Whirlpool Cabrio WTW6400S, Cabrio WTW6600S, Cabrio WTW6400SW, Cabrio WTW6600SW, Cabrio WTW6600SG Technical Manual

...

L-80

JOB AID

Part No. 8178582

AUTOMATIC

WASHER

WITH 6TH SENSE

™

TECHNOLOGY

CONSUMER CARE TECHNICAL

EDUCATION GROUP PRESENTS

MODELS: WTW6400S & WTW6600S

FORWARD

This Whirlpool Job Aid, “Cabrio™ Automatic Washer With 6th Sense™ Technology” (Part No.8178582),

provides the In-Home Service Professional with information on the installation, operation, and

service of the Cabrio

™

Automatic Washer With 6th Sense™ Technology. For specific information

on the model being serviced, refer to the “Use and Care Guide,” or “Tech Sheet” provided with

the washer.

The Wiring Diagram used in this Job Aid is typical and should be used for training purposes only.

Always use the Wiring Diagram supplied with the product when servicing the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide information that will enable the In-Home Service Professional

™

to properly diagnose malfunctions and repair the Cabrio

Technology.

The objectives of this Job Aid are to:

• Understand and follow proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the washer to its proper operational status.

Automatic Washer With 6th Sense™

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on

our products by anyone other than authorized In-Home Service Professionals.

Copyright © 2006, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

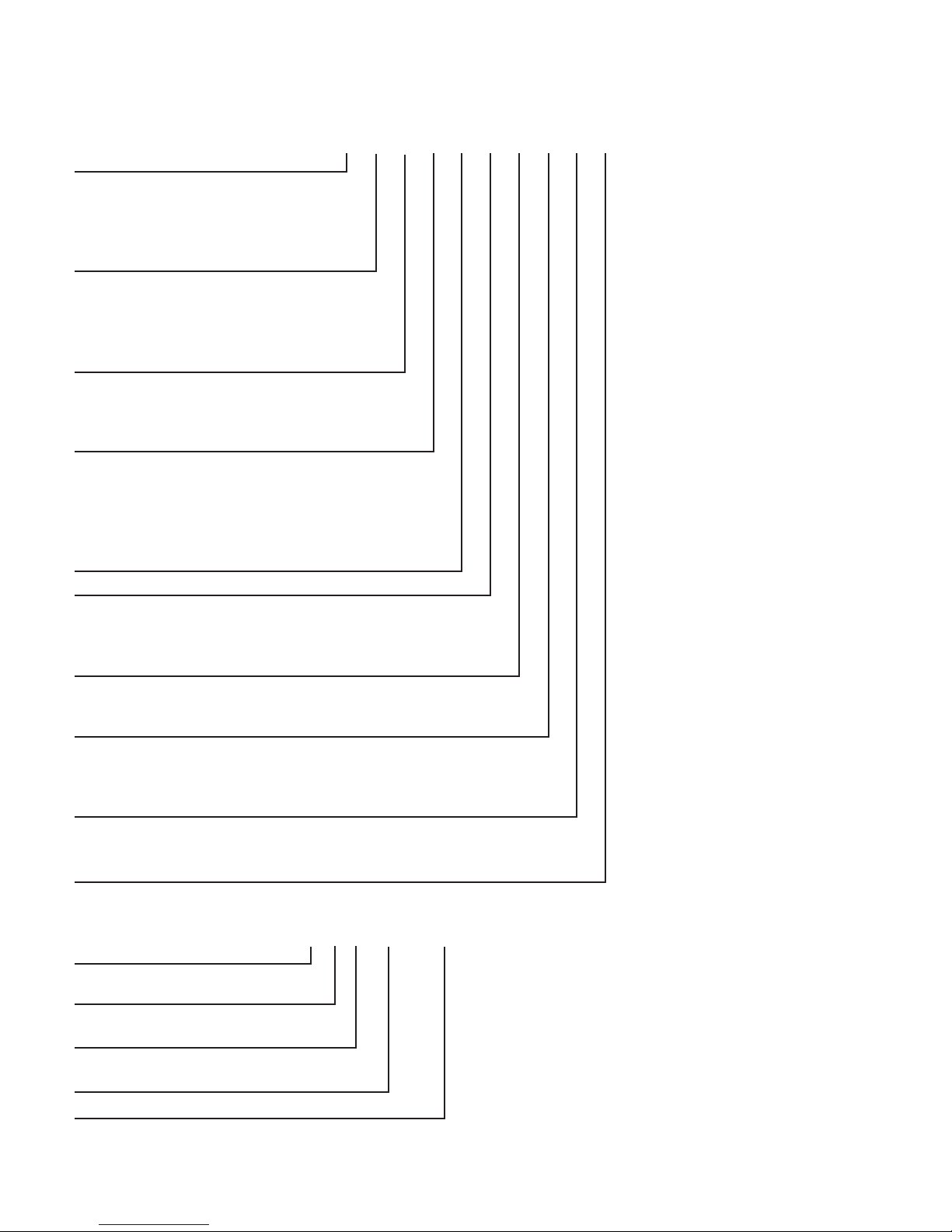

TABLE OF CONTENTS

Page

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Washer Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model & Serial Number Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Model & Serial Number Label & Tech Sheet Locations . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Impeller Wash Program/Selectability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-3

1-6

INSTALLATION INFORMATION

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

PRODUCT OPERATION

Theory Of Operation

Washer Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Washer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPONENT ACCESS

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Removing The Encoder And The User Interface Board

Removing The Water Inlet/Dispenser Valve Assembly, Power Supply Cord,

And Machine/Motor Control & Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing A Dispenser, The Fresh Fill Inlet Valve, And The Lid Lock . . . . . . . . . . . . . . . .

Removing The Lid And A Hinge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing The Basket, Basket Hub, & Lint Filter

Removing The Drain And Recirculation Pumps

Removing The Drive Motor & Rotor Position Sensor

Removing The Tub

Accessing The Pressure Transducer Tubing, Recirculation Tube,

And Drain Pump Harness

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3-3

3-12

3-14

. . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-4

4-6

4-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

COMPONENT TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Water Inlet/Dispenser Valve Assembly

Drain Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Recirculation Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Lid Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Drive Motor Stator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

DIAGNOSTICS & TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Display Fault/Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Diagnostic Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Diagnostic Tests

Troubleshooting Guide

Troubleshooting Tests

Accessing & Removing The Electronic Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

6-15

- iii -

— NOTES —

- iv -

GENERAL

DANGER

WARNING

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING.” These words mean:

You can be killed or seriously injured if you don’t

immediately follow instructions.

You can be killed or seriously injured if you don’t

follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

1-1

MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER W T W 6 6 00 S W 0

BRAND

W = Whirlpool

E = Estate

R = Roper

I = Inglis

ACCESS / FUEL

T = Top Load G = Gas

F = Front Load H = Horizontal

W = Work Space V = Vertical

E = Electric

PRODUCT

W = Washer P = Pedestal

D = Dryer B = Combo

T = Thin Twin C = Compact

SERIES

1 = Innovation 6 = Oasis

2 = Commercial 7 = Merloni

3 = Compact 8 = Horizon

4 = Stack 9 = Duet/Combo

5 = LEAP

PRICE POINT LEVELS (1 - 7)

TRADE PARTNER

00 = Brand 30 = NATM

10 = SBC 40 = Lowe’s

20 = Best Buy

YEAR OF INTRODUCTION

S = 2006

T = 2007

COLOR CODE

W = White w/Silver Metallic Console

G = Biscuit w/Gold Metallic Console

B = Black w/Black Metallic Console

ENGINEERING CHANGE

0 = Basic Original Release

1 = First Revision

SERIAL NUMBER

SERIAL NUMBER C T 41 10200

MANUFACTURING SITE

C = Clyde, OH

YEAR OF PRODUCTION

T = 2006

WEEK OF PRODUCTION

41 = 41st Week

PRODUCT SEQUENCE NUMBER

1-2

MODEL & SERIAL NUMBER LABEL &

TECH SHEET LOCATIONS

The Model/Serial Number Label and Tech Sheet locations are shown below.

Model/Serial Number Location

Tech Sheet Location

(Access Under Cabinet Top)

