Page 1

Link 1000

Owner’s Guide

Page 2

About Xantrex

Xantrex Technology develops, manufactures, and markets advanced power

electronic products. The company’s products convert raw electrical power from

any source into high-quality power required by electronic and electrical

equipment.

Trademark

Xantrex is a registered trademark of Xantrex International

Other trademarks, registered trademarks, and product names are the property of

their respective owners and are used herein for identification purposes only.

Notice of Copyright

Link 1000 Owner’s Guide © July 2003 Xantrex International. All righ ts res erv ed.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX

TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR

SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN

ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE,

WHETHER DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH

MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY

SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

July 2003, Revision A

Part Number

975-0056-01-01

Contact Information

Web: www.xantrex.com

Email: CustomerSupport@xantrex.com

Phone: 1-800-670-0707 (toll free in North America) 1-604-422-2777 (direct)

Fax: 1-604-420-2145

Page 3

Contents

Contents

1 Introducing Link 1000

Introducing the Link 1000- - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Inverter/Charger Control Functions - - - - - - - - - - - - - - - - - - - - 2

Monitoring F unctions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Reading the Link 1000 Control Panel - - - - - - - - - - - - - - - - - - - - 4

Where to go Fr om Here - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

2 Installing the Link 1000

Planning the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Supplied Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Materials You Need to Supply - - - - - - - - - - - - - - - - - - - - - - 8

Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Installatio n Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Performance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Color-Coded Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Twisted Pair Wires - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Separate Engine Starting Battery - - - - - - - - - - - - - - - - - - - 1 0

Installing the Link 1000 - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Overview of Installation Steps - - - - - - - - - - - - - - - - - - - - - - 11

Mounting the Link 1000 Control Panel- - - - - - - - - - - - - - - - - 13

Mounting and Cabling the Shunt - - - - - - - - - - - - - - - - - - - - - 14

Wiring the Terminal Block - - - - - - - - - - - - - - - - - - - - - - - - - 15

Connecting Terminal Block Wires to Shunt and Battery - - - - - 16

Installing Fuses- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Connecting the Phone Cable - - - - - - - - - - - - - - - - - - - - - - - - 17

Testing the Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

iii

Page 4

Contents

Maintenance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Disconnecting the Inverter/Charger - - - - - - - - - - - - - - - - - - - 18

3 Setting up the Link 1000

About Link 1000 Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Probable Changes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Possible Changes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Other Settin gs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

How to Enter Setup Mode and Change a Value - - - - - - - - - 20

Locking Your Setup Values - - - - - - - - - - - - - - - - - - - - - - - - 21

Resetting Values- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Battery Capacity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Estimated Capacities for 12 Volt Flooded Batteries - - - - - - - 22

Estimated C apacities for G el Cell Batteri es - - - - - - - - - - - - 22

Estimated Capacities for Multiple Batteries - - - - - - - - - - - - 22

Changing th e Battery Capacity Setting - - - - - - - - - - - - - - - 23

Changing th e Battery Type S etting - - - - - - - - - - - - - - - - - - 23

Changing the Ambient Temperature Setting - - - - - - - - - - - 24

Charged Par ameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Changing th e Charged Volta ge Setting - - - - - - - - - - - - - - - 25

Changing the Charged Current Percentage Setting - - - - - - - 25

Changing th e Time Remaining Setting - - - - - - - - - - - - - - - 26

Changing the Power Share Setting - - - - - - - - - - - - - - - - - - 2 7

Changing the Idle Mode Settin g - - - - - - - - - - - - - - - - - - - - 28

Advanced F unction Values - - - - - - - - - - - - - - - - - - - - - - - - - 29

How to Enter Setup Mode and Change a Value: Reminder - - 29

F01 Auto Display Scanning - - - - - - - - - - - - - - - - - - - - - - 29

F02 Display Sleep - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

F03 Set or Display Ambient Battery Temperatures - - - - - - - 30

F04 Toggle Display Between Ah and kWhr - - - - - - - - - - - - 30

F05 Turn on Alternative Energy Mode - - - - - - - - - - - - - - - 31

F06 Manually Set CEF - - - - - - - - - - - - - - - - - - - - - - - - - - 31

F07 Set Temperature Coefficient - - - - - - - - - - - - - - - - - - - 31

F08 Set Peukert’s Exponent - - - - - - - - - - - - - - - - - - - - - - 32

F09 Set Low Battery Discharge Floor - - - - - - - - - - - - - - - - 32

iv

Page 5

F10 Select B attery Type - - - - - - - - - - - - - - - - - - - - - - - - - 33

F11 Turn on Second Battery Voltage Sense - - - - - - - - - - - - 33

F12 Number of Overload Conditions Experienced - - - - - - - 33

F13 Number of Inverter Low Battery Shutdowns - - - - - - - - 33

F14 Test Control Panel Display - - - - - - - - - - - - - - - - - - - - 34

F15 Display Software Revis ion Number - - - - - - - - - - - - - - 34

F16 Turn on Active Temperature Compensation - - - - - - - - 34

4 Using the Link 1000

Monitoring F unctions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Choosing a Display Unit: Volts, Amps, Ah, or Time- - - - - - - - 36

Reading the Battery State-of-Charge - - - - - - - - - - - - - - - - - - 37

Scaling the BATTERY STATUS Light Bar - - - - - - - - - - - - 37

Inverter Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Turning on the Invert Func tion - - - - - - - - - - - - - - - - - - - - - - 38

Changing the Idle Mode Settin g - - - - - - - - - - - - - - - - - - - - - 38

Charging Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Summary of C HARGER STATUS LEDs - - - - - - - - - - - - - - 39

Charging th e Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4 0

Equalizing the Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Equalizing G el Cell Batteries - - - - - - - - - - - - - - - - - - - - - 42

Activating Power Share - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Battery Capacity Testing - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Synchronizing the Link 1000 to the Battery- - - - - - - - - - - - - - 44

Over-charge Ah (Accumulation of Positive Ah) - - - - - - - - - 45

Battery History - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Interpreting Battery History - - - - - - - - - - - - - - - - - - - - - - 46

Reading Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 48

Contents

v

Page 6

Contents

A Specifications

Control Pan el: Electrical Specifications- - - - - - - - - - - - - - - - - - 52

Control Panel: Physical Specifications - - - - - - - - - - - - - - - - - - 52

Default Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

B

Product and System Information

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 56

Disclaimer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Product - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Exclusions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Warning: Lim itations On Use - - - - - - - - - - - - - - - - - - - - - - - 59

Return Mater ial Authorizatio n Policy - - - - - - - - - - - - - - - - - - - 59

Return Material Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - 59

Product Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Record of System Settings - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

vi

Page 7

Figures

Link 1000 Control Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

System Overview (Wiring)- - - - - - - - - - - - - - - - - - - - - - - - - 12

Display Panel and Mounting Plate - - - - - - - - - - - - - - - - - - - - 13

Link 1000 Mounting Plate - - - - - - - - - - - - - - - - - - - - - - - - - -14

BATTERY STATUS Light Bar - - - - - - - - - - - - - - - - - - - - - 37

vii

Page 8

viii

Page 9

Introducing Link 1000

Chapter 1 describes:

• The Link 1000’s control and monitoring

functions

• The features on its control panel

1

Page 10

Introducing the Link 1000

Introducing the Link 1000

The Link 1000 gives you complete remote control of the

Freedom 458, Freedom, and Freedom Marine Inverter/

Chargers. It also lets you monitor the performance of your

battery power system.

Inverter/Charger Control Functions

From the Link 1000 control panel, you can:

• Turn the invert function on and off

• Start or end an equalization cycle

• Activate the Power Share feature. This automatically

lowers the charger’s output to prevent AC breakers from

tripping if too many loads come on at once.

• Place the inverter/charger in Idle (standby) mode so it

only begins inverting at a level that you choose. This

power-saving feature minimizes t he draw on you r batter y

by turning the inverter off until it’s really needed.

• Make custom settings for numerous functions including

battery type, battery capacity, and Power Share mode.

These let you set up the Link 1000 so it suits the

characteristics of your system.

• Lock your setup values so no one can inadvertently

change them

Monitoring Functions

The Link 1000 control panel lets you see:

• The battery’s state-of-charge at a glance

• The voltage of the battery being monitored and the

voltage of a second (starting) battery

• The flow of current into the battery (charge rate)

• The flow of current out of the battery (consumption rate)

• The number of Ah (Amp-hours) that have been

consumed

2

Page 11

Introducing the Link 1000

• The time remaining in your battery before it is

completely discharged

• Which charging stage the batteries are in (Bulk,

Acceptance, Float, or Equalization)

• Battery history including:

• Present charge efficiency

• The number of deep cycles the battery has had

• The deepest level of discharge

• The average level of discharge

3

Page 12

Reading the Link 1000 Control Panel

Reading the Link 1000 Control Panel

The Link 1000 control panel lets you monitor the battery

system and control the inverter/charger. Its features are

described below. Further details are provided as you need

them throughout the guide.

