Page 1

Machine Controller MP920

Motion Module

USER'S MANUAL

YASKAWA

YASKAWA

MANUAL NO. SIEZ-C887-2.5C

Page 2

Copyright © 1999 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

Using this Manual

Please read this manual to ensure correct usage of the MP920 system. Keep this manual in a

safe place for future reference.

Overview

This manual describes the Motion Modules designed for MP920 Machine Controller.

The following Motion Modules can be used with MP920 Machine Controller.

• SVA-01A 4-axis Servo Module

• SVA-02A 2-axis Servo Module

• SVB-01 MECHATROLINK Interface Servo Module

• PO-01 Pulse Output Module

This manual describes the following items required to use these Motion Modules.

• Motion Module setup

• Installation and connection methods

• Parameters

• Troubleshooting

Read this manual carefully to ensure that motion control is correctly performed using the

MP920 Machine Controller. Also, keep this manual in a safe place so that it can be referred

to whenever necessary.

Intended Audience

This manual is intended for the following users.

• Those responsible for estimating the MP920 system

• Those responsible for deciding whether to apply the MP920 system

• Those responsible for designing the MP920 system so that it can be mounted in the con-

trol and operating panels

• Those responsible for making, inspecting, testing, adjusting, and maintaining the control

and operating panels in which the MP920 is mounted

Basic Terms

Unless otherwise specified, the following definitions are used:

• MP920 = MP920 Machine Controller

• PC: Programmable Logic Controller

• MPE720: The Programming Device Software or a Programming Device (i.e., a personal

computer) running the Programming Device Software

• PLC = Programmable Logic Controller

• “⎯” in “MOV [axis1]⎯...” represents numeric data for axis 1.

iii

Page 4

EXAMPLE

TERMS

Visual Aids

The following aids are used to indicate types of information for easier reference.

IMPORTANT

INFO

Indicates important information that should be memorized.

Indicates supplemental information.

Indicates application examples.

Describes technical terms that are difficult to understand, or in the text

without an explanation being given.

Indication of Reverse Signals

In this manual, the names of reverse signals (ones that are valid when low) are written with a

forward slash (/) before the signal name, as shown in the following example:

• S-ON = /S-ON

• P-CON = /P-CON

iv

Page 5

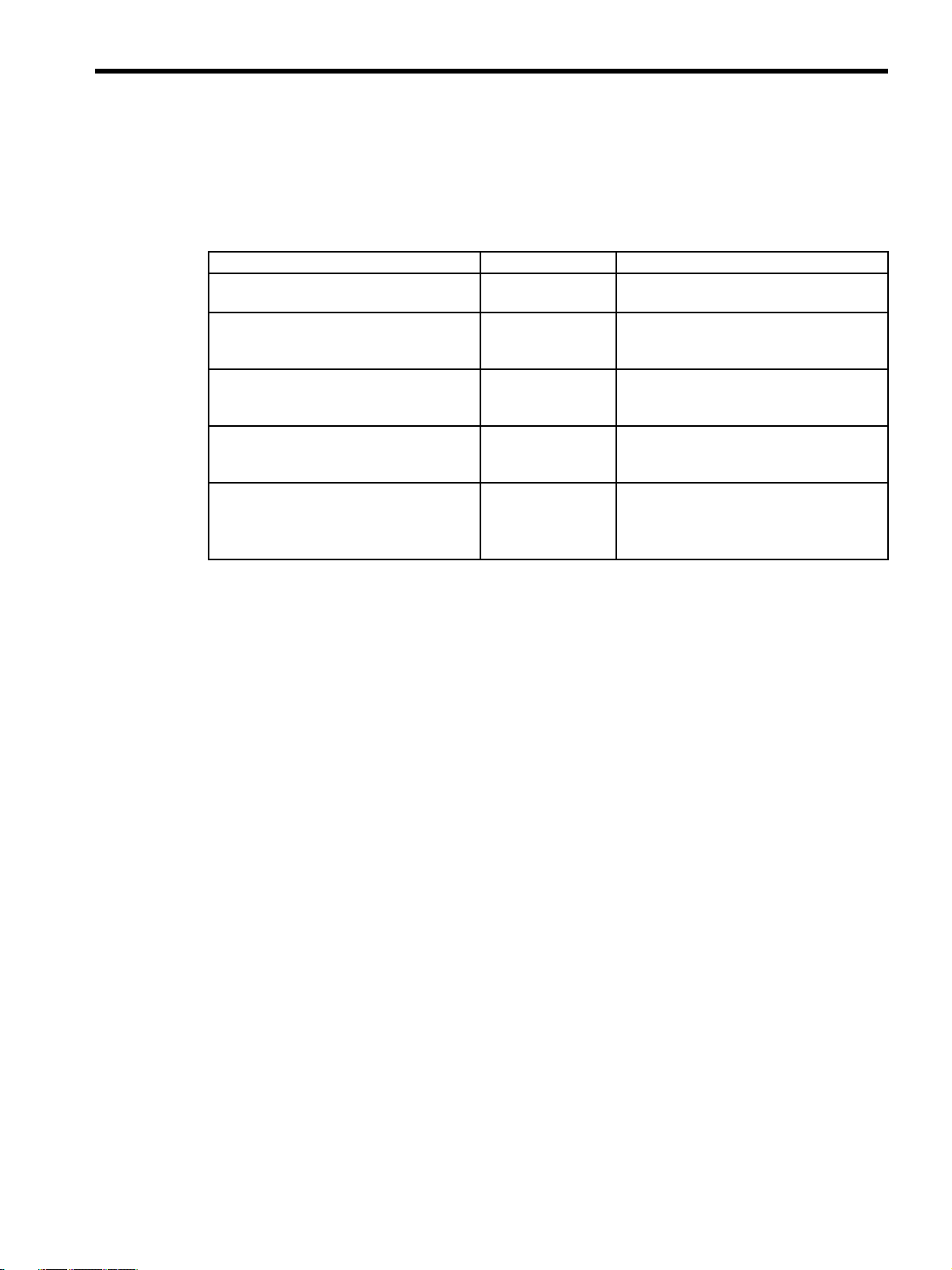

Related Manuals

Refer to the following related manuals as required.

Thoroughly check the specifications, restrictions, and other conditions of the product before

attempting to use it.

Manual Name Manual Number Contents

Machine Controller MP920 User’s

Manual: Design and Maintenance

Machine Controller MP920

Communications Module User’s Manual

Machine Controller MP900/MP2000

Series Ladder Logic Programming

User’s Manual

Machine Controller MP900/MP2000

Series Motion Programming

User’s Manual

Machine Controller MP900/MP2000

Series User’s Manual

MPE720 Software for Programming

Device

SIEZ-C887-2.1 Describes the design and maintenance for

the MP920 Machine Controller.

SIEZ-C887-2.6 Describes the functions, specifications, and

usage of the MP920 Communications Modules (215IF, 217IF, and 218IF).

SIEZ-C887-1.2 Describes the instructions used in MP900/

MP2000 Series ladder logic programming.

SIEZ-C887-1.3 Describes the motion programming language

used for MP900/MP2000 Series Machine

Controllers.

SIEPC88070005 Describes how to install and operate the

MP900/MP2000 Series programming system MPE720.

v

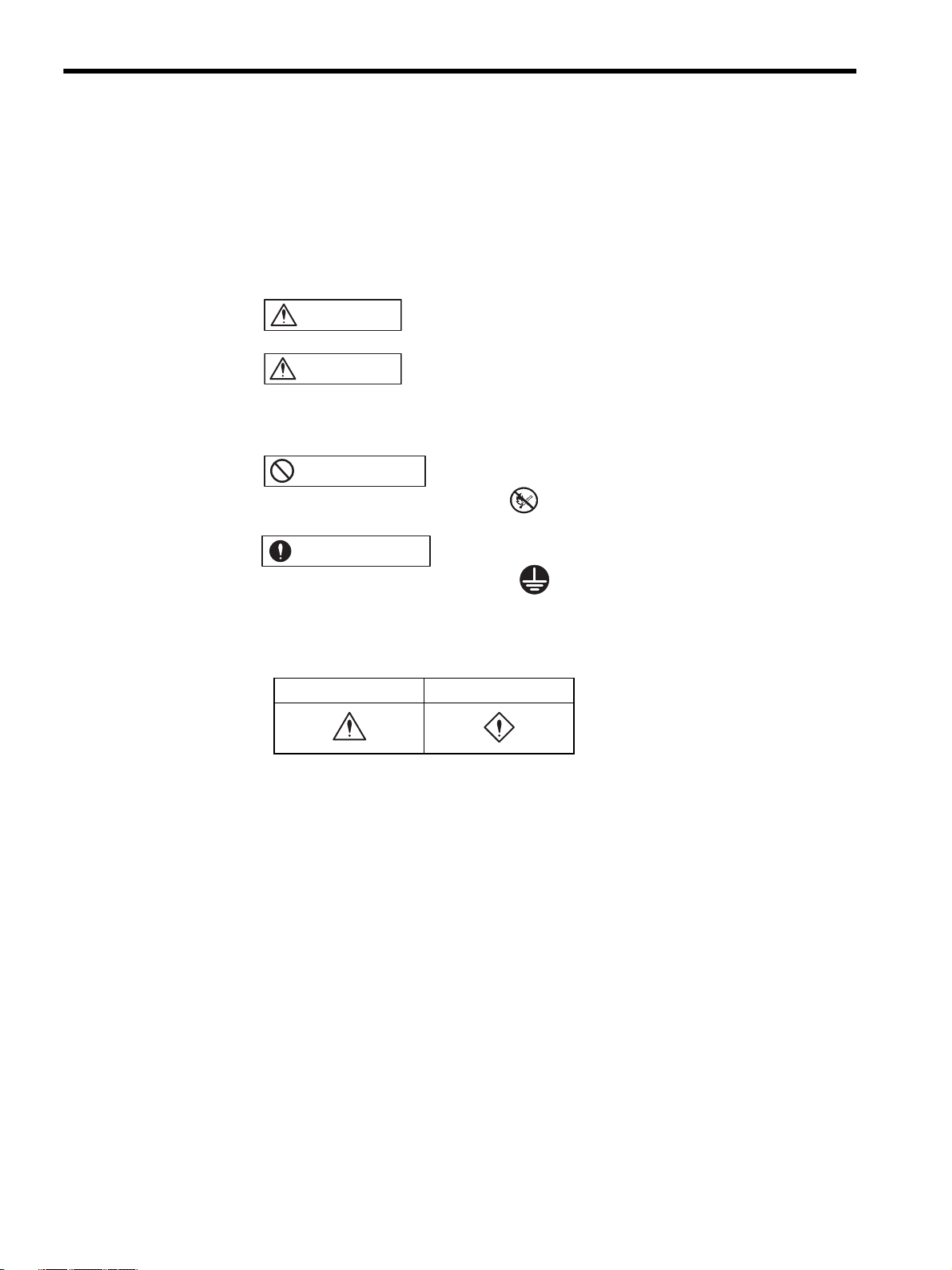

Page 6

MANDATORY

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed

provided in this manual can result in serious or possibly even fatal injury or damage to he

products or to related equipment and systems.

WARNING

CAUTION

Indicates precautions that, if not heeded, could possibly result in loss of

life, serious injury.

Indicates precautions that, if not heeded, could result in relatively serious

or minor injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have serious consequences if not heeded.

Indicates prohibited actions that must not be performed. For

PROHIBITED

example, this symbol would be used as follows to indicate that fire is

prohibited: .

Indicates compulsory actions that must be performed. For example,

this symbol would be used as follows to indicate that grounding is

compulsory: .

The warning symbols for ISO and JIS standards are different, as shown below.

ISO JIS

The ISO symbol is used in this manual.

Both of these symbols appear on warning labels on Yaskawa products. Please abide by these

warning labels regardless of which symbol is used.

vi

Page 7

Safety Precautions

CAUTION

This section describes precautions to ensure the correct application of the product. Before

installing, operating, maintaining, or inspecting the product, always read this manual and all

other documents provided to ensure correct work procedures and application. Before using

the equipment, familiarize yourself with equipment details, safety information, and all other

precautions.

Handling

• Do not subject the product to halogen gases, such as fluorine, chlovine, bromine, and

iodine, at any time even during transportation or installation.

Failure to observe this caution may cause damage or failure of the product.

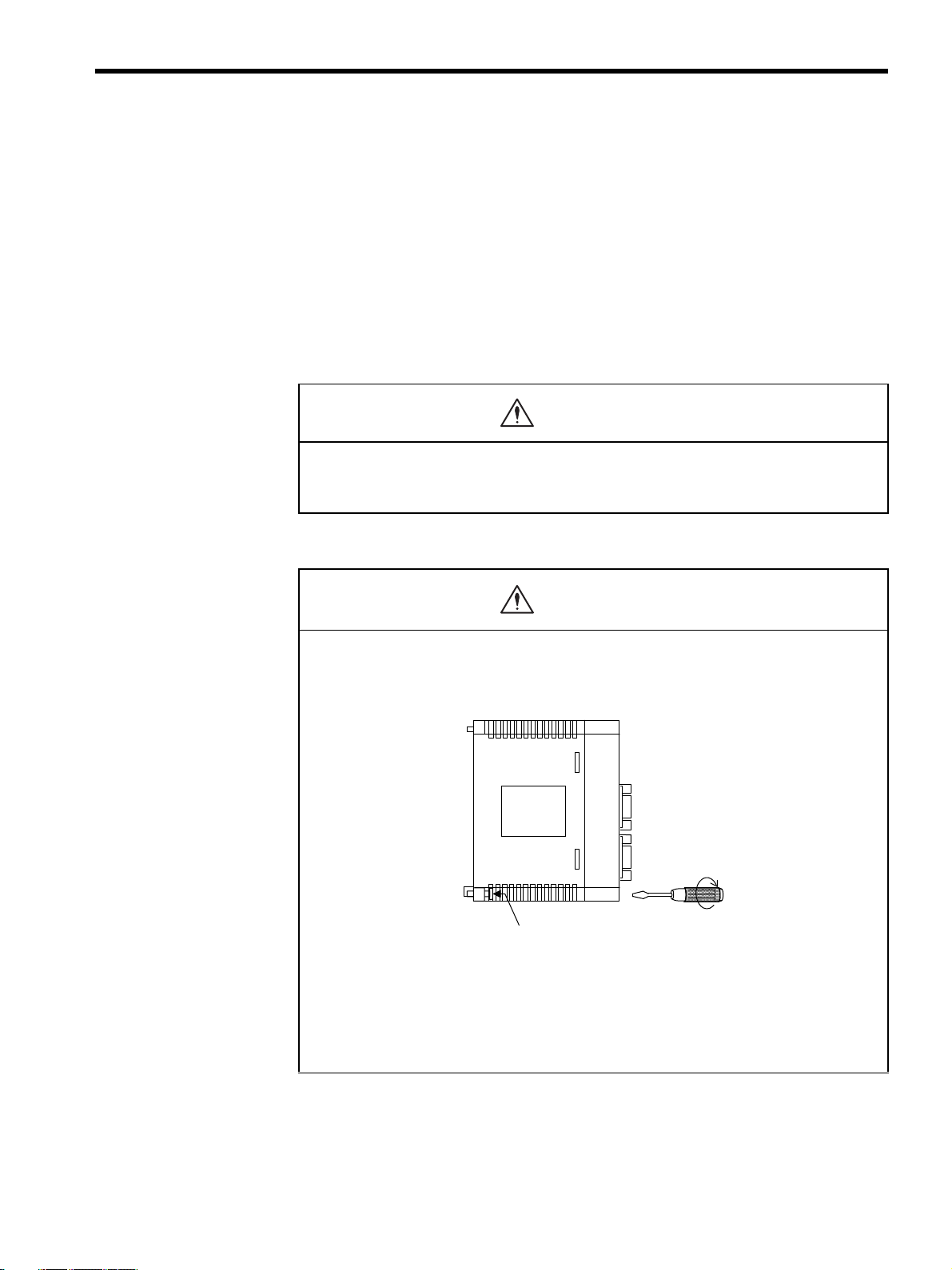

Installation

CAUTION

• Firmly tighten the Module mounting screws and terminal block mounting screws to pre-

vent them from loosening during operation.

