Page 1

Global Water

800-876-1172 • globalw.com

Global DO Monitor Software Manual

For Use With WQ-FDO Sensor and

GL500-7-2 Data Logger

Global Water

Instrumentation, Inc.

151 Graham Road

P.O. Box 9010

College Station, TX 77842-9010

T: 800-876-1172

Int’l: (979) 690-5560, Fax: (979) 690-0440

E-mail : globalw@globalw.com

02-095

Publication Number 39360712

- 1 -

Page 2

Global Water

800-876-1172 • globalw.com

Congratulations on your purchase of a Global Water WQ-FDO Dissolved

Oxygen Sensor and GL500 Data Logger. These instruments have been

quality tested and approved for providing accurate and reliable

measurements. We are confident t hat you will find the logger to be a

valuable asset to your applications. Should you require assistance, our

technical staff will be happy to help.

Table of Contents

I. Overview ▫ ▫ ▫ ▫ ▫ 3

II. System Requirements ▫ ▫ ▫ 3

III. Software and Driver Installation ▫ ▫ 4

IV. Direct Connection ▫ ▫ ▫ ▫ 7

V. Modem Connection ▫ ▫ ▫ ▫ 9

VI. Main Screen ▫ ▫ ▫ ▫ ▫ 11

VII. On-Line Help Files ▫ ▫ ▫ ▫ 15

VIII. Get History ▫ ▫ ▫ ▫ ▫ 16

IX. Setup Menus ▫ ▫ ▫ ▫ ▫ 17

X. General Setup ▫ ▫ ▫ ▫ ▫ 18

XI. Analog Setup ▫ ▫ ▫ ▫ ▫ 21

XII. Digital Setup ▫ ▫ ▫ ▫ ▫ 24

XIII. DO Setup ▫ ▫ ▫ ▫ ▫ 26

XIV. Programming ▫ ▫ ▫ ▫ ▫ 29

XV. Connections ▫ ▫ ▫ ▫ ▫ 30

XVI. Modem C able Diagrams ▫ ▫ ▫ 31

XVII. Maintenance ▫ ▫ ▫ ▫ ▫ 32

XVIII. Troubleshooting ▫ ▫ ▫ ▫ 32

XIX. Cust om er Support ▫ ▫ ▫ ▫ 34

Copyright Global Water Instrumentation, Inc. 2012

- 2 -

Page 3

Global Water

800-876-1172 • globalw.com

I. Overview

The Global DO Monitor software is an enhanced vers ion of the Global Logger II data

logger interface; and used to conver t dissolved oxygen partial pressure and

temperature, along with conduct iv ity and atmospheric pressure, into DO

concentration and saturation. Calc ulating dissolved oxygen concentration and

saturation can be complicated; t hes e v alues are dependant on the partial pressure of

oxygen, temperature, conductivity or salinity, and atmospheric pressure or altitude.

All of these parameters are required to acc ur ately determine concentration and

saturation levels under all conditions.

This software is intended for use wit h the G lobal Water WQ-FDO sensor and the

GL500-7-2 Data Logger. The WQ-FDO sensor provides two 4-20mA outputs whic h

are proportional to oxygen partial pressur e and water temperature. Optionally the

WQ-COND Conductivity Sensor and the WE100 Barometric P ressure Sensor can be

connected to the logger to provide all the nec es s ar y data needed to calculate the

concentration and saturation levels. If conductivity and atmospheric pressure ar e

constant, and these values are known, pr ov is ion is m ade to manually enter these

values instead of connecting the optional s ens or s . Any or all of these 4 sensor

parameters can be displayed and downloaded to a spreadsheet. The software uses

these parameters to calculate concent r ation, saturation, and salinity; and these

calculated values can also be displayed and dow nloaded as needed. All other

features of the Global Logger II soft war e are also supported.

II. System Requirements:

Desktop or Lapto p c o m put e r wit h:

1) W indows 98, ME, 2000, XP, Vista or Windows 7 Operating Systems

2) CDROM Dr ive

3) RS-232 or U S B P ort

Note that this software is for r unning on des k top and laptop computers only.

- 3 -

Page 4

Global Water

800-876-1172 • globalw.com

III. Software and Driver Installation:

Global DO Monitor S o f twa r e Installation: This software is for use on Windows

based desktop and laptop computers only . Insert the software installation CD and

run the Setup program. This will install t he Global Logger application in the Program

Files folder and automatically put the Global Logger icon on the desktop.

Serial communication: If you are using the RS-232 serial port to access the data

logger, no further action is needed. Y ou c an s tart using the logger by opening the

Global Logger application program. If you plan to use the USB port, you must install

the driver. You may consider installing the driver now, even if you plan to use the

serial port.

USB Driver Installation: With the installation CD in the CDROM drive and DC

power applied to the logger, plug the USB c able into the data logger to open the

ADD New Hardware Wizard. The menus that follow will look dif ferent for different

operation systems but the procedure is the sam e. Do not allow the H a r dwa r e

Wizard to automatically search for the driver. Instead, specify the location

(CDROM). If a generic driver gets, or has been previously ins talled, it must be

uninstalled before proceeding by using the Add or R em ov e P r ogr ams section of the

Control Panel. Instead, click the S ear c h Ext er nal Media box or S pec ify a Location

box and install the driver from the CDROM. Running the Setup progr am that installs

the Global Logger software also installs a folder with the driver in it. This location

can also be specified if the CDROM is not available; alt hough, it is recommended

that the driver be installed at the same tim e the Global Logger is installed.

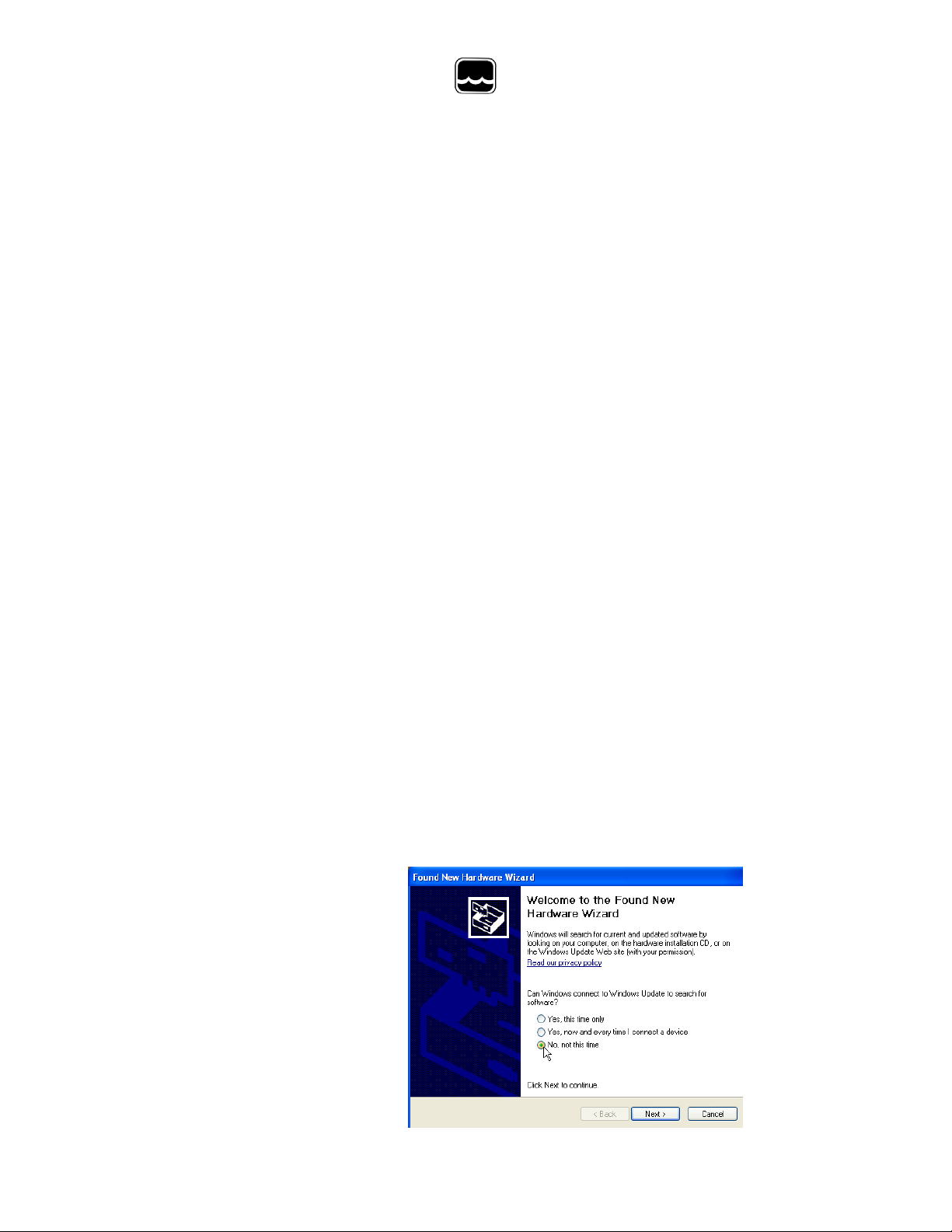

The following menus apply to the Windows X P operating s y s tem.

