

Inputs: 64 points

24 VDC, 5 mA, combined sinking/sourcing

Outputs: 64 points

24 VDC, 50 mA, sinking outputs (all points ON) *

Signal connection method: Connector (FCN360 Series)

MECHATROLINK (high-speed field network)

24 VDC (20.4 to 28.8 V)

Rated current: 0.5 A; inrush current: 1 A

120 (W) × 130 (H) × 105 (D) mm

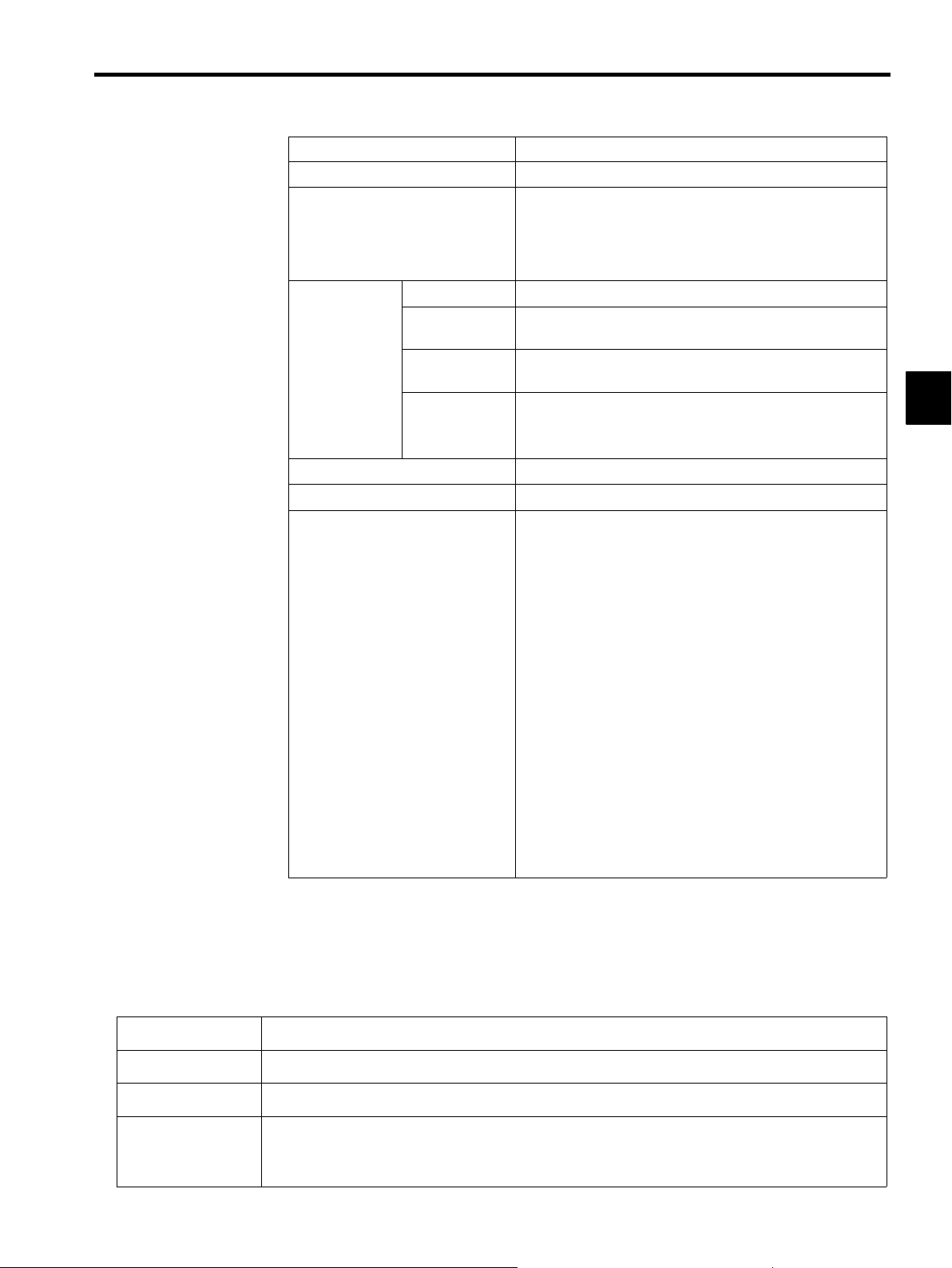

Table 2.4 lists the motion control function specifications for the MP930.

Table 2.4 MP930 Motion Control Function Specifications

Item

Number of Controlled Axes

Control

Specifications

Reference Unit

Reference Unit Minimum

Setting

Maximum Programmable Value

Speed Reference Unit

Acceleration/Deceleration Type

Override Function

PTP Control

Interpolation

Speed Control

Torque Limit

1 to 14 axes

Linear, rotary, infinite-length, and independent axes

Up to 14 linear axes, 2 circular axes, and 3 helical axes

None

Yes (According to parameter setting only)

mm, inch, deg, pulse

1, 0.1, 0.01, 0.001, 0.0001, 0.00001

−2147483648 to +2147483647 (signed 32-bit value)

mm/min, inch/min, deg/min, pulse/min

Linear, asymmetric, S-curve

Asymmetric acceleration/deceleration is not possible with

POSITIONING (MOV).

Positioning: 0.01% to 327.67% by axis

Interpolation: 0.01% to 327.67% by group

Specification

2-4

Page 30

Item Specification

Coordinate System

Zero Point Return

Programs

Applicable Servopack

Encoder

Command Words

Language

Number of

Tasks

Number of

Programs

Program

Capacity

2.1 Specifications

Rectangular coordinates

Four types

Dog + phase C, zero point limit switch, dog + zero point

limit switch, phase C

Home position setting function provided.

Special motion language

Multiple programs can be executed in parallel.

Up to 256

Equivalent to 80 Kbytes (characters)

(Can be increased or decreased according to the size of ladder

logic program used; maximum of 100 Kbytes.)

SGD-jjjN/SGDB-jjAN

Incremental or absolute

Axis Move Commands: 8 commands

MOV, MVS, MCW, MCC, ZRN, SKP, MVT, EXM

2

Basic Control Commands: 6 commands

ABS, INC, POS, PLN, MVM, PLD

Speed and Acceleration/Deceleration Commands: 7 commands

ACC, SCC, VEL, IAC, IDC, IFP, FMX

High-level Control Commands: 4 commands

PFN, INP, SNG, UFC

Control Commands: 10 commands

MSEE, TIM, IOW, END, RET, EOX, IF ELSE IEND,

WHILE WEND, PFORK JOINTO PJOINT, SFORK JOINTO SJOINT

Math and Sequence Control Commands: 32 commands

=, +, −, *, /, MOD, |, ^, &, !, (), S{}, R{}, SIN, COS, TAN,

ASN, ACS, ATN, SQRT, BIN, BCD, ==, <>, >, <, >=, <=,

SFR, SFL, BLK, CLR

J PLC Function Specifications

Table 2.5 lists the PLC function specifications.