1-3

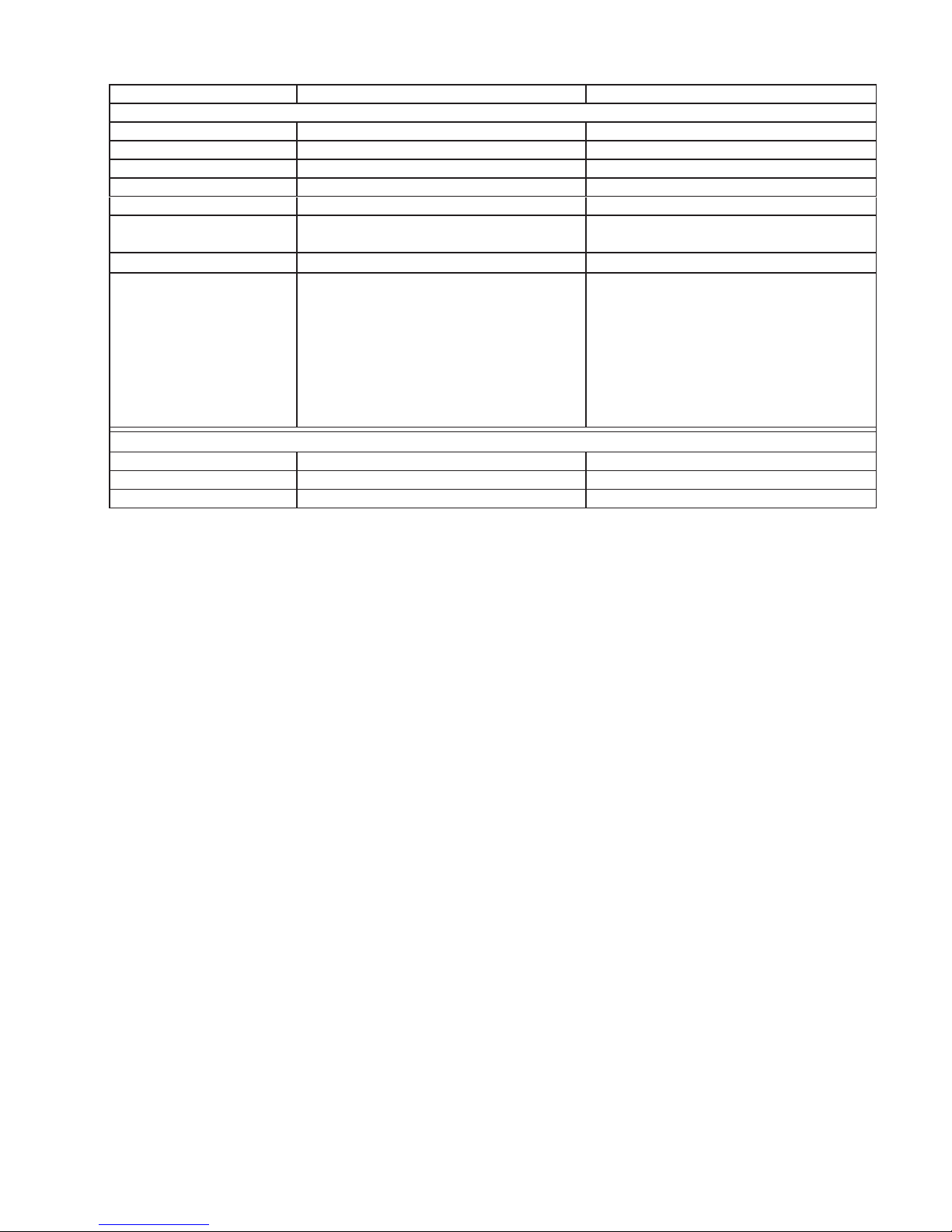

SPECIFICATIONS

MODEL NUMBERS WTW6400SW WTW6600SW, G, B

PRIMARY FEATURES

CAPACITY (IEC) 4.5 CU FT 4.5 CU FT

USABLE CAPACITY 18 LBS (8.16 KG) 18 LBS (8.16 KG)

MAX SPIN SPEED 950 1000

EXTERIOR

LID FINISH PORCELAIN POWDER COAT

LID SOLID GLASS

TOP FINISH PORCELAIN PORCELAIN

AGITATOR --- -- WASHPLATE IMPELLER IMPELLER

SOUND PACK Q. WASH PLUS Q. WASH ULTRA

TUB WRAP NO YES

MASTIC (FRONT) 1 - 4 X 12 PIECE 1 - 4 X 12 PIECE

CABINET PAD YES YES

LID SEALS NO YES

MAIN DRIVE MOTOR BRUSHLESS PERM MAGNET BRUSHLESS PERM MAGNET

DISPENSERS

MAIN DETERGENT YES YES

TYPE FLUSH FLUSH

CAPACITY 2/3 CUP 2/3 CUP

BLEACH YES YES

TYPE FLUSH/TIMED FLUSH/TIMED

CAPACITY 1 CUP 1 CUP

FABRIC SOFTENER YES YES

TYPE FLUSH/TIMED FLUSH/TIMED

CAPACITY 1/2 CUP 1/2 CUP

CYCLE DEFINITIONS

# OF CYCLES

WHITEST WHITES

DELICATES/HANDWASH

PERM PRESS / CASUAL

SHEETS/TOWELS

DARKS / COLORS

DELAY START

10

HEAVY DUTY

NORMAL

QUICK WASH

BULKY

WOOL

—

—

RINSE / SPIN

DRAIN / SPIN

CLEAN WASHER

11

HEAVY DUTY

NORMAL

WHITEST WHITES

DELICATES/HANDWASH

PERM PRESS / CASUAL

SHEETS/TOWELS

DARKS / COLORS

QUICK WASH

BULKY

WOOL

SOAK

YES -10 HOURS

RINSE / SPIN

DRAIN / SPIN

CLEAN WASHER

OPTIONS

FINAL SPIN SPEEDS SELECTABLE (3) L, M, H SELECTABLE (4) NO SPIN, L, M, H

SOAK PRE SOAK PRE SOAK

CATALYST OPTIONS

DEEP CLEAN

EXTRA RINSE

1-4

DEEP CLEAN

EXTRA RINSE

MODEL NUMBERS WTW6400SW WTW6600SW, G, B

SECONDARY

EOC OFF / SOFT / LOUD OFF / SOFT / LOUD

TIME REMAINING YES YES

TEMPS 5 - 4 ATC 5 - 4 ATC

ATC TEMPS H/C , W/W, W/C, C/C H/C , W/W, W/C, C/C

AUTO WATER LEVEL YES YES

WATER LEVELS

SOIL LEVELS 4 4

STATUS LED’S

ADDITIONAL INFORMATION

COLORS WHITE WHITE / BISCUIT / BLACK

SIZE ( W X D X H ) 28 X 27 X 42 IN (71.2 x 68.5 X 106.6 CM) 28 X 27 X 42 IN (71.2 x 68.5 X 106.6 CM)

WEIGHT (IN CARTON) 165 LBS (74.8 KG) 165 LBS (74.8 KG)

AUTO - NON SELECTABLE MIN. LEVEL = 3.5

(9 CM) ABOVE BASKET BOTTOM

WASH (4) / STATUS (3)

SOAK

WASHING

RINSING

SPIN

DONE

ADD-A-GARMENT

LID LOCKED

AUTO - NON SELECTABLE MIN. LEVEL =

˝

3.5˝ (9 CM) ABOVE BASKET BOTTOM

WASH (4) / STATUS (3)

