Page 1

マシンコントローラMP3000シリーズ

MP3200 CPUユニット

取扱説明書

形式:JEPMC-CP3201-E, -CP3202-E

製品を安全にお使い頂くために,本書を必ずお読みください。

また,本書をお手元に保管していただくとともに,最終的に本製品をご使用になる

ユーザー様のお手元に確実に届けられるよう,お取り計らい願います。

Machine Controller MP3000 Series

MP3200 CPU Unit

INSTRUCTIONS

Model: JEPMC-CP3201-E, -CP3202-E

To properly use the product, read this manual thoroughly and retain

for easy reference, inspection, and maintenance. Ensure the end user

receives this manual.

Contrôleur de Machine Série MP3000

Unité CPU MP3200

INSTRUCTIONS

Modèle: JEPMC-CP3201-E, -CP3202-E

Pour utiliser correctement le produit, lisez attentivement ce manuel.

Conservez-le comme références et pour les cas d’inspections et de

maintenance. Assurez-vous que l’utilisateur final reçoive ce manuel.

MANUAL NO. TOMP C880725 16A

Page 2

Copyright © 2014 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored

in a retrieval system, or transmitted, in any form, or by any means,

mechanical, electronic, photocopying, recording, or otherwise, without

the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover,

because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from

the use of the information contained in this publication.

Page 3

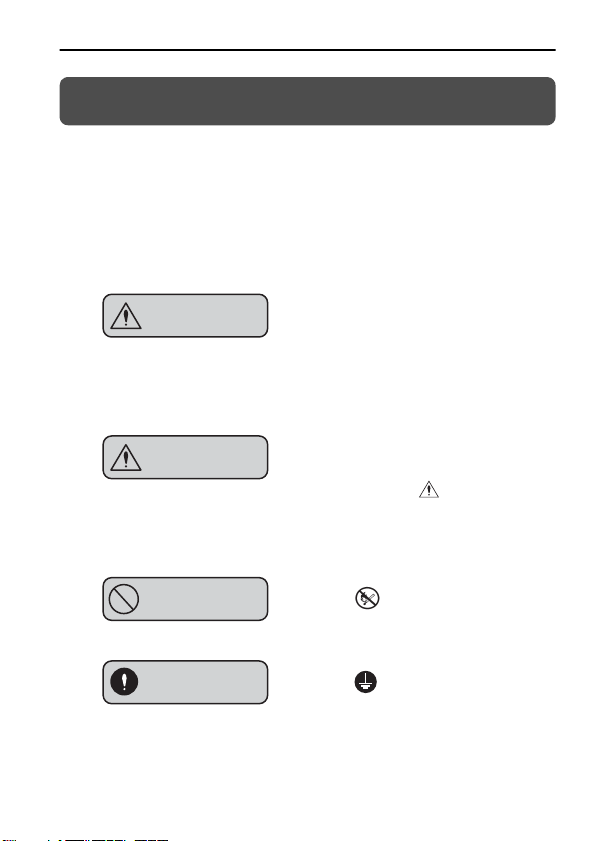

Safety Precautions

The following signal words and marks are used to indicate

safety precautions in this manual.

Information marked as shown below is important for safety.

Always read this information and heed the precautions that are

provided.

Indicates precautions that, if not

WARNING

CAUTION

PROHIBITED

MANDATORY

heeded, could possibly result in loss

of life or serious injury.

Indicates precautions that, if not

heeded, could result in relatively

serious or minor injury, or property

damage.

If not heeded, even precautions classified as cautions ( )

can lead to serious results depending

on circumstances.

Indicates prohibited actions. For

example, indicates prohibition

of open flame.

Indicates mandatory actions. For

example, indicates that grounding is required.

CAUTION

E-1

Page 4

The following precautions are for storage, transportation,

installation, wiring, operation, maintenance, inspection, and

disposal. These precautions are important and must be

observed.

E-2

Page 5

General Precautions

WARNING

• The installation must be suitable and it must be performed only by an experienced technician.

There is a risk of electrical shock or injury.

• Before connecting the machine and starting operation, make sure that an emergency stop procedure

has been provided and is working correctly.

There is a risk of injury.

• Do not approach the machine after a momentary

interruption to the power supply. When power is

restored, the Machine Controller and the device connected to it may start operation suddenly. Provide

safety measures in advance to ensure human safety

when operation restarts.