Table 2.5 PLC Function Specifications

Item Specifications

Program Capacity

Control Method

Programming

Language

Equivalent to 4 Ksteps (varies according to amount of motion program used; 20 Ksteps max.)

Sequence: High-speed and low-speed scan methods

CP language

Ladder logic diagram: Relay circuit

Text-type language: Numeric operations, logic operations, etc.

2-5

Page 31

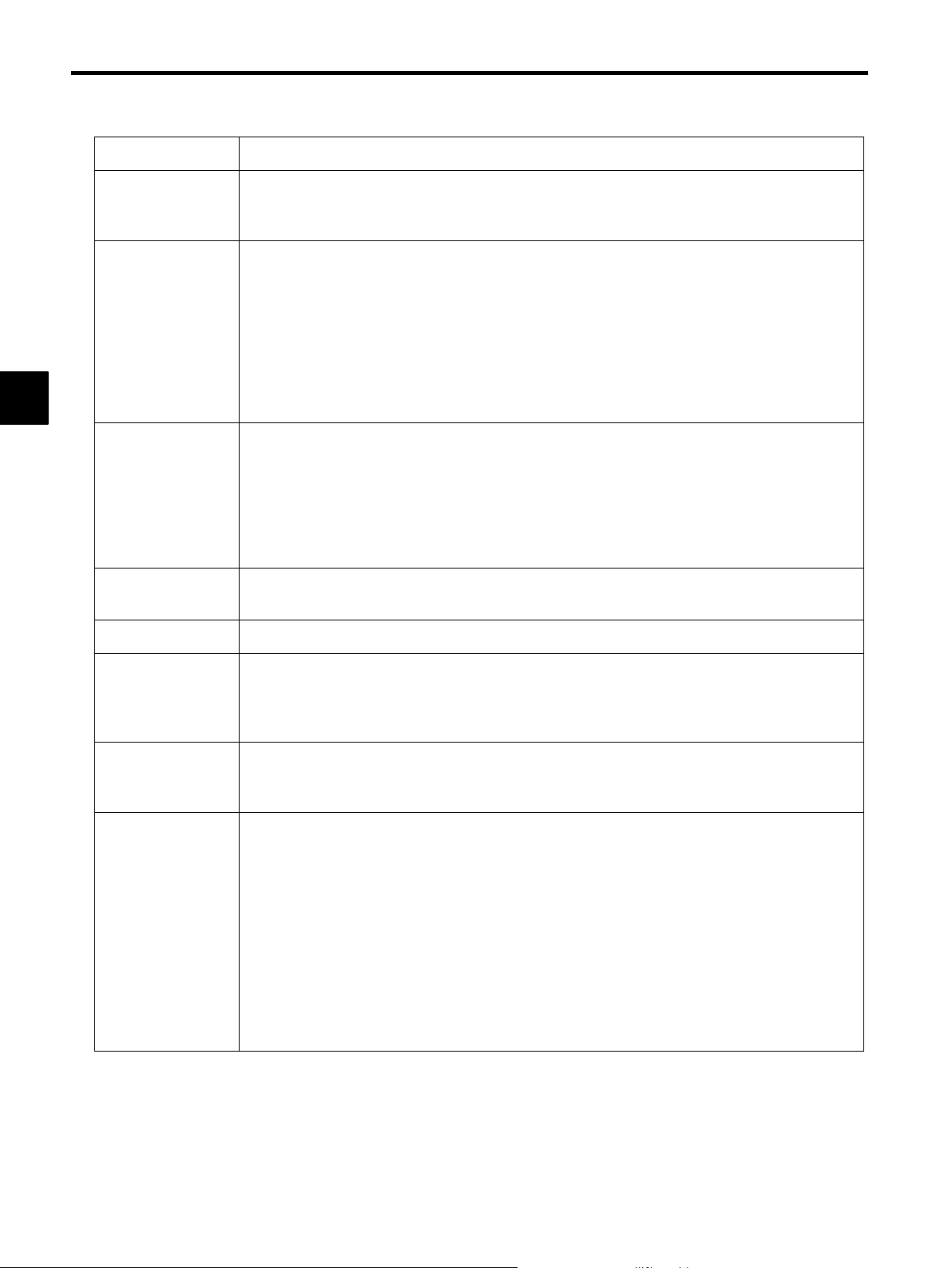

MP930 Specifications and System Configuration

2.1.3 Function Lists

Item Specifications

2

Scanning

User Drawings and

Functions

Motion Programs

Data Memory

Trace Memory

Memory Backup

Two scan levels: High-speed scan and low-speed scan

High-speed scan time setting: 2 to 32 ms (2 ms units)

Low-speed scan time setting: 2 to 300 ms (0.1 ms units)

Start drawings (DWG.A): 64 drawings max. Up to three hierarchical drawing levels

High-speed scan process drawings (DWG.H): 100 drawings max. Up to three hierarchical drawing levels

Low-speed scan process drawings (DWG.L): 100 drawings max. Up to three hierarchical drawing levels

Number of steps: Up to 500 steps per drawing

User functions: Up to 200 functions

Motion programs: Up to 256

Revision history of drawings and motion programs

Security function for drawings and motion programs

Common data (M) registers: 32 Kwords

System (S) registers: 1 Kwords

Drawing local (D) registers: Up to 16 Kwords per drawing

Drawing constant (#) registers: Up to 16 Kwords per drawing

Input (I) registers: 2 Kwords (including internal input registers)

Output (O) registers: 2 Kwords (including internal output registers)

Constant (C) registers: 4 Kwords

Data trace: 128 Kwords (32 Kwords × 4 groups), 16 points defined

Failure trace: 32 Kwords, 500 items defined

User memory: CMOS battery backup

Data Types

Register

Designation

Method

Instructions

Bit (relay): ON/OFF

Integer:

Double integer: −2147483648 to +2147483647

Real number: ± (1.175E − 38 to 3.402E + 38)

Register number: Direct designation of register number

Symbolic designation: Up to 8 alphanumeric characters (up to 200 symbols per drawing)

With automatic number or symbol assignment

Program control instructions: 14 instructions

Direct I/O instructions: 2 instructions

Relay circuit instructions: 14 instructions (including set and reset coils)

Logic operation instructions: 3 instructions

Numeric operation instructions: 16 instructions

Numeric conversion instructions: 9 instructions

Numeric comparison instructions: 7 instructions

Data manipulation instructions: 14 instructions

Basic function instructions: 10 instructions

Table data manipulation instructions: 11 instructions

DDC instructions: 13 instructions

System functions: 14 instructions

32768 to +32767

−

2-6

Page 32

J Motion Commands

Deceleration

Commands

Table 2.6 lists the motion commands.

