Page 1

Global Water

800-876-1172 • globalw.com

Global Water

Instrumentation, Inc.

11390 Amalgam Way

Gold River, CA 95670

T: 800-876-1172

Int’l: (916) 638-3429, F: (916) 638-3270

Circle Chart Recorder: CR500

- 1 -

Page 2

Global Water

800-876-1172 • globalw.com

Warning Symbol

This Symbol calls attention to an operating procedure, practice, or the like, which, if

not correctly performed or adhered to, could result in personal injury or damage to or

destruction of part or all of the product and system. Do NOT proceed beyond a warning

symbol until the indicated conditions are fully understood and met.

Use the Manual

Installers Read Sections I, II, and III

System Read All Sections

NOTE:

Information in this user's manual is subject to change without notice.

Global Water Instrumentation, Inc.

11390 Amalgam Way

Gold River, CA 95670

T: 800-876-1172

Int’l: (916) 638-3429, F: (916) 638-3270

Website: www.globalw.com

Email: globalw@globalw.com

- 2 -

Page 3

Global Water

800-876-1172 • globalw.com

Table of Contents

I) OVERVIEW................................................................................................................................... 4

GENERAL ......................................................................................................................................... 4

II) INSTALLATION........................................................................................................................... 5

CR500 CHECKLIST.......................................................................................................................... 5

INSPECTION ..................................................................................................................................... 5

MOUNTING....................................................................................................................................... 6

CASE LOCATION.............................................................................................................................. 6

WIRING PRECAUTIONS .................................................................................................................... 7

POWER WIRING............................................................................................................................... 7

4-20MA INPUT WIRING PEN1/PEN2................................................................................................ 9

THERMOCOUPLE (TC) INSTALLATION GUIDELINES.................................................................... 10

THERMOCOUPLE INPUT WIRING .................................................................................................. 11

ALARM RELAYS............................................................................................................................. 13

CHANGING THE CHART................................................................................................................. 14

MARKING SYSTEMS - "INK TYPE PENS"...................................................................................... 14

MARKING SYSTEMS - THERMAL TYPE ......................................................................................... 15

REPLACEMENT OF PEN “INK TYPE”............................................................................................. 15

REPLACEMENT OF THERMAL STYLUS.......................................................................................... 15

BATTERY BACKUP “INK STYLE” UNITS ....................................................................................... 16

III) PROGRAMMING....................................................................................................................... 18

RECORDER SETUP - "SINGLE PEN INK TYPE"............................................................................. 18

RECORDER SETUP - DUAL PEN (UNIVERSAL) INPUT INK STYLE................................................. 19

RECORDER SETUP - THERMAL RECORDERS 1 & 2 PEN............................................................... 19

ALARM SETTINGS INK STYLE RECORDERS.................................................................................. 21

ALARM SETTINGS THERMAL STYLE RECORDERS .......................................................................22

ALARM SETTINGS DISPLAY OPTION FEATURES .......................................................................... 23

IV) CALIB R A T I O N - INK TYP E ONLY......................................................................................... 24

PEN ARM CALIBRATION (ZERO AND SPAN)................................................................................... 24

PROBE OFFSET ADJUST - INK STY L E (PEN OFFSET) ..................................................................... 25

PROBE OFFSET - THERMAL STYLE (PEN OFFSET)........................................................................ 26

THERMAL PRINT CONTRAST ADJUSTMENT .................................................................................. 26

V) SPECIFICATIONS...................................................................................................................... 27

VI) DEFAULT SETTINGS................................................................................................................29

VII) TROUBLESHOOTING............................................................................................................... 30

VIII) WARRANTY................................................................................................................................ 31

IX) APPE N D IX A SPAR E PARTS.................................................................................................... 32

X) GLOSSARY: ................................................................................................................................ 33

- 3 -

Page 4

Global Water

800-876-1172 • globalw.com

I) Overview

General

The CR500 is a microprocessor based circle chart recorder. Programmable alarm options

combined with “ease of setup” provide the flexibility required for multiple recording

applications. This manual will cover both ink type and thermal print versions.

The CR500 is the first recorder to “self document” setup configuration during initial

setup and can operate using standard or competitive charts. The battery backup option (on

ink type units) provides up to 48 hours of recording in the event of power loss, thereby

providing an additional degree of protection for customer processes. A green status LED

indicates battery condition; see Battery Backup (Page 17).

The Thermal print version offers a single chart inventory for all recording needs. “Print

your own” chart technology includes real time trend and printed time and date directly on

the chart. The Thermal Recorder provides dual channel recording as standard. Each

channel is configurable for universal inputs. The unit can easily be configured, in field, to

single channel via keypad.

The unit is powered by 110/220VAC, 50/60Hz. Programmable inputs for thermocouple

types J, K, T, R, B and S as well as 4-20mA are standard. Optional alarm relays are

available and are programmable for low, high or band operation. The green LED

indicates unit is powered.

A unique setup chart provides the user with an “on the spot” manual. This setup chart

will also self-document the current setup for quick review by an operator.

High accuracy, maximum flexibility, fast response, and a simple user interface are the

main benefits of the CR500 recorder.

- 4 -

Page 5

Global Water

800-876-1172 • globalw.com

II) Installation

Dangerous voltages capable of causing death are sometimes present when wiring

the instrument. Before installation or beginning any troubleshooting procedures, the

power to all equipment must be switched off and isolated. Units suspected of being at

fault must be disconnected and removed to a properly equipped workshop for testing and

repair. Component replacement and internal adjustments must be made by qualified

personnel only. This recorder operates on 110 or 220 (50-60 Hz), be sure line voltage is

OFF before connecting recorder.

This symbol represents Earth Ground connection

To minimize the possibility of fire or shock hazards, do not expose this instrument

to rain or excessive moisture.

Do not use this instrument in areas under hazardous conditions such as excessive

shock, vibration, dirt, moisture, corrosive gases or oil. The ambient temperature of the

areas should not exceed the maximum rating specified.