Loose screws may result in a malfunction of the MP920.

Module mounting screw

(Use an M4 Phillips screw driver.)

• Always turn OFF the power supply to the Module before installing it.

• Insert the connectors of the cables that are to be connected to the MP920 Modules and

secure them well.

Incorrect insertion of the connectors may result in a malfunction of the MP920.

vii

Page 8

MANDATORY

r

Wiring

CAUTION

• Always connect a power supply that meets the given specifications.

Connecting an inappropriate power supply may cause fires.

• Wiring must be performed by qualified personnel.

Incorrect wiring may cause fires, product failure, or electrical shocks.

• Do not accidentally leave foreign matter such as wire chips on the Mounting Base or in

the Module when wiring.

This may cause fires, failures, and malfunctions.

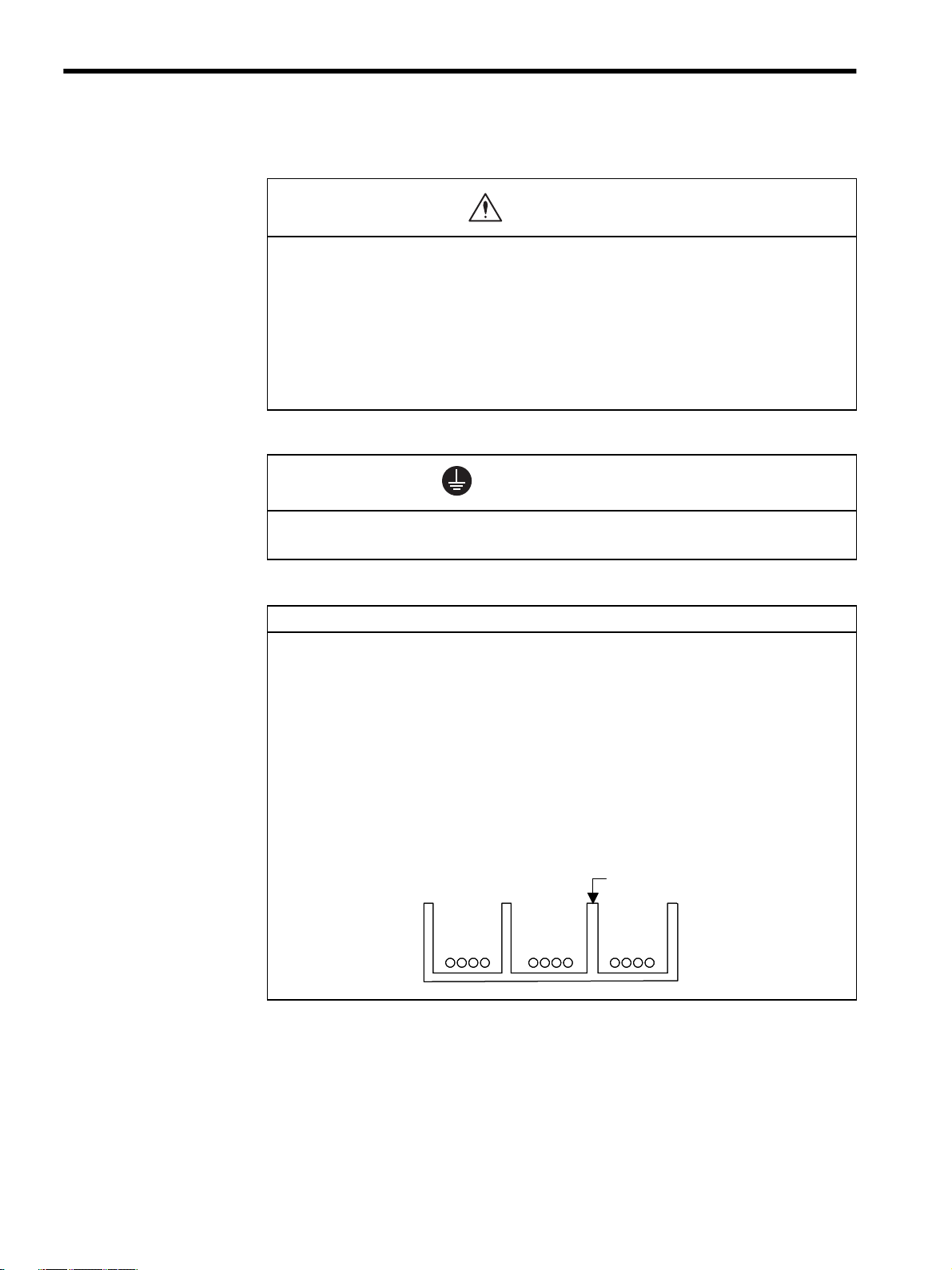

• Always ground the FG terminal to a ground resistance 100Ω or less.

Failure to ground the MP920 may result in electrical shocks or malfunctioning.

Select, separate, and lay external cables correctly.

• Consider the following items when selecting the I/O signal lines (external cables) to

connect the MP920 Module to external devices.

• Mechanical strength

• Noise interference

• Wiring distance

• Signal voltage, etc.

• Separate the I/O signal lines from the power lines both inside and outside the control

panel to reduce the influence of noise from the power lines.

If the I/O signal lines and power lines are not separated properly, malfunctioning may result.

Example of Separated External Cables

Steel separato

Power

circuit

cables

General

control circuit cables

Digital I/O

signal

cables

viii

Page 9

Application

WARNING

PROHIBITED

• Do not touch any Module terminals when the system power is ON.

There is a risk of electrical shock.

• Do not attempt to modify the MP920 programs, force outputs, switch between RUN and

STOP, or perform other similar operations while the MP920 is operating without know-

ing the direct and indirect consequences of the operation.

Incorrect programming or operation may damage the equipment or cause an accident.

Maintenance

• Make sure that the polarity of the Module’s built-in battery is correct. The battery must

be installed correctly and must not be charged, disassembled, heated, thrown into fire,

or short-circuited.

Improper handling may cause the battery to explode or ignite.

WARNING

CAUTION

• Do not attempt to disassemble or modify the MP920 Modules in any way.

Doing so can cause fires, product failure, or malfunctions.

• The customer must not replace any built-in fuses.

If the customer replaces a built-in fuse, the MP920 Module may malfunction or break down.

The built-in fuse must always be replaced by Yaskawa service staff.

ix

Page 10

General

Always note the following to ensure safe use.

• MP920 was not designed or manufactured for use in devices or systems directly related

to human life. Users who intend to use the product described in this manual for special

purposes such as devices or systems relating to transportation, medical, space avia-

tion, atomic power control, or underwater use must contact Yaskawa Electric Corpora-

tion beforehand.

• MP920 has been manufactured under strict quality control guidelines. However, if this

product is to be installed in any location in which a failure of MP920 involves a life and

death situation or in a facility where failure may cause a serious accident, safety

devices MUST be installed to minimize the likelihood of any accident.

• Drawings in this manual show typical product examples that may differ somewhat from

the product delivered.

• This manual may change without prior notice due to product improvements and specifi-

cation changes or for easier use. We will update the manual number of the manual and

issue revisions when changes are made. The revision number of the revised manual

appears on the back of the manual.

• Contact your nearest Yaskawa sales representative or the dealer from whom you pur-

chased the product and quote the manual number on the front page of the manual if

you need to replace a manual that was lost or destroyed.

• Contact your nearest Yaskawa sales representative or the dealer from whom you pur-

chased the product to order new nameplates whenever a nameplate becomes worn or

damaged.

• Products modified by the customer are not covered by the Yaskawa warranty, nor does

Yaskawa assume any liability for injury or damage that may result from such modifica-

tions.

x

Page 11

CONTENTS

Using this Manual- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - iii

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

1 Overview of Motion Modules

1.1 Module Overview and Features - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.1 Motion Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

1.1.2 SVA-01A Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

1.1.3 SVA-02A Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

1.1.4 SVB-01 Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-6

1.1.5 PO-01 Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-8

1.2 System Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1.2.1 System Configuration Examples - - - - - - - - - - - - - - - - - - - - - - - - - - -1-9

1.3 Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.3.1 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-10

1.3.2 Function Lists- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

2 Motion Control

2.1 Overview of Motion Control - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.1 Motion Control for the MP920 - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

2.1.2 Motion Control Methods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-4

2.1.3 Examples of Motion Control Applications - - - - - - - - - - - - - - - - - - - - -2-5

2.2 Control Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.2.1 Overview of Control Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-7

2.2.2 Speed Reference Output Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-8

2.2.3 Torque Reference Output Mode - - - - - - - - - - - - - - - - - - - - - - - - - - -2-12

2.2.4 Phase Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-15

2.2.5 Zero Point Return Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-22

2.3 Position Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-26

2.3.1 Prerequisites for Position Control - - - - - - - - - - - - - - - - - - - - - - - - - -2-26

2.3.2 Position Control Without Using Motion Commands - - - - - - - - - - - - -2-41

2.4 Position Control Using Motion Commands - - - - - - - - - - - - 2-45

2.4.1 Overview of Motion Commands - - - - - - - - - - - - - - - - - - - - - - - - - - -2-45

2.4.2 Positioning (POSING) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-48

2.4.3 External Positioning (EX_POSING) - - - - - - - - - - - - - - - - - - - - - - - -2-51

2.4.4 Zero Point Return (ZRET) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-55

2.4.5 Interpolation (INTERPOLATE, END_OF_INTERPOLATE) - - - - - - - -2-70

2.4.6 Interpolation with Position Detection (LATCH) - - - - - - - - - - - - - - - - -2-73

2.4.7 Fixed Speed Feed (FEED)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-74

2.4.8 Fixed Length Feed (STEP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-77

2.4.9 Zero Point Setting (ZSET) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-81

xi

Page 12

3 Motion Module Allocations and Setup

3.1 Allocations and Configuration Definitions - - - - - - - - - - - - - - 3-2

3.1.1 Motion Module Allocation Method - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

3.1.2 Setting Module Definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-4

3.1.3 Saving Module Definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-6

3.2 Individual Module Definitions - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.2.1 MECHATROLINK Definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-7

3.2.2 Setting Motion Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-10

4 Parameters

4.1 Overview of Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.1.1 Parameter Classifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-2

4.1.2 Modules and Motion Parameter Registers - - - - - - - - - - - - - - - - - - - - 4-3

4.2 Parameter List by Module - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.2.1 Motion Fixed Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-5

4.2.2 Motion Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-10

4.2.3 Motion Monitoring Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - 4-18

5 SVA Module Specifications and Handling

5.1 SVA-01A Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.1 Hardware Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2

5.1.2 Handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3

5.2 SVA-02A Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-24

5.2.1 Hardware Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-24

5.2.2 Handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-25

5.3 Differences between SVA-01A and SVA-02A Modules - - - - 5-43

5.3.1 Differences in Hardware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-43

5.3.2 Differences in Servo Connectors - - - - - - - - - - - - - - - - - - - - - - - - - - 5-44

5.3.3 Differences in External I/O Signals - - - - - - - - - - - - - - - - - - - - - - - - 5-46

5.3.4 Precautions on Connecting the SVA-02A Module - - - - - - - - - - - - - - 5-47

5.3.5 Connection with SGDA-S SERVOPACK - - - - - - - - - - - - - - - - 5-48

5.4 SVA-01A and SVA-02A Parameters - - - - - - - - - - - - - - - - - 5-52

5.4.1 Motion Fixed Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-52

5.4.2 Motion Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-62

5.4.3 Motion Monitoring Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-83

6 SVB Module Specifications and Handling

6.1 SVB-01 Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.1 Hardware Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

6.1.2 Handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-3

xii

Page 13

6.2 SVB-01 Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-16

6.2.1 Motion Fixed Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-16

6.2.2 Motion Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-23

6.2.3 Motion Monitoring Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-38

6.2.4 Σ Series SERVOPACK parameters - - - - - - - - - - - - - - - - - - - - - - - -6-45

6.2.5 Σ-II Series SERVOPACK Parameters - - - - - - - - - - - - - - - - - - - - - - -6-52

6.2.6 Relationship of SERVOPACK Parameters to SVB-01 Parameters - - - 6-64

7 PO-01 Module Specification and Handling

7.1 PO-01 Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-2

7.1.1 Hardware Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-2

7.1.2 Handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-3

7.2 Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-16

7.2.1 Motion Control Functions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-16

7.2.2 Motion Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-19

7.2.3 Program Example- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-22

7.2.4 Out-of-step Detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-25

7.2.5 Emergency Stop- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-29

7.3 PO-01 Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7-31

7.3.1 Motion Fixed Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-31

7.3.2 Motion Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-39

7.3.3 Motion Monitoring Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-49

8 Troubleshooting

8.1 Overview of Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8-2

8.1.1 Description of Motion Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-2

8.1.2 Processing Flow for Motion Alarms - - - - - - - - - - - - - - - - - - - - - - - - -8-5

8.2 Alarms and Actions Taken - - - - - - - - - - - - - - - - - - - - - - - - - 8-6

8.2.1 Alarm IL22 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-6

8.2.2 Motion Alarm Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-20

8.2.3 Motion Module Error Displays and Actions Taken - - - - - - - - - - - - - -8-22

9 Application Precautions

9.1 Vertical Axis Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-2

9.1.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-2

9.1.2 SGDA SERVOPACK Connections - - - - - - - - - - - - - - - - - - - - - - - - - -9-3

9.1.3 SGDB SERVOPACK Connections - - - - - - - - - - - - - - - - - - - - - - - - - -9-5

9.1.4 SGDM/SGDS SERVOPACK Connections - - - - - - - - - - - - - - - - - - - - -9-8

9.2 Overtravel Function - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

9.2.1 Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-10

9.2.2 Overtravel Input Signal Connections- - - - - - - - - - - - - - - - - - - - - - - -9-10

9.2.3 Parameter Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9-12

xiii

Page 14

9.3 Software Limit Function - - - - - - - - - - - - - - - - - - - - - - - - - 9-16

9.3.1 Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-16

9.3.2 Fixed Parameter Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-16

9.3.3 Processing after an Alarm- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-17

9.4 Reverse Rotation Mode - - - - - - - - - - - - - - - - - - - - - - - - - 9-18

9.4.1 Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-18

9.4.2 Absolute Encoder Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-20

9.4.3 Incremental Encoder Setting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9-21

10 CNTR-01 Module Specifications and Handling

10.1 CNTR-01 Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.1.1 Hardware Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-2

10.1.2 Handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-3

10.2 Using the CNTR-01 Module- - - - - - - - - - - - - - - - - - - - - 10-11

10.2.1 Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-11

10.2.2 Fixed Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-13

10.2.3 Setting I/O Data - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-15

10.3 Counter Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-22

10.3.1 Reversible Counter Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-22

10.3.2 Interval Counter Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-24

10.3.3 Frequency Measurement - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-26

10.4 CNTR-01 Module I/O Circuits - - - - - - - - - - - - - - - - - - - 10-30

10.4.1 Pulse Input Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-30

10.4.2 Latch Input Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-32

10.4.3 Coincidence Output Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-33

10.5 CNTR-01 Counter Module Connections - - - - - - - - - - - - 10-34

10.5.1 Connections to Pulse Generators - - - - - - - - - - - - - - - - - - - - - - - 10-34

10.5.2 Pulse C Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10-36

Appendix A Module Appearance

A.1 Motion Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-2

A.2 Counter Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A-5

INDEX

Revision History

xiv

Page 15

1

Overview of Motion Modules

This chapter provides an overview of the Motion Modules and describes their

features.

