Page 1

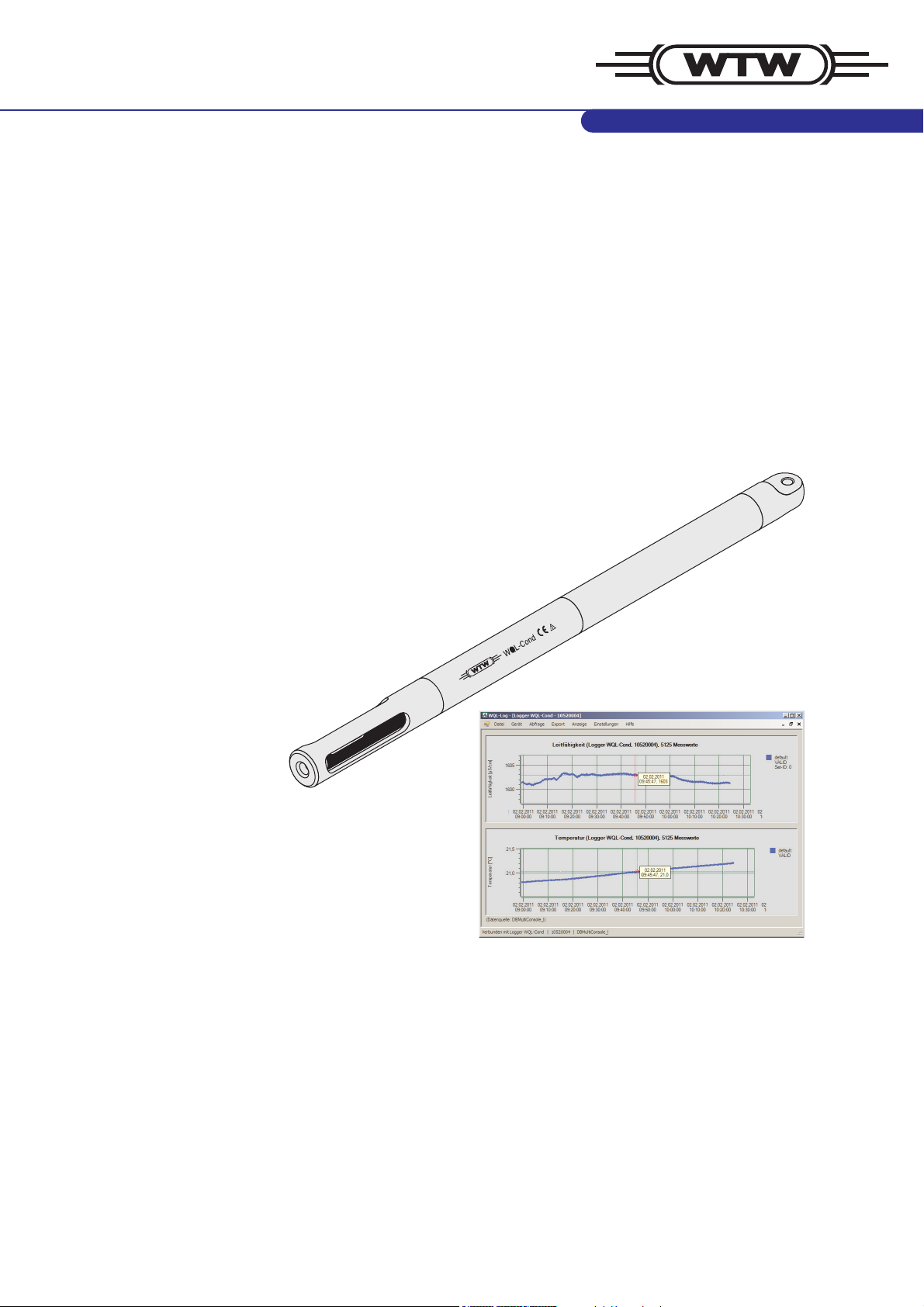

Operating manual

Logger WQL-Cond

PC program WQL-Log

Logger for conductivity measurement and PC program

to display and evaluate data from the logger

ba75822de01 03/2011

DRAFT: Thursday, 17. March 2011

Page 2

Note

The latest version of the present operating manual can be found on the

Internet under www.WTW.com.

Copyright © Weilheim 2011, WTW GmbH

Reproduction in whole - or even in part - is prohibited without the

express written permission of WTW GmbH, Weilheim.

Printed in Germany.

Page 3

WQL-Cond Contents

Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

1.1 Logger WQL-Cond . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

1.2 PC program WQL-Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

3.1 Inserting the battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

3.2 Mounting suspension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

3.3 Installing the WQL-Log program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.3.1 PC requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.3.2 Installation routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

3.4 Initial commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

3.5 Connection types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

3.6 Starting the WQL-Log program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

4 Setting the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.1 Setting the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.2 Setting the temperature unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

4.3 Setting the cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .122

5 Setting the measuring mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

6 Calibration in control standard (determining the cell constant) . . . . . . . . . . . . . . 127

6.1 Calibration settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

6.2 Calibrating (automatic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

6.3 Calibrating (manual) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

6.4 Viewing the calibration history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

6.5 Exporting the calibration history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

7 Measuring directly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

8 Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

8.1 Typical sequence of a logging job (checklist) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

8.2 Setting up a logging job - setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

8.3 Setting the parameters and starting the logging job . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

8.4 Logging job - storing or loading the configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

8.5 Signal LED and logger key button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.5.1 Signal LED to indicate the operating conditions of the logger . . . . . . . . . . . . 153

8.5.2 Logger key button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.6 Importing data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

8.7 Overview of the data window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

8.8 Managing the logging jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

ba75822e01 03/2011

99

Page 4

Contents WQL-Cond

9 Working with the database and measurement data . . . . . . . . . . . . . . . . . . . . . . . . 159

9.1 General information on the database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

9.2 Creating a database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

9.3 Opening a database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

9.4 Backing up a database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

9.5 Restoring a database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

9.6 Erasing a database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

9.7 Querying data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

9.8 Exporting data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

10 Info menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

10.1 Database information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

10.2 Device information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

10.3 Program info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

11 Resetting the logger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

12 Maintenance, cleaning, storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

12.1 General maintenance instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

12.2 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

12.3 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

12.3.1 Battery service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

12.3.2 Ascertaining the battery status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

12.3.3 Resetting the battery counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

12.3.4 Battery replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

12.4 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

12.5 Replacement parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

13 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.1 Calibration and measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

13.2 Communication of the logger and PC program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

13.3 Communication between PC program and SQL server . . . . . . . . . . . . . . . . . . . . . . . . . 186

14 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

14.1 Measurement characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

14.2 Application characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

14.3 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

14.4 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

100

ba75822e01 03/2011

Page 5

WQL-Cond Overview

Control panel

1

2

3

4

5

6

9

7

8

10 11

12

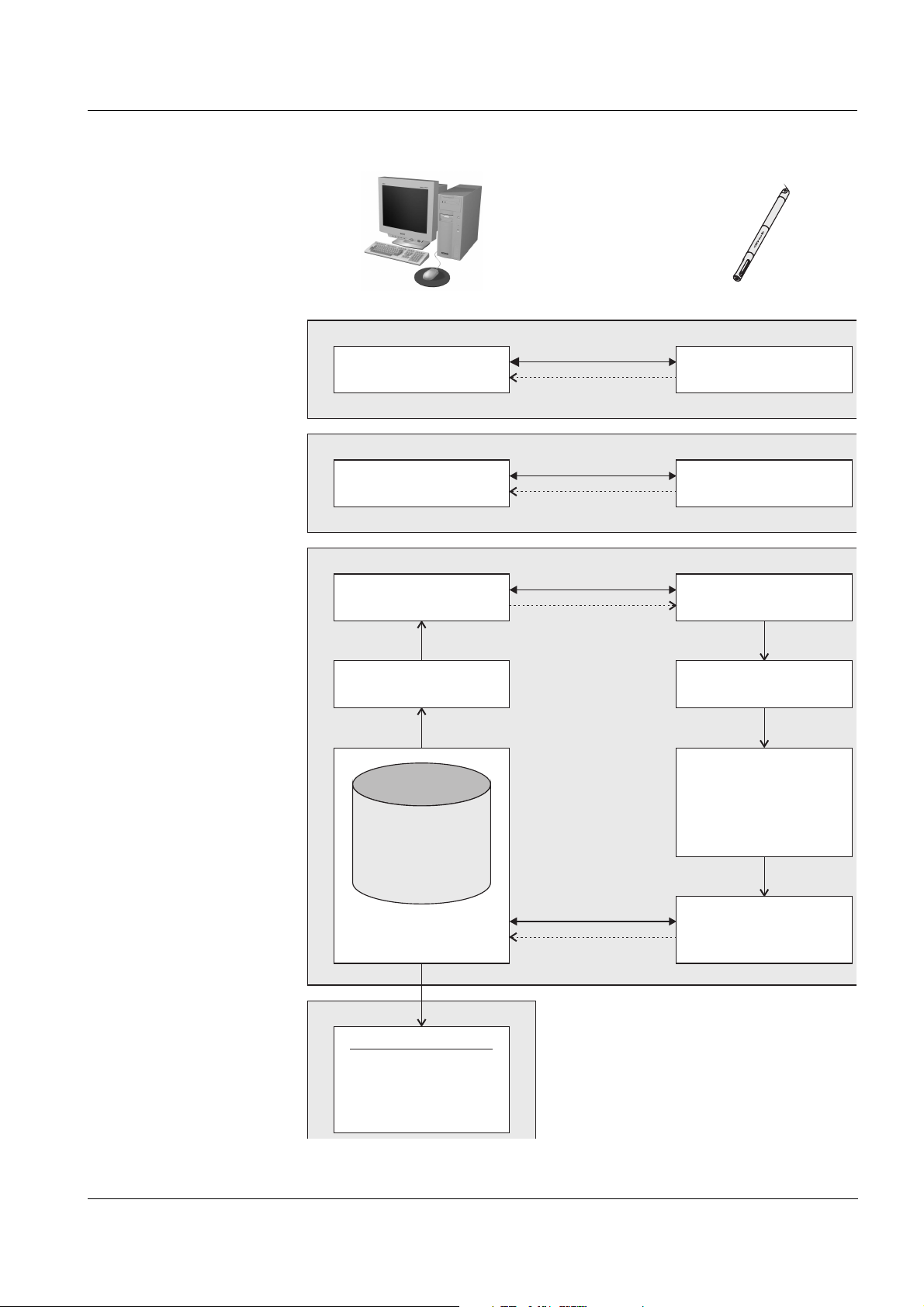

1 Overview

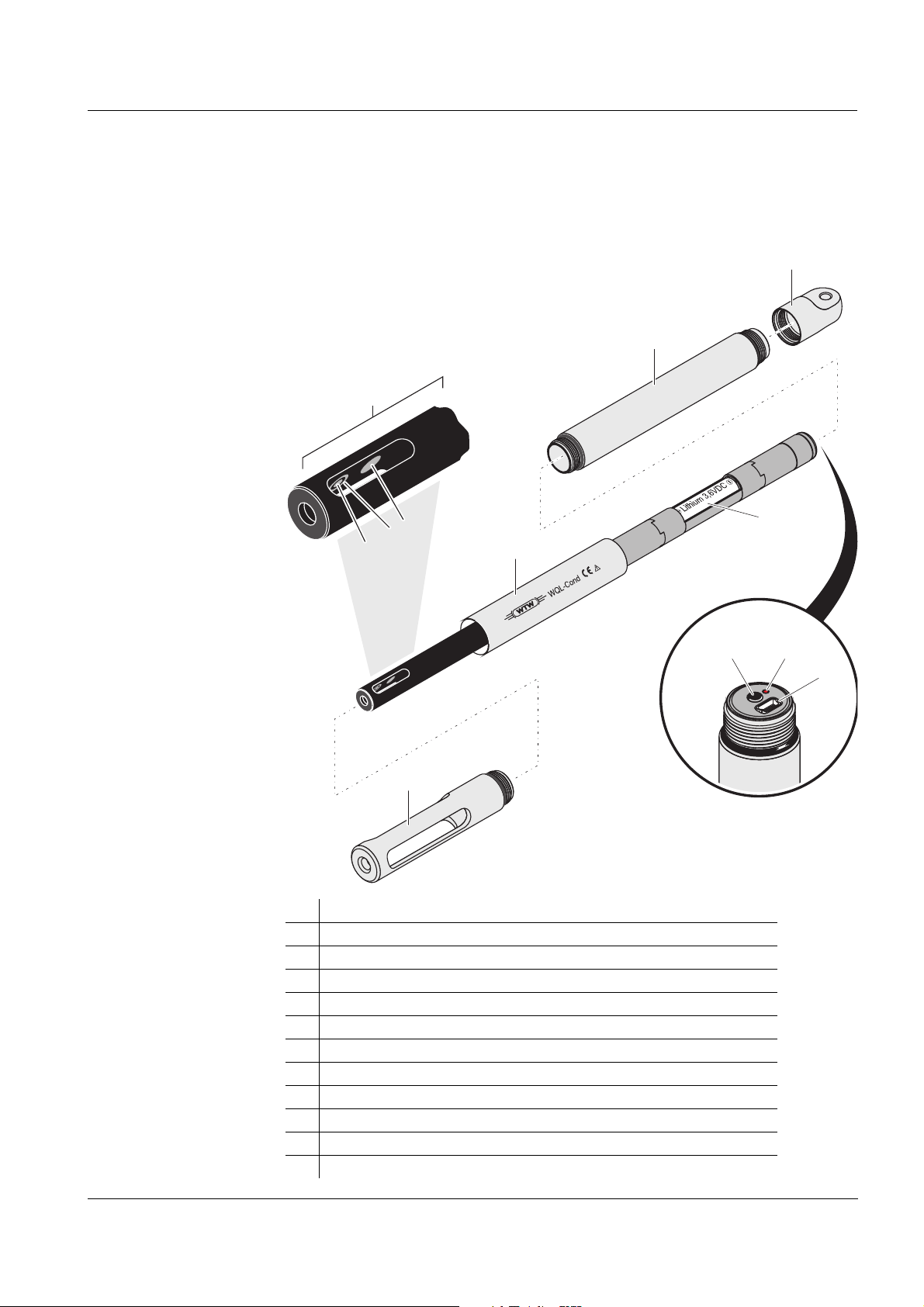

1.1 Logger WQL-Cond

Structure of the

logger

1 Protective hood

2 Conductivity measuring cell (permanently installed)

3 Voltage electrode (inside, 2x)

4 Current electrode (ring, 2x)

5 Temperature sensor in graphite enclosure

6 Shaft

7 Sleeve

8 Cap

9 Battery compartment with battery

10 Key button

11 Signal LED

12 USB socket

ba75822e01 03/2011

101

Page 6

Overview WQL-Cond

Recommended

fields of

application

Conductivity measurements in wells, bore holes, rivers, water bodies and

other surface water, drinking water, ground water, leachate, waste water.