SOAK

WASHING

RINSING

SPIN

DONE

ADD-A-GARMENT

LID LOCKED

1-5

IMPELLER WASH PROGRAM / SELECTABILITY

WTW 6400S

D = Default Setting

x = Selectable Setting

o = Not Selectable

1-6

WTW 6600S

D = Default Setting

x = Selectable Setting

o = Not Selectable

1-7

— NOTES —

1-8

INSTALLATION INFORMATION

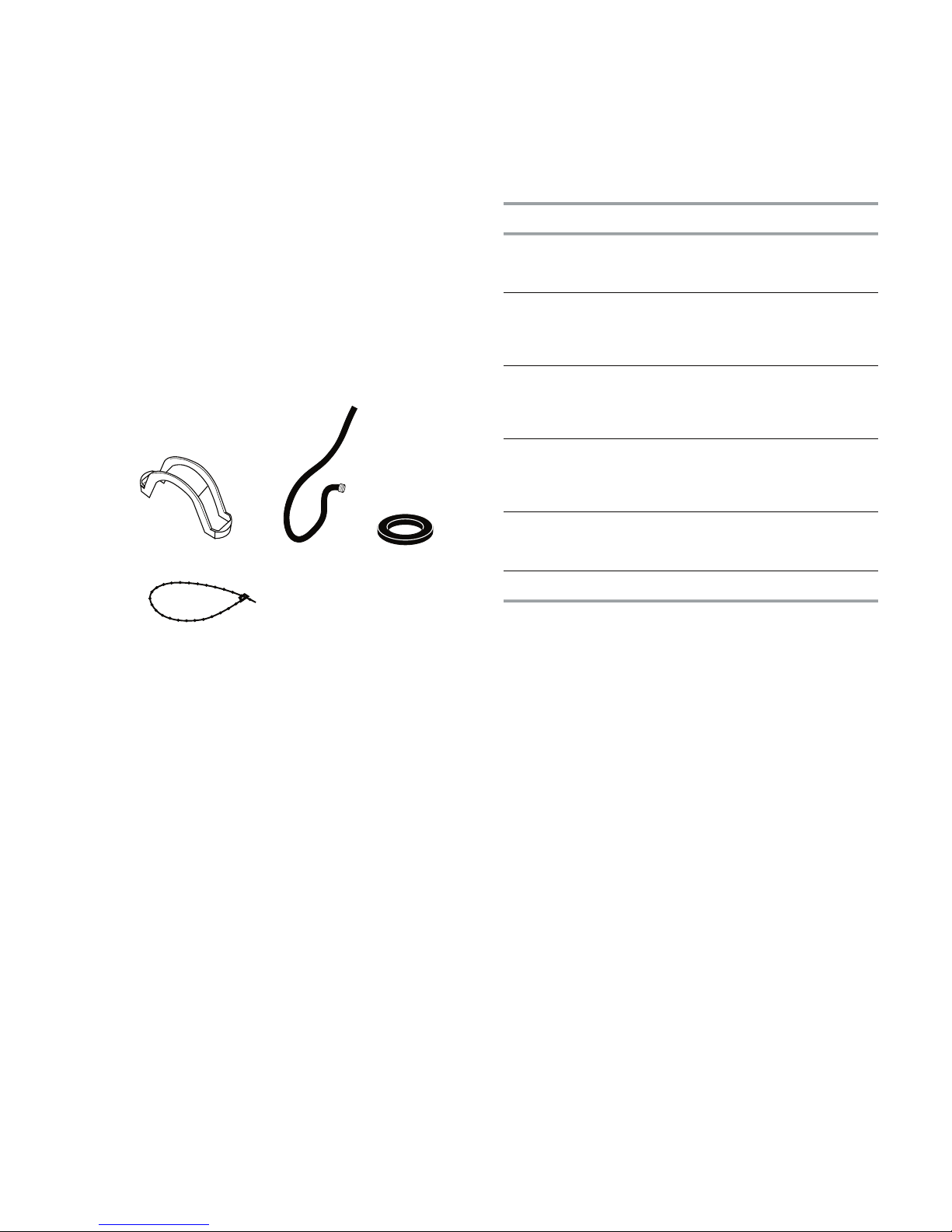

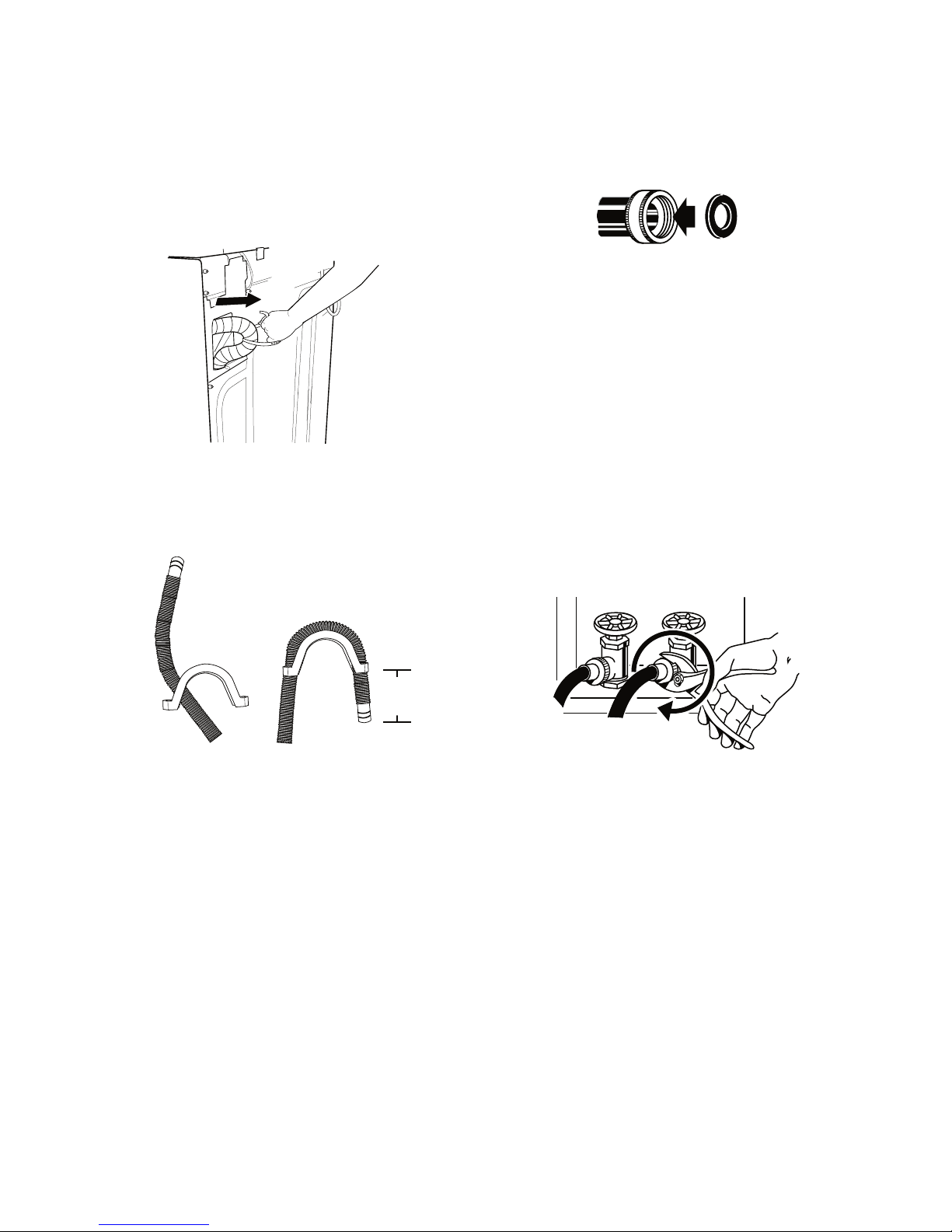

A. Drain hose form

B. Water inlet hoses (2

)

C. Flat water inlet hose washers (4

)

D. Beaded tie stra

p

A B

C

D

If You Have: You Will Need to Buy:

Laundry tub or

standpipe taller

than 96˝ (2.4 m)

Sump pump system (if not already

available)

1˝ (2.5 cm)

diameter

standpip

e

2˝ (5 cm) diameter to 1˝ (2.5 cm)

diameter standpipe adapter,

Part Number 3363920 and

connector kit

Part Number 285835

Overhead sewer Standard 20 gal. (76 L) 39˝ (99 cm) tall

drain tub or utility sink, sump pump and

connectors (available from local

plumbing su

ppliers)

Floor drain Siphon break, Part Number 285834;

additional drain hose,

Part Number 8318155 and connector

kit, Part

Number 285835

Water faucets

beyond reach of

fill hose

s

2 longer water fill

hoses:

6 ft (1.8 m) Part Number 76314,

10 ft (3.0 m) Part Number 350008

Lint clogged drain Drain protector, Part Number 367031

INSTALLATION REQUIREMENTS

TOOLS AND PARTS

Gather the required tools and parts before

starting installation. The parts supplied are in

the washer basket.

Tools needed for connecting the drain

hose and water inlet hoses:

Pliers that open to 1-9/16˝ (3.95 cm)

•

Flashlight (optional)

•

Parts Supplied:

Alternate Parts

Tools needed for securing the drain hose

and leveling the washer:

Adjustable or open end wrench 9/16˝

•

(14 mm)

Level

•

•

Wood block

Ruler or measuring tape

•

2-1

LOCATION REQUIREMENTS

A. Front view

B. Side view

C. Closet door with vents

A

B

C

17"*

(43.2 cm)

1"

(2.5 cm)

1"

(2.5 cm)

27-1/2

"

(69.9 cm)

1"*

(2.5 cm)

27"

(68.6 cm)

5"*

(12.7 cm)

14"* max.

(35.6 cm)

3"*

(7.6 cm)

3"*

(7.6 cm)

24 in. *

(155 cm )

2

2

48 in. *

(310 cm )

2

2

Selecting the proper location for your washer

improves performance and minimizes noise

and possible washer “walk.”

The washer can be installed in a basement,

laundry room, closet, or recessed area. See

“Drain System,” page 2-3.

IMPORTANT: Do not install or store the washer where it will be exposed to the weather.

Proper installation is your responsibility.

You will need:

•

A water heater set to deliver 120°F (49°C)

water to the washer.

•

A grounded electrical outlet located with

in 4 ft (1.2 m) of where the power cord is

attached to the back of the washer. See

“Electrical Requirements.”

Hot and cold water faucets located within

•

3 ft (90 cm) of the hot and cold water fill

valves, and water pressure of 20-100 psi

(138-690 kPa) for best performance.

A level floor with a maximum slope of

•

1˝(2.5 cm) under entire washer. Installing the washer on carpeting is not recom

mended.

A sturdy floor to support the washer

•

weight (washer, water and load) of 315 lbs

(143 kgs).

Do not store or operate your washer in tem

peratures at or below 32°F (0°C). Some wa

ter can remain in the washer and can cause

damage in low temperatures.

INSTALLATION SPACING FOR RECESSED

AREA AND CLOSET INSTALLATIONS

The following spacing dimensions are rec

ommended for this washer. This washer has

been tested for installation with spacing of 0

(0 cm) clearance on the sides. Recommend

ed spacing should be considered for the fol

lowing reasons:

Additional spacing should be considered

•

for ease of installation and servicing.

Additional spacing should be considered

•

on all sides of the washer to reduce noise

transfer.

For closet installation with a door, minimum

•

-

ventilation openings in the top and bottom

of the door are required. Louvered doors

with equivalent ventilation openings are

acceptable.

Companion appliance spacing should also

•

be considered.

