Page 1

Machine Controller MP3000 Series

MP3300

Product Manual

CPU Module model: JAPMC-CP3301-1-E, -CP3301-2-E, -CP3302-1-E, -CP3302-2-E

Base Unit model: JEPMC-BU3301-E, -BU3302-E, -BU3303-E, -BU3304-E

MANUAL NO. SIEP C880725 21D

Introduction

Appearances and Parts

CPU Module Functionality

Specifications

External Dimensions

1

2

3

4

5

Page 2

Copyright © 2014 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission

of Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to

improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation

of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of

the information contained in this publication.

Page 3

About this Manual

This manual describes the specifications and system configuration of MP3300 Machine Controllers

and the functionality of the CPU Modules.

Read this manual carefully to ensure the correct usage of the Machine Controller and apply the

Machine Controller to control your manufacturing system.

Keep this manual in a safe place so that it can be referred to whenever necessary.

Using this Manual

Basic Terms

Unless otherwise specified, the following definitions are used:

Basic Terms Meaning

MP2000 A Machine Controller in the MP2000 Series

MP3000 A Machine Controller in the MP3000 Series

MPE720 The Engineering Tool or a personal computer running the Engineering Tool

PLC A Programmable Logic Controller

MP3300 A generic name for the CPU Module and Base Unit.

Machine Controller An MP3300 Machine Controller in the MP3000 Series

Motion Control Function Modules

Communications Function Modules

The Function Modules in the Motion Modules and the Function Modules in the

SVC, SVC32, SVR, or SVR32 built into the CPU Modules.

The Function Modules in the Communications Modules and the Function Modules in the 218IFD built into the CPU Module.

MPE720 Engineering Tool Version Number

In this manual, the operation of MPE720 is described using screen captures of MPE720 version 7.

Indication of Reverse Signals

In this manual, the names of reverse signals (ones that are valid when low) are written with a forward slash (/) before the signal name, as shown in the following example:

Notation Examples

• S-ON

• P-CON

= /S-ON

= /P-CON

Terms Used to Describe “Torque”

Although the term “torque” is commonly used when describing rotary Servomotors and “force” is

used when describing linear Servomotors, this manual uses “torque” when describing either one

(excluding parameter names).

Copyrights

• MECHATROLINK is a trademark of the MECHATROLINK Members Association.

• DeviceNet is a registered trademark of the ODVA (Open DeviceNet Venders Association).

• PROFIBUS is a trademark of the PROFIBUS User Organization.

• Ethernet is a registered trademark of the Xerox Corporation.

• Other product names and company names are the trademarks or registered trademarks of the

®

respective company. “TM” and the

manual.

mark do not appear with product or company names in this

iii

Page 4

Important

Example

Information

Term

Visual Aids

The following aids are used to indicate certain types of information for easier reference.

Indicates precautions or restrictions that must be observed.

Indicates alarm displays and other precautions that will not result in machine dam-

age.

Indicates items for which caution is required or precautions to prevent operating mis-

Note

takes.

Indicates operating or setting examples.

Indicates supplemental information to deepen understanding or useful information.

Indicates definitions of difficult terms or terms that have not been previously

explained in this manual.

iv

Page 5

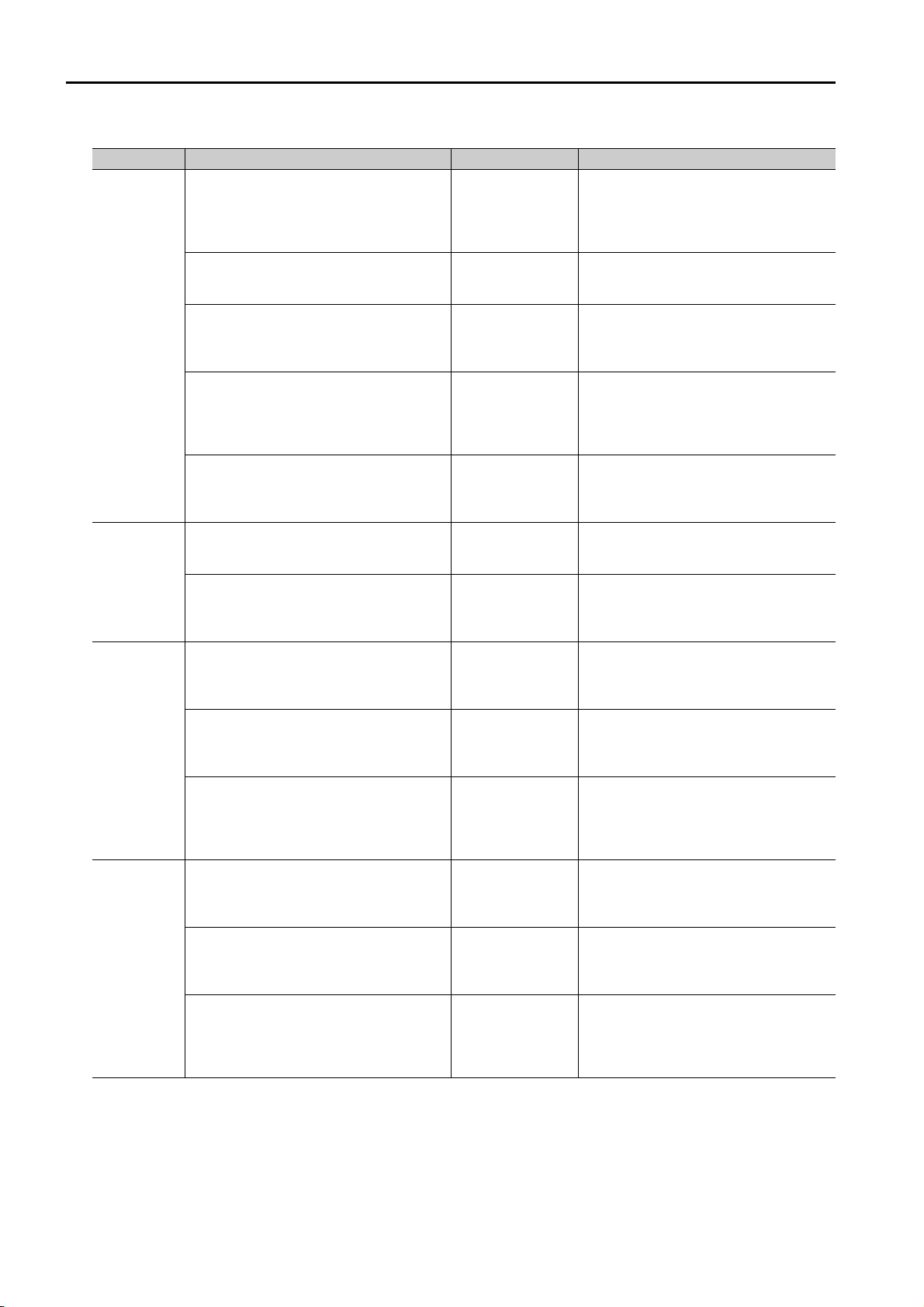

Related Manuals

The following table lists the related manuals. Refer to these manuals as required.

Be aware of all product specifications and restrictions to product application before you attempt to

use any product.

Category Manual Name Manual Number Contents

Describes the functions of the

MP2000/MP3000-series Machine Controllers and the procedures that are

required to use the Machine Controller,

from installation and connections to

settings, programming, trial operation,

and debugging.

Describes troubleshooting an MP3000series MP3200 Machine Controller.

Describes the specifications and system configuration of an MP3000-series

MP3200 Machine Controller and the

functions of the CPU Unit.

Describes the functions, specifications, and application methods of the

MP2200 Machine Controller.

Describes the functions, specifications, operating methods, maintenance, inspections, and

troubleshooting of the MP2000-series

MPU-01 Multi-CPU Module.

Describes the specifications, system

configuration, and communications

connection methods for the Ethernet

communications that are used with an

MP3000-series Machine Controller.

Provides information on the Communications Modules that can be connected

to an MP2000-series Machine Controller and describes the communications

methods.

Describes the specifications and communications methods for the FL-net

Communications Module that can be

connected to an MP2000-series

Machine Controller.

Describes the specifications and communications methods for the EtherNet/

IP Communications Module that can be

connected to an MP2000-series

Machine Controller.

Describes the specifications and communications methods for the CompoNet Communications Module that

can be connected to an MP2000-series

Machine Controller.

Continued on next page.

Basic functionality

Communications functionality

Machine Controller MP2000/MP3000

Series

Machine Controller System

Setup Manual

Machine Controller MP3000 Series

MP3200/MP3300

Troubleshooting Manual

Machine Controller MP3000 Series

MP3200 User’s Manual

Machine Controller MP2200

User’s Manual

Machine Controller MP2000 Series

MPU-01 Multi-CPU Module

User’s Manual

Machine Controller MP3000 Series

Communications

User’s Manual

Machine Controller MP2000 Series

Communication Module

User’s Manual

Machine Controller MP2000 Series

262IF-01 FL-net Communication Module

User’s Manual

Machine Controller MP2000 Series

263IF-01 EtherNet/IP Communication

Module User’s Manual

Machine Controller MP2000 Series

265IF-01 CompoNet Module

User’s Manual

SIEP C880725 00

SIEP C880725 01

SIEP C880725 10

SIEP C880700 14

SIEP C880781 05

SIEP C880725 12

SIEP C880700 04

SIEP C880700 36

SIEP C880700 39

SIEP C880700 44

v

Page 6

Continued from previous page.

Category Manual Name Manual Number Contents

Describes the specifications, system

Motion control functionality

Programming

Engineering

Tools

I/O Modules

Machine Controller MP3000 Series

Motion Control

User’s Manual

Machine Controller MP2000 Series

Pulse Output Motion Module PO-01

User’s Manual

Machine Controller MP2000 Series

SVA-01 Motion Module

User’s Manual

Machine Controller MP2000 Series

Built-in SVB/SVB-01 Motion Module

User’s Manual

Machine Controller MP2000 Series

SVC-01 Motion Module

User’s Manual

Machine Controller MP3000 Series

Ladder Programming Manual

Machine Controller MP3000 Series

Motion Programming Manual

Machine Controller MP2000/MP3000

Series

MPLoader Ver. 4

User’s Manual

Machine Controller MP2000/MP3000

Series

MPLoad Maker Version 4

User’s Manual

Machine Controller MP2000/MP3000

Series

Engineering Tool

MPE720 Version 7

User’s Manual

Machine Controller MP2000 Series

Analog Input/Analog Output Module

AI-01/AO-01 User’s Manual

Machine Controller MP2000 Series

Counter Module CNTR-01

User’s Manual

Machine Controller MP2000 Series

I/O Module

User’s Manual

SIEP C880725 11

SIEP C880700 28

SIEP C880700 32

SIEP C880700 33

SIEP C880700 41

SIEP C880725 13

SIEP C880725 14

SIEP C880761 01

SIEP C880761 02

SIEP C880761 03

SIEP C880700 26

SIEP C880700 27

SIEP C880700 34

configuration, and operating methods

for the SVC32/SVR32 Motion Function

Modules that are used in an MP3000series Machine Controller.