CR500 Checklist

a) CR500 Chart Recorder

b) Battery (for optional battery backup)

c) Ferrite Bead

d) Installation manual

Inspection

e) Your CR500 unit was carefully inspected and certified by our Quality Assurance

Team before shipping. If any damage has occurred during shipping, please notify

Global Water Instrumentation, Inc. and file a claim with the carrier involved.

Use the checklist to ensure that you have received everything needed to operate

the CR500.

- 5 -

Page 6

Global Water

800-876-1172 • globalw.com

Mounting

Make panel cutout to dimension shown in Figure 2.0.

Install both mounting clamps and insert the case into panel cutout.

Figure 2.0 Mounting Diagram

Case Location

Upon unpacking, find a suitable location to mount the recorder before wiring power to

the unit. Refer to Wiring Precautions (Page 8). After the recorder has been connected to

the main AC power supply, connect the battery (optional) to the battery strap and place

the battery in its holder.

Select a location that is well lighted, free from dust, dirt, or corrosive fumes. The

instrument should not be located near any sources of heat or be subject to sudden or

extreme temperature changes. It should be mounted on a rigid support that is not subject

to vibration. Refer to Figure 2.0 for recorder case dimensions.

- 6 -

Page 7

Global Water

800-876-1172 • globalw.com

Wiring Precautions

1) Before wiring, verify the label for correct model number and options. Switch off

the power when checking.

2) Care must be taken to ensure that maximum voltage rating specified on the label

is not exceeded.

3) It is recommended that power of these units to be protected by fuses or circuit

breakers rated at the minimum value possible. All units should be installed inside

a suitably grounded metal enclosure to prevent live parts being accessible from

human hands and metal tools.

4) All wiring must conform to appropriate standards of good practice and local

codes and regulations. Wiring must be suitable for maximum voltage, current,

and temperature rating of the system.

5) Take care not to over-tighten the terminal screws.

6) Unused control terminals should not be used as jumper points as they may be

internally connected, causing damage to the unit.

7) Verify that the ratings of the output devices and the inputs are not exceeded.

Refer to Specifications (Page 27).

8) Electric power in industrial environments contains a certain amount of noise in

the form of transient voltage and spikes. This electrical noise can enter and

adversely affect the operation of microprocessor-based controls. For this reason,

we strongly recommend the use of shielded thermocouple extension wire, which

connects the sensor to the unit. This wire is a twisted-pair construction with foil

wraps and drains wire. The drain wire is to be attached to earth ground at the

sensor end only.

Power Wiring

The unit is supplied to operate at 110/220VAC 50/60Hz. Check that the installation

voltage corresponds with the power rating indicated on the product label before

connecting power to the unit.

The recorder uses AC power when it is operating normally. The battery back-up option

on ink recorders will allow the recorder to operate for approximately 48 hours in case of a

power loss. The AC input can be fused with a 250VAC, .5 Amp fuse.

In order to connect the recorder to the main AC power, you must first gain access to the

PC board that is mounted to the back of the chart plate. Your recorder will have a hinged

chart plate held in place by two (2) screws located on the right hand side of the chart

plate. Remove these two screws and open the hinged chart plate. If you are not sure how

- 7 -

Page 8

Global Water

800-876-1172 • globalw.com

to access the back of the chart plate, please contact GLOBAL WATER

INSTRUMENTATION before continuing.