1

2

3

4

Figure 1 Link 1000 Control Panel

1

BATTERY STATUS light bar

7

When the battery system is operating, the four

LEDs in this light bar act like a “fuel gauge”. The

LEDs light in different sequences and colors to

show the battery’s present state-of-charge. The

statuses are described on page 37.

8

5

9

6

4

Page 13

Reading the Link 1000 Control Panel

2, 3 Numeric display and display units.

You can choose from four display un its depending on the

type of information you want to see:

• Volts

•Amps

• Ah (Amp-hours)

• Time Remaining

The procedure for changing display units is given on

page 36 along with an explanation of each display unit.

Note

: The numeric display also shows Error Codes. If

an error occurs, the display alternates between the

monitoring function you have selected and the Error

Code. For details about Error Codes, see page 48.

4

SEL and SET buttons

SET lets you access Setup mode and advanced

functions. Once you are in Setup mode, you press

SEL to choose a function or a setting . Procedu res for

changing values are given in Chapter 3.

5 CHARGE/PWR SHARE button and LED

Lets you start a charge cycle (see page 40) or change the

Power Share mode setting (see page 27).

6

7

INVERT/IDLE MODE button and LED

Lets you activate the invert function (see page 38) or

change the Idle mode setting (see page 28).

RESET, DATA, LOCK, FUNC LEDs

•

RESET: When it is on, this LED indicates that you are

resetting Ah (Amp-hours) to zero or that you are

returning all settings to the factory defaults. (See

page 21.)

•

DATA: Indicates that you are looking at historical

information about your batteries. (See “Interpreting

Battery History” on page 46.)

•

LOCK: Indicates you are choosing the setting that

prevents people from inadvertently changing your

setup values. (See page 21.)

•

FUNC: Indicates you are accessing the advanced

functions. (See “Advanced Function Values” on

page 29.)

5

Page 14

Reading the Link 1000 Control Panel

8 AC IN LED

Indicates that AC power is present.

9 CHARGER STATUS LEDs:

•

CHG (Red): When this LED is on solid, the battery is

in Bulk charge mode. When this LED is flashing, the

battery is equalizing.

•

ACCEPT (orange): The battery is in Acceptance

mode.

•

FLOAT (green): The battery is in Float mode.

Where to go From Here

• To install the Link 1000, see page 7.

• To set up the Link 1000, see page 19.

• To use the Link 1000, see page 35.

• To call for technical support, see page 56.

6

Page 15

Installing the Link 1000

Chapter 2 gives:

• An overview of the installation process

• A list of installation tools and equipment

• Installation procedures

We recommend that you read the entire

chapter so you can plan the installation and

obtain all the materials you need before

starting the installation.

7

Page 16

Planning the Installation

Planning the Installation

Supplied Parts

❐ Link 1000 control panel and 4 mounting screws

❐ 500 amp precision shunt

❐ 25 foot RJ11 phone cable

❐ Owner’s guide

Materials You Need to Supply

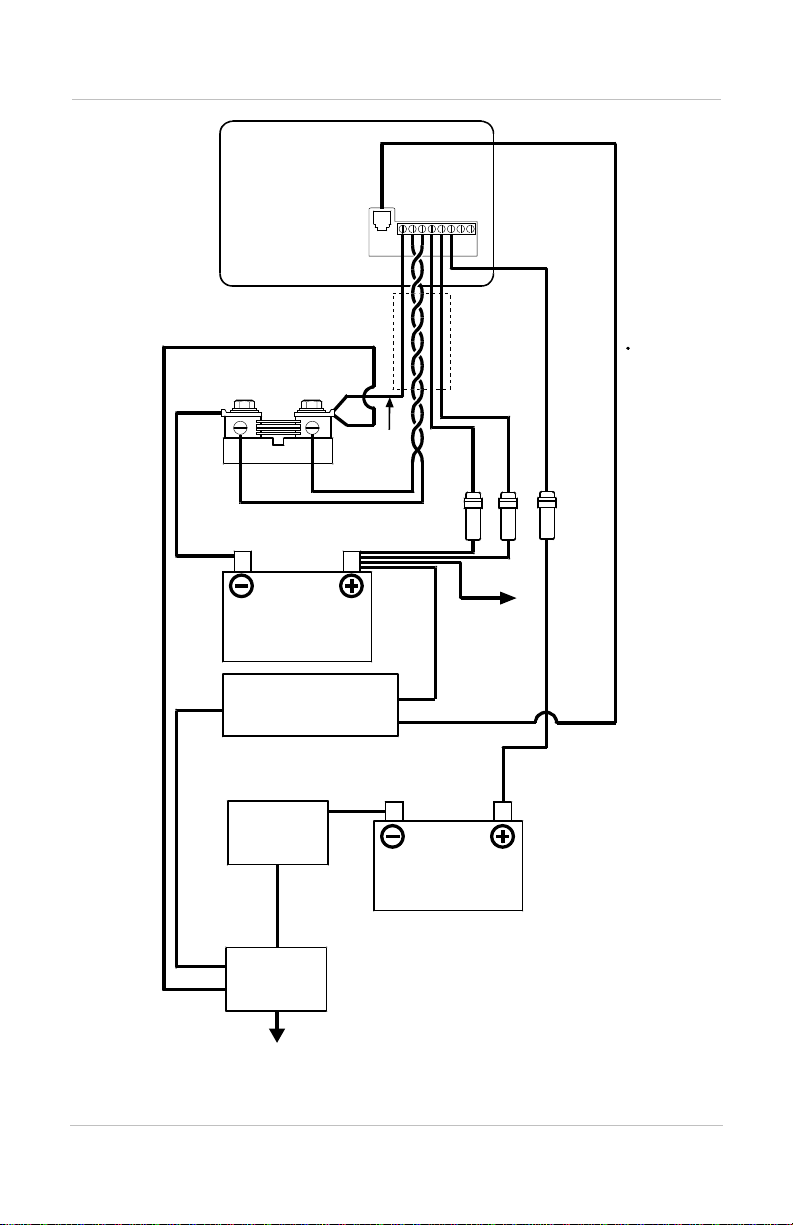

Refer to Figure 2 on page 12.

❐ Wire harness to connect the Link 1000 control panel to

the shunt and to the positive battery terminal. You can

use 18AWG, twisted pair, for this wiring. You can also

buy the harness from the dealer you bought the Link

1000 from or from West Marine.

Contact West Marine at:

• 1-800-BOATING (Canada and US)

• Fax: 1-831-761-4421 (Canada and US)

When ordering the harness, quote these part numbers:

• 84-2014-00: 25 foot (7.62m) 8-conductor twisted pair

wire

• 84-2015-00: 50 foot (15. 24m) 8-co nductor twiste d pair

wire

❐ Appropriately sized copper cable and connectors to

connect the shunt to the battery and the negative bus for

DC loads

Consult a local cable supplier about cable size and

connector type. You may find it convenient to have the

cable supplier attach the connectors.

❐ 2, 2 amp fuses and fuse holders. (Three fuses and fuse

holders if you are monitoring a second battery.)

❐ 2 screws to mount the shunt

8

Page 17

Tools

Planning the Installation

❐ 2 strain reliefs (cable clamps) for the wires and phone

cable coming out the back of the control panel

❐ Anti-corrosive spray

❐ High current shunt. If your starter current exceeds 500

amps for more than ten seconds, you will need a heavy

duty (1000 amp) shunt instead of the 500 amp shunt that

is supplied with the Link 1000. (You can also use a

separate engine starting battery whose negative is

connected directly to the engine.) The heavy duty shunt

part number is 84-2-13-00.

❐ Wire cutt er and stripper

❐ Small slot head screwdriver (for the screws on the

terminal block)

❐ Phillips screwdriver (for the control panel mounting

screws)

❐ Needle-nose pliers

❐ 9/16 in. wrench to secure cables to the shunt

Installation Considerations

Safety

• If you are using flooded lead-acid batteries, install them

in a separate battery compartment.

• Wiring should be in accordance with NEC, ABYC, or

other applicable national or regional codes.

Performance

• Do not connect anything other than the shunt to the

negative battery terminal. Connect all other loads and

sources to the load side of the shunt. (See Figure 2.)

9

Page 18

Planning the Installation

• The shunt sense leads must be 18AWG twisted pair

wires.

• Install fuses within seven inches (18cm) of the battery.

Color-Coded Wiring

To avoid confusion during installation, Xantrex recommends

that you buy wires that have the same color coding as shown

in Figure 2.

Twisted Pair Wires

If you wish, you can make you r own twist ed pairs by t wisting

together two wires with a twist every inch. If you make your

own twisted pair, wrap tape around the wire s ev ery twelve or

sixteen inches (30 to 40cm) to keep the wires together and to

make them easier to pull through holes and raceways.

Separate Engine Starting Battery

In order to monitor start batte ry volta ge, you need to connect

a sense lead from the Link 1000 terminal blo ck to the positi ve

battery terminal of the starting battery. This procedure also

requires a 2 amp fuse and fuse holder. See step 6 on page 16

for installat io n de ta ils, and see page 33 for i nf ormat ion about

turning this function on.