-

-

-

* Required spacing

-

˝

-

-

2-2

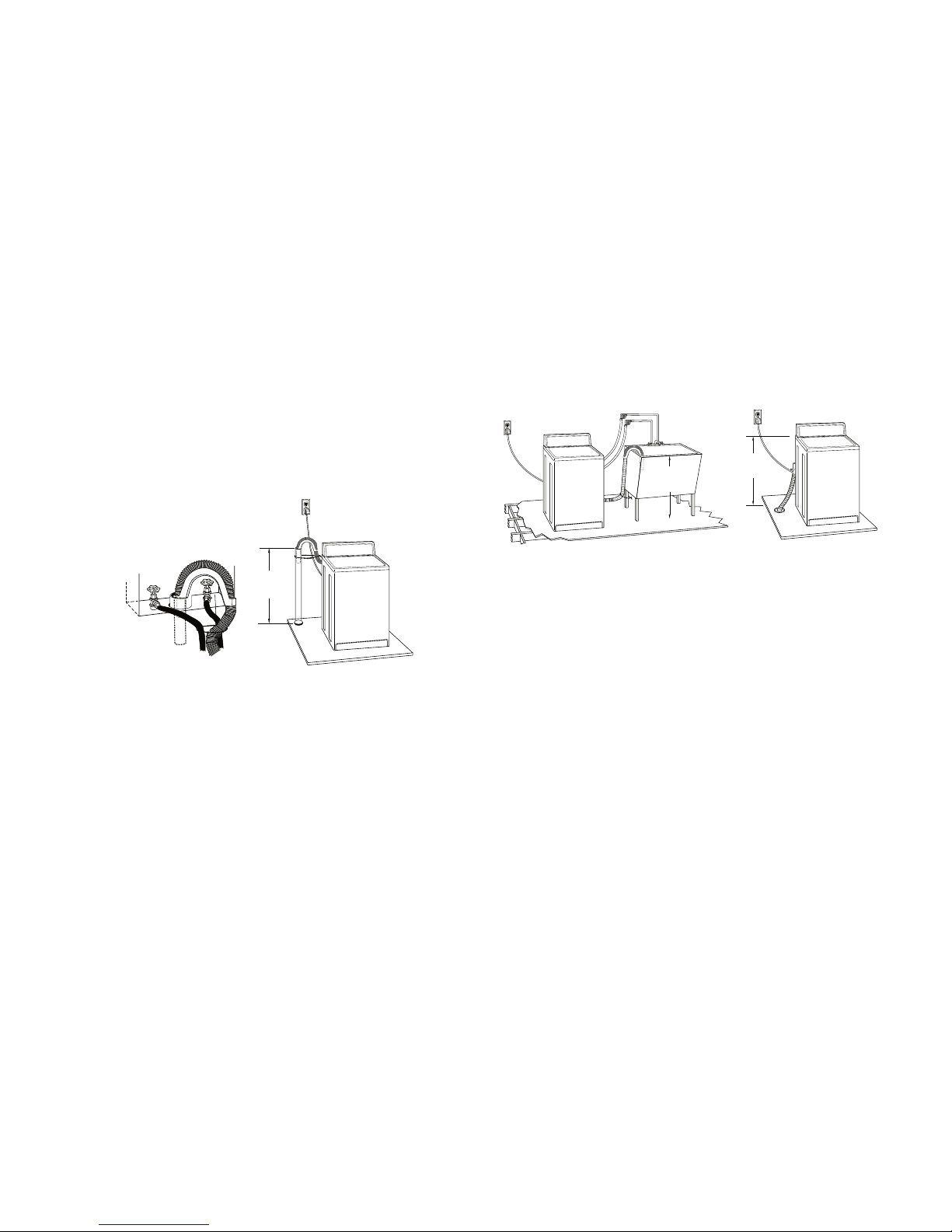

DRAIN SYSTEM

A

B

(99 cm)

39"

C

D

39"

(99 cm)

28"

(71 cm)

The washer can be installed using the standpipe drain system (floor or wall), the laundry

tub drain system, or the floor drain system.

Select the drain hose installation method you

need. See “Tools and Parts,” page 2-1.

LAUNDRY TUB DRAIN SYSTEM (VIEW C)

The laundry tub needs a minimum 20 gal.

(76 L) capacity. The top of the laundry tub

must be at least 39

and no higher than 96

˝ (99 cm) above the floor

˝ (244 cm) from the

bottom of the washer.

STANDPIPE DRAIN SYSTEM—WALL OR

FLOOR (VIEWS A & B)

The standpipe drain requires a minimum diameter standpipe of 2

˝ (5 cm). The minimum

carry-away capacity can be no less than 17

gal. (64 L) per minute. A 2

˝ (5 cm) diameter to

1˝ (2.5 cm) diameter standpipe adapter kit is

available. See “Tools and Parts,” page 2-1.

The top of the standpipe must be at least 39

(99 cm) high and no higher than 96

˝ (244 cm)

˝

from the bottom of the washer.

FLOOR DRAIN SYSTEM (VIEW D)

The floor drain system requires a siphon break

that may be purchased separately. See “Tools

and Parts,” page 2-1.

The siphon break must be a minimum of 28˝

(71 cm) from the bottom of the washer. Addi

tional hoses might be needed.

-

2-3

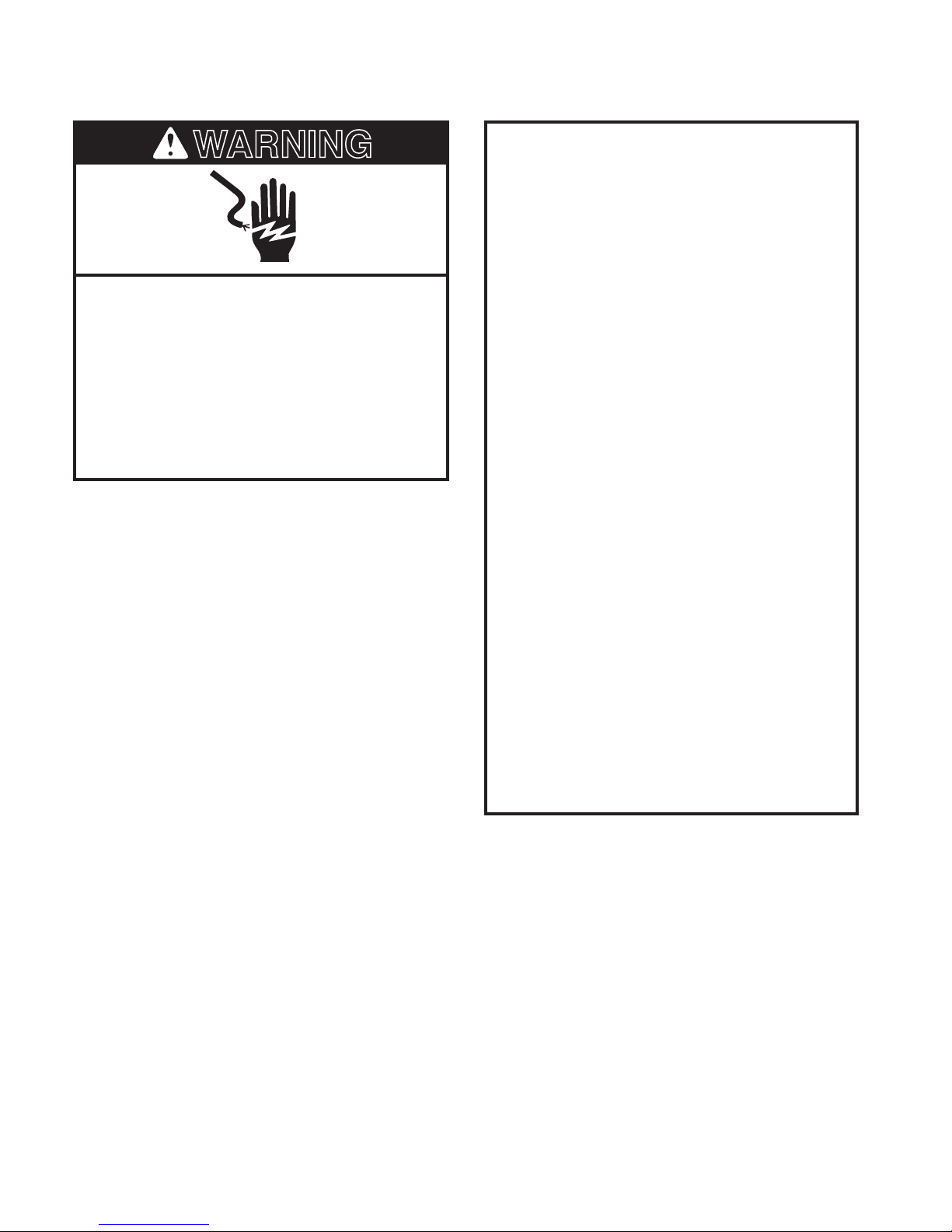

ELECTRICAL REQUIREMENTS

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

A 120 volt, 60 Hz., AC only, 15- or 20-

•

amp, fused electrical supply is required. A

time-delay fuse or circuit breaker is recom

mended. It is recommended that a sepa

rate circuit serving only this appliance be

provided.

This washer is equipped with a power sup-

•

ply cord having a 3 prong grounding plug.

To minimize possible shock hazard, the

•

cord must be plugged into a mating, 3

prong, grounding-type outlet, grounded

in accordance with local codes and ordinances. If a mating outlet is not available,

it is the personal responsibility and obli

gation of the customer to have the prop

erly grounded outlet installed by a qualified

electrician.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the event

of a malfunction or breakdown, grounding

will reduce the risk of electrical shock by

providing a path of least resistance for electric current. This washer is equipped with a

cord having an equipment-grounding con

ductor and a grounding plug. The plug must

be plugged into an appropriate outlet that

is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the

equipment-grounding conductor can result

in a risk of electric shock. Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly

-

-

-

-

grounded.

Do not modify the plug provided with the

appliance—if it will not fit the outlet, have a

proper outlet installed by a qualified electri

cian.

For a permanently connected washer:

This washer must be connected to a ground

ed metal, permanent wiring system, or an

equipment-grounding conductor must be

run with the circuit conductors and connected to the equipment-grounding terminal or

lead on the appliance.

-

-

-

If codes permit and a separate ground wire

•

is used, it is recommended that a qualified

electrician determine that the ground path

is adequate.

Do not ground to a gas pipe.

•

Check with a qualified electrician if you are

•

not sure the washer is properly grounded.

Do not have a fuse in the neutral or ground

•

circuit.

2-4

INSTALLATION INSTRUCTIONS

WARNING

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

NOTE: To avoid floor damage, set the washer

onto cardboard before moving across floor.