There is a risk of injury.

• Do not touch anything inside the Machine Controller.

There is a risk of electrical shock.

• Do not remove the front cover, cables, connector, or

options while power is being supplied.

There is a risk of electrical shock, malfunction, or damage.

• Do not damage, pull on, apply excessive force to,

place heavy objects on, or pinch the cables.

There is a risk of electrical shock, operational failure of the

product, or burning.

• Do not attempt to modify the Machine Controller in

any way.

There is a risk of injury or device damage.

E-3

Page 6

Storage and Transportation

CAUTION

• Do not store the Machine Controller in any of the following locations.

• Locations that are subject to direct sunlight

• Locations that are subject to ambient temperatures that

exceed the storage conditions

• Locations that are subject to ambient humidity that exceeds

the storage conditions

• Locations that are subject to rapid temperature changes and

condensation

• Locations that are subject to corrosive or inflammable gas

• Locations that are subject to excessive dust, dirt, salt, or

metallic powder

• Locations that are subject to water, oil, or chemicals

• Locations that are subject to vibration or shock

There is a risk of fire, electrical shock, or device damage.

• Hold onto the main body of the Machine Controller

when transporting it.

Holding the cables or connectors may damage them or

result in injury.

• Do not overload the Machine Controller during transportation. (Follow all instructions.)

There is a risk of injury or an accident.

• Never subject the Machine Controller to an atmosphere containing halogen (fluorine, chlorine, bromine, or iodine) during transportation.

There is a risk of malfunction or damage.

E-4

Page 7

CAUTION

• If disinfectants or insecticides must be used to treat

packing materials such as wooden frames, pallets, or

plywood, the packing materials must be treated

before the product is packaged, and methods other

than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to

a core temperature of 56°C for 30 minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are packed with

fumigated wooden materials, the electrical components

may be greatly damaged by the gases or fumes resulting

from the fumigation process. In particular, disinfectants

containing halogen, which includes chlorine, fluorine, bromine, or iodine can contribute to the erosion of the capacitors.

E-5

Page 8

Installation

CAUTION

• Do not install the Machine Controller in any of the following locations.

• Locations that are subject to direct sunlight

• Locations that are subject to ambient temperatures that

exceed the operating conditions

• Locations that are subject to ambient humidity that exceeds

the operating conditions

• Locations that are subject to rapid temperature changes and

condensation

• Locations that are subject to corrosive or inflammable gas

• Locations that are subject to excessive dust, dirt, salt, or

metallic powder

• Locations that are subject to water, oil, or chemicals

• Locations that are subject to vibration or shock

There is a risk of fire, electrical shock, or device damage.

• Never install the Machine Controller in an atmosphere containing halogen (fluorine, chlorine, bromine, or iodine).

There is a risk of malfunction or damage.

• Do not step on the Machine Controller or place heavy

objects on the Machine Controller.

There is a risk of injury or an accident.

• Do not block the air exhaust ports on the Machine

Controller. Do not allow foreign objects to enter the

Machine Controller.

There is a risk of internal element deterioration, malfunction, or fire.

E-6

Page 9

CAUTION

• Always mount the Machine Controller in the specified

orientation.

There is a risk of malfunction.

• Leave the specified amount of space between the

Machine Controller, and the interior surface of the

control panel and other devices.

There is a risk of fire or malfunction.

• Do not subject the Machine Controller to strong

shock.

There is a risk of malfunction.

• Suitable battery installation must be performed and it

must be performed only by an experienced technician.

There is a risk of electrical shock, injury, or device damage.

• Do not touch the electrodes when installing the Battery.

Static electricity may damage the electrodes.

E-7

Page 10

Wiring

CAUTION

• Check the wiring to be sure it has been performed

correctly.

There is a risk of motor run-away, injury, or accidents.

• Always use a power supply of the specified voltage.

There is a risk of fire or accident.

• In places with poor power supply conditions, ensure

that the input power is supplied within the specified

voltage range.

There is a risk of device damage.

• Install breakers and other safety measures to provide

protection against shorts in external wiring.

There is a risk of fire.

• Provide sufficient shielding when using the Machine

Controller in the following locations.

