Xantrex Technology SW Plus 4048, SW Plus 4024, SW Plus 2548, SW Plus 2524, SW Plus 5548 User Manual

Sine Wave Plus Inverter/Charger

SW Plus 2524

SW Plus 2548

SW Plus 4024

SW Plus 4048

SW Plus 5548

Owner’s Manual

Sine Wave Plus Inverter/Charger

Owner’s Manual

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobi le units to one MW utility- sc ale systems for wind, solar, batteries, fuel cells, micro turbines, and backup

power applications in both grid-co nnected and stand-alon e systems. Xantrex products include inverters, battery

chargers, programmable power s upplies, and variable speed drives that convert, supply, control, clean, a nd distribute

electri cal power.

Trademarks

Sine Wave Plus Inverter/Char ger is a trademark of Xantrex International. Xantrex is a registered trademark of

Xantrex International.

Other trademarks, registered tra demarks, and product names a re the property of their respective owners and are used

herein for identi fication purposes onl y.

Notice of Copyrigh t

Sine Wave Plus Inverter/Charger Owner’s Manual © September 2003 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMAT ION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Due to continuous q uality improvement and product updates, the photographs shown in this manual may not exactly

match the unit purchased.

Date and Revision

September 2003, Revision B

Part Number

976-0043-01-02 Rev B3

Contact Inform ation

Telephone: 1-800-670-0707 (toll free in North America)

Telephone: 1-360-925-5097 (dir ect)

Fax: 1-800-994-7828 (tol l free in North America)

Fax: 1-360-925-5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

About This Manual

Purpose

The purpose of this Owner’s Manual is to provide explanations and

procedures for insta lling, operating, maintaining, and troubl eshooting the

Sine Wave Plus Inverter/Charger.

Scope

The Manual provides safety guidelines, detaile d planning and setup

information, procedures for installing the inverter, as well as information

about operating and troubleshooting the unit. It does not provide details

about particular brands of batteries. You need to consult individual batter y

manufacturers for this information.

Audience

The Manual is intended for anyone who needs to install and operate the

Sine Wave Plus Inverter/Charger. Installers should be certified

technicians or electricians.

976-0043-01-02 iii

About this Guide

Organization

This guide is organized into nine chapters and nine appendices.

Chapter 1, “Introduction” lists and describes the basic features and parts

of the Sine Wave Plus Inverter/Charger.

Chapter 2, “System Configuration” contai ns information to help you plan

for a Sine Wave Plus installation in an off-grid, on-grid, or backup power

application.

Chapter 3, “Installation” describes how to mount and install the Sine

Wave Plus Inverter/Charger and perform wiring and cabling procedures

for various configurations.

Chapter 4, “Functional Test” explains how to conduct a functional test of

the inverter.

Chapter 5, “Navigation” explains how to navi gate through the Sine Wave

Plus Inverter/Charger menus using the Control M odule and the menu

maps.

Chapter 6, “Basic Setup Progr amming” expla ins how to progra m the Sine

Wave Plus Inverter/Charger to operate under basic conditions.

Chapter 7, “Advanced Setup” explains how to program the Sine Wave

Plus Inverter/Char ger to operate under speci al, advance d conditions , such

as automatic generator starting, energy manage ment and auxiliary load

applications.

Chapter 8, “Operation” expla ins how to operate the Sine Wave Plus

Inverter/Char ger . It also explains how to read the LED indicators and

User Menus to determine system status.

Chapter 9, “Troubleshooting” contai ns inf ormation and procedures for

solving possible prob lems with the Sine W ave Plus.

Appendix A, “Inverter Specifications” provides the electrical and

environmental spe cifications of this inverter. This section also provide s

information about how an inverter works, as well as efficiency statistics.

Appendix B, “Configuration Settings” provides worksheet s for

programming your inver ter/charger for user-specific parameters. Use this

chapter to record the settings specific to your installat ion. This will make

programming or reprogramming easier.

Appendix C, “Battery Information” supplies general information about

batteries s uch as ba tter y types, ba tter y bank s izing, batte ry confi gurations,

and battery care. For detaile d information, see your battery manufacturer

or your system designer. Reading this chapter will help you determine the

battery bank specific ations required by your specific system (e. g., types

of batteries, size of battery bank, configuration of the battery bank etc.).

Appendix D, “Generators” supplies information about generator starting.

Reading this chapter will he lp you deter mine what kind of generator to

use, if any.

976-0043-01-02 iv

Appendix E, “Over-Charge Protection” supplies information about

options for over -charge protection.

Appendix F, “Multi-wire Branch Circuit Wir ing” supplies information

about Multi-wire Branch Circ uit Wiring Precautions when using standalone 120 Vac inverters or generators. Rea ding this chapter will provide

information regar ding identifying and correcting the potential fire hazard

that exists when using inverters in this situation.

Appendix G, “Emergency Power Off Swi tches” supplies information

about the requirements for installing an Emergency Power Off Switch.

“Glossary” contai ns a glossary of technical terms used in this manual.

The glossary also defines some common electrical terms. It also provides

a list of acronyms used in this manual.

“Warranty and Product Information” Reading this chapter will pr ovide

clarificat ion of the Limited Warranty and instruct ions for obtaining a

Return Material Authoriz ation, if the product needs to be returned to

Xantrex or one of its authorized service centers.

Conventions Used

The following conventions are used in this guide.

About this Guide

WARNING

Warnings identify conditions or practices that could result in personal

injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to

the Sine Wave Plus Inverter/Charger or other equipment.

v 976-0043-01-02

About this Guide

Related Information

You can find more information about Xantrex Technology, Inc. as well as

its products and servic es at www.xantrex.com

You may also need to reference the following installat ion guides to assist

with this installa tion. These guides (with the exception of the NEC/CEC

Reference G uides) are all provide d wi th the speci fic co m p one n ts wh en

purchased.

