Page 1

Book Version 1.0

April 2017

702P04576

Xerox

®

Versant

®

180 Press

Optional Devices User Guide

Page 2

©2017 Xerox Corporation. All rights reserved. Xerox®, Xerox and Design®, FreeFlow®,

SquareFold®, CentreWare®and Versant®are trademarks of Xerox Corporation in the

United States and/or other countries.

Adobe PDF is a registered trademarks of Adobe Systems, Inc. PostScript is an Adobe

registered trademark used with the Adobe PostScript Interpreter, the Adobe page

description language, and other Adobe products.

Fiery®and EFI™are trademarks or registered trademarks of Electronics For Imaging, Inc.

GBC®and AdvancedPunch™are trademarks or registered trademarks of General Binding

Corporation.

Microsoft, Windows, Windows XP, Windows Vista, Internet Explorer, and Word are

registered trademarks of Microsoft Corporation in the United States and/or other

countries.

3-IN-ONE®and WD-40®are a registered trademarks of the WD-40 Company.

BR4005

Page 3

Table of Contents

1 1-Tray High Capacity Feeder (HCF / Tray 6), Letter-Size / A4

Only............................................................................................................1-1

Loading Paper in Tray 6.....................................................................................................1-1

Tray 6 Troubleshooting......................................................................................................1-2

Tray 6 Paper Jams..................................................................................................1-2

Clearing Paper Jams in the HCF (Tray 6).........................................1-2

Clearing HCF Paper Jams in the Lower Left Cover.......................1-3

Tray 6 Fault Messages..........................................................................................1-4

Tray 6 Fault Code Information............................................................1-4

Tray 6 Specifications..........................................................................................................1-4

2 1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays

6 and 7).....................................................................................................2-1

Overview of the Oversized High Capacity Feeder (Trays 6 and 7) ..................2-1

Paper and Media in Trays 6 and 7................................................................................2-2

Loading Paper in Trays 6 and 7........................................................................2-2

Loading Tabs in Trays 6 and 7...........................................................................2-2

Loading Transparencies in Trays 6 and 7......................................................2-3

Loading Hole Punch Paper in Trays 6 and 7................................................2-4

Postcard Bracket......................................................................................................2-4

Using the Postcard Bracket...................................................................2-5

Skew Adjustment Levers for OHCFs (Trays 6/7 and 8/9)........................2-6

Trays 6/7 Maintenance......................................................................................................2-8

Consumable Supplies for the OHCF (Trays 6 and 7)................................2-8

Replacing the OHCF Bypass Tray Feed Rolls (Trays 6 and 7)................2-8

Replacing the OHCF Feed Rolls (Trays 6 and 7).........................................2-9

Trays 6/7 Troubleshooting.............................................................................................2-12

Trays 6/7 Paper Jams.........................................................................................2-12

Paper Jams When the Bypass is Installed on Trays 6 and

7..........................................................................................................2-12

Paper Jams Inside the OHCF Trays (6 and 7).............................2-13

OHCF Paper Jams at Lever 1a and Knob 1c (Trays 6 and

7).........................................................................................................2-13

OHCF Paper Jams at Lever 1b and Knob 1c (Trays 6 and

7).........................................................................................................2-14

OHCF Paper Jams at Lever 1d and Knob 1c (Trays 6 and

7).........................................................................................................2-15

Trays 6/7 Fault Messages.................................................................................2-16

Trays 6/7 Fault Code Information...................................................2-16

Optional Devices User Guide

iXerox®Versant®180 Press

Page 4

Table of Contents

OHCF Specifications (Trays 6 and 7).........................................................................2-16

3 Chained (Second) Oversized High Capacity Feeder (OHCF /

Trays 8 and 9).........................................................................................3-1

OHCF (Trays 8 and 9) Overview.....................................................................................3-1

Paper and Media for Trays 8 and 9..............................................................................3-2

Loading Paper in Trays 8 and 9........................................................................3-2

Loading Tabs in Trays 8 and 9...........................................................................3-2

Loading Transparencies in Trays 8 and 9......................................................3-3

Loading Hole Punch Paper in Trays 8 and 9................................................3-3

Tray 8/9 Maintenance........................................................................................................3-4

Replacing the Bypass Tray Feed Rolls for the OHCF (Trays 8 and

9).........................................................................................................................3-4

Replacing the OHCF Feed Rolls for the OHCF (Trays 8 and 9)..............3-6

Trays 8 and 9 Troubleshooting.......................................................................................3-9

Trays 8/9 Paper Jams............................................................................................3-9

Clearing OHCF (Trays 8 / 9) Jams.......................................................3-9

Paper Jams When the Bypass is Installed on Trays 8 and

9..........................................................................................................3-10

Paper Jams Inside Trays 8 and 9......................................................3-11

Trays 8 and 9 Paper Jams at Lever 1a and Knob 1c.................3-11

Trays 8 and 9 Paper Jams at Lever 1b and Knob 1c.................3-12

Trays 8 and 9 Paper Jams at Lever 1d and Knob 1c.................3-13

Trays 8/9 Fault Messages.................................................................................3-13

Trays 8/9 Fault Code Information...................................................3-13

Trays 8 and 9 Specifications.........................................................................................3-14

4 Business Ready (BR) Finisher and Optional Booklet

Maker.........................................................................................................4-1

Business Ready (BR) Finisher Overview.......................................................................4-1

Identifying the BR Finisher Components...................................................................4-2

BR Finisher Maintenance..................................................................................................4-2

Consumable Supplies for the BR Finisher.....................................................4-2

Replacing Staples in the Main Stapler Unit.................................................4-3

Replacing Staples in the Booklet Maker........................................................4-3

Emptying the Hole Punch Waste Container................................................4-4

BR Finisher Troubleshootinng.........................................................................................4-5

BR Finisher Paper Jams........................................................................................4-5

Clearing Jams in the BR Finisher at Position 3a...........................4-5

Clearing Jams in the BR Finisher at Position 3c............................4-6

Clearing Jams in the BR Finisher at Position 3d...........................4-6

Clearing Jams in the BR Finisher at Position 4..............................4-7

Clearing Jams in the Booklet Tray......................................................4-8

Xerox®Versant®180 Pressii

Optional Devices User Guide

Page 5

Table of Contents

BR Finisher Fault Messages and Fault Codes..............................................4-8

BR Finisher Specifications.................................................................................................4-9

5 Interface Decurler Module / Interface Decurler Module with

ILS...............................................................................................................5-1

Interface Decurler Module (IDM) Components......................................................5-4

IDM Control Panel..................................................................................................5-4

IDM Curl Correction............................................................................................................5-5

IDM Curl Correction Modes and Functions..................................................5-6

IDM Troubleshooting.........................................................................................................5-8

IDM Paper Jams......................................................................................................5-8

Clearing IDM Paper Jams......................................................................5-9

IDM Fault Messages...........................................................................................5-10

IDM Fault Code Information.............................................................5-11

6 Inserter..........................................................................................................6-1

Inserter Components..........................................................................................................6-1

Inserter Control Panel...........................................................................................6-2

Paper and Media for Inserter Tray T1.........................................................................6-3

Supported Paper for the Inserter Tray T1.....................................................6-3

Loading Paper in Inserter Tray T1...................................................................6-3

Printing on Special Media...................................................................................6-4

Purge Function for Tray T1...............................................................................................6-5

Tray T1 Purge Function Settings......................................................................6-6

Changing the Purge Function Setting for Tray T1.....................................6-6

Inserter Troubleshooting..................................................................................................6-7

Inserter Paper Jams...............................................................................................6-7

Clearing Paper Jams from Inserter E1 Area...................................6-8

Clearing Paper Jams from Inserter E2 Area...................................6-8

Clearing Paper Jams from Inserter E3 Area...................................6-9

Inserter Fault Messages....................................................................................6-11

Inserter Fault Code Information......................................................6-11

7 GBC AdvancedPunch Pro........................................................................7-1

8 High Capacity Stacker (HCS)................................................................8-1

High Capacity Stacker (HCS) Components................................................................8-1

HCS Circuit Breaker................................................................................................8-2

Output Trays.............................................................................................................8-3

Control Buttons.......................................................................................................8-3

Unloading the Stacker Tray / Cart...................................................................8-3

HCS Troubleshooting..........................................................................................................8-4

HCS Paper Jams......................................................................................................8-4

Optional Devices User Guide

iiiXerox®Versant®180 Press

Page 6

Table of Contents

Clearing Paper Jams from HCS Area E1...........................................8-5

Clearing Paper Jams from HCS Area E2...........................................8-6

Clearing Paper Jams from HCS Area E3...........................................8-7

Clearing Paper Jams from HCS Area E4...........................................8-8

Clearing Paper Jams from HCS Area E5...........................................8-9

Clearing Paper Jams from HCS Area E6........................................8-10

Clearing Paper Jams from HCS Area E7........................................8-11

HCS Fault Messages............................................................................................8-12

HCS Fault Code Information..............................................................8-12

Additional HCS Troubleshooting Information.........................................8-13

Hints and Tips for Using the HCS.....................................................8-13

HCS Specifications............................................................................................................8-13

HCS Media Guidelines.......................................................................................8-14

9 Two-Sided Trimmer..................................................................................9-1

Two-Sided Trimmer Components..................................................................................9-1

Two-Sided Trimmer Maintenance.................................................................................9-2

Emptying the Two-Sided Trimmer Waste Container................................9-2

Two-Sided Trimmer Troubleshooting..........................................................................9-4

Two-Sided Trimmer Paper Jams.......................................................................9-4

Clearing Paper Jams from Trimmer Area E1..................................9-5

Clearing Paper Jams from Trimmer Area E2..................................9-6

Clearing Paper Jams from Trimmer Area E3..................................9-8

Clearing Paper Jams from Trimmer Area E4..................................9-9

Clearing Paper Jams from Trimmer Area E5................................9-11

Clearing Paper Jams from Trimmer Area E6................................9-12

Clearing Paper Jams from Trimmer Area E7................................9-14

Two-Sided Trimmer Fault Messages............................................................9-16

Two-Sided Trimmer Fault Code Information..............................9-16

Two-Sided Trimmer Specifications.............................................................................9-17

10 C/Z Folder................................................................................................10-1

C/Z Folder Components..................................................................................................10-1

Trifold Output........................................................................................................10-2

C/Z Folder Troubleshooting...........................................................................................10-3

C/Z Folder Paper Jams.......................................................................................10-3

Clearing Paper Jams from Folder Area E10..................................10-4

Clearing Paper Jams from Folder Area E11..................................10-5

Clearing Paper Jams from Folder Area E12..................................10-6

C/Z Folder Fault Messages...............................................................................10-7

C/Z Folder Fault Code Information..................................................10-8

C/Z Folder Specifications................................................................................................10-8

Xerox®Versant®180 Pressiv

Optional Devices User Guide

Page 7

Table of Contents

11 Production Ready (PR) Finisher / Production Ready (PR)

Booklet Maker Finisher.....................................................................11-1

Finisher Components.......................................................................................................11-3

Finisher Output Trays.........................................................................................11-3

Top Tray......................................................................................................11-4

Stacker Tray..............................................................................................11-5

Booklet Tray..............................................................................................11-5

Paper Curl Correction with the PR Finishers..............................................11-5

Bi-Fold Feature (PR Booklet Maker Finisher Only)...................................11-5

Booklet Output Button......................................................................................11-6

Finisher Maintenance......................................................................................................11-6

Finisher Consumable Supplies........................................................................11-6

Checking the Status of Finisher Consumables.........................................11-7

Replacing the Basic Staple Cartridge (for Side Stitching)....................11-8

Replacing the Booklet Staple Cartridge (for Saddle

Stitching).......................................................................................................11-9

Replacing the Finisher Staple Waste Container....................................11-11

Emptying the Hole Punch Waste Container...........................................11-13

Finisher Troubleshooting.............................................................................................11-15

Finisher Paper Jams..........................................................................................11-15

Clearing Paper Jams from Finisher Area E1..............................11-16

Clearing Paper Jams from Finisher Area E2..............................11-17

Clearing Paper Jams from Finisher Area E3..............................11-18

Clearing Paper Jams from Finisher Area E4..............................11-18

Clearing Paper Jams from Finisher Area E5..............................11-19

Clearing Paper Jams from Finisher Area E6..............................11-20

Clearing Paper Jams from Finisher Booklet Area E7..............11-20

Clearing Paper Jams from Finisher Booklet Area E8..............11-21

Clearing Paper Jams from Finisher Booklet Area E9..............11-22

Finisher Staple Faults.......................................................................................11-23

Clearing Staple Jams in the Basic Stapler..................................11-24

Reinserting the Basic Staple Cartridge........................................11-25

Clearing Staple Jams in the Booklet Stapler.............................11-28

Finisher Fault Messages..................................................................................11-29

Finisher Fault Code Information....................................................11-30

Finisher Specifications..................................................................................................11-30

Staple Output Capacity..................................................................................11-34

12 SquareFold Trimmer............................................................................12-1

SquareFold Trimmer Components..............................................................................12-2

SquareFold Trimmer Circuit Breaker.............................................................12-3

Optional Devices User Guide

vXerox®Versant®180 Press

Page 8

Table of Contents

Square Fold and Trim Features....................................................................................12-5

SquareFold Trimmer Maintenance.............................................................................12-9

SquareFold Trimmer Troubleshooting....................................................................12-11

SquareFold Trimmer Specifications.........................................................................12-15

Output Trays..........................................................................................................12-3

Control Panel.........................................................................................................12-4

SquareFold Trimmer Paper Path....................................................................12-4

Square Fold Feature............................................................................................12-5

Square Fold Adjustment Settings....................................................12-6

Trim Feature...........................................................................................................12-7

Trim Options.............................................................................................12-7

Trim Guidelines........................................................................................12-7

Emptying the SquareFold Trimmer Waste Container............................12-9

SquareFold Trimmer Paper Jams................................................................12-11

Clearing Paper Jams from SquareFold Trimmer Areas E1

and E2............................................................................................12-12

Clearing Paper Jams from SquareFold Trimmer Area

E3.....................................................................................................12-13

SquareFold Trimmer Fault Messages........................................................12-13

SquareFold Trimmer Fault Code Information..........................12-14

Guidelines for Using the SquareFold Trimmer.......................................12-14

Full-Page Images on Booklets.........................................................12-14

Booklet Considerations......................................................................12-14

Considerations for Obtaining Desired Booklet

Output............................................................................................12-15

13 Production Ready (PR) Finisher Plus.............................................13-1

PR Finisher Plus Components.......................................................................................13-2

PR Finisher Plus Maintenance......................................................................................13-2

PR Finisher Plus Troubleshooting................................................................................13-3

PR Finisher Plus Paper Jams.............................................................................13-3

Clearing Paper Jams in Finisher Module Areas E1-E6..............13-4

Clearing Paper Jams in the Finisher Module Area E7..............13-4

Clearing Paper Jams in the Finishing Transport.........................13-5

Stapler Faults in the PR Finisher Plus...........................................................13-8

PR Finisher Plus Fault Messages.....................................................................13-9

PR Finisher Plus Fault Code Information.......................................13-9

PR Finisher Plus Specifications.....................................................................................13-9

14 Job Workflows.......................................................................................14-1

Booklets with Full Bleed Using Four Optional Finishing Devices....................14-1

Creating Booklets with Full Bleed on the EX Fiery Print

Servers............................................................................................................14-1

Xerox®Versant®180 Pressvi

Optional Devices User Guide

Page 9

Table of Contents

Creating Booklets with Full Bleed on the FreeFlow Print

Server..............................................................................................................14-3

Optional Devices User Guide

viiXerox®Versant®180 Press

Page 10

Table of Contents

Xerox®Versant®180 Pressviii

Optional Devices User Guide

Page 11

1-Tray High Capacity Feeder (HCF / Tray 6), Letter-Size / A4 Only

The 1-tray High Capacity Feeder (HCF), otherwise known as Tray 6, provides a

2,000-sheet, letter-size (8.5 x 11 in./A4) paper source.

1

Note

Only letter-size (8.5 x 11 in.)/A4 paper, Long Edge Feed (LEF) can be used in this tray.

Loading Paper in Tray 6

Tips about the 1-tray HCF (Tray 6):