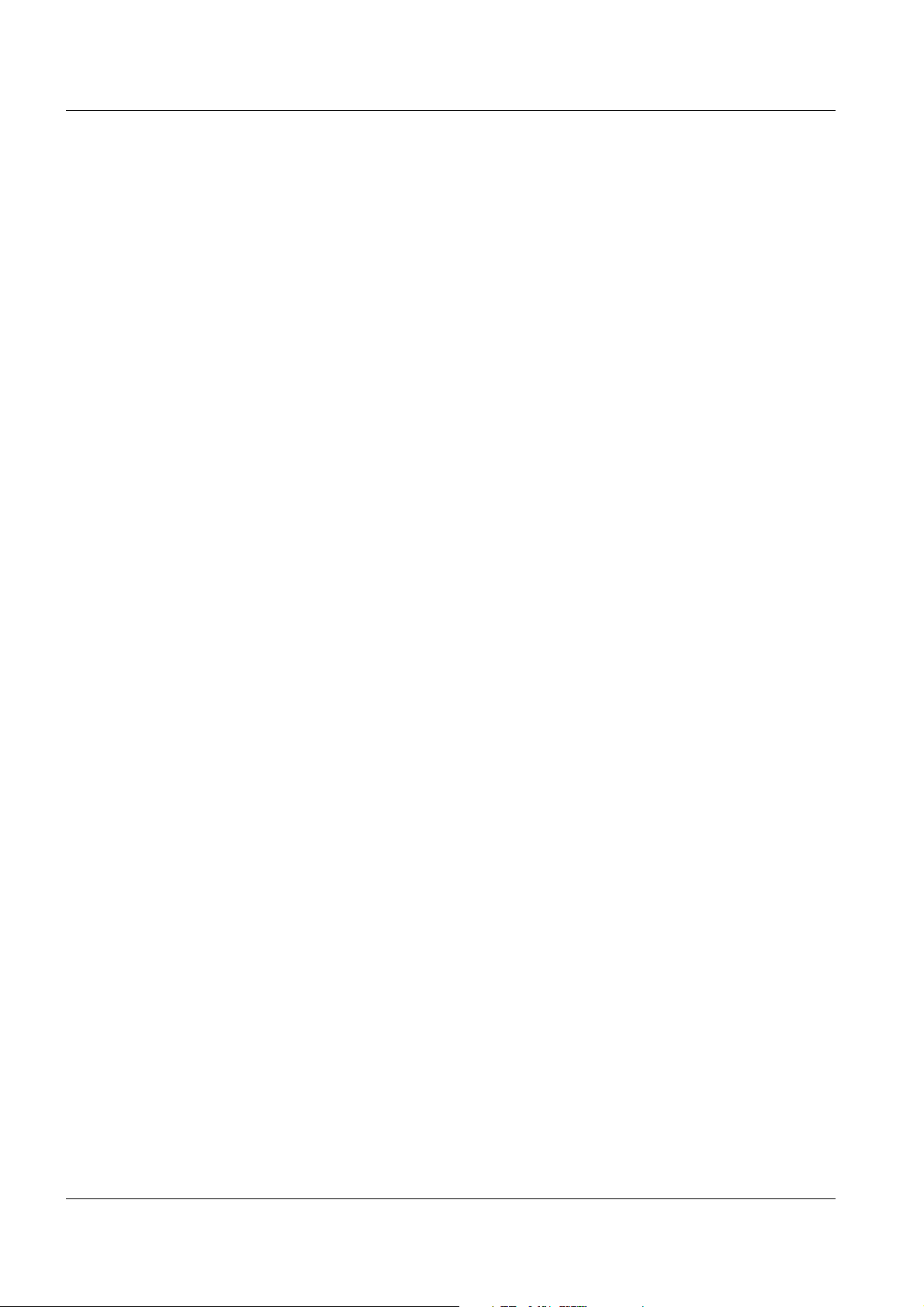

1.2 PC program WQL-Log

The WQL-Log PC program serves to operate a connected WTW data logger

of the WQL series type. The WQL-Log PC program automatically recognizes

the logger when it is connected to the USB interface and controls the menus

according to the type and measured parameter.

The PC program can carry out the following functions:

z Calibrate the measuring system

z Set up and start a logging job

z Measure directly: The logger is connected to the PC via USB and the PC

program displays the current measured values.

z Read in measurement data of the logging job: Consistent data copying to

a PC-based database.

z Database-supported evaluation of measurement data, export functions

Note

The current version of the WQL-Log PC program and the current firmware

for the WQL-Cond logger is available on the Internet on the website of the

manufacturer of your meter.

102

ba75822e01 03/2011

Page 7

WQL-Cond Overview

Logger

Carry out logging jobSet up logging jobLogging

(chapter 6)

Processing the

measurement

data

(chapter 7)

Calibrate in

standard solution

Stop

(e.g. logging job

completed)

(Log)

Measurement dataset 1

Measurement dataset 2

Measurement dataset 3

...

Measurement dataset 1

Measurement dataset 2

Measurement dataset 3

...

Measurement dataset n

Connect

Connect

Connect

Connect

Calibration record

Current values

(real time)

Parameterize,

send

Read in completed

logging job

PC + WQL-Log

CalibrateCalibrating

(chapter 4)

Measure directlyMeasuring

(chapter 5)

Measure

Stop communication

with WQL-Log

Clear the

logger memory

Measurement data

- Query

- Display

- Export (*.csv)

Save in database

ba75822e01 03/2011

Fig. 1-1 Overview of the communication of the logger and PC program

103

Page 8

Overview WQL-Cond

104

ba75822e01 03/2011

Page 9

WQL-Cond Safety

2 Safety

This component operating manual contains special instructions that must be

followed during the operation of the logger and PC program.

Always keep this operating manual in the vicinity of the logger and PC

program.

Symbols

used

Note

indicates notes that draw your attention to special features.

Note

indicates cross-references to other documents, e.g. application reports.

Warning

indicates instructions that must be followed precisely in order to avoid the

possibility of slight injuries or damage to the instrument or the environment.

ba75822e01 03/2011

105

Page 10

Safety WQL-Cond

106

ba75822e01 03/2011

Page 11

WQL-Cond Commissioning

1

3

2

3 Commissioning

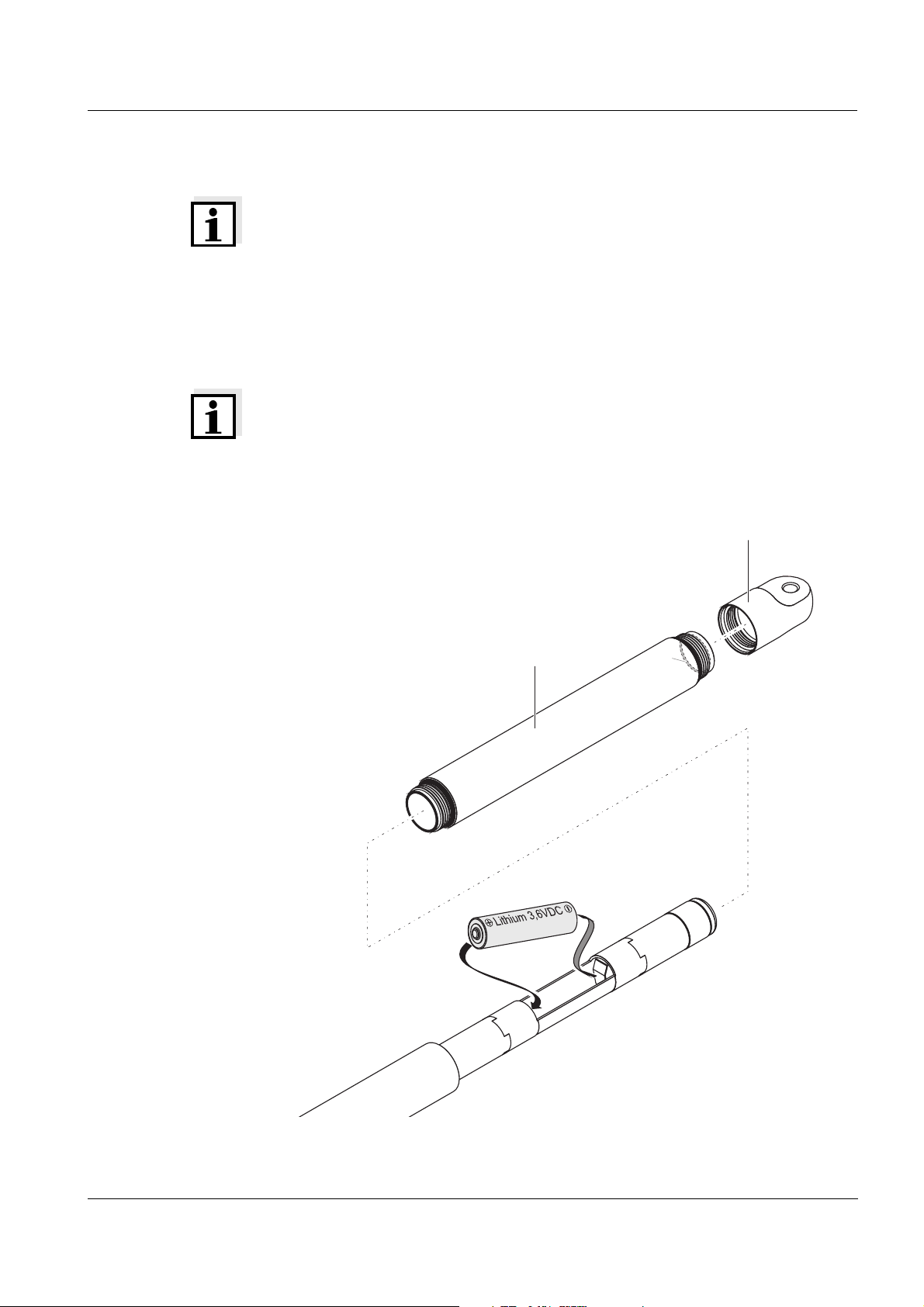

Note

z Normally, all screw joints of the logger housing can be opened and closed

by hand, without using any tools. If necessary, use a paper towel so you

can get a better grip on the parts.

z Insert the battery in a clean and preferably dry environment.

3.1 Inserting the battery

Note

The logger is powered by a 3.6 V lithium battery, size AA, as provided in the

scope of the delivery (see chapter 14 T

same size such as alkaline manganese batteries do not provide the required

operational voltage.

Operating time, see section 12.3 B

ECHNICAL DATA). Other batteries of the

ATTERY.

Fig. 3-1 Inserting the battery

ba75822e01 03/2011

107

Page 12

Commissioning WQL-Cond

1 Unscrew the cap (Pos. 1 in Fig. 3-1).

2 Unscrew the sleeve (Pos. 2).

3 Insert the battery. When doing so, make sure that the battery is

correctly positioned (see label in the battery compartment).

Corrosion

protection

4 Screw the sleeve on the shaft with the shorter

thread. At the rear end

of the sleeve there is a thin O-ring inside (Pos. 3). Make sure that this

O-ring is evenly positioned in the groove and is not twisted.

5 Screw on the sleeve and cap again. In the screwed condition, no gap

may be visible at the joints.

After the battery was inserted the signal LED lights up for 2 seconds. This

means the logger has to be connected with the PC to set the date and time

(see section 8.3 S

and section 8.5 S

ETTING THE PARAMETERS AND STARTING THE LOGGING JOB

IGNAL LED AND LOGGER KEY BUTTON).

3.2 Mounting suspension

To attach the logger to a rope or chain, a suitable shackle is provided whose

bolt fits through the cross hole in the cap. As an alternative, you can screw

some different sling gear into the M6 threaded hole at the cap end (e.g. M6

eye bolt).

In water, metal (e.g. zinc-plated) parts of the mounting suspension such as

thimbles, shackles or swivel connectors create voltages (chemically caused

according to the electrochemical series), which can cause corrosion of the

stainless steel of the logger or the above mentioned suspension parts.

Lightning

protection

Electrically conductive ropes or chains harbor the danger of the logger being

damaged by lightning.

Recommendation For reasons of corrosion and lightning protection, we recommend to use a

nonconductive suspension, e.g. one with low-wear, resistant polypropylene

ropes.

108

ba75822e01 03/2011

Page 13

WQL-Cond Commissioning

3.3 Installing the WQL-Log program

3.3.1 PC requirements

The WQL-Log software program requires the following system components:

Hardware

requirements

z Computer with Intel or Pentium III 500 MHz processor or higher

(1 GHz or quicker recommended.)

z At least 192 MB RAM (512 MB recommended)

z Hard disk with at least 600 MB available memory

z CD-ROM drive

z A free USB interface. Only one logger can be connected. If a new logger

is registered, the previous one is logged off.

Software

requirements

z 32-bit

-operating system Windows 7, Windows Vista, Windows XP,

Windows Server 2003 and higher or Windows 2000 Service Pack 4

User rights z Administrator rights are required for the initial installation. Contact your

system administrator if necessary.

Note

The program WQL-Log stores the database files with the stored data in the

directory where the SQL server is installed (because of access

authorization), i.e. normally on C:\. Make sure that there is enough storage

capacity available on the hard disk for this directory. An empty database

requires 3 MB storage space, a database with 50,000 datasets requires

approx. 7 MB storage space. A database can be max. 4 GB, containing

approx. 12.5 million datasets.

3.3.2 Installation routine

Note

The software is continuously developed further. The current version of the

WQL-Log program is available for download on the Internet under http://

www.WTW.com.

Note

The following files and/or directories are on the supplied CD-Rom:

z The installation file for the PC program and the database server

z A directory with the installation program for the driver of the USB

interface

z A directory with the operating manual for the logger and the PC program.

ba75822e01 03/2011

109

Page 14

Commissioning WQL-Cond

1 Insert the enclosed CD-Rom in the corresponding disk drive of the

PC.

Installing the

driver

Installing the PC

program and

database server

2 Open the directory, USB_VCP_driver.

3 Execute the file, CP210xVCPInstaller with a double click.

4 Follow the user guidance (click Install).

5 Confirm the installation with OK. A virtual COM Port has been created

with the installation.

6 Execute the WQLLog_Vxxxx.exe file with a double click (xxxx =

current version number).

The installation wizard appears.

110

7 Follow the user guidance (click OK).

ba75822e01 03/2011

Page 15

WQL-Cond Commissioning

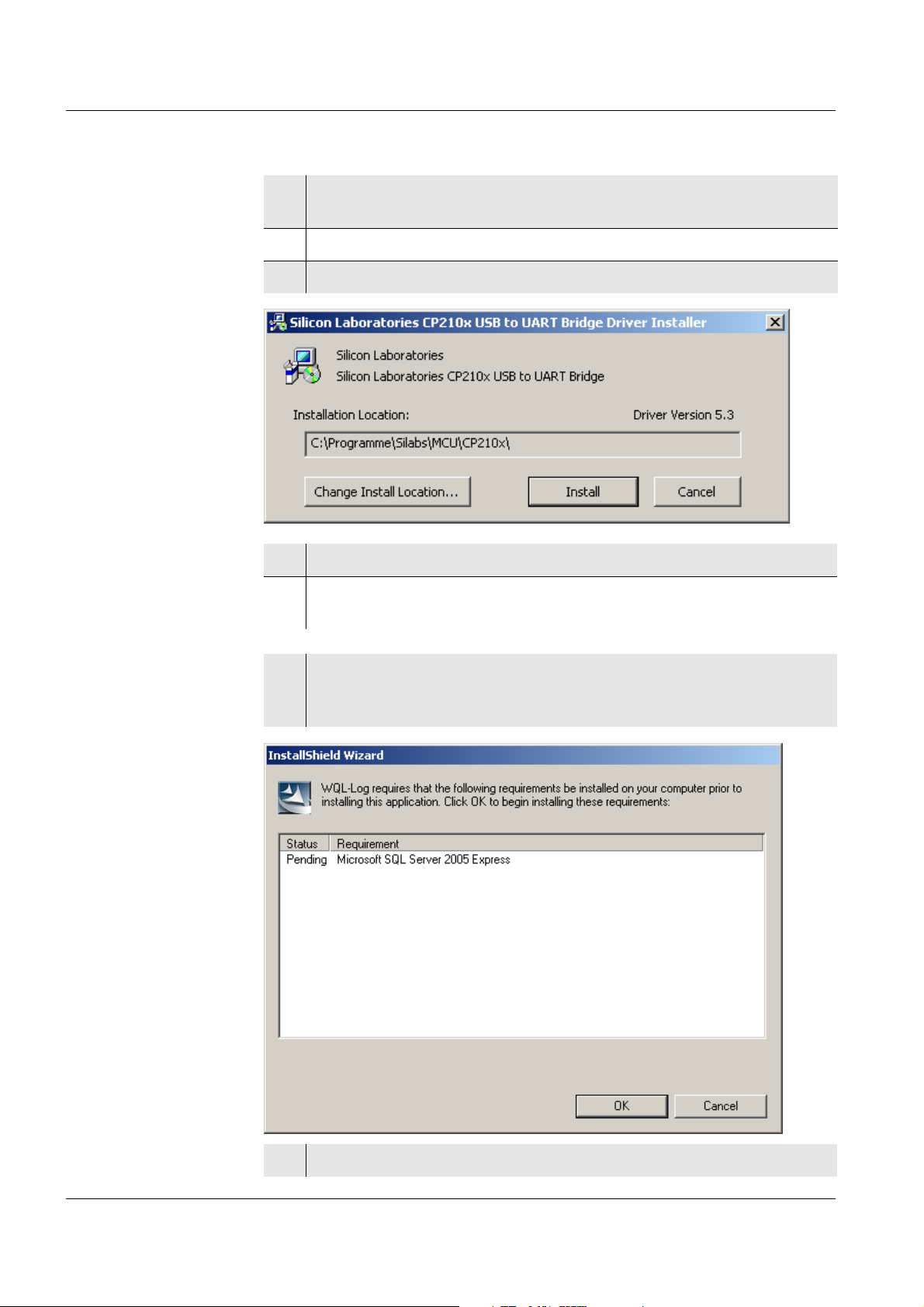

Note

If the SQL server was already installed for another application, the

installation of the server is automatically skipped. The program continues

with step 15.