• Generator Star t Module (GSM) Installation Guide

• Auxiliary Load Module (ALM) Instal lation Guide

• Inverter St acking Control – Series (ISC-S) Cable Owner’ s Guide

• Inverter Communicati ons Adapter (ICA) Owner’s Guide

• Inverter Control Module (IC M) Installation Guide

• AC Conduit Box (ACCB) Owner’s Guide

• DC Conduit Box (DCCB) Installation Guide

• AC and/or DC Conduit Installati on Instructions

• T240 Autotransformer Installation Guide

• Manufacturer’s instructions for Electric al Panels (Main, Sub, and

generator disconnec t panels)

• Manufacturer’s instructions for battery installation and use

• Manufacturer’s instructions for generator installation and use

• NEC Guide for related electrical, grounding, and bonding

information.

• CEC Guide for related electric al, grounding, and bonding

information.

976-0043-01-02 vi

Important Safety Instructions

WARNING

This chapter contains important safety and operating instructions as

prescribed by UL and CSA standards for inverters used in residential

applications. Read and keep this Installation Guide for future reference.

1. Before using the inverter, read all instructions and cautionary

markings on the unit, the batteries, a nd all appropriate sections of this

manual.

2. Use only attachments recommend ed or sold by the manufa cturer.

Doing otherwise may result in a risk of fir e, electric shock, or injury

to persons.

3. The inverter is designed to be permanentl y connecte d to your AC and

DC electrical systems. Xantrex recommends that all wiring be done

by a certified technician or electrician to ensure adherence to the local

and national electric al codes applicable in your jurisdiction.

4. T o avoid a risk of fire and electric shock, make sure that existing

wiring is in good condition and that wire is not unde rsized. Do not

operate the inverte r with damaged or substandard wiring. See

Appendix, F “Multi-wire Branch Circuit Wiring” for information

about multi-wire branch circuits.

5. Do not operate the inverter if it has been damaged in any way. If the

unit is damaged, see the W arranty and Product Infor mation section at

the end of this manual.

6. This unit does not have any user -serviceable parts. Do not

disassemb le the i nve rt er. See “How do you get service?” on page I–1

for instructions on obtaining service. Atte mpting to service the unit

yourself may result in a risk of electrical shock or fire. Internal

capacitors remain charged after all power is disconnected.

7. T o reduce the risk of electrical shock, disconnect both AC and DC

power from the inverter before attempting any maintenance or

cleaning or working on any components con nected to the inverter.

Turning off controls will not reduce this risk.

8. The inverter must be provided with an equipm ent-grounding

conductor connected to the AC input ground.

976-0043-01-02 vii

Important Safety Instructions

9. Do not expose this unit to rain, snow, or liquids of any type. This

product is designed for indo or use only. Damp environments will

significantly shor ten the life of this product and corrosion caused by

dampness will not be covered by the product warr a nty.

10. T o reduce the chance of short-circuits, always use insulated tools

when installing or working with the inverter, the batteries, or the PV

arrays.

11. Remove all jewelry while insta lling this system. This will great ly

reduce the chance of accidental exposure to live circuits.

Explosive gas precautions

1. Working in the vicinity of lead acid batteries is dangerous. Batteries

generate explosive gases during normal operation. Therefore, you

must read this guide and follow the inst ructions exactly before

installing or using your inverter/charge r.

2. To reduce the risk of battery explosion, follow these instructions and

those published by the batter y manufacturer and the manufacturer of

the equipment in which the battery is installed.

FCC Information to the User

This equipment ha s been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rule s. These limits

are designed to provide reasonable protection against harmf ul

interference in a residentia l installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructi ons, may cause harmful interference t o radio

communications. However, there is no guarant ee tha t i nterfer ence wil l not

occur in a particular installation. If this equipment does cause harmful

interference to radio or tele vision reception, which can be deter mined by

turning the equipment off and on, the user is encouraged to try to correct

the interferenc e by one or more of the followi ng measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment receiver.

• Connect the equipment into an outl et on a circu it different from that

to which the receiver is connected.

• Consult the dealer or an experienced ratio/TV technician for help.

viii 976-0043-01-02

Contents

Important Safety Instructions

Explosive gas precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

FCC Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

1

Introduction

Basic Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

AC Side - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–4

Emergency Power Off (EPO) Option - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–5

Certification Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–5

DC Side - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

Battery Temperature Sensor (BTS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–7

Top - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–8

2

System Configuration

Pre-Configuration Planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Types of Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

System Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

System Output Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

System Input Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Location Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–5

Mounting Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Ventilation Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Grounding Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–7

DC System Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–7

Inverter Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–8

Equipment or Chassis Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Grounding Electrodes/Gr ound Rods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Bonding the Grounding System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–10

Battery Considerat ions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Battery Bank Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–12

Battery Cable Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–12

Battery Requirements for Dual Inverter Systems - - - - - - - - - - - - - - - - - - - - - -2–15

Battery Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Wiring Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Generator Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–19

Types of Generators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–20

976-0043-01-02 ix

Contents

Generator start types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–20

Additional/Optiona l Equipment Considerati ons - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

AC Conduit Box (ACCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

DC Conduit Box (DCCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Fuse Block - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

DC Disconnect Boxes (DC175/DC250) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

Battery Status Meter (TM500A) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Remote Monitors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

Inverter Control Module (ICM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Inverter Communications Adapte r (ICA) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Generator Start Module (GSM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

Auxiliary Load Module (ALM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

240 Vac Application Requiremen ts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–29

Autotransformer fo r 240 VAC Applications (T240) - - - - - - - - - - - - - - - - - - - - - - 2–29

Inverter Stackin g Control – Series (ISC-S) Cable - - - - - - - - - - - - - - - - - - - - - - - - 2–29

Renewable Energy DC Input Sources - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–30

Off-Grid Applicati ons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–32

Renewable Energy Systems with/ without Generator Backup - - - - - - - - - - - - - - - - 2–32

Single-Inverter Confi gurations (120 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–32

Single-Inverter Confi gurations (120/240 Vac) - - - - - - - - - - - - - - - - - - - - - - - 2–32

Dual-Inverter Configur ations (240 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–34

Generator-Only Syste ms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–36

Single-Inverter Confi gurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–36

Dual-Inverter Configur ations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–38

240 Vac-only Input Source - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–38

On-Grid Application s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–40

Backup Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–40

Single-Inverter Confi gurations (120 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–40

Single-Inverter Confi gurations (240 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–40

Dual-Inverter Configur ations (240 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–42