• This tray accommodates only 8.5 x 11 in./A4 Long Edge Feed (LEF) stock

• Stock weights between 18 lb./64gsm bond to 80 lb./220 gsm cover may be used in

this tray

• It holds a maximum of 2000 sheets of 20lb./75 gsm paper

• Stock must be loaded only in LEF direction

• Do not load materials above the MAX line

1. Select the appropriate paper stock for your job.

Optional Devices User Guide

1-1Xerox®Versant®180 Press

Page 12

1-Tray High Capacity Feeder (HCF / Tray 6), Letter-Size / A4 Only

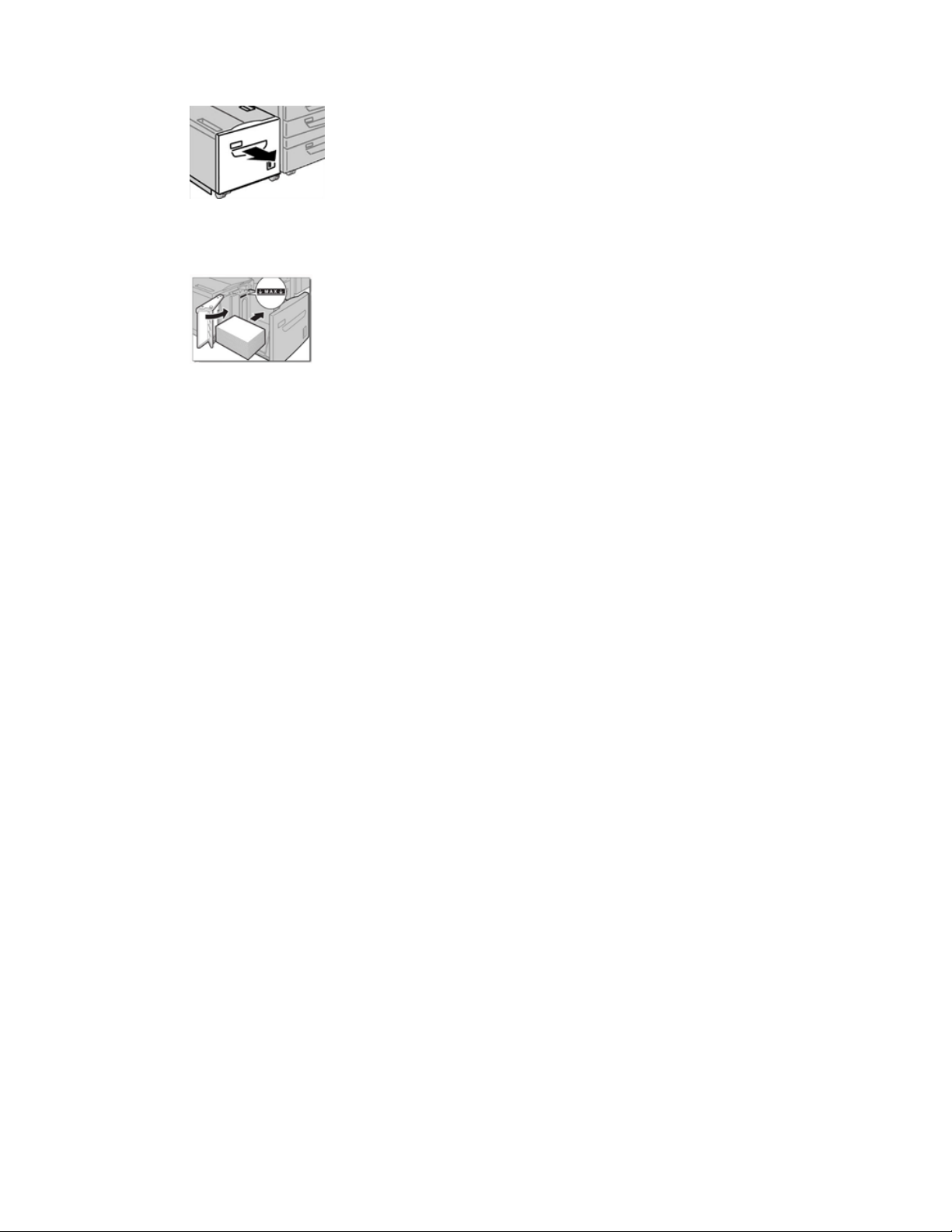

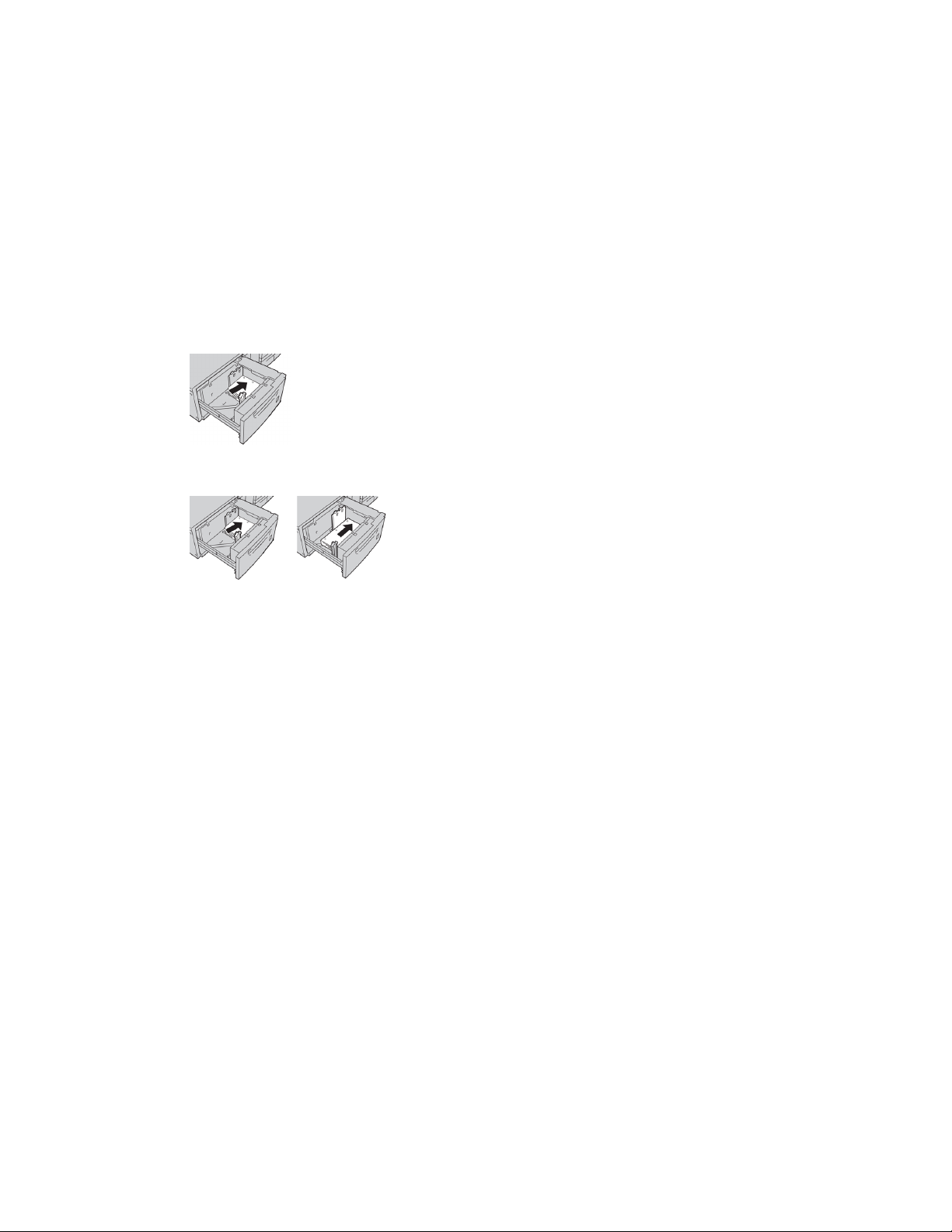

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

5. Load the paper in the tray.

a) Align the edge of the paper against the RIGHT edge of the tray.

b) Move the paper guides to just touch the edges of the paper stack.

Do not load materials above the MAX line.

6. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray settings screen may be

displayed on the UI.

7. If changes have been made to the paper tray, select the Change Settings button;

otherwise, proceed to the next step.

a) Make the desired selections for Paper Type/Paper Weight, Paper Size, and

Paper Color.

b) If necessary, makethedesiredchangestopaper curl and alignment adjustment.

Note

Refer to the System Administration Guide for detailed information on the paper

curl and alignment adjustment options.

c) Select Save until you are returned to the tray settings window.

8. Select Confirm to close the window.

Tray 6 Troubleshooting

Tray 6 Paper Jams

Clearing Paper Jams in the HCF (Tray 6)

1. Open Tray 6 and remove any jammed paper.

Note

If paper is torn, check for any torn pieces of paper inside the machine.

Xerox®Versant®180 Press1-2

Optional Devices User Guide

Page 13

1-Tray High Capacity Feeder (HCF / Tray 6), Letter-Size / A4 Only

2. Gently close the tray.

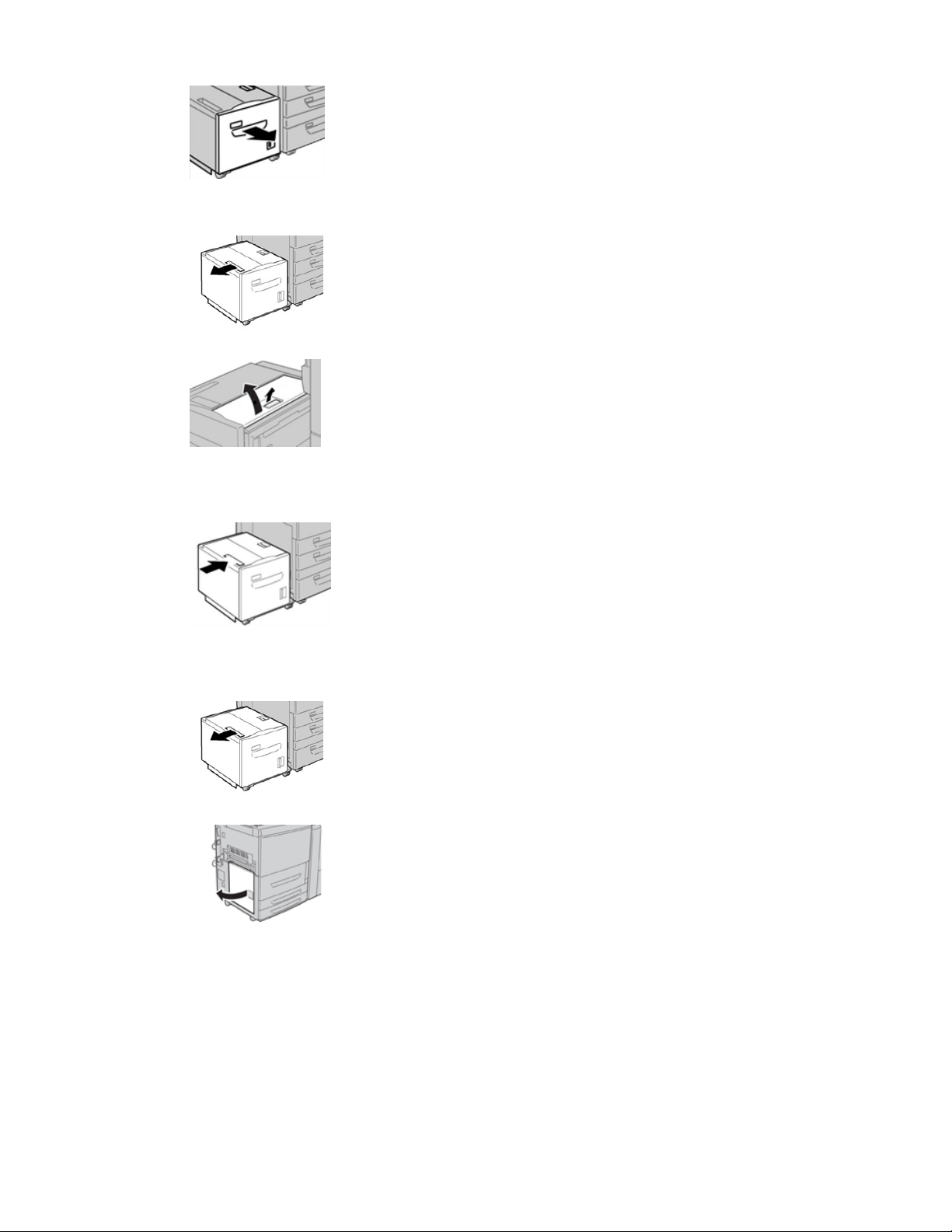

3. Gently move Tray 6 to the left until it stops.

4. Grasp the top cover handle and open the top cover.

5. Remove any jammed paper from the top cover area of Tray 6.

6. Close the Tray 6 top cover.

7. Return Tray 6 to its original position.

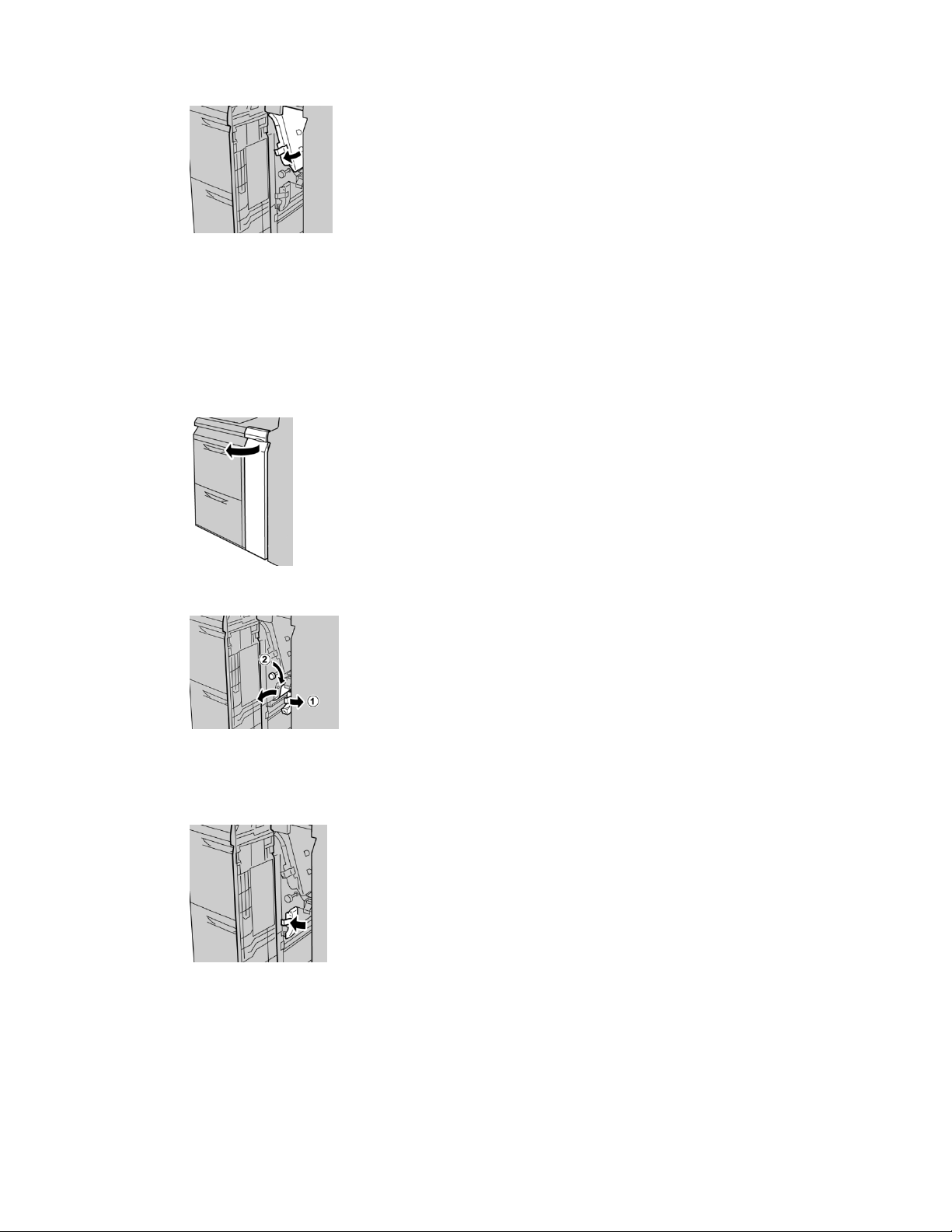

Clearing HCF Paper Jams in the Lower Left Cover

1. Gently move Tray 6 to the left until it stops.

2. Gently open the lower left cover while gripping the release handle.

3. Remove the jammed paper.

Note

If paper is torn, check for any torn pieces of paper inside the machine.

Optional Devices User Guide

1-3Xerox®Versant®180 Press

Page 14

1-Tray High Capacity Feeder (HCF / Tray 6), Letter-Size / A4 Only

4. Gently close the lower left cover.

5. Gently move Tray 6 back into position.

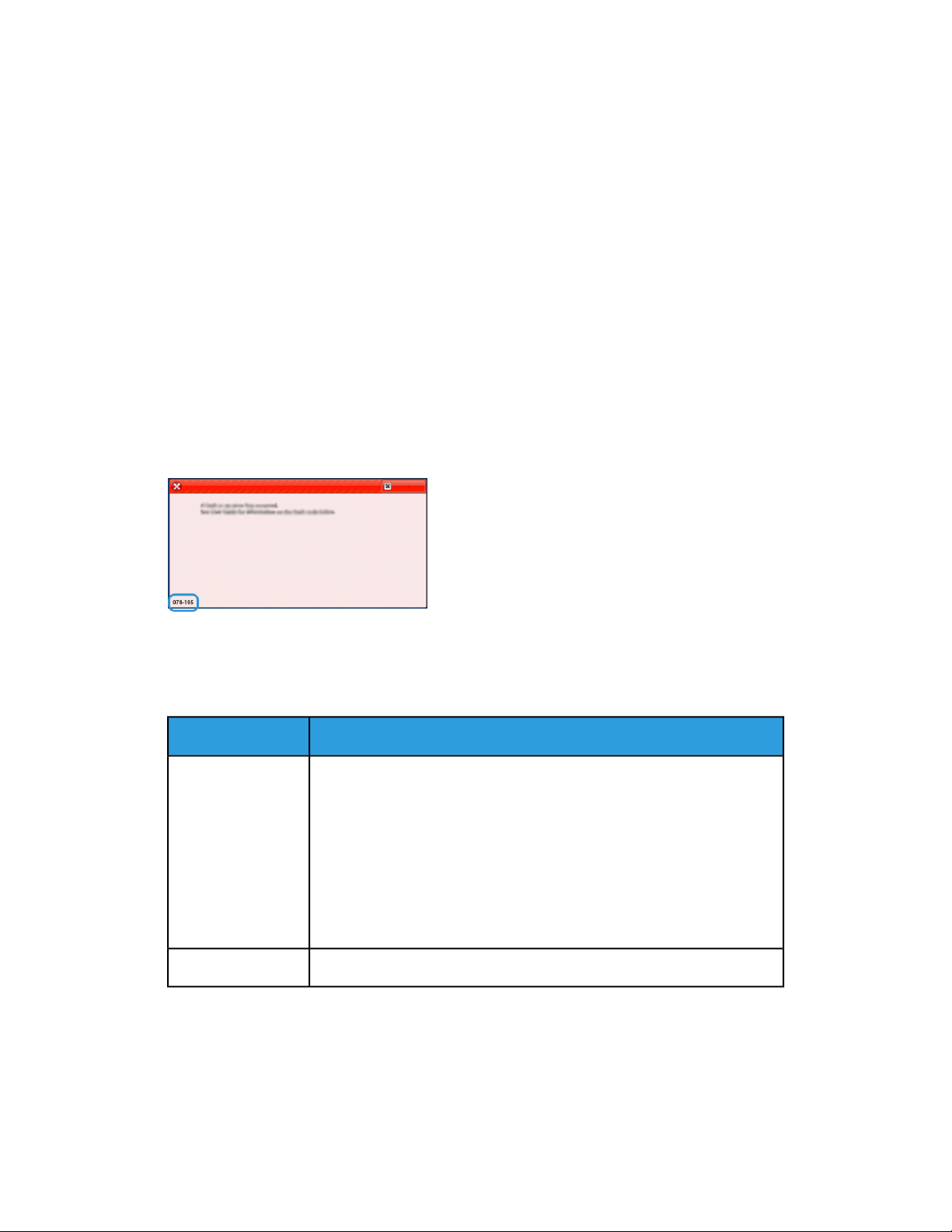

Tray 6 Fault Messages

When an fault occurs, such as paper jams, open doors or covers, or a press malfunction,

the press stops printing, and a message appears on the press UI. A graphical illustration

shows the location of the fault with a brief explanation of corrective actions for clearing

the fault. If a fault occurs in more than one location, the illustration changes to indicate

the multiple locations and the required corrective actions.

Tray 6 Fault Code Information

When an fault occurs, such as paper jams, open doors or covers, or a press malfunction,

the press stops printing, and a message appears on the press UI.

The UI also displays a Faults button which provides information about the fault and

detailed instructions for correcting the fault.

Tip

Tray 6 faults are identified by the codes which start with the three-digit numbers “024”

and “078.”