1.1 Module Overview and Features - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.1 Motion Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

1.1.2 SVA-01A Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

1.1.3 SVA-02A Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-4

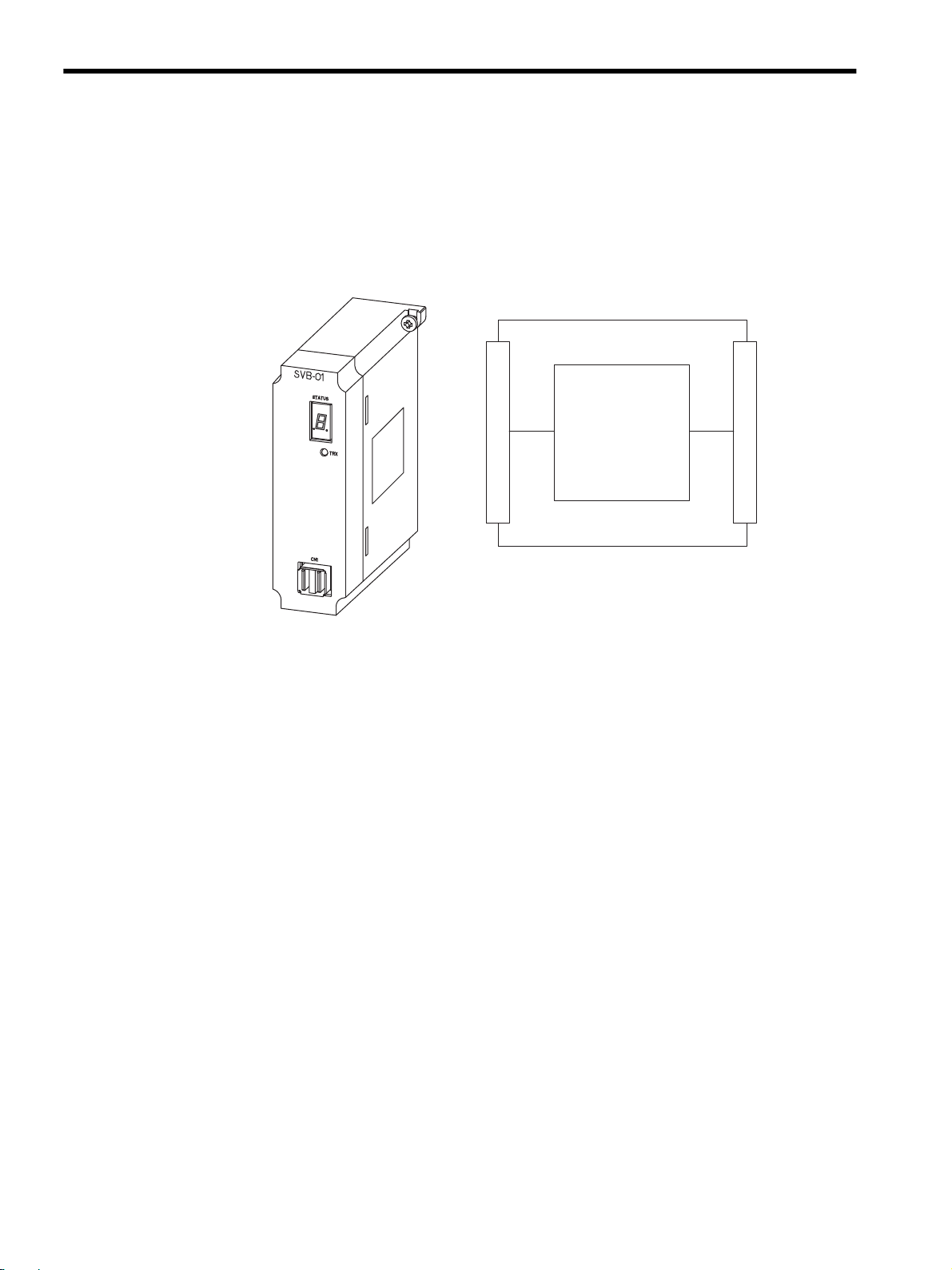

1.1.4 SVB-01 Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-6

1.1.5 PO-01 Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-8

1.2 System Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-9

1.2.1 System Configuration Examples - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-9

1

1.3 Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.3.1 General Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-10

1.3.2 Function Lists - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-11

1-1

Page 16

1 Overview of Motion Modules

1.1.1 Motion Modules

1.1 Module Overview and Features

This section provides an overview of the Motion Modules and describes their features.

1.1.1 Motion Modules

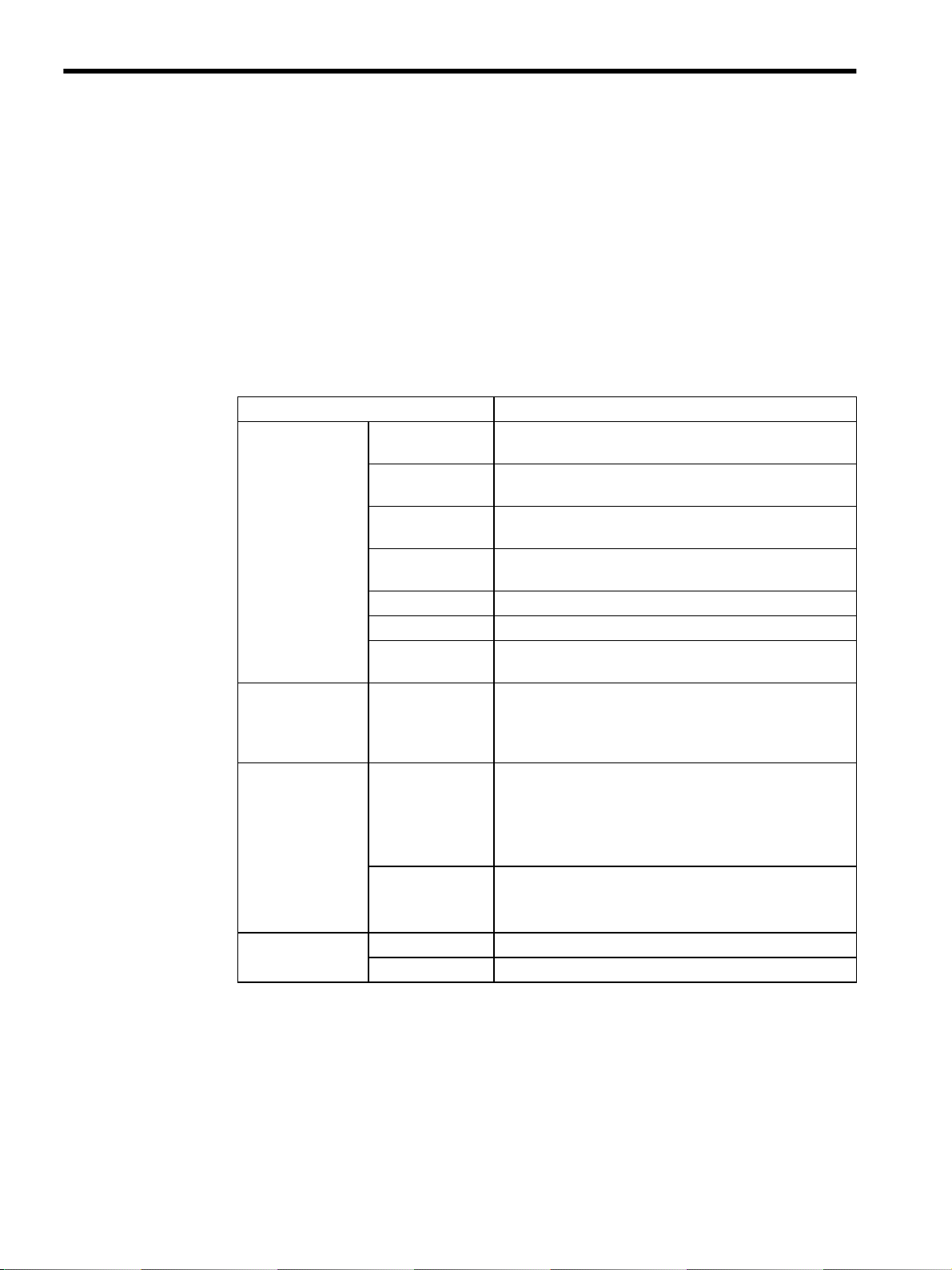

The following table lists the Motion Modules that can be used with the MP920.

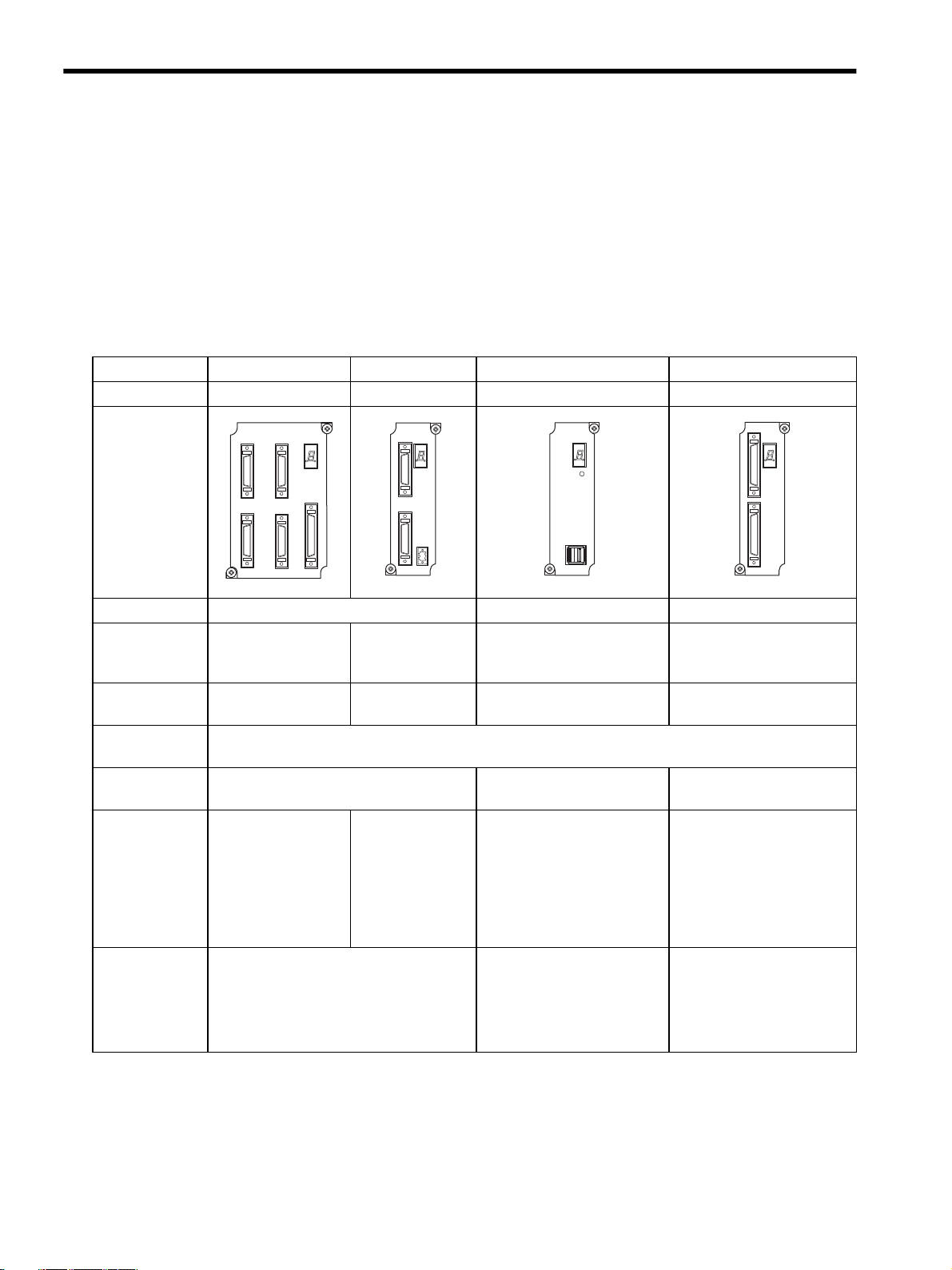

Description SVA-01A SVA-02A SVB-01 PO-01

Model Number JEPMC-MC200A JEPMC-MC220A JEPMC-MC210 JEPMC-PL210

Appearance

SVA-01

CN3

CN1

CN2

STATUS

CN5

CN4

SVA-02

CN1

STATUS

CN2

SVB-01

STATU S

TRX

PO-01

CN1

STATUS

CN2

Interface

Number of Controlled Axes per

Module

Maximum Number of Modules

Total Number of

Modules

Pulse Counting

Methods

Control

Functions

Motion

Functions

CN3

+24V

0V

CN1

Analog MECHATROLINK Pulse

4 2 14 4

15 16 16 16

16 max.

A/B, Up/Down, sign, ×1/2/4 ×4 −

• Speed reference

output

• Synchronized phase

control

• Position control

• Speed reference

output

• Synchronized

phase control

• Position control

• Position control only

Position loop is performed

by Servo Drivers. The SVB01 Module outputs position

reference values.

• Torque reference output

• Positioning

• Linear interpolation

• Circular interpolation

• Helical interpolation

• External positioning

• Positioning

• Linear interpolation

• Circular interpolation

• Helical interpolation

• External positioning

• Position control only

Open loop control

The PO-01 Module outputs

reference pulses.

• Positioning

• Linear interpolation

• Circular interpolation

• Helical interpolation

1-2

Page 17

1.1 Module Overview and Features

Description SVA-01A SVA-02A SVB-01 PO-01

Model Number JEPMC-MC200A JEPMC-MC220A JEPMC-MC210 JEPMC-PL210

Applicable Servo Drivers and

Inverters

• Servo Drivers

SGDA-S

SGDB-

SGDM-

SGDS-

• Inverters

• Servo Drivers

SGD-N

SGDB-AN

SGDH-E+JUSPNS100

• Inverters

Pulse Motor Drivers

(216IF Card required)

VS-616G5

VS-676H5

VS-676H5T

Features Analog control High-speed network control

Low-cost and simple control

• Transmission speed:

4 Mbps

• Communications cycle: 2 ms

• Transmission distance: 50 m

max.

Multi-axis control:

14 axes max. per Module

(cont’d)

1

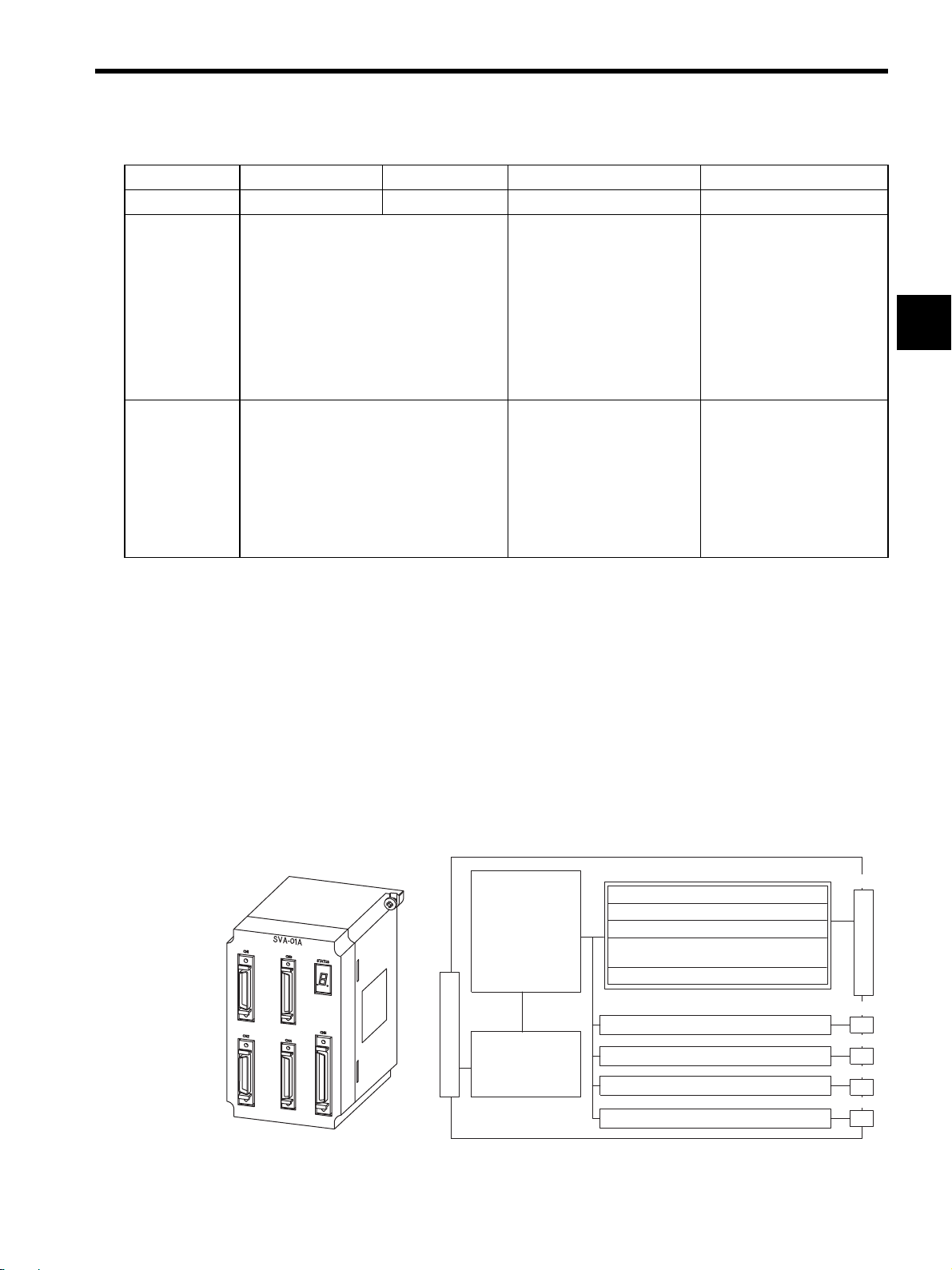

1.1.2 SVA-01A Module

Overview of the SVA-01A Module

The SVA-01A Module is a Motion Control Module with analog outputs. One SVA-01A

Module can control servos for up to four axes. Four connectors (CN1 to CN4) are provided

for connections to SERVOPACKs. Each connector is equipped with a speed reference ana-

log output, phase-A/B/C pulse inputs (5 V differential), a pulse latch digital input, and gen-

eral-purpose digital I/O signals. The CN5 connector is equipped with positive and negative

overtravel signals, deceleration limit inputs, zero point latch inputs, external positioning

latch inputs, brake control outputs, and other external I/O signals for four axes.