Energy Management - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–44

RE Backup with Utility (SB Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–44

Peak Load Management - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–44

Time-of-Use (TOU) Metering - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–45

AC Load Support - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–46

Renewable Energy with Grid Backup (BX Mode) - - - - - - - - - - - - - - - - - - - - 2–47

3

Installation

Pre-Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Tools Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

x 976-0043-01-02

Contents

Hardware / Materials Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–3

Optional System Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–3

Battery Bank Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–4

Unpacking and Inspecting the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Knockout Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Shelf-Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Wall-Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–14

Preparing the Batter y Bank - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Grounding the DC System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

Connecting DC Input Sources – Renewable Ener gy Configurations - - - - - - - - - - - - 3–18

Installing the Batte ry Temperature Sensor (BTS) - - - - - - - - - - - - - - - - - - - - - - - - 3–18

Connecting the Batteri es to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–20

Procedure for Single Inverte r Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–22

Procedure for Dual-Inverte r Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–24

AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–26

Accessing the AC Terminal Block and Ground Bar - - - - - - - - - - - - - - - - - - - - - - 3–28

AC Wiring for Single Inverter Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–30

Manual and Auto Start Generators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–30

Install AC Output Wiring to the Inverter AC Distribution Panel - - - - - - - - - - - 3–33

Install Generator Wiring to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–35

Install Utility Wiring to the Inverter Input (On-Grid Applicati ons only) - - - - - -3–38

Optional Equipment- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–39

Stacking Dual Inverter Sys tems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–39

Installing the ISC-S Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–40

Remote Monitoring Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–41

Auxiliary Load Module (ALM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–42

Emergency Power Off (EPO) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–43

EPO Port - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–43

4

Functional Test

Basic Functional Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Confirm all Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Applying Battery Power to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Turning ON the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–3

AC Voltage Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–4

Confirming Battery Charger Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–4

Confirming Inverter Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–5

976-0043-01-02 xi

Contents

5

Navigation

Navigating the Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

The Inverter Control Module (ICM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Inverter Control Module Fea tures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

The display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

The cursor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Display contrast - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Push-buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

ON/OFF Menu Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Menu Heading Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Menu Item Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Set Point Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Reset Factory Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Menu Map - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7

6

Basic Setup Programming

Basic Setup Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

Before You Begin Programming - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–8

DC Amps verses AC Amps - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–8

Basic Setup Process - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–9

Accessing the Basic Setup Menu- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–10

Menu Item Descriptions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

10 Time of Day Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

10A Set Hour - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

10B Set Minute - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

10C Set Seconds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–12

11 Inverter Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–12

11A High Battery Cut Out VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–12

11B Low Battery Cut In VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–12

11C Low Battery Cut Out VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–13

11D LBCO Delay Minutes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–13

11E Search Watts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–14

Battery Charger Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–15

Multi-Stage Charging Proces s - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–16

Equalize Charging the Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–18

12 Battery Charging Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–19

12A Finish Stage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–19

12B Bulk Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–20

12C Float Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–20

12D Equalize Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–20

xii 976-0043-01-02

12E Max Charge Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–22

12F Bulk Done Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–23

12G EQ VDC Done Timer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–24

12H Max Bulk/EQ Timer h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–25

12I Temp Comp - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–25

13 AC Inputs Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–26

13A Grid (AC1) Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–27

13B Gen (AC2) Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–27

13C Input Upper Limit VAC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–28

13D Input Lower Limit VAC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–28

14 Save/Restore Settings Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–29

14A Push INV now to Save Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–29

14B Push GEN to Restore Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–29

14C Push GEN for Factory Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–30

End Basic Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–30

7

Advanced Setup

Advanced Setup Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–2

Before You Begin Advanced Programming - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–10

Accessing the Advanced Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–11

Menu Item Descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–13

20 Silent Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–13

20A Refloat High Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–15

20B Refloat Low Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–15

20C Float Done Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–15

20D Must Float Time Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–16

21 Grid (AC1) Usage Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–16

21A Grid Usage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–17

21B Grid Usage Begin h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–17

21C Grid Usage End H:M - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–18

22 Battery Xfer (BX) Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–18

22A High Xfer (HBX) VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–19

22B Low Xfer (LBX) VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–19

23 ALM Relays Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–19

23A RY9 VDC Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–20

23B RY9 VDC DeEnergized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–20

23C RY9 Delay At DeEngz. Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–20

23D RY10 VDC Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–20

23E RY10 Vdc DeEnergized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–21

23F RY10 Delay at Engz. Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–21

Contents

976-0043-01-02 xiii

Contents

23G RY11 Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–21

Generator Starti ng Scenarios - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–23

Manual Generator Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–23

Automatic Generator Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–24

24 Generator Timers Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–26

24A Gen Run Time Start h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–27

24B Gen Run Time Stop H:M - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–27

24C Quiet Time Begin h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–27

24D Quiet Time End h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–28

24E Gen Exercise Period Days - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–28

24F Gen Exercise Timer Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–28

24G Gen Cooldown Timer Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–28

24H RN2/Max Gen Run h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–29

25 Gen Starting Details Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–29

Generator Start Module (GSM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–29

25A RY7 Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–30

25B Gen Warm-up Seconds/minutes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–37

25C Pre Crank Seconds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–37

25D Max Cranking Seconds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–37

25E Post Crank Seconds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–37

26 Gen Auto Run Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–38

26A Load Start Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–38

26B Load Start Delay Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–38

26C Load Stop Delay Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–38

26D 24 Hr Start Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–38

26E 2 Hr Start Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–38

26F 15 Min Start Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–39

26G Read LBCO 30 Sec Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–39

27 Save/Restore Settings Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–39

27A Push INV now to Save Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–39

27B Push GEN to Restore Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–40

27C Push GEN for Factory Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–40

End Advanced Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–40

8

Operation

Operating the Sine Wave Plus- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–2

Operational Status Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–3

LED Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–3

Inverter Operation Status (Yellow) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–4

AC Input Status (Green) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–5

xiv 976-0043-01-02

Contents

Charge Status (Yellow and Green) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–6

Operational Status Indication (Red and Yellow) - - - - - - - - - - - - - - - - - - - - - - -8–7

Error LED Reset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–8

LED Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–9

The User Menu Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–11

Accessing the User Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–14

User Menu Description- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–15

01 Inverter ON/OFF Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–15

01A Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–15

01B EQ Charge OFF ON - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–16

01C Search Watts (SRCH) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–16

01D Bypass Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–17

02 Generator ON/OFF Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–17

02A Generator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–18

02B Gen Start Load Amps - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–19