8 Check off the checkbox, I accept the licensing terms and conditions.

9Click Next. An information window appears with the components

required for the installation.

10 Click Install. The installation is carried out. Follow the user guidance

(click Next) until the Authentication Mode window appears.

ba75822e01 03/2011

111

Page 16

Commissioning WQL-Cond

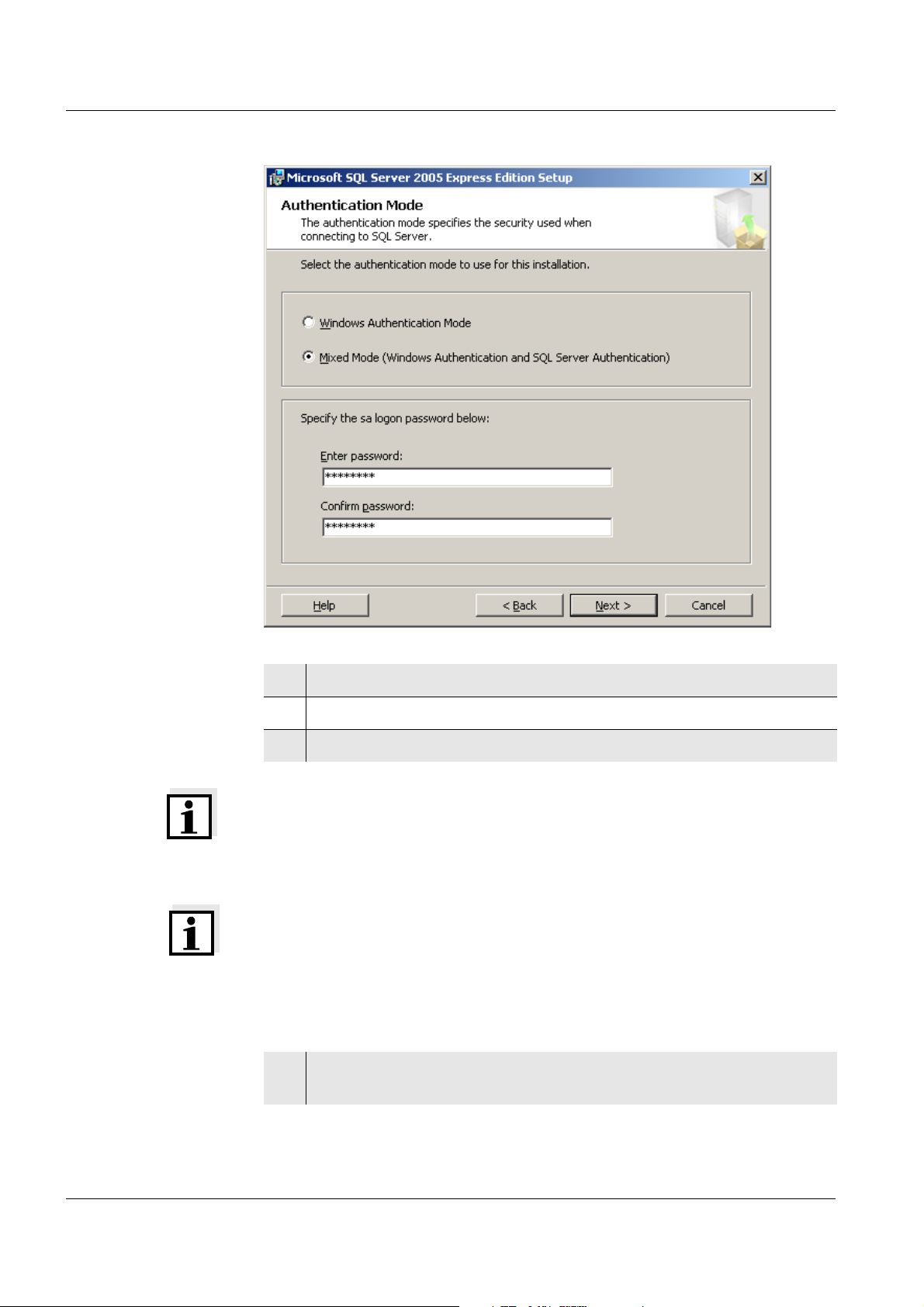

11 Select the Mixed Mode option.

12 In the Enter password field, enter the password WTW!2009.

13 Repeat the password entry WTW!2009 in the Confirm password field.

Note

The password WTW!2009 must be entered twice. If a different password is

entered, the PC program is not granted access to the database.

Note

If the SQL server was already installed for another application, you have to

change the password for the SQL server first before the WQL-Log program

can create a database. To change the password see section

13.3 C

OMMUNICATION BETWEEN PC PROGRAM AND SQL SERVER.

14 Click Next. Then follow the user guidance (the default settings should

not be changed) until the following display appears:

112

ba75822e01 03/2011

Page 17

WQL-Cond Commissioning

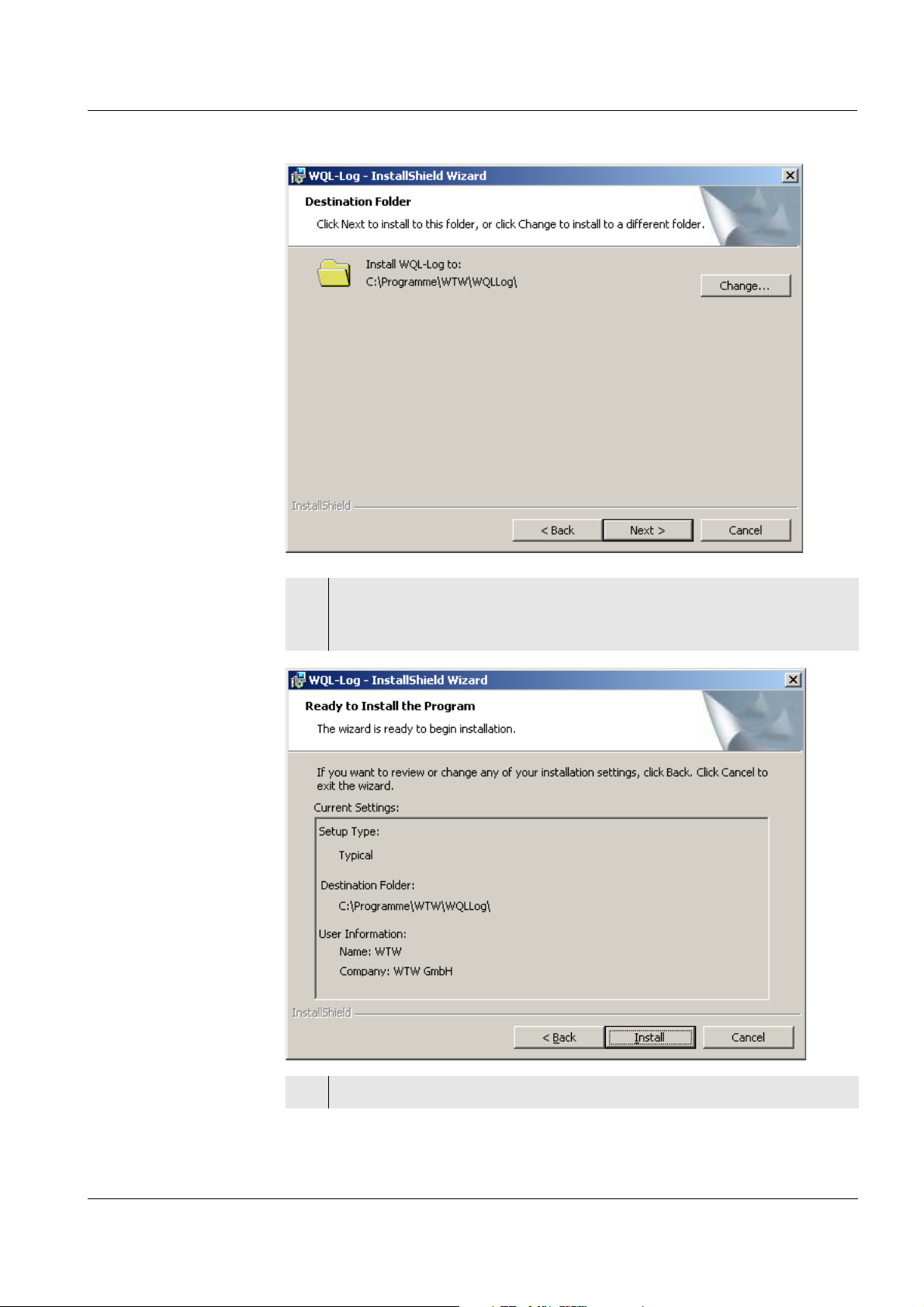

15 Here you can change the location where the PC program should be

stored (click Change... ).

When the required location is displayed, click Next.

ba75822e01 03/2011

16 Here you find information on the installation. Click Install.

113

Page 18

Commissioning WQL-Cond

17 Click Finish to complete the installation.

114

ba75822e01 03/2011

Page 19

WQL-Cond Commissioning

3.4 Initial commissioning

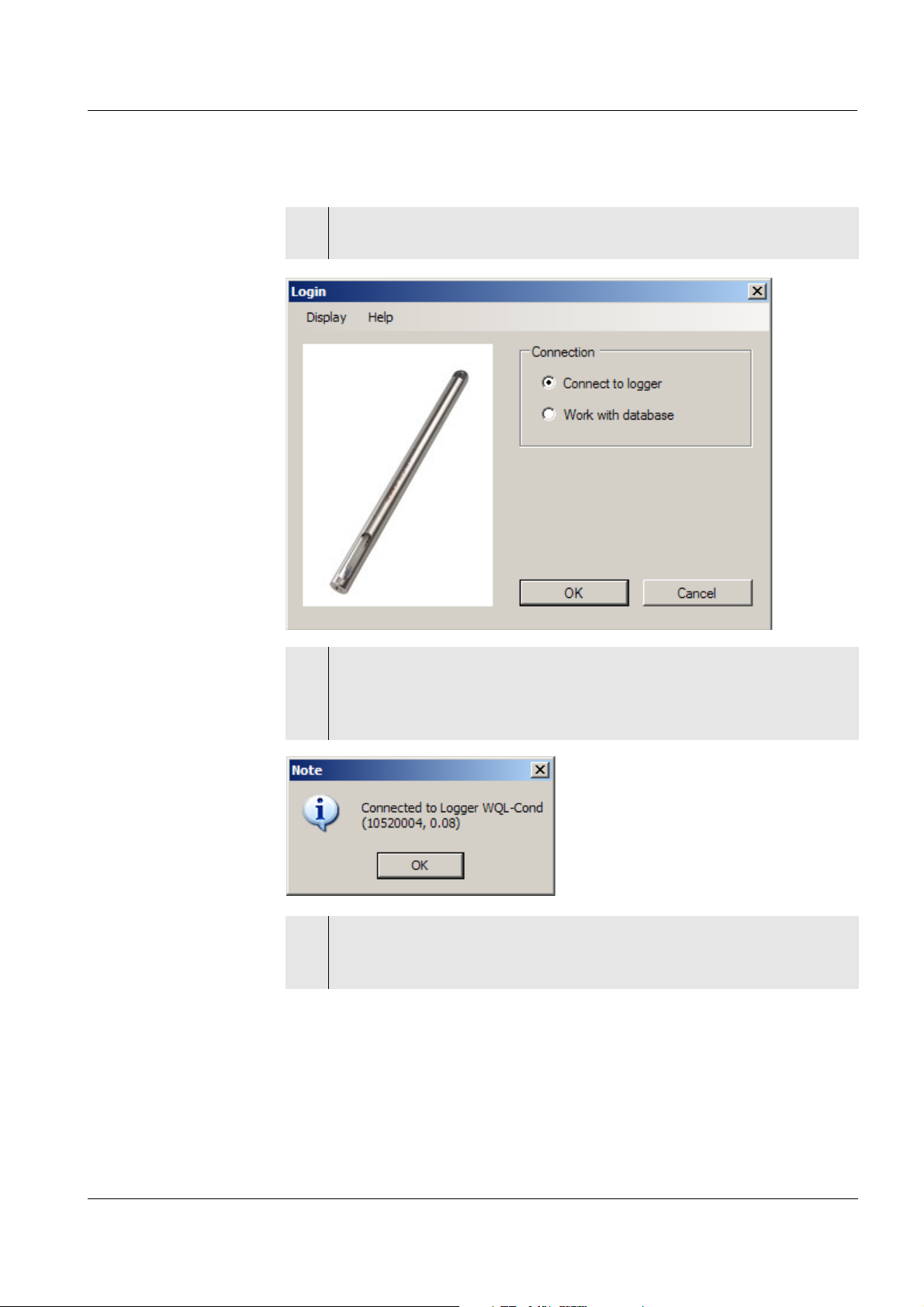

1 Start the WQL-Log program (the relevant icon is on the desktop).

The Login window appears.

2 If the WQL-Cond logger is connected to the PC via a USB cable and

should communicate with the WQL-Log PC program:

Confirm with OK. The WQL-Log program searches for the connection

with the logger.