Motion Control

Speed control

Position control

Phase control

Zero point return

function

Monitor function

System Bus

Interface

Servo parameters

OW

System Bus Connector

IW

Analog output: Speed ref.

Pulse input: Phase A/B/C

General-purpose digital inputs (3) DI0 to D12

General-purpose digital outputs

Sensor ON output (5 V/24 V)

Same as above.

Same as above.

Same as above.

External (Field) I/O signals

NREF

(5) DO0 to DO2

DO4, DO5

SENS/DO3

CN1

Servo Connector

CN2

CN3

CN4

CN5

1-3

Page 18

1 Overview of Motion Modules

1.1.3 SVA-02A Module

Features of the SVA-01A Module

• Analog-output 4-axis Servo Module

• Independent position control, speed reference output, torque reference output, and phase

control are possible for each axis.

• Up to 60 axes (up to 15 Modules) can be controlled.

• Interpolations and complex processing operations can be easily programmed in motion

programs.

15 Modules max.

Inverters

Analog servos

SVA-01A

SGDA

SGDB

SGDM

SGDS

M M M M

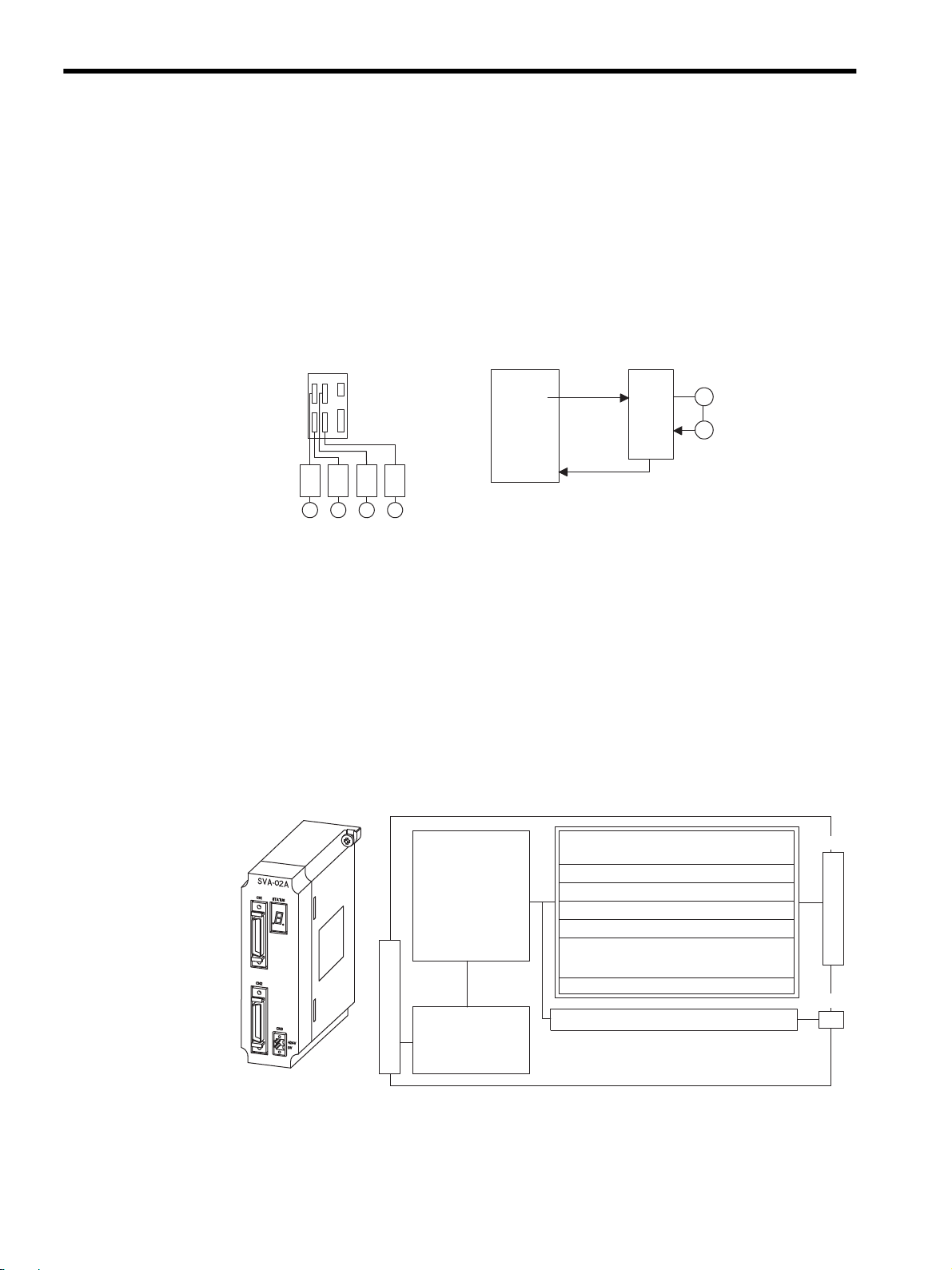

1.1.3 SVA-02A Module

Overview of the SVA-02A Module

The SVA-02A Module is a Motion Control Module with analog outputs. One SVA-02A

Module can control servos for up to two axes. Two connectors (CN1 and CN2) are provided

for connections to SERVOPACKs and external I/O devices. Each connector is equipped

with a speed reference analog output, a torque reference output, a torque monitoring analog

output, phase A/B/C pulse inputs (5 V differential), a pulse latch digital input, and general-

purpose digital I/O signals.

Speed, Position, and Phase Control

D/A

Speed

reference

Encoder

pulse

SERVOPAC K

SVA-01A

Counter

M

PG

Servo Control

Speed control

Position control

Torque control

Phase control

Zero point return

function

Monitor function

System Bus

Interface

Servo parameters

OW

System Bus Connector

IW

1-4

Analog outputs: Speed ref.

Positive torque ref.

Analog input: Speed monitor

Pulse input: Phase A/B/C

Pulse latch digital input

General-purpose digital inputs (5)+PI

General-purpose digital outputs (6)

Sensor ON output (5 V/24 V)

Same as above.

NREF

TLIMP

NREF

PIL

DI0 to DI5

DO0 to DO2

DO4, DO5

SENS/DO3

CN1

Servo Connector

CN2

Page 19

1.1 Module Overview and Features

SVA-02A

16 Modules max.

Inverters

Analog servos

SGDA

SGDB

SGDM

SGDS

MM

Speed, Position, and Phase Control

SVA-02A

M

PG

Speed reference

SERVOPACK

SERVOPACK

D/A

Counter

Counter

Torque control

D/A

Speed monitor

A/D

Encoder pulse

Torque reference

Speed control

Torque monitor

Encoder pulse

Torque Control

SVA-02A

M

PG

D/A

D/A

A/D

Features of the SVA-02A Module

• Analog-output 2-axis Servo Module

• Independent position control, speed reference output, torque reference output, and phase

control are possible for each axis.

• Up to 32 axes (up to 16 Modules) can be controlled.

• Interpolations and complex processing operations can be easily programmed in motion

programs.

1

1-5

Page 20

1 Overview of Motion Modules

CN1

System Bus Connector

MECHATROLINK Connector

MECHATROLINK

Control

Servo Control

Remote I/O Control

Inverter Control

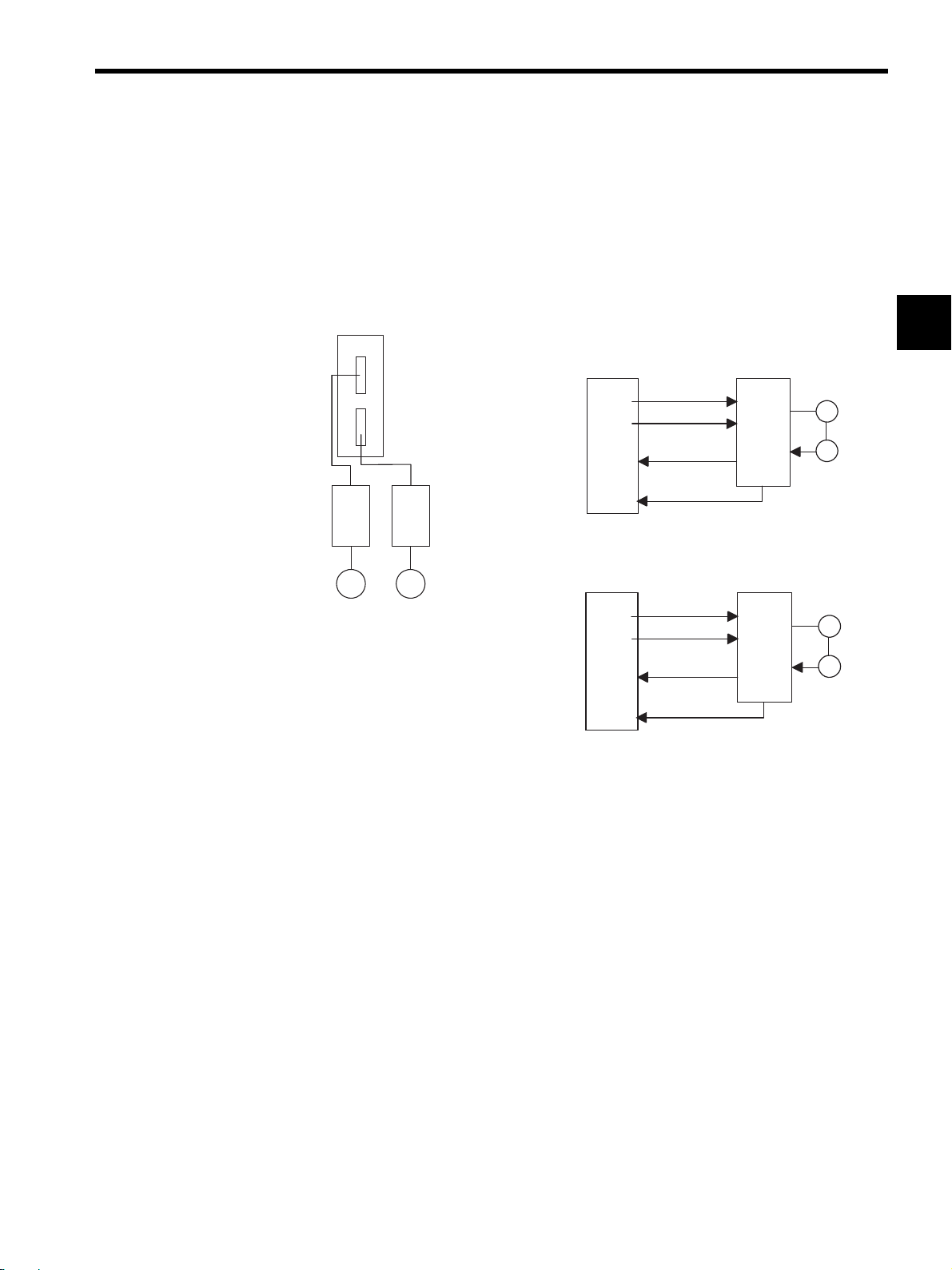

1.1.4 SVB-01 Module

1.1.4 SVB-01 Module

Overview of the SVB-01 Module

The SVB-01 Module has a single MECHATROLINK connector and can control up to 14

Module Devices with MECHATROLINK interfaces.

The SVB-01 Module can be connected to I/O Modules (such as the JEPMC-IO350) or

Inverters (such as the VS-616G5 or VS-675H5) to transmit control signals and messages.

1-6

Page 21

1.1 Module Overview and Features

Features of the SVB-01 Module

• By using the MECHATROLINK high-speed field network interface, up to 14 axes can

be controlled with less wiring. A total of 224 axes can be controlled using a maximum

of 16 Modules.

• Using the position control functions, motion programs can perform positioning, zero

point returns, and interpolations.

SVB

16 Modules max.

SGD-N or SGDB-N

(connecting

14

stations

max.

M M M M

MECHATROLINKcompatible servos)

1

SW1

IN2

SW2 IN1

OUT2

OUT1

DC24V

DC 0V

YASKAWA

JEPMC-IO350

CN1

IN1 OUT1 IN2 OUT2

A1 A1 A1 A1B1B1 B1 B1

RIO

616G5

1-7

Page 22

1 Overview of Motion Modules

Motion functions

Override function

Stroke limit function

Emergency stop

function

CN2

CN1

System Bus Connector

Pulse Motor Driver

Connector

System Bus

Interface

Servo Parameters

OW

IW

Same as above.

2 Pulse-train Outputs:CCW

CW

1 Excitation ON

2 General-purpose

1 Excitation monitor/zero point

3 General-purpose

1 Emergency/deceleration stop

4 Digital Outputs:

5 Digital Inputs:

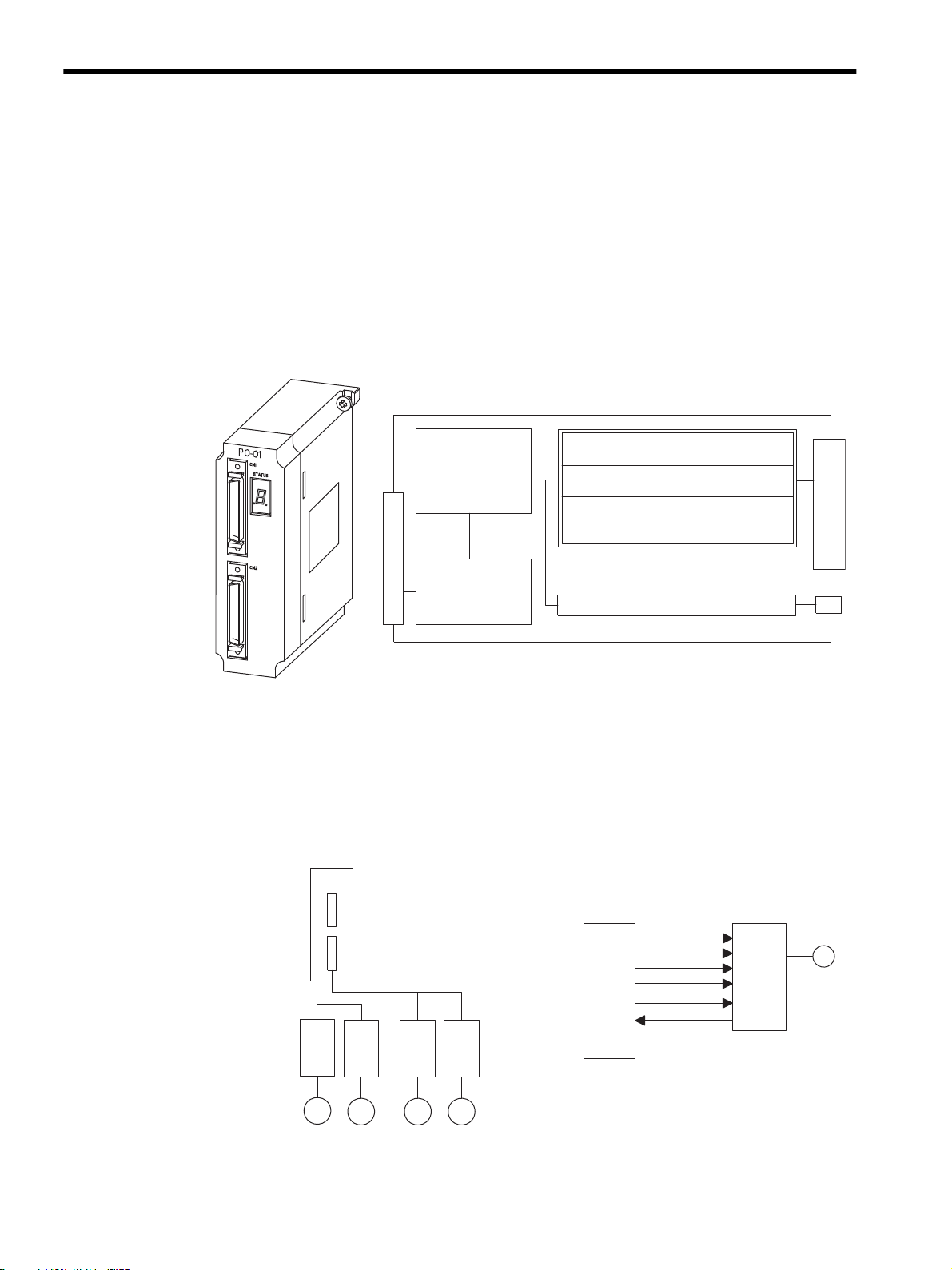

1.1.5 PO-01 Module

1.1.5 PO-01 Module

Overview of the PO-01 Module

The PO-01 Module is a Motion Control Module with pulse-train outputs. One PO-01 Mod-

ule can be connected to pulse motor drivers for up to 4 axes.

