Page 1

MP920 QRG Rev1.5

MP900 Quick Reference Guide

(QRG)

Contents

MP920 Memory Map

MP920 Register Addressing

General Startup Procedure

MPE720 Serial and Ethernet Connection

Module Configuration Procedure for Demo

Basic Register Set

Motion Command Code: Indexing

Function Block Startup Procedure

Motion Program Startup Procedure

Motion Program Work Registers

Data Trace

Reference Units

Page 1 of 15

Page 2

MP920 QRG Rev1.5

9

e

F

F

A

F

MP920 Memory Map

S (Global)

System information and status (read only) Constant, Read only registers. General Multi-Purpose read/write registers

SW0000-1023

Example: Flicker relays, Calendar, *Function Block RDA: MW00000-0399

Scan time setting, error codes, ect. Axis#1: MW100-199, Axis#2: MW200-299…

(Global)

C

Data that end user can change without needing to

access the program.

CW00000-04095

(Global)

M

MW00000-32767

Fixed Parameters (for each axis) Example: User Free: MW04000-32767

Written to in Module Configuration Mechanical system specifications Convention:

Define axis units, motor specs.

(pulley ratios, encoder counts per load rev) Axis#1:MW1000-1999, Axis#2:MW2000-2999

Cannot be written by ladder Reference: RDA Spreadsheet

Changes usually require power cycl

Reference: * If using motion function blocks.

I (Input) IW0000-FFFF "Motion Monitoring" O (Output) OW0000-FFFF "Motion Setting"

general purpose & motion data (Read only by application program) general purpose &motion data (Read/Write by application program)

Physical Inputs: IW0000-7FF

Register MemoryProgram Memory

Convention: IW0000-0100 for Local IO modules Convention: OW0000-0100 for Local IO modules

Physical Outputs: OW0000-7FF

IW0100+ for M-LINK Network I/O OW0100+ for SVB and M-LINK I/O

Axis (Motion) Input: IWC000-FFFF (for axis #1)

40h

"motion monitoring" Offset

per axis

xis (Motion) Output: OWC000-FFFF (for axis #1)

"motion setting" Offset

40h

per axis

400h per module/circuit 400h per module/circuit

Example: IBC000 0 = axis#1 controller ready Example: OBC000 0 = turn axis#1 servo on

Reference: Motion Module User Man 6.2.2 Reference: Motion Module User Man 6.2.3

D (Local Registers)* DW00000-16383

Used as general purpose read/write in the defined Drawing only.

Suggested Bits: DW00000-00008 (DB000000~DB00008F)

Convention: One-Shot DW00009 (DB000090~DB00009F)

Word Operations: DW00010-00025 (These can be 16-bit integers, 32-bit integers, or 32-bit

Accumulators: DW00026 (16-bit Integer accumulator)

DW00027 (16-bit Logic [Hexadecimal] Accumulator)

DL00028 (32-bit Long Accumulator)

DF00030 (32-bit Floating point Accumulator)

Long DW00032-00089

Float DW00100-00256

If local registers are increased as mentioned below.

*Default is 32 D-registers per drawing. R-click drawing in File Manager - increase to 256 when using Function Blocks.

Reference:

#

("Sharps")

Local Constants. General purpose, read-only by the specifed Drawing they

are defined in.

Set up via a table in the "properties" dialog box for each

drawing. Rarely Used

#W00000-16383 Module Configuration

Each hardware module on the rack has several configuration files. This data is

stored in program memory.

New project requires setting Module Configuration first. Select

from File Manager under Definition Folder"

Drawings: H, L, A, I

H (High Scan) Use for all code that runs motion related functions. 2ms is usually good.

L (Low Scan) Use for code that runs HMI, or user operated switches, lights, etc. 20ms is usually good

A (Startup) Use for drawings that should automatically run once at controller power up.

S (System) MP940 only - rarely used. Scan as fast as 250us for short drawings.

I (Interrupt) Use to run a special interrupt routine after receiving a local input defined as a dedicated "Interrupt."

