Page 1

PV225S 225 kW

Grid-Tied

Photovoltaic

Inverter

PV225S-480-P

Planning and Installation Manual

Page 2

Page 3

PV225S 225 kW Grid-Tied

Photovoltaic Inverter

Planning and Installation Manual

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to 1.5 MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connec ted and stand-alone syst em s . Xantrex products include inverters, battery

chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute

electri cal powe r.

Trademarks

PV225S 225 kW Grid-Tied Photovoltaic Inverter is a trademark of Xantr ex International. Xantrex is a registered

trademark of Xantrex International.

Other trademarks, registered trademarks, and product names ar e the property of their respe ctive owners and are used

herein for identi fication purposes onl y.

Notice of Copyright

PV225S 225 kW Grid-Tied Photovoltaic Inverter Planning and Installation Manual© August 2005 Xantrex

International. All rights reserv ed.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY , SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMAT ION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

August 2005 Revision B

Part Number

152606

Contact Information

Telephone: 1 800 670 0707 (toll free North America )

1 360 925 5097 (direct)

Fax: 1 800 994 7828 (toll free North America )

1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

Page 5

About This Manual

Purpose

The purpose of this Planning and Inst allation Manual is to provide explanations

and procedures for planning a nd installing the PV225S 225 kW Grid-Tie d

Photovoltaic Inverter.

Scope

The Manual provides safety guidelines, detaile d planning and setup information,

and procedures for installing the inverter.

Audience

The Manual is intended for use by anyone who plans to construct or install a

system involving the PV225S 225 kW Grid-Tied Photovoltaic Inverter. Installers

must meet all loca l and st ate code requ irements for licensing a nd training for the

installati on of Electrical Power Systems with AC and DC voltage to 600 volts.

Organization

This Manual is organized into four chapters:

Chapter 1, “Introduction” provides information about the features and functions

of the PV225S 225 kW Grid-Tied Phot ovoltaic Inverter.

Chapter 2, “Planning” provides information to help plan the installation of the

PV225S 225 kW Grid-Tied Phot ovoltaic Inverter.

Chapter 3, “Installation” describes the procedures needed to install the PV225S

225 kW Grid-Tied Phot ovoltaic Inverter. This section includes unpacking and

moving instructions, mounting instructions, and cabling instructions.

Chapter 4, “Verification” provides a checklist to ensure the installation of the

PV225S is correct and complete.

152606 iii

Page 6

About This Manual

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions or pract ices that could result in pe rsonal injury or loss of life.

CAUTION

Cautions ide ntify conditions or practices that could result in damage to th e unit or other

equipment.

Important:

serious as a caution or warning.

This Manual contains information for the PV225S-480-P 225 kW Grid-Tied

Photovoltaic I nverter. Throughout the manual it will be ref erred to a s the P V225S,

unless otherwise noted.

These notes descri be thi ngs whic h are im portant for you to kno w , but not as

iv 152606

Page 7

Abbreviations and Acronyms

ANSI American National S tandards Institut e

CCU2 Converter Control Unit 2

CFM Cubic Feet per Minute

CW Clockwise

DSP Digital Signal Processor

FPGA Field Prog r am ma b le Gate Array

GUI Graphical User Interface

IEEE Institute of Electrical and Electronics Engineers

IGBT Insulated Gate Bipolar Transi stor

IPM Intelligent Power Module

kcmil 1000 circular mils

LAN Local Area Network

LCD Liquid Crysta l Display

About This Manual

NFPA National Fire Protection Association

PBX Private Branch Exchan g e

PSL Phase-Shift Loop

POTS Plain Old Telephone Service

PV Photovoltaic

UFCU Universal Frontpanel Control Unit

Related Information

You can find more information about Xantrex Technology Inc. as well as its

products and services at www.xantrex.com.

152606 v

Page 8

vi

Page 9

Important Safety Instructions

SAVE THESE INSTRUCTIONS - DO NOT DISCARD

This manual contains importa nt safety instructions for the PV225S that shal l be

followed during insta llation and maintenance procedures.

WARNING: Shock Hazard

Read and keep this Planning and Installation Ma nual for future reference. Before

installing t he PV225S, read a ll ins truct ions, cauti onary marki ngs, a nd all other ap propriat e

sections of this manual. Failure to adhere to these warnings could result in severe s hock or

possible death. Exercise extreme caution at all times to prevent accidents.

WARNING: Shock Hazard

The PV225S enclosures contain exposed high-voltage conductors. The enclosure doors

should remain cl osed with the latches tightened, except during installation, maintenance

or testing. These servicing instructions are for use by qualified personnel who meet all

local and state code requirements for li ce nsing and training for the installation of

Electrical Power Systems with AC and DC voltage to 600 vol ts. To reduce the risk of

electric shock, do not perform any servicing other than that specified in the installation

instructi ons unless you are qualified to do so. Do not open the cabinet doors if extreme

moisture is present (rain or heavy dew).

WARNING: Lethal Voltage

In order to remove all sources of voltage from the PV225S, the incoming power must be

de-energized at the source. This may be done at the main utility circ uit breaker and by

opening the AC Disconnect and the DC Disconnect Swi tches on the PV225S. Review th e

system configuration to determine all of the possible sources of energy . In addition, allow

5 minutes for the DC bus capacitors, located on the cei ling of the cabinet, to dis charge

after removing power.

152606 vii

Page 10

Safety

General Safety Precautions

1. When installing the PV225S use only components recommended or sold by

Xantrex. Doing otherwise may result in a risk of fire, electric shock, injury to

persons, and will void the warranty.

2. Do not attempt t o oper ate the PV225S if i t ha s been d rop ped, or recei ved more

than cosmetic damage during transport or shipping. If the PV225S is

damaged, or suspected to be damaged, see the Warranty for this unit in the

PV225S 225 kW Grid- Tied Photovoltaic Inverter Operation and Maintenance

Manual.

3. To reduce the risk of electrical shock, lock-out and tag the PV225S before

attempting any maintena nce, service, or cleaning.

Personal Safety

Follow these instructions to ensure your safety while working with the PV225S.

Safety Equipment

Authorized servic e perso nnel must be equipped with standard safety equipment

including the following:

• Safety glasses

• Ear protection

• Steel-t oed safety boots

• Safety hard hats

• Padlocks and tags

• Appropriate meter to veri fy that the circuits are de-ener gized

(600 Vac and DC rated, minimum)

Check local safety regul ati ons for other requirements.

Wiring Requirements

1. All wiring methods and materials shall be in accordance with the National

Electrical Code ANSI/NFPA 70. When sizing conductors and conduits

interfacing to the PV225S, both shall be in accordance with the National

Electric Code ANSI/NFPA 70, as well as all state and local code

requirements.

2. Use copper conductors only with insulation rated for 90 °C.

3. The PV225S has a three-phase output. It is marked with this symbol:

4. The AC power conductor wiring interfacing with the AC terminals in the

Transformer Enclosure are located at T6-X1, T6-X2, and T6-X3. These

terminals should be tightened to a torque value of 420 in-lbs (47.5 Nm).

Conductors terminate d to these terminals must use a crimp-on type ring

viii 152606

Page 11

Safety

terminal or compression- type lug. The terminals can accommodate up to two

conductors per phase. See Figure 3-14 on page 3–15 for the location of these

terminals.

5. The AC power conductor wiring interfacing with the AC terminals in the

Main Inverter Enclosure are located at TB5, TB6, and TB7. These terminals

are to be tightened to a torque value of 375 in-lbs (42.4 Nm). The terminals

will accept a conductor size of 350 kcmil and can accommodate up to six

conductors per phase. See Figure 3-15 on page 3–16 for the location of these

terminals.

6. The AC power conductor wiring interfacing with the AC terminals in the

AC Interface Enclosure are located at S1-2T1, S1-4T2, and S1-6T3. These

terminals should be tightened to a torque value of 310 in-lbs (35.0 Nm). See

Figur e 3-16 on page 3–16 for the location of these terminals and the

cautionary note on page 3–18.

7. The AC neutral conductor from the util ity is te rminated in the AC Interface

Enclosur e at the TB 11 terminal . Th is termi n al req u ires the us e of a crim p- o n

type ring terminal or compression-type lug and should be tightened to a

torque value of 228 in-lbs (25.7 Nm). See Figure 3-18 on page 3–18 for the

location of these termin als.

8. The DC power conductor wiring interfacing with the DC terminals at S2-6,

K2-6T3, and TB4 are to be tightened to a torque value of 600 in-lbs

(67.8 Nm). These terminals will accept a conductor size of 600 kcmil a nd can

accommodate up to four conductors per pole at S2-6 and K2-6T3 and up to

two conductors at TB4. Keep these cables together as much as possible and

ensure that all cables pass through the same knockout and conduit fittings,

thus allowing any i nductive currents to canc el. See Figure 3-19 on page 3–19

for the location of these terminals.

9. This product is intended to be installed as part of a permanently grounded

electrical system per the National Electric Code ANSI/NFPA 70. A copper

ground rod must be installed within three feet of the PV225S enclosure. This

is the single point earth ground for the inverter system. The single point

ground for the system is to be made at the AC ground bus bar (TB12) in the

AC Interface En closure. This te rminal requi res the use of a cri mp-on t ype ring

terminal or c ompression-type lug and should be tightened to a torque value of

420 in-lb (47.5 Nm).

10. The equipment grounds on the PV225S are marked with this symbol:

11. AC overcurrent protect ion fo r the utility interconnect (Grid-tie) must be

provided by the installers a s part of the PV225S installation.

CAUTION: Fire Hazard

In accordance wi th the Nationa l Ele ctric al Code , ANSI/NFPA 70, connect onl y to a c ircuit

provided with 400 amperes maximum branch circuit overcurrent protection for the

PV225S.

152606 ix

Page 12

Safety

Operational Safety Procedures

Never work alone when servicing thi s equipment. A team of two is required until

the equipment is properly de-energized, locked-out and tagged, and verified deenergized with a meter.

Thoroughly inspect the equipment prior to energizing. Verify that no tools or

equipment have inadvert ently been left behind.

Lockout and Tag

Safety requirements mandate that this equipment not be servi ced while energi zed.

Power sources for the PV225S must be locked-ou t and tagged prior to servicing.

A padlock and tag should be installed on each energy source prior to

servicing.

WARNING: Shock Hazard

Review the system schematic for the in stallation to v erify that all avail able energy sources

are de-ener gize d. DC bus vol tage may a lso be present . Be su re to wait the full 5 m inutes to

allow th e capacito rs to disch arge comp letely.

The PV225S can be energized from both the AC source and the DC source. To

ensure that the inverte r is de- energized prior to servicing, lockout and tag the

PV225S using the following procedure.

1. Open, lockout, and tag the incomin g power at the utility main circuit breaker.

2. Open, lockout, and tag the AC Disconnect Switch (S1) on the AC Interface

Enclosure. See Figure 1-4 on page 1–9 for the location of the AC Disconnec t

Switch.

3. Open, lockout, and tag the DC Disconnect Switch (S2) on the DC Interface

Enclosure. See Figure 1-4 on page 1–9 for the location of the DC Disconnec t

Switch.

4. Using a confirmed, accurate meter, verify all power to the inverter is deenergized. A confirmed, accurate meter must be verified on a known voltage

before use. Ensure that all incoming energy sources are de-energized by

checking the following loc ations.

a) Inverter Terminals: TB5, TB6 , TB7 (Phase A, B, C)

See Figure 3-15 on page 3–16.

b) Utility Terminals: Botto m of S1-2T1, S1-4T 2, S1 -6T3

See Figure 3-16 on page 3–16.

c) PV Terminals: Bottom of S2-6, K2-6T3, TB4 (PV+, PV-, GND)

See Figure 3-19 on page 3–19.

x 152606

Page 13

De-Energize/Isolation Procedure

The following procedure should be followed to de-energize the PV225S for

maintenance.

WARNING

The terminals of the DC input may be energize d if the PV arrays are energized. In

additi on , all o w 5 min u tes for all capacit or s w i th in th e main enc lo s u r e to dis c harge after

disconnecting the PV225S from AC and DC sources.

To isolate the PV225S:

Safety

1. Turn the O

2. Open the D C Di sco nne ct Sw itch.

3. Open the A C Di sco nne ct Sw itch.

4. Open the utility connection c ircuit breaker.

5. Install lockout devi ces on the utility connection circu it brea ker and DC

Disconnect Switch.

N/OFF swit c h to the OFF position.

Interconnection Standards Compliance

The PV225S has been tested and listed by Underwriters Laboratories to be in

compliance with UL1741 Static Inverters And Charge Controllers For Use In

Photovoltaic Power Syste ms, as well as IEEE-929-2000 Recommended Practice

For Utility Interfac e of Photovoltaic (PV) Systems.

IEEE-929-2000 provides guida nce regarding equipment and functions necessary

to ensure compatible operation of photovoltaic systems which are connected in

parallel with the elect ric u t ility.

UL1741 is the standard applied by Underwriters Laboratory to the PV225S to

verify it meets the recommendat ions of IEEE-929-2000.

Refer to both documents for detai ls of these recommendations and test

procedures.

152606 xi

Page 14

xii

Page 15

Contents

Important Safety Instructions

1

Introduction

Description of the PV225S - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

System Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Over Voltage, Under Voltage and Frequency Ranges - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

System Ground Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

System Neutral Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Utility Side Isolation Transformer Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Environmental Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Operator Interface Controls- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Main Enclosure Door Interlock Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

On/Off Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

AC and DC Disconnect Switches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Communication Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

System Status and Fault Reporting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Data Logging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

Communication Methods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Universal Front Panel Contr ol Unit (UFCU) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

PC Connection Methods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–12

POTS Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Wireless Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Ethernet LAN Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

Direct Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -vii

2

Planning

Overview of PV225S Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

PV Planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Ventilation and Serviceability Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Ground Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

System Neutral Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Communication Requirements- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Utility Side Is ola tion Tr ans fo rm er Req ui rem en ts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2 – 5

Electrical Diagrams and Schematics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Layout Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Conduit Penetrati on- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Conductor and Conduit Sizing- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Anchoring the PV225S- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

152606 xiii

Page 16

Contents

3

Installation

Equipment Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Unloading - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Moving the PV225S - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Unpacking the PV225S - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Removing the Pallet and Moving the PV225S - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Mounting and Anchoring the Units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Opening or Closing Access Doors- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Conduit Installat ion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Wiring - General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–10

Overcurrent Protec tion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–11

Conductor Termination - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–11

Wire Gauge and Torque Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12

Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12

System Neutral Requirement s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–13

Utility Side Isolat ion Transformer Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–13

Wiring - Specific - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–14

AC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–14

PV Array Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–19

PC Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–20

PC Connection Methods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–20

Establishing a POTS Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–21

Establishing Wireless Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–22

Establishing an Ethernet LAN Connect ion - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–22

Direct Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–23

4

Verification

Verification Procedure Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Visual Inspection of Mechanical Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Visual Inspection of Electrical Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Visual Inspection, Isolation Transformer Wye:Wye - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Corrective Action - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

A

Schematics

Index

xiv 152606

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - IX–1

Page 17

Figures

Figure 1-1 Dimensions (Not to scale) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-2 PV225S Operator Interface Components- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Figure 1-3 On/Off Switch (S3) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Figure 1-4 AC and DC Disconnect Switches (S1 and S2) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Figure 1-5 LCD Display and UFCU Location- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–11

Figure 1-6 PC Connections in the Communications Enclosure- - - - - - - - - - - - - - - - - - - - - - - - - 1–12

Figure 1-7 POTS Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Figure 1-8 Wireless Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–13

Figure 1-9 Ethernet LAN Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

Figure 1-10 Direct Access - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–14

Figure 2-1 PV225S Layout Option A- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Figure 2-2 PV225S Layout Option B- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Figure 2-3 Conduit Entry Figure Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Figure 2-4 Inductor Enclosure Conduit Entry, Left Side - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Figure 2-5 Transformer Enclosure Conduit Entry, Right Side - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Figure 2-6 AC Interface Enclosure Conduit Entry, Left Side- - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Figure 2-7 DC Interface Enclosure, Bottom Side- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Figure 2-8 Communications Enclosure Conduit Entry, Bottom Side- - - - - - - - - - - - - - - - - - - - - 2–10

Figure 2-9 Main Inverter Anchor Bolt Pattern (Not to scale) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Figure 2-10 AC Interface/Transformer Anchor Bolt Pattern (Not to Scale) - - - - - - - - - - - - - - - - - 2–14

Figure 3-1 Moving the crated PV225S- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Figure 3-2 Forklift Lifting Locations - Underneath Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Figure 3-3 Mounting Hole Locations- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Figure 3-4 Inverter Enclosure Access Doors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Figure 3-5 AC Interface Access Door - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Figure 3-6 DC Interface Access Door - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Figure 3-7 Transformer Access Panels- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Figure 3-8 Inductor Access Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Figure 3-9 Conduit Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Figure 3-10 Single-point Ground (TB12) Ground Bar - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Figure 3-11 Chassis Ground Bar (TB1) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Figure 3-12 Route AC Cables through the Conduit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Figure 3-13 Tie-wraps on the AC Sense Harness- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

Figure 3-14 AC Terminal Connections in the AC Interface/Transformer Enclosure - - - - - - - - - - - 3–15

Figure 3-15 AC Terminal Connections in the Main Inverter Enclosure- - - - - - - - - - - - - - - - - - - - 3–16

Figure 3-16 AC Terminal Connections in the AC Interface Enclosure - - - - - - - - - - - - - - - - - - - - 3–16

Figure 3-17 Connecting the AC Sense Harness - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–17

152606 xv

Page 18

Figures

Figure 3-18 AC Terminal Connections from the Utility- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–18

Figure 3-19 PV Array Cable Routing and Terminations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–19

Figure 3-20 Telephone Cable Routing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–21

Figure 3-21 RS232/FO Converter Kit Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–23

Figure 3-22 Direct Connect Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–24

Figure A-1 Electrical Diagram (sample)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Figure A-2 PV225S Schematic for Main Power Distribution (152812 A1) - - - - - - - - - - - - - - - - - A–4

Figure A-3 PV225S Schematic for Control Power Distribution (152812 A2) - - - - - - - - - - - - - - - - A–5

Figure A-4 PV225S Schematic for Converter Control Unit (152812 A3)- - - - - - - - - - - - - - - - - - - A–6

xvi 152606

Page 19

Tables

Table 1-1 Ele ct rical Sp ec if icat ions 1–4

Table 1-2 Over/Under Voltage and Over/Under Frequency Ranges 1–4

Table 1-3 Environmental Specifications 1–6

Table 3-1 AC Terminal Wire Gauge, Bolt Size, and Torque Values 3–12

Table 3-2 DC Terminal Wire Gauge, Bolt Size, and Torque Values 3–12

152606 xvii

Page 20

xviii

Page 21

1

Introduction

Chapter 1, “Introduction” provides information about the features and

functions of the PV225S 225 kW Grid-Tied Photovoltaic Inverter.

Page 22

Introduction

Description of the PV225S

The PV225S 225 kW Grid-Tied Photovoltaic Inverter is a UL 1741 Listed, utility

interactive, three-phase po wer c onversion system for grid-connected photovoltaic

arrays with a power rating of 225 kW. Designed to be easy to install and operate,

the PV225S automates start- up, shutdown, and fault detection scenarios. With

user-defin able power tracki ng that matc hes the inv erte r to the a rray and ad justabl e

delay periods, users are able to customize start up and shut down sequences.

Multiple PV225S inverter s are easily paralleled for larger power installations .

The PV225S power conversion system consists of a pulse-width modulated

(PWM) inverter, switch gear for isolation and prote ction of the conne cted AC and

DC power sources, and a custom high-efficiency Wye:Wye isolation transformer.

Housed in a rugged NEMA-3R rated, powder-coated steel enclosu re, the PV225S

incorporates sophisticated Intellimod

(IGBTs) as the main power switching devices. An advanced, field-proven,

Maximum Peak Power Tracke r (MPPT) integrated within the PV225S control

firmware ensures the opti mum power throughput for harvesting ener gy from the

photovoltaic arra y.

The advanced design of the PV225S includes an EMI output filter and the main

AC contactor located electrically on the utility side of the isolation transformer.

The location of the main AC contactor, and the ability to de-energize the isolation

transformer during times of non-operation, greatly reduces the night-time tare

losses consumed by an idle isolation transformer. An integrated soft-start circuit

precludes nuisanc e utility-tie circuit breaker trips as the result of isolation

transform er inr u sh current.

®

(IPM) Insulated Gate Bipolar Transistors

Additionally, the PV225S integrated controller contains self-protection features

including over and under volt age and frequency safeguards. An integral

anti-island pro tection sch eme prevents the in verter from feeding power to the grid

in the event of a utility outage. The PV225S includes a local user interface

comprised of an O

user-frie ndly, Graphic User Interface (GUI) provides a remote interface for

operator interroga tion of PV225S system status, control, metering/data logging

and protective functions within the PV225S. The status, control, and logging

features are also supported by the choice of three communication mediums,

allowing the informat ion to be acce ssed or commanded remotely.

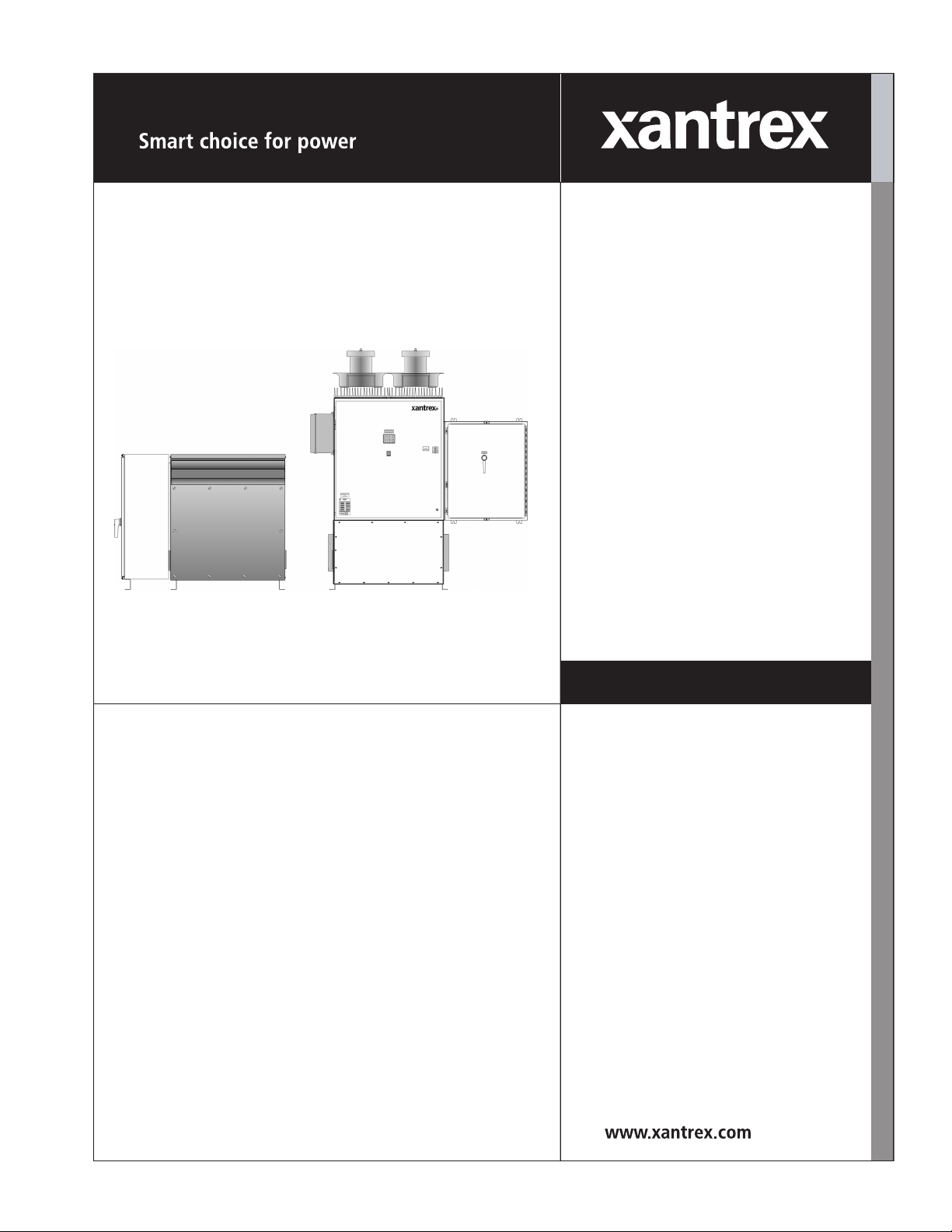

The PV225S comes in two modules comprised of six enclosur es to house the

electronics descr ibed above. The first module includes the Main Inverter

Enclosure, Inductor Enclosure, DC Interface Enclosure, and Communications

Enclosure. The sec ond module includes the Transformer Enclosure and AC

Interface Enclosure. These components are identified in Figure 1-1 on page 1–3.

Figure 1-1 also shows the dimens ions and locations of the var ious enclosures that

comprise the PV225S.

See “Layout Options” on page 2–6 for information on configuration options.

1–2 152606

N/OFF switch, keypad, and 4-line, 80 character LCD di splay. A

Page 23

Front View

AC

Interface

Enclosure

Communications

Enclosure

Transformer

Enclosure

Main

Inverter

Enclosure

Inductor

Enclosure

Description of the PV225S

DC Interface

Enclosure

Back

Figure 1-1

Front

Communications

Enclosure

AC Interface

Enclosure

AC Side View

Dimensions (Not to scale)

Front

DC Interface

Enclosure

Back

Inductor

Enclosure

DC Side View

152606 1–3

Page 24

Introduction

System Specifications

The PV225S has been designed for photovoltaic power systems, which operate

within the following spec ifications.

CAUTION: Equipment Damage

Operation of the PV225S in a manner other than specif ied in this manual may cause

damage to the PV225S and other system components and will void the terms of the

warranty.

Electrical Specifications

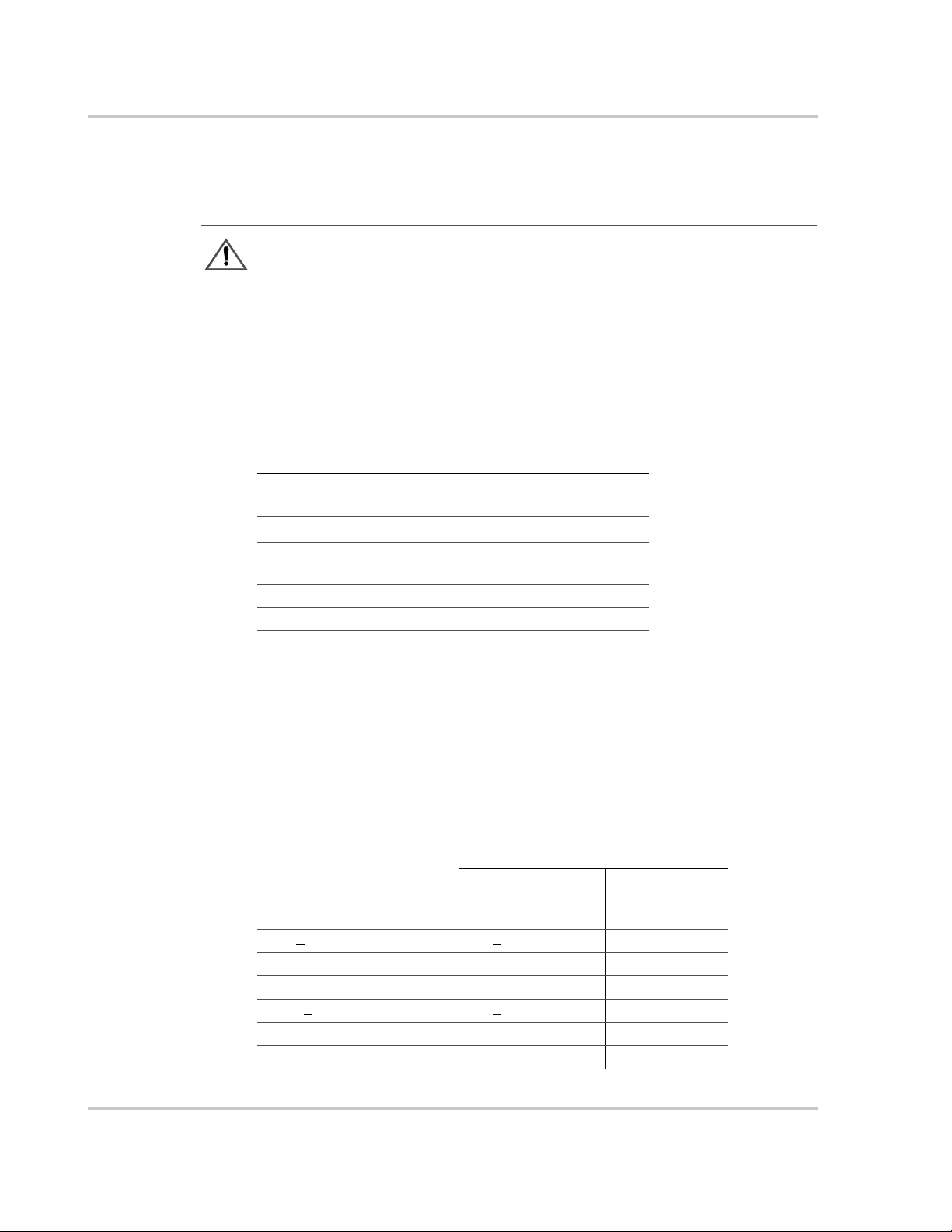

Table 1-1 provides the AC and DC specifications for the PV225S.

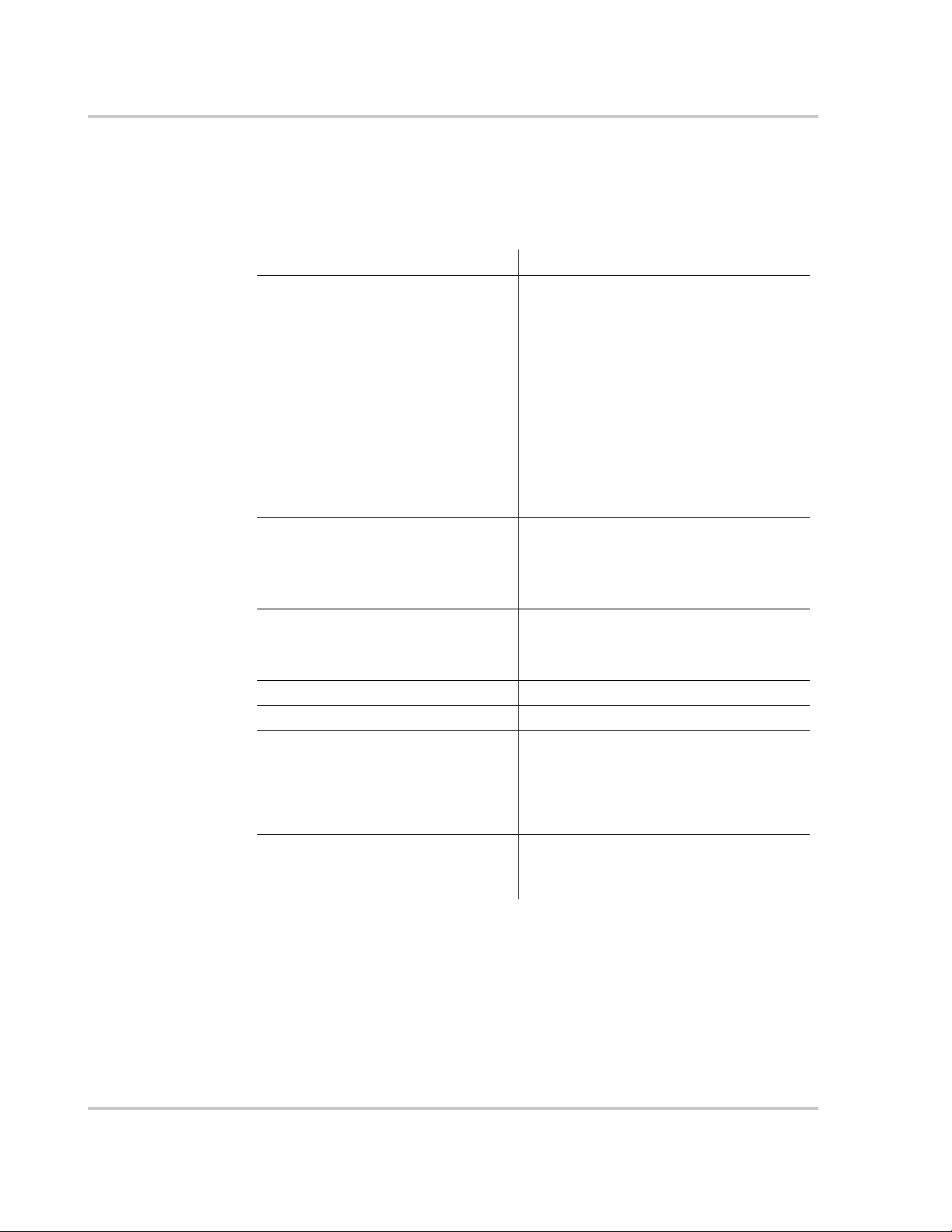

Table 1-1

Specification PV225S-480-P

Nom in al AC In pu t Voltage

(+10% to -12% acceptable range)

Maximum AC Output Current 271 A

Nom inal AC I n pu t Freq uency

(+0.5 to -0.7 Hz acceptable r ange )

Output Power 225 kW

Peak Power Tracking Window 300 to 600 Vdc

Maximum Open Circuit Voltage 600 Vdc

Maximum DC Input Current 781 amps

Electrical Specifications

Over Voltage, Under Voltage and Frequency Ranges

T able 1-2 provides the over voltag e, under voltage, over-frequency , and

under-frequency detection limits for the PV225S. These detection limits have

been factory tested and deemed to be in compli an ce with IEEE-292 and UL 1741

requirements for uti lity interaction.

Table 1-2

Vac Condition

(% of Nominal)

Vac < 50% Vac < 240 6 cycles

50% <

88% < Vac <

110% < Vac < 137% 528 < Vac < 657 2 seconds

137% <

f < rated -0.7 f < 59.3 6 cycles

f > rated +0.5 f > 60.5 6 cycles

Over/Under Voltage and Over/Under Frequency Ranges

Voltage Range Trip Time

Vac < 88% 240 < Vac < 422 2 seconds

110% 422 < Vac < 528 normal operation

Vac 657 < Vac 2 cycles

480 Vac

(422 to 528 Vac)

rms

60 Hz

(59.3 to 60.5 Hz)

PV225S-480-P

1–4 152606

Page 25

System Ground Requirements

This product is intended to be installed as part of a permanently grounded

electrical system pe r the National El ectric Code ANSI/NFPA 70. A copper gro und

rod must be installed within thr ee feet of the PV225S enclosures and connec ted to

the unit as described in “System Grounding” on page 3–12. The single-point

ground for the system is to be made at the AC ground bus bar (TB12) in the AC

Interface En clo sur e.

System Neutral Requirements

The PV225S is designed to be installed as a 4-wir e system. As required by the

UL 1741 listing, a neutral conductor from the util ity-interconnect must be

terminated at TB11 within the AC Interface Enclosure to ensure that the AC

voltage sensing circuit can per form an individual phase voltage (line-to-neutral)

measurement. The function of the neutral connection is to provide a point of

reference for measurement purposes that is essentiall y at ground potential. No

power will flow through the neutral conductor.

Utility Side Isolation Transformer Requirements

The PV225S is supplied with a high-efficiency custom Wye:Wye, isolation

transformer as part of the AC Interface/Transformer assembly. The utility side

windings of the isolation tr ansformer are configured Wye and must match the

voltage at the utilit y inter-tie. The PV225S is a balanced, three -phase,

current-sourcing inverter and only operates with the pres ence of a stable utility

voltage. The transformer is also supplied with a neutral connection on the utility

interconnect. Connection of this utility-side neutral does not affect the operation

of the inverter, however connection of the neutral on the inverter-side does affect

the operation and must be left floating or disconnected. Single-phase, grounded

loads which may be present between the transformer and utility, will maintain

their existing grou nd refer ence at the utility distribution transformer.

System Specifications

CAUTION: Equipment Damage

If the Isolation Transformer (T6-X0) neutral terminal is tied to ground, it will cause

irreparable damage to the PV225S. Check local regu lations for their requirements

regarding the connec tion of the neutral.

WARNING: Lethal Voltage

Grounding the neutra l of a W ye -wound transfor mer may create an “open delta ” condit ion ,

depending on the utility configuration. This condition may keep the PV225S from

detecting a loss of phase condition on the utility system, which may allow potentially

lethal volta ge to be present on the open-pha s e wiring.

152606 1–5

Page 26

Introduction

Environmental Specifications

The following environment al specifications are the same for both models of the

PV225S 225 kW Grid-Tied Phot ovoltaic Inverter.

Table 1-3

Specification Value

Dimensions

Weight

Allowab le A mb ien t Temperature

Relative Humidity To 95%, Non-condensing

Elevation Power Derated above 6600 ft

Clearan ce (ven t ila tion an d

serviceability)

Environmental Specifications

Inverter and DC Interface

Transformer and AC Interface

Overall System Footprint:

Layout Option A

Layout Option B

Inverter and DC Interface

Transformer and AC Interface

Overall Weight

Operating

Storage

88.5 in H x 80 in W x 32 in D

(225 cm H x 203 cm W x 81 cm)

49.5 in H x 61.5 in W x 35.5 in D

(126 cm H x 156 cm W x 90 cm D)

14 ft W x 5 ft L (approximate)

(4.3 m x 1.5 m)

10 ft W x 9 ft L (approximate)

(3 m W x 2.7 m L)

2300 lbs (approximate)

2350 lbs (approximate)

4650 lbs (approximate)

-20 °C to 50 °C Maximum

-40 °C to 50 °C Maximum

In front of access doors: 36 in (91 cm)

In front of access panels: 36 in (91 cm)

Sides: 12 in (30 cm)

Back: 6 in (15 cm)

Maximum Distance between Main

Inverter E ncl o sur e an d AC

Interface/Transformer Enclosure

1–6 152606

15 ft (4.5 m)

Page 27

Operator Interface Controls

Operator interface controls are located on the front door of the main inverter

enclosure. Thes e con tro l s includ e an O

keypad called the Universal F ron tpanel Control Unit (UFCU). Additionally there

is an AC and DC Disconnect on the AC Inter face Enclosure and the DC Inter fac e

Enclosure Doors.

Communication

Enclosure

Operator Interface Controls

N/OFF Switch, 4-line LCD display and

DC Disconnect

Switch (S2)

AC

Disconnect

Switch (S1)

Figure 1-2

AC Interface Enclosure

(AC Side View)

PV225S Operator Interface Components

LCD

Display

Universal

Frontpanel

Control

(UFCP)

ON/OFF

Switch

(S3)

Main Enclosure Door Interlock Switch

The front door of the P V225S main e nclosur e is equipped wit h a n interloc k s witch

to preclude operation while the front door is open. Opening the door of the main

inverter enclosu re will initiate an immediate controlled shutdown of the PV225S

and opens both the main AC and DC contac tors. The main AC and DC contactors

cannot be closed unless the door’s interlock is in the engaged position. The

PV225S is prevented from being resta rted until the door is again closed and the

switch is in the engaged position.

DC Interface

Enclosure

Main Inverter Enclosure

(Front View)

It is required tha t the PV225S main enclosure door must be locked during normal

operation. The door interlock switch does NOT remove all hazardous voltages

from inside the inverter. Before attempting to service the PV225S, follow the

de-energize Lockout and Tag procedure on page x.

152606 1–7

Page 28

Introduction

On/Off Switch

WARNING: Shock Hazard

Disengaging the main enclosure door interlock s witch does NOT remove all hazardous

voltages from inside the inverter. Before attempting to service the PV225S, follow the

de-energize Lockout and Tag procedure on page x.

The PV225S incorporates a maintained position ON/OFF switch (S3) located on

the front door of the main enclos ure. Under normal cond itio ns, the ON/OFF switch

is in the O

N position. Turning the switch to the OFF position will initiate an

immediate controlle d shutdown of the PV225S and opens both the main AC and

DC contactors within the unit . The main AC and DC contactors cannot be closed

unless the switch is in the

restarted until the O

ON position. The PV225S is prevented from being

N/OFF switch is turned back to the ON position.

WARNING: Shock Hazard

Turn ing the ON/OFF switc h to th e OFF position does NOT remove all hazardous voltages

from inside the in verter . Before attempting t o service the PV225S, follow the de-energize

Lockout and Tag procedure on page x.

Figure 1-3

ON/OFF Switch

(S3)

On/Off Switch (S3)

1–8 152606

Page 29

AC and DC Disconnect Switches

Both AC and DC In terface Enclos ures are eq uipp e d wi th loc k out ha s ps for

personnel safety. The enclosure doors should not be opened while the PV225S is

operating.

The switch handles and shafts pro vide a door interlock for both the AC and DC

Interface Enclos ures. The doors cannot be opened when the switch is in the

position.

The DC Disconnect Switch (S2) is equipped wit h an auxiliary contact block

which enables the switch to be used as a load break DC disconnect. In the event

the DC Disconnect Switch is opened while the PV225S is pr ocessing power from

the PV array, the early-break contact block will signal the CCU2 (Converter

Control Unit 2) to stop processing power prior to the opening DC Disconnect

Switch.

Additionally, opening the DC Disconnect Switch will cause the PV225S to

execute an immediate orderly shutdown, open both the main AC and DC

contactors, and report a PV disconnect fault on the LCD of the UFCU.

Communication Features

ON

DC Disconnect

Switch (S2)

AC Disconnect

Switch (S1)

AC Interface Enclosure

Figure 1-4

AC and DC Disconnect Switches (S1 and S2)

DC Interface Enclosure

Communication Features

The PV225S provides two types of information to the user:

• system status and/or fault information, and

• data logging informati on.

System status and fault info rmation can be accessed using the Universal Front

Panel Control Unit (UFCU) or a personal comput er using the Xantrex Solar

Graphic User Interface (GUI) software. Data logging requires the use of a PC

using the GUI software.

152606 1–9

Page 30

Introduction

System Status and Fault Reporting

Basic system status and all fault conditions rising from within the PV225S are

reported to the UFCU. The unit stores the time and det ails of all faults in

non-volatile memory. The 4-line LCD will display a hexadecimal value and a

brief text description of the fault.

This information can also be acce ssed using a personal computer using the GUI

software eit her directly or remote ly.

T ypes of status informatio n include:

• Current Oper at ing State o r Goa l State

• Fault Code (if applicable )

• Inverter St ate

• Line Voltage and Current

• Inverter Matrix Temperature

• Inverter Power

•PV State

• PV Voltage and Current

• PV Power

• Grid Frequency

• Peak Power Tracker Enabled

Data Logging

The inverter stores dat a values and software metrics for debugging. Thes e values

are stored within the CCU2 controller board in non-vola tile memory . Data logging

requires the use of a PC connection using the Xantrex Solar Graphic Use r

Interface (GU I) soft ware.

• The Data Logging features include :

• Operational Values

• Internal Metrics

• Data Log Acq ui s itio n

• Graphic Data Analysis

• Fault Log Acquisition

• Software Upgrade

• Accumulated Values

• Configurable Parameters

1–10 152606

Page 31

Communication Methods

The PV225S communicates system statu s information to the user using the

following methods.

• The Front Panel Control Unit (UFCU) Display

• PC Connection (Direct or Remote) - Xantr ex Solar Graphic User Interface

(GUI) Software required. Communication with a PC requires the selection of

one of the following options.

• Remote Connection -- This method has thre e options available. One of

these options will be field- installed prior to commission ing.

• POTS Connection

• Wireless Connection

• Ethernet LAN Connection

• Direct Connection -- This method is most commonly used by field

technicians for loca l connection and troubleshooting purposes.

Communication Methods

Important:

to support a PC connection. (i.e., makin g arra ngements for an analog phone line, wireless

service or local area network.)

The customer is responsible for providing the appropriate support service

Universal Front Panel Control Unit (UFCU)

The UFCU keypad is located on the front of the Main Inverter Enclosure to

manipulate and view system operation and status.

The keypad is comprised of 20 touch-sensitive keys that provide a means to

navigate through the menus and alter user-changeable settings.

Communications Enclosure

LCD

Display

Universal Front Panel

Control Unit (UFCU)

Figure 1-5

LCD Display and UFCU Location

See the PV225S 225 kW Grid-Tied Phot ovoltaic Inverter Operation and

Maintenance Manual for details.

152606 1–11

Page 32

Introduction

PC Connection Methods

Personal computers can be used to access the system status and programming

features of the PV225 S. A computer can be connected either dir e ctly or remotely.

1. Remote Connect - uses one of the three kits below.

• POTS Kit - uses a MultiTech® 56K Modem, RS232/Fiber Optic

• Wireless Kit - uses a GSM Wireless Modem.

• Ethernet LAN Kit - uses a da ta communication device to enable the unit

2. Direct Connect - This method is used for troubleshooting. It uses a

RS232/Fiber Optic Converter (configur ed for a PC), a DB25-to-DB25 gender

changer , and a DB25-to-DB9 Serial Cable.

Software is included to provide a graphic user interface that relates important

system information. This software is called Xantrex Solar Graphic Interface

(GUI). See "Computer Communications with the PV225S" in the PV225S 225

kW Grid-Tied Pho tovoltaic Inverter Operation and Maintenance Manual for

additional infor mation.

The GUI can dial up the inverter and receive fault report calls from it through a

standard Hayes-compatible, landline modem. When the GUI initiates a call

through the mode m at the GU I comp u ter, the inve rter’s modem answers the ca ll

and initiates a 9600 baud serial connection, effectively as if the GUI was

connected directly. Or, if the inverter experiences a fault, it will initiate a call to

the GUI and report the fault details.

Converter (configu red for ethernet) and SA2 Surge Arrest or.

to connect to a loca l area ne tw or k.

Communications

Enclosure

RS232/FO

Converter

MultiTech®

56K Modem

SA2 Surge

Arrestor

Figure 1-6

1–12 152606

PC Connections in the Communications Enclosure

POTS connection option shown.

Page 33

POTS Access

Communication Methods

Figure 1-7 illustra tes the PV225S connected remotely to a personal computer.

Figure 1-7

POTS Access

Wireless Access

Figure 1-8

Wireless Access

Figure 1-8 illustra tes the PV225S connected remotely to a personal computer

using a wireless network.

152606 1–13

Page 34

Introduction

Ethernet LAN Access

The PV225S can be remotely accessed throug h a local area network.

Figure 1-9

Ethernet LAN Access

Direct Access

Figure 1-10

Figure 1-10 illustra tes the PV225S connected directly to a personal computer.

Direct Access

1–14 152606

Page 35

2

Planning

Chapter 2, “Planning” provides informati on to help p la n the inst allat ion of

the PV225S 225 kW Grid-Tie d Photovoltaic Inverter.

Page 36

Planning

Overview of PV225S Installation

WARNING: Shock Hazard

Installations of this equipment should only be performed by qualified technicians.

Installers must meet all loc al and state code requirements for licensing and

training for the installation of Electrical Power Systems with AC and DC voltage

to 600 volts.

Planning Planning for a system requires complete understanding of all the components that

are involved to successfully install the PV225S to meet the required national,

state, and local codes.

Definition A power system (such a s the PV225S) is a collection of devices designed to

supply AC power to the utility grid from a solar energy (PV) source.

Components All types of gri d-tie d inve rter inst allations, re sident ial or industr ial, shar e common

components. This chapter describes each component and suggests the minimum

requirements for a safe installation.

Location The PV225S 225 kW Grid-Tied Photovolta ic Inverter is designed to be inst alled

in either an indoor or outdoor location. The PV225S must be anchored to a level,

concrete floor or pad.

Ideally the AC In terface Enclosur e/ Transf ormer Assembl y is placed on the lef t

side of the Main Inverter Enclosur e. The AC Interface Enclosure/Transformer

Assembly may be co-located adjacent to the left side of the Main Inverter

Enclosure up to, but not exceeding, 15 feet away.

Clearance Adequate ventilation and servic e access must be taken into consideration when

installing the PV225S. See “Ventilation and Serviceability Requirements” on

page 2–3 for specific clearance requirements and ambient temperature

requirements.

Conduits and

Conductors

Given the flexibility to co-locate the AC Interface Enclosure/Transformer

Assembly to fit a desired system layo ut, the conduits and conductors are to be

supplied by the installe r.

See “Conduit Penetration” on page 2–8 for recommendations on enclosure

penetration loca tions and conduit routing.

See “Conductor and Conduit Sizing” on page 2–11 for information on sizing the

conductors and conduits.

All interconnect wir ing and power conductors interfacing to the PV225S must be

in accordanc e with the Nati onal Electric Code ANSI/NFPA 70 and any applicable

local codes.

2–2 152606

Page 37

PV Planning

Large gauge wire must conform to the minimum bend radius specified in the

NEC, Article 373-6B, Ninth Edition.

T ake c are t o keep the wir e bund les away from a ny sharp e dges whi ch may da mage

wire insulation over time.

All conductors should be made of copper and rat ed for 90 °C (minimum).

If the installation of the PV225S is to be outdoors, all interconnect condui t and

fittings must be NEMA-4 rated as requir ed by the NEC.

PV Planning

To determine the number of photovoltaic panels that are required for the PV

power plant, please use the PV planning tool from the Xantrex website:

http://www.xantrex.com/support/pvsizing/disclaimer.asp

Ventilation and Serviceability Requirements

The following environment al conditions must be established and mainta ine d to

ensure the safe and efficient operation and servicing of the PV225S. Adequate

space must be provi ded aro und t he unit for v ent ilat io n and access during

servicing. If locating the unit indoors, ambient air temper ature cannot exceed the

maximum temperature for which the unit is rated.

Ventilation Maintain a minimum cleara nce of 12 inche s on both sides and 6 inches behind the

Main Inverter Enclosure and the AC Interface Enclosure for proper cooling fan

operation.

Maintenance and

Serviceability

Indoor Temperature

Control

152606 2–3

Maintain a minimum clearance of 36 inches in front of the Main Inverter access

door, the Transformer Enclosure access panel, and the AC Interface access door

for maintenance and serviceability.

See Figure 2-1 on page 2–6 and Figure 2-2 on page 2–7 for illustrations of these

clearance requirements.

If the PV225S is to be installed indo ors and external a ir is used for venti lation, the

required cubic feet per minute (CFM) rate must be no less than 1000 CFM. This

assumes the temperature inside the building is allowed to rise only 10 °C above

the outside temperatur e. There fore, the maximum allowable outside ambient

temperature is 50 °C (50 °C minus 10 °C equals 40 °C Maximum Ambient

Temperature).

If air conditioning is planned for an indoor installation, the heat load of the

PV225S is 42,000 BTU/Hour at full load.

Page 38

Planning

Ground Requirements

This product is intended to be installed as part of a permanently grounded

electrical syst em per National Electric Code ANSI/NFPA 70. A copper ground

rod must be insta lled within three f eet of the PV225S enclosur e. This is the single

point earth gr ound for the inverter s ystem. The single point ground for the system

is to be made at the AC ground bus bar (TB12) in the AC Interface Enclosure.

System Neutral Requirements

The PV225S is designed to be installed as a 4-wir e system. As required by the

UL 1741 listing, a neutral conductor from the util ity-interconnect must be

terminated at TB11 within the AC Interface Encl os u re to ens ure that the

AC voltage sensing circuit can perform an individual phase voltage (line-toneutral) measurement. The function of the neutr al connec tion is to provide a point

of reference for measurement purposes that is essentially at ground potential. No

power will flow through the neutral conductor.

Communication Requirements

The PV225S can accommodate any one of the following options f or PC

Communication:

• POTS Co nn ect Kit - uses a MultiTech

Converter (configu red for ethernet) and SA2 Surge Arrest or. A direct analog

phone line to the local phone service is requir ed to use this f eature . The phone

line used for PV225S communication cannot be routed through a Private

Branch Exchange (PBX) unless an analog PBX card is used.

• Wireless Connect - uses a GSM Wireless Modem.

• Ethernet LAN Connect - uses a data communication device to enable the

unit to connect to a local area networ k.

• Direct Connect Kit - uses a RS232/Fiber Optic Converter (configured for a

PC), a DB25-to-DB25 gender changer, and a DB25-to-DB9 Serial Cable.

Determine which communications options are required for the installa tion and

procure the a ppropria te ser vice or phone a ccess. The per sonal computer to be used

with this unit must have the appropriate hardware as well, such as a 56K modem

for dial up connection or a Network Interface Card (NIC) for a LAN connection.

®

56K Modem, RS232/Fiber Optic

2–4 152606

Page 39

Utility Side Isolation Transformer Requirements

Utility Side Isolation Transformer Requirements

The PV225S is supplied with a a high-eff iciency custom W ye:W ye isolation

transformer as part of the AC Interface/Transformer assembly. The utility side

windings of the isolation tr ansformer are configured Wye and must match the

voltage at the utilit y inter-tie. The PV225S is a balanced, three -phase, currentsourcing inverter and only operates with the presence of a stable utility voltage.

The transformer is also supplie d with a neutral connection on the utility

interconnect. Connection of this utility-side neutral does not affect the operation

of the inverter, however connection of the neutral on the inverter-side does affect

the operation and must be left floating or disconnected. Single-phase, grounded

loads which may be present between the transformer and utility, will maintain

their existing grou nd refer ence at the utility distribution transformer.

CAUTION: Equipment Damage

If the Isolation Transformer (T6-X0) neutral terminal is tied to ground, it will cause

irreparable damage to the PV225S. Check local regu lations for their requirements

regarding the connec tion of these neutrals.

WARNING: Lethal Voltage

Grounding the neutra l of a W ye -wound transfor mer may create an “open delta ” condit ion ,

depending on the utility configuration. This condition may keep the PV225S from

detecting a loss of phase condition on the utility system, which may allow potentially

lethal volta ge to be present on the open-pha s e wiring.

Electrical Diagrams and Schematics

Since installations vary widely, a sample electrical diagram of the PV225S is

provided in Figure A-1 on page A–3. This diagram is to be used for system

planning purposes only.

For mo re de tailed infor m atio n , r e fer to the schema t i c il lustr ations.

• Figure A-2, “PV225S Schematic for Main Power Distribution (152812 A1)”

on page A–4

• Figure A-3, “PV225S Schematic for Control Power Distribution

(152812 A2)” on page A–5

• Figure A-4, “PV225S Schematic for Conv erter Control Unit (152812 A3)” on

page A–6

152606 2–5

Page 40

Planning

Layout Options

The PV225S is shipped as two separ ate assemblies and can be arranged as shown

in Figure 2-1 or Figure 2-2.

The PV225S can be arrang ed in a number of different system layout options to fit

specific site requir ements. The AC Interface/T ransformer assembly may be colocated adjacent to the left side of (or behind) the Main Inverter Enclosure up to,

and not exceeding, 15 feet away.

Given the flexibili ty to co-locate the AC Interface/Transformer assembly to fit a

desired system layout , the interconnect AC power conductors and conduit

between the Main Inverter Encl osure and the AC interface/transformer assembly

are to be supplied by the installe r. See Figure 2-1 and Figure 2-2, depicting two

options for locatin g the AC interface/transformer assembly adjacent to the main

inverter.

Minimum Dimension of Base:

Approximately 14 ft. by 5 ft. (4.3 m x 1.5 m)

Figure 2-1

2–6 152606

PV225S Layout Option A

Page 41

Minimum Dimension of Base:

Approximately 10 ft by 9 ft (3 m x 2.7 m)

Layout Options

Figure 2-2

152606 2–7

PV225S Layout Option B

Page 42

Planning

Conduit Penetration

The following il lustrati ons sho w the r ecommended loc ations f or ele ctri cal condu it

entry into the PV225S enclosures. These drawings are to be used for system

planning purposes, such that the shaded areas are representative of the maximum

allowable area and locat ion in which electrical conduit may penetrate the

enclosures of the PV225S, see Figure 2-3 through Figure 2-8. Xantrex

recommends a standard trade-size conduit knock-out set for cutting/punching the

PV225S enclosures and panels for conduit entry.

AC Interface

Enclosure

AC side view

of PV225S

E

Transformer

Enclosure

B

A

AC Interface

Enclosure

C

Main Inverter

Enclosure

Inductor

Enclosure

Front view of PV225S

Figure 2-4 on page 2–9

A

B

Figure 2-5 on page 2–9

C

Figure 2-6 on page 2–10

Figure 2-7 on page 2–10

D

E

Figure 2-8 on page 2–10

DC Interface

Enclosure

D

Figure 2-3

Conduit Entry Figure Reference

2–8 152606

Page 43

Conduit Penetration

5 ½" (15 cm)

1 ½" (4 cm)

18" (46 cm)

6" (15 cm)

Figure 2-4

Inductor Enclosure Conduit Entry, Left Side

1 ½" (4 cm)

5 ½" (15 cm)

18" (46 cm)

6" (15 cm)

Figure 2-5

152606 2–9

Transformer Enclosure Conduit Entry, Right Side

Page 44

Planning

Backside of

Transformer

Enclosure

(partial view)

8"

(20 cm)

AC Disconnect Switch (S1)

10" (25 cm)

1" (2.5 cm)

12" (30 cm)

5" (13 cm)

Figure 2-6

Figure 2-7

AC Interface Enclosure Conduit Entry, Left Side

DC Interface Enclosure, Bottom Side

3" (8 cm)

1" (2.5 cm)

18"

(45 cm)

2" (5 cm)

10" (25 cm)

4" (10 cm)

10.5" (27 cm)

1" (2.5 cm)

Figure 2-8

2–10 152606

Communications Enclosure Conduit Entry, Bottom Side

Page 45

Conductor and Conduit Sizing

All wiring methods and materials shall be in accordance with the National

Electrical Cod e ANSI/NFPA 70. When sizing conducto rs and condu its i nterfa cing

to the PV225S, both shall be in accordance with the National Electric Code ANSI/

NFPA 70, as well as all state and local code requirements.

Large gauge wire must confo rm to the minimum bend radius dependent upon the

wire gauge (refer to the National Electric Code, Article 373-6B (Ninth Edition).

CAUTION: Equipment Damage

Be careful to keep the wire bundles away from any sharp edges which may damage wire

insulation over time.

The following provide s information on sizing the con ductors and conduits for the

system.

To calc ul ate the proper condui t size :

1. Determ in e the req ui red cab l e am p acit y.

2. Determine the conduit length be tween the inverter and the transformer.

Conductor and Conduit Sizing

3. Determine the prope r size for the cable according to the allowable ampacitie s

indicated by NEC Table 310.16 (Ninth Edition).

4. Determine the proper size for the conduit.

The following is an example of the steps outlined above. Assumptions were made

in this example which may not match your application, and the resulting design

may not comply with all code requirements. Consult a licensed electrician on

recommendations for specific installations.

Step 1. Determine the required cable ampacity.

AC Phase Cab les from Inv erter t o Transfo rm er:

225 kW / 208 Vac / 1.732 = 624.5 A

624.5 x 125% = 780.69 A (required ampacity)

Step 2. Determine the conduit length between inverter and transformer.

• If the conduit length between the inverter and the transformer is less than

24 inches, then the cable can be sized using the NEC Table 310.16

(in raceway) (Ninth Edition).

• If the conduit length is greater than 24 inches, then the cable m ust be sized

using NEC Table 310.16 (in Raceway) (Ninth Edit ion) and by using the

adjustment factors in NEC Table 310-15(b)(2)(a).

(full load current)

rms

152606 2–11

Page 46

Planning

Step 3. Size the cable.

This example assumes that the condui t length is less than 24 inches. NEC

Table 310.16 (Ninth Edition) indicates the Temperature Correction Factor for

90 °C THHN cable in a 50 °C ambient is 0.82. With a required ampacity from

Step 1 above of 780.6 amps, it can be calcul ated that the required cable ampacity

at 50 °C in this application is 952 amps. (780.6 divided by 0.82)

In this example, four cables per phase termination are used, so from NEC Table

310.17 (Ninth Edition) it is apparent that the 90 °C THHN cable must be

262 kcmil or larger. Four each 262 kcmil conductors at 50°C have an allowable

ampacity of 984 amps (246 multiplied by 4).

Step 4. Size the conduit.

In this step, the cross sectional area of all the individual cables is first calculated.

Once calculated, the total cross sectional area of the cables is determined by

summing their values. In this example, 262 kcmil DLO, 2000 V cable is selected

for the AC Phase connections:

DLO 262 Phase Cable:

262 MCM DLO, 2000V, 90 °C per Phase

262 MCM has an O.D. of 0.973

0.973 x 0.973 x 12 x 0.7854 = 8.923 in²

Ground Cable:

1 Each #2 A WG (per NEC Tabl e 250. 122 (Ninth Edition),

using 400 A Breaker)

#2 AWG has an O.D. of 0.384 for THHN and 0.565 for DLO

0.565 x 0.565 x 0.7854 = 0.250 in²

Sense/Control Wires:

8 Each #16 A WG, UL1015, THHN, Hook-up Wire

#16 AWG has an O.D. of 0.096

0.096 x 0.096 x 8 x 0.7854 = 0.058 in²

Total:

DLO 262 Phase Cable = 8.923 in² (8.923 divided by 2 = 4.46)

Ground Cable = 0.250 in²

Sense/Control Wires = 0.058 in²

2 runs of conduit between the Isolation Transformer (T6-X1, T6-X2, and T6-

X3) and the Main Inverter Enclosure (T B5, TB6, and TB7)

1st conduit run; 4.46 + 0.25 = 4.71 in²

2nd conduit run; 4.46 + 0.058 = 4.52 in²

2–12 152606

Page 47

Using the "Over 2 Wires" column per NEC Chapter 9, Table 4, (Ninth Edition)

indicates that the fol lowing minimum permitted conduit trade size is acceptable

for the 21 w i re s in this ex erc ise:

EMT = 3 ½" Trade size

IMC = 4" Trade size

RMC = 4" Trade size

Anchoring the PV225S

The PV225S is designed to be installed in eithe r an indoor or outdoor location. It

must be placed on and anchored to a level concrete floor or pad. The concrete

floor or pad, upon which the PV225S is anchored, must be structurally de signed to

meet any local, stat e, or nati onal requi rement s for weight, seismic, and wind shee r

if applicable.

Four 5/8" holes are provid ed in the feet of the main inve rter, and six 5/8" holes are

provided in the feet of the AC interfa ce/t ransformer assembly for ancho ring to the

floor or pad.

Figure 2-9 and Figure 2-10 depict the layout patterns of the anchoring holes for

both the PV225S main inverter and the AC interface/transformer assembly.

Anchoring the PV225S

23 ¼"

(59 cm)

Figure 2-9

(43 1/8”)

(110 cm)

Main Inverter Anchor Bolt Pattern (Not to scale)

5/8"

(1.5 cm)

(x4)

152606 2–13

Page 48

Planning

(30”)

(76 cm)

17 ¼"

(43 cm)

(38”)

(97 cm)

¾" (1.9 cm)

(x6)

Figure 2-10

AC Interface/Transformer Anchor Bolt Pattern (Not to Scale)

The floor or pad should either be pre-drilled to accept masonry anchors or have

pre-install ed anchoring bolts.

2–14 152606

Page 49

3

Installation

Chapter 3, “Installation” describes the procedures needed to install

the PV225S 225 kW Grid-Ti ed Photovoltaic Inverter. This section

includes unpacking and moving instructions, mounting instructions,

and cabling instructions.

Page 50

Installation

Equipment Required

The following is a list of required tools and equipment to ai d in the installation of

the PV225S. This list is not a comprehensive list, but is intended to help identify

the minimum recommended tools and equipment used during the installation.

• Forklift (26" minimum fork span) and/or pallet jack

• Claw hammer or pry bar

• Standard and metri c socket set

• Standard and metri c wrench set

• Standard Allen

• Large slip-j oint pliers

• Standard and Phil lips screwdrivers

• T orque wrench with 0 - 600 in-lbs minimum range

• Appropriate voltage meter (6 00 Vac and DC rated, minimum)

• Phase rotation meter (600 Vac rated, minimum)

• Hammer drill and masonry bits

• Trade-size conduit knock-out set

®

Hex wrenches (5/16, 3/8, and 1/2)

Unloading

The PV225S is shipped partially as sembled in two separate shipping crates and

one cardboard box.

❐ One crate is the main inverter and is marked "1-152287-01".

❐ The other crate is the AC Interface Enclosure and transformer assembly and is

marked "1-152448-01".

❐ The cardboard box contains one of the three remote connection kits:

• POTS Connection 1-152674-01,

• Wire less Connection 1-152659-01, or

• Ethernet Connection 1-152658-01.

WARNING: Heavy Equipment

The main inverter weighs approximately 230 0 lbs. The AC Interface Enclosure and

transformer as sembly weigh approximately 2350 lbs. Attempting to lift the equipment by

other than the recommended lifting points may damage the equipment or present a

personnel safety hazard and void the warranty. Keep all t he doors closed and lat che d when

moving the enclos ures. Leaving the door latches unsecured may result in damage to the

unit and void the warranty.

3–2 152606

Page 51

Moving the PV225S

CAUTION: Equipment Damage

c

To move the PV225S, use a forklift that has a sufficient lift capacity and has a 26" fork

span.

To move the PV225S while it is still inside the shipping crates:

1. Place the forks of the forklift below the shipping crate at the points specified

2. Lift the main inverter and the AC Inter face Enclosure and Transformer

Unloading

on the shipping crate.

Enclosure from beneath their shipping crates.

Figure 3-1

Moving the crated PV225S

Unpacking the PV225S

To unpack the main inverter and the AC Interface Enclosure and

transformer assembly from their shipping crates:

1. Using a claw ha mmer or pry bar, remove the c rate’s wood top and si de panels.

2. Remove the main inverter’ s an chor hardware that attaches it to the shippi ng

pallet.

3. Remove the AC Interface Enclosure and trans former assembly anchor

hard w are th a t a t taches them to their sh ippin g pall e t .

152606 3–3

Page 52

Installation

Removing the Pallet and Moving the PV225S

CAUTION: Equipment Damage

c

To move the PV225S, use a forklift that has a sufficient lift capacity and a 26" fork span.

To move the PV225S using a forklift:

1. Place the forks of the forklift below the unit at the points specified in

Figure 3-2.

2. Lift the PV225S from beneath the respective enclosures.

Be sure to use a forklift with a 26" fork span.

3. Remove the pallet from beneath the unit.

4. Once the pallets are removed from the units, use the same lifting locations to

lift the units into the place where they are to be per ma n ently loca t ed.

Lift Here

26" (66 cm)

fork span

Figure 3-2

3–4 152606

Forklift Lifting Locations - Underneath Unit

Lift Here

26" (66 cm)

fork span

Page 53

Mounting and Anchoring the Units

Important:

of the components , conduit penetrati on locations, conductor and conduit sizing, and

method for anchoring the unit. Ensure adequate space is provided for clearance for

ventilation and serviceabilit y. Review Chapter 2, “Planning” if necessary before

proceeding.

Before proceeding with the installa tion, determine th e loc ation and layout

Mounting and Anchoring the Units

To mount and anchor the PV225S:

1. Predrill the floor or pad to accept 1/2" diameter masonry anchors or ensure it

has pre-installe d anchoring bolts that will fit the 5/8" mount ing holes.

2. Lift the main inverter from beneath the lower enclosure with a forklift or

pallet jack as shown in Figure 3-2 on page 3–4. Move the Main Inverter

Enclosure into place.

3. Lift the AC Interface/Transformer assembly from beneath the enclosure with

a forklift or pallet ja ck as shown in Figure 3-2 on page 3–4. Move the AC

interface/t ransformer assembly into place.

4. Secure the Main Inverter Enclosure feet to the floor with a 1/2" diameter

anchor bolts.

5. Secure the AC Interface/Transformer assembly enclosure feet to the floor

with 1/2" diameter anchor bolts.

Mounting Holes for

securing and anchoring

the units.

Figure 3-3

152606 3–5

Mounting Hole Locations

Page 54

Installation

Opening or Closing Access Doors

To lock or unlock the front door on the main inverter:

1. Use the 7 mm triangle key provided with the unit.

a) Insert the key in each lock and turn counterclockwise to open;

clockwise to lock.

b) Pull front door open from the right sid e.

Main Inverter Front Door Locks

Main Inverter Front Door Lock

Figure 3-4

3–6 152606

Inverter Enclosure Access Doors

Page 55

Door Latches

h

Opening or Closing Access Doors

To Op en A cce s s Doo r:

1. Confirm that th e AC Di sconne ct Switc h

handle is placed in the OFF (Open)

position prior to opening the door.

2. Loosen the bolts on door latches and

slide away from the d oor.

3. Pull open from right side.

To Close Access Door:

1. Confirm that the AC Disconnect Switch

handle is pl aced i n the OFF (O p en)

position prior to closing the door.

2. Close the door and slide the latches

back over the edge of the door .

3. Tighten the bolts on door latches.

Figure 3-5

AC Interface Access Door

T o Open Access Door:

1. Confirm that the DC Dis connect Switch

handle is placed in the OFF (Open)

position prior to opening the door.

2. Loosen the bolts on door latches and

slide away from the door.

3. Pull open from the left side.

To Clos e A cce ss Do o r:

1. Confirm that t he DC Disconne ct Switc

handle is placed in the OFF (Open)

position prior to closing the door.

2. Close the door and slide the latches

back over the edge of the door.

3. Tight en the bolts on door latches.

Door Latches

Figure 3-6

152606 3–7

DC Interface Access Door

Page 56

Installation

Transformer Access Panel

Figure 3-7

Transformer Access Panels

To Remove the Access Panel

Loosen and remove the 1/4"

self-tapping sheet metal screws

(x9).

To Replace the Access Panel

Replace and tighten the 1/4"

self-tapping sheet metal screws.

Main Inverter Front Door

Inductor Access Panel

:

:

Figure 3-8

To Remove the Access Panel

Use a Phillips screwdriver to loosen

and remove the 1/4-20 Phillips

round-head bolts (x12).

To Replace the Access Panel

Replace and tighten the 1/4-20

Phillips round-head bolts to 78 in-lb

(8.6 nm).

Inductor Access Panels

:

:

3–8 152606

Page 57

Conduit Installation

Given the flexible nature of the syste m, conduit installation will be depende nt

upon the final configuration of the system. Procurement and installation of the

conduit, therefore, is the responsibility of the installer. Since the layout will be

dependent upon the locati on availa ble for the installation and the siz e of the