Heavy Duty Inverter/Charger

1000 Watt Weatherproof

Owner’s Guide

Model RM1012

For Volvo Trucks

About Xantrex

Xantrex Technology develops, manufactures, and markets advanced power electronic products. The

company’s products convert raw electrical power from any source into high-quality power required by

electronic and electrical equipment.

Trademarks

Xantrex HD is a trademark of Xantrex International. Xantrex is a registered trademark of

Xantrex International.

© 2001 Xantrex International. All rights reserved.

Notice of Copyright

Xantrex™ Heavy Duty Inverter/Charger Owner’s Guide © November 2001 Xantrex International.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”):

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

November 2001, Revision 2

Part number

445-0128-01-01 (Volvo)

Contact information

Volvo Trucks North America, Inc.

P.O. Box 26115 Greensboro, NC 27402

Volvo Trucks Canada, Inc.

6490 Vipond Drive, Mississauga, Ontario L5T 1W8

1-800-52-VOLVO (1-800-528-6586)

www.volvotrucks.com

Contents

Important Safety Information

General precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Precautions when working with batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - v

Precautions for using appliances - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vi

1Introduction

Introduction to the Xantrex HD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Operating features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

2Operation

Planning for AC loads- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Type of loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

AC loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

DC loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Problem loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Ambient temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Calculating size of an AC load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Driving the truck while operating AC and DC loads - - - - - - - - - - - - - - - - - - -2–7

Using the toggle switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Operating the Inverter/Charger- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Turning the inverter on and running loads - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Running in extremes of hot or cold temperatures - - - - - - - - - - - - - - - - - - - - 2–11

Restarting after a shutdown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Battery charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Using shorepower - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Miscellaneous hints - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

iii

Contents

3Maintenance

Checking terminals- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Disconnecting and connecting Xantrex HD from the batteries - - - - - - - - - - - - - -3–3

Disconnecting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Connecting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Replacing the fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–4

Removing and reconnecting AC cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–6

4 Troubleshooting

Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Common problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Blinking lights on the remote switch- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–3

Calling your authorized Volvo dealer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–5

A

Specifications

Physical specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Inverter specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Charger specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Transfer and general specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Rating curves and charging profiles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - IX–1

iv

Important Safety Information

WARNING

Before using your Inverter/Charger, read and save these safety

instructions.

General precautions

1. Before using the inverter/charger, read all appropriate sections of

this guide and any cautionary markings on the inverter and the

batteries.

2. Use only a grounded AC extension cord when connecting to AC

input power (shorepower). Do not remove or attempt to defeat the

ground connection to any shorepower source in any way.

3. If possible, plug the inverter/charger into an AC source outlet that is

protected by a Ground Fault Circuit Interrupting (GFCI) device;

either a breaker or outlet.

4. Do not operate the inverter/charger if it has received a sharp blow,

been dropped, or otherwise damaged. If the unit is damaged, return

it to your authorized Volvo dealer.

5. Do not dismantle the inverter/charger; it contains no userserviceable parts. Attempting to service the unit yourself could

cause electrical shock or fire. Internal capacitors remain charged

after all power is disconnected.

6. To reduce the risk of electrical shock, turn off the inverter/charger

from the remote switch, then disconnect both AC (shorepower) and

DC (battery) power from the unit before working on any circuits

connected to it. Turning off the remote On/Off switch alone will not

reduce this risk.

Precautions when working with batteries

1. Follow all instructions published by the battery manufacturer and

the manufacturer of the equipment in which the battery is installed.

2. Make sure the area around the battery is well ventilated.

v

Important Safety Information

3. Never smoke or allow a spark or flame near the engine or battery.

4. Use caution to reduce the risk of dropping a metal tool on the

battery. It could spark or short circuit the battery or other electrical

parts and cause an explosion.

5. Remove metal items like rings, bracelets, and watches when

working with lead-acid batteries. These batteries produce a shortcircuit current high enough to weld a ring, other metal jewellery or

tools, thus causing severe burns.

6. If you need to remove a battery, always remove the negative

terminal from the battery first. Make sure all accessories are off so

you don’t cause an arc.

7. Before making the final connection to a battery, be sure the polarity

is correct; negative-to-negative, and positive-to-positive.

8. When you are making the final connection to a battery, you will see

a spark and hear a loud pop. This is normal.

Precautions for using appliances

Most battery-operated equipment uses a separate charger or transformer

that is plugged into an AC receptacle and produces a low voltage output.

If the label on the AC adapter or charger states that the adapter or

charger produces a low voltage AC or DC output (less than 30 volts),

the inverter/charger can power this charger or adapter safely.

Some rechargers for small nickel-cadmium batteries can be damaged if

connected to the inverter/charger. Do not use the following loads and

appliances:

• Small battery-operated appliances like flashlights, razors, and night

lights that can be plugged directly into an AC receptacle to

recharge.

• Chargers for battery packs used in hand power tools. These types of

chargers display a warning label stating that dangerous voltages are

present at the battery terminals.

vi

1

Introduction

Chapter 1, “Introduction” describes the main

performance and protection features of the

inverter/charger.