3 Confirm with OK.

During the initial commissioning, the Select database window

appears.

ba75822e01 03/2011

115

Page 20

Commissioning WQL-Cond

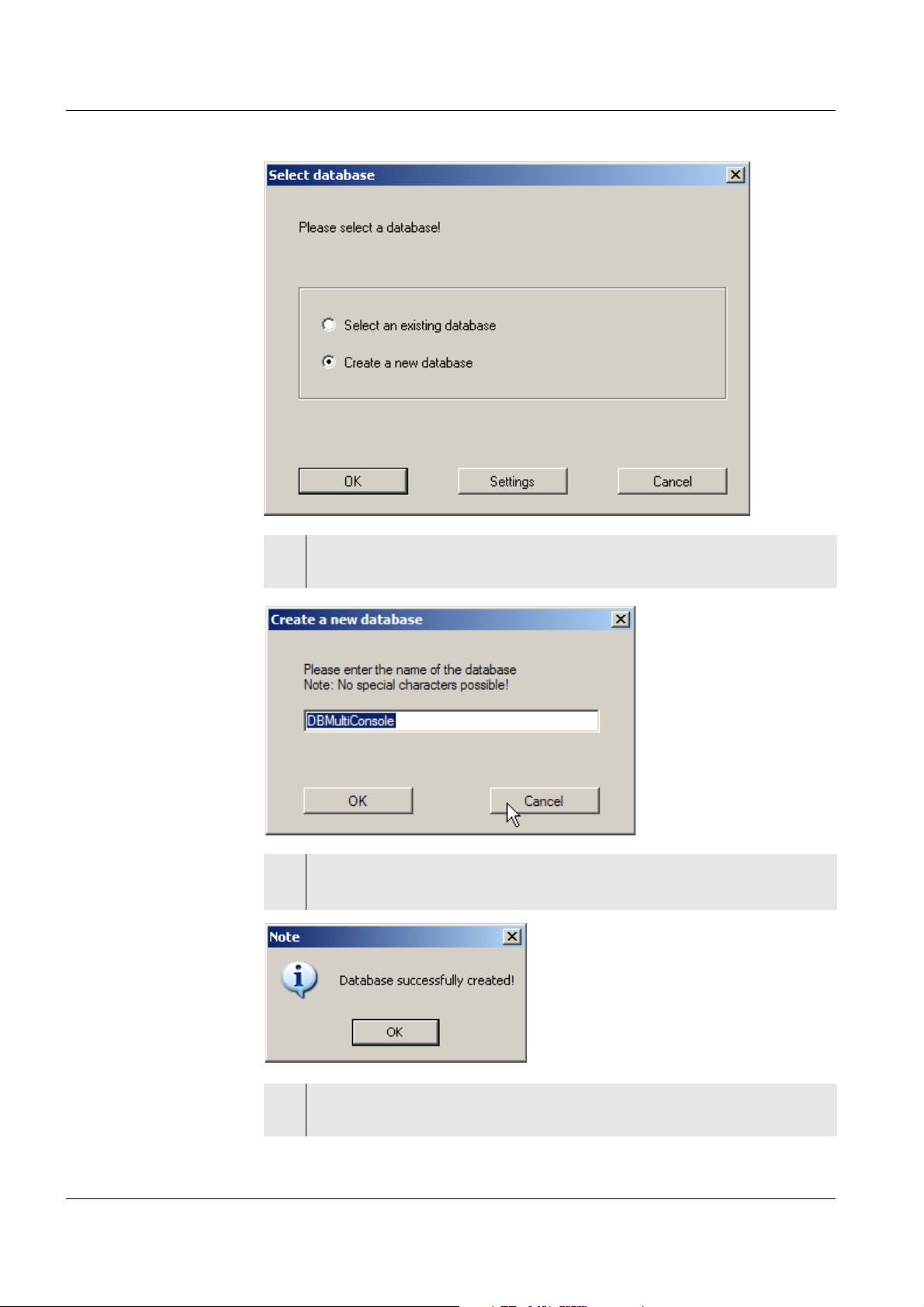

4 Confirm the option, Create a new database with OK. The window to

save the newly created database appears.

5 Change the name of the database as necessary.

Click OK. The database is stored and a message appears:

116

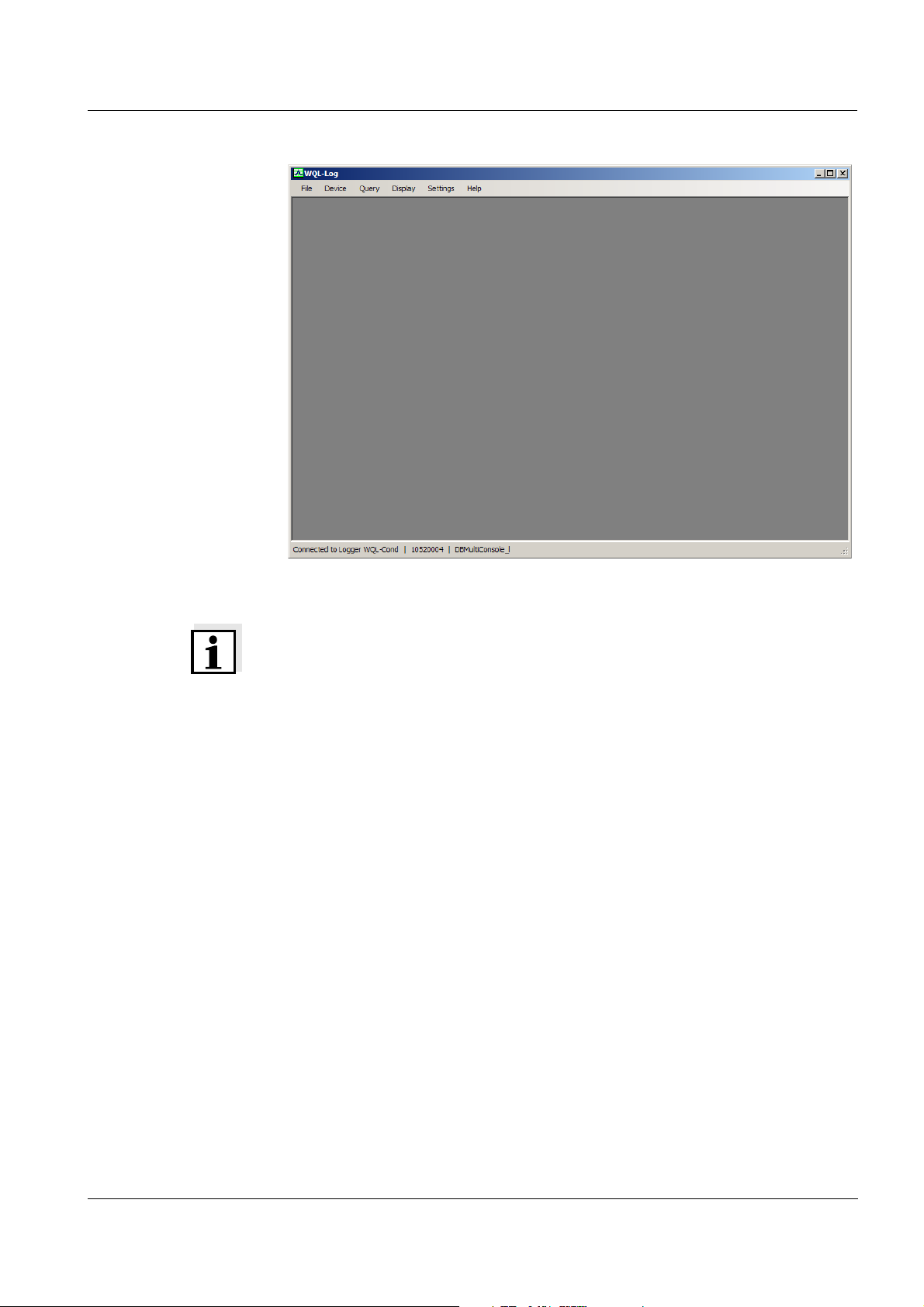

6 Confirm with OK. An empty data window appears, as the database is

still empty:

ba75822e01 03/2011

Page 21

WQL-Cond Commissioning

Note

If the SQL server was already installed for another application, you have to

change the password for the SQL server first before the WQL-Log program

can create a database. To change the password see section

13.3 C

OMMUNICATION BETWEEN PC PROGRAM AND SQL SERVER.

ba75822e01 03/2011

117

Page 22

Commissioning WQL-Cond

3.5 Connection types

The PC program WQL-Log works with two types of connection:

z Work with database

(the logger and PC program do not communicate)

z Connected to logger

(the logger and PC program communicate)

Working with the

database

Connected to the

logger

In this type of connection it is only possible to process the measurement data

stored in a database and to change the system settings.

When the logger is logged on and connected to the WQL-Log PC program,

the program and the logger communicate with each other. The measurement

datasets present in the logger can be imported to the database and are thus

available for processing.

You can configure the logger according to your requirements and set up a

logging job. When the logging job is started, the connection between the

logger and the WQL-Log PC program is cut. The cable connection between

the logger and PC does not have to be disconnected for this.

118

ba75822e01 03/2011

Page 23

WQL-Cond Commissioning

3.6 Starting the WQL-Log program

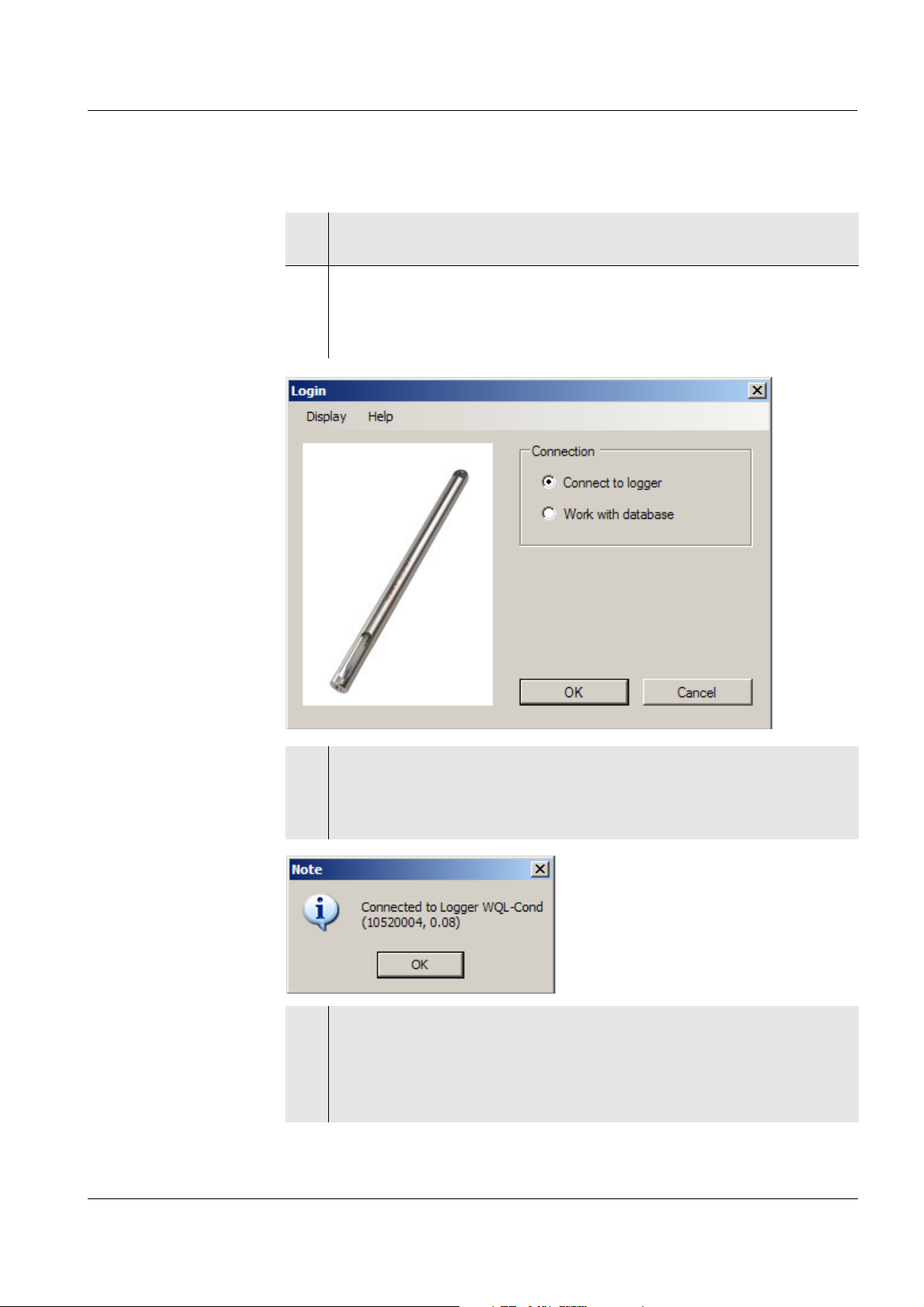

1 Start the WQL-Log program.

The Login window appears.

2 If necessary, you can change the display language here with the

menu item, Display (see section 4.1 S

out which software version of the WQL-Log program is installed with

the menu item, Help (see section 10.3 P

ETTING THE LANGUAGE) and find

ROGRAM INFO).

Connection to

logger

3 If the WQL-Cond logger is connected to the PC via a USB cable and

should communicate with the WQL-Log PC program:

Confirm with OK. The WQL-Log program searches for the connection

with the logger.

4 Confirm with OK. The data window appears.

If there are no data in the database (such as during the initial

commissioning), an empty data window appears.

If data are stored in the logger, an overview of the logging jobs

appears first (see section 8.8 M

ANAGING THE LOGGING JOBS).

ba75822e01 03/2011

119

Page 24

Commissioning WQL-Cond

Working with the

database

5 If you want to work with the database:

Select Work with database and confirm with OK.

The data window appears with the logger data that was last read in

(during the initial commissioning, an empty data window appears).

120

6 To continue, see chapter 9 WORKING WITH THE DATABASE AND

MEASUREMENT DATA.

ba75822e01 03/2011

Page 25

WQL-Cond Setting the display

4 Setting the display

Under the Display menu item you can set the language and temperature for

the WQL-Log PC program and the WQL-Cond logger. You can additionally

set whether or not a cursor with a value field with time, date and measured

value should appear for each measured parameter in the data window.

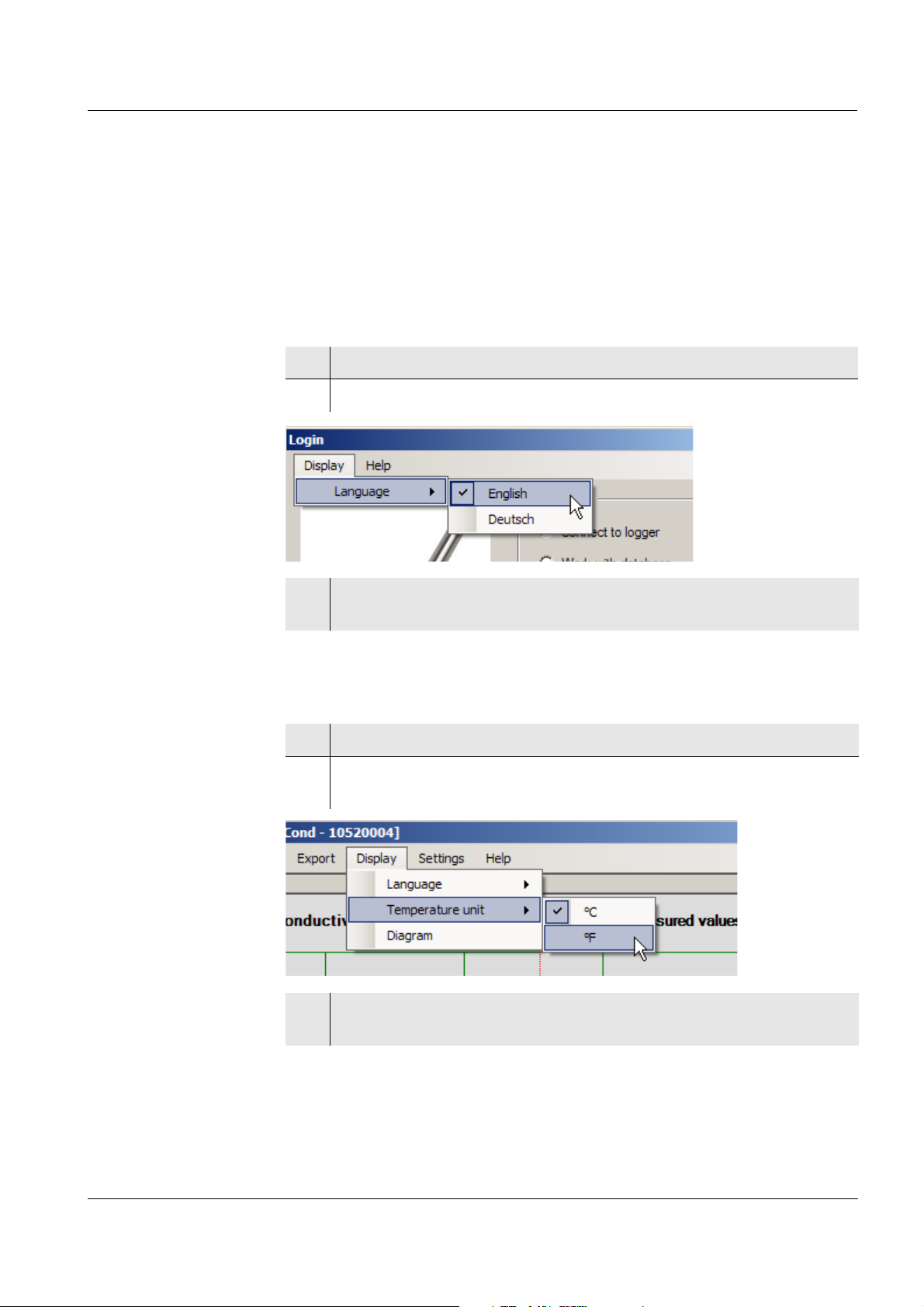

4.1 Setting the language

1 In the Display menu, select the menu item, Language.

2 The options Deutsch (German) and Englisch (English) appear.

3 Select the required language with a mouse click.

The setting is immediately active.