10

Page 19

Installing the Link 1000

Overview of Installation Steps

Complete the installation in this order. Refer to Figure 2.

1. Mount the control panel (page 13).

2. Mount the shunt, and cable it to the negative battery

terminal. Cable the load side of the shunt to the negative

bus for DC loads (page 14).

3. Connect wires to the Link 1000 terminal block (page 15).

4. Connect wires from th e terminal block to the shunt and to

the battery’s positive terminal (page 16).

5. Install the fuses (page 17).

6. Connect the phone cable to the control panel and the

inverter/charger (page 17).

Installing the Link 1000

11

Page 20

Installing the Link 1000

Rear of Link 1000

Control Panel

12345

678

Violet

Phone

Cable

System Negative

500A

Shunt

Battery

Side

Orange

Negative

Gnd.

Stud

Load

Side

Green

Battery

Inverter/Charger

Engine

Starter

Black

Cable

Jacket

Blue

Distribution

Start

Battery

Red

Pos.

2 Amp

Fuses

12

Neg.

Distribution

Figure 2 System Overview (Wiring)

Page 21

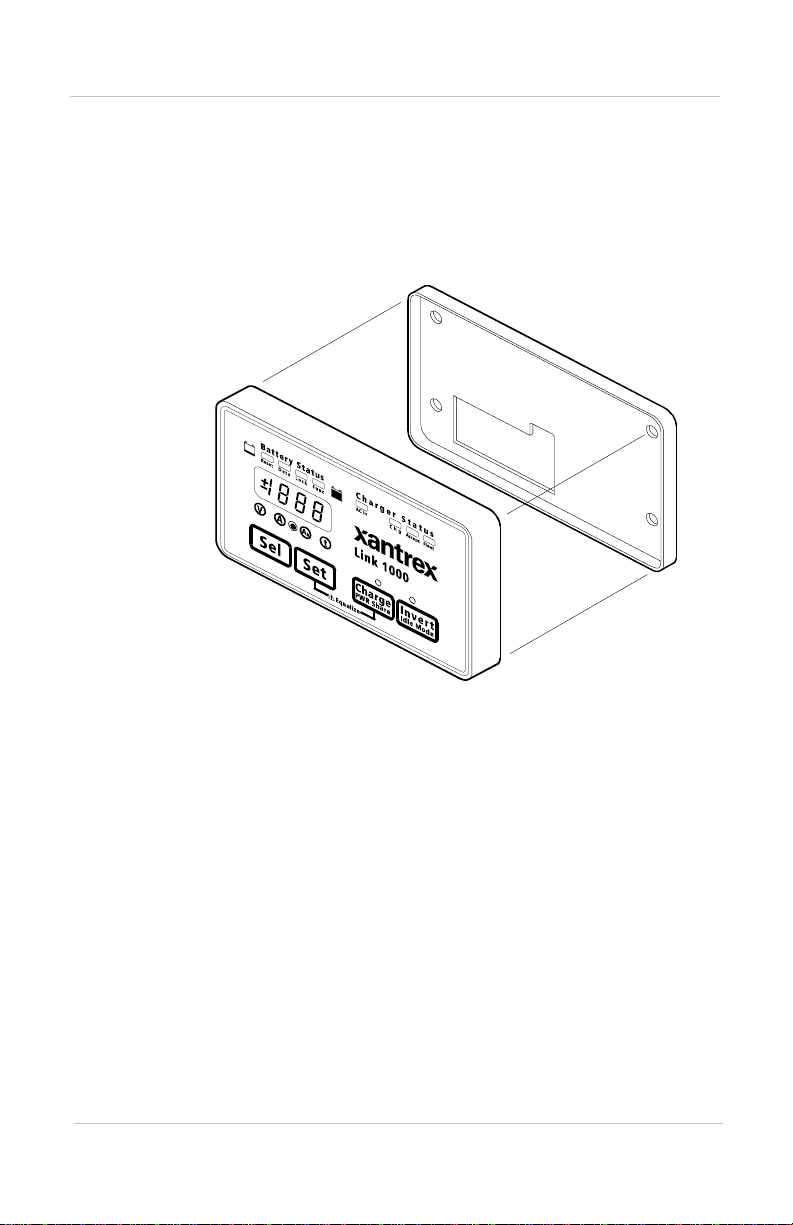

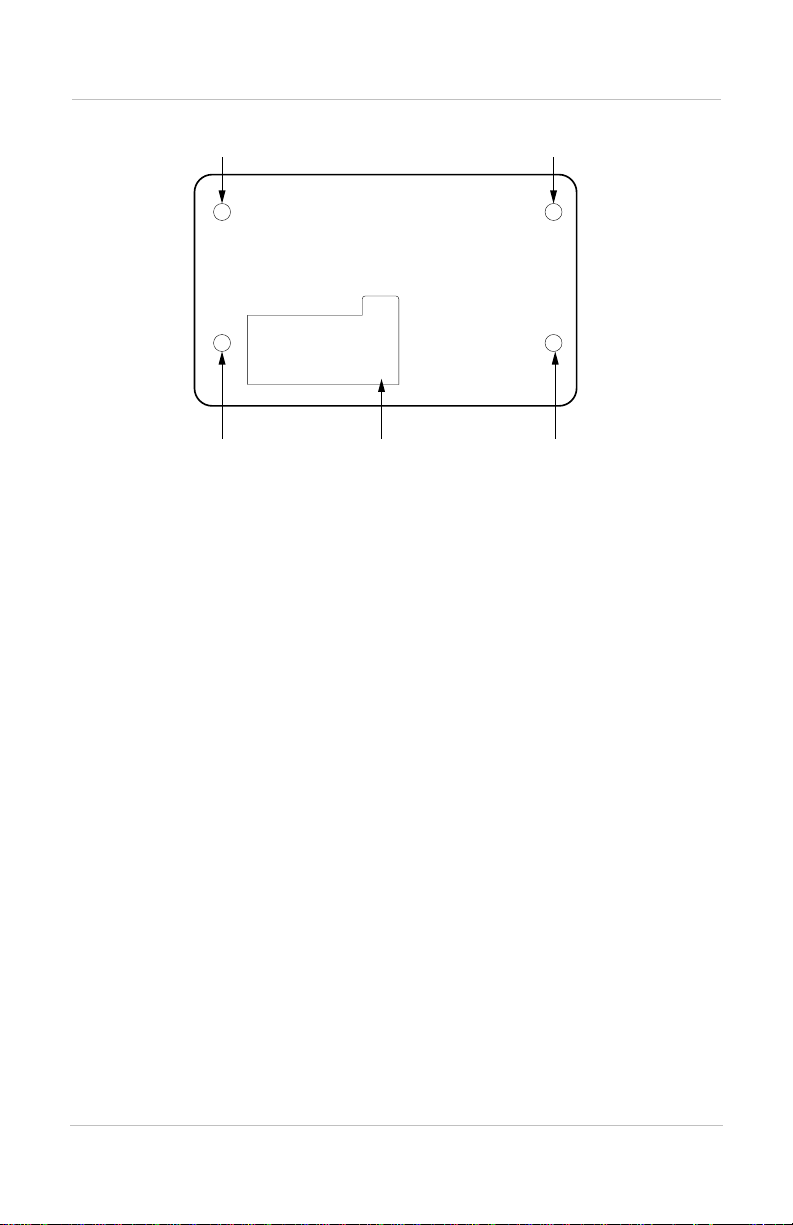

Mounting the Link 1000 Control Panel

The Link 1000 control panel c onsist s of a displ ay panel and a

mounting plate.

To mount the control panel:

1. Separate the display panel and the mounting plate.

Display Panel

Installing the Link 1000

Mounting Plate

Figure 3 Display Panel and Mounting Pl ate

2. If you are going to run the phone cord and wires through

the opening in the rear of the mounting plate, make a

cutout in the mounting surface using the mounting plate

as a template. (You can also run the phone cord and wires

down from the bottom of the mounting plate.)

3. Screw the mounting plate to the mounting surface as

shown in Figure 4.

13

Page 22

Installing the Link 1000

Countersunk

Screw

Pan Head

Screw

Figure 4 Link 1000 Mounting Plate

Cutout for Cables

and Phone Cable

Mounting and Cabling the Shunt

To mount and cable the shunt:

1. Screw the shunt to a suitable mounting surface.

2. Connect the shunt to the negative terminal of the battery

using ring terminals or locked spade terminals on a

copper cable that is sized appropriately for the current

carrying capacity of the system.

Pan Head

Screw

Countersunk

Screw

14

Ensure that no other wires are connected directly to the

negative battery terminal or to the negative side of the

shunt. All current must flow through the shunt.

3. Connect the loa d si de of the shunt to the negative bus for

DC loads using a copper cable that is size d appr opriately

for the current carrying capacity of the system.

If you are not using a ne gative bus for DC loads, connect

the load side of the shunt to the negative side of the

system.