Introduction

Introduction to the Xantrex HD

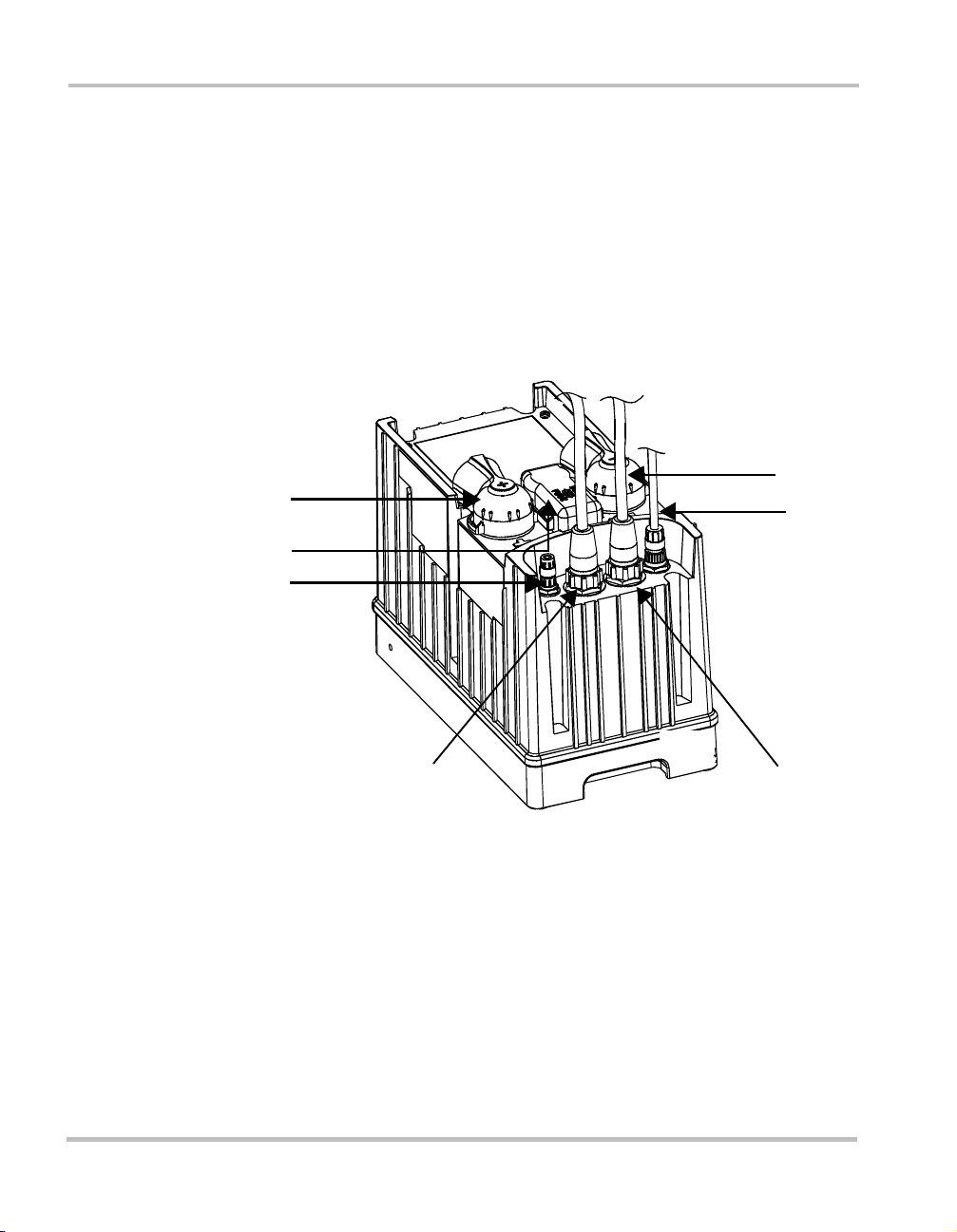

Features The Xantrex HD inverter/charger is a weatherproof, modified sine wave

inverter/charger designed to be mounted on main frame rail of the truck. It

is a sealed, dust and water resistant unit weighing approximately 30

pounds (13.6 kg). Figure 1-1 shows its main features.

Consult Appendix A, “Specifications” for more detailed information

about the unit.

⑦

①

}

②

③

1–2

④

Figure 1-1 Features of the inverter/charger

⑤

Feature Description

Introduction to the Xantrex HD

①

②

③

④

⑤

}

⑦

Location The inverter/charger is mounted on the main rail of the truck adjacent to

the battery compartment as shown in Figure 1-2.

Positive terminal connecting to positive terminal of battery

Over-current protection fuse which blows in case of a fault

within the unit or if it is connected to the battery with reverse

polarity.

Battery temperature sensor

AC output to vehicle

AC input from shorepower

Remote toggle switch connection. The connection must be

secure for the inverter to work

Negative terminal connecting to negative terminal of battery

Figure 1-2 Location of the inverter/charger

1–3

Introduction

Operating features

Inverter/charger The inverter/charger operates as an inverter and as a charger depending

upon the operational conditions. When the unit is inverting, it is said to be

in invert mode and is referred to as an inverter. When the unit is charging,

it is in charge mode and is referred to as a charger.

The unit can only operate in charge mode when external AC power

referred to as “shorepower” is connected.

