Page 1

INSTRUCTION MANUAL

IM007

Models 3642/3742

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

Page 2

SUBJECT PAGE

Safety Instructions ......................................................................................................................................................... 3

Description and Specifications ....................................................................................................................................... 3

Engineering Data ........................................................................................................................................................... 3

Installation

Location .................................................................................................................................................................... 3

Foundation ................................................................................................................................................................3

Frame-Mounted ......................................................................................................................................................... 3

Piping

Suction ...................................................................................................................................................................... 4

Discharge ................................................................................................................................................................... 4

Wiring and Grounding ..................................................................................................................................................4

Coupling Alignment ...................................................................................................................................................... 4

Rotation ........................................................................................................................................................................ 5

Operation ...................................................................................................................................................................... 5

Maintenance..................................................................................................................................................................5

Disassembly

Liquid End ................................................................................................................................................................. 6

Bearing Frame ............................................................................................................................................................6

Reassembly

Bearing Frame ............................................................................................................................................................6

Liquid End ................................................................................................................................................................. 6

Repair Parts ................................................................................................................................................................... 7

Troubleshooting ............................................................................................................................................................8

Limited Warranty ..........................................................................................................................................................8

Declaration of Conformity .......................................................................................................................................... 29

Pump Model Number:

Pump Serial Number:

Dealer:

Dealer Phone No.:

Date of Purchase:

Date of Installation:

Current Readings at Startup:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Volts: Volts:

MODELS

3642 3742

1 x 1¼ - 5 1 x 1¼ - 5

1¼ x 1½ - 5 1¼ x 1½ - 5

2

Page 3

SAFETY INSTRUCTIONS

DANGER

WARNING

CAUTION

WARNING

Hazardous fluids

can cause fire,

burns or death.

Sleeve

Washer

Lug

Top of foundation –

clean and wet down

Grout

Leveling wedges or shims – left in place

BaseGrout Hole

1

∨4”(6.35 mm)

Finished Grouting

1

∨2 to 3∨4”

(12.7 to 19 mm)

Allowance for

Leveling

Wood

Frame

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert

to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause personal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

UNIT NOT DESIGNED FOR USE

WITH HAZARDOUS LIQUIDS OR

FLAMMABLE GASES. THESE

FLUIDS MAY BE PRESENT IN

CONTAINMENT AREAS.

Starts per Hour: 20 - Evenly distributed

3642/3742

Model Suction Discharge

1 x 1¼ - 5 1¼” NPT 1” NPT

1¼ x 1½ - 5 1½” NPT 1¼” NPT

INSTALLATION

Location:

Locate pump as near liquid source as practical; below

level of liquid for repriming capability.

Allow adequate space for servicing and ventilation.

Protect the unit from weather and water damage due

to rain, flooding or freezing temperatures.

Close - Coupled Units

Units may be installed horizontally, inclined or vertically with the motor above the pump.

NOTICE: DO NOT INSTALL WITH MOTOR BELOW

PUMP. ANY LEAKAGE OR CONDENSATION

WILL AFFECT THE MOTOR.

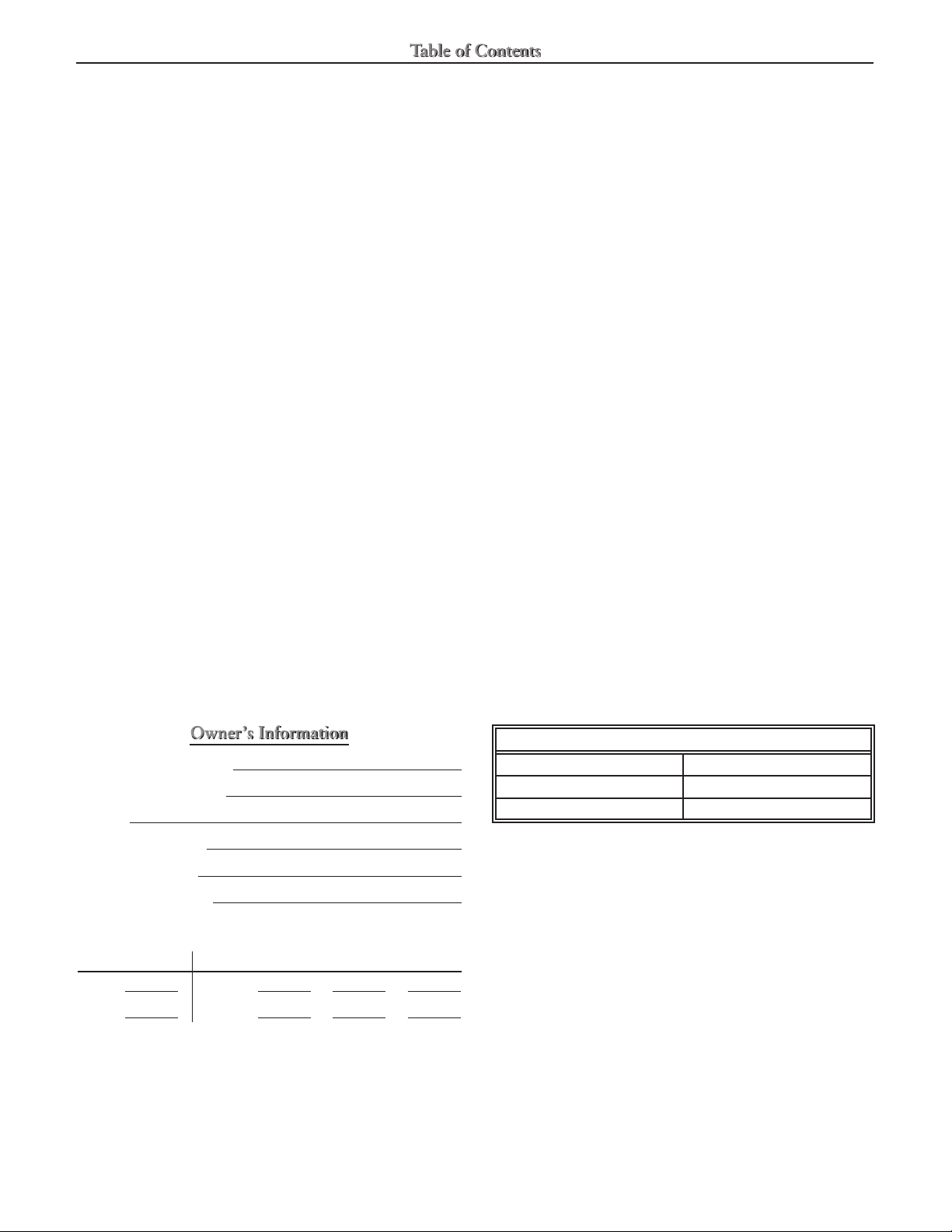

Foundation:

A flat and substantial foundation surface MUST be

provided to avoid distortion and/or strain when

tightening the foundation bolts. A rubber mounting is

acceptable to reduce noise or excessive vibration.

Tighten motor hold-down bolts BEFORE connecting

piping to pump.

Frame-Mounted Units:

DESCRIPTION and SPECIFICATIONS:

The 3642 (closed-coupled) and 3742 (frame-mounted) are single stage, end suction, centrifugal pumps

for water circulation, booster service, liquid transfer,

spraying systems, jockey pump and general service

pumping. Pumps are available in three different materials of construction: all iron, bronze-fitted and all

bronze.

Pump impellers are enclosed design for high efficiency, threaded directly on the motor shaft.

Close-coupled units have NEMA standard frame motors with C-face mounting and threaded shaft extensions. Frame mounted units can be coupled to motors

through a spacer coupling, or belt driven.

ENGINEERING DATA

Maximum Liquid Temperature:

212º F (100º C) – standard seal

250º F (120º C) – Optional high temp. seal

Maximum Working Pressure: 125 psi

Figure 1

Bedplate must be grouted to a foundation with solid

footing. Refer to Figure 1.

Place unit in position on wedges located at four

points, two below approximate center of driver and

two below approximate center of pump. Adjust wedges to level unit. Level or plumb suction and discharge

flanges.

Make sure bedplate is not distorted and final coupling

alignment can be made within the limits of movement

of motor and by shimming, if necessary.

Tighten foundation bolts finger tight and build dam

around foundation. Pour grout under bedplate mak-

3

Page 4

ing sure the areas under the pump and motor feet

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous

voltage

Hazardous machinery

can cause personal

injury or death.

WARNING

are filled solid. Allow grout to harden 48 hours before

fully tightening foundation bolts.

Tighten pump and motor hold-down bolts before

aligning shaft or connecting the piping to pump.

H min.

D

H min.

D

PIPING

Piping should be no smaller than pump’s discharge

and suction connections and kept as short as possible,

avoiding unnecessary fittings to minimize friction

losses.

All piping MUST be independently supported and

MUST NOT place any piping loads on the pump

NOTICE: DO NOT FORCE PIPING INTO PLACE

AT PUMP SUCTION AND DISCHARGE

CONNECTIONS.

All pipe joints MUST be airtight.

Piping – Suction

For suction lifts over 15 ft. (4.6 m), consult pump performance curve for net positive suction head required

(NPSHR).

If a pipe size larger than pump suction is required,

an eccentric pipe reducer, with the straight side up,

MUST be installed at the pump suction.

If pump is installed below the liquid source, install

a gate valve in the suction for pump inspection and

maintenance.

NOTICE: DO NOT USE THE GATE VALVE TO

THROTTLE PUMP. THIS MAY CAUSE LOSS

OF PRIME, EXCESSIVE TEMPERATURES

AND DAMAGE TO PUMP, VOIDING

WARRANTY.

