Page 1

Machine Controller MP2000 Series

Analog Input/Analog Output Module

AI-01/AO-01 USER'S MANUAL

Model: JAPMC-AN2300-E

JAPMC-AN2310-E

AI-01

RUN

AO-01

RUN

CN1

CN2

MANUAL NO. SIEP C880700 26B

CN1

Page 2

Copyright © 2005 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording,

or otherwise, without the prior written permission of Yaskawa. No patent liability is assumed

with respect to the use of the information contained herein. Moreover, because Yaskawa is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this

manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is

any liability assumed for damages resulting from the use of the information contained in this

publication.

Page 3

Using this Manual

AI-01 and AO-01 indicates the analog input module and the analog output module for the MP2000 series Machine

Controller.

Please read this manual to ensure correct usage of the AI-01 and AO-01. Keep this manual in a safe place for future

reference.

Graphic Symbols Used in this Manual

■

The graphic symbols used in this manual indicate the following type of information.

• This symbol is used to indicate important information that should be memorized or minor precautions,

such as precautions that will result in alarms if not heeded.

Indication of Reverse Signals

■

In this manual, the names of reverse signals (ones that are valid when low) are written with a forward slash (/) before

the signal name, as shown in the following example:

Notation Examples

• S-ON

• P-CON

Copyrights

■

• MECHATROLINK is a trademark of the MECHATROLINK Members Association.

• Microsoft, Windows, Windows NT, and Internet Explorer are registered trademarks of the Microsoft Corporation.

• Pentium is a registered trademark of the Intel Corporation.

• Other product names and company names are the trademarks or registered trademarks of the respective company. “TM”

and the ® mark do not appear with product or company names in this manual.

= /S-ON

= /P-CON

3

Page 4

Related Manuals

■

Refer to the following related manuals as required.

Thoroughly check the specifications, restrictions, and other conditions of the product before attempting to use it.

Manual Name Manual Number Contents

Machine Controller MP2300 Communication

Module

User’s Manual

Machine Controller MP900 Series

User's Manual

Ladder Programming

Machine Controller MP

User's Manual

Motion Programming

Machine Controller MP900/MP2000 Series

MPE720 Software for Programming Device

User’s Manual

Series SGM/SGD

Σ

User’s Manual

Series SGM/SGDB

Σ

User’s Manual

-II Series

Σ

SGMH/SGDM User’s Manual

-II Series

Σ

SGMH/SGDM User’s Manual

-III Series SGMS/SGDS

Σ

User’s Manual

-III Series SGMS/SGDS

Σ

Digital Operator

Instructions

-III Series SGMS/SGDS

Σ

User’s Manual

For MECHATROLINK-II communications

Machine Controller MP900/MP2000 Series

Linear Servomotor Manual

Machine Controller MP900 Series

New Ladder Editor

Programming Manual

Machine Controller MP900 Series

New Ladder Editor

User’s Manual

Machine Controller MP900/MP2000 Series

User’s Manual

MECHATROLINK System

SIEPC88070004

SIEZ-C887-1.2

SIEZ-C887-1.3

SIEPC88070005

SIE-S800-26.3

SIE-S800-26.4

SIEPS80000005

SIEPS80000015

SIEPS80000000

TOBPS80000001

SIEPS80000011

SIEPC88070006

SIE-C887-13.1

SIE-C887-13.2

SIEZ-C887-5.1

Describes the functions, specifications, and application

methods of the MP2300 Communication Modules (217IF,

218IF, 260IF, 261IF).

Describes the instructions used in MP900/MP2000 ladder

programming.

Describes the instructions used in MP900/MP2000 motion

programming.

Describes how to install and operate the MP900/MP2000

Series programming system (MPE720).

Describes the Σ Series SERVOPACK models, specifications

and capacity selection methods.

Describes the Σ Series SERVOPACK models, specifications

and capacity selection methods.

Describes the installation, wiring, trial operation, function

applications methods, maintenance, and inspection of the Σ-II

Series SERVOPACKs.

Describes the installation, wiring, trial operation, function

applications methods, maintenance, and inspection of the Σ-II

Series SERVOPACKs.

Describes the models, capacities, selection methods, ratings,

characteristics, diagrams, cables, peripheral devices, wiring,

panel installation, trial operation, adjustment, function

application methods, maintenance, and inspection of the Σ-III

Series SERVOPACKs and Servomotors.

Describes the operation methods of the JUSP-OP05A Digital

Operator.

Describes the models, capacities, selection methods, ratings,

characteristics, diagrams, cables,

panel installation, trial operation, adjustment, function

application methods, maintenance, inspection, and

MECHATROLINK communication of the ∑-III Series

SERVOPACKs and Servomotors.

Describes the connection methods, setting methods, and other

information for Linear Servomotors.

Describes the programming instructions of the New Ladder

Editor, which assists MP900/MP2000 Series design and

maintenance.

Describes the operating methods of the New Ladder Editor,

which assists MP900/MP2000 Series design and maintenance.

Describes the distributed I/O Module for the MECHATROLINK Modules for MP900/MP2000 Series Machine Controllers.

peripheral devices, wiring

,

4

Page 5

Safety Information

WARNING

CAUTION

CAUTION

PROHIBITED

MANDATORY

●

The following conventions are used to indicate precautions in this manual. These precautions are provided to ensure

the safe operation of the MP2000 series and connected devices. Information marked as shown below is important for

the safety of the user. Always read this information and heed the precautions that are provided.

The conventions are as follows:

Indicates precautions that, if not heeded, could possibly result in loss of life, serious

injury, or property damage.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury,

or property damage.

If not heeded, even precautions classified under can lead to serious results

depending on circumstances.

Indicates prohibited actions. Specific prohibitions are indicated inside .

For example, indicates prohibition of open flame.

Indicates mandatory actions. Specific actions are indicated inside .

For example, indicates mandatory grounding.

5

Page 6

WARNING

CAUTION

Safety Precautions

The following precautions are for checking products on delivery, storage, transportation, installation, wiring, operation,

maintenance, inspection, and disposal. These precautions are important and must be observed.

• Before starting operation in combination with the machine, ensure that an emergency stop procedure

has been provided and is working correctly.

There is a risk of injury.

• Do not touch anything inside the MP2000 series.

There is a risk of electrical shock.

• Always keep the front cover attached when power is being supplied.

There is a risk of electrical shock.

• Observe all procedures and precautions given in this manual for trial operation.

Operating mistakes while the servomotor and machine are connected can cause damage to the machine or even

accidents resulting in injury or death.

• Do not remove the module, front cover, cables, connector while power is being supplied.

There is a risk of electrical shock.

• Do not damage, pull on, apply excessive force to, place heavy objects on, or pinch cables.

There is a risk of electrical shock, operational failure or burning of the MP2000 series.

• Do not attempt to modify the MP2000 series in any way.

There is a risk of injury or device damage.

• Do not approach the machine when there is a momentary interruption to the power supply. When

power is restored, the machine controller and the connecting devices may start operation suddenly.

Provide suitable safety measures to protect people when operation restarts.

There is a risk of injury.

• Do not allow installation, disassembly, or repairs to be performed by anyone other than specified

personnel.

There is a risk of electrical shock or injury.

6

Storage and Transportation

■

• Do not store or install the MP2000 series in the following locations.

• Direct sunlight

• Ambient temperature exceeds the storage or operating conditions

• Ambient humidity exceeds the storage or operating conditions

• Rapid changes in temperature or locations subject to condensation

• Corrosive or flammable gas

• Excessive dust, dirt, salt, or metallic powder

• Water, oil, or chemicals

• Vibration or shock

• Do not subject the MP2000 series to halogen gases, such as fiuorine, chlovine, bromine, and iodine,

at any time even during transportation or installation.

There is a risk of device damage or injury.

• Do not overload the MP2000 series during transportation.

There is a risk of injury or an accident.

Page 7

Storage and Transportation(cont’d

CAUTION

CAUTION

CAUTION

■

• If disinfectants or insecticides must be used to treat packing materials such as wooden frames,

pallets, or plywood, the packing materials must be treated before the product is packaged, and

methods other than fumigation must be used.

Example: Heat treatment, where materials are kiln-dried to a core temperature of 56°C for 30

minutes or more.