1) Do not let Windows search

for software. Click “No, not

at this time” when asked if

Windows Update can search

for software.

Click Next.

- 4 -

Page 5

Global Water

800-876-1172 • globalw.com

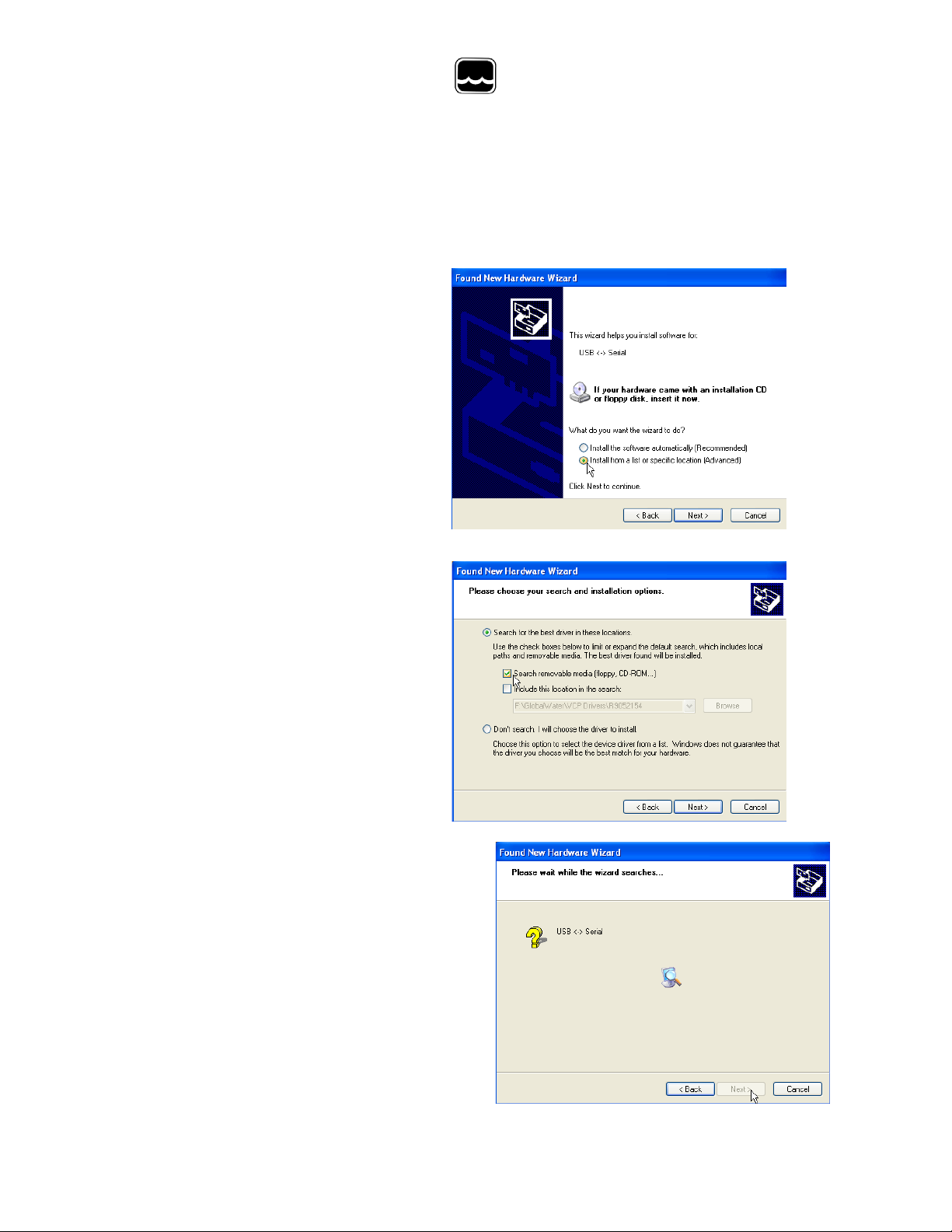

2) Do not let Windows automatically

install the software. Click “Inst all

from a specific location”.

Click Next.

3) Specify the location of the driver.

Make sure the Global Logger CDROM

is in the CD drive and click “Search

removable media” only.

Click Next.

4) The Hardware Wizard searches

for the driver.

If Windows advises that the software

is not certified, click:

“Continue Anyway”.

- 5 -

Page 6

Global Water

800-876-1172 • globalw.com

This only means that Microsoft has not

licensed the software. Second party

software is allowed and no harm will

come to your computer.

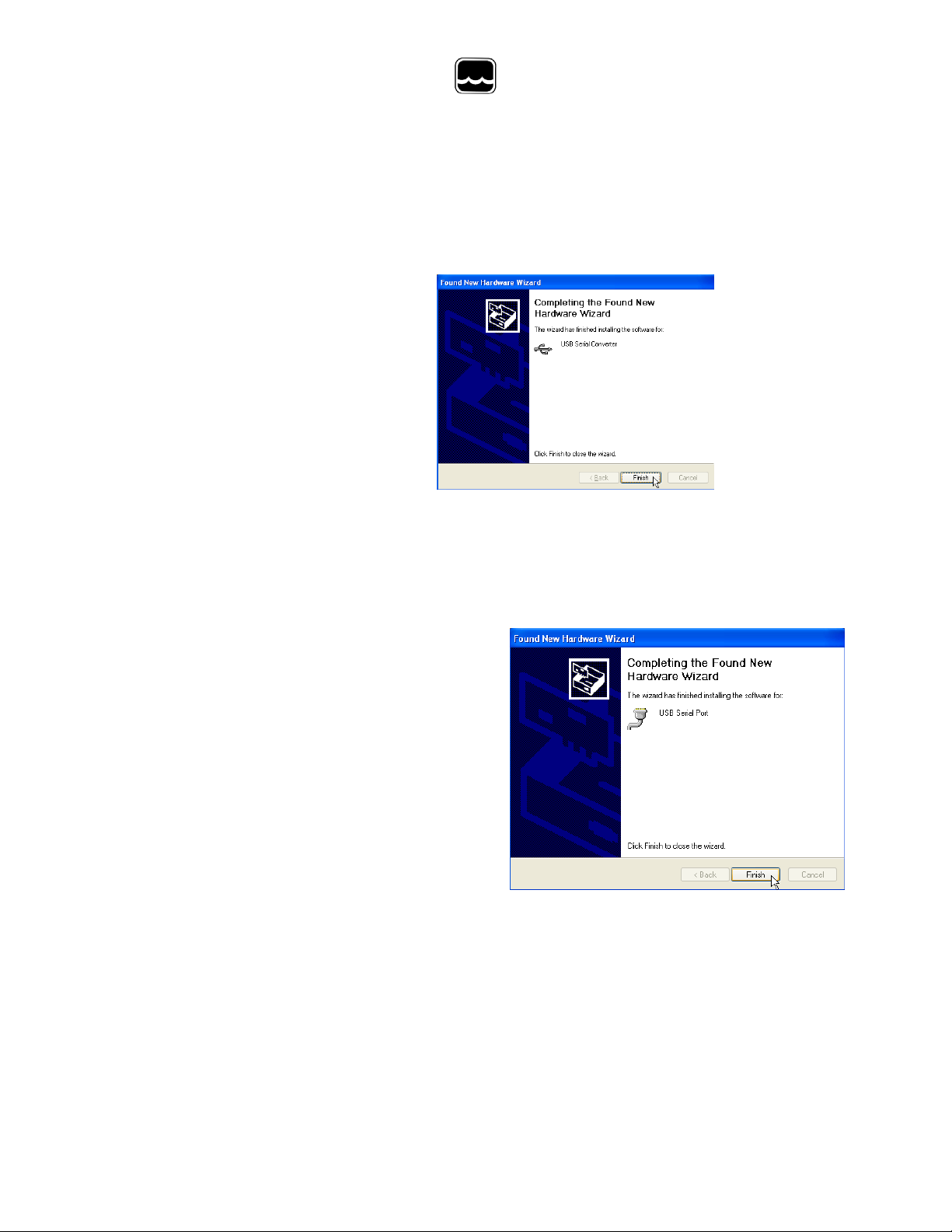

5) The first half of the installation is

complete. The Hardware Wizard

may need to make two passes.

Click Finish.

6) Two drivers are sometimes required so t he Hardware Wizard may repeat the

exact same process again. As before; a: do not let the W indow s Update do a

search, b: tell Windows to search from a specific location instead of automatically

installing software, c: tell W indows to search from removable media (CDROM).

7) The installation is complete.

Click Finish.

