Page 1

MP3300iec

Machine Controller

Hardware Manual

Type: MP3300iec

To properly use the product, read this manual

thoroughly and retain for easy reference, inspection,

and maintenance. Ensure the end user receives this manual.

YAI-SIA-IEC-7

Page 2

Page 3

Table of Contents

1. Basic Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2. System Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3. Component Part Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4. Base Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

5. CPU Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6. Installatio n and Usage Co n d itions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 3

7. Base Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

8. Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

9. Display and Indi c at ors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

10. Self-Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

11. MECHATROLINK-III Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

12. MECHATROLINK-III Network Topologies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

13. MECHATROLINK-III Synchronization between Modules . . . . . . . . . . . . . . . . . . . . . .24

14. Devices Connectable via MECHATROLINK-III. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

15. Connecting the RLY OUT Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

16. Ethernet Connector Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

17. Option Module - AI-01 (Analog Input) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

18. Option Module - AO-01 (Analog Output) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

19. Option Module - DO-01 (Digital Output) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

20. Option Module - LIO-01/02 Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

21. Option Module - LIO-04/05 Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

22. Option Module - LIO-06 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

23. Option Module – 218IF-Y1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

24. Terminal Block Kit CBK-U-MP2A-xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

25. Terminal Block Kit CBK-U-MP2B-xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

26. Terminal Block Kit CBK-U-MP2C-xx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

27. Cable Shielding, Segregation and Noise Immunity . . . . . . . . . . . . . . . . . . . . . . . . . .78

Copyright © 2014 YASKAWA AMERICA, INC.

All rights reserved. No part of this publ ic at ion may be repr oduc ed, st ore d in a retrieval system, or transmitted,

in any form, or by any means, mechanical, ele ct ron ic , ph oto copy ing , recording, or otherwise, without the prior

written permission of Yaskawa. No patent liability is assumed with respect to the use of the information

contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the

information contained in this manual is subject to change without notice. Every precaution has been taken in

the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained in this

publication.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 3

Page 4

4 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 5

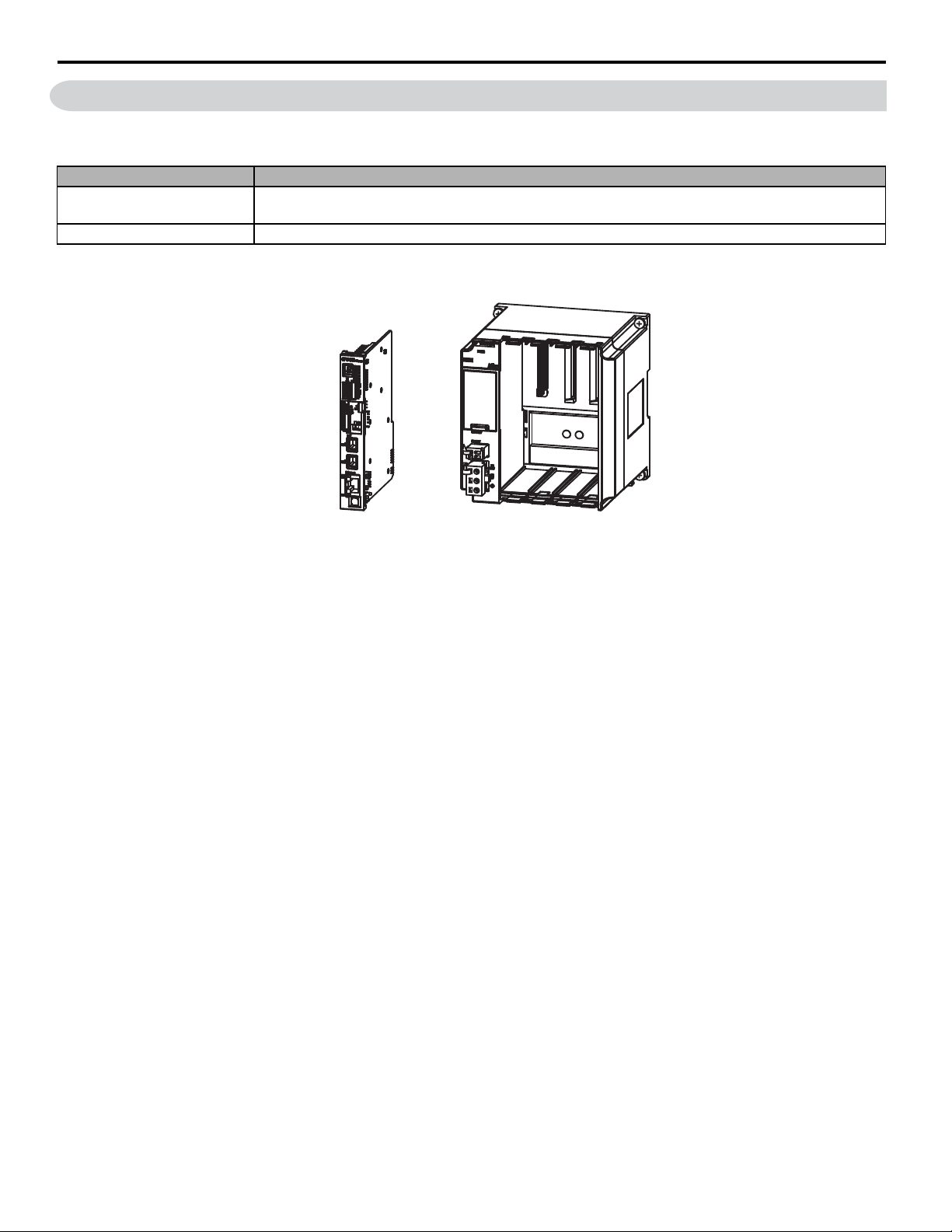

1 Basic Units

CPU Module

+

Base Unit

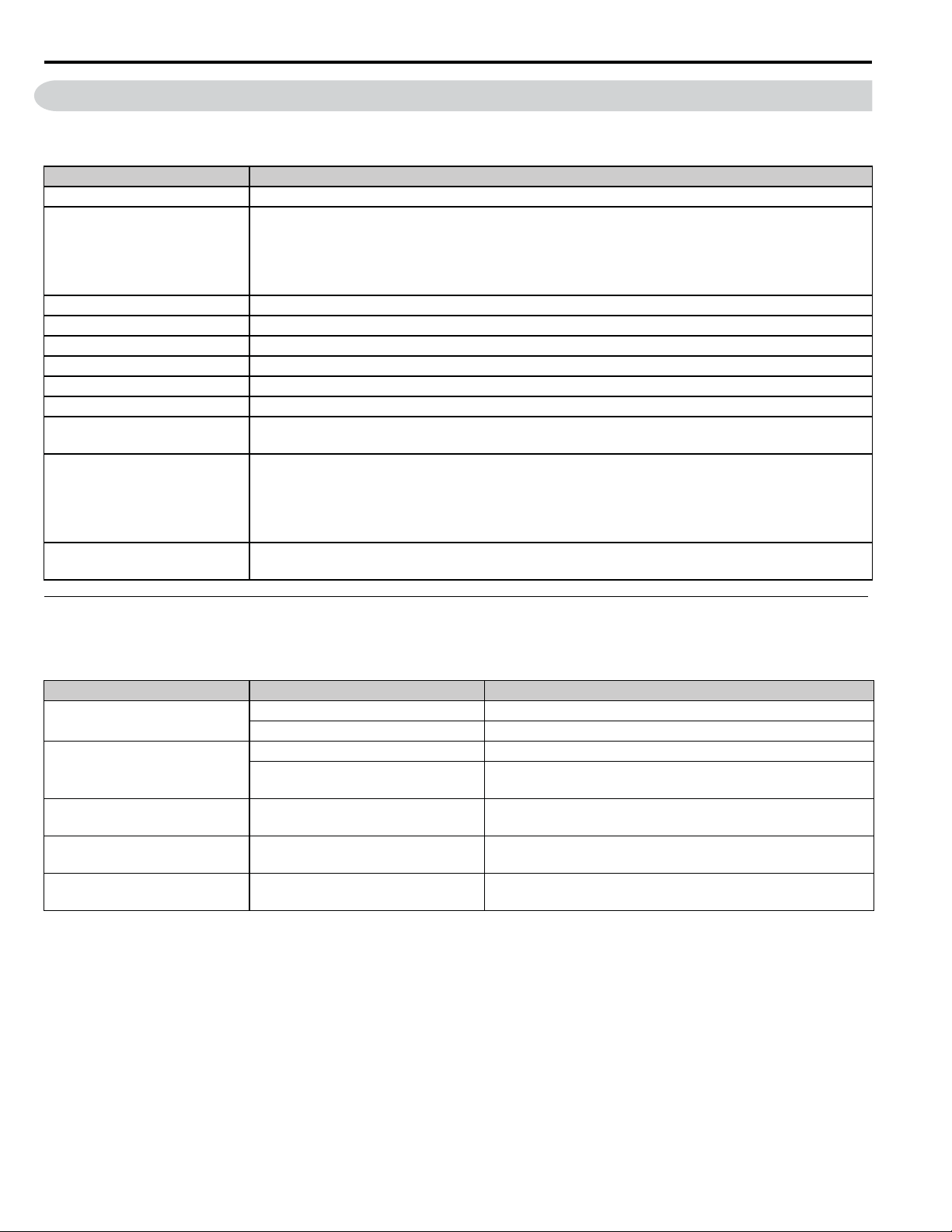

“Basic Unit” is a collective term that refers to the modules in the following table.

Unit Name Primary Function

CPU Module

Base Unit Contains the power supply and provides the backplane to which Modules are mounted.

The Basic Modules are typically connected as shown in the following examples.

Stores the module definitions and programs, and interprets the programs. The CPU Module also controls the

Optional Modules.

1 Basic Units

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 5

Page 6

2 System Configuration Example

2 System Configuration Example

The following figure shows a typical system configuration.

MotionWorks IEC version

3.0.0 or higher

RLYOUT

connector cable

24-VDC power

supply, AC power

supply, or status

monitoring device

Power supply cable

24-VDC power

supply or AC

power supply

Another PLC

Ethernet communications cables

MP3300

Battery

MECHATROLINK-III

SERVOPACK with

MECHATROLINK-III

Communications

PC

HUB

Front cover

for unused slot

MECHATROLINK-III Cable

I/O Module with

MECHATROLINK-

Communications

Optional Modules

I/O Modules

LIO-05

LIO-04

LIO-02

LIO-01

LIO-06

Communications Modules

218IF-Y1

III

AI-01

DO-01

AO-01

External outputs

External inputs

RS-232C

Ethernet

I/O

Servomotor

Servomotor

Servomotor

Up to 62 stations, including I/O

6 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 7

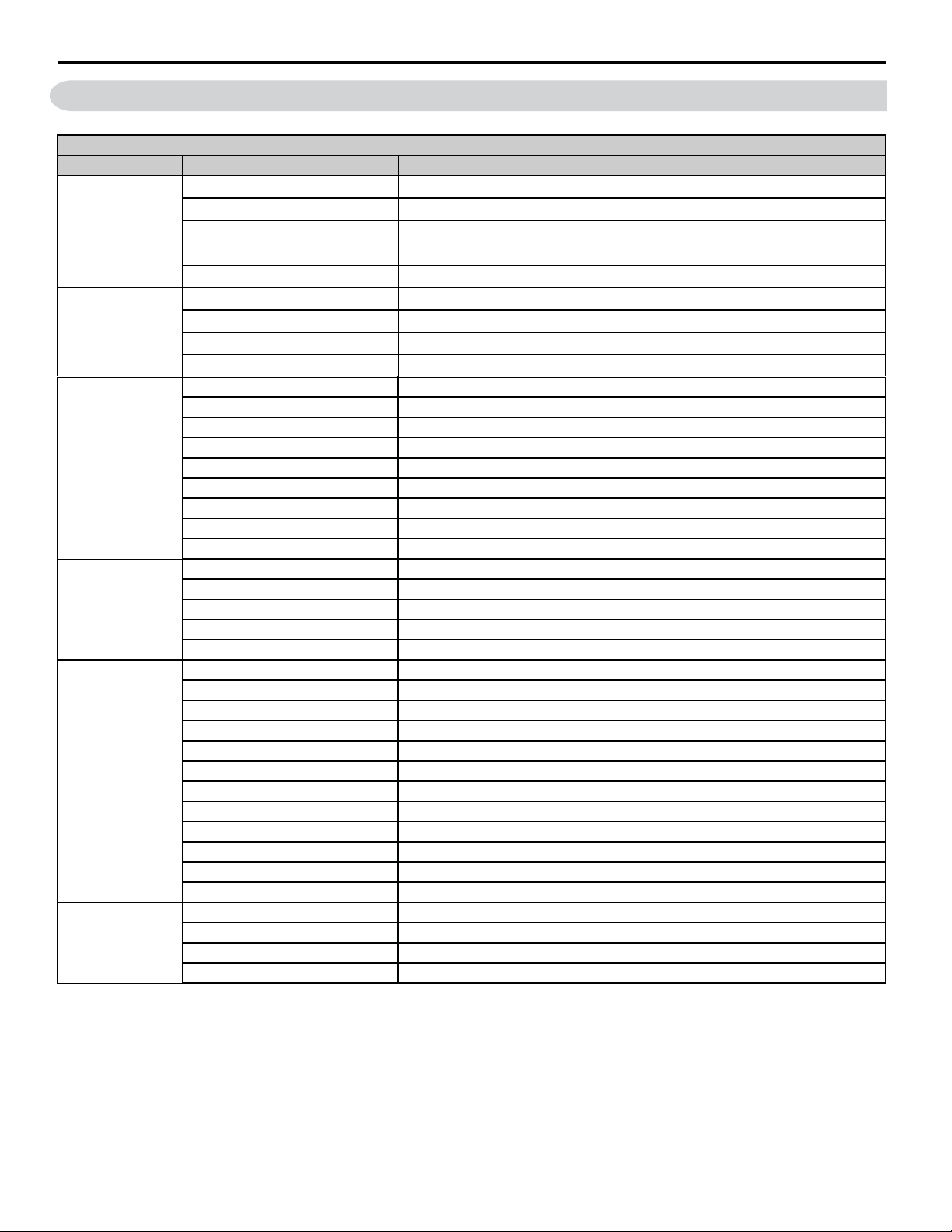

3 Component Part Numbers

System Components

Type Part Number Description

PMC-U-MP33004 CPU, MP3300, 4 axis, 400 MHz, 4MB SRAM

PMC-U-MP33008 CPU, MP3300, 8 axis, 400 MHz, 4MB SRAM

CPU

Base Unit

Option Card

MECHATROLINK

Network

MECHATROLINK

Cables

Accessories

PMC-U-MP33020 CPU, MP3300, 20 axis, 40 0 MHz, 4MB SRAM

PMC-U-MP33320 CPU, MP3300, 20 axis, 80 0 MHz, 8MB SRAM

PMC-U-MP33332 CPU, MP3300, 32 axis, 80 0 MHz, 8MB SRAM

JEPMC-BU3304-E Base Unit with DC Power Supply, 1 Slot, MP3300iec

JEPMC-BU3303-E Base Unit with DC Power Supply, 3 Slots, MP3300iec

JEPMC-BU3302-E Base Unit with DC Power Supply, 8 Slots, MP3300iec

JEPMC-BU3301-E Base Unit with AC Power Supply, 8 Slots, MP3300iec

JAPMC-AN2300 Analog Inputs (AI-01)