D

E

C

I

M

A

L

H

E

X

A

D

E

C

I

M

A

L

D

E

C

I

M

A

L

Page 2 of 15

Page 3

MP920 QRG Rev1.5

A

A

MP900 Register Addressing

DRAWINGS

All registers except Input and Output : S, C, M, D, #, A

Address FEDCBA9876543210

MW2008 ML2008

MW2009

MW2010 MF2010

MW2011

M B 2008 C i

Register Type

S: System

C: Global Constant

M: Multi-Purpose User

D: User Local

#: Local Constant

: Startup

DRAWINGS

Input and Output Registers

Data Type

B: Bit

W: 16-bit Word

L: 32-bit Long

F: 32-bit Float

: Address

Register

Number

(Decimal)

Bit Number

(Hex)

If Bit Data Type

Subscript

(optional)

i or j

Address FEDCBA9876543210

OW8018

OW8019

OW801A OL201A

OW801B

O B 8019 A

Register Type

O: Output (Motion Setting)

I: Input (Motion Monitoring)

Data Type

B: Bit

W: 16-bit Word

L: 32-bit Long

F: 32-bit Float

Register

Number

(Hex)

Bit Number

(Hex)

If Bit Data Type

Page 3 of 15

Page 4

MP920 QRG Rev1.5

MP900 Startup Procedure

All equipment must be properly wired and installed.

Rotary switch for M-LINK node number must be set on all axes and I/O nodes

Communication Manager must be configured for serial communication

Step Instruction Detail

1 Power OFF Prepare for first Power ON

Set only TEST and INIT

2

dipswitches ON

3 Power ON Wait for RDY and RUN to flash. Takes about 3sec.

Set only RUN dipswitch ON &

4

Cycle power

5 Start MotionWorks MPE720 Connect Serial Cable JEPMC-W5311-03B

Create new Group folder, Order

6

subfolder, and Controller

subfolder

R-Click CPU folder and select

7

"Online"

Double-click CPU folder to Log

8

On

Prepare to erase all RAM (not FLASH)

The controller is initialized to factory settings

R-click to create. Type any name 8 characters or less, no spaces. Choose

"Controller Type" as MP920

Changes will be made to files on the computer as well as on the controller,

instead of just the computer.

The default User Name and Password are both USER-A

Click the Black Diskette Icon

10*

(FLASH Save)

* Step 10 is optional as all settings are saved by battery backup.

When the window pops up, click the leftmost button (Save/Compare) and

accept other defaults. Close window when complete.

SERVOPACK Default Set Procedure

(Optional Procedure) When servopack is not brand new, use this procedure to restore default parameter settings

Step Instruction Detail

R-Click CPU folder, Log OFF. R-Click CPU folder, check "online". Double-

1 Log On ONLINE

Open Servopack Module

2

Configuration

3 Save defaults for each axis

click Controller folder to log on. The default User Name and Password are

both USER-A

From file manager, under Definition folder, open Module Configuration.

Engineering Manager application opens.

Double-click SVB slot number (or R-click - Open Slot).

In the SVB Definition window, Select SERVOPACK tab

Choose the Axis number from the pull-down list (top left)

Under Edit menu, choose Default Set, click OK and Save

Repeat for each axis as necessary

Cycle Servopack Power

Symbol Import Procedure

Step Instruction Detail

1 Log On (Online or Offline)

Close everything except File

2

Manager

3 Open Symbol Manager

4 Open Symbol List

Double-click CPU folder to log on. The default User Name and Password are

both USER-A

Close Ladder Editor, Engineering Manager, etc

From File Manager, under Database folder, open Symbol Manager. Symbol

Manager Application opens.

Under View menu, be sure Data Tree is checked. Expand Data Tree to open

Symbol List and double-click All Register to open.

5 Import Symbols

6 Save Symbols

Repeat process for additional symbol list *.CSV files

Under File menu, choose Import. Locate desired *.CSV symbol file (such as

MotionImport.csv) and open.

Use the SAVE icon, CTRL-S, or File-Save. It may take a few seconds for

saving to complete, depending on the number of symbols in the project and

the speed of the computer.

Page 4 of 15

Page 5

MP920 QRG Rev1.5

Serial & Ethernet Connection Procedure (To MPE720)

Serial Connection

Instruction Step Detail

1 Connect serial cable from MP900 port 1 to PC's COM port.

2

Define the PC's Serial

port as a valid way to

communicate via

MPE720

Ethernet Connection

First complete the

MP900 Startup

Procedure

MW/MPE720 communicates to the MP900's 218IF-01 Ethernet module through the Communication Manager

program. All 3 must be configured to log on online over Ethernet.