Two connectors (CN1 and CN2) are provided for connections to pulse motor drivers. Each

connector is equipped with a 5-V differential pulse-train output as well as 4 digital outputs

(DO) and 5 digital inputs (DI) for various pulse driver control applications.

Features of the PO-01 Module

• The PO-01 Module can be connected to up to four axes.

• A total of 64 axes can be controlled using a maximum of 16 Modules.

• This Module provides positioning, zero point returns, interpolations, and other functions,

all of which can be specified in motion programs.

PO-01

16 Modules max.

PO-01

M

M M M

Pulse Motor

Driver

1-8

CW+

CW-

CCW+

CCW-

DO

DI

Pulse

Motor

Driver

M

Page 23

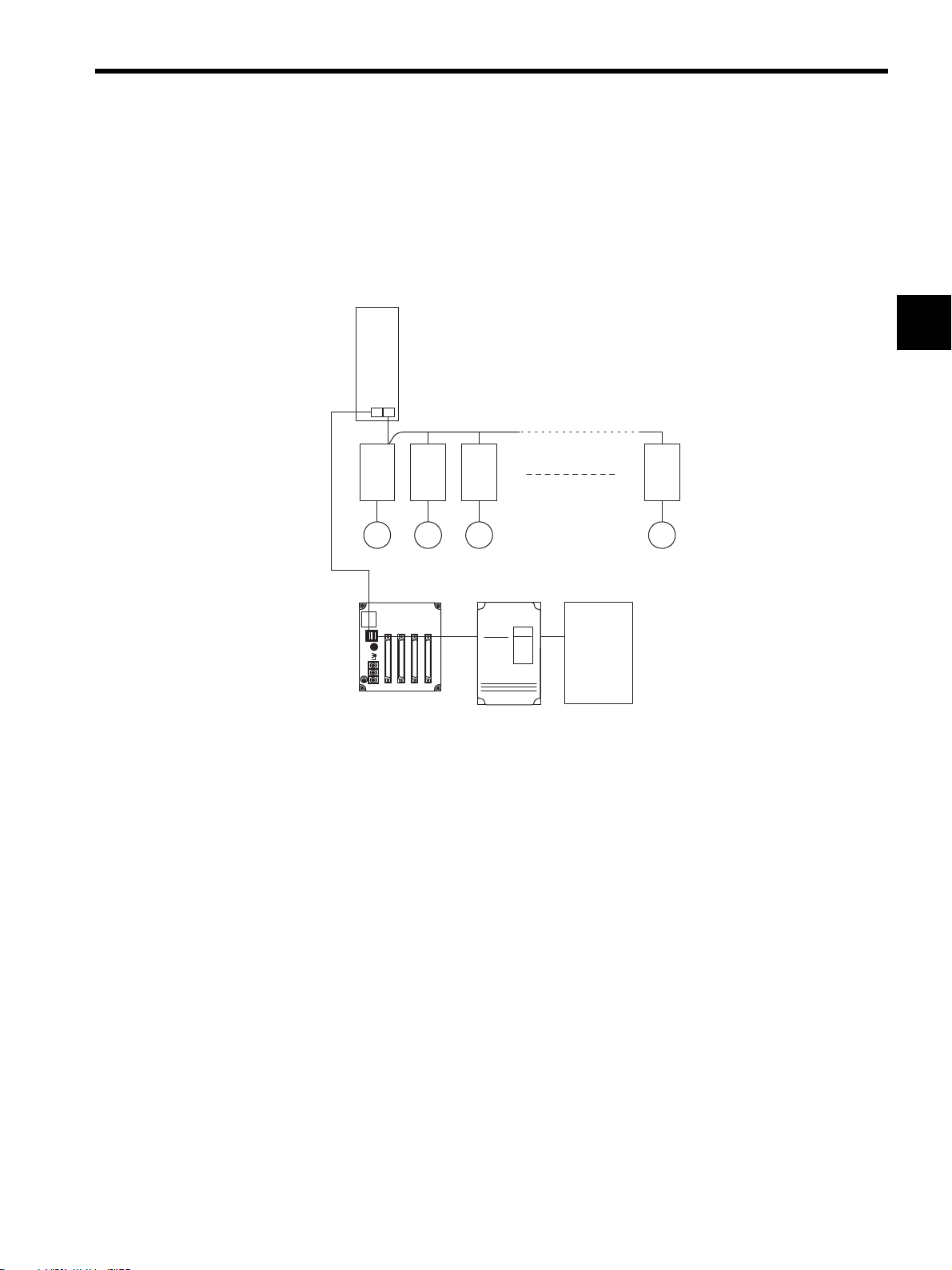

1.2 System Configuration

ON

1.2.1 System Configuration Examples

The MP920 Motion Modules are available with analog outputs, pulse outputs, and field net-

work interfaces. Modules can be freely selected to configure the system best suited to the

application.

PS-03 SVA-01A

DC24V

TB1

+24V

0V

FG

SG

CPU-01

MP920 CPU-01PS-03

POWER

SW1

1

L.RST

BATTERY

2

RUN

3

INIT

4

TEST

5

6

MULTI

7

FLASH

8

M.RST

OFF

ON

PORT2

PORT1

CN1

RLY OUT

1.2 System Configuration

1

SVA-02A

SVA-01A

RDY

RUN

ALM

ERR

BAT

ALM

PRT2

PRT1

CN3

CN1

CN2

CN4

SVA-02A

CN1

STATUS

STATUS

CN5

CN2

CN3

SVB-01

SVB-01

+24V

0V

STATUS

CN1

PO-01

TRX

PO-01

LIO-01

LIO-01

CN1

CN1

STATUS

CN2

CN1

RUN

RUN

FUSE

FUSE

CN2

CN2

Analog outputs for 4 axes

Analog output for 2 axes

M M

Pulse outputs for 4 axes

Pulse Motor Driver

M M M MM M M M

MECHATROLINK communications

MECHATROLINK-compatible servos

M M M M

IO-350

216IF Inverter

Two analog outputs per axis

One analog input per axis

1-9

YASKAWA

JEPMC-IO350

CN1

IN1 OUT1 IN2 OUT2

SW1

IN2

SW2 IN1

OUT2

OUT1

DC24V

DC 0V

A1 A1 A1 A1B1B1 B1 B1

616G5

Up to 14 Modules can be connected.

Page 24

1 Overview of Motion Modules

1.3.1 General Specifications

1.3 Specifications

1.3.1 General Specifications

This section gives an overview of the specifications and functions of the MP920 Modules.

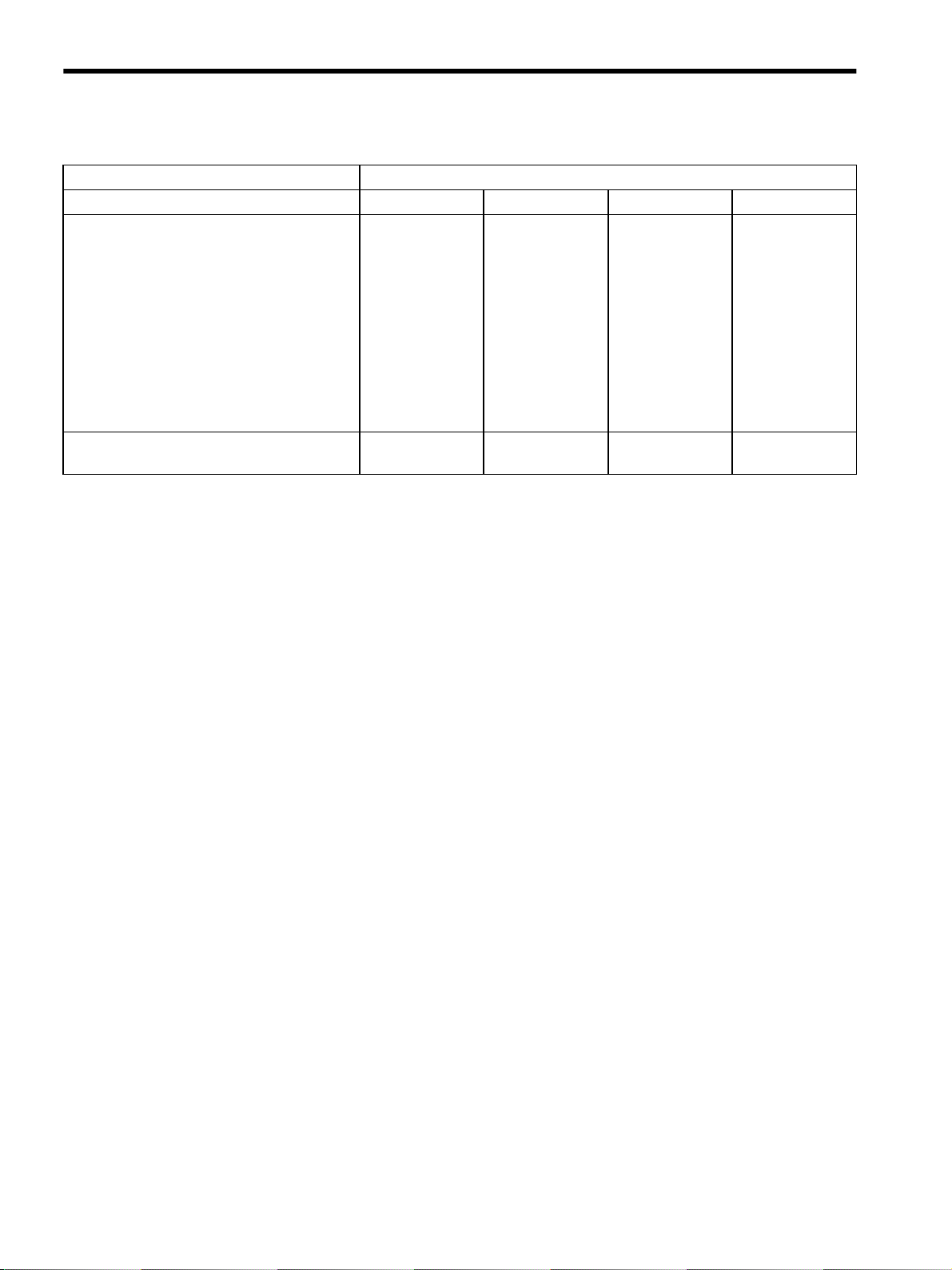

General Specifications of the MP920 Modules

Table 1.1 lists the general specifications of the MP920 Modules.

Table 1.1 General Specifications of the MP920 Modules

Item Specifications

Environmental

Conditions

Electrical

Operating

Conditions

Mechanical

Operating

Conditions

Installation

Requirements

Ambient Operating Temperature

Storage Temperature

Ambient Operating Humidity

Ambient Storage

Humidity

Pollution Level Pollution level 1 (conforming to JIS B 3501)

Corrosive Gas There must be no combustible or corrosive gas.

Operating

Altitude

Noise Resistance Conforming to JIS B 3502:

Vibration

Resistance

Shock

Resistance

Ground Ground to 100Ω max.

Cooling Method Natural cooling

0 to 55°C

-20 to 85°C

30% to 95% RH (with no condensation)

5% to 95% RH (with no condensation)

2,000 m above sea level or lower

1,500 V (p-p) in either normal or common modes with a

pulse width of 100 ns/11μs and a rise time of 1 ns (tested

with impulse noise simulator)

Conforming to JIS B 3502:

10 to 57 Hz with single-amplitude of 0.075 mm

57 to 150 Hz with fixed acceleration of 9.8 m/s

10 sweeps each in X, Y, and Z directions

(sweep time: 1 octave/min)

Conforming to JIS B 3502:

2

Peak acceleration of 147 m/s

the X, Y, and Z directions

(15G) twice for 11 ms each in

2

(1G)

1-10

Page 25

1.3 Specifications

1.3.2 Function Lists

Table 1.2 lists the motion control function specifications for the MP920.

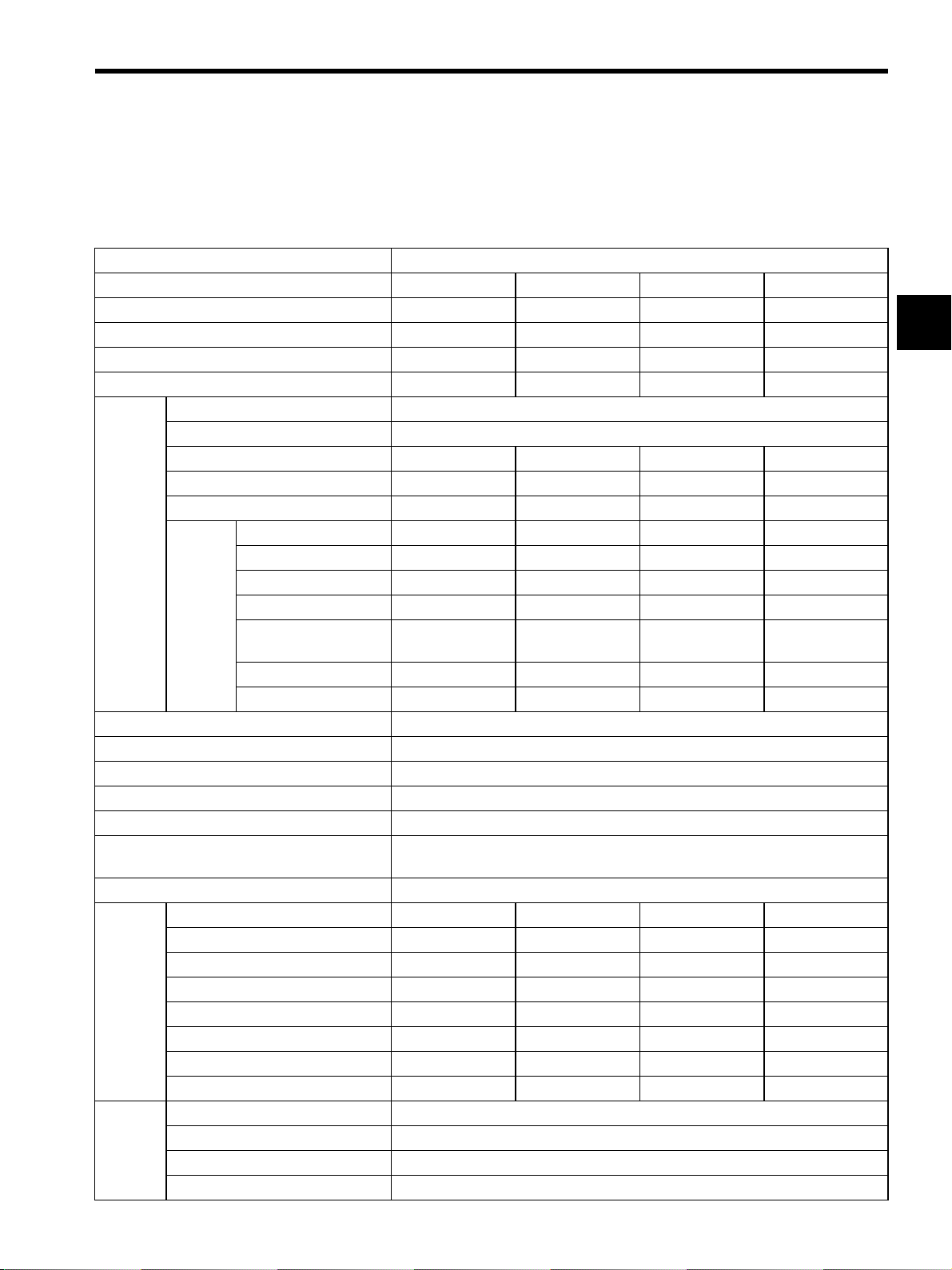

Table 1.2 MP920 Motion Control Function Specifications

Item Specification

Description SVA-01A SVA-02A SVB-01 PO-01

Model Number

Interface

Number of Controlled Axes per Module

Maximum Number of Modules

Control

Specifications

Reference Unit mm, inch, deg, pulse

Reference Unit Minimum Setting 1, 0.1, 0.01, 0.001, 0.0001, 0.00001

Maximum Programmable Value -2147483648 to +2147483647 (signed 32-bit value)