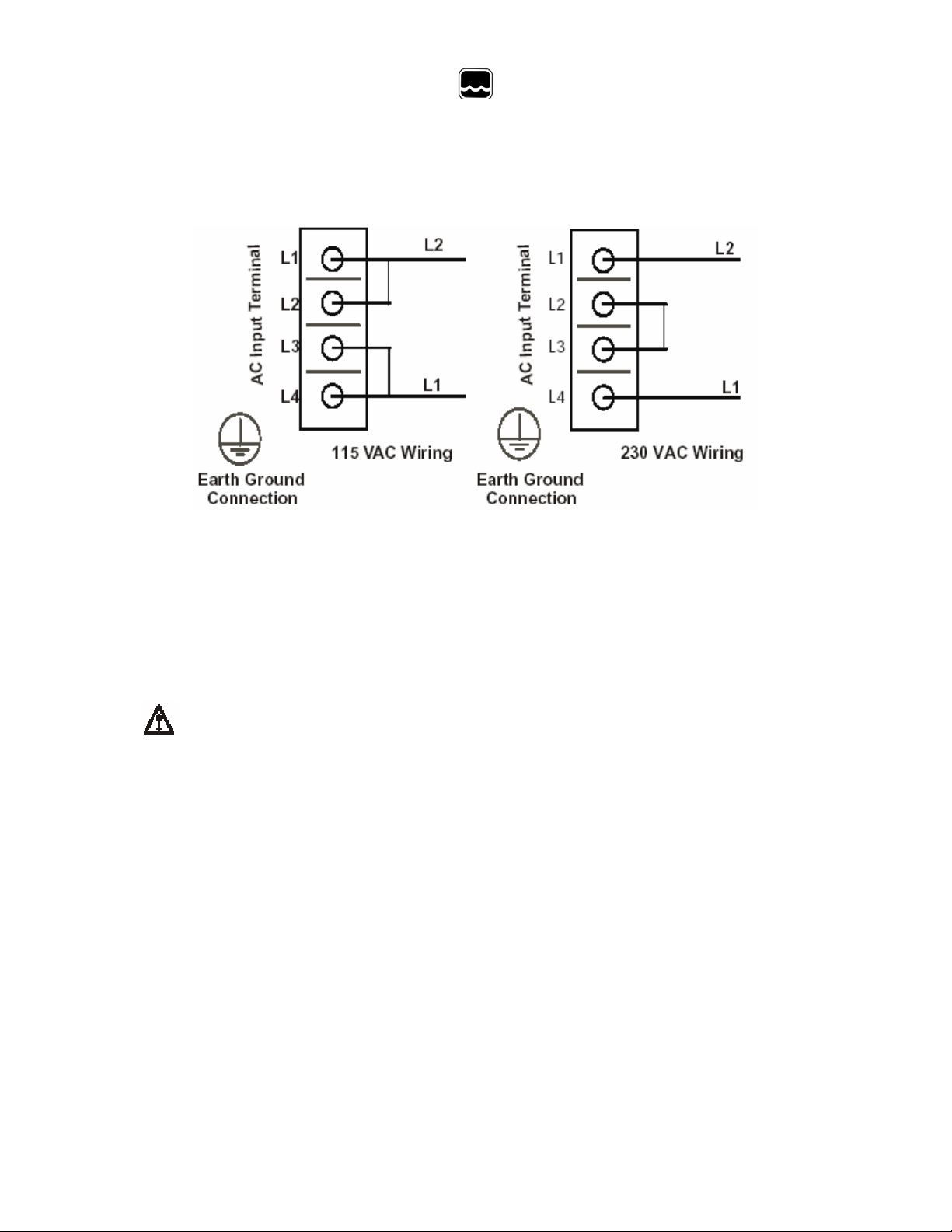

Figure 2.1 Power Supply

The AC power connections are made to the 4 pin terminal block located on back side of

platen. All AC and ground wires must be a minimum of 16 AWG.

Refer to Figure 2.1 for proper connection to the main AC power.

Earth Ground must be connected at ground lug provided. See Figure 2.1

This equipment is designed for installation in an enclosure which provides adequate

protection against electric shock. Grounding of this recorder must meet national and local

codes. Ground wire should be Color coded GREEN or GREEN with a YELLOW stripe.

Local requirements regarding electrical installation should be rigidly observed.

Proper steps should be taken to prevent unauthorized persons from gaining access to the

power terminals.

- 8 -

Page 9

Global Water

800-876-1172 • globalw.com

4-20mA Input Wiring Pen1/Pen2

Transmitters and sensors with 4-20mA outputs can also be connected to the recorder as

shown in the following input wiring figures (Figure 2.2). No voltage is provided to power

these sensors and must be supplied externally or an optional sensor power supply can be

purchased from Global Water.

Figure 2.2

- 9 -

Page 10

Global Water

800-876-1172 • globalw.com

Thermocouple (TC) Installation Guidelines

Proper sensor installation can eliminate many problems in a control system. The probe

should be placed so that it can detect any temperature change with minimal thermal lag.

In a process that requires fairly constant heat output, the probe should be placed close to

the heater. In a process where the heat demand is variable, the probe should be close to

the work area. Some experiments with probe location are often required to find this

optimum position.

Proper sensor type is also a very important factor to obtain precise measurements. The

sensor must have the correct temperature range to meet the process requirements. In

special processes, the sensor might need to have different requirements such as leakproof, anti-vibration,

Standard thermocouple sensor limits of error are 4° F (2° C) or 0.75% of sensed

temperature plus drift caused by improper protection or an over-temperature occurrence.

This error is far greater than controller error and cannot be corrected at the sensor except

by proper selection and replacement.

In order to connect the probe input device to the recorder, you must first gain access to

the PC board that is mounted to the back of the chart plate.

A ferrite bead has been included to provide additional protection for electrical “Noise”

sensor signal wires can pick up. See drawing below for correct installation of this device.

(Figure 2.3)

Ungrounded thermocouples recommended on 2 pen units.

Figure 2.3

CAUTION! DO NOT TOUCH the terminals of the transformer while the

recorder is connected to the main AC power supply. To avoid the risk of possible electric

shock, unplug or disconnect the recorder from the main power supply before attempting

to open the recorder. If the recorder is installed with the battery back-up option,

disconnect the 9 Volt battery to avoid damaging the recorder and draining the battery.

Your recorder will have a hinged chart plate held in place by two (2) screws located on

the right hand side of the chart plate. Remove these two screws and open the hinged chart

- 10 -

Page 11

Global Water

800-876-1172 • globalw.com

plate. If you are not sure how to access the back of the chart plate, please contact

GLOBAL WATER INSTRUMENTATION before continuing.

Thermocouple Input Wiring

Thermocouple input connections are shown in the following figures. The correct type of

thermocouple extension lead-wire or compensating cable must be used for the entire

distance between the unit and the thermocouple, ensuring that the correct polarity is

observed throughout. Splices in the cable should be avoided, if possible. A Ferrite bead is

supplied with the CR500 recorder to provide additional isolation against input noise.

Input wiring should be wrapped around the core before wiring to the recorder inputs. See

Figure 2.3.

If the length of thermocouple plus the extension wire is too long, it may affect the

temperature measurement. A 400 ohms K type or a 500 ohms J type thermocouple lead

resistance will produce approximately 1 degree C temperature error.

Figure 2.4 Single Pen Ink Style Inputs

- 11 -

Page 12

Global Water

800-876-1172 • globalw.com

Fig. 2.6 Two Pen Universal and Thermal Inputs

- 12 -

Page 13

Global Water

800-876-1172 • globalw.com

RTD Input Wiring

RTD connections are shown in the previous, with the compensating lead connected to

terminal 4. For two-wire RTD inputs, terminals 2 and 4 should be linked. The three-wire

RTD offers the capability of lead resistance compensation provided that the three leads

are of same gauge and equal length.

Two-wire RTD should be avoided, if possible, for the purpose of accuracy. A 0.4 ohm

lead resistance of a two-wire RTD will produce 1 degree C temperature error.

Alarm Relays

If your recorder has the optional relay contacts installed, then terminal blocks J1 and J2

have been provided for connection to the relay on the microprocessor PC board of the

recorder.

Refer to Figure 2.4 (Page 11) for Single Pen Units.

Refer to Figure 2.6 (Page 12) for Dual Pen Ink and Thermal Units.

CAUTION! DO NOT TOUCH the terminals of the transformer while the recorder

is connected to the main AC power supply. To avoid the risk of possible electric shock,

unplug or disconnect the recorder from the main power supply before attempting to

access the terminals of the relay. If the recorder is installed with the battery back-up

option, disconnect the 9 Volt battery to avoid damaging the recorder and draining the

battery.