Tray 6 Specifications

SpecificationItem

2,000 sheetsPaper Capacity

8.5 x 11 in. or A4Sheet Size

Xerox®Versant®180 Press1-4

Optional Devices User Guide

Page 15

1-Tray High Capacity Feeder (HCF / Tray 6), Letter-Size / A4 Only

SpecificationItem

18 lb. bond to 80 lb. cover / 64-220 gsm (uncoated or coated)Paper Weight

Optional Devices User Guide

1-5Xerox®Versant®180 Press

Page 16

1-Tray High Capacity Feeder (HCF / Tray 6), Letter-Size / A4 Only

Xerox®Versant®180 Press1-6

Optional Devices User Guide

Page 17

2

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

Overview of the Oversized High Capacity Feeder (Trays 6 and 7)

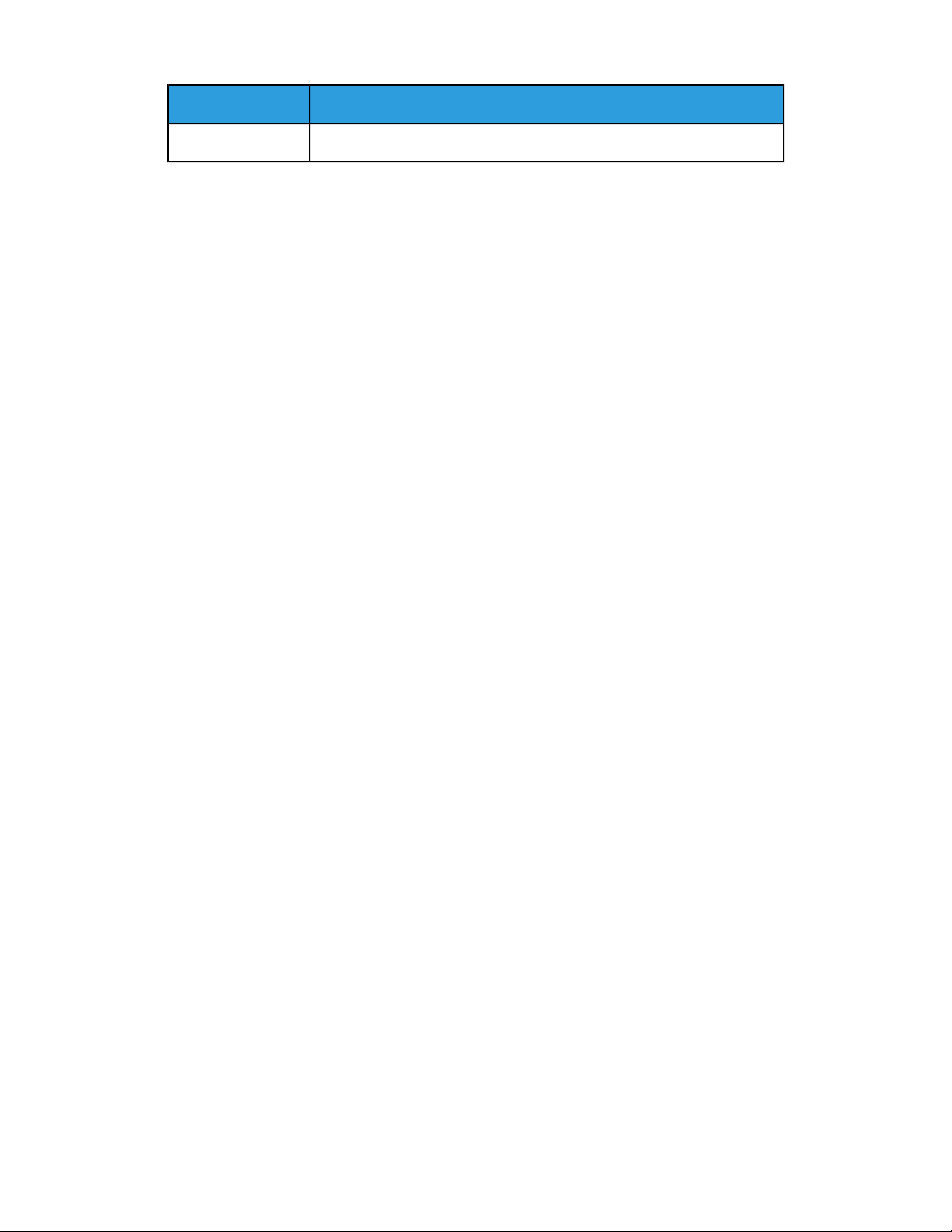

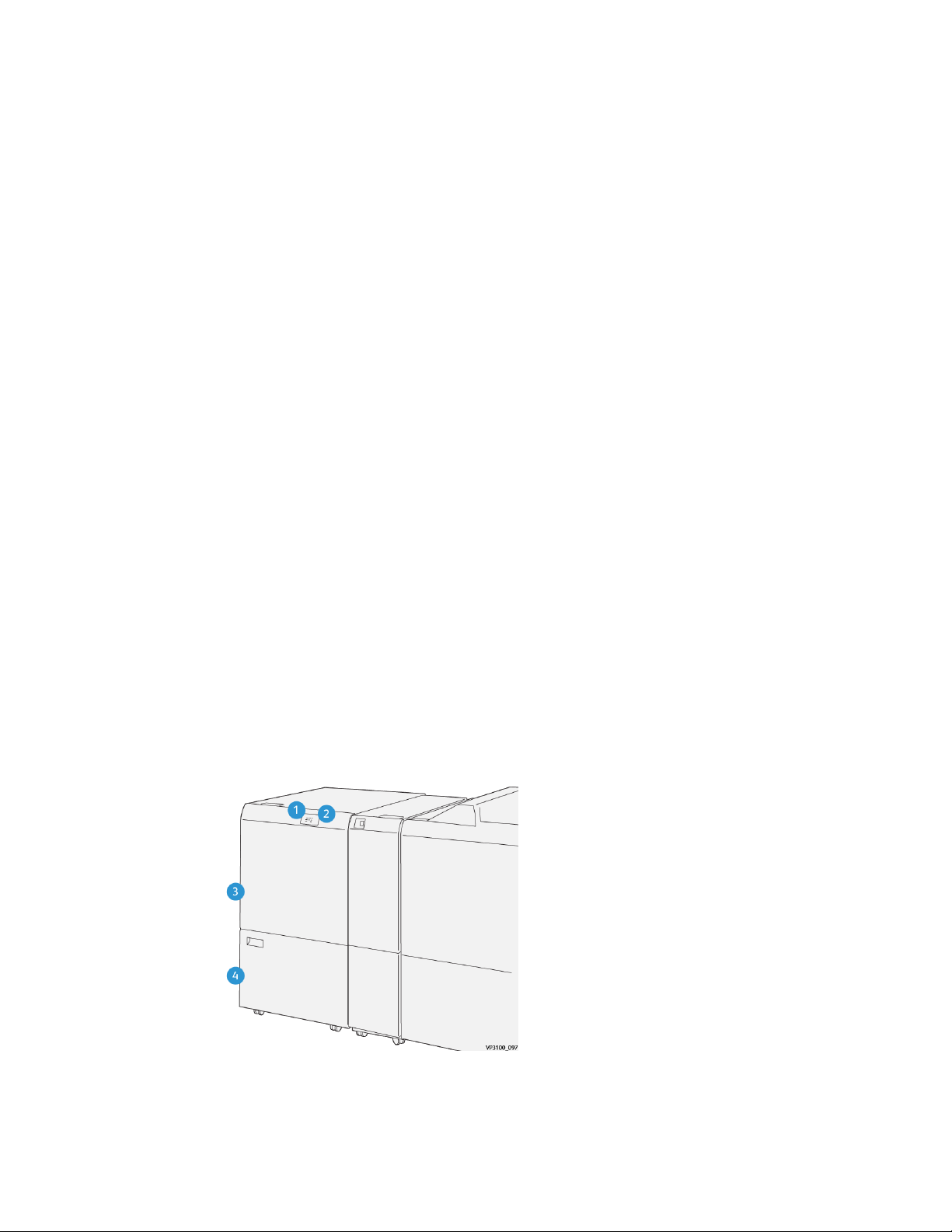

The Oversized High Capacity Feeder (OHCF) is available in a 1-tray or 2-tray option. The

OHCF feeds a variety of stock sizes, including standard and oversized stock up to 13 x

19.2 in./330.2 x 488 mm. Each tray holds 2,000 sheets.

2-tray OHCF (with Bypass)1

1-tray OHCF (with Bypass and storage cabinet above the tray)2

Optional Devices User Guide

2-1Xerox®Versant®180 Press

Page 18

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

Paper and Media in Trays 6 and 7

Note

Each feeder tray has a stock loading label. When loading media into the tray, refer to

the labels on the inside panel of the feeder tray for the correct orientation of that stock

type.

Note

It is recommended that you use the Bypass Tray (Tray 5) to feed envelopes. However,

if you use Trays 6 and / or 7, C5 and #10 envelopes must be fed SEF with the Postcard

Bracket installed. Stack height is limited to 200 envelopes.

Loading Paper in Trays 6 and 7

1. Select the appropriate paper stock for your print/copy job.

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

5. Load paper into the tray.

6. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

7. Gently push in the tray until it comes to a stop.

The Paper Tray settings/Tray Properties window displays on the UI. You can view

and set stock attributes and verify trays are assigned with the correct stock.

8. From the Paper Tray settings/Tray Propertieswindow,enterorverifythecorrectpaper

information,includingsize,type,weight and, if necessary, paper curl and/or alignment

option. Select the stock and assign the stock to the tray to be used.

9. Select Confirm or OK to save the information and close the Paper Tray settings/Tray

Properties window.

Loading Tabs in Trays 6 and 7

Refer to the following tips before loading tab stock in the tray:

• You can load either single straight collated or single reverse collated tab stock.

• For network print jobs, refer to your print server customer documentation for

instructions on loading tab stock into a tray.

• If a jam occurs while running tabbed sets, cancel the job and start again.

1. After programming your tab job at the print server, select the appropriate and

matching tab stock for your print job.

2. Pull out the tray slowly until it stops.

3. Fan the tab paper before loading into the tray.

Xerox®Versant®180 Press2-2

Optional Devices User Guide

Page 19

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

4. Load the tab stock LEF (portrait) and align the straight edge of the tab stock against

the right edge of the tray (tabstotheleft or trailingedge).For single straightcollated

tabs, the first blank tab cutout in the stack will be toward the front of the tray. For

single reverse collated tabs, the first blank tab cutout in the stack will be toward the

rear of the tray.

Tab stock is loaded so the straight edge of the stock is in the feed direction. Also, you

can only load the tab stock LEF.

5. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the stock in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

6. Gently push in the tray until it comes to a stop.

The Paper Tray settings/Tray Properties window displays on the press UI.

7. From the Paper Tray settings/Tray Properties window, confirm the correct tray to

which it is printing and other information, including size (9 x 11 inches), type (precut

tab), and, if necessary, paper curl and/or alignment option.

8. Select Confirm or OK to save the information and close the Paper Tray settings/Tray

Properties window.

Loading Transparencies in Trays 6 and 7

Read these tips before using transparencies:

• Do not use transparencies with the white side strip (either permanent or removable).

• Do not mix paper and transparencies in a tray. Jams may occur.

• Do not load more than 100 transparencies in a paper tray at one time.

• Load 8.5 x 11 in (A4) transparencies long edge feed only (landscape).

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Fan the transparencies to stop them from sticking together before loading into the

tray.

4. Load transparencies LEF on top of a small stack of same-size paper and align the

strip edge of the transparency against the right edge of the paper tray, with the side

to be printed on facing down.

5. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

6. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray settings/Tray Properties

window displays on the UI.

Optional Devices User Guide

2-3Xerox®Versant®180 Press

Page 20

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

7. From the Paper Tray settings/Tray Properties window, enter the correct paper

information,includingsize,type,weight and, if necessary, paper curl and/or alignment

option.

8. Select Confirm or OK to save the information and close the Paper Tray settings/Tray

Properties window.

Loading Hole Punch Paper in Trays 6 and 7

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

5. Load and register the paper against the right side of the tray for LEF direction.

6. Load and register the paper against the right side of the tray as depicted below for

SEF direction.

7. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the stock in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

8. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray settings/Tray Properties

window displays on the UI.

9. From the Paper Tray settings/Tray Properties window, enter the correct paper

information,includingsize,type,weight and, if necessary, paper curl and/or alignment

option.

10. Select Confirm or OK to save the information and close the Paper Tray settings/Tray

Properties window.

Postcard Bracket

The Postcard bracket is delivered with the OHCF from manufacturing. The Postcard

bracket allows you to print on smaller size media without requiring post-processing

cutting or sorting. The Postcard bracket specifically accommodates 4 x 6 in. (101.6 x

152.4 mm) SEF media.

Xerox®Versant®180 Press2-4

Optional Devices User Guide

Page 21

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

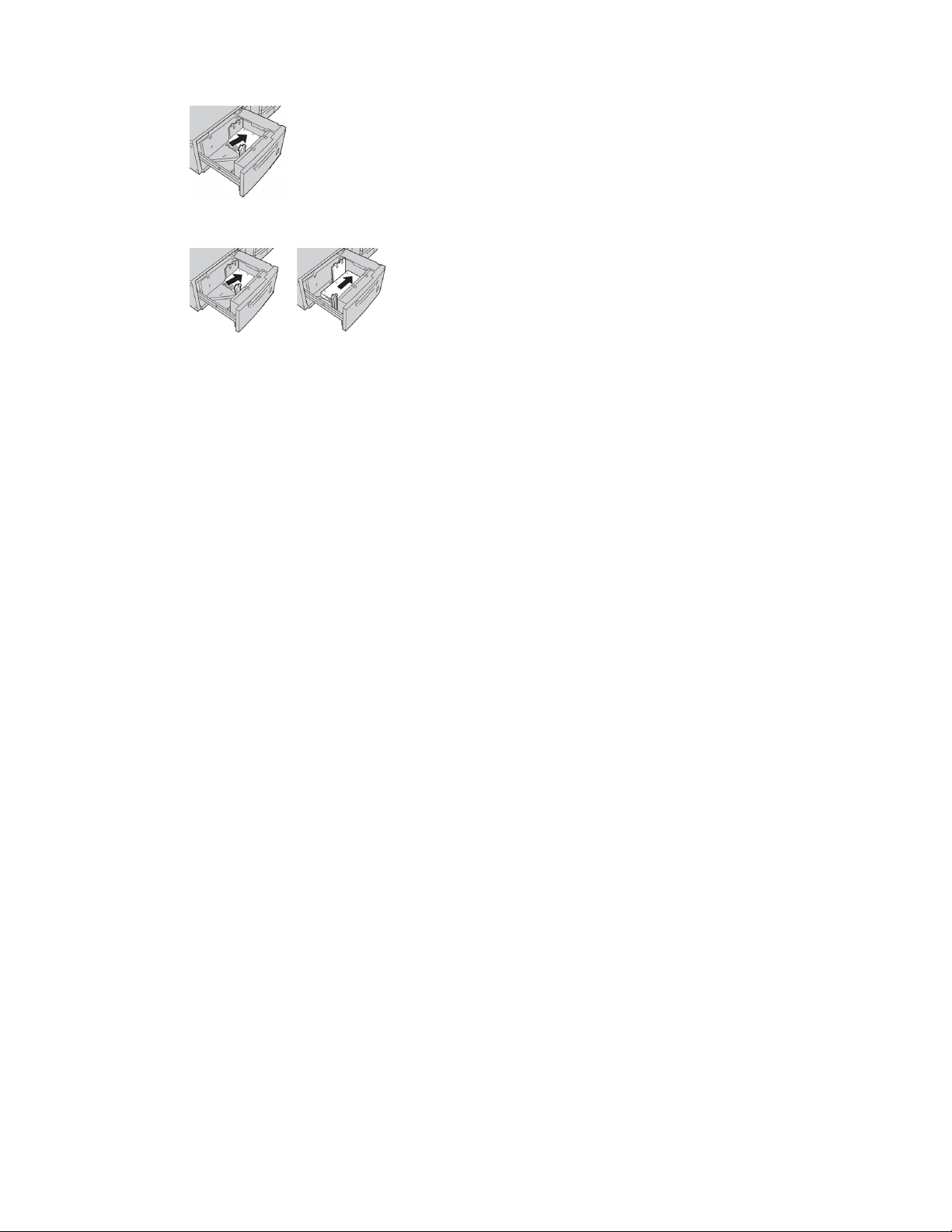

Using the Postcard Bracket

Use the following procedure for installing and using the Postcard bracket when printing

on smaller media (4 x 6 in./101.6 x 152.4 mm).

With the Postcard Bracket installed, you could print envelopes from Trays 6 and 7. The

stack height is up to 200 envelopes.