Open Communication manager from system tray

3

Double click a "logical port number", choose "serial" and click "Detail"

Choose desired "physical port" number that the serial cable is connected to on

4

the PC.

5 Save and close communication manager

6

Restart MPE720

Be sure the 218-IF TEST and INIT dipswitches are both off (right)

Instruction Step Detail

Logged On, Online via serial port (CP-217)

1

2 From file manager, under Definition folder, open Module Configuration.

3 Select 218-IF. Highlight the column of 218IF-01 slot

Give the 218IFmodule an

IP address

Define the PC's Ethernet

port as a valid way to

communicate via

MPE720

Tell MW/MPE720 to

connect via Ethernet

4 Double-click slot 2 (or R-click - Open Slot)

Enter the IP address for the controller and save. (The table at the bottom of the

5

screen is for other Ethernet devices controlled by the MP900).

Cycle unit power (be sure only RUN dipswitch is ON on both the base unit and

6

the 218IF-01 dipswitches are OFF to avoid overwriting upon power up)

Open Communication Manager (from windows system tray, near clock)

1

2 Double click a blank logical port to open the settings

3 Choose CP-218 (scroll down), click detail

4 Select the IP address of the PC.

5 Turn "Default" to OFF

6 Click "OK" twice, save, and close communication manager

7 Close MW/MPE720, then re-open so that the data is refreshed

Remain Logged Off

1

2 R-click controller folder, choose properties

Under Network tab, choose port number with CP-218 that you just made in

3

Communication Manager

4 Type the IP address of the controller, as defined in Module Configuration

6 Log On, Online

NOTES:

It is assumed that a valid IP address has been acquired from the network administrator.

To connect directly, use a crossover cable and configure your PC to use a static IP address.

As noted on the 218IF module, the network must be 10mbps, or switchable from 100mbps to 10mbps.

If a 218IF error does not go away after power is cycled, turn on the 218IF INIT dipswitch and cycle power.

Page 5 of 15

Page 6

MP920 Module Configuration

g

g

In general, when you are prompted with "save ok" or "new file", just click OK.

Open Module configuration - maximize the window

Under Slot Number 00, select MP920 and click SAVE. The hardware will appear in the STATUS field according to the slot it is located at.

Setup SVB-01

Choose module type "SVB-01" at the corresponding slot number

Specify IO range: Use Memory Map conventions - start at 100

Double click "Mechatrolink" in Details field

Select "IO assignment" tab. Choose the correct hardware (type) according to its corresponding rotary

address switch (ST#), save and close

"Unsetting" appears in the SVB-01 Status. Save, cycle power, to clear. "Running" status appears

MP920 QRG Rev1.5

Open SVB - double click the SLOT NUMBER

Setup LIO-01

Choose module type "LIO-01" at the corresponding slot number

Specify IO range: Use Memory Map conventions - start at 0

Open LIO - double click the SLOT NUMBER

Set Scan Time

Definition Folder - Scan time setting

High Scan setting = 2 ms, Low Scan settin = 30 ms

Save

Setup SVA

Power Off. Remove option card & clear A.E7 with Fn014. Reset parameters with Fn005 & cycle power. Absolute encoder unplugged will

produce A.81. Use Fn008, pressing ^(arrow) to select PGCL5 and press Mode/Set. Then cycle power to clear the A.81.

Connect cable from desired SVA output CNx to SDGH IO connecter CN1.

Wire overtravels or mask off with Pn50A.3 and Pn50B.0 using Digital Operator or SigmaWin+ & cycle power.

Choose module type "SVA-01" at the corresponding slot number

Type a Circuit Number higher than any other SVA or SVB circuit

Save. "Unsetting" appears in SVA status. Save, cycle power and "running" status appears

Open SVA - doubleclick SLOT NUMBER

Fixed Parameters Tab: Verify No.1, 3, 7. Save & Cycle power. Many of the other parameters only

apply when the programming unit is changed from encoder pulses.

SERVOPACK Tab: Edit Menu choose "default set" and save. Over-Travels ARE wired on the demo.

