Yaesu VX-8GRSM Service Manual

144/430 MHz

Dual-Band FM Transceiver

with GPS

VX-8GR

Technical Supplement

©2010 VERTEX STANDARD CO., LTD. Printed in Japan.

EH041M90A

Introduction

This manual provides the technical information necessary for servicing the VX-8GR

144/430 MHz Dual-Band FM Transceiver.

Servicing this equipment requires expertise in handing surface-mount chip components.

Attempts by non-qualified persons to service this equipment may result in permanent

damage not covered by the warranty, and may be illegal in some countries.

Two PCB layout diagrams provided for each double-sided board in this transceiver.

Each side of the board is referred to by the type of the majority of components installed on

that side ("Side A" or "Side B"). In most cases one side has only chip components, and the

other has either a mixture of both chip and leaded components (trimmers, coils, electrolytic

capacitors, ICs, etc.), or leaded components only.

While we believe the information in this manual to be correct, VERTEX STANDARD

assumes no liability for damage that may occur as a result of typographical or other errors

that may be present. Your cooperation in pointing out any inconsistencies in the technical

information would be appreciated.

VERTEX STANDARD CO., LTD.

4-8-8 Nakameguro, Meguro-Ku, Tokyo 153-8644, Japan

VERTEX STANDARD

US Headquarters

10900 Walker Street, Cypress, CA 90630, U.S.A.

YAESU UK LTD.

Unit 12, Sun Valley Business Park, Winnall Close

Winchester, Hampshire, SO23 0LB, U.K.

VERTEX STANDARD HK LTD.

Unit 5, 20/F., Seaview Centre, 139-141 Hoi Bun Road,

Kwun Tong, Kowloon, Hong Kong

VERTEX STANDARD (AUSTRALIA) PTY., LTD.

Normanby Business Park, Unit 14/45 Normanby Road

Notting Hill 3168, Victoria, Australia

Important Note

1) This transceiver was assembled using Pb (lead) free solder, based on the RoHS specification.

Only lead-free solder (Alloy Composition: Sn-3.0Ag-0.5Cu) should be used for repairs performed on this apparatus. The solder stated

above utilizes the alloy composition required for compliance with the lead-free specification, and any solder with the above alloy

composition may be used.

2) Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according to the instructions.

Contents

Specification ........................................................................................................................................................................... 2

Exploded View & Miscellaneous Parts ............................................................................................................................. 4

Block Diagram ....................................................................................................................................................................... 5

Alignment ............................................................................................................................................................................... 7

Board Unit (Schematics, Layouts & Parts)

RF Unit Circuit Diagram ............................................................................................................................................... 19

RF Unit Parts Layout ..................................................................................................................................................... 20

RF Unit Parts List ........................................................................................................................................................... 21

CNTL Unit Circuit Diagram ......................................................................................................................................... 37

CNTL Unit Parts Layout ............................................................................................................................................... 38

CNTL Unit Parts List ..................................................................................................................................................... 39

CABLE Unit Circuit Diagram ....................................................................................................................................... 49

CABLE Unit Parts Layout ............................................................................................................................................. 49

CONNECT Unit Circuit Diagram ................................................................................................................................ 50

CONNECT Unit Parts Layout ...................................................................................................................................... 50

MAIN VCO Unit Circuit Diagram ............................................................................................................................... 51

MAIN VCO Unit Parts Layout ..................................................................................................................................... 51

MAIN VCO Unit Parts List ........................................................................................................................................... 53

SUB VCO Unit Circuit Diagram ................................................................................................................................... 55

SUB VCO Unit Parts Layout ........................................................................................................................................ 55

SUB VCO Unit Parts List .............................................................................................................................................. 57

1VX-8GR Technical Supplement

Specifications

GENERAL

Frequency Ranges: A (Main) Band RX: 108-137 MHz (Air Band)

137-174 MHz (144 MHz HAM)

174-222 MHz (VHF-TV)

222-420 MHz (General 1)

420-470 MHz (430 MHz HAM)

470-800 MHz (UHF-TV, Cellular Blocked)

800-999.90 MHz (General 2, Cellular Blocked)

B (Sub) Band RX: 108-137 MHz (Air Band)

137-174 MHz (144 MHz HAM)

174-222 MHz (VHF-TV)

222-420 MHz (General 1)

420-470 MHz (430 MHz HAM)

470-580 MHz (UHF-TV)

TX: 144-146 MHz or 144-148 MHz

430-440 MHz or 430-450 MHz

Channel Steps: 5/6.25/8.33/10/12.5/15/20/25/50/100 kHz

Emission Type: F1D, F2A, F2D, F3E

Frequency Stability: ±5 ppm (–10 °C to +60 °C [+14 °F to +140 °F])

Repeater Shift: ±600 kHz (144 MHz), ±1.6/5.0/7.6 MHz (430 MHz)

Antenna Impedance: 50 Ohms

Supply Voltage: Nominal: 7.4 V DC (Negative Ground)

Operating: 4-14 V DC (Negative Ground, EXT DC jack)

Operating with Charging: 11-16 V DC (Negative Ground, EXT DC jack)

Current Consumption: 200 mA (Mono Band Receive)

(@7.4 VDC, approx.) 240 mA (Dual Band Receive)

85 mA (Mono Band Receive, Standby, Saver Off)

120 mA (Dual Band Receive, Standby, Saver Off)

35 mA (Mono Band Receive, Standby, Saver On “Save Ratio 1:5”)

42 mA (Dual Band Receive, Standby, Saver On “Save Ratio 1:5”)