If the electronic products, which include stand-alone products and products installed in machines, are packed

with fumigated wooden materials, the electrical components may be greatly damaged by the gases or fumes

resulting from the fumigation process. In particular, disinfectants containing halogen, which includes chlorine,

fluorine, bromine, or iodine can contribute to the erosion of the capacitors.

Installation

■

• Never use the MP2000 series in locations subject to water, corrosive atmospheres, or flammable

gas, or near burnable objects.

There is a risk of electrical shock or fire.

• Do not step on the MP2000 series or place heavy objects on the MP2000 series.

There is a risk of injury.

• Do not allow foreign objects to enter the MP2000 series.

There is a risk of element deterioration inside, an accident, or fire.

• Always mount the MP2000 series in the specified orientation.

There is a risk of an accident.

• Do not subject the MP2000 series to strong shock.

There is a risk of an accident.

)

Wiring

■

• Check the wiring to be sure it has been performed correctly.

There is a risk of motor run-away, injury, or an accident.

• Always use a power supply of the specified voltage.

There is a risk of burning.

• In places with poor power supply conditions, take all steps necessary to ensure that the input power

supply is within the specified voltage range.

There is a risk of device damage.

• Install breakers and other safety measure to provide protection against shorts in external wiring.

There is a risk of fire.

• Provide sufficient shielding when using the MP2000 series in the following locations.

There is a risk of device damage.

• Noise, such as from static electricity

• Strong electromagnetic or magnetic fields

• Radiation

• Near to power lines

7

Page 8

CAUTION

鉄板製のセパレータ

ディジタル

入出力信号

ケーブル

一般制御回路

のケーブル

動力回路の

ケーブル

外部配線の分離例

Example of Separated External Cables

Steel separator

Power

circuit

General

control

Digital I/O

signal

CAUTION

CAUTION

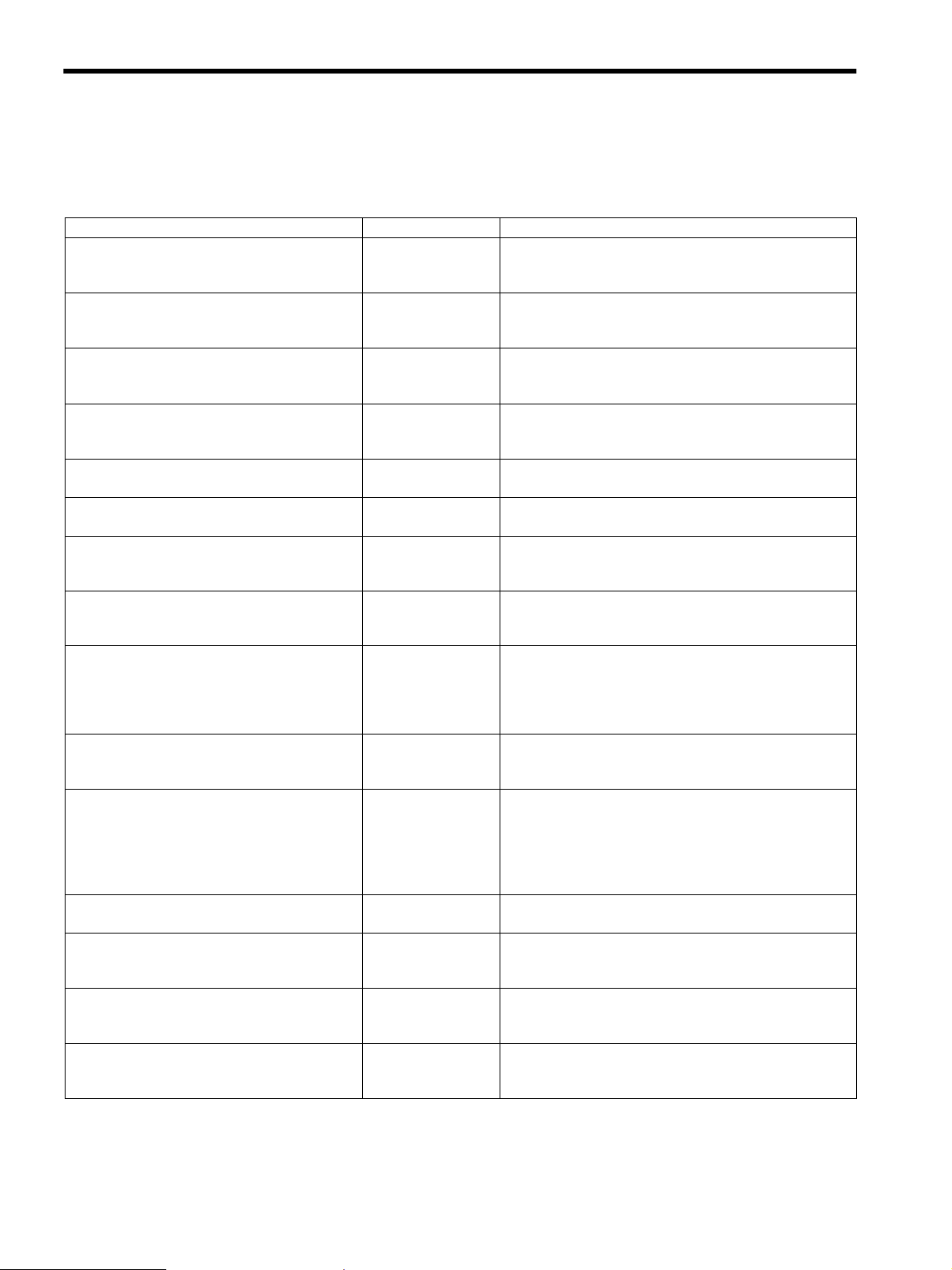

Selecting, Separating, and Laying External Cables

■

• Consider the following items when selecting the I/O signal lines (external cables) to connect the

MP2000 series to external devices.

• Mechanical strength

• Noise interference

• Wiring distance

• Signal voltage, etc.

• Separate the I/O signal lines from the power lines both inside and outside the control box to reduce

the influence of noise from the power lines.

If the I/O signal lines and power lines are not separated properly, malfunctioning may result.

Maintenance and Inspection Precautions

■

• Do not attempt to disassemble the MP2000 series.

There is a risk of electrical shock or injury.

• Do not change wiring while power is being supplied.

There is a risk of electrical shock or injury.

Disposal Precautions

■

• Dispose of the MP2000 series as general industrial waste.

General Precautions

■

• The products shown in illustrations in this manual are sometimes shown without covers or protective guards. Always

replace the cover or protective guard as specified first, and then operate the products in accordance with the manual.

• The drawings presented in this manual are typical examples and may not match the product you received.

8

• If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or one of the

offices listed on the back of this manual.

Observe the following general precautions

to ensure safe application.

Page 9

Warranty

(1) Details of Warranty

Warranty Period

■

The warranty period for a product that was purchased (hereinafter called “delivered product”) is one year

from the time of delivery to the location specified by the customer or 18 months from the time of shipment

from the Yaskawa factory, whichever is sooner.

Warranty Scope

■

Yaskawa shall replace or repair a defective product free of charge if a defect attributable to Yaskawa occurs

during the warranty period above. This warranty does not cover defects caused by the delivered product

reaching the end of its service life and replacement of parts that require replacement or that have a limited

service life.

This warranty does not cover failures that result from any of the following causes.

1. Improper handling, abuse, or use in unsuitable conditions or in environments not described in product catalogs or manuals, or in any separately agreed-upon specifications

2. Causes not attributable to the delivered product itself

3. Modifications or repairs not performed by Yaskawa

4. Abuse of the delivered product in a manner in which it was not originally intended

5. Causes that were not foreseeable with the scientific and technological understanding at the time of shipment from Yaskawa

6. Events for which Yaskawa is not responsible, such as natural or human-made disasters

(2) Limitations of Liability

1. Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer that arises

due to failure of the delivered product.

2. Yaskawa shall not be responsible for any programs (including parameter settings) or the results of program execution of the programs provided by the user or by a third party for use with programmable

Yaskawa products.

3. The information described in product catalogs or manuals is provided for the purpose of the customer purchasing the appropriate product for the intended application. The use thereof does not guarantee that there

are no infringements of intellectual property rights or other proprietary rights of Yaskawa or third parties,

nor does it construe a license.

4. Yaskawa shall not be responsible for any damage arising from infringements of intellectual property

rights or other proprietary rights of third parties as a result of using the information described in catalogs

or manuals.