4.2 Setting the temperature unit

1 In the Display menu, select the menu item, Temperature unit.

2 The options, ° C (degrees Celsius) and ° F (degrees Fahrenheit)

appear.

3 Select the required temperature unit with a mouse click.

The setting is immediately active.

ba75822e01 03/2011

121

Page 26

Setting the display WQL-Cond

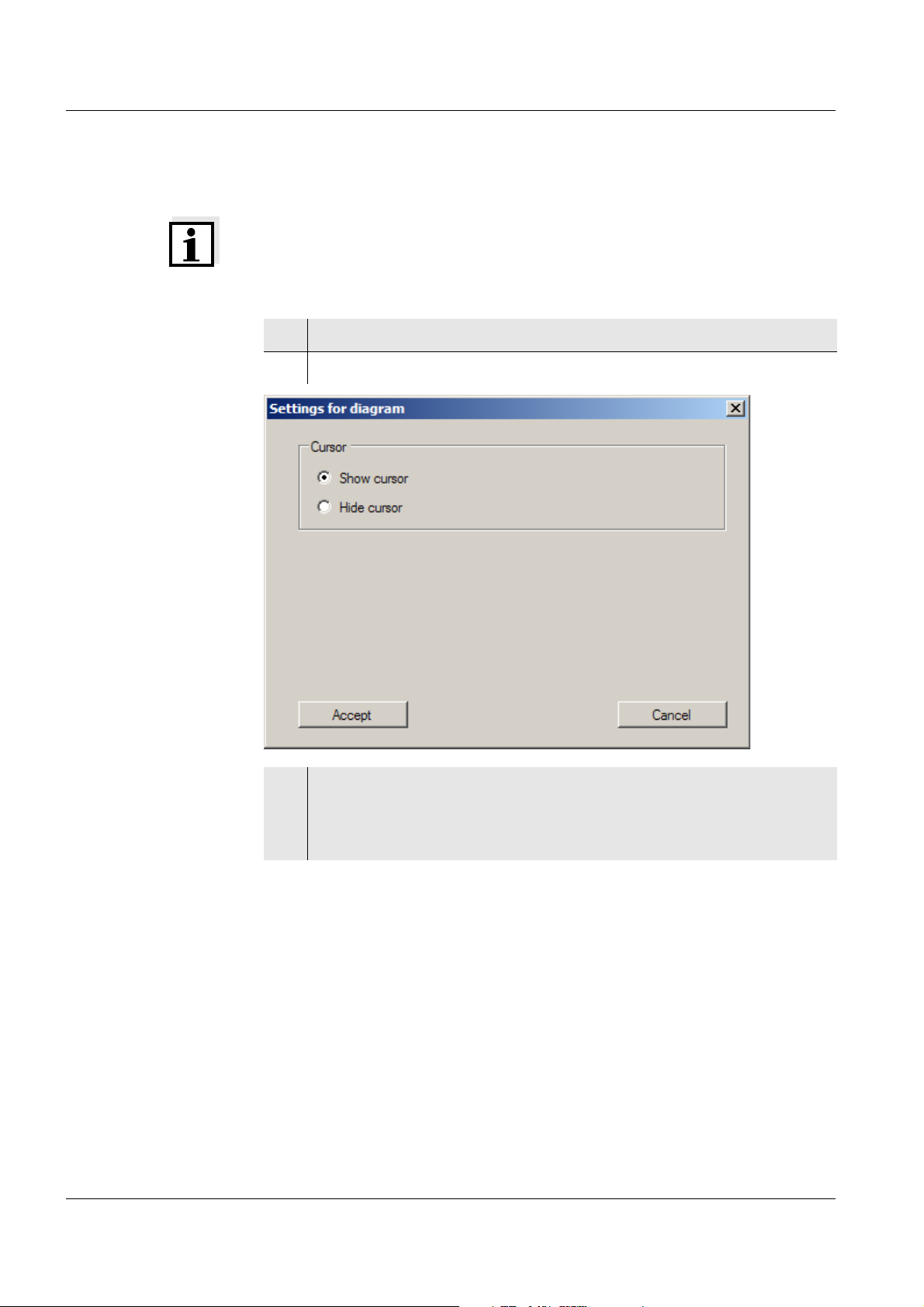

4.3 Setting the cursor

Note

The Diagram menu item appears only if data are available in the database.

1 In the Display menu, select the menu item, Diagram.

2 The options, Show cursor and Hide cursor appear.

122

3 Select the required option with a mouse click.

After clicking on Accept the setting is immediately active. The data

window appears with the cursor and value field. You can change the

position of the cursor by moving the data window with the mouse.

ba75822e01 03/2011

Page 27

WQL-Cond Setting the display

ba75822e01 03/2011

123

Page 28

Setting the measuring mode WQL-Cond

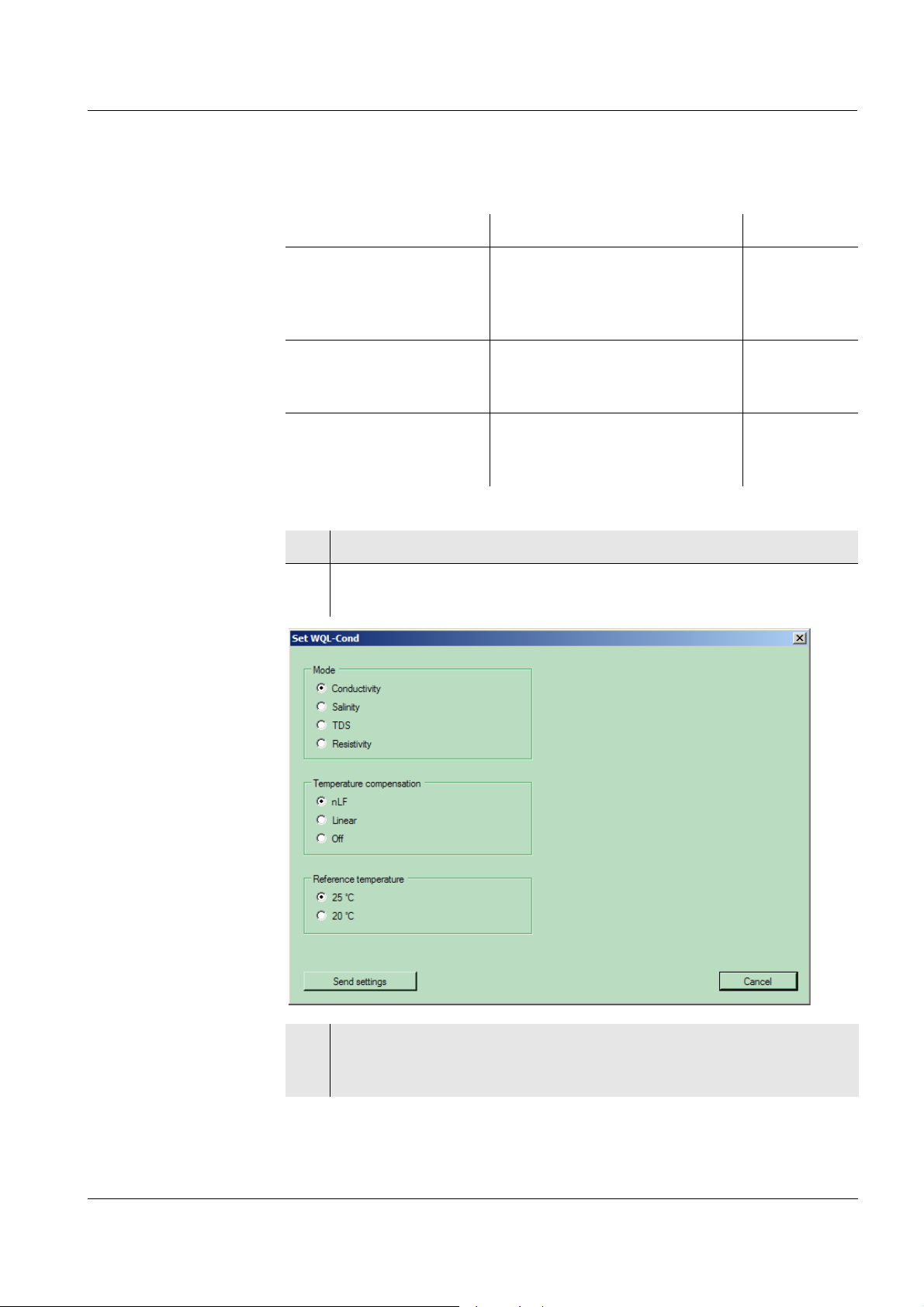

5 Setting the measuring mode

You can make the following settings in the Device / Set menu (default setting

in bold):

Measuring mode z Conductivity

[μS/cm] / [mS/cm]

z Salinity Sal [ ]

z TDS

[mg/l] / [g/l] with adjustable TDS factor

in the range 0.40 ... 1.00

z Resistivity

[Ω·cm] / [kΩ·cm] / [MΩ·cm]

Temperature compensation z Nonlinear temperature

compensation (nLF) according to EN

27 888

z Linear temperature compensation (lin)

with adjustable coefficients in the

range 0.000 ... 2.000 ... 3.000 %

/K

z No temperature compensation (off)

Reference temperature z 25 °C

z 20°C

TDS factor The factor to calculate the total dissolved solids is set to 1.00 in the factory.

You can adjust this factor to meet your requirements in the range of 0.40 to

1.00. The factor is set in the menu for the parameter, TDS.

Temperature

compensation

-Temperature

coefficient

The calculation of the temperature compensation is based on the preset

reference temperature, 20 °C or 25 °C. The reference temperature is shown

on the display.

The temperature coefficient for the linear temperature compensation is set to

2.000 %/K in the factory. You can adjust this factor to meet your requirements

in the range 0.000 ... 3.000 %/K. The factor is set in the menu for the setting

of the temperature compensation.

Note

More information on conductivity measurements is given in the WTW

conductivity primer.

124

ba75822e01 03/2011

Page 29

WQL-Cond Setting the measuring mode

Application tips Select the temperature compensations given in the table according to the

respective test sample:

Test sample Temperature compensation Display

Natural water

(ground water, surface

nLF

according to EN 27 888

nLF

water, drinking water,

waste water)

Other aqueous solutions Set linear

Linear

temperature coefficient

0.000 ... 3.000 %/K

Salinity (seawater) Automatic according to IOT

(International Oceanographic

Tables)

1 In the Device menu, select the menu item, Set.

2 The window for the selection of the measuring mode, temperature

compensation and reference temperature appears.

ba75822e01 03/2011

3 Select the required settings with a mouse click.

Clic Send settings.

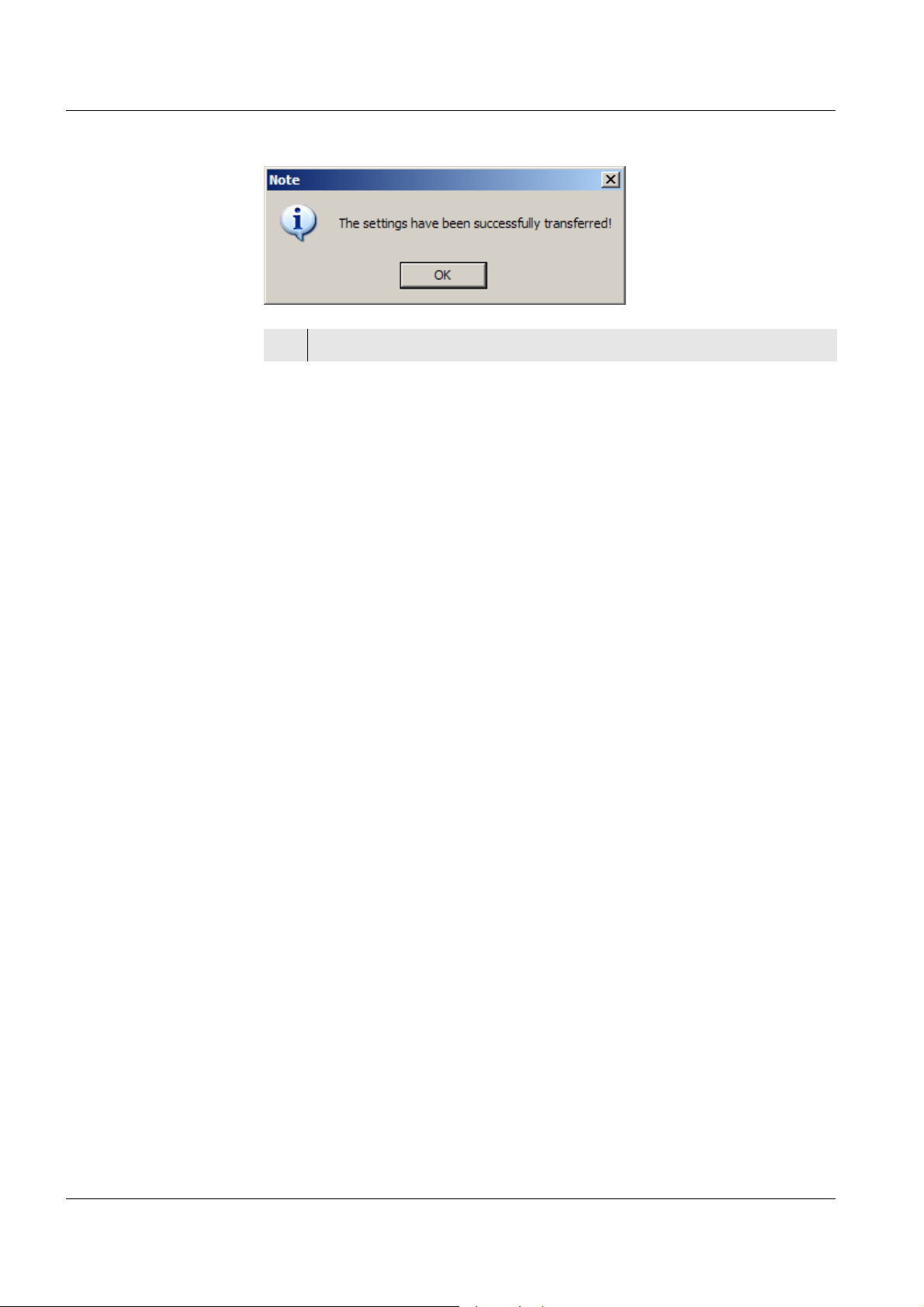

A confirmation message appears:

125

Page 30

Setting the measuring mode WQL-Cond

4 Confirm with OK.

126

ba75822e01 03/2011

Page 31

WQL-Cond Calibration in control standard (determining the cell constant)

6 Calibration in control standard (determining

the cell constant)

Why determine the

cell constant?

Procedure You can determine the actual cell constant of the WQL-Cond logger by

Aging slightly changes the cell constant, e. g. due to coatings. As a result, an

inexact measured value is displayed. The original characteristics of the cell

can often be restored by cleaning the cell. Calibration determines the current

value of the cell constant and stores this value in the logger.

Thus, we recommend calibrating at regular intervals:

z on initial commissioning

z before starting a logging job.

calibrating with the control standard in the following range:

0.450 ... 0.500 cm

(nominal cell constant 0.475 cm

-1

-1

)

The cell constant is determined in the control standard,

0.01 mol/l KCl.