Table 2.6 Motion Command List

2.1 Specifications

Classification

Axis Move

Commands

Basic Control

Commands

Command Function

MOV

MVS

MCC

MCW

ZRN

SKP

MVT

EXM

ABS

INC

POS

PLN

MVM

Positioning

Linear interpolation

Counterclockwise circular interpolation, Helical circular interpolation (counterclockwise)

Clockwise circular interpolation, Helical circular interpolation

(clockwise)

Zero point return

Skip

Set time positioning

External positioning

Absolute mode

Incremental mode

Current position set

Coordinate plane setting

Move on machine coordinate

2

Speed and

Acceleration/

Deceleration

Commands

High-Level

Control

Commands

PLD

ACC

SCC

VEL

IAC

IDC

IFP

FMX

PFN

INP

SNG

UFC

Program current position updating

Acceleration time change

S-curve time constant change

Set velocity

Interpolation acceleration time change

Interpolation deceleration time change

Interpolation feed speed ratio setting

Maximum interpolation feed speed setting

In-position check

Second in-position check

Ignore single block signal

User function call

2-7

Page 33

MP930 Specifications and System Configuration

2.1.3 Function Lists

Classification FunctionCommand

2

Control

Commands

MSEE

TIM

IOW

END

RET

EOX

IF

ELSE

IEND

WHILE

WEND

PFORK

JOINTO

PJOINT

SFORK

JOINTO

Subroutine call

Dwell time

I/O wait

Program end

Subroutine end

One scan wait

Branching commands

Repeat commands

Parallel execution commands

Selective execution commands

Sequence

Commands

SJOINT

=

+, −, *, /, MOD

|, ^, &, !

SIN, COS,

TAN, ASN,

ACS, ATN,

SQRT, BIN

BCD

==, <>, >, <,

>=, <=

SFR, SFL,

BLK, CLR

(),S{},R{}

Substitution

Arithmetic operations

Logic operations

Function commands

Numeric comparison commands

Data operation

Others

2-8

Page 34

J Motion Command Descriptions

Table 2.7 describes the motion commands.

Table 2.7 Motion Command Description

2.1 Specifications

Classification

Axis Move

Commands

Command Name Programming Format Function/Meaning

MOV

MVS

MCW

MCC

MCW

MCC

POSITIONING MOV [axis1] − [axis2] − ⋅⋅⋅;

(Up to 14 axes can be designated.)

LINEAR INTERPOLATION

CLOCKWISE CIRCULAR INTERPOLATION

COUNTERCLOCKWISE CIRCULAR

INTERPOLATION

CLOCKWISE HELICAL INTERPOLATION

COUNTERCLOCKWISE HELICAL INTERPOLATION

MVS [axis1] − [axis2] − ⋅⋅⋅F−;

(Up to 14 axes can be designated.)

MCW [axis1] − [axis2] − R−

F−; MCC [axis1] − [axis2] −

U− V− T− F−;

MCW [axis1] − [axis2] −U−V−

[axis3] −T− F−;

MCC [axis1] − [axis2]

−R−[axis3] −F−;

Executes positioning at rapid traverse

speed for up to 14 axes simultaneously.

In programming, replace “−” with the nu-

merical data for each axis.

Executes linear travel at interpolation feed

speed F for up to 14 axes simultaneously.

Executes circular interpolation at tangential

speed F for two axes simultaneously following radius R (or designated center point

coordinates).

With the center point coordinate designation, multiple circles can be designated

with T−.(T− can also be omitted.)

Moves three axes simultaneously in a combination of circular interpolation and linear

interpolation outside of the circular interpolation plane. Speed F will be the circular

interpolation tangential speed.

With the center point coordinate designation, the number of turns can be designated

with T−.(T− can also be omitted.)

2

ZRN

SKP

MVT

EXM

ZERO POINT RETURN

SKIP SKP [axis1]− [axis2]−

SET TIME POSITIONING

EXTERNAL POSITIONING

ZRN [axis1] − [axis2] − ⋅⋅⋅;

(Up to 14 axes can be designated.)

(Up to 14 axes can be designated.)

MVT [axis1]− [axis2]− ⋅⋅⋅ T−;

(Up to 14 axes can be designated.)

EXM [axis1]− D−;

2-9

Returns each axis to its zero point.

SS−;

⋅⋅⋅

If the SKIP signal turns ON during a linear

interpolation operation, skips the remaining movement and proceeds to the next

block.

Executes positioning by clamping the feed

speed so that travel can be completed at the

designated time.

When an external positioning signal is input while external positioning is being

executed, only the travel distance designated by “D−” is positioned with an incremental value, and then the next command

is executed.

Page 35

MP930 Specifications and System Configuration

C

2.1.3 Function Lists

Classification Function/MeaningProgramming FormatNameCommand

2

Basic Control

Commands

ABS

INC

POS

PLN

MVM

PLD

ABSOLUTE MODE ABS;

INCREMENTAL

MODE

CURRENT POSITION SET

COORDINATE

PLANE SETTING

MOVE ON MACHINE COORDINATE

PROGRAM CURRENT POSITION

UPDATE

INC;

POS [axis1] − [axis2] − ⋅⋅⋅;

PLN [axis1][axis2]

MVM MOV [axis1]− [axis2]−;

or

MVM MVS [axis1]− [axis2]−;

PLD [axis1] − [axis2] − ⋅⋅⋅; Updates the program current position for

Treats all subsequent coordinate words as

absolute values.

Treats all subsequent coordinate words as

incremental values.

Changes the current values to the desired

coordinate values for up to 14 axes simultaneously. Subsequent move commands

use this new coordinate system.

Designates the coordinate plane to be used

for a command requiring a plane designation command.

Goes to the target position on the machine

coordinate system. The coordinate system

set automatically on completion of the zero

point return is called a machine coordinate

system. This coordinate system is not affected by the POS command.

axes shifted by manual intervention. Up to

14 axes can be designated.

Speed and

Acceleration/

Deceleration

ommands

ACC

SCC

VEL

IAC

IDC

IFP

FMX

ACCELERATION

TIME CHANGE

S-CURVE TIME

CONSTANT

CHANGE

SET VELOCITY VEL [axis1] − [axis2] − ⋅⋅⋅;

INTERPOLATION

ACCELERATION

TIME CHANGE

INTERPOLATION

DECELERATION

TIME CHANGE

INTERPOLATION

FEED SPEED RATIO SETTING

MAXIMUM INTERPOLATION FEED

SPEED SETTING

ACC [axis1] − [axis2] − ⋅⋅⋅;

SCC [axis1] − [axis2] −

IAC T−;

IDC T−;

IFP P−;

FMX T−;

⋅⋅⋅

Sets the acceleration time for linear acceleration/deceleration for up to 14 axes simultaneously.