JAPMC-AN2310-E Analog Outputs (AO-01)

JAPMC-DO2300 Digital Output Modul e (DO-01)

JAPMC-IO2300-E Digital I/O Module (LIO-01)

JAPMC-IO2301-E Digital I/O Module (LIO-02)

JAPMC-IO2303 Digital I/O Module (LIO-04)

JAPMC-IO2304 Digital I/O Module (LIO-05)

JAPMC-IO2305-E Digital Multi-Function I/O Module (LIO-06)

JAPMC-CM2301-E Ethernet & RS232C Communication (218IF-Y1)

JEPMC-MT2000-E HUB, MECHATROLINK-III NETWORK, 8 SLAVE PORTS

JEPMC-MT2020-E ADAPTER, ETHERNET TO MECHATROLINK

JEPMC-MTD2310-E I/O MODULE, MECHATROLINK NETWORK, 64 IN, 64 OUT

JEPMC-MTA2900-E ANALOG MODULE, MECHATROLINK NETWORK, 8 INPUT

JEPMC-MTA2910-E ANALOG MODULE, MECHATROLINK NETWORK, 4 OUTPUT

JEPMC-W6012-A2-E MECHATROLINK-III CABLE, 0.2 M

JEPMC-W6012-A5-E MECHATROLINK-III CABLE, 0.5 M

JEPMC-W6012-01-E MECHATROLINK-III CABLE, 1.0 M

JEPMC-W6012-02-E MECHATROLINK-III CABLE, 2.0 M

JEPMC-W6012-03-E MECHATROLINK-III CABLE, 3.0 M

JEPMC-W6012-04-E MECHATROLINK-III CABLE, 4.0 M

JEPMC-W6012-05-E MECHATROLINK-III CABLE, 5.0 M

JEPMC-W6012-10-E MECHATROLINK-III CABLE, 10 M

JEPMC-W6012-20-E MECHATROLINK-III CABLE, 20 M

JEPMC-W6012-30-E MECHATROLINK-III CABLE, 30 M

JEPMC-W6012-40-E MECHATROLINK-III CABLE, 40 M

JEPMC-W6012-50-E MECHATROLINK-III CABLE, 50 M

JEPMC-BA3001 Replacement Battery

JEPMC-OP2300 Option Slot Cover

JEPMC-OP3001 Replacement Power Supply Side Cover

JEPMC-OP3002 Replacement Option Base Side Cover

3 Component Part Numbers

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 7

Page 8

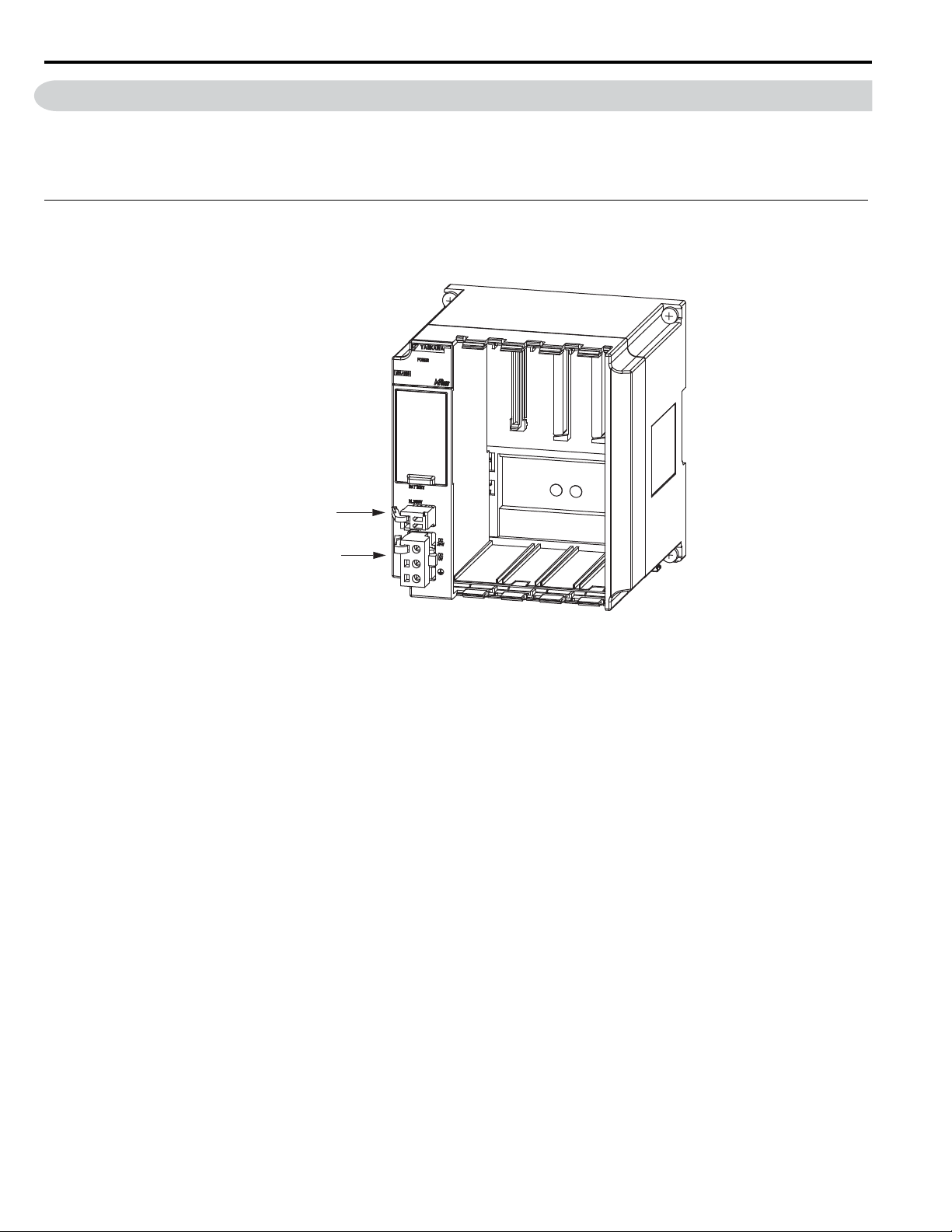

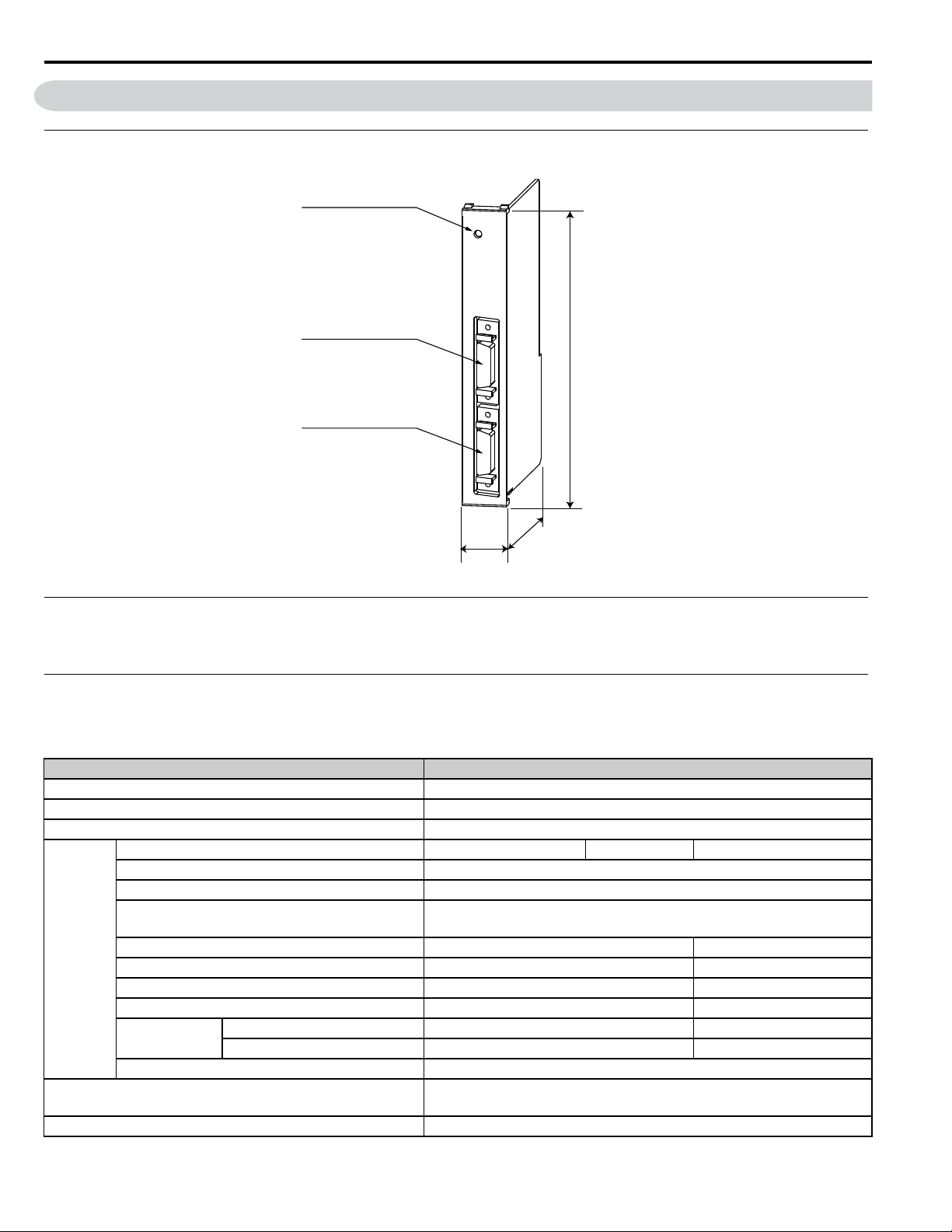

4 Base Units

4 Base Units

The Base Unit provides the backplane to which Modules are mounted and supplies the required power to the Modules.

There are three models of Base Units, a one-slot model, a three-slot model, and an eight-slot model. This section shows

the appearance and part names of the Base Unit and describes the connector.

Appearance and Part Names

Figure 1 illustrates the appearance of the Base Unit and a part name.