In the default condition, the calibrated cell constant of the WQL-Cond logger

-1

is set to 0.475 cm

.

AutoRead During calibration, the AutoRead function is automatically activated. The

AutoRead function checks the stability of the measurement signal and the

stability of the temperature signal. The stability has a considerable effect on

the reproducibility of the measured value.

The current AutoRead measurement can be terminated at any time

(accepting the current value).

ba75822e01 03/2011

127

Page 32

Calibration in control standard (determining the cell constant) WQL-Cond

6.1 Calibration settings

Calibration

procedures

Selecting the

calibration

procedure

Two calibration procedures can be selected:

z Manual (with a control standard of your choice)

z Automatic (with 0.01 mol/l KCl control standard)

1 In the Device menu, click the menu item, Calibrate.

2 The calibration window appears.

Here you can select the Manual or Automatic calibration procedure.

128

3 In the mode menu, highlight the required calibration procedure and

select it with a mouse click.

The selected setting is immediately active.

ba75822e01 03/2011

Page 33

WQL-Cond Calibration in control standard (determining the cell constant)

6.2 Calibrating (automatic)

Note

We recommend to always calibrate with the protective hood screwed on so

the measuring cell is protected. Use a stand as necessary.

Preparatory

activities

1 Connect the WQL-Cond logger to a USB port of your PC with the

USB cable.

2 Have the 0.01 mol/l KCl control standard ready.

3 In the Device menu, click the menu item, Calibrate.

The calibration window appears.

Calibration

4 Immerse the logger in the 0.01 mol/l KCl control standard.

5 Use the Next button to start the measurement.

ba75822e01 03/2011

129

Page 34

Calibration in control standard (determining the cell constant) WQL-Cond

Calibration record

6 The note, AutoRead is running... appears.

As soon as a stable value is recognized, the calibration record

appears.

Note

You can prematurely terminate the AutoRead function manually with Accept

at any time. If the AutoRead function is prematurely terminated, the current

measurement data are accepted immediately.

130

ba75822e01 03/2011

Page 35

WQL-Cond Calibration in control standard (determining the cell constant)

7 Accept the calibration with Accept. The message Calibration

successful appears and the new calibration will now be used for

measurement.

If you press Cancel, the logger discards the new calibration and will

continue to use the previous calibration values.

Note

The calibration history with the data of the last 20 calibration procedures can

be displayed at any time (see section 6.4 V

HISTORY).

IEWING THE CALIBRATION

ba75822e01 03/2011

131

Page 36

Calibration in control standard (determining the cell constant) WQL-Cond

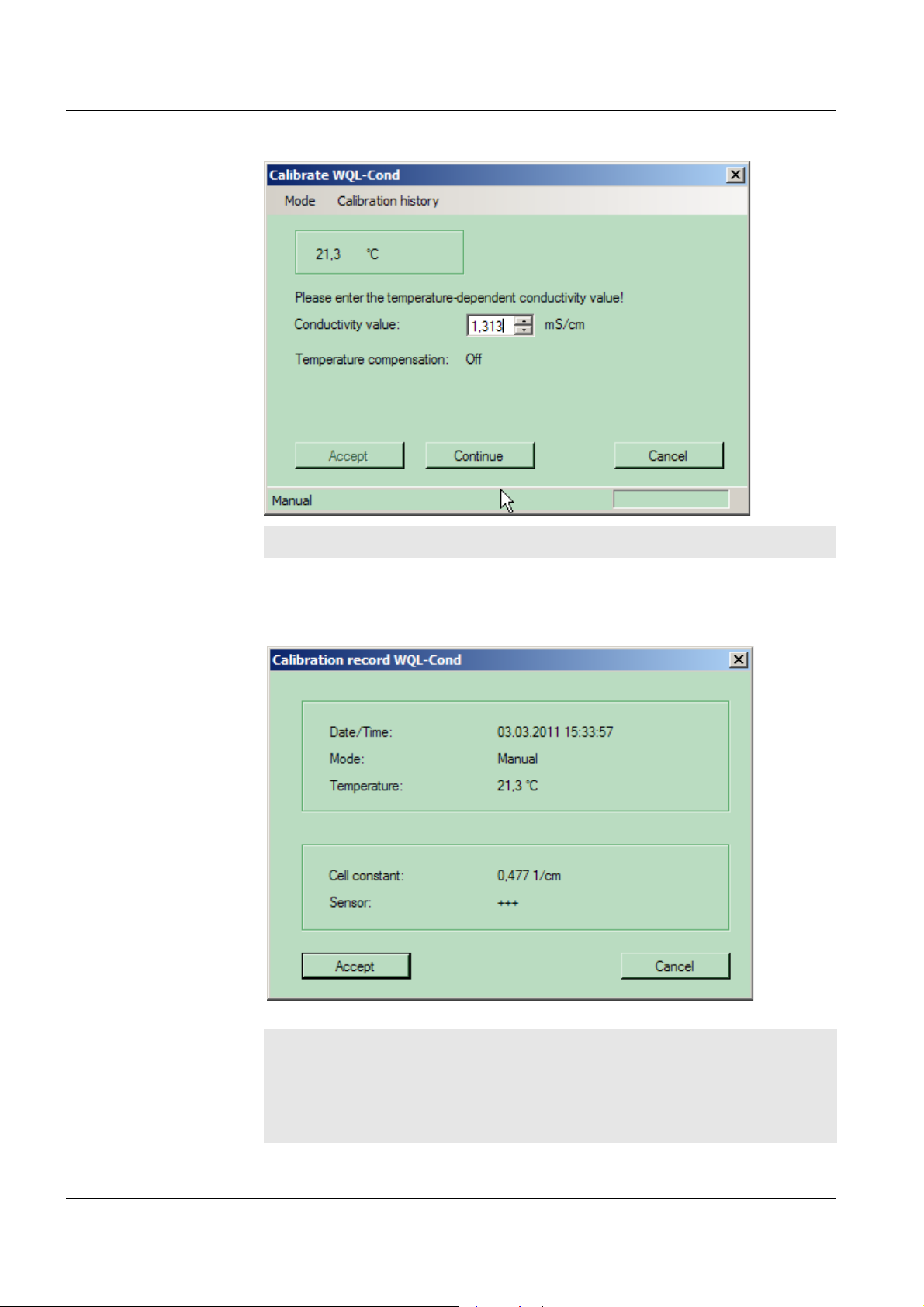

6.3 Calibrating (manual)

Note

We recommend to always calibrate with the protective hood screwed on so

the measuring cell is protected. Use a stand as necessary.

Note

For manual calibration with a control standard, the temperature dependent

conductivity values of the standard are required. Normally a table with these

values is enclosed with the control standard.

z Prior to manual calibration, please switch off the temperature

compensation (menu, Device / Set).

z Determine the conductivity of the used standard solution using the

temperature measured by the logger during calibration (interpolate the

table values as necessary).

z After the calibration is completed, restore the required setting for the

temperature compensation.

Preparatory

activities

Calibration

1 Connect the WQL-Cond logger to a USB port of your PC with the

USB cable.

2 Keep a control standard of your choice ready.

3 In the Device menu, click the menu item, Calibrate.

The calibration window appears.

4 Immerse the logger in the control standard.

132

ba75822e01 03/2011

Page 37

WQL-Cond Calibration in control standard (determining the cell constant)

5 Use the Continue button to start the measurement.

ba75822e01 03/2011

6 The note, AutoRead is running... appears.

As soon as the value is stable, the prompt to enter the temperature

dependent conductivity value appears.

Note

You can prematurely terminate the AutoRead function manually with Accept

at any time. If the AutoRead function is prematurely terminated, the current

measurement data are accepted immediately.

133

Page 38

Calibration in control standard (determining the cell constant) WQL-Cond

7 Enter the conductivity value for the displayed temperature.

Calibration record

8Click Continue. As soon as a stable value is recognized, the

calibration record appears.

134

9 Accept the calibration with Accept. The message Calibration

successful appears and the new calibration will now be used for

measurement.

If you press Cancel, the logger discards the new calibration and will

continue to use the previous calibration values.

ba75822e01 03/2011

Page 39

WQL-Cond Calibration in control standard (determining the cell constant)

Note

The calibration history with the data of the last 20 calibration procedures can

be displayed at any time (see section 6.4 V

HISTORY).

IEWING THE CALIBRATION

Calibration

evaluation

After calibration, the system automatically evaluates the current status of the

calibration. The evaluation appears also in the calibration record.

Calibration record Cell constant [cm-1]

+++ Within the range

-1

-1

Error

0.450 ... 0.500 cm

Outside the range

0.450 ... 0.500 cm

Eliminate the error according to

chapter 13 W

HAT TO DO IF...

Note

The logger can store up to 20 logging jobs with the respective calibration

records and setting data. If, however, you calibrated several times for one

logging job and the logger would thus have to store more than 20 calibration

records with the 20th logging job, a message informs you of this.

This is to ensure that no calibration record for which there are measured

values can be lost. In this case the logger will prompt you to delete the

logger memory.

ba75822e01 03/2011

Make sure that you have read in all data you want to use before deleting the

logger memory. The logger memory can only be deleted completely.

135

Page 40

Calibration in control standard (determining the cell constant) WQL-Cond

6.4 Viewing the calibration history

The last 20 calibration records are stored in the logger and can be recalled.

Proceed as follows:

1 In the Device menu, select the Set menu item, and select the

measuring mode for which the calibration history should be

displayed.

2 In the Device menu, click the menu item, Calibrate.

3 The calibration window appears.

4 Click the menu item, Calibration history. The program reads the

calibration data of the set measuring mode.

136

5 The calibration history with the data of the last 20 calibration

procedures appears. Use the arrows on the side to scroll up or down.

ba75822e01 03/2011

Page 41

WQL-Cond Calibration in control standard (determining the cell constant)

6 Return to the calibration window with Cancel.

Note

Each calibration is given an individual calibration ID, which is stored with the

logged measured values together with the calibration date and time (see

section 9.8 E

XPORTING DATA).

ba75822e01 03/2011

137

Page 42

Calibration in control standard (determining the cell constant) WQL-Cond

6.5 Exporting the calibration history

The last 20 calibration records are stored in the logger as the calibration

history and can be exported as a csv file. Proceed as follows:

1 In the calibration history window, select the Export menu item.

2 Select the option, Export as *.csv file. The window to save the

calibration history appears.

138

3 Change the location and name of the file as necessary.

4 Confirm with the Save button.

5 A message appears, confirming that the file with the calibration

history was stored.

6 Confirm with OK.

ba75822e01 03/2011

Page 43

WQL-Cond Measuring directly

7 Measuring directly

The WQL-Log PC program in conjunction with the WQL-Cond logger can

measure and display the value of a solution directly according to the set

parameter. The directly measured values are not stored in the logger.

Proceed as follows when you want to measure directly:

1 Connect the WQL-Cond logger to the PC with the USB cable.

2 In the Device/Login menu, connect the logger to the WQL-Log PC

program.

3 If a logging job is running, terminate or interrupt it (measuring directly

is not possible while a logging job is running).

4 In the Device menu, click the Set menu item and select the settings

for the measuring mode and temperature compensation (see chapter

ETTING THE MEASURING MODE).

5S

5 In the Device menu, click the Measure directly menu item.

6 Immerse the WQL-Cond logger in the measuring solution.

7 The measured value window pops up with the measured value

(depending on the setting) and the temperature value of the test

sample.

Next to the measured value, the set temperature compensation and

if necessary, the temperature coefficient or TDS factor and reference

temperature are displayed.

ba75822e01 03/2011

8 Terminate the direct measurement with Quit.

139

Page 44

Logging WQL-Cond

8 Logging

Listed below are the typical operating steps with which to set up and carry out

a logging job. The chapters where the operating steps are described in detail

are also mentioned.

8.1 Typical sequence of a logging job (checklist)

1 Connect the logger to the PC with the USB cable.

2 Start the WQL-Log program (see section 3.6 S

PROGRAM).

TARTING THE WQL-LOG

3 Register the logger (see section 3.6 STARTING THE WQL-LOG

PROGRAM ).

4 If a logging job is running, terminate or interrupt it (see section

ANAGING THE LOGGING JOBS).

8.8 M

5 Erase the logger memory if necessary (see section 8.8 MANAGING THE

LOGGING JOBS).

6 Calibrate the logger (see chapter 6 C

STANDARD (DETERMINING THE CELL CONSTANT)

ALIBRATION IN CONTROL

7 Set up the logging job and send it (see section 8.3 SETTING THE

PARAMETERS AND STARTING THE LOGGING JOB).

8 Disconnect the USB cable from the logger.

9 If necessary, start the logger with the key button.

10 Check the operation of the logger based on the behavior of the signal

LED (see section 8.5 S

IGNAL LED AND LOGGER KEY BUTTON).

11 Tightly close the logger with the cap.

140

12 Install the logger at the measuring location.

13 After completion of the logging job: Connect the logger to the PC with

the USB cable (see step 1 etc.).

ba75822e01 03/2011

Page 45

WQL-Cond Logging

8.2 Setting up a logging job - setting parameters

You can set the following parameters for a logging job (i.e. the job to

determine and record measured values according to your requirements over

a certain period of time):

Tab Setting Setting options

(default setting in bold)

Recording Interval z User-defined (set the hours,

minutes, seconds)

z 1 second, 5 seconds,

10 seconds, 30 seconds

z 1 minute, 5 minutes, 10 minutes,

15 minutes, 30 minutes

z 1 hour, 2 hours, 3 hours,

6 hours, 9 hours, 12 hours,

24 hours

Start z Immediately (when the setting mode

is quit and the logger is separated

from the PC program)

z Logger key button

(when the key button at the control

panel of the logger is pressed)

z Delay

Set the time before the logger should

start logging: 1 hour ... 7 days

z Time

Set the date and time

Stop z Memory full (the loggers stops

logging only when the memory is full,

i.e. when 600,000 datasets have

been stored)

z Time period

(1 hour ... 365 days)

z Time

Set the date and time

Measured

value ID

You can assign a measured value ID

(consisting of up to 20 alphanumerical

character, no special characters) e.g.

the name of the measuring site).

Default setting: default

ba75822e01 03/2011

This tab provides you with information on the free memory capacity and

battery status.

141

Page 46

Logging WQL-Cond

Tab Setting Setting options

(default setting in bold)

Time Automatic time

adjustment

z Yes (date/time for the logger is

automatically synchronized with that

of the PC)

z No

(Enter the date/time for the logger)

Parameter Mode z Conductivity

[μS/cm] / [mS/cm]

z Salinity Sal [ ]

z TDS

[mg/l] / [g/l] with adjustable TDS

factor in the range 0.40 ... 1.00

z Resistivity

[Ω·cm] / [kΩ·cm] / [MΩ·cm]

Temperature

compensation

z Nonlinear temperature

compensation (nLF) according to

EN 27 888

z Linear temperature compensation

(lin) with adjustable coefficients in

the range 0.000 ... 2.000 ... 3.000 %/

K

z No temperature compensation (off)

Temperature

compensation

Reference

temperature

The calculation of the temperature compensation is based on the preset

reference temperature, 20 °C or 25 °C. The reference temperature is shown

z 25 °C

z 20°C

on the display.

Temperature

coefficient

The temperature coefficient for the linear temperature compensation is set to

2.000 %/K in the factory. You can adjust this factor to meet your requirements

in the range 0.000 ... 3.000 %/K. The factor is set in the menu for the setting

of the temperature compensation.

TDS factor The factor to calculate the total dissolved solids is set to 1.00 in the factory.