;

Sets the time constant for moving average

acceleration/deceleration for up to 14 axes

simultaneously.

Sets the feed speed for up to 14 axes.

Sets the acceleration time for linear acceleration/decelerationforinterpolationtravel.

Sets the deceleration time for linear acceleration/decelerationforinterpolationtravel.

Designates the maximum feed % for the

speed designation during an interpolation

feed.

Sets the maximum speed during an interpolation feed.

The interpolation acceleration time is the

time from “0” until this speed is reached.

2 -10

Page 36

Classification Function/MeaningProgramming FormatNameCommand

2.1 Specifications

High-Level

Control

Commands

Sequence

Commands

PFN

INP

SNG

UFC

=

IN-POSITION

CHECK

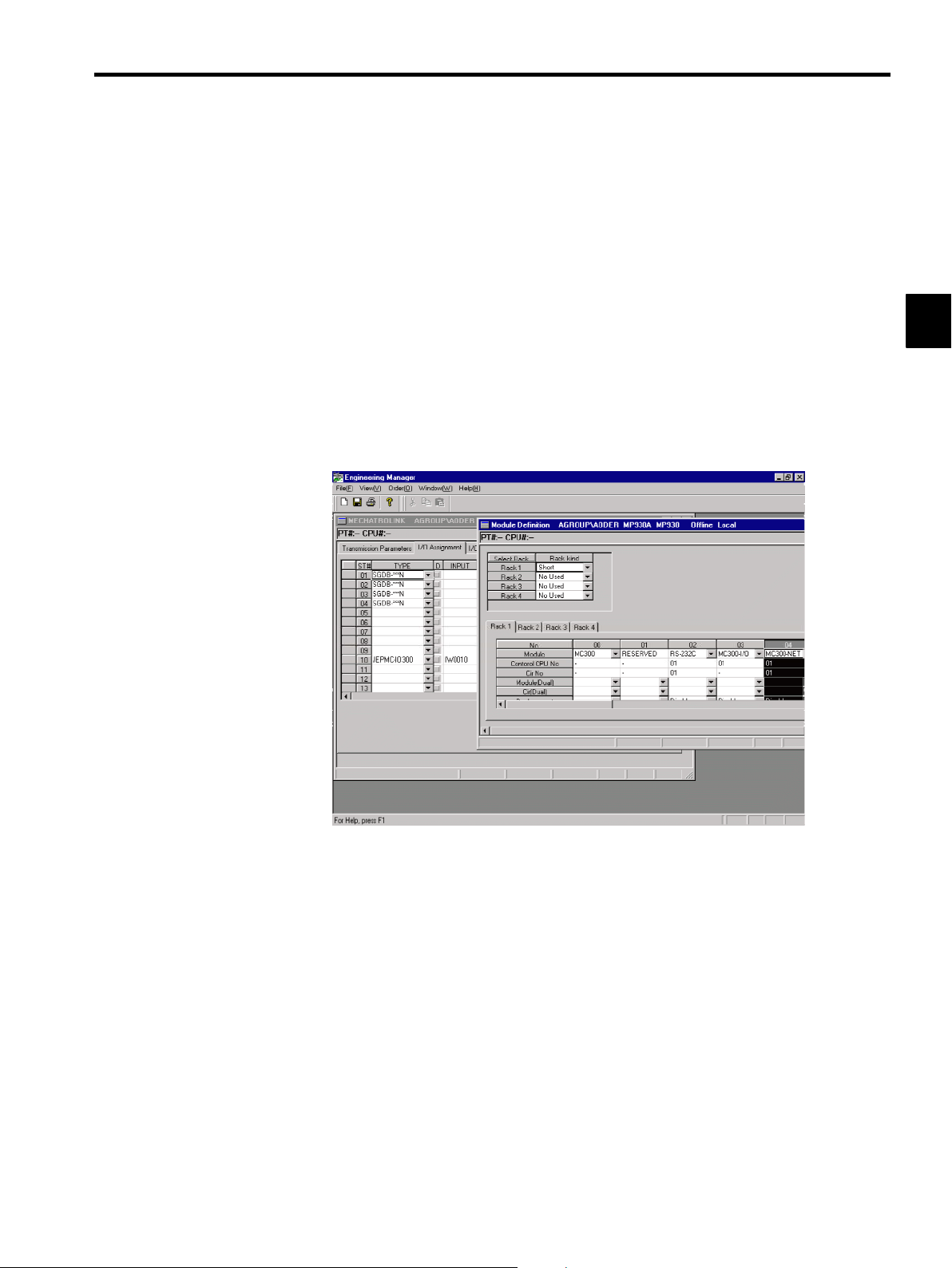

SECOND IN-POSITION CHECK

IGNORE SINGLE

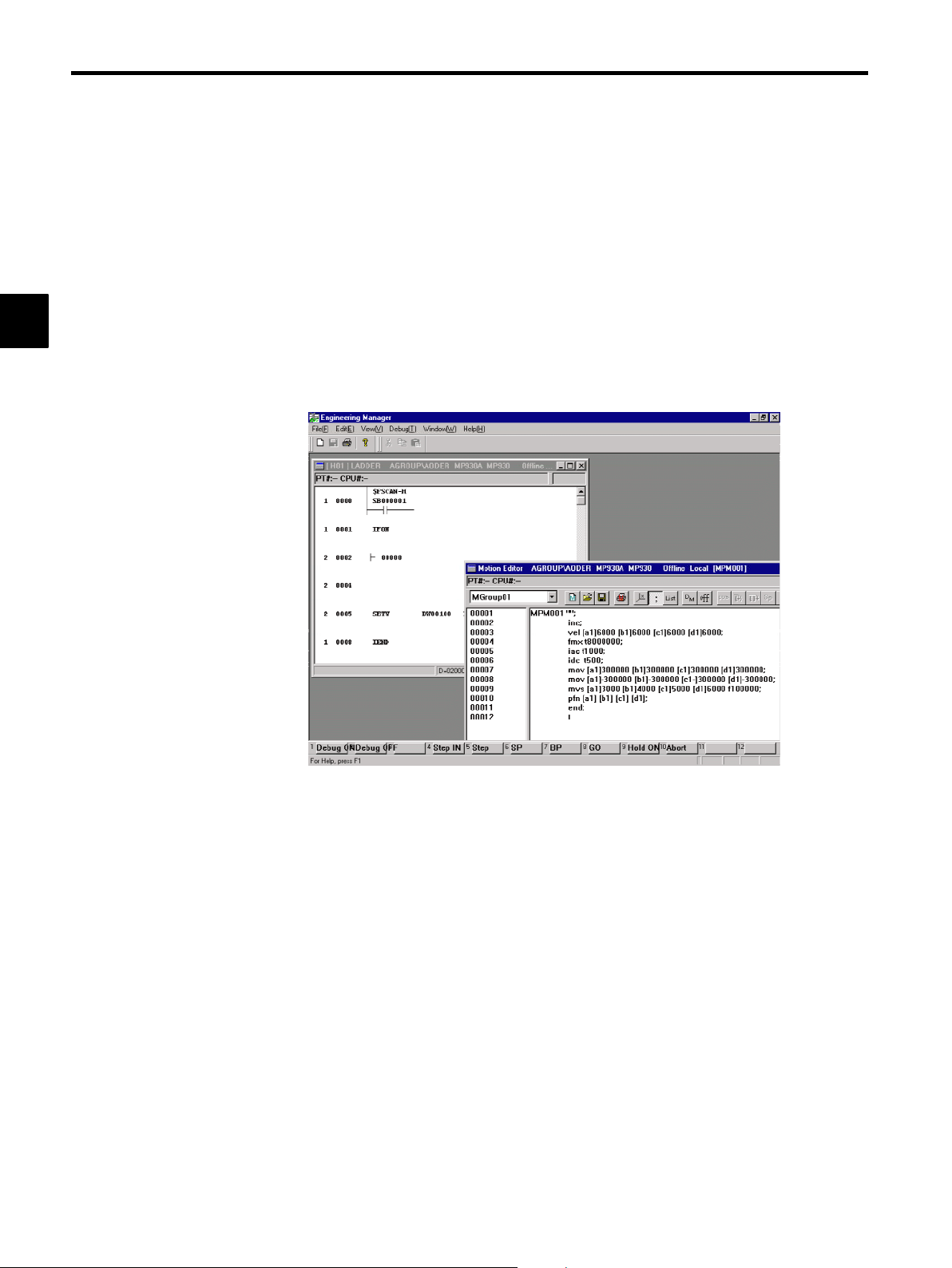

BLOCK SIGNAL

USER FUNCTION

CALL

SUBSTITUTE (Result) = (Arithmetic expres-

MVS [axis1] − [axis2] − ⋅⋅⋅

PFN;

or

PFN [axis1][axis2];

INP [axis1] − [axis2] −

SNG MVS [axis1] 100. [axis2]

200. F1000;

UFC Function_name

Input_data, Input_address,

Output_data;

sion)

;

⋅⋅⋅

Proceeds to the next block after the positioning commanded by the interpolation

travel command in the same block or a previous block enters the positioning completion range (parameter setting).

Proceeds to the next block after the positioning subsequently commanded by the

interpolation travel command with PFN

enters the second positioning completion

range.

A block with this command will be executed continuously, even in single-block operation mode.

SNG cannot be designated on its own.

Calls a function created by the user.

Substitutes operation results. Performs calculations from left to right (with no order

of priority).

2

+

−

:

/

MOD

ADD MW− =MW− +MW−;

MW− =MW− + 123456;

MW− = 123456 + MW−;

SUBTRACT MW− =MW−−MW−;

MW− =MW−−123456;

MW− = 123456 − MW−;

MULTIPLY MW− =MW− : MW−;

MW− =MW− : 123456;

MW− = 123456 : MW−;

DIVIDE MW− =MW−/MW−;

MW− =MW−/123456;

MW− = 123456/MW−;

REMAINDER MW− =MW−/MW−;

MW− = MOD;

Performs integer and real number addition.

Calculates combinations of integers and

real numbers as real numbers.

Performs integer and real number subtraction. Calculates combinations of integers

and real numbers as real numbers.

Performs integer and real number multiplication. Calculates combinations of integers and real numbers as real numbers.

Performs integer and real number division.

