Book Version 1.0

February 2017

702P04572

®

Xerox

Versant

User Guide

®

180 Press

©2017 Xerox Corporation. All rights reserved. Xerox®, Xerox and Design®, FreeFlow®,

SquareFold®, CentreWare®and Versant®are trademarks of Xerox Corporation in the

United States and/or other countries.

Adobe PDF is a registered trademarks of Adobe Systems, Inc. PostScript is an Adobe

registered trademark used with the Adobe PostScript Interpreter, the Adobe page

description language, and other Adobe products.

Fiery®and EFI™are trademarks or registered trademarks of Electronics For Imaging, Inc.

GBC®and AdvancedPunch™are trademarks or registered trademarks of General Binding

Corporation.

Microsoft, Windows, Windows XP, Windows Vista, Internet Explorer, and Word are

registered trademarks of Microsoft Corporation in the United States and/or other

countries.

3-IN-ONE®and WD-40®are a registered trademarks of the WD-40 Company.

BR4005

Table of Contents

1 Product Symbols........................................................................................1-1

2 Getting Started..........................................................................................2-1

Print Server Overview..........................................................................................................2-1

Press Components...............................................................................................................2-1

Locating the Press Serial Number....................................................................2-2

User Interface (UI).................................................................................................2-3

Features......................................................................................................................2-4

Logon.............................................................................................................2-4

Language ....................................................................................................2-5

Optional Performance Package...........................................................2-5

Power On/Off.........................................................................................................................2-7

The Power Switches...............................................................................................2-7

Power On/Off the Press........................................................................................2-8

Power On the Press...................................................................................2-8

Power Off the Press...................................................................................2-8

Power Saver...............................................................................................................2-8

Low Power Mode.......................................................................................2-8

Sleep Mode..................................................................................................2-9

Exiting Power Saver..................................................................................2-9

Getting Help...........................................................................................................................2-9

Help on the Xerox Web Site................................................................................2-9

Print Server Customer Documentation..........................................................2-9

3 Press Apps.....................................................................................................3-1

Print...........................................................................................................................................3-1

Print Job Submission.............................................................................................3-1

Printing from a Computer...................................................................................3-1

Printing a Job from the Print Server................................................................3-2

Printing from the FreeFlow Print Server............................................3-2

Printing from the EX Print Server.........................................................3-2

Printing on Tabs from the Print Server...........................................................3-3

Basic Procedure for Printing on Tabs from a Print

Server...................................................................................................3-3

Tips for Printing on Tabs from the EX Print Server.......................3-3

Copy..........................................................................................................................................3-4

Document Feeder and Glass..............................................................................3-4

Document Feeder Tips............................................................................3-4

User Guide

iXerox®Versant®180 Press

Table of Contents

Document Glass.........................................................................................3-4

Basic Copying Steps..............................................................................................3-4

Basic Copying with the Document Feeder (DADF)......................3-4

Basic Copying with the Document Glass.........................................3-5

Selecting Copy Options for a Third-Party Finishing

Device..................................................................................................3-5

Copy Feature............................................................................................................3-6

Copy Feature Overview...........................................................................3-6

Reduce/Enlarge..........................................................................................3-7

Paper Supply...............................................................................................3-8

Output Color................................................................................................3-8

Copy Output................................................................................................3-9

2 Sided Copying.........................................................................................3-9

Original Type............................................................................................3-10

Darken/Lighten........................................................................................3-11

Image Quality Feature......................................................................................3-11

Image Quality Feature Overview.....................................................3-11

Selecting Image Quality Options.....................................................3-11

Original Type............................................................................................3-12

Image Options.........................................................................................3-12

Image Enhancement............................................................................3-13

Color Effects..............................................................................................3-13

Color Balance...........................................................................................3-14

Color Shift..................................................................................................3-14

Layout Adjustment Feature.............................................................................3-14

Layout Adjustment Feature Overview............................................3-14

Selecting Layout Adjustment Options...........................................3-15

Book Copying...........................................................................................3-15

2 Sided Book Copying...........................................................................3-16

Original Size..............................................................................................3-16

Edge Erase.................................................................................................3-16

Image Shift...............................................................................................3-17

Image Rotation.......................................................................................3-17

Invert Image............................................................................................3-18

Original Orientation...............................................................................3-18

Output Format Feature......................................................................................3-18

Output Format Feature Overview....................................................3-18

Selecting Output Format Options....................................................3-19

Booklet Creation.....................................................................................3-20

Covers..........................................................................................................3-21

Page Layout..............................................................................................3-22

Xerox®Versant®180 Pressii

User Guide

Table of Contents

Poster...........................................................................................................3-22

Annotations..............................................................................................3-22

Watermark.................................................................................................3-23

Tab Margin Shift.....................................................................................3-23

Face Up/Down Output..........................................................................3-24

ID Card Copy............................................................................................3-24

Transparency Options...........................................................................3-25

Folding (optional)...................................................................................3-25

Job Assembly Feature........................................................................................3-26

Job Assembly Feature Overview.......................................................3-26

Build Job.....................................................................................................3-26

Sample Job................................................................................................3-27

Combine Original Sets..........................................................................3-28

Delete Outside/Delete Inside............................................................3-28

Scan........................................................................................................................................3-29

Scan Overview.......................................................................................................3-29

Basic Scanning......................................................................................................3-30

Basic Scanning Procedure...................................................................3-30

Previewing Scanned Images..............................................................3-31

Changing Scan Settings/Options.....................................................3-31

Canceling a Scan Job............................................................................3-31

Stopping a Scan Job..............................................................................3-31

Scan Options..........................................................................................................3-32

Scan Options Overview.........................................................................3-32

Basic Scan Options.................................................................................3-32

Advanced Settings.................................................................................3-33

Layout Adjustment................................................................................3-35

E-mail Options.........................................................................................3-36

Filing Options...........................................................................................3-39

Resolving a File Name Conflict.........................................................3-40

E-mail........................................................................................................................3-41

E-mail Overview.......................................................................................3-41

E-mail Components...............................................................................3-41

Scanning to an E-mail Address.........................................................3-42

Network Scanning...............................................................................................3-43

Network Scanning Overview..............................................................3-43

Network Scanning Components.......................................................3-43

Network Scanning Procedure............................................................3-44

Scan to PC...............................................................................................................3-44

Scan to PC Overview..............................................................................3-44

Scan to PC Components......................................................................3-44

User Guide

iiiXerox®Versant®180 Press

Table of Contents

Send from Folder (Folder / File Management)......................................................3-52

Job Flow................................................................................................................................3-57

Web Applications..............................................................................................................3-62

How to Use the Scan to PC Feature................................................3-45

Store to Folder.......................................................................................................3-47

Store to Folder Overview......................................................................3-47

Store to Folder Components..............................................................3-47

Using the Store to Folder Feature....................................................3-47

Store to USB...........................................................................................................3-47

Store to USB Overview.........................................................................3-47