2 mA (Auto Power Off)

1.7A (144 MHz, 5W TX)

1.9 A (430 MHz, 5W TX)

Operating Temperature: –20 °C to +60 °C (–4 °F to +140 °F)

Case Size (W x H x D): 60 x 95 x 28 mm (2.4” x 3.7” x 1.1”) w/o knob & antenna

Weight (Approx.): 250 g (8.8 oz) with FNB-101LI & antenna

2 VX-8GR Technical Supplement

TRANSMITTER

RF Power Output: 1.0 W (@4.5 V: AA x 3)

5.0 W (@7.4 V or EXT DC)

L3: 2.5 W, L2: 1 W, L1: 0.05 W (@7.4 V)

Modulation Type: F2E, F3E: Variable Reactance

Maximum Deviation: ±5 kHz (F2E/F3E)

Spurious Emission: At least 60 dB below (@ TX power HI/L3/L2)

At least 50 dB below (@ TX power L1)

Microphone Impedance: 2k Ohms

RECEIVER

Circuit Type: Double-Conversion Superheterodyne

IF: 1st: 47.25 MHz (A (Main) Band),

46.35 MHz (B (Sub) Band),

2nd: 450 kHz

Sensitivity: 1.5 µV (TYP) for 10 dB SN (108-137 MHz @AM)

0.2 µV for 12 dB SINAD (137-140 MHz @NFM)

0.16 µV for 12 dB SINAD (140-150 MHz @NFM)

0.2 µV for 12 dB SINAD (150-174 MHz @NFM)

1.0 µV for 12 dB SINAD (174-222 MHz @NFM)

0.5 µV for 12 dB SINAD (300-350 MHz @NFM)

0.2 µV for 12 dB SINAD (350-400 MHz @NFM)

0.18 µV for 12 dB SINAD (400-470 MHz @NFM)

1.5 µV for 12 dB SINAD (470-540 MHz @NFM)

3.0 µV (TYP) for 12 dB SINAD (540-800 MHz @NFM)

1.5 µV (TYP) for 12 dB SINAD (800-999.90 MHz @NFM)

(Cellular Blocked)

Selectivity: 12 kHz/35 kHz (–6dB/–60dB: NFM, AM)

AF Output: 200 mW @ 8 Ohms for 10 % THD (@ 7.4 V DC)

400 mW @ 8 Ohms for 10 % THD (@ 13.8 V DC)

Specifications

Specifications are subject to change without notice, and are guaranteed within the 144/430 MHz amateur bands only.

Cellular Blocked per FCC rule Part 15.121, may not receive 900 MHz Amateur band.