IMPORTANT:

•

Be sure the foam shipping base has been

removed from the bottom of the washer as

directed in the Unpacking Instructions.

If foam shipping base has not been re-

•

moved, be sure lid is secured with tape be

fore laying washer on its back.

Removing the foam shipping base is nec-

•

essary for proper operation.

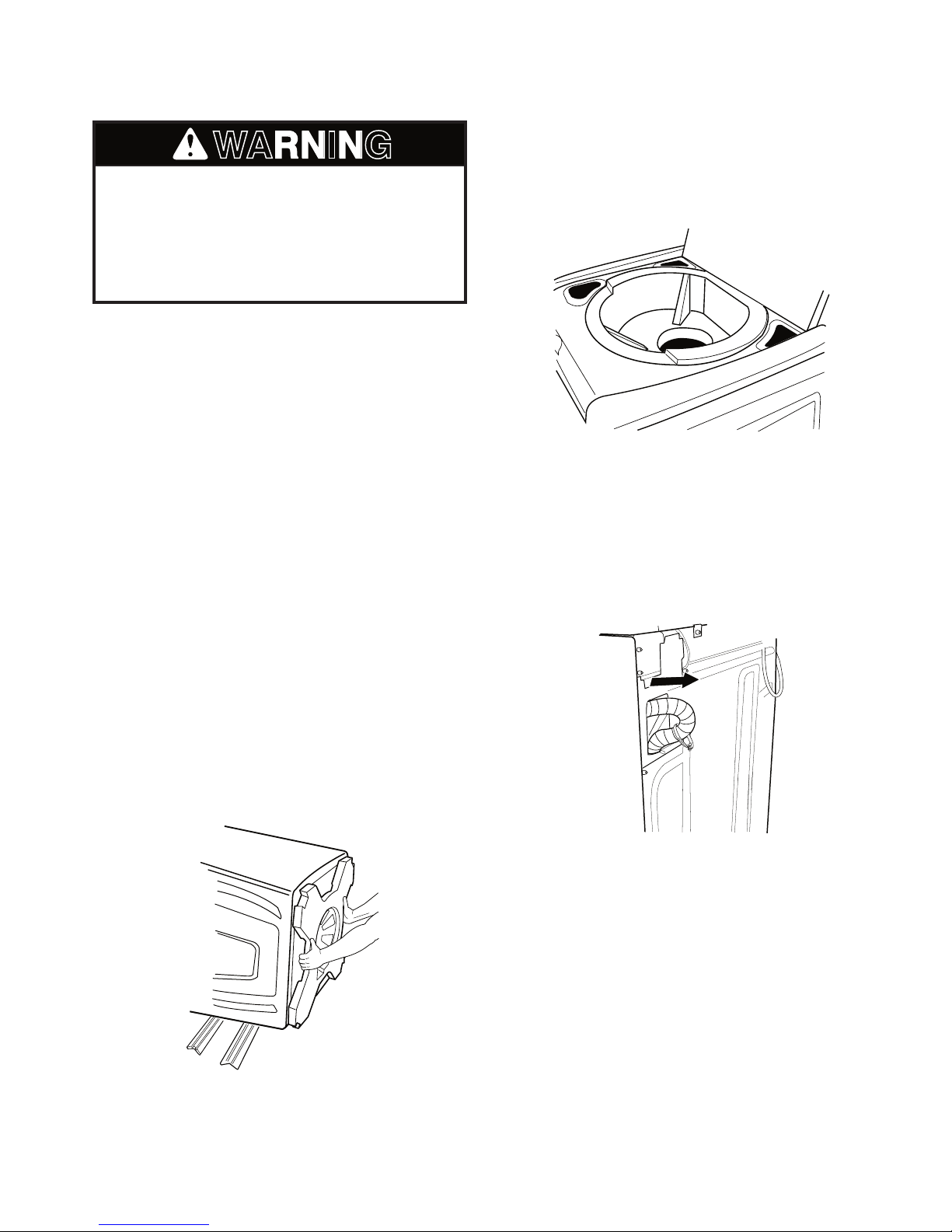

REMOVE SHIPPING BASE

AND PACKING RING

5. Remove tape from lid. Open lid and remove foam packing ring from washer tub.

Keep foam packing ring in case you need

to move the washer in the future.

CONNECT THE DRAIN HOSE

Proper connection of the drain hose protects

your floors from damage due to water leak

age. Read and follow these instructions.

The drain hose is connected to your washer

and is stored inside the washer cabinet.

-

1. Place cardboard supports from shipping

carton on floor behind washer for sup

port.

2. Using 2 or more people, tip the washer

onto its back and place on cardboard

supports.

3. Remove foam shipping base.

4. Set washer upright.

-

2-5

REMOVE DRAIN HOSE

A. Coupling

B. Washer

A B

A B

A

. Feed end of drain hose into one end of form. Secure the lip of the

form into one of the hose ribs.

B. Bend the hose over the top of the form and feed into the other en

d

of the form, extending it 6-8˝ (15.2 cm - 20.3 cm) beyond the form.

Secure the lip of form into one of the hose ribs.

6 - 8˝

(15.2 cm

-

20.3 cm

)

Tighten the couplings with an additional two-thirds turn.

FROM WASHER CABINET

Pull the corrugated drain hose out of the

washer by first grabbing the pull tie. Continue

to pull the hose until the end emerges. Do not

force excess drain hose back into the rear of

the washer.

LAUNDRY TUB DRAIN

OR STANDPIPE DRAIN

Connecting the drain hose form to the cor

rugated drain hose

CONNECT THE INLET HOSES

1. Insert new flat washers (supplied) into

each end of the inlet hoses. Firmly seat

the washers in the couplings.

CONNECT THE INLET HOSES TO

THE WATER FAUCETS

Make sure the washer basket is empty.

2. Attach the hose labeled hot to the hot

water faucet. Screw on coupling by hand

until it is seated on the washer.

3. Attach the hose labeled cold to the cold

water faucet. Screw on coupling by hand

-

until it is seated on the washer.

4. Using pliers, tighten the couplings with

an additional two-thirds turn.

To keep drain water from going back into

the washer:

Do not force excess drain hose into stand-

•

pipe. Hose should be secure but loose

enough to provide a gap for air.

Do not lay excess hose on the bottom of

•

the laundry tub.

FLOOR DRAIN

Do not install the drain hose form on to the

corrugated drain hose. You may need addi

tional parts. See Floor drain under “Tools and

Parts,” page 2-1.

NOTE: Do not overtighten or use tape or sealants on the valve. Damage to the valves can

result.

Clear the water lines

Run water through both faucets and inlet

•

hoses, into a laundry tub, drainpipe or buck

et, to get rid of particles in the water lines

that might clog the inlet valve screens.

Check the temperature of the water to

•

make sure that the hot water hose is con

nected to the hot water faucet and that the

cold water hose is connected to the cold

-

water faucet.

2-6

-

-

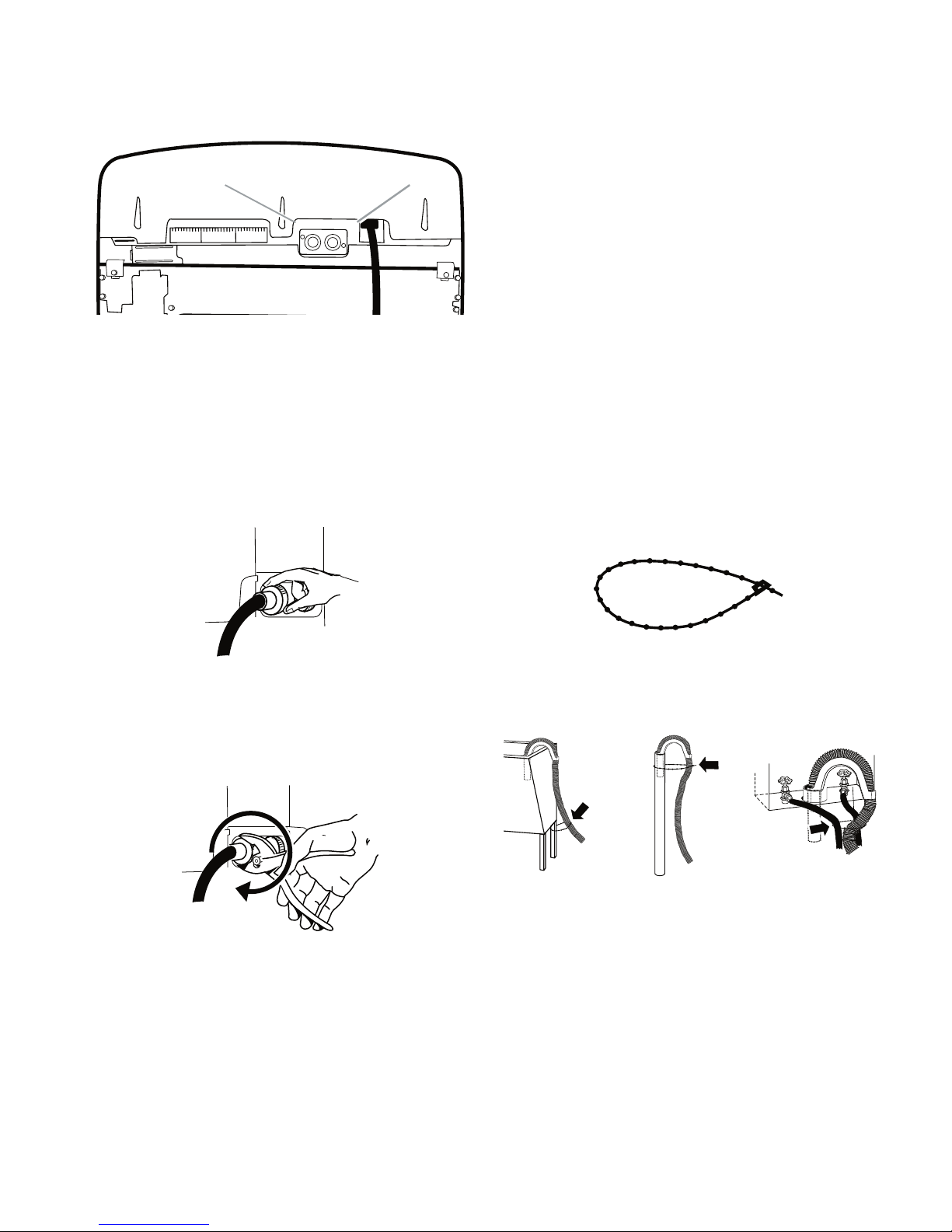

CONNECT THE INLET HOSES

COLD

HOT

A. Hot water inlet valve

B. Cold water inlet valve

HO

T

COL

D

A

B

COLD

HO

T

Beaded tie strap

CBA

TO THE WASHER

1. Attach the hot water hose to the inlet

valve labeled hot.