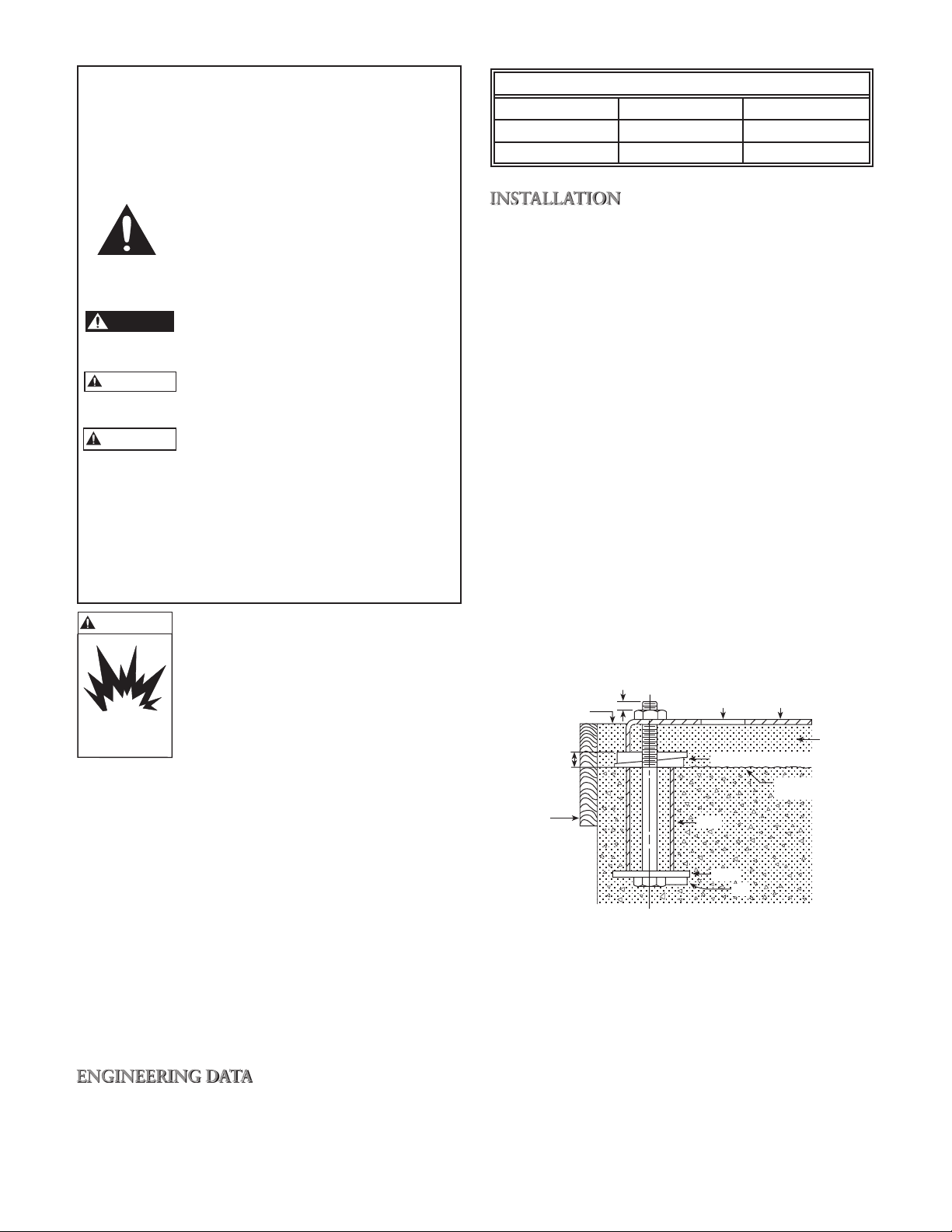

If the pump is installed above the liquid source, the

following MUST be provided:

To avoid air pockets, no part of the piping should

be above the pump suction connection.

Slope the piping upward from liquid source.

Use a foot valve or check valve ONLY if neces-

sary for priming or to hold prime during intermittent duty.

The suction strainer or suction bell MUST be at

least three times the suction pipe diameter area.

Insure that the size and minimum submergence

over suction inlet is sufficient to prevent air from

entering pump through a suction vortex. See Figures 2 through 5.

Piping – Discharge

Install a check valve suitable to handle the flow, liquids and to prevent backflow. After the check valve,

install an appropriately sized gate valve to be used to

regulate the pump capacity, pump inspection and for

maintenance.

When required, pipe increaser should be installed

between the check valve and the pump discharge.

4

Figure 2 Figure 3

3.0D

min.

1.5D

min.

H min.

D min.

D D

2

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

H = Min. Submergence in feet

1

12345678910111213 141516

V = Velocity in feet per second

= GPM x 0.321

Area

PM x 0.4085

2

D

Figure 4 Figure 5

WIRING AND GROUNDING

Install, ground and wire according to local and National

Electrical Code Requirements.

Install an all leg disconnect

switch near the pump.

Disconnect and lockout electrical power before installing or

servicing the pump.

Electrical supply MUST match pump’s nameplate specifications. Incorrect voltage can cause

fire, damage to the motor and voids the warranty.

Motors not protected MUST be provided with

contactors and thermal overloads for single

phase motors, or starters with heaters for three

phase motors. See motor nameplate.

Use only copper wire to motor and ground. The

ground wire MUST be at least as large as the wire to

the motor. Wires should be color coded for ease of

maintenance.

Follow motor manufacturer’s wiring diagram on the

motor nameplate or terminal cover carefully.

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN CAUSE

SHOCK, BURNS OR DEATH.

COUPLING ALIGNMENT

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE SEVERE

PERSONAL INJURY.

V

Page 5

Alignment MUST be checked prior to running. See

WARNING

Hazardous voltage

can shock, burn or

cause death.

Extreme heat can

cause personal injury

or property damage.

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

Hazardous pressure can

cause personal injury or

property damage.

CAUTION

Hazardous machinery

can cause personal

injury or death.

WARNING

Figure 6.

Tighten all hold-down bolts before checking the align-

ment.

If realignment is necessary, always move the motor.

Shim as required.

SPLASHING OR IMMERSING OPEN

DRIP PROOF MOTORS IN FLUID

CAN CAUSE FIRE, SHOCK, BURNS

OR DEATH.

OPERATION AT OR NEAR ZERO

FLOW CAN CAUSE EXTREME HEAT,

PERSONAL INJURY OR PROPERTY

DAMAGE.

NOTICE: NO NOT RUN PUMP DRY OR SEAL

DAMAGE WILL RESULT.

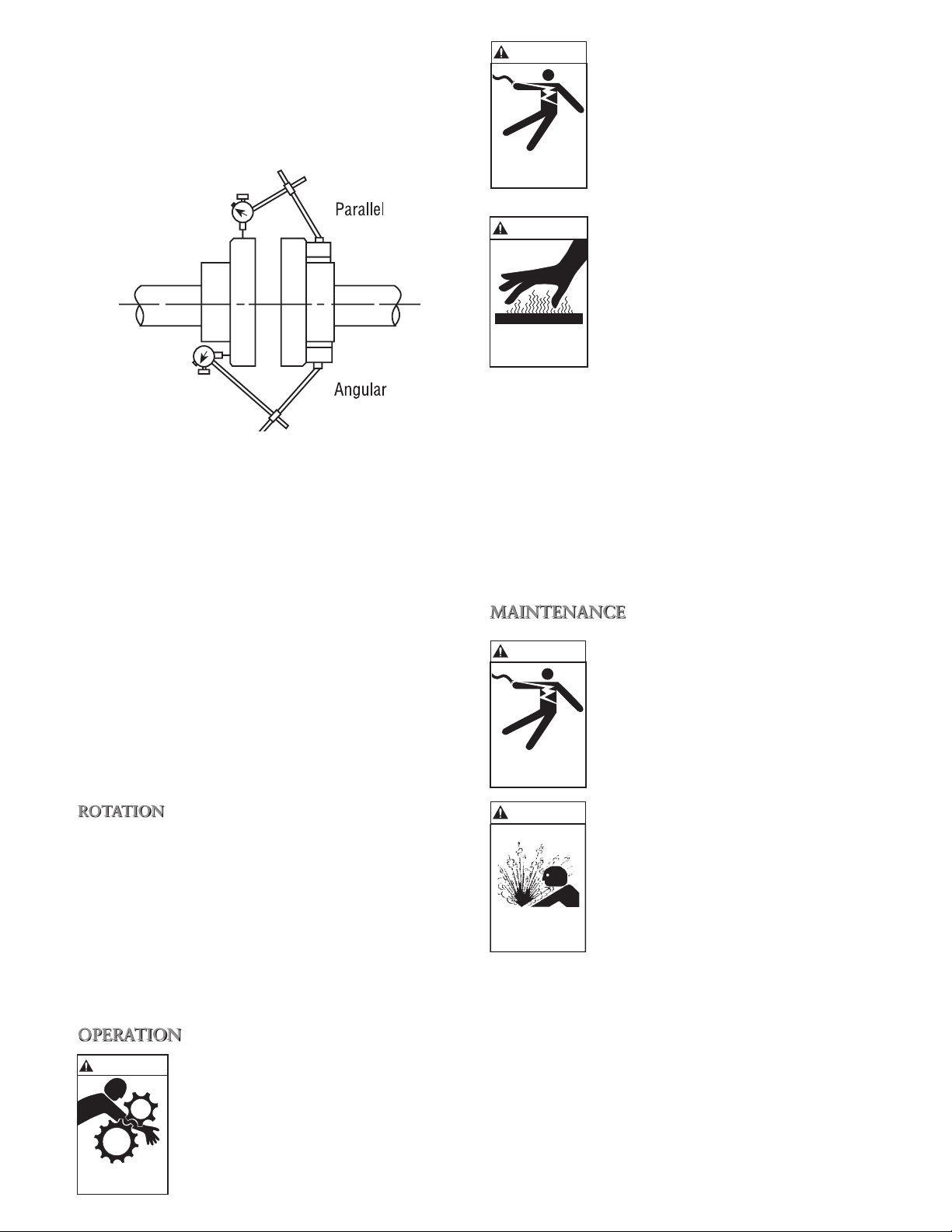

Parallel misalignment (shafts with axis parallel but not

concentric). Place dial indicator on one hub and rotate

this hub 360º while taking readings on the outside diameter of the other hub. Parallel alignment is achieved

when reading is 0.005” (0.127 mm) TIR, or less.

Angular misalignment (shaft with axis concentric but

not parallel). Place dial indicator on one hub and

rotate this hub 360º while taking readings on the face

of the other hub. Angular alignment is achieved when

reading is 0.005” (0.127 mm) TIR, or less.

Final alignment is achieved when parallel and angular

requirements are satisfied with motor hold-down bolts

tight.

NOTICE: ALWAYS RECHECK BOTH ALIGNMENTS

ROTATION

NOTICE: INCORRECT ROTATION MAY CAUSE

Correct rotation is right-hand, CLOCKWISE when

viewed from the motor end. Remove motor end plug

or cover to observe rotation.

To reverse three phase motor rotation, interchange

any two power supply leads.

OPERATION

Figure 6

AFTER MAKING ANY MECHANICAL

ADJUSTMENTS.

DAMAGE TO THE PUMP AND VOIDS

THE WARRANTY.

DO NOT OPERATE FRAME

MOUNTED UNITS WITHOUT SAFETY

GUARDS IN PLACE OR SEVERE

PERSONAL INJURY MAY RESULT.

After stabilizing the system at normal operating conditions, check the piping. If necessary, adjust the pipe

supports.

On frame-mounted units, coupling alignment may

have changed due to the temperature differential

between pump and motor. Recheck alignment following procedures and hazard warnings in “COUPLING

ALIGNMENT” section of this manual.

MAINTENANCE

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

SHOCK, BURNS OR DEATH.

FAILURE TO RELIEVE SYSTEM

PRESSURE AND DRAIN SYSTEM

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

Close-Coupled Units:

Bearings are located in and are part of the motor. For

lubrication information, refer to motor manufacturer’s

instructions.

Frame-Mounted Units:

Pump bearing frames have greased for life bearings.

No lubrication is possible or necessary.

Follow motor and coupling manufacturer’s lubrication

instructions.

5

Page 6

Seasonal Service:

To REMOVE pump from service, remove drain plug

and drain all unprotected piping.

To RETURN pump to service, replace drain plug using

Teflon™ tape or equivalent.

Reconnect suction line if removed, examine union and

repair if necessary.

Refer to “OPERATION” section of manual.

DISASSEMBLY

Follow ALL warnings and instructions in the “MAINTENANCE” section of this manual.

Close-coupled units: Remove motor hold-down

bolts.

Frame-mounted units: Remove coupling guard,

spacer, coupling and frame hold-down bolts.

Liquid End:

1. Remove casing bolts (370).

2. Remove back pull-out assembly from casing (100).

3. Remove casing gasket (351). Discard.

4. On close-coupled units, remove motor end plug or

cover to expose screwdriver slot or flats on end of

motor shaft.

5. While restraining shaft with an appropriate tool

(close-coupled units) or with a strap wrench

(frame-mounted units) remove impeller nut (304)

by turning COUNTERCLOCKWISE. Impeller nut

may need to be heated with torch to remove.

NOTICE: EXERCISE CAUTION WHEN HANDLING

HOT IMPELLER NUT.

6. While restraining shaft, remove impeller (101) by

turning COUNTERCLOCKWISE. Impeller may

need to be heated to remove.

NOTICE: EXERCISE CAUTION WHEN HANDLING

HOT IMPELLER.

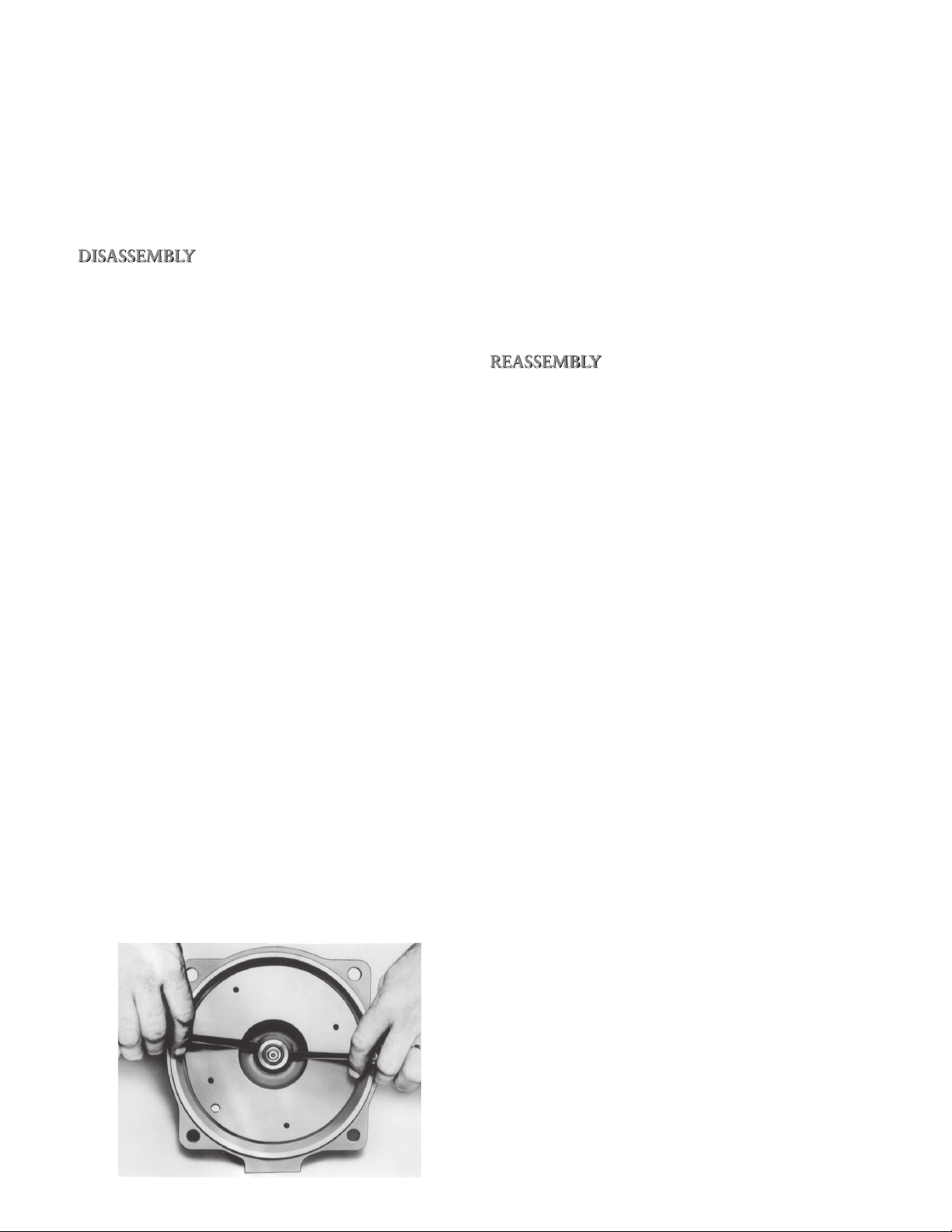

7. Using two screwdrivers, pry off rotating section of

mechanical seal assembly (383), discard. See

Figure 7.

6

Figure 7

8. Remove adapter bolts (371) and adapter (108),

pulling with it the mechanical seal stationary seat.

9. Push out the mechanical seal stationary seat from

the motor side of the adapter. Discard.

Bearing Frame:

1. Remove bearing cover (109).

2. Remove retaining ring (361).

3. Remove shaft assembly from frame.

4. If worn or damaged, remove lip seals (138, 139)

from bearing frame (228) and bearing cover (109).

6. Use bearing puller or arbor press to remove ball

bearings (112, 168).

REASSEMBLY

All parts should be cleaned before assembly.

Refer to parts list for description of replacement items.

Specify pump index number when ordering parts.

Bearing Frame:

1. Replace lip seals if removed.

2. Replace ball bearings if loose, rough or noisy

when rotated.

3. Check shaft (122) for runout. Maximum permis-

sible is 0.002” (0.051 mm) TIR.

Liquid End:

1. Inspect shaft removing any debris or burrs.

2. Treat shaft threads with LOCQUIC® Primer “T”, or

equivalent, following manufacturer’s instructions

carefully.

NOTICE: MECHANICAL SEAL MUST BE REPLACED

WHENEVER SEAL HAS BEEN REMOVED.

FOLLOW SEAL MANUFACTURER’S

INSTRUCTIONS CAREFULLY.

3. Stationary seal seat may be dipped in water or

glycerin to ease installation. Place stationary

seal seat squarely into adapter seal bore. Cover

the polished face of the seat with a thin piece of

cardboard or paper towel. Press seat firmly into

bore using a round piece of plastic or wood that

disperses the force over the entire seal face.

4. Place adapter, concave face pointing up, over

motor shaft and lower it onto the motor adapter.

Exercise care in that the motor shaft does not

dislodge or damage seal seat.

5. Fully and squarely install the rotary assembly of

seal against the stationary seat.

6. Apply LOCTITE® #262 or equivalent, to shaft

threads and install impeller on shaft by turning

CLOCKWISE until it bottoms on the motor shaft.

7. Apply LOCTITE® #262 or equivalent, to impeller

nut and tighten to 20 lbs. ft. (27 N•m).

8. Replace casing gasket.

Page 7

9. Replace casing bolts, tightening to 37 lbs. ft. (50

361

138

122

228

168

112

400

109

370C

139

N•m) in a crossing sequence.

10. Check reassembled unit for binding by rotating

shaft.

11. If rubbing exists, loosen casing bolts and proceed

with tightening sequence again.

12. On close-coupled units, replace motor end plug

or cover and motor hold-down bolts.

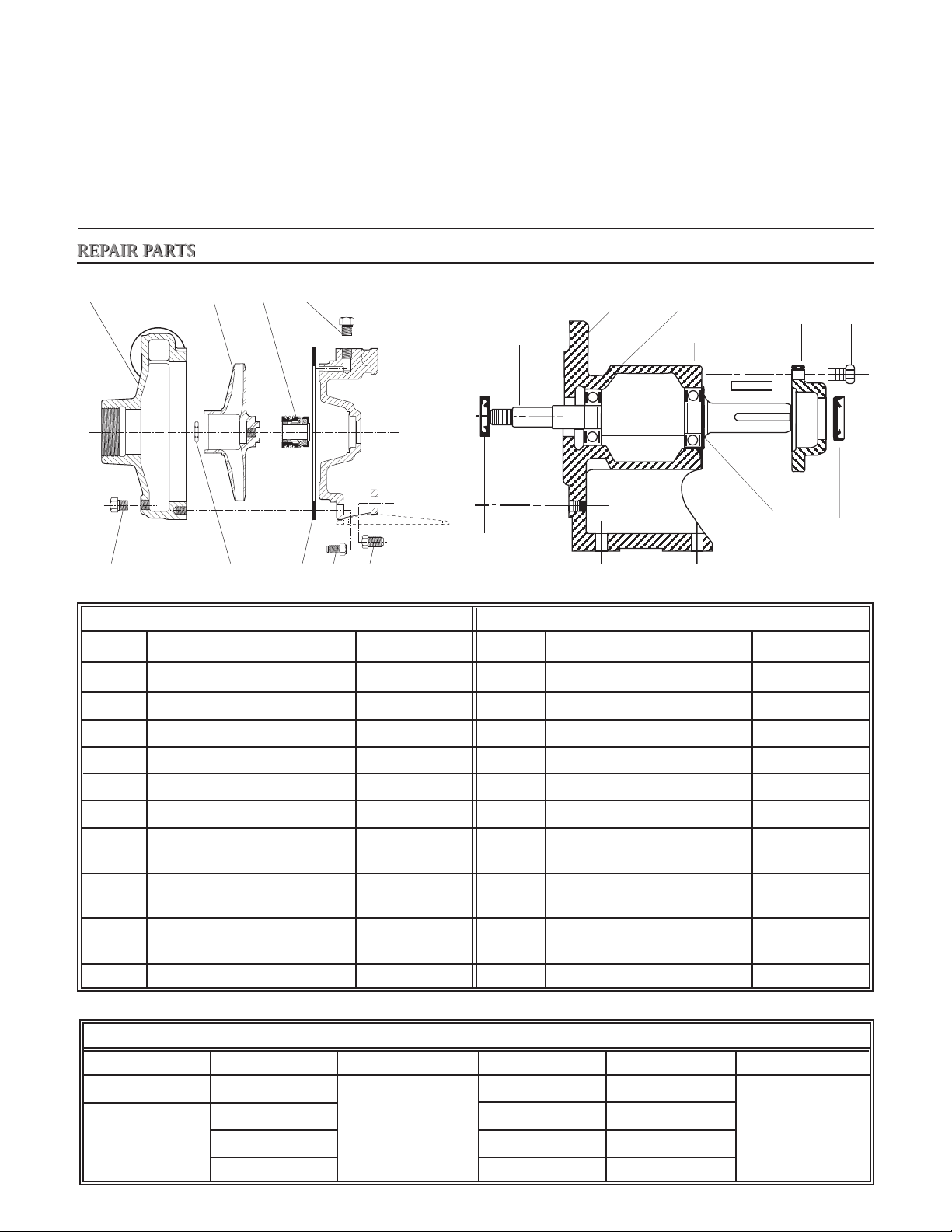

REPAIR PARTS

13. On frame-mounted units, replace coupling, spacer, coupling guard and frame hold-down bolts.

NOTICE: ALWAYS RECHECK BOTH COUPLING

ALIGNMENTS AFTER MAKING ANY

ADJUSTMENTS.

14. Refer to “COUPLING ALIGNMENT” section of

manual to realign shaft.

15. Assembly is complete.

100

358

101

304

383

408

381

370

108

371

LIQUID END COMPONENTS POWER END COMPONENTS

Item # Description Material Item # Description Material

100 Casing Iron/Bronze 109 Bearing Cover Cast Iron

101 Impeller Iron/Bronze 112 Bell Bearing (Outboard) Stainless Steel

108 Adapter Iron/Bronze 122 Pump Shaft Stainless Steel

304 Impeller Nut Stainless Steel 138 Lip Seal - Inboard BUNA-N/Steel

351 Casing Gasket Composite 139 Lip Seal - Outboard BUNA-N/Steel

358 Drain Plug Steel 168 Ball Bearing-Inboard Stainless Steel

Hex Head Cap Screw

370

(Casing to Adapter)

Hex Head Cap Screw

371

(Adapter to Motor)

383 Mechanical Seal See Chart 370C

(Frame to Cover)

408 Prime Plug - ¼” NPT Steel/Brass 400 Shaft Key Stainless Steel

Steel 228 Bearing Frame Cast Iron

Steel 361 Retaining Ring BUNA-N/Steel

Hex Head Cap Screw

Mechanical Seal Options

Equipment Service Rotary Stationary Elastomers Metal Parts

Standard General Ceramic BUNA-N

Heavy-Duty

Carbon

Optional Hi-Temperature Ni-Resist EPR

Chemical Ceramic Viton

Ni-Resist BUNA-N

Stainless Steel

Steel

300 Series

7

Page 8

TROUBLESHOOTING

WARNING

Hazardous voltage

can shock, burn or

cause death.

FAILURE TO DISCONNECT AND LOCKOUT ELECTRICAL

POWER BEFORE ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR DEATH.

SYMPTOM:

Motor Not Running

See Probable Cause – 1 through 5

Little or No Liquid Delivered

See Probable Cause – 6 through 13

Excessive Power Consumption

See Probable Causes – 3, 13, 14, 15

Excessive Noise and Vibration

See Probable Causes – 3, 6, 7, 10, 12, 14, 16, 17

PROBABLE CAUSES:

1. Motor thermal protector tripped

2. Open circuit breaker or blown fuse

3. Impeller binding

4. Motor improperly wired

5. Defective motor

6. Pump is not primed, air or gases in pumpage

7. Discharge, suction plugged or valve closed

8. Incorrect rotation (3 phase only)

9. Low voltage or phase loss

10. Impeller worn or plugged

11. System head too high

12. NPSHA too low – Excessive suction lift or losses

13. Incorrect impeller diameter

14. Discharge head too low – excessive flow rate

15. Fluid viscosity, specific gravity too high

16. Worn bearing

17. Pump, motor or piping loose

8

Page 9

GOULDS WATER TECHNOLOGY LIMITED WARRANTY

This warranty applies to all water systems pumps manufactured by Goulds Water Technology.

Any part or parts found to be defective within the warranty period shall be replaced at no charge to the dealer during the warranty period. The warranty period shall exist for a

period of twelve (12) months from date of installation or eighteen (18) months from date of manufacture, whichever period is shorter.

A dealer who believes that a warranty claim exists must contact the authorized Goulds Water Technology distributor from whom the pump was purchased and furnish

complete details regarding the claim. The distributor is authorized to adjust any warranty claims utilizing the Goulds Water Technology Customer Service Department.

The warranty excludes:

(a) Labor, transportation and related costs incurred by the dealer;

(b) Reinstallation costs of repaired equipment;

(c) Reinstallation costs of replacement equipment;

(d) Consequential damages of any kind; and,

(e) Reimbursement for loss caused by interruption of service.

For purposes of this warranty, the following terms have these definitions:

(1) “Distributor” means any individual, partnership, corporation, association, or other legal relationship that stands between Goulds Water Technology and the dealer in

purchases, consignments or contracts for sale of the subject pumps.

(2) “Dealer” means any individual, partnership, corporation, association, or other legal relationship which engages in the business of selling or leasing pumps to customers.

(3) “Customer” means any entity who buys or leases the subject pumps from a dealer. The “customer” may mean an individual, partnership, corporation, limited liability

company, association or other legal entity which may engage in any type of business.

THIS WARRANTY EXTENDS TO THE DEALER ONLY.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Phone: (800) 453-6777

Fax: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds is a registered trademark of Goulds Pumps, Inc. and is used under license.

Loctite and Locquic are registered trademarks of Loctite Corporation.

© 2012 Xylem Inc. IM007 Revision Number 5 July 2012

9

Page 10

MANUEL D'UTILISATION

IM007

Modèles 3642 et 3742

DIRECTIVES D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN

10

Page 11

SUJET PAGE

Consignes de Sécurité ................................................................................................................................................. 12

Description et caractéristiques .................................................................................................................................... 12

Données techniques .................................................................................................................................................... 12

Installation

Endroit ................................................................................................................................................................... 12

Assise ...................................................................................................................................................................... 12

Pompes montés sur socle (palier) ............................................................................................................................. 12

Tuyauterie

Aspiration ............................................................................................................................................................... 13

Refoulement ........................................................................................................................................................... 13

Câblage et mise á la terre ............................................................................................................................................ 13

Centrage de l’accouplement ........................................................................................................................................ 14

Rotation ..................................................................................................................................................................... 14

Utilisation ................................................................................................................................................................... 14

Entretien .................................................................................................................................................................... 15

Démontage

Pompe .................................................................................................................................................................... 15

Palier ...................................................................................................................................................................... 16

Remontage

Palier ...................................................................................................................................................................... 16

Pompe .................................................................................................................................................................... 16

Peéces de rechange ..................................................................................................................................................... 17

Diagnostic des anomalies ............................................................................................................................................ 18

Garantie limitée .......................................................................................................................................................... 18

Declaration of Conformity ......................................................................................................................................... 29

Informations pour le propriétaire

Numéro de modèle de la pompe :

Numéro de série de la pompe :

Détaillant :

Nº de téléphone du détaillant :

Date d’achat :

Date d’installation :

Courant mesuré au démarrage :

1 Ø 3 Ø L1-2 L2-3 L3-1

A : A :

V : V :

MODÉLES

3642 3742

1 x 1¼ - 5 1 x 1¼ - 5

1¼ x 1½ - 5 1¼ x 1½ - 5

11

Page 12

DANGER

AVERTISSEMENT

AVERTISSEMENT

Les fluides dangereux

peuvent causer un

incendie, des brûlures

ou la mort.

Manchon

Rondelle

Patte de blocage

Dessus de la dalle,

propre et humecté

Coulis

Coins ou cales de nivellement —

laissés en place

Plaque

d’assise

Trou de

remplissage

(Coulis)

6,35 mm (

1

∨4 po)

Coulis arasé

Espace de

nivellement:

12,7 á 19 mm

(

1

∨2 á 3∨4 po)

Coffrage

en bois

CONSIGNES DE SÉCURITÉ

AFIN DE PRÉVENIR LES BLESSURES GRAVES OU

MORTELLES ET LES DOMMAGES MATÉRIELS

IMPORTANTS, LIRE ET SUIVRE TOUTES LES

CONSIGNES DE SÉCURITÉ FIGURANT DANS LE

MANUEL ET SUR LA POMPE.

LE PRÉSENT MANUEL A POUR BUT DE FACILITER

L’INSTALLATION ET L’UTILISATION DE LA POMPE ET DOIT RESTER PRÈS DE CELLE-CI.

Le symbole ci-contre est un SYMBOLE

DE SÉCURITÉ employé pour signaler

les mots-indicateurs dont on trouvera la

description ci-dessous. Sa présence sert à

attirer l’attention afin d’éviter les blessures et les dommages matériels.

Prévient des risques qui VONT causer

des blessures graves, la mort ou des

dommages matériels importants.

Prévient des risques qui PEUVENT

causer des blessures graves, la mort ou

des dommages matériels importants.

ATTENTION

Prévient des risques qui PEUVENT

causer des blessures ou des dommages

matériels.

AVIS : SERT À ÉNONCER LES DIRECTIVES

SPÉCIALES DE GRANDE IMPORTANCE

QUE L’ON DOIT SUIVRE.

LIRE SOIGNEUSEMENT CHAQUE DIRECTIVE ET

AVERTISSEMENT AVANT D’EFFECTUER TOUT

TRAVAIL SUR LA POMPE.

N’ENLEVER AUCUN AUTOCOLLANT DE SÉCURITÉ.

APPAREIL NON CONÇU POUR LES

LIQUIDES DANGEREUX NI POUR

LES GAZ INFLAMMABLES. CES

FLUIDES POURRAIENT ÊTRE PRÉSENTS DANS LES INSTALLATIONS

DE CONFINEMENT (PUITS COLLECTEURS).

DESCRIPTION et CARACTÉRISTIQUES

Les pompes de la série 3642 (montées sur moteur) et

de la série 3742 (montées sur socle) sont des pompes

centrifuges á un étage et á orifice d’aspiration situé

á l’extrémité. Elles sont utilisées pour la circulation

d’eau, le gavage, le transfert de liquides, l’arrosage,

la régulation de pression et le pompage de nature

générale. Elles sont offertes dans trois versions distinctes: tout en fonte, avec composants en bronze ou tout

en bronze.

L’impulseur est de type fermé pour un meilleur rendement et est vissé directement sur l’arbre du moteur.

Les pompes montées sur moteur le sont au moyen

d’une entretoise en C. II s’agit de moteurs á carcasse

conformes á la NEMA et munis de bouts d’arbre

filetés. Les pompes montées sur socle peuvent être

reliées au moteur par un accouplement á entretoise

ou par une courroie.

DONNÉES TECHNIQUES

Température maximale du liquide:

100º C (212º F) – avec joint standard

120º C (250º F) – avec joint pour hautes

températures en option.

Pression de service maximale: 862 kPa (125 lb/po2)

3642 ET 3742

Modéle Aspiration Refoulement

1 x 1¼ - 5 1¼ po NPT 1 po NPT

1¼ x 1½ - 5 1½ po NPT 1¼ po NPT

Démarrages par heure: 20, répartis uniformément

INSTALLATION

Endroit:

Placer la pompe aussi prés de la source de liquide

que possible: au-dessous du niveau du liquide pour le

réamorçage.

Laisser suffisamment d’espace pour l’entretien et

l’aération. Protéger l’appareil contre les intempéries,

les inondations et le gel.

Pompes montés sur moteur:

Les pompes peuvent être installés sur une surface

horizontale, incliné ou verticale, mais le moteur ne

doit pas être plus bas que la pompe.

AVIS: NE PAS PLACER LE MOTEUR PLUS BAS

QUE LA POMPE AFIN DE LE PROTÉGER

CONTRE LES FUITES ET L’EAU DE

CONDENSATION.

Assise:

Une assise plane et solide DOIT être prévue pour

empêcher que le serrage des boulons d’ancrage ne

cause de déformation ni de contrainte. Le montage

sur caoutchouc est permis pour réduire le bruit et les

vibrations.

Serrer les boulons de fixation de la pompe avant de la

raccorder á la tuyauterie.

Pompes montées sur socle (palier):

Figure 1

12

Page 13

Notes

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

et la mort.

On doit fixer la plaque d’assise á une dalle reposant

sur une semelle de fondation solide et remplir de coulis l’espace sépareant la plaque et la dalle (V. fig. 1).

Placer l’appareil sur des coins de nivellement situés

en quatre points distincts: deux sous le centre approximatif du moteur et deux sous celui de la pompe.

Mettre l’appareil de niveau, ainsi que la bride des tuyaux d’aspiration et de refoulement (avec un fil á plomb

ou un niveau).

S’assurer que la plaque d’assise n’est pas déformé et

que le centrage définitif de l’accouplement est possible dans les limites de déplacement ou de calage du

moteur.

Serrer les boulons d’ancrage á la main et construire un

coffrage pour l’assise. Verser du coulis sous la plaque

d’assise et s’assurer que les zones situées sous les

pieds de la pompe et du moteur sont entiérement

pleines. Laisser le coulis durcir pendant 48 heures

avant de serrer les boulons d’ancrage á fond.

Serrer les boulons de fixation de la pompe et du

moteur avant de centrer l’arbre ou de raccorder les

tuyaux á la pompe.

Si la pompe est placée plus haut que la source de

liquide, on DOIT suivre les directives suivantes:

- Afin de prévenir les poches d’air, aucun élément

de la tuyauterie d’aspiration ne devrait être plus

haut que l’orifice d’aspiration de la pompe.

- La tuyauterie devrait être sans cesse inclinée

vers le haut á partir de la source de liquide.

- Utiliser un clapet de pied ou un clapet de nonretour SEULEMENT si cela est nécessaire pour

amorcer la pompe ou la maintenir amorcée au

cours des interruptions de service.

- La section de passage de la crépine ou de

l’évasement du tuyau d’aspiration DOIT être au

moins le triple de celle du tuyau.

- S’assurer que le diamétre (d) et la hauteur de

submersion (h) de l’orifice d’entrée du tuyau

d’aspiration sont suffisants pour empêcher

l’aspiration d’air par vortex (V. fig. 2 á 5).

TUYAUTERIE

II est préférable que la tuyauterie soit aussi courte

que possible. Elle ne devrait cependant pas avoir

un calibre inférieur á celui des raccords des tuyaux

d’aspiration et de refoulement ni comporter de raccordement superflu pouvant réduire la charge par

frottement.

Tous les tuyaux DOIVENT posséder leurs propres

supports afin de n’appliquer AUCUNE contrainte sur

la pompe.

AVIS: LES TUYAUX D’ASPIRATION ET DE REFOULE-

Chaque joint de tuyaux DOIT être étanche.

Tuyauterie — aspiration

Si la hauteur d’aspiration totale dépasse 4,6 m (15 pi),

consulter la courbe de débit de la pompe pour obtenir la charge nette requise á l’aspiration.

Si un tuyau de calibre supérieur á celui du tuyau

d’aspiration est requis, on DOIT installer un raccord

réducteur excentrique dont la partie droite est orientée vers le haut prés de l’orifice d’aspiration de la

pompe.

Si la pompe est plus bas que la source de liquide,

poser un robinet-vanne sur le tuyau d’aspiration pour

pouvoir effectuer l’inspection et l’entretien de la

pompe.

AVIS: NE PAS EMPLOYER LE ROBINET-VANNE

MENT DOIVENT ÊTRE POSÉS DE FAÇON Á

CE QU’ON N’AIT PAS Á LES RACCORDER DE

FORCE Á LA POMPE.

POUR DIMINUER LA SECTION DE PASSAGE

VERS LA POMPE, CAR CELA PEUT CAUSER

UN DÉSAMORÇAGE, UNE SURCHAUFFE ET

DES DOMMAGES Á LA POMPE, ANNULANT

AINSI LA GARANTIE.

Figure 2 Figure 3

Figure 4 Figure 5

Tuyauterie — refoulement

Poser un clapet de non-retour convenant au d´bit et

aux liquides pompés et empêchant tout retour de

liquide. Aprés le clapet, installer un robinet-vanne

de calibre approprié permettant la régularisation du

débit, l’inspection et l’entretien de la pompe.

Au besoin, un raccord agrandisseur devrait être posé

entre le clapet de non-retour et l’orifice de refoulement de la pompe.

CÂBLAGE ET MISE Á LA TERRE

Poser le fil de terre et les autres

fils suivant les prescriptions du

code provincial ou national de

l’électricité.

Poser un sectionneur tout

conducteur prés de la pompe.

Couper le courant avant de

procéder á l’installation ou á

l’entretien de la pompe.

13

Page 14

L’alimentation électrique DOIT être conforme aux

AVERTISSEMENT

Tension

dangereuse

La machinerie dangereuse peut causer des

blessures ou la mort.

AVERTISSEMENT

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

et la mort.

AVERTISSEMENT

Les hautes températures

peuvent causer des

blessures et des

dommages matériels.

La machinerie dangereuse peut causer des

blessures ou la mort.

AVERTISSEMENT

spécifications de la plaque signalétique. Une tension inappropriée peut causer un incendie ou des

dommages au moteur et annule la garantie.

Les moteurs monophasés sans protection intégrée

DOIVENT être munis de contacteurs et de dispositifs de protection contre les surcharges thermiques, et les moteurs triphasés, de démarreurs

á dispositif de protection contre la surcharge.

Consulter la plaque signalétique du moteur.

N’utiliser que du fil de cuivre pour la mise á la terre et

l’alimentation du moteur. Le calibre du fil de terre DOIT

être au moins égal á celui des fils d’alimentation, et

les fils devraient tous être chromocodés pour faciliter

l’entretien.

Suivre soigneusement le schéma de câblage sur la

plaque signalétique ou le cache-bornes du moteur.

OMETTRE LA MISE Á LA TERRE

PERMANENTE DE LA POMPE, DU

MOTEUR OU DES COMMANDES

AVANT LE BRANCHEMENT Á LA

SOURCE DE COURANT PEUT SE

TRADUIRE PAR UNE COMMOTION

ÉLECTRIQUE, DES BRÛLURES OU LA

MORT.

OMETTRE LA MISE HORS SERVICE

ET LE VERROUILLAGE EN POSITION

OUVERTE DE LA SOURCE DE

COURANT AVANT D’EFFECTUER

L’ENTRETIEN PEUT ENTRAÎNER DES

BLESSURES GRAVES.

Désalignement paralléle (arbres paralléles mais non

concentriques) — Fixer sur un moyeu un comparateur

á cadran que l’on tourne de 360º le long de la circonférence de l’autre moyeu tout en notant l’amplitude de

déplacement de l’aiguille. L’alignement est correct si le

faux-rond total est de 0,127 mm (0,005 po) ou moins.

Désalignement angulaire (arbres concentriques mais

non Paralléles) — Fixer sur un moyeu un comparateur

á cadran que l’on tourne de 360º le long d’une face

plane de l’autre moyeu tout en notant l’amplitude de

déplacement de l’aiguille. L’alignement est correct si le

faux-rond total est de 0,127 mm (0,005 po) ou moins.

Le centrage convient lorsqu’il satisfait aux exigences

relatives á l’alignement paralléle et angulaire, aprés le

serrage á fond des boulons de fixation du moteur.

AVIS: ON DOIT TOUJOURS VÉRIFIER LES DEUX

TYPES D’ALIGNEMENT APRÉS CHAQUE RÉGLAGE MÉCANIQUE.

AVIS: LA ROTATION DANS LE MAUVAIS SENS PEUT

ENDOMMAGER LA POMPE ET ANNULE LA

GARANTIE.

La rotation appropriée s’effectue en sens HORAIRE

(vers la droite), vue de l’extrémité du moteur. On peut

vérifier le sens de rotation de l’arbre des moteurs

triphasés par le couvercle ou l’obturateur situé á

l’extrémité du moteur.

Pour inverser la rotation, intervertir deux des trois

conducteurs du moteur.

On DOIT vérifier le centrage avant la mise en service

(V. fig. 6).

Serrer tous les boulons de fixation avant de vérifier le

centrage.

Si un recentrage est nécessaire, on ne doit déplacer

que le moteur. Suivre les directives pour le calage.

Paralléle

Angulaire

N’UTILISER AUCUNE POMPE

MONTÉE SUR SOCLE DÉPOURVUE

DE GRILLAGE OU D’ÉCRAN

PROTECTEUR, CAR CELA PEUT

ENTRAÎNER DES BLESSURES

GRAVES.

L’ÉCLABOUSSEMENT OU

L’IMMERSION DES MOTEURS

ABRITÉS (Á OUVERTURES DE

VENTILATION PROTÉGÉES) PEUT

CAUSER UN INCENDIE, UNE

COMMOTION ÉLECTRIQUE, DES

BRÛLURES OU LA MORT.

LE FONCTIONNEMENT Á DÉBIT

NUL OU PRESQUE PEUT PRODUIRE

DES TEMPÉRATURES ÉLEVÉES, DES

BLESSURES OU DES DOMMAGES

MATÉRIELS.

14

Figure 6

Page 15

AVIS: NE PAS UTILISER UNE POMPE DÉSAOR-

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

et la mort.

Les pressions dangereuses

peuvent causer des

blessures et des

dommages matériels.

AVERTISSEMENT

CÉES AFIN DE NE PAS EN ENDOMMAGER LE

JOINT.

Aprés la stabilisation du systéme dans des conditions

de service normales, vérifier la tuyauterie. Au besoin,

régler la position des supports de tuyauterie.

La différence de température entre le moteur et la

pompe montée sur socle peut altérer le centrage de

l’accouplement. Vérifier le centrage de nouveau en

suivant les directives et les avertissements figurant á la

section CENTRAGE DE L’ACCOUPLEMENT ci-dessus.

la section ENTRETIEN de ce manuel.

Dans le cas des pompes montées sur moteur, enlever

les boulons de fixation de ce dernier.

Quant aux pompes montées sur socle, enlever le gril-

lage ou l’écran protecteur, l’entretoise, l’accouplement

et les boulons de fixation du socle.

Pompe:

1. Enlever les vis de fixation du corps de pompe

(370).

2. Écarter l’ensemble pompe du corps de pompe

(100).

OMETTRE DE COUPER LE COURANT

AVANT D’EFFECTUER L’ENTRETIEN

PEUT SE TRADUIRE PAR UNE

COMMOTION ÉLECTRIQUE, DES

BRÛLURES OU LA MORT.

OMETTRE DE RÉDUIRE LA

PRESSION DU SYSTÉME ET DE LE

VIDANGER AVANT D’EFFECTUER

L’ENTRETIEN PEUT CAUSER DES

DOMMAGES MATÉRIELS, DES

BLESSURES OU LA MORT.

Pompes montés sur moteur:

Les roulements sont situés á l’intérieur du moteur.

Pour la lubrification, consulter les directives du fabricant du moteur.

Pompes montées sur socle (palier):

Les roulements du palier de la pompe sont graissés á

vie. Leur lubrification est donc impossible et inutile.

Suivre les directives de lubrification du fabricant du

moteur et de l’accouplement.

3. Enlever le joint du corps de pompe (351), puis le

jeter.

4. Dans le cas des pompes montées sur moteur, enlever l’obturateur ou le couvercle d’extrémité du

moteur pour accéder á la fente ou aux méplats de

blocage situés á l’extrémité de l’arbre.

5. Bloquer l’arbre de la pompe montée sur moteur

avec l’outil approprié (ou celui de la pompe

montée sur socle avec un serre-tubes á sangle),

dévisser l’écrou (304) de l’impulseur dans le SENS

ANTIHORAIRE: il peut être nécessaire de faire

chauffer d’abord l’écrou au chalumeau.

AVIS: FAIRE ATTENTION EN MANIPULANT

L’ÉCROU CHAUD DE L’IMPULSEUR.

6. Maintenir l’arbre bloqué et dévisser (SENS AN-

TIHORAIRE) et enlever l’impulseur (101): il peut

être nécessaire de le faire d’abord chauffer.

AVIS: FAIRE ATTENTION EN MANIPULANT

L’IMPULSEUR CHAUD.

7. Employer deux tournevis en guise de leviers et

extraire l’élément tournant du joint mécanique

(383), puis le jeter (V. fig. 7).