Figure 1

RLYOUT connector

Power connector

Figure 1 Base Unit

8 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 9

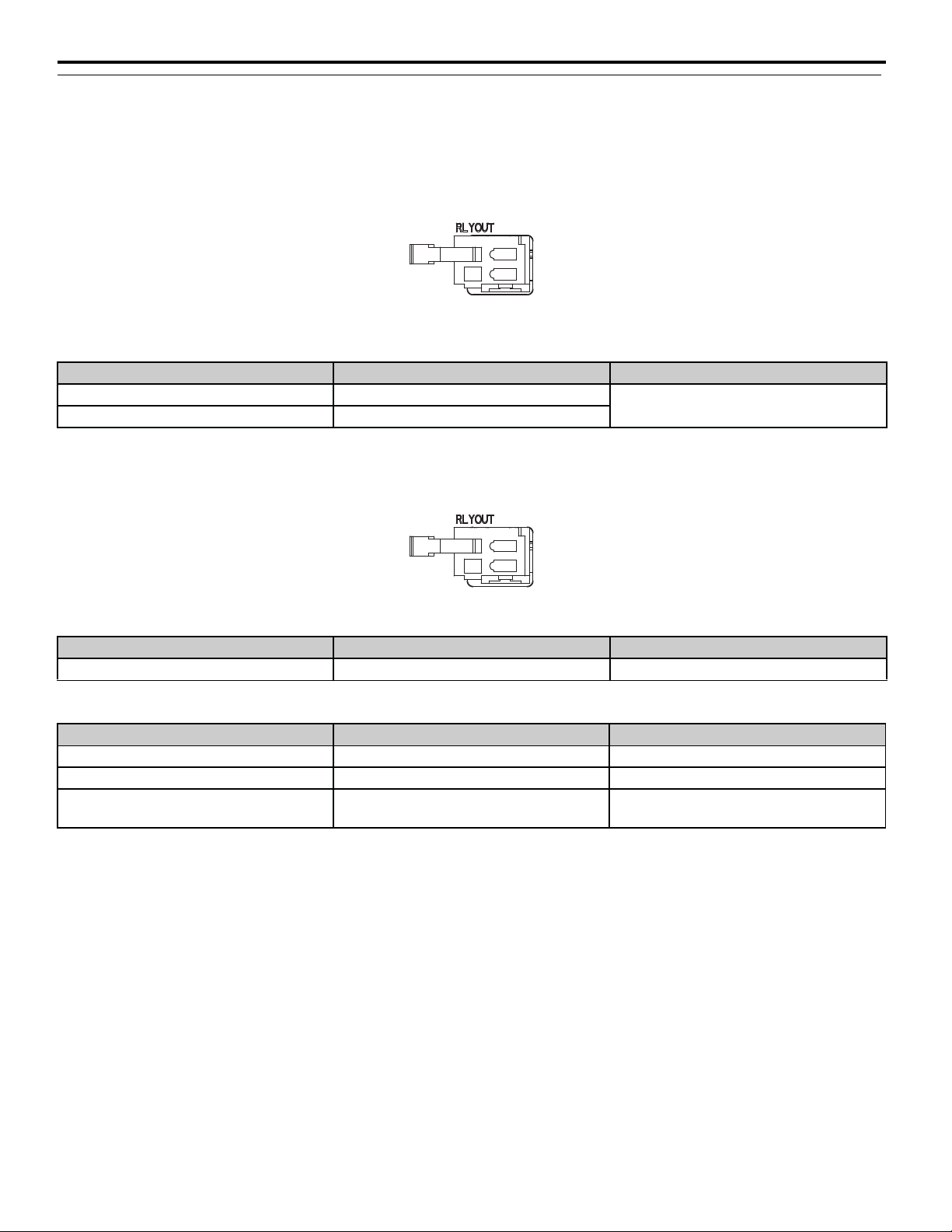

Connector

The Base Unit has two connectors: an RLYOUT connector and a power connector.

RLYOUT Connector

The RLYOUT connector outputs the status of the CPU Module.

Figure 2

Figure 2 RLYOUT Connector Model: 734-302

Pin Assignme n ts

No. Signal Label Description

1 OUT

2 OUT

Power Connector

Connect the power supply to this connector.

Figure 3

4 Base Units

Normal operation: Circuit closed.

Error: Circuit open.

DC power supply 4-2013522-3 White

Pin Assignme n ts

Figure 3 RLYOUT Connector Model: 734-302

Type Model Color

No. Signal Label Description

3 24 VDC Power input wire for 24 VDC

2 0 VDC Power input wire for 0 VDC

1FG

Connects to the frame ground. (Ground to

100 W max.)

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 9

Page 10

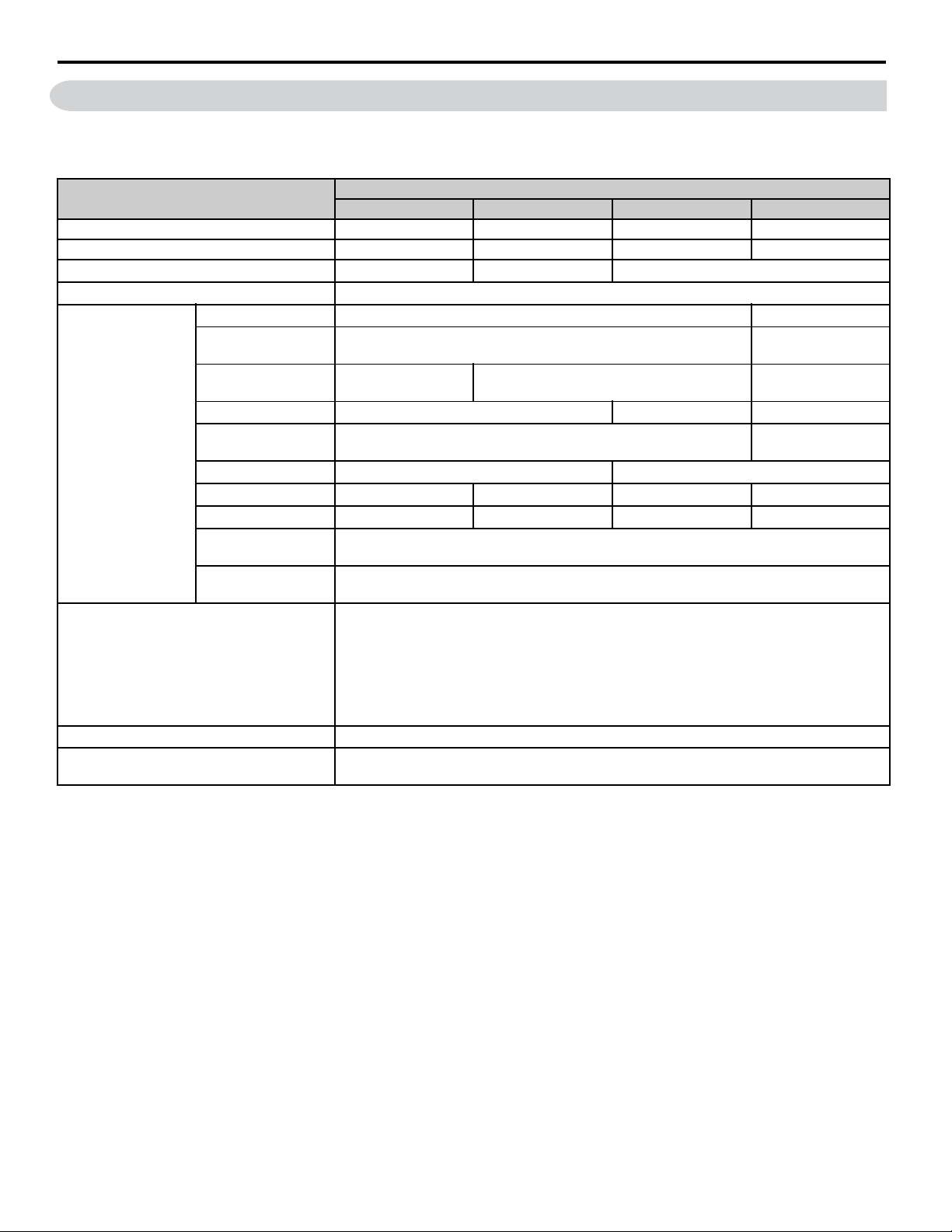

5 CPU Specifications

5 CPU Specifications

The hardware specifications of the CPU Unit are given in the following table.

Item CPU Specification

Model PMC-U-MP330xx

• PMC-U-MP33004: CPU, MP3300, 4 axis, 400 MHz, 4MB SRAM

• PMC-U-MP33008: CPU, MP3300, 8axis, 400 MHz , 4MB SRAM

Part Number: Description

Flash Memory Capacit y: 40 MB (32 MB of user me mo ry )

SDRAM Capacity: 128 MB

SRAM Capacity: 8 MB (battery backup)

Calendar Seconds, minutes, hour, day, week, month, year, day of week, and timing (battery backup)

Ethernet 10Base-T or 100Base -TX

MECHATROLINK MECHATROLINK-III: 1 circuit with 2 ports

USB

Indicators and Displays

Switches

• PMC-U-MP33020: CPU, MP3300, 20 axis, 400 MHz, 4MB SRAM

• PMC-U-MP33320: CPU, MP3300, 20 axis, 800 MHz, 8MB SRAM

• PMC-U-MP33332: CPU, MP3300, 32 axis, 800 MHz, 8MB SRAM

USB 2.0 Type A host, 1 port

Compatible devices: USB storage

Seven-segment disp lay

Status indicators

USB status indicator

MECHATROLINK-III status indicators

Ethernet status indicators

DIP switch: Mode switch

STOP/SAVE switch. Refer to Switches on page 16 for detailed switch information.

CPU Communications Specifications

The specifications of the Communications Protocols built into the CPU Module are given in the following table.

Protocol Mode Detail

Modbus TCP

Ethernet/IP

OPC read/write

Custom Protocol n/ a

Network Variables read/writ e

MP3300iec as Master (Client) Maximum Number of Data Bl ocks = 20

MP3300iec as Slave (Server) 1000 registers in, 1000 registers out, 256 coils in, 256 coils out

MP3300iec as Master (Scanner) Maximum Number of Data Blocks = 10 0

MP3300iec as Slave (Adapter)

Total of 16 instances in, 16 instances out, arranged as 3 instances of

256 bytes, 3 instances of 128 bytes, and 10 instances of 496 bytes.

Any Global variable can be configured, requires OPC Server running

on PC

Use the YDeviceComm firmware library to create a cu stom

communication protocol.

Variables configured with MotionWorks IEC software that allow

automatic data transfer from controller to controller.

10 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 11

Display

MECHATROLINK-III status indicators

MECHATROLINK-III connectors

Status indicators

Mode switches

Ethernet status indicators

Ethernet connector

USB status indicator

CPU Module Appearance and Component Names

Figure 4 shows the appearance of the CPU Module and the compnent names.

Figure 4

5 CPU Specifications

Figure 4 CPU Module Component Names

CPU Module Connectors

The CPU Module has three types of connectors: MECHATROLINK-III, Ethernet, and USB.

MECHATROLINK-III Connectors

Figure 5 illustrates connectors used to connect MECHATROLINK-III communications devices.

Figure 5

Figure 5 MECHATROLINK-III Connectors

Ethernet Connectors

Figure 6 illustrates the connector used to connect Ethernet communications devices.

Figure 6

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 11

Figure 6 Ethernet Connector

Page 12

5 CPU Specifications

r

USB Connector

Figure 5 illustrates the connector used to connect a USB memory device.

Figure 7

USB connecto

Open the cover.

Figure 7 USB Connector

NOTICE: Equipment Hazard. Before removing the USB memory device, press the STOP/SAVE switch and wait until the USB status

indicator goes out. If the USB memory device is removed while the USB status indicator is lit or flashing, the data may become

corrupted.

12 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 13

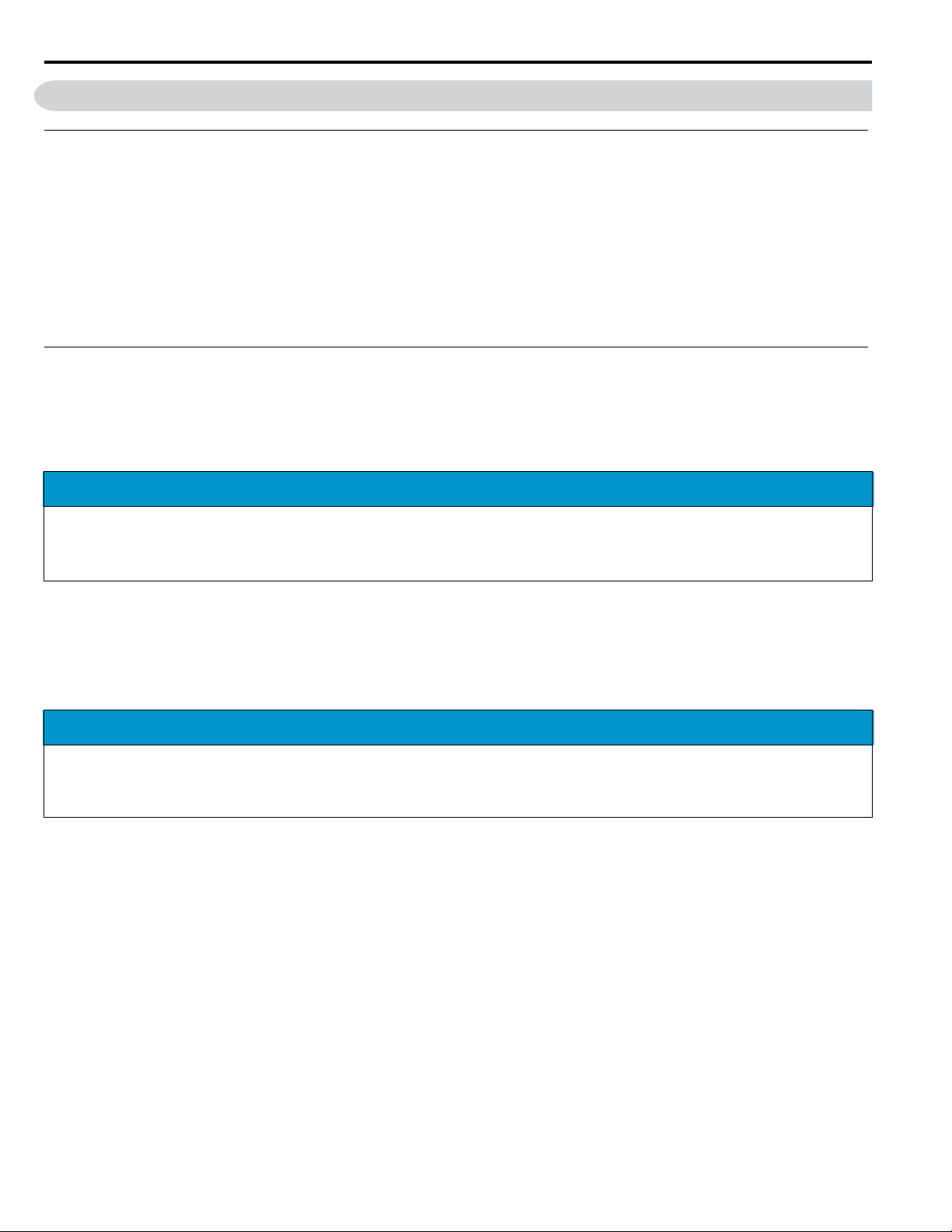

6 Installation and Usage Conditions

6 Installation and Usage Conditions

This section describes installation and usage conditions for the MP3300iec Series Machine Controllers.

Install the MP3300iec Series Controllers in an environment with the following conditions.

Installation and Usage Conditions

Ta ble 1 MP3300iec Installation and Usage Conditions

Item Specification

Environmental

Conditions

Mechanical

Operating

Conditions

Electrical

Operating

Conditions

Installation

Conditions

Ambient Operating

Temperature

Ambient Storage Temperature -25 to 85°C

Ambient Operating Humidity 10% to 95% RH (with no condensation)

Ambient Storage Humidity 10% to 95% RH (with no condensation)

Pollution Level Conforms to JIS B 3502 Pollution Degree 2.

Corrosive Gas There must be no combustible or corrosive gas.

Operating Altitude 2,000 m max.

Vibration Resistance

Shock Resistance

Noise Resistance

Ground Ground to 100 Ω max.

Cooling Method Natural cooling or forced-air cooling. Refer to Control Panel Cooling Method on page 14

0 to 60°C (Forced cooling is required if 55°C is exceeded.)

Conforms to JIS B 3502.

Continuous vibration: 5 to 9 Hz with single-amplitude of 1.75 mm

9 to 150 Hz with fixed acceleration of 4.9 m/s

Intermittent vibration: 5 to 9 Hz with single-amplitude of 3.5 mm

9 to 150 Hz with fixed acceleration of 9.8 m/s

10 sweeps each in X, Y, and Z directions for both intermittent and continuous vibration

Size of shock: Peak accel eration of 147 m/s

Duration: 11 ms

3 times each in X, Y, and Z directions

Conforms to EN 61000-6-2, EN 61000-6-4, and EN 55011 (Group 1 Class A).

Power supply noise (FT noise): ±2 kV min. for one minute

Radiation nois e (F T noise): ±1 kV min. for one minute

Ground noise (impulse noise): ±1 kV min. for 10 minutes

Electrostatic noise (contact disch a rge method): ±6 kV or more, 10 times

2

2

2

(15 G)

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 13

Page 14

6 Installation and Usage Conditions

Fan

Fan

40 mm min.

10 mm

min.*

* For a control panel with natural cooling with the MBU-303 Base Unit: 30 mm min.

10 mm

min.*

40 mm min.

Approx.

40 mm

Direction

of air ow

Direction

of air ow

Approx.

40 mm

Control Panel Cooling Method

The components that are used in the Machine Controller require the ambient operating temperature to be between 0 and

60 °C. Use one of the methods described below to ensure adequate cooling in the control panel.

NOTICE: Equipment Damage. Use forced-air cooling if the ambient temperature exceeds 55°C.

Control Panels with Natural Cooling

• Do not mount t h e Mac hi ne Controller at the top of the control panel, where the hot a ir t hat i s g ene rat ed inside the panel

collects.

• Leave sufficient space above and below the Machine Controller, and maintain adequate distances from other devices,

cable ducts, and other objects to ensure suitable air circulation.

• Do not mount the Machine Controller in any direction other than the specified direction.

• Do not mount the Machine Controller on top of any device that generates a significant amount of heat.

• Do not subject the Machine Controller to direct sunlight.

Control Panels with Forced-air Cooling

Install a fan near the center of and at the top or bottom of the Machine Controller for either of the following methods.

• Forced draft method (A fan or a similar device is used to circulate the air in the interior and the exterior of the panel.).

• Forced circulation method (A fan or a similar device is mounted to the airtight panel to circulate the air inside.).

Note: 1. Use the following guideline when selecting the fan:

• 80 x 80 mm min., Maximum air flow: 0.9 m3/min, Maximum static pressure: 26.5 Pa or higher.

Figure 8

2. Adjust the fan installation location and the direction of air flow as shown in Figure 8.

14 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Figure 8 Fan installation location and air flow direction

Page 15

7 Base Unit Specifications

The specifications of the Base Units are listed in Table 2.

Table 2 Base Unit Specifications

7 Base Unit Specifications

Item

Model JEPMC-BU3304-E JEPMC-BU3303-E JEPMC-BU3302-E JEPMC-BU3301-E

Abbreviation MBU-304 MBU-303 MBU-302 MBU-301

Number of Slots 138

Mountable Modules MP2000-series Optional Modules

Input Voltage 24 VDC 110/220 VAC

Allowable Input

Voltage Range

Input Current

Inrush Current 40 A, 10 ms max. 30 A, 10 ms max. 40 A, 10 ms max.

Allowable Power Loss

Power Supply Section

RLY OUT

Indicators POWER

Connectors

Time

Rated Voltage 5.15 V 5.0 V

Rated Current 2.5 A 4.5 A 4.0 A 8.0 A

Output Current Range 0 to 2.5 A 0 to 4.5 A 0.0 to 4.0 A 0.0 to 8.0 A

Rated Voltage

Accuracy

Battery

1 slot 3 slots 8 slots DC 8 slots AC

19.2 to 28.8 VDC

1.0 A max. (at rated

input/output)

1 ms 20 ms

5.15 V ±2% max. (5.05 to 5.25 V)

You can mount a memory backup Battery for retained variables, absolute encoder offsets, and

alarm history.

A normally open relay output that is linked to the CPU Module status

Normal operation: Circuit closed .

Error: Circuit open.

Contact Ratings:

• 125 Vac, 0.4 A resistive load, 0.20 A inductive load

• 24 Vdc, 0.5 A resistive load, 0.25 A inductive load

POWER: Power supply connector

RLY OUT: Relay contact connector

1.5 A max. (at rated input/output)

Specification

85 to 132 VAC/ 198 to

276 VAC

3.0 A max. (at rated

input/output)

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 15

Page 16

8 Switches

8Switches

The CPU Module has the following two types of switches.

• DIP switches: Mode switches

• STOP/SAVE switch

DIP Switches: Mode Switches

The SW1 and SW2 switches are checked at start-up, and their behavior is described in the following tables:

Table 3 SW1 Switches

SW Description

STOP When ON, prevents PLC from running.

E-INIT When ON, overrides Ethernet configuration according to Table 5.

INIT When ON, the controller uses the fixed, default configuration

CNFG When ON, the controller creates Axes and I/O for all connected devices. (Auto-configuration)

Table 4 SW2 Switches

SW Description

LOAD When ON, load either the user project or firmware from the USB thumb dri ve. See Table 6 for details.

TEST When ON, the IP ad dress is scrolled across the seven segment display.

MNT

-- / DHCP DHCP Selection when E-INIT is ON.

When ON, controller starts up in supervisor mode. In this mode MECHA TROLINK III, PLC, Modbus/TCP and Ethernet/IP

do not start. The controller firmware can be updated, and clearing DOS FS alarms will repair the DOS FS.

E-INIT and - switches can override the Ethernet configuration according to Table 5.

Table 5 Operation of E-INIT, E-PM0 and E-PM1 for Configuring Ethernet

E-INIT -- / DHCP

Static Configuration OFF N/A

192.168.1.1 ON OFF

DHCP ON ON

On start-up, the controller will aut omat ic ally l oad f ir mware or use r pr oje cts bas ed on t he LOAD and MNT swi tc hes . The

USB thumb drive is available in any other circumstances.

Table 6 Operation of LOAD and MNT for USB Thumb Drive

E-INIT -- / DHCP

Load user project from USB thumb drive ON OFF

Install firmware and user project from USB

thumb drive

16 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

ON ON

Page 17

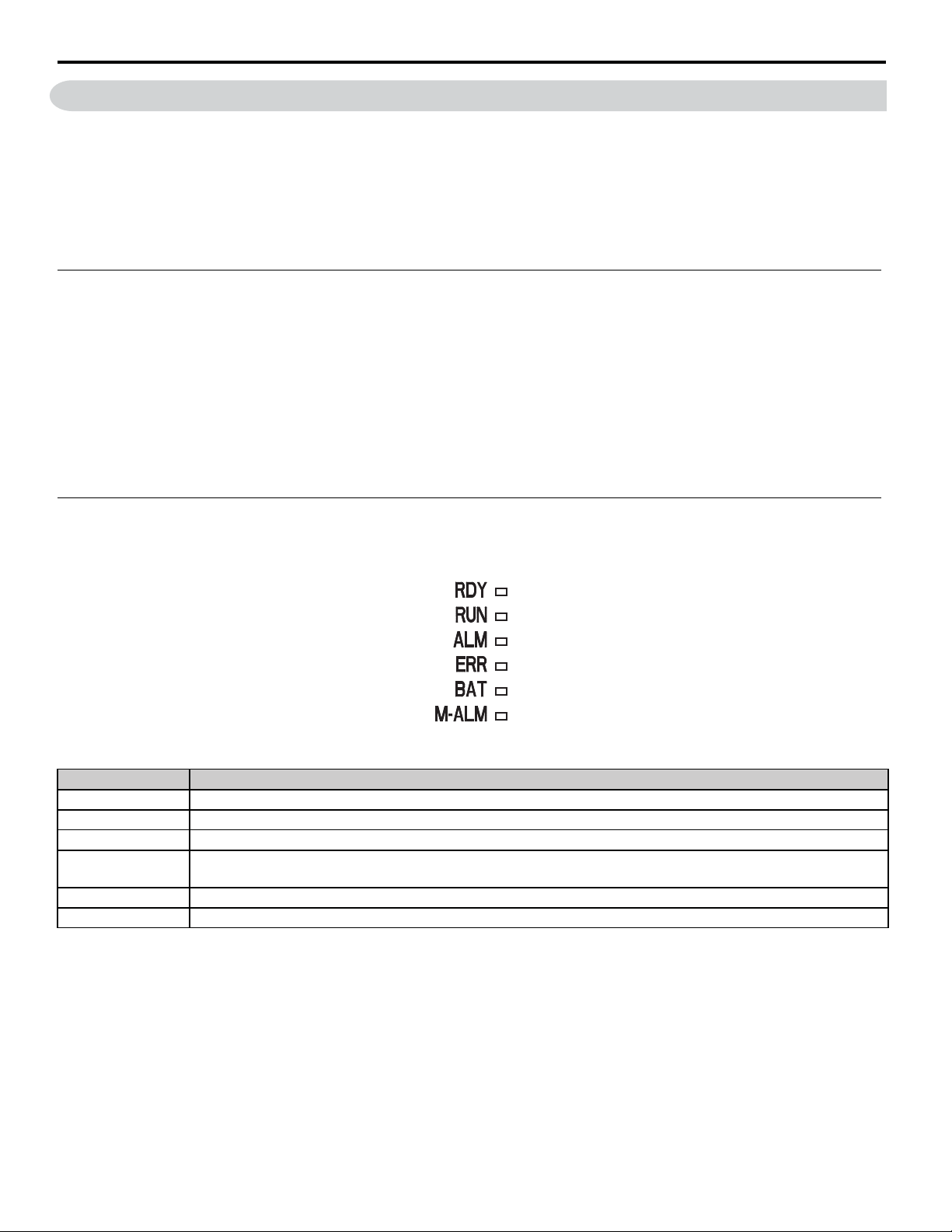

9 Display and Indicators

9 Display and Indicators

The CPU Module has the following display and four types of indicators.

•Display

• Status indicators

•USB status indicator

• MECHATROLINK-III status indicators

• Ethernet status indicators

Display

The following situations use the seven segment display:

• Manufacturing: During programming the seven segment display outputs “FLASH...”. When finished, the seven

segment display outputs “donE”.

• Startup: If the controller cannot boot because of a bad firmware image check sum, the seven segment display outputs

“bOOt ERROR”

• IP Address: If the TEST switch is ON, then the seven segment display outputs the IP address.

• Firmware update: During programming the seven segment display outputs “FLASH...”. When finished, the seven

segment display outputs “donE”.

Status Indicators

These indicators show the status of the CPU Module.

Table 7 Status LED

LED Description

RDY ON when the controller has detected valid firmware and has started.

RUN ON when PLC is running.

ALM ON when an alarm is active.

ERR

BAT ON when the battery needs replacing.

M-ALM ON when JL100 (Mechatrolink Master) chip initialization fails.

ON at initial power up while firmware is loading. Turns off if firmware is valid.

ON when a critical error occurs requiring a power cycle to recover.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 17

Page 18

9 Display and Indicators

USB Status Indicator

This indicator shows the status of the USB memory.

Indicator Name Indicator Status Status Description

Not lit No USB memory device

USB

ACTIVE

MECHATROLINK-III Status Indicators

Lit USB memory device inserted A USB memory device is inserted.

Flashing Accessing USB memory The USB memory is being accessed.

No USB memory device has been inserted ye t, or the

USB memory device is ready to be removed.

These indicators show the status of the MECHATROLINK-III communications.

Indicator Name Color Status When Lit

Ethernet Status Indicators

CN Green

LK1 Green MECHATROLINK-III communications are active on PORT1.

LK2 Green MECHATROLINK-III communications are active on PORT2.

MECHATROLINK-III communications is established with the CPU Module as a slave (i.e.,

the Connect command is ON).

These indicators show the status of Ethernet communications.

Indicator Name Color Status When Not Lit, Lit, or Flashing

LINK/ACT Yellow

100M Green

Lit: Ethernet link established.

Flashing: Ethernet communications activity.

Not lit: 10 M connection

Lit: 100 M connection. We do not support GB connections.

18 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 19

10 Self-Configuration

10 Self-Configuration

DIP Switch

Self-Configuration after Adding Devices such as Servopacks

The controller ca n aut omatica lly config ure a ll t he M echatr olink devi ces. Fi rst, co nnect and p ower up all the Mecha troli nk

nodes (making sure they all have unique station numbers). Then, set the CNFG switch to the ON position and power up

the controller. Wait for the RDY LED to come on and the controller will now have the new auto configuration.

Note: Controllers with an existing saved configuration cannot be auto configured until the currect conf iguration is deleted.

MotionWorks IEC

The MotionWorks IEC (Express or Pro) configuration can detect the configuration and provide the user with

configuration choice s. If a S tar tUp Config urati on was alre ady save d on the controll er, the self-configure funct ion will not

allow new devices to be discovered. In this case, add them offline manually first.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 19

Page 20

11 MECHATROLINK-III Specifications

11 MECHATROLINK-III Specifications

The specifications of the MECHATROLINK-III Network Master that is built into th e CPU Unit are given in the following

table.

Item Specification Remarks

Communications ASIC JL-100 Number of Communications Lines 1 -

MECHATROLINK

communications

settings

Number of Communicat ions Ports

(Connectors)

Communications Method M-III Baud Rate 100 Mbps -

Communications Cycle

Number of Connected

Master

Stations

Message Relaying Not Supported. C2 Messages Not Supported. Retries Supported. 0 to 4 retries

Asynchronous Setting of

High-speed Scan Cycle

and Communications

Cycle

2-

250 μs/0.5 ms/

1 ms/1.5 ms/2 ms/2.5 ms/3 ms/

3.5 ms/4 ms

62 stations -

Not supported. An alarm will occur if setting is attempted.

-

CPU Unit Specifications

Item Specification

Calendar Battery backup accurate to 1 minute of error per month.

Ethernet

M-III 1981386-1 ×2 (TycoAMP)

USB

Protection Hardware watchdog timer (PLD): 0 to 510 ms (register setting)

Relay Output

Backup Circuit Battery: BR-1/2AA (Panasonic), 3.0 V

Connector DUSB-ARA42-T11A-FA (DDK), type A connector

Function USB 2.0 ho st, 3 speeds (HS/FS/LS), 1 port

10BASE-T, 100BASE-TX

Auto-Negotiation / Baseline Wander Correction / Auto-MDIX

Contacts normally open for RUN status (RDY indicator lit), and OFF for WDT error status. The relay

is built into the Power Supply Unit.

20 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 21

12 MECHATROLINK-III Network Topologies

12 MECHATROLINK-III Network Topologies

You can connect the MP3300iec Series Controller and drives or I/O with cascaded connections, star connections, or

mixed cascaded/star network topologies. The following figures show examples of these types of network topologies.

Cascaded Connection

Cascaded connections allow you to connect one or more series of slave stations from the CPU Unit MECHATROLINKIII ports. Regardless of whether a single MECHATROLINK-III port is used, as shown in Figure 9, or two CPU Unit

MECHATROLINK-III ports are used, as shown in Figure 10, these are called cascaded connections.

Figure 9

CPU Unit

Figure 10

Up to 32 stations, including Servos and I/O

Figure 9 Cascaded Connections Using Only One Port

CPU Unit

No terminating

resistor is

required.

Up to 32 Servo stations

Up to 62 stations, including I/O

No terminating resistor is required.

No terminating

resistor is required.

Figure 10 Cascaded Connections Using Two Ports

Note: 1. Do not connect more than 32 stations up to the final slave station to any one CPU Unit port.

2. The maximum number of stations that you can connect with cascaded co nnections depends on the c ommunications cycle.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 21

Page 22

12 MECHATROLINK-III Network Topologies

Star Connections

Star connections al low you to connect slave stations through Hub Modul es. Each port on a Hub Module connects to only

one slave station. You can also connect one additional Hub Module to the first Hub Module.

CPU Unit

Hub Module

Note: 1. Terminating resistors are not required.

2. The maximum number of stations that you can connect with star connections depends on the communications cycle.

Hub Module

22 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 23

Mixed Cascaded/Star Connections

You can combine both cascaded and star network topologies.

CPU Unit

Hub Module

12 MECHATROLINK-III Network Topologies

No terminating

resistor is required.

No terminating

resistor is required.

Note: 1. Do not connect more than 32 stations to a single CPU Unit port, including the Hub Modules.

2. The maximum number of stations that you can connect with a mixed cascaded/star connections depends on the communications cycle.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 23

Page 24

13 MECHATROLINK-III Synchronization between Modules

NOTICE

NOTICE

13 MECHATROLINK-III Synchronization between Modules

Timing at Which Modules Are Synchronized

Modules are automatically synchronized when the power supply is cycled.

If you perform any of the following operations after turning ON the power supply, save the settings to flash memory and

then cycle the power supply again.

• When operation changes from asynchronized to synchronized as a result of changing the communications cycle

• When operation changes from synchronized to asynchronized or from asynchronized to synchronized as a result of

changing the high-speed scan setting

• When the minimum response time in the MPiec controller is changed.

Changing Synchronization Cycles

When the scan cycle is changed, MECHATROLINK communications with all slave stati ons conne ct ed to the SVC32 ar e

reset. Operation automatically changes to synchronized when communications are restored.

MECHATROLINK communications continue for all other Modules.

1. When you change the MECHATROLINK cycle, do so either with the CPU Function Module stopped or when motion commands are not being

executed. Otherwise, application operations may be affected.

2. When changing the MECHATROLINK setting, the following operation will occur because MECHATROLINK communications are reset.

• Position inform ation and zero point return completion information for Servo axes will be lost.

Changing the MECHATROLINK Communications Cycle

Operation is automatically synchronized as long as the high-speed scan setting is an integral multiple of the

communic ations cycle.

It is not necessary to cycle the power supply.

If asynchronous operation is set as a result of changing the communications cycle, an alarm will occur for the Servo

axis and an I/O error will occur for the I/O station. If this happens, change the setting back to synchronized, save the

settings to flash memory, and then cycle the power supply.

24 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 25

14 Devices Connectable via MECHATROLINK-III

14 Devices Connectable via MECHATROLINK-III

Servopacks

The following table shows Servopacks that are compatible with MECHATROLINK-III and can be connected to the

controller.

Model Details

SGDV-

SGDV-

SGDV-

SGDV-

SGDV-

SGD7S-

SGD7W-

I/O Modules

ƑƑƑƑ

ƑƑƑ

ƑƑƑ

ƑƑƑ

ƑƑƑƑ

ƑƑƑ

ƑƑƑ

21

E21

H21A

J21A

25

A20A

A20A

Σ-V Series AC Servo amplifiers for rotary motors

Σ-V Series Mini AC Servo amplifiers for rotary motors

Σ-V Series 200 VAC Large Capacity AC Servo amplifiers for rotary motors

Σ-V Series 400 VAC Large Capacity AC Servo amplifiers for rotary motors

Σ-V Series AC Servo amplifiers for linear motors

Σ-7 Series 200 VAC Large Capacity AC Servo amplifiers

Σ-7 Series 200 VAC Large Capacity dual motor AC Servo amplifiers

The following table shows the module that is compatible with MECHATROLINK-III and can be connected to the

controller.

Model Details

JEPMC-MTD2310-E

64-point I/O Module

24VDC, 64 inputs, 64 outputs

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 25

Page 26

15 Connecting the RLY OUT Connector

RLY OUT

24 VDC

0 VDC

POWER

Ground to 100 Ω max.

24-VDC

power supply

Power

supply

Error: OFF

Normal operation: ON

RLY OUT output

15 Connecting the RLY OUT Connector

The RLY OUT connector connects the status output terminal. It is a normally open contact relay output. The RLY OUT

connector is linked to the operation of the RDY indicator: The contacts close when the indicator lights, and they open

when the indicator goes out.

Note: When the RDY indicator is lit, the Controller is operating normally. It does not necessarily mean that the user programs are being

executed.

RLY OUT Connector Specifications

The operation of the RLY OUT connector is linked to the operation of the RDY indicator on the CPU Unit.

RDY indicator lit: Circuit closed

RDY indicator not lit: Circuit open

Contact Ratings

Input

Voltage

24 VDC

125 VAC

RLY OUT Connector Connection Cable

Current Capacity

0.5 A (resistive load)

0.25 A (inductive load)

0.4 A (resistive load)

0.2 A (inductive load)

To connect the RLY OUT connector, use a cable with a wire size of AWG 28 to AWG 14 (0.08 to 2.0 mm2) and a

maximum outer diameter of 3.4 mm.

The procedure to make the RLY OUT connector cable is the same as for the 24-VDC power supply cable.

Note: You can use the RLY connector on the Power Supply Unit only on the Rack to which the CPU Unit is mounted. On Racks without

the CPU Unit, the power supply circuit is always open.

RLY OUT Connector Connection Example

Refer to the following figure for an example of connecting the RLY OUT connector.

26 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 27

16 Ethernet Connector Details

'VJGTPGV

.+0-

/

Connects to other devices by Ethernet (100Base-TX/10Base-T).

Ethernet Connector Specification and Pin Array/Indicator Light

The following table provides the Ethernet connector specifications.

16 Ethernet Connector Details

Connector

Name

Ethernet 8 RJ-45 CAT5 Socket RJ-45 CAT5 Plug Pulse Engineering

Number of

Pins

Module Side Cable Side Manufacturer

Connector Model

The following table provides Ethernet connector pin array / indicator light details.

Pin Number Signal Name Description

1 TXD+ Transmitted data + side

2 TXD- Transmitted data – side

3 RXD+ Received data + side

4––

5––

6 RXD- Received data – side

7––

8––

Display Name Display Color Description

LINK Yellow

100M Green

Ethernet Cable

Lit: Connect

Unlit: Unconnected

Lit: Connected at 100Mbps, or automatically negotiating

Unlit: Connected at 10Mbps

For the Ethernet cable, use a twisted pair cable with RJ-45 connector. Yaskawa strongly recommends the use of shielded

ethernet cables.

Ethernet

Type

10Base-T Category 3 or more

100Base-T Category 5 or more

Ethernet Connection Examples

Category Remarks

• When connecting to remote equipment through a hub: Straight cable

• When connecting to remote equipment without using a hub: Cross cable

The following are examples of Ethernet network connections via 10Base-Tx cable:

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 27

Page 28

16 Ethernet Connector Details

Hub

or Switch

MP3300iec

Hub

or Switch

10Base-T

(Straight cable)

Station

StationStation

Up to 100mUp to 100m

Up to 100m

Up to 100m

Up to 100m

Station

Up to 100m

When connecting to a HUB without using the

auto-negotiation function, set the HUB side to

half-duplex mode.

10 Base-T (crossover cable, up to 100m)

MP3300iec

Connection Example 1 (When using a hub or switch)

Specification

Item When Connecting to a Repeater HUB When Connecting to a Switching HUB

Cable Length between Node-HUB 100m or less 100 m or less

Cable Length between HUBs 100m or less 100 m or less

Number of HUBs between Nodes Up to four Unlimited

Connection Example 2

The following are examples of Ethernet network connections via 100Base-Tx cable:

28 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 29

16 Ethernet Connector Details

CAUTION

Hub

or Switch

MotionWorks IEC

MP3300iec

YASKAWA SERVOPACK

200V

SGDS-01A12A

SW1

CHARGE

C

N

3

A/B

C

N

1

C

N

2

C

N

4

L1

L2

L2C

L1C

B1/

B2

U

V

W

C

N

6

SERVOPACK

Core

Core

Core

100Base-T

(straight cable)

Servomotor

Other station

High frequency wave noise from other devices in the installation environment may cause errors in

communications using Ethe rnet or MECHATROLINK-III connections. Wh en designi ng a syst em, use pr otectiv e

measures to avoid the influence of high frequency wave noise as follows:

1. Wiring

2. Communication system (Ethernet)

Wire Ethernet or MECHATROLINK-III cables so that they are well-separated from other cable systems such as the main circuit or

power lines.

• Communicate data to a remote device through TCP/IP communication.

• If necessary, increase the number of communication retries.

• Yaskawa strongly recommends shielded Ethernet cables.

3. Attach a ferrite core.

Ethernet: Attach it to the communication port side and the external equipm ent side of the MP3300iec unit.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 29

Note: Recommended ferrite core.

Model Manufacturer

E04SR301334 Seiwa Electric Mfg. Co., Ltd

Page 30

17 Option Module - AI-01 (Analog Input) Module

AI-01

LED indicator

Analog input

connector CN1

RUN

CN1

CN2

Analog input

connector CN2

125 mm

95 mm

19.3 mm

17 Option Module - AI-01 (Analog Input) Module

Appearance

Module Functions

The AI-01 module is an analog input module with voltage and/or current input modes.

Module Specifications

The following table shows the AI-01 Module hardware specifications.

Item Specifications

Classification I/O Module

Name AI-01

Model JAPMC-AN2300

Analog Input

Accuracy

Analog Input Range -10 to +10V 0 to +10V 0 to 20 mA

Number of Channels 8 ((4/ connector)×2)

Number of Channels to be Used Any number from 1 to 8

Isolation

Max. Rated Input ±15V ±30 mA

Input Impedance 20 kΩ 250 kΩ

Resolution 16-bit (-31276 to +31276) 15-bit (0 to +31276)

Absolute Accuracy 100 mV Max 0.3 mA Max

Input Conversion Time 1.4 msec Max

Connectors

LED Indicator RUN (green)

25°C ±0.1% (±10 mV) ±0.1% (±0.02 mA)

0 to 55°C ±0.3% (±30 mV) ±0.3% (±0.06 m A )

Between input connector and system power supply: Photocoupler isolation

Between channels: Not isolated.

CN1: Input connector

CN2: Input connector

30 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 31

L 150 mm

26-core

Loose wires

NP JEPMC-W6080-05

Marking tube (Label)

LED Indicator

17 Option Module - AI-01 (Analog Input) Module

Item Specifications

Current Consumption 500 mA Max

Dimensions 125×95 (H×D)

Mass 100 g

Indicator

RUN Green Normal operation Operation stopped (no access from CPU)

Connector Specifications

Connector Name # of Pins

CN1/CN2 26 10226-52A3PL

Indicator

Color

Status when Lit Status when not Lit

Module Side Cable Side Manufacturer

Applicable Cable: JEPMC-W6080-oo

Standard Cable Model and External Appearance

Model Length External Appearance (JEPMC-W6080-oo)

JEPMC-W6080- 05 0.5 m

Connector Model

• Connector

10126-3000VE

•Shell

10326-52A0-008

(Screw locking), or

10326-52F0-008

(One-touch lock ing)

Sumitomo 3M Corporation

JEPMC-W6080- 10 1.0 m

JEPMC-W6080- 30 3.0 m

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 31

Page 32

17 Option Module - AI-01 (Analog Input) Module

25

26

13

12

15

1

2

14

1

V1

14

MDP1

2

G1

15

G1

3 A1 16 MDN1

4 V2 17 MDP2

5G2 18G2

6 A2 19 MDN2

7 V3 20 MDP3

8G3 21G3

9 A3 22 MDN3

10 V4 23 MDP4

11 G4 24 G4

12 A4 25 MDN4

13 26

25

26

13

12

15

1

2

14

1

V5

14

MDP5

2

G5

15

G5

3 A5 16 MDN5

4 V6 17 MDP6

5G6 18G6

6 A6 19 MDN6

7 V7 20 MDP7

8G7 21G7

9 A7 22 MDN7

10 V8 23 MDP8

11 G8 24 G8

12 A8 25 MDN8

13 26

Connector Pin Arrangement

The AI-01 Module Connector (CN1/CN2) pin arrangement is shown below.

CN1 Connector Pin Arrangement

Pin Arrangement Viewed from Wiring Side

CN2 Connector Pin Arrangement

Pin Arrangement Viewed from Wiring Side

Standard Cable Wiring Table

The wiring table for the standard cable JEPMC-W6080- is shown below.

Pin Wire Color

1

2

3

14

16

4

5

32 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Gray Red – – – V1/V5 V1/V5 Voltage input 1/5

Gray Black – – – G1V/G5V

Orange Red – – – G1A/G5A

Orange Black – – – A1/A5 A1/A5 Current input 1/5

Yellow Red – DP1/DP5 MDP1/MDP5 Mode switching terminal 1/5

Yellow Black – DN1/DN5 MDN1/MDN5 Mode switching terminal 1/5

Pink Red – – V2/V6 V2/V6 Voltage input 2/6

Pink Black – – G2V/G6V

Yellow Black – – G2A/G 6A

Marking

Color Marking

Label on Marking

Tube

Signal Name Function

G1/G5 Ground 1/5

G2/G6 Ground 2/6

Page 33

17 Option Module - AI-01 (Analog Input) Module

DANGER

Pin Wire Color

6 Yel low Black – – A2/A6 A2/A6 Current input 2/6

17 White Red – DP2/DP6 MDP2/MDP6 Mode switching terminal 2/6

19 White Black – DN2/DN6 MDN2/MDN6 Mode switching terminal 2/6

7 White Red – – V3/V7 V3/V7 Voltage input 3/7

8

9

20 Gray Red – DP3/DP7 MDP3/MDP7 Mode switchi ng terminal 3/7

22 White Black – DN3/DN7 MDN3/MDN7 Mode switching terminal 3/7

10

11

12

23

25 Orange Black – – DN4/DN8 MDN4/MDN8 M ode switching terminal 4/8

White Black – – G3V/G7V

Gray Red – – G3A/G7A

Gray Black – – A3/A7 A3/A7 C urrent input 3/7

Orange Red – – V4/V8 V4/V8 Voltage input 4/8

Orange Black – – GV4/GV8

Pink Red – – G4A/G8A

Pink Black – – A4/A8 A4 /A8 Current input 4/8

Orange Red – – DP4/DP8 MDP4/MDP8 Mode switching terminal 4/8

Marking

Color Marking

Label on Marking

Tube

Signal Name Function

G3/G7 Ground 3/7

G4/G8 Ground 4/8

Columns “Label on M arkin g T u be”, “Si gnal Name”, and “Fu nction ” dis play t he val ues f or conn ector s CN1 and CN2 in

the format “CN1 /CN2”, respec tively.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 33

Page 34

17 Option Module - AI-01 (Analog Input) Module

DC/DC

Converter

+5V

0V

+15V

-15V

0V

D/A

Converter

Internal circuit

+5V

Photocoupler

Voltage input

Current input

Mode

10

12

25

23

+

GND

CH8

11

Multiplexer

Ground

Voltage input

Current input

Mode

4

6

19

17

+

GND

CH2

5

Voltage input

Current input

Mode

Ground

1

3

16

14

2

+

GND

CH1

Ground

Shell

R R

R

RR

R

RR

R

10k

10k

256.5

10k

10k

256.5

10k

10k

256.5

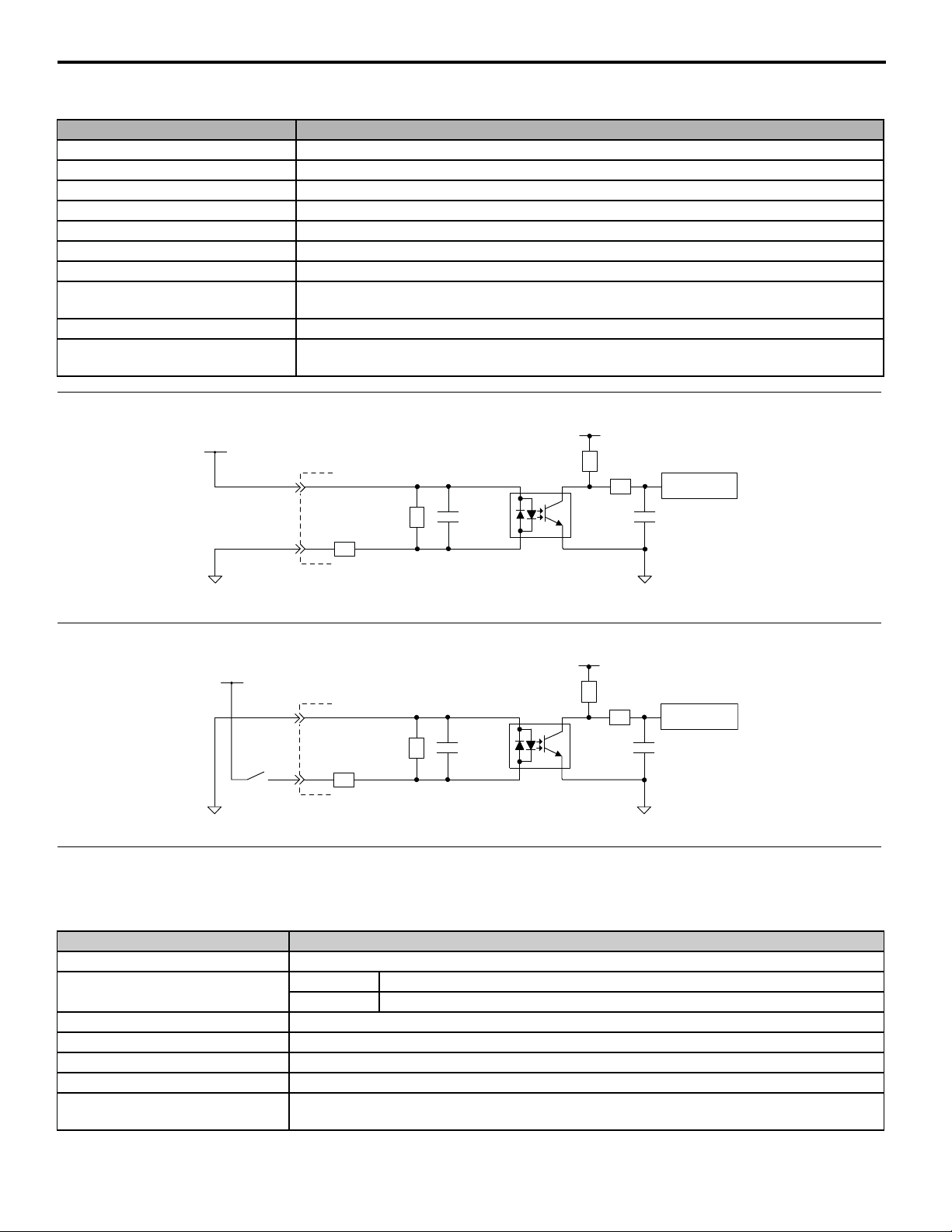

Circuit Configuration

34 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 35

DANGER

DC/DC

Converter

+5V

0V

+15V

-15V

0V

D/A

Converter

Internal circuit

+5V

Photocoupler

Voltage input

Current input

Mode

10

12

25

23

-

+

GND

CH8

11

Multiplexer

Ground

Voltage input

Current input

Mode

4

6

19

17

-

+

GND

CH2

5

Voltage input

Current input

Mode

Ground

1

3

16

14

2

-

+

GND

CH1

Ground

Shell

R R

R

RR

R

RR

R

10k

10k

256.5

10k

10k

256.5

10k

10k

256.5

CN1 Connector Connection Example

17 Option Module - AI-01 (Analog Input) Module

• Use the standar d cable (JEPMC- W6080- ) f or AI -01 Mo dules t o connec t to ex te rnal de vices . Use a rel ay termina l

block to connect the AI-01 module to external devices because the wiring distance varies between the AI-01 module

and each external device.

• Ground the cable shield between an external device and the relay terminal block on the external device side.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 35

Page 36

18 Option Module - AO-01 (Analog Output) Module

A

O

-01

LED indicator

Analog output

connector CN1

RUN

CN1

125 mm

95 mm

19.3 mm

18 Option Module - AO-01 (Analog Output) Module

Appearance

Module Functions

The AO-01 module has four channels for anal og output. Two types of analog outpu t ranges a re availabl e; -10 to +10V and

0 to +10V.

Module Specifications

The following table shows the AO-01 Module hardware specifications.

Item Specifications

Name AO-01

Model JAPMC-AN2310-E

Number of Channels 4

Isolation

Analog Output Rang e ±10V 0 to +10V

Resolution 16-bit (-31276 to +31276) 15-bit (0 to +31276)

Absolute Accuracy 100 mV Max 0.3 mA Max

Analog Output

Accuracy

Input Conver sion Time 1.2 msec Max

Connectors CN1: Out put connector

LED Indicator RUN (green)

Current Consum ption 500 mA Max

Dimensions 125 × 95 (H×D)

Mass 90 g

Indicators

25°C ±0.1% (±10 mV)

0 to 55°C ±0.3% (±30 mV)

Between channels: Not isolated.

Between output connector and system power supply: Photo c oupler isolation

Indicator

RUN Green Normal operation Operation stopped (no access from CPU)

36 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Indicator

Color

Status when Lit Status when not Lit

Page 37

Connector Specifications

18 Option Module - AO-01 (Analog Output) Module

Name

Analog Output

Connector

Connector

Name

CN1 20 10220-52A3PL

# of Pins

Module Side Cable Side Manufacturer

Applicable Cable: JEPMC-W6090-oo

Standard Cable Model and External Appearance

Model Length External Appearance (JEPMC-W6090-oo)

JEPMC-W6090-05 0.5 m

JEPMC-W6090-10 1.0 m

JEPMC-W6090-30 3.0 m

CN1 Pin Layout Diagram

Connector Model

• Connector 10 126-3000VE

• Shell 10326-52 A 0-0 08

(Screw locking), or

10326-52F0-008

(One-touch locking)

Sumitomo 3M

Corporation

Standard Cable Wiring Table

The following shows the pin arrangement for standard cable JEPMC-W6090.

Pin Wire Color

1 Orang e Red Analog Output 0

2 Gray Red Analog Output 1

3

4

5

6 White Red Pulse input ground

7

8 White Black (-)

9

10~20 Twisted-pair cable

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 37

Orange Black Ground 0

Gray Black A_Pulse+

Yellow Red (-)

Yellow Black C-Phase latch input common (5V)

Marking

Color

Function

Page 38

18 Option Module - AO-01 (Analog Output) Module

DANGER

AO-01 Module Connector Connection Example

CN1 Connector Connection Example

• Use the AO-01 standard cable (JEPMC-W6090-) for the connection to the external device. Use the junction

terminal block because the distance between the external devices and the module are different as seen on the above

diagram.

• Ground the cable shield between the external devices and the junction terminal block by the external device side.

38 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 39

19 Option Module - DO-01 (Digital Output) Module

DANGER

0

24

DO_24V

Output

register

DO_OUT

DO_COM

+24V

R

Photocoupler

R

Transistor

19 Option Module - DO-01 (Digital Output) Module

Appearance/Indicators

Module Functions

The DO–01 module is equipped with 64 digital outputs.

Output Circuit Specifications

The following table shows the DO-01 Module output circuit specifications.

Item Specifications

Outputs 64 points

Output Format Transistor/open collector, sink mode output

Isolation Method Photocoupler

Output Voltage + 24VDC (+19.2 to +28.8V)

Output Current 100 mA Max

Leakage Current When OFF 0.1 mA Max

ON Time/OFF Time

Number of Commons 8 points

Protection Circuit Fuse connected to each common line

Fuse Rating 1A

Error Detection Fuse blowout detection

ON: 0.5 ms Max

OFF: 1 ms Max

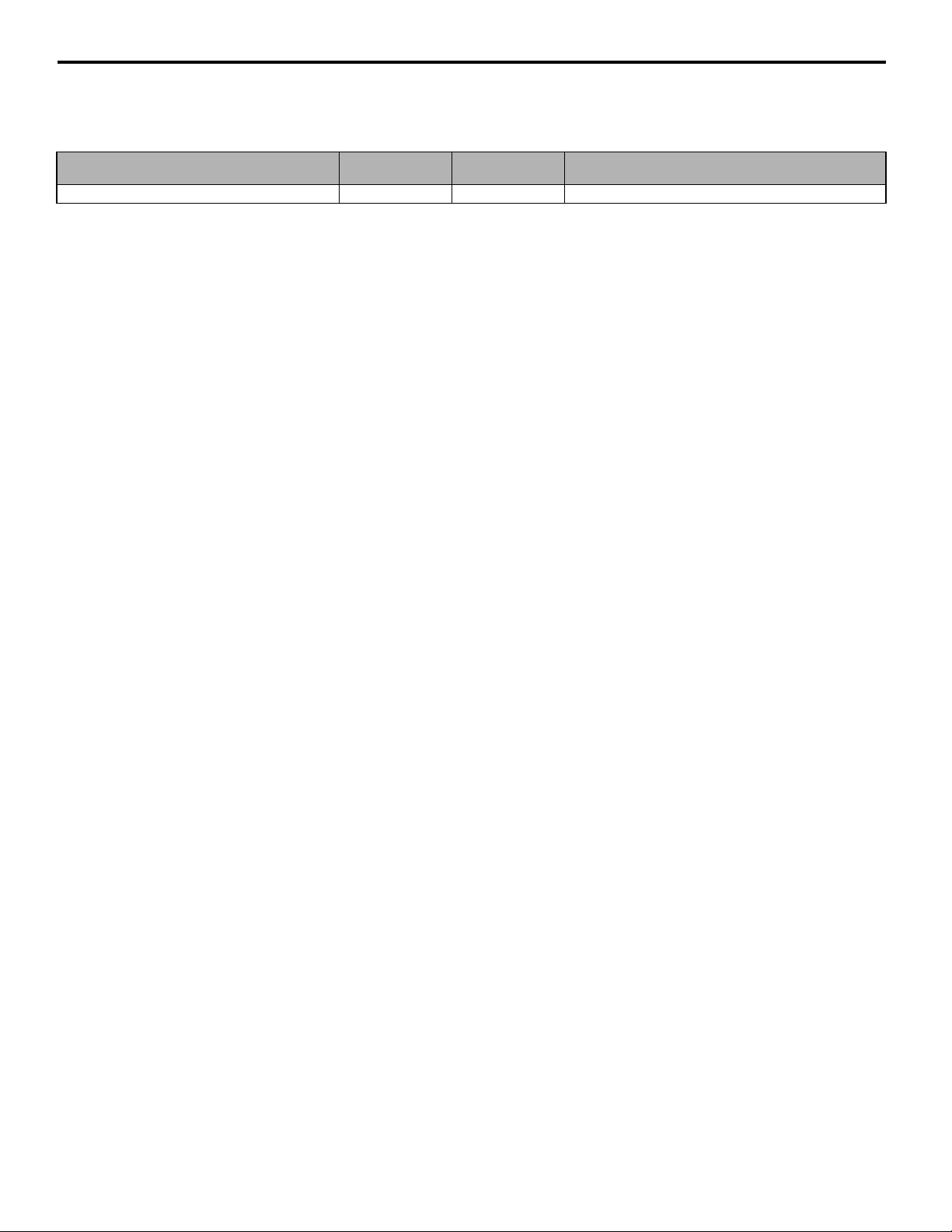

DO-01 Digital Output Circuit (Sink Mode Output) Connection Example

A fuse is inserted into the output commo n line of th e DO-01 Module for circuit protection. However , the fuse may not

be blown out in the cases such as layer shorts in outputs. To ensure the circuit protection, provide a protective element

such as fuse in each output as shown in the above diagram.

DO-01 Module Connections

Connects the DO-01 Module to external output signals.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 39

Page 40

19 Option Module - DO-01 (Digital Output) Module

50-core

Loose wires

1

3

5

7

9

11

13

15

17

19

21

23

25

+24V_1

DO_02

DO_06

+24V_2

DO_10

DO_14

+24V_3

DO_18

DO_22

+24V_4

DO_26

DO_30

N.C.

26

28

30

32

34

36

38

40

42

44

46

48

50

OV_1

DO_03

DO_07

OV_2

DO_11

DO_15

OV_3

DO_19

DO_23

OV_4

DO_27

DO_31

N.C.

27

29

31

33

35

37

39

41

43

45

47

49

DO_01

DO_15

OV_1

DO_09

DO_13

OV_2

DO_17

DO_21

OV_3

DO_25

DO_29

OV_4

50

49

25

24

26

27

1

2

Pin Arrangement Viewed from Wiring Side

2

4

6

8

10

12

14

16

18

20

22

24

DO_00

DO_04

OV_1

DO_08

DO_12

OV_2

DO_16

DO_20

OV_3

DO_24

DO_28

OV_4

External outputs: 64 points

Name

External I/O

Connector

Connector

Name

CN1/CN2 50 10250-52A2JL

No of

Pins

Module Side Cable Side Manufacturer

Applicable Cable: JEPMC-W6060-oo

Standard Cable Model and External Appearance

Name Model Length External Appearance (JEPMC-W6060-oo)

JEPMC-W6060-05 0.5 m

Cables for DO-01

Modules

JEPMC-W6060-10 1.0 m

JEPMC-W6060-30 3.0 m

Connector Model

• Connector

• 10150-3000VE

•Shell

• 10350-52A0-008

• (Screw lo c king), or

• 10350-52F0-008

• (One-touch locking)

Sumitomo 3M

Corporation

Connector Pin Arrangement

The DO-01 Module Connector (CN1 and CN2) pin arrangement is shown below.

CN1 Connector Pin Arrangement

40 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 41

CN2 Connector Pin Arrangement

Pin Arrangement Viewed from Wiring Side

1

26

27

2

49

24

50

25

Standard Cable Wiring Table

19 Option Module - DO-01 (Digital Output) Module

1

DO_32

2

DO_36

4

OV_5

6

DO_40

8

DO_44

10

OV_6

12

DO_48

14

DO_52

16

OV_7

18

DO_56

20

DO_60

22

OV_8

24

+24V_5

3

DO_34

5

DO_38

7

+24V_6

9

DO_42

11

DO_46

13

+24V_7

15

DO_50

17

DO_54

19

+24V_8

21

DO_58

23

DO_62

25

N.C.

DO_33

27

DO_37

29

OV_5

31

DO_41

33

DO_45

35

OV_6

37

DO_49

39

DO_53

41

OV_7

43

DO_57

45

DO_61

47

OV_8

49

OV_5

26

DO_35

28

DO_39

30

OV_6

32

DO_43

34

DO_47

36

OV_7

38

DO_51

40

DO_55

42

OV_8

44

DO_59

46

DO_63

48

N.C.

50

The wiring table for the standard cable JEPMC-W6060- is shown below

Pin Wire Color Marking Signal Name Function

1 Orange — +24V_1/5 24V power supply 1/5

2 Gray — DO_00/32 Digital output 0/32

3 White — DO_02/34 Digital output 2/34

4

Yellow — DO_04/36 Digital output 4/36

5 Pink — DO_06/38 Digital output 6/38

6

Orange — — 0V_1/5 Common ground 1/5

7

Gray — — +24V_2/6 24V power supply 2/6

8 White — — DO_08/40 Digital output 8/40

9

Yellow — — DO_10/42 Digital output 10/42

10 Pink — — DO_12/44 Digital output 12/44

11

Orange — — — DO_14/46 Digital output 14/46

12

Gray — — — 0V_2/6 Commo n ground 2/6

13 White — — — +24 V_3/7 24V po wer supply 3/7

14

Yellow — — — DO_16/48 Digital output 16/48

15 Pink — — — DO_18/50 Digital output 18/50

16 Orange — — — — DO_20/52 Digital output 20/52

17

Gray — — — — DO_22/54 Digital output 22/54

18 White — — — — 0V_3/7 Common ground 3/7

19

Yellow — — — — +24V_4/8 24V power supply 4/8

20

Pink — — — — DO_24/58 Digital output 24/58

21 Orange — — — — Continuous DO_26/68 Digital output 26/60

22 Gray — — — — Continuous DO_28/60 Digital output 28/62

23 White — — — — Continuous DO_30/62 Digital output 30/64

24

Yellow — — — — Continuous 0V_4/8 Common gro und 4/8

25 Pink — — — — Continuous N.C

26

Orange — 0V_1/5 Common ground 1/5

27 Gray — DO_01/33 Digital output 1/33

28 White — DO_03/35 Digital output 3/35

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 41

Page 42

19 Option Module - DO-01 (Digital Output) Module

DANGER

Pin Wire Color Marking Signal Name Function

29 Yellow — DO_05/37 Digital output 5/37

30

Pink — DO_07/39 Digital output 7/39

31 Orange — — 0V_1/5 Common ground 1/5

32 Gray — — 0V_2/6 Common ground 2/6

33 White — — DO_09/41 Digital output 9/41

34

Yellow — — DO_11 /43 Digital output 1 1 /43

35 Pink — — DO_13/45 Digital output 13/45

36

Orange — — — DO_15/47 Digital output 15/47

37 Gray — — — 0V_2/6 Common ground 2/6

38 White — — — 0V_3/7 Common ground 3/7

39

Yellow — — — DO_17/49 Digital output 17/49

40 Pink — — — DO_19/51 Digital output 19/51

41

Orange — — — Continuous DO_21/53 Digital output 21/53

42

Gray — — — Continuous DO_23/55 Digital output 23/55

43 White — — — Continuous 0V_3/7 Common groun d 3/7

44

Yellow — — — Continuous 0V_4/8 Common ground 4/8

45

Pink — — — Continuous DO_25/57 Digital output 25/57

46

Orange — — — — DO_27/59 Digital output 27/59

47 Gray ———————— DO_29/61 Digital output 29/61

48 White ———————— DO_31/63 Digital output 31/63

49

Yellow ———————— 0V_4/8 Common ground 4/8

50

Pink ———————— N.C

Columns “Signal Name” and “Function” display the values for connectors CN1 and CN2 in the format “CN1/CN2”

respectively.

42 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 43

20 Option Module - LIO-01/02 Module

LIO-01

LED indicators

Switch

I/O connector

20 Option Module - LIO-01/02 Module

Appearance

External Appearance

The following figure shows the external appearance of the LIO-01/02 Modules

The LIO-01 Module provides digital I/O and encoder input functions. There are 16 digital inputs (DI) and 16 digital

outputs (DO) for the digital I/O function. There is also one encoder input.

The following diagra m giv es an outli ne of the LI O-01 Mo dule f uncti ons. The only f unctiona l d iff erenc e betwe en the LIO01 and the LIO-02 is the active state of the output circuits

Refer to LIO-01 Digital Output Circuit (Sink Mode Output) Connection Example on page 46 and Refer to LIO-02

Digital Output Circuit (Source Mode Output) Connection Example on page 46.

The LIO-02 Module status display LED indicators (LD1 to LD8) change based on the SW1 rotary switch settings. The

following table shows the ON/OFF indicator display for digital input and digital output.

Outline of Functions

LED Indicators and Switch Settings

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 43

Page 44

20 Option Module - LIO-01/02 Module

LD3

LD2

LD1

LD4

LD7

LD6

LD5

LD8

SW1

0

5

1

2

3

4

6

7

8

9

Indicators

Indicator Color SW1 Status when Lit

Board Status Indicators

LD1 Normal operation: Lit, Error: Not lit

LD2 DI-00 to DI-07 status. Lit when any digital input is turned ON.

LD3 DO-00 to DO-07 status. Lit when any digital output is turned ON.

0

LD1 to LD8 Green

1 Digital input indicators: When DI00 to DI07 turn ON, corresponding indicators (LD1 to LD8) are lit.

2 Digital input indicators: When DI08 to DI15 turn ON, corresponding indicators (LD1 to LD8) are lit.

3 Digital output indicators: When DO00 to DO07 turn ON, corresponding indicators (LD1 to LD8) are lit.

4 Digital output indicators: When DO08 to DO15 turn ON, corresponding indicators (LD1 to LD8) are lit.

5

LD4 Pulse A/B input. Lit when phase A/B is turned ON.

LD5 Normal operation: Lit, Error: Not lit

LD6 DI-08 to DI-15 status. Lit when any digital input is turned ON.

LD7 DO-08 to DO-15 status. Lit when any digital output is turned ON.

LD8 Pulse Z input. Lit when phase Z is turned ON.

PI input Indicators

LD1

LD2

LD3

LD4

Pulse A input

Pulse B input

Pulse Z input

-

LD5

LD6

LD7

LD8

High speed output set

Phase-Z latch

Digital input latch

-

Specifications

Module Specifications

Item Specifications

Name LIO-01/02

Model JAPMC-IO2300/JAPMC-IO2301

16 inputs

Digital Inputs

24VDC, 4.1 mA, combined sink mode/source mode inputs

(DI_01 also used for position registation latch.)

Digital Outputs

16 outputs

24VDC transistor open-collector outputs, sink mode (-01)/Source mode (-02) outputs.

Phase A/B/Z inputs

Phase-A/B: 5V differential input, not isolated, Max frequency: 4 MHz

Encoder Input

Phase-Z: 5V/12V photocoupler inp ut, Max frequency: 500 kHz

Latch input

Position registration latch on phase-C or DI _0 1.

Switches Rotary switch (SW1)

Dimensions (mm) 125 x 95 (H x D)

Mass 80 g

44 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 45

20 Option Module - LIO-01/02 Module

5.6k Ω/0.5 W

Vcc

DI_COM

+24 V

DI_IN

Input register

0

24

R

R

R

R

5.6 k

Ω/ 0.5 W

Vcc

680 Ω

DI_COM

+24 V

DI_IN

22 kΩ

1 k

Ω

2200PF

0.01 μF

Input register

0

24

R

R

R

R

Input Circuit Specifications

Item Specifications

Inputs 16 points

Input Format Sink mode/Source mode input

Isolation Method Photocoupler

Input Voltage ±24VDC, ±20mv

Input Current 4.1 mA (typ.)

ON Voltage/Current 15V min./2.0 mA min.

OFF Voltage/Current 5V Max/1.0 mA Max

ON Time/OFF Time

Number of Commons 8 points (DI_COM0: DI_00 to DI_07, DI_COM1: DI_08 t o DI _15)

Other Functions

Digital Input Circuit (Sink Mode Input) Connection Example

ON: 0.5 ms Max

OFF: 0.5 ms Max

DI_01 is shared with position registration latch. If DI_01 is turned ON while position registration latch

inputs are enabled, the encoder position will be latched.

Digital Input Circuit (Source Mode Input) Connection Example

Output Circuit

The following table shows the LIO-01/02 Module output circuit specifications.

Item Specifications

Outputs 16 points

Output Format

Isolation Method Photocoupler

Output Voltage +24VDC, ±20mv

Output Current 100 mA Ma x

Leakage Current When OFF 0.1 mA Max

ON Time/OFF Time

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 45

LIO-01 Transistor, open collector sink mode outputs

LIO-02 Transistor, open collector source m ode outputs

ON: 1 ms Max

OFF: 1 ms Max

Page 46

20 Option Module - LIO-01/02 Module

R

R

R

0

24

DO_24V

Output

register

DO_OUT

DO_COM

+24 V

0

24

+24V

DO_24V

Output

register

DO_OUT

DO_COM

R

R

R

Item Specifications

Number of Commons 16 points

Protection Circuit

Error Detection Blown fuse detection

Other Functions DO_01 is shared with encoder position detection

LIO-01 Digital Output Circuit (Sink Mode Output) Connection Example

The fuses are not for circuit protection. Th ey are for fire protection at output shorts. Attach a fuse

externally to each output if circuit protection is required.

LIO-02 Digital Output Circuit (Source Mode Output) Connection Example

Pulse Input Circuit

The following table shows the LIO-01/02 Module encoder circuit specifications.

Item Specifications

Number of Encoders 1 (Phase-A/B/Z input)

Encoder Circuit

Input Mode Phase-A/B, signed, incremental /d ecremental

Latch Input

Phase-AB: 5V differential input, not isolated, Max frequency: 4 MHz

Phase-Z: 5V/12V photocoupler input, Max frequency: 500 kHz

Position registration latch on phase-Z or DI_01.

Response time: 5 ms Max for phase-Z input; 60 ms Max for DI_01 input.

46 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 47

20 Option Module - LIO-01/02 Module

+5 V

0 V

Phase-A

A1

220Ω

Pulse Generator

Phase-B

PA

PAL

PB

PBL

GND

B1

A2

B2

B3

B4

A4

A3

+5 V

Latch input or

phase-Z pulse

PC

PCL5

PCL12

R

R

R

220Ω

R

B1A1

B24A24

Encoder Circuit Connection Example

LIO–01/02 Standard Cable Wiring Table

Connector Pin Arrangement

The following table shows the connector pin arrangement for LIO-01/02 Modules viewed from the wiring side.

Pin Wire Color

A1

Orange Red — PA I Phase-A pulse (+)

Wire Marking

Color Marking

Signal

Name

I/O Function

A2 Gray Red — PB I Phase-B pulse (+)

A3 White Red — PC I Phase-C pulse (+)

A4

Yellow Red — GND I Pulse input ground

A5 Pink Red — DO_COM P Output common

A6

Orange Red — — DO_24V P +24VDC input

A7 Gray Red — — DO_15 O Output 15

A8 White R ed — — DO_13 O Output 13

A9

Yellow Red — — DO_11 O Output 11

A10 Pink Red — — DO_09 O Output 9

A11

A12

Orange Red — — — DO_07 O Output 7

Gray Red — — — DO_05 O Output 5

A13 White Red — — — DO_03 O Output 3

A14

A15

A16

Yellow Red — — — DO_01 O Output 1

Pink Red — — — DI_15 I Input 15

Orange Red — — — — DI_13 I Input 13

A17 Gray Red — — — — DI_11 I Input 11

A18 White Red — — — — DI_09 I Input 9

A19

Yellow Red — — — — DI_07 I Input 7

A20 Pink Red — — — — DI_05 I Input 5

A21

Orange Red — — — — Continuous DI_03 I Input 3

A22 Gray Red — — — — Continuous DI_01 I Input 1

A23 White Red — — — — Continuous DI_COM0 P Input common 0

A24 Shield FG - Frame ground

B1

B2 Gray Black — PBL I Phase-B pulse (–)

Orange Black — PAL I Phase-A pulse (–)

B3 White Black — PCL5 I

B4

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 47

Yellow Black — PCL12 I

Phase-C pulse

(-5V input)

Phase-C pu lse

(-12V input)

Page 48

20 Option Module - LIO-01/02 Module

Pin Wire Color

B5 Pink Black — DO_COM P Output common

B6 Orange Black — — DO_24V P +24V input

B7 Gray Black — — DO_14 O Output 14

B8 White Black — — DO_12 O Output 12

B9

B10 Pink B lack — — DO_08 O Output 8

B11

B12 Gray Black — — — DO_04 O Output 4

B13 White Black — — — DO_02 O Output 2

B14

B15 Pink Black — — — DI_14 I Input 14

B16

B17

B18 White Black — — — — DI_08 I Input 8

B19

B20

B21

B22 Gray Black — — — — Continuous DI_00 I I nput 0

B23 White Black — — — — Continuous DI_COM1 P Input common 1

B24 Shield FG - Frame ground

Yellow Black — — DO_10 O Output 10

Orange Black — — — DO_06 O Output 6

Yellow Black — — — DO_00 O Output 0

Orange Black — — — — DI_12 I Input 12

Gray Black — — — — DI_10 I Input 10

Yellow Black — — — — DI_06 I Input 6

Pink Black — — — — DI_04 I Input 4

Orange Black — — — — Continuous DI_02 I Inp ut 2

Color Marking

Wire Marking

Signal

Name

I/O Function

• P: Power supply input; I: Input signal; O: Open-collector output

Connector Specifications

Connects the external I/O signals and encoder input signals.

External output: 16 points, Encoder input: 1 channel

Name

I/O Connector I/O 48 FCN-365P048-AU

Cables

Name Model Number Length (JEPMC-W2061-oo)

Cable for LIO01/02 Modules

Connector

Name

JEPMC-W2061-A5 0.5 m

JEPMC-W2061-01 1.0 m

JEPMC-W2061-03 3.0 m

# of Pins

Module Cable Manufacturer

Connector Model

FCN-360C048-E (cover),

FCN-361J048-AU (jack)

Fujitsu

component

48 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 49

DANGER

Phase-A

Pulse Generator

Fuse

Pulse input

Latch input

or phase-Z

pulse

Latch input or phase-Z pulse

Digital input

Digital input

Digital output

External input signals

External input signals

External output signals

Phase-B

24 VDC

24 VDC

Fuse blown

detection circuit

Fuse

220Ω

220Ω

+5V

0V

+5V

5V

A2

B2

A4

PB

PBL

GND

PC

PCL5

PCL12

A3

A24

B24

B3

B4

PA

PAL

A1

B1

DI_COM0

DI_01

DI_02

DI_03

DI_04

DI_05

DI_06

DI_07

DI_00

A23

B22

A22

B21

A21

B20

A20

B19

A19

R

R

DI_COM1

DI_09

DI_10

DI_11

DI_12

DI_13

DI_14

DI_15

DI_08

B23

B18

A18

B17

A17

B16

A16

B15

A15

R

R

R

R

R

R

R

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

DO_00

DO_01

DO_02

DO_03

DO_04

DO_05

DO_06

DO_24V

DO_07

DO_08

DO_09

DO_10

DO_11

DO_12

DO_13

DO_14

DO_15

DO_COM

DO_COM

B6

A6

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B9

A9

B8

A8

B7

A7

A5

B5

R

LIO-01 Module Connections

20 Option Module - LIO-01/02 Module

• Connect a fuse suitable for the load specif ications in the output signal circuit in series with the load. If an external

fuse is not connected, load shorts or overloads could result in fire, destruction of the load device, or damage to the

output element.

• The pins A5 and B5, and the pins A6 and B6 are internally connected. Connect them externally as well.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 49

Page 50

20 Option Module - LIO-01/02 Module

+5V

0V

Phase-A

Pulse generator

+5V

Pulse input

Latch input

or phase-Z

pulse

Latch input or

phase-Z pulse

Phase-B

5V

A2

B2

A4

PB

PBL

GND

PC

PCL5

PCL12

A3

A24

B24

B3

B4

PA

PAL

A1

B1

External input

signals

DI_COM0

DI_01

DI_02

DI_03

DI_04

DI_05

DI_06

DI_07

DI_00

A23

B22

A22

B21

A21

B20

A20

B19

A19

24 VDC

Digital input

R

R

External input

signals

DI_COM1

DI_09

DI_10

DI_11

DI_12

DI_13

DI_14

DI_15

DI_08

B23

B18

A18

B17

A17

B16

A16

B15

A15

24 VDC

Digital input

R

R

R

R

R

R

R

L

L

L

L

L

L

L

Digital output

External output

signals

L

L

L

L

L

L

L

L

L

Fuse open

detection circuit

Fuse

24 VDC

Fuse

DO_24V

DO_24V

DO_00

DO_01

DO_02

DO_03

DO_04

DO_05

DO_06

DO_07

DO_08

DO_09

DO_10

DO_11

DO_12

DO_13

DO_14

DO_15

DO_COM

DO_COM

B6

A6

B14

A14

B13

A13

B12

A12

B11

A11

B10

A10

B9

A9

B8

A8

B7

A7

A5

B5

R

L

Load

External Fuse

LIO-02 Module Connections

50 YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7

Page 51

21 Option Module - LIO-04/05 Modules

DANGER

LED indicators

I/O connector

(CN1)

LIO-04

RUN

FU

CN2

CN1

I/O connector

(CN2)

FURUN

21 Option Module - LIO-04/05 Modules

External Appearance

The following figure shows the external appearance of the LIO-04/05 Modules.

Outline of Functions

The LIO-04/05 Modules are Optional Boards for the MP2300Siec which provide a digital I/O function. There are 32

digital inputs (DI) and 32 digital outputs (DO) (sink mode outputs) for the digital I/O function.

Indicators

The following table shows the status of LIO-04/05 Module LED indicators.

Indicator Name Indicator Color Status

RUN Green

FU Red

Lit: Module normal

Not lit: Module error

Lit: One of the output protection fuses is blown.

Not lit: All of the output protection fuses are normal.

The burnout detection circuit will not function when there is no external 24V power supply.

YASKAWA America, Inc. MP3300iec Hardware Manual YAI-SIA-IEC-7 51

Page 52

21 Option Module - LIO-04/05 Modules

LD3

LD2

LD1

LD4

LD7

LD6

LD5

LD8

SW1

0

5

1

2

3

4

6

7

8

9

Indicators

Switch Settings

The LIO-04/05 Module status display the LED indicators (LD1 to LD8) change based on the SW1 rotary switch setting.

The following table shows the ON/OFF indicator display for digital input and digital output.

Indicator Color SW1 Status when Lit

Board Status Indicators

LD1 Normal operation: Lit, Error: Not lit

LD2 DI_00 to DI_07 status. Lit when any digital input is turned ON.

LD3 DO_00 to DO_07 status. Lit when any digital output is turned ON.

LD4 Pulse A/B input. Lit when phase A/B is turned ON.

0

LD5 Normal operation: Lit, Error: Not lit

LD6 DI_08 to DI_15 status. Lit when any digital input is turned ON.

LD7 DO_08 to DO_15 status. Lit when any digital output is turned ON.

LD1 to LD8 Green

LD8 Pulse Z input. Lit when phase Z is turned ON.

1 Digital input indicators: When DI_00 to DI_07 turn ON, corresponding indicators LD1 to LD8 are lit.

2 Digital input indicators: When DI_08 to DI_15 turn ON, corresponding indicators LD1 to LD8 are lit.

3 Digital output indicators: When DO_00 to D O _07 tur n ON , corre spo ndin g in d icators LD 1 to LD8 a re lit.

4 Digital output indicators: When DO_08 to D O _15 tur n ON , corre spo ndin g in d icators LD 1 to LD8 a re lit.

PI Input Indicators

LD1

5

LD2

LD3

LD4

Pulse A input

Pulse B input

Pulse Z input

-

LD5

LD6

LD7

LD8

Coincidence detection

Phase-Z latch

Digital input latch

-

Module Specifications

The following table shows the hardware specifications of the LIO-04/05 Module.

Item Specifications

Name LIO-04/LIO-05

Model JAPMC-IO2303/JAPMC-IO2304

32 inputs

24VDC, 4.1 mA, combined sink mode/source mode inputs

(DI_00, 01, 16, and 17 also used for interrupts.)