If they are not wired, disable them in Pn50A and Pn50B and cycle power.

Setup Parameters Tab: Turn on the servo with OWC001 to test the configuration. Don't save anythin

here unless you want it to be the default on power-up. Use the Edit menu - Default Set and save to

restore defaults.

Monitor Tab: Look at "feedback position" (No. 9 in the list) and move motor by hand to verify motor

position

Repeat for each axis controlled by the SVB module. (select axis in upper left corner)

Click "save" and the Current Value will update with the IO status. Test by monitoring inputs and

setting outputs from this screen.

(On demo they are wired through the SVA cable)

Check axis number and adjust according to number of connector used for servopack.

Fixed Parameters Tab: Check No.1, 3, 7. Many of the other parameters only apply when the

programming unit is changed from encoder pulses.

Setup Parameters Tab: Turn on the servo with OWC001 to test the configuration. Don't save anythin

here unless you want it to be the default on power-up. Use the Edit menu - Default Set and save to

restore defaults.

Monitor Tab: Look at "feedback position" (No. 9 in the list) and move motor by hand to verify motor

position

Repeat for each axis under SVA control (select axis in upper left corner)

Page 6 of 15

Page 7

Basic Set of Registers for Register-Based Programming

Assume Module(Circuit) #1, Axis #1. Add 400h per circuit, 40h per axis.

Motion Setting Registers (OWxxxx)

Name Word Bit [Unit] / Note Reference

Servo On

Alarm Clear

Speed ("Feed" Speed)

OBC001 0

OBC000 6

OLC022

[10^3 R.U./minute (by default)]

Motion Command Code

Position Reference

Abs/Inc Position Mode

Step Distance

Direction (Step,Jog)

Acceleration

Deceleration

OWC020

OLC012

OBC001 E

OLC028

OBC021 2

OWC00C

OWC00D

1=Position, 3=Home, 7=Jog, 8=Step

[R.U.]

0=Abs, 1=Inc

[R.U.]

0=Fwd, 1=Rev

[ms to rated speed (FP7)] SVB: Use

OWC020=10 to send accel to

servopack Pn80B

[ms to rated speed (FP7)] SVB: Use

OWC020=11 to send accel to

servopack Pn80E

Motion Monitoring Registers ( I Wxxxx)

Name Word Bit [Unit] / Note Reference

Servo Alarm

Mtn Cmd Code confirm

Main Power On

Servo On Confirm

Feedback Position

ILC022

IWC014

IBC001 4

IBC001 3

ILC008

=0 when no alarm. Each bit

represents different alarm

[counts or Reference Units]

Page 8

Motion Command Code

Indexing Example

Move from position 5000 to position 8000, assuming the following for module (circuit) #1, Axis #1

ILC008=5000 Current position is 5000

ILC022=0 No alarms

IBC0013=1 Servo is ON

Solution using STEP

OLC028=3000 Step Distance 3000

1

OBC0202=0 Direction Forward

OLC022>=0 Set Feed Speed

2 OWC020=8 MtnCmdCd starts motion

Solution using POSITION (INCremental)

OLC012=0 Initial position 0

1

OBC001E=1 Incremental Positioning Mode

OLC022>=0 Set Feed Speed

2 OWC020=1 MtnCmdCd defines initial position

3 OLC012=3000 Position reference incremented starts motion

Solution using POSITION (ABSolute)

OBC001E=0 Absolute Positioning Mode

1

OLC022>=0 Set Feed Speed

OWC012=8000 Position Reference to Absolute position

2 OWC020=1 MtnCmdCd starts Motion

Page 9

MP920 QRG Rev1.5

y

Function Block Startup Procedure

First complete the MP900 Startup Procedure

A controller folder should already exist

Step Instruction Detail

1 Acquire project file

Log ON (online)2

Extract MAL file to

3

controller files on hard

drive

Transfer Function blocks

4

to Controller*

5 Save to Flash

6 Cycle Power Cycle power is needed for initialization drawings (A drawings) to run

To start a totally blank Function Block project, only check FUNC box and all detail. To start with the pre-

*

made Function Block template, check both DWG and FUNC and under each detail select "all".

*.MAL extension Download to C:\ or an

R-Click Controller folder, Log OFF. R-Click controller folder, check "online".