Calculates combinations of integers and

real numbers as real numbers.

When programmed in the next block after

a division, MOD stores the remainder in

the designated register.

2-11

Page 37

MP930 Specifications and System Configuration

2.1.3 Function Lists

Classification Function/MeaningProgramming FormatNameCommand

2

Sequence

Commands

|

^

&

!

()

S{ }

R{ }

OR (logical OR) MB− =MB− |MB−;

MB− =MB− |1;

MW− =MW− |MW−;

MW− =MW− | H00FF;

XOR (logical exclusive OR)

AND (logical AND) MB− =MB− &MB−;

NOT (logical complement)

PARENTHESES MW− =MW− & (MW− |

SET BIT S{MB−}=MB− &MB−;

RESET BIT R{MB−}=MB− &MB−;

MW− =MW− ^MW−;

MW− =MW− ^ H00FF;

MB− =MB− &1;

MW− =MW− &MW−;

MW− =MW− & H00FF;

MB− = !MB−;

MB− = !1;

MW− = !MW−;

MW− = !H00FF;

MW−);

Performs bit/integer logical OR.

Performs integer logical exclusive OR.

Performs bit/integer logical AND.

Performs bit/integer logical complement

(inverts bits).

The logical arithmetic expression inside

parentheses is calculated first.

If the logical operation result is “true,” the

designated bit turns ON. The designated bit

does not turn OFF, even if the logical operation result is “false.”

If the logical operation result is “true,” the

designated bit turns OFF. The designated

bit does not turn ON, even if the logical

operation result is “false.”

SIN

COS

TAN

ASN

ACS

SINE SIN (MW−);

SIN (90);

COSINE COS (MW−);

COS (90);

TANGENT TAN (MF−);

TAN (45.0);

ARC SINE ASN (MF−);

ASN (45.0);

ARC COSINE ACS (MF−);

ACS (90.0);

Obtains the sine of the integer or real number (deg), and returns a real value.

Obtains the cosine of the integer or real

number (deg), and returns a real value.

Obtains the tangent of the real number

(deg), and returns a real value.

Obtains the arc sine of the real number

(deg), and returns a real value.

Obtains the arc cosine of the real number

(deg), and returns a real value.

2 -12

Page 38

Classification Function/MeaningProgramming FormatNameCommand

2.1 Specifications

Sequence

Commands

ATN

SQRT

BIN

BCD

==

<>

>

<

>=

ARC TANGENT ATN (MW−);

ATN (45);

SQUARE ROOT SQT (MW−);

SQT (100);

BCD-TO-BINARY BIN (MW−);

BINARY-TO-BCD BCD (MW−);

MATCH IF MW− ==MW−;

WHILE MW− ==MW−;

MISMATCH IF MW− <>MW−;

WHILE MW− <>MW−;

GREATER THAN IF MW− >MW−;

WHILE MW− >MW−;

LESS THAN IF MW− <MW−;

WHILE MW− <MW−;

GREATER THAN

OR EQUAL TO

IF MW− >= MW−;

WHILE MW− >= MW−;

Obtains the arc tangent of the integer or

real number (deg), and returns a real value.