3VX-8GR Technical Supplement

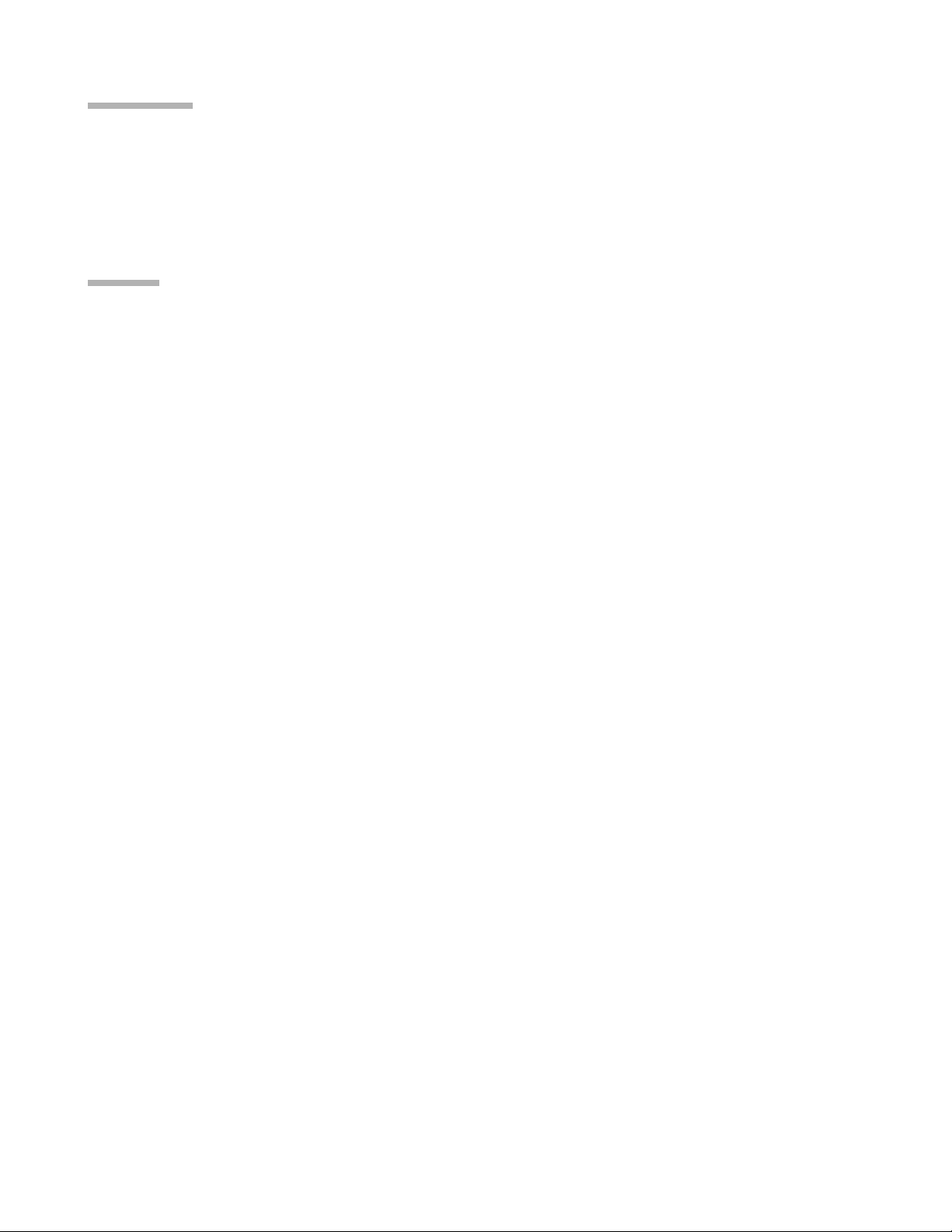

Exploded View & Miscellaneous Parts

CONNECT Unit

RA1016900

SUPPORT (PTT)

RA101320B

RUBBER (PTT)

RA107300A

SPACER(PTT)

RA1230000

KEY PAD

RA1229400

GASKET (SP)

M4090189

SPEAKER(0.5W/16-ohm)

RA101370B

SP HOLDER

RA1229300

RUBBER PACKING (LCD)

RA1228900 (X2pcs)

LIGHT GUIDE (WIN)

RA1271800

DIFFUSER SHEET (LCD)

RA1271700

SHADING SHEET(LCD)

RA1013800

SHEET (LCD)

RA1257100 (X2pcs)

SPACER(SP)

CNTL Unit

CP9697002 (USA)

CP9697003 (EXP)

FRONT CASE ASSY

RA1231200

MASK SHEET (MOTOR)

RA1229500

BRACKET (MOTOR)

M2190034

VIBRATION MOTOR

Removing the Rear Case Assy

1. Please order the screw M2.6X30 (P/N;

U00230001).

2. Remove the ENCODER KNOB (A) and SPECIAL SCREW (B).

3. Remove the two screws (C).

4. Turn the M2.6x30 screw several times to

affix the screw to the bottom right corner.

5. Press the top of the screw toward to a panel

top to remove the rear case Assy from the

front panel.

(C)

(B)

(A)

screw M2.6X30

(C)

RA1229100

RUBBER PACKING (LED)

RA1228800

LIGHT GUIDE (LED)

RA1228600

ENCODER KNOB

RA124430A

WINDOW ASSY (YAESU)

RA1229000

CAP (SIDE)

RA060450B

SPECIAL NUT (M)

RA1037500

O RING (6.5X2)

Q7000614A

LCD MODULE

RA1273400

LCD SHEET(B)

RA1228700

LCD HOLDER

RA1229200

MIC HOLDER RUBBER

RA1266400

MASK SHEET (DATA)

RA1257000

MASK SHEET (EXT)

RA0434100

SHEET (M-TEX1131)

RA1267500

DOUBLE FACE (RUBBER)

RA0603600

O RING (1X4.2)

RA1012700

GASKET

RA1012800

PACKING PAD (POW)

CP9698001

CHASSIS ASSY

(w/ PACKING PAD, O RING,

SMA CONNECTOR)

CABLE Unit

Q7000642

GPS MODULE

RA1037400

O RIN G (4.8X1.9)

RA1272300 (X2pcs)

SHEET(CNT)

SUB VCO Unit

RA1229700

STUD A

RA1229800

STUD B

RA0337300

SHEET

RA1007400

SHIELD CASE VCO

RA1007400

SHIELD CASE VCO

MAIN VCO Unit

RA1274400

SUPPORT(CONT)

RF Unit

Non-designated parts are available only as part of a

designated assembly.

RA1229800

STUD B

RA1229700

STUD A

RA1267700

SHEET (LABEL)

RA1231300

MASK SHEET (SW)

RUBBER ANTENNA YHA-72

AC-DC ADAPTOR NC-86B (USA)

AC-DC ADAPTOR NC-86C (EXP)

U07230102

U9900241

U9900181

U9900242

U9900239

U9900243

U9900240

U07240202

PAN HEAD SCREW M2X3NI #1

PAN HEAD TAPTITE-B 2X10SUS #3

TAPTITE SCREW 2X3.5(CAP)