• Locations that are subject to noise, such as from static elec-

tricity

• Locations that are subject to strong electromagnetic or mag-

netic fields

• Locations that are subject to radiation

• Locations that are near power lines

There is a risk of device damage.

E-8

Page 11

CAUTION

• Configure the circuits to turn ON the power supply to

the CPU Unit before the 24-V I/O power supply.

If the power supply to the CPU Unit is turned ON after the

external power supply, e.g., the 24-V I/O power supply, the

outputs from the CPU Unit may momentarily turn ON

when the power supply to the CPU Unit turns ON. This

can result in unexpected operation that may cause injury or

device damage.

• Provide emergency stop circuits, interlock circuits,

limit circuits, and any other required safety measures

in control circuits outside of the Machine Controller.

There is a risk of injury or device damage.

• If you use MECHATROLINK I/O Modules, use the

establishment of MECHATROLINK communications

as an interlock output condition.

There is a risk of device damage.

• Connect the Battery with the correct polarity.

There is a risk of battery damage or explosion.

• Suitable battery replacement must be performed and

it must be performed only by an experienced technician.

There is a risk of electrical shock, injury, or device damage.

• Do not touch the electrodes when replacing the Battery.

Static electricity may damage the electrodes.

E-9

Page 12

Example of Separated Cables

Power cable

I/O signal

cables in

control circuits

Steel separator

CAUTION

• Select the I/O signal wires for external wiring to connect the Machine Controller to external devices

based on the following criteria:

• Mechanical strength

• Noise interference

• Wiring distance

• Signal voltage

• Separate the I/O signal cables for control circuits

from the power cables both inside and outside the

control panel to reduce the influence of noise from

the power cables.

If the I/O signal lines and power lines are not separated

properly, malfunction may occur.

E-10

Page 13

Operation

CAUTION

• Follow the procedures and instructions in the user’s

manuals for the relevant products to perform normal

operation and trial operation.

Operating mistakes while the Servomotor and machine are

connected may damage the machine or even cause accidents resulting in injury or death.

• Implement interlock signals and other safety circuits

external to the Machine Controller to ensure safety in

the overall system even if the following conditions

occur.

• Machine Controller failure or errors caused by external fac-

tors

• Shutdown of operation due to Machine Controller detection

of an error in self-diagnosis and the subsequent turning OFF

or holding of output signals

• Holding of the ON or OFF status of outputs from the

Machine Controller due to fusing or burning of output relays

or damage to output transistors

• Voltage drops from overloads or short-circuits in the 24-V

output from the Machine Controller and the subsequent

inability to output signals

• Unexpected outputs due to errors in the power supply, I/O, or

memory that cannot be detected by the Machine Controller

through self-diagnosis.

There is a risk of injury, device damage, or burning.

E-11

Page 14

CAUTION

Maintenance and Inspection

CAUTION

• Do not attempt to disassemble or repair the Machine

Controller.

There is a risk of electrical shock, injury, or device damage.

• Do not change any wiring while power is being supplied.

There is a risk of electrical shock, injury, or device damage.

• Do not forget to perform the following tasks when you

replace the CPU Unit:

• Back up all programs and parameters from the CPU Unit that

is being replaced.

• Transfer all saved programs and parameters to the new CPU

Unit.

If you operate the CPU Unit without transferring this data,

unexpected operation may occur. There is a risk of injury

or device damage.

Disposal

• Dispose of the Machine Controller as general industrial waste.

E-12

Page 15

CAUTION

• Observe all local laws and ordinances when you dispose of used Batteries.

Other General Precautions

Observe the following general precautions to

ensure safe application.

• The products shown in the illustrations in this manual

are sometimes shown without covers or protective

guards. Always replace the cover or protective guard

as specified first, and then operate the products in

accordance with the manual.

• The illustrations that are presented in this manual are

typical examples and may not match the product you

received.

• If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or

one of the offices listed on the back of this manual.

E-13

Page 16

Warranty

Details of Warranty

Warranty Period

The warranty period for a product that was purchased (hereinafter called “delivered product”) is one year from the time of

delivery to the location specified by the customer or 18 months

from the time of shipment from the Yaskawa factory, whichever is sooner.