- 6 -

Page 7

Global Water

800-876-1172 • globalw.com

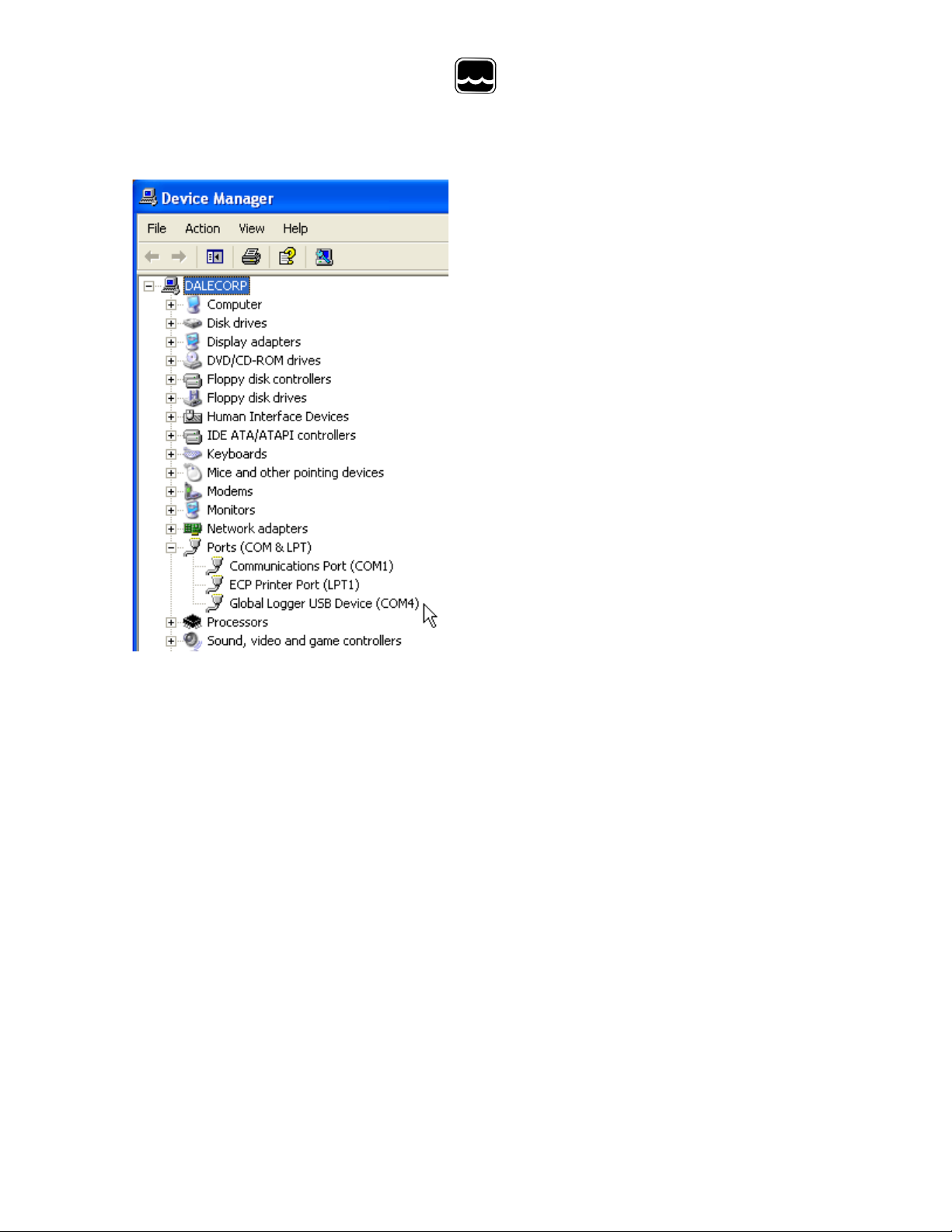

8) To confirm the installation, look in the

Device Manager and find the USB Ser ial

Port. The COM setting following that will

show the virtual COM port that has been

automatically assigned to the driver . As

you will see in the following section, this

COM port will be automatically detect ed

by the Global Logger software so it is not

necessary to note which port is being

used by the driver.

IV. Direct Connection:

Important: This data logger supports an Auto Baud Rate Mode which automatically

detects the connecion speed. However; this communication software also

supports loggers which may be programmed in a Fixed Baud Rate Mode.

This is useful in telemetry applications, particularly when using Global Water

data loggers with our Global Access radio m odem software. The upcoming

discussion assumes that the logger is pr ogr ammed in auto detect mode. If

you cannot connect to the logger and suspect that the logger may be using a

fixed rate mode; try each connection speed separately, especially 38400

which is required when using the Global Acces s s oftware.

- 7 -

Page 8

Global Water

800-876-1172 • globalw.com

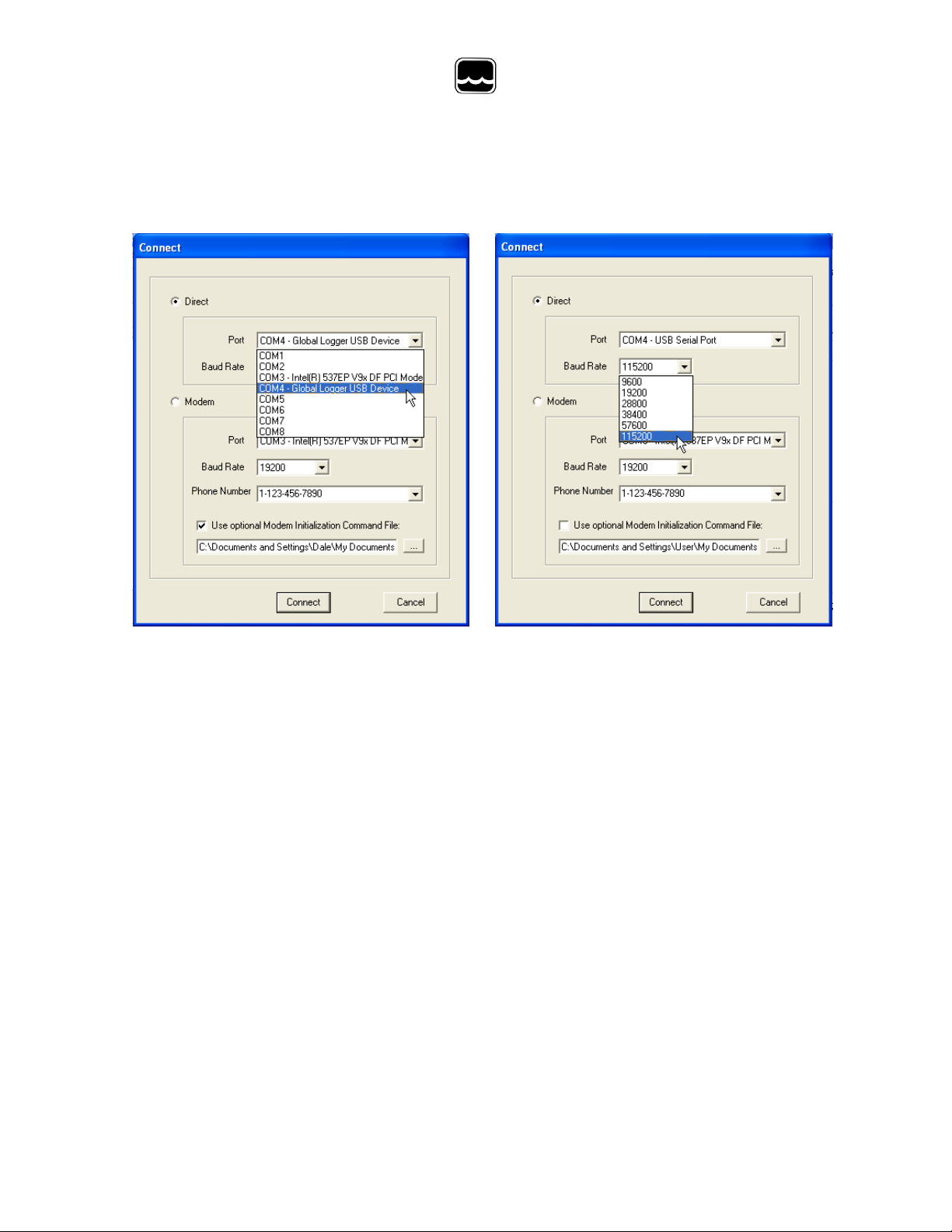

There are 3 ways to connect to the GL500 data Logger, direc t connection through

the RS-232 serial port or USB port and dial out through an installe d m odem.

To make a direct connection to the logger, c lic k t he “Direct” option and from the

“Port” menu, select the port you wish to use. For USB access select the USB serial

port at the COM port the driver was assigned, whic h is automatically shown in the

list. Serial connection is generally done t hr ough the 9-pin COM1 connector although

COM2 can also be used. When an external modem or other device is assigned t o

COM1, the port can still be used for access ing the logger, but the external device

must be disconnected. Both the serial and US B port s c an be c onnec ted to the

logger at the same time but you must select which of them is to be used. No

difference will be noticed by the us er ex c ept while downloading historical data.