Speed Reference Unit mm/min, inch/min, deg/min, pulses/min

Acceleration/Deceleration Type Linear, asymmetric, S-curve, exponential

Override Function Positioning: 0.01% to 327.67% by axis

Coordinate System Rectangular coordinates

Zero

Point

Return

Programs

PTP Control Linear, rotary, infinite-length, and independent axes

Interpolation Up to 16 linear axes, 2 circular axes, and 3 helical axes

Speed Reference Output

Torque Reference Output

Phase Control

Position

Control

DEC1 + Phase-C

DEC2 + Phase-C

DEC1 + LMT + C

Phase-C

DEC1 + ZERO

DEC2 + ZERO

DEC1 + LMT + ZERO

ZERO

Language Special motion language, ladder logic program

Number of Tasks Up to eight programs can be executed in parallel.

Number of Programs Up to 256

Program Capacity 80 Kbytes

Positioning

External Positioning

Zero Point Return

Interpolation

Interpolation with

Position Detection

Fixed-speed Feed

Fixed-length Feed

JEPMC-MC200A JEPMC-MC220A JEPMC-MC210 JEPMC-PL210

Analog Analog MECHATROLINK Pulse

4 2 14 4

15 16 16 16

Yes Yes No No

No Yes No No

Yes Yes No No

Ye s Ye s Yes Ye s

Ye s Ye s Yes N o

Ye s Ye s Yes Ye s

Ye s Ye s Yes Ye s

Ye s Ye s Yes N o

Ye s Ye s Yes Ye s

Ye s Ye s Yes Ye s

Interpolation: 0.01% to 327.67% by group

Ye s Ye s Yes N o

Yes Yes No No

Yes Yes No No

Ye s Ye s Yes N o

Ye s N o Ye s Ye s

Ye s N o No Ye s

Ye s N o No Ye s

Ye s N o Ye s N o

1

1-11

Page 26

1 Overview of Motion Modules

1.3.2 Function Lists

Table 1.2 MP920 Motion Control Function Specifications (cont’d)

Item Specification

Description SVA-01A SVA-02A SVB-01 PO-01

Applicable SERVOPACKs and Inverters SERVOPACKs

• SGDA-S

• SGDB-

• SGDM-

• SGDS-

Inverters

SERVOPACKs

• SGDA-S

• SGDB-

• SGDM-

• SGDS-

Inverters

SERVOPACKs

• SGD-N

• SGDB-AN

• SGDH-

E+

JUSP-NS100

Pulse Motor

Drivers

Inverters (216IF

board required)

• VS-616G5

• VS-676H5

• VS-676H5T

Encoder Incremental or

absolute

Incremental or

absolute

Incremental or

absolute

No

Note: Yes: Can be controlled, No: Cannot be controlled.

1-12

Page 27

2

Motion Control

This chapter gives an overview of motion control and describes the motion

commands.

2.1 Overview of Motion Control - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.1 Motion Control for the MP920 - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

2.1.2 Motion Control Methods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

2.1.3 Examples of Motion Control Applications - - - - - - - - - - - - - - - - - - - - 2-5

2.2 Control Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-7

2.2.1 Overview of Control Modes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-7

2.2.2 Speed Reference Output Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-8

2.2.3 Torque Reference Output Mode - - - - - - - - - - - - - - - - - - - - - - - - - - 2-12

2.2.4 Phase Control Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-15

2.2.5 Zero Point Return Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-22

2

2.3 Position Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-26

2.3.1 Prerequisites for Position Control - - - - - - - - - - - - - - - - - - - - - - - - - 2-26

2.3.2 Position Control Without Using Motion Commands - - - - - - - - - - - - 2-41

2.4 Position Control Using Motion Commands - - - - - - - - - - - - 2-45

2.4.1 Overview of Motion Commands - - - - - - - - - - - - - - - - - - - - - - - - - - 2-45

2.4.2 Positioning (POSING) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-48

2.4.3 External Positioning (EX_POSING) - - - - - - - - - - - - - - - - - - - - - - - 2-51

2.4.4 Zero Point Return (ZRET) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-55

2.4.5 Interpolation (INTERPOLATE, END_OF_INTERPOLATE) - - - - - - - 2-70

2.4.6 Interpolation with Position Detection (LATCH) - - - - - - - - - - - - - - - - 2-73

2.4.7 Fixed Speed Feed (FEED) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-74

2.4.8 Fixed Length Feed (STEP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-77

2.4.9 Zero Point Setting (ZSET) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-81

2-1

Page 28

2 Motion Control

M

M

M

M

M

Operation

panel

I/O

processing

Ladder logic program

SERVOPACK

Inverter

Pulse motor

driver

Sequence

control

Analog Module

Analog Device

Motion control

MC program

Communications

control

Programming

Device

Other

company's

sequencer

I/O Module

Motion Module

Communications

Module

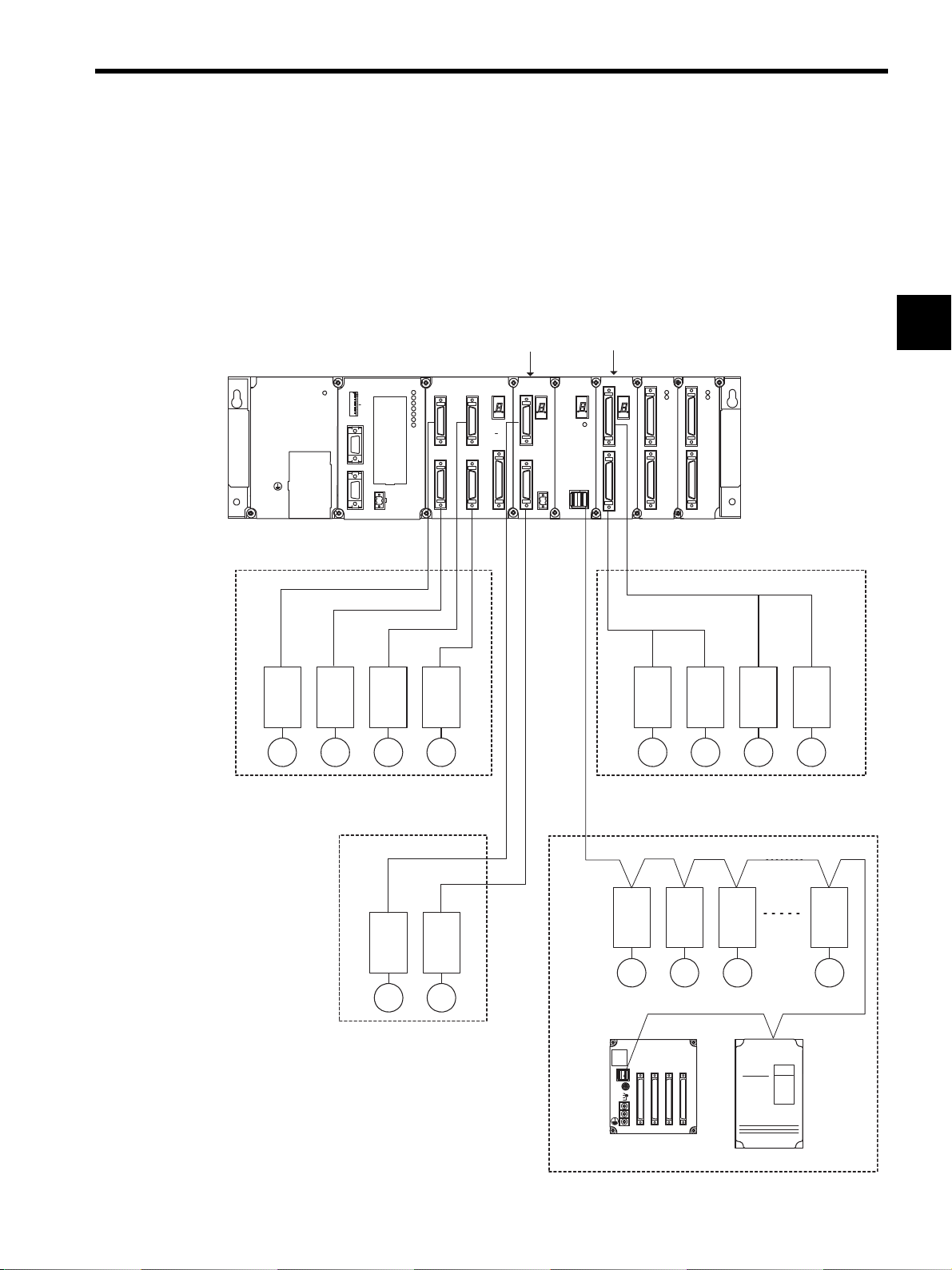

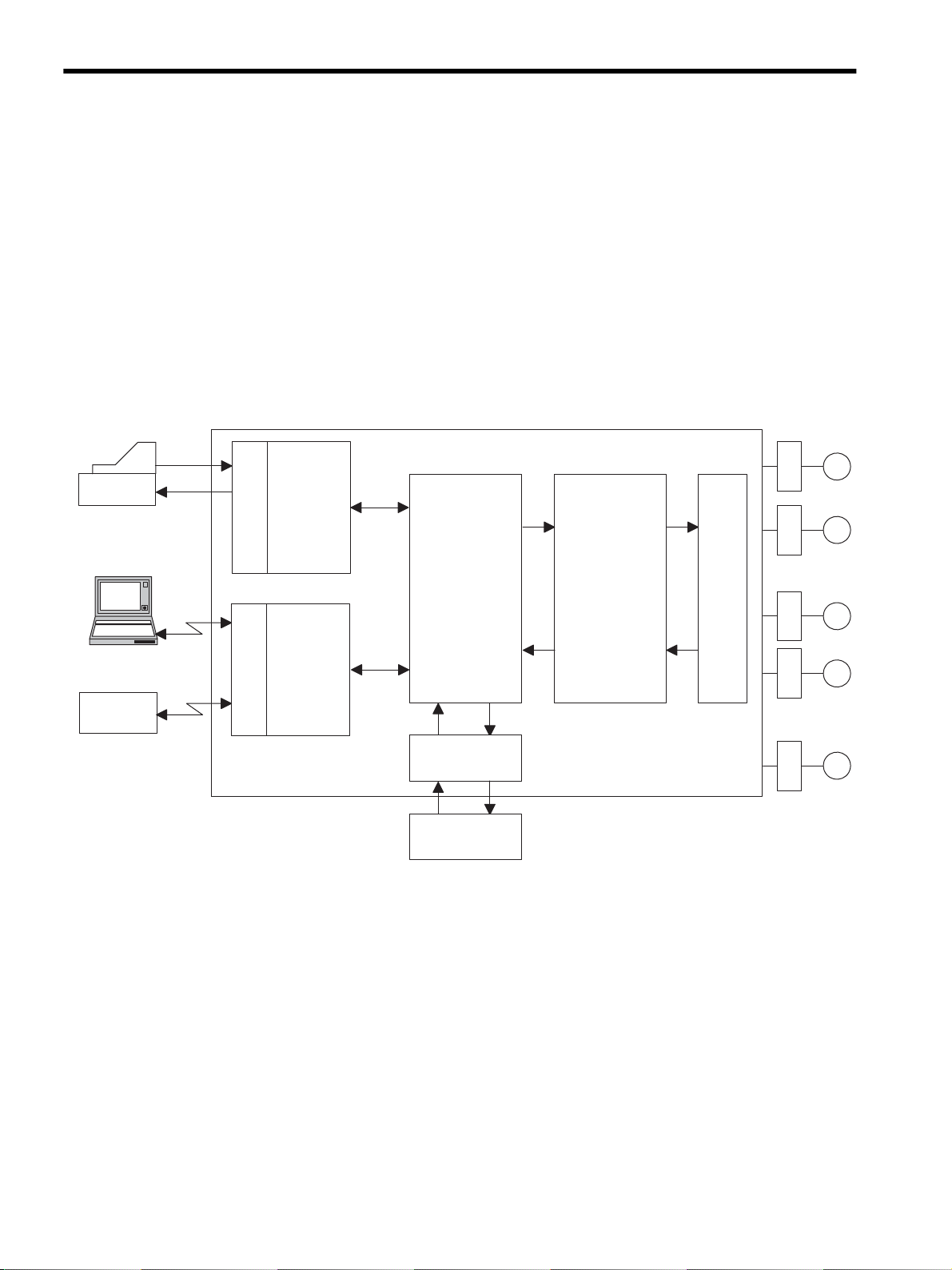

2.1.1 Motion Control for the MP920

2.1 Overview of Motion Control

This section describes the methods used for motion control and gives some examples of their

use.

2.1.1 Motion Control for the MP920

The MP920 Machine Controller provides fully integrated sequence control and motion con-

trol.

The following diagram shows a conceptual diagram of the MP920 system.

A wide range of Motion Modules is provided for the MP920, and these can be selected

according to the purpose.