02C Gen Start Volts/Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–19

02D Gen Start Exercise Run - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–19

02E Gen Start Run Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–19

02F Days Left To Gen Exercise - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–19

03 Time Of Day Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–20

03A SW Plus Software Level - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–20

03B System Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–20

03C Company Name and Address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–20

03D City, State, and Zip Code - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–20

03E Xantrex Phone Numbers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–20

Press Reset for Factory Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–21

04 Meters Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–22

04A Battery Actual Vdc - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–22

04B Battery Comp Vdc - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04C Inverter/Charger Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–23

04D Input Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04E Load Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04F Inverter Volts AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04G Grid (AC1) Volts AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

04H Gen (AC2) Volts AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–24

04I Frequency Hertz - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

04J Max Bulk/EQ Time h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–24

04K Battery Temp Degrees C - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

04L Fan Speed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–24

05 Error Causes Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–25

05A Over Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–25

976-0043-01-02 xv

Contents

05B Transformer Overtemp - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–25

05C Heatsink Overtemp - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–26

05D Low Battery Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–26

05E High Battery Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–27

05F External Err (Stacked) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–27

05G Input Relay Failure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–27

05H Gen Failed to Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–28

05I Gen Stopped Due to V/F - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–28

06 Status Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–28

06A Bypass Mode Selected - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–29

06B Chr Selected (No Backup) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–29

06C Gen Signaled to Run - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–29

06D Gen In Cooldown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–29

06E EQ Charge Selected - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

6F Battery VDC < LBCO - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

6G Battery VDC > HBCO - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

06H EPO Shutdown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

07 GSM/ALM Options Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

07A RY7 (GSM) Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

07B RY8 (GSM) Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07C RY9 (ALM) Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07D RY9 DeEngz. Time Minute - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07E RY10 (ALM) Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07F RY10 Engz. Time Minute - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07G RY11 Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

9

Troubleshooting

Inverter Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9–2

Battery Charger Troubl eshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9–4

Error Causes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9–7

A.

Inverter Specifications

Electrical Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–4

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–6

Power Versus Efficiency - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–8

Inverter Capacity versus Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–12

Time versus Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–13

xvi 976-0043-01-02

B

Configuration Settings

User Menu Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Basic Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Advanced Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–10

C

Battery Information

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Battery Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Deep-cycle Flooded Lead Acid (FLA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Sealed Batteries (Gel and AGM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

NiCad and NiFe Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

Understanding Battery Capacity Ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

Battery Bank Sizing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

Understanding Amp-hour Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–5

Calculating Amp Hours - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–6

Amp Hour Example Worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–7

Battery bank size worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

Battery Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–9

Wiring Batteries in Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–9

Wiring Batteries in Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–10

Wiring Batteries in Series-Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–11

Battery Connections for Stacked Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–12

Battery Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–13

Battery charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–13

Equalization Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–15

General Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–16

Contents

D

Generators

Two-Wire Start Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Three-Wire Start Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Honda™ 3-Wire Type Generators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Onan™ 3-Wire Type Generators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–3

3-2 Wire Converters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–3

E

Over-Charge Protection

Overvoltage Protection using a Charge Controller- - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Diversion Load Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

976-0043-01-02 xvii

Contents

F

Multi-wire Branch Circuit Wiring

Multi-wire Branch Circuits- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–2

Identifying Multi-wire Branch Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–4

Correcting Multi-wire Branch Circuit Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–5

G

Emergency Power Off Switches

The Purpose of an EPO switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -G–2

How to use the EPO Port for an EPO Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - -G–4

Warranty and Product Information

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I–1

Return Material Authorization Policy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I–3

Out of Warranty Service- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I–4

Information About Your System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I–5

xviii 976-0043-01-02

Figures

Figure 1-1 The Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Figure 1-2 The Front Side of the Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Figure 1-3 The AC side of the Sine Wave Plus- - - - - - - - - - - - - - - - - - - - - - - - - - - -1–4

Figure 1-4 Certification Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–5

Figure 1-5 The DC side of the Sine Wave Plus- - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

Figure 1-6 Battery Temperature Sensor (BTS) - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–7

Figure 1-7 External Output Circuit Breaker - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–8

Figure 2-1 AWG Wire Size Reference Chart - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–13

Figure 2-2 Sample Warning Sticker for Backfeed Conditions- - - - - - - - - - - - - - - - -2–17

Figure 2-3 AC Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–22

Figure 2-4 DC Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–23

Figure 2-5 Sine Wave Plus with AC and DC Conduit Boxes Installed - - - - - - - - - - -2–23

Figure 2-6 Fuse Blocks- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–24

Figure 2-7 DC250 Disconnect Box and TM500A Battery Status Meter - - - - - - - - - -2–25

Figure 2-8 Accessories for Remote Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - -2–26

Figure 2-9 Inverter Control Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Figure 2-10 Inverter Communications Adapter - - - - - - - - - - - - - - - - - - - - - - - - - - -2–27

Figure 2-11 Generator Start Module- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–28

Figure 2-12 Auxiliary Load Module- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–28

Figure 2-13 T240 Autotransformer- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–29

Figure 2-14 ISC-S Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–29

Figure 2-15 Xantrex C-Series Charge Controllers- - - - - - - - - - - - - - - - - - - - - - - - - -2–31

Figure 2-16 PV Ground Fault Protection (PVGFP)- - - - - - - - - - - - - - - - - - - - - - - - -2–31

Figure 2-17 Off-Grid Application – Renewable Energy System using a Single Inverter 2–33

Figure 2-18 Off-Grid Application – Renewable Energy System using Dual Inverters - -2–35

Figure 2-19 Off Grid Application - Generator-only System using a Single Inverter - - -2–37

Figure 2-20 Off Grid Application – Generator-only Syst em using Dual Inverters,

Series-stacked - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–39

Figure 2-21 On-Grid Application – Backup System using a Single Inverter - - - - - - - -2–41

Figure 2-22 On-Grid Application – Backup System using Dual Inverters,

Series-stacked - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–43

Figure 2-23 Time-of-Use Metering - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–45