Because of the excessive handshaking done by the USB port, the serial port will run

about 50% faster at the same baud rate. Next, select the desired baud rate from the

“Baud Rate” menu. Generally, the fast es t rate of 115,200 is used although; long

cables or other factors may require a slower setting. Click “Connect” to make the

connection. If a connection is not made, a message will appear. Check the power

connection, communication cable, dr iv er ins tallation and COM port settings.

- 8 -

Page 9

Browse

Global Water

800-876-1172 • globalw.com

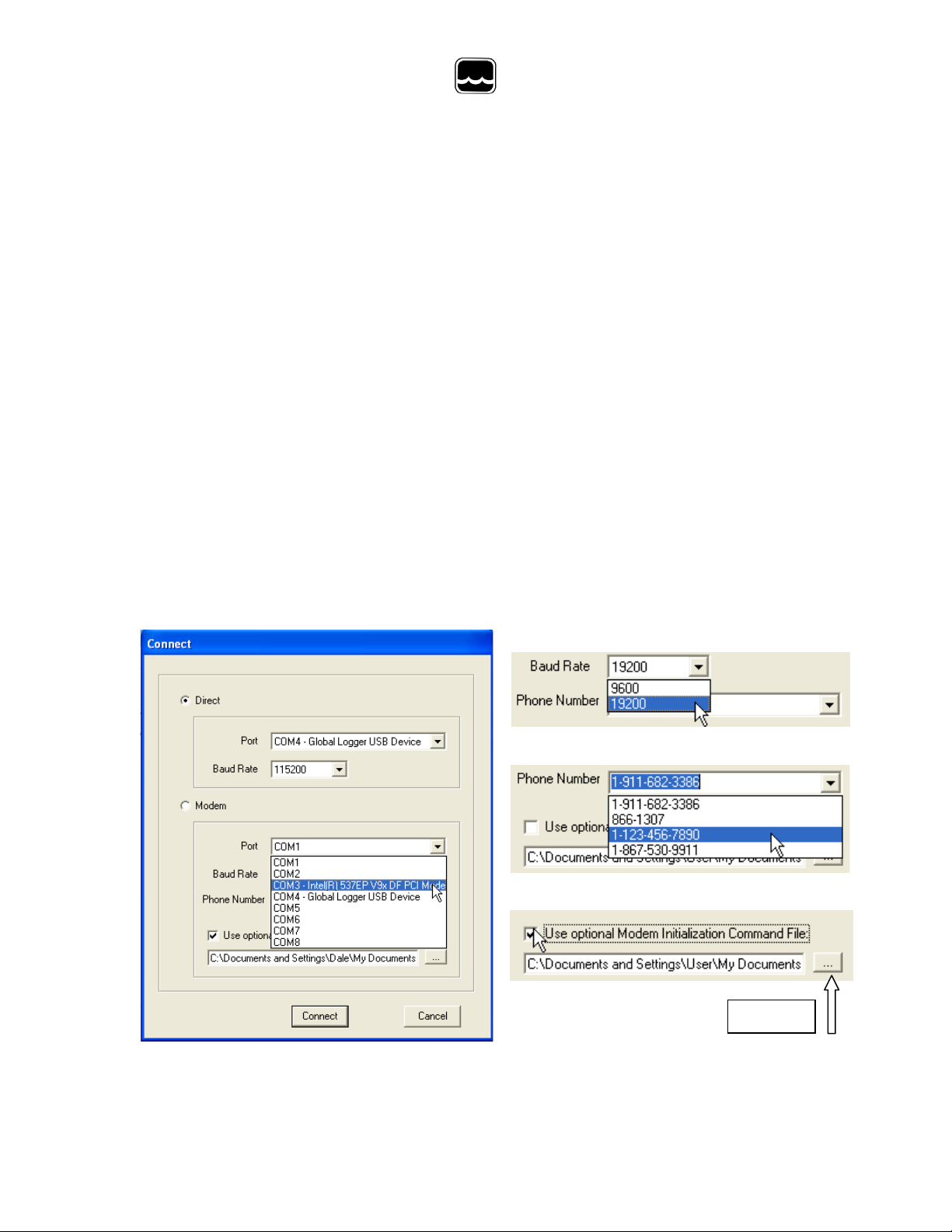

V. Modem Connection:

Access to the GL500 can be made through dial-out to a remote modem by clicking

the “Modem” option. The connection from modem to logger requires an RS-232

serial modem, USB modems are not support ed as an interface to the logger. Also,

some switch settings must be made to the remote m odem and an initialization string

may be required to properly configure the hos t modem.

Two baud rates are supported 9600 and 19200. Should you ex per ienc e difficulty

establishing a reliable connection at 19200, use the slower connection speed. N ote

that due to the slower baud rates and the additional hands haking performed during

modem communication, The Global Logger s oftware will operate significantly slower

than during a direct connection.

The Global Logger software will remember the las t 4 numbers dialed and has a

provision for using a stored text file (.txt extension) for initialization of the hos t

modem using standard AT commands. Some experience may be r equir ed to

configure your modem but a sample comm and file and some useful tips follow.

Select the baud rate

Ty pe in or find the phone number

Use init ializ ation file

Select the modem’s COM port

- 9 -

Page 10

Global Water

800-876-1172 • globalw.com

Sample initialization text file:

This is for reference and applies to

an external US Robotics modem only.

ATM1 ; speaker off when connects

AT&B1 ; fixed serial port rate

AT&D2 ; normal DTR

AT&H1&R2 ; h/w flow control

Connect 19200

AT&I0 ; disable s/w flow control

AT&K0 ; disable compression

AT&M4 ; normal error control

Select the COM port for your modem

and the baud rate. Type in the phone

number or select it from the list of prestored numbers. If necessary, clic k the “Use I nitialization File” box and use

the browse button to search for t he initialization text file for your modem. Click

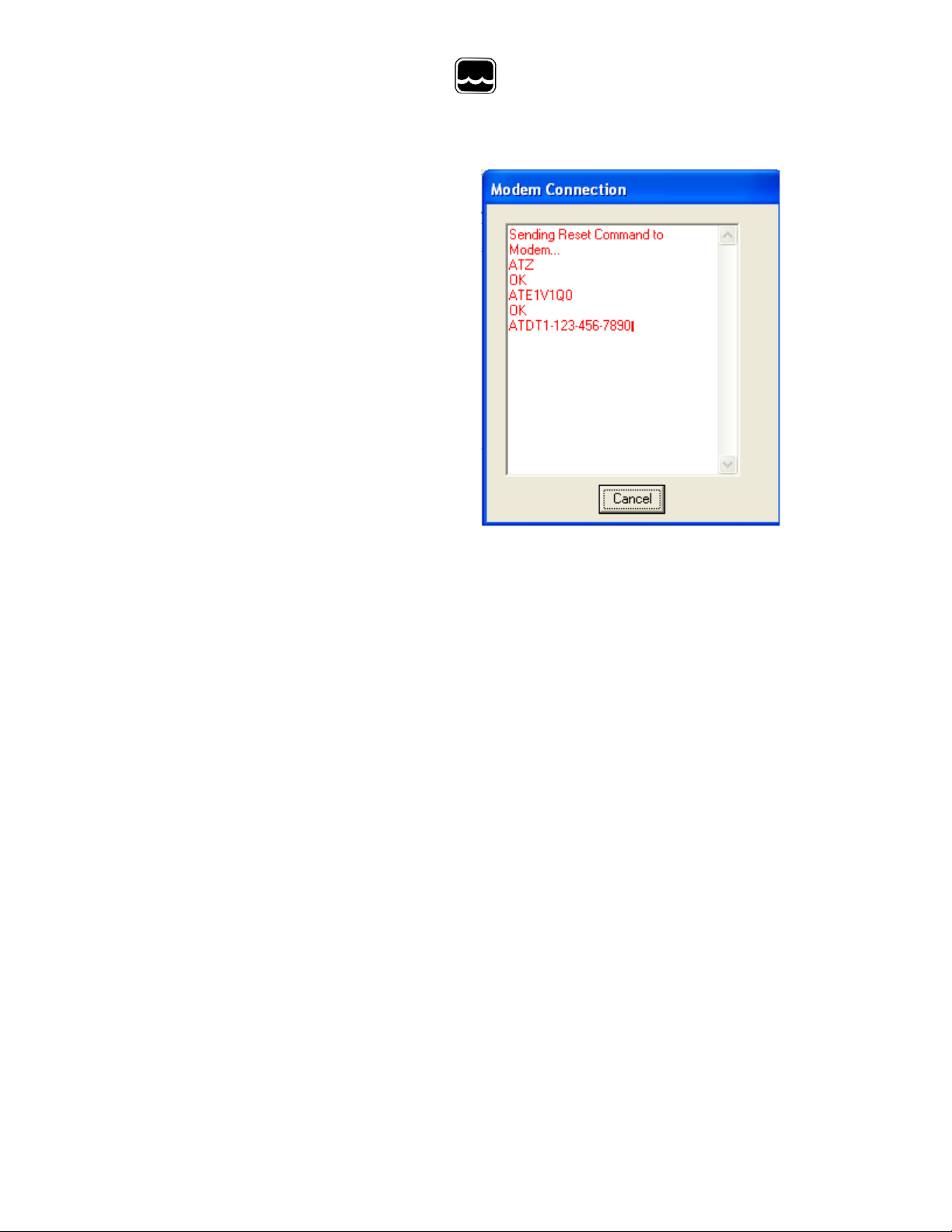

“Connect” and the software will dial out, s how ing the status screen shown above.