Warranty Scope

Yaskawa shall replace or repair a defective product free of

charge if a defect attributable to Yaskawa occurs during the

warranty period above. This warranty does not cover defects

caused by the delivered product reaching the end of its service

life and replacement of parts that require replacement or that

have a limited service life.

This warranty does not cover failures that result from any of

the following causes.

• Improper handling, abuse, or use in unsuitable conditions

or in environments not described in product catalogs or

manuals, or in any separately agreed-upon specifications

• Causes not attributable to the delivered product itself

• Modifications or repairs not performed by Yaskawa

• Abuse of the delivered product in a manner in which it

was not originally intended

E-14

Page 17

• Causes that were not foreseeable with the scientific and

technological understanding at the time of shipment from

Ya sk a wa

• Events for which Yaskawa is not responsible, such as

natural or human-made disasters

Limitations of Liability

• Yaskawa shall in no event be responsible for any damage

or loss of opportunity to the customer that arises due to

failure of the delivered product.

• Yaskawa shall not be responsible for any programs

(including parameter settings) or the results of program

execution of the programs provided by the user or by a

third party for use with programmable Yaskawa products.

• The information described in product catalogs or manuals is provided for the purpose of the customer purchasing the appropriate product for the intended application.

The use thereof does not guarantee that there are no

infringements of intellectual property rights or other proprietary rights of Yaskawa or third parties, nor does it

construe a license.

• Yaskawa shall not be responsible for any damage arising

from infringements of intellectual property rights or

other proprietary rights of third parties as a result of

using the information described in catalogs or manuals.

E-15

Page 18

Suitability for Use

• It is the customer’s responsibility to confirm conformity

with any standards, codes, or regulations that apply if the

Yaskawa product is used in combination with any other

products.

• The customer must confirm that the Yaskawa product is

suitable for the systems, machines, and equipment used

by the customer.

• Consult with Yaskawa to determine whether use in the

following applications is acceptable. If use in the application is acceptable, use the product with extra allowance

in ratings and specifications, and provide safety measures to minimize hazards in the event of failure.

• Outdoor use, use involving potential chemical contamination

or electrical interference, or use in conditions or environments

not described in product catalogs or manuals

• Nuclear energy control systems, combustion systems, railroad

systems, aviation systems, vehicle systems, medical equipment, amusement machines, and installations subject to separate industry or government regulations

• Systems, machines, and equipment that may present a risk to

life or property

• Systems that require a high degree of reliability, such as systems that supply gas, water, or electricity, or systems that operate continuously 24 hours a day

• Other systems that require a similar high degree of safety

E-16

Page 19

• Never use the product for an application involving seri-

ous risk to life or property without first ensuring that the

system is designed to secure the required level of safety

with risk warnings and redundancy, and that the Yaskawa

product is properly rated and installed.

• The circuit examples and other application examples

described in product catalogs and manuals are for reference. Check the functionality and safety of the actual

devices and equipment to be used before using the product.

• Read and understand all use prohibitions and precau-

tions, and operate the Yaskawa product correctly to prevent accidental harm to third parties.

Specifications Change

The names, specifications, appearance, and accessories of

products in product catalogs and manuals may be changed at

any time based on improvements and other reasons. The next

editions of the revised catalogs or manuals will be published

with updated code numbers. Consult with your Yaskawa representative to confirm the actual specifications before purchasing

a product.

E-17

Page 20

Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1

Confirmations Upon Delivery . . . . . . . . . 19

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2

Installation . . . . . . . . . . . . . . . . . . . . . . . 21

3

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Wiring Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4

Inspections . . . . . . . . . . . . . . . . . . . . . . . 28

Daily Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Periodic Inspections . . . . . . . . . . . . . . . . . . . . . . . . . 30

Replacement Guidelines for Machine Controller

Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5

EMC Standard Compliance . . . . . . . . . . 32

Revision History . . . . . . . . . . . . . . . . . . . 33

E-18

Page 21

1 Confirmations Upon Delivery

1

Confirmations Upon Delivery

Please confirm the following items as soon as you receive the

Machine Controller.

Item Confirmation Method

Have you received the correct

Machine Controller as

ordered?

Is the Machine Controller

damaged in any way?

Check the model number on the

nameplate on the side of the

Machine Controller. Check all

accessories as well.

Check the appearance of the entire

Machine Controller for any damage

that might have occurred during

shipment.