Describes the functions, specifications, and operating methods of the

MP2000-series PO-01 Motion Module.

Describes the functions, specifications, and operating methods of the

MP2000-series SVA-01 Motion Module.

Describes the functions, specifications, and operating methods of the

MP2000-series Motion Module (built-in

Function Modules: SVB, SVB-01, and

SVR).

Describes the functions, specifications, and operating methods of the

MP2000-series SVC-01 Motion Module.

Describes the ladder programming

specifications and instructions of

MP3000-series Machine Controller.

Describes the motion programming

and sequence programming specifications and instructions of MP3000series Machine Controller.

Describes how to install and operate

the MPLoader.

Describes how to install and operate

the MPLoad Maker.

Describes how to operate MPE720 version 7.

Describes the functions, specifications, and operating methods of the AI01 and AO-01 I/O Modules for

MP2000-series Machine Controllers.

Describes the functions, specifications, and operating methods of the

CNTR-01 Counter Module for MP2000series Machine Controllers.

Describes the

tions,

and operating methods of the

LIO-01, LIO-02, LIO-04, LIO-05, LIO06, and DO-01 I/O Modules for

MP2000-series Machine Controllers.

functions, specifica-

Continued on next page.

vi

Page 7

Continued from previous page.

Category Manual Name Manual Number Contents

Describes the functions, specifica-

MECHATROLINK

I/O

MECHATROLINK-III Compatible I/O

Module

User’s Manual

Machine Controller MP900/MP2000

Series

Distributed I/O Module

User’s Manual

MECHATROLINK System

SIEP C880781 04

SIE-C887-5.1

tions, operating methods, and MECHATROLINK-III communications for the

Remote I/O Modules for MP2000/

MP3000-series Machine Controllers.

Describes MECHATROLINK distributed I/O for MP900/MP2000-series

Machine Controllers.

vii

Page 8

DANGER

WARNING

CAUTION

NOTICE

Safety Precautions

Safety Information

To prevent personal injury and equipment damage in advance, the following signal words are used

to indicate safety precautions in this document. The signal words are used to classify the hazards

and the degree of damage or injury that may occur if a product is used incorrectly. Information

marked as shown below is important for safety. Always read this information and heed the precautions that are provided.

Indicates precautions that, if not heeded, are likely to result in loss of life, serious injury, or fire.

Indicates precautions that, if not heeded, could result in loss of life, serious injury, or fire.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury, or in

fire.

Indicates precautions that, if not heeded, could result in property damage.

viii

Page 9

Safety Precautions That Must Always Be Observed

WARNING

CAUTION

General Precautions

The installation must be suitable and it must be performed only by an experienced technician.

There is a risk of electrical shock or injury.

Before connecting the machine and starting operation, make sure that an emergency stop pro-

cedure has been provided and is working correctly.

There is a risk of injury.

Do not approach the machine after a momentary interruption to the power supply. When power

is restored, the Machine Controller and the device connected to it may start operation suddenly.

Provide safety measures in advance to ensure human safety when operation restarts.

There is a risk of injury.

Do not touch anything inside the Machine Controller.

There is a risk of electrical shock.

Do not remove the front cover, cables, connector, or options while power is being supplied.

There is a risk of electrical shock, malfunction, or damage.

Do not damage, pull on, apply excessive force to, place heavy objects on, or pinch the cables.

There is a risk of electrical shock, operational failure of the Machine Controller, or burning.

Do not attempt to modify the Machine Controller in any way.

There is a risk of injury or device damage.

Storage and Transportation Precautions

Do not store the Machine Controller in any of the following locations.

• Locations that are subject to direct sunlight

• Locations that are subject to ambient temperatures that exceed the storage conditions

• Locations that are subject to ambient humidity that exceeds the storage conditions

• Locations that are subject to rapid temperature changes and condensation

• Locations that are subject to corrosive or inflammable gas

• Locations that are subject to excessive dust, dirt, salt, or metallic powder

• Locations that are subject to water, oil, or chemicals

• Locations that are subject to vibration or shock

There is a risk of fire, electrical shock, or device damage.

Hold onto the main body of the Machine Controller when transporting it.

Holding the cables or connectors may damage them or result in injury.

Do not overload the Machine Controller during transportation. (Follow all instructions.)

There is a risk of injury or an accident.

Never subject the Machine Controller to an atmosphere containing halogen (fluorine, chlorine,

bromine, or iodine) during transportation.

There is a risk of malfunction or damage.

If disinfectants or insecticides must be used to treat packing materials such as wooden frames,

pallets, or plywood, the packing materials must be treated before the product is packaged, and

methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56°C for 30 minutes or more.

If the electronic products, which include stand-alone products and products installed in machines,

are packed with fumigated wooden materials, the electrical components may be greatly damaged

by the gases or fumes resulting from the fumigation process. In particular, disinfectants containing

halogen, which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the

capacitors.

ix

Page 10

CAUTION

Installation Precautions

Do not install the Machine Controller in any of the following locations.

• Locations that are subject to direct sunlight

• Locations that are subject to ambient temperatures that exceed the operating conditions

• Locations that are subject to ambient humidity that exceeds the operating conditions

• Locations that are subject to rapid temperature changes and condensation

• Locations that are subject to corrosive or inflammable gas

• Locations that are subject to excessive dust, dirt, salt, or metallic powder

• Locations that are subject to water, oil, or chemicals

• Locations that are subject to vibration or shock

There is a risk of fire, electrical shock, or device damage.

Never install the Machine Controller in an atmosphere containing halogen (fluorine, chlorine,

bromine, or iodine).

There is a risk of malfunction or damage.

Do not step on the Machine Controller or place heavy objects on the Machine Controller.

There is a risk of injury or an accident.

Do not block the air exhaust ports on the Machine Controller. Do not allow foreign objects to

enter the Machine Controller.

There is a risk of internal element deterioration, malfunction, or fire.

Always mount the Machine Controller in the specified orientation.

There is a risk of malfunction.

Leave the specified amount of space between the Machine Controller, and the interior surface

of the control panel and other devices.

There is a risk of fire or malfunction.

Do not subject the Machine Controller to strong shock.

There is a risk of malfunction.

Suitable Battery installation must be performed and it must be performed only by an experi-

enced technician.

There is a risk of electrical shock, injury, or device damage.

Do not touch the electrodes of the Battery.

Static electricity may damage the Battery.

x

Page 11

Wiring Precautions

CAUTION

Check the wiring to be sure it has been performed correctly.

There is a risk of motor run-away, injury, or accidents.

Always use a power supply of the specified voltage.

There is a risk of fire or accident.

In places with poor power supply conditions, ensure that the input power is supplied within the

specified voltage range.

There is a risk of device damage.

Install breakers and other safety measures to provide protection against shorts in external wir-

ing.

There is a risk of fire.

Provide sufficient shielding when using the Machine Controller in the following locations.

• Locations that are subject to noise, such as from static electricity

• Locations that are subject to strong electromagnetic or magnetic fields

• Locations that are subject to radiation

• Locations that are near power lines

There is a risk of device damage.

Configure the circuits to turn ON the power supply to the CPU Module before the 24-V I/O

power supply. Refer to the following manual for details on circuits.

MP3000 Series MP3300 CPU Module Instructions Manual (Manual No.: TOBP C880725 23)

If the power supply to the CPU Module is turned ON after the external power supply, e.g., the 24-V

I/O power supply, the outputs from the CPU Module may momentarily turn ON when the power

supply to the CPU Module turns ON. This can result in unexpected operation that may cause injury

or device damage.

Provide emergency stop circuits, interlock circuits, limit circuits, and any other required safety

measures in control circuits outside of the Machine Controller.

There is a risk of injury or device damage.

If you use MECHATROLINK I/O Modules, use the establishment of MECHATROLINK communi-

cations as an interlock output condition.

There is a risk of device damage.

Connect the Battery with the correct polarity.

There is a risk of battery damage or explosion.

Select the I/O signal wires for external wiring to connect the Machine Controller to external

devices based on the following criteria:

• Mechanical strength

• Noise interference

• Wiring distance

• Signal voltage

Separate the I/O signal cables for control circuits from the power cables both inside and outside

the control panel to reduce the influence of noise from the power cables.

If the I/O signal lines and power lines are not separated properly, malfunction may occur.