Using the Store to USB Feature........................................................3-48

Store and Send Link Feature (Send to Folder)..........................................3-49

Store and Send Link (Send to Folder) Overview.........................3-49

Storing and Sending a Link (Sending to Folder)........................3-50

Store to Web Services for Devices (WSD)...................................................3-50

Store to WSD Overview........................................................................3-50

How to Use the Store to Web Services for Devices (WSD)

Feature..............................................................................................3-51

Send from Folder (Folder / File Management) Overview.....................3-52

File Options............................................................................................................3-52

Managing Folders and Scanned Files..........................................................3-54

How to Configure/Start a Job Flow..............................................................3-54

Configuring/Starting a Job Flow......................................................3-54

Using Send from Folder to Link a Job Flow Sheet to a

Folder.................................................................................................3-56

Job Flow Overview...............................................................................................3-57

Job Flow Settings and Options.......................................................................3-58

Overview of Job Flow Options...........................................................3-58

Additional Job Flow Options..............................................................3-58

Sheet Filtering Options.........................................................................3-59

Send as E-mail Options........................................................................3-59

Transfer via FTP (1) / Transfer via FTP (2) Options...................3-59

Transfer via SMB (1) / Transfer via SMB (2) Options................3-60

Print Options.............................................................................................3-60

E-mail Notification Options................................................................3-60

Job Flow Procedures...........................................................................................3-60

Creating a Job Flow Sheet..................................................................3-60

Linking a Job Flow Sheet with a Folder..........................................3-61

Starting a Job Flow Manually............................................................3-62

Confirming/Changing a Job Flow....................................................3-62

Web Applications Overview.............................................................................3-62

Accessing Web Applications............................................................................3-63

Xerox®Versant®180 Pressiv

User Guide

Table of Contents

Job Status.............................................................................................................................3-63

Job Status Overview............................................................................................3-63

Job Status Area.....................................................................................................3-63

Active Jobs Tab.....................................................................................................3-63

Completed Jobs Tab............................................................................................3-63

Machine Status..................................................................................................................3-64

Machine Status Overview.................................................................................3-64

Device Information Tab....................................................................................3-64

Faults Tab................................................................................................................3-65

Supplies Tab...........................................................................................................3-66

Billing Information Tab......................................................................................3-66

Accessing Billing Information............................................................3-66

Billing Impressions Information.......................................................3-66

Usage Counters.......................................................................................3-67

Tools Tab..................................................................................................................3-68

Changing the Paper Tray Attributes.............................................................3-69

4 Paper and Media.......................................................................................4-1

Supported Paper...................................................................................................................4-1

Paper Specifications..............................................................................................4-1

Paper Tray Information........................................................................................4-3

Throughput / Productivity Information ........................................................4-3

Loading Media in Trays 1, 2, and 3...............................................................................4-5

Information About Loading Media in Trays 1, 2, and 3..........................4-5

Loading Paper in Trays 1, 2, and 3...................................................................4-5

Loading Tab Stock in Trays 1, 2, and 3...........................................................4-6

Loading Transparencies in Trays 1, 2, and 3................................................4-7

Loading Pre-drilled Stock in Trays 1, 2, and 3..............................................4-7

Loading Media in the Bypass (Tray 5).........................................................................4-8

Loading Paper in the Bypass (Tray 5).............................................................4-9

Loading Tab Stock in the Bypass (Tray 5).....................................................4-9

Loading Transparencies in the Bypass (Tray 5).......................................4-10

Loading Pre-drilled Stock in the Bypass (Tray 5).....................................4-10

Loading Envelopes in the Bypass (Tray 5).................................................4-11

5 Maintenance...............................................................................................5-1

Cleaning the Press Overview............................................................................................5-1

Cleaning the Exterior............................................................................................5-1

Cleaning the Document Cover and Glass.....................................................5-1

Cleaning the Document Feeder Rollers.........................................................5-3

Cleaning the Drum Drawer Area......................................................................5-4

Cleaning the ROS Windows................................................................................5-4

User Guide

vXerox®Versant®180 Press

Table of Contents

Cleaning the Fuser Assembly.............................................................................5-5

Replacing Consumable Supplies....................................................................................5-5

Ordering Supplies...................................................................................................5-6

Checking the Status of Consumables.............................................................5-7

Replacing a Dry Ink/Toner Cartridge..............................................................5-7

Replacing the Dry Ink/Toner Waste Bottle...................................................5-8

Replacing a Drum Cartridge...............................................................................5-9

Replacing the Suction Filter.............................................................................5-11

6 Troubleshooting.........................................................................................6-1

General Troubleshooting..................................................................................................6-1

Reducing Toner Consumption...........................................................................6-7

Image Quality Problems...................................................................................................6-8

Custom Paper Settings Troubleshooting.................................................................6-11

Custom Paper Settings - Default Settings..................................................6-20

Paper Jams...........................................................................................................................6-27

Paper Jams Overview..........................................................................................6-27

Information about Paper Jams......................................................................6-27

Jam Recovery Offset Feature..........................................................................6-27

Setting Up the Jam Recovery Offset Feature..............................6-28

Paper Jams in the Document Feeder...........................................................6-29

Document Feeder Jams.......................................................................6-29

Document Jams Under the Document Feeder Belt..................6-31

Press Paper Jams..................................................................................................6-31

Paper Jams Inside the Press...............................................................6-31

Paper Jams in Trays 1-3.......................................................................6-33

Paper Jams in the Bypass (Tray 5)................................................................6-33

Paper Jams in the Standalone Bypass (Tray 5)..........................6-33

Troubleshooting Help......................................................................................................6-34

Locating the Press Serial Number.................................................................6-34

Calling for Service................................................................................................6-34

Fuser Hints and Tips.........................................................................................................6-35

Extending Fuser Life............................................................................................6-35

Preventing Fuser Damage................................................................................6-35

Fuser Paper Width Information.....................................................................6-35

7 Specifications..............................................................................................7-1

First Print-Out Time.............................................................................................................7-2

Press Warm-up Time...........................................................................................................7-2

Document Feeder Specifications...................................................................................7-2

Copy Specifications.............................................................................................................7-2

Scan Specifications.............................................................................................................7-4

Xerox®Versant®180 Pressvi

User Guide

Table of Contents

Environmental Specifications.........................................................................................7-5