Obtains the square root of the integer or

real number, and returns a real value.

Converts BCD data to binary data.

Converts binary data to BCD data.

Used in an IF or WHILE conditional expression. If the left side and right side

match, the condition is “true.”

Used in an IF or WHILE conditional expression. If the left side and right side do

not match, the condition is “true.”

Used in an IF or WHILE conditional expression. If the left side is greater than the

right side, the condition is “true.”

Used in an IF or WHILE conditional expression. If the left side is less than the

right side, the condition is “true.”

Used in an IF or WHILE conditional expression. If the left side is greater than or

equal to the right side, the condition is

“true.”

2

<=

SFR

SFL

BLK

CLR

LESS THAN OR

EQUAL TO

RIGHT SHIFT SFR MB− N− W−;

LEFT SHIFT SFL MB− N− W−;

BLOCK MOVE BLK MW− MW− W−;

CLEAR CLR MB− W−;

IF MW− <= MW−;

WHILE MW− <= MW−;

Used in an IF or WHILE conditional expression. If the left side is less than or equal

to the right side, the condition is “true.”

Shifts only the designated number of word

variables to the right.

Shifts only the designated number of word

variables to the left.

Moves the block (constant designation) beginning with the designated bit (word)

variable.

Sets the number of constants specified in

the variable group beginning with the designated bit (word) variable to OFF (“0”).

2 -13

Page 39

MP930 Specifications and System Configuration

2.1.3 Function Lists

Classification Function/MeaningProgramming FormatNameCommand

2

Control

Commands

MSEE

TIM

IOW

END

RET

EOX

IF

ELSE

IEND

WHILE

WEND

SUBROUTINE

CALL

DWELL TIME TIM T−;

I/O WAIT IOW MB− = = ***;

PROGRAM END END;

SUBROUTINE

RETURN

ONE SCAN WAIT EOX; Separates continuous sequence instructions

Branching commands

Repeat commands WHILE (conditional expres-

MSEE MPS− ;

RET;

IF (conditional expression) ;

(process 1)

ELSE;

(process 2)

IEND;

sion) ;

…

WEND;

Executes the MPS− subroutine.

Waits for the period of time specified by T,

and then proceeds to the next block.

Stops execution of the motion program until the conditional expression given in the

command is satisfied.

Ends the motion program.

Ends the subroutine.

and forces a wait of one scan before continuing execution.

Executes process 1 if the conditional expression is satisfied, and executes process 2

if the conditional expression is not satisfied.

Repeatedly executes WHILE to WEND

processing for as long as the conditional

expression is satisfied.

PFORK

JOINTO

PJOINT

SFORK

JOINTO

SJOINT

Parallel execution

commands

Selective execution

commands

PFORK label 1, label 2,…;

Label 1: Process 1

JOINTO label X

Label 2: Process 2

JOINTO label X

Label

S

S

Label X: PJOINT;

SFORK conditional expression

1? label 1, Conditional expression 2? label 2,…;

Label 1: Process 1

JOINTO label X

Label 2: Process 2

JOINTO label X

Label

S

S

Label X: SJOINT;

Executes the blocks designated by the labels in parallel. With a subroutine, a maximum of two labels can be designated. Also,

a motion command cannot be used in the

block designated by the second label.

END and RET cannot be used during parallel execution processing.

Executes process 1 if conditional expression 1 is satisfied, and executes process 2 if

the conditional expression 2 is satisfied.

2 -14

Page 40

J Ladder Instructions

Table 2.8 lists the ladder instructions.

Table 2.8 Ladder Instructions

2.1 Specifications

Type of Instruction Word

Instructions with [ ]

Program Control Instructions

Direct I/O Instructions

Relay Circuit Instructions

Logic Operation Instructions

Numeric Operation Instructions

Numeric Conversion Instructions

Number Comparison Instructions

Data Manipulation Instructions

Symbols

−

SEE, MSEE, FOR FEND, WHILE ON/OFF WEND, IFON/

IFOFF ELSE IEND, FSTART, FIN, FOUT, DEND, COMMENT, XCALL

INS, OUTS

S

,, ,,

T

,

,

T

s

,,

R

,,

s

,

AND (∧), OR (∨), XOR (¨)

,,⇒,+,−,++,−−, ×, ÷, MOD, REM, INC, DEC,

TMADD, TMSUB, SPEND

INV, COM, ABS, BIN, BCD, PARITY, ASCII, BINASC,

ASCBIN

<, ≦,=,¸, ≧, >, RCHK

ROTL, ROTR, MOVB, MOVW, XCHG, SETW, BEXTD,

BPRESS, BSRCH, SORT, SHFTL, SHFTR, COPYW,

BSWAP

2

Basic Function Instructions

DDC Instructions

Table Data Manipulation

Instructions

System Functions

SQRT, SIN, COS, TAN, ASIN, ACOS, ATAN, EXP, LN,

LOG

DZA, DZB, LIMIT, PI, PD, PID, LAG, LLAG, FGN, IFGN,

LAU, SLAU, PWM

TBLBR, TBLBW, TBLSRL, TBLSRC, TBLCL, TBLMV,

QTBLR, QTBLRI, QTBLW, QTBLWI, QTBLCL

COUNTER, FINFOUT, TRACE, DTRC-RD, FTRC-RD,

ITRC-RD, INC-WR, ICNS-RD, MSG-SND, MSG-RCV

2 -15

Page 41

MP930 Specifications and System Configuration

C

l

2.1.3 Function Lists

J Ladder Instructions and Standard System Functions

Table 2.9 lists the ladder instructions and standard system functions.

Table 2.9 Ladder Instructions and Standard System Functions

2

Type

Program

ontro

Instructions

Name Symbol Abbreviated

Instructions

Instructions with [ ] − − −

CHILD DRAWING

CALL

DRAWING END DEND END End of drawing (DWG)

MOTION PROGRAM CALL

FOR Structure FOR

WHILE Structure WHILE

SEE SEE Designate the child drawing number or the grandchild draw-

ing number to be referenced after SEE.

SEE H01

MSEE MSEE Designate the motion program number and the MSEE work

register address to be referenced after MSEE.

MSEE MPM001 DA00000

FOR Repeats execution statement 1

:

:

FEND

:

ON/OFF

:

WEND

WHILE

ON

OFF

FOR V = a to b by c

V: Can designate any integer register I or J.

a, b, c: Can designate an any integer value

(b>a>0,c>0).

FEND: End of FOR instruction.

Repeats execution statement 2

WEND: End of WHILE-ON/OFF instruction

Description

IF Structure -1, -2 IFON/IFOFF

:

ELSE

:

IEND

FUNCTION CALL

FUNCTION IN-

PUT

FUNCTION OUT-

PUT

COMMENT “nnnnnnn” ” A character string enclosed in quotation marks is treated as a

EXTENSION

PROGRAM CALL

FSTART FSTART

FIN FIN Function input instruction

FOUT FOUT Function output instruction

XCALL XCALL Calls an extension program.