Page 23

Wiring the Terminal Block

Prepare for wiring by following these guidelines:

• Pull the wi res and th e phone c able thro ugh the openi ng in

the mounting plate (unless you are running them down

from the bottom of the mounting plate).

• Prepare the wires by giving each:

• A clean cut

•A clean strip

• A tightly twisted end

• Loosen the terminal block screws, pry the wire clamps

open with a paper clip, and insert the wires using needlenose pliers.

• Tighten the screws firmly, but do not overtighten.

To wire the terminal block:

• Insert the wires in the terminal block following the

sequence shown below.

Note: Terminal 1 is next to the phone cable jack.

Installing the Link 1000

Terminal

1Black. Control panel negative to the large bolt on the

2 Green. Sense lead to the load side of the shunt.

3Orange. Sense lead to the battery side of the shunt.

4Blue. Vo ltage se nse lead to the positive b attery

5Red. Power lead to the positive battery terminal.

6 Violet. Voltage sense lead to the positive battery

7 Not used

8 Not used

Wire Color and Function

load side of the shunt.

terminal.

terminal. Connect this lead if you are monitoring the

voltage of a second (starting) battery.

15

Page 24

Installing the Link 1000

Connecting Terminal Block Wires to Shunt and Battery

To connect the terminal block wires:

1. Connect the black DC power wire (terminal 1) to the

large bolt on the load side of the shunt. This wire should

be on the top of the stack of large cables on the load side

of the shunt. Do not connect this wire to the small

screw terminal with the green shunt sense lead.

2. Connect the gr een le ad (te rminal 2) to t he sm all sc rew on

the load side of the shunt. This wire must be one half of

the twisted pair mad e up of wir es 2 and 3 . Do not connect

any other wires to this screw.

3. Connect the orange lead (terminal 3) to the small screw

on the battery side of the shunt. This wire must be one

half of the twisted pair made up of wires 2 and 3. Do not

connect any other wires to this screw.

4. Connect the blue voltage sense lead (terminal 4) to a 2

amp fuse holder located within 7 in. (18 cm) of the

battery. Connect the other side of the fuse holder to the

positive battery terminal. Do not install the fuse yet.

16

5. Connect the red power wire (terminal 5) to a 2 amp fuse

holder located within 7 in. (18 cm) of the battery.

Connect the other side of the fuse holder to the positive

battery ter minal. Do not in stall the fuse yet.

6. If you are goi ng t o mon it or a starting battery, connect the

violet second battery voltage sense lead (terminal 6) to a

2 amp fuse holder located within 7 in. (18 cm) of the

second (starting) battery. Connect the other side of the

fuse holder to the positive battery termina l o f t he starting

battery. Do not install the fuse yet.

Note: If you are going to monitor the starting battery,

you must enable Function F11 during setup. See

page 33.

Page 25

Installing Fuses

CAUTION

Install the fuses in the sequence listed below to

prevent damage to the Link 1000.

To install fuses:

1. Install a 2 amp fuse in the fuse holder in the blue wire.

2. If you are using a starting battery, insert a 2 amp fuse in

the fuse holder in the violet wire.

3. Install a 2 amp fuse in the fuse holder in the red wir e. The

fuse should be connected in a smooth motion. A

“ragged” power up may cause the Link 1000 to lock up.

The

BATTERY STATUS LEDs and the Numeric Display

come on. The

AC IN LED comes on if AC power is being

supplied to the inverter.

Connecting the Phone Cable

Installing the Link 1000

CAUTION

Make sure you have made all DC power and shunt

connections before connecting the phone cable to

the inverte r/charger.

• Plug the phone cable into the jack on the display panel

and the jack on the inverter/charger, and then clip the

display panel into the mounting plate.

Testing the Installation

After installing the Link 1000, test its operation.

To verify that the shunt leads are connected correctly:

1. Select Amps as the display unit by pressing

Amps LED comes on.

2. Make a note of the Amps reading.

SEL until the

17

Page 26

Installing the Link 1000

3. Turn the charger off.

4. Turn on a load (for example, a light bulb).

5. Make a note of the Amps reading.

It should be less than the reading you took in step 2. If it

is not, the shunt leads are r evers ed (that is, t he gre en wir e

from terminal 2 and the orange wire from terminal 3 are

reversed).

Maintenance

Because the shunt senses very small currents, use an anticorrosive spray to k eep the leads fr ee from cor rosion. ( Do not

spray the leads at the terminal block end.)

Disconnecting the Inverter/Charger

CAUTION

If you need to disconnect the inverter/charger,

unplug the phone cord from the inverter/charger

before you remove the DC power and shunt

connections.

18

Page 27

Setting up the

Link 1000

Chapter 3 explains:

• How to set up the Link 1000 to best suit

your battery system

• Each setting as well as the options for

each setting

• Whether you should change settings or

leave the default setting

(See “Reading the Link 1000 Control Panel”

on page 4 for locations and descriptions of

the buttons, displays, and indicators on the

Link 1000 control panel.)

19

Page 28

About Link 1000 Settings

About Link 1000 Settings

The Link 1000 is designed to operate out of the box, and

except when noted, you shouldn’t need to change the default

settings. (The default settings are listed on page 53.)

Probable Changes

You will probably need to change the defau lt settings for:

• Battery capacity (page 23)

• Battery type (page 23)

Possible Changes

You may need to change the default settings for:

• Ambient temperature if your inverter/charger doesn’t

have a battery temperature sensor (page 24).

•Power sharing (page 27)

Other Settings

Review this chapter completely to determine whether you

need to change any other settings in order to monitor and

control your battery system.

How to Enter Setup Mode and Chan ge a Value

You must be in Setup mode to change settings.

To enter Setup mode and change a value:

1. Press and hold

SET until SEL appears in the display

(about three seconds). This puts you in Setup mode.

2. Press

SEL until you reach the function you want.

3. Once you have selected the function you want, hold or

repeatedly press

4. Release

SET when the value you want appears. After five

SET to change the value.

to ten second s, the display returns to normal. This

indicates that the setting you chose is now stored in

memory.

20

Page 29

Locking Your Setup Values

After you have set up th e Link 1000, you can lo ck the settin gs

to prevent anyone from inadvertently changing them.

To lock the setup:

About Link 1000 Settings

1. Hold down

2. Press

3. Press

4. If OFF appears, press

Resetting Values

You can reset Ah to zero, or you can reset all values to their

factory defaults:

• Resetting Ah to zero does not remove historical battery

data.

• Resetting all values to factory defaults (Reset All)

removes historical battery data. You usually use Reset

All when you change a battery or a battery bank.

To reset values:

1. Hold down

2. Press

AH appears.

3. At this point you can reset Ah only, or you can Reset All:

• T o res et Ah on ly, press

release

• To restore all factory settings, press

appears, and then con ti nue t o ho ld

seconds until 00.0 appears quickly and disappears.

SET until SEL appears.

SEL until the LOCK LED comes on.

SET. The word ON or OFF appears

SET to turn the lock On.

SET until SEL appears in th e display.

SET five times until the RESET LED comes on and

SET until ALL appears, and then

SET.

SET until ALL

SET for another fi ve

21

Page 30

About Link 1000 Settings

Battery Capacity

The default setting is for a battery with a 200Ah capacity.

Change this setting if your battery has a different capacity.

You can test battery capacity by following the procedure on

page 42.

The most accurate way to find the capacity is to ask for the

manufacturer’s 20 hour rating.

Estimated Capacit ie s for 12 Volt Flooded Batteries

The values listed below are estimates for 12 V flooded

batteries except when noted.

Battery Size

U1 34–40

Group 24 80

Group 27 100

Group 30 120

Group 31 95–125

4-D 140–160

8-D 200

Golf cart & T-105

(6 volt)

L-16 (6 volt) 340–415

Estimated Capacities for Gel Cell Batteries

Capacity (Ah)

120–220

Gel cell batteries usua lly hold 15% fewe r Ah for a given size.

For example, a Group 27 gel cell stores about 85Ah.

Estimated Capacities for Multiple Batteries

Parallel Connection

If you are using a single battery bank

that consists of two or more batteries connected in paral lel,

multiply the Ah capaci ty of a single battery by the number of

batteries used. For example, if three 12 volt Group 27

batteries are connected in parallel, use 300 Ah (100 Ah x 3)

for the battery capacity.

22

Page 31

Series Connection If you are using a single battery b ank tha t

consists of two or more batteries connected in series, use the

Ah capacity of one batter y. For example, if two Trojan T-105

6 volt golf cart batteries are connected in series, use the

factory default 200 Ah for capacity.

Changing the Battery Capacity Setting

To change the Battery Capacity setting:

About Link 1000 Settings

1. Press

2. Press

SET until SEL appears in the di splay.

SEL three times. The LED comes on and 200

(the default) appears.

3. Press

Changing the Battery Type Setting

SET and hold it until the value you want appears.