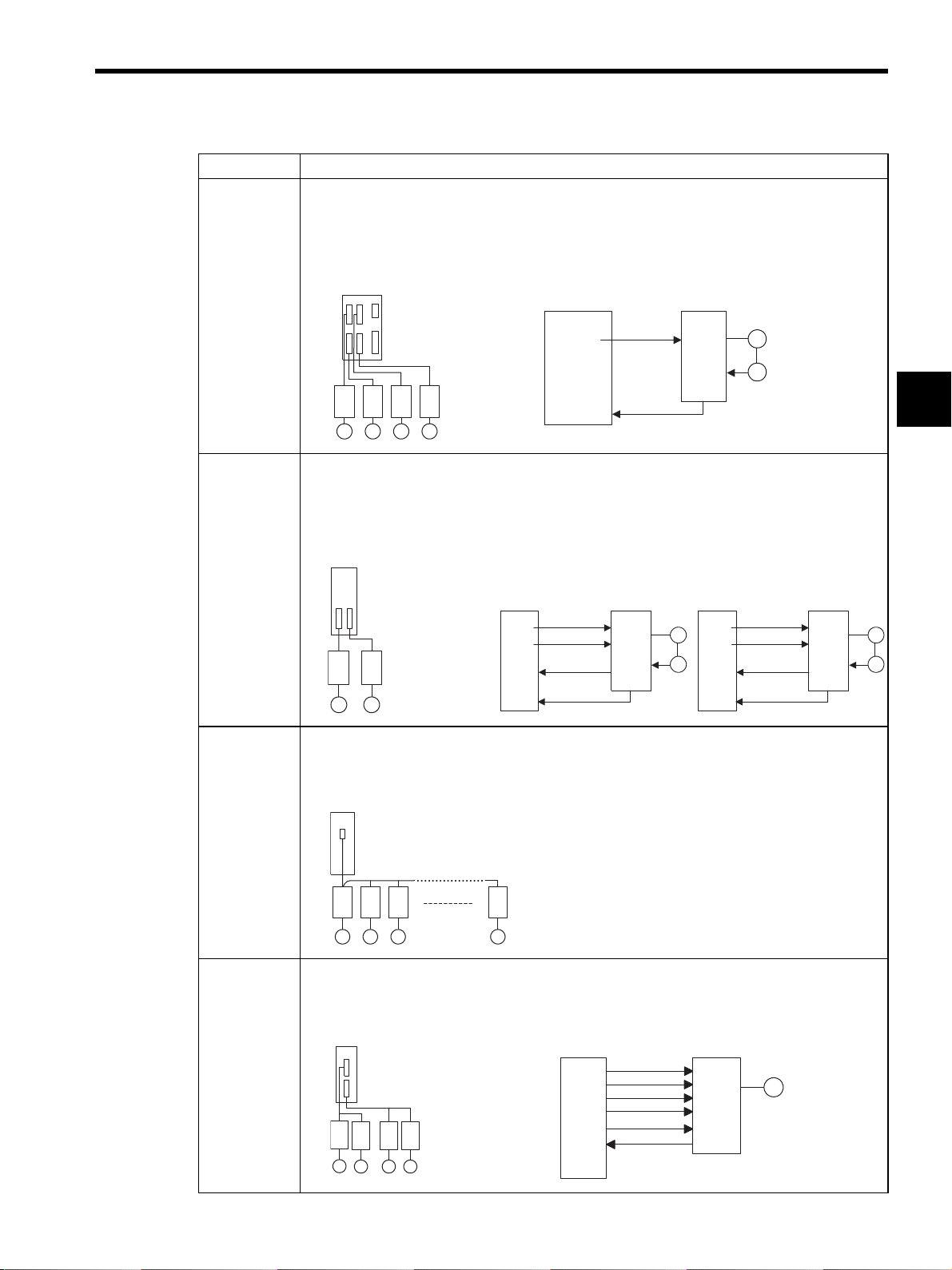

The following table shows the types of Motion Module and their features.

2-2

Page 29

Name Features

r

PO-01

M

M

16 Modules max.

Pulse motor driver

M M

PO-01

M

CW+

CCW+

DI

CW-

CCW-

DO

Pulse

motor

driver

SVA-01A • Analog-output 4-axis Servo Module

• Independent position control, speed control, and phase control are possible for each axis.

• Up to 60 axes (up to 15 Modules) can be controlled.

• Interpolations and complex processing operations can be easily programmed in motion programs.

15 Modules max.

SVA-01A

Inverters

Analog servos

SGDA-S

Speed, position, and phase control

SVA-01A

SGDB

SGDM

M M M M

SVA-02A • Analog-output 2-axis Servo Module

• Independent position control, speed control, torque, and phase control are possible for each axis.

• Up to 32 axes (up to 16 Modules) can be controlled.

• Interpolations and complex processing operations can be easily programmed in motion programs.

D/A

Counter

Speed

reference

Encoder

Pulse

2.1 Overview of Motion Control

SERVOPACK

M

PG

2

16 Modules max.

SVA-02A

Inverters

Analog servos

SGDA-S

SGDB

SGDM

M M

Speed, position, and phase control

SVA-02A

D/A

D/A

A/D

Counter

Speed reference

Torque limit

Speed monitor

Encoder

Pulse

SERVOPACK

Torque control

SVA-02A

Torque reference

D/A

M

PG

Counter

D/A

A/D

Speed limit

Torque monitor

Encoder

Pulse

SERVOPACK

SVB-01 • By using the high-speed field network (MECHATROLINK) interface, up to 14 axes can be con-

trolled with less wiring. (Using a maximum of 16 Modules, 224 axes can be controlled.)

• Using the position control functions, motion programs can perform positioning, zero point

returns, and interpolations.

SVB

16 Modules max.

14 axes max.

SGD-N o

SGDB-N

M M M M

PO-01 • Pulse output type 4-axis Pulse Output Module

• Up to 64 axes (up to 16 Modules) can be controlled.

• Using the position control functions, motion programs can perform positioning, zero point

returns, and interpolations.

M

PG

2-3

Page 30

2 Motion Control

H0101 OWC000

B00105

IFON

500 OWC015

0 OWC015

ELSE

Ladder logic program

Motion

processing

Setting Parameters

Monitoring Parameters

CPU Module SVA Module

SERVO-

PACK

PGM

PGM

PGM

PGM

Status

Status

information

SERVO-

PACK

SERVO-

PACK

SERVO-

PACK

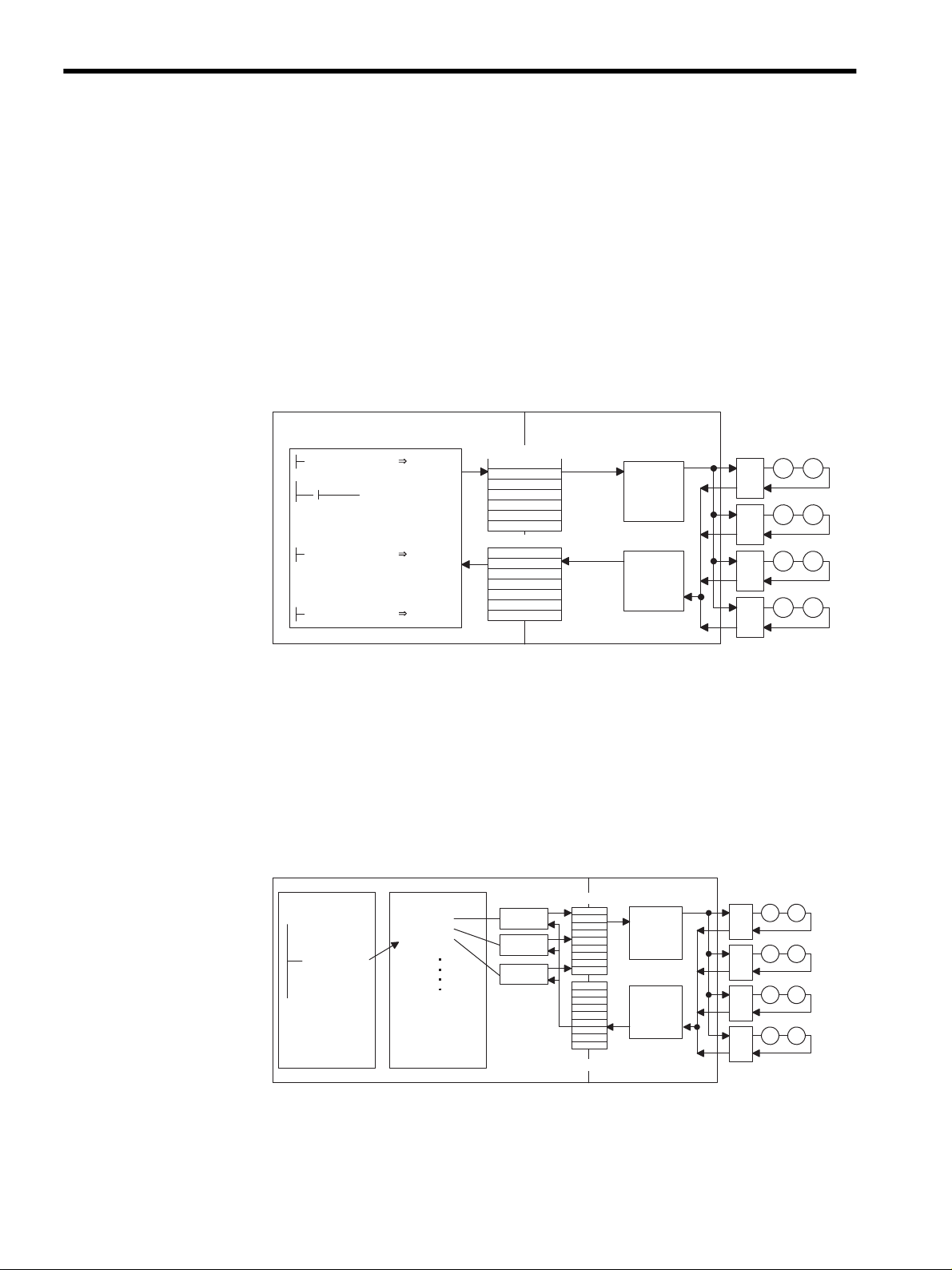

2.1.2 Motion Control Methods

2.1.2 Motion Control Methods

By using Motion Modules, motions for a wide variety of applications can be controlled.

There are two programming methods for controlling motions: Ladder logic programs and

motion programs. An overview of each programming method is given below.

Ladder Logic Programming

Ladder logic programs are designed mainly for sequence control. The motion setting param-

eters and motion monitoring parameters used as interfaces with the Motion Modules are

directly written to and read by the ladder logic programs to perform motion control.

Special operations can be programmed and combined as user functions. For details, refer to

Chapter4 Parameters and the section describing the parameters of each Motion Module.

Motion Programming

The motion programs that have been created using a special motion language perform

motion control. Up to 256 programs can be created, and these can also be executed in paral-

lel.

The use of the special motion language enables complex operations to be easily pro-

grammed. The system performs command end checks and other processing. The special

motion commands shown in the following table are provided as standard in the MP9

Series.

CPU Module

MSEE MPM001

CPU Module SVA Module

Motion program

MOV [X] 100

MVS [X] 100

MCC - - - EXT

Setting Parameters

MOV

command

MOV

command

MOV

command

Monitoring Parameters

Command

processing

Status

information

2-4

SERVO-

PACK

SERVO-

PACK

SERVO-

PACK

SERVO-

PACK

PGM

PGM

PGM

PGM

Page 31

2.1 Overview of Motion Control

Commands

Axis move commands: 8 types

MOV, MVS, MCW, MCC, ZRN, SKP, MVT, EXM

Basic control commands: 6 types

ABS, INC, POS, PLN, MVM, PLD

Speed and acceleration/deceleration commands: 7 types

ACC, DCC, SCC, VEL, IAC, IDC, IFP, FMX

High-level control commands: 4 types

PFN, INP, SNG, UFC

Control commands: 10 types

MSEE, TIM, IOW, END, RET, EOX, IF ELSE IEND, WHILE WEND,

PFORK JOINTO PJOINT, SFORK JOINTO SJOINT

Math and sequence control commands: 32 types

=. +. -, *, /, MOD, |, ^, &, !, ( ), S{ }, R { }, SIN, COS, TAN, ASN, ACS,

ATN, SQRT, BIN, BCD, = =, < >, >, <, >=, <=, SFR, SFL, BLK, CLR

2.1.3 Examples of Motion Control Applications

The following illustrations show examples of the use of each control mode for Motion Mod-

ules.

Speed Reference Output Control and Torque Reference Output

Control

2

Winder A

Tension setting

Winder B

Servomotor

Tension

Servomotor

detector

MP920

Speed limit

SERVOPACK

Tension rollers

Servomotor

MP920

2-5

Page 32

2 Motion Control

Servomotor

MP920

Y axis

Z axis

X axis

C axis

A axis

2.1.3 Examples of Motion Control Applications

Phase Control

Conveyor Synchronization

Position Control

Conveyor

Coater

2-6

Page 33

2.2 Control Modes

This section describes the motion control modes that can be used by the MP920.

2.2.1 Overview of Control Modes

Five control modes are available for MP920 Motion Modules. These modes can be switched

in real time, according to the purpose.

The following table shows the control mode that can be used by MP920 Motion Modules,

and gives an overview and some examples of their uses.

Control Mode Overview Typical

Speed Reference

Output Mode

Torque Reference

Output Mode

Position Control

Mode*

Phase Control

Mode

Zero Return

Mode*

Rotates the motor at the

specified speed.

Outputs the specified torque. Injection mold-

Specifies the target position

and speed. Executes a position loop, identifies the difference to the target position

from the encoder, converts

the difference to the speed

reference, and performs

position control.

While executing speed control using a standard speed

reference, generates the target position from the speed

reference, and performs

phase control.

Performs zero point positioning when an incremental

encoder is used.

Module

Applications

Conveyors or

main axes

ing machines or

presses

Conveyors or

XY tables

Electronic cams

or electronic

shafts

− Yes Yes No No

SVA-

SVA-

01A

Yes Yes No No

YesYesYesYes

Yes Yes No No

02A

No Yes No No

2.2 Control Modes

2

SVB-01PO-

01

* There are two methods for returning to the zero point:

• Using ZERO POINT RETURN command for position control

• Using Zero Return Mode

Note: Yes: Available, No: Not available

2-7

Page 34

2 Motion Control

2.2.2 Speed Reference Output Mode

2.2.2 Speed Reference Output Mode

Overview

This mode is used to rotate the motor at the desired speed.

A speed reference is output to the servo drive according to the specified speed reference, lin-

ear acceleration/deceleration time constant, and filter time constant.

The acceleration/deceleration time can be set as desired.

S-curve acceleration/deceleration can be easily performed by the user program (one com-

mand).

The speed reference output mode can also be used for a general-purpose D/A converter. In

this case, set the linear acceleration/deceleration time constant and the filter time constant to

“0.”

IMPORTANT

The speed reference output mode is available only with the SVA-01A and SVA-02A Modules. It can-

not be used with the SVB-01 and PO-01 Modules.

Details

Use the following procedure to perform operation in the speed reference output mode.

1. Set the motion fixed parameters.

2. Set the motion setting parameters.

Set the speed reference output mode (NCON).

3.

4. Set the RUN command (RUN) to ON.

Output the speed reference and torque limit reference*

5.

Set the speed reference output mode to OFF.

*: SVA-02A Module only

: System execution

: User settings

NCON

RUN

Speed

(%)

(100%)

Speed

reference

0

Linear acceleration time constant Linear deceleration time constant

Time (t)

2-8

Page 35

2.2 Control Modes

1. Set the motion fixed parameters according to the user’s machine.

Table 2.1 Examples of Fixed Parameters

No. Name Setting Range Meaning Setting

Example

7 Rated Motor Speed Setting 1 to 32000 Rated motor speed

8 Number of Feedback Pulses per

Motor Rotation

9 D/A Output Voltage at 100%

Speed

Number of Feedback Pulses per

Motor Rotation

(For high-resolution) *

10 D/A Output Voltage at 100%

Torque Limit*

* 1. Valid only with an SVB-01 Module.

* 2. Valid only with an SVA-02A Module.

2

1

4 to 65532 Number of pulses

before multiplication

0.001 to 10.000 0.001 = 0.001 V

1 = 1 V

4 to 2147483647 1 = 1 pulse/rev 2048 pulses/

0.001 to 10.000 0.001 = 0.001 V

1 = 1 V

3000 min

2048

6.000 V

rev

3.000 V

2. Set the motion parameters to be used in the speed reference output mode.

The following three methods can be used to set the motion setting parameters.

-1

2

• Using the MPE720 Setting Parameter Window

• Using a ladder logic program

• Using a motion program

Name Register No. Setting

Positive Torque Limit

Setting (TLIMP)*

Positive Speed Limiter Setting (NLIMP)

Negative Speed Limiter Setting (NLIMN)

Linear Acceleration

Time Constant

(NACC)

Linear Deceleration

Time Constant

(NDEC)

Filter Time Constant

Setting (NNUM)

Speed Reference

Setting (NREF)

Table 2.2 Examples of Setting Parameters

Meaning Setting

Range

OW02 -327.68 to

327.67

OW04 0.00 to

327.67

OW05 0 to 327.67 0.01 = 0.01%

OW0C 0 to 32767 Linear acceleration time con-

OW0D 0 to 32767 Linear deceleration time

OW14 0 to 255 For simple S-curve accelera-

OW15 -327.68 to

327.67

0.01 = 0.01%

1 = 1%

0.01 = 0.01%

1 = 1%

1 = 1%

stant (ms) at speed pattern

generation

constant (ms) at speed pattern generation

tion

Speed reference value

0.01 = 0.01%

1 = 1%

Example

-100.00

(-100.00%)

130.00

(130.00%)

130.00

(130.00%)

1000

(1 second)

1000

(1 second)

0

50.00

(50.00%)

* Valid only with an SVA-02A Module.