Once a connection is established, “Connect ” wil l appear for a few seconds along with

the baud rate of the connection. After c onnec ting, the normal Global Logger screen

will appear and operate exactly as if a direct c onnection was m ade. All options and

features work the same but at a reduced communicat ion s peed.

When connecting the GL500 Data Logger to an external modem, a special cable is

required. Wiring diagrams are provided at the end of this manual and pre-wired

cables are available from Global W ater. The remote modem is configured by setting

DIP switches. They should be set to auto-answer on, DTR Normal, carrier detect

normal and smart mode. Global Water can provide ext er nal m odems and interface

cables at an additional cost if requested. Contact our sales department for more

information.

It may not be necessary to use an initializat ion s tring to configure the host modem

but if problems arise the modem should be set with software handshaking off (Xoff),

DTR normal, fixed baud rate, compression of f and error correction on. This

configuration is done by building an init ializ ation file using the standard AT

commands and loading it into the connection screen. Global Water suggests that

you test the modems operation before installing in the field.

- 10 -

Page 11

Global Water

800-876-1172 • globalw.com

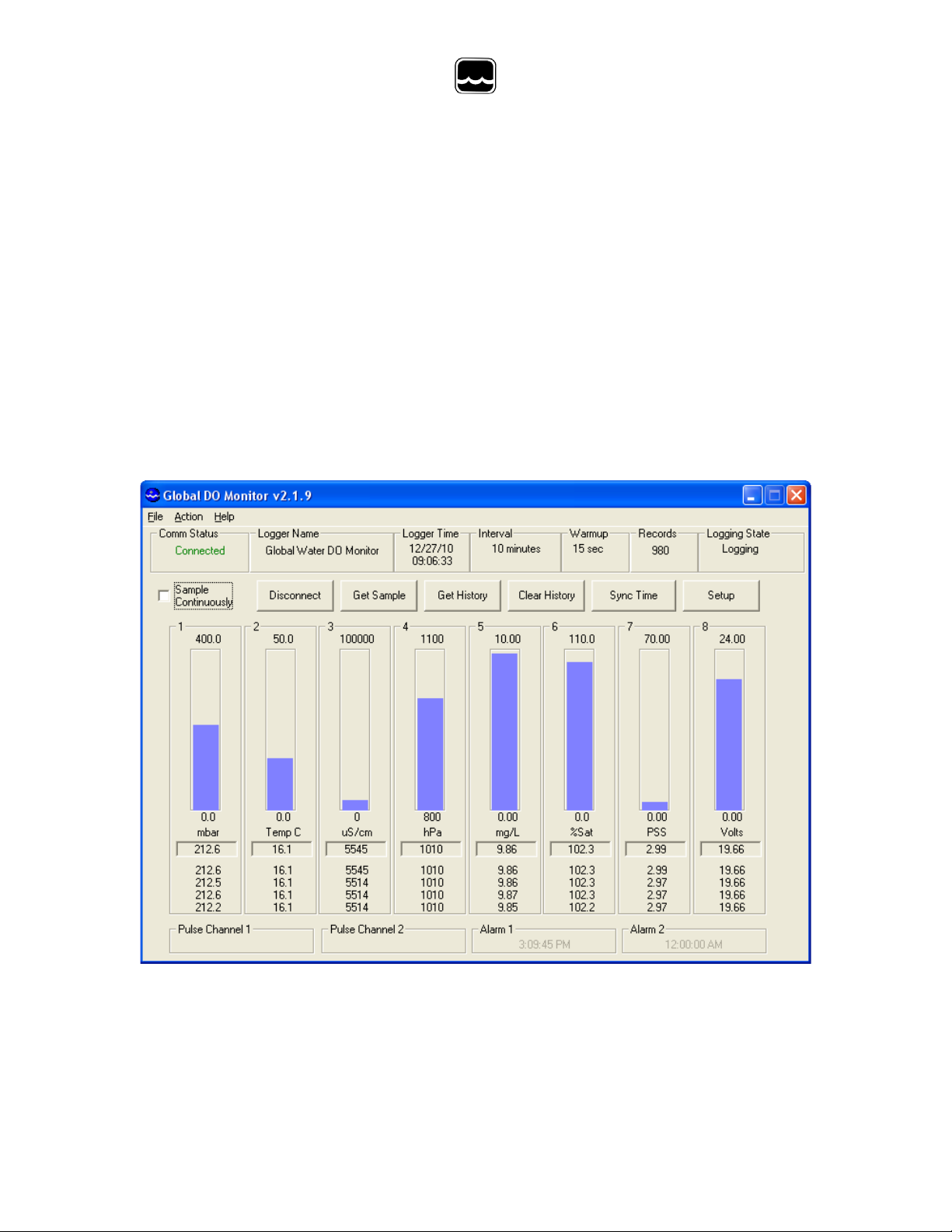

VI. Main Screen:

The main screen is where the status and option menus ar e ac c es s ed. The GL500

data logger will continue to log at norm al intervals while connected to the Global

Logger software. While connected, t he logger will draw an addition current from the

power supply of 5-10mA so it is advised that, if you are operating on battery power

and plan not to access the logger for extended periods of time, you disconnect from

the logger to increase battery lif e. I nterface cables may remain connected. To

disconnect, click on the “Disconnect” button. The label on this button will change to

“Connect” and clicking on it will return y ou to the connection screen as previously

discussed.

The functions and information in this sc r een are disc us s ed in the following sections.

- 11 -

Page 12

Global Water

800-876-1172 • globalw.com

Tool Bar: The tool bar at the top of the screen has 3 options; File, Action and Help.

In this screen, the File option is used to exit the program only. Action allows a menu

driven interface to the various functions and displays the hot-keys, which can be

used for faster access. In the Help menu; Help allows you t o v iew the on-line help

files (see section X, Page 16), About s hows c ontact information and Revision

information for the Global Logger soft war e and Firmware Version displays the GL500

Data Logger revision number.

COM Status: This reads “Connected” in green or “Not Connected” in red,

depending on the current connection st atus.

Logger Name: The logger name is a us er defined name associated with a particular

logger to identify one from another. It is progr am m ed in the Setup menu as

described later and is limited to 32 c har ac ters.

Logger Time: The time and date displayed is that of the real-time clock in the

logger. It is only updated upon initial connection and certain functions that cause

data to be read from the logger. These include Sample C ontinuously, Get Sample,

Sync Time and Setup whose functions are to be described later .

Interval: This field displays the logging mode. “Fast” indicates high-speed mode

and “Logarithmic” is shown in logarithmic m ode. If the logger is in the normal fixed

interval sampling mode, the time between samples will be displayed. These modes

are to be described later.

Warmup: This displays the sensor warm -up time.

- 12 -

Page 13

Global Water

800-876-1172 • globalw.com

Records: This field indicates the number of data recordings in memory.

Logging State: This shows whether the GL500 is currently logging wait ing to be

started or stopped by the alarm timers. These featur es ar e des c r ibed in detail later.

Sample Continuously: Clicking this check box causes the Global Logger software

to take and display a real-time reading once per s ec ond until stopped by clicking it

again, as well as update the rest of the fields on the s c r een. These data readings

are not stored in the historical record and do not affect the normal recording of the

logger. The initial reading has a sensor war m-up time of 50mS and the sensor is left

powered up until this feature is turned off.

Get Sample: Clicking this button causes the Global Logger software to take and

display a single reading as well as update t he rest of the fields on the screen. This

data reading is not stored in the historical rec or d and does not affect the normal

recording of the logger. The sensor war m-up time is fixed at 50mS.

Get History: This button starts the download of all the historical data stored in the

logger memory. Oldest data is collected fir s t and Clicking “Stop” halts the process.

This function is described in detail later.

Clear History: This resets the number of r ec ordings in memory to zero. The user is

warned first and must confirm the act ion before the memory is cleared.

Sync Time: This button causes the data logger’s internal clock to be set to the

system time of the computer it is connected to. The user is warned first and must

confirm the action before the tim e is set.

Setup: Clicking this button enters the setup screen where the user can change and

program all parameters into the data logger. This function is described in detail later.

- 13 -

Page 14

Global Water

800-876-1172 • globalw.com

Bar Graphs: The bar graphs show a vis ual r epr es entation of the most recent data

reading taken by using the Sample Continuousl y or Get Sample functions. The

upper and lower limits of the display are defined by the user as discussed in detail

later.

Numerical Reading: The numerical reading at the bottom of the bar graph shows

the actual data reading and is updated at the s am e time as the bar graph.

Successive numerical readings taken by us ing S am ple C ontinuously or Get Sample

are shown in a list below the bar, up to 5.