If you find any problems with the above items, contact the

place of purchase or your Yaskawa representative immediately.

E-19

Page 22

1 Confirmations Upon Delivery

cpu

Nameplate

Model number

Version

MAC address

Serial number

/1&'.

8'4

/#%#&&$

+0&%106'3

E-20

Page 23

2

Installation

Refer to the following manual for details on installing the

Machine Controller.

MP2000/MP3000 Series Machine Controller System Setup Manual

(Manual No.: SIEP C880725 00)

Precautions for the installation location are given in the following table.

2 Installation

Installation

Condition

Installation in a

control panel

Installation near

heat-generating

objects

Installation near

sources of vibration

Installation Precautions

• Design the control panel size, Machine Controller location, and cooling method so that

the ambient temperature around the Machine

Controller does not exceed 55°C.

• If you install Machine Controllers side by

side, install a cooling fan above them.

• Provide gaps above and below the Machine

Controller.

Suppress temperature increases due to radiant

heat or convection from the heat-generating

object so that the ambient temperature around

the Machine Controller does not exceed 55°C.

Install a vibration-absorbing device on the

installation surface for the Machine Controller

to prevent vibration from reaching the Machine

Controller.

Continued on next page.

E-21

Page 24

2 Installation

Installation

Installation in

locations subject

to corrosive gas

Others

Condition

Continued from previous page.

Installation Precautions

Take measures to prevent corrosive gas from

entering the Machine Controller. Although the

Machine Controller would not be affected

immediately, the Machine Controller or contact

devices may fail in the future if exposed to corrosive gas.

• Do not install the Machine Controller in locations that are subject to high temperatures or

high humidity, or subject to excessive

amounts of dust, dirt, or iron powder.

• Do not subject the Machine Controller to

freezing or condensation.

• For long-term reliability, use the Machine

Controller at an ambient temperature of 45°C

or less.

E-22

Page 25

3

CAUTION

Wiring

Refer to the following manual for details on connecting the

Machine Controller.

MP2000/MP3000 Series Machine Controller System Setup Manual

(Manual No.: SIEP C880725 00)

Wiring Precautions

Wiring precautions are given below.

• Configure the circuits to turn ON the power

supply to the CPU Unit before the 24-V I/O

power supply.

If the power supply to the CPU Unit is turned ON

after the external power supply, e.g., the 24-V I/O

power supply, the outputs from the CPU Unit may

momentarily turn ON when the power supply to the

CPU Unit turns ON. This can result in unexpected

operation that may cause injury or device damage.

• If you use MECHATROLINK I/O Modules, use

the establishment of MECHATROLINK communications as an interlock output condition.

There is a risk of device damage.

3 Wiring

E-23

Page 26

3 Wiring

cpu

A power-ON sequence and an example circuit configuration

are given below.

Outputs Connected to Relays or Solenoids

Configure circuits that will turn ON the power supply to the

output devices (relays, solenoids, etc.) only after the CPU

RUN output (interlock output) from the CPU Unit turns ON.

<Power-ON Sequence>

Power source to

Power Supply Unit

CPU RUN signal

Power source to

output devices

OFF

OFF

OFF

ON

ON

ON

E-24

Page 27

3 Wiring

cpu

<Example Circuit Configuration>

Power supply

MP3200 and Output Module

Interlock output

SB000004

CPU RUN

OB000000

RA1

Power supply ON relay

for output devices

DC power supply

RA1

DC power supply

Output Module

Output devices

SB000004: Always ON Coil

(ON while the CPU Unit is operating normally.)

OB000000: Interlock output

Note: The MP3200 includes the Power Supply Unit, CPU Unit, and

Base Unit.

The circuit configuration example is for an Output Module added

to the MP3200.

E-25

Page 28

3 Wiring

cpu

Outputs Connected to Other Input and

Output Devices

Connect the CPU RUN output (interlock output) from the

CPU Unit to other input and output devices as an interlock

signal, and confirm that the CPU RUN output from the CPU

Unit is ON before using inputs and outputs on other devices.

The other inputs and outputs are not valid until the CPU RUN

output turns ON.

<Power-ON Sequence>

Power source to

Power Supply Unit

CPU RUN output

Interlock single input to other

input and output devices

Inputs and outputs on

other devices

OFF

OFF

Inputs and outputs are valid.