9

Page 10

(3) Suitability for Use

1. It is the customer’s responsibility to confirm conformity with any standards, codes, or regulations that

apply if the Yaskawa product is used in combination with any other products.

2. The customer must confirm that the Yaskawa product is suitable for the systems, machines, and equipment used by the customer.

3. Consult with Yaskawa to determine whether use in the following applications is acceptable. If use in the

application is acceptable, use the product with extra allowance in ratings and specifications, and provide

safety measures to minimize hazards in the event of failure.

• Outdoor use, use involving potential chemical contamination or electrical interference, or use in condi-

tions or environments not described in product catalogs or manuals

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, vehicle sys-

tems, medical equipment, amusement machines, and installations subject to separate industry or gov-

ernment regulations

• Systems, machines, and equipment that may present a risk to life or property

• Systems that require a high degree of reliability, such as systems that supply gas, water, or electricity,

or systems that operate continuously 24 hours a day

• Other systems that require a similar high degree of safety

4. Never use the product for an application involving serious risk to life or property without first ensuring

that the system is designed to secure the required level of safety with risk warnings and redundancy, and

that the Yaskawa product is properly rated and installed.

5. The circuit examples and other application examples described in product catalogs and manuals are for

reference. Check the functionality and safety of the actual devices and equipment to be used before using

the product.

6. Read and understand all use prohibitions and precautions, and operate the Yaskawa product correctly to

prevent accidental harm to third parties.

(4) Specifications Change

The names, specifications, appearance, and accessories of products in product catalogs and manuals may be

changed at any time based on improvements and other reasons. The next editions of the revised catalogs or

manuals will be published with updated code numbers. Consult with your Yaskawa representative to confirm

the actual specifications before purchasing a product.

10

Page 11

CONTENTS

Using this Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Safety Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Applicable Machine Controllers

1

Applicable Machine Controllers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

1.1

AI-01 Module Applicable Machine Controllers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

1.1.1

AO-01 Module Applicable Machine Controllers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

1.1.2

Mounting/Removing Optional Modules on Machine Controller- - - - - - - - - - - - - - 16

1.2

Mounting Optional Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

1.2.1

1.2.2 Removing Optional Modules- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

AI-01 Module

2

AI-01 Module Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

2.1

2.1.1

2.1.2

2.1.3

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -21

AI-01 Module Functions and External Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Input Characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -13

AI-01 Module Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

2.2

Specifications on Cable and Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

2.2.1

Connector Pin Arrangement - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

2.2.2

Circuit Configuration and Connection Example- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

2.2.3

AI-01 Module Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

2.3

Setting the Input Mode- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

2.3.1

Setting the Offset/Gain- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

2.3.2

Self Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

2.3.3

11

Page 12

AO-01 Module

3

AO-01 Module Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

3.1

3.1.1

3.1.2

3.1.3

AO-01 Module Connections- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -37

3.2

3.2.1

3.2.2

3.2.3

AO-01 Module Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -40

3.3

3.3.1

3.3.2

3.3.3

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

AO-01 Module Function and External dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

Output Characteristics- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Specifications on Cable and Connector- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Connector Pin Arrangement - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

AO-01 Module Connection Example (CN1) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Setting the Output Range - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Setting the Offset/Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Self Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

INDEX

Revision History

12

Page 13

Applicable Machine Controllers

This chapter explains on the MP2000 series Machine Controller, that can install the AI-01/AO-01

Module.

Applicable Machine Controllers

1.1

AI-01 Module Applicable Machine Controllers

1.1.1

AO-01 Module Applicable Machine Controllers

1.1.2

Mounting/Removing Optional Modules on Machine Controller

1.2

Mounting Optional Modules

1.2.1

1.2.2 Removing Optional Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -18

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -14

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -15

- - - - - - - - - - 16

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -16

1

1

13

Page 14

Applicable Machine Controllers

1

AI-01 Module Applicable Machine Controllers

1.1.1

1.1 Applicable Machine Controllers

1.1.1 AI-01 Module Applicable Machine Controllers

The table below lists the MP2000-series Machine Controllers on which the AI-01 Module can be mounted.

Name Model

100/200VACInput

Base Unit

MP

2200

24-VDC

Input Base

Unit

MP2300 JEPMC-MP2300

MP2100M

* 1. CPU Module for MP2200. Model: JAPMC-CP2200.

* 2. CPU Module for MP2200. Model: JAPMC-CP2210, with one slot for CF card and one USB port

* 3. The Connection Module EXIOIF (Model: JAPMC-EX2200) is required between racks.

A1-01 Module cannot be mounted on the following MP2000-series Machine Controllers: MP2100, MP2500, and

MP2500M

JEPMC-BU2200

JEPMC-BU2210

JAPMC-MC2140

Applicable

CPU Version

Ver. 2.40 or

later

Ver. 2.40 or

later

Ver. 2.40 or

later

Ver. 2.40 or

later

Applicable

MPE720 Ver-

sion

Ver. 5.31 or

later

Ver. 5.31 or

later

Ver. 5.31 or

later

Ver. 5.31 or

later

Max. Number of AI-

01 Modules that

Can Be Connected

(AI-01+AO-01

When using the

*1:

CPU-01

30 modules,

When using the

*2

CPU-02

2 modules

24 modules

:

31 modules

Remarks

)

Max. Number of AI-01 Modules that

Can Be Connected when using 4

racks (extended to the maximum)

Can be mounted on an expansion

rack when mounting an expansion I/F

board MP2100MEX (model:

JAPMC-EX2200) and connecting an

expansion rack (can be used also as

the MP2200 base unit).

Max. Number of AI-01 Modules that

Can be Connected when using 3

racks (extended to the maximum)

*3

*3

.

14

Page 15

1.1.2 AO-01 Module Applicable Machine Controllers

The table below lists the MP2000 series Machine Controllers to which the AO-01 Module can be mounted.

Max. Number of

Name Model

100/200VAC Input

Base Unit

MP

2200

24-VDC

Input

Base Unit

MP2300 JEPMC-MP2300

MP2100M

* 1. CPU Module for MP2200. Model: JAPMC-CP2200

* 2. CPU Module for MP2200. Model: JAPMC-CP2210, with one slot for CF card and one USB port

* 3. A connection module EXIOIF (Model: JAPMC-EX2200) is required between racks.

The AO-01 Module cannot be mounted on the following models of MP2000-series Machine Controllers: MP2100,

MP2500, MP2500M

JEPMC-BU2200

JEPMC-BU2210

JAPMC-MC2140

Applicable

CPU Version

Ver. 2.44 or

later

Ver. 2.44 or

later

Ver. 2.44 or

later

Ver. 2.44 or

later

Applicable

MPE720 Ver-

sion

Ver. 5.33 or

later

Ver. 5.33 or

later

Ver. 5.33 or

later

Ver. 5.33 or

later

AO-01 Modules

that Can be Con-

AI-01+AO-01

(

When using a

CPU-01

30 modules

When using a

CPU-02

31 modules

2 modules

24 modules

nected

*1

:

*2

:

Applicable Machine Controllers

1.1

Remarks

)

Max. Number of AO-01 Modules

that Can be Connected when using 4

racks (extended to the maximum)

Can be mounted on a expansion rack

when mounting a expansion I/F board

MP2100MEX (model: JAPMCEX2200) and connecting a expansion

rack (can be used also as the MP2200

base unit).

Max. Number of AO-01 Modules

that Can be Connected when using 3

racks (extended to the maximum)

1

*3

*3

.

15

Page 16

Applicable Machine Controllers

1

Mounting Optional Modules

1.2.1

1.2 Mounting/Removing Optional Modules on Machine Controller

Use the following procedure to mount or remove Optional Modules.

In the photos given here to explain the procedure, a Machine Controller MP2200 and an Optional Module 217-IF-01

are used. The procedure to mount an Optional Module AI-01 or AO-01 on a Machine Controller MP2300 or

MP2100M is the same as that to mount 217-IF-01 on MP2200.

1.2.1 Mounting Optional Modules

Use the following procedure to mount Optional Modules.

For the replacement of Optional Module, refer to 1.2.2

Optional Module to be replaced.

( 1 ) Preparation

Backup the Programs

1.

Save the programs written to the Machine Controller in the personal computer using MPE720. (Right-click the

Controller Folder, and select Transfer - All Files - Dump from the pop-up menu.)