Your recorder will have a hinged chart plate held in place by two (2) screws located on

the right hand side of the chart plate. Remove these two screws and open the hinged chart

plate. If you are not sure how to access the back of the chart plate, please contact

GLOBAL WATER INSTRUMENTATION before continuing.

The relays are rated for the following maximum Values:

2.0 AMPS at 25VDC

1.0 AMP at 120VAC

Warning: Damage to the recorder may result if the ratings for the relays are exceeded.

- 13 -

Page 14

Global Water

800-876-1172 • globalw.com

Changing the Chart

Press and release the CHANGE CHART key (3 on Figure 2.7). The pen(s) will move to

the left of the chart and green LED will flash rapidly. Wait until the pen(s) stops above

outer ring AND green LED goes to on steady.

Unscrew the chart "hub" knob at the center of the chart. Remove the old chart paper and

position the new one so that the correct time line coincides with the time line groove on

the chart plate. Refer to Figure 2.10 (Page 17) for the location of the time line groove.

Re-attach the chart "hub" knob and screw securely (by hand) against the chart. Press and

release the CHANGE CHART key (3). The pen(s) will move to the outer ring, and then

pause. The green LED will remain on continuously or blink, depending upon the state of

the backup battery. Pen(s) will then go to current recording value. If ink pen(s) did not

accurately pause at the 100% line, see Pen Arm Calibration (Page 25).

If unit has display option, see Display Function (page 24). Check to make sure that the

pen(s) is marking on the chart paper. If it is not, then carefully adjust the pen arm to

establish contact with the paper. On a thermal print recorder, the thermal stylus does not

need adjustment.

Marking Systems - "Ink Type Pens"

This type of pen consists of a self-contained ink reservoir with a porous plastic stylus,

which is snapped around the outer edge of the metal pen arm.

A pen cap is provided to extend the life of the ink pen during shipping, or when the

recorder is not in service. To remove the pen cap, gently lift the pen arm away from the

chart paper. Remove the black plastic pen cap to expose the fiber tip of the ink pen and

gently place the pen back onto the chart paper. Do not let the pen arm "snap" back onto

the chart paper. This will flatten the fiber tip of the pen and will no longer give you a fine

line marking on the chart paper. Place the pen cap in a safe place for future use.

If the stylus does not touch the chart, adjustment can be made by slightly bending the

metal pen arm in the center towards the chart paper. Do not use more pressure than is

necessary to create a fine line marking on the chart paper. Note: As the pen ink supply

runs out, the pen color will become lighter. This indicates that the pen should be replaced.

- 14 -

Page 15

Global Water

800-876-1172 • globalw.com

Replacement of Pen “Ink Type”

Recorders that are equipped with fiber tipped cartridge pens are colored coded RED for

pen 1 and BLUE for pen 2.

The pen cartridge is securely fastened to the metal pen arm using a special "U" clip tab.

For ease of replacement, it is suggested that the two (2) screws that hold the pen arm be

loosened and the pen cartridge and metal pen arm be removed as an assembly. Refer to

Figure 2.10 (Page 17) for the location of the pen arm screws. Unsnap the plastic "U" clip

tab of the pen cartridge from the metal pen arm, remove and discard the old pen cartridge.

Replace the new cartridge by opening the hinge and snapping it securely around the metal

pen arm. Refer to Figure 2.8 for pen cartridge replacement.

Figure 2.8 Pen Replacement

Marking Systems - Thermal Type

This type of pen consists of a self-contained thermal print head that is attached to a metal

“Stylus” pen arm assembly.

Periodic maintenance is not required for this pen type. Since the thermal print head

creates its own chart, adjustment for outer ring are made automatically during each chart

change. Refer to Replacement of Thermal Stylus (page 15).

Replacement of Thermal Stylus

The thermal print head is securely fastened to the metal stylus arm, which is attached to

the pen motor drive assembly.

For ease of replacement, it is suggested that the stylus (with print head attached) be

removed as a complete assembly.

1. Disconnect AC power from unit.

2. Remove the two platen screws located on the front of the platen at the right center

of the platen.

- 15 -

Page 16

Global Water

800-876-1172 • globalw.com

3. Follow the thermal pen leads to the main “mother” board located on the back of

the recorder platen.

4. Remove the “plug in” thermal print head leads from the main “mother” board.

5. Remove the pen arm screws that attach the pen arm stylus to the pen arm motor

assembly located on the front of the platen.

6. Remove the pen arm assembly.

7. Install new pen arm assembly in the reverse order of disassembly.

8. Reconnect AC power to unit. Pen will align itself and begin normal recording.

9. Contrast can be adjusted if darker recording required. See Thermal Print Contrast

Adjustment (Page 27).

Figure 2.9 Thermal Recorder Platen Layout

Battery Backup “Ink Style” Units

The 9-volt DC battery back up will allow the recorder to continue to function normally

for approximately 48 hours in the event of a power failure. Units with display option will

maintain 24 hour of operation upon power loss.

The state of the green LED (listed below) assists in indicating battery condition when a

recorder has this option feature.

• If green LED is on continuous, battery voltage is acceptable.

• If green LED is flashing rapidly, battery voltage is below 7.5 VDC, replace

battery.

• If green LED is not on battery voltage is insufficient and AC power off.

The battery strap and battery holder are located on the front of the chart plate. Refer to

Figure 2.10 (Page 17). In order to change the battery, you must open the recorder case

door. Note: Use only NEW 9-volt alkaline replacement batteries.

- 16 -

Page 17

Global Water

800-876-1172 • globalw.com

NOTE: Units with optional display. Display will go BLANK upon AC power loss.

Figure 2.10 Recorder Platen Layout/Battery Installation

- 17 -

Page 18

Global Water

800-876-1172 • globalw.com

III) Programming

Recorder Setup - "Single Pen Ink Type"

In order to configure the recorder, you will need the recorder SET-UP CHART.

This chart contains the configuration categories of the recorder (Probe Input, Inner Chart

Values, Outer Chart Values, Units, Chart Rotation, Input Averaging, and Relay Options).

Place the SET-UP CHART onto the recorder. This setup chart should be saved for future

reference once setup is complete.