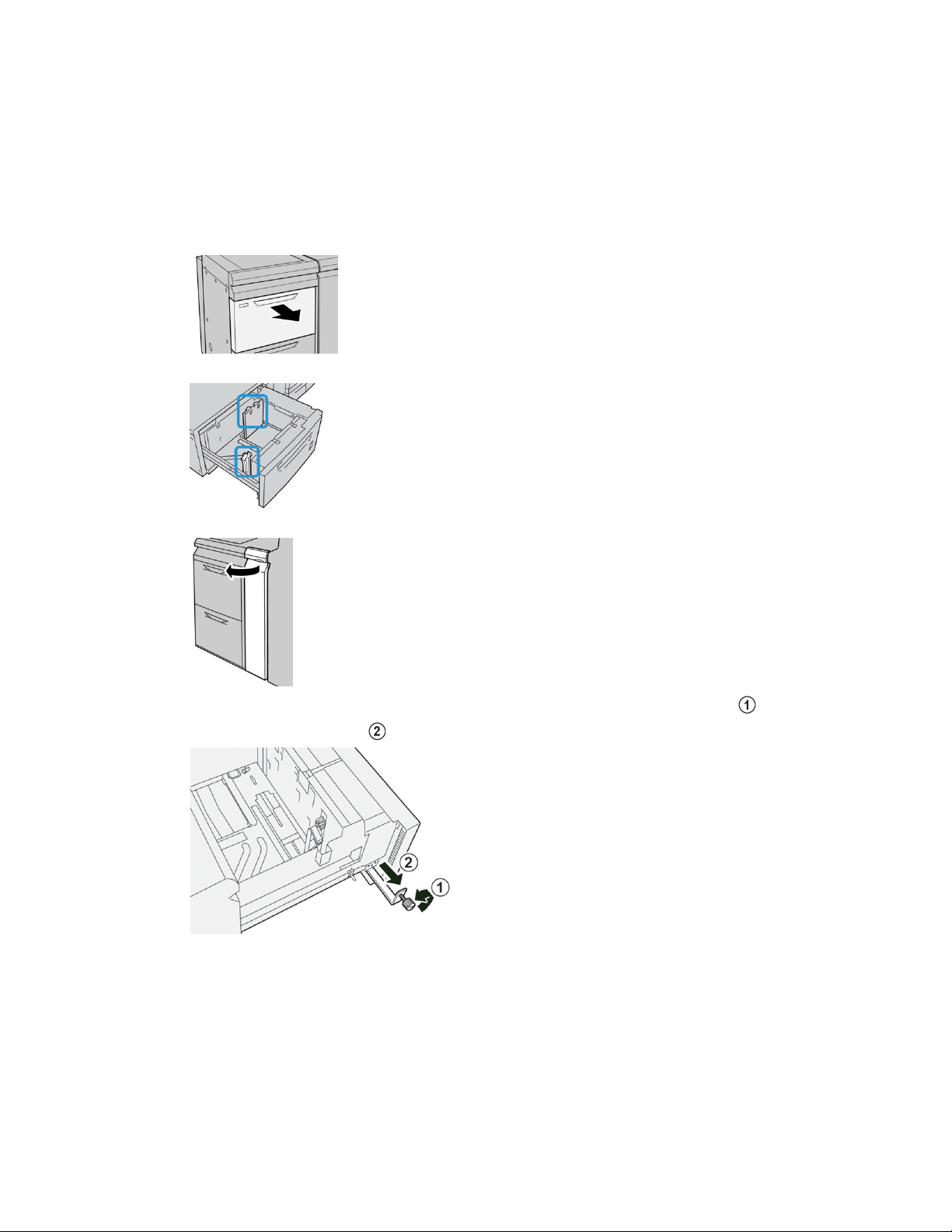

1. Slowly open one of the paper trays until it stops and remove the paper.

2. Move the paper guides out to their largest position.

3. Open the front cover of the OHCF.

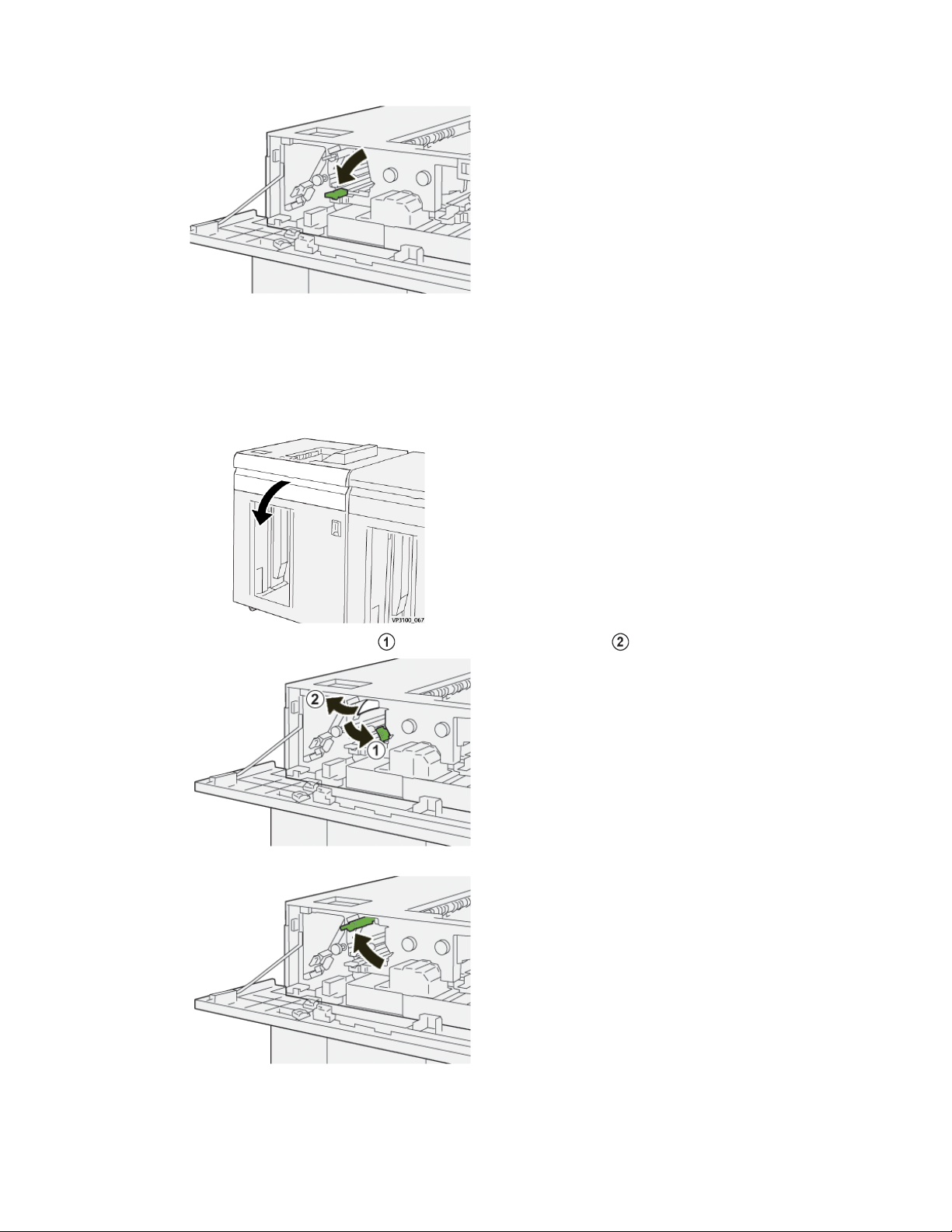

4. To remove the postcard bracket, loosen the screw on the left side of the tray ( )

and remove the bracket ( ).

Optional Devices User Guide

2-5Xerox®Versant®180 Press

Page 22

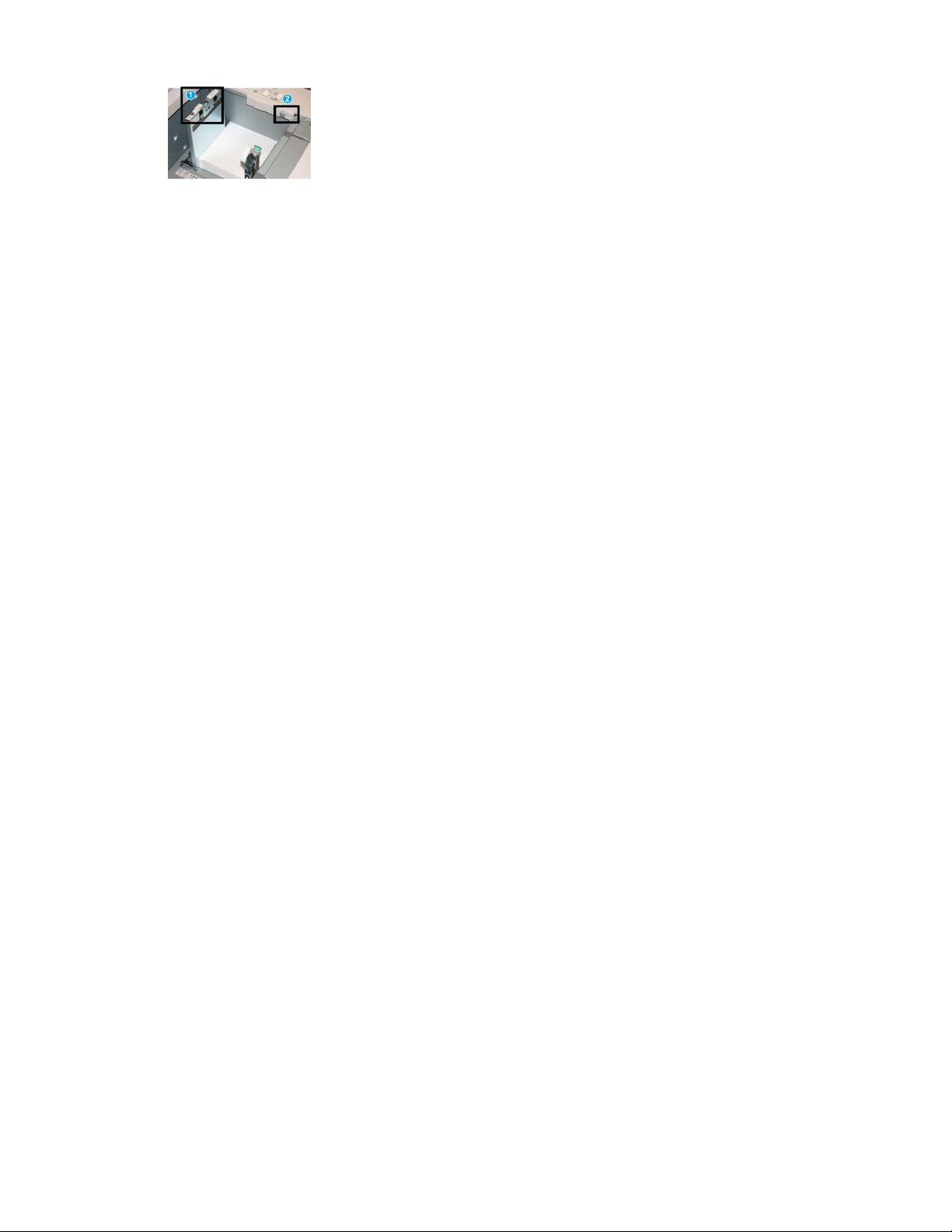

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

5. Install the Postcard bracket so that it sits on the locating pins on the upper frame

and in the grooves on the bottom of the tray.

6. Tighten the thumb screw so it locks the Postcard bracket in place.

7. Load the postcard stock and adjust the paper guides against the stock.

8. Close the paper tray and confirm the new settings on the press UI and if necessary

at the print server.

9. Run your print job.

10. Upon completion of your print job, remove the postcard stock and the Postcard

bracket from the tray.

11. Store the postcard bracket by inserting it into the storage area on the left side of the

tray ( ) and tightening the screw ( ).

Skew Adjustment Levers for OHCFs (Trays 6/7 and 8/9)

The skewadjustmentleversare foundinallpapertrays. These levers areusedtoimprove

paper feed accuracy and to reduce paper skew problems.

Xerox®Versant®180 Press2-6

Optional Devices User Guide

Page 23

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

1. Rear Skew Adjustment Lever

2. Right Side Skew Adjustment Lever

Note

These levers should remain in their default position. The position of these levers should

be changed only if there is a skew problem when running a specific print job and/or

media type. Changing the levers may cause more skew problems when running certain

media types such as coated, label, transparency and film.

Use the following procedure to set the skew adjustment levers:

1. Pull out the tray slowly until it stops.

The Tray Properties / Settings automatically display at the press User Interface (UI).

2. From the Tray Properties window, verify that the correct paper information is being

used including size, type, weight and paper curl or alignment option for the tray.

Select OK and close the Tray Properties window.

3. At the tray, slide the rear skew adjustment lever to the right.

4. Gently push in the tray until it comes to a stop.

5. Run your print job.

• The paper is fed accurately without skew and the printed output is satisfactory;

your task is complete.

• The paper is skewed and the printed output is unsatisfactory; proceed to the next

step.

6. Pull out the tray slowly until it stops.

7. Verify the tray and paper settings at the print server.

8. Return the rear skew adjustment lever to its left, default position.

9. Slide the right-side skew adjustment lever toward the front of the paper tray.

10. Gently push in the tray until it comes to a stop.

11. Run your print job.

• The paper is fed accurately without skew and the printed output is satisfactory;

your task is complete.

• The paper is skewed and the printed output is unsatisfactory; proceed to the next

step.

12. Pull out the tray slowly until it stops.

13. Return the right-side skew adjustment lever toward the rear of the paper tray; this is

its default position.

14. Gently push in the tray until it comes to a stop.

Optional Devices User Guide

2-7Xerox®Versant®180 Press

Page 24

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

Trays 6/7 Maintenance

Consumable Supplies for the OHCF (Trays 6 and 7)

Reorder QuantityCRUs (Supply Item)

Approximate Print Yield (Full

Color 8.5x11/A4 Prints)

500,0001 kitOHCF Feed Roll Kit

Replacing the OHCF Bypass Tray Feed Rolls (Trays 6 and 7)

Tip

The feed rolls for OHCF bypass tray should be replaced when experiencing frequent

multifeeds, single feeds, or blank prints in the stack of the output prints.

Use this procedure to replace the OHCF Bypass tray feed rolls, which includes:

• Feed Roll

• Nudger Roll

• Retard Roll

Note

After you replace all of the feed rolls, contact your system administrator who will reset

the HFSI usuage counter for these CRU components to zero (0).

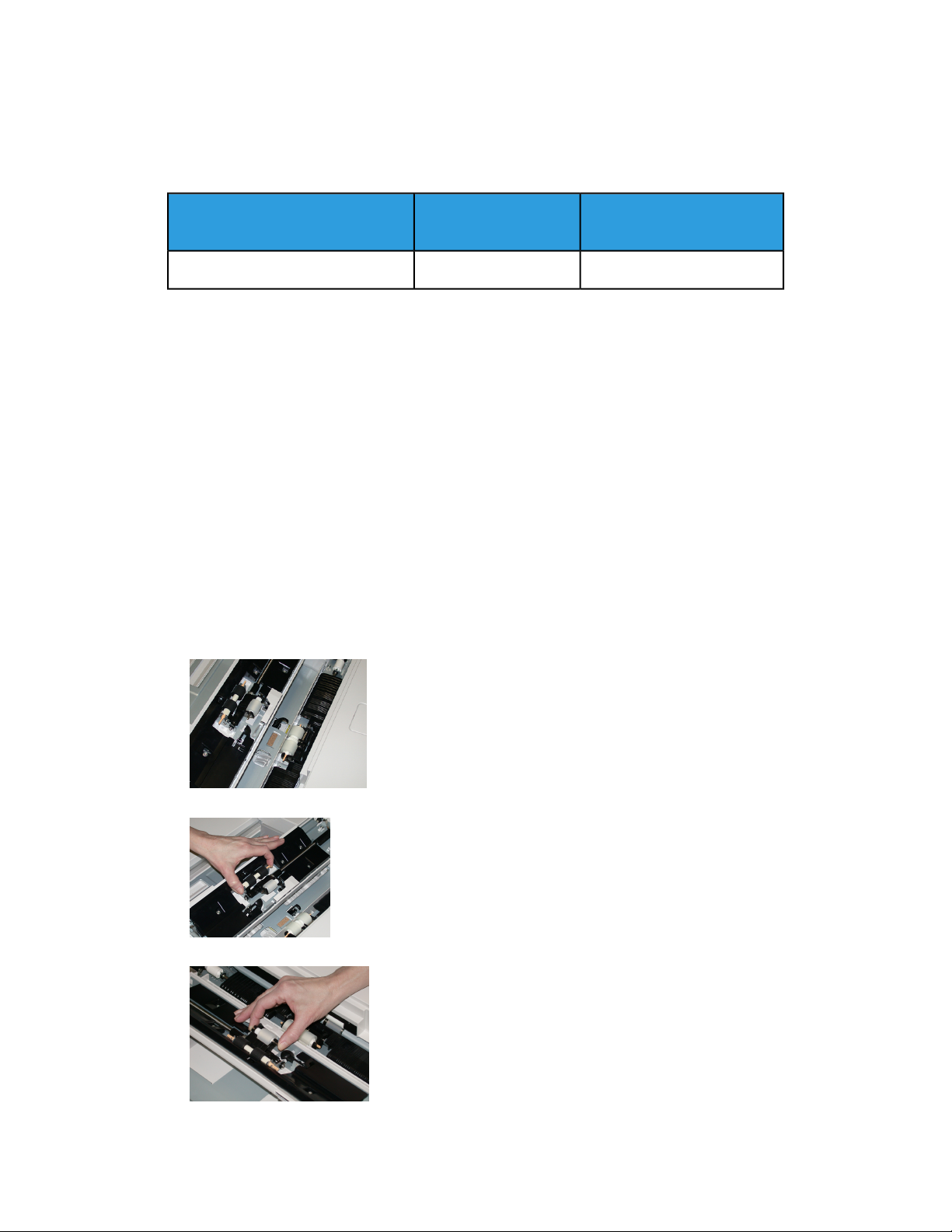

1. Locate and access the Bypass Tray on top of the OHCF.

2. Lift up and open the Bypass Tray cover to access the feed roll components.

3. Remove and replace the feed roll by squeezing the metal shaft and lifting out.

4. Remove and replace the nudger roll using the same technique.

Xerox®Versant®180 Press2-8

Optional Devices User Guide

Page 25

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

5. Remove and replace the retard roll using the same technique.

6. Close the bypass tray cover.

7. Verify that the tray is operating correctly by feeding paper from the bypass tray.

8. Either log in as the administrator or ask the administrator to perform the following

steps to reset the HFSI count to zero (0):

a) At the UI press the Machine Status button.

b) Select the Tools tab.

c) Select System Settings > Common Service Settings > Maintenance.

d) Use the up/down arrow buttons to access the next Maintenance screens.

e) Select the Technical Key Operator icon. The Technical Key Operator feature

displays.

f) Select the MSI rolls item that corresponds with the newly-replaced components.

g) Select Reset Current Value. The system resets the HFSI to 0.

9. Exit the administrator mode by pressing the Log In/Out button on the UI. When

prompted, selectLogout.

Replacing the OHCF Feed Rolls (Trays 6 and 7)

The OHCF feed rolls should be replaced every 300,000 prints or when experiencing

frequent multifeeds, single feeds, or blank prints in the stack of the output prints.

Use this procedure to replace the OHCF feed rolls, which includes:

• Feed Roll

• Nudger Roll

• Retard Roll

Note

After you replace all of the feed rolls, contact your system administrator who will reset

the HFSI usuage counter for these CRU components to zero (0).