User Guide

viiXerox®Versant®180 Press

Table of Contents

Xerox®Versant®180 Pressviii

User Guide

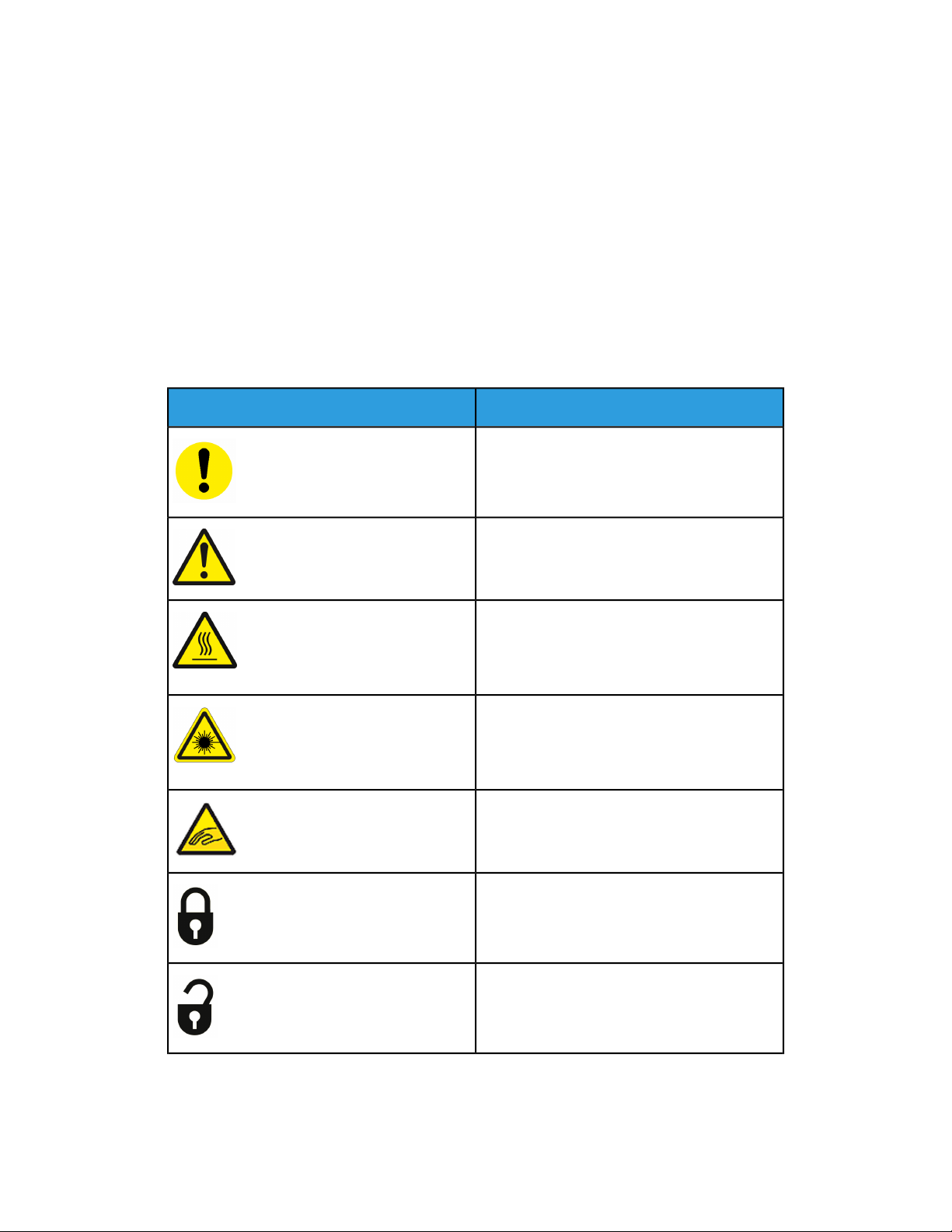

Product Symbols

DefinitionSymbol

Caution

This symbol indicates a mandatory action to

take in order to avoid damage to these areas.

Warning

This symbol alerts users to areas where there

is the possibility of personal injury.

Hot Warning

This symbol alerts users to areas where there

are heated surfaces which should not be

touched.

1

User Guide

Laser Warning

This symbol indicates a laser is being used and

alerts the usertorefertotheappropriate safety

information.

Pinch Hazard

This warning symbol alerts users to areas where

there is the possibility of personal injury.

Lock

Unlock

1-1Xerox®Versant®180 Press

Product Symbols

DefinitionSymbol

Do Not Touch

Do Not Touch the Drum Cartridge

To avoid damage, do not touch the surface of

the Drum Cartridge.

Do Not Dispose into an Open Flame / Incinerate

Do Not Incinerate the Toner Cartridge

Always refer to the recycling instructions for

your region / marketplace for correct disposal

information and procedures.

Do Not Incinerate the Toner Waste Bottle

Do Not Incinerate the Drum Cartridge

Do Not Incinerate the Second Bias Transfer

Roll

Ground / Common / Earth Terminal

LAN

Local Area Network

USB

Universal Serial Bus

Xerox®Versant®180 Press1-2

User Guide

Product Symbols

DefinitionSymbol

Keep Area Clear

Do not store any objects in this location.

Keep Area Clear

Do Not Use Transparencies with a White Strip

/ Overhead Projector Sheets with a White

Strip

Do Not Use Envelopes with Open Flaps

Do Not Use Folded, Creased, Curled, or

Wrinkled Paper

Do Not Use Ink Jet Paper

Do Not Load Postcards in the Indicated Direction

Do Not Use Media Attached with Staples or

Paper / Metal Clips

Do Not Copy Money

User Guide

1-3Xerox®Versant®180 Press

Product Symbols

DefinitionSymbol

Tray Guides Must Touch Media

Load Postcards in the Indicated Direction

Load Hole-punched Paper as Indicated

Load Media / Documents Face Down

IC Card Reader

Integrated Circuit Card Reader / Smart Card

Reader / Chip Card Reader

On

This symbol indicates the main power switch is

in the ON position.

Off

This symbol indicates the main power switch is

in the OFF position.

Standby

This symbol indicates the secondary power

switch is in the Standby position.

Do Not Dispose in Normal Household Waste

Stream

• Application of this symbol is confirmation

that you should not dispose of items, such

as Customer Replaceable Units (CRUs), in

the normal household waste stream. You

must dispose of these items in compliance

with agreed national procedures.

• This symbol often accompanies batteries

and indicates that used electrical and electronic products and batteries should not be

mixed with general household waste.

• For more information about collection and

recycling, please contact your local municipality, your waste disposal service, or the

Xerox®Versant®180 Press1-4

User Guide

Product Symbols

DefinitionSymbol

point of sale where you purchased the

items.

User Guide

1-5Xerox®Versant®180 Press

Product Symbols

Xerox®Versant®180 Press1-6

User Guide

2

Getting Started

The Xerox®Versant®ColorPress is a full color/black and white, auto-duplex copier/printer

that operates at a speed of 80 prints per minute (when printing on 8.5 x 11 inch/A4

paper).

Print Server Overview

The print server networked with your press accepts, processes, and manages document

files for job submission to the press.

One of the following print servers may be used with your press:

• Xerox®FreeFlow®Print Server

• Xerox®EX Print Server, Powered by Fiery

• Xerox®EX-P Print Server, Powered by Fiery

®

®

Note

For detailed information on your specific print server, refer to the customer

documentation that was delivered with it. Documentation may also be downloaded

from www.xerox.com by searching for the press and selecting the Support link.