1. Place SETUP CHART on recorder.

2. Press and release CHANGE CHART key (3).

3. Wait until pen moves above scale and green LED stops flashing.

4. Press and hold LEFT arrow key (1) until LED goes off, then release key.

5. Pen will move to outer ring of chart. Wait for LED to flash slowly. (.8sec on / .8

sec off) LED will continue to flash slowly during setup.

6. Loosen Chart knob and rotate chart to position RED pen in the middle of the

START CIRCLE.

7. Tighten chart knob. Press and release the CHANGE CHART key (3). Pen will

move to PROBE INPUT column on the setup chart.

8. Position pen to the desired selection using LEFT (1) and RIGHT (2) keys.

9. Press and release CHANGE CHART key (3) to store selection and advance to

next category.

10. Repeat selection process until all categories are selected. You must

Press and release CHANGE CHART key (3) after last category.

11. After all categories are selected, pen will m ove off scale and LED will stop

flashing. (Steady on)

12. Remove SETUP CHART and save. Install actual recording chart.

13. Press and release CHANGE CHART key (3).

14. LED will remain on steady, pen will stop at 100% ring, and then to alarm setpoint

values (if enabled). LED will turn off when pen(s) reaches alarm setpoint. Use the

RIGHT/LEFT arrow keys to adjust alarm value(s) for pen. LED is on steady when

pen(s) is recording actual values. If the optional battery backup is installed and the

battery is weak or not plugged in, the LED will blink until the battery is replaced.

Note: Units with optional display, display goes to ---- during setup.

- 18 -

Page 19

Global Water

800-876-1172 • globalw.com

Recorder Setup - Dual Pen (Universal) Input Ink Style

In order to configure the recorder, you will need the recorder SET-UP CHART.

Universal Inputs allow the user to select a different type of input for each pen.

The setup chart contains the configuration categories of the recorder (Probe Input, Inner

Chart Values, Outer Chart Values, Units, Chart Rotation, Input Averaging, and Relay

Options). Place the SET-UP CHART onto the recorder. This setup chart should be saved

for future reference once setup complete.

1. Place SETUP CHART on recorder .

2. Press and release CHANGE CHART key (3).

3. Wait until pens moves above scale and green LED stops flashing.

4. Press and hold LEFT arrow key (1) until LED goes off, then release key.

5. Blue Pen will move to outer ring of SETUP CHART. Red pen will then move to

outer ring. Please note Blue pen setup selections allowed are categories Input

Probe and Relay selections only. Wait for LED to flash slowly. (.8sec on / .8 sec

off) LED will continue to flash slowly during setup.

6. Loosen Chart knob and rotate chart to position RED pen in the middle of the

START CIRCLE.

7. Tighten chart knob. Press and release the CHANGE CHART key (3). Pen will

move to PROBE INPUT column on the setup chart.

8. Position pen to the desired selection using LEFT (1) and RIGHT (2) keys.

9. Press and release CHANGE CHART key (3) to store selection and advance to

next category.

10. Repeat selection process until all categories are selected. You must

Press and release CHANGE CHART key (3) after last category.

11. After all categories are selected, pen will m ove off scale and LED will stop

flashing. (Steady on)

12. Remove SETUP CHART and save. Install actual recording chart.

13. Press and release CHANGE CHART key (3).

14. LED will remain on steady, pen will stop at 100% ring, and then to alarm setpoint

values (if enabled). LED will turn off when pen(s) reaches alarm setpoint. Use

RIGHT/LEFT arrow keys to adjust alarm value(s) for pen. LED is on steady when

pen(s) are recording actual values and blinks when the battery backup needs

replacing.

Note: If unit has optional display, display goes to ---- during setup.

Recorder Setup - Thermal Recorders 1 & 2 Pen

All thermal recorders come standard setup for dual channel operation. Units can

be configured for single channel operation as follows:

- 19 -

Page 20

Global Water

800-876-1172 • globalw.com

1. Disconnect power from the unit to be configured.

2. To configure unit for single channel operation, depress and hold the

LEFT arrow (1) key. While holding key re-apply power to unit.

3. Hold key depressed for 15 seconds after which, Green LED will turn

on. Print arm will begin to move. Unit is now configured for single

channel operation.

If conversion back to DUAL channel required. Please perform the above operation,

only depress the RIGHT arrow (2) key and hold upon power up.

After configuring, please proceed with recorder SET-UP procedure below.

In order to configure the recorder, you will need the recorder SET-UP CHART.

Thermal print recorders use a single thermal printhead for single and two

channel units.

The setup chart contains the configuration categories of the recorder (Probe Input,

Inner Chart Values, Outer Chart Values, Units, Chart Rotation, Input Averaging, and

Relay Options). Place the SET-UP CHART onto the recorder. This setup chart

should be saved for future reference once setup complete.

1. Place SETUP CHART on recorder.

2. Press and release CHANGE CHART key (3).

3. Wait until stylus moves to top of chart and green LED stops flashing.

4. Press and hold LEFT arrow key (1) until LED goes off, then release

key.

5. Thermal stylus will move to outer ring of setup chart. The left and right arrow

keys can be used to adjust the centerline on the print head to the outer ring of the

setup chart at this time. Wait for LED to flash slowly. (.8sec on / .8 sec off) LED

will continue to flash slowly during setup.

6. Loosen Chart knob and rotate chart to position the center of the printhead in the

middle of the START CIRCLE.

7. Tighten chart knob. Press and release the CHANGE CHART key (3).Pen will

move to PROBE INPUT column on the setup chart.

8. Position pen to the desired selection using LEFT (1) and RIGHT (2) keys.

9. Press and release CHANGE CHART key (3) to store selection and advance to

next category.

10. Repeat selection process until all categories are selected. You must Press and

release CHANGE CHART key (3) after last category.

11. After all categories are selected, pen will m ove off scale and LED will stop

flashing. (Steady on)

12. Remove SETUP CHART and save. Install actual recording chart.

13. Press and release CHANGE CHART key (3).

14. The thermal stylus will now begin printing the chart. The thermal stylus will print

all scales, date/time and trend lines automatically. NOTE: if unit has optional

display, display goes to ---- during setup.