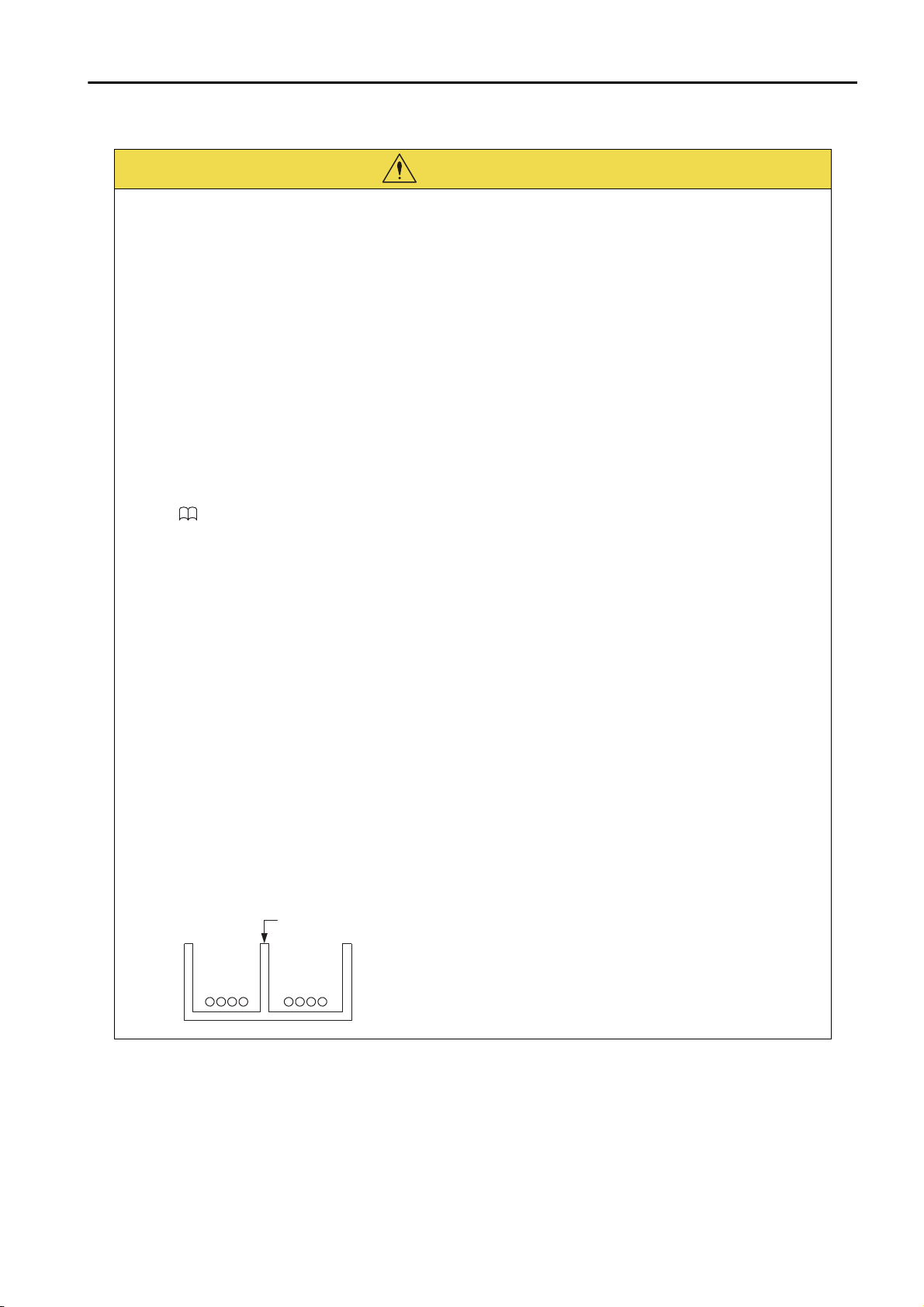

Example of Separated Cables

Power cable

Steel separator

I/O signal

cables in

control circuits

xi

Page 12

CAUTION

CAUTION

Operation Precautions

Follow the procedures and instructions in the user’s manuals for the relevant products to per-

form normal operation and trial operation.

Operating mistakes while the Servomotor and machine are connected may damage the machine or

even cause accidents resulting in injury or death.

Implement interlock signals and other safety circuits external to the Machine Controller to

ensure safety in the overall system even if the following conditions occur.

• Machine Controller failure or errors caused by external factors

• Shutdown of operation due to Machine Controller detection of an error in self-diagnosis and the sub-

sequent turning OFF or holding of output signals

• Holding of the ON or OFF status of outputs from the Machine Controller due to fusing or burning of

output relays or damage to output transistors

• Voltage drops from overloads or short-circuits in the 24-V output from the Machine Controller and

the subsequent inability to output signals

• Unexpected outputs due to errors in the power supply, I/O, or memory that cannot be detected by

the Machine Controller through self-diagnosis.

There is a risk of injury, device damage, or burning.

Maintenance and Inspection Precautions

Do not attempt to disassemble or repair the Machine Controller.

There is a risk of electrical shock, injury, or device damage.

Do not change any wiring while power is being supplied.

There is a risk of electrical shock, injury, or device damage.

Suitable Battery replacement must be performed and it must be performed only by an experi-

enced technician.

There is a risk of electrical shock, injury, or device damage.

Do not forget to perform the following tasks when you replace the CPU Module:

• Back up all programs and parameters from the CPU Module that is being replaced.

• Transfer all saved programs and parameters to the new CPU Module.

If you operate the CPU Module without transferring this data, unexpected operation may occur.

There is a risk of injury or device damage.

Do not touch the heat sink on the CPU Module while the power supply is turned ON or for a suf-

ficient period of time after the power supply is turned OFF.

The heat sink may be very hot, and there is a risk of burn injury.

Disposal Precautions

Dispose of the Machine Controller as general industrial waste.

Observe all local laws and ordinances when you dispose of used Batteries.

General Precautions

The products shown in the illustrations in this manual are sometimes shown without covers or

protective guards. Always replace the cover or protective guard as specified first, and then

operate the products in accordance with the manual.

The illustrations that are presented in this manual are typical examples and may not match the

product you received.

If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representa-

tive or one of the offices listed on the back of this manual.

xii

Page 13

Warranty

Details of Warranty

Warranty Period

The warranty period for a product that was purchased (hereinafter called “delivered product”) is

one year from the time of delivery to the location specified by the customer or 18 months from the

time of shipment from the Yaskawa factory, whichever is sooner.

Warranty Scope

Yaskawa shall replace or repair a defective product free of charge if a defect attributable to

Yaskawa occurs during the warranty period above. This warranty does not cover defects caused

by the delivered product reaching the end of its service life and replacement of parts that require

replacement or that have a limited service life.

This warranty does not cover failures that result from any of the following causes.

• Improper handling, abuse, or use in unsuitable conditions or in environments not described in

product catalogs or manuals, or in any separately agreed-upon specifications

• Causes not attributable to the delivered product itself

• Modifications or repairs not performed by Yaskawa

• Abuse of the delivered product in a manner in which it was not originally intended

• Causes that were not foreseeable with the scientific and technological understanding at the time

of shipment from Yaskawa

• Events for which Yaskawa is not responsible, such as natural or human-made disasters

Limitations of Liability

• Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer

that arises due to failure of the delivered product.

• Yaskawa shall not be responsible for any programs (including parameter settings) or the results of

program execution of the programs provided by the user or by a third party for use with programmable Yaskawa products.

• The information described in product catalogs or manuals is provided for the purpose of the customer purchasing the appropriate product for the intended application. The use thereof does not

guarantee that there are no infringements of intellectual property rights or other proprietary rights

of Yaskawa or third parties, nor does it construe a license.

• Yaskawa shall not be responsible for any damage arising from infringements of intellectual property rights or other proprietary rights of third parties as a result of using the information described

in catalogs or manuals.

Suitability for Use

• It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations

that apply if the Yaskawa product is used in combination with any other products.

• The customer must confirm that the Yaskawa product is suitable for the systems, machines, and

equipment used by the customer.

• Consult with Yaskawa to determine whether use in the following applications is acceptable. If use

in the application is acceptable, use the product with extra allowance in ratings and specifications, and provide safety measures to minimize hazards in the event of failure.

• Outdoor use, use involving potential chemical contamination or electrical interference, or use in conditions

or environments not described in product catalogs or manuals

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, vehicle systems,

medical equipment, amusement machines, and installations subject to separate industry or government

regulations

• Systems, machines, and equipment that may present a risk to life or property

• Systems that require a high degree of reliability, such as systems that supply gas, water, or electricity, or

systems that operate continuously 24 hours a day

• Other systems that require a similar high degree of safety

xiii

Page 14

• Never use the product for an application involving serious risk to life or property without first

ensuring that the system is designed to secure the required level of safety with risk warnings and

redundancy, and that the Yaskawa product is properly rated and installed.

• The circuit examples and other application examples described in product catalogs and manuals

are for reference. Check the functionality and safety of the actual devices and equipment to be

used before using the product.

• Read and understand all use prohibitions and precautions, and operate the Yaskawa product

correctly to prevent accidental harm to third parties.

Specifications Change

The names, specifications, appearance, and accessories of products in product catalogs and

manuals may be changed at any time based on improvements and other reasons. The next editions of the revised catalogs or manuals will be published with updated code numbers. Consult

with your Yaskawa representative to confirm the actual specifications before purchasing a product.

xiv

Page 15

1

Contents

About this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Using this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Introduction

2

1.1

1.2

1.3

1.4

Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.1 MP3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2 Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.3 Main Rack and Expansion Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.4 Rack Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.5 Slot Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Devices and Components That Are Required to Build a System. . . 1-6

1.3.1 MP3300 Module/Unit List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.2 Optional Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Precautions When Setting the Parameters . . . . . . . . . . . . . . . . 1-9

1.4.1 Precautions When Setting the Circuit Numbers . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.2 Precautions When Setting Module Configuration Definitions . . . . . . . . . . . . 1-9

Appearances and Parts

2.1

CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1 Appearance and Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2 Display and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1.3 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.1.4 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.1.5 Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2

Base Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.2.1 Appearance and Part Names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.2.2 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

xv

Page 16

CPU Module Functionality

3

4

3.1

3.2

Basic Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1 Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.1.2 Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.1.3 Execution Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3.1.4 Scans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Function Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

3.2.1 Self Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

3.2.2 Communications Function Module (218IFD) . . . . . . . . . . . . . . . . . . . . . . . .3-45

3.2.3 Motion Control Function Modules (SVC, SVC32, SVR, and SVR32) . . . . . .3-47

3.2.4 The M-EXECUTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3.2.5 Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-66

3.2.6 USB Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-80

3.2.7 File Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-84

3.2.8 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-94

3.2.9 Calendar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-94

3.2.10 Maintenance Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-95

Specifications

4.1

Installation and Usage Conditions . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.1 Installation and Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.1.2 Control Panel Cooling Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.2

4.3

CPU Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.1 Hardware Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.2.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.2.3 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.2.4 Motion Control Function Module Specifications . . . . . . . . . . . . . . . . . . . . . .4-9

4.2.5 M-EXECUTOR Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

4.2.6 USB Memory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

4.2.7 System Register Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Base Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

External Dimensions

5

5.1

5.2

Index

Revision History

CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Base Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

xvi

Page 17

Introduction

This chapter introduces the MP3300.