Press Components

User Guide

2-1Xerox®Versant®180 Press

Getting Started

1 Bypass Tray

The Bypass Tray is also called Tray 5 or Multisheet Inserter; the tray accommodates

all types of stock in various sizes and weight ranges.

Note

The mounting location for the Bypass tray varies when optional feeding devices are

added to the machine configuration.

2 User Interface (UI)

The User Interface (UI) consists of the touch screen and control panel with the buttons

and keypad.

3 Duplex Automatic Document Feeder (DADF)

Automatically feeds 1- and 2-sided original documents. A maximum of 250 two-sided

documents can be scanned at one time.

4 Offset Catch Tray (OCT)

This tray receives the completed print job. Output print sheets can be offset for easy

separation. The maximum capacity of the OCT is determined by the tray sensor as well

as stock weight, but is approximately 500 sheets of 24 lb. (90 gsm) paper.

Note

Offsetting per set in the stack continues up to the point when the tray reaches the

maximum height or weight allowed.

5 Dry Ink/Toner Waste Bottle Door

Open this door to access the waste bottle when replacement of the bottle is required.

6 Trays 1-3

Trays 1, 2, and 3 accommodate a variety of paper sizes and weights; refer to the

Technical Specifications chapter for detailed information.

7 Front Door

Open this door to clear paper jams and to replace various Customer Replaceable Units

(CRUs).

8 Dry Ink/Toner Cover

Open this cover to access and replace the dry ink/toner cartridges.

Locating the Press Serial Number

The press serial number can be accessed from either the press User Interface or from

the serial number plate which is located on the inside frame of Tray 1.

1. Press the Machine Status button on the User Interface.

2. Fromthe Machine Status screen, ensure that the Device Information tab is displayed.

The press serial number is displayed under Device Serial Information near the bottom

of the screen.

Xerox®Versant®180 Press2-2

User Guide

Getting Started

3. If there is a loss of power and it is not possible to access the Machine Status screen,

the press serial number can also be found on the inside frame of the press near the

Paper Tray 1 drawer:

a) At the press, fully open Tray 1.

b) At the left of the tray, on the press frame,locate the plate with the serial number

(SER#).

User Interface (UI)

1 Touch Screen

Directly touch the screen to select and set features. Displays instructional and

informational messages, fault clearance procedures and general press information.

2 Home button

Press this button to display the main window. Provides access to features such as Copy,

E-Mail, and Network Scanning, just to name a few features. Other features may be

available depending on your marketplace.

3 Services

This button lights when the main power is on.

4 Job Status button

Use to check the progress of active jobs and detailed information about completed

jobs or pending jobs. This area also allows you to delete a job (cancel printing or copying)

and pause jobs.

5 Machine Status button

Use to access the Tools feature, check the press configuration, the software version,

the press billing meters and counter information, and to access and print job history

or error reports.

6 Log In/Out button

Use to log in and out of Administrator mode or Authentication mode with user ID and

password.

User Guide

2-3Xerox®Versant®180 Press

Getting Started

7 Energy / Power Saver button

Use this button if the press has been inactive and the touch screen is dark (system is

in Energy Saver mode). This button manually exits the system fromEnergy Saver mode;

it does not place the press in Energy Save mode.

8 Clear All button

Use this button to return all selections to the same state as when the press was powered

on. Press once to clear a current entry. Press twice to return to default settings.

9 Stop button

Press to stop and pause the print or copy job in progress.

10 Start button

Use this button to perform certain functions, such as scanning/copying a document or

printing a selected report from the print engine. This button is also used by the Customer

Service Engineer (CSE) during diagnostic routine procedures.

11 Interrupt button

Use this button to suspend a copy or print job in progress and have the machine stop

to process another job. During the Interrupt mode, the Interrupt button lights. Pressing

the Interrupt button again exits the Interrupt mode and resumes the suspended job.

12 Numeric Keypad

Use to enter alphanumeric characters.The C (Cancel) Entry cancels the previous entry

made on the numeric keypad.

13 Language button

Use to select a different language for the touch screen options.

14 Help button

Displays the Help System; this feature may not be available in all marketplaces.

Features

Logon

There are two logon levels:

• Guest/Operator: This is the default logon user. You are automatically logged on as

Guest.

• Administrator: This logon level is required to customize the system and network

defaults for your press and to customize particular print jobs by setting, or changing

parameters for certain features. Press the Guest button (or the Log in button on the

Control Panel) to access the Login screen.

Xerox®Versant®180 Press2-4

User Guide

Getting Started

Note

Refer to the System Administration Guide for more information on the Administrator

features.

Language

Note

The number of languages available on your system depends on what was installed during

the initial installation process.

Selecting a particular Language button immediately changes the language. No

confirmation is required.

Changing the Language

1. Press the Language button on the press User Interface

The Language window displays on the touch screen.

2. Choose one of the following:

• Select the desired language from the list, and select Save. The language on the

screen changes to the new language and closes the Language window.

• Select the Cancel button to return to the main screen.

Optional Performance Package

Important

The Performance Package must be ordered prior to initial installation of the system. It

is not possible to upgrade an existing press with the Performance Package after the

system has been ordered and installed.

The optional Performance Package is a suite of technologies and tools that enhances

the capabilities of the base press in three areas: operational speed, color management

automation, and print shop productivity.

The Performance Package is comprised of the following technologies and tools:

• All Stocks Rated Speed (ASRS) software

• Automated Color Quality System (ACQS) software

• Inline Spectrophotometer (ILS) - which is included with the InterfaceCooling Module

• Xerox EX 80 Print Server

User Guide

2-5Xerox®Versant®180 Press

Getting Started

All Stocks Rated Speed (ASRS)

The All Stocks Rated Speed (ASRS) feature eliminates the slower speeds created by

heavier weight stocks. With ASRS, the speed of the press is governed by the size of the

stock only and not by its weight. This means that all stock weights up to 350 gsm for a

given sheet size will run at the rated speed (the top speed) for that stock size.

Automated Color Quality System (ACQS)

The Automated Color Quality System (ACQS) is an advanced color management

technology that transfersthe complex decisions about color maintenance fromoperators

to an automated system. ACQS automates the printing and measuring of calibration

charts and then calculates and makes precise adjustments to color tables based on the

results.

Note

The ACQS suite is available only with the external Xerox EX 80 Print Server Powered by

Fiery; it is not available with the Xerox EX-i 80 Print Server Powered by Fiery.

ACQS takes the variability out of the color equation by incorporating standardized color

measurements using the Inline Spectrophotometer (on the Interface Cooling Module)

to calibrate color on the press as well as generating accurate destination profiles for

different stocks.

Procedures are automated in that they eliminate the need for an operator to manually

scan target sheets using an external spectrophotometer. The operator must initiate the

procedure at the print server, but all target sheets are then generated and scanned

automatically, and all measurements, calculations, and corrections are performed

automatically.

Inline Spectrophotometer (ILS)

The Inline Spectrophotometer (ILS) is housed in the Interface Cooling Module. The ILS

enables the Automated Color Quality Suite, which automates the process of ensuring

stable and accurate color from job to job, by eliminating the need for operators to use

a hand-held spectrophotometer during print server calibration. It also facilitates the

creation of custom destination profiles for each stock on which the press prints.

With the ILS is strategically placed within the paper path, automated processes like

measurements forcalibration and destination profiling are quick to perform and require

less down-time for the press. Workingtogether, the ACQS software and the ILS hardware

gives accurate color faster, and provides more stable color over time.

Besides the Inline Spectrophotometer (ILS), the Interface Cooling Module contains

additional cooling to support the higher speeds of the press when running at higher

speeds, and a Decurler to ensure flat sheets for finishing.

Configuration Information Regarding the Performance Package

1. The Performance Package must be ordered when the press is ordered. Once the

press has been configured without the Performance Package option, it cannot be

upgraded at a later time to include the package.

Xerox®Versant®180 Press2-6

User Guide

Getting Started

2. The Performance Package is not available with the Xerox EX-i 80 Print Server.

Customers must order the external Xerox EX 80 Print Server.

3. If customers configure the press with the Business Ready (BR) Finisher, the Business

Ready Finisher with Booklet Maker, or the Offset Catch Tray, then the Performance

Package option is not available for the configuration.

4. When the Performance Package is ordered, the Interface Cooling Module must be

used. The package cannot be used with the Interface Module.

5. Finishing options enabled by the Interface Cooling Module include these finishers

and their options:

• High Capacity Stacker (HCS)

• Standard Finisher

• Booklet Maker Finisher

• Standard Finisher Plus

• SquareFold Trimmer Module (which requires the Booklet Maker Finisher)

• Plockmatic Pro 35 and Plockmatic Pro 50 (which requires the Standard Finisher

Plus)

Power On/Off

The Power Switches

There are three power switches involved with the press:

• The Breaker switch located at the rear of the press. Initially check to make sure this

switch is set to On when the press is shipped.

• The Main Power switch located inside the Front Door. This switch is used mainly by

the Xerox Service Representative when servicing the press. In rare problem solving

cases, you may be directed to power off the press with this switch.

• The Power On/Off button located on the top of the press near the Document Feeder.

This button is the primary way for you to switch on or off the press. It is used by the

operator as workflow requires.

Use the Power On/Off button to power ON or power OFF the press.

User Guide

2-7Xerox®Versant®180 Press

Getting Started

Important

Always use the Power On/Off button first, and then power off the Main Power Switch.

Power On/Off the Press

Power On the Press

1. Check that the Main Power switch behind the Front Door is On.

2. Press the Power On/Off button on top of the press to the ON position.

The Ready Indicator light displays green.

A screen message advises of a short wait while the fuser warms up and the press runs

a system check. Youcan set featuresfor a job during this time and the printing process

will start automatically when the press is ready.

Power Off the Press

Important

Always power off the Power Switch first and then power off the Main Power Switch.

1. Press the Power On/Off button on the top of the press to Off.

Wait until the lights on UI stop blinking, as this allows the fuser to begin cooling.

2. Switch Off the Main Power switch behind the Front Door.

Note

Allow the press to remain off for a minimum of 10 seconds before switching on the

power again.

Power Saver

The Power Saver feature allows the press to enter a reduced power consumption mode

when all print jobs have completed and there are no jobs currently processing. There

are two energy saving modes: Low Power and Sleep.

By default, the press automatically enters the Low Power mode after 1 minute of

inactivity. After 1 minute of inactivity, the press then enters Sleep mode. These time

intervals for both modes can be changed by the system administrator.

Refer to the following example:

• Low Power Mode is set to 1 minute.

• Sleep Mode is set to 10 minutes.

• Sleep Mode activates after 10 minutes of total inactivity and not 10 minutes after

the Low Power Mode begins.

Low Power Mode

In this mode, the power to the User Interface (UI) and fuser unit is lowered to save

power. The display goes out and the Energy Saver button on the UI lights. To use the

press, press the Energy Saver button. The Energy Saver button is no longer lit, indicating

that the Energy Saver feature is canceled.

Xerox®Versant®180 Press2-8

User Guide

Getting Started

Sleep Mode

In this mode, the power is lowered more than in the Low Power mode. The display goes

out and the Energy Saver button on the UI lights. To use the press, press the Energy

Saver button. The Energy Saver button is no longer lit, indicating that the Energy Saver

feature is canceled.

Exiting Power Saver

The press exits Power Saver mode by doing one of the following:

• Pressing the Power Saver button on the press UI,

• Receiving print data for an incoming job to be printed, or

• Programming and performing a copy or scan job.

Getting Help

Help on the Xerox Web Site

For technical product support, Xerox supplies, customer documentation, and answers to

frequently-asked questions, go to www.xerox.com. You will find the latest documentation

and the knowledge base under Support & Drivers. Use the Contact link for specific

contact information/telephone numbers in your area.

Note

Be sure to periodically check this website for the latest information on your product.

It may be helpful to know your press serial number before calling for support. The press

serial number is shown on the Device Information tab: Machine Status > Device

Information.

Print Server Customer Documentation

• The FreeFlow Print Server features are documented in the Online Help system from

the Help menu shown on the main print server window. Additional FreeFlow Print

Server user documentation can be found at www.xerox.com.

• The EFI Print Server Help menu on the Command WorkStation window is designed

to provide informationon specific work flows when using the Command WorkStation.

Additional user documentation supplied by EFI is available to you from www.xerox.com

under the Support and Drivers link.

User Guide

2-9Xerox®Versant®180 Press

Getting Started

Xerox®Versant®180 Press2-10

User Guide

3

Press Apps

Print Job Submission

There are several ways in which to submit your job for printing:

• From your computer workstation (PC or Mac), using print drivers such as PostScript

and Printer Command Language (PCL), you can submit a document file to the print

server queue. From the print server, you would then submit the job to the press.

Note

Make sure the appropriate print drivers have been installed on your computer. Refer

to your print driver documentation or the Xerox web site for more information on

how to download or install print drivers.

• At any remote workstation, using a Hot Folders application to submit the document

file to the print server.

• At the print server, importing/adding a document file to a print queue. Manage the

job settings of the document and then submit to the press for printing.

Printing from a Computer

The system supports either Xerox FreeFlow or Fiery EX print drivers. Through print drivers

installed on your computer or Mac, you can send a document file from your desktop to

the print server, which can then be submitted to the press for printing.

Note

You can also use a drag and drop Hot Folders feature by which to send your files to the

print server for printing to the press.