- 20 -

Page 21

Global Water

800-876-1172 • globalw.com

Alarm Settings Ink Style Recorders

Alarm setpoint values are selected by positioning the pen to the actual value on the

recording chart. Alarm settings can be selected or viewed after CHART CHANGE,

recorder setup or during initial power up. To set the alarm setpoint during normal

recording operation, complete the following steps.

Press and release the CHANGE CHART key (3 on Figure 3.2). Wait until pen(s) moves

off scale and LED status changes from flashing to steady. Press and release the

CHANGE CHART (3) again, the pen will begin to move back onto the chart briefly

stopping at (or close to) the outermost graduation of the chart. Green LED remains on

steady during this time.

Single Alarm Setting

After the above operation is complete, the active pen(s) arm will move to the current

alarm setpoint position on the chart (one pen at a time). The green LED will go out,

during this time the alarm setpoint (for each pen) can be adjusted using the LEFT arrow

(1) or the RIGHT arrow (2) keys on the keypad. Once the alarm setpoint is set, wait for

the green LED will turn on and the pen arm will move to indicate the probe's temperature

and the unit will begin normal recording operation.

Band Alarm Setting

When programming the recorder for band alarm operation, the active pen(s) will move to

the first band setpoint on the chart. The green LED will go out. The alarm band 1 setpoint

can now be adjusted using the LEFT arrow (1) or the RIGHT arrow (2) keys, once set,

wait for the green LED to turn on. The active pen will then move to the second band

alarm setpoint. The green LED will go out. The alarm band 2 can now be adjusted. When

pen(s) alarm setpoints adjustments are completed, wait for the green LED to turn on and

the pen arm will move to indicate the probe's temperature and the unit will begin normal

recording operation.

The “Change Chart” key is the “RESET” when the recorder is programmed for latching

alarm operation.

NOTE: Alarm reset occurs upon depressing “Change Chart” (3) key regardless of alarm

condition.

- 21 -

Page 22

Global Water

800-876-1172 • globalw.com

Alarm Settings Thermal Style Recorders

Thermal alarm relay settings can only be set or reviewed from the Setup mode. The

SETUP chart must be used for this.

Install setup chart. Follow the thermal setup instructions found (See page 10).

Alarm settings are set under Alarm #1 and Alarm # 2 setpoint categories. The setup

procedure must be followed completely in order to properly store selected alarm values.

Alarms are programmable for hi or low alarm action as well as latching or non-latching.

Latching alarms require a manual “reset” which is performed by depressing “change

chart” key (3).

Note: Alarms will “reset” when pressing the “Change Chart” key REGARDLESS of

the current alarm condition.

Thermal alarms can be programmed as follows:

P1(Hi): Process high alarm (on above setpoint) assigned to Pen1.

P1(Low): Process low alarm (on below setpoint) assigned to Pen 1.

LP1(Hi): Latching high alarm assigned to Pen 1.

LP1(Low): Latching low alarm assigned to Pen 1.

P2(Hi) or P2(Low): Same as P1 operation only for Pen 2

LP2(Hi) or: LP2(Low): Same as LP1 operation only for Pen 2

OR can use both relays if available for PEN 1 ONLY

P1(Hi/Low): Pen 1 uses both optional relays for alarm.

Alarm 1 is a high alarm. Alarm 2 is a low alarm

LP1(Hi/Low): Pen 1 uses both optional relays for latching alarms.

Alarm 1 is a high latching alarm. Alarm 2 is a low latching alarm.

P2(Hi) or P2(Low): Same as P1 operation only for Pen 2

LP2(Hi or: LP2(Low): Same as P1 operation only for Pen 2

NOTE: Units with optional display, Alarm setpoint will be indicated on LED.

- 22 -

Page 23

Global Water

800-876-1172 • globalw.com

Alarm Settings Display Option Features

The single red LED display indicates input(s) process variable value with unit(s)

during normal operation. In 2 pen units with display, LED display cycles between

Pv1 value and Pv2 value. As PV value cycles an additional LED indicates which Pv

(1 or 2) value is being displayed.

LED display will indicate Hi or Lo if process input variable goes above(Hi) or

below(Lo) the programmed range of the recorder scale.

When battery option is included on Ink style recorders, display will go to ----- upon

loss of AC power. Green LED indicator will remain on, see Battery Backup

information (page 17).

When OFFSET is used to adjust a pen recording position, the LED display will

indicate the actual number of units the selected recording pen has been adjusted

(OFFSET) by. This can be a positive(+) or negative(-) value.

For Thermal units ONLY, if alarm setpoints are used, these values will be shown

upon any chart change operation. See information on Changing the Chart (page 15.)

- 23 -

Page 24

Global Water

800-876-1172 • globalw.com

IV) Calibration - Ink Type Only

Pen Arm Calibration (Zero and Span)

Pen calibration applies to ink type units only and is a two-point calibration. Since

Thermal stylus units print their own outer/inner ring, calibration is not necessary. To

check and/or adjust the recording pen(s) calibration to the inner and outer graduations of

the chart on ink type units, perform the following.

1. Remove power to instrument. If unit has battery option, also remove battery.

2. With all power removed, press and hold the CHANGE CHART key (3). While

holding the CHANGE CHART key (3), re-apply power. Release key upon

applying power, either AC or battery which ever is convenient.

3. The pen(s) will move off scale, LED will flash rapidly. Green LED will then go

to on steady. If 1 pen ink unit go to step 5 next.

4. The blue pen will then move to 100% ring. Adjust blue pen, if necessary, using

LEFT (1) and RIGHT (2) keys to position pen on 100% ring, then wait.

5. Red pen will then move to 100% ring. Adjust this pen, if necessary, to 100%

ring, using LEFT (1) and RIGHT (2) keys, then wait.

6. Red pen will then move to 0% ring. Adjust pen using LEFT (1) and RIGHT (2)

keys, then wait. Pen will then move full upscale. If 1 pen unit go to step 8.