ON

ON

E-26

Page 29

3 Wiring

cpu

<Example Circuit Configuration>

MP3200 and Output Module

Interlock

SB000004

SB000004: Always ON Coil

(ON while the CPU Unit is operating normally.)

OB000000: Interlock output

output

CPU RUN

OB000000

* Design the circuits so that input and output signals from other input

Other Input and Output Devices

Interlock

signal input

Input and

output signals

and output devices are used only after the interlock signal turns ON.

Note: The MP3200 includes the Power Supply Unit, CPU Unit, and

Base Unit.

The circuit configuration example is for an Output Module added

to the MP3200.

∗

E-27

Page 30

4 Inspections

4

Inspections

Perform inspections and part replacements according to the

information that is provided in this section.

Daily Inspections

The daily inspection items are given in the following table.

Inspection Item Description Criteria Correction

Installation

condition

Connection

conditions

Loose screws

or covers

Loose terminal screws

Connectors

Separation

between

crimped terminals

All screws

and covers

must be

secure.

Screws must

not be loose.

Connectors

must not be

loose.

Suitable gaps

must be maintained.

Continued on next page.

Tighten the

screws.

Tighten the

terminal

screws.

Tighten the

lock screws

on the connectors.

Correct the

gaps.

E-28

Page 31

4 Inspections

Continued from previous page.

Inspection Item Description Criteria Correction

Must be lit.

RDY indicator

Check the

status.

(Otherwise,

there is an

error.)

Must be lit.

(Otherwise,

there is an

error.)

Must not be

lit. (Other-

wise, there is

an error.)

Must not be

lit. (Other-

wise, there is

Refer to the

relevant man-

*

ual.

Indicators

RUN indicator

ALM indicator

ERR indicator

Check the

status in

RUN mode.

Check the

status.

Check the

status.

an error.)

Must not be

BAT indicator

Check the

status.

lit. (Other-

wise, the bat-

Replace the

Battery.

tery is low.)

M_ALM

indicator

Check the

status.

Must not be

lit. (Other-

wise, there is

an axis alarm.)

Refer to the

relevant man-

*

ual.

* MP3000-series MP3200/MP3300 Troubleshooting Manual

(Manual No.: SIEP C880725 01)

E-29

Page 32

4 Inspections

Periodic Inspections

Perform the following inspections at least once a year.

*

Inspection

Period

At least 1 or 2

times every 6

to 12 months

At least 1 time

a year

Description Correction

Measure the

temperature and

humidity with a

hydrometer and

thermometer and

measure corrosive gas. They

must be within

specifications.

There must be

no dirt, dust, oil,

or other foreign

matter on the

Machine Controller.

There must be

no looseness in

terminal screws

or connector

lock screws.

Inspection Item

Ambient

tempera-

ture

Ambient

Ambient

condi-

humidity

tions

Atmosphere

Vis ua l ex ter ior

inspection

Loose screws

Remove

sources of

contamination or

improve the

installation

environment.

Clean the

Machine

Controller

with air or a

cloth.

Tighten the

screws.

E-30

* If the Machine Controller is installed in a panel, the temperature

inside the panel is the ambient temperature.

Page 33

4 Inspections

Replacement Guidelines for Machine Controller Parts

Electrical and electronic parts have a limited service life due

to mechanical wear and deterioration over time. Perform periodic inspections for preventive maintenance.

Contact your Yaskawa representative for replacements based

on the standard replacement periods that are given in the following table. Yaskawa will inspect your Machine Controller

and determine if part replacement is required.

Yaskawa will initialize the settings of all parameters to the

default values in Machine Controllers that are returned for

overhaul. Before you start operation again, make sure that you

reset the parameters that are required for operation.

Standard

Part Name

Battery

FAN 5 years

Replacement

Period

3 years

2 years

*

*

Application Conditions

• Ambient temperature:

55°C or less

• Operation: 16 hours/day

• Ambient temperature:

55°C or less

• Operation: 12 hours/day

Ambient temperature:

40°C or less

* Replace the Battery when the total time that the product is not in

operation reaches 1 year (8,760 hours).