You can adjust this factor to meet your requirements in the range of 0.40 to

1.00. The factor is set in the menu for the parameter, TDS.

142

ba75822e01 03/2011

Page 47

WQL-Cond Logging

Application tips Select the temperature compensations given in the table according to the

respective test sample:

Test sample Temperature compensation Display

Natural water

(ground water, surface

nLF

according to EN 27 888

water, drinking water)

Other aqueous solutions Set linear

temperature coefficient

0.000 ... 3.000 %/K

Salinity (seawater) Automatic according to IOT

(International Oceanographic

Tables)

nLF

Linear

ba75822e01 03/2011

143

Page 48

Logging WQL-Cond

8.3 Setting the parameters and starting the logging job

To change one or several of the above listed settings proceed as follows:

1 Connect the WQL-Cond logger to the PC with the USB cable.

2 Start the WQL-Log program.

The Login window appears.

3 Confirm with OK. The WQL-Log program searches for the connection

with the logger.

4 Confirm with OK.

5 If the logger contains new data:

A window with the current logging jobs appears.

144

ba75822e01 03/2011

Page 49

WQL-Cond Logging

6 If a logging job is still running, click Stop.

7 To go to the data window without reading in any data, click Exit the

list.

If you wish to import the data, click Import.

The read-in process can take some time (depending on the number

of datasets to be read in).

ba75822e01 03/2011

145

Page 50

Logging WQL-Cond

Note

Do not unplug the cable connecting the logger to the PC during the read-in

process. If the connection is cut, the read-in process is terminated and has

to be repeated from scratch.

Note

Only click Delete all logging jobs if you want to discard all data stored in the

logger. This action will delete all jobs in the logger memory, and the data will

be irretrievably lost!

The jobs that were already imported and stored in the database are

retained.

8 When the import of the measured values is completed, a message

appears (confirm with OK) and the query to erase the complete

measured value memory.

9 Press OK or Cancel.

The data window appears with a graphic of the imported data, no

matter whether or not the data memory was erased.

146

ba75822e01 03/2011

Page 51

WQL-Cond Logging

10 In the Device menu, select the menu item, Set up logging job. A note

on calibration appears.

11 Confirm with OK. The Logging tab appears, the first tab of the

window, Set up logging job.

12 Based on the displayed percentages check whether the storage

capacity and battery charge are sufficient for the intended logging

job.

ba75822e01 03/2011

147

Page 52

Logging WQL-Cond

13 Interval: To set the logging interval, click the arrow on the right side

of the setting field. A drop-down menu appears with the possible

intervals. Select the required interval with a mouse click.

If User-defined was selected, click the arrows on the right side of the

selection fields and set the hours, minutes and seconds for the

interval.

14 Start: To set the start of the logging, click the arrow on the right side

of the setting field. A drop-down menu appears with the starting

times. Select the required starting time with a mouse click.

If Delay or Time was selected, click the arrows on the right side of the

selection fields and select the required period of time or set the point

in time.

15 Stop: To set the end of the logging, click the arrow on the right side

of the first setting field. A drop-down menu appears with the possible

settings. Select the required starting time with a mouse click.

If Time period or Time was selected, click the arrows on the right side

of the selection fields and select the required period of time or set the

point in time.

16 Measured value ID: Enter the measured value ID (up to 20

alphanumerical characters, no special characters).

148

17 Click the Time tab.

18 Select Yes or No for adjustment to PC time. If No was selected, click

the arrows on the right side of the selection fields and set the date

and time for the logger.

ba75822e01 03/2011

Page 53

WQL-Cond Logging

19 Click the Parameter tab.

20 Make the settings for the measuring mode and temperature

compensation and if necessary, for the reference temperature and

temperature compensation as well.

21 Save the settings for the logging job (configuration) as required (see

section 8.4 L

OGGING JOB - STORING OR LOADING THE CONFIGURATION).

Note

In the Logging tab, the memory capacity required with the selected settings

is displayed at the bottom (number x of 600,000 possible datasets).

ba75822e01 03/2011

149

Page 54

Logging WQL-Cond

Starting the

logging job

22 To start the logging job, click the button, Send logging job. The

message, The settings have been successfully transferred appears.

23 Confirm with OK. A window pops up with an overview of the logging

job just sent.

24 Confirm with OK. A note appears with the message that the logger

will now be disconnected from the PC program and, depending on the

setting, the information that the logging is started immediately or that

the logging is started when the logger key button is pressed.

25 Confirm with OK.

Note

The setting routine for the logging job can be canceled at any time with the

Cancel button. In this case the logger does not start the logging job; instead,

the data window appears after a note.

150

ba75822e01 03/2011

Page 55

WQL-Cond Logging

8.4 Logging job - storing or loading the configuration

You can store to a file the settings for a logging job and call them up later for

another logging job. To do so, proceed as follows:

1 In the File menu, select the submenu, Set up logging job.

2 After making the settings, click File in the Set up logging job window.

Storing the

configuration

3 To save the configuration of a logging job, click Save configuration.

The window to save the configuration appears.

ba75822e01 03/2011

151

Page 56

Logging WQL-Cond

Notes

z The program suggests a storage location and name for the file: the name

of the logger and the storing date and time (e.g. Logger WQLCond_Config_20110124_1619).

z The file has the file extension, ".xml".

z The suggested location and name can be changed.

4 Confirm with the Save button.

5 A message appears, confirming that the file with the configuration

was stored.

6 Confirm with OK.

Loading the

configuration

7 To load the configuration of a logging job, click Load configuration.

The Open window of the configuration appears.

152

8 Select the file and click Open.

9 A window with the stored configuration of the logging job appears.

Change the settings if necessary and set up the logging job as usual.

ba75822e01 03/2011

Page 57

WQL-Cond Logging

8.5 Signal LED and logger key button

8.5.1 Signal LED to indicate the operating conditions of the logger

Next to the key button on the control panel of the logger there is a signal LED.

When the logger is not connected to the WQL-Log PC program, this red LED

indicates the different operating conditions of the logger as follows:

Mode of flashing Operating condition

On for 2 seconds, then off z The logging job is completed.

z The power supply of the logger

was interrupted. The logger has to

be connected to the PC program in

order to set the date and time.

A short flashing every 2 seconds The logger is ready to log and can be

started with the logger key button.

A short flashing every 0.5 seconds The logging job is running (the logger

is logging).

Notes

z The flashing stops after 15 seconds to save energy. Short pressing of the

logger key button starts the flashing for 15 seconds again.

z Important: The logger can be started with the logger key button only while

the signal LED is flashing (if starting the logger with the key button was

set during the setting up of the logging job).

8.5.2 Logger key button

Next to the signal LED on the control panel of the logger there is a key button.

It has the following functions:

z With the corresponding setting, a logging job can be started by pressing

the key button. The pressure must last for at least 3 seconds, and the LED

lights up when the 3 seconds have passed.

z A running logging job can be stopped by pressing the key button for at

least 3 seconds. If you press the key button again for at least 3 seconds,

a new logging job with the same settings will be started (e.g for logging at

different locations).

z Pressing the key shortly activates the LED that indicates the operating

state of the logger for 15 seconds (see section 8.5.1 S

INDICATE THE OPERATING CONDITIONS OF THE LOGGER).

IGNAL LED TO

ba75822e01 03/2011

153

Page 58

Logging WQL-Cond

8.6 Importing data

Depending on the logging job, the WQL-Cond logger measures for a certain

period of time and at certain intervals the conductivity and temperature of a

solution. The data is stored in the logger. The WQL-Log PC program has to

import and store to a database the data before the data can be displayed and

processed.

Note

If the logger contains data, the list with the query for the use of the data

appears automatically when the logger is connected to the PC program.

To import the data of a logging job, proceed as follows:

1 Connect the WQL-Cond logger to the PC with the USB cable.

2 The list of logging jobs with their respective status appears.

154

3 If you wish to import the data of the highlighted job, click Import.

Further information, see section 8.8 M

ANAGING THE LOGGING JOBS.

Note

Only click Delete all logging jobs if you want to discard all data stored in the

logger. This action will delete all jobs in the logger memory, and the data will

be irretrievably lost!

The jobs that were already imported and stored in the database are

retained.

ba75822e01 03/2011

Page 59

WQL-Cond Logging

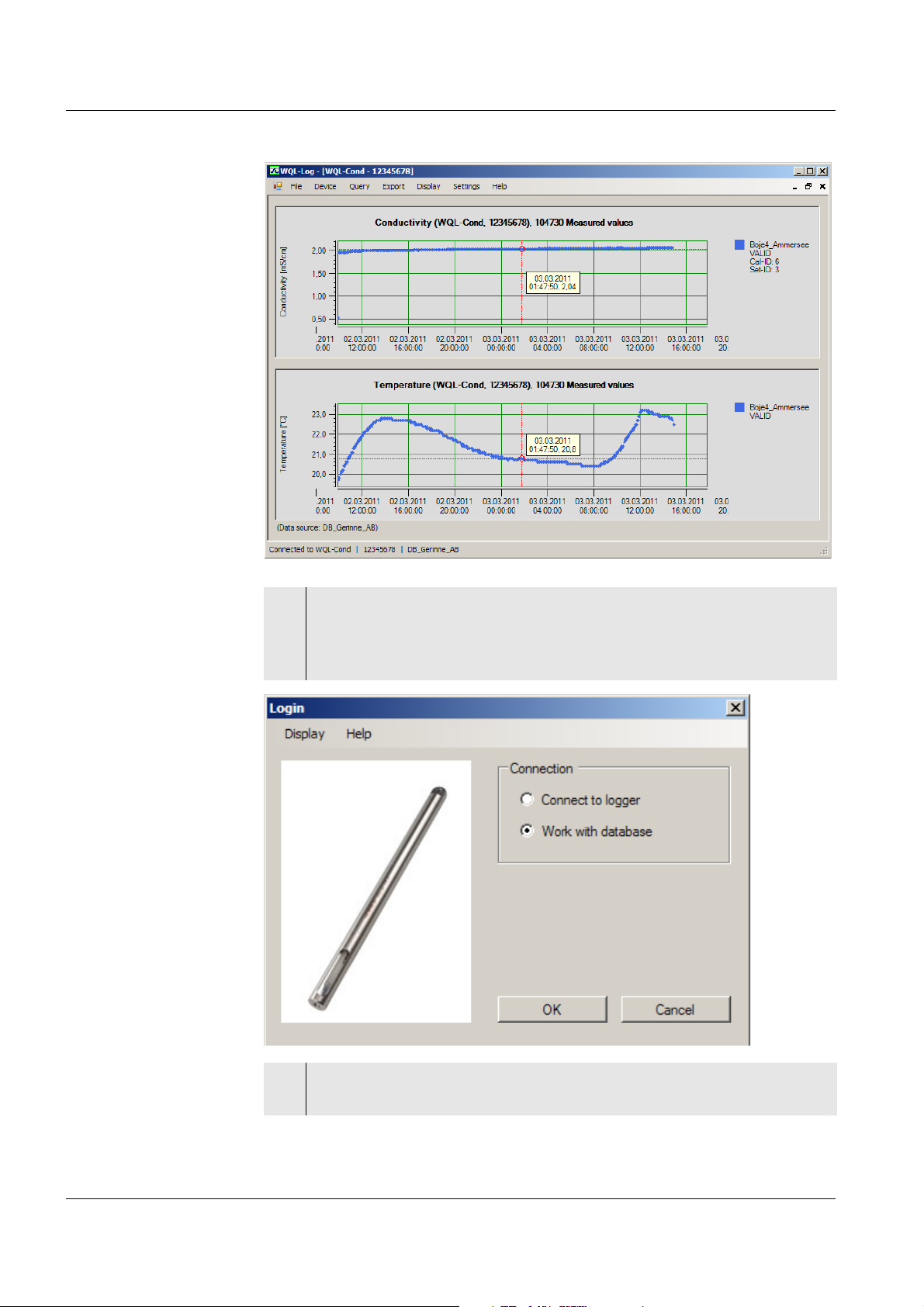

Cursor

Name and series

number of the

connected logger

Menu bar

Measured value ID,

status, Cal ID and

Set ID of the

displayed data.

Name and series

number of the logger

that provided the data

Name of the currently

connected (=open) database

Name of the database

providing the pictured

data

Number of

selected

datasets

Value

window (for

cursor

position)

8.7 Overview of the data window

The measurement datasets imported from the logger are stored in a

database and graphically displayed in a data window.

The data window is structured as follows:

ba75822e01 03/2011

155

Page 60

Logging WQL-Cond

8.8 Managing the logging jobs

The WQL-Cond logger can store up to 20 logging jobs with the respective

calibration data and setting data. You can view an overview of the logging

jobs stored in the logger, read them in individually, display each logging job

as a graphic or clear the logger memory.

Possible status

displays of a

logging job

Status display Explanation Options

Running.... The logger is logging. Stop logging job or

Cancel

Waiting... – The logger is waiting to

be started with the key

button

– The logger was

Start the logging job with

the logger key button,

Stop logging job or

Cancel

stopped with the key

button

– The waiting time/delay

of the start option Time

or Delay has not yet

expired.

Finished The logging job is finished

or was stopped. The data

Exit the list, Import or

Cancel

were not yet imported to the

database.

Imported The logging job is finished

Diagram view or Cancel

and the data were imported

to the database.

156

Viewing the

logging jobs

Note

After being imported, the logging jobs shown in the overview can be

individually shown as a graphic, but they can only be deleted completely.

Proceed as follows to view the list of logging jobs stored in the logger:

1 Connect the WQL-Cond logger to the PC with the USB cable.

2 In the Device menu, click the menu item, Manage logging jobs.

If a logging job is presently running, the following display with

information on the running job appears:

ba75822e01 03/2011

Page 61

WQL-Cond Logging

3 To stop the running job, click Stop logging job. The list of logging jobs

is displayed.

With Cancel the logging job goes on running and the logger is logged

off.

ba75822e01 03/2011

157

Page 62

Logging WQL-Cond

Showing a logging

job as a diagram

Clearing the

logger memory

4 Select a logging job with the arrow keys or with the mouse.

5 If the status is Finished, import the data of the highlighted logging job

to the database with Import (the diagram view is only available after

the data have been imported).

6 To show the data of the highlighted and imported logging job as a

graphic, click Diagram view.

7 If a logging job is selected that is finished but was not imported, the

Exit the list button appears. Use this button to go to the empty data

window.

8 To show the next logging job, select the menu item Manage logging

jobs in the Device menu.

Show the next job of the list of logging jobs as a diagram.

9Use Cancel to return to the data window with the last displayed

diagram view.

1 In the list of logging jobs, click the Delete all logging jobs button. A

security prompt appears:

158

Note

Only click Delete all logging jobs if you want to discard all data stored in the

logger. This action will delete all jobs in the logger memory, and the data will

be irretrievably lost!

The jobs that were already imported and stored in the database are

retained.

2 To delete all logging jobs, click the Yes button.

3 The data is cleared. A message appears after the clearing that

informs you that the memory was cleared. Confirm the message with

OK.

If No is selected, the program returns to the list of logging jobs.

ba75822e01 03/2011

Page 63

WQL-Cond Working with the database and measurement data

9 Working with the database and

measurement data

9.1 General information on the database

The WQL-Cond logger can generate large amounts of measurement data,

which can subsequently be stored, managed and used for evaluation with the

WQL-Log program. The WQL-Log program uses the Microsoft SQL Server

2005 Express database for this. All generated measurement data are

provided with additional information (such as measurement ID, sensor) and

stored in the currently connected database.

Database storage considerably differs from the file-based storage known

from one's daily PC work with word processing or spreadsheet programs. A

database is created and managed by a program, in our case WQL-Log. The

WQL-Log program creates several files and works with them.

Warning

z Always use the WQL-Log program to make any changes on the

database (such as creating, erasing, saving, restoring a database).

z Never erase any files created by the WQL-Log program with another

program (e.g. with MS Windows Explorer). In this case, WQL-Log might

not be able to access the database and the stored data are lost.

With a database you can use queries to select/filter certain events from the

stored measured values. You can e.g., search for measured values from

certain periods or individual locations. This enables the secure and userfriendly handling of large amounts of data.

ba75822e01 03/2011

159

Page 64

Working with the database and measurement data WQL-Cond

9.2 Creating a database

If no database is available on initial commissioning, its creation is enforced,

i.e. a database must first be created prior to storing data in it. If a database

already exists, newly generated data can be stored in it or you can create a

new database and store the data there.