TAPPING SCREW 2X2.5NI

PAN HEAD TAPTITE-B 2X3NI #3

TAPPING SCREW M2X3NI

PAN HEAD TAPTITE-B 1.4X3NI #3

PAN HEAD SCREW M2X4NI#2

Q3000236

Q9500149

Q9500150

1

2

1

6

9

2

2

2

4 VX-8GR Technical Supplement

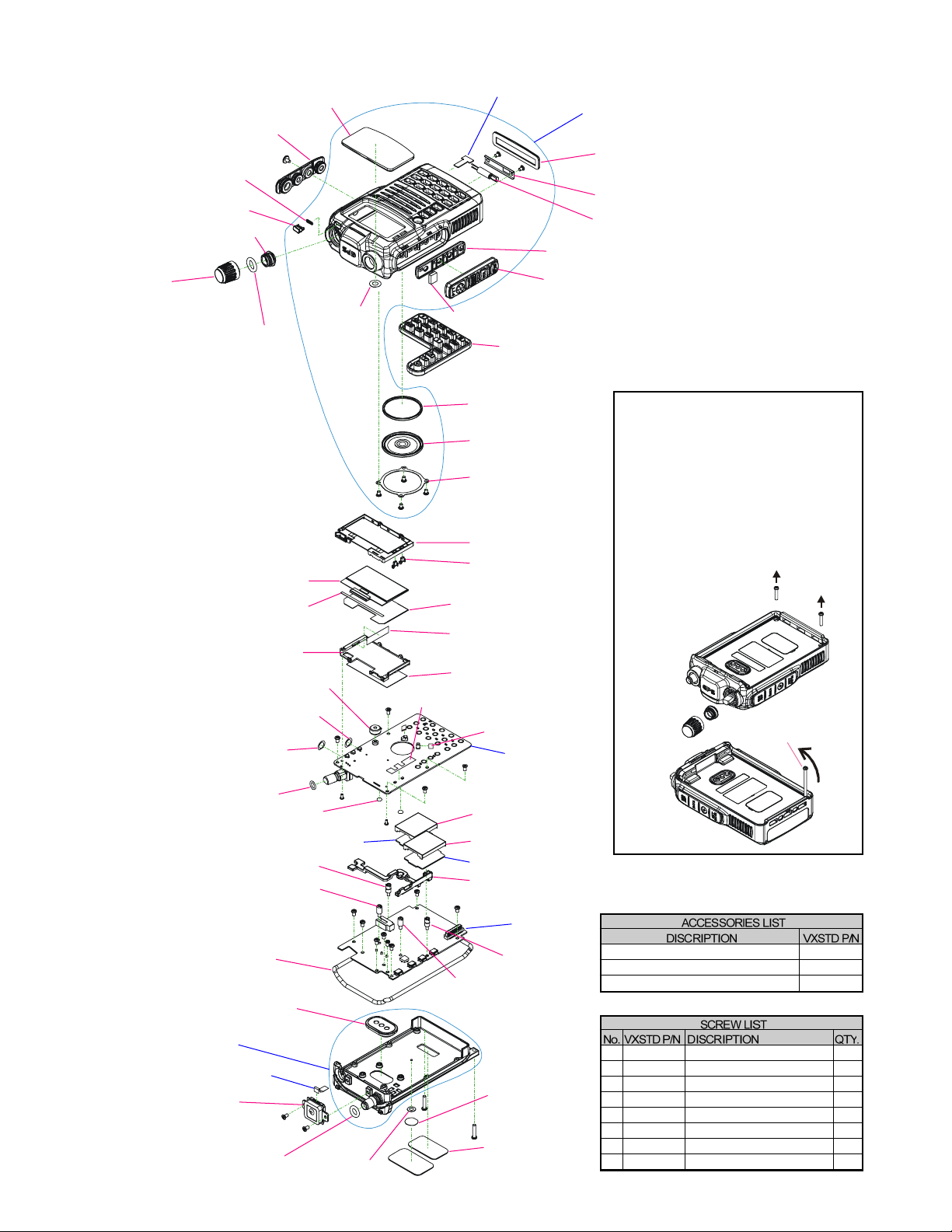

Block Diagram

5VX-8GR Technical Supplement

Block Diagram

Note

6 VX-8GR Technical Supplement

Alignment

Introduction and Precautions

The has been carefully aligned at the factory

for the specified performance across the specified ama-

teur bands. Realignment should therefore not be neces-

sary except in the event of a component failure. All com-

ponent replacement and service should be performed only

by an authorized VERTEX STANDARD representative,

or the warranty policy may be voided.

The following procedures cover the sometimes critical

and tedious adjustments that are not normally required

once the transceiver has left the factory. However, if dam-

age occurs and some parts are replaced, realignment may

be required. If a sudden problem occurs during normal

operation, it is likely due to component failure; realign-

ment should not be done until after the faulty compo-

nent has been replaced.

We recommend that servicing be performed only by

authorized VERTEX STANDARD service technicians,

who are experienced with the circuitry and fully

equipped for repair and alignment. Therefore, if a fault

is suspected, contact the dealer from whom the trans-

ceiver was purchased for instructions regarding repair.

Authorized VERTEX STANDARD service technicians

realign all circuits and make complete performance

checks to ensure compliance with factory specifications

after replacing any faulty components.

Those who do undertake any of the following align-

ments are cautioned to proceed at their own risk. Prob-

lems caused by unauthorized attempts at realignment

are not covered by the warranty policy. Also, VERTEX

STANDARD must reserve the right to change circuits

and alignment procedures in the interest of improved

performance, without notifying owners.

Under no circumstances should any alignment be at-

tempted unless the normal function and operation of the

transceiver are clearly understood, the cause of the mal-

function has been clearly pinpointed and any faulty com-

ponents replaced, and the need for realignment deter-

mined to be absolutely necessary.

Required Test Equipment

H RF Signal Generator with calibrated output level at 500 MHz

H Deviation Meter (linear detector)

H In-line Wattmeter with 5% accuracy at 500 MHz

H 50-ohm, 10-W RF Dummy Load

H 8-ohm AF Dummy Load

H Regulated DC Power Supply adjustable from 8 to 16 V DC, 3A

H Frequency Counter: 0.2-ppm accuracy at 500 MHz

H AF Signal Generator

H AC Voltmeter

H DC Voltmeter: high impedance

H UHF Sampling Coupler

H SINAD Meter

Alignment Preparation & Precautions

A 10-W RF dummy load and in-line wattmeter must

be connected to the main antenna jack in all procedures

that call for transmission, alignment is not possible with

an antenna. After completing one step, read the next step

to see if the same test equipment is required. If not, re-

move the test equipment (except dummy load and watt-

meter, if connected) before proceeding.