Figure 2-24 AC Support Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–47

Figure 3-1 Certification Label Location- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–6

Figure 3-2 Serial Number Sticker and Knockout Locations and Sizes- - - - - - - - - - - - -3–7

976-0043-01-02 xix

Figures

Figure 3-3 Dimensional Drawing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Figure 3-4 Wall-Mounting Method using 2 x 4’s - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Figure 3-5 Wall Mounting using Plywood - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Figure 3-6 Chassis Ground Lug Location on Inverter DC End - - - - - - - - - - - - - - - - 3–15

Figure 3-7 DC Grounding of a Single Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - 3–16

Figure 3-8 DC Grounding of Dual Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–17

Figure 3-9 BTS (RJ11) Port Location and Installation- - - - - - - - - - - - - - - - - - - - - - 3–19

Figure 3-10 DC Terminal Connections on the Inverter- - - - - - - - - - - - - - - - - - - - - - 3–20

Figure 3-11 Battery Cable Connection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

Figure 3-12 Battery Terminal Covers and Associated Hardware - - - - - - - - - - - - - - - 3–21

Figure 3-13 DC Connections to a Single Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

Figure 3-14 DC Connections to Dual Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–25

Figure 3-15 AC Wiring Access Cover Plate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–28

Figure 3-16 AC Input/Output Wiring Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - 3–29

Figure 3-17 Connecting the GSM Communications Cable to the Sine Wave Plus- - - - 3–31

Figure 3-18 AC Input and Output Wiring to a Single Inverter

with an Auto-Start AC Generator- - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–32

Figure 3-19 AC Output Wiring to the Inverter AC Panel - - - - - - - - - - - - - - - - - - - - 3–34

Figure 3-20 Generator Input Wiring to a Single Inverter - - - - - - - - - - - - - - - - - - - - - 3–37

Figure 3-21 Utility Wiring to the Inverter Input- - - - - - - - - - - - - - - - - - - - - - - - - - - 3–39

Figure 3-22 Series-stacked Inve rters with ISC-S Cable- - - - - - - - - - - - - - - - - - - - - - 3–40

Figure 3-23 Remote Monitor Port Locations- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–41

Figure 3-24 Connecting the ALM Communications Cable to the Si ne Wave Plus- - - - 3–42

Figure 3-25 Connecting the EPO - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–43

Figure 4-1 Power Up Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Figure 5-1 ICM Display Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Figure 5-2 ICM Display and Contrast Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Figure 5-3 ICM ON/OFF Push-buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Figure 5-4 ICM Menu Heading Push-buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Figure 5-5 ICM Menu Item Push-uttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Figure 5-6 ICM Set Point Push-buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Figure 5-7 ICM Reset Defaults button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Figure 5-8 Menu Structure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7

Figure 5-9 User Menu Map - Part 1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Figure 5-10 User Menu Map - Part 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Figure 5-11 Basic Setup Menu Map Part 1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Figure 5-12 Basic Setup Menu Map Part 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–11

xx 976-0043-01-02

Figures

Figure 5-13 Advanced Setup Menu Map Part 1 - - - - - - - - - - - - - - - - - - - - - - - - - - -5–12

Figure 5-14 Advanced Setup Menu Map Part 2 - - - - - - - - - - - - - - - - - - - - - - - - - - -5–13

Figure 5-15 Complete User Menu Map- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–14

Figure 5-16 Complete Basic Setup Menu Map- - - - - - - - - - - - - - - - - - - - - - - - - - - -5–15

Figure 5-17 Complete Advanced Setup Menu Map- - - - - - - - - - - - - - - - - - - - - - - - -5–16

Figure 6-1 Accessing the Basic Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–10

Figure 6-2 Multi-Stage Battery Charging Process - - - - - - - - - - - - - - - - - - - - - - - - -6–16

Figure 7-1 Accessing the Advanced Setup Menu - Method 1 - - - - - - - - - - - - - - - - -7–11

Figure 7-2 Accessing the Advanced Setup Menu - Method 2 - - - - - - - - - - - - - - - - -7–12

Figure 7-3 Relay 11 Wiring Example to Dual Inverters with Cooldown selecte d - - - - 7–22

Figure 7-4 Generator Control Mode (GS and RN1)- - - - - - - - - - - - - - - - - - - - - - - - 7–29

Figure 7-5 Generator Control Mode (RN2) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–30

Figure 7-6 RY7’s COM and N.O. Contacts Close (energize) to Run Generator - - - - -7–31

Figure 7-7 Wiring examples of Honda™ and Onan™ Generators - - - - - - - - - - - - - -7–33

Figure 7-8 RY7 and RY8 Timing Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–34

Figure 7-9 RY7/RY8 Sequence of Events for RN1 or RN2 Selection- - - - - - - - - - - -7–35

Figure 7-10 RY7/RY8 Sequence of Events for GS Selection - - - - - - - - - - - - - - - - - - 7–36

Figure 8-1 LED Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–3

Figure 8-2 Inverter Operation Status LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–4

Figure 8-3 AC Status LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–5

Figure 8-4 Charge Status LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–6

Figure 8-5 Error and Status LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–7

Figure 8-6 Inverter ON/OFF Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–14

Figure 8-7 Generator ON/OFF Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–14

Figure 8-8 Resetting Factory Default Settings - - - - - - - - - - - - - - - - - - - - - - - - - - -8–21

Figure A-1 Sine Wave Plus Simple Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - A–6

Figure A-2 Sine Wave Plus Inverter Output Waveform - - - - - - - - - - - - - - - - - - - - - A–7

Figure A-3 Power Versus Efficiency Curves for All Models - - - - - - - - - - - - - - - - - - A–9

Figure A-4 Sine Wave Plus Efficiency Curve for the SW Plus 2524- - - - - - - - - - - - - A–9

Figure A-5 Sine Wave Plus Efficiency Curve for the SW Plus 2548 - - - - - - - - - - - - A–10

Figure A-6 Sine Wave Plus Efficiency Curve for the SW Plus 4024 - - - - - - - - - - - - A–10

Figure A-7 Sine Wave Plus Efficiency Curve for the SW Plus 4048 - - - - - - - - - - - - A–11

Figure A-8 Sine Wave Plus Efficiency Curve for the SW Plus 5548 - - - - - - - - - - - - A–11