1. From your computer, select the file you want to print and open it in its application.

2. Select File > Print.

3. Select the desired print server queue.

4. Select the Properties button for the queue.

5. Select the desired output options such as quantity or 1 sided/2 sided printing.

3-1Xerox®Versant®180 Press

User Guide

Press Apps

6. Select OK to close the Properties window.

7. Select Print to send the job to the print server queue.

Printing a Job from the Print Server

The following is a basic workflow for setting up a job and submitting it from the print

server:

1. At the press, load the appropriate paper to be used for the job.

2. From the press UI, ensure that the Paper Tray settings/Tray Properties window

matches the stock properties for the paper you will use, and that it assigned to the

same feeder tray where the paper is loaded.

3. At the print server main window, customize your job such as inserting special pages

and tabs, and create your print queue that defines the attributes of those jobs sent

to the queue.

4. Submit the job file from the print server to the networked press for printing.

Printing from the FreeFlow Print Server

From your computer, you can submit your document files (select Print) to a directory on

the print server through the use of installed print drivers. You could also copy the

document files onto a USB flash drive or CD/DVD and then connect those devices to the

print server for importing.

1. If you copied the file onto a storage device, connect your device to the print server

and from the top menu bar select Services > Print From File.

2. From the Print From File window, select the Files tab and Browse.

3. From Look In, locate your storage device or other network directory containing the

document files you want.

4. Select and highlight one of the document files. Select OK.

5. From the Queue field at the top right of the Print From File window, select the desired

print queue.

6. Using the other tabs on the screen, select the desired output options such as quantity

or 1 or 2-sided printing.

7. Select Print.

The job is sent to the desired queue and either held or immediately printed.

8. Select Close.

Printing from the EX Print Server

From your computer, you can submit your document files (select Print) to a directory on

the print server through the use of installed print drivers. You could also copy the

document files onto a USB flash drive or CD/DVD and then connect those devices to the

print server for importing.

1. If you copied the file onto a storage device, connect your device to the print server

and select Services > Print From File.

2. From the EX Print Server, select File > Import Job.

3. Select Add.

4. Locate your storage device or other directory containing the document files.

5. Select and highlight one of the document files. Select Open.

Xerox®Versant®180 Press3-2

User Guide

Press Apps

6. Select Import.

7. Select the desired queue such as Process and Hold or Print and Hold.

The job is sent to the selected queue or to the press for immediate printing.

Printing on Tabs from the Print Server

Basic Procedure for Printing on Tabs from a Print Server

There are many types of tab stock and tab sequences available. Precut tabs are commonly

used and have two different orientations: the single straight collated tab stock or the

single reverse collated tab stock.

When programming tab jobs and loading tab stock, consider the following:

• Precut tabs can only print 1-sided

• There are specific job settings that you need to define such as tab order/sequence,

number of bank sets, stock weight, paper size, and insertion before or after body

pages. Refer to your print server documentation formore detailed setting information.

• Always load tab stock LEF into the tray where the straight edge of the stock is the

lead edge and the tabs are oriented at the trail edge.

• Always use a complete set or bank or tabs in the paper tray.

• If staple or punch finishing, use tray 5 or trays 6 or 7 (if available).

The following are the basic steps for printing tabs on your press.

1. From the print server, create and define the Tab stock for the paper tray you will be

using.

2. Load the Tab stock in Trays 1, 2, 3, 5, 6 or 7.

3. From the print server window, access the Held queue that contains your document.

Select the document you want to configure with tabs. Double click to open the file’s

properties.

4. Once all settings are made, select Print.

The press prints the complete set of tabs with the body pages defined. Any extra

tabs not used in the job are sent to the output tray.

Tips for Printing on Tabs from the EX Print Server

Use the following tips for printing on tabs from the EX Print Server:

• The EX Print Server allows for setting up your job to print on tabs. Otherwise, you can

set up your job to insert preprinted tabs into your document. Use one tray for the

body pages, another tray for the preprinted tab stock, and another tray for cover or

back pages.

• While you can print tab stock from any of the paper trays on the system (Trays 1, 2,

3, 5, 6 or 7), Trays 6 and 7 should be used for best results. If you plan to apply staple

or punch finishing, use Trays 5, 6 or 7 only.

• Loading orientation depends on what tray you are using.

User Guide

3-3Xerox®Versant®180 Press

Press Apps

Copy

Document Feeder and Glass

Document Feeder Tips

Tips for using the Duplex Automatic Document Feeder (DADF):

• For best output, ensure that the documents are in good condition.

• A maximum of 250 documents can be scanned at one time by using the document

feeder.

• Mixed-size original documents can be used; however, the top left corners of the

original documents must be aligned in the document handler.

• Remove any staples and paper clips from the documents before loading them in the

document feeder.

Document Glass

Use the Document Glass for scanning and copying various types documents, such as

bound originals (books), odd size documents or poor quality originals. Documents should

be placed face down on the glass and aligned with the tip of the registration arrow in

the top left corner.

The document glass accommodates document sizes up to a maximum of 11 x 17 in./A3.

Basic Copying Steps

Basic Copying with the Document Feeder (DADF)

1. Adjust the movable document guides to their widest position.

2. Load the documents faceup with the first page on top and with the headings toward

the back or left of the machine.

The confirmation indicator lights to show that the documents are loaded correctly.

3. Press the Home button on the press UI.

4. Select Copy on the Home window.

5. Select the desired Copy features/options:

• Paper Supply

• Reduce/Enlarge

Xerox®Versant®180 Press3-4

User Guide

• Output Color

• 2-Sided Copying

• Original Type

• Lighten/Darken

The features displayed on the main Copy window vary depending on how it is

configured by the administrator.

6. Enter the quantity.

7. Press Start.

Basic Copying with the Document Glass

1. Open the document feeder.

2. Place the document face down by aligning it as shown in the illustration.

Press Apps

3. Press the Home button on the press UI.

4. Select Copy on the Home window.

5. Select the desired Copy features/options:

• Paper Supply

• Reduce/Enlarge

• Output Color

• 2-Sided Copying

• Original Type

• Lighten/Darken

The features displayed on the main Copy window vary depending on how it is

configured by the administrator.

6. Enter the quantity.

7. Press Start.

Selecting Copy Options for a Third-Party Finishing Device

Read the following list before performing the procedure:

• If your machine has an optional, third-party, Document Finishing Architecture (DFA)

device attached, then this profile feature is available, and specific copy options may

be selected for a job.

User Guide

3-5Xerox®Versant®180 Press

Press Apps

• Prior to physically attaching the DFAdevice to the machine, device profiles are created.

The profiles represent the characteristics of your finishing device.

• Refer to the third-party customer documentation for information on setting the

profile values for the specific DFA device attached to the machine.

• A profile for the job can be selected from either the print server, the print driver on

your computer, or the press User Interface.Depending on the DFA device, a maximum

of twelve profiles are available.

1. Place your original documents either in the document feeder or on the document

glass.

2. Press the Home button on the press UI.

3. Select Copy on the Home window.

4. Select the Output Format tab.

a) Select the DFA Finisher.

The DFA Finisher Profile screen displays.

b) From the displayed list, select the profile for the job.

If the device is an e-binder, select the binding position.

c) Select Save.

d) Select the desired Face Up/Down Output option.

5. Select the desired Copy features/options.

The features displayed on the main Copy window vary depending on how it is

configured by the administrator.

6. Enter the quantity.

7. Press Start.

If prompted on the UI, followthe instructions provided to correct any job submission

errors. If there is a DFA problem, refer to your DFA documentation.

Copy Feature

Copy Feature Overview

Tip

Depending on how the Copy tab is configured by the administrator, this tab may contain

different features than the ones listed here.

The Copy feature includes the following options:

• Reduce/Enlarge (R/E)

• Paper Supply (Auto Select)

• Output Color

• Copy Output

• 2 Sided Copying

• Original Type

• Darken/Lighten

Xerox®Versant®180 Press3-6

User Guide

Press Apps

Reduce/Enlarge

Reduce / Enlarge (R/E)

The reduce / enlarge (R/E) feature provides a variety of reduction and enlargement

options to adjust the size of the output image. Originals can be enlarged or reduced

from25-400%. Variousautomatic and preset selections are available to help you choose

the most common reductions or enlargements, while a custom setting enables you to

select the ratio that suits your requirements. Basic reduction/enlargement options include:

100% or R/E entry box

The default setting in the R/E entry box is 100%. This selection produces an image on

your copy exactly the same size as the image on your original document.

You can also set the R/E ratio by using the plus or minus buttons. In this case, the ratio

is displayed in the R/E entry box.

Auto%

This selection proportionally reduces or enlarges the image so that it will fit onto your

chosen paper. If this option is selected, you must also select a specific paper tray.

Preset R/E buttons

Depending on what the System Administratorhas selected, you see severalpercentage

options for reduction or enlargement. These buttons can be customized by the

Administrator to display the reduction/enlargement ratios that you frequently use.

More

When the Reduce/Enlarge (R/E) More button is selected, a new window opens and

displays additional R/E options.

More Reduce/Enlarge (R/E) Options

The Reduce/Enlarge (R/E) More options include:

Proportional %

All of the options will reduce or enlarge the image by the same ratio in both directions

so that the image gets bigger or smaller, but the proportion remain the same.

Auto %

Proportionally reduces or enlarges the image so that it will fit onto your chosen paper.

If this option is selected, you must also select a specific paper tray.

Independent X-Y%

This option allows you to specify different height and width ratios to scale the height

and width independently.

Auto X-Y% ensures copies are made with the height and width ratiosset automatically

to match the paper size.

Auto Center

This option allows you to specify individually the height and width values.

User Guide

3-7Xerox®Versant®180 Press

Press Apps

Preset percentage buttons

The percentagebuttons are preset for specific magnification levels by the administrator

to reflect the percentages used most frequently.

Paper Supply

Select the desired tray to be used for your job; options include:

Auto Select

This option automatically detects the size of the original document and selects the

proper tray for output.

Tray buttons

Allows you to select a specific tray containing the desired media for your job.

More button

Displays the Paper Supply screen showing all available trays for the machine and their

media content.

Output Color

Select the desired Output Color option which best applies to the job. The options include:

Auto Detect

This option allows the machine to automatically detect if the original document is in

color or black and white.

Color

This option generates copies with full color output, using all four printing colors - cyan,

magenta, yellow, and black.

Black and White

This option copies in black and white only. Colors in the original are converted to shades

of gray.

Dual Color

This option allows you to separate the colors of the original into two groups of colors

for copying. The source color is extracted from the original and replaced by the target

area color. The rest of the colors are replaced by the non-target area color that you

select.

Single Color

This option allows you to copy in one of the preset or custom colors.

More

This options allow you to customize the color for the copied output.

Xerox®Versant®180 Press3-8

User Guide

Press Apps

Copy Output

Important

CopyOutput options vary depending on the finishing devices attached to your machine.

Note

Copy Output may be accessed either from the Copy tab or from the Output Format tab.

Use the Copy Output feature to select the desired options for your output; options

include:

• Auto

• Collated

• Uncollated

• Uncollated with Separators

• Original Orientation

• Optional finishing features, including:

- Output Destination/Offset

- Stapling

- Hole Punching

- C/Z Folding

2 Sided Copying

Note

The 2 Sided Copying option may be accessed either from the main Copy screen or from

the Output Format tab.

Makeone or two-sided copies from one or two-sided originals using either the document

feeder or the document glass. The two-sided option enables you to select your output

in book or calendar orientation. Options include:

1-1 Sided

Use this option if your originals are printed on one side and you want single-sided

copies.

1-2 Sided

Use this option if your originals are printed on one side and you want two-sided copies.

2-2 Sided

Use this option if you want to make two sided copies from two-sided originals.

2-1 Sided

This option will make one-sided copies from two-sided originals.

Originals/Copies

Select the orientation of both your original documents and the output copies. Options

include Head to Head and Head to Toe.

User Guide

3-9Xerox®Versant®180 Press

Press Apps

Head to Head

This option is sometimes called Top-to-Top. For your original documents, select this

option when all the pages of your original documents have the same orientation. For

copy output, select this option to copy/print the reverse side of a page so that the

finished document opens like a book.

Head to Toe

This option is sometimes called Top-to-Bottom. Foryour original documents, select this

option when the pages of your original documents have the opposite orientation such

as on a calendar. For copy output, select this option to copy/print the reverse side of a

page so that the finished document opens like a calendar.

Original Orientation

Upright Images

Select this option when placing the top edge of the document against the top side

of the document glass or document feeder.

Sideways Images

Select this option when placing the top edge of the document against the left side

of the document glass or document feeder.

Original Type

Note

The Original Type option may be accessed either from the main Copy screen or from

the Image Quality tab.

The Original Type feature provides a convenient way to enhance the quality of your

output based on the type of original images you are copying. Select the Original Type

button on the Image Quality tab, and select the desired option.

Auto

This option sets the output color according to the document type preset in the System

Administration mode.

Photo and Text

Use this option if your original is from a magazine or other source that contains high

quality photographs with text. This setting produces better pictures, but slightly reduces

sharpness for text and line art.

Text

Use this option if your original contains only text or line art. The result is sharper edges

for the text and line art.

Photo

This option is specifically designed to copy photographs or magazine pictures without

any text or line drawings. This option prevents faint reproduction of colors.

Xerox®Versant®180 Press3-10

User Guide

Press Apps

Map

Use this option formaking copies of documents that have text on colored backgrounds

such as maps.

Darken/Lighten

Note

The Darken/Lighten option may be accessed either from the main Copy screen or from

the Image Quality tab and then by selecting Image Options.

The Darken/Lighten option provides manual control to adjust the lightness or darkness

of the scanned images.

• Select the Left scroll button to darken the scanned image from light originals such

as pencil images.

• Select the Right scroll button to lighten the scanned image from dark originals such

as half tones or originals with colored backgrounds.