7. Blue pen will move to 0% ring. Adjust pen to 0%, using LEFT (1) and RIGHT

(2) keys, then wait. Blue pen will now travel full upscale.

8. Pen(s) calibration is now complete.

Pen(s) will then go directly to actual recording values.

Each time the chart paper or fiber tip pen cartridge is changed, you should make sure

that each pen stops at the outer most temperature graduation of the chart paper. If ink

pens do not accurately stop at outer graduation recording error can occur and recorder s

calibration should be reviewed.

Figure 4.1 Keypad

- 24 -

Page 25

Global Water

800-876-1172 • globalw.com

Probe Offset Adjust - Ink Style (Pen Offset)

This recorder has been accurately calibrated at the factory. Before making any

adjustments, this instrument should be in service for 24 hours. Thereafter, if any

adjustment is required, perform the following procedure.

1. Place a Certified Test Thermometer(s) alongside the recorder's sensor probe(s) in

a monitored controlled condition.

2. Once the temperature has leveled out, compare the position of the pen on the

recorder to the test thermometer's reading. Also compare the Certified Test

Thermometer s reading to the second pen of the recorder.

3. If an adjustment is required, for a single pen unit, depress and hold either the

LEFT (1) or RIGHT (2) arrow key. The pen will begin to move after

approximately ten (10) seconds. Using the LEFT arrow (1) or RIGHT (2) arrow

keys, position the pen on the chart to correspond to the temperature of the

Certified Thermometer. Once the corrected value is obtained no further

keystrokes are required.

4. For two (2) pen ink recorders, you must first select the pen that you wish to

calibrate. This is done by pressing the LEFT (1) arrow key to select the Red pen

or the RIGHT (2) arrow key to select the Blue pen. The appropriate arrow key

must be held down for approximately five (5) seconds, after which the green

LED will go out. Release the key. The green LED will begin to flash. Adjust the

pen to the desired value. This is done using the LEFT (1) or RIGHT (2) arrow

keys. Once the corrected value is obtained, wait. The green LED will come on

steady (approximately 10 seconds). Unit will then resume normal print operation.

The remaining pen can now be selected and adjusted, if necessary, using

instructions above.

NOTE: If unit has optional display, OFFSET value will be shown on LED.

Figure 4.2 Keypad Layout

- 25 -

Page 26

Global Water

800-876-1172 • globalw.com

Probe Offset - Thermal Style (Pen Offset)

This recorder has been accurately calibrated at the factory. Before making any

adjustments, this instrument should be in service for 24 hours. Thereafter, if any

adjustment is required, perform the following procedure.

1. Place a Certified Test Thermometer(s) alongside the recorder's sensor probe(s) in

a monitored controlled condition.

2. Once the temperature has leveled out, compare the position of the pen on the

recorder to the test thermometer's reading. Also compare the Certified Test

Thermometers reading to the second pen of the recorder.

3. If an adjustment is required, for a single pen unit, depress and hold either the

LEFT (1) or RIGHT (2) arrow key. The printhead will move to current trend line

value. Using the LEFT (1) and RIGHT (2) arrow keys adjust the center scribe

mark on printhead to desired recording location. Once adjusted wait. Green LED

will go to on steady (approx. 10 sec.). Printhead will then resume normal print

operation.

4. For two (2) pen thermal recorders, you must first select the trend line that you

wish to calibrate. This is done by pressing the LEFT (1) arrow key to select trend

for pen 1 or the RIGHT (2) arrow key to select trend for pen 2. Hold the selected

key until green LED goes out. Then release the key. The green LED will begin to

flash. The printhead will now move to the current trend line value. Using LEFT

(1) and RIGHT (2) arrow keys adjust the center scribe mark on printhead to

desired recording location. Once adjusted, wait. Green LED will get to on steady

(approx. 10 sec.). Printhead will then resume normal print operation.

The remaining pen can now be selected and adjusted, if necessary using

instructions above.

NOTE: if unit has optional display, display will indicate the OFFSET value.

Thermal Print Contrast Adjustment

If print recording is light, the contrast can be darkened by the following procedure.

Please note the darker the print setting can shorten printhead life span. Adjust only if

print contrast is needed to improve readability.

1. Remove power from instrument.

2. Prior to powering up depress and hold the Change Chart (3) key.

3. While holding key, power instrument up.

4. Upon power up, release key. Pen will travel full upscale. Pen will then begin to

sweep across chart printing a line with current contrast value.

5. Depress and hold LEFT arrow (1) key to DECREASE contrast. Depress and hold

RIGHT arrow (2) key to INCREASE contrast.

6. Once contrast setting is acceptable, depress the Change Chart (3) key to store

contrast setting.

7. Unit will begin recording properly with new setting applied.

- 26 -

Page 27

Global Water

800-876-1172 • globalw.com

V) Specifications

Power

Line Voltage: 110/220VAC, 50/60Hz

Power Consumption: 15VA maximum

Battery Backup: Standard 9 volt, up to 48 hours of operation

Error Protection: De-energized during sensor break

NOTE: The CR500 circular chart recorders are not recommended for use in remote non-powe red

areas.

Inputs

Thermocouple (T/C)

Type J, K, T, R, B, S, RTD: PT 100 ohm RTD (385 curve)

Linear: 4-20 mA, 1-5 VDC

Range: Per table in manual

Common Mode Rejection: > 120dB at 60 Hz

Cold Junction Accuracy: ± 0.2°C @ 25°C ambient

Ambient Error: ± 0.01% span/°C from 25°C ambient

Isolation: Inputs share common ground on 2-pen units

Input: Impedance Linear = 249 ohm, TC = 470Kohm

Recording

Chart Size: 10"

Recording Accuracy: ± 0.5% of span (100 division span)

Sensor Break: Full scale pen < 10 seconds

Chart Speed: Configurable

Input Filtering: Programmable up to 120 seconds

Environmental & Physical

Operating Temperature: 0 to 60°C

Storage Temperature: -40 to 65°C

Humidity: 0-90% RH (non-condensing)