Pulse channels: The GL500-7-2 Data Logger has two independent pulse c hannels ,

each with a maximum count of 65,535. At the time of the logger’s normal sampling

interval, the counts are stored in mem or y along w ith the other sensor data and time

stamp, and then the counters are set to zer o to start the counting sequence over

again. The Pulse Channel 1 and Pulse Channel 2 fields show how m any puls es

have been counted since the last logger r ec or ding for each of the 2 pulse channels.

For example: If the logger is set to record onc e per minut e and it is put into Sample

Continuously mode, the display will be updated onc e per s ec ond and as puls es ar e

applied to the pulse inputs, the Pulse Channel f ields will update the count. At the

end of the normal one minute sampling interv al, the total number of pulses will be

stored in memory and the Pulse Channel fields will s how z er o until more pulses are

applied. Note that the pulse channels can be scaled to s how r ainfall, water flow etc.

by multiplying the count by a user definable num ber as described in detail later.

Alarm 1: This field shows the time that the logger is s et to start logging. The start

alarm is a 24-hour timer which will initiate logging, when enabled, at the next

occurrence of that time.

Alarm 2: This field shows the time that the logger is s et to stop logging. The stop

alarm is a 24-hour timer which will halt logging, when enabled, at the next

occurrence of that time after the logger has started recording. If the Alarm 1 timer is

set to initiate logging, the Alarm 2 t imer will halt logging at the next occurrence of the

Alarm 2 time after the logger has been started by A lar m 1. If the Alarm 1 timer is not

enabled, the Alarm 2 timer will halt logger on the next occurrence of that time.

Note: Use care when programming the alarm times. If left enabled, changing

and reprogramming any of the setup parameters will restart the alarm timers.

- 14 -

Page 15

Global Water

800-876-1172 • globalw.com

VII. On-Line Help Files:

Clicking on Help displays the on-line help files whic h giv e eas y ac c es s to the

information contained in this m anual. There are 3 ways to access the information.

The first tab is Contents which accesses the table of contents for the manual.

Clicking on any of the topics opens up the

body of text on that

subject. Within each

body of text is a

discussion of that

subject and links to

related topics

underlined in blue.

Clicking on the link

will bring up a new

window with specific

information on that

topic. In this case,

Sensor Warm-up time

in the General Setup

menu.

Click the Index tab to find a listing of topics. Type lett er s into the keyword field and

the program automatically sorts the topics alphabetically. To find relevant topic s

based on a keyword, click the Search tab. Information on the DO Monitor operation

is contained in a separate section. From the Help pulldown menu, select Dissolved

Oxygen Sensor Help to access informat ion r elated t o the DO Monitor section.

- 15 -

Page 16

Global Water

800-876-1172 • globalw.com

VIII. Get History:

Clicking the Get History button begins the downloading of the historical data into an

information screen. This screen allows the viewing of the recorded data and also

provides a path to export the data to an Excel compat ible file. Note that the logger

continues to log as data is downloaded. Thus, more data points may be downloaded

than originally indicated.

At the top of the screen is shown the name assigned to t he logger and the number of

recordings that have been retrieved. A t t he bottom of the screen are four buttons,

Pack, Save to File, Options and OK.

Pack: The Pack function removes recordings that are identical to the previous ones.

All the channels must be the same as the row above for it to be rem ov ed. If ev en a

single channel has data that differs from the previous sample, the row will not be

removed. This function works best when a single c hannel is being r ec orded and

allows only the data showing changing conditions to be viewed.

- 16 -

Page 17

Global Water

800-876-1172 • globalw.com

Save to File: Clicking this but ton

allows the data to be exported to an

Excel compatible .CSV file.

Specify the path and the file name

and click the Save button

Options: This opens a menu which

Allows you to select if you want the

Time and date in the time stamp to

Be in one column or two in the saved .CSV file. Click Close to r eturn.

OK: Clicking the OK button

returns you to the main screen.

IX. Setup Menus:

Clicking the Setup button enters the setup menu which is composed of four sections,

Analog, Digital, General, and DO. The first screen to appear is General Setup. At

the top of the setup screen is a toolbar with t hree opt ions , File, Action and Help.

File: The File option allows you to exit the setup screen but most important ly , it

allows all of the configuration information for the logger to be saved to a file or

restored from a file. Select “Load Setup File” to r es tore a configuration from a file

that has been previously saved or “Save Setup File” to sav e the current setup and

calibration information. The last 4 files are shown for convenience. Setup files have

a .SET extension. It is advised that after y ou calibrate and conf igur e the logger, you

save the configuration to a file as a backup precaution before exiting the setup

menu.

- 17 -

Page 18

Global Water

800-876-1172 • globalw.com

Action: The Action menu has two options, “Program Settings” and “Initialize to

Default Values”. Program sett ings w ill r epr ogr am the data logger with all the setup

and calibration information and works the same as the Program Settings Button at

the bottom of the screen. Initialize

will restore all of the analog, digital

and general setup information fields

to default values. Only the setup

menus are changed, the data logger

must still be programmed with the

new default values. A warning message will appear before this action is taken.

Help: The Help menu provides access to the on-line help files and Global Water

contact information as described prev iously.

X. General Setup:

In the General Setup menu, the logger name, sensor warm -up time, logging mode,

logging interval and alarm times ar e entered.

- 18 -

Page 19

Global Water

800-876-1172 • globalw.com

Name: The logger is a user definable name to identify the logger. Up to 32

characters are allowed however, a cont inuous s tring of characters of more than 16

with no spaces may not be displayed correctly . Click on the field to enter

information.

Sensor Warm-up Time: To conserve battery life, the

sensors do not normally have power applied to them.

Before taking a reading, the logger powers up the

sensors for the sensor warm-up time, and then removes

power from them again. The allowable times are zero

(50mS) to 60 seconds. The sensor warm-up t ime f or the

WQ-FDO sensor is 15 seconds. Click on the field to enter or

select the time in seconds from the pull-down menu.

Baud Rate: Leave this set to Auto Baud Rate.

Only change this to a fixed baud rate if planning t o

use this logger in a telemetry application, such as

using Global Water’s Global Access radio m odem

software. Once programmed in a fixed rat e mode,

you must set the baud rate in the opening connect ion menu of the Global Logger II

software to this speed, or the logger will not communicate.

Sample Periodically: Sampling at regular intervals is the most common recording

mode. Click the Sample Periodically option, s elect the units from the pull-down

menu and click the numerical field to enter the number of those units up to 65,535.

Fast Sampling Mode : In Fast mode, the sample rate is fixed at 10 times per

second. The time stamp will not read fractions of a second so there will be 10

samples per time stamp. Click the Fast m ode option t o s elec t this feature.

- 19 -

Page 20

Global Water

800-876-1172 • globalw.com

Logarithmic Timing: Typically used in groundwater pump studies, this mode

speeds up the sample rate over time. Click the “Logarithmic” option to select this

mode. This a logarithmic approximation t hat steps up the sample rate:

a. 10 times per second for 20 seconds, 200 samples

b. 1 second interval for 100 seconds, 100 sam ples

c. 10 second interval for 10 minutes, 60 samples

d. 1 minute interval for 60 minutes, 60 sam ples

e. 10 minute interval for 10 hours, 60 samples

f. 1 hour interval for 48 hour s , 48 samples

g. 1 day interval until memory s full

Log Upon Deviation: Clicking the “Log only if Channel 1 change exceeds +/-“ box

causes the logger to record the current r eading in m emory only if it exceeds the

previously reading by the preset am ount entered in the numeric field. This logging

exception applies to channel 1 only and the deviation is measured in Raw Data units

where the approximate raw data range is f r om 0-65535, cor responding to 0-20mA.

To find the actual number of raw data unit s per engineering unit, use the calibration

numbers in the Analog Setup screen for c hannel 1 as follow s : Raw Data Units per

Engineering Unit = (High Raw – Low Raw) / (High EU – Low EU) . For example:

Assume a 15 foot water level sensor has a High EU of 15, a Low EU of zero, a High

Raw of 62256 and a Low Raw of 13104. (62256-13104) / (15-0) = 3277 unit s /foot.

Thus, if you want to log only when a reading exceeds t he pr ev ious on by 0.5 feet, set

the deviation to about 1638. Click the num er ic field t o enter the desired range.

Wrap records: If the “Wrap records

at End of Storage” box is checked,

once the memory is full, the oldest data points will be replaced with the newest.

Thus, the memory block represents only the newest. If this feature is not checked,

the logger will halt recording once the memory is full.

Sample-On-Demand: When this box is checked, applying a pulse to t he S am pleOn-Demand input will cause the logger to take a data reading and stor e it in

memory. This feature works in all sampling modes and will not interrupt normal data

recording. If the sample interval is one hour, the historical record will show data

- 20 -

Page 21

Global Water

800-876-1172 • globalw.com

once per hour as well as the time that the sample-on-demand was triggered. This

feature is used to record the time that s pec ial ev ents occurred such as when water

sampler was triggered, a door was opened, etc.

Alarm Times: Check the box

associated with each alarm to

enable that feature and enter

the desired start or stop time.