Removing Optional Modules

on page 1-18 to remove the

Remove the Machine Controller and Expansion Racks

2.

a) For MP2300

Turn OFF the power supply and disconnect all the cables from the MP2300. Then, remove the MP2300 from the

panel or rack, and place it on a place with sufficient space, such as working table.

b) For MP2200 and MP2100M

Turn OFF the power supply and disconnect all the cables from the expansion rack (MP2200 base unit) where the

Optional Module to be replaced is mounted. Then remove the expansion rack and place it in a place with sufficient space, such as working table.

( 2 ) Removing Optional Cover

Use the following procedure if the optional cover (JEPMC-OP2300) is installed on the slot.

Remove the battery cover.

1.

Pull the notch on the side of the MP2000 series towards you to remove the battery cover.

16

Page 17

Remove the cover of Optional Module.

Guide

rail

2.

Insert the protruding part of the battery cover into the slot on top of the cover of Optional Module to unhook, as

shown in the diagram. Face the front of the battery cover towards you for this operation.

Unhook the bottom in the same way.

( 3 ) Installing Optional Modules

Mounting/Removing Optional Modules on Machine Controller

1.2

1

Insert Optional Modules.

1.

Guide rails are visible at the top and bottom of the Option Slot, as shown in the following diagram. Line up the

Module with the guide rail and insert the Module straight.

The FG bar on the inside bottom of the Unit Case may be damaged if the Module is inserted without following

the guide rail.

Mount on to the mounting base.

2.

Once the Optional Module has been completely inserted, place your hand on the front face of the Optional

Module and push hard until the Optional Module has been inserted into the mounting base connectors. The front

face of the Optional Module and the hook will be aligned when the Optional Module has been installed properly.

17

Page 18

Applicable Machine Controllers

1

1.2.2 Removing Optional Modules

Install the panel of the Optional Module.

3.

Place the hole on the bottom of the

This completes the installation procedure.

1.2.2

Removing Optional Modules

( 1 ) Preparation

Backup the Programs

1.

Save the programs written to the Machine Controller in the personal computer using MPE720. (Right-click the

Controller Folder, and select Transfer - All Files - Dump from the pop-up menu.)

Remove the Machine Controller and Expansion Racks

2.

panel of the Optional Module

onto the hook on the bottom of the MP2300.

a) For MP2300

Turn OFF the power supply and disconnect all the cables from the MP2300. Then, remove the MP2300 from the

panel or rack, and place it on a place with sufficient space, such as working table.

b) For MP2200 and MP2100M

Turn OFF the power supply and disconnect all the cables from the expansion rack (MP2200 base unit) where the

Optional Module to be replaced is mounted. Then remove the expansion rack and place it in a place with sufficient space, such as working table.

( 2 ) Removing Optional Modules

Remove the battery cover.

1.

Pull the notch on the side of the MP2000 series towards you to remove the battery cover.

18

Page 19

Mounting/Removing Optional Modules on Machine Controller

Round knob

Notch

Fulcrum

1.2

Remove the panel of Optional Module.

2.

Insert the protruding part of the battery cover into the slot on top of the panel of Optional Module to unhook, as

shown in the diagram. Face the front of the battery cover towards you for this operation.

Unhook the bottom in the same way.

1

Remove the Optional Module from the mounting base.

3.

Pull the top of the panel of the Optional Module towards you to remove it. A notch on the Optional Module will

be visible from the gap in the cover. Hook the round knob on the battery cover, shown in the diagram, into the

notch in the Optional Module.

Hold the center of the battery cover as shown in the following diagram. Push the battery cover down and out,

rotating from the round knob to disconnect the Module and mounting base connectors, and then pull the Optional

Module forward.

19

Page 20

Applicable Machine Controllers

1

1.2.2 Removing Optional Modules

Pull out the Optional Module.

4.

Hold the Module on the top and bottom and pull it out straight. Hold the edges of the Module and avoid touching

the parts on the Module.

Put the removed Module into the bag that it was supplied with and store it in this bag.

The optional cover must be installed on the empty slot.

20

Page 21

AI-01 Module

This chapter explains the detailed specifications and functions, connection methods, and settings of

the AI-01 Module.

AI-01 Module Specifications

2.1

AI-01 Module Functions and External Dimensions

2.1.1

Specifications

2.1.2

Input Characteristics

2.1.3

AI-01 Module Connections

2.2

Specifications on Cable and Connector

2.2.1

Connector Pin Arrangement

2.2.2

Circuit Configuration and Connection Example

2.2.3

AI-01 Module Settings

2.3

Setting the Input Mode

2.3.1

Setting the Offset/Gain

2.3.2

Self Configuration

2.3.3

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -22

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

- - - - - - - - - - - - - - - - - - - - - - - - - - -22

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -26

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -28

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -30

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

2

2

21

Page 22

AI-01 Module

AI-01 Module Appearance

External Dimensions when installing

the cable connector (side view)

2

AI-01 Module Functions and External Dimensions

2.1.1

2.1 AI-01 Module Specifications

This section explains the appearance, function, and specifications of AI-01 module.

2.1.1 AI-01 Module Functions and External Dimensions

The AI-01 module has eight channels for analog input. Three types of analog-input ranges are available −

Voltage: -10 V to +10 V, Voltage: 0 V to +10 V, Current: 0 mA to 20 mA.

A maximum of two modules can be mounted in the MP2300 option slot, 30 modules in the MP2000 base unit if four

units are connected and CPU-01 is used or 31 if CPU-02 is used; and 24 modules in the MP2100M or MP2100MEX

expansion racks if three racks are connected.

Indicators (LED)

Analog input

connector CN1

Analog input

connector CN2

2.1.2 Specifications

The following table shows the general and hardware specifications, and the details of LED of the AI-01 module.

AI-01

RUN

CN1

CN2

(19.3)

(41)

(6)

(125)

Units: mm

(95)

22

( 1 ) General Specifications

Item Specifications

Ambient

Operating

Temperature

Ambient Storage

Temperature

Ambient

Environmental

Conditions

Operating

Humidity

Ambient Storage

Humidity

Pollution Level Pollution level 1 (conforming to JIS B 3501)

Corrosive Gas There must be no combustible or corrosive gas.

Operating

Altitude

0 to 55 °C

-25 to 85 °C

30% to 95% (with no condensation)

5% to 95% (with no condensation)

2,000 m above sea level or lower

Page 23

Mechanical

RUN

Operating

Conditions

Item Specifications

Conforming to JIS B 3502:

Vibration

Resistance

Shock Resistance

10 to 57 Hz with single-amplitude of 0.075 mm

57 to 150 Hz with fixed acceleration of 9.8 m/s

10 sweeps each in X, Y, and Z directions

(sweep time: 1 octave/min)

Conforming to JIS B 3502:

Peak acceleration of 147 m/s

directions

2

(15 G) twice for 11 ms each in the X, Y, and Z

AI-01 Module Specifications

2.1

2

Electrical

Operating

Conditions

Installation

Requirements

Noise Resistance

Ground

Cooling Method Natural cooling

Conforming to EN 61000-6-2, EN 55011 (Group 1, Class A)

Power supply noise (FT noise): 2 Kv min., for one minute

Radiation noise (FT noise): 1 Kv min., for one minute

Ground to 100 Ω max.

( 2 ) Hardware Specifications

Items Specifications

Description I/O Module

Name AI-01

Model No. JAPMC-AN2300-E

Number of Channels

Setting of the channels

used

Insulation

Analog Input Range -10V to +10V 0 to +10V 0 to 20 mA

Analog

Input

Connector

Indicator RUN (Green )

Current Consumption 500mA or less

Dimensions Height: 125 mm Depth: 95 mm

Mass 100 g

* 1. Indicates if the offset and gain adjustment not to be performed in the MPE720.

* 2. Indicates if the offset and gain adjustment is performed in the MPE720.

* 3. Input conversion time = Delay time from input filter (1 ms or less) + (50 × number of channels used);

Max. Rated Input

Input Impedance

Digital Resolution 16Bit (-31276 to +31276) 15Bit (0 to +31276)

Absolute Accuracy

Accuracy

Input Conversion Time

Delay time from the input filter peaks at 1 ms between -10 V and +10 V.