Double-click Controller folder to log on. The default User Name and

Password are both USER-A

R-click Controller folder, Transfer, Selected Files, From Another Drive to

MPE720. Find *.MAL file. *Check the FUNC box. Under "detail", be sure

"select all" is checked. Then click "transfer" button. Takes about 30

seconds. Close window when complet

R-Click controller folder, Transfer, Selected Files, From MPE720 to

Controller. *Check the FUNC box. Under "detail", be sure "select all" is

checked. Then click "transfer" button. Transfer takes almost 4 minutes with

serial connection. Close window

Optional. Click the Black Diskette Icon. When the window pops up, click the

leftmost button (Compar/save) and accept other defaults. Close window

when complete.

directory without spaces.

Page 10 of 15

Page 10

Motion Program Startup Procedure

First complete the MP900 Commissioning Procedure

There should be a new controller folder

Group Definition (axes used in motion program)

Step Instruction Detail

1 Log on Offline

2 Open Group Definition

3 Enter & Save a Group Name

Enter the number of axes that

4

will be used in the Motion

Program

Define Module Number, Axis

5

Number, and Axis Name

6 Define Other Fields

7 Save Group Definition Save Icon

8 Log on Online

Transfer Group Definition to

9

Controller

R-Click Controller folder and select Log Off. R-click again

and uncheck "online". Double-click controller folder to log

on

In File Manager-> Programs -> High Scan Programs ->

Motion Programs -> DoubleClick "Group Defnition"

Under the "Group List" Tab. When saved a new "Group01"

tab will appear.

Under the "Group01" Tab, in the "Axis" area.

Under "Group01" Tab, in the "Axis Definition" area. In the

"Physical" row, 01.01 means motion module 1, axis 1.

Usually the default is fine. In the "Logical" row, enter a text

name for the axis. X and Y are common.

Task: ____, Create Ladder Dwgs: OFF, Alarm Out:

MW500, Shared Drawing: MW502

R-Click Controller folder and select Log Off. R-click again

and check "online". Double-click controller folder to log on

In File Manager, R-click Controller folder, Transfer->

Selected Files-> From MPE720 to Controller. Check the

box for "Group Definition" and click the Transfer button.

Accept defaults.

MP920 QRG Rev1.5

Motion Program

Step Instruction Detail

1 Start a new Motion Program

Things to know before a Motion

2

Program is started

3 Write Motion Program

4 Save Motion Program Use save icon. Also save to flash.

In File Manager-> Programs -> High Scan Programs ->

Motion Programs, R-click "Motion Group01" and select

"New Program".

There are no commands for SERVO ON or JOG in the

Motion Programming Language. These steps are to be

accomplished in Ladder.

First line must be 'MPM001' and last line must be 'END;'.

Instructions terminate with semicolon. Comments enclosed

in quotes ("comment"). Refer to Motion Programming User

Manual (SIEZ-C887-1.3) for extensive details on each

command.

Call From Ladder

Step Instruction Detail

MSEE is located under the "Motion" tab in Ladder Editor. It

1 Use the MSEE instruction

2 Rules before starting

3 Start the motion program

4 Rules while running

can only be used in an H-drawing. Define a starting

address for the two 16-bit work registers in the Data field.

Often DA00000 is used defining DW00000 through

DW00003, but be sure to use M or

All axes in the group must have: 1) Servo On, 2) Motion

Command Code =0 and not continually updated to 0, 3) No

other motion program in same group runnin, in alarm, or

paused

Bit 0 of the second word defined in the Data field

(DB000010 in the above example) must go high for the

motion program to start. See Motion Program Work

Registers in this QRG for more information.