Battery Capacity

(Ah)

20 to 40 1

40 to 100 5

more than 100 20

Note: If you contin ue to hold

after four increments. If you go past your battery’s capacity,

you have to scroll to 1980Ah. The display then rolls over and

begins scrolling up from 20Ah.

Change the Battery Type setting if you are not using flooded

lead-acid b atteries. For d etails about battery types, see

page 33.

To change the Battery Type setting:

Incremental step

in Ah

SET, the display scrolls faster

1. Press and hold

2. Press

3. Press

SEL until Func F10 appears.

SET to select one of the following battery types: 0

SET until SEL appears.

(liquid cell), battery type 1 (gel cell, standard), battery

type 2 (gel cell, fast charge), or battery type 3 (AGM –

Absorbed Glass Mat).

23

Page 32

About Link 1000 Settings

Changing the Ambient Temperature Setting

When you have a battery temperature sensor:

If you have a

battery temperature sensor:

1. Leave the default Ambient Temperature setting as is.

2. Turn on Active Temperature Compensation (F16).

page 34.)

When you do not have a battery temperature sensor:

(See

If you

do not have a battery temperature sensor, and if the

temperature around the battery will be substantially different

from 70 °F (21 °C) when the batteries are being charged:

1. Turn the Active Temperature Compensation setting Off.

(See page 34.)

2. Change the Ambient Temperature setting to an

appropriate value.

Note: The Activ e Temperature Compensation setting must be

Off if you are going to change the Ambient Temperature setting.

Otherwise the Link 1000 reports the present battery temperature.

To change the Ambient Temperature setting:

1. Press and hold

2. Press

3. Press

SEL until Func 03 appears.

SET to change the temperature in 10 °F increments.

SET until SEL appears.

24

4. Release

SET when the correct temperature appears.

Page 33

Charged Parameters

There are two charged parameters: Charged Voltage and

Charged Current Percentage (%). During a charging cycle,

when the battery voltage exceeds the Charged Voltage

parameter and the charging current has dropped below the

Charged Current parameter, the battery is considered to be

fully charged. At this point the Link 1000 resets its state-ofcharge to fully charged (which appears as 0 Ah on the

display).

Changing the Charged Voltage Setting

About Link 1000 Settings

If your system uses 12 or 24 Volt batteries:

to change the default Charged Voltage setting. On power up,

the Link 1000 automatically selects an appropriate Charged

Voltage for 12 or 24 volt liquid cells and gel cells. (If you

have gel cell batteries, see “Changing the Battery Type

Setting” on page 23 .)

If your system does not use 12 or 24 Volt batteries: You must

set an appropriate Charged Voltage. Use a value of 2.2 volts

per cell at normal temperatures for liquid cell batteries.

To change th e Charged Voltage setting:

1. Press and hold

2. Press

SEL once. The LED comes on and 13.2

SET until SEL appears.

appears (or 26.4 if you are using a 24 volt battery).

3. Hold down

SET until the voltage you want is displayed.

(The display moves up in 0. 1 volt steps . Once t he d isplay

reaches 50.0 volts, it then rolls over and starts

counting up from 8.0 volts.)

Changing the Charged Current Percentage Setting

If your system’s charging current does not fall below 2% of

battery capacity at the end of the ch arging c ycle (that is , when

the battery should be full), you will need to change the

Charged Current Percentage setting. (A fully charged battery

is indicated when the green LED flashes on the

STATUS light bar.)

You don’t need

BATTERY

25

Page 34

About Link 1000 Settings

To change the Charged Current Percentage:

1. Press and hold

2. Press

SEL twice. The LED comes on and 002 is

SET until SEL appears.

displayed.

3. Press and hold

SET.

The display moves up in one percent steps until 7

percent is displayed. The display then rolls over and

starts counting up from 1 percent.

4. Release

Changing the Time Remaining Setting

SET when the appropriate percentage appears.

The Link 1000 has four ways of calculating the amount of

operating time that remains. You can select:

• Present cons umpti on level

• A four minute average

• A sixteen minute average

• A thirty-two minute average

The best setting dep ends on your type of i nstallat ion.The four

minute average is appropriate for most installations.

To change the Time Remaining setting:

26

1. Press

2. Press

SET until SEL appears.

SEL four times until the LED comes on and

001 appears.

3. Press

SET until the number you want appears. The

display moves up in 1 unit steps with choices of:

000

001

002

003

4. Release

Present consumption

4 minute average

16 minute average

32 minute average

SET when the value you want appears.

Page 35

Changing the Power Share Setting

Power Share is a load management feature that helps to

prevent external source AC breakers from tripping when the

charger and a number of other loads all come on at once.

Power Share automatically reduces the charger output if the

loads exceed the Power Sharing current limit.

When you plug in to an external AC power supply, set the

Power Share level to the breaker size.

If your charger trips the shore power breaker, choose a lower

Power Share setting.

To change Power Share values:

Note: The CHARGE button LED must be on before you can

change Power Share values.

About Link 1000 Settings

1. Press and hold

2. Press the

CHARGE/PWR SHARE button. The present value

appears.

3. Press and hold

through other values.

4. Release

SET when the value you want appears.

SET until SEL appears.

SET until the display begins scrolling

27

Page 36

About Link 1000 Settings

Changing the Idle Mode Setting

The Idle mode setting determines the size of AC load that is

needed to wake the inverter from its Idle (or standby) mode.

The settings are 0 W, 4 W, 6 W, and 15 W. The default is 4 W.

If you set th e Idle mode to 0 W, Idle mode is act ually

defeated and the inverter stays on all the time. When the

inverter is on, it draws approximately 0.5 amps. This setting

is useful if you want to ensure uninterrupted power to a very

small load like an electric clock.

The other three settings let you conserve battery power

because the inverter stays off until an adequate-sized load

brings the inverter out of Idle mode.

To change the Idle mode setting:

Note: The INVERT button LED must be on before you can

change the Idle mode setting.

28

1. Press and hold

2. Press the

INVERT/IDLE MODE button. The present value

appears.

3. Press and hold

other values.

4. Release

SET when the value you want appears.

SET until SEL appears.

SET until the display scrolls through the

Page 37

About Link 1000 Settings

Advanced Function Values

The Link 1000 has sixteen advanced functions. The default

setting is appropriate for most, and you should not change a

value unless you understand the consequence of the change.

Note: If you are monitoring more than one battery:

• Change Function F11, Second Battery Voltage Sense.

• Record the software revision number on page 60. (See “F15

Display Software Revision Number” on page 34.)

How to Enter Setup Mode and Change a Value: Reminder

The procedure for entering Setup mode and chan ging a value

is given on page 20.

F01 Auto Display Scanning

Default: Off

Range: Off, On

When Auto Display Scanning is On, the display

automatically scrolls through Volts, Amps, Ah, and Time

remaining. Each value is displayed for four seconds.

If Second Battery Voltage Sense (F11) is also on, two

voltages are shown. The flashing Volts status LED

indicates that the voltage displayed is that of the second

battery bank.

F02 Display Sleep

Default: On

Range: On, Off

This function turns off the Numeric Display and the Display

Units LEDs. All the other LEDs—

bar,

AC IN, Charger status LEDs, CHARGE LED, and INVERT

LED—stay on.

BATTERY STATUS light

29

Page 38

About Link 1000 Settings

F03 Set or Display Ambient Battery Temperatures

Default: If F16 (Active Temperature Compensation) is On,

the present battery temperature is displayed in °F. If F16 is

Off, the declared battery temperature is displayed.

Range: 30° F–120° F (–1.11° C–48.8° C) in 10° increments.

Set a different value from the default only if the battery

environment is significantly different from 70° F (21.11° C)

when the batteries are being charged by the Freedom

Inverter/Charger.

For more information about bat tery char ging and temperat ure

compensation, see “F07 Set Temperature Coefficient” on

page 31.

F04 Toggle Display Between Ah and kWhr

Default: Off

Range: Off = Ah display mode; On = kWhr display mode.

When this function is On, the Ah display is changed to a

kilowatt-hour display.

30

Kilowatt-hours are a very precise measurement of energy

removed from or returned to t he batt ery bank. The Lin k 1000

uses kilowatt-h ours to d etermine whether 100% of th e ener gy

consumed from the battery has been returned.

A recalculation of the CEF (Charge Efficiency Factor) is not

permitted unless this counter is greater than 0.00 kWhr. This

counter counts down during discharge, and the kWhrs

consumed are displayed with a negative number. While the

battery is charg ing, the Link 1000 counts back up with 100%

efficiency. CEF recalculation is prevented until a positive

number is in the kWhr counter. This prevents a premature

CEF reset.

Page 39

F05 Turn on Alternative Energy Mode

Default: Off

Range: Off and On. On = use alternative energy defaults.

Turn Alternative Energy mode on if the Link 1000 is used in

an alternative energy system.

This function reduces the time needed to satisfy the charged

parameters from five minutes to one minute. If you are using

a semi-mechanical photovoltaic controller, we strongly

recommend that you also co nsider cha nging Char ged Curre nt

to 4%. (See “Changing the Charged Current Percentage

Setting” on page 25 .)