Inverter

features

Xantrex HD offers the following inverter features:

• Ability to run many of the same appliances that you use at home

You can operate TVs, VCRs, satellite receivers, computers, hair

dryers, and small power tools for example. You can also run multiple

loads up to 1000 watts in total.

• Surge capability

Xantrex HD will manage loads up to 3000 watts for short periods of

time as long as the peak current is less than 36 A peak.

• Low voltage shutdown

The inverter shuts off when your batteries reach a predetermined

voltage set in the microprocessor to ensure you will always have

enough engine starting power. Low voltage shutdown also monitors

frequency and voltage, and protects against overload, short circuits

and over-temperature.

• Automatic shutdown when the unit does not detect a load greater than

20 watts for 24 hours

This feature prevents the inverter from draining the batteries if it is

left on without a load.

1–4

Operating features

Charger

features

Xantrex HD offers the following charger features:

• 50 amp charging, when shorepower is connected, to ensure your truck

batteries are always charged

• Automatic transfer to invert mode

When your truck’s AC shorepower cord is disconnected, the unit

automatically switches to invert mode. When AC shorepower is

available again, the inverter automatically switches to charging/passthrough mode.

• Load management capability which temporarily reduces charging

current to the batteries when a large AC load is applied to the inverter

output. This capability helps reduce the chance of tripping the

shorepower breaker.

1–5

1–6

2

Operation

Chapter 2, “Operation” explains how to calculate

the size of the loads you can run from the

Xantrex HD Inverter/Charger. It also provides

guidelines to help you run loads safely and

efficiently.

Operation

Planning for AC loads

AC load AC load refers to an AC product you want to operate from the

inverter/charger. Loads include most products that you can plug into a

standard 120 volt household electrical outlet.

Va ri a bl e s

affecting AC

loads

The Xantrex HD inverter/charger inverter can power a wide range of

loads. The size of the load and the length of time you can operate it

depends on variables such as

• type of load

• ambient temperature

• size, state of charge, temperature, and condition of batteries.

The larger your battery capacity and the higher the state of charge, the

longer the inverter/charger can run your AC loads. Battery capacity is

reduced as battery temperature lowers.

Type of loads

AC loads

The way in which an AC load draws power may determine how

effectively it can be powered from the inverter/charger.

Resistive loads Toasters, coffee pots and incandescent lights are examples of loads which

do not need a high start-up current to start running. They use a resistive

heater element to generate heat or light. They are the simplest and most

efficient for an inverter/charger to run. Large resistive loads, such as

electric stoves and water heaters, are impractical since their high current

demands quickly drain the batteries.

Inductive loads TVs, VCRs, stereos, computers, and electric motors (power tools,

vacuum cleaners, for example) are examples of AC loads which surge on

start up, that is, they require a high startup current compared to a resistive

load such as toasters or coffee pots. These loads are known as inductive or

electronic loads. Depending upon the size of the motor, it can take as

much as six times its running current to start it than it does to keep it

running once it has started. This surge can sometimes exceed the

inverter/charger’s maximum output rating and the inverter will shut

down.

2–2

DC loads

Problem loads

Planning for AC loads

DC loads are those that run off the 12 V electrical system on the truck. A

few examples of DC loads are:

• marker lights, headlights, cab lighting, other lights using DC power

• DC refrigerators

• CBs

• factory-installed radios or sound systems

DC loads and the inverter/charger both rely on the batteries for power.

Many DC loads running at one time will shorten the operating times of

AC loads.

These are loads you should not operate from inverter/charger because

they may be damaged or may not operate properly:

• dimmer switches

• some small rechargeable hand power tool chargers

• small battery-operated appliances such as flashlights, razors, night

lights

• variable speed motors

Ambient temperature

Ambient

temperature

Temperature

and power

The ambient temperature, that is, the air temperature around the

inverter/charger will affect its output power.

The air temperature around the inverter may be much hotter than away

from the vehicle. If your truck is standing on hot pavement, the

temperature may be quite high near the inverter.

Generally, the output power decreases as the temperature increases. For

example, at 77 °F (25 °C) the unit delivers 1000 watts for as long as you

have sufficient battery power. At 104 °F (40 °C) it delivers 1000 watts for

up to 10 minutes before shutting down or 750 watts continuous, or 2000

watts for 2 1/2 minutes.

Figure 2-1 shows the relationship between ambient temperature and the

length of time the unit will supply an output power level. Choose the

curve with temperature range most closely approximating that of the

inverter/charger location, then look for the time in minutes. The

2–3

Operation

intersection of the time and temperature will indicate approximately the

output power of the unit. For example, between – 40 °F (– 40 °C) and

77 °F (25 °C), you will get 3000 watts for approximately two minutes or

2500 watts for 3 minutes.

3000

2500

2000

1500

1000

Output Power (VA)

500

0

1 10 100

-40 to 25C 40C 55C 70C 85C

– 40 to 77 F 104 F

2

4

3

Figure 2-1 Output power versus time and temperature

6

5

78

9

Time (min utes)

131 F

158 F

185 F

Calculating size of an AC load

Operating time To determine how long you can run your appliances:

1. List all the AC loads you think you will use and determine their

power requirement. You can usually find this information on a label

near the power cord on the appliance.