1

1.1

1.2

1.3

1.4

Definition of Terms . . . . . . . . . . . . . . . . . . . 1-2

1.1.1 MP3300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2 Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.3 Main Rack and Expansion Racks . . . . . . . . . . . . 1-2

1.1.4 Rack Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.1.5 Slot Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Configuration Example . . . . . . . . . . 1-5

Devices and Components That Are Required to Build a System . . 1-6

1.3.1 MP3300 Module/Unit List . . . . . . . . . . . . . . . . . . 1-7

1.3.2 Optional Modules . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Precautions When Setting the Parameters . . .1-9

1.4.1 Precautions When Setting the Circuit Numbers . . . 1-9

1.4.2 Precautions When Setting Module

Configuration Definitions . . . . . . . . . . . . . . . . . . . 1-9

Page 18

1.1 Definition of Terms

CPU Module

+

Base Unit

1.1.1 MP3300

1.1

1.1.1

1.1.2

Definition of Terms

This section defines terms that have specific meanings in this manual.

MP3300

“MP3300” is a collective term that refers to the following CPU Modules and Base Units.

Name Primary Function

CPU Module

Base Unit

Racks

A Rack is a Base Unit with Modules mounted to it.

Connection Example

Stores the module definitions and programs, and interprets the programs. The CPU

Module also controls the Optional Modules.

Provides the backplane to which Modules are mounted and supplies the required

power to the Modules.

1.1.3

Main Rack and Expansion Racks

You can add Units and Optional Modules to a Rack to expand functionality. However, if a

restriction such as the power supply capacity or number of Base Unit slots for one Rack is

exceeded, you must add an Expansion Rack.

You can achieve the following things by adding Units or Optional Modules to a Rack.

• Increase the number of Optional Modules that you can use.

• Increase the number of axes that are controlled.

If you add Racks, the Racks are classified into the Main Rack and Expansion Racks.

Typ e Description

Main Rack

Expansion

Racks

Refer to the following section for an expansion example.

MP3300 Expansion Example

The Main Rack contains the Main CPU Module.

There can be only one Main Rack in any one system configuration.

Expansion Racks are connected to the Main Rack.

You can connect up to three Expansion Racks to the Main Rack. (The Expansion Racks use

EXIOIF Modules.)

on page 1-3

1-2

Page 19

1

Introduction

MP3300 Expansion Example

MP2200

M

B

U

-02

PO

W

ER

DC

EXIOIF

MP2200

M

B

U

-02

PO

W

ER

DC

EXIOIF

MP2200

M

B

U

-02

PO

W

ER

DC

EXIOIF

Main Rack

CPU Module

EXIOIF Module

MP2200 Base Unit*

MP2200 Base Unit*

EXIOIF Module

MP2200 Base Unit*

EXIOIF Module

Expansion Racks with EXIOIF Modules

(up to 3 Racks)

EXIOIF Module*

Rack 1

Rack 2 Rack 3 Rack 4

MP2200

M

BU-02

PO

WER

DC

EXIOIF

MP2200

M

BU-02

PO

WER

DC

EXIOIF

MP2200

M

BU-02

PO

WER

DC

EXIOIF

次回用

An MP3300 expansion example is given in the following figure.

1.1 Definition of Terms

1.1.4 Rack Numbers

1.1.4

*

Refer to the following manual for details on the MP2200 Base Unit and EXIOIF Module.

MP2200 Series User's Manual (Manual No.: SIEP C880700 14)

Rack Numbers

When you add Expansion Racks, the MPE720 automatically assigns a number to each Rack so that the Racks

can be identified.

Rack No. Description

Rack 1 Main Rack

Rack 2

Expansion Racks added by using EXIOIF ModulesRack 3

Rack 4

The following figure illustrates Rack numbers.

1-3

Page 20

1.1 Definition of Terms

1.1.5 Slot Numbers

1.1.5

Slot Numbers

The MPE720 automatically assigns slot numbers to the slots on the Base Unit so that the slots

can be identified.

Numbers 1 to 9* are assigned to the slots in order from the left.

* The highest slot number depends on the specifications of the Base Unit.

1-4

Page 21

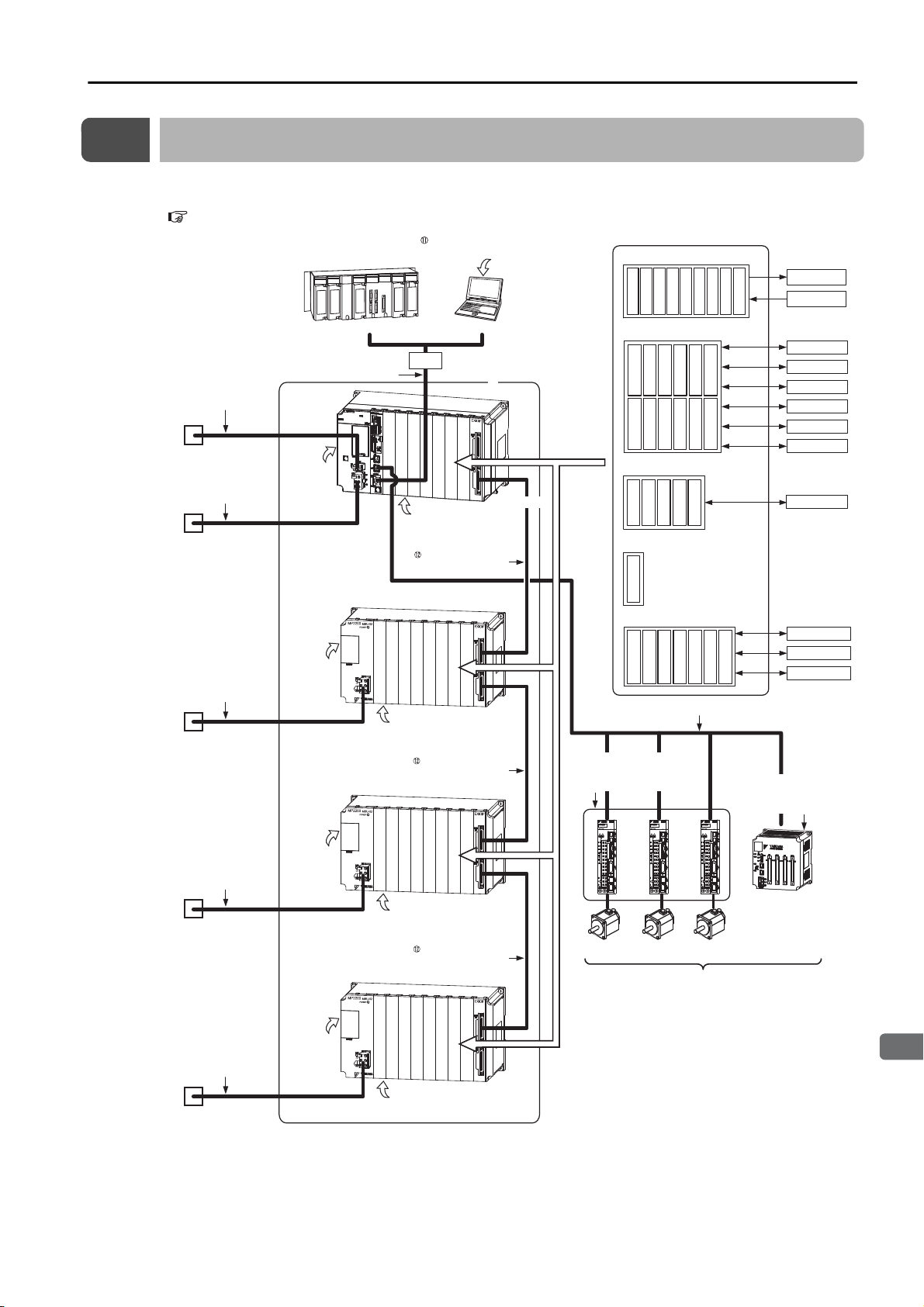

1.2 System Configuration Example

1

Introduction

PC

266IF-02

217IF-01

218IF-01

218IF-02

260IF-01

261IF-01

263IF-01

264IF-01

265IF-01

266IF-01

Communications Modules

SVA-01

SVB-01

PO-01

SVC-01

MPU-01

Motion Modules

EXIOIF

Expansion Rack Module

MPALL00-0

MPAL000-0

AFMP-01

MPANL00-0

AFMP-02-C/-CA

MPAN000-0

Other Modules (including those from

other manufacturers)

External outputs

External inputs

RS-232C

Ethernet

DeviceNet

PROFIBUS

RS422/485

215 communications

SERVOPACK

AnyWire

A-net/A-link

I/O Modules

CC-Link

Up to 21 stations, including I/O (with up to 16 Servo axes.)

Host PLC

LIO-01

LIO-02

LIO-04

LIO-05

DO-01

LIO-06

AI-01

AO-01

CNTR-01

I/O

Servomotor

Servomotor

Servomotor

Optional Modules

MP3300

RLYOUT

connector cable

MPE720 Integrated

Engineering Tool Version 7

Expansion Interface

Module Cable

Expansion Interface

Module Cable

Front cover for unused slot

Front cover for unused slot

Battery

Battery

24-VDC power supply,

AC power supply, or

status monitoring device

Power cable

24-VDC power supply

or AC power supply

262IF-01

215AIF-01

MPCUNET-0

Power cable

24-VDC power supply

or AC power supply

Battery

Power cable

24-VDC power supply

or AC power supply

Expansion Interface

Module Cable

Front cover for unused slot

Battery

Power cable

24-VDC power supply

or AC power supply

MECHATROLINK-III Cable

MECHATROLINK-III

I/O Module with

MECHATROLINK-III

Communications

SERVOPACKs with

MECHATROLINK-III

Communications

Ethernet communications cable

HUB

Front cover for

unused slot

*

Up to 4 Racks

1.2

System Configuration Example

The following figure shows a typical system configuration. Refer to the following section for

details on 1 to 12 in the following figure.

1.3 Devices and Components That Are Required to Build a System on page 1-6

* This manual primarily describes this area.

Note: Supplying Power When Using Expansion Racks

• Either supply power simultaneously to both the Main Rack and Expansion Racks or supply power to the

Expansion Racks first.

• If you turn the power supply OFF and ON again to an Expansion Rack, turn the power supply OFF and

ON again to the Main Rack as well. (Unless of course you turn the power supply OFF and ON again

simultaneously.)