Correct alignment requires that the ambient tempera-

ture be the same as that of the transceiver and test equip-

ment, and that this temperature be held constant between

68~86°F (20~30°C). When the transceiver is brought into

the shop from hot or cold air, it should be allowed some

time to come to room temperature before alignment.

Whenever possible, alignments should be made with os-

cillator shields and circuit boards firmly affixed in place.

Also, the test equipment must be thoroughly warmed

up before beginning.

Note: Signal levels in dB referred to in the alignment proce-

dure are based on 0 dBµ=0.5 µV (closed circuit).

7VX-8GR Technical Supplement

Alignment

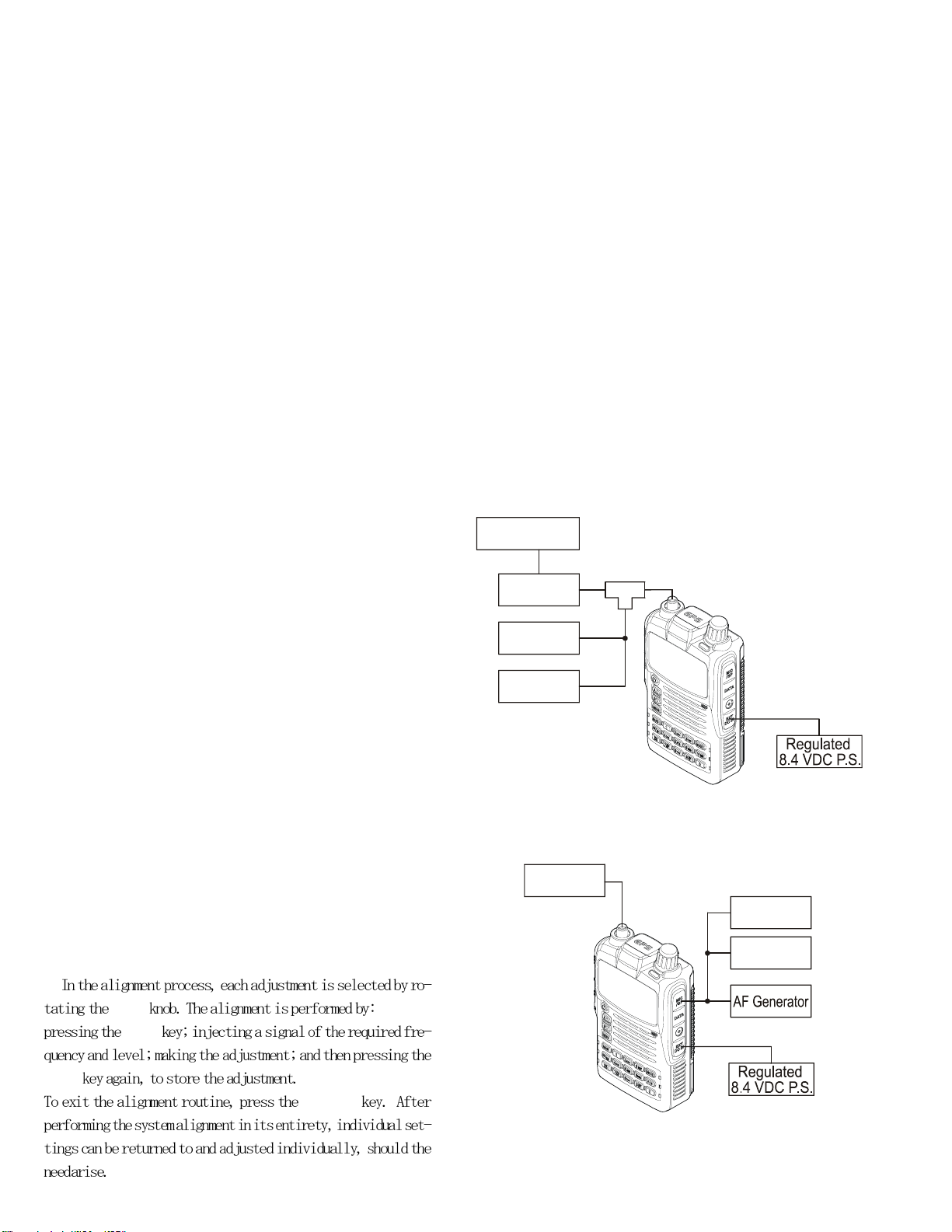

Internal System Alignment Routine

This uses a programmed routine in the transceiver

which simplifies many previously complex discrete com-

ponent settings and adjustments with digitally-con-

trolled settings via front panel buttons and LCD indica-

tions.

1. To begin, set the transceiver to the VFO mode on the

"A-Band" in the "Mono" band mode.

2. Program a password for the Alignment (AH041M) ac-

cording to the following procedure:

1) Press and hold the [

enter the Set mode.

2) Rotate the DIAL knob to select Set Mode Item 16:

CW ID.

3) Press the [

of this Set Mode Item.

4) Rotate the

5) Press the [

[

HM/RV

entry.

6) Program the password "AH041M" using the DIAL

knob (select the character), and [

key (move the cursor).

7) When you have completed the password, press the

[

MENU

exit to normal operation.

Remember to delete the password "AH041M"from the

Set Mode Item 16: CW ID when the alignment adjust-

ments are finished by pressing and holding in the [

] key for two seconds (as in step 5 above).

RV

3. Press the [PWR] switch for two seconds to turn the

transceiver "off".