E-31

Page 34

5 EMC Standard Compliance

5

EMC Standard Compliance

The Machine Controller complies with the following EMC

standards: EN 55011 group 1 class A, EN 61000-6-2, and EN

61000-6-4. However, the Machine Controller is an electric

device that is used as part of a machine or manufacturing

equipment. Therefore, the EMC performance will also depend

on the configuration of the actual system, wiring conditions,

and other conditions. It is the user’s responsibility to confirm

EMC standard compliance for the overall machine or equipment.

E-32

Page 35

Revision History

MANUAL NO.

TOMP C880725 16A

<1>

Published in Japan

November 2014

Date of publication

Revision number

cpu

The revision dates and numbers of the revised manuals are given on

the bottom of the back cover.

Date of

Publication

May 2015 <2>

November 2014 <1>

September 2014 −

Rev.

Section Revised Contents

No.

Front cover,

back cover

Back cover Revision: Address

− First edition

Revision: Format

E-33

Page 36

Machine Controller MP3000 Series

MP3200 CPU Unit

INSTRUCTIONS

IRUMA BUSINESS CENTER (SOLUTION CENTER)

480, Kamifujisawa, Iruma, Saitama, 358-8555, Japan

Phone 81-4-2962-5151 Fax 81-4-2962-6138

http://www.yaskawa.co.jp

YASKAWA AMERICA, INC.

2121, Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone 1-800-YASKAWA (927-5292) or 1-847-887-7000 Fax 1-847-887-7310

http://www.yaskawa.com

YASKAWA ELÉTRICO DO BRASIL LTDA.

777, Avenida Piraporinha, Diadema, São Paulo, 09950-000, Brasil

Phone 55-11-3585-1100 Fax 55-11-3585-1187

http://www.yaskawa.com.br

YASKAWA EUROPE GmbH

185, Hauptstraβe, Eschborn, 65760, Germany

Phone 49-6196-569-300 Fax 49-6196-569-398

http://www.yaskawa.eu.com

YASKAWA ELECTRIC KOREA CORPORATION

9F, Kyobo Securities Bldg. 26-4, Yeouido-dong, Yeongdeungpo-gu, Seoul, 150-737, Korea

Phone 82-2-784-7844 Fax 82-2-784-8495

http://www.yaskawa.co.kr

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151, Lorong Chuan, #04-02A, New Tech Park, 556741, Singapore

Phone 65-6282-3003 Fax 65-6289-3003

http://www.yaskawa.com.sg

YASKAWA ELECTRIC (THAILAND) CO., LTD.

252/125-126, 27th Floor, Muang Thai-Phatra Tower B, Rachadapisek Road, Huaykwang, Bangkok, 10310, Thailand

Phone 66-2693-2200 Fax 66-2693-4200

http://www.yaskawa.co.th

YASKAWA ELECTRIC (CHINA) CO., LTD.

22F, One Corporate Avenue, No.222, Hubin Road, Shanghai, 200021, China

Phone 86-21-5385-2200 Fax 86-21-5385-3299

http://www.yaskawa.com.cn

YASKAWA ELECTRIC (CHINA) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No.1, East Chang An Ave.,

Dong Cheng District, Beijing, 100738, China

Phone 86-10-8518-4086 Fax 86-10-8518-4082

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei, 104, Taiwan

Phone 886-2-2502-5003 Fax 886-2-2505-1280

In the event that the end user of this product is to be the military and said product is

to be employed in any weapons systems or the manufacture thereof, the export will

fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign

Trade Regulations. Therefore, be sure to follow all procedures and submit all relevant

documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications

and improvements.

© 2014-2015 YASKAWA ELECTRIC CORPORATION

MANUAL NO. TOMP C880725 16A <2>-0

Published in Japan May 2015

14-9-10

Page 37

한국 전파법에 관한 주의사항

韓国電波法に関連する注意事項

Precautions for Korean Radio Waves Act

针对韩国电波法的注意事项

Précautions pour la Loi coréenne relative aux ondes radio

사용자 안내문

기종별 사용자 안내문

A급 기기

( 업무용 방송

통신기 자재 )

이 기기는 업무용 (A 급 ) 전자파 적합 기기로서 판매자

또는 , 사용자는 이 점을 주의하시기 바라며 , 가정외의

지역에서 사용하는 것을 목적으로 합니다 .

Loading...

Loading...