Vibration: 0.3 to 100Hz @ 0.2g

Mounting: ± 20 degrees of vertical, ± 10 degrees of horizontal

Moldings: Fire retardant Noryl w/acrylic window

Panel Rating: Nema 3 std (Nema4 option)

Dimensions: 14.0" (H) x 14.0" (W) x 3.8" (D)

Panel Cutout: Industry Standard 12.7" x 12.7"

Weight: 7 pounds maximum

Chart Recorder Relays (Optional)

Relay: DPDT, 1.0 Amps @ 120 VAC resistive

Relay Program: Process, Band, Non-latching, Latching

Hysteresis: Set at 2 units, activation is safe sided

Chart Recorder Powered Sensor Option

Transmitter Power Supply: 12VDC @ 1.0A

- 27 -

Page 28

Global Water

800-876-1172 • globalw.com

5-1 Input Range Table:

Type Range

J

K

T

B

R

S

PT100

(DIN)

mA

-130° C / 760° C

(-202° F / 1400° F)

-130° C / 1370° C

(-202° F / 2498° F)

-200° C / 400° C

(-328° F / 752° F)

100° C / 1824° C

(212° F / 3315° F)

0° C / 1650° C

(32° F / 3002° F)

0° C / 1649° C

(32° F / 3000° F)

-210° C / 440° C

(-346° F / 824° F)

4-20 Ma

Table 5-1 Input Characteristics

Lower Chart Range Selection:

Programmable from - 999 to 9999 Units

Upper Chart Range Selection:

Programmable from - 999 to 9999 Units

Table 5-2 Upper/Lower Chart Ranges

Note: Recommended minimum chart span for thermocouple inputs is 100

Color

Code Polarity

White

Red

Yellow

Red

Blue

Red

Gray

Red

Black

Red

Black

Red

+

-

+

-

+

-

+

-

+

-

+

-

- 28 -

Page 29

Global Water

800-876-1172 • globalw.com

VI) Default Settings

FACTORY SET DEFAULTS

Defaults settings are identical for 1 and 2 pen ink or thermal recorders.

Input ------------- J T/C *

Unit -------------- Fahrenheit

Scale ------------ 0-100

Rotation -------- 24 hour

Input Average ----- 8

Optional alarms when ordered

Alarms - High Alarm

Setpoint - 90° F

- 29 -

Page 30

Global Water

800-876-1172 • globalw.com

VII) Troubleshooting

GREEN LED LIGHT SEQUENCE GUIDE

1. LED on steady and pen(s) within chart range, unit is recording normally

2. LED on steady and pen(s) above 100 % ring indicates unit is in CHART CHANGE

mode.

Action: Press and release CHART CHANGE key to return to normal recording

mode.

3. LED flashing RAPIDLY and pen(s) within chart range indicates battery voltage is

low.

Action: Replace battery.

4. LED flashing RAPIDLY and pen(s) at 0 or 100 % ring indicates that input sensor(s)

are in a break condition or input out of programmed chart range.

Action: Check or replace sensor, validate setup information for sensor and chart

range programmed. Validate both inputs for 2 pens.

5. LED flashing slowly (0.8 sec. On/ 0.8 sec. off) unit in setup mode.

Action: Complete setup procedure of recorder. Or performing Probe offset

procedure.

6. LED not on indicates no power to unit.

Action: Check to see if AC present on power terminals. If battery option exists check

and/or replace battery.

7. Other issues:

a. Call us for tech support: 800-876-1172 or 916-638-3429 (many problems

can be solved over the phone). Fax: 916-638-3270 or Email:

globalw@globalw.com

Be prepared to describe the problem you are experiencing including

specific details of the application and installation and any additional

pertinent information.

b. In the event that the equipment needs to be returned to the factory for any

reason, please call to obtain an RMA# (Return Material authorization). Do

not return items without an RMA# displayed on the outside of the

package.

Clean and decontaminate the CR500 if necessary.

Include a written statement describing the problems.

Send the package with shipping prepaid to our factory address. Insure your

shipment, as the warranty does not cover damage incurred during transit.

.

- 30 -

Page 31

Global Water

800-876-1172 • globalw.com

c. When calling for tech support, please have the following information

ready;

1) Model #.

2) Unit serial number.

3) P.O.# the equipment was purchased on.

4) Our sales number or the invoice number.

5) Repair instructions and/or specific problems relating to the product.

VIII) Warranty

a) Global Water Instrumentation, Inc. warrants that its products are free from defects

in material and workmanship under normal use and service for a period of one

year from date of shipment from factory. Global Water’s obligations under this

warranty are limited to, at Global Water’s option: (I) replacing or (II) repairing;

any products determined to be defective. In no case shall Global Water’s liability

exceed the products original purchase price. This warranty does not apply to any

equipment that has been repaired or altered, except by Global Water

Instrumentation, Inc., or which has been subject to misuse, negligence, or

accident. It is expressly agreed that this warranty will be in lieu of all warranties

of fitness and in lieu of the warranty of merchantability.

b) The TWO year warranty begins on the date of your invoice.

- 31 -

Page 32

Global Water

800-876-1172 • globalw.com

IX) Appendix A Spare Parts

Red Pens (6pcs/pk) P/N CP400 (Pen 1 )

Blue Pens (6pcs/pk) P/N CP401 (Pen 2 only)

Green Pens (6pcs/pk) P/N CP402 (Pen 2 only)

- 32 -

Page 33

Global Water

800-876-1172 • globalw.com

X) GLOSSARY:

Input Averaging - The number of input readings (in seconds) held and averaged as pen is

recording. The larger the number the more pen response is dampened.

High Alarm (Hi) - Output relay energized when process variable above set value.

Low Alarm (Low) - Output relay energized when process variable below set value.

Band Alarm (Band) - Output relay is energized when process variable is above high set

value or below low set value.

NOTE: Band alarm only available programming on ink style recorders.

Latching - Output relay requires a reset (depress 3 key) to de-energize relay after

activating.

NOTE: Reset occurs regardless of alarm condition.

- 33 -

Loading...

Loading...