4. Press and hold in the [

the transceiver "on" again. The transceiver will enter

the adjustment mode, and the display will show the

first alignment setting. Thereafter, the frequencies used

during alignment will automatically be set without

action by the technician.

] key for two seconds to clear any previous

] key briefly, then press the PTT switch to

] key briefly to enable adjustment

MENU

DIAL knob to select "ON".

] key, then press and hold in the

MODE

] key for one second to

MENU

BAND

HM/RV

] key while powering

]/[

MODE

HM/

As each transceiver is individually optimized at the

factory, the precise settings for the transceiver on your

bench may be slightly different.

PLL Reference Frequency Adjustment (PLL REF)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"PLL REF".

Ì Press the [V/M] button (the "" icon will appear on the

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the frequency counter setting is 440.000

MHz (±100 Hz).

Ì Release the PTT switch, then press the [

(the "" icon will disappear from the display).

V/M

] button

50-ohm RF

Dummy Load

Sampling

Coupler

]

In-Line

Wattmeter

Deviation

Meter

Frequency

Counter

Figure 1: TX Alignment Setup

RF Signal

Generator

8-ohm

AF Load

SINAD

Meter

DIAL

[V/M]

[V/M]

[

HM/RV

]

Figure 2: RX Alignment Setup

8 VX-8GR Technical Supplement

A-Band 430 MHz Band Adjustment

Receiver Sensitivity Adjustment (TUNE DC)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"TUNE DC".

Ì Set the RF Signal Generator output to 435.100 MHz, at

a level of -10 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

display).

Ì Rotate the DIAL knob for maximum deflection on the

SINAD meter.

Ì Press the [

the display).

] button (the "" icon will appear on the

V/M

] button (the "" icon will disappear on

V/M

Alignment

FM S-Meter S-1 Adjustment (S1 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S1 LEVEL" with "NFM" icon.

Ì Set the RF Signal Generator output to 435.100 MHz, at

a level of -7 dBµ, ±3.5 kHz deviation with a 1 kHz au-

dio tone.

Ì Press the [

display).

Ì Press the [

S-1 level.

Ì Press the [

the display).

] button (the "" icon will appear on the

V/M

] key two times to store the FM SMeter

F/W

] button (the "" icon will disappear on

V/M

Squelch Hysteresis Confirmation (HIS SQL)

Ì Rotate the DIAL knob to select the Alignment Menu

"HIS SQL".

Ì Confirm that the alignment value is "0".

Squelch Threshold Adjustment (THLD SQL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"THLD SQL".

Ì Set the RF Signal Generator output to 435.100 MHz, at a level

of -12 dBµ, ±3.5 kHz deviation with a 1 kHz audio tone.

Ì Press the [

display).

Ì Press the [

Threshold level

Ì Press the [

the display).

Tight Squelch Adjustment (TIGH SQL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"TIGH SQL".

Ì Set the RF Signal Generator output to 435.100 MHz, at a level

of -4 dBµ, ±3.5 kHz deviation with a 1 kHz audio tone.

Ì Press the [

display).

Ì Press the [

Tight level.

Ì Press the [

the display).

] button (the "" icon will appear on the

V/M

] key two times to store the Squelch

F/W

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on the

V/M

] key two times to to store the Squelch

F/W

] button (the "" icon will disappear on

V/M

FM S-Meter Full-Scale Adjustment (S9 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S9 LEVEL" with "NFM" icon.

Ì Set the RF Signal Generator output to 435.100 MHz, at

a level of +20 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

display).

Ì Press the [

Full Scale level.

Ì Press the [

the display).

] button (the "" icon will appear on the

V/M

] key two times to store the FM SMeter

F/W

] button (the "" icon will disappear on

V/M

9VX-8GR Technical Supplement

Alignment

TX Power (HI) Adjustment (HI POWER)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"HI POWER".

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Power Meter reading is 4.9 W (±0.1

W).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

TX Power (L3) Adjustment (L3 POWER)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"L3 POWER".

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Power Meter setting is 2.5 W (±0.1

W).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

TX Power (L2) Adjustment (L2 POWER)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"L2 POWER".

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Power Meter setting is 1.0 W (±0.1

W).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

] button (the "" icon will appear on the

V/M

] button (the "" icon will appear on the

V/M

] button (the "" icon will appear on the

V/M

V/M

V/M

V/M

] but-

] but-

] but-

TX Power (L1) Adjustment (L1 POWER)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"L1 POWER".

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Power Meter setting is 50 mW (+30

mW/ -0 W).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

TX Deviation Adjustment (MAX DEV)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"MAX DEV".

Ì Set the AF Signal Generator output to 50 mVrms with

a 1 kHz audio tone.

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Deviation Meter setting is 4.2 kHz ±

0.05 kHz (USA version) or 4.5 kHz ± 0.05 kHz (EXP

version).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

CTCSS TX Deviation Adjustment (100.0Hz)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"100.0Hz".

Ì Press the [

display).

Ì Press the PTT switch to transmit without the micro-

phone input and rotate the DIAL knob so that the De-

viation Meter setting is 0.65 kHz (±0.05 kHz).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

] button (the "" icon will appear on the

V/M

] button (the "" icon will appear on the

V/M

] button (the "" icon will appear on the

V/M

V/M

V/M

V/M

] but-

] but-

] but-

10 VX-8GR Technical Supplement

DCS TX Deviation Adjustment (DCS 023)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"DCS 023".

Ì Press the [

display).