In the examples, SERVOPACK is used as axis 1 of Module No. 1. When the Module

number and the axis number are different, see 4.1.2 Modules and Motion Parameter

Registers, and change the register numbers.

3. Select the Speed Reference Output Mode (NCON) (bit 0 of OW00).

2-9

Page 36

2 Motion Control

0

NACC

Speed reference

1 second 1 second

NACC Time (t)

Speed

(%)

NR

(100%)

NREF

(50%)

2.2.2 Speed Reference Output Mode

User Program Examples

4. To start operation, set the Servo ON (RUN) to ON (bit 0 of OW01).

The speed reference will be output for the axis according to the specified motion param-

eters.

With an SVA-02A Module (2-axis), the speed reference is output with an NREF signal

from channel 1 (or channel 2), and the torque limit reference is output with an AO-OUT

signal.

Even while the speed reference output mode is being selected, the motion parameter set-

tings can be changed.

5. To stop operation, set the RUN command (RUN) and the speed reference output mode

(NCON) to OFF.

Example of RUN Operation

Fig. 2.1 Speed Pattern

2-10

Page 37

Ladder Logic Program Example

2.2 Control Modes

H0101

RUNPB

IB00104

ACCEL

IB00105

IFON

500

ELSE

0

IEND

DEND

RUNMOD

OWC000

RUN

OBC0010

NREF

OWC015

NREF

OWC015

Set the speed reference output mode to ON.

Driver RUN command (RUN)

When IB00104 turns ON, the speed

reference output mode starts.

When the acceleration command (IB00105)

turns ON, a speed reference of 50% is

output for the acceleration time constant

(ACC).

When IB00105 turns OFF, the deceleration

time constant (DEC) causes deceleration

stop (a speed reference of 0% is output).

Fig. 2.2 RUN Commands (DWG H01)

The example in the above illustration has been greatly simplified. In actual operation, each

register can be controlled from the user program.

2

2-11

Page 38

2 Motion Control

2.2.3 Torque Reference Output Mode

2.2.3 Torque Reference Output Mode

Overview

This mode is used to generate a constant torque, regardless of the speed.

Select this mode to keep the metal mold of a plastic molding machine, such as an injection

molding machine, at a constant pressure.

When the torque reference output mode is selected, the specified torque reference and speed

limit reference are output by the servo drive.

This mode can be used only with an SVA-02A Module.

IMPORTANT

The torque reference output mode is available only with the SVA-02A Module. It cannot be used with

the SVA-01A, SVB-01, and PO-01 Modules.

Details

Use the following procedure to perform operations in the torque reference output mode.

1. Set the motion fixed parameters.

2. Set the motion setting parameters.

Set the torque reference output mode (TCON)

3.

4. Set the RUN command (RUN) to ON.

Output the torque reference and speed limit reference.

5.

Set the torque reference output mode to OFF.

: System execution

: User settings

TCON

RUN

.

Torque speed

(%)

Torque reference

0

Time (t)

2-12

Page 39

2.2 Control Modes

1. Set the motion fixed parameters according to the user’s machine.

Table 2.3 shows the related parameters when the torque reference output mode is used.

Table 2.3 Examples of Fixed Parameters

No. Name Setting Range Meaning Setting

Example

7 Rated Motor Speed Setting 1 to 32000 Rated motor speed

8 Number of Feedback Pulses per

Motor Rotation

9 D/A Output Voltage at 100%

Speed

Number of Feedback Pulses per

Motor Rotation

(For high-resolution)

10 D/A Output Voltage at 100%

Torque Limit

* 1. Valid only with an SVB-01 Module.

* 2. Valid only with an SVA-02A Module.

*1

*2

4 to 65532 Number of pulses

before multiplication

0.001 to 10.000 0.001 = 0.001 V

1 = 1 V

4 to 2147483647 1 = 1 pulse/rev 2048 pulses/

0.001 to 10.000 0.001 = 0.001 V

1 = 1 V

3000 min

2048

6.000 V

rev

3.000 V

2. Set the motion parameters to be used in the torque reference output mode.

-1

2

Table 2.4 Examples of Setting Parameters

Name Register No. Meaning Setting

Example

Torque Reference

Setting (TREF)

Speed Limit Setting

(NLIM)

OW1B Sets the torque reference value at

0.01%.

OW1C Sets the speed limit value at 0.01%. 50.00

50.00

(50.00%)

(50%)

3. Select the Torque Reference Output Mode (TCON) (bit 1 of OW00).

4. To start operation, set the RUN Servo ON (RUN) to ON (bit 0 of OW01).

The torque reference and the speed limit reference will be output for the axis according

to the specified motion parameters.

Even while the torque reference output mode is being selected, the motion parameter

settings can be changed.

5. To stop operation, set the RUN command (RUN) and the torque reference output mode

(TCON) to OFF.

2-13

Page 40

2 Motion Control

2.2.3 Torque Reference Output Mode

User Program Example

Example of RUN Operation

Torque

(%)

TREF

0

Torque reference

Fig. 2.3 Torque Pattern

Ladder Logic Program Example

H0102

RUNPB

IB00204

IB00205

IFON

5000

ELSE

RUNMOD

OWC040

RUN

OBC0410

TREF

OWC05B

Time (t)

Set the torque reference output mode to ON.

Driver RUN command (RUN)

When IB00204 turns ON, the torque

reference output mode starts.

When IB00205 turns ON, 50% is output as

the torque reference.

When IB00205 turns OFF, 0% is output as

the torque reference.

0

IEND

DEND

TREF

OWC05B

Fig. 2.4 RUN Commands (DWG H02)

The example in the above illustration has been greatly simplified. In actual operation, each

register can be controlled from the user program.

2-14

Page 41

2.2.4 Phase Control Mode

Overview

This mode is used to rotate the motor according to the specified speed reference, and at the

same time to strictly control the number of rotations.

Phase control uses multiple axes, ensuring that no deviation occurs in the angle of rotation

(phase) for the motors and enabling endless rotation for printing and other machines being

controlled.

Electronic shafts and electronic cams can thus be used in the servomotors of complex

machine configurations. Phase alignment and synchronous operation, as well as ratio opera-

tion and cam variable speed operation have all been replaced by software.

2.2 Control Modes

2

IMPORTANT

Using a machine to perform conventional

synchronous operation

(Line shaft and cam system)

Controller

Driver

Gear

No.1 roll No.2 roll Cam machine

Fig. 2.5 Electronic Cam and Electronic Shaft Illustration

The phase control mode is available only with the SVA-01A and SVA-02A Modules. It cannot be used

with the SVB-01 and PO-01 Modules.

Gear Gear

M

Cam

Using the MP920 to perform synchronous

operation (Electronic shaft and electronic

cam system)

MP920

Driver

MMM

No.1 roll No.2 roll

Cam machine

2-15

Page 42

2 Motion Control

2.2.4 Phase Control Mode

Details

Use the following procedure to perform phase control operation.

1. Set the motion fixed parameters.

2. Set the motion setting parameters.

3.

Select the phase control mode (PHCON).

4. Set the RUN command (RUN) to ON.

Phase control operation is performed.

5.

Set the phase control mode to OFF.

: System execution

: User settings

PCON

RUN

Speed (%)

(100%)

Reference

speed

Position

0

Time (t)

2-16

Page 43

2.2 Control Modes

1. Set the motion fixed parameters according to the user’s machine.

Table 2.5 Examples of Fixed Parameters

No. Name Setting Range Meaning Setting

Example

7 Rated Motor Speed Setting 1 to 32000 Rated motor speed

8 Number of Feedback Pulses per

Motor Rotation

9 D/A Output Voltage at 100%

Speed

Number of Feedback Pulses per

Motor Rotation

(For high-resolution)

10 D/A Output Voltage at 100%

Torque Limit

* 1. Valid only with an SVB-01 Module.

* 2. Valid only with an SVA-02A Module.

*1

*2

4 to 65532 Number of pulses

before multiplication

0.001 to 10.000 0.001 = 0.001 V

1 = 1 V

4 to 2147483647 1 = 1 pulse/rev 2048 pulses/

0.001 to 10.000 0.001 = 0.001 V

1 = 1 V

3000 min

2048

6.000 V

rev

3.000 V

2. Set the motion parameters to be used in the phase control mode. Use the user program to

control the reference speed so that no shock occurs.

-1

2

The following three methods can be used to set the motion setting parameters.

• Using the MPE720 Setting Parameter Window

• Using a ladder logic program

• Using a motion program

Table 2.6 shows the related parameters when the phase control mode is used.

Name Register No. Setting

Positive Torque Limit

Setting (TLIMP)*

Positive Speed Limiter

Setting (NLIMP)

Negative Speed Limiter Setting (NLIMN)

Error Count Alarm Detection Setting (EOV)

Speed Reference

Setting (NREF)

Phase Bias Setting

(PHBIAS)

Speed Compensation

Setting (NCOM)

Proportional Gain

Setting (PGAIN)

Integral Time Setting

(TI)

Table 2.6 Examples of Setting Parameters

Meaning Electronic Shaft

Range

OW02

OW04

OW05

OW0F

OW15

OL16

OW18

OW19

OW1A

-327.68 to

327.67

0.00 to

327.67

0.00 to

327.67

0 to 65535 1 = 1 pulse 65535 65535

-327.68 to

327.67

31

to 231-1

-2

-327.68 to

327.67

0.0 to 3276.7 0.1 = 0.1 /s

0 to 32767 1 = 1 ms 300

0.01 = 0.01%

1 = 1%

0.01 = 0.01%

1 = 1%

0.01 = 0.01%

1 = 1%

0.01 = 0.01%

1 = 1%

1 = 1 pulse Set by the ladder

0.01 = 0.01%

1 = 1%

1 = 1 /s

Electronic Cam

Setting Example

-100.00

(-100.00%)

130.00

(130.00%)

130.00

(130.00%)

50.00

(50.00%)

logic program.

0.00 0.00

1.5

(1.5)

(300 ms)

-100.00

(-100.00%)

130.00

(130.00%)

130.00

(130.00%)

Set by the ladder

logic program.

Set by the ladder

logic program.

250.0

(250.0)

0

(0 ms)

Setting

Example

* Valid only with an SVA-02A Module.

2-17

Page 44

2 Motion Control

Speed

control

OWCO15

D/A

Integration

PI

Counter

OLCO16

NREF

SVA Module

To other

machine

CPU Module

Standard

speed

reference

setting

Position

compensation

setting

PHBIAS

M

PG

Servo drive

+

ε

+

-

+

+

APOS

IL08

*2

*1

*3

±

*1 Integrates the reference speed reference, and calculates the corresponding position (pulse).

*2 Generates the speed reference from the target position (CPOS) and current position

(APOS) error ε. This is the position (phase) compensation.

*3 To move the phase, the distance to be moved (the angle of rotation of the motor axis

converted to the number of pulses) can be added as the phase compensation setting.

2.2.4 Phase Control Mode

3. Select the Phase Control Mode (PHCON) (bit 3 of OW00).

At this time, also set Phase Reference Disable (PHREFOFF: bit 7 of OW00). Nor-

mally, this bit is set to OFF for electronic shaft applications, and it is set to ON for elec-

tronic cam applications.

4. To start operation, set the RUN Servo ON (RUN) to ON (bit 0 of OW01).

Phase control will be performed for the axis according to the specified motion parame-

ters. Even while phase control is being performed, the motion parameter settings can be

changed.

5. To stop operation, set the RUN command (RUN) and the phase control mode (PHCON)

to OFF.

User Program Example 1: Electronic Shaft

Example of RUN Operation

Phase control can be called “speed control with position compensation” or “position control

with 100% speed feed forward.” “Position” means the motor angle of rotation, and is there-

fore called “phase control.” An electronic shaft can be configured using this phase control.

Fig. 2.6 shows a block diagram of a phase control loop.

The rotational phase of the motor can be managed (controlled) using the above method.

This control loop is processed in the SVA-02A Module. Therefore, the user can easily con-

trol the electronic shaft simply by selecting the phase control mode on the CPU Module and

providing the required parameters for the SVA Module.

Fig. 2.6 Block Diagram of Phase Control Loop

2-18

Page 45

Ladder Logic Program Example

RUN

OBC0010

PREPARE

MB010010

MW01010

×

×

MW01020 +

ML02012

VERF GEAR1 AMARI

÷

MW01021

GEAR2

NREF

OWC015

MOD 00001

AMARI

ML02012

ML01012

PHBIAS

OLC016

ISO-HOSE

DEND

H0108

RUNMOD

OWC000

Set the phase control mode to ON.

Set Phase Reference Generation Operation

Disable to OFF.

Driver RUN command (RUN)

When MB01010 turns ON, phase control

starts.

Set the reference speed reference (NREF).

The speed reference is stored in advance in

MW01010. The gear ratios are stored in

advance in MW01020 and NW01021. If gears

are not required, "1" is stored in advance.

To move the phase, set the phase

compensation (OLC016). The distance to be

moved (the angle of rotation of the motor axis

converted to the number of pulses) is stored in

advance in ML01012.

2.2 Control Modes

2

Fig. 2.7 RUN Commands (DWG H04)

The example in the above illustration has been greatly simplified. In actual operation, each

register can be controlled from the user program.

User Program Example 2: Electronic Cam

Example of RUN Operation

Cams are one of the conventional methods for changing a rotational movement to a linear

movement, and they are used to obtain the desired operation curve (displacement drawing)

during a cycle.

• A mechanical cam forms a cam with a shape corresponding to this displacement draw-

ing. Placing a follower on the circumference and rotating the cam enables the desired

linear operation to be obtained.

• An electronic cam holds the actual displacement drawing data in the controller as a posi-

tion pattern, and performs regular position control for the so-called continuous path

(CP) by changing the phase.

2-19

Page 46

2 Motion Control

2.2.4 Phase Control Mode

Follower displacement

Mechanical cam

Follower

When the mechanical

cam rotates, the follower

moves linearly, as shown

in the displacement

Mechanical camElectronic cam

Phase θ

drawing.

MP920

Displacement pattern generation

Follower displacement

Phase

reference θ

Phase

θ

S

Position control

Xref

+

+

+

+

Speed control

-

-

Ball screw

Follower

M

M

PG

Servo

motor

Encoder

An electronic cam control loop can be configured using phase control. With normal phase

control, the position reference is generated by integrating the reference speed reference into

the SVA Module (see Fig. 2.8).

An electronic cam control loop cuts the integral circuit of the reference speed reference, and

provides the position reference from the phase compensation settings (see Fig. 2.9).

The following illustration shows a block diagram of a phase control loop.

CPU Module

Standard

speed

reference

setting

Position

compensation

NREF

OWCO15

To other

machine

PHBIAS

OLCO16

SVA Module

+

Integration

+

±

+

setting

Fig. 2.8 Block Diagram of Phase Control Loop

CPU Module

One scan change

calculation

Position reference

generation

×

θ

θ

S

Position

reference

NREF

OWCO15

PHBIAS

OLCO16

SVA Module

Integra-

+

tion

When Phase Reference Generation Operation Disable

(bit 7 of OWC000) turns ON, the integral circuit is cut.

Fig. 2.9 Block Diagram of Electronic Cam Control Loop

PI

ε

-

APOS

IL08

±

PI

ε

-

+

APOS

IL08

D/A

Counter

D/A

Counter

Servo driver

Speed

control

Servo driver

Speed

control

M

PG

M

PG

The electronic cam control loop is processed in the SVA Module. Therefore, the user can

easily control the electronic cam simply by selecting the phase control mode on the CPU

Module and providing the required parameters for the SVA Module.

2-20

Page 47

Ladder Logic Program Example

2.2 Control Modes

H0188

K1 TsH

MW00040×S

10000

PREPARE

MB010010

PHASE REFERENCE

ML03030

FGN

W00004

K2

÷

MW00041

DISPLACEMENT PATTERN

MA03050

RUNMOD

OWC000

KS

ML03010

FFGAIN

MW03012

RUN

OBC0010

DISPLACEMENT X

ML03020

Set the phase control mode to ON.

Set Phase Reference Generation Operation

Disable to ON.

Calculate the speed scalling constant (ks).