Usage saisonnier:

Pour mettre une pompe HORS service, déposer tous

les bouchons de vidange et vider tous les tuyaux.

Pour remettre une pompe EN service, reposer tous

les bouchons de vidange aprés en avoir recouvert les

filets de ruban de TéflonMC ou l’équivalent.

Raccorder le tuyau d’aspiration á la pompe s’il a été

désaccouplé, examiner le raccord union et effectuer

les réparations n´cessaires.

Réamorcer et faire fonctionner la pompe suivant les

directives et les avertissements figurant á la section

UTILISATION.

Suivre CHAQUE directive et avertissement figurant á

Figure 7

8. Enlever les vis de fixation (371) de l’adaptateur

(108) et retirer celui-ci.

9. Pousser l’élément immobile du joint mécanique

hors de l’adaptateur. Jeter l’élément immobile.

15

Page 16

Palier:

1. Enlever le couvercle (109) de palier.

2. Enlever la bague de retenue (361).

3. Sortir l’arbre du palier.

4. Si les joints á lévre (138 et 139) sont usés ou

endommagés, les extraire du palier (228) et du

couvercle (109) de palier.

5. Á l’aide d’un arrache-roulement ou d’une presse

á mandriner, extraire les roulements (112 et

168).

REMONTAGE

Nettoyer et inspecter chaque piéce de la pompe

lorsque l’on commande des piéces.

Voir la liste des piéces pour obtenir la description des

piéces de rechange. Préciser le numéro de piéce de la

pompe lorsque l’on commande des piéces.

Palier:

1. Remplacer les joints á lévre s’ils ont été enlevés.

2. Remplacer les roulements á billes s’ils ont du jeu,

s’ils ne tournent pas rond ou s’ils sont bruyants.

3. Vérifier si l’arbre (122) comporte des faux-ronds:

le faux-rond maximal admissible est de 0,051 mm

(0,002 po).

4. Insérer l’arbre par le côté convexe de l’adaptateur

(V. illustration suivante). Prendre garde que l’arbre

ne déloge ni n’endommage le joint.

5. Pousser l’ensemble joint tournant á fond et á angle

droit contre le joint immobile.

6. Appliquer du LOCTITEMD no 262 ou l’équivalent

sur les filets de l’arbre et visser l’impulseur á bloc

(SENS HORAIRE) sur l’arbre.

7. Mettre du LOCTITEMD no 262 ou l’équivalent sur

les filets de l’écrou de l’impulseur et serrer l’écrou

á 27 N•m (20 lbf•pi).

8. Remettre le joint du corps de pompe.

9. Reposer et serrer les vis de fixation du corps de

pompe á 50 N•m (37 lbf•pi) et en croix.

10. Une fois la pompe remontée, faire tourner l’arbre

pour vérifier s’il y a grippage.

11. En cas de frottement, desserrer les vis du corps de

pompe et procéder á un nouveau resserrage.

12. S’il s’agit d’une pompe montée sur moteur,

reposer l’obturateur ou le couvercle d’extrémité

du moteur ainsi que les boulons de fixation de ce

dernier.

13. S’il s’agit d’une pompe montée sur socle, reposer

l’accouplement, l’entretoise, le grillage ou l’écran

protecteur ainsi que les boulons de fixation du

socle.

Pompe:

1. Inspecter l’arbre et enlever les aspérités et les

résidus.

2. Appliquer de l’apprêt Primer “T” de LOCQUICMD

ou l’équivalent sur les filets de l’arbre: suivre les

directives du fabricant avec soin.

AVIS: LE JOINT ÉCANIQUE DOIT ÊTRE REMPLACÉ

CHAQUE FOIS QU’ON L’ENLÉVE. SUIVRE LES

DIRECTIVES DU FABRICANT AVEC SOIN.

3. On peut mouiller ou glycériner le joint immobile

pour en faciliter la pose. Placer le joint correctement contre son siége (sur l’adaptateur). Recouvrir la face polie du joint d’un morceau de carton

mince ou d’essuie-tout. Pousser le joint á fond

dans son siége avec un objet rond en plastique ou

en bois pour répartir la pression sur tout le joint.

AVIS: ON DOIT TOUJOURS VÉRIFIER LES DEUX

TYPES D’ALIGNEMENT APRÉS CHAQUE RÉGLAGE MÉCANIQUE.

14. Pour recentrer l’arbre, voir la section CENTRAGE

DE L’ACCOUPLEMENT ci-dessus.

15. Le remontage est maintenant terminé.

16

Page 17

PIÉCES DE RECHANGE

361

138

122

228

168

112

400

109

370C

139

100

358

101

304

383

408

381

370

108

371

COMPOSANTS DE LA POMPE ORGANES D’ENTRAÎNEMENT

Article Article

no

100 Corps de pompe Fonte, bronze 109 Couvercle de palier Fonte

Description

Matériau

no

Description Matériau

101 Impulseur Fonte, bronze 112 Roulement á billes extérieur Inox

108 Adaptateur Fonte, bronze 122 Arbre de pompe Inox

304 Écrou de l’impulseur Inox 138 Joint á lévre intérieur Buna-N, acier

351 Joint du corps de pompe Composite 139 Joint á lévre extérieur Buna-N, acier

358 Bouchon de vidange Acier 168 Roulement á billes intérieur Inox

370

(corps de pompe)

371

(adaptateur)

383 Joint mécanique

ci-dessous

408

Joints Service Joint tournant Joint immobile Elastómeros Métal

Vis de fixation á tête hexagonale

Vis de fixation á tête hexagonale

Bouchon d’amorçage, ¼ po NPT

Acier 228 Palier Fonte

Acier 361 Bague de retenue Buna-N, acier

V. tableau

370C

Vis de fixation á tête hexagonale

(couvercle de palier)

Acier, laiton 400 Clavette d’arbre Inox

Choix de joints mécaniques

Acier

Standard Général Céramique Buna-N

Grand rendement

Optionnels

Hautes températures

Carbone

Fonte Ni-Résist

Fonte Ni-Résist Buna-N

Éthyléne-propyléne

Inox de série

(nuance) 300

Produits chimiques

Céramique Viton

17

Page 18

DIAGNOSTIC DES ANOMALIES

AVERTISSEMENT

Les tensions dangereuses

peuvent causer un choc

électrique, des brûlures

et la mort.

OMETTRE DE COUPER LE COURANT AVANT

D’EFFECTUER L’ENTRETIEN PEUT SE TRADUIRE

PAR UNE COMMOTION ´ELECTRIQUE, DES

BRÛLURES OU LA MORT.

ANOMALIES

Moteur ne fonctionne pas:

Voir les causes 1 á 5 ci-contre.

Débit de liquide faible ou nul:

Voir les causes 6 á 13 ci-contre.

Consommation d’électricité excessive:

Voir les causes 3, 13, 14 et 15 ci-contre.

Vibration et bruit excessifs:

Voir les causes 3, 6, 7, 10, 12, 14, 16 et 17 ci-contre.

CAUSES PROBABLES

1. Protecteur thermique du moteur déclenché.

2. Disjoncteur ouvert ou fusible sauté.

3. Impulseur grippé.

4. Moteur mal connecté.

5. Moteur défectueux.

6. Pompe non amorcée, pompage d’air ou de gaz.

7. Tuyaux d’aspiration ou de refoulement obstrués,

robinet fermé.

8. Mauvais sens de rotation (moteur triphasé

seulement).

9. Basse tension électrique ou perte de phase.

10. Impulseur usé ou obstrué.

11. Hauteur du systéme trop grande.

12. Charge nette absolue á l’aspiration trop faible —

hauteur ou perte d’aspiration excessives.

13. Mauvais diamétre de l’impulseur.

14. Hauteur de refoulement trop faible — vitesse

d’écoulement excessive.

15. Viscosité ou densité du fluide trop élevée.

16. Roulement usé.

17. Fixation de la pompe, du moteur ou de la

tuyauterie lâche.

18

Page 19

GARANTIE LIMITÉE DE GOULDS WATER TECHNOLOGY

La présente garantie s’applique à chaque pompe de système d’alimentation en eau fabriquée par Goulds Water Technology.

Toute pièce se révélant défectueuse durant la période de garantie sera remplacée sans frais pour le détaillant durant ladite période, qui dure douze (12) mois à compter de la

date d’installation ou dix-huit (18) mois à partir de la date de fabrication, soit la période qui expirera la première.

Le détaillant qui, aux termes de cette garantie, désire effectuer une demande de règlement doit s’adresser au distributeur Goulds Water Technology agréé chez lequel la pompe

a été achetée et fournir tous les détails à l’appui de sa demande. Le distributeur est autorisé à régler toute demande par le biais du service à la clientèle de Goulds Water

Technology.

La garantie ne couvre pas :

a) les frais de main-d’oeuvre ou de transport ni les frais connexes encourus par le détaillant ;

b) les frais de réinstallation de l’équipement réparé ;

c) les frais de réinstallation de l’équipement de remplacement ;

d) les dommages indirects de quelque nature que ce soit ;

e) ni les pertes découlant de la panne.

Aux fins de la présente garantie, les termes ci-dessous sont définis comme suit :

1) «Distributeur» signifie une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique servant d’intermédiaire entre Goulds

Water Technology et le détaillant pour les achats, les consignations ou les contrats de vente des pompes en question.

2) «Détaillant» veut dire une personne, une société de personnes, une société de capitaux, une association ou autre entité juridique dont les activités commerciales sont la

vente ou la location de pompes à des clients.

3) «Client» signifie une entité qui achète ou loue les pompes en question chez un détaillant. Un «client» peut être une personne, une société de personnes, une société de

capitaux, une société à responsabilité limitée, une association ou autre entité juridique se livrant à quelque activité que ce soit.

CETTE GARANTIE SE RAPPORTE AU DÉTAILLANT SEULEMENT.

Xylem, Inc.

2881 East Bayard Street Ext., Suite A

Seneca Falls, NY 13148

Téléphone: (800) 453-6777

Télécopie: (888) 322-5877

www.xyleminc.com/brands/gouldswatertechnology

Goulds est une marque déposée de Goulds Pumps, Inc. et est utilisé sous le permis.

Loctite et Locquic sont des marques déposées de Loctite Corporation.