Figure A-9 Time versus Current for the Sine Wave Plus 2524- - - - - - - - - - - - - - - - A–13

Figure A-10 Time versus Current for the Sine Wave Plus 2548- - - - - - - - - - - - - - - - A–14

Figure A-11 Time versus Current for the Sine Wave Plus 4024- - - - - - - - - - - - - - - - A–14

976-0043-01-02 xxi

Figures

Figure A-12 Time versus Current for the Sine Wave Plus 4048 - - - - - - - - - - - - - - - - A–15

Figure A-13 Time versus Current for the Sine Wave Plus 5548 - - - - - - - - - - - - - - - - A–15

Figure C-1 6-volt Battery Wiring - “Series” Configuration - - - - - - - - - - - - - - - - - - - C–9

Figure C-2 12-volt Ba tter y Wirin g - “Series ” Con fi gu rat io n- - - - - - - - - - - - - - - - - - C–10

Figure C-3 Battery W iring in Par al le l (Exam p l e Only ) - - - - - - - - - - - - - - - - - - - - - C–10

Figure C-4 Step 1 - Wiring Batteries in “Series” - - - - - - - - - - - - - - - - - - - - - - - - - C–11

Figure C-5 Step 2 - Two series strings wiring in “Parallel” - - - - - - - - - - - - - - - - - - C–11

Figure C-6 “Series-Parallel” Configuration Wired to the Inverter - - - - - - - - - - - - - - C–12

Figure C-7 Example of Battery Connections for Stacked Inverte rs (24 Vdc shown) - - C–12

Figure E-1 Overvoltage using a C-Series Charge Controller- - - - - - - - - - - - - - - - - - - E–2

Figure E-2 Diversion Load Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

Figure F-1 Conventional Home-type Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–2

Figure F-2 Multi-wire Branch Circuit Wiring and Current Flow - - - - - - - - - - - - - - - - F–3

Figure F-3 120 Vac Inverter Incorrectly Wired in a Multi-wire Branch Circuit - - - - - - F–3

Figure F-4 Multi-wire Branch Circuit Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–4

Figure F-5 Using a Step-down Autotr ansformer in Multi-wire Branch Circuit Wiring - F–6

Figure G-1 Emergency Power OFF Disconnect Switch - - - - - - - - - - - - - - - - - - - - - -G–2

Figure G-2 Modifying a 6-conductor Cable to connect to the EPO Port - - - - - - - - - - -G–4

xxii 976-0043-01-02

Tables

Table 2-1 Recommended Minimum Safety Ground Wire and DC Disconnect

Sizes per NEC 2–8

Table 2-2 Recommendced Battery Cable Size Versus Length - - - - - - - - - - - - - - - 2–14

Table 2-3 Battery Cable to Maximum Breaker/Fuse Size - - - - - - - - - - - - - - - - - - 2–15

Table 3-1 AC Disconnect and Wire Sizing- - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–27

Table 6-1 Basic Setup Menu Default Settings for the Sine Wave Plus

2524 and 2548 Models 6–2

Table 6-2 Basic Setup Menu Default Settings for the Sine Wave Plus

4024 and 4048 Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6–4

Table 6-3 Basic Setup Menu Default Settings for the Sine Wave Plus

5548 Model 6–6

Table 6-4 Battery Voltages For Setting Charging Par amet ers- - - - - - - - - - - - - - - - 6–21

Table 6-5 Battery Charging Current and Timer Default Settings - - - - - - - - - - - - - 6–21

Table 6-6 Calculating the Maximum Charge Amps for a 24-volt,

700 amp-hour Battery 6–22

Table 6-7 Calculating the Maximum Charge Amps for a 48-volt,

350 amp-hour Battery 6–23

Table 6-8 Calculating the Bulk Done Amps for a 24-volt, 700 amp-hour Battery - - 6–24

Table 6-9 Calculating the Bulk Done Amps for a 48-volt, 350 amp-hour Battery - - 6–24

Table 6-10 Inverter Temperature Compensation Calc ulation using the BTS- - - - - - - 6–26

Table 7-1 Advanced Setup Default Settings f or the Sine Wave Plus

2524 and 2548 Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–2

Table 7-2 Advanced Setup Default Settings f or the Sine Wave Plus

4024 and 4048 Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–5

Table 7-3 Advanced Setup Default Settings f or the Sine Wave Plus Plus 5548 Models 7–7

Table 7-4 Calculating the Float Done Amps for a 24-volt, 700 amp-hour Battery - - 7–16

Table 7-5 Calculating the Float Done Amps for a 48-volt, 350 amp-hour Battery - - 7–16

Table 8-1 LED Summary Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–9

Table 8-2 User Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–11

Table A-1 Derating from continuous power (VA) at elevated ambient te mperatures- A–12

Table B-1 User Menu Default and User Settings - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Table B-2 Basic Setup Default and User Settings for the Sine Wave Plus

2524 and 2548 Models - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

976-0043-01-02 xxiii

Tabl es

Table B-3 Basic Setup Default and User Settings for the Sine Wave Plus

4024 and 4048 Models- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

Table B-4 Basic Setup Default and User Settings for the Sine Wave Plus

5548 Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–8

Table B-5 Advanced Setup Default and User Settings for the Sine Wave Plus

2524 and 2548 Models- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–10

Table B-6 Advanced Setup Default and User Settings for the Sine Wave Plus

4024 and 4048 Models- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–12

Table B-7 Advanced Setup Default and User Settings for the Sine Wave Plus

5548 Model - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–14

Table C-1 Determining Average Daily Load in Amp-hours - - - - - - - - - - - - - - - - - C–7

Table C-2 Determining Battery Bank Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

Table C-3 Typical Appliance Wattage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

Table C-4 Variances in Charging Voltage based on Battery Temperature - - - - - - - C–14

Table C-5 Temperature Compensation Calculation - - - - - - - - - - - - - - - - - - - - - - C–14

Table C-6 Battery State-of-Charge - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–17

xxiv 976-0043-01-02

1

Introduction

Chapter 1, “Introduction” lists and describes the basic features

and parts of the Sine Wave Plus Inverter/Charger.