*1

*2

25 °C

0 to 55 °C

8 channels ((4 channels /1connector)×2)

1 to 8 channels (Optional)

Between channels: non-insulated

Between input connector and system power supply: photocoupler insulation

15V

±

20k

Ω

100 mV or less

0.1% (±10 mV)

±

0.3% (±30 mV)

±

*3

1.4msec or less

CN1: Input connector

CN2: Input connector

∗

30 mA

±

250

Ω

0.3 mA or less

0.1% (±0.02 mA)

±

0.3% (±0.06 mA)

±

2

( 3 ) LED Indicator

Indicator

name

RUN Green Operates correctly No operate

Indicator

Color

Status when ON Status when OFF

23

Page 24

AI-01 Module

2

Input Characteristics

2.1.3

2.1.3 Input Characteristics

This section explains the input characteristics table corresponding to the analog input value and voltage and current

mode, and input characteristic drawings.

( 1 ) Input Characteristics and Corresponding Modes

Analog input value

-10.5V

10.0V

-

5.0V

-

0.0 V (0.0 mA)

+5.0 V (10 mA)

+10.0 V (20 mA)

+10.5 V (21 mA)

If the voltage exceeds +10.0 V or more, the linearity is not guaranteed.

Voltage mode 1 Voltage mode 2 Current mode

-10V to +10V

32768

-

31276

-

15638

-

000

15638 15638 15638

31276 31276 31276

32767 32767 32767

( 2 ) Voltage Mode 1 (-10V to +10V)

-10.5V

-10V

32767

31276

Input register

0 to +10V 0 to 20 mA

−−

−−

−−

0

0V

Analog input

10V

10.5V

24

-31276

-32768

( 3 ) Voltage Mode 2 (0V to +10V) and Current Mode (0 to 20 mA)

32767

31276

Input register

10.5V

(21mA)

0

0V

Analog input

10V

(20mA)

Page 25

2.2 AI-01 Module Connections

2.2.1 Specifications on Cable and Connector

AI-01 Module Connections

2.2

( 1 )

Connector

Specifications

Connector

Connector

Analog Input

Connector

CN1/CN2

Name

No. of

Pins

26

Connector Model

Module Cable Manufacturer

Connector

・

10126-3000PE

Shell

・

10226-52A3PL

10326-52A0-008

Screw-locked type

(

10326-52F0-008

One-touch- lock type

(

( 2 ) Connector Models and External Appearance of Standard Cable

Cable Model Length

JEPMC-W6080-05-E

Cable for AI-01

Module

JEPMC-W6080-10-E

JEPMC-W6080-30-E

0.5 m

1 m

3 m

Appearance(JEPMC-W6080--E

CN1 CN2

NP㧦JEPMC-W6080-05-E

L 150

( 3 ) Standard Cable Wiring

)

)

Sumitomo

3M Limited

)

Mark tube (label)

2

Loose wire

The following table shows the wiring for the JEPMC-W6080--E standard cable loose wire.

CN1

26-pin Terminal

No.

1 Gray Red

2

3 Orange Red

14 Ye l lo w R ed

16 Ye l lo w B la c k

4 Pink Red

5

6 Ye l lo w R e d

17 White Red

19 White Black

7 White Red

8

9 Gray Red

20 Gray Red

22 Gray Black

Wire Color Dot Color Dot Mark

Gray Black

Orange Black

Pink Black

Ye ll o w Bl ac k

White Black

Gray Black

---

---

---

---

-

-

--

--

--

--

-

-

--

--

--

--

-

-

CN2

Mark Tube

Label

(

)

V1

G1V

G1A

A1

DP1

DN1

V2

G2V

G2A

A2

DP2

DN2

V3

G3V

G3A

A3

DP3

DN3

Twisted-pair Wire

25

Page 26

AI-01 Module

2

Connector Pin Arrangement

2.2.2

CN1

26-pin Terminal

No.

Wire Color Dot Color Dot Mark

10 Orange Red

11

Orange Black

Pink Black

12 Pink Red

23 Orange Red

25 Orange Black

Note: The cable is shielded twisted-pair and connected to connector shell of CN1 by metal-clamp.

2.2.2 Connector Pin Arrangement

The following table shows the connector (CN1, CN2) of the pin arrangement and the terminal layout for the AI-01

module.

( 1 ) CN1 Pin Arrangement and Terminal Layout

Pin Arrangement at Connection Side

1

14

2

15

G1

2

4 V2 17 MDP2

25

12

26

13

6 A2 19 MDN2

8G3 21㧔G3㧕

10 V4 23 MDP4

12 A4 25 MDN4

1

3 A1 16 MDN1

5G2 18㧔G2㧕

7 V3 20 MDP3

9 A3 22 MDN3

11 G4 24 㧔G4㧕

13 – –26

--

--

-

-

-

-

V1

Mark Tube

(

15

CN2

Label

V4

G4V

G4A

A4

DP4

DN4

㧔G1㧕

Twisted-pair Wire

)

MDP1

14

26

[ a ] Terminal Specifications

No.

1 V1

2 G1

3 A1

4 V2

5 G2

6 A2

7 V3

8 G3

9 A3

10 V4

11 G4

12 A4

13 –– 26 ––

Signal

Name

Voltage input

Ground

Current input

Voltage input

Ground

Current input

Voltage input

Ground

Current input

Voltage input

Ground

Current input

Function No.

1

1

1

2

2

2

3

3

3

4

4

4

Signal

Name

14 MDP1

15

(G1)

16 MDN1

17 MDP2

18

(G2)(

19 MDN2

20 MDP3

21

(G3)(

22 MDN3

23 MDP4

24

(G4)(

25 MDN4

Function

Mode selection terminal

Ground

(

1)

Mode selection terminal

Mode selection terminal

Ground 2

)

Mode selection terminal

Mode selection terminal

Ground 3

)

Mode selection terminal

Mode selection terminal

Ground 4

)

Mode selection terminal

1

1

2

2

3

3

4

4

Page 27

( 2 ) CN2 Pin Arrangement and Terminal Layout

25

26

13

12

15

1

2

14

1

V5

14

MDP5

2

G5

15

G5

3 A5 16 MDN5

4V6 17MDP6

5G6 18

G6

6 A6 19 MDN6

7V7 20MDP7

8G7 21

G7

9 A7 22 MDN7

10 V8 23 MDP8

11 G8 24

G8

12 A8 25 MDN8

13 26

[ a ]

Pin Arrangement at Connection Side

AI-01 Module Connections

2.2

2

[ b ] Terminal Specifications

No.

1 V5

2 G5

3 A5

4 V6

5 G6

6 A6

7 V7

8 G7

9 A7

10 V8

11 G8

12 A8

Signal

Name

Function No.

Voltage input

Ground

5

Current input

Voltage input

Ground

6

Current input

Voltage input

Ground

7

Current input

Voltage input

Ground

8

Current input

5

14 MDP5 Mode selection terminal 5

15

5

6

16 MDN5 Mode selection terminal 5

17 MDP6 Mode selection terminal 6

18

6

7

19 MDN6 Mode selection terminal 6

20 MDP7 Mode selection terminal 7

21

7

8

22 MDN7 Mode selection terminal 7

23 MDP8 Mode selection terminal 8

24

8

25 MDN8 Mode selection terminal 8

13 26

Signal

Name

(G5)(

(G6)(

(G7)(

(G8)(

Ground 5

Ground 6

Ground 7

Ground 8

Function

)

)

)

)

27

Page 28

AI-01 Module

2

Circuit Configuration and Connection Example

2.2.3

2.2.3 Circuit Configuration and Connection Example

( 1 ) AI-01 Module Circuit Configuration

CH1

Voltage input

Current input

Mode

Ground

Voltage input

Current input

Mode

Ground

1

3

16

14

2

GND

CH2

4

6

19

17

5

GND

256.5 Ω

R

256.5 Ω

R

R R

10 kΩ

10 kΩ

10 kΩ

RR

10 kΩ

-

+

-

+

Multiplexer

D/A

Converter

+5V

Photocoupler

Internal

circuit

28

Voltage input

Current input

Mode

Ground

CH8

10

12

25

23

11

GND

Shell

256.5 Ω

R

10 kΩ

RR

10 kΩ

-

+5V

+

+15V

-15V

0V

DC/DC

Converter

0V

Page 29

AI-01 Module Connections

2.2

( 2 ) AI-01 Module Connection Example (CN1

Junction-terminal block

External device

V

FG

-10 to +10V

External device

Voltage input modeCurrent input mode

V

FG

-10 to +10V

External device

A

FG

0 to +20mA

External device

A

FG

0 to +20mA

)

1

Voltage input1

2

Ground 1

3

Current input1

14

16

Mode selection1

)

4

Voltage input 2

5

Ground 2

6

Current input 2

17

19

Mode selection 2

)

7

Voltage input 3

8

Ground 3

9

Current input 3

20

22

Mode selection 3

)

10

Voltage input 4

11

Ground 4

12

Current input 4

23

25

Mode selection 4

)

AI-01

2

FG (Connector shell)

Use a standard cable (JEPMC-W6080--E) to connect the AI-01 Module to an external device. Use the junction-

terminal block, because the distances between each external device and the module vary.