2. Attaching one hose coupling first makes

it easier to tighten the connection with pli

ers.

Check for leaks

Turn on the water faucets and check for

•

leaks. A small amount of water might en

ter the washer. You will drain this in a later

step.

NOTE: Replace inlet hoses after 5 years of

use to reduce the risk of hose failure. Record

hose installation or replacement dates for fu

ture reference.

If you connect only one water hose, you

•

must cap off the remaining water inlet

port.

Periodically inspect and replace hoses

•

if bulges, kinks, cuts, wear, or leaks are

found.

-

SECURE THE DRAIN HOSE

-

-

3. Screw on coupling by hand until it is seated on the washer.

4. Using pliers, tighten the coupling with an

additional two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the valve. Damage to the valves can

result.

5. Attach the cold water hose to the inlet

valve labeled cold.

6. Screw on coupling by hand until it is seated on the washer.

1. Drape the power cord over the console.

2. Remove any cardboard used to move

washer.

3. Fasten the drain hose to the laundry tub

leg or drain standpipe with the beaded tie

strap. See view A or B.

If the washer faucets and the drain stand-

pipe are recessed, put the formed end of

the drain hose into the standpipe. Tightly

wrap the tie strap around the water inlet

hoses and the drain hose. See view C.

7. Using pliers, tighten the coupling with an

additional two-thirds turn.

NOTE: Do not overtighten or use tape or sealants on the valve. Damage to the valves can

result.

2-7

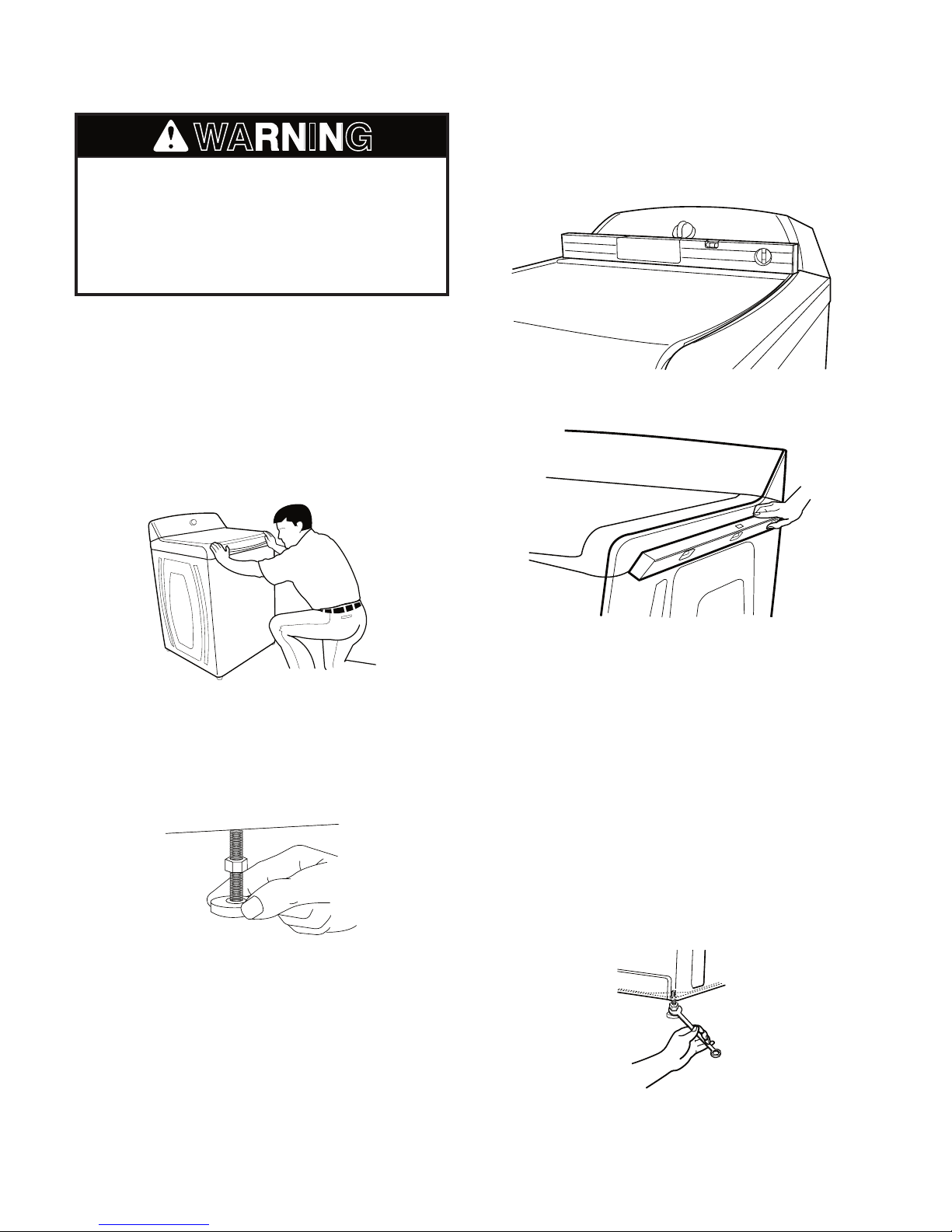

LEVEL THE WASHER

WARNING

Level the front.

Level the side

.

Excessive Weight Hazard

Use two or more people to move and

install washer.

Failure to do so can result in back or

other injury.

One washer foot has been installed at a different height on the washer. The other three

feet were preset at the factory. Properly level

ing your washer will minimize noise and vibra

tion.

1. Slide the washer to its final location.

2. Push on upper front panel to be sure the

washer is on its rear feet.

4. Check the levelness of the washer by

first placing a level on the lid near the

console. Next, place the level on the side

of the washer in the crease between the

top of the washer and the cabinet.

-

-

3. Lower right front foot until it contacts the

floor. By hand, firmly rotate foot as much

as an additional 1-1/2 turns. The other

three feet have been preset at the factory.

5. If the washer is not level, move the washer out slightly, tip back, prop up the front

of the washer on a wood block. Adjust the

feet up or down as necessary by twisting

the feet. Repeat steps 1 through 4 until

washer is level.

6. Use a 9/16˝ or 14 mm open-end wrench

to turn the locknut counterclockwise on

the foot tightly against the washer cabi

net.

IMPORTANT: If the locknut is not tight against

the washer cabinet, the washer may vibrate.

-

2-8

COMPLETE INSTALLATION

WARNING

1. Check the electrical requirements. Be

sure that you have the correct electrical

supply and the recommended grounding

method. See “Electrical Requirements,”

page 2-4.

2. Check that all parts are now installed. If

there is an extra part, go back through the

steps to see which step was skipped.

3. Check that you have all of your tools.

4. Keep the foam packing ring from the

washer tub for future relocation of the

washer. Dispose of or recycle all other

packaging materials.

5. Check that the water faucets are on.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

6. Check for leaks around faucets and inlet

hoses.

7. Plug into a grounded 3 prong outlet.

8. Remove any protective film or tape remaining on the washer.

9. Read “Washer Use,” page 3-3.

10. To test and to clean your washer, mea

sure 1/2 of the detergent manufacturer’s

recommended amount of High Efficiency

(HE) powdered or liquid detergent for a

medium size load and pour it into the de

tergent dispenser. Close the lid. Press

POWER. Select a normal cycle and press

Start. Allow it to complete one whole cycle.

-

-

2-9

— NOTES —

2-10

PRODUCT OPERATION

THEORY OF OPERATION

INTRODUCTION

The Cabrio™ Automatic Washer represents a

new design that differs from the traditional top

load machine. This washer operates without a

transmission, motor coupler, belt, basket drive

tube, or brake assembly.

NEW COMPONENTS

The washer has the following new components:

Drive Motor—The drive motor is an electronically commutated direct drive 3-phase brush

less DC design that moves the impeller/agitator

and spin basket without the use of a transmis

sion. The motor is comprised of a stator that

is bolted to the base of the washer tub and a

rotor that is attached to the drive shaft. The

motor direction and speed is controlled by the

machine/motor controller, and is monitored by

a rotor position sensor, (RPS), located on the

stator.