Introduction

Basic Features

Congratulation s on your purchase of a Sine W ave Plus Inverter/Char ger

from Xantrex Technology, Inc. The Sine Wave Plus is one of the finest

inverter/chargers on the market today, incorporating state-of-the-art

technology, high reliability, and convenient control features.

Specific features include:

• FCC Part B comp lian t

• 2.5 kW, 4.0 kW, or 5.5 kW continuous output of sine wave power f or

120 Vac/60 Hz applications (depending on model)

• expandable up to 11 kW for 120/240 Vac/60 Hz applications by

combining dual inverters using the Inverter Sta cking Cont rol – Series

(ISC-S) cabl e

• 24-volt or 48-volt models

• multi-stage batte ry charging

• battery temperatu re sen sor which provides automatic temperat ure

compens ation fo r batter y charg i ng

• push-button control mod ule with a liquid crystal display (LCD) for

easy programming a nd troubleshooting

• light emitting diode (LED) display of system operational stat us

• automatic on/off control of electric-start generators

(requires additional equipment)

• remote monitoring (requir es additional equipment)

• auxiliary load contr ol (requires additional equipm ent )

• high surge/ current capacity (depending on the unit, it will surge up to

5.9 times the continuous current rating for a minimum of 2 seconds).

See Appendix A, “Electrical Specific ations”.

• energy management fea tures control utility and/ or generator usage

• energy eff icient to 95% peak and less than 20 watts of idle current;

less than 2 watts in Search Mode

The default settings of the Sine Wave Plus Inverter/Charge r allow the

system to perform in many installations without the need for additional

setup. However, if additional setup pa rameters are required, the pushbutton featur es on the I nvert er Control Mo dule (ICM) disp la y on the fr ont

panel of the unit enables the syst em to be easil y reprogrammed to meet

specific custom er configurations.

1–2 976-0043-01-02

Basic Features

Front Panel

Figure 1-1

The Sine Wave Plus

The front of the Sine Wave Plus has the following features:

• the Inverter Control Module (ICM) Display

• the AC Access Cover

Inverter Control Module Display

AC Access Cover

Figure 1-2

976-0043-01-02 1–3

The Front Side of the Sine Wave Plus

Introduction

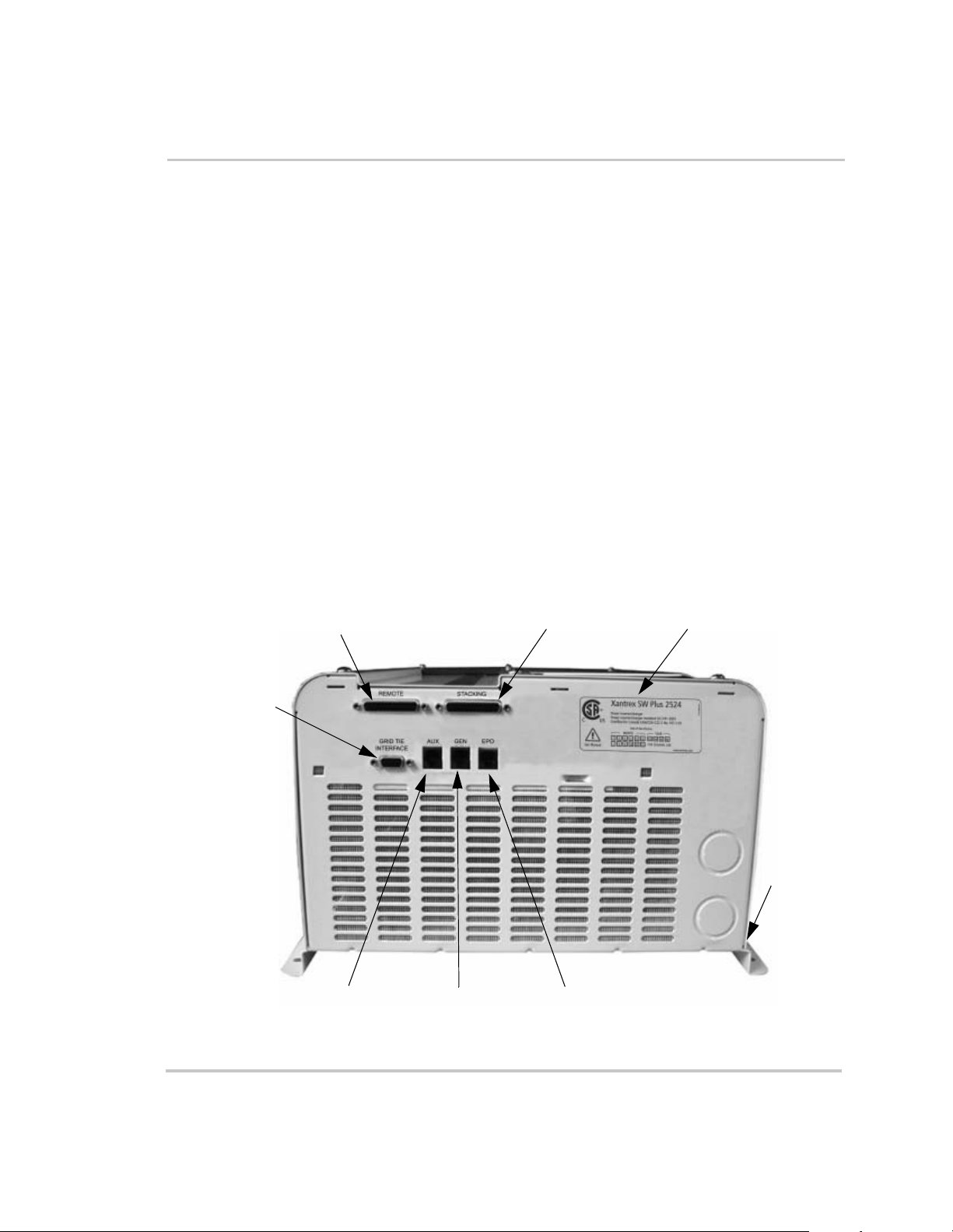

AC Side

The AC side of the Sine Wave Plus has the following features:

• The Remote Monitor Port for connecti ng a remote Inverter Control

Module (ICM) or the Inverter C ommunications Adapter (ICA)

• The Stacking Port for connecting two Sine W ave Plus inverters

• The AUX Port for connecting the Auxiliary Load Module (ALM)

• The GEN Port for connecting the Generator Start Module (GSM)

• The EPO Port for connecting an Emerge ncy Power Off (EPO) switch

• Certification Label

• The Grid Tie Interfa ce Port . Th e G rid Tie featur e is curren t ly not

available with the Sine Wave Plus models. However, the port has

been included in the even t tha t the feat ure can b e enab l ed wit h an

upgrade at a future date. Continue to check our website

www .xantrex.com for more inform at ion and future enhancements on

the Sine Wave Plus Inverter/Charger.