1-5

Page 22

1.3 Devices and Components That Are Required to Build a System

1.3

Devices and Components That Are Required to Build a System

The following table lists the devices and components that are required to build the system that

is shown in 1.2 System Configuration Example on page 1-5. The numbers 1 to 12 correspond

to the numbers in the figure in 1.2 System Configuration Example on page 1-5.

No. Name Use Model Remarks

Stores the module definitions and programs, and

CPU Module

MP3300

Base Unit

Ethernet communica-

tions cables

Battery with Special

Connector

Power supply cable

RLYOUT connector

cable

Front cover for unused

slot

Optional Modules

MECHATROLINK-III

Cable

SERVOPACK with

MECHATROLINK-III

Communications

interprets the programs. The

CPU Module also controls

the Optional Modules.

Provides the backplane to

which Modules are mounted

and supplies the required

power to the Modules.

Used to connect the CPU

Module to Ethernet communications devices or to connect the CPU Module to a

PC that has the MPE720

installed on it.

Provides power for the calendar and backup memory

while the power is turned

OFF.

Connects the power supply

of the Base Unit to a 24VDC power supply or an AC

power supply.

Connects the power supply

of the Base Unit to a 24VDC power supply, an AC

power supply, or a status

monitoring device.

Used to cover unused slots

on the Base Unit.

Motion Modules, I/O Modules, and Communications

Modules are selected based

on the application.

Connects the CPU Module

to MECHATROLINK-III communications devices.

Used to control Servomotors.

Refer to the following section for details.

1.3.1 MP3300 Module/Unit List

Use a commercially available cable that meets

the following conditions:

• Ethernet specification: 100Base-TX

• Category 5 or higher

• Twisted-pair cable with RJ-45 connectors

JZSP-BA01

Use a commercially available cable that meets

the following conditions:

• Wire size: AWG18 to AWG13 (0.8 to 2.6

2

mm

)

• Twisted-pair cable

Use a commercially available cable that meets

the following conditions:

• Wire size: AWG28 to AWG14 (0.08 to 2.0

2

mm

)

JEPMCOP3301-E

Refer to the following section for details.

1.3.2 Optional Modules on page 1-8

JEPMCW6012-E

JEPMCW6013-E

JEPMCW6014-E

SGD7S-

20

SGD7W-

20

The Battery is provided with

the CPU Module.

−

Standard cable

Length: 0.2 to 50 m

Cable with ferrite cores

Length: 10 to 50 m

Cable with loose wires at one

end

Length: 0.5 to 50 m

Σ

7S (Single-axis)

AC SERVOPACK with

MECHATROLINK-III Communications

Σ

7W (Two-axis)

AC SERVOPACK with

MECHATROLINK-III Communications

Continued on next page.

on page 1-7

1-6

Page 23

1.3 Devices and Components That Are Required to Build a System

1

Introduction

11

12

1.3.1 MP3300 Module/Unit List

Continued from previous page.

No. Name Use Model Remarks

64-point I/O

Module

Analog Input

Module

Communications

I/O Modules with MECHATROLINK-III

Analog Output Module

Pulse Train

Input Module

Pulse Train

Output Module

MPE720 Integrated

Engineering Tool Version

7

Expansion Interface

Module Cables

− Panel-mounting Bracket

Used to input or output digital, analog, or pulse train

signals.

Used to adjust, maintain,

and program AC Servo

Drives and Inverters that are

connected to the network.

Used to use an Expansion

Interface Module to connect

the Main Rack to an Expansion Rack or to connect two

Expansion Racks.

Used to mount the MP3300

inside a control panel.

JEPMCMTD2310-E

JEPMCMTA2900-E

JEPMCMTA2910-E

JEPMCMTP2900-E

JEPMCMTP2910-E

CPMCMPE780D

JEPMCW2094-A5-E

JEPMCW2094-01-E

JEPMCW2094-2A5-E

JEPMCOP2300S-E

24 VDC, 64 inputs, 64 outputs

8 analog input channels

4 analog output channels

2 pulse-train inputs

4 pulse-train outputs

−

Length: 0.5 m

Length: 1.0 m

Length: 2.5 m

−

1.3.1

MP3300 Module/Unit List

The following table lists the MP3300 Modules and Units.

Typ e Abbreviation Model Description

CPU Module for 16 axes

Motion Control

Function Modules

Communications

Function Module

CPU Module for for 32 axes

Motion Control

Function Module

Communications

Function Module

Base Unit

* Refer to the following section for details.

3.2.3 Motion Control Function Modules (SVC, SVC32, SVR, and SVR32) on page 3-47

CPU-301 (16 axes) JAPMC-CP3301-1-E −

CPU-302 (16 axes) JAPMC-CP3302-1-E −

SVC − MECHATROLINK-III

SVR − Virtual axes*

218IFD − Ethernet

CPU-301 (32 axes) JAPMC-CP3301-2-E −

CPU-302 (32 axes) JAPMC-CP3302-2-E −

SVC32 − MECHATROLINK-III

SVR32 − Virtual axes*

218IFD − Ethernet

MBU-303 JEPMC-BU3303-E 3 slots

MBU-304 JEPMC-BU3304-E 1 slot

1-7

Page 24

1.3 Devices and Components That Are Required to Build a System

1.3.2 Optional Modules

1.3.2

Optional Modules

You can add the Optional Modules that are listed in the following table for as many open slots

there are in the Base Unit.

Unit Abbreviation Model Description

SVC-01 JAPMC-MC2320-E MECHATROLINK-III × 1

SVB-01 JAPMC-MC2310-E MECHATROLINK-II × 1

Motion

Modules

Communications Modules

I/O

Modules

Expansion

Interface

Module

* Refer to the manuals for individual Optional Modules for details.

SVA-01 JAPMC-MC2300 2-axis analog servo interface

PO-01 JAPMC-PL2310-E 4-axis control with pulse-train output

Optional Module with CPU Module and SVC-01

MPU-01 JAPMC-CP2700-E

217IF-01 JAPMC-CM2310-E RS-232C/RS-422 communications

218IF-01 JAPMC-CM2300-E RS-232C/Ethernet communications (10Base-T)

218IF-02 JAPMC-CM2302-E

260IF-01 JAPMC-CM2320-E RS-232C/DeviceNet communications

261IF-01 JAPMC-CM2330-E RS-232C/PROFIBUS communications

262IF-01 JAPMC-CM2303-E FL-net communications

263IF-01 JAPMC-CM2304-E EtherNet/IP communications

264IF-01 JAPMC-CM2305-E EtherCAT (EtherCAT slave)

265IF-01 JAPMC-CM2390-E

266IF-01 JAPMC-CM2306-E PROFINET master

266IF-02 JAPMC-CM2307-E PROFINET slave

267IF-01 JAPMC-CM23A0 CC-Link master

215AIF-01

AFMP-01 − Anywire-Master DB by Anywire Corporation

AFMP-02-C − CC-Link by Anywire Corporation

AFMP-02-CA −

MPANL00-0 − A-net/A-Link by ALGO System

MPALL00-0 − A-Link/A-Link by ALGO System

MPAL000-0 − A-Link by ALGO System

MPAN000-0 − A-net by ALGO System

MPCUNET-0 − CUnet by ALGO System

LIO-01 JAPMC-IO2300-E 16 inputs, 16 sinking outputs, 1 pulse-train input

LIO-02 JAPMC-IO2301-E 16 inputs, 16 sourcing outputs, 1 pulse-train input

LIO-04 JAPMC-IO2303-E 32 inputs, 32 sinking outputs

LIO-05 JAPMC-IO2304-E 32 inputs, 32 sourcing outputs

LIO-06 JAPMC-IO2305-E

DO-01 JAPMC-DO2300-E 64 sinking outputs

AI-01 JAPMC-AN2300-E 8 analog input channels

AO-01 JAPMC-AN2310-E 4 analog output channels

CNTR-01 JAPMC-PL2300-E 2 counter channels, input circuits: 5 V or 12 V

EXIOIF JAPMC-EX2200-E −

JAPMC-CM2360-E RS-232C/MPLINK communications

JAPMC-CM2361 RS-232C/CP-215 communications

functionality

MECHATROLINK-III × 1

RS-232C/Ethernet communications (100Base-TX/

10Base-T)

CompoNet (I/O communications and message

communications)

CC-Link and Anywire-Master DB by Anywire Corporation

8 digital inputs, 8 digital sinking outputs

1 analog input channel and 1 analog output channel

1 pulse-train counter channel

1-8

Page 25

1.4 Precautions When Setting the Parameters

1

Introduction

1.4.1 Precautions When Setting the Circuit Numbers

1.4

1.4.1

Precautions When Setting the Parameters

Observe the following precautions when setting the Machine Controller.

Precautions When Setting the Circuit Numbers

When assigning circuit numbers to the Motion Control and Communications Function Modules,

the numbers must be within the following ranges.

Circuit

numbers

1 to 16

1 to 8

Function Modules in

CPU Module

Optional Modules

Unit Abbreviations of Built-in Modules

Motion Control

Function Module

Communications

Function Module

Motion Modules

Communications

Modules

SVC and SVR 1 to 16

SVC32 and SVR32 1 to 16

218IFD 1 to 8

SVA-01 (SVA), SVB-01 (SVB01),

SVC-01 (SVC), MPU-01 (MPUIF),

PO-01 (PO)

217IF-01 (217IF) 1 to 16

218IF-01 (218IF), 218IF-02 (218IFB),

260IF-01 (260IF (DeviceNet)),

261IF-01 (261IFS (Profibus)),

262IF-01 (FL-net),

263IF-01 (EtherNet/IP),

264IF-01 (EtherCAT-S),

265IF-01 (Componet),

266IF-01, 266IF-02,

215AIF-01 (MPLINK),

215AIF-01 (CP-215),

267IF-01 (CC-Link)

1.4.2

Precautions When Setting Module Configuration Definitions

Observe the following precautions when writing module configuration definitions.

• Write the module configuration definitions only when the high-speed scan has sufficient

unused processing time.

Otherwise, processing may exceed the time limit of the high-speed scan.

• Before writing module configuration definitions, make sure the machine is not in operation.

• Before you use the Machine Controller, save any written data to flash memory and turn the

power supply to the Racks OFF and ON again.

1-9

Page 26

Appearances and Parts

This section describes the appearance and parts of the

MP3300.

2

2.1

2.2

CPU Module . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1 Appearance and Part Names . . . . . . . . . . . . . . . 2-2

2.1.2 Display and Indicators . . . . . . . . . . . . . . . . . . . . 2-4

2.1.3 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.1.4 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.1.5 Temperature Sensor . . . . . . . . . . . . . . . . . . . . . 2-10

Base Units . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.2.1 Appearance and Part Names . . . . . . . . . . . . . . 2-11

2.2.2 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Page 27

2.1 CPU Module

Display

MECHATROLINK-III status indicators

MECHATROLINK-III connectors

Status indicators

Mode switches

Ethernet status indicators

Ethernet connector

USB status indicator

Display

MECHATROLINK-III status indicators

MECHATROLINK-III connectors

Status indicators

Mode switches

Ethernet status indicators

Ethernet connector

USB status indicator

2.1.1 Appearance and Part Names

2.1

2.1.1

CPU Module

The CPU Module stores the module definitions and programs, and interprets the programs.

The CPU Module also controls the Optional Modules.

This section shows the appearance and part names of the CPU Module and describes the indicators, switches, and connectors.

Appearance and Part Names

The following figure shows the appearance of the CPU Module and the part names.

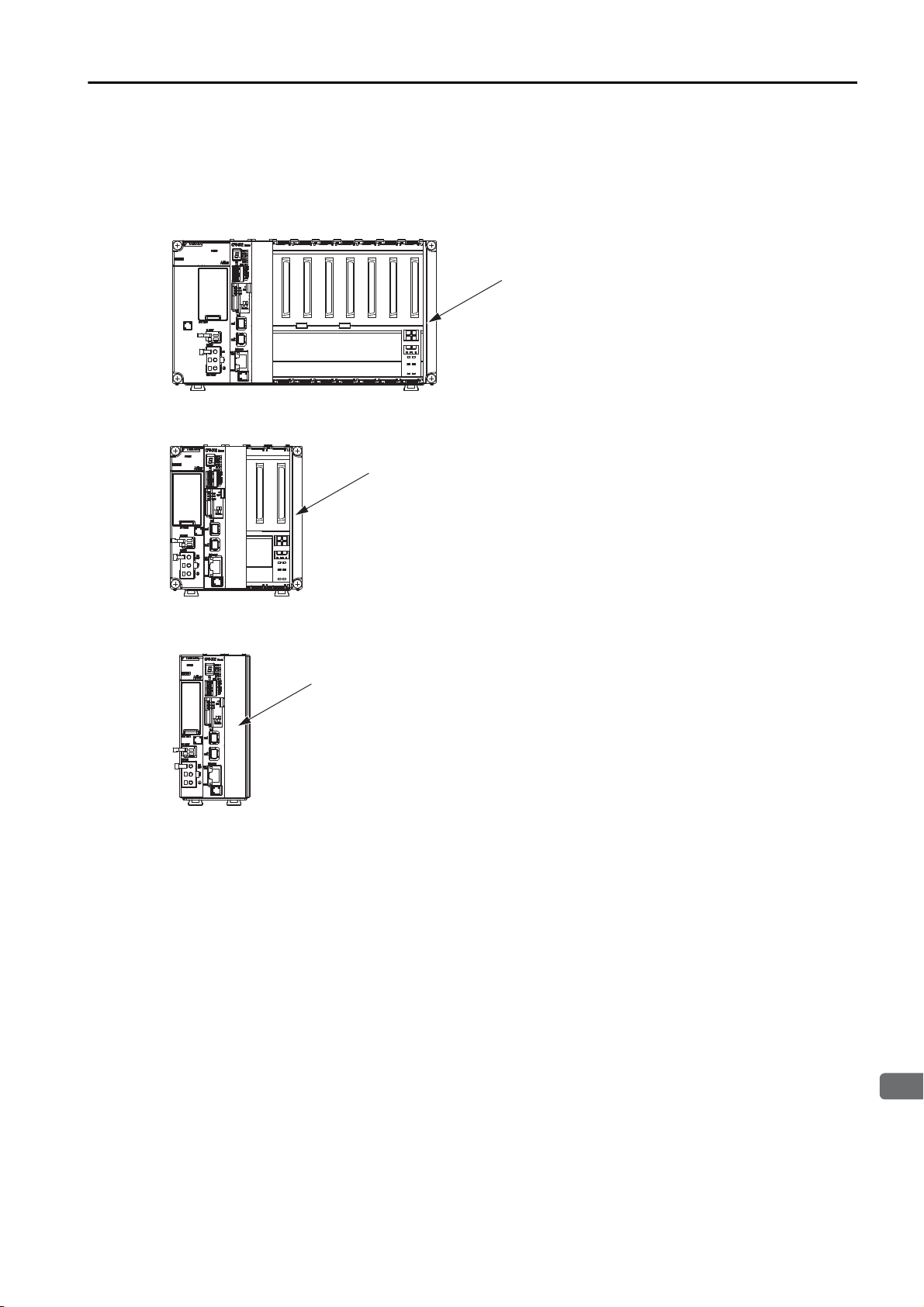

CPU-301

CPU-302

2-2

Page 28

2.1 CPU Module

2

Appearances and Parts

You can mount seven

Optional Modules.

You can mount two

Optional Modules.

You cannot mount any

Optional Modules.

2.1.1 Appearance and Part Names

Precautions When Using a CPU-302 Module

The CPU-302 Module uses the CPU Slot and one option slot. As shown below, the number of

usable Option Modules will be reduced by one when you mount the CPU-302 to any Base Unit.

MBU-01 or MBU-02 (Eight Slots)

MBU-03 (Three Slots)

MBU-04 (One Slot)

2-3

Page 29

2.1 CPU Module

2.1.2 Display and Indicators

2.1.2

Display and Indicators

The CPU Module has the following display and four types of indicators.

• Display

• Status indicators

• USB status indicator

• MECHATROLINK-III status indicators

• Ethernet status indicators

Display

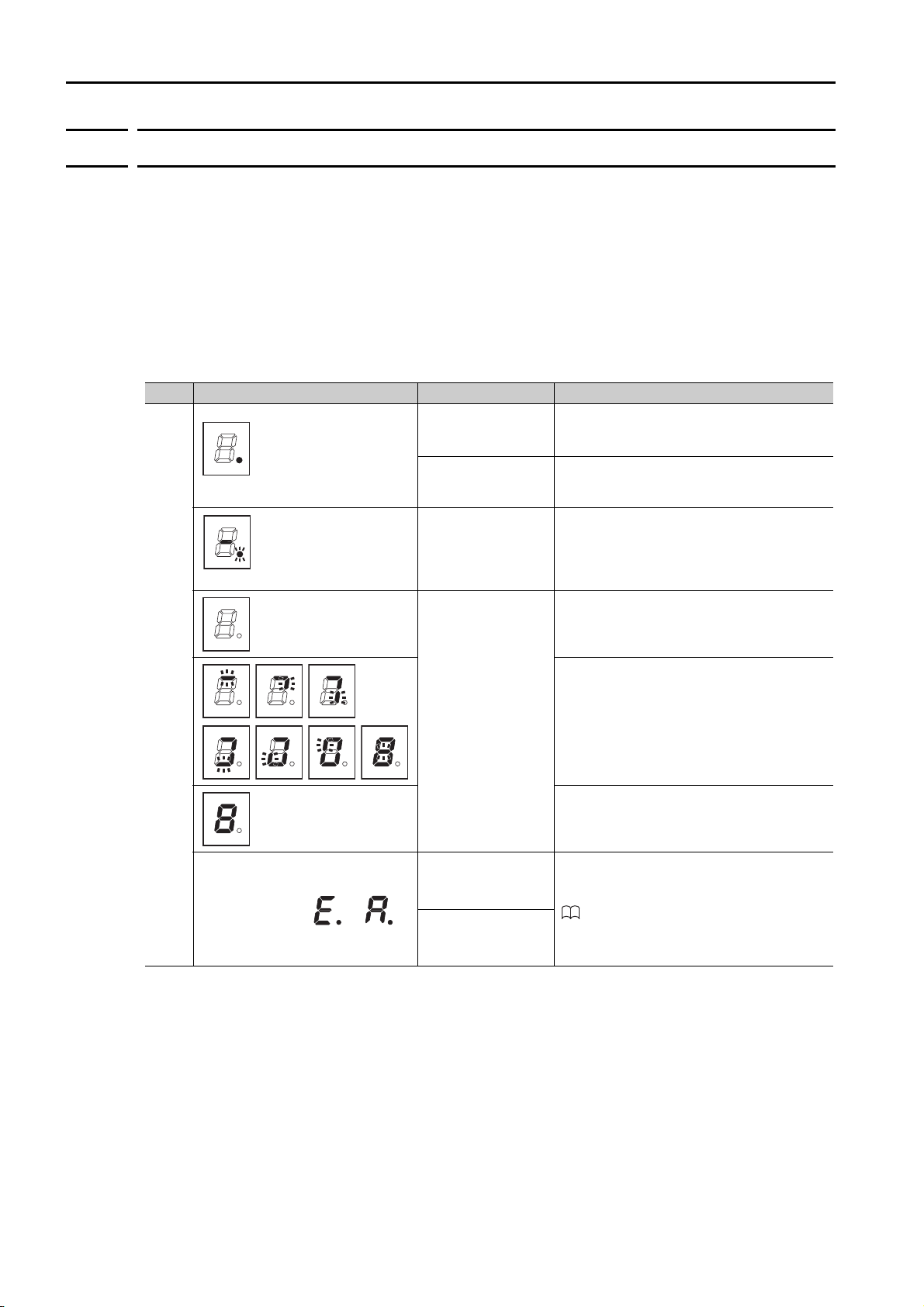

The display shows the execution or error status of the CPU Module.

Color Display Status Description

Lit dot at lower right

Flashing dot at lower right

Initializing

(The RDY status

indicator is not lit.)

Normal operation

(The RDY status

indicator is lit.)

CPU stopped The CPU is stopped.

The CPU Module started normally after the

power was turned ON or after the system

was reset.

The CPU Module is operating normally.

Red

Three digits after or

USB memory batch

transfer

A system error

occurred.

An alarm occurred.

Save or load is starting.

Save or load is in progress.

Save or load was completed.

After 2 seconds, the display will indicate

the status of the CPU Module.

Refer to the following manual for details on

errors.