2. Look in Table 2-1 to find its operating time or the operating time of a

similarly sized appliance. The operating times shown in the table are

the maximum time the appliance will operate. The unit will shut

down after that time so the battery is not drained past a safe level.

3. To find the running time for several appliances running

simultaneously add the total watts of the appliances and look for an

appliance with similar power requirement in Table 2-1.

Battery

condition

2–4

The information in Table 2-1 assumes:

• there is a properly maintained 400 amp-hour battery bank

• the batteries have not been damaged by deep discharge and are

relatively new

Planning for AC loads

Factors

affecting load

Consider these factors when you are calculating loads:

• Loads that exceed 1000 watts may be run for a short time (less than

five minutes)

• Loads which run continuously, (reading light, TV, computer) should

not exceed more than 1000 watts in total

• Poor battery condition, low battery capacity, low battery temperature,

and high ambient temperature will shorten the operating times listed

in the table

• The presence of DC loads will reduce the operating times

2–5

2–6

Operation

Table 2-1 Typical operating time with fully-charged 400 amp-hour batteries

Appliance Watts Minutes Hours

10 20 30 40 50 1 2 3 4 5 6 9 18 24

Electric shaver

Tab le fan

Video game

Reading Lamp

Notebook computer

Computer printer

Hand-held vacuum cleaner

19 in TV/VCR combo

3 cu. ft. refrigerator

Electric blanket

Electric buffer

Electric drill 1/2”

Halogen work light

Coffee maker

Toa ste r

Microwave oven

Hair dryer

*

15

15

25

40

75

100

100

100

180

200

400

500

750

800

1000

1200

1500

†

* Average

The inverter/charger shuts down after 24 hours if it does not detect a load (or loads less than 20 W).

†

Based on four minute operation timeout and shutdown at 11.8 V for loads more than 150 W

and 12.3 V timeout and shutdown for loads less than 150 W at 77 °F (25 °C).

Planning for AC loads

Driving the truck while operating AC and DC loads

Recharging Driving your truck does not guarantee that the battery is being fully

recharged by the alternator if you are running a combination of large AC

and DC loads.

The alternator must provide more power than the combined DC and AC

loads draw for your battery to fully recharge.

Example This example shows what happens if the alternator is overloaded.

92 A

1110 W (DC)

AC Loads

(1000 W)

Alternator

(130 A)

12 Volt Battery

38 A

Xantrex HD

Driver Installed

Loads

Factory Installed

Loads

DC Loads

Figure 2-2 AC and DC loads powered by the alternator

The alternator is charging at 130 amps while the truck is being driven at

highway speeds and there is a 1000 W (AC) load.

2–7

Operation

The efficiency of the inverter/charger is approximately 90%, which means it

is drawing about 1100 W (DC) from the battery or 92 amps. This leaves

38 amps for all DC loads. If the DC loads require more than 38 amps, the

battery will actually discharge even though the alternator is running.

Indication If the alternator is overloaded the:

• battery voltage gauge on the dashboard begins dropping from

approximately 14 V towards 12 V

• inverter LED signals a low battery with a slow blink

• inverter shuts down at 11.8 V and AC loads will stop operating

• battery voltage gauge will climb again as the alternator now has enough

power to charge the battery

Solutions You can reduce the AC or DC load on the battery or, for continuous

operation of large AC and DC loads you can consider installing a larger

alternator.

Comment Small alternator overloads may not be immediately noticeable and can take

several hours to discharge the batteries. Large overloads will discharge the

battery in a shorter time.

At low engine RPMs the alternator current will drop significantly causing

alternator overload to occur even with reduced AC and DC loads.

2–8

Using the toggle switch

Using the toggle switch

Location The inverter/charger is controlled from the remote toggle switch on the

control panel in the cabin as shown in Figure 2-3.

Toggle switch

Switch

settings

Figure 2-3 Remote switch

The switch is used to disable the inverter. The charger is always on as long

as shorepower is connected.

If the switch is … The inverter is …

On Providing AC to the vehicle when there is no

shorepower and the battery voltage is acceptable.

Off Providing pass-through AC to the vehicle only if

there is shorepower. The inverter is disabled and

will not provide AC power in the absence of

shorepower.

2–9

Operation

Switch LEDs The LEDs provide information about the operating state of the

inverter/charger. Under normal operating conditions the lights will behave

like this:

AC LED: Illuminated when there is shorepower.

Blinks slowly (once per second) when first connecting

to shorepower then lights steadily or it will continue to

blink if the AC voltage is not within range (100 V to

130 V).

Inverter LED: Illuminated when the unit is inverting and there is no

shorepower.

If the LED is blinking once every two seconds (very

slow blink), it means the unit has shut down to avoid

draining the batteries.

A fast-blinking Inverter LED light indicates a unit

fault. Refer to Chapter 4, “Troubleshooting” for more

information.

Note: Some switches may also have a center position. The center position also

enables the inverter.

2–10

Inverter disabled (off)

when switch pushed up

Inverter LED

AC LED

Inverter enabled (on)

when switch is pushed

down

Figure 2-4 Inverter/charger switch positions

Operating the Inverter/Charger

Operating the Inverter/Charger

This section provides guidelines for operating the Xantrex HD.

Turning the inverter on and running loads

To run loads:

• Put the switch in the On position by pressing down.