Recirculation PumpDrain Pump

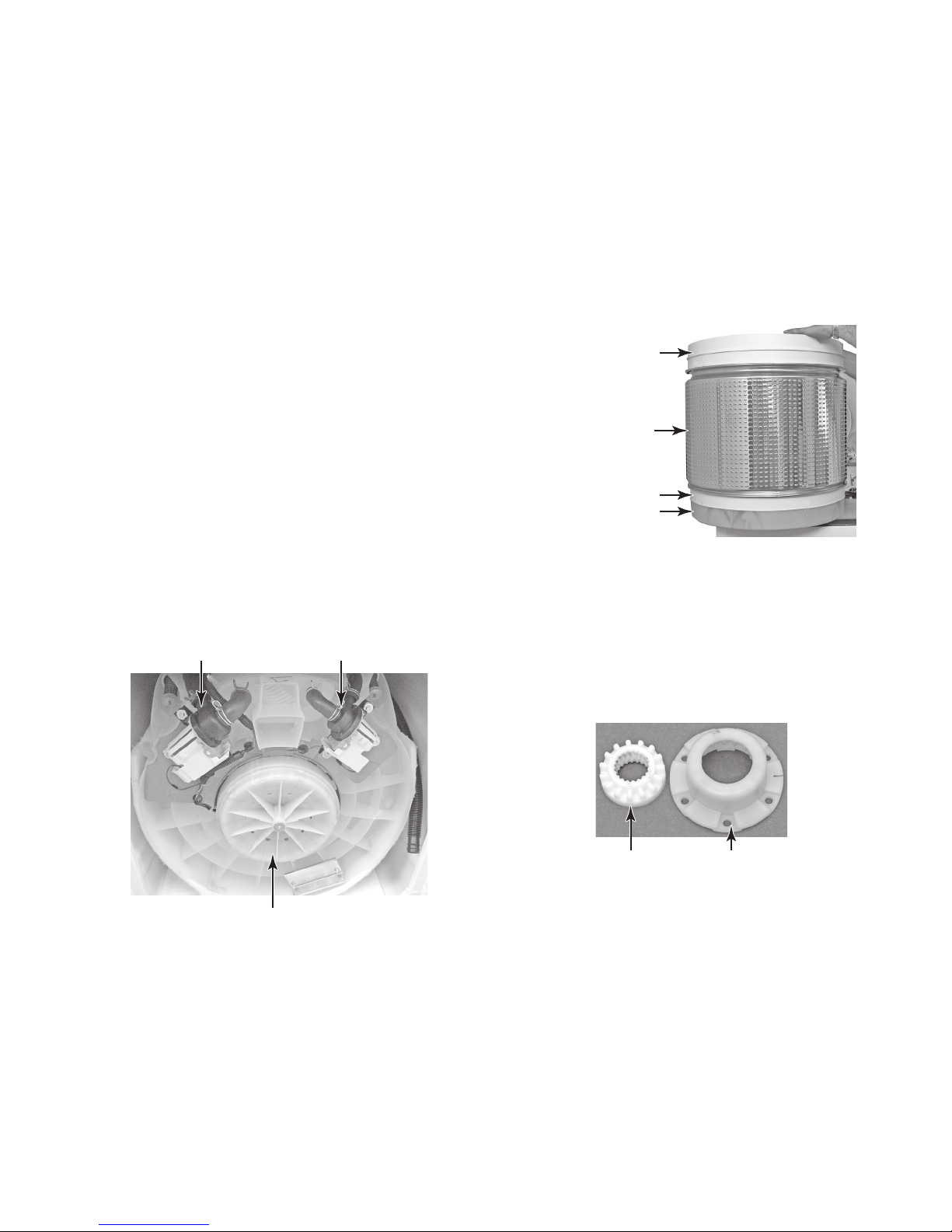

Basket—The basket is designed with a tra

ditional balance ring at the top and a flotation

chamber at the base. The outside surface of

the basket is punched to allow lint to catch on

the holes during the wash cycle. When the

water drains, the lint will be flushed off and

out the drain.

Balance Ring

-

-

Flotation Chamber

Basket Hub—The basket hub consists of two

splined components that engage or disengage

based on the position of the basket in the

vertical direction. The outer hub component

is fastened to the bottom of the basket, while

the inner component is attached to the end of

the drive shaft.

Basket

Balance Ring

-

Drive Motor

3-1

Inner Hub

(Drive Shaft)

Continued on the next page.

Outer Hub

(Basket)

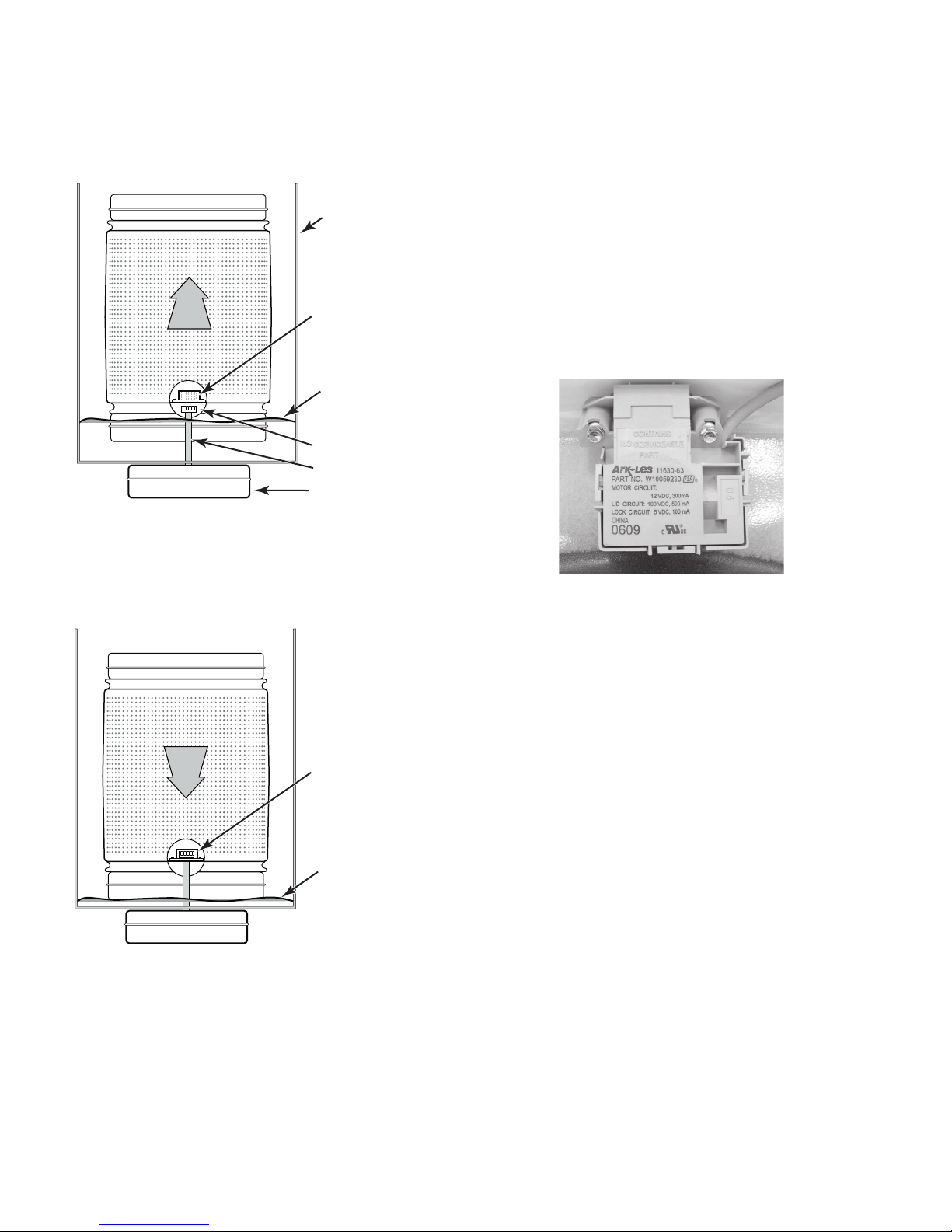

As the tub fills with water, the basket begins to

float and to rise. The splined hub components

now separate, and allow the basket to move

independently of the drive shaft.

Tub

Outer Basket Hub

Disengages

Water Level

Rises & Basket

Floats

Inner Hub Free

Drive Shaft

(Drive Motor)

When the tub drains, the basket drops back to

it’s original position, and the hub components

re-engage, connecting the basket to the shaft,

and permitting the basket to spin.

Lid Lock Mechanism—Since this washer

does not utilize a brake, a lid lock is used to

prevent access during the spin cycles. During

the drain and spin portions of the cycle, a lid

lock mechanism will lock the lid. The lid locks

are based on cycle phase. In general, the lid

locks when the basket spins greater than 23

rpm. After main wash, the lid is locked, and

remains locked until the end of the cycle. The

lid must be closed for the machine to fill, wash,

drain, or spin. Magnets in the washer lid close

a reed switch in the lid lock. This acts as the

lid switch.