Ladder code must not manipulate Motion Command Code,

unless motion language is not using the Motion Command

Code register the time, and proper interlocks are used to

flag the ladder code

Page 11 of 15

Page 11

MP920 QRG Rev1.5

Motion Program Work Registers for MSEE instruction

OUTPUT (Motion Program Status)

DW00000

Bit Name Description

DB000000 Program Running ON while running

DB000001 Program Paused ON while paused

DB000004

DB000008 Program Alarm ON when Motion Program Alarm has occurred

DB00000B Program Debugging Mode ON during Windows (EWS) debug mode

1st Work Register2nd Work Register

DB00000E Program Duplication Error

DB00000F Program Number Limit Error ON when the number of steps in program exceeded maximum

INPUT (Motion Program Control Signals)

DW00001

Bit Name Description

DB000010 Program Start Request ON with rising edge. (if it CAN start it will, otherwise alarm)

DB000011 Program Pause Request ON will pause motion blocks

DB000012 Program Stop Request

DB000013 Program Debug Mode Select "Single block mode". ON will force debugging mode

DB000014 Program Debug Start "Single Block Mode" start. ON (transition) debug block by block

DB000015 Program alarm Reset ON will clear the program alarm (stop program before issuing alarm reset)

DB000018 Block Skip 1 Operation

DB000019 Block Skip 2 Operation

Program in Debug (Single

Block) Mode

ON during debug via ladder (registers)

ON when another Motion Program in the same group has started while this

program is running

ON will stop all group motion, exit the Motion Program, and generate a motion

program alarm

ON will cause the program to skip an interpolated motion block if the SKP ss1

instruction was used instead of MVS

ON will cause the program to skip an interpolated motion block if the SKP ss2

instruction was used instead of MVS

INTERPOLATION OVERRIDE (Speed)

MW00001

Interpolation speed set by F designation and IFP is scaled by the value in this register [units 0.01%].

SPEED OVERRIDE

OW**2C

The speed set by the VEL command (OLC022) will be scaled by the value in OWC02C [units 0.01%] when

Fixed Parameter 17, bit 9 =1.

Error Code Register

MWxxxx

(Defined in Group

Definition)

See Section 8.2.2 in Motion Module Manual (SIE-887-2.5).

To clear a motion program alarm:

A. Determine and resolve the cause of the alarm (Alarm Register

Page 12 of 15

Page 12

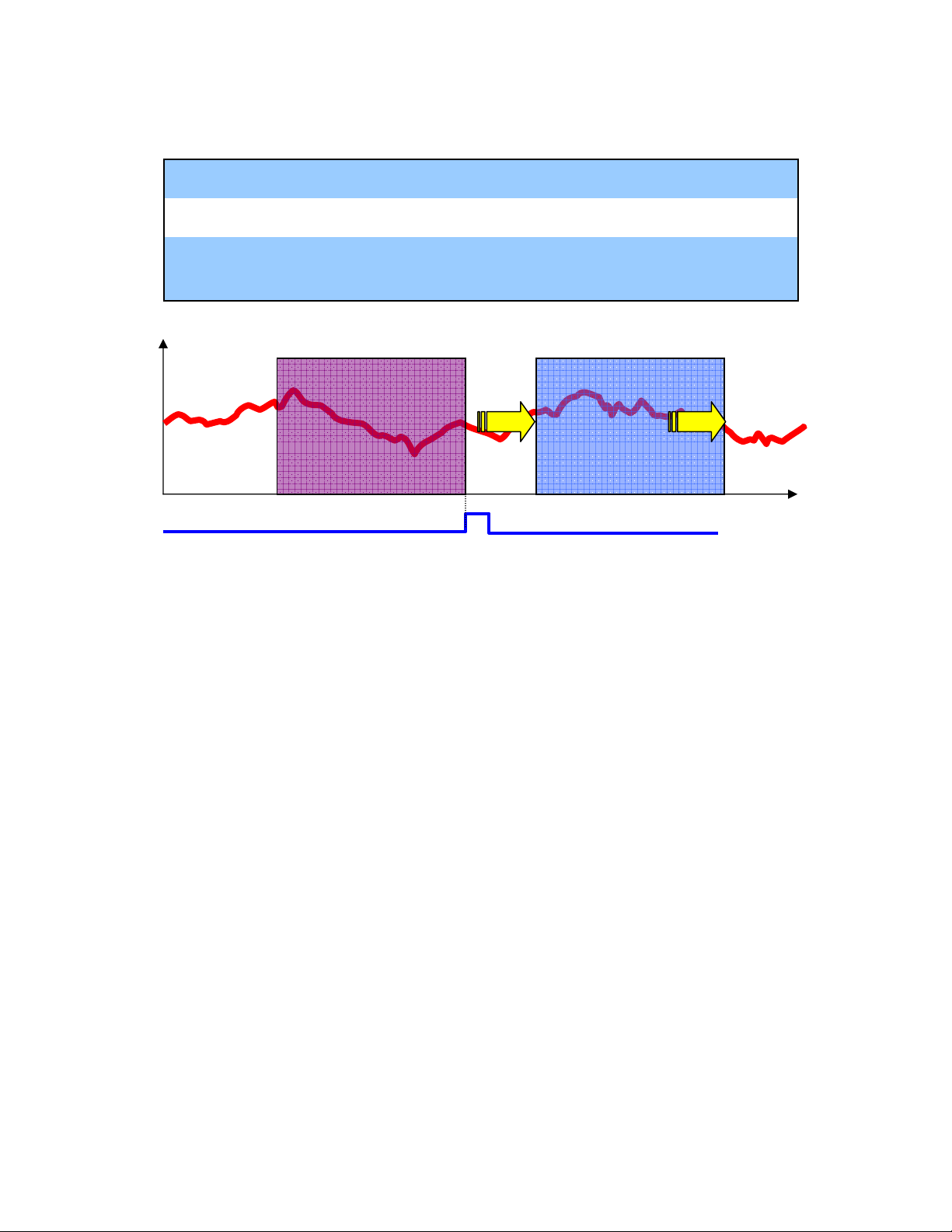

Data Trace

A

Quick Method

dd registers to

configuration

Snap the data

Illustration

trace

Save

R-Click in ladder, select "register to trace", or type registers manually. To

graph speed, create it in ladder using position scan differential.

CTRL-S or from menu. The selected data starts filling the trace buffer

(FIFO) immediately

Click the Snap button to display the data currently in the trace buffer. Click

Snap AFTER the motion completes. Although the data displayed is fixed,

data continues to fill the buffer.

Notes

Old Data

data

Snap

By default, the data saved in the list is updated every H-scan

The trace buffer is limited to 32,000 16-bit words per "group". Once it is full, old data is

pushed out by the new data.

Four (4) groups of trace data can be collected simultaneously.

Set the trigger condition to capture an event, such as a fault, or to change sample rate.