F06 Manually Set CEF

Default: Off = Auto recalculation of CEF

Display: A95

Range: 65–99 in 1 number increments

This setting allows manual set up of CEF (Charging

Efficiency Factor). The default display A95 indicates the

automatic CEF recalculation feature. Returning to A95 from

a user-set CEF turns the automatic CEF feature back on. If a

user-set CEF h as been selected, it will appear as a Uxx in

Data mode (where xx is the number the user has selected).

About Link 1000 Settings

F07 Set Tempera ture Coefficient

Default: 0.5

Range: 0.1–0.5 in 0.1 step increments

We recommend that you use the default value.

This factor compensates for the impact that temperature has

on battery capacity. A typical value is 0.5% Capacity per °C.

This coefficient must be supplied by the battery

manufacturer. The default value is typ ical for l iquid lead- acid

or gel batteries.

31

Page 40

About Link 1000 Settings

F08 Set Peukert’s Exponent

Default: 1.25 for liquid lead-a cid ba tter ies. (Bat tery Type set

to Type 0.)

The Peukert exponent refers to the “shrink rate” of your

battery bank. The more rapidly you discharge the batteries,

the more their effective size shrinks. For example, a battery

that can supply 200Ah when discharged over twenty hours

may only provide 95Ah if discharged in one hour.

When you select Battery Type (see “Changing the Battery

Type Setting” on page 23 and “F10 Select Battery Type” on

page 33), the Link 1000 automatically sets an appropriate

Peukert exponent. When the Battery Type is gel or AGM

(Type 1, 2, or 3), a default exponent of 1.11 is used.

If your battery manufacturer has given you another value,

you can enter it. Otherwise, leave the default value.

F09 Set Low Battery Discharge Floor

Default: 100%

Range: 50%–100% in 5% increments

32

The Link 1000 lets you set the discharge floor that it uses for

calculations. The factory-set discharge floor is 100% of Ah

capacity, corrected for high discharge rates. If you set the

discharge floor to 100%, the Time Remaining display

reports the time that remains until you have a dead battery.

We recommend that you begin charging when two yellow

battery status LEDs are on in order to conform to the “Mid

Capacity Rule” (see page 39).

Note: If you discharge below the discharge floor, and then

partially charge but remain below the discharge floor, the Time

Remaining display will continue to read zero. The Time Remaining

display will not show meaningful readings until you have recharged

above the discharge floor you have set.

Page 41

F10 Select Battery Type

Default: 0 (Liquid Cell)

Range: 0 = Liquid Cell; 1 = Gel Cell (standa rd); 2 = Gel Cell

(fast charge); 3 = AGM (Absorbed Glass Mat)

This function sets the appropriate charge and float voltages

for the Freedom charger and sets an appropriate Peukert

exponent. Gel cell owners can use Type 1 or Type 2, but

should consult the battery manufacturer before using Type 2.

Type 3 sets Acceptance and Float voltages suited to AGM

type batteries.

F11 Turn on Second Battery Voltage Sense

Default: Off

Range: On, Off

When this function is On, two voltages are displayed. When

the Volts LED is on solid, you see the voltage of the

monitored battery. If the battery Volts LED is flashing,

the second (starting) battery voltage is being displayed.

About Link 1000 Settings

If you use this function, keep in mind that the displayed

voltage is only an indica tion of the batt ery’s state-of-charge if

the battery has been at rest for at least eight hours.

A battery with an eight hour at-rest voltage of 12.4 volts or

more will probably start an engine. A battery with an eight

hour at-rest voltage of 11.1 volts will probably not start an

engine, particularly if you have dirty injectors and if the

engine doesn’t start right away.

F12 Number of Overload Conditions Experienced

Displays the number of inver ter shut downs sinc e the l ast high

level meter reset. This is primarily a troubleshooting tool.

F13 Number of Inverter Low Ba tt er y S hut do wn s

Displays the number of inverter low battery shutdowns since

the last hig h level meter reset. This is prim arily a

troubleshooting too l.

33

Page 42

About Link 1000 Settings

F14 Test Control Panel Display

Default: Off

Range: On while the SET button is pressed when this

function is active. Off when

This function lets you confirm that the Link 1000 control

panel display is operating properly. When you press

F14 mode:

SET is released.

SET in

•The

RESET and DATA LEDs are orange-yellow.

• All other LEDs display their normal color.

• The Numeric Display reads 188.8.

The display returns to normal when you release

Operation of the

LOCK and FUNC LEDs is confirmed when

power is initially applied to the Link 1000.

F15 Display Software Revision Number

•Press SET to display the Software Revision Number.

This function displays the soft ware re visio n number ins tall ed

in your Link 1000. Record this number on page 60 in case

you need to call Customer Service.

F16 Turn on Active Temperature Compensation

Default: Off

Range: Off, On

Turn this function On if your inverter/charger has a

temperature sensor.

Leave this function Off if you are not using a temperature

sensor.

SET.

34

When this function is On, the Link 1000 uses the actual

battery temperatur e repor ted to t he Freed om Inverte r/Char ger

by a Heart TC2+2 unit, the Freedom 458 or the Freedom

Marine Inverter/Charger temperature sensor.

Page 43

Using the

Link 1000

Chapter 4 tells you how to:

• Read the battery’s state-of-charge

• Turn on the invert function

• Change the Idle mode setting

• Charge and equalize the batteries

• Determine battery capacity

• Activate the Power Share feature

• Synchronize the Link 1000 to the

batteries

• Read battery history

• Respond to Error Codes

35

Page 44

Monitoring Functions

Monitoring Functions

Choosing a Display Unit: Volts, Amps, Ah, or Time

By default, the numeric display shows Volts , but it can

also show Amps, Ah, and Time Remaining.

To change the display unit:

•Press

SEL until the , , or LED comes on.

The units of display are explained below.

VOLTS

A

MPS

Ah

T

IME

R

EMAINING

Displays the voltage of the battery being monitored.

(The Link 10 00 can also display the voltage of an

additional battery.)

Displays the flow of current into or out of the battery.

Discharging appears as a negative number. Charging

appears as a positive (unsigned) number.

For example, if 6 amps are going into the battery, the

numeric display shows 6. If 6 amps are being

consumed, the numeric display shows –6.

Displays the Ah (amp-hours) consumed.

This is the amount of energy that has been consumed

from the battery. For example, if you have operated a

10 amp load for one hour, 10 Ah have been

consumed, and the display shows –I0.

When the battery is fully charged, the Link 1000

displays 0 Ah.

This is an estimate of the hours that the battery can

operate at its present load until it is completely

discharged. The estimate is based on a selectable,

time- averaged, rate of discharge. The default is the

average of the last four minutes of use.

While the batteries are charging, this display shows

CCC.

36

Note

: The numeric display also shows Error Codes. If an error

occurs, the display alternates between the moni toring function you

have selected and the Error Code. For details about Error Codes,

see page 48.

Page 45

Reading the Battery State-of-Charge

The BATTERY STATUS light bar (see Figure 5) shows the

battery’s state-of-charge. The table explains how to read the

light bar.

BA TTERY ST ATUS

Figure 5 BATTERY STATUS Light Bar

These lights Indicate this %

Monitoring Functions

3 green + 1

flashing green

4 green 80–100%

3 green 60–79%

2 yellow 40–59%

1 red 20–39%

1 flashing red 0–19%

Scaling the BATTERY STATUS Light Bar

The CEF has been recalculated.

Enough charge to start an eng ine-dr iven char gi ng

source.

The battery is more than 80% discharged (based

on the facto ry settings).

You can scale the BATTERY STATUS light bar to show a

flashing red LED when your battery is more than 40%

discharged. To adjust the battery discharge f loo r, see page 32.

37

Page 46

Inverter Functions

Inverter Functions

Turning on the Invert Function

When the inverter is operating, power is taken from the

batteries and converted to AC current to power your loads.

To turn on the invert function:

•Press

The

inverting. It indicates that the inverter function is enabled.

The invert function only operates when the inverter is

connected to the battery, no external AC power is available,

and the batteries have enough power for the loads.

When the inverter is initially powered up, the invert function

is off.

Changing the Idle Mode Setting

The Idle mode setting determines the size of AC load that is

needed to wake the inverter from its Idle (or standby) mode.

INVERT.

The

INVERT button LED comes on.

INVERT LED does not indicate that the system is

38

To change the Idle mode setting:

•See page 28.

Page 47

Charging Functions

Charge your batteries when two yellow LEDs are lit on the

BATTERY STATUS light bar (if you are using the default setting

for F09: Low Battery Discharge Floor). The two yellow

LEDs indicate that 50% of battery capacity has been used.

Charging at this level is called the Mid-Capacity Rule. In

marine and RV systems, which try to minimize ch ar ging time

with an engine-driven alternator, or generator-powered

charging, the battery is normally charged to the 85% level.

This means that only 35% of the battery capacity is actually

available for use.

The Mid-Capacity Rule is designed to optimize battery life.

Four charging cycles are available: Bulk, Acceptance, Float,

and Equali zation. When you start a charge cycle, the charger

automatically completes a Bulk, Accept, and Float charge.

You can also start an Equalization charge manually.

CHARGER STATUS LEDs are explained below, and then

The

procedures are given for charging and equalizing the

batteries.

Charging Functions

Summary of CHARGER STATUS LEDs

This LED Indicates

AC IN (green) AC power is present.

CHG (red)

on solid

CHG (red)

flashing

ACCEPT (orange) The batteries are in Acceptance mode.

FLOAT (green) The charge is in Float mode.

The batteries are in Bulk charge mode.

An Equalization charge is being applied.

39

Page 48

Charging Functions

Charging the Batter ie s

To start a charge cycle:

•Press the

CHARGE button on, and the cycle will start

CHARGE button. (You can also leave the

automatically.)

The

CHG LED and the CHARGE button LED come on.

The charger automatically cycles through the Bulk,

Acceptance, and Float charge stages.

The charge function only operates when the inverter is

connected to a battery and external AC is available.

(On inverter/chargers that have a serial number lower than

100,000, charging is enabled when the

Equalizing the Batteries

Equalization is the controlled overcharging of a lead-acid

battery (or battery bank) to remove lead sulfate that is not

removed during normal charging. Controlled overcharging

helps the battery reach and maintain peak capacity by

equalizing the chemistry in the individual battery cells.

INVERT button is on.)

Precautions

40

• Equalize your batteries ever y thirt y days whe n they are in

a daily cycling service or every thirty deep cycles.

• Equalize your batteries when the battery capacity has

decreased (that is, when the bat teries do not ho ld loads as

well as they previously did).

WARNING: Explosion Hazard

Equalization produces explosive gases which must be

vented.

Read these precautions before you start an equalization

charge:

• Equalization causes batteries to gas. Make sure they are

well ventilated.

Page 49

Charging Functions

• Check the electrolyte level of all batteries before and

after equalization. Make sure the electrolyte is at the

correct level, but do not overfill because the electrolyte

may expand and overflow.

• Leave the filler caps screwed on loosely, or remove them

and cover the opened cell tops with a folded paper towel.

• Make sure you are present during equalizatio n so you can

monitor the charging cycle.

To start an equalization cycle:

CAUTION

Turn off all DC loads before you start equalization. The

voltages required during equalization can damage

sensitive equipment.

1. Make sure the charger is on and the batteries are fully

charged.

2. Press

3. Press

SET until SEL appears.

SET and CHARGE simultaneously until the CHG

LED starts flashing and 00E goes out (about five

seconds). The

CHG LED flashes throughout the

equalizati on cycle.

To end an equalization cycle manually:

•Press

SET until SEL appears, and then press SET and

CHARGE simultaneously.

The

CHG LED goes out and the Freedom Inverter/

Charger is forced to float when equalization ends (the

FLOAT LED comes on).

If you do not stop the equalization process manually, the

cycle ends automatically after eight hours. It also ends if

external AC power is interrupted.

To end equalization early on Freedom inverters that have a

serial number lower than 100,000, turn off both the

and

INVERT buttons.

CHARGE

41

Page 50

Charging Functions

Equalizing Gel Cell Batteries

You don’t normally equalize gel cell batteries. If they have

been severely disc harged, however , t hi s may be t he only way

to get them to begin accepting a charge. The voltage is

limited to the Acceptance charging level, but the cycle lasts

for eight hours.

Be sure that battery t ype is se t to 002 befor e you equal ize gel

cell batteries.

Activating Power Share

Power Share is a load management feature that helps prevent

external source AC breakers fr om tripp ing when the charger

and a number of other loa ds al l come o n at on ce. Power sh are

automatically reduces the output of the Freedom Inverter/

Charger if the A C loads exceed a specified current limit.

To change the Power Share setting:

•See page 27.

Battery Capacity Testing

42

To determine the actual amount of energy your batteries can

store, you conduct periodic capacity tests. A capacity test

should start with a batt ery t hat ha s been proper ly cha r ge d and

equalized.

Deep cycle battery capacity is usually stated as a 20 hour

discharge rate (a 100 Ah battery will provide 5 amps for

twenty hours). At discharge rates above 5 amps, the battery

will supply less than 100 Ah. For exampl e, if you are drawing

100 amps out of the battery, it will last less than half an hour.

The following table shows battery capacity at various

discharge rates.

Battery Capacity at Various Discharge Rates

Capacity (as a percent of the

Hours to Discharge

20 100%

20 hour rate)

Page 51

Charging Functions

Battery Capacity at Various Discharge Rates

Capacity (as a percent of the

Hours to Discharge

10 89%

5 78%

3 66%

1 45%

20 hour rate)

To test battery capacity:

1. Charge the battery until the charged parameters are met.

This resets Ah to zero.

2. Turn on a load that draws approximately 5% of the

expected battery capacity.

3. Check the current by looking at the Amps display. The

load should be constant (for example, a light bulb).

4. Put the Link 1000 in Volts display mode.

5. When the voltage drops to 10.5 volts (or 21 volts if you

are testing a 24 volt system), turn the load off. (It should

take about twenty hours for the voltage to drop.)

6. Look at the Ah display. The number of Ah displayed

is the actual battery capacity.

If less than twenty hours passed before the voltage fell to

10.5, you can still determine the capacity by completing a

simple calculation. For example, assume that you have a 12

volt battery rated at 100 Ah. Apply a 5 amp load. If it only

took ten hours for the voltage to reach 10.5, the Link 1000

would display –50Ah. This number is the 10 hour capacity.

By dividing 50 by 89% (see the preceding table), you

determine that the actual 20 hour capacity is 56 Ah. You

could repeat the te st at 5% of the tes ted capacity (2.8 amps) to

verify the actual capacity.

43

Page 52

Charging Functions

Synchronizing the Link 1000 to the Battery

When the battery is fully charged, the Link 1000 displays 0

Ah. This indicates that no energy has been removed from the

battery. (The display can also show a positive number; this

changes to 0 as soon as you place a load on the battery. See

page 45 for details about over-charge Ah).

As the battery discharges, the display shows how much

energy has been used. For example, when you run a 10 amp

load for one hour, the display shows –10 to indicate that 10

Ah have been used.

In other words, the Ah dis play tells you how much ener gy has

been removed from the battery as long as the Link 1000 is

synchronized with the battery.

• If you install the Link 1000 on a fully charged battery, it

is automatically synchronized to the battery.

• If you install the Link on a battery that is partially

charged, you mus t sync hroniz e the Link by fol lowing the

procedure given here.

• Once the Link 1000 is synchronized, it stays

synchronized as the battery runs through discharge /

charge cycles. If the Link every gets out of sync with the

battery (this ra rely hap pens), you ca n synch ronize it once

again by following the procedure given here.

To synchronize the Link 1000 to the battery:

1. Discharge the battery by at least 10% of its declared

capacity.

2. Set the Ah reading to 0 by:

a) Holding down

b) Pressing

on and AH appears.

c) Pressing

SET as soon as ALL appears.)

4. Charge the battery until the gre en

(For battery charging procedures, see page 40.)

Overcharge Ah are display ed as a positive number. When

the battery starts to discha rge, the Link resets Ah to zero.

SET until SEL appears in th e display.

SET five times until the RESET LED comes

SET until ALL appears. (Be sure to release

FLOAT LED comes on.

44

Page 53

Over-charge Ah (Ac c umulation of Positive Ah)

If the battery is 100% charged, and the Link 1000 is

synchronized with the battery, over-charge Ah are displayed

as a positive Ah number. Some accumulation of over-charge

Ah is normal with syste ms that are continuou sly conn ected to

a charger. For example, a 100 Ah battery at Fl oat v olt age wi ll

normally have a little less than 0.1 amps flowing into it. This

means you would expect about 2.4 Ah of over-charge to

accumulate each day. If your battery system is larger, more

current flows and more over-charge Ah accumulate.

If the charging system is a constant voltage type set at 14.2

volts, as much as 1 amp may be flowing all the time after the

battery has reached the charged parameters. Prolonged high

voltage applied to a fully c harged battery will likely cause

gassing, and you would expect to see a large Ah over-charge

every day. This is a indicates that you are shortening the life

of your battery by over charging. Check your Link 1000

before turning off a charging source to see that you have not

accumulated too many over-charge Ah. (When discharging

begins, the Link 1000 resets to zero and begins to report Ah

consumed.)

Charging Functions

If you equalize your batteries, some over-charge Ah will

accumulate. This is normal and ensures that the Link 1000

stays synchronized with the battery state-of-charge.

45

Page 54

Battery History

Battery History

The Link 1000 stores four kinds of information about the

battery.

To access battery history:

1. Hold down

2. Press

SET until SEL appears.

SEL until the DATA LED comes on.

E99 is displayed. This is the Charging Efficiency Factor

(CEF).

3. Press

SEL again.

+I999 is displayed. This is the number of CEF

Recalculations.

4. Press

SEL again.

–999 is displayed. This is the Dee pest Depth of

Discharge.

5. Press

SEL again.

i999 is displaye d. This is the Average Depth of

Discharge.

Interpreting Battery History

E99: Charging Efficiency Factor

Factor (CEF) is the energy efficiency of the battery. This

indicates the health of the battery. The lower the efficiency,

the worse the health of the battery.

The Ah CEF, not the kilowatt-hour CEF, is displayed. A

display of E99 indicates a 99% CEF based on Ah. The

Default setting is 95%.

The Charging Efficiency

46

If the CEF display has a u in f ront of it, this means the CEF

has been selected by the user. See page 31 for details about

changing the CEF settings.

+I999: Number of CEF Recalculations This is the number of

times the battery has been discharged more than 10% and

then completely recharged (recharged until the Charged

Page 55

Battery History

Parameters have been met) since the last time it was reset to

the factory defaults. A discharge of less than 10% of battery

capacity is not counted as a “cycle”.

–999: Deepest Discharge This is the deepest discharge in Ah

since the last time the Link 1000 was reset to the factory

defaults.

i999: Average Discharge This is the average of all discharges

as an Ah value since t he last reset to factory d efaults . For best

battery life, you should not routinely discharge more than

50% of your battery ’s capacity. If yo u do, you shor ten i ts li fe.

An average discharge of 500Ah on a 900Ah battery is

demanding but not unreasonable. An average discharge of

180Ah from a 200Ah battery is exc essive and will shorten the

battery’s life.

47

Page 56

Readi ng Error Codes

Reading Error Codes

When the Link 1000 detects a prob lem, an error code ap pears

in the numeric display. The display alternates between

showing the monitoring function you have selected and the

error code. The error code flashes until the error is corrected.

The following table list s each Error Code, de scribes the cau se

of the error, and indicates the action to take, if any.

Error

Code Meaning

E01 High battery voltage shutdown

(Inverter/charger error)

Battery voltage has risen above 15.5 V for 12 V

inverters or above 31 V for 24 V inverters.

Check all charging sources (that is, solar panels,

alternators, etc.

E02 Low battery voltage shutdown

(Inverter/charger error)

Battery voltage has dropped below 10.5 V for 12 V

inverters or below 21 V for 24 V inverters.

Check for a dead battery or poor battery connections.

E03 Over temperature shutdown

(Inverter/charger error)

The inverter has overheated and shut down. It will reset

automatically after it has cooled sufficiently.

Make sure there is adequate ventilation around the

inverter.

48

E04 Battery overload

(Inverter/charger error)

The battery is excessively discharged or there is a

shorted battery.

See your inverter/charger owner’s manual for

information about charging excessively discharged

batteries.

Page 57

Reading Error Codes

Error

Code Meaning

E05 AC backfeed

(Inverter/charger error)

AC power from an outside source has been fed to the

AC output of the inverter. This could damage the

inverter.

Disconnect incoming AC power and correct the fault

immediately. Consult a qualified electrician if you do

not know how to diagnose and treat this problem.

E06 Electronic overload

(Inverter/charger error)

The inverter is connected to a load that is too large for it,

or the inverter output has shorted out.

Remove the load. Reset the inverter by cycling the

charger on and off, or connect AC power from an

outside source.

E07 Triac control error

(Inverter/charger error)

A switch inside the charger has overheated.

Turn the charger off and let it cool. Make sure there is

adequate ventilation around the inverter.

E08 High battery voltage shutdown during charging

(Inverter/charger error)

Check all charging sources (solar panels, alternators,

other battery chargers, etc.) for proper voltage.

Reset the inverter by cycling the charger off and on.

E09 Spare

E010 Depowered

(Link 1000)

This code appears when the Link 1000 is first powered

up and whenever power has been interrupted or has

dipped below the operating voltage of the Link 1000.

This code can be triggered by voltage dips during engine

starting if the Link 1000 i s p owered by t h e same b at tery

that starts the engine.

E011 Spare

49

Page 58

Readi ng Error Codes

Error

Code Meaning

E012 Battery voltage sense lead open

E013 Spare

E014 Inappropriate charged voltage selected for the

E015 Incoming AC polarity reversed

(Link 1000)

Check the fuse or any other connections in the voltage

sense lead (blue wire) to the battery.

sensed voltage

(Link 1000)

This code appears if the Charged Voltage parameter is

above 20 V and the sensed voltage is below 20 V, or if

the sensed voltage is above 20 V and Charged Voltage

parameter is below 20 V.

This code will help you avoid an incorrect setup.

(Inverter/charger error)

Check the incoming AC wiring for reversed polarity

(positive and neutral reversed).

Consult a qualified electrician if you do not know how

to diagnose and correct this condition.

50

0L Link 1000 reading out of range

(Link 1000)

Page 59

Specifications

Appendix A lists:

• Electrical and physical specifications for

the Link 1000

• Default settings

Specifications are subject to change without

notice.

51

Page 60

Control Panel: Electrical Specifications

Control Panel: Electrical Specifications

DC Power supply voltage 8–4 0 VDC. (Not for use with 32 v olt

systems.)

Power consumption For 12 volt systems:

• 90 mA (typical)

• 170 mA (full display brightness)

• 25 mA (sleep mode; only

BATTERY STATUS LE DS on.)

Values are approximately half on 24

volt systems.

Voltage measurement range 0.1–50 VDC

Voltage resolution 0.05 VDC

Voltage accuracy ±0.10 VDC at full scale

Current measurement range ±500 Amps DC

Current resolution • 0.1 amp DC (from ±0–±42.0

amps)

• 1 amp DC (from ±42–±500

amps)

Current accuracy • ±0.1 amp DC at full scale low

range

• ±1 amp DC at full scale high

range

Current shunt ±0.25% ratio: 50mV @ 500A

Amp hour range ±1,999Ah

Time remaining range 255 hours maximum

Control Panel: Physical Specifications

Width 4.725 in. (120 mm)

Height 2.975 in. (75.5 mm)

Depth 1.075 in. (27.3 mm)

Weight 4.6 oz. (2 g)

Front panel finish Water resistant, splash proof

52

Page 61

Default Settings

Inverter/Charger Controls

Default Settings

CHARGE

INVERT

Idle Mode 4 W atts ( 5 Watts on Series 458 units)

Power Sharing 30 amps (Off for Freedom 25 units)

Monitoring Functions

Charged Voltage 13.2 volts for 12 volt systems

Charged Current 2% (of battery capacity, 4 amps @

Battery Capacity 200Ah

CEF 95% (Charge Efficiency Factor)

Ambient Temperature 70 °C

Battery Type 0 (liquid cell)

Peukert Exponent 1.25

On

Off

26.4 volts for 24 volt systems

200 Ah)

53

Page 62

54

Page 63

Product and System Information

Appendix B contains:

• The warranty for your Link 1000

• Instructions for returning the product for

servicing

• A table (see page 61) where you can

record information about your system in

case you need to contact Customer

Service

55

Page 64

Warranty

Warranty

What does this warranty cover? This warr anty is provided by

Xantrex Technology Inc. (“Xantrex”) and covers defects in

workmanship and materi als in your Xant rex Link 100 0 Battery

Monitor. This warranty lasts for a Warranty Period of 12 months

from the date of purchase at point of sale to you, the original end

user customer .

This Limited Warranty is not transferable.

What will Xantrex do? Xantrex will, at its option, repair or

replace the defective product free of charge, provided that you

notify Xantrex of the product defect within the Warranty Period,

and provided that Xantrex through inspection establishes the

existence of such a defect and that it is covered by this Limited

Warranty.

Xantrex will, at its option, use new and/or reconditioned parts in

performing warranty repair and building replacement products.

Xantrex reserves the right to use parts or products of original or

improved design in the repair or replacement. If Xantrex repairs or

replaces a product, its warranty continues for the remaining portion

of the original Warranty Period or 90 days from the date of the

return shipment to the customer, whichever is greater. All replaced

products and all parts removed from repaired products become the

property of Xantrex.

56

Xantrex covers both parts and labo r necessary to repair the pro duct,

and return shipment to the customer via a Xantrex-selected nonexpedited surface freight within the contiguous United States and

Canada. Alaska and Hawaii are excluded. Contact Xantrex

Customer Service for details on freight policy for return shipments

outside of the contiguous United States and Canada.

How do you get service? If your product requires

troubleshooting or warranty service, contact your merchant. If you

are unable to contact your merchant, or the merchant is unable to

provide service, contact Xantrex directly at:

Phone: 1-800-670-0707 (toll-free in North America) 1-604-4222777 (direct)

Fax: 1-604-420-2145

Email: CustomerService@xantrex.com

Page 65

Warranty

Direct returns may be performed according to the Xantrex Return

Material Authorization Policy described in your product manual.

For some products, Xantrex maintains a network of regional

Authorized Service Centers. Call Xantrex or check our website to

see if your product can be repaired at one of these facilities.

In any warranty claim, dated proof of purchase must accompany the

product and the product must not have been disassembled or