IFON

IFOFF

ELSE

Conditional execution statement

IEND: End of IFON/IFOFF instruction

Calls a function.

Stores input data from the designated input register in the

function input register.

Stores output data from the function output register in the

designated output register.

comment.

2 -16

Page 42

2.1 Specifications

O

Type DescriptionAbbreviated

SymbolName

Instructions

Direct I/O

Instructions

INPUT

STRAIGHT

OUTPUT

INS INS INS MA00100

OUTS OUTS OUTS MA00100

STRAIGHT

Relay

NO CONTACT ][ No limit in a series circuit.

Circuit

Instruction

NC CONTACT ]/ No limit in a series circuit.

COIL @

SET COIL

RESET COIL

S

R

@S

@R

Executes the input and storage of data with interrupts disabled.

Executes the setting and output of data with interrupts disabled.

Bit designation of any register as a relay number is possible.

2

Bit designation of any register as a relay number is possible.

MB000000

MW0200 = 0001

MB000000

IFON

MB000010MB000000

S

MB000010MB000020

R

Logic

peration

Instructions

RISING PULSE ]P No limit in a series circuit.

Bit designation of any register as a relay number is possible.

FALLING PULSE ]N No limit in a series circuit.

Bit designation of any register as a relay number is possible.

10-MS ONDELAY TIMER

10-MS OFFDELAY TIMER

1-S ON-DELAY

TIMER

1-S OFF-DELAY

TIMER

Branching/convergence

T

T

s

s

[ON

[OFF

Set value: Timer register

T

Set value = any register or constant (setting unit: 10 ms)

Timer register = M or D register

[SON

[SOFF

Set value: Timer register

S

Set value = any register or constant (setting unit: 10 ms)

Timer register = M or D register

,.,. A branching or convergence symbol can be connected to any

of the above relay instructions.

AND < & Integer designation of any register or constant is possible.

OR > | Integer designation of any register or constant is possible.

XOR

¨

^ Integer designation of any register or constant is possible.

2 -17

Page 43

MP930 Specifications and System Configuration

Instructions

2.1.3 Function Lists

2

Type DescriptionAbbreviated

Numeric

Operation

INTEGER ENTRY ; Starts an integer operation.

REAL NUMBER

ENTRY

STORE ⇒ : Stores the operation result in the designated register.

ADDITION + + Ordinary numeric addition (with operation error)

SUBTRACTION − − Ordinary numeric subtraction (with operation error)

EXTENDED

ADDITION

EXTENDED SUBTRACTION

MULTIPLICATION

SymbolName

Instructions

;; Starts a real number operation.

++ ++ Closed numeric addition (without operation error)

−− −− Closed numeric subtraction (without operation error)

× *

⊦ MW00280 + 00100 ⇒ MW00220

MW00280 + 00100 ⇒ MW00220

⊦ MW00280 +00100 ⇒ MW00220

⊦ MW00280 −00100 ⇒ MW00220

0 → 32767 → −32768 → 0

0 → 32768 → −32767 → 0

For integer and long integers, use × and ÷ in combination.

DIVISION ÷ /

MOD MOD MOD Gets the remainder of the division result.

⊦ MW00100 × 0100 ÷ 00121

MOD ⇒ MW00101

REM REM REM Gets the remainder of the division result.

MF00200 REM 1.5⇒ MF00202

INCREMENT INC INC Adds 1 to the designated register.

INC MW00100

DECREMENT DEC DEC Subtracts 1 from the designated register.

DEC MW00100

ADD TIME TMADD TMADD Addition of hours, minutes, and seconds

TMADD MW00000, MW00100

SUBTRACT TIME TMSUB TMSUB Subtraction of hours, minutes, and seconds

TMSUB MW00000, MW00100

SPEND TIME SPEND SPEND Calculates the elapsed time between two times.

SPEND MW00000, MW00100

2 -18

Page 44

2.1 Specifications

Instructions

C

00000

10000

Type DescriptionAbbreviated

SymbolName

Instructions

Numeric

SIGN INVERSION INV INV

Conversion

1’S COMPLE-

COM COM

MENT

ABSOLUTE VAL-

ABS ABS

UE CONVERSION

BINARY CON-

BIN BIN

VERSION

BCD CONVER-

BCD BCD

SION

PARITY CON-

PARITY PARITY Calculates the number of binary bits that are ON.

VERSION

ASCII CONVER-

ASCII ASCII The designated character string is converted to ASCII code

SION 1

⊦ MW00100 INV

If MW00100 = 99, the operation result = −99.

⊦ MW00100 COM

If MW00100 = FFFFH, the operation result = 0000H.

⊦ MW00100 ABS

If MW00100 = −99, the operation result = 99.

⊦ MW00100 BIN

If MW00100 = 1234H (hexadecimal), the operation result =

1234 (decimal).

⊦ MW00100 BCD

If MW00100 = 1234 (decimal), the operation result = 1234H

(hexadecimal).

If MW00100 = F0F0H, the operation result = 8.

and substituted in the register.

MW00200 “ABCDEFG”

2

Numeric

omparison

Instructions

ASCII CONVERSION 2

BINASC BINASC Converts 16-bit binary data to 4-digit hexadecimal ASCII

code.

BINASC MW00100

ASCII CONVERSION 3

ASCBIN ASCBIN Converts the numeric value indicated by a 4-digit hexadeci-

mal ASCII code to 16-bit binary data.

ASCBIN MW00100

< < <

≦ ≦

= = =

<=

MW

MB000010

IFON

<

MB000010

≠ ≠ <>

≧ ≧

>=

> > >

RANGE CHECK RCHK RCHK Checks whether or not the value in the A register is in range.

⊦ MW00100 RCHK −1000, 1000

2 -19

Page 45

MP930 Specifications and System Configuration

2.1.3 Function Lists

2

Type DescriptionAbbreviated

Data

Operation

Instructions

BIT ROTATION

LEFT and BIT

ROTATION

RIGHT

MOVE BITS MOVB MOVB Source Desti. Width

MOVE WORD MOVW MOVW Source Desti. Width

EXCHANGE XCHG XCHG Source1 Source2 Width

SET WORDS SETW SETW Desti. Data Width

BYTE-TO-WORD

EXPANSION

WORD-TO-BYTE

COMPRESSION

SymbolName

Instructions

ROTR

ROTL

BEXTD BEXTD Expands the byte data stored in the word registers into

BPRESS BPRESS Collects the lower bytes of the word data stored in the word

ROTR

ROTL

Example: ROTR

Bit-addr Count Width

ROTR MB00100A → N=1 W=20

MOVB MB00100A → MB00200A W = 20

MOVW MB00100 → MB00200 W = 20

XCHG MB00100 → MB00200 W = 20

SETW MW00200 D = 00000 W = 20

words.