MP3000 Series MP3200/MP3300 Troubleshooting Manual (Manual No.: SIEP

C880725 01)

2-4

Page 30

2

Appearances and Parts

Status Indicators

These indicators show the status of the CPU Module.

Indicator Name Color Status When Lit*

RDY Green Operation is normal.

RUN Green A user program is being executed.

ALM Red An alarm occurred.

ERR Red An error occurred.

BAT Red The battery alarm occurred.

An error occurred with one of the Servo

axes:

M-ALM Red

* Refer to the following manual for details.

MP3000 Series MP3200/MP3300 Troubleshooting Manual (Manual No.: SIEP C880725 01)

• Warning

• Alarm

• Command Error Completed Status

2.1 CPU Module

2.1.2 Display and Indicators

USB Status Indicator

This indicator shows the status of the USB memory.

Indicator Name Indicator Status Status Description

No USB memory device has been inserted yet,

or the USB memory device is ready to be

removed.

A USB memory device is inserted.

The USB memory is being accessed.

USB

ACTIVE

Not lit

Lit

Flashing

No USB memory device

USB memory

device inserted

Accessing USB

memory

MECHATROLINK-III Status Indicators

These indicators show the status of the MECHATROLINK-III communications.

Indicator

Name

CN Green

LK1 Green MECHATROLINK-III communications are active on PORT1.

LK2 Green MECHATROLINK-III communications are active on PORT2.

Color Status When Lit

MECHATROLINK-III communications is established with the CPU

Module as a slave (i.e., the Connect command is ON).

2-5

Page 31

2.1 CPU Module

2.1.2 Display and Indicators

Ethernet Status Indicators

These indicators show the status of Ethernet communications.

Indicator Name Color Status When Not Lit, Lit, or Flashing

LINK/ACT Yellow

100M Green

Lit: Ethernet link established.

Flashing: Ethernet communications activity.

Not lit: 10 M connection

Lit: 100 M connection

2-6

Page 32

2.1 CPU Module

2

Appearances and Parts

2.1.3 Switches

2.1.3

Switches

The CPU Module has the following two types of switches.

• DIP switches: Mode switches

• STOP/SAVE switch

DIP Switches: Mode Switches

These DIP switches primarily set the operating mode of the CPU Module.

Pin Name Status Operating Mode Default Remarks

STOP

E-INIT

INIT

CNFG

ON Stops the user programs.

OFF

ON

OFF

ON Resets memory.

OFF Normal operation

ON Configuration Mode

OFF Normal operation

Executes the user programs.

Sets the default IP

address.

Does not set the default IP

address.

OFF

OFF

OFF

OFF

Turn ON the pin to stop execution of the user

program.

If this pin is set to ON, the IP address is set to

192.168.1.1.

If this pin is set to OFF, the IP address for the

definition that is stored in flash memory is

used. If there is no definition stored in flash

memory, the IP address is set to 192.168.1.1.

Turn OFF the pin to execute the programs that

are stored in the flash memory.

Turn ON the pin to perform self configuration.

Turn OFF the pin to operate according to the

definitions that are stored in the flash memory.

LOAD

TEST

MNT

−

ON Loads data.

OFF Does not load data.

ON Reserved for system.

OFF Normal operation

ON Reserved for system.

OFF Normal operation

ON Reserved for system.

OFF Normal operation

Turn ON the pin and then turn ON the power

to batch load data from the USB memory to

OFF

OFF Keep this pin OFF at all times.

OFF Keep this pin OFF at all times.

OFF −

the CPU Module.

Refer to the following section for details.

3.2.6 USB Memory on page 3-80

2-7

Page 33

2.1 CPU Module

Open the cover.

STOP/SAVE switch

2.1.3 Switches

STOP/SAVE Switch

This switch is used when removing the USB memory device, or when batch saving data to the

USB memory.

• Lightly press this switch to prepare the USB memory device for removal. The USB memory

device can be safely removed when the USB status indicator changes from flashing to not lit.

• Press and hold this switch for at least 2 seconds to save all of the data to the USB memory.

The display will show the progress of saving.

2-8

Page 34

2.1 CPU Module

2

Appearances and Parts

Open the cover.

USB connector

Note

2.1.4 Connectors

2.1.4

Connectors

The CPU Module has three types of connectors: MECHATROLINK-III, Ethernet, and USB.

MECHATROLINK-III Connectors

These connectors are used to connect MECHATROLINK-III communications devices.

Ethernet Connectors

These connectors are used to connect Ethernet communications devices.

USB Connector

This connector is used to connect a USB memory device.

Before removing the USB memory device, press the STOP/SAVE switch and wait until the USB

status indicator goes out. If the USB memory device is removed while the USB status indicator is

lit or flashing, the data may become corrupted.

2-9

Page 35

2.1 CPU Module

Important

2.1.5 Temperature Sensor

2.1.5

Temperature Sensor

A temperature sensor is built into the CPU Module.

The temperature sensor constantly monitors for abnormal temperatures in the CPU Module. If a

temperature error is detected, an alarm is displayed on the CPU Module.

There are four levels of alarms, as shown in the following table.

Display

A.241 Lit A rise in the internal temperature was detected.

E.081 Lit

E.082 Lit

hLit

ALM Indi-

cator

The temperature continued to increase after A.241 was detected and is

approaching the permissible temperature of the internal parts.

(The CPU Module will stop.)

The temperature continued to increase after E.081 was detected and

has reached the permissible temperature of the internal parts.

(The CPU Module will stop.)

The failsafe function was activated for E.082 (Temperature Warning).

(The CPU Module will stop.)

(This alarm is displayed if the temperature continues to increase after

E.082 was detected.)

If any one of the above alarms occurs, take the following actions.

• A.241: Check the ambient environment and installation conditions.

If you are using natural cooling for the control panel, we recommend that you change to

forced-air cooling.

• E.081, E.082, or h: Turn OFF the power supply to the Machine Controller immediately and

check the ambient environment and installation conditions.

Refer to the following section for details on the ambient environment and installation requirements.

4.1 Installation and Usage Conditions on page 4-2

Error Description

2-10

Page 36

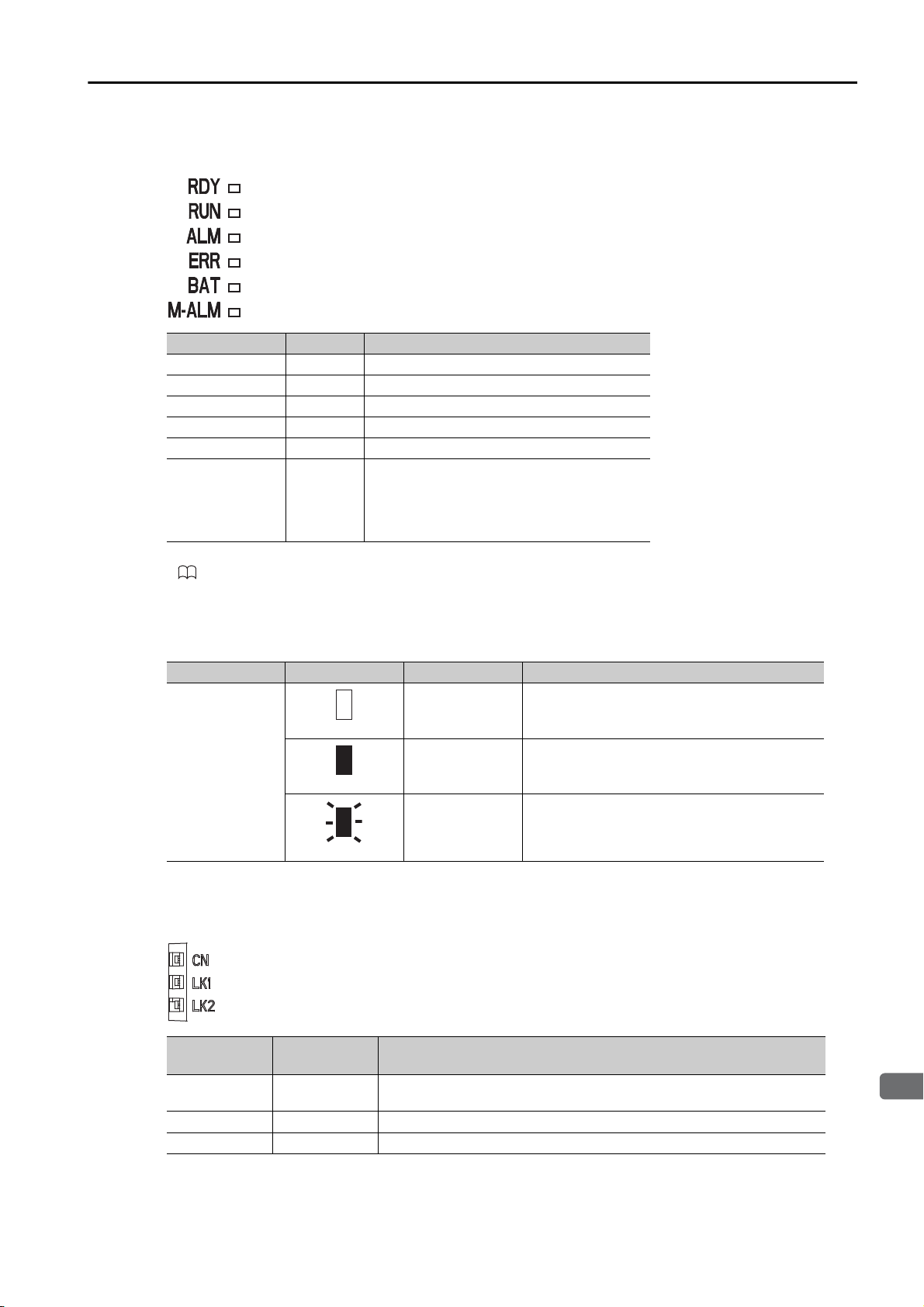

2.2 Base Units

2

Appearances and Parts

RLYOUT connector

Power connector

2.2.1 Appearance and Part Names

2.2

2.2.1

Base Units

The Base Unit provides the backplane to which Modules are mounted and supplies the

required power to the Modules. There are two models of Base Units, a one-slot model and a

three-slot model.

This section shows the appearance and part names of the Base Unit and describes the connector.

Appearance and Part Names

The following figure shows the appearance of the Base Unit and a part name.