• Check that the inverter LED is illuminated and AC LED is off if you are

not connected to shorepower.

• Connect appliances one at a time to the inverter. Don’t connect too

many high-surge appliances at once. You may notice some appliances

halt or dim momentarily while another is starting up.

Running in extremes of hot or cold temperatures

Hot In extremely hot conditions, the inverter may shut down sooner than it

would in normal or cold temperatures. The unit may be hotter than the

outside air temperature when parked on hot pavement, for example.

When the ambient temperature is high, reduce the number of loads.

Cold In extreme cold temperatures, your batteries may have less stored energy. At

0 °F (– 18 °C) your battery has only half the standby power than it has at

77 °F (25 °C).

Restarting after a shutdown

If the appliances stop operating suddenly, it usually means that the battery

voltage is too low or you have drawn too much power for too long. Try

restarting the inverter by turning the switch off, then on again. If you are

running several loads, try disconnecting one or two of them. If it doesn’t

start right away, let the inverter rest a few minutes, then try again. The

batteries should be recharged as soon as possible. If it still refuses to power

your loads, start the vehicle to charge the batteries.

Note: Turning the switch off, then on again to restart after a shutdown

should only be considered a temporary measure. The batteries likely

need to be recharged.

2–11

Operation

Battery charging

When you are connected to shorepower, the AC LED is illuminated and the

unit is both passing power through to the appliances and charging the

batteries. To avoid low voltage problems, make sure your connection cord to

shorepower is not too long and that it is heavy enough to support the loads

you are running. A 14 or 12 gauge extension cord is recommended.

If the AC LED flashes slowly (about twice per second), this means the AC

voltage is out of range and your batteries are not charging.

Using shorepower

If you are running too many appliances you may either trip the 15 amp truck

breaker or the shorepower breaker. Reduce the load and reset the affected

breaker.

Note that the charger will automatically reduce battery charging if other AC

loads are connected. This helps to prevent nuisance tripping of the

shorepower breaker.

Miscellaneous hints

Automatic

shutdown

The inverter automatically turns off if it has not detected any AC loads for

24 hours or the loads are so small the inverter cannot detect them, such as an

alarm clock or very small television (less than 10-20 watts).

Output

power

.

Remember that the total output of the inverter/charger is 1000 watts and not

1000 watts per outlet (if there is more than one).

Note: The Xantrex HD does not provide any warning before it shuts

down. If you need to operate a critical AC load, be sure there are no

heavy loads connected and that the batteries have been recently charged.

Connect

delay to AC

power

If you are connected to shorepower, the AC LED should be on and the

inverter LED off. The AC LED may blink slowly when you first apply

shorepower because of a connect delay (about 30 seconds), but then will

illuminate steadily.

Load failure If any loads fail to operate, or the inverter shuts down, refer to Chapter 4,

“Troubleshooting” for suggestions.

2–12

3

Maintenance

Chapter 3, “Maintenance” provides procedures for checking

the terminal connections on the inverter/charger,

disconnecting Xantrex HD from the batteries, changing the

overcurrent protection fuse, and removing or connecting the

AC input and output cables.

3–1

Maintenance

Checking terminals

To check that the battery cables are firmly connected, you will need to

remove the terminal caps.

To remove the terminal cap:

1. Using a flathead screwdriver as shown in Figure 3-1, place the blade

in the lip of the cap and push it gently against the cap until it lifts off.

2. To replace the cap, place it over the terminal and push down until it

snaps into place.

3

3–2

1

2

Figure 3-1 Lifting the terminal cap

Disconnecting and connecting Xantrex HD from the batteries

Disconnecting and connecting Xantrex HD from the

batteries

Before doing any work with your batteries or with the inverter/charger,

review “Important Safety Information” on page v.

Disconnecting

WARNING: Explosion or Fire

Make sure the battery compartment is well ventilated.

Flammable fumes are often present when working with

batteries.

To disconnect from the battery:

1. Disconnect the shorepower cable and turn the

inverter/charger off.

2. Remove the inverter/charger cables from the battery.

Disconnect the negative connection first at the inverter/charger

terminal and then disconnect the positive at the battery terminal.

Connecting

3. If you are replacing batteries, make sure they are the same kind and

capacity as you are currently using.

4. Disconnect the ground wire if the unit must be removed from its

mounting bracket.

To connect to the batteries:

1. Ensure shorepower is disconnected and the inverter/charger is off.

2. Connect the ground wire if it was previously removed

CAUTION: Reverse Polarity

Do not connect cables in reverse polarity. If you do, the fuse will

blow the fuse and the unit could be damaged.

3–3

Maintenance

3. Connect the positive battery cable from the inverter/charger to the

positive terminal on the battery; then the negative to the negative with

the last connection made at the Xantrex HD terminal to prevent

sparks. You may hear an audible “pop” and see a spark when you

make the last connection.

4. Tighten to a torque of 14.5 ft-lbs (+/-10%).

5. Check that the inverter is operating by enabling it from the toggle

switch as explained in “Using the toggle switch” on page 2–9.

Replacing the fuse

WARNING: Correct fuse type

WARNING: Explosion or Fire

Do not complete the next step if flammable fumes are

present. Explosion or fire may result. Thoroughly ventilate

the battery compartment before making this connection.