Ì Press the PTT switch to transmit without the micro-

phone input and rotate the DIAL knob so that the De-

viation Meter setting is 0.65 kHz (±0.05 kHz).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

] button (the "" icon will appear on the

V/M

V/M

] but-

Alignment

11VX-8GR Technical Supplement

Alignment

A-Band 144 MHz Band Adjustment

Press the [BAND] key to select the 144 MHz Amateur

band.

Receiver Sensitivity Adjustment (TUNE DC)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"TUNE DC".

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of -10 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

display).

Ì Rotate the DIAL knob for maximum deflection on the

SINAD meter.

Ì Press the [

the display).

Squelch Hysteresis Confirmation (HIS SQL)

Ì Rotate the DIAL knob to select the Alignment Menu

"HIS SQL".

Ì Confirm that the alignment value is "0".

Squelch Threshold Adjustment (THLD SQL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"THLD SQL".

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of -12 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

display).

Ì Press the [

Threshold level.

Ì Press the [

the display).

] button (the "" icon will appear on the

V/M

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on the

V/M

] key two times to store the Squelch

F/W

] button (the "" icon will disappear on

V/M

Tight Squelch Adjustment (TIGH SQL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"TIGH SQL".

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of +4 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

display).

Ì Press the [

Tight level.

Ì Press the [

the display).

FM S-Meter S-1 Adjustment (S1 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S1 LEVEL" with "NFM" icon.

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of -7 dBµ, ±3.5 kHz deviation with a 1 kHz au-

dio tone.

Ì Press the [

display).

Ì Press the [

S-1 level.

Ì Press the [

the display).

FM S-Meter Full-Scale Adjustment (S9 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S9 LEVEL" with "NFM" icon.

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of +20 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

display).

Ì Press the [

Full Scale level.

Ì Press the [

the display).

] button (the "" icon will appear on the

V/M

] key two times to store the Squelch

F/W

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on the

V/M

] key two times to store the FM S-Meter

F/W

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on the

V/M

] key two times to store the FM S-Meter

F/W

] button (the "" icon will disappear on

V/M

12 VX-8GR Technical Supplement

Alignment

Wide FM S-Meter S-1 Adjustment (S1 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S1 LEVEL" with "WFM" icon.

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of 0 dBµ, ±20 kHz deviation with a 1 kHz audio

tone.

Ì Press the [

display).

Ì Press the [

Meter S-1 level.

Ì Press the [

the display).

Wide FM S-Meter Full-Scale Adjustment (S9 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S9 LEVEL" with "WFM" icon.

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of +20 dBµ, ±20 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

display).

Ì Press the [

Meter Full Scale level.

Ì Press the [

the display).

TX Power (HI) Adjustment (HI POWER)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"HI POWER".

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Power Meter setting is 5.0 W (±0.1

W).

Ì Release the PTT switch, then press the [

(the "" icon will disappear on the display).

] button (the "" icon will appear on the

V/M

] key two times to store the Wide FM S-

F/W

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on the

V/M

] key two times to store the Wide FM S-

F/W

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on the

V/M

V/M

] button

TX Power (L3) Adjustment (L3 POWER)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"L3 POWER".

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Power Meter setting is 2.5 W (±0.1

W).

Ì Release the PTT switch, then press the [

(the "" icon will disappear on the display).

TX Power (L2) Adjustment (L2 POWER)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"L2 POWER".

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Power Meter setting is 1.0 W (±0.1

W).

Ì Release the PTT switch, then press the [

(the "" icon will disappear on the display).

TX Power (L1) Adjustment (L1 POWER)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"L1 POWER".

Press the [

the display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Power Meter setting is 50 mW (+30

mW/ -20 mW) (VX-8E Type: 0.2W±0.05W).

Ì Release the PTT switch, then press the [

(the "" icon will disappear on the display).

] button (the "" icon will appear on the

V/M

V/M

] button (the "" icon will appear on the

V/M

V/M

] button (the "" icon will appear on

V/M

V/M

] button

] button

] button

13VX-8GR Technical Supplement

Alignment

TX Deviation Adjustment (MAX DEV)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"MAX DEV".

Ì Set the AF Signal Generator output to 50 mVrms with

a 1 kHz audio tone.

Ì Press the [

display).

Ì Press the PTT switch to transmit and rotate the DIAL

knob so that the Deviation Meter setting is 4.2 kHz ±

0.2 kHz (USA version) or 4.5 kHz ± 0.2 kHz (EXP/EU

versions).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

CTCSS TX Deviation Adjustment (100.0Hz)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"100.0Hz".

Ì Press the [

display).

Ì Press the PTT switch to transmit without the micro-

phone input and rotate the DIAL knob so that the De-

viation Meter setting is 0.65 kHz (±0.05 kHz).

Ì Release the PTT switch, and then press the [

ton (the "" icon will disappear on the display).

DCS TX Deviation Adjustment (DCS 023)

Ì Connect the test equipment as shown in Figure 1: TX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"DCS 023".

Ì Press the [

display).

Ì Press the PTT switch to transmit without the micro-

phone input and rotate the DIAL knob so that the De-

viation Meter setting is 0.65 kHz (±0.05 kHz).

Ì Release the PTT switch, then press the [

(the "" icon will disappear on the display).

] button (the "" icon will appear on the

V/M

] button (the "" icon will appear on the

V/M

] button (the "" icon will appear on the

V/M

V/M

] but-

V/M

] but-

V/M

] button

B-Band 430 MHz Band Adjustment

Press and hold in the [B] key for two seconds to change

the operating band to the "B-Band".