BEXTD MW00100 to MW00200 B = 10

register area.

BPRESS MW00100 to MW00200 B = 10

BINARY SEARCH BSRCH BSRCH Retrieves the register position that matches the data within

the designated register range.

BSRCH MW00000 W = 20 D = 100 R = MW00100

SORT SORT SORT Sorts registers within the designated register range.

SORT MW00000 W = 100

BIT SHIFT LEFT SHFTL SHFTL Shifts the designated bit strings to the left.

SHFTL MB00100A N = 1 W = 20

BIT SHIFT RIGHT SHFTR SHFTR Shifts the designated bit strings to the right.

SHFTR MB00100A N = 1 W = 2

COPY WORD COPYW COPYW Copies the designated register range.

COPYW MW00100 → MW00200 W = 20

BYTE SWAP BSWAP BSWAP The upper and lower bytes of the designated word are

swapped.

BSWAP MW00100

2 -20

Page 46

2.1 Specifications

Type DescriptionAbbreviated

Basic

Function

Instructions

SQUARE ROOT SQRT SQRT Taking the square root of a negative number will result in the

SINE SIN SIN Input = degrees

COSINE COS COS Input = degrees

TANGENT TAN TAN Input = degrees

ARC SINE ASIN ASIN MF00100 ASIN

ARC COSINE ACOS ACOS MF00100 ACOS

ARC TANGENT ATAN ATAN MF00100 ATAN

EXPONENT EXP EXP MF00100 EXP

NATURAL LOGARITHM

SymbolName

Instructions

LN LN MF00100 LN

square root of the absolute value multiplied by −1.

MF00100 SQRT

MF00100 SIN

MF00100 COS

MF00100 TAN

e MF00100

log

(FM00100)

e

2

COMMON LOGARITHM

LOG LOG MF00100 LOG

log

(FM00100)

10

2 -21

Page 47

MP930 Specifications and System Configuration

I

2.1.3 Function Lists

2

Type DescriptionAbbreviated

DDC

nstructions

DEAD ZONE A DZA DZA

DEAD ZONE B DZB DZB

UPPER/LOWER

LIMIT

PI CONTROL PI PI

PD CONTROL PD PD

PID CONTROL PID PID

FIRST-ORDER

LAG

PHASE LEAD/

LAG

FUNCTION GENERATOR

INVERSE FUNCTION GENERATOR

SymbolName

Instructions

LIMIT LIMIT

LAG LAG

LLAG LLAG

FGN FGN

IFGN IFGN

⊦ MW00100 DZA 00100

⊦ MW00100 DZB 00100

⊦ MW00100 LIMIT −00100 00100

⊦ MW00100 PI MA00200

⊦ MW00100 PD MA00200

⊦ MW00100 PID MA00200

⊦ MW00100 LAG MA00200

⊦ MW00100 LLAG MA00200

⊦ MW00100 FGN MA00200

⊦ MW00100 IFGN MA00200

LINEAR ACCELERATOR/DECELERATOR 1

LINEAR ACCELERATOR/DECELERATOR 2

PULSE WIDTH

MODULATION

LAU LAU

SLAU SLAU

PWM PWM

⊦ MW00100 LAU MA00200

⊦ MW00100 SLAU MA00200

⊦ MW00100 PWM MA00200

2 -22

Page 48

2.1 Specifications

O

Type DescriptionAbbreviated

Table Data

peration

Instructions

TABLE READ TBLBR TBLBR TBLBR TBL1, MA00000, MA00100

TABLE WRITE TBLBW TBLBW TBLBW TBL1, MA00000, MA00100

ROW SEARCH TBLSRL TBLSRL TBLSRL TBL1, MA00000, MA00100

COLUMN

SEARCH

TABLE CLEAR TBLCL TBLCL TBLCL TBL1, MA00000

TABLE BLOCK

MOVE

QUEUE TABLE

READ

QUEUE TABLE

READ AND INCREMENT

QUEUE TABLE

WRITE

QUEUE TABLE

WRITE AND INCREMENT

SymbolName

Instructions

TBLSRC TBLSRC TBLSRC TBL1, MA00000, MA00100

TBLMV TBLMV TBLMV TBL1, TBL2, MA00000

QTBLR QTBLR QTBLR TBL1, MA00000, MA00100

QTBLRI QTBLRI QTBLRI TBL1, MA00000, MA00100

QTBLW QTBLW QTBLW TBL1, MA00000, MA00100

QTBLWI QTBLWI QTBLWI TBL1, MA00000, MA00100

2

QUEUE POINTER

CLEAR

QTBLCL QTBLCL QTBLCL TBL1

2 -23

Page 49

MP930 Specifications and System Configuration

2.1.3 Function Lists

2

Type DescriptionAbbreviated

Standard

System

Functions

DATA TRACE

READ

TRACE TRACE TRACE Data trace execution control

FAILURE TRACE

READOUT

SEND MESSAGE MSG-SND MSG-SND Sending a message from a Communications Module

RECEIVE MESSAGE

COUNTER COUNTER COUNTER Increments or decrements a counter.

FIRST-IN FIRSTOUT

INVERTER

TRACE READ

INVERTER

CONSTANT

WRITE

SymbolName

Instructions

DTRC-RD DTRC-RD Data readout from data trace memory to user memory

FTRC-RD FTRC-RD Data readout from failure trace memory to user memory

MSG-RCV MSG-RCV Receiving a message from a Communications Module

FINFOUT FINFOUT First-in, first-out

ITRC-RD ITRC-RD Reads inverter trace data to store it in user register.

ICNS-WR ICNS-WR Writes inverter constant.

INVERTER

CONSTANT

READ

ICNS-RD ICNS-RD Reads inverter constant to register.

2 -24

Page 50

2.1 Specifications

Hard

Definiti

Confi

J Program Development Support Tool Function Specifications

Table 2.10 lists the program development support tool specifications.

Table 2.10 Program Development Support Tool Specifications

Item

Basic

ware

Basic

Software

Printer

Functions File Manager

Model

CPU

Main Storage

Display

Resolution

HDD

Pointing Device

Operating System

System

ons

Specifications

IBM PC/AT or compatible

Pentium 133 MHz or better, or equivalent

64 MB min.

640 × 480 min.

(800 × 600 min. recommended)

200 Mbytes min. of unused capacity is required.

PS/2 interface

Windows 95

Windows 95-compatible

File management

User management

File transfer

System definitions

Scan time settings

2

Unit

guration

Definitions

Application information settings

Failure monitoring

Data traces

Group definitions

Motion parameters

Configuration definitions