Snap Data Current Data

time

Page 13

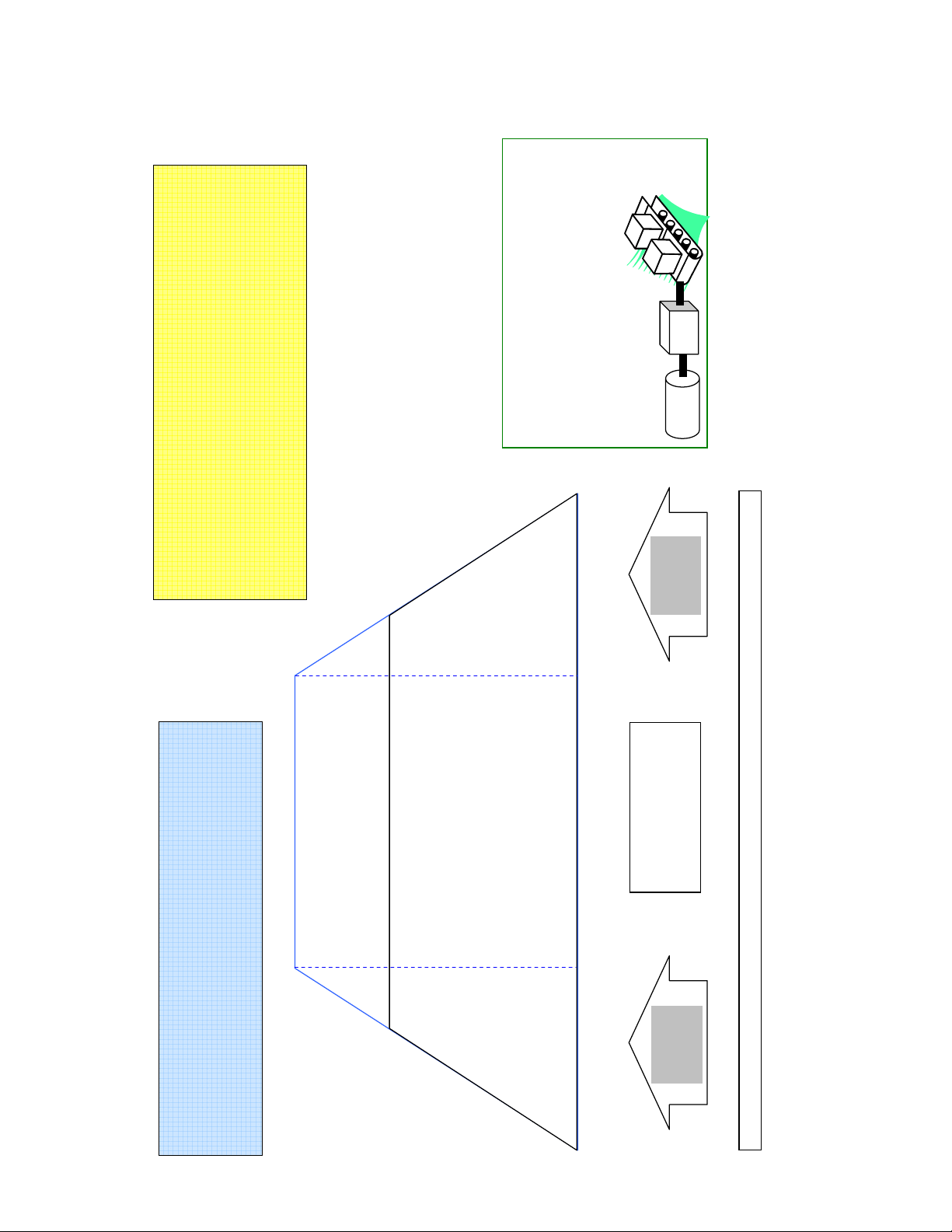

RU = FP17 bits0-3

p

A

0: Pulse (post quad)

1: mm

2: deg

3: inch

19

22

G.B.

21

NOTES:

MP920 QRG Rev1.5

FP17 bit 4 =1 Activates RU Feature

arameters to define the relationship between

If PULSE is not chosen as the RU, use the following

* Register Addresses assume Circuit#1, Axis#1

* Reference Units not compatible with Function Block programming.

* Default Positioning units are [encoder pulses (post quad)]

* Default Speed Reference units are [1000 pulses/min]

* Default Accel/Decel units are [ms to rated motor rpm]

* MPE720 5.31B "Units" in module configuration do not update

* Motion Module Manual incorrectly lists MCC=11 and Decel (OLC00D) as

not used

n = 3 when FP17 bit 4 =0 (RU not used)

n = FP18 when FP17 bit 4 =1 (RU is used)

Motor

PULSE and RU.

FP8: Encoder Pulses (pre-quad) per motor rev

FP21: Motor Revs into gearbox

FP22: Machine Shaft Revs out of gearbox

FP19: RU per Machine Shaft Revolution

Servopack Pn80E: Deceleration Rate

[10,000 RU/sec^2] (Default 65535)

8

Use MCC=11

to change

Deceleration

OWC00D: Deceleration [ms to Rated Speed (FP7)] (Default 0)

NOT SVA

Use of MCC to change

Servopack Parameters

Applies to SVB ONLY and

Page 15 of 15

FP7: Rated Speed [RPM] (Default 3000)

KEY

* RU = "reference unit" = "user unit" = "command unit"

* FP = Fixed Parameter

* MCC = Motion Command Code (OWxx20)

* Register Values given for Circuit#1, Axis#/1

* Bold type represents default setting

OLC022: Speed Reference (when OBC001D=0) [10^n RU/min] (Default 3000)

OLC015: Speed Reference (when OBC001D=1) [0.01% of Rated Speed (FP7)] (Default 0)

OLC012: Position Reference [RU]

OBC001E: Incremental / Absolute

or

OLC028: Step Distance [RU]

OBC0212: Step Direction

Servopack Pn80B: Acceleration Rate

[10,000 RU/sec^2] (Default 65535)

cceleration

Use MCC=10

to change

OWC00C: Acceleration [ms to Rated Speed (FP7)] (Default 0)

OWC00C=0 & OWC00D =0 sets servopack acceleration/deceleration rate to 65535[10,000 RU/sec^2]

Reference Units (User Units)

Loading...

Loading...