Ground the cable shield between the external devices and the junction-terminal block on the external-device end.

Using with Voltage Input Mode 1 and 2

■

Open each mode-selection terminal, terminals 1 to 8, and do not connect to the current-input terminals 1 to 8.

Using with Current Input Mode

■

Short-circuit each mode-selection terminal, terminals 1 to 8, and do not connect to the voltage-input terminals 1 to 8.

29

Page 30

AI-01 Module

2

Setting the Input Mode

2.3.1

2.3 AI-01 Module Settings

This section describes the items to be set using the MPE720 after connecting the AI-01 Module.

After connecting the AI-01 Module, use the following procedures to select the input mode, offset/gain, and self con-

figuration. If self configuration is performed after setting the input mode and offset/gain, the values will return to their

default values.

2.3.1 Setting the Input Mode

The AI-01 Module has three input modes

• Voltage Mode 1 (Input range:

• Voltage Mode 2 (Input range: 0 V to +10 V

• Current Mode (Input range: 0 mA to 20 mA)

The input mode for each channel must be selected both on the machine and in the MPE720 program. Both settings must match.

For information on how to select the input mode on the machine, refer to 2.2.3 ( 2 ) AI-01 Module Connection

Example (CN1) on page 2-29.

In the MPE720 program ver. 5.31 or later, select the input mode for the channel to be used in the AI-01 Configuration

window.

-10 V to +10 V)

30

Page 31

2.3.2 Setting the Offset/Gain

The offset/gain settings do not usually have to be adjusted. The AI-01 Module has been adjusted before shipment so the

appropriate value is input for the specified voltage or current. If more precise adjustments are required, use the following procedure to adjust the offset/gain.

After selecting the channel number in the AI-01 Configuration window, select Set and then Offset/

1.

Gain.

AI-01 Module Settings

2.3

2

The Set Offset/Gain box will be displayed.

The voltage of the external device can be set to 0 V, 5 V, or 10 V. After changing the voltage, the cur-

2.

rent value displayed for the AI-01 Module will also change. Adjust the offset/gain accordingly so they

are in accordance with the current value displayed for the AI-01 Module. Then click the OK button.

Repeat steps 1 and 2 for all channels to be used.

3.

The offset/gain adapted value will be stored in the input register (I register):

Input register = A/D conversion value ×Gain+Offset

The default values of the offset and gain are as follows.

Offset:

If using the default values, the Input register value equals the A/D conversion value.

0000

Gain: 1.000

31

Page 32

AI-01 Module

8 words (fixed) are allocated starting from the register number that

can be used.

All channels are in unused status.

2

Self Configuration

2.3.3

2.3.3 Self Configuration

The MP2300, MP2200, and MP2100M machine controllers in the MP2000-series have a self configuration function.

With self configuration, the I/O leading and end registers for the AI-01 Module will be automatically allocated and all

of the channels will be shown as being unused if (no channel has been selected in the AI-01 Configuration window).

32

Page 33

3

AO-01 Module

This chapter explains the detailed specifications and functions, connection methods, and settings of

the AI-01 Module.

AO-01 Module Specifications

3.1

AO-01 Module Function and External dimensions

3.1.1

Specifications

3.1.2

Output Characteristics

3.1.3

AO-01 Module Connections

3.2

Specifications on Cable and Connector

3.2.1

Connector Pin Arrangement

3.2.2

AO-01 Module Connection Example (CN1)

3.2.3

AO-01 Module Settings

3.3

Setting the Output Range

3.3.1

Setting the Offset/Gain

3.3.2

Self Configuration

3.3.3

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -42

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

- - - - - - - - - - - - - - - - - - - - - - - - - - -34

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -37

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -38

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -39

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -40

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -41

3

33

Page 34

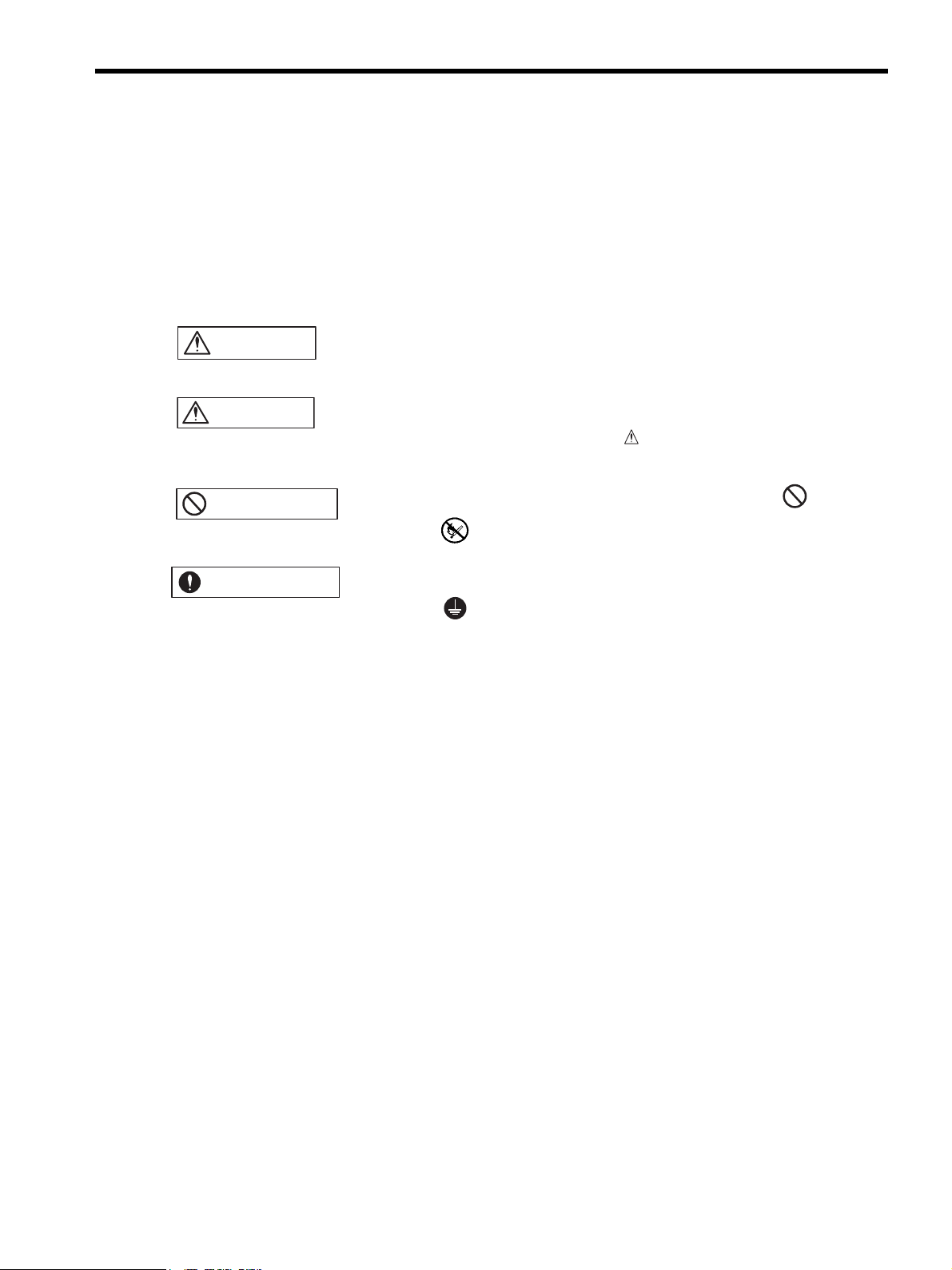

AO-01 Module

AO-01

RUN

CN1

(19.3)

(95)

(125)

Units: mm

(6)

(41)

Indicators (LED)

Analog output

connector CN1

AO-01 Module Appearance

External Dimensions when installing

the cable connector (side view)

3

AO-01 Module Function and External dimensions

3.1.1

3.1 AO-01 Module Specifications

This section explains the appearance, function, and specifications of the AO-01 module.