© 2012, Xylem Inc. IM007 Révision numéro 5 Juillet 2012

19

Page 20

MANUAL DE INSTRUCCIÓN

IM007

Modelos 3642 y 3742

INSTRUCCIONES DE INSTALACIÓN, FUNCIONAMIENTO Y MANTENIMIENTO

20

Page 21

TEMA PÁGINA

Instrucciones de seguridad ........................................................................................................................................... 22

Descripción y especificaciones ..................................................................................................................................... 22

Datos técnicos ............................................................................................................................................................. 22

Instalación

Localización ............................................................................................................................................................. 22

Cimentación ............................................................................................................................................................ 22

Montado en caja ...................................................................................................................................................... 22

Tubería

Succión .................................................................................................................................................................... 23

Descarga .................................................................................................................................................................. 23

Cableado y conexión a tierra ....................................................................................................................................... 23

Alineación de Acoplamiento ........................................................................................................................................ 24

Rotación ......................................................................................................................................................................24

Operación ................................................................................................................................................................... 24

Mantenimiento ............................................................................................................................................................ 25

Desmontaje ................................................................................................................................................................. 25

Extremo sumergido ................................................................................................................................................. 25

Caja del cojinete ...................................................................................................................................................... 25

Reensamble

Caja del cojinete ...................................................................................................................................................... 26

Extremo sumergido ................................................................................................................................................. 26

Piezas de reparación .................................................................................................................................................... 27

Investigación de averías ............................................................................................................................................... 28

Garantía limitada ......................................................................................................................................................... 28

Declaration of Conformity .......................................................................................................................................... 29

Número de modelo de la bomba:

Número de serie de la bomba:

Representante:

Número telefónico del representante:

Fecha de compra:

Fecha de Instalación:

Lecturas actuales de la puesta en servicio:

1 Ø 3 Ø L1-2 L2-3 L3-1

Amps: Amps:

Voltios: Voltios:

MODELOS

3642 3742

1 x 1¼ - 5 1 x 1¼ - 5

1¼ x 1½ - 5 1¼ x 1½ - 5

21

Page 22

INSTRUCCIONES DE SEGURIDAD

Camisa

Arandela

Uña

Tope de la fundación limpie y moje

Lechada

Cuñas o calzas de nivelación - dejadas

en el lugar

Placa de base

Agujero para

la lechada

(

1

∨4”) (6.35 mm)

Lechada terminada

(

1

∨2 a 3∨4”)

permitida

para la

nivelación

Encofrado o

formaleta de

madera

PARA EVITAR LESIONES PERSONALES GRAVES

O FATALES, Y DAÑOS SIGNIFICATIVOS A LA

PROPIEDAD, LEA Y SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD QUE SE ENCUENTRAN

EN ESTE MANUAL O EN LA BOMBA.

ESTE MANUAL TIENE LA FUNCIÓN DE ASISTIRLO

EN LA INSTALACIÓN Y OPERACIÓN DE ESTA UNIDAD Y DEBE CONSERVARSE CON LA BOMBA.

Éste es un SÍMBOLO DE ALERTA DE

SEGURIDAD. Cuando vea este símbolo

sobre la bomba o en el manual, localice

una de las siguientes palabras de señalización y esté alerta ante posibles lesiones personales o daños a la propiedad.

PELIGRO

ADVERTENCIA

PRECAUCIÓN

AVISO: INDICA QUE EXISTEN INSTRUCCIONES

EXAMINE COMPLETAMENTE TODAS LAS INSTRUCCIONES Y ADVERTENCIAS ANTES DE REALIZAR CUALQUIER TRABAJO EN ESTA BOMBA.

CONSERVE TODAS LAS CALCOMANÍAS.

ADVERTENCIA

Los fluidos peligrosos

pueden causar

incendios, quemaduras

o la muerte.

Advierte sobre los peligros que PROVOCARÁN lesiones graves, muerte o daños

significativos a la propiedad.

Advierte sobre los peligros que

PUEDEN PROVOCAR lesiones graves,

muerte o daños significativos a la propiedad.

Advierte sobre los peligros que PRO-

VOCARÁN o PUEDEN PROVOCAR

lesiones o daños a la propiedad.

ESPECIALES MUY IMPORTANTES QUE

DEBEN RESPETARSE.

ESTA UNIDAD NO SE ENCUENTRA

DISEÑADA PARA SER USADA CON

LÍQUIDOS O GASES INFLAMABLES.

ESTOS FLUIDOS PUEDEN ESTAR

PRESENTES EN ÁREAS CONTAMINADAS.

Máxima presión de trabajo: 125 lib/pulg2 (9 barias)

Arranques por hora: 20 - distribuidos uniformemente

3642/3742

Modelo Succión Descarga

1 x 1¼ - 5 1¼” NPT 1” NPT

1¼ x 1½ - 5 1½” NPT 1¼” NPT

INSTALACIÓN

Lugar:

Coloque la bomba tan cerca de la fuente del líquido

como sea práctico; abajo del nivel del líquido para

darle la capacidad de recebado.

Deje espacio adecuado para poder darle servicio y

ventilación. Proteja la unidad de la intemperie y daños

del agua debido a la lluvia, inundaciones o temperaturas de congelación.

Unidades compactas:

Las unidades se pueden instalar horizontalmente,

inclinadas o verticalmente con el motor arriba de la

bomba.

AVISO: NO INSTALE CON EL MOTOR ABAJO

DE LA BOMBA. CUALQUIER FUGA O

CONDENSACIÓN AFECTARÁ AL MOTOR.

Cimentación:

Una cimentación de superficie plana y substancial

DEBE proporcionarse para evitar la distorsión y/o

deformaciones cuando se aprieten los pernos de la

cimentación. Un montaje de goma es aceptable para

disminuir el ruido o las vibraciones excesivas.

Apriete los pernos de sujeción del motor antes de

conectar la tubería a la bomba.

Unidades montadas en caja:

DESCRIPCIÓN Y ESPECIFICACIONES

La 3642 (compacta) y la 3742 (montada en caja) son

bombas centrifugas, de aspiración axial y de una etapa, para circulación de agua, servicio aumentador de

presión, transferencia de líquidos, sistemas de aspersión, bomba auxiliar de mantener presión, y servicio

de bombeo general. Las bombas se ofrecen en tres

materiales de construcción diferentes, a saber: toda de

hierro, con accesorios de bronce y toda de bronce.

Los impulsores de la bomba son de diseño cerrado para

alta eficiencia, roscados directamente al eje del motor.

Las unidades compactas tienen motores de caja estándar NEMA con montaje de cara C y extensiones del eje

roscadas. Las unidades montadas en caja se pueden

acoplar a los motores por medio de un acoplamiento

espaciador, o accionado por correa.

DATO TÉCNICOS

• Máxima temperatura del liquido:

212º F (100º C) Sello estándar

250º F (120º C) Sello de alta temperatura, opcional

22

Figura 1

La placa de base debe instalarse con lechada a una cimentación con una zapata sólida. Refiérase a la Figura

1.

Coloque la unidad en posición sobre las cuñas pues-

tas en cuatro puntos, dos aproximadamente debajo

del centro del motor y dos aproximadamente debajo

Page 23

del centro de la bomba. Ajuste las cuñas para nivelar

ADVERTENCIA

Un voltaje peligroso puede

producir golpes el ctricos,

quemaduras o la muerte.

la unidad. Nivele o ponga a plomo las bridas de succión y descarga.

Asegúrese de que la placa de base no esté distorsionada y se pueda hacer la alineación de acoplamiento

final dentro de los límites de movimiento del motor, o

calzas del motor, si fuere necesario.

Apriete los pernos de la cimentación apretando a

mano y construya una presa alrededor de la cimentación. Derrame la lechada debajo de la placa de base

asegurándose de que las áreas debajo de la bomba y

de la pata del motor estén llenas sólidas. Deje que la

lechada fragüe por 48 horas, antes de apretar totalmente los pernos de la cimentación.

Apriete los pernos de sujeción de la bomba y del motor, antes de alinear el eje o de conectar la tubería a la

bomba.

TUBERÍA

La tubería no debe ser más pequeña que las conexiones de la succión y descarga y se deben mantener tan

cortas como sea posible, evitando accesorios innecesarios para minimizar las pérdidas de fricción.

Toda la tubería DEBE estar soportada independientemente y NO DEBE agregar ninguna carga de la

tubería a la bomba.

AVISO: NO FUERCE LA TUBERÍA AL HACER LAS

Todas las juntas de tubería DEBEN ser estancas.

Tubería - Succión

Para alturas de aspiración mayores de 15 pies (4,6 m.)

consulte la curva de rendimiento de la bomba para la

altura de succión positiva neta requerida (ASPNR).

Si se requiere una tubería de tamaño mayor que la

succión de la bomba DEBE instalarse una reducción

excéntrica de tubería, con el lado recto hacia arriba,

en la succión de la bomba.

Si se instala la bomba debajo de la fuente de líquido,

instale una válvula de compuerta en la succión para la

inspección y mantenimiento de la bomba.

AVISO: NO USE LA VÁLVULA DE COMPUERTA

Si la bomba es instala arriba de la fuente del líquido,

se DEBE proporcionar lo siguiente:

CONEXIONES DE SUCCIÓN Y DESCARGA

CON LA BOMBA.

PARA ESTRANGULAR LA BOMBA. ESTO

PUEDE CAUSAR LA PÉRDIDA DE CEBADO,

TEMPERATURAS EXCESIVAS Y DAÑO A LA

BOMBA, ANULANDO LA GARANTÍA.

- Evitar bolsas de aire, ninguna parte de la tubería debe estar arriba de la conexión de succión

de la bomba.

- Incline hacia arriba la tubería, partiendo de la

fuente del líquido.

- Use una válvula de pie o válvula de retención

SÓLO si es necesario para cebar o sostener el

cebado durante el trabajo intermitente.

- El colador de succión o campana de succión

DEBE ser por lo menos tres veces el área del

diámetro del tubo de succión.

- Asegure que el tamaño y la mínima inmersión

sobre la entrada de succión sea suficiente para

impedir que entre aire a través de un vórtice de

succión. Vea las Figuras 2 a 5.

H mín.

D

Figura 2 Figura 3

3.0D

mín.

1.5D

mín.

H mín.

D mín.

D D

2

H mín.

H

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

H = Sumersión mín. en pies

1

12345678910111213 141516

V = Velocidad en pies por segundo

= GPM x 0.321

Área

GPM x 0.4085

D

V

2

D

Figura 4 Figura 5

Tubería - Descarga

• Instale una válvula de retención adecuada para

manejar el caudal, líquidos e impedir el contraflujo.

Después de la válvula de retención, instale una válvula de compuerta de tamaño apropiado para usar

en la regulación de la capacidad de la bomba, en la

inspección y mantenimiento de la bomba.

• Cuando se requiera, se debe instalar el aumentador

de tubería entre la válvula de retención y la descarga

de la bomba.

CABLEADO Y CONEXIÓN A TIERRA

Instale la conexión a tierra y el

cableado de acuerdo con los requerimientos del Código Nacional de Electricidad.

Instale un interruptor de alimentación en todos los alambres

exteriores con corriente, cerca de

la bomba.

Desconecte la alimentación

eléctrica antes de instalar o dar

servicio a la bomba.

La alimentación eléctrica DEBE estar de acuerdo

con las especificaciones de la placa del fabricante.

La tensión incorrecta puede causar incendio o

dañar el motor y anular la garantía.

Los motores sin protección incorporada DEBEN

estar provistos de contactores y sobrecargas

térmicas para los motores monofásicos, o arrancadores con calentadores para los trifásicos. Vea la

placa del fabricante del motor.

23

Page 24

Use sólo cables de cobre al motor y a tierra. El alambre

Tensión

p

eligrosa

ADVERTENCIA

Las maquinarias

peligrosas pueden

causar lesiones

personales o la muerte.

ADVERTENCIA

ADVERTENCIA

Un voltaje peligroso puede

producir golpes el ctricos,

quemaduras o la muerte.

Las maquinarias

peligrosas pueden

causar lesiones

personales o la muerte.

ADVERTENCIA

a tierra DEBE ser por lo menos tan grande como el

alambre al motor. Los alambres deben ser de color codificado para facilitar el mantenimiento.

Siga cuidadosamente el diagrama del alambrado del

fabricante del motor en la placa del fabricante del motor

o en la tapa terminal.

LA OMISIÓN DE CONECTAR A

TIERRA PERMANENTEMENTE

LA BOMBA, EL MOTOR Y LOS

CONTROLES, ANTES DE CONECTAR

A LA ALIMENTACIÓN ELÉCTRICA,

PUEDE CAUSAR CHOQUES,

QUEMADURAS O LA MUERTE.