The logger will start at the next

occurrence of the Alarm 1 time and stop at the next occurrence of the Alarm 2 time

after the Alarm 1 timer has expired. Either or both alarm s c an be enabled.

Note: The alarm start and stop cycle is a one time occurrence. Once stop ped

by the Alarm 2 timer, the logger will not resume logging again until the logger

is reprogrammed. Reprogramming the logger with the timers enabled will

restart the alarm cycle. Reprogramming t he logger with the timers disabled

will return the logger to a normal logging state

Use care when programming the alarm times. If l ef t enabled, changing and

reprogramming any of the setup parameters will restart the alarm timers and

could cause the logger to stop recording.

XI. Analog Setup:

The Analog Setup screen sets the engineering units and c alibr ation numbers for

each of the analog channels, the endpoints of the bar graphs in the main screen and

which of the analog channels are enabled. These channels ar e c alibr ated in the

same way so only a single channel will be discuss ed.

It is important to note here that the infor mation

stored in the data logger’s memory is just the

sensors output level before it is adjus ted by the

following calibration paramet er s. These

parameters are used to adjust the stor ed

data for display and storage purposes only, at

the time the data is downloaded. If they ar e

changed, the same stored data can be

downloaded again and the data will be scaled

differently according to the new settings.

- 21 -

Page 22

Global Water

800-876-1172 • globalw.com

The calibration of channel one to the DO partial pressure output sensor is discussed

in the following example:

Enable: If the “Enable” box at the top of a column is checked,

data for that channel will be shown in the hist or ic al r ec or d and

be available for export to a spreadsheet. The data for all of the

analog channels is always being recorded w hether the channel

is enabled or not. A channel can be re-enabled at any time to

view recorded data.

Units: This field shows the units that will

appear at the top of the data column for

that channel in the historical record as well

as the display of data in the main screen.

Click on the field to enter the unit or select

from a predefined list.

High EU: The High EU field is the engineering unit where the

highest output from the sensor is achieved during the calibration process, in this

case a oxygen partial pressure of 400mbar c or responding to a 20.00mA output.

Low EU: The Low EU field is the engineering unit where the lowest output from the

sensor is achieved during the calibrat ion pr oc ess, in this case zero mbar

corresponding to 4.00mA

High Raw: This is the raw data value as measured by the GL500 Data Logger that

corresponds to the High EU value and is automatic ally s et by the calibration process.

In this case, the raw data value returned by t he logger at a pr es s ur e of 400 mbar.

Low Raw: This is the raw data value as measured by the logger that corresponds to

the Low EU value and is automatically set by the calibrat ion pr oc es s . In this case,

the raw data value returned by the logger for a partial pr es s ur e of zero.

Disp High: This field sets the upper limit of the bar graph displayed in the main

screen and provides a way of scaling the graph beyond the upper limit used to

calibrate the logger. In this example, the upper display value is 400mbar.

- 22 -

Page 23

Global Water

800-876-1172 • globalw.com

Disp Low: This field sets the lower limit of the bar graph displayed in the main

screen and provides a way of scaling the gr aph bey ond the lower limit used to

calibrate the logger. In this case the lower c alibr ation was zero.

Decimal Places: From the pull-down menu, select the

number of decimal places to the right of the decim al

point that should appear in the histor ic al data and in the

numerical data field at the bottom of the bar gr aph.

Calibrate: The “Calibra te” button provides a simple 4-step process for calibr ating

the GL500 Data Logger to a particular sens or . Click t he Calibr ate button and follow

the menu instructions.

Click on the High EU field and enter the

high engineering unit that will be used

to calibrate the sensor, not the highest

reading the sensor can output. In the

example of pH, enter 10 which is the

highest calibration solution to be us ed.

Click Next.

Place the sensor in the condition that will

cause it to output the level corresponding

to the high EU entered in the previous menu.

Wait for the data reading to stabilize.

Click Next.

- 23 -

Page 24

Global Water

800-876-1172 • globalw.com

Click on the Low EU field and enter the

low engineering unit that will be used

to calibrate the sensor, not the lowest

reading the sensor can output. In the

example of pH, enter 4 which is the

lowest calibration solution to be us ed.

Click Next.

Place the sensor in the condition that will

cause it to output the level corresponding

to the low EU entered in the previous menu.

Wait for the data reading to stabilize.

Click Next to complete the calibration.

XII. Digital Setup:

The Digital Setup screen is used for s ett ing up the t w o digital pulse channels.

- 24 -

Page 25

Global Water

800-876-1172 • globalw.com

Enable: Checking the Enable box allows the display of the data for that channel in

the historical record. The pulse channels are alway s being monitored and the counts

between sampling intervals stor ed w hether they are enabled or not.

Units: To enter a Sensor Name or Units, click on

the field and enter it or select from a list of unit s

predefined in the pull-down menu

Value for a Single Pulse: The number of pulses

is multiplied by this number to scale it to rainfall,

water flow, etc. If a pulse channel is connected to

a rain gauge that puts out a pulse every 1/ 100” of

rain, click on the field and enter 0.01 to display rainfall in Inches.

Decimal Places: This field determines how many plac es to the right of the decimal

point the data will be displayed in the main screen and historical data record. Select

the desired number of decimal places fr om the pull-down menu.

- 25 -

Page 26

Global Water

800-876-1172 • globalw.com

XIII. DO Setup

To calculate dissolved oxygen concentr ation and saturation levels, several

environmental factors must be known. In a state if equilibrium; the partial pressure

of oxygen in the air and in the water are equal, as stated by Henr y ’s Law. The partial

pressure of oxygen in air is 20.1% of the t otal atmospheric pressure. The WQ-FDO

sensor, as do most or all dissolved oxygen sensors, measure the dissolved oxygen

in water by measuring the partial pressure of ox y gen pr es ent. At sea level the

average atmospheric pressure is about 1013 m bar , and the partial pressure of

oxygen in the air is 20.1% of that or about 204 mbar. In a state of equilibrium

between water and air, this partial pressur e would be the 100% saturation level of

oxygen in water. Since atmospheric pressur e dec reases with increasing altitude, the

partial pressure of oxygen in water required to reach a 100% saturation level also

decreases. Even weather activity c an cause c hanges in bar om etric pressure and

effect the concentration and saturation levels in water. Besides atmospheric

pressure, temperature also changes the ox y gen concentration levels. At higher

temperatures, less oxygen can be dissolved in water. Therefore; the concentration

of oxygen in water required to achieve 100% sat uration decreases with increasing

temperature. Conductivity, or salinity , also decreases the ability of oxygen to

dissolve in water. So to accurat ely determine the oxygen concentration and

saturation levels, the oxygen partial pr es s ur e in the water, temperature, atmospheric

pressure, and conductivity mus t all be known. Since other biological factors als o

affect oxygen levels, such as fis h depleting oxygen and algae enriching it, oxy gen

saturation is a dynamic and constantly changing measurement. Due to these factors

and the delay time required to reach equilibrium, the saturation levels can fall well

below 100%, and can increase well above 100% as well.

Certain assumptions can be made in cases wher e the salinity and atmospheric

pressure are not changing excessively. Changes in atmospheric pressure due to

storm activity does not usually m ak e s ignificant changes in calculations and can

sometimes be ignored. In many cases, changes in s alinity can also be ignored,

especially when making measurements in fresh water. In other situations where

salinity is changing dramatically due to tidal activity, a conductivity sensor c an be

added to the WQ-FDO sensor and data logger system to provide a real-time salinity

compensation. The WQ-FDO software also provides f or the connection of a

barometric pressure sensor that will give r eal-time compensation for pressure

changes as well. This software allows the ability to either connect the optional

conductivity and barometric sens or s , or enter values for these parameters manually.

- 26 -

Page 27

Global Water

800-876-1172 • globalw.com

The Dissolved Oxygen Setup Tab shown above is m ade up of two sections, Inputs

and Outputs. The Inputs section t ells the software which input channel is used for

each sensor, and what the engineering units are. In the case of the optional

conductivity and barometric pres s ur e s ens ors; there is a checkbox for indicating

manual entry, and a numerical field for inputting manual conductivity and pressure

settings should a sensor not be used. The Outputs section controls the display of

the calculated values of dissolved oxygen c onc entration, percent saturation and

salinity. These values are calculated based on the sensor inputs, or manual entry.

There is a checkbox to enable the display and download of eac h par am eter, which

channel it will be displayed on, and the dis play units for concentration. The units of

saturation are fixed as percent, salinity is fixed at PSS (Practical Salinity Scale).

The Inputs Section in the screen above shows the W Q-FDO O

2 Sensor connected to

the logger input channel 1, with units in mbar. The water temperature sensor is

connected to channel 2, and is the temper ature output of the WQ-FDO sensor

calibrated in degrees Centigrade. F or the conductiv ity input, channel 3 is selected

in units of uS/cm. Manual entry is selected f or the barometric pressure sensor in

units of feet, zero feet is entered in t he data field (sea level).

The Outputs section shows the calculated ox y gen c onc entration displayed and

downloaded to channel 5 in units of mg/L, O

2 Saturation in percent displayed on

channel 6, and salinity calculated from c onduc tivity displayed on channel 7.

- 27 -

Page 28

Global Water

800-876-1172 • globalw.com

In the DO Setup tab the input channel number and units are defined; however, this is

only for the purpose of telling the software whic h c hannel data to use for

calculations. It is in the Analog setup tab t hat the calibration of each sensor is

performed, see section XI. If the DO sens or is physically connec ted to channel 1 of

the data logger; it must be defined in the DO t ab as channel 1, be pr oper ly c alibr ated

on channel 1 in the analog setup tab, and the units in eac h tab must match. A

warning message will appear when the units bet ween these two tabs do not match.

This is an example of a message warning

that the units for the WQ-FDO sensor on

channel 1 do not match in the Analog and

DO tabs. The units must match and be

spelled the same.

Below is an example of the Analog Setup screen for the FDO sensor system. Note

that the display channels for each s ens or and calculat ed r es ults match between this

screen and the DO Setup tab previously shown. Also that the Enable checkboxes

are checked to allow the display and download of the data. The WQ-FDO sensor is

required for this software to operate, both the partial pressure and temperatur e

outputs of the sensor must be connected to the logger. They need not be enabled

for display, but they must be connect ed. If the optional conductivity and barometric

pressure sensors are not connected and a m anual entry is used, the unused analog

channels can be connected to any other sensor . If any of the calculated output

values of saturation, concentration and salinity are not wanted for display and

download, they do not need to be enabled and the sens or c hannel c an be us ed for

any other type of sensor. If they are displayed, the analog channel they are

assigned to is unavailable, even

though there is no sensor

connected to it.

Calibration is required on all channels

that have a sensor connected.

Calculated channels of concentration,

saturation and salinity do not require

calibration values of Low and High

EU and Raw Data. Low and High

Display values for these calculated

numbers scale the display only.

- 28 -

Page 29

Global Water

800-876-1172 • globalw.com

XIV. Programming

Program Settings: The Program S ett ings button at the bottom of the setup menus

will cause all the setup and calibration inform ation to be programmed into the data

logger. A warning will

appear requiring the

use to confirm the

action. Click Yes to

program the logger

and No to cancel the

operation.

Back to Main Window: The Back to Main Menu button exits bac k to t he main

screen. If no settings have

changed, Exit will occur

immediately. If settings have

changed but not saved yet,

a message will appear that

asks the user if they would

like to save them now. If the

settings have changed but

not yet programmed into the

logger, another message will

be shown asking if the logger should be reprogr am m ed. These layers of protection

are designed to prevent the user from unintentionally changing settings or forgetting

to save the configuration file. Should t he s ett ings ac c identally be changed, a saved

configuration file can be loaded and used to r es tore the original settings.

- 29 -

Page 30

Global Water

800-876-1172 • globalw.com

XV. Connections:

Left Connector:

P2+ Pulse channel 2 +, connected to VBAT

P2 IN Pulse channel 2 pulse input

P1+ Pulse channel 1 +, connected to VBAT

P1 IN Pulse channel 2 pulse input

SMP+ Sample-On-Demand +, VBAT

SMPL Sample-On-Demand pulse input

GND Spare Ground

GND Spare Ground

VBAT Spare positive battery connection

VBAT Spare positive battery connection

GND Negat iv e battery connection

VBAT Positive battery connection

Right Connector:

V+ Switched sensor power

CH1 Analog channel 1 input

GND Sensor ground

V+ Switched sensor power

CH2 Analog channel 2 input

GND Sensor ground

V+ Switched sensor power

CH3 Analog channel 3 input

GND Sensor ground

V+ Switched sensor power

CH4 Analog channel 4 input

GND Sensor ground

V+ Switched sensor power

CH5 Analog channel 5 input

GND Sensor ground

V+ Switched sensor power

CH6 Analog channel 6 input

GND Sensor ground

V+ Switched sensor power

CH7 Analog channel 7 input

GND Sensor ground

GND Spare gr ound c onnec tion

- 30 -

Page 31

Global Water

800-876-1172 • globalw.com

XVI. Modem Cab le Diagram s:

Use the following wiring diagrams to m ak e a cable to c onnec t the GL500 Data

Logger to an external modem. Pre-wired c ables ar e av ailable from Global Water.

- 31 -

Page 32

XVII. Maintenance:

a. There are no user-serviceable parts inside the Dat a Logger .

b. Global Water recommends checking the battery on a regular basis, the

period depending on the number of sensors, sample interval,

temperature and the type of batter y used.

c. Consult the WQ-FDO Sensor manual for information on the dissolved

oxygen sensor maintenance.

XVIII. Troubleshooting:

Issue: Logger is reading incorrectly .

a. Verify the power source is supplying enough voltage. The data logger

requires about 5 volts to operate. Consult the power requirements for

the individual sensors. The Global Wat er WQ-FDO sensor requires a

minimum of 10 volts between the red and black leads.

b. The WQ-FDO sensor cap has a limited lifespan of approxim ately one

year, depending on use. If the sensor is not operating pr oper ly ,

replace the membrane cap. Calibration of the WQ-FDO sensor should

not be necessary when replacing the cap. All calibrat ion information

for each sensor cap is stored in a memory c hip inside the c ap itself.

This information is used to recalibrate the sensor each time the cap is

replaced.

c. The WQ -FDO sensor partial pressure output has been fact or y

calibrated for an output of 4.00-20.00mA ov er the range of 0-400mbar;

and for the temperature output 4.00-20.00mA over 0-50ºC. Because

dissolved oxygen levels vary wit h tem per ature, atmospheric pressure

and salinity; an exact calibration can be diff ic ult using the sensor

alone. A current loop meter is the best way to recalibrate the DO

sensor to the logger.

d. An approximate check of the WQ-FDO sensor perform anc e c an be

done using this method. Place a clean glass of fres h water with the

surface exposed to the open air for at least 24 hours. Maintaining a

fairly constant temperature will im pr ov e the accuracy of this test. The

percentage of oxygen in air is 20.1% and in 100% saturated water the

partial pressure of the oxygen in water will be the s ame as in the air.

Multiple the atmospheric pressure in y our ar ea by 20.1% to find out the

Global Water

800-876-1172 • globalw.com

- 32 -

Page 33

Global Water

800-876-1172 • globalw.com

partial pressure of the oxygen in the water. The sensor should read

about this pressure. For example, at sea level the average

atmospheric pressure is 1013mbar. The partial pressure of oxygen in

water exposed to air for a period of time will be about 0. 21 x 1013mbar

or 212mbar. Because factors like atmospheric pressure and

temperature are constantly changing, this is not a recommended way

of calibration. This should be done for perfor m anc e c hec k s only .

e. Besides oxygen partial pressure, temperature is also important in

calculating oxygen levels. The WQ-FDO sensor has a temperature

output than can be checked. Compare the temperatur e r eading of the

sensor in water to that of another measurem ent device. A stable

temperature can also be made with ice wat er . A mixture of water with

lots of ice being stirred constantly can achieve a stable ice water

temperature of 32ºF (or 0º C) +.2F.

f. Check the logger and other sensor calibrations and recalibrate if

necessary, saving the setup file first as described in section IX.

Because dissolved oxygen is dependent on t em per ature, pressure and

conductivity; it is important to have accurate data for the software to

make these calculations. Save the new set up file under a different

name each time the logger is recalibrated.

Issue: Cannot communicate with t he logger .

a. Verify that sufficient power is applied and wired correctly.

b. Check the communication cable.

c. If the connection is through the USB port, use the Windows Device

Manager to confirm that the driver is loaded and the correct virtual

COM port is selected in the connection menu of the G lobal Logger

software, as described in sections I II and IV.

d. Check the Device Manager in your operating sy s tem and confirm that

the USB COM port is not being used by another device.

e. Try reducing the baud rate in the connection screen of the Global

Logger software.

f. Try switching fr om R S -232 to USB or USB to RS-232.

- 33 -

Page 34

XIX. Customer Support:

Call Global Water for tech support: 800-876-1172 or 979-690-5560 (many

problems can be solved over the phone). Fax: 979-690-0440 or E-mail:

globalw@globalw.com.

When calling for tech support, have the following information ready:

1. Model #.

2. Unit serial number.

3. P.O.# the equipment was purchased on.

4. Our sales number or the invoice number.

5. Repair instructions and/or specific problems relating to the

product.

Be prepared to describe the problem you are experiencing including

specific details of the application, installation, and any additional pertinent

information.

In the event that the equipment needs to be returned t o the factory for any

reason, please call to obtain an RMA# (Ret ur n Material Authorization). Do

not return items without an RMA# displayed on the outside of the

package. Include a written statement desc ribing the problems.

Global Water

800-876-1172 • globalw.com

Send the package with shipping prepaid to our factory address. Insure

your shipment; Global Water’s warr anty does not cover damage incurred

during transit.

- 34 -

Loading...

Loading...