3.1.1 AO-01 Module Function and External dimensions

The AO-01 module has four channels for analog input. Two types of analog-output ranges are available −

Voltage: -10 V to +10 V, Voltage: 0 V to +10 V.

A maximum of two modules can be mounted in the MP2300 option slot, 30 modules in the MP2000 base unit if four

units are connected and CPU-01 is used or 31 if CPU-02 is used; and 24 modules in the MP2100M or MP2100MEX

expansion racks if three racks are connected.

3.1.2 Specifications

The following table shows the general and hardware specifications, and the details of LED of the AO-01 module.

( 1 ) General Specifications

Item Specifications

Ambient

Operating

Temperature

Ambient Storage

Temperature

Ambient

Environmental

Conditions

Operating

Humidity

Ambient Storage

Humidity

Pollution Level Pollution level 1 (conforming to JIS B 3501)

Corrosive Gas There must be no combustible or corrosive gas.

Operating

Altitude

0 to 55 °C

-25 to 85 °C

30% to 95% (with no condensation)

5% to 95% (with no condensation)

2,000 m above sea level or lower

34

Page 35

Mechanical

RUN

Operating

Conditions

Item Specifications

Conforming to JIS B 3502:

Vibration

Resistance

Shock Resistance

10 to 57 Hz with single-amplitude of 0.075 mm

57 to 150 Hz with fixed acceleration of 9.8 m/s

10 sweeps each in X, Y, and Z directions

(sweep time: 1 octave/min)

Conforming to JIS B 3502:

Peak acceleration of 147 m/s

directions

2

(15 G) twice for 11 ms each in the X, Y, and Z

AO-01 Module Specifications

3.1

2

Electrical

Operating

Conditions

Installation

Requirements

Noise Resistance

Ground

Cooling Method Natural cooling

( 2 ) Hardware Specifications

Items Specifications

Description I/O Module

Name AO-01

Model No. JAPMC-AN2310-E

Number of Channels 4 channels

Setting of the channels

used

Insulation

Analog

Output

Connector CN1: Output connector

Indicator RUN (Green )

Current Consumption 500mA or less

Dimensions Height: 125 mm Depth: 95 mm

Mass 90 g

* After change with a full scale of -10 V to + 10 V.

Analog Output Range

Digital Resolution

Accuracy

Max. Allowable Load

Current

Output Conversion

Time

25°C

0 to 55°C

*2

Conforming to EN 61000-6-2, EN 55011 (Group 1, Class A)

Power supply noise (FT noise): 2 Kv min., for one minute

Radiation noise (FT noise): 1 Kv min., for one minute

Ground to 100 Ω max.

1 to 4 channels (Optional)

Between channels: non-insulated

Between output connector and system power supply: photocoupler insulation

-10V to +10V 0 to +10V

16Bit (-31276 to +31276) 15Bit (0 to +31276)

0.1% (±10mV)

±

0.3% (±30mV)

±

5mA

±

*

1.2msec

3

( 3 ) LED Indicator

Indicator

name

RUN Green Operates correctly No operate

Indicator

Color

Status when ON Status when OFF

35

Page 36

AO-01 Module

32767

31276

10V

10.5V

0V

0

Output

register

Analog output

3

Output Characteristics

3.1.3

3.1.3 Output Characteristics

This section explains the output characteristics table corresponding to the analog output value and voltage and current

mode, and output characteristic drawings.

( 1 ) Output Characteristics Corresponding Table

Analog output value

-10.5V

-10.0V

-5.0V

0.0V

+5.0V

+10.0V

+10.5V

If the mode exceeds +10.0V or more, the linearity is not guaranteed.

Output range 1 (-10V to +10V) Output range 2 (0 to +10V)

-32768

-31276

-15638

15638 15638

31276 31276

32767 32767

Output Register

-

-

-

00

( 2 ) Output Characteristics Drawing for Output Range 1 (-10V to +10V)

32767

31276

Output

register

-10.5V

-10V

0

0V

Analog output

10V

10.5V

36

-31276

-32768

( 3 ) Output Characteristics Drawing for Output Range 2 (-10V to +10V)

Page 37

3.2 AO-01 Module Connections

3.2.1 Specifications on Cable and Connector

AO-01 Module Connections

3.2

( 1 )

Connector

Specifications

Connector

Connector

Analog Output

Connector

Name

CN1

No. of

Pins

20

Connector Model

Module Cable Manufacturer

Connector

・

10120-3000PE

Shell

・

10220-52A3PL

10320-52A0-008

Screw lock

(

10320-52F0-008

One-touch lock

(

( 2 ) Connector Models and External Appearance of Standard Cable

Cable Model Length

JEPMC-W6090-05-E

Cable for

AO-01Module

JEPMC-W6090-10-E

JEPMC-W6090-30-E

0.5 m

1 m

3 m

Appearance(JEPMC-W6090--E

CN1

NP㧦JEPMC-W6090-05-E

( 3 ) Standard Cable Wiring

)

)

)

Mark tube (label)

L 150

Sumitomo

3M Limited

3

CN2

Loose wire

The following table shows the wiring for the JEPMC-W6090--E standard cable loose wire.

CN1

20-pin Terminal

No.

1 Orange Red

3 Orange Black

2 Gray Red

4 Gray Black

6 White Red

8 White Black

7 Ye l lo w R e d

9 Ye l lo w B la ck

Note: The cable is shielded twisted-pair and connected to connector shell of CN1 by metal-clamp.

Wire Color Dot Color Dot Mark

-

-

-

-

-

-

-

-

CN2

Mark Tube

Label

(

)

AO0

AO0G

AO1

AO1G

AO2

AO2G

AO3

AO3G

Twisted-pair Wire

37

Page 38

AO-01 Module

20

19

9

10

12

1

2

11

1

AO0

11

N.C.

2

AO1

12

N.C.

3 AO0G 13 N.C.

4 AO1G 14 N.C.

5 N.C. 15 N.C.

6 AO2 16 N.C.

7 AO3 17 N.C.

8 AO2G 18 N.C.

9 AO3G 19 N.C.

10 N.C. 20 N.C.

3

Connector Pin Arrangement

3.2.2

3.2.2 Connector Pin Arrangement

The following table shows the connector (CN1) of the pin arrangement and the terminal layout for the AO-01 module.

( 1 ) CN1 Pin Arrangement and Terminal Layout

Pin Arrangement at Connection Side

( 2 ) Terminal Specifications

No.

1 AO0 Analog output 0 11 N.C Unused

2 AO1

3 AO0G Ground 0 13 N.C Unused

4 AO1G Ground 1 14 N.C Unused

5 N.C. Unused 15 N.C Unused

6 AO2

7 AO3

8 AO2G Ground 2 18 N.C Unused

9 AO3G

10 N.C Unused 20 N.C Unused

Signal

Name

Analog output

Analog output

Analog output

Ground

Function No.

1

2

3

3

Signal

Name

12 N.C Unused

16 N.C Unused

17 N.C Unused

19 N.C Unused

Function

38

Page 39

3.2.3 AO-01 Module Connection Example (CN1)

AO-01 Module Connections

3.2

AO-01

Voltage

output 1

Ground 1

Voltage

output 2

Ground 2

Voltage

output 3

Ground 3

Voltage

output 4

Ground 4

Junction-terminal block

䋱

3

2

4

6

8

7

9

External device

RL

-10 to +10V

FG

External device

RL

-10 to +10V

FG

External device

RL

-10 to +10V

FG

External device

RL

3

-10 to +10V

FG

(Connector shell)

Use the AO-01 standard cable (JEPMC-W6090--E) for the connection to the external device. Use the junction

terminal block because the distance between the external devices and the module are different as seen on the

above diagram.

Ground the cable shield between the external devices and the junction terminal block by the external device side.