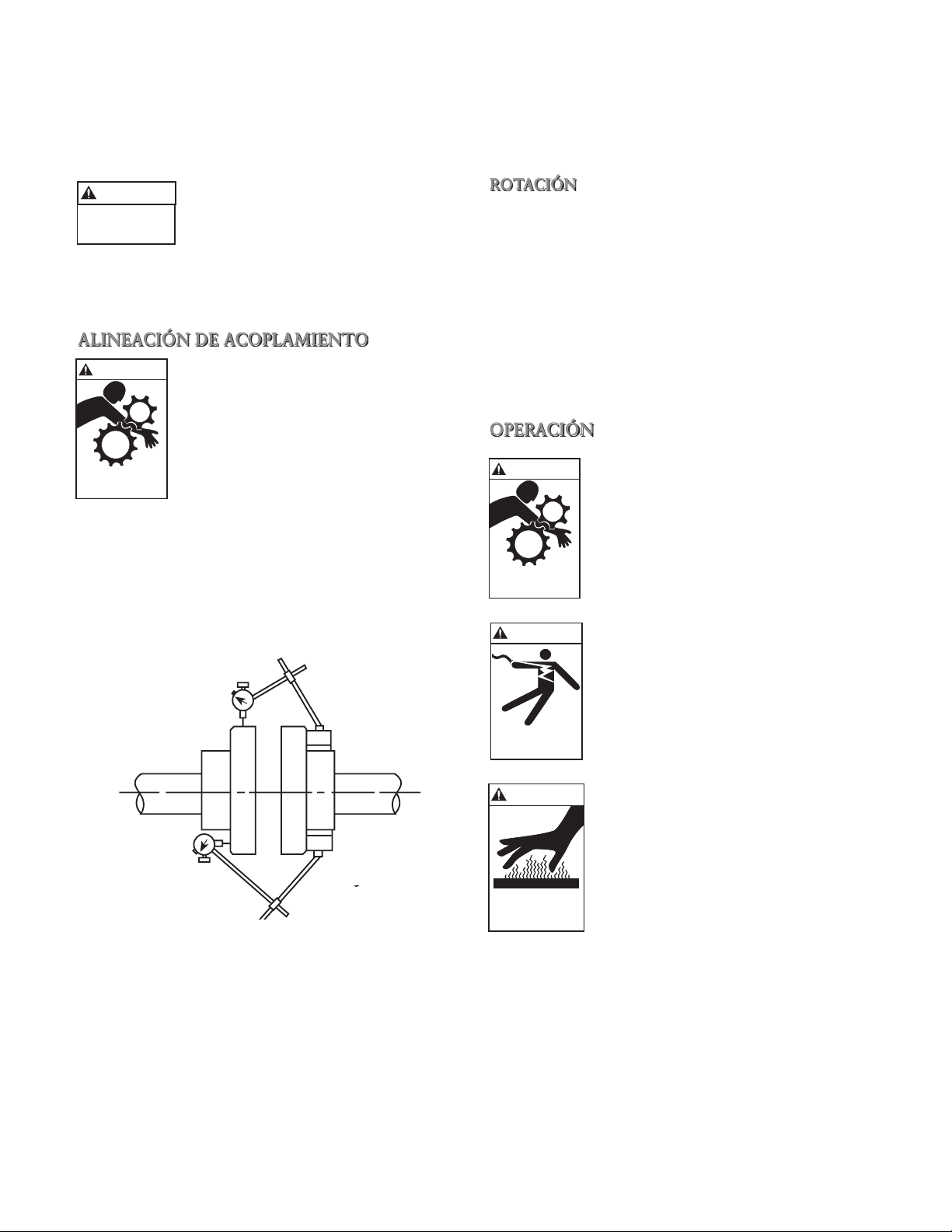

ALINEACIÓN DE ACOPLAMIENTO

LA OMISIÓN DE DESCONECTAR

LA ALIMENTACIÓN ELÉCTRICA

ANTES DE INTENTAR CUALQUIER

MANTENIMIENTO PUEDE CAUSAR

CHOQUES, QUEMADURAS O LA

MUERTE.

La alineación DEBE verificarse antes del funcionamiento. Vea la Figura 6.

Apriete todos los pernos de sujeción antes de verificar la alineación.

La alineación final se obtiene cuando se satisfacen los

requerimientos de alineación paralela y angular, con

los pernos de sujeción del motor apretados.

AVISO: SIEMPRE VUELA A VERIFICAR LAS ALIN-

EACIONES DESPUÉS DE HACER AJUSTES

MECÁNICOS CUALESQUIERA.

ROTACIÓN

AVISO: LA ROTACIÓN INCORRECTA PUEDE CAU-

SAR DAÑOS A LA BOMBA Y ANULAR LA

GARANTÍA.

La rotación correcta es a la derecha, en sentido DEXTRORSO, vista desde el extremo del motor. La rotación

se puede verificar quitando la tapa extrema del motor

o el tapón y observando la rotación del eje del motor.

Para invertir la rotación, invierta dos cualesquiera de

los tres conductores del motor.

OPERACIÓN

NO HAGA FUNCIONAR LAS

UNIDADES MONTADAS EN

CAJA SIN LOS RESGUARDOS DE

SEGURIDAD INSTALADOS YA QUE

PODRÍAN RESULTAR SEVERAS

LESIONES CORPORALES.

Si es necesaria la realineación, siempre mueva el motor. Ponga calzas según se requiera.

Mala alineación paralela (eje con ejes paralelos pero

no concéntricos). Ponga el indicador de cuadrante en

un cubo y gire este cubo 360º mientras hace lecturas

en el diámetro exterior del otro cubo. La alineación

paralela se obtiene cuando la lectura indicada total es

0,005” (0,127 mm) o menos.

Mala alineación angular (ejes con ejes concéntricos

pero no paralelos). Ponga el indicador de cuadrante

en un cubo y gire este cubo 360º mientras se hacen

lecturas en la cara del otro cubo. La alineación angular se obtiene cuando la lectura indicada total es de

0,005” (0,127 mm) o menos.

24

Figura 6

Paralelo

Angular

SALPICAR O SUMERGIR LOS

MOTORES DE CUBIERTA ABIERTA A

PRUEBA DE GOTEO EN UN FLUIDO

PUEDE CAUSAR INCENDIOS,

CHOQUES, QUEMADURAS O LA

MUERTE.

PRECAUCIÓN

EL FUNCIONAMIENTO CON

CAUDAL CASI IGUAL A CERO O

CERO PUEDE CAUSAR CALOR

EXCESIVO, LESIONES PERSONALES

O DAÑOS A LA PROPIEDAD.

El calor excesivo puede

causar lesiones o

daños a la propiedad.

AVISO: NO HAGA FUNCIONAR LA BOMBA SIN

CEBAR O EL SELLO RESULTARÁ DAÑADO.

Después de estabilizar el sistema en condiciones de

funcionamiento normal, verifique la tubería. Si es necesario, ajuste los apoyos de la tubería.

En las unidades montadas en caja, la alineación del

acoplamiento puede haber cambiado debido a la

diferencial de temperatura entre la bomba y el motor.

Vuelva a verificar la alineación siguiendo los procedimientos y advertencias de peligro dados en la sección

“ALINEACIÓN DE ACOPLAMIENTO” de este manual.

Page 25

MANTENIMIENTO

ADVERTENCIA

Un voltaje peligroso puede

producir golpes el ctricos,

quemaduras o la muerte.

ADVERTENCIA

La tensión peligrosa

puede causar choques,

quemaduras o la

muerte.

LA OMISIÓN DE DESCONECTAR

LA ALIMENTACIÓN ELÉCTRICA

ANTES DE INTENTAR CUALQUIER

MANTENIMIENTO PUEDE CAUSAR

CHOQUES, QUEMADURAS O LA

MUERTE.

LA OMISIÓN DE ALIVIAR LA

PRESIÓN DEL SISTEMA Y DRENAR

EL SISTEMA ANTESDE INTENTAR

CUALQUIER MANTENIMIENTO

PUEDE CAUSAR DAÑOS A

LA PROPIEDAD, LESIONES

CORPORALES O LA MUERTE.

Unidades compactas:

Los cojinetes están localizados y son parte del motor.

Para información de lubricación, consulte las instrucciones del fabricante del motor.

3. Quite la junta de empaque (351). Deséchela.

4. En las unidades compactas, quite el tapón del ex-

tremo del motor o la tapa para exponer la ranura

del destornillador o los filos normales del eje en

el extremo del eje del motor.

5. Mientras sujeta el eje con la herramienta apropiada (unidades compactas) o con una llave de correa (unidades montadas en caja) quite la tuerca

(304) del impulsor girando en sentido SINISTRORSO. La tuerca del impulsor puede necesitar que

se caliente con una antorcha para quitarla.

AVISO: TENGA CUIDADO CUANDO MANEJE LA

TUERCA CALIENTE DEL IMPULSOR.

6. Mientras sujeta el eje, quite el impulsor (101)

girando en sentido SINISTRORSO. El impulsor

puede que se necesite calentar para quitarlo.

AVISO: TENGA CUIDADO CUANDO MANEJE UN

IMPULSOR CALIENTE.

7. Usando dos destornilladores, haga palanca

girando la sección del conjunto (383) del sello

mecánico. Deseche. Vea la Figura 7.

Unidades montadas en caja:

Las cajas de cojinete de las bombas han sido engrasadas por la vida del cojinete. No es posible o necesario

lubricarlas.

Siga las instrucciones de lubricación del fabricante del

motor y del acoplamiento.

Servicio de temporada:

Para RETIRAR la bomba del servicio, quite todos los

tapones de drenaje y drene toda la tubería.

Para DEVOLVER la bomba al servicio, vuelva a poner

todos los tapones usando cinta Teflon’ o equivalente.

Reconecte la línea de succión si se quitó, examine la

unión y repare si es necesario.

Vuelva a cebar y hacer funcionar la bomba siguiendo

todas las instrucciones y advertencias en la sección

“OPERACIÓN” de este manual.

DESMONTAJE

Siga TODAS las advertencias e instrucciones de la

sección “MANTENIMIENTO” de este manual.

Unidades compactas, quite los pernos de sujeción del

motor.

Unidades montadas en caja, quite el resguardo del

acoplamiento, el espaciador, el acoplamiento y los

pernos de sujeción de la caja.

Extremo sumergido:

1. Quite los pernos (370) de la carcasa.

Figura 7

8. Quite los pernos (371) del adaptador y el adaptador (108), tirando con éste el asiento estacionario

del sello mecánico.

9. Presione hacia afuera el asiento estacionario del

sello mecánico del lado del motor del adaptador.

Deséchelo.

Caja del cojinete:

1. Quite la tapa del cojinete (109).

2. Quite el anillo de sujeción (361).

3. Quite el conjunto del eje de la caja.

4. Si está desgastado o dañado, quite los sellos de

reborde (138, 139) de la caja del cojinete (228) y

la tapa del cojinete (109).

5. Use un extractor de cojinete o prensa del eje para

quitar el cojinete de bolas (112, 168).

2. Quite el conjunto de desmontaje de la caja de

rodamientos de la carcasa (100).

25

Page 26

Notas

REENSAMBLE

Limpie e inspeccione todas las piezas antes de reensamblar.

Consulte la lista de piezas para la descripción de los