Outer Basket Hub

Re-engages With Inner

Drive Shaft Hub

Water Level Drains

& Basket Drops

3-2

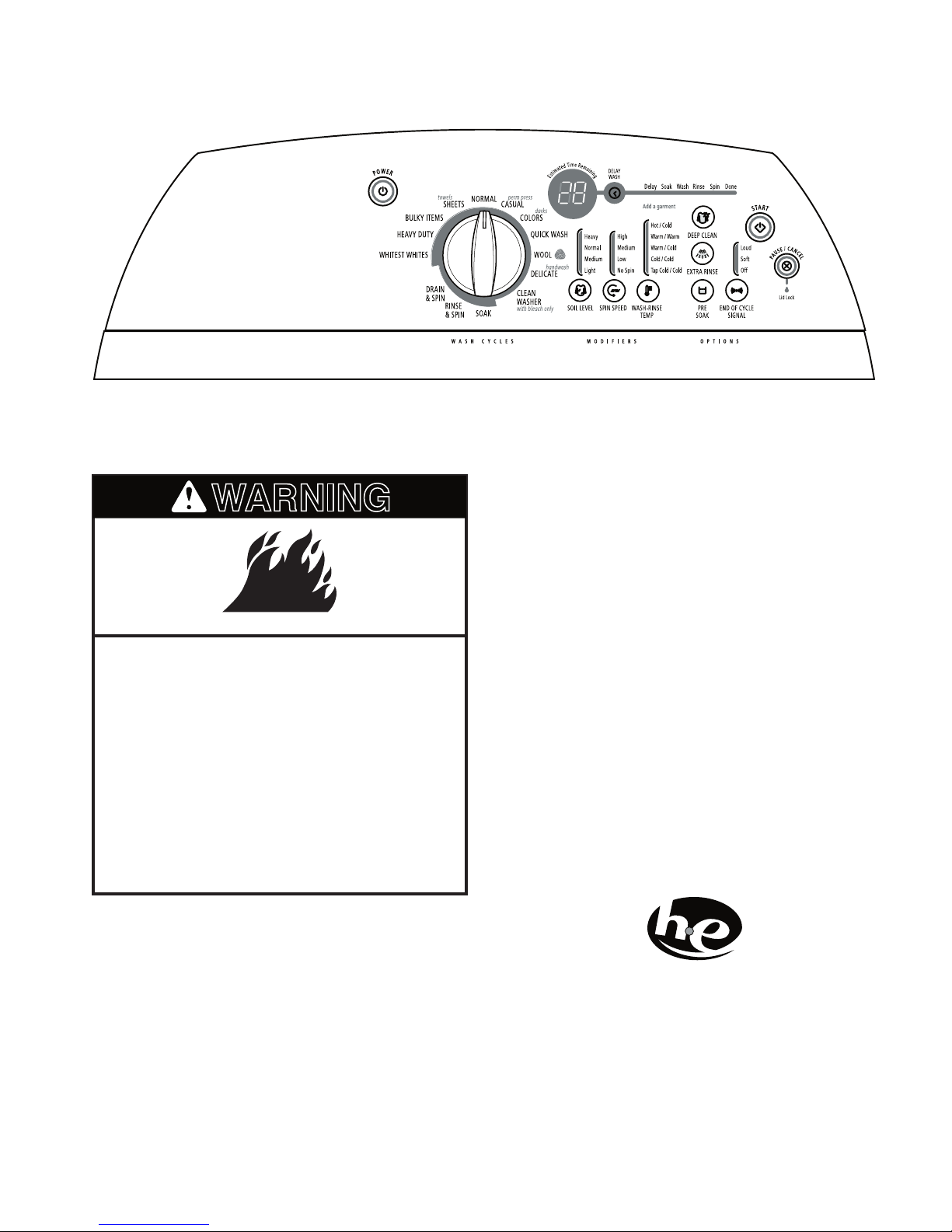

WASHER USE

WARNING

NOTE: Your washer model may differ slightly.

STARTING THE WASHER

Fire Hazard

Never place items in the washer that

are dampened with gasoline or other

flammable fluids.

No washer can completely remove oil.

Do not dry anything that has ever had

any type of oil on it (including cooking

oils).

Doing so can result in death, explosion,

or fire.

The following is a guide to starting the washer.

Periodic references to other sections of this

manual provide more detailed information.

USING THE PROPER DETERGENT

Use only High Efficiency (HE) detergents.

The package for this type of detergent will be

marked “HE” or “High Efficiency.” HE detergents

such as TIDE® HE are made to produce the

right amount of suds for the best performance

in low water wash systems. Follow the deter

gent manufacturer’s instructions to determine

the correct amount of detergent to use. The

washer’s new wash system will create too

much sudsing if regular non-HE detergent is

used. Using regular detergent will likely result in

washer errors, longer cycle times and reduced

rinsing performance.

It may also result in component failures and

noticeable mold or mildew.

-

3-3

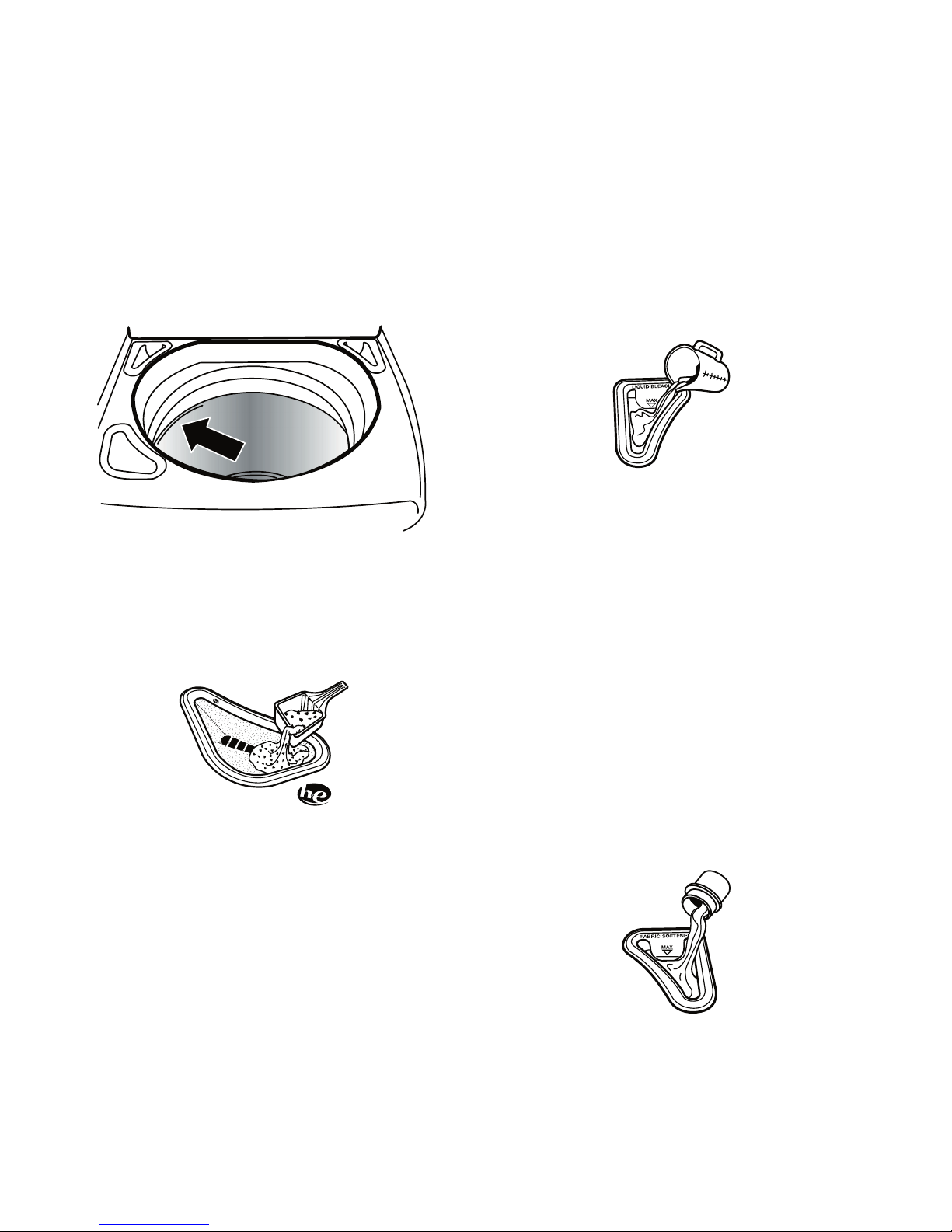

1. Place a load of sorted clothes into the

H

i

g

h

E

f

f

i

c

i

e

n

c

y

D

e

t

e

r

g

e

n

t

washer.

Load evenly to maintain washer bal

•

ance. Mix large and small items. Items

should move easily through the wash

water.

Load only to the top of the basket as

•

shown. Overloading can cause poor

cleaning. Items should move easily

through the wash water.

2. Pour measured powdered or liquid High

Efficiency (HE) detergent into the detergent

dispenser. Do not put detergent directly

into the wash tub or onto clothes in the

washer.

3. Add color-safe bleach, (powdered or liquid) to this dispenser, if needed. Be sure

-

to match powdered color-safe bleach with

powdered detergent or match liquid colorsafe bleach with liquid detergent.

4. Pour measured liquid chlorine bleach into

the liquid chlorine bleach dispenser, if

needed. Bleach is diluted and automati

cally dispensed at the proper time during

the wash cycle.

Do not overfill. Do not dilute. Do not use

•

more than 1 cup (250 mL) for a full load.

Use less with a smaller load size.

Follow the garment and the chlorine

•

bleach manufacturer’s directions for

proper use.

To avoid spilling, use a cup with a pour

•

ing spout. Do not let bleach splash, drip,

or run down into the washer basket.

At the end of the cycle, a small amount

•

of water may be left in the dispenser.

This is normal.

-

-

NOTE: Use only liquid chlorine bleach

in this dispenser.

5. Pour measured liquid fabric softener into

the fabric softener dispenser, if desired.

3-4

Loading...

Loading...