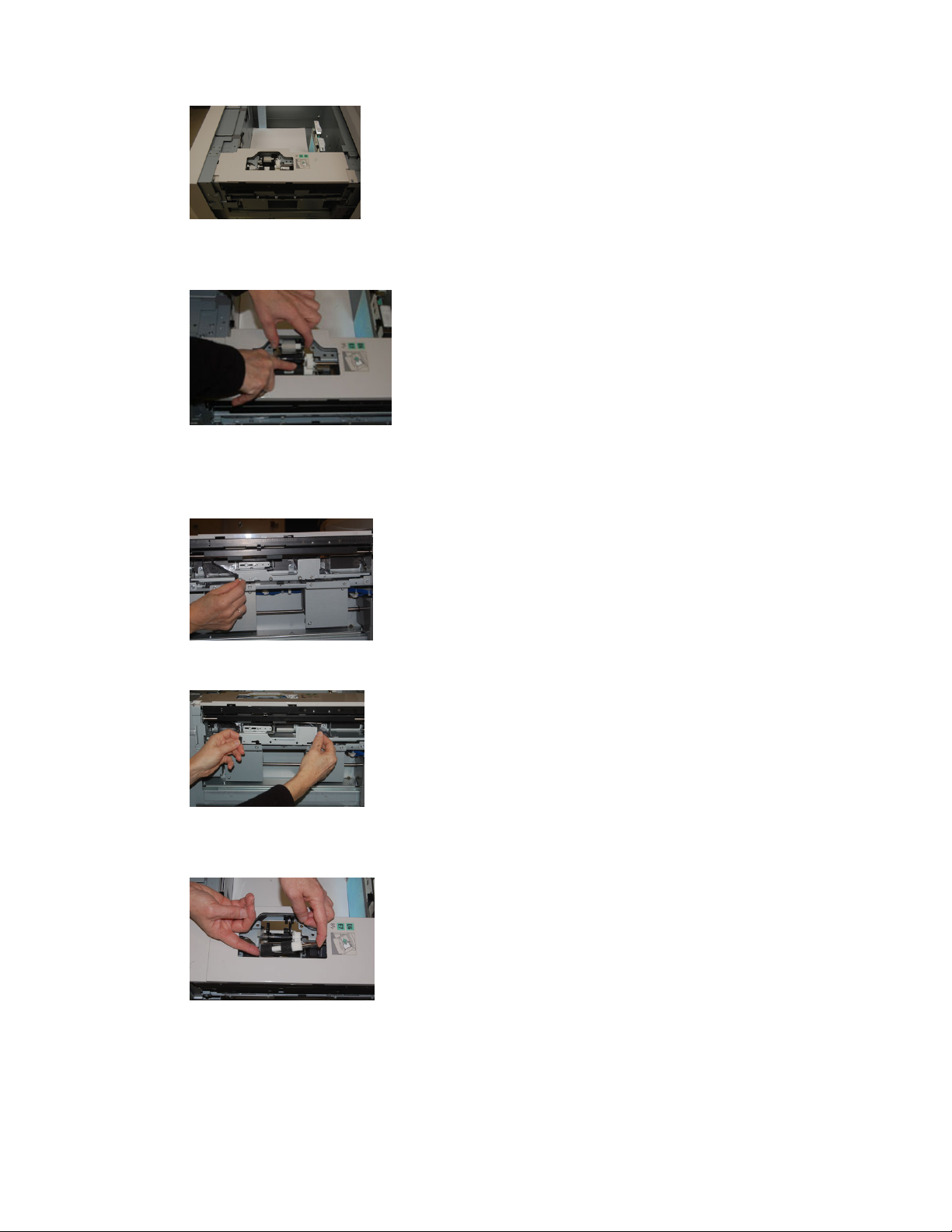

1. Pull open the top tray of the OHCF to access the feed components.

Optional Devices User Guide

2-9Xerox®Versant®180 Press

Page 26

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

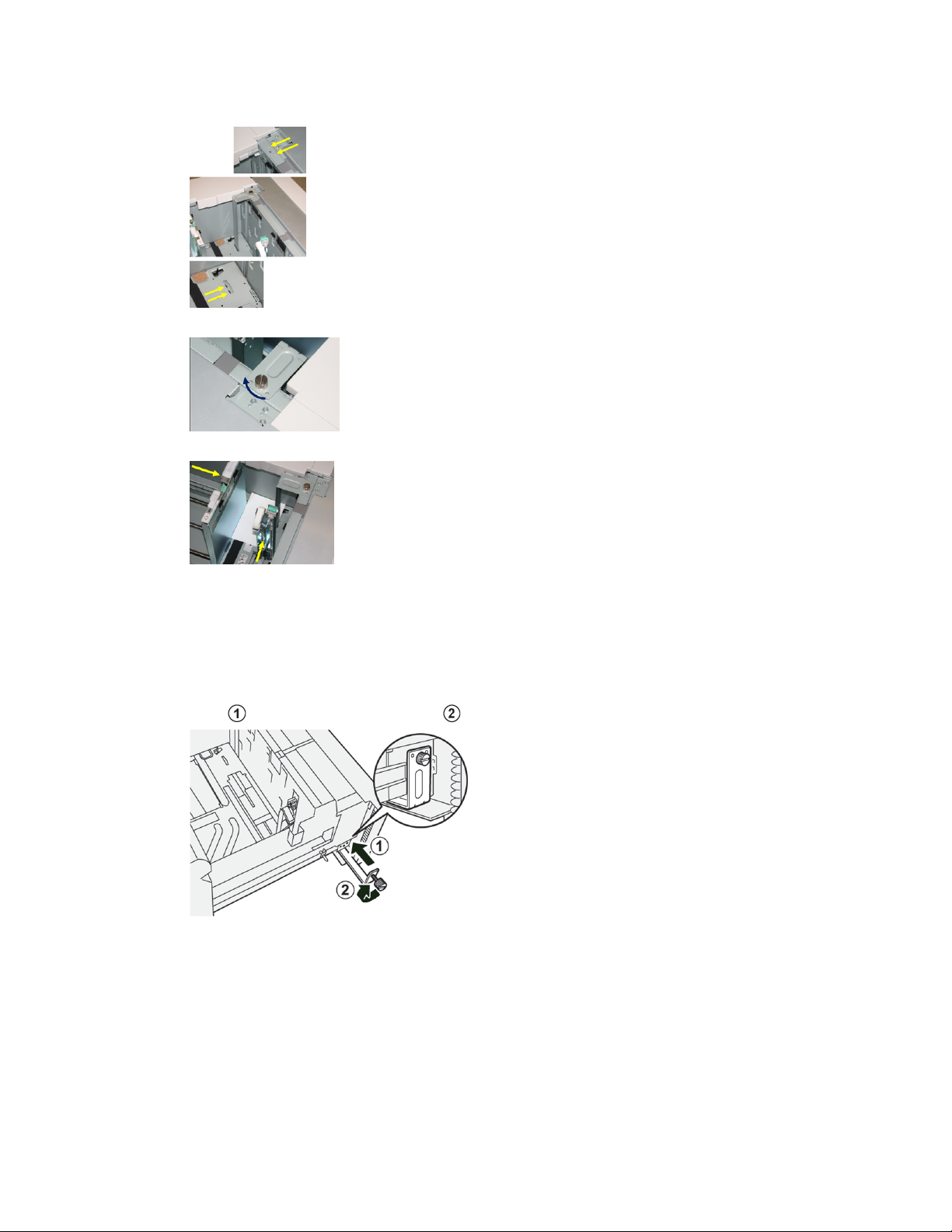

2. Notice the feed roll compartment on the right side panel of the drawer.

3. Remove thenudgerrollby pushing downontheblacktabwith one hand (which raises

the roll upward) and then squeezing the metal shaft on both ends with your other

hand. Lift out the nudger roll.

4. Replace the new roll by squeezing both ends of the metal shaft, and pushing down

on the black tab, insert and release the roll ends into the notches.

5. Next, remove the retard roll assembly at the side of the feeder tray to access the

retard roll. Unscrew the 3 thumbscrews.

6. Slide the retard assembly all the way to the left so it is out of the slots. Pull the

asssemly out towards you until completely removed from the tray. Set aside.

7. With the retard assembly out, access and remove the feed roll. To remove, squeeze

both ends of the metal shaft and lift out. To replace, squeeze both ends of the new

roll shaft, and insert and release the roll ends into the notches.

Xerox®Versant®180 Press2-10

Optional Devices User Guide

Page 27

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

8. Finally, replace the retard roll. Squeeze the orange shafts of the retard roll and lift

out of the assembly.

9. Replace a new retard roll into the black notches of the assembly using the same

technique.

10. Reinstall the retard assembly into the tray. Align the cutout holes of the assembly

with the frame of the tray so the pin holes match up. Insert the assembly into the

frame.Slide the assembly all the way to the right using the pin as a guideline. Ensure

the device is all the way into the slots and the 3 screw areas align.

11. Screw in the 3 thumbscrews to attach the assembly. Do not overtighten.

12. Close the tray and verify that the tray is operating successfully by feeding paper

using that tray.

13. Either log in as the administrator or ask the administrator to perform the following

steps to reset the HFSI count to zero (0).

a) At the UI press the Machine Status button.

b) Select the Tools tab.

c) Select System Settings > Common Service Settings > Maintenance.

d) Use the up/down arrow buttons to access the next Maintenance screens.

e) Select the Technical Key Operator icon.

The Technical Key Operator feature displays.

f) Select the item (HCF) that corresponds with the newly-replaced components.

g) Select Reset Current Value. The system resets the HFSI to 0.

14. Exit administrator mode by pressing the Log In/Out button on the UI.

When prompted, select Logout.

Optional Devices User Guide

2-11Xerox®Versant®180 Press

Page 28

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

Trays 6/7 Troubleshooting

Trays 6/7 Paper Jams

Paper Jams When the Bypass is Installed on Trays 6 and 7

Tip

Always ensure that all paper jams, including any small, ripped pieces of paper, are cleared

before proceeding with any print jobs.

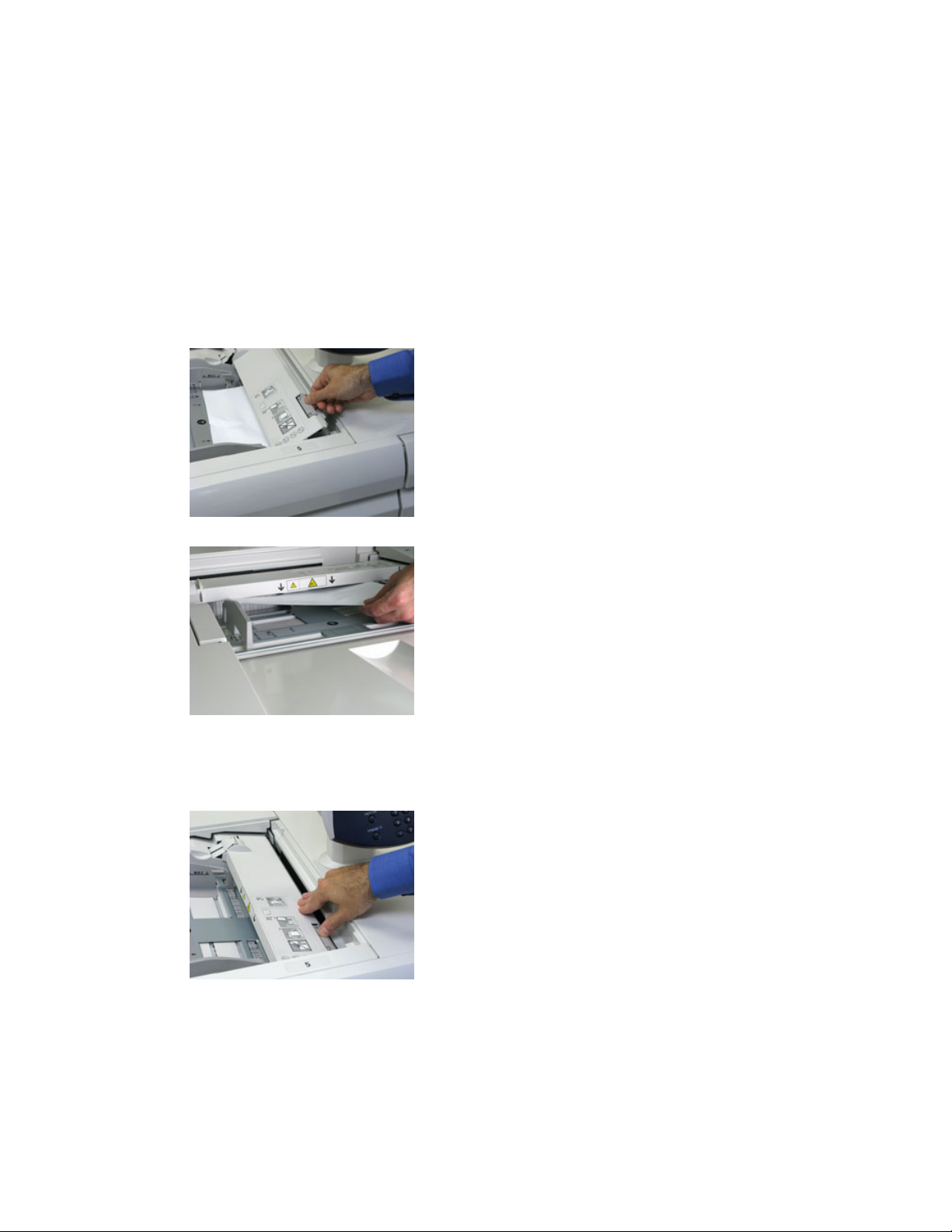

1. Remove the paper currently loaded in the Bypass (Tray 5).

2. Lift and open the Top Cover of the Bypass (Tray 5).

3. Remove any jammed paper.

Note

If paper is torn, check inside the press and remove it.

4. Close the Top Cover of the Bypass (Tray 5).

5. Reload paper into the tray and resume printing.

Xerox®Versant®180 Press2-12

Optional Devices User Guide

Page 29

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

Paper Jams Inside the OHCF Trays (6 and 7)

1. Pull out the tray where the paper jam occurred.

2. Remove the jammed paper.

Note

If paper is torn, check inside the machine and remove it.

3. Gently push in the tray until it comes to a stop.

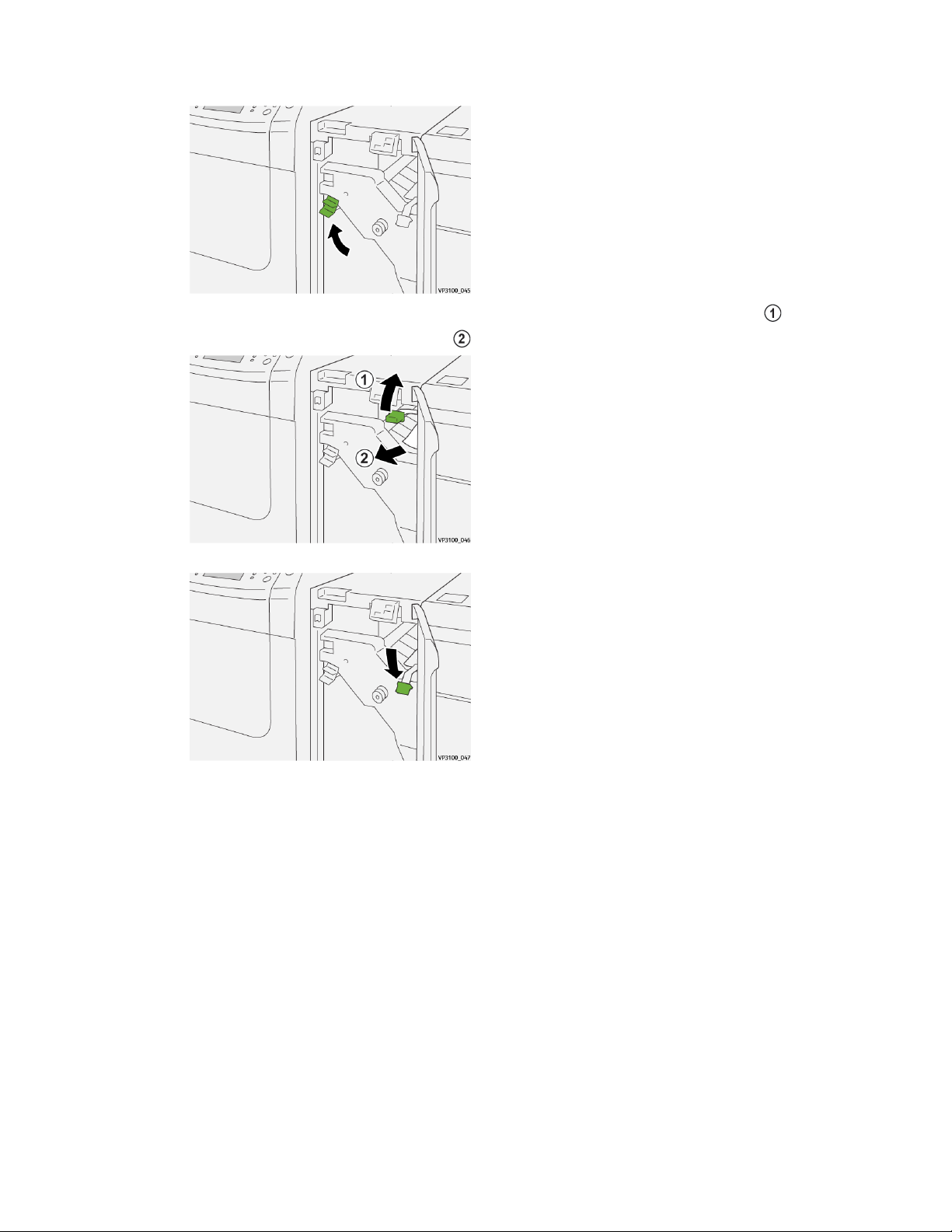

OHCF Paper Jams at Lever 1a and Knob 1c (Trays 6 and 7)

1. Open the front cover of the OHCF.

2. Move the lever1a to the right and turn the knob 1c to the right. Remove the jammed

paper.

Note

If paper is torn, check inside the machine and remove it.

Optional Devices User Guide

2-13Xerox®Versant®180 Press

Page 30

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

3. Return the lever 1a to the original position.

4. Close the front cover of the OHCF.

Note

If the front cover of the OHCF is not completely closed, a message will appear and

the machine will not operate.

OHCF Paper Jams at Lever 1b and Knob 1c (Trays 6 and 7)

1. Open the front cover of the OHCF.

2. Move the lever1b to the right and turn the knob 1c to the right. Removethe jammed

paper.

Note

If paper is torn, check inside the machine and remove it.

3. Return the lever 1b to the original position.

4. Close the front cover of the OHCF.

Note

If the front cover of the OHCF is not completely closed, a message will appear and

the machine will not operate.

Xerox®Versant®180 Press2-14

Optional Devices User Guide

Page 31

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

OHCF Paper Jams at Lever 1d and Knob 1c (Trays 6 and 7)

1. Open the front cover of the OHCF.

2. Move the lever 1d upward and remove the jammed paper.

Note

If paper is torn, check inside the machine and remove it.

3. If the paper cannot be removed, turn the knob 1c clockwise, and then remove the

jammed paper.

Note

If paper is torn, check inside the machine and remove it.

4. Return the lever 1d to the original position.

5. Close the front cover of the OHCF.

Note

If the front cover of the OHCF is not completely closed, a message will appear and

the machine will not operate.

Optional Devices User Guide

2-15Xerox®Versant®180 Press

Page 32

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

Trays 6/7 Fault Messages

When an fault occurs, such as paper jams, open doors or covers, or a press malfunction,

the press stops printing, and a message appears on the press UI. A graphical illustration

shows the location of the fault with a brief explanation of corrective actions for clearing

the fault. If a fault occurs in more than one location, the illustration changes to indicate

the multiple locations and the required corrective actions.

Trays 6/7 Fault Code Information

When an fault occurs, such as paper jams, open doors or covers, or a press malfunction,

the press stops printing, and a message appears on the press UI.

The UI also displays a Faults button which provides information about the fault and

detailed instructions for correcting the fault.

Tip

Trays 6 and 7 faults are identified by the codes which start with the three-digit number

“078.”

OHCF Specifications (Trays 6 and 7)

SpecificationItem

Paper Capacity

Sheet Sizes

1 Tray: 2,000 sheets plus top Storage Cabinet

2 Tray: 2,000 sheets per tray (total of 4,000 sheets)

Important

When using up to Xerox 24 lb. / 90 gsm paper.

1 Tray: 7.2 x 10 in. / 182 x 250 mm (B5) to 13 x 19.2 in. / 330 x 488 mm

(SRA3)

2 Tray: 4 x 6 in. / 102 x 152 mm to 13 x 19.2 in. / 330 x 488 mm (SRA3)

18 lb. bond to 110 lb. cover / 64 to 300 gsm (uncoated and coated)Paper Weight

Xerox®Versant®180 Press2-16

Optional Devices User Guide

Page 33

3

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

OHCF (Trays 8 and 9) Overview

Important

The second, chained OHCF (Trays 8 and 9) can be added only to a system which includes

a 2-Tray OHCF (Trays 6 and 7).

A second, chained Oversized High Capacity Feeder (OHCF) may be added to the system

to extend the paper capacities by providing two additional trays. This second, chained

OHCF is referred to as Trays 8 and 9, and it feeds a variety of stock sizes, including

standard sizes and oversized stock up to 13 x 19.2 in. / 330 x 488 mm paper. Each tray

holds 2,000 sheets of 24 lb. (90 gsm) paper. The weight range supported is 52 to 350

gsm.

Note

The OHCF comes equipped frommanufacturingwith the Postcardbracket (trayinserter).

Optional Devices User Guide

3-1Xerox®Versant®180 Press

Page 34

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

Paper and Media for Trays 8 and 9

Loading Paper in Trays 8 and 9

1. Select the appropriate paper stock for your print/copy job.

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

5. Load paper into the tray.

6. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

7. Gently push in the tray until it comes to a stop.

The Paper Tray settings/Tray Properties window displays on the UI. You can view

and set stock attributes and verify trays are assigned with the correct stock.

8. From the Paper Tray settings/Tray Propertieswindow, enter or verify the correct paper

information,including size, type, weight and, if necessary, paper curl and/or alignment

option. Select the stock and assign the stock to the tray to be used.

9. Select Confirm or OK to save the information and close the Paper Tray settings/Tray

Properties window.