2.2.2

Connector

The Base Unit has two connectors: an RLYOUT connector and a power connector.

RLYOUT Connector

This connector outputs the status of the CPU Module.

Model: 734-302

Pin Assignments

No. Signal Label Description

1OUT

2OUT

• Normal operation: Circuit closed.

• Error: Circuit open.

2-11

Page 37

2.2 Base Units

2.2.2 Connector

Power Connector

Connect the power supply to this connector.

AC Power Supply DC Power Supply

AC power supply 3-2134249-3 Black

DC power supply 4-2013522-3 White

Pin Assignments: AC Power Supply

Ty pe Model Color

Pin No. Signal Label Description

3AC AC input

2AC AC input

1 FG Connects to the frame ground. (Ground to 100 Ω max.)

Pin Assignments: DC Power Supply

Pin No. Signal Label Description

3 DC24 V 24-VDC input

2DC0 V 0-VDC input

1 FG Connects to the frame ground. (Ground to 100 Ω max.)

2-12

Page 38

CPU Module Functionality

This chapter describes the functionality of the MP3300

CPU Module.

3

3.1

3.2

Basic Functionality . . . . . . . . . . . . . . . . . . . 3-2

3.1.1 Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

3.1.3 Execution Scheduling . . . . . . . . . . . . . . . . . . . . 3-28

3.1.4 Scans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Function Modules . . . . . . . . . . . . . . . . . . . 3-35

3.2.1 Self Configuration . . . . . . . . . . . . . . . . . . . . . . . 3-35

3.2.2 Communications Function Module (218IFD) . . . 3-45

3.2.3 Motion Control Function Modules

(SVC, SVC32, SVR, and SVR32) . . . . . . . . . . . . 3-47

3.2.4 The M-EXECUTOR . . . . . . . . . . . . . . . . . . . . . . 3-53

3.2.5 Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . 3-66

3.2.6 USB Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-80

3.2.7 File Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-84

3.2.8 Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-94

3.2.9 Calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-94

3.2.10 Maintenance Monitoring . . . . . . . . . . . . . . . . . . 3-95

Page 39

3.1 Basic Functionality

3.1.1 Programs

3.1

3.1.1

Basic Functionality

This section describes the basic functionality of the CPU Module.

Programs

A program is a list of instructions to be processed by the CPU Module.

This section describes the types of programs and gives an overview of each type.

Types of Programs

There are three types of user programs:

• Ladder programs

• Motion programs

• Sequence programs

This section describes these programs.

Ladder Programs

Ladder programs are managed as drawings (ladder diagrams) that are identified by their drawing numbers (DWG numbers). These drawings form the basis of the user program.

Drawing Types and Hierarchical Configuration

This section describes the types of ladder drawings and their hierarchical configuration.

• Ty pe s

Ladder drawings are divided into four different types based on their purpose.

• DWG.A (Startup Drawings)

This type of ladder drawing is used to set register data. These ladder drawings are executed before high-speed scan process drawings and low-speed scan process drawings.

• DWG.I (Interrupt Drawings)

This type of ladder drawing is used to perform processing with priority given to signals

input from an Optional Module. These ladder drawings are executed with higher priority

than high-speed scan process drawings regardless of the scan cycle.

• DWG.H (High-speed Scan Process Drawings)

This type of ladder drawing is used to perform motion control or high-speed I/O control.

• DWG.L (Low-speed Scan Process Drawings)

This type of ladder drawing is used for communications with HMIs and external devices

as well as for standard I/O control.

The following table lists the priority, execution conditions, and maximum number of drawings

for each type of ladder drawing.

Maximum

Drawing Type Priority* Execution Condition

DWG.A (Startup Drawings) 1

DWG.I (Interrupt Drawings) 2

DWG.H (High-speed Scan

Process Drawings)

DWG.L (Low-speed Scan

Process Drawings)

* Drawings with lower numbers have higher priority.

3

4

Power ON (These drawings are executed once

when the power supply is turned ON.)

External interrupt (These drawings are executed

when a DI interrupt or counter match interrupt is

received from an Option Module.)

Started at fixed intervals. (These drawings are

executed once every high-speed scan.)

Started at fixed intervals. (These drawings are

executed once every low-speed scan.)

Number of

Drawings

64

64

1,000

2,000

3-2

Page 40

3.1 Basic Functionality

3

CPU Module Functionality

User Functions

Grandchild

Drawings

Child

Drawings

Parent

Drawing

Note: = A, I, H, or L

DWG. DWG.01

DWG.nn

DWG.01.01

DWG.01.02

FUNC-001

FUNC-006

FUNC-032

FUNC-064

DWG.01.03

DWG notation:

Grandchild drawing number

Parent drawing type (A, I, H, or L)

Child drawing number

Note: The following notation is used for operation error drawings.

Parent drawing type (A, I, H, or L) of the

drawing where the error occurs

Fixed value (00)

DWG. .

DWG. 00

3.1.1 Programs

• Hierarchical Configuration

There are four types of ladder drawings: parent drawings, child drawings, grandchild drawings, and operation error drawings.

• Parent Drawings

These drawings are automatically executed by the system program when the execution

conditions are met.

• Child Drawings

These drawings are executed when they are called from a parent drawing with a SEE

instruction.

• Grandchild Drawings

These drawings are executed when they are called from a child drawing with a SEE

instruction.

• Operation Error Drawings

These drawings are automatically executed by the system program when an operation

error occurs.

A parent drawing cannot call a child drawing from a different type of drawing. Similarly, a child

drawing cannot call a grandchild drawing from a different type of drawing. A parent drawing

cannot call a grandchild drawing directly. The parent drawing first must call the child drawing,

and then the child drawing must call the grandchild drawing. This is called the hierarchical

configuration of drawings.

The following figure shows the parent-child-grandchild structure in which a program is created.

3-3

Page 41

3.1 Basic Functionality

Information

3.1.1 Programs

The breakdown of the number of ladder drawings in each category is given in the following

table.

Drawings

DWG.A DWG.I DWG.H DWG.L

Number of Drawings

Parent Drawings 1111

Operation Error Drawings 1 1 1 1

Child Drawings

Grandchild Drawings

Total of 62 max. Total of 62 max.

Total of 998

max.

Total of 1,998

max.

There are separate functions that can be called from the drawings as required. Functions

are executed when they are called from a parent, child, or grandchild drawing with the

FUNC instruction. You can create up to 2,000 functions.

Execution Processing of Drawings

The drawings are executed by calling them from the top to the bottom, following the hierarchy

of the drawings. The following figure illustrates the execution processing of a high-speed scan

drawing (DWG.H).

Execution is started by the

system program when the

execution condition is met.

Parent Drawing

DWG.H

SEE

H01

Child Drawings Grandchild Drawings

DWG.H01

SEE

H01.H01

DWG.H01.01

FUNC

01

Functions

FUNC 01

END

END

END

SEE

H02

END

Note: 1. The parent drawing is automatically called and executed by the system. Child drawings and grandchild

drawings are executed by calling them from a parent drawing or a child drawing using the SEE instruction.

2. You can call functions from any drawing. You can also call functions from other functions.

3. If an operation error occurs, the operation error drawing for the drawing type will be started automatically.

4. Always specify 00 as the drawing number for operation error drawings.

H02

An operation

error occurs.

END

Execution is

automatically

started by the

system.

H00

END

3-4

Page 42

3.1 Basic Functionality

3

CPU Module Functionality

Information

3.1.1 Programs

Functions

Functions are executed when they are called from a parent, child, or grandchild drawing with

the FUNC instruction.

Functions can be freely called from any drawing. The same function can be called simultaneously from different types of drawings or different levels of drawings. You can also call functions

from other functions that you have created.

The use of functions provides the following merits:

• Easy user program modularization

• Easy user program creation and maintenance

You can use standard functions that are provided by the system, and you can define user functions.

• Standard System Functions

The following functions for communications and other purposes are provided as standard functions in the system. You cannot change the system functions.

Function Name

COUNTER Counter

FINFOUT First-in First-out

TRACE Trace

DTRC-RD Read Data Trace

DTRC-RDE Read Data Trace Extended

MSG-SND Send Message

MSG-SNDE Send Message Extended

MSG-RCV Receive Message

MSG-RCVE Receive Message Extended

ICNS-WR Inverter Parameter Write

ICNS-RD Inverter Parameter Read

MLNK-SVW Write SERVOPACK Parameters

MOTREG-W Write Motion Register

MOTREG-R Read Motion Register

IMPORT Import

IMPORTL Import Extended

EXPORT Export

EXPORTL Export Extended

• User Functions

You can freely program the body of a user function and program the user function definitions.

A maximum of 2,000 user function drawings can be defined.

Refer to the following manual for details on how to define functions.

MP3000 Series Ladder Programming Manual (Manual No.: SIEP C880725 13)

Motion Programs

A motion program is a program that is written in a text-based motion language.

There are two types of motion programs.

Ty pe

Main programs

Subprograms

Designation

Method

MPM

(

=

1 to

512)

MPS

(

=

1 to

512)

Features Number of Programs

• Main programs are called

from a DWG.H drawing.

• Main programs are called

from the M-EXECUTOR program execution definitions.

Subprograms are called from

a main program.

You can create up to 512 motion programs, including the following programs:

• Motion main programs

• Motion subprograms

• Sequence main programs

• Sequence subprograms

3-5

Page 43

3.1 Basic Functionality

Important

MPM001 MPM002 MPM003

MPS010

Main program

Call (MSEE) Call (MSEE) Call (MSEE)

The common

process is

written as a

subprogram.

Subprogram

Main program Main program

3.1.1 Programs

Term

1. The same numbers are used to manage the motion programs and sequence programs. Use a

unique number for each program.

• Motion program numbers are given in the form MPM or MPS.

• Sequence program numbers are given in the form SPM or SPS.

2. The number of motion programs that can be executed simultaneously depends on the model

of the Machine Controller. If the number of simultaneously executable programs is exceeded,

an alarm will occur (No System Work Available Error).

Motion Subprograms

Subprograms are created to perform common operations. They help minimizing the number of

program steps and allow efficient use of memory.

Motion Program Execution

Motion programs are called with an MSEE instruction from a ladder program in an H drawing.

You can also register the motion program in the M-EXECUTOR (Motion Executor) to call it. Refer