3–4

To reduce the risk of fire and electrical hazards, replace the fuse

with a fuse of the same type and rating.

Using the wrong fuse type can damage the unit and void your

warranty.

The inverter/charger over-current protection fuse, shown in Figure 1-1,

protects the unit from internal failure or reverse polarity when connecting

it to the battery. If it blows for any reason, replace it with only the fuse

types listed below.

• Littelfuse Mega® Fast Blow, 250 A, 32 V; part number 298250

• Bussmann® 250 A 48 V; part number AMG-250

To replace the fuse:

1. Lift the fuse cover off as shown in Figure 3-2.

2. Remove the spent fuse and install the new fuse.

Be sure to use a lock washer when replacing the nuts. Tighten to a

torque of 4-5.5 ft-lb (5.5-7.5 Nm).

Replacing the fuse

.

CAUTION: Do not overtighten fuse nuts!

3. Replace the fuse cover by placing it over the fuse and pressing down

until it snaps into place.

If the fuse blows a second time without being able to operate the unit,

do not change the fuse again. Call your authorized Volvo dealer.

3

1

2

Figure 3-2 Removing the fuse cover

3–5

Maintenance

Removing and reconnecting AC cables

To remove the AC cables:

➣ Grasp the knurled surface of the connector housing as shown in

Figure 3-3 and turn counter clockwise approximately one-half turn.

Gently pull the cable out by grasping the connector.

To reconnect:

➢ Insert the plug firmly. Turn the connector housing clockwise 1/2 turn

until you feel resistance, then another

1/8 turn until it locks into place.

Shorepower

Figure 3-3 AC input and output cables

Power to vehicle

Turn these counterclockwise

to remove

3–6

4

Troubleshooting

Chapter 4, “Troubleshooting” provides

information to help you identify common

problems which may occur. Read this chapter

before calling your authorized Volvo dealer. If

you cannot solve the problem, record the details

as suggested on page 4–5, then call your dealer.

Troubleshooting

Troubleshooting

Common problems

The unit shuts down during operation for four main reasons:

• low battery—when the battery reaches approximately 11.8 Vdc (for

loads greater than 150 watts) for more than four minutes, or 12.3 Vdc

for loads less than 150 watts.

• high battery—when the battery voltage exceeds 16 Vdc

• overload—when the AC load connected to the inverter exceeds the

rated load

• over temperature—when the internal temperature thresholds are

reached

This table lists problems you may encounter and offers suggestions to fix

them. Refer to Table 4-2 and Table 4-3 for explanation of the blinking

LEDs.

Table 4-1 Troubleshooting reference

Symptom Possible Problem Remedy

Loads will not start when there

is no shorepower

Loads stop running almost as

soon as they start

4–2

Inverter not turned on

Batteries at low voltage

Inverter too hot

Load is too heavy

Batteries at low voltage level

Bad battery cable or corroded

battery terminals

Batteries in poor condition

Turn the inverter on

Recharge batteries by running the

engine or connect to shorepower

Wait until inverter has cooled

down

Reduce the load

Recharge batteries by running the

engine or plug into shorepower

Check cable and connectors

Test and replace, if necessary

Table 4-1 Troubleshooting reference (Continued)

Symptom Possible Problem Remedy

Troubleshooting

Loads stop operating without

warning after they have been

running for awhile

Shorepower not connected

Inverter will not work even

after toggling switch and

batteries are charged and the

inverter is cold

AC voltage at receptacles

reads low

In inverter mode, times to

shutdown are getting shorter

for the same kind of AC load

Too many appliances have

reduced battery voltage to

shutdown level

Ambient temperature is too

high

Remote switch may be

disconnected at the unit (not

likely)

Fuse on the unit (shown in

Figure 1-1) may have blown

(not likely)

Wrong type of volt meter being

used

Bad battery cable or corroded

battery terminals

Batteries too old or damaged

Reduce number of loads. Allow

inverter to cool and restart. Start

the truck to recharge the batteries.

Disconnect appliances and let the

unit cool down

Check that the remote switch is

firmly connected

Replace fuse or return unit to an

authorized Volvo dealer

Use a true RMS meter

Check cables and connectors

Replace batteries

Blinking lights on the remote switch

This table describes the different sequences of blinking lights you may

encounter when the inverter is enabled (switch is on) or the unit is

charging (switch is off). Light sequences are described as follows:

L

Fast blink Light is on for 1/4 second and off for 1/4 second

Slow blink Light is on for 1/2 second and off for 1/2 second

Very slow blink Light is on for one second and off for one second

4–3

Troubleshooting

Table 4-2 explains the blinking pattern of the AC input LED when the

inverter is connected to shorepower.

Table 4-2 Interpreting AC input LED blink patterns

Inverter

LED AC input LED Condition

Off ON Connected to shorepower within 100

to 130 Vac range and battery charger is

operational

Off Very slow blink • Delay on transfer from the inverter

to shorepower

• AC power is not in range (outside

100 to 130 Vac range)

• Battery is not being charged. AC

output load may be too great

• Extension cord to shorepower may

be too long or not of sufficient

conductor size, resulting in voltage

drop

4–4

Table 4-3 explains the inverter LED flashing pattern when the unit is in

invert mode or in charge mode.

Table 4-3 Inverter LED blink patterns

Unit in invert

mode

Slow blink N/A Low battery

Fast blink Fast blink High battery

Fast blink Slow blink Unit over temperature and has shut down

Fast blink Slow blink Ambient temperature too high and unit

Slow blink N/A Over current

Very slow blink N/A Auto shutdown. Inverter has shut down

Unit in charge

mode Condition

has shut down

because no load has been detected in 24

hours or the load is too small to detect

Calling your authorized Volvo dealer

Calling your authorized Volvo dealer

If none of the troubleshooting suggestions work, you will need to call

your authorized Volvo dealer. If possible, note the circumstances

surrounding the failure. They may help the service technician diagnose

the problem quickly.

How long have you had

the inverter?

Serial number

Battery types and sizes

Appliances running at

shutdown

Were the LEDs flashing

and if so, what pattern

(slow blinks? fast blinks?)

Was the ambient

temperature extremely hot

or cold?

Were any DC appliances

affected?

Has this happened before?

4–5

4–6

A

Specifications

Appendix A “Specifications” contains the

Xantrex HD product specifications, which

include the inverter, charger, and transfer

specifications. It shows derating curves for

output surge, current versus temperature, and

pass-through current. It also illustrates the threestage charging profile used by the unit.

Note that all specifications are subject to change

without notice.

Specifications

Physical specifications

Physical specifications

Enclosure Sealed; dust and water-resistant

Dimensions Approximately. 8.5" (21.8 cm)H x 7”

Net weight 30 lbs. maximum without mounting brackets or

External finish Base - Clear anodized aluminium.

Mounting Orientation Upright only

Mounting method Four M8x1.25 threaded holes accessible from

(17.7 cm)W x 13.0"(33.0 cm)D, excluding DC

ground connector (similar to Group 31 battery

dimensions)

external cables

Cover -Black polycarbonate/ABS plastic

bottom only, one in each corner, and /or battery

hold-down bar over center top of cover.

Recommended torque: 5-6 ft-lb (7-8 Nm)

A–2

Battery cable #2/0 AWG Minimum, maximum 6 feet long,

each way

Battery size 300 Ah acceptable; 400 Ah recommended

Inverter specifications

All inverter specifications are at nominal conditions; 77 °F (25 °C,)

1000 W resistive load, 12 Vdc inverting, 120 Vac, unless otherwise

specified.

Inverter specifications

Output wave form Modified sine wave

Output power continuous 1000 VA continuous at 77 °F (25 °C)

Surge rating 3000 VA for 2 min at –40 °F to 77 °F (–40 °C to

Operating voltage range 10.5 Vdc–16.0 Vdc

Input DC voltage rating 12 Vdc

Output voltage 120 Vac RMS

Output voltage regulation 108 to 125 Vac under steady state 0 to 1000 W

Inverter specifications

25 °C)

See Figure A-1 for output at different

temperatures.

load with 11.8 to 14.5 Vdc input at 25 °C

108 to 132 Vac up to 1000 W, 10.5to 16 Vdc

input at – 40 to 185 °F (–40 °C –85 °C)

Output frequency 60.0 ± 0.1 Hz – 40 °F to 185 °F (– 40 °C to

85 °C ambient temperature)

Power factor allowed All (0 to 1, leading or lagging)

Peak efficiency Greater than 93% at 12.6 Vdc input at 77 °F

(25 °C)

Idle power consumption Less than15 W (inverting with 120 Vac output

and no load)

Auto-shutdown mode Inverter output is less than 15 ±5 W and battery

is less than 13 Vdc for 24 hours

A–3

Specifications

Inverter specifications (continued)

Shutdowns and Restarts

DC low voltage shutdown 1. Battery voltage drops below 11.8 ±0.15

DC low voltage restart 12.5 ± 0.15 Vdc

DC high voltage shutdown 16.0 ± 0.2 Vdc

DC high voltage restart Less than 16.0 Vdc, same as DC high voltage

Charger specifications

All charging specifications are at nominal conditions, 77 °F (25 °C), 14.0

Vdc at 50 A charging, 120 Vac, 60 Hz unless otherwise specified.

Vdc at heavy loads (more than 150 W) or

12.3 Vdc at light loads (less than 150 W)

for more than 4 min and 10 sec (± 30 s)

2. Battery voltage is below 10.5 ± 0.2 Vdc for

3 seconds

shutdown; there is no hysteresis

A–4

Charger specifications

Charging method • Three-stage charging with battery

temperature compensation.

See Figure A-3.

• Algorithm for generic flooded batteries

only

• No equalization mode

AC input voltage 100–130 Vac

AC input frequency 54–66 Hz

Minimum battery voltage 8 Vdc

The charger does not operate below this level

Maximum charger input current 13.0 Aac

Maximum charge rate 50 ± 5 Adc. See Figure A-2

Charger efficiency Greater than 80%

Absorption charge voltage 14.3 ± 0.3 Vdc at 77 °F (25 °C)

Float charge voltage 13.4 ± 0.3 Vdc at 77 °F (25 °C)

rms

Charger specifications (continued)

Temperature compensation – 0.023 Vdc/ °C from -2 °C to 85 °C.