Loading Tabs in Trays 8 and 9

Refer to the following tips before loading tab stock in the tray:

• You can load either single straight collated or single reverse collated tab stock.

• For network print jobs, refer to your print server customer documentation for

instructions on loading tab stock into a tray.

• If a jam occurs while running tabbed sets, cancel the job and start again.

1. After programming your tab job at the print server, select the appropriate and

matching tab stock for your print job.

2. Pull out the tray slowly until it stops.

3. Fan the tab paper before loading into the tray.

4. Load the tab stock LEF (portrait) and align the straight edge of the tab stock against

the right edge of the tray (tabs to the left or trailing edge). Forsingle straight collated

tabs, the first blank tab cutout in the stack will be toward the front of the tray. For

single reverse collated tabs, the first blank tab cutout in the stack will be toward the

rear of the tray.

Tab stock is loaded so the straight edge of the stock is in the feed direction. Also, you

can only load the tab stock LEF.

Xerox®Versant®180 Press3-2

Optional Devices User Guide

Page 35

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

5. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the stock in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

6. Gently push in the tray until it comes to a stop.

The Paper Tray settings/Tray Properties window displays on the press UI.

7. From the Paper Tray settings/Tray Properties window, confirm the correct tray to

which it is printing and other information, including size (9 x 11 inches), type (precut

tab), and, if necessary, paper curl and/or alignment option.

8. Select Confirm or OK to save the information and close the Paper Tray settings/Tray

Properties window.

Loading Transparencies in Trays 8 and 9

Read these tips before using transparencies:

• Do not use transparencies with the white side strip (either permanent or removable).

• Do not mix paper and transparencies in a tray. Jams may occur.

• Do not load more than 100 transparencies in a paper tray at one time.

• Load 8.5 x 11 in (A4) transparencies long edge feed only (landscape).

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Fan the transparencies to stop them from sticking together before loading into the

tray.

4. Load transparencies LEF on top of a small stack of same-size paper and align the

strip edge of the transparency against the right edge of the paper tray, with the side

to be printed on facing down.

5. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

6. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray settings/Tray Properties

window displays on the UI.

7. From the Paper Tray settings/Tray Properties window, enter the correct paper

information,including size, type, weight and, if necessary, paper curl and/or alignment

option.

8. Select Confirm or OK to save the information and close the Paper Tray settings/Tray

Properties window.

Loading Hole Punch Paper in Trays 8 and 9

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

Optional Devices User Guide

3-3Xerox®Versant®180 Press

Page 36

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

5. Load and register the paper against the right side of the tray for LEF direction.

6. Load and register the paper against the right side of the tray as depicted below for

SEF direction.

7. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the stock in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

8. Gently push in the tray until it comes to a stop.

If enabled by your System Administrator, the Paper Tray settings/Tray Properties

window displays on the UI.

9. From the Paper Tray settings/Tray Properties window, enter the correct paper

information,including size, type, weight and, if necessary, paper curl and/or alignment

option.

10. Select Confirm or OK to save the information and close the Paper Tray settings/Tray

Properties window.

Tray 8/9 Maintenance

Replacing the Bypass Tray Feed Rolls for the OHCF (Trays 8 and

9)

Tip

The feed rolls for Tray 5 (Bypass) should be replaced when experiencing frequent

multifeeds, single feeds, or blank prints in the stack of the output prints.

Use this procedure to replace the following feed rolls for Tray 5:

• Feed Roll

• Nudger Roll

• Retard Roll

Note

After you replace all of the feed rolls, contact your system administrator who will reset

the High Frequency Service Item (HFSI) usage counter for these CRU components to

zero (0).

1. Locate and access the Tray 5 (Bypass); depending on your system configuration, it

is on top of either Trays 6/7 or optional Trays 8/9.

Xerox®Versant®180 Press3-4

Optional Devices User Guide

Page 37

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

2. Lift up and open the Bypass Tray cover to access the feed roll components.

3. Remove and replace the feed roll by squeezing the metal shaft and lifting out.

4. Remove and replace the nudger roll using the same technique.

5. Remove and replace the retard roll using the same technique.

6. Close the bypass tray cover.

7. Verify that the tray is operating correctly by feeding paper from the bypass tray.

Optional Devices User Guide

3-5Xerox®Versant®180 Press

Page 38

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

8. Either log in as the administrator or ask the administrator to perform the following

steps to reset the High Frequency Service Item (HFSI) count to zero (0):

a) At the Control Panel, press the Tools button.

b) From the screen that displays, select the Tools icon.

c) Select System Settings > Common Service Settings > Maintenance.

d) Use the up / down arrow buttons to access the next Maintenance screens.

e) Select the Technical Key Operator icon. The Technical Key Operator feature

displays.

f) Select the bypassroll items that corresponds with the newly-replaced components.

g) Select Reset Current Value. The system resets the High Frequency Service Item

(HFSI) to 0.

9. Exit the administrator mode by pressing the Log In / Outbutton on the ControlPanel.

When prompted, select Logout.

Replacing the OHCF Feed Rolls for the OHCF (Trays 8 and 9)

The Trays 6/7 feed rolls should be replaced every 300,000 prints or when experiencing

frequent multifeeds, single feeds, or blank prints in the stack of the output prints.

Use this procedure to replace the feed rolls, which includes:

• Feed Roll

• Nudger Roll

• Retard Roll

Note

After you replace all of the feed rolls, contact your system administrator who will reset

the High Frequency Service Item (HFSI) usage counter for these CRU components to

zero (0).

1. Pull open the top tray to access the feed components.

Xerox®Versant®180 Press3-6

Optional Devices User Guide

Page 39

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

2. Notice the feed roll compartment on the right side panel of the drawer.

3. Remove the nudger roll by pushing down on the black tab with one hand (which raises

the roll upward) and then squeezing the metal shaft on both ends with your other

hand. Lift out the nudger roll.

4. Replace the new roll by squeezing both ends of the metal shaft, and pushing down

on the black tab, insert and release the roll ends into the notches.

5. Next, remove the retard roll assembly at the side of the feeder tray to access the

retard roll. Unscrew the 3 thumbscrews.

Optional Devices User Guide

3-7Xerox®Versant®180 Press

Page 40

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

6. Slide the retard assembly all the way to the left so it is out of the slots. Pull the

assembly out towards you until completely removed from the tray. Set aside.

7. With the retard assembly out, access and remove the feed roll. To remove, squeeze

both ends of the metal shaft and lift out. To replace, squeeze both ends of the new

roll shaft, and insert and release the roll ends into the notches.

8. Finally, replace the retard roll. Squeeze the orange shafts of the retard roll and lift

out of the assembly.

9. Replace a new retard roll into the black notches of the assembly using the same

technique.

Xerox®Versant®180 Press3-8

Optional Devices User Guide

Page 41

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

10. Reinstall the retard assembly into the tray. Align the cutout holes of the assembly

with the frame of the tray so the pin holes match up. Insert the assembly into the

frame.Slide the assembly all the way to the right using the pin as a guideline. Ensure

the device is all the way into the slots and the 3 screw areas align.

11. Screw in the 3 thumbscrews to attach the assembly. Do not over tighten.

12. Close the tray and verify that the tray is operating successfully by feeding paper

using that tray.

13. Either log in as the administrator or ask the administrator to perform the following

steps to reset the High Frequency Service Item (HFSI) count to zero (0).

a) At the Control Panel, press the Tools button.

b) From the screen that displays, select the Tools icon.

c) Select System Settings > Common Service Settings > Maintenance.

d) Use the up / down arrow buttons to access the next Maintenance screens.

e) Select the Technical Key Operator icon.

The Technical Key Operator feature displays.

f) Select the item that corresponds with the newly-replaced components.

g) Select Reset Current Value. The system resets the High Frequency Service Item

(HFSI) to 0.

14. Exit administrator mode by pressing the Log In / Out button on the Control Panel.

When prompted, select Logout.

Trays 8 and 9 Troubleshooting

Trays 8/9 Paper Jams

Clearing OHCF (Trays 8 / 9) Jams

Nip Release levers inside of the Transport area of the Feeder hold back large size sheets

(such as A3, 11 x 17 inches, 12 x 18 inches) to reduce the chance of jamming as paper

enters the print engine.

Note

Follow the jam clearance instructions displayed on the touch screen. Always ensure that

all paper jams, including any small ripped pieces of paper, are cleared before proceeding

with your print jobs.

Optional Devices User Guide

3-9Xerox®Versant®180 Press

Page 42

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

Paper Jams When the Bypass is Installed on Trays 8 and 9

Tip

Always ensure that all paper jams, including any small, ripped pieces of paper, are cleared

before proceeding with any print jobs.

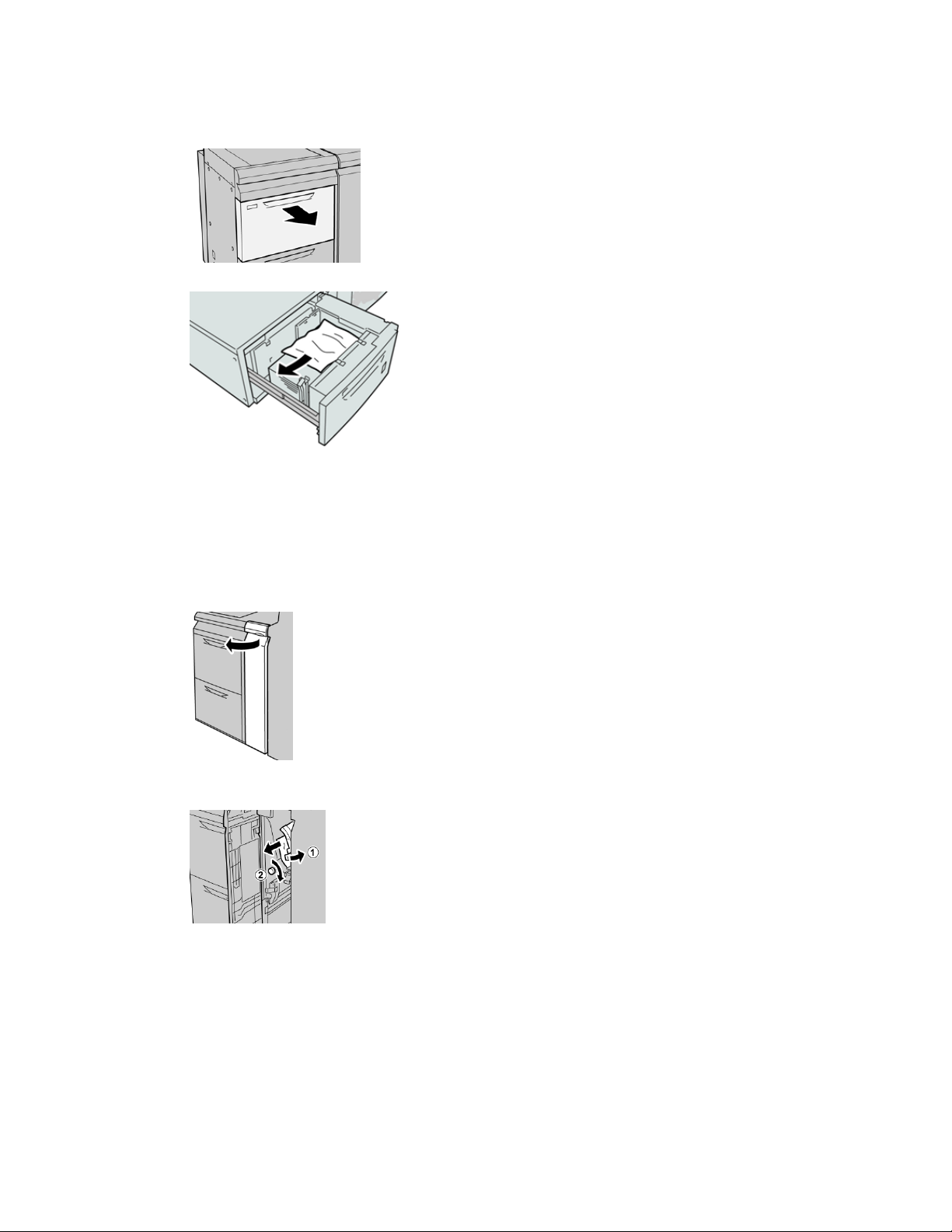

1. Remove the paper currently loaded in the Bypass (Tray 5).

2. Lift and open the Top Cover of the Bypass (Tray 5).

3. Remove any jammed paper.

Note

If paper is torn, check inside the press and remove it.

4. Close the Top Cover of the Bypass (Tray 5).

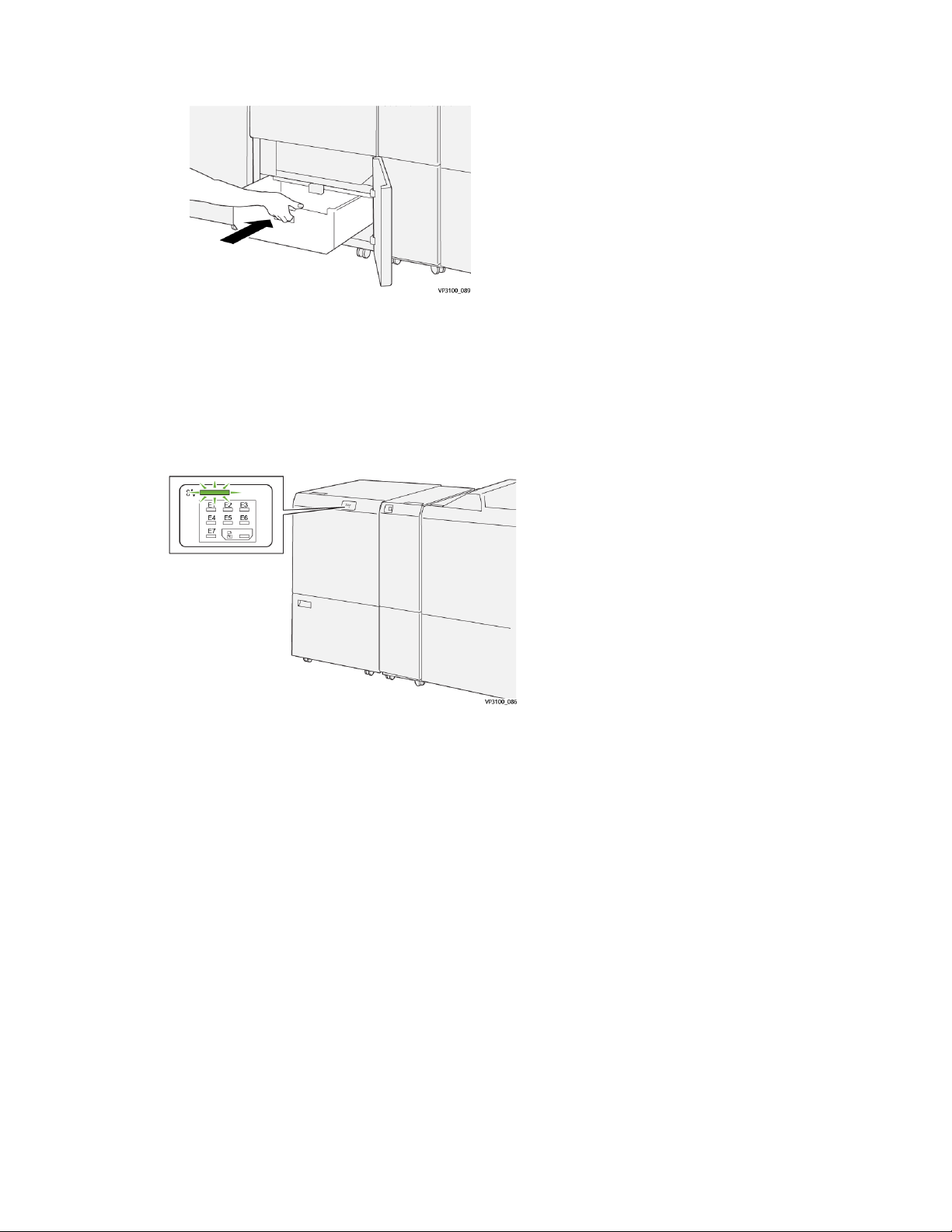

5. Pull open the Top Drawer (located at the top of Trays 6 and 7).

Xerox®Versant®180 Press3-10

Optional Devices User Guide

Page 43

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

6. Lift levers 2a and 2b, and remove any paper jams.

7. Close levers 2a and 2b.

8. Close the Top Drawer.

9. Reload paper into the tray and resume printing.

Paper Jams Inside Trays 8 and 9

1. Pull out the tray where the paper jam occurred.

2. Remove the jammed paper.

Note

If paper is torn, check inside the machine and remove it.

3. Gently push in the tray until it comes to a stop.

Trays 8 and 9 Paper Jams at Lever 1a and Knob 1c

1. Open the front cover of the feeder module.

Optional Devices User Guide

3-11Xerox®Versant®180 Press

Page 44

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

2. Move the lever1a to the right and turn the knob 1c to the right. Remove the jammed

paper.

Note

If paper is torn, check inside the machine and remove it.

3. Return the lever 1a to the original position.

4. Close the front cover of the feeder module.

Note

If the frontcover of the feedermodule is not completely closed, a message will appear

and the machine will not operate.

Trays 8 and 9 Paper Jams at Lever 1b and Knob 1c

1. Open the front cover of the feeder module.

2. Move the lever1b to the right and turn the knob 1c to the right. Removethe jammed

paper.

Note

If paper is torn, check inside the machine and remove it.

3. Return the lever 1b to the original position.

4. Close the front cover of the feeder module.

Note

If the frontcover of the feedermodule is not completely closed, a message will appear

and the machine will not operate.

Xerox®Versant®180 Press3-12

Optional Devices User Guide

Page 45

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

Trays 8 and 9 Paper Jams at Lever 1d and Knob 1c

1. Open the front cover of the feeder module.

2. Move the lever 1d upward and remove the jammed paper.

Note

If paper is torn, check inside the machine and remove it.

3. If the paper cannot be removed, turn the knob 1c clockwise, and then remove the

jammed paper.

4. Return the lever 1d to the original position.

5. Close the front cover of the feeder module.

Note

If the frontcover of the feedermodule is not completely closed, a message will appear

and the machine will not operate.

Trays 8/9 Fault Messages

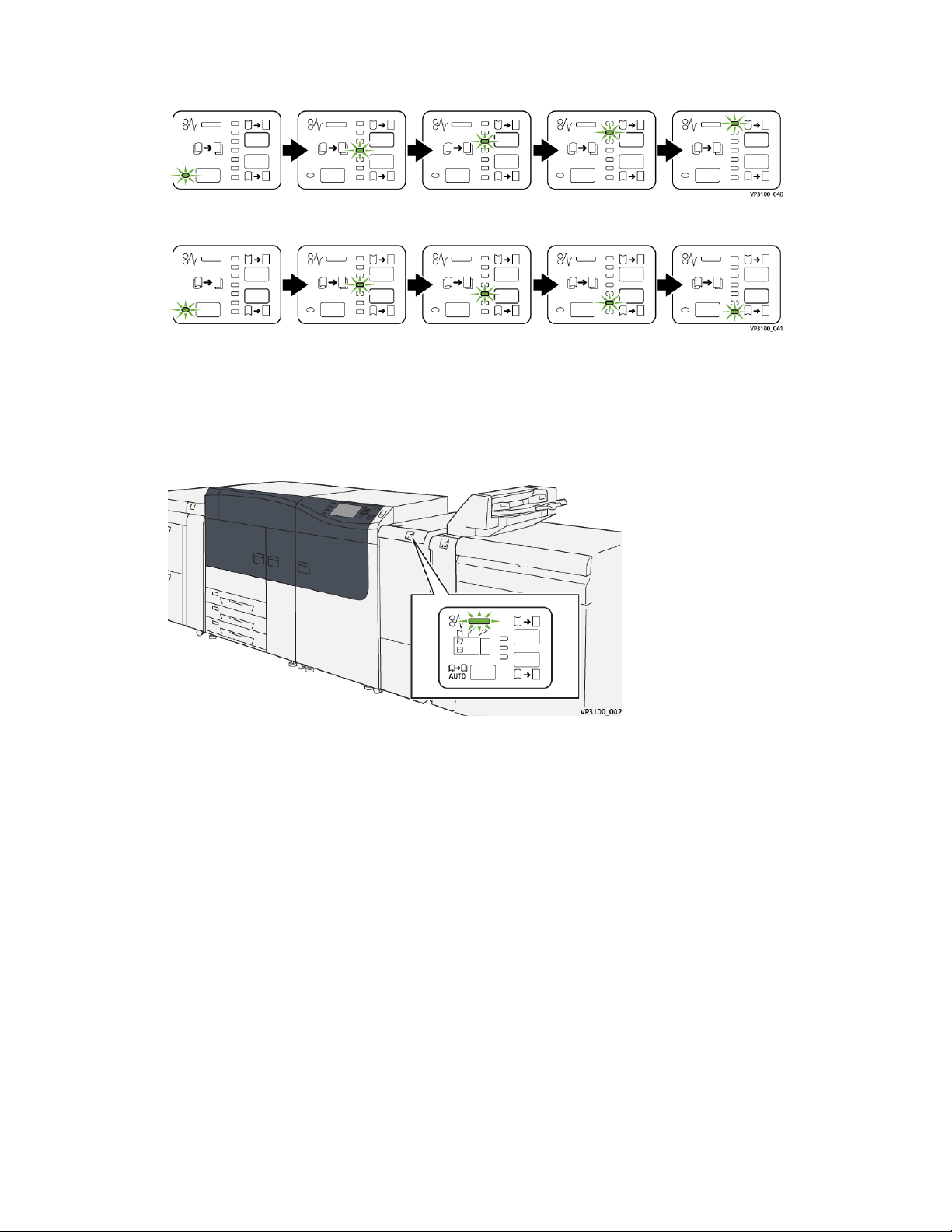

When an fault occurs, such as paper jams, open doors or covers, or a press malfunction,

the press stops printing, and a message appears on the press UI. A graphical illustration

shows the location of the fault with a brief explanation of corrective actions for clearing

the fault. If a fault occurs in more than one location, the illustration changes to indicate

the multiple locations and the required corrective actions.

Trays 8/9 Fault Code Information

When an fault occurs, such as paper jams, open doors or covers, or a press malfunction,

the press stops printing, and a message appears on the press UI.

The UI also displays a Faults button which provides information about the fault and

detailed instructions for correcting the fault.

Optional Devices User Guide

3-13Xerox®Versant®180 Press

Page 46

Chained (Second) Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

Tip

Trays 8 and 9 faults are identified by the codes which start with the three-digit number

“178.”

Trays 8 and 9 Specifications

SpecificationItem

Short Edge Feed (SEF):Sheet size

• 8.5 x 11 in. / A4

• 8.5 x 13 in.

• 8.5 x 14 in.

• 10 x 14 in. / B4

• 11 x 17 in. / A3

• 12 x 18 in.

• 12.6 x 17.7 in. / SRA3

• 13 x 18 in.

• 13 x 19 in.

• 12.6 x 19.2 in.

• B5

Long Edge Feed (LEF):

Paper capacity

• B5

• 7.25 x 10.5 in. (executive)

• A4

• 8.5 x 11 in.

• 8.0 x 10 in.

Custom sizes: 182-330 mm (7.2-13 in.) Width and 182-488 mm (7.2-19.2

in.) Length

16 lb. to 130 lb. cover / 52-350 gsmPaper weight

2,000 sheets per tray

Important

When using up to Xerox 24 lb. / 90 gsm paper.

Xerox®Versant®180 Press3-14

Optional Devices User Guide

Page 47

4

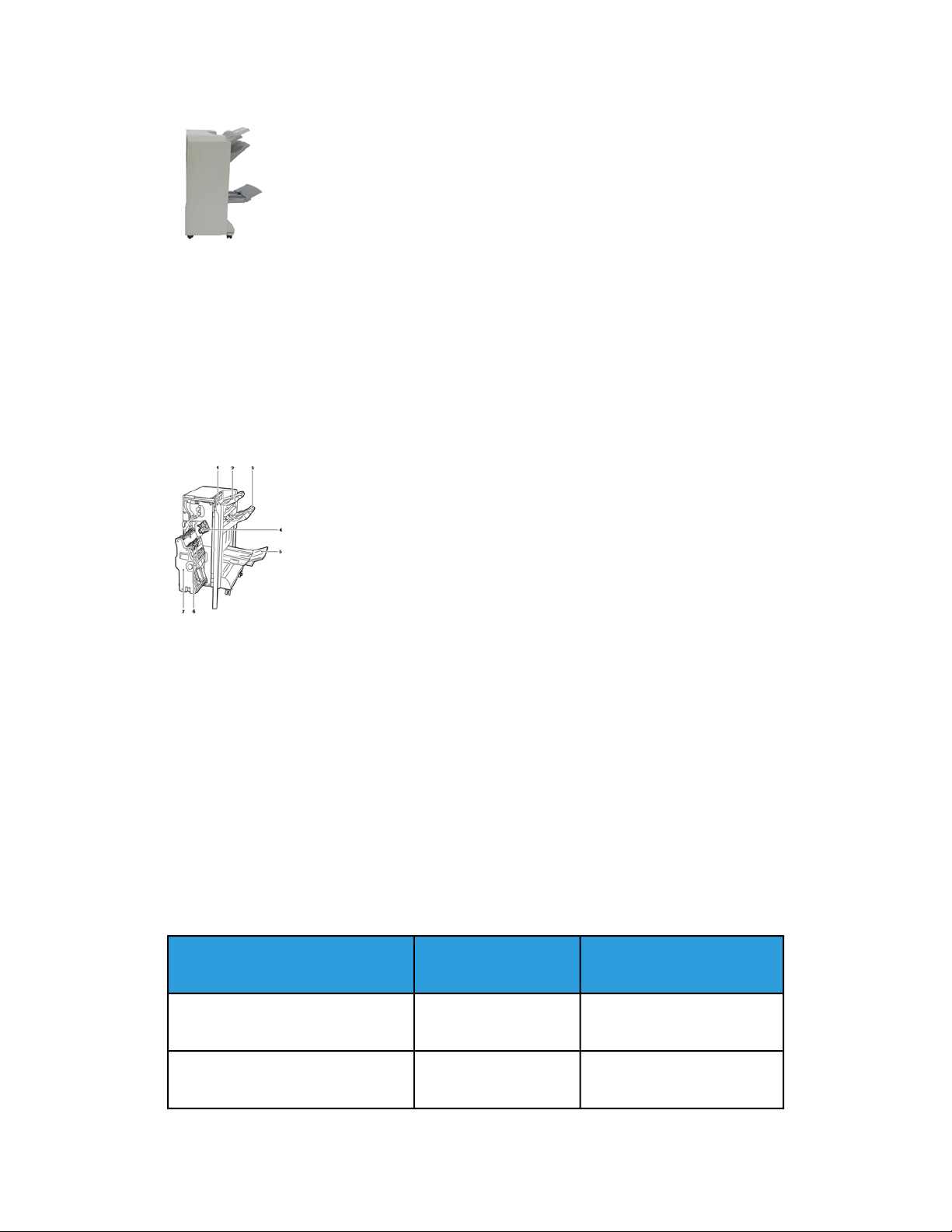

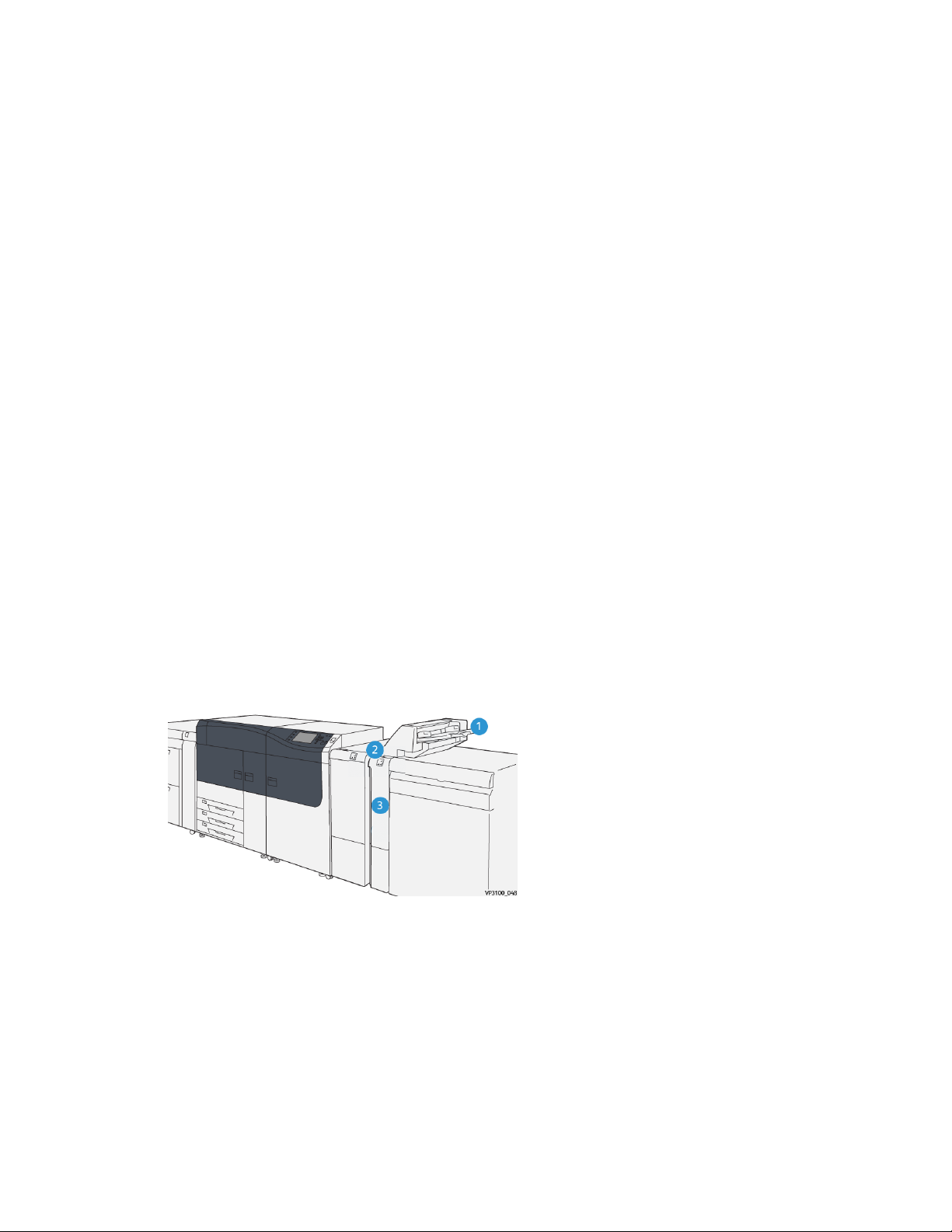

Business Ready (BR) Finisher and Optional Booklet Maker

Business Ready (BR) Finisher Overview

Tip

The BR Finisher (with or without Booklet Maker) attaches directly to the press and does

not require the Interface Module/Interface Cooling Module.

The Business Ready (BR) Finisher adds several professional-level finishing options to the

press while requiring minimal additional space for the finisher. The finisher is available

with or without an optional booklet maker.

Business Ready (BR) Finisher without Booklet Maker

The BR Finisher supports hole punching and stapling. The Right Top Tray is used for

stacked output, and can receive up to 500 sheets of paper. The Stacker is used for

offset and/or stapled output, and can hold up to 3,000 sheets.

Optional Devices User Guide

4-1Xerox®Versant®180 Press

Page 48

Business Ready (BR) Finisher and Optional Booklet Maker

Business Ready (BR) Finisher with the optional Booklet Maker

The BR Finisher with the optional Booklet Maker supports hole punching, stapling, and

booklet making. The Right Top Tray is used for stacked output, and can receive up to

500 sheets of paper. The Right Center Tray is used for offset and/or stapled output

and can hold up to 1,500 sheets. Both trays can be used for hole punched output

(optional). The Bottom Finisher Tray is used for receiving saddle-stapled booklets.

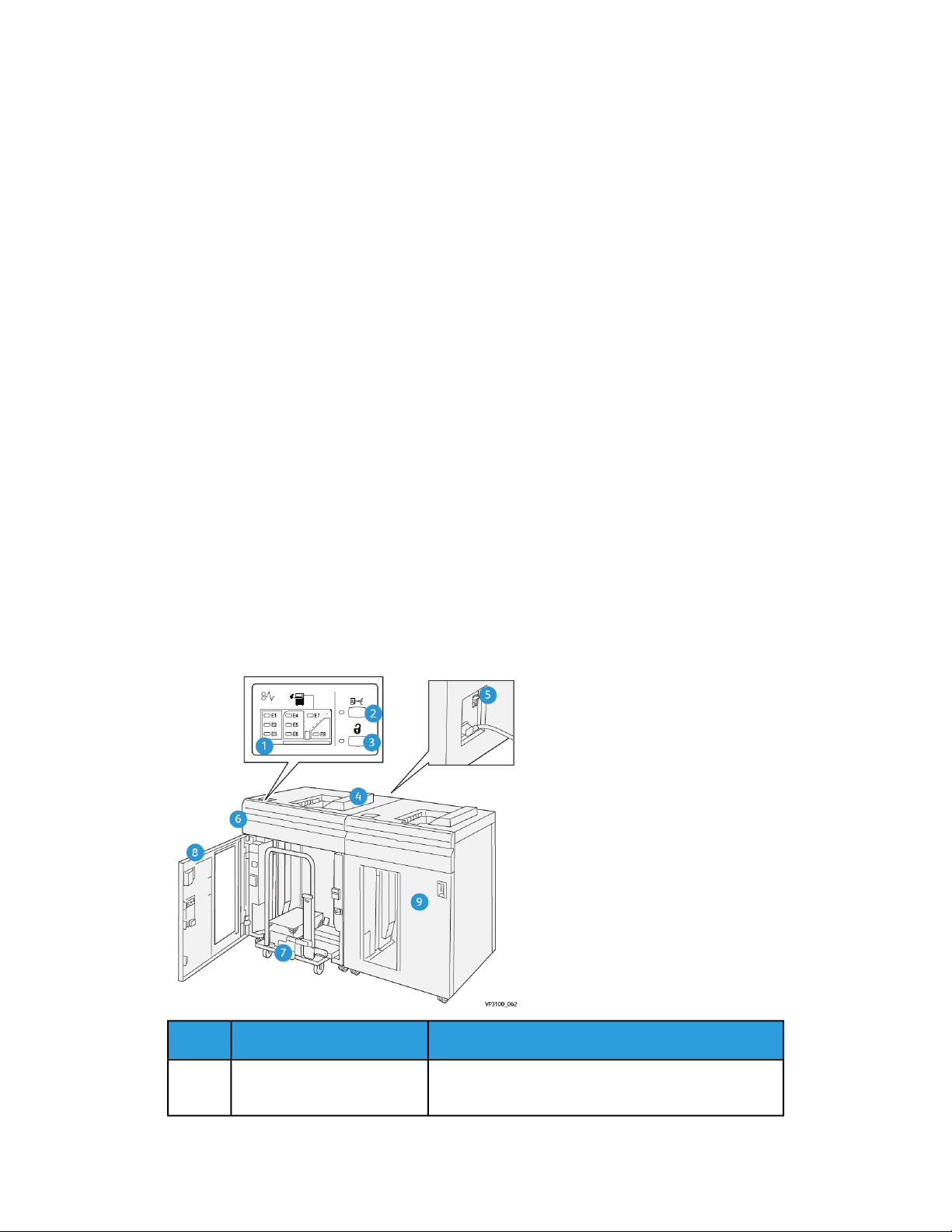

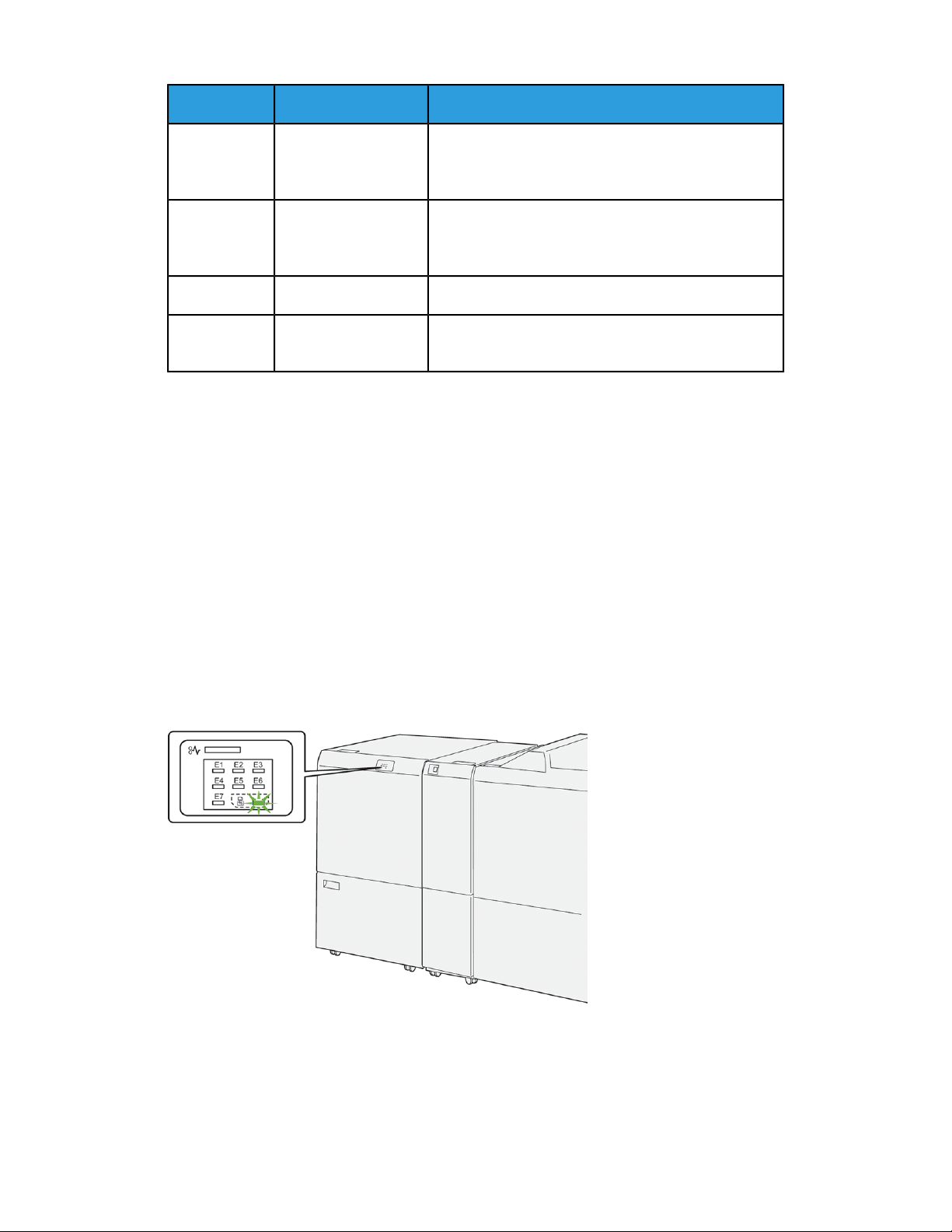

Identifying the BR Finisher Components

1. Finisher Front Cover

2. Right Top Tray

3. Right Middle Tray

4. Staple Cartridge

5. Booklet Maker Tray (optional)

6. Booklet Staple Unit (optional)

7. Booklet Maker Unit (optional)

BR Finisher Maintenance

Consumable Supplies for the BR Finisher

Reorder QuantityCRUs (Supply Item)

Cartridge

Business Ready (BR) Finisher with

Booklet Maker Staple Cartridge

fills each

Approximate Print Yield (Full

Color 8.5x11/A4 Prints)

5,000 staples per cartridge1 Staple CartridgeBusiness Ready (BR) Finisher Staple

5,000 staples per cartridge4 pack: 5,000 staple re-

Xerox®Versant®180 Press4-2

Optional Devices User Guide

Page 49

Business Ready (BR) Finisher and Optional Booklet Maker

Reorder QuantityCRUs (Supply Item)

3 refills per cartonStaple Refills for the Business Ready

Finisher and Business Ready Finisher

with Booklet Maker

Approximate Print Yield (Full

Color 8.5x11/A4 Prints)

5,000 each refill for a total of

15,000

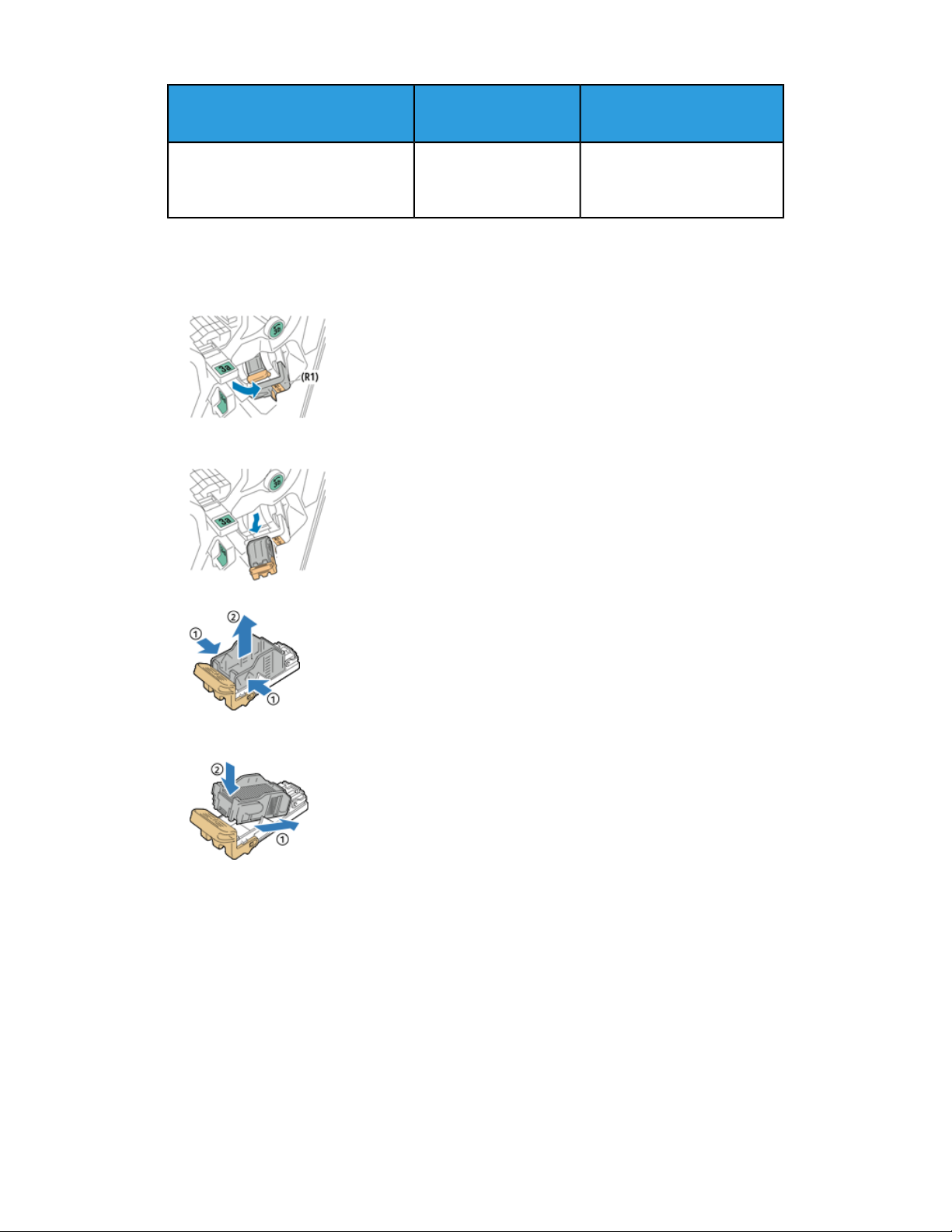

Replacing Staples in the Main Stapler Unit

1. Open the front door of the Business Ready Finisher.

2. Hold the stapler assembly by the orange lever R1 and push it to the right.

3. Grip the staple cartridge by the orange handle and pull it firmly towardyou to remove

it.

4. Pinch both sides of the staple refill (1)and remove it from the cartridge (2).

5. Insert the front side of the new staple refill into the staple cartridge (1), then push

the rear side into the cartridge (2).

6. Close the front door of the Business Ready Finisher.

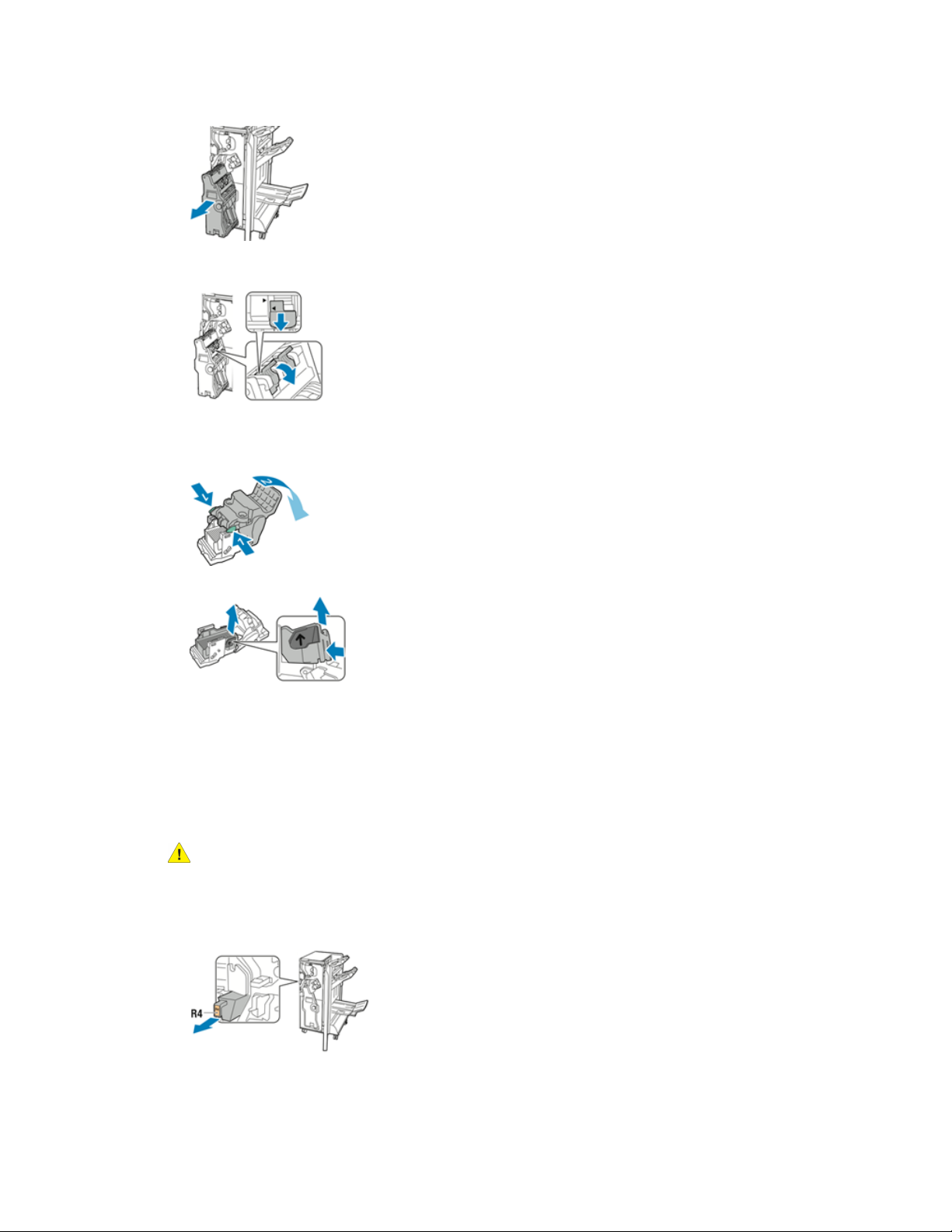

Replacing Staples in the Booklet Maker

1. Open the front door of the Business Ready Finisher.

Optional Devices User Guide

4-3Xerox®Versant®180 Press

Page 50

Business Ready (BR) Finisher and Optional Booklet Maker

2. Grasp the booklet maker handle and pull the unit toward you until the staple cartridges

appear on the top edge of the device.

3. To remove the staple cartridge from the booklet maker, push down on the staple

cartridge handle as shown, then pull the cartridge out and up.

4. Turn the staple cartridge over.

5. To permit the staple cartridge handle to open out and away from the staple refill,

press in the green tabs, then pull back the handle.

6. To remove the staple refill, press the rear of the refill container as shown.

7. Replace the staple refill, then return the staple cartridge to the booklet maker.

8. Close the front door of the Business Ready Finisher.

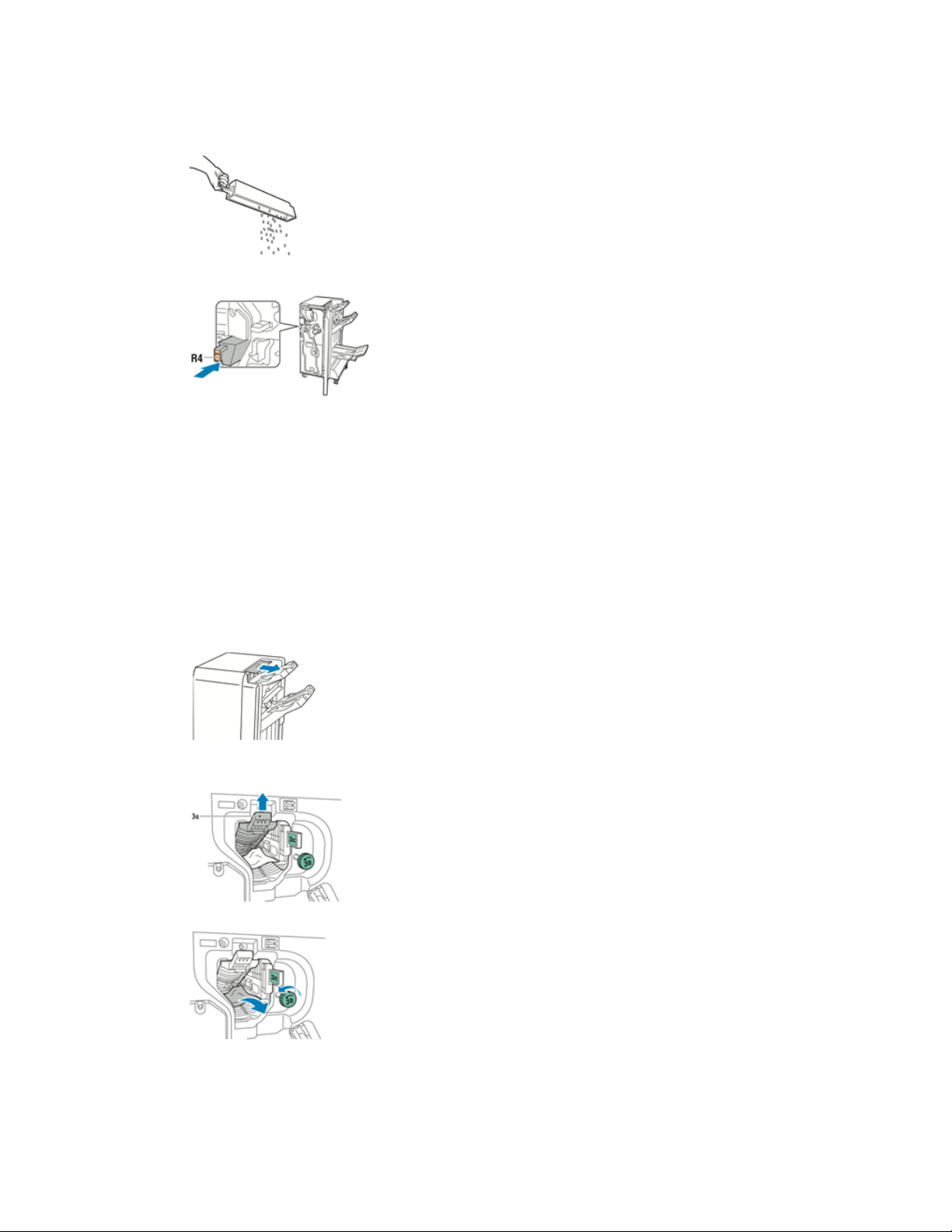

Emptying the Hole Punch Waste Container

A message appears on the press User Interface(UI) when the hole punch waste container

is full.

Warning

Do not perform this procedure while the printer is copying or printing.

1. Open the front door of the Business Ready Finisher.

2. Remove the hole punch waste container fromits slot near the top left of the finisher.

• Wait 10 seconds before reinserting the container into the printer. The hole punch

counter resets after 10 seconds.

Xerox®Versant®180 Press4-4

Optional Devices User Guide

Page 51

Business Ready (BR) Finisher and Optional Booklet Maker

• If you remove the hole punch waste container before the device instructs you

to, empty the container before you reinsert it into the finisher.

3. Empty the container.

4. Insert the container all the way into the finisher.

5. Close the front door of the Business Ready Finisher.

BR Finisher Troubleshootinng

BR Finisher Paper Jams

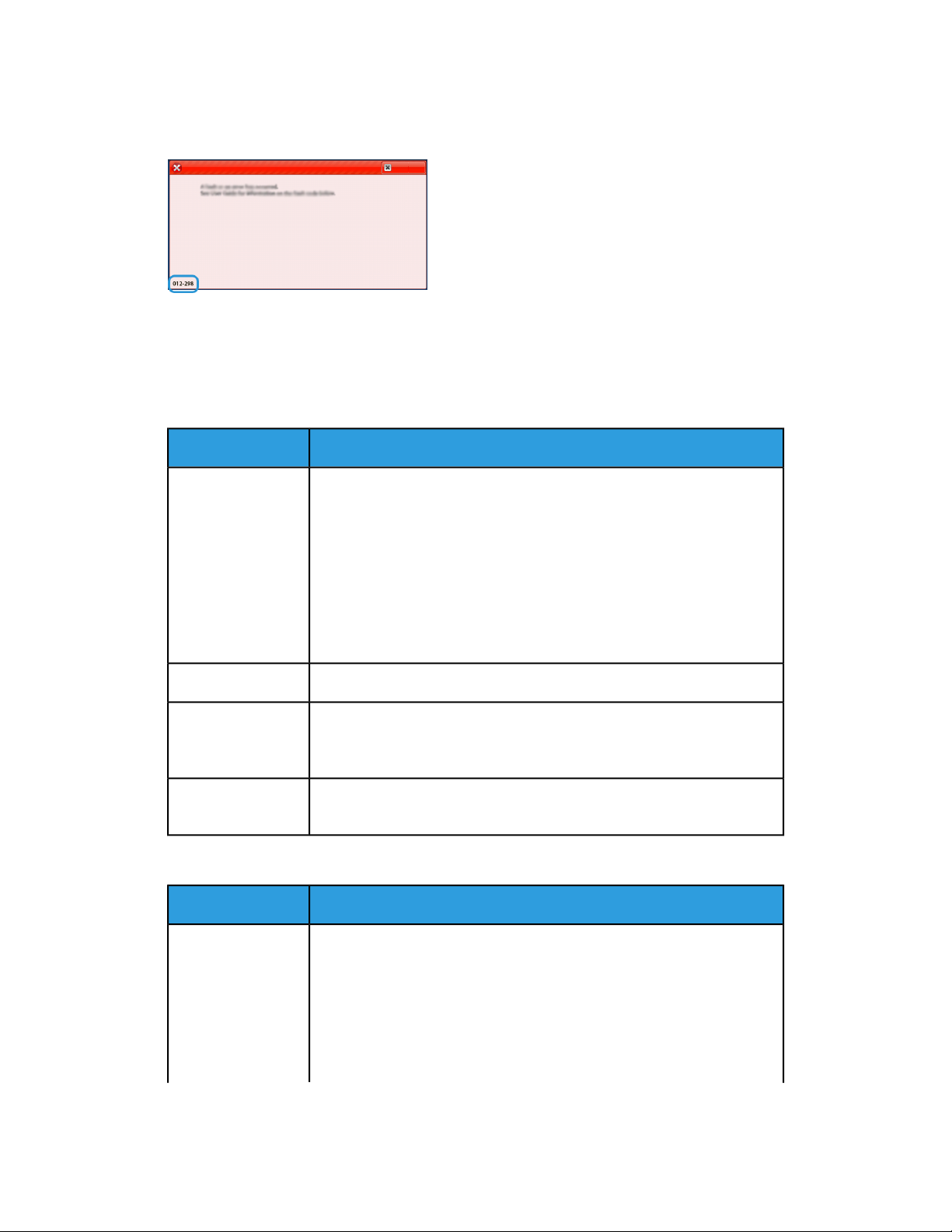

Clearing Jams in the BR Finisher at Position 3a

1. If the paper is visible at the output tray exit, remove the paper by pulling it gently in

the direction shown.

2. Open the front door of the Business Ready Finisher.

3. Lift green handle 3a.

4. Carefully remove the paper.

• If the paper is torn, remove all torn pieces from the finisher.

Optional Devices User Guide

4-5Xerox®Versant®180 Press

Page 52

Business Ready (BR) Finisher and Optional Booklet Maker

• If the paper is inaccessible, or if the press User Interface (UI) prompts you to

release the paper, turn green handle knob 3b in the direction shown.

5. Return green handle 3a to its original position.