Image Quality Feature

Image Quality Feature Overview

The Image Quality feature includes the following options:

• Original Type

• Image Options

• Image Enhancement

• Color Effects

• Color Balance

• Color Shift

Selecting Image Quality Options

1. Load the document or documents either onto the Document Glass or into the

Document Feeder.

2. Press the Home button on the press UI.

3. Select Copy on the Home window.

4. Select the Image Quality tab.

5. From the Image Quality window, select the desire options:

• Original Type

• Image Options

• Image Enhancement

• Color Effects

• Color Balance

• Color Shift

6. Select the Copy tab.

7. Select the desired Copy options including:

• Paper Supply

User Guide

3-11Xerox®Versant®180 Press

Press Apps

• Reduce/Enlarge

• 2-Sided Copying

8. Select any other desired Copy features/options (such as LayoutAdjustment, Output

Format).

9. Enter the quantity.

10. Press Start on the UI.

Original Type

Note

The Original Type option may be accessed either from the main Copy screen or from

the Image Quality tab.

The Original Type feature provides a convenient way to enhance the quality of your

output based on the type of original images you are copying. Select the Original Type

button on the Image Quality tab, and select the desired option.

Auto

This option sets the output color according to the document type preset in the System

Administration mode.

Photo and Text

Use this option if your original is from a magazine or other source that contains high

quality photographs with text. This setting produces better pictures, but slightly reduces

sharpness for text and line art.

Text

Use this option if your original contains only text or line art. The result is sharper edges

for the text and line art.

Photo

This option is specifically designed to copy photographs or magazine pictures without

any text or line drawings. This option prevents faint reproduction of colors.

Map

Use this option formaking copies of documents that have text on colored backgrounds

such as maps.

Image Options

Use the Image Options feature to make adjustments to the following options:

Lighten/Darken

This option provides manual control to adjust the lightness or darkness of the scanned

images.

• Select the Down scroll button to darken the scanned image from light originals such

as pencil images.

• Select the Up scroll button to lighten the scanned image from dark originals such as

half tones or originals with colored backgrounds.

Xerox®Versant®180 Press3-12

User Guide

Press Apps

Sharpness

This option controls the balance between sharp text and moiré (patterns within the

image). Move the slider control down (Soften) to produce an image with a smooth,

uniform appearance ideally suited for photographic scanned images. Move the slider

control up (Sharpen) to produce an image with better quality text or line art.

Saturation

This option allows colors to become more or less vivid. To make the colors on your

output more vivid, move the slide bar up. To create a less vivid output, or a pastel effect,

move the slide bar down. To keep the output normal, do not adjust the saturation.

Image Enhancement

Use the Image Enhancement settings when your scanned image requires more than

the basic image quality. There are two features associated with Image Enhancement:

Suppress Background

This option prevents reproduction of unwanted shading from originals where the

opposite side printing shows through.

Off

Auto Suppression: This option automatically reduces or eliminates any background

on the copies caused by colored paper or newspaper originals.

Contrast

Selections are either Auto Contrast or Manual Constrast. The Constrastfeaturecontrols

the difference between the image densities within the scanned image. Lower contrast

settings reproduce more detail in light and dark areas of the original. Higher contrast

settings produce vivid blacks and whites for sharper text and lines, but produce less

detail in pictures. Auto Correction automatically chooses the best settings foryour job.

Color Effects

This feature produces balanced image tones on your output. Options include:

Lively

This option uses the highest color saturation to produce rich, vivid output colors. The

option increases the color saturation of the most vivid setting in order to produce

fresher images.

Bright

This option produces images that have a brighter appearance and enhanced contrast.

Warm

This option produces a soft image on the output and adding a warm, reddish tint to

low density colors. Use this setting to apply a light pink tone to skin colors and to give

a soft tone to dark, warm colors.

User Guide

3-13Xerox®Versant®180 Press

Press Apps

Cool

This option produces a strong, clear blue tone on the output. This setting makes blue

color stronger and makes dark, cold colors clearer.

Shadow Suppression

This option reduces or eliminates any background shadow caused by colored paper or

newspaper originals.

Color Balance

This feature allows you to adjust the balance between colors and the overall amount of

color on the output copies. You can adjust the levels of all four process colors (Yellow,

Magenta, Cyan, and Black) for their low, medium, and high density ranges.

• The default option is Normal.

• Basic Color adjusts the density.

• Advanced Color adjusts the Highlights, Midtones, and Shadows.

Color Shift

This feature allows you to shift all hues in an image simultaneously in order to make the

overall character of the output image warmer or cooler. For example, if you select one

of the:

Normal

This is the default option.

Plus buttons

The red colors shift toward the yellow hue, the green colors shift toward the cyan hue,

and the blue colors shift toward the magenta hue. All colors between these original

colors also shift in the same direction.

Minus buttons

The red colors shift toward the magenta hue, the blue colors shift toward the cyan hue,

and the green colors shift toward the yellow hue. Again, all colors between these original

colors also shift in the same direction.

Layout Adjustment Feature

Layout Adjustment Feature Overview

The Layout Adjustment feature includes the following options:

• Book Copying

• 2 Sided Book Copying

• Original Size

• Edge Erase

• Image Shift

• Image Rotation

• Invert Image

Xerox®Versant®180 Press3-14

User Guide

Press Apps

• Original Orientation

Selecting Layout Adjustment Options

1. Load the document or documents either onto the Document Glass or into the

Document Feeder.

2. Press the Home button on the press UI.

3. Select Copy on the Home window.

4. Select the Layout Adjustment tab.

5. From the Layout Adjustment window, select the desire options:

• Book Copying

• 2 Sided Book Copying

• Original Size

• Edge Erase

• Image Shift

• Image Rotation

• Invert Image

• Original Orientation

6. Select the Copy tab.

7. Select the desired Copy options including:

• Paper Supply

• Reduce/Enlarge

• Darken/Lighten

8. Select any other desired Copy features/options (such as Image Quality, Output

Format).

9. Enter the quantity.

10. Press Start on the UI.

Book Copying

Bound originals (such as books) can be placed on the document glass to make 1-sided

or 2-sided copies. The bound original should be placed face down and registered to the

rear left corner of the document glass. Align the top of the bound original against the

rear edge of the document glass.

Book Copying options include:

Both Pages

Copies both pages in page order.

User Guide

3-15Xerox®Versant®180 Press

Press Apps

Left Page Only

Copies the left page only.

Right Page Only

Copies the right page only.

Binding Edge Erase

This option erases or deletes the shadow from your copies that is caused by the center

binding of the bound original.

2 Sided Book Copying

You can make 2-sided copies from two pages of a bound original. This feature allows

you to assign pages when making copies of a bound original so that the copied pages

face each other in the same way as the bound original. 2 Sided Book Copying options

include:

• Select a starting and ending page

• Select Starting Page (Left Page or Right Page), and

• Selecting Ending Page (Left Page or Right Page).