Proceed as follows:

1 In the File menu, select the submenu, Create new database.

2 Confirm with OK.

3 A message appears informing you that the database was created.

4 Confirm with OK. The new database was created and is connected

with the WQL-Log program.

160

ba75822e01 03/2011

Page 65

WQL-Cond Working with the database and measurement data

9.3 Opening a database

When being started, the WQL-Log program automatically opens the

database last used. If there are several databases, you can select another

database to be opened.

Proceed as follows:

1 In the File menu, select the submenu, Open database. A window to

select the database pops up.

2 Click the arrow next to the Database name field and select the

required database.

3 Confirm with OK. The selected database is opened.

ba75822e01 03/2011

161

Page 66

Working with the database and measurement data WQL-Cond

9.4 Backing up a database

You can create a backup copy of an open database at any time.

Proceed as follows:

1 In the File menu, select the submenu, Back up database.

162

Notes

z The program suggests a storage location and name for the backup copy:

the name of the original database with the addition "backup" and the date

and time the backup copy is created.

z The backup copy has the file extension, ".bak".

z The suggested location and name can be changed.

2 Change the location and name of the backup copy as necessary.

3 Confirm with the Save button.

4 A message appears informing you that the database was saved.

5 Confirm with OK. The backup copy of the database has been

created.

ba75822e01 03/2011

Page 67

WQL-Cond Working with the database and measurement data

9.5 Restoring a database

You can restore a database from a backup copy (see section 9.4 BACKING UP

A DATABASE) at any time by opening the backup copy from a connected

database. This can either be an existing database you want to restore to a

previous state or a newly created, empty database into which you want to

store the saved data in case the original database was destroyed or

inadvertently erased.

Warning

z The database from where you open the copy to be restored is

overwritten with the backup copy to be restored. Data that were stored

in the database will be irrevocably lost on restoring the backup copy!

z If you are in any doubt, open a backup copy to be restored from an

empty, newly created database (see section 9.2 C

Proceed as follows:

REATING A DATABASE).

1 In the File menu, select the submenu, Open database.

2 Select the database into which you want to import the database to be

restored.

3 In the File menu, select the submenu, Restore database.

4 Select the location and name of the backup copy (*.bak) to be

restored.

ba75822e01 03/2011

163

Page 68

Working with the database and measurement data WQL-Cond

5 Confirm with the Open button.

A security prompt appears:

6 Click the option Yes and confirm with OK.

A message appears:

164

7 Confirm with OK.

The database has been restored.

ba75822e01 03/2011

Page 69

WQL-Cond Working with the database and measurement data

9.6 Erasing a database

You can erase any connected database of the WQL-Log program.

Proceed as follows:

1 Make sure that the database you want to erase is connected (=

open), or open the database with the menu, File / Open database.

2 Open the menu, File / Delete database. A security prompt appears:

3 Click the option Yes and confirm with OK. The database is erased. If

it was the only database, a window to create a new database pops

up.

ba75822e01 03/2011

165

Page 70

Working with the database and measurement data WQL-Cond

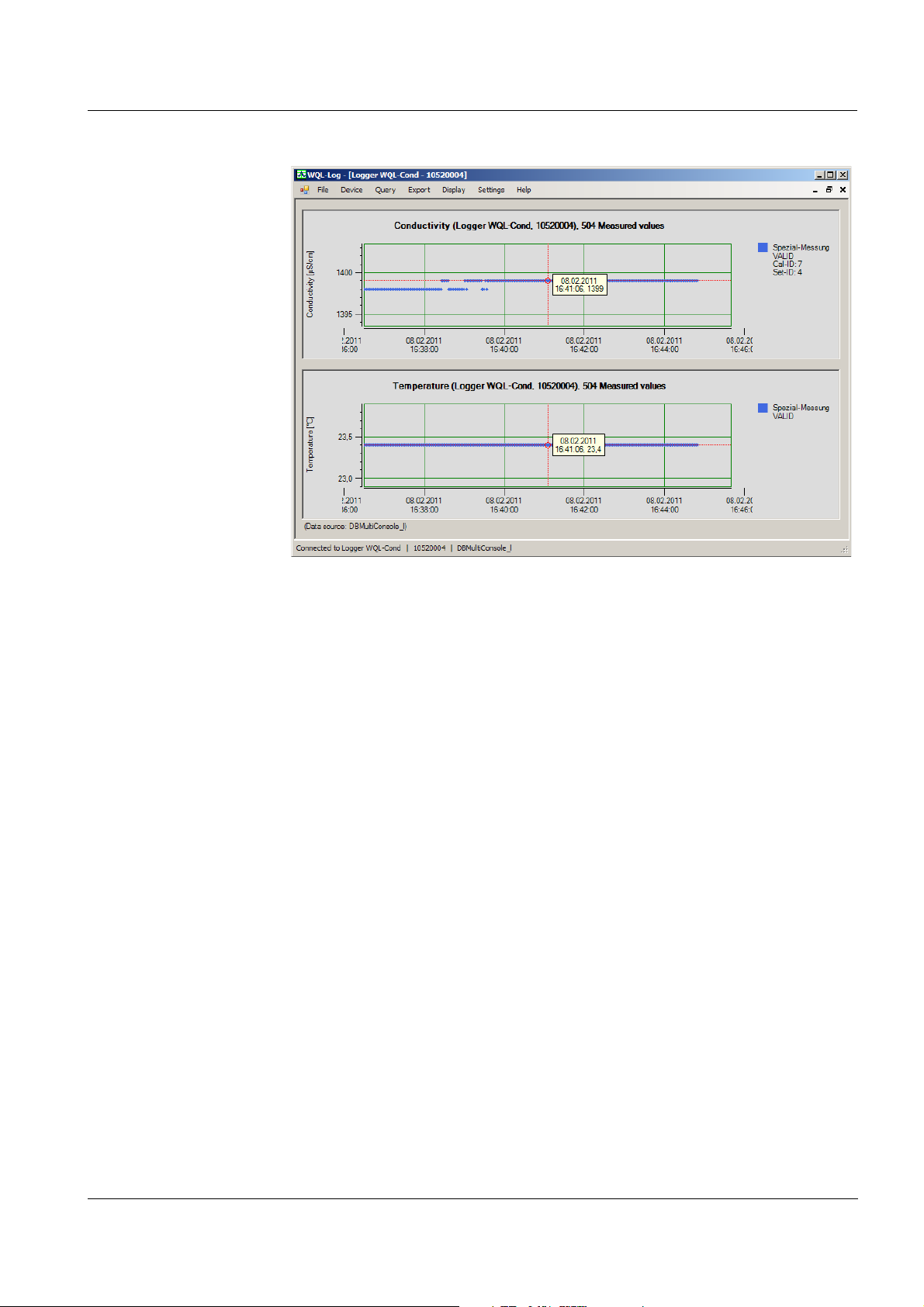

9.7 Querying data

The data recorded by the logger and stored in the database can be displayed

as a graphic via the Query menu item. Proceed as follows:

Querying current

data

1 In the Query menu, click the menu item, New.

The New query window appears.

2 The Standard tab appears when a logger is connected.

3 To graphically display the data last imported from the connected

logger, click Apply. The data appear as a graphic, broken according

to conductivity value and temperature.

166

ba75822e01 03/2011

Page 71

WQL-Cond Working with the database and measurement data

Note

You can change the position of the cursor by moving the data window with

the mouse.

Note

The series number of the connected logger is displayed in the bottom left

corner of the data window (see section 8.7 O

VERVIEW OF THE DATA WINDOW).

ba75822e01 03/2011

167

Page 72

Working with the database and measurement data WQL-Cond

Querying user-

defined data

1 Click the User-defined tab in the New query window. The User-

defined tab appears immediately in the Query menu if no logger is

connected.

2 If you only want to query datasets with a certain measured value ID,

check off the box for Measured value ID and then click the arrow next

to the selection field for the Measured value ID. Select the required

measured value ID.

3 In the Sensors field, select one or two measured values to be

queried.

4 If you only want to query datasets with a certain date, check off the

box for Time period and then click the arrow next to the selection

fields for the time (from and to). Select the required date in both fields.

Next to the date fields are the time fields where you enter the time

(hours, minutes, seconds) either with the arrow keys or by entering

the number with the keyboard.

5Click Apply to display the selected datasets.

168

ba75822e01 03/2011

Page 73

WQL-Cond Working with the database and measurement data

6 The queried data appear as a graphic.

Note

Always make the settings for the user-defined query from the top down, as

the data are filtered in this sequence.

Note

If you do several queries, even from several databases, an additional

window with a graphic appears for each query. You can cascade these

windows with the Restore down ( ) button. You can also arrange the

windows side by side in order to compare several graphics.

ba75822e01 03/2011

169

Page 74

Working with the database and measurement data WQL-Cond

9.8 Exporting data

The data displayed as a graphic with the aid of the Query menu can be

exported to a *.csv file. The WQL-Log program creates three csv files with

each export procedure: One with the measurement data, one with the

calibration data and a third one with the setting data.

In this form the data can be read and processed with Microsoft Excel and

many other spreadsheets.

Note

If the number of datasets to be exported is more than 60,000 and the data

are to be processed with Microsoft Excel 2007 or older, export the data with

the function, "Export as *.csv file (splitted)", as Excel versions 2007 and

older can store only 60,000 datasets in one worksheet. The number of

datasets is given in the header of the graphic, next to the series number of

the logger that provided the data.

Proceed as follows to export the datasets displayed as a graphic:

1 In the Export menu, click the menu item, Export as *.csv file or Export

as *.csv file (splitted).

The Save as window appears.

170

2 The WQL-Log PC program suggests a directory and file name. Store

the data to be exported in the selected directory under the required

name with the Save button.

3 A note on the successful data export appears. Confirm with OK.

ba75822e01 03/2011

Page 75

WQL-Cond Working with the database and measurement data

Notes

The WQL-Log program creates three csv files with each export procedure:

z A csv file with the measurement data and information on the logger and

logging job (suggested name with date and time)

z A csv file with the relevant setting data (suggested name with date and

time and the addition, "Set")

z A csv file with the relevant calibration data (suggested name with date

and time and the addition, "Cal")

z If the number of datasets to be exported is more than 60,000 and the data

is exported with the function, Export as *.csv file (splitted), the WQL-Log

program automatically divides the data into files with max. 60,000

datasets and adds a 1, 2 etc. to the suggested file names.

ba75822e01 03/2011

171

Page 76

Working with the database and measurement data WQL-Cond

Example: Exported

measurement data

opened with MS

Excel

The csv file with the measurement data includes the following information:

z Sensor name

z Series number of the logger (SerNo)

z Start and stop (time) of the exported data

z Date and time of the measured values

AutoRange

function

z Measured value

z Measured value status (Valid; Invalid; OFL/UFL = outside the measuring

range; Ranging = optimal measuring range is being searched)

z Temperature

z Measured value status (Valid; Invalid; OFL/UFL = outside the measuring

range)

z Measured value ID (MeasID)

z Calibration ID (CalProtID) so you can allocate the calibration data if there

are several calibration procedures for the exported data - see csv file with

calibration data).

z Date and time of the calibration (CalDateTime)

z Settings ID (SetID) so you can allocate the settings for the exported data

- see csv file with setting data).

Due to the large scope of conductivity measurements ( 1 ... 1.000.000 μS/cm)

the WQL-Cond logger automatically searches for the suitable measuring

range. In the most unfavorable case (changing from the largest to the

smallest measuring range or vice versa) it takes the logger a response time

of approx. 8 seconds to do this.

172

In the case of extreme conductivity jumps, the logger can determine the real

conductivity value only approximately because of this response time.

Approximate values are indicated with the measured value status,

RANGING.

When measuring directly, the conductivity value is only displayed after the

suitable measuring range has been found.

ba75822e01 03/2011

Page 77

WQL-Cond Working with the database and measurement data

Example: Exported

calibration data

opened with MS

Excel

The csv file with the calibration data includes the following information:

z Sensor name

z Series number of the logger (SerNo)

z Calibration ID, so you can allocate the calibration data if there are several

calibration procedures for the exported data

z Date and time of the calibration

z Calibration mode (Mode)

z Calibration temperature (Temp)

Example: Exported

setting data

opened with MS

Excel

z Cell constant (CellConst)

z Calibration evaluation

(CalStatus - similar to C

ALIBRATION EVALUATION, page 135)

The csv file with the setting data includes the following information:

z Sensor name

z Series number of the logger (SerNo)

z Settings ID (ID) so you can allocate the settings for the exported data

z Temperature compensation (TempComp)

z Reference temperature (TRef [°C])

z Temperature coefficient (LinCoeff [%/K])

ba75822e01 03/2011

z TDS factor

173

Page 78

Info menus WQL-Cond

10 Info menus

10.1 Database information

The data read in from the logger are saved in a database. You can query the

name, version and type of the opened database.

To do so, proceed as follows:

Database

information

1 In the File menu, click the menu item, Database info.

The Database info window appears.

2 Confirm with OK. The Database info window disappears.

Note

The size of a database file can be 4 GB max. When this amount of data is

stored, a new database file must be created. The new database file is

created in the Device/Create new database menu.

A database with 50,000 datasets requires approx. 7 MB storage space. Thus

the database can store approx. 12,5 million datasets.

174

ba75822e01 03/2011

Page 79

WQL-Cond Info menus

10.2 Device information

If a logger is connected to the PC, you can query the device name, series

number and firmware version of the connected logger via the Device/Info

menu item.

To do so, proceed as follows:

Device information

1 In the Device menu, click the menu item, Info.

The Device info window appears.

2 Confirm with OK. The Device info window disappears.

ba75822e01 03/2011

175

Page 80

Info menus WQL-Cond

10.3 Program info

In the Help/About WQL-Log menu you can look up which version of the WQLLog PC program was installed.

To do so, proceed as follows:

1 In the Help menu, click the About WQL-Log menu item.

The About WQL-Log

Program info

window appears.

2 Confirm with OK. The About WQL-Log window disappears.

176

ba75822e01 03/2011

Page 81

WQL-Cond Resetting the logger

11 Resetting the logger

You can reset to the default condition the logger and the PC program with its

settings.

In the default condition, the settings are as follows:

Configuration parameters Setting

Logging interval 1 second

Start of the logging Logger key button

End of the logging Time period

1 hour

Measured value ID default

Measuring mode Conductivity

Temperature compensation nLF

Resetting to

default condition

Temperature coefficient 2.000

Reference temperature 25 °C

Cell constant 0.475 cm

-1

TDS factor 1.00

Date, time 01.01.2003, 00:00

Calibration records None

Notes

z The Device / Reset function deletes the calibration records as well as all

measurement data from the logger! Before deleting the logger memory,

make sure that you have imported to the database all data you want to

keep.

z The battery counter is not reset with the Device / Reset function. It has to

be reset with the reset function of the battery manager.

To reset the logger and PC program to the default condition, proceed as

follows:

ba75822e01 03/2011

1 In the Device menu, click the menu item, Reset. A security prompt

appears.

2 Confirm with OK. The settings are reset to the default condition.

177

Page 82

Resetting the logger WQL-Cond

178

ba75822e01 03/2011

Page 83

WQL-Cond Maintenance, cleaning, storage

12 Maintenance, cleaning, storage

12.1 General maintenance instructions

General

information

Cleaning the

measuring cell

z Normally, all screw joints of the logger housing can be opened and closed

by hand, without using any tools. If necessary, use a paper towel so you

can get a better grip on the parts.

z In the screwed condition, no gaps may be visible at the joints.

z Prior to unscrewing any screw joints, clean the exterior of the logger (see

section 12.2 E

XTERIOR CLEANING) and dry it thoroughly.

z Prior to reassembly, clean all internal and external threads thoroughly.

Contaminated threads can get stuck by-and-by. Normally, the threads can