Note: When the transceiver recalls Alignment Menu "PLL

REF", the [B] key operation is ignored. In this case, rotate

the DIAL knob to select an Alignment Menu other than

"PLL REF".

Receiver Sensitivity Adjustment (TUNE DC)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"TUNE DC".

Ì Set the RF Signal Generator output to 435.100 MHz, at

a level of -10 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

the display).

Ì Rotate the DIAL knob for maximum deflection on the

SINAD meter.

Ì Press the [

the display).

Squelch Hysteresis Confirmation (HIS SQL)

Ì Rotate the DIAL knob to select the Alignment Menu

"HIS SQL".

Ì Confirm that the alignment value is "0".

Squelch Threshold Adjustment (THLD SQL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"THLD SQL".

Ì Set the RF Signal Generator output to 435.100 MHz, at

a level of -11 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

the display).

Ì Press the [

Threshold level.

Ì Press the [

the display).

] button (the "" icon will appear on

V/M

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on

V/M

] key two times to store the Squelch

F/W

] button (the "" icon will disappear on

V/M

14 VX-8GR Technical Supplement

Alignment

Tight Squelch Adjustment (TIGH SQL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"TIGH SQL".

Ì Set the RF Signal Generator output to 435.100 MHz, at

a level of -3 dBµ, ±3.5 kHz deviation with a 1 kHz au-

dio tone.

Ì Press the [

the display).

Ì Press the [

Tight level.

Ì Press the [

the display).

FM S-Meter S-1 Adjustment (S1 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S1 LEVEL" with "NFM" icon.

Ì Set the RF Signal Generator output to 435.100 MHz, at

a level of -7 dBµ, ±3.5 kHz deviation with a 1 kHz au-

dio tone.

Ì Press the [

the display).

Ì Press the [

S-1 level.

Ì Press the [

the display).

] button (the "" icon will appear on

V/M

] key two times to store the Squelch

F/W

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on

V/M

] key two times to store the FM S-Meter

F/W

] button (the "" icon will disappear on

V/M

FM S-Meter Full-Scale Adjustment (S9 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S9 LEVEL" with "NFM" icon.

Ì Set the RF Signal Generator output to 435.100 MHz, at

a level of +20 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

the display).

Ì Press the [

Full Scale level.

Ì Press the [

the display).

NOTICE: Do not touch the following Alignment Menus:

"PLL REF"

"HI POWER"

"L3 POWER"

"L2 POWER"

"L1 POWER"

"MAX DEV"

"HI POWER"

"100.0Hz"

"DCS 023"

] button (the "" icon will appear on

V/M

] key two times to store the FM S-Meter

F/W

] button (the "" icon will disappear on

V/M

15VX-8GR Technical Supplement

Alignment

B-Band 144 MHz Band Adjustment

Press the [BAND] key to select the 144 MHz Amateur

band.

Receiver Sensitivity Adjustment (TUNE DC)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"TUNE DC".

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of -10 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

the display).

Ì Rotate the DIAL knob for maximum deflection on the

SINAD meter.

Ì Press the [

the display).

Squelch Hysteresis Confirmation (HIS SQL)

Ì Rotate the DIAL knob to select the Alignment Menu

"HIS SQL".

Ì Confirm that the alignment value is "0".

Squelch Threshold Adjustment (THLD SQL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"THLD SQL".

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of -11 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

the display).

Ì Press the [

Threshold level.

Ì Press the [

the display).

] button (the "" icon will appear on

V/M

] button (the "" icon will disappear on

V/M

] button (the "" icon will appear on

V/M

] key two times to store the Squelch

F/W

] button (the "" icon will disappear on

V/M

Tight Squelch Adjustment (TIGH SQL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"TIGH SQL".

Ì Set the RF Signal Generator output to 145.100 MHz, at a

level of -3 dBµ, ±3.5 kHz deviation with a 1 kHz audio tone.

Ì Press the [

the display).

Ì Press the [

Tight level.

Ì Press the [

on the display).

FM S-Meter S-1 Adjustment (S1 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

"S1 LEVEL" with "NFM" icon.

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of -7 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

the display).

Ì Press the [

S-1 level.

Ì Press the [

on the display).

] button (the "" icon will appear on

V/M

] key two times to store the Squelch

F/W

] button (the "" icon will disappear

V/M

] button (the "" icon will appear on

V/M

] key two times to store the FM S-Meter

F/W

] button (the "" icon will disappear

V/M

16 VX-8GR Technical Supplement

FM S-Meter Full-Scale Adjustment (S9 LEVEL)

Ì Connect the test equipment as shown in Figure 2: RX

Alignment Setup.

Ì Rotate the DIAL knob to select the Alignment Menu

" " with "NFM" icon.

Ì Set the RF Signal Generator output to 145.100 MHz, at

a level of +20 dBµ, ±3.5 kHz deviation with a 1 kHz

audio tone.

Ì Press the [

the display).

Ì Press the [

Full Scale level.

Ì Press the [

the displayy).

NOTICE: Do not touch the following Alignment Menus:

"PLL REF"

"HI POWER"

"L3 POWER"

"L2 POWER"

"L1 POWER"

"MAX DEV"

"HI POWER"

"100.0Hz"

"DCS 023"

] button (the "" icon will appear on

V/M

] key two times to store the FM S-Meter

F/W

] button (the "" icon will disappear on

V/M

Alignment

This completes the internal alignment routine for all

bands. To save all settings and exit, press the [HM/RV]

button.

17VX-8GR Technical Supplement

Alignment

Note

18 VX-8GR Technical Supplement

Loading...

Loading...