Below -2 °C, the charger voltage defaults to

the – 2 °C voltage

Overvoltage shutdown Greater than or equal to 15.3 ± 0.3 Vdc

Transfer and general specifications

Transfer and general specifications

AC input/bypass current 20 Aac maximum continuous at 77 °F (25 °C)

Derates after 30 °C to 5 Aac at 185 °F (85 °C)

Transfer speed 10–40 ms typical

AC low voltage transfer 90 ±5 Vac

AC low voltage restart 95 ±5 Vac, 30 second delay

AC high voltage transfer None

Transfer and general specifications

Standby/off consumption < 0.7 at 12.5 Vdc with charger and inverter

both off

Operating temperature range – 40 °F to +185 °F (– 40 °C to +85 °C)

Storage temperature range – 40 °F to +185 °F (– 40 °C to +85 °C)

Altitude limit 15 000 feet (5000 metres)

AC neutral to ground bonding Invert mode: AC output neutral is connected

to AC ground (chassis)

Charge mode: AC output neutral is connected

to AC input neutral

AC input neutral is always isolated form AC

ground

A–5

Specifications

Rating curves and charging profiles

3000

2500

2000

1500

1000

Output Power (VA)

500

0

1 10 100

2

4

3

-40 to 25C 40C 55C 70C 85C

– 40 to 77 F 104 F

Figure A-1 Output surge rating

6

5

78

9

Time (min utes)

131 F

158 F

185 F

A–6

M ax. charger current vs Tem peratu re

60

50

40

30

20

Charger current (Amps)

-40-20 0 20406080

10

0

R M 1012

A m bien t tem perature (C)

Figure A-2 Charging current versus temperature derating curve

Rating curves and charging profiles

Bulk

Charging

Started

DC Voltage

Constant Current

@ Maximum

Charge Rate

DC Current

Time

Absorption Charge

Bulk Volts Setting

Constant Voltage

Figure A-3 Three-stage charging profile

Float Charge

Float Volts Setting

Reduced Voltage

Reduced Current and Voltage

Load current on demand

A–7

A–8

Index

A

AC cables, removing or connecting 3–6

AC load

calculating size

definition

factors affecting

types of

AC power, connect delay

alternator, effects of overloading

ambient temperature

effect on operation

effect on output power

appliances

see AC load

battery-operated

authorized dealer, calling

auto shutdown feature

automatic shutdown

automatic transfer between AC and DC

2–2

1–5

2–4

2–2

2–2

2–12

2–7

2–2, 2–11

2–3

vi

4–5

1–4

2–12

B

batteries

charging with Xantrex HD

nickel-cadmium

precautions for working with

battery cables, disconnecting

battery condition, effect on AC loads

battery operated appliances see problem

loads

vi

2–12

v

3–3

2–5

battery packs

breaker switch

resetting

vi

2–12

C

charger features 1–5

charger specifications

charging current

common problems, suggestions for

connect delay to AC power

current vs temperature derating curve

6

A–4

1–5

D

DC loads

effect on alternator

effect on operating times of AC loads

2–3

derating curves, current vs temperature

A–6

dimmer switch see problem loads

disconnecting Xantrex HD from

batteries

2–7

3–3

E

explosive fumes 3–4

extension cord, length of

4–4

4–2

2–12

A–

Index

F

flashlights see problem loads

fuse, over-current protection

fuse, replacing

3–4

1–3

H

high battery shutdown 4–2

I

inductive load see AC loads

inverter features 1–4

inverter specifications

A–3

L

LEDs

blinking patterns

load management capability

loads

see AC load 2–2

loads, effect of large loads on alternator

low AC, causes of

low battery shutdown

low voltage shutdown

4–2

1–5

4–4

4–2

1–4

M

maintenance

checking terminal connections

disconnecting battery cables

replacing the fuse

3–4

3–2

3–3

2–7

P

physical specifications A–2

problem loads

2–3

R

rating curves

output surge rating

razors see problem loads

rechargeable tools see problem loads

remote switch

blinking lights on the

resistive load see AC load, type of

resistive loads, examples of

restarting after shutdown

A–5

4–3

2–2

2–11

S

safety information v

safety monitoring feature

servicing, no user-serviceable parts

shorepower, definition

shutdown

automatic

restarting after

size of AC load, calculating

surge capability

surge loads, examples of

2–12

2–11

1–4

1–4

v

1–4

2–4

2–2

N

nickel-cadmium batteries vi

O

operating time of AC loads (table) 2–6

over temperature shutdown

overload shutdown

IX–2

4–2

4–2

T

temperature see ambient temperature

temperature and power, relationship of

temperature and time derating curve (figure)

terminals caps, removing

three-stage charging profile

time, running time of AC loads

toggle switch

purpose

torques for fuse replacement

transfer specifications

troubleshooting reference

2–9

3–2

A–6

3–4

A–5

4–2

2–3

2–4

U

using Xantrex HD, guidelines for 2–11

V

variable speed motor see problem loads

X

Xantrex HD

as a charger

as an inverter

common problems

condition for shutdown

derating curves for

disconnecting from batteries

location in truck

main features

maintaining

turning on

Xantrex HD features (figure)

1–4

1–4

4–2

4–2

A–5

3–3

1–3

1–2

3–1

2–11

1–2

Index

2–4

IX–3

Loading...

Loading...