FG

39

Page 40

AO-01 Module

3

Setting the Output Range

3.3.1

3.3 AO-01 Module Settings

This section describes the items to be set using the MPE720 after connecting the AO-01 Module.

After connecting the AO-01 Module, use the following procedures to select the input mode, offset/gain, and self con-

figuration. If the self configuration is executed after having set the output range and offset/gain, the set values will

be reset to their default values.

3.3.1 Setting the Output Range

The AO-01 Module has two output ranges

• Output Range 1:

• Output Range 2: 0 V to +10 V

Start the MPE720 program. In the AO-01 Configuration window, select the output range for each channel to be used.

-10 V to +10 V

40

Page 41

3.3.2 Setting the Offset/Gain

The offset/gain settings do not usually have to be adjusted. The AO-01 Module has been adjusted before shipment so

the appropriate value is input for the specified voltage or current. If more precise adjustments are required, use the following procedure to adjust the offset/gain.

After selecting the channel number in the AO-01 Configuration Window, select Set and the Offset/

1.

Gain.

AO-01 Module Settings

3.3

3

The Set Offset/Gain box will be displayed.

Set the output register to 0 (0 V), and measure the output voltage of the AO1 Module.

2.

Calculate the offset of the output voltage using the following equation. Enter the result in the Offset

3.

Input box in the Set Offset/Gain box.

Offset value = AO1×(

Click the OK button to save the offset value, and the dialog box will close.

4.

Repeat step 1 to view the Set Offset/Gain box.

5.

Set the output register to 31276 (10 V), and measure the output voltage of the AO2 module.

6.

3127.6) (round off below decimal point)

−

Calculate the gain of the output voltage using the following equation. Enter the result in the Gain Input

7.

box in the Set Offset/Gain box.

If the voltage of AO2 is less than 10 volts,

・

Gain = 10.0÷AO2 (Round to three decimal places.)

If the voltage of AO2 is greater than 10 volts, gradually reduce the value of the output register from

・

31276 until the output voltage 10 V. The value of the output register if the output voltage is approximately 10 V is REG1.

Gain = REG1÷31276.0 (Round to three decimals places.)

41

Page 42

AO-01 Module

4 words (fixed) are allocated starting

from the register number that can be

used.

All channels are in unused status.

3

Self Configuration

3.3.3

Click the OK button to save the gain, and the dialog box will close.

8.

Offset default: 0000, Gain default: 1,000.

3.3.3 Self Configuration

The MP2300, MP2200, and MP2100M machine controllers in the MP2000-series have a self configuration function.

With self configuration, the I/O leading and end registers for the AO-01 Module will be automatically allocated and all

of the channels will be shown as being unused if (no channel has been selected in the AO-01 Configuration window).

42

Page 43

Index

INDEX

AI-01 module

applicable machine controllers

circuit configuration

connection example

connections

connector

connector pin arrangement

current input mode

current mode

external dimensions

functions

input characteristics

LED indicator

self configuration

setting the input mode

setting the offset/gain

settings

specifications

standard cable

standard cable wiring

voltage input mode

voltage mode

analog input

analog output

AO-01 module

applicable machine controllers

connection example

connections

connector

connector pin arrangement

external dimensions

function

LED indicator

output characteristics

self configuration

setting the offset/gain

setting the output range

settings

specifications

standard cable

standard cable wiring

applicable machine controllers

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - 29

- - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - 22

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - 23

- - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - 31

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - 25

- - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

- - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - -42

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

- - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - 37

A

21

- - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - -26

- - - - - - - - - - - - - - - - - - 14

- - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - 13

14

28

25

25

29

30

22

24

32

30

30

22

25

29

30

23

35

39

37

38

34

35

36

41

40

34

37

M

mounting/removing optional modules on machine controller

- - - -

O

optional cover

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

R

removing optional modules - - - - - - - - - - - - - - - - - - - - - -18

16

16

installing optional modules

I

- - - - - - - - - - - - - - - - - - - - - -

17

43

Page 44

Revision History

3

2

1

The revision dates and numbers of the revised manuals are given on the bottom of the back cover.

MANUAL NO.ޓSIEP C880700 26A

Published in Japan September 200905-8

Date of

publication

1 -1

WEB revision number

Revision number

Date of original publication

Date of

Publication

April 2011

March 2011

November 2010

May 2010

October 2009

September 2009

September 2008

August 2005

Rev.

No.

WEB

Rev.

No.

1

0

1

0

2

1

0

––

Section Revised Contents

2.1.3 (2), (3) Revision: Voltage range for mode 1 and 2

– SIEP C880700 26A<2>-1, available on the Web.

Front cover Revision: Format

2.2.1 (1), 3.2.1 (1) Revision: Connector model

2.2.1 (2), (3),

2.2.3 (2),

3.2.1 (2), (3),

3.2.3

Back cover Revision: Address, format

Front cover Revision: Model

2.2.1 (3), 3.2.1 (3) Revision: Table of standard cable wiring

– SIEP C880700 26A<1>-2, available on the Web.

2.1.2 (2) Revision: Model No.

Preface Addition: Warranty

Back cover Revision: Address

Preface Addition: PL on fumigation

2.2.1 (2), 3.2.1 (2) Revision: Length and external appearance of standard cable

2.2.1 (3) Revision: Table of standard cable wiring

Back cover Revision: Address

– First edition

Revision: Cable model

Page 45

Machine Controller MP2000 Series

Analog Input/Analog Output Module

AI-01/AO-01 USER'S MANUAL

IRUMA BUSINESS CENTER (SOLUTION CENTER)

480, Kamifujisawa, Iruma, Saitama 358-8555, Japan

Phone 81-4-2962-5151 Fax 81-4-2962-6138

YASKAWA AMERICA, INC.

2121 Norman Drive South, Waukegan, IL 60085, U.S.A.

Phone (800) YASKAWA (800-927-5292) or 1-847-887-7000 Fax 1-847-887-7310

YASKAWA ELETRICO DO BRASIL LTDA.

Avenida Fagundes Filho, 620 Sao Paulo-SP CEP 04304-000, Brazil

Phone 55-11-3585-1100 Fax 55-11-5581-8795

YASKAWA EUROPE GmbH

Hauptstraβe 185, Eschborn 65760, Germany

Phone 49-6196-569-300 Fax 49-6196-569-398

YASKAWA ELECTRIC UK LTD.

1 Hunt Hill Orchardton Woods Cumbernauld, G68 9LF, United Kingdom

Phone 44-1236-735000 Fax 44-1236-458182

YASKAWA ELECTRIC KOREA CORPORATION

7F, Doore Bldg. 24, Yeoido-dong, Yeoungdungpo-gu, Seoul 150-877, Korea

Phone 82-2-784-7844 Fax 82-2-784-8495

YASKAWA ELECTRIC (SINGAPORE) PTE. LTD.

151 Lorong Chuan, #04-01, New Tech Park 556741, Singapore

Phone 65-6282-3003 Fax 65-6289-3003

YASKAWA ELECTRIC (SHANGHAI) CO., LTD.

No.18 Xizang Zhong Road. 17F, Harbour Ring Plaza Shanghai 200001, China

Phone 86-21-5385-2200 Fax 86-21-5385-3299

YASKAWA ELECTRIC (SHANGHAI) CO., LTD. BEIJING OFFICE

Room 1011, Tower W3 Oriental Plaza, No.1 East Chang An Ave.,

Dong Cheng District, Beijing 100738, China

Phone 86-10-8518-4086 Fax 86-10-8518-4082

YASKAWA ELECTRIC TAIWAN CORPORATION

9F, 16, Nanking E. Rd., Sec. 3, Taipei 104, Taiwan

Phone 886-2-2502-5003 Fax 886-2-2505-1280

YASKAWA ELECTRIC CORPORATION

In the event that the end user of this product is to be the military and said product is to be employed in any weapons systems or the manufacture

thereof, the export will fall under the relevant regulations as stipulated in the Foreign Exchange and Foreign Trade Regulations. Therefore, be sure

to follow all procedures and submit all relevant documentation according to any and all rules, regulations and laws that may apply.

Specifications are subject to change without notice for ongoing product modifications and improvements.

© 2005-2011 YASKAWA ELECTRIC CORPORATION. All rights reserved.

MANUAL NO. SIEP C880700 26B

Published in Japan April 2011 05-8

10-10-4

3 -1

Loading...

Loading...