• The Serial Number Stick er is on the rail as shows in Figure 1-3.

Grid Tie

Interface

Port

(not used)

Figure 1-3

Remote Monitor Port

AUX Port

GEN Port EPO Port

The AC side of the Sine Wave Plus

Stacking Port

Certification Label

Serial

Number

Sticker

1–4 976-0043-01-02

Emergency Power Off (EPO) Option

The Sine Wave Plus offers an Emergency Power Off (EPO) option

through the use of the EPO Port. The EPO feature is designed to shut

down the inverter from a remote location (or switch).

Since the type of the switch will be dependent on the installation, EPO

switches are not provided with the Sine Wave Plus. However, many

commonly availabl e emergency shut off switches will work with the Sine

Wave Plus EPO. Consult your local system designer or qualified

technician for assistance.

The EPO is connected to the Sine Wave Plus with a telephone cord

(RJ11type connector) to the dedicated EPO port on the AC (left ) side of

the inverter.

See Appendix G, “Emergency Power Off Switches” for additional

information about this f eature and how to prepare a cable for it.

Certification Label

The Sine Wave Plus has been tested to nationally r ecognized safety

standards and has been found to be free from reasonably foreseeable risk

of fire, electric shock, and related hazards when installe d and operate d in

accordance with all the instructions provided in this manual and in

accordance with all applicable local and national codes.

Basic Features

Please refer to the Certification Label affixed to the AC side of the

inverter for specific agency information.

See Figure 1-3, “The AC side of the Sine Wave Plus” on page 1–4 for the

location of this information.

Model Number

Certification

Statement

Date of

Manufacture

Figure 1-4

976-0043-01-02 1–5

Certification Label

Introduction

DC Side

The DC side of the Sine Wave Plus has the following features:

• the positive (+) battery terminal

• the negative (–) battery terminal

• the battery temperature sensor port

• the chassis ground lug

Chassis

Ground

Lug

Figure 1-5

Positive (+)

Battery Terminal

The DC side of the Sine Wave Plus

Negati ve (–)

Battery Termin al

Battery

Temperature

Sensor

1–6 976-0043-01-02

Battery Temperature Sensor (BTS)

A BTS is provide d with each Sine Wave Plus Inverter/Charger. This

sensor can easily be installed in the system to ensure proper charging of

the batteries based on tempe ratur e. Installing a BTS extends battery life

by preventing overchar ging in warm temperatures and undercharging in

cold temperatures .

If more tha n one BTS is being used, install them adjacent to each other so

that they all detect a common temperature.

Basic Features

Figure 1-6

Battery Temperature Sensor (BTS)

See Table C-4, “Variances in Charging Voltage based on Battery

T emperature” on page C–14 and Table C-5, “Temperature Compensation

Calculation” on page C–14 for additional information.

976-0043-01-02 1–7

Introduction

Top

The top of the unit has the following featur e s:

• Circuit Breaker - This circuit breaker protects the unit’s internal

wiring while the unit is inverte r or charging. It is not used for the

pass-through curr ent. This is not a branch-circuit rated bre aker.

Separate output breake rs are still required. If the button is protruding

from the chassis as shown in Figure 1-7, it means the circuit breaker

has tripped open. Press the break er back in to reset it.

• Warnings Label

• Ratings Label

Top View of Sine Wave Plus Inverter/charger

Circuit Breaker

AC End

Warnings Label

Circuit Breaker Open Circuit Breaker Reset

Ratings Label

DC End

Figure 1-7

1–8 976-0043-01-02

External Output Circuit Breaker

2

System Configuration

Chapter 2, “System Configuration” contains informat ion to

help you plan for a Sine Wave Plus installation in an off-grid,

on-grid, or backup power application.

System Configuration

Pre-Configuration Planning

Importance Pre-configura tion planning is essential to ensure opti mal performance for

your system. This section outlines the components of a system and how

you can plan for them.

Types of Applications

The Sine Wave Plus Inverter/Charger can be configured for the following

applications:

• OFF-GRID (stand-alone) app lications where no utility power is

available.

See Figure 2-17 through Figure 2-20 for illustrations of off-grid

applications.

• ON-GRID applications where it can ope rate the AC loads when the

Utility System (grid) fails, ke ep the batter ies charge d, and/ or function

as an energy management cont roller .

See Figure 2-21 and Figure 2-22 for illustrations of on-grid

applications.

Important: Be sure to consult with your local utility company and/or permit

office to ensure that the desired configuration will be code-compliant. Be sure to

obtain the proper licenses and permits as required by law.

Important: Installatio ns of this equipment s hould only be performed by skille d

personnel such as qualified electricians and Certi f ied Renewable Ener gy (RE)

System Installers. For a list of Xantrex Certified RE dealers, ple ase visit our

website at www.XantrexREdealers.com.

System Considerations

You need to consider the following issues as you design your system.

System output How much power will be required and how it will be produced:

❐ Single or dual inverters (based on output voltage and output

watts required)

❐ Output watts required (i.e., continuous capacity and surge capacity)

❐ Output voltage (120 Vac or 240 Vac)

See “System Output Requirements” on page 2–4 fo r more information.

System input What are the sources of power for your system:

❐ Utility power

❐ AC generator (See “Generator Considerations” on page 2–19)

2–2 976-0043-01-02

Pre-Configuration Planning

❐ Renewable energy systems (e.g., PV arrays, wind turbines etc.)

See “System Input Requirements” on page 2–4 for more information.

Location What are the